Patents

Literature

59results about How to "Overcome shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

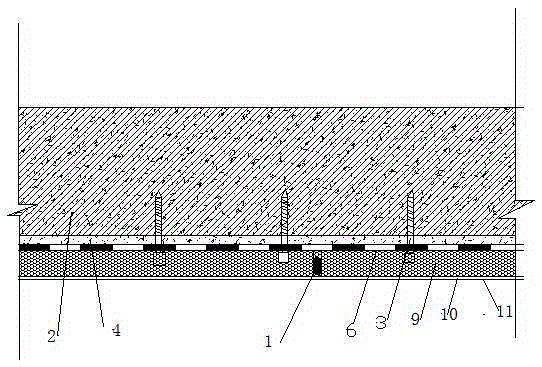

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

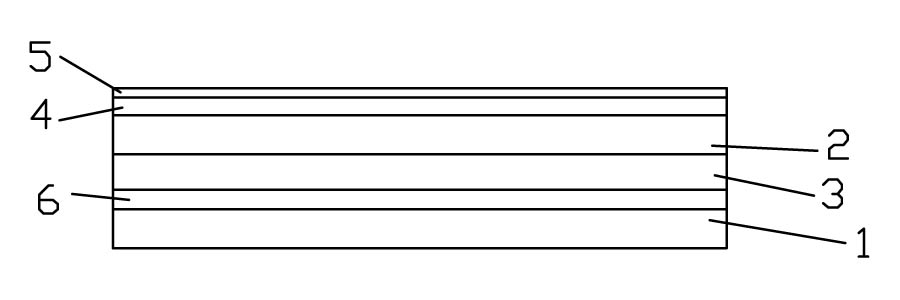

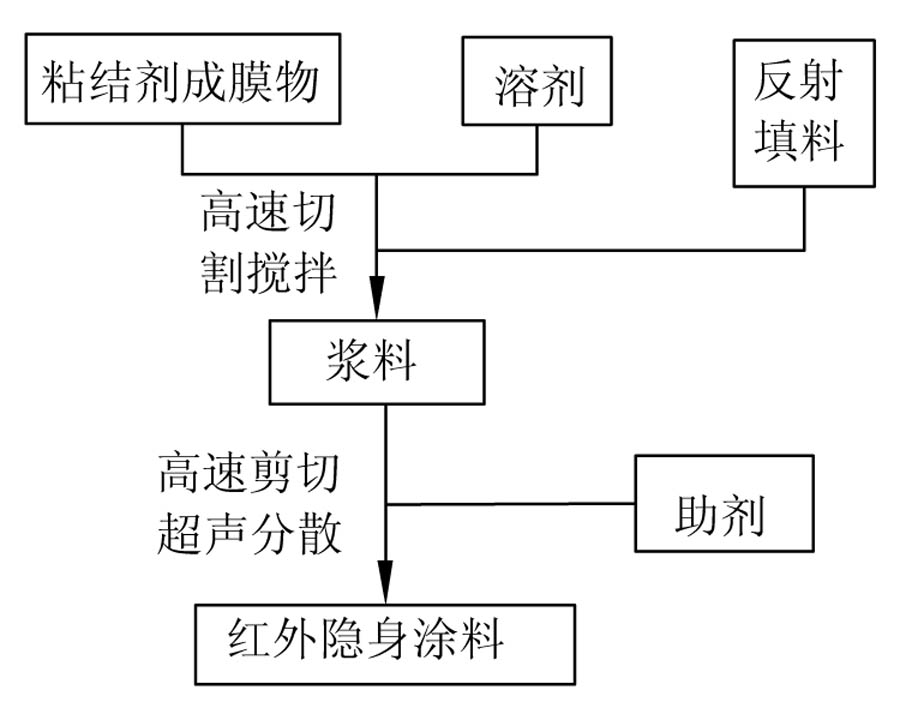

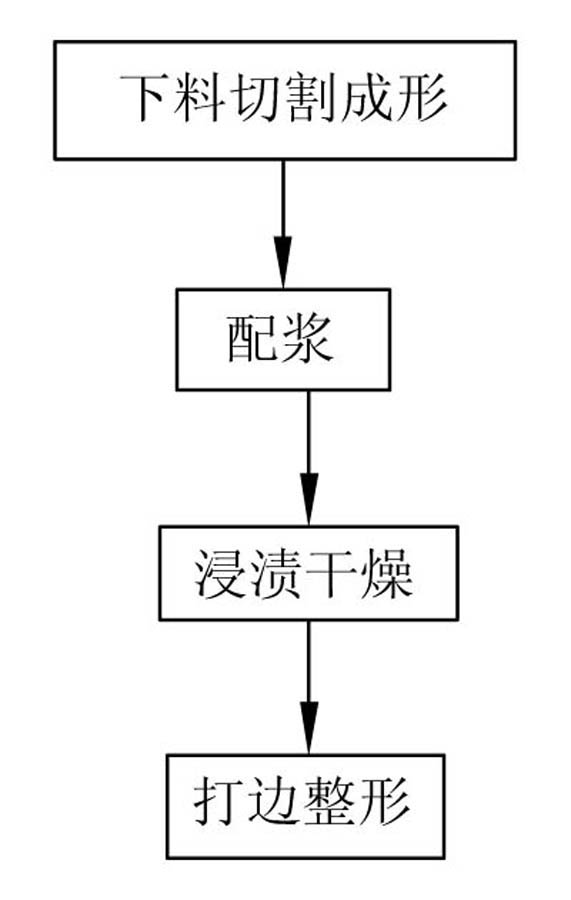

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

Double-component ceramic tile interface agent as well as preparation method and using method thereof

The invention aims at solving a ceramic tile dropping problem caused by low water absorption and a smooth interface of the existing ceramic file, especially a vitrified porcelain tile, and provides a double-component ceramic tile interface agent for improving interface performance and construction performance of a ceramic tile. The double-component ceramic tile interface agent comprises a component A and a component B, wherein the component A comprises cement, quartz sand, metakaolin and a thickener; the component B comprises a water reducing agent, a flexibilizer, a penetrating agent, a dispersing agent, an antifoaming agent, a bactericide, an accelerator, a season regulator and water. According to the invention, two strength forming materials of multiple polymers and cement are used at the same time, so that possibility of forming an interface for a second time is reduced, and bonding strength of the interface agent and the ceramic tile is improved. Besides, while construction time is ensured, setting time is shortened, construction performance is effectively improved, and long-term aesthetic sense of the ceramic tile is ensured.

Owner:湖北鲁邦建材股份有限公司

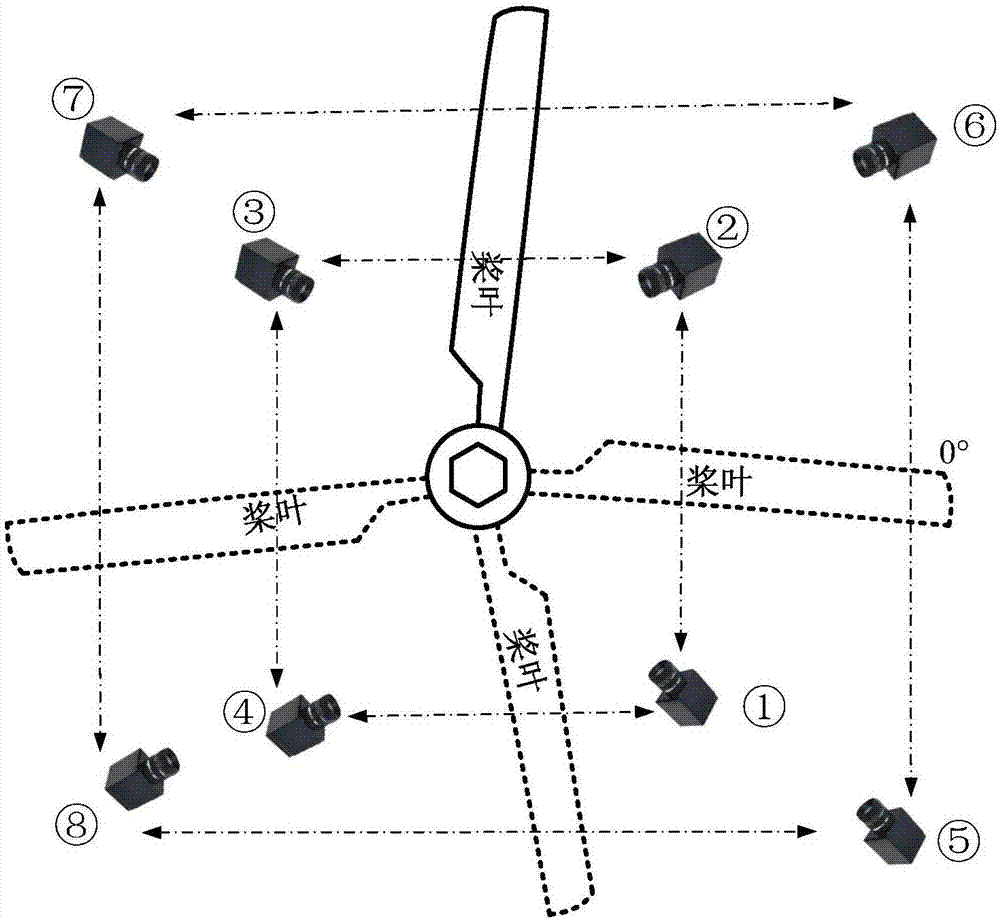

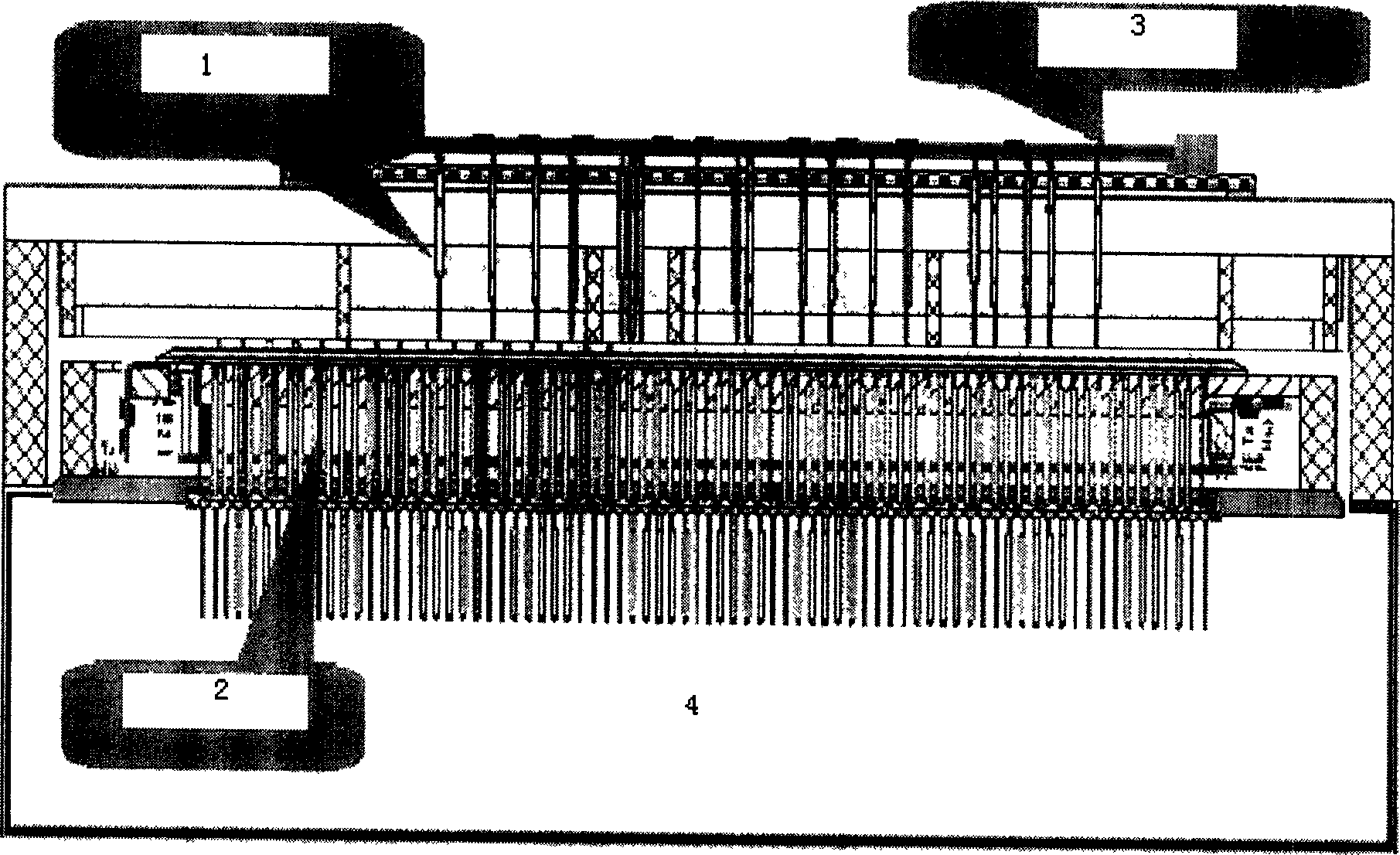

Method for measuring motion parameter of large-size rotor wing

InactiveCN107966112AOvercome sheddingOvercome unclear imagingUsing optical meansMulti cameraFull field strain

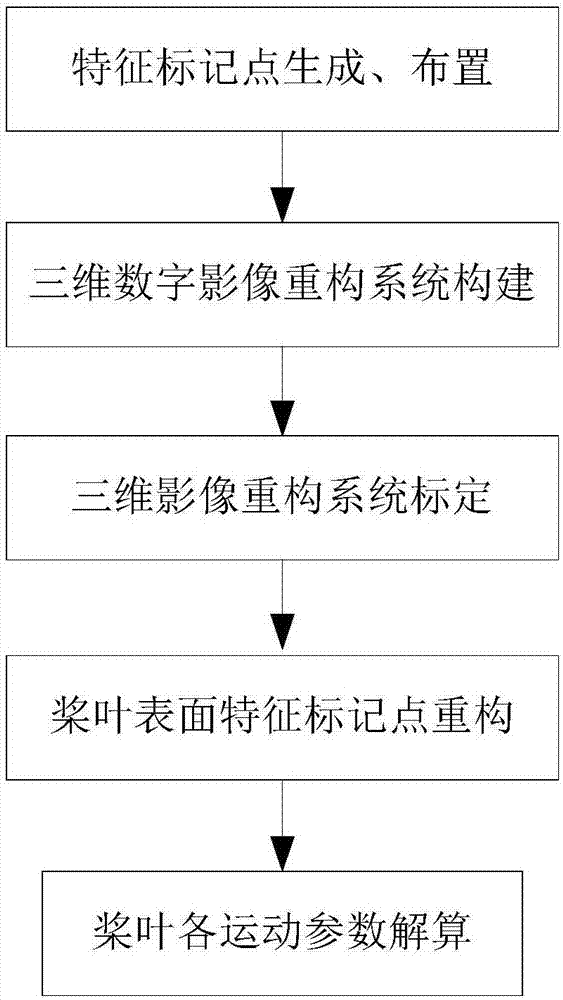

The invention, which belongs to the technical field of test measurement of a helicopter, relates to a method for measuring a motion parameter of a large-size rotor wing. Motion track image data of a large-size rotor blade in high-speed rotation are collected at different azimuthal angles by a calibrated multi-camera motion attitude video measurement and dynamic characteristic analyzer; after calculation, three-dimensional coordinates of the rotor blade at different azimuthal angles are reconstructed; and then according to definitions of all motion parameters, all motion parameters of the bladeare calculated. According to the method provided by the invention, with the employed feature marking point generation plan and process, defects of marking point shedding, low image definition, and poor measuring effect and the like during the high-speed rotation of the large-size rotor blade are overcome. And the full-field strain of the large-size blade can be measured effectively; measurement becomes flexible; and on-line measurement of the motion parameter of the rotor blade is realized.

Owner:CHINA HELICOPTER RES & DEV INST

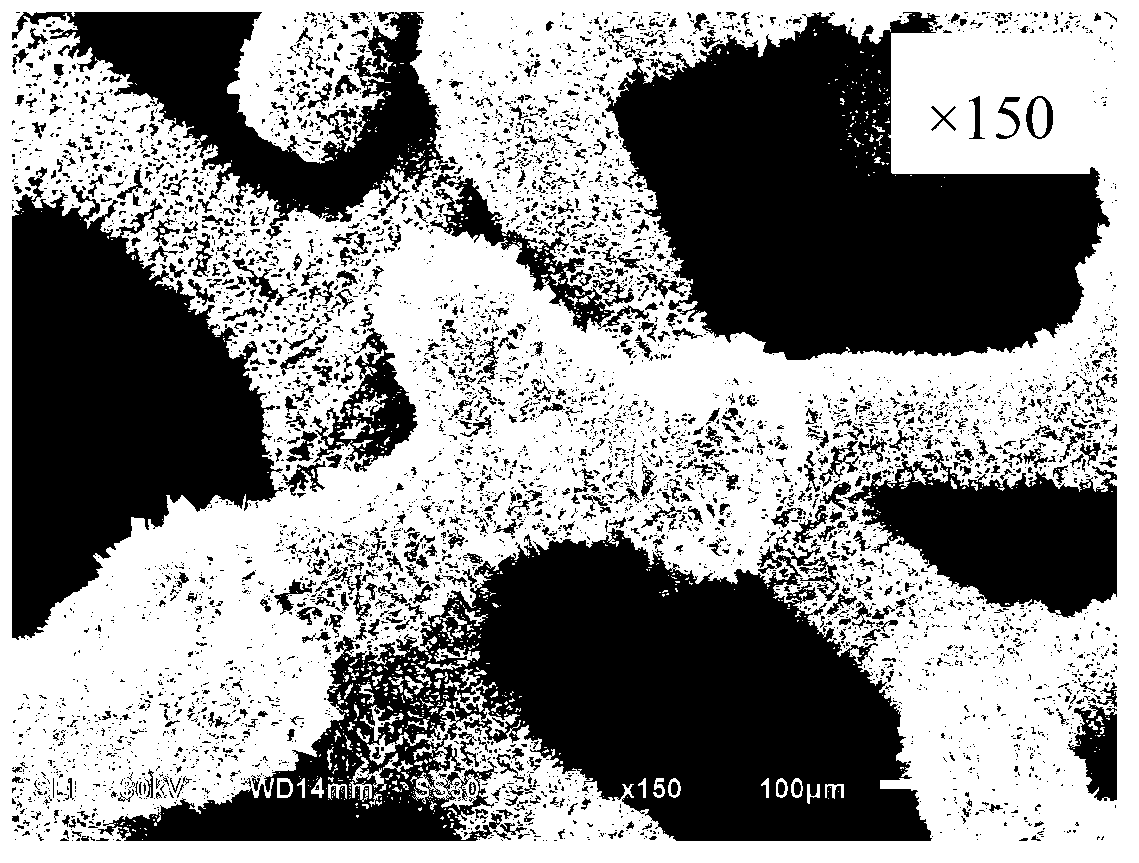

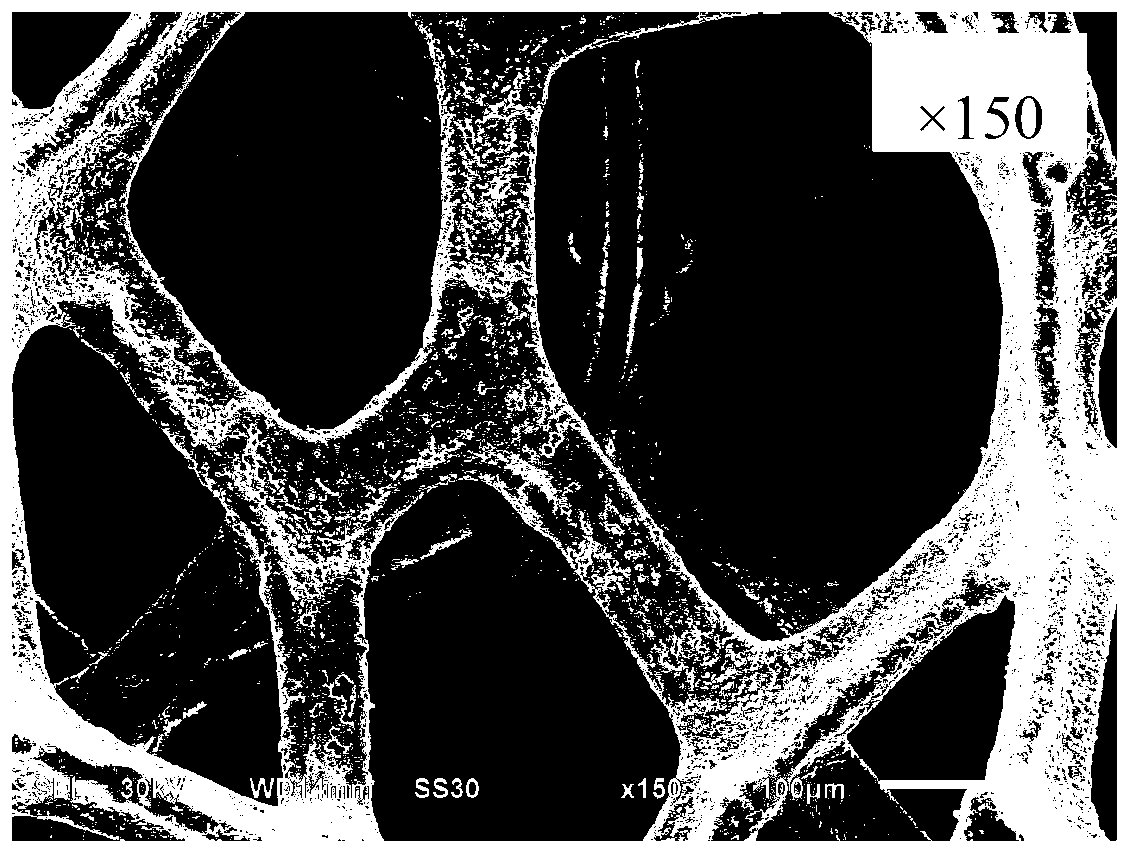

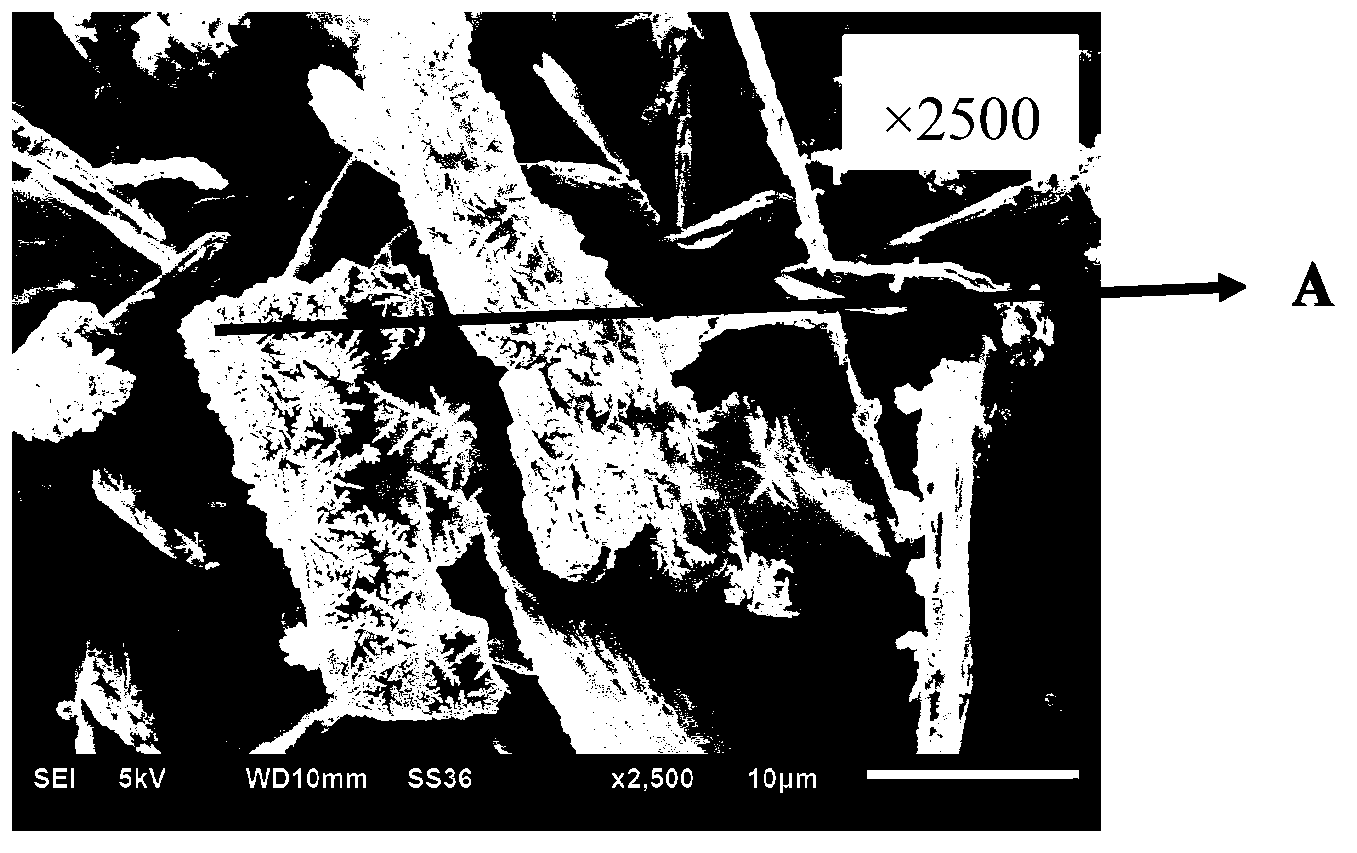

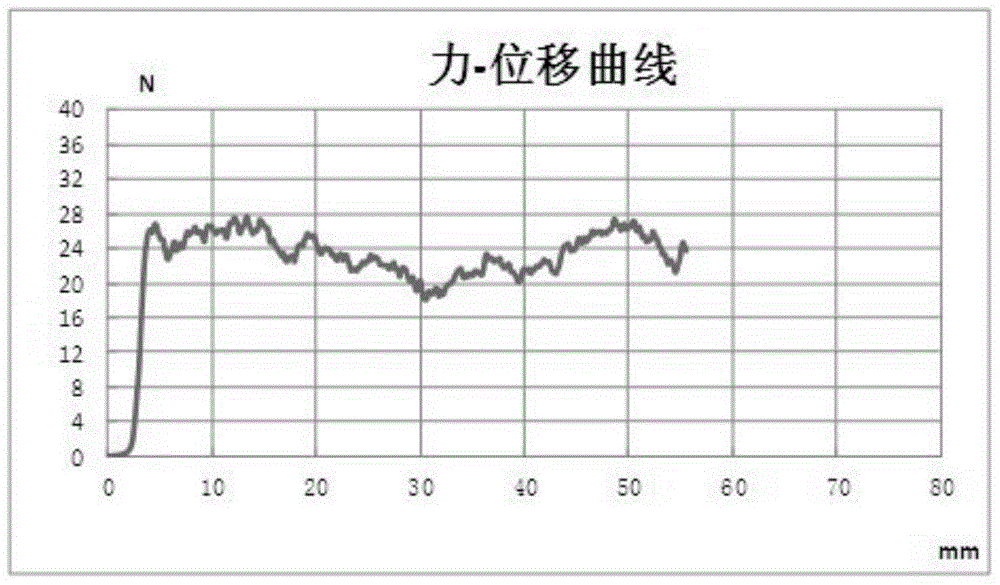

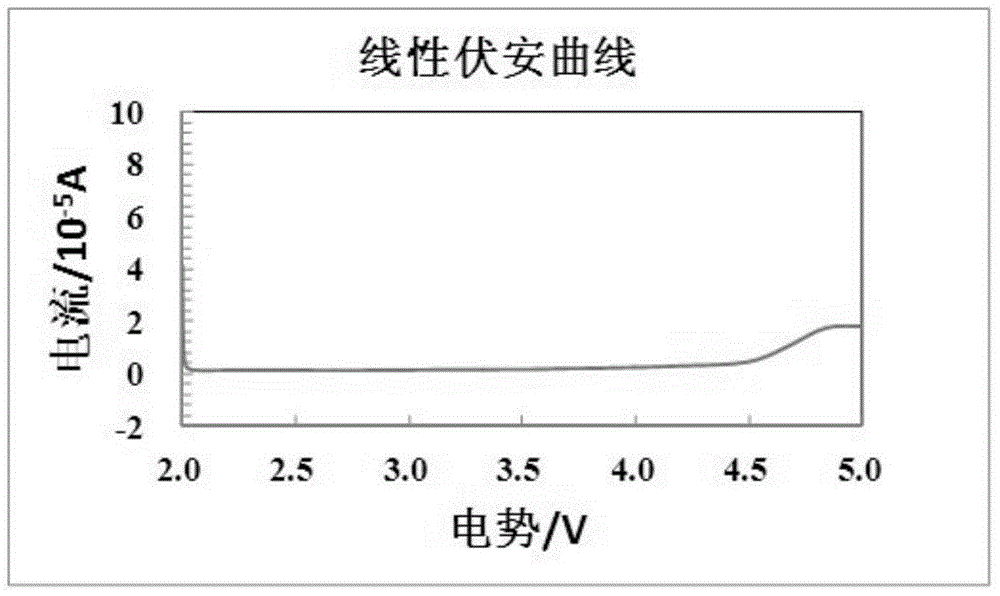

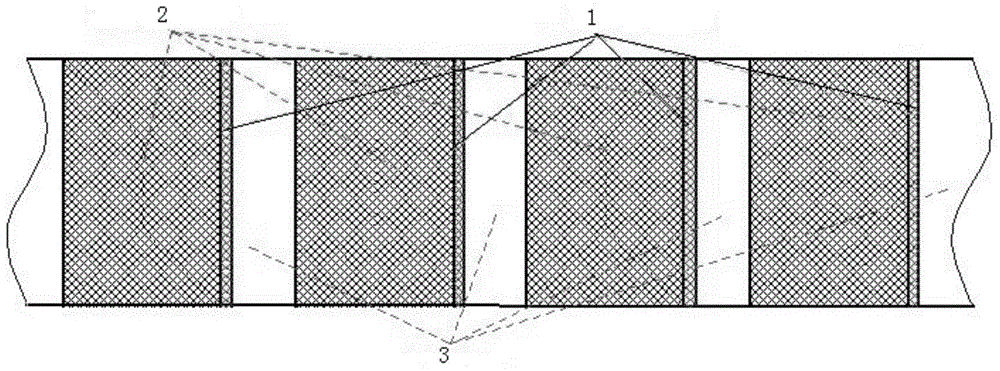

Copper sulfide anode and preparation method thereof

The invention provides a copper sulfide anode and a preparation method thereof, solving the problems of the conventional copper sulfide electrode that the bonding force of active substances and current collectors is poor and the anode conductivity is lowered because of a binder and also solving the problems of the integrated copper sulfide electrode which is synthesized in situ in a solution that the quantity of active substances is small and the preparation period is long. The copper sulfide anode is prepared by the following steps: uniformly spreading elemental sulfur which is prepared according to the sulfur carrying amount of foamy copper is 0.03-0.3g / cm<2> on the foamy copper, putting into a furnace, and carrying out in-situ reaction under a protection gas at a temperature of 155-350 DEG C so as to obtain the laminated copper sulphide which takes a foamy copper three-dimensional network structure as a framework, namely an integrated porous copper sulphide anode. By utilizing the copper sulfide anode, the application of the three-dimensional structured integrated porous anode in a lithium battery is widened, the energy density of a lithium battery anode is improved, and the performances of a lithium battery are improved. The copper sulfide anode is simple in preparation process, low in equipment requirement, low in cost and convenient for industrial production.

Owner:XIANGTAN UNIV

Lithium ion battery insulating coating, preparation method and pole piece and lithium ion battery using insulating coating

InactiveCN104449011AImprove electrochemical performanceElectrochemical performance does not affectConjugated diene hydrocarbon coatingsSecondary cellsElectrical resistance and conductanceElectrical battery

The invention discloses a lithium ion battery insulating coating, a preparation method and a pole piece and a lithium ion battery using the insulating coating, and belongs to the technical field of lithium ion batteries. The effective components of the lithium ion battery insulating coating disclosed by the invention is formed by inorganic powder, an adhesive and a dispersing agent, wherein the three components generate a synergistic effect to improve the uniformity and stability of the insulating coating and improve the resistance uniformity of an insulating coating layer formed by the insulating coating, and the bonding strength with an aluminum foil matrix for the pole piece is high, thereby being unlikely to drop. The preparation method of the lithium ion battery insulating coating disclosed by the invention is easy to operate and is suitable for industrialized promotion and application, the inorganic powder, the adhesive and the dispersing agent are mixed in a high speed stirring and dispersing manner, so as to improve the uniformity and stability of the insulating coating, and the insulating coating is free of such phenomena as lamination and settlement after being stored for a long term. The lithium ion battery prepared by the insulating coating disclosed by the invention is good in safety performance and is stable in electrochemical performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Quick connection joint for plastic pipeline

InactiveCN102654224AOvercome sheddingOvercome the breakPipe connection arrangementsPlastic pipeworkEngineering

The invention provides a quick connection joint for plastic pipeline, relating to a connection structure of the plastic pipeline. The connection joint is made of a hard material, wherein a connection head (1) is a section from one external end to the middle part of the connection joint; a round-about groove (5) is arranged on the outer edge face of the connection head; an opening part stopping ring (2) is arranged on an inner wall (4) at one end inside an end face (6) at one end of the connection joint; clamps which are clamped with the external face of a rubber pipe (8) and are circularly distributed are arranged on the inner wall at one end; and a section from an inner face at the other end to the middle part of the connection joint is a horn opening (9) with a large external part and a small internal part at the other end. The quick connection joint provided by the invention is locked at an end head of the plastic pipeline through a mechanical effect, and forms a tight quick connection structure through the annular-distributed clamps. The quick connection joint ensures the good sealing property due to the specific structural design, so as to achieve rapid, efficient and convenient mounting, dismounting and maintenance. Therefore, the phenomena of releasing, breaking, and water and gas leakage of the pipeline, caused by the conventional connection manner, can be effectively overcome.

Owner:山东鼎鑫矿用新材料有限公司

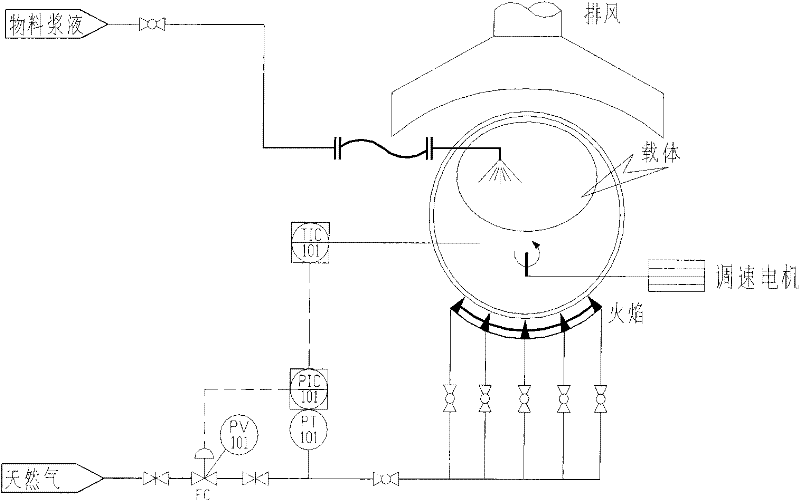

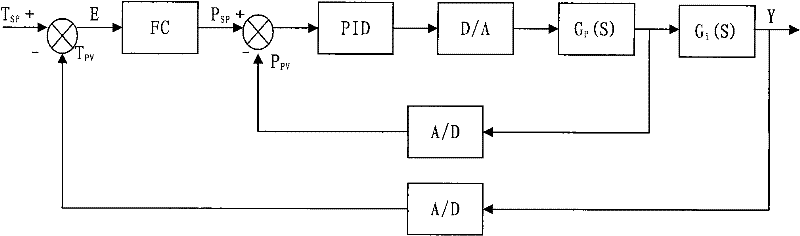

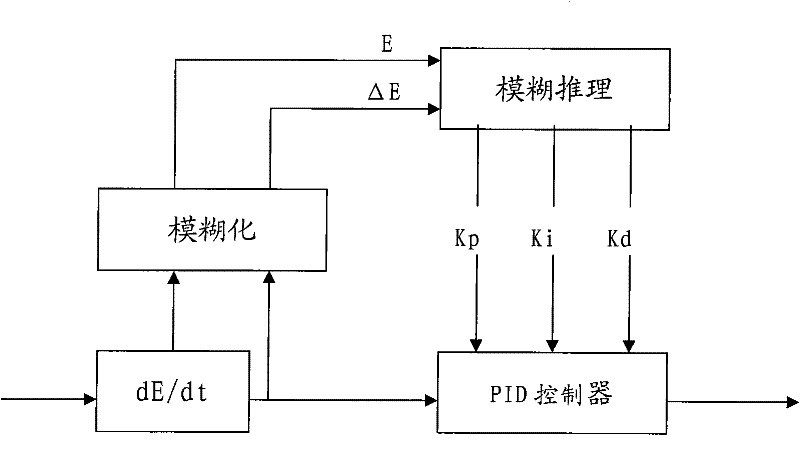

Temperature control system in catalyst production device, temperature control method and application of temperature control system

ActiveCN102455718ASmooth and precise temperature controlImprove product qualityOrganic chemistryTemperatue controlTime lagAutomatic control

The invention belongs to a design of temperature control in an intermittent catalyst production process, belongs to the field of automatic control of production processes, and in particular relates to a method for controlling the process reaction temperature of a sugar coating pot serving as main equipment in a maleic anhydride catalyst production device. A proportion integration differentiation (PID) fuzzy controller is researched and developed; and aiming at the characteristics of high temperature inertia in the sugar coating pot, obvious time lag, high coupling and difficulty in establishing an accurate mathematical model in the maleic anhydride catalyst preparation process, the temperature deviation in a maleic anhydride catalyst control system is controlled by adopting the controlling method combining fuzzy control and cascade control, so that automatic control of the temperature in the pot is realized. The application shows that the control algorithm completely meets the control requirements of the temperature parameters of the sugar coating pot, the dynamic performance of the system is improved and the performance and the quality of a maleic anhydride catalyst product are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Underfill composition

ActiveCN110358483AImprove resin fluidityLower flow temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesFlexural strengthInorganic filler

The invention discloses an underfill composition. The underfill composition comprises 30-65 wt% of a filler, 15-55 wt% of an epoxy resin, 7-20 wt% of a curing agent, 0.1-2.0 wt% of a silane coupling agent and 1.5-45 wt% of assistants, the filler is an inorganic filler, the filler includes spherical silica particles, and the assistants includes any one or any combination of a promoter, a diluent, aplasticizer, a defoaming agent, a dispersant and a pigment. The above formula and the combination of the above components are combined, so the underfill composition has the advantages of low viscosity, low thermal expansion coefficient, high thermal conductivity, high flexural strength, can solve the problem of the frequent occurring solder joint drop or fracture in the thermal cycle test, and also has the advantages of long-term usability, good adhesion and excellent mechanical properties.

Owner:深圳泰研半导体装备有限公司

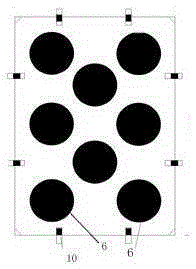

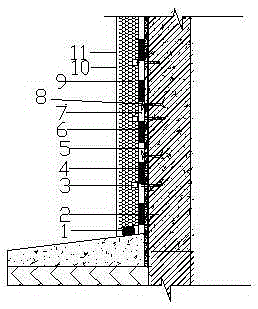

AEPS (class-A expandable polystyrene) zinc-magnesium steel plate fireproof insulation decorative integrated board and construction process thereof

InactiveCN105298054AMeet fire protection requirementsImprove stain resistanceCovering/liningsLaminationMaximum dimensionPolystyrene

The invention discloses an AEPS (class-A expandable polystyrene) zinc-magnesium steel plate fireproof insulation decorative integrated board, comprising an AEPS polystyrene board and a zinc-magnesium steel plate composited together. The zinc-magnesium steel plate is 0.5-1.5 mm in thickness. The minimum dimensions of a rectangular plate of the zinc-magnesium steel plate are 100*200 mm. The maximum dimensions of the rectangular plate of the zinc-magnesium steel plate are 1250*12000 mm; two sides of the AEPS polystyrene board are provided with grooves; the zinc-magnesium steel plate has a planarity deviation, is not less than 2 mm in thickness and not greater than 0.2% in long side allowable deviation, and is less than 2 mm in thickness and not greater than 0.5% in long side allowable deviation.

Owner:山东雅达节能建材科技有限公司

PCB on-line testing system and realization thereof

InactiveCN1746692AReduce design costReduce manufacturing costSemiconductor/solid-state device testing/measurementElectronic circuit testingDesign softwareIn-circuit test

A system for carrying out ICT test on PCB applies switching PCB (printed circuit board) as connection unit to connect probe of tested PCB to ICT test device and switching PCB is designed and prepared by PCB design software. It features that switching PCB is used to replace traditional wire connection clamp for avoiding wire loose and wire broken problem existed on wire connection clamp.

Owner:HUAWEI TECH CO LTD

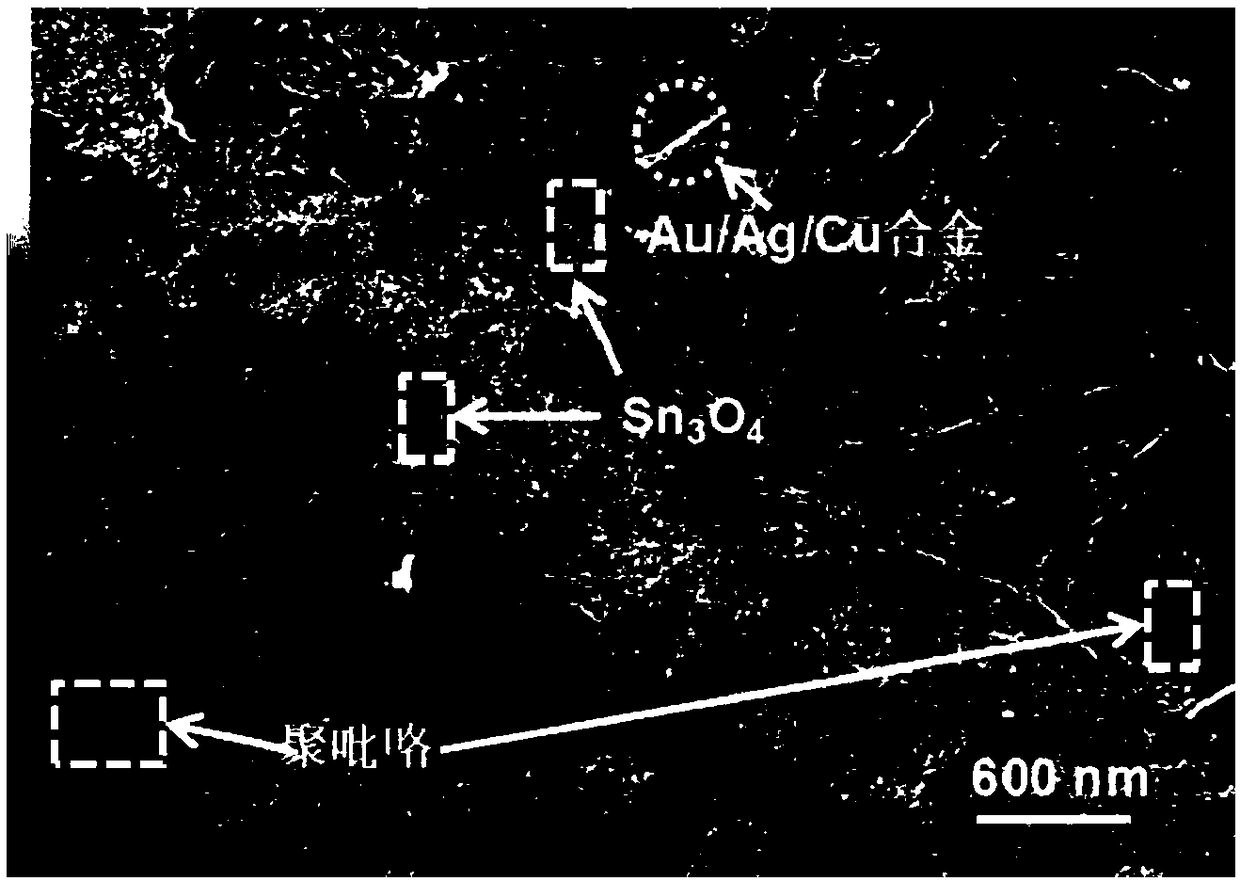

Preparation method of polypyrrole/metal-modified Sn3O4 nano composite photocatalytic material

InactiveCN109107614AEnhanced Broad Spectrum Light AbsorptionImprove photocatalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHeterojunctionPhotocatalytic reaction

The invention discloses a preparation method of a polypyrrole / metal-modified Sn3O4 nano composite photocatalytic material. The nano composite material is a composite photocatalyst material obtained byloading and dispersing metal-modified Sn3O4 semiconductor heterojunction on polypyrrole in a chemical bond complexing form; and the metal-modified Sn3O4 is obtained by separately loading metal nano particles of a single-component metal or multi-component alloy of Pt, Au, Ag, Cu and the like having a plasma resonant effect onto Sn3O4. The photo-induced electron-hole separation rate in the photocatalytic reaction can be sufficiently improved by utilizing the visible light photocatalytic oxidation and reduction characteristics of Sn3O4, the plasma resonant effect of metal nano particles, photo conduction and conductivity of polypyrrole as well as the chemical bond heterojunction structure among different components, so that the performance for degrading pollutants in a photocatalytic oxidation and reduction manner and generating hydrogen by photocatalytic and decomposition of water can be improved. The easy-to-mold characteristic of polypyrrole can effectively avoid the recycling difficulty of the powder material.

Owner:PINGDINGSHAN UNIVERSITY

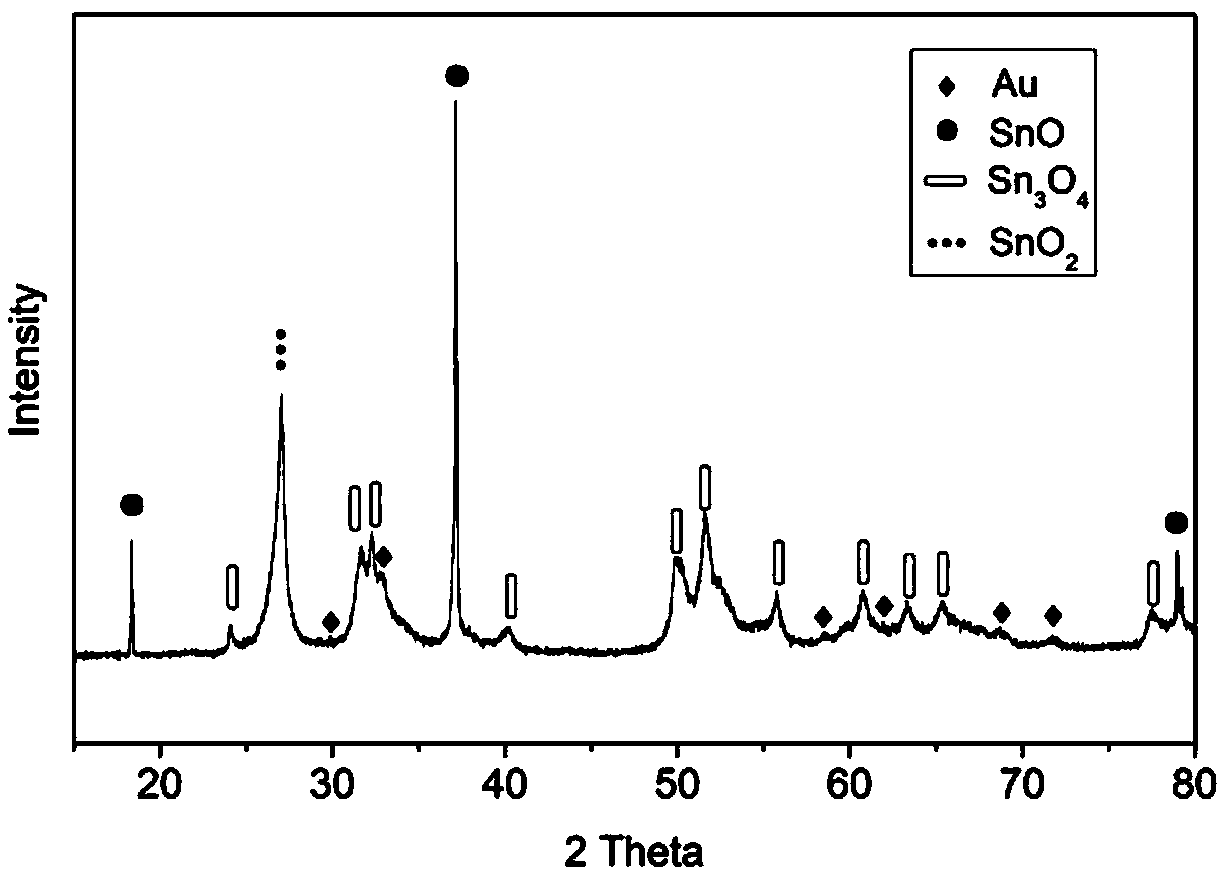

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

Processing method for large-caliber buried glass reinforced plastic sand inclusion pipe

The invention discloses a processing method for a large-caliber buried glass reinforced plastic sand inclusion pipe, and belongs to the technical field of composite pipes. The processing method includes the steps that modified steel fibers, modified carbon fibers and modified glass fibers are woven into a fiber mat, the fiber mat is subjected to plastic soaking treatment, and a fiber mat layer A is obtained; modified glass fibers and modified carbon fibers are woven into a fiber mat, the fiber mat is subjected to plastic soaking treatment, and a fiber mat layer B is obtained; then the fiber mat layer A is processed into a lining layer on a sand inclusion pipe mold, and the fiber mat layer B is processed into an inner protection layer on the lining layer; quartz sand, chopped glass fibers, magnesium borate whiskers and unsaturated polyester resin are mixed into sand strips, the sand strips are processed into a sand inclusion layer on the inner protection layer, then the fiber mat layer B is processed into an outer protection layer on the sand inclusion layer, then unsaturated polyester resin, and chopped glass fibers and magnesium borate whiskers are mixed on the outer protection layer to be processed into an outer surface layer till the designed wall thickness is completed; finally, finishing, demolding, cleaning and testing are carried out after solidifying, and the finished product can be obtained.

Owner:民勤县威瑞环保有限责任公司

Construction technology for preparing kiln lining by compounding ceramics and unshaped refractory materials

The invention relates to a construction technology for preparing a kiln lining by compounding ceramics and unshaped refractory materials and belongs to a construction technology. The construction technology mainly solves the problem of short service life of an existing unshaped refractory material of a kiln lining. The technical scheme includes that a ceramic composite is arranged on a mold plate or a ceramic composite inserting piece is inserted into the unset unshaped refractory materials during construction, so that the unshaped refractory materials is mechanically connected with the ceramics. The advantages of the ceramics and the unshaped refractory materials are combined, and the shortcomings of the ceramics and the unshaped refractory materials are overcome, so that service life of the kiln lining is prolonged.

Owner:江西中烨高新技术有限公司

Titanium gypsum waste residue plastering mortar and preparation method thereof

The invention discloses titanium gypsum waste residue plastering mortar which comprises the following raw materials in parts by weight: 20-40 parts of titanium gypsum, 15-50 parts of coal ash, 15-40 parts of an alkali additive, 0-0.4 part of a modifier and 0.1-5 parts of a water reduction agent. A preparation method of the titanium gypsum waste residue plastering mortar comprises the following steps: firstly, uniformly blending and stirring dried, crushed, grinded and screened titanium gypsum powder and coal ash powder according to a certain ratio, controlling a water-binder ratio, further adding alkali additive powder and the modifier, and performing uniform blending and stirring, so as to finally obtain the titanium gypsum waste residue plastering mortar. The titanium gypsum waste residue plastering mortar disclosed by the invention has good mechanical properties and good adhesiveness, and common faults such as wall hollowing, cracking and dropping can be eliminated; in addition, theworking intensity of operators can be alleviated, the working environment can be improved, and pollution caused by lime paste preparation on a construction site can be avoided; and the mortar has thecharacteristics of being low in production and processing cost, simple in process operation, and the like, and can be widely applied to the field of building materials, and a novel way is provided for reasonable utilization and recycling of titanium gypsum waste residues.

Owner:广西藤县广峰钛白有限公司

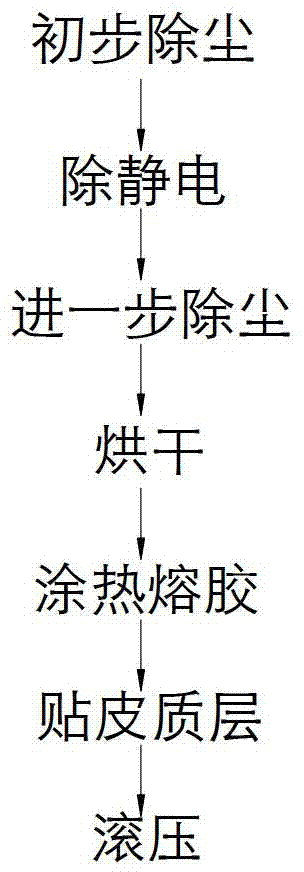

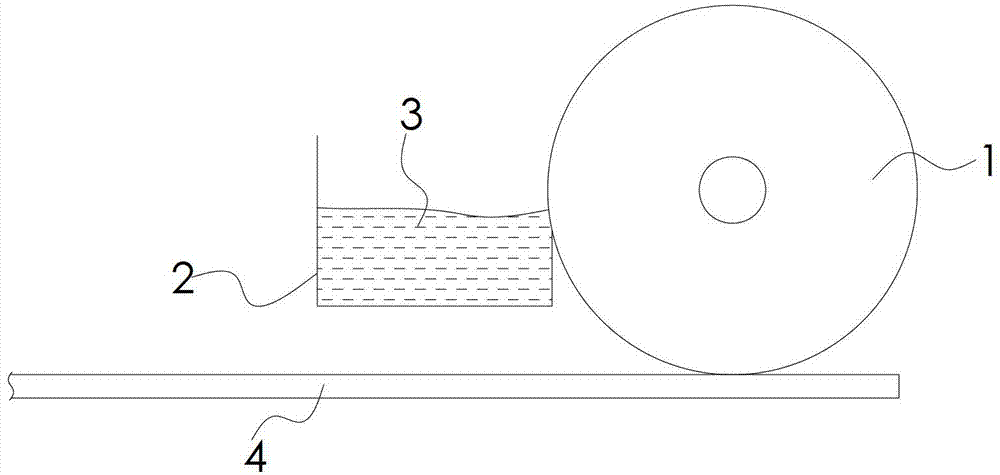

Manufacture method of soft clad door

ActiveCN103395273AImprove bindingOvercome sheddingLaminationLamination apparatusMedium density fiberboardEngineering

The invention discloses a manufacture method of a soft clad door. The manufacture method comprises the following steps: A, carrying out primary dedusting treatment on the surface of a medium density fiberboard; B, removing the static electricity on the medium density fiberboard; C, placing the medium density fiberboard into a dedusting chamber so as to carry out further dedusting treatment; D, feeding the medium density fiberboard after further dedusting into a dryer, wherein the temperature of the internal environment of the dryer is 30-50 DEG C, and the drying time is 30-50 seconds; E, coating a hot melt adhesive on the surface of the dried medium density fiberboard, and scraping the hot melt adhesive on the surface of the medium density fiberboard flatly by utilizing a scraper; F, fitting a cortical layer onto the surface of the medium density fiberboard coated by the hot melt adhesive, and gluing the cortical layer and the hot melt adhesive; and G, rolling the surface of the medium density fiberboard fitted with the cortical layer by utilizing a roll shaft, and fully fitting the cortical layer and the medium density fiberboard to manufacture the soft clad door. The method disclosed by the invention is capable of effectively overcoming a phenomenon that the cortical layer falls off, and no hardwares such as rivets are required to fix the cortical layer and the medium density fiberboard.

Owner:SUOFEIYA HOME COLLECTION

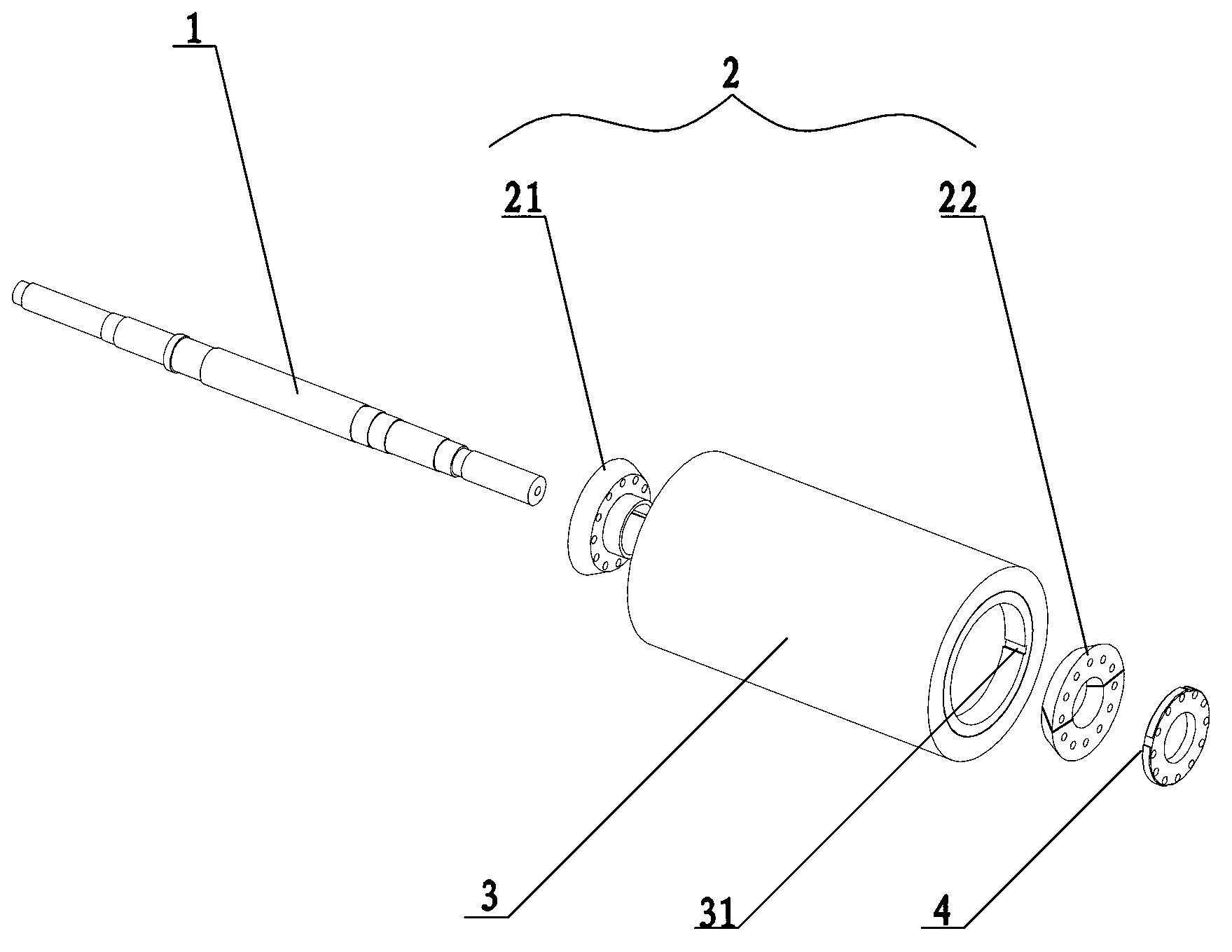

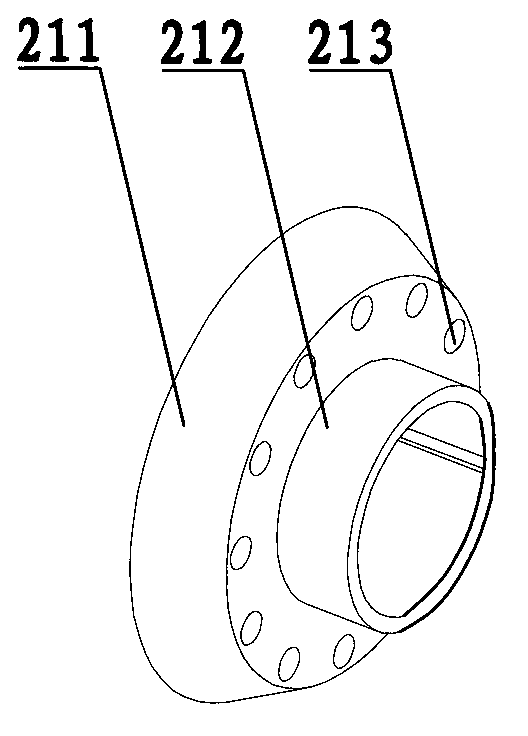

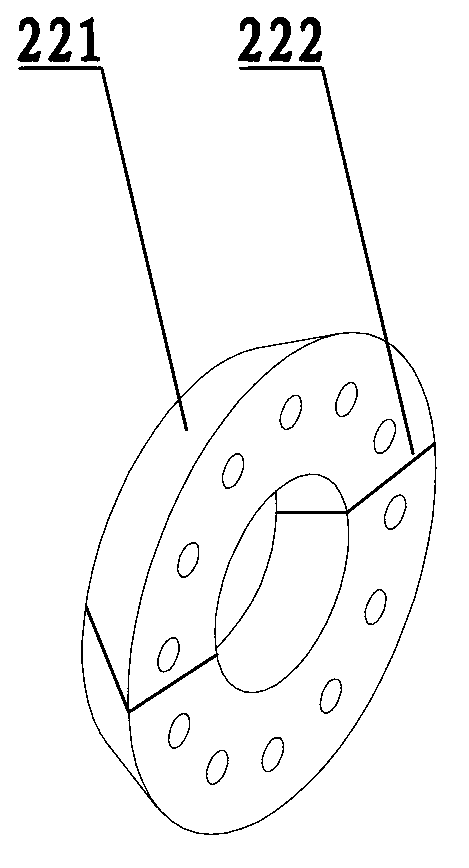

Rubber roller device of grain huller

InactiveCN103230815AAvoid rubber roller falling offEasy to disassembleGrain huskingGrain polishingEngineering

The invention relates to a rubber roller device of a grain huller and belongs to the technical field of grain processing auxiliary devices. The rubber roller device of the grain huller comprises a rubber roller and a main shaft, both ends of the rubber roller are arranged on the main shaft through nuts, the rubber roller is mounted on the machine base of the grain huller through the main shaft, a pair of jam nuts are arranged between the end portion of the rubber roller and the nuts, the inside of the rubber roller is provided with a groove, the jam nuts and the rubber roller are mounted in a matching mode, and the jam nuts fix the rubber roller onto the main shaft along with the nuts. The rubber roller device can be applied to an existing grain huller, can prevent the rubber roller from dropping, is easy to use, and has higher working efficiency during grain processing.

Owner:ZHEJIANG ZHANCHENG MACHINERY

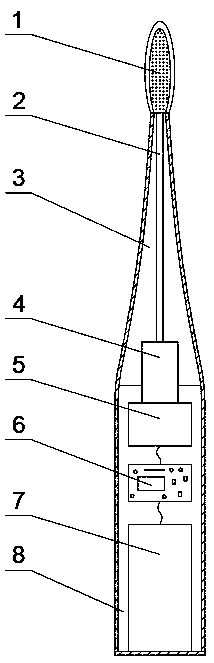

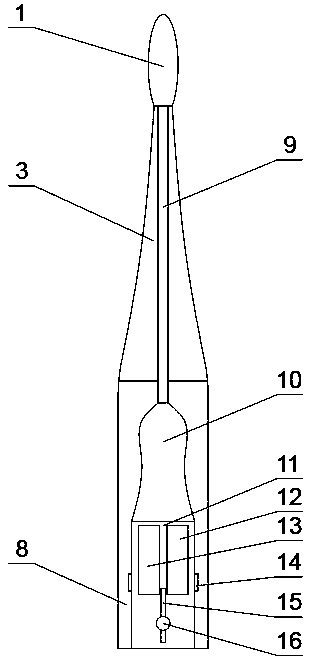

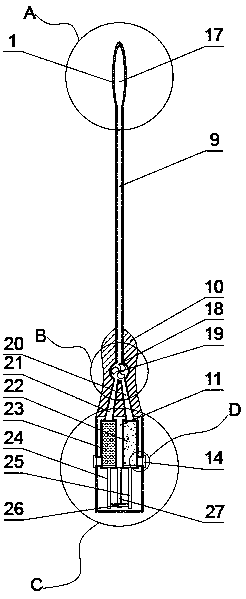

Electric toothbrush containing toothpaste

InactiveCN108926403AOvercome the vibration of the brush head easilyOvercome sheddingTooth cleaningToothpasteEngineering

The invention discloses an electric toothbrush containing toothpaste. According to the electric toothbrush containing toothpaste, a front end flow distribution chamber is arranged in a brush head; thefront end flow distribution chamber is communicated with a plurality of through holes; a guide pipe is fixedly arranged on a brush rod; one end of the guide pipe is communicated with the front end flow distribution chamber; a holding part and a storage box are fixedly arranged on a brush handle; an annular mixing chamber is arranged in the holding part; the annular mixing chamber is communicatedwith the other end of the guide pipe; the annular mixing chamber is communicated with a first output pipe and a second output pipe; the center of the annular mixing chamber is provided with a mixing paddle; a first storage tank and a second storage tank are fixedly arranged in the storage box; the two storage tanks are communicated with the annular mixing chamber; a piston type pushing mechanism used for pushing contents in the first storage tank and the second storage tank toward the annular mixing chamber is adopted. In applications of the electric toothbrush, toothpaste turbid solution is injected into the gaps among brush hair, the toothpaste turbid solution is sprayed onto tooth surfaces under action of brush hair vibration, so that a problem in the prior art that shedding of toothpaste is easily caused because of brush head vibration is solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

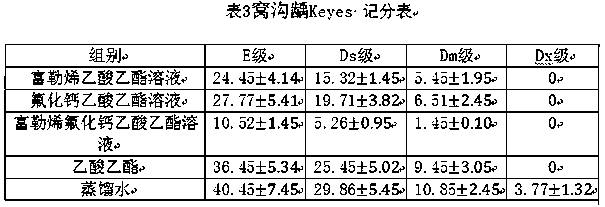

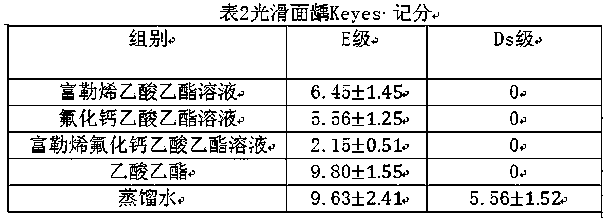

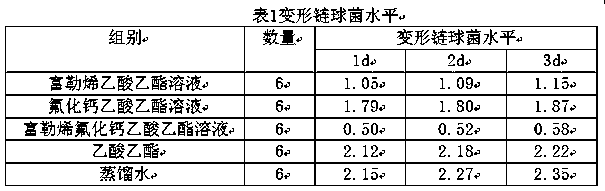

Composition used for tooth protection

ActiveCN109966315ALong-term protectionOvercome sheddingAntibacterial agentsDigestive systemMedicineFissure sealing

The present invention provides a composition used for tooth protection. The composition can be combined with a pit and fissure sealing technology to effectively prevent and treat caries. After the pitand fissure sealing technology is implemented, the tooth protection agent is coated on tooth surfaces to form a fullerene calcium fluoride protection layer. The composition can overcome a problem offalling off of a sealing agent on the one hand and can more effectively protect teeth for a long time on the other hand.

Owner:赵云峰

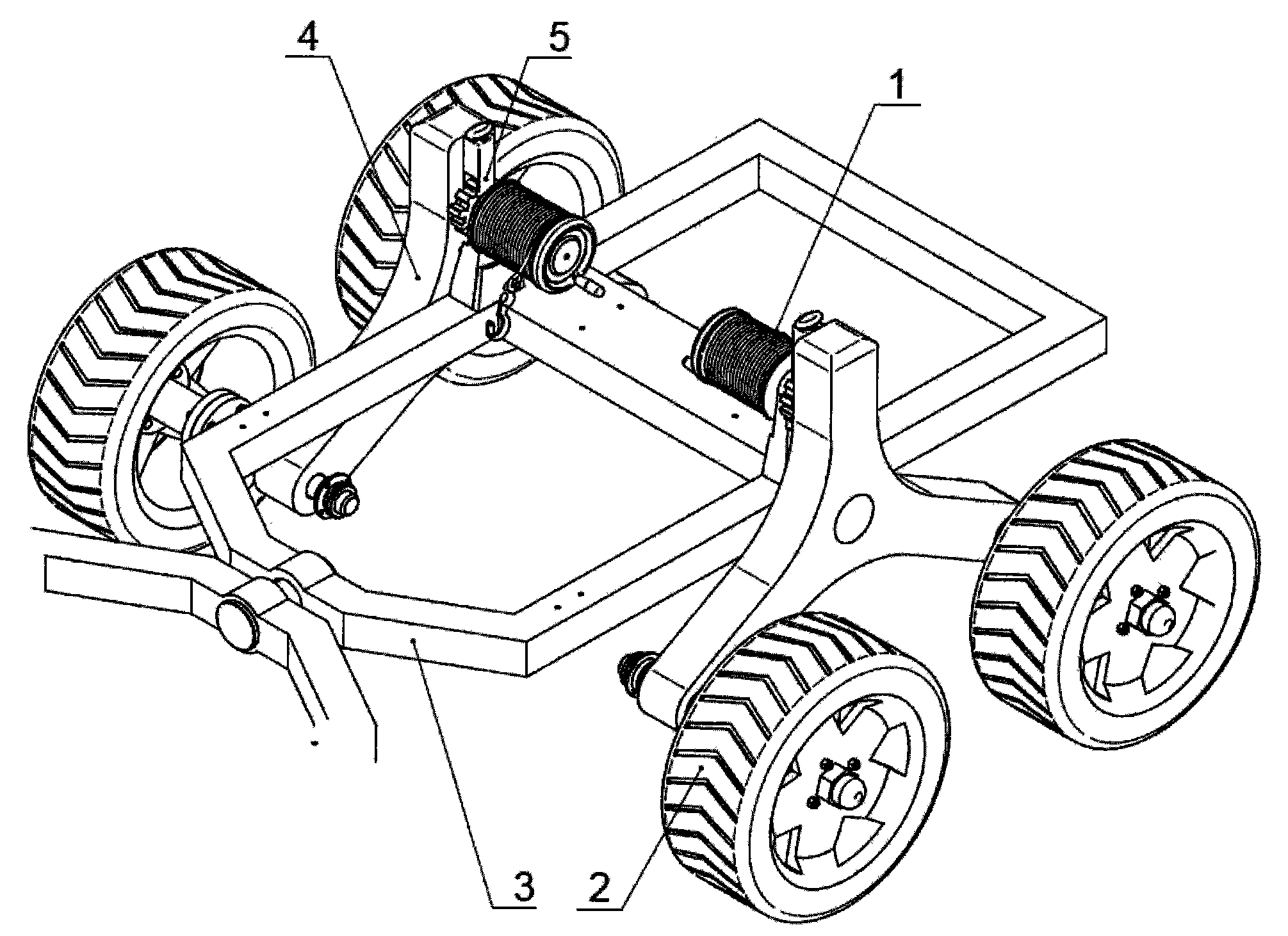

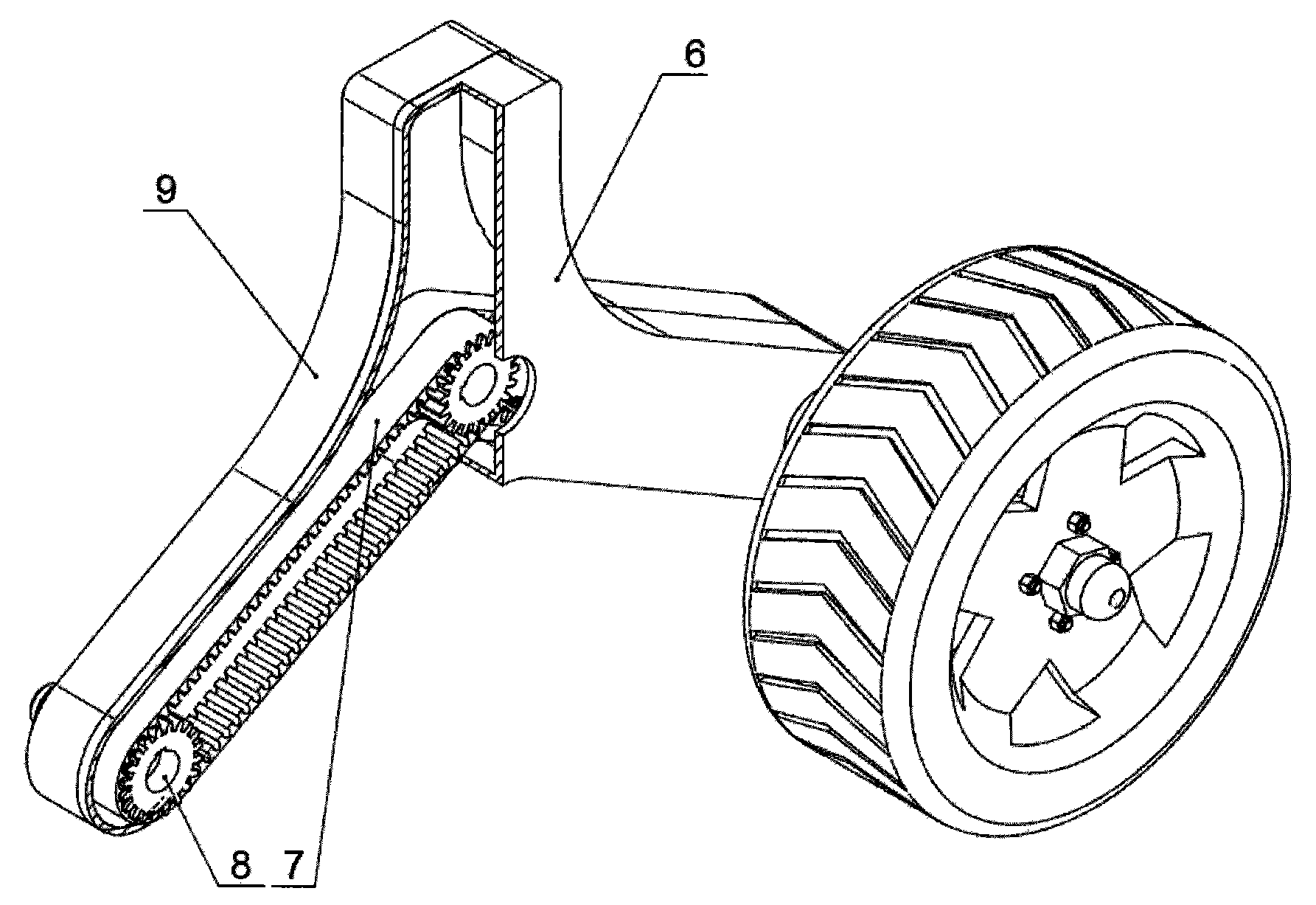

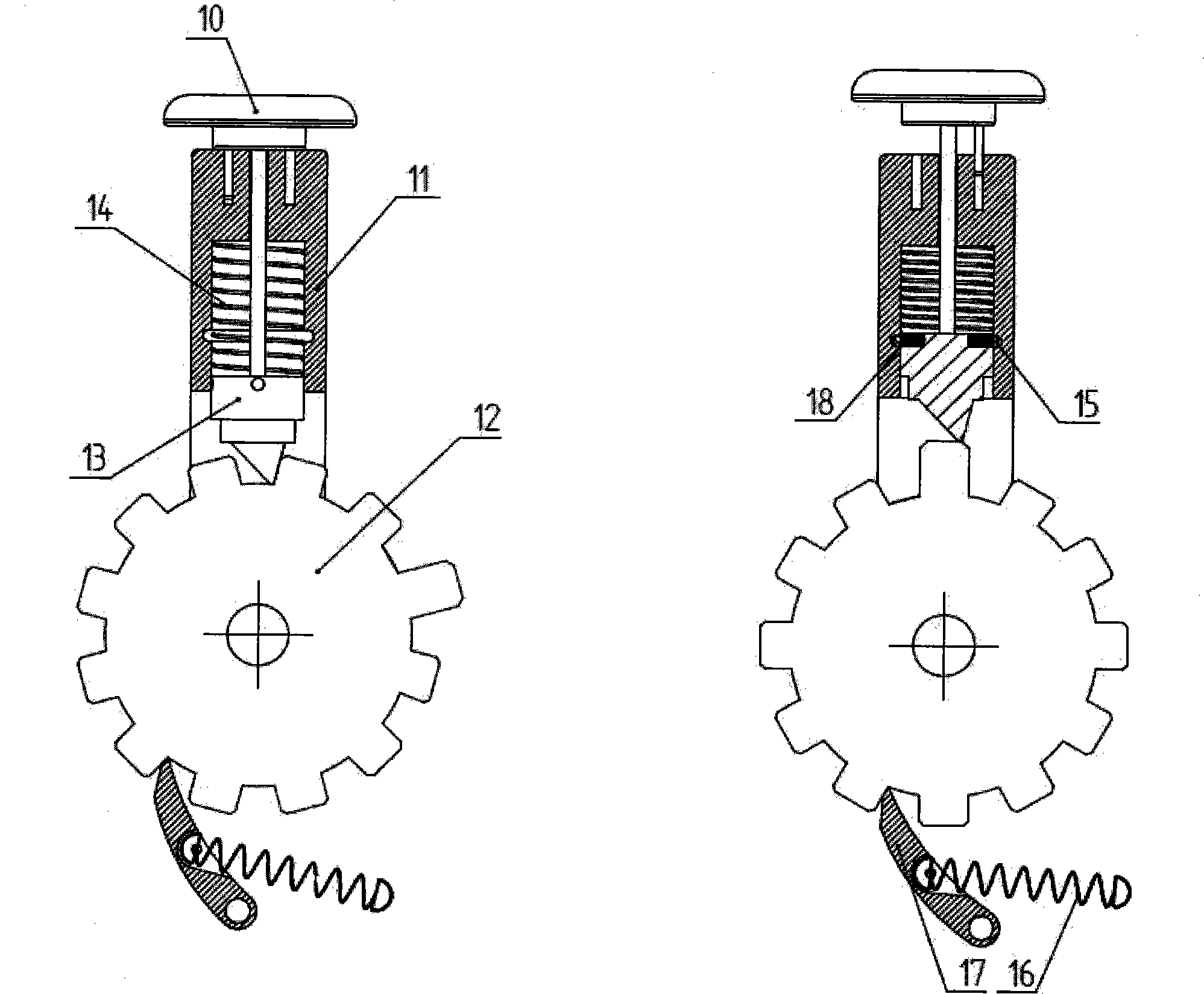

Self pretightening buffering herringbone forest wheel disc

ActiveCN104175805AImprove mobility off-road performanceSimple configurationPivoted suspension armsWheel-axle combinationsMotor driveEngineering

The invention relates to a self pretightening buffering herringbone forest wheel disc and belongs to the technical field of forest vehicle chassis. The forest wheel disc comprises wheels and a base disc. Each wheel comprises a herringbone wheel bone and a self pretightening buffering device. The herringbone wheel bones are installed on two sides of the middle of the base disc, two arms at the bottom are wheel arms, the wheels are installed on the end portions of the wheel arms, a top single arm is a traction arm, and the self pretightening buffering devices are installed on the traction arm. A wheel bone outer casing and a wheel bone inner casing are installed in a matching mode to form an enclosed casing. Direct gears are installed on the end portions of the inner sides of the wheel arms of the two casings, direct gears are coaxially installed in the middle of the inner sides of the two casings, and the gears are in meshing transmission through a tooth-shaped meshing belt. The self pretightening buffering device achieves a self pretightening buffering function, achieves wheel arm high-amplitude swinging and restrains the borne materials in the vehicle cross-country running process. The wheel disc can improve the motor-driven country crossing performance of forest vehicles, simplify the vehicle whole structure and improve the vehicle carrying performance.

Owner:BEIJING FORESTRY UNIVERSITY

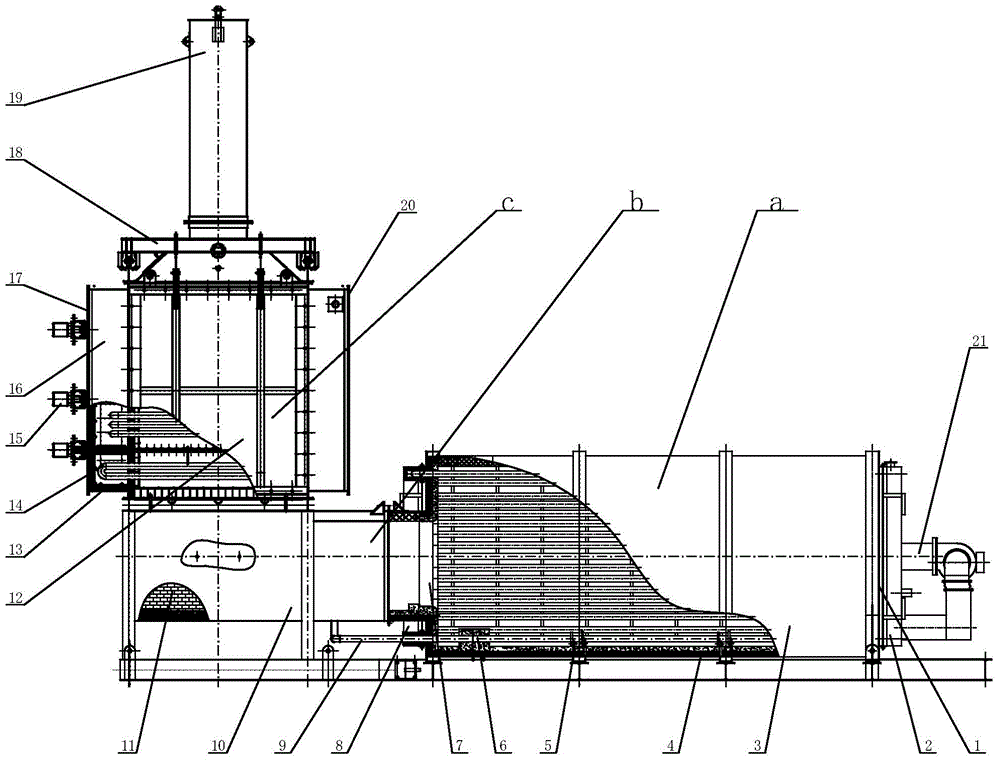

Heating medium furnace for long-distance-delivery crude oil pipeline

ActiveCN104633932AImprove atomization effectAvoid phenomena such as bias currentStorage heatersDirect heatingSoot

The invention discloses a heating medium furnace for a long-distance-delivery crude oil pipeline for crude oil delivery. The heating medium furnace for the long-distance-delivery crude oil pipeline mainly comprises a radiation chamber, a burner, a transition section, a convection chamber, a convection chamber soot blowing system and a chimney, wherein multiple horizontal radiation furnace tubes are erected in the radiation chamber, and the two ends of the radiation furnace tubes are communicated through elbows, so that it is guaranteed that a one-way passage is formed for each radiation furnace tube; multiple horizontal convection furnace tubes are erected in the convection chamber, the two ends of the convection furnace tubes are communicated through elbows, so that it is guaranteed that a one-way passage is formed for each convection furnace tube; the convection furnace tubes and the radiation furnace tubes are communicated through oil transferring lines. By the adoption of the heating medium furnace for the long-distance-delivery crude oil pipeline, various problems of a direct heating type heating furnace are solved, the safety performance and the operating heat efficiency are improved, and operating cost is reduced; due to the fact that finned tubes and a single-tube-pass structure are adopted, the size of equipment is reduced, and the phenomenon that a medium flows in a deflected direction is avoided; the medium atomizing burner is adopted, the fuel atomizing effect is improved, the combustion performance is improved, dust emission is reduced, and operating heat efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

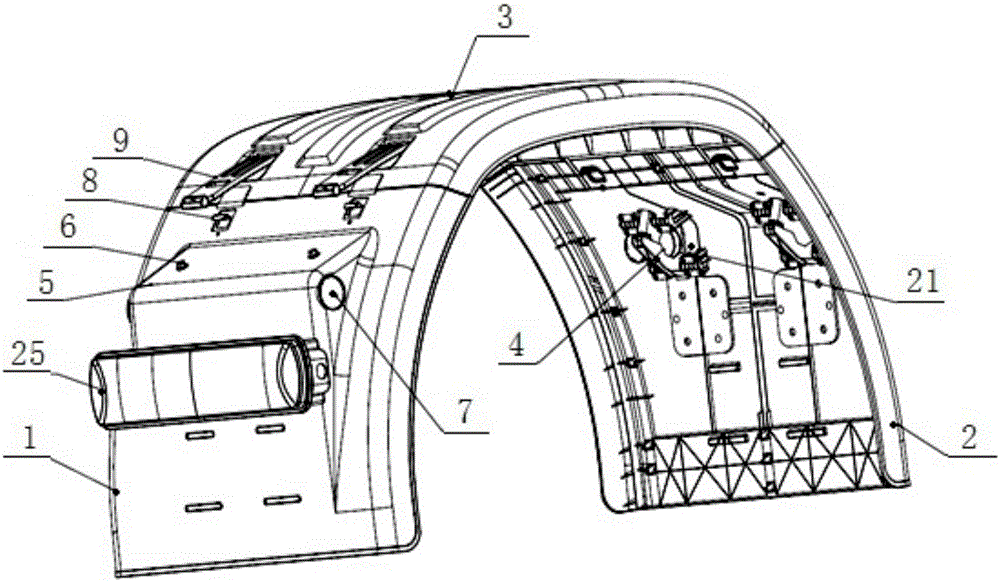

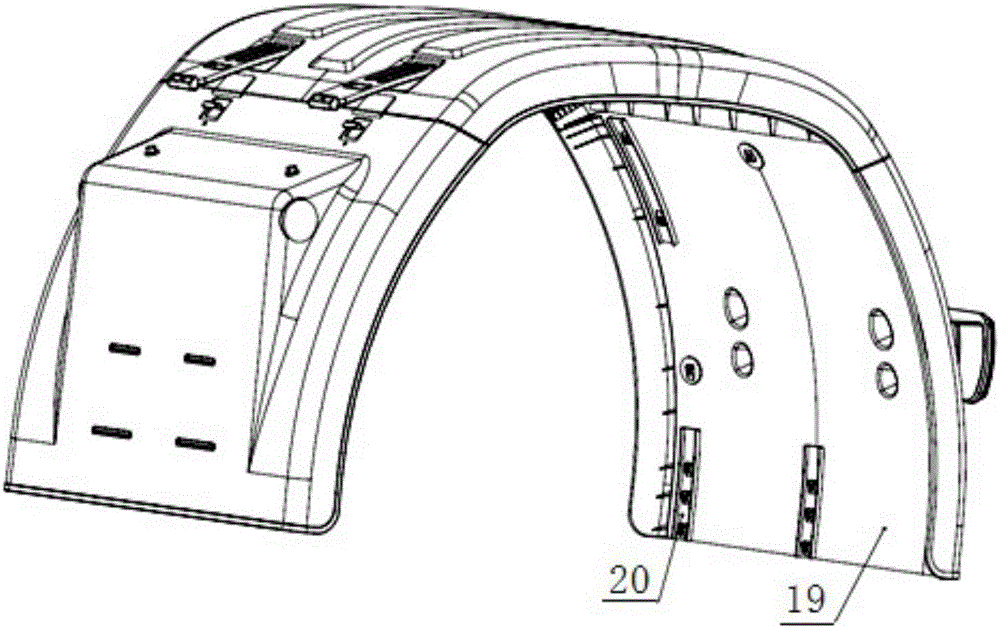

Light-weight overall mud guard assembly

ActiveCN105774914ASolve the flash seamSolve misalignmentSuperstructure subunitsLocking mechanismEngineering

The invention discloses a light-weight overall mud guard assembly which comprises a front mud guard, a rear mud guard, a top cover and a locking mechanism assembly, wherein bulges are arranged in the middles of the front mud guard and the rear mud guard; bolt adjusting holes are formed in upper platforms of the bulges; transverse through holes are formed in outer sides of the bulges; pressing plates are arranged on the front mud guard and the rear mud guard; the top cover is fixed together with the front mud guard and the rear mud guard through pull belts and the pressing plates; the locking mechanism assembly comprises a bottom plate, a fixed side, a movable side and fixing hinge pins; the bottom plate, the front mud guard and the rear mud guard are integrally formed in an injection molding manner; the fixed side is welded with the bottom plate; the movable side is connected with the fixed side; fastening bolts penetrate through the bolt adjusting holes, the bottom plate and long holes in the fixed side and are connected with screw nuts; a double-arched toothed round hole is formed in the middle of the fixed side; a mud guard bracket penetrates through the transverse through holes and is arranged inside the double-arched toothed round hole. Problems that a mud guard is cracked, rotated, disassembled and loosened to cause pivoting can be overcome, an assembling process is simplified, and the light-weight overall mud guard assembly has the advantages of simple structure, light weight and high reliability.

Owner:SINO TRUK JINAN POWER

Silicon-based/graphene nanobelt composite material with high capacity and high cycle efficiency and preparation method thereof

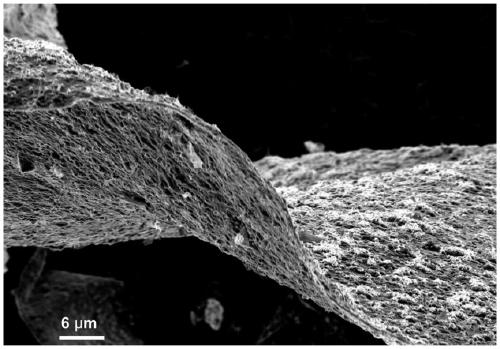

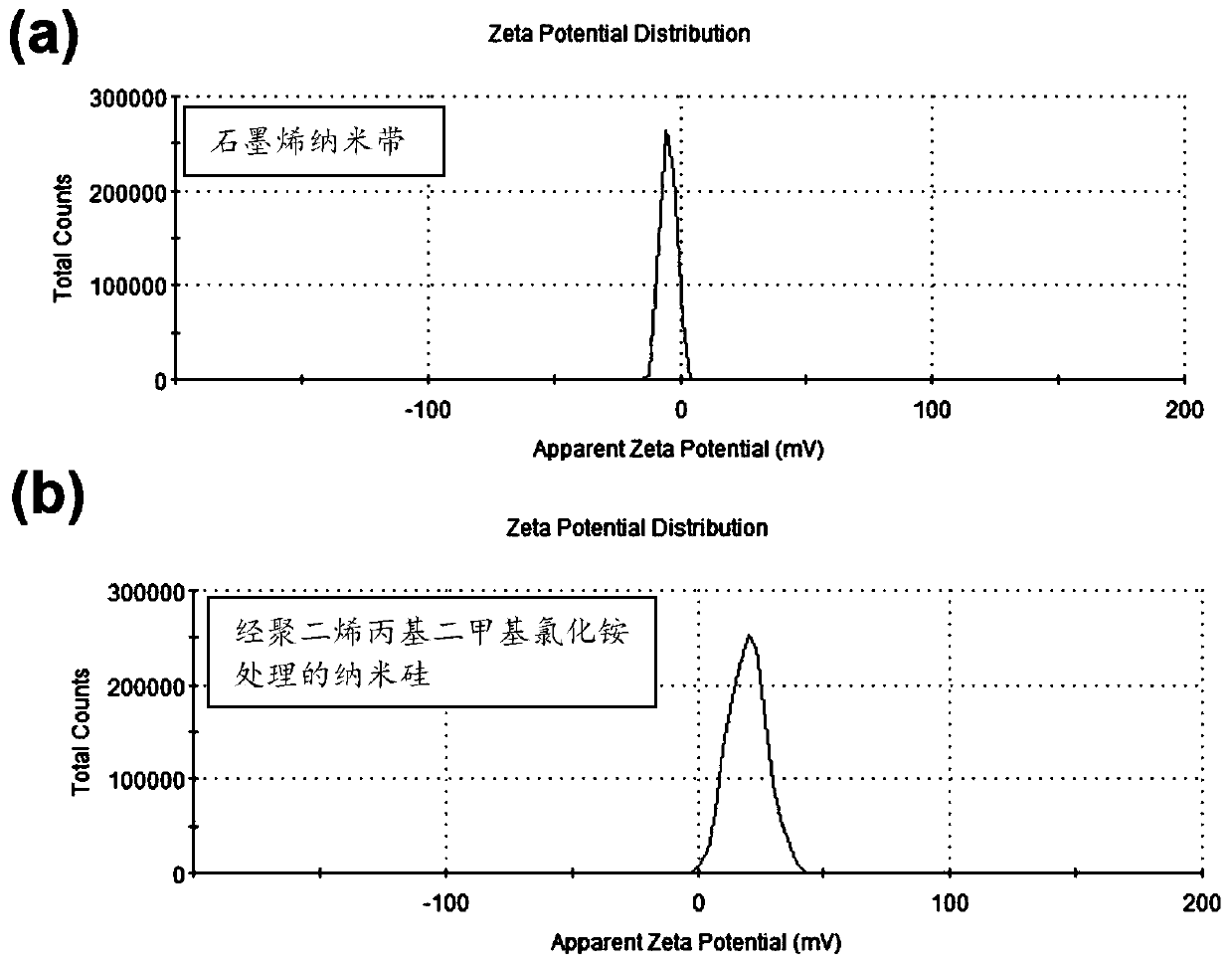

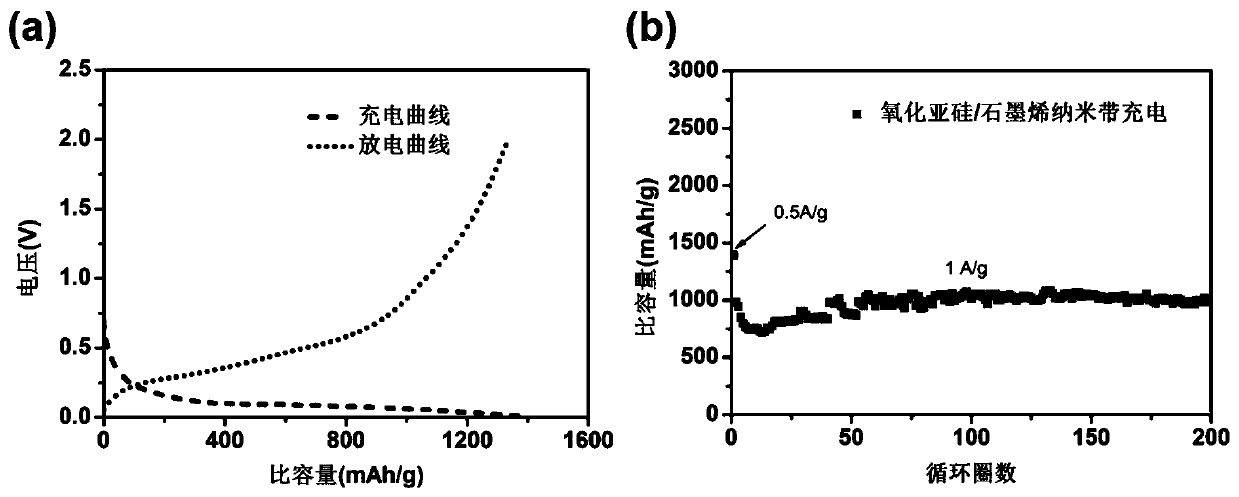

ActiveCN111533115ADoes not involve the use ofReduce processMaterial nanotechnologySiliconGraphene nanoribbonsGraphite

The invention discloses a silicon-based / graphene nanobelt composite material with high capacity and high cycle efficiency and a preparation method thereof, and belongs to the technical field of chemical power supplies. The composite material comprises the following components in percentage by mass: 10-98% of a silicon-based material, 1-89% of graphene nanoribbons and 1-10% of a lithium element, the preparation method comprises the following steps: treating a silicon-based material with a surfactant to enable the silicon-based material to be charged with positive static charges, then stirring and mixing the treated silicon-based material and graphene nanoribbons, collecting, drying, carrying out high-temperature treatment to obtain a composite material, then making the obtained composite material directly in mechanical contact with a lithium sheet, and adjusting external pressure and pressure time so that controllable pre-lithiation is realized. The preparation method has the characteristics of simple process and convenience in operation, and the silicon-based / graphene nanobelt composite material prepared by the preparation method is high in specific capacity, high in initial coulombic efficiency, long in cycle life and high in rate capability, and can be applied to a lithium ion battery with high specific energy.

Owner:重庆锦添翼新能源科技有限公司 +1

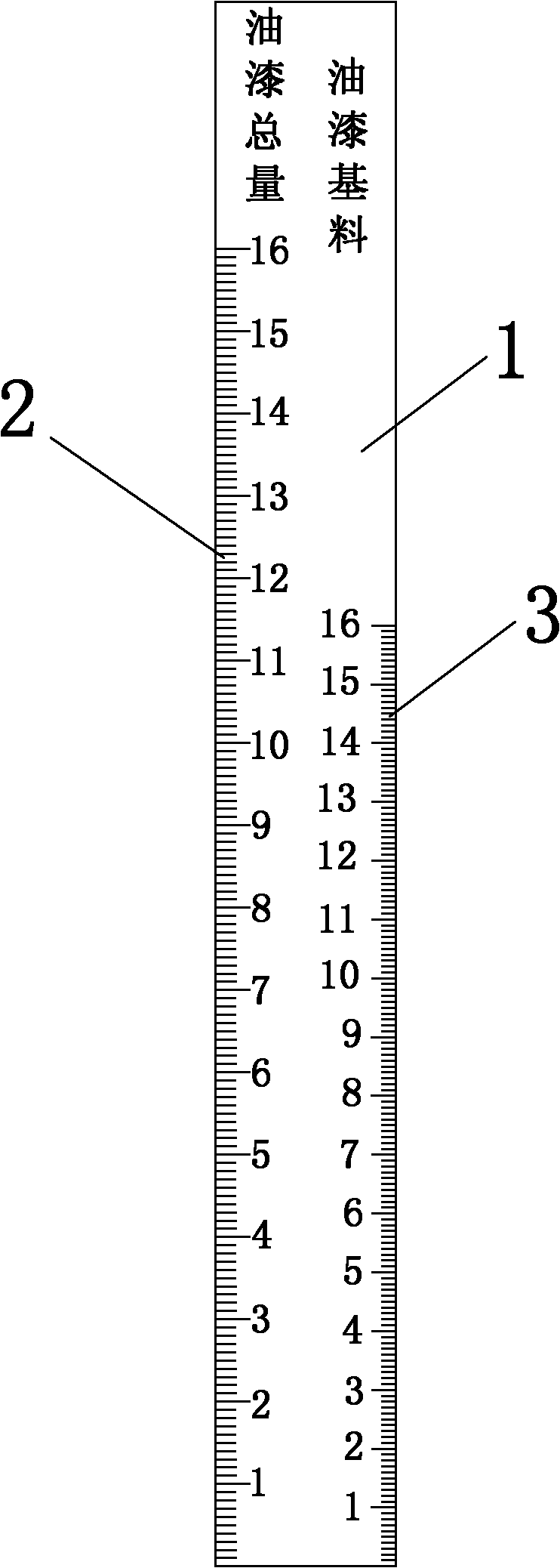

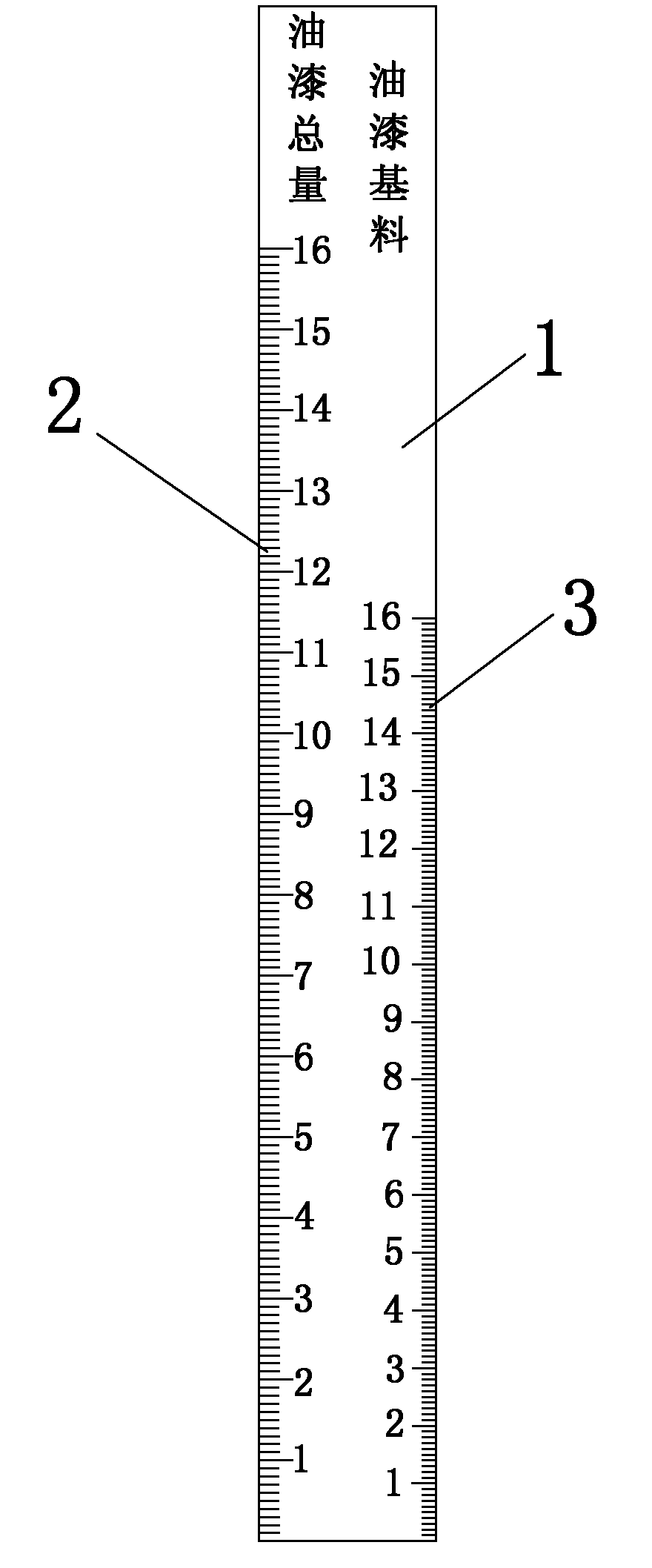

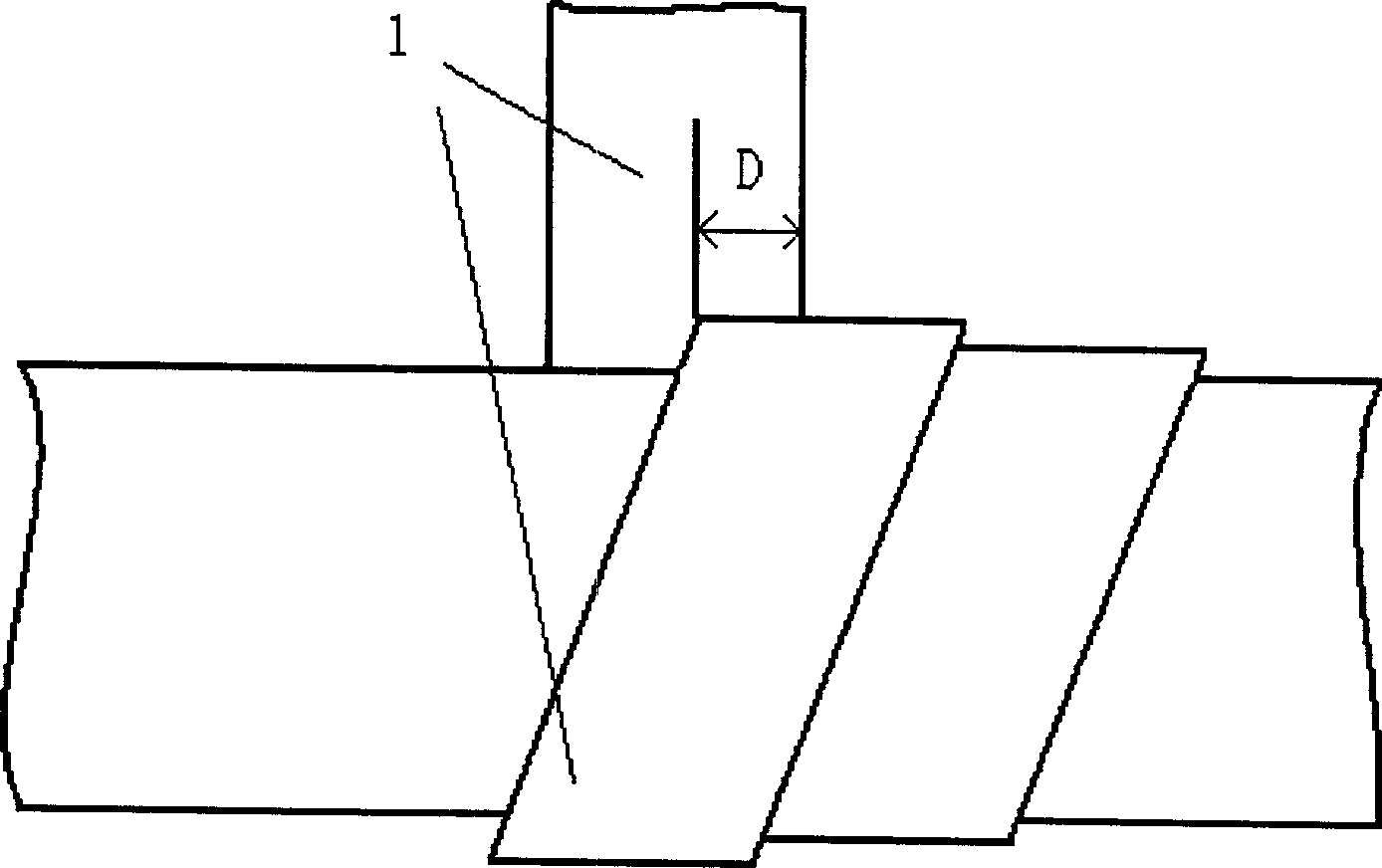

Oil paint coating method for external identifier of metro vehicle

ActiveCN102166563AOvercomes easy fadingOvercome agingCoatingsSpecial surfacesWeather resistanceRoom temperature

The invention discloses an oil paint coating method for an external identifier of a metro vehicle, which comprises the steps of blending oil paint and a curing agent according to a certain volume ratio; manufacturing a silk-screen template according to the content of the identifier, and fixing the silk-screen template at an external corresponding region of the vehicle; coating the blended oil paint on the silk-screen template, and performing the blade coating by a scratch board; and removing the silk-screen template, and drying the identifier under a room temperature. Due to the oil paint coating method, the external identifier of the metro vehicle is good in weather resistance, ultraviolet ray resistance, aging resistance and the like, so that the use durability of the external identifier of the metro vehicle can be guaranteed, the aging, the fading and the falling of the external identifier of the metro vehicle through wind blowing, raining and solarizing and the cleaning of vehiclecleaning liquid caused by lamination can be completely eradicated, the passenger safety can be guaranteed, and the metro vehicle can be conveniently overhauled. Meanwhile, due to the oil paint coating method of the external identifier of the metro vehicle, the quality of the metro vehicle is greatly improved.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Transfer printing process for automobile identification

InactiveCN108237799ALow costReduce lossOther printing apparatusPrinting after-treatmentCooking & bakingPrinting ink

The invention relates to the field of automobile transfer printing, in particular to a transfer printing process for automobile identification. The process comprises the following steps that 1), printing ink is proportioned, wherein the automobile identification printing ink is proportioned according to the proportion; 2), equipment is debugged, wherein transfer printing equipment is debugged; 3),a material is printed, wherein the printing ink coats the surface of an automobile part according to a shape selected in advance; 4), baking is carried out, wherein the automobile part subjected to printing ink coating is baked, and the printing ink is dried; and for the step 1 of proportioning the printing ink, the printing ink is 85-90%wt, a curing agent is 3-7%wt, a diluting agent is 1-5%wt, and a drawing agent is 1-3%wt. Compared with the prior art, the process has the advantages that the cost of raw materials is low, the loss of printing ink is low, the production efficiency is high, theprocess is optimized, meanwhile, the problem that the automobile identification subjected to transfer printing falls off is solved, and the problem that the printing ink falls off in the traditionalautomobile transfer printing process is solved.

Owner:SHANGHAI HUAGU VEHICLE IND CO LTD

Composite dry-type wall-pie

InactiveCN1815832AReduce internal stressImprove securityElectrical apparatusPipesEngineeringHigh pressure

Frame by frame backing method is adopted in the invention to wrap Teflon strap. In wrapping procedure, strain of Teflon strap is controlled. Reducing internal stress of wall bushing, the method overcomes issues that insulating wrapping layer for dry type wall bushing in high pressure is easy of sliding frame, and falling off. The invention increases safety and operating life of wall bushing.

Owner:SHANGHAI ZHUOGAO ELECTRIC

Furniture edge sealant

InactiveCN102101989AOvercome warpingOvercome sheddingMonocarboxylic acid ester polymer adhesivesCellulose adhesivesCellulosePolymer science

The invention belongs to the technical field of adhesives, and in particular relates to a furniture edge sealant. The furniture edge sealant comprises the following raw materials in percentage by weight: 30 to 60 percent of wood glue powder, 15 to 40 percent of white latex and 10 to 40 percent of marine glue, wherein the wood glue powder is lignocelluloses; the marine glue is polymer cement-base marine glue; and the white latex is polyvinyl acetate white latex. The furniture edge sealant has high bonding strength, ageing resistance, certain flexibility and service life of 30 years, and can overcome the defects of warping and falling off of furniture edge bands due to wet expansion and dry shrinkage.

Owner:李角

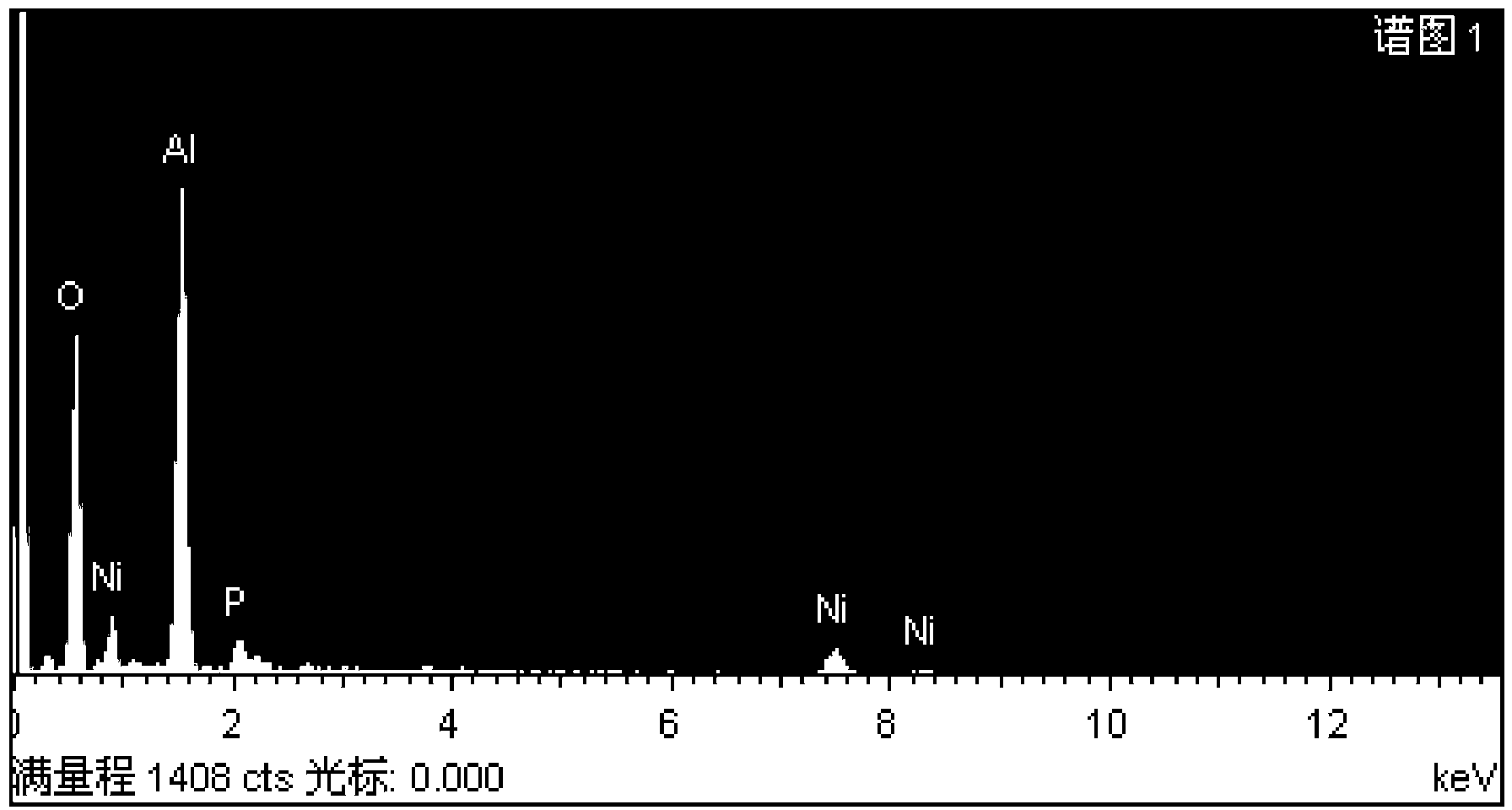

Method for preparing aluminum trioxide-nickel oxide ceramic coating on nickel electrode surface

InactiveCN103633302AImprove corrosion resistanceGood adhesionAnodisationAlkaline accumulator electrodesPorosityMicro arc oxidation

The invention discloses a method for preparing an aluminum trioxide-nickel oxide ceramic coating on a nickel electrode surface. A preformed coating (chemical conversion coating) is produced on a metal nickel surface by a rare-earth conversion process, and the nickel electrode subjected to rare-earth conversion treatment is arranged in a sodium-aluminate-containing electrolyte. The micelle formed by hydrolyzing the sodium aluminate can be adsorbed to the surface of the chemical conversion coating to form a complete barrier layer. The method disclosed by the method prepares the aluminum trioxide-nickel oxide ceramic coating on the nickel electrode surface of a nickel-hydrogen battery by a microarc oxidation technique, thereby effectively relieving the problem of corrosion of the nickel electrode in the electrolyte. The coating with the surface features of coarseness and porosity enhances the adhesive power of active substances, and relieves the problem of lower capacity of the nickel-hydrogen battery caused by shedding of the active substances of the nickel electrode. The method has the advantages of simple and reliable technique and no environmental pollution, and has wide application prospects.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

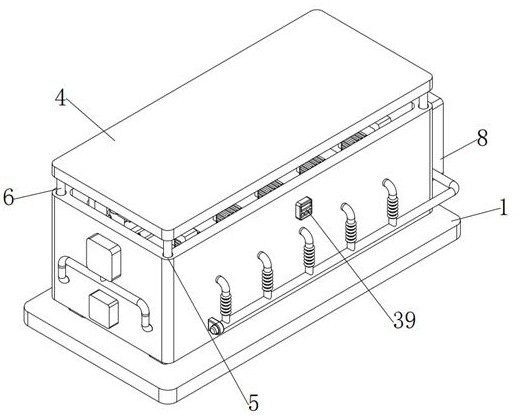

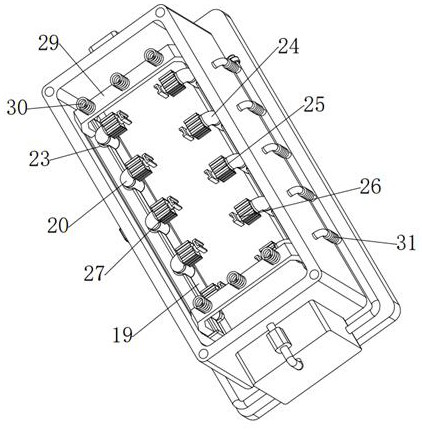

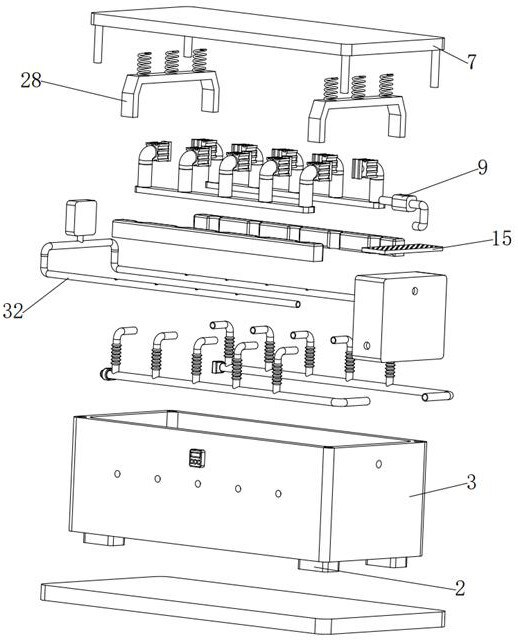

Double-bubble resistance reduction type anti-loosening springback type cleaning device based on electrical automation

ActiveCN114535206ARapid deoiling treatmentOvercome sheddingWatercraft hull designCleaning using liquidsStructural engineeringCleansing Agents

The invention discloses an electrical automation-based double-bubble resistance-reducing anti-loosening springback type cleaning device, which comprises a bottom plate, a plurality of groups of cushion blocks, a cleaning box, a sealing mechanism, an environment-friendly refined impact type cyclic adsorption utilization mechanism and a supercavitation resistance-reducing intermittent anti-falling springback mechanism, the cushion blocks are arranged on the upper wall of the bottom plate, the cleaning box is arranged on the upper walls of the cushion blocks, and the sealing mechanism is arranged on the cleaning box. The cleaning box is a cavity with an opening in the upper end, the sealing mechanism is arranged on the upper wall of the cleaning box, and the supercavity resistance reduction type intermittent anti-falling rebound mechanism is arranged in the cleaning box. The invention belongs to the technical field of electrical automation, and particularly relates to a double-bubble resistance reduction type anti-loosening springback type cleaning device based on electrical automation. According to the double-bubble resistance reduction type anti-loosening springback type cleaning device based on electrical automation, stubborn oil contamination treatment on the surfaces of parts is completed through the double-bubble acting force, and a cleaning agent can be recycled after oil absorption.

Owner:祁大鹏

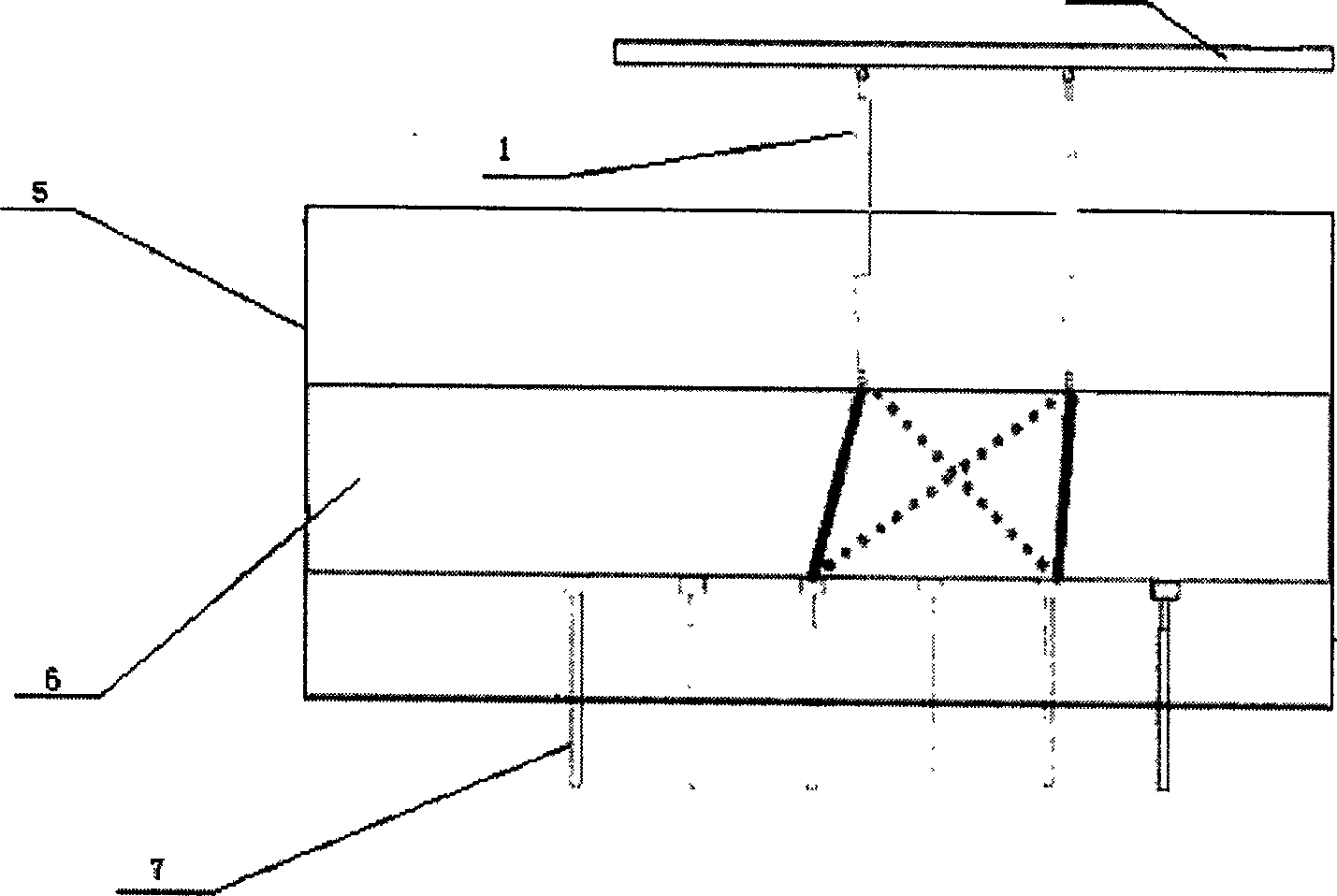

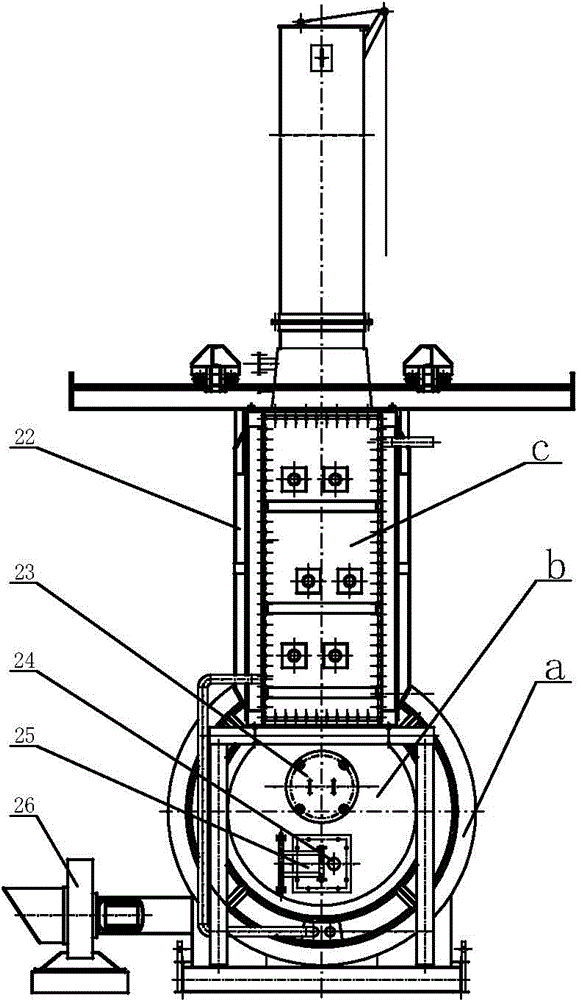

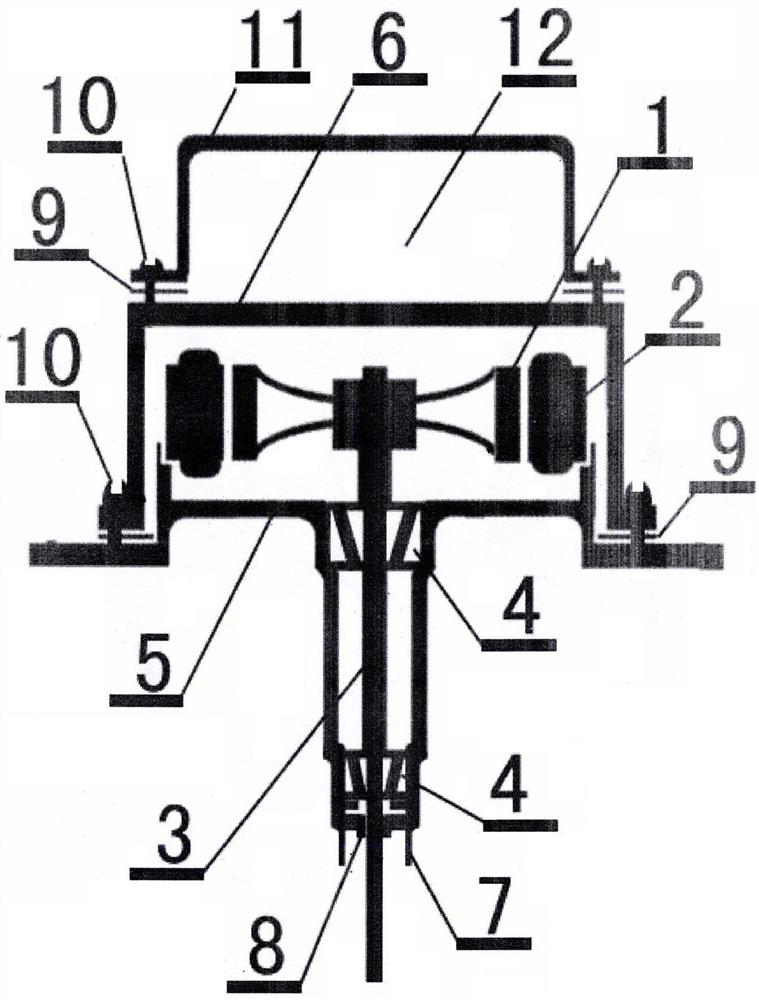

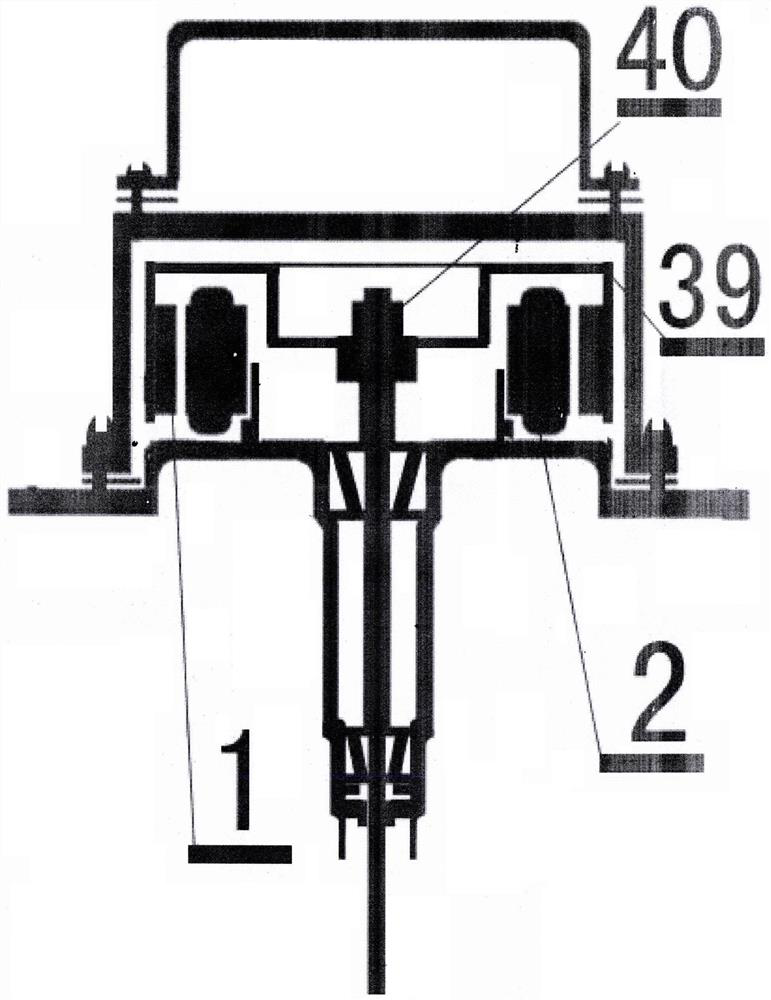

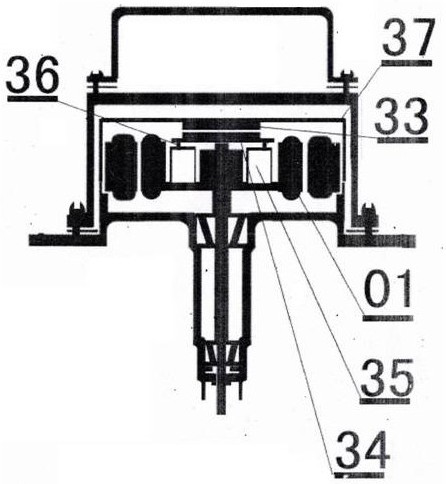

Specialized wind power and water power amphibious generator

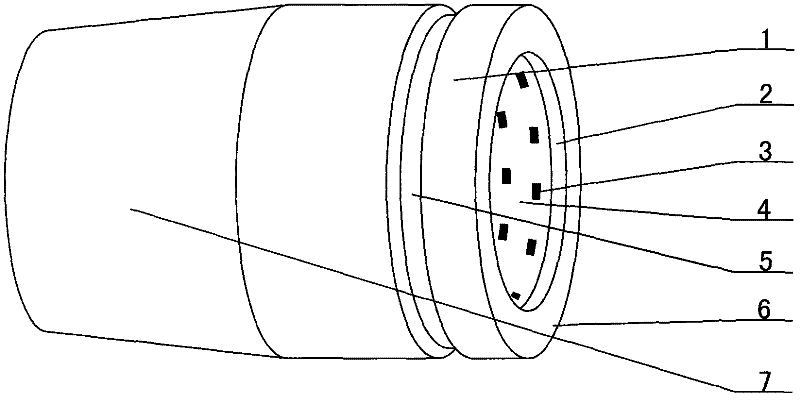

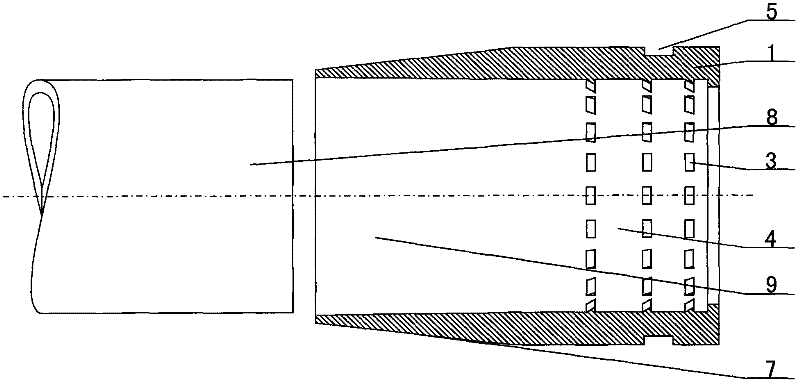

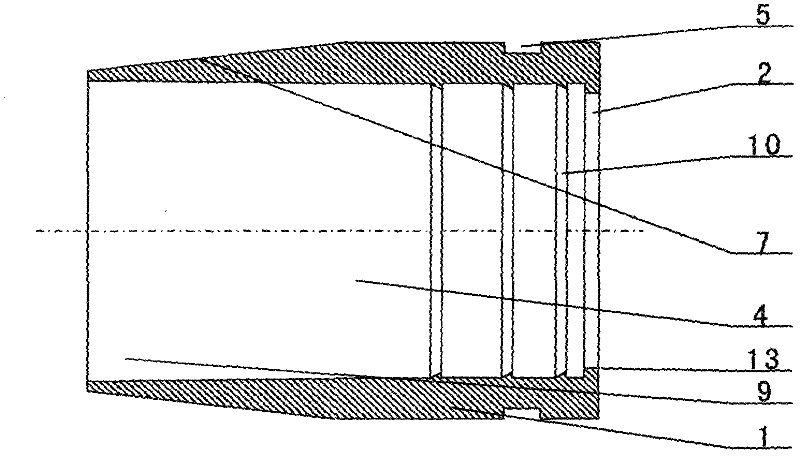

PendingCN111637013AExtended service lifeIncreased resistance to collisions and beatingsFinal product manufactureElectric circuit arrangementsElectric generatorStator

A specialized wind power and water power amphibious generator is characterized in that the specialized wind power and water power amphibious generator is an amphibious specialized generator special for vertical wind power generation and water power generation, that is, the specialized wind power and water power amphibious generator can be used for only vertical wind power generation and vertical water power generation; the specialized wind power and water power amphibious generator comprises permanent magnet multipolar generator rotors of which the circumferential surfaces are annularly provided with multipolar ferrite beads or a plurality of strong magnetic steel 1 with N and S being at intervals, multipolar generator stator windings 2, a generator rotation shaft 3, generator conical bearings 4, a generator shell body 5, a generator protective housing 6, a generator waterproof sunproof shield 7, a high-quality anti-aging rubber or other anti-aging macromolecular flexible waterproof sealing ring 8, waterproof rubber gaskets 9, fastening screws 10, a switchhouse cover 11, a switchhouse 12, generator supporting columns 13, tile-shaped wind power generator fan blades 14, a wind powergenerator base 16, wind power generator fan blade brackets 17, a wind power generator extending shaft 18, an extending shaft matched shaft sleeve 19, a shaft sleeve fixing bolt 20 and the like.

Owner:吴宸至

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com