Patents

Literature

68results about How to "Reduce wax content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

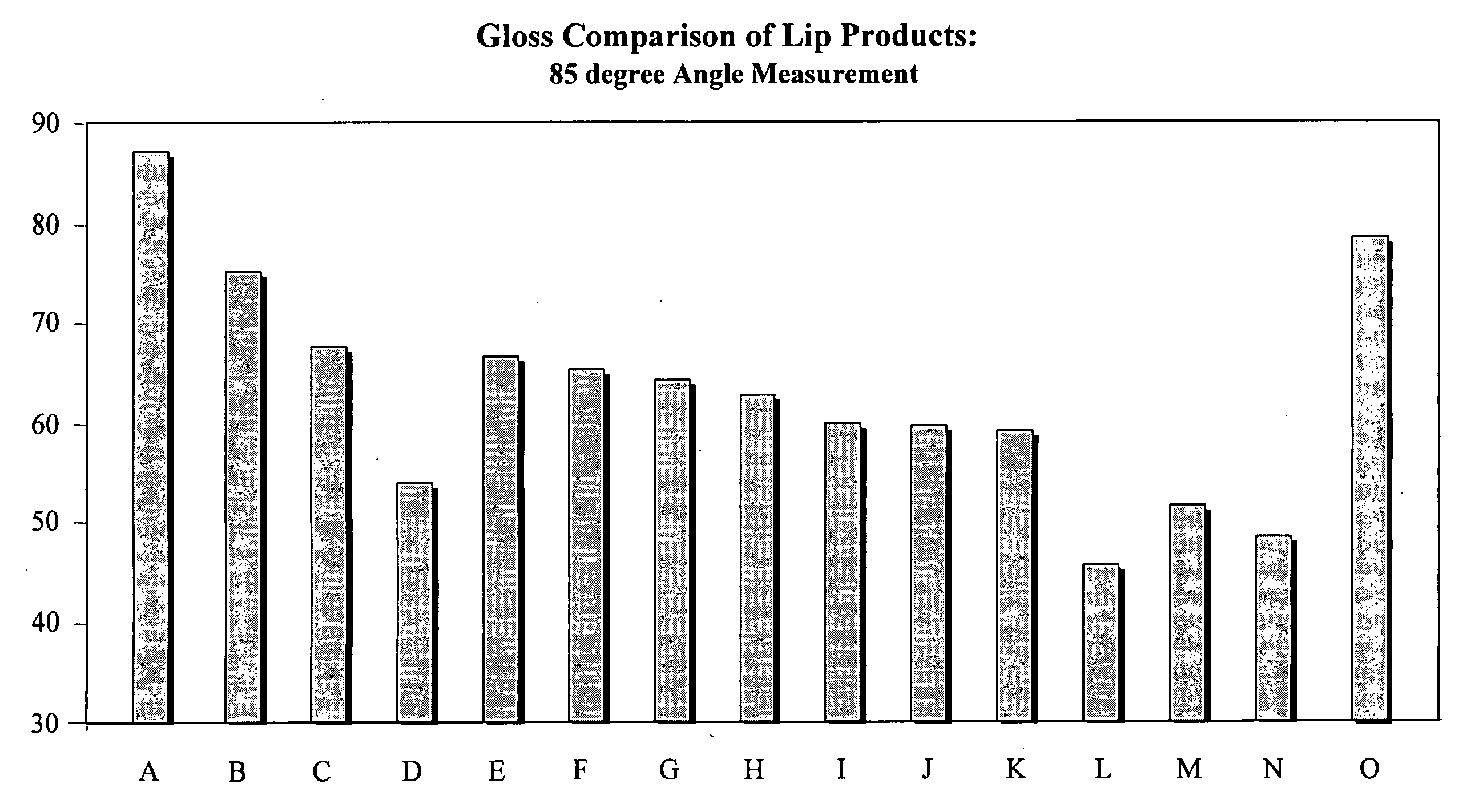

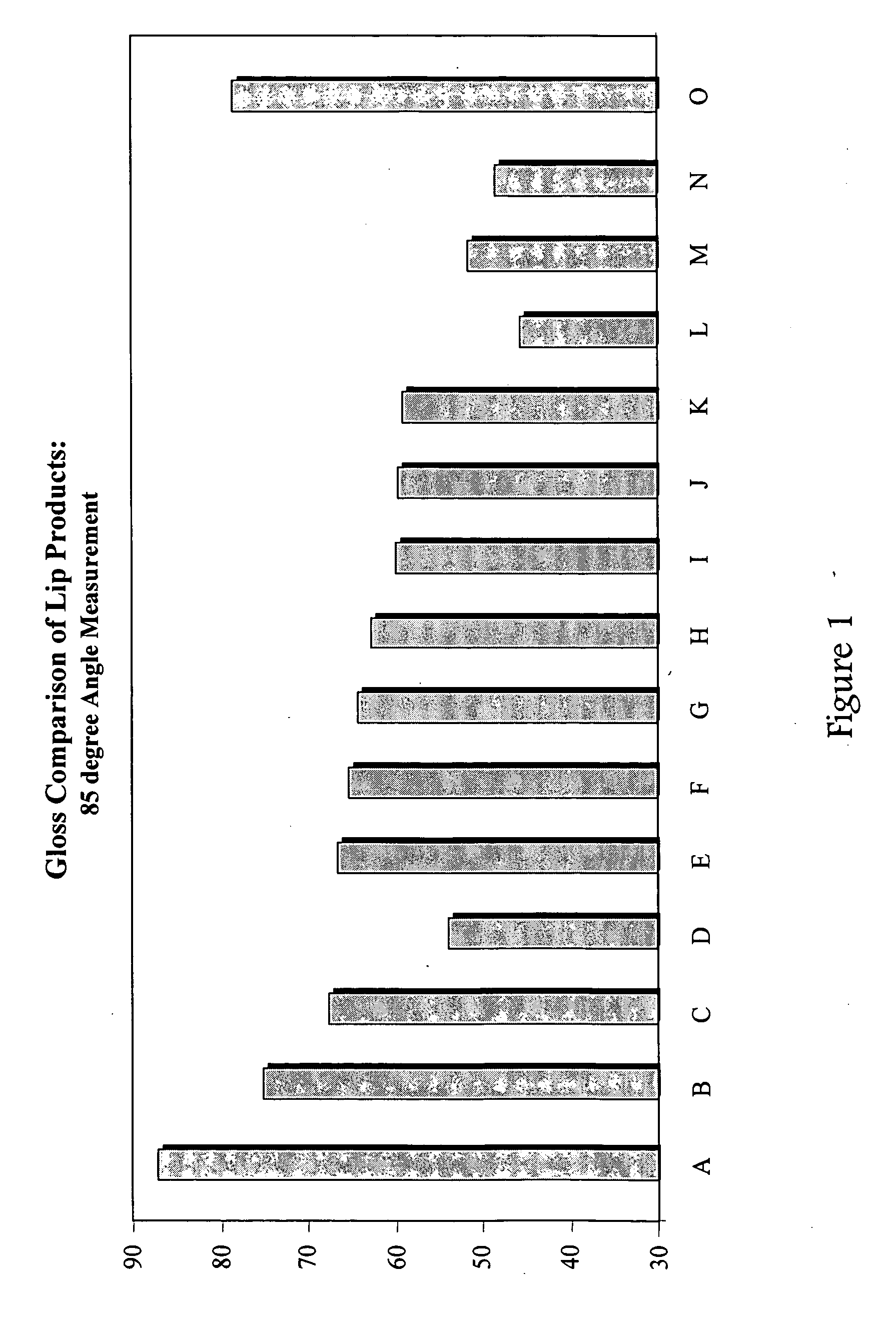

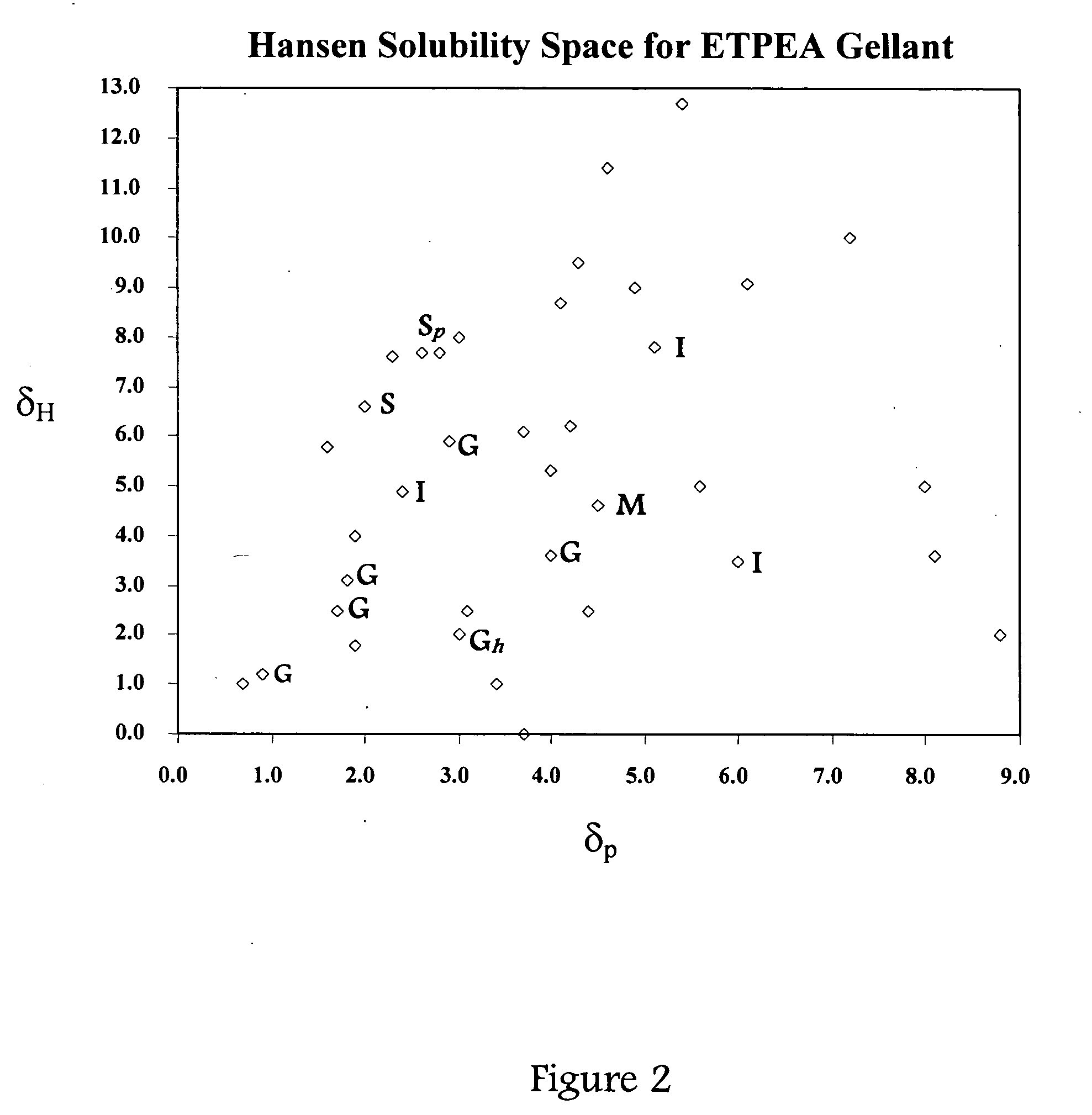

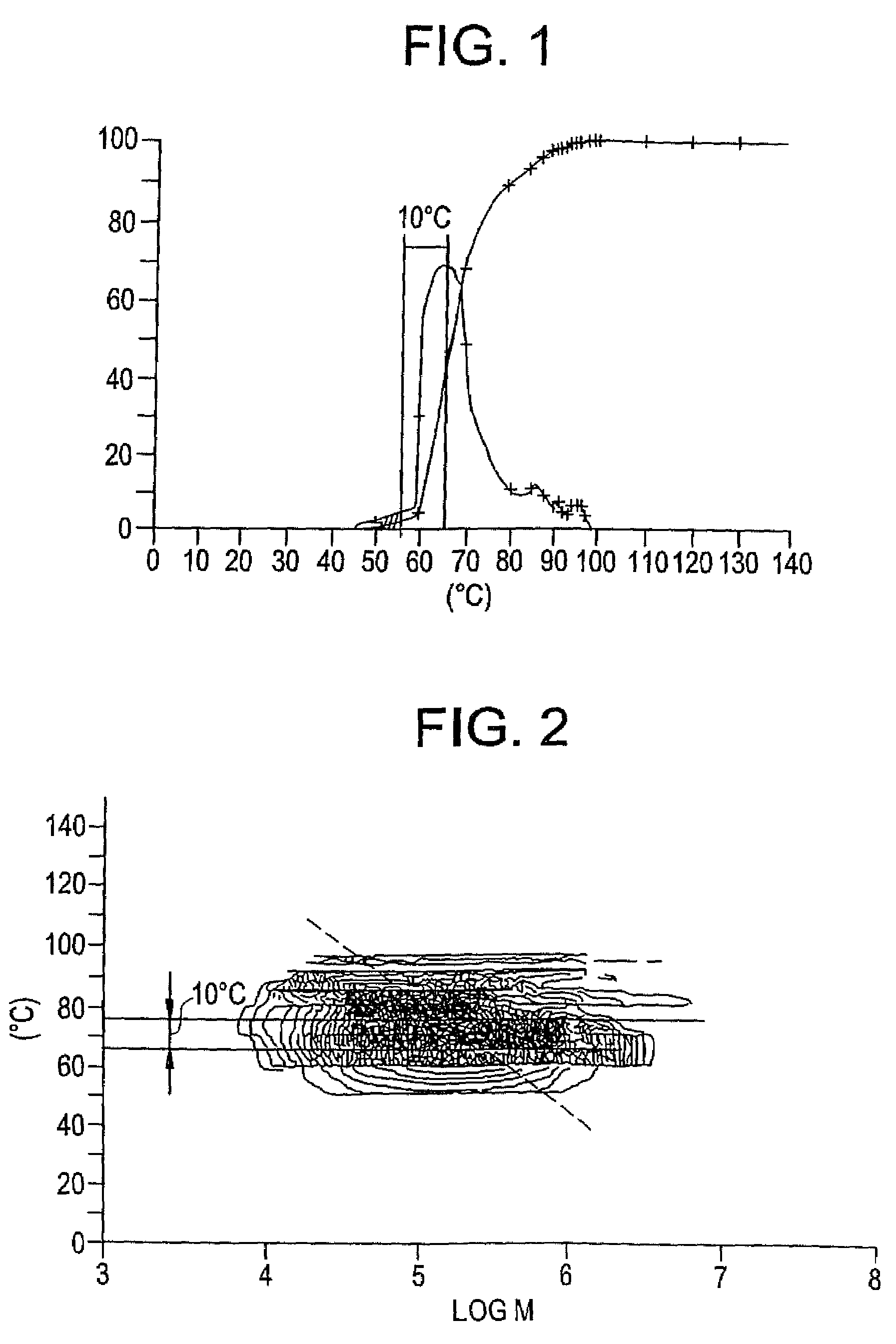

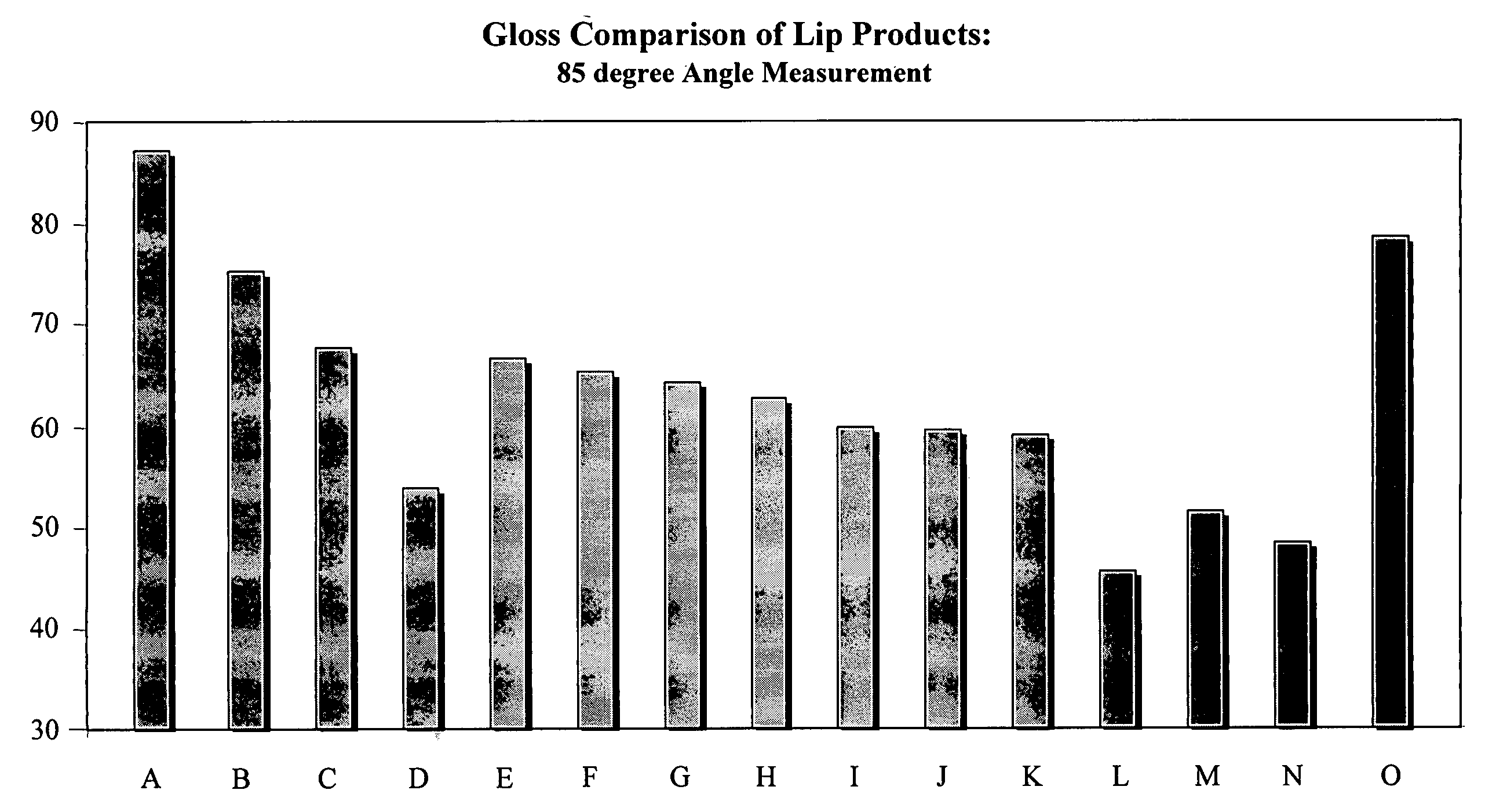

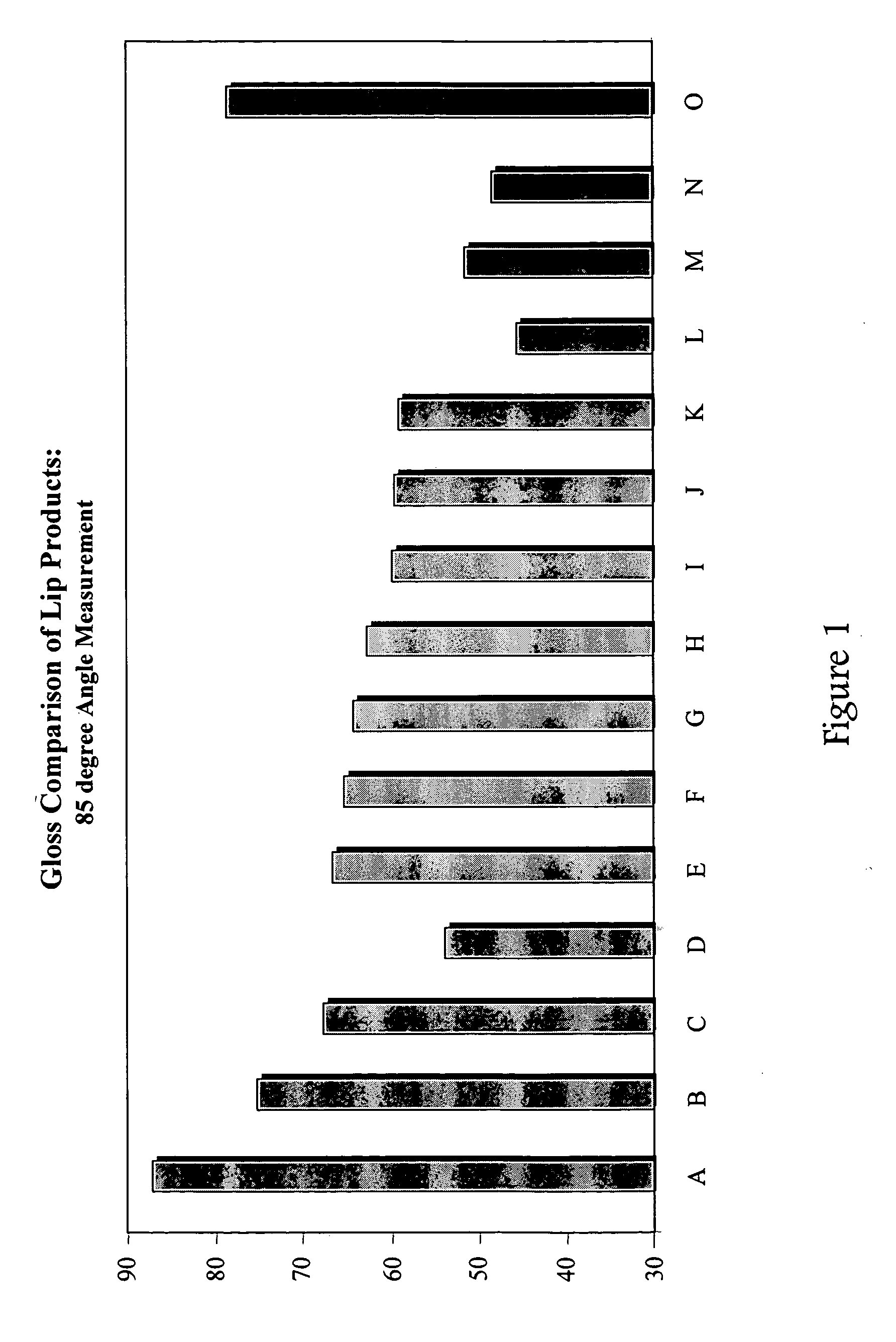

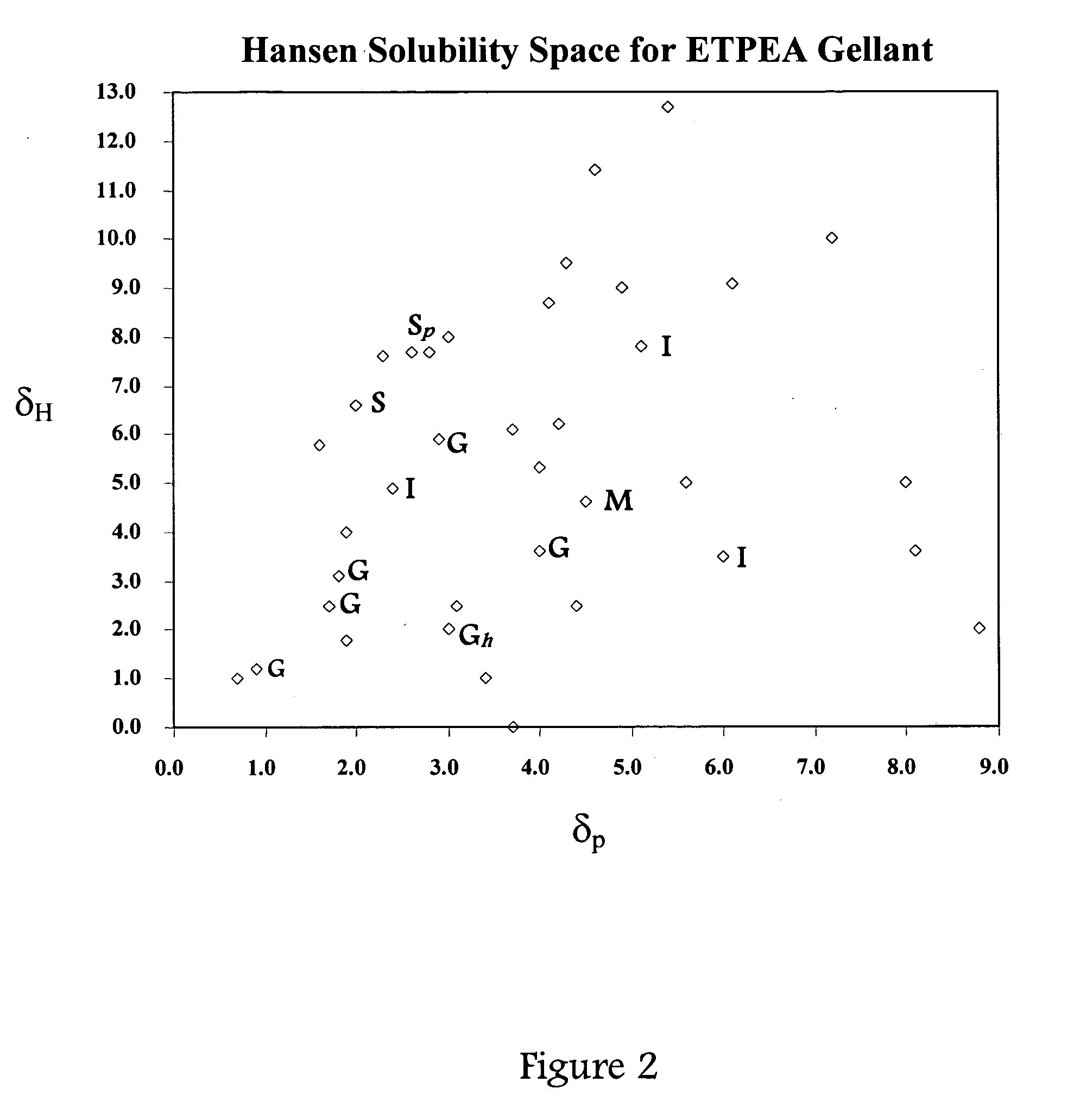

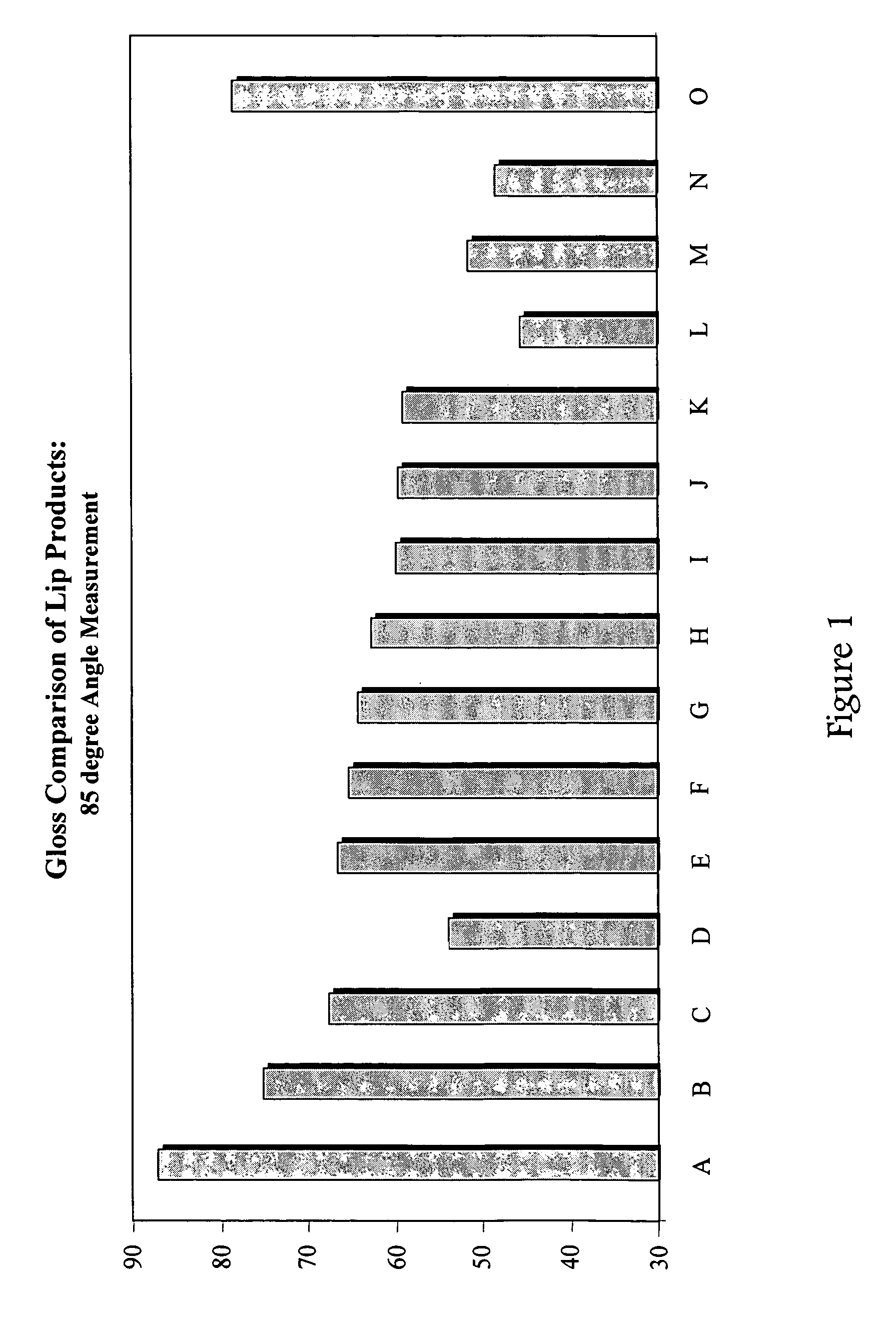

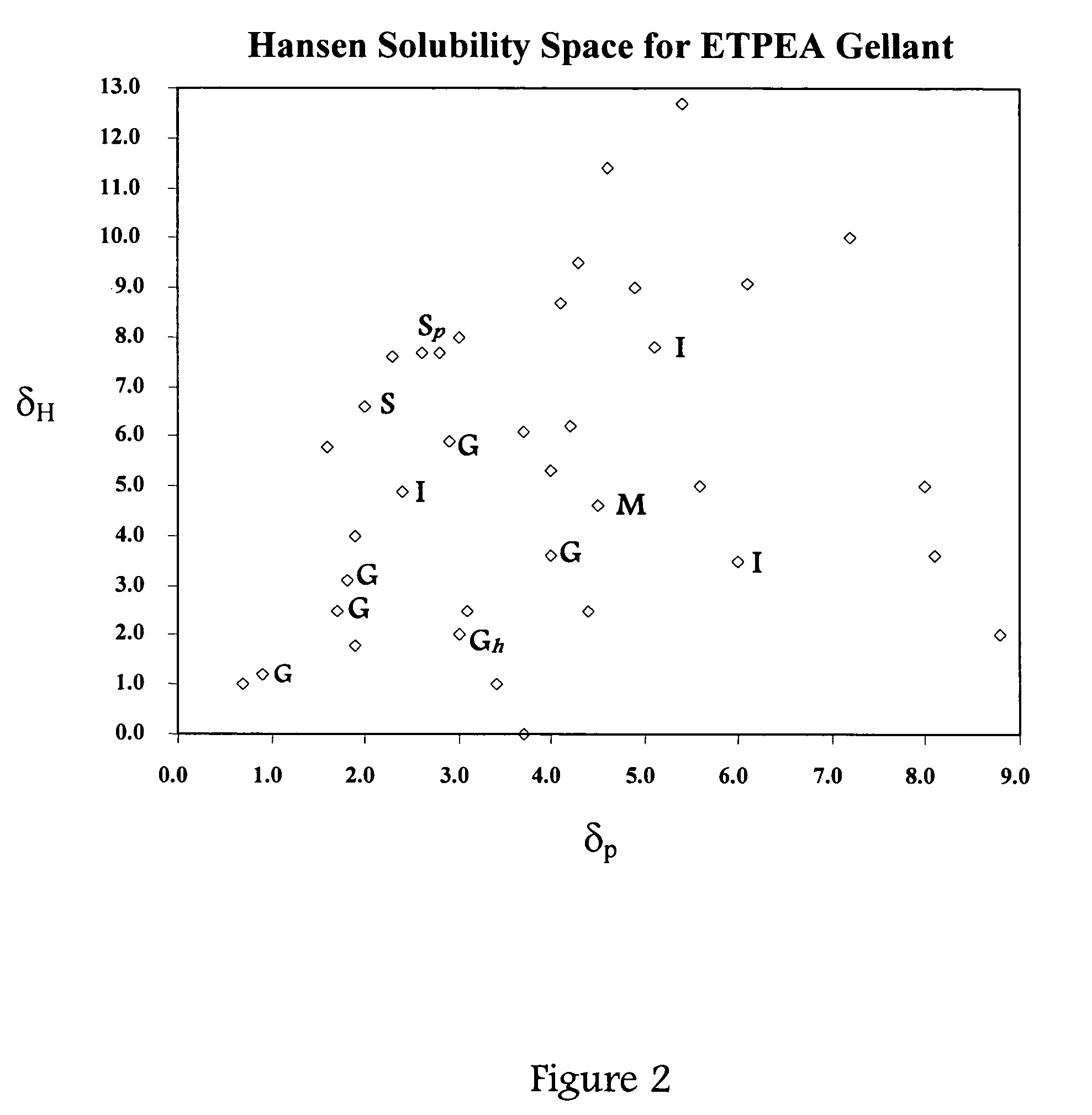

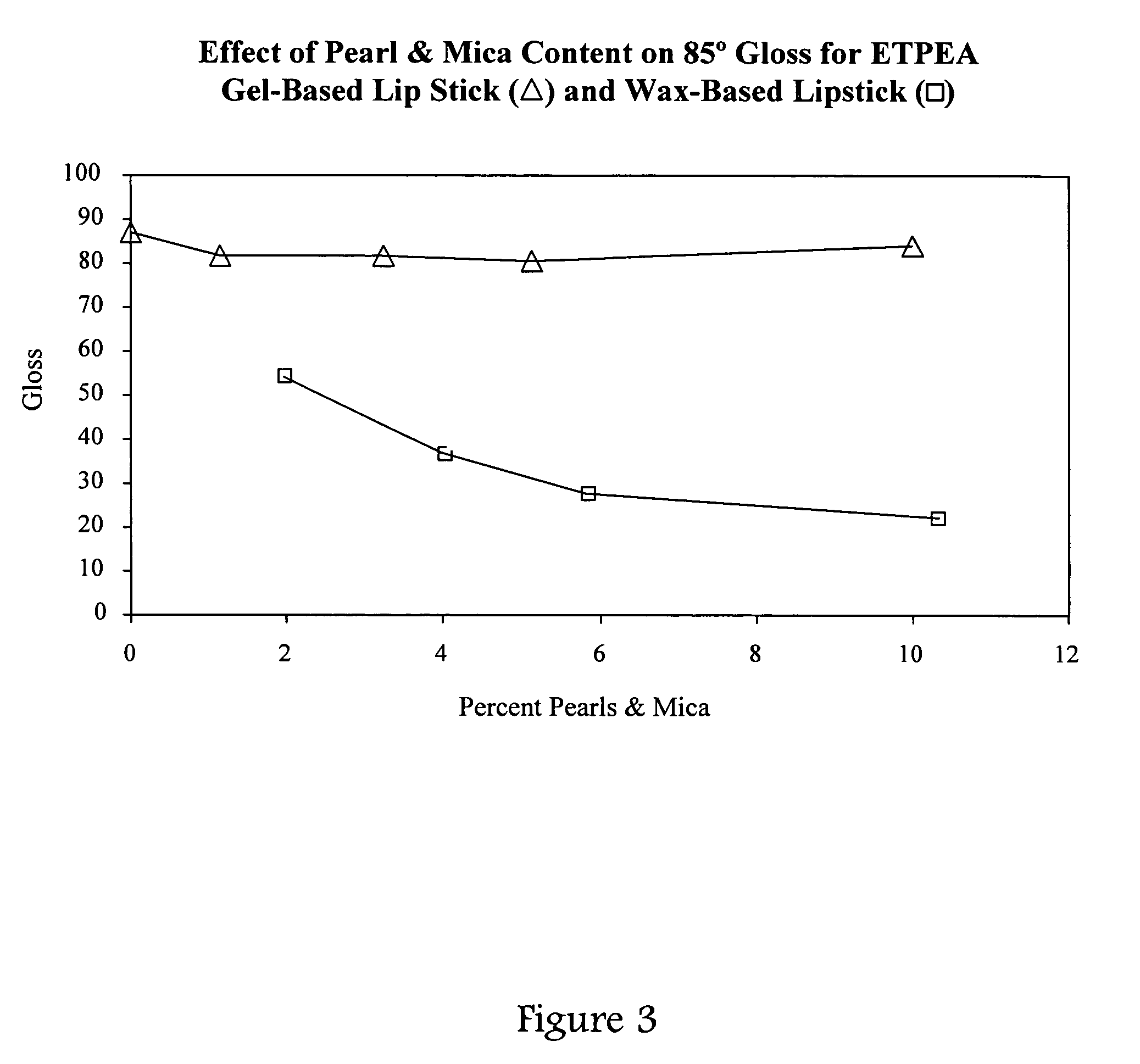

High gloss gel-based lipstick

ActiveUS20080152678A1Improve rheologyReduce wax contentOrganic active ingredientsCosmetic preparationsPolymer chemistryMelting point

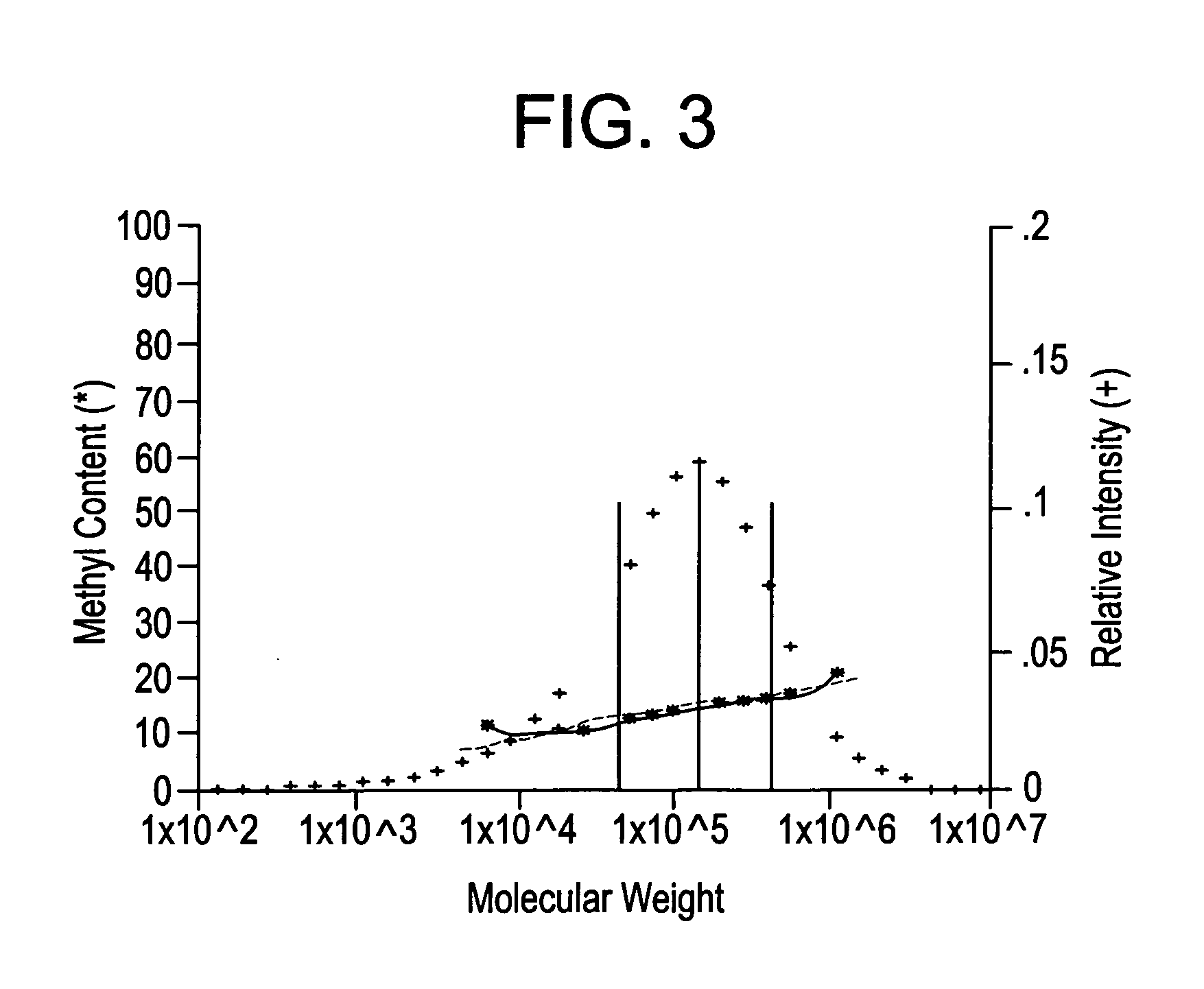

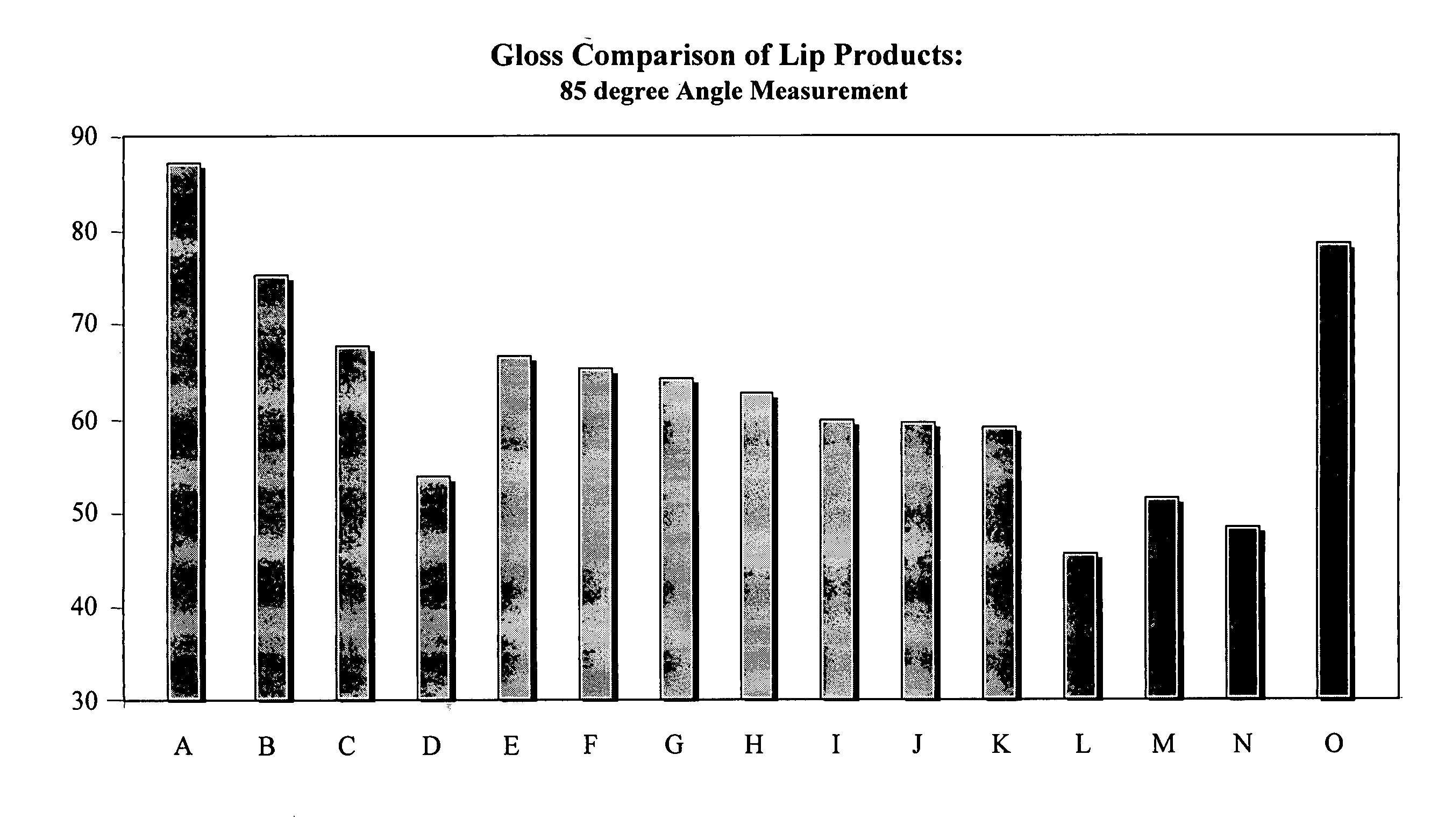

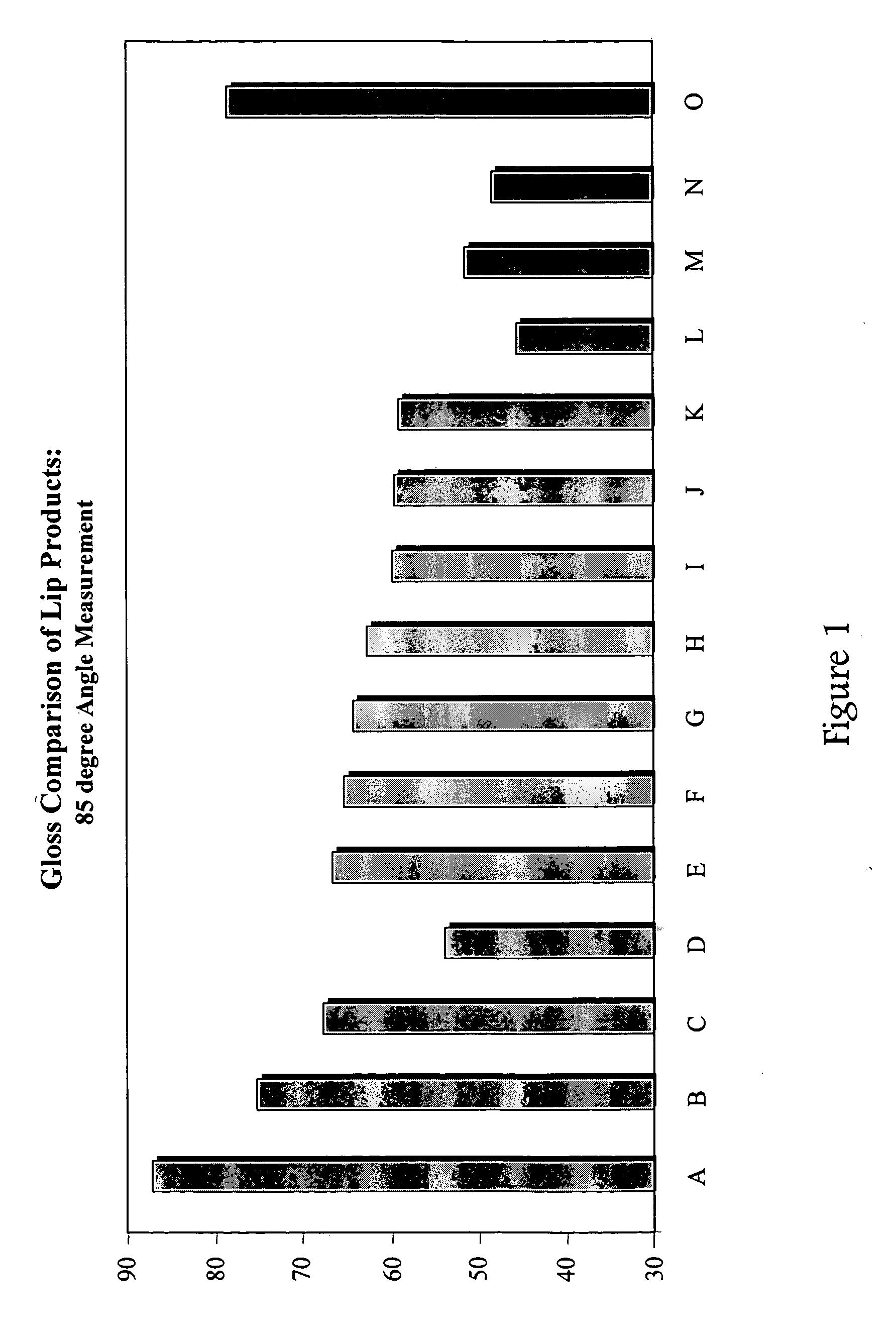

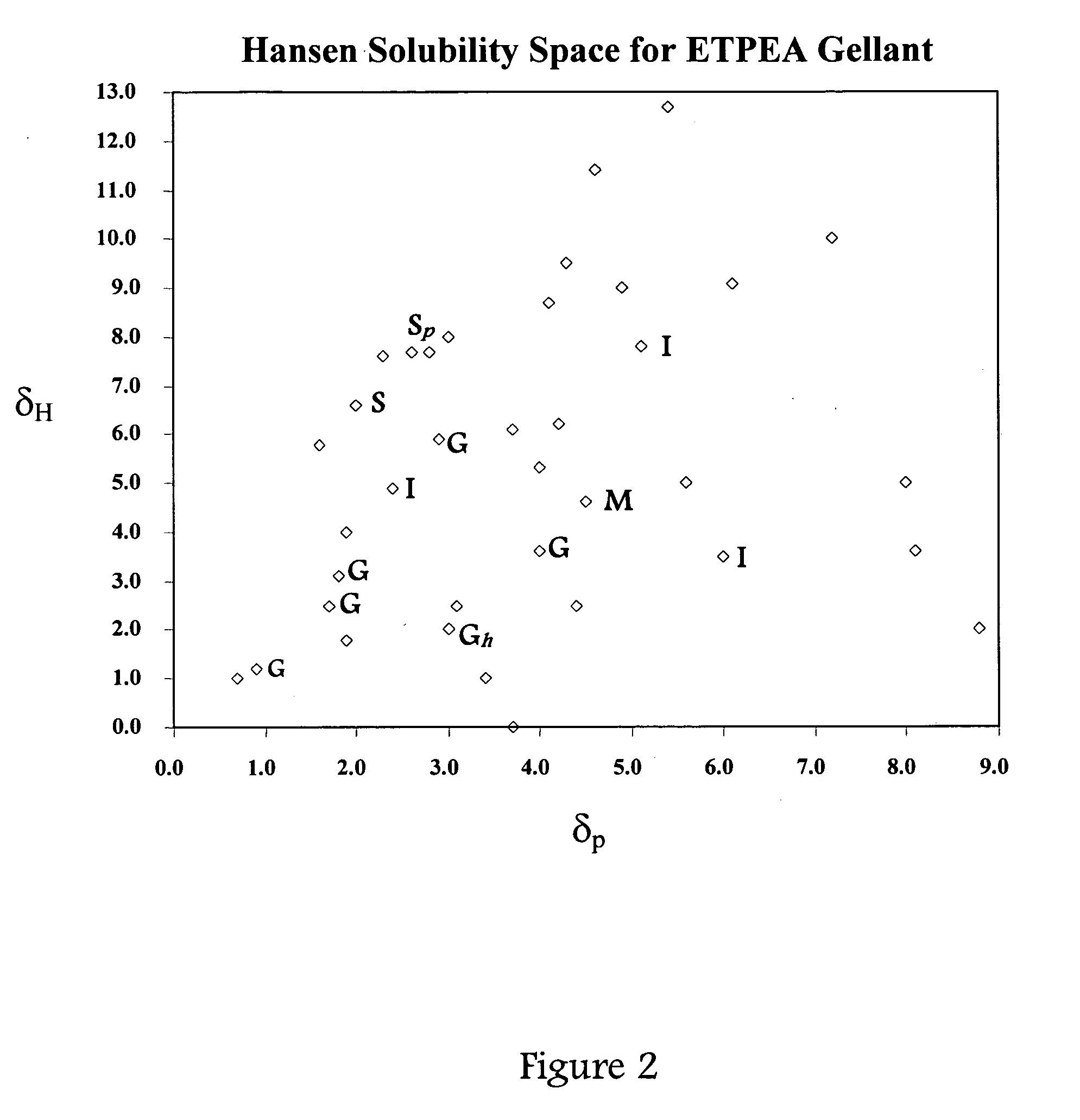

Gel-based lipstick compositions are disclosed comprising an ester terminated poly(ester-amide) (ETPEA) polymeric gellant, a first wax component having a melting point above the sol-gel transition temperature of the ETPEA gellant, a second wax compositions having a melting point equal to of below the sol-gel transition temperature of the ETPEA gellant, optionally a silicone T-resin co-gellent, and one or more oils capable of forming a gel with the ETPEA gellant. The gel compositions are solid or semi-solid at room temperature and are capable of being molded into self-supporting sticks. The disclosed gels provide high gloss films when applied to the lips and / or provide a rheology characterized by a high viscosity over repeated shear cycles.

Owner:AVON PROD INC

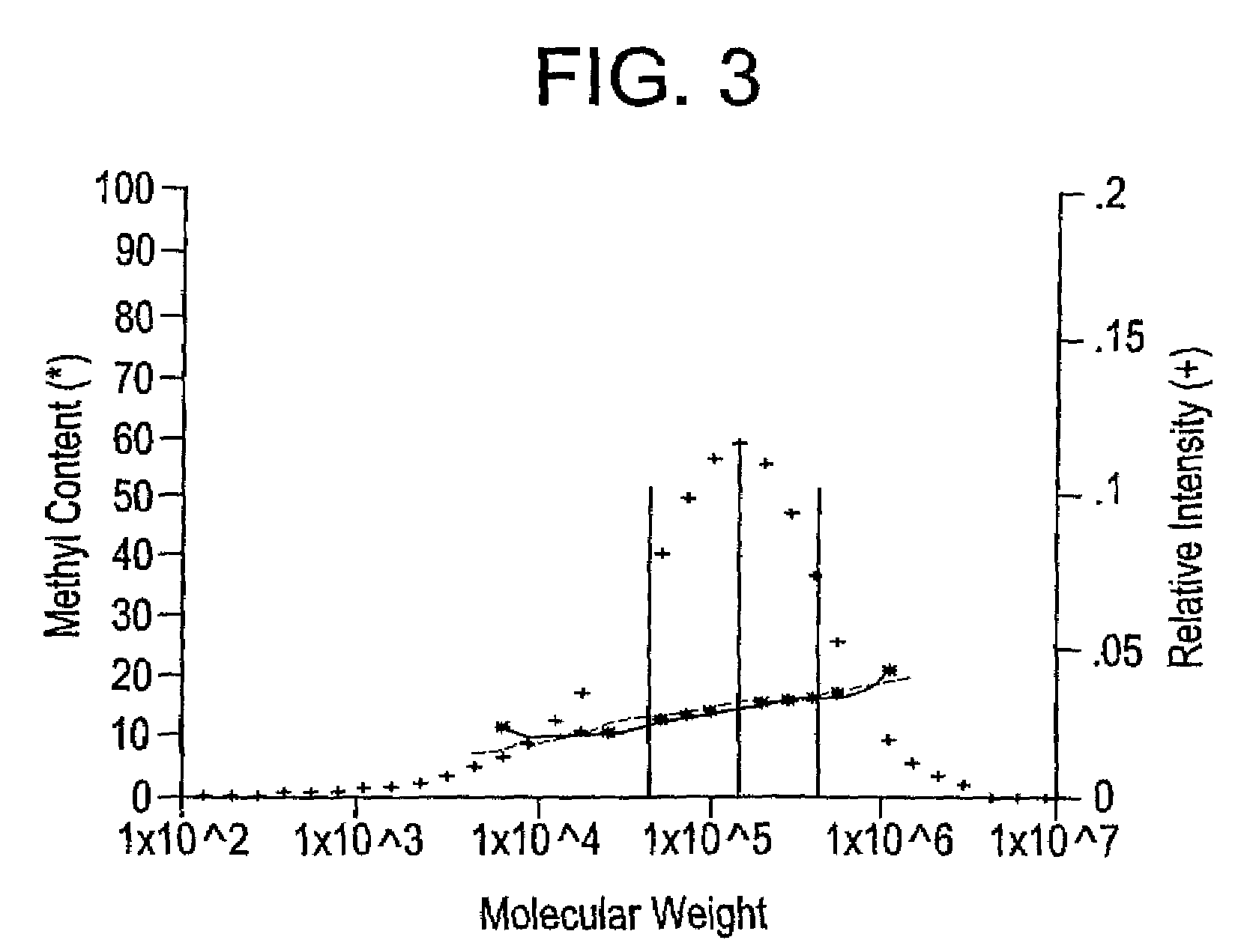

Ethylene copolymers and blend compositions

InactiveUS7714073B2Reduce molecular weightReduce wax contentMonocomponent polyolefin artificial filamentArylEthylene

The invention provides blends comprising an ethylene copolymer formed from ethylene with at least one comonomer selected from (a) the group comprising compounds represented by the formula H2C═CHR wherein R represents a C1-C20 linear, branched or cyclic alkyl group or a C6-C20 aryl group, and (b) a C4-C20 linear, branched or cyclic diene. Each copolymer has a specific density, a specific molecular weight distribution, and a specific comonomer content distribution characteristic.

Owner:DOW GLOBAL TECH LLC

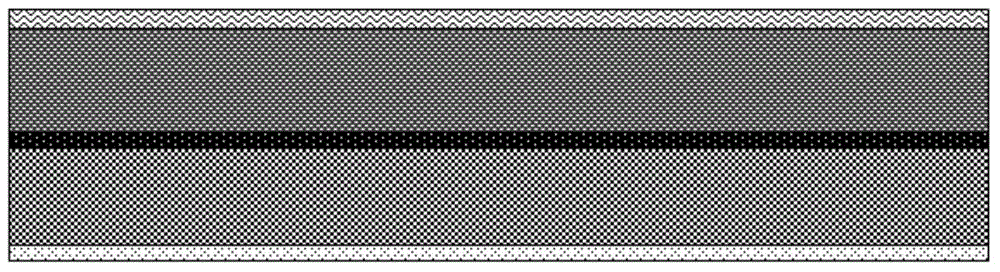

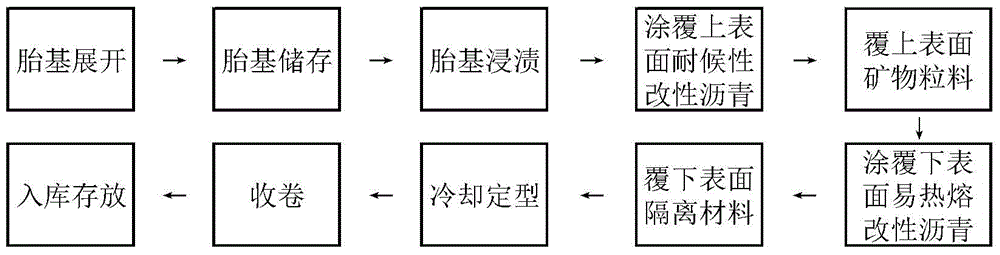

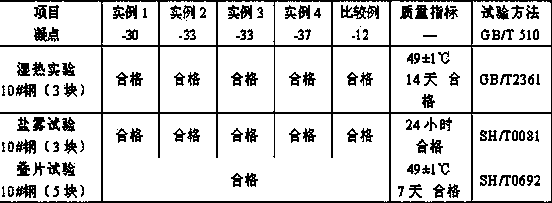

Weathering resistance modified asphalt waterproof coiled material

ActiveCN104369445AHigh nitrogen contentHigh molecular weightSynthetic resin layered productsConstructions elementsPolyesterGlass fiber

The present invention discloses a weathering resistance modified asphalt waterproof coiled material, wherein a glass fiber felt or polyester felt is adopted as a reinforcement, a weathering resistance modified asphalt layer is coated on the upper surface of the reinforcement, a modified asphalt layer with the characteristic of easy hot melting is coated on the lower surface of the reinforcement, a mineral particle layer is covered on the upper surface of the weathering resistance modified asphalt layer, and a polyethylene film is covered on the lower surface of the modified asphalt layer with the characteristic of easy hot melting. According to the present invention, the weathering resistance modified asphalt waterproof coiled material has characteristics of long service life, high waterproof performance, low construction temperature, reduction of aging of the modified asphalt at the high temperature, and reduction of environment pollution, and can be used for industrial and civil building roofing waterproof projects at different temperatures in different regions.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

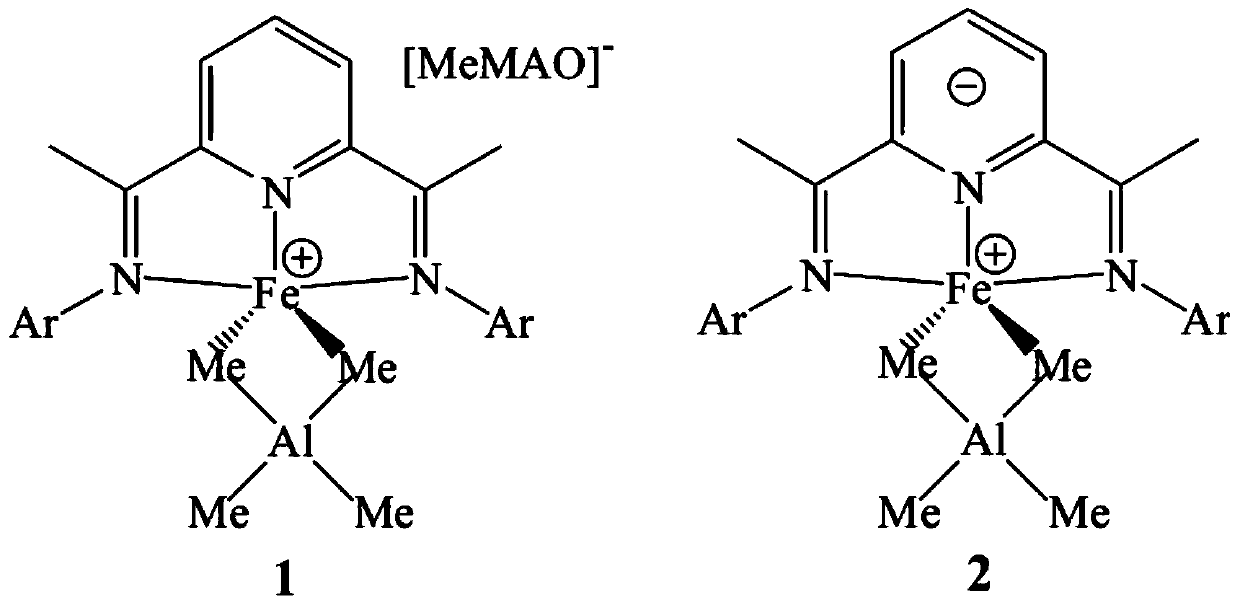

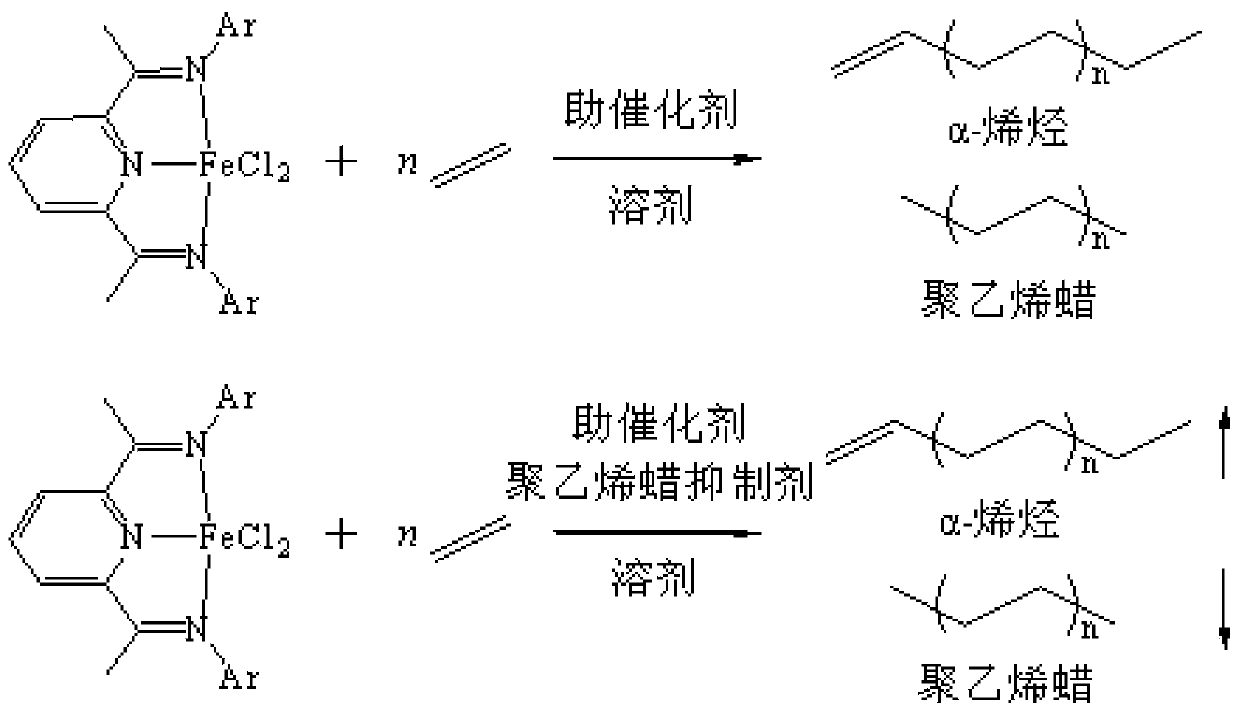

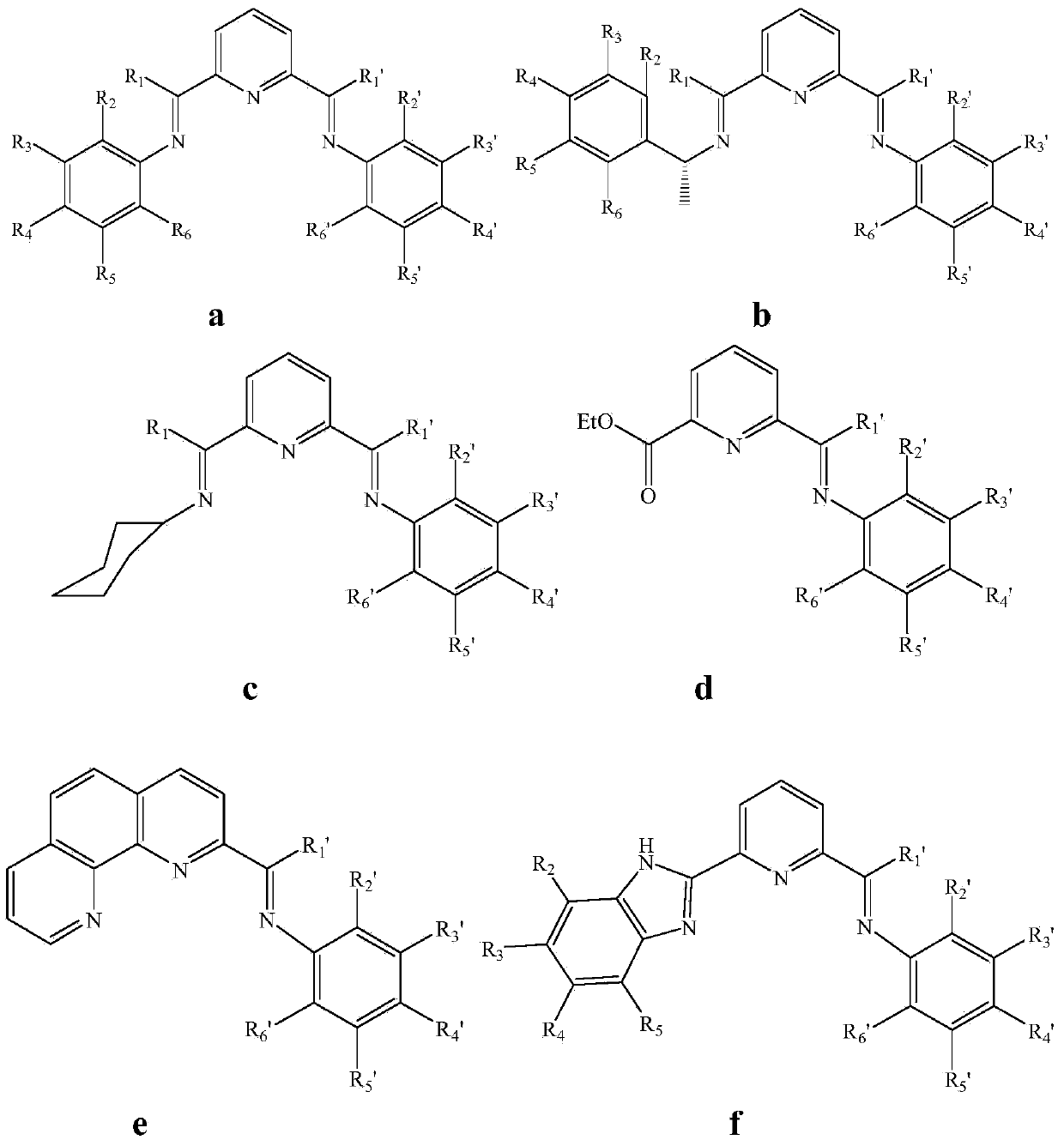

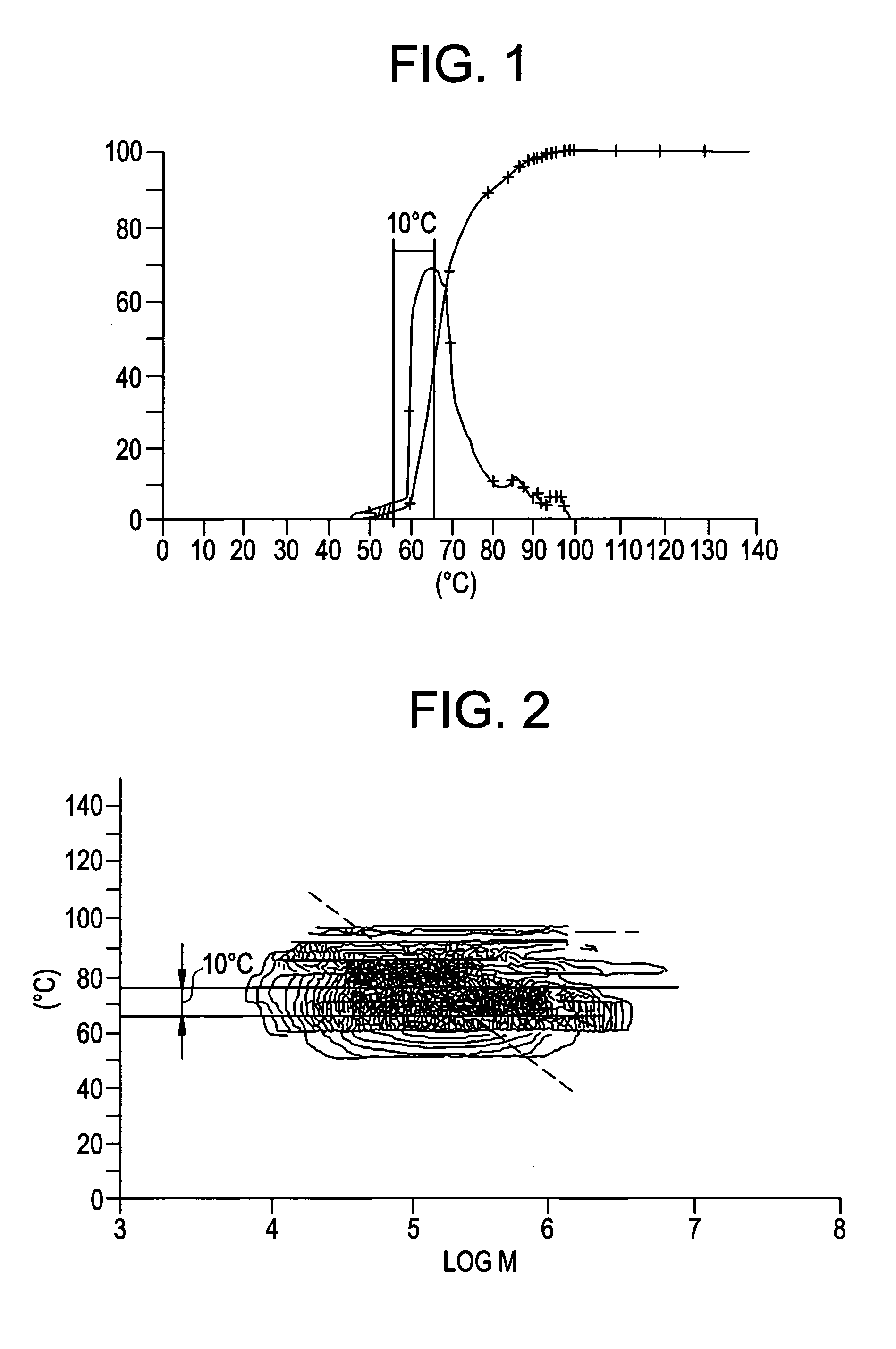

Method for reducing content of polyethylene wax during ethylene oligomerization reaction

InactiveCN103724146AReduce outputSuppress generationHydrocarbonsHydrocarbon preparationReaction temperatureKetone

The invention discloses a method for reducing the content of polyethylene wax during ethylene oligomerization reaction. The method comprises the steps as follows: adding a polyethylene wax inhibitor, a promoter and a primary catalyst into oligomerization reactor containing reaction medium, controlling the reaction temperature to be proper, introducing a vinyl monomer to reaction pressure, and performing oligomerization reaction. The polyethylene wax inhibitor is selected from one or more of ether, ketone, inner ester, a heterocyclic compound, an organic phosphine compound, a monocarboxylate or polycarboxylic compound and a silicon compound containing at least one Si-OR bond, wherein R adopts a hydroxy group. The method can effectively inhibit the generation of polyethylene wax, and meanwhile, obviously improve the yield of liquid phase alpha-olefin, thereby greatly reducing the content of the polyethylene wax during ethylene oligomerization reaction, and the method is beneficial to the safe and reliable operation of devices, so as to obtain high economic benefits.

Owner:ZHEJIANG UNIV

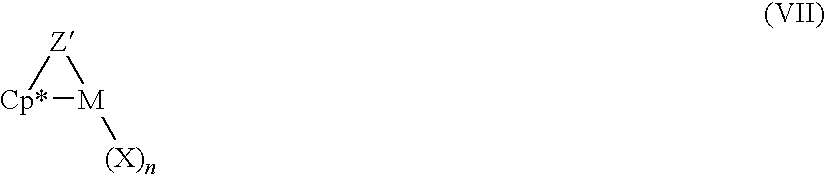

Process for preparing copolymers and blend compositions containing the same

InactiveUS20070088129A1Lower in molecular weightHigh comonomer contentMonocomponent polyolefin artificial filamentPolymer blendMetal

A process for the preparation of blends comprising an ethylene copolymer, which is prepared by polymerizing ethylene and at least one comonomer selected from (a) a compound represented by the formula H2C═CHR, wherein R is an alkyl group, an aryl group, or (b) a diene. The polymerization takes place in the presence of a solid catalyst system comprising a support, a transition metal compound and an activator capable of converting the transition metal compound into a catalytically active transition metal complex.

Owner:DOW GLOBAL TECH LLC

Gel-based lipstick having improved rheology

Gel-based lipstick compositions are disclosed comprising an ester terminated poly(ester-amide) (ETPEA) polymeric gellant, a first wax component having a melting point above the sol-gel transition temperature of the ETPEA gellant, a second wax compositions having a melting point equal to of below the sol-gel transition temperature of the ETPEA gellant, optionally a silicone T-resin co-gellent, and one or more oils capable of forming a gel with the ETPEA gellant. The gel compositions are solid or semi-solid at room temperature and are capable of being molded into self-supporting sticks. The disclosed gels provide high gloss films when applied to the lips and / or provide a rheology characterized by a high viscosity over repeated shear cycles.

Owner:AVON PROD INC

Technique for producing different softening point special bitumen by using native asphalt bitumen

InactiveCN101195758ASolve the problems of industrial productionReduce wax contentWorking-up pitch/asphalt/bitumen by selective extractionResidual oilSolvent

The invention discloses a process method for producing special asphalt with different softening points by utilizing natural asphalt. The invention solves the problem of a present lack of a production process of processing the special asphalt by utilizing the natural asphalt with a blending method, and provides the process method which has the advantages the process is simple, the production cost is low, and the temperature of the softening points is high, the method comprises the steps that firstly, residual oil or petroleum asphalt is taken as solvent; secondly, the solvent is heated to be in the state of Newtonian fluid; thirdly, natural asphalt powder is taken, according to the difference of product softening points, the natural asphalt powder and the solvent are uniformly added into the solvent with proportion of 2 to 65 : 100; fourthly, the natural asphalt powder is heated continuously and stirred to be melted, and the development is performed for 30 to 120 minutes; fifthly, for asphaltic products with the softening point being above 120 DEG C, material charging is performed for cooling, special machinery is used for performing crushing process, special asphalt power with the high softening point is obtained, and products with the softening point lower than 120 DEG C are fed into a finished product tank.

Owner:邱玉玲

Asphalt tile

ActiveCN103821282AGood weather resistanceGood performance and stabilityRoof covering using tiles/slatesSynthetic resin layered productsGlass fiberAsphalt shingle

The invention discloses an asphalt tile. The asphalt tile is of a multilayer structure, and consists of a mineral particle layer, a glass fiber felt, modified asphalt coating layers and an isolation material layer from top to bottom, wherein the mineral particle layer and the glass fiber felt are arranged on the upper surface, the modified asphalt coating layers are arranged at the two surfaces of the glass fiber felt, and the isolation material layer is arranged on the lower surface. The asphalt tile has the advantages that the good mineral particle adhering performance, anti-aging performance and flame-retardant performances are realized; the asphalt tile can be applied to various types of building roofs, especially the slope roofs of civil houses and villas.

Owner:东方雨虹建筑修缮技术有限公司

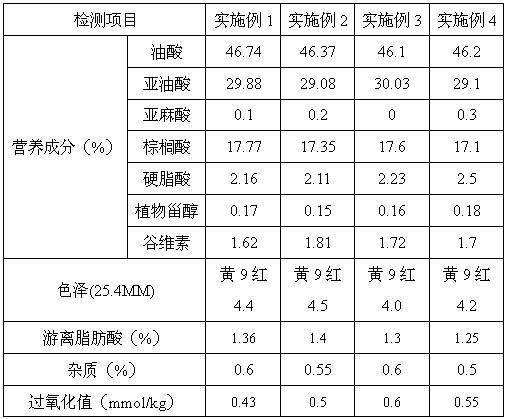

Method for dry degumming and refining of edible rice bran oil

The invention belongs to the field of edible oil processing, in particular to a method for dry degumming and refining of edible rice bran oil. The dry degumming utilizes the mixing and flocculation of phosphoric acid and gum impurities to form larger particles so as to facilitate to remove out of oil by filter after the larger particles are mixed with waste clay. The secondary decolorization absorbs and removes pigments formed in physical deacidification and original pigments in oil by utilizing the adsorption of the clay to the pigments. The deordorization utilizes a steam distillation principle, i.e., under high vacuum and certain temperature, direct steam is pumped into the oil to reduce the partial pressure of odor substances in the oil, so that the substances are gasified and discharged from the oil along with the steam, and thereby, the oil has no peculiar smell. The invention has no water adding hydration process and no oil sediment and waste water, and the product yield can be increased by more than 3%; the secondary decolorization is adopted, and the color is good; the deodorization process is added, the oil has no peculiar smell; and the second dewaxing process is adopted, the wax content in the oil is extremely low, and the oil quality is improved.

Owner:ANHUI SIRUN GRAIN OIL REFINERY

Gel-based lipstick having improved rheology

Gel-based lipstick compositions are disclosed comprising an ester terminated poly(ester-amide) (ETPEA) polymeric gellant, a first wax component having a melting point above the sol-gel transition temperature of the ETPEA gellant, a second wax compositions having a melting point equal to of below the sol-gel transition temperature of the ETPEA gellant, optionally a silicone T-resin co-gellent, and one or more oils capable of forming a gel with the ETPEA gellant. The gel compositions are solid or semi-solid at room temperature and are capable of being molded into self-supporting sticks. The disclosed gels provide high gloss films when applied to the lips and / or provide a rheology characterized by a high viscosity over repeated shear cycles.

Owner:AVON PROD INC

High gloss gel-based lipstick

ActiveUS7989002B2High gloss filmImprove rheologyBiocideCosmetic preparationsPolymer chemistryChemistry

Gel-based lipstick compositions are disclosed comprising an ester terminated poly(ester-amide) (ETPEA) polymeric gellant, a first wax component having a melting point above the sol-gel transition temperature of the ETPEA gellant, a second wax compositions having a melting point equal to of below the sol-gel transition temperature of the ETPEA gellant, optionally a silicone T-resin co-gellant, and one or more oils capable of forming a gel with the ETPEA gellant. The gel compositions are solid or semi-solid at room temperature and are capable of being molded into self-supporting sticks. The disclosed gels provide high gloss films when applied to the lips and / or provide a rheology characterized by a high viscosity over repeated shear cycles.

Owner:AVON PROD INC

Low-temperature antirust oil used in bearing sealing, and production process thereof

The invention relates to low-temperature antirust oil used in bearing sealing. The oil is composed of the components of, by weight: 13-17% of an antirust agent, 0.2-0.8% of a pour point depressant, and 82-87% of base oil. The antirust agent is composed of lanolin magnesium soap, calcium dinonyl naphthalene sulfonate, and calcium petroleum sulfonate. The pour point depressant is polymethacrylate. The base oil is polymethyl cycloalkyl transformer oil or hydraulic oil. The antirust oil provided by the invention has good low-temperature fluidity. Coagulation crack is prevented under low temperature. The base oil has low pour point. Especially, the pour point depressant is added, such that the pour point is lower. Therefore, the antirust oil can be used in an environment with a temperature of -10 DEG C and lower. Also, the antirust oil provided by the invention is clear and transparent, and has no precipitate or film. The oil has the advantages of good application performance, good oil film maintenance, simple production process, and convenient application. The process is mainly used in bearing antirust sealing under low temperatures, and can be applied on both open-type and sealed bearings. No adverse influence is caused on bearing lubricating grease. The antirust oil can also be used in sealing and rust prevention of other black metal products.

Owner:LUOYANG BEARING RES INST CO LTD

Fracturing process in oil and water well by means of biological enzyme preparation

InactiveCN1766283AImprove work efficiencyDoesn't take into account the reverse dischargeFluid removalWater wetFracturing fluid

The invention discloses an oil field oil-water well fracturing craft method of biological enzyme agent, which is characterized by the following: building the mixed biological enzyme agent and water or biological acid or antisludging agent or liquid nitrogen as fracturing fluid; forcing the fracturing fluid into the oil well or water well through the fracturing vehicle; pressing the fracturing fluid into the crack; opening the well after 72 hours. The biological enzyme agent penetrates the hole throat then enters into the microscopic hole gap, which attaches the rock surface and denudes the raw oil to improve the earth penetration factor. The method improves the water wet effect and washes the spalling oil film, which improves the recovery factor of raw oil.

Owner:SUNCOO PETROLEUM TECH

Dewaxing method of rice oil

InactiveCN102676294AEnsure safetyReduce wax contentFatty substance recovery/refiningFatty-oils/fats refiningVegetable oilPhysical chemistry

The invention relates to a dewaxing method of rice oil, which belongs to the technical field of processing of edible oil. The dewaxing method of the rice oil comprises the steps of: (1) heating the rice oil to be dewaxed to be at 50-80 DEG C, inputting to a crystallization tank to be cooled to be at 10-15 DEG C at 3-6 DEG C / h and maintaining the temperature for 18-25 hours, and seeding out wax in the rice oil; and (2) conveying products obtained from the step (1) at a flow rate capable of maintaining laminar condition to a wax and oil separator which is 15-25 meters lower than the crystallization tank, and filtering by a plurality of 300-1500 mesh filter screens at the pressure of 1-3kg / cm<2> and the temperature of 10-15 DEG C so that oil filtered is the rice oil without wax. According to the method provided by the invention, in the process is simple, parameters can be controlled easily, the equipment investment is low, and the dewaxing effect is excellent so that the method is applicable for dewaxing of other edible plant oil within a wide application range.

Owner:劲旺粮油食品有限公司 +1

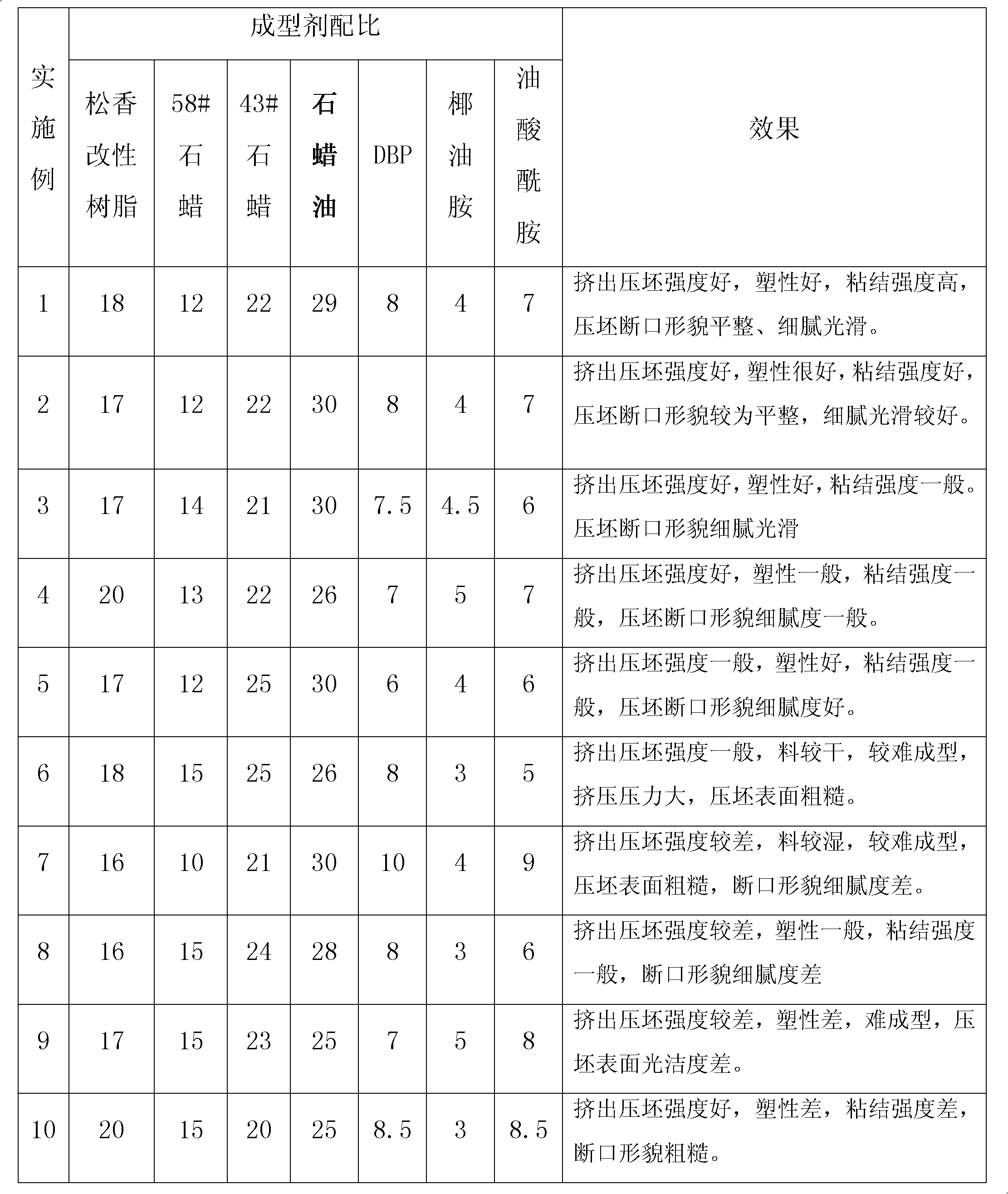

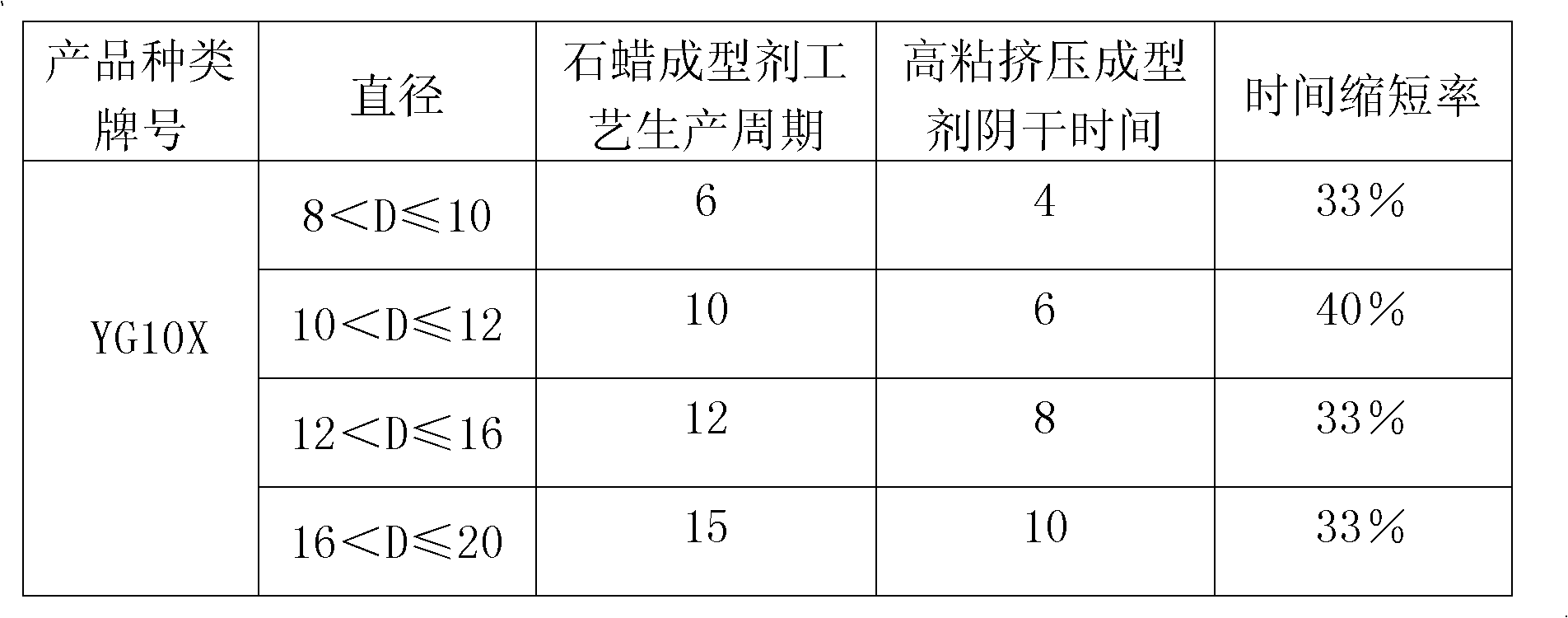

High-viscosity extrusion forming agent

The invention discloses a high-viscosity extrusion forming agent, comprising the following ingredients: 15-20 wt% of rosin modified resin, 10-15 wt% of paraffin No.58, 20-25 wt% of paraffin No.43, 25-30 wt% of paraffin oil, 5-10 wt% of dibutyl phthalate (DBP), 1-5 wt% of coconut amine, and 5-10 wt% of oleamide. According to the invention, extrusion billets can be prevented from cracking in the quick drying process, the extruded billets can be guaranteed to have good shape retention, and the qualified rate of the products is raised.

Owner:XIAMEN TUNGSTEN

Microbial paraffin removing and preventing method for high wax content oil well

The invention belongs to the technical field of oilfield chemistry, and particularly relates to a microbial paraffin removing and preventing method for a high wax content oil well. The microbial paraffin removing and preventing method comprises the following steps that screening of a test oil well is conducted; optimization of microbial paraffin removing and preventing bacteria is conducted; the dilution capacity of the microbial paraffin removing and preventing bacteria is evaluated; field dosage is determined; the dosing timing is determined; and the field test and the effect are evaluated. According to the microbial paraffin removing and preventing method for the high wax content oil well, scientific basis is provided for determination of the bacteria adding amount and the bacteria adding timing of the test oil well; and meanwhile the method has the characteristics that the application range of an oil deposit is wide, the technology is simple, the operability is high, and the field testing effect is good, the hot washing period is effectively prolonged by over 200 d, and over five times of well hot washing of a single well are saved every year. In this way, the method can be widely applied to paraffin removing and preventing operation for the high wax content oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

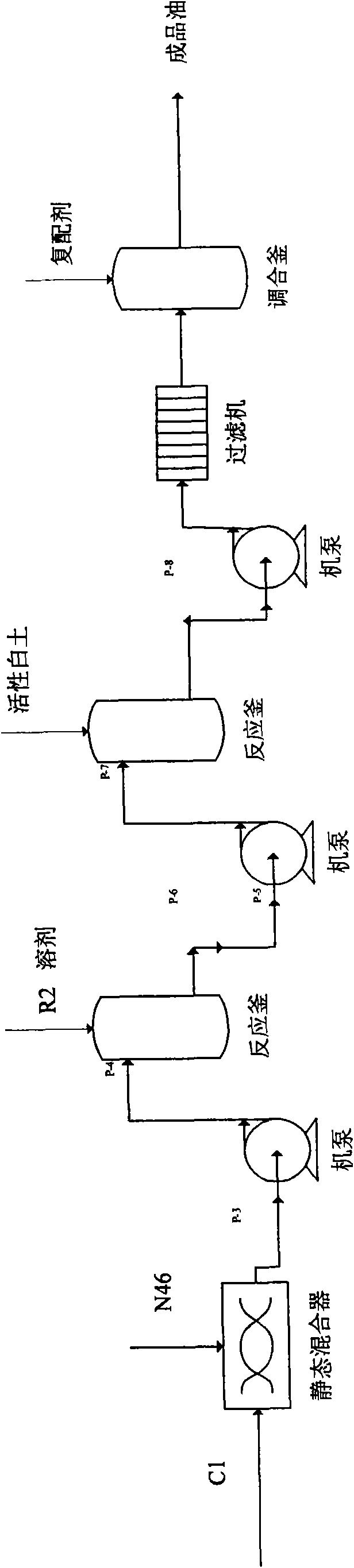

Color printing ink solvent oil and preparation method thereof

The invention relates to a preparation method of color printing ink solvent oil. The color printing ink solvent oil is prepared by utilizing naphthenic base crude oil fractions, adopting a special dearomatization process and a clay decoloring and refining process to produce base oil and adding proportioned unique compound additive, i.e. the solvent-refining process and the clay decoloring and refining process are carried out to the base oil which is then proportioned by a complex additive to finally prepare finished oil. The method does not generate aromatic toxicity and lessens damage to human beings; the color printing ink solvent oil keeps balance between the dissolving capacity and the release property of resin, solves the problems of unstable product indexes, such as water resistance,penetrability, and the like and has good printing performance, printing stability and storage stability of printing ink, light colors, good water resistance, strong penetrability, suitable aniline point, balanced dissolving capacity and release property to resin, no pungent odor and environmental protection. A printing ink product manufactured by the product has good printing quality, thick printing layer, uniform and full colors, bright colors and luster and strong printability.

Owner:TIANJIN LIANDA GROUP

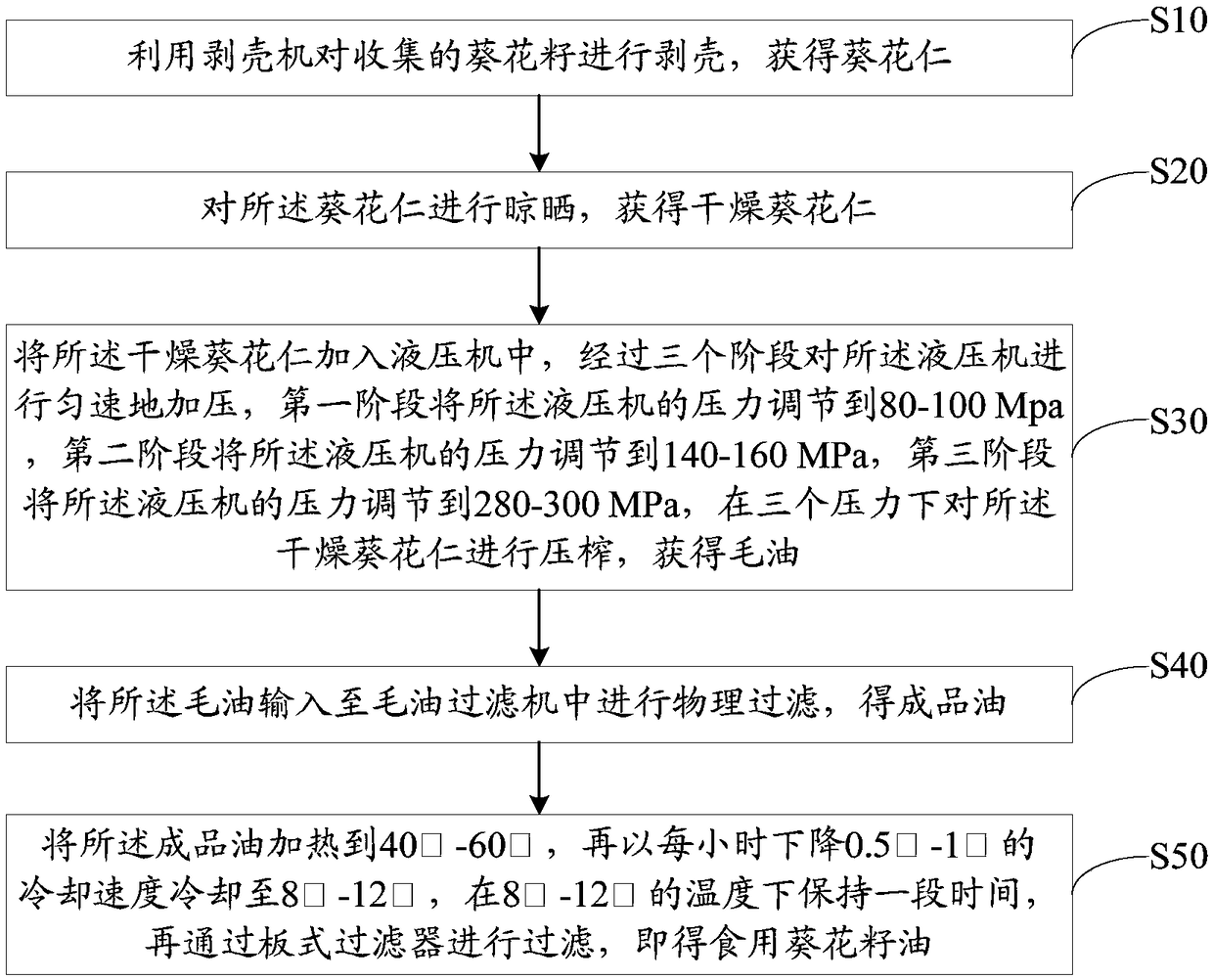

Production method of sunflower seed oil and edible sunflower seed oil

InactiveCN108753438AReduce wax contentImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionSunflower seedWax

The invention discloses a production method of sunflower seed oil and the edible sunflower seed oil. The production method of the sunflower seed oil comprises the following steps: shelling collected sunflower seeds by a shelling machine to obtain sunflower kernels; airing the sunflower kernels to obtain dried sunflower kernels; adding the dried sunflower kernels to a hydraulic press, regulating pressure of the hydraulic press to 80-100 MPa at the first stage, regulating pressure of the hydraulic press to 140-160 MPa at the second stage, regulating pressure of the hydraulic press to 280-300 MPaat the third stage, and pr essing the dried sunflower kernels under three kinds of pressure to obtain crude oil; feeding the crude oil into a crude oil filter for physical filtration to obtain finished product oil, heating the finished product oil to 40-60 DEG C, cooling the finished product oil to 8-12 DEG C at a cooling rate of 0.5-1 DEG C / h, keeping the temperature at 8-12 DEG C for a period of time, and then performing filtering by a plate filter to obtain the edible sunflower seed oil. The provided production method of sunflower seed oil has the advantages that the oil yield can be increased, and the wax content of the edible sunflower seed oil is reduced.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

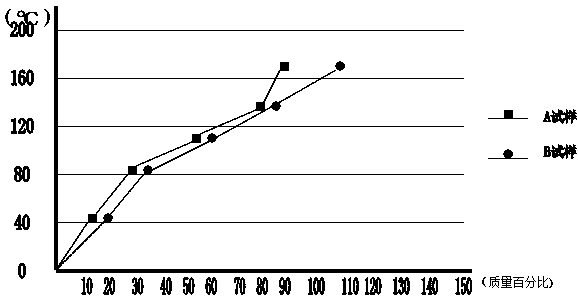

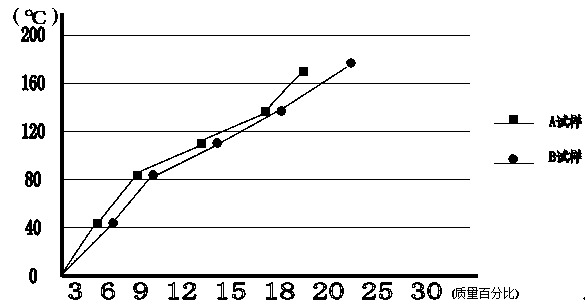

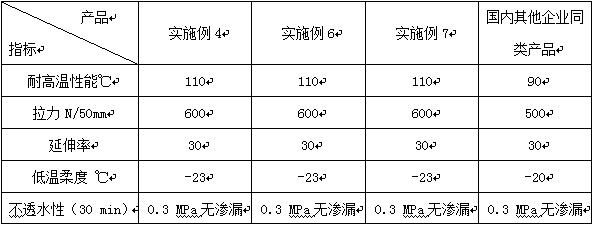

Elastic modified asphalt waterproof coil material and preparation method thereof

InactiveCN109762358AImprove aging resistanceReduce wax contentSynthetic resin layered productsBuilding insulationsPolyesterElastomer

The invention relates to a modified asphalt waterproof coil material and a preparation method thereof, and belongs to the technical field of chemical engineering. The modified asphalt waterproof coilmaterial is prepared from 90# asphalt, 10# asphalt, butadiene styrene rubber, activating glue powder, polyethylene membranes, polyester blanks, engine oil and filling materials. The 90# asphalt, 10# asphalt, YP03 activating glue powder, engine oil and other filling materials are added into the elastomer modified asphalt waterproof coil material; through the modification on the elastomer modified asphalt waterproof coil material by YP03 active rubber powder, the ingredient stirring process is studied; the process control parameters are changed; the proceeding of the ingredient stirring processin production at the lower temperature is realized; the high-temperature-resistant performance and the low-temperature softness performance are improved.

Owner:WEIFANG BOYUAN NEW WATERPROOF MATERIAL

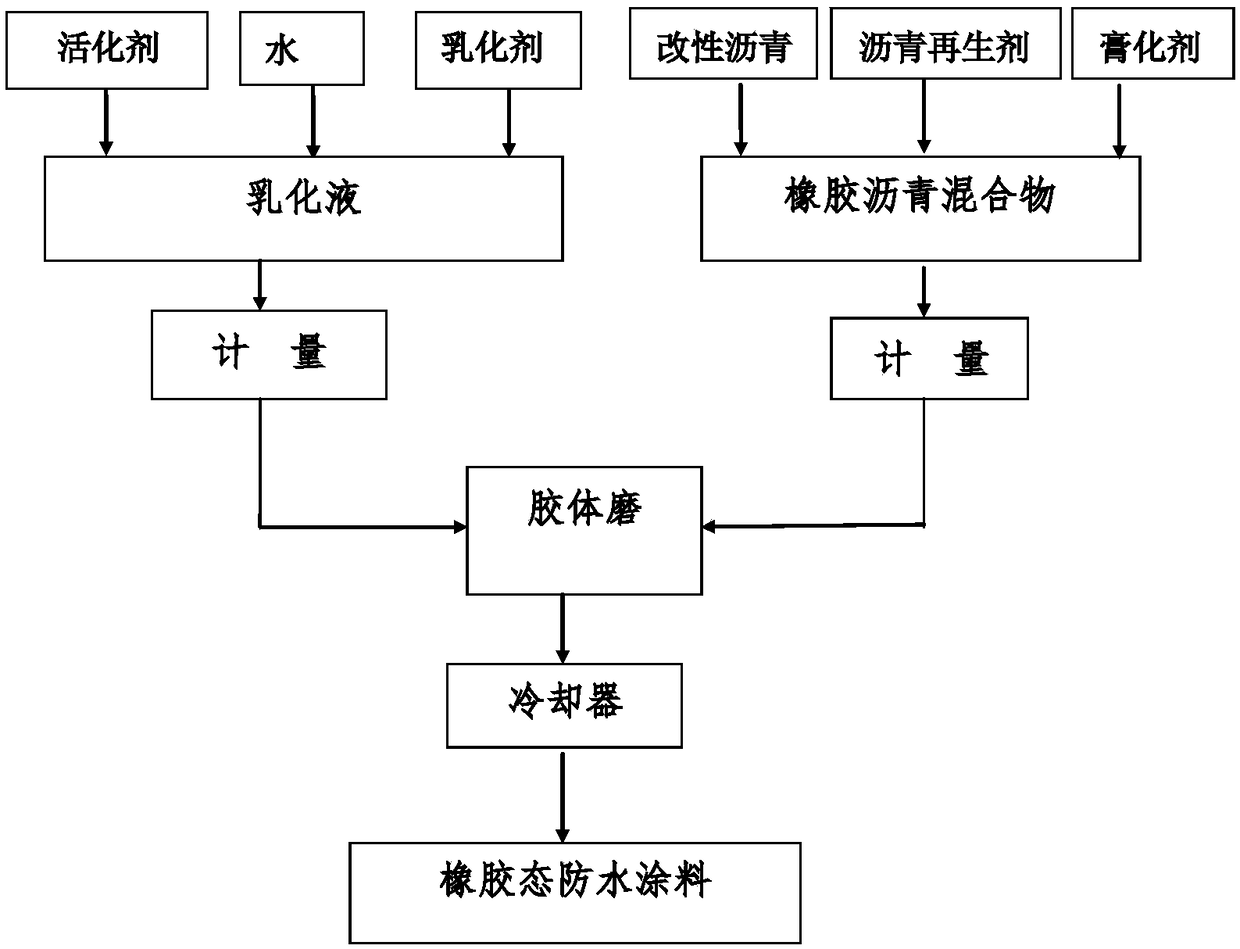

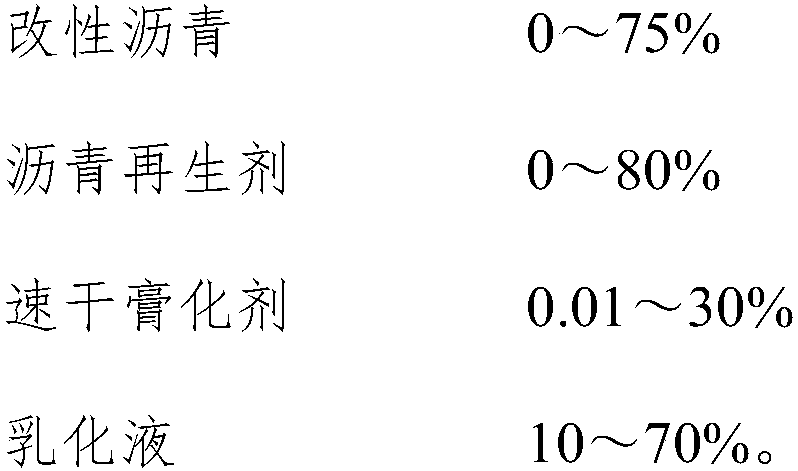

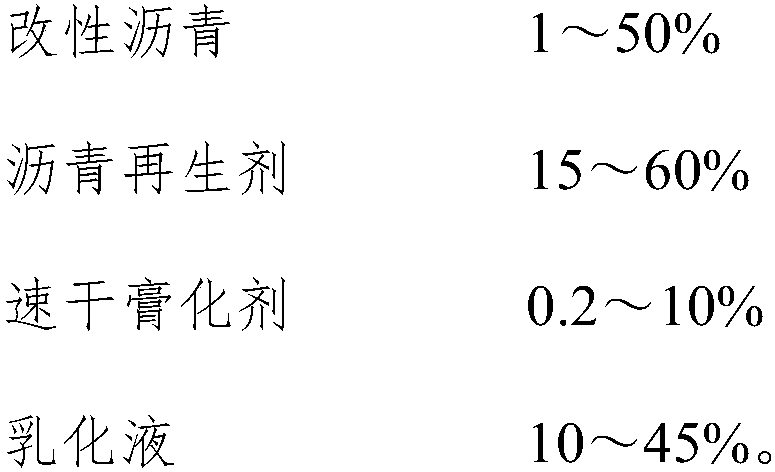

Multi-path thick coating and one-step molded rubber-state waterproof coating and preparation method thereof

InactiveCN108395844AReduce wax contentImprove performanceRoof covering using flexible materialsProtective foundationColloidAsphalt

The invention relates to multi-path thick coating and one-step molded rubber-state waterproof coating and a preparation method thereof and belongs to the technical field of sealing water prevention. The rubber-state waterproof coating provided by the invention is mainly prepared from the following raw materials in percentage by mass: 0 to 75 percent of modified asphalt, 0 to 80 percent of asphaltregeneration agent, 0.01 to 30 percent of quick-drying creaming agent and 10 to 70 percent of emulsified liquid; the rubber-state waterproof coating is prepared through steps of preparing a rubber asphalt mixture, preparing the emulsified liquid, emulsifying and creaming and de-foaming. According to the rubber-state waterproof coating, an inorganic creaming agent is used as the quick-drying creaming agent and the emulsified liquid is used for emulsifying and creaming the rubber asphalt mixture through a colloid mill by adopting a one-pot method and the prepared rubber-state waterproof coatingis uniform, fine and smooth and has high quality; the rubber-state waterproof coating has very good thixotropic performance, rapid dehydration and drying properties and excellent construction and application performance; the production efficiency is improved by applying the one-pot method and quality stability of a product and environment protection are facilitated.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

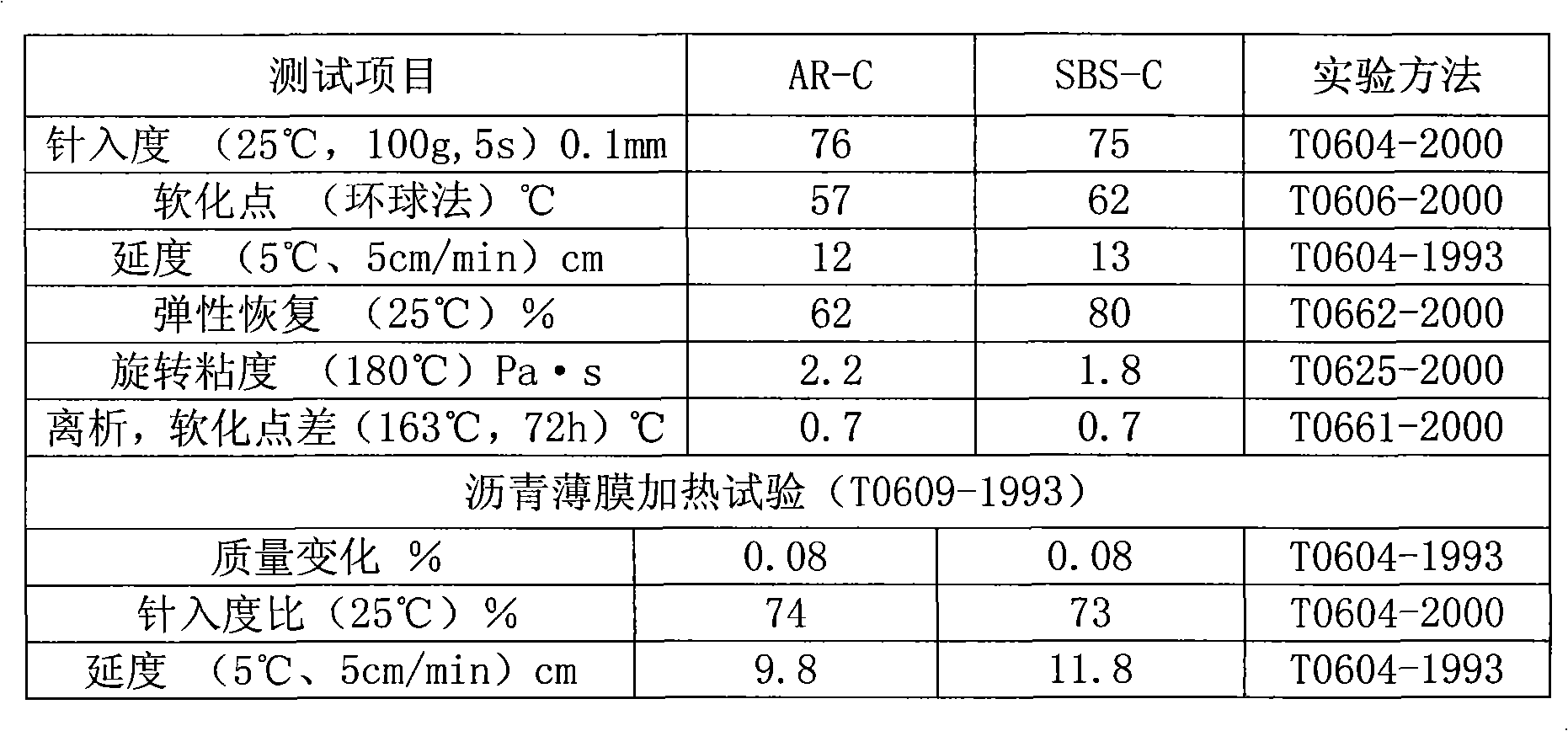

Compound SBS modified asphalt and preparation method thereof

The invention provides compound SBS modified asphalt and a preparation method thereof. The method comprises the following steps: metering petroleum asphalt, rapidly heating the petroleum asphalt to 170-180 DEG C and sending the petroleum asphalt to a mixer; metering and adding SBS polymers, rubber powder, coal tar, dimethylamino pyridine and butyl americium rubbers, and after the substances are mixed and fully swollen in the mixer, fully grinding the mixture in a colloid grinder to reach the required disperse mixed melt state; sending the ground mixture to a development tank, adding a stabilizing agent dibenzoic acid dibutyl tin and developing the mixture for 1h under stirring at 180 DEG C and low speed, thus obtaining the qualified product. The asphalt is prepared by mixing 42.3% of petroleum asphalt, 35% of rubber powder, 15% of coal tar, 2% of SBS polymers, 3% of dimethylamino pyridine, 2.5% of butyl americium rubbers and 0.2% of dibenzoic acid dibutyl tin. The rubber powder can be added at high proportion and the high / low temperature performance value and the storage stability of the finished product are improved.

Owner:中国禾森石化控股有限公司

Pressing processing technology of sunflower seed oil

InactiveCN106635398AKeep the scentImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionEngineeringEdible oil

The invention belongs to the field of processing of edible oil, and relates to a pressing processing technology of sunflower seed oil. The processing technology comprises the following steps of sorting, and removing impurities; baking and frying for 50min at the temperature of 160 DEG C; cooling by a fan, naturally cooling to room temperature, crushing the obtained raw material into oil paste, adding water of which the mass is equal to 8 to 10% of the mass of the raw material, and uniformly stirring; pressing by a hydraulic oil press at the pressure equal to or less than 80MPa, obtaining crude oil, and filtering; degumming by edible salt solution; dewaxing by food-level perlite at the system temperature equal to or lower than 0DEG C, so as to obtain the sunflower seed oil. The sunflower seed oil obtained by the processing technology has the advantages that the oil yield rate is higher, and is 38 to 40%; the content of wax is lower, and is 12 to 18mg / kg; the flavor is good, the quality is high, and the heavy oil fragrance is obtained.

Owner:宁夏苏酥粮油工贸有限公司

Environment friendly process for biodiesel

InactiveCN101486923AReduce consumptionReduce investmentBiofuelsLiquid hydrocarbon mixture productionLiquid wasteWax

The invention discloses environmental protection technology for bio-diesel production, which comprises the following units: 1) raw material preparation; 2) pre-esterification; 3) fine esterification; 4) washing desulphurization esterification; 5) refined methyl ester separation; 6) low-temperature dewaxing; 7) emission recovery; and 8) wastewater treatment. The environmental protection technology has the advantages that: 1. energy saving and emission reduction: the low temperature is served as technology heat and reduces the consumption of the energy; after the unit separation and purification, the produced exhaust gas and waste liquid can be reused in the technology, thus reducing the pollution emissions; 2. rapid esterification speed: high esterification rate; the hydrous grease is separated promptly by a liquid separating tank, thus avoiding a reverse reaction and reducing the esterification time to 1 hour; the acid value recovery problem is solved, so that the esterification is more thorough; the esterification rate can reach more than 98%; 3.output improving: the environmental protection technology has compact technology and reasonable procedure and can realize continuous and large-scale flowing production; and 4. low bio-diesel solidifying point: the wax in the bio-diesel is removed effectively by using a jacketed crystallizer and a full-automatic pressing filter, and the solidifying point is reduced.

Owner:迟洪军

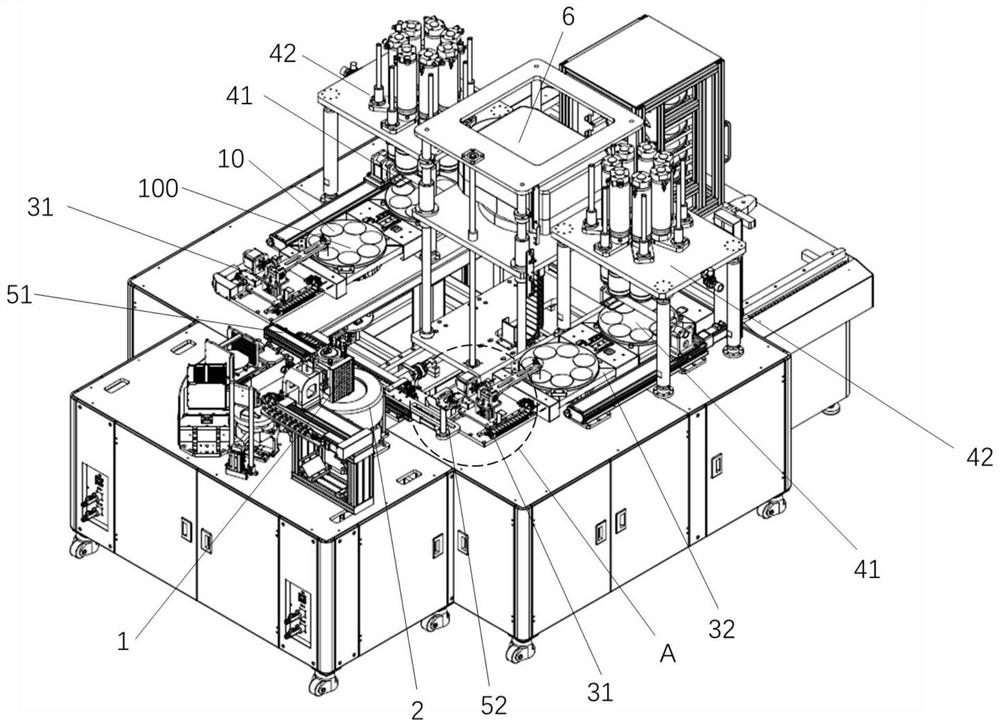

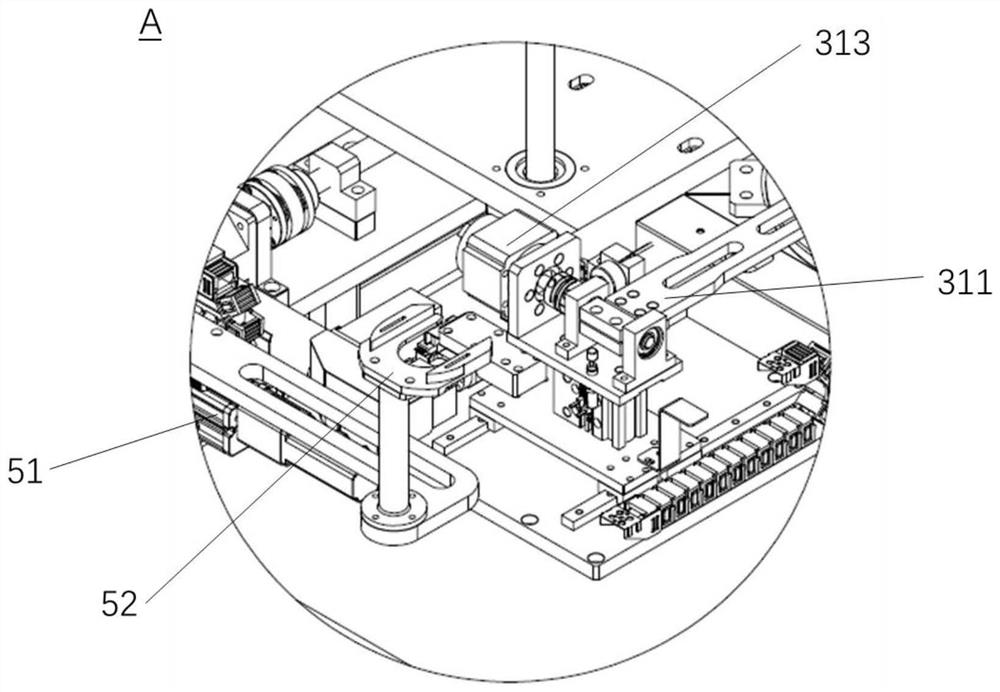

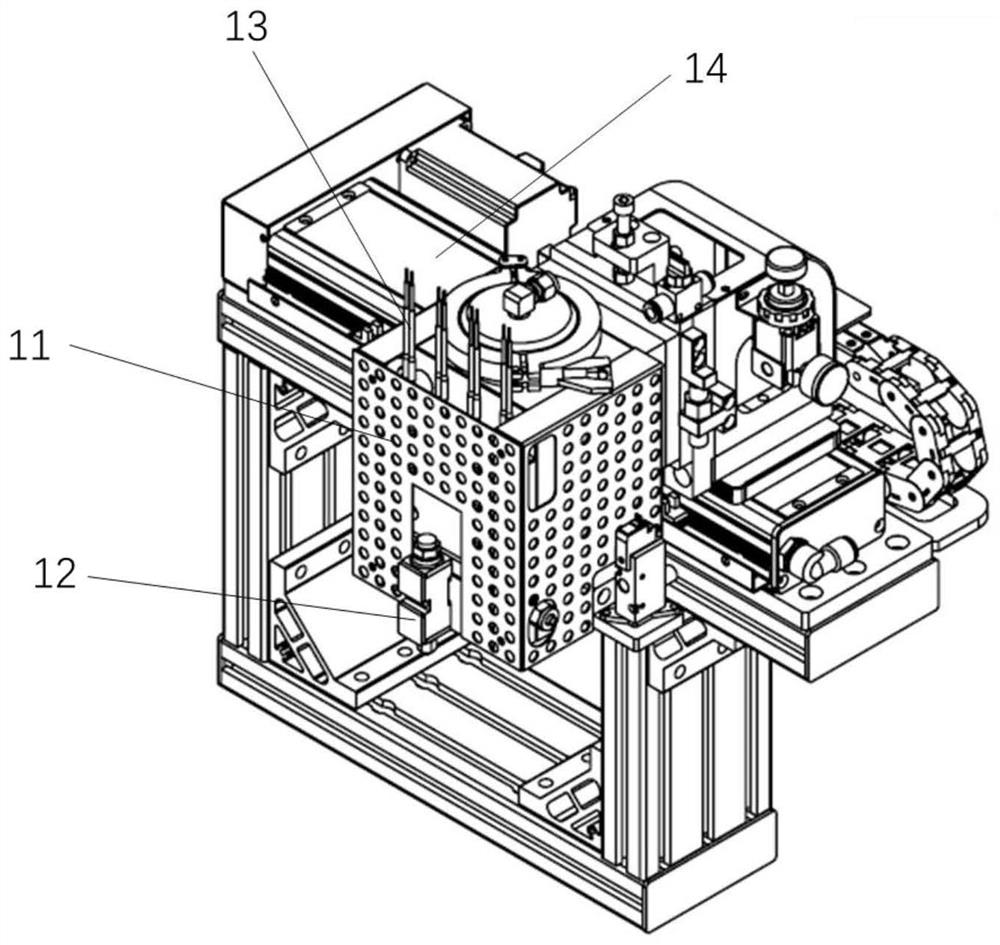

Chip mounting equipment for solid wax

PendingCN111681970AEvenly distributed waxGood flatnessLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses chip mounting equipment for solid wax. The equipment comprises a wax dripping device, a wax throwing device, a pre-patching device and a pressing and attaching device, whereinthe wax dripping device is used for dripping wax to the back surface of a wafer; the wax throwing device is used for melting wax on the wafer and throwing the wax on the wafer; the pre-patching deviceis used for pre-positioning the wafer subjected to wax throwing on a bearing workpiece; the pressurizing device is used for pressurizing a wafer and a bearing workpiece, therefore, the wafer is adhered to the bearing workpiece, the pressurizing device comprises a third bearing platform and a pressing machine module arranged above the third bearing table, the third bearing platform is used for bearing a bearing workpiece to which a wafer is pre-pasted; the pressing machine module is used for pressurizing the wafer on the bearing workpiece, a third heating mechanism and a cooling mechanism arearranged on the third bearing platform, the third heating mechanism is used for heating wax between the bearing workpiece and the wafer, and the cooling mechanism is used for cooling the wax between the bearing workpiece and the wafer. The scheme has the advantages of saving solid wax, saving consumables such as wax absorbing paper, improving the production efficiency, reducing the mounting spaceand the like.

Owner:苏州辰轩光电科技有限公司

Eucommia seed oil refining technology

ActiveCN103113983AReduce gum contentReduce wax contentFatty-oils/fats refiningChemical reactionOil quality

The invention belongs to the field of oil refining technology, and particularly relates to a eucommia seed oil refining technology which comprises the following steps of: washing the crude eucommia seed oil; dehydrating and decoloring; performing deacidification and deodorization at the same time after the decoloring; and finally performing polishing treatment. According to the invention, deacidification and deodorization are performed at the same time, and physical operation is adopted to avoid chemical reaction and high-temperature operation, thereby greatly improving the oil quality.

Owner:LINGBAO JINDI EUCOMMIA IND

Method for preparing rice bran crude oil from rice bran

InactiveCN103451008AReduce wax contentHigh transparencyFatty-oils/fats refiningFatty-oils/fats productionRice Bran ExtractRice bran oil

The invention relates to a method for preparing rice bran crude oil from rice bran, and particularly relates to a method for preparing low-bran wax rice bran crude oil rich in physiologically active substances from the rice bran at a low temperature. The lixiviation of the existing rice bran oil mostly pursues high extraction rate purely and ignores the influence of process conditions on oil characteristics. In order to solve the problem of how to keep good nutritive value of oil on the premise of obtaining high extraction rate during bran oil extraction, the method is as follows: the rice bran crude oil is extracted by adopting a low-temperature extraction process. According to the invention, the oryzanol and tocopherol content of the rice bran crude oil lixiviated under the condition of 20 DEG C is far higher than that of the rice bran crude oil lixiviated at a high temperature, in such a way, the nutritive value of the rice bran oil can be effectively enhanced; in addition, waxes are difficult to separate out and enter the rice bran crude oil under the condition of low temperature according to the hot melting and cold separating principle of the bran waxes on n-hexane, so that the quality, such as transparency, smell and color, of the rice bran oil is enhanced, and the separation of the physiologically active substances during wax freezing treatment is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for separating high-purity rice bran crude oil from rice bran

InactiveCN105349252AIncrease contentHigh purityFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyDistillation

The present invention discloses a method for separating high-purity rice bran crude oil from rice bran. The method comprises: weighing 100 g of puffed rice bran, extracting by using n-hexane as a solvent, sequentially carrying out centrifugation and evaporation to obtain primary pure rice bran crude oil, carrying out film distillation on the primary pure rice bran crude oil raw material at a temperature of 120-130 DEG C under an absolute vacuum of 30-50 Pa to remove water and organic small molecule impurities, carrying out distillation twice to obtain fatty acid, and carrying out distillation twice on the remnants of the two distillations to obtain the high-purity rice bran oil. According to the present invention, the method has characteristics of high physiologically active substance content, low wax content, rice bran oil purity improving, physiologically active substance precipitation reducing during the freezing wax treatment, and complete impurity removing.

Owner:JIANGSU KANG ZHI YUAN GRAIN & OIL

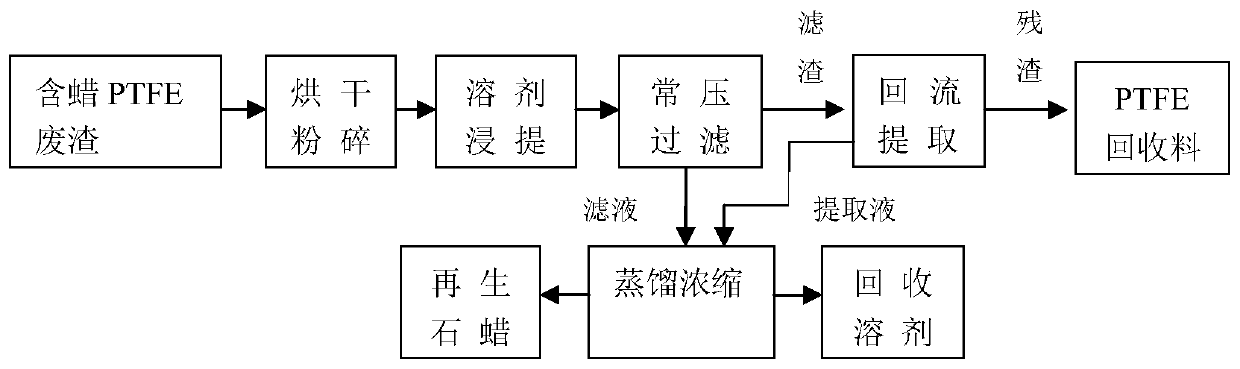

Method for recovering polytetrafluoroethylene dispersion resin

The invention relates to a method for recovering polytetrafluoroethylene dispersion resin, and the method comprises the following steps: 1) extracting a polytetrafluoroethylene dispersion resin material containing paraffin once or multiple times by using an extracting agent until the paraffin content in the material is less than 10%; and (2) continuously carrying out continuous reflux extraction on the material treated in the step (1) by using the extracting agent until the paraffin is fully leached, and controlling the outflow volume of leach liquor in unit time to be the same as the drippingvolume of the condensed extracting agent in the extraction process. Firstly, by carrying out first-step solvent extraction, most of the paraffin in waste residues is extracted; and then a small amount of tightly wrapped paraffin is subjected to continuous reflux extraction, so that the separation effect of the paraffin and the polytetrafluoroethylene dispersion resin can be effectively improved,and the method has the advantages of short separation time, low heating temperature, low solvent consumption and low energy consumption in the whole separation process, and is suitable for industriallarge-scale application.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Low-temperature-resistant asphalt waterproof coating and method for preparing same

ActiveCN106967362AImprove low temperature resistanceGood anti-aging performanceBituminous coatingsNeedle penetrationCrack resistance

The invention belongs to the technical field of building waterproof coating, and particularly relates to low-temperature-resistant asphalt waterproof coating. The low-temperature-resistant asphalt waterproof coating comprises, by weight, 70-80 parts of asphalt, 3-5 parts of modification auxiliaries, 10-16 parts of modified plant ash, 6-8 parts of amylopectin, 3-6 parts of sulfur powder, 6-8 parts of natural rubber powder, 1-3 parts of anti-aging agents, 2-4 parts of 2, 6-di-tert cresol, 3-5 parts of carbon black and 1-3 parts of talc powder. The invention further discloses a method for preparing the low-temperature-resistant asphalt waterproof coating. The low-temperature-resistant asphalt waterproof coating and the method have the advantages that the low-temperature-resistant asphalt waterproof coating prepared by the aid of the method is excellent in low-temperature crack resistance and is still excellent in needle penetration in low-temperature environments, excellent toughness can be kept, and accordingly the low-temperature-resistant asphalt waterproof coating and the method have excellent market prospects.

Owner:深圳市朗迈新材料科技有限公司

Waterproof coil and preparation method thereof

InactiveCN107938953AGood weather resistanceGood adhesionRoof covering using flexible materialsBituminous coatingsPolyolefinPolyester

The invention discloses a waterproof coil. Glass fiber felt or polyester felt is used as a reinforcement body, the upper face of the reinforcement body is coated with a modified asphalt layer, the upper surface of the modified asphalt layer is coated with a mineral particle layer, and the lower face of the reinforcement body is coated with a thermoplastic polyolefin layer; a modified asphalt rubber layer is arranged between an upper covering surface layer and an intermediate matrix layer; and the modified asphalt rubber layer is composed of the following raw materials of, by weight, 50-62 parts of asphalt, 8-10 parts of SBS synthetic rubber, 15-25 parts of waste rubber powder and 1.5-2.5 parts of softening oil. The waterproof coil is long in service life and good in waterproof performance,aging resistant performance and heat resistant performance.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com