A kind of environmental protection waterproof asphalt and preparation method thereof

An asphalt and environmental protection technology, applied in building insulation materials, buildings, building components, etc., can solve the problems of high softening point increment, high volatility, low penetration retention rate, etc., to improve molecular weight, reduce volatilization, reduce The effect of volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

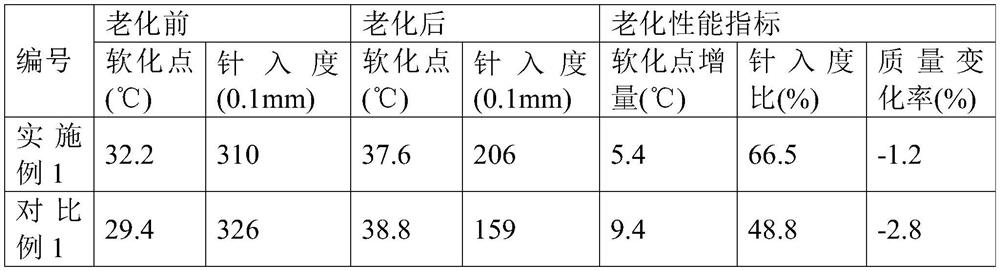

Embodiment 1

[0023] Heat 67.6 parts (mass parts, the same below) of vacuum residue (softening point 45°C, penetration 216dmm at 25°C) to 160°C, add 22 parts of catalytic cracking oil slurry (aromatic content 65%) and reduced third-line oil 8 parts, mixed for 30 minutes at a speed of 2000rmp, then added 0.4 part of phosphomolybdic acid, stirred for 60 minutes, finally added 2 parts of natural zeolite (fineness 1000 mesh), stirred for 15 minutes, to obtain environmentally friendly waterproof asphalt.

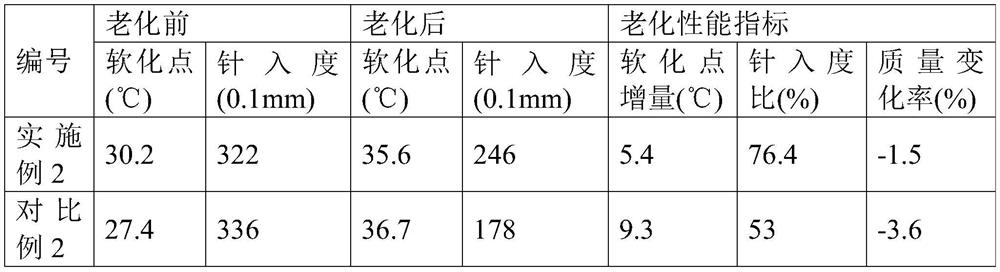

Embodiment 2

[0035] Heat 69.4 parts of vacuum residue (softening point 42°C, penetration 238dmm at 25°C) to 155°C, add 20 parts of catalytic cracking oil slurry (aromatic content 60%) and 6 parts of reduced second-line oil, rotate at 2000rmp Mixing for 30min, then adding 0.6 part of phosphomolybdic acid, stirring for 60min, finally adding 4 parts of natural zeolite (fineness 1000 mesh), stirring for 15min, to obtain environmental protection waterproof asphalt.

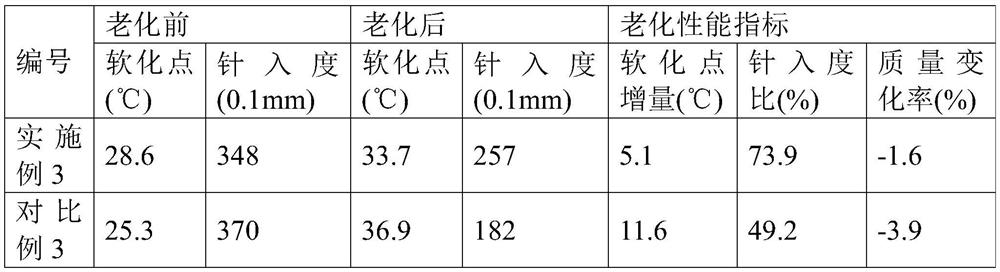

Embodiment 3

[0043] Heat 73.2 parts of vacuum residue (softening point 41°C, penetration 253dmm at 25°C) to 150°C, add 16 parts of catalytic cracking oil slurry (aromatic content 65%) and 5 parts of reduced third-line oil, and rotate at 2000rmp Mixing for 30min, then adding 0.8 part of phosphomolybdic acid, stirring for 60min, finally adding 5 parts of natural zeolite (fineness 1000 mesh), stirring for 15min, to obtain environmentally friendly waterproof asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com