Expansion-broken softened cork preparation method

A cork, expanding and crushing technology, which is applied in the direction of cork machining, mechanical equipment, etc., can solve pollution and other problems, achieve high efficiency, improve sound insulation, and solve the effects of pollution and health hazards to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

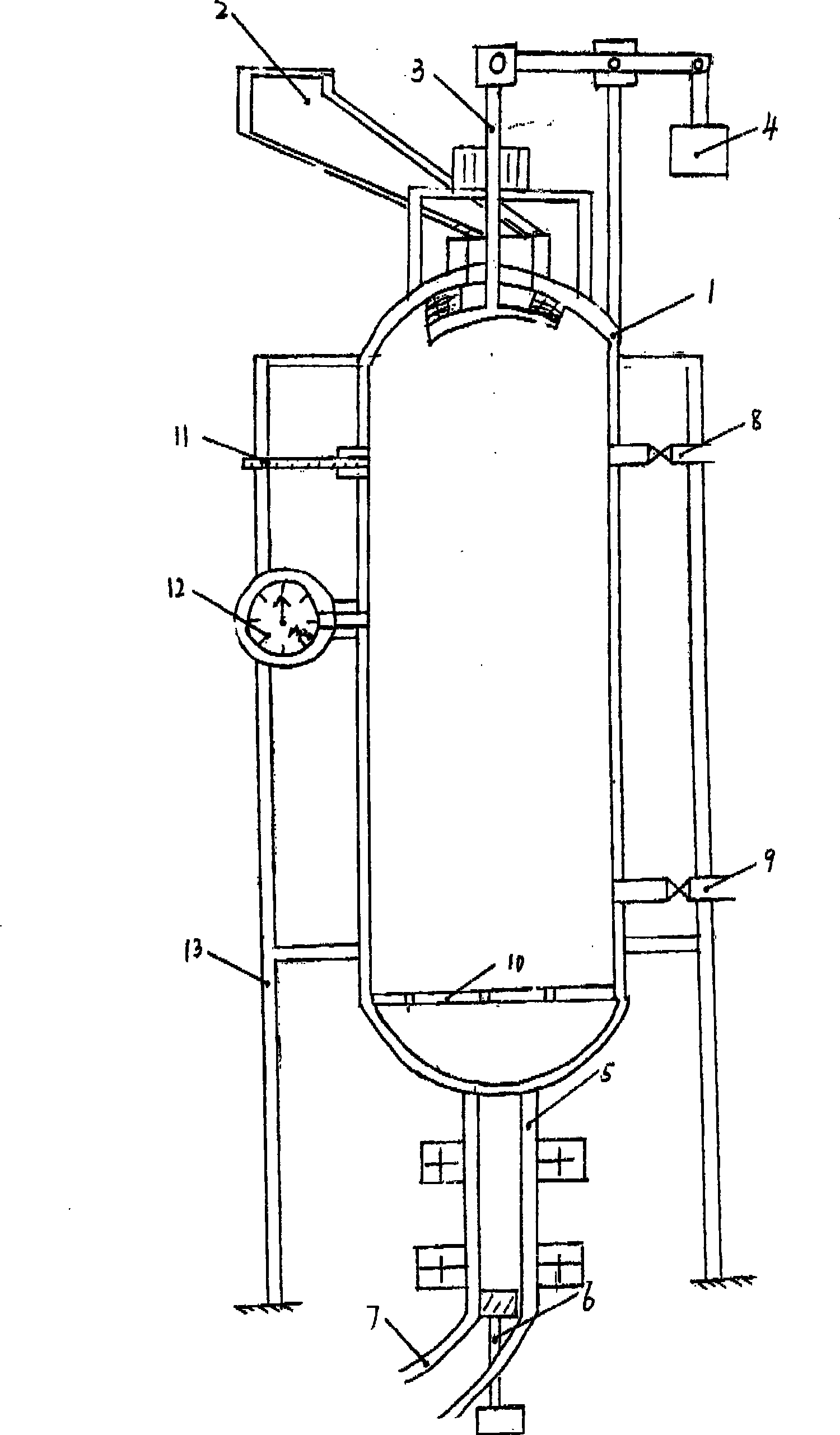

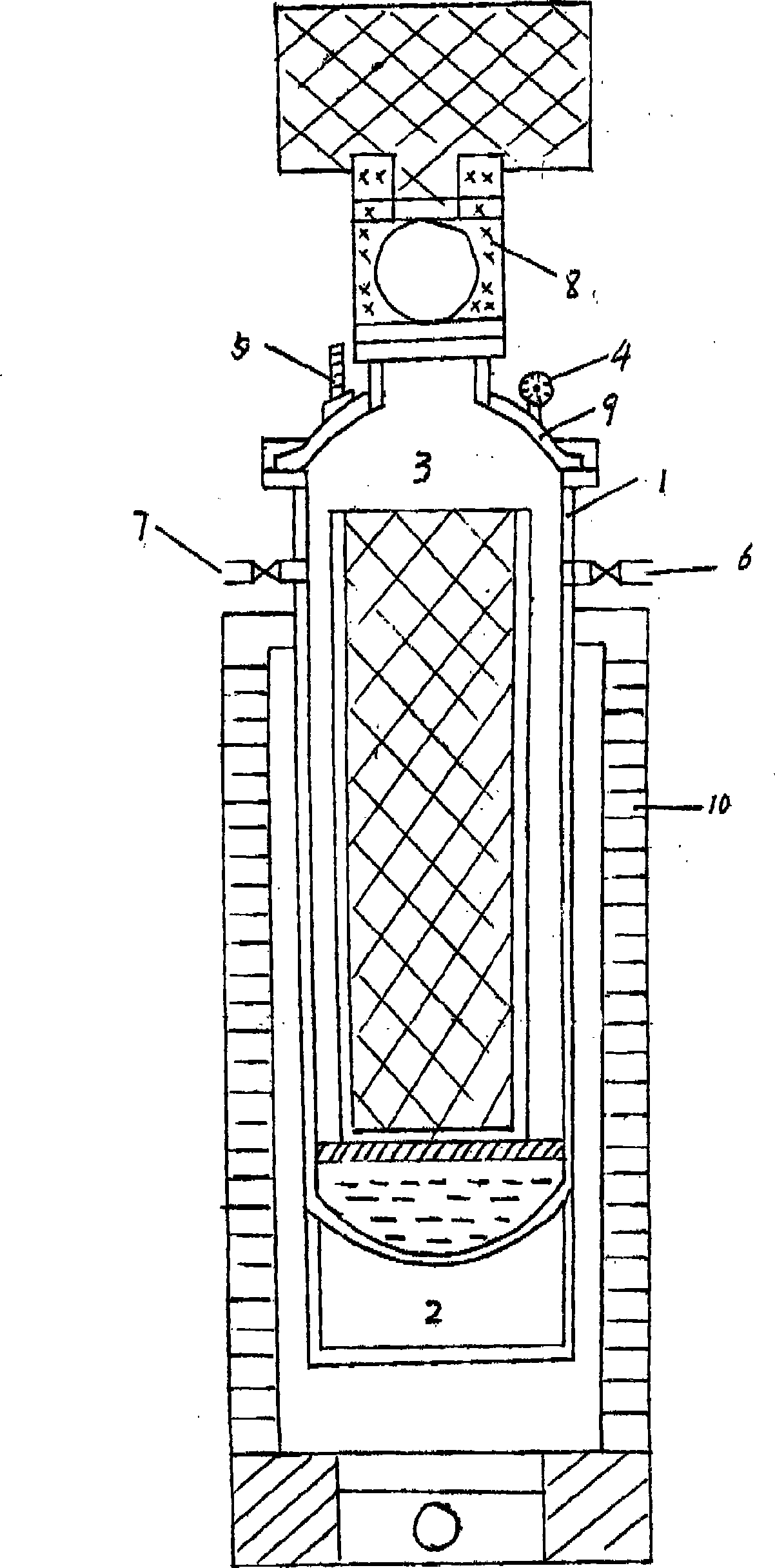

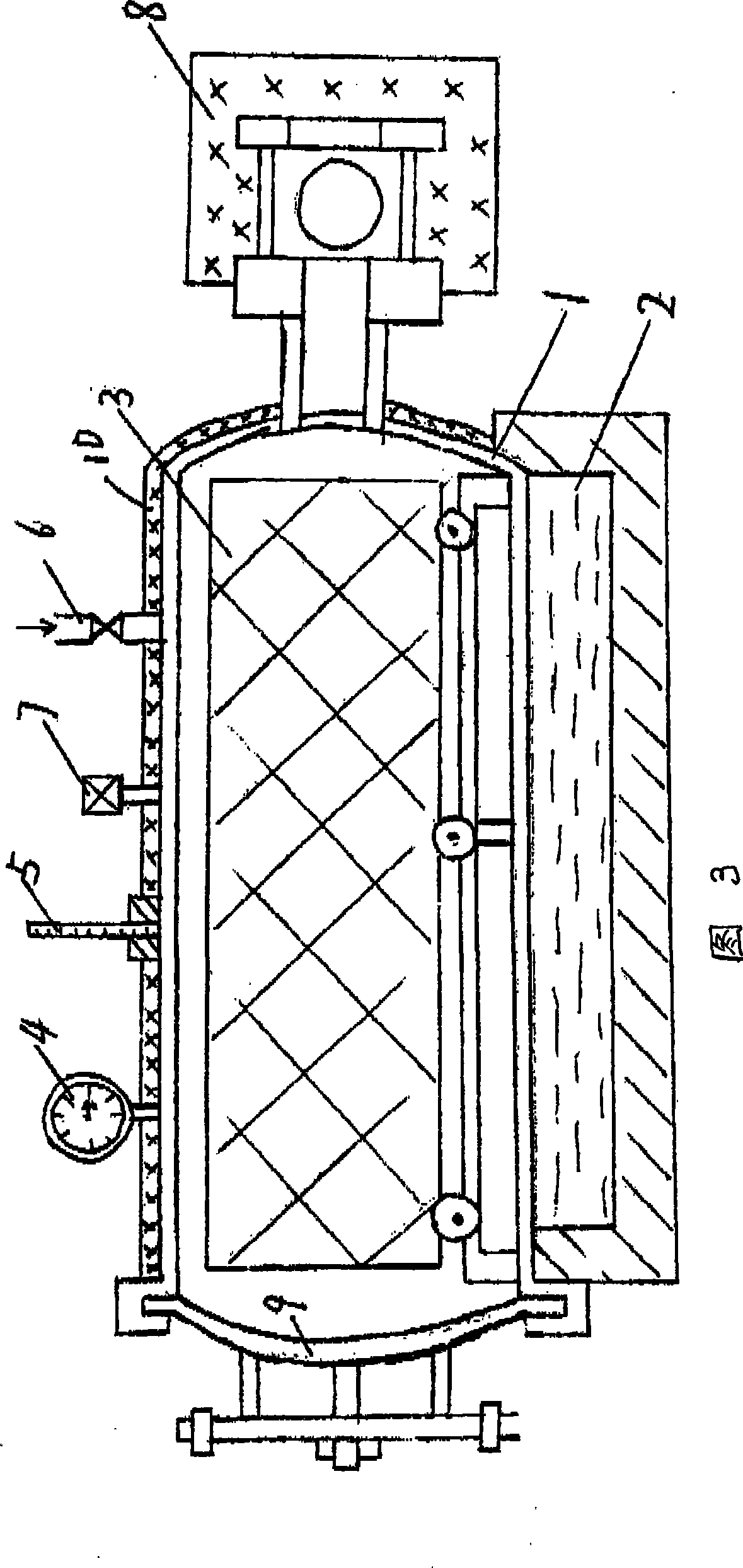

[0031] 1. First, soak the whole piece of original bark in water and remove the black skin. The primary skin may not be removed. The primary skin is brushed with a leather brushing machine, the secondary skin is planed, and the small pieces are ground with a roller ball mill to remove the black skin. It can also be processed by a mill without black skin bulk particles. 2. Add the above-mentioned peeled cork or large-grained cork without or with penetrating agent, mix and soak for 24 hours, let it permeate on the surface, heat and penetrate better, boil it in water at 100-120°C for 2 hours to make it contain water The rate reaches 15-50%. 3. Put the cork chips and blocks with high moisture content into the expansion pot ( Figure 1 ), add saturated steam, the pressure rises to 0.5Mpa-3Mpa, the temperature is 140-230°C, and the cork is quickly deflated and decompressed to discharge. Water and compressed air cooling, set different cooling temperatures to achieve the purpose of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com