Novel method for obtaining concoction soft component of high-grade road asphalt

A technology for road asphalt and soft components, applied in the petrochemical field, can solve the problem of difficult utilization of deoiled hard asphalt, and achieve the effects of improving the utilization rate and added value, ensuring the operating rate, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

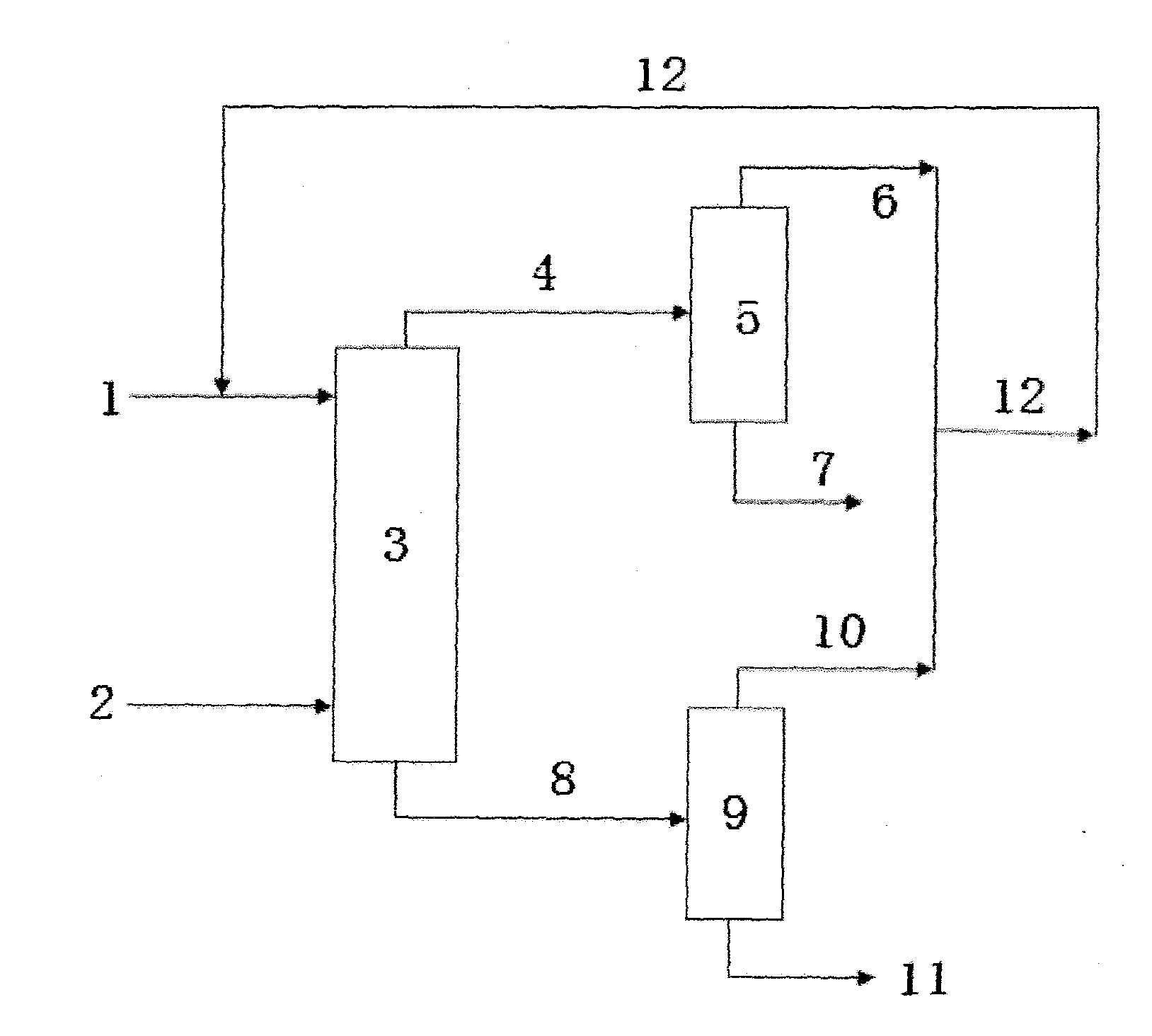

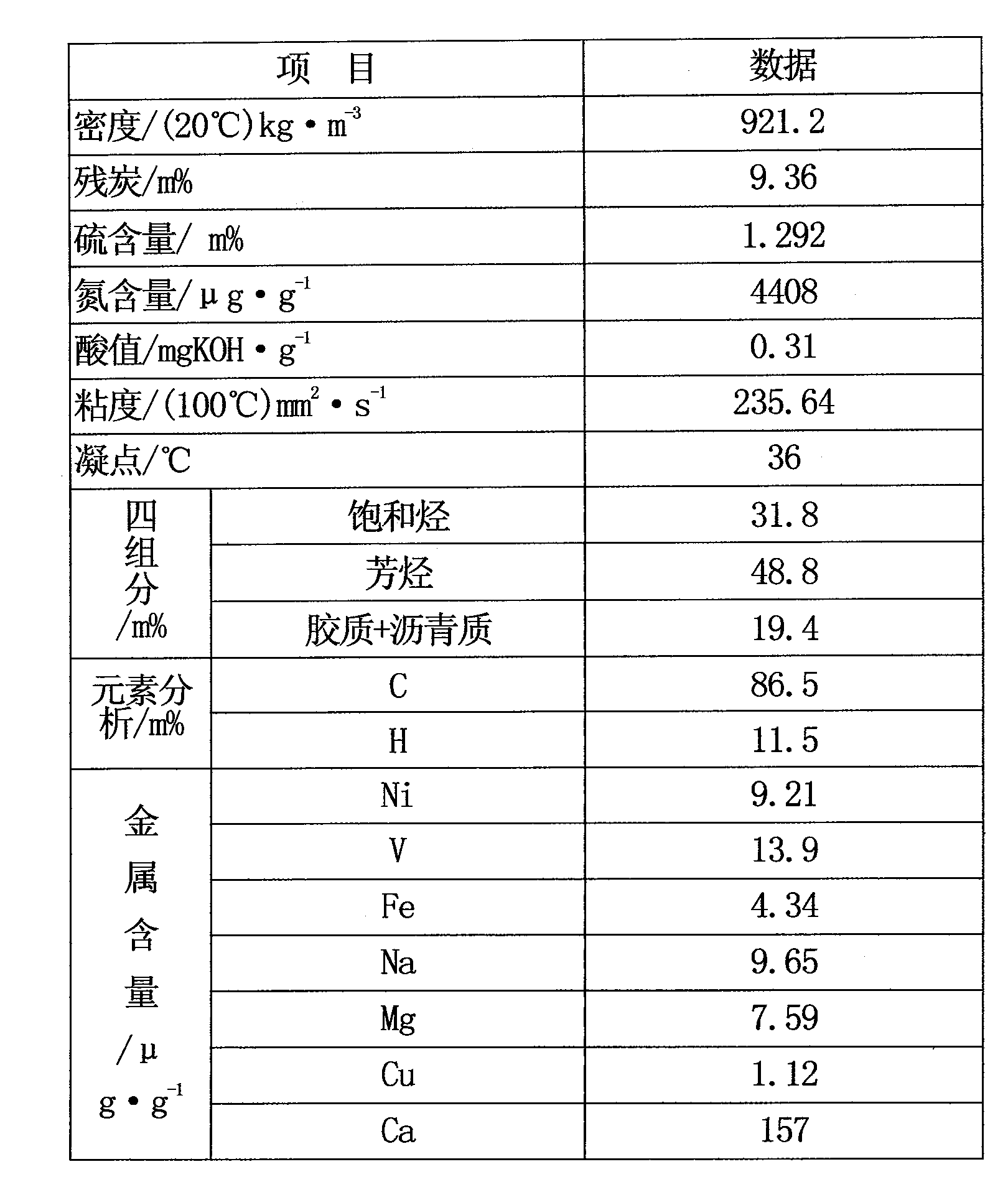

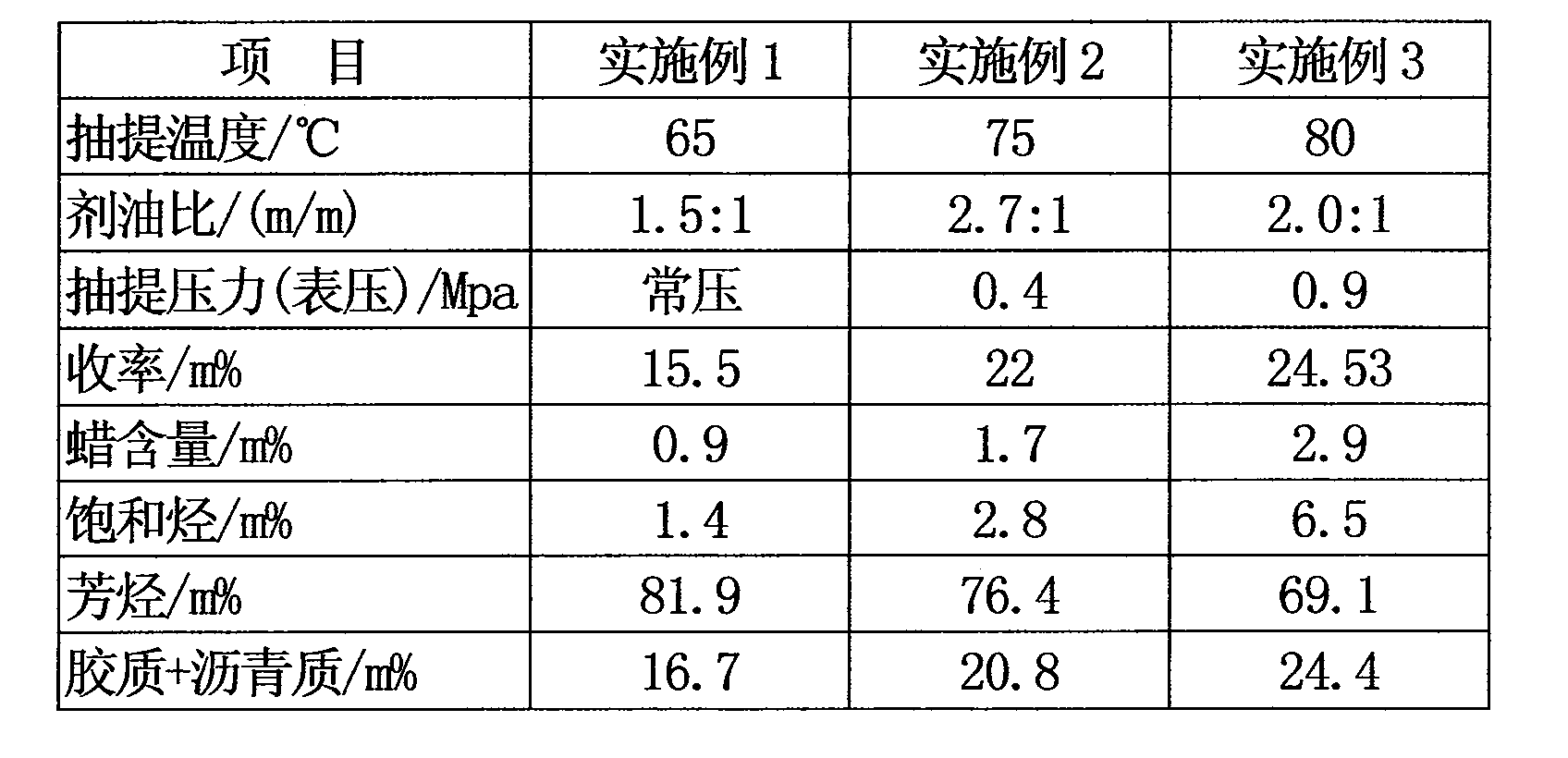

[0026]Using furfural as the extraction solvent, heat furfural 1 to 65-75°C by means of steam or heat exchange, and enter from the upper part of the extraction tower 3 after metering. After metering, it is carried out from the lower part of the extraction tower, and the two are reversely contacted in the extraction tower for liquid-liquid extraction. The operating pressure of the extraction tower is normal pressure (gauge pressure), 0.4Mpa (gauge pressure) and 0.9Mpa (gauge pressure), the extraction temperature is respectively selected at 65°C, 75°C and 80°C, and the ratio of agent to oil is 1.5: 1 (mass), 2.7:1 (mass) and 2.0:1 (mass). The tower top raffinate 4 is distilled and separated in the raffinate separation tower 5, the furfural solvent 6 recovered at the top of the tower, and the raffinate oil 7 is obtained at the bottom of the tower; the tower bottom raffinate 8 is distilled and separated in the raffinate separation tower 9 , the furfural solvent 10 recovered at the...

Embodiment 4

[0028] Extraction solvent is sulfolane, and operating process is with embodiment 1~3, and extraction condition is normal pressure (gauge pressure), and extraction temperature is 75 ℃, and agent-oil ratio is 1.7: 1 (quality), extracts the yield of oil and nature see Figure 4 .

Embodiment 5

[0030] Extraction solvent is N-formylmorpholine, and operating process is with embodiment 1~3, and extraction condition is: operating pressure 0.6Mpa (gauge pressure), and extraction temperature is 80 ℃, and agent-oil ratio is 1.5: 1 (mass ), the yield and properties of the extracted oil are shown in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com