Patents

Literature

248 results about "Vivid color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display device

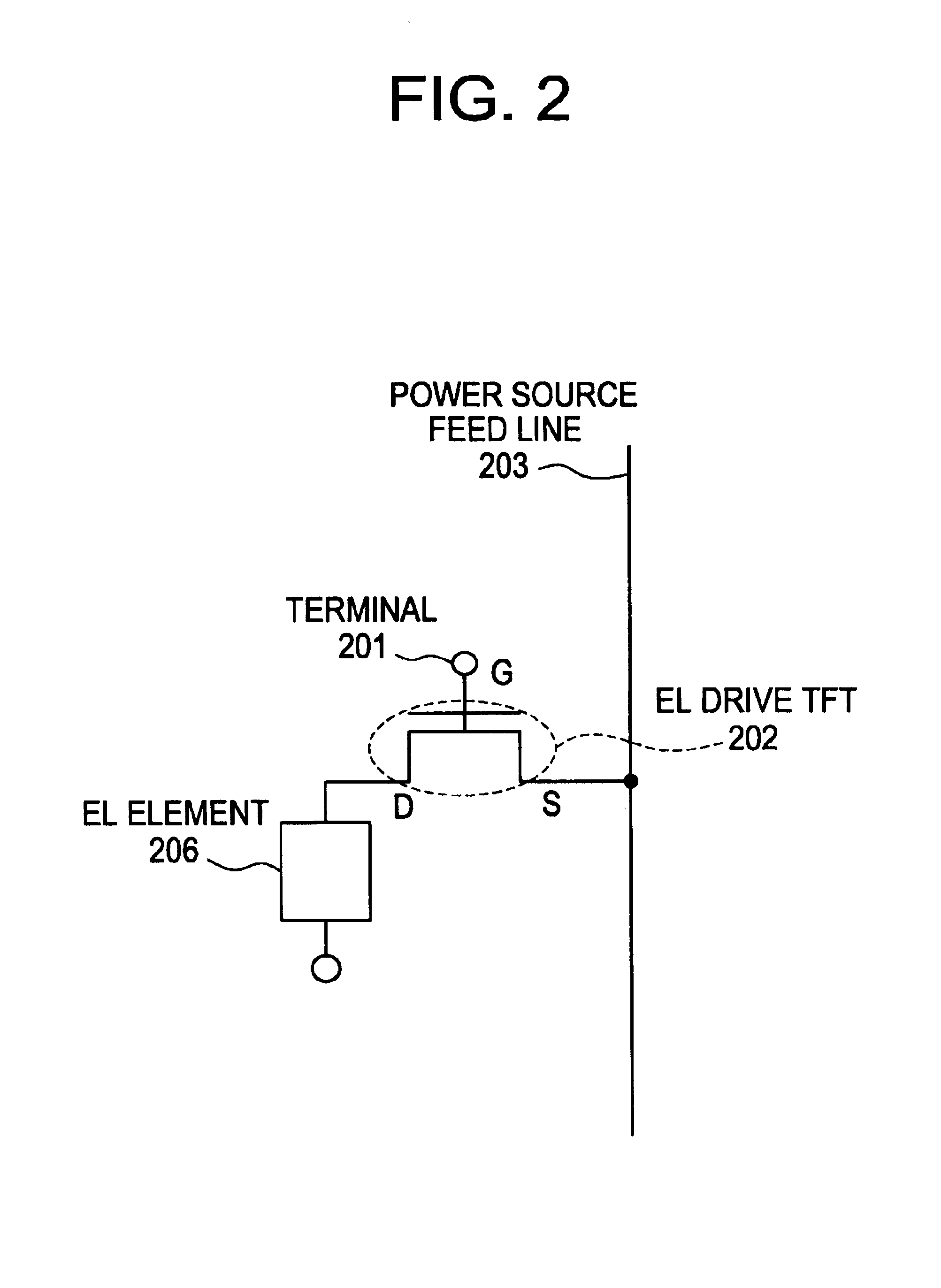

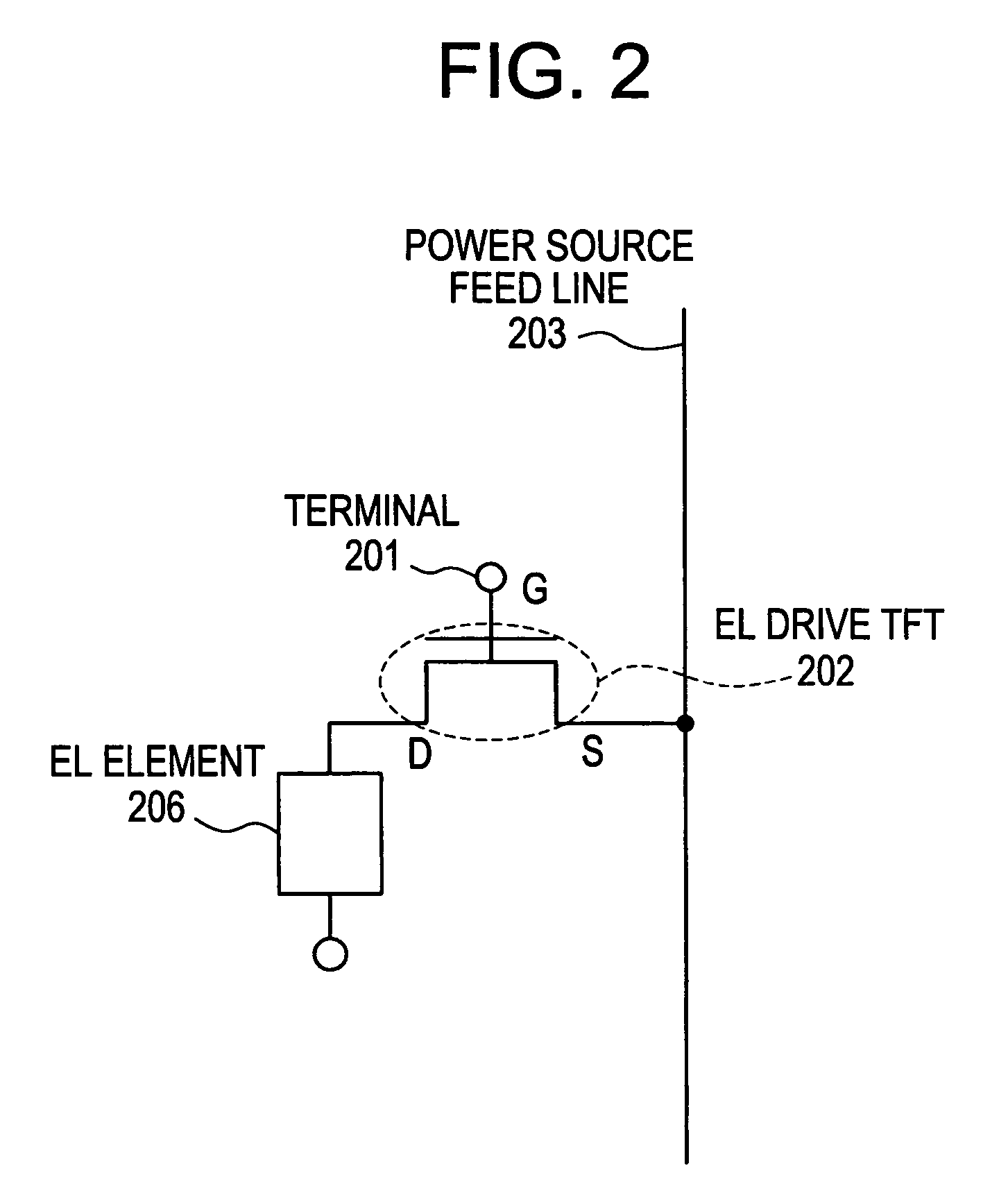

An active matrix display device capable of vivid color display having many tones is provided. The display device is characterized in that each of a plurality of pixels comprises a first TFT for switching, a second TFT for switching, a TFT for erasing, a TFT for EL driving, and an EL element, driving of the TFT for EL driving is controlled by the first TFT for switching, the second TFT for switching, and the TFT for erasing, and light emission by the EL element is controlled by the TFT for EL driving.

Owner:SEMICON ENERGY LAB CO LTD

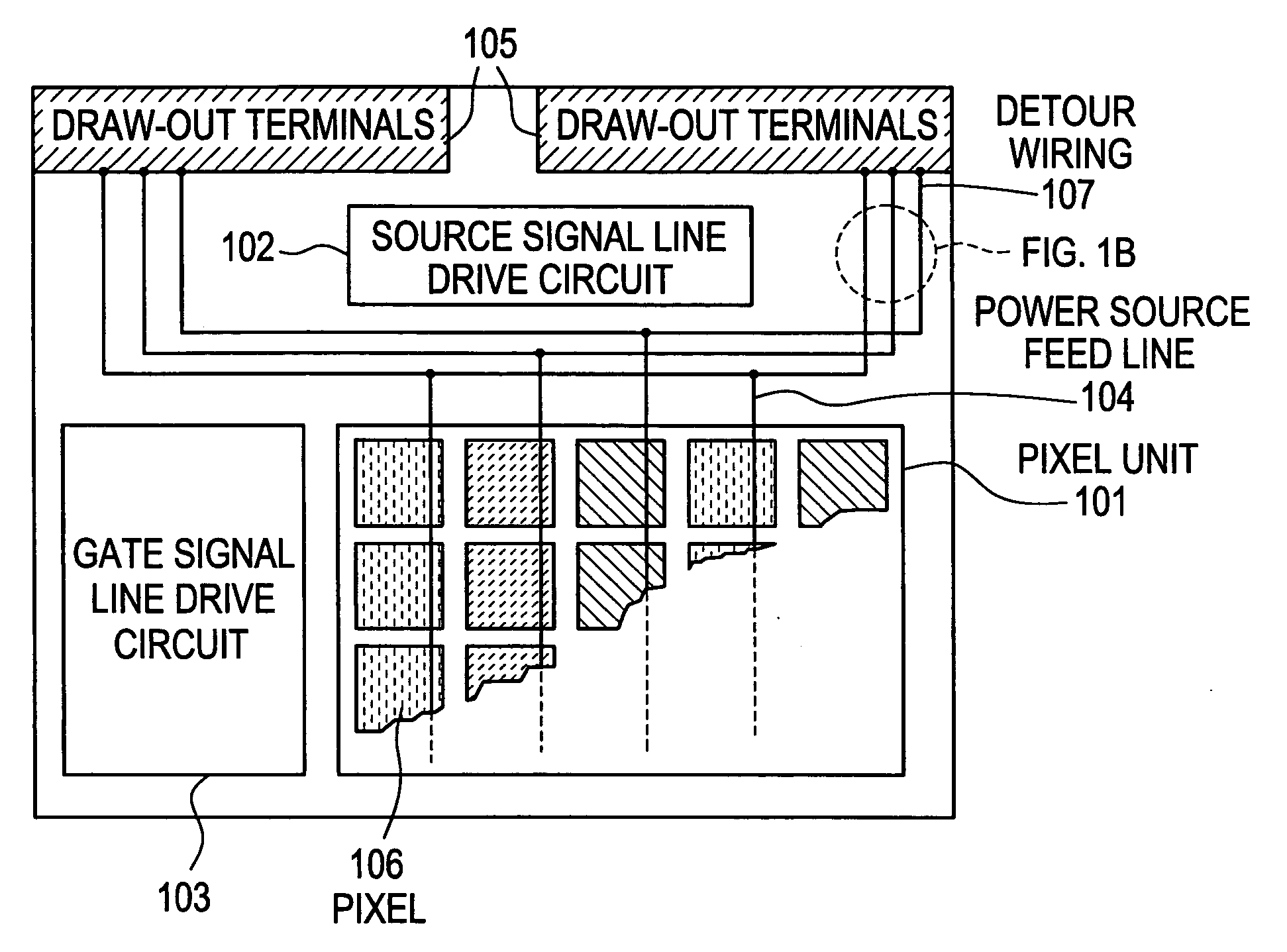

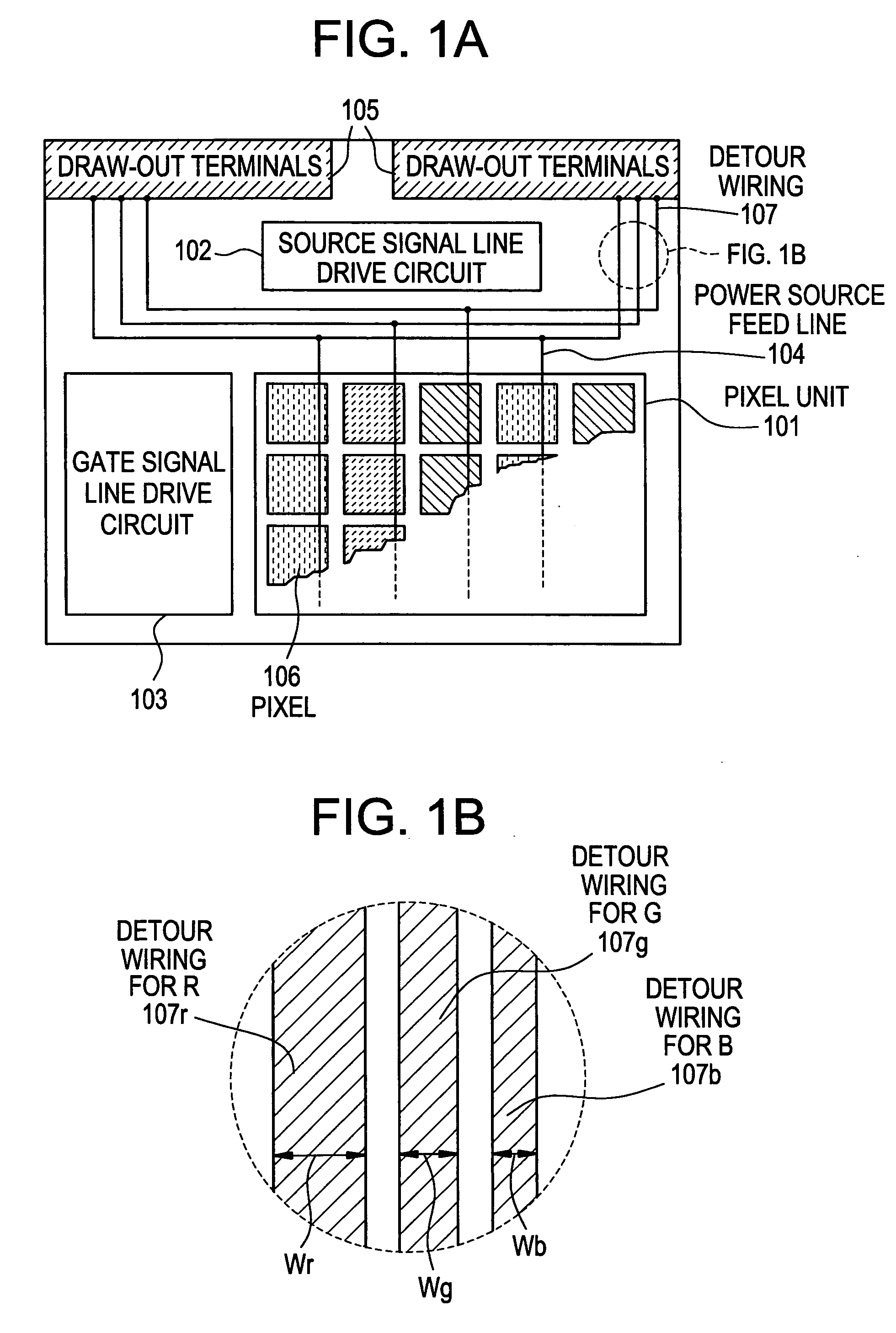

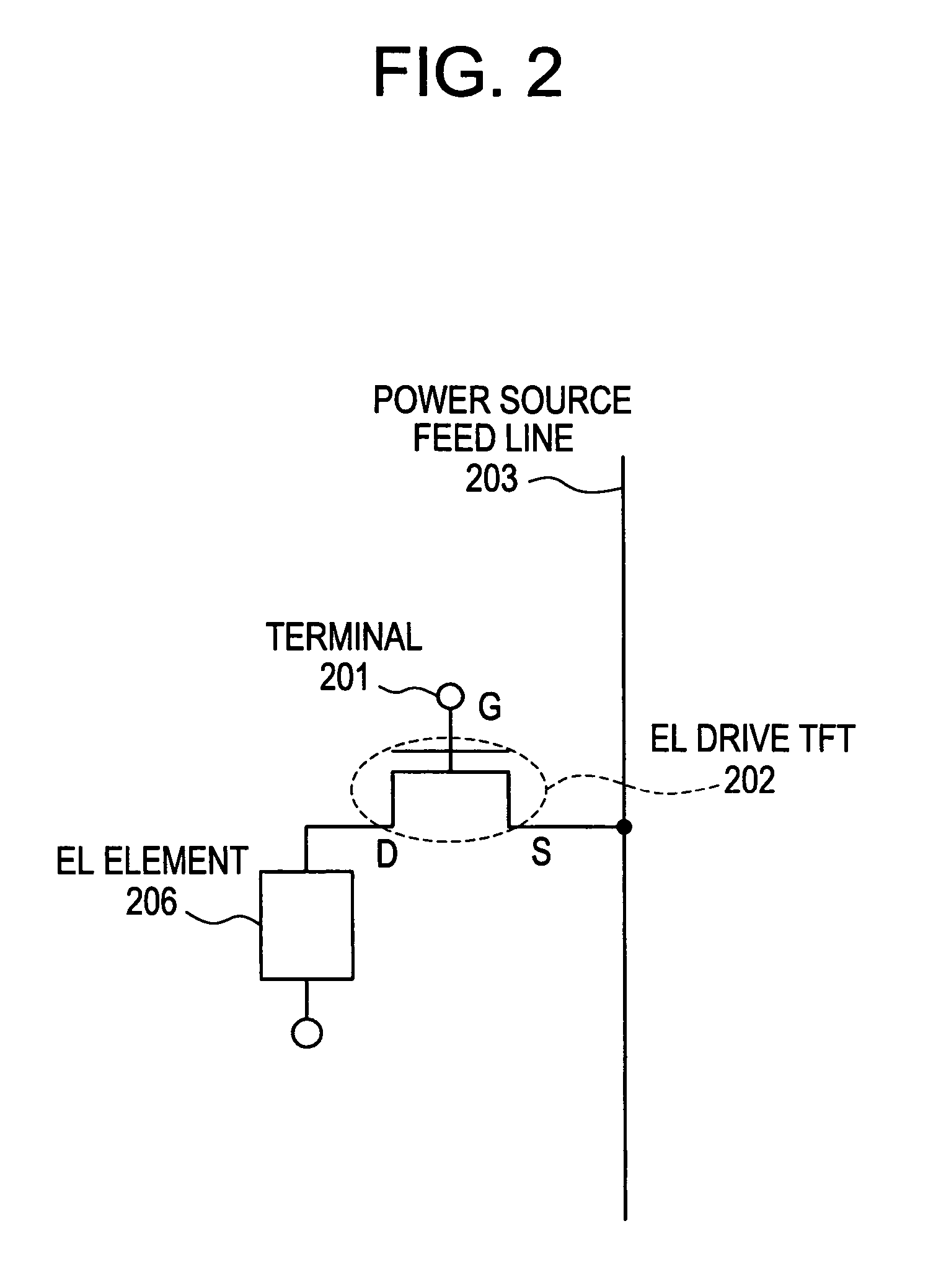

Display device and electronic device

InactiveUS6825820B2Static indicating devicesElectroluminescent light sourcesElectrical resistance and conductanceDisplay device

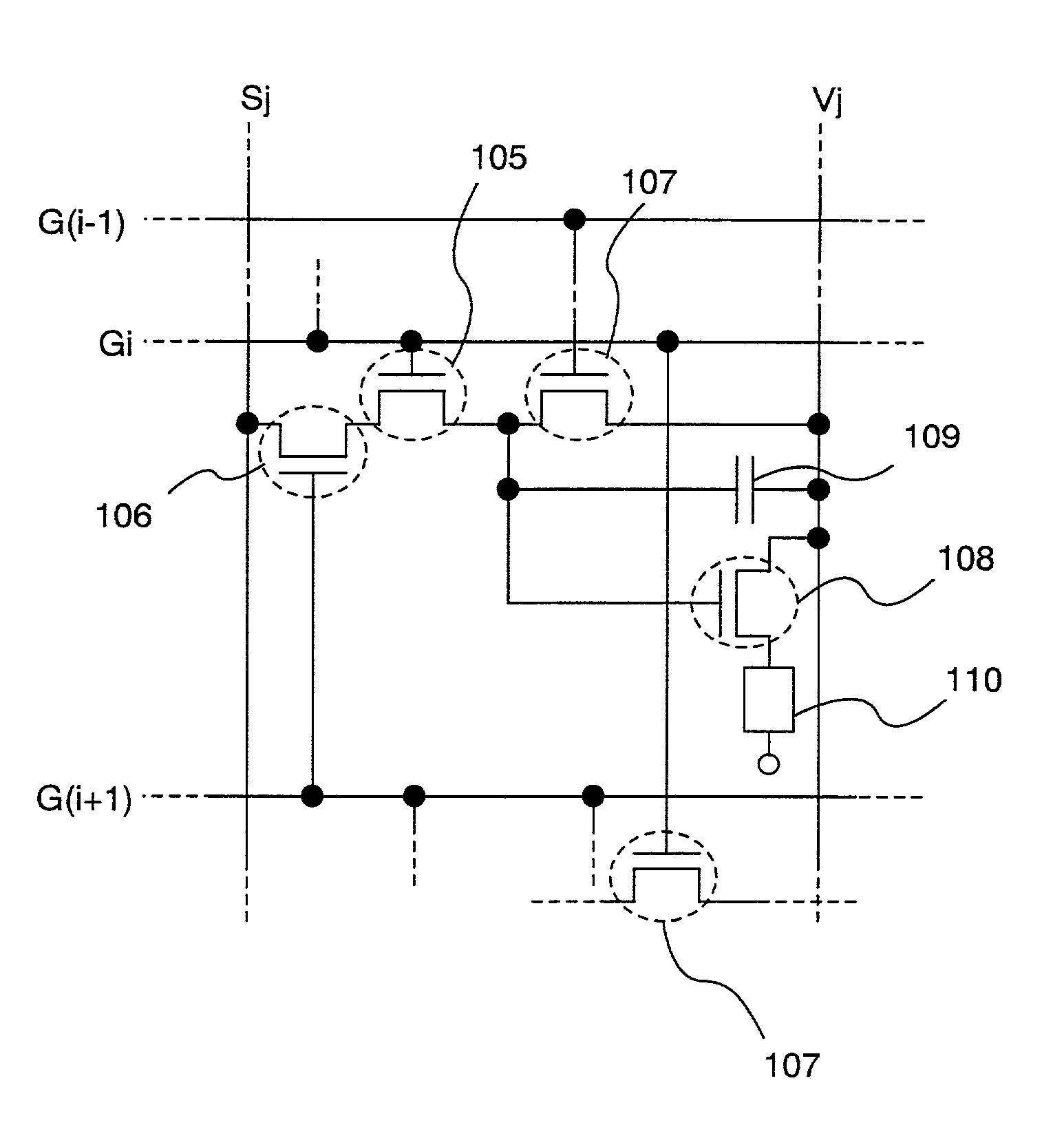

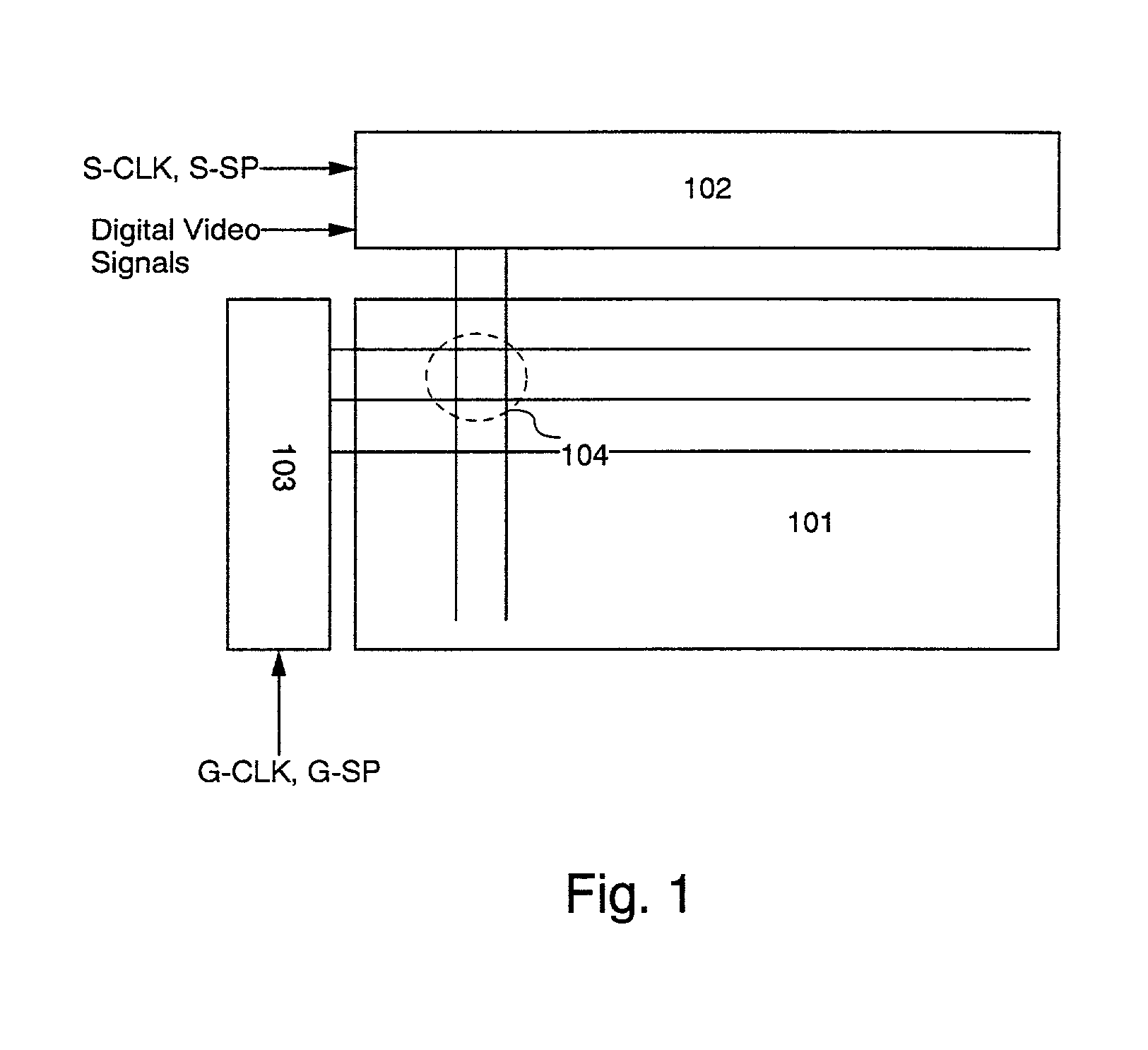

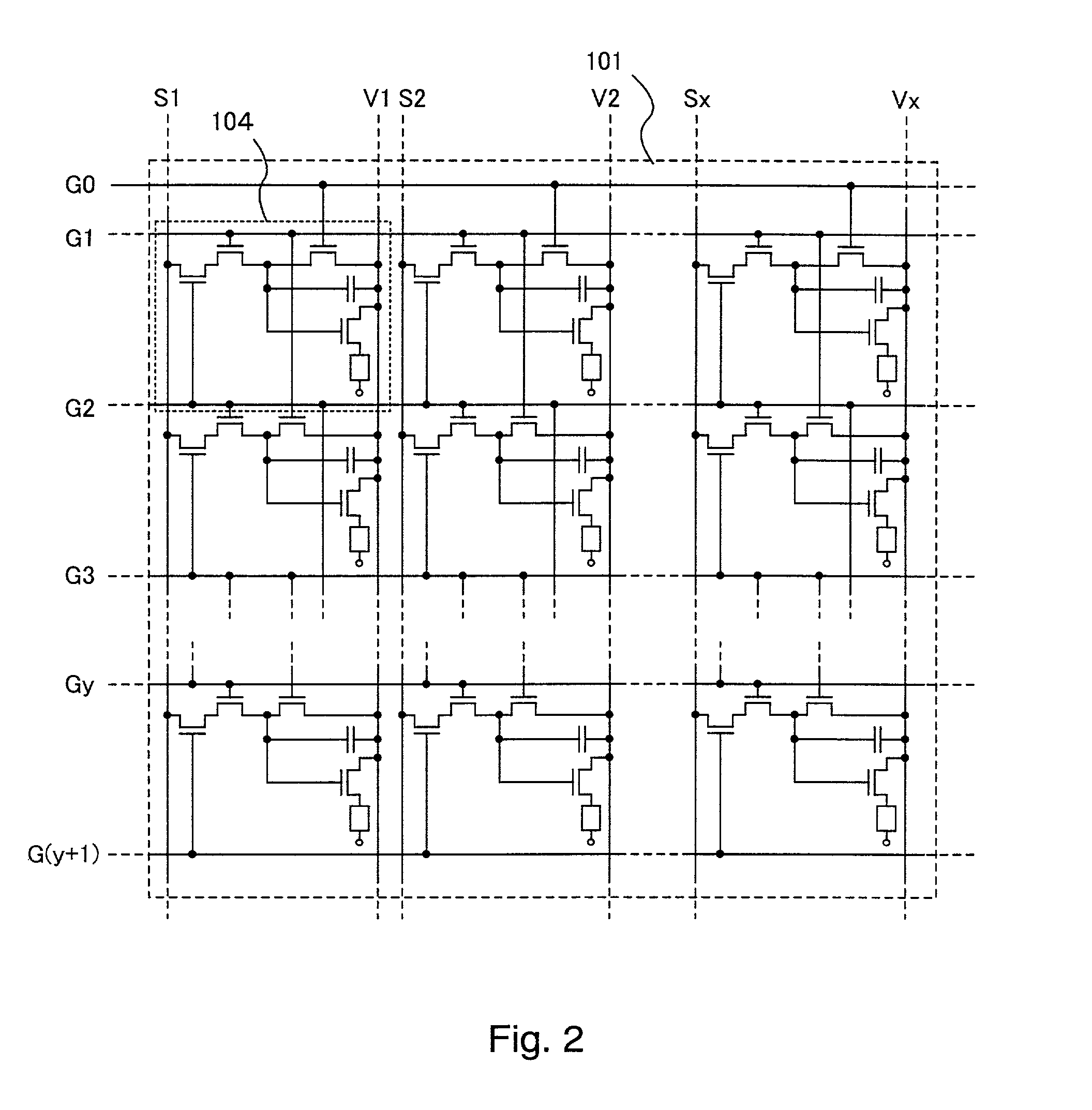

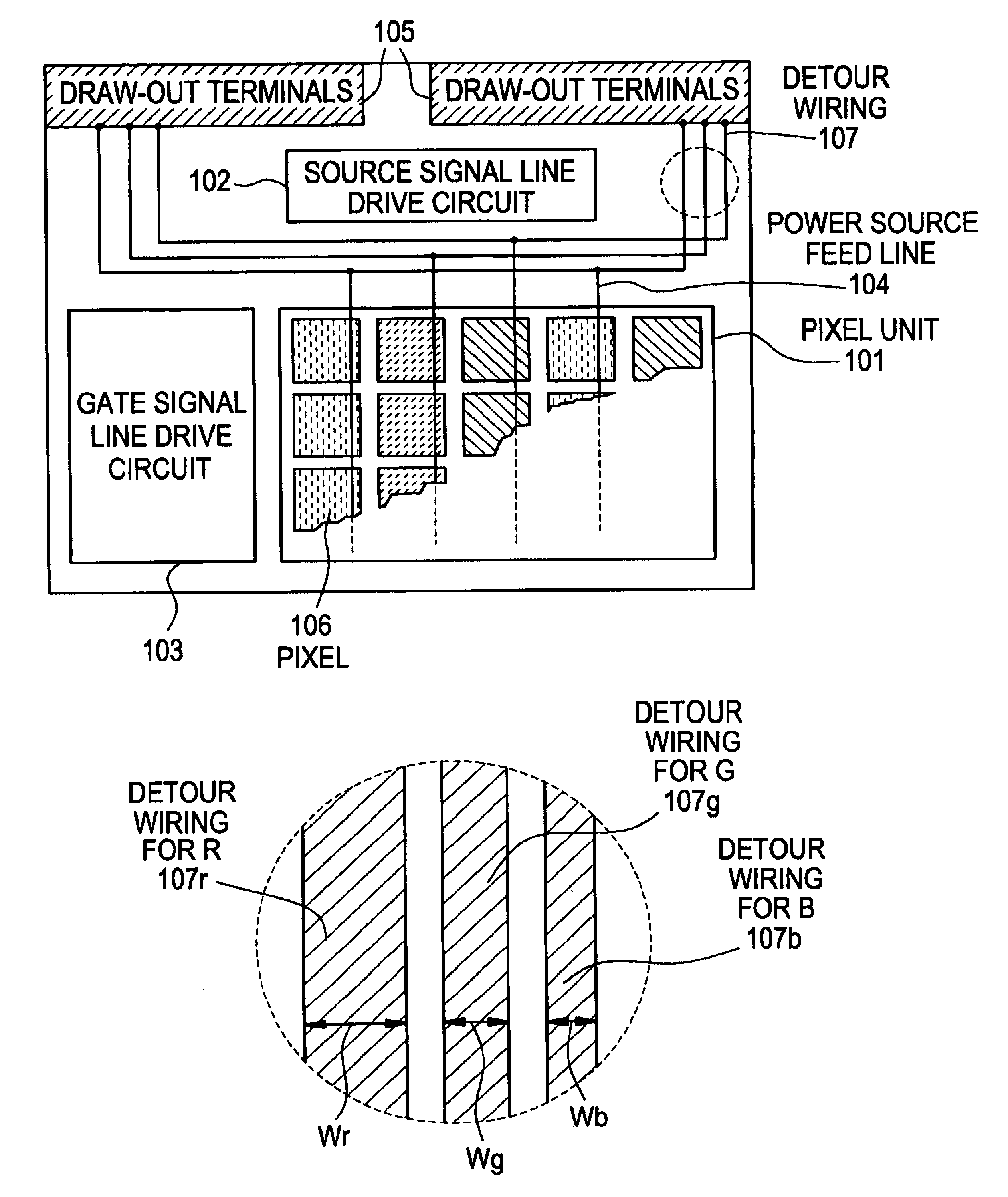

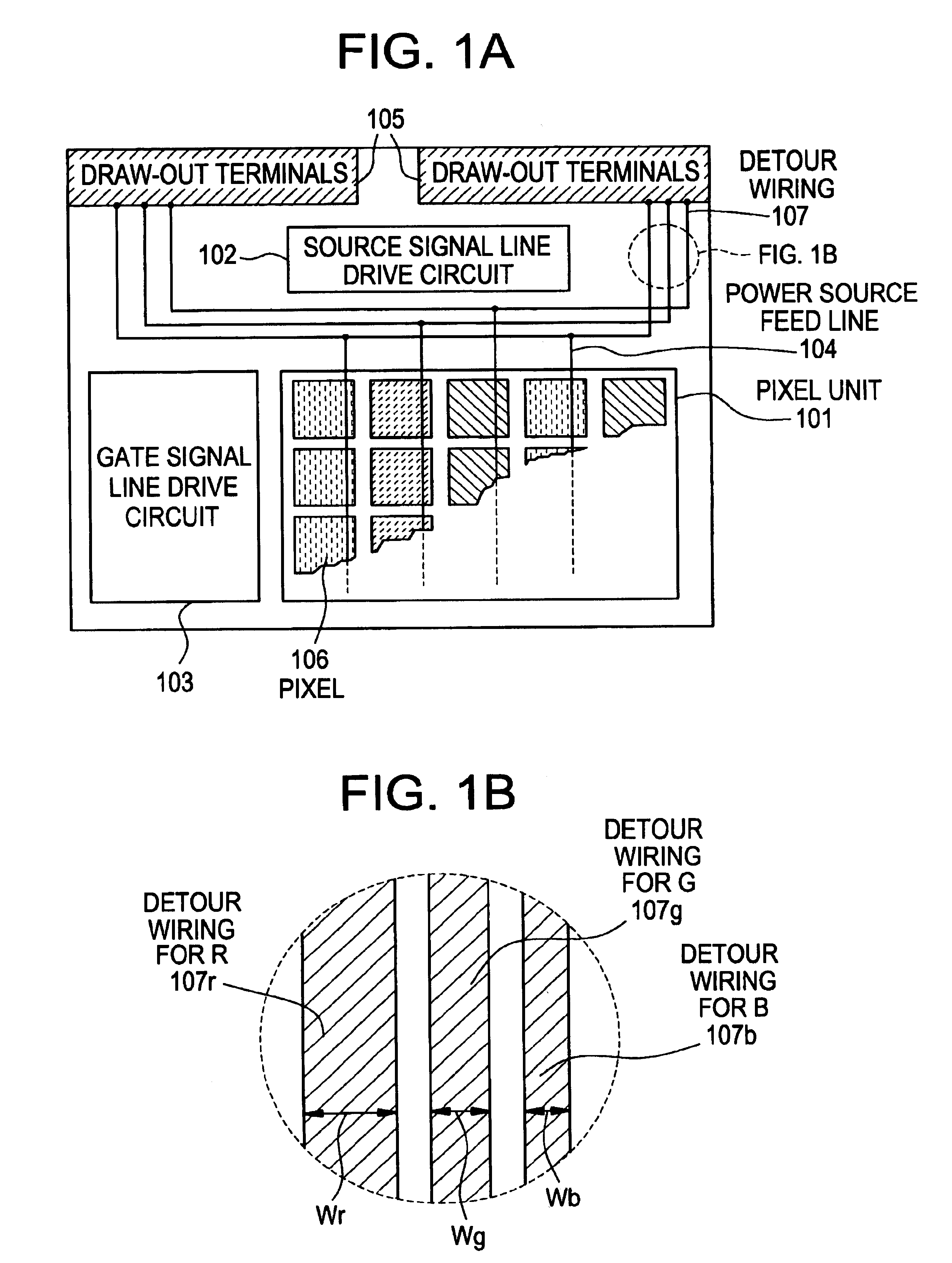

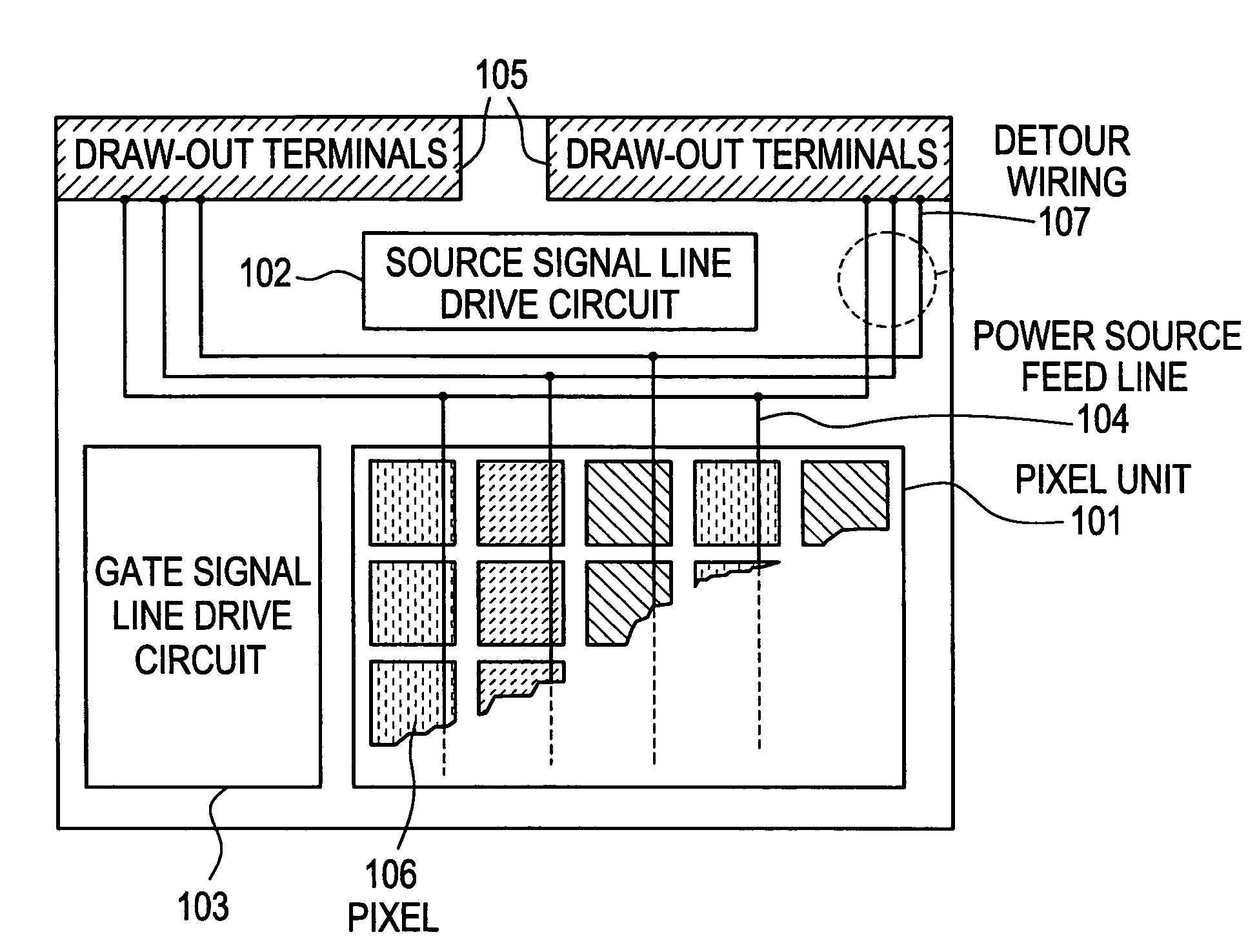

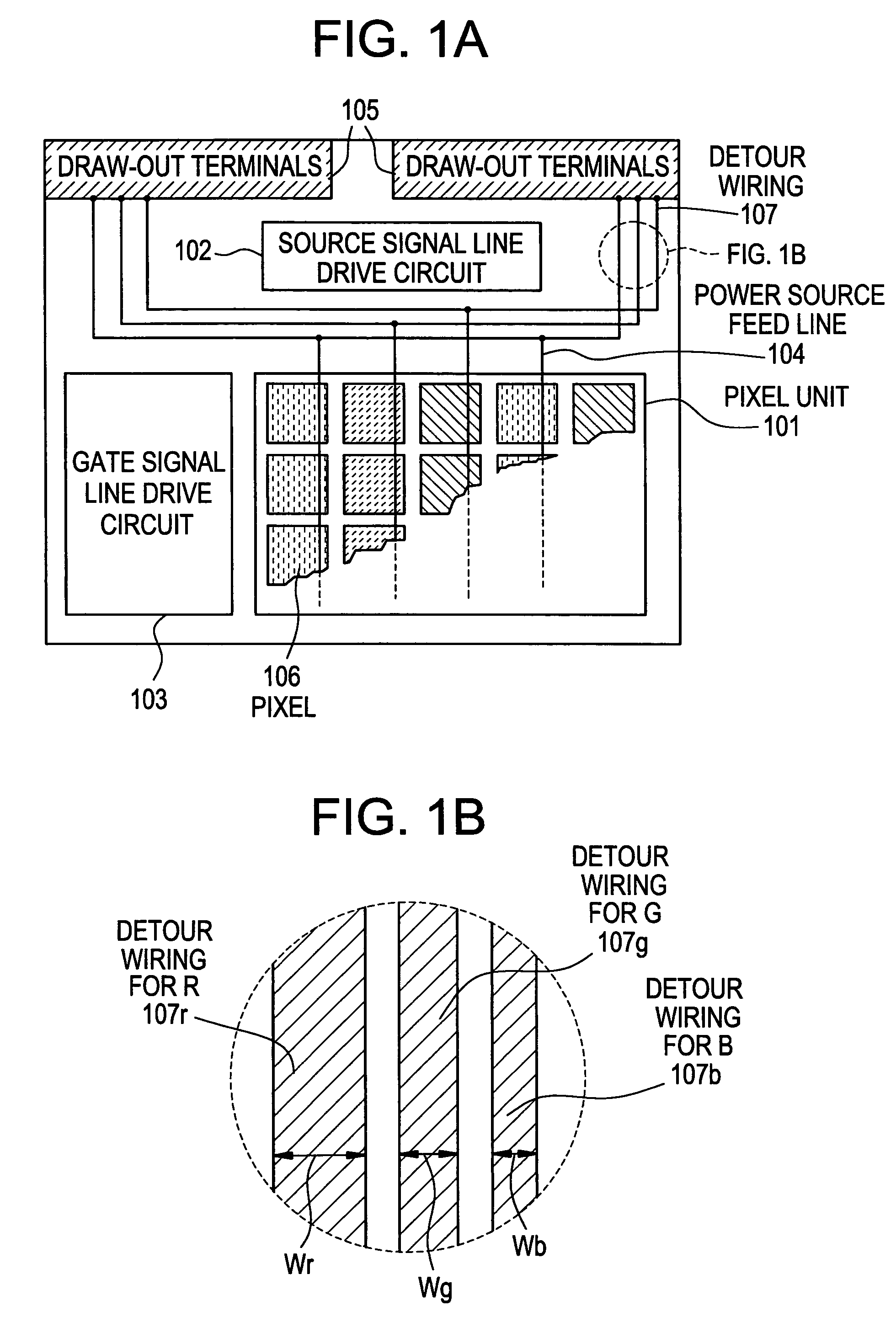

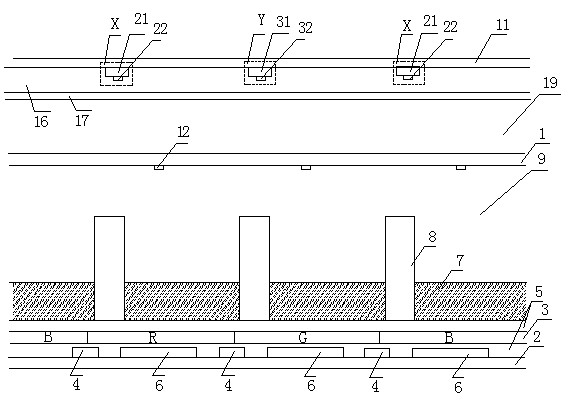

A display device capable of displaying a picture of vivid colors maintaining a good balance of colors and a good balance of light-emitting brightnesses of the EL elements. The widths of the detour wirings supplying current to the power source feed lines are increased for those EL elements into which a current of a large density flows. This constitution decreases the wiring resistances of the detour wirings, decreases the potential drop through the detour wirings, and suppresses the amount of electric power consumed by the detour wirings.

Owner:SEMICON ENERGY LAB CO LTD

Optical method and system for rapid identification of multiple refractive index materials using multiscale texture and color invariants

ActiveUS20050126505A1Rapid and accurate identificationRapid and accurate and classificationClimate change adaptationCharacter and pattern recognitionGabor wavelet transformFeature set

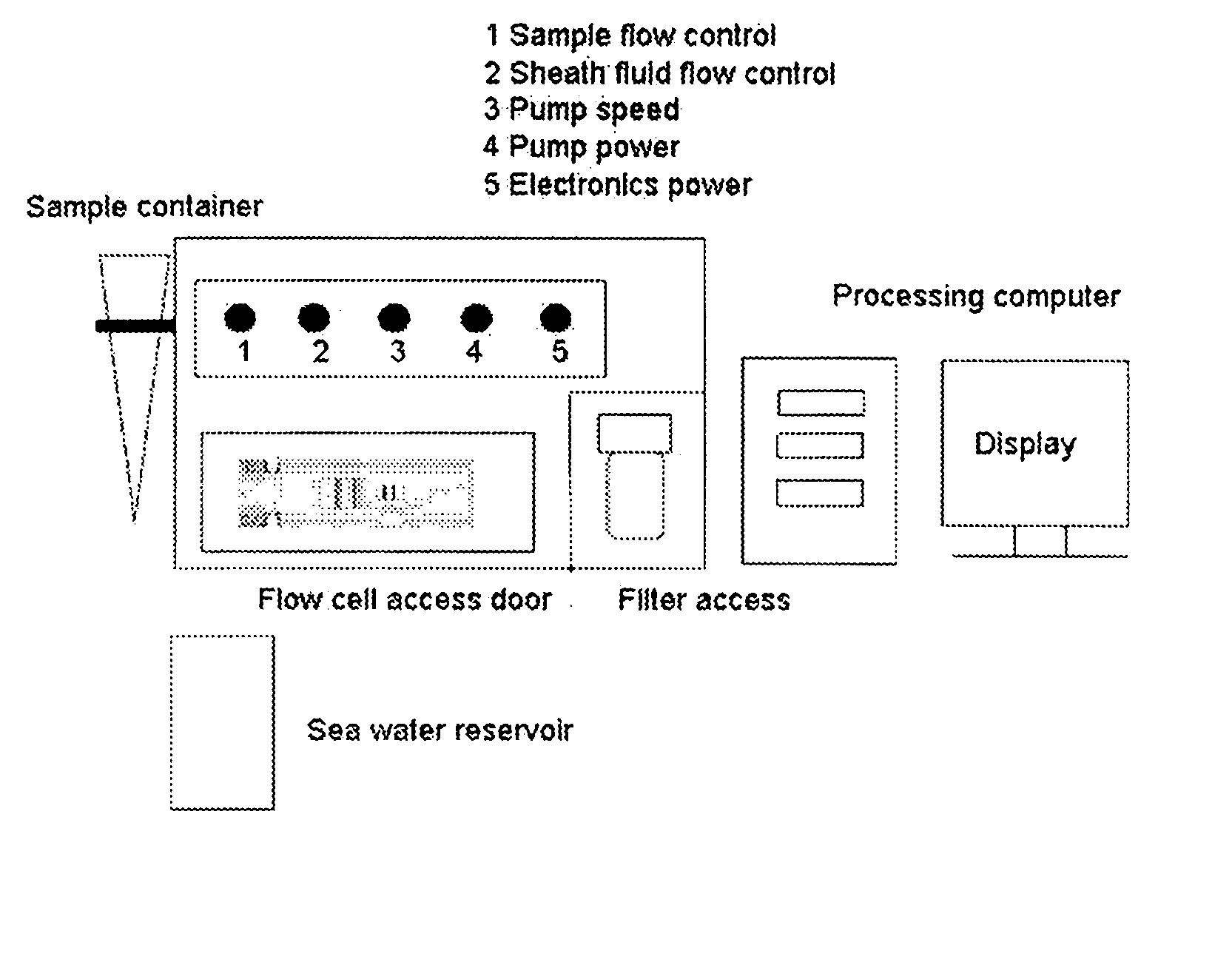

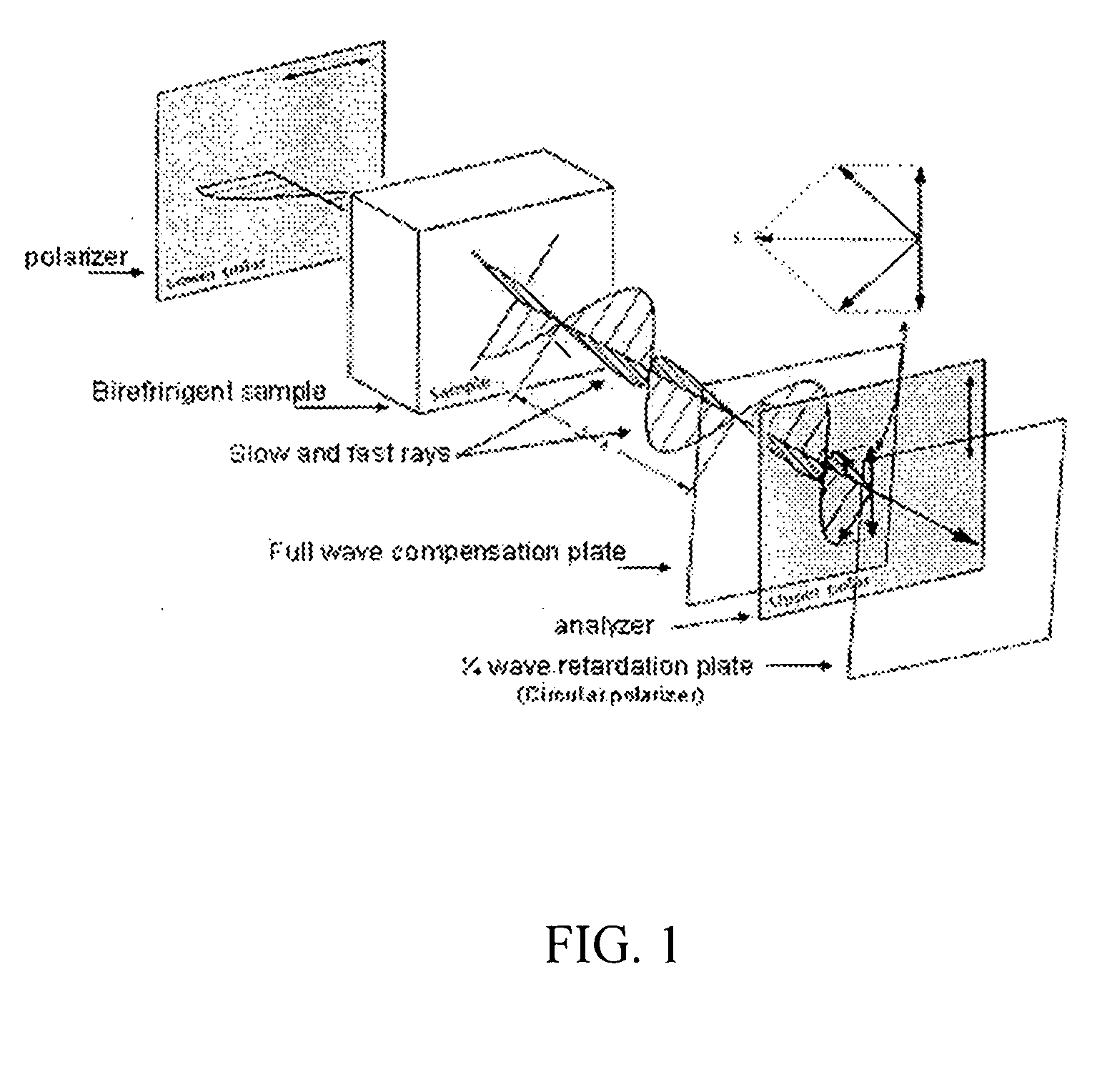

An innovative optical system and method is disclosed for analyzing and uniquely identifying high-order refractive indices samples in a diverse population of nearly identical samples. The system and method are particularly suitable for ultra-fine materials having similar color, shape and features which are difficult to identify through conventional chemical, physical, electrical or optical methods due to a lack of distinguishing features. The invention discloses a uniquely configured optical system which employs polarized sample light passing through a full wave compensation plate, a linear polarizer analyzer and a quarter wave retardation plate for producing vivid color bi-refringence pattern images which uniquely identify high-order refractive indices samples in a diverse population of nearly visually identical samples. The resultant patterns display very subtle differences between species which are frequently indiscernable by conventional microscopy methods. When these images are analyzed with a trainable with a statistical learning model, such as a soft-margin support vector machine with a Gaussian RBF kernel, good discrimination is obtained on a feature set extracted from Gabor wavelet transforms and color distribution angles of each image. By constraining the Gabor center frequencies to be low, the resulting system can attain classification accuracy in excess of 90% for vertically oriented images, and in excess of 80% for randomly oriented images.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

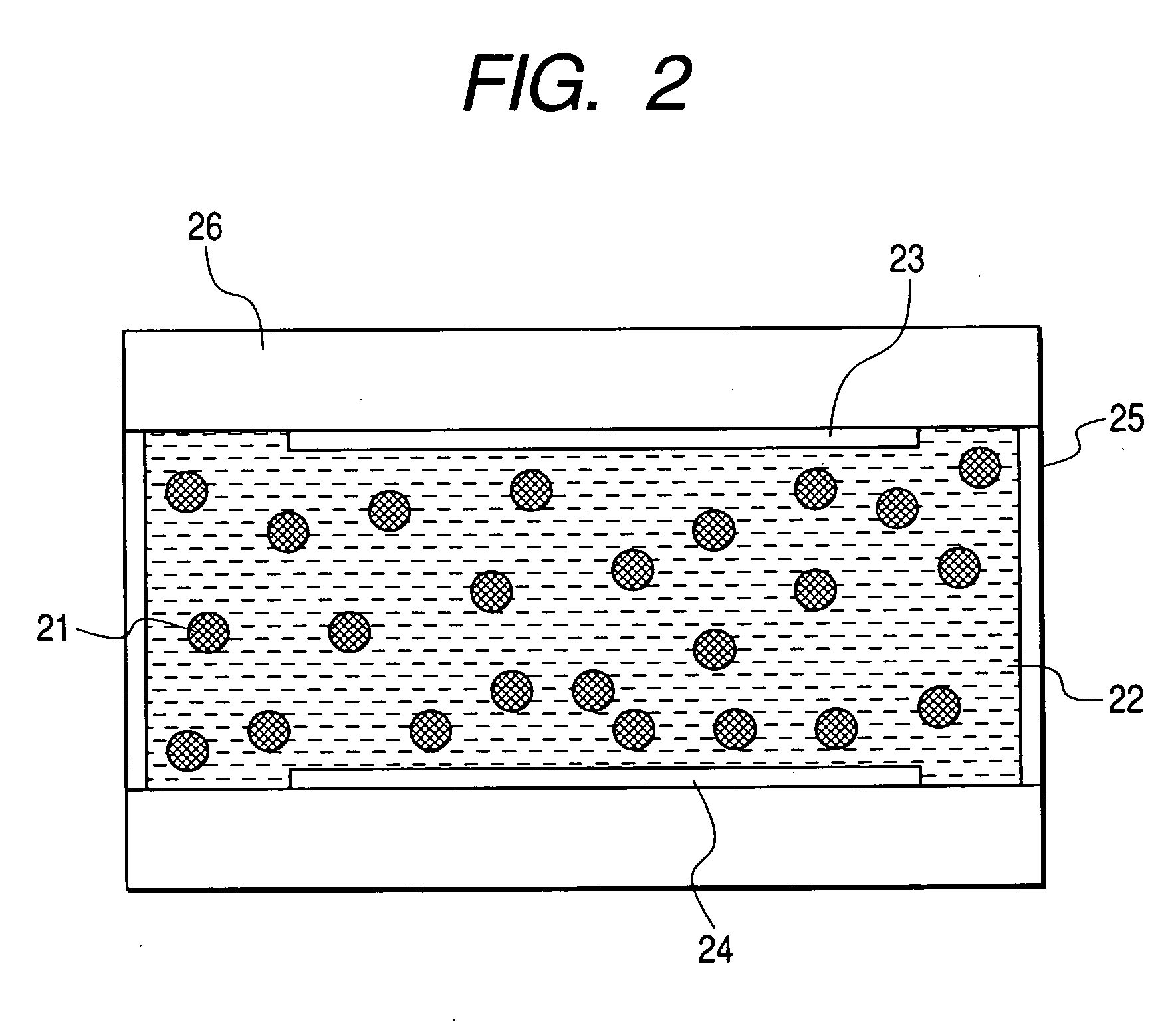

Display device and electronic device

InactiveUS20050093802A1Improve color displayIncrease widthElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A display device capable of displaying a picture of vivid colors maintaining a good balance of colors and a good balance of light-emitting brightnesses of the EL elements. The widths of the detour wirings supplying current to the power source feed lines are increased for those EL elements into which a current of a large density flows. This constitution decreases the wiring resistances of the detour wirings, decreases the potential drop through the detour wirings, and suppresses the amount of electric power consumed by the detour wirings.

Owner:SEMICON ENERGY LAB CO LTD

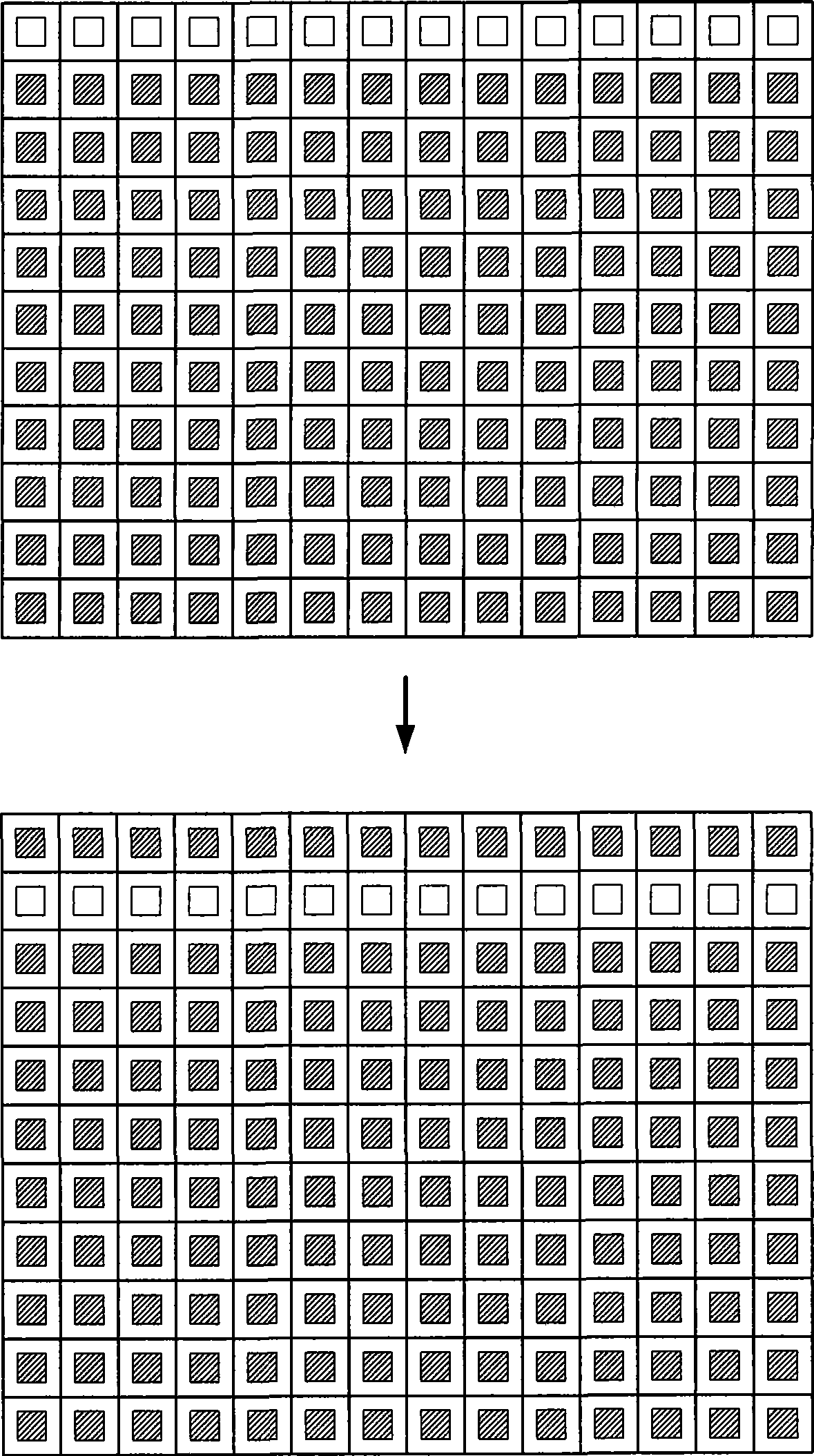

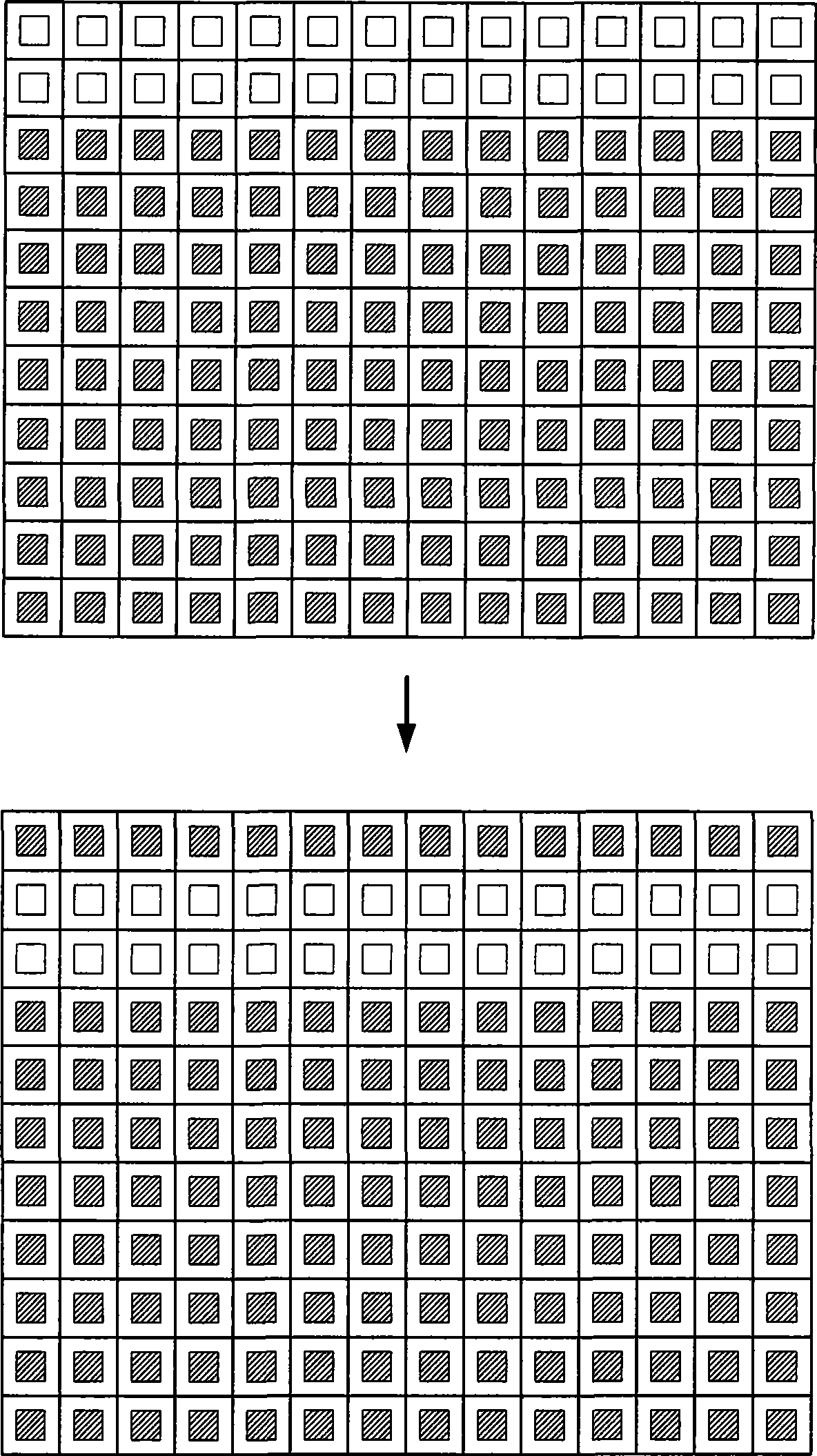

Monochromatic liquid crystal display for colors

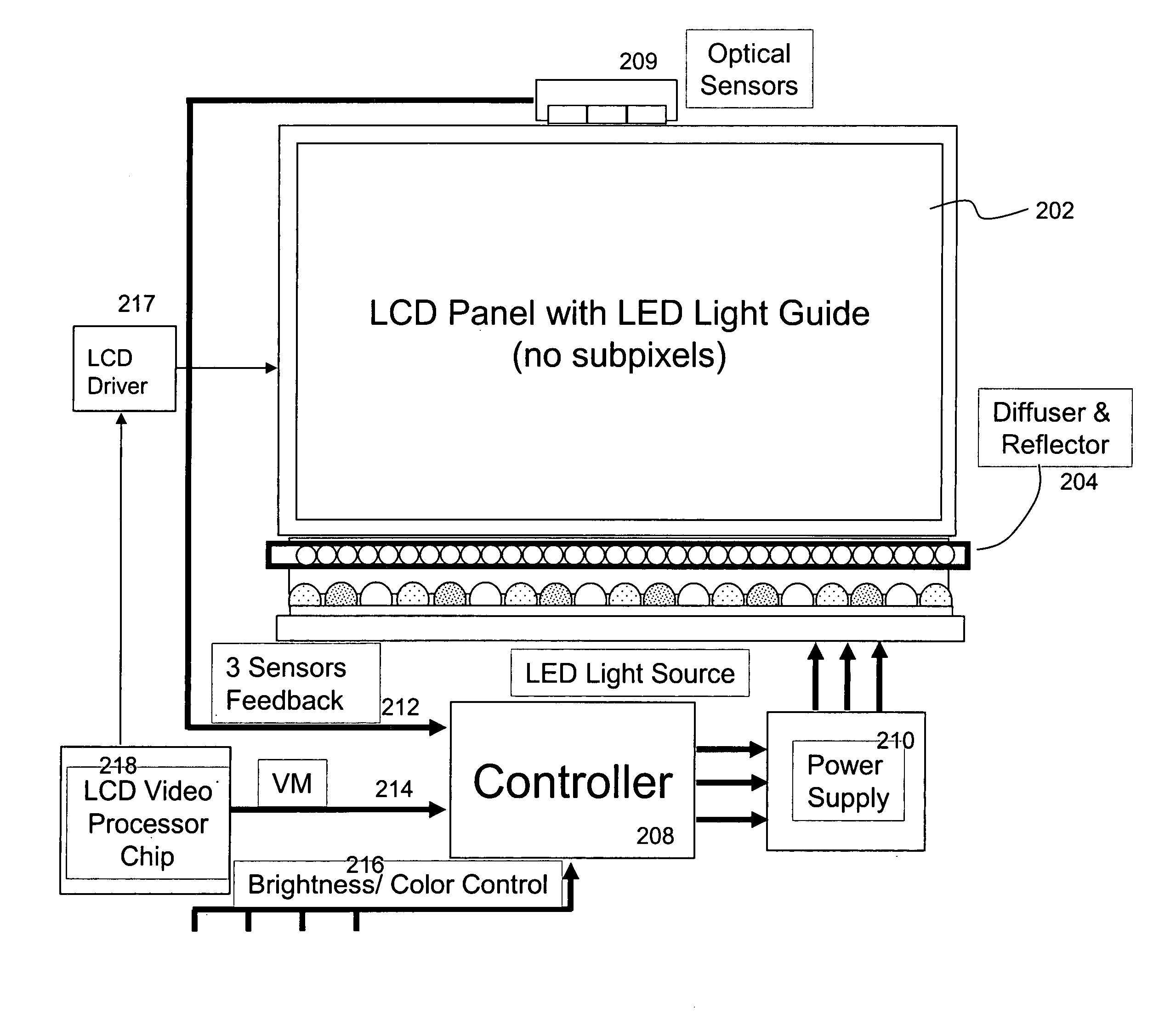

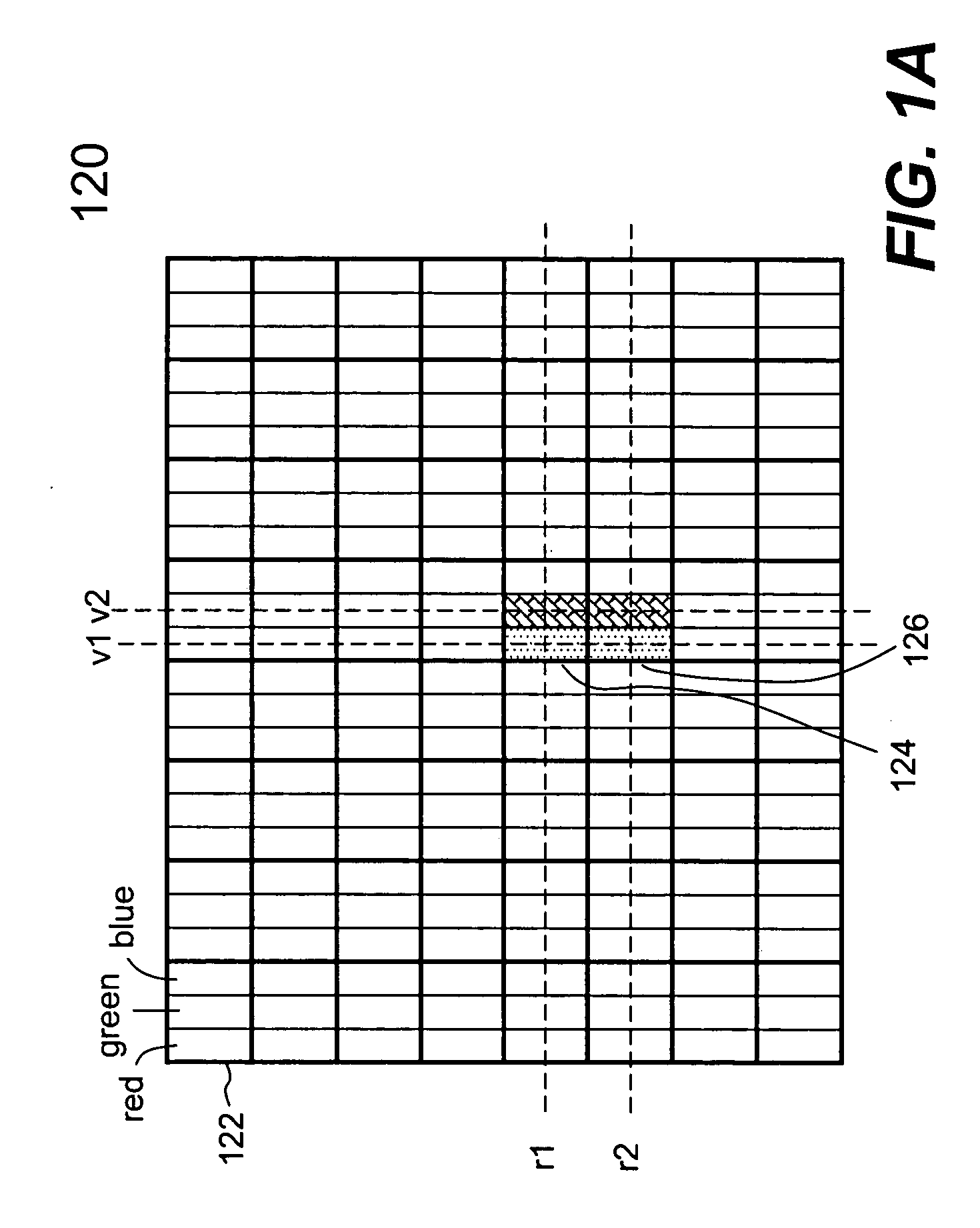

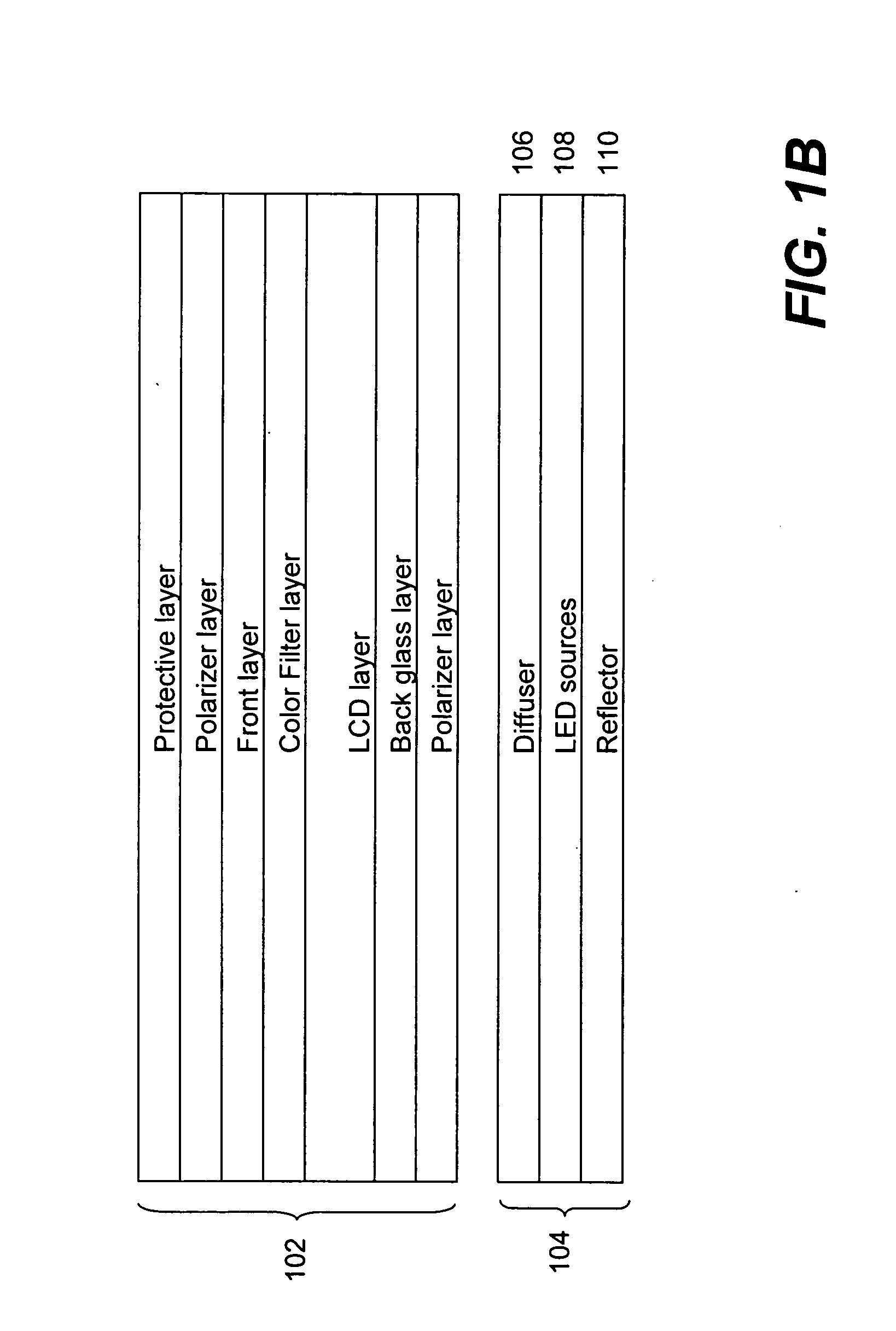

ActiveUS20090021461A1Loss of display resolutionIncreasing additional pixelDwelling equipmentCathode-ray tube indicatorsLiquid-crystal displayDisplay device

Techniques for providing backlight techniques in liquid crystal flat panel displays are disclosed. According to embodiment, the backlighting includes three color groups of light emitting diodes that are turned on successively. Pixels in an LCD are controlled in accordance with a display signal to transmit none, all or a determined amount of one or more of the colored lights from the three color groups of light emitting diodes in a cycle, resulting in an LCD with vivid colors and minimized tailing effects.

Owner:XENOGENIC DEV LLC

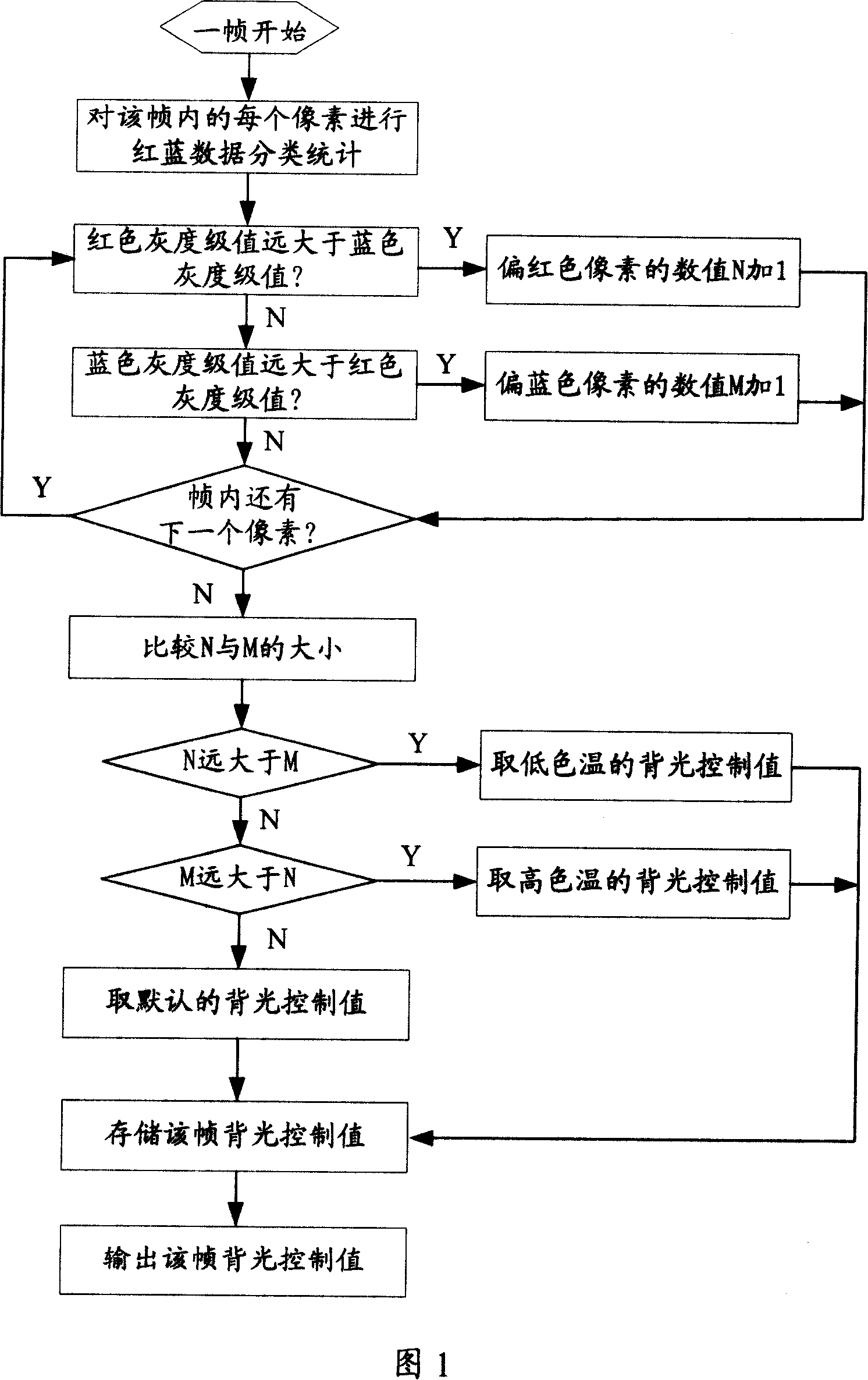

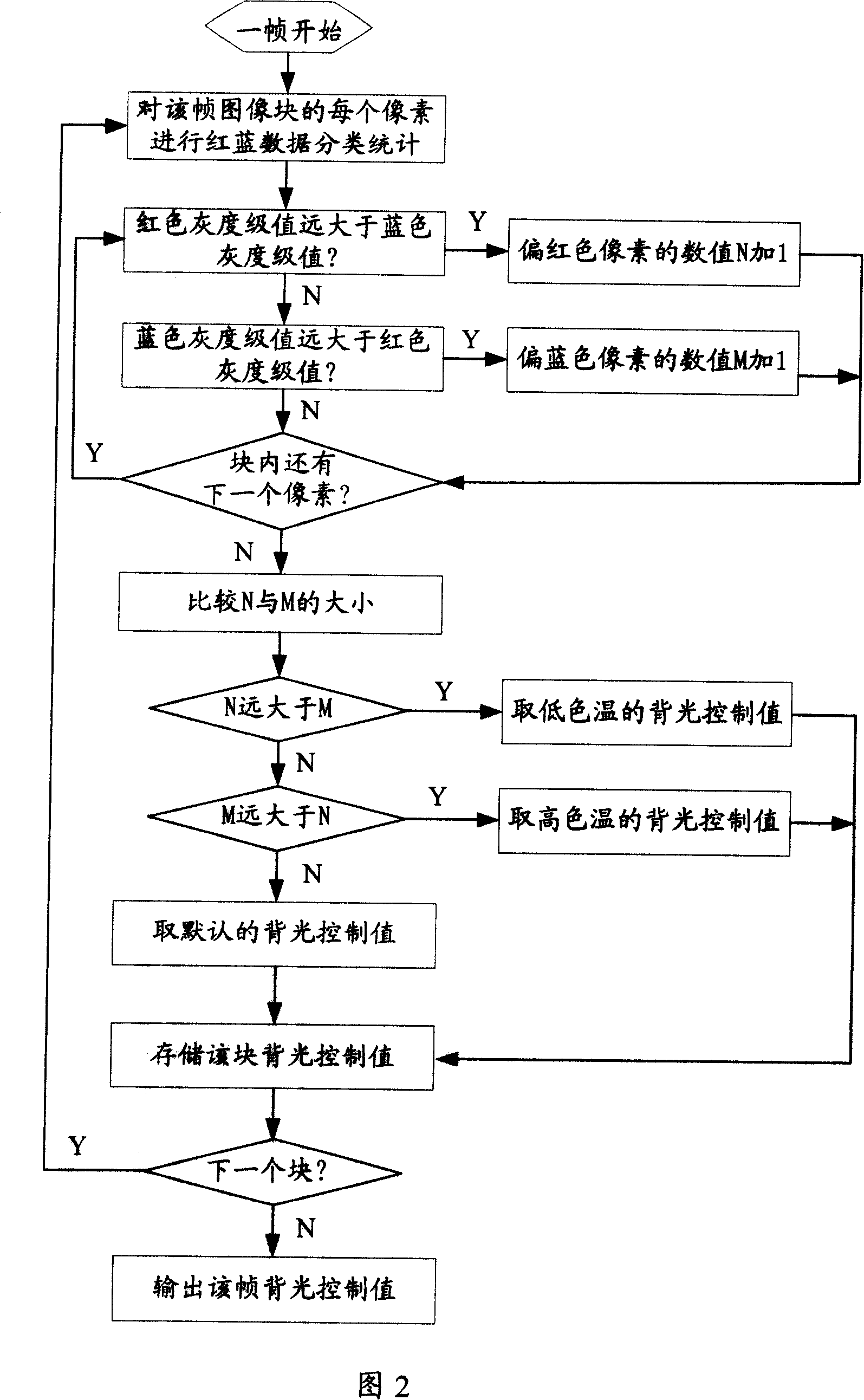

Color temperature dynamic regulation method

ActiveCN101083774AVivid colorsReduced luminous efficiencyColor signal processing circuitsCathode-ray tube indicatorsHueLuminescence

Via recognizing the image hue info of each frame and adopting accordingly different color temperatures (CT), the background lights (BL) of different CT are adopted for different pictures to ensure more lively beautiful pictures. This CT dynamically regulation method includes steps of: (1) firstly, determining the hue tropism (HT) of single image element (IE) on one frame picture; (2) making statistic of numbers of lean-red / lean-blue IEs of this frame picture; (3) comparing numbers of lean-red / lean-blue IEs of this frame picture to determine HT of this frame; (4) according to the determined HT, regulating CT of BL, i.e. controlling the brightness values of the red / blue LEDs. This offered CT dynamically regulation method ensures the vivid color of the picture and boosts the visible enjoyment. Besides, the brightness of blue light is reduced relatively when the picture appears low CT. It raises the luminescence efficiency of BL and reduces energy consumption.

Owner:SHENZHEN TCL IND RES INST

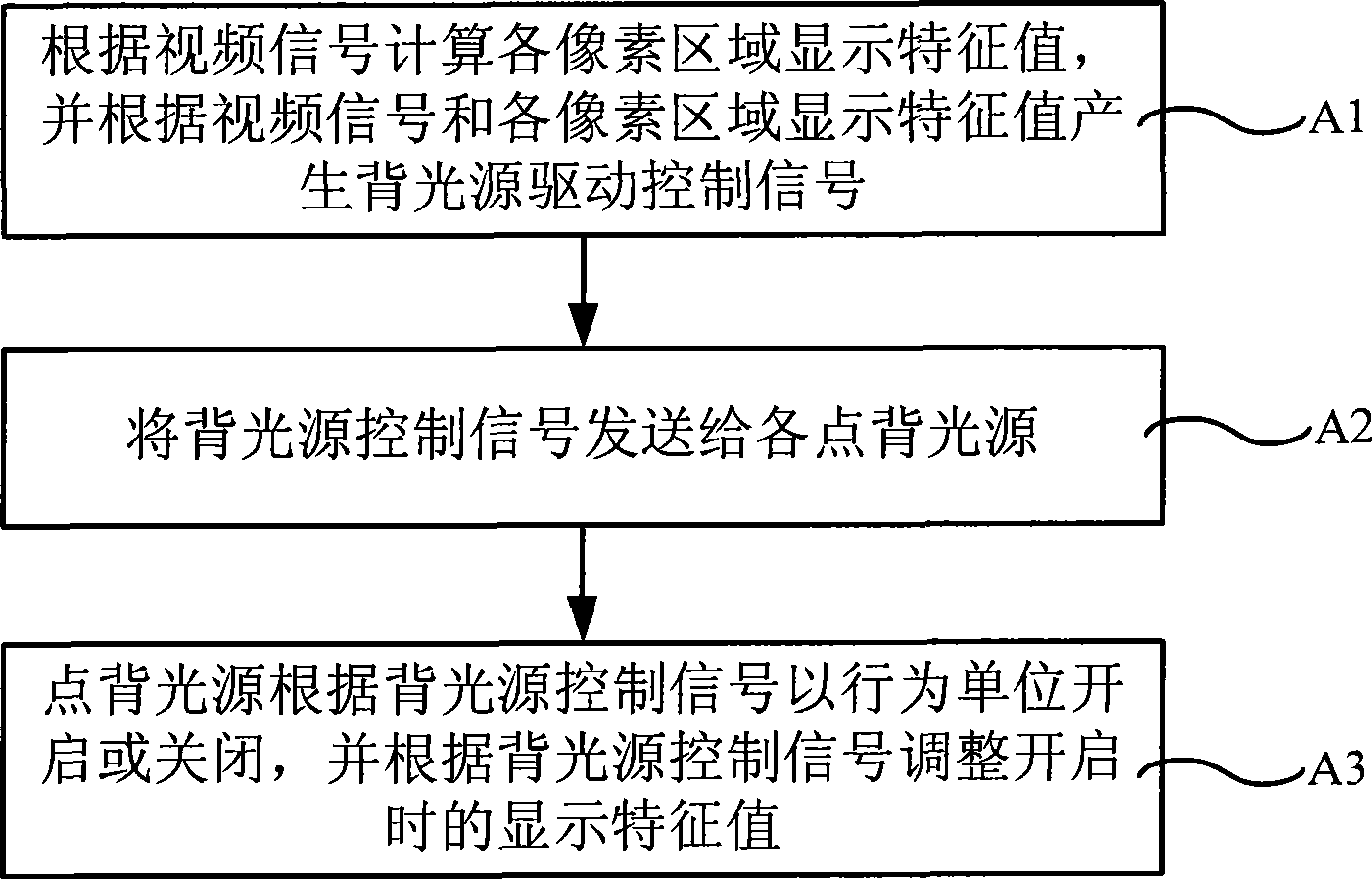

Method for driving backlight source of liquid crystal display apparatus and backlight source

ActiveCN101377901AIndividually control the display of eigenvaluesAvoid smearingStatic indicating devicesElectric light circuit arrangementLiquid-crystal displayControl signal

The invention relates to a backlight source drive method and a backlight source of a liquid crystal display, and the backlight source drive method comprises: a display characteristic value of each pixel region is computed according to a video signal, and a backlight source control signal is generated according to the display characteristic value and the video signal; the backlight source control signal is transmitted to each point backlight source; the point backlight source controls the opening or closing of an action unit and adjusts the display characteristic value when opening according to the control signal. The backlight source comprises a backlight source lattice which consists of the point backlight sources that are arranged correspondingly to a pixel unit and a control device which is used for controlling the opening or closing of the point backlight sources, wherein, the point backlight sources are colored point backlight sources with controllable colors, and the control device is respectively connected with each point backlight source and used for controlling the opening or closing of each point backlight source as well as the color or the brightness when opening. The backlight source drive method and the backlight source can effectively avoid the trailing smear phenomenon, raise the image contrast ratio and have more vivid color and better display effect, and can simultaneously lower the energy consumption of the backlight sources.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Soaking finishing agent of rattan and corn straw as raw materials for weaving crafts and use method thereof

The invention discloses a soaking finishing agent of rattan and corn straw as raw materials for weaving crafts. The soaking finishing agent is prepared from the following raw materials in percentage by weight: 10-20 parts of kuh-seng, 10-15 parts of frutus cnidii, 10-15 parts of stemona root, 10-15 parts of betelnut, 1-2 parts of entomomycete pesticide, 20-30 parts of lime and 20-30 parts of tea.When the soaking finishing agent is in use, the raw materials are mixed and dissolved in water according to a certain proportion, and weaving materials are soaked in a soaking solution for a certain of time, taken out and dried or aired. The soaking finishing agent provided by the invention is non-toxic, harmless and environment-friendly, and the products woven with straw or rattan soaked by the soaking finishing agent provided by the invention can not be mildewed and damaged by worms for dozens of years and keep vivid color and luster.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Hot melt wetness indicator adhesive composition with controllable color change

InactiveCN1471410AAvoid defectsFilm/foil adhesivesAcid polymer adhesivesAdditive ingredientColor changes

The present invention is directed towards a hot melt wetness indicator composition based on an ethylene-alkylacrylate-acrylic acid terpolymer. The wetness indicator composition comprises the terpolymer, a tackifying resin, a compatible surfactant having a HLB value less than 20 and a pH indicator or a dye that is capable of changing color when insulted with urine, as the primary ingredients. One embodiment of the present invention is to provide a wetness indicator that has excellent heat and environmental stability, improved fastness, vivid color change, easy manufacturing, and easy application. Another embodiment is directed towards a composition having a delayed response and therefore can withstand multiple insults daily.

Owner:ATO FINDLEY

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

Display device and electronic device

InactiveUS7639248B2Improve color displayIncrease widthElectroluminescent light sourcesSolid-state devicesDisplay deviceLightness

A display device capable of displaying a picture of vivid colors maintaining a good balance of colors and a good balance of light-emitting brightnesses of the EL elements. The widths of the detour wirings supplying current to the power source feed lines are increased for those EL elements into which a current of a large density flows. This constitution decreases the wiring resistances of the detour wirings, decreases the potential drop through the detour wirings, and suppresses the amount of electric power consumed by the detour wirings.

Owner:SEMICON ENERGY LAB CO LTD

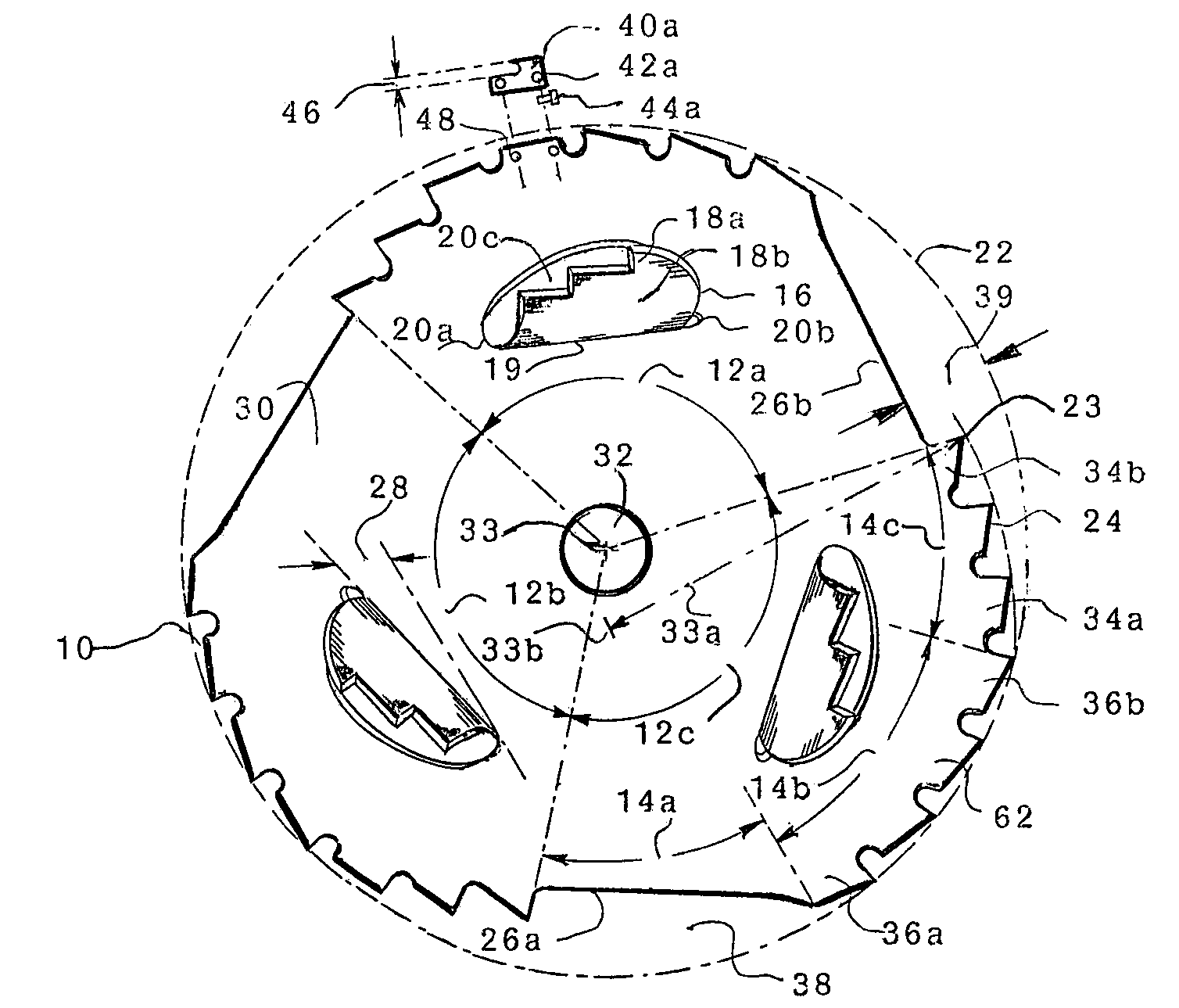

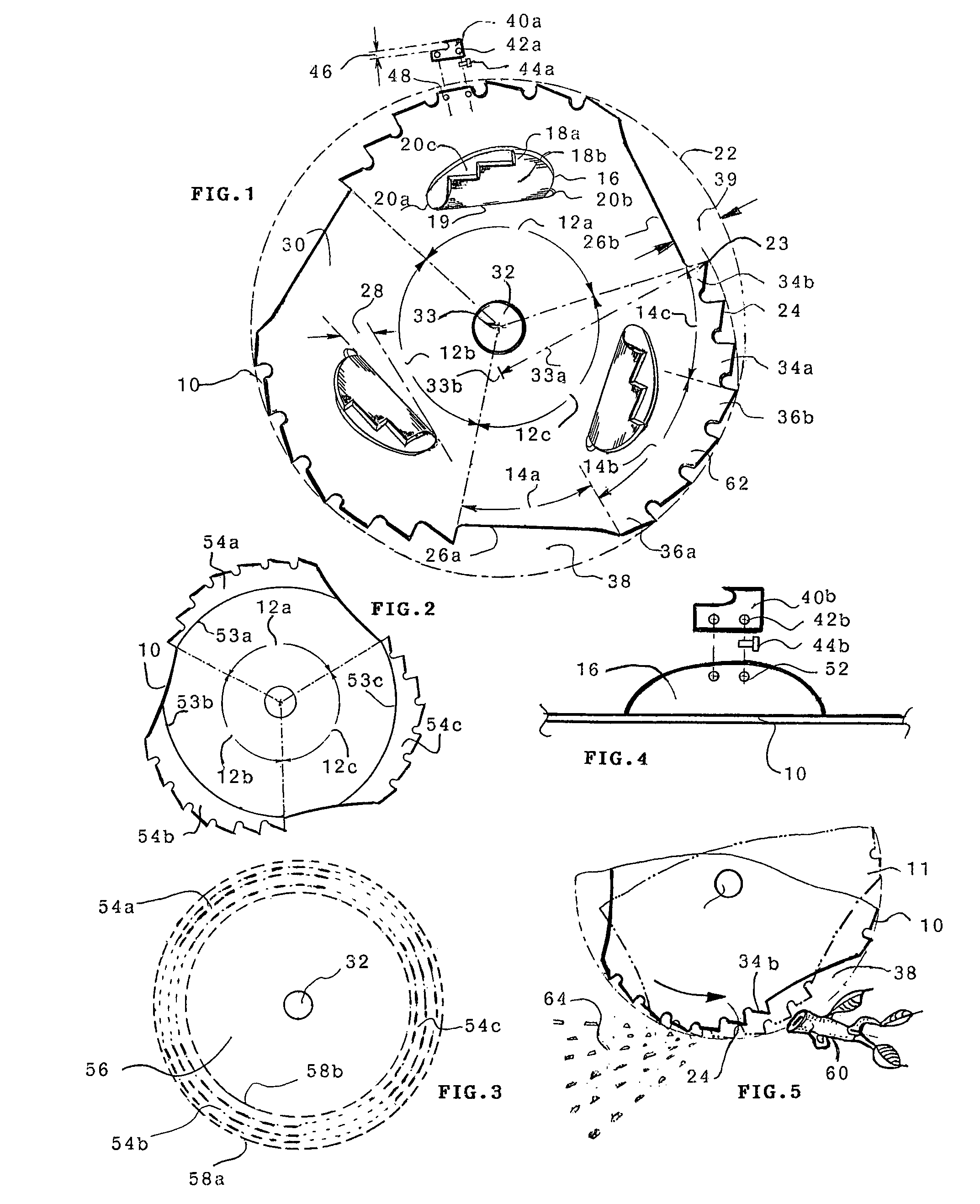

Brushcutter blade

A brushcutter blade with an undulated peripheral cutting edge, wherein the edge alternates partly circular cutting sections, with partly arcuate, radially recessed cutting sections. Recessed cutting sections provide accelerated radial cutting and also additional axial shredding. Auxiliary axial segments are formed or deflected out of the blade body around a base line or juncture with the blade, at angles acute to the plane of the blade, and the openings through the blade created thereby, are radially outward of the juncture. The segments are configured to provide an inclined leading edge for each segment, that cuts a laterally extended path with the movement of the blade, and enhances both radial and axial shredding. A contrasting vivid color band on distal cutting sections optically merges into a distinctively visible cutting edge for obstacle avoidance and safety enhancement.

Owner:BERNARDY ECKHARD

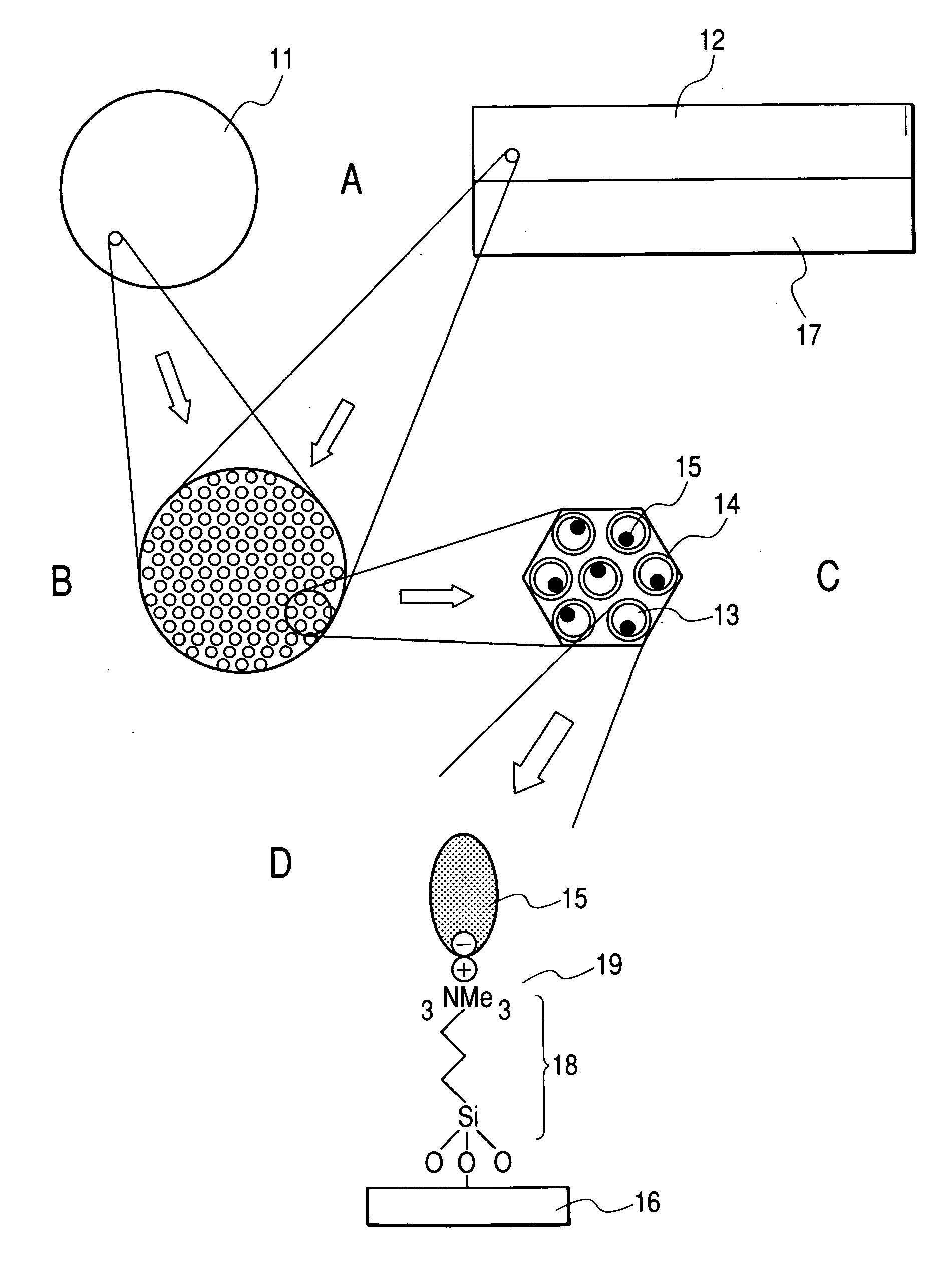

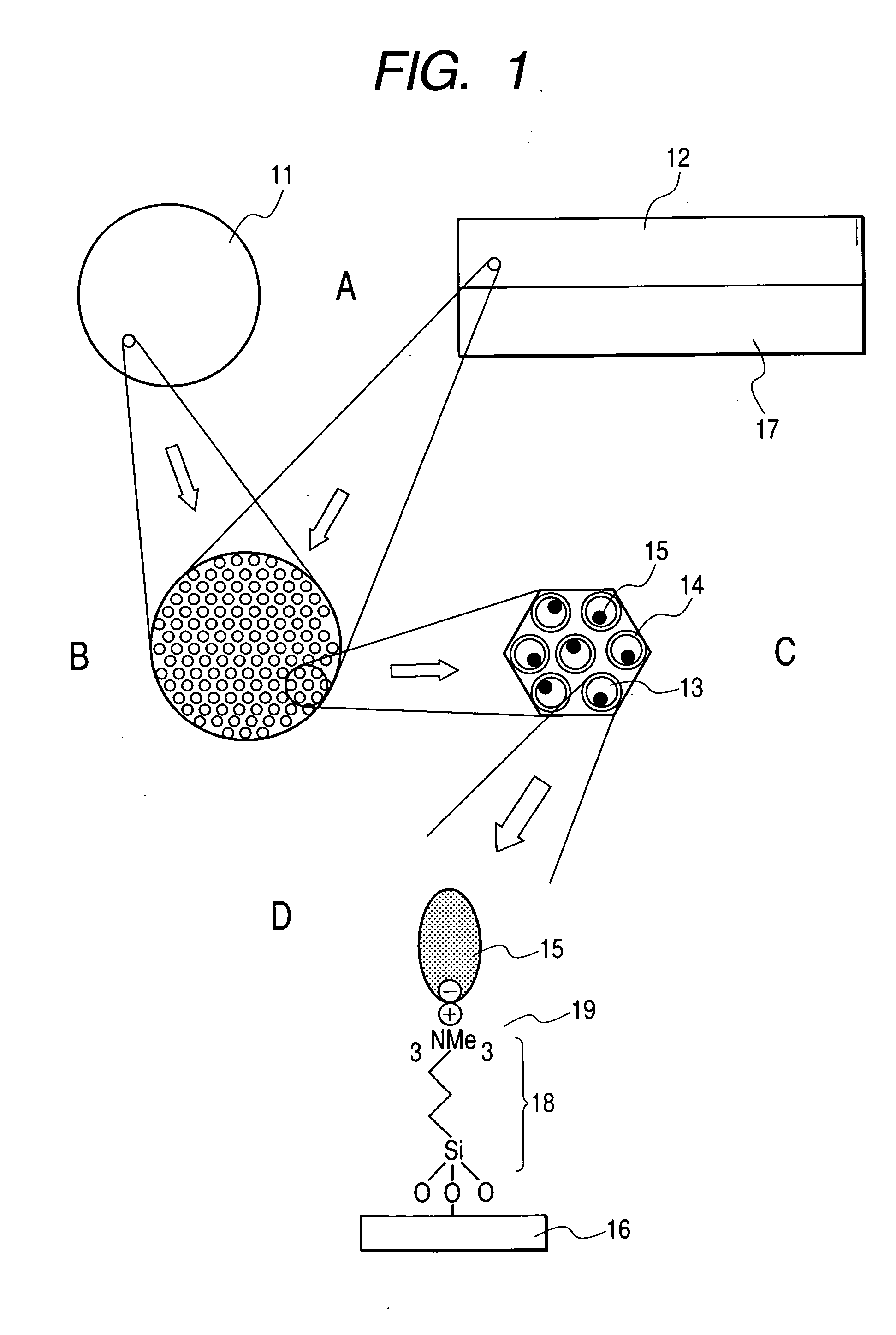

Colored material and method for producing the colored material

InactiveUS20050256224A1Bright color effectLittle bleedingInksCoatingsElectrophoresisCOLORED MATERIAL

A coloring material (11, 12) carrying an anionic dye (15) on porous silica (16) having mesopores (13) of a uniform size, of which at least a part of the surface is covered with a material (14) capable of binding an anionic substance. The coloring material shows vivid color and is applicable to ink, electrophoretic particles and color filters.

Owner:CANON KK

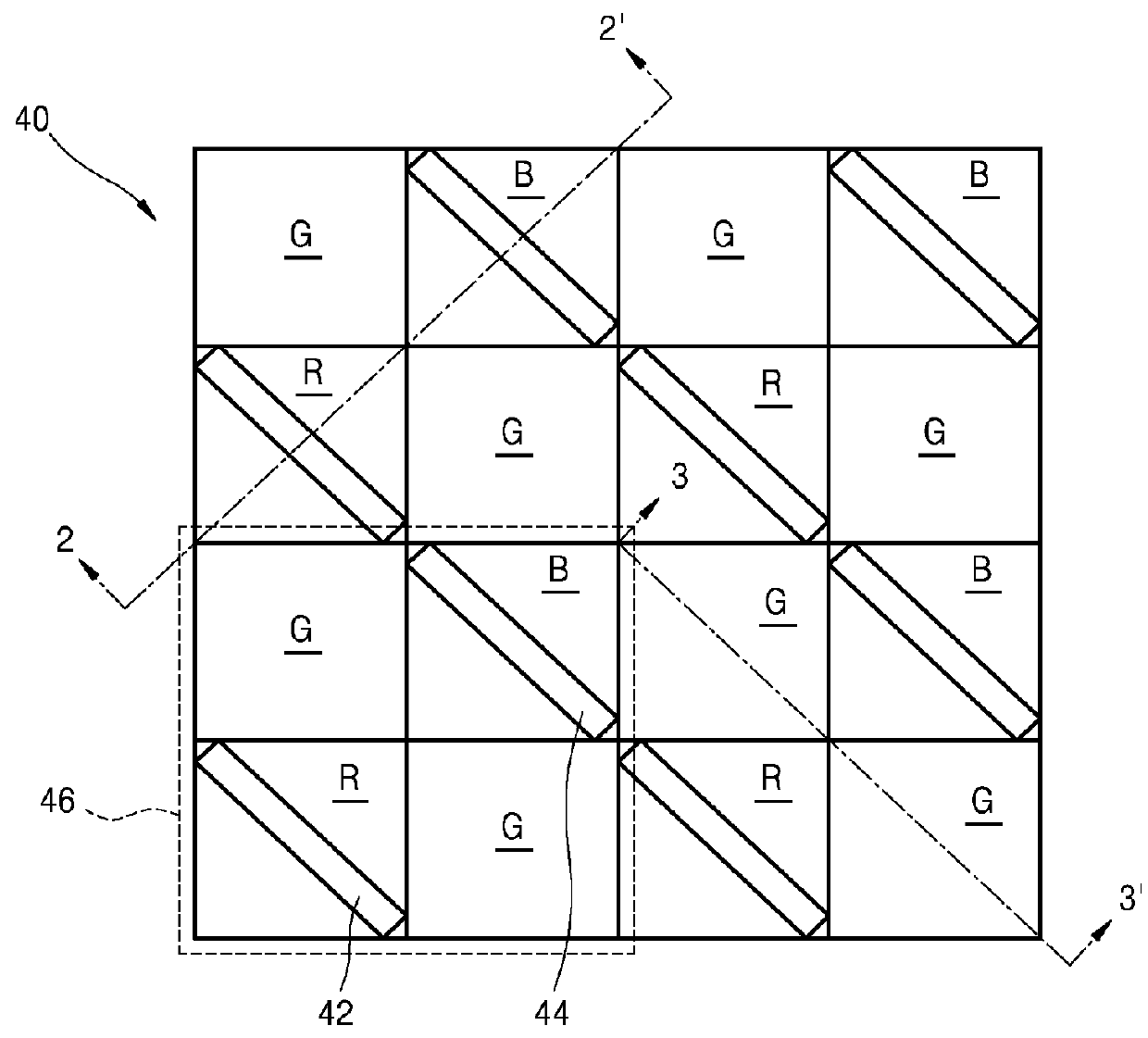

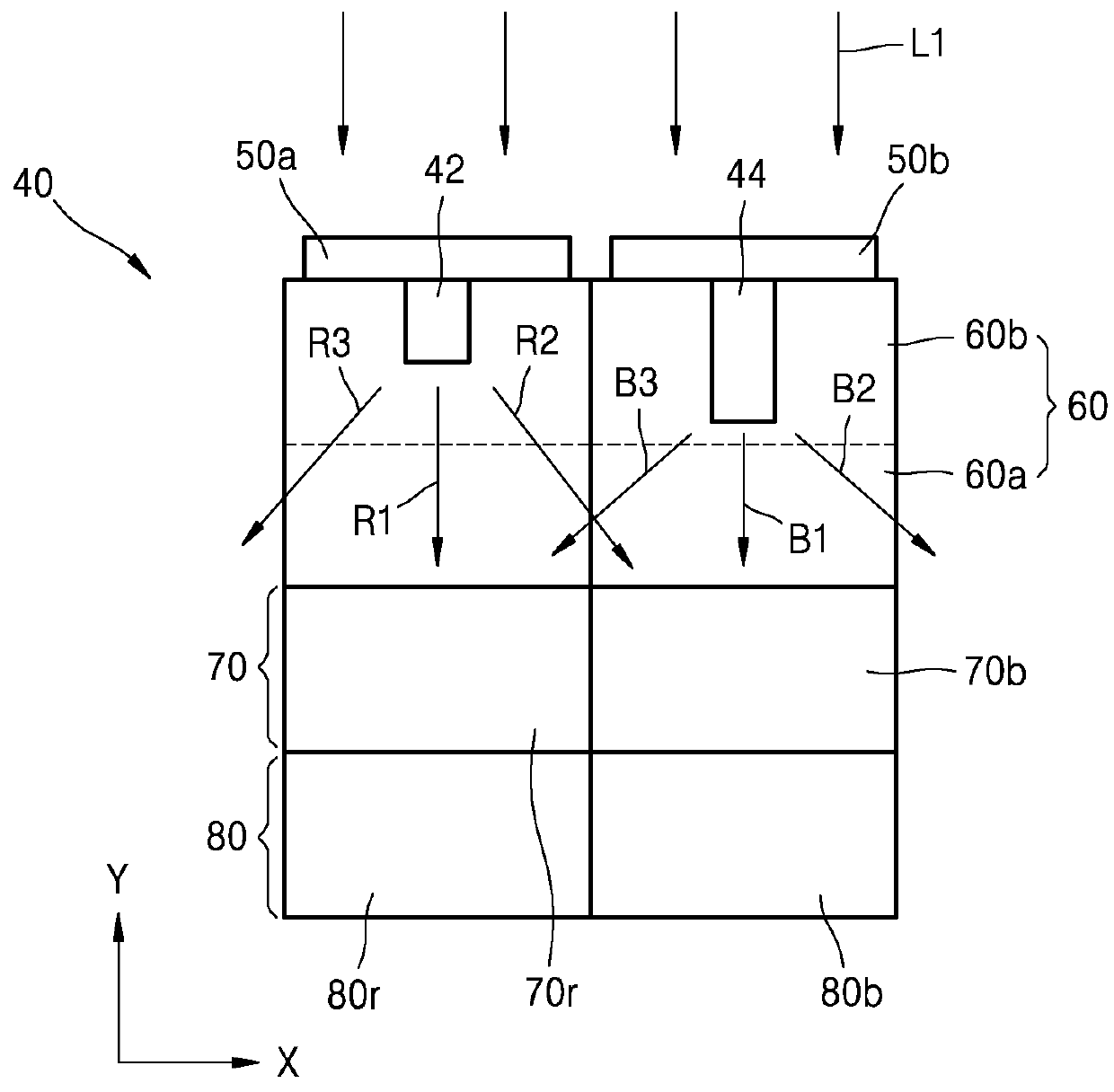

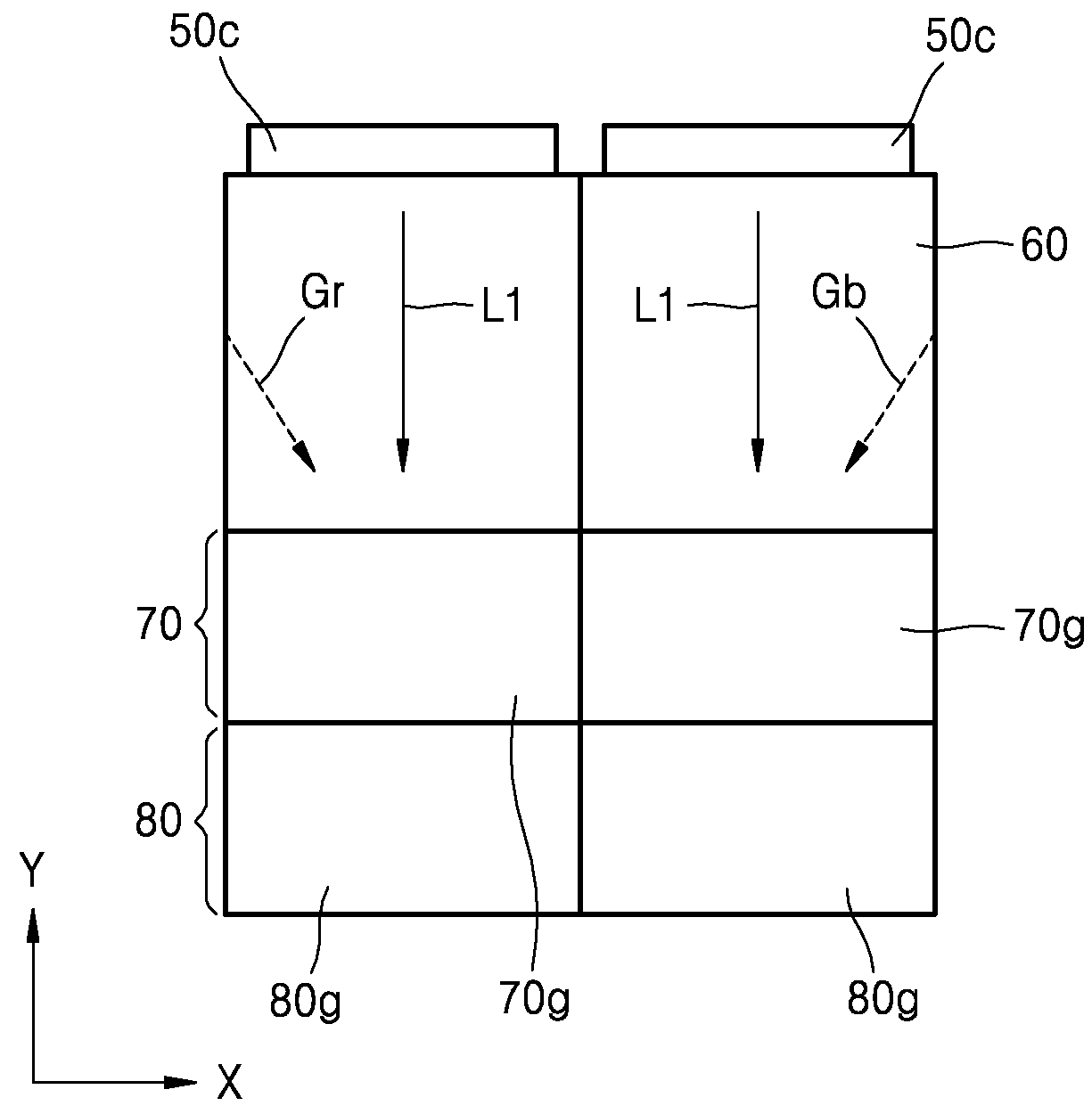

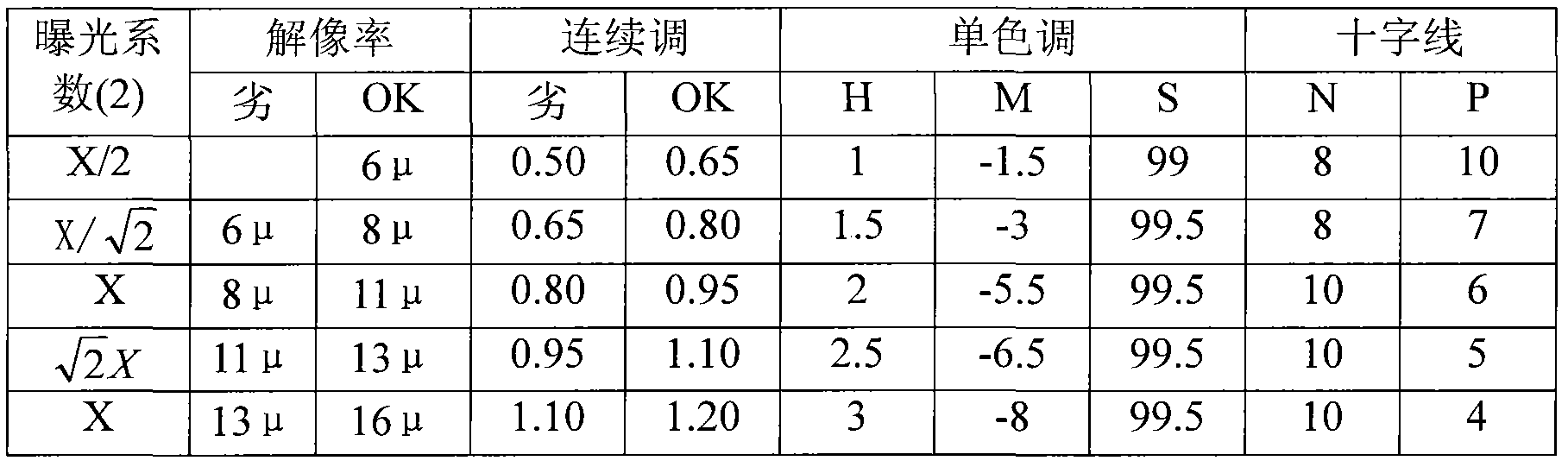

Image sensor for producing vivid colors and method of manufacturing the same

ActiveUS20160054172A1Reduce lossesImprove lighting efficiencySolid-state devicesMaterial analysis by optical meansBeam splitterRefractive index

An image sensor and a method of manufacturing the same are provided. The image sensor includes a photoelectric conversion layer; a color filter disposed on the photoelectric conversion layer; a low refractive index layer disposed on the color filter; a beam splitter disposed within the low refractive index layer; and a lens layer disposed on the low refractive index layer and covering the beam splitter. The beam splitter extends in a diagonal direction of a pixel area of the color filter, in a plan view.

Owner:SAMSUNG ELECTRONICS CO LTD

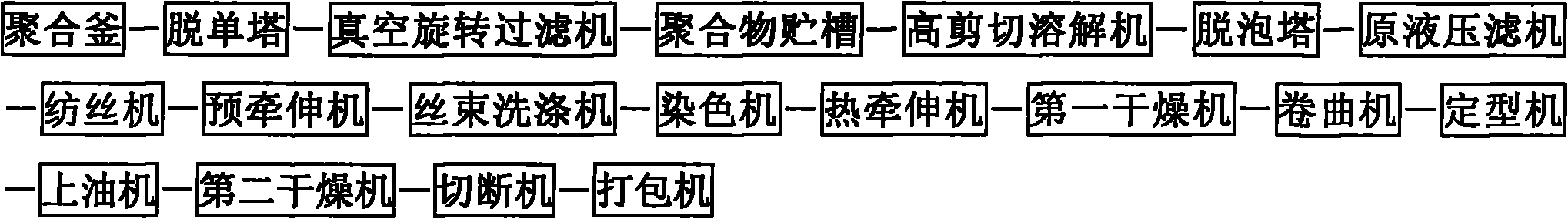

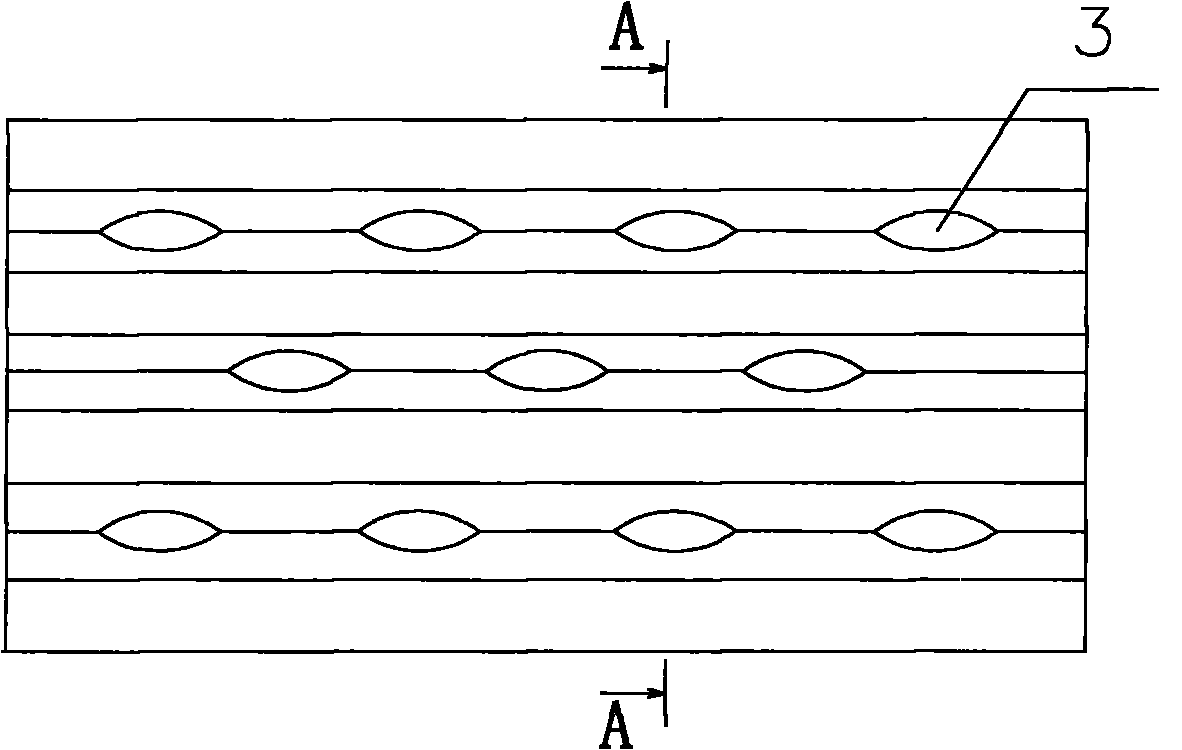

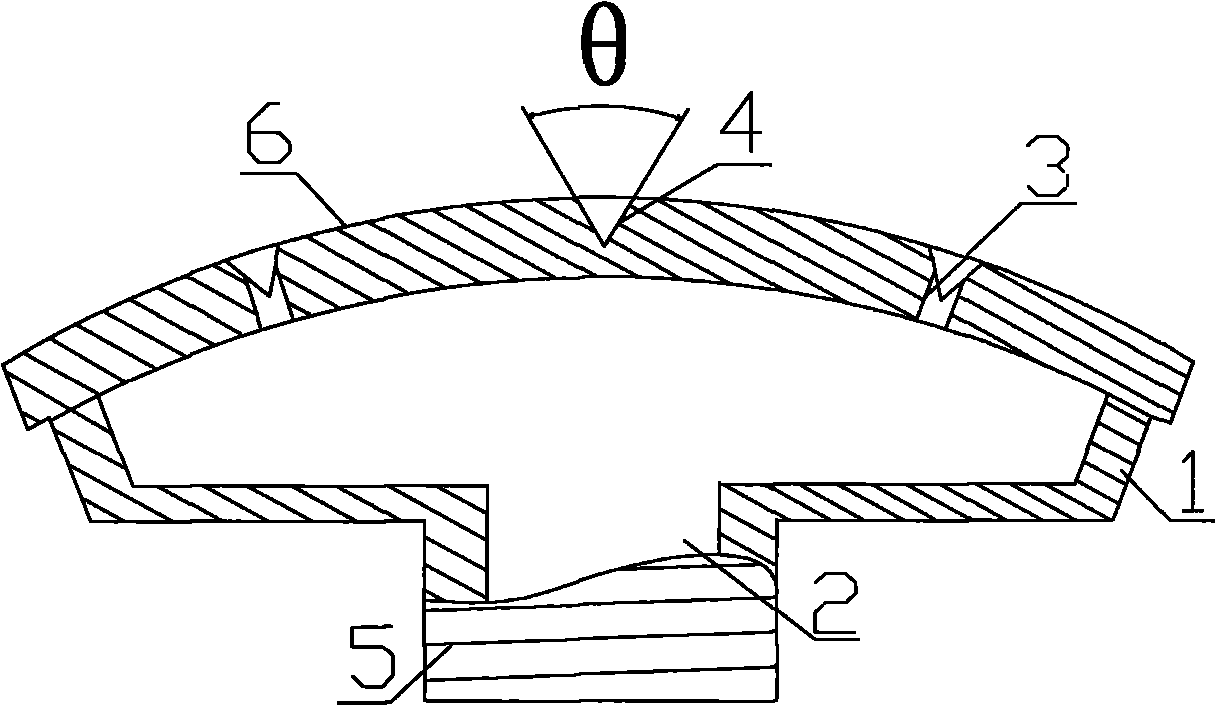

Production process of colored flat acrylic fiber and production line thereof

InactiveCN101922059AIncrease extrusion speedSolve the problem of uneven spinning and dyeingArtificial thread manufacturing machinesWet spinning methodsProduction lineSodium sulfocyanate

The invention relates to a production process of colored flat acrylic fiber and a production line thereof, which are a production process and a production line thereof for producing the colored flat acrylic fiber in a plurality of color systems with vivid colors, little chromatic aberration and great flatness by adopting a cationic dye, in particular to a spinning production line for producing the colored flat acrylic fiber by adopting a ternary aqueous suspension polymerization and sodium sulfocyanate wet method. In the invention, a long-strip arc dye liquor spray head is used for dying, and the long-strip arc dye liquor spray head is an arc spray head which comprises a spray head seat, a spray head cover and a dye liquor inlet pipe and has a hollow T-shaped cross section, wherein the spray head is a long-strip semi-cylindrical surface, and a plurality of penetrative spraying holes are arranged on the spray head cover in a staggered way. The invention overcomes the defects of stripy and uneven dyeing, great chromatic aberration, large volume of colored wastewater, long product processing period, and the like commonly existing in a production process and a production line thereof for producing white flat acrylic fiber by adopting a traditional dyeing mode of steaming loose fibers at a high temperature.

Owner:DONGHUA UNIV

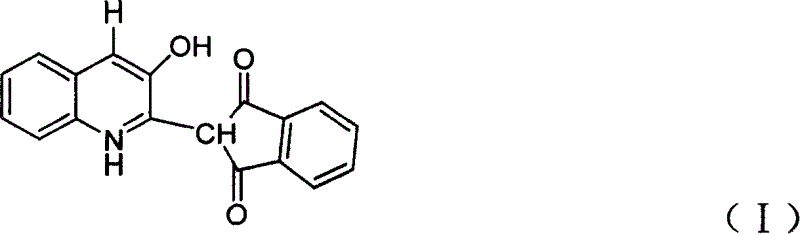

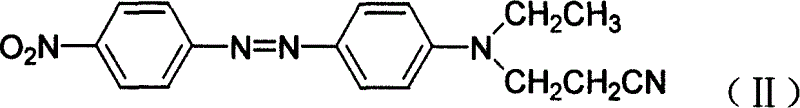

Low-temperature environmentally friendly disperse dye

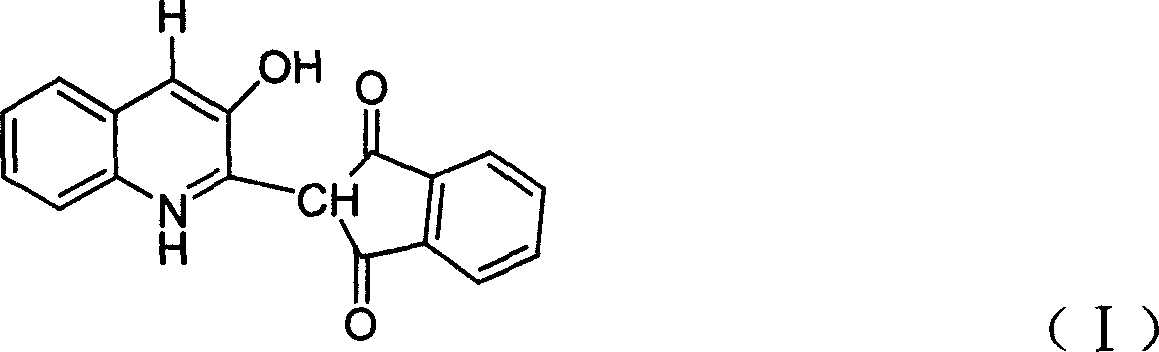

ActiveCN1580133ASolve head and tail chromatic aberrationSolve the phenomenon of color flower and so onOrganic dyesDisperse dyeMonomer

The invention refers to a kind of low-temperature green disperse dyes and is especially adaptable to the printing and dyeing of polyester material and vinegar acyl material. The low-temperature green disperse dyes in the invention is composed of the following components: in amounts of weight, between 15% and 50% of chromatid A, between 3% and 25% of chromatid B and the rest of the auxiliary agent. The low-temperature green disperse dyes in the invention has strong fastness, high tintage, vivid color, good level-dyeing property and building up properties, can be used as homochromy products, also can mix with blue of 2BLN and red of 3B and has excellent compatibility.

Owner:ZHEJIANG LONGSHENG GROUP

Sorona/wool semi-worsted spinning yarn as well as manufacturing process thereof and application thereof

The invention relates to the textile field, in particular to a sorona / wool semi-worsted spinning yarn as well as a manufacturing process thereof and an application thereof. The invention provides the yarn; and the key technical point is as follows: the yarn is a three-stranded knitted yarn with count of 36 N / 3, which is obtained through spinning 70% of wools and 30% of sorona fiber by weight. The invention further provides the manufacturing process of the sorona / wool semi-worsted spinning yarn; and the process comprises the following steps of dyeing, blending, cotton carding, drawing of three strands, rough yarn forming, spun yarn forming, spooling and doubling. The invention further provides a sweater using the sorona / wool semi-worsted spinning yarn. According to the invention, an environment-friendly sorona fiber with a certain ratio is adopted for the knitted sweater, so that the finished product sweater has the advantages of soft and rich handle, vivid color, good moisture absorbing property, good air permeability and excellent heat retention property; and compared with the traditional sweater product, the sweater has the advantages of better water washing size stability and machine washability.

Owner:劲霸男装(上海)有限公司

Processing technology of Chinese red glass metal

The invention provides a processing technology of Chinese red glass metal. The processing technology of a Chinese red glass product comprises the following steps: (a) preparing mixture according to the following main raw materials: 100 portions of quartz sand, 30-50 portions of calcined soda, 4-6 portions of potassium carbonate, 9-11 portions of borax, 6-10 portions of feldspar powder, 10-14 portions of zinc oxide, 1.7-1.9 portions of cadmium yellow, 0.5-0.7 portion of cadmium red, 0.4-0.6 portion of selenium powder, 0.1-0.3 portion of antimony oxide, 0.6-1.4 portions of fluorite powder and 0.4-0.6 portion of salt; and (b) melting the prepared mixture at high temperature to obtain the Chinese red glass metal. The Chinese red glass metal prepared by the processing technology of the invention has the characteristics of vivid color and stable coloring and can be widely applied to different glass products.

Owner:常熟市万利特种玻璃厂

Shoe upper patter forming method and shoe uppers thereof

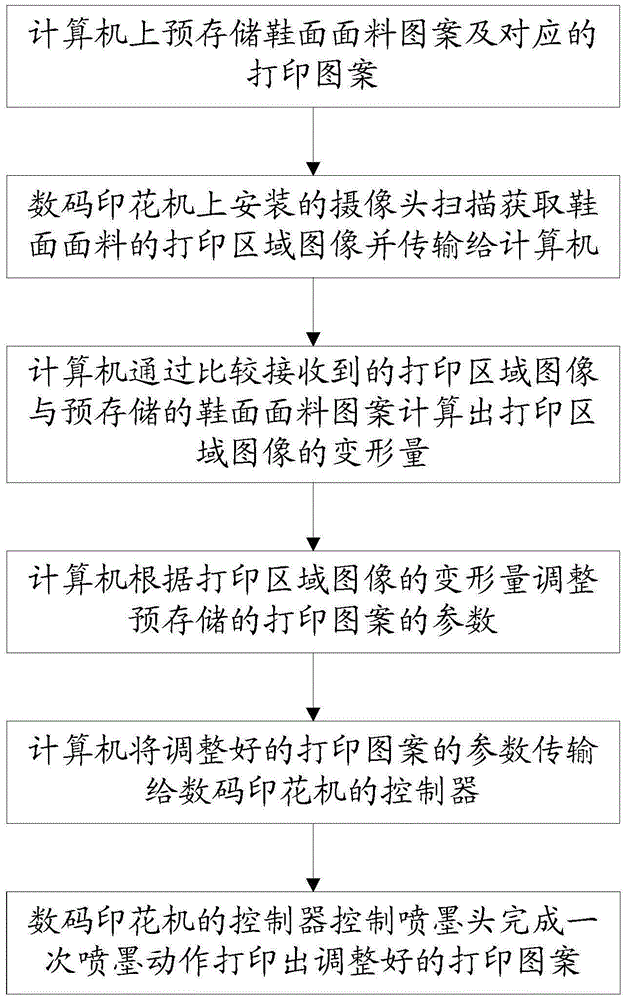

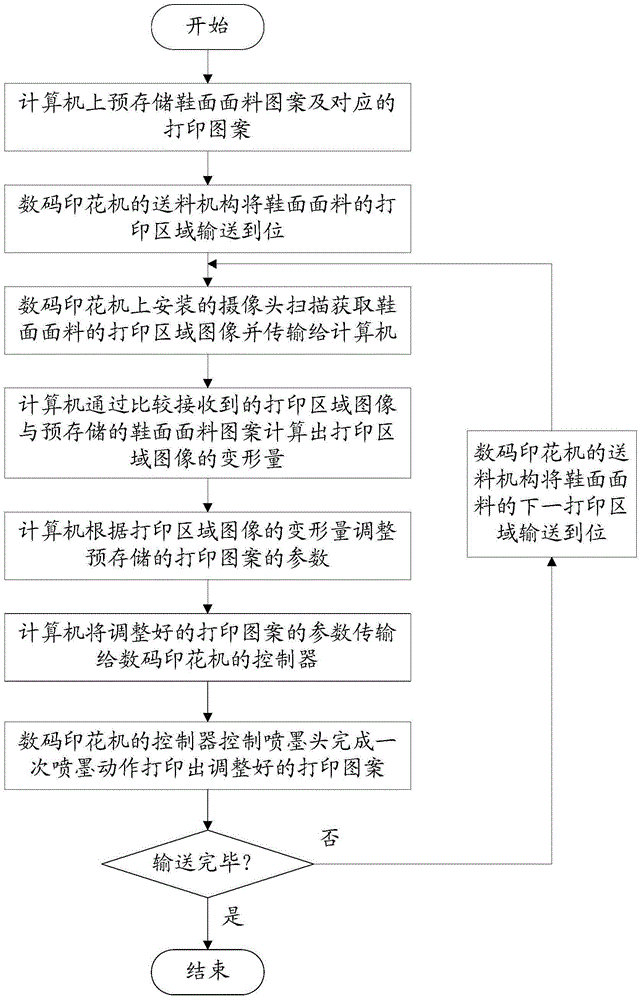

ActiveCN106476459AEliminate the effects ofSmall amount of deformationDuplicating/marking methodsUpperImage resolutionEngineering

The invention provides a shoe upper pattern forming method and shoe uppers thereof. The method comprises the following steps: S1, prestoring shoe upper fabric patterns and corresponding printing patterns in a computer; S2, scanning and obtaining printing area images of shoe upper fabrics via a camera mounted on a digital printing machine; S3, comparing the received printing area images with the pre-stored shoe upper patterns to calculate deformation of the printing area images via the computer; S4, adjusting parameters of the pre-stored printing patterns according to the deformation of the printing area images via the computer; S5, transmitting the adjusted parameters of the printing patterns to a controller of the digital printing machine; and S6, controlling an ink jetting head to complete ink jetting action for one time via the controller of the digital printing machine and printing the adjusted printing patterns. The shoe uppers produced by the method have the advantages of comfortable foot feeling, low pattern deformation, high pixel resolution and vivid colors.

Owner:FUJIAN HUAFENG SPORTING GOODS TECH CO LTD

Wool and nylon blended yarn and manufacture process thereof

The invention discloses a wool and nylon blended yarn and a manufacture process thereof. The blended yarn consists of the following ingredients in percentage by weight: 80 wool, 20 nylon and 40S yarn counts. The manufacture process of the wool and nylon blended yarn is characterized in that the manufacture technical process comprises the following steps: (1) carrying out wool pretreatment; (3) respectively carrying out loosening scotching on the wool and the nylon; (4) carrying out cotton carding on the wool and the nylon; (5) carrying out drawing and doubling; (6) obtaining coarse yarns; (7) obtaining coarse yarns; (8) obtaining fine yarns; and (8) carrying out cheese winding. The invention has the advantages that: 1). the defect of the wool is perfectly overcome after a certain proportion of nylon is added into the wool, the heat insulation performance of the products is improved, the surface material has vivid color and good laser, people feel more comfortable after wearing the products made of the wool and nylon blended yarns, and the wool and nylon blended yarn belongs to the preferred surface material for manufacturing various high-grade competitive clothes; and 2) the problem of the difficulty of the existing protein fiber blended yarn production process is solved, and good effects are reached through the improvement on each work procedure.

Owner:SHANDONG HONGYE TEXTILE

Electrowetting display device based on photoluminescence effect

InactiveCN102279464AIncrease brightnessBright colorStatic indicating devicesOptical elementsElectricityPhotoluminescence

The present invention relates to an electrowetting display device based on the photoluminescence effect. By arranging the fluorescent layer or the hydrophobic insulating fluorescent layer between the second substrate and the first fluid, ultraviolet light, purple light or blue light can After the fluorescent layer is irradiated, a photoluminescent effect occurs to form actively luminescent color graphics, which makes the electrowetting display device have high brightness, brighter colors and more vivid colors.

Owner:陈明晖

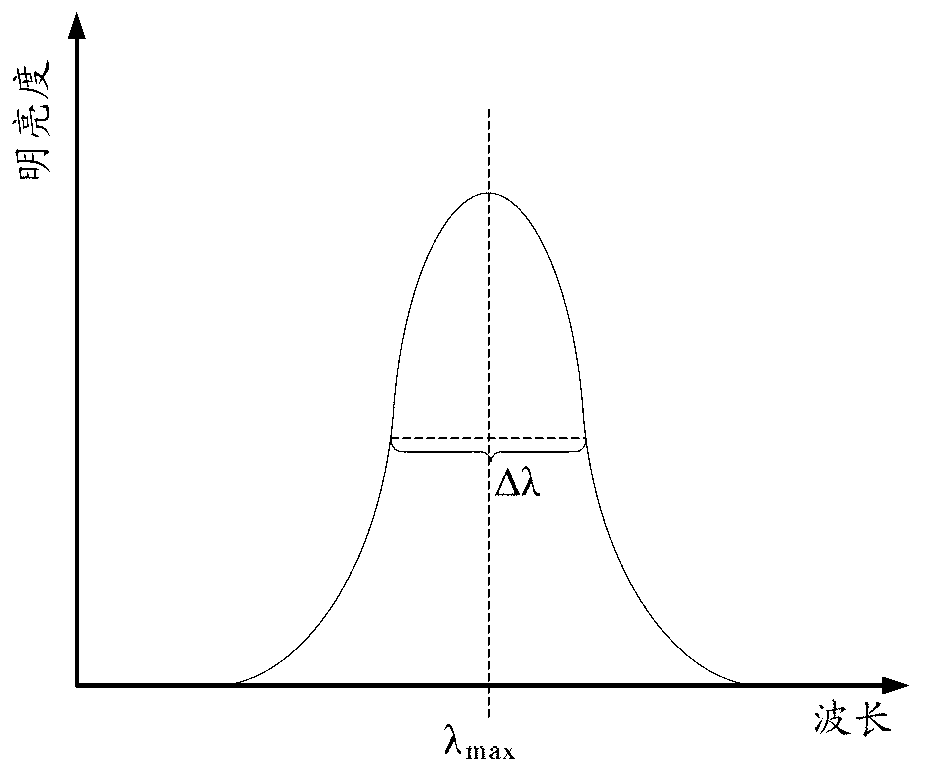

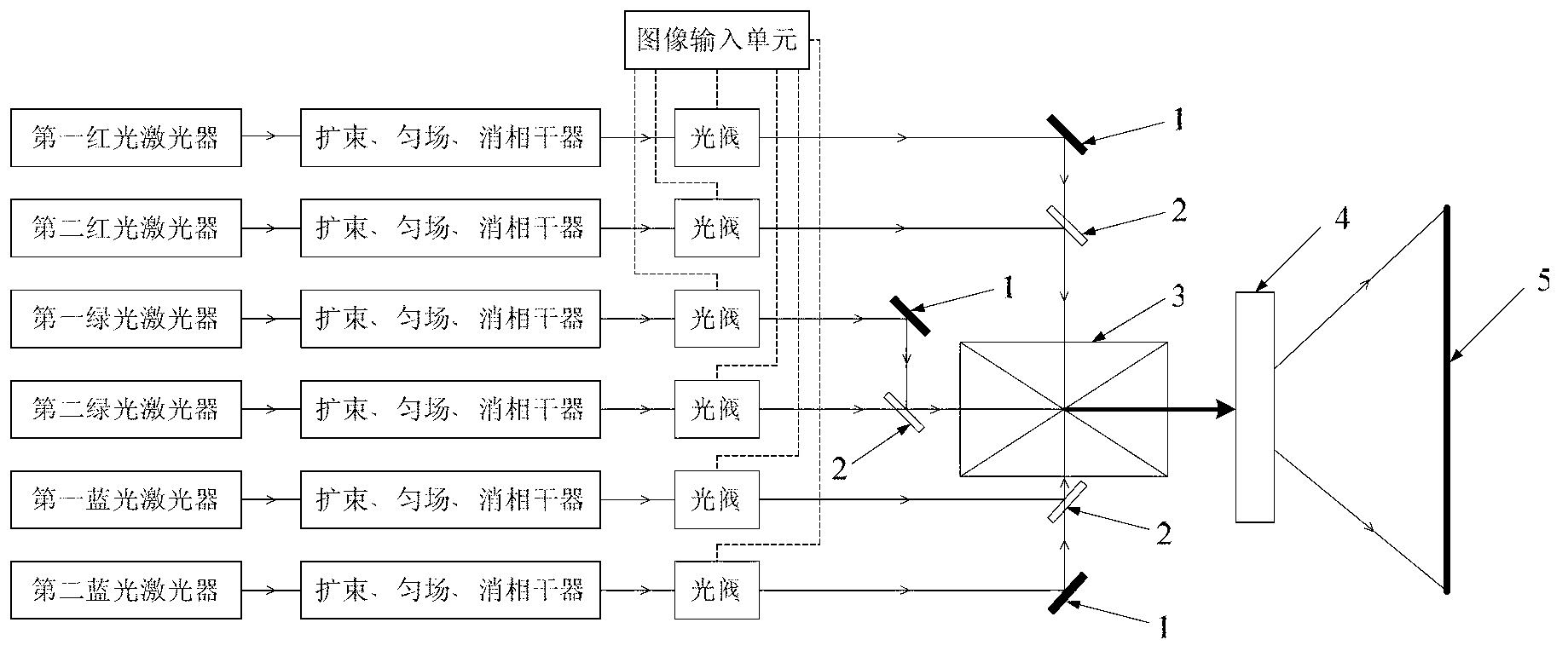

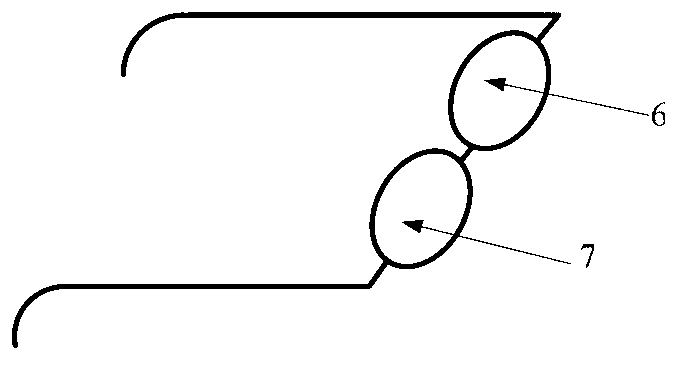

3D (three-dimensional) display device and glasses matched with same

ActiveCN102798979AAchieve a high degree of separationImprove experienceSteroscopic systemsOptical elementsImage resolutionDisplay device

The invention provides a 3D display device, which comprises a display light source, wherein the display light source is spectrally unmixed two or more groups of laser light sources; peak wavelengths of homochromatic lasers generated by each group of laser light sources in the two or more groups of laser light sources are different. Correspondingly, the invention further provides glasses matched with the 3D display device. The 3D display device has the advantages that the displayed picture has vivid colors, the resolution ratio is not lost, crosstalk is not easy to generate, and the angle of view is not influenced.

Owner:BOE TECH GRP CO LTD +1

Decorative film and manufacturing method thereof

InactiveCN101670744ASimple processing technologyReduce manufacturing costSpecial ornamental structuresOther printing apparatusPhotogravureUltraviolet lights

The invention relates to the technical fields of decorative materials and manufacturing methods thereof, in particular to a decorative film and a manufacturing method thereof. The decorative film comprises a substrate layer, a printing layer and a protective layer positioned on the surface of the printing layer from bottom to top, wherein the printing layer is printed on the surface of the substrate layer through a photogravure press; and the protective layer is a layer of UV paint. The printing layer in the decorative film is directly printed by a printer, and has vivid color. The surface of the decorative film is provided with the protective layer formed by the layer of UV paint, and the protective layer is automatically painted to the surface of the printing layer in a rolling way through machinery equipment, and promotes the decomposition of an initiator under the radiation of ultraviolet light to generate free radicals to initiate resin reaction for instant curing. The UV paint can well protect the printing layer, and improves the wear resistance and acid and alkali resistance of products; and glue-water adhesion or multi-layer attachment by heating is not used, so the environment is protected. The decorative film has simple process, and stable physical and chemical performance of the products.

Owner:莫金发

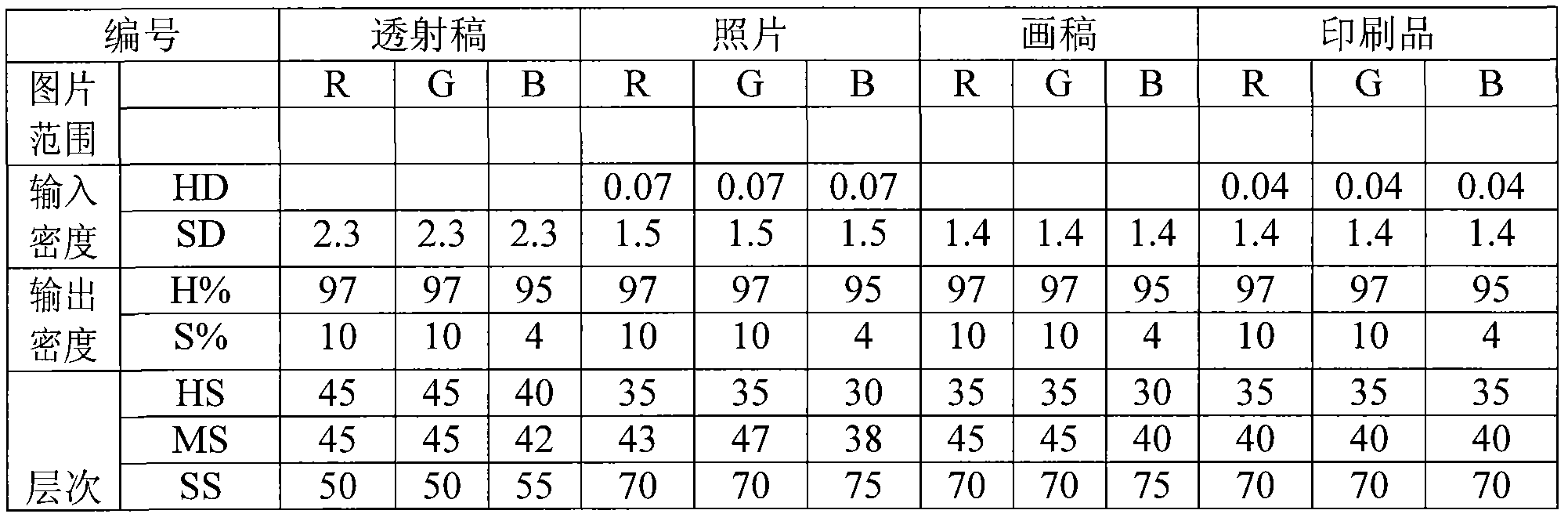

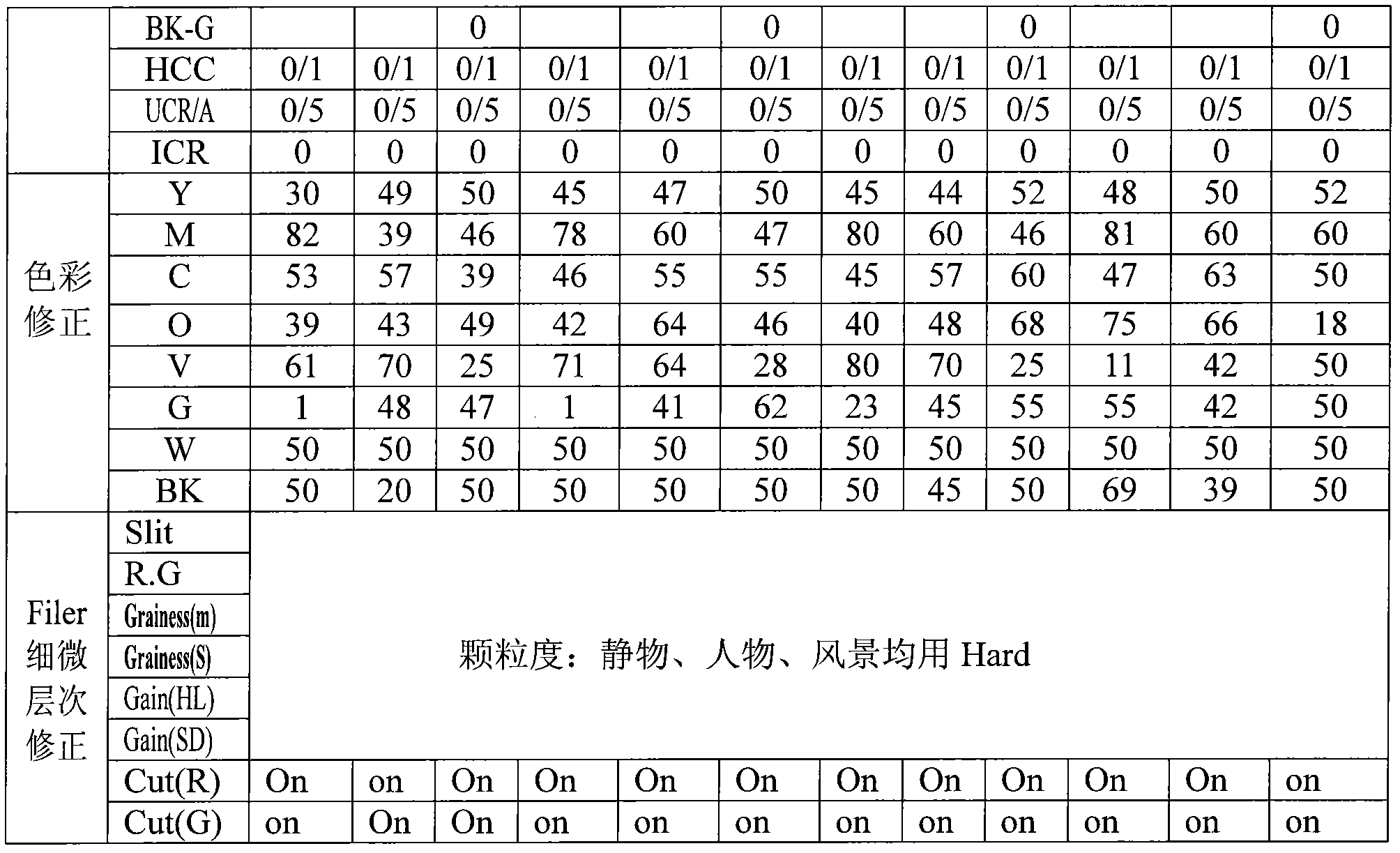

Method for making high-definition high-fidelity color picture of TPW 10 mu m on surface of paper

The invention provides a method for making a high-definition high-fidelity color picture of TPW 10 mu m on a surface of paper. The method comprises the following steps of: inputting a pattern of original color picture to be made into a computer through USM scanning of an electronic color scanner and synthesizing a 1,200 dpi TIF electronic file picture; toning and optimizing the electronic file picture by using color management software; performing color separation on three primary colors of the electronic file picture into seven channels, namely Cyan, Magenta, Yellow, Black, Orange, Green and Blue, by using GSM 2.0 software; maximizing the coverage of various colors in a chromatogram; transferring and outputting the processed electronic file picture to a PS printing plate by using sensitization; and finally transferring the pattern to the paper by using a planographic press. The image made by the method has high definition and rich hierarchy and represents the natural color of the original picture and the vivid color gamut.

Owner:苏州工业园区美柯乐制版印务有限责任公司

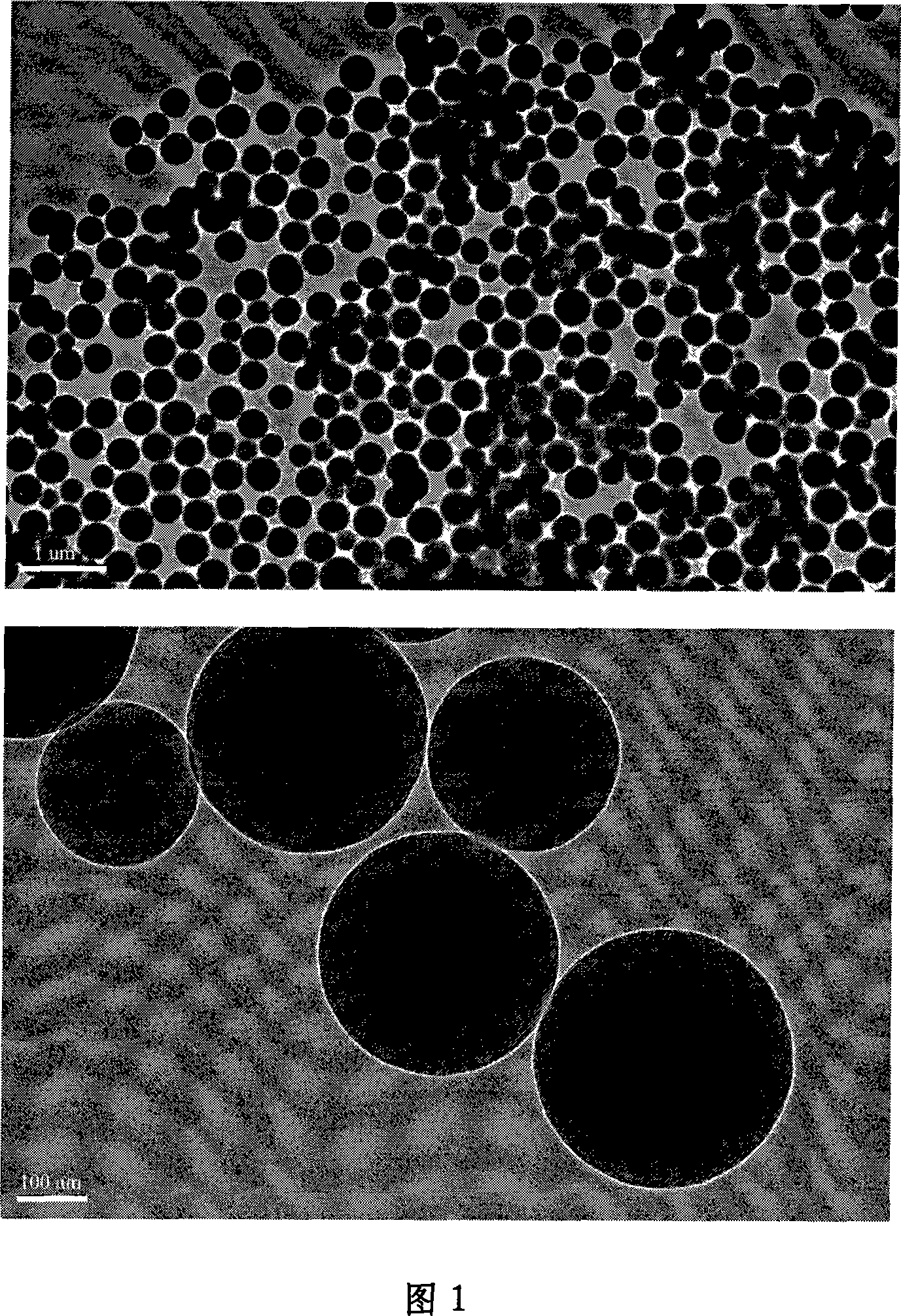

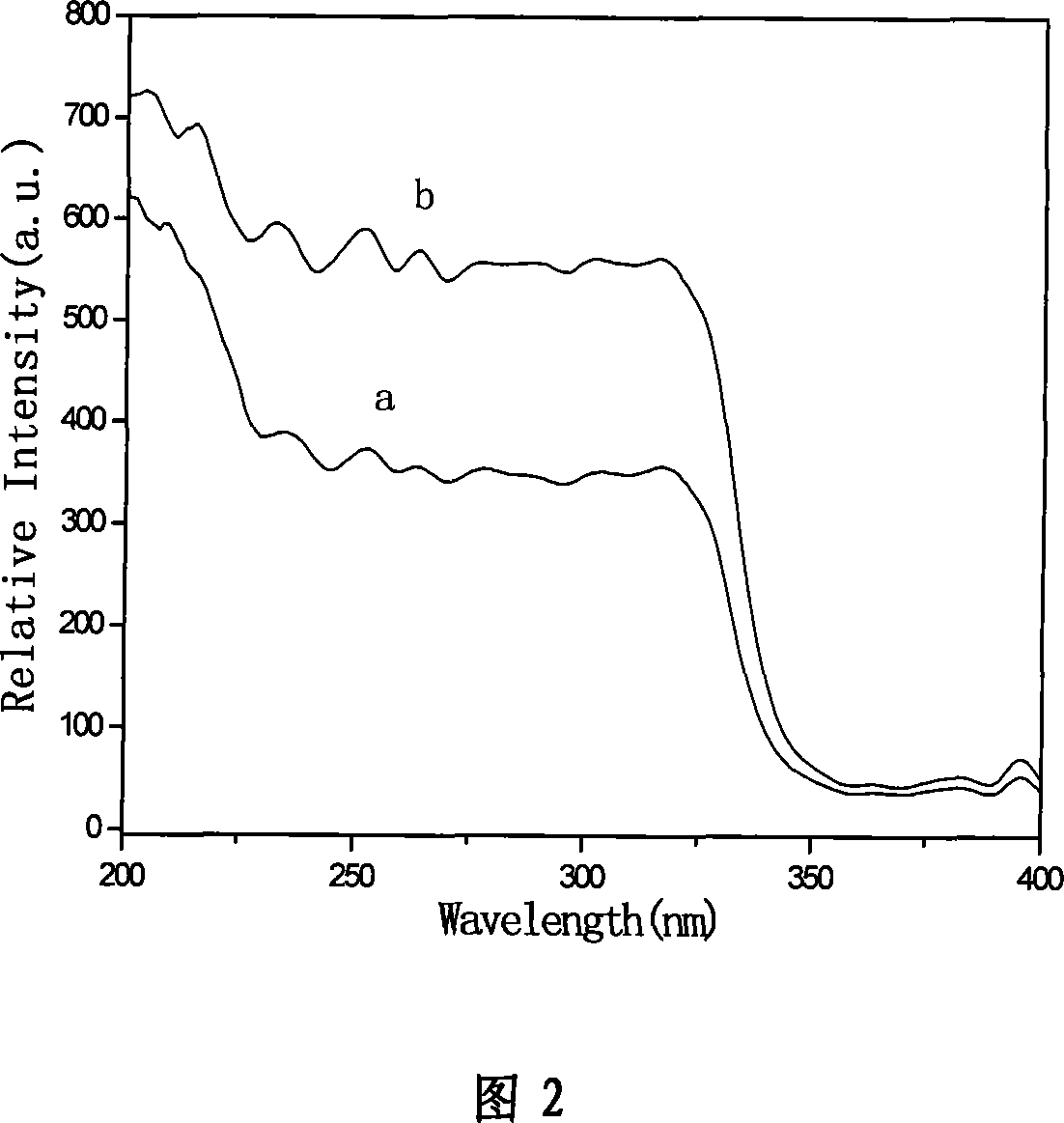

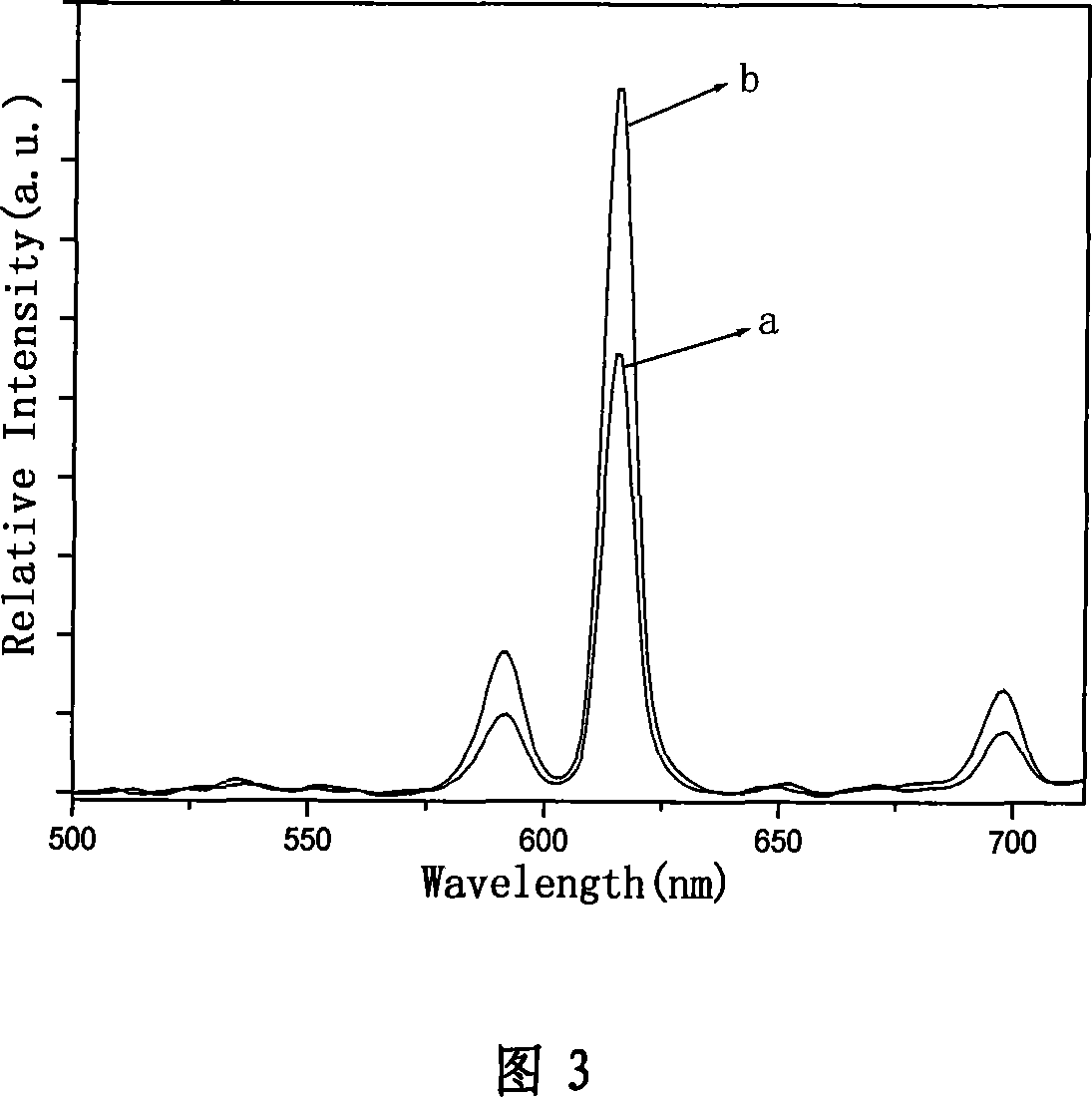

Nanometer hybridized phosphor in core-shell structure and its prepn process

InactiveCN101067079AImprove thermal stabilityGood chemical stabilityLuminescent compositionsPhosphorFluorescence

The present invention discloses one kind of nanometer hybridized phosphor in core-shell structure with complex of RE element and terephthalic acid as the core and SiO2 as the shell, and is especially red phosphor with complex of RE element Eu and terephthalic acid as the core and green phosphor with complex of RE element Tb and terephthalic acid as the core. The present invention also discloses the nanometer hybridized phosphor preparing sol-gel-wrapping process. The nanometer hybridized phosphor material has the features of light emitting RE complex, including high light emitting strength, high monochromaticity, vivid color, etc and the features of inorganic SiO2 material including high light, heat and chemical stability, and possesses excellent application performance.

Owner:SHANGHAI NORMAL UNIVERSITY

Coloring pearlescent flake pigment, manufacturing method of the same and cosmetic product containing the same

InactiveUS6837925B2Smoothness is lostShorten speedCosmetic preparationsPigmenting treatmentRefractive indexDouble coating

A coloring pearlescent flake pigment capable of providing pearl-like luster caused by interference color and a vivid color caused by a tar color is provided as a new material which contributes to the diversification of cosmetics and paints thanks to its powdery smoothness and the visual effect as well as covering protection effect in an application layer. The coloring pearlescent flake pigment having a double coating layer which is formed on inorganic flake-like particles and which is composed of a high-refraction-index metal oxide (e.g., titanium dioxide) and a hydrotalcite-like coloring composition is produced by the following process: In an aqueous suspension containing inorganic flake-like particles coated with a high-refraction-index metal oxide, a soluble anionic dye, a plurality of soluble metallic salts which are the raw materials of a double hydroxide, and a neutralizing base including urea are allowed to react, so that a hydrotalcite-like coloring composition precipitates on the inorganic flake-like particles.

Owner:KUBO YASUSHI +1

Method for producing electric-melting zirconia used for turquoise pigment and glaze

ActiveCN101703958ANarrow particle size distributionThe particle size distribution range is reasonableGrain treatmentsZirconium oxidesCalorescenceAtmospheric pressure

The invention relates to a method for producing electric-melting zirconia used for turquoise pigment and glaze, which is characterized in that: in a process of fine crushing, a feed particle size D50 is controlled between 20 and 25mu m, the working air pressure of a nozzle of a jet mill is 0.8MPa, a cyclonecluster is adjusted to 45Hz, a grader is adjusted to 18Hz, and the size distribution after the crushing meets the conditions that: D10 is not less than 3mu m, D50 is kept between 14 and 15mu m, and the difference between D90 and D10 is not more than 30mu m. The method has the advantages that: the narrow size distribution range of zirconia powder is realized, and reasonable grain size distribution is realized; and the electric-melting zirconia is favorable for color development of the turquoise pigment and glaze compared with the traditional electric-melting zirconia, comprehensively improves the blue degree of corresponding pigment and glaze, reduces a brightness value, makes the pigment develop more bright and vivid color in the glaze, and improves the beautifulness of corresponding ceramic products. The electric-melting zirconia after reasonable particle size control and adjustment can improve the high temperature resistance of the turquoise pigment and glaze more obviously than the electric-melting zirconia which is not controlled, and still can keep bright tone at the temperature higher than 1,200DEG C so as to promote the application to high temperature pigments.

Owner:BENGBU ZHONGHENG NEW MATERIALS SCI & TECH CO LTD

Pollution-free low temperature bronze red pastel pigment and preparation method thereof

The invention relates to a pollution-free low temperature bronze red pastel pigment and a preparation method thereof. The pollution-free low temperature bronze red pastel pigment consists of the following industrial raw materials in percentage by weight: 30 to 38 percent of quartz, 14 to 24 percent of feldspar, 20 to 28 percent of boric acid, 5 to 15 percent of alumina, 5 to 8 percent of lithium carbonate, 5 to 12 percent of calcium carbonate, 5 to 8 percent of magnesium oxide and 7 to 12 percent of zirconium silicate; and the preparation method comprises the following steps: melting the industrial raw materials at a temperature between 1,260 and 1,280DEG C, preserving heat for 30min, performing water quenching and ball milling, and passing through a 325-mesh sieve to prepare a pollution-free turbid solvent; and mixing the pollution-free turbid solvent with a bronze red agent in a ratio of 20:1 in percentage by weight, resintering at a temperature between 640 and 660DEG C, preserving heat for 10min, performing ball milling, passing through the 325-mesh sieve, and drying to prepare the product. The preparation method prepares the pollution-free low temperature bronze red pastel pigment of which the red value a* is more than 30 and the gloss is higher than 80, and which has pink and vivid color, good bonding with glaze, and no cracks and has the decorative effect of the traditional bronze red pastel pigment of Jingdezhen.

Owner:JINGDEZHEN CERAMIC INSTITUTE

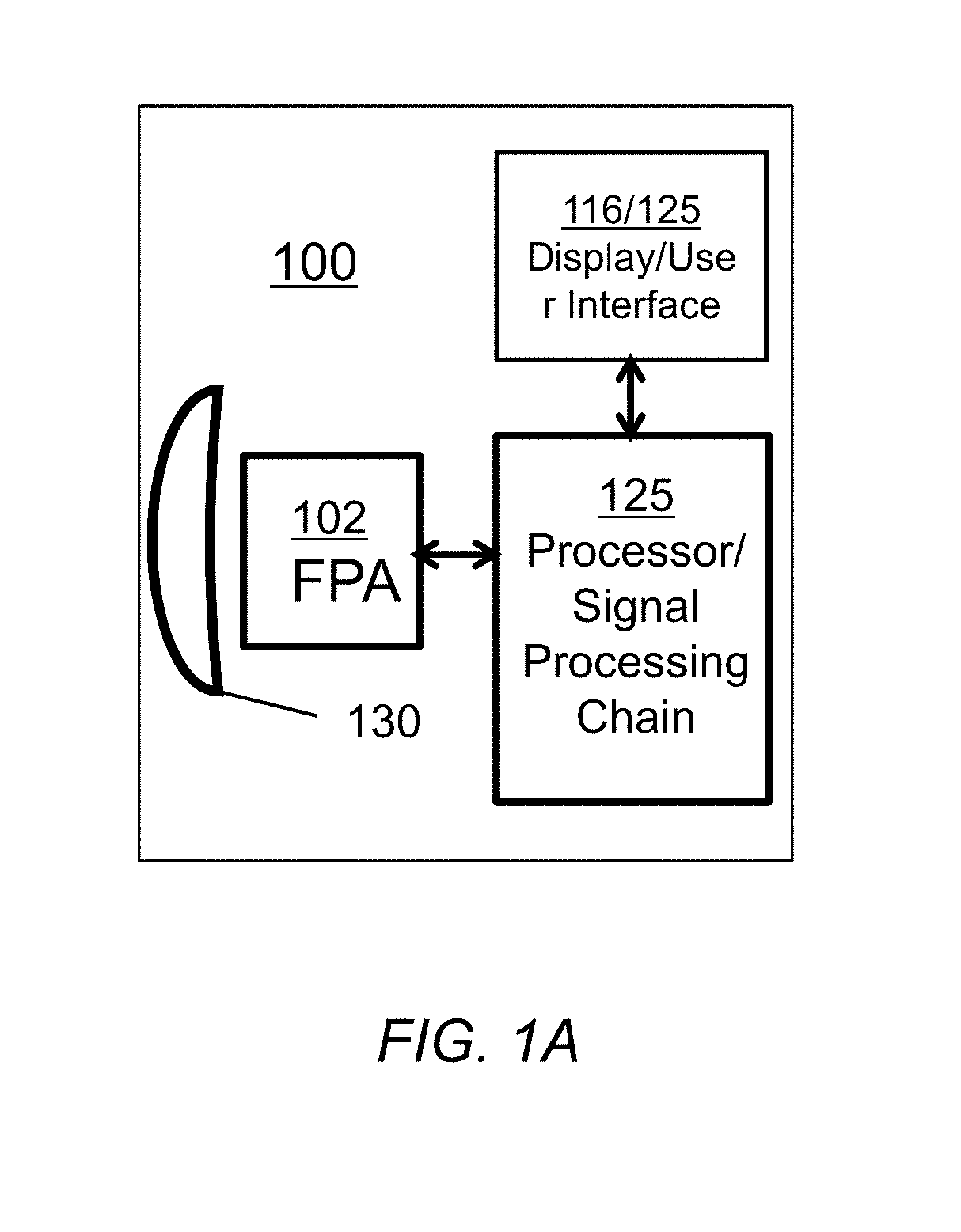

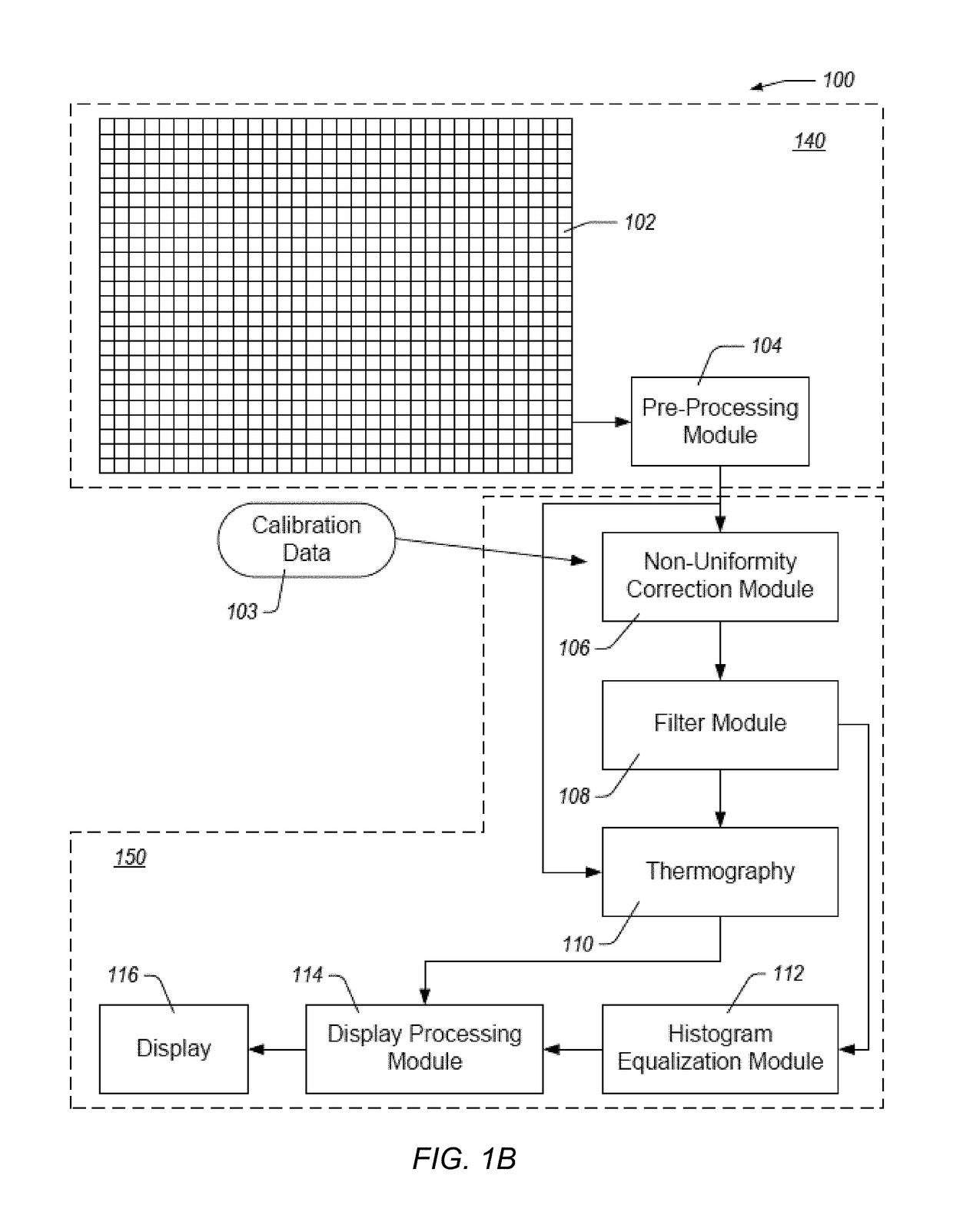

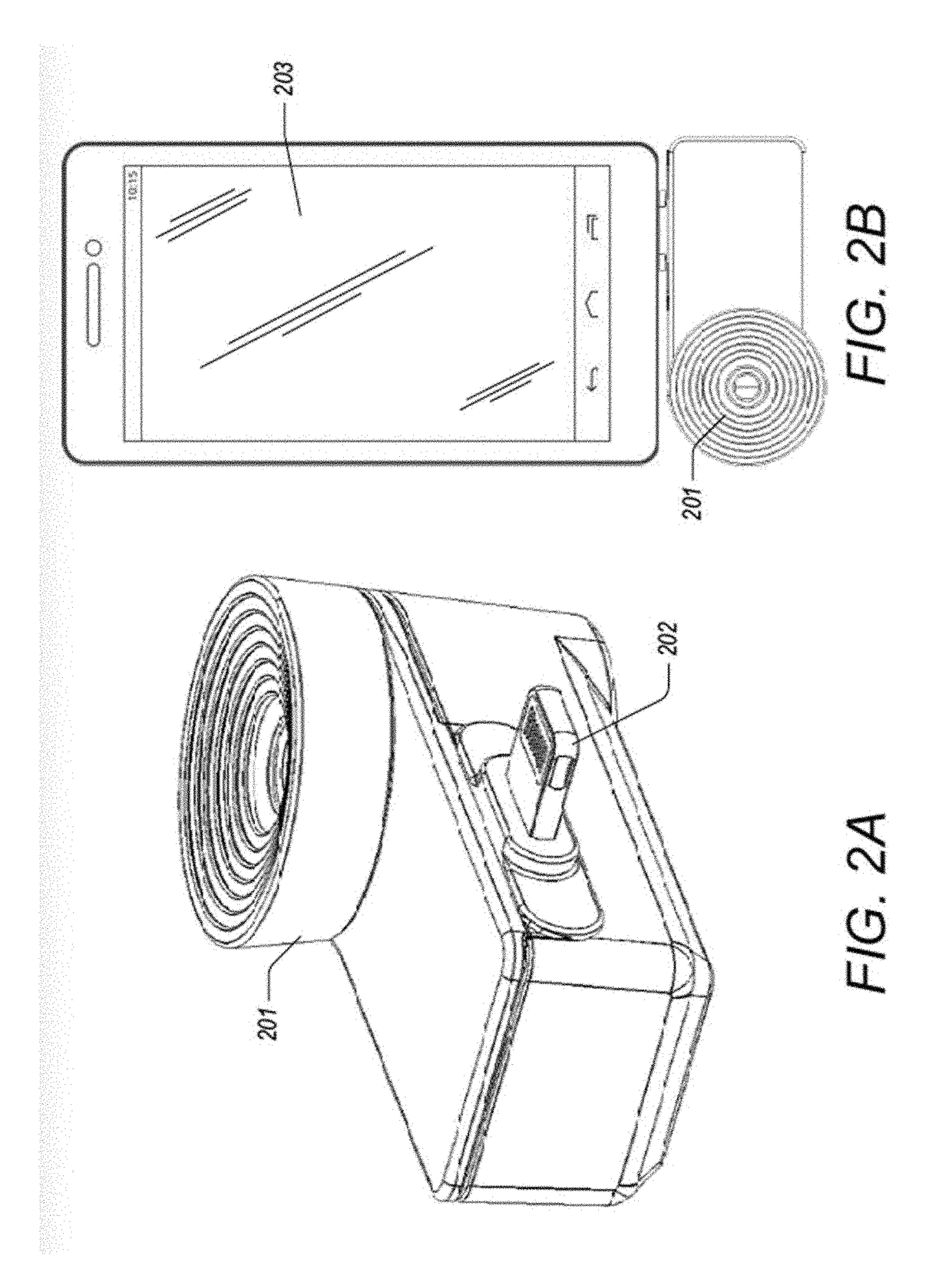

Selective color display of a thermal image

An imaging system includes an array of photodetectors configured to produce an array of intensity values corresponding to light intensity at the photodetectors. The imaging system can include a display for display images acquired with the array of photodetectors, after some image and display processing. The image and display processing components of the imaging system produce an array of display-formatted pixels for display on the imaging system display. The display-formatted pixels include at least a first plurality of pixels formatted for display using a first lookup table and a second plurality of pixels formatted for display using a second lookup table. Threshold criteria for choosing which pixels belong to which plurality are determined from analysis of a scene indicated by a user as a background scene. Once the threshold criteria are determined from the background the criteria are applied to pixels in subsequent image frames, and the pixels that meet the criteria are displayed in at least one color table LUT and the pixels that do not are displayed in a at least one different color table LUT. In a particular embodiment. The criteria may be above or below the max scene value (or temperature) from the background scene and pixels below the criteria may be displayed in a monochrome or non-vivid color table and pixels above the criteria are displayed in a vivid color table.

Owner:SEEK THERMAL

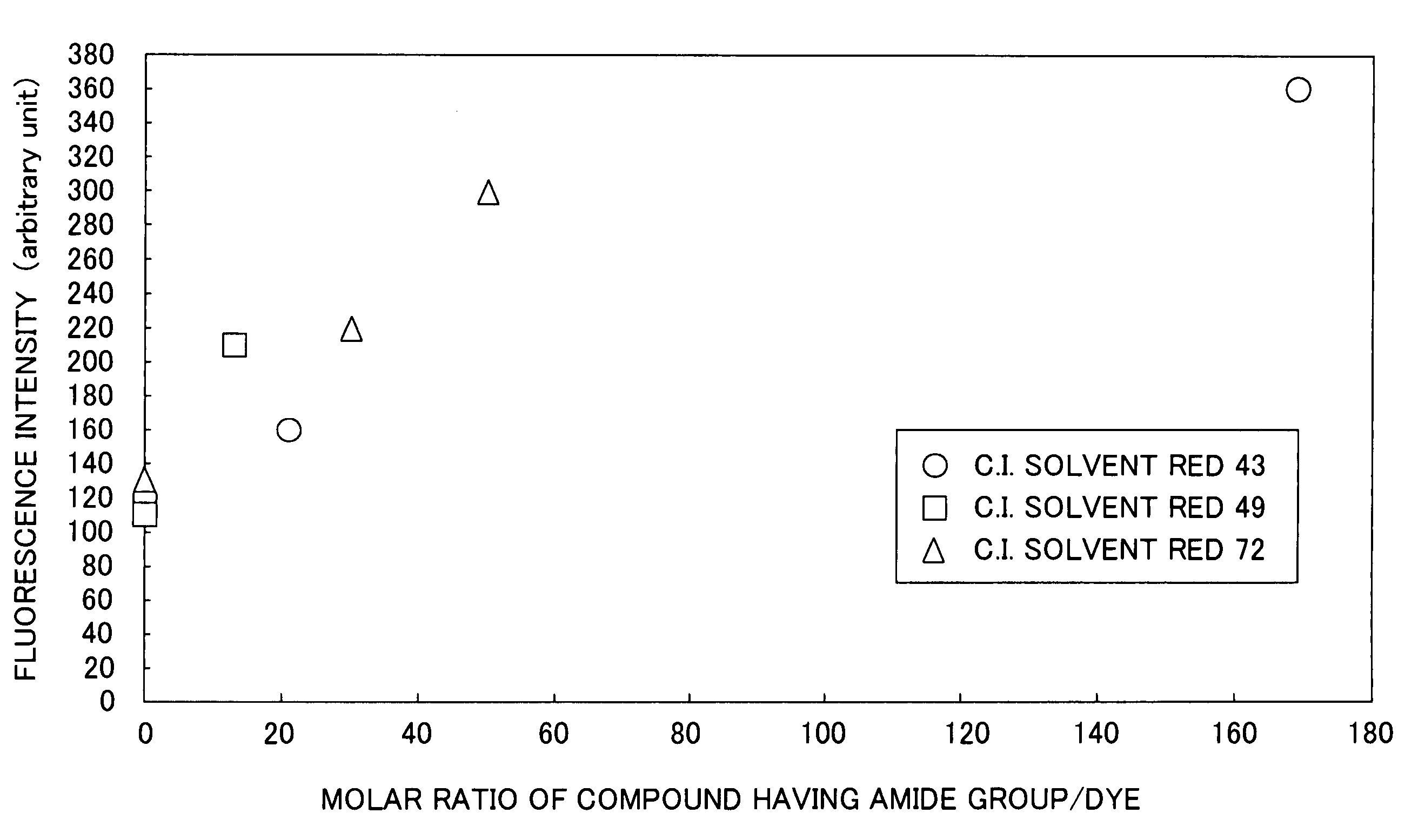

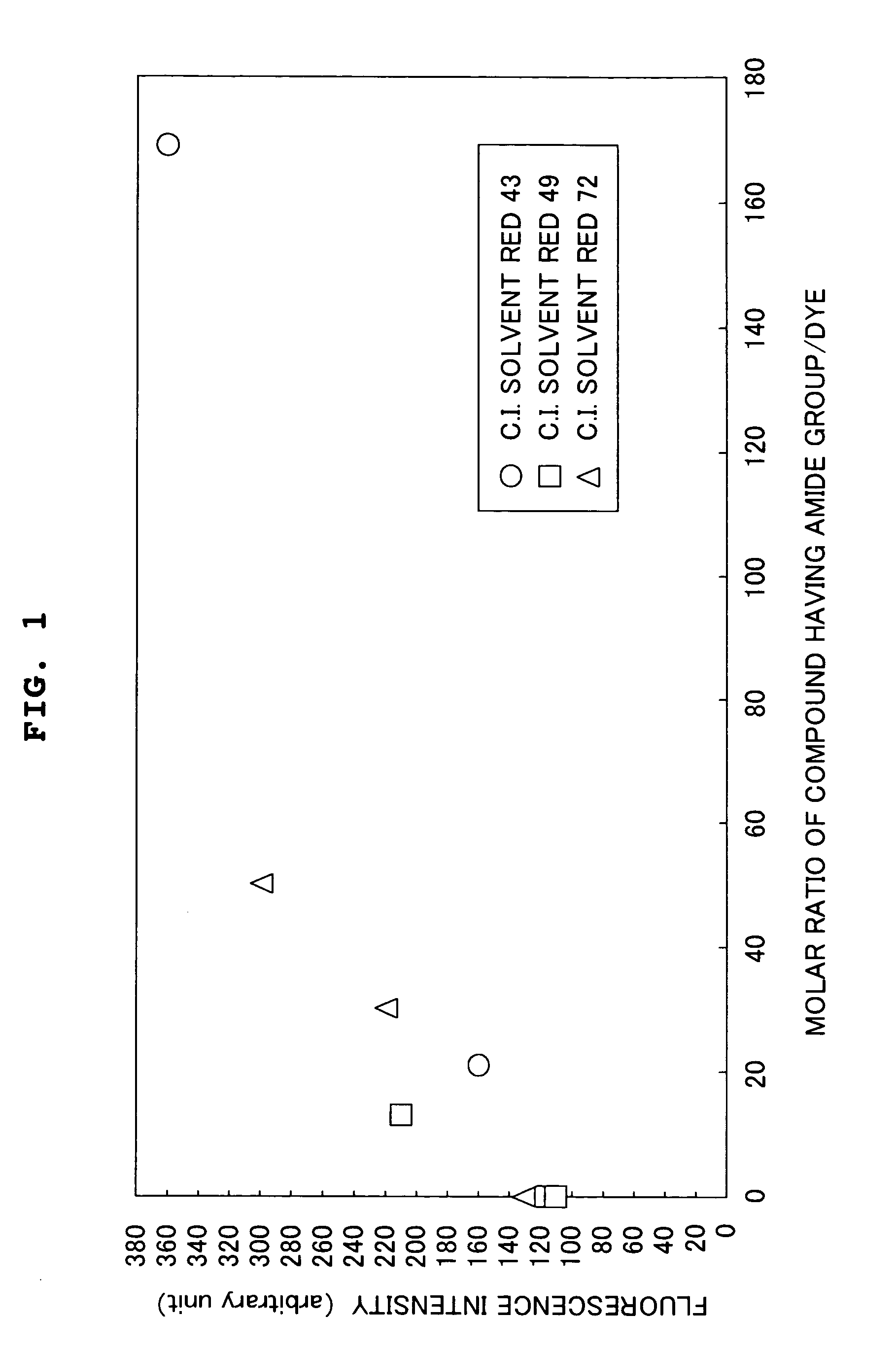

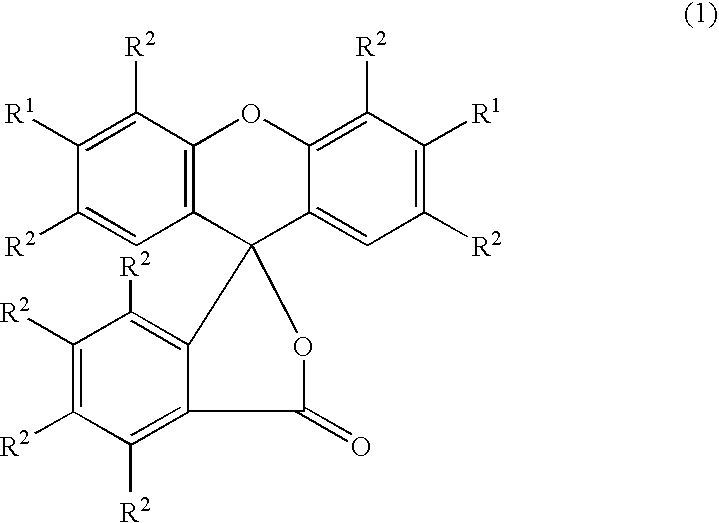

Fluorescent water base ink for ink-jet recording

ActiveUS20050039633A1Sufficient OD value and a fluorescence valueImprove waterproof performanceInksWater basedHydrogen atom

A fluorescent water base ink for ink-jet recording to be used for an ink-jet printer contains water, a pigment, a compound having primary or secondary amide group, and a fluorescent dye represented by the following formula (1): wherein R1 represents OH or N(R3)R4, R2 represents hydrogen atom or halogen atom, and each of R3 and R4 represents hydrogen atom or alkyl group. A sufficient OD value and a fluorescence value are obtained while securing the vivid color development and the excellent water resistance principally in accordance with the interaction of the fluorescent dye and the compound having the amide group.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com