Patents

Literature

177results about How to "Overcome cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

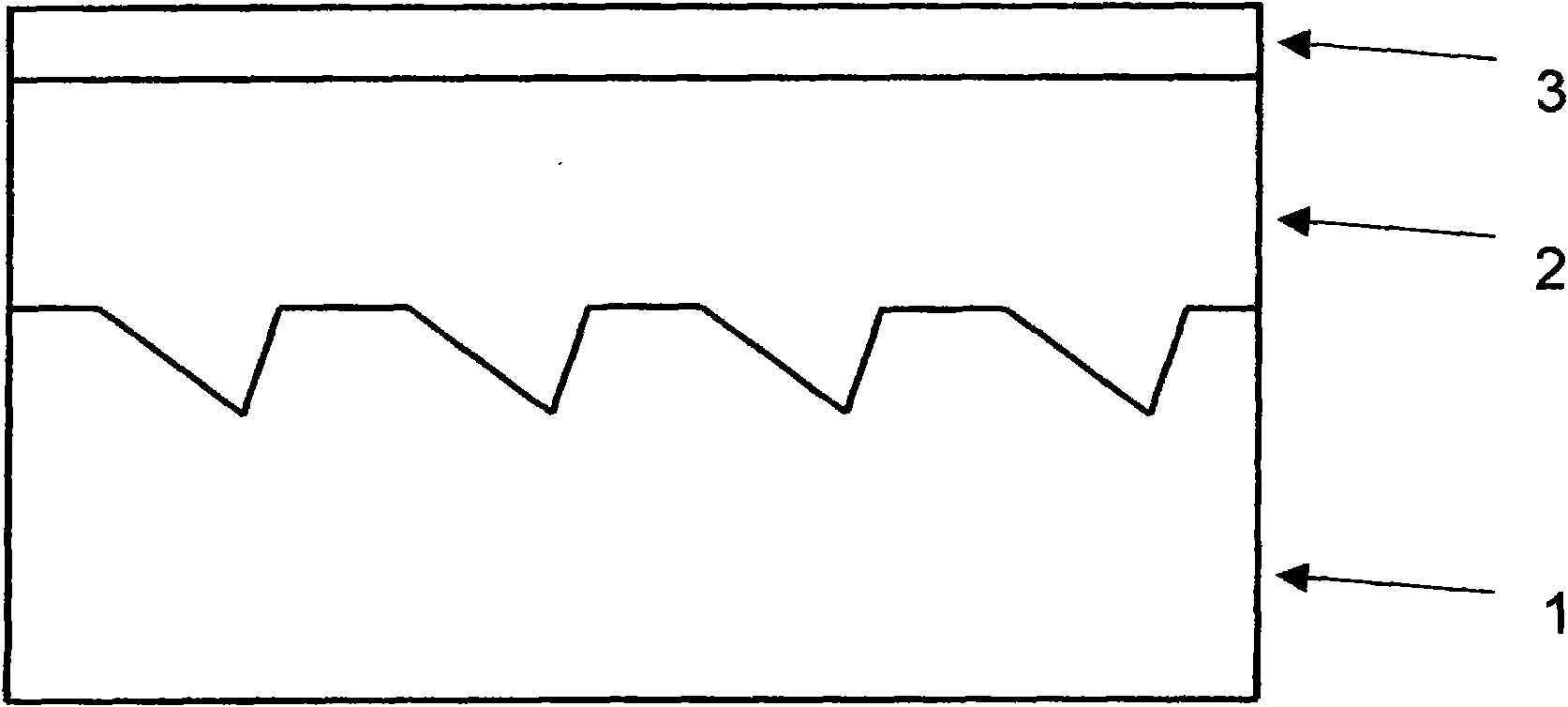

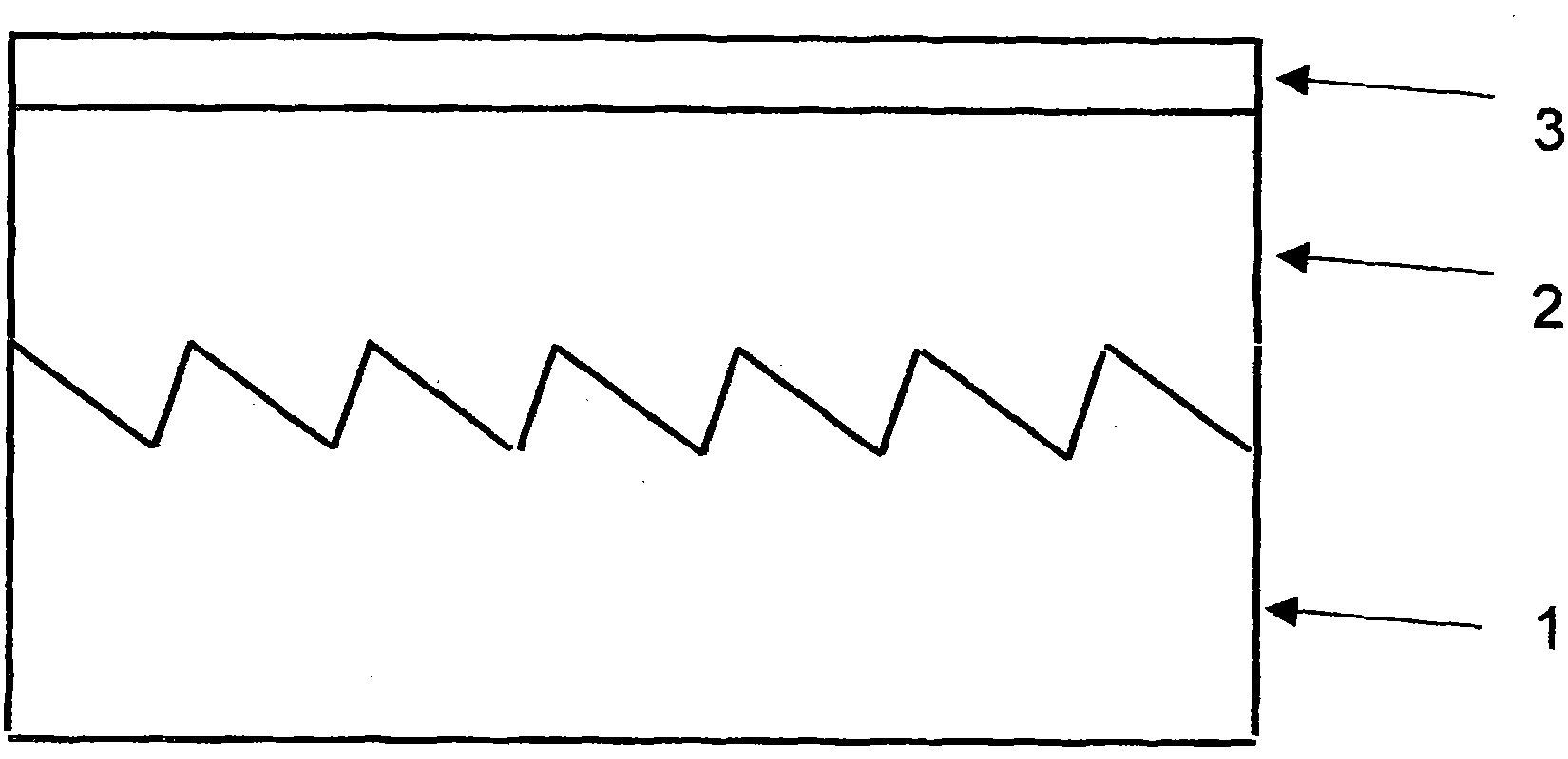

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

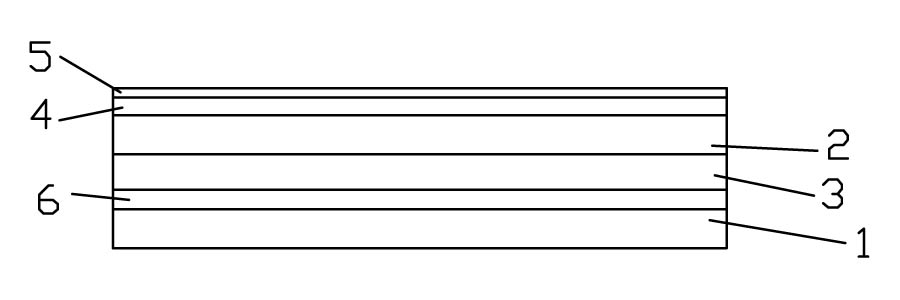

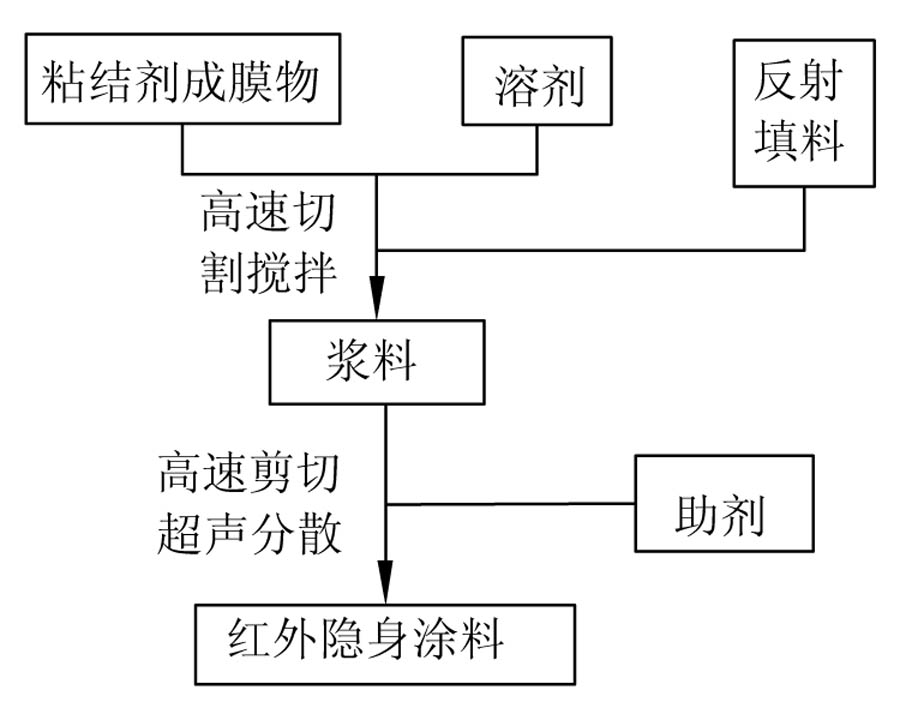

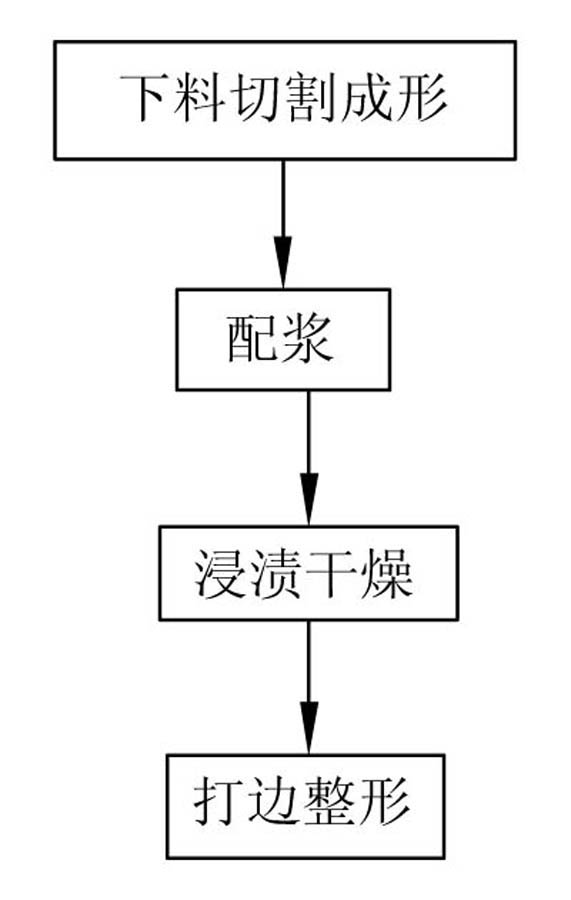

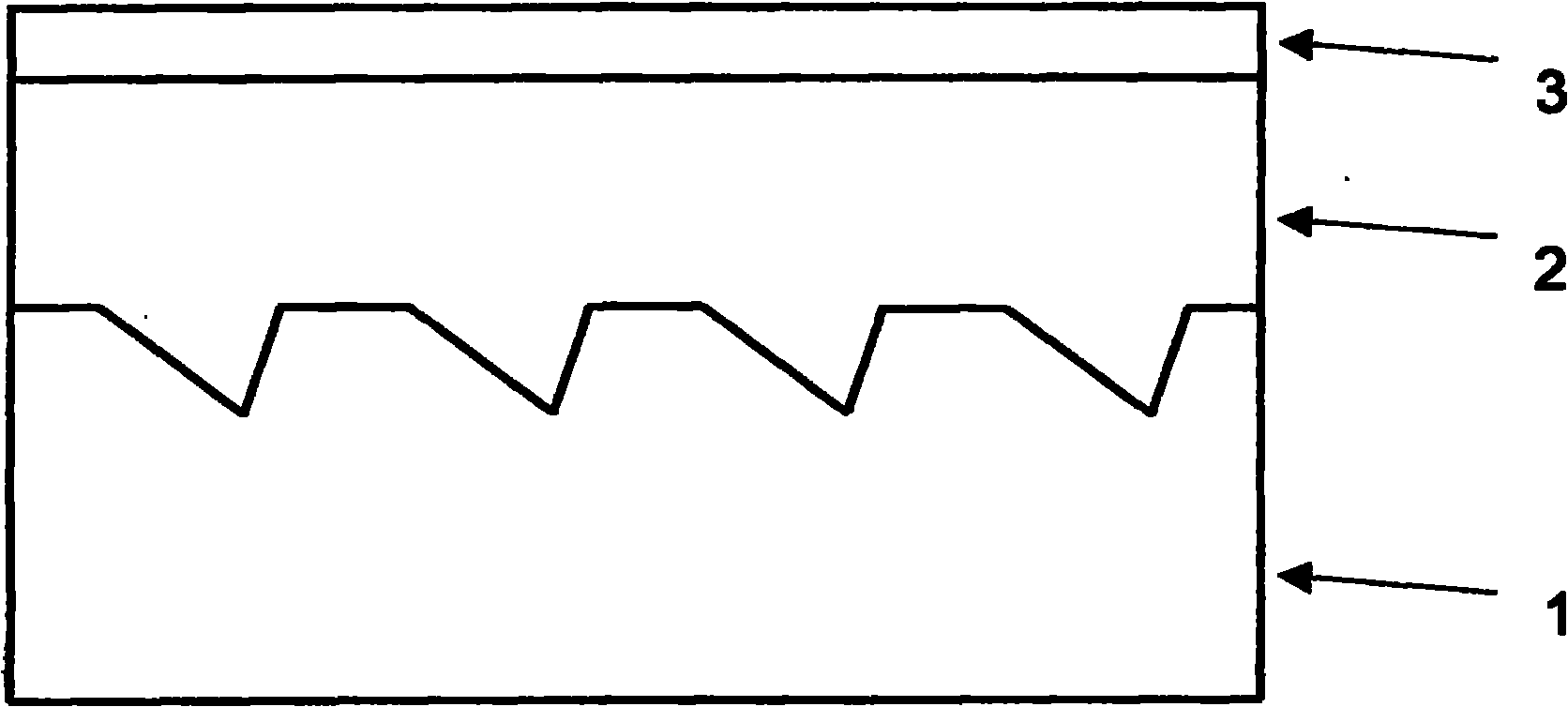

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

Composite foamed cement heat retaining panel using high-volume fly ash and preparation method thereof

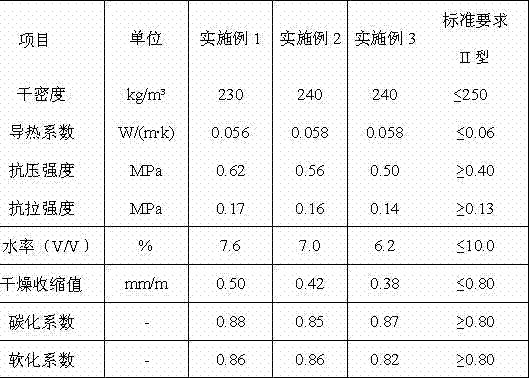

The invention discloses a composite foamed cement heat retaining panel using high-volume fly ash and a preparation method thereof; the composite foamed cement heat retaining panel is prepared by 60-80 parts of cement, 20-40 parts of fly ash, 0.6-3.0 parts of moisture repellent, 0.12-0.30 part of a water reducing agent, 0.8-3.0 parts of an exciting agent, 0.3-0.50 part of anti-crack fiber, 30-60 parts of water and 4-8 parts of a foaming agent (by weight); the preparation method comprises the following steps: weighing each raw material; adding the water, the anti-crack fiber, the moisture repellent, the cement, the fly ash, the water reducing agent; stirring a mixture; adding the exciting agent; stirring the mixture; adding the foaming agent; stirring the mixture so as to prepare mixed slurry; then, injecting the mixed slurry into a mould; putting the mould statically for 4-5 hours; removing the mould; after 24 hours, cutting and packaging a product; and maintaining the product until age is 28 days. According to the invention, a part of the cement is substituted by fly ash; cost is low; environment pollution is reduced; and social efficiency and economic benefit are obvious.

Owner:JIANGSU NIGAO SCI & TECH +1

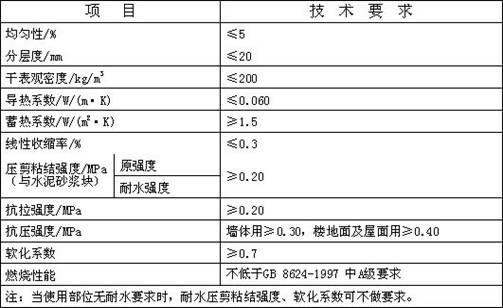

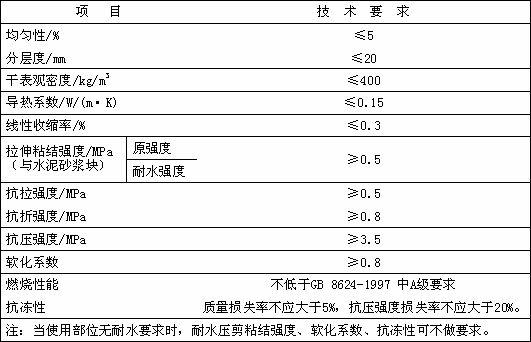

Inorganic thermal insulation light mortar and construction method thereof

InactiveCN102372476AReduce loadImprove integrityBuilding material handlingMass ratioThermal insulation

The invention discloses an inorganic thermal insulation light mortar, the mortar is mainly composed of a raw material and water in the following percentage by mass: the raw material is composed of 45-55% of lightweight aggregate, 15-20% of hydraulic material, 12-18% of air-setting material, 7-10% of active stuffing and 5-8% of additives; and the mass ratio of the water to the raw material is 0.15-0.25. The mortar in the invention is selected based on a principle of combining a hydraulic cementing material with an air-setting cementing material to satisfy material strength development and application quality demand and effect under a wall body environment condition; a non-gravity gasification suspension stirring technique is applied for achieving an expected stirring effect of generating no damage on a light thermal insulation material; and a one-time continuous jetting construction technique is utilized for not only solving the air bubbling and cracking problems of a wall body, but also greatly improving the construction quality, thermal insulation effect and construction efficiency.

Owner:MINGYUAN NEW MATERIALS TECH DEV CO LTD

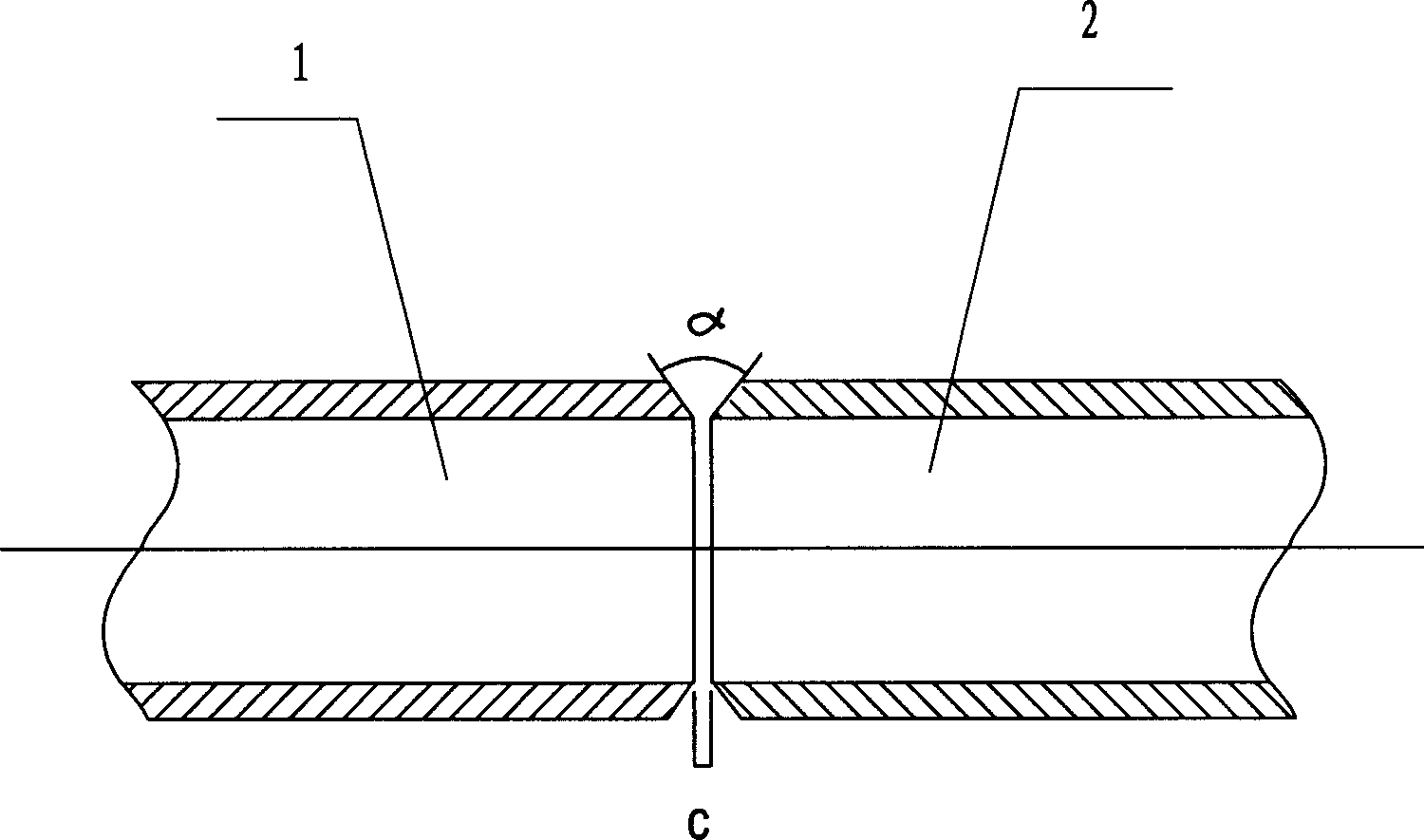

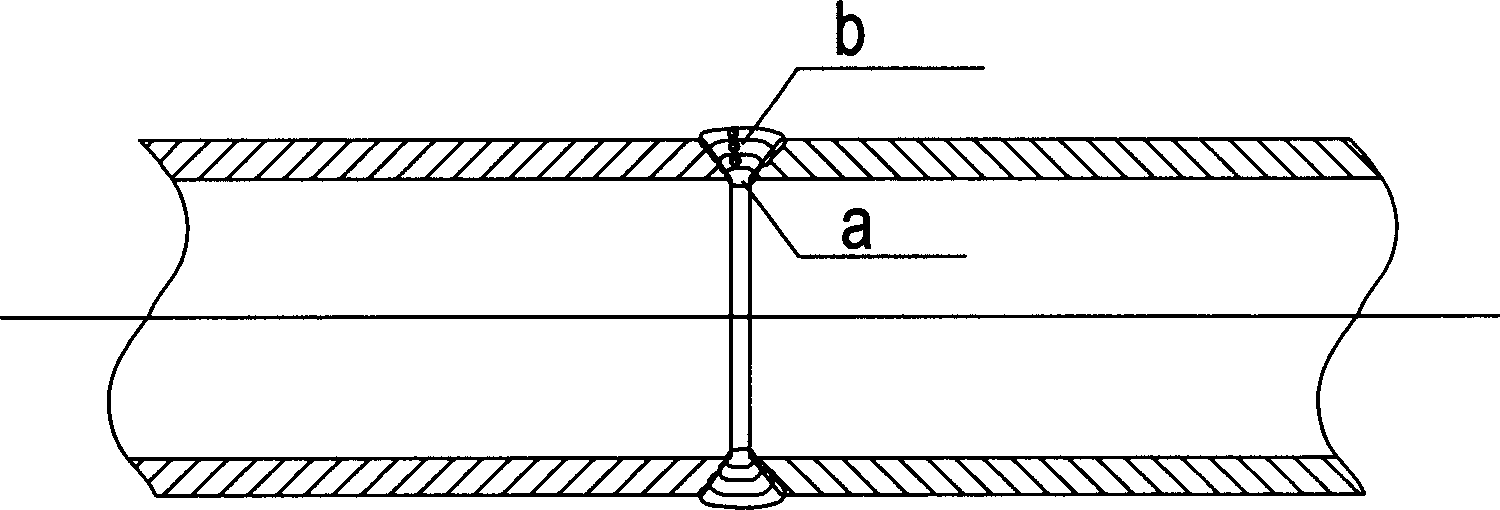

12Cr1MoV alloy steel pipe welding method

InactiveCN1814387AImprove mechanical propertiesImprove toughnessWelding/cutting auxillary devicesArc welding apparatusSteel tubePipe welding

The invention involves a method of welding 12Cr1MoV alloy steel pipes. Process the welding surfaces of the two pipes into a sloping groove, and clean the welding surfaces and its neighboring area, fix the two pipes which to be welded along using a clamp. Preheat and insulate the pipe area near the weld. First weld the pipes with welding rod H08CrMoVA, then weld several layers manually with stainless steel welding rod, and at last impose a heat treatment to the pipe. The invention uses refractory stainless steel welding rod A242 taking the place of R317 as the bonding material of the weld. And the steel welding rod improves the mechanical performances and toughness. The weld will not have cracks and will not penetrated in the conditions of high temperature, high pressure and high alkali, and greatly extends the service life of the welding line.

Owner:CHINA SIXTH METALLURGICAL CONSTR

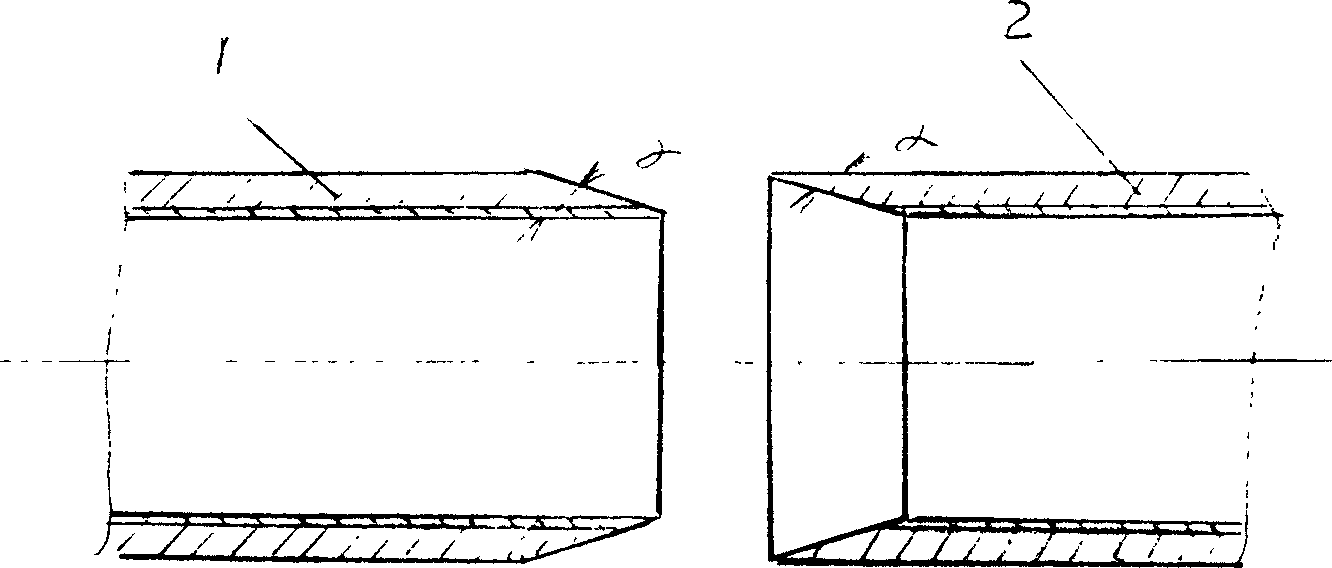

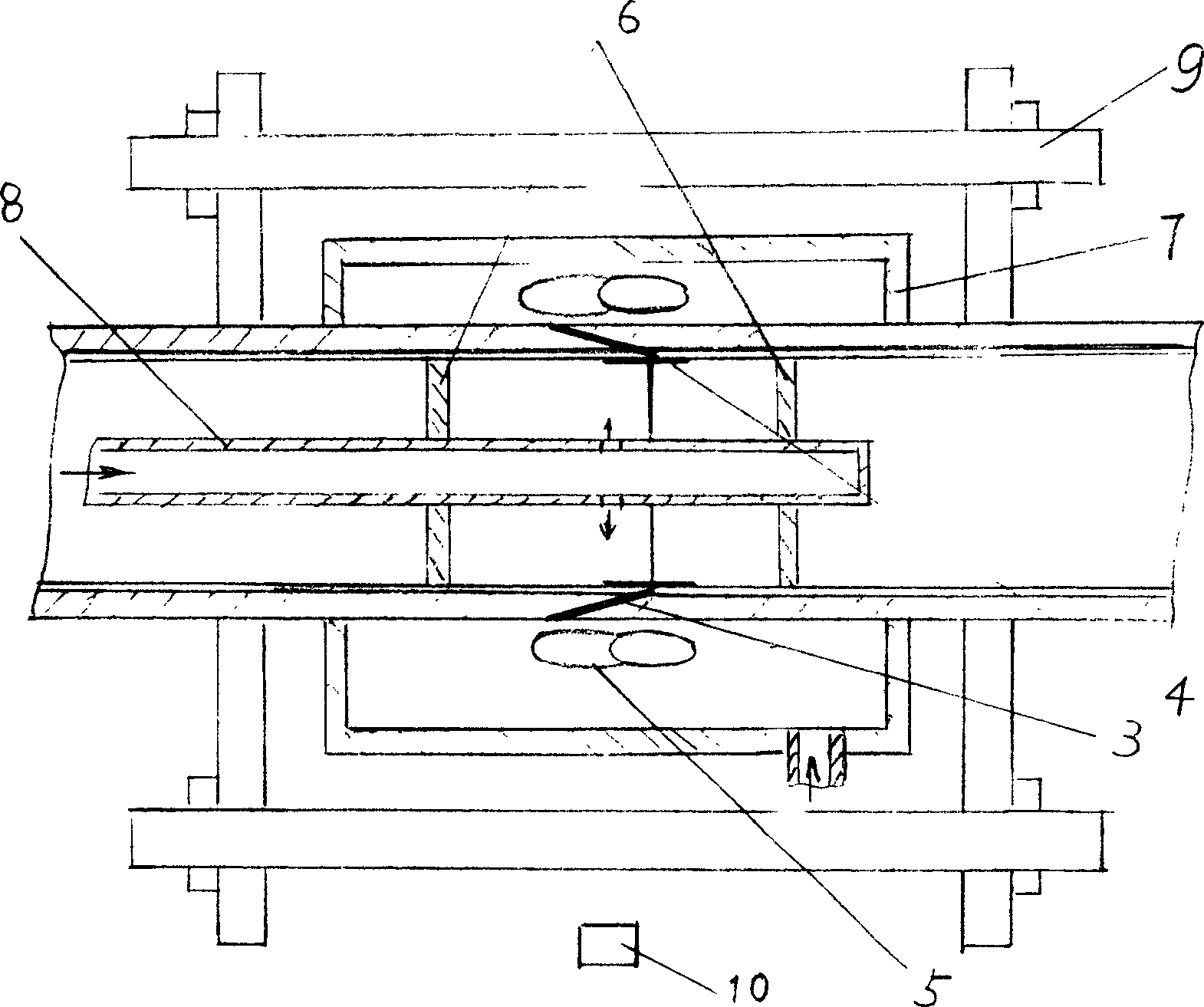

Modified high-speed steel roller and preparation method thereof

InactiveCN101797630AImprove wear resistanceShorten the production cycleRollsProcess efficiency improvementDuctile ironFerrochrome

The invention discloses a modified high-speed steel roller and a preparation method thereof. The modified high-speed steel roller is formed by adopting a centrifugal composite casting method and has a roller outer layer of high-speed steel and a roller inner layer of ductile iron or high-strength cast iron. The preparation method comprises the following steps of: forming the roller outer layer on a centrifugal casting machine; then, filling a static roller core with melted iron; and casting into a high-speed steel composite roller. The roller outer layer of the high-speed steel roller is prepared from raw materials in percentage by weight: 60-65 percent of M2 high-speed waste steel (W6Mo5Cr4V2), 1.0-1.4 percent of metal aluminum, 5.0-5.5 percent of boron iron, 9.2-9.4 percent of carbon ferrochrome iron, 0.2-0.4 percent of titanium iron, 1.0-1.2 percent of nickel-magnesium alloy and 18-23 percent of waste steel Q235. The roller can be produced by utilizing an electric furnace, has high hardness, simple and convenient process, low production cost and favorable wear resistance without adding noble iron alloy or quenching treatment and can have favorable economic benefits by popularization and use.

Owner:BEIJING UNIV OF TECH

High-strength and vibration-free self-compacting concrete prepared from machine-made sand

InactiveCN104230223AImprove performanceImprove liquidityArchitectural engineeringStructural engineering

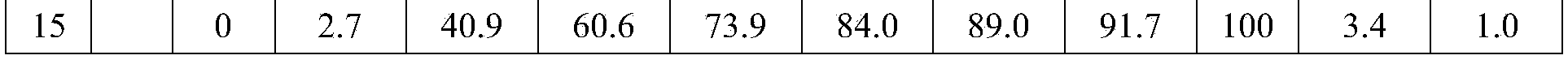

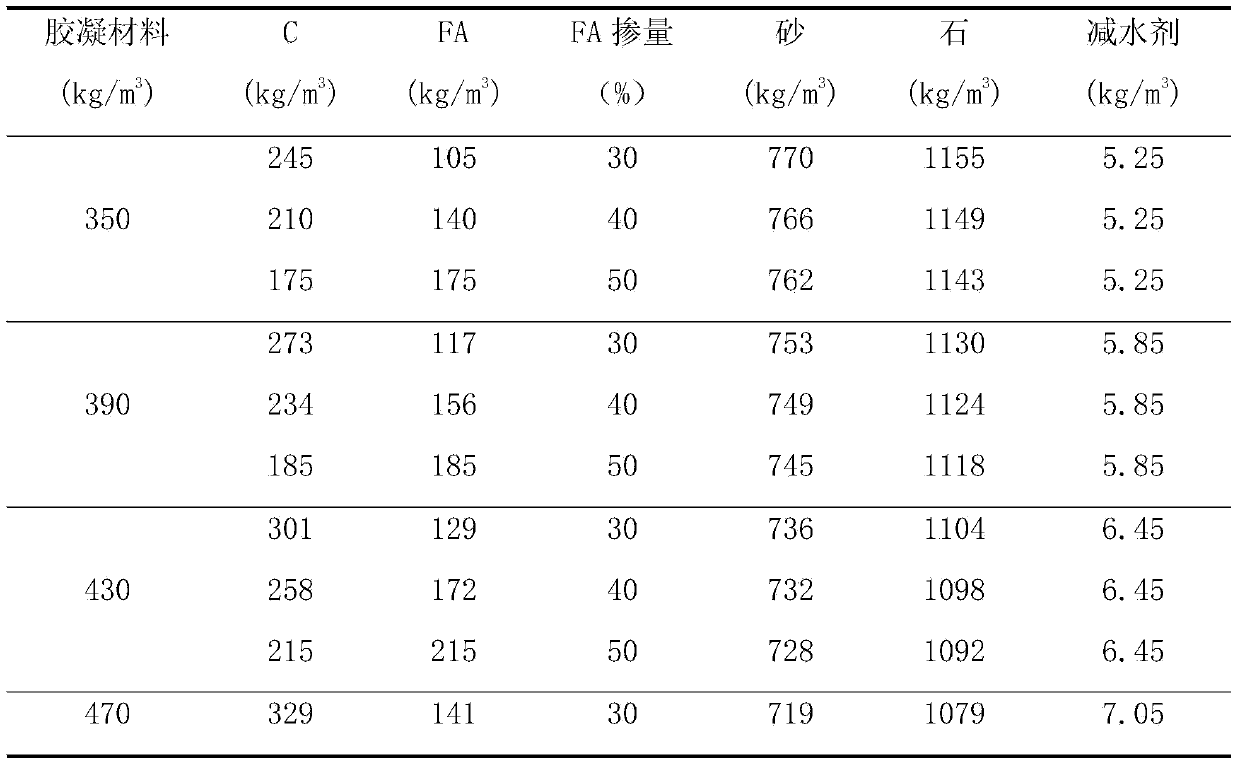

The invention discloses high-strength and vibration-free self-compacting concrete prepared from machine-made sand. The high-strength and vibration-free self-compacting concrete mainly comprises water, a cementing material, machine-made sand and gravels and is characterized in that the main technical parameters of the concrete are as follows: in the concrete, the water-binder ratio is 0.21-0.32, the water-powder ratio is 0.65-0.83, the sand ratio is 44-60%, and the unit paste volume dose is 0.45-0.53. The high-strength and vibration-free self-compacting concrete prepared from the machine-made sand, which is disclosed by the invention, has high flowability, non-segregation, uniformity and stability, flows relying on the self weight of the concrete in the process of pouring, and achieves a compacted effect without vibrating, so that the problem of cracking in section conversion in the process of construction is solved, and thus a series of purposes of reducing the amount of labor, accelerating the construction speed, reducing the construction noise, saving the construction cost, and the like are achieved.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

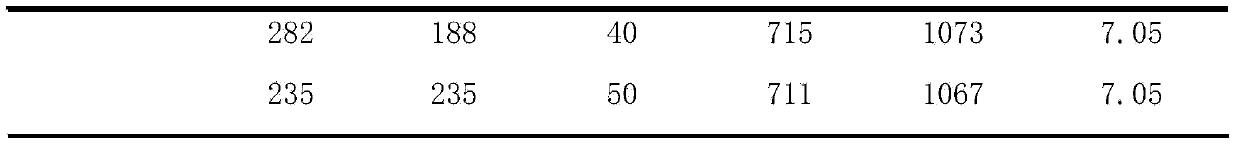

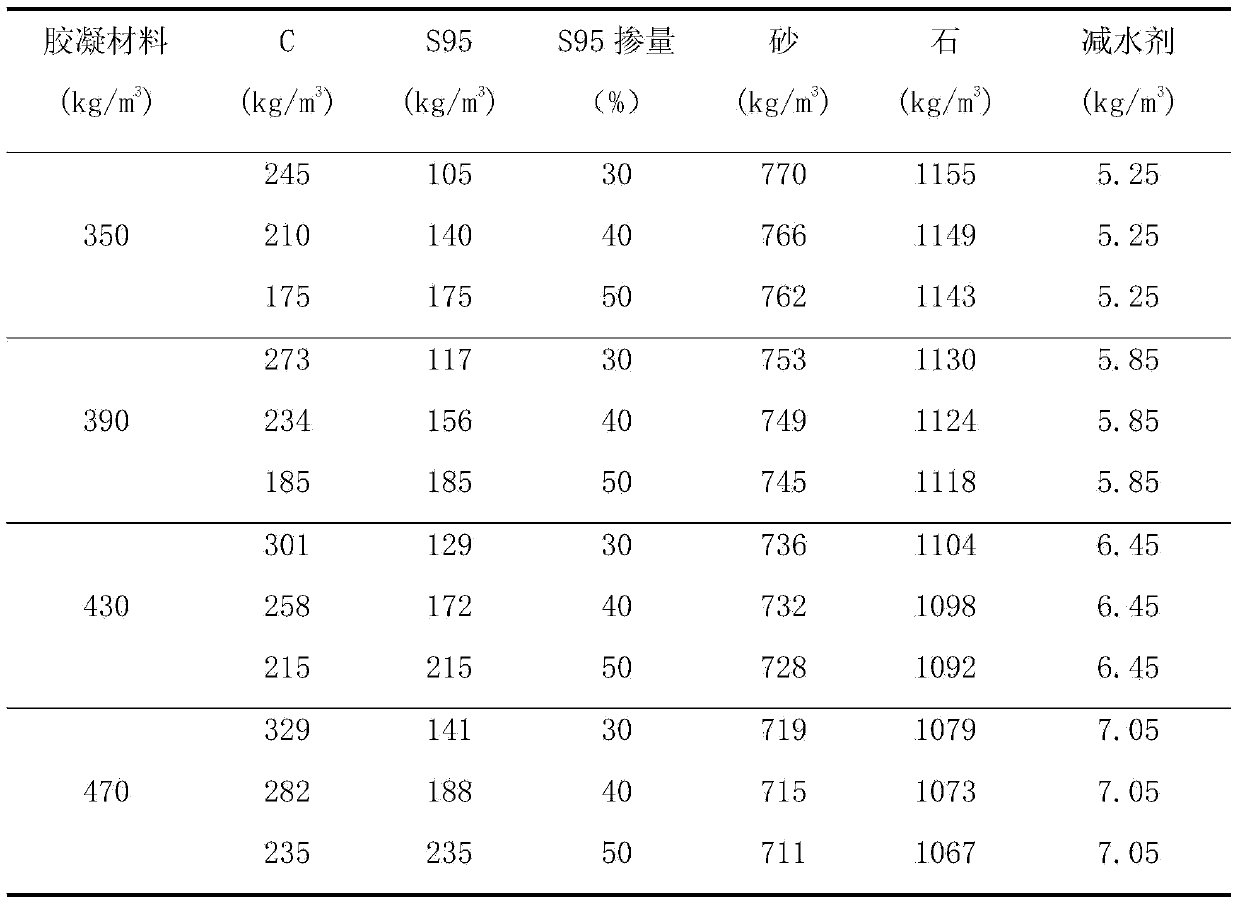

Underground anti-cracking and impermeable concrete with strength grade no more than C50 and preparation method thereof

ActiveCN103739254AOvercome crackingOvercoming Water Seepage ProblemsSocial benefitsMining engineering

The invention discloses underground anti-cracking and impermeable concrete with strength grade no more than C50. The underground anti-cracking and impermeable concrete is mainly prepared from a binding material, clastic rock, sand water and admixture, wherein the binding material is cement, mineral powder and coal ash; the admixture is a water reducer or an anti-cracking and impermeable agent and a water reducer. According to the underground anti-cracking and impermeable concrete prepared by the preparation method, green high-performance concrete is prepared from a lot of mineral powder and coal ashes in a compounding manner; the dosage of the cement for C30-C50 anti-cracking and impermeable concrete is reduced by 30-50% in comparison with that of common concrete, the production cost of the concrete is reduced, and the underground anti-cracking and impermeable concrete plays a protective role on the environment, and has significant economic benefits and social benefits.

Owner:QINGDAO QINGJIAN NEW MATERIAL GRP CO LTD

Manufacturing method for improving cupping value of 3104 aluminum alloy strip

The invention provides a manufacturing method for improving cupping value of a 3104 aluminum alloy strip. In the smelting process of 3104 aluminum alloy, the mass accounted by chemical components of the 3104 aluminum alloy in aluminum alloy raw materials is adjusted and optimized again; compared with the cupping value index of an aluminum alloy strip obtained through conventional chemical components and the subsequent treatment technology, the cupping value index of the aluminum alloy strip obtained through treatment of conventional working procedures of refining, grain refinement, degassing, filtering, casting, saw cutting, milling, homogenization heating, hot rolling, cold rolling, cleaning, side cutting, finished product perfect recrystallization annealing, inspecting packing and the like is greatly improved. The defect that the 3104 aluminum alloy strip produced through the conventional chemical components is prone to cracking after stamping is overcome, and therefore the deep drawability of 3104 alloy materials is improved.

Owner:DALISHEN ALUMINUM

Water exterior wall paint and its preparing process

The invention relates to a water fluorocarbon paint for external-wall painting, comprising solvent (water), water fluorocarbon latex, filler, composite film-forming auxiliary agent, disperser, moistening agent, leveling agent, thickening agent and germicidal agent. In the paint, solvent (water) covers 5 to 15 percent, water fluorocarbon latex covers 40 to 70 percent, composite film-forming auxiliary agent covers 5 to 14 percent, rutile titanium pigment covers 10 to 25 percent, talc powder covers 5 to 10 percent, disperser covers 0.1 to 0.5 percent, moistening agent covers 0.001 to 0.003 percent, leveling agent covers 0.004 to 0.01 percent, thickening agent covers 1 to 1.8 percent, and antifoaming agent covers 0.01 to 0.05 percent. The invention provides an efficient novel water fluorocarbon paint for external-wall painting by changing fillers and increasing the dose of composite film-forming auxiliary agent. The preparation process is simple, the paint is free of dehiscence, spurging and whitening; the painted wall-surface is smooth, and the light and color are well reserved; the paint has sound flexibility, weathering resistance, corrosion resistance, heat / cold resistance, acid / alkali resistance and better film-forming performance; the paint is environment-friendly, low-cost and construction friendly; and the prospect of development is very bright.

Owner:JIANGSU UNIV OF SCI & TECH

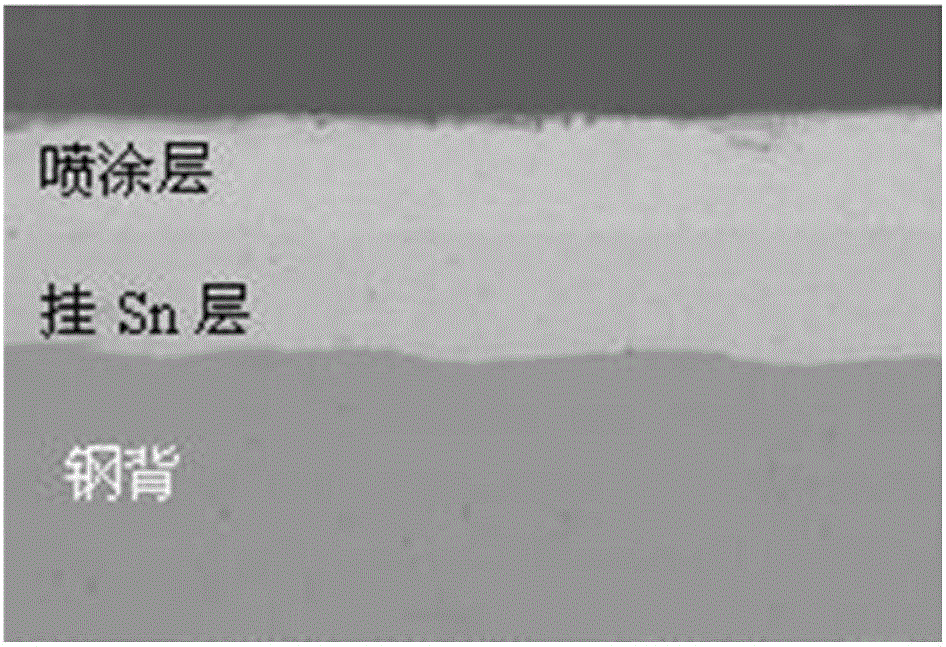

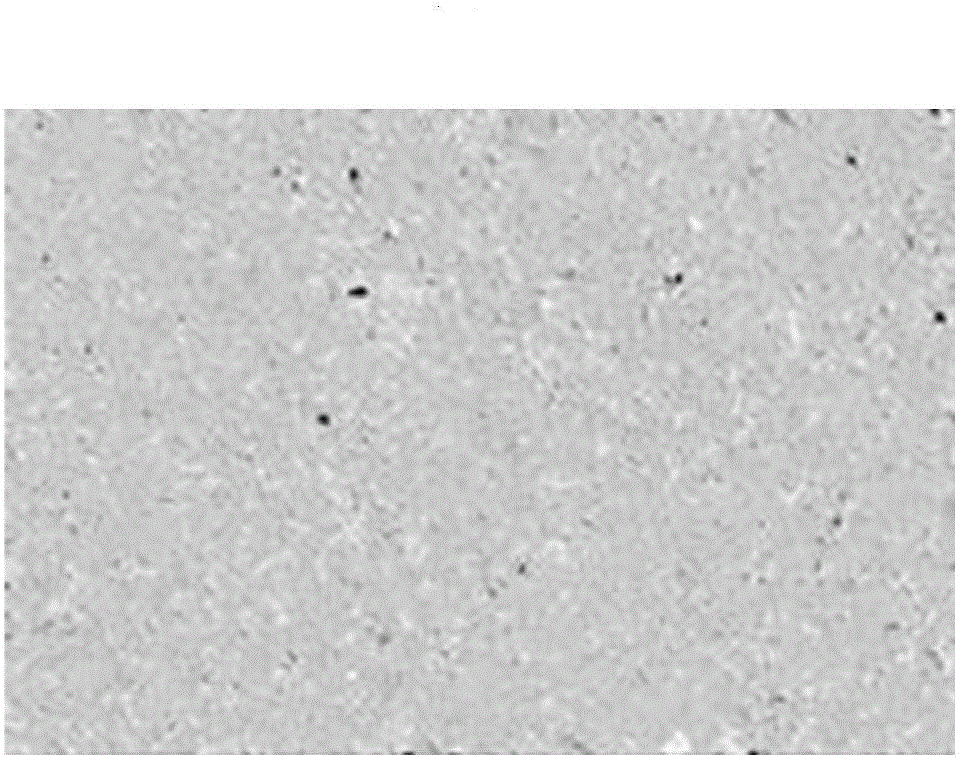

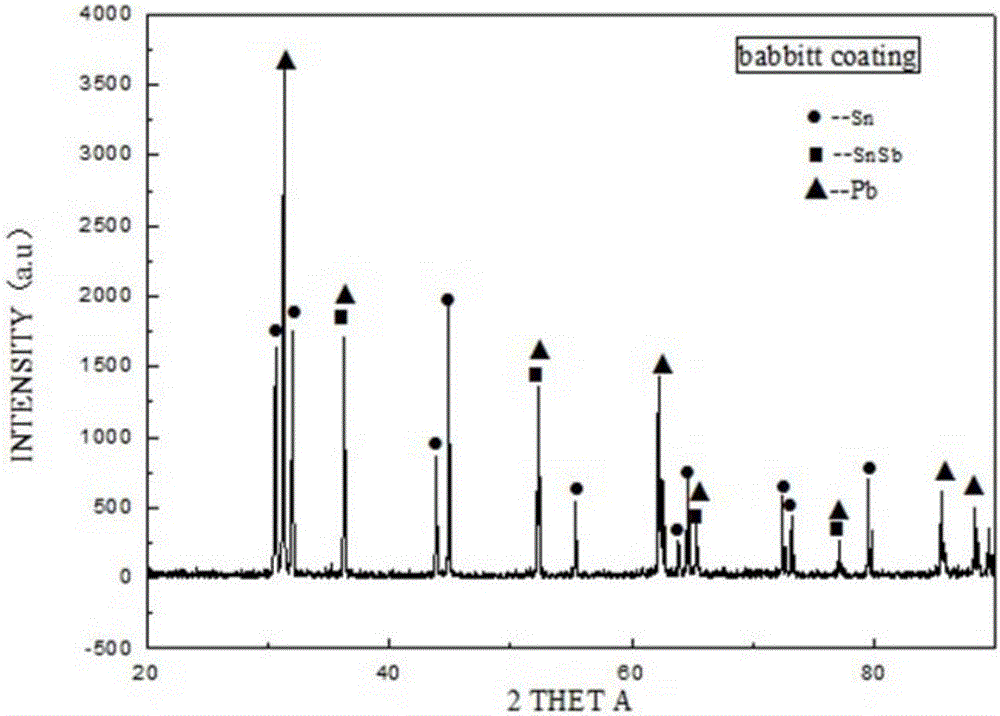

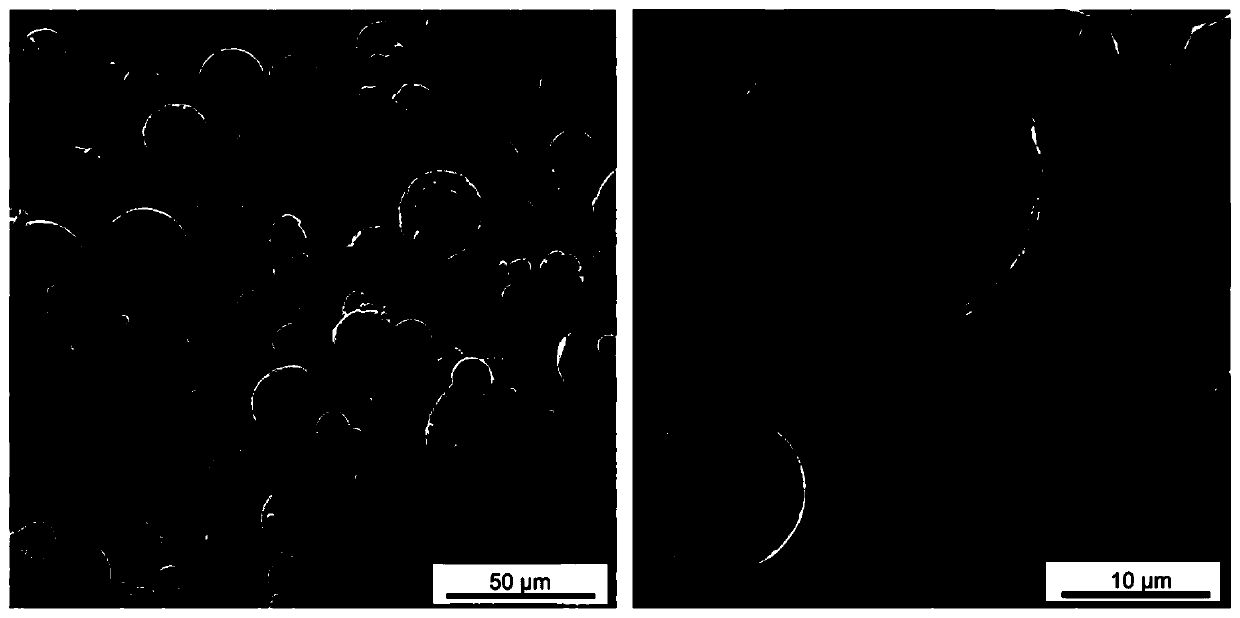

Method for coating bearing bush steel backing with Babbitt metal coating

ActiveCN106435563AImprove product qualityImprove the level ofHeat inorganic powder coatingSocial benefitsThermal spraying

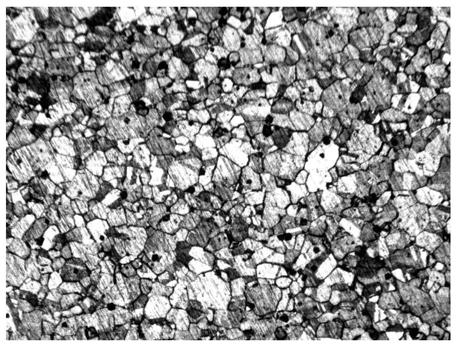

The invention relates to the technical field of preparation and repair of sliding bearing Babbitt metal anti-friction layers. The novel cold spraying technology is introduced into manufacturing and repair remanufacturing of a Babbitt metal sliding bearing bush lining anti-friction layer, atomization powder feeding is adopted to obtain coating microstructures with uniform components and fine dispersely-distributed and uniformly-dense crystal grains and second phases through cold spraying, and the good interface bonding characteristic is obtained through tinning layer setting and sprayed thermal treatment; the defects of poor structure uniformity, thermal impact, stress, cracking and oxidizing burning losses existing in the technologies such as a traditional casting method, an overlaying method and a thermal spraying method are overcome, the bearing bush component preparation quality and level are improved, the bush burning frequency is decreased, stopping supercritical vibration is lowered, the stability, accuracy and reliability of a bearing transmission unit are improved, and the service life of the bearing transmission unit is prolonged; the method is rapid, efficient and environmentally friendly, is used for bearing bush manufacturing and repair remanufacturing, and has good economic benefits and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Method for making micro powder ceramic polished brick have vivid stone effect

The method of making polished fine powder ceramic tile possess vivid stone material effect is the secondary material distributing process with the facing material. The present invention features the facing material powder for secondary material distributing, and the fine powder is prepared with the materials including clay, quartzite, feldspar powder, calcspar powder, talcum powder and silicate melt of expansion coefficient 200-250, and consists of CaO 10-25 wt%, MgO 0.5-5 wt%, Al2O3 3-16 wt%, SiO2 57-63 wt%, B2O3 1-2 wt%, ZnO 2-8 wt% and K2O+Na2O 1-8 wt%. The polished fine powder ceramic tile of the present invention has vivid stone effect and may be used in replace decorating natural stone material.

Owner:叶荣崧

Sound equipment spray polyurea coating

ActiveCN106189762AQuick responseOvercome crackingPolyurea/polyurethane coatingsHardnessAssembly line

The invention discloses sound equipment spray polyurea coating. The coating is composed of a component A and a component B, the NCO content ranges from 17 wt% to 19 wt%, after paint film is cured, the hardness reaches up to Shore A 60 to Shore A 75, the elongation at break reaches about 100%, the tear strength and tensile strength are high, excellent flexibility is shown, no catalyst is added, the curing speed is increased, rapid curing and surface granulation are conducted, a pitted surface effect is produced, abrasion resistance is greatly improved, the coating cannot be scratched, and the requirements of polyurea coating protection and long-term use can be met; the problems that for sound equipment spray polyurea coating in the prior art, the high hardness surface coating is fractured, the abrasion resistance is poor, and the mechanical property, surface hardness and surface drying time have difficulty in meeting assembly line production requirements in actual audio industry are solved.

Owner:KESHUN WATERPROOF TECH CO LTD

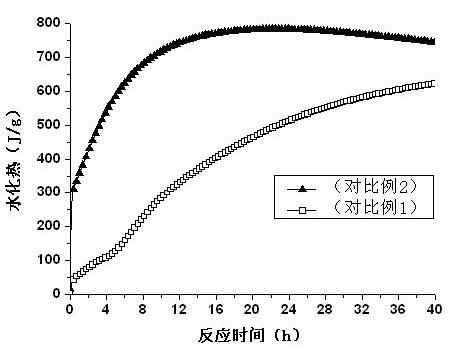

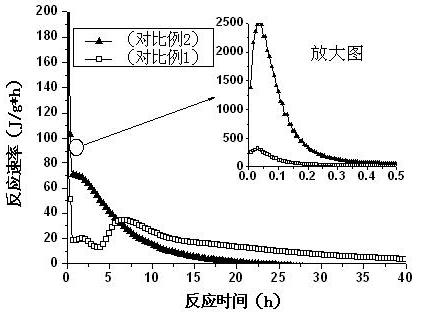

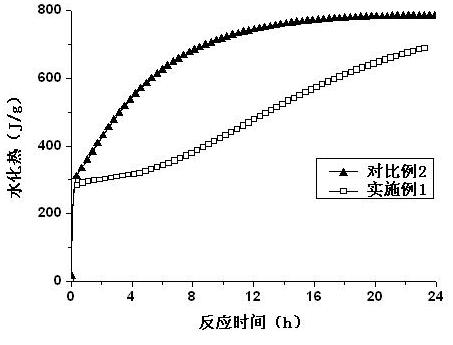

Novel magnesium oxychloride cement mixed by water

The invention relates to novel magnesium oxychloride cement mixed by water, which is obtained by mixing and grinding 50-100 parts of a part of pyrolysis product of bischofite, 0.5-5 parts of organic acid, 0-50 parts of active mixed materials and 0-5 parts of monocalcium phosphate into 180 meshes. The novel magnesium oxychloride cement has the characteristics of low solution heat, low hydration heat and high strength.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

High-strength Al-Cr-SC alloy through 3D printing

ActiveCN111001800AReduce anisotropyEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityMetal powder

The invention discloses a high-strength Al-Cr-SC alloy through 3D printing. The metal powder for a high-strength aluminum-chromium alloy through 3D printing comprises the following components, by masspercentage, 2.5-10% of Cr, 0.5-2.5% of Mg, 0.1-0.9% of Sc, 0.2-0.7% of Zr, 0.1-0.3% of Si, 0.2-0.45% of Mn, 0.1-0.35% of Fe, 0.1-0.25% of Ti, 0.05-0.5% of AlCl3 powder, 0.05-0.3% of CaCl2 + NaCl andthe balance Al. The preparation method of the metal powder comprises the following steps that Al, Cr, Mg, Sc, Zr, Si, Mn, Fe, Ti pure metal block raw materials are weighed to be heated and melted, atomized for powder making, sieving and heat preservation for drying are conducted, AlCl3, CaCl2 and NaCl powder are added, and milling and mixing are conducted. According to the high-strength Al-Cr-SC alloy through 3D printing, the printed aluminum alloy part has no cracks and has high density, and the mechanical properties, wear resistance, corrosion resistance and high temperature and oxidation resistance are high.

Owner:CENT SOUTH UNIV +1

Stainless steel composite steel pipe welding method

InactiveCN1669714AOvercome crackingEnhanced binding mechanical propertiesSoldering apparatusWorkpiece edge portionsLiquid diffusionJoint surface

This invention relates to pipe-welding method, especially for stainless steel compound pipe, mainly used to solve the defect that when welding compound pipe, it easily comes to gas hole and crackle, and improving the weld efficiency and lowering cost. The invention includes the following steps: washing the joint surface, coating intermediate material, assembling and clamping, induction heating to melt the intermediate material and actualize liquid diffusion weld. The method also can be used in welding other metal pipes.

Owner:凌星中

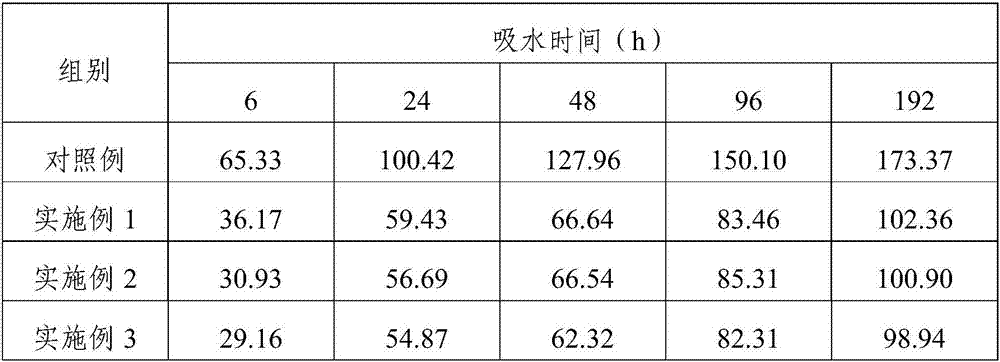

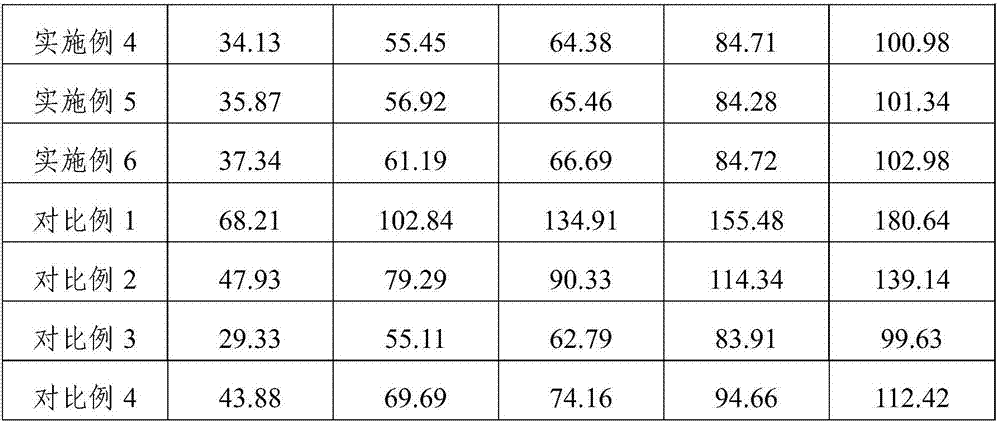

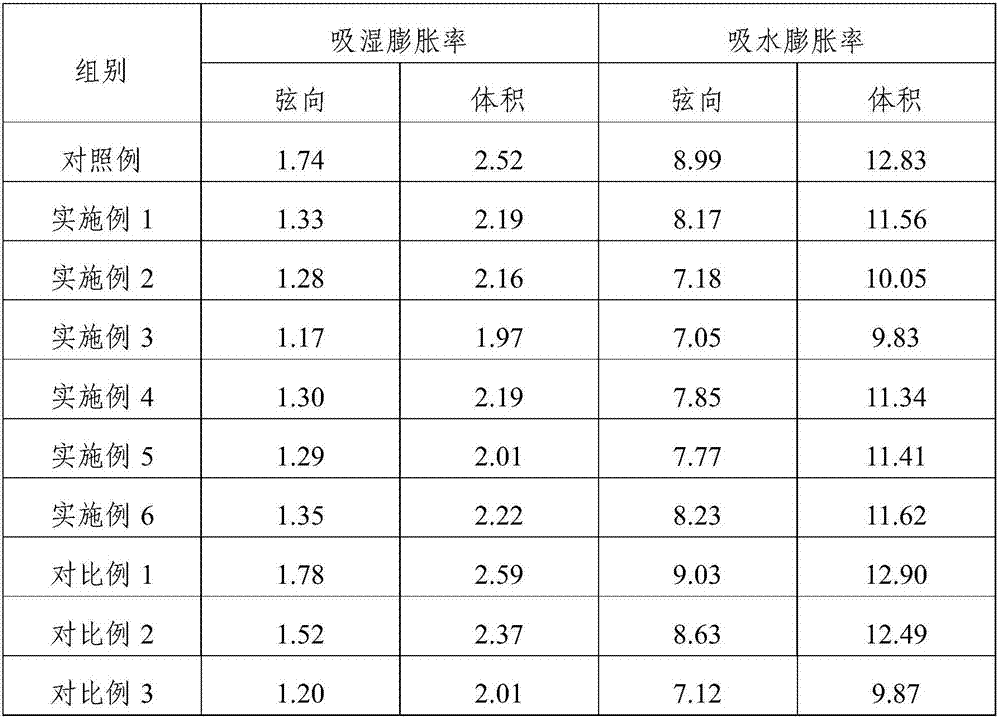

Method for preparing modified wood by compounding heat treatment based on alkali lignin

InactiveCN107972144AImprove waterproof performanceOvercome crackingWood treatment detailsThermal wood treatmentCompound aHeat treated

The invention relates to a method for preparing modified wood by compounding heat treatment based on alkali lignin. The method comprises the following steps: (1) soaking the wood treated in vacuum ina 1,4-dioxane solution with alkali lignin, adjusting the pressure to 0.2-0.8MPa and retaining the pressure for 50-90 minutes; and (2) taking the wood soaked in the step (1) out, drying the wood, putting the wood under the condition at the temperature of 120-200 DEG C, and carrying out heat treatment for 1.5-4 hours to obtain the modified wood. The method is used as a non-toxic and long-acting woodmodification manner with low cost and simple process; the modified wood with high water resistance and high size stability is prepared by compounding a heat treatment method; the defects of high possibility of cracking and high possibility of deformation of the fast-growing wood can be effectively overcome; the bottleneck problem of utilization of the fast-growing wood at present can be solved.

Owner:BEIJING FORESTRY UNIVERSITY

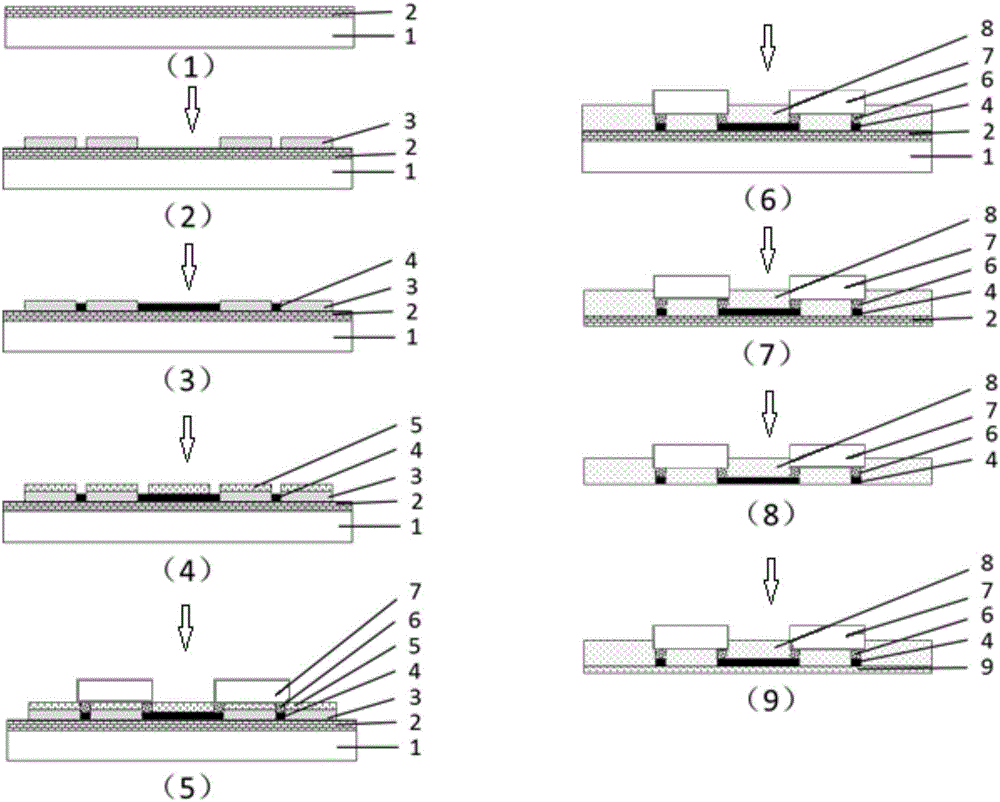

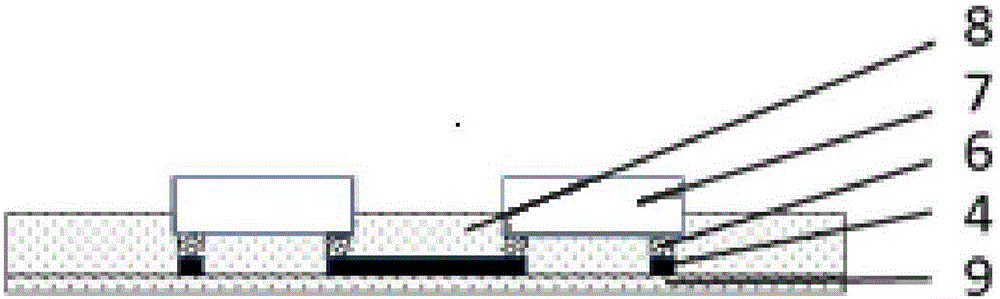

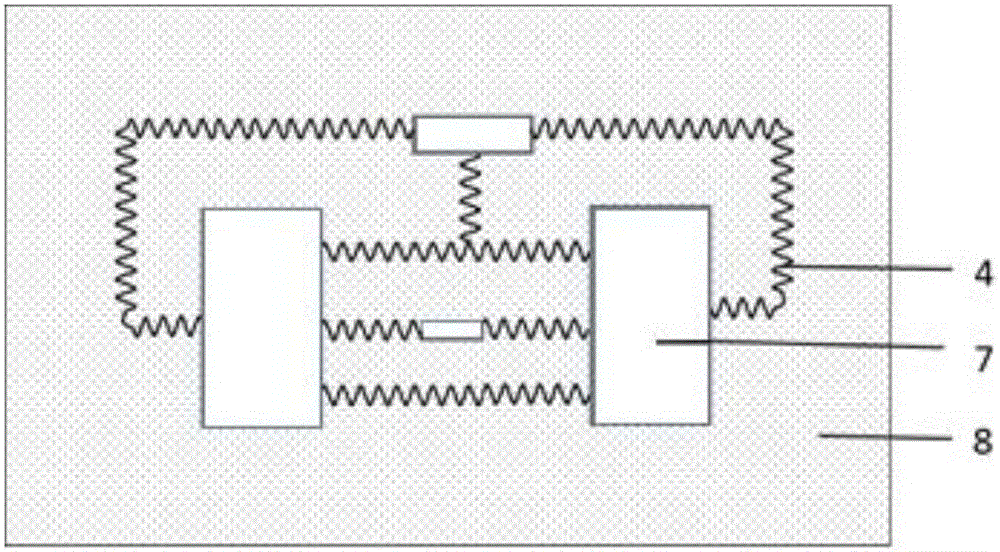

Elastic circuit fabrication method based on metal sacrificial layer process

InactiveCN106376180AOvercome crackingOvercome the open circuit problemPrinted circuit assemblingConductive material chemical/electrolytical removalElectronic componentPhotoresist

The invention discloses an elastic circuit fabrication method based on a metal sacrificial layer process. The elastic circuit fabrication method comprises the following steps of pasting a metal thin film on a substrate; spin-coating photoresist on a surface of the metal thin film, and photoetching a circuit and bonding pad layout; fabricating metal circuits and bonding pads on a circuit and bonding pad layout region, spin-coating photosensitive organic soluble polymers, and photoetching a soldering mask layout; welding electronic components on the bonding pads; removing the photoresist and the photosensitive organic soluble polymers, casting an upper-layer elastic polymer and curing the upper-layer elastic polymer; stripping the metal thin film and an upper-layer structure thereof from the substrate; etching the metal thin film; and spin-coating and curing a lower-layer elastic polymer. By the elastic circuit fabrication method, a metal seed layer is not needed to be deposited, and the problem of metal wire crack or open circuit caused by different matching of the elastic polymers and metal heat is thoroughly solved; and meanwhile, a stress buffer layer is omitted, the process flow is simplified, only processes of photoetching, electroplating and etching are needed, and the elastic circuit fabrication method has the advantages of high yield, simplicity in welding and compatibility of a reflow soldering process.

Owner:SHANGHAI JIAO TONG UNIV

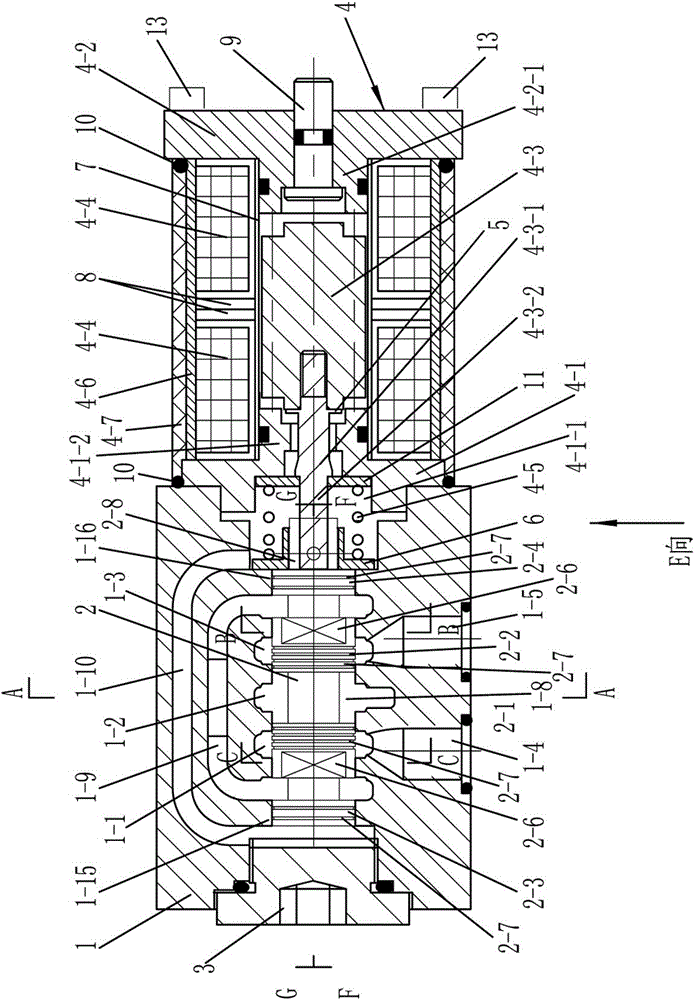

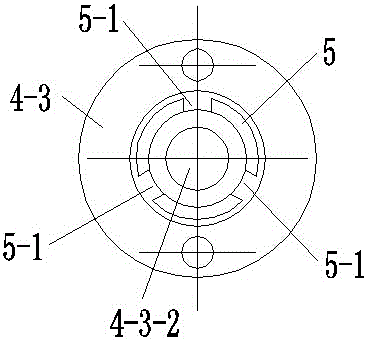

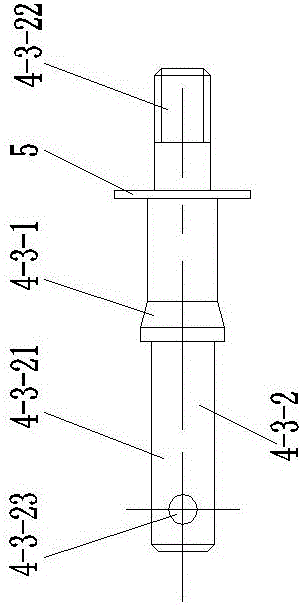

Solenoid directional valve and push rod and armature structure thereof

ActiveCN105952951AOvercome crackingImprove reliabilityOperating means/releasing devices for valvesMultiple way valvesEngineeringDirectional Valve

The invention relates to a solenoid directional valve and a push rod and armature structure thereof. The push rod and armature structure comprises a push rod and an armature, wherein a valve element connecting section is arranged at one end of the push rod; an armature connecting section is arranged at the other end of the push rod; and a push rod radial pin hole is formed in the valve element connecting section of the push rod. The push rod and armature structure is characterized in that the armature connecting section of the push rod is provided with left-hand threads, a left-hand threaded hole is formed in one end of the armature, and the left-hand threads of the armature connecting section of the push rod is in left-hand thread connection with the left-hand threaded hole in one end of the armature. By the push rod and armature structure, the push rod is effectively prevented against being separated from the armature, the long-time existing circumstance that the push rod and the armature in the prior art are separated from each other due to counterclockwise rotation of the push rod is avoided, furthermore, the long-time existing circumstance of cracking caused by the reason that the push rod and the armature are welded integrally in the prior art is avoided, and therefore, work reliability is greatly improved.

Owner:CHANGZHOU KANGSHIDA ELECTROMECHANICAL CO LTD

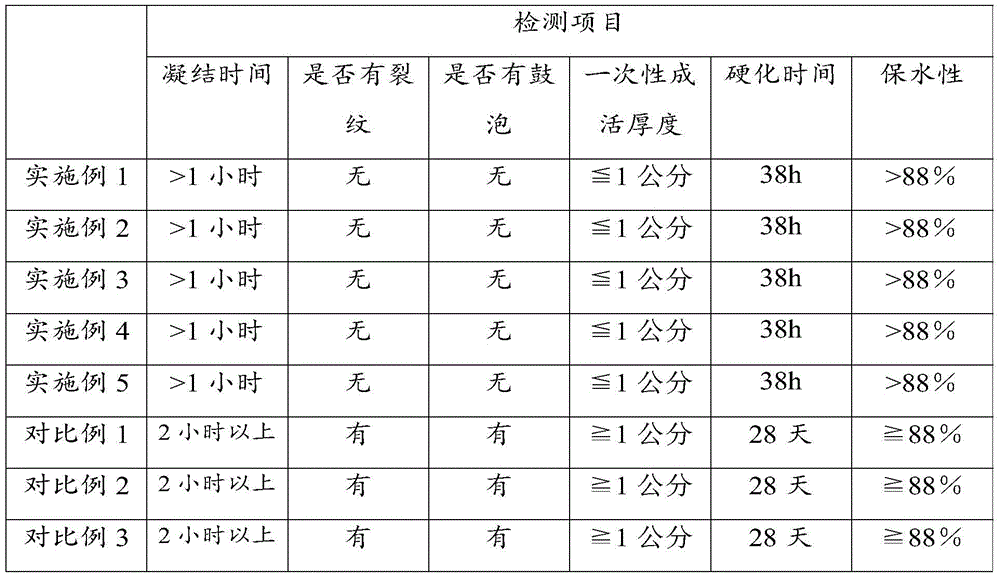

Gypsum-based pre-mixed mortar and preparation method thereof

The invention provides a gypsum-based ready-mixed mortar and a preparation method thereof. The ready-mixed mortar comprises 450-500 parts of hemihydrate gypsum, 550-600 parts of aggregate, 0.7-1.5 parts of compound modification additive, 0.2-1.0 part of foaming agent and 1-10 parts of setting retarder. The preparation method includes the following steps: mixing hemihydrate gypsum, aggregate, compound modification additive, foaming agent and retarder to obtain ready-mixed mortar. The gypsum-based ready-mixed mortar has strong adhesion to the substrate, which overcomes the shortcomings of easy cracking and hollowing in the use of traditional cement-based ready-mixed mortar; the one-time survival thickness is 4mm-2cm, which is smooth to the wall surface The requirements for the degree of strength are not high, and the construction requirements are greatly reduced; the hardening is fast, which can speed up the construction progress; the cost is low, and at the same time, it also has the advantages of good fire resistance, automatic temperature adjustment function, and light weight.

Owner:GUIZHOU TENGFENG TECH CO LTD

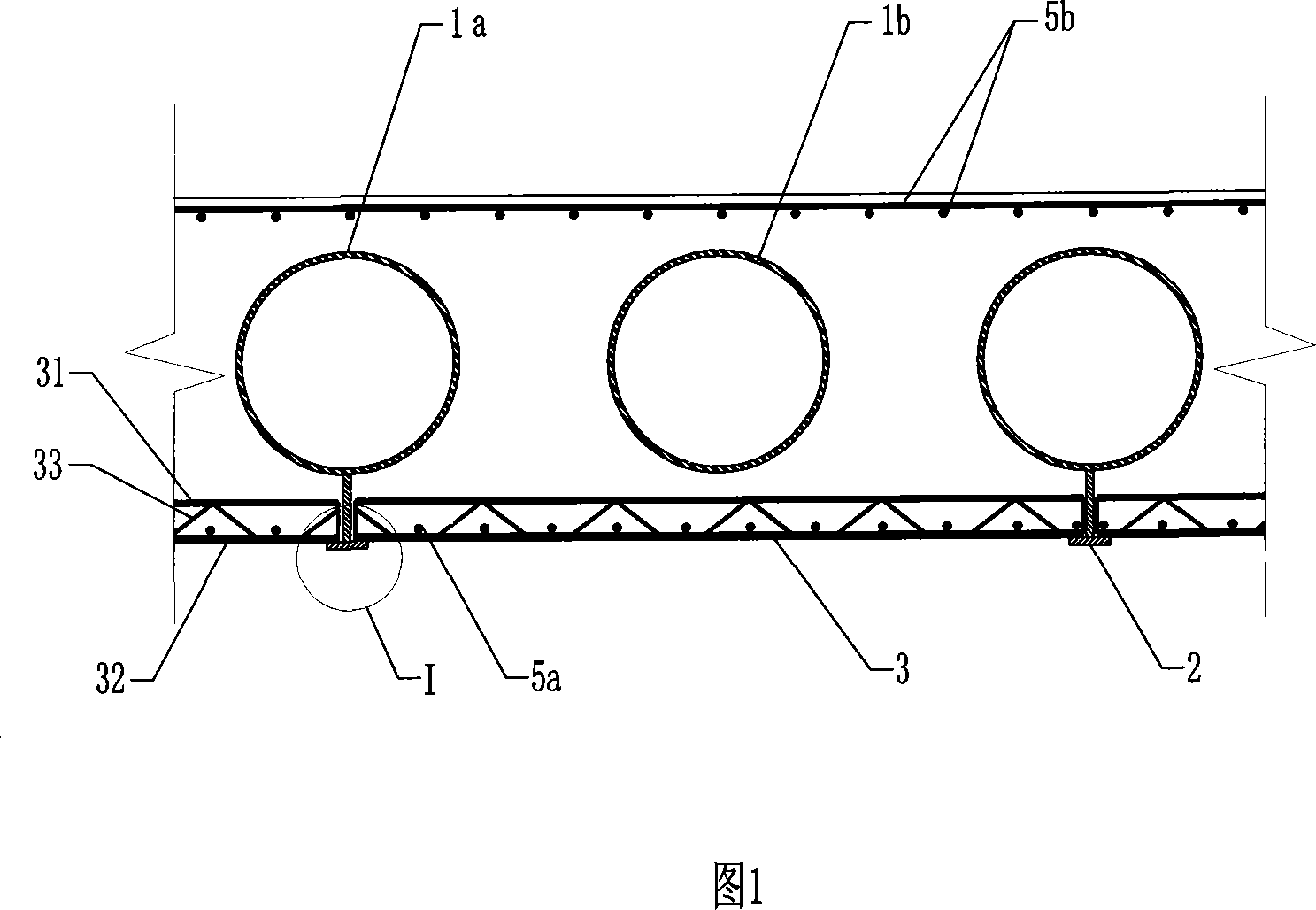

Steel pipe hollow concrete building floor and construction method thereof

A steel pipe hollow concrete floor is equipped with a number of steel pipes in itself, the steel pipes are surrounded by concrete structure and forms hollow floor; two ends of the steel pipes are fixed on the frame beam combined with the floor. Said steel pipes not only can be used as the molding template, the poured concrete need not be demounted but as one part of hollow floor. The steel pipe hollow concrete floor in the invention has small floor integral section, light weight and large bearing capacity.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

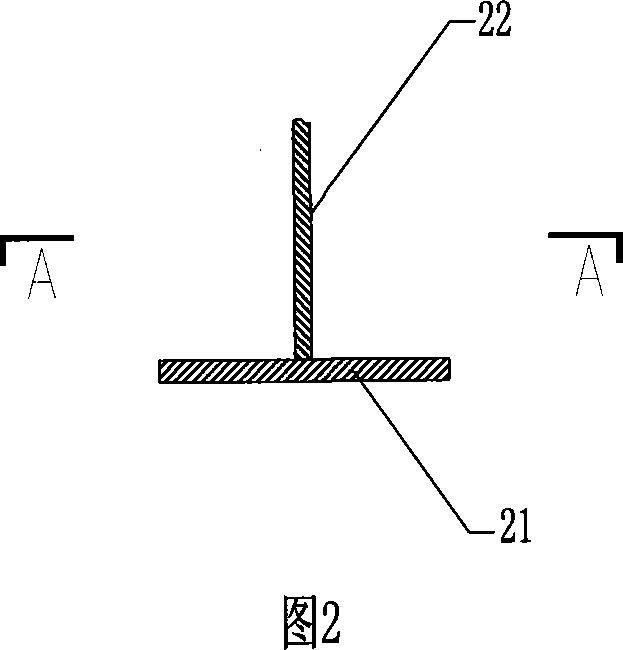

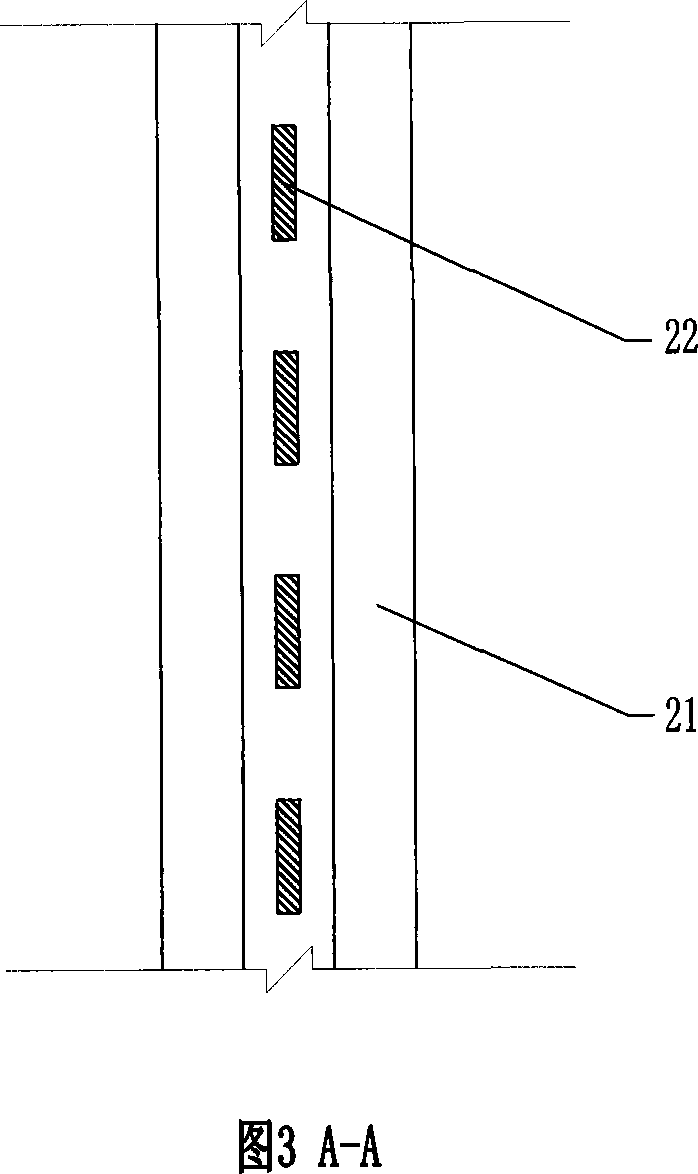

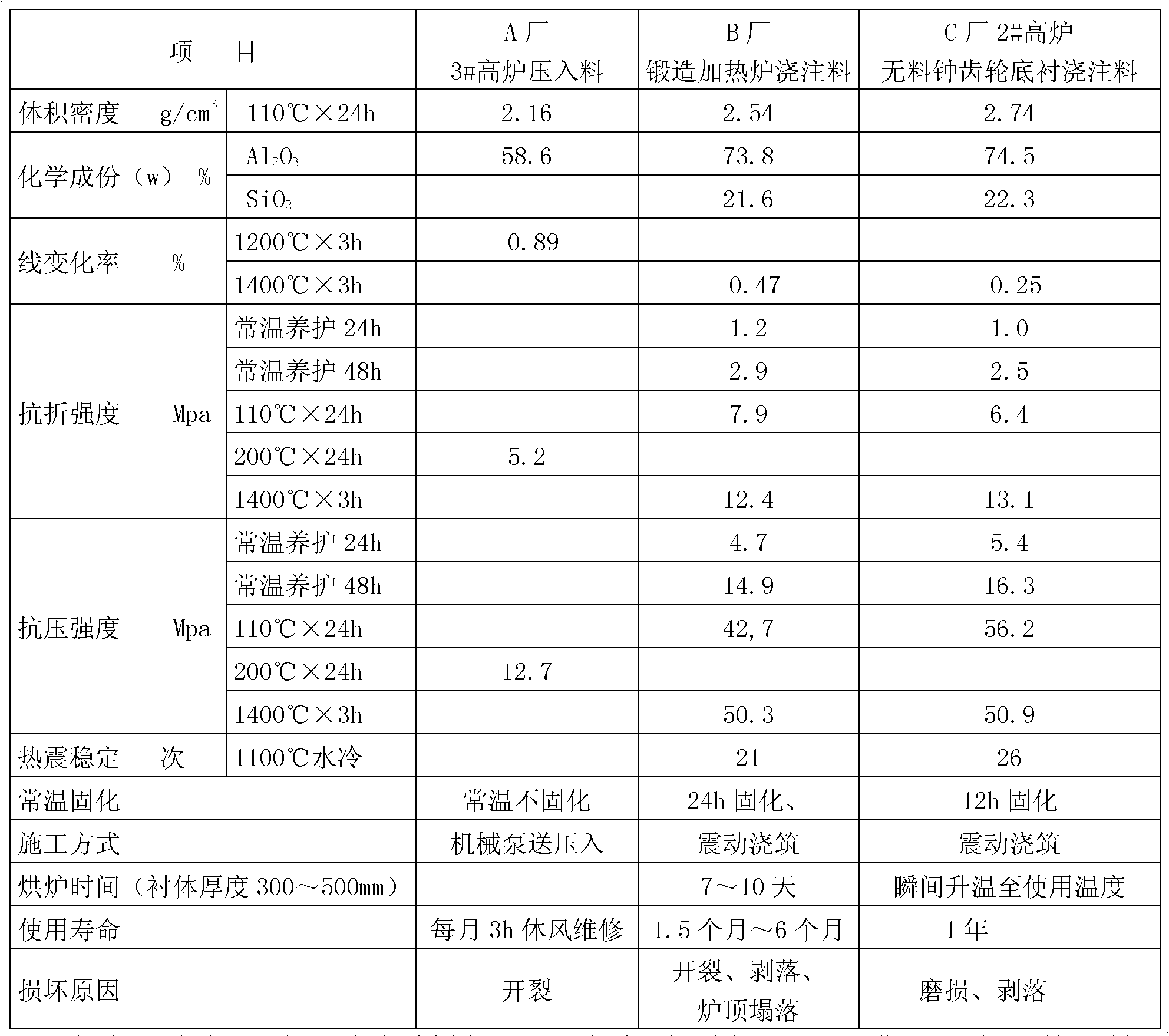

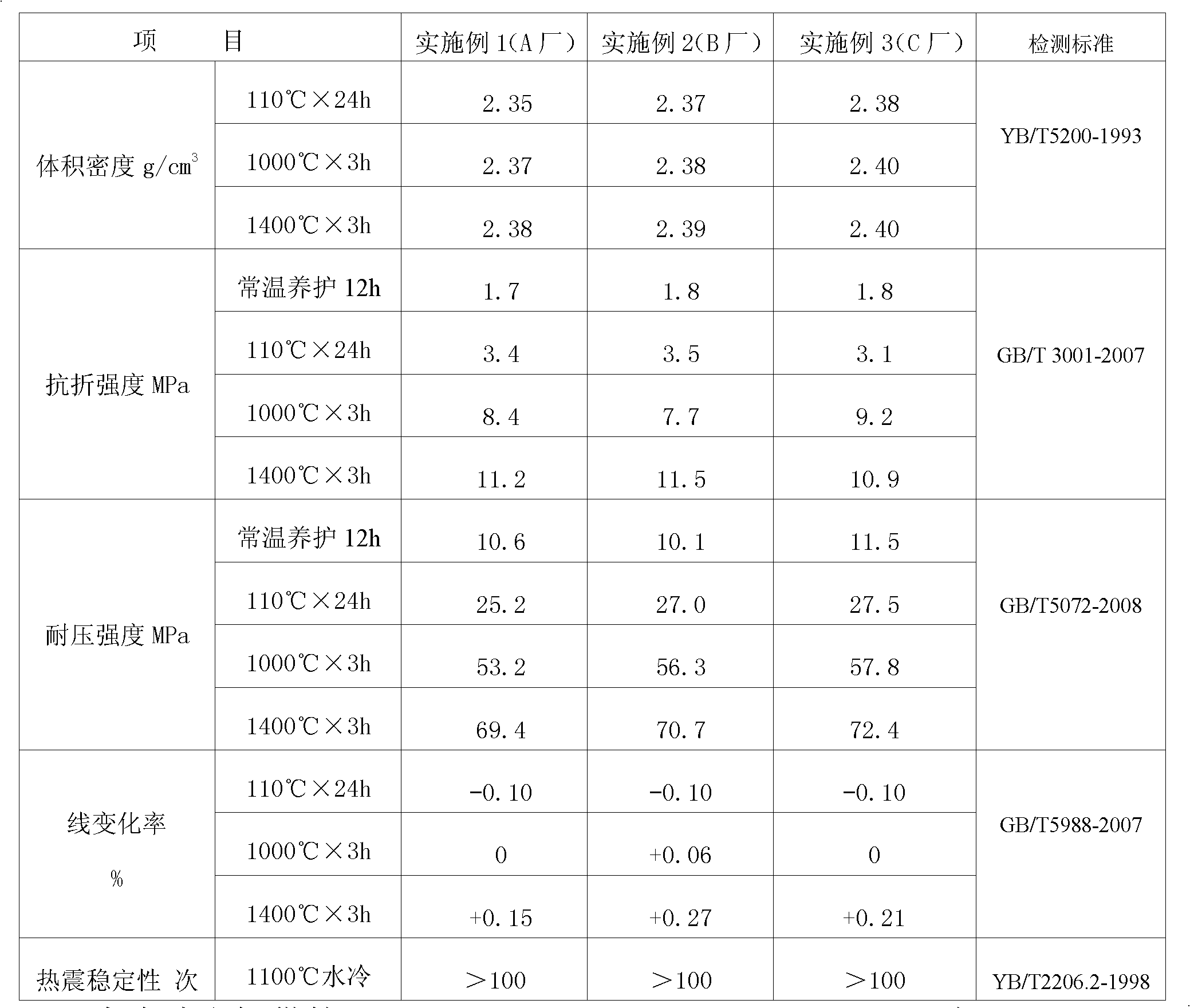

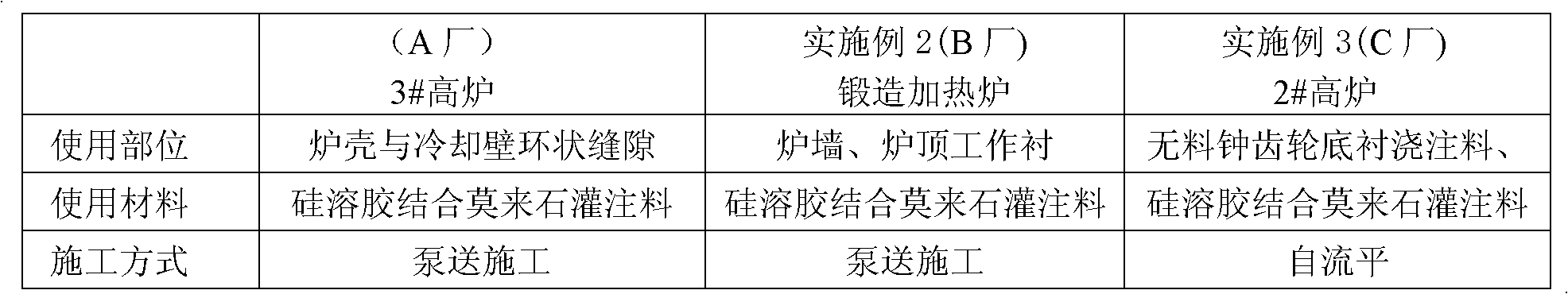

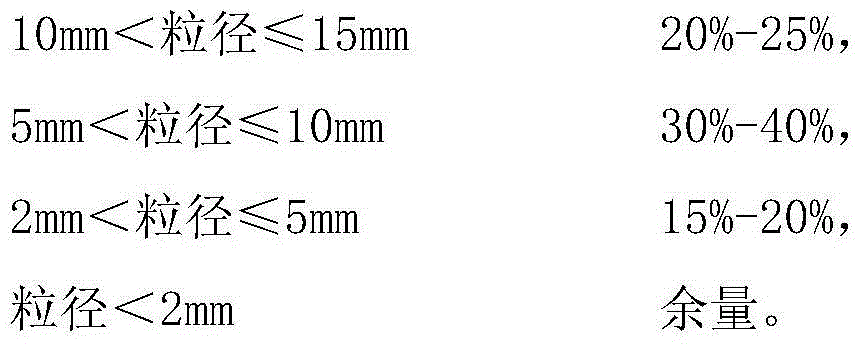

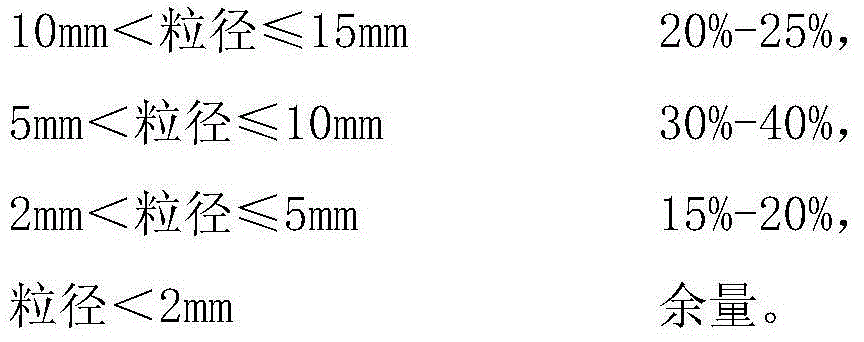

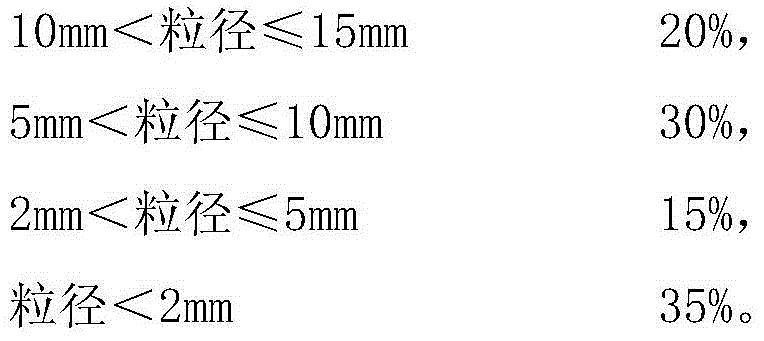

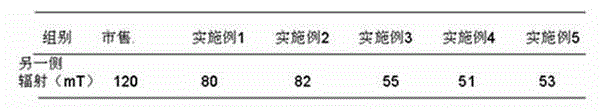

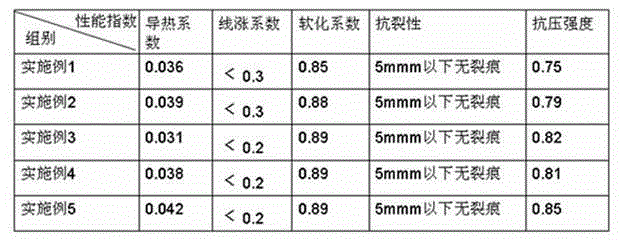

Silica sol-combined mullite perfusion material adapted to rapid repair of industrial furnace

The invention discloses a silica sol-combined mullite perfusion material adapted to rapid repair of an industrial furnace, which belongs to the refractory material technical field. The perfusion material comprises the following raw materials by weight: 50-60% of mullite granules, 10-20 % of mullite powder, 5-10% of white alundum powder, 4-15% of alpha-active alumina micro powder, 0.6-1.0% of magnesium oxide powder, 0.5-0.7% of dextrin, 10-16% of silica sol and 1-2% of dispersing alumina. The silica sol-combined mullite perfusion material is characterized in that the silica sol is individually packaged; other components are weighted according to ratio and mixed through mechanical stirring to uniform aggregates in a dry state; on construction site, the individually packaged silica sol and uniform aggregates in the dry state are weighted according to ratio, and uniformly mixed and stirred and pumped for construction. The perfusion material has the advantages of excellent physical and chemical property and good application property, pumping for construction can be used, manpower and material resources can be saved, rapid repair requirement for various industrial furnaces can be satisfied, and the perfusion material is the excellent repair refractory material with strong adaptability.

Owner:中冶武汉冶金建筑研究院有限公司

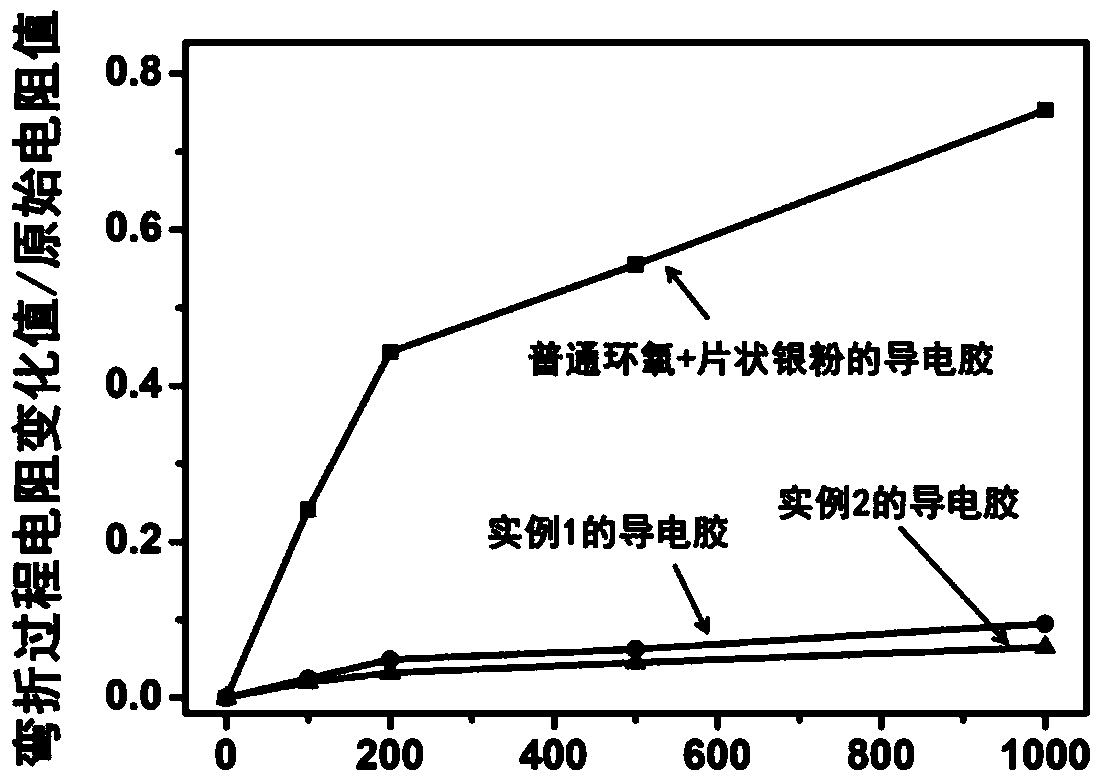

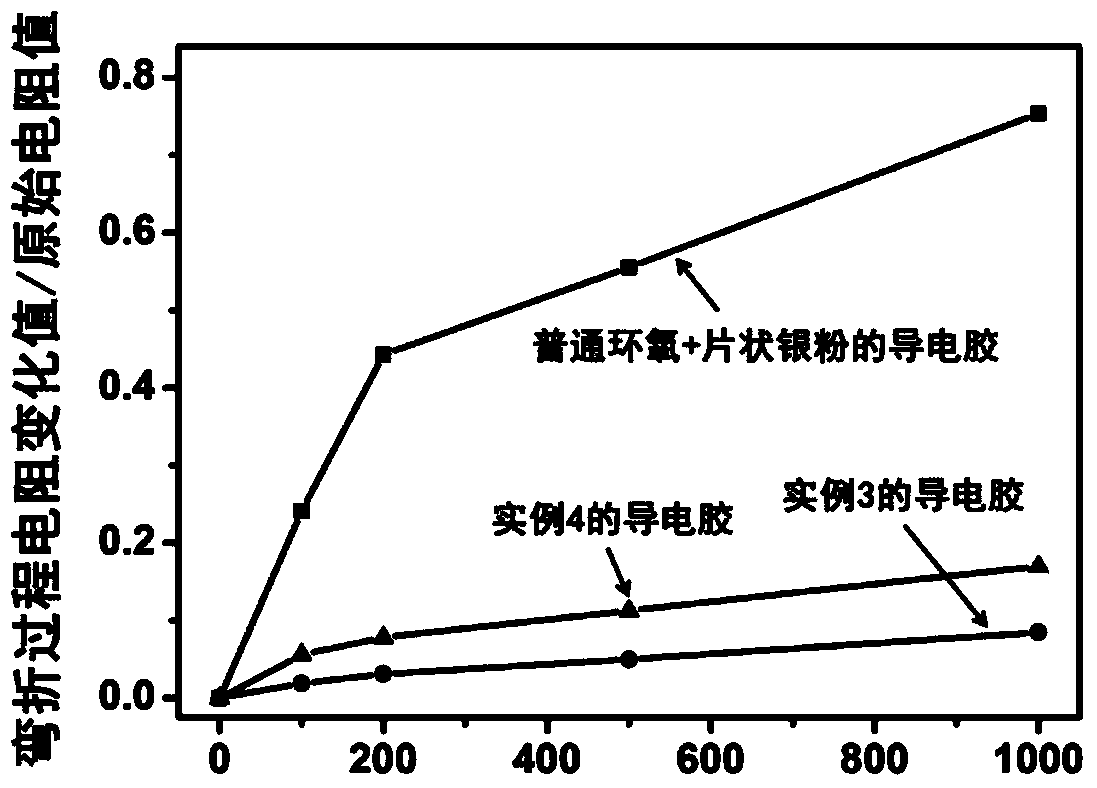

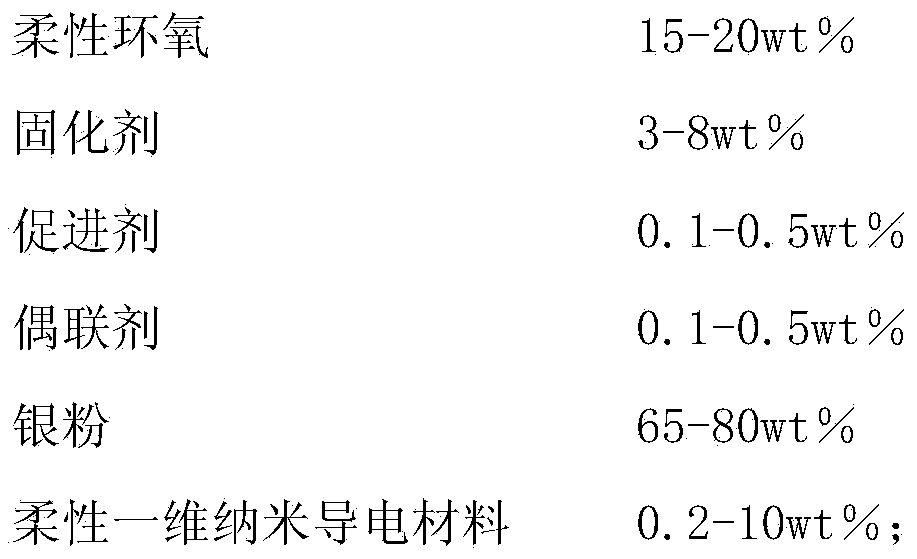

Flexible conductive adhesive capable of being used in direct coating manner and preparation method of flexible conductive adhesive

InactiveCN104263303AImprove conductivityGood flexibilityEpoxy resin adhesivesGraft polymer adhesivesTetrahydrophthalamic acidAdhesive

The invention discloses a flexible conductive adhesive capable of being used in a direct coating manner and a preparation method. The flexible conductive adhesive consists of 15-20wt% of flexible epoxy, 3-8wt% of a curing agent, 0.1-0.5wt% of an accelerant, 0.1-0.5wt% of a coupling agent, 65-80wt% of silver powder and 0.2-10wt% of flexible one-dimensional nano conductive material, wherein the flexible epoxy is a mixture of bisphenol-A epoxy resin with ethylene-vinyl acetate copolymer soft segments grafted and aliphatic glycidyl ether epoxy resin; the curing agent is one or more of methylhexahydrophthalic anhydride, methyl tetrahydrophthalic anhydride and tetrahydrophthalic anhydride; the accelerant is an imidazole compound; the coupling agent is one or more of KH 550, KH560 and KH570; the flexible one-dimensional nano conductive material is a carbon nano tube or a conductive metal nano wire. The flexible conductive adhesive has the excellent conductivity and the good flexibility, the conductivity is almost not changed after being bent repeatedly, and the flexible conductive adhesive can meet requirements of flexible electronic products.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

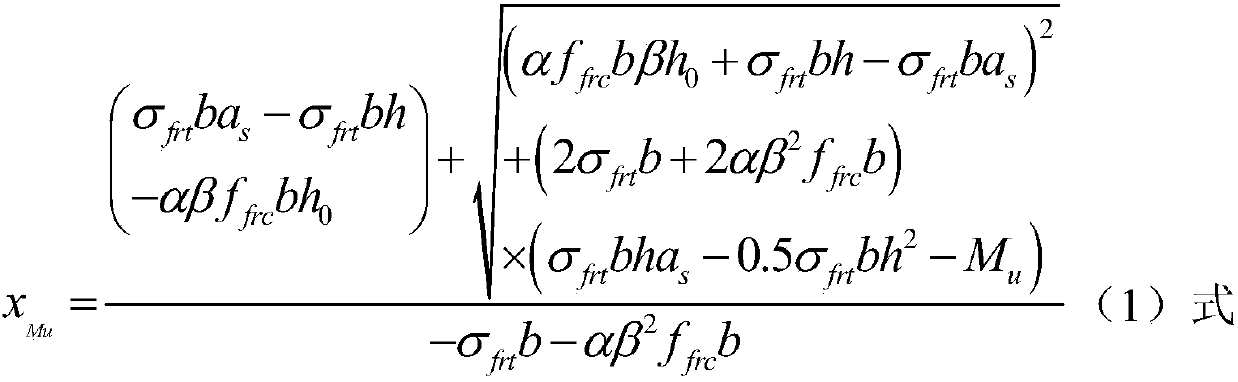

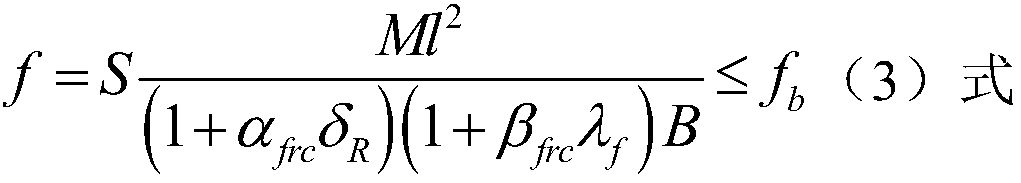

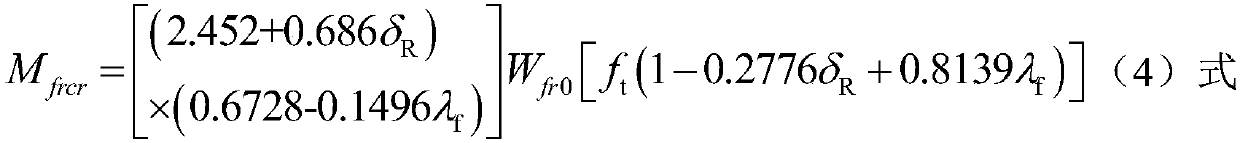

Design method of steel fiber recycled concrete beam

ActiveCN107563049AOvercoming easy cracking and poor stiffnessGuaranteed structural stabilitySpecial data processing applicationsRebarStructural stability

The invention belongs to the technical field of architectural design structures, particularly relates to a design method of a steel fiber recycled concrete beam, and mainly provides a novel design structure method of steel fiber recycled concrete to effectively solve the technical problems of easy cracking and poor stiffness of the recycled concrete. The design method of the steel fiber recycled concrete beam comprises the steps of 1, determining the sectional width b and sectional height h of the designed reinforcement steel fiber recycled concrete beam; 2, determining the reinforcement ratiopMu of the reinforcement steel fiber recycled concrete beam; 3, determining the deflection value f of the reinforcement steel fiber recycled concrete beam; 4, conducting cracking checking calculation; 5, calculating the width of cracks. The design structure method not only effectively solves the technical problems of easy cracking and poor stiffness of the recycled concrete, but also effectivelyensures the structural stability of the steel fiber recycled concrete, and meanwhile the method is also effectively applied to weighing or non-weighing structure beams.

Owner:ZHENGZHOU UNIV +1

One-time roasting method for isostatic graphite product

The invention belongs to the field of processing of isostatic graphite materials, and in particular relates to a one-time roasting method for an isostatic graphite product. The one-time roasting method for the isostatic graphite product comprises the step of performing one-time roasting on a pressed green body in a sagger, wherein the one-time roasting includes three temperature rising stages: when the temperature is 100-300 DEG C, temperature rising rate is 0.5-1.0 DEG C / h; when the temperature is 300-650 DEG C, temperature rising rate is 0.2-0.3 DEG C / h; when the temperature is 650 -1000 DEG C, temperature rising rate is 1.0-1.5 DEG C / h. Compared with the prior art, by optimizing and improving the temperature rising curve, heating duration and like factors of the one-time roasting, the method disclosed by the invention can be used for improving the coking rate of a binder, and the method can be also used for overcoming the shortcomings of crack and low product rate caused by small particles.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Environment-friendly thermal insulation mortar

The invention discloses an environment-friendly thermal insulation mortar comprising the following components in parts by weight: 40-65 parts of Portland cement, 10-20 parts of thermal insulation aggregate, 5-10 parts of reinforced fibers, 5-10 parts of redispersible latex powder, 10-20 parts of filler, 1-5 parts of light calcined magnesia and 5-10 parts of kieselguhr. The environment-friendly thermal insulation mortar has excellent cracking resistance, high bonding strength, strong adhesive force and good thermal insulation heat insulation property, weather resistance, fire and water resistance and freezing resistance. By utilizing the environment-friendly thermal insulation mortar, such common problems of the thermal insulation mortar as cracking and flaking are overcome. The thermal insulation mortar is good in volume stability, generates volume microdilatancy during setting and hardening, does not crack or hollow and is strong in water resistance and ageing resistance and long in service life. The environment-friendly thermal insulation mortar is non-toxic, odorless, non-radioactive and harmless to a human body. By utilizing the environment-friendly thermal insulation mortar, the environment can not be polluted, energy is saved, the environment is protected, and electromagnetic radiation is absorbed.

Owner:QINGDAO WINCHANCE TECH

Expansion-broken softened cork preparation method

The invention relates to a method for preparing expansion and breaking softened cork. The method comprises: (1) a step of removing impurities in raw materials, during which impurities on the surface of cork bark are planed and brushed to remove a black skin; (2) a step of adding water directly for expansion and breaking softening, in which cork is filled in an expansion and breaking softening tank with a heating system before impregnating smoldering, steaming and boiling, added with water on the basis of the prior water content till the total water content reaches 15 to 50 percent, closed and heated till the pressure rises to 0.5 to 3MPa / cm<2> and the temperature reaches between 100 and 230 DEG C, and kept at the temperature to be fully impregnated, the air is released quickly for pressure reduction, the air is compressed for cooling, and thus the expansion and breaking softened cork is obtained. The method has the advantages of avoiding pollution in the whole process, improving the utilization rate and excellent rate of natural materials due to environmentally-friendly production and fundamentally improving the quality of China cork raw material and products.

Owner:郑林义

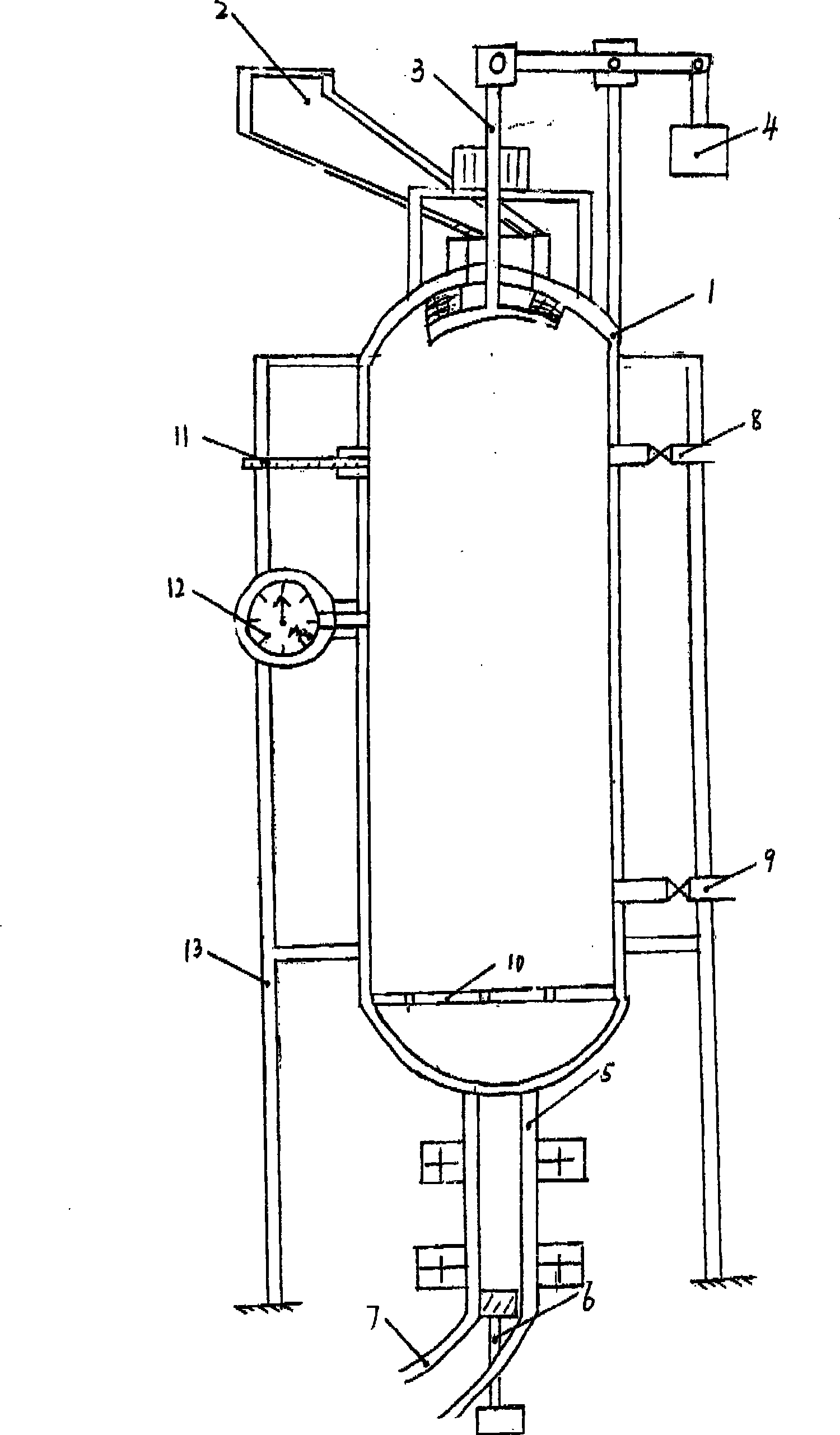

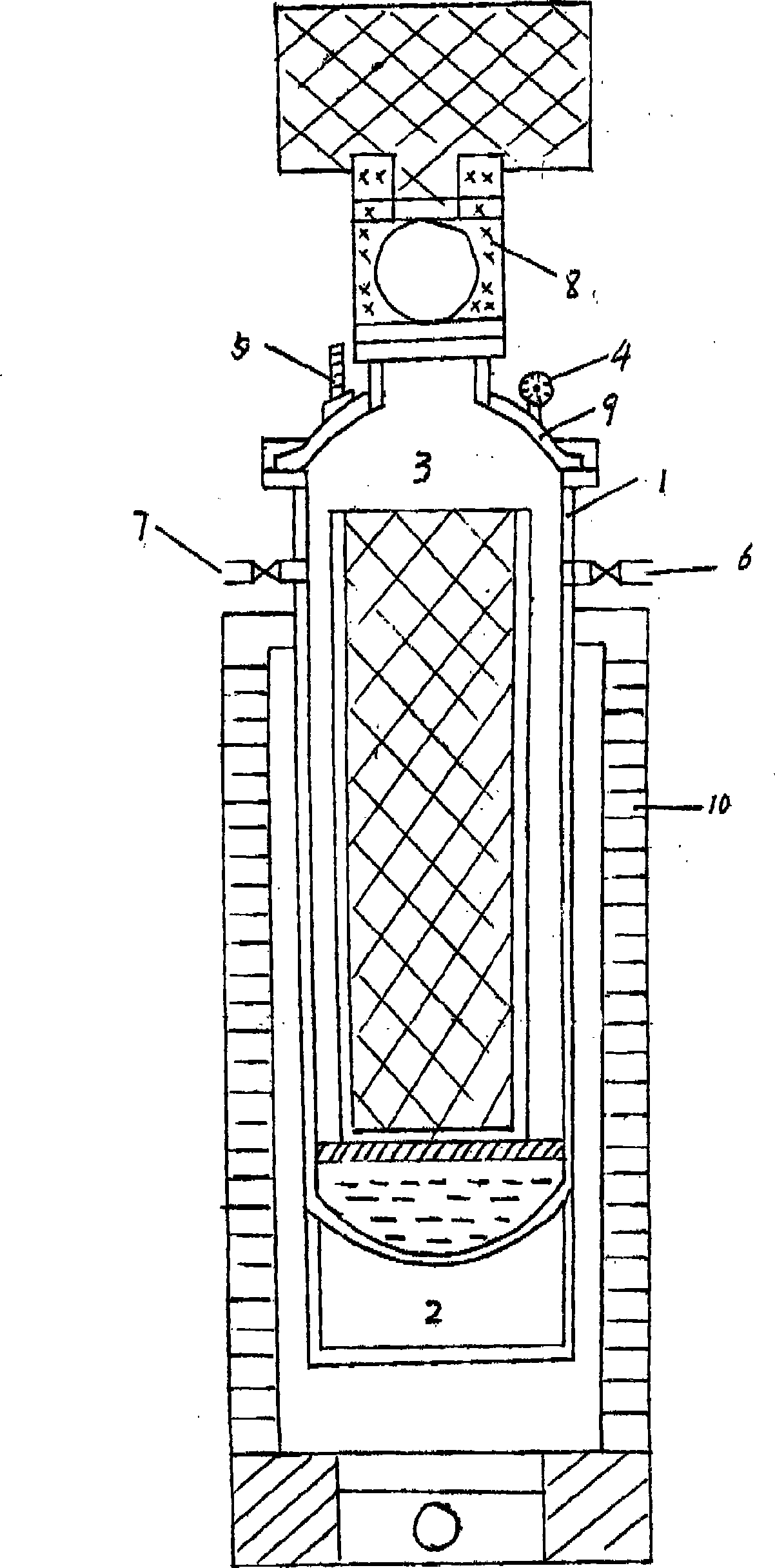

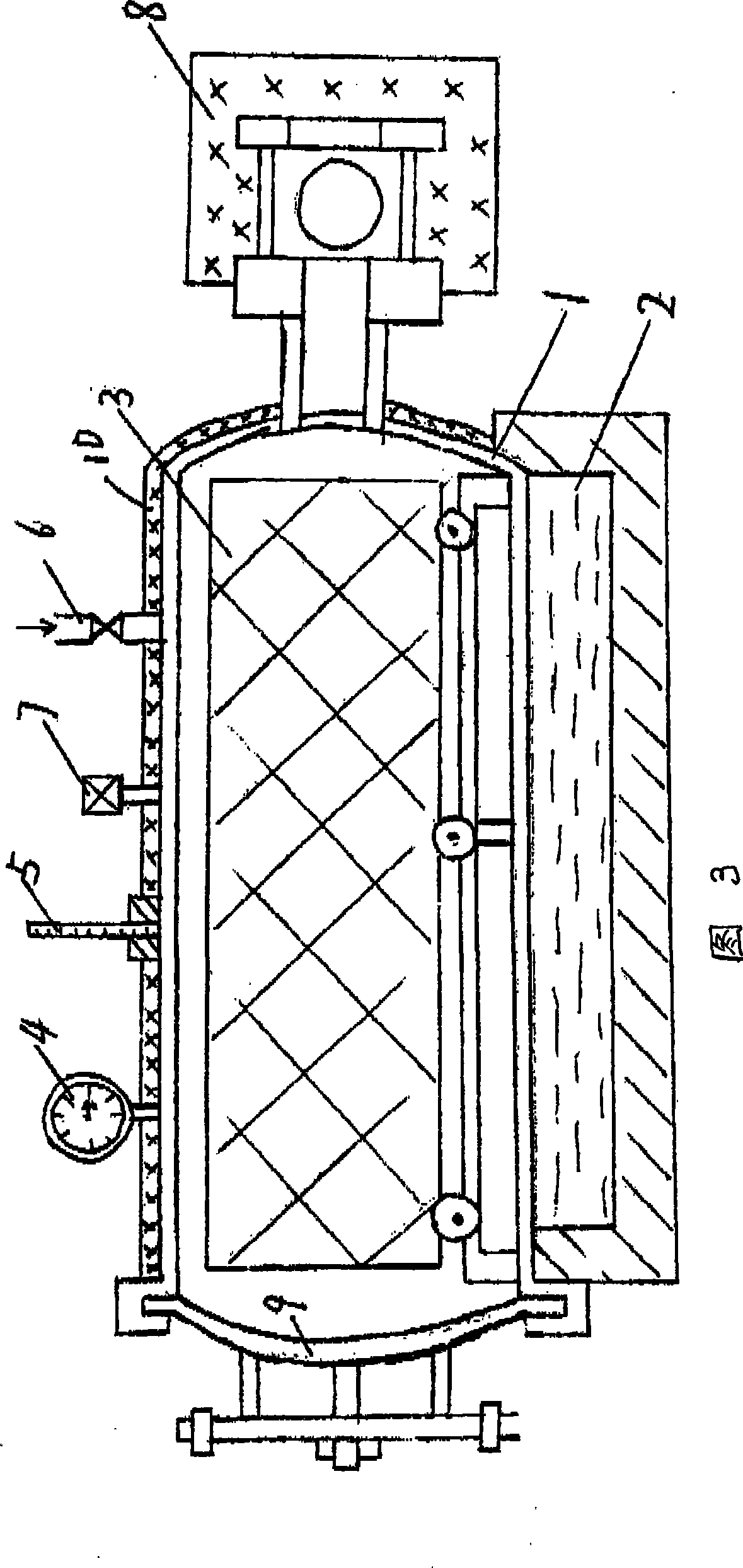

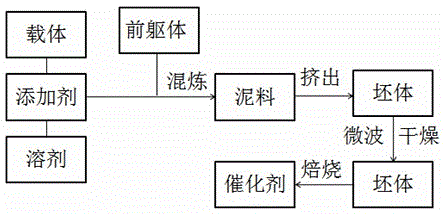

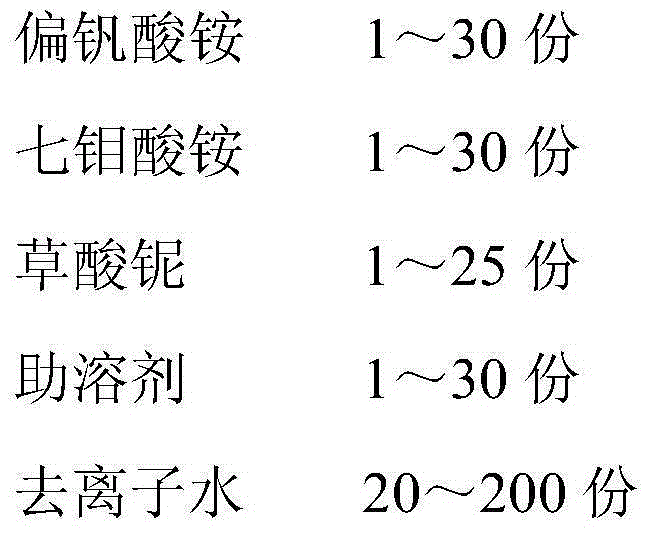

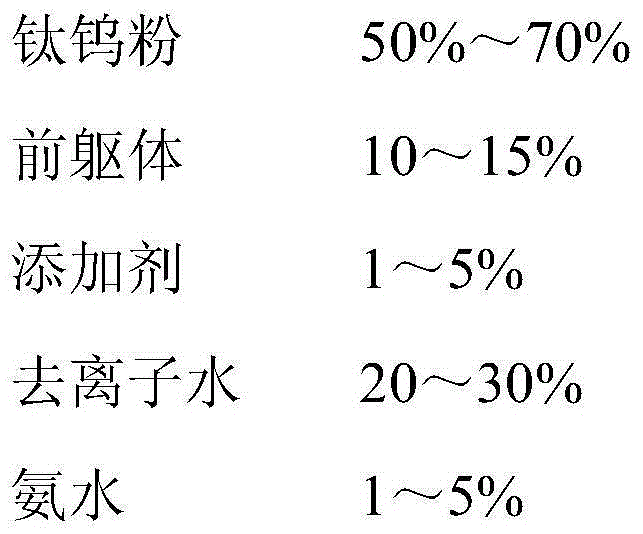

Preparation method for high-temperature flue gas denitrification catalyst and product of high-temperature flue gas denitrification catalyst

InactiveCN105080605ASolve the problem of low denitrification efficiencyOvercome crackingOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationTwo stepDrying time

The invention relates to a preparation method for a high-temperature flue gas denitrification catalyst and belongs to the technical field of flue gas denitrification. The preparation method comprises the following two steps: preparing a precursor; and preparing a catalyst. According to the technical scheme, the preparation method comprises the steps: by taking V2O5 as a main active component and Nb2O5 and MoO3 as an auxiliary active component, preparing the precursor of V2O5, Nb2O5 and MoO3; and then mixing the precursor by titanium tungsten powder taking TiO2 and WO3 as main components through extrusion molding, drying and water removal and roasting processes to prepare the catalyst. The problem that the SCR denitration efficiency is relatively low when the flue gas temperature of a coal-fired power plant is 280-300 DEG C is solved. Moreover, in the catalyst preparation process, a microwave drying technology is adopted to overcome the defect of cracking and uneven size distribution caused by temperature gradient in a conventional drying technology, so that the drying time is shortened and the production efficiency is improved. The invention further relates to a denitrification catalyst prepared by the method, so that the low-temperature activity of the catalyst is improved and the active temperature window is expanded, and the preparation method has beneficial technical effects.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Method for preparing stress-free GaN thick film on sapphire patterned substrate

InactiveCN102034693AAvoid pollutionAvoid damageSemiconductor/solid-state device manufacturingSilicon nitridePhotolithography

The invention relates to a method for preparing a stress-free GaN thick film on a sapphire patterned substrate, which comprises the following steps: 1, depositing a silicon oxide or silicon nitride film on a C-plane sapphire substrate; 2, photoetching bar-shaped silicon oxide or silicon nitride mask patterns in a [11-20] direction on the C-plane sapphire substrate of the deposited silicon oxide or silicon nitride film by the conventional photoetching technology; 3, transferring the photoetched bar-shaped silicon oxide or silicon nitride mask patterns onto the substrate by wet-process etching; 4, removing the silicon oxide or silicon nitride film by corrosion, and cleaning the substrate to obtain a clean sapphire patterned substrate; and 5, directly using a hydride gas-phase epitaxy system to epitaxially grow a GaN thick film on the obtained sapphire patterned substrate, and thus finishing the preparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Large-pipe-diameter Ni-V rotary target material containing microelements and preparation method of large-pipe-diameter Ni-V rotary target material

ActiveCN110468382AEasy feedingImprove grain boundary binding forceVacuum evaporation coatingSputtering coatingOxygenBinding force

The invention discloses a large-pipe-diameter Ni-V rotary target material containing microelements and the preparation method of the large-pipe-diameter Ni-V rotary target material. The rotary targetmaterial comprises the following components of, in percentage by mass, 0.01%-0.05% of C, 0.01%-0.08% of B, 0.001%-0.006% of Ti, 0.01%-0.05% of Mg, 6%-8% of V, and the balance Ni and inevitable impurities; and the preparation method comprises the following steps of vacuum melting, hot forging, machining, hot extrusion, acid pickling treatment, solid solution treatment, cold rolling or boring, annealing treatment, the machining or binding. According to the target material and the method, on the basis of Ni-V, trace elements of the C, the B, the Ti and the Mg are added for component optimization,the contents of oxygen, sulfur and the like are reduced, the generation of cracks can be inhibited, the grain boundary binding force and strength of the target material are improved, and crystal grains are refined, so that the yield is improved; and the rejection rate is reduced by optimizing hot working process parameters.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

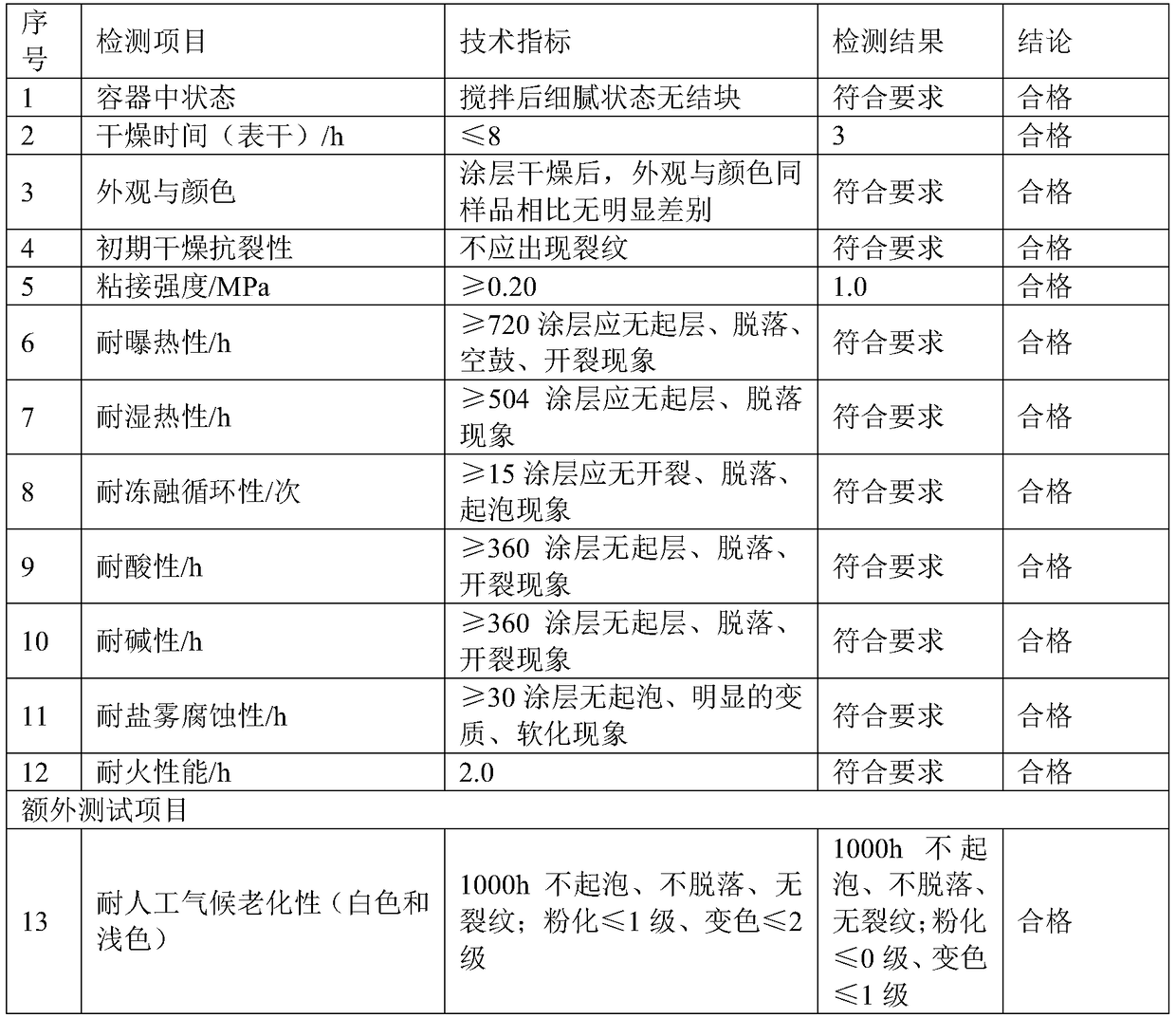

Ultra-thin weather-proof and anit-cracking organosilicon fire-proof paint

ActiveCN109468058AExcellent heat resistance and UV resistanceExtended service lifeFireproof paintsAnti-corrosive paintsAmmonium polyphosphateOrganosilicon

The invention discloses ultra-thin weather-proof and anit-cracking organosilicon fire-proof paint which is prepared from the following raw materials by mass percentage: 25-35% of modified nano polysiloxane oligomer, 5-8% of tri-functional organosilicon cross-linking agent, 2-5% of tetra-functional organosilicon cross-linking agent, 5-10% of hydrophobic fumed silica, 5-8% of titanium dioxide, 20-25% of ammonium polyphosphate, 8-12% of melamine, 9-15% of surface coating pentaerythritol, 2-5% of aluminum hydroxide, 2-6% of glass fiber powder, 3-10% of hydroxyl silicone oil, 1-2% of amino silane coupling agent, 0.5-3% of epoxy silane coupling agent and 0.1-0.3% of catalyst. Construction procedures of the paint are reduced; the use cost of the paint is lowered; and at the same time, a service life of the paint is further ensured.

Owner:浙江凌志新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com