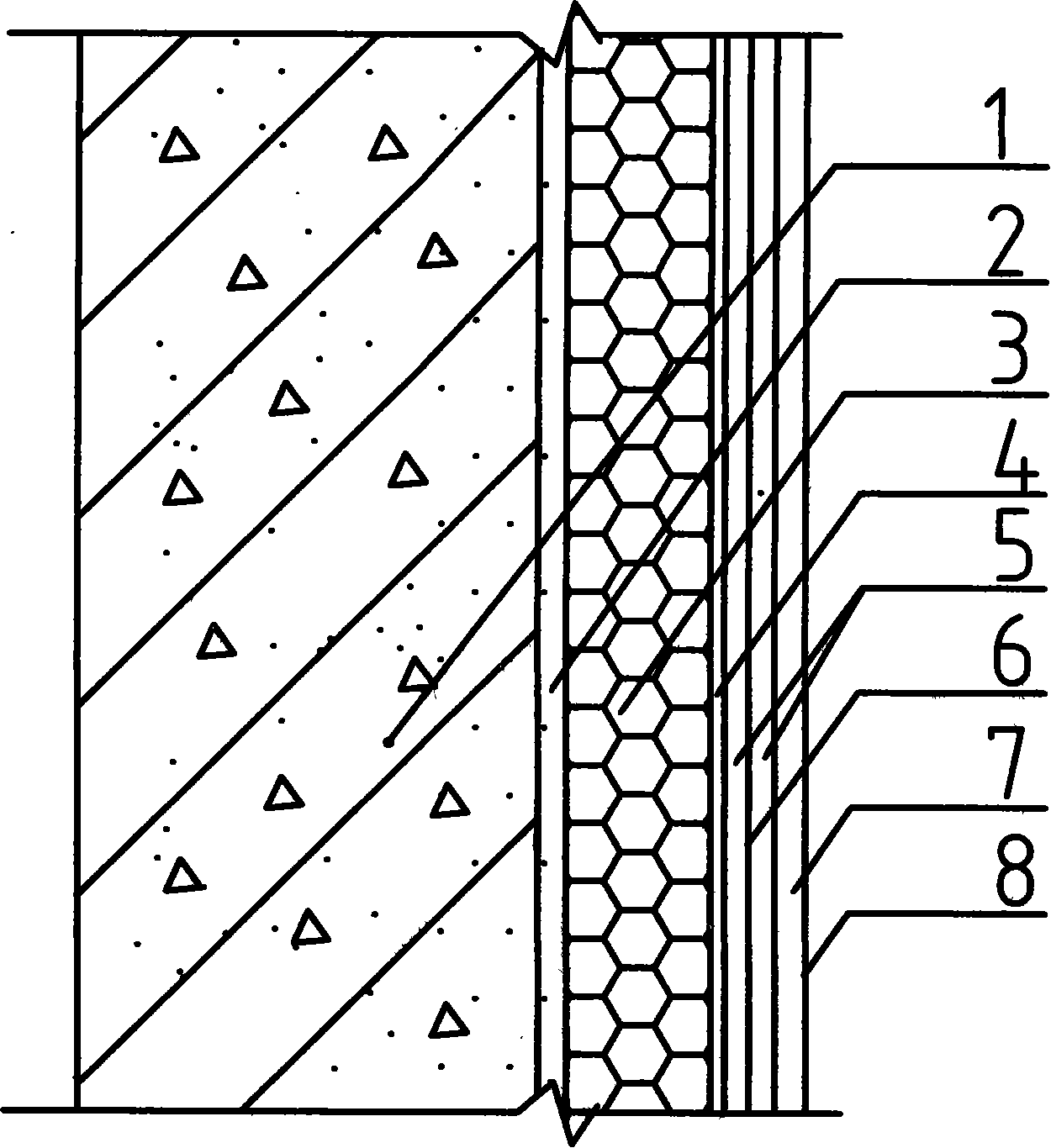

Spray coating rigid foam polyurethane water-proof fireproof heat-preserving wall as well as construction method thereof

A kind of rigid foam polyurethane, fireproof and thermal insulation technology, applied in building thermal insulation materials, walls, building components and other directions, can solve the problems of poor waterproof and thermal insulation of walls, and achieve the effects of good filling, light weight and crack reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Prepare rigid foam polyurethane raw materials, raw materials for inorganic lightweight aggregate cement mortar, interface agent matching rigid foam polyurethane, alkali glass fiber mesh cloth, flexible putty or polyurea waterproof coating or polymer cement waterproof coating, exterior Wall paint or face brick or stone and various construction tools and equipment (the above materials and equipment are general products in the construction industry and can be purchased from the market), spare;

[0028] b. Preparation of inorganic lightweight aggregate cement mortar:

[0029] Weigh the raw materials of inorganic lightweight aggregate cement mortar according to the following formula: cement 15%-30%, sand 40%-60%, inorganic lightweight aggregate 10%-25%, redispersible rubber powder 1.0%-3.0 %, cellulose ether 0.05%~0.3%, microfoam agent 0.02%~0.05%, thickener 0.2%~1.5%, lignocellulose 0.1%~0.2%, modified bentonite or attapulgite 1%~2% , the above are percentages by weight...

Embodiment 2

[0042] Basically the same as Example 1, the difference is: the formula of the inorganic lightweight aggregate cement mortar in the step b is mixed with chopped polypropylene fibers, thereby increasing the crack resistance of the leveling anti-crack layer 5, in the formula , the chopped polypropylene fibers mixed in account for up to 0.2% (weight), and the specific amount of mixing can be determined according to the building cost and quality requirements;

Embodiment 3

[0044] Basically the same as Example 1, the difference is: the formula of the inorganic lightweight aggregate cement mortar in step b is mixed with one or both of silica fume or fly ash, thereby reducing the amount of inorganic lightweight aggregate The dry density of cement mortar improves the construction performance and increases the thermal insulation effect of the wall. In the formula, the silica fume mixed in is at most 5% (weight), and the fly ash is at most 15% (weight). The specific mixing amount can be According to the building cost, quality requirements and source of raw materials;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com