Composite device of composite wiredrawing film

A composite device and composite film technology, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of low processing efficiency, unsatisfactory composite effect, complex equipment structure, etc., achieve high processing efficiency, save manpower and material resources , The effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

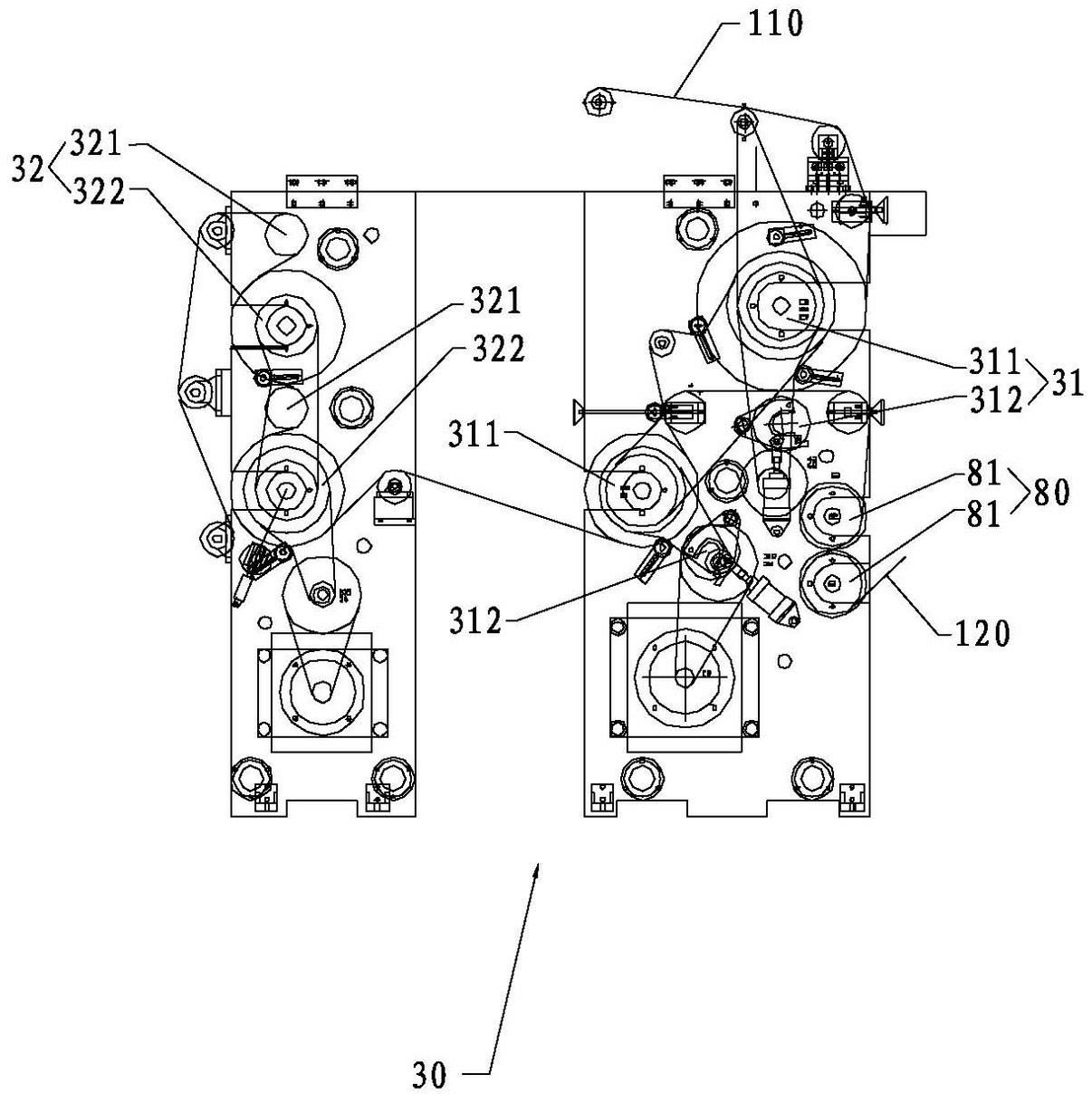

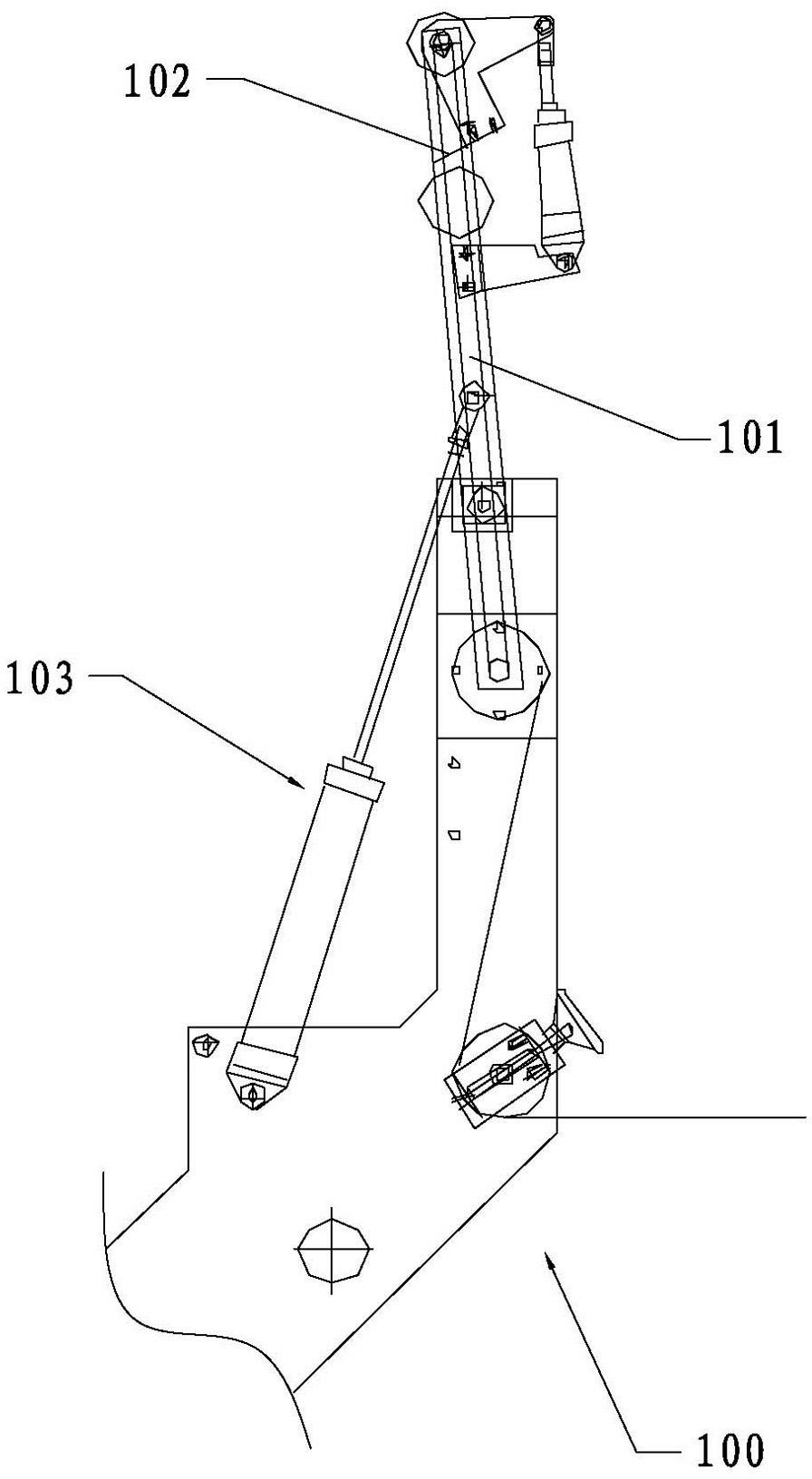

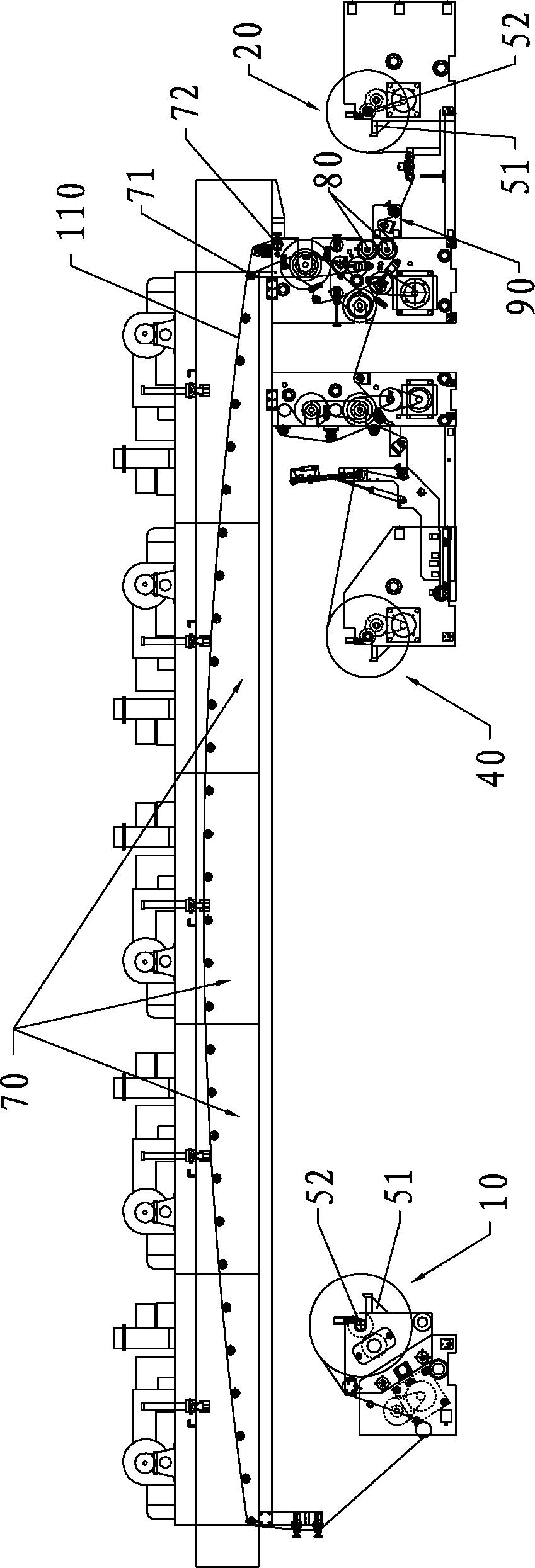

[0041] Such as figure 1 , image 3 and Figure 4 As shown, a composite device for drawing a composite film includes a frame and a control device, and also includes a first unwinding device 10, a second unwinding device 20, a composite mechanism 30 and a winding device 40 arranged on the frame. , the control device is electrically connected to the first unwinding device 10, the second unwinding device 20, the composite mechanism 30 and the winding device 40 respectively, and the composite mechanism 30 includes thermal composite rollers arranged in sequence along the film feeding direction Set 31 and chill roll set 32.

[0042] When using, pre-set the predetermined parameters of each equipment in the control device, such as setting the tension coefficient of unwinding and rewinding, setting the decrement rate of unwinding and the increasing rate of rewinding; Rewinding preparation rate; set the maximum and minimum values of the roll diameter, etc., and then each circuit mod...

Embodiment 2

[0063] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment is that the second unwinding device 20 and the winding device 40 of the present embodiment respectively include a rotating support frame 61, a double unwinding rotating roll 62 and a driving mechanism 63, so The rotating support frame 61 is gear-connected with the driving mechanism 63, the double-release rotating roll 62 is arranged on the rotating support frame 61, and the double-release rotating roll 62 includes at least two rotating rolls with adjustable roll diameters. Rollers 52, gears are provided at one end of each of the rotating rollers 52, wherein the gears of each rotating roller 52 of the second unwinding device 20 are connected with the deviation correcting device.

[0064] Specifically, the driving mechanism 63 is a driving motor. This embodiment uses a rotating support frame 61 and a double-release rotating roll 62. When a roll film is finished or has been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com