Patents

Literature

69 results about "Sorona" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorona is DuPont's brand of triexta (polytrimethylene terephthalate). It was named and commercialized in 2000. Sorona is a co-polymer of 1,3-propanediol (obtained by fermentation) and petroleum-derived terephthalic acid (TPA) or dimethyl terephthalate (DMT). Related polymers in this series include polyethylene terephthalate (2GT) and polybutylene terephthalate (polytetramethylene terephthalate) (4GT).

Processing method of Sorona and silk clothes fabric

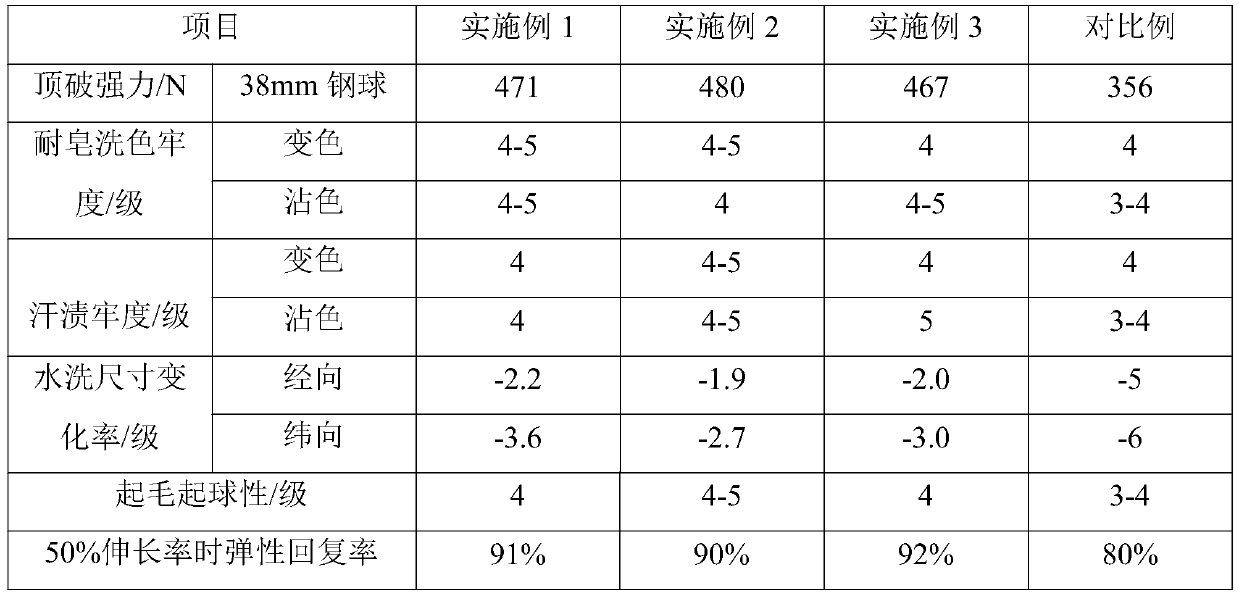

ActiveCN102797104AGood smooth feelEnvironmentally friendlyWeft knittingTextile treatment with treating outlet contectAdhesiveEngineering

The invention provides a processing method of a Sorona and silk clothes fabric, relating to a processing method of a knitting fabric. The method comprises the following steps of: selecting raw materials; splicing threads; weaving to obtain a gray fabric; washing with water; sizing a finished product; and decating. The characteristics of ecological environmental protection, excellent rebound elasticity and the like of Sorona are fully utilized, and excellent moisture absorption, air permeability and chromatophilia of adhesives and smooth hand feel of mulberry silk are combined, so that the fabric has the advantages of functionality, environmental protection and high grade. A knitting fabric rather than a woven fabric is obtained by processing.

Owner:劲霸男装(上海)有限公司

Ecological warm-keeping cotton and manufacturing process thereof

InactiveCN105603634AImprove the bactericidal effectNot easy to passNon-woven fabricsCardingEngineering

The invention provides ecological warm-keeping cotton and a manufacturing process thereof. The ecological warm-keeping cotton has good wind-resistant water-repellent effects, also has a certain sterilization function and is better in warm-keeping effect, lots of raw materials are renewable raw materials, and an environmental protection effect is good. The ecological warm-keeping cotton comprises a warm-keeping layer and a waterproof breathable sterilization layer adhered to one side of the warm-keeping layer, wherein the thickness of the waterproof breathable sterilization layer is 10%-15% of the thickness of the warm-keeping layer, the warm-keeping layer is manufactured from, by weight, 30% of Sorona polymer fiber, 30% of superfine warm-keeping fiber, 30% of three-dimensional hollow warm-keeping fiber and 10% of native cotton fiber through mixing, the waterproof breathable sterilization layer is manufactured from, by weight, 40% of collagen fiber, 20% of bamboo fiber, 20% of seaweed carbon fiber and 20% of nanoscale antibacterial silver ion masterbatch native fiber through mixing, the surfaces of the two sides of the waterproof breathable sterilization layer are coated with treatment layers formed by blending silicon nanoparticles and nano titanium dioxide, and the surfaces of the treatment layers are coated with hydrophobic fluorine quaternary amine silane coupling agent coatings. The manufacturing process of the ecological warm-keeping cotton comprises the steps of automatic material preparation and mixing through a machine, opening, carding, web laying, adhesive spraying, heat setting and rolling.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

Sorona/wool semi-worsted spinning yarn as well as manufacturing process thereof and application thereof

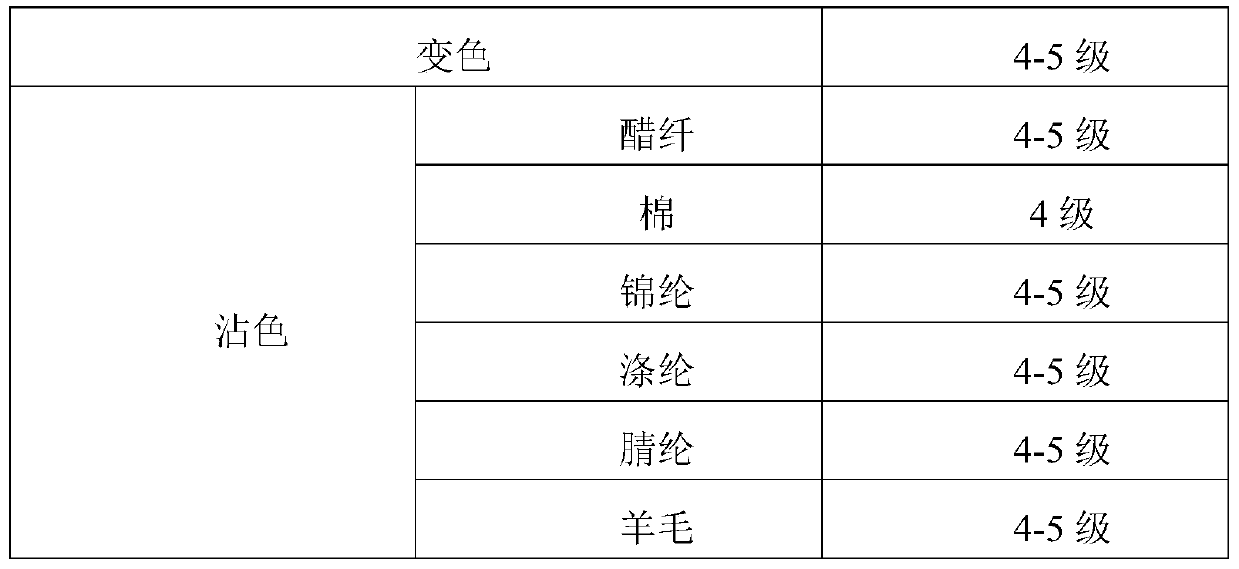

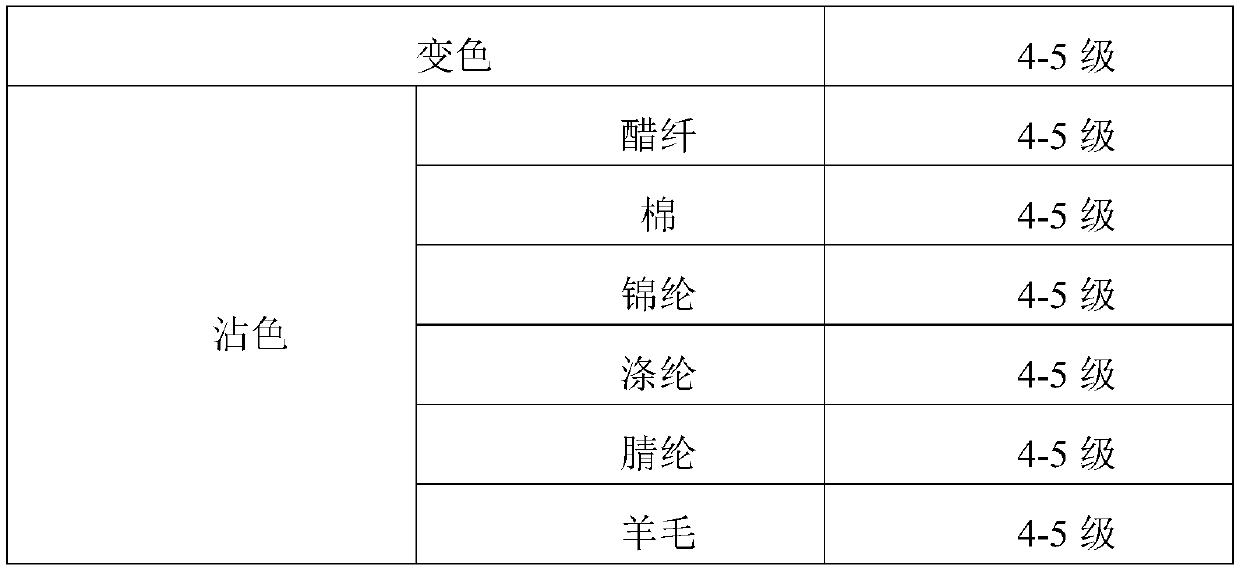

The invention relates to the textile field, in particular to a sorona / wool semi-worsted spinning yarn as well as a manufacturing process thereof and an application thereof. The invention provides the yarn; and the key technical point is as follows: the yarn is a three-stranded knitted yarn with count of 36 N / 3, which is obtained through spinning 70% of wools and 30% of sorona fiber by weight. The invention further provides the manufacturing process of the sorona / wool semi-worsted spinning yarn; and the process comprises the following steps of dyeing, blending, cotton carding, drawing of three strands, rough yarn forming, spun yarn forming, spooling and doubling. The invention further provides a sweater using the sorona / wool semi-worsted spinning yarn. According to the invention, an environment-friendly sorona fiber with a certain ratio is adopted for the knitted sweater, so that the finished product sweater has the advantages of soft and rich handle, vivid color, good moisture absorbing property, good air permeability and excellent heat retention property; and compared with the traditional sweater product, the sweater has the advantages of better water washing size stability and machine washability.

Owner:劲霸男装(上海)有限公司

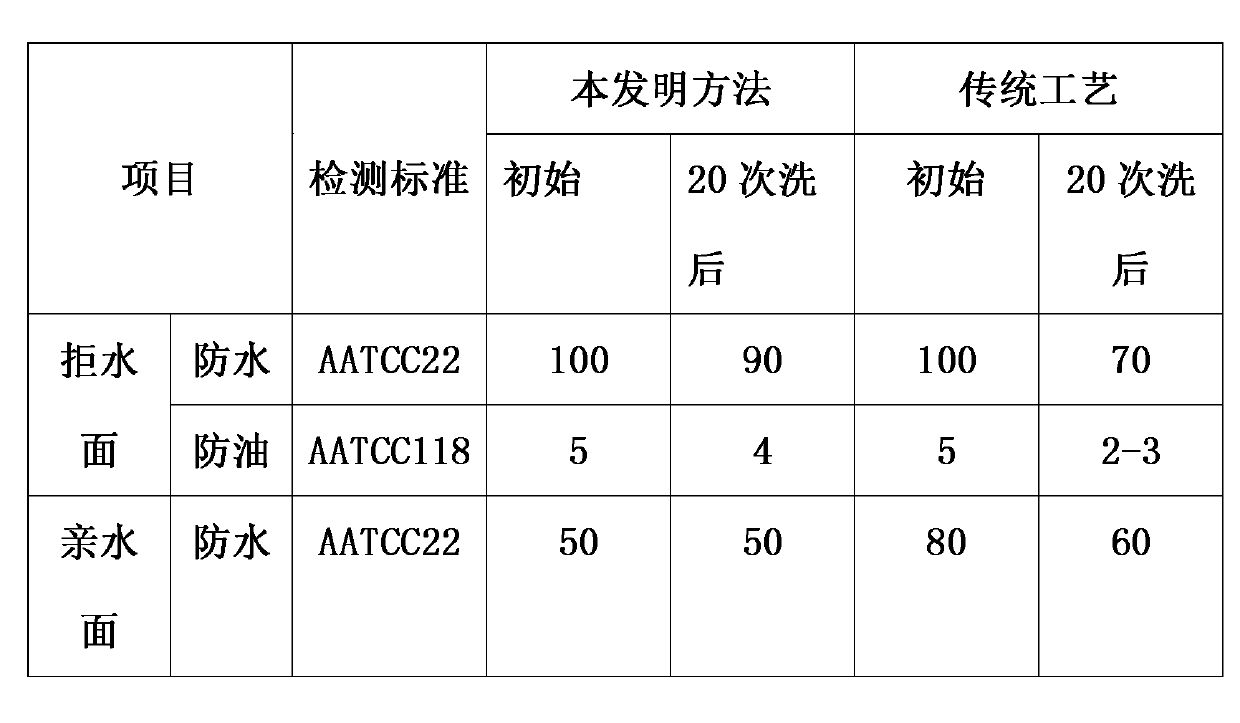

Method for processing quick-drying air-permeable fabric with double surfaces functioning differently

ActiveCN102912645AReduce cross-linking reactionReduce osmosisBiochemical fibre treatmentDyeing processCooking & bakingEngineering

The invention discloses a method for processing quick-drying air-permeable fabric with double surfaces functioning differently. The method includes the steps of (1) preprocessing, mercerizing and whitening SORONA fiber textile to obtain a material A; (2) printing pigment on the material A and baking to obtain a material B; (3) performing antarafacial effect treatment on the material B by sizing C; (4) baking at low temperature, padding moisture absorption and sweat releasing agent, calendaring and preshrinking finally, wherein the sizing C with viscosity ranging from 16000 to 18000 mpa.s is formed by mixing, by mass, 10-15 parts of fluorocarbon, 2-5 parts of blocked isocyanate, 2-3 parts of thickening agent, 0.1-0.3 part of ammonia water containing 20% of ammonia by mass, 0.1-0.3 part of acid-releasing agent, with water. By the method, stability of the quick-drying air-permeable fabric with the double surfaces functioning differently can be improved, and washable capability of the fabric can be greatly improved.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

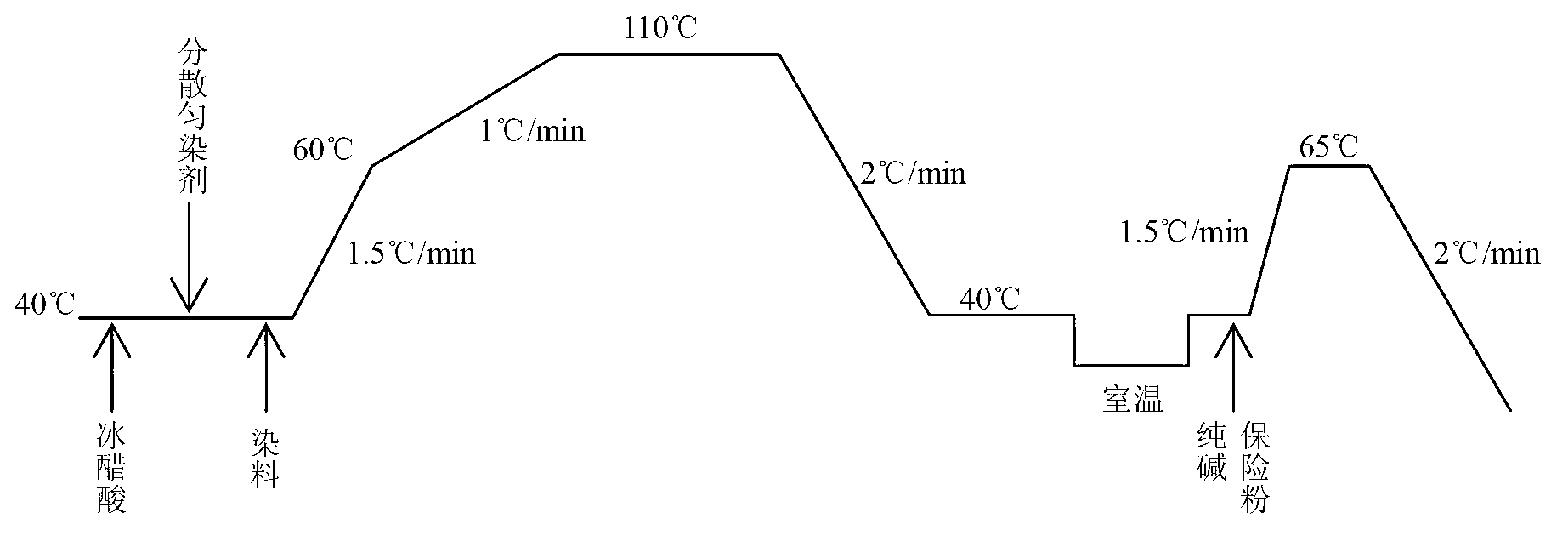

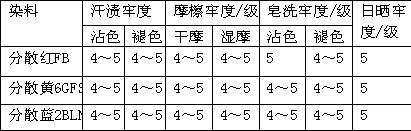

Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

InactiveCN103215831AImprove qualityShade stabilityDry-cleaning apparatus for textilesDyeing processDisperse dyeColour fastness

The invention relates to a polyester / sorona mixed fabric disperse dye one-bath process dyeing method. According to the determined optimal dyeing process of polyester / sorona mixed fabric, the dye dosage is greater than or equal to 2% (owf), the pH value is 5.5, the dyeing time is 50 minutes, the dyeing temperature is 110 DEG C, and the carrier dosage is 1.5g / L. The result indicates that the dyeing method can obtain a product with stable color light, good homochromatism and high color fastness; and the process is simple, the time is short, and the production cost is low.

Owner:JIANGYIN POLYTECHNIC COLLEGE

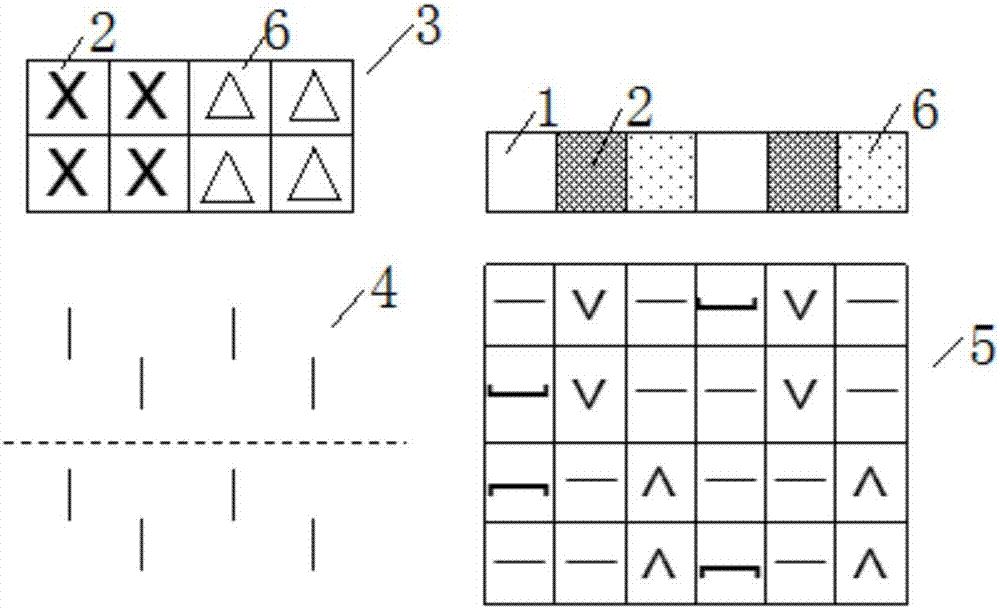

Knitted fabric of graphene and bio-based fiber and production method thereof

ActiveCN107190404AGood moisture conductivityGood skin affinityWeft knittingHeating/cooling textile fabricsEngineeringGraphene

The invention discloses a knitted fabric of graphene and bio-based fiber and a production method thereof, and belongs to the field of textiles. The fabric is of a single-face weft-knitting structure, the front surface of the fabric is C / R blended yarns containing the graphene, and the back surface of the fabric is composed of the bio-based fiber sorona containing a tubular moisture conducting structure. By adoption of covering and interweaving of the graphene and the bio-based fiber, the fabric has not only a health-caring and therapeutic efficacy of far infrared internal warming, but functions of mosquito repelling, bacteria resistance, mite resistance, static resistance, radiation protection, breathability and unidirectional moisture conducting for fast drying and an effect of elastic force memory for shape preservation on clothes and beddings.

Owner:江门市大兴针织厂有限公司

Method for preparing high-grade and casual fabric with special leather feel using biologically corn-based fibres

InactiveUS20130312236A1Improves fabric sizing processSpeed up the processCrochetingInspecting textilesPolyesterEngineering

A method for preparing high-grade and casual fabric with special leather feel using a corn-based fiber that comprises the steps of: 1) selecting 0.3-0.5 D / PF ultrafine corn-based SORONA fiber from DuPont (U.S.) and 0.2-0.4 D / PF long porous bright polyester yarns as raw materials; 2) compositing by air-jet texturing: having the above raw materials composited by low tension air-jet texturing in an air texturing machine, with the tension force controlled in the range of 4.5-6.0 cN, so as to form ATY yarns with a denier number of 120-180 D; 3) weaving, which includes yarn sizing, preliminary drying, oil applying and plain weaving; 4) dyeing and finishing, which include treating a fabric by pre-treating, presetting, splitting and alkali detaching, water washing and dehydrating, dyeing, water repellent treatment, instant ultrahigh temperature treatment, and one-sided lustering. The fabric prepared according to the present invention has the following advantages: it has smooth surface and soft feel, is waterproof, antifouling and antistatic, has excellent anti-wrinkle properties, has the luster and texture of natural leather material, and is good in breathability and moisture penetrability, it can be used for making both winter clothing and summer clothing, can be water-washed or dry cleaned, it has no need for ironing, is easy to care for, etc.

Owner:DANYANG DANQI YUYUE TEXTILE

Ecological cotton and production technology thereof

ActiveCN105926157AGood drapabilityEfficient thermal effectLiquid surface applicatorsLayered productsCardingSurface layer

The invention provides ecological cotton and a production technology thereof. The ecological cotton has a better warm-keeping effect and comprises a warm-keeping cotton core, a 3D flocking layer and a soft close-fitting layer, wherein the warm-keeping cotton core is made of 30% of Sorona polymer fibers, 60% of superfine warm-keeping fibers and 10% of raw cotton fibers through mixing; the 3D flocking layer comprises elastic base cloth, a 3D flocking surface layer arranged on the surface of the elastic base cloth and a vacuum cotton filling layer arranged between the elastic base cloth and the warm-keeping cotton core; the soft close-fitting layer comprises a metal aluminum foil film layer fixed with the warm-keeping cotton core and a planar flocking lining arranged on the surface of the metal aluminum foil film layer, and the 3D flocking surface layer and the planar flocking lining are both made of short fibers with the length of 0.05-0.2 cm. The production technology of the ecological cotton comprises steps as follows: automatic blending and mixing by a machine, opening and scutching, carding, lapping, adhesive spraying, heat setting and coiling.

Owner:广西鹏锦床上用品有限公司

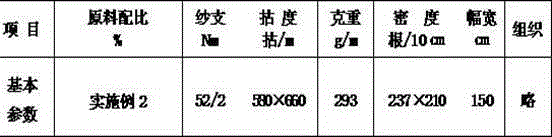

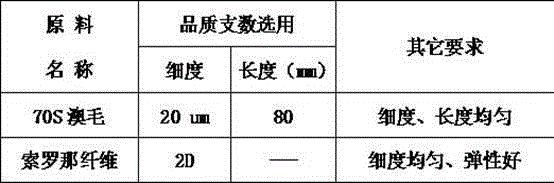

Preparation method for elastic fabric

ActiveCN105200621AGuaranteed dimensional stabilityIncrease elasticityLiquid/gas/vapor removalDyeing processEngineeringRaw material

The invention discloses a preparation method for an elastic fabric. 60-70% of 70S wool and 30-40% of Sorona fiber are used to prepare the new elastic fabric though the processes of dyeing, spinning, weaving and finishing. The product is the elastic environment-friendly new fabric, is prepared by blending wool and Sorona fiber, has the characteristics of being waxy and smooth in wool and full in elasticity, is comfortable to wear and not uptight. Due to the addition of Sorona fiber, the original properties of the raw materials are reserved, the quality of wool is reflected, the softness and skin-touch are improved, the drapability and the fabric luster are improved, and the fabric is endowed with natural soft feeling, replaces polyurethane, has better stretching and elastic recovery properties, is warm, comfortable, dry, breathable, good in washability, pendulous, crease-resistant, environment-friendly and pollution-free, and is the ideal fabric for making high-grade casual clothes.

Owner:JIANGSU JIANLU WOOLEN

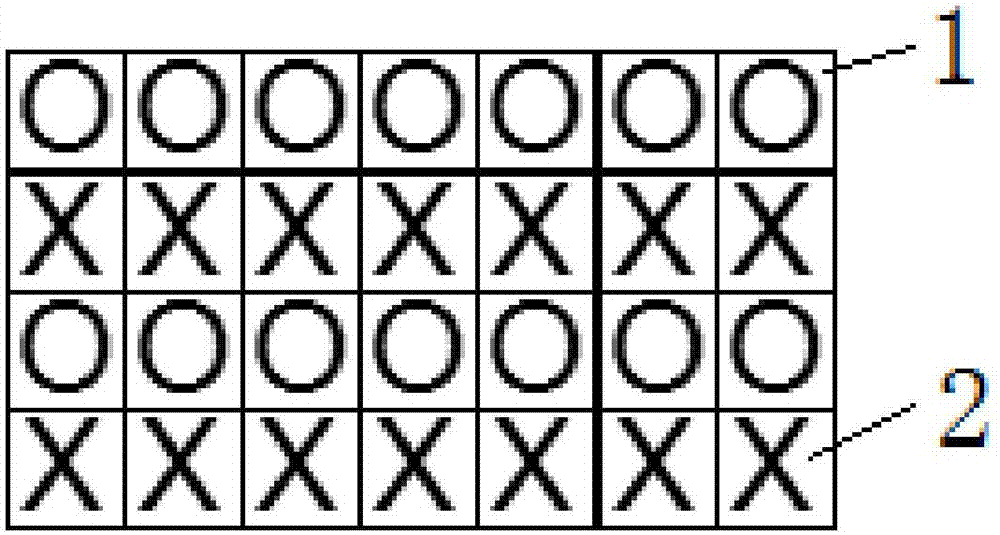

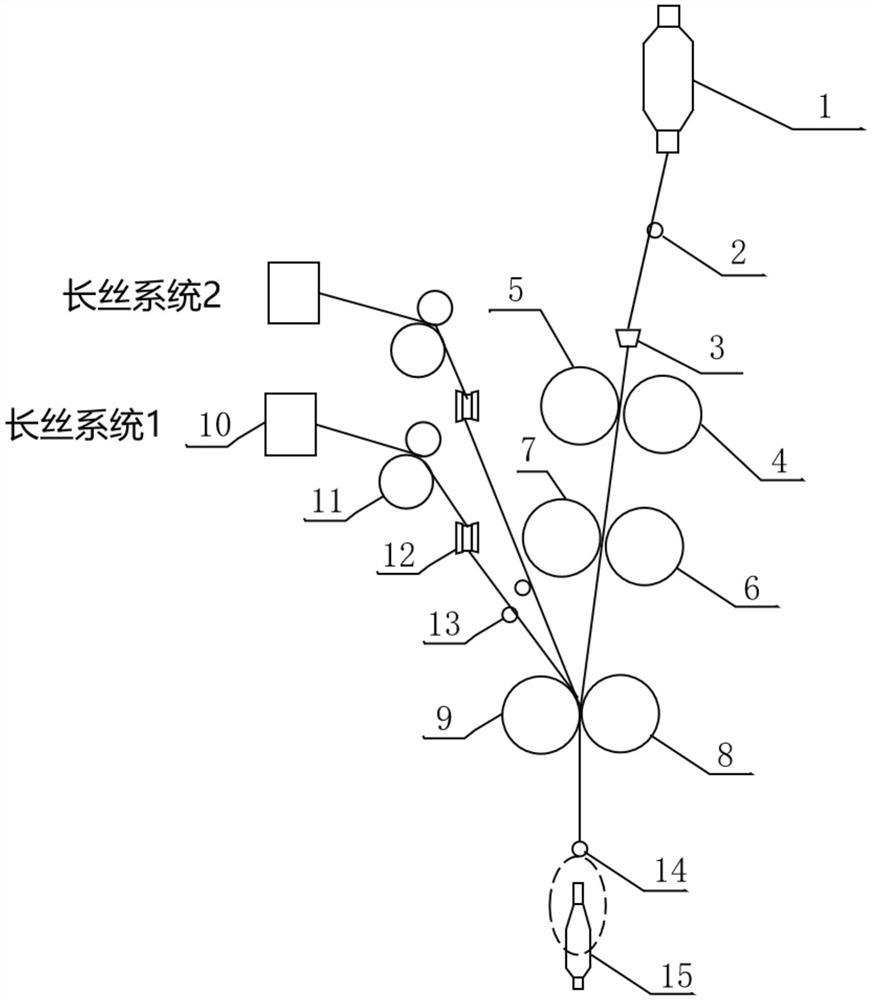

Weaving, dyeing and finishing process of antibacterial unidirectional water-guiding eyelet fabric

InactiveCN113136729ASoft touchGood antibacterial effectBiochemical fibre treatmentFibre typesProcess engineeringAnti bacteria

The invention discloses a weaving, dyeing and finishing process of antibacterial unidirectional water-guiding eyelet fabric. The weaving, dyeing and finishing process comprises the following steps: preparing Cleancool, Sorona and binding yarn, weaving the Cleancool, Sorona and binding yarn by adopting a filament machine according to a warp and weft weaving method, weaving gray fabric by adopting a 8*4 double weft interweaving rule, soaking the gray fabric into a dyeing agent, then rolling the gray fabric by using a roller, squeezing the dye liquor into weave gaps of the fabric, removing the redundant dye liquor to uniformly distribute dye on the fabric, drying the dyed grey fabric, soaking the grey fabric in antibacterial and deodorant liquor, and performing moderate steaming and shaping on the woven and dip-dyed grey fabric to obtain finished fabric. The antibacterial effect, the moisture-absorbing and quick-drying effect, the soft and smooth hand feeling and the like of the eyelet fabric are highlighted, and in cooperation with the eyelet weaving process, the eyelet fabric is suitable for military and civilian products and has elegant, beautiful and attractive appearance.

Owner:湖北际华针织有限公司

Production process of back piece of backpack

ActiveCN111041713AImprove breathabilityAir permeability effectSevering textilesNon-woven fabricsMechanical engineeringIndustrial engineering

The invention discloses a production process of a back piece of a backpack, relates to a backpack and aims to solve the problem of lack of breathability. The technical scheme of the production processof the back piece of the backpack is characterized by comprising steps as follows: S1, Dupont sorona fiber is carded in a thin net state through a roller carder and sent into a net paving machine onstandby, oyster fiber mixed hot-melt short fiber is carded in a thin net state by a roller carder, sent into the net paving machine and paved above sorona fiber, and a fiber net with 10-40 g / m<2> is prepared from the paved net and finally coiled to form a fiber net; S4, an inner-core blank is sent into a hot cutting press and is cut into a required appearance by a hot cutting die of the hot cutting press, and a filling inner core is prepared; and S5, the filling inner core is wrapped with fabric, and the back piece of the backpack can be made. By means of the production process of the back piece of the backpack, the breathability of the back piece of the backpack is effectively improved, so that the sweating capability is improved, and the hidden danger of breeding of bacteria is further reduced.

Owner:孙福胜 +1

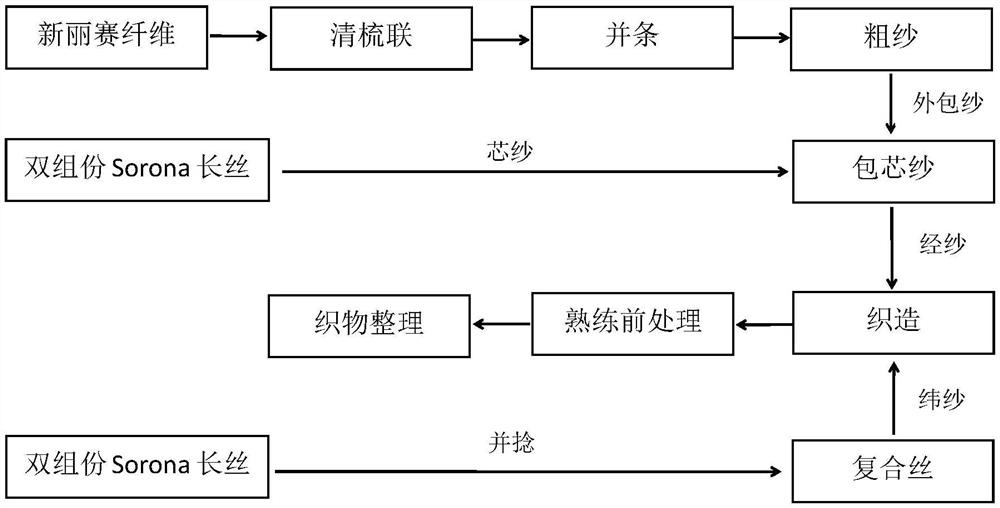

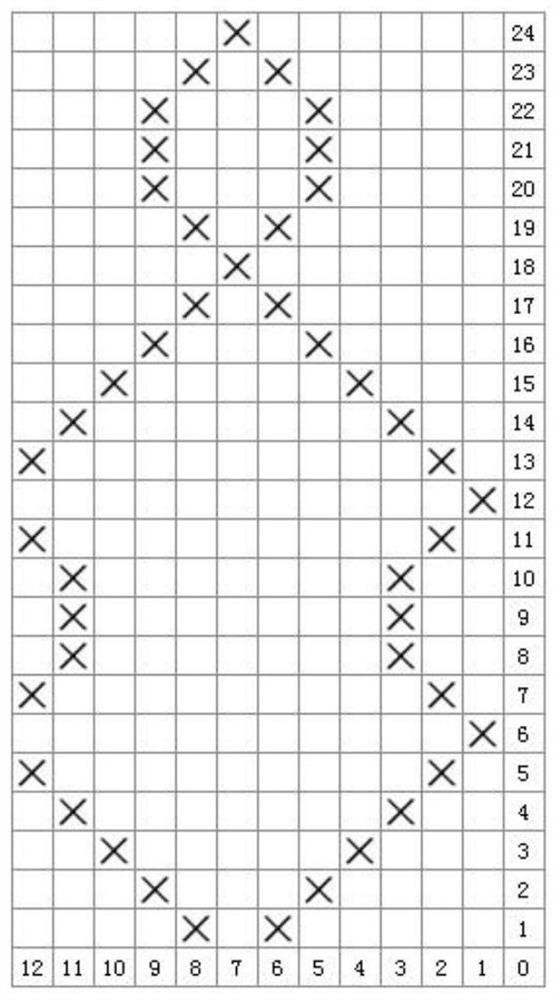

Preparation process of two-component Sorona side stretch fabric

InactiveCN112981667AIn line with the concept of environmental protectionIn line with fashion trendsWoven fabricsYarnCotton fibreNatural fiber

The invention discloses a preparation process of two-component Sorona side stretch fabric, which is tatting side stretch fabric, and relates to the technical field of textile fabric. The preparation process is as follows: warp yarn is two-component Sorona elastic core-spun yarn, and weft yarn is two-component Sorona filament composite elastic yarn. The elastic core-spun yarn takes a two-component Sorona filament as core yarn and takes natural fibers or chemical fibers as outer wrapping fibers; and the composite elastic yarn is formed by cabling two two-component Sorona filaments. According to the prepared side stretch fabric, the biomass Sorona is combined with the fibers such as the cotton fibers and the viscose fibers which are good in comfort, and the side stretch fabric is safe, environmentally friendly, high in comfort, capable of absorbing moisture and releasing sweat, good in rebound resilience, not prone to deformation and easy to care. The side stretch fabric has a good market application prospect in clothing and home textile fabrics, changes the characteristics and style of the traditional side stretch fabric, and improves the use quality of the side stretch fabric.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Antibacterial healthcare high-elastic blanket and production process thereof

InactiveCN107630285ARetain propertiesEmbody qualityWarp knittingAnimal fibresPolyesterLight treatment

The invention discloses an antibacterial healthcare high-elastic blanket and a production process thereof. The blanket comprises 65-80wt% of wool, 13-30wt% of Sorona fiber, 2-5wt% of fine polyester and 1-2wt% of mulberry silk. The production process of the blanket includes the steps of raw material selection, weaving, hot light treatment, sizing, printing and fixation, afterfinish, and finished product storage. By adding the Sorona fiber which is modified elastic polyester, the original characteristics of the raw materials are retained, the quality of the wool is embodied, the softness and skin friendliness of the fabric are improved, the drapability and luster of the fabric are improved, and the fabric has good warmth retention, comfortableness, washability, drapability, crease resistanceand environmental friendliness and is free of pollution; besides, as the Sorona fiber, the mulberry silk and the fine polyester are subjected to antibacterial treatment, the finished product has theantistatic, antibacterial, flame-resistant and deodorant functions, the blood circulation promoting function and the like.

Owner:SUQIAN SHENLONG HOME TEXTILE

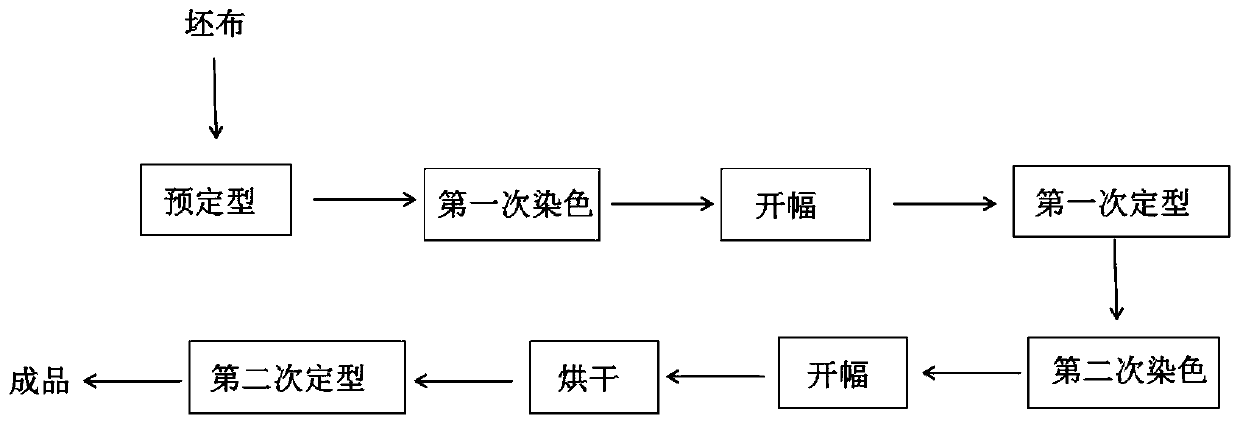

Dyeing and finishing process for Sorona-cotton lycra elastic French terry

ActiveCN110735337AReduced risk of creasesReduce consumptionSucessive textile treatmentsLiquid/gas/vapor removalPolymer scienceEngineering

The invention discloses a dyeing and finishing process for Sorona-cotton lycra elastic French terry. The dyeing and finishing process includes pre-setting, primary dyeing, opening, primary setting, secondary dyeing, opening, drying and secondary setting to obtain the dyed Sorona-cotton lycra elastic French terry. Based on the characteristics of Sorona fibers, the Sorona fibers are subjected to high-temperature setting for two times, and the Sorona fibers and cotton are dyed respectively. The Sorona-cotton lycra elastic French terry is dyed and finished by the dyeing and finishing process, theelasticity of the Sorona fibers and spandex is retained, the dyeing time is short, the problem of creases on cloth surfaces is solved, and the French terry has a unique super-elastic style.

Owner:湖北际华针织有限公司

Production technology of wool light-weight elastic fabric

InactiveCN105908339ALoose fabric styleIncrease elasticityWoven fabricsTextile shapingState of artEngineering

The invention discloses a production technology of a wool light-weight elastic fabric. The production technology comprises the steps of raw material fiber configuration, spinning, weaving, vinylon dissolution, after finishing and the like. According to the production technology of the wool light-weight elastic fabric, water-soluble fibers are configured in the fabric, vinylon dissolution treatment is conducted for removing, the fabric can show a soft fabric covering style, compared with the technical scheme that fibers with low fineness serve as a raw material fiber textile fabric in the prior art, the manufacturing difficulty is small, yarn hairiness is less, configuration of Sorona fibers can increase the elasticity of the fabric, and the production technology facilitates widening of the range of fabrics for clothing.

Owner:JIANGSU SUNSHINE

Elastic fabric preparation technology

InactiveCN109295594ASufficient flexibilityEmbody qualityDyeing processWoven fabricsAfter treatmentEngineering

The invention discloses an elastic fabric preparation technology. 80S wool is subjected to graphene fixation and then blended with Sorona fiber, dyeing, spinning, weaving and after treatment are conducted, and a new elastic fabric is obtained. The elastic fabric is a new elastic environmentally-friendly fabric which is formed by blending graphene wool / Sorona fiber, and has the advantages of beingsoft, smooth and sufficient in elasticity of the wool and the good electrical conductivity, stability and wearing property. Due to the fact that the Sorona fiber is added, the original characteristicsof the raw materials are retained, the quality of the wool is embodied, the softness and skin friendliness of the fabric are improved, the draping property and fabric luster are improved, natural soft hand feeling is given to the fabric, spandex is replaced, good stretching and elastic recovery are achieved, warmth retention, comfort, dryness, air permeability, good washability, the draping property, crease resistance and environmental friendliness are achieved, pollution does not exist, and the fabric is an ideal fabric for making high-end casual clothing.

Owner:海宁市晶森经编有限公司

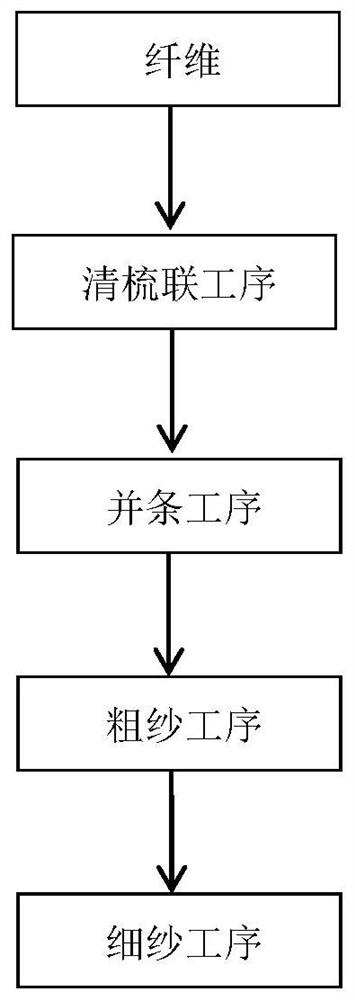

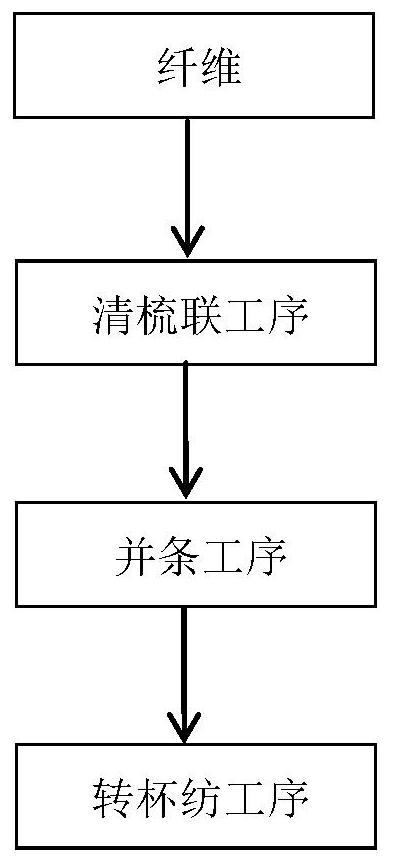

Preparation method of multifunctional blended yarn

The invention discloses a preparation method of blended multifunctional yarn. The method comprises the following steps of arranging, packaging and mixing 20-40% of Sorona fiber, 20-60% of cotton fiber and 20-40% of graphene polyester fiber according to a certain proportion, and preparing the multifunctional yarn through a spinning process flow (mainly comprising a blowing-carding process, a drawing process, a roving process, a spinning process and the like). The spinning process flow is a ring spinning production flow and comprises common ring spinning and compact spinning. Or the spinning process flow is a rotor spinning production flow. The invention provides the preparation method of the multifunctional yarn with the properties of far infrared health care, ultraviolet protection, negative ion generation, bacteria resistance and inhibition, mite inhibition, static electricity resistance, excellent (resilience) elasticity and the like. The process is simple, the requirements for equipment and the environment are not high, the requirement of people for the multifunctional health care yarn is met, and the development plan of the national massive health industry is met.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Preparation process of denim yoga fabric

ActiveCN111172653AImprove breathabilityIncrease elasticityWeft knittingPattern makingPolyesterPolymer science

The present invention relates to a preparation process of a denim yoga fabric. The process comprises the following steps of S1, material selection, wherein core spun yarns formed by coating polyesterwith cellulose fibers, Sorona and polyurethane are selected as raw materials, and the core spun yarns formed by coating the polyester with the cellulose fibers comprise polyester core layers and cellulose fiber skin layers; S2, weaving, wherein the core spun yarns formed by coating the polyester with the cellulose fibers, the Sorona and the polyurethane are knitted into a knitted grey fabric; S3,dyeing, wherein the knitted grey fabric in the step S2 is dyed for coloring the cellulose fiber skin layers to obtain a dyed fabric; and S4, physical friction, wherein the dyed fabric in the step S3 is subjected to physical friction treatment for removing part of the cellulose fiber skin layers by brushing, thereby exposing the polyester core layers. The denim yoga fabric can absorb and release sweat, is good in air permeability, skin fitting feel and elasticity, has the denim style, and is suitable for producing yoga clothing.

Owner:DONGGUAN TEXWINCA HLDG

High-brightness hemp/sorona blended fabric and machining process thereof

InactiveCN108823957AGood hygroscopicityImprove breathabilityLiquid/gas/vapor textile treatmentMoisture absorptionPulp and paper industry

The invention belongs to the technical field of spinning dyeing and printing and in particular relates to a high-brightness hemp / sorona blended fabric and a machining process thereof. The machining process comprises the following steps: singeing hemp / sorona blended blank cloth, carrying out desizing and scouring, carrying out specific bleaching, carrying out terylene whitening, carrying out whitening washing, washing with water and air flow, carrying out super softening, and carrying out tentering, wherein a water washing machine with a rolling groove and a vapor tank is adopted for whiteningwashing; the rolling groove is a guide roller groove; the cloth is soaked and rolled once, is steamed for 50-60 seconds at 95-100 DEG C in the vapor tank, and is further washed with water in ten waterwashing tanks; the ninth water washing tank has a pH value of 3.0-3.5; the cloth is further washed with clean water of 50-52 DEG C and dried by using a drying cylinder of 120-122 DEG C; the surface of the cloth has a pH value of 6-6.5. The fabric provided by the invention has the characteristics of high whiteness and high soaping fastness, a hemp fiber is good in moisture absorption and air permeability, and the fabric has natural styles of coolness and comfort. The invention further provides a machining process of the fabric. The machining process has continuity, is capable of achieving continuous production of large-scale products and high in efficiency.

Owner:鲁丰织染有限公司

Self-formed slubbed knitted fabric preparation process and knitted fabric

ActiveCN109837769AGood effectResponsiveness is fully reflectedDyeing processPolymer sciencePolymer chemistry

The invention discloses a self-formed slubbed knitted fabric preparation process and a knitted fabric. The preparation process includes steps: (1) pretreatment; (2) Sorona dyeing; (3) Sorona washing;(4) Sorona centralizing; (5) cotton dyeing; (6) cotton washing; (7) gray cloth shaping. In the process, a Sorona dyeing temperature is controlled in a range of 120-140DEG C, and a cotton dyeing temperature is controlled in a range of 55-65DEG C. A slubbed effect of the knitted fabric is naturally formed without fixed slub length and distance. By limitation of the Sorona material and cotton dyeingtemperatures, resilience of the knitted fabric is embodied completely, and excellent effects of a finished fabric product are achieved. In addition, the slubbed effect of the product is naturally formed, the knitted fabric without fixed slub length and distance can be obtained, and irregular slub distribution is realized.

Owner:佛山市中汇纺织印染有限公司

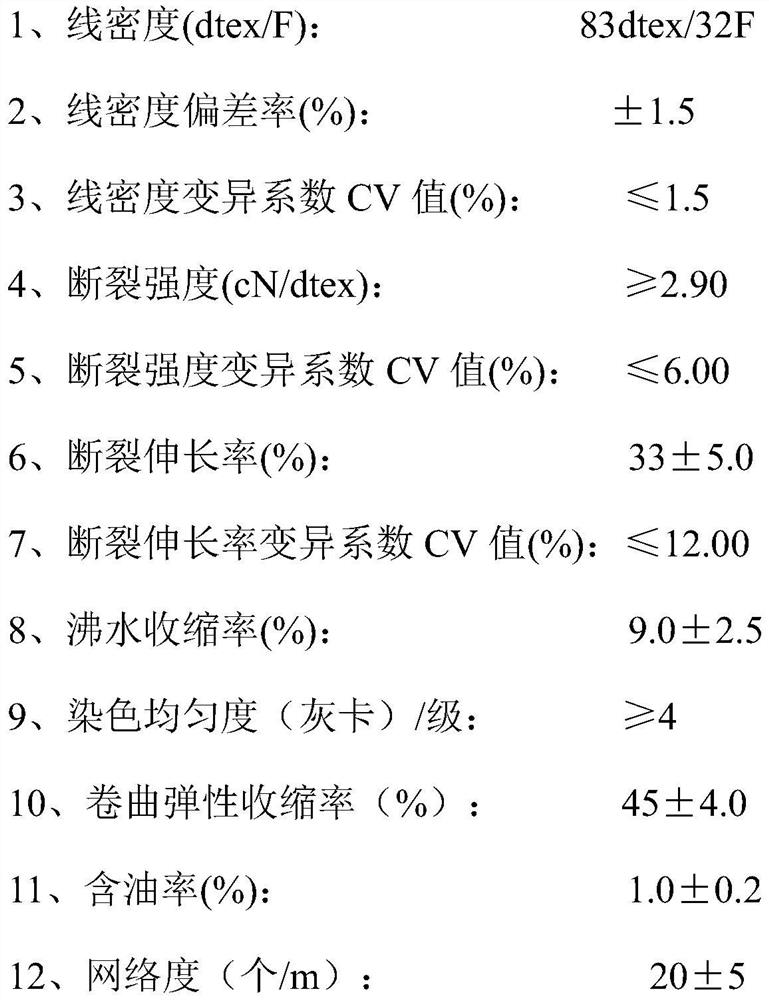

Production method of cool-feeling Sorona fiber

InactiveCN113445142ABright colorHigh fastnessArtificial thread manufacturing machinesFilament/thread formingDisperse dyeColour fastness

The invention relates to a production method of a cool-feeling Sorona fiber. Dupont PTT slices are adopted, cool-feeling master batches are added in the spinning process, a drum is adopted for tackifying, and a low-temperature and long-time drying mode, a lower spinning temperature, a continuous Roots blower flexible conveying mode, a dust separation device, a high-precision master batch injection machine, a parallel spinneret plate for composite spinning and a side blowing cooling rectifier are adopted, so that a produced new product has the characteristics of more uniform elasticity and fineness and more stable product quality, and has good durability and a good dyeing property; and ordinary disperse dye can be used for normal-pressure boiling dyeing, no carrier is needed, and dyed fibers are bright in color and excellent in color fastness and chlorine resistance. The product has the advantages of soft hand feeling, stain resistance, fluffiness, moisture absorption and quick drying, and the processed fabric is flat, smooth, crease-resistant, easy-care, stable in size and moderate in elasticity. Particularly, after being worn in summer, the sportswear made of the fiber is cool, light in skin, moisture-absorbing, sweat-releasing, comfortable and healthy.

Owner:TONGKUN GRP +1

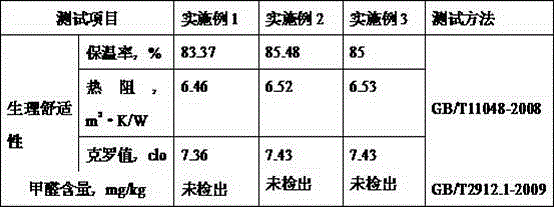

Environment-friendly high-temperature-resistant comfortable stretch yarn for garment stuffing and production method thereof

The invention relates to an environment-friendly high-temperature-resistant comfortable stretch yarn for garment stuffing and a production method thereof and belongs to the technical field of garment filling materials.The production method of the environment-friendly high-temperature-resistant comfortable stretch yarn for garment stuffing comprises the following steps: step one, mixing prepared materials; step two, pretreating; step three, drying; step four, opening; step five, combing.Maize fiber, hollow fine-denier polyester staple fiber and Sorona fiber are mixed and pre-impregnated so that the produced comfortable stretch yarn has excellent handle and softness and comfortableness and also has excellent warmth retention, has a warmth retention rate up to 85.48% and is as warm as downs, the comfortable stretch yarn produced according to the method of the invention is twice as warm as an existing common comfortable stretch yarn; in addition, the comfortable stretch yarn produced by the invention is safe and environmentally friendly.

Owner:福建亿泰隆化纤股份有限公司

Moisture-absorbing and sweat-releasing knitted fabric capable of forming bamboo joint effect and production process thereof

ActiveCN110952217AImprove washabilityPromote environmental protectionWeft knittingWarp knittingTextile technologyPolymer science

The invention relates to the technical field of textiles, and particularly relates to a moisture-absorbing and sweat-releasing knitted fabric capable of forming the bamboo joint effect and a production process thereof. The knitted fabric is formed by making cotton fibers, modal fibers and Sorona fibers into blended yarns and performing knitting; the fabric is prepared through the design of the characteristics and proportions of the three types of fibers; the functional moisture-absorbing and sweat-releasing effects are obtained; the situation that the moisture-absorbing and sweat-releasing effects are obtained by using a functional additive in the prior art is avoided; and therefore, the knitted fabric has the advantages of good washability and environmental protection property. Accordingto the production process of the moisture-absorbing and sweat-releasing knitted fabric capable of forming the bamboo joint effect, by utilizing different dyeing characteristics and shrinkage characteristics of the cotton fibers, the modal fibers and the Sorona fibers, the dyeing temperature and the grey fabric setting temperature are controlled in a dyeing process, so that the shrinkage rates of the fibers are enabled to be different and then the cloth cover effect of bamboo joints is obtained. Therefore, the production process has the advantages of easy dyeing, good bamboo joint effect, smooth hand feeling and no trace sense.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

Production technology of wool blended antistatic fabric

InactiveCN105908332ACrisp and softImprove breathabilityWoven fabricsYarnMaterials scienceRaw material

The invention discloses a production technology of a wool blended antistatic fabric. The production technology comprises the steps of raw material fiber configuration, spinning, weaving, after finishing and the like. According to the production technology of the wool blended antistatic fabric, proper raw material fiber proportions, technological routes and technological parameters are determined, wool, Sorona fibers and pttato blended fiber with an excellent antistatic property are blended to be made into the antistatic fabric, the obtained fabric is stiff and soft in handfeel, and good air permeability and wearability are achieved.

Owner:JIANGSU SUNSHINE

Production process of double-layer knitted fabric with comfortable stretch yarn self-fuzzing effect

The invention relates to the technical field of textiles, in particular to a production process of a double-layer knitted fabric with a comfortable stretch yarn self-fuzzing effect. According to the production process of the double-layer knitted fabric with the comfortable stretch yarn self-fuzzing effect, the sorona fiber spun yarns are used as the bottom surface of the base yarn woven fabric, dyeing is performed under the action of temperature and disperse dye in the dyeing process, the sorona fibers emerge from the bottom surface, a layer of fluff is formed on the surface of the fabric, andthe effect of fuzzing process is achieved without the fleece treatment so that one more processing procedure is avoided, one time of damage to the fibers is avoided, the strength of the fabric is notdamaged, and the fleece effect is more compact and neater than the fleece effect of the fleece process in the prior art and fluff is not liable to fall off. In addition, the phenomena in the prior art tta the fibers are damaged by the fleece process and holes are formed in the fabric can be avoided by using the sorona fiber fleece effect.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

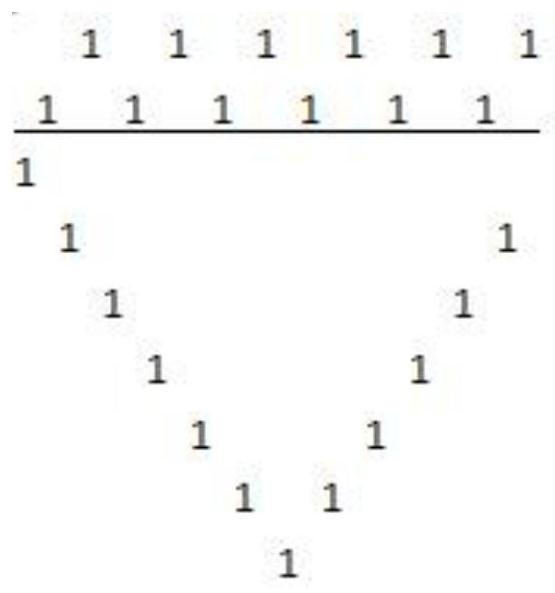

Preparation method of Sorona filament and graphene staple fiber elastic core-spun yarn

The invention discloses a preparation method of a Sorona filament and graphene staple fiber elastic core-spun yarn, belongs to the technical field of textile engineering, and particularly relates to a preparation method of the elastic core-spun yarn. The Sorona filaments are two-component comfortable stretch yarns, and the graphene staple fibers are graphene modified polyester staple fibers. The elastic core-spun yarn is formed in the mode that graphene modified polyester staple fibers are made into rough yarn and then core-spun into two two-component Sorona composite filaments with different draft multiples. The prepared elastic core-spun yarn is good in elasticity, high in resilience and easy to color, and meanwhile, the functionality of graphene is combined, and the functionality of the elastic core-spun yarn is reflected in antibiosis, far infrared heating, microcirculation promotion, ultraviolet prevention and the like. The elastic core-spun yarn has a wide application prospect in the fields of woven elastic fabrics and knitted sports and leisure.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Healthy knitted fabric

InactiveCN107604520ANatural warmthSoft touchWeft knittingOrnamental textile articlesEngineeringNatural fiber

The invention discloses a healthy knitted fabric. Natural fiber or viscose fiber, sorona and spandex are adopted for weft knitting, then a double-surface structure is formed, the natural fiber or theviscose and the spandex are adopted for one surface, sorona is adopted for the other surface, and the component proportions of the natural fiber or the viscose fiber, the sorona and the spandex are 50-60%, 30-40% and 5-20% respectively. The healthy knitted fabric has excellent tensile elasticity and recovery characteristics and forming and wrapping characteristics, a user wears the fabric and feels comfortable, and the fabric accords with modern health and environmental protection ideas.

Owner:GUANGZHOU SAMYAMA CO LTD +1

Novel knitted fabric

InactiveUS20190093263A1Function increaseImprove recoverabilityWeft knittingOrnamental textile articlesAdditive ingredientEngineering

A novel knitted fabric includes a double-sided structure which is weft-knitted by a natural fiber or a viscose, a sorona and a polyurethane fiber. A first side of the double-sided structure is constituted by the natural fiber or the viscose and the polyurethane fiber, a second side of the double-sided structure is constituted by the sorona, and a yarn ingredient proportion comprises 60-50% of the natural fiber or the viscose, 40-30% of the sorona, and 5-20% of polyurethane fiber. The novel knitted fabric can have advantages of excellent stretchability, recoverability, plastic and packaging functions, wearing comfort, and conformation of modern environmental thoughts.

Owner:GUANGZHOU SAMYAMA CO LTD +1

SORONA fiber spinnability preprocessing method

ActiveCN104846626ATroubleshoot technical issues with agglomerationEasy to operateFibre typesWaxPretreatment method

The invention provides a SORONA fiber spinnability preprocessing method, which can improve the spinnability of the SORONA fiber, so that the spinning becomes possible. The technical flow process is simple, and the processing cost is low. The method comprises the following steps that (a) liquid wax and water are mixed and uniformly stirred according to a mass ratio being 1:9; (b) the SORONA fiber is subjected to bale breaking and uniform spreading; (c) the mixing liquid obtained in the step (a) is uniformly sprayed onto the SORONA fiber, and in the step, the mass ratio of the mixing liquid to the SORONA fiber is (0.5 to 1.5):1000; (d) a plastic film is used for covering the SORONA fiber, and the heat insulation is carried out for at least 24 hours under the condition of 25 to 30 DEG C. In the steps (b) and (c), the relative humidity of the work environment is maintained at 55 to 60 percent, and the temperature is maintained at 25 to 30 DEG C.

Owner:ANHUI HUAMAO TEXTILE

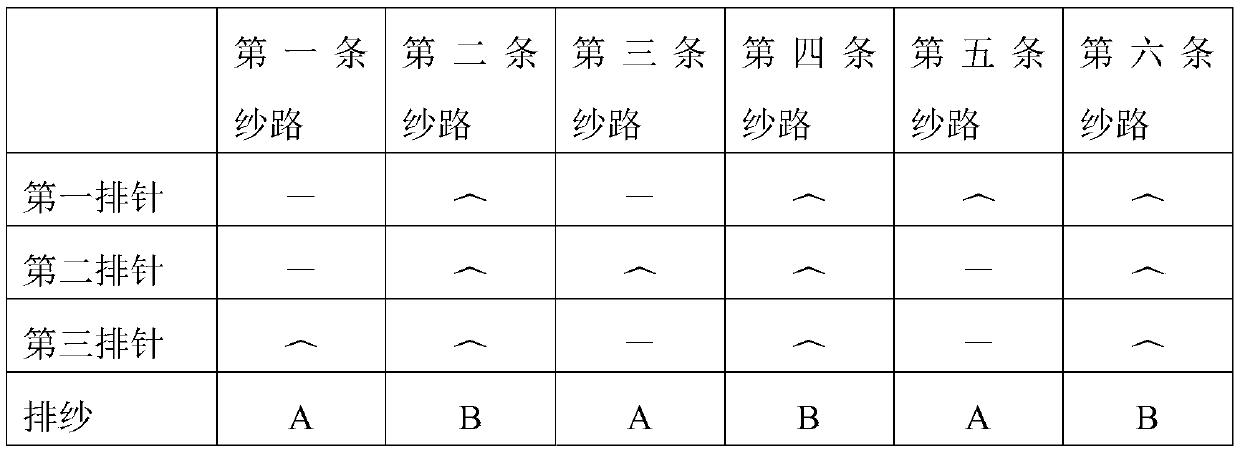

Three-dimensional concave-convex jacquard liner warm-keeping knitted fabric and preparation method thereof

PendingCN113981595ANot easy to tearStrong sense of textureWeft knittingYarnPolymer scienceFilament yarn

The invention provides a three-dimensional concave-convex jacquard liner warm-keeping knitted fabric and a preparation method thereof, gray fabric is knitted through a double-faced knitting jacquard circular knitting machine, the fabric has the three-dimensional concave-convex jacquard effect on the basis of a common double-faced structure, and the concave-convex jacquard face is made of siro compact spinning yarn, so that the surface of the fabric is smooth and clean, and the anti-pilling performance is good; the horizontal stripe jacquard surface is formed by interweaving SORONA two-component composite filaments and polyester cotton short fiber blended yarns, so that the fabric is compact and elastic and is not easy to tear; the lining yarns filled in the middle adopt the heavy-net polyester filament yarns, so that the fabric is fluffy and comfortable and does not move. One side of the double-sided structure has a concave-convex jacquard effect, and the other side of the double-sided structure has a horizontal stripe jacquard effect, so that the whole fabric is three-dimensional, fluffy, elastic, warm-keeping, strong in texture feeling and unique in style.

Owner:NINGBO DAQIAN TEXTILE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com