Wire wrapping and looping device of metal heating wire and wire wrapping and looping method thereof

A heating wire and metal wire technology, which is applied in the field of metal heating wire winding and looping devices, can solve the problems of low looping efficiency, unfavorable work efficiency, and large manpower, so as to ensure the quality of looping and improve looping Productivity, Consistency, and Integrity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

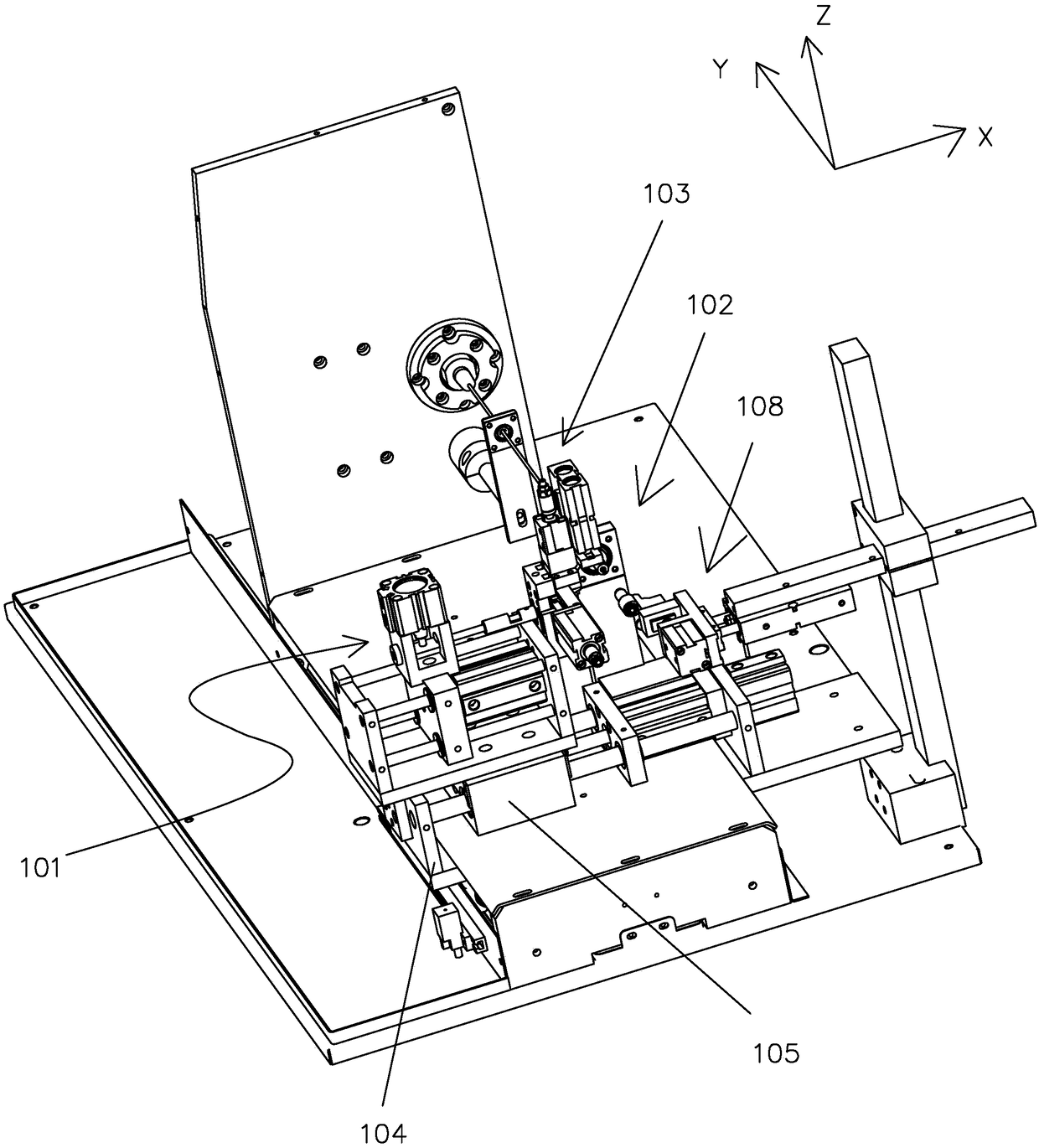

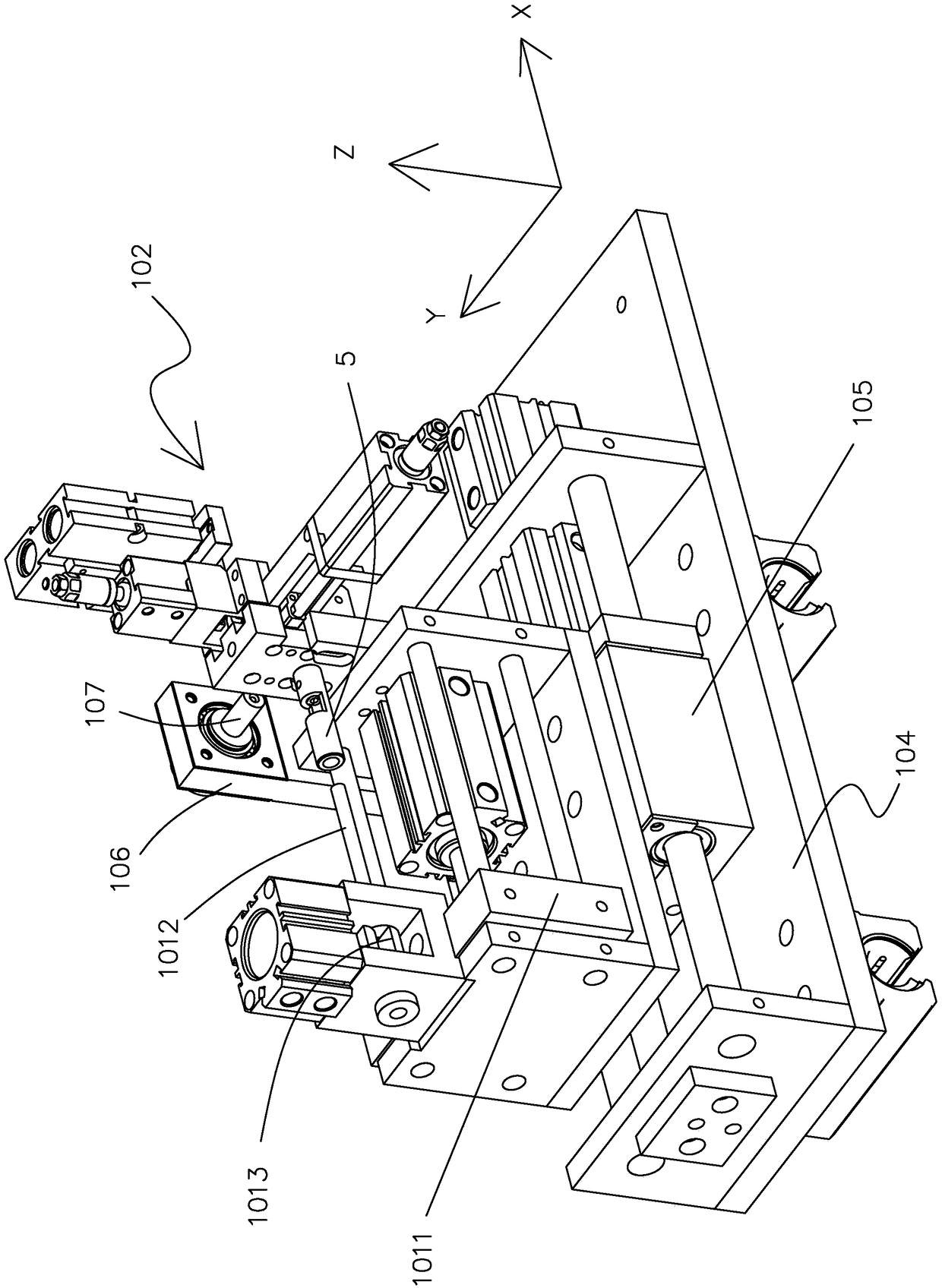

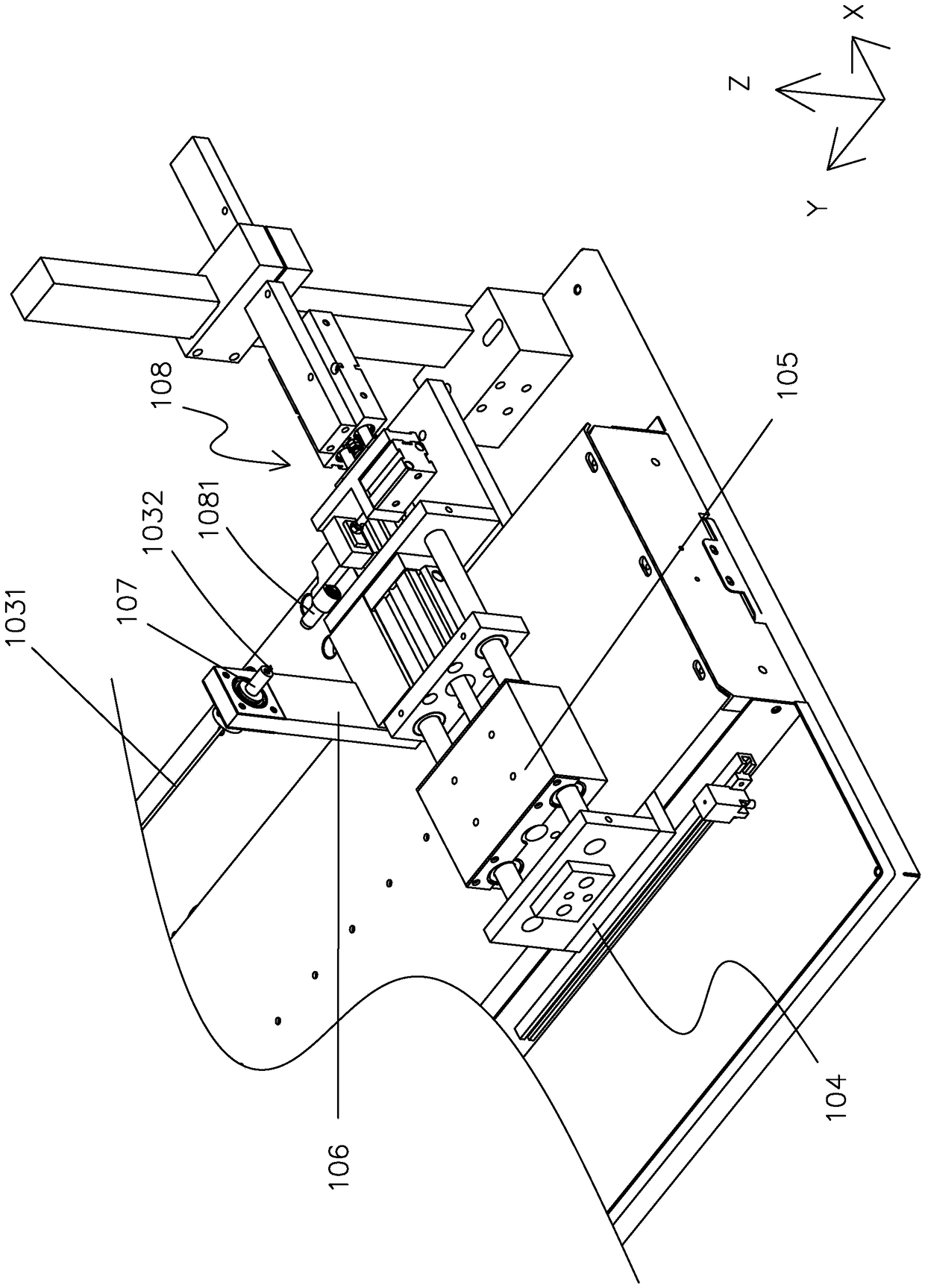

[0042] A winding and looping device for a metal heating wire, comprising:

[0043] The incoming line pressing mechanism 101, the incoming line pressing mechanism 101 includes the incoming line pressing seat 1011 and the incoming line push rod 1012 which is arranged on the incoming line pressing seat 1011 and allows the wire to pass through, and the incoming line pressing seat 1011 There is also a pressing block 1013 for pressing through the incoming line push rod 1012;

[0044] The looping mechanism 102, the looping mechanism 102 includes a looping seat 1, the looping seat 1 is provided with an incoming line pipe 5 facing the incoming line push rod 1012, and the incoming line pipe 5 is provided along the axial direction for the wire to penetrate. The threading hole 51, the lower part of the looping mechanism 102 is provided with a guide block 109 for guiding the wire passing through the threading hole 51, and the incoming line pressing seat 1011 can move along the X-axis direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com