High strength composite wall panel system

a composite wall and panel technology, applied in the field of high-performance composite wall structures, can solve the problems of poor k value of concrete, little or no structural strength, and little thermal insulation, and achieve the effect of improving, being stronger and less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

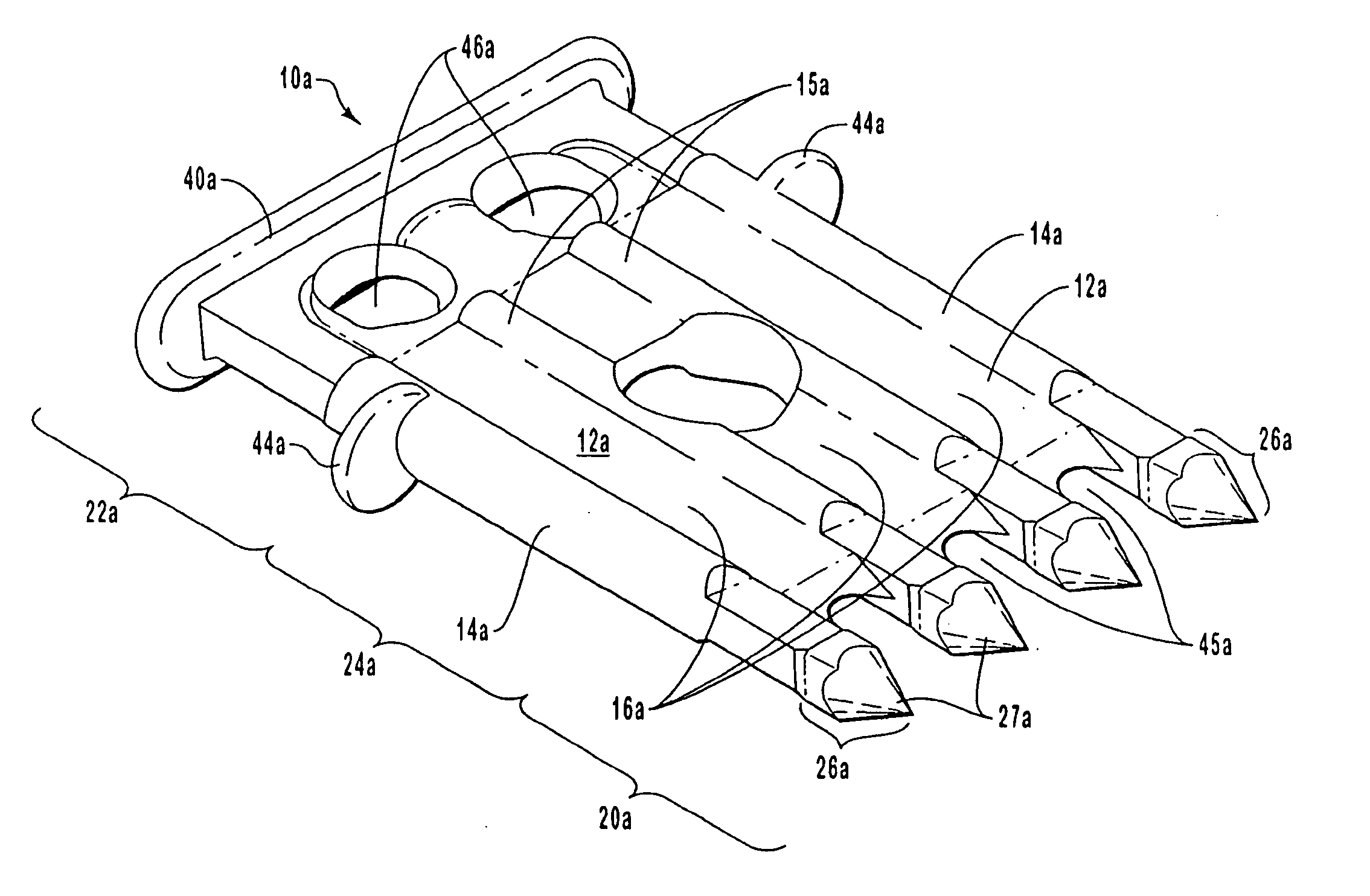

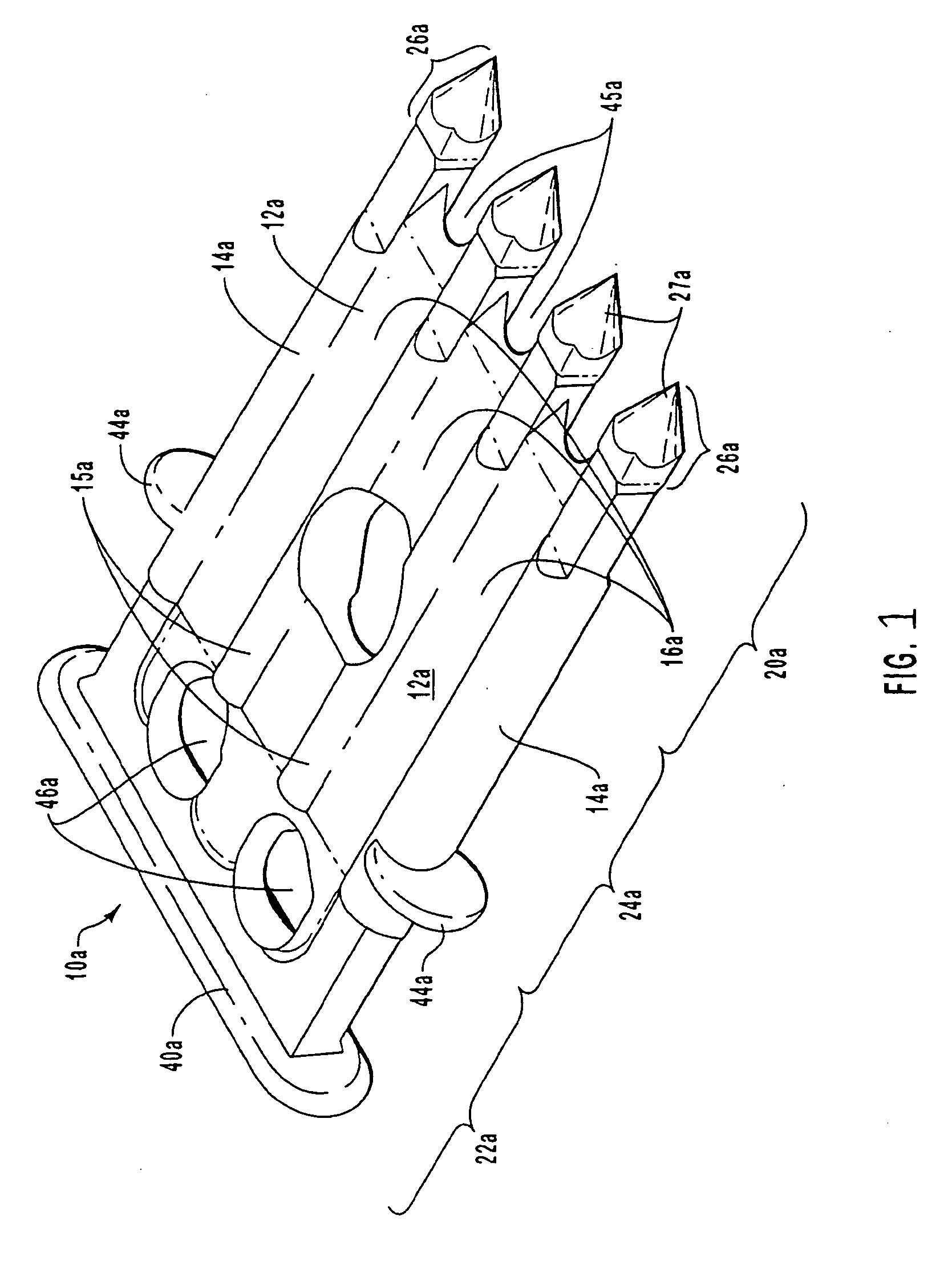

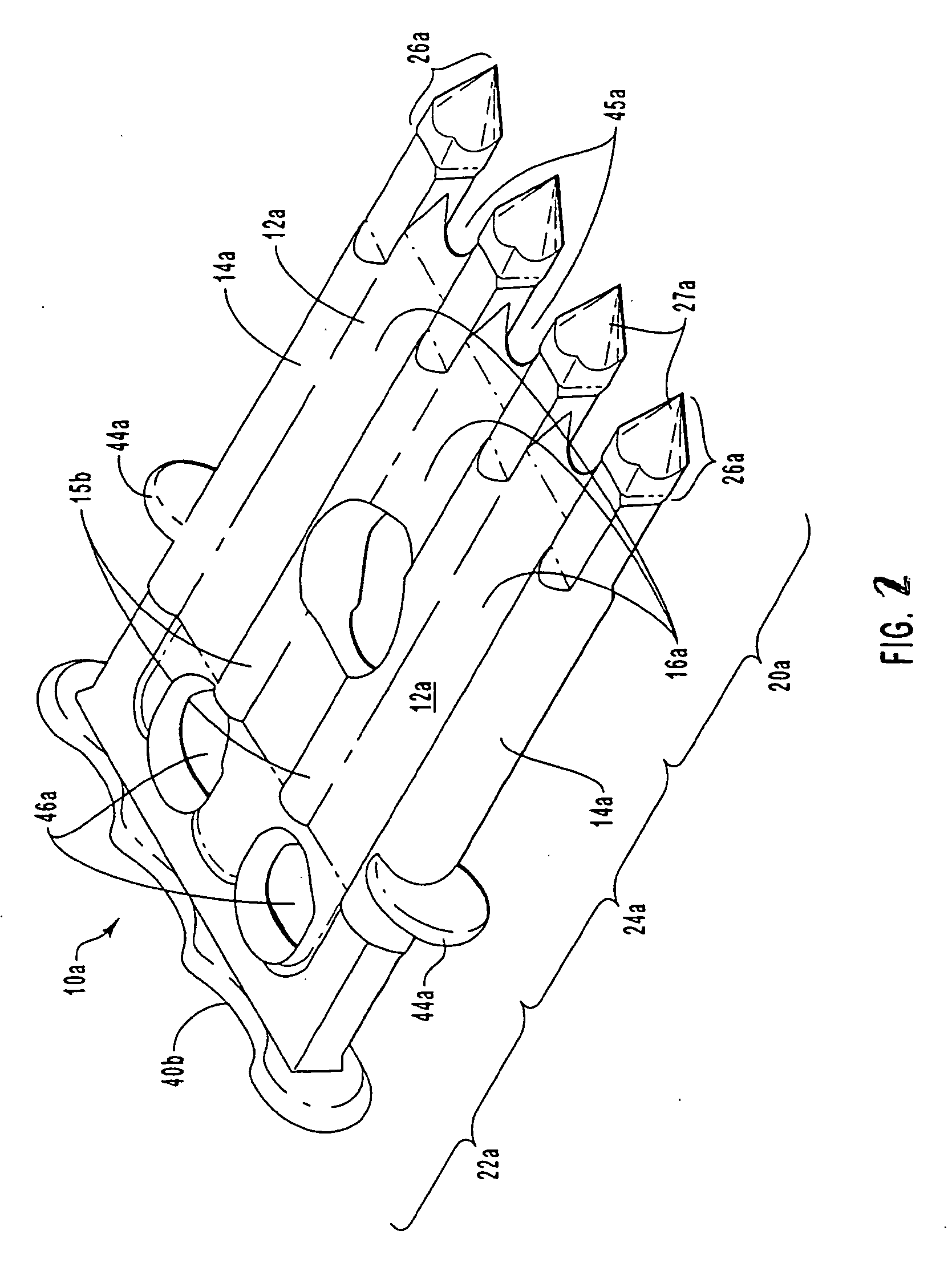

Image

Examples

examples

[0060] Three structural panels, each having two wythes of concrete and an internal wythe of polystyrene foam insulation were prepared for testing. The concrete wythes were 3 in thick and the polystyrene layer was 2 in. thick. The polystyrene foam was FOAMULAR F250 (available from Owens Coming of Toledo, Ohio) having horizontal dovetail grooves having a depth of 0.5 in.; a base width of 1.0 in.; and a surface width of 0.75 in. The grooves were spaced along the length of the board by 6.0 in. (on center).

[0061] The finished panel was 8 in thick by 8.0 feet wide and 32.0 feet high. The panels included 144 connectors as shown in FIG. 5B in 18 rows and 6 columns. The rows were 16 inches on center apart and the connectors with in each row were 16 inches on center apart apart.

[0062] The panels were supported by a span equal to 31 feet and load tests were performed using negative air pressure to simulate uniform wind loading. The panel properties compressive strength of concrete (f′c-avg),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| 90° angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com