Patents

Literature

654results about How to "Improve composite effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

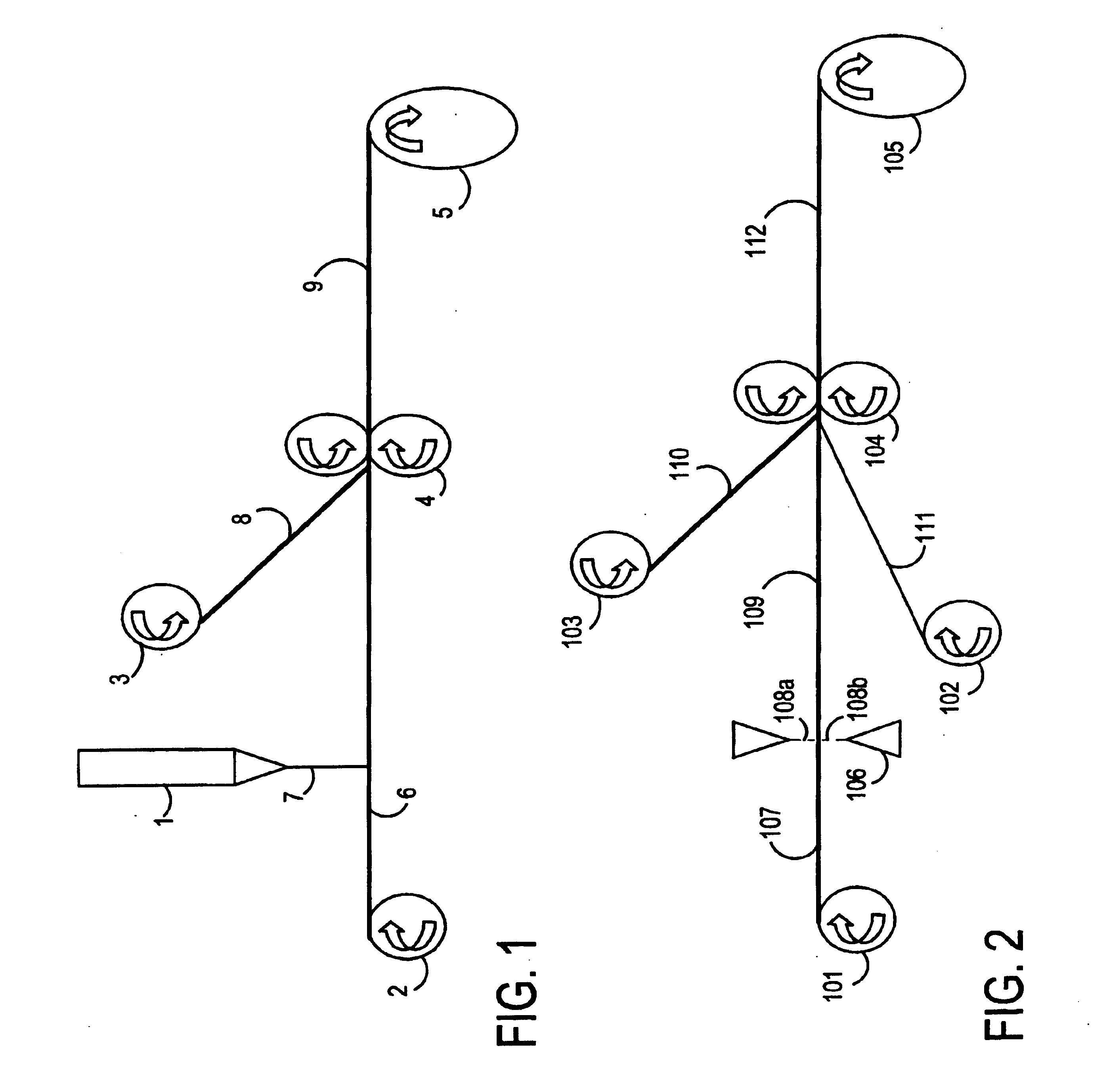

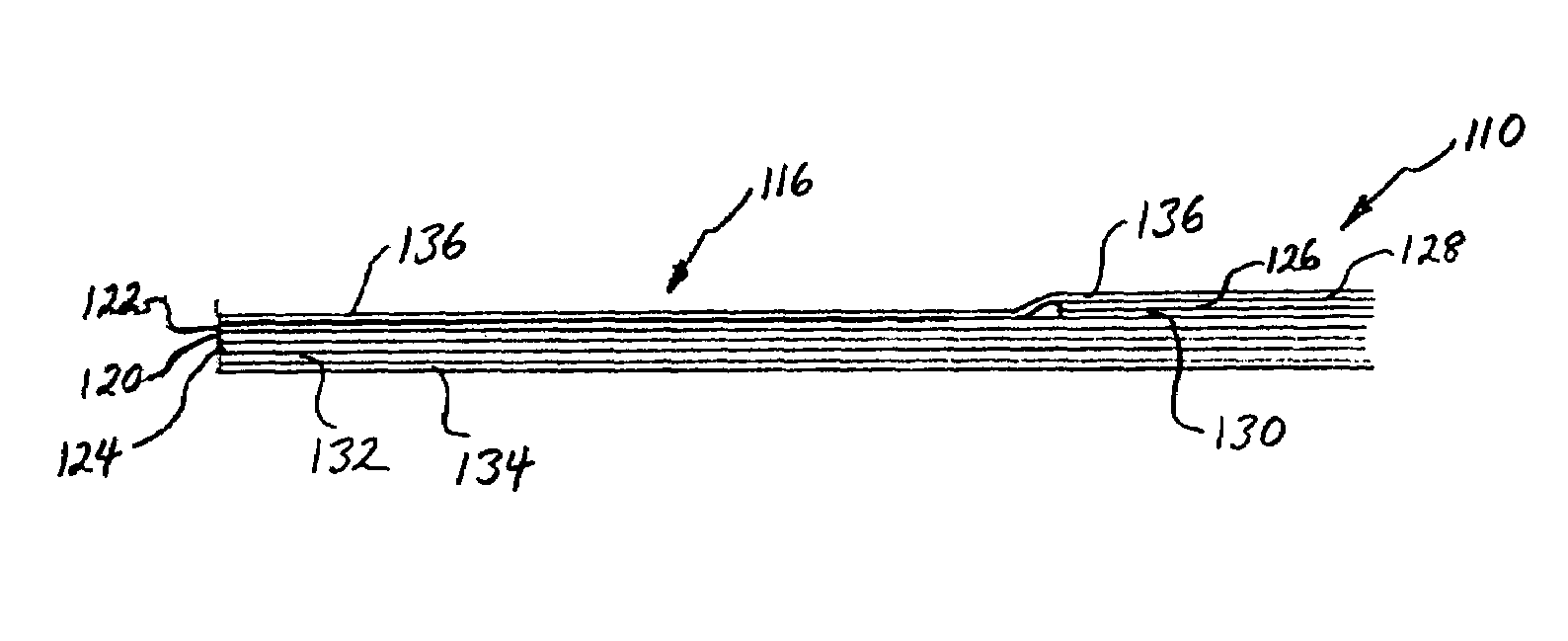

Fully elastic nonwoven-film composite

InactiveUS20050106980A1Excellent abrasion resistanceImprove conformitySynthetic resin layered productsLaminationEngineeringNonwoven fabric

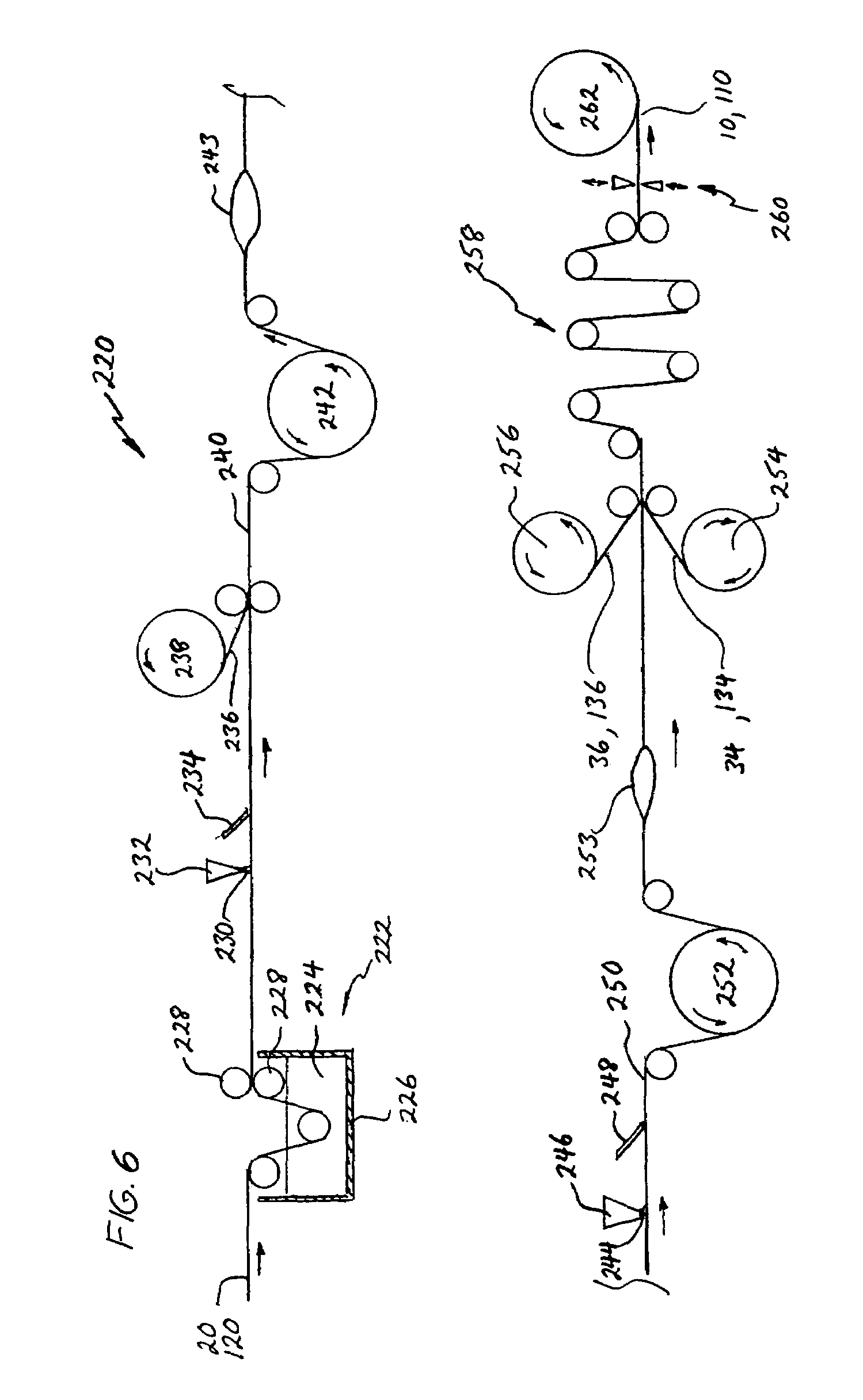

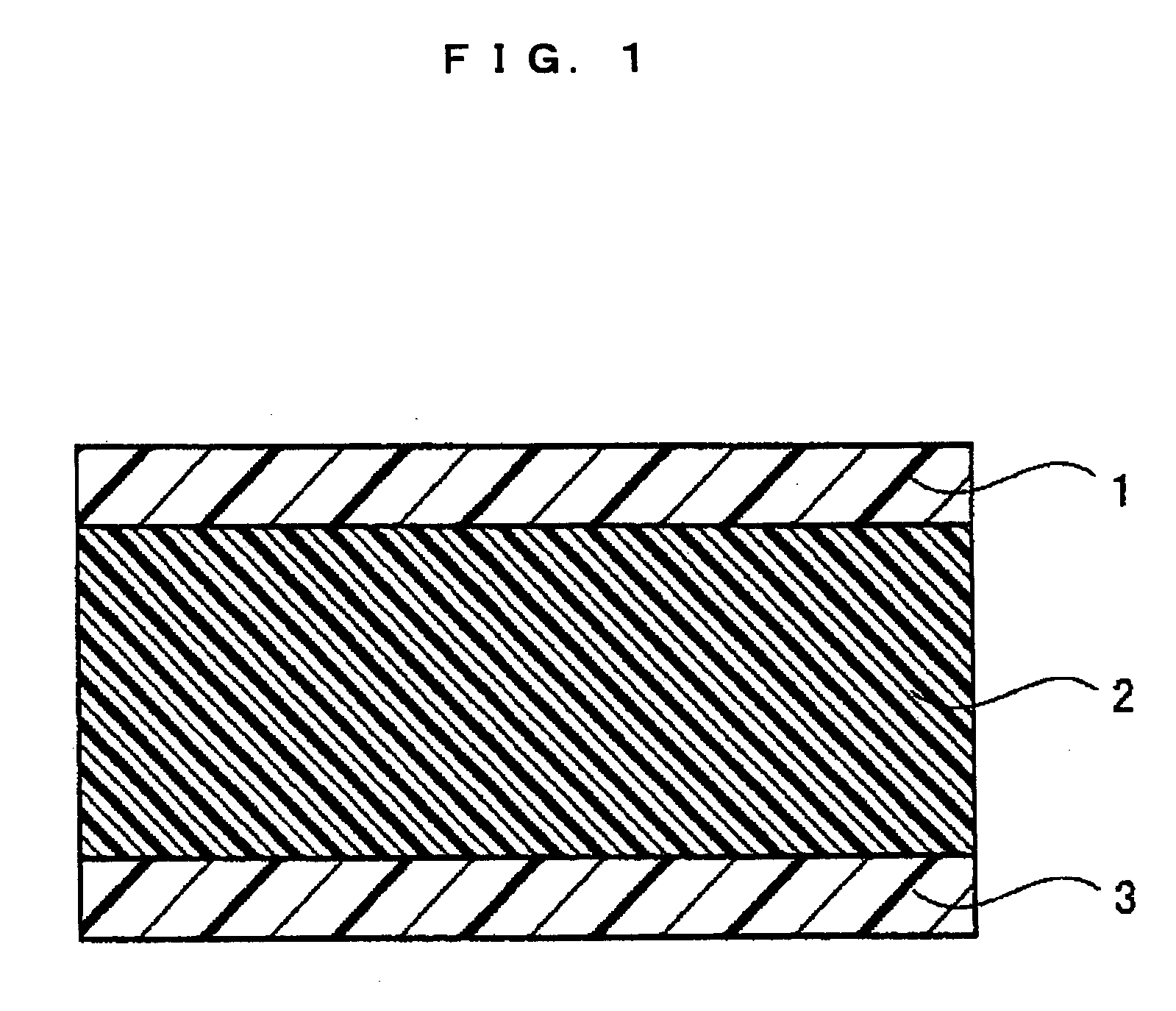

This invention concerns an elastic multilayer composite, comprising an elastic film layer sandwiched between a first elastic nonwoven layer and an optional second elastic nonwoven layer, and a process for making the same. The laminate is stabilized via bonding according to either: adhesive bonding between the film and nonwoven layer(s), direct extrusion lamination of the film to one or more nonwoven layer(s), or attachment of the film to one or more of the nonwoven layers at a plurality of points via thermopoint bonding. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under neutral tension or substantially neutral tension at least one elastic film layer to at least one elastic nonwoven layer. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under differential tension or stretch at least one elastic film layer to at least one elastic nonwoven layer, where either the film or the nonwoven or both are stretched Further the invention relates to a process whereby the elastic nonwoven(s), the film, the composite or any combination is activated, especially stretch activated, to create or enhance elasticity or the touch of the nonwoven, to create pores in the elastic film, or to soften the composite.

Owner:ADVANCED DESIGN CONCEPTS GMBH

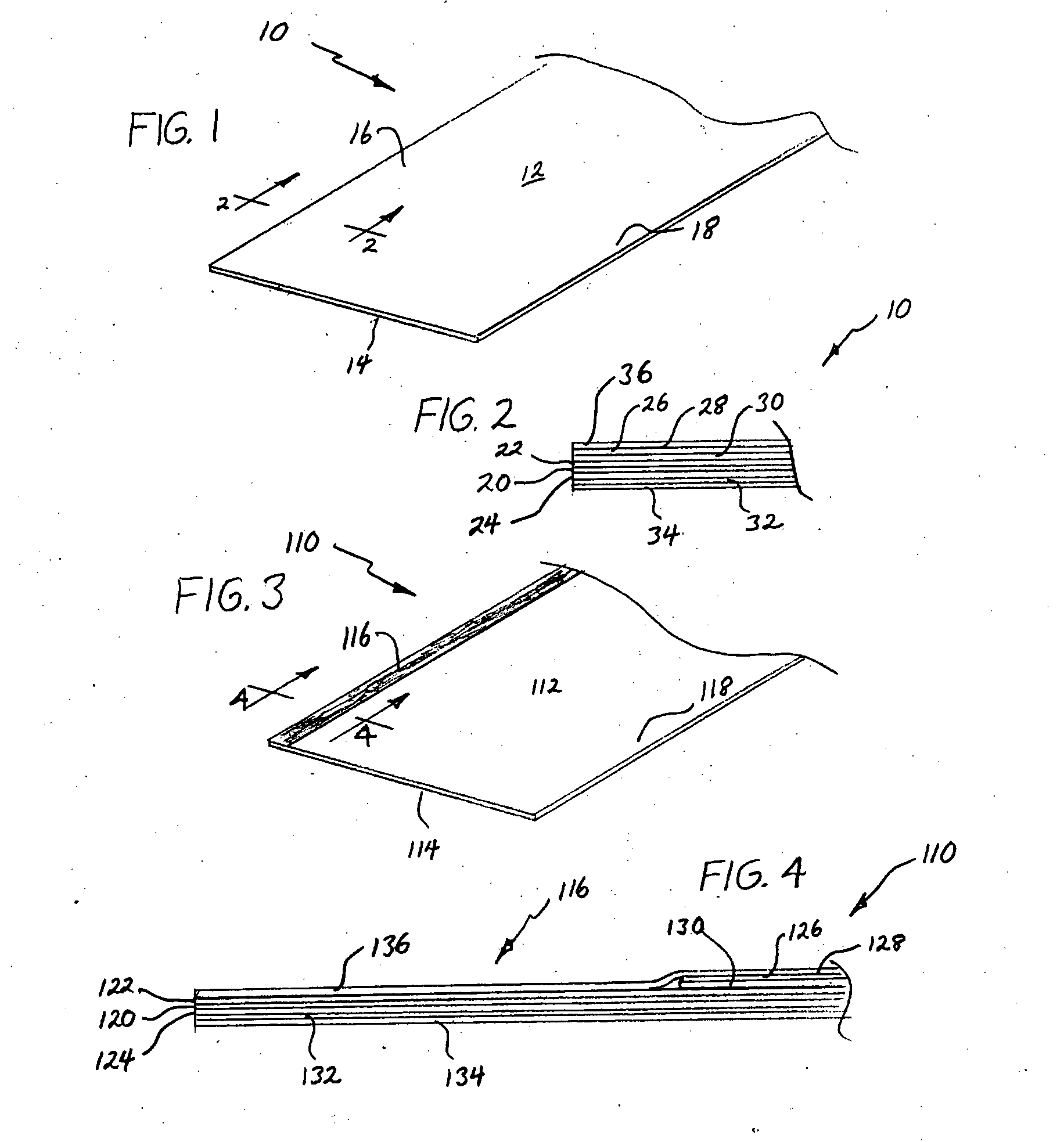

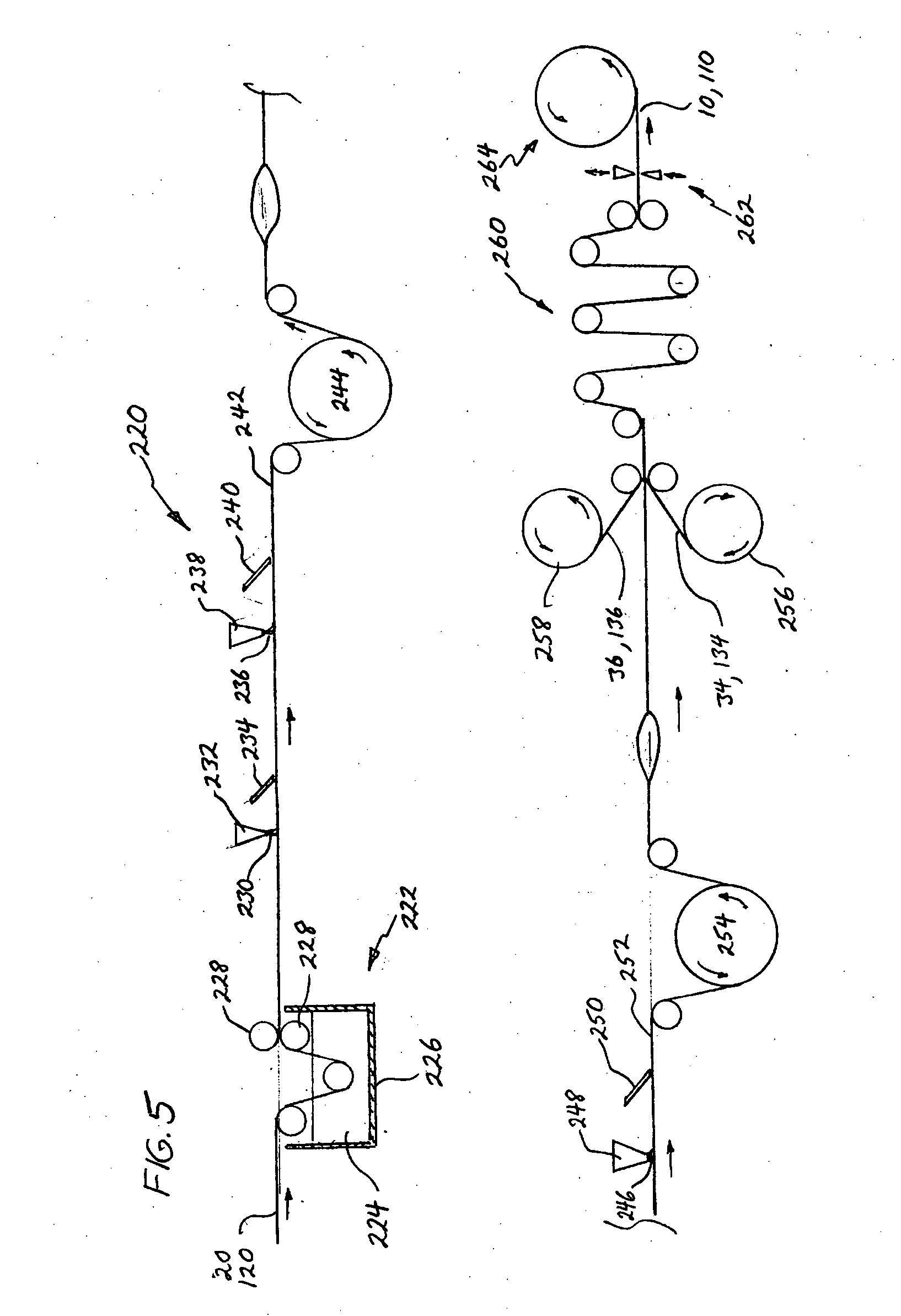

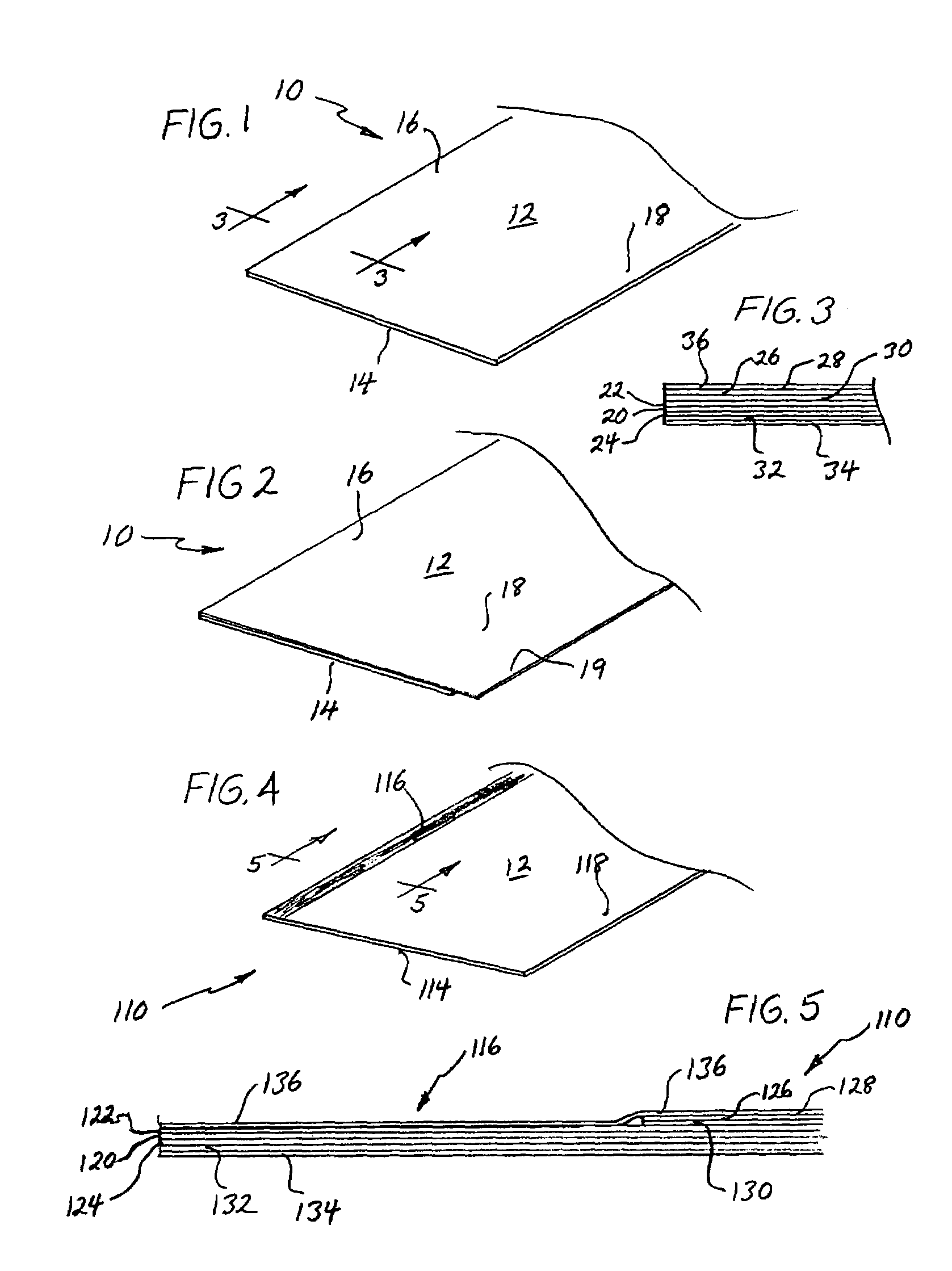

Highly reflective asphalt-based roofing membrane

ActiveUS20050053745A1Efficient use ofImprove reflectivitySpecial ornamental structuresCeramic layered productsEngineeringAsphalt

A prefabricated asphalt-based waterproof roofing membrane for use in a multi-ply asphalt-based commercial roofing system, e.g. a cap sheet that forms the exposed layer of a multi-ply built-up roofing system, is manufactured at a factory to have a highly reflective non-asphalt based elastomeric top coating layer with an upper surface that meets current EPA Energy Star requirements. Preferably, a polymer primer layer is interposed between the highly reflective coating layer and an asphalt saturated and coated reinforcing substrate to keep oils and other colored components in the asphalt from exuding into the highly reflective coating layer.

Owner:JOHNSON MANVILLE INT

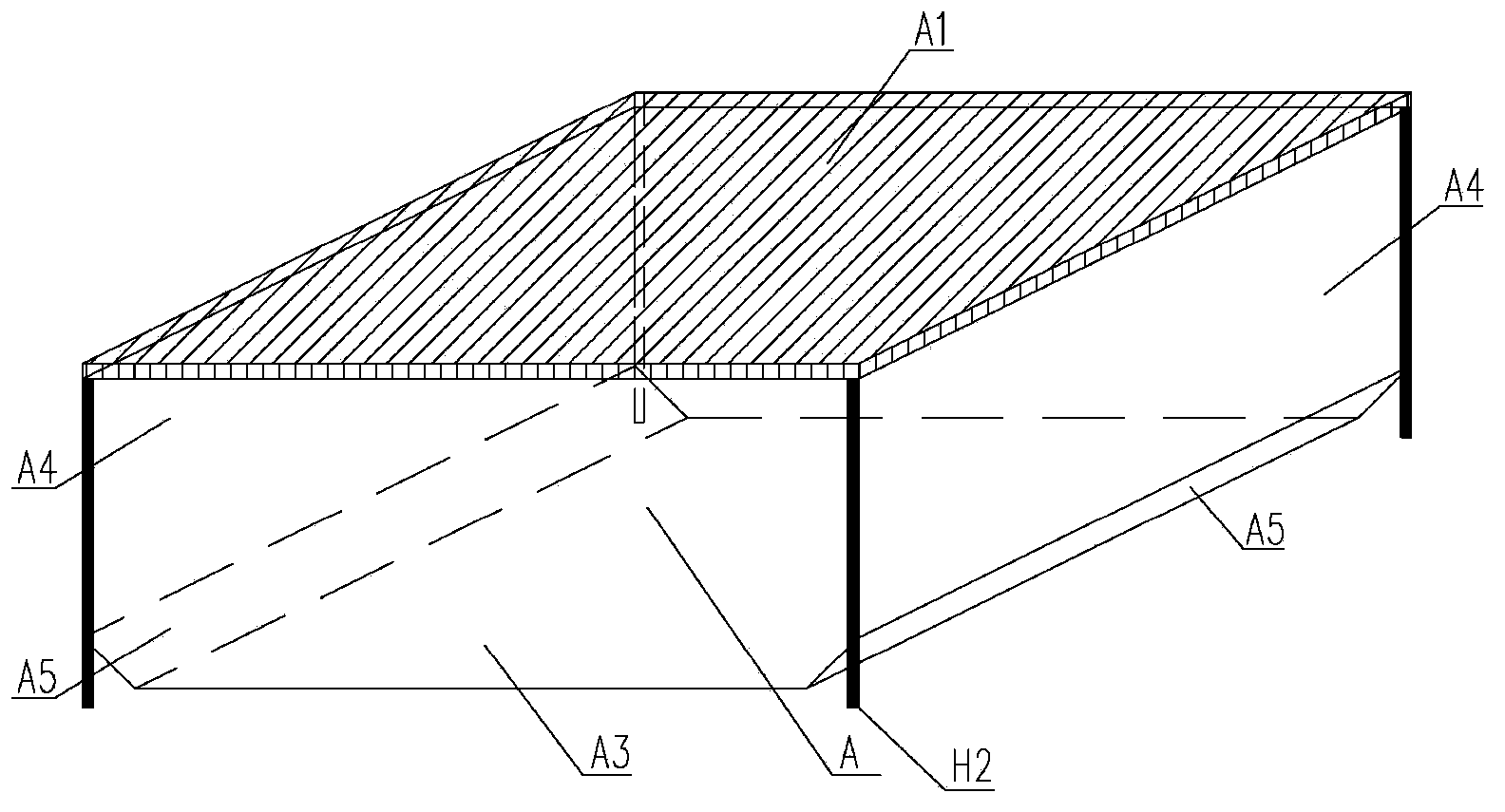

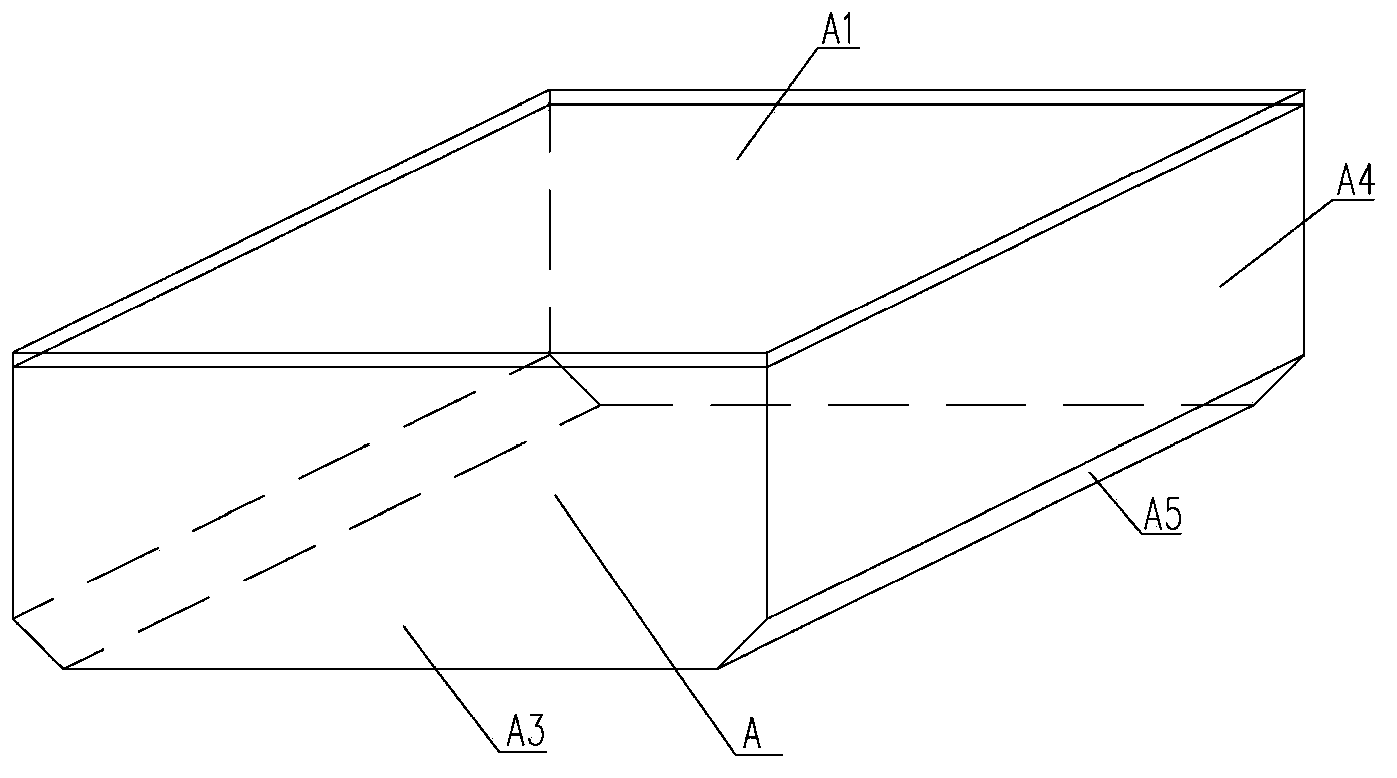

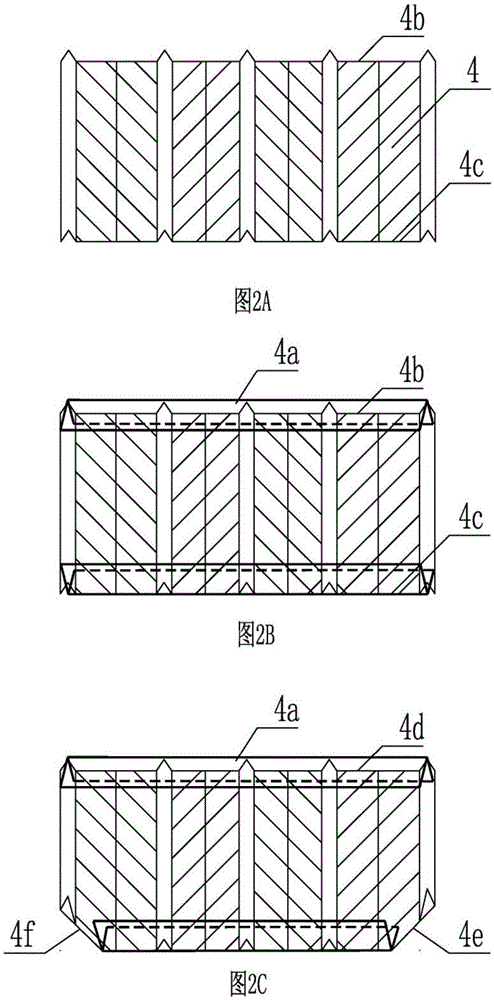

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

Highly reflective asphalt-based roofing membrane

InactiveUS7070844B2Good lookingImprove composite effectSpecial ornamental structuresCoatingsThermoplastic elastomerEngineering

A prefabricated asphalt-based waterproof roofing membrane for use in a multi-ply asphalt-based commercial roofing system, e.g. a cap sheet that forms the exposed layer of a multi-ply built-up roofing system, is manufactured at a factory to have a highly reflective thermoplastic elastomeric sheet layer with a top surface that has a reflectance that meets current EPA Energy Star requirements. Preferably, a polymer primer layer is interposed between the highly reflective thermoplastic elastomeric sheet layer and an asphalt saturated and coated reinforcing substrate to keep oils and other colored components in the asphalt from exuding into the highly reflective thermoplastic elastomeric sheet layer.

Owner:JOHNS MANVILLE CORP

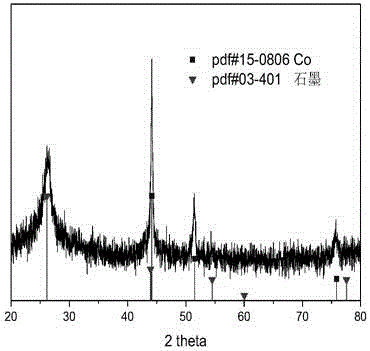

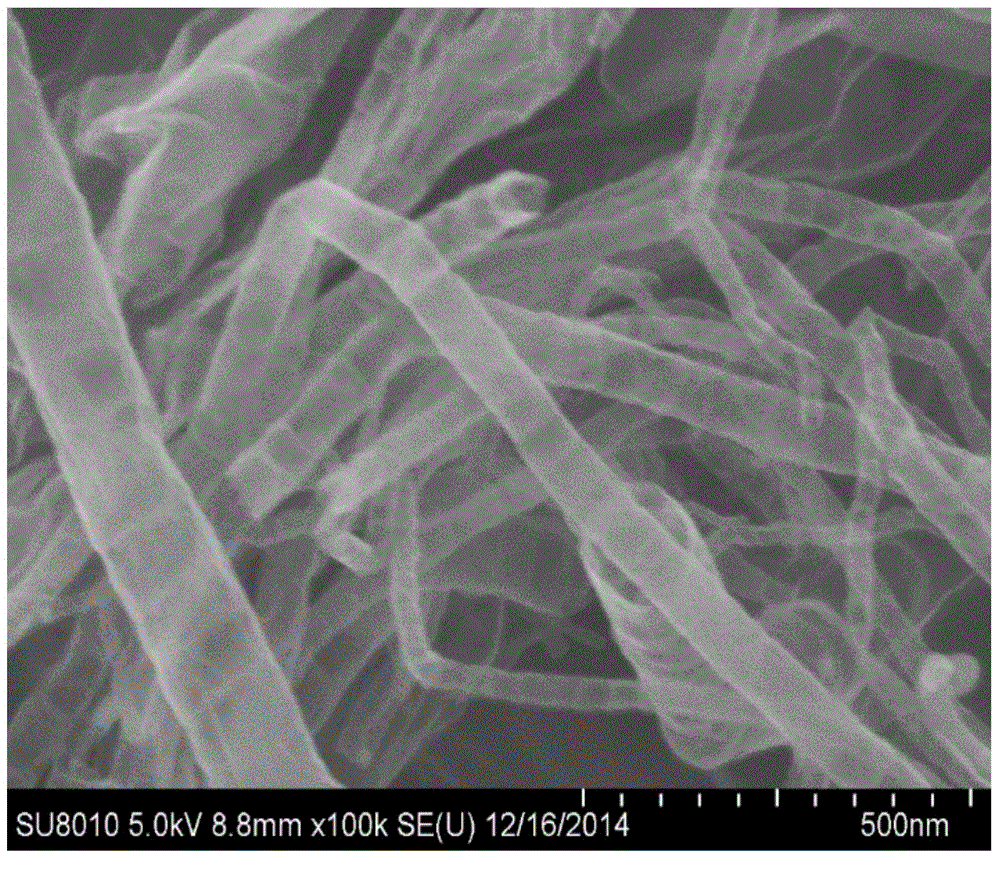

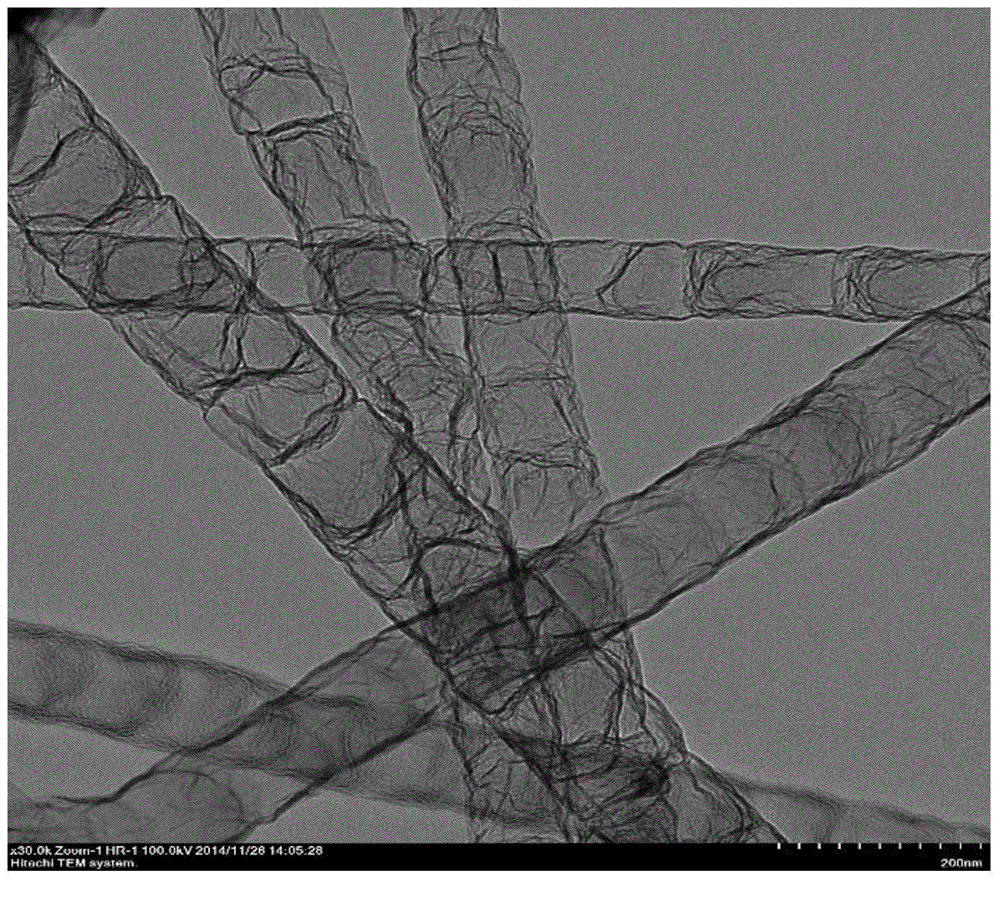

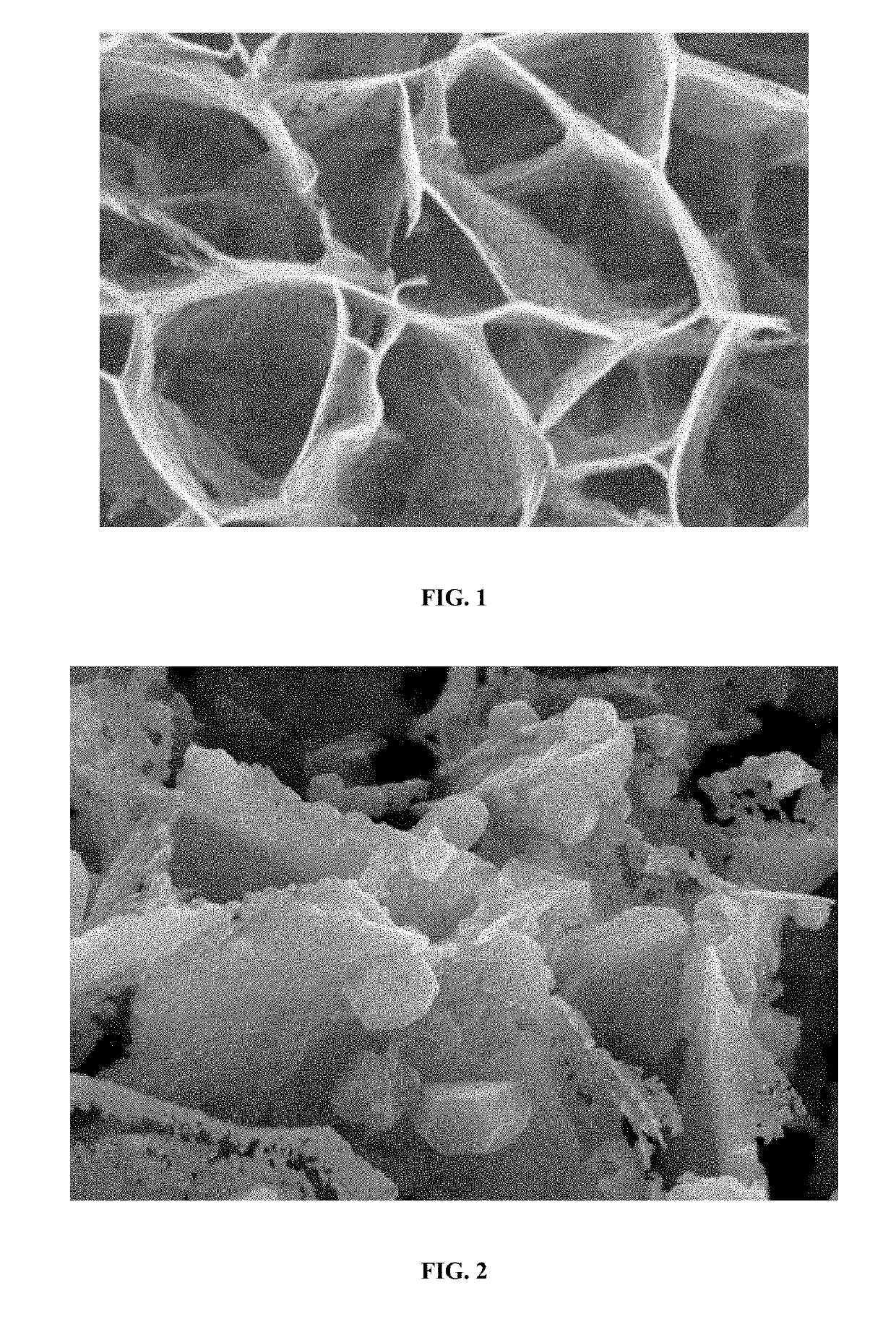

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

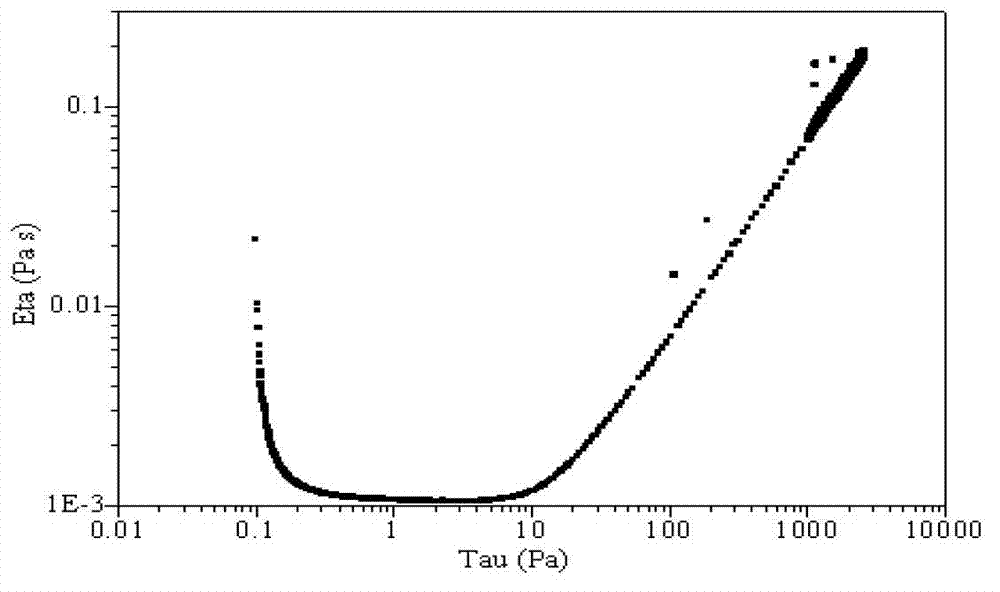

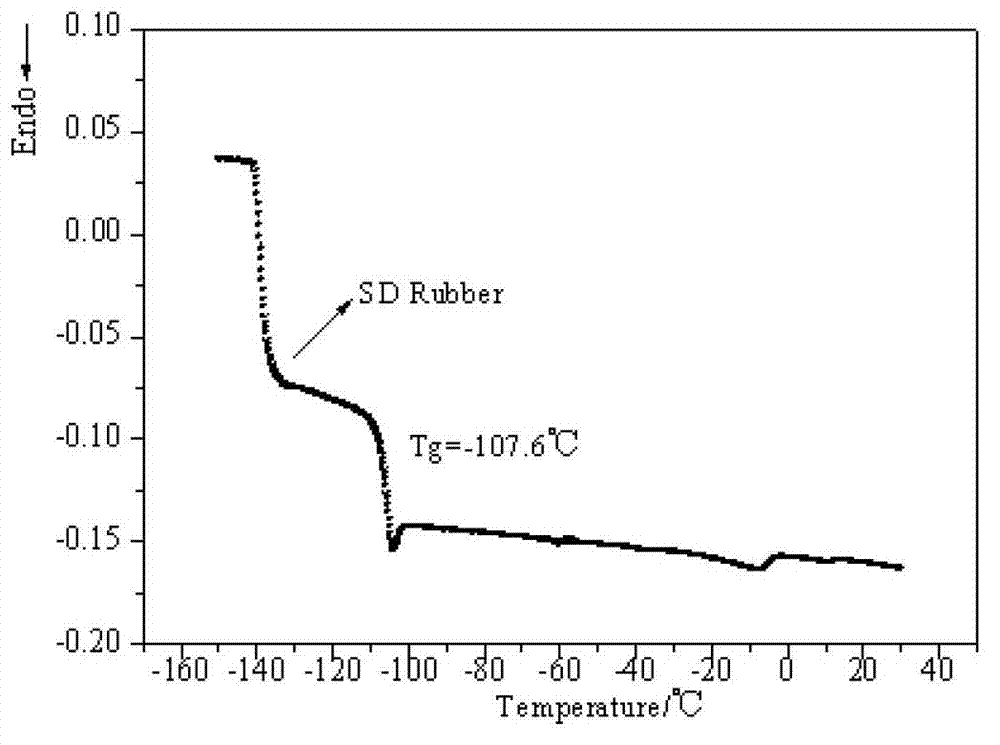

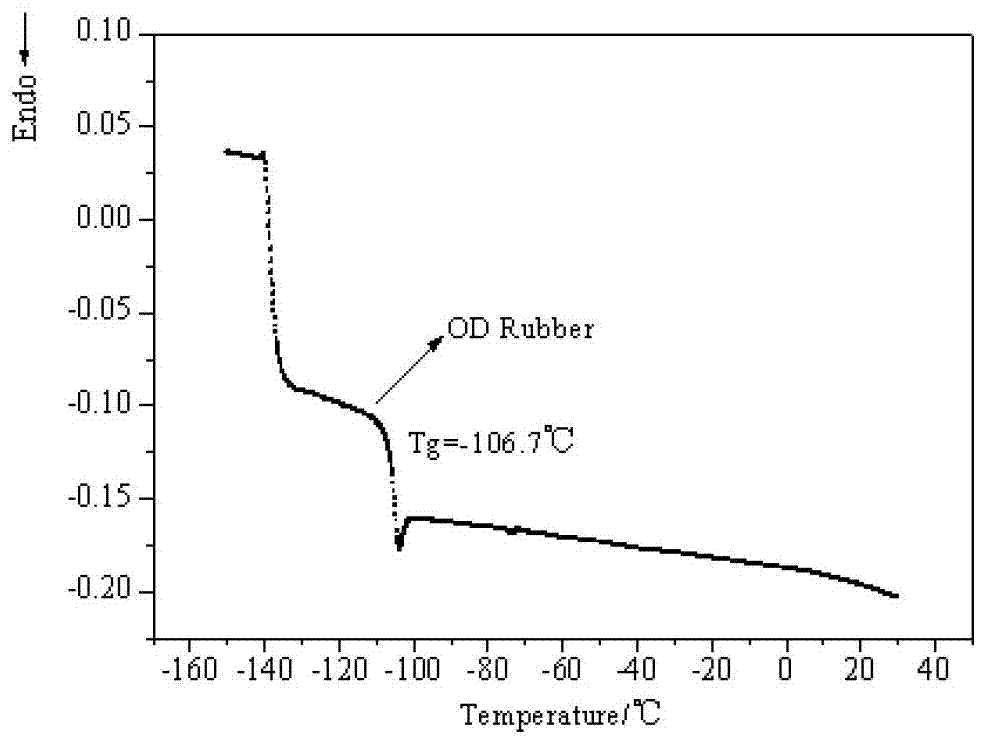

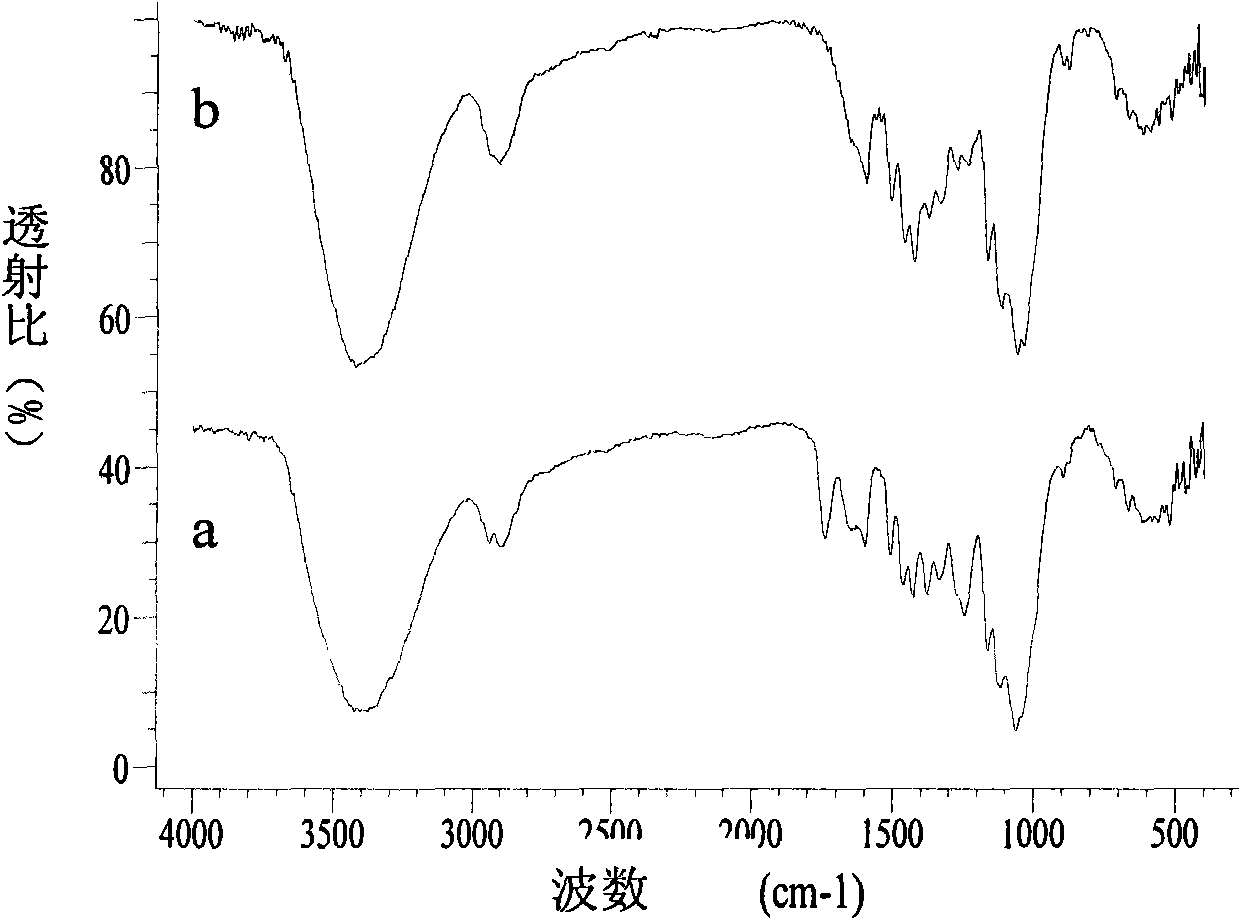

Shear thickening fluid based on molecular colloid and preparation method and application of shear thickening fluid

ActiveCN102926211AImprove the protective effectAvoid reunionGroup 4/14 element organic compoundsFibre treatmentFiberOrganic solvent

The invention relates to shear thickening fluid based on a molecular colloid, as well as a preparation method and an application of the shear thickening fluid. The shear thickening fluid consists of an organic solvent and a molecular colloid system formed by inorganic nano grains, boric acid, hydroxyl silicone oil and a plasticizing agent, and is used for dipping high-property fiber fabric and preparing a protective material to improve a puncture-proof property of the material; the preparation technology is simple; the preparation period is short; the controllability of an operation is high; the stability of the property of a product is improved; the energy consumption is reduced; and moreover, large-scale production is facilitated.

Owner:BEIJING UNIV OF CHEM TECH

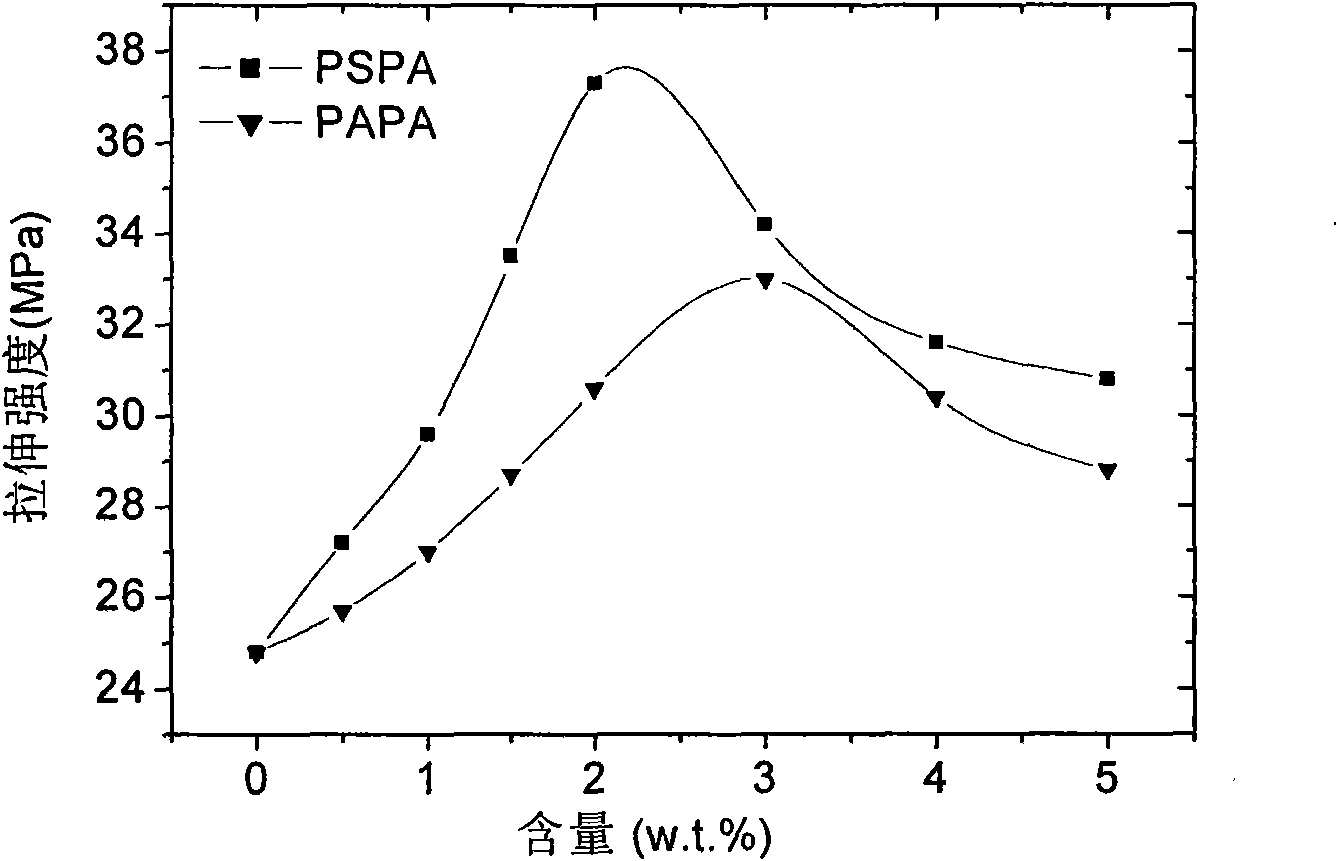

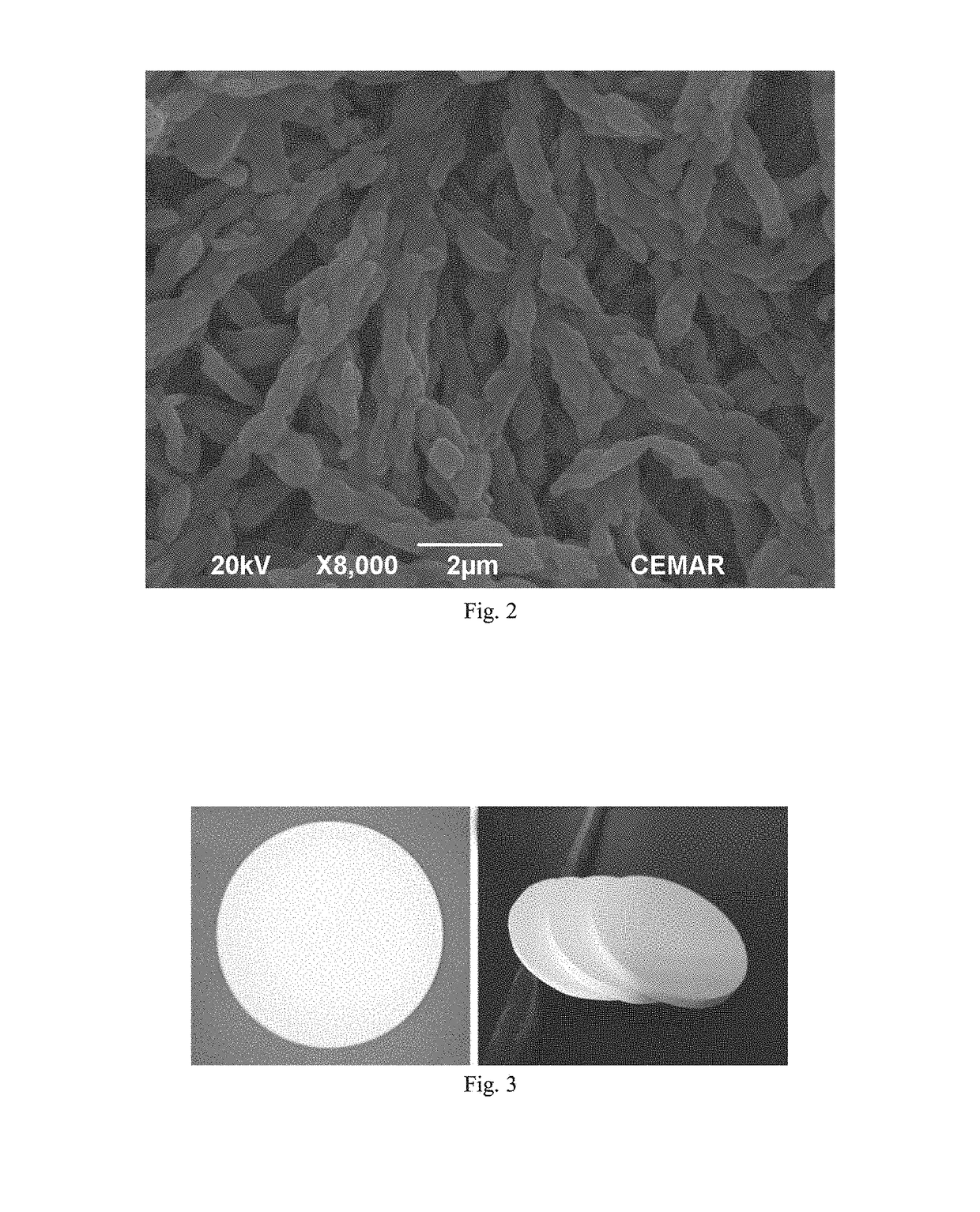

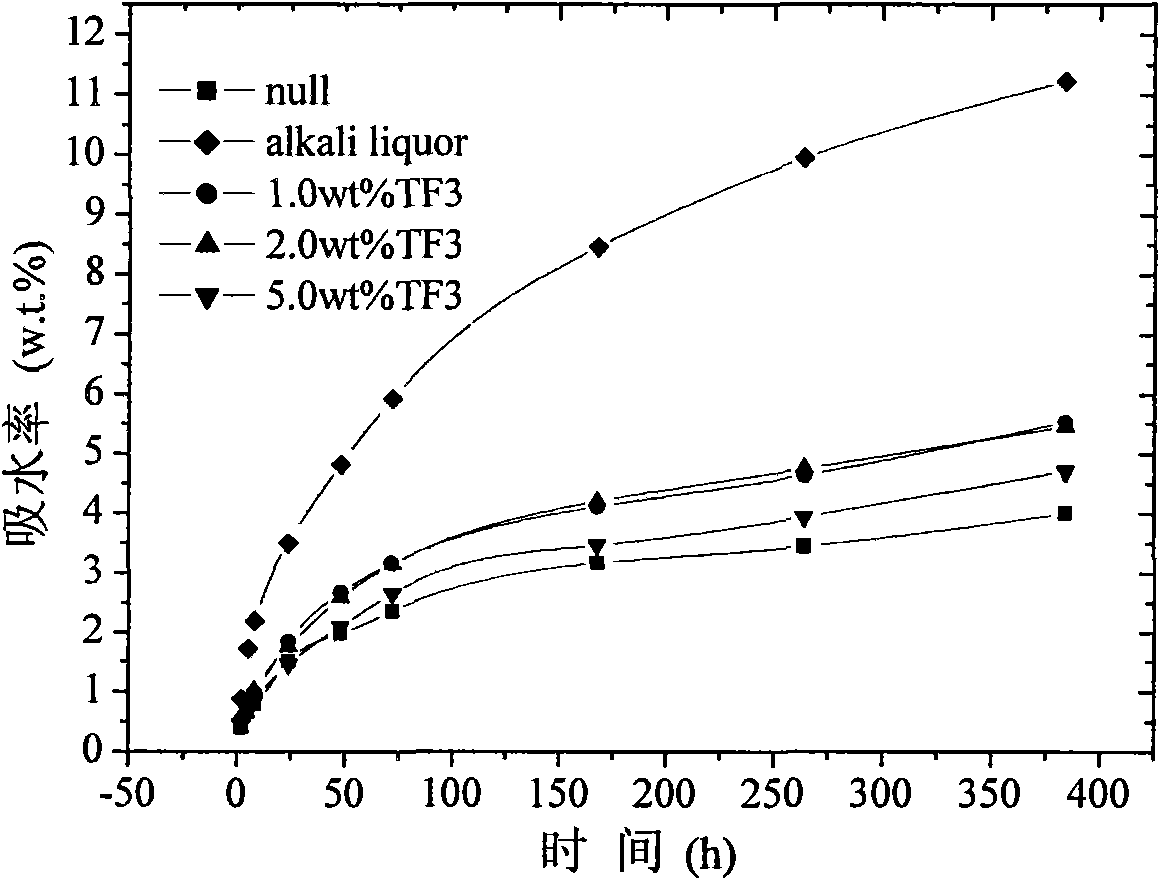

Water-resistant wood-plastic composite material and preparation method thereof

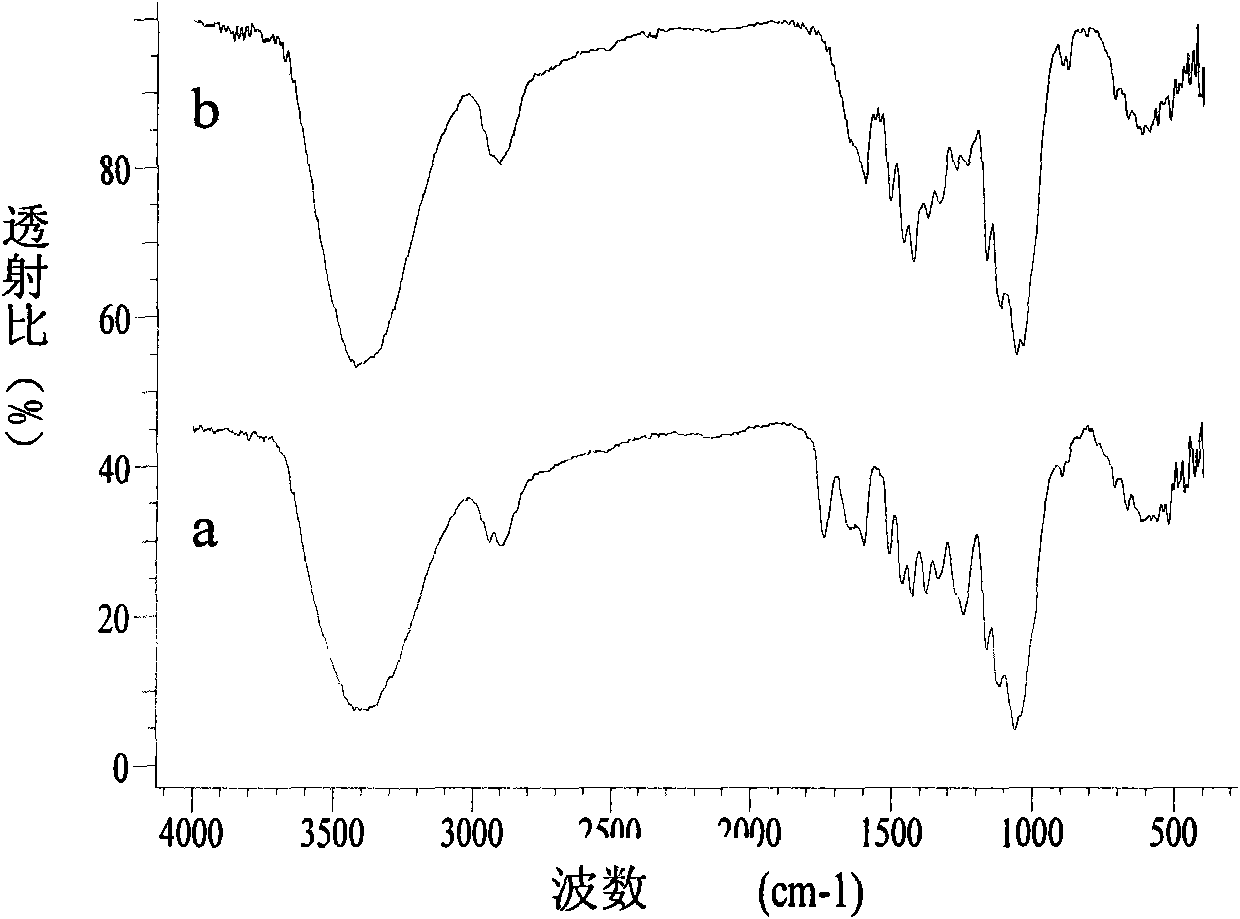

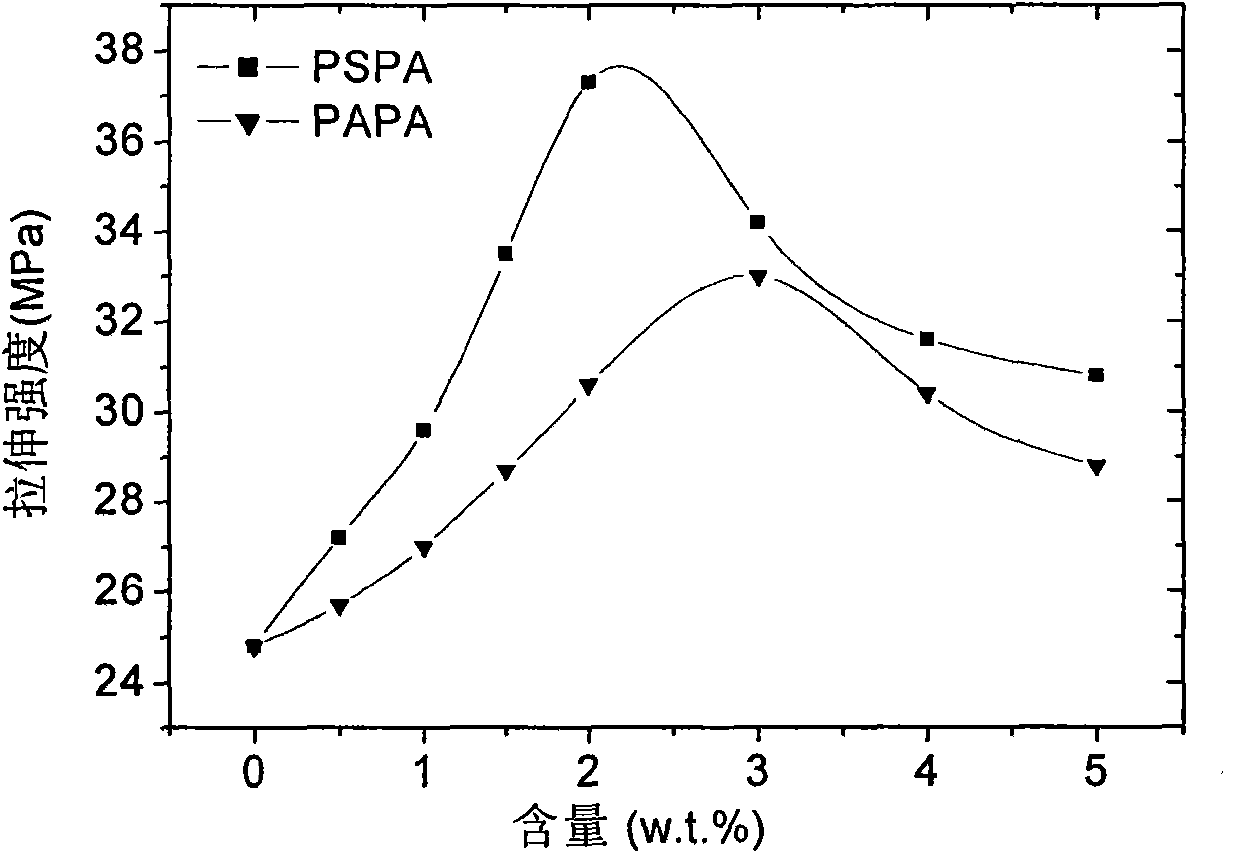

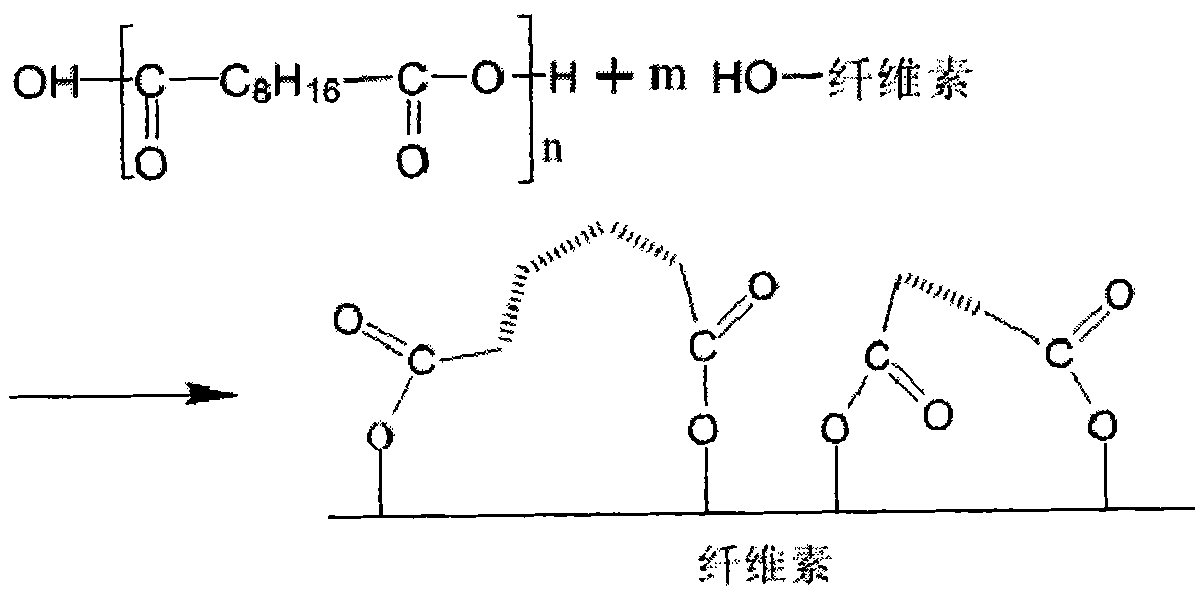

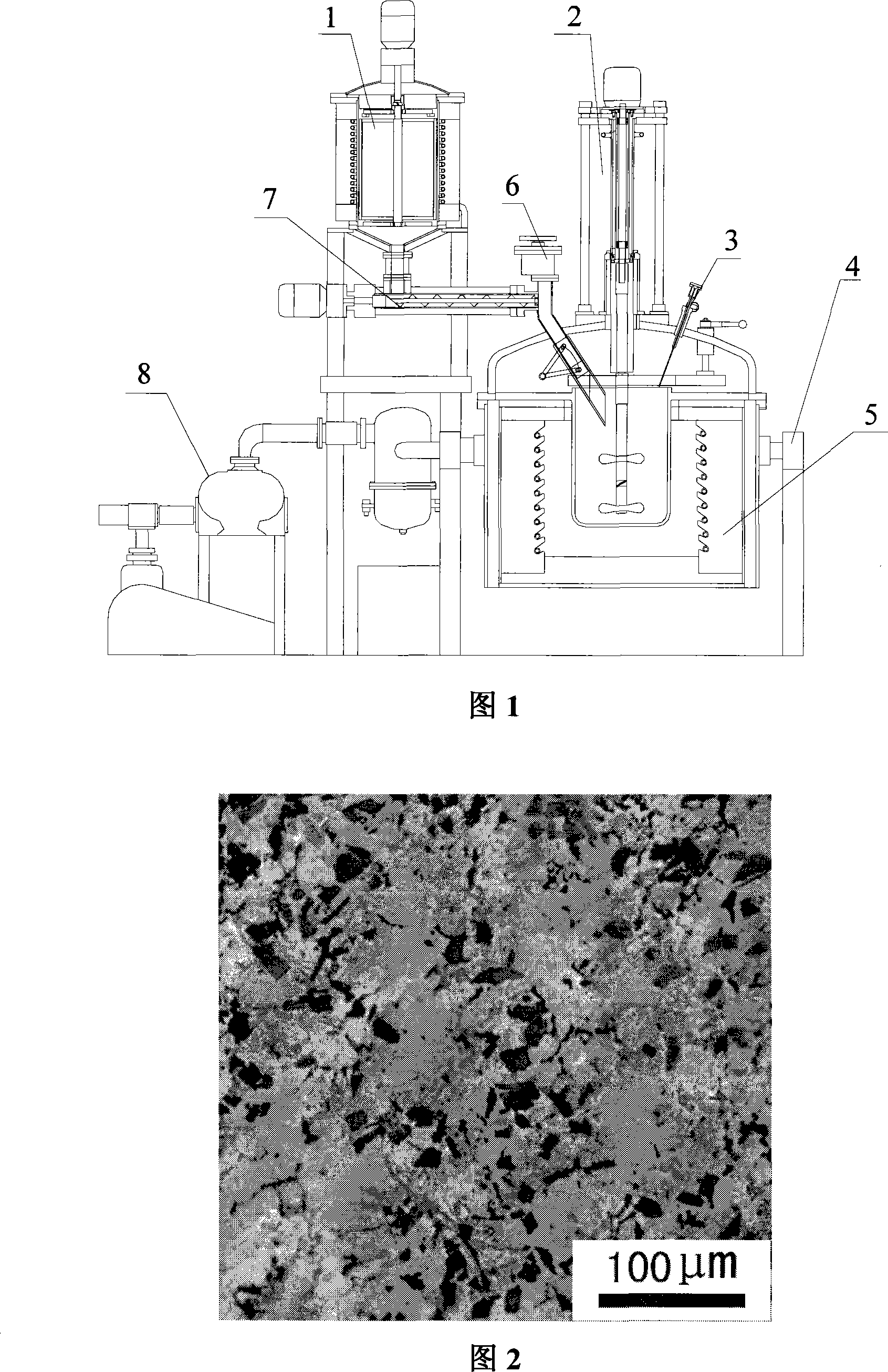

InactiveCN101613503AImprove interface compatibilityImprove composite effectPolyolefinPolymer substrate

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

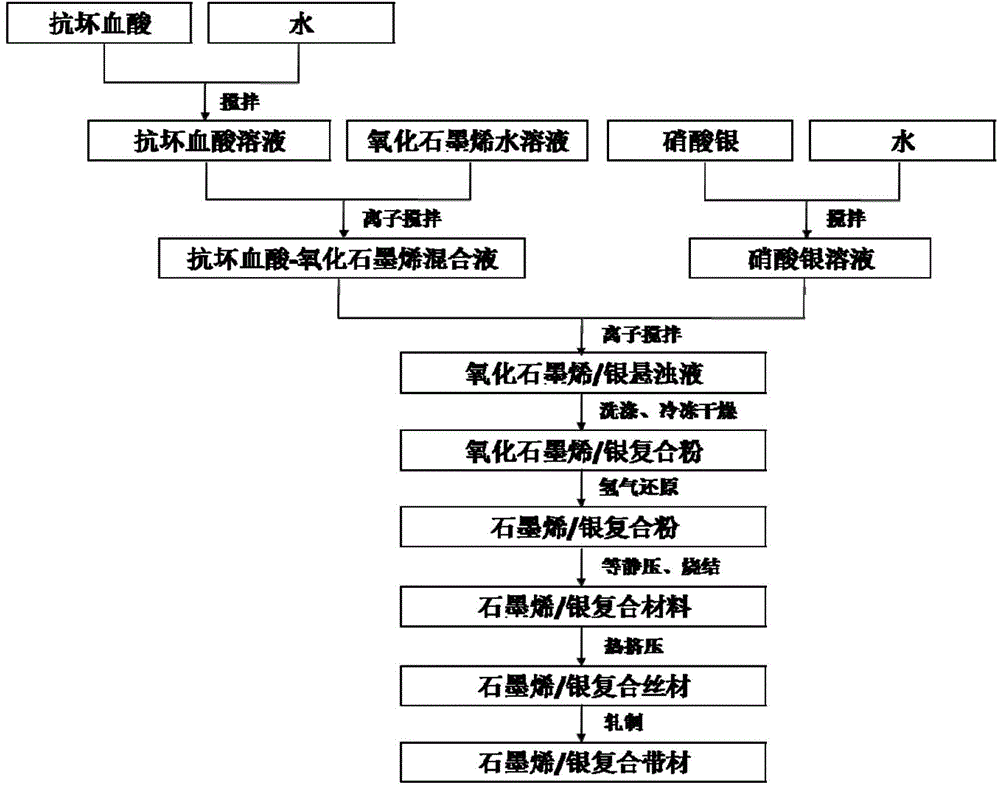

Graphene/silver composite material and preparation method thereof

ActiveCN104700961AEvenly distributedTo achieve the effect of continuous productionMetal/alloy conductorsCarbon-silicon compound conductorsReducing agentGraphite oxide

The invention provides a graphene / silver composite material and a preparation method thereof. The preparation method comprises the steps of adding a reducing agent and silver nitrate successively into a graphene oxide solution, combining silver powder obtained by reduction and graphene oxide in the solution, so as to obtain graphene oxide / silver composite powder; drying the graphene oxide / silver composite powder to obtain graphene / silver composite powder; and obtaining graphene / silver composite blocks, composite wires and composite strips through powder metallurgy, hot extrusion and rolling techniques. According to the graphene / silver composite material and the preparation method provided by the invention, the graphene is dispersed uniformly in the composite material, the interface bonding between a substrate and an enhanced body is good, and the composite materials is excellent in physical performance; meanwhile, the preparation method is simple in process, is likely to control the process and likely to realize large-scale production and application.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

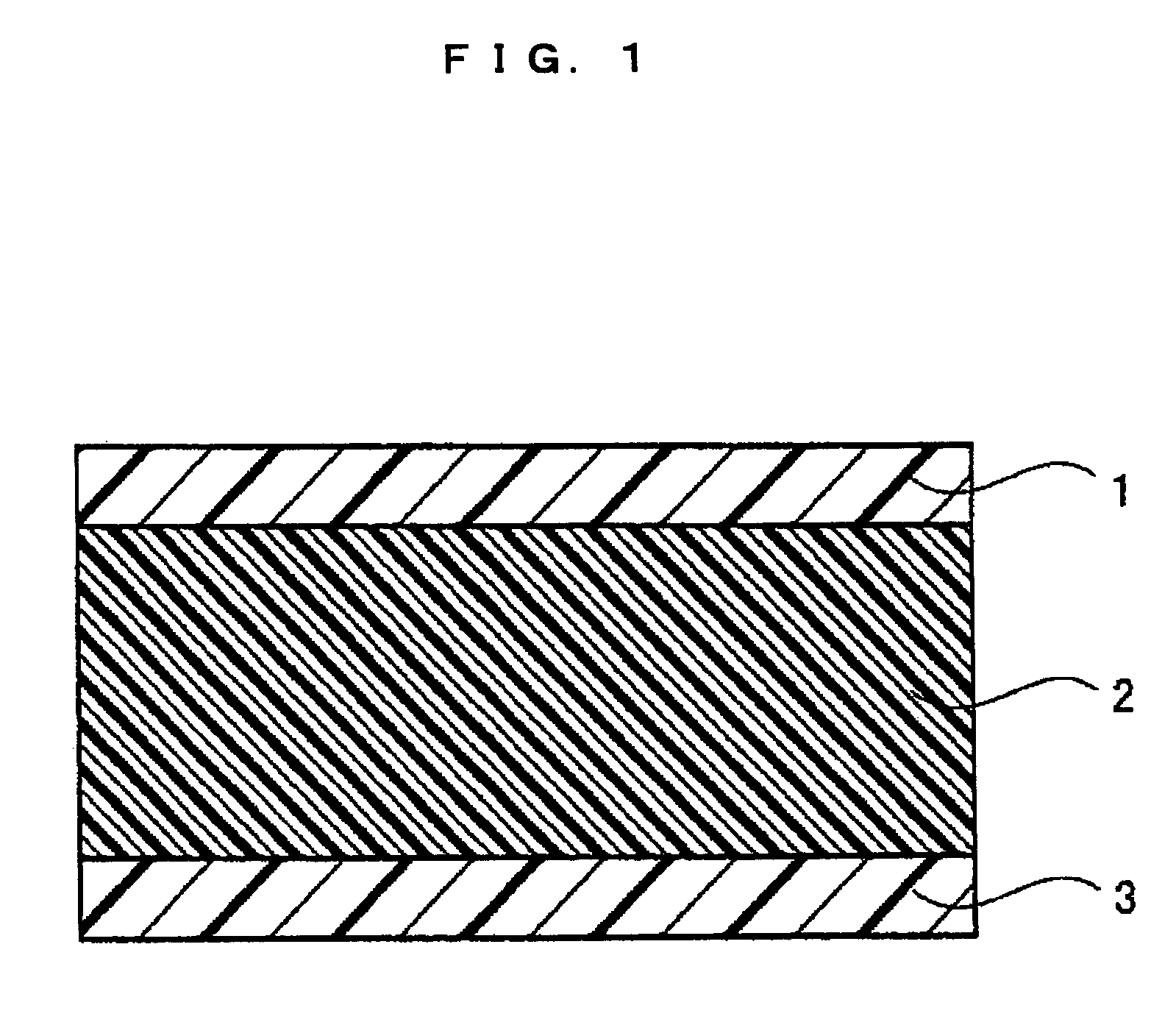

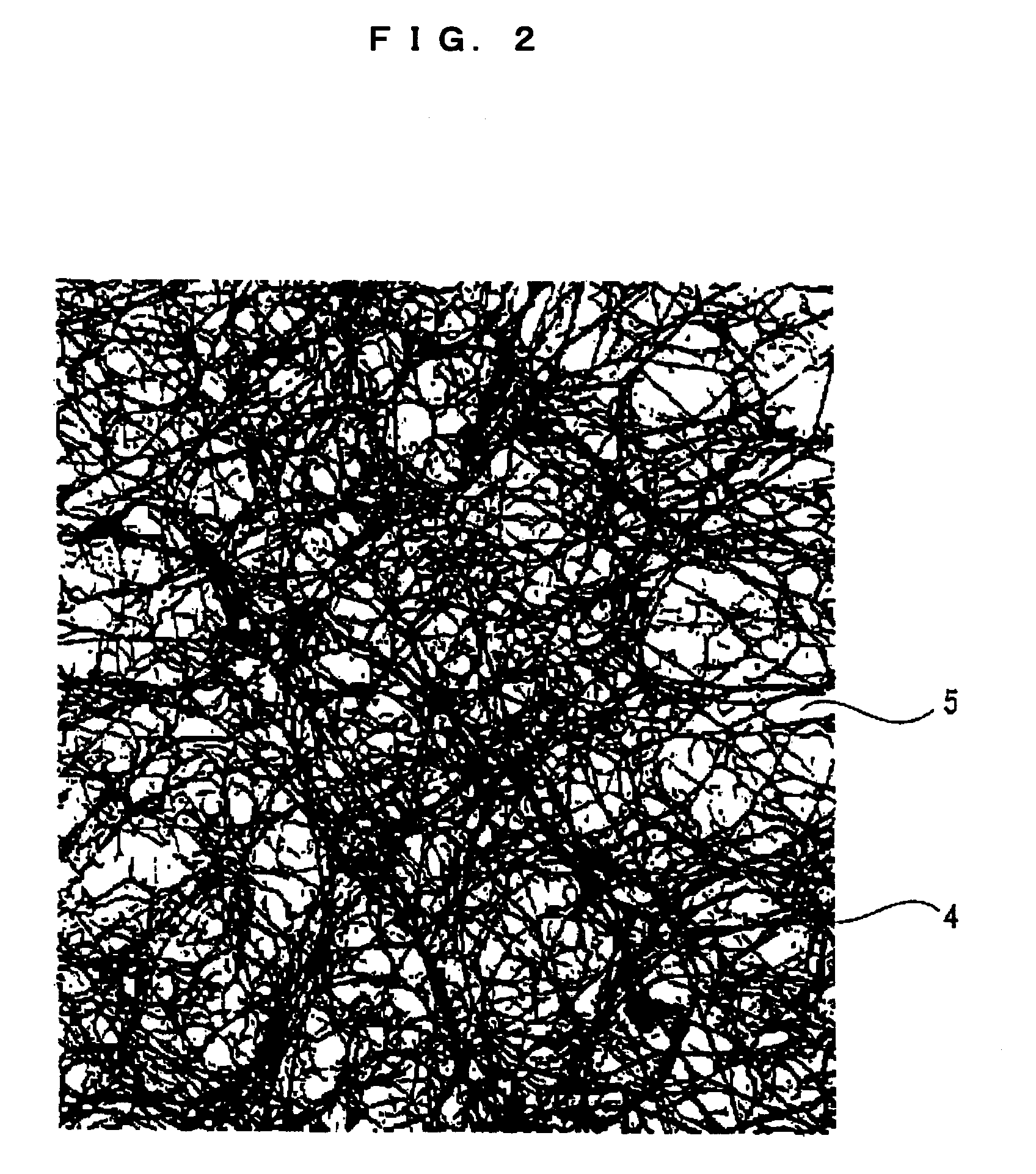

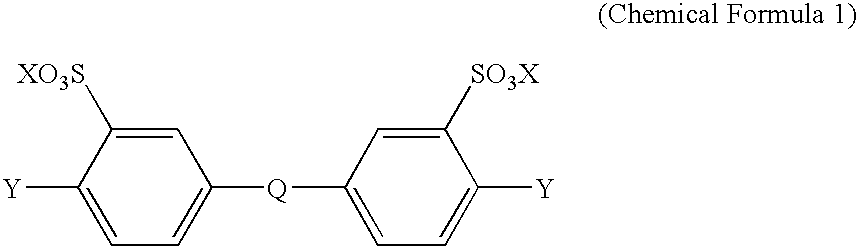

Composite ion-exchange membrane

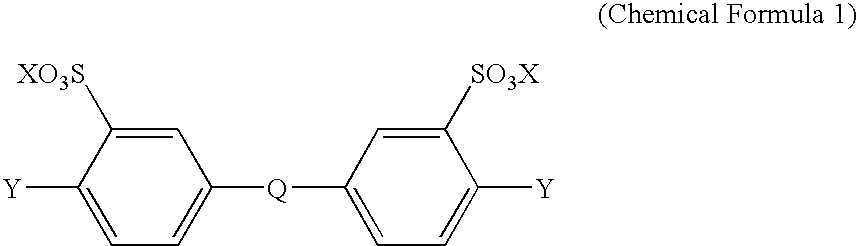

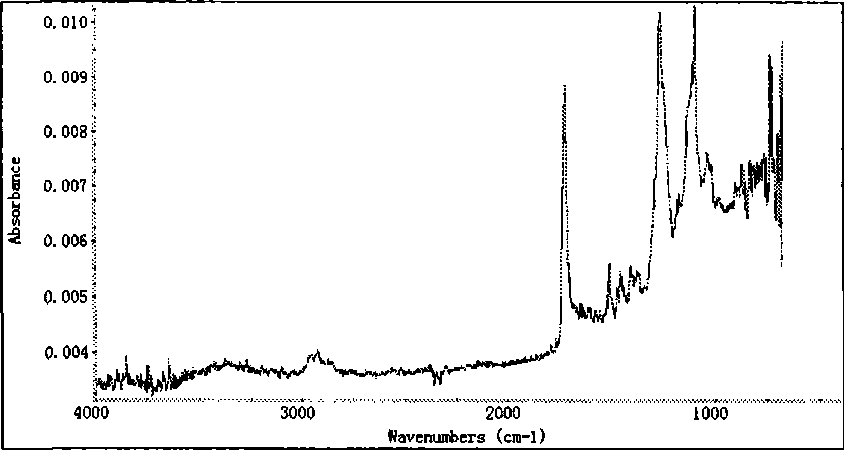

InactiveUS7649025B2Increased swelling resistanceImprove conductivityElectrolyte holding meansSolid electrolytesOrganic solventIon-exchange membranes

A composite ion exchange membrane having a high swelling resistance and being superior in mechanical strength and ion conductivity can be provided by means of an composite ion exchange membrane including an ion exchange resin composition and a support membrane having a continuous pore penetrating the support membrane, wherein the support membrane is one which accepts the ion exchange resin composition within the pore, and wherein the ion exchange resin composition is one which contains an ion exchange resin containing, as a main component, an aromatic polyether and / or its derivative, the aromatic polyether being obtained by mixing a compound having a specific structure, an aromatic dihalogenated compound and a bisphenol compound with a carbonate and / or a bicarbonate of an alkali metal and polymerizing the mixture in an organic solvent.

Owner:TOYOBO CO LTD

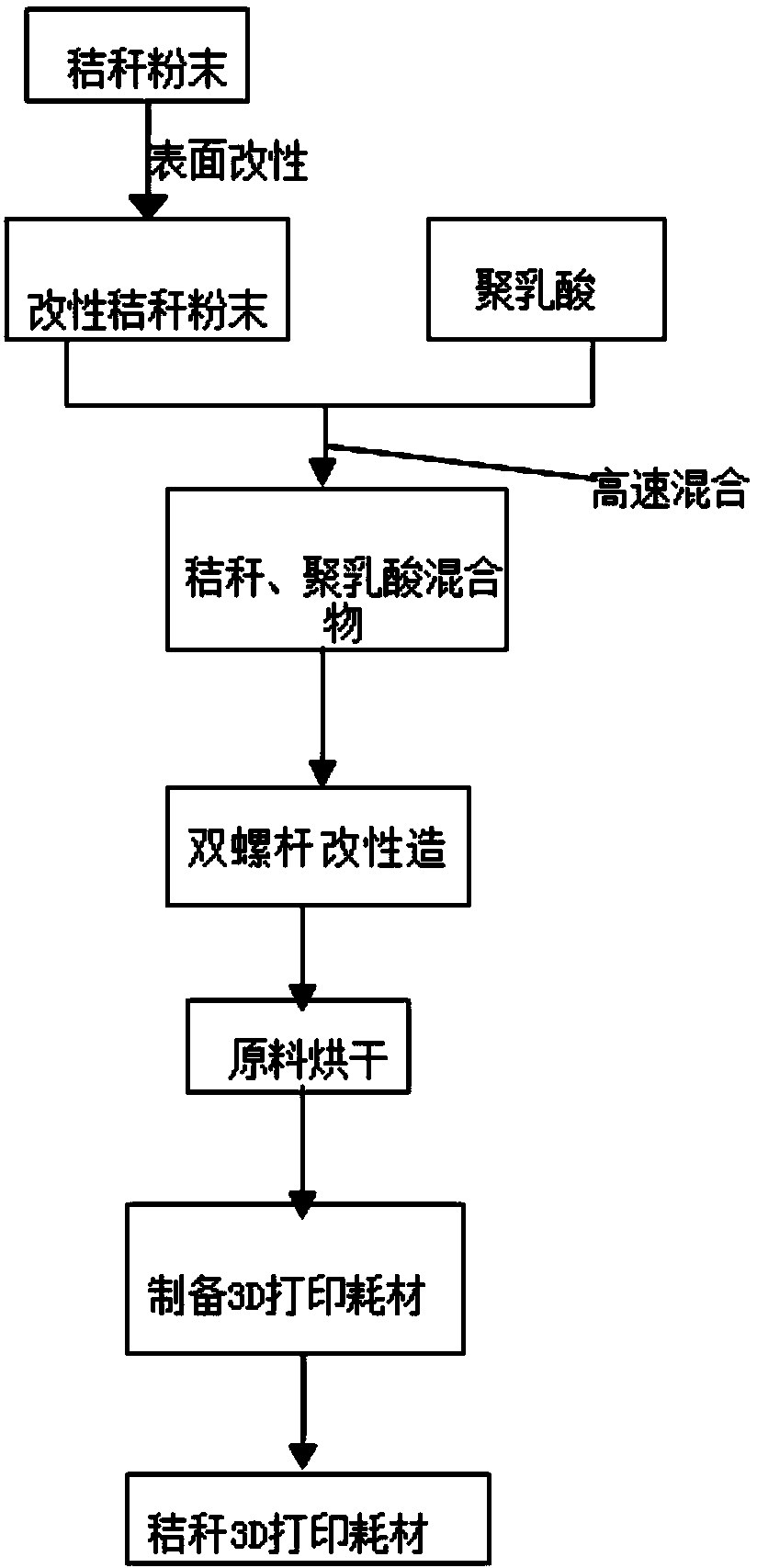

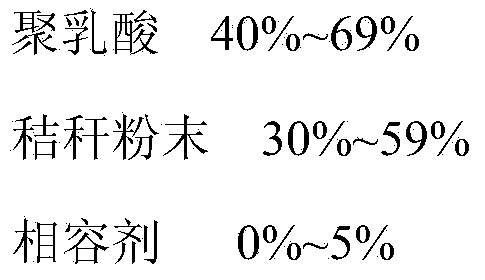

Straw 3D printing consumable and preparation method thereof

The invention provides a straw 3D printing consumable and a preparation method thereof. The formula includes the following raw materials in mass percentage: 40 to 69 percent of polylactic acid, 30 to 59 percent of straw powder, 0 to 5 percent of a compatilizer, and 0.2 to 3 percent of other additives. Straws, a crop byproduct, are fully utilized by the straw 3D printing consumable for surface modification, and the degradable material polylactic acid is added for melt blending. Compared with the prior art, the 3D printing material provided by the invention has stable performances, can replace common 3D plastic consumables in 3D printing, is non-toxic, low-carbon and environment-friendly, and has superior comprehensive performances, thereby achieving considerable economic value and broad market prospects.

Owner:芜湖瀚博电子科技有限公司

Composite ion-exchange membrane

InactiveUS20060241192A1High swelling resistanceSuperior in mechanical strength and ion conductivityElectrolyte holding meansSolid electrolytesIon-exchange membranesDicarbonate

A composite ion exchange membrane having a high swelling resistance and being superior in mechanical strength and ion conductivity can be provided by means of an composite ion exchange membrane including an ion exchange resin composition and a support membrane having a continuous pore penetrating the support membrane, wherein the support membrane is one which accepts the ion exchange resin composition within the pore, and wherein the ion exchange resin composition is one which contains an ion exchange resin containing, as a main component, an aromatic polyether and / or its derivative, the aromatic polyether being obtained by mixing a compound having a specific structure, an aromatic dihalogenated compound and a bisphenol compound with a carbonate and / or a bicarbonate of an alkali metal and polymerizing the mixture in an organic solvent.

Owner:TOYO TOYOBO CO LTD

Nano-pore SiO2 aerogel thermal insulation composite material and preparation method thereof

The invention discloses a nano-pore SiO2 aerogel heat-insulating composite material and a preparation method thereof. The nano-pore aerogel heat-insulating composite material comprises SiO2 aerogel, an infrared opacifier and reinforced fibers. The preparation method comprises: mixing silicasol and indium-tin oxide ITO nano alcohol slurry or nano composite alcohol slurry of ITO and TiO2 through supersonic wave action, mixing the mixture and the reinforced fibers, directly pouring the mixture into a die to form a wet gel complex, and performing supercutical fluid drying. The material has good heat transfer function and good obstructing function on solid heat conduction, air heat convection and infrared radiation heat conduction, simultaneously has good hydrophobicity, simple technique, low cost and wide application scope, has the mechanical strength reaching more than 1.2 MPa, and can be used in situations with higher heat protection requirement in the fields of avigation, spaceflight, military affairs and domestic use.

Owner:CHANGSHA XINGNA AEROGEL

Method to prepare processable polyimides with reactive endgroups using 1,3-bis (3-aminophenoxy) benzene

InactiveUS6133401AImprove adhesionImprove composite effectSynthetic resin layered productsThin material handlingSolubilityAdhesive

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300 DEG C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NAT AERONAUTICS & SPACE ADMINSTRATION NASA THE

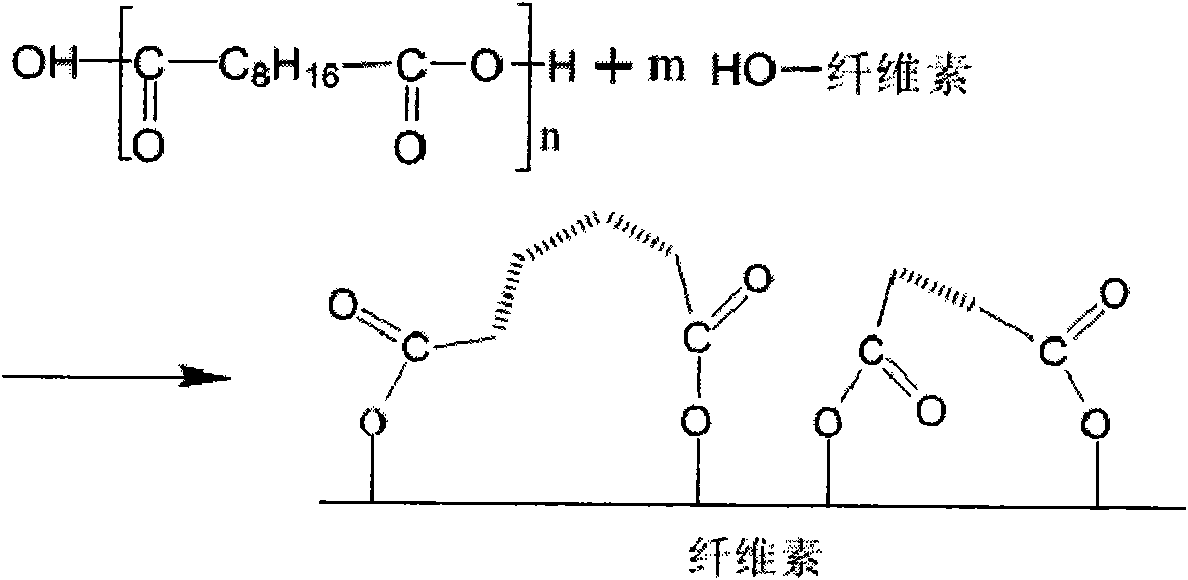

Cellulose filled thermoplastic composites

InactiveUS7041716B2Improve composite effectImproved flexural and strength and impact propertyCosmetic preparationsToilet preparationsCellulosePolyolefin

The present invention provides a thermoplastic composite comprising: a polyolefin; a cellulosic filler; a carboxylic acid and / or carboxylic acid anhydride graft polyolefin having an acid number greater than 15 mgKOH / g; and, a basic reactive filler present in an amount of 5–25 wt %, based on the weight of the composite. Such composites may be used in structural and non-structural applications and exhibit improved mechanical properties, thermal properties and / or resistance to biological degradation.

Owner:NAT RES COUNCIL OF CANADA

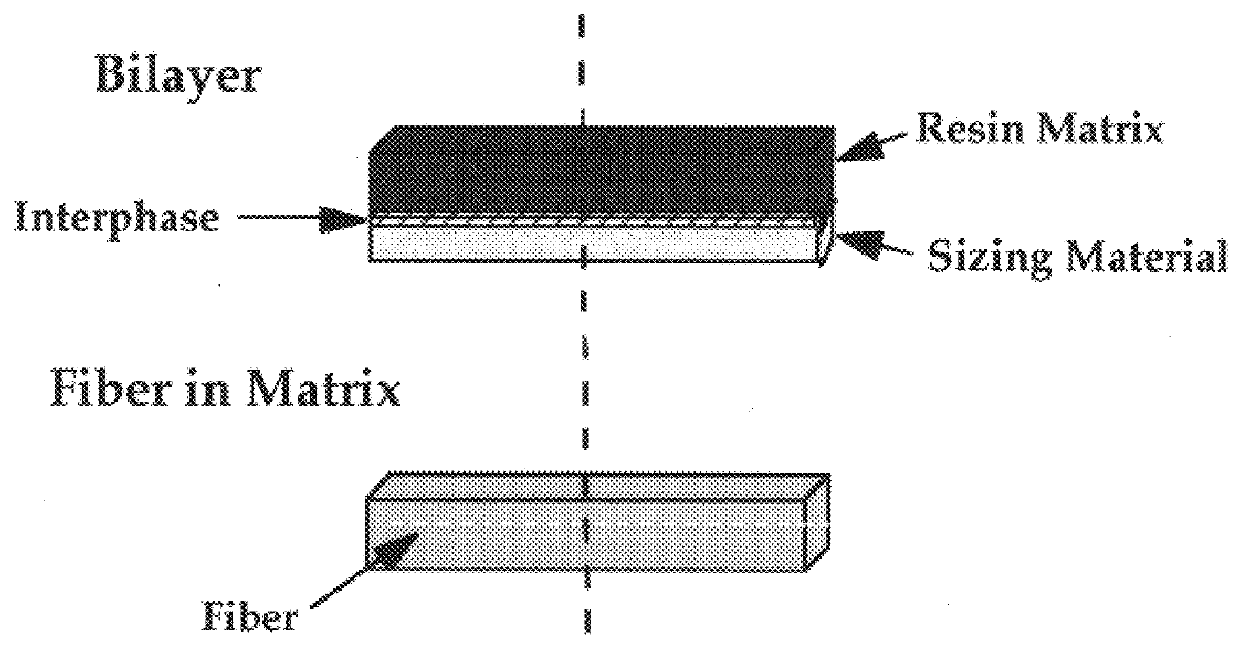

Composites of thermosetting resins and carbon fibers having polyhydroxyether sizings

InactiveUS6020063AImprove adhesionIncreased durabilityGlass/slag layered productsNatural mineral layered productsFiberPolymer science

Composite material having carbon fibers embedded in a polymeric matrix comprising a thermoset resin, where the carbon fibers are precoated with a sizing agent comprising a saturated polyurethane or polyhydroxyether before being embedded in the resin. The invention also contemplates processes for making this composite material and intermediate products thereof.

Owner:VIRGINIA TECH INTPROP INC

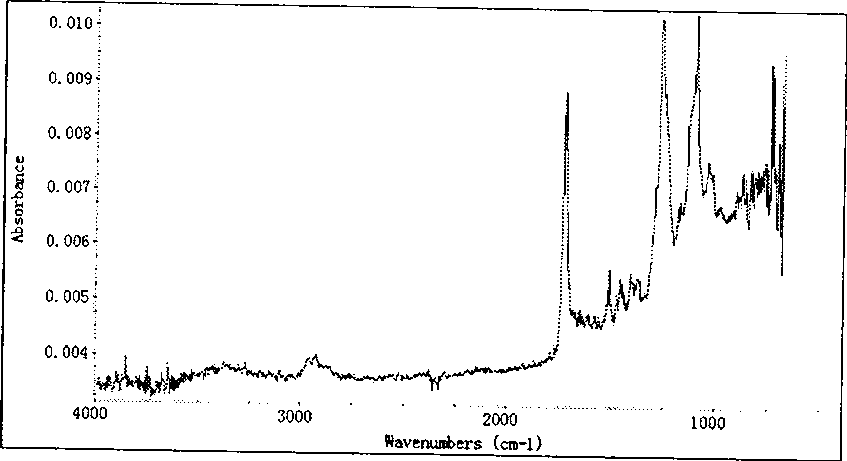

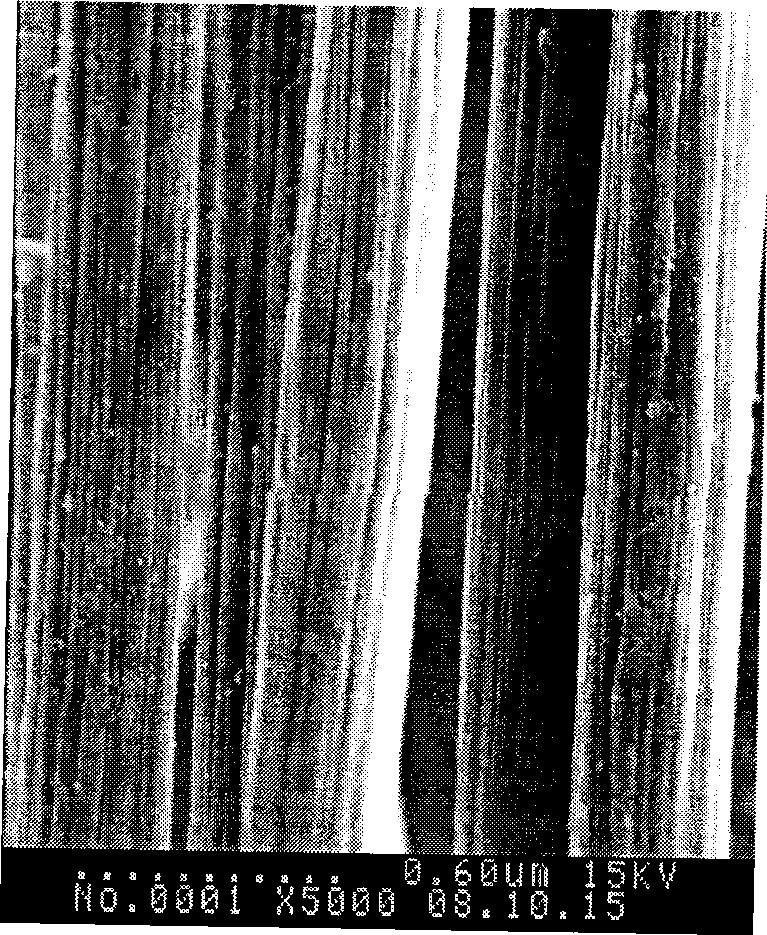

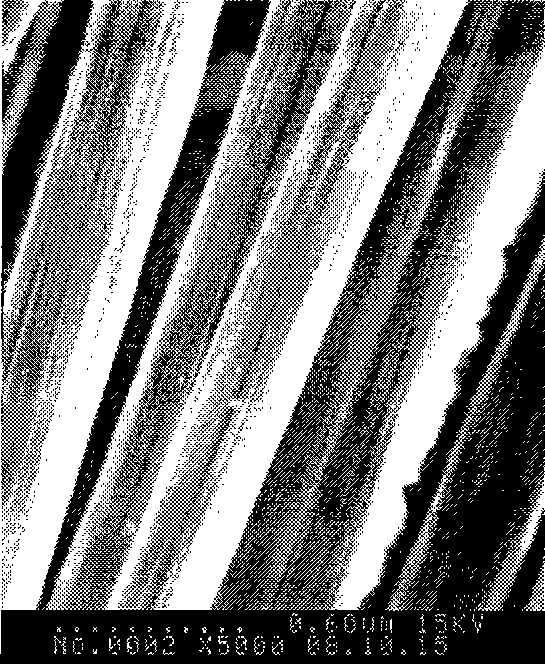

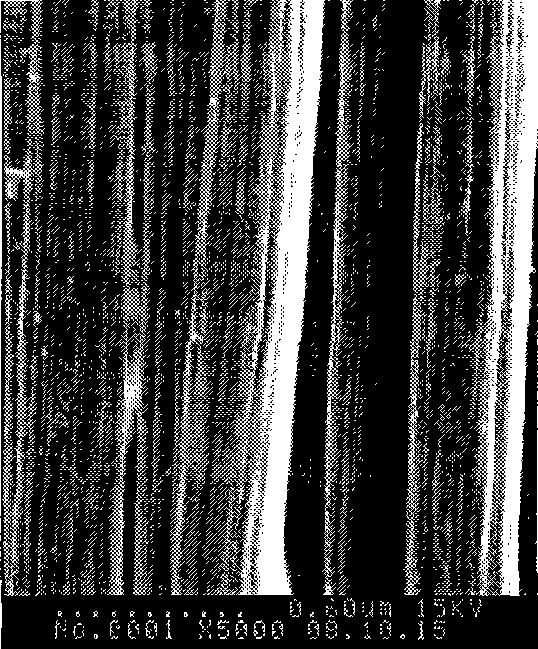

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

InactiveCN101413209AImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Aerogel heat insulation composite material containing nano semiconductor infrared light screening agent and preparation thereof

The invention discloses an aerogel thermal insulation composite material containing an infrared opacifier of nanometer semiconductor antimony tin oxide (ATO) or aluminum zinc oxide (AZO) and a method for preparing the same. The aerogel thermal insulation composite material comprises the components of SiO2 aerogel, the infrared opacifier which is nanometer ATO or nanometer AZO particles, and reinforcing fiber. Silicasol and ATO or AZO nanometer alcohol slurry can be mixed together through mechanical agitation or ultrasonic action, and the mixture flows to a fiber felt or fiber prefabricated part through a seepage process to form a wet gel complex to further perform supercritical fluid drying. The aerogel thermal insulation composite material has good thermal conductivity and good barrier effect on solid heat conduction, air heat convection and infrared radiation heat transfer, and has good hydrophobicity, simple process and low cost simultaneously; the mechanical strength of the material can reach 0.10 to 2 MPa; besides, the aerogel thermal insulation composite material has wide application range and can meet the applications in occasions with higher thermal protection requirements for aviation, aerospace, military and civil use.

Owner:CHANGSHA XINGNA AEROGEL

Cellulose filled thermoplastic composites

ActiveUS20050009960A1Enhance performanceImprove composite effectCosmetic preparationsToilet preparationsPolyolefinCellulose

The present invention provides a thermoplastic composite comprising: a polyolefin; a cellulosic filler; a carboxylic acid and / or carboxylic acid anhydride graft polyolefin having an acid number greater than 15 mgKOH / g; and, a basic reactive filler present in an amount of 5-25 wt %, based on the weight of the composite. Such composites may be used in structural and non-structural applications and exhibit improved mechanical properties, thermal properties and / or resistance to biological degradation.

Owner:NAT RES COUNCIL OF CANADA

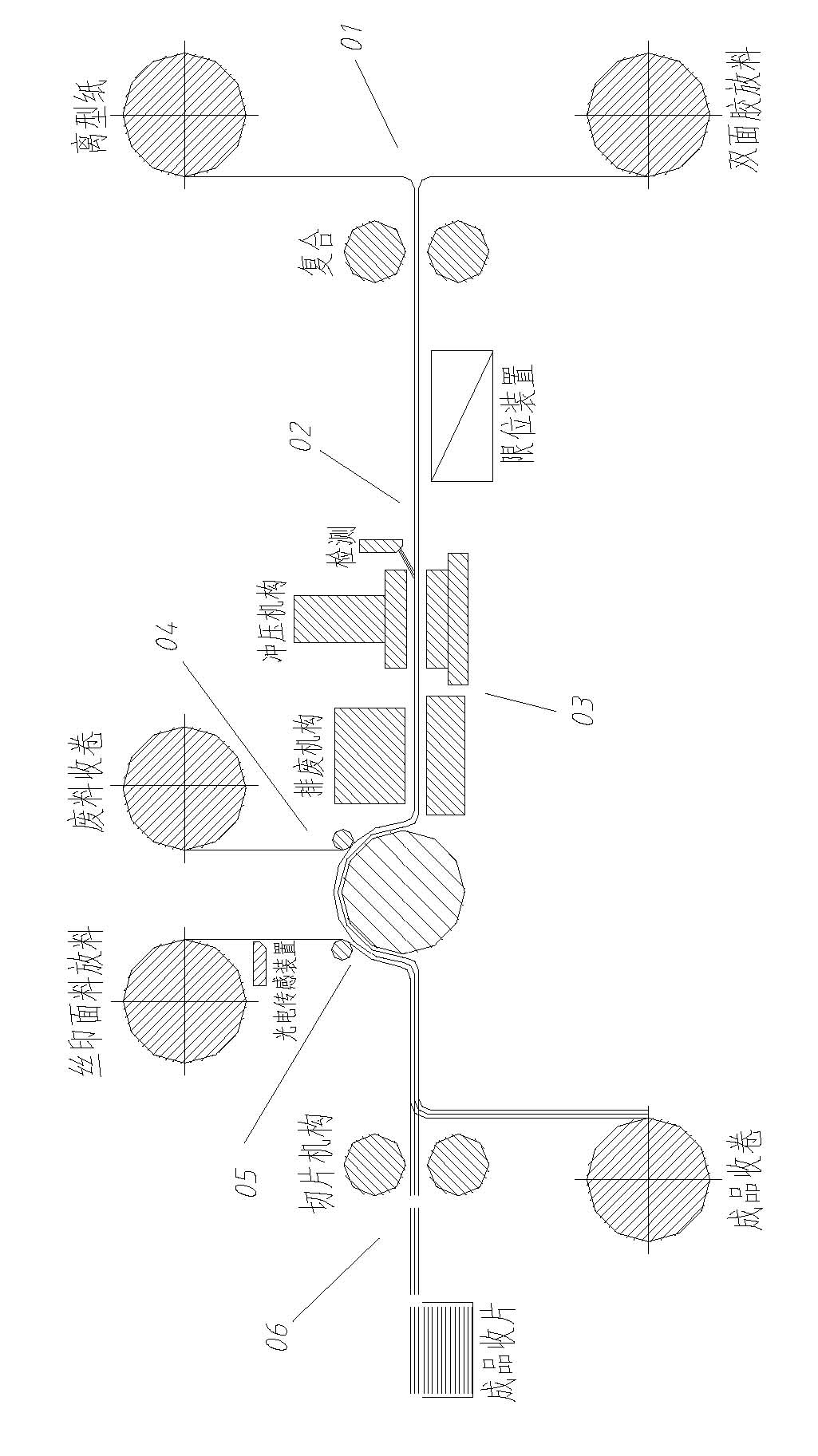

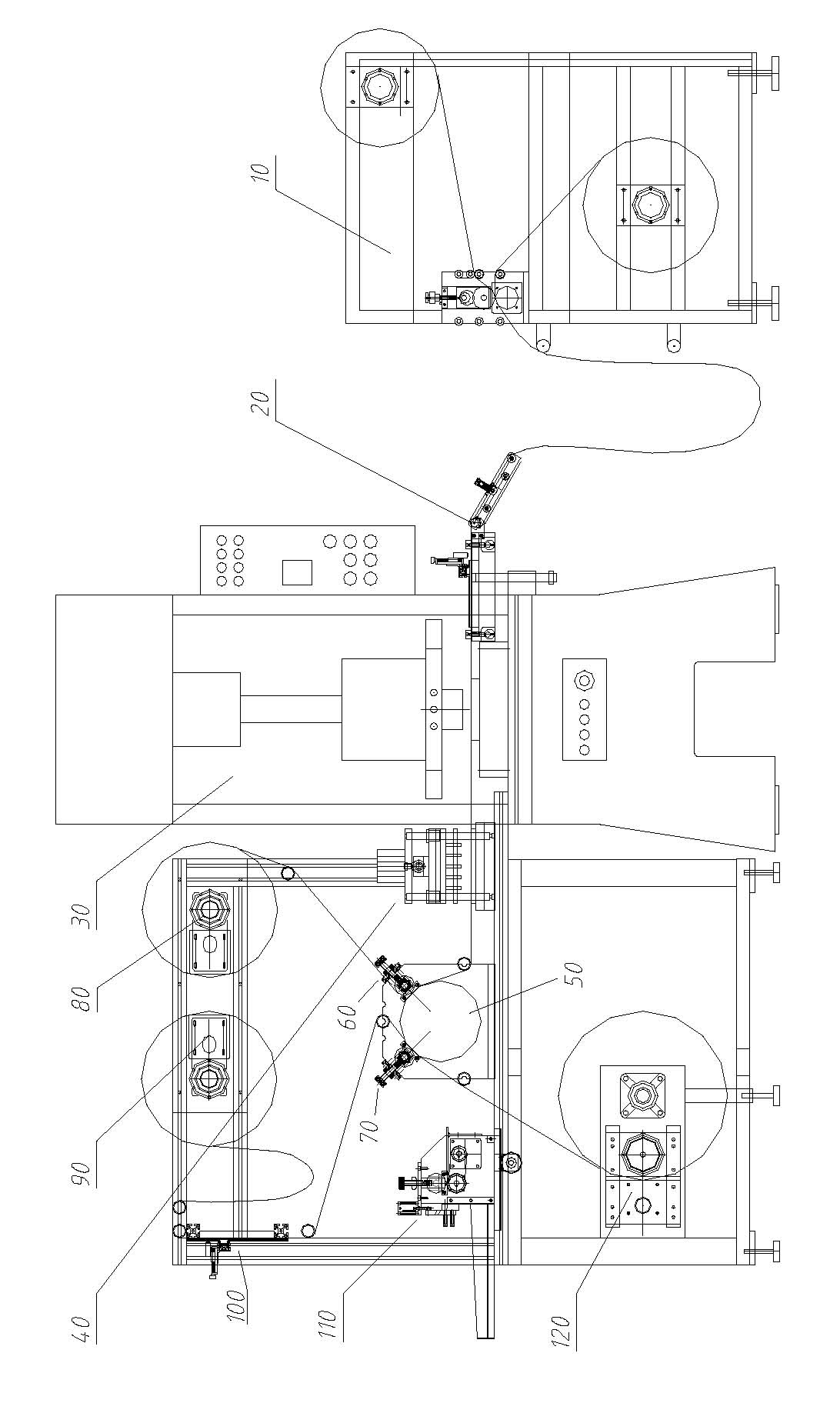

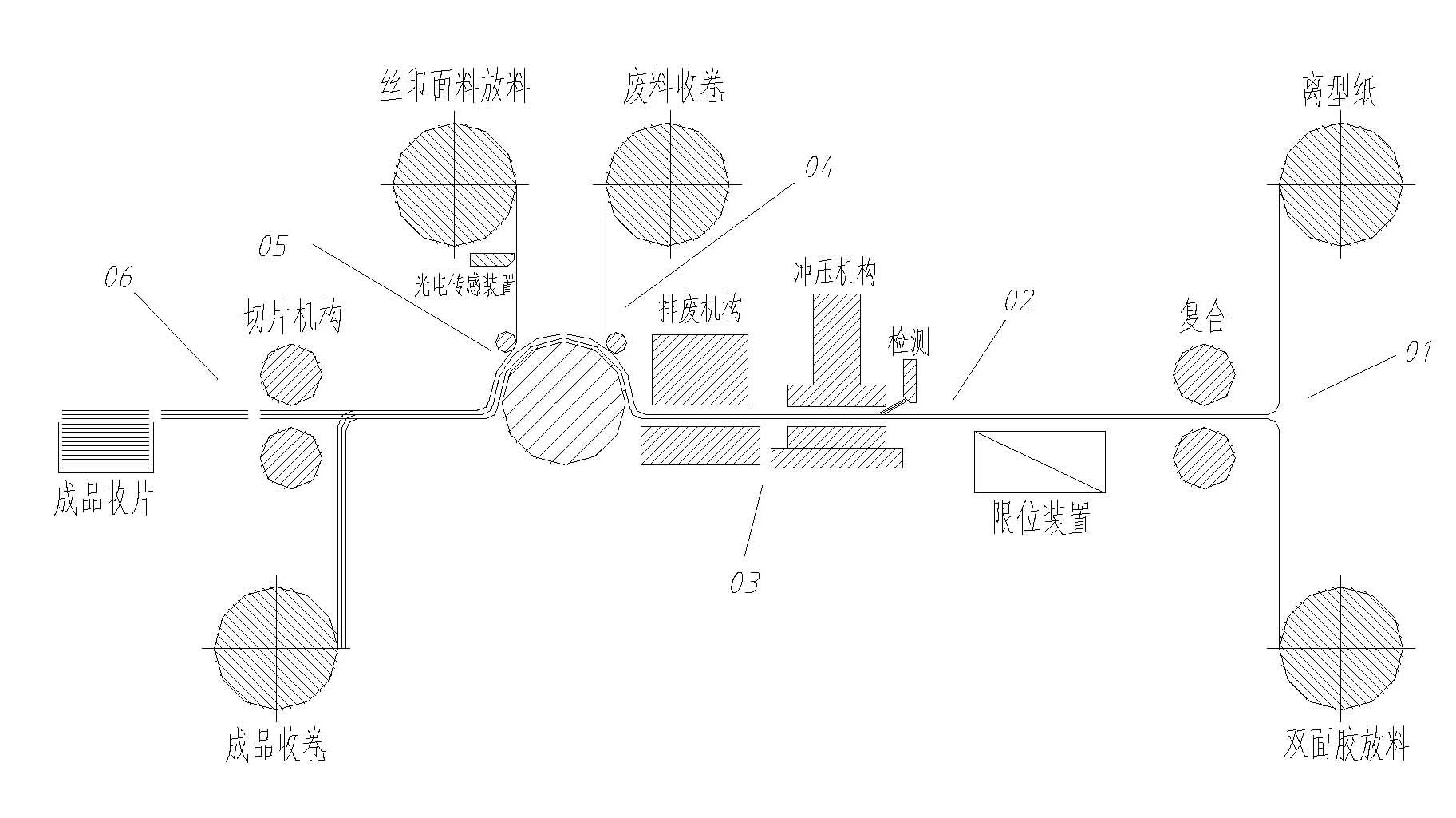

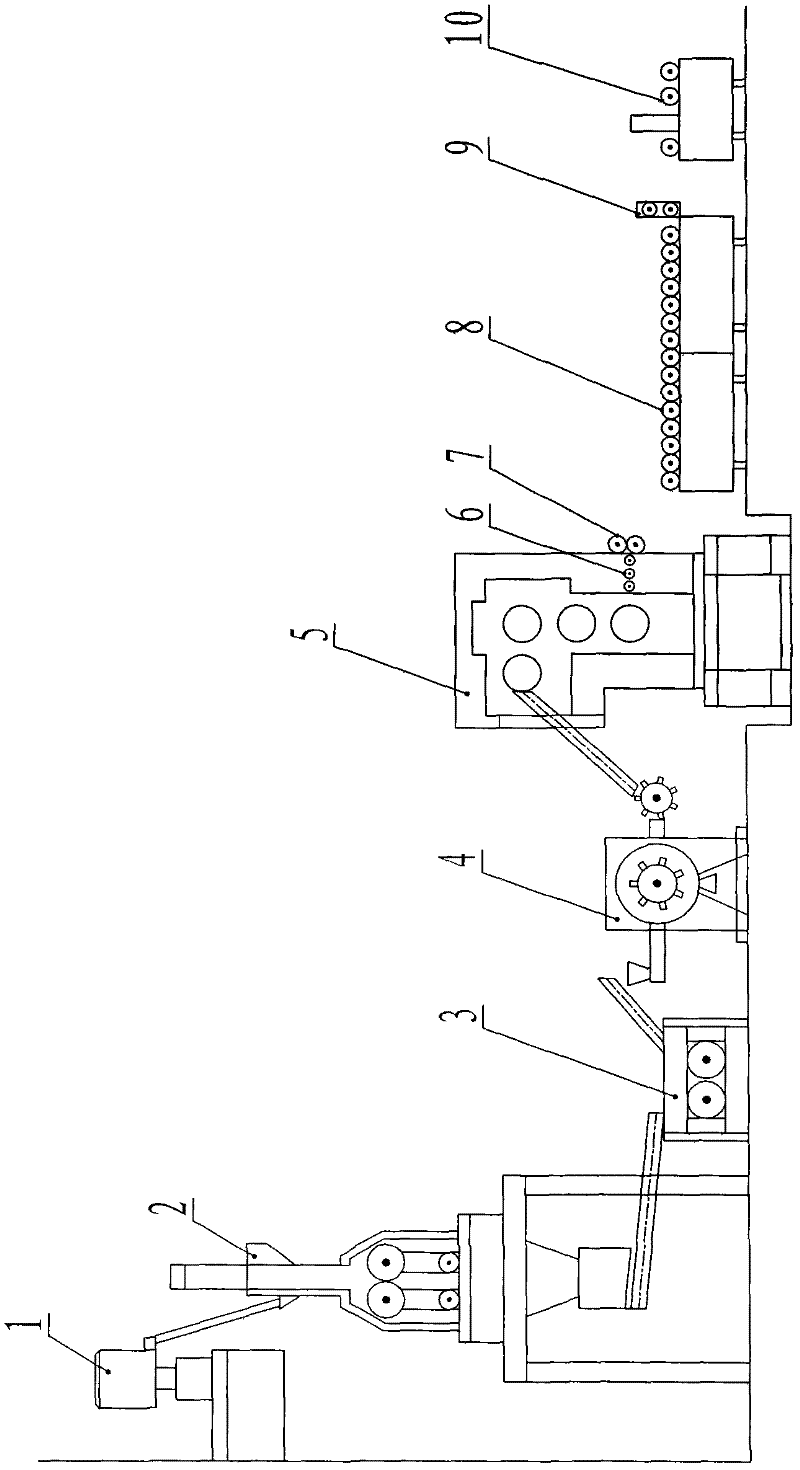

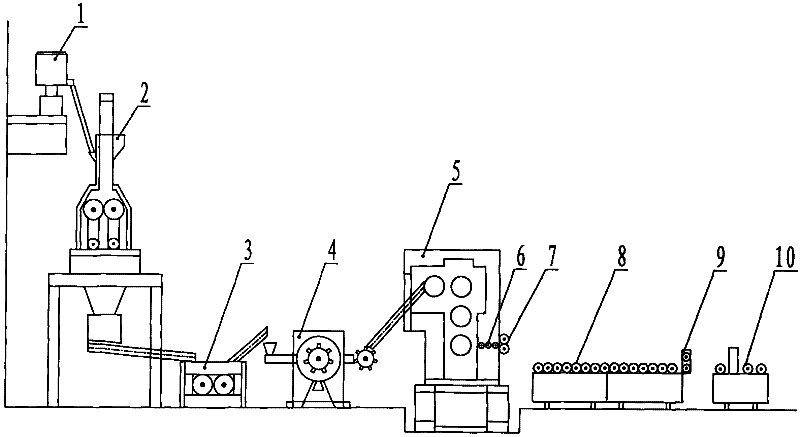

Production method and equipment for full-automatically aligning and gluing name plate

InactiveCN101850635AIncrease productivityImprove machining accuracyStampsPaper/cardboard articlesPunchingWaste collection

The invention relates to a production method and production equipment for full-automatically aligning and gluing a name plate. The method comprises the following steps of: 1, feeding; 2, detection and correction; 3, die cutting and waste punching; 4, waste discharging; 5, aligning and gluing; and 6, material collection. The production equipment comprises a composite feeding component, a loading component, a punching and die cutting machine, a waste punching mechanism, a driving roll mechanism, a driven roll pressing and discharging mechanism, a driven pressing and feeding mechanism, a waste collection shaft mechanism, a collection and discharge shaft mechanism and a photoelectric sensor, wherein the punching and die cutting machine is used for performing the die cutting process of the die cutting and waste punching by using a wood plate cutter as a cutting die; the waste punching mechanism is used for performing the punching process of the die cutting and waste punching; and the driving roll mechanism, the driven roll pressing and discharging mechanism and the driven pressing and feeding mechanism are assembled together through a machine shell. The method and the equipment have the advantages of improving the production efficiency, overcoming the potential safety hazard, improving the machining accuracy and the machining quality of the product, saving a large amount of cost and ensuring high safety of the complete machine.

Owner:深圳市瑞虎自动化科技有限公司 +1

Manufacture method of high-strength TPU (thermoplastic polyurethane) compound fabric

ActiveCN102390152AUniform thicknessHigh film strengthLamination ancillary operationsSynthetic resin layered productsThermoplastic polyurethaneHigh intensity

The invention discloses a manufacture method of a high-strength TPU (thermoplastic polyurethane) compound fabric, which solves the problems of uneven film, low yield and high cost of the TPU compound fabric produced by adopting the traditional production method of the TPU compound fabric. A TPU film is produced with high production efficiency and low cost by adopting a process of calendering with a four-roller calendar. Because the produced TPU film has uniform thickness, the produced high-strength fabric has the advantages of uniform cloth, good compound fabric, high coating strength, high airtightness and high abrasive resistance, and can be widely applied to the fields of airships, surface-effect ships, oil containment booms, lifesaving devices, supplementary restraint systems and the like.

Owner:无锡翔隆高分子面料有限公司

Concrete air-entrainer

The preparation method for a concrete air-entrainer comprises: 1) putting the rosin, tallol, triterpenoid saponin and lignin by weight ratio into a reaction kettle to heat and fuse while stirring evenly to prepare the mixed resin A; 2) adding the maleic anhydride and quinone to modify the resin A and obtain the resin B; 3) dripping the carbowax or the mixture of carbowax and pentaerythrite for graft esterification reaction at 180~250Deg to obtain the product C; 4) cooling the kettle temperature to 50~100Deg, adding foam stabilizer D and E; 5) cooling the temperature to 20~95Deg, dripping lye and water to control the solid material in solution as 29~31% and pH value as 9~11, and obtaining the final product. This invention has wide application.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

Method for carbon fiber surface modification of plasma coated with silicon dioxide by plasma treatment

InactiveCN101413210AImprove surface propertiesImprove performancePhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano dioxide sol through plasma treatment, which comprises the following steps: firstly, nano silicon dioxide is prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles and silicon dioxide nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating or padding and so on, and dried; and thirdly, the carbon fiber is placed on a plasma transport unit and a plasma is sprayed on the surface of the carbon fiber to generate modification, wherein the treating power is between 10 and 15,000 watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the carbon fiber, improves the molded manufacturability and the overall properties of composite materials of the carbon fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Nano-hole aerogel heat-insulating composite material and preparation method thereof

The invention discloses a nano-hole aerogel heat-insulating composite material and a preparation method thereof. The nano-hole aerogel heat-insulating composite material comprises SiO2 aerogel, ITO nano powder material or nano compound powder material of ITO and TiO2, and reinforced fiber felt or prefabricated body. Through action of ultrasonic wave, silicon gel and ITO nano alcohol slurry or nano compound alcohol slurry of ITO and TiO2 are mixed and then flow into the fiber felt or the prefabricated body through infiltration technology to form wet gel compound to be subjected to supercritical fluid drying. The material has good heat transfer and obstruction functions for solid heat transfer, air heat convection and far infrared radiation heat transfer, has good hydrophobic property at the same time, and has simple process and low cost; the mechanical strength can reach 0.10 to 2MP; and the material has wide application range, and can meet higher requirement of heat protection in navigation, spaceflight, military affairs and civilian use.

Owner:CENT SOUTH UNIV

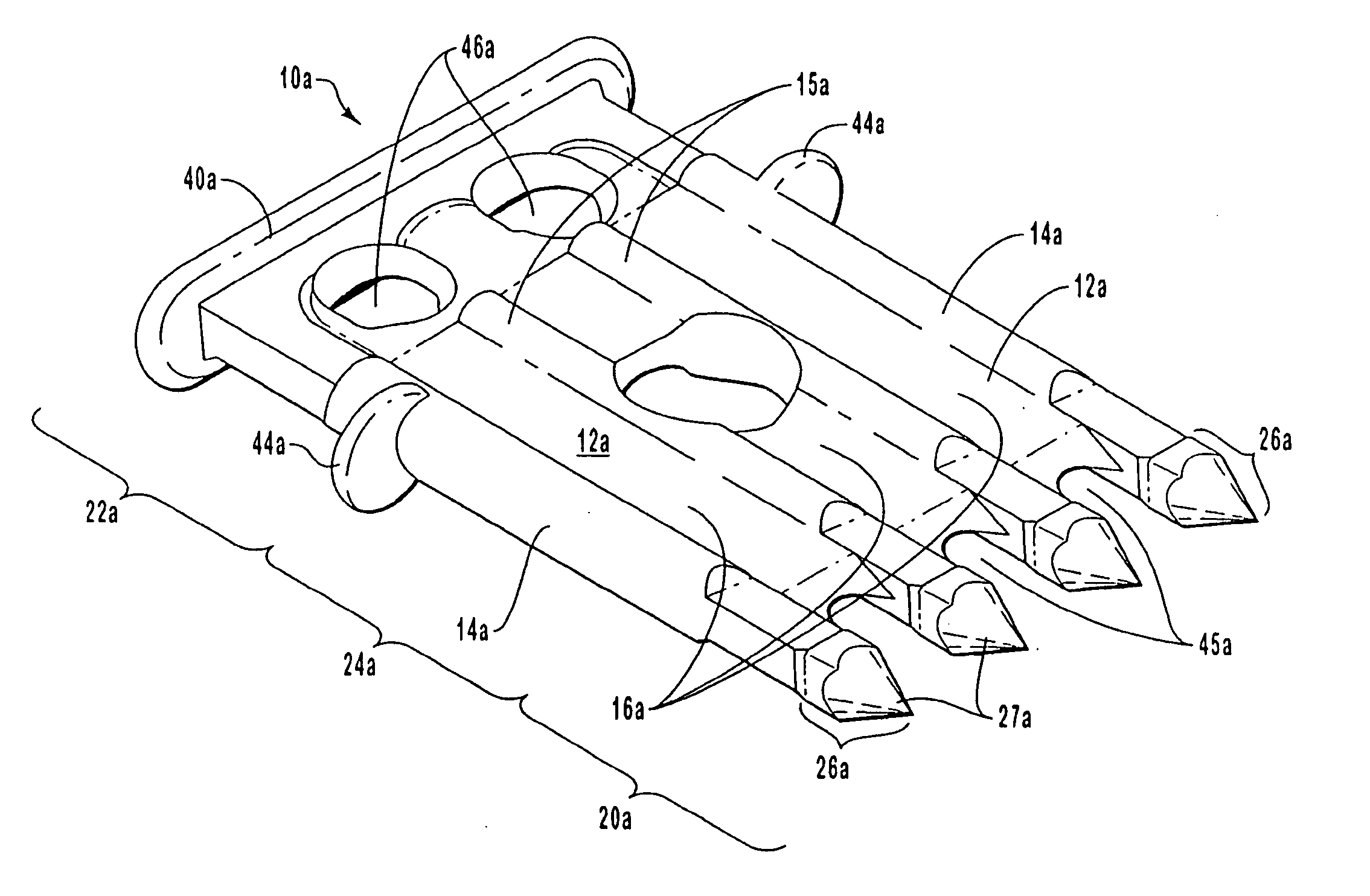

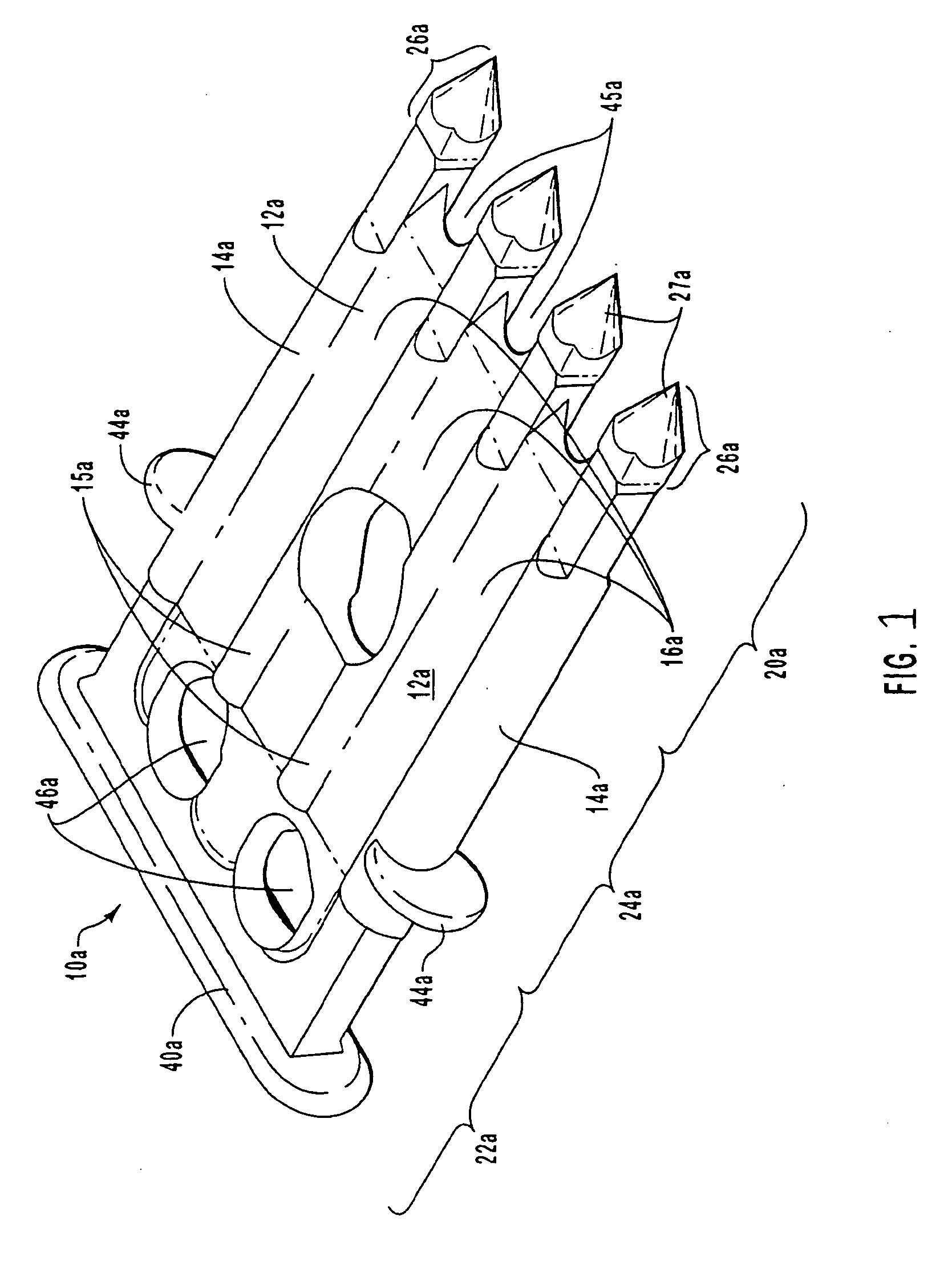

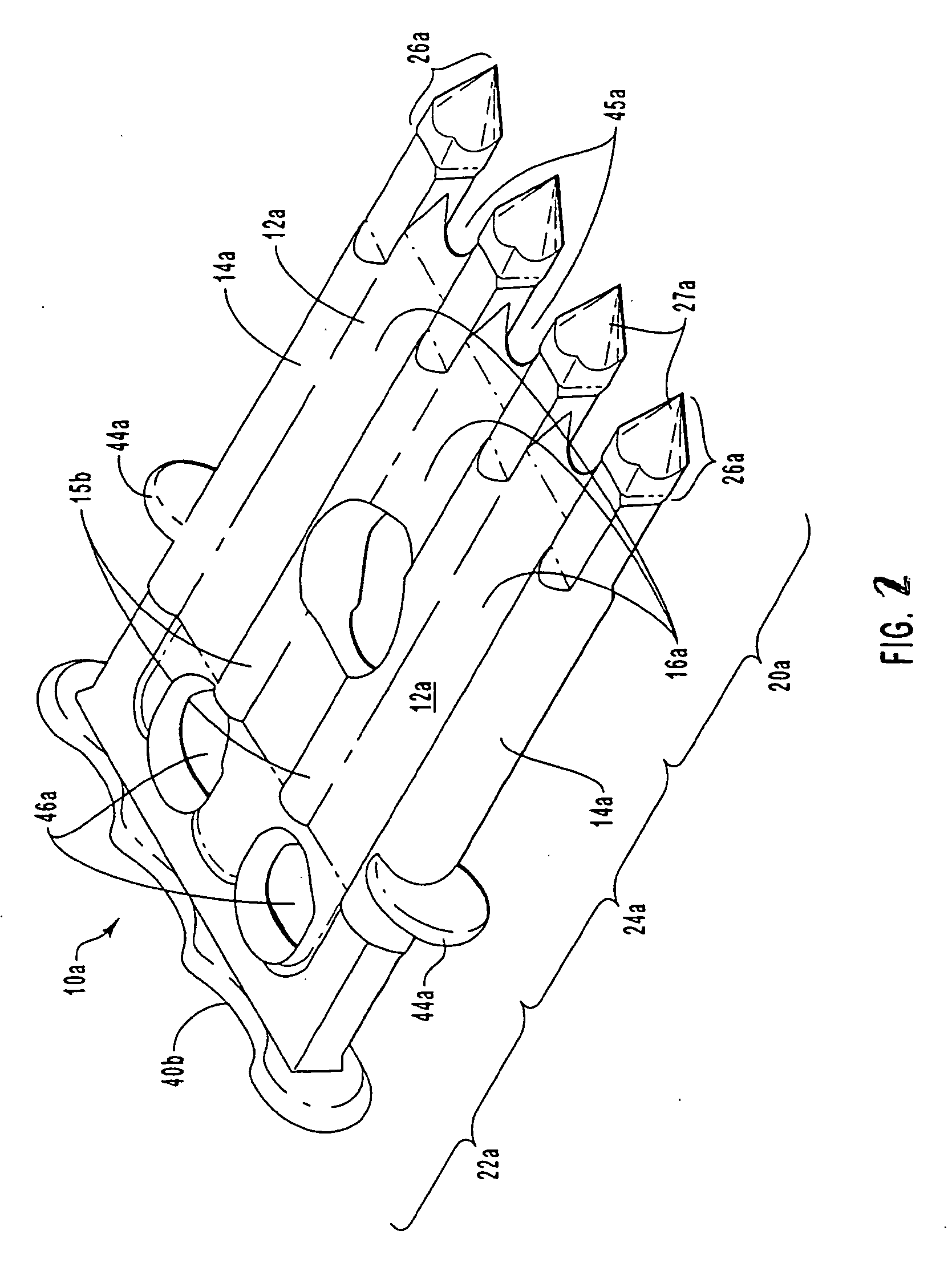

High strength composite wall panel system

InactiveUS20060032166A1Improved and strong and less-expensiveImprove composite effectBuilding componentsConstructions elementsMechanical bondEngineering

The present invention is directed to improved composite action walls having an insulation wythe sandwiched between structural wythes. The structural wythes provide the load-bearing function and prevent the collapse of the wall under high wind loads. The structural wythes demonstrate composite action existing between the structural wythes such that an improved, stronger and less expensive wall may be constructed. The present invention is also directed to an insulation wythe, which is useful in the composite action wall of the present invention, having grooves formed therein such that the material of the structural wythes flow into the groove to form a mechanical bond between the structural wythes and the insulation wythe. The walls of the present invention are simple to manufacture and provide a verifiable and consistent composite action between about 50% to about 100% composite action.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

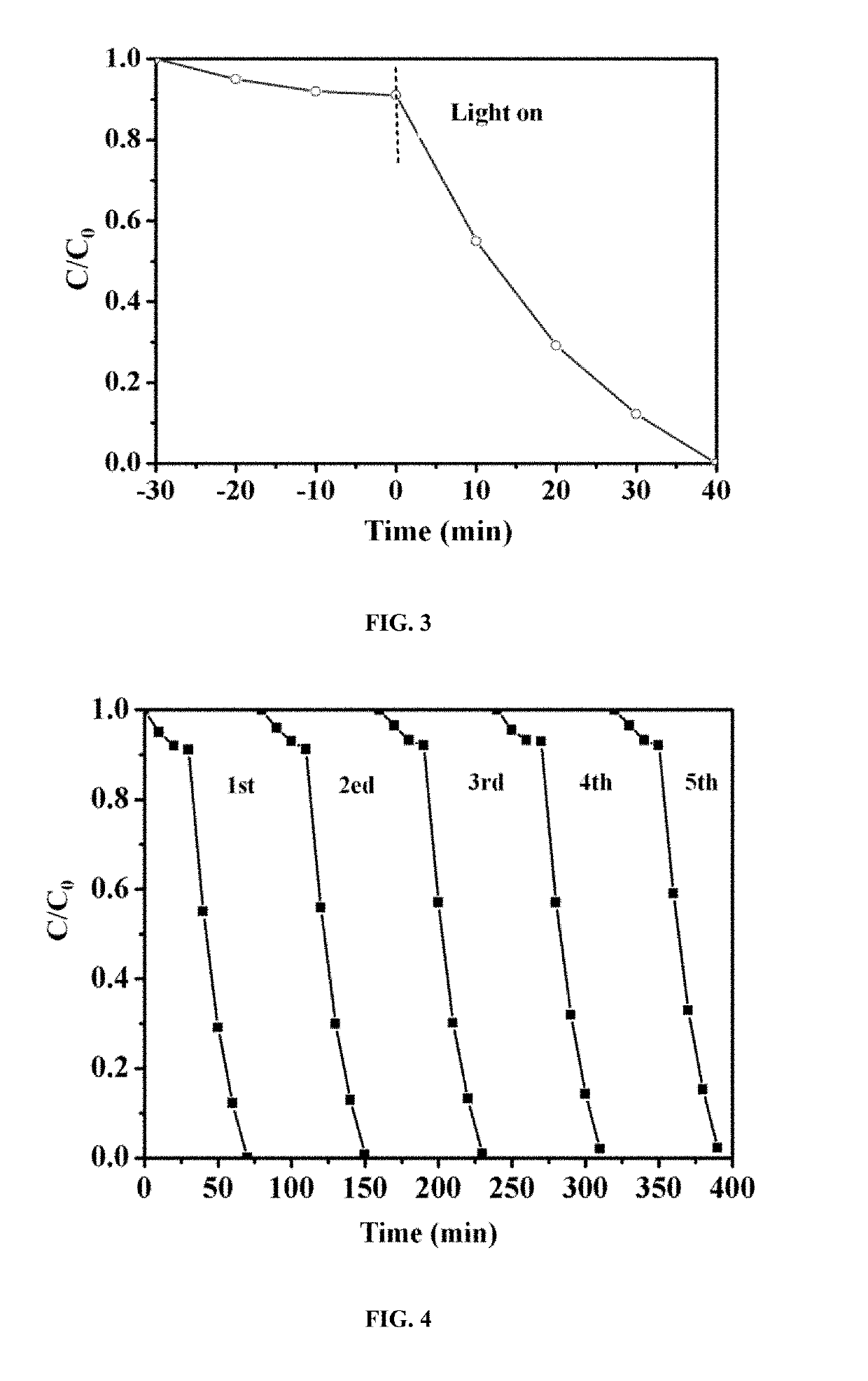

Loaded multifunctional catalysis composite material, preparation method thereof and application of composite material to catalytic removal of water pollutants

ActiveUS20190329236A1Promote full accessReduce recombination rateMaterial nanotechnologyWater/sewage treatment by irradiationPhoto catalysisNickel

The invention discloses a loaded multifunctional catalysis composite material, a preparation method thereof and an application of the composite material to catalytic removal of water pollutants. The preparation method includes the steps: preparing a zinc oxide nano-sheet loaded nickel foam (Ni@ZnO) composite material by an electro-deposition method; compounding molybdenum disulfide micro-nano particles on ZnO porous nano-sheets by an electro-deposition method to obtain Ni@ZnO / MoS2. The composite material Ni@ZnO / MoS2 combines the advantages of components such as nickel foam, the zinc oxide nano-sheets and molybdenum disulfide from the point of material performances, high catalytic degradation activity and recycled performances are achieved, photo-catalysis and electro-catalysis are combined from the point of material application, and the catalytic activity of the composite material is improved by the aid of synergistic effects of photo-catalysis and electro-catalysis.

Owner:SUZHOU UNIV

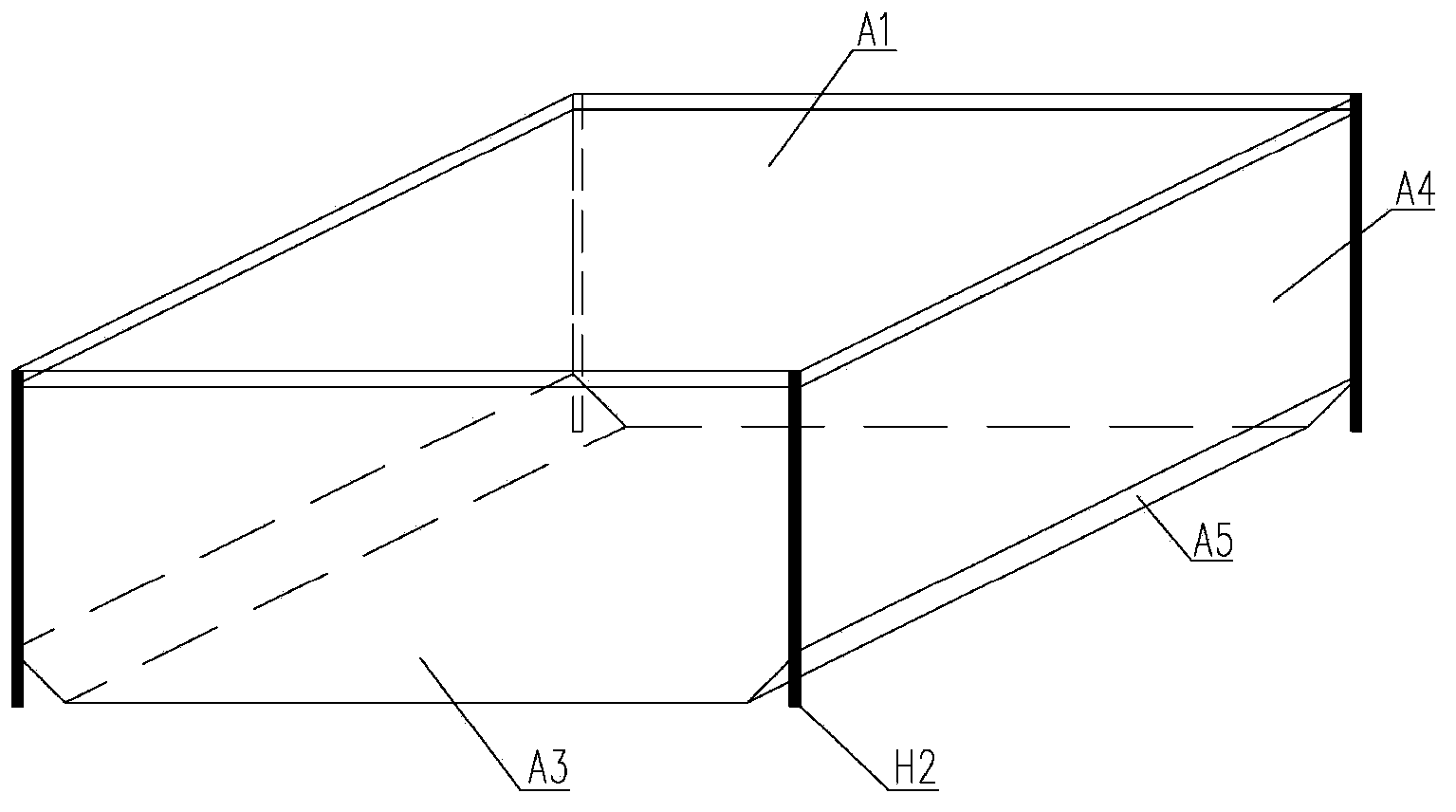

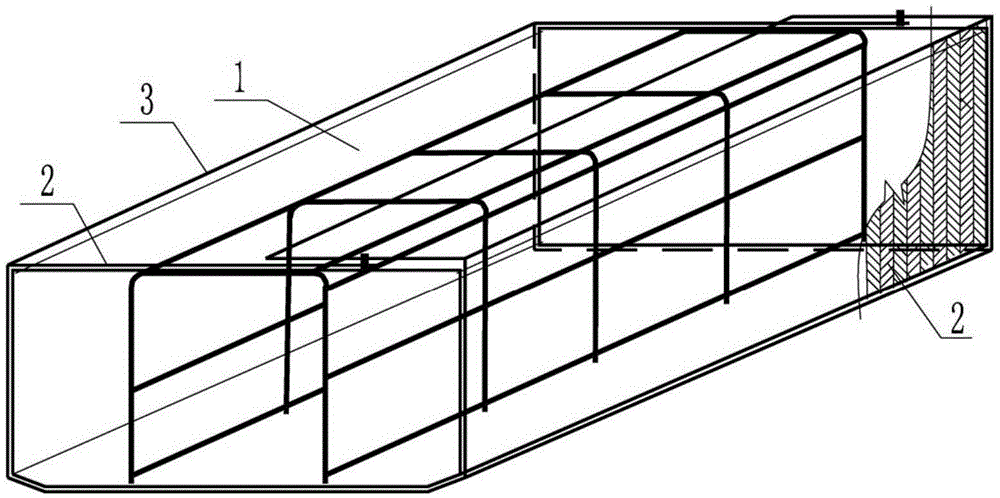

Ribbed steel engraved mesh for cast-in-place cavity floor

InactiveCN105421663AInhibitionFast productionFloorsBuilding reinforcementsSheet steelMetallic materials

The invention provides a ribbed steel engraved mesh for a cast-in-place cavity floor. The ribbed steel engraved mesh is composed of an engraved mesh, a supporting mesh and an engraved end mesh; the engraved mesh, the supporting mesh and the engraved end mesh all are made of a pure metal material; the engraved mesh forms a periphery of the ribbed steel engraved mesh; the engraved end mesh closes the ribbed steel engraved mesh and the supporting engraved mesh to form an engraved end section shape of the ribbed steel engraved mesh; the supporting mesh controls a height of an internal space of the ribbed steel engraved mesh; the engraved mesh and the engraved end mesh are fabricated from steel mesh bodies, and each steel mesh body comprises steel sheet dilated mesh holes, a V-shaped rib and a steering connecting piece; the dilated mesh holes on two sides of the steering connecting pieces are not in the same direction; the V-shaped rib is greater than 6mm high; at least four measuring fixed marks are formed by pressing on the V-shaped rib of the steel mesh body of the engraved mesh in a vertical direction; and the supporting mesh is a steel mesh body or a reinforcing mesh body; the ribbed steel engraved mesh is used for casting the cavity floor, and the ribbed steel engraved mesh is directly buried in concrete cast in place at edges of a cavity to achieve a suppression effect on temperature cracks of the floor.

Owner:王本淼 +2

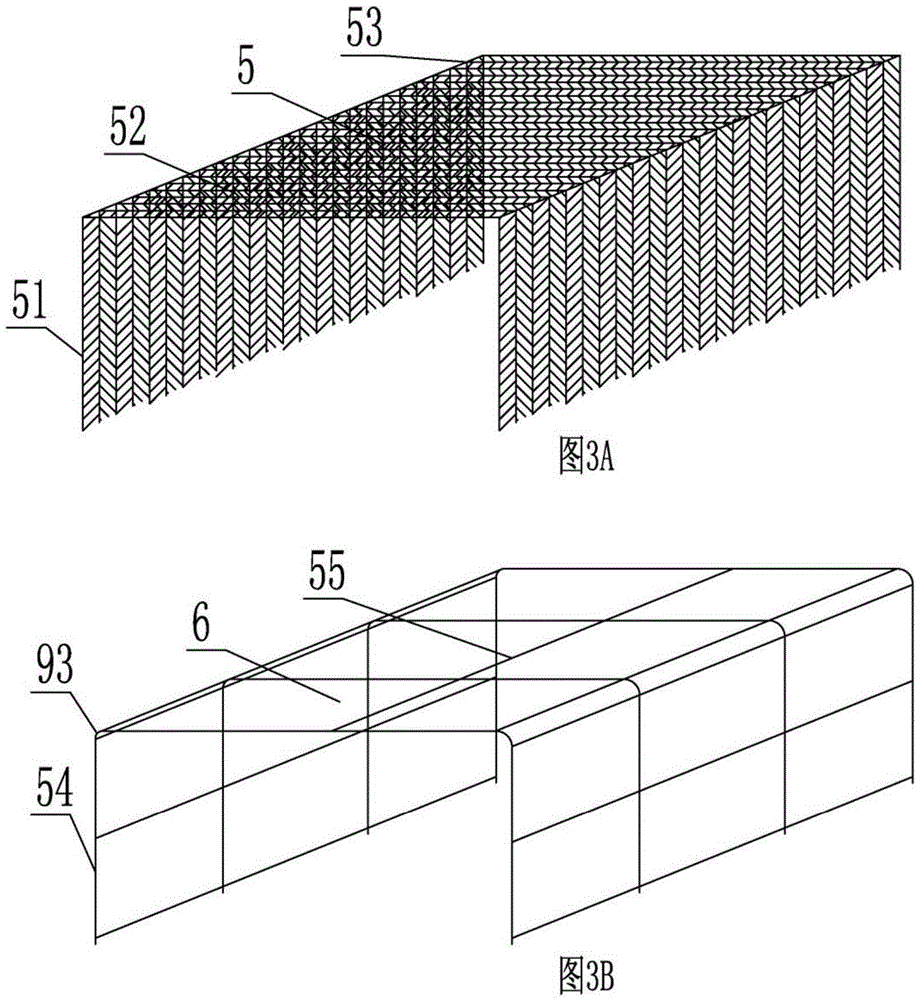

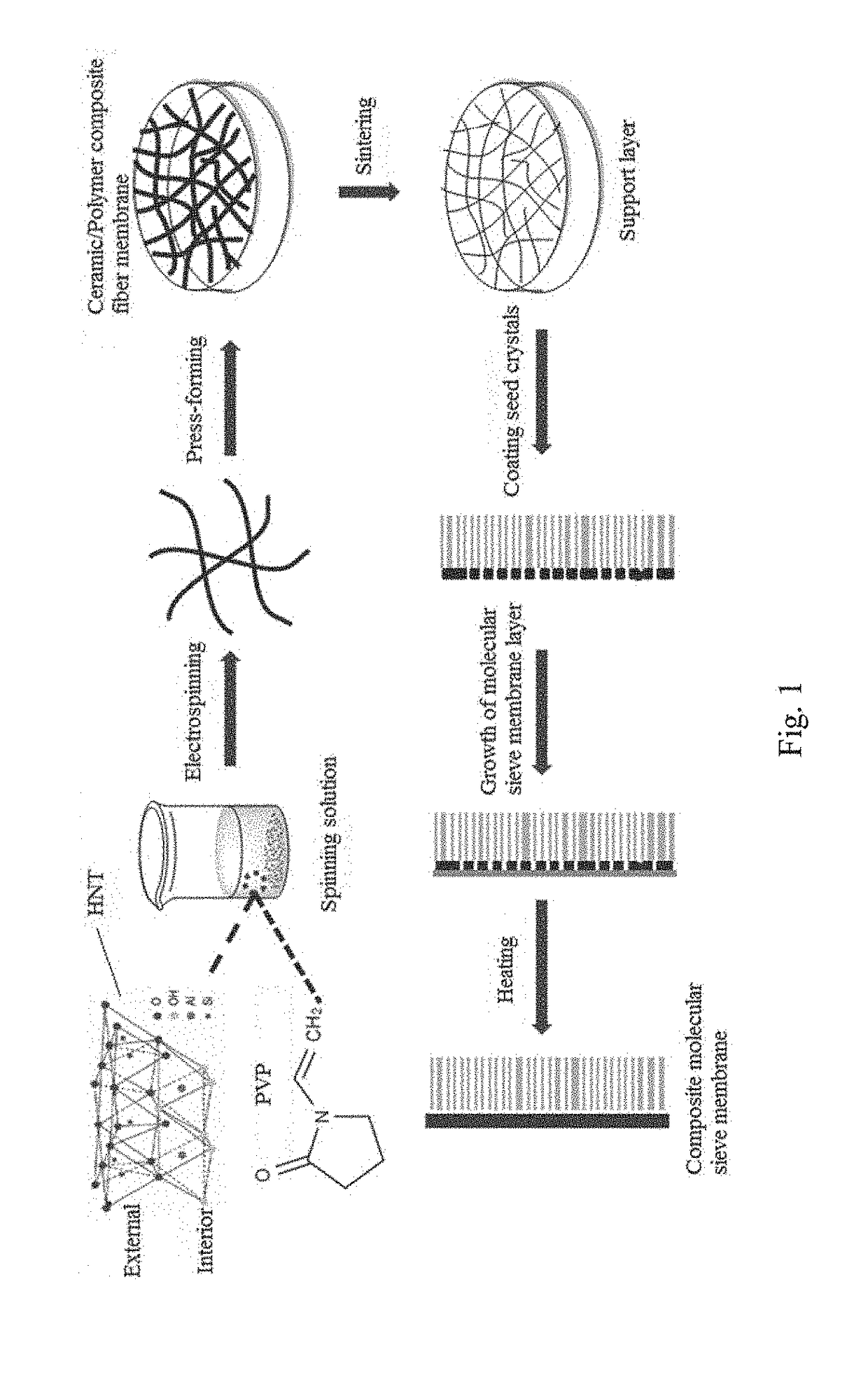

Composite molecular sieve membrane, preparation process and use thereof

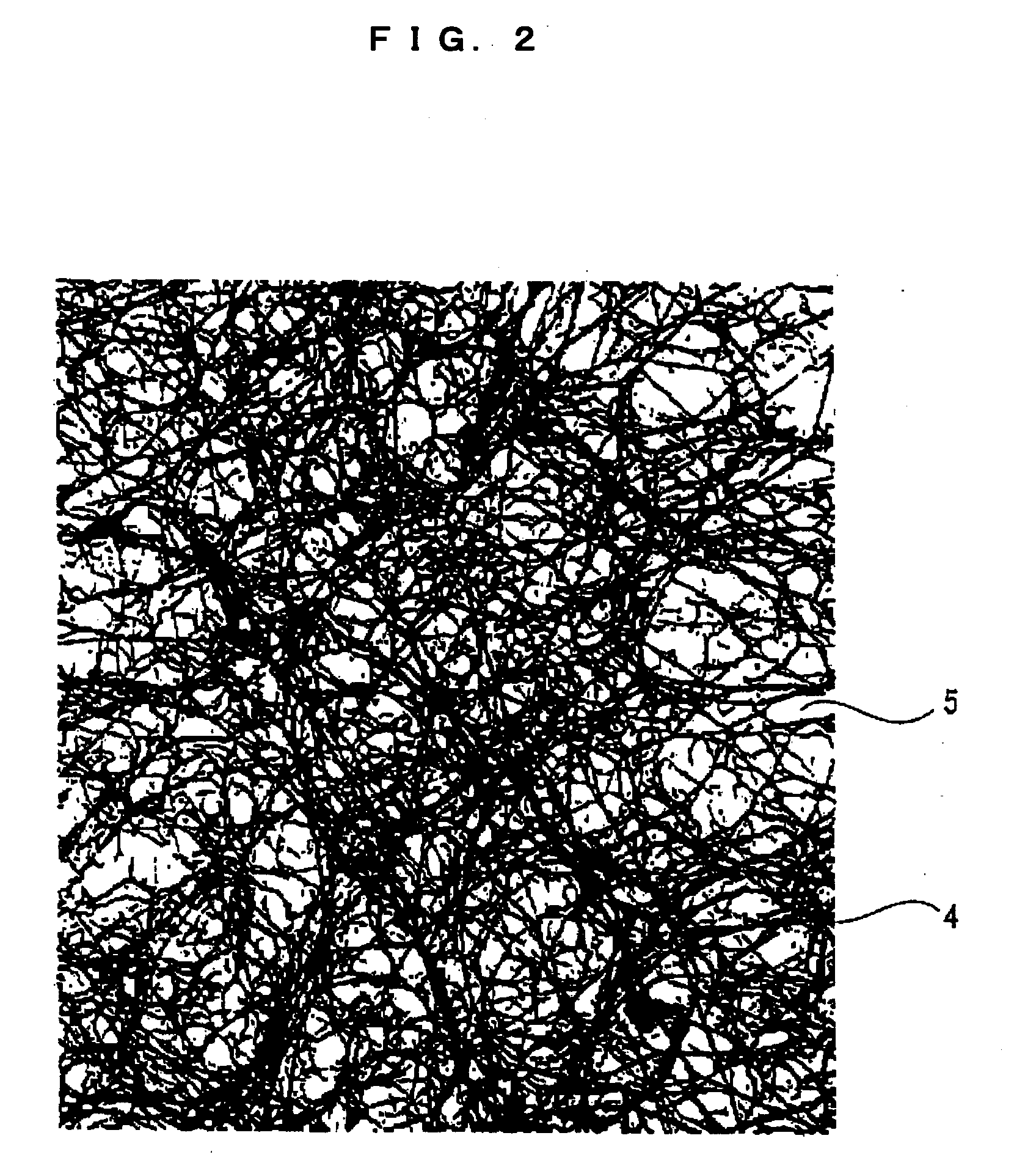

InactiveUS20180008937A1High porosityUniform and adjustable pore sizeMembranesSemi-permeable membranesMolecular sieveFiber

A composite molecular sieve membrane, preparation method and use thereof are provided in the embodiments. The composite molecular sieve membrane includes a support layer and a molecular sieve membrane layer, wherein the support layer is a high-porosity and porous ceramic which is made of nano- or submicron ceramic powder materials or ceramic material precursors prepared through an electrospinning process. The high-porosity and porous ceramic, is adjustable from 40% to 83%. The composite molecular sieve membrane of the embodiments uses the porous ceramic prepared through an electrospinning process as the support layer, and the support layer has a flat and continuous surface, high porosity, uniform and adjustable pore sizes, low-tortuosity pore channels, and high mechanical strength; the flux of the composite molecular sieve membrane is increased, besides, the seed crystals can attach effectively due to the fibrous pore channels of the support layer, ensuring the adhesion amount of seed crystals.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

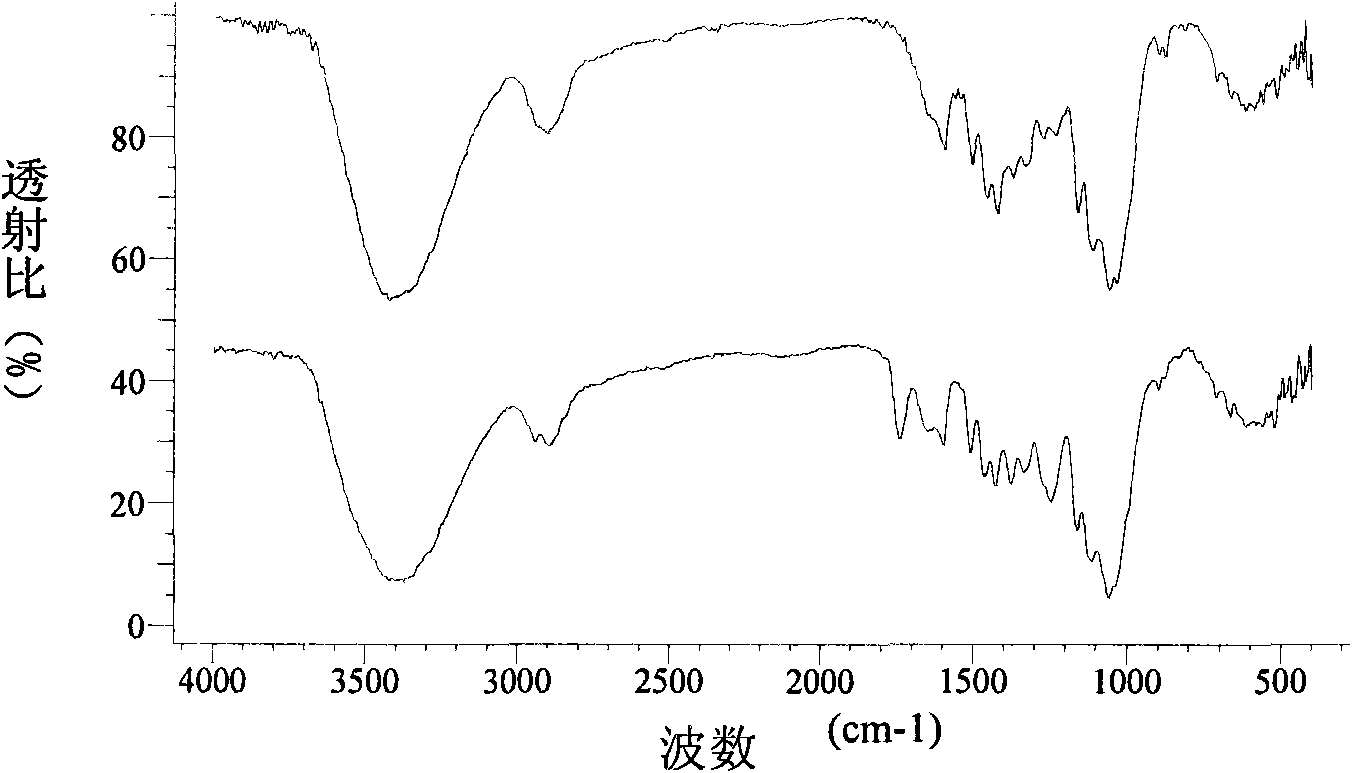

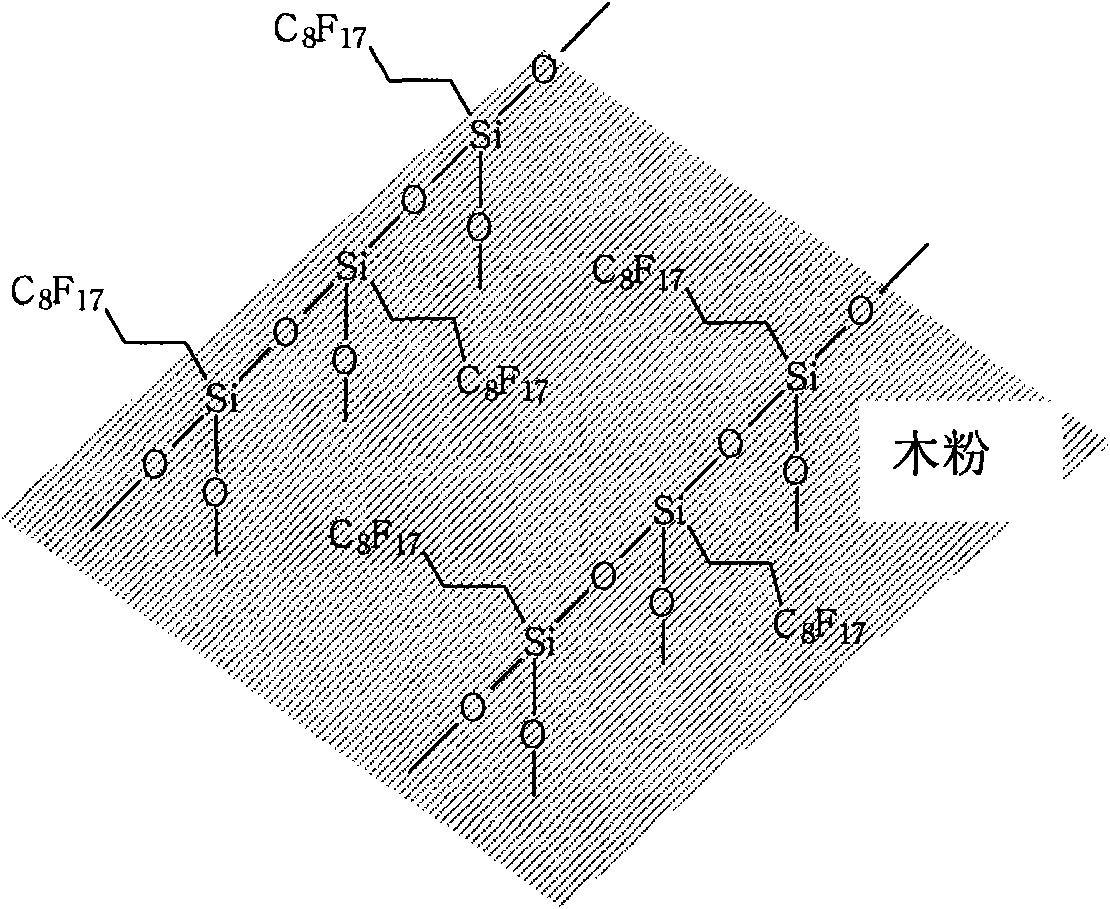

Wood-plastic composite material and preparation method thereof

The invention discloses a wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-70% of modified wood powder, 25-99% of polymer matrix and 0-5% processing aid. The invention also discloses a preparation method of the wood-plastic composite material. The method is as follows: fluorine silane coupling agent is utilized to carry out treatment on surface of the wood powder, the modified wood powder and the polymer matrix are melted and compounded to prepare the wood-plastic composite material, and the wood powder is pretreated by alkali liquor to remove unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining excellent mechanical property, low water absorption capacity, and better apparent form; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503BImprove interface compatibilityImprove composite effectComposite effectPolyolefin

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

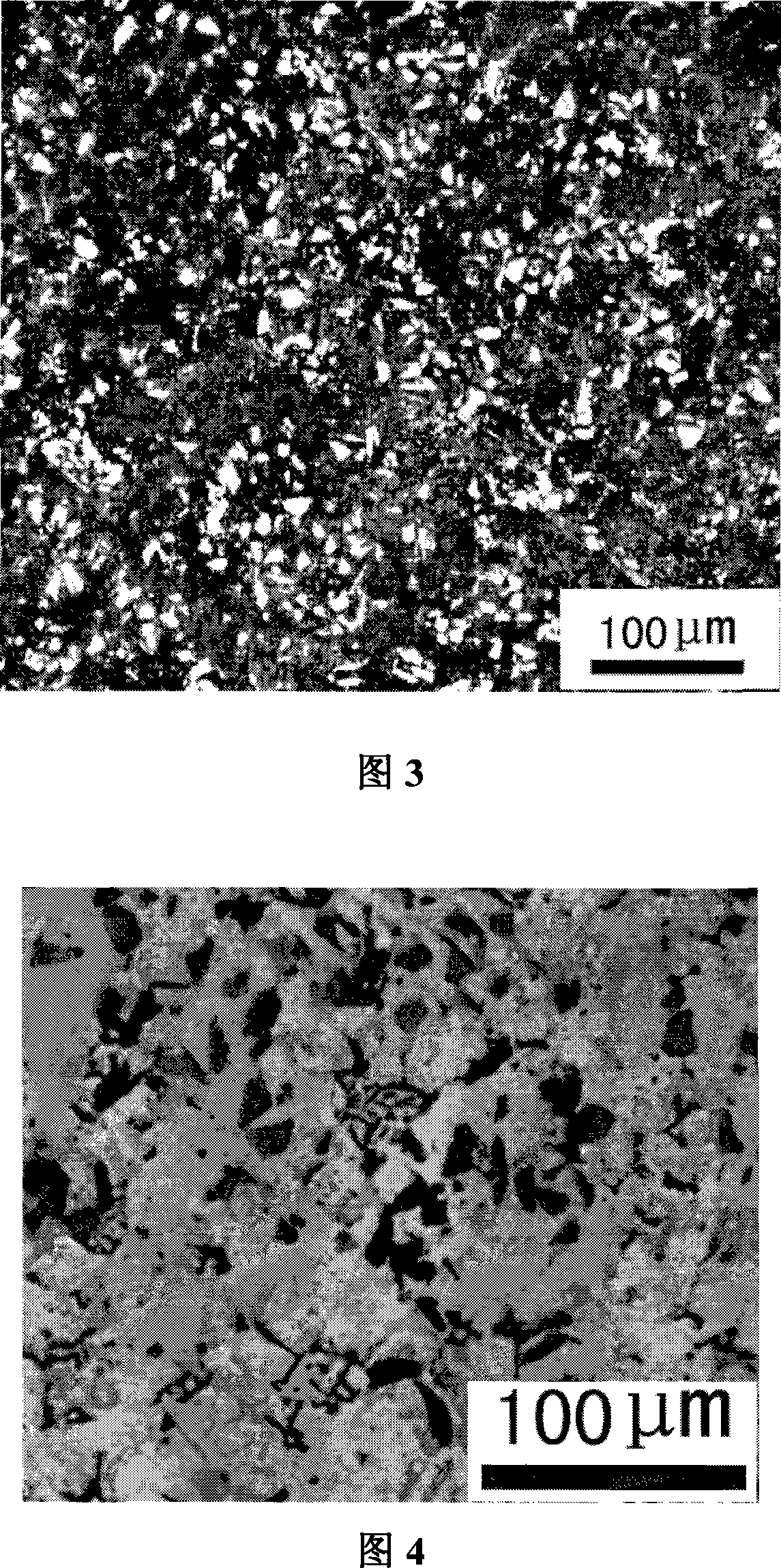

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com