Self-flame-retardant heat-preservation water-based polyurethane composition and foaming body, and preparation method of foaming body

A water-based polyurethane, flame retardant and heat preservation technology, applied in the field of polyurethane synthesis, can solve the problems of easy combustion, smoke generation, and difficulty in meeting flame retardant standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Preparation of water-based polyurethane emulsion:

[0073] Mix 2220g of isophorone diisocyanate, 12000g of silicone polyether polyol, 500g of zwitterionic polyester diol and stannous octoate, stir and react at 80°C for 4 hours to obtain a polyurethane prepolymer; add 120g of N,N-bis(2-hydroxyethyl)aminomethylene phosphate diethyl ester (FRC-6) and 90g 1,4-butanediol, stirred at 78°C for 2h to obtain an intermediate product; add water to the intermediate product , Aqueous polyurethane emulsion with a solid content of 60% was obtained after stirring and dispersing.

[0074] Wherein, the consumption of catalyst is 100ppm;

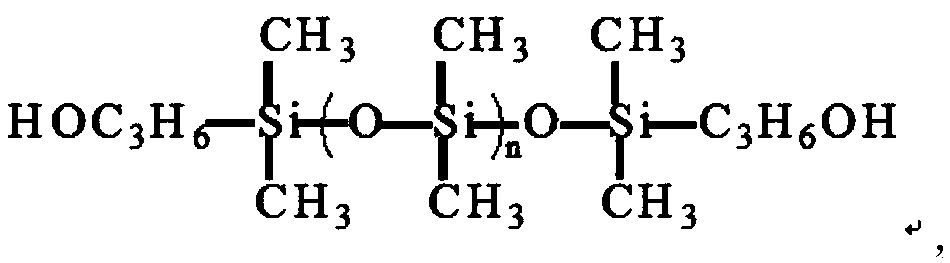

[0075] The molecular structure of silicone polyether polyol is shown in the following formula:

[0076]

[0077] The molecular weight of silicon polyether polyol is about 1500;

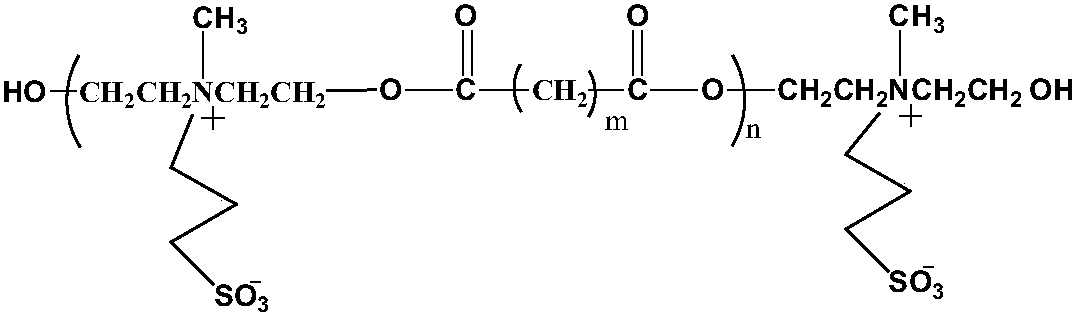

[0078] The molecular structure of zwitterionic polyester diol is shown in the following formula:

[0079]

[0080] The molecular weight of zwitterionic polyester diol...

Embodiment 2

[0082] Preparation of water-based polyurethane emulsion:

[0083] Mix 1680g of hexamethylene diisocyanate, 8000g of silicone polyether polyol, 800g of zwitterionic polyester diol and catalyst, stir and react at 75°C for 6h to obtain a polyurethane prepolymer; add 130g of N to the polyurethane prepolymer, N-bis(2-hydroxyethyl)aminomethylene phosphate diethyl ester (FRC-6) and 70g chain extender trimethylolpropane, stirred and reacted at 95°C for 3h to obtain an intermediate product; add water to the intermediate product , after stirring and dispersing, obtaining a water-based polyurethane emulsion with a solid content of 55%; wherein, the consumption of the catalyst is 200ppm;

[0084] The molecular structure of silicone polyether polyol is shown in the following formula:

[0085] Where x=5, y=10, the molecular weight of silicone polyether polyol is about 1000;

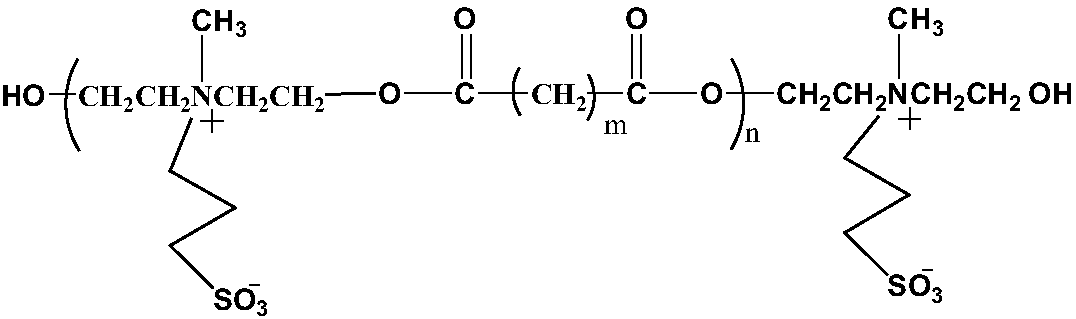

[0086] The molecular structure of zwitterionic polyester diol is shown in the following formula:

[0087]

...

Embodiment 3

[0090] The aqueous polyurethane emulsion prepared by 1000g embodiment 1, 50g airgel powder, 10g sodium dodecyl sulfonate, 1g succinic acid, 10g carboxymethyl cellulose are mixed to form an aqueous polyurethane composition; the aqueous polyurethane composition Combining the use of mechanical stress stirring and micro-bubble generator to form a foamed water-based polyurethane composition; wherein, the mechanical stress stirring is: the speed is 1500 rpm, all the slurry is beaten into foam, and the expansion ratio is controlled at 2; the micro-bubble generator Generate fine air bubbles of 20-100 microns and pass into the slurry; coat the foamed water-based polyurethane composition on the base material, and form the water-based polyurethane foam under dry aging conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com