Patents

Literature

209results about How to "Stable network structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technology of phosphosilicate enamel

The invention provides a preparation technology of phosphosilicate enamel, which comprises the raw materials based on weight percentage as follows: 15%-30% of P205, 20%-35% of SiO2, 8%-15% of B2O3, 5%-12% of Al2O3, 1%-4% of TiO2, 1%-5% of ZrO2, 0-1% of CoO, 0-2% of NiO, 5%-10% of Na2O, 2%-6% of K2O, 0-4% of 'ZnO, 2%-6% of CaO and 1%-5% of MaO. The preparation technology comprises the steps of dosing, founding under a high temperature, preparing enamel dried powder or glazeslip, coating the enamel, and sintering. After the phosphosilicate enamel which is prepared by the method is used, the abrasion resistance and the shock resistance of the enamel are effectively improved, and the enamel with better performances is developed for the industrial application of the enamel which is taken as an abrasion resistant structure, a building decoration material, and the like.

Owner:湘潭宏润金属科技有限公司

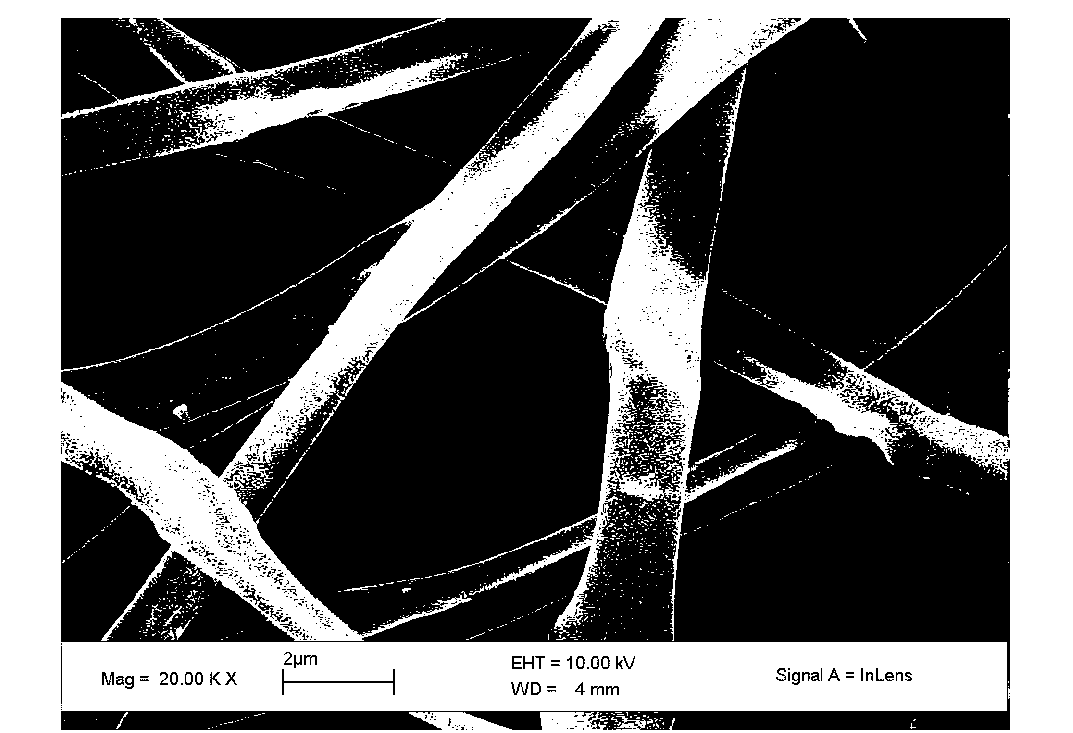

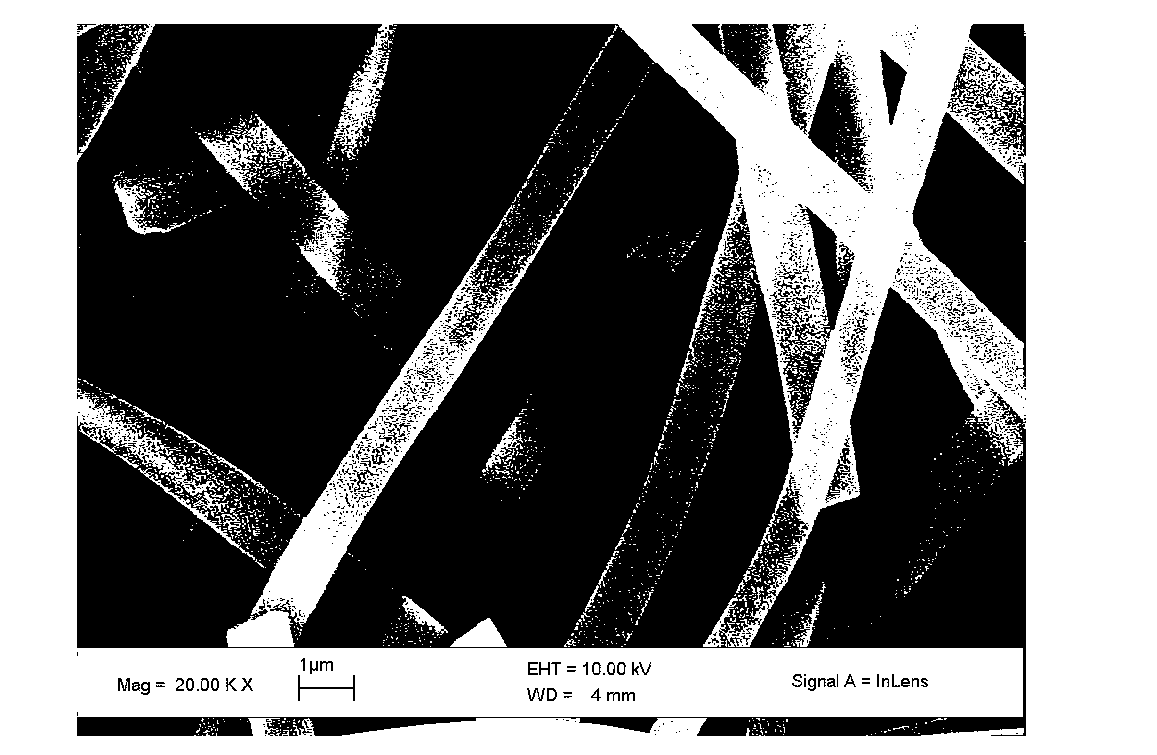

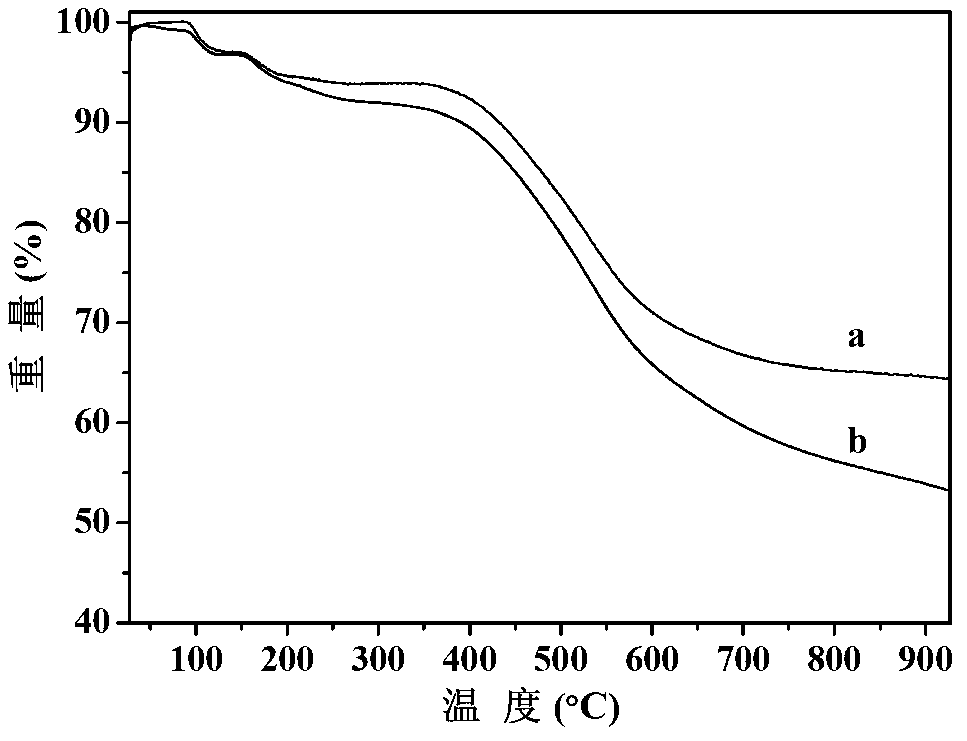

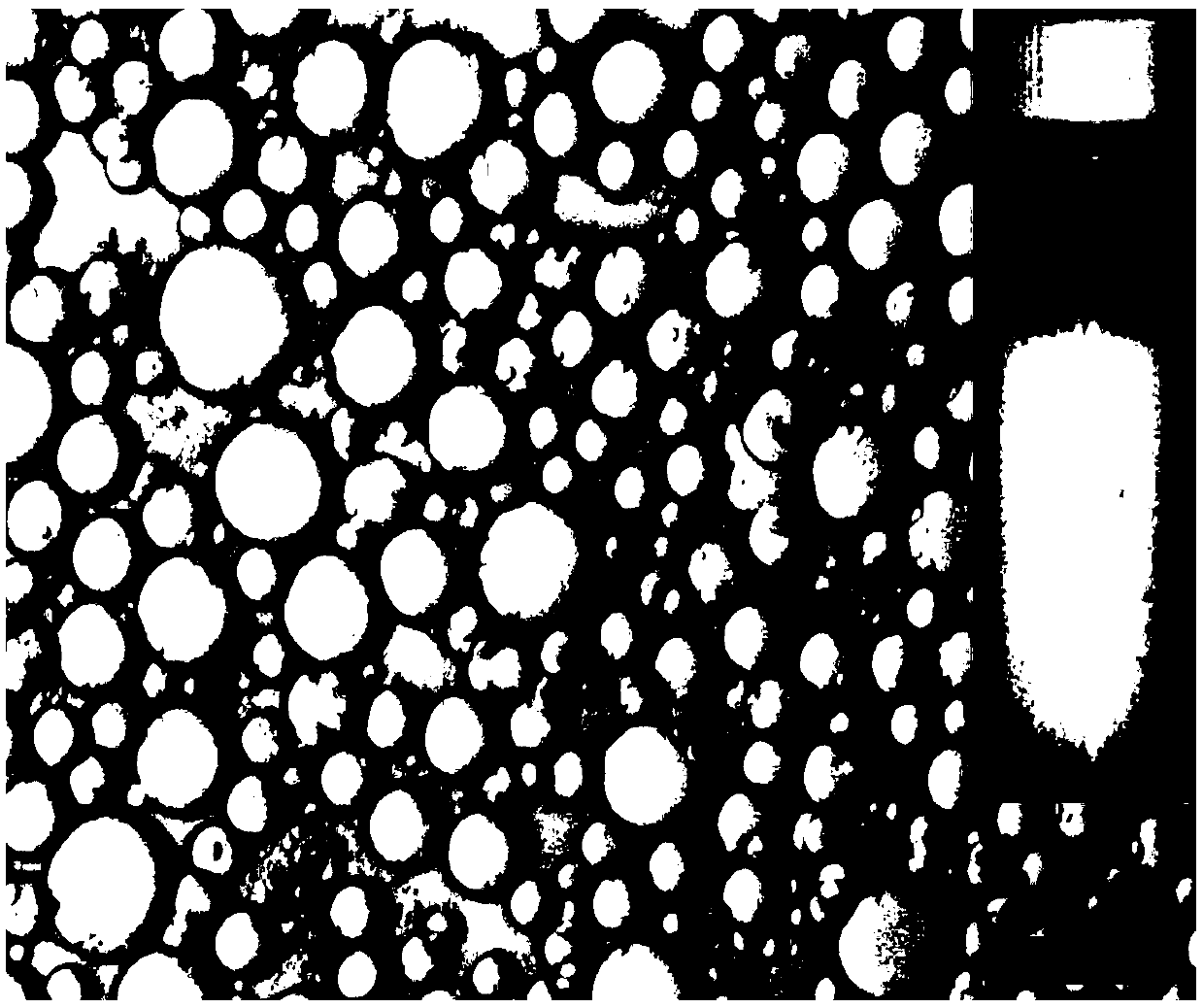

Graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and preparation method thereof

ActiveCN103215693AEvenly dispersedGood flexibilityFibre chemical featuresOrganic solventPorous carbon

The invention relates to graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and a preparation method thereof. The diameter of the fiber is in a range of 0.3-1.7mum, and the specific surface area of the fiber is 500-900m<2> / g. The fiber has a porous structure which is formed by microporous mainly. Micro-pore volume is 0.20-0.50cm<3> / g, and surface oxygen atomic ratio is lower than 10%. The preparation method comprises the steps that: graphene oxide is added into an organic solvent and is subjected to ultrasonic dispersion, such that a graphene oxide solution is formed; termosetting phenolic resin and a high-molecular-weight linear polymer are added into the graphene oxide organic solution, and are completely dissolved by stirring; the mixed solution is spun into composite fiber, and solidification and carbonization are carried out, such that porous phenolic-resin-based carbon / graphite oxide composite ultrafine fiber is obtained. The sources of adopted raw materials are rich. The prepared composite fiber has the advantages of high structural stability, good flexibility, developed pore structure, controllable surface oxygen content, and suitability for practical application.

Owner:TSINGHUA UNIV

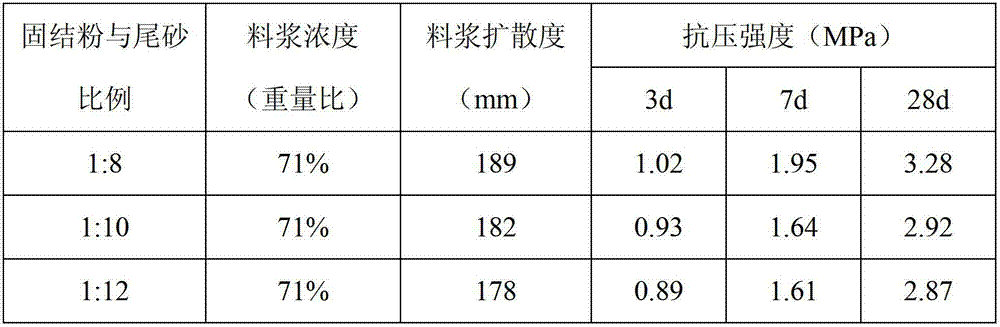

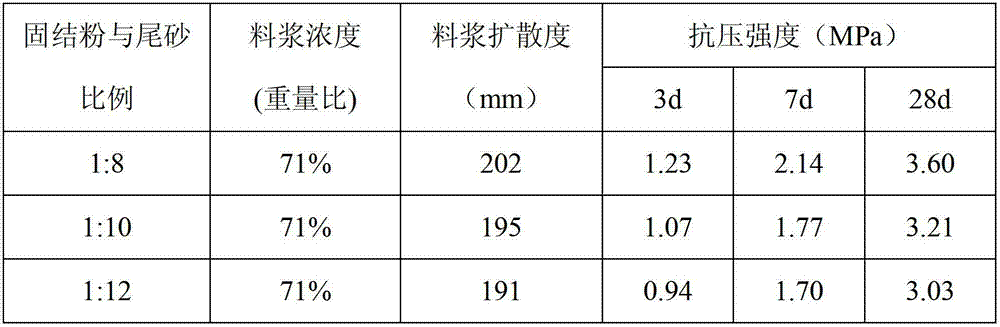

Filling and consolidating powder for mining purposes and use thereof

The invention discloses filling and consolidating powder for mining purposes and a use thereof. The filling and consolidating powder comprises the following raw materials in percentage by weight: 3-5% of portland cement clinker, 8-10% of metakaolin, 5-15% of carbide slag, 18-24% of phosphogypsum, 18-22% of fly ash, 9-14% of red mud, 15-19% of blast furnace slag, 4-10% of limestone, 0.8-1.2% of polycarboxylic acid type water reducing agent and 0.4-0.7% of sodium hydroxide and is prepared by uniformly mixing and grinding to get fine powder with 400 meshes-600 meshes. When the filling and consolidating powder is used, mining tailing or coal gangue is firstly mixed with water according to a proportion in a mixing machine for forming uniform slurry, and then the consolidating powder is further added, uniformly mixed and then conveyed to a downhole place by a pipeline for filling. The cost of the filling material blended by the consolidating powder disclosed by the invention is 50-70 yuan / ton, while the cost of the similar filling and consolidating powder is 90-110 yuan / ton; and compared with the prior art, the cost is greatly reduced and the filling effect is good.

Owner:ZIBO GEOLOGICAL MINE TECH SERVICE CENT

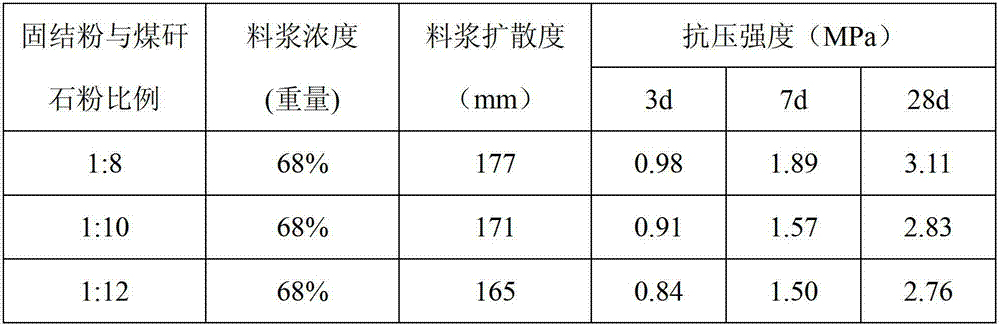

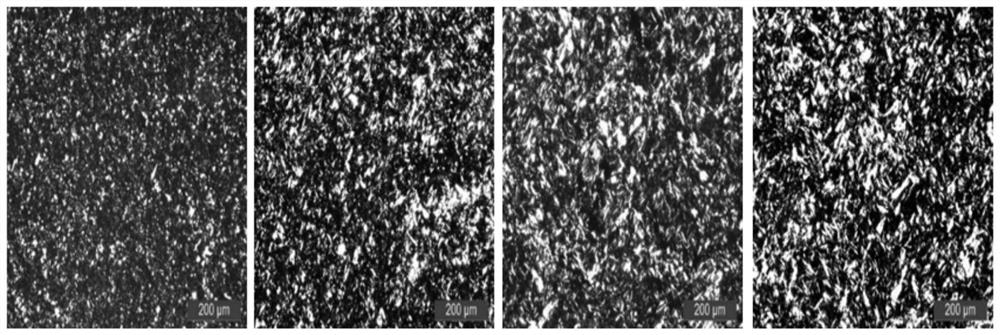

Preparation method and application of bicontinuous emulsion gel

The invention discloses a preparation method and application of bicontinuous emulsion gel, and belongs to the technical field of food gel emulsification. The method comprises the following steps: respectively adding food-grade gel factors into an oil phase, and generating a fat crystal network in the oil phase to solidify the oil phase; adding polysaccharide into a water phase to form a hydrogel three-dimensional network space structure to solidify the water phase; and performing high-speed shearing on the two phases to form the ultra-stable bicontinuous emulsion gel. The emulsion gel obtainedby the invention has extremely low contents of trans-fatty acid and saturated fatty acid, can be applied to the filling of smearing fat and baking products, serves as an effective way for reducing the content of fat in food, can also transport hydrophobic and hydrophilic nutrient substances with high loading capacity simultaneously, and has potential application value in the fields of food, medicine and the like.

Owner:JIANGNAN UNIV

Preparation method of blocky silicon-carbon composite aerogel

ActiveCN102343285ARich network structureStable network structureCatalyst carriersCarbon compositesSupercritical drying

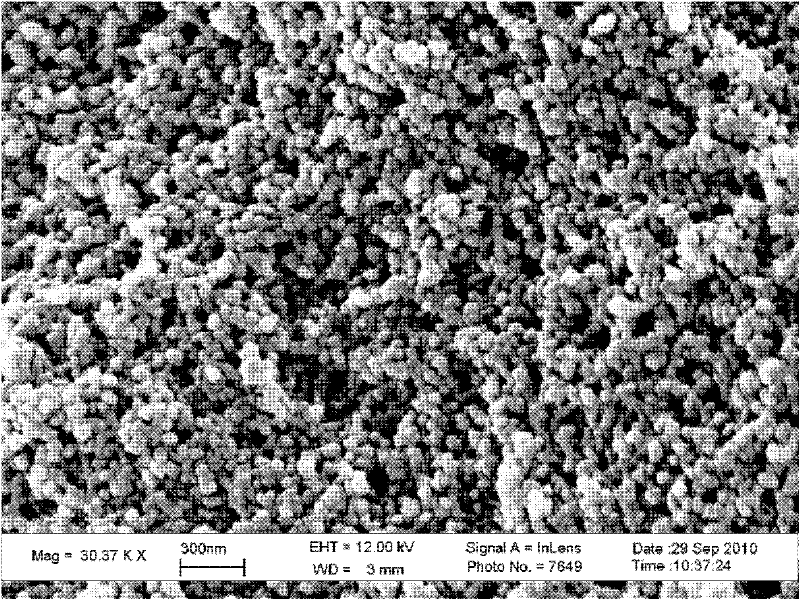

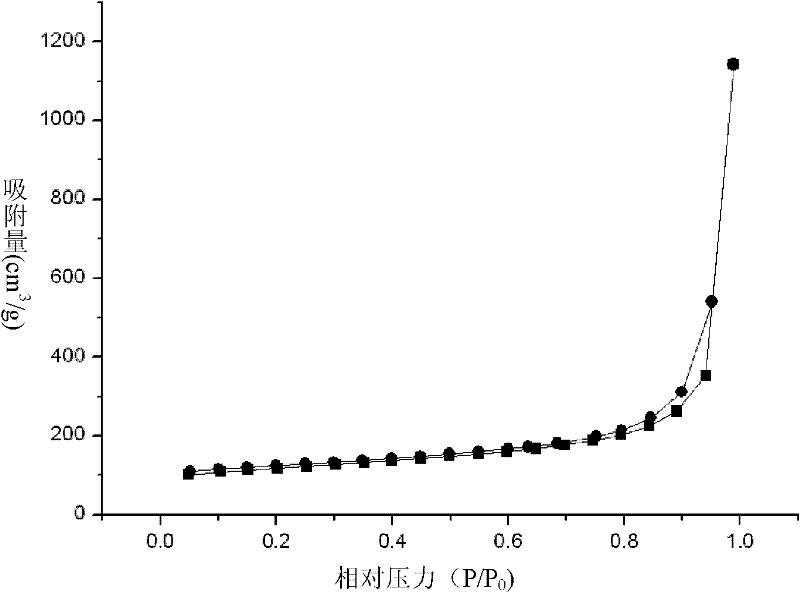

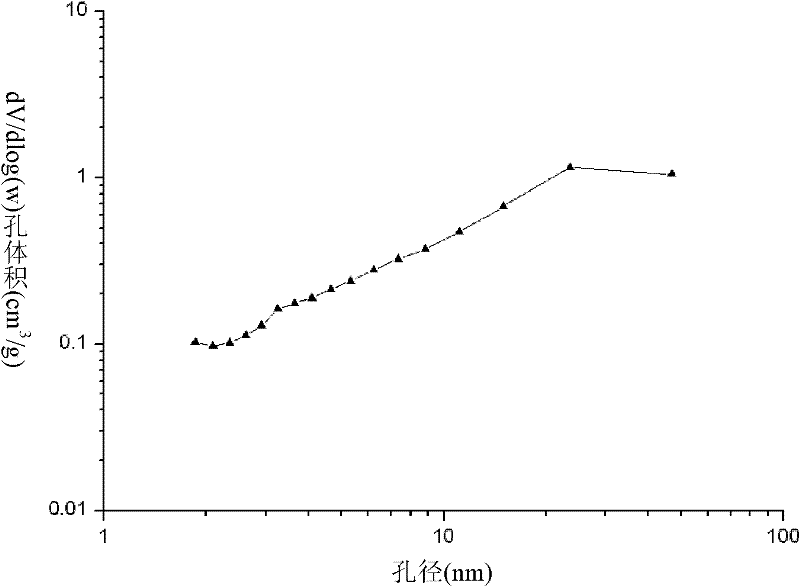

The invention provides a preparation method of blocky silicon-carbon composite aerogel. The preparation method comprises the steps of: by taking resorcinol, formaldehyde and tetraethyl orthosilicate as reactants, respectively preparing silica sol and organic sol, mixing the silica sol and the organic sol, then reacting at constant temperature to obtain wet gel, performing low-temperature carbon dioxide supercritical drying and high-heat treatment processes on the wet gel to obtain the blocky silicon-carbon composite aerogel. The blocky silicon-carbon composite aerogel prepared by adopting thepreparation method provided by the invention has the characteristics of high strength, large specific surface area, low density and thermostability, can be used at the temperature as high as more than 1000 DEG C, and is beneficial to overcoming of the defects of low strength, difficult in forming and poor thermostability of the aerogel.

Owner:NANJING UNIV OF TECH

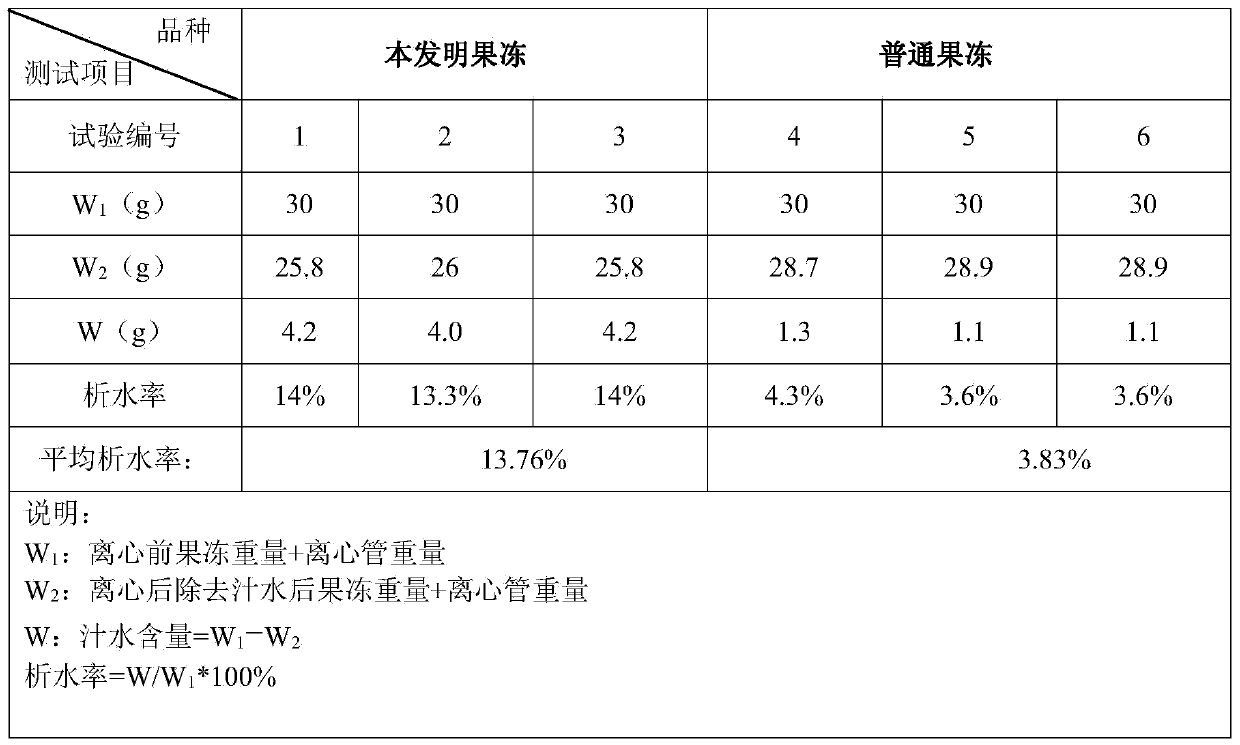

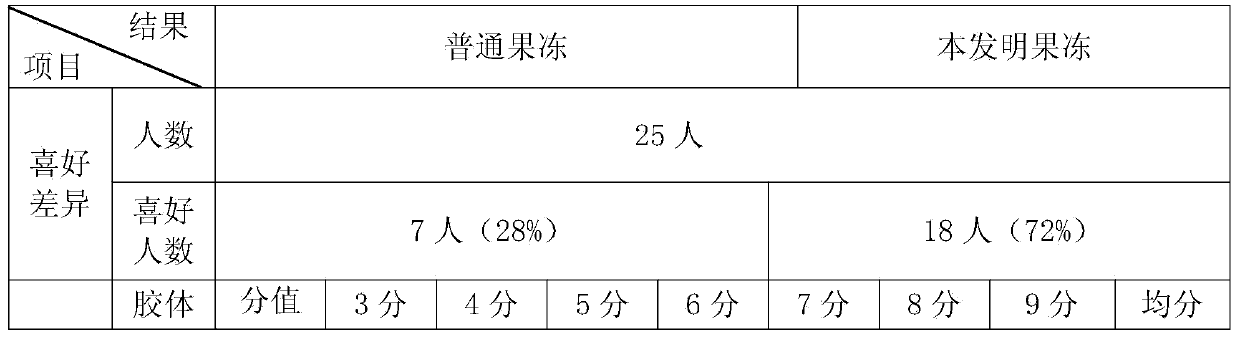

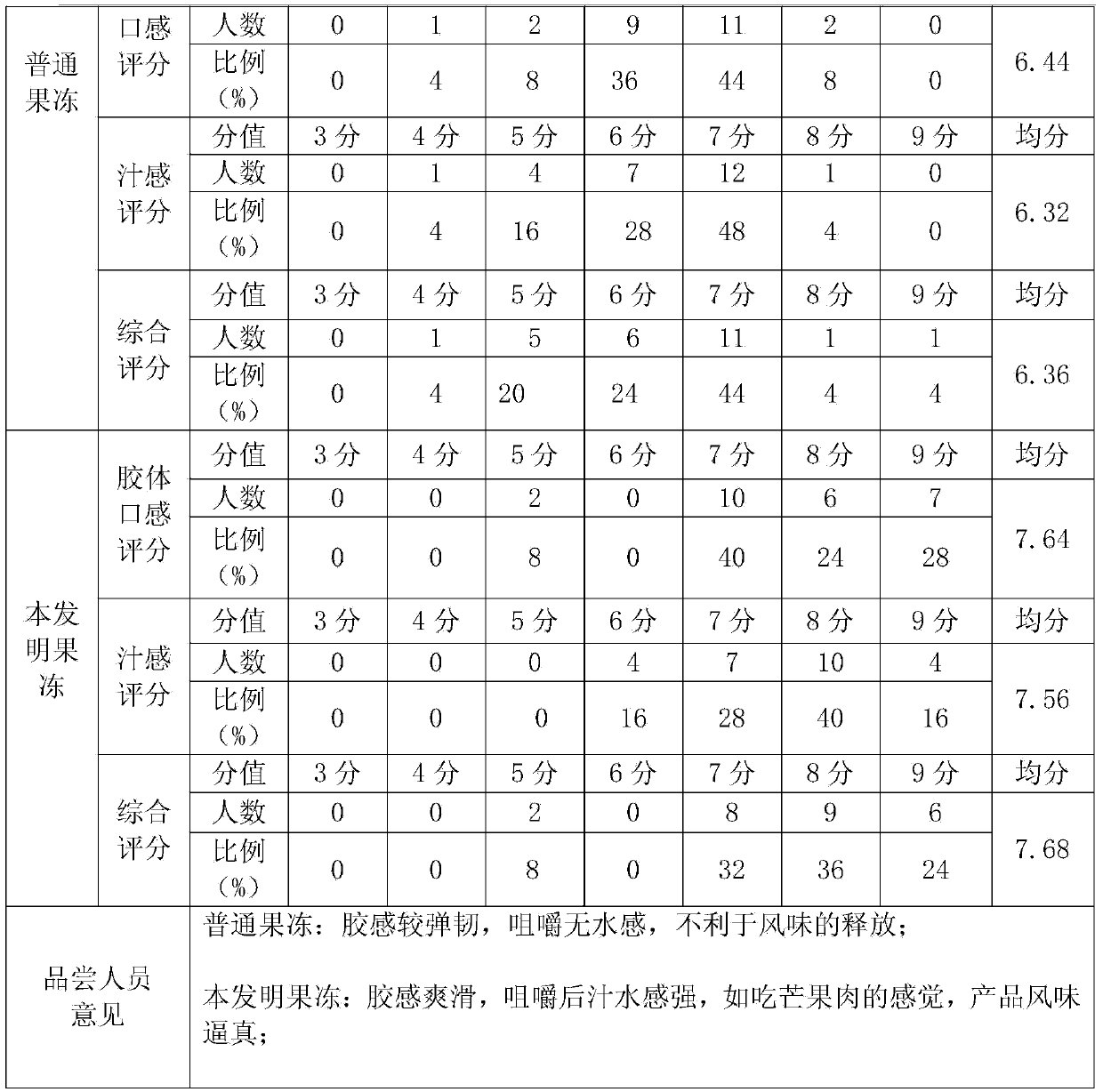

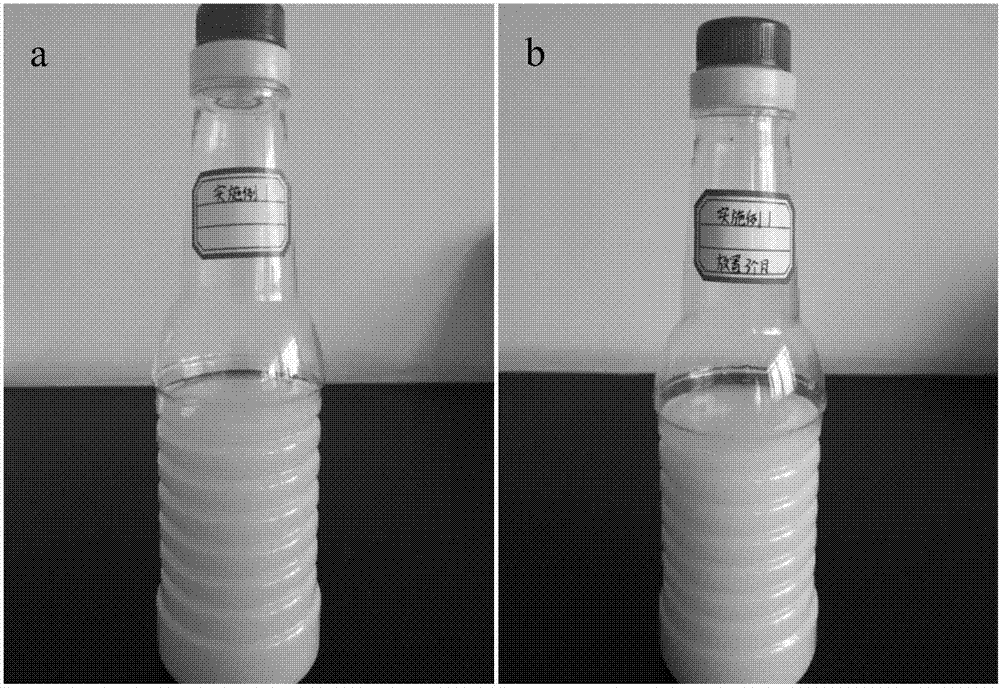

Jelly and making method thereof

ActiveCN104171780AReduce surface water precipitationIncrease contentFood preparationHigh-fructose corn syrupColloid

The invention discloses a jelly and a making method thereof, belonging to the field of food processing. The jelly comprises the following components in parts by weight: 5-10 parts of compound starch, 1.0-2.0 parts of thickening agent, 5-10 parts of fruit pulp, 10-20 parts of white granulated sugar, 10-15 parts of high fructose corn syrup, 0.6-0.8 part of citric acid, 0.05-0.1 part of sodium citrate and 45-75 parts of process water. In the Jelly disclosed in the invention, through the addition of the compound starch, a technological process is changed, the water dissolving amount on the colloid surface of the jelly can be reduced, the organization and texture of the jelly are both changed, and the jelly state achieves a taste close to that of true fruits. Through the control of the gelatinization temperature of the compound starch and the utilization of the mutual synergistic effect of the gelatinized starch and the thickening agent, a special texture is generated inside the jelly gel, water retention is achieved, and the prepared jelly has rich and juicy mouthfeel.

Owner:HEBEI STRONG FOOD

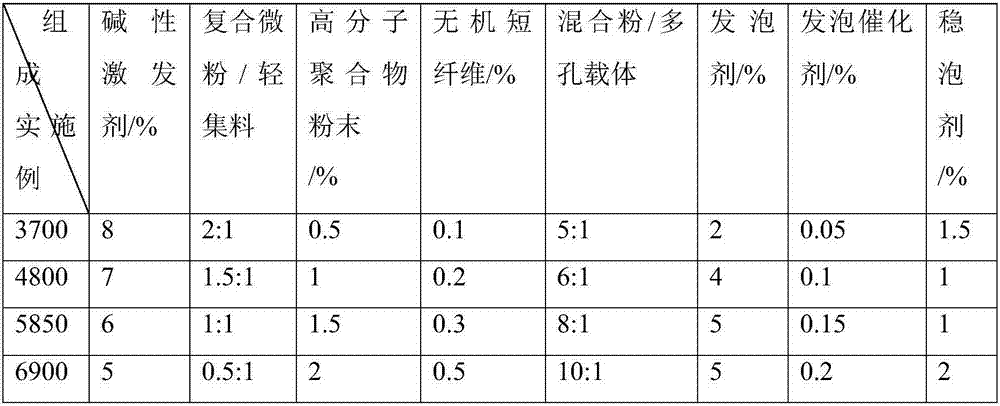

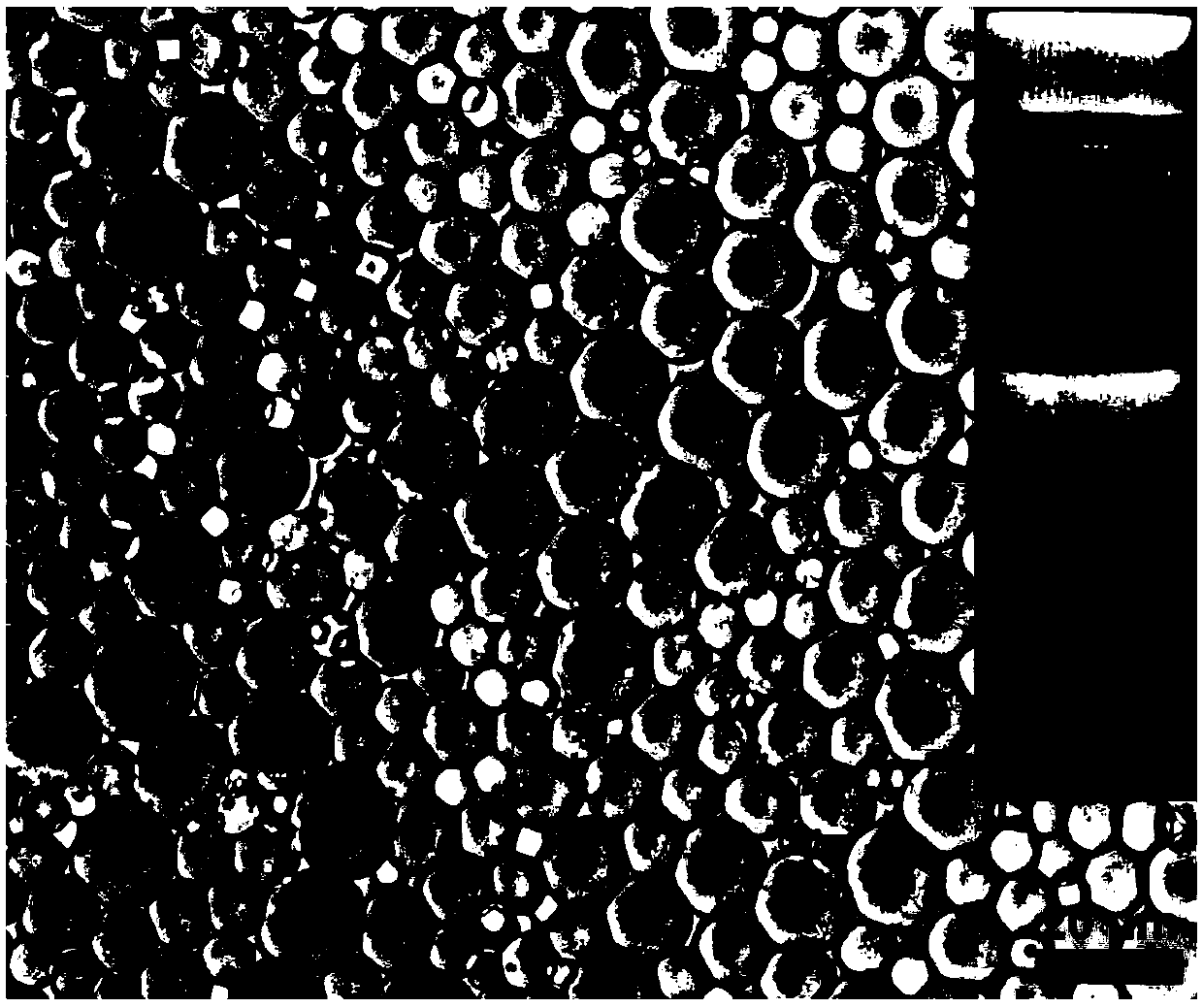

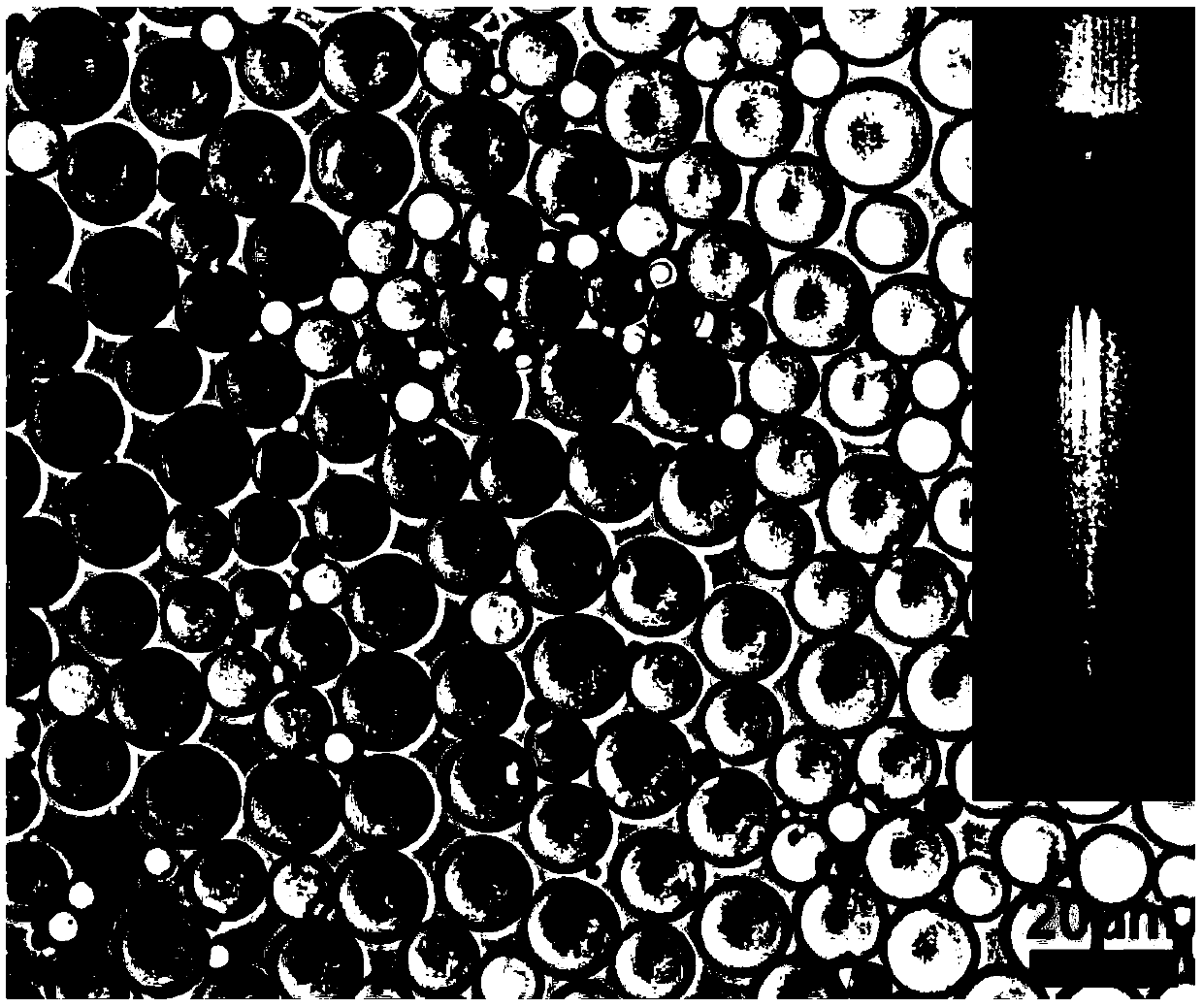

Hydrophobically associating crosslinked polymer microspheres, preparation method and application

ActiveCN107337762AGood temperature and salt resistanceSpatial cross-linking density is highDrilling compositionSodium acetatePolymer science

The invention relates to hydrophobically associating crosslinked polymer microspheres. The hydrophobically associating crosslinked polymer microspheres are prepared from acrylamide, sodium acetate, a hydrophobic monomer, alkenyl sulfonic acid, a cationic monomer and a crosslinking agent through inverse emulsion polymerization, wherein the hydrophobic monomer is selected from one or more of methyl methacrylate, styrene, vinyltrimethylsilane, N-dodecylacrylamide and N-n-butylphenyl acrylamide. The provided hydrophobically associating crosslinked polymer microspheres have obvious temperature resistance and salt tolerance, large space crosslink density, stable network structure and better viscoelasticity; meanwhile, the expansion rate of the hydrophobically associating crosslinked polymer microspheres can be controlled to a certain extent; the hydrophobically associating crosslinked polymer microspheres have low viscosity and better stability, can be prepared from oilfield waste water through dilution, and can enter the deep formation successfully under lower pressure and block the matched formation after expansion in water.

Owner:SHANDONG NUOER BIOLOGICAL TECH

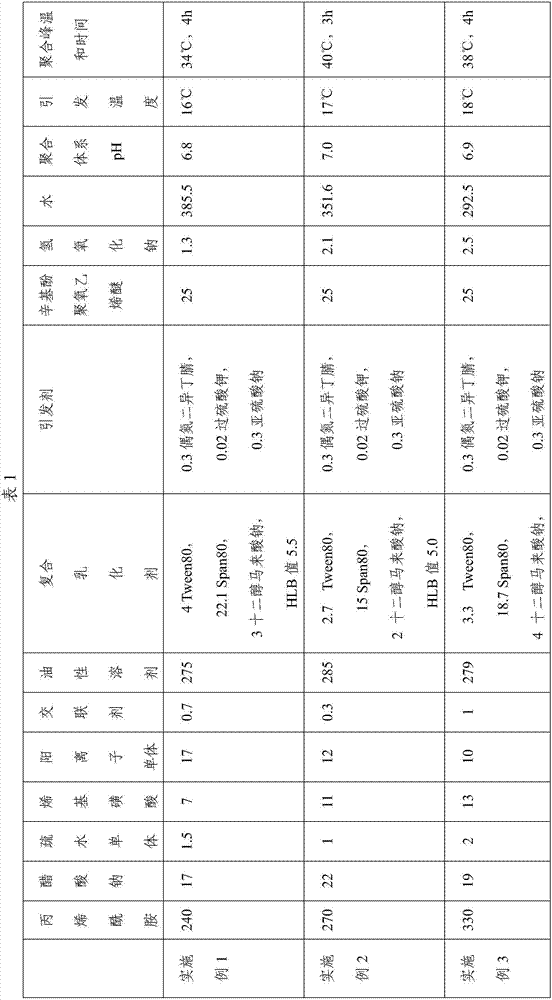

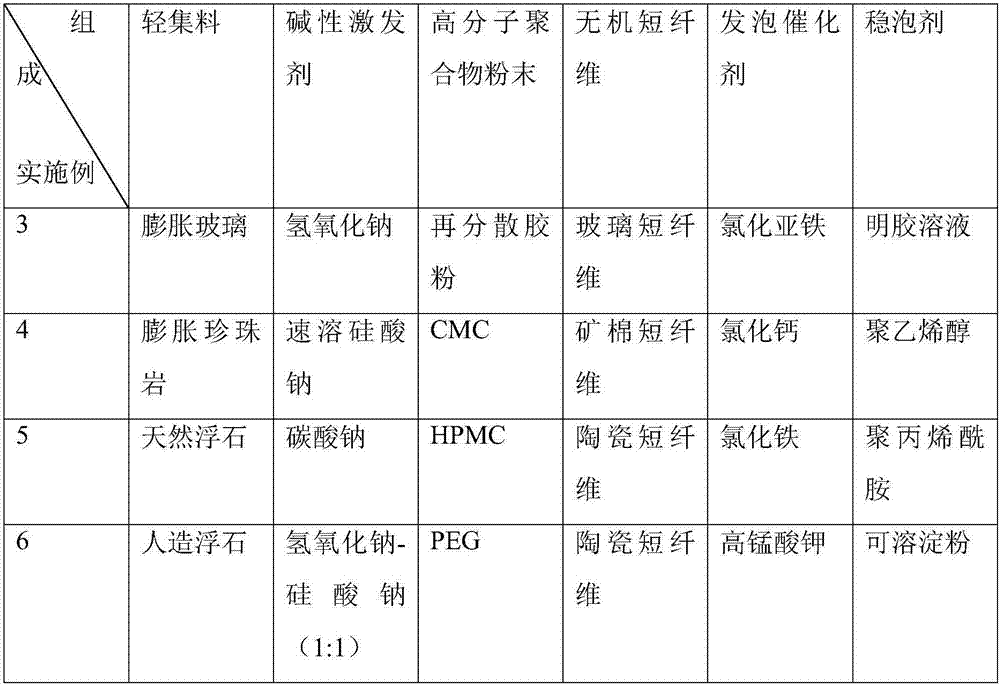

Geopolymer foamed light aggregate concrete and preparation method thereof

The invention discloses geopolymer foamed light aggregate concrete. The material is composed of slag-fly ash composite micro powder, an alkali activator, inorganic super-light aggregate, high-molecular polymer powder, inorganic staple fibers, a hydrogen peroxide chemical foaming agent, a foaming catalyst, an inorganic porous carrier and a foam stabilizer. The method for preparing the geopolymer foamed light aggregate concrete comprises the following steps: mixing and manufacturing various components according to a certain ratio. The problems that the strength of the conventional cement-based foam concrete material is greatly decreased when used for high-temperature insulation and foams and bubbles difficultly grow due to too fast setting of slag-based geopolymer foamed cement and the like can be effectively solved. Therefore, the durability of the foamed light aggregate geopolymer concrete layer is obviously improved, and the light aggregate concrete can be used for promoting energy-saving insulation of low-temperature and normal-pressure building envelopes, decreasing the dead weight of walls and reducing CO2 emission, contributes to improving ecological and economic benefits and is extremely convenient in construction. The construction cost and material cost can be greatly reduced.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

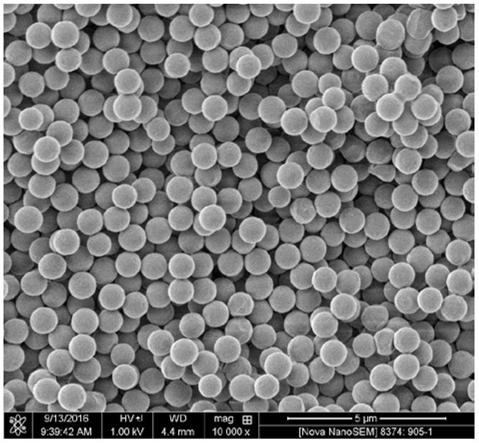

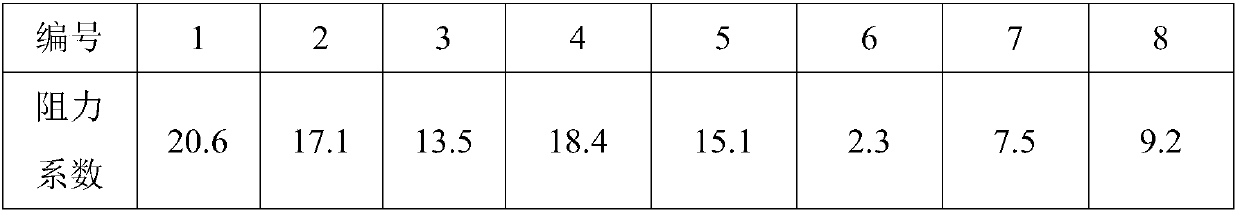

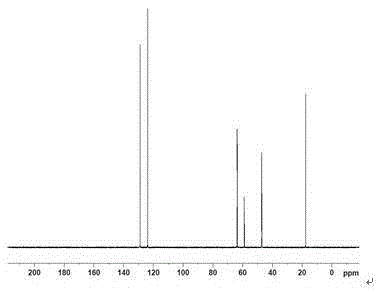

Multi-network type monodispersed polyacrylamide-based polymer gel microsphere and preparation method thereof

ActiveCN109666469AEnhanced network structureStable network structureDrilling compositionCross-linkPolymer science

The invention relates to a multi-network type monodispersed polyacrylamide-based polymer gel microsphere and a preparation method thereof. A purpose of the present invention is mainly to solve the problem of insufficient stability of the existing polymer microspheres under high temperature and high salt conditions. According to the technical scheme, the polyacrylamide-based polymer gel microspherecomprises an acrylamide structure unit, an anionic monomer structure unit, a cationic monomer structure unit and a nonionic monomer structure unit, and further comprises a covalent bond cross-linkingagent structure unit, a high-valent metal cross-linking agent structure unit and a stabilizer structure unit, wherein the acrylamide structure unit, the anionic monomer structure unit, the cationic monomer structure unit and the nonionic monomer structure unit form a polymer main chain structure. With the technical scheme, the problem in the prior art is well solved. The product of the present invention can be used for deep profile control in oilfield development.

Owner:CHINA PETROLEUM & CHEM CORP +1

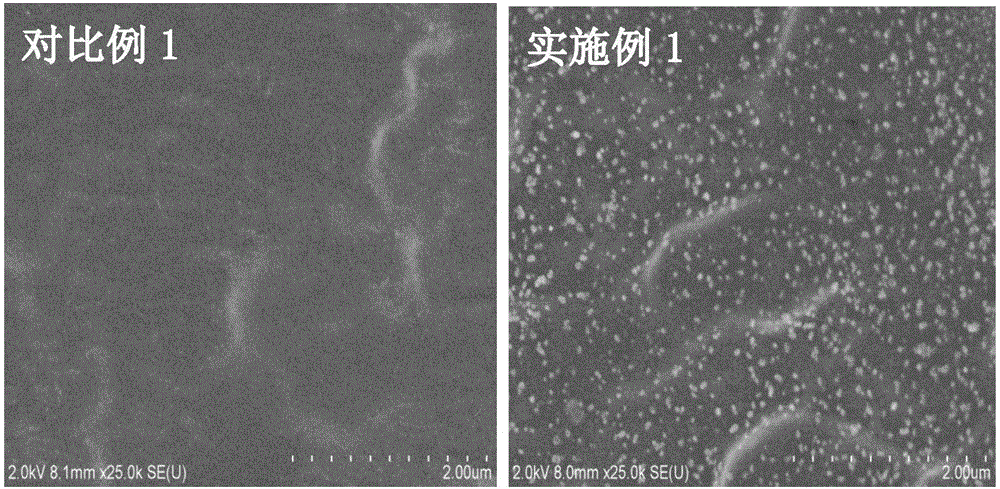

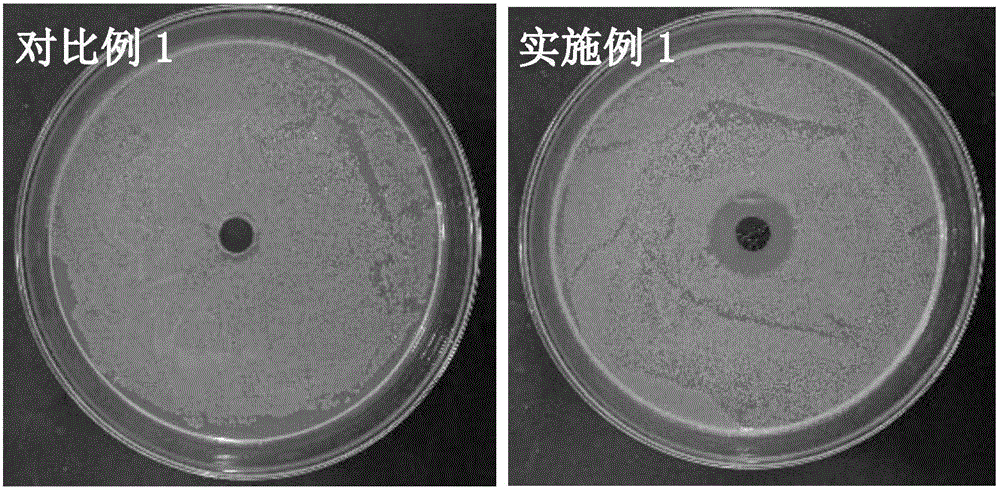

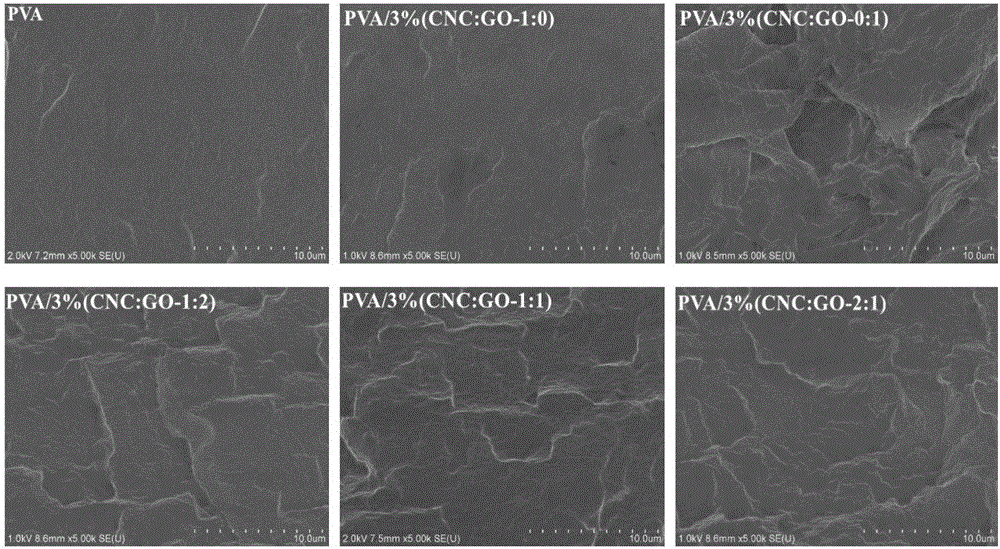

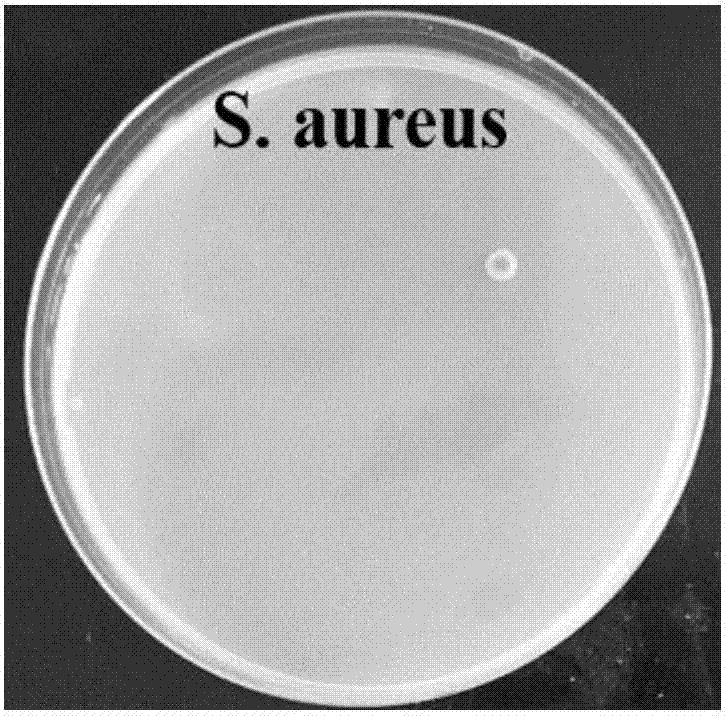

Preparation method of antibacterial polyvinyl alcohol/cellulose nanocrystal-graphene oxide (PVA/CNC-GO) composite film

ActiveCN106810800AImprove water resistanceImprove water barrier propertiesComposite filmAntibacterial activity

The invention relates to a preparation method of an antibacterial polyvinyl alcohol / cellulose nanocrystal-graphene oxide (PVA / CNC-GO) composite film. The preparation method comprises the following steps: dispersing CNC and GO into deionized water and performing ultrasonic dispersion uniformly to obtain composite dispersing liquid CNC-GO of CNC and GO; stirring PVA at a temperature of 90 DEG C to dissolve into deionized water, adding the CNC and GO composite dispersing liquid, stirring uniformly and casting in a glass mold to form a film; immersing the PVA / CNC-GO composite film into an ethanol / aqueous solution of AgNO3 and performing stirring reaction at a temperature of 50 DEG C for 24 hours to prepare the PVA / CNC-GO composite film with antibacterial activity. The PVA composite film provided by the invention synthesizes the excellent performance of GO, CNC, PVA and nano-silver, and has the advantages of high water resistance, high heat stability, high tensile strength, high antibacterial activity and the like.

Owner:JIANGNAN UNIV

Optical plastic protection coating and preparation method thereof

InactiveCN104231914AImprove chemical structureStable network structureCoatingsPtru catalystSilicic acid

The invention discloses an optical plastic protection coating and a preparation method thereof. The optical plastic protection coating comprises the following raw materials in parts by weight: 2 parts of ethyl orthosilicate, 5-6.5 parts of phenyl trimethoxy silane, 1.5-2 parts of a coupling agent, 3-4 parts of distilled water, 0.02-0.03 part of a curing agent and 0.02-0.04 part of a catalyst. The preparation method comprises the following steps: adding the raw materials into a container, stirring, standing at the room temperature for 24 hours to obtain colorless transparent liquid, coating an optical plastic plate with the liquid, and drying at 80 DEG C to form a layer of coating on the optical plastic plate, wherein the coating is the optical plastic protection coating. The optical plastic protection coating has the characteristics of high transparency, high hardness and the like, can be widely used in the field of optical plastic protection, and also can be used in the fields of coatings, printing ink and the like.

Owner:SHANGHAI INST OF TECH

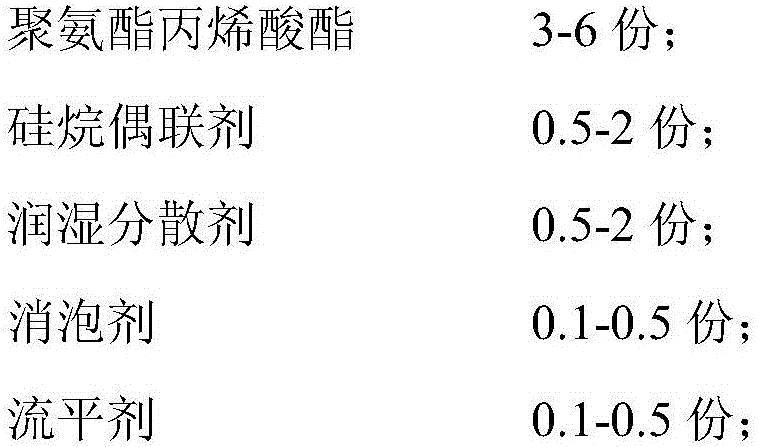

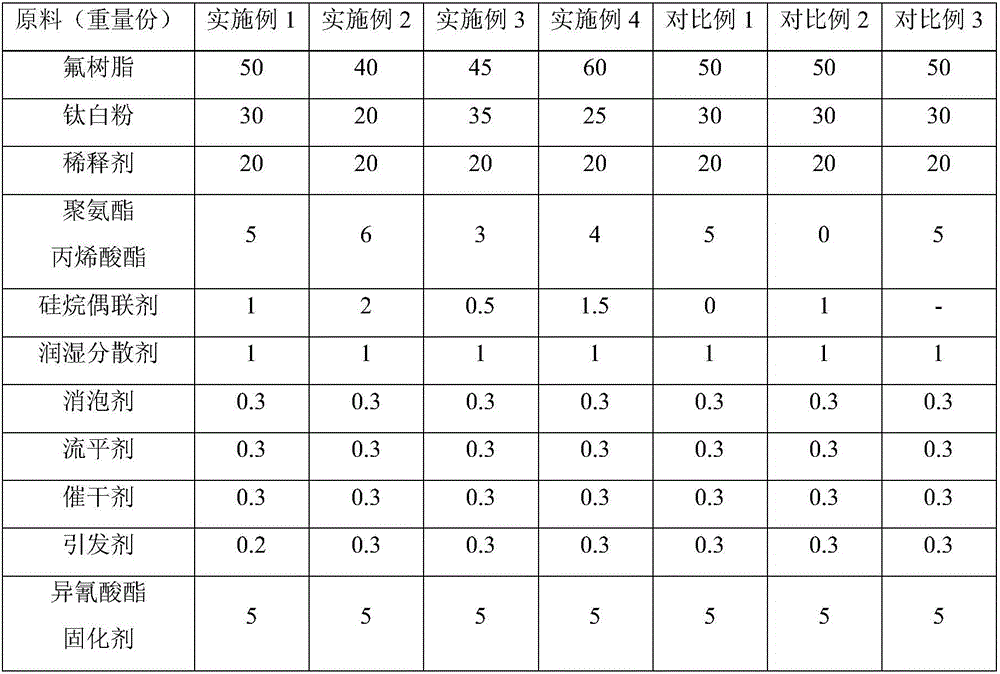

Bi-component fluororesin coating and application thereof to photovoltaic module back plates

ActiveCN106833164AImprove aging resistanceImprove dispersion stabilityPolyurea/polyurethane coatingsPhotovoltaic energy generationPolymer networkEngineering

The invention relates to a bi-component fluororesin coating and application thereof to photovoltaic module back plates. The bi-component fluororesin coating comprises a component A and a component B, wherein the component A comprises, by weight, 40-60 parts of fluororesin, 20-35 parts of titanium dioxide, 15-30 parts of diluent, 3-6 parts of urethane acrylate, 0.5-2 parts of silane coupling agent, 0.5-2 parts of wetting dispersant, 0.1-0.5 part of defoaming agent and 0.1-0.5 part of flatting agent, and the component B comprises, by weight, 0.1-0.5 part of dryer, 0.1-0.5 part of initiator and 1-10 parts of isocyanate curing agent. The bi-component fluororesin coating has the advantages that a coating layer prepared from the bi-component fluororesin coating forms an interpenetrating polymer network structure after being cured, and is smooth in surface without marks and aftertack, high in solvent resistance and excellent in adhesive force, early peeling strength of the coating layer with EVA is more than 50 N / cm, peeling strength of the coating layer with the EVA is not less than 20 N / cm after 48 hours' PCT accelerated ageing, and all indexes of the coating layer meet or are superior to industry requirements of back plate coating layers.

Owner:SUZHOU YISHENG OPTICAL MATERIAL CO LTD

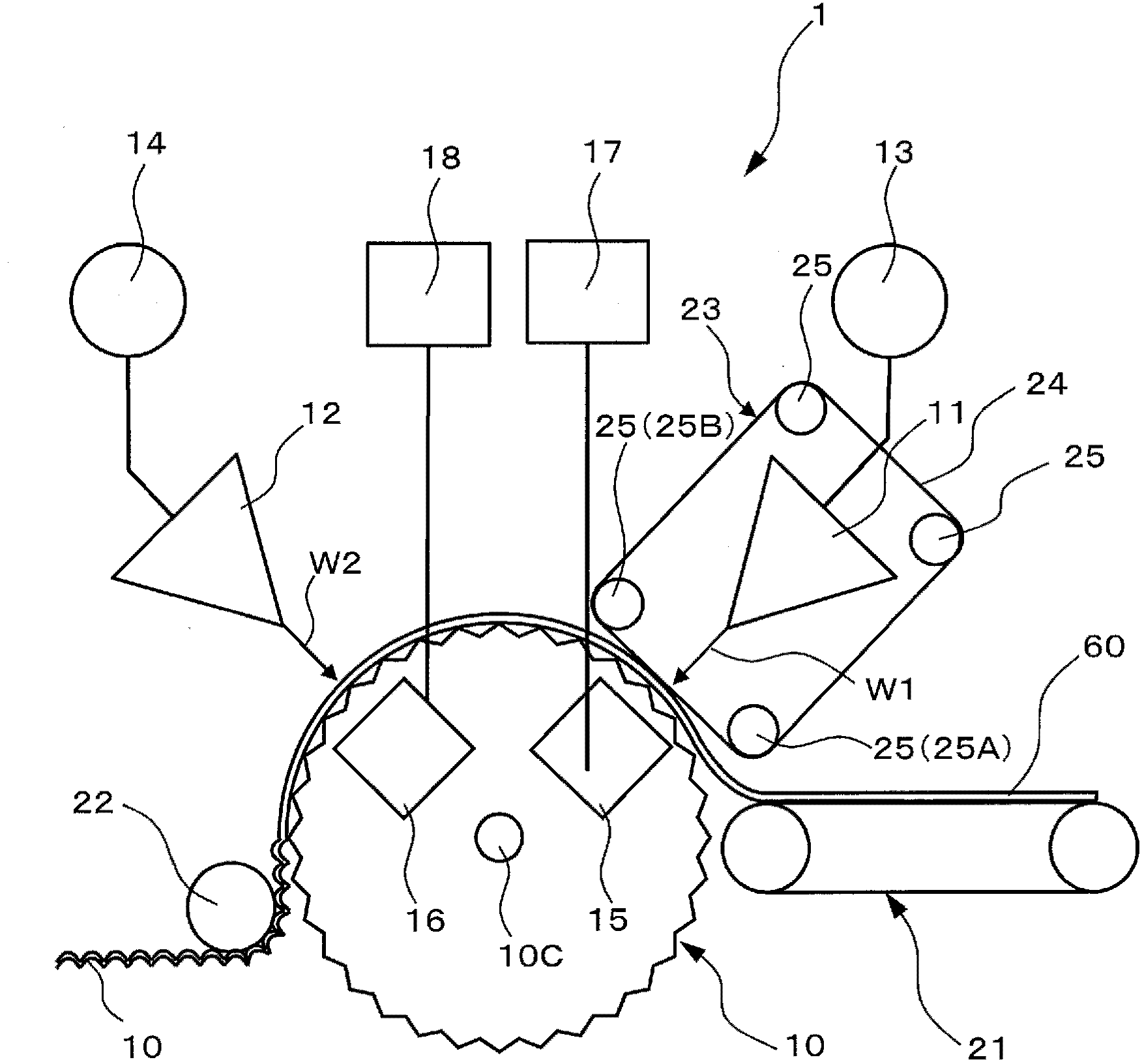

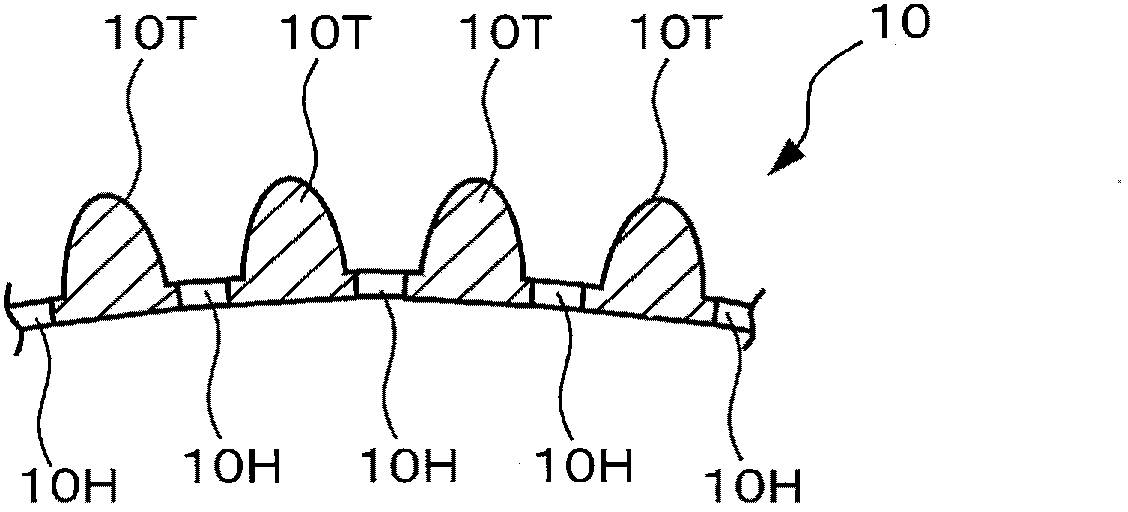

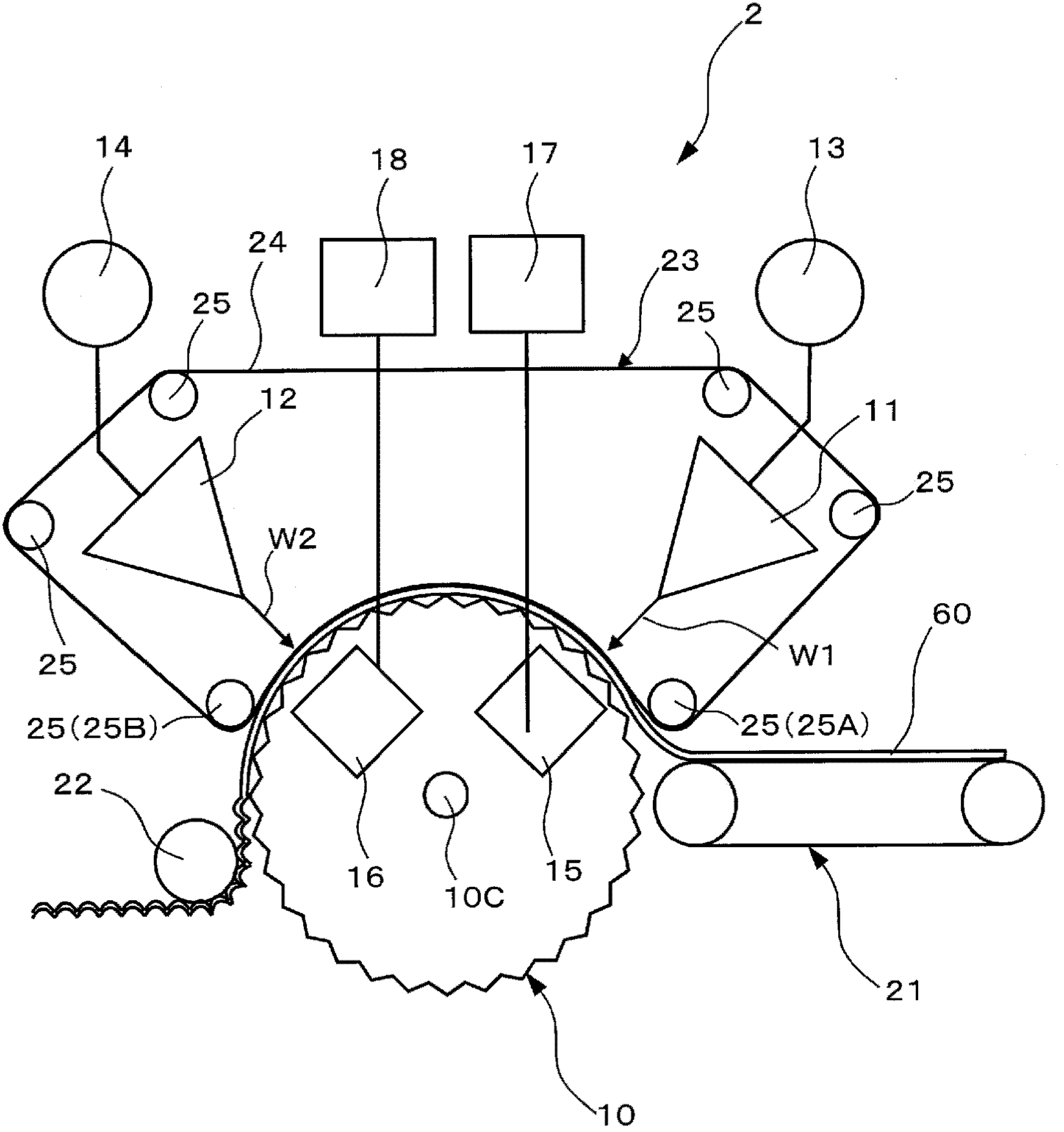

Method for producing non-woven fabric, non-woven fabric, device for producing non-woven fabric, and support for producing non-woven fabric

ActiveCN103261503APrevent heat stickingAvoid intertwiningPattern makingNon-woven fabricsEngineeringNonwoven fabric

Provided is a method for producing non-woven fabrics, wherein a web containing thermoplastic fibers is carried onto a support having a concavo-convex shape (projections and vents), and hot air is blown from above the web toward the support so as to make the concavo-convex shape on the web (5). The hot-air blowing is provided with: a step for blowing a first hot air, and temporarily fusion bonding the fibers of the web by the blowing of the first hot air so as to hold the concavo-convex shape; and a step for blowing a second hot air having a higher temperature than the first hot air, and fixing the concavo-convex shape by fusion bonding the fibers of the web while the concavo-convex shape is held, wherein the concavo-convex shape is provided on the web while the web follows the shape of the support, thereby manufacturing the non-woven fabric.

Owner:KAO CORP

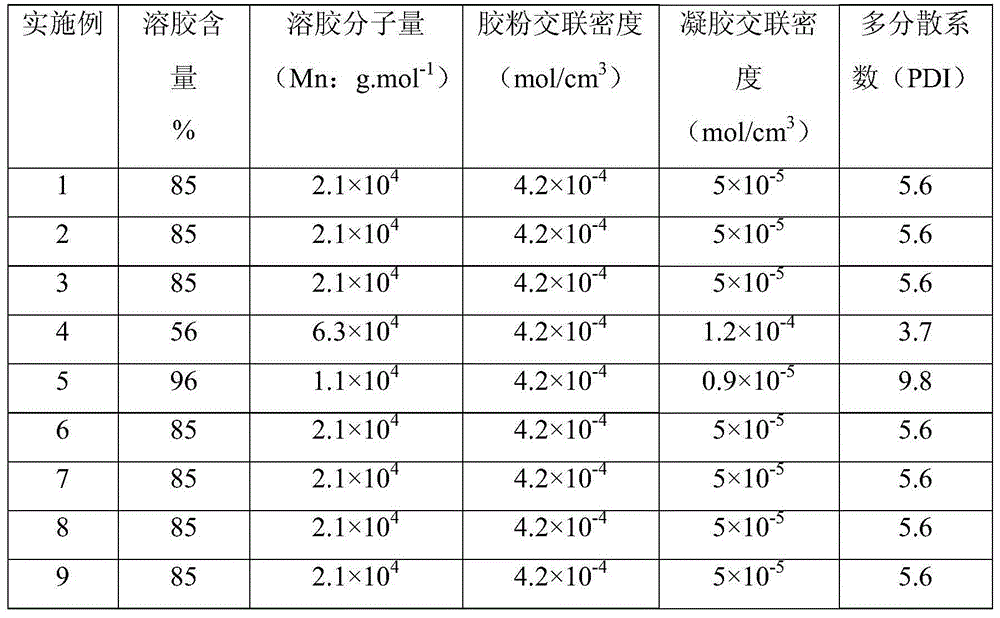

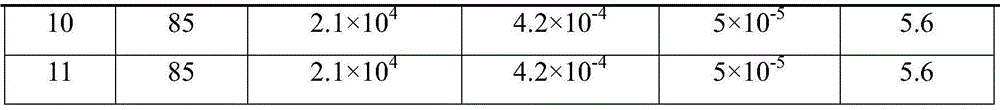

Composite waste-rubber-powder particles capable of being stored stably and preparation method thereof

ActiveCN104693565AControl "Secondary Pollution"High linear molecular contentPlastic recyclingCross-linkPolymer science

The invention relates to composite waste-rubber-powder particles capable of being stored stably and a preparation method thereof. The preparation method comprises the steps of firstly carrying out deep-desulfurization degradation on low-mesh rubber powder so as to prepare high-desulfurization-degree reclaimed rubber, and then, mixing high-mesh rubber powder, the high-desulfurization-degree reclaimed rubber and a small amount of cross-linking agent according to a certain ratio, thereby preparing the composite waste-rubber-powder particles. According to the composite waste-rubber-powder particles, linear macromolecules in the high-desulfurization-degree reclaimed rubber are uniformly attached to the surface of the rubber powder, and meanwhile, a linear macromolecule-cross-linked structured core-shell structure is formed by using the micro-cross-linking action of the cross-linking agent. Due to the structure, a large number of linear molecules can intermesh in asphalt, and then, a stable rubber powder-asphalt mesh structure is formed, so that the aim of preparing stably-stored rubber powder modified asphalt is achieved.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Preparation method for high-barrier water-resistant polyvinyl alcohol (PVA)/cellulose nanocrystal (CNC)/graphene oxide (GO) composite film

ActiveCN106519268AImprove dispersionImprove mechanical properties and processabilityCelluloseGraphite oxide

The invention provides a preparation method for a high-barrier water-resistant polyvinyl alcohol (PVA) / cellulose nanocrystal (CNC) / graphene oxide (GO) composite film, and belongs to the field of high polymer materials. According to the preparation method, firstly, CNC aqueous dispersion and GO aqueous dispersion are prepared and then the CNC aqueous dispersion and GO aqueous dispersion are mixed, CNC and GO are evenly dispersed through ultrasounds, hydroxys on the surface of the CNC and polar groups on the surface of the GO interact, the dispersion effect of the GO in PVA is improved, part of hydroxys on PVA chains can be closed through the stable structure formed by the CNC and the GO, and the water resistance of the PVA can be improved; and on the other hand, by means of the two-dimensional flaky GO, the transmission route of water molecules in a PVA film can be increased, and the water barrier property of the PVA film can be improved. The composite film has the excellent water resistance, the excellent water barrier property and the excellent mechanical property, and application of the composite film in the field of biodegradable packaging materials is made possible.

Owner:JIANGNAN UNIV

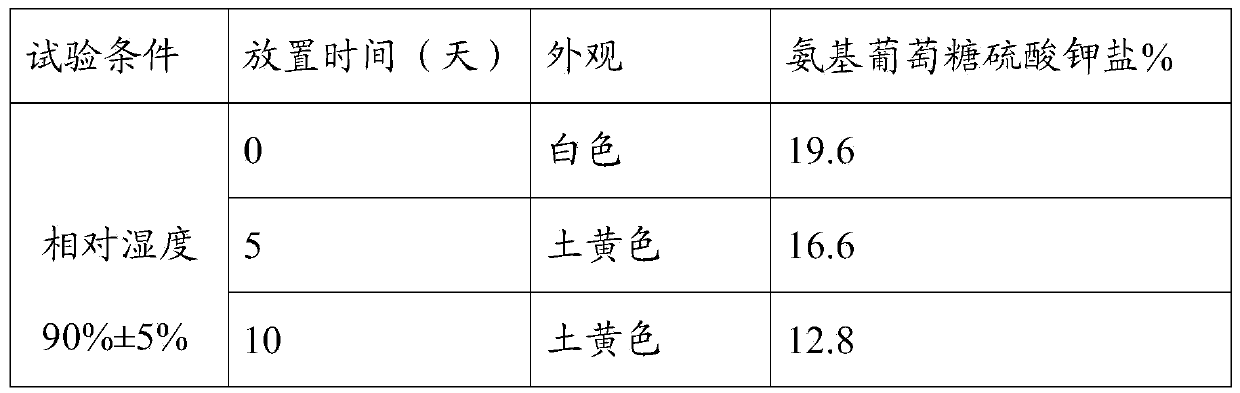

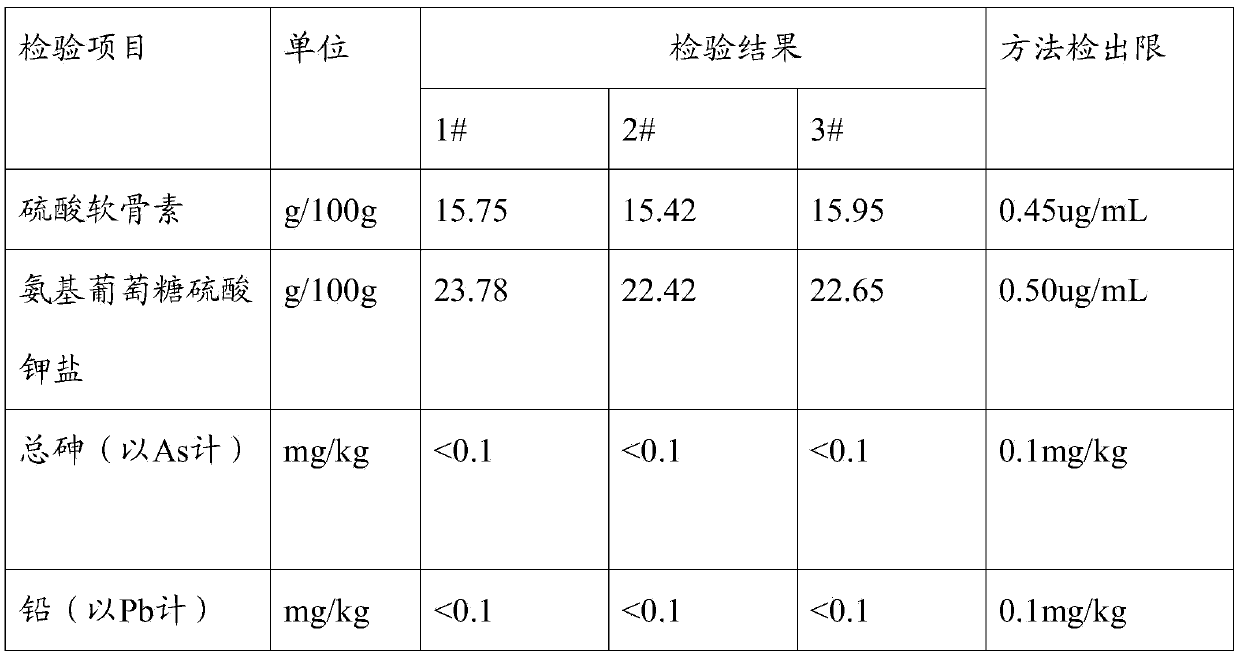

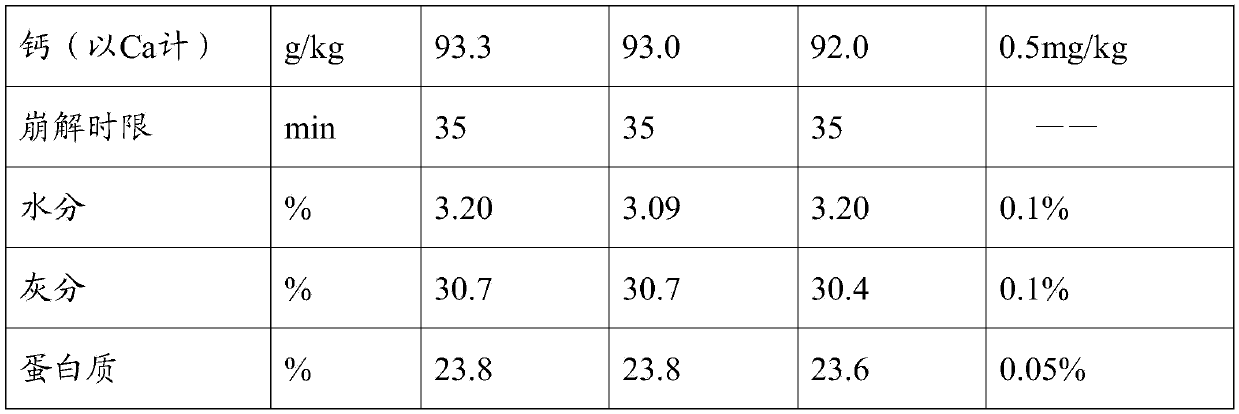

Composition with effects of protecting joints and increasing bone mineral density and preparation method of composition

PendingCN105363023APromote absorptionTo promote metabolismPeptide/protein ingredientsSkeletal disorderChemistryCompounded preparations

The invention provides a composition with effects of protecting joints and increasing bone mineral density. The composition is prepared from the following components in parts by weight: 250-400 parts of calcium citrate malate, 150-300 parts of N-Sulfo-glucosamine potassium salt, 100-200 parts of chondroitin sulfate, 50-150 parts of bone collagen peptide powder, and 10-50 parts of casein phosphopeptides. According to the composition provided by the invention, the active ingredients achieve the synergistic effect, the bioavailability is high, and the composition can be used for increasing the bone mineral density and restoring the bone functions. Through a preparation method provided by the invention, the composition can be prepared into a compound preparation, the curative effects are definite, the quality is controllable, no toxic or side effect exists, and the composition is suitable for large-scale popularization and application.

Owner:SHENZHEN TAITAI PHARMA IND +2

Preparation method of cellulose based conductive hydrogel

InactiveCN106519287AUniform network structureStable network structureBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a preparation method of a cellulose based conductive hydrogel. The preparation method comprises the following steps: (1) dissolving microcrystalline cellulose (MCC) with 1-Butyl-3-methylimidazolium chloride, reacting in a N2 protective atmosphere, and adding N,N-methylenebisacrylamide and benzoyl peroxide to prepare a pure microcrystalline cellulose hydrogel; and (2) soaking the pure microcrystalline cellulose hydrogel obtained in the step (1) in a mixed solution of FeCl3 and sodium p-benzenesulfonate, and immersing in a pyrrole water solution to prepare the cellulose based conductive hydrogel. The cellulose based conductive hydrogel prepared by the method has the advantages of uniform stable network structure, excellent conductivity, swelling property and heat stability, favorable electric conductivity and favorable swelling property; and the equilibrium swelling rate can be up to about 500%.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

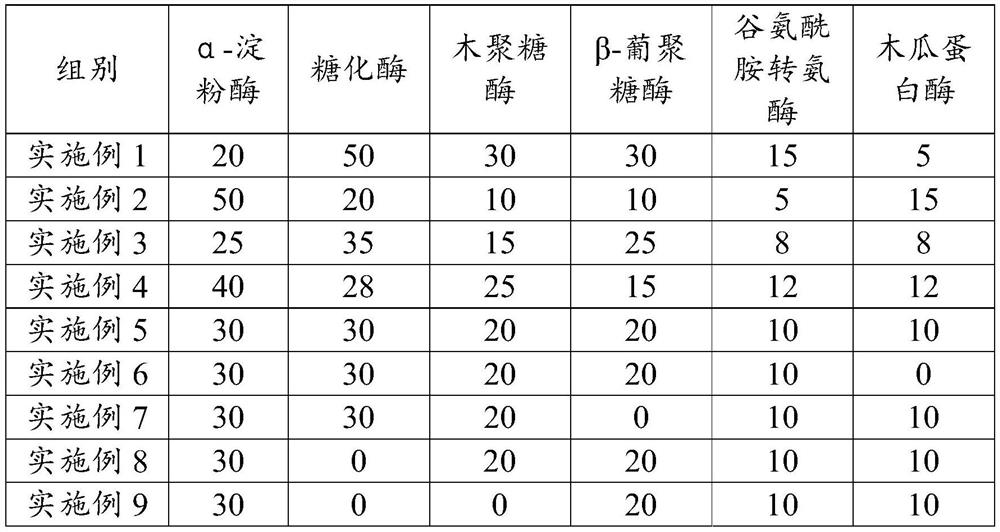

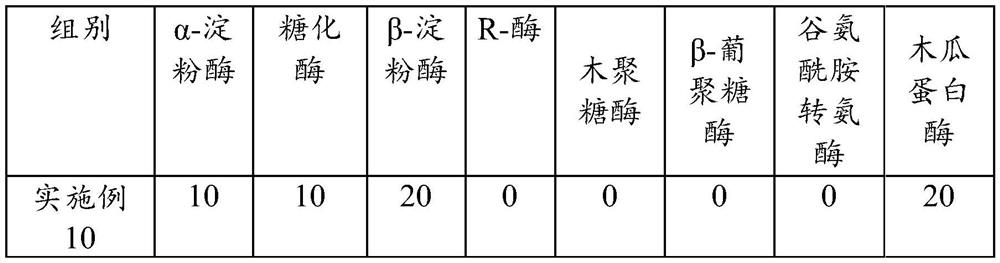

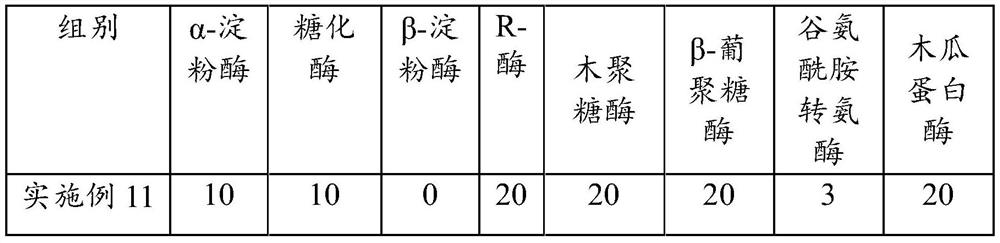

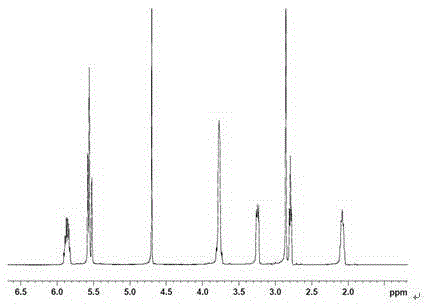

Complex enzyme preparation and beverage prepared by using complex enzyme preparation

The invention provides a compound enzyme preparation and a beverage prepared by using the compound enzyme preparation, and relates to the technical field of foods and beverages. The compound enzyme preparation is prepared from amylase, cellulase, papain and glutamine transaminase. The compound enzyme preparation can effectively hydrolyze starch, fiber and protein, improve the content of soluble components of the starch, fiber and protein, and catalyze intramolecular and intermolecular covalent crosslinking of oat protein or polypeptide, so that the structure of the oat protein can be changed in the enzymolysis process, bitter peptides can be hidden, umami peptides can be exposed, and the enzymolysis efficiency can be improved. The problem that an existing oat plant protein beverage can generate bitter taste is effectively relieved; meanwhile, the compound enzyme preparation also has the effect of improving the emulsifying and stabilizing performance of the oat protein beverage, and the step of adding an emulsifying agent and a stabilizing agent for blending in the later period of the existing oat protein beverage is avoided.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Tackifier copolymerization associate used for drilling fluid and preparation method of tackifier copolymerization associate

ActiveCN106608946AHigh temperature and salt resistanceHigh apparent viscosityDrilling compositionMethacrylamideChemistry

The invention discloses a tackifier copolymerization associate used for a drilling fluid and a preparation method of the tackifier copolymerization associate. The copolymerization associate comprises a constitutional unit A, a constitutional unit B, a constitutional unit C and a constitutional unit D. The constitutional unit A is N, N-dimethylacrylamide, the constitutional unit B is N-methyl diallyl propylsulfonate (MAPS) which is an amphoteric ionic monomer, the constitutional unit C is an ionic associate of the constitutional unit B and cationic polyamine, and the constitutional unit D is starch. Based on the total amount of the copolymerization associate, the copolymerization associate comprises 6-45% by weight of N, N-dimethylacrylamide, 5-35% by weight of the N-methyl diallyl propylsulfonate which is an amphoteric ionic monomer, 2-30% by weight of the cationic polyamine, and 5-35% by weight of starch. A tackifier obtained through the preparation method can resist temperature as high as 180 DEG C, can resist a saturated NaCl solution, and resist a CaCl2 solution with the concentration being 20%. The tackifier is excellent shale inhibition and filtrate reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-permeability composite modified sodium silicate-bonded sand easy to strip for pump valve castings and preparation method of high-permeability composite modified sodium silicate-bonded sand

InactiveCN105414468AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresSodium BentoniteAdhesive

The invention discloses high-permeability composite modified sodium silicate-bonded sand easy to strip for pump valve castings. Compared with a conventional modified sodium silicate adhesive, a modified sodium silicate adhesive in the sodium silicate-bonded sand is more excellent in normal-temperature wet strength, the thixotropy and rheological property are better, and the reaction binding activity is high; in addition, environmental friendliness is achieved, and the use amount of the sodium silicate is greatly reduced; through spherical sealed expanded perlite and negative ion rock flour added in raw materials, the plasticity and permeability of the molding sand can be improved; nano calcium fluoride carried by bentonite is dispersed in the sand, the lubricating effect and the reinforcing effect are achieved, and a non-stick impermeable layer can be formed, so that the sand is prevented from adhering to the castings. The composite modified sodium silicate-bonded sand is excellent in comprehensive performance, stable network structures are formed between sand materials, compact and permeable sintered layers can be formed on the surfaces of the castings, the sand is easy to strip and scatter, and accordingly the casting products with bright and clean surfaces are obtained.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Preparation method of high oil-carrying emulsion rich in fibrous polysaccharides

The invention relates to a preparation method of a high oil-carrying emulsion rich in fibrous polysaccharides. The preparation method comprises the following steps: protein powder is taken and added into distilled water, and is magnetically stirred and dissolved at a normal temperature to prepare a protein solution by hydration in a refrigerator at 4 DEG C; the protein solution and fibrous polysaccharide aqueous dispersion powder are mixed, and the pH value of the system is adjusted to obtain a protein / fiber complex; and an oil phase is dispersed in the protein / fiber complex and emulsificationis performed to prepare an oil-in-water emulsion. According to the preparation method of the high oil-carrying emulsion rich in the fibrous polysaccharides, the protein and fibrous polysaccharide complex is used as an emulsifying stabilizer to synergistically improve the wettability and stability of particles, and proteins and fibrous polysaccharides jointly adsorb on an oil-water interface to form a stable three-dimensional network structure to obtain the viscoelastic and highly stable emulsion. Natural food grade materials are adopted. The preparation process is simple and convenient, no surfactant is added, and green and safety are achieved. The content of the required compound stabilizer is low, and good emulsification stability is achieved. The oil phase and a water phase are removedfrom the prepared oil-in-water emulsion, a porous and stable network structure can be formed, and the high oil-carrying emulsion can be used as a porous polymer scaffold material in tissue engineering.

Owner:HUAZHONG AGRI UNIV

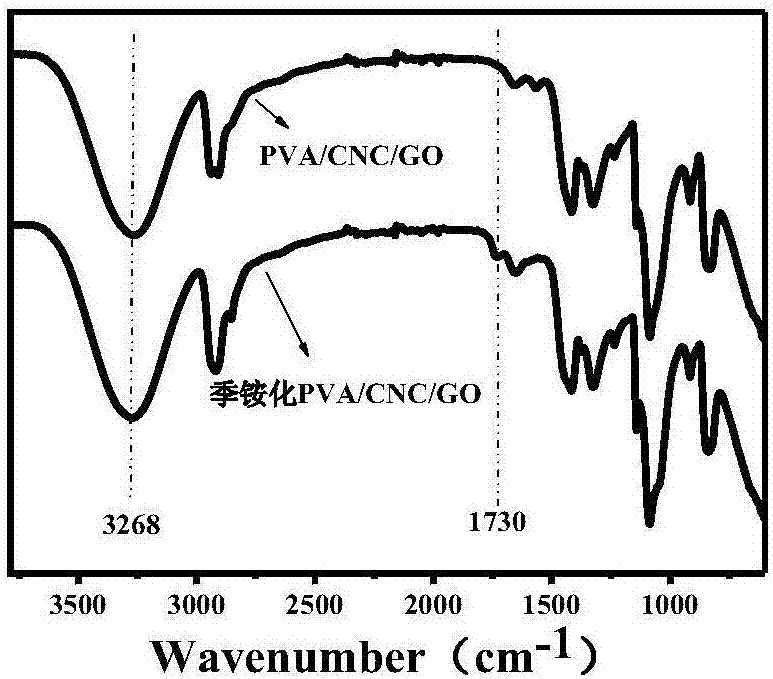

Preparation method of quaternary ammonium salt polyvinyl alcohol-cellulose-graphene oxide composite membrane

ActiveCN107446153AImprove water resistanceStrong antibacterial activityPhotoinitiatorPVA - Polyvinyl alcohol

The invention relates to a preparation method of a quaternary ammonium salt polyvinyl alcohol-cellulose-graphene oxide composite membrane. The preparation method comprises the following steps: dispersing cellulose nanocrystals (CNC) and graphene oxide (GO) into deionized water, and carrying out uniform ultrasonic dispersion to obtain composite dispersion liquid (CNC / GO) of the CNC and the GO; dissolving polyvinyl alcohol (PVA) into deionized water at the temperature of 90 DEG C by stirring, adding the CNC / GO dispersion liquid, evenly stirring and then pouring into a glass mould to form a membrane; immersing the PVA / CNC / GO composite membrane into an ethanol / aqueous solution which contains quaternary ammonium salt (DMAEMA-OB), a photocrosslinking agent (ethylene glycol dimethyl acrylate (EGDMA)) and a photoinitiator 2959 for 3h, and enabling the quaternary ammonium salt to be subjected to cross-linking reaction under the radiation of ultraviolet light for fixing the quaternary ammonium salt into a PVA matrix so as to obtain the quaternary ammonium salt polyvinyl alcohol / cellulose / graphene oxide composite membrane. The composite membrane has excellent water resistance, mechanical properties and thermal stability, thus being possibly applied to the field of active package.

Owner:JIANGNAN UNIV

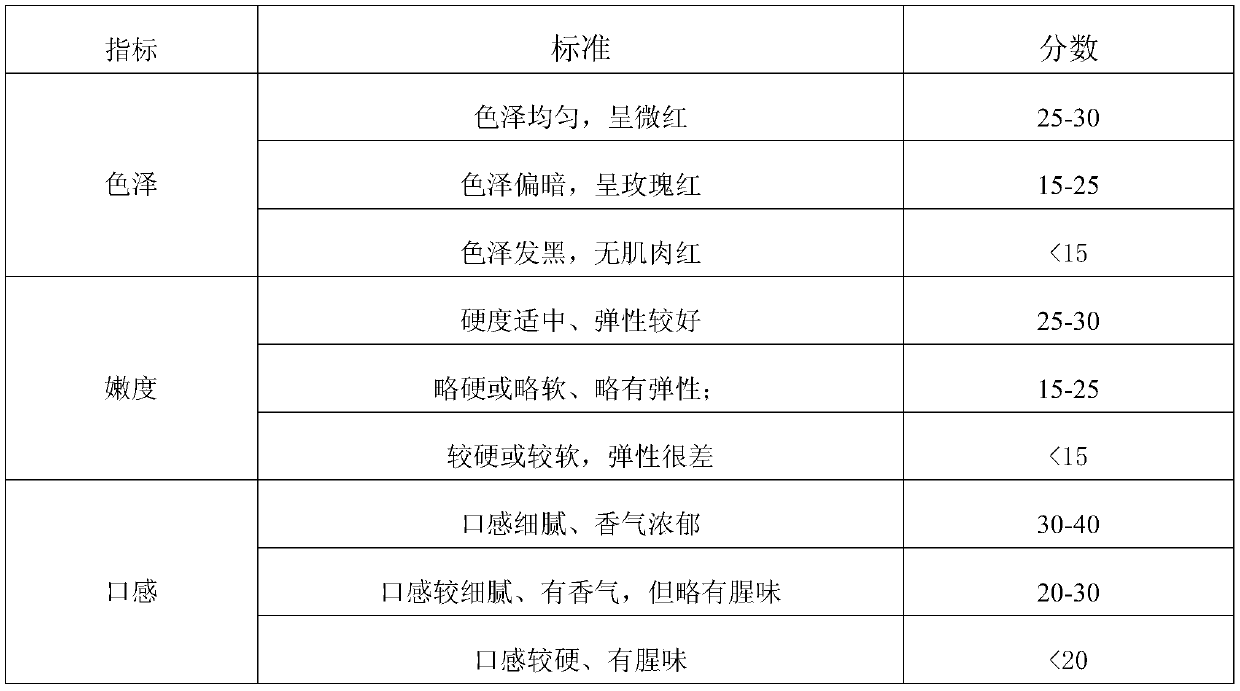

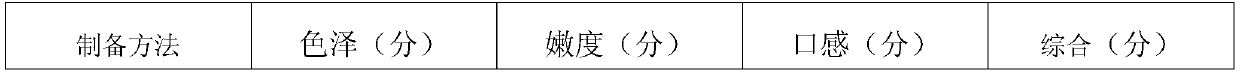

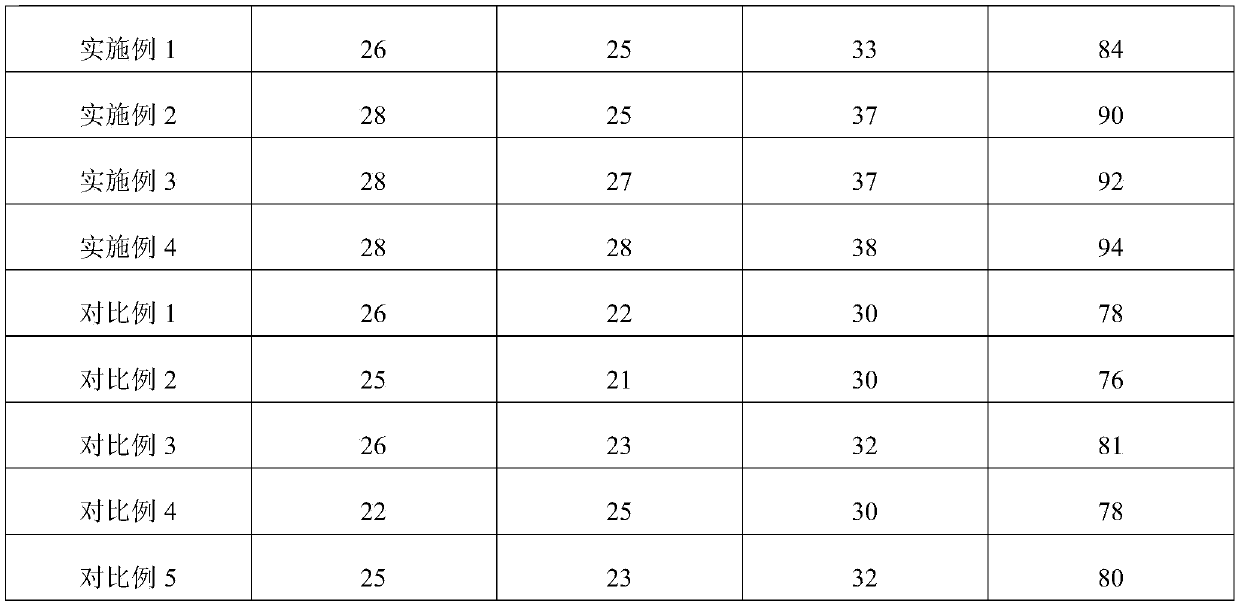

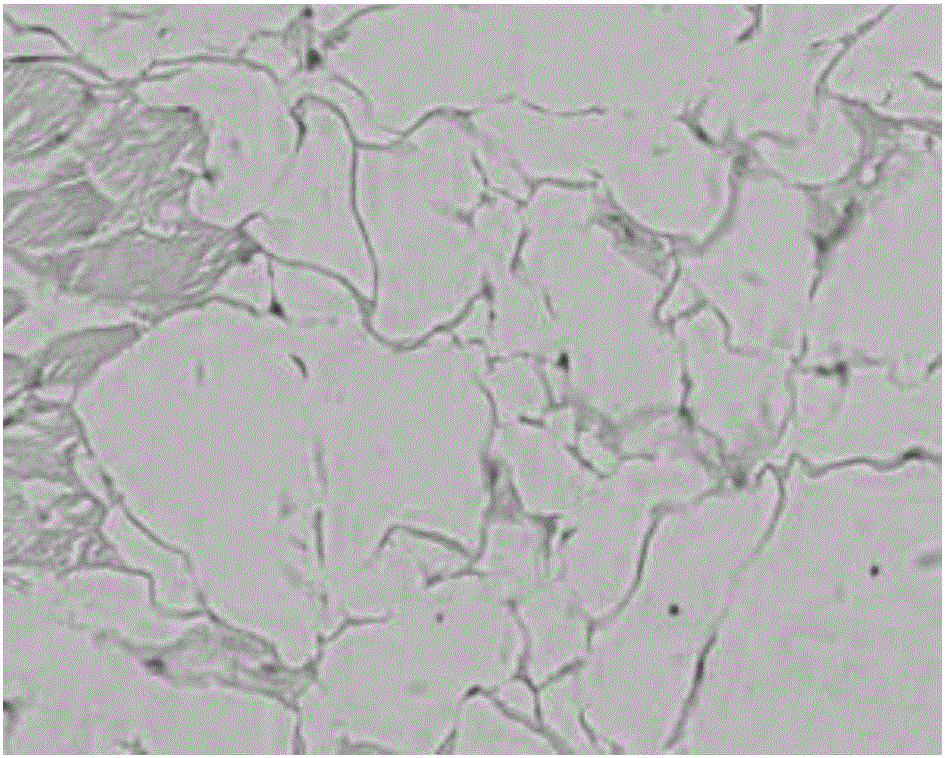

Preparation method of instant pickled beef

ActiveCN109730238AIncrease elasticityImprove tendernessClimate change adaptationFood scienceCarrageenanPhosphate

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Production method for fish oil microcapsule product with ultrafine edible fungus powder as main wall material

ActiveCN103340398ASuppress fishy smellFragrant smellFood shapingFood preparationBiotechnologyTremella

The invention provides a production method for a fish oil microcapsule product with ultrafine edible fungus powder as a main wall material. Main materials for microcapsule encapsulation are ultrafine mushroom and tremella powder and perilla oil used as a deodorization substance for fish oil. The production method comprises the following steps: preparation of the ultrafine mushroom and tremella powder; preparation of composite fish oil; and preparation of a fish oil microcapsule. The prepared fish oil microcapsule product has a pure white color and good appearance and can effectively encapsulate a core material. The product has strong antibacterial activity, effectively inhibits fishy smell of the fish oil, supplements and reinforces the function of unsaturated fatty acid of the fish oil and has the excellent characteristics of water solubility, thickening performance, gelatinization, film formation, etc. The wall material of the fish oil microcapsule becomes a nutrition component for the product and enriches nutritional functions of the fish oil product.

Owner:浙江天顺控股集团有限公司

Mixed hyaluronic-acid gel and preparation method thereof

ActiveCN106397795AStable network structureExtended retention timePharmaceutical delivery mechanismProsthesisCross-linkFiber

The invention provides mixed hyaluronic-acid gel and a preparation method thereof, wherein the method comprises the following steps of making sodium hyaluronate react with a cross-linking agent in a condition that a pH (potential of Hydrogen) value is 9 to 13, so as to obtain cross-linked sodium-hyaluronate gel; making polynucleotide react with the cross-linking agent in a condition that a pH value is 2 to 5, so as to obtain cross-linked nucleotide gel; mixing the cross-linked sodium-hyaluronate gel with the cross-linked nucleotide gel, then making an obtained mixture react with the cross-linking agent once again, and finally preparing to obtain the mixed hyaluronic-acid gel. According to the mixed hyaluronic-acid gel and the preparation method thereof, through two cross linking reactions, the problems that a hyaluronic acid type filling agent or gel in the prior art cannot be used for not only guaranteeing the in-vivo persistence time of hyaluronic acid, but also enabling a cell growth factor to effectively promote the growth of the self collagenous fiber of an organism are solved.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

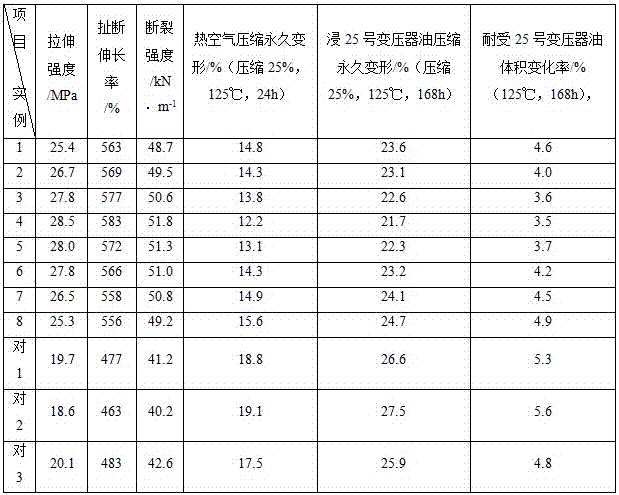

Rubber material for sealing ring of transformer and preparation method of rubber material

ActiveCN106883472AGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialCross-link

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

Aluminum alloy substrate thick film circuit intermediate-temperature sintering dielectric paste and preparation method thereof

InactiveCN106571172ALower melting temperatureAvoid harmQuartz/glass/vitreous enamelsInhomogenous insulation materialBreakdown strengthRare earth

The invention discloses an aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste and a preparation method thereof. The preparation method is used for preparing the aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste. The aluminum alloy substrate thick film circuit middle-temperature sintering dielectric paste comprises the following materials in part by weight: 60%-80% of lead-free microcrystalline glass powders, 1%-10% of rare earth oxide and 19%-30% of organic bonding phase, wherein the lead-free microcrystalline glass powders are formed by SiO2, Bi2O3, B2O3, ZnO, K2O, SrO2 and CaO; and the organic bonding phase is a mixture formed by an organic solvent, a high-polymer thickener, a surfactant, a plasticizer, a dispersant, an antifoaming agent and a thixotropic agent. A dielectric layer formed by printing the dielectric paste on an aluminum alloy substrate has the advantages of large adhesive force, large breakdown strength and high insulation resistance, and is capable of being compatible with a thick film circuit of the aluminum alloy substrate with a resistance paste and an electrode paste.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Roll-position-controllable polypropylene super hydrophobic film or block material and their preparing method

The present invention belongs to the field of polypropylene film or mass materials, especially relates to the rolling-angle controllable, super-hydrophobic, polypropylene film or mass and its preparation method. Solving polypropylene in solvent, and passing through processes of shearing, heat treatment, cooling, phase separation / crystallization, solidification, shaping, and drying at last, the films or masses with different morphological crystal networks are formed. With the minimum rolling ability on film or mass surface, water drops will roll, while the rolling angle is between 0 degree and 1 degree, and with the maximum rolling ability, the drops will not roll, while the rolling angle is 90 degree or 180 degree. The contact angle between film or mass surface and water is larger than 150 degree. The present invention achieves the control of super-hydrophobic property and rolling angle of general polyolefin resin film, without any later modification by low-surface-energy materials (containing fluoride materials or silane, etc.), and has good surface-structure stability, wind and rain resistance, and chemical corrosion resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

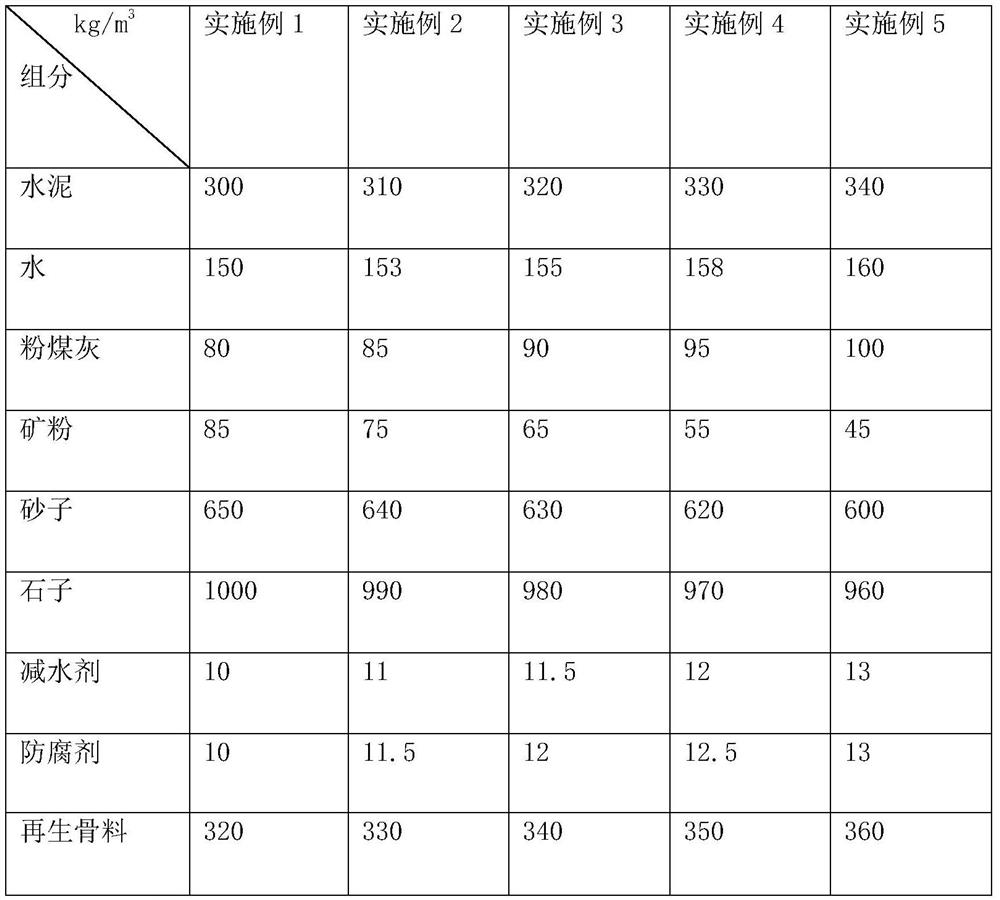

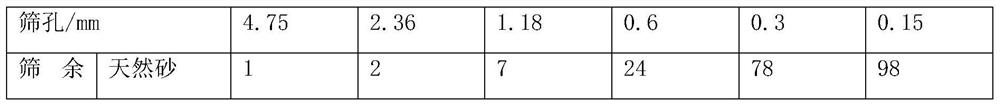

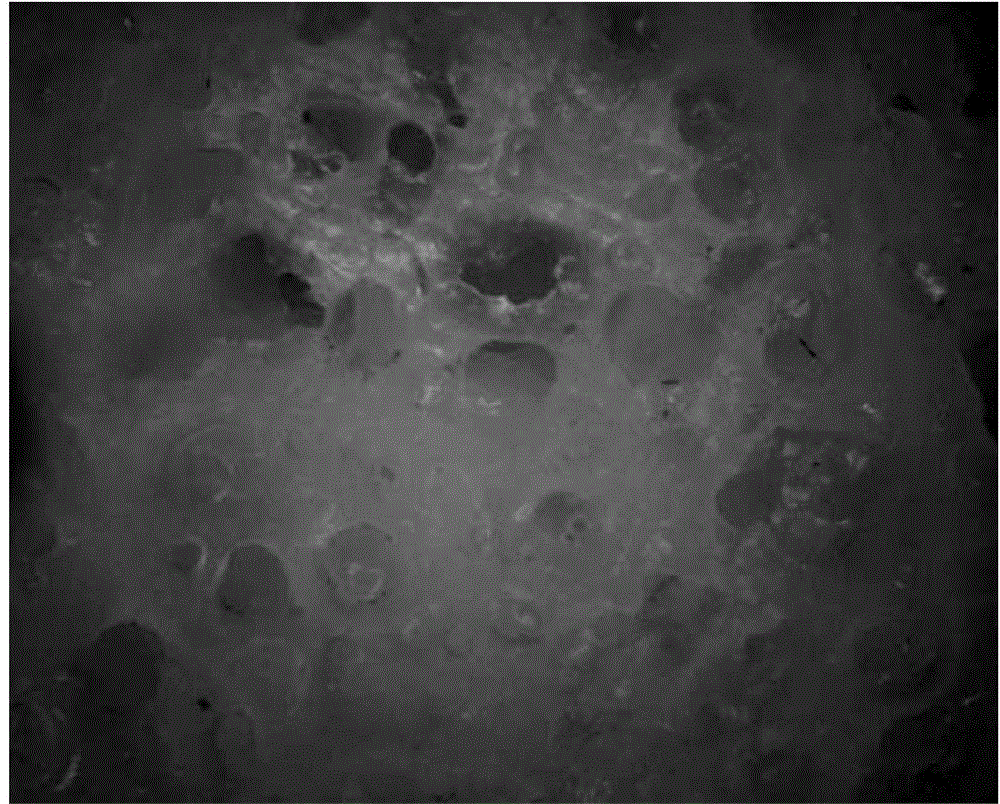

Recycled aggregate concrete and preparation method thereof

The invention relates to the field of building materials, and particularly discloses recycled aggregate concrete and a preparation method thereof. The recycled aggregate concrete is prepared from the following components in parts by weight: 300 to 340 parts of cement, 150 to 160 parts of water, 85 to 100 parts of fly ash, 65 to 85 parts of mineral powder, 600 to 650 parts of sand, 960 to 1000 parts of stones, 8 to 10 parts of a water reducing agent, 10 to 13 parts of a preservative and 320 to 360 parts of recycled aggregate, the preparation method comprises the following steps: S1, uniformly mixing the cement, the water, the fly ash and the mineral powder to obtain a premixed mixture; and S2, adding the recycled aggregate, the stones, the sand, the water reducing agent and the preservative into the premixed mixture, and uniformly mixing. The recycled aggregate concrete disclosed by the invention has the advantages of strong scouring resistance, good chloride ion corrosion resistance and excellent durability when being used for ocean engineering construction.

Owner:深圳市宝金华混凝土有限公司

Preparation method and driving method of shape-memory polycaprolactone foam

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com