Patents

Literature

52 results about "Wrapping procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual and interactive wrapper generation, automated information extraction from Web pages, and translation into XML

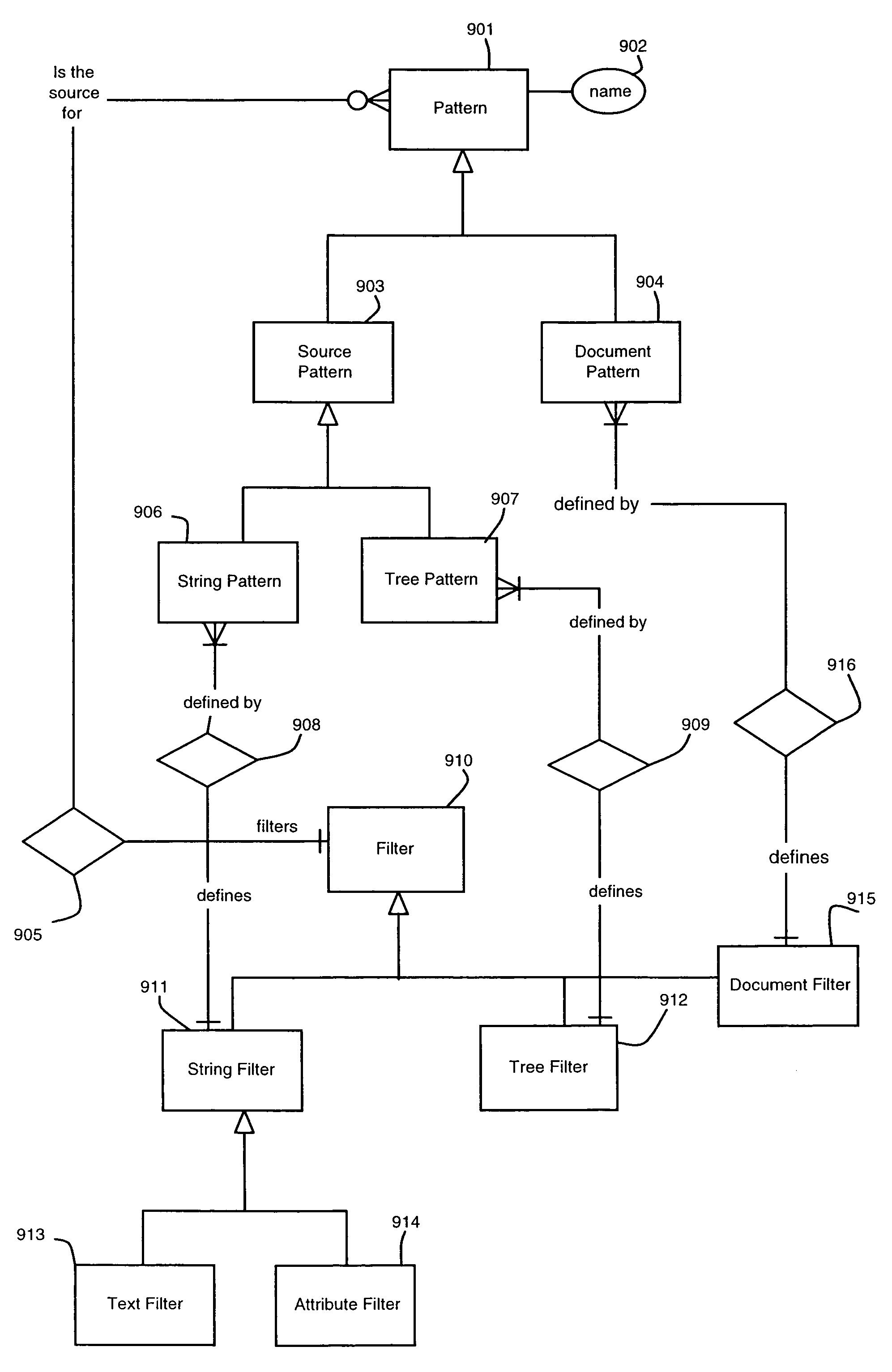

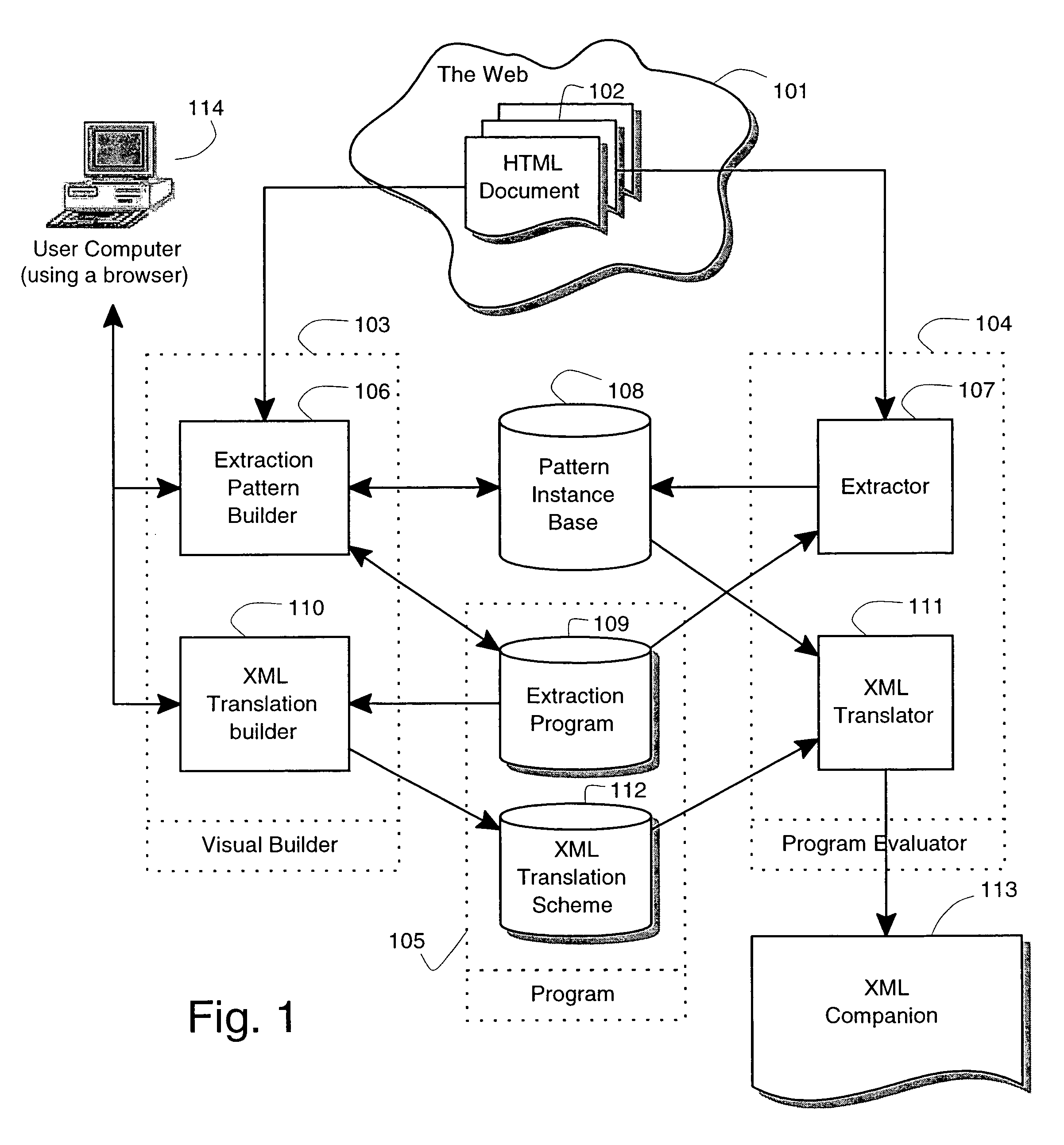

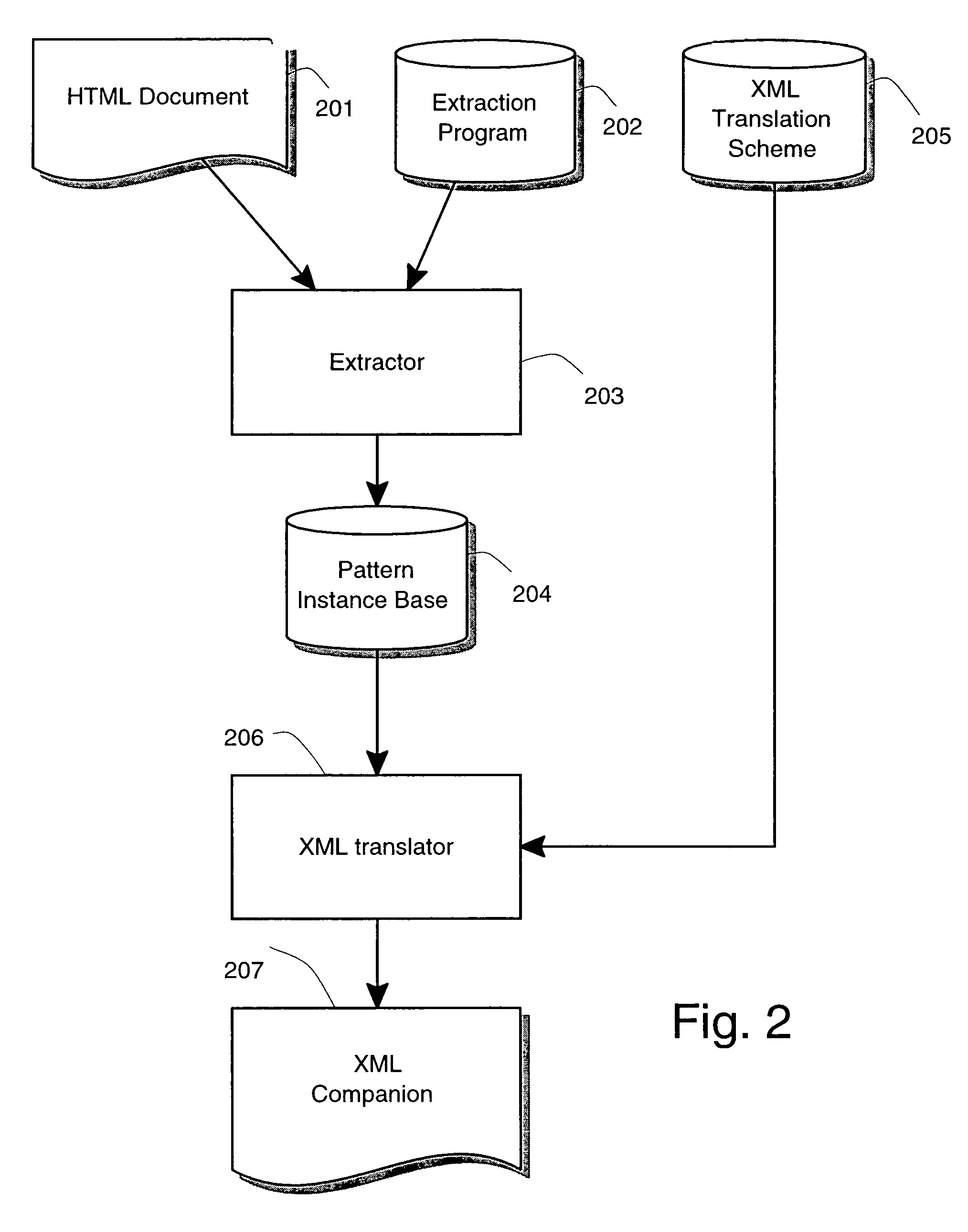

A method and a system for information extraction from Web pages formatted with markup languages such as HTML [8]. A method and system for interactively and visually describing information patterns of interest based on visualized sample Web pages [5,6,16-29]. A method and data structure for representing and storing these patterns [1]. A method and system for extracting information corresponding to a set of previously defined patterns from Web pages [2], and a method for transforming the extracted data into XML is described. Each pattern is defined via the (interactive) specification of one or more filters. Two or more filters for the same pattern contribute disjunctively to the pattern definition [3], that is, an actual pattern describes the set of all targets specified by any of its filters. A method and for extracting relevant elements from Web pages by interpreting and executing a previously defined wrapper program of the above form on an input Web page [9-14] and producing as output the extracted elements represented in a suitable data structure. A method and system for automatically translating said output into XML format by exploiting the hierarchical structure of the patterns and by using pattern names as XML tags is described.

Owner:LIXTO SOFTWARE

Baler

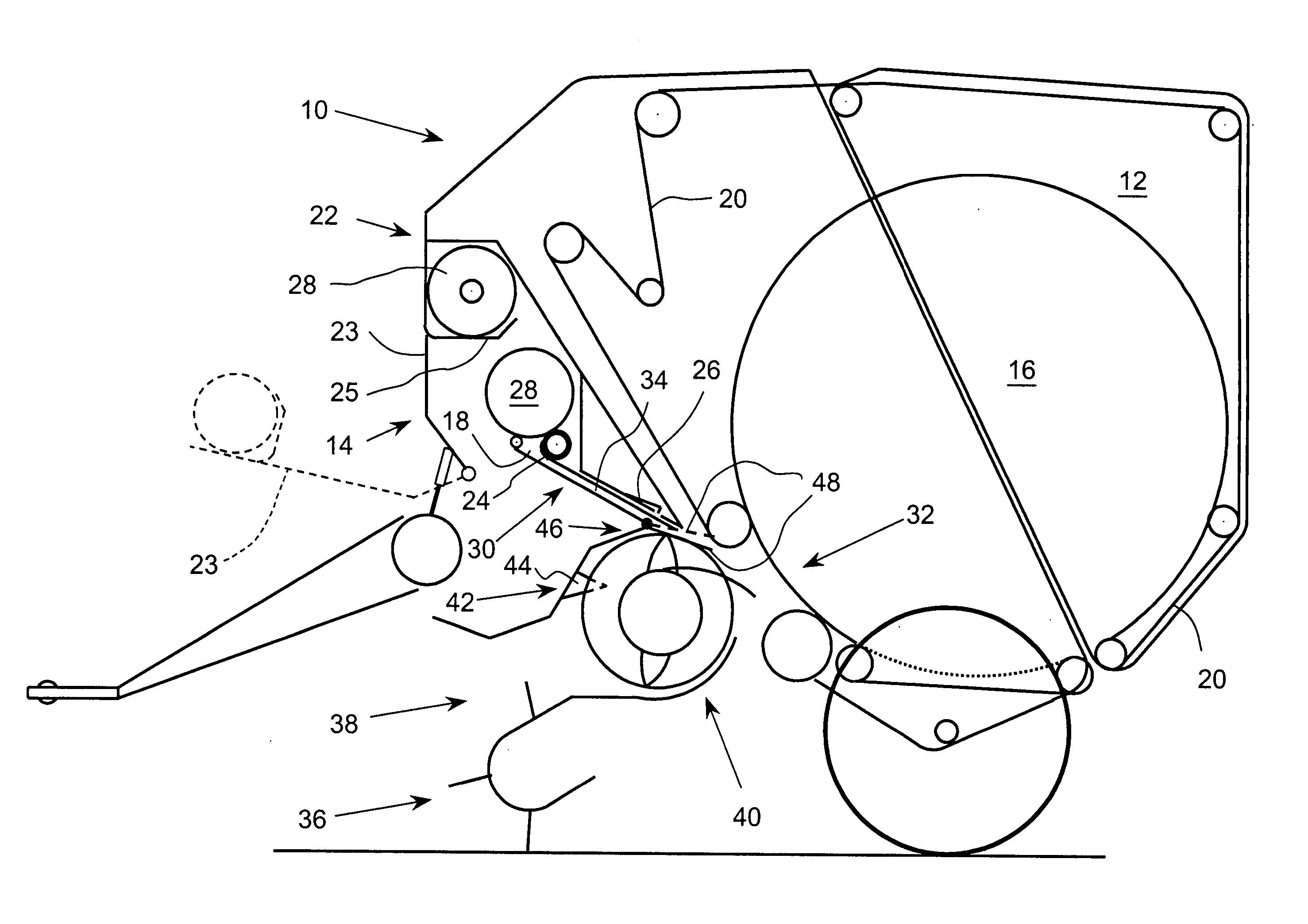

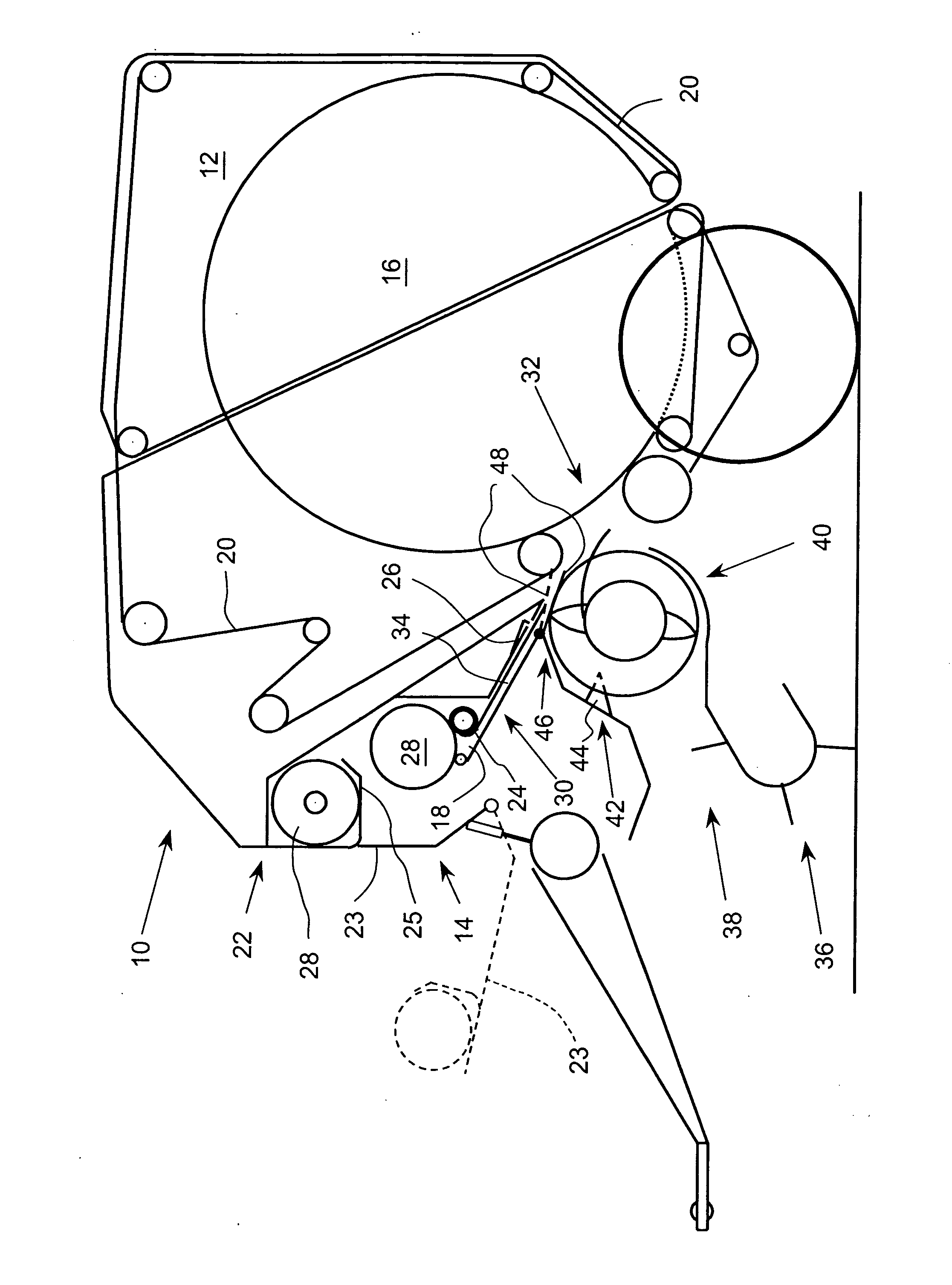

A large round baler includes a device for introducing a wrapping web to the baling chamber for wrapping a bale with the wrapping web. During a wrapping procedure, the wrapping web is pulled off a supply roll and directed to a location in front of the baling chamber where it is engaged by a crop supply unit and introduced into the baling chamber where the rotating bale carries the wrapping web about it and becomes wrapped.

Owner:DEERE & CO

Apparatus and method for extending shelf-life and prevention of discoloration of meat

InactiveUS20060228449A1Zero shrinkageReduce Shrinkage ProblemsReady-for-oven doughsPackaging meatNitrogen richGas exchange

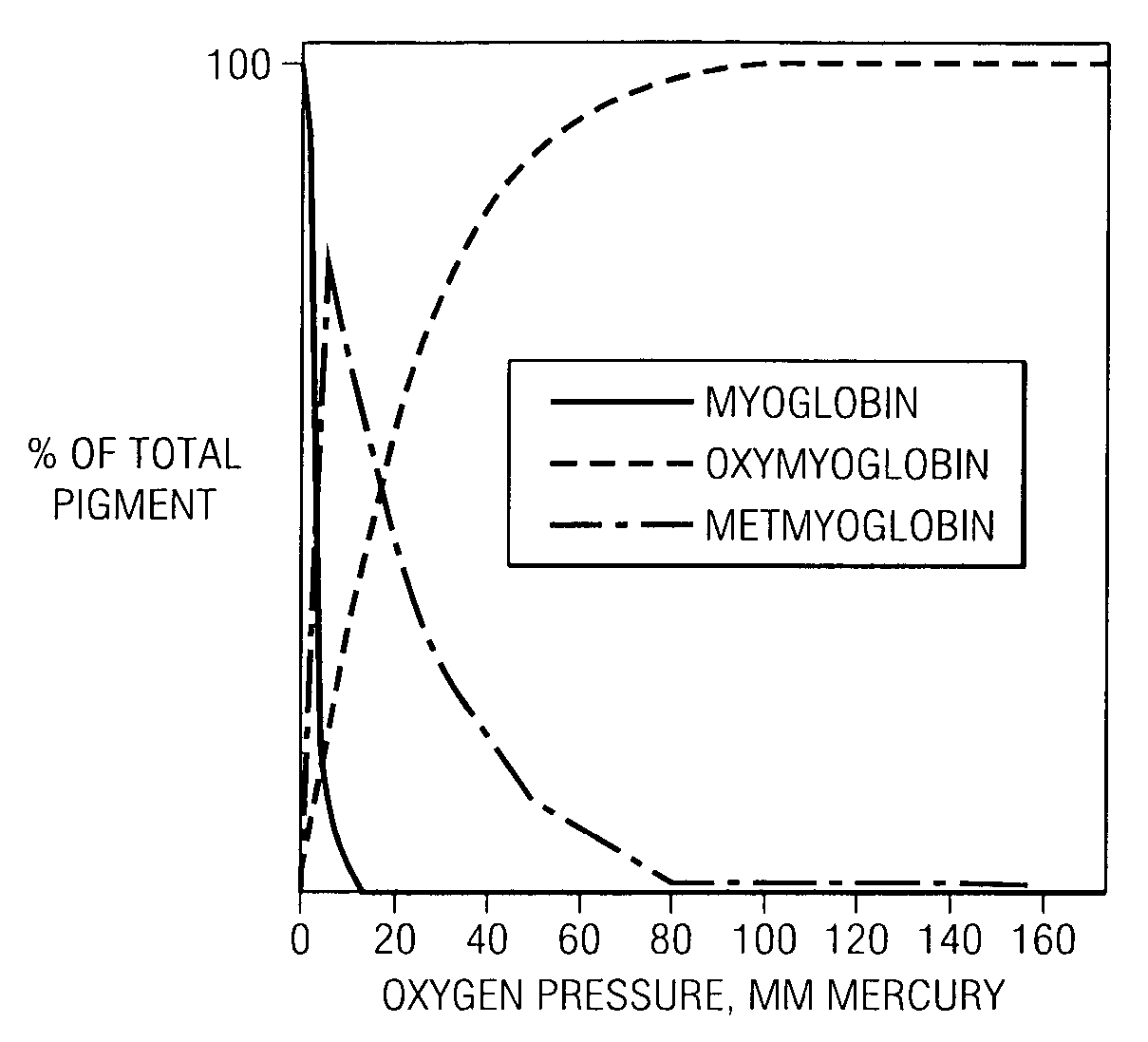

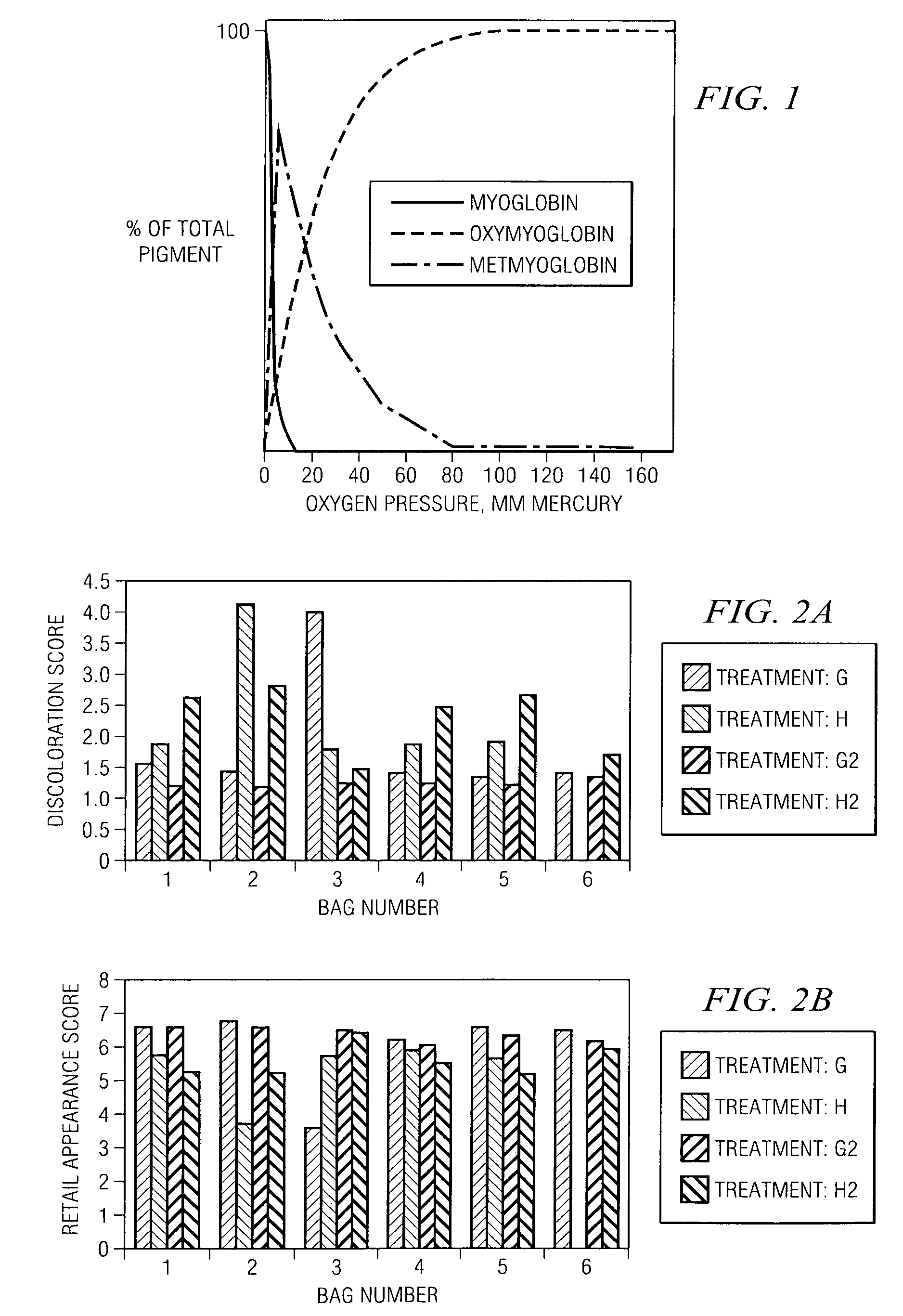

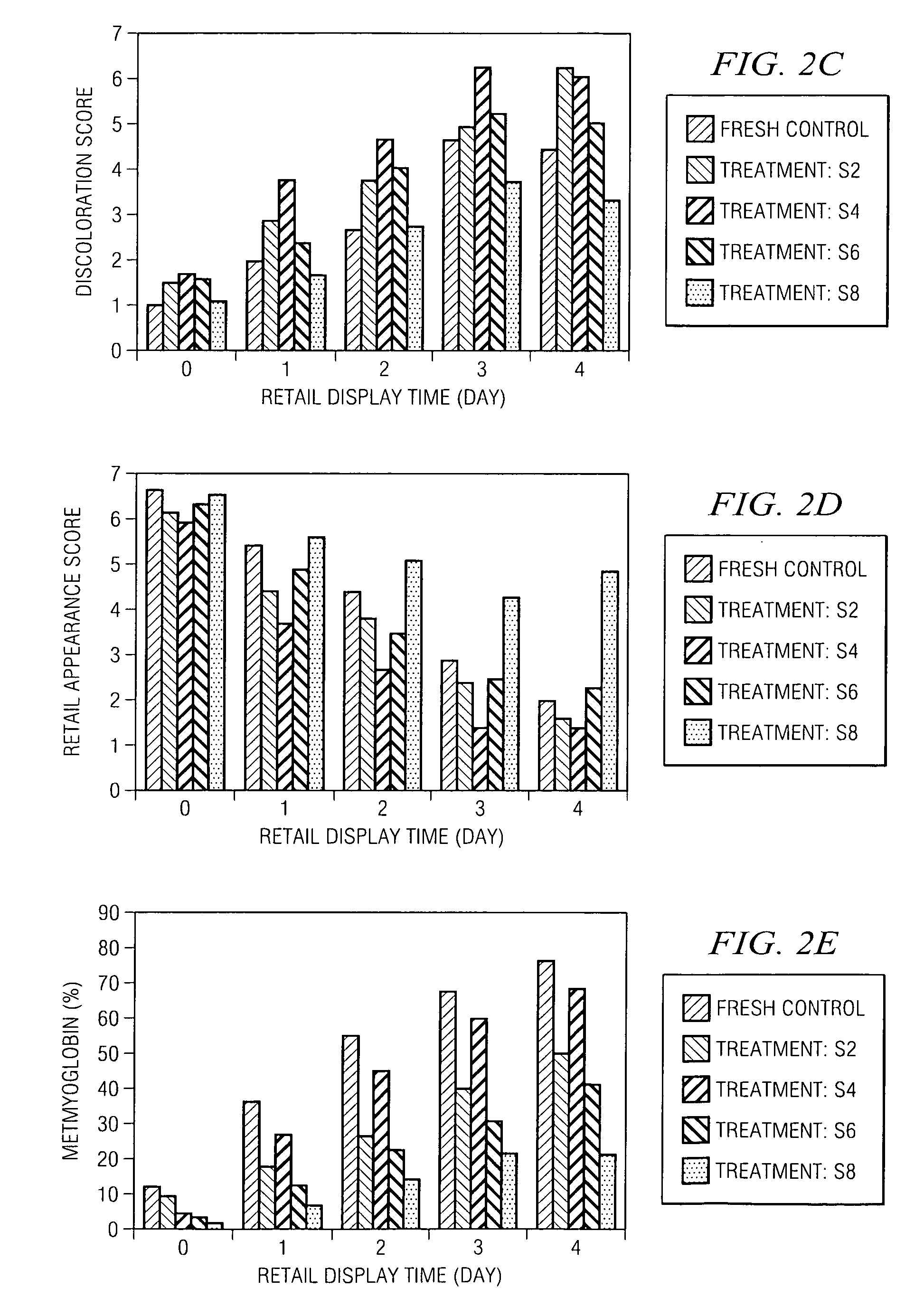

The current invention covers an improved meat-packaging procedure and machine for packaging meat cuts for long-term storage at temperatures of between 28° and 32° F. The process includes sealing meat cuts within a master bag containing oxygen scavenger materials capable of reducing the residual oxygen content of the atmosphere within the bag to 0 ppm within 24 hours of sealing. Gas is injected into the master bag to form a nitrogen-rich storage environment of at least 50% nitrogen. A small amount of carbon monoxide gas (0.1% to 5%) is preferred for the storage environment, as this helps to preserve the red coloration of meat under long-term storage conditions. The over-wrap of the meat trays can be perforated so that gas exchange occurs within the master bag between the interior and exterior of the meat tray to absorb the residual oxygen inside the meat trays. For meat trays containing meat with poor color stability, oxygen scavengers are preferably placed within the meat trays. For cuts with good color stability, the oxygen scavengers may be placed outside the meat trays. Meat can be stored by this system for up to 15 weeks and up to nine days of retail display life.

Owner:TEXAS MEAT PACKAGING SYST

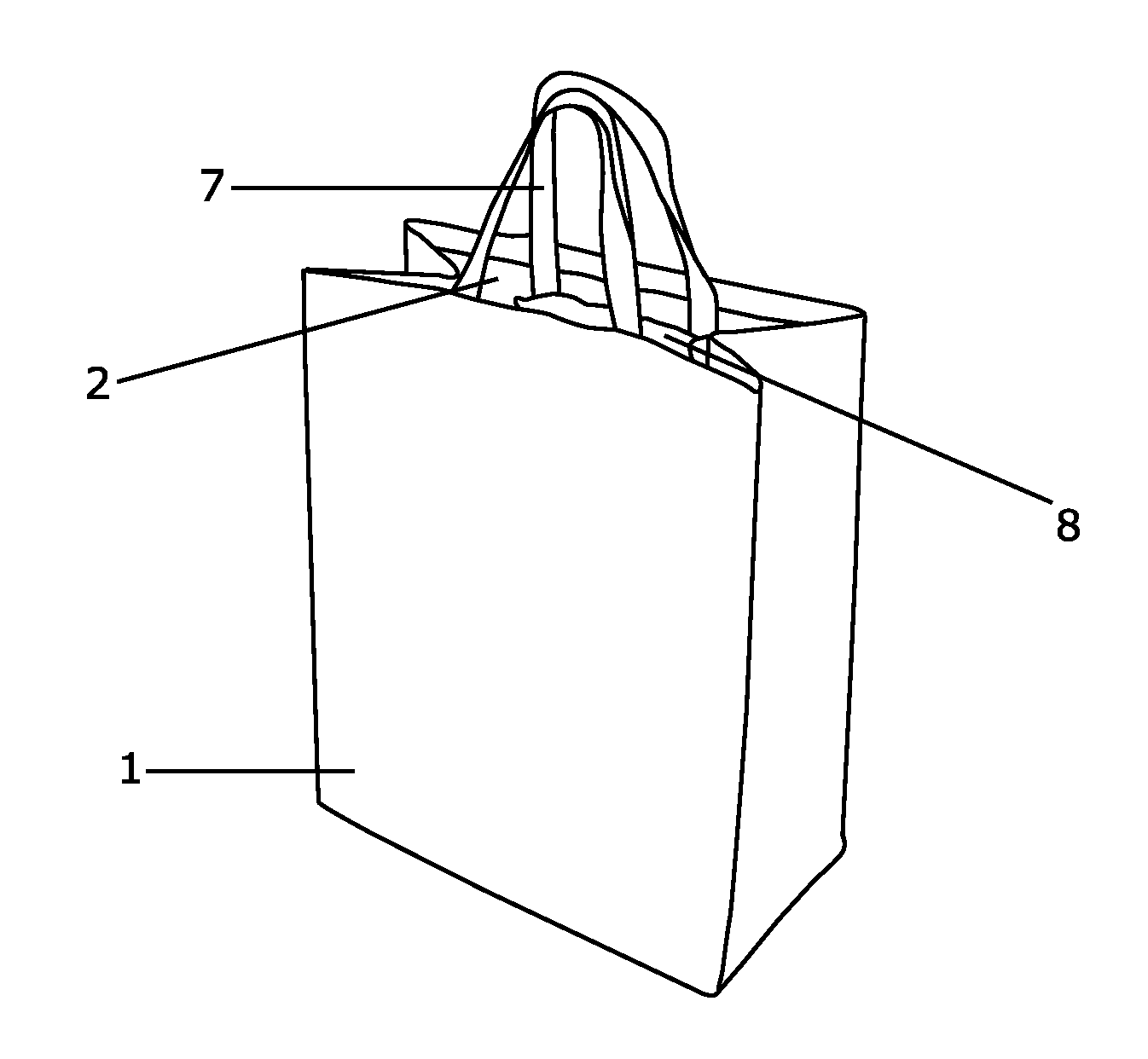

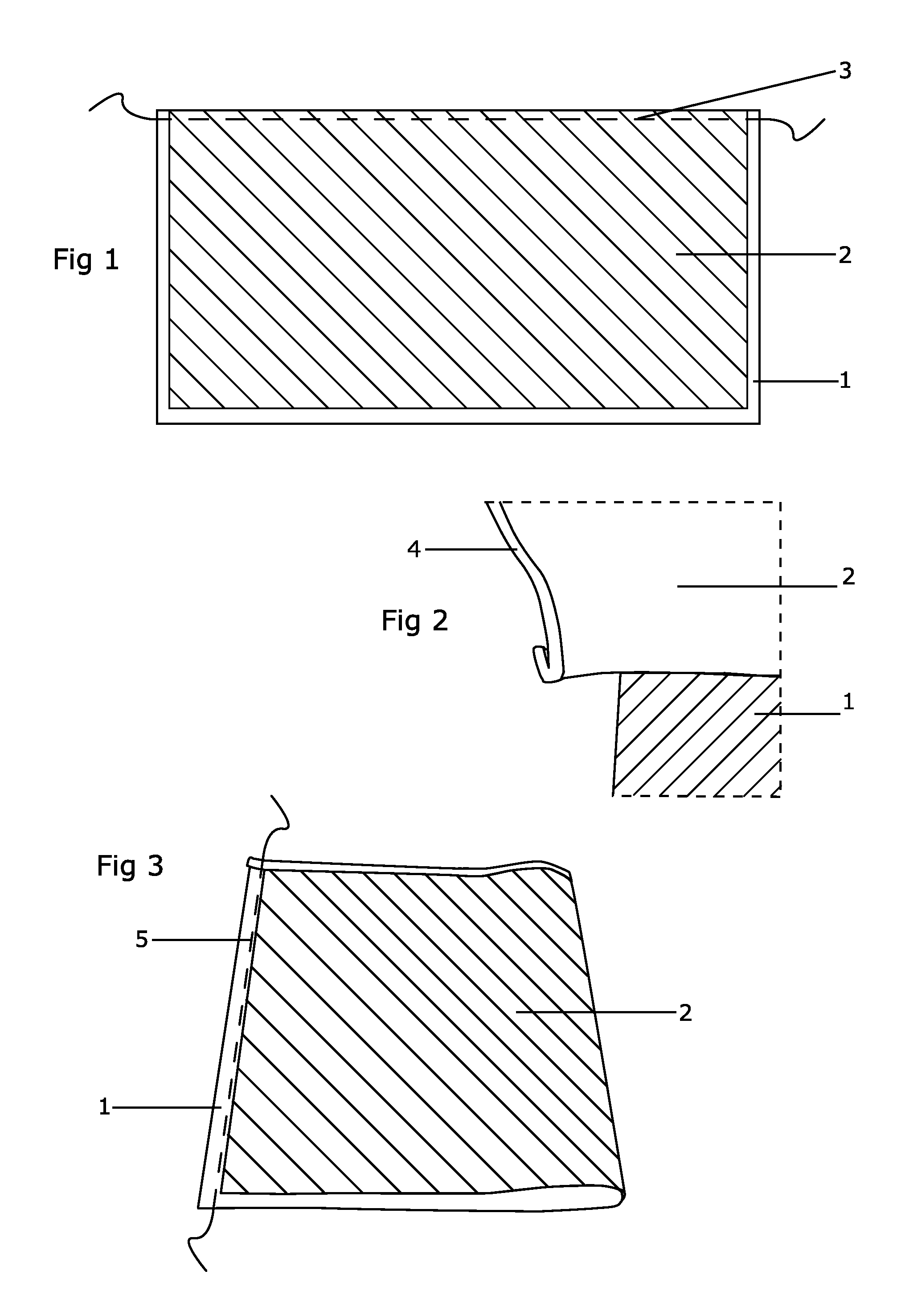

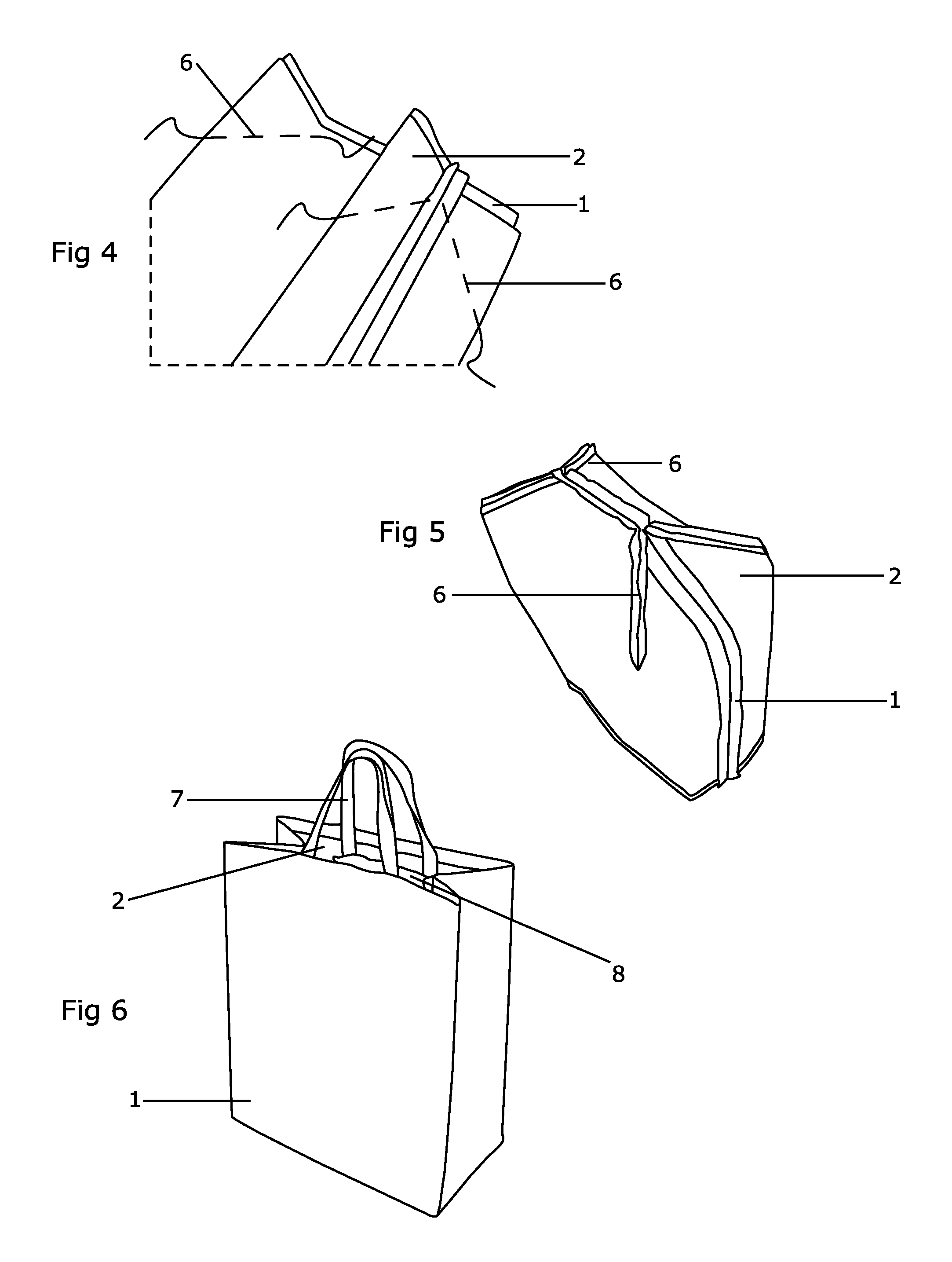

Reusable Fabric Gift Bag With Reusable Fabric "Tissue" Wrapping

InactiveUS20110243480A1Envelopes/bags making machineryPackage recyclingFacial tissueWrapping procedure

Owner:COWMAN JEAN MARIE

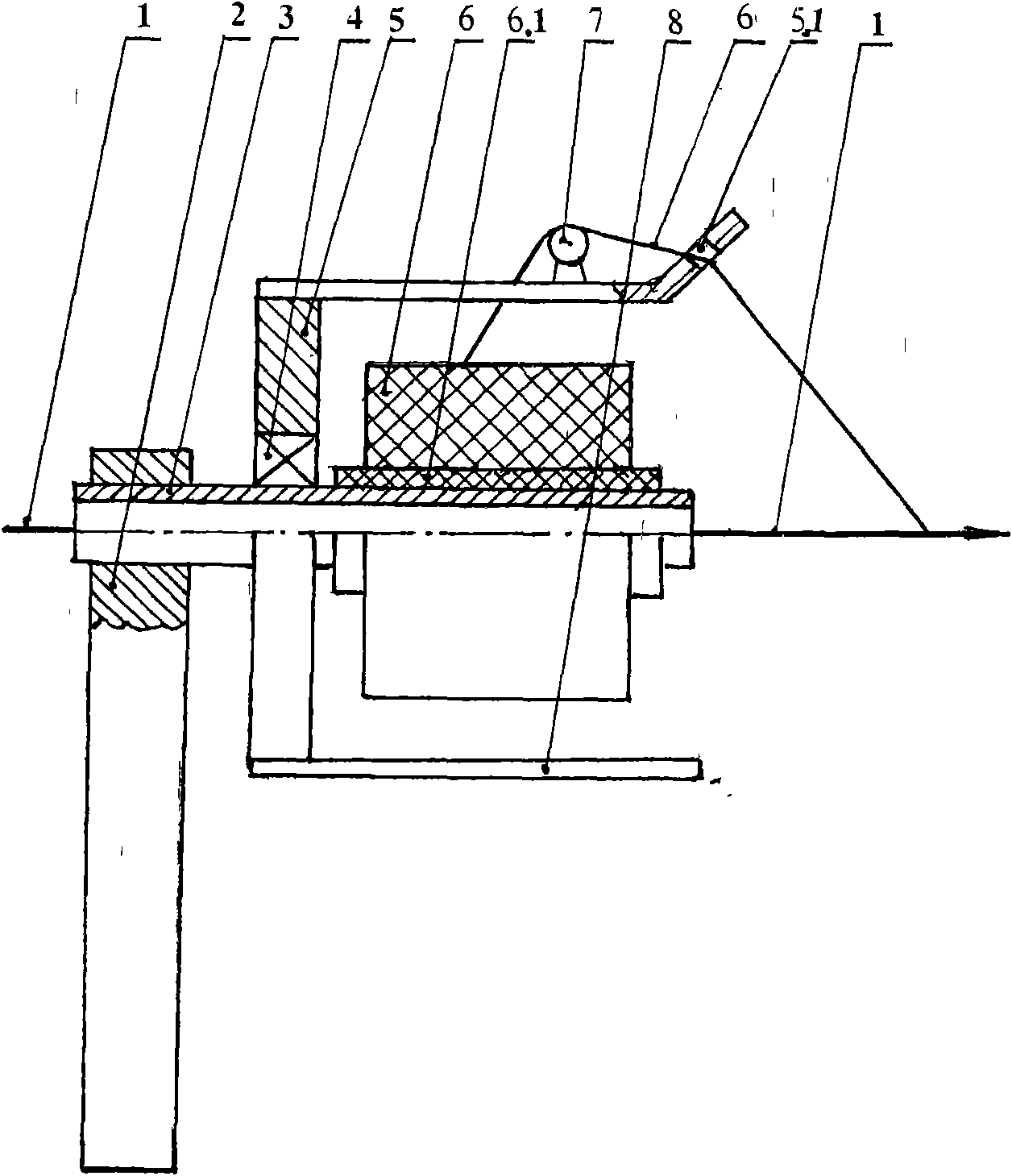

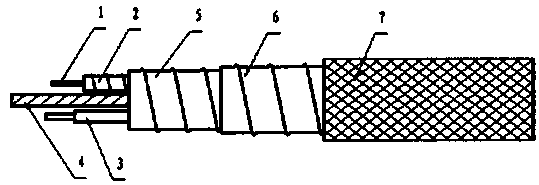

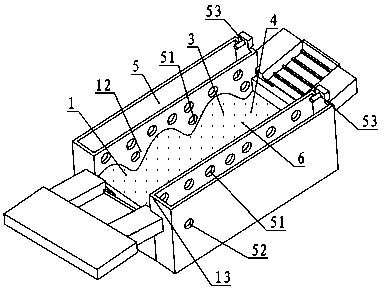

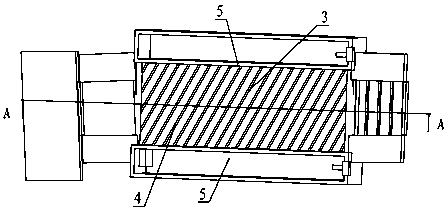

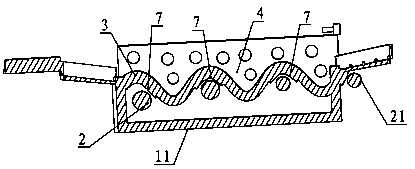

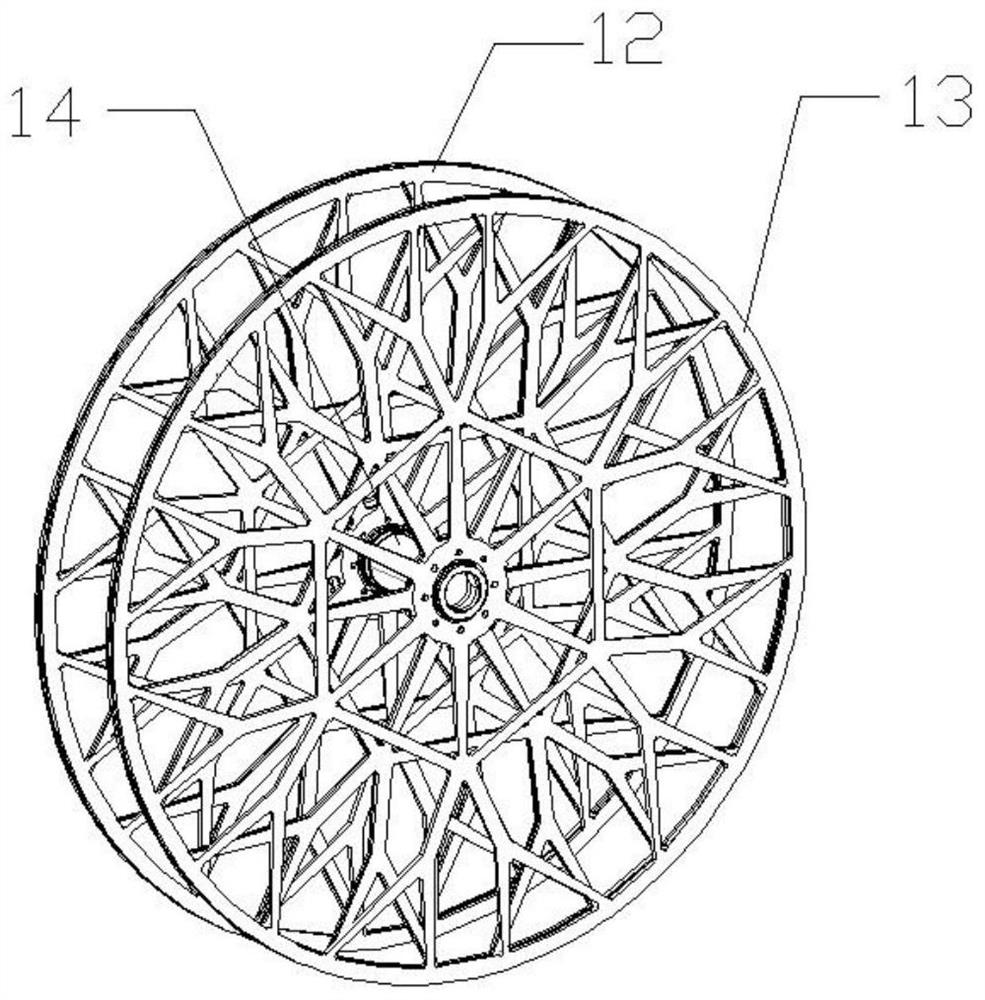

Method and device for wrapping reinforcement yarn around long optical fiber cable

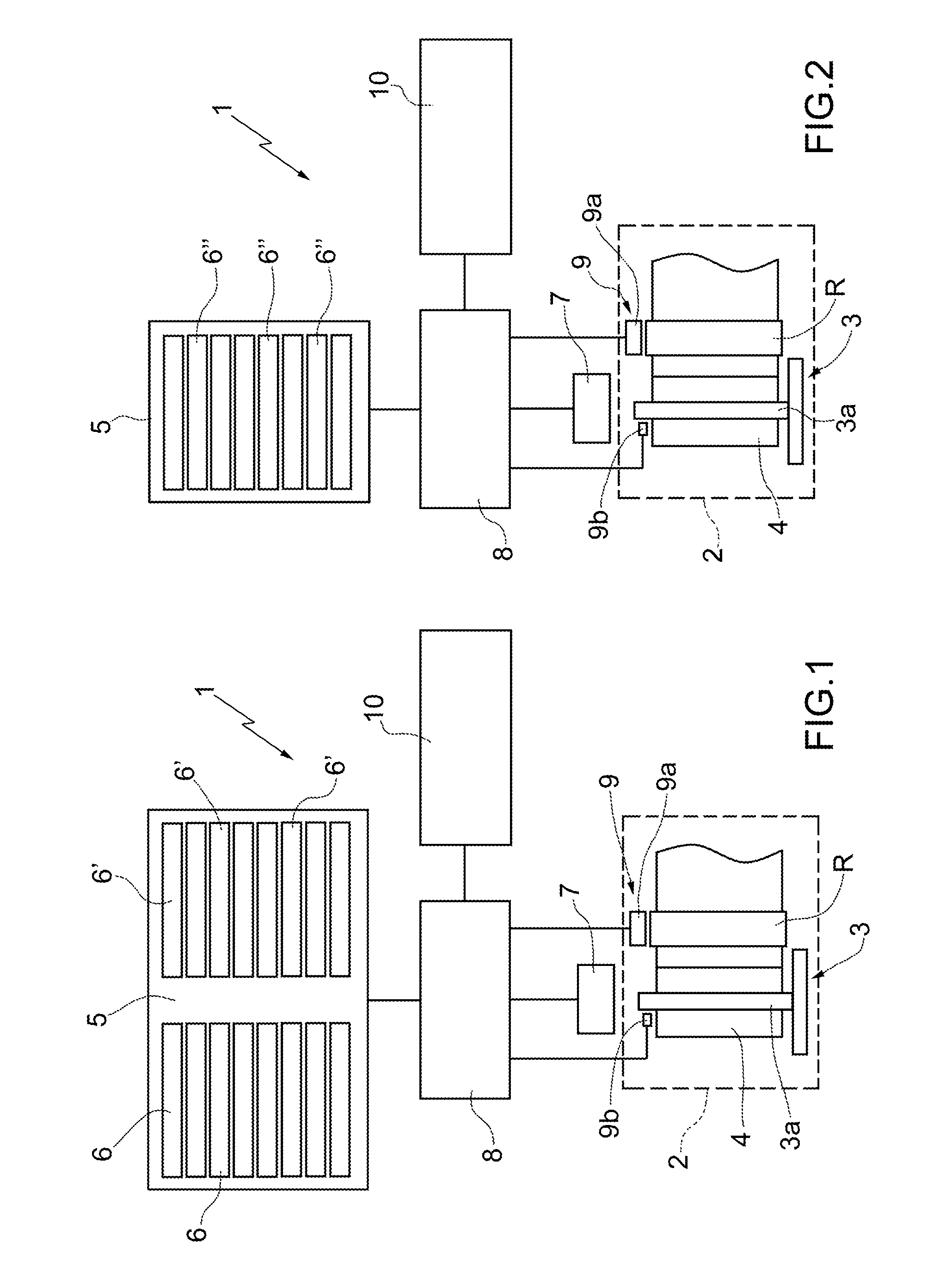

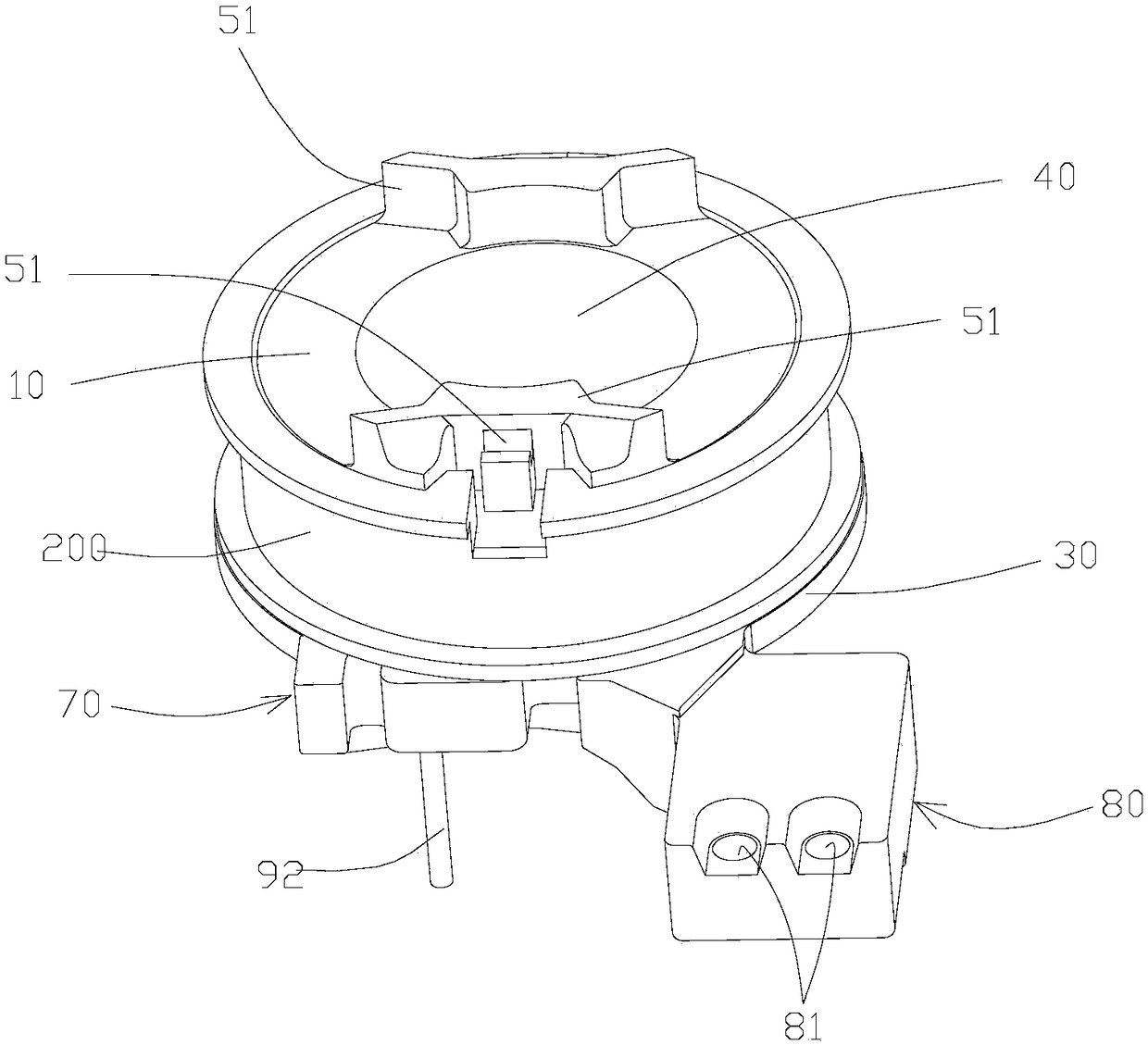

The invention relates to a method and a device for wrapping reinforcement yarn around a long optical fiber cable. The device is characterized in that a stationary part is formed in such a way that an arranged horizontally hollow stationary shaft is fixedly connected with a frame, and a yarn cylinder and the hollow stationary shaft are in stationary fit connection; a rotating part is formed in such a way that a rotating pay-off rack is in movable fit connection with the stationary shaft through bearings, a yarn guide wheel is fixedly connected with the rotating pay-off rack, and both ends of the rotating pay-off rack are provided with yarn guide holes. The method is characterized in that optical fibers are led forwards in the hollow axis of the hollow stationary shaft, the yarn is taken out from the side of the yarn cylinder and continuously wrapped outside the moving-forward optical fibers through the yarn guide wheel and the yarn guide holes of the rotating pay-off rack, and the transformation between the left-rotating wrapping way and the right-rotating wrapping way outside the optical fibers can be realized by changing the yarn cylinder by 180 degrees in the axial direction. The invention is applied to the wrapping procedure of untwisted reinforcement yarn around the optical fiber cable and has the advantages of simple equipment, low cost, high speed for conveying the optical fiber cable, obviously increased production efficiency and good product quality.

Owner:江苏通光海洋光电科技有限公司

Device and method for checking the quality of extensible film for packaging

ActiveUS20160229573A1Increase heightGood conditionWrapping material feeding apparatusWrapper supporting apparatusEngineeringWrapping procedure

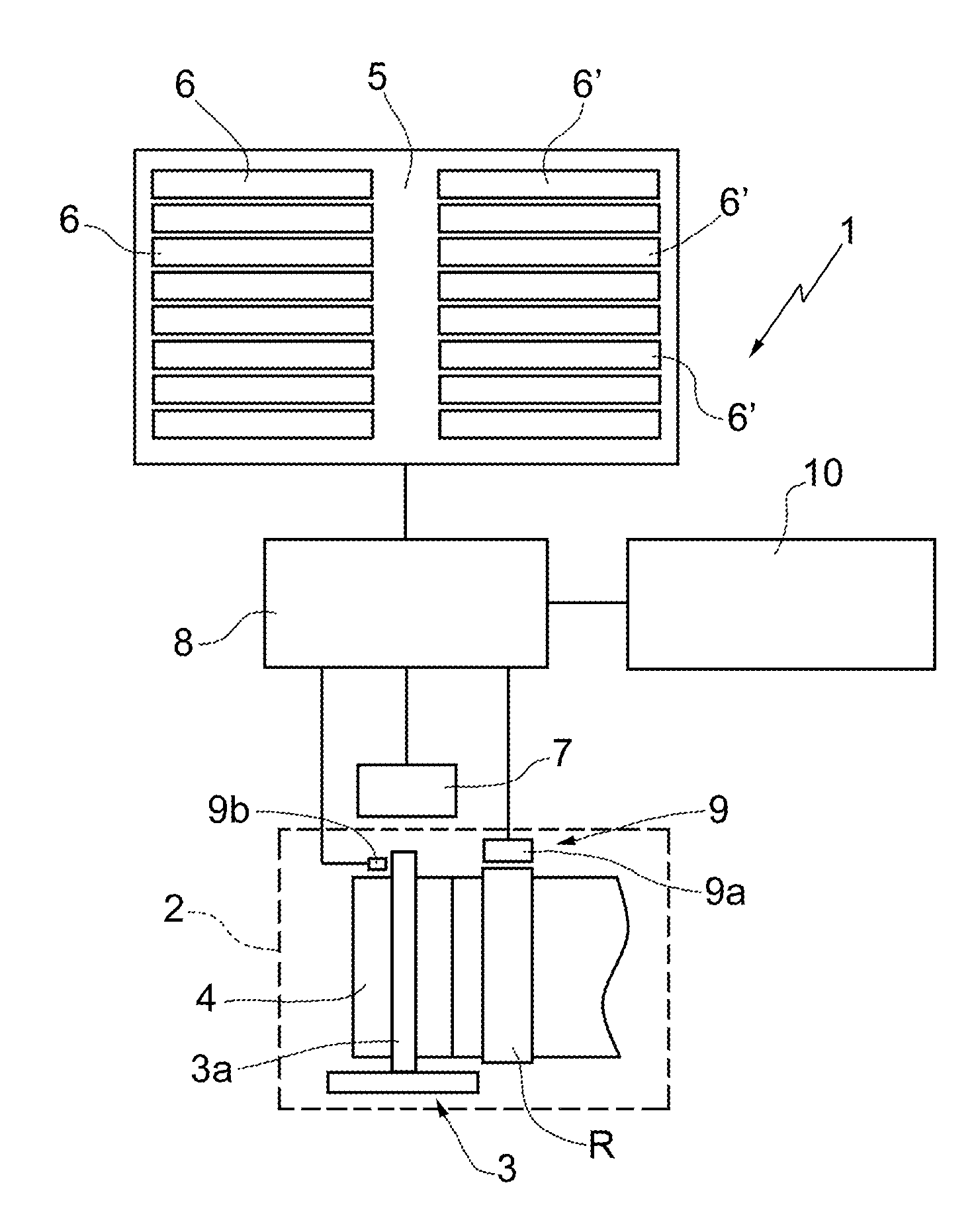

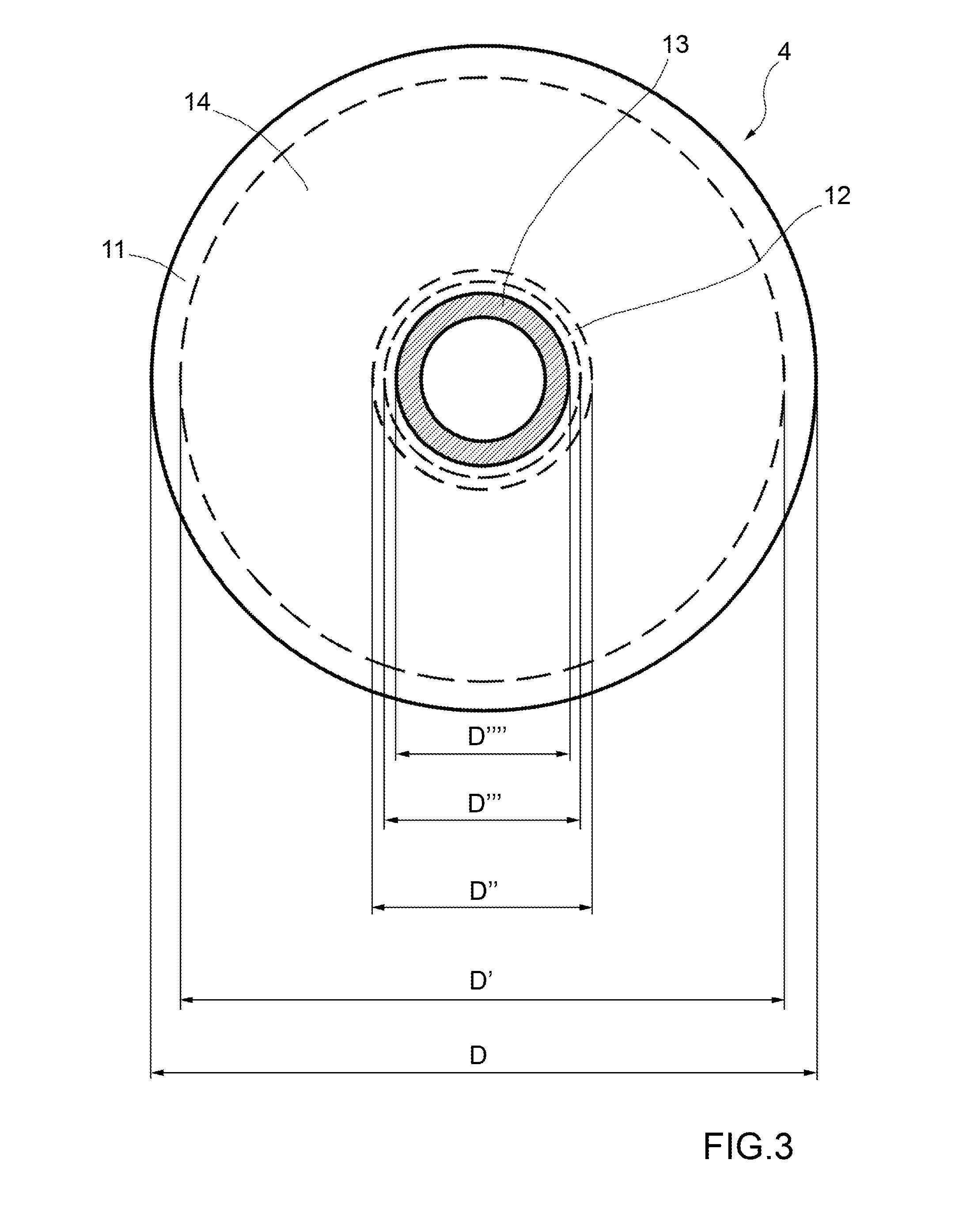

A device for checking the quality of extensible film for wrapping purposes available in reels, operatively associable to a wrapping machine including means for supporting at least one reel of extensible film, including at least one storage memory of a plurality of wrapping programs of a palletized load, each characterised by different operating parameters to carry out the wrapping operation, the means of detection of at least one parameter representative of the quality of the film on the reel, the means for measuring, instant by instant, the present diameter of the reel, an electronic processor, operatively associated with the storage memory, with said detection means and with said measuring means, suitable for selecting and / or changing a given wrapping program according to at least said parameter representative of the quality of the film on the reel. A method to inspect the quality of the packaging stretch film available in reels.

Owner:E80 GRP SPA

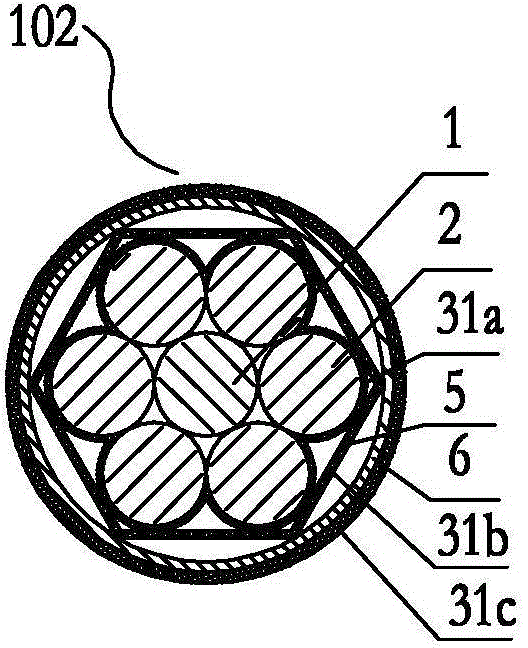

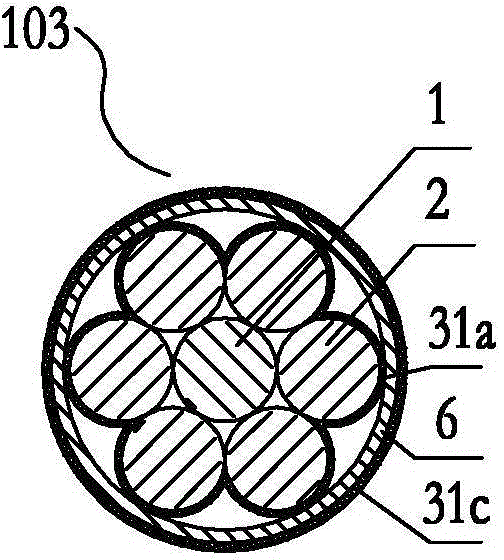

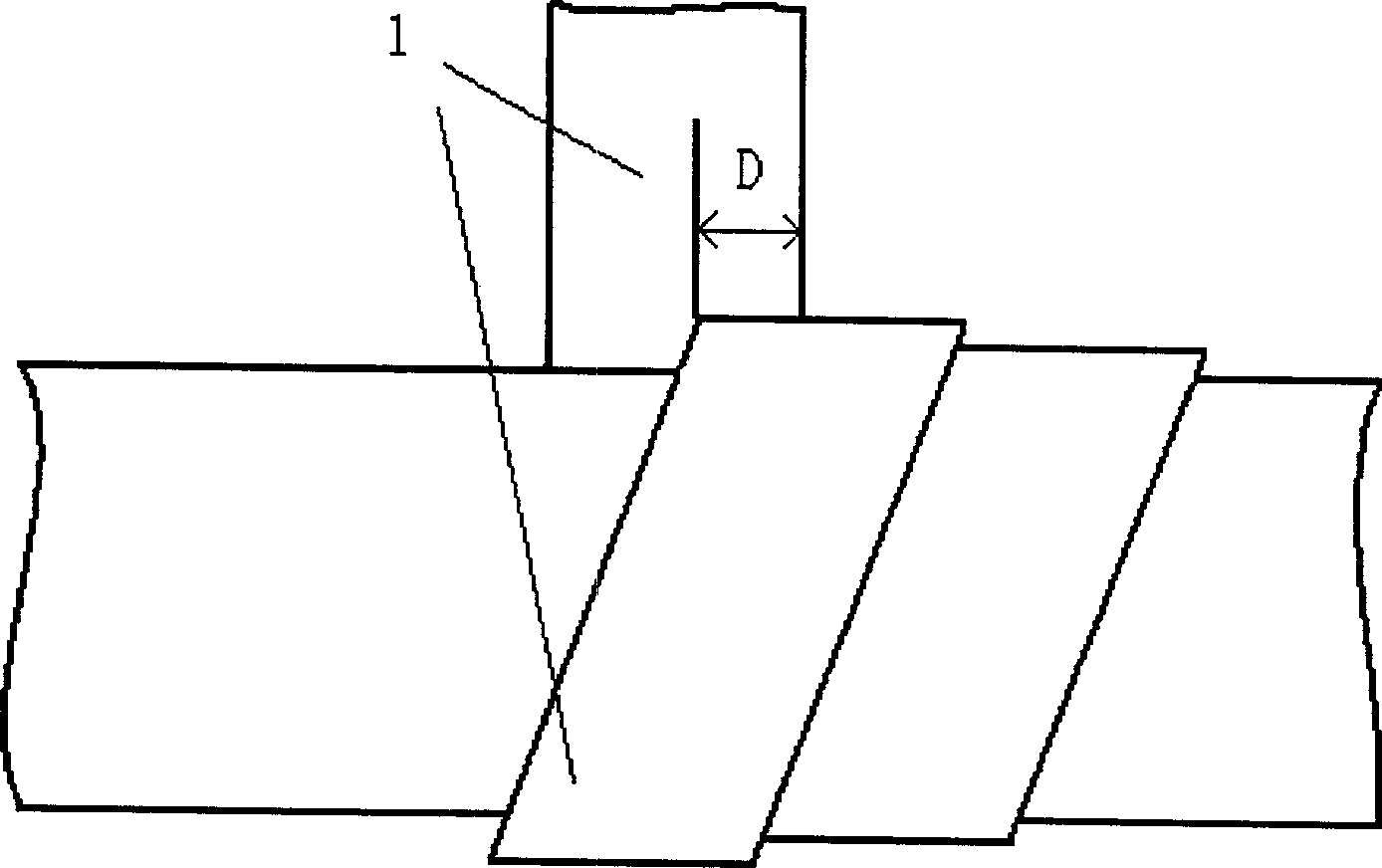

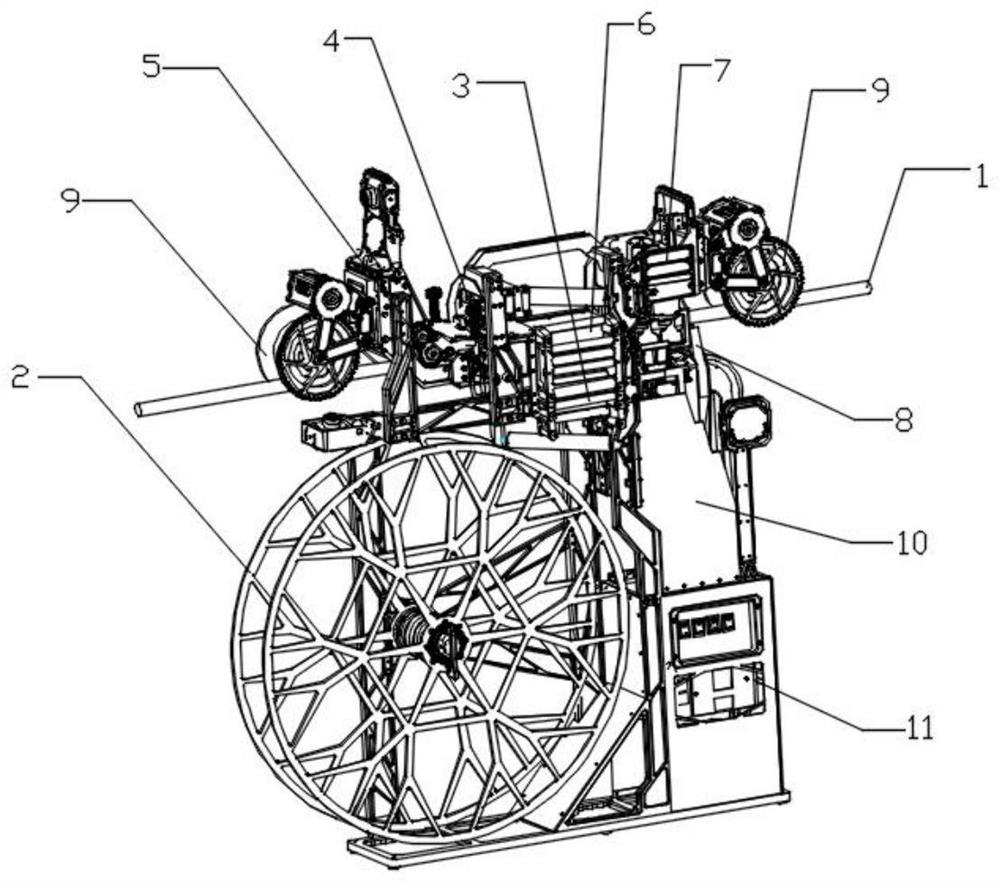

Super-strong, super-soft and high-temperature-resistant photoelectric hybrid cable as well as manufacturing method and wrapping machine thereof

ActiveCN109637712AAvoid damageThe overall thickness is thinPower cablesFibre mechanical structuresYarnPolyester

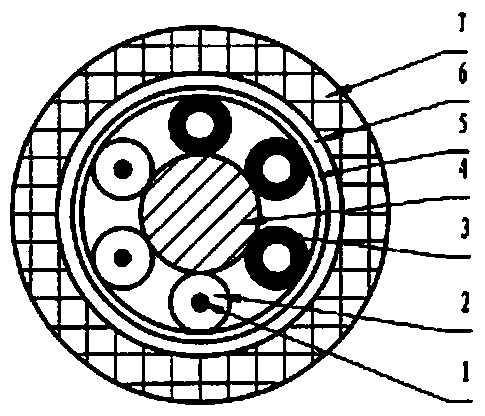

The invention discloses a super-strong, super-soft and high-temperature-resistant photoelectric hybrid cable as well as a manufacturing method and a wrapping machine thereof, and relates to the fieldof photoelectric hybrid cable manufacturing, the photoelectric hybrid cable comprises a cable core, the cable core is formed by stranding wires and optical fibers on a reinforced aramid yarn inner layer in a star shape, the cable core is sequentially wrapped with a polyester film layer and a flame-retardant belt layer, and the flame-retardant belt layer is wrapped with a woven aramid yarn outer layer. The wrapping machine comprises a rack, a wrapping device, a belt releasing transmission mechanism, a wrapping transmission mechanism and a speed measuring device, wherein the wrapping device comprises a wrapping disc, a belt coil, a central pipe, a belt releasing shaft and a wrapping shaft, the belt releasing transmission mechanism and the wrapping transmission mechanism are respectively composed of a motor, a speed reducer and a belt transmission device, and the speed measuring device comprises a fixing frame, a spring a, a lower pressing wheel, a fixing wheel, a guide pipe and a speed sensor and is further provided with a controller used for controlling according to detection signals. The photoelectric hybrid cable can be suitable for high-temperature and strong-stress environmentswith narrow spaces, and is simple to process and manufacture, and the wrapping machine can complete each wrapping procedure.

Owner:CHENGDU DATANG CABLE

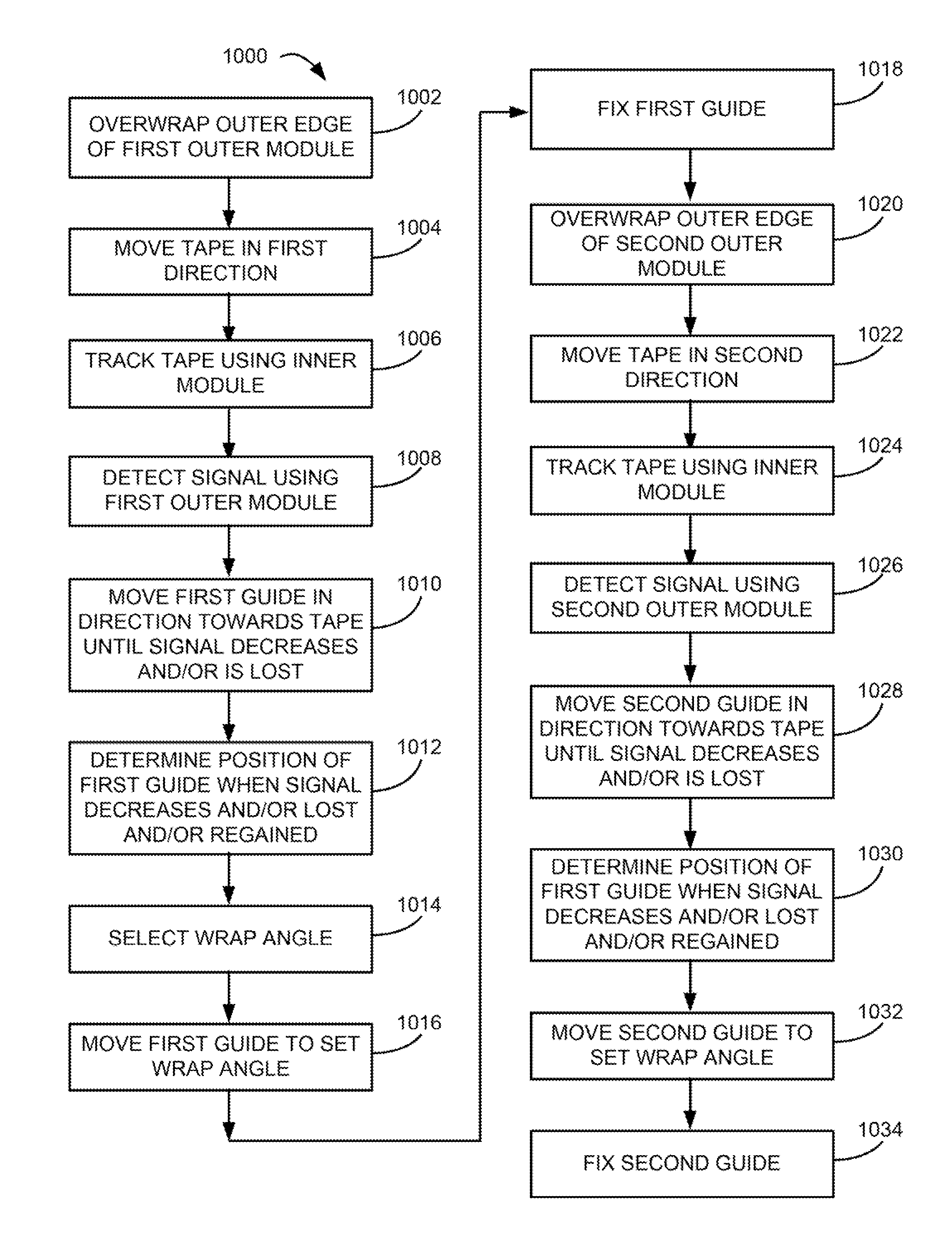

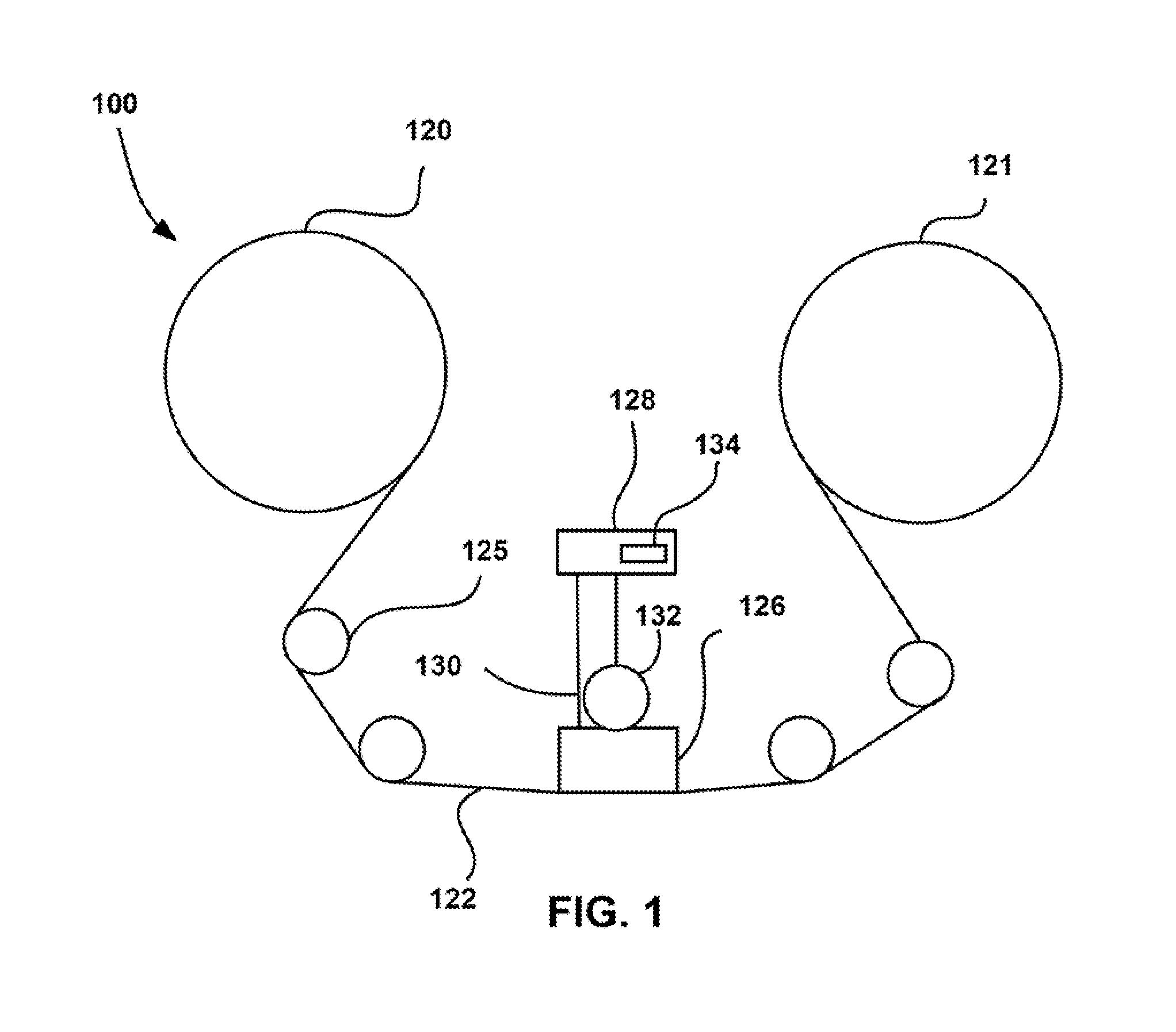

Head wrap procedure

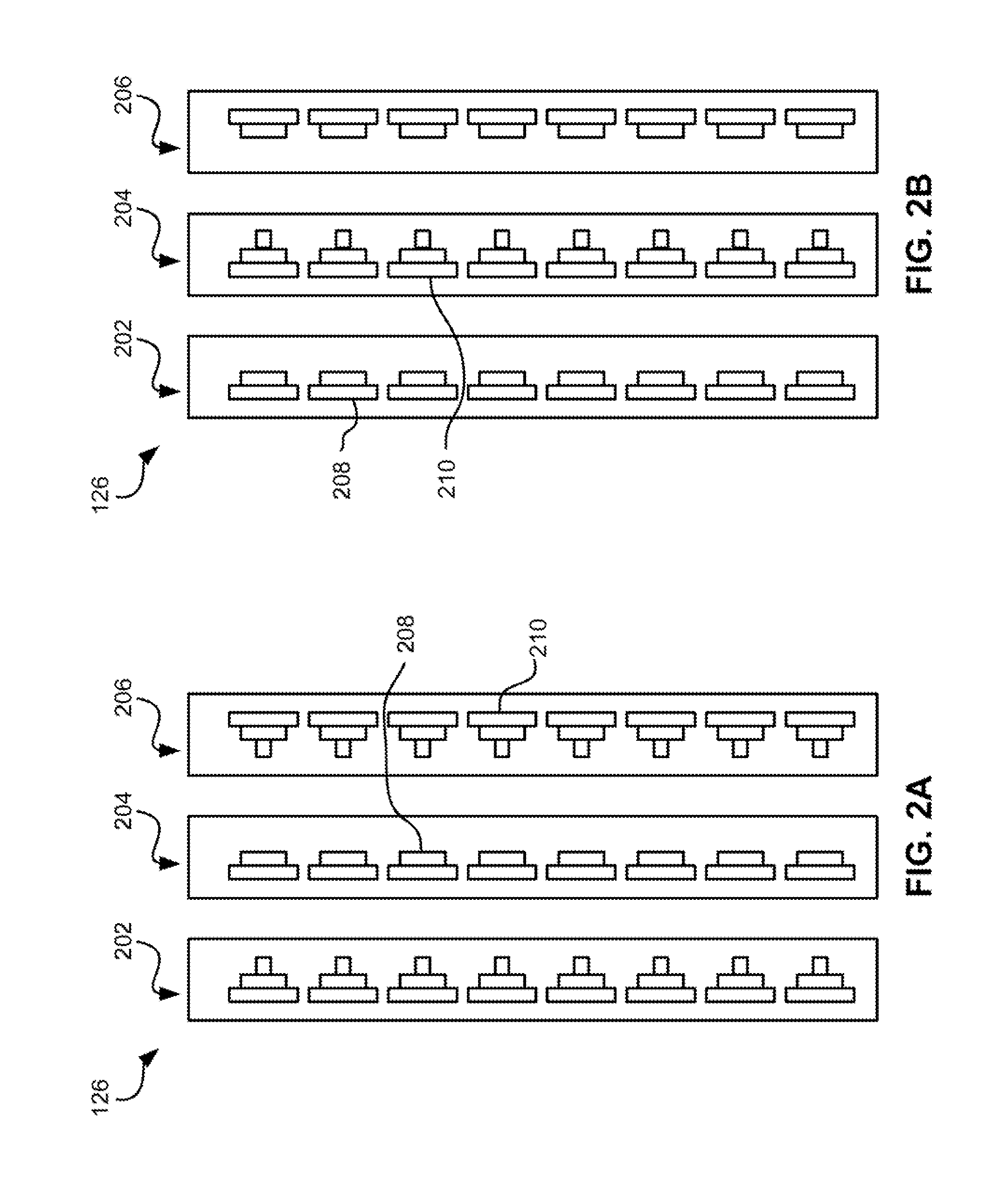

InactiveUS8493682B2Record information storageFluid-dynamic spacing of headsMagnetic tapeComputer module

According to one embodiment, a method includes tracking a magnetic tape moving in a first direction using at least one reader of an inner module of a head having at least the inner module and first and second outer modules positioned on opposite sides of the inner module and aligned with the inner module in a tape travel direction, detecting a signal using at least one reader of the first outer module as the tape passes thereacross, moving a guide positioned in front of the first outer module in a direction towards the tape until the signal detected by the first outer module decreases by a predetermined amount, and moving the guide directionally away from the tape to a position to set about a predetermined wrap angle of the tape relative to the first outer module after the signal detected by the first outer module decreases by the predetermined amount.

Owner:INT BUSINESS MASCH CORP

High-efficiency ice wrapping device for quick-frozen food

ActiveCN104856189BImprove the preservation effectGood fresh-keeping effectFood preservationIce waterReciprocating motion

The present invention discloses a high efficient ice wrapping device for quick-frozen food and the device is connected between a quick-freezing plant and a low temperature preserving device and includes a working groove and a vibration device. The cross-section of the working groove is an I-shaped groove body which comprises a bottom surface, a left side surface and a right side surface; a transmission mesh belt is parallel to the above of the bottom surface of the groove body and encloses the left side and right side surfaces of the working groove to form a ice wrapping groove which contains ice-water mixtures. The vibration device comprises a vibrating section disposed between the transmission mesh belt and the bottom surface of the working groove, the vibrating section moves back and forth in a direction perpendicular to the transmission mesh belt, thus turning over the quick-frozen food transmitted in the ice wrapping groove, and then wrapping the transmitted quick-frozen food with ice. The ice wrapping device improves the working efficiency of the ice wrapping procedure for quick-frozen food after being frozen, thus improving the freshness preserving performance of quick-frozen food, and has superior promotion and application value.

Owner:上海荷裕冷冻食品有限公司

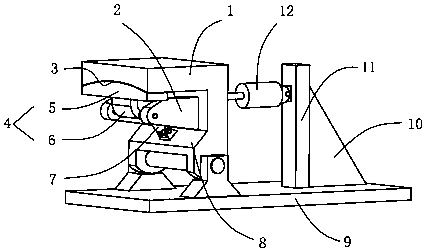

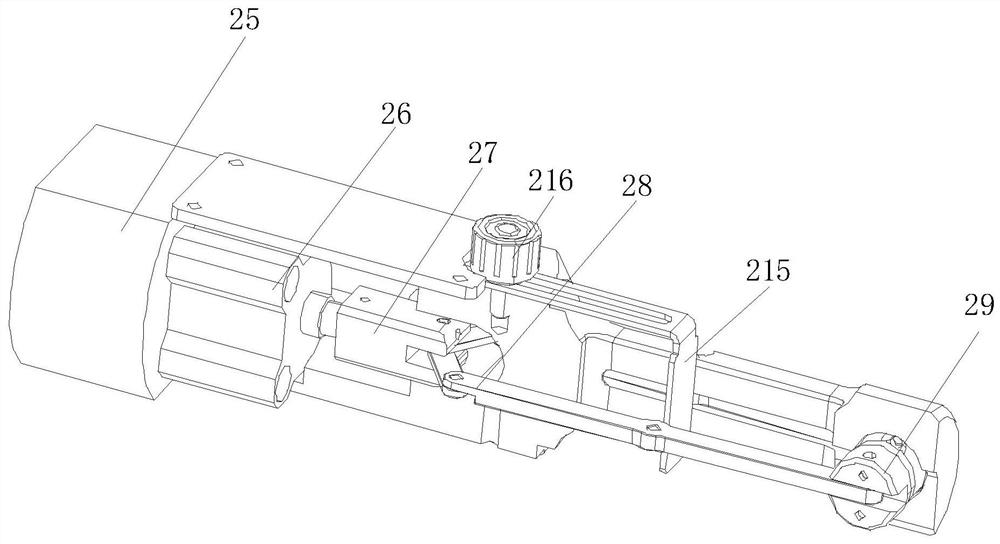

Wire wrapping and looping device of metal heating wire and wire wrapping and looping method thereof

PendingCN109079057AImprove the efficiency of circle workMaintain consistencyWire articlesWire cuttingEngineering

The invention provides a wire wrapping and looping device of a metal heating wire. The wire wrapping and looping device comprises a feeding compressing mechanism, a looping mechanism and a wrapping mechanism. A wire wrapping and looping method comprises the following steps of feeding, clamping, wire cutting, looping, knocking over, wire pushing, wire wrapping, resetting, cutting off, discharging and the like. A metal wire sequentially penetrates through a feeding push rod of the feeding compressing mechanism and a feeding pipe of the looping mechanism. A driving device of the looping mechanismdrives a looping assembly to achieve metal wire looping. The looping assembly moves in the z-axis direction to enable the looping assembly to separate from the metal wire after looping. The metal wire after looping is pushed to the wrapping mechanism for wrapping forming. The looping and wrapping procedures are conducted automatically by the wire wrapping and looping device instead of manual looping. In this way, the looping working efficiency can be greatly improved. Rotation of the looping mechanism is mechanical, and therefore the looping and rotation are in consistency and integrity, andthe looping quality can be guaranteed.

Owner:中山市协展机械有限公司

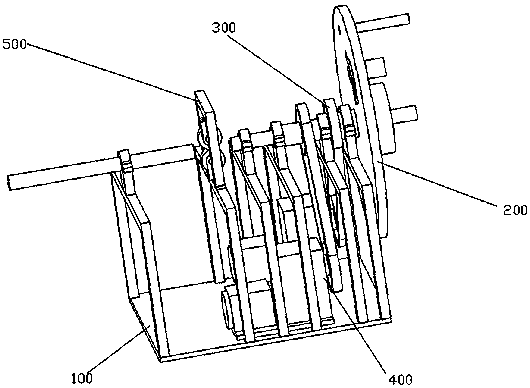

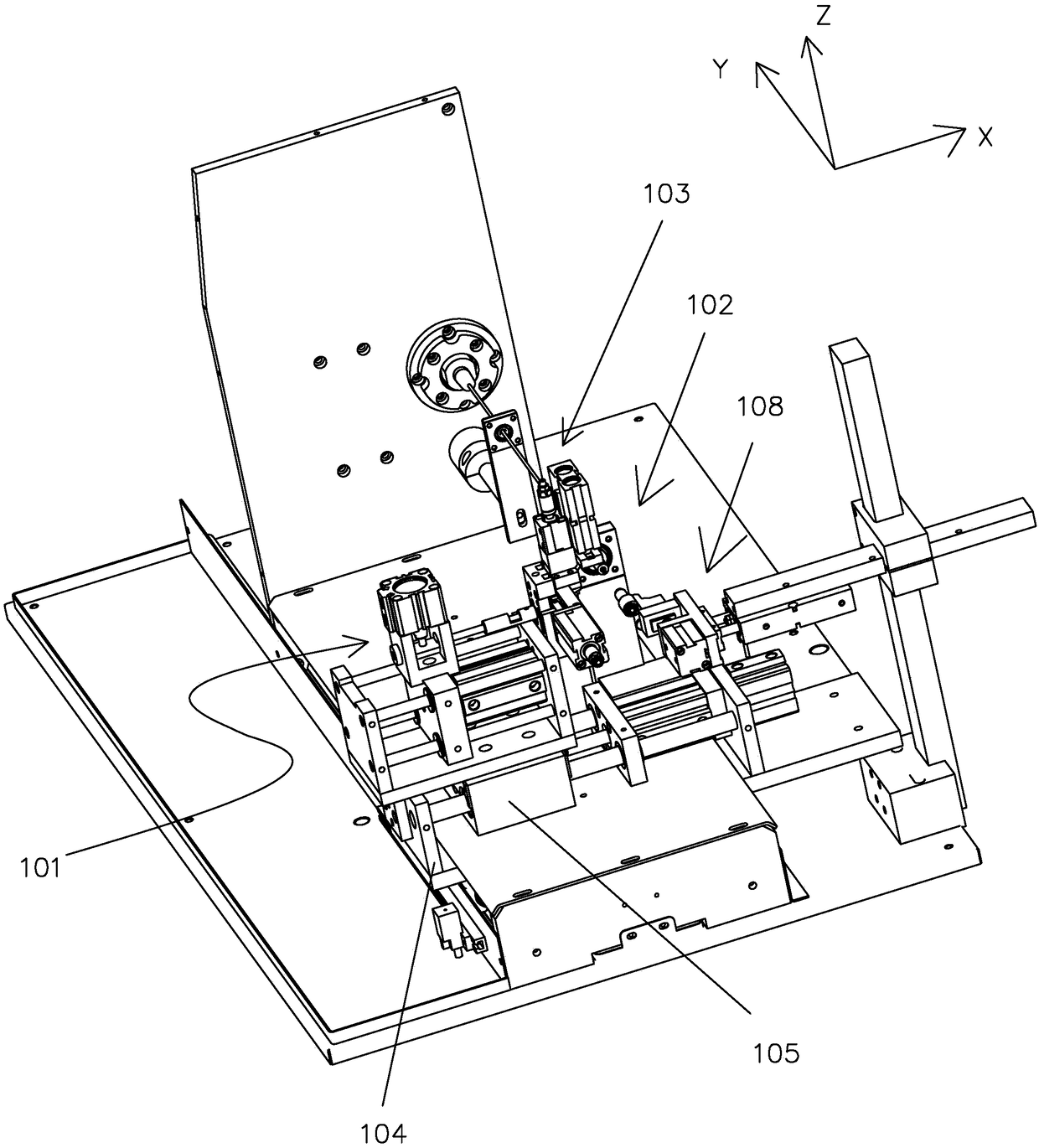

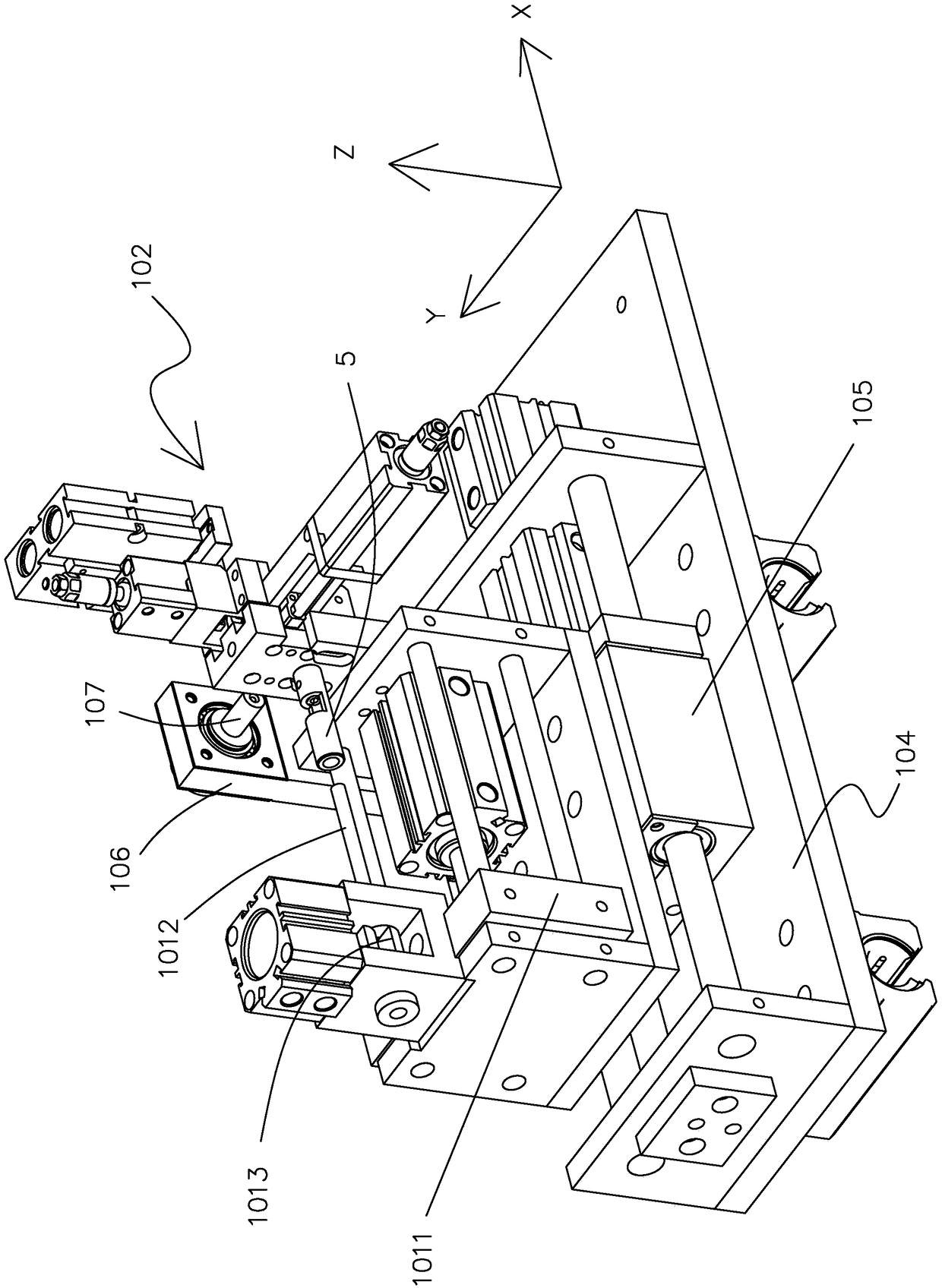

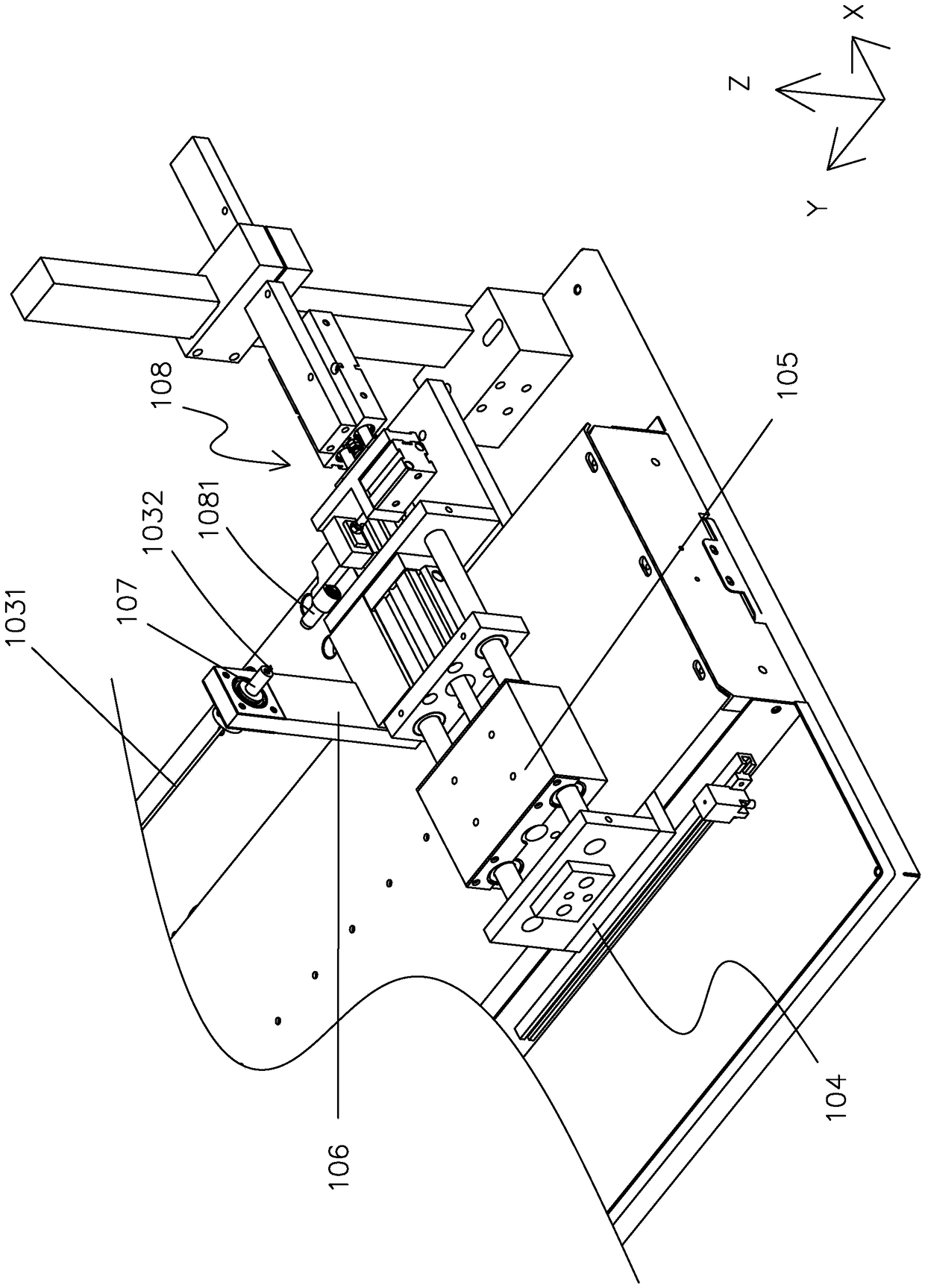

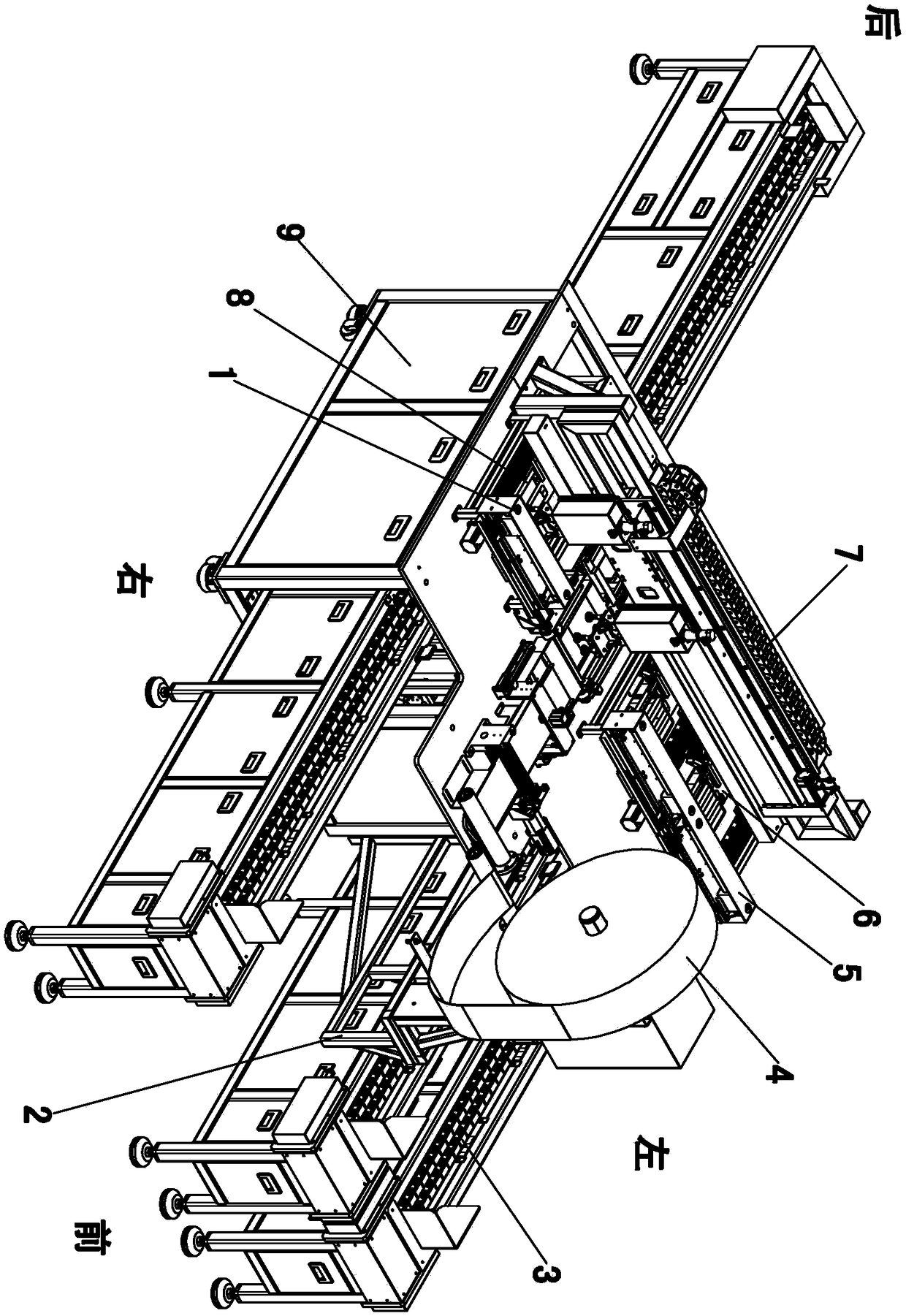

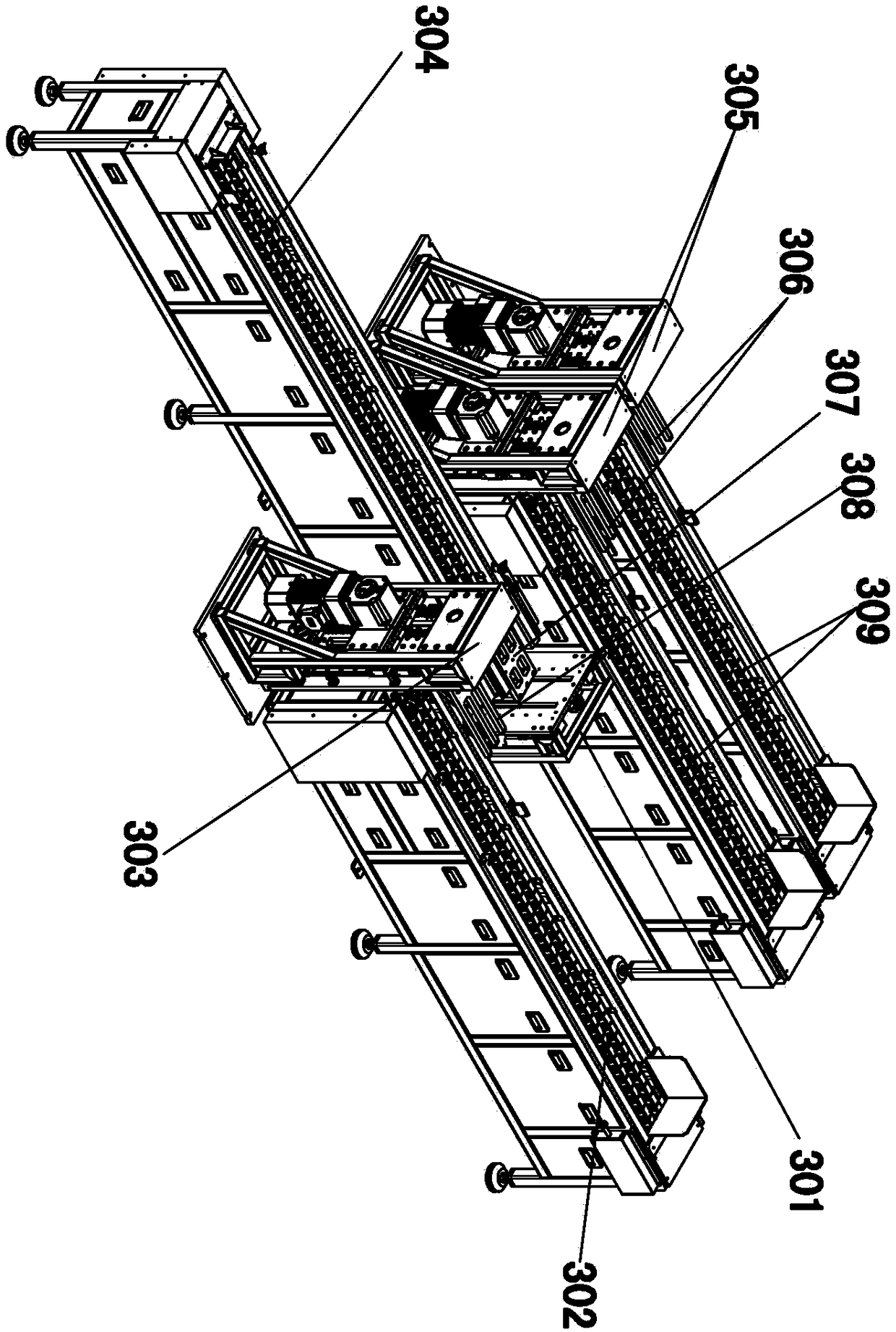

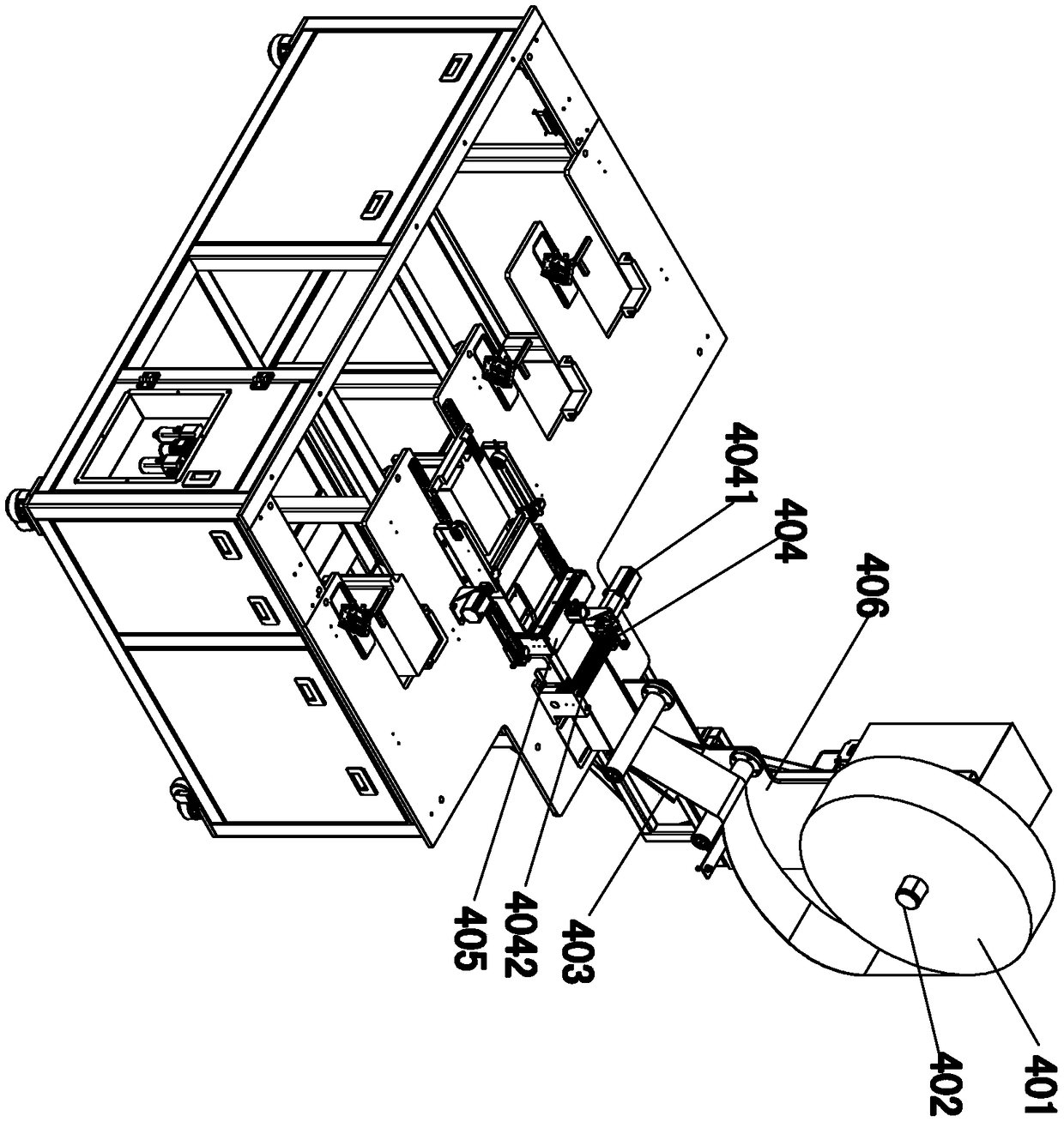

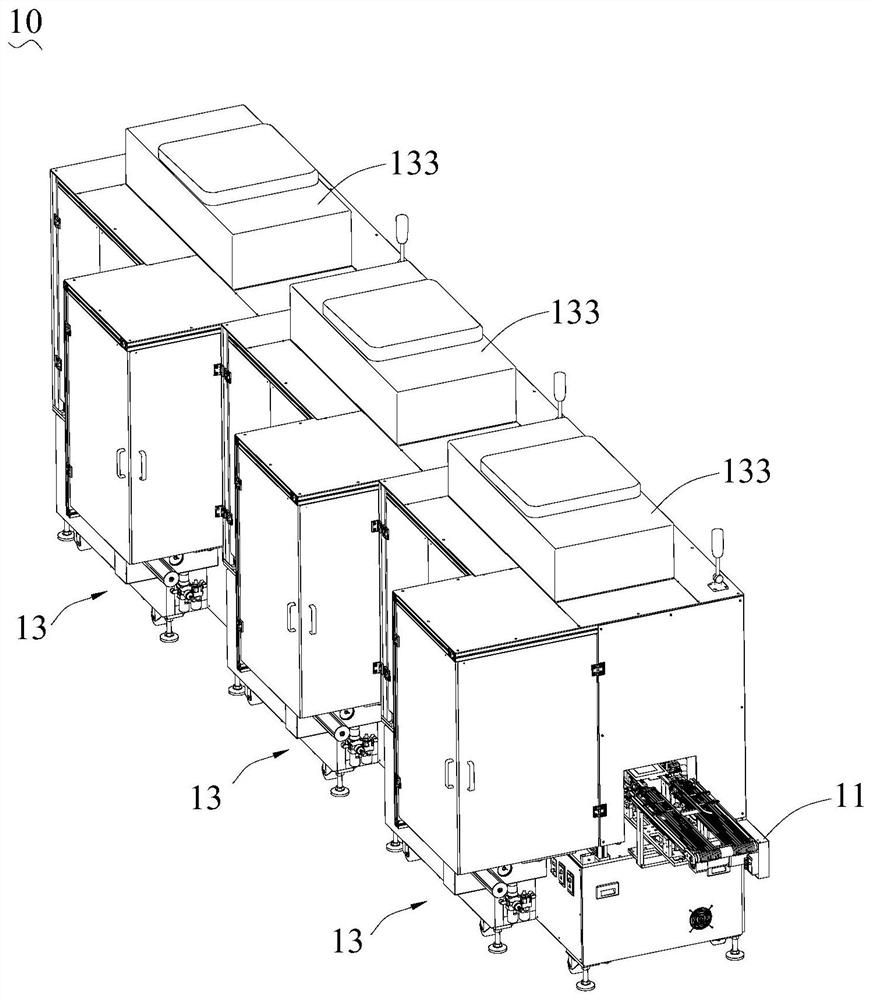

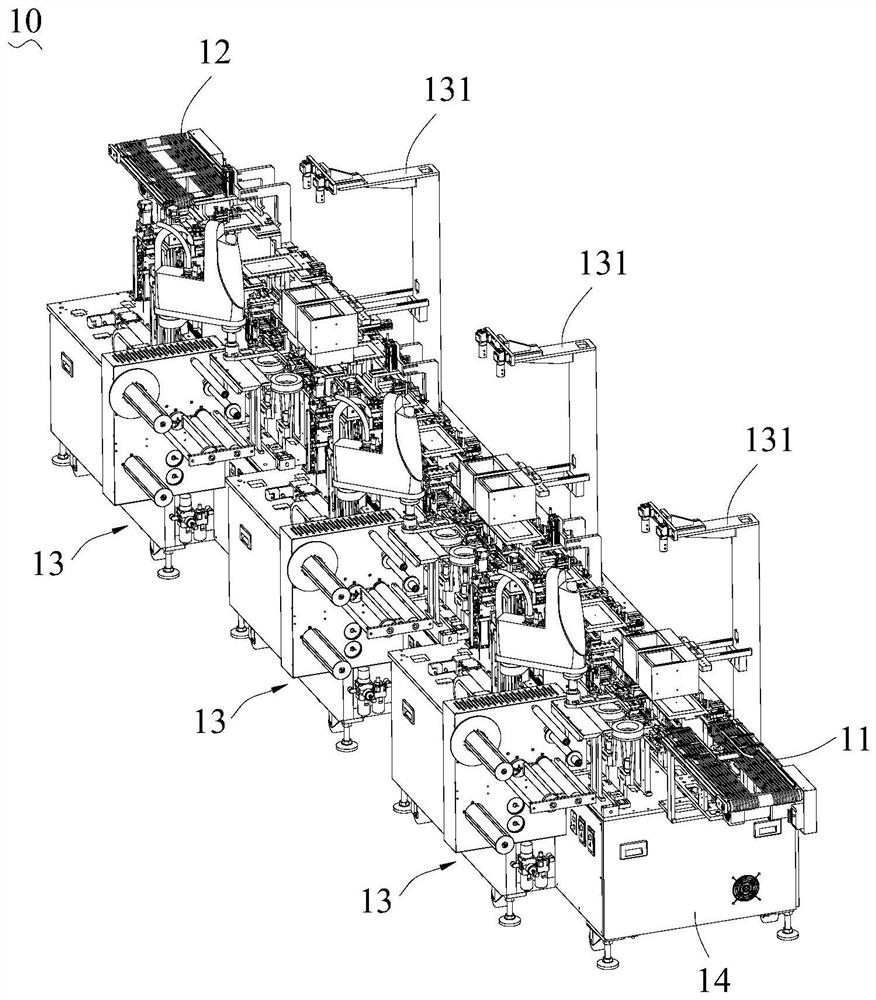

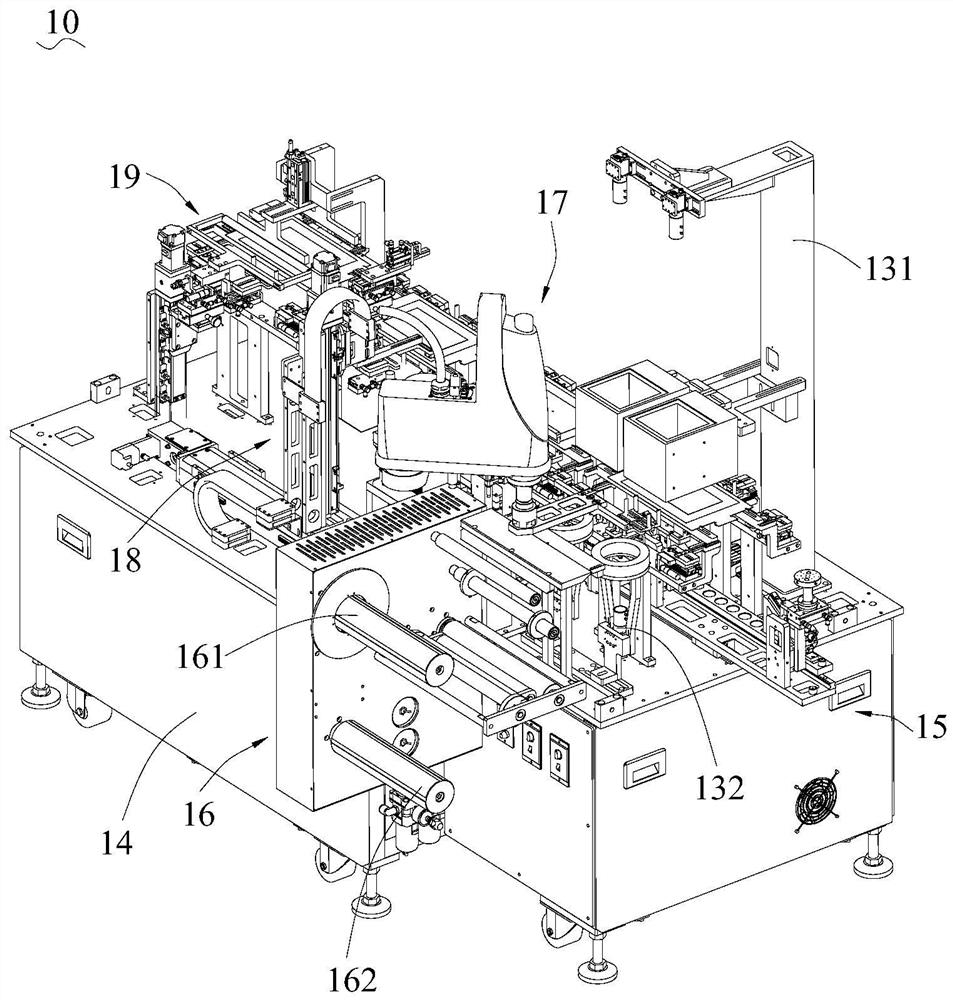

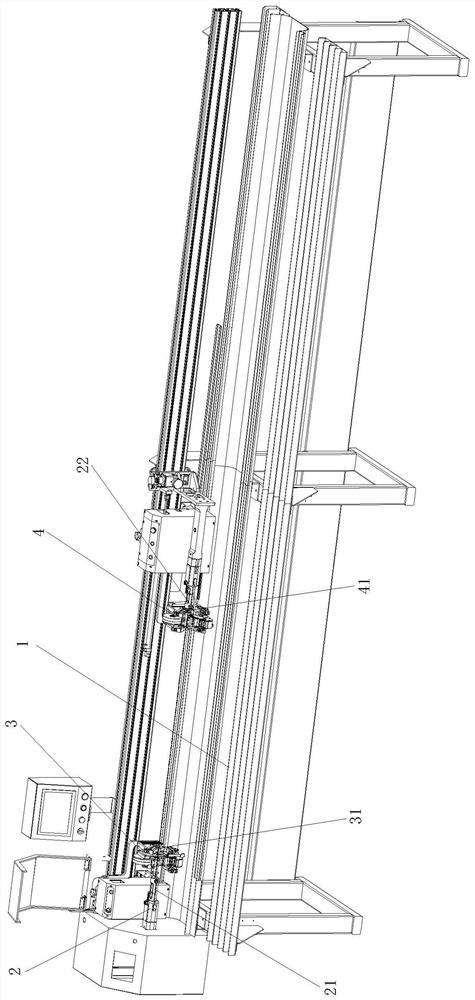

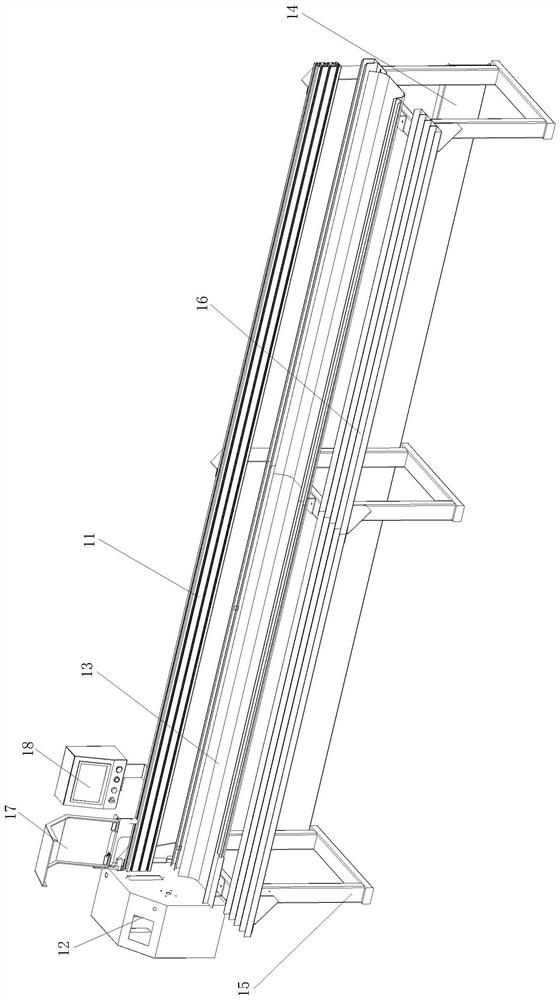

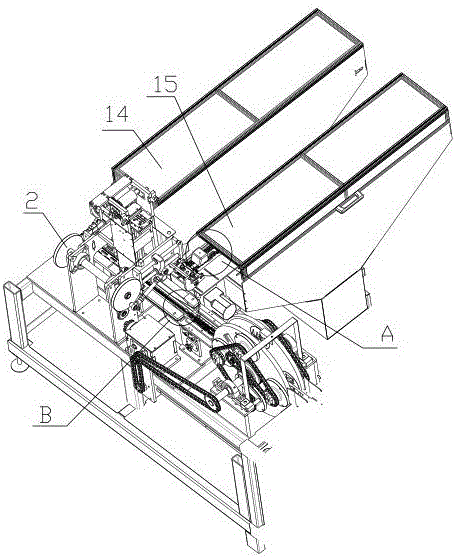

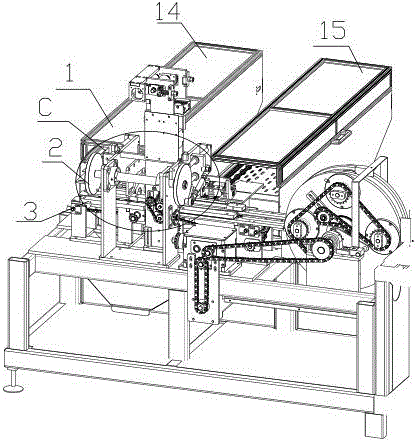

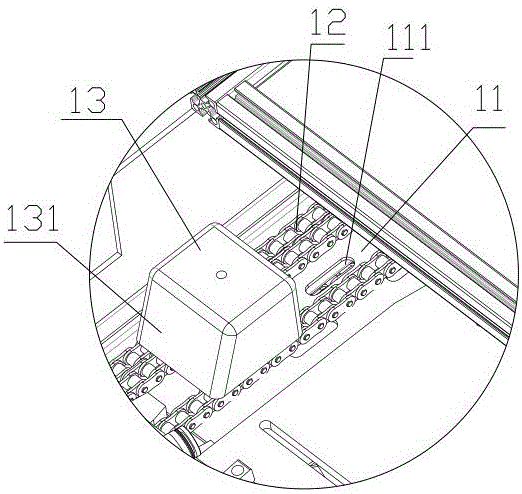

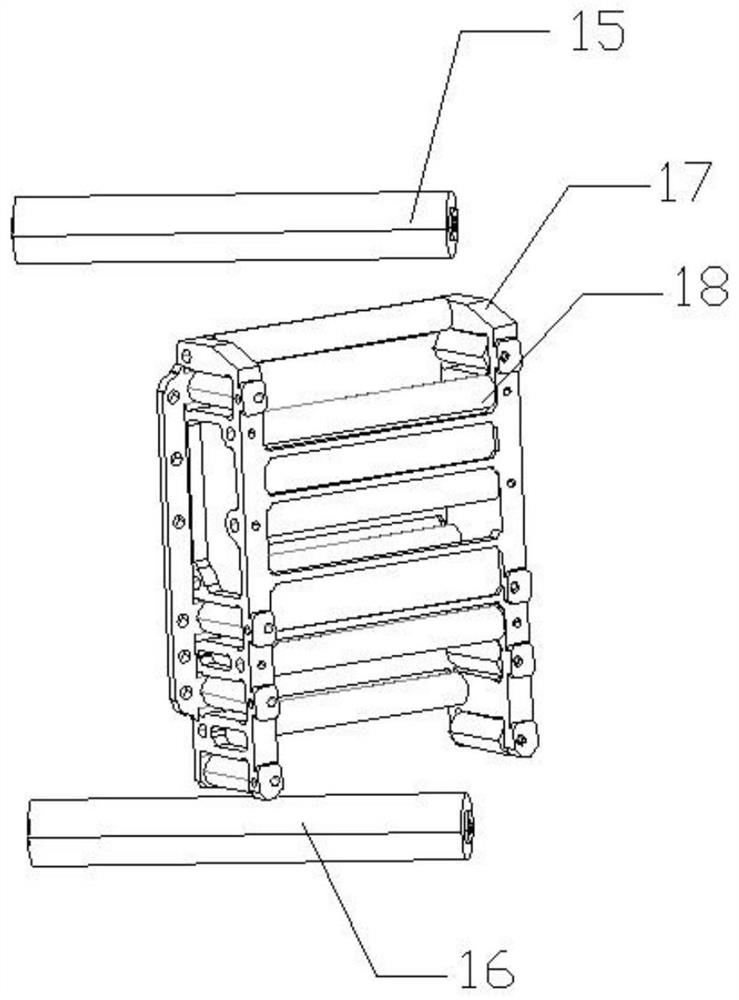

Novel automatic plate wrapping equipment for large lead-acid storage battery pole group

PendingCN108199093ASimple structureShort positioning timeFinal product manufactureLead-acid accumulator electrodesPhysical well beingEngineering

The invention discloses novel automatic plate wrapping equipment for a large lead-acid storage battery pole group and belongs to the technical field of battery production equipment and aims to solve the problems that existing plate wrapping procedures for battery production are performed manually, are low in efficiency and high in labor intensity, require a large quantity of manual labor, cause dust pollution to the environment and ruin body health of relevant employees. A finished product lifting conveying mechanism is fixedly connected with a rack, a positive pole arrangement cylinder and two negative pole arrangement cylinders are fixed on the rack, the positive pole arrangement cylinder is arranged above a positive pole lifting mechanism of the finished product lifting conveying mechanism, the negative pole arrangement cylinders are arranged above two negative pole lifting mechanisms of the finished product lifting conveying mechanism, a diaphragm coiled material discharging mechanism is fixedly mounted on the rack and arranged between the positive pole arrangement cylinder and the negative pole arrangement cylinders, a positive and negative plate transferring mechanism is fixed on the rack and arranged on the rear sides of the positive pole arrangement cylinder and the negative pole arrangement cylinders. The production efficiency is improved.

Owner:中山慧能科技有限公司

Preparation method of fragrant Tieguanyin

The invention discloses a preparation method of fragrant Tieguanyin. The method comprises the following steps of (S1) tea harvesting; (S2) sun withering; (S3) rocking green; (S4) tea parching: frying the rocked tea at 120-130 DEG C, and completing tea parching when the green leaves turn yellow from green; (S5) twisting and wrapping: alternately carrying out rolling and wrapping-twisting treatment on the tea and carrying out light baking when the tea is in a granular form; (S6) light baking: drying the tea after the twisting and wrapping procedures in hot air of 40-50 DEG C until the moisture content is reduced to 40-60%; (S7) baking: baking at 60-70 DEG C until the moisture content of the tea is reduced to 4-5%; and (S8) selecting. A traditional preparation method of the fragrant Tieguanyin is improved, and various process steps in the whole preparation method are integrated and associated with one another, so that strengthening of the brewing persistence is facilitated through control on specific process routes, process parameters and indexes, the aroma and taste of the tea are effectively improved, and the quality of the tea is improved.

Owner:FUJIAN EIGHT HORSES TEA

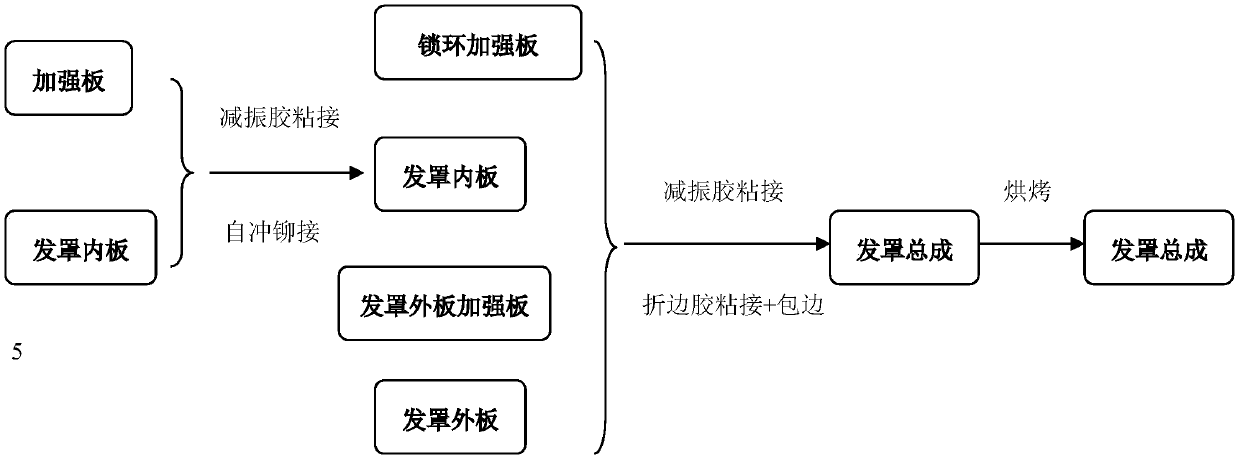

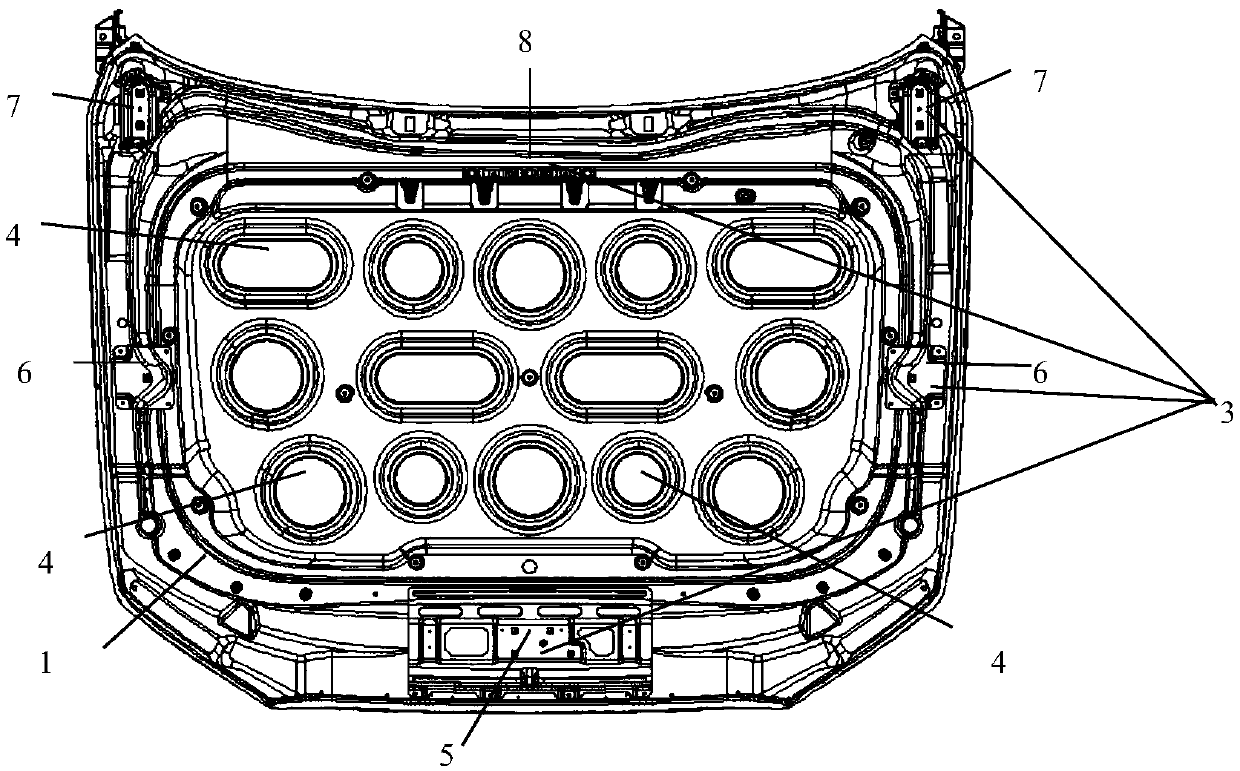

Passenger car aluminum alloy engine cover riveting and bonding composite connection method

InactiveCN109513868AGuaranteed stiffnessGuaranteed StrengthFastening meansEngineeringWrapping procedure

The invention provides a passenger car aluminum alloy engine cover riveting and bonding composite connection method. The method comprises the steps that an engine cover reinforcing plate is pre-fixedto an engine inner plate through a vibration reduction glue bonding manner, reinforcing plates are completely fixed to the engine cover inner plate through a self-piercing riveting manner; a protruding edge of a lightening hole of the engine cover inner plate, a lock ring reinforcing plate and an engine outer plate reinforcing plate are coated with vibration reduction glue, and an engine cover outer plate of the engine cover falls down to finish bonding; the edge of the engine cover inner plate is coated with folding glue, the edge of the engine cover outer plate is subjected to side wrappingtowards the engine cover inner plate, the side wrapping procedure of the engine cover can be finished, and an engine cover assembly can be obtained; the engine cover assembly is baked, vibration reduction glue and folding glue are cured, and connection of the engine cover can be achieved. The self-piercing riveting and bonding composite process is used for replacing the welding process, connectionof the aluminum alloy engine cover is achieved, and whole rigidity, whole strength and size precision of connection of the aluminum alloy engine cover can be better ensured.

Owner:CHINA FIRST AUTOMOBILE

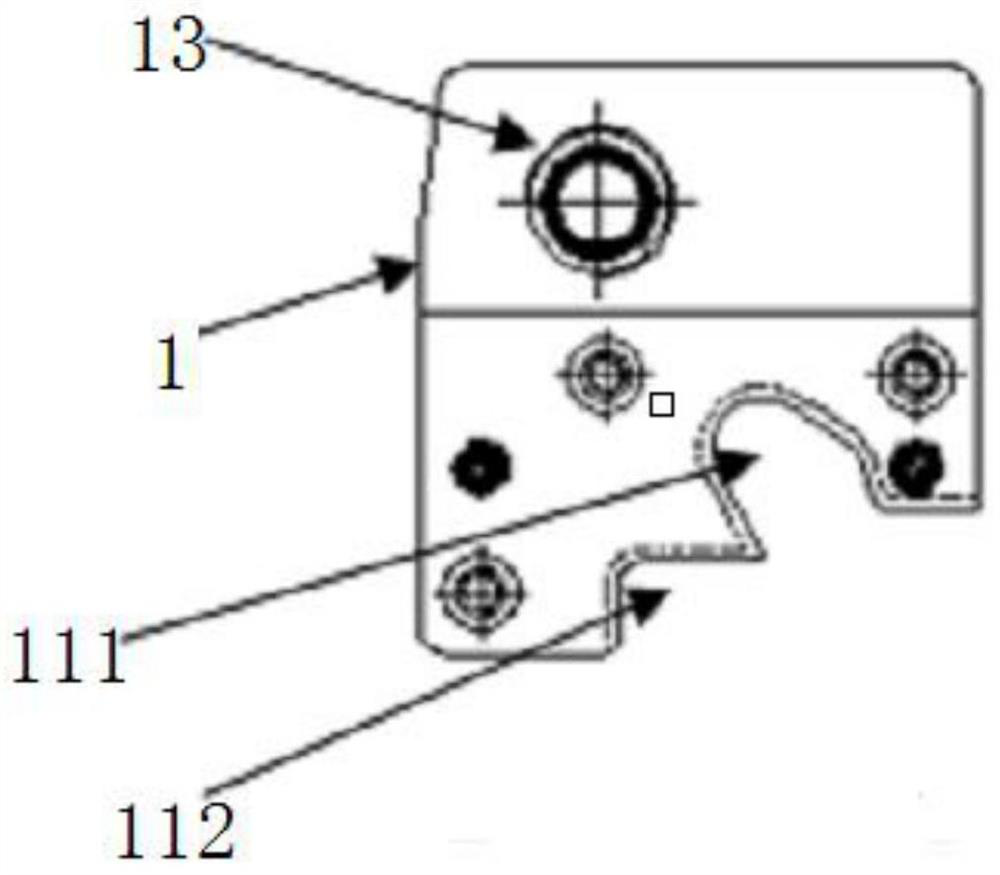

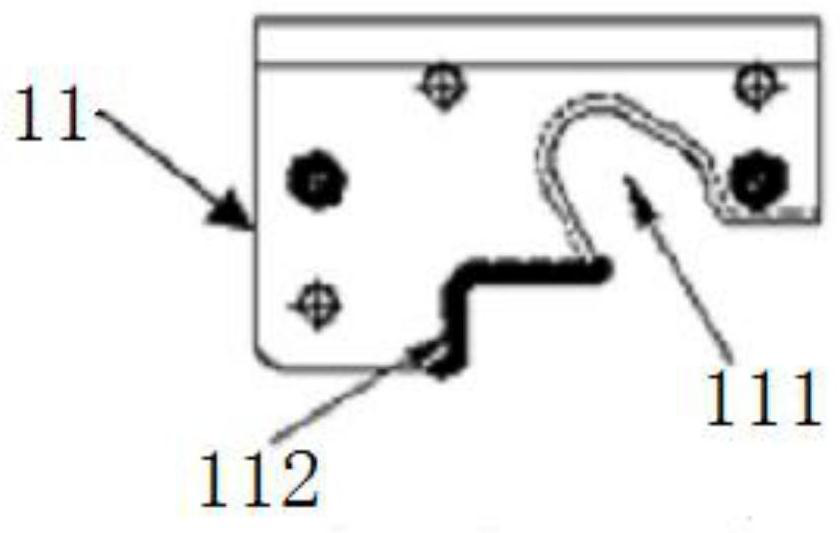

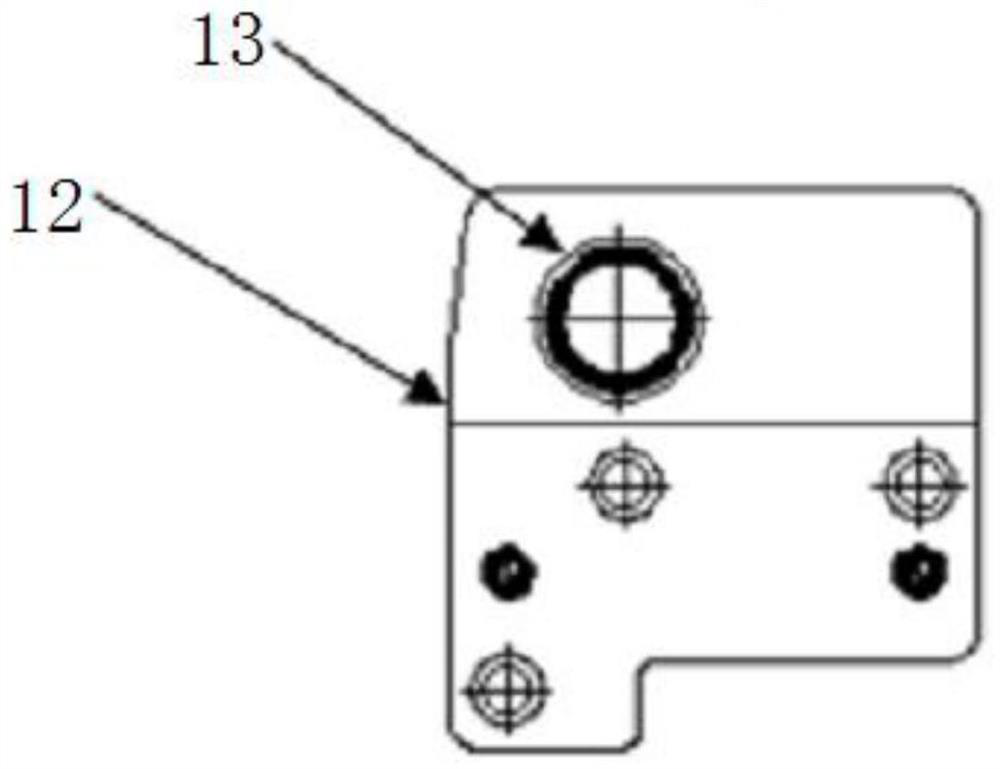

Edge film wrapping device and edge wrapping equipment

PendingCN112848257AFully automatedIncrease productivityDomestic articlesEngineeringStructural engineering

The invention belongs to the technical field of automation equipment, and particularly relates to an edge film wrapping device and edge wrapping device.The edge film wrapping device comprises a lifting module, a damping air cylinder, a pushing frame and an edge wrapping roller, wherein the lifting module is fixedly arranged, the damping air cylinder is arranged on the lifting module, the pushing frame is connected with the damping air cylinder and are arranged corresponding to a transfer path of an edge wrapping object apparatus, and the edge wrapping roller is rotatably arranged on the pushing frame. Thus, the edge of the edge wrapping object apparatus is laminated in a rolling and wrapping manner. In the process, the edge wrapping roller can drive the part, extending out of the upper surface of the edge of the edge wrapping object apparatus, of a film material to wrap the edge of the edge wrapping object apparatus, and finally the part is attached to the lower surface of the edge of the edge wrapping object apparatus. Finally, an edge wrapping procedure of the edge wrapping object apparatus is accurately and reliably completed.

Owner:SHENZHEN WEIHONGKE TECH

Production method of knitted fabric with high wear resistance

The invention discloses a production method of knitted fabric with high wear resistance. The fabric is woven by weaving polyester fibers, cotton fibers and polypropylene fibers. The weft materials are cotton yarn and polyester cotton yarn, and the wrap materials are the polypropylene fibers. The polyester fibers, the cotton fibers and the polypropylene fibers are interwoven after being washed by water, and are dried by a dryer finally. Wrapping procedure is performed on the polypropylene fibers before weaving, the polypropylene fibers are dyed by processing solution, and the ingredients of the processing liquid, by proportion, include 15 to 20% of modified starch, 11 to 16% of polyvinyl alcohol, 10 to 15% of acrylic ester, 0.02 to 0.03% of fatty alcohol polyoxyethylene ether and 50 to 70% of distilled water. The method is simple, acid and alkali resistant capacities of the obtained clothes are improved greatly, strength is high, and wear resistance is fine.

Owner:QINGDAO TONGGUANWANG IND

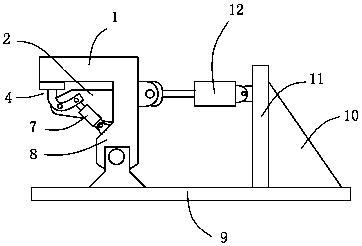

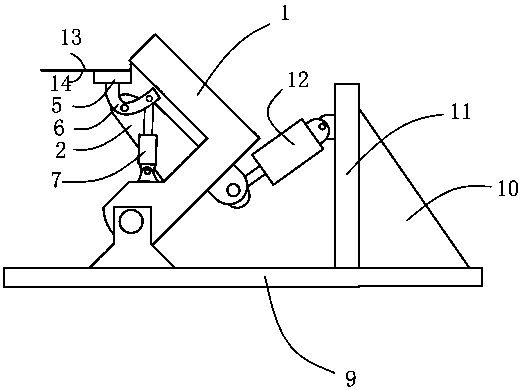

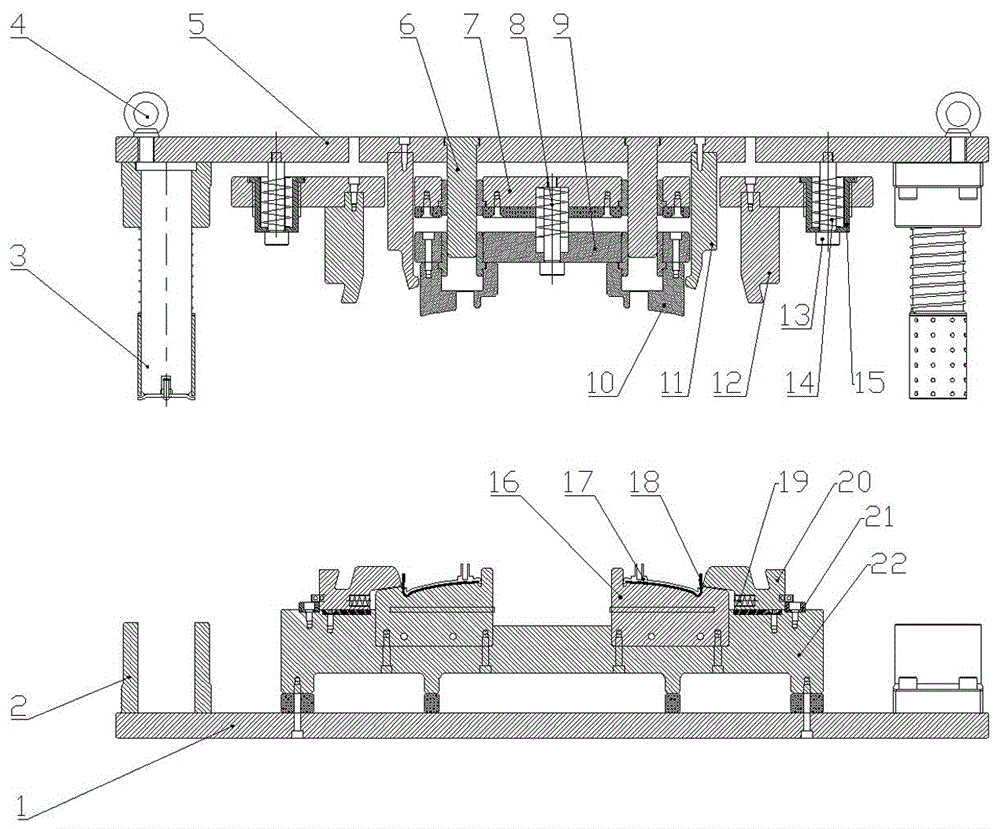

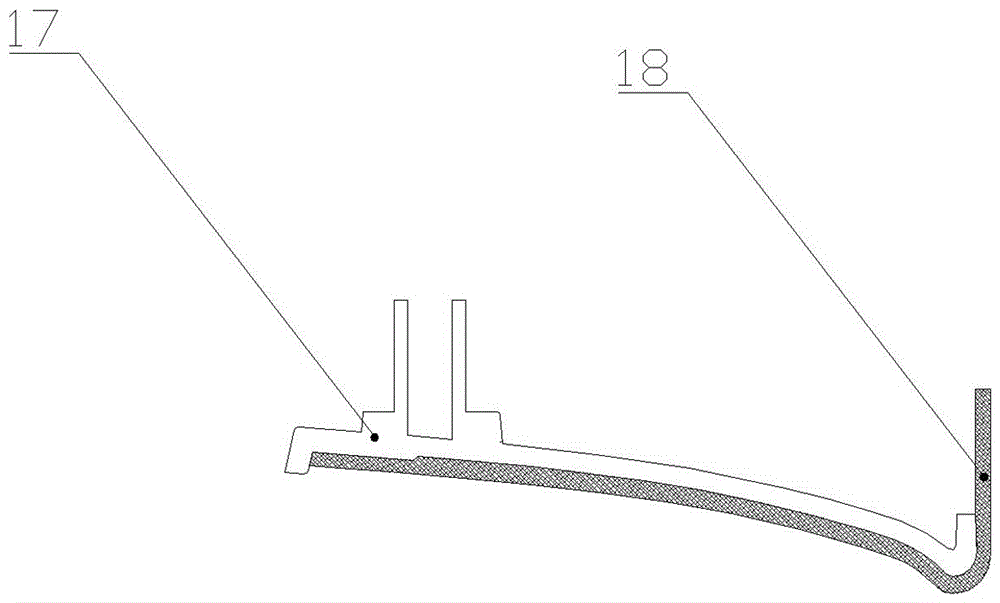

Rapid automobile sheet metal part edge wrapping mechanism

The invention relates to a rapid automobile sheet metal part edge wrapping mechanism. The defects that an existing edge wrapping machine needs to conduct edge wrapping on a sheet metal part with two steps, the work efficiency is low, and the consistence precision requirement for folded points needed for the two procedures is high, and control is not easy are overcome. After an upper edge wrappingdie and a lower edge wrapping die are folded, a workpiece profiling part is formed, the upper edge wrapping die is hinged to a base, and an upper die drive cylinder is connected between the upper edgewrapping die and the base. The lower edge wrapping die is hinged to the upper edge wrapping die and rotates along with the upper edge wrapping die. A lower die drive cylinder is connected between thelower edge wrapping die and the upper edge wrapping die. The lower edge wrapping die is hinged to the upper edge wrapping die and can rotate along with the upper edge wrapping die, independent rotation can be achieved, 90-degree overturning of an outer sheet metal part spigot can be achieved through the motion combination of the upper edge wrapping die and the lower edge wrapping die, the pre-edge-wrapping procedure is not needed, and one-time sheet metal part edge wrapping is achieved. The work efficiency is improved, precision control is convenient, and consistent folded points can be guaranteed.

Owner:ZHEJIANG GEELY AUTOMOBILE +2

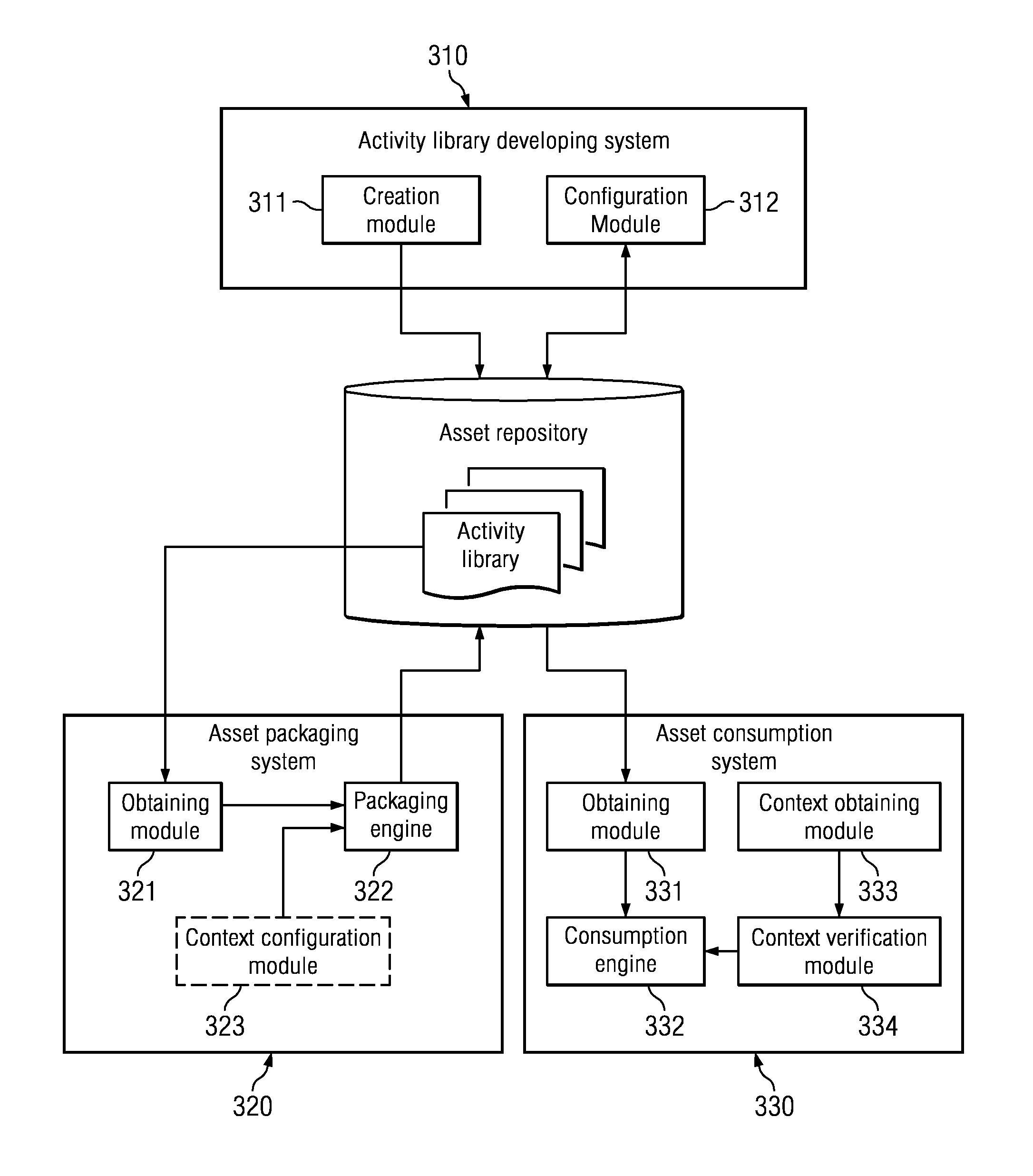

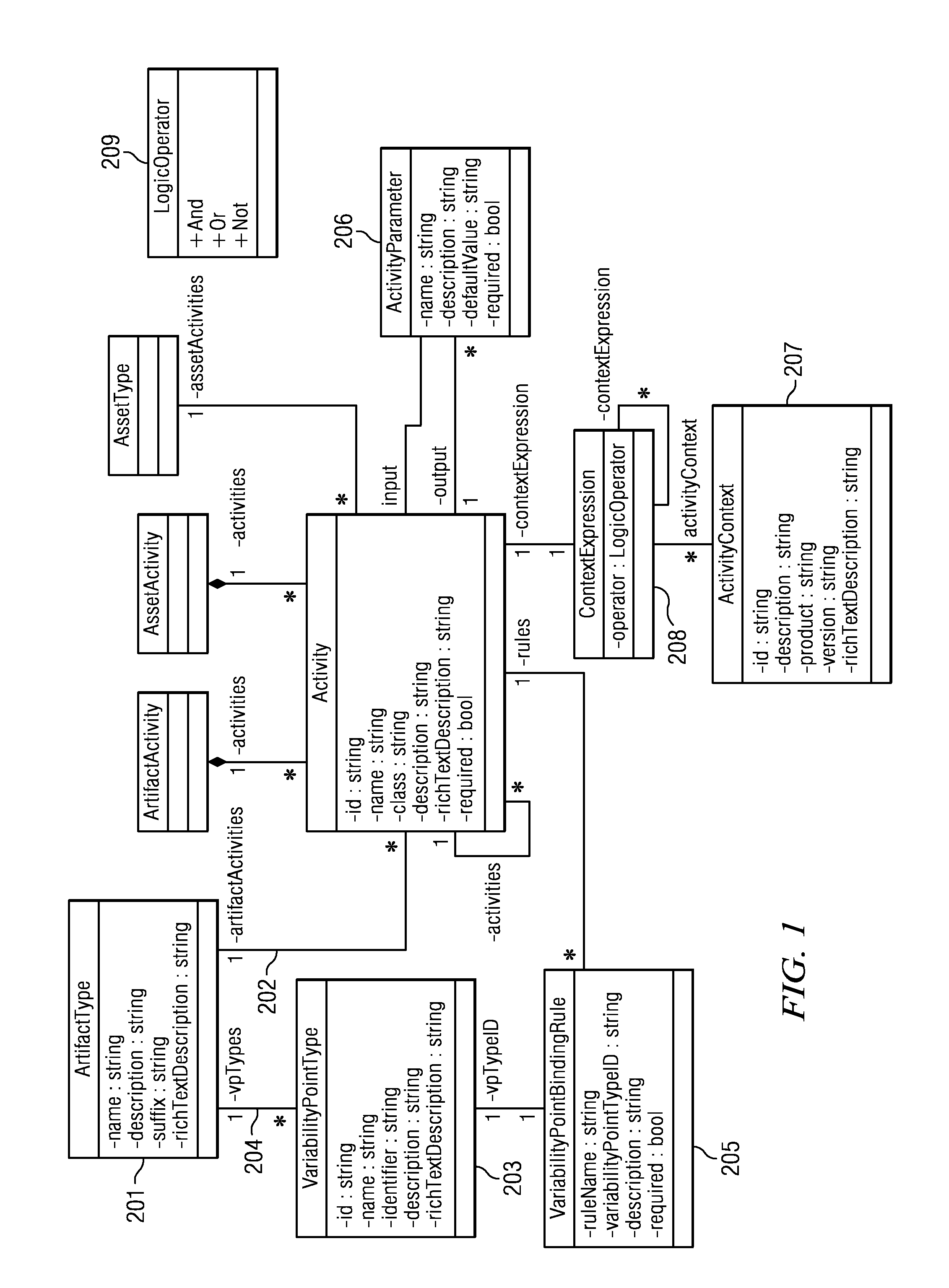

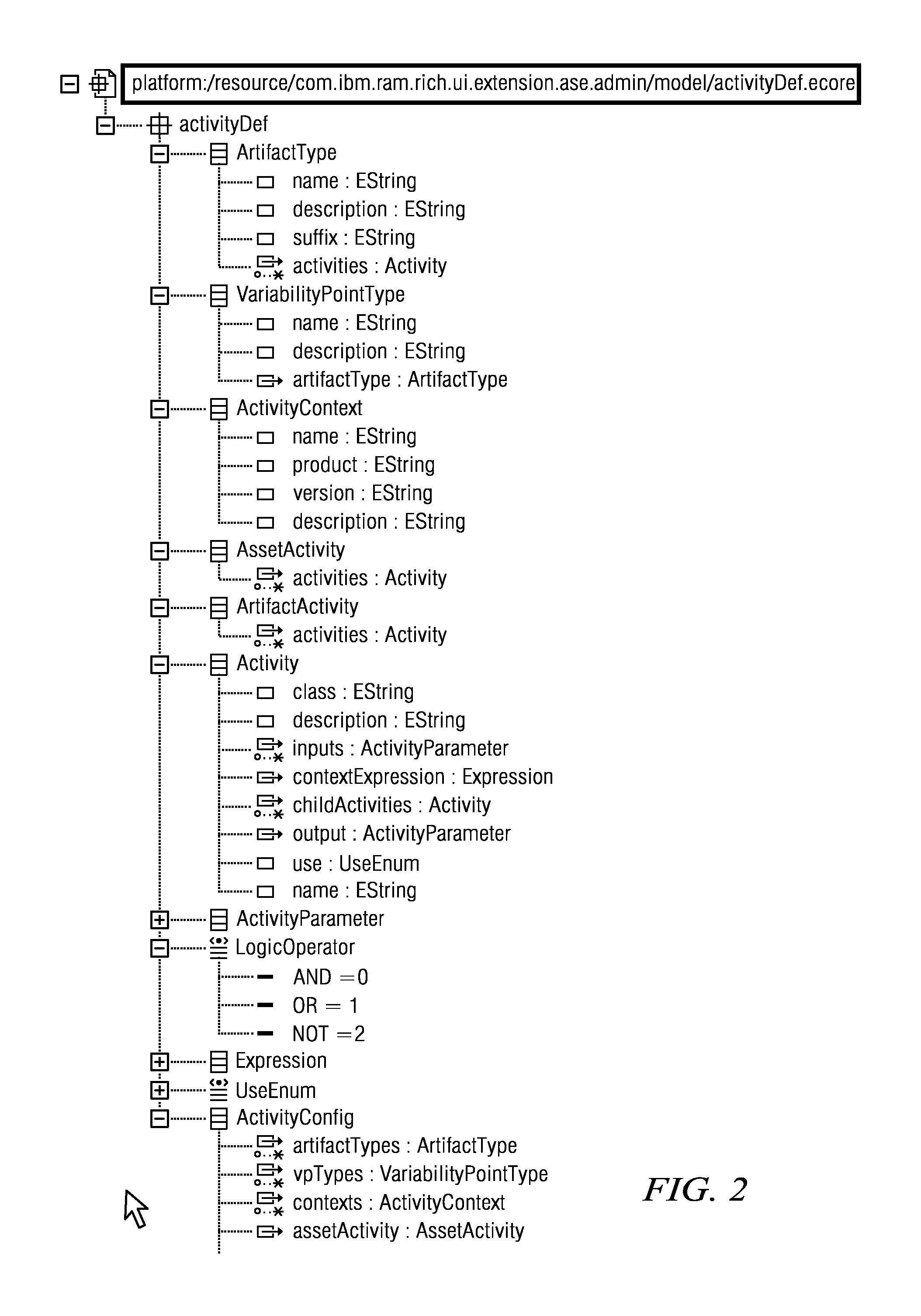

Software asset packaging and consumption

A reusable asset packaging and consumption method and system that support consumption activities and variability point instances associated with asset types or artifact types. Generic consumption activities and variability point types for different asset types or artifact types and developed and stored in a repository. When an asset packager packages an asset, a needed activity is selected from the activities associated with the type of the asset. The activity, a variability point instance bound with the activity, and the context constraints, together with the artifacts is packaged into the asset package, where the asset package is then stored in a repository. During consumption, the asset consumer obtains the asset package, verifies the context, and executes the activity packaged in the asset, while specifying variability point values for the bound variability instance.

Owner:IBM CORP

Automatic edge wrapping mold

The invention discloses an automatic edge wrapping mold. The automatic edge wrapping mold comprises a product skeleton and a product cover, and is characterized by comprising an upper mold structure, a lower mold structure, a guide column sleeve, a mold frame guide column and a lifting ring; the upper mold structure is connected and provided with the mold frame guide column and the lifting ring; the lower mold structure is provided with the guide column sleeve; and the mold frame guide column is matched and connected with the guide column sleeve. The automatic edge wrapping mold is applied to an edge wrapping procedure of a decoration plate cover of a product door sheet to the skeleton, can realize automatic edge wrapping of the product through self mold opening and closing kinetic energy of a hot press in the procedure, and is low in cost investment compared with edge wrapping by a robot or edge wrapping by an electric control slide block unit. The automatic edge wrapping mold is simple in operation, can effectively control the edge wrapping quality, is stable in product quality, and saves a lot of labor costs.

Owner:YANFENG WEISHITONG LIUZHOU AUTOMOBILE ACCESSORIES

Wire twisting and adhesive tape wrapping machine

PendingCN111816379AEasy to processManufacturing wire harnessesInsulating conductors/cablesElectric machineryEngineering

The invention discloses a wire twisting and adhesive tape wrapping machine. The invention belongs to the technical field of harness processing. The machine comprises a supporting part, a wire twistingpart, a first adhesive tape machine and a second adhesive tape machine. The supporting part comprises a moving plate and a machine box; the machine box is arranged on the left side of the moving plate; the first adhesive tape machine and the second adhesive tape machine are arranged on the moving plate from left to right; and the first adhesive tape machine and the second adhesive tape machine are used for wrapping adhesive tape on a to-be-processed raw wire. The wire twisting part is arranged on the front side of the moving plate; the wire twisting part is arranged on the right side of the second adhesive tape machine; the wire twisting part comprises a first chuck, a second chuck, a mounting plate and a fixing plate; the first chuck is arranged on the right side of the machine box, a motor is further arranged in the machine box, and a main shaft of the motor is fixedly connected with the first chuck; and in the working process, the first chuck and the second chuck clamp the two endsof the raw wire respectively, then, the motor drives the first chuck to rotate, and the wire twisting and adhesive tape wrapping procedures are completed.

Owner:惠州市纳智工业设备有限公司

Method for manufacturing lotus leaf packaging bag

InactiveCN103753684ASimple and fast operationReduce manufacturing costBagsSacksBiotechnologyMicrowave

The invention discloses a method for manufacturing a lotus leaf packaging bag which is suitable for food packaging. According to the technical scheme, lotus leaves are processed according to the procedures of drying, flattening, slicing, bonding, sterilizing and packaging. The method includes the first step of collecting a complete lotus leaf, cleaning the surface, drying the lotus leaf and carrying out dehydration on the lotus leaf, the second step of flattening the dehydrated lotus leaf, the third step of slicing the flattened lotus leaf, the fourth step of bonding lotus leaf slices by sticky rice paste and enabling the lotus leaf slices to form the lotus leaf packaging bag, the fifth step of carrying out sterilization on the lotus leaf packaging bag through microwaves, and the sixth step of sealing sterilized lotus leaf packaging bag. According to the technical scheme, the method is easy to operate, and the lotus leaf packaging bag is low in production cost, harmless and friendly to environment.

Owner:万世凤

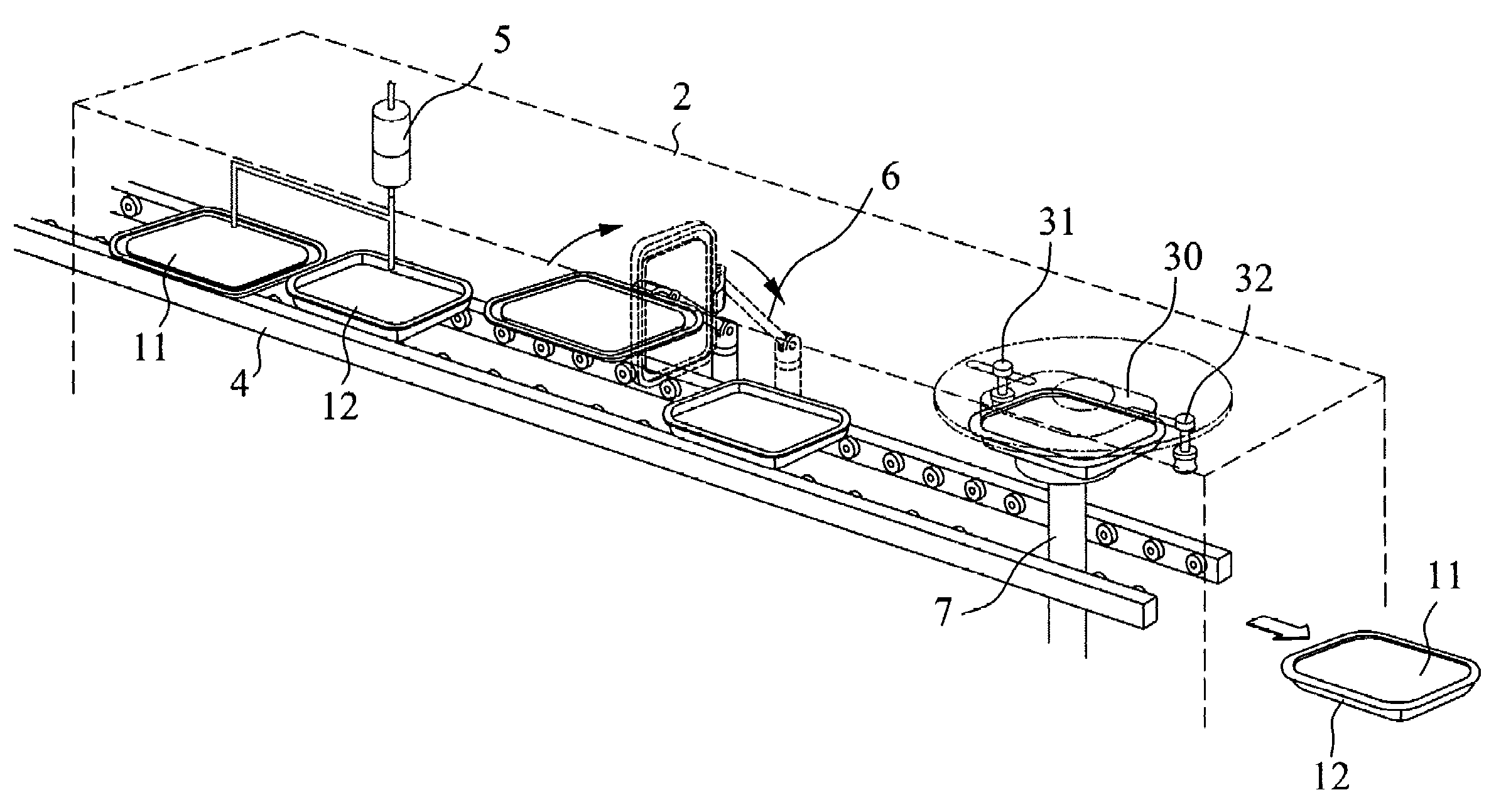

Edge wrapping device suitable for film wrapping and edge wrapping machine

InactiveCN106628840AEasy to moveGuaranteed vertical contactConveyorsElectrode manufacturing processesMechanical equipmentWrapping procedure

The invention relates to the field of mechanical equipment, in particular to an edge wrapping device suitable for a film wrapping and edge wrapping machine. According to the technical scheme, the edge wrapping device suitable for the film wrapping and edge wrapping machine comprises a transferring device which is arranged on a main machine frame and used for transferring electrode plates, and a supply device. The supply device comprises a positive electrode plate supply device for containing positive electrode plates and a negative electrode plate supply device for containing negative electrode plates. A paper feeding device is arranged between the positive electrode plate supply device and the negative electrode plate supply device according to the transferring direction of the electrode plates, and comprises a paper unwinder used for unwinding a separation plate paper coil and a cutter. According to the edge wrapping device suitable for the film wrapping and edge wrapping machine, workers need not carry out manual transferring or alignment of the electrode plates, the electrode plates can be automatically transferred from a feeding device, and the edge wrapping procedure is completed automatically.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

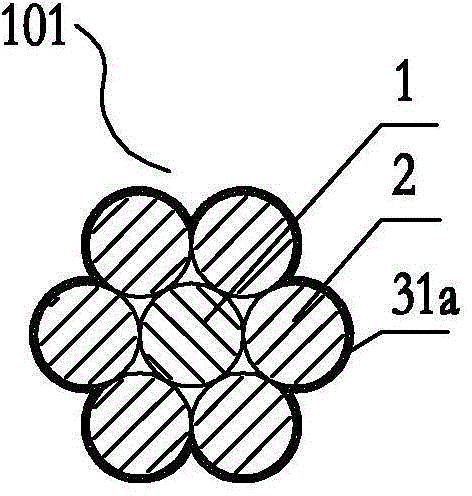

Steel strand with polyurea protection material on outer layer and manufacturing method of steel strand

ActiveCN105088954AHigh tensile strengthGood flexibilityRope making machinesBridge structural detailsUltimate tensile strengthPolyurea

The invention discloses a steel strand with a polyurea protection material on the outer layer. A steel strand body with the polyurea protection material on the outer layer is formed in the manner that a polyurea protection coating I made of the polyurea material is arranged on the periphery of the whole steel strand, or the gap formed through twisting of a center wire and side wires is filled with the polyurea material, and a steel strand body with the polyurea protection material on the outer layer is formed in the manner that the polyurea protection coating I made of the polyurea material is arranged on the periphery of the whole steel strand. A manufacturing method of the steel strand comprises the steps that in steel wire preprocessing, surface processing and priming are carried out, the preprocessed center wire and the preprocessed side wires are twisted to form the steel strand, one or more of the polyurea material coating procedure I, the twining and wrapping procedure, the polyurea material coating procedure II, the polyurea material coating procedure III, the extrusion molding procedure and other procedures are carried out, and the series steel strand with multiple protection is manufactured. The manufacturing method is easy and convenient to conduct. The manufactured steel strand is high in tensile strength, good in flexibility, high in damping, resistant to ageing and abrasion, and good in vibration damping performance; and the anti-corrosion capability of the steel strand can be greatly improved, and the service life of the steel strand is prolonged.

Owner:LIUZHOU OVM MASCH CO LTD +1

Composite dry-type wall-pie

InactiveCN1815832AReduce internal stressImprove securityElectrical apparatusPipesEngineeringHigh pressure

Frame by frame backing method is adopted in the invention to wrap Teflon strap. In wrapping procedure, strain of Teflon strap is controlled. Reducing internal stress of wall bushing, the method overcomes issues that insulating wrapping layer for dry type wall bushing in high pressure is easy of sliding frame, and falling off. The invention increases safety and operating life of wall bushing.

Owner:SHANGHAI ZHUOGAO ELECTRIC

Novel distribution line insulation wrapping device

The invention relates to the technical field of mechatronics, in particular to a novel distribution line insulation wrapping device. Comprising a rack, and the rack is provided with a material disc, a conveying channel, a shearing device, a conveying device, a package gradual change closing-up device, a pressing sealing device, a button sewing device and a walking lifting device. According to the invention, the insulation wrapping sheet stored on the material disc is drawn out, is folded and turned through the conveying channel, bypasses the electric wire, is conveyed under the action of the conveying device, is changed into a U-shaped structure from a flattened state and covers the electric wire, and is sealed under the action of the pressing and sealing device; the electric wire wrapped with the insulation wrapping piece is twisted and conveyed to the button sewing device, then a C-shaped nail is clamped into an opening of the insulation wrapping piece, firm sealing of the insulation wrapping piece is guaranteed, after the wrapping procedure is completed, the insulation wrapping piece is cut off under the action of the shearing device, and then driving walking along the electric wire is effectively completed under the action of the walking lifting device; and insulating wrapping work of the wire is completed.

Owner:HUAINAN POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CORPORATIO +2

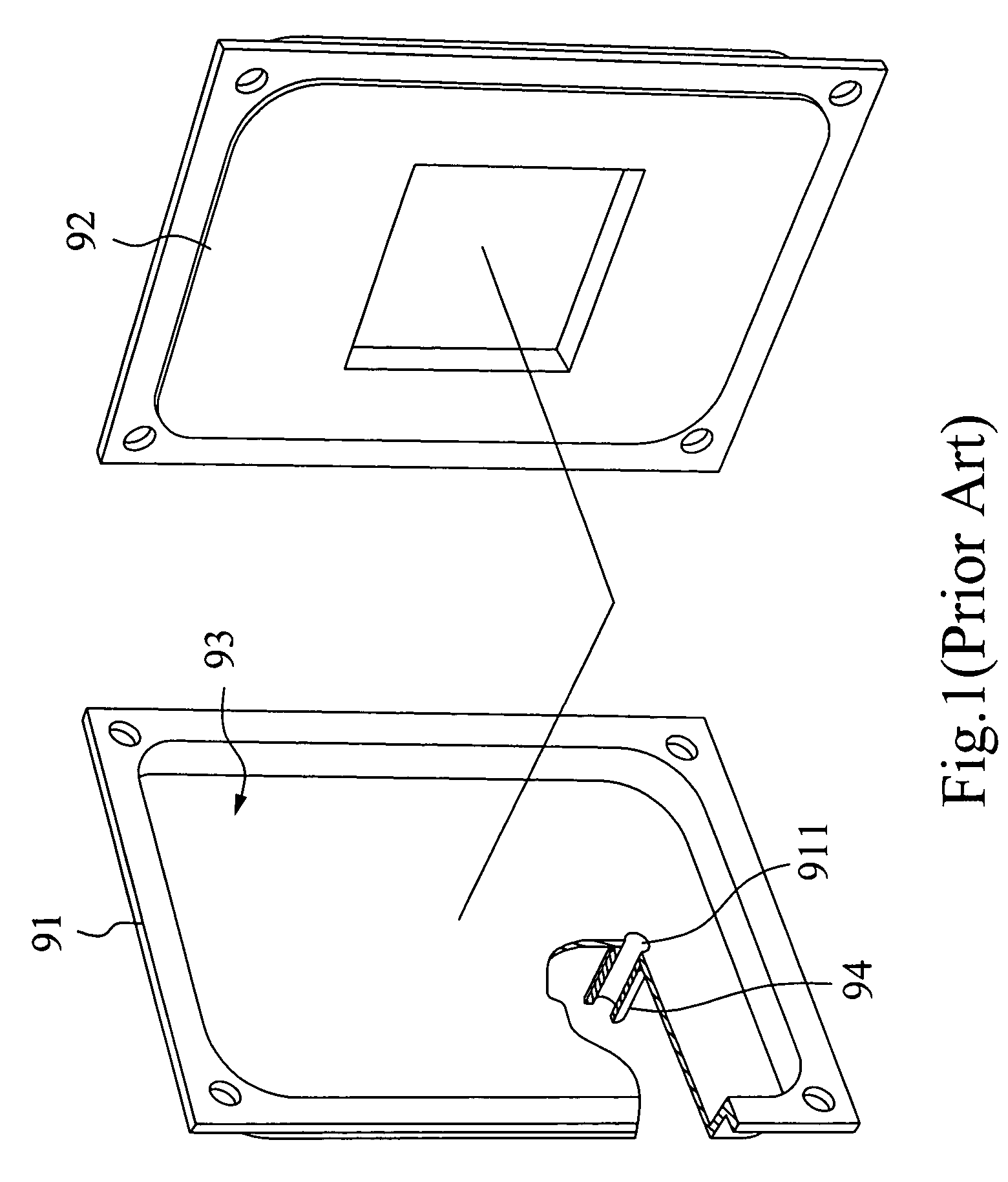

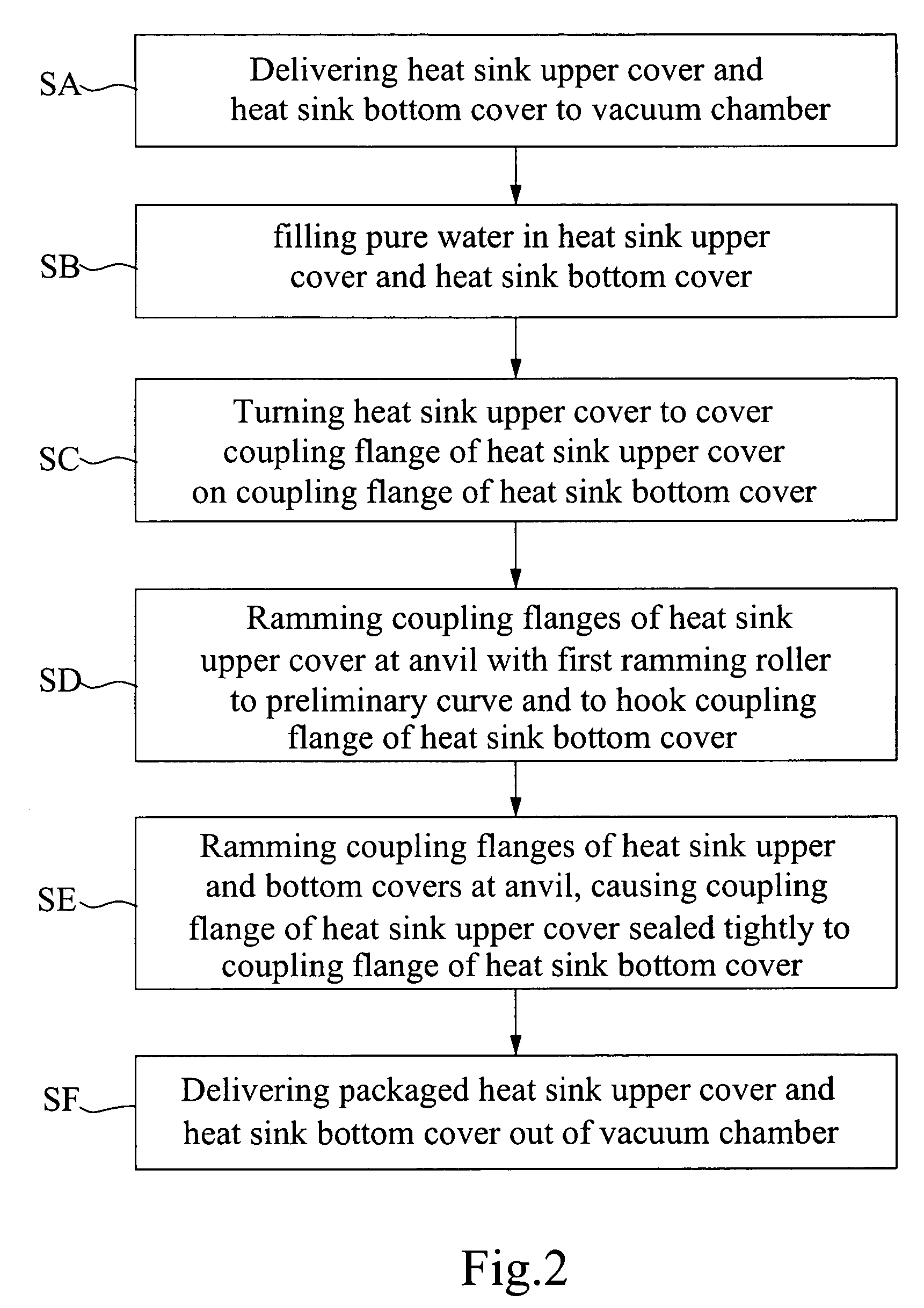

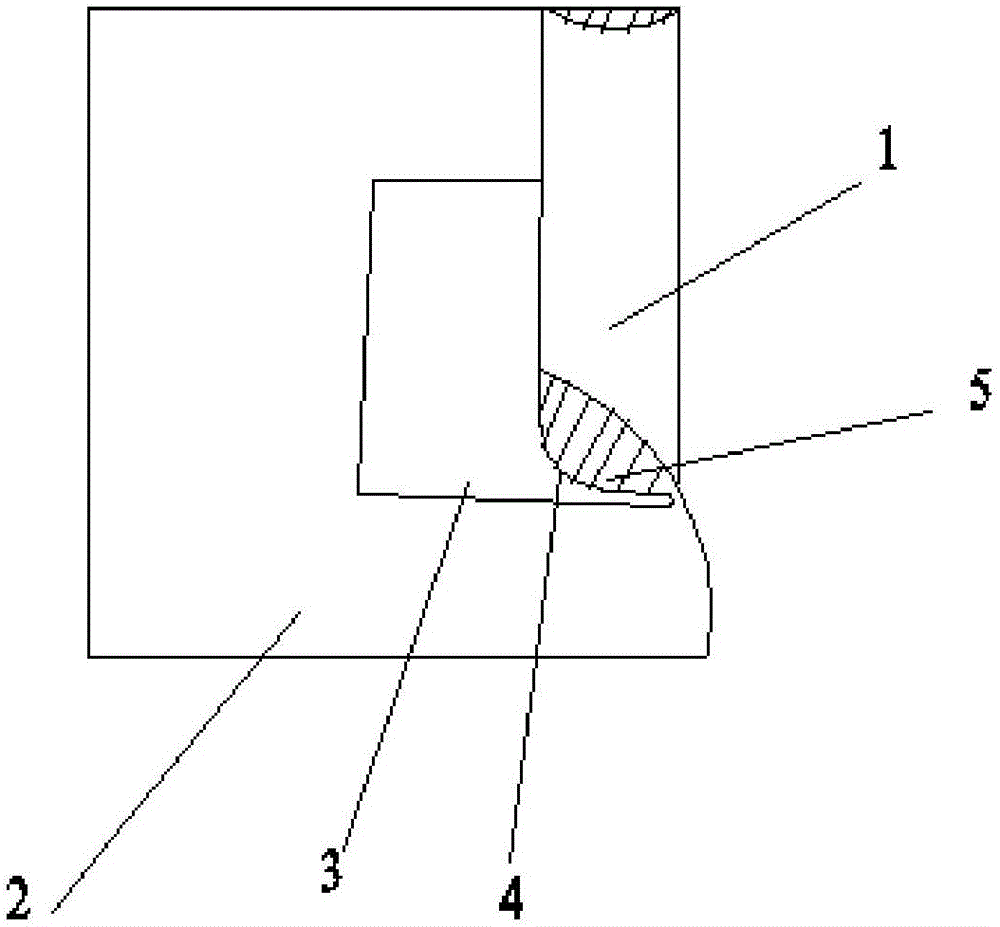

Heat sink vacuum packaging procedure

InactiveUS7185434B2Drawback can be obviatedLess laborIndirect heat exchangersHeat exchange apparatusVacuum pumpingEngineering

A heat sink vacuum packaging procedure to rapidly complete the packaging of a heat sink without drilling, pipe welding, vacuum pumping, or other processes. Because the packaging procedure saves much time and labor, the manufacturing cost of the heat sink is relatively reduced. During packaging, no welding process is employed, therefore the invention prevents accidentally flowing of tin solder into the inside of the heat sink to affect the quality of the heat sink, and the quality of the heat sink is maintained.

Owner:TATUNG COMPANY

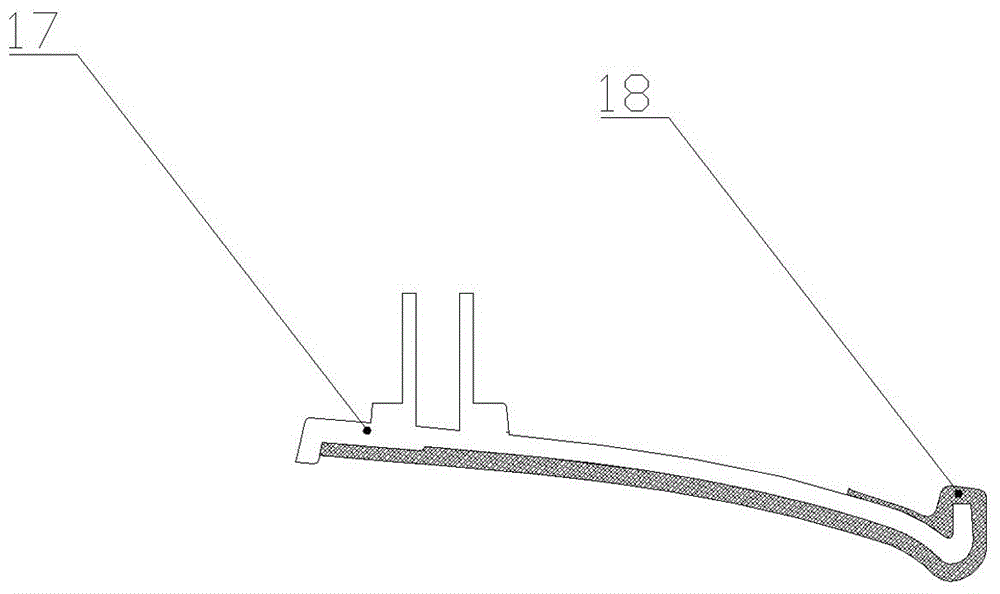

Flat machine halter used for single thread side seam wrapping

InactiveCN106245244AThe width of the upper and lower hems is the sameImprove processing efficiencyWork-feeding meansEngineeringWrapping procedure

The invention relates to a flat machine halter used for single thread side seam wrapping. The flat machine halter comprises a hem halter body, wherein the hem halter body is fixedly installed on a flat machine by a bolt and comprises a cloth rolling sleeve, a fixed plate and a cloth guide plate; the fixed plate and the cloth guide plate are arranged at the same side of the cloth rolling sleeve; a cloth inlet is formed at the front end of the cloth rolling sleeve; an arc-shaped hollow part is arranged at the upper end of the cloth inlet of the cloth rolling sleeve; a cloth outlet is formed at the rear end of the cloth rolling sleeve; the fixed plate is connected with the upper end face of the cloth rolling sleeve in an arc shape; the cloth guide plate is connected with the lower end face of the cloth rolling sleeve in an arc shape. The flat machine halter has a simple structure, is compact in design and convenient to use, can be used for rapidly sewing covered edges for the first time, has the effect of reducing the procedure of ironing hems and is fixed in the hemming width, thus ensuring the consistency of the width of the upper and lower hems of side seams and improving the processing efficiency of the single thread side seam wrapping procedure while improving the product quality.

Owner:JIANGSU HONGDOU INDUSTRIAL CO LTD

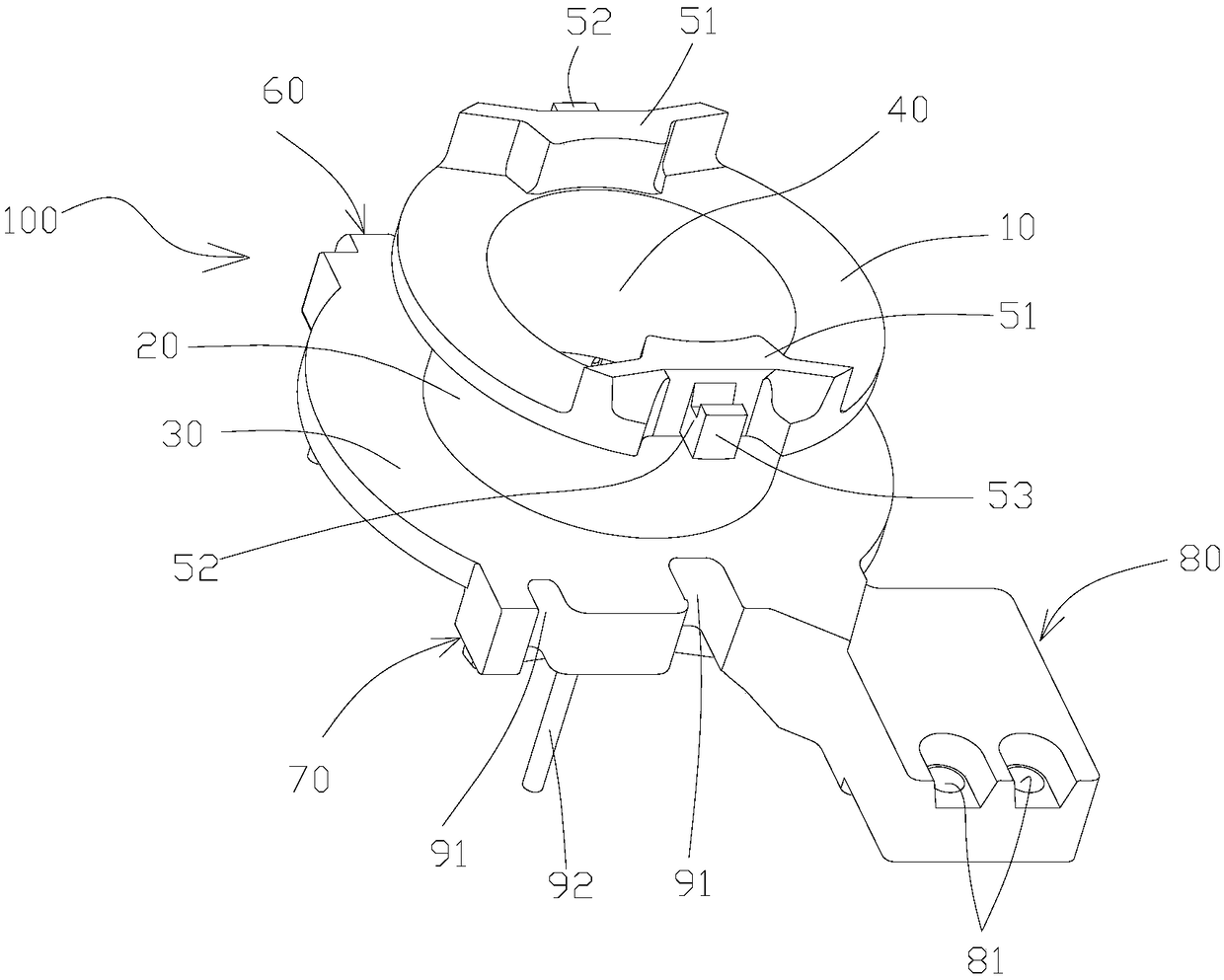

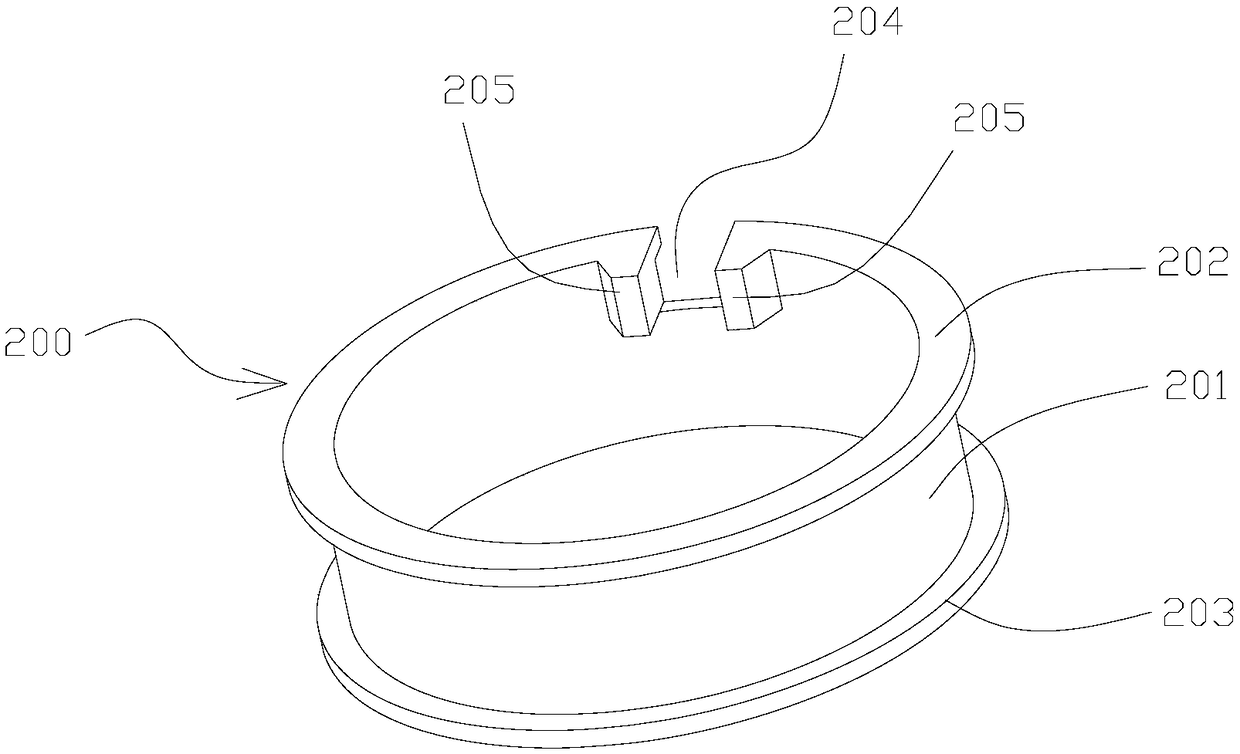

Transformer framework for preventing winding lead crossing and use method thereof

InactiveCN109494062AAvoid damageAchieve isolationTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention provides a transformer framework for preventing winding lead crossing. A framework body comprises a primary wrapping post, a top blade and a bottom blade, the top blade and the bottom blade are arranged at the top and the bottom of the primary wrapping post, and a magnetic core groove is formed by the center of the primary wrapping post. Magnetic core baffles are arranged on the twosides of the top face of the top blade. A first primary part is arranged on one side of the bottom blade, and a second primary part and a secondary part are arranged on the other side of the bottom blade. Primary wire passing grooves are formed in the side faces, away from the wrapping post, of the first primary part and the second primary part respectively, and the bottom face of the first primary part and the bottom face of the second primary part are connected with primary pins. A sheath is further included, and comprises a hollow cylindrical secondary wrapping post, a top baffle and a bottom baffle, and the top baffle is arranged at the top of the secondary wrapping post, and the bottom baffle is arranged at the bottom of the secondary wrapping post. The outer diameter of the top bladeis smaller than that of the bottom blade. The sheath adaptively sleeves the periphery of the top blade from top to bottom, and the sheath is in adaptive clamped connection with the framework body. Space isolation of a secondary coil, a primary coil and a primary lead is achieved. According to the transformer framework, automation of the wire wrapping procedure of the secondary coil is achieved, and the product quality and the production efficiency are improved.

Owner:DONGGUAN AOHAI TECH CO LTD

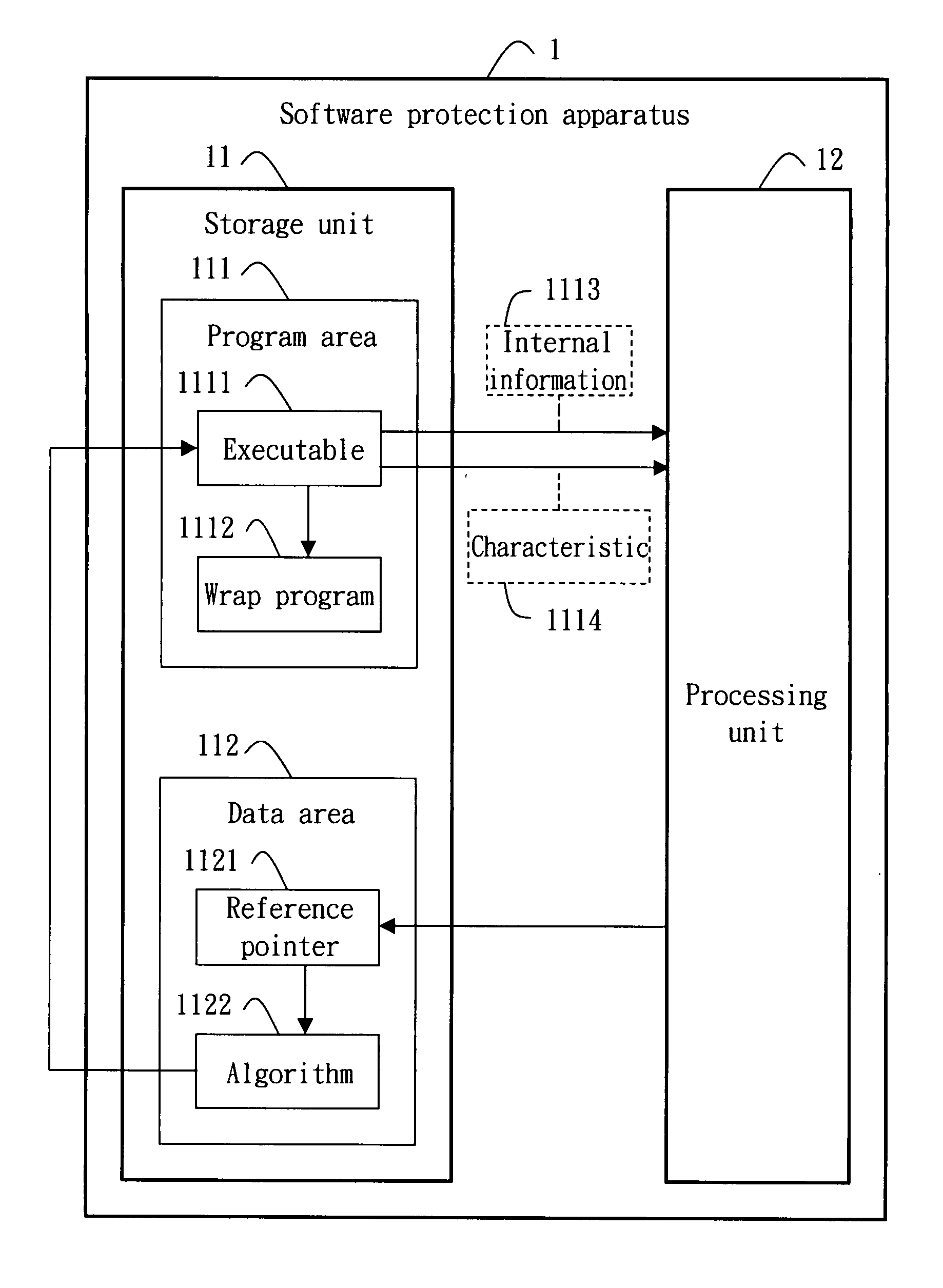

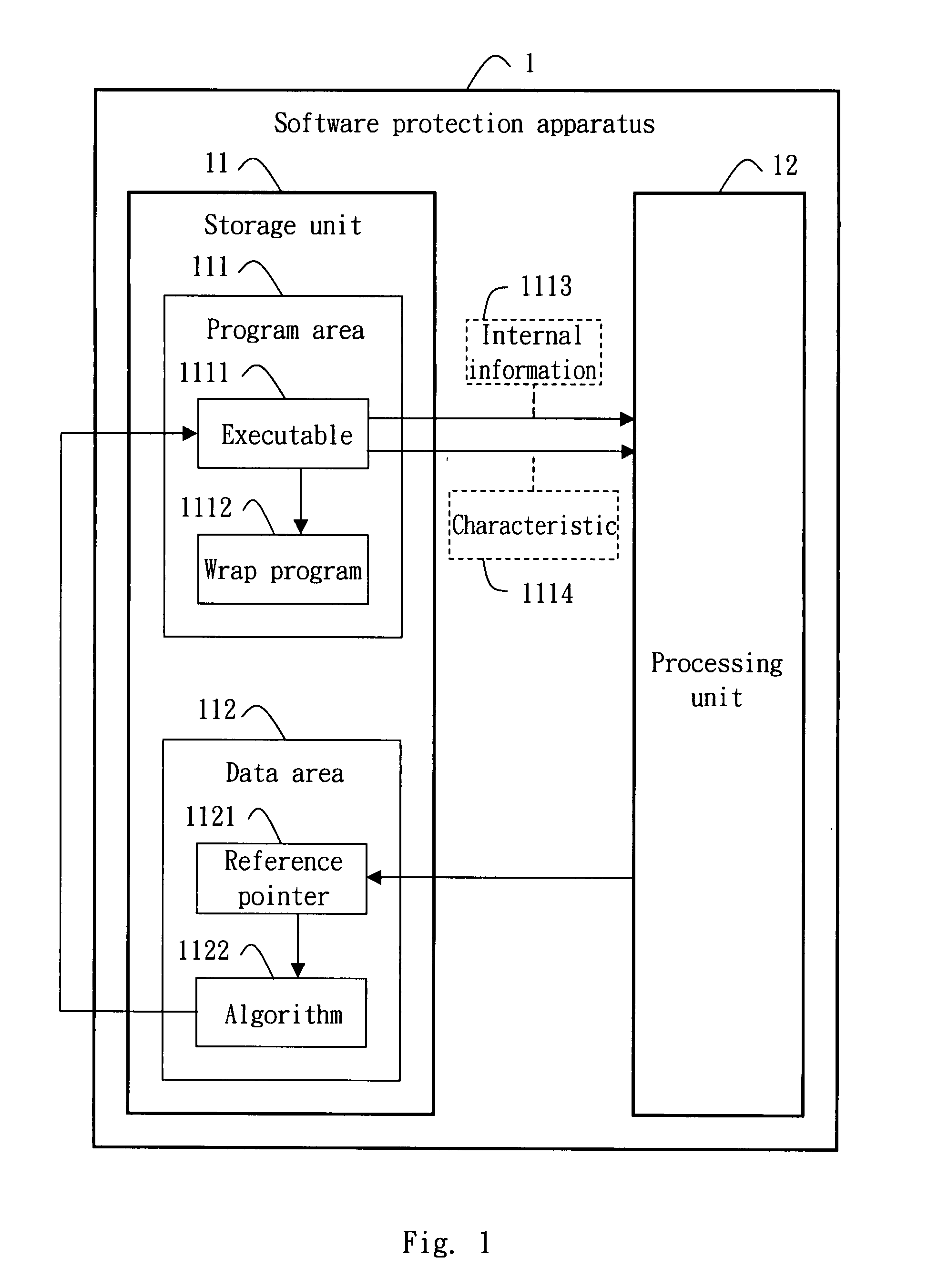

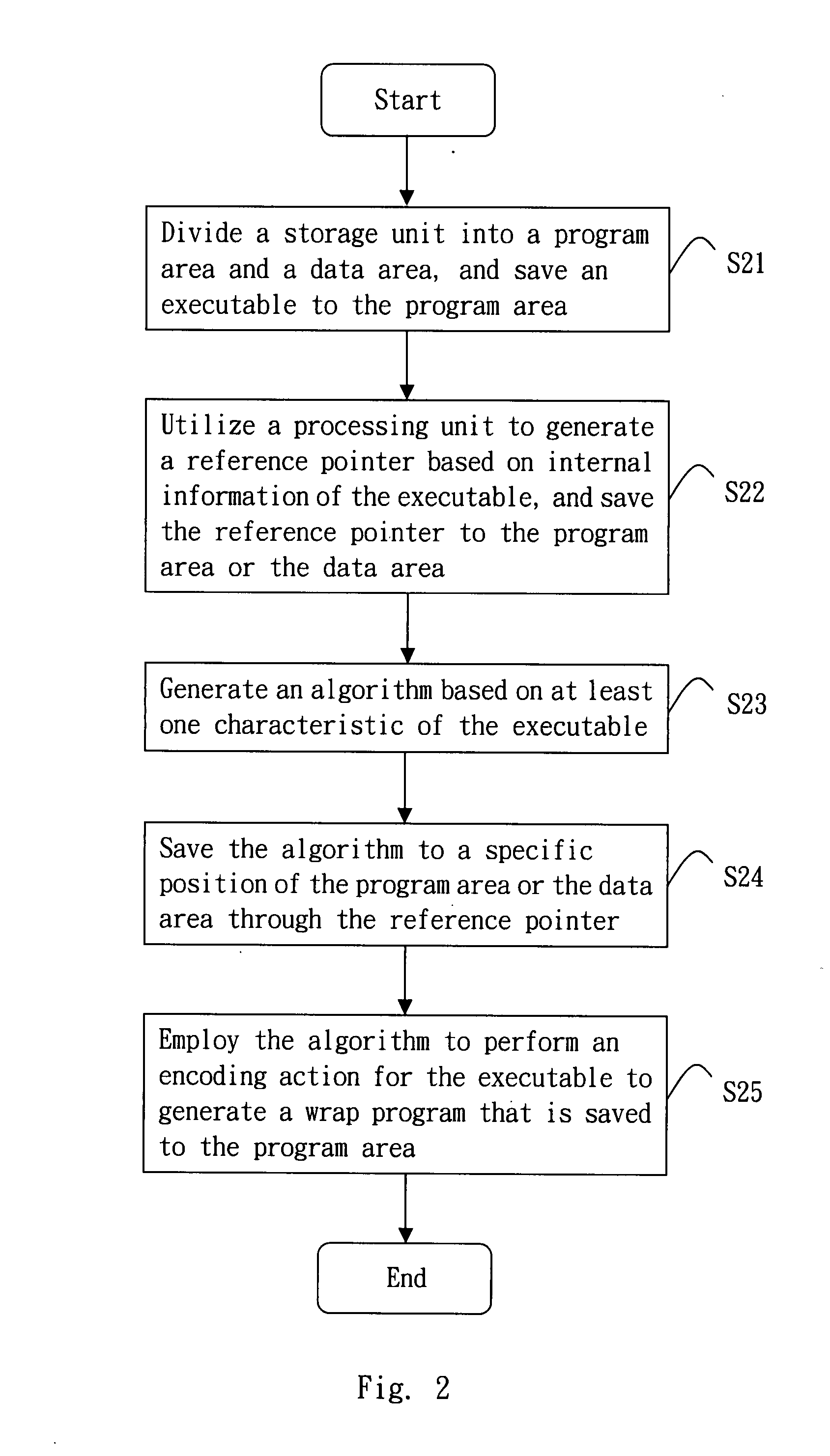

Software protection apparatus and protection method thereof

InactiveUS20080295084A1Preclude obtainingUnauthorized memory use protectionHardware monitoringSoftware protectionComputer science

A software protection apparatus and its protection method are disclosed. The software protection apparatus includes a storage unit and a processing unit. The storage unit has a program area and a data area. The program area is used to save an executable. The processing unit generates a reference pointer based on internal information of the executable, and the reference pointer then is saved to the program area or the data area. The processing unit then generates an algorithm based on at least one characteristic of the executable to save the algorithm to a specific position of the program area or the data area through the reference pointer, and employs the algorithm to perform an encoding action for the executable to generate a wrap program that is saved to the program area. When the wrap program is decoded, the reference pointer is obtained through a restore program to take the algorithm out. The wrap program then is restored to become the executable by using the algorithm.

Owner:SERCOMM

Bending and angle wrapping die and bending and angle wrapping method

ActiveCN114029401AImprove appearance qualityReduce contact areaShaping toolsStructural engineeringIndustrial engineering

The invention discloses a bending and angle wrapping die and a bending and angle wrapping method. The bending and angle wrapping die comprises a first die body and a second die body which are oppositely arranged, an angle wrapping knife is installed on the side, facing the second die body, of the first die body, and the angle wrapping knife is rotationally connected with the first die body through a first fixing shaft; the bending and angle wrapping method comprises the steps that the dies start to run, and the first die and the second die are reset; the first die moves downwards, a first stripping plate on the first die presses the plate, the first die continues to move downwards, and a bending knife on the first die starts to bend the plate; and after the bending procedure is completed, the first die continues to move downwards, a limiting shaft on the first stripping plate enters a guide groove in the angle wrapping knife, the angle wrapping knife rotates along a track set by the first fixing shaft and the limiting shaft, and the angle wrapping procedure is completed. Through the arrangement, a rotary angle wrapping method is adopted, so that the contact area between the angle wrapping knife and the plate is reduced, the friction between the angle wrapping knife and the plate is reduced, and the problems of film rupture and paint peeling of the plate are solved.

Owner:QINGDAO HAIER MOLDS

Method for manufacturing dragon ball embroidery product

InactiveCN102505380ASimple preparation processLow costAutomatic machinesAuxillary devicesEngineeringBall type

The invention relates to a method for manufacturing a dragon ball embroidery product. The method comprises the following steps of: designing a pattern and making a template, pricking holes along the pattern, copying the pattern on an embroidery basic fabric, performing laser carving and auxiliary fabric cutting, embroidering with a lockstitch sewing machine, embroidering by hand, cleaning the embroidery product with water, ironing, inspecting and packaging. The invention is characterized in that the laser carving and auxiliary material cutting step comprises cutting a cotton voile auxiliary fabric into round fabric pieces by laser and cold-cutting the auxiliary fabric into strip fabric pieces; the lockstitch sewing machine embroidery step comprises fixing the strip cotton voile fabric pieces with the half pressers of the lockstitch sewing machine, sewing one side of the strip cotton voile fabric pieces on the embroidery basic fabric, putting cotton ropes with a density of 180-270 g / m2 on the strip cotton voile fabric pieces, turning over the strip cotton voile fabric pieces to wrap the cotton ropes, and manually sewing and fixing the strip cotton voile fabric pieces on the embroidery basic fabric, to form a raised line skeleton; and the hand embroidering step comprises wrapping 10-15 g cotton with the round cotton voile pieces, manually sewing the edges to form spherical pieces, and sewing and fixing the spherical pieces on the embroidery basic fabric to form raised round small balls. The method is based on computerized laser technique and cold cutting technique, adopts combination of hand embroidery and lockstitch sewing machine embroidery, and has the advantages of simple manufacture process, low product cost and high production efficiency. The embroidery product is advantageous in integration of points, lines, planes and color, and has a strong three-dimensional effect, a vivid color and a beautiful appearance.

Owner:WENDENG YUNXIANG EMBROIDERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com