Patents

Literature

562 results about "Foam polyurethanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane can be a solid or can have an open cellular structure, in which case it is called foam… and foams can be flexible or rigid. As simple explanation, manufacturers make polyurethane foam by reacting polyols and diisocyanates, both products derived from crude oil.

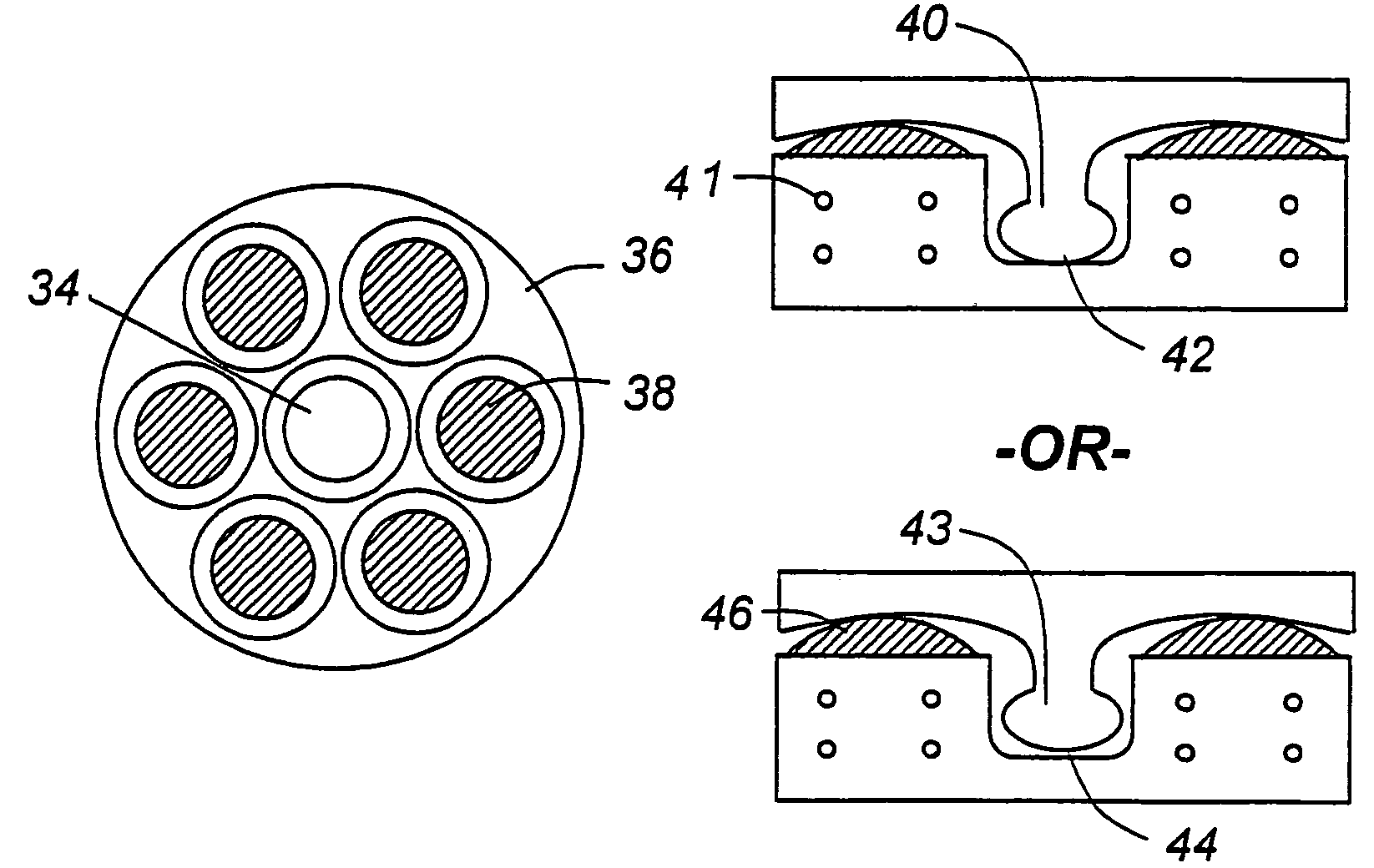

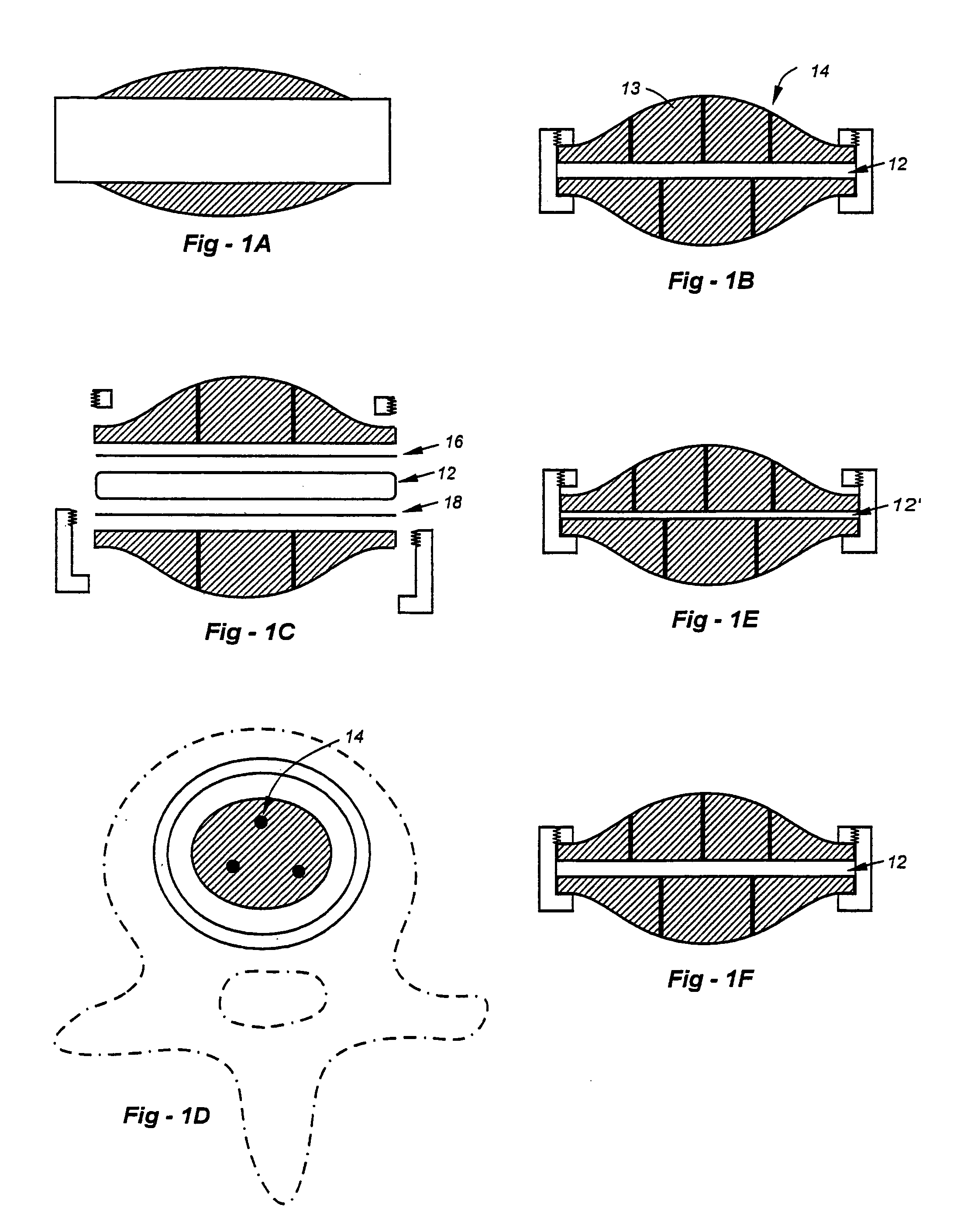

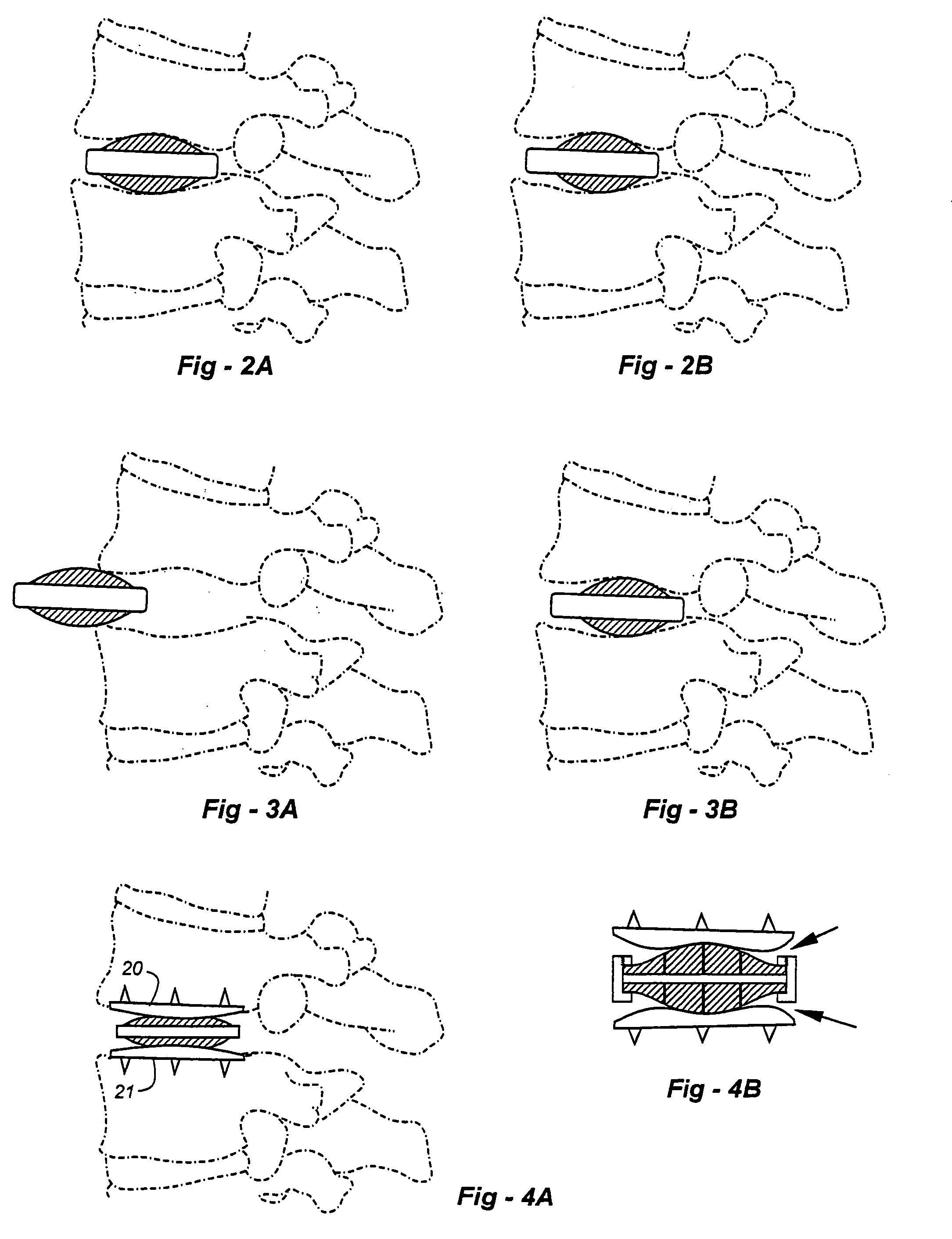

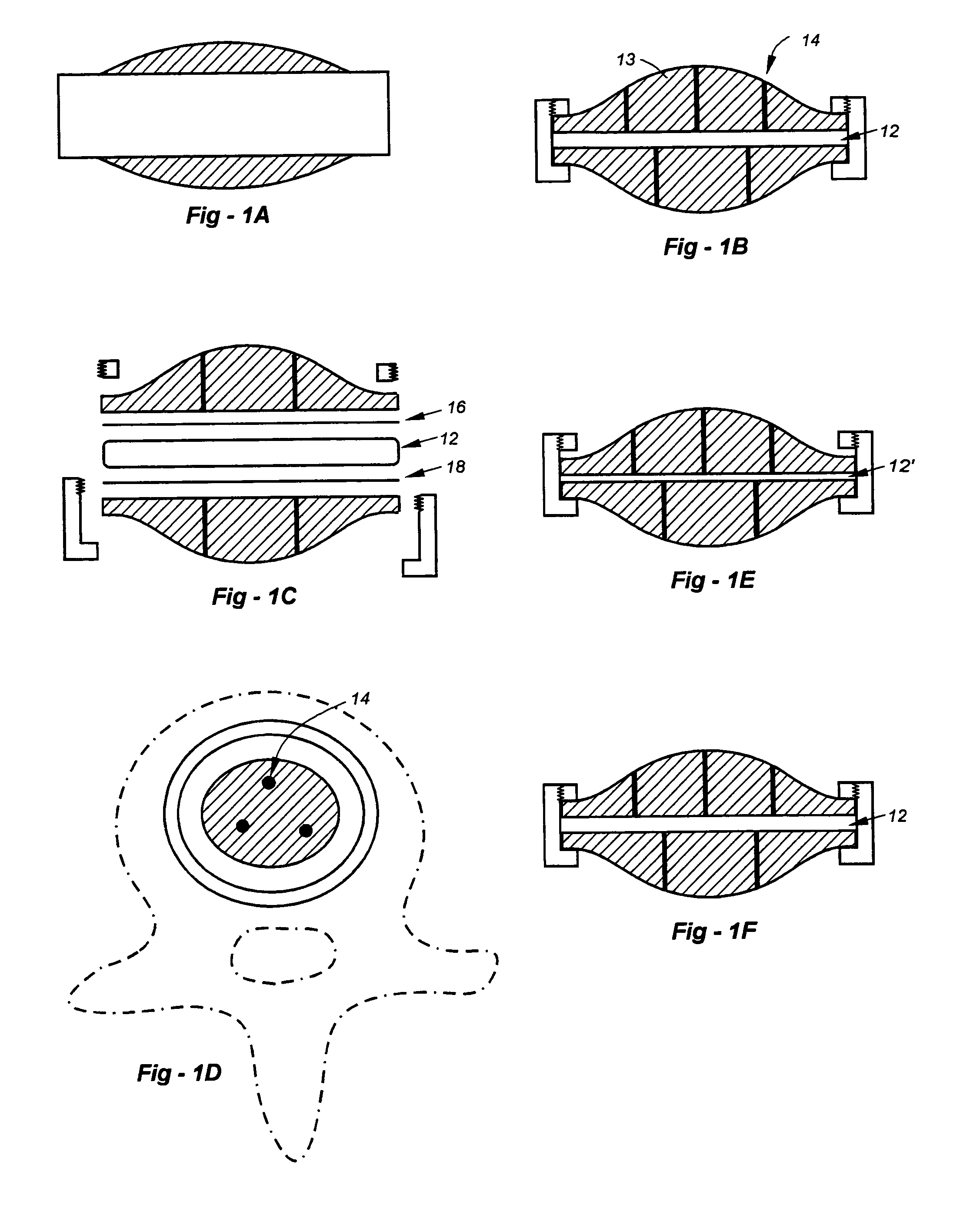

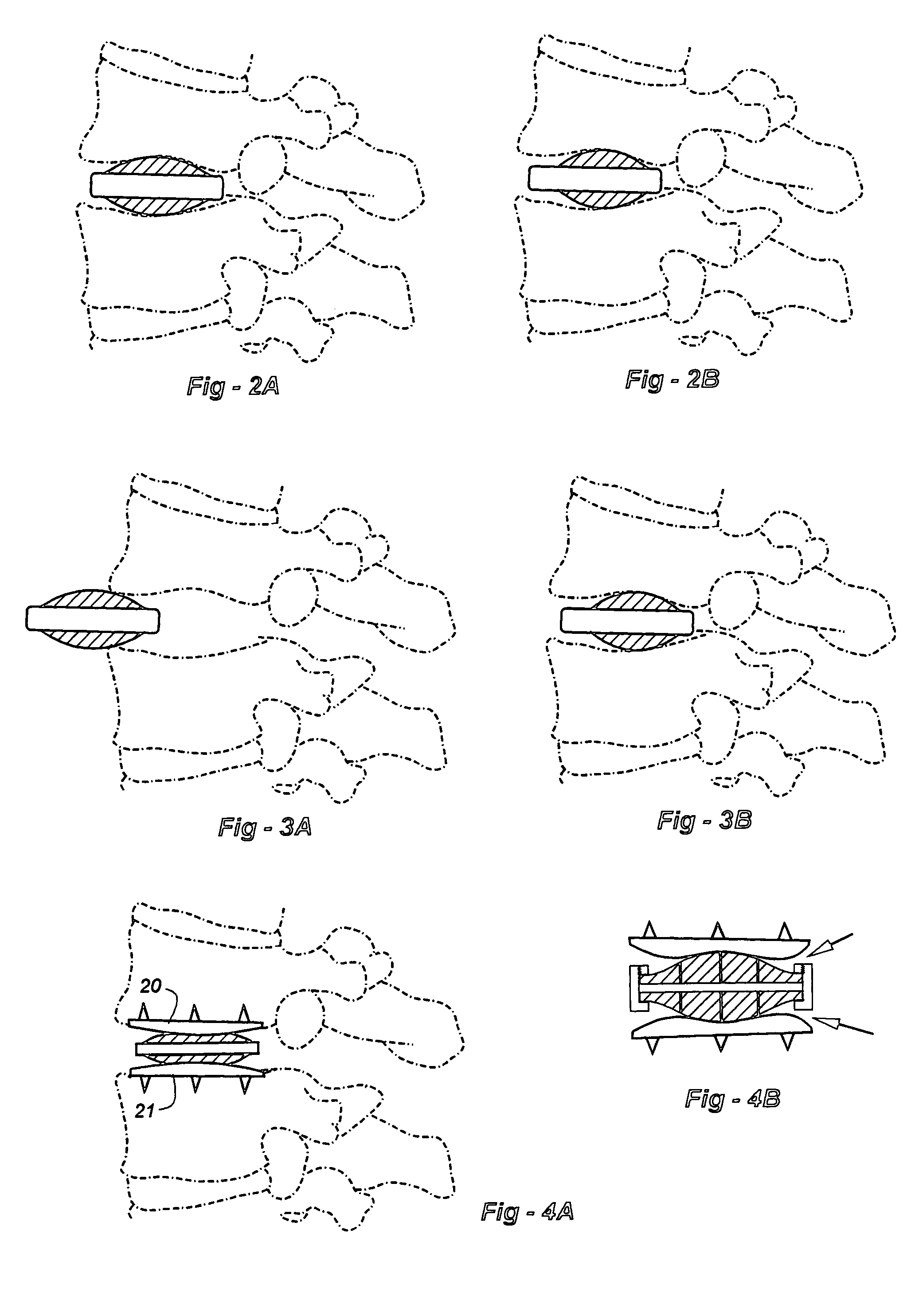

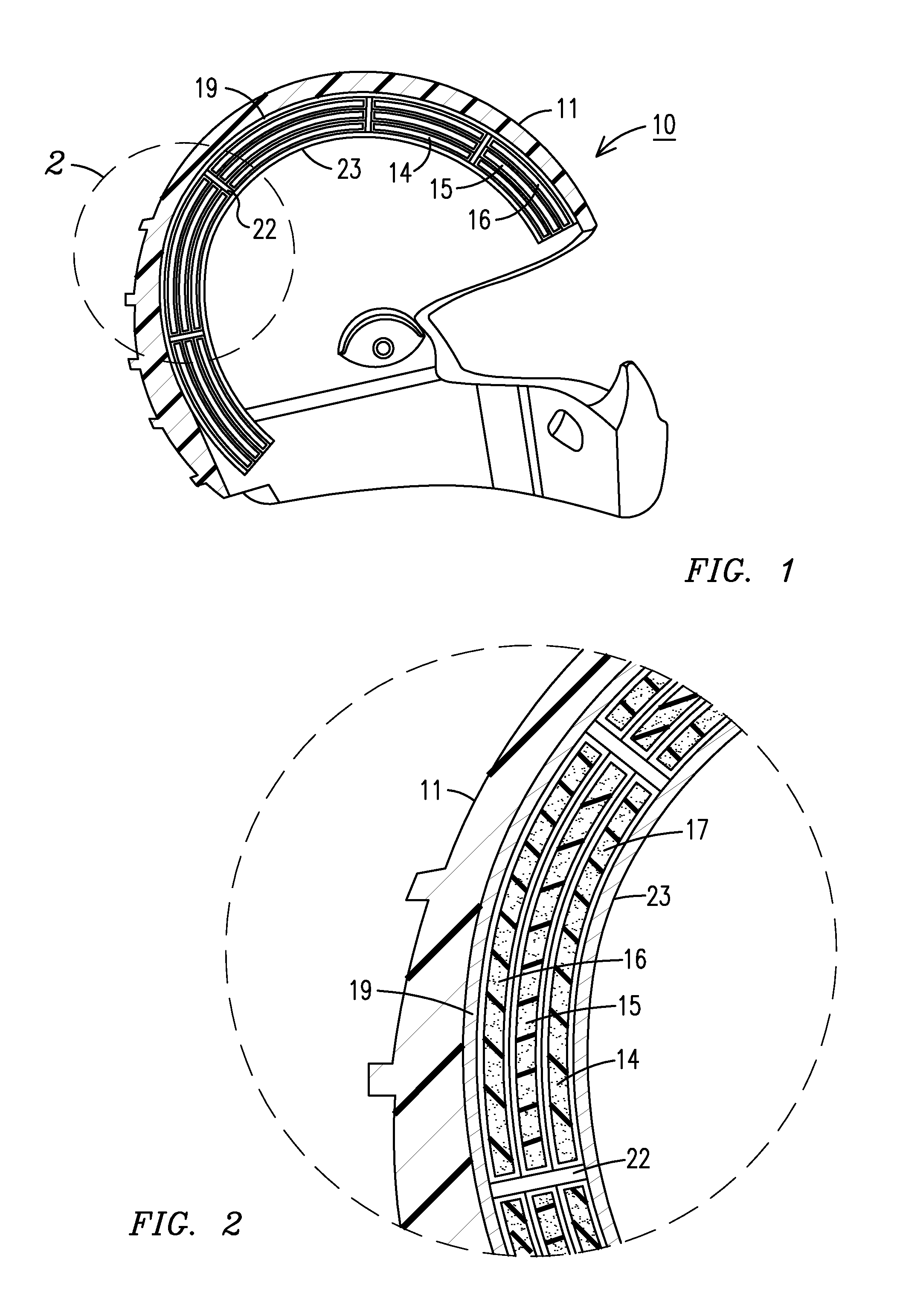

Prosthetic components with partially contained compressible resilient members

InactiveUS7066958B2Improve protectionEliminate shear stressJoint implantsSpinal implantsElastomerShape-memory alloy

One or more rigid components associated with an articulating bone are used to encase, encapsulate, contain, or otherwise protect a compressible / resilient member. The embodiments are applicable not only to artificial disc replacement (ADR) devices, but also to joint situations including total knee and hip arthroplasty. The cushion elements in the preferred embodiments include synthetic rubbers, hydrogels, elastomers, and other polymeric materials such as viscoelastic polymers and foam polyurethanes. The invention effectively combines the advantages of such materials (cushioning, shape memory, and expansion after insertion in the case of hydrogels), while providing increased protection, particularly the elimination of shear stresses. When applied to an ADR, the invention also minimizes the risk of extrusion.

Owner:FERREE BRET A

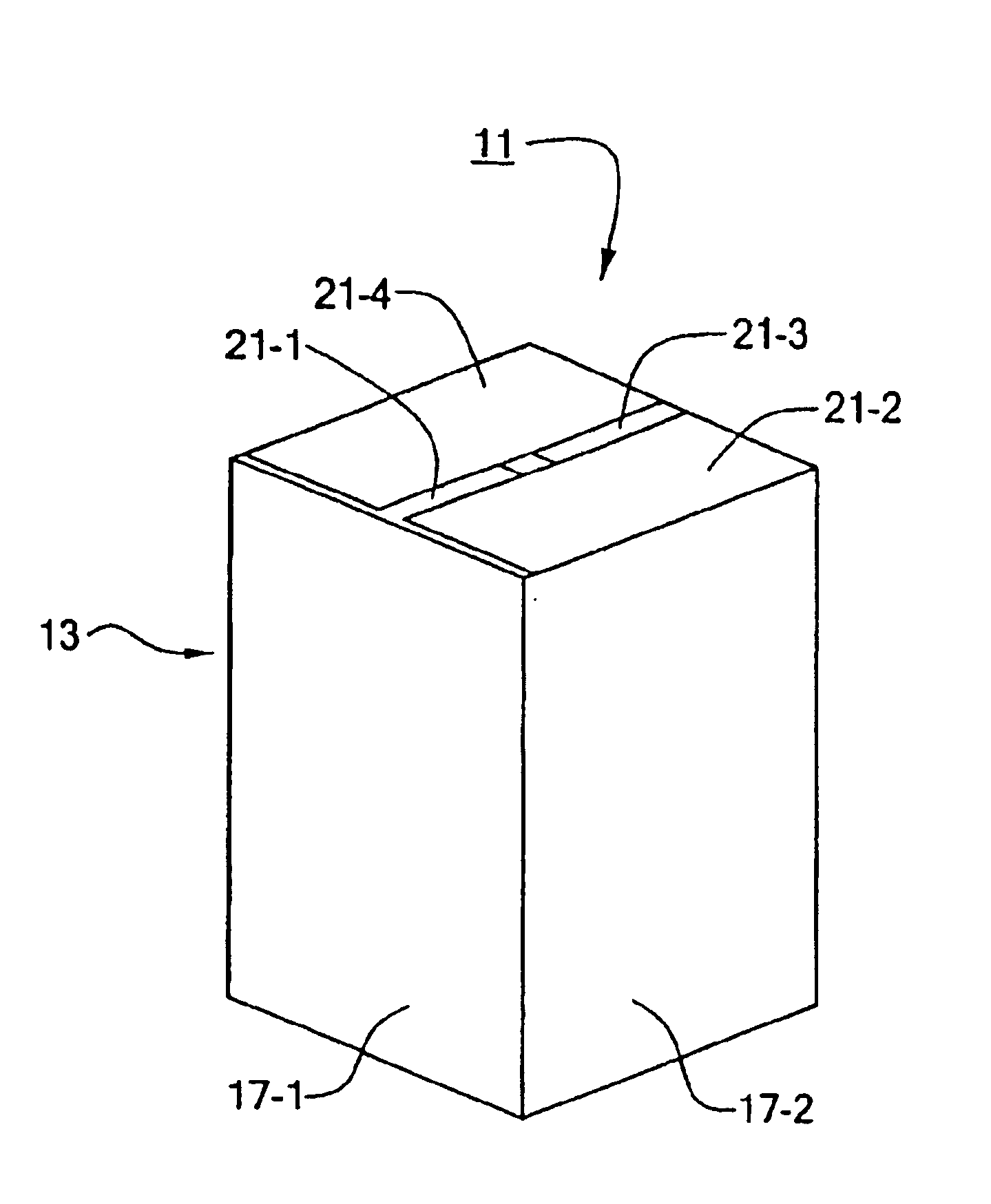

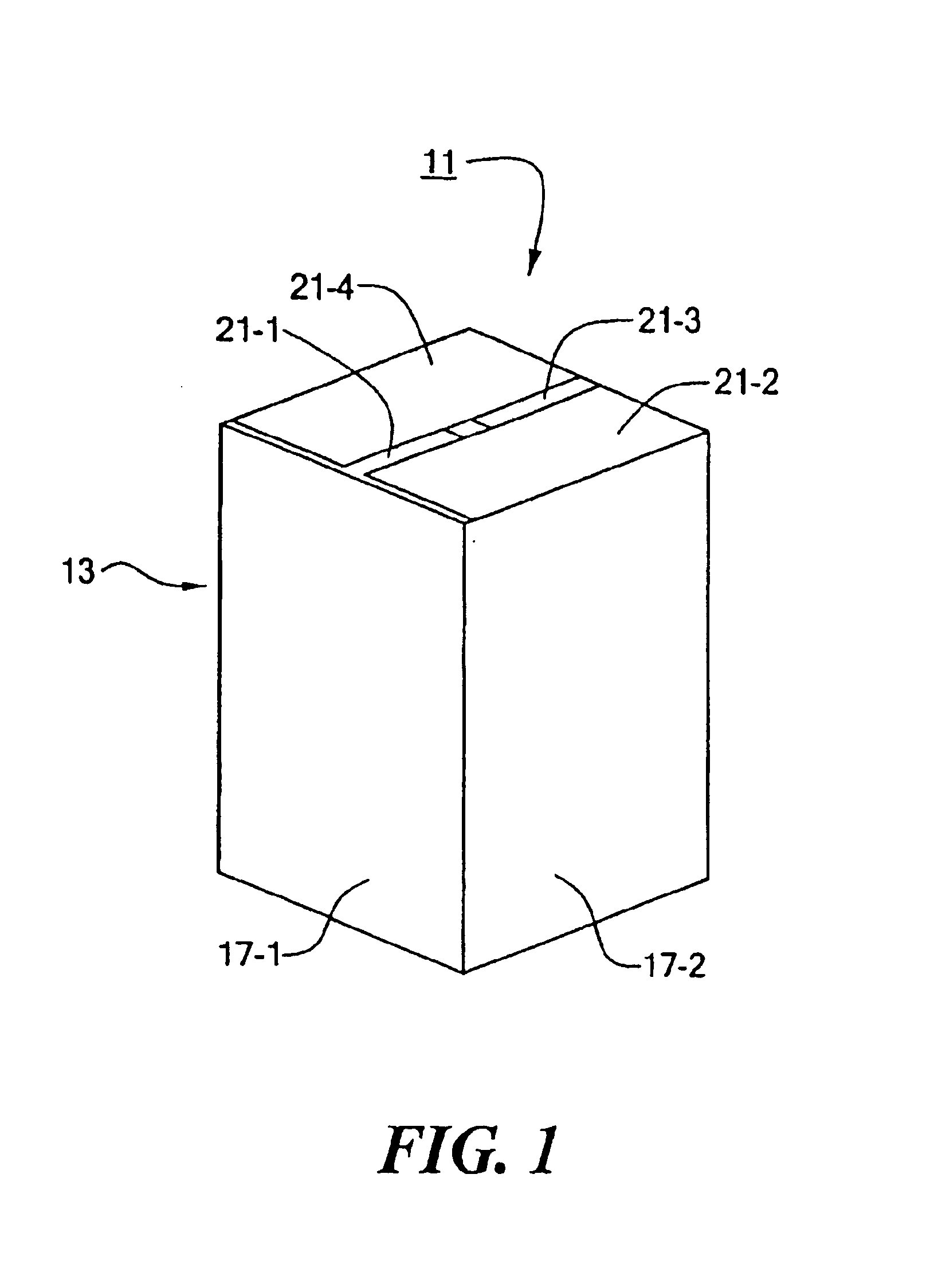

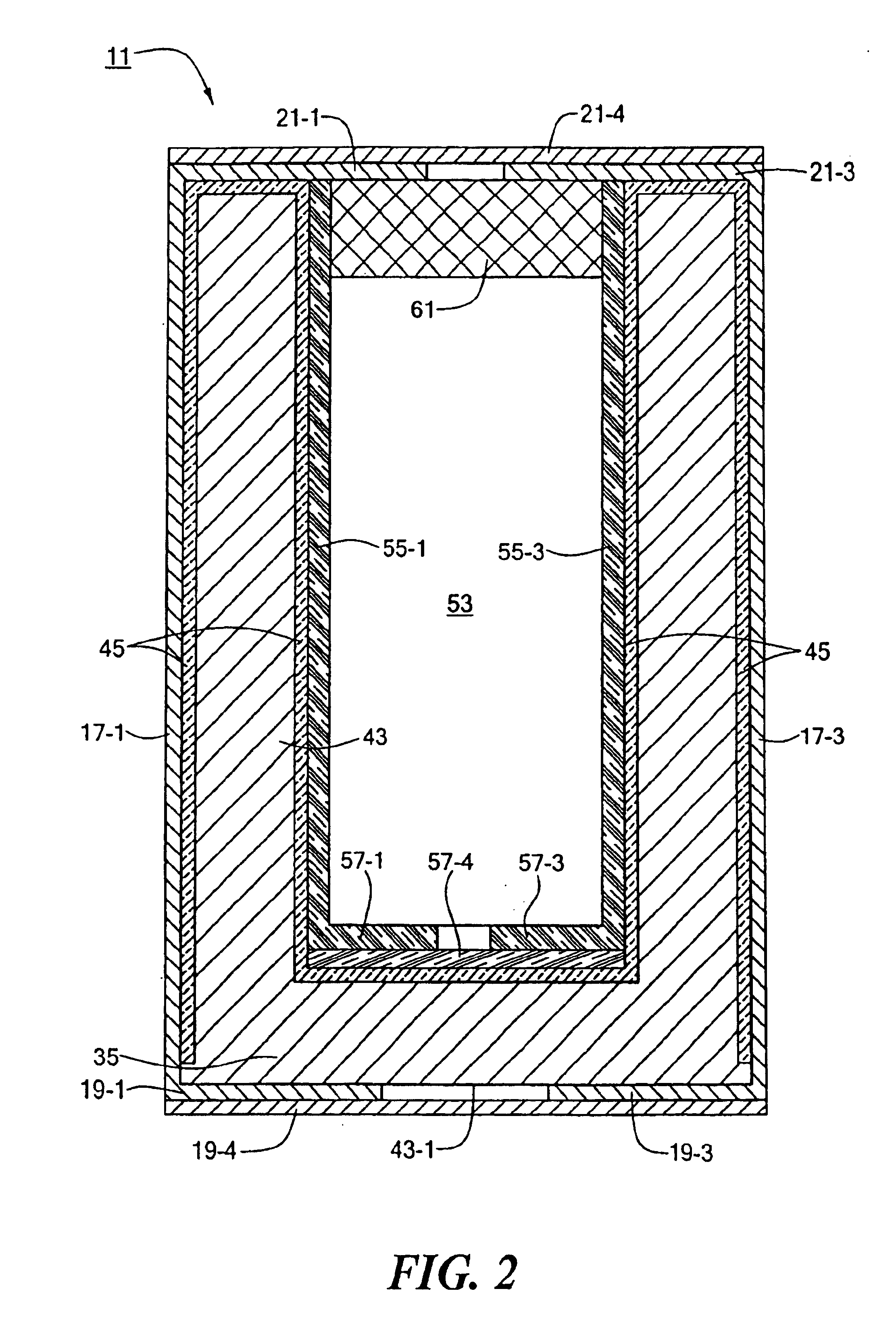

Insulated shipping container and method of making the same

InactiveUS6868982B2Domestic cooling apparatusLighting and heating apparatusEngineeringFoam polyurethanes

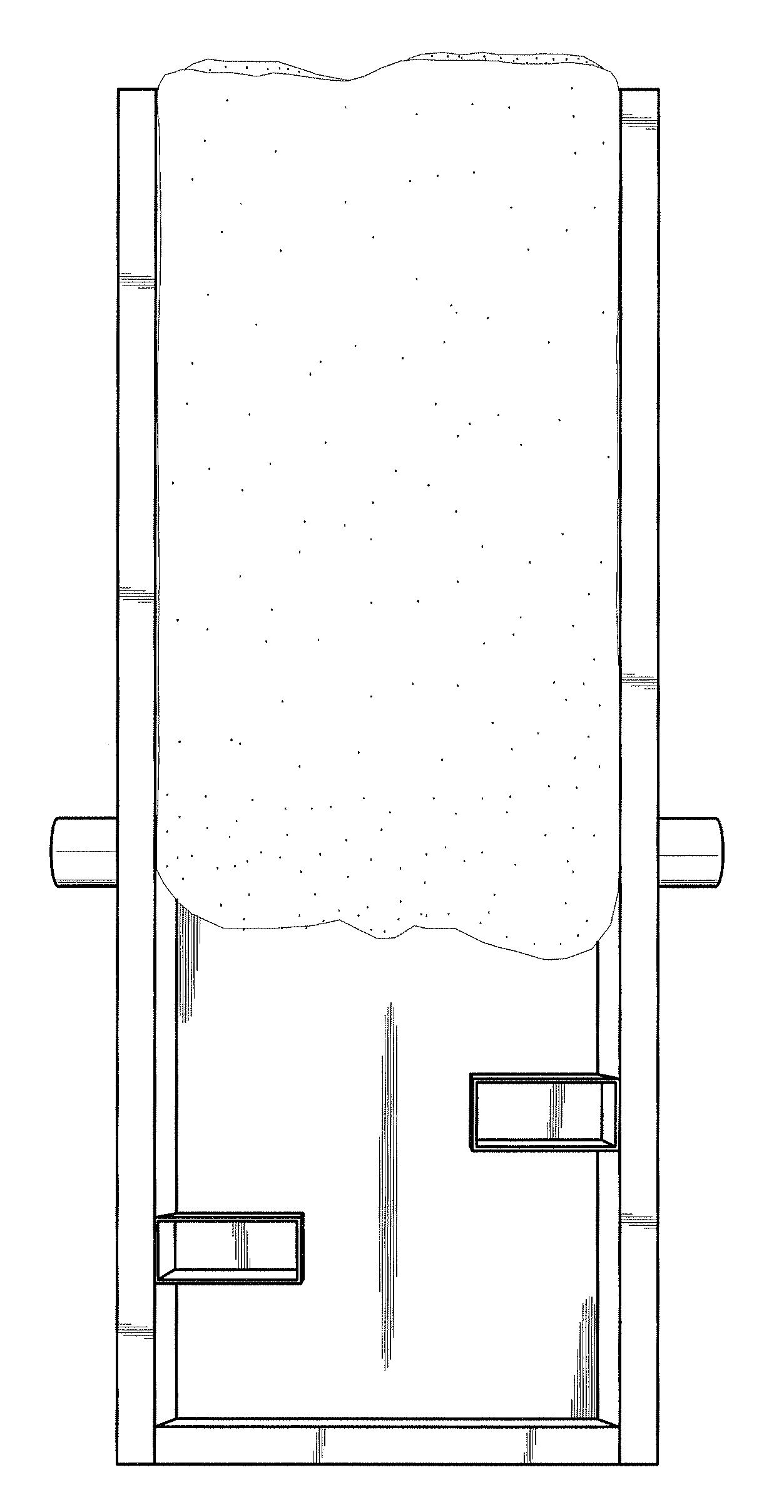

Insulated shipping container and method of making the same. In a preferred embodiment, the insulated shipping container comprises an outer box, an insulated insert, an inner box and a closure member. The outer box, which is preferably made of corrugated fiberboard, comprises a rectangular prismatic cavity bounded by a plurality of rectangular side walls, a closed bottom end, and top closure flaps. The insulated insert is snugly, but removably, disposed within the outer box and is shaped to define a rectangular prismatic cavity bounded by a bottom wall and a plurality of rectangular side walls, the insulated insert having an open top end. The insulated insert is made of a foamed polyurethane body to which on all sides, except its bottom, a thin, flexible, unfoamed polymer bag is integrally bonded. The bag is a unitary structure having a generally uniform rectangular shape, the bag being formed by sealing shut one end of a tubular member with a transverse seam and forming longitudinal creases extending from opposite ends of the seam. The inner box, which is snugly, but removably, disposed within the insert, is preferably made of corrugated fiberboard and is shaped to include a rectangular prismatic cavity bounded by a plurality of rectangular side walls and a closed bottom end, the top end thereof being open. The closure member is a thick piece of foam material snugly, but removably, disposed in the open end of the inner box.

Owner:COLD CHAIN TECH

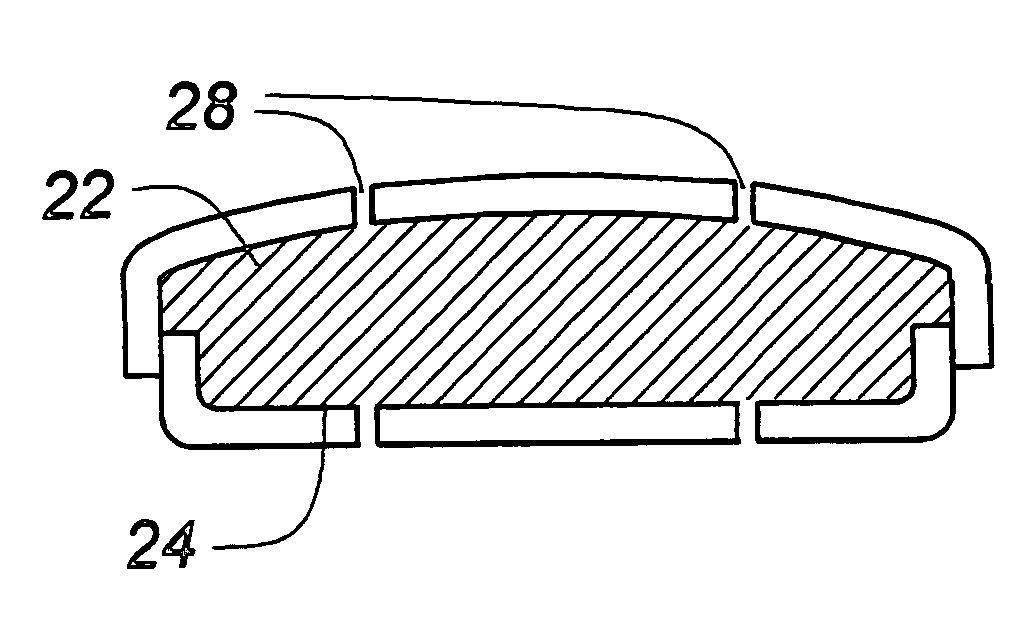

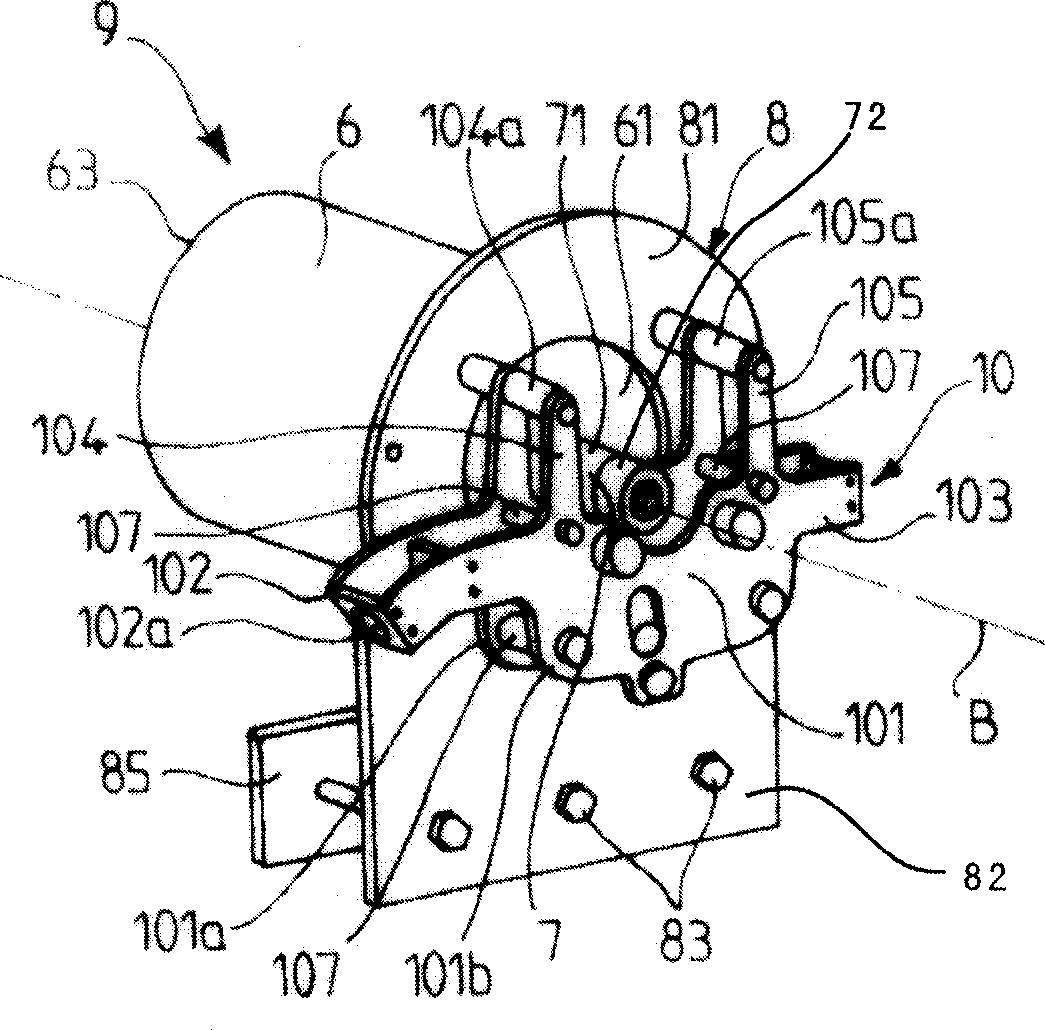

Prosthetic components with contained compressible resilient members

InactiveUS7235102B2Improve protectionEliminate shear stressJoint implantsSpinal implantsElastomerShape-memory alloy

One or more rigid components associated with an articulating bone are used to encase, encapsulate, contain, or otherwise protect a compressible / resilient member. The embodiments are applicable not only to artificial disc replacement (ADR) devices, but also to joint situations including total knee and hip arthroplasty. The cushion elements in the preferred embodiments include synthetic rubbers, hydrogels, elastomers, and other polymeric materials such as viscoelastic polymers and foam polyurethanes. The invention effectively combines the advantages of such materials (cushioning, shape memory, and expansion after insertion in the case of hydrogels), while providing increased protection, particularly the elimination of shear stresses. When applied to an ADR, the invention also minimizes the risk of extrusion.

Owner:ANOVA

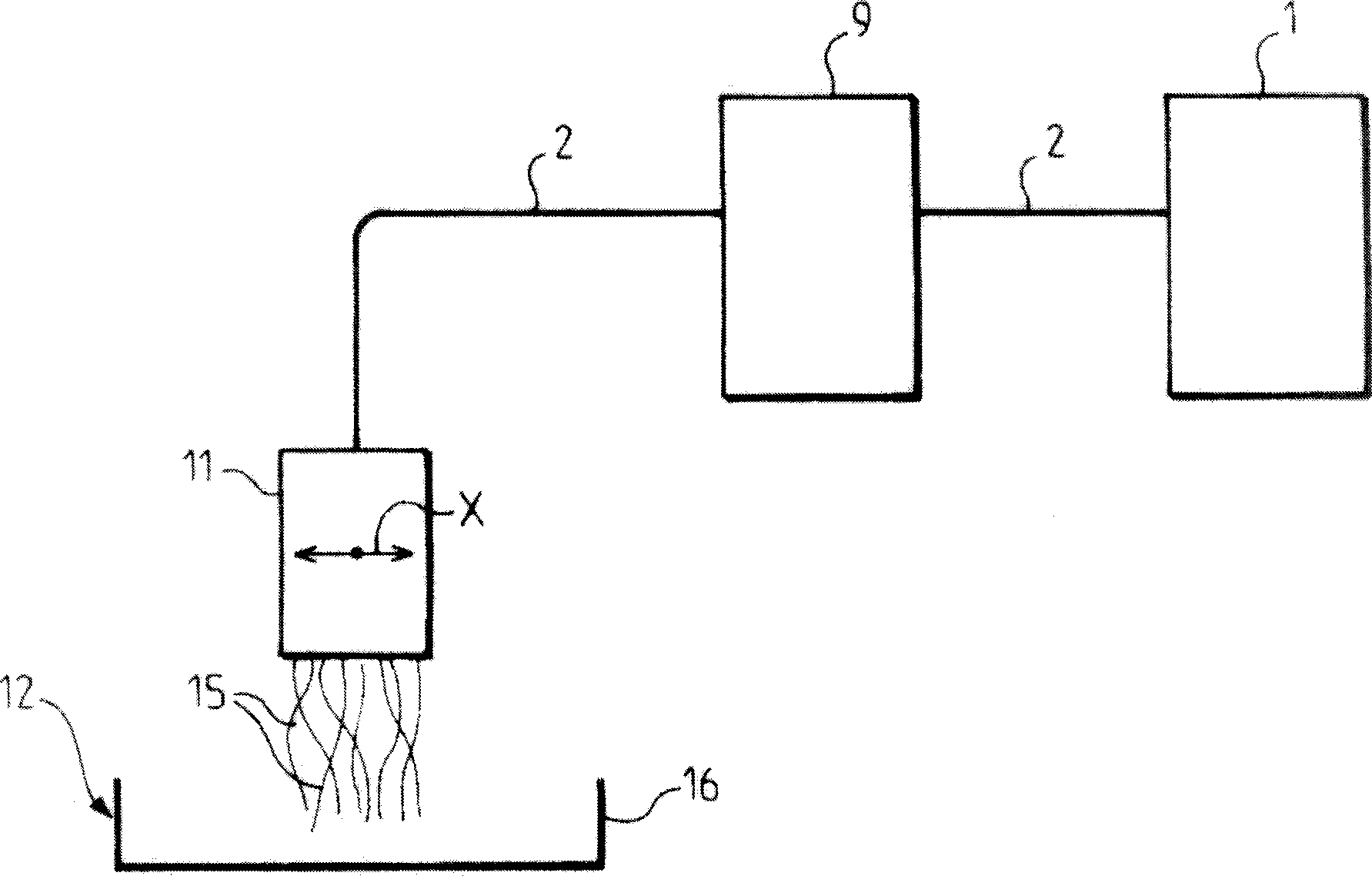

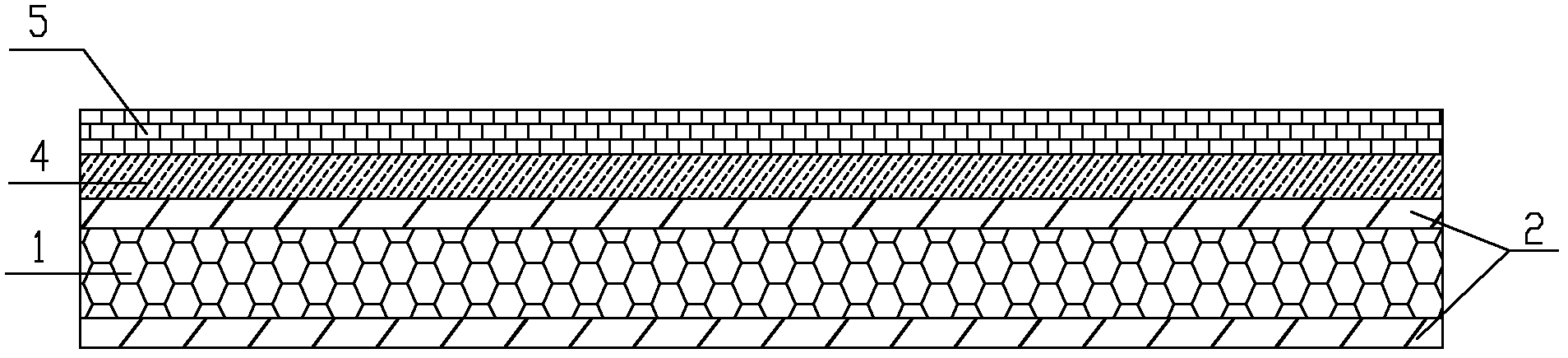

Continuous fibre enhancement polyurethane foam material and manufacturing method thereof

A continuous fiber reinforce polyurethane foaming material and a relative production method relate to a polyurethane foaming material, wherein the continuous fiber reinforce polyurethane foaming material has strong rigidity, strength and shock resistance to produce foaming polyurethane material with reinforced glass fiber, which eliminates breaking and premixing with any component of polyurethane, is directly mixed and immersed with polyurethane mixture in an immerser and is foamed and shaped continuously, and contains A, B and C components. A comprises polyatomic alcohol, foaming agent, catalyst, foaming stabilizer, chain extender and adjuvant, B is polyisocyanate, C is fiber material. The preparation method comprises mixing the materials of A in A pot, the materials of B in B pot, immersing fiber via an immerser with the mixture discharged from a high-speed pouring head, feeding immersed material into a continuous foaming mold to be foamed and solidified, cooling, removing mould, taking off and cutting to obtain final product.

Owner:厦门高特高新材料有限公司

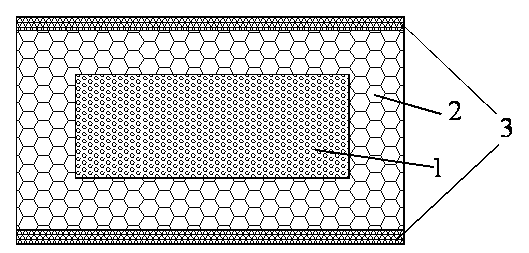

Building wall insulation composite board and preparation method thereof

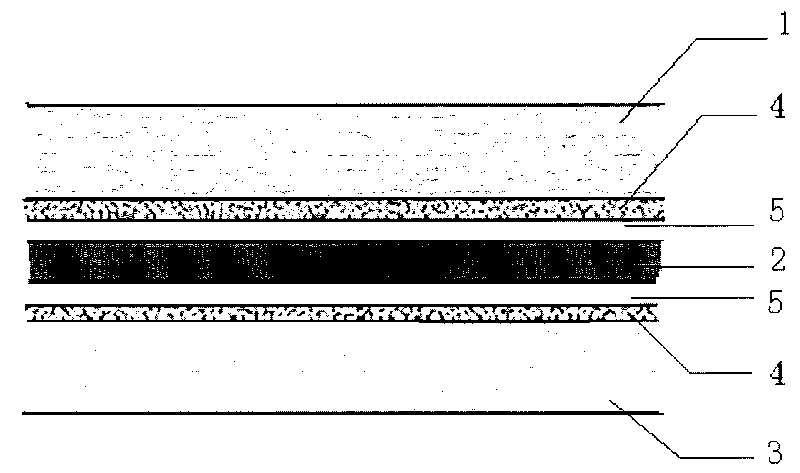

ActiveCN103104046AReasonable structural designImprove fire performanceClimate change adaptationPolyureas/polyurethane adhesivesBuilding energyThermal insulation

The invention relates to a building wall insulation composite board and a preparation method of the building wall insulation composite board, and belongs to the technical field of building energy-saving insulation materials and preparation methods. A wall insulation hard foam polyurethane composite board comprises inner cores, protective layers coated on the peripheries of the inner cores and interface layers coated on the upper surfaces and the lower surfaces of the protective layers in an attached mode. The inner cores are vacuum insulation boards. The preparation method of the wall insulation hard foam polyurethane composite board comprises preparation of interface coiled materials: coating prepared flame-retarded polymer mucilage on base materials to produce the interface coiled materials, and manufacturing of the protective layers and the wall insulation hard foam polyurethane composite board. The insulation composite board has good thermal insulation performance, waterproof performance and heat insulation performance, can satisfy 65% requirements of building energy efficiency very well, is high in bonding strength and convenient to construct and operate, greatly increases overall fireproof performance of the whole wall heat-insulation system after being arranged on a wall, and can be widely applied to the inner portions of walls, outer walls, and roof covering thermal insulation systems, heat insulation systems and waterproof systems.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

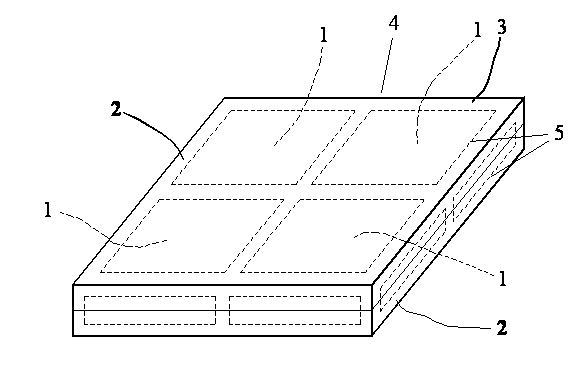

Production method for multifunctional rigid foam polyurethane composite heat-conservation board

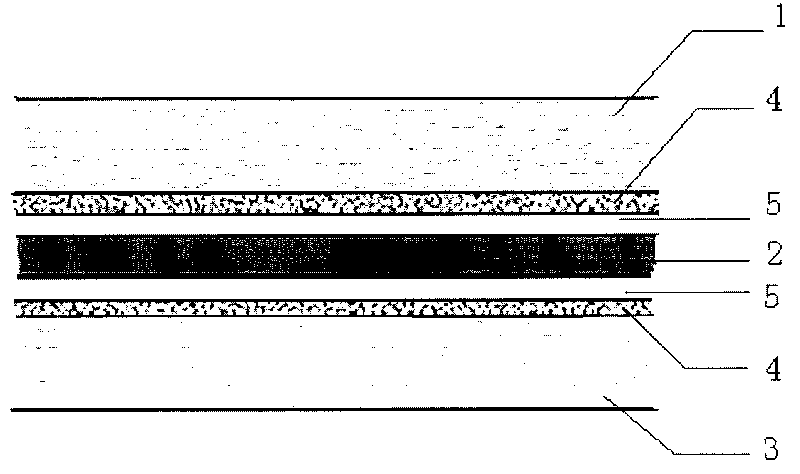

InactiveCN101487297AImprove flame retardant performanceGood weather resistanceWallsHeat proofingTO-18Polymer science

The invention discloses a preparation method used for preparing a multifunctional polyurethane hard foam insulation composite board. The method includes the following steps: a waterproof and fireproof polymer cement sheet is prefabricated; a polyurethane foaming machine manufacturing line is adopted to froth a foam material into the polyurethane hard foam board and the waterproof and fireproof polymer cement sheet is simultaneously compounded on two surfaces of the polyurethane hard foam board to prepare the multifunctional polyurethane hard foam insulation composite board. The method is characterized in that the foam material is prepared by the following materials according to the weight portions: 54 to 64 percent of PAPI, 10 to 15 percent of flame-retardant polyether polyol, 13 to 18 percent of polyether polyol, 4 to 7 percent of vesicant, 0.8 to 1 percent of catalyzer, 5 to 8.5 percent of flame retardant and 0.7 to 1 percent of foam-leveling agent. The polyurethane hard foam insulation composite board prepared by the method not only has the waterproof and insulation properties, but also has the high intensity and fireproof property; and the board can be used for the outer-wall large-area waterproof, fireproof and insulation engineering of buildings.

Owner:夏良强

Polyurethane gel foams

ActiveUS8673992B2Improved permeation kineticsKind to skinBaby linensTamponsWound dressingPolymer science

Polyurethane gel foams are proposed as is their use in modern wound treatment. In particular, wound dressings comprise polyurethane gel foams for treating moderately to severely exuding wounds. The polyurethane gel foams are thereby produced from an isocyanate component A having a functionality f of fB≦3, a polymeric polyol component B having a functionality f of fB≦6, and a polysaccharide C, comprising at least one uronic acid or a salt thereof, wherein the ratio of the number of isocyanates groups of the isocyananate component A to the total number of hydroxyl groups, carboxy groups and carboxylate groups in the polymeric polyol component B and the polysaccharide C corresponds to the ratio 1:2 to 1:30.

Owner:PAUL HARTMANN AG

Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

ActiveCN105350342AStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

100% water-base foamed polyurethane foam and preparation method thereof

InactiveCN103012737AGood sound absorption and noise reductionGood moisture-wicking and self-dryingPolyesterFiber

The invention relates to the field of polyurethane, particularly a preparation method and application of 100% water-base foamed polyurethane foam. The 100% water-base foamed polyurethane foam is characterized by comprising a component A and a component B in a mass ratio of 1:1, wherein the component A is polymethylene polyphenyl isocyanate; the component B comprises polyalcohol, catalysts, foam stabilizer, pore opening agent, foaming agent, emulsifier and flame retardant; and the polyalcohol comprises polyether glycol, polyester polyol and flame-retardant polyether glycol. The invention is characterized by adopting high-proportion water. The invention adopts multiple assistants, and especially ingeniously uses three or two catalysts to ensure the open pore foam to have an open pore structure, the foam pores are compact and open, the meridian fibers of the foam pores are thin and soft, and the heat conductivity coefficient of the foam can still reach 0.036-0.040 (W / M.K).

Owner:JIANGSU STEADY NEW ENERGY TECH DEV

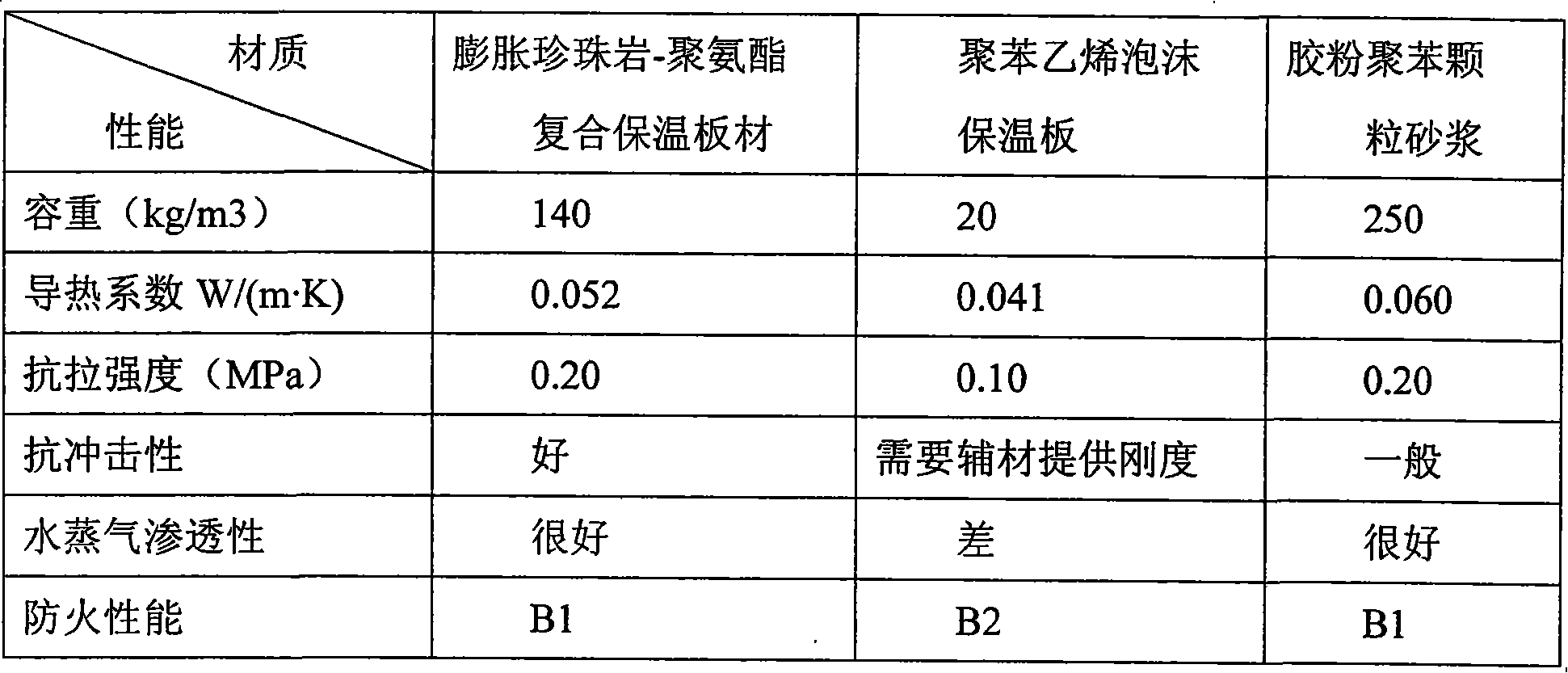

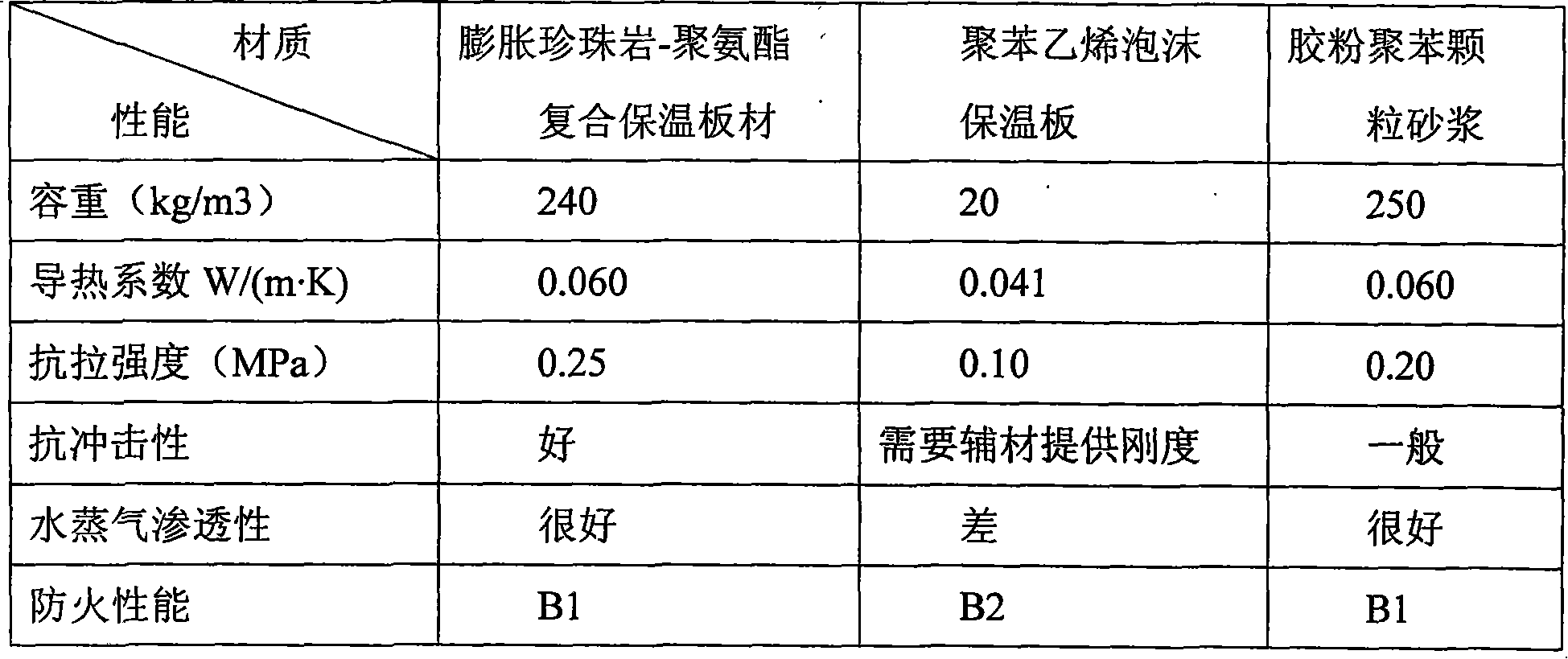

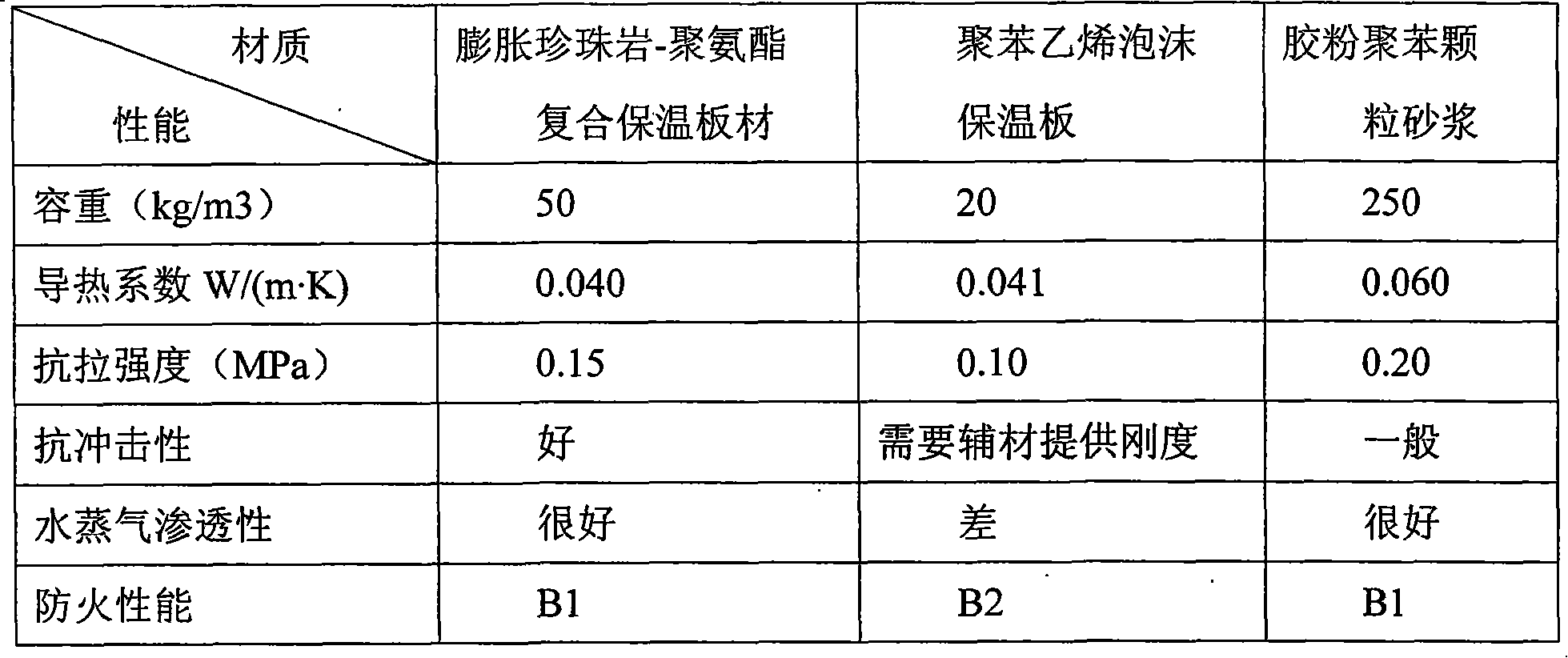

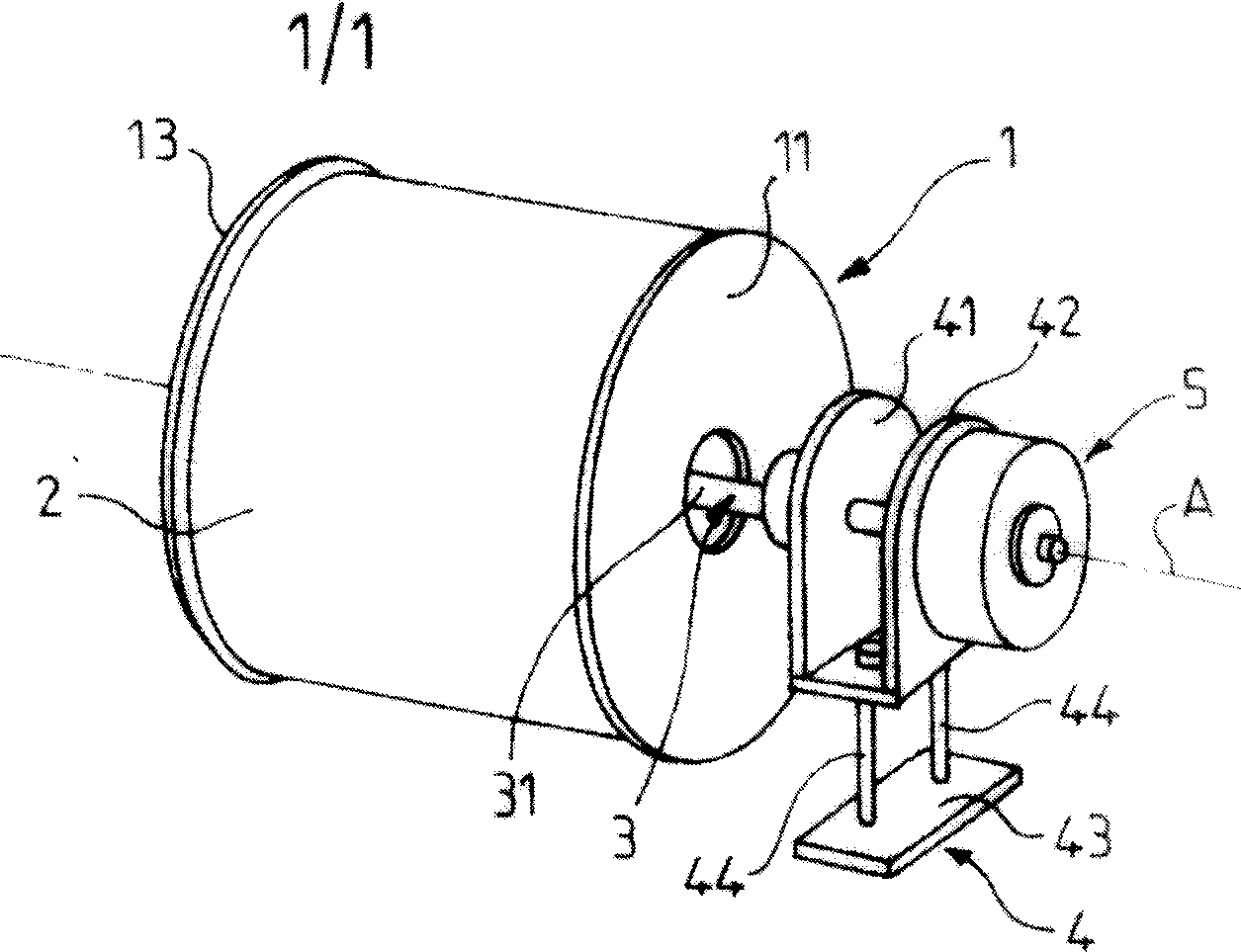

Expanded perlite-polyurethane composite insulating board and manufacturing technique thereof

InactiveCN101139186AGood physical and mechanical propertiesGood weather resistanceWater vaporFoam polyurethanes

The present invention discloses a heat preservation plate compounded by expanded perlite and polyurethane and the manufacturing process. The present invention is a plate using the expanded perlite as aggregate, and the polyurethane as glue material. The manufacturing process is that: the expanded perlite is sent to a rotating rotary drum, and at the same time, the polyurethane is ejected into the rotary drum according to the weight ratio; the expanded perlite in the rotary drum is being mixed and contacted with the polyurethane flog enough and continually; and then the mixture is taken out from a material-out mouth and then is to be put in a mould with some size for shaking and pressed. After being hardened in the stated temperature, the mixture is to be cut and then the heat preservation plate compounded by expanded perlite and polyurethane will be obtained. The present invention solves the shortcomings that the mixing for the mortar heat preservation products is not even and the quality is difficult to be controlled and so on. The heat preservation plate compounded by expanded perlite and polyurethane is with much lower density, much lower heat conductivity coefficient, much better heat preservation effect and much better water permeability, which overcomes the shortcomings in the foam polyurethane plate and the extruded plate that the vapor is hard to be permeated. The present invention has the advantages of low cost and convenient construction. The present invention can be manufactured in the industrialized mode and the quality can be controlled effectively.

Owner:宁波荣山建筑节能科技有限公司

Glassfiber-reinforced polyurethane-polyisocyanurate foam

ActiveCN1834130ASatisfactory thermal insulation propertiesSurprising mechanical propertiesPressure vesselsFor bulk goodsGlass fiberPolymer science

Polyurethane polyisocyanurate foam reinforced by glass fibers, obtained by: reacting an isocyanate component and a polyol component comprising first, second and third polyols, in the presence of a catalyst, a physical and / or chemical blowing agent, an emulsifier and optionally a flame retarding agent to obtain a composition; impregnating, the composition in a glass fiber stacking; and expanding and solidifying the composition to form a reinforced foam block containing the glass fiber stacking. Said reinforced foam block has an average density of 115-135 kg / m3>, and an isocyanate index of 100-180.

Owner:GAZTRANSPORT & TECHNIGAZ

Preparation method of special foamed ceramic filter for magnesium alloy

InactiveCN1410393ALow priceGood chemical stabilityProcess efficiency improvementFiltration separationAluminum sulphateFoam polyurethanes

Owner:SHANGHAI HAOHUA MOLD

Rigid foamed polyurethane-forming compositions, foamed polyurethane moldings and models made of the same

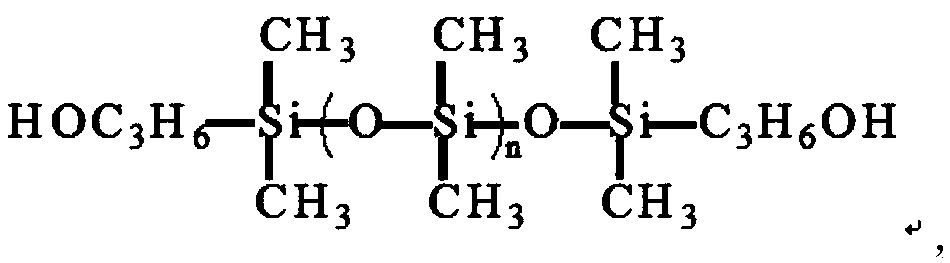

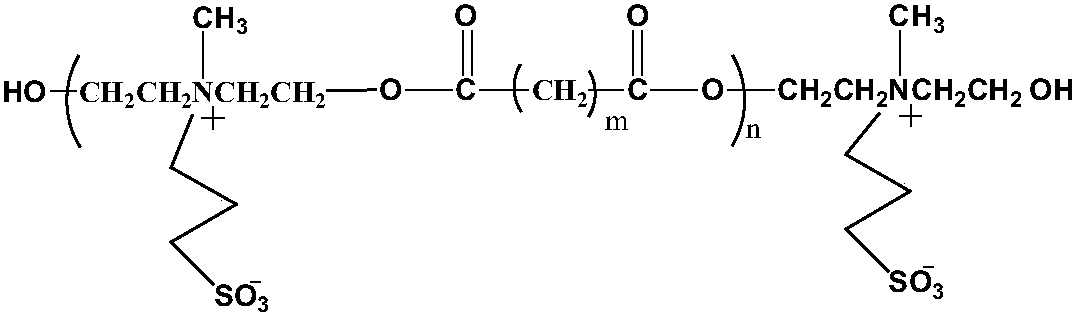

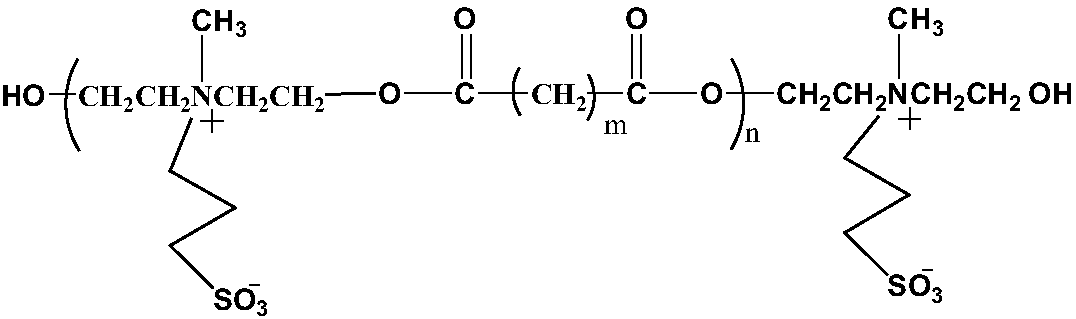

A rigid foamed polyurethane molding which reduce dust-scattering in cutting and is useful to a modeling stock. Said molding is produced by curing a composition by a mechanical frothing method, said composition comprising: a polyol with a filler (c); and a slight amount of dehydrating agent (d);wherein said composition further contains 3 to 30 percent, based on the total weight of the composition, of a (poly) oxyalkylene compound (e) expressed by the general formulain which "A" represents an alkylene group with two to four carbon atoms; "X" is a hydrocarbyl group or an acyl group; "m" is a value of one to one hundred; "n" is an integer of one to six; and "Z" is a residue produced by removing the active hydrogen atoms from a compound containing n active hydrogen atoms, in which at least one of Z and n X's has 5 to 20 carbon atoms.

Owner:SANYO CHEM IND LTD

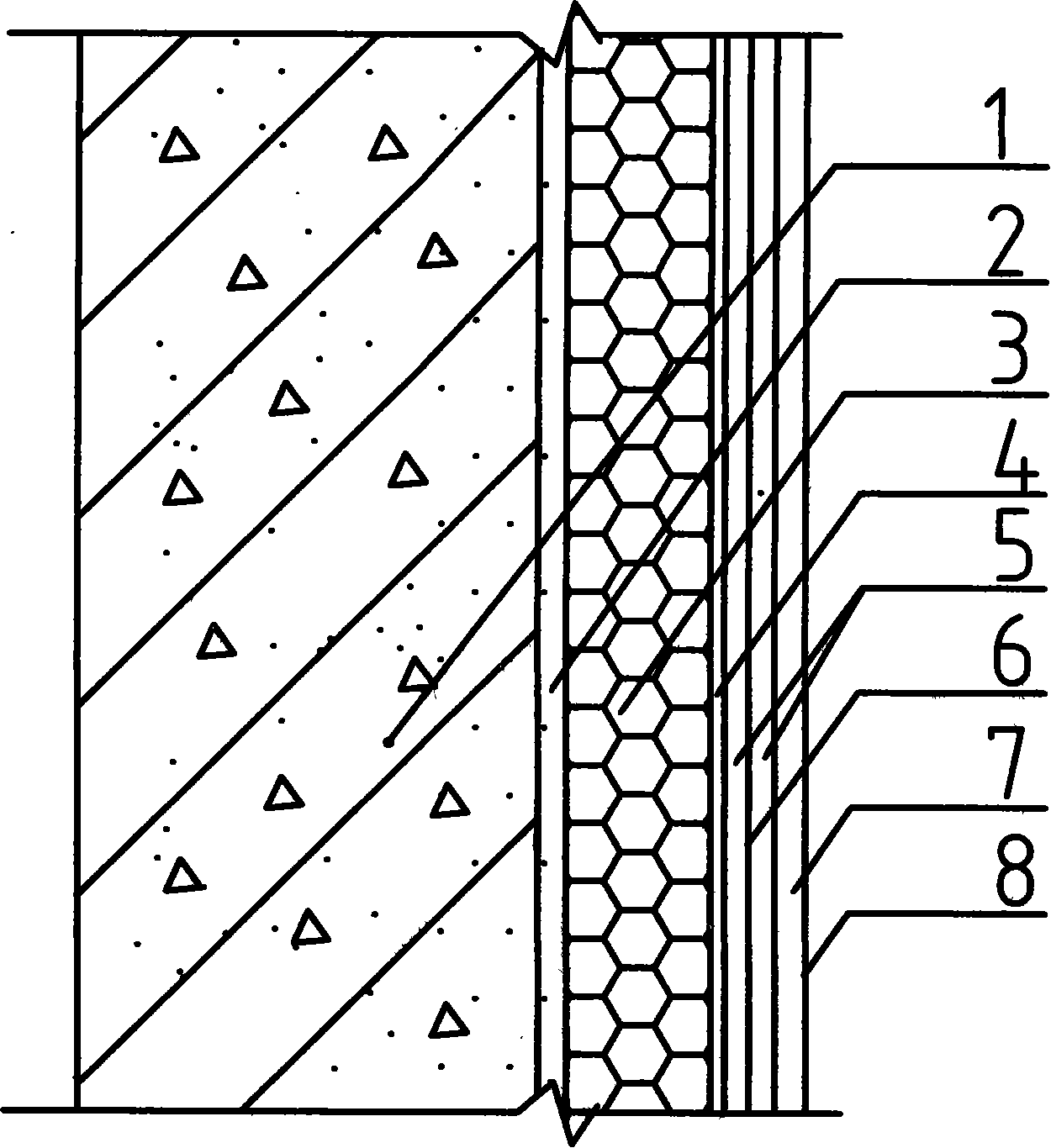

Spray coating rigid foam polyurethane water-proof fireproof heat-preserving wall as well as construction method thereof

InactiveCN101250910AQuality assuranceReduce crackingCovering/liningsWallsInsulation layerSpray coating

The invention relates to a sprayed rigid foam polyurethane waterproof fireproof heat insulation wall and a construction method thereof. The structure of a composite layer of the wall from the inside to the outside in order is as follows: a base course wall (1), an interfacial agent plugging lower layer (2), a sprayed rigid foam polyurethane waterproof heat insulation layer (3), an interfacial agent seal course (4), an inorganic lightweight aggregate cement mortar screeding cracking resistant layer (5) which is buried with alkali-resistant glass fiber gridding cloth (6), a flexible waterproof layer (7) and a finishing coat (8), which are solidified into a whole, wherein, the dry powder of the inorganic lightweight aggregate cement mortar contains inorganic lightweight aggregate (one or the mixture of expanded vermiculite, obturator perlite or pumice) with 10-25 weight percent and the grain diameter less than or equal to 1 mm. The wall of the invention has light self-weight and good integrity, and solves the problem of bad waterproof heat insulation of the whole wall due to the rugged surface of the sprayed rigid foam polyurethane heat insulation layer. The construction method is easy to operate and low in cost.

Owner:JIANGSU NIGAO SCI & TECH +1

Flexible Polyurethane and Polyurethane/Polyorganosiloxane Foam Materials that Absorb Impact Energy

A polyurethane foam, a polyurethane / polyorganosiloxane foam, and a polyurethane foam polyurethane / polyorganosiloxane foam material are disclosed and described herein. The materials are formed in the presence of a polymerization reaction initiator (an isoprenoid compound), and a polymerization reaction accelerator. The polyurethane foam is formed from an isocyanate and a polyol. The polyurethane foam polyurethane / polyorganosiloxane foam material comprises the polyurethane foam which is cross-linked to the polyurethane backbone to a polyurethane / polyorganosiloxane foam. Optional gelling agents, emulsification control agents, reinforcement fillers, cross-linkers, reinforcement polymers, rubber reinforcers, silk proteins, emollients, stabilizers and colorants are also described. The polyurethane and polyurethane-polyorganosiloxane foam materials exhibit a high degree of flexibility, resilience and excellent impact absorption.

Owner:VIRFEX LLC

Self-flame-retardant heat-preservation water-based polyurethane composition and foaming body, and preparation method of foaming body

InactiveCN108129628AImprove insulation effectImprove flame retardant performanceWater basedPolymer science

The invention discloses a self-flame-retardant heat-preservation water-based polyurethane composition and foaming body, and a preparation method of the foaming body. The invention can be applied to different fields such as artificial synthetic leather, heat preservation of water heaters, heat-insulation coatings and the like. According to the invention, an aerogel material is introduced into water-based foaming polyurethane, and the heat-insulation and heat-preservation properties of a resin water-based polyurethane foam base material can be improved. The foaming water-based polyurethane provided by the invention has a plurality of synergistic flame retardant mechanisms, and can endow the foaming polyurethane with excellent flame retardancy and low toxicity.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Method for preparing solvent-free wet-process foaming polyurethane for synthetic leather and method for preparing synthetic leather by using solvent-free wet-process foaming polyurethane

The invention provides a method for preparing solvent-free wet-process foaming polyurethane for synthetic leather and a method for preparing the synthetic leather by using the solvent-free wet-process foaming polyurethane. The method for preparing the solvent-free wet-process foaming polyurethane comprises the steps of: dewatering polyalcohol, adding isocyanate and a catalyst in a reaction kettle at the temperature of 25-50 DEG C and reacting the temperature of 55-85 DEG C, thus obtaining the solvent-free wet-process foaming polyurethane. The method for preparing the synthetic leather comprises the steps of: filling the solvent-free wet-process foaming polyurethane in a non-woven fabric by soakage or forming a film on the non-woven fabric by blade coating; and putting the non-woven fabric in a water bath for solidifying the solvent-free wet-process foaming polyurethane and generating carbon dioxide gas, thus forming a porous polyurethane filler in the non-woven fabric or a porous polyurethane coating layer on the surface of the non-woven fabric, and finally obtaining various types of polyurethane synthetic leather by adopting a conventional processing technology. By virtue of the method, the pollution problem of a DMF (Dimethyl Formamide) solvent in the current wet-process solidification technology of a solvent type polyurethane synthetic leather can be solved; and in addition, the solvent-free wet-process foaming polyurethane belongs to a self-foaming product and is low in preparation cost and simple in technology.

Owner:SHAANXI UNIV OF SCI & TECH

Method for filling wall cavities with expanding foam insulation

ActiveUS20120121805A1Significant obstructionLiquid surface applicatorsCoatingsBoiling pointPolyisocyanurate

The invention described herein generally pertains to the use of low boiling point, low vapor pressure blowing agents with froth polyurethane or polyisocyanurate foams to achieve superior cavity filling than when using conventional higher vapor pressure or more ozone-depleting blowing agents.

Owner:ICP CONSTR INC

Production method for multifunctional rigid foam polyurethane composite heat-conservation board

InactiveCN101487299AHigh hardnessImprove flame retardant performanceWallsHeat proofingTO-18Polymer science

A preparation method used for preparing a multifunctional polyurethane hard foam insulation composite board includes the following steps: a waterproof-fireproof polymer cement sheet is prefabricated; after an adhesive and an inorganic powder are mixed according to the proportion of 1:1.5 to 2, the mixture is pressed with a non-woven cloth by the manufacturing line; the adhesive is prepared by the polymer emulsion, a flame retardant, film-forming additives, deionized water and a thickener by a certain proportion and the inorganic powder is prepared by the stuffing, a solid flame retardant and cement by a certain proportion; the foam material is formed by the following materials according to the weight portions: 54 to 64 percent of PAPI, 10 to 15 percent of flame-retardant polyether polyol, 13 to 18 percent of polyether polyol, 4 to 7 percent of vesicant, 0.8 to 1 percent of catalyzer, 5 to 8.5 percent of flame retardant and 0.7 to 1 percent of foam-leveling agent; a polyurethane foaming machine manufacturing line is adopted to froth the foam material into the polyurethane board and the polymer cement sheet is simultaneously compounded on two surfaces of the polyurethane board so as to prepare the polyurethane insulation composite board; and the composite board prepared by adopting the method can be used for the outer-wall waterproof, fireproof and insulation engineering of buildings.

Owner:夏良强

Production process of sponge-structured high-elasticity non-woven three-dimensional cotton

InactiveCN101962873AIncrease elasticityImprove stress resistanceNon-woven fabricsPolyesterMolding machine

The invention discloses a production process of sponge-structured high-elasticity non-woven three-dimensional cotton, which comprises the following steps of: blending high-elasticity and low-melting-point modified polyester short fibers, thermoshrinking modified polyester short fibers and other fibers according to a ratio and processing the mixed fibers by using an opener; delivering the processed materials into a cotton feeding machine through a cotton conveying fan; combining by a feeding combing machine of the cotton feeding machine to form a fiber web with a continuous structure; feeding the fiber web into a vertical web-laying molding machine for vertical molding treatment; conveying the obtained product into an oven for thermal molding by an oven conveying belt; cooling, setting, molding and winding strips to obtain the sponge-structured high-elasticity non-woven three-dimensional cotton. The longitudinal and transverse tension and the density uniformity of the three-dimensional cotton produced by the production process are both similar to those of sponge, and the three-dimensional cotton is suitable for shaped shearing processing such as splitting and chipping, has a structure similar to that of the sponge, has high rebound resilience, compression resistance and air permeability, can replace a foaming polyurethane material and can be applied in many fields in which the foaming polyurethane material cannot be applied.

Owner:DONGGUAN CITY ZHIAI UNDERWEAR

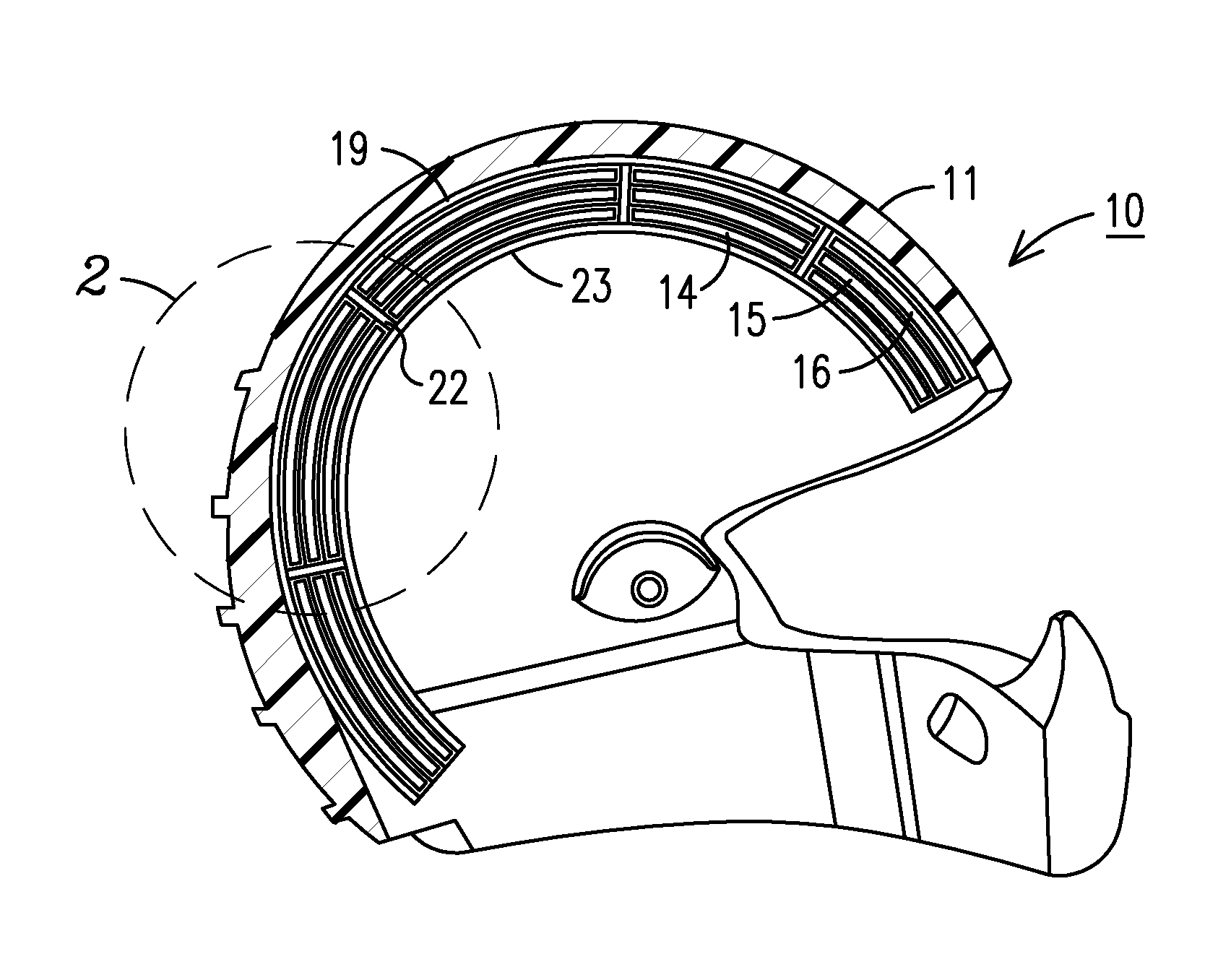

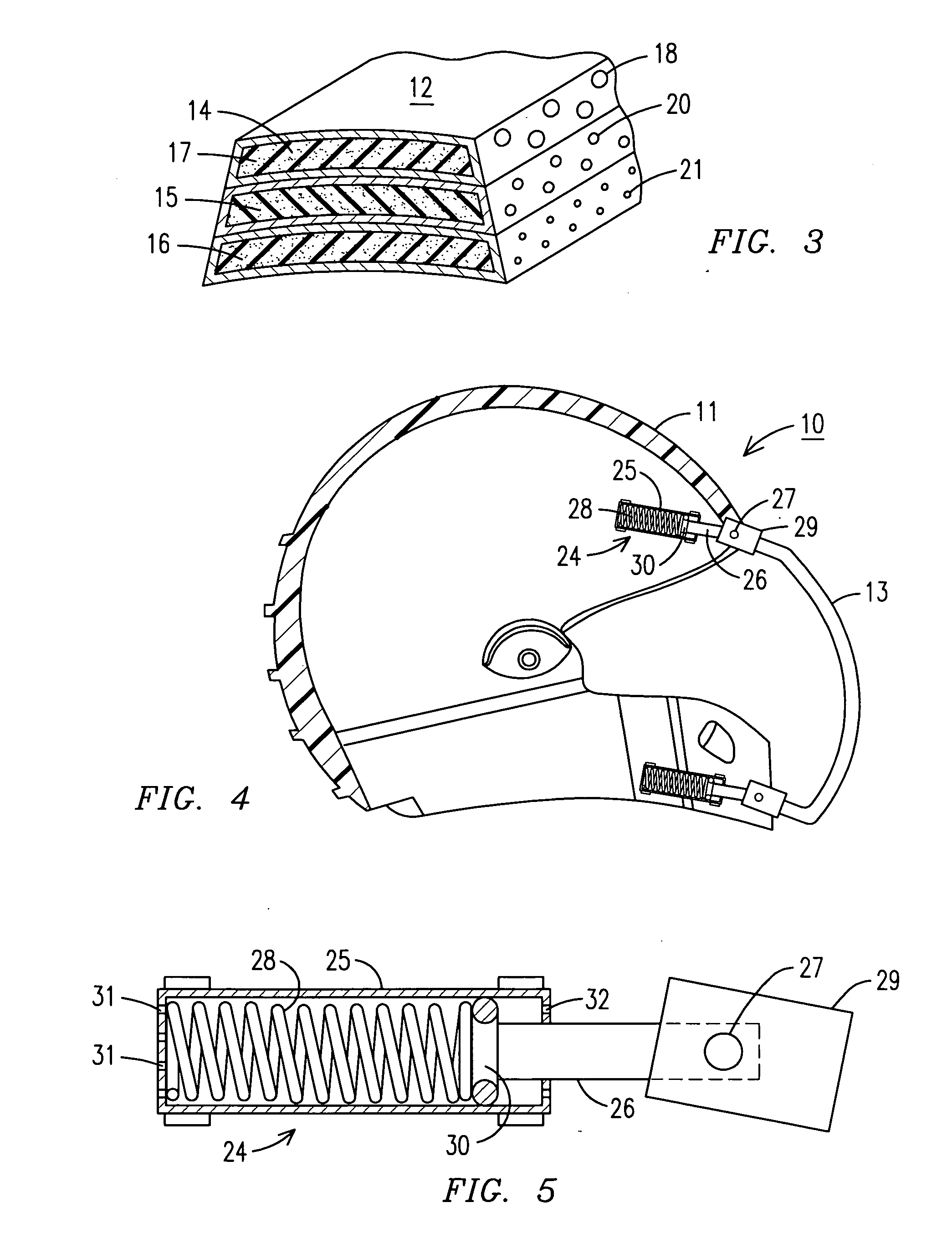

Safety helmet

The present invention is for a safety helmet having a hard outer shell having a plurality of protective flexible air bags for protecting a person's head against blows to the helmet outer shell and having a shock absorbing face guard. Each air bag may have a plurality of cushioning air bags enclosure layers mounted to a thin foamed polymer shell lining. Each enclosure layer of each air bag has an interior filled with a resilient multi-cellular sponge like material, such as a shaped foamed polyurethane sponge, and has a plurality of air escapement openings sized to meter the release of air under impact to the helmet hard shell under predetermined pressure with a different air release pressure for each enclosure layer.

Owner:BRANTLEY CHARLES W

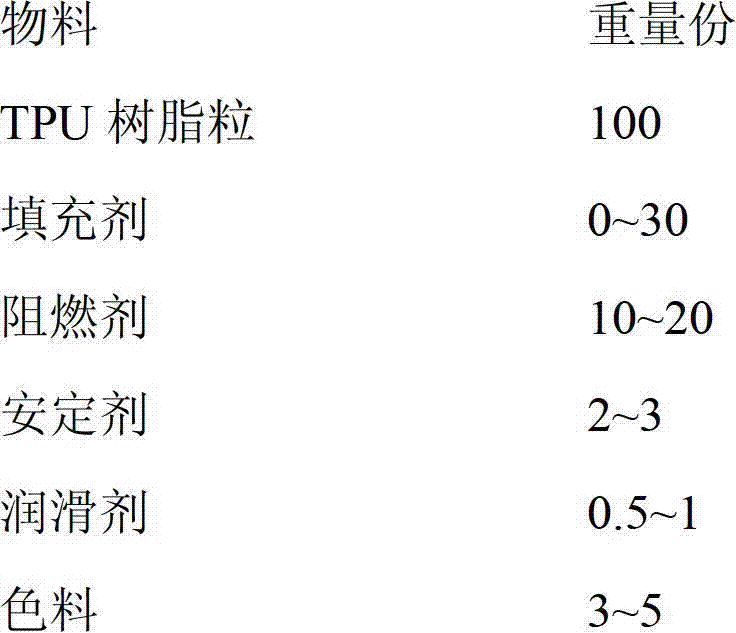

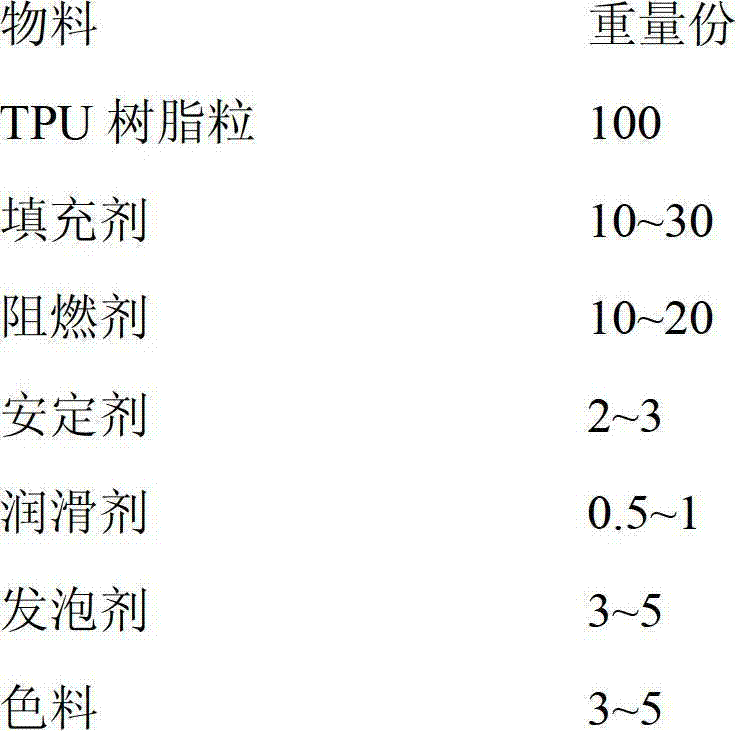

Thermoplastic foaming polyurethane fiber board, production method and uses thereof

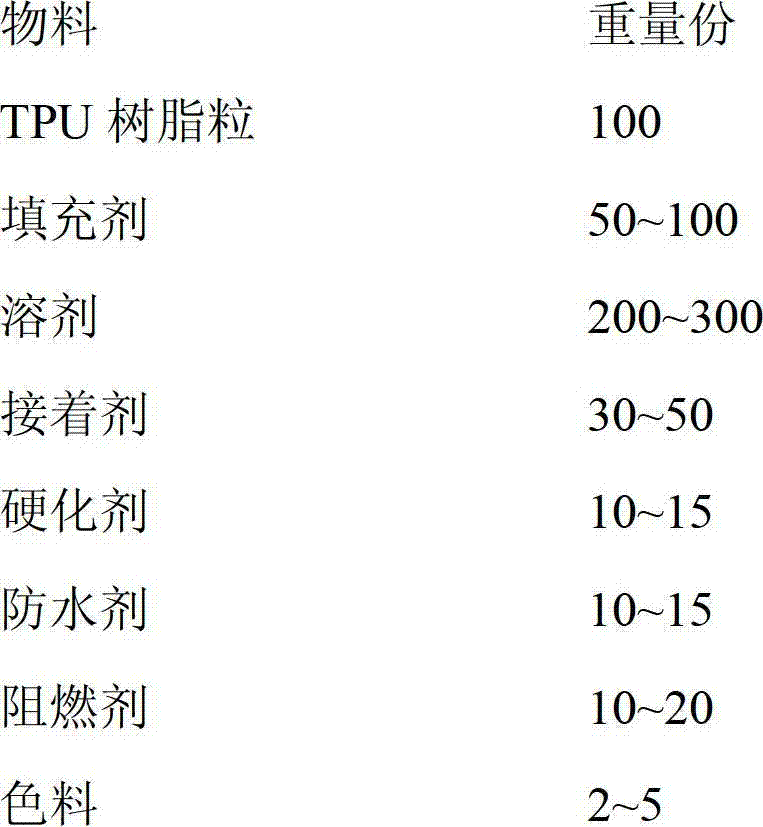

ActiveCN103072346AAntifoulingWaterproofCovering/liningsSynthetic resin layered productsFiberThermoplastic

The present invention relates to a thermoplastic foaming polyurethane fiber board, a production method and uses thereof. The thermoplastic foaming polyurethane fiber board comprises an A surface layer, a B middle layer and a C bottom layer, wherein the A surface layer, the B middle layer and the C bottom layer are integratedly compounded from top to bottom, the A surface layer is a sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, the B middle layer is a layer prepared by foaming the sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, and the C bottom layer is a layer prepared by drying a fiber cloth impregnated with a TPU composition. The thermoplastic foaming polyurethane fiber board can be used as flooring boards, wall panels, roof hanging plates and indoor partition boards, and can be used for production of furniture materials and various building materials.

Owner:JIANGSU BIDE SCI & TECH CO LTD

Production method for multifunctional rigid foam polyurethane composite board

InactiveCN101487296AImprove waterproof functionHigh strengthWallsHeat proofingPolymer scienceAdhesive

The invention discloses a preparation method used for preparing a multifunctional polyurethane hard foam composite board. The method comprises the following steps: a polymer cement sheet is prefabricated; a polyurethane foaming machine manufacturing line is adopted to froth the PAPI and conjugate polyether into the polyurethane board and the cement sheet is simultaneously compounded on two surfaces of the polyurethane board to prepare the polyurethane insulation composite board. The preparation method of the polymer cement sheet comprises the following steps: after an adhesive and an inorganic powder are mixed according to the proportion of 1:1.5 to 2, the mixture is pressed with a non-woven cloth by the manufacturing line; the adhesive is prepared by the following materials according to the weight portions: 75 to 85 percent of polymer emulsion, 5 to 10 percent of flame retardant, 1 to 6 percent of film-forming additives, 5 to 10 percent of deionized water and 0 to 1.5 percent of thickener; the inorganic powder is prepared by the following materials according to the weight portions: 40 to 60 percent of stuffing, 10 to 25 percent of solid flame retardant and 25 to 40 percent of cement. The composite board prepared by the method integrates the fireproof, waterproof, high-intensity and insulation functions into a whole and can be used for the outer-wall waterproof, fireproof and insulation engineering of buildings.

Owner:夏良强

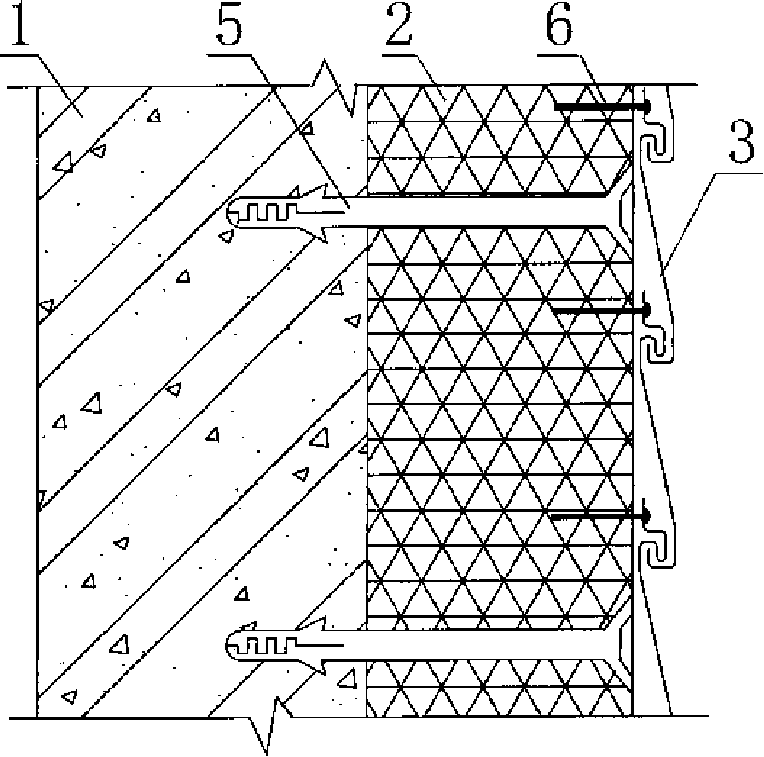

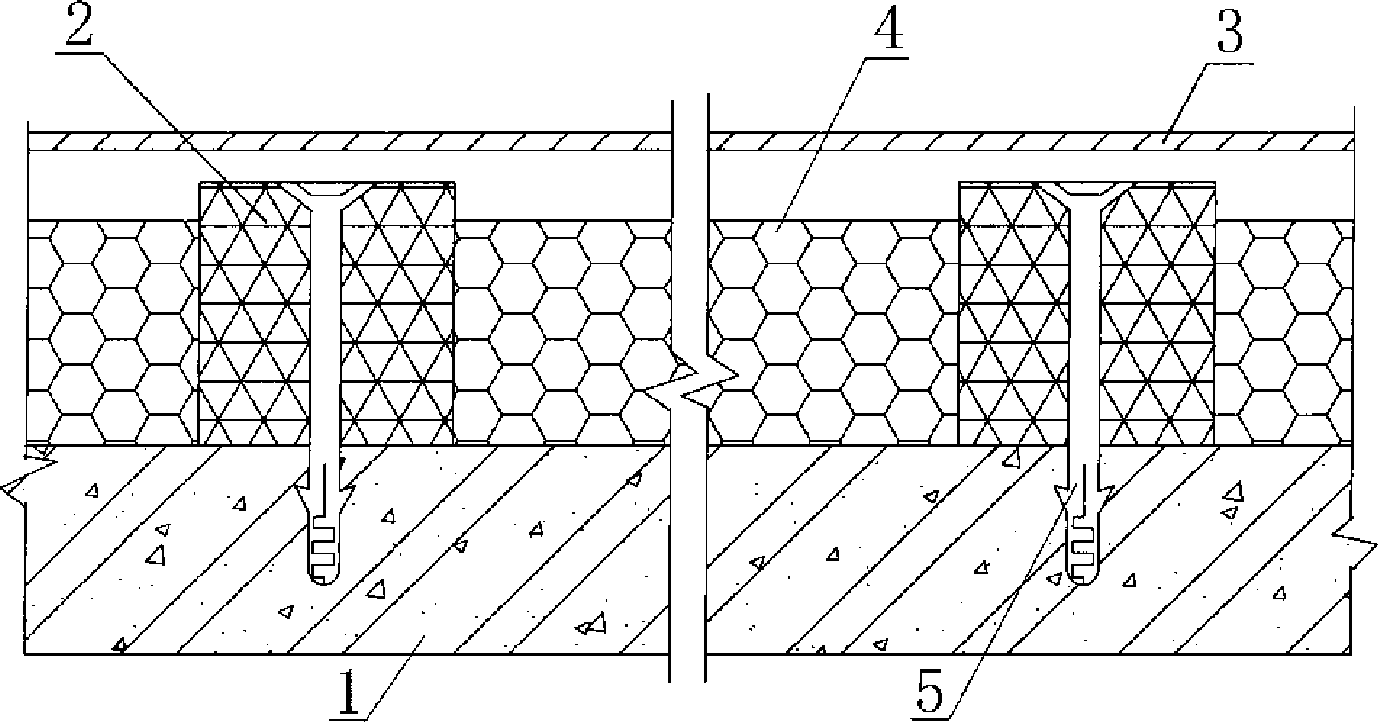

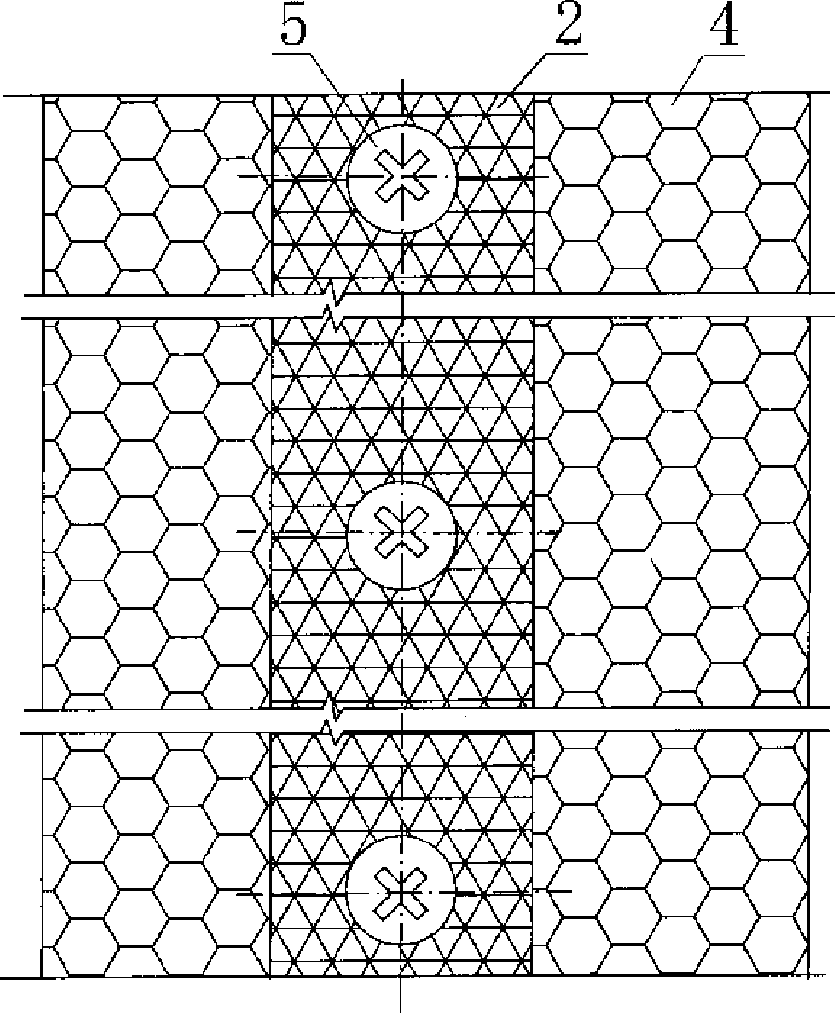

Dry-hanging keel decorative board heat insulation composite wall and its construction method

The invention relates to a thermal insulation compound wall body of a dry hanging keel decoration plate and a construction method, wherein a prefabricated thermal insulation keel is mounted on a basal layer wall body through a mechanical anchor firmware, and then a negative angle column and a positive angle column are mounted, heat-insulating material is filled between the positive angle column and the negative angle column, both lateral sides of the invention are respectively equipped with two thermal insulation keels, and J-shaped slotted plates are respectively mounted on the two thermal insulation keels, and a prefabricated door-window insulating sleeve hole is mounted on a door-window opening, the periphery of a sash is filled and infused with foaming polyurethanes, a heat-insulating board is filled between the thermal insulation keels, and the thermal insulation keels are fixed by an anchor firmware with a round plate, and the foaming polyurethanes are infused in gaps, at last a cladding decoration panel is fixedly mounted on the outer side of the thermal insulation keels by self-threading screws. The thermal insulation property of the thermal insulation compound wall body is excellent, and the thermal insulation compound wall body achieves an integral dry construction, the architectural exterior facing is rich and colorful, the cubic effect is strong, the invention is not easy to be polluted, which can be widely applied to civilian constructions which are newly constructed, enlarged, and rebuilt and needs thermal insulation and heat insulation, in particular to villas whose heights of eaves are less than 20m and floors are less than 3 to 4, and outer-eaves decoration of middle grade and high grade constructions.

Owner:北京住总集团有限责任公司 +1

Method for producing rigid foam polyurethane heat-insulation and decorative integrated plate

ActiveCN102587609AReduce weightImprove insulation effectCovering/liningsFoam polyurethanesIntegrated systems

The invention relates to a method for producing rigid foam polyurethane heat-insulation and decorative integrated plate. The method can be used for continuous production, production efficiency is high, large quantities of production cost and construction cost are saved, the plate is light in weight, high in flatness and fine in decorative effect, and can be optionally cut, requirements of a construction method for a heat-insulation and decorative integrated system can be met, and requirements of a construction method for a thin plastering system can also be met.

Owner:烟台市顺达聚氨酯有限责任公司

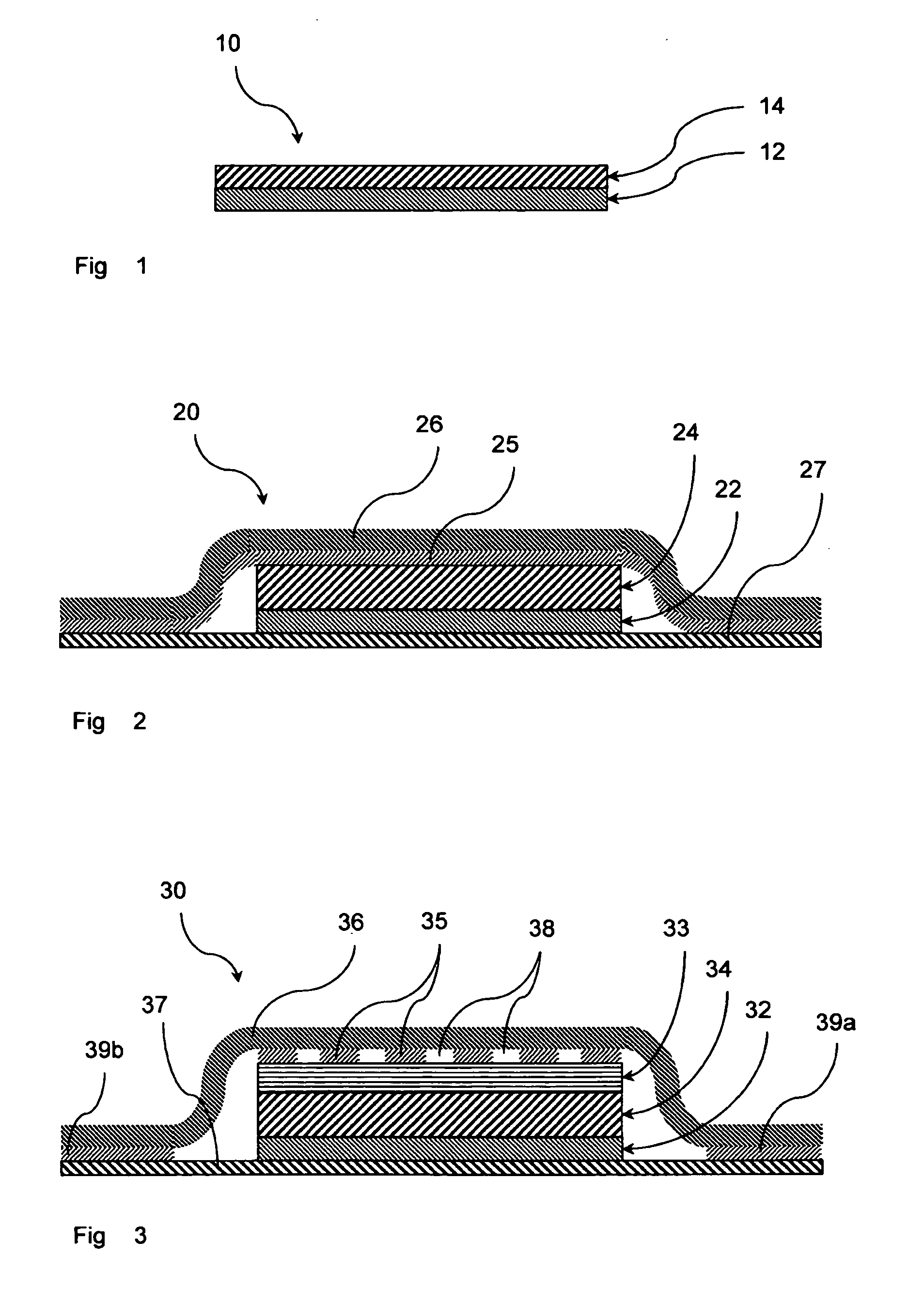

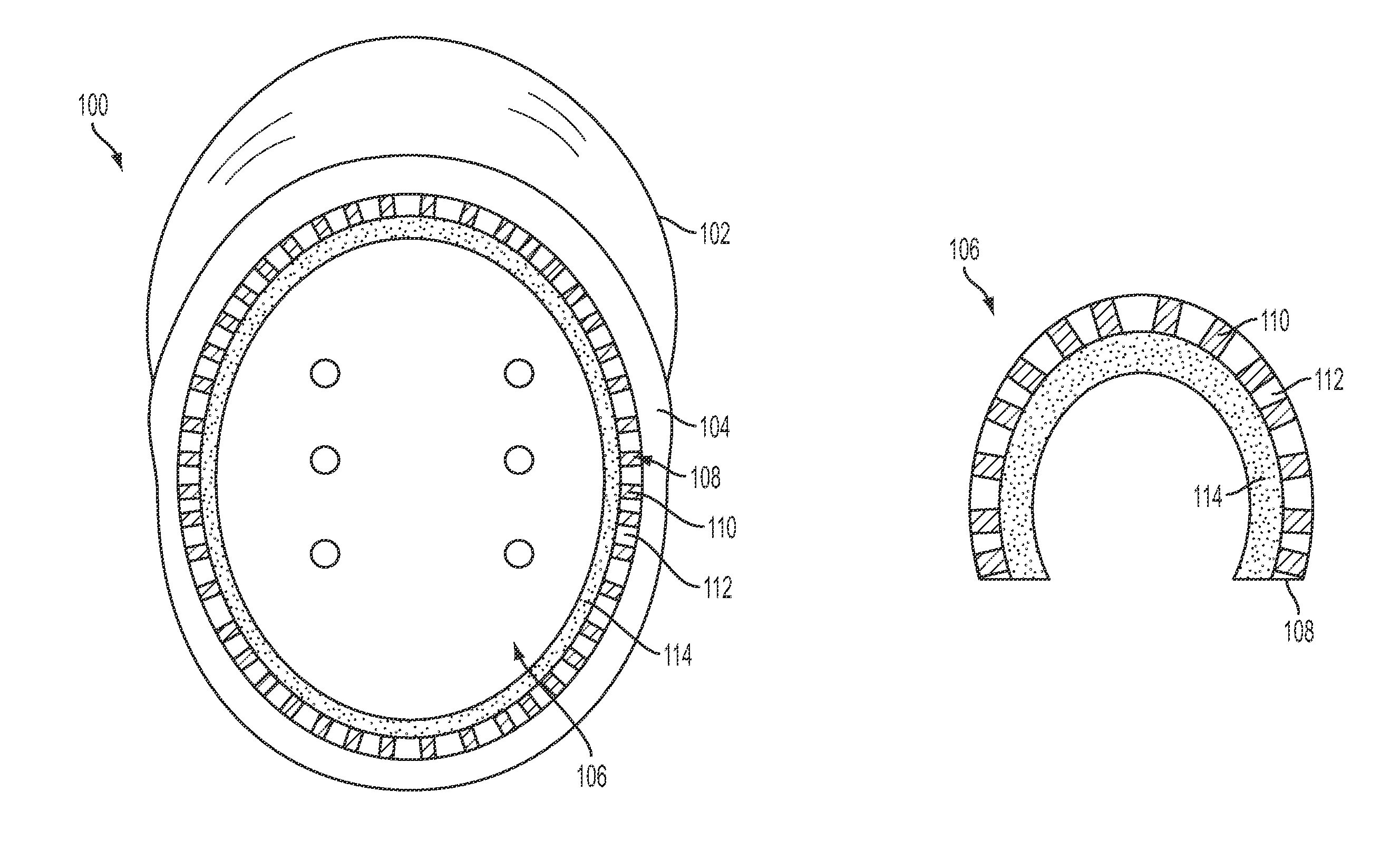

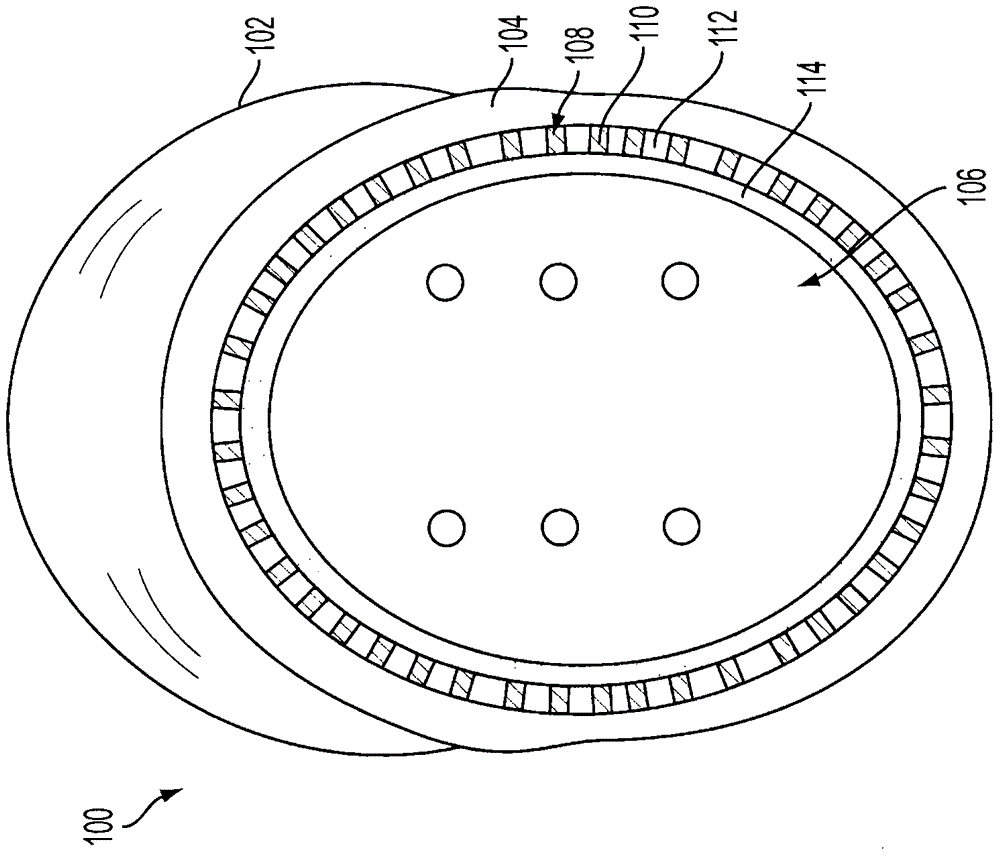

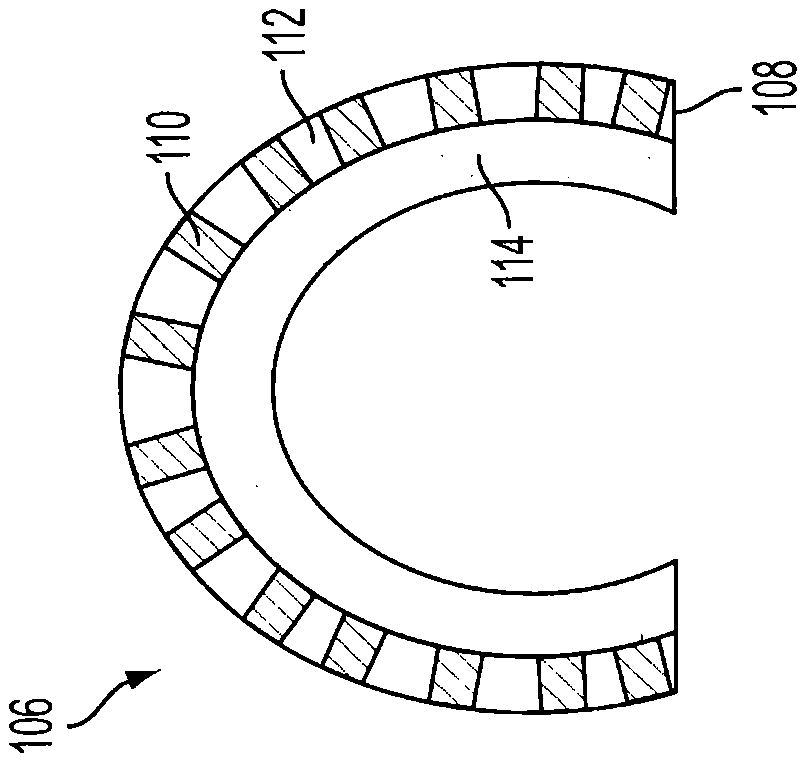

Flexible polyurethane and polyurethane/polyorganosiloxane foam materials that absorb impact energy

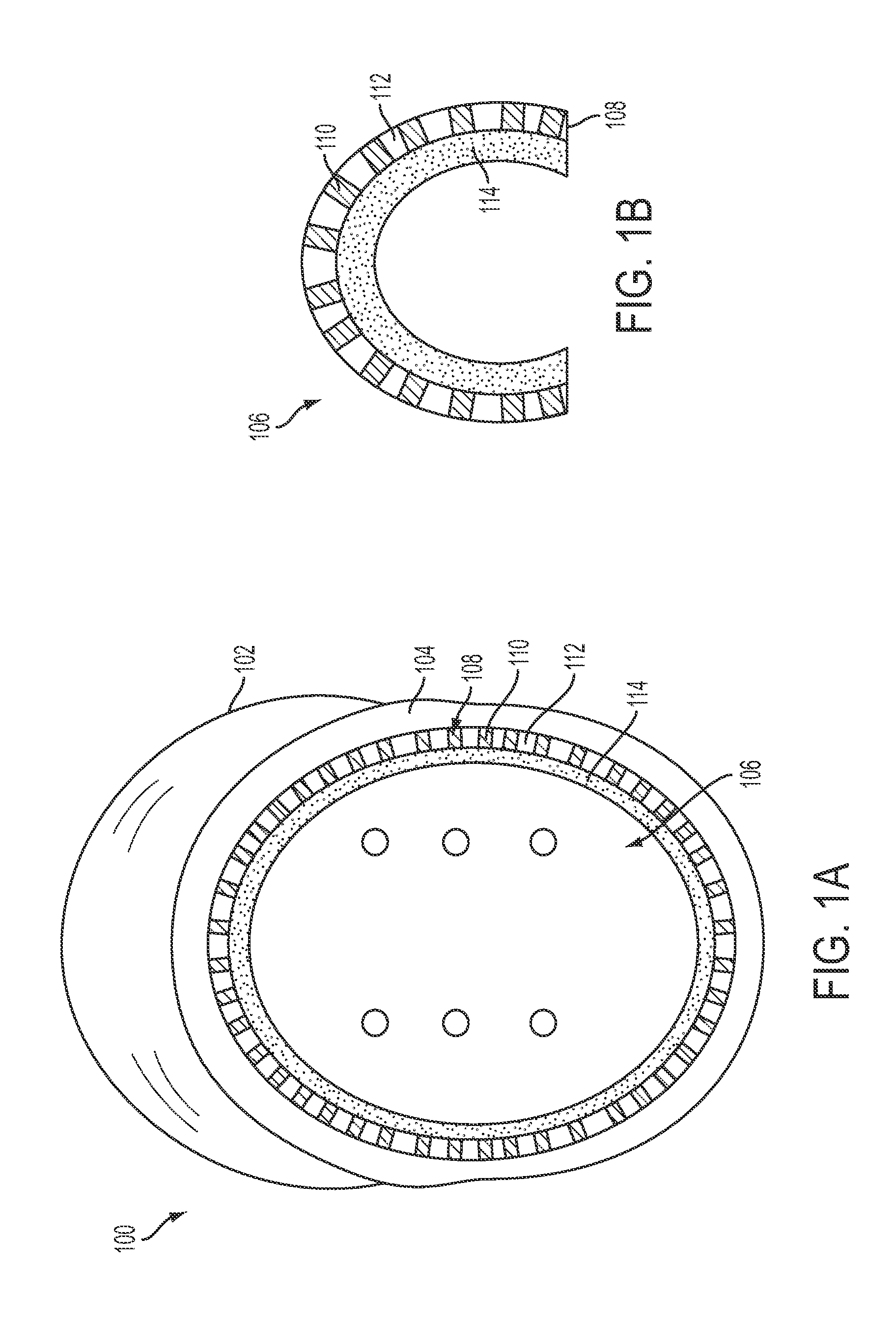

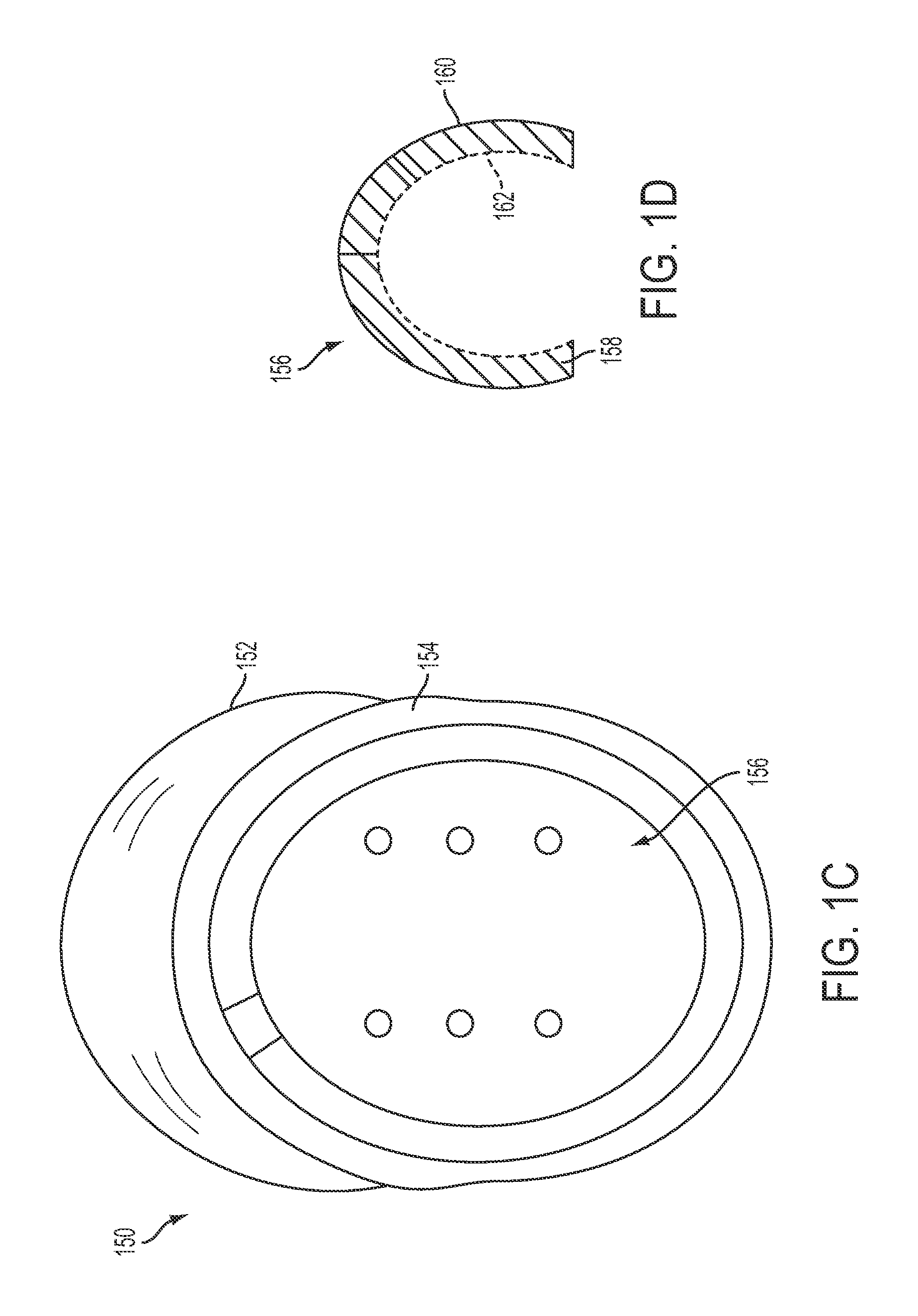

A polyurethane foam (110), a polyurethane / polyorganosiloxane foam (112), and a polyurethane foam polyurethane / polyorganosiloxane foam composite (108) are disclosed and described herein. The materials are formed in the presence of a polymerization reaction initiator (an isoprenoid compound), and a polymerization reaction accelerator. The polyurethane foam (110) is formed from an isocyanate and a polyol. The polyurethane foam polyurethane / polyorganosiloxane foam material comprises the polyurethane foam which is cross-linked to the polyurethane backbone to a polyurethane / polyorganosiloxane foam (112).

Owner:G·德恩

Method for producing aqueous polyurethane synthetic leather for costume by using physically-foamed pore forming coating technology

InactiveCN102425069AImprove hygieneQuality improvementSynthetic resin layered productsTextiles and paperWater vapor permeabilitySolvent based

The invention relates to a method for producing aqueous polyurethane synthetic leather for costume by using a physically-foamed pore forming coating technology. According to the present invention, a physically-foamed polyurethane coating dry film transferring process replaces the original solvent-based polyurethane wet coagulation coating process, such that the problems of pollution and residue of the DMF solvent are solved; with adopting the aqueous polyurethane dry film transferring process to replace the solvent-based polyurethane dry film transferring process, the solvent pollution problem during the production process is eliminated; the synthetic leather for the costume is washed in hot water, the pore forming agent is lixiviated by the hot water, such that the penetrating pores are formed in the aqueous polyurethane coating of the synthetic leather, the water vapor permeability and the air permeability of the synthetic leather for the costume are improved, and the synthetic leather with the good-sanitary property is obtained; with the method, the DMF solvent recovery apparatus and the DMF solvent recovery process are saved, the production cost is reduced, and the technical process is simplified; when the conventional physical properties and the conventional mechanical properties are met, the water vapor permeability of the synthetic leather for the costume is more than or equal to 1.6 mg / cm<2>.h, and the air permeability of the synthetic leather for the costume is more than or equal to 2500 ml / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

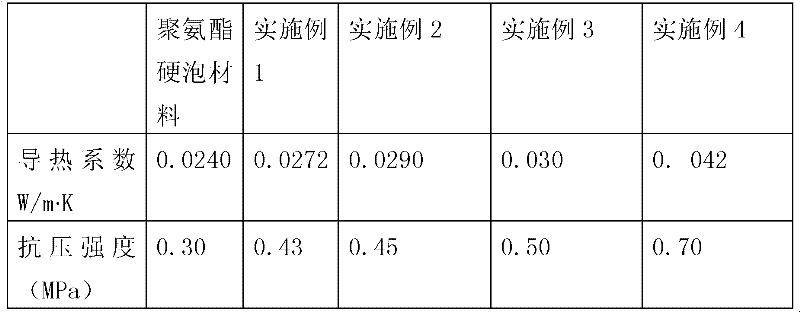

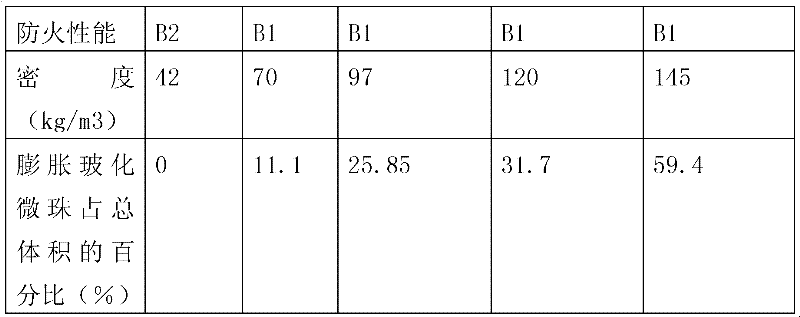

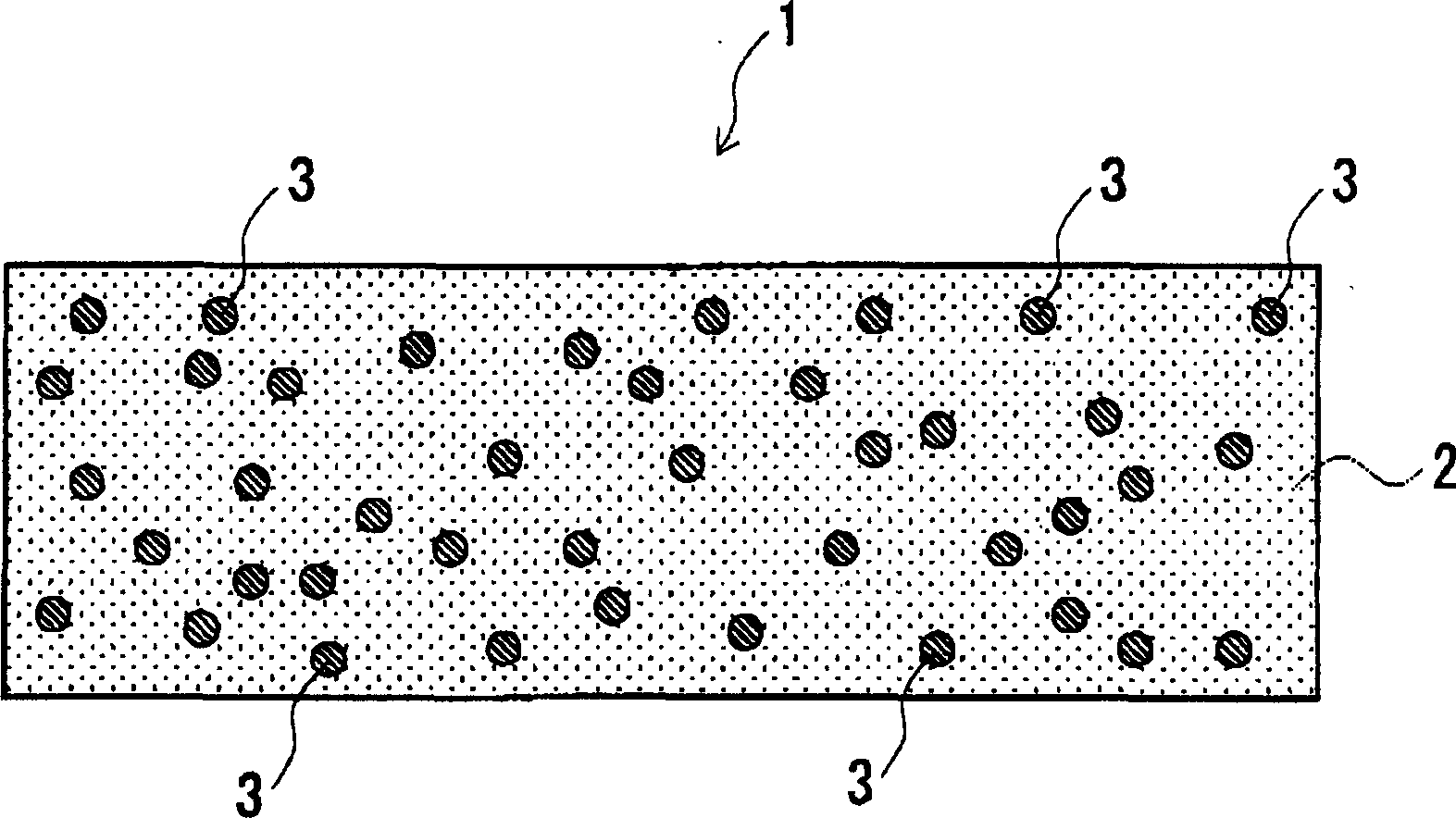

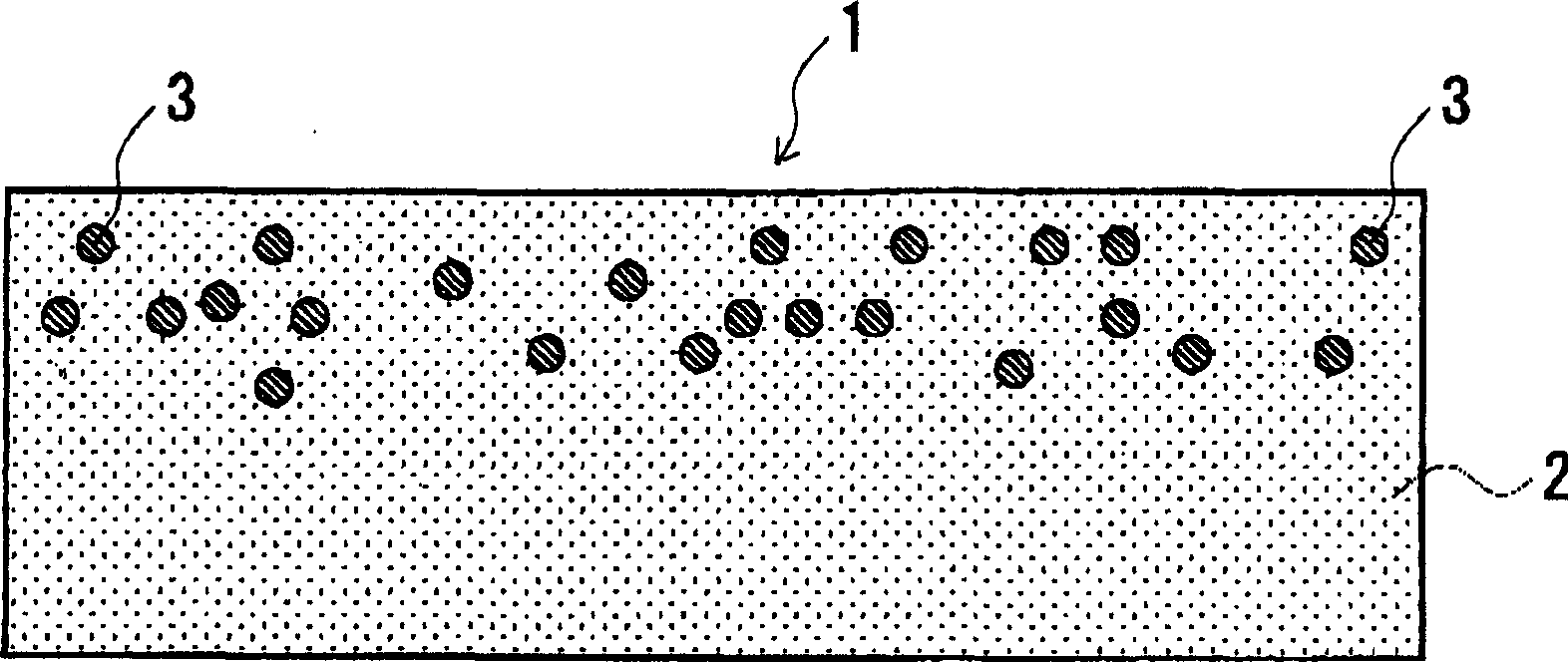

Hard-foam polyurethane-expanded and vitrified microbead composite heat insulation flame-retardant board and preparation method thereof

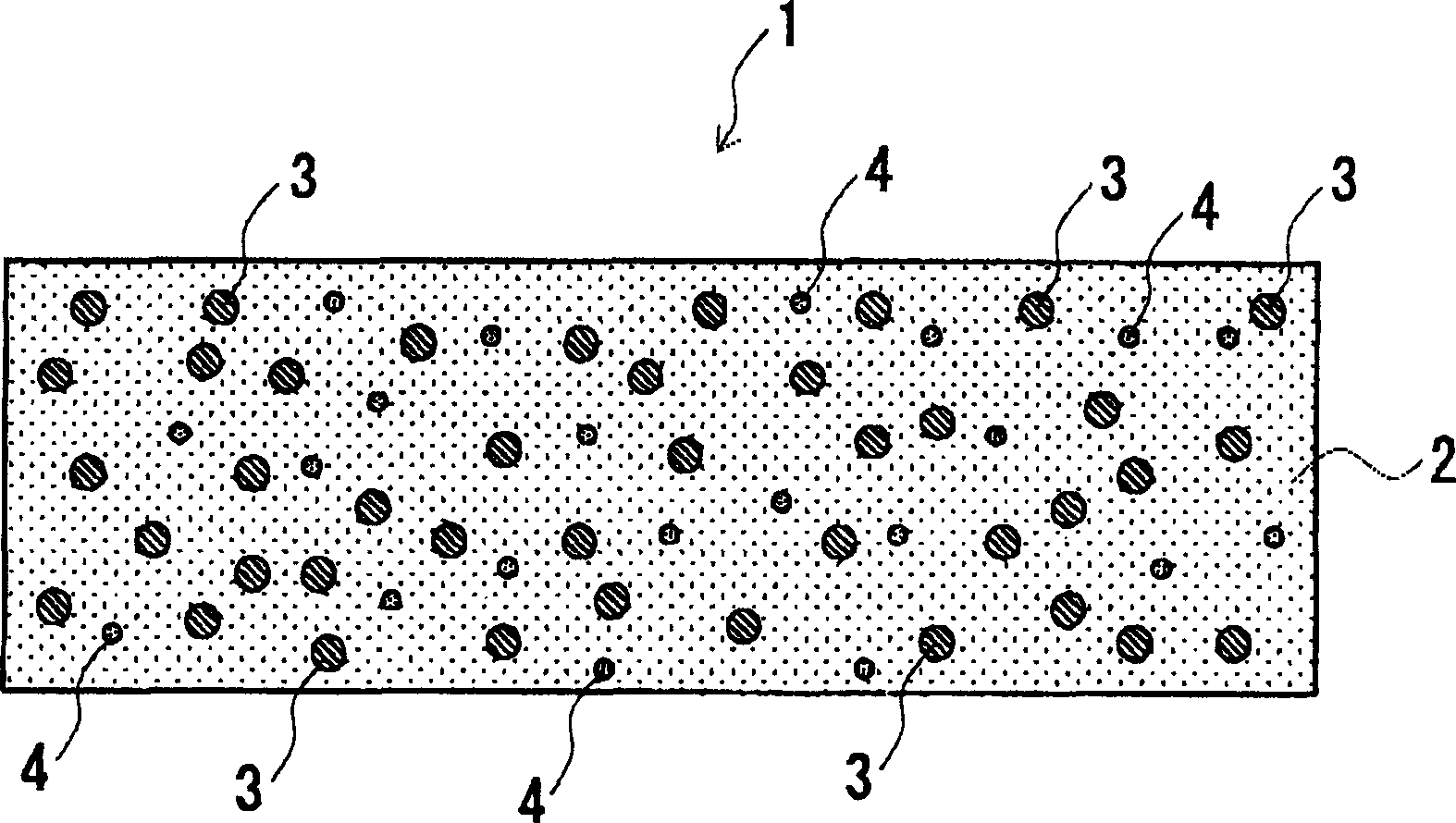

ActiveCN102531467AHigh tensile strengthHigh compressive strengthCeramic shaping apparatusFoam polyurethanesMaterials science

The invention discloses a hard-foam polyurethane-expanded and vitrified microbead composite heat insulation flame-retardant board and a preparation method of the flame-retardant board, wherein the hard-foam polyurethane-expanded and vitrified microbead composite heat insulation flame-retardant board takes an expanded and vitrified microbead as a dispersed phase, and takes polyurethane material A and polyurethane material B as a continuous phase. The heat insulation flame-retardant board has the characteristics of good heat insulation effect and superior flame retardant property.

Owner:建研建材有限公司

Polyurethane foam plastics with deodorizing or antibiotic property

ActiveCN1673246AImprove adsorption capacityExcellent moisture performanceDeodorantFoam polyurethanes

The present invention provides one kind of foamed polyurethane plastic with excellent stink and moisture adsorption or excellent antibiotic property, and the foamed polyurethane plastic has visible compounded deodorant, antiseptic and other additives. The foamed polyurethane plastic features that it contains carbon powder and / or inorganic antiseptic and is preferably foamed polyurethane plastic with rebound elasticity.

Owner:TAKASHIMA & CO LTD

Vamp material and method for preparing same

InactiveCN101693414AImprove deformation resistanceImproved waterproof and flex resistanceSynthetic resin layered productsLaminationFoam polyurethanesMildew

The invention relates to breathable composite vamp material with functions of resisting mildew, bacteria and water and a method for preparing the vamp material. The vamp material comprises an outer synthetic fiber plain cloth layer, a medium polytetrafluoroethylene film layer with urethane foam coatings on both faces and an inner conventional tricot layer, wherein the tricot layer, the polytetrafluoroethylene film layer and the fiber plain cloth layer all contain inorganic nano mildew-proof antibacterial agent. The method for preparing the vamp material primarily comprises the mildew-proof antibacterial treatment of the inner and the outer layers, the preparation of the mildew-proof antibacterial polytetrafluoroethylene film and the binding of all the layers. Because the vamp material contains the inorganic nano mildew-proof antibacterial agent, the vamp material can inhibit the growing of fungi and bacteria, thereby better protecting foot heath, and keeping good water-proof permeability. Both faces of the polytetrafluoroethylene film are provided with the special urethane coatings, therefore the functions of resisting water and folding are obviously improved, and peeling resistance between layers is increased.

Owner:中山市坦洲镇银峰服装鞋材厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com