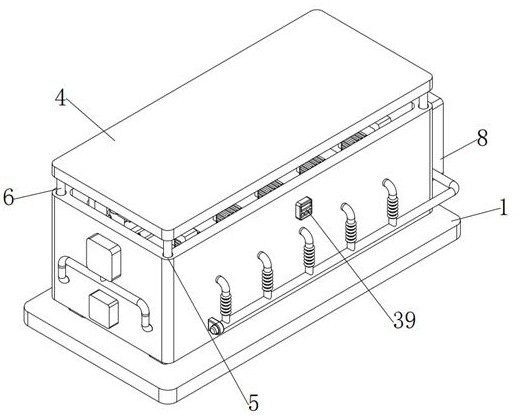

Double-bubble resistance reduction type anti-loosening springback type cleaning device based on electrical automation

An electric automation and cleaning device technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning of oil stains, slow ultrasonic cleaning speed, low efficiency of cleaning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

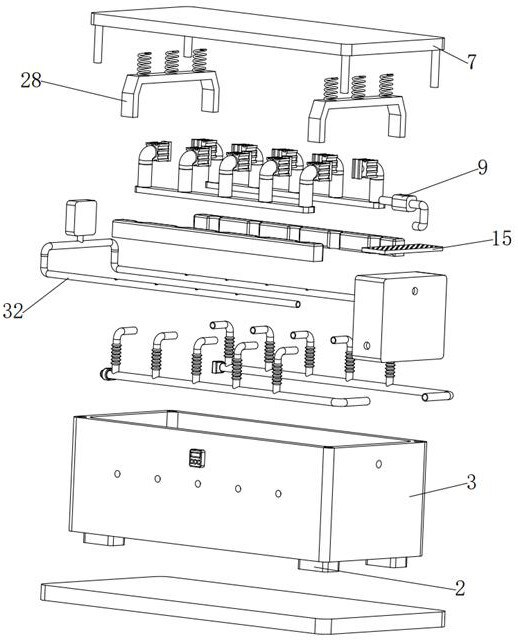

[0042] The second embodiment, based on the above-mentioned embodiment, starts to vibrate and clean the components.

[0043] Specifically, the controller 39 controls the ultrasonic oscillator 34 to start, the ultrasonic oscillator 34 starts to oscillate the cleaning agent through the power end, and a large number of air bubbles are generated in the cleaning agent to impact the parts, so that the oil stains adsorbed on the surface of the parts are shedding.

Embodiment 3

[0044] The third embodiment, based on the above-mentioned embodiment, filters the oil stains in the cleaning agent.

[0045] Specifically, the controller 39 controls the atomizing motor 11 to start, the atomizing motor 11 extracts the cleaning agent inside the cleaning box 3 through the atomizing pipe 12 , and the cleaning agent containing oil is atomized by the atomizing motor 11 and enters through the water mist pipe 13 Inside the adsorption box 10, the mist impacts the oil-stain adsorption particle layer 15, so that the mist and the oil-stain adsorption particle layer 15 are fully combined, the oil-stain adsorption particle layer 15 adsorbs the oil molecules contained in the mist, and the filter screen plate 16 adsorbs the oil stain The particle layer 15 is filtered, the oil-stain adsorption particle layer 15 is blocked by the filter screen plate 16 in the adsorption box 10 , and the filtered mist is discharged into the adsorption box 10 through the discharge pipe 17 .

Embodiment 4

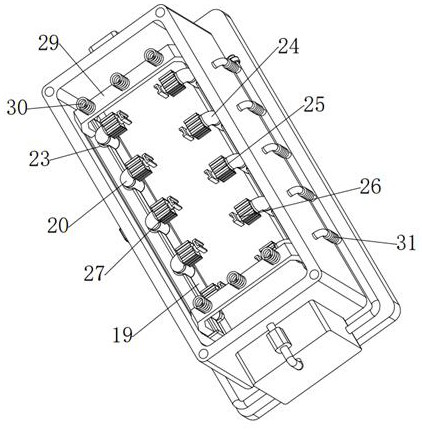

[0046]Embodiment 4, this embodiment is based on the above-mentioned embodiment, and performs impact treatment on stubborn oil stains.

[0047] Specifically, for some oil stains with strong adsorption force, it is difficult to make them fall off through air bubbles. At this time, the controller 39 controls the pulse generator 33 to start, and the pulse generator 33 transmits the generated pulse wave to the inside of the shunt pipe 36 through the power pipe 35 , the shunt pipe 36 ejects the pulse wave through the impact port 37, the pulse wave impacts the linkage plate 38, the linkage plate 38 moves upward under the impact force, and the linkage plate 38 drives the sliding block 22 to slide up along the chute 21 through the clamping pipe 24, and the sliding The block 22 drives the bracket 29 to squeeze the spring 30, and the spring 30 deforms so that the components move upward. After the impact force disappears, the spring 30 quickly resets under the action of elasticity. Because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com