Wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and wood powder, which is applied in the field of composite materials to achieve the effects of good appearance, low water absorption and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

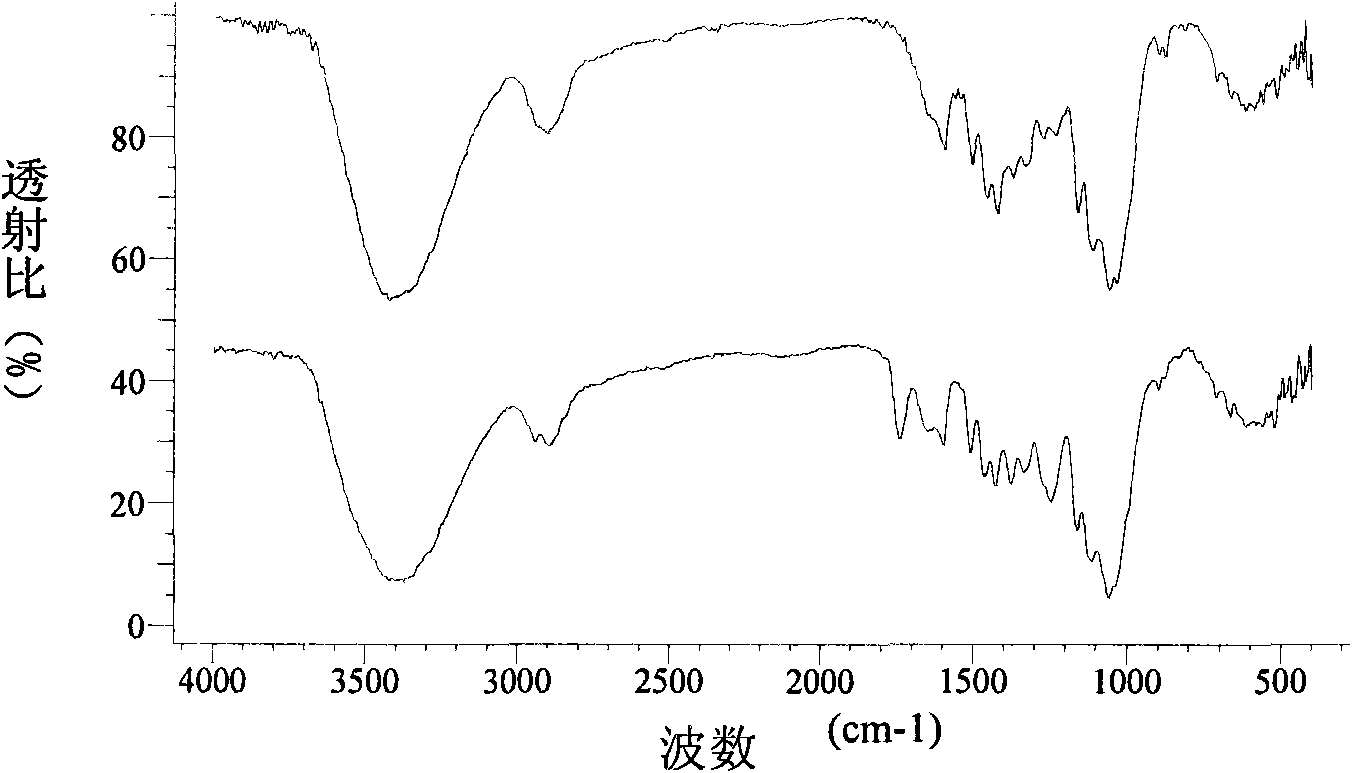

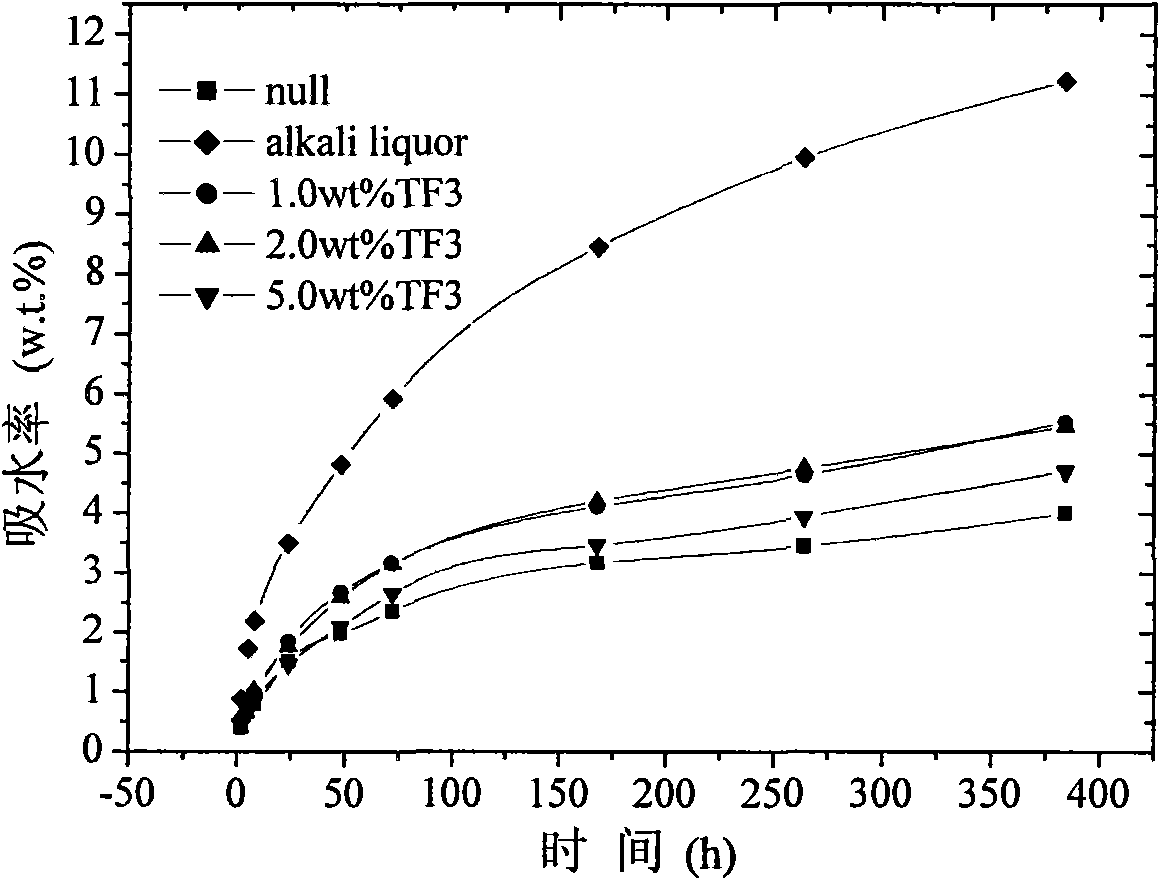

[0058] Soak the wood flour with 1mol / L NaOH aqueous solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:15, then wash with deionized water until neutral, and then dry at 105°C for 24h to obtain the pretreated of wood flour.

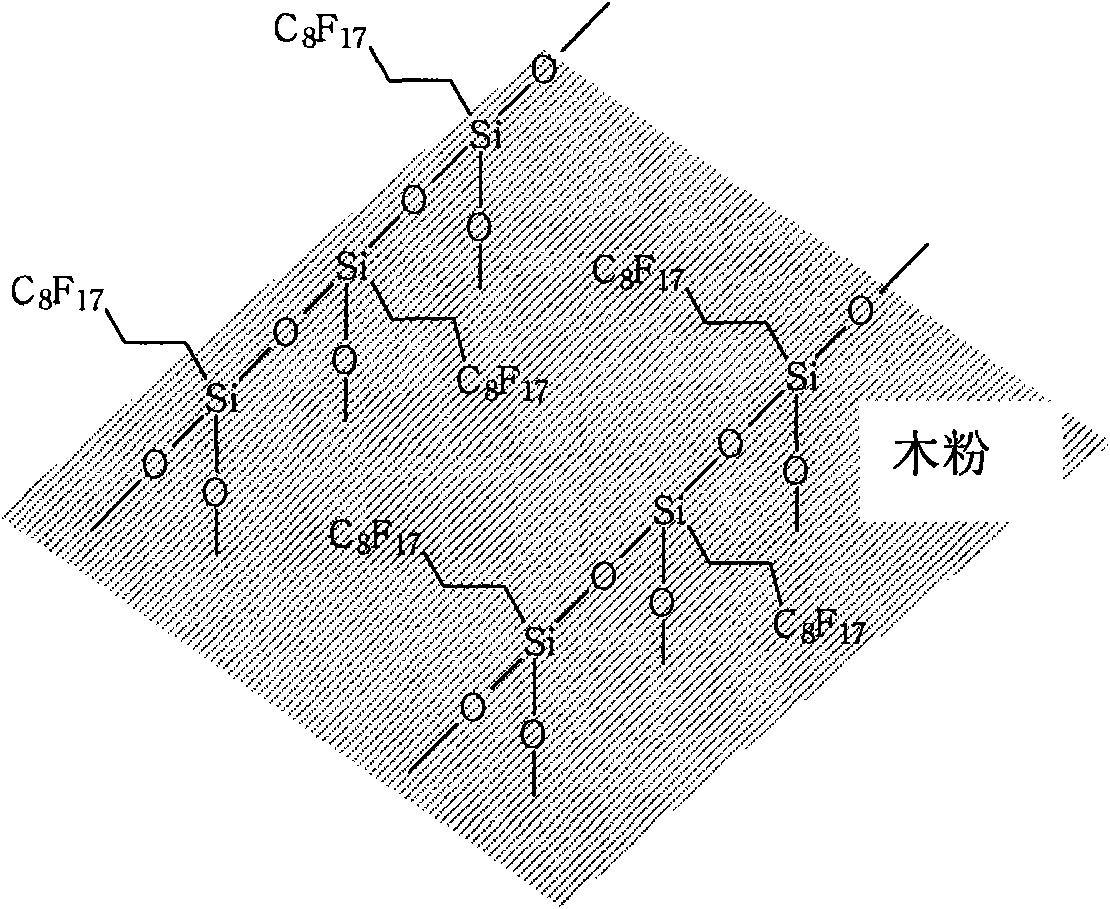

[0059] Trifluoropropyltrimethoxysilane is dissolved in ethanol aqueous solution (wherein, the volume ratio of ethanol and water is 80: 20) the concentration of preparation trifluoropropyltrimethoxysilane is 9.17 * 10 -3 mol / L ethanol aqueous solution, adjust the pH value to 3.5 with acetic acid, add ethanol to the pretreated wood flour at a ratio of 0.02 to the mass ratio of trifluoropropyltrimethoxysilane to pretreated wood flour at 60°C In the aqueous solution, stir for 3 hours and filter, dry at 60°C for 24h, and then heat-treat at 120°C for 2h to obtain modified wood powder.

[0060] 40Kg modified wood flour, 58Kg polyvinylidene fluoride and 2Kg maleic anhydride grafted polypropylene were premixed together for 1...

Embodiment 2

[0062] Soak the wood flour with 2mol / L NaOH solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:15, then wash with deionized water until neutral, and then dry at 105°C for 24h to obtain the pretreated of wood flour.

[0063] Dissolve heptadecafluorodecyltrimethoxysilane in aqueous ethanol (wherein the volume ratio of ethanol to water is 80:20) to prepare heptadecafluorodecyltrimethoxysilane with a concentration of 3.52×10 -3 mol / L ethanol aqueous solution, adjust the pH value to 3.5 with acetic acid, add the pretreated wood flour at 60°C according to the mass ratio of heptadecafluorodecyltrimethoxysilane to pretreated wood flour is 0.02 in ethanol aqueous solution, stirred for 1 hour, filtered, dried at 60°C for 24h, and then heat-treated at 120°C for 2h to obtain modified wood powder.

[0064] 40Kg modified wood flour, 58Kg polyvinylidene fluoride and 2Kg maleic anhydride grafted polypropylene were premixed together for 10min in a SHR-1...

Embodiment 3

[0066] Soak the wood flour with 0.1mol / L NaOH solution, the bath ratio (i.e. the mass ratio of wood flour to NaOH aqueous solution) is 1:20, then wash with deionized water until neutral, and then dry at 105°C for 24h to obtain pretreatment over wood flour.

[0067] Trifluoropropyltrimethoxysilane is dissolved in ethanol aqueous solution (wherein, the volume ratio of ethanol and water is 80: 20) the concentration of preparation trifluoropropyltrimethoxysilane is 4.6 * 10 -4 mol / L ethanol aqueous solution, adjust the pH value to 6.5 with acetic acid, add ethanol at a ratio of 0.001 to the mass ratio of trifluoropropyltrimethoxysilane to pretreated wood flour at 60°C In the aqueous solution, stir for 5 hours and filter, dry at 60°C for 24h, and then heat-treat at 100°C for 3h to obtain modified wood powder.

[0068] Premix 40Kg modified wood flour, 58Kg polyvinylidene fluoride and 2Kg maleic anhydride grafted polypropylene in a SHR-10A high-speed mixer (Zhangjiagang Light Indust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com