Patents

Literature

236 results about "Composite effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite Effects, or CFX for short, is the culmination of years of independent research on professional technique and materials in the theatrical and production industry. They are currently a growing company located in Baton Rouge, Louisiana and have a history of quality craftsmanship that meets and exceeds their client's expectations.

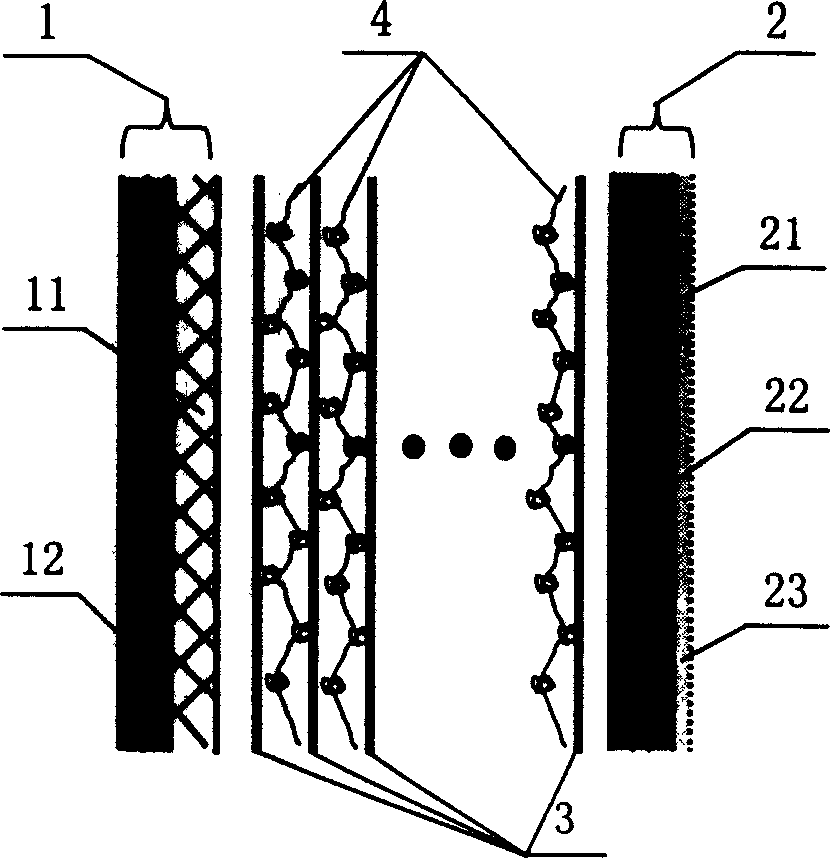

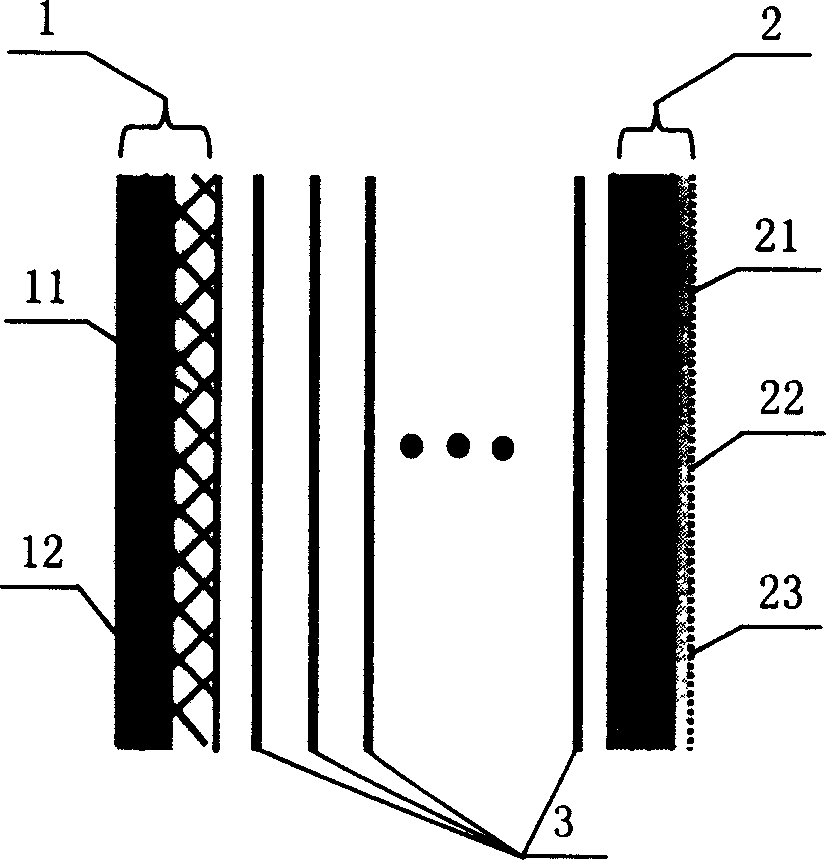

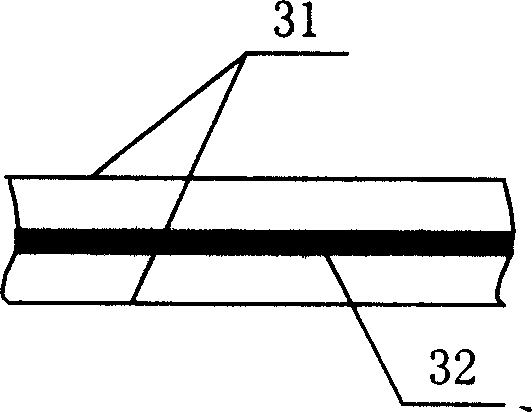

Heat insulation soft thin composite fabric, preparing method and its use

InactiveCN1586884ASimple compositionWell formedSynthetic resin layered productsProtective garmentComposite effectRoom temperature

The present invention relates to the composite fabric structure with one side capable of bearing high temperature, low temperature or composite effect of high temperature and low temperature, and the other side maintained at room temperature state of 5-35 deg.c. The fabric structure has heat and cold resisting high performance coated fabric in one side; soft, comfortable, antifrosting and condensation-preventing fabric in the other side; and composite fabric of heat insulating polymer and compounded metal film as the middle layer, which may have also net lining fabric with stable thickness and size. The composite fabric has natural thickness of 3-12 mm, practical densified thickness of 1-3 mm and unit area weight of 150-550 g / sq m, may be adhered and sawn, and is completely sealed suitable for use as heat insulating protecting material in the environment condition from -130 deg.c to 120 deg.c.

Owner:DONGHUA UNIV

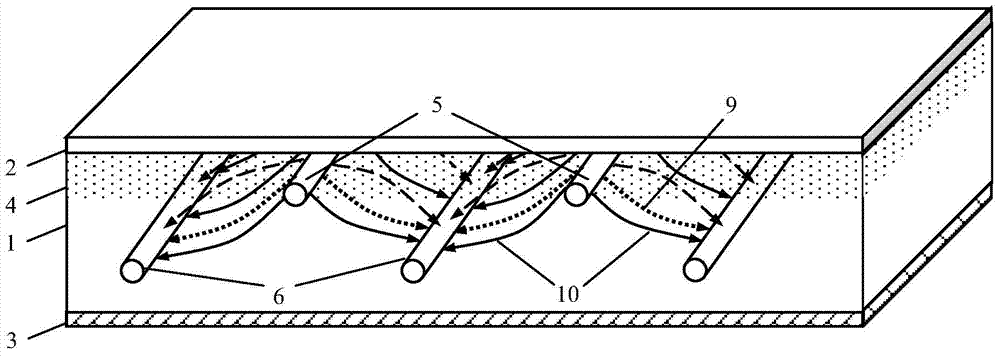

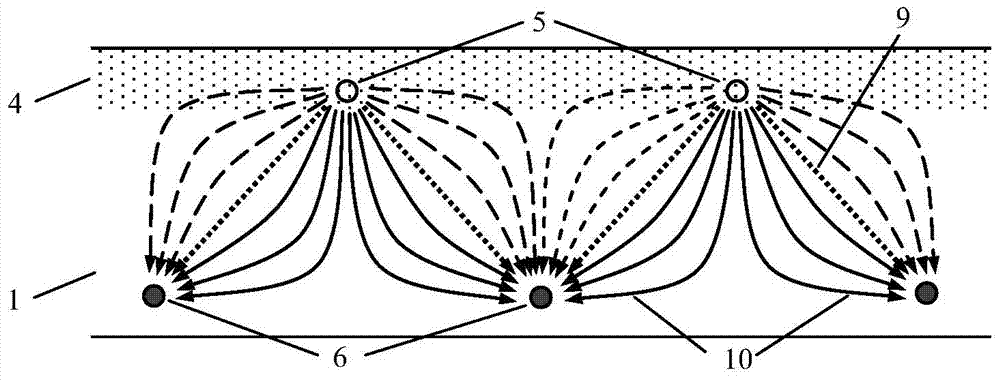

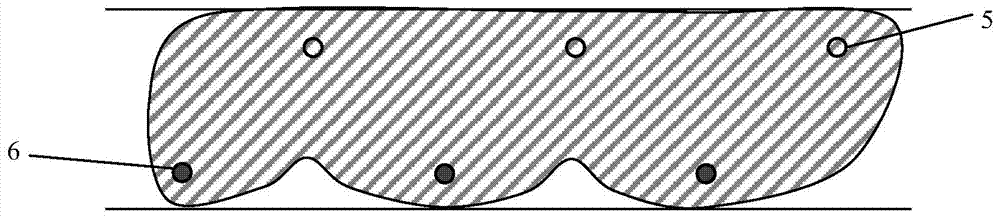

Steam-gas displacement and gravity oil drain composite exploiting method

ActiveCN103939069AEnlarging the heating chamberImprove heating efficiencyFluid removalComposite effectHorizontal wells

The invention provides a steam-gas displacement and gravity oil drain composite exploiting method. According to the method, at least one horizontal well or a row of vertical wells close to the top of an oil pool are adopted as injection well sets, horizontal wells with the number same as that of wells in the injection well sets or with one more well are close to the bottom of the oil pool and are used as extraction well sets, the injection well sets and the extraction well sets are arranged in parallel in a non-direct-facing mode, and lower extraction wells are located in the middle portions of two upper injection wells. Steam huff and puff or steam and gas composite huff and puff are carried out on the injection wells and the extraction wells at the same time or in sequence, heat communication is built between the injection wells and the extraction wells to low the formation pressure, then high-temperature steam and non-condensation gas are injected into the injection wells at the same time or in an alternating mode, the injected steam seeps in the oil pool and heats the oil pool, the steam is condensed into hot water at the same time, and the gas expands a heating cavity, lowers heat loss and increases the pressure of the oil pool, so that crude oil flows to the extraction wells and is extracted under the composite effect of pressure displacement and gravity oil drain.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

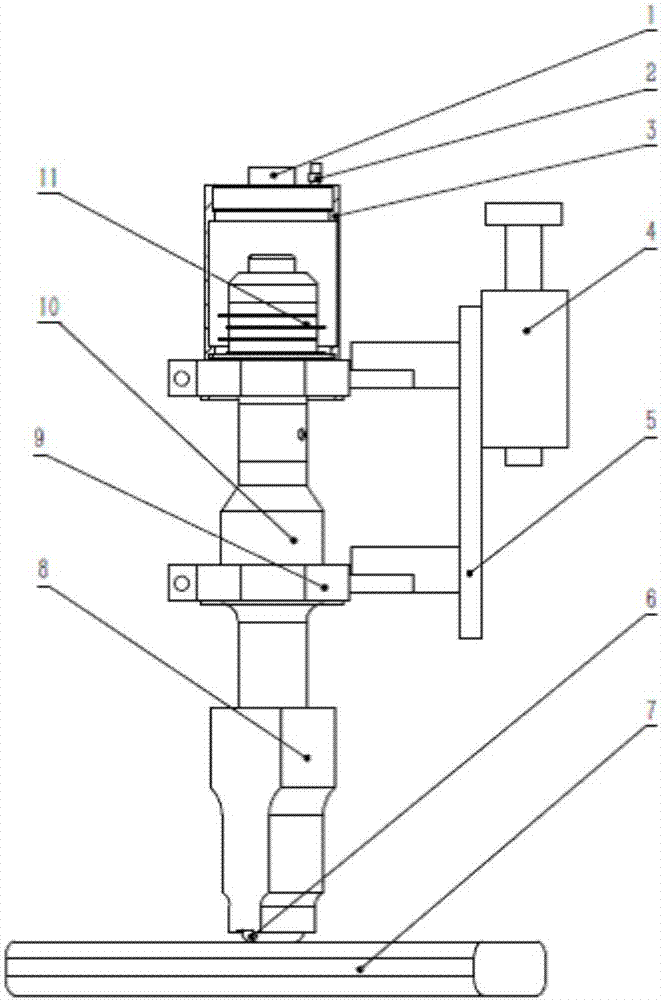

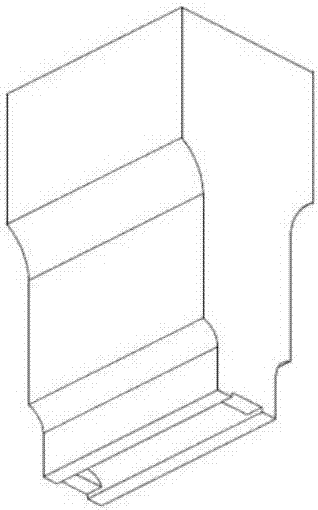

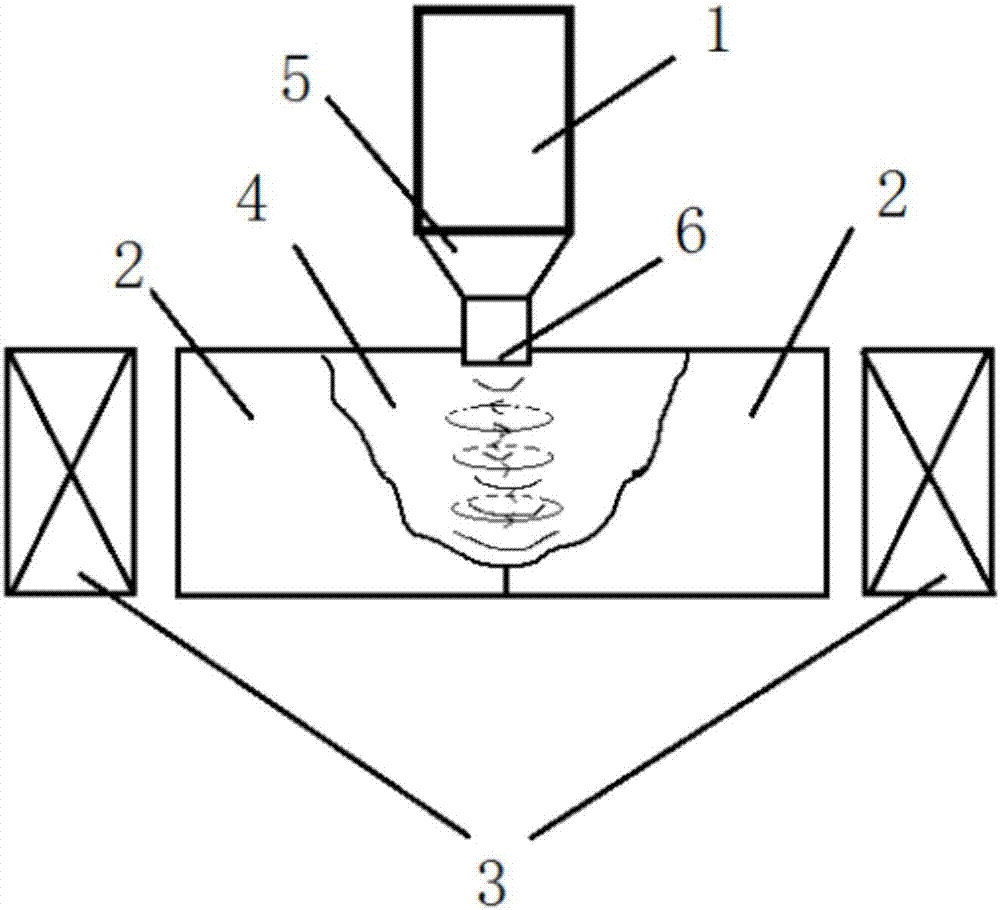

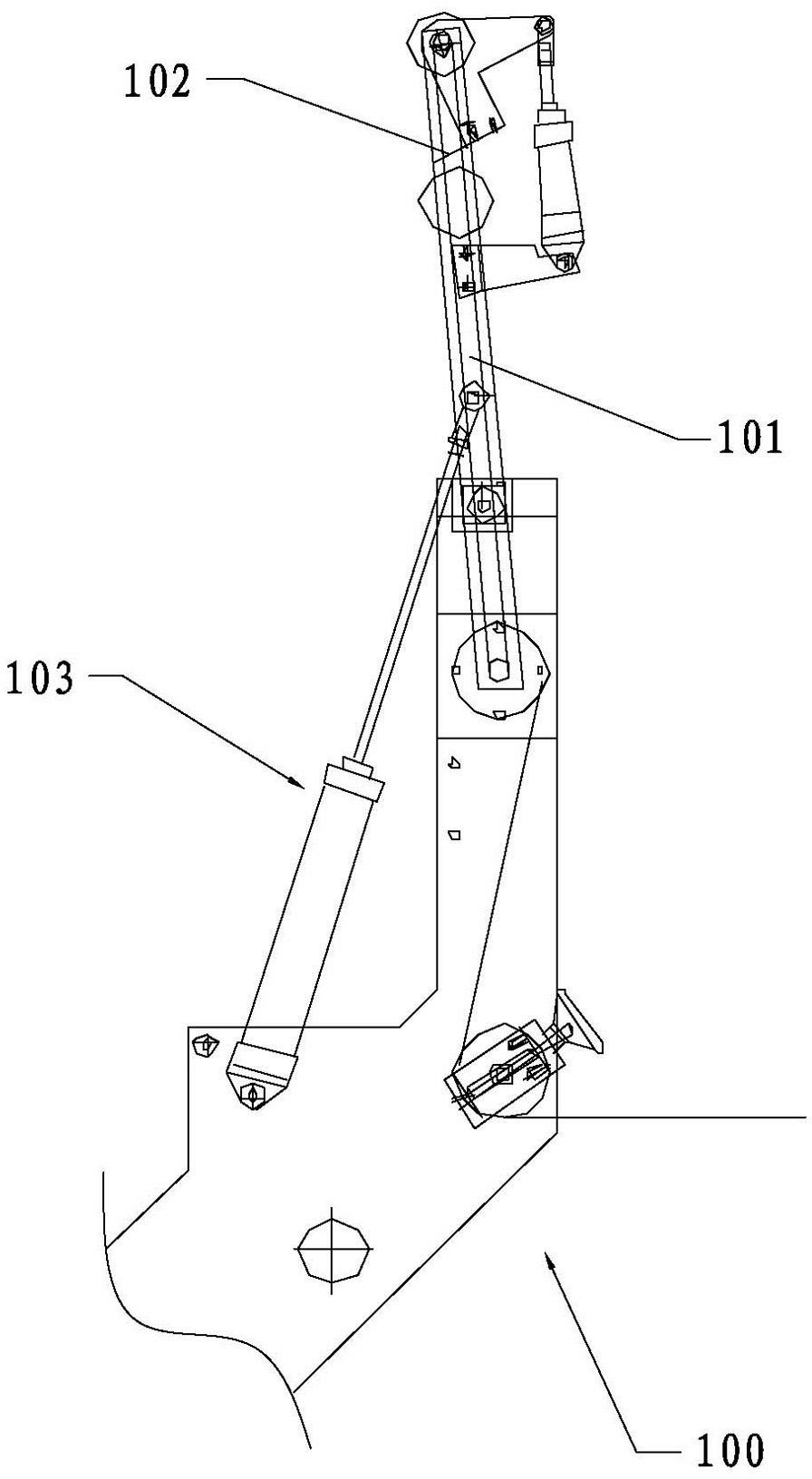

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

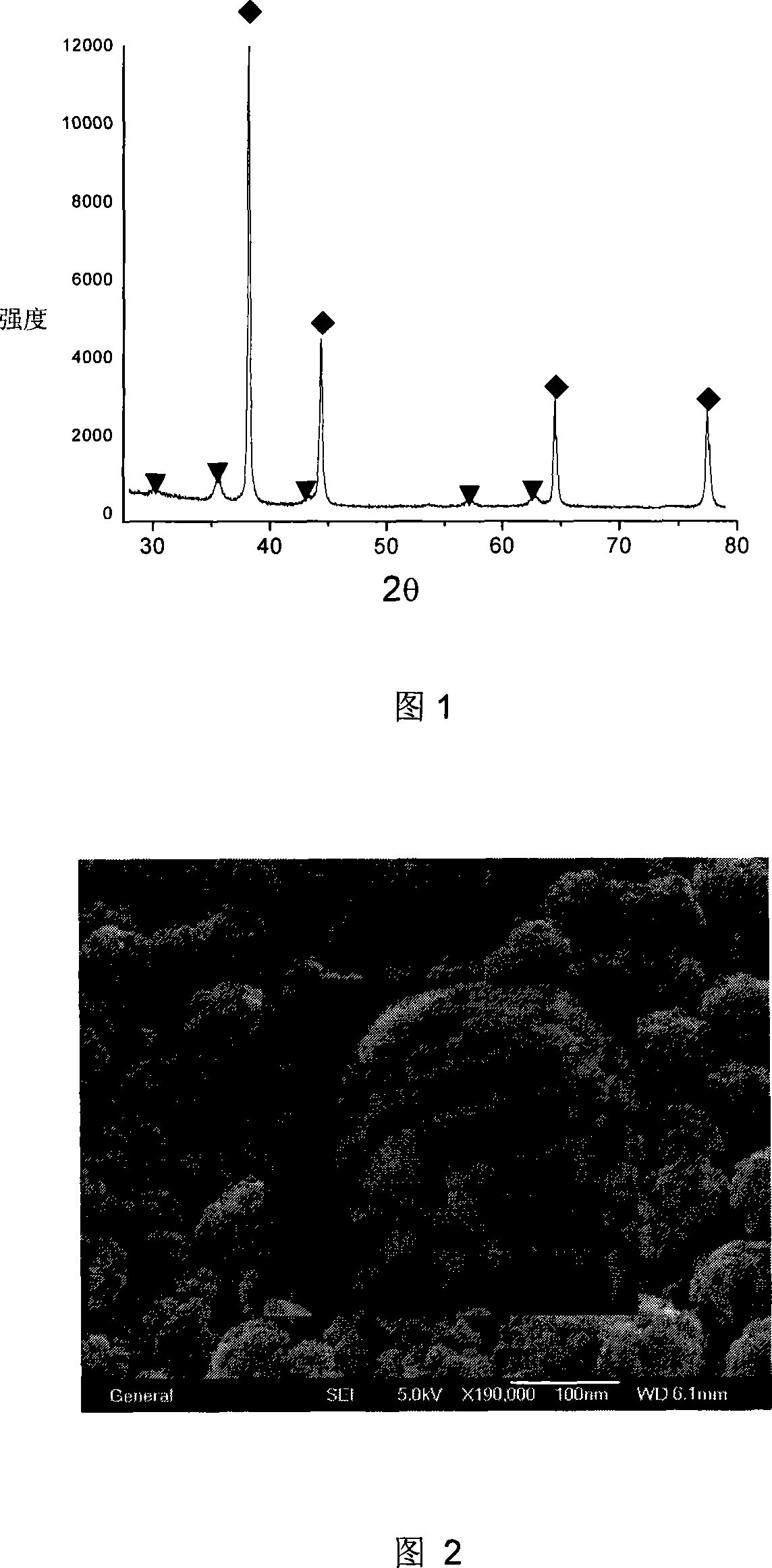

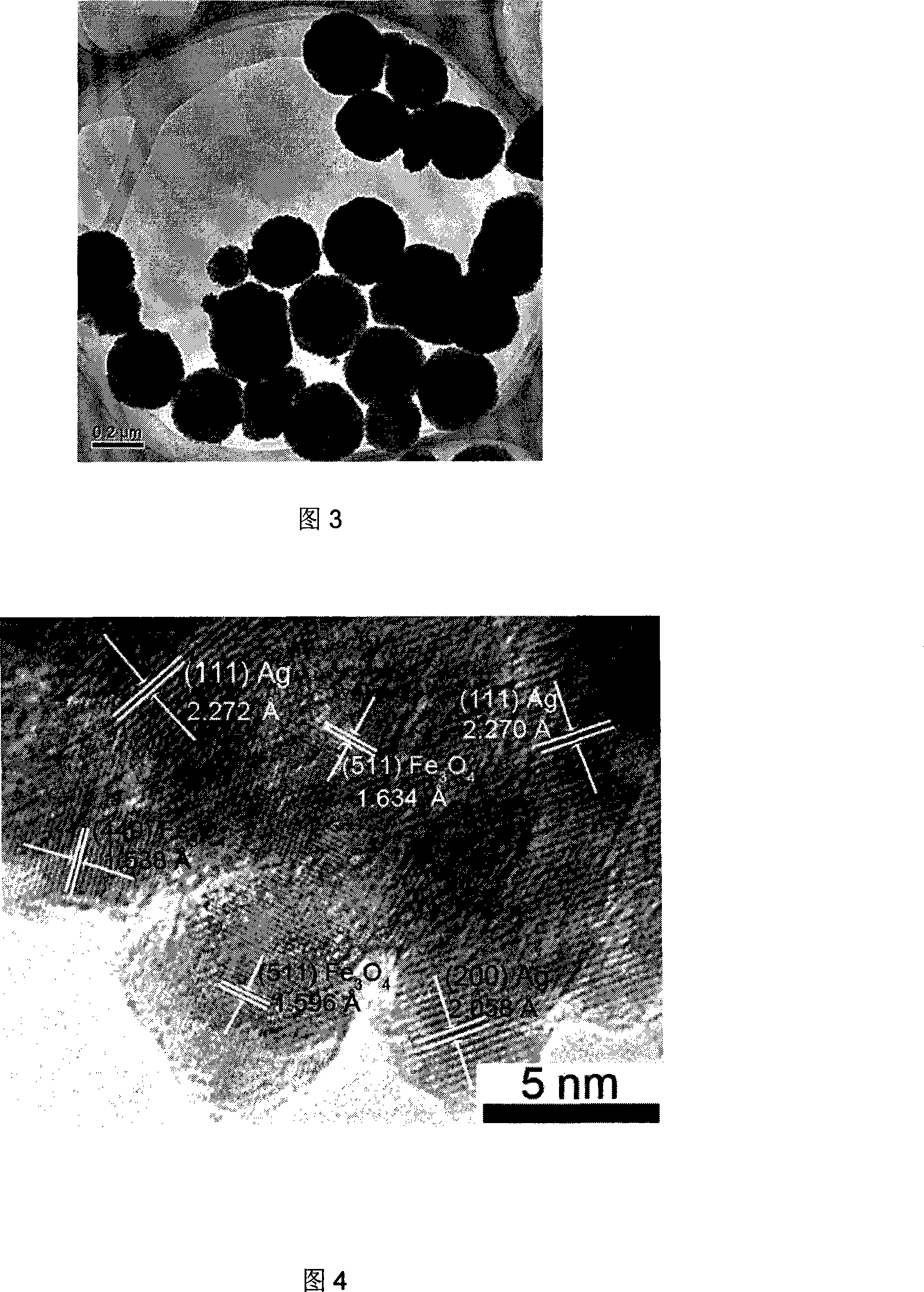

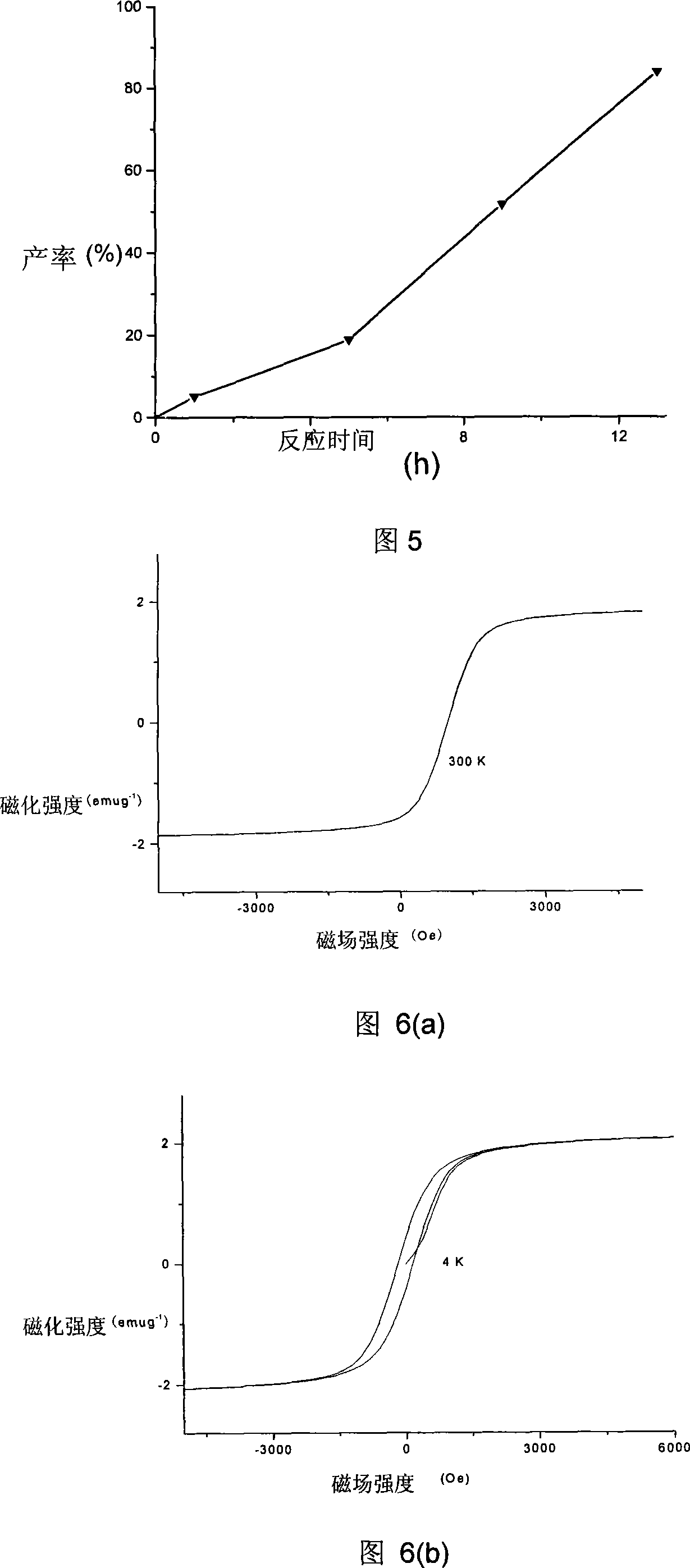

Ag-Fe3O4 magnetic nano catalyst and its application in phenylethene epoxidation

InactiveCN101181687AHigh catalytic activityEasy to separateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNano catalystStyrene oxide

The invention belongs to the field of magnetic catalysts, and particularly relates to Ag-Fe3O4 magnetic nano-catalysts compounded under the action of polymers and their application in a styrene catalytic epoxidation system. The synthesis method is to use Fe3Cl6·6H2O and AgNO3 as raw materials to synthesize Ag-Fe3O4 composite magnetic nano-catalyst in ethylene glycol system containing NaAc by solvothermal technology with the assistance of polymer PVP; this catalyst can be used to use TBHP as oxidant, Styrene epoxidation system with toluene as solvent. The preparation method of the present invention is simple, the reactants are cheap and easy to obtain, the solvent pollution is small, the synthesis time is low, the catalyst can be conveniently separated from the reaction system under the action of an external magnetic field, and the problem that the non-magnetic nano-catalyst is difficult to recover is solved. The catalyst showed excellent catalytic activity and stability for styrene epoxidation, the yield of ethylene oxide was 84.0%, and there was no deactivation phenomenon after repeated use.

Owner:JILIN UNIV

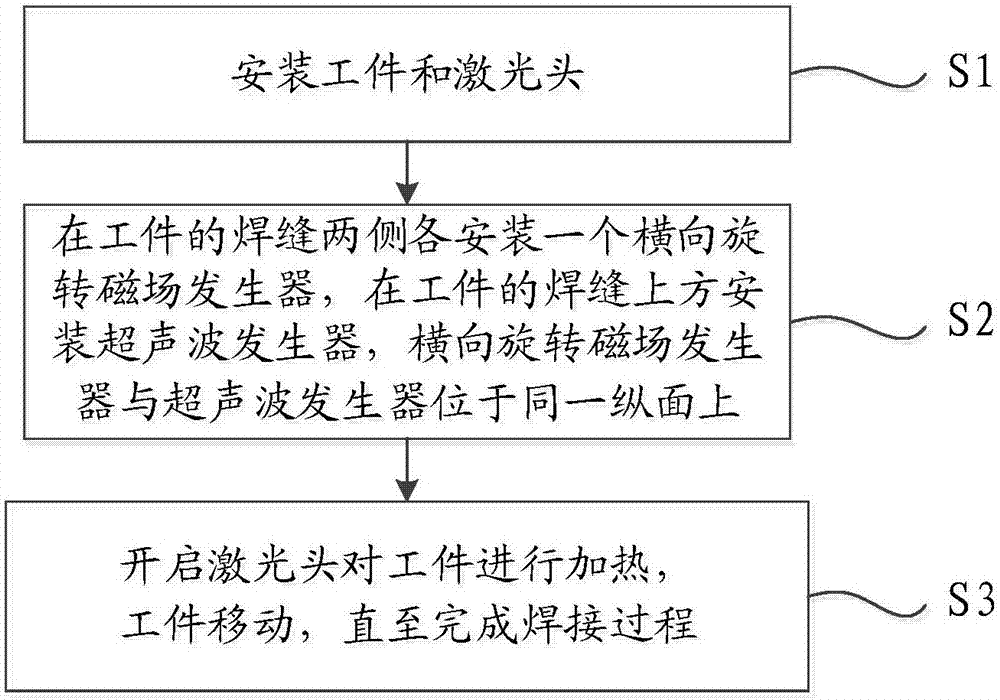

Laser welding system and method

PendingCN107252970AReduce generationImprove mechanical propertiesLaser beam welding apparatusComposite effectCavitation

The invention discloses a laser welding system and method. The system comprises two transversely-rotating magnetic field generators located on the two sides of a welding seam of a welding piece and an ultrasonic generator located above the welding seam of the welding piece. The transversely-rotating magnetic field generators and the ultrasonic generator are located on the same longitudinal face. According to the laser welding system, overlaying of transversely-rotating magnetic fields and an ultrasonic field can be achieved, and in the molten pool solidifying process, Lorentz force and longitudinal waves are exerted in the horizontal direction and the vertical direction to enable a molten pool to be sufficiently stirred in all the directions, so that the solidified welding seam is made to obtain more fine crystal grains; under the composite effect of the ultrasonic field and the electromagnetic fields, the defect that the range of the ultrasonic treatment effect is small can be effectively overcome, the refining effect of electromagnetic stirring over a structure can also be reinforced through the ultrasonic field cavitation effect, and great help is achieved for refining of the molten pool solidified structure; and through involving of the composite field, the crystal grains of all the positions of the molten pool are refined, generation of air holes is reduced, and the ranges of all welding parameters can be optimized.

Owner:GUANGDONG UNIV OF TECH

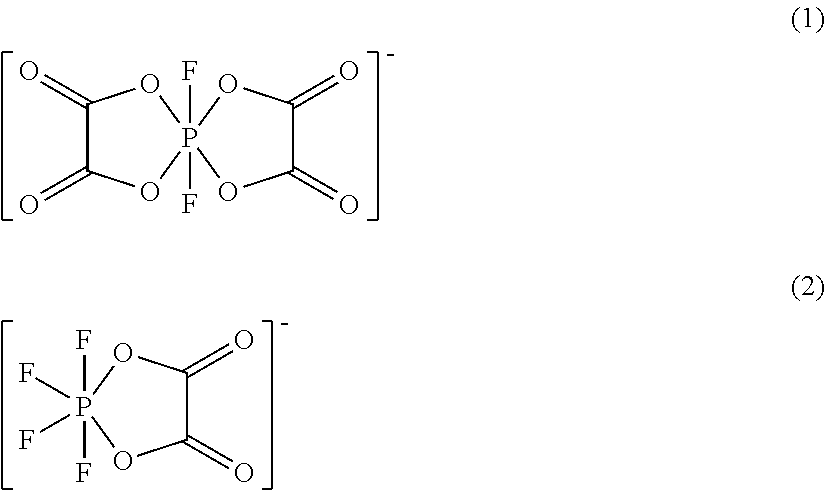

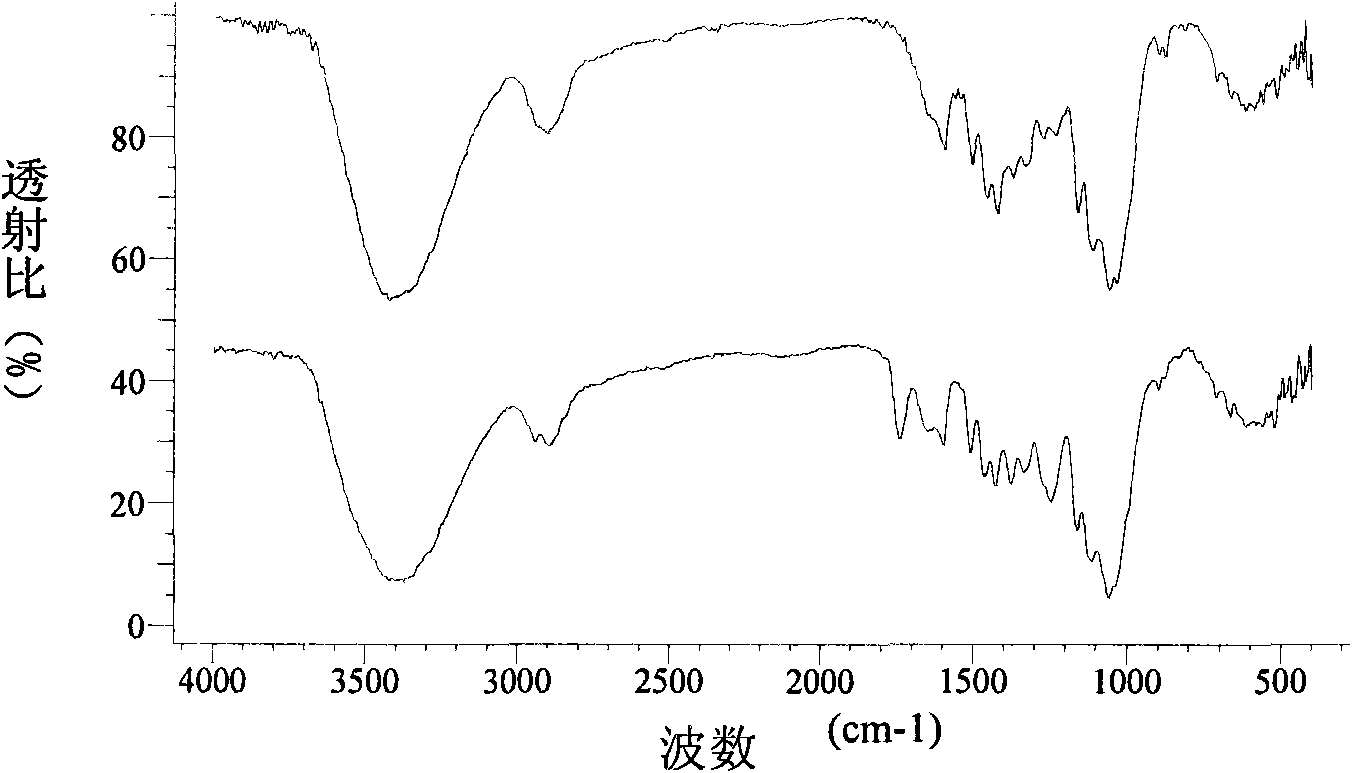

Electrolyte for Non-Aqueous Electrolyte Batteries and Non-Aqueous Electrolyte Battery Using the Same

ActiveUS20130022880A1Sufficient performanceReduced characteristicsHybrid capacitor electrolytesLi-accumulatorsComposite effectHigh temperature storage

An electrolyte for a non-aqueous electrolyte battery according to the present invention contains a non-aqueous organic solvent; a solute; and both of difluorobis(oxalato)phosphate and tetrafluoro(oxalate)phosphate as additives. A non-aqueous electrolyte battery according to the present invention uses the above electrolyte. By the composite effect of the difluorobis(oxalato)phosphate and tetrafluoro(oxalate)phosphate in the non-aqueous electrolyte and the non-aqueous electrolyte battery, it is possible to improve not only the cycle characteristics and high-temperature storage stability of the battery but also the low-temperature characteristics of the battery at temperatures of 0° C. or lower.

Owner:CENT GLASS CO LTD

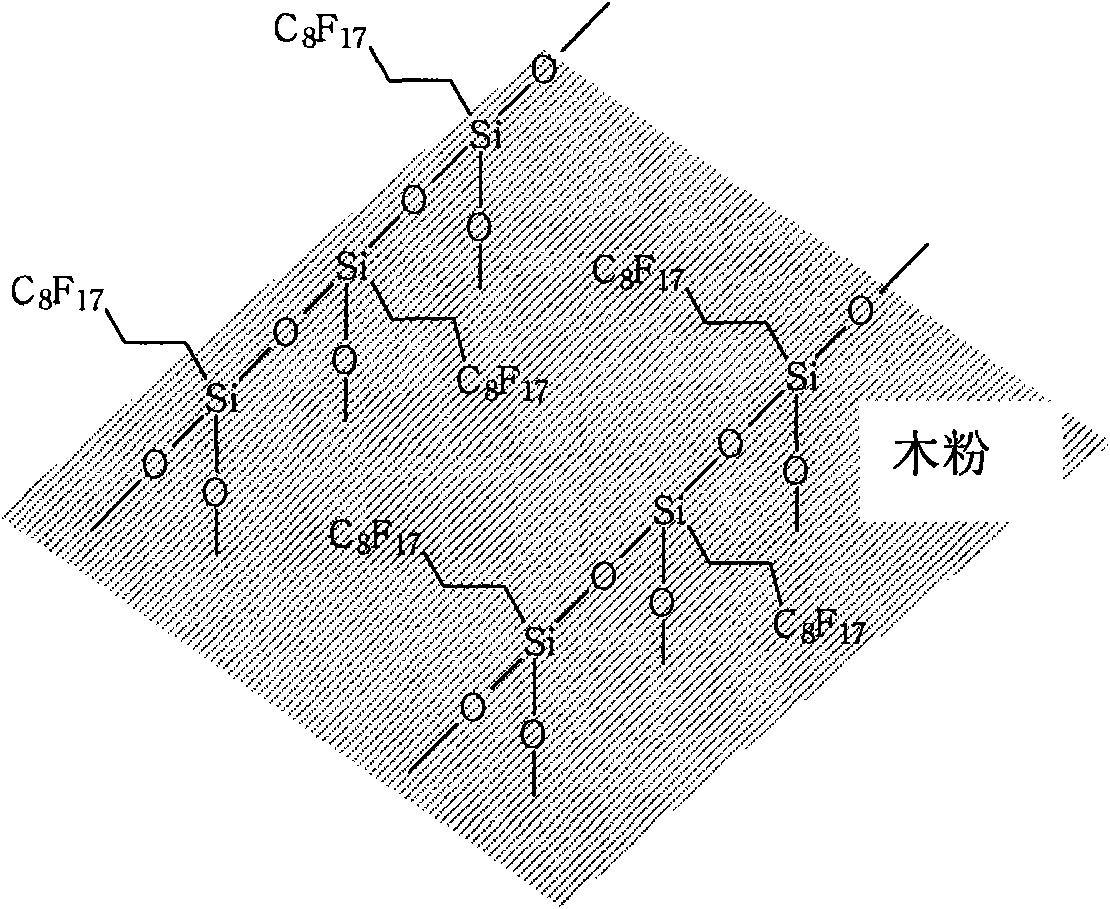

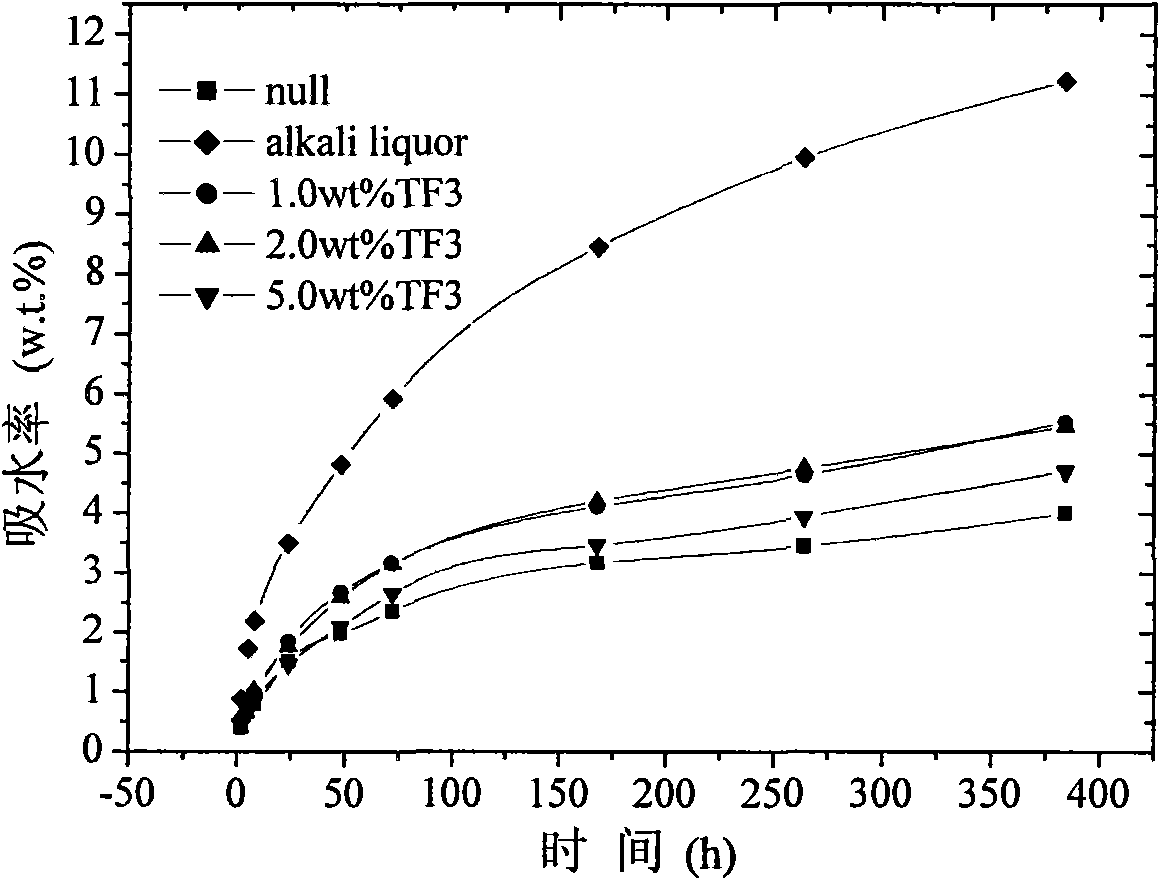

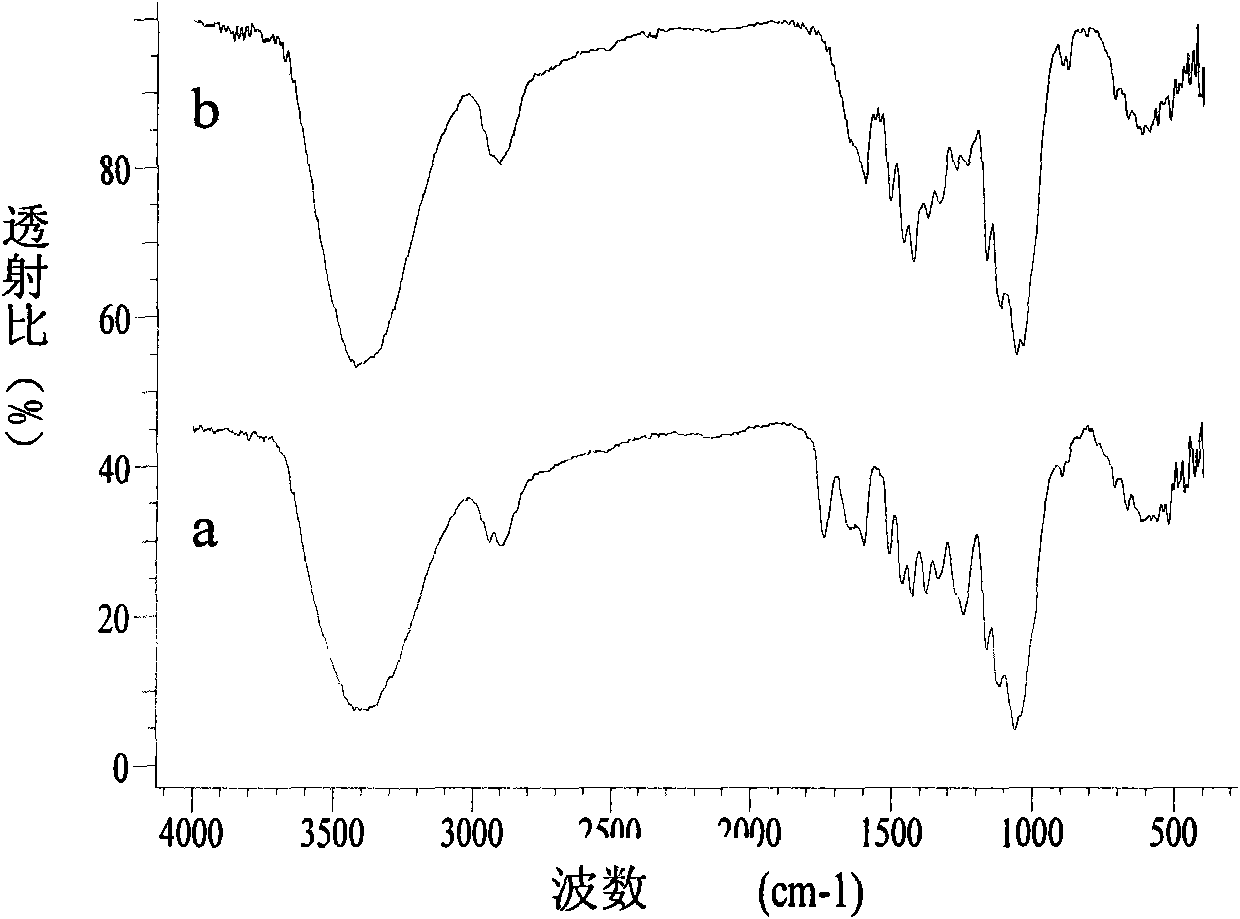

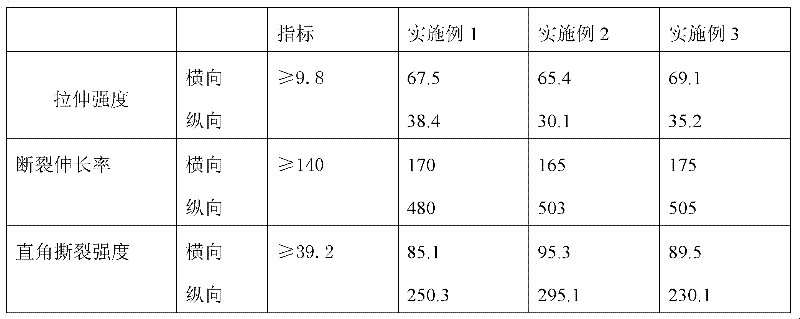

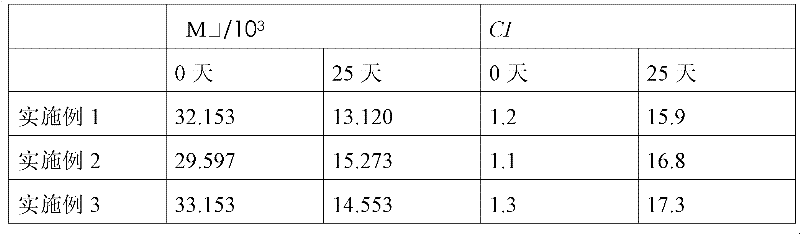

Wood-plastic composite material and preparation method thereof

The invention discloses a wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-70% of modified wood powder, 25-99% of polymer matrix and 0-5% processing aid. The invention also discloses a preparation method of the wood-plastic composite material. The method is as follows: fluorine silane coupling agent is utilized to carry out treatment on surface of the wood powder, the modified wood powder and the polymer matrix are melted and compounded to prepare the wood-plastic composite material, and the wood powder is pretreated by alkali liquor to remove unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining excellent mechanical property, low water absorption capacity, and better apparent form; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV

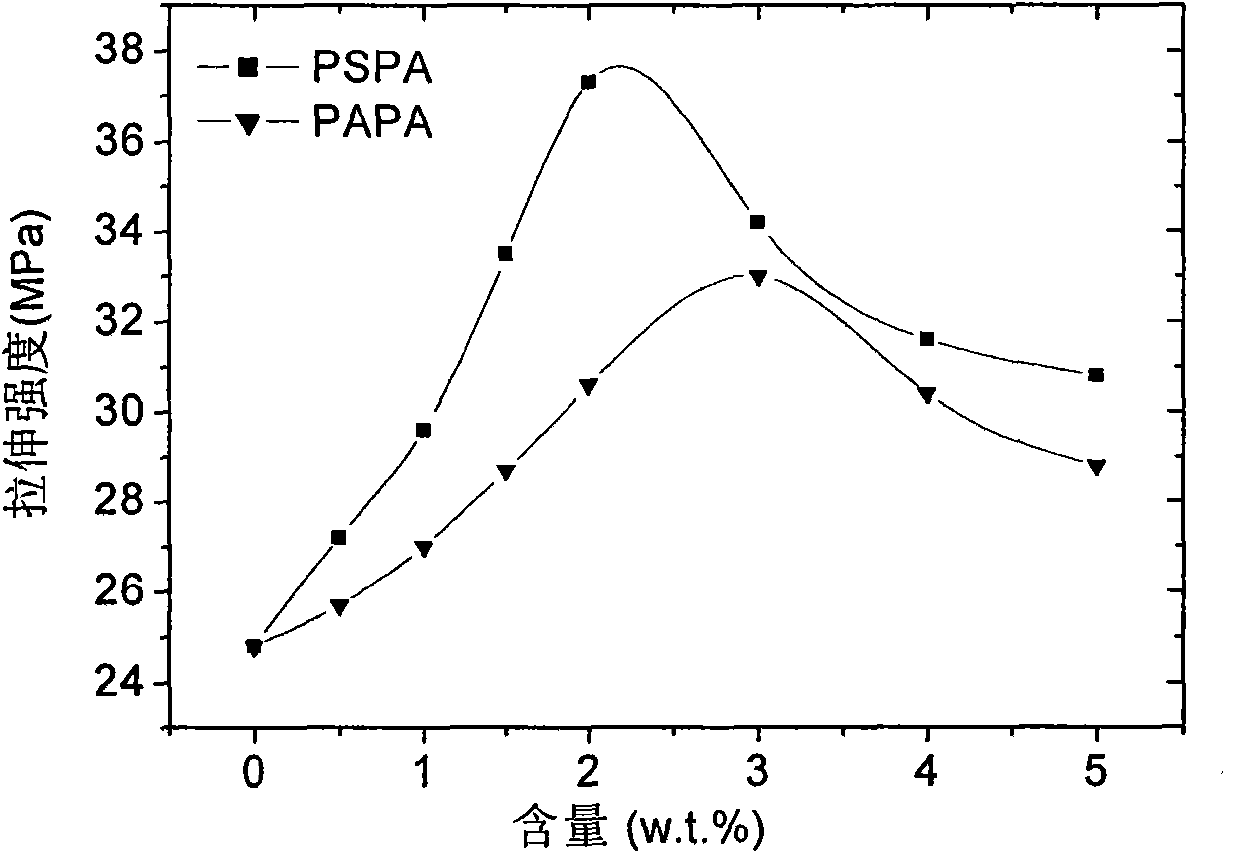

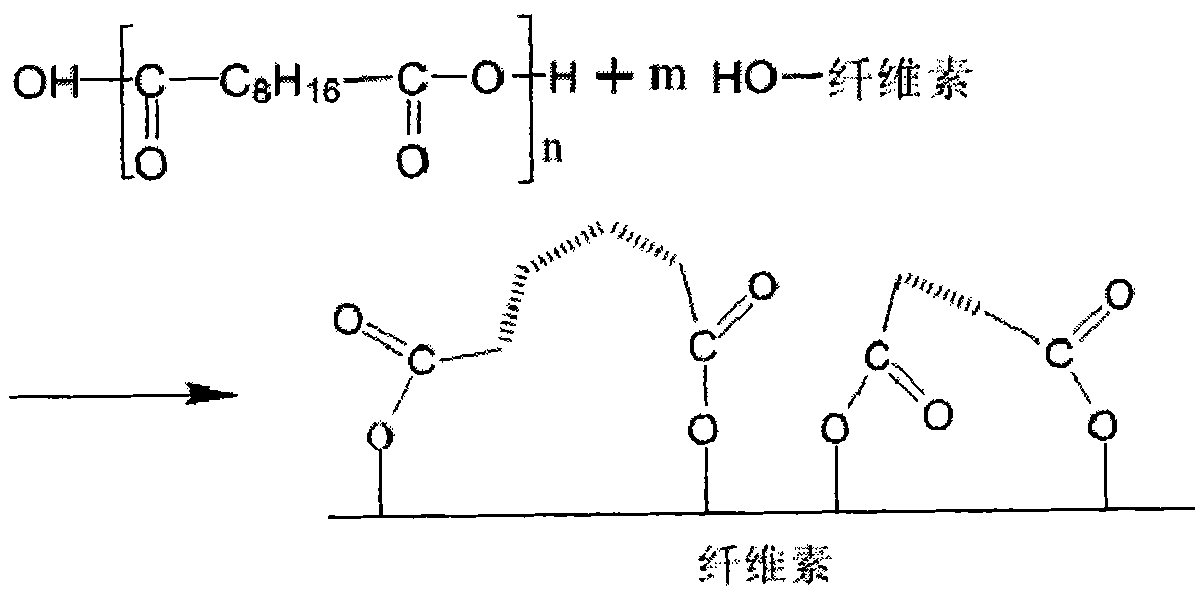

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503BImprove interface compatibilityImprove composite effectComposite effectPolyolefin

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

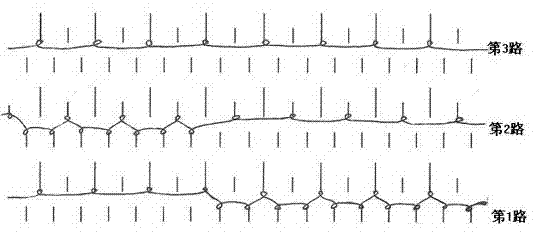

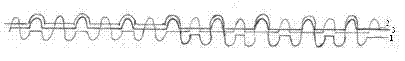

Composite effect type aloe fiber knitted fabric and weaving method thereof

The invention provides a composite effect type aloe fiber knitted fabric and a weaving method thereof. The knitted fabric is characterized in that: a jacquard stitch of the knitted fabric is woven by a pattern wheel, and is compounded by two variable rib stitches and one variable plain stitch; and the knitted fabric is woven by using Modal / aloe fiber blended yarns, acrylic fiber / viscose blended air conditioning yarns and Lycra silk, so that acrylic fiber / viscose fiber blended yarns are shown on the front side of the fabric, and Modal / aloe fiber blended air conditioning yarns are shown on the back side of the fabric. The Modal / aloe fiber blended yarns are Modal / aloe 70 / 3040S yarns. By selection of raw materials and adoption of a reasonable organization structure as well as reasonable weaving and dyeing and finishing process routes, the warm keeping, moisture transport, comfort and health care of the knitted fabric are remarkably improved.

Owner:QINGDAO XUEDA GRP

Photodegradable and biodegradable polyethylene plastic bag

InactiveCN102408612APhotodegradationReach biodegradationBio-packagingBagsLow-density polyethyleneComposite effect

The invention discloses a photodegradable and biodegradable polyethylene plastic bag, which is characterized by comprising the following components in parts by weight: 100 parts of LDPE (Low-Density Polyethylene), 5-10 parts of filler, 0.1-1.5 parts of compatibilizer, 0.1-1 part of photosensitizer, 1-10 parts of corn starch, 1-10 parts of microcrystalline cellulose and 2-11 parts of silane coupling agent. A preparation process comprises the following steps of: (1) crushing the corn starch, calcium carbonate powder and the microcrystalline cellulose into superfine grains; (2) drying the corn starch, adding the silane coupling agent to perform surface treatment, and adding the compatibilizer for later use; (3) adding an activating agent and a dispersing agent into the calcium carbonate powder for later use; (4) mixing the materials obtained by the steps (2) and (3), adding the LDPE, the microcrystalline cellulose and the photosensitizer, mixing with two rolls, crushing, extruding and granulating to obtain parent stock; and (5) mixing the photodegradable and biodegradable parent stock with the LDPE, drying, performing blow molding, reeling, and making bags to obtain the photodegradable and biodegradable polyethylene plastic bag. The plastic bag obtained by the invention can be broken into pieces in the time of about 15 days, can also be eroded and broken down by fungi, and achieves the photodegradation and biodegradation composite effect.

Owner:WUJIANG MINGFENG POLYURETHANE PROD

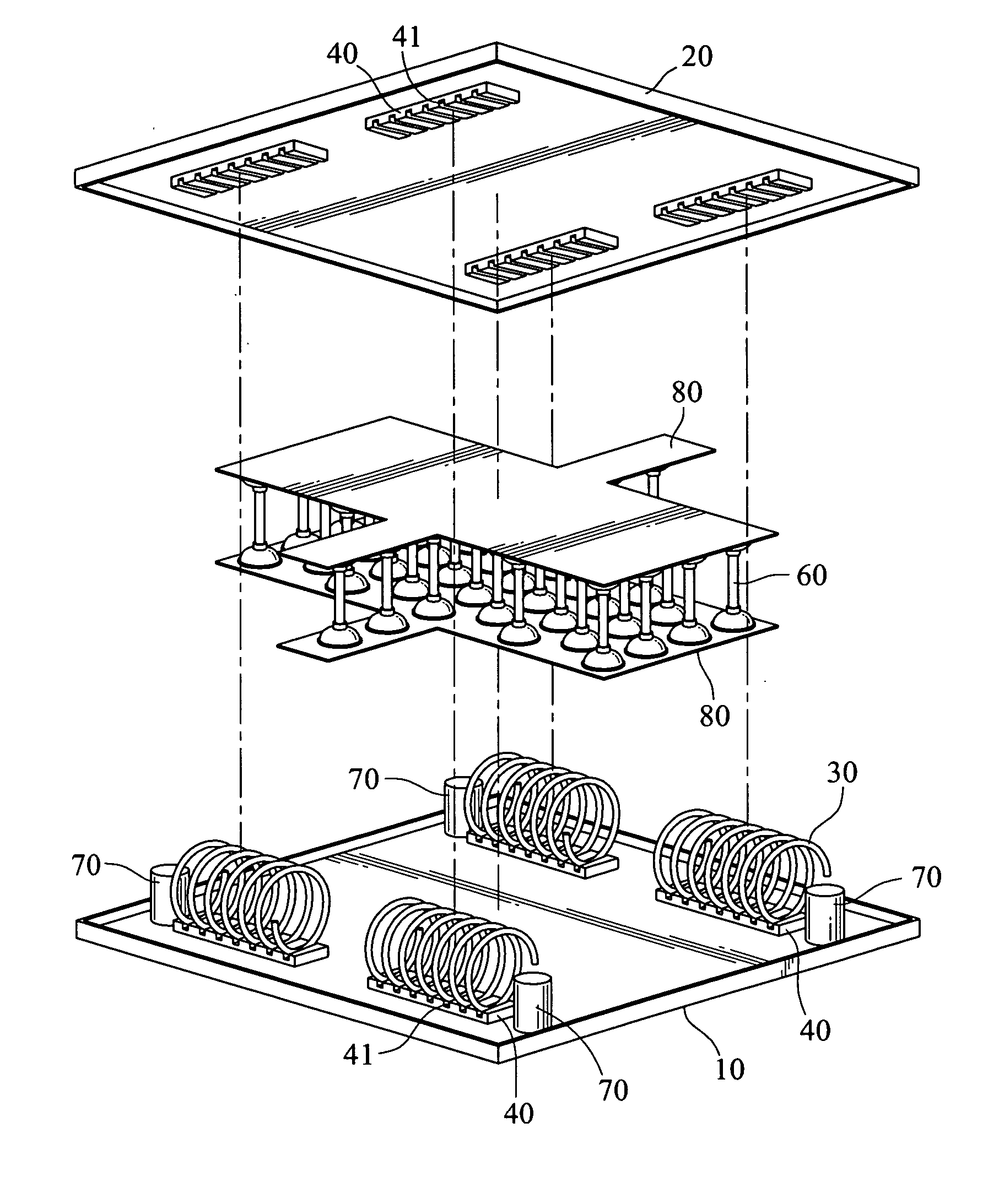

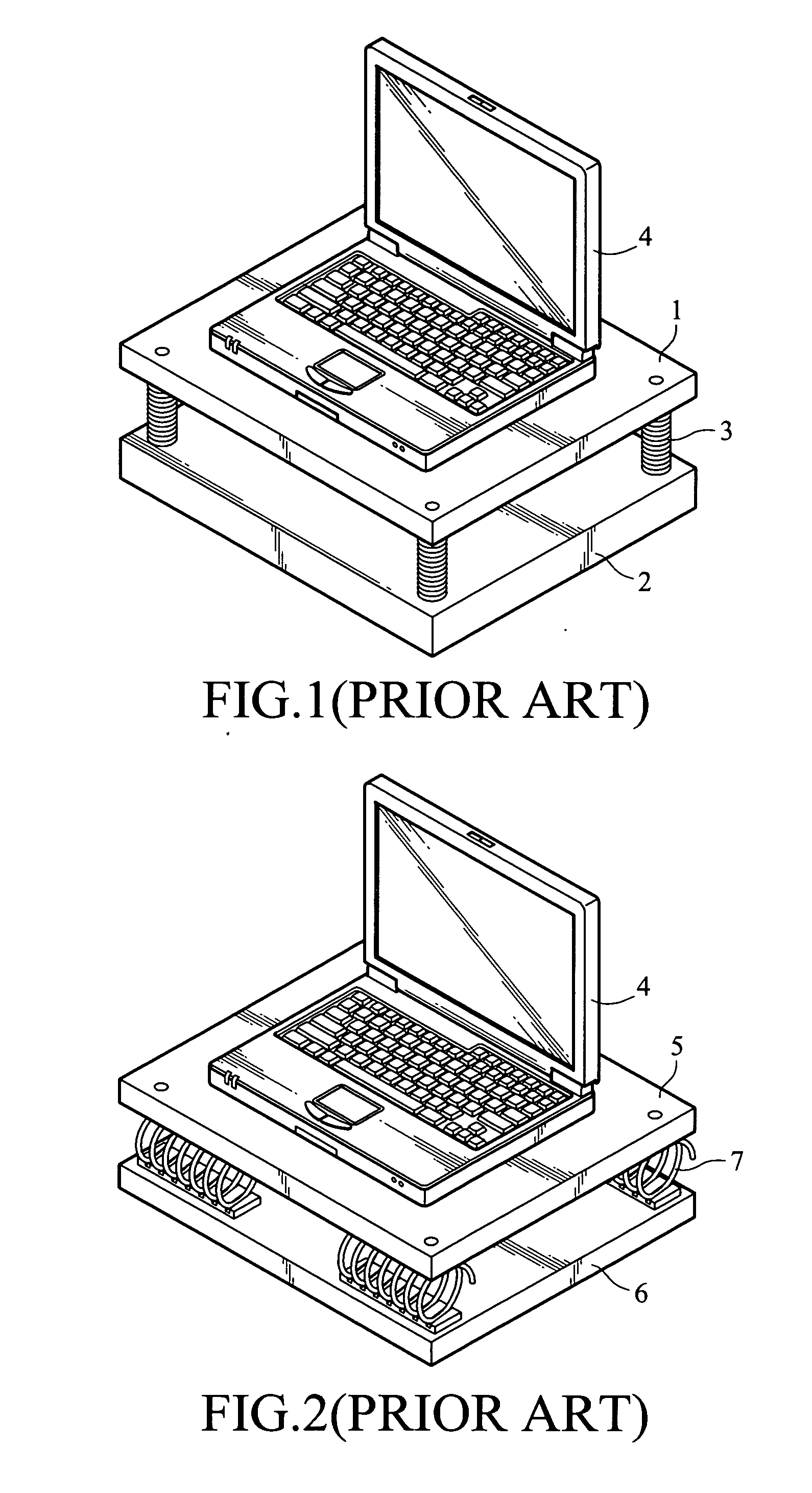

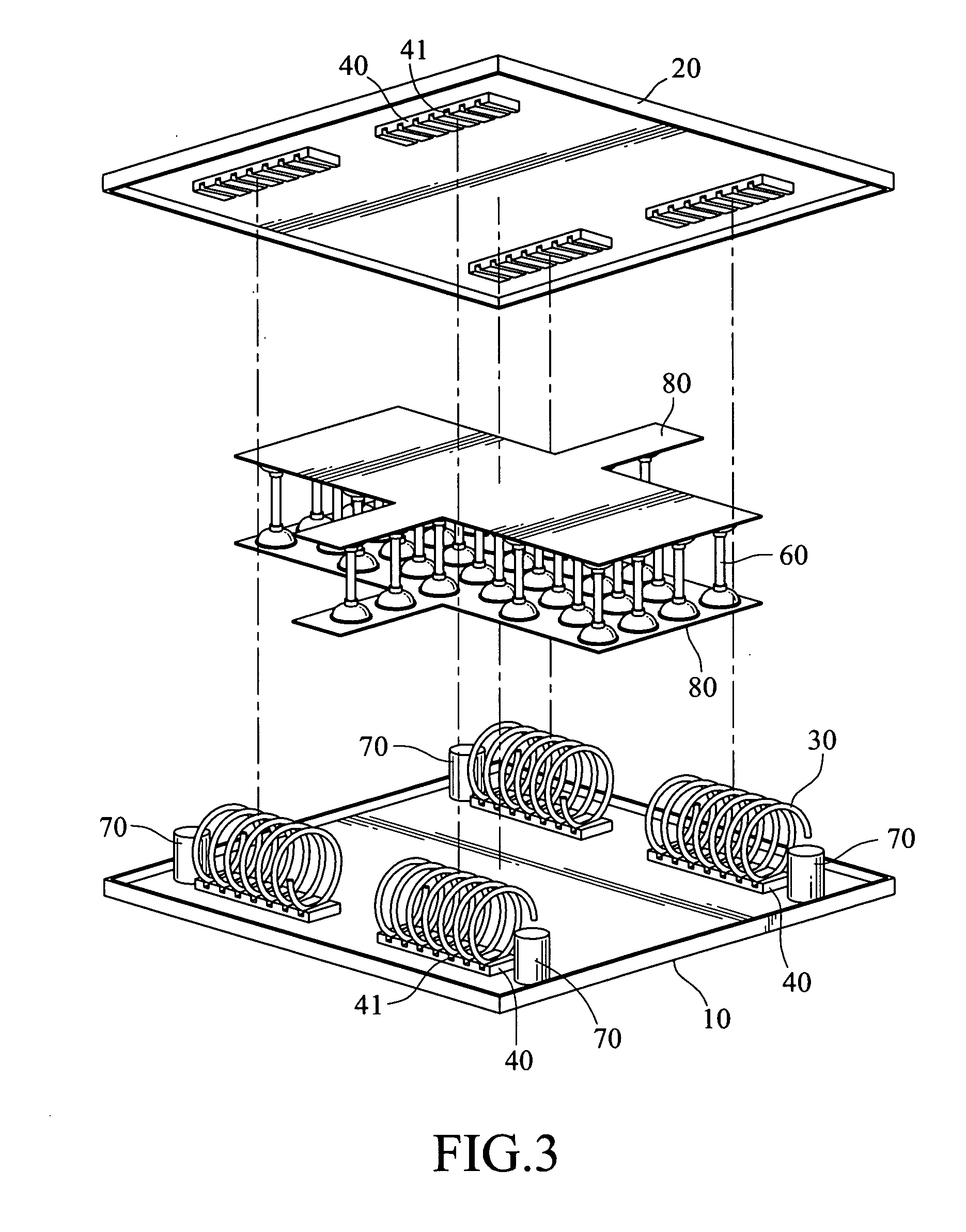

Shock isolation system for electronic devices

InactiveUS20060255517A1Limited damping characteristicDissipate energyHigh internal friction springsRubber-like material springsVibration amplitudeComposite effect

A shock isolation system for electronic devices includes a first baseboard, a second baseboard and a plurality of helical springs interposed transversely between the first baseboard and the second baseboard. The helical springs can deform horizontally and vertically to isolate horizontal and vertical vibration-impact on the electronic devices. The first baseboard and the second baseboard further are bridged by a plurality of damping elements, which have damping characteristics to dissipate kinetic energy and reduce the vibration amplitude and instantaneous acceleration between the first baseboard and the second baseboard, thereby to enhancing the composite effect. The first baseboard further has a plurality of buffer struts to separate the first baseboard and the second baseboard, and prevent the second baseboard from directly hitting the first baseboard.

Owner:MITAC TECH CORP

Compositing method of dovetail groove metal plate clearance fit interface

ActiveCN104289810AIncrease profitReduce pollutionMetal working apparatusNon-electric welding apparatusComposite effectInterference fit

The invention discloses a composting method of a dovetail groove metal plate clearance fit interface. The compositing method is realized through the explosive cladding method, the rolling method and the like. According to the method, after a base plate with dovetail grooves and a surface plate with dovetail grooves are in interference fit, the base plate and the surface plate are composited together through combination of a metallurgical bonding mode and a squeezing meshing mode of the dovetail grooves under the actions of energy of explosives or a rolling mechanism. Physical and chemical properties of metal sheets on the two sides of a dovetail groove combination interface are not changed, and large-area metal sheet composition can be conducted; the explosive charge for a unit of compositing area is small, and atmospheric pollution, noise pollution, explosion vibration and overpressure are reduced; during explosive welding of the metal sheets with the dovetail grooves, no boundary effect exists, the compositing effect on the periphery is good, and the lower limit and the upper limit of an explosive welding window are both increased. The compositing technology of the dovetail groove metal plate clearance fit interface can be applied to the fields such as chemical reaction containers and ships so as to meet the requirement for large-area metal composite plates.

Owner:UNIV OF SCI & TECH OF CHINA

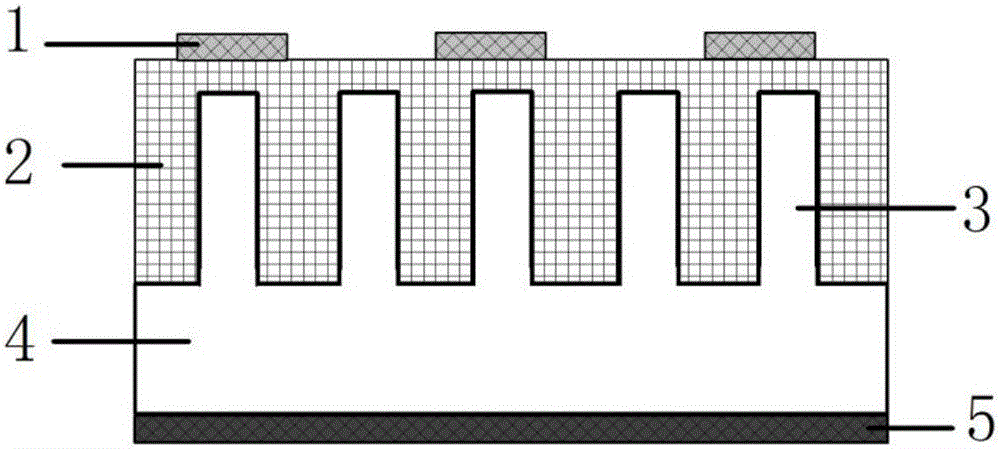

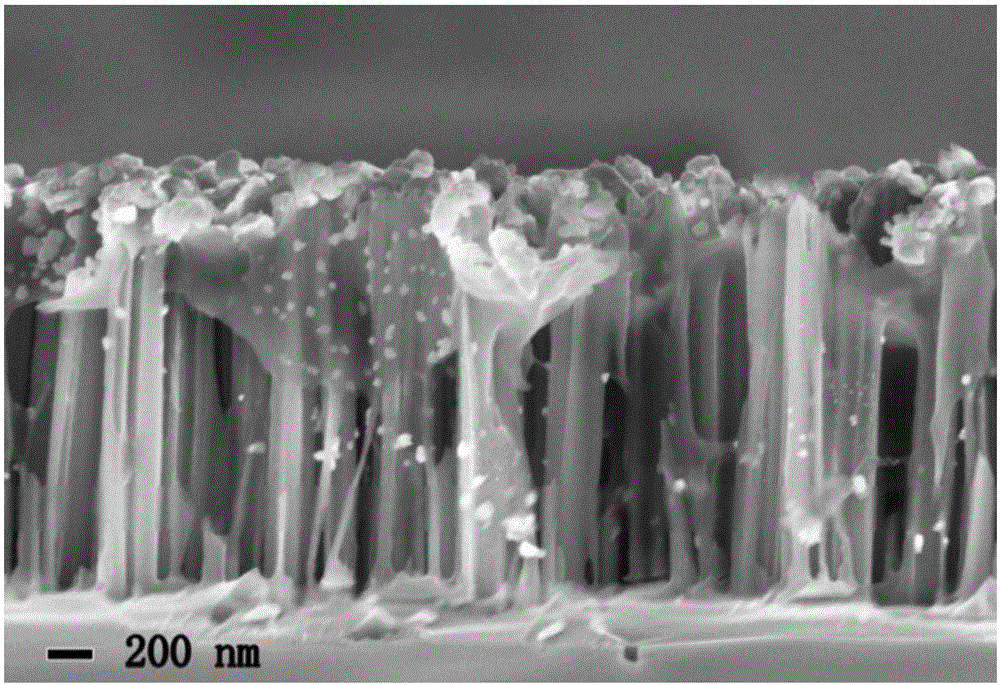

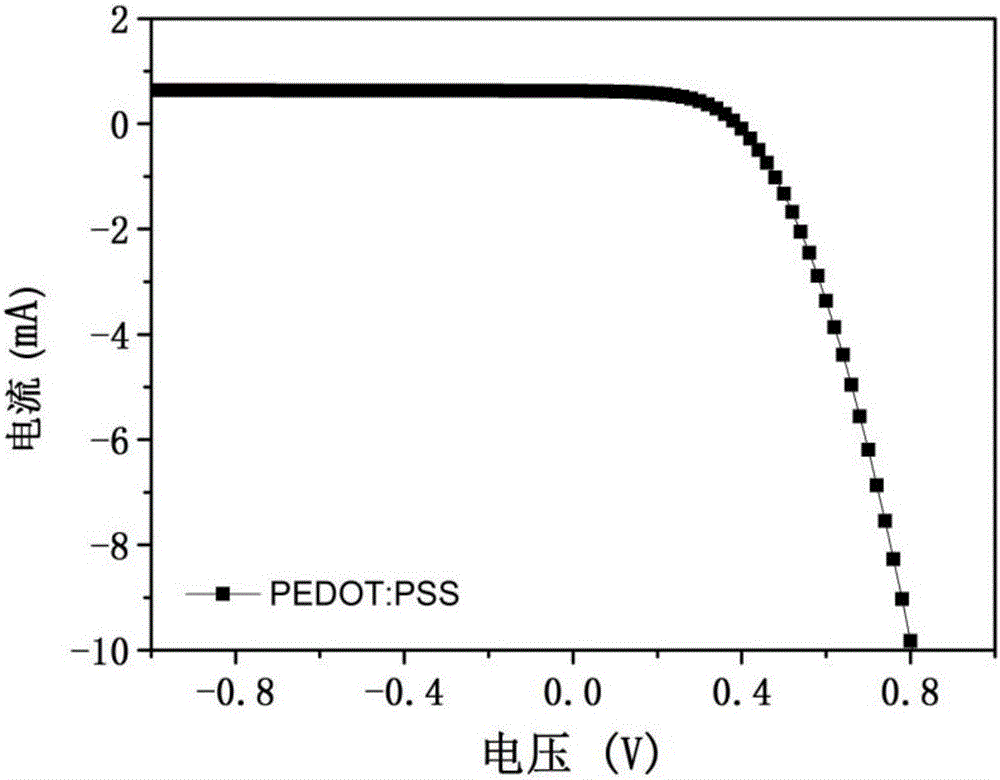

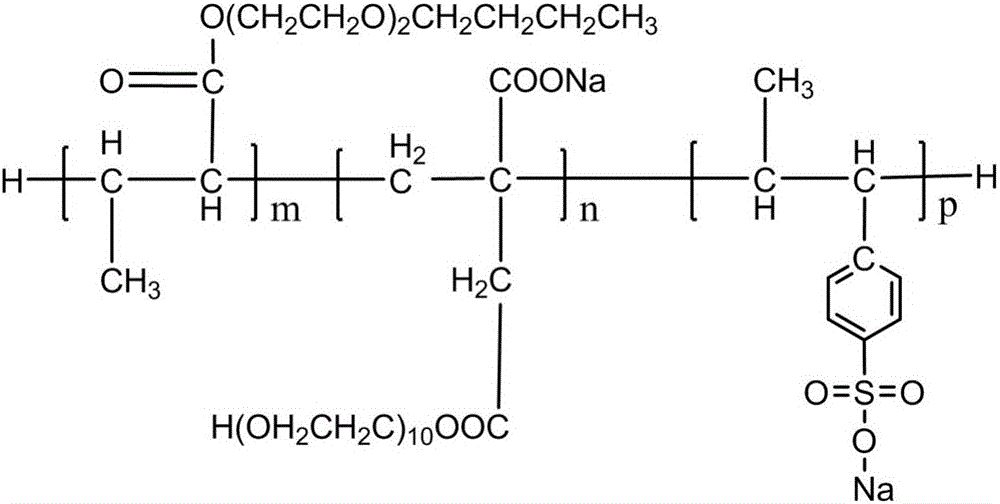

Self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and preparation method therefor

ActiveCN105720197AReduce usageReduce manufacturing costFinal product manufactureSolid-state devicesHeterojunctionMicro nano

The invention discloses a self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and a preparation method therefor. The photoelectric sensor comprises a metal back electrode, an N type silicon substrate, an N type silicon nanowire array, an organic polymer semiconductor thin film and a sensor positive electrode, wherein the hybrid photoelectric sensor is characterized in that the N type silicon nanowire array and the organic polymer semiconductor thin film form three-dimensional heterojunction contact, so that the transmission path of photo-generated carriers is effectively shortened; the separation efficiency is improved; a surface / interface composite effect is reduced through interface alkylation processing; the silicon-based micro-nano structure is taken as the main light absorption layer and the generation and transmission layers for the photo-generated carriers as well; and a P type organic semiconductor thin film is processed to be used as a hole transport layer. The photoelectric sensor provided by the invention has the characteristics of self powering, wide spectral response, low cost large-area preparation, high photoelectric response speed and the like.

Owner:JINAN UNIVERSITY

Sulfoaluminate-Portland cement composite system additive, fast-hardening early-strength concrete and preparation method of concrete

The invention provides a sulfoaluminate-Portland cement composite system additive and prepared sulfoaluminate-Portland cement-based fast-hardening early-strength concrete. The sulfoaluminate-Portland cement composite system additive is prepared from components in percentage by mass as follows: 70%-78% of a water reducing agent, 1.2%-2.5% of an early-strength agent, 18%-25% of a retarder and 2%-4% of an anti-freezing agent. The sulfoaluminate-Portland cement composite system additive can significantly improve the initial flow performance of the sulfoaluminate-Portland cement-based concrete, delay the setting time of a cement composite system, reduce the slump loss and effectively resolve the contradiction between liquidity and early strength and has composite effects of water reduction, delayed coagulation, early strength and the like, and a related preparation method is simple and suitable for popularization and application.

Owner:HUBEI UNIV +1

Fireworks spraying pyrotechnic compound composition with composite effect

InactiveCN101386558AImprove performanceSuitable for industrial mass productionExplosivesComposite effectFireworks

The invention discloses a flower-spraying pyrotechnic composition with composite effects. The flower-spraying pyrotechnic composition comprises the following components in weight portion: 30 to 60 portions of potassium perchlorate, 8 to 20 portions of magnalium, 5 to 25 portions of strontium carbonate, 5 to 15 portions of polyvinyl chloride, hexachlorobenzene or chlorinated paraffin, 2 to 15 portions of phenolic resin and 10 to 20 portions of 40 to 60 mesh aluminum dross. A flower-spraying product manufactured according to the formulation of the invention can simultaneously and compositely reveal the effects of slowly burning, landing, flowering and showing red light, and is stable in performance and suitable for industrialized batch production.

Owner:王贤凤

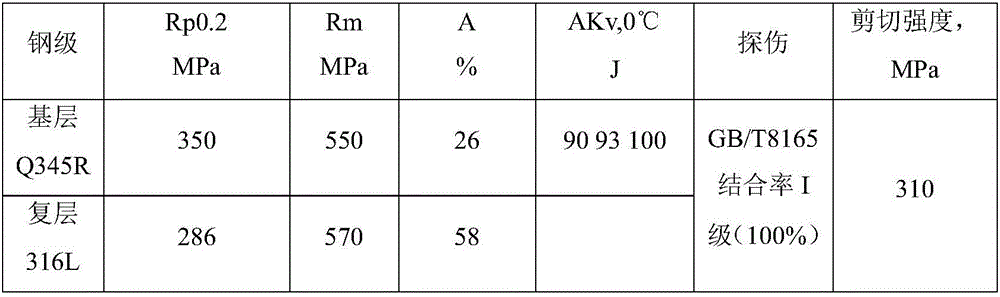

Production method of rolled thick-specification composite steel plate

InactiveCN106808785AAchieve productionComposite goodLamination ancillary operationsLaminationComposite effectSheet steel

The invention discloses a production method of a rolled thick-specification composite steel plate, and belongs to the technical field of metal composite plate production. The composite steel plate is produced by surface treatment of a base plate and a composite plate, ply rolling, welding and vacuumizing of a matching board, wherein the vacuum degree is 10<-3> Pa to 10<-2> Pa; rolling and thermal treatment, wherein the rolling temperature is 1100-1200 DEG C, and the pressing rate for single time is 8-25%; separate cutting and flaw detection, detection, finishing and package. The production method has the advantages of realizing the production of the composite steel plate of which thickness is not less than 50 mm; the composite effect is good; the interface shearing intensity is 210 MPa or above; the performance of every layer can meet the standard requirement of corresponding materials.

Owner:SHOUGANG CORPORATION

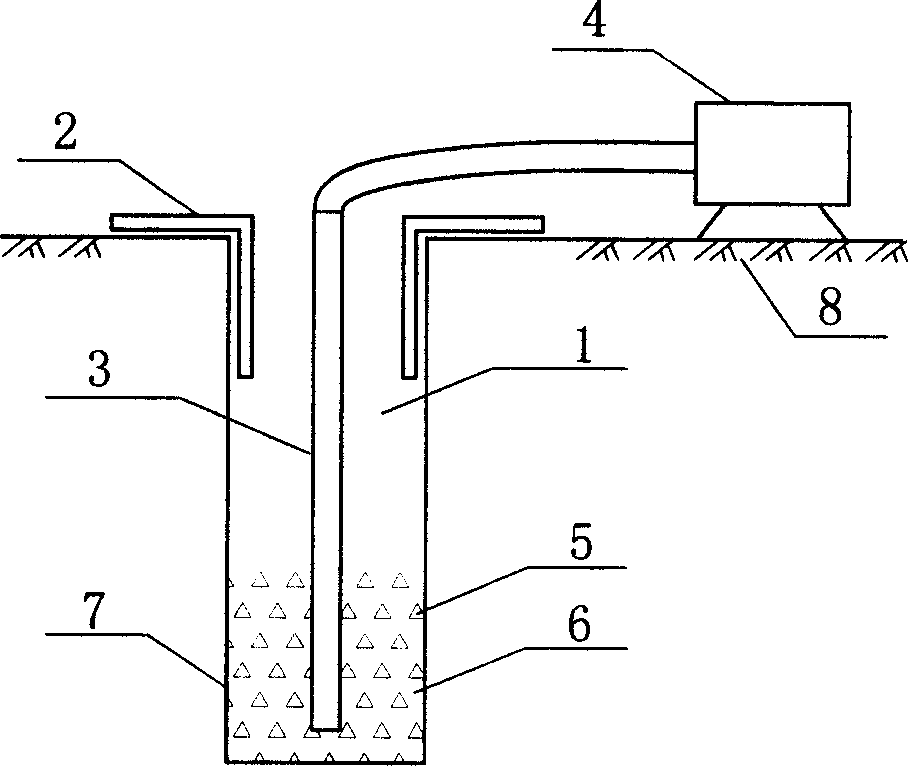

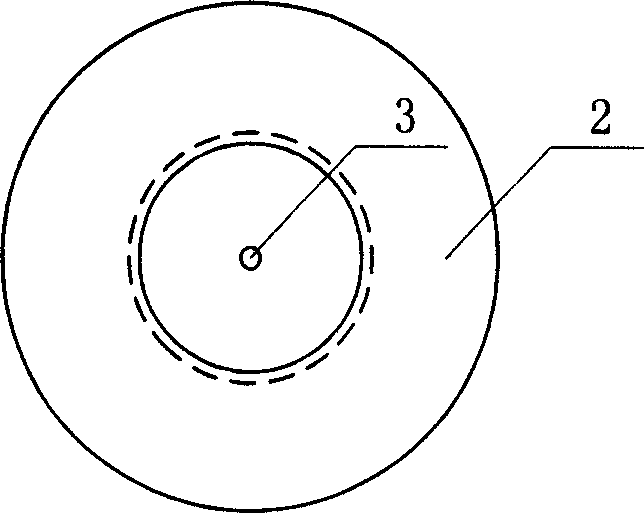

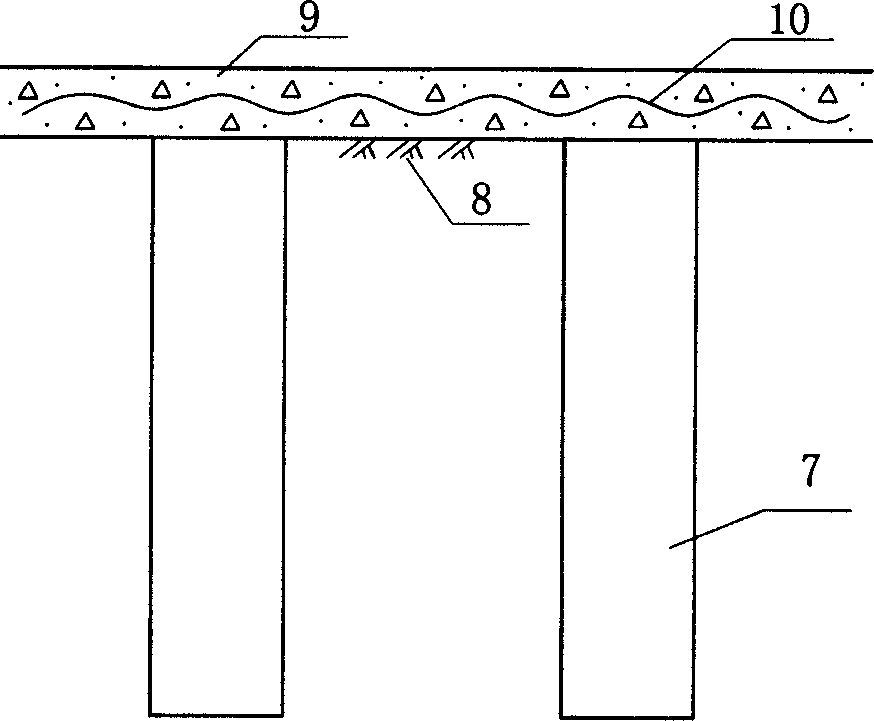

Method for constructing composite foundation of piles and ground interactive slurry bonded dispersed body material

The present invention discloses a new pile-soil interacting slurry fixing dispersed material pile composite foundation construction method. The present invention forms a pile hole from drill getting into foundation to the designed depth. Around the pile hole it adopts slurry to breast wall. Lay slurry fixing pipe in the pile hole, and put aggregate into the pile hole. Infuse serum into the pile hole from grouting pump through slurry fixing. When the serum and aggregate solidify into pile and inleak into the soil body around the pile. Spread underlay layer on top of the pile to form composite foundation. The present invention solves the disadvantages of present technology comprising flexible and rigidit pile composite foundation method, or the pile body intensity is low, or the cost is high. In the present invention, the serum solidifies into pile together with aggregate the pile hole, inleaks into the soil body, and extends to the three parts (the pile body, the serum infiltrating reinforcing body and the natural soil body) of the slurry grouting pile composite foundation, to achieve the composite effect of improving the foundation carrying capability and reducing the settlement. Besides it can protect environment, decrease building costs and break through the ground space limit.

Owner:HOHAI UNIV

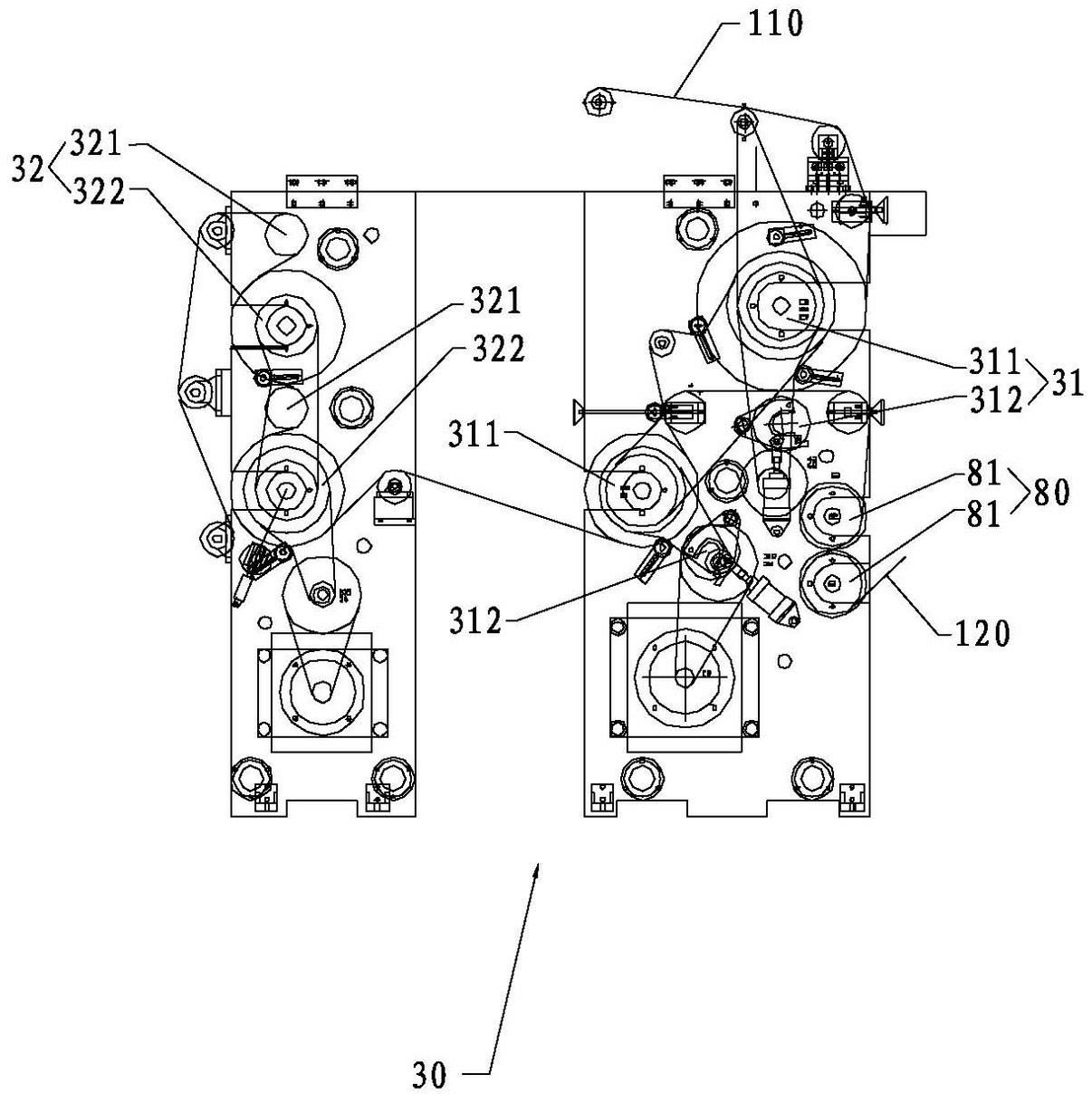

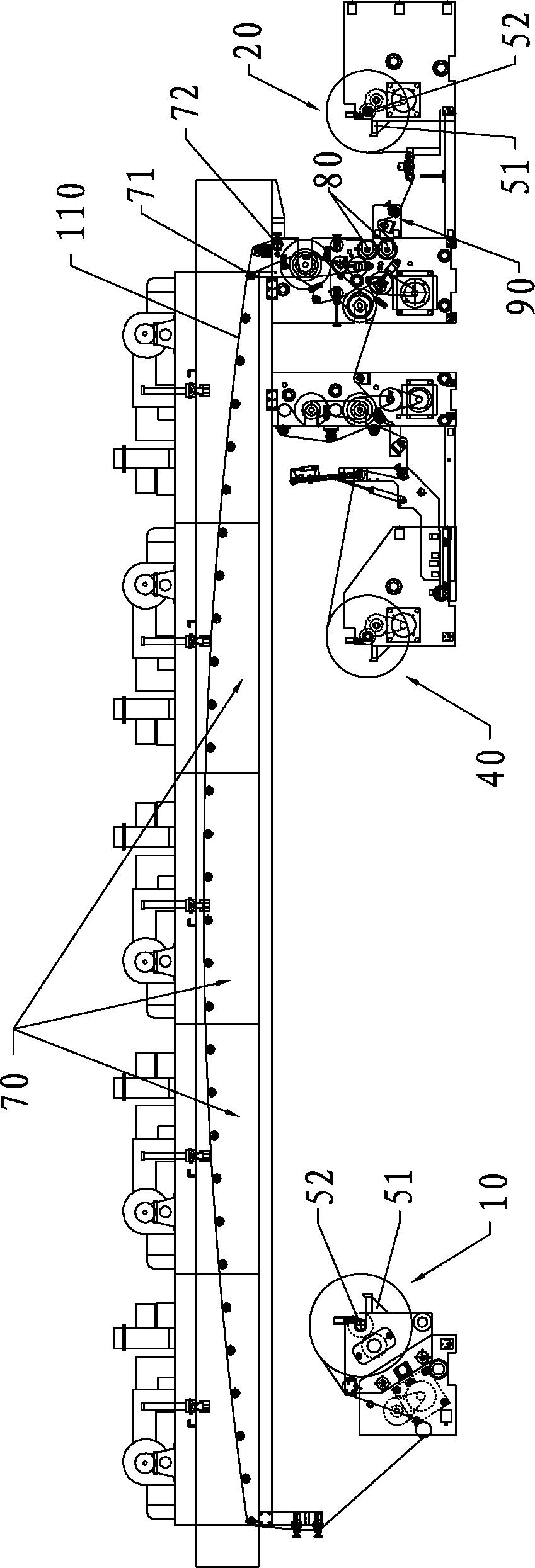

Composite device of composite wiredrawing film

InactiveCN102689488AImprove product qualityImprove composite effectControlling laminationLaminationComposite effectMechanical engineering

The invention relates to the technical field of composite devices, and in particular relates to a composite device of a composite wiredrawing film. The composite device comprises a stand, a control device, a first uncoiling device, a second uncoiling device, a composite mechanism and a coiling device, wherein the first uncoiling device, the second uncoiling device, the composite mechanism and the coiling device are arranged on the stand, the control device is respectively electrically connected with the first uncoiling device, the second uncoiling device, the composite mechanism and the coiling device, the composite mechanism comprises a hot composite roll set and a cooling roll set, and the hot composite roll set and the cooling roll set are sequentially arranged in a film feeding direction. When the composite device is used, preset parameters of each device for regular operation are firstly preset in the control device; and the wiredrawing film and a base film respectively simultaneously enter the composite mechanism through the first uncoiling device and the second uncoiling device, are pressed to form the composite wiredrawing film under an extrusion action of the hot composite roll set, and can be coiled in the coiling device after being cooled and formed by the cooling roll set. The composite device of the composite wiredrawing film, disclosed by the invention, has the advantages of capability of effectively saving labors and materials, simple device structure, low production cost, high machining efficiency, good composite effect of the wiredrawing film and the base film and high product quality.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Formula for improving recovery ratio of authigenic CO2

A formula for improving the recovery ratio of authigenic CO2 comprises, by mass, 5-15 parts of ammonium bicarbonate, 1-5 parts of bioactive agents, and the balance water which is not beyond 35 DEG C. In use, the formula is directly injected in the stratum and dissolved to generate CO2 through heat of the stratum; when the temperature of the stratum is below 35 DEG C, the CO2 is obtained through composite effect of the heat of the stratum and the bioactive agents. The formula can be applied to the fields of oil field oil displacement, fracturing and well repair, and achieves the purposes of improving the recovery ratio, and promoting fracturing fluid flowing-back. Foams are generated while gas is formed, stability of the foams is high, gas channeling can be effectively prevented, and the formula has the advantages of foam displacement of reservoir oil and foam well killing.

Owner:SUNCOO PETROLEUM TECH

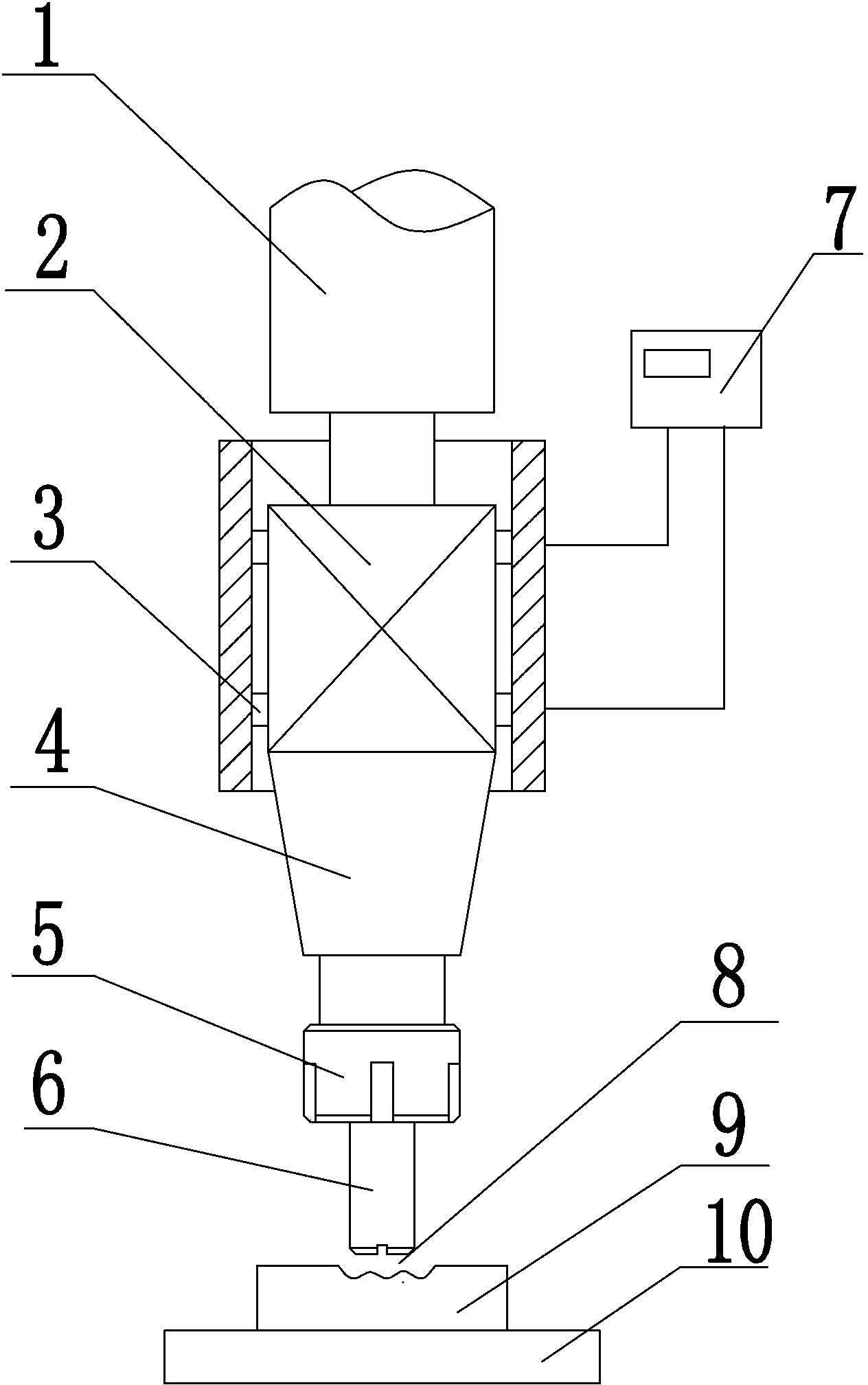

Ultrasonic wave and magnetic force composite grinding device for jade emboss craftwork and grinding process

ActiveCN103447892AImprove processing efficiencyImprove processing qualityComposite effectNumerical control

The invention belongs to the technical field of stone processing, particularly relates to an ultrasonic wave and magnetic force composite grinding device for a jade emboss craftwork and a grinding process. The grinding device comprises a numerical control auxiliary machine frame, as well as an ultrasonic wave generating mechanism and a magnetic force grinding mechanism which are arranged on the auxiliary machine frame, the ultrasonic wave generating mechanism comprises an ultrasonic generator, a piezoelectric transducer, an amplitude transformer and an elastic cylinder clamp, wherein a collecting ring is arranged on the outer side of the piezoelectric transducer, the piezoelectric transducer is connected with a driving main shaft on the numerical control auxiliary machine frame, and the magnetic force grinding mechanism comprises a permanent magnet and a magnetic grinding material. According to the invention, ultrasonic wave vibration is used for forming impulse pressure on the surface of jade, the magnetic grinding material can be used for effectively improving the processing efficiency and the processing quality to the concave-convex surface of the jade under the composite effect of magnetic force and impulse pressure, mechanical polishing to the jade emboss craftwork can be achieved, and defects of manual polishing are overcome.

Owner:ECO POWER WUXI

Controllable-shape long-carbon-chain polyamide powder base and controllable-shape high-conductivity composite powder material

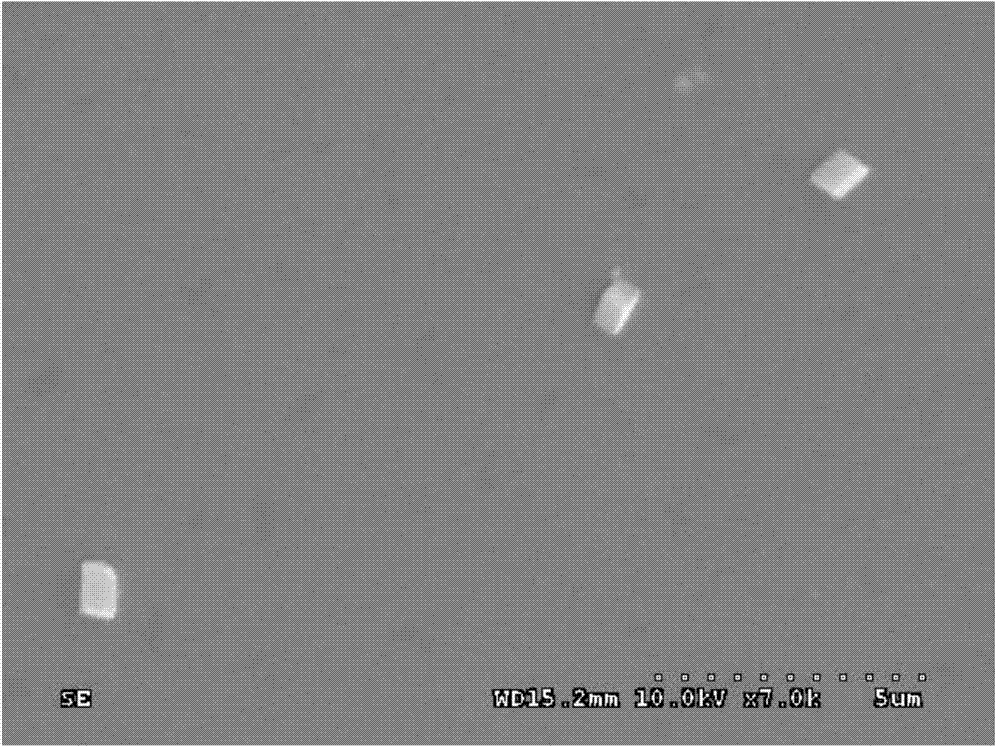

ActiveCN104262646AShape is easy to controlParticle size controllableComposite effectIn situ polymerization

The invention belongs to the field of high polymers, and particularly relates to a controllable-shape long-carbon-chain polyamide powder base and a controllable-shape high-conductivity composite powder material. The long-carbon-chain polyamide powder base is spherical, acicular or rhombic. The controllable-shape high-conductivity composite powder material is composed of 85-95 wt% of long-carbon-chain polyamide powder base and 5-15 wt% of polyaniline. The long-carbon-chain polyamide powder base with certain pattern is subjected to controlled production, and polyaniline in-situ polymerization is performed on the powder base to implement polymerization and coating of the conductive polyaniline, so that the finally obtained composite material has the advantages of controllable microscopic shape, uniform interface, favorable composite effect and high conductivity. The conductivity of the obtained long-carbon-chain polyamide / polyaniline composite powder material is 10<-5>-10<3>S / cm, and the composite powder material can satisfy the antistatic requirement of the polymer material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High elasticity fiber blended spinning method and elastic fabric thereof

InactiveCN107557938AGood hygroscopicityImprove wearing comfortLayered productsWoven fabricsComposite effectPerspiration

The invention discloses a high elasticity fiber blended spinning method and an elastic fabric thereof. The high elasticity fiber is prepared by blending cotton fiber, nylon filament embedded with polyamide fiber, spandex, and worsted fiber, the mass ratio of the four components of cotton fiber, nylon filament embedded with polyamide fiber, spandex, and worsted fiber is 3: 1: 2: 1. The elastic fabric comprises a bottom layer, an interlayer and a face layer, the three layers of materials are fixed by stitching, a lining fabric layer is arranged on the back of the bottom layer, and the fabric layer comprises warp and weft; the interlayer is provided with an elastic layer and a thermal storage layer; high elasticity fiber is arranged in the elastic layer. According to the high elasticity fiberblended spinning method, composite effects and functional complementarities are produced by utilizing four different fiber combinations for the first time, moisture absorption and wear comfort of thefabric are improved, on the basis of ensuring wear resistance and dimensional stability of the fabric, the elasticity of the fabric is improved, and the properties of anti-bacteria, bacteriostasis, anti-ultraviolet, moisture absorption, deodorization and perspiration are added.

Owner:NANTONG SUZHONG TEXTILE

A natural environmental-friendly tableware detergent

InactiveCN104789386AGood decomposition and adsorption functionEasy to cleanOrganic non-surface-active detergent compositionsComposite effectDecomposition

A natural environmental-friendly tableware detergent is disclosed. The detergent is characterized by comprising following raw materials by weight: 5-7 parts of Chinese soapberry seed, 8-12 parts of washing water of rice, 2-4 parts of green tea saponin, 1-2 parts of ginger juice, 1.2-1.5 parts of sodium carbonate, 0.4-0.6 part of a thickening agent, 0.2-0.4 part of a preservative, 0.6-0.8 part of sodium carboxymethylcellulose and 3-5 parts of a honeysuckle bud and flower extract. The Chinese soapberry seed, the washing water of rice, and other components in the formula are purely natural clean raw materials. The detergent is simple to prepare, low in cost, and free of any influence on human health. The green tea saponin is extracted from tea seed powder and has good decomposition and adsorption functions for oil stains. By synergistic effects of the raw materials, the detergent has a good oil stain removing function for tableware, can effectively clean oil stains on surfaces of the tableware, sterilize bacteria on surfaces of the tableware, and is easy in biodegradation and environmental-friendly. Composite effects combining oil stain removing, sterilization and environment protection are achieved. The detergent is prone to industrial production.

Owner:吕鹏飞

Method for preparing salt-resistant alkali-resistant special algal biological water-soluble fertilizer by enzymatic hydrolysis fermentation

InactiveCN105622293AAvoid strong basesAvoid high temperatureCalcareous fertilisersBio-organic fraction processingComposite effectPlant hormone

The invention discloses a method for preparing salt-resistant alkali-resistant special algal biological water-soluble fertilizer by enzymatic hydrolysis fermentation, characterized by comprising: (1), pretreating algae; (2), carrying out ultrasonic-assisted enzymatic hydrolysis; (3), preparing fermentation broth; (4), aerobically fermenting; (5), fermenting in two steps; (6), filtering; (7), concentrating. refractory macromolecular substances in algae are degraded into small molecule polysaccharides, monosaccharides and nitrogen-bearing compounds by means of composite enzymatic hydrolysis and multi-bacteria co-fermentation, a great amount of soil beneficial bacteria and various specially-effective metabolites are generated, bioactivity of the algal fertilizer is improved, strong alkali, high temperature and high pressure are avoided being destroyed during algal fertilizer production, and rich nutrients in algae are fully reserved. This product integrates natural nutrients, antibiotics and plant hormones, has the composite effect of 'triple in one', organic fertilizer, microbial fertilizer and trace element fertilizer, is effective in improving saline and alkali soil and has a promising application prospect.

Owner:青岛海大生物集团股份有限公司

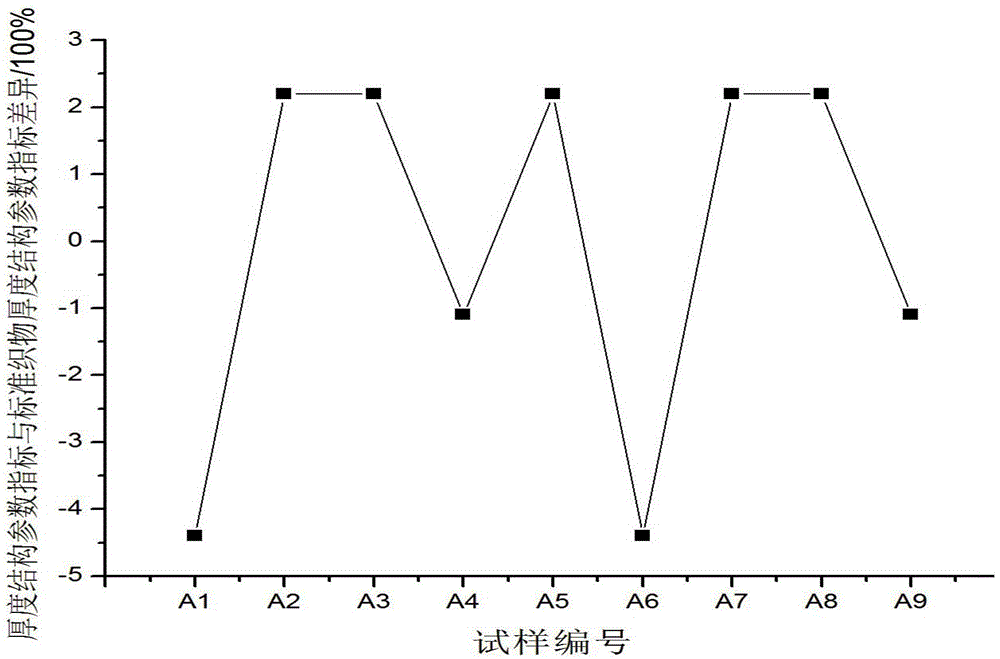

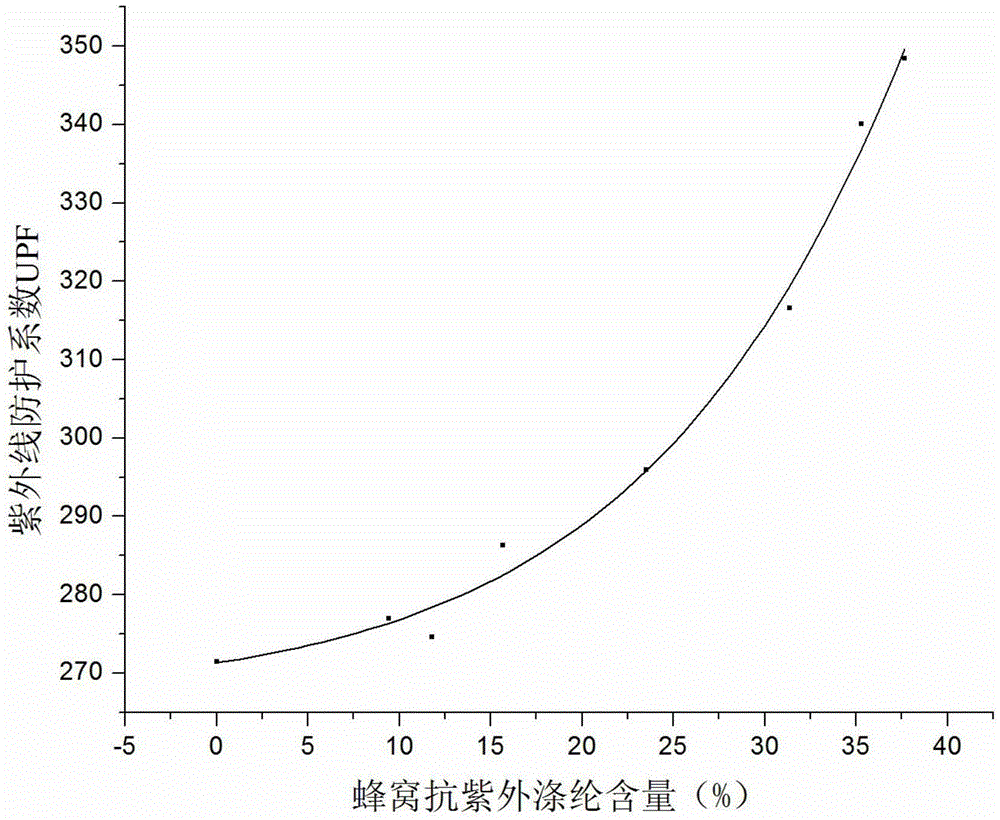

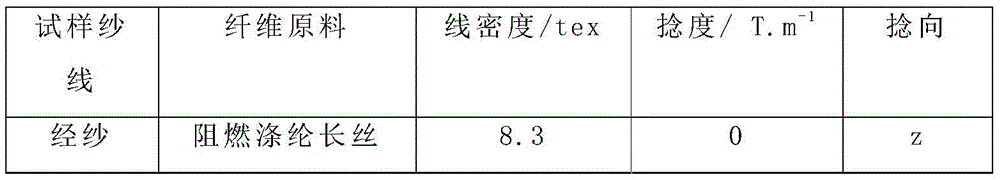

Fabrication process for curtain fabric with flame-retardant and uvioresistant combined function

ActiveCN105463648AImprove flame retardant performanceImproves UV resistanceCurtain accessoriesDyeing processComposite effectAfter treatment

The invention provides a fabrication process for curtain fabric with a flame-retardant and uvioresistant combined function and belongs to the technical field of textiles. The fabrication process comprises the following process steps of firstly, selection of functional fiber materials; secondly, process flow of yarn forming; thirdly, weaving of the fabric through an interweaving process; fourthly, a dyeing and finishing process of the fabric; fifthly, an after treatment process of the fabric. According to the fabrication process, through reasonable selection of the functional fibers, on one hand, excellent properties of the fibers need to be fully maintained, on the other hand, the functional fiber composite effect is affected by many factors so that an unknown composite effect can be produced. Functional yarn is interwoven according to different interweaving proportions, the three kinds of functional fibers produce a positive coordination effect, and interweaving of flame-retardant polyester filament yarn, flame-retardant acrylic fibers and honeycomb uvioresistant polyester fibers reduces longitudinal and latitudinal damage length and stops production of droplets and enhances the flame-retardant and uvioresistant combined function.

Owner:ZHEJIANG HEXIN TEXTILE

Composite calcium-based solid desulfurizer and production method thereof

InactiveCN102068898ALow costImprove desulfurization effectSolid waste disposalDispersed particle separationComposite effectSlag

The invention relates to a solid desulfurizer and a production method thereof, in particular to a composite calcium-based solid desulfurizer which is prepared from industrial waste residues and the production method thereof. The desulfurizer is prepared by the following steps of: directly mixing carbide slag slurry, dicyandiamide slag serving as a modifier, a chemical drying agent and magnesium slag powder which serves as another modifier; stirring and mixing; performing wet milling to prepare slurry; performing dry milling to prepare powder; and sieving. The prepared composite calcium-based solid desulfurizer is mainly compounded by calcium hydroxide or calcium hydroxide and calcium carbonate, wherein the desulfurizer contains an active magnesium oxide component, integrates the characteristics of a single calcium base or a magnesium-based desulfurizer and has composite effects. Moreover, the desulfurizer has the characteristics of saving a large amount of energy, protecting environment and reducing the cost of a flue gas desulfurizer, along with cheap and wide raw material resource, large amount of doped magnesium slag, carbide slag and dicyandiamide slag, no heat source, high dehydration speed, stable physical performance and the like; in addition, the desulfurizer has the advantages of small equipment investment, low operation cost, capability of eliminating the damage of limestone exploitation to the environment and the like.

Owner:宁夏博浩环保技术有限公司

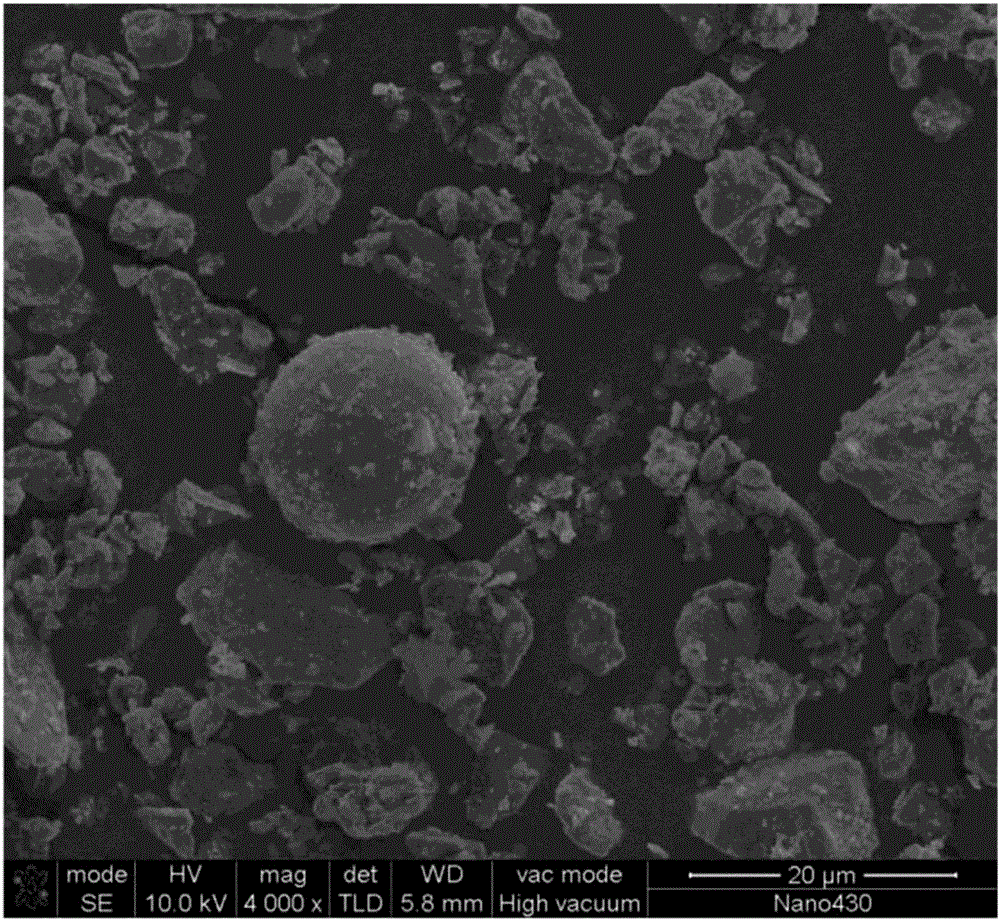

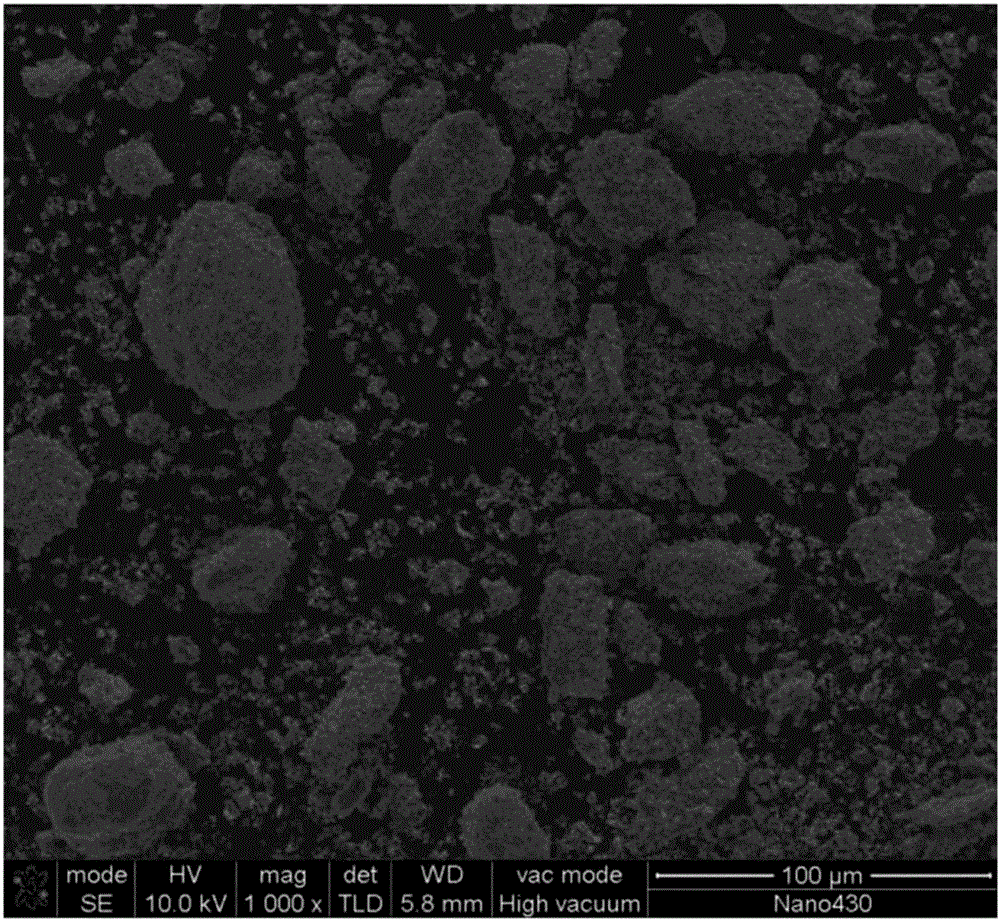

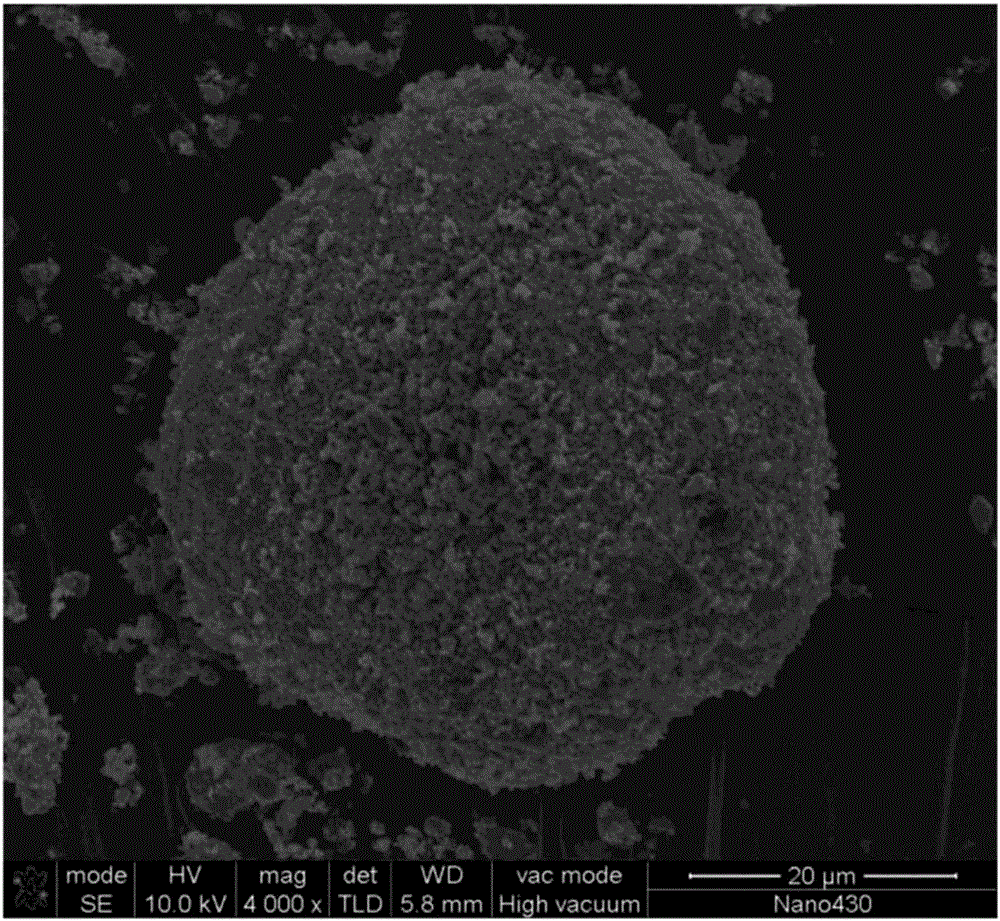

Nanometer composite structure feed and preparing method thereof

ActiveCN105970140AQuality improvementImprove composite effectMolten spray coatingComposite effectHigh energy

The invention discloses nanometer composite structure feed. The nanometer composite structure feed is prepared through the reaction of TiB2 and NiCrCoAlY via a high energy ball milling method. The mass ratio of the TiB2 to the NiCrCoAlY is 1:1.2-2. A preparing method comprises the following steps that firstly, TiB2 powder and NiCrCoAlY powder are premixed, and mixed powder is obtained; secondly, the mixed powder is subjected to wet milling, and composite powder A is obtained; thirdly, the composite powder A is dried, and dried composite powder A is obtained; fourthly, the dried composite powder A is subjected to dry grinding, and dried composite powder B is obtained; and fifthly, the dried composite powder B is filtered, and the nanometer composite structure feed is obtained. The prepared nanometer NiCrCoAlY-TiB2 composite structure feed is good in composite effect, excellent in mobility and capable of being directly used for high velocity oxygen fuel (HVOF) coating. The preparing method is simple and easy to operate and friendly to the environment. The various properties of the prepared NiCrCoAlY-TiB2 composite structure feed are excellent.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

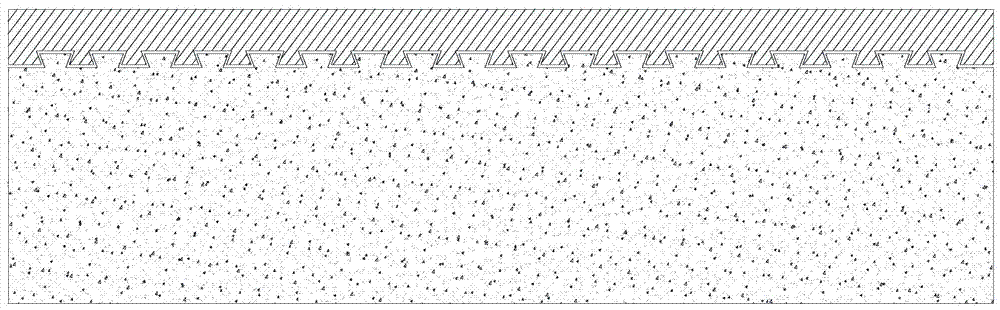

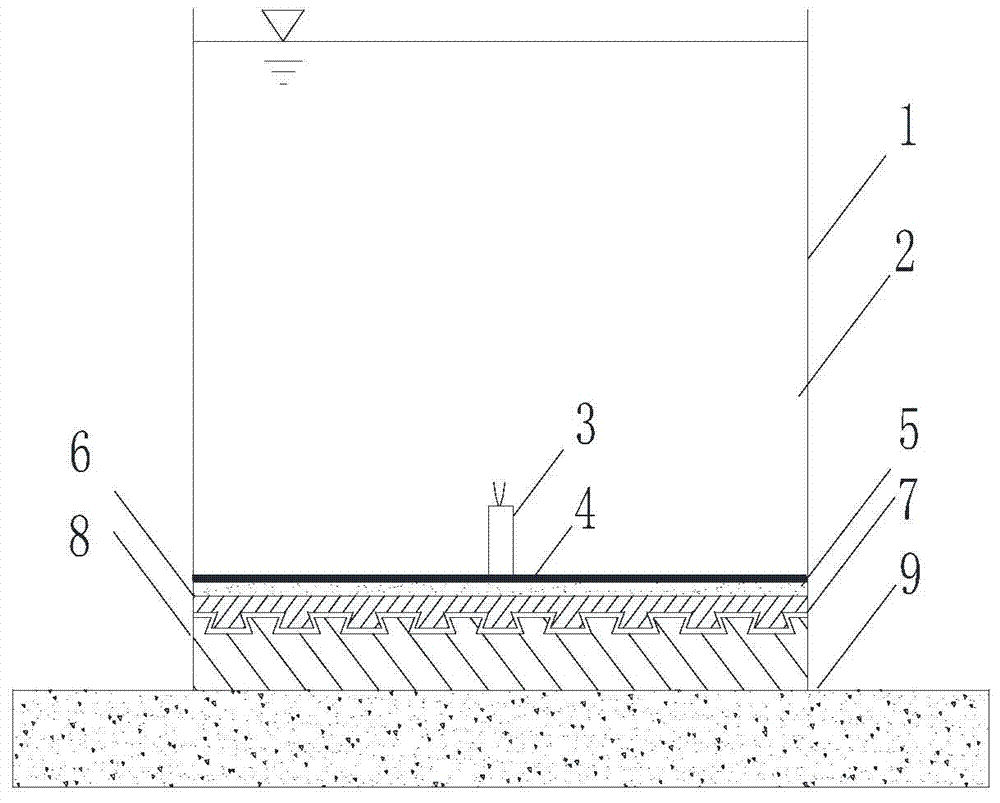

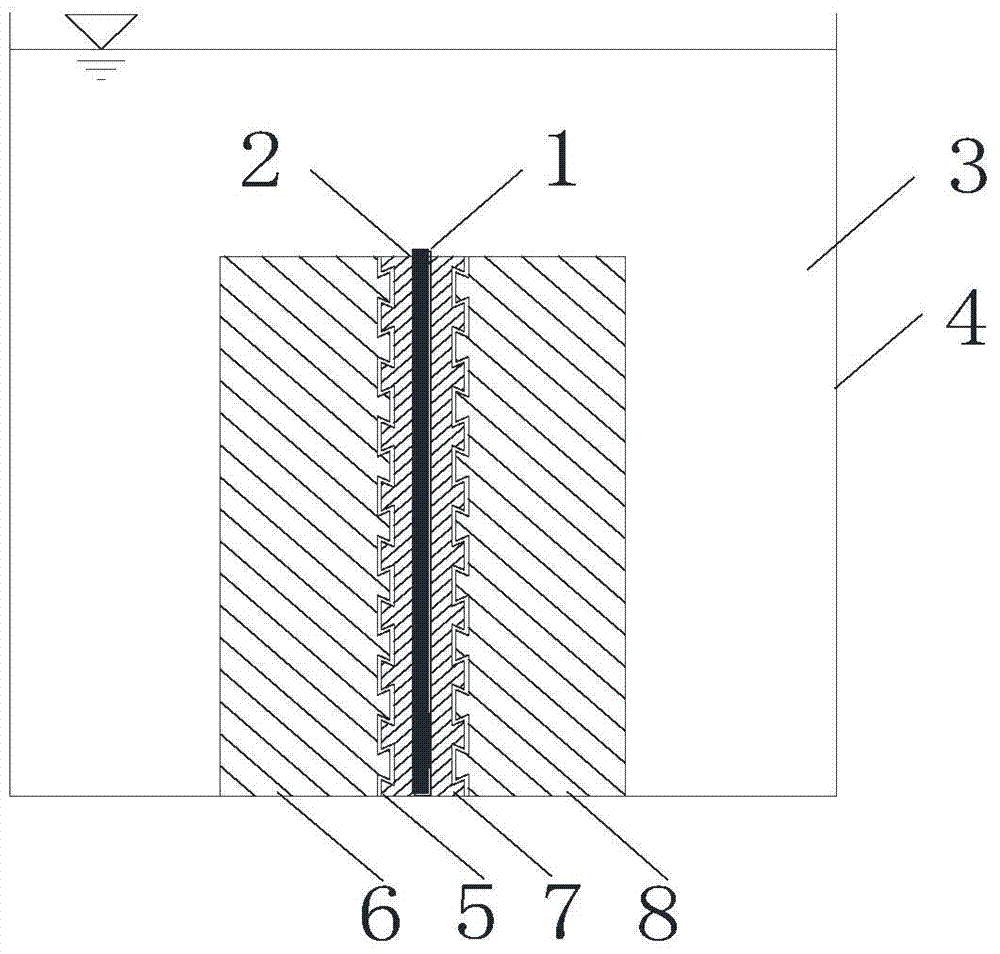

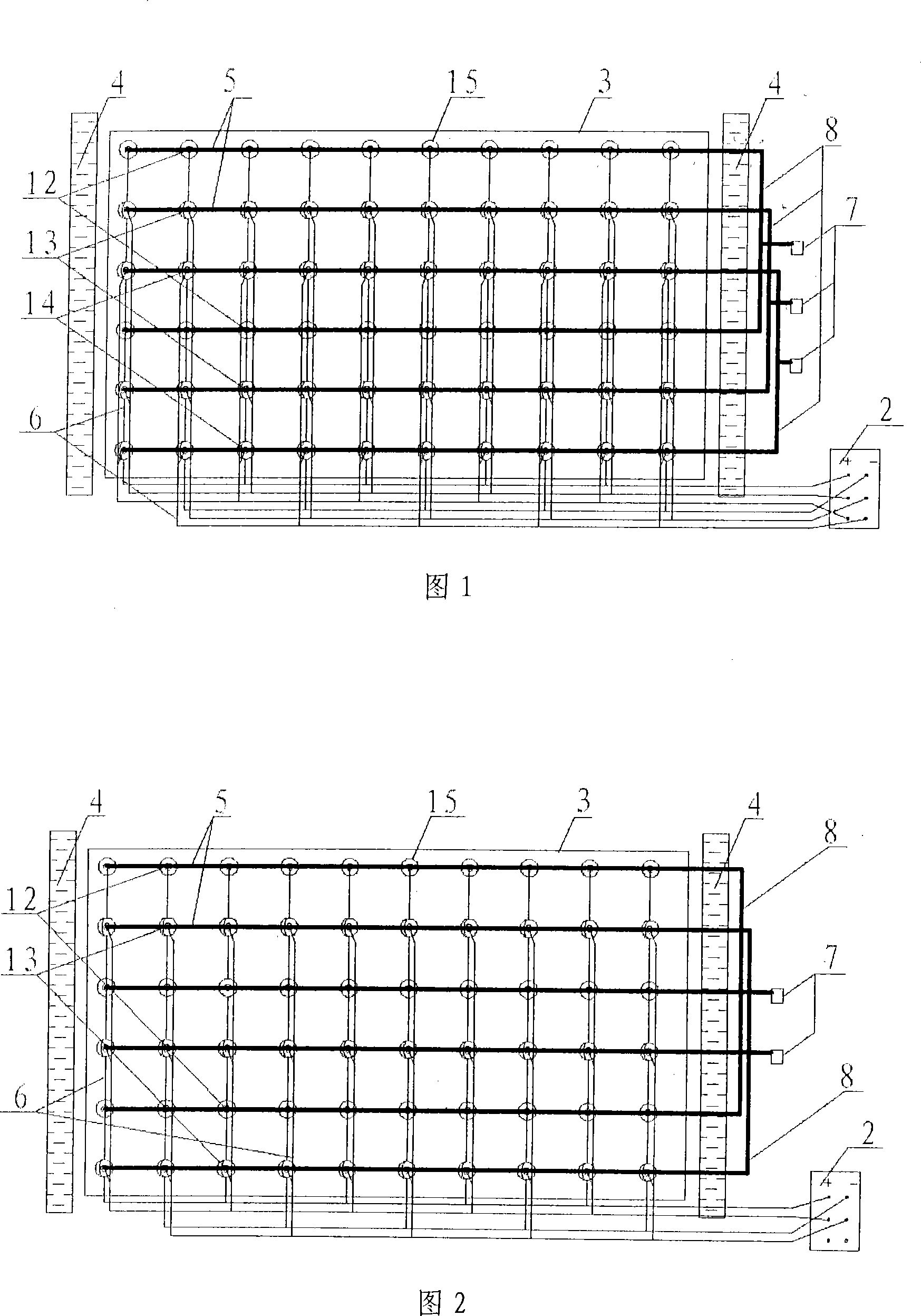

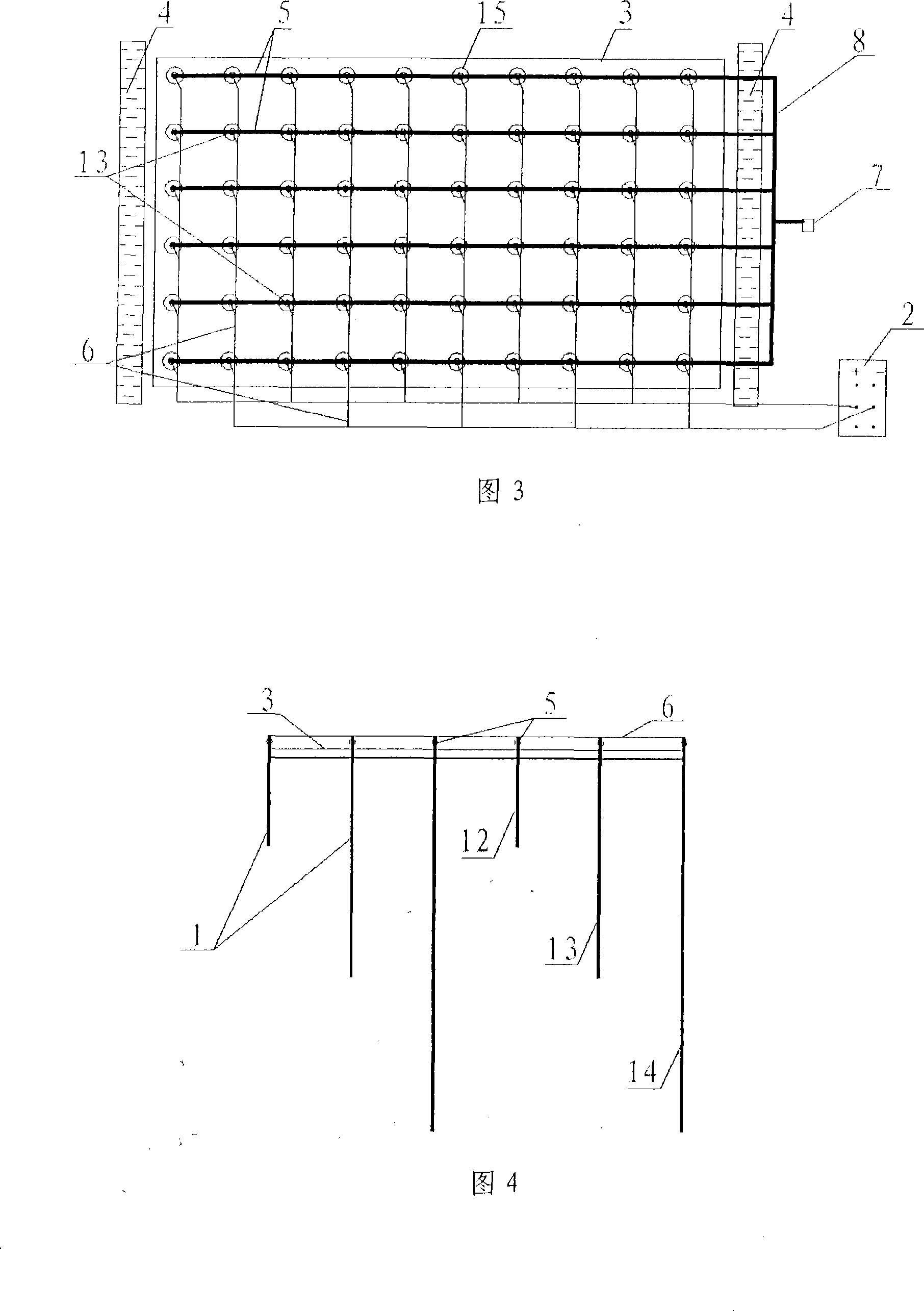

Covering type composite vacuum electroosmosis, method for forced ramming reinforcing foundation and device thereof

The invention discloses a covering composite vacuum electroosmosis and heavy tamping method for the groundwork reinforcement and a device thereof, and aims to provide a groundwork treatment method and a relevant device, and in particular a complete groundwork treatment method for the large-area soft soil with the penetration factor less than 10<-5>cm / s, and a device thereof. The device of the invention adopts a composite pipe and a holed redundant film or a reticular multilens film. With the method of the invention, the composite effect of the multi-layer electroosmosis and the multi-layer vacuum dewatering completely covered and sealed under the holed redundant film or the reticular multilens film replaces the single effect of electromomosis and vacuum dewatering, and the heavy tamping with the medium and low energy covered under the sealed films replaces the direct medium and low energy heavy tamping. The invention is provided with the advantages of the equilibrium treatment, the convenient construction, the short construction term, the high performance-cost ratio, and so on.

Owner:陈江涛 +3

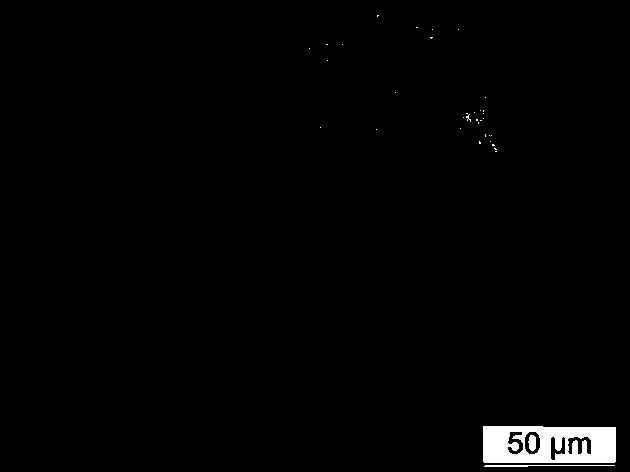

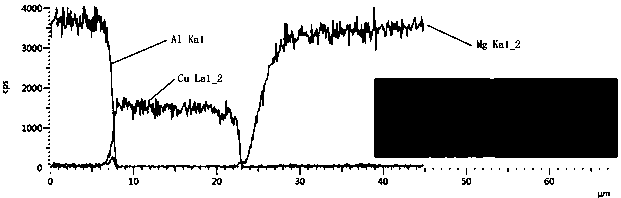

Preparation method of magnesium/aluminum-based laminated composite plate

ActiveCN108188523AEnhanced interface bindingSuppression of interfacial brittle phasesSoldering apparatusComposite effectWater cycling

The invention relates to a preparation method of metal composite plates, in particular to a preparation method of a magnesium / aluminum-based laminated composite plate in order to solve the problems that an existing preparation method of the magnesium / aluminum-based laminated composite plate has the disadvantages that the required preparation conditions are strict, the composite effect is poor, andthe requirements for equipment are high in the prior art. The preparation method comprises the steps of 1, conducting grinding, ultrasonic cleaning and air-drying; 2, sputtering copper coatings on the surfaces of a magnesium-aluminum alloy plat under an argon environment and the conditions of arc-added glow discharge and external water circulating cooling; 3, selecting a graphite die to conduct hot-pressing sintering on the magnesium / aluminum-based laminated composite plate in a plasma discharge sintering furnace under the conditions of current heating, pressurization and external water circulating cooling; and 4, conducting grinding and sanding treatment. The preparation method has the advantages that interface bonding of the magnesium / aluminum-based laminated composite plate is good, and the magnesium / aluminum-based laminated composite plate has no defects such as cracks and pores; a 3-micron element diffusion layer exists at the magnesium / copper interface, a 7-micron element diffusion layer exists at the copper / aluminum interface, and generation of brittle phases is restrained through the copper coatings sputtered at the interfaces; the interface bonding strength of the magnesium / aluminum-based laminated composite plate can reach 80 MPa.

Owner:TAIYUAN UNIV OF TECH

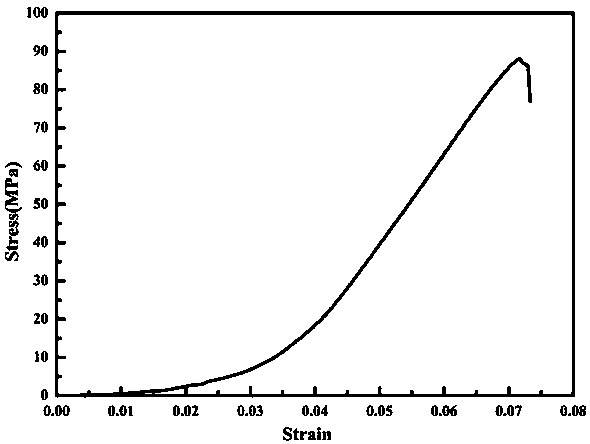

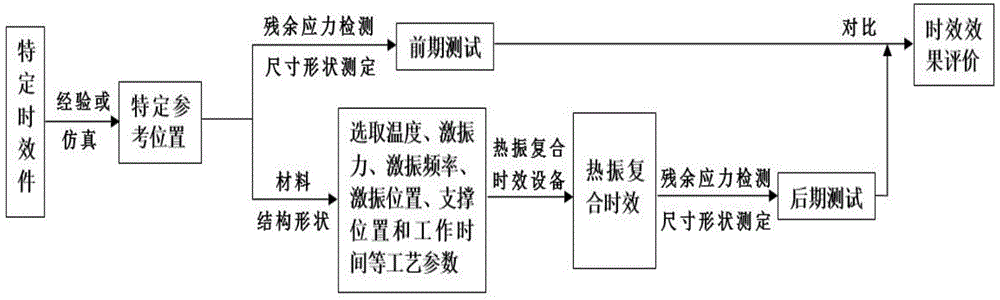

Thermal vibration composite residual stress homogenization method

InactiveCN103602801AInput is controlled and effectiveImprove molecular activityProcess efficiency improvementComposite effectMaterials science

The invention relates to a thermal vibration composite residual stress homogenization method. The method comprises the following steps: one, analyzing the residual stress distribution of an aging element, so as to know a residual stress integral level; two, determining an application mode for evaluating residual stress homogenization effect, and completing a thermal vibration composite aging early-period test; three, establishing a thermal and vibration implementation scheme of the thermal vibration composite residual stress homogenization method, deciding a process flow, selecting the temperature, the excitation force, the excitation frequency, the excitation position, the support position and the work time and other process parameters; four, on the basis of the selected process parameters, implementing thermal vibration composite aging residual stress homogenization of the workpiece; and five, carrying out thermal vibration composite aging post-period test, and evaluating the thermal vibration composite residual stress homogenization effect. The thermal and vibration composite effect is utilized to realize residual stress homogenization, the vibration aging effect is strengthened, and the using stability of the workpiece is improved.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com