Weathering resistance modified asphalt waterproof coiled material

A technology of modified asphalt and waterproof membrane, which is applied in the field of construction chemical materials, can solve the problems that various properties cannot be maintained for a long time, prone to volatile environment, and narrow application range, etc., to achieve fast aging, good construction performance, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

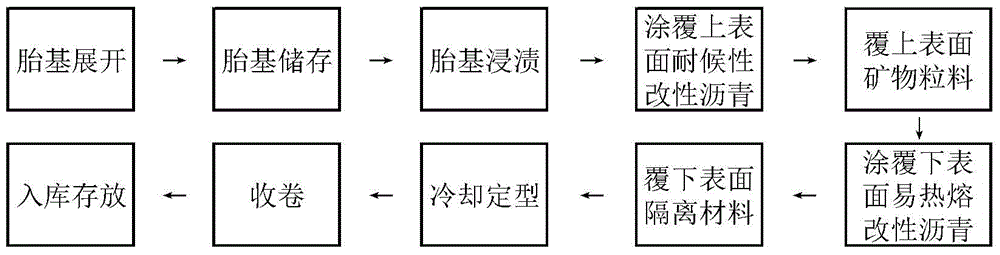

Method used

Image

Examples

Embodiment 1

[0025] Preparation of weather resistance modified asphalt

[0026] Add 20g of 90# petroleum asphalt to 80g of molten lake asphalt, heat up to 185°C, add 12g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 20g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0027] Preparation of heat-melt modified asphalt

[0028] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, heat up to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

Embodiment 2

[0030] Preparation of weather resistance modified asphalt

[0031] Add 30g of 90# petroleum asphalt to 70g of molten lake asphalt, heat up to 185°C, add 15g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 30g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0032] Preparation of heat-melt modified asphalt

[0033] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, raise the temperature to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

Embodiment 3

[0035] Preparation of weather resistance modified asphalt

[0036] Add 50g of 90# petroleum asphalt to 50g of molten lake asphalt, heat up to 185°C, add 18g of thermoplastic elastomer SBS4402, heat up to 185°C-195°C, start colloidal grinding, homogenization time is 2 hours; add 40g For light calcium carbonate, keep the temperature at 180°C to 185°C. After stirring for 1 hour, add 0.10g of ultraviolet absorber and stir for 0.5h to make weather-resistant modified asphalt for later use.

[0037] Preparation of heat-melt modified asphalt

[0038] Heat 100g of 200# liquid petroleum asphalt to 170°C, add 18g of thermoplastic elastomer SBS4402 and 6g of plastomer APAO, raise the temperature to 185°C-195°C, start colloidal grinding, and homogenize for 2 hours; add 50g of light Calcium carbonate, the temperature is kept at 180 ℃ ~ 185 ℃ and stirred for 1 hour, and then it is made into a hot-melt modified asphalt for later use.

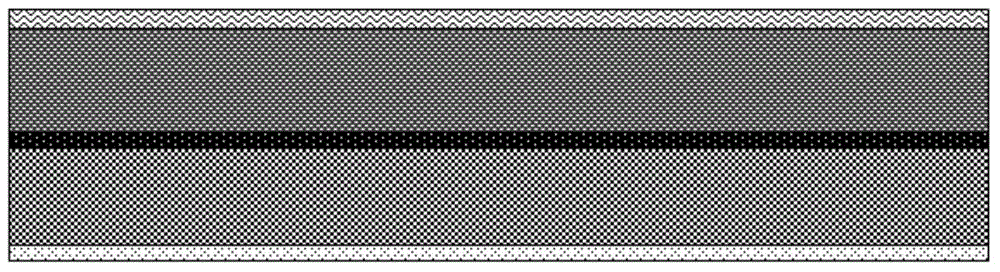

[0039] Based on the two specifications of modified asph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com