Water-resistant wood-plastic composite material and preparation method thereof

A wood-plastic composite material and wood powder technology, applied in the field of composite materials, can solve the problems of poor impact resistance and easy combustion, and achieve the effects of good dimensional stability, low water absorption, and enhanced composite effect and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

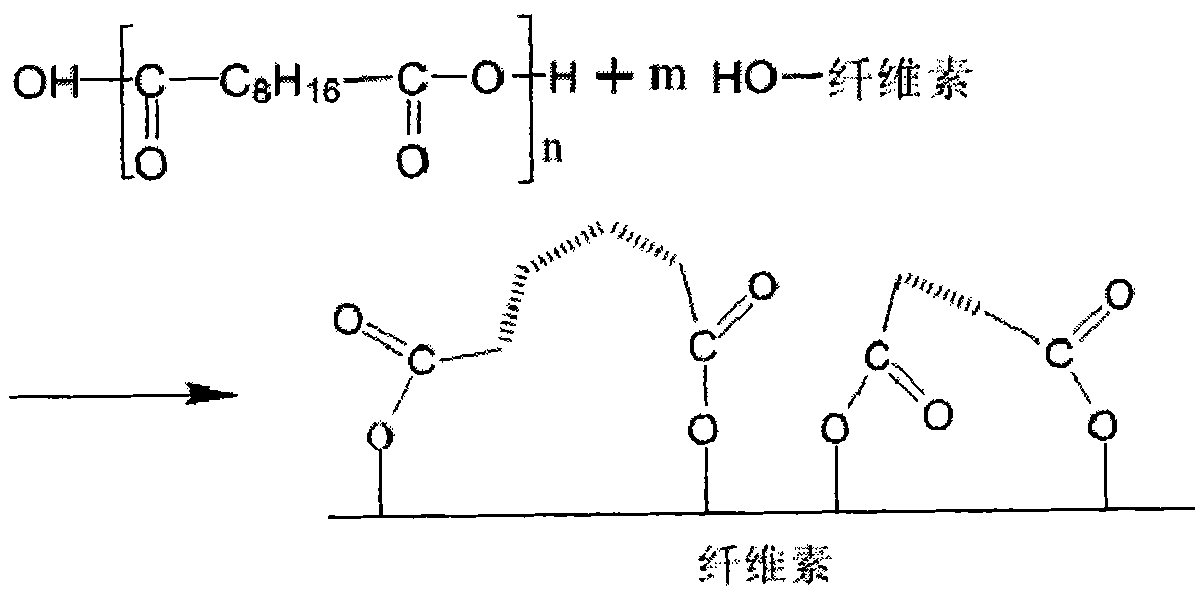

[0044] Soak the wood flour with 1mol / L NaOH aqueous solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:15, then wash with deionized water until neutral, and then dry at 105°C for 24 hours to obtain the modified wood powder. pink.

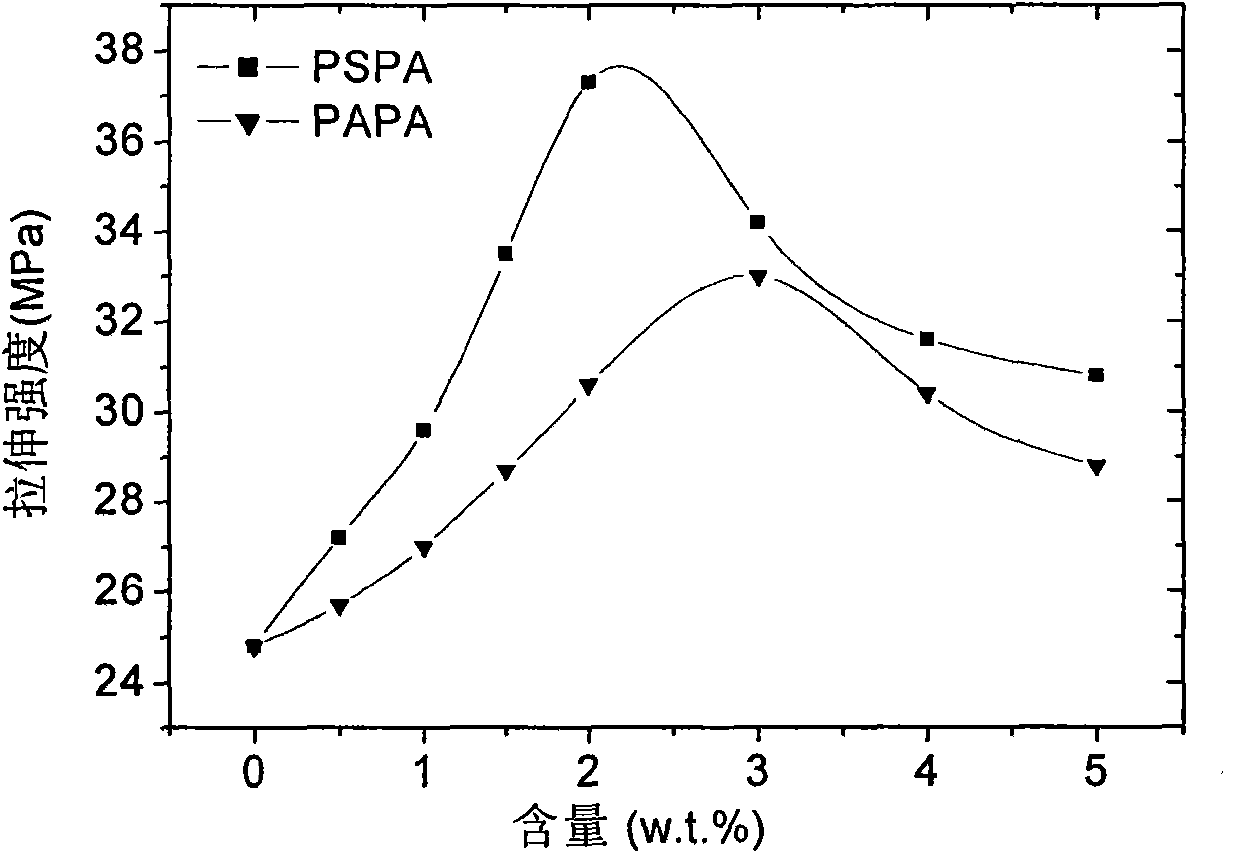

[0045] Add 40Kg of modified wood flour and 3Kg of polysebacic anhydride to a SHR-10A high-speed mixer (Zhangjiagang Light Industry Machinery Factory), pass cooling water, pre-mix at 70°C for 10 minutes, then add 57Kg of high-density polyethylene to continue mixing , after mixing evenly, discharge the mixed powder and cool it for later use.

[0046] Add the above-mentioned mixed powder into a TSE-16-TC twin-screw extruder (PRISM company), melt, blend, extrude and granulate at 200 ° C, and use the HTF86 × 1 injection molding machine (Haitian company) at 200 °C after drying. ℃, 22.5MPa injection molding, made of water-resistant wood-plastic composites.

Embodiment 2

[0048] Soak the wood flour with 1mol / L NaOH aqueous solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:15, then wash with deionized water until neutral, and then dry at 105°C for 24 hours to obtain the modified wood powder. pink.

[0049] Add 40Kg of modified wood flour and 3Kg of polyazelaic anhydride to a SHR-10A high-speed mixer (Zhangjiagang Light Industry Machinery Factory), pass cooling water, pre-mix at 70°C for 10 minutes, then add 57Kg of high-density polyethylene to continue mixing , after mixing evenly, discharge the mixed powder and cool it for later use.

[0050] Add the above-mentioned mixed powder into a TSE-16-TC twin-screw extruder (PRISM company), melt, blend, extrude and granulate at 200 ° C, and use the HTF86 × 1 injection molding machine (Haitian company) at 200 °C after drying. ℃, 22.5MPa injection molding, made of water-resistant wood-plastic composites.

Embodiment 3

[0052] Soak the wood flour with 0.1mol / L NaOH aqueous solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:20, then wash with deionized water until neutral, and then dry at 103°C for 25 hours to obtain modified wood flour.

[0053] Add 65Kg of modified wood flour and 10Kg of polysebacic anhydride to a SHR-10A high-speed mixer (Zhangjiagang Light Industry Machinery Factory), pass cooling water, pre-mix at 80°C for 20 minutes, then add 25Kg of high-density polyethylene to continue mixing , after mixing evenly, discharge the mixed powder and cool it for later use.

[0054] Add the above-mentioned mixed powder into a TSE-16-TC twin-screw extruder (PRISM company), melt, blend, extrude and granulate at 200 ° C, and use the HTF86 × 1 injection molding machine (Haitian company) at 200 °C after drying. ℃, 22.5MPa injection molding, made of water-resistant wood-plastic composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com