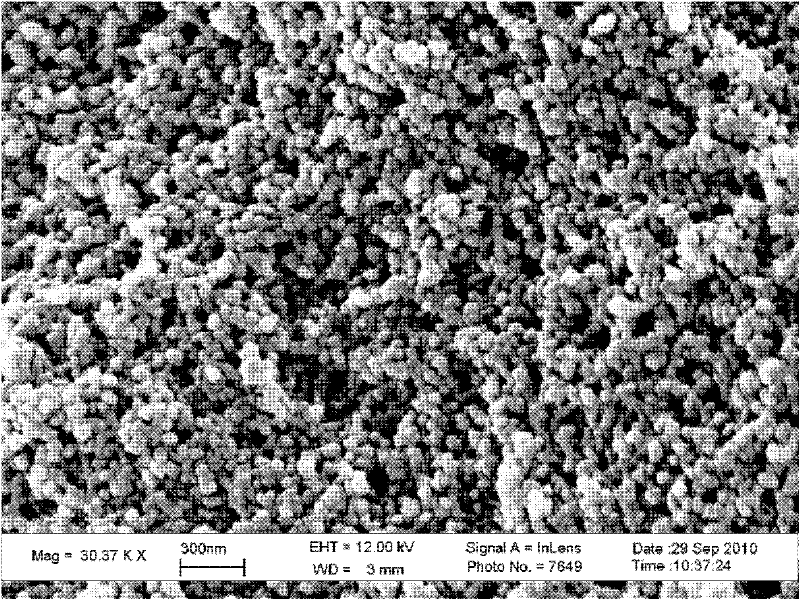

Preparation method of blocky silicon-carbon composite aerogel

A composite technology of airgel and carbon, which is applied in chemical instruments and methods, catalyst carriers, physical/chemical process catalysts, etc., can solve the problems of low strength, low airgel density, airgel fragmentation, etc., and achieve durability Good high temperature performance, perfect network structure, good molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

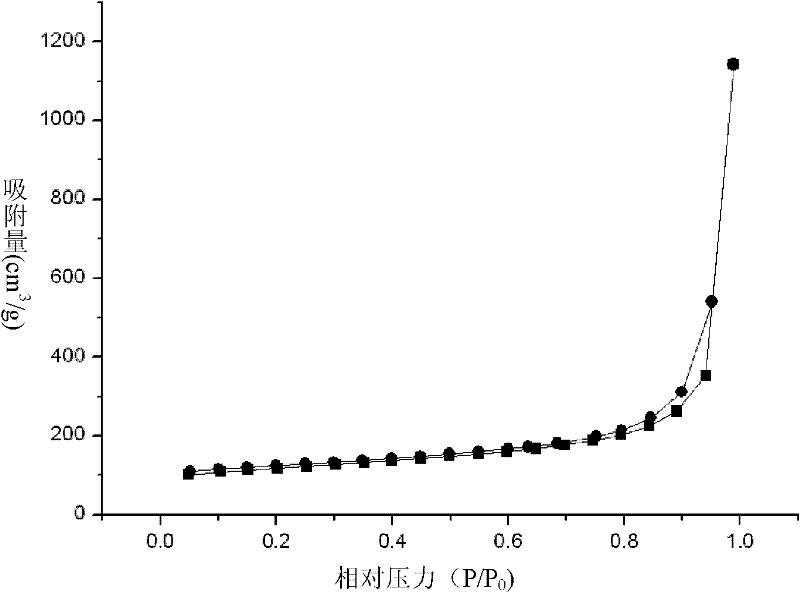

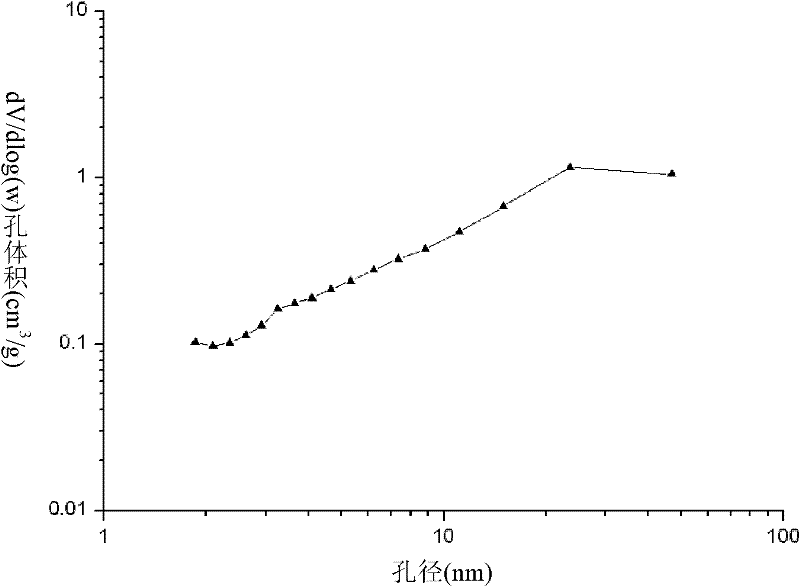

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix tetraethyl orthosilicate, nitric acid, deionized water, and absolute ethanol in a molar ratio of 1:0.1:4:60 to form solution A, and pre-hydrolyze at 35°C for 40 minutes;

[0026] (2) Mix resorcinol, formaldehyde, potassium hydroxide, and absolute ethanol in a molar ratio of 1:2:300:1 to form solution B, and pre-react at 50° C. for 60 minutes.

[0027] (3) According to the molar ratio of tetraethyl orthosilicate and resorcinol being 1:1, solution A and solution B were mixed under stirring, and ammonia water was added to adjust the pH value to 8.5.

[0028] (4) Place the solution obtained in step (3) in a 40°C oven for 300 minutes to obtain a wet gel. The wet gel is aged in a 60°C water bath for 10 days, and then the wet gel is solvent-substituted with methanol. Methanol was replaced once every 12 hours, a total of 4 replacements, and CO was carried out after the solvent replacement was completed. 2 Supercritical drying, at 10MPa and 25°C, replace with a gas rele...

example 2

[0032] (1) Mix tetraethyl orthosilicate, acetic acid, deionized water, and absolute ethanol in a molar ratio of 1:0.1:6:43 to form solution A, and pre-hydrolyze at 25°C for 35 minutes;

[0033] (2) Mix resorcinol, formaldehyde, sodium hydroxide, and absolute ethanol in a molar ratio of 1:2:200:0.5 to prepare solution B, and pre-react at 60° C. for 35 minutes.

[0034] (3) According to the molar ratio of tetraethyl orthosilicate and resorcinol being 1:1, solution A and solution B were mixed under stirring, and ammonia water was added to adjust the pH value to 9.2.

[0035] (4) Place the solution obtained in step (3) in a 50°C oven for constant temperature reaction for 25 minutes to obtain a wet gel. The wet gel is aged in a 60°C water bath for 10 days, and then acetone is used for solvent replacement of the wet gel. Acetone was replaced every 6 hours, a total of 4 replacements, and CO was carried out after the solvent replacement was completed. 2 Supercritical drying, replace ...

example 3

[0039] (1) Mix tetraethyl orthosilicate, hydrochloric acid, deionized water, and absolute ethanol in a molar ratio of 1:0.03:8:38 to form solution A, and pre-hydrolyze at 35°C for 30 minutes;

[0040] (2) Mix resorcinol, formaldehyde, sodium carbonate, and absolute ethanol in a molar ratio of 1:2:200:0.5 to form solution B, and pre-react at 70°C for 20 minutes.

[0041](3) According to the molar ratio of tetraethyl orthosilicate and resorcinol being 1:1, solution A and solution B were mixed under stirring, and then ammonia water was added to adjust the pH value to 9.

[0042] (4) Place the solution obtained in step (3) in a 30°C oven for constant temperature reaction for 50 minutes to obtain a wet gel. The wet gel is aged in a 50°C water bath for 15 days, and then the wet gel is solvent-substituted with ethanol. Ethanol was replaced once every 24 hours, a total of 5 replacements, and CO was carried out after the solvent replacement was completed. 2 Supercritical drying, at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com