Preparation method for elastic fabric

A technology of reactive dyes for elastic fabrics and wool, which is applied in the processing of textile materials, dyeing methods, textiles, etc. It can solve problems such as poor dimensional stability, insufficient elastic elongation, and difficult production, achieve the best anti-wrinkle performance and save energy. , pure color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

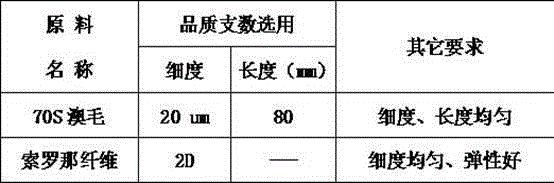

[0032] A kind of preparation method of elastic fabric, is characterized in that, comprises steps:

[0033] 1) Dyeing process

[0034] The wool is made of environmentally friendly imported wool reactive dye Lanersol Red 6G, the dyeing temperature is controlled at 80°C, and the temperature is kept for 55 minutes; and the imported leveling agent Abaig B is used, and the bath ratio is 1:10;

[0035] Solona fibers are dyed with disperse dyes at low temperature, and the holding temperature is controlled at 100-110°C.

[0036] When rewashing, in order to ensure that the sliver is easy to dry and comb, the temperature of the rewashing tank is controlled at 65 °C in the first tank, 40 °C in the second and third slots, and 55 °C in the fourth slot. When mixing and combing, add 40% printed wool tops to match mixed comb,

[0037] 2) Spinning process

[0038] In the re-combing process, each channel adopts small gauge and small draft (B306 gauge 45mm, 6 times draft), and re-combing ensur...

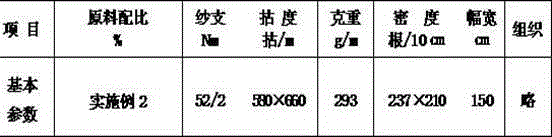

Embodiment 2

[0048] A kind of preparation method of elastic fabric, is characterized in that, comprises steps:

[0049] 1) Dyeing process

[0050] The wool is made of environmentally friendly imported wool reactive dye yellow 4G, the dyeing temperature is controlled at 85°C, and the temperature is kept for 60 minutes; and the imported leveling agent Abaig B is used, and the bath ratio is 1:20;

[0051] Solona fibers are dyed with disperse dyes at low temperature, and the holding temperature is controlled at 110°C.

[0052] When rewashing, in order to ensure that the sliver is easy to dry and comb, the temperature of the rewashing tank is controlled at 65°C in the first slot, 40°C in the second and third slots, and 55°C in the fourth slot. When mixing and combing, add 50% printed wool tops to match mixed comb,

[0053] 2) Spinning process

[0054] In the re-combing process, each channel adopts small gauge and small draft (B306 gauge 45mm, 6 times draft), and re-combing ensures that the w...

Embodiment 3

[0064] A kind of preparation method of elastic fabric, is characterized in that, comprises steps:

[0065] 1) Dyeing process

[0066] The wool is made of environmentally friendly imported reactive dye black CE for wool, the dyeing temperature is controlled at 82°C, and the temperature is kept for 58 minutes; and the imported leveling agent Abaig B is used, and the bath ratio is 1:15;

[0067] Solona fibers are dyed with disperse dyes at low temperature, and the holding temperature is controlled at 105°C.

[0068] When rewashing, in order to ensure that the sliver is easy to dry and comb, the temperature of the rewashing tank is controlled at 65 °C in the first tank, 40 °C in the second and third slots, and 55 °C in the fourth slot. When mixing and combing, add 45% printed wool tops to match mixed comb,

[0069] 2) Spinning process

[0070] In the re-combing process, each channel adopts small gauge and small draft (B306 gauge 45mm, 6 times draft), and re-combing ensures that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com