Composite dry-type wall-pie

A wall-penetrating bushing, dry-type technology, applied in the direction of pipes, pipes/pipe joints/pipes, electrical components, etc., can solve problems such as falling off, sliding screen, broken screen, etc., to reduce internal stress, overcome easy sliding screen, The effect of improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

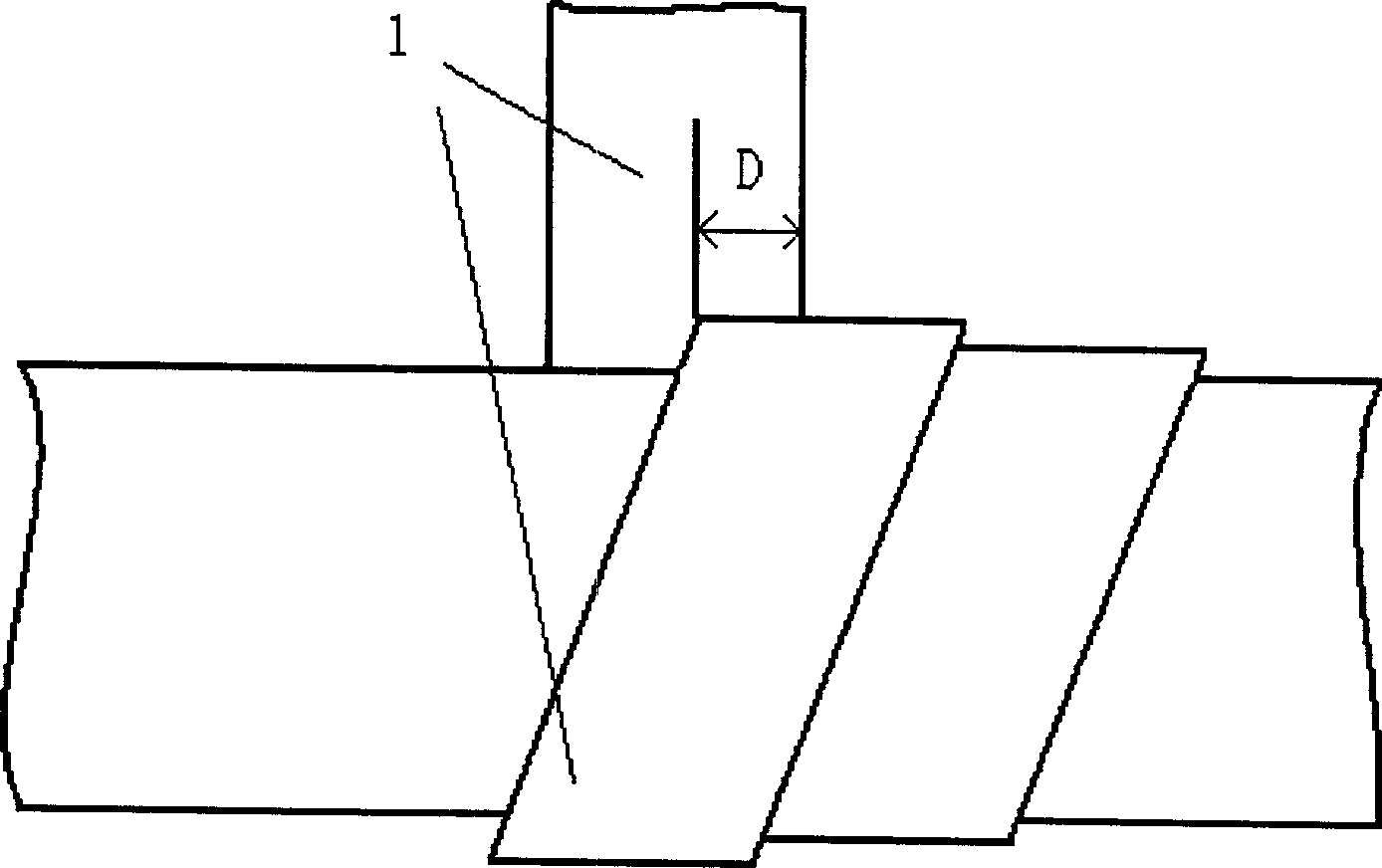

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

[0033] A composite dry-type wall casing wrapping process, including:

[0034] In the first step, the zeroth screen wraps the semi-conductive tape on the conductive rod.

[0035] Two more layers are required at both ends, tapered inwards. And flatten the overlapping part of the semi-conductive tape. The semi-conductive tape should be evenly wrapped around the stainless steel wrapping area, and no stainless steel tube should be exposed.

[0036] The second step is to apply silicone oil.

[0037] Before applying silicone oil, clean off the semi-conductive foam on the conductive rod. Then, apply a layer of silicone oil on the surface of the flattened semi-conductive tape. The amount of silicone oil is moderate, spread evenly, so that the silicone oil can fully fill the gaps in the pits.

[0038] The third step is to wrap the PTFE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com