Patents

Literature

70 results about "Wythe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wythe is a continuous vertical section of masonry one unit in thickness. A wythe may be independent of, or interlocked with, the adjoining wythe(s). A single wythe of brick that is not structural in nature is referred to as a veneer.

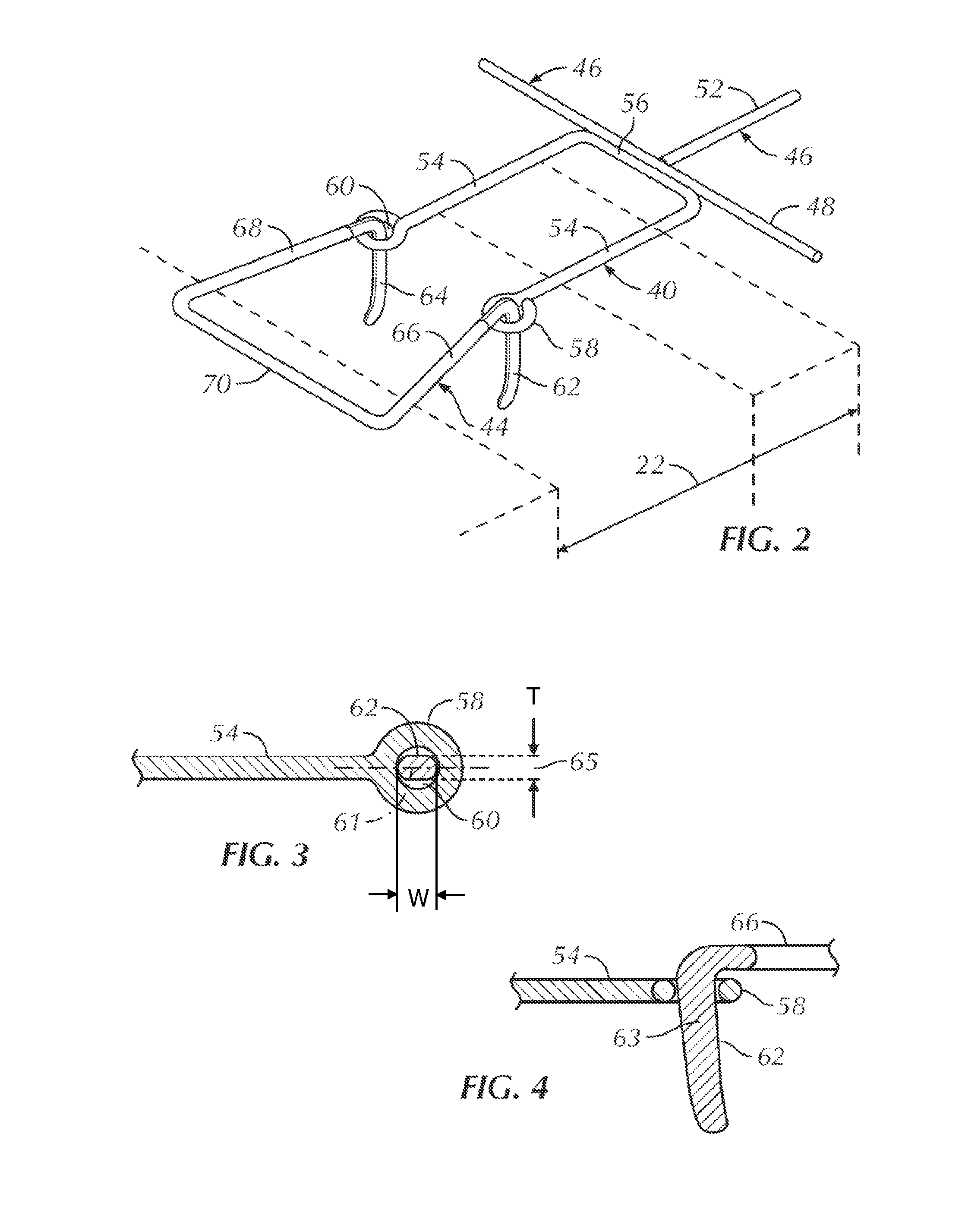

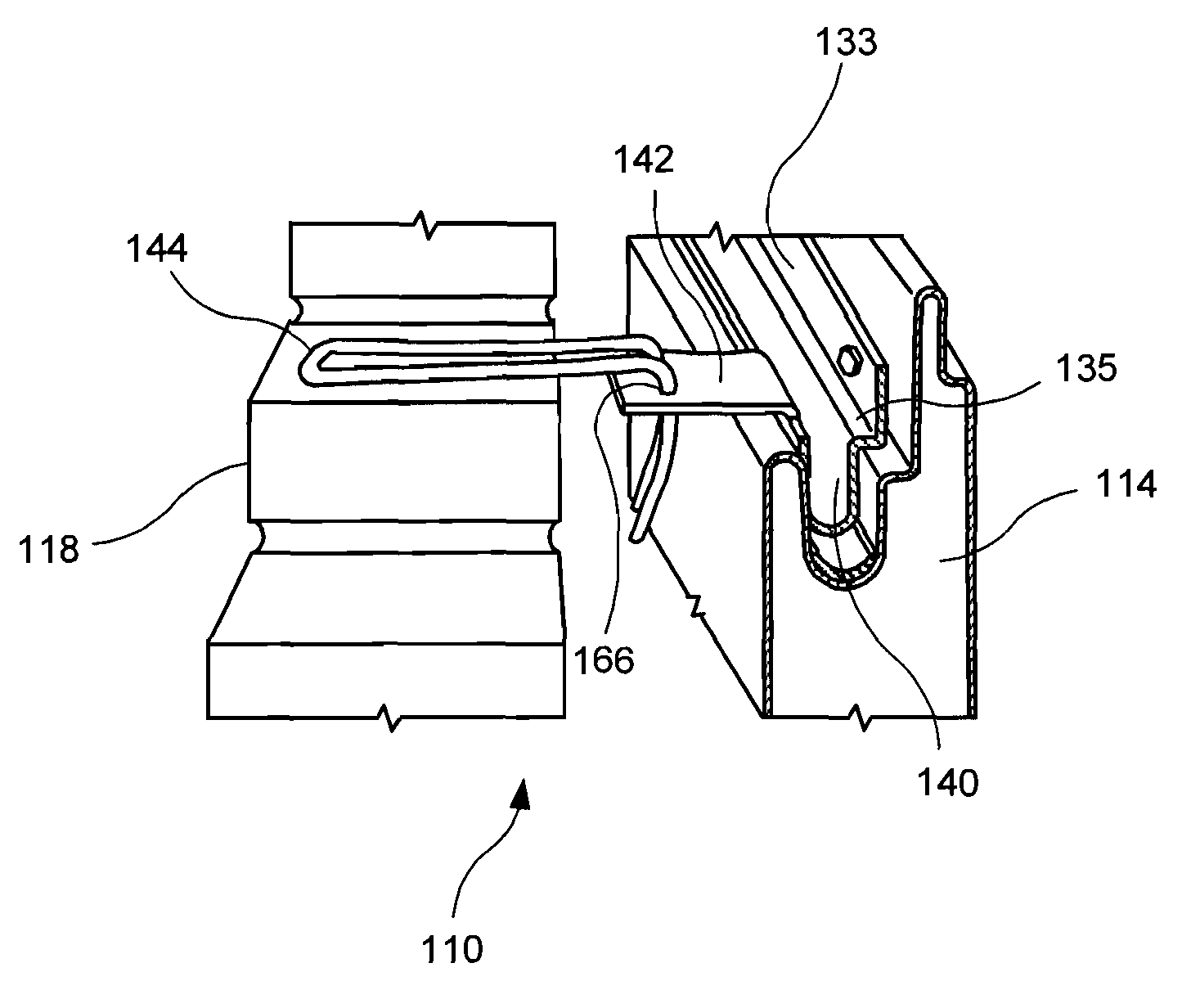

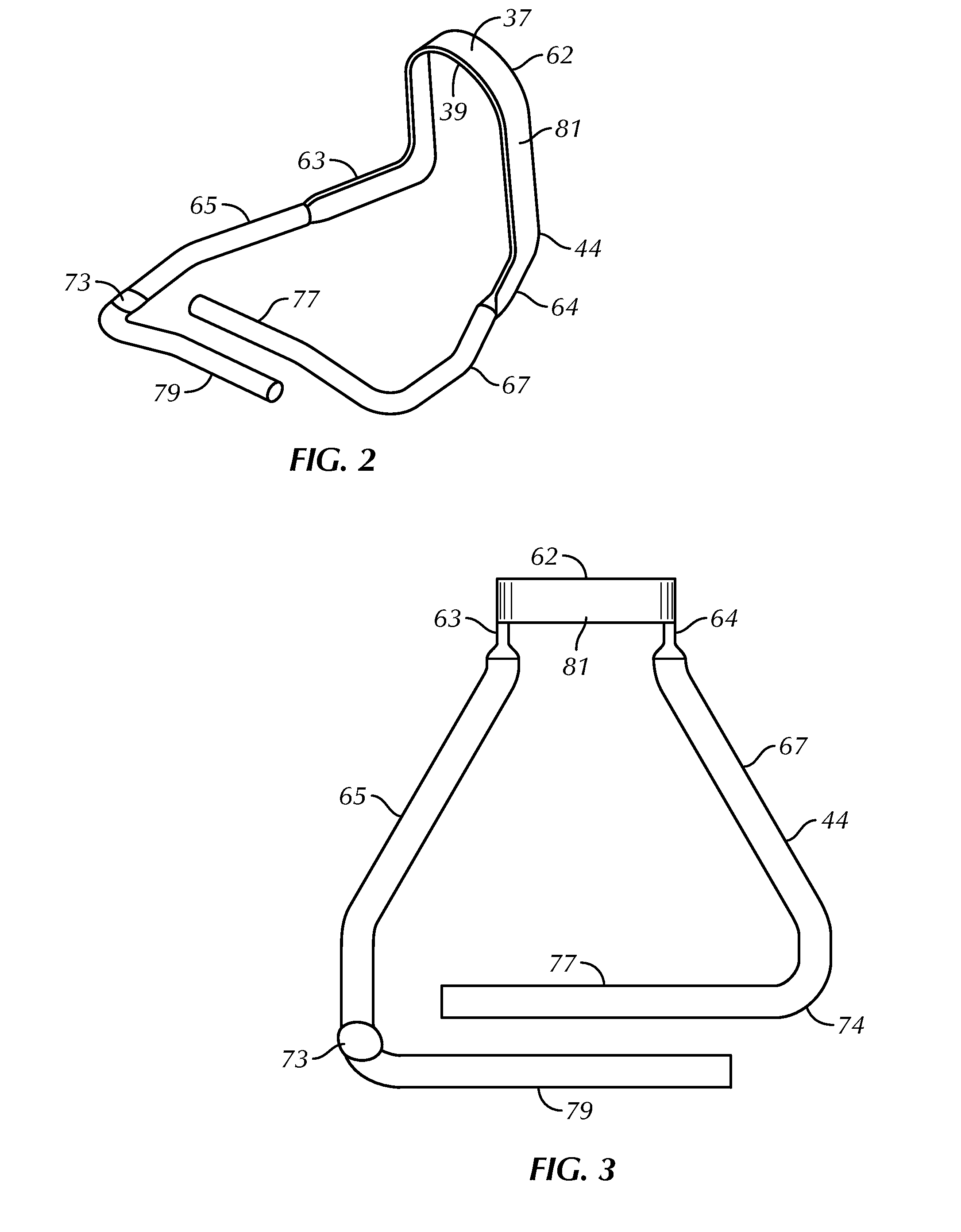

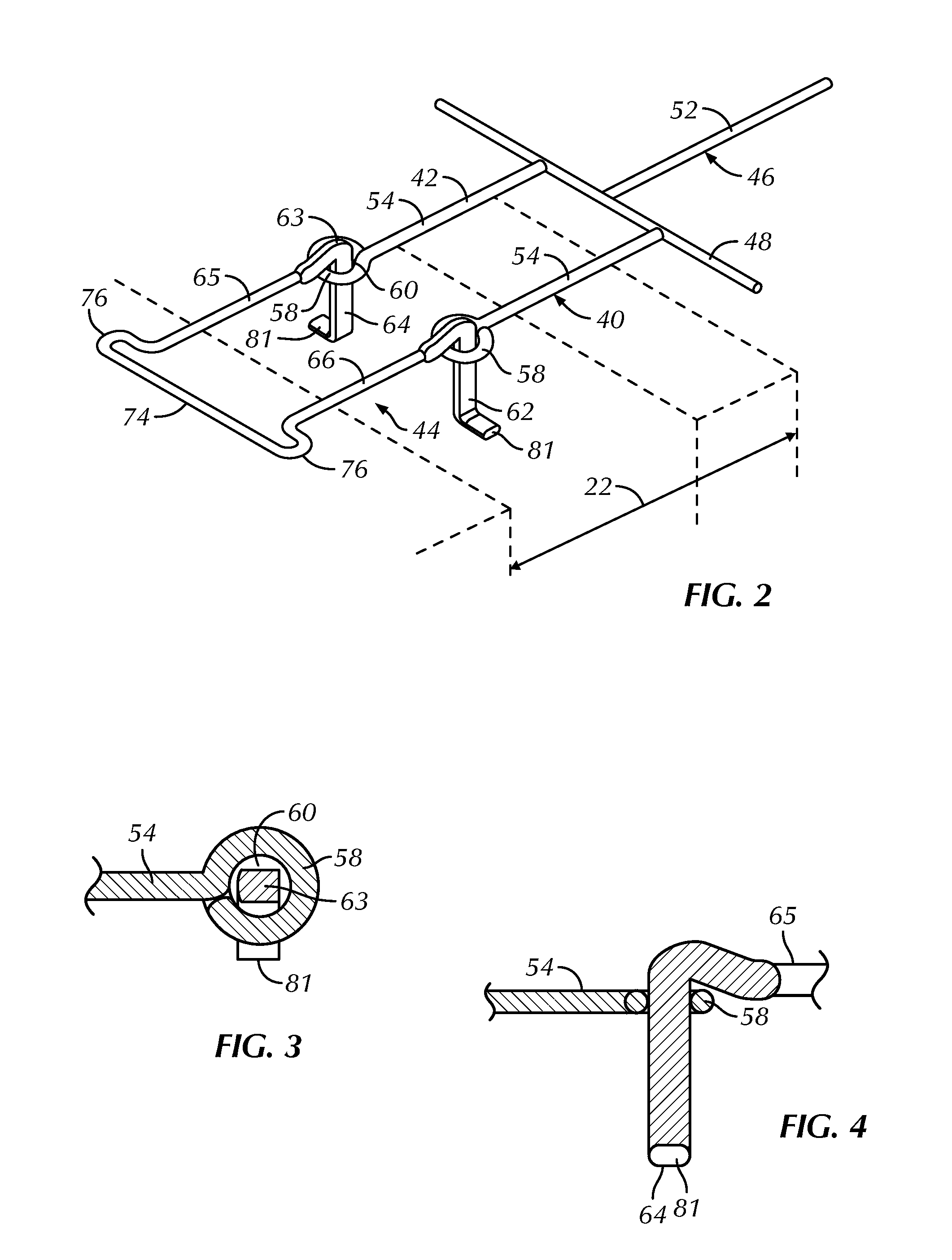

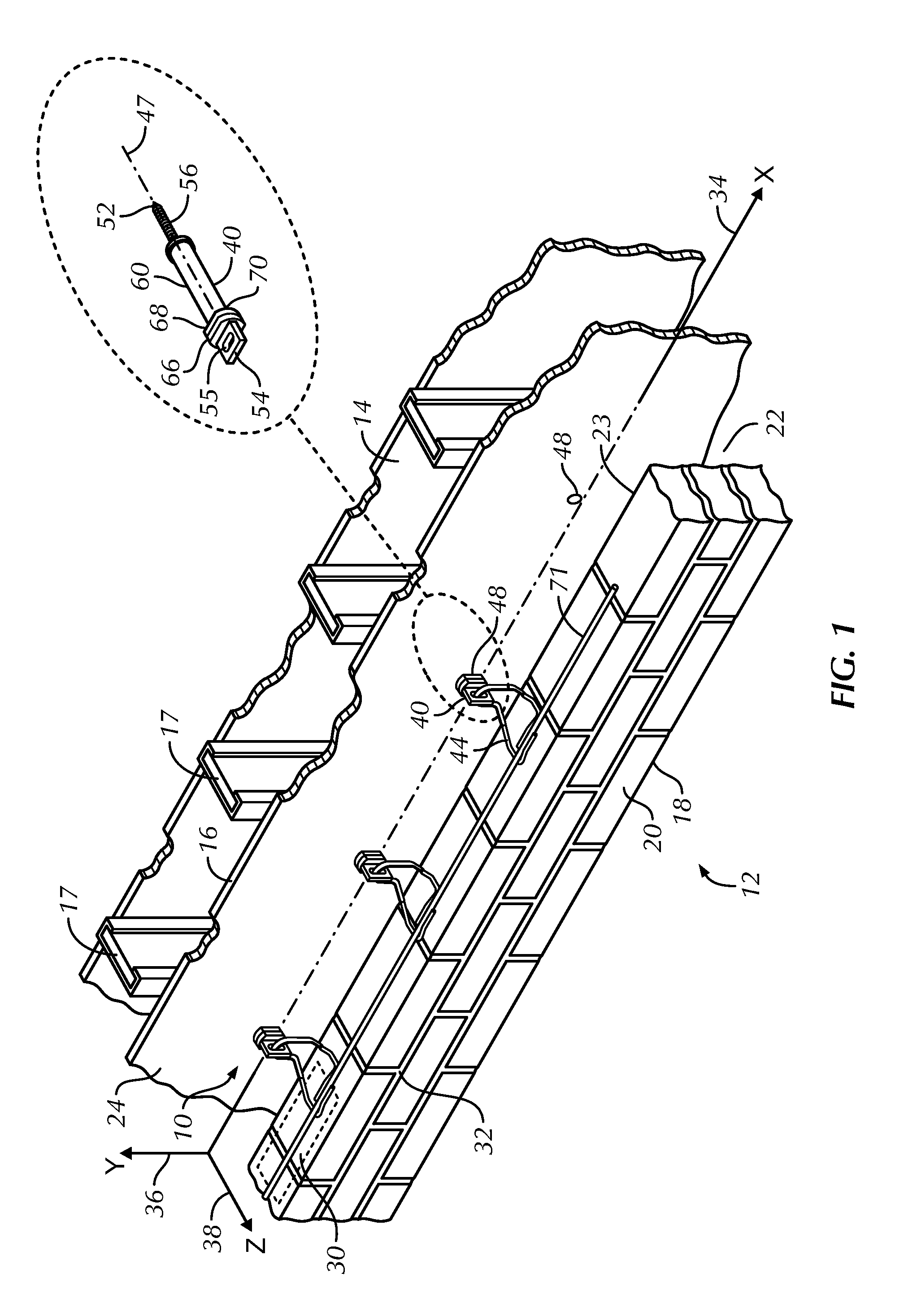

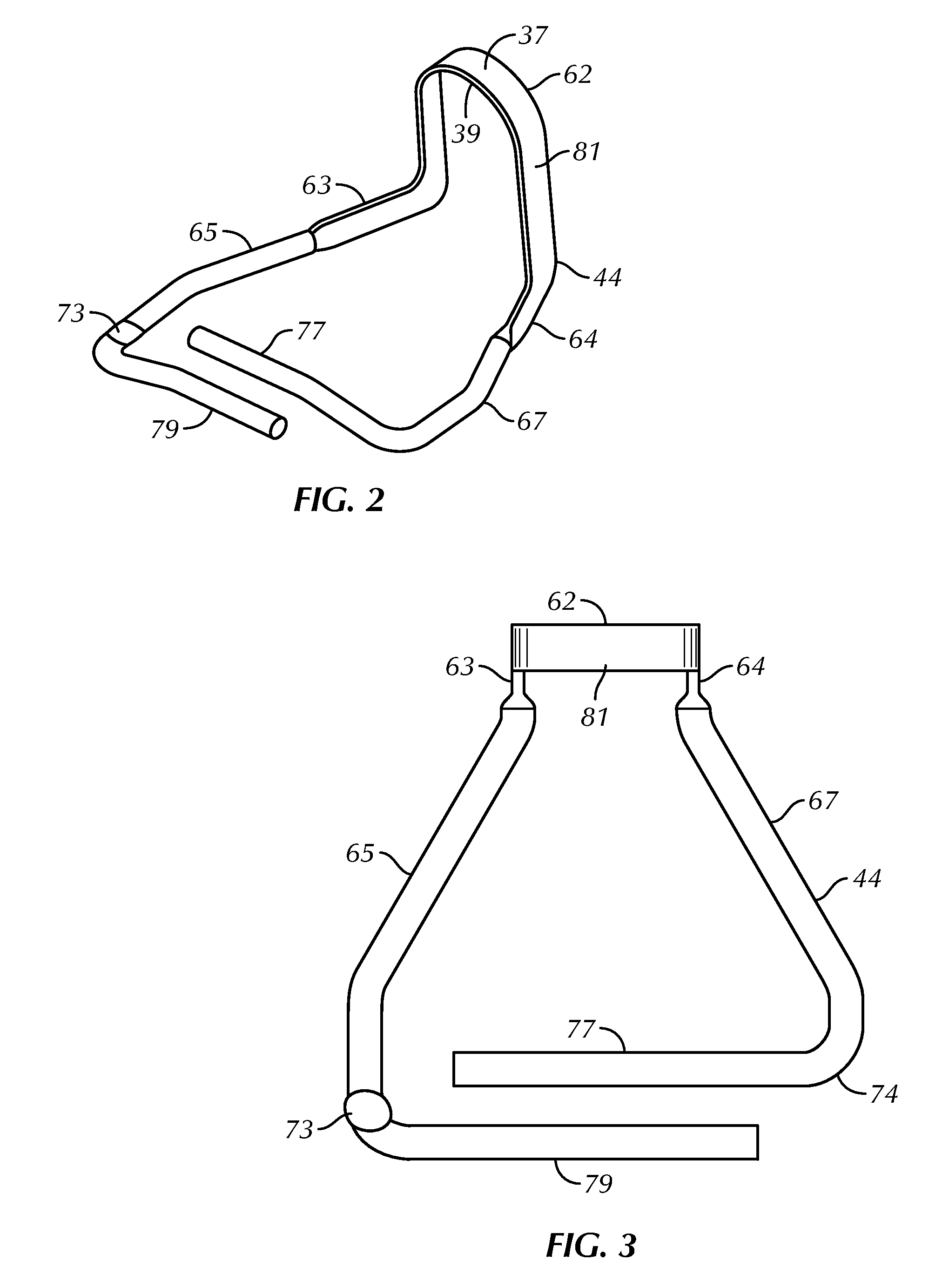

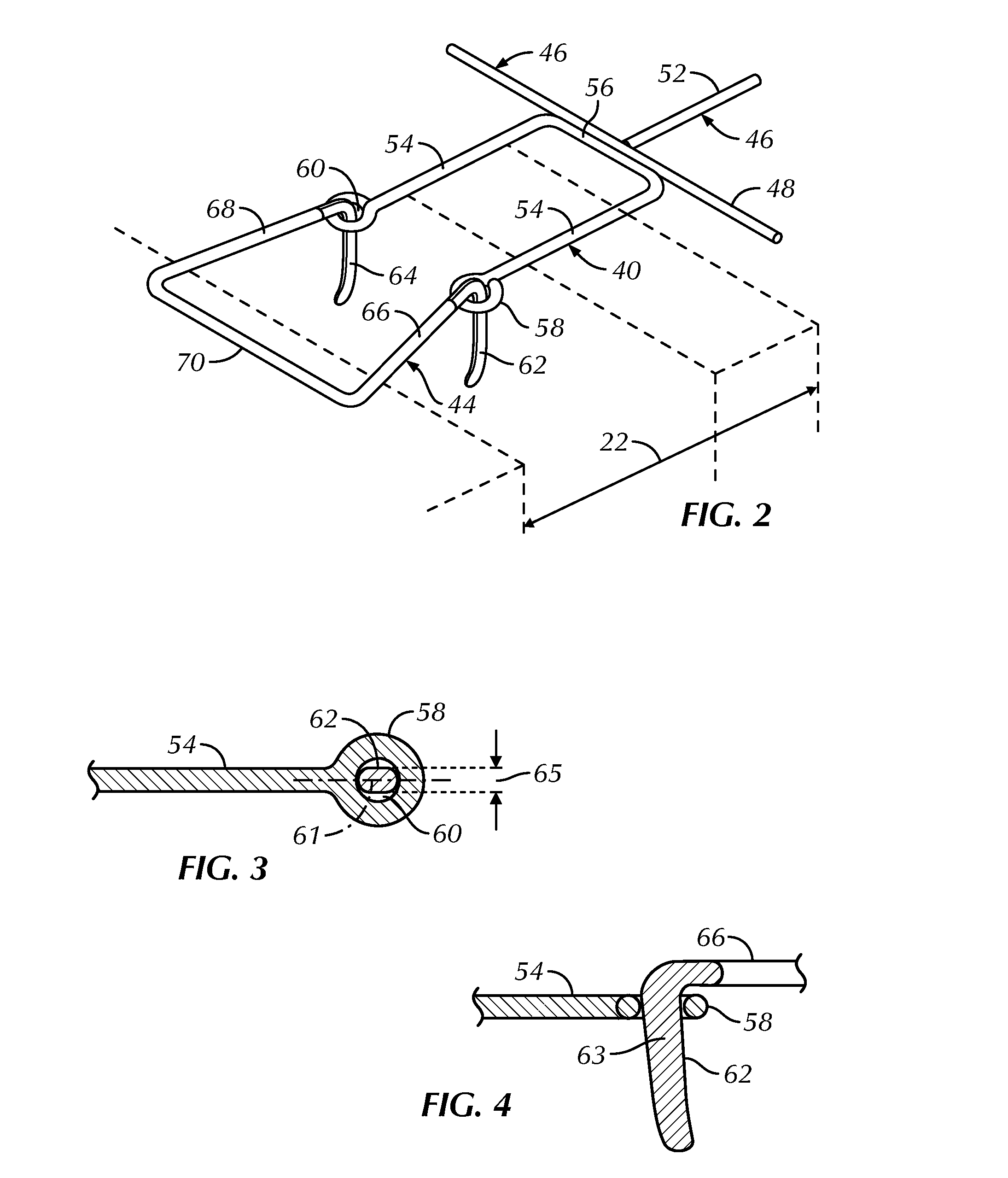

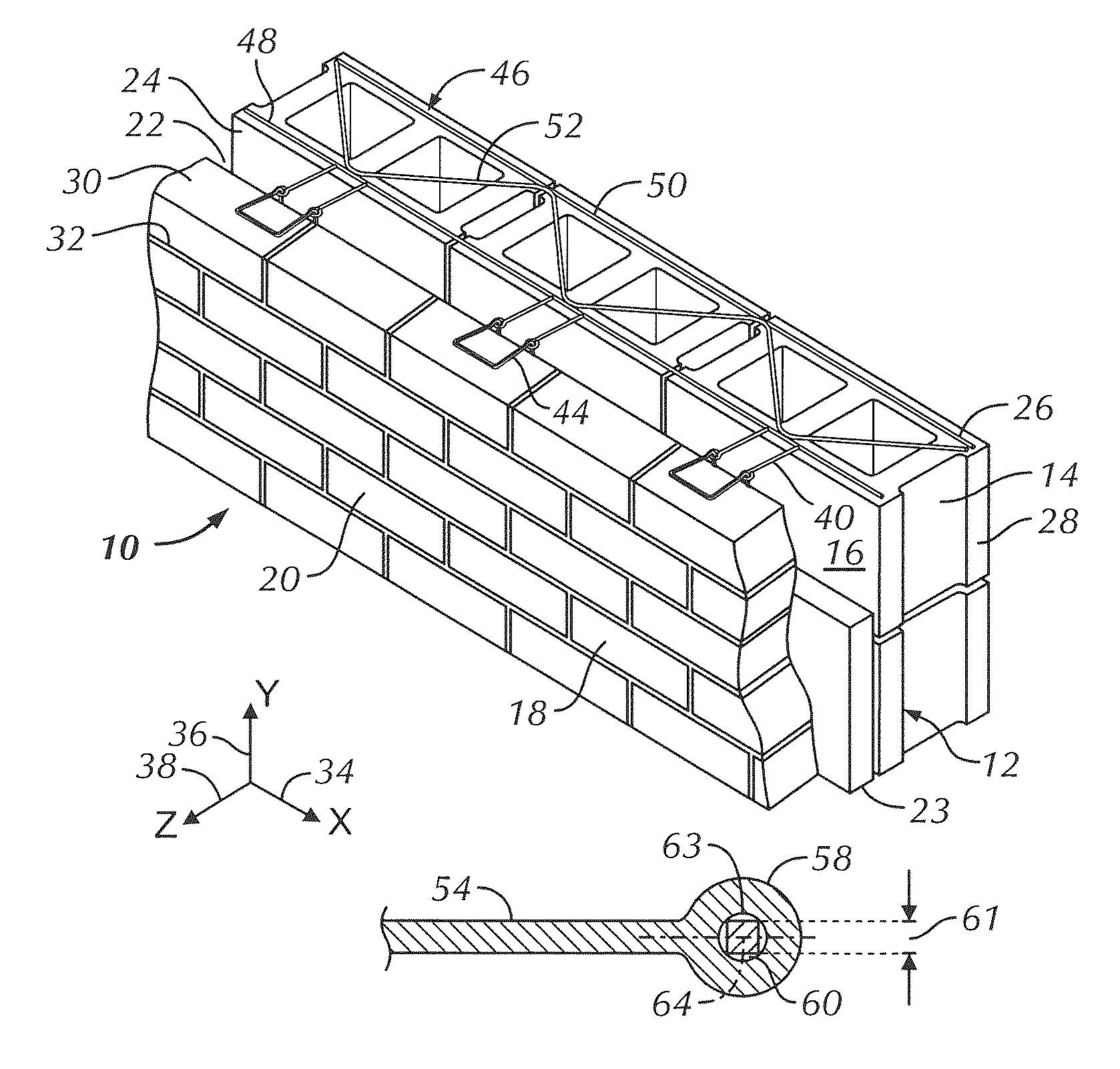

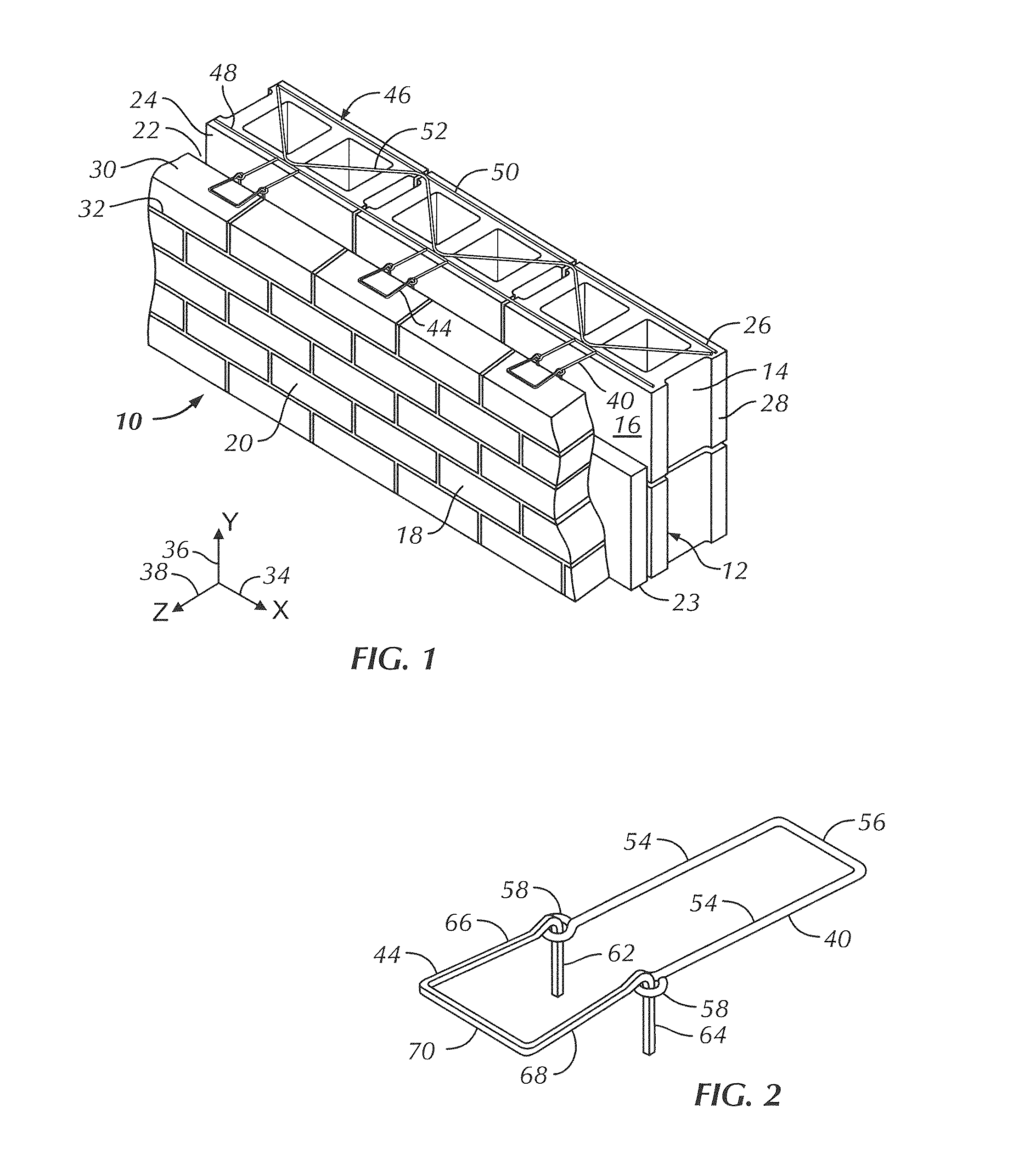

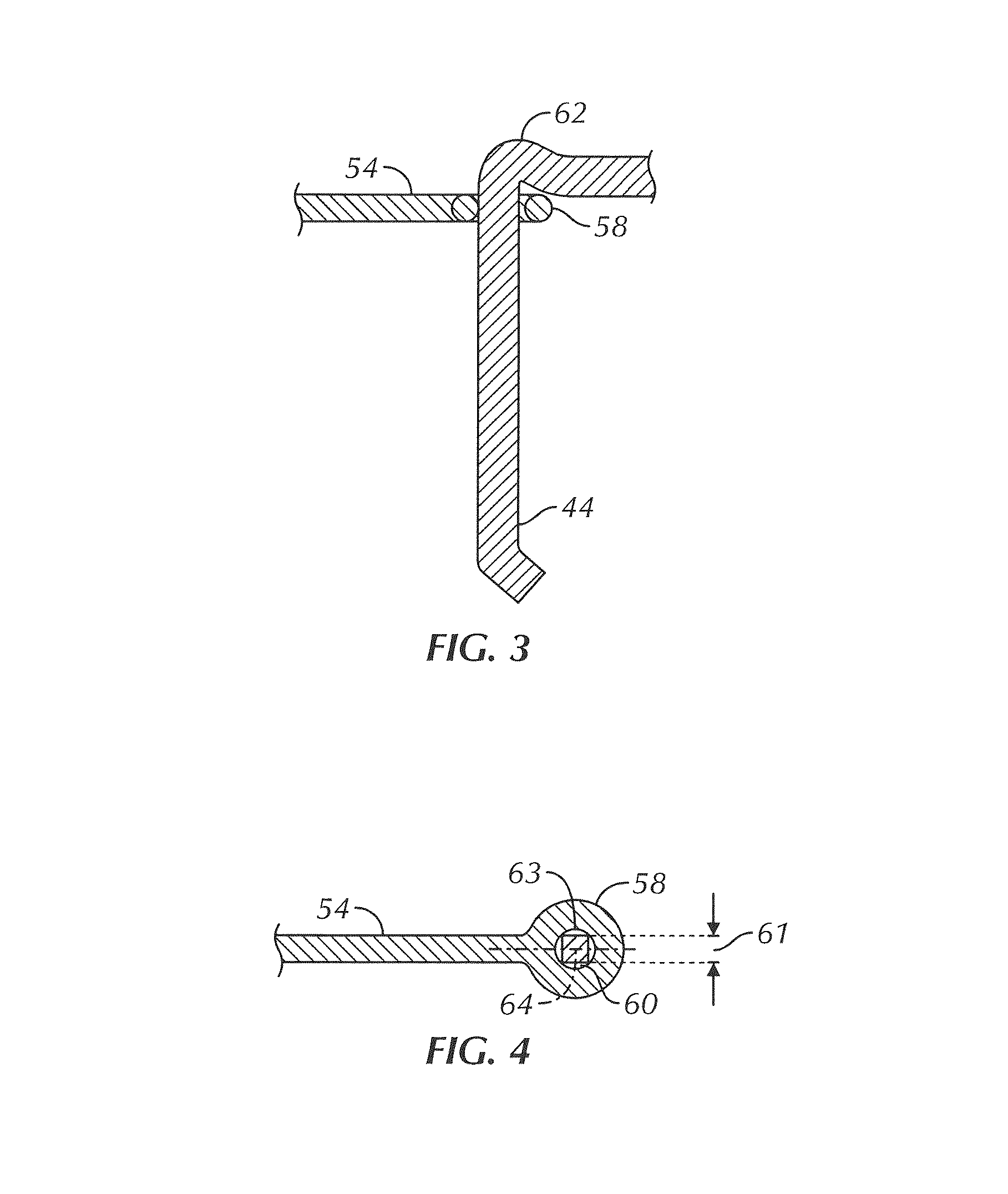

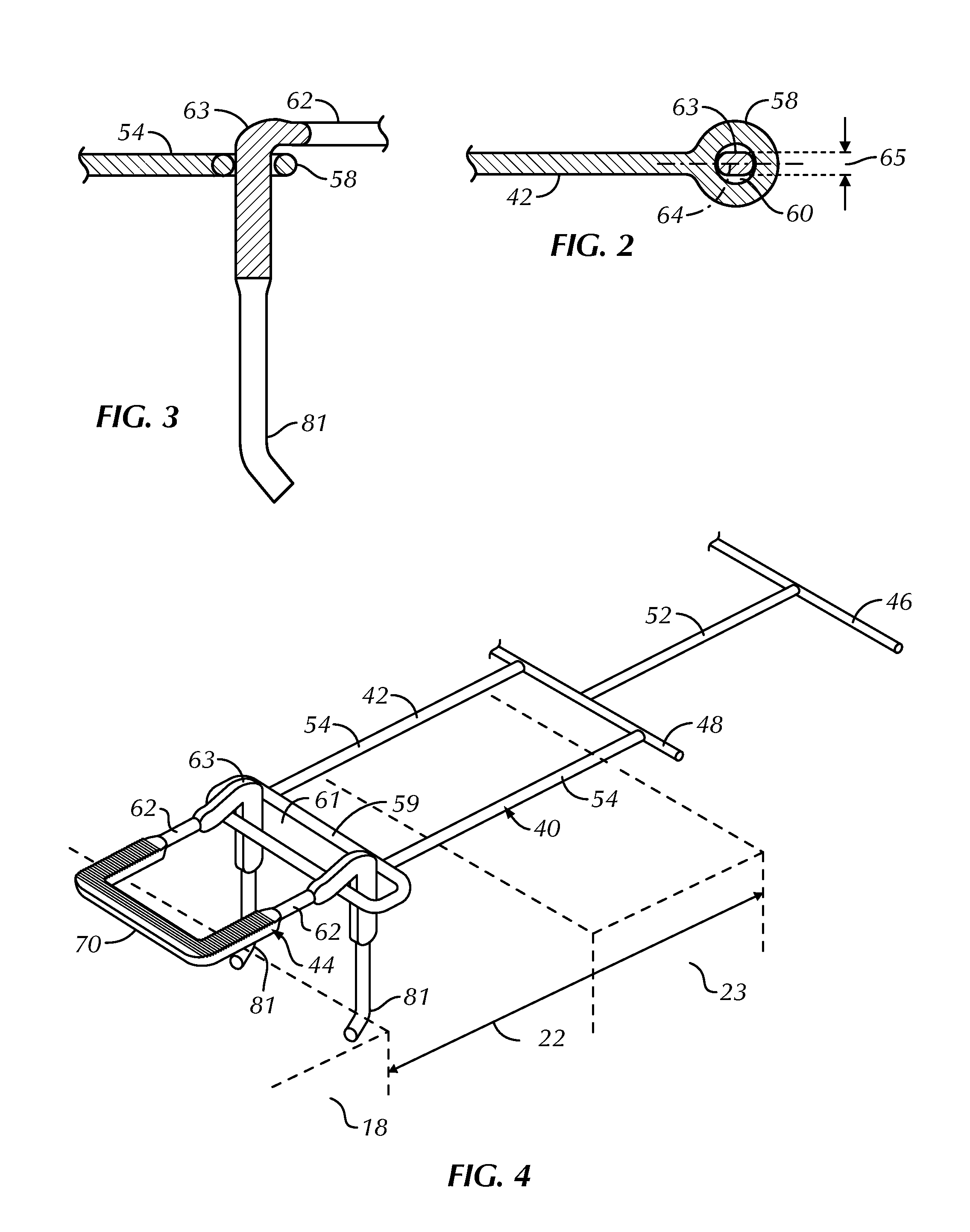

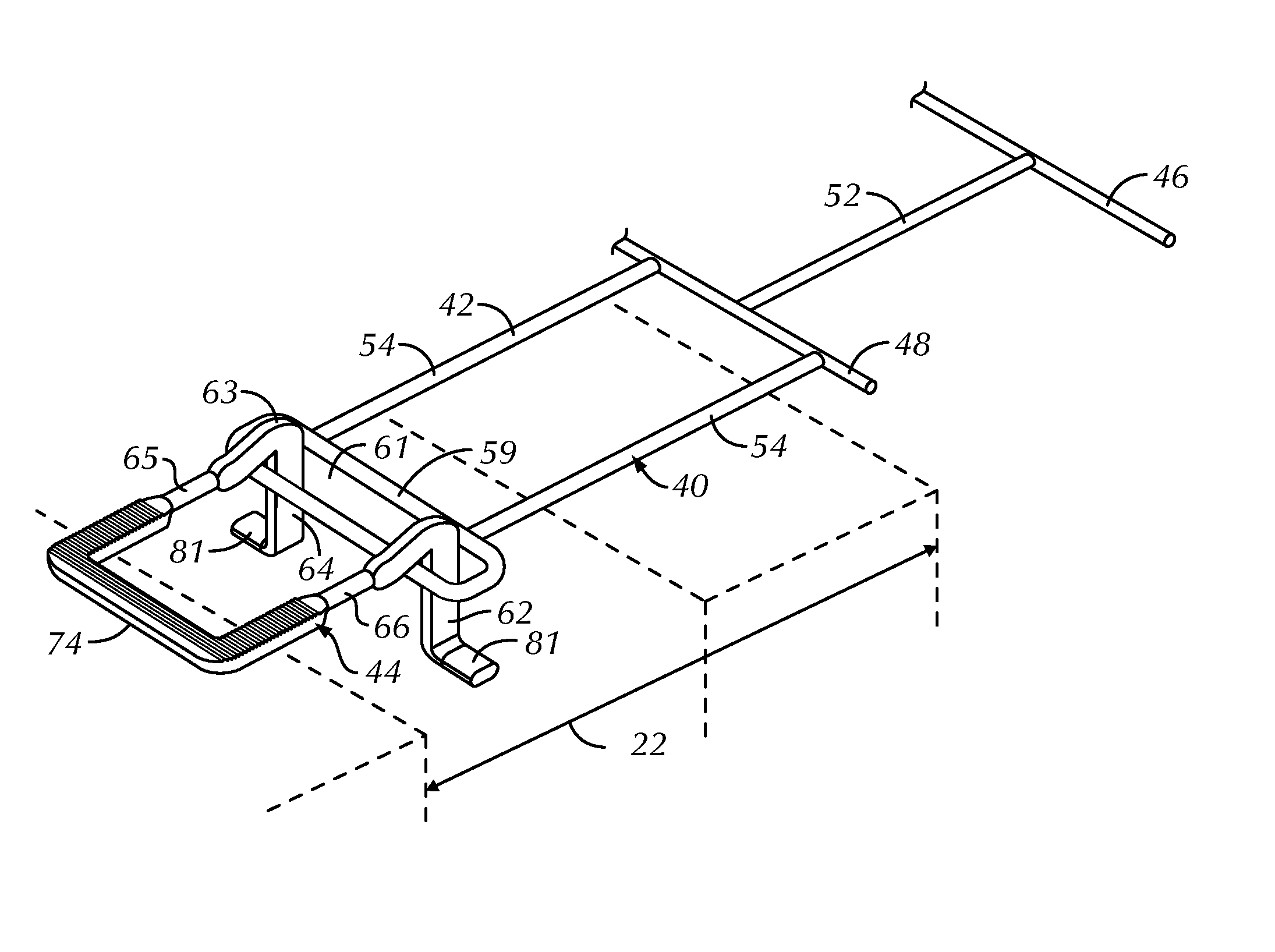

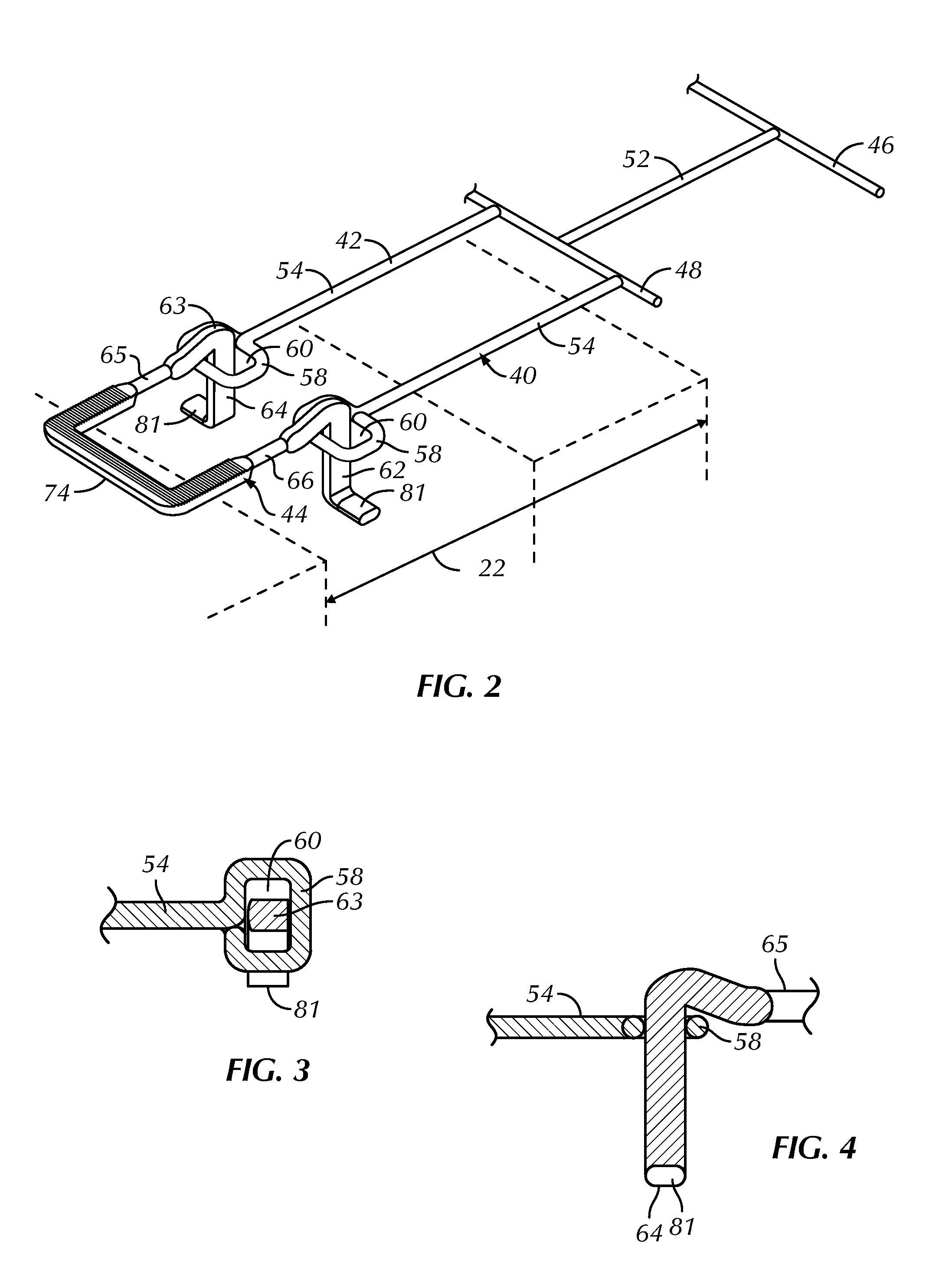

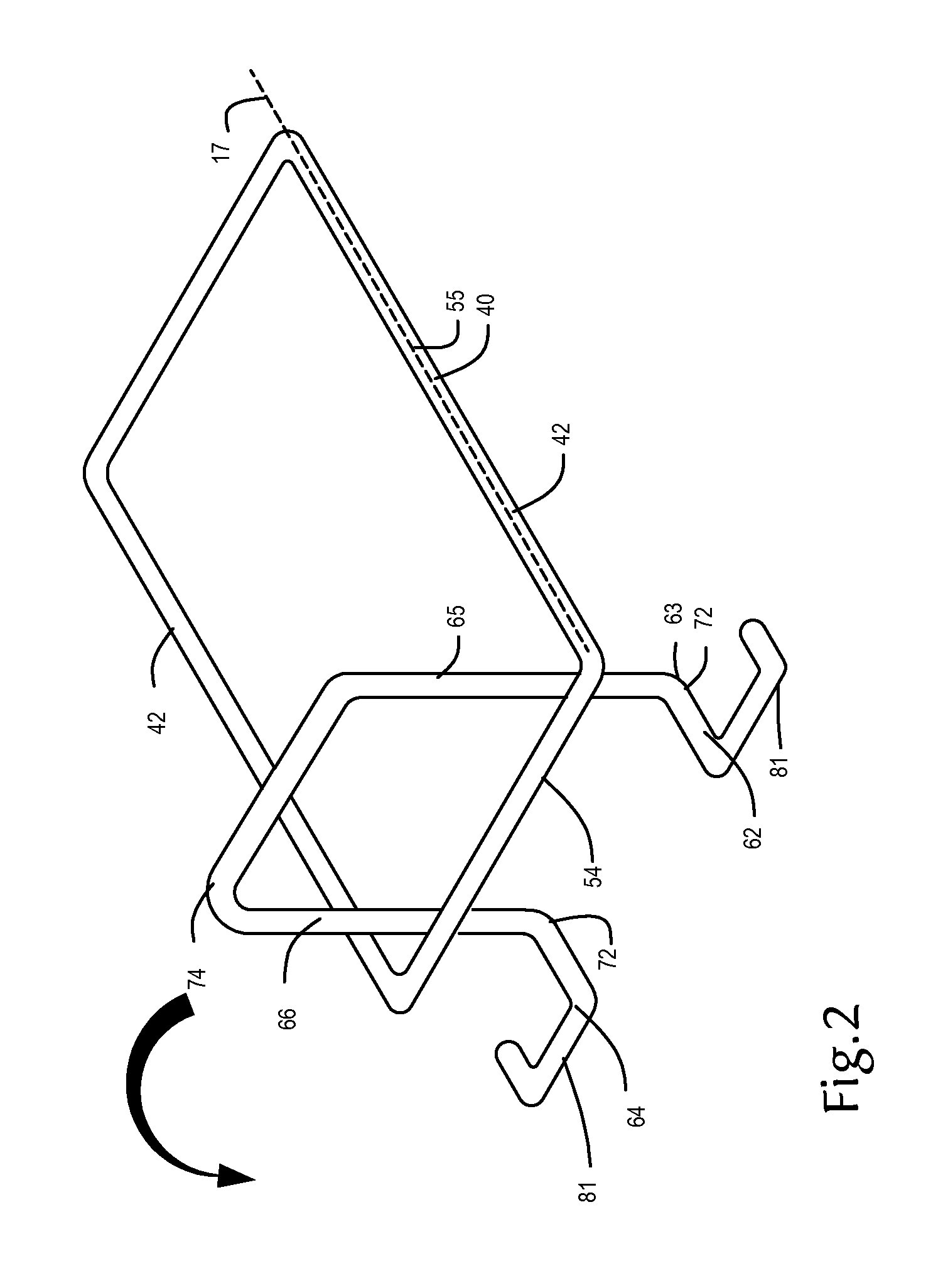

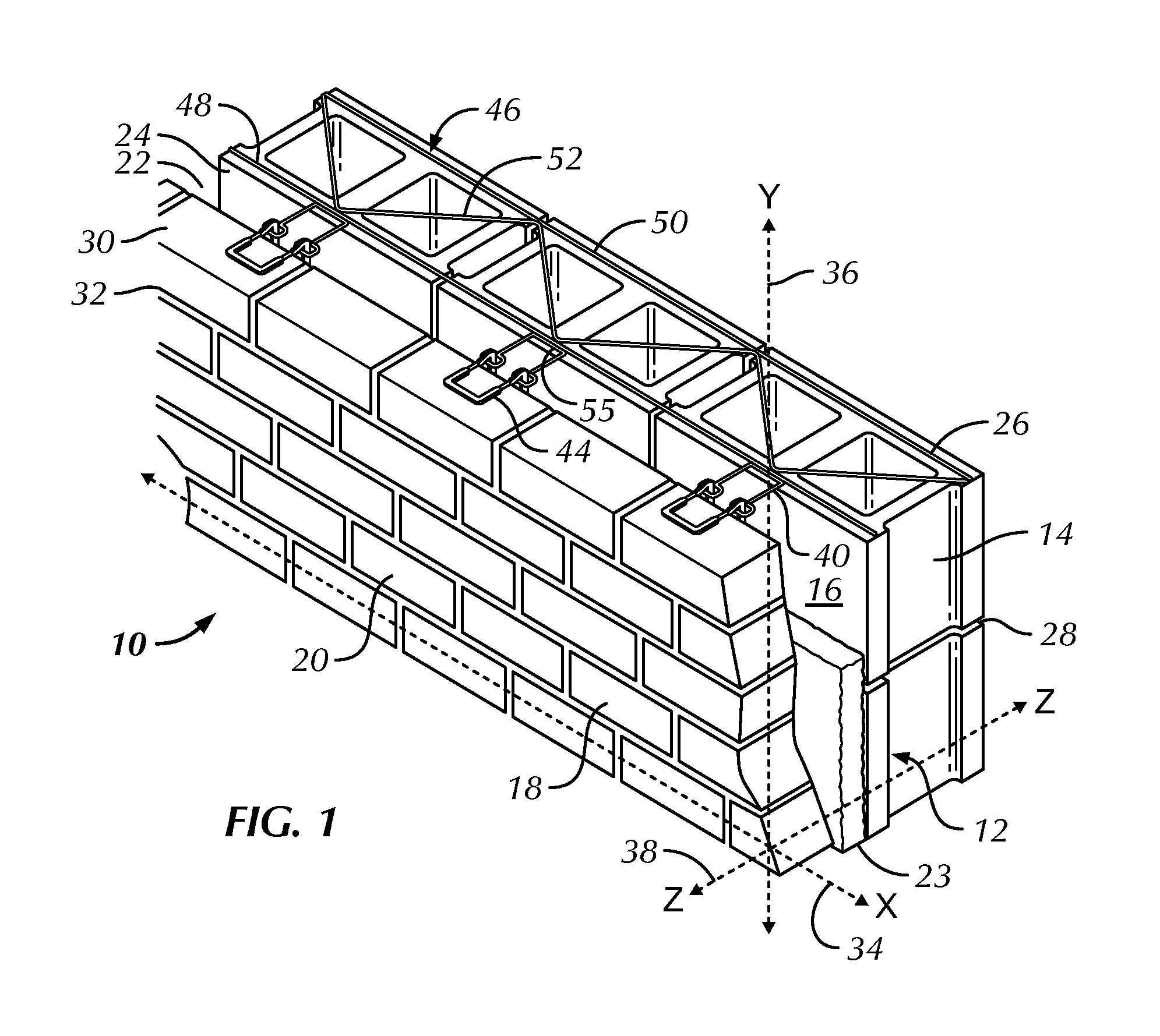

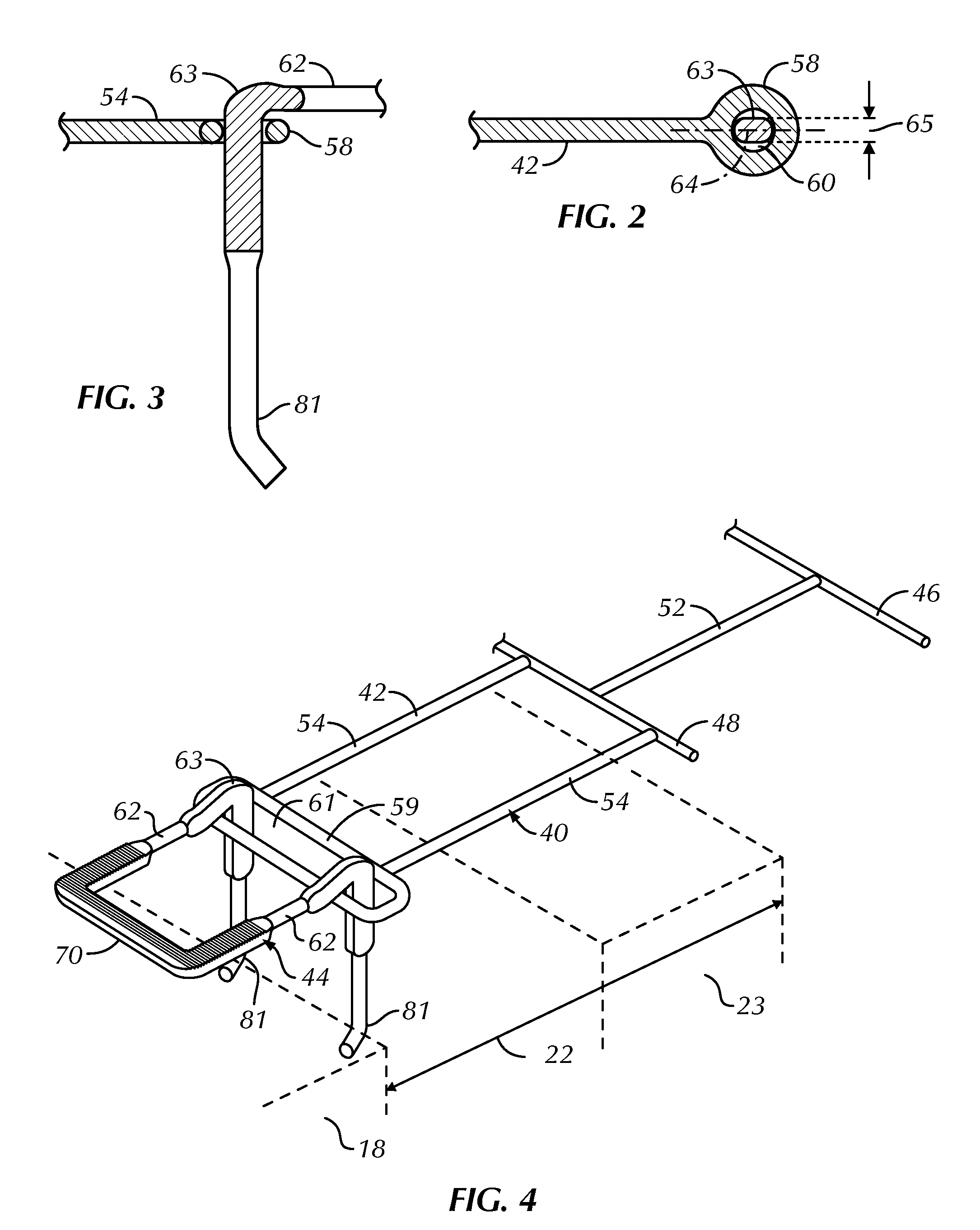

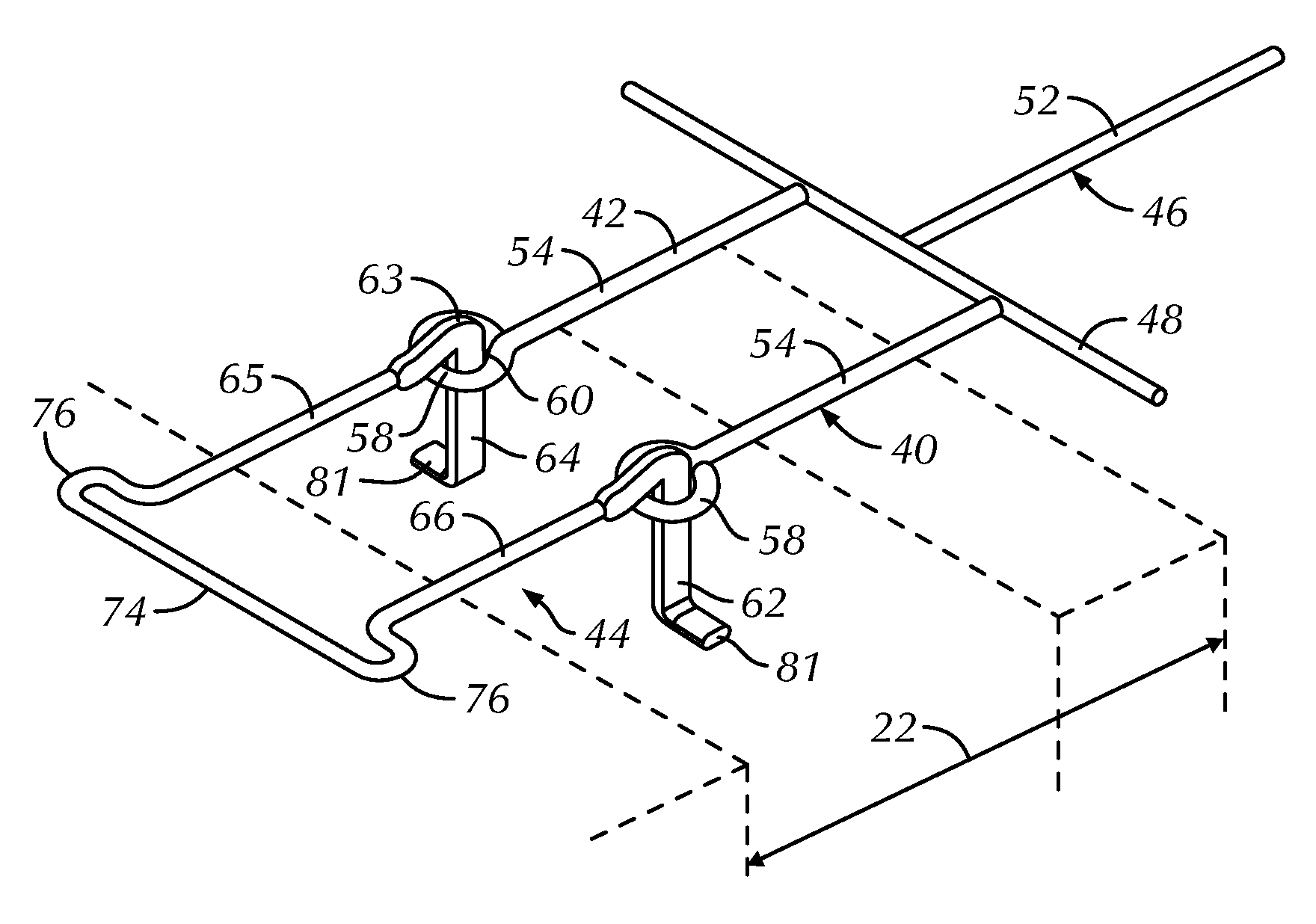

Snap-in wire tie

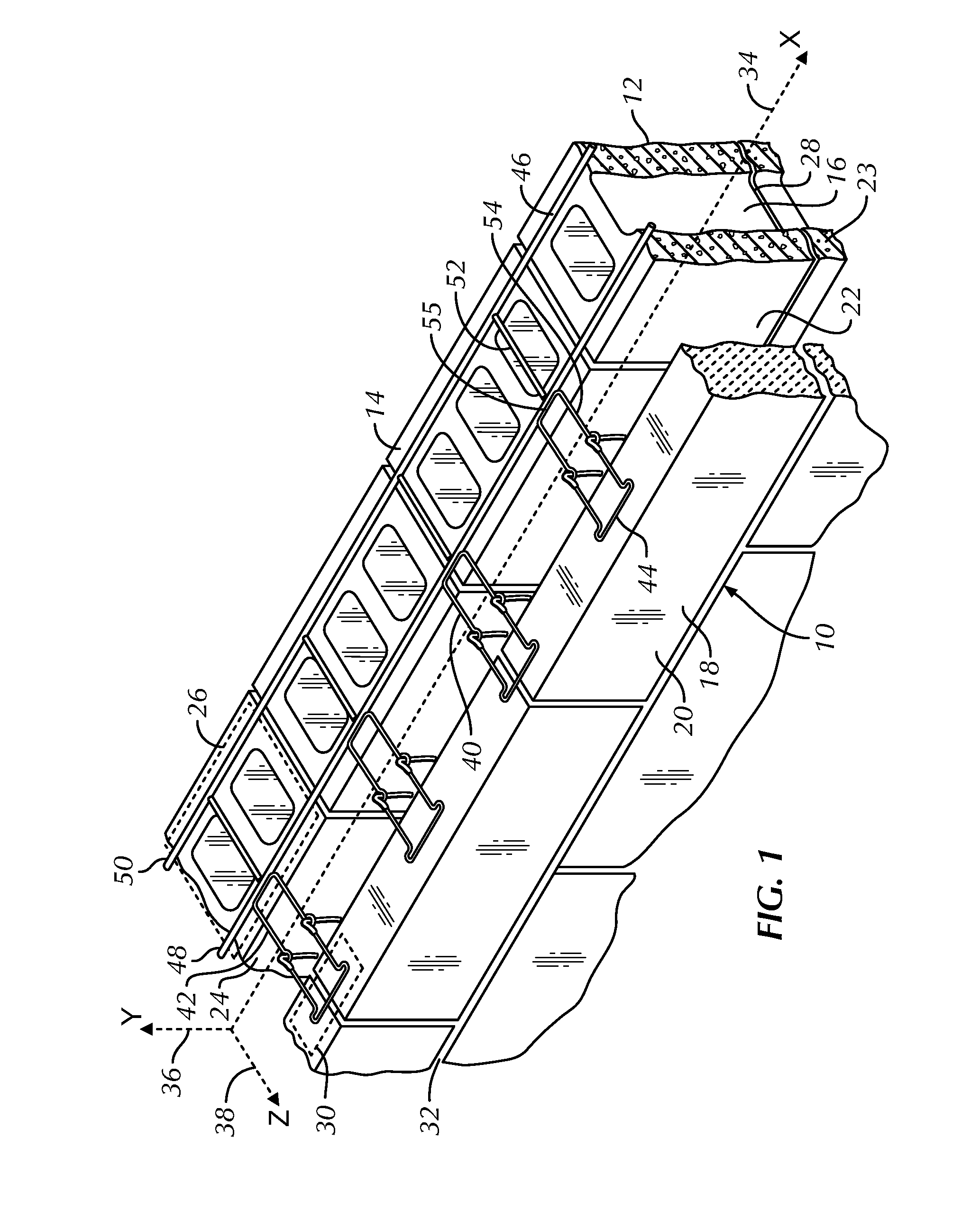

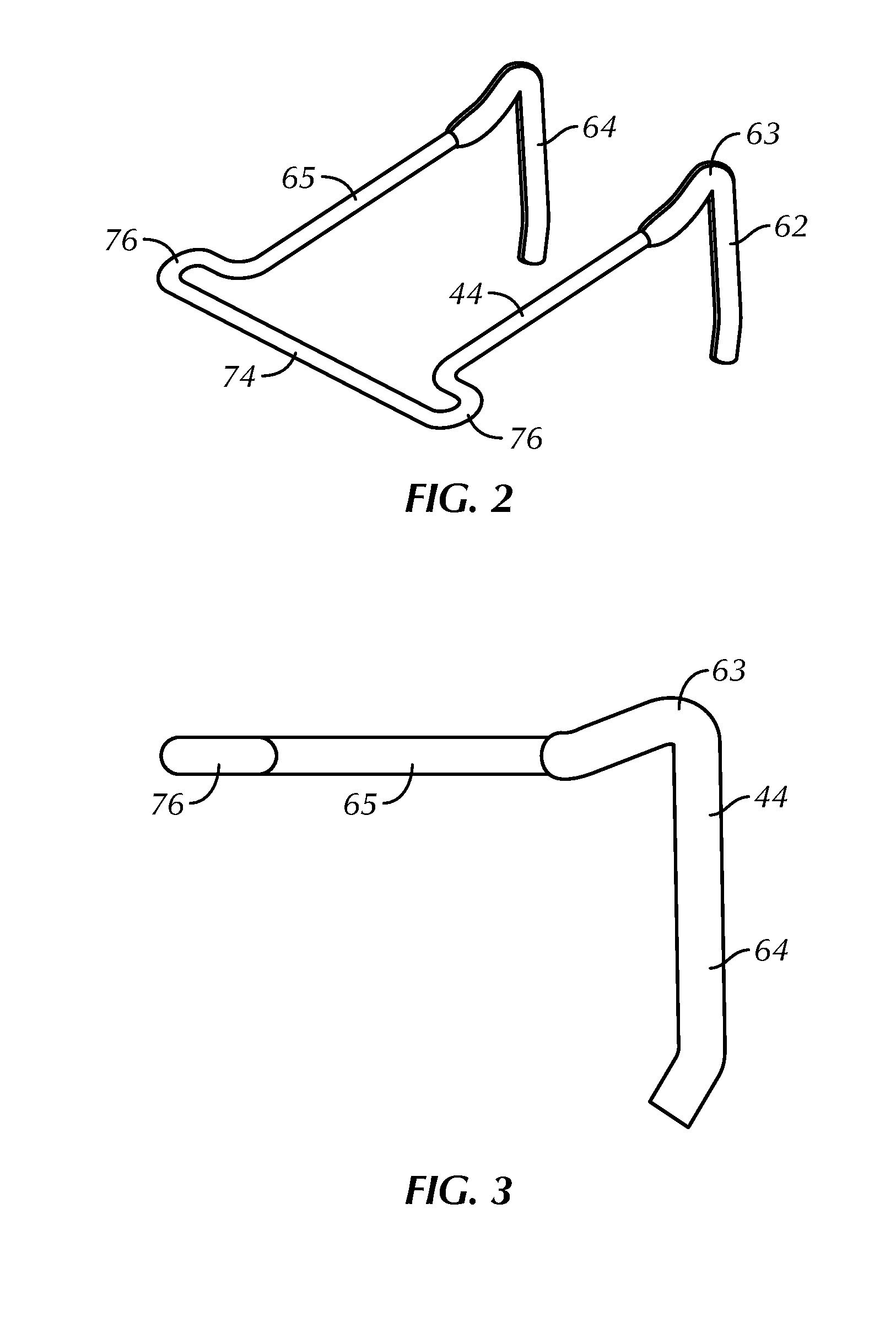

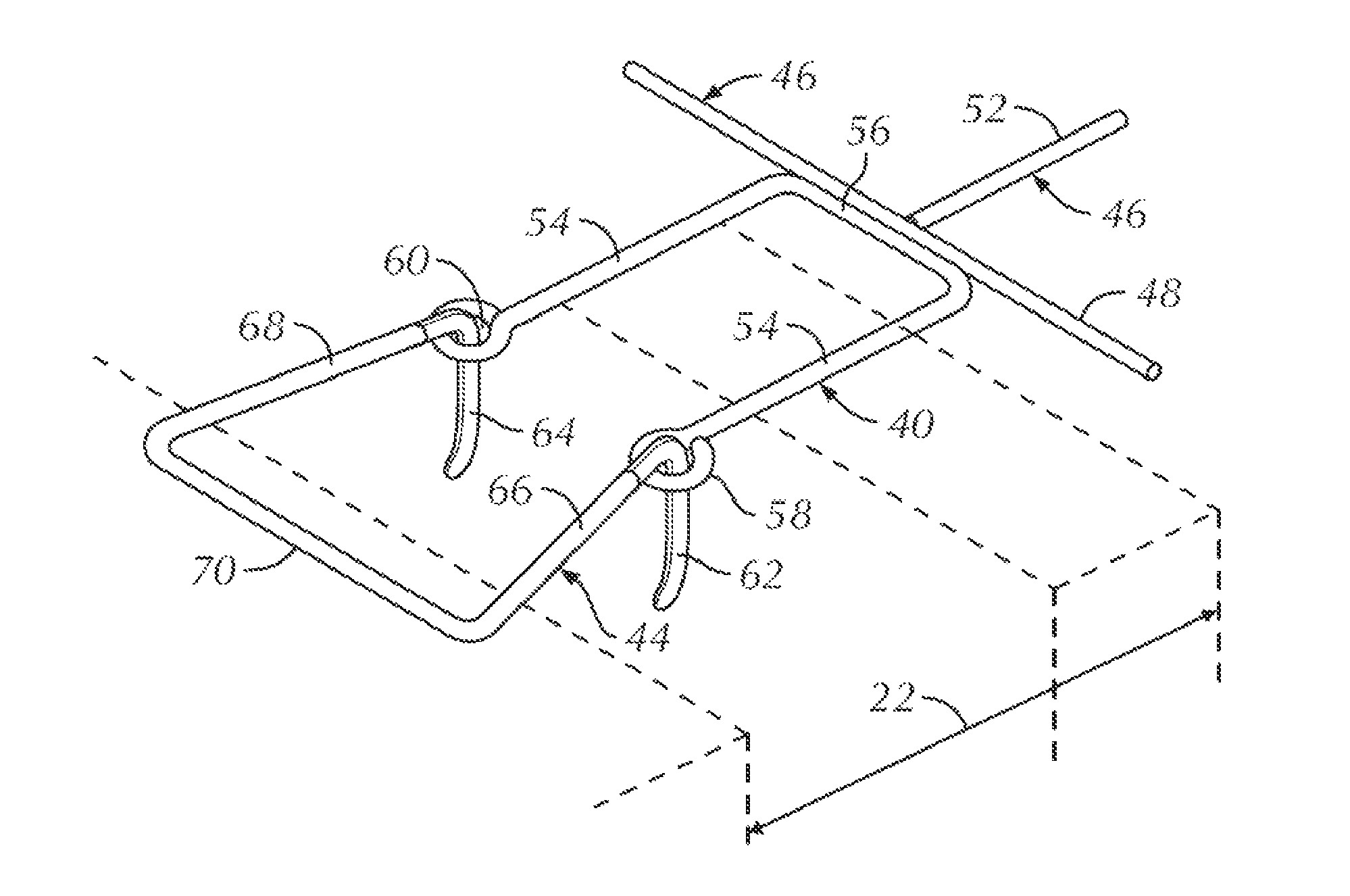

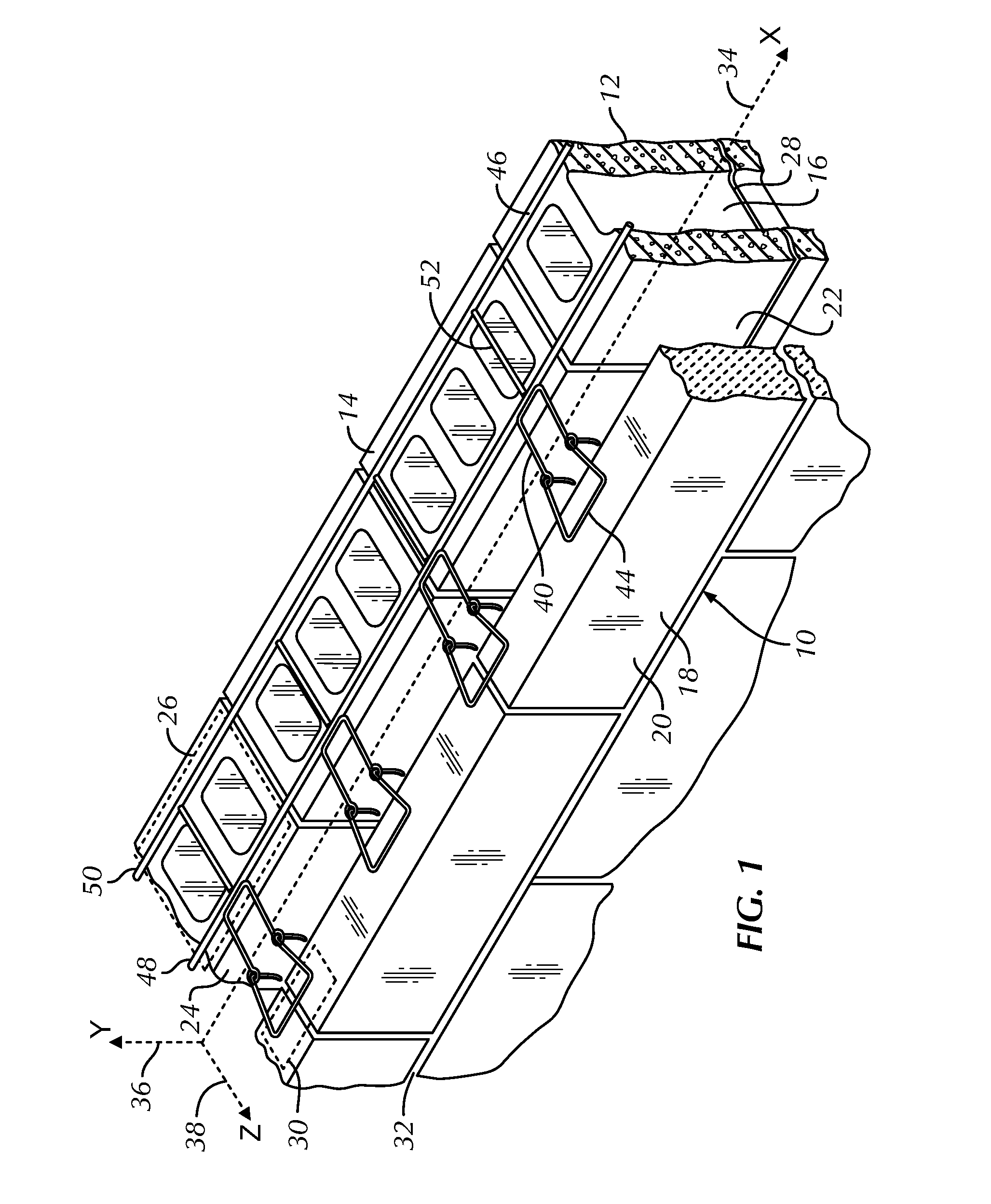

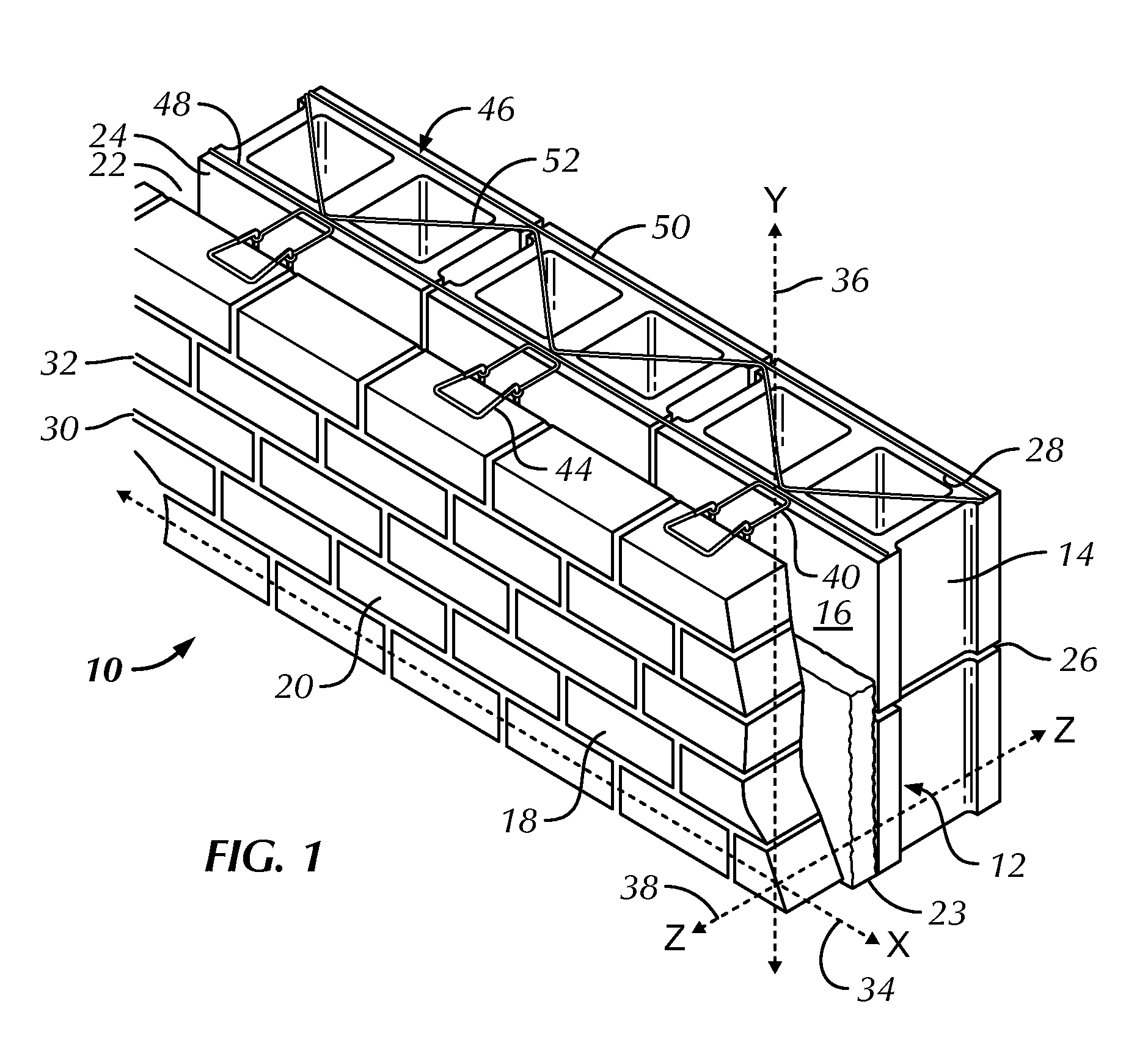

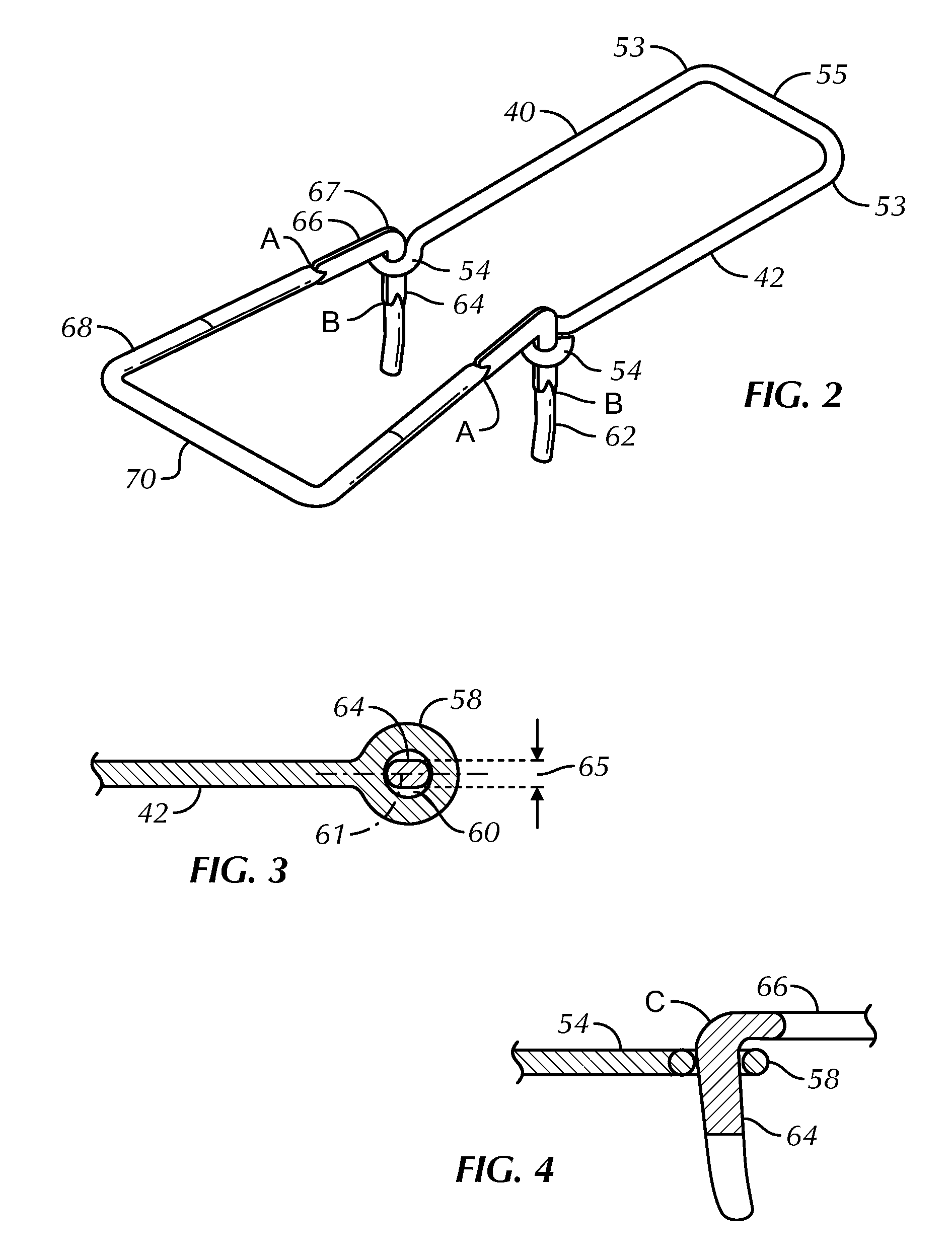

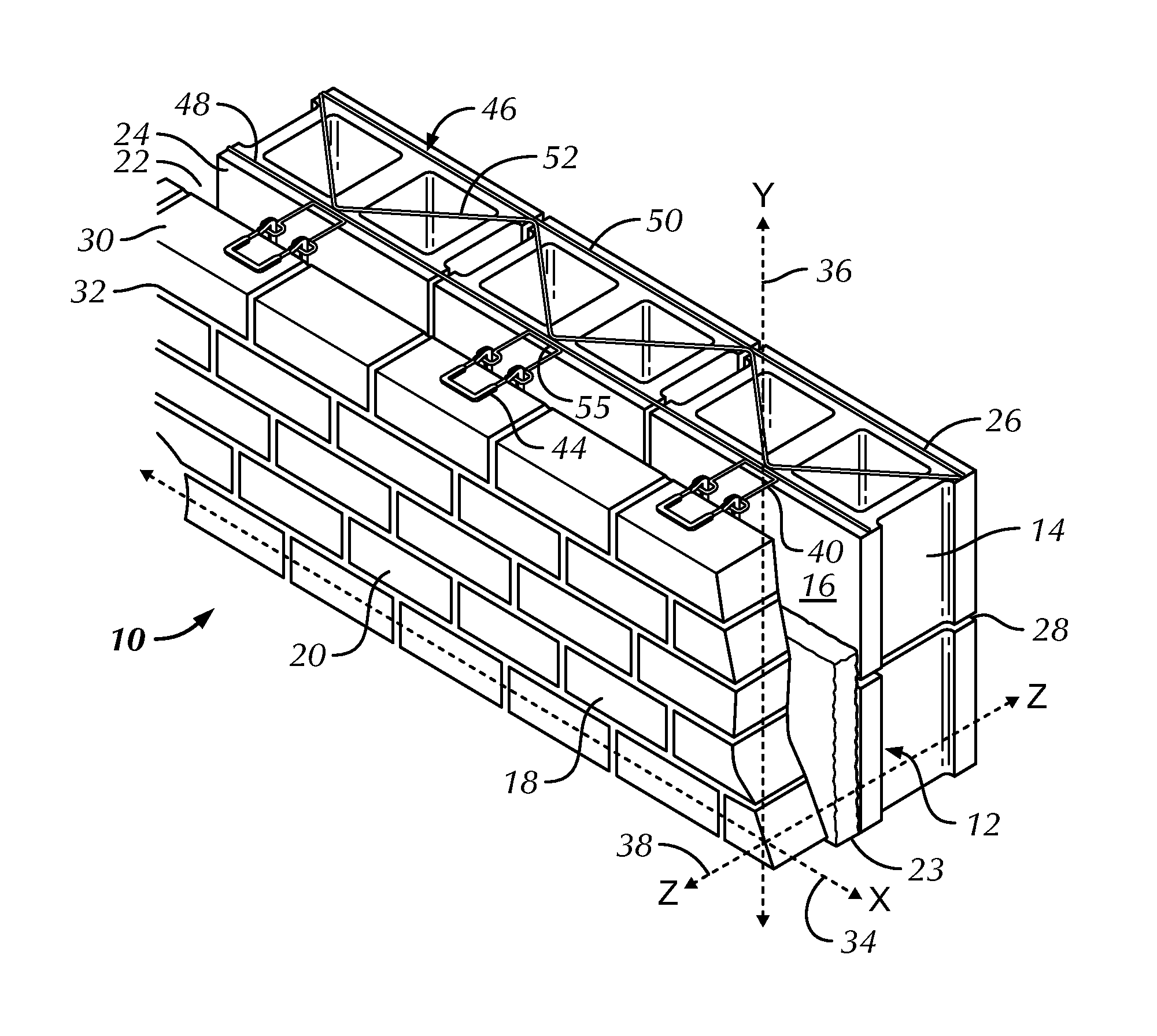

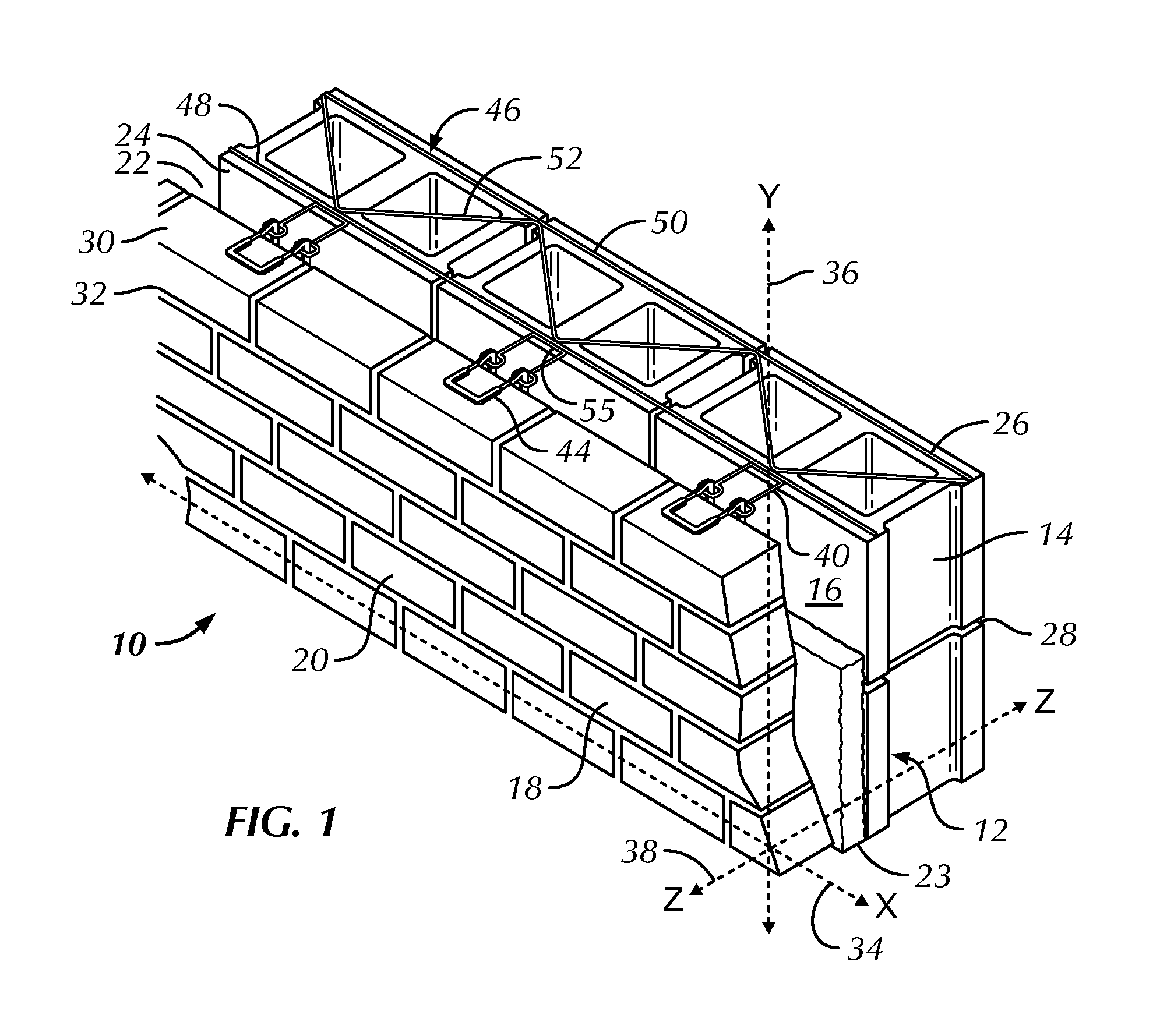

ActiveUS7325366B1Reduce manufacturing costLower unit costConstruction materialFloorsEngineeringCavity wall

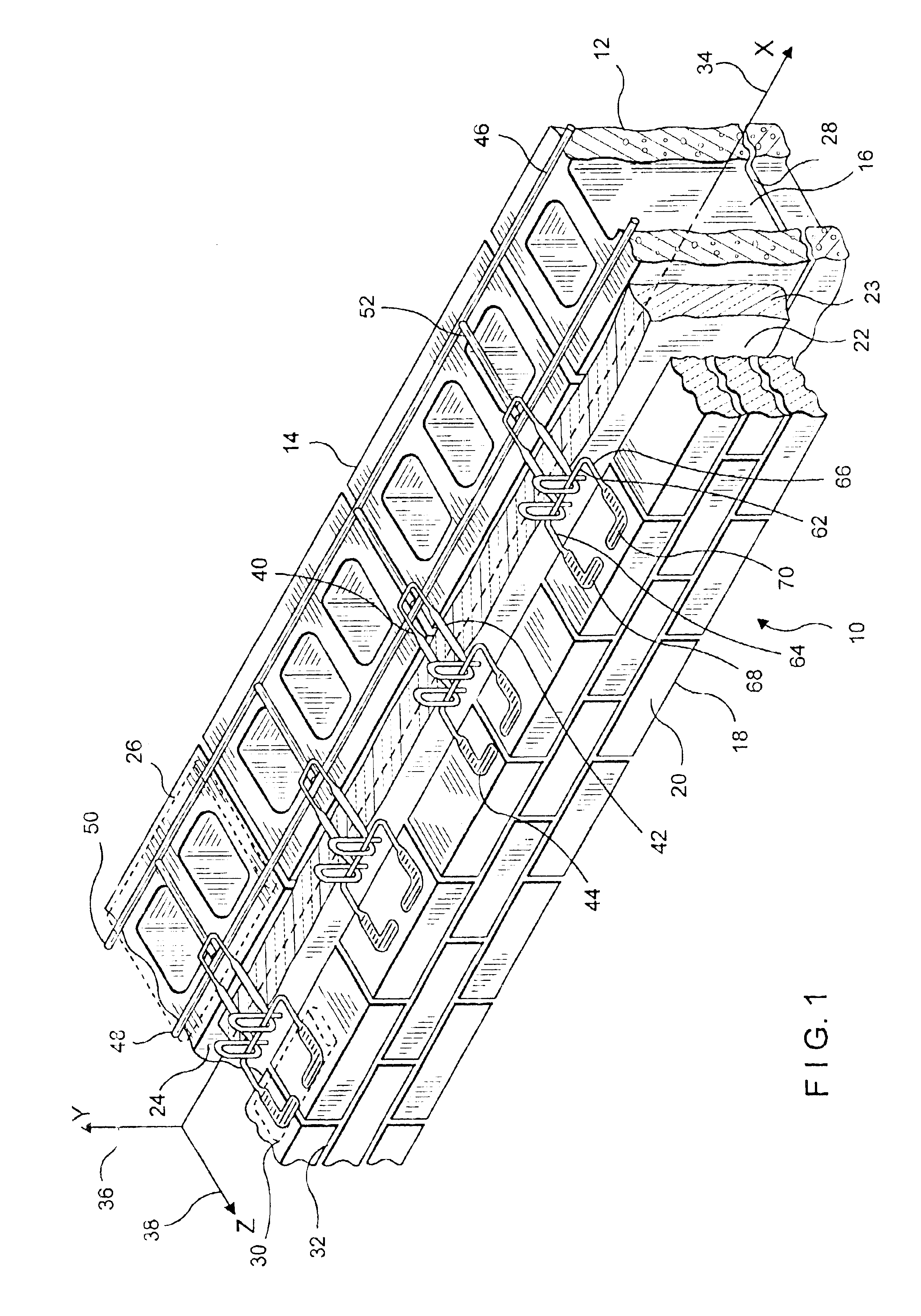

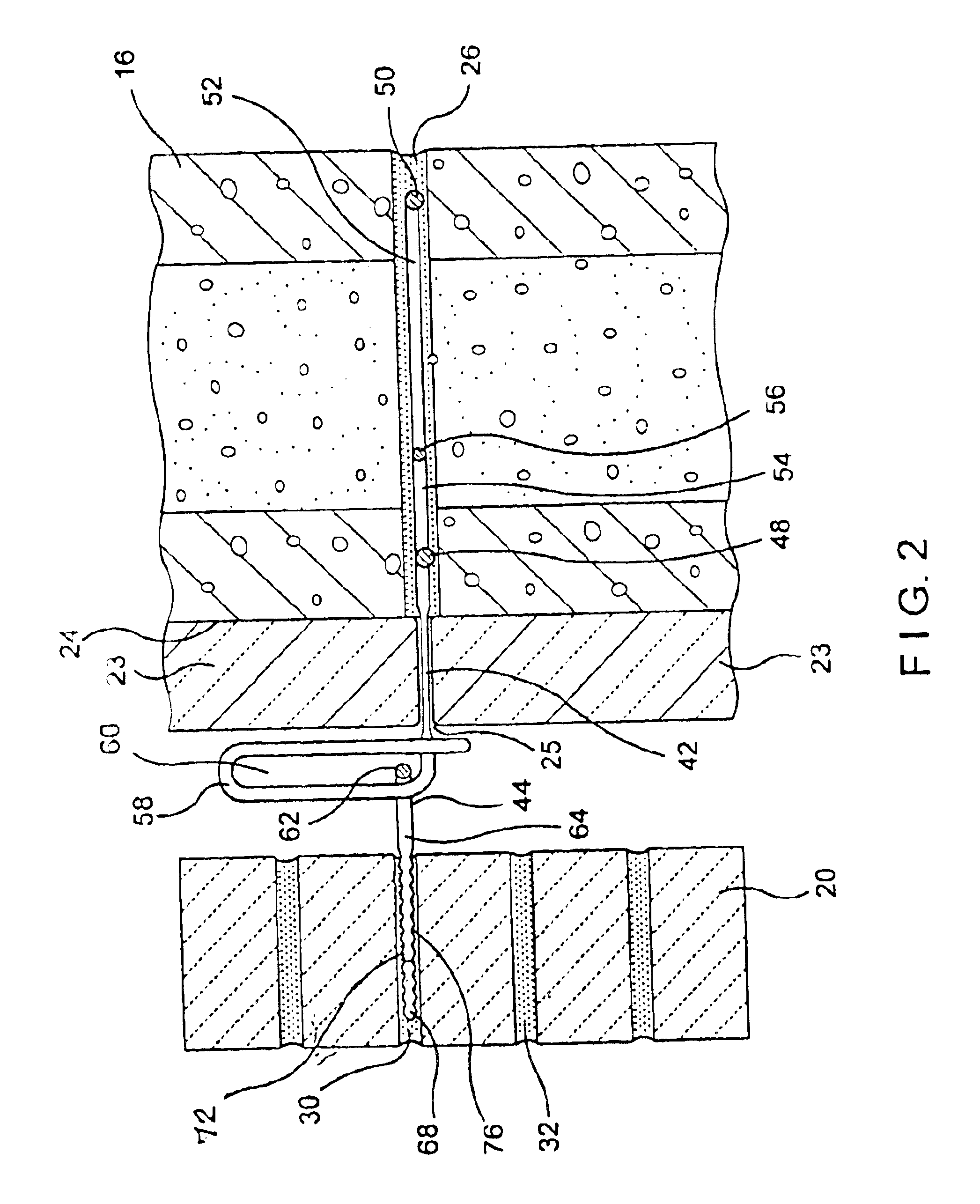

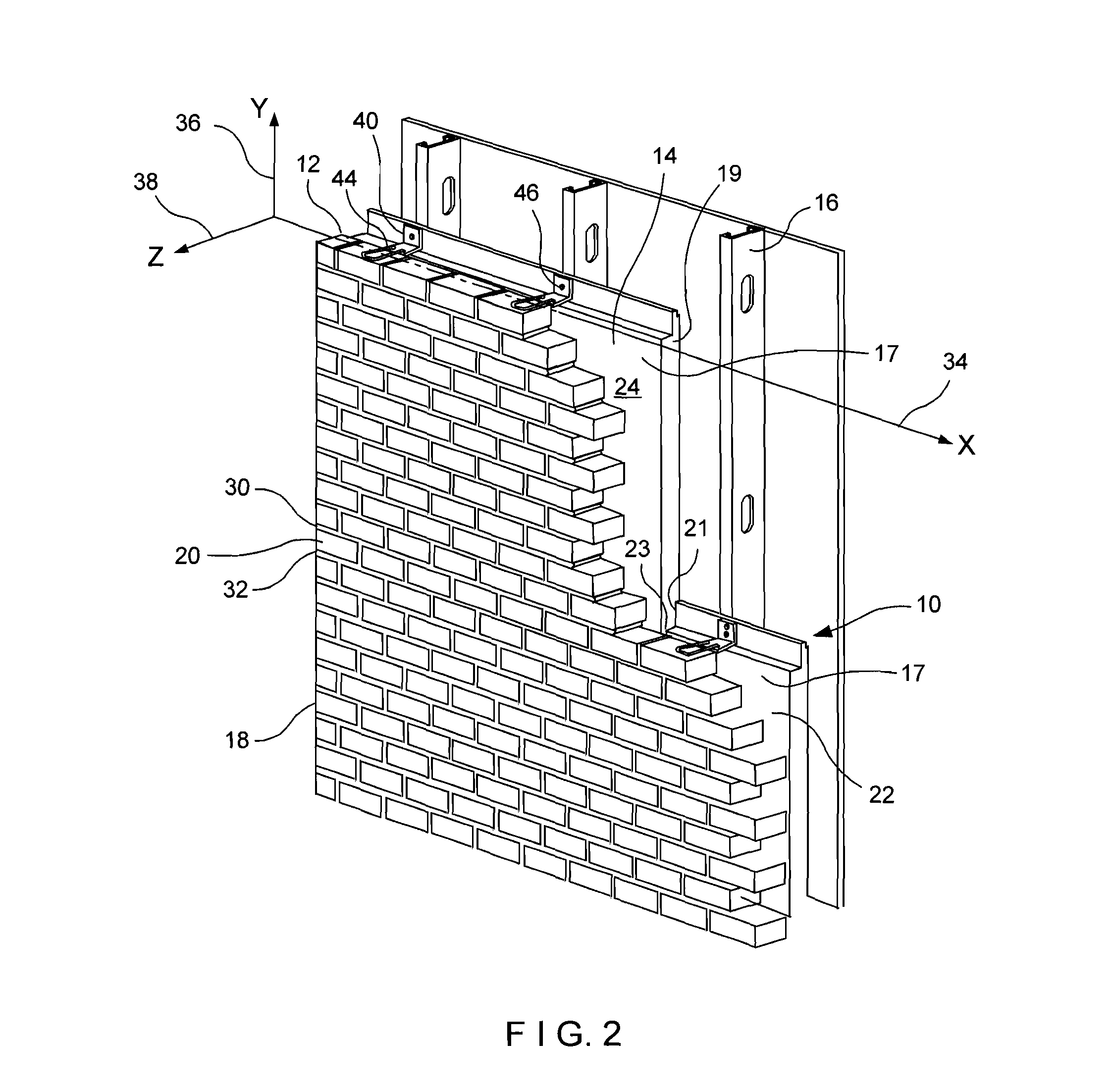

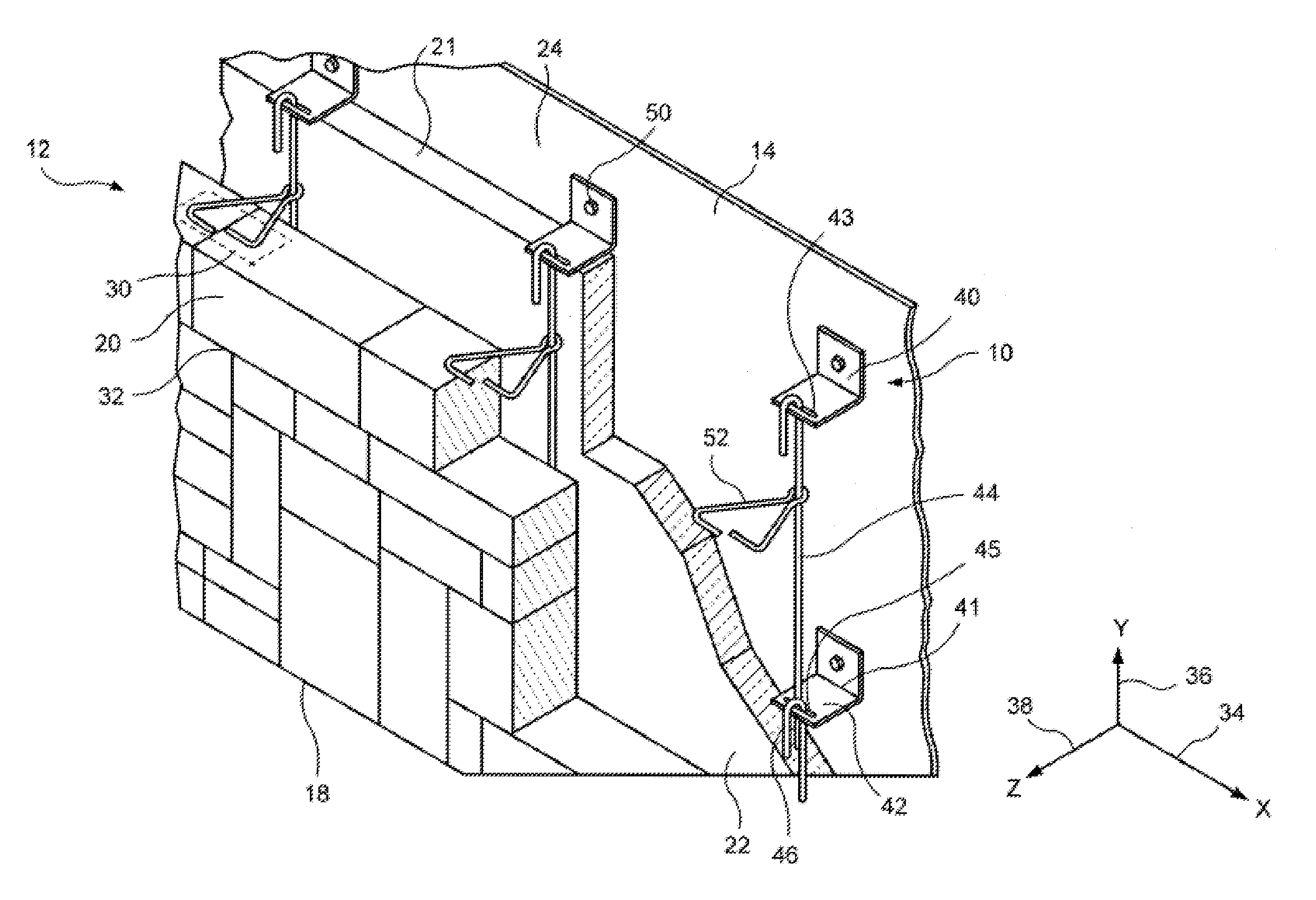

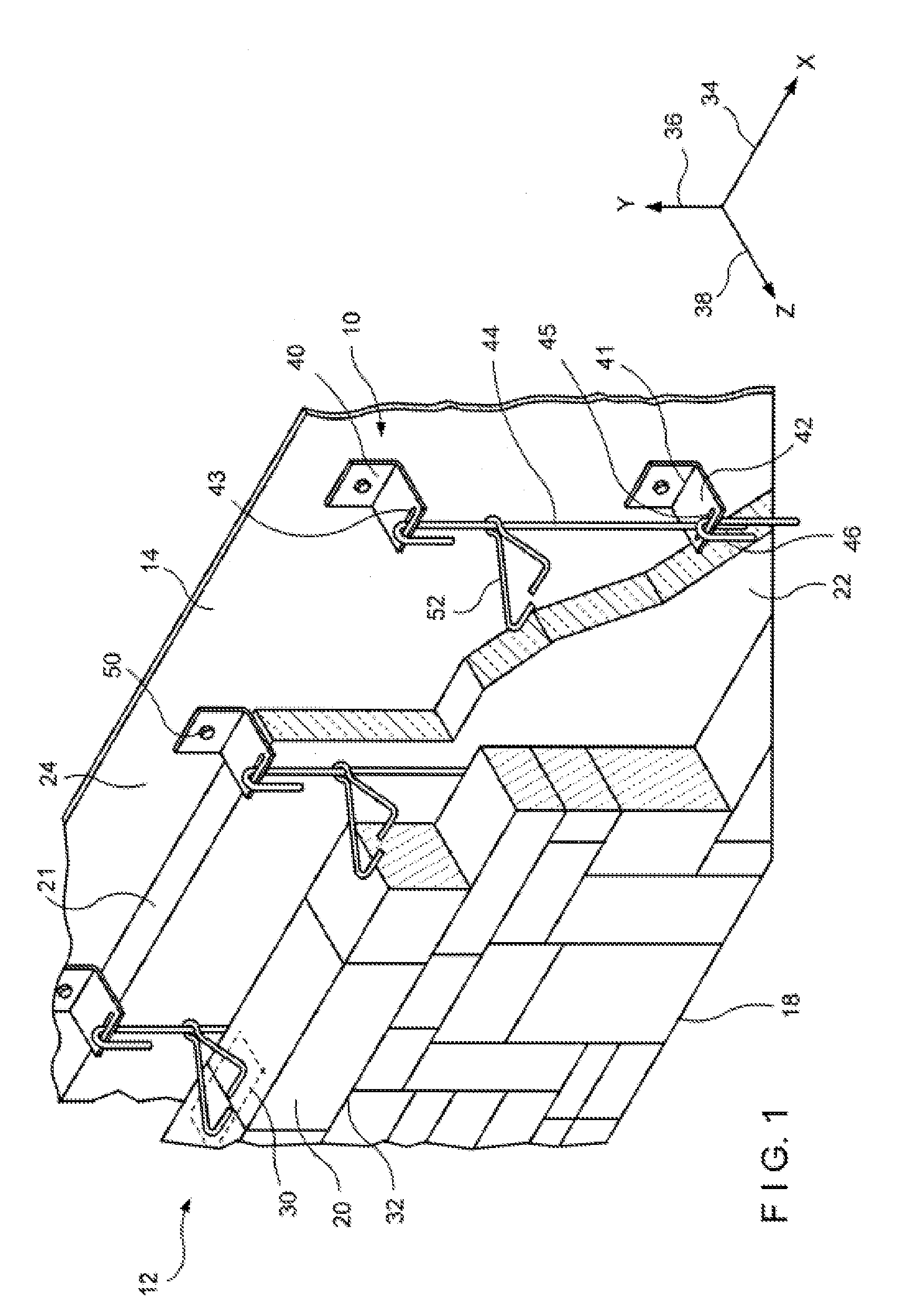

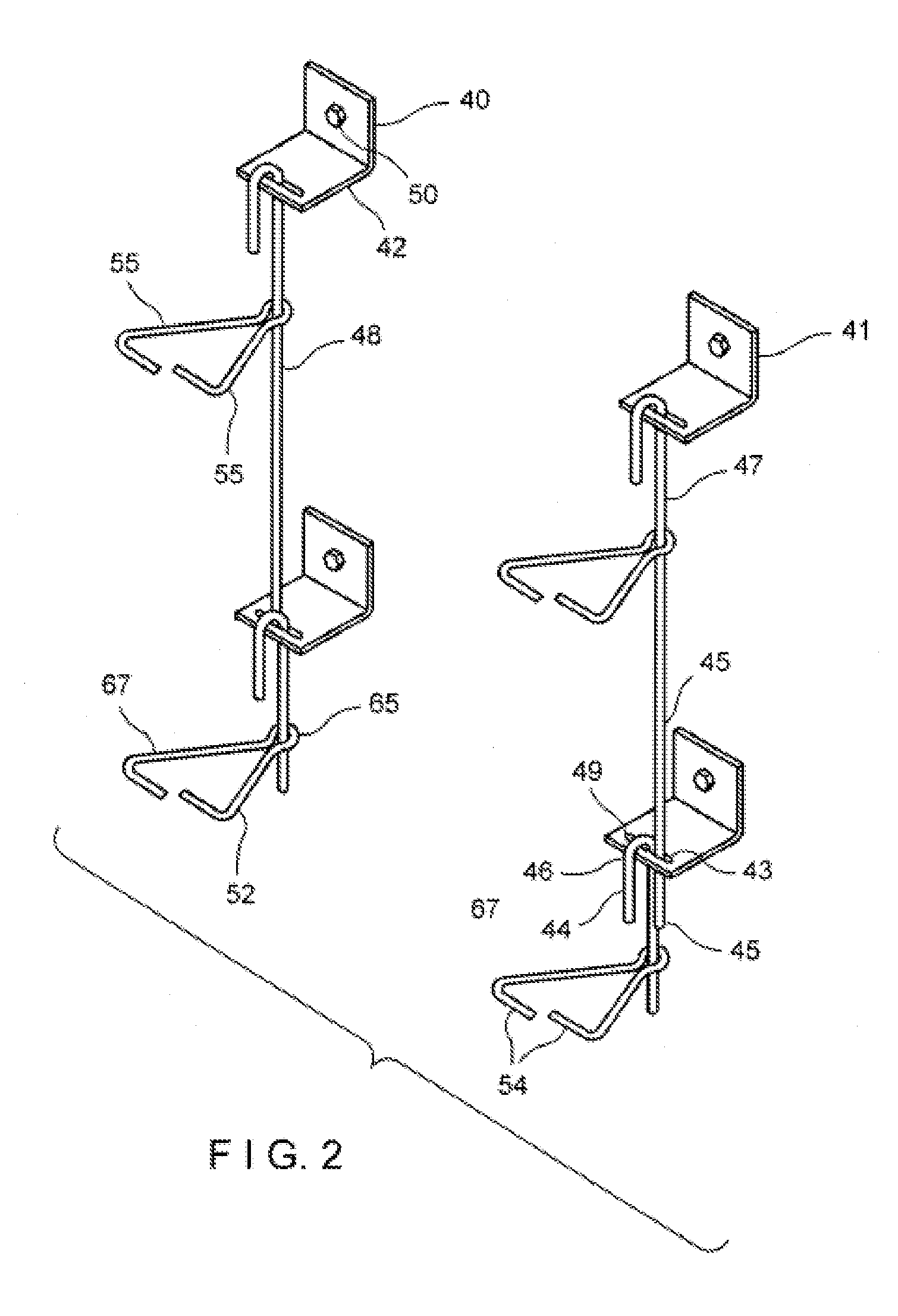

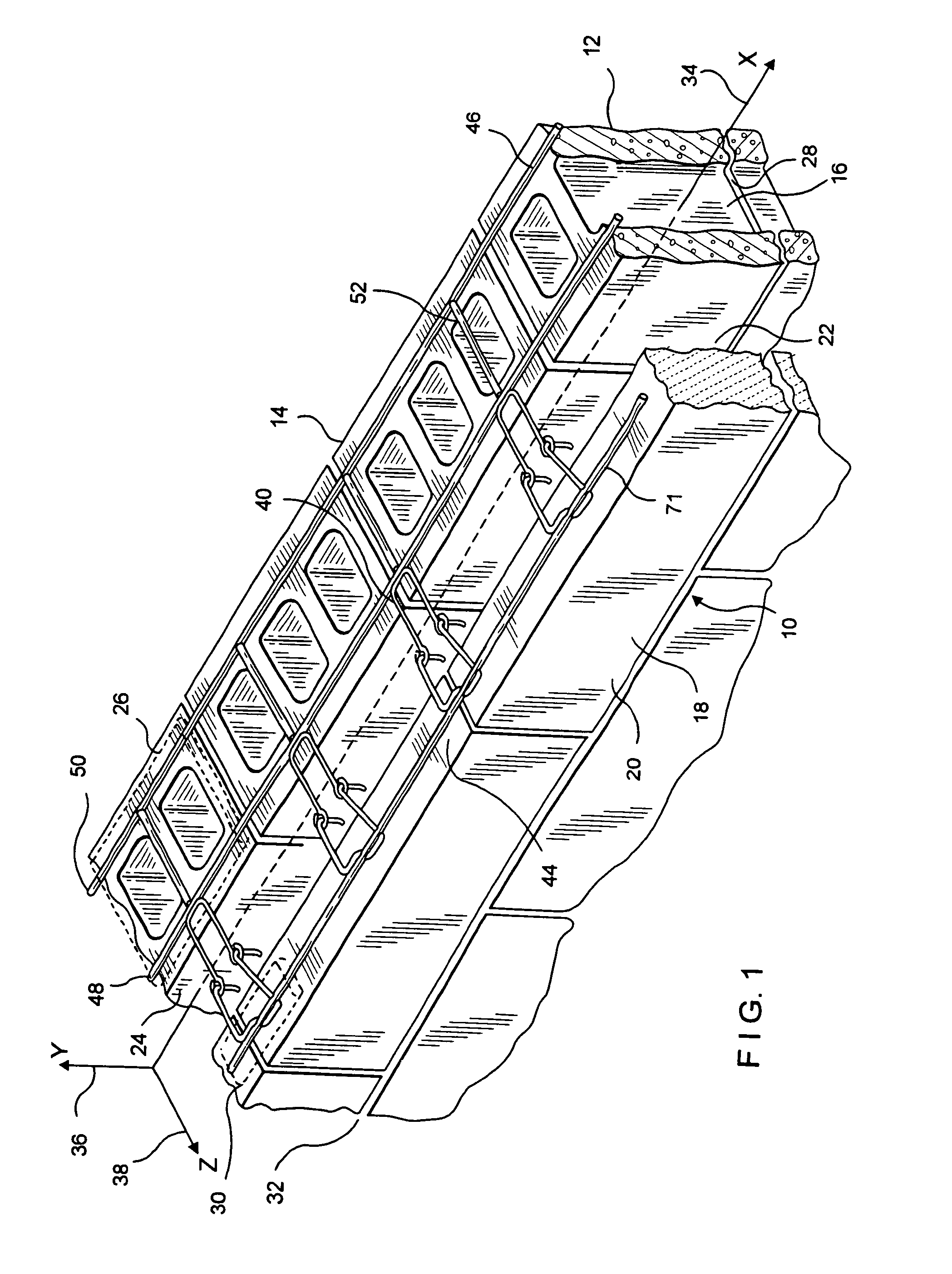

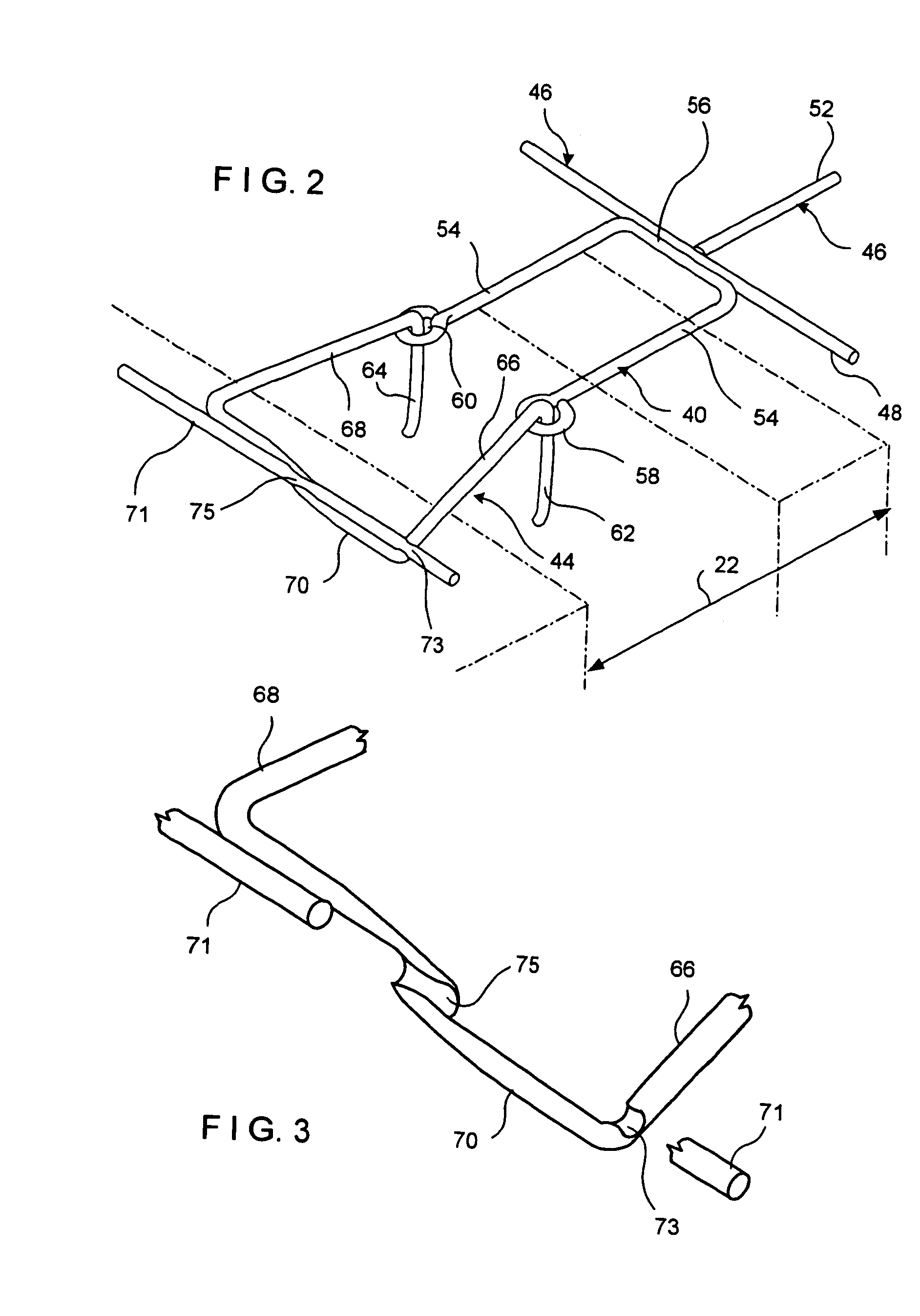

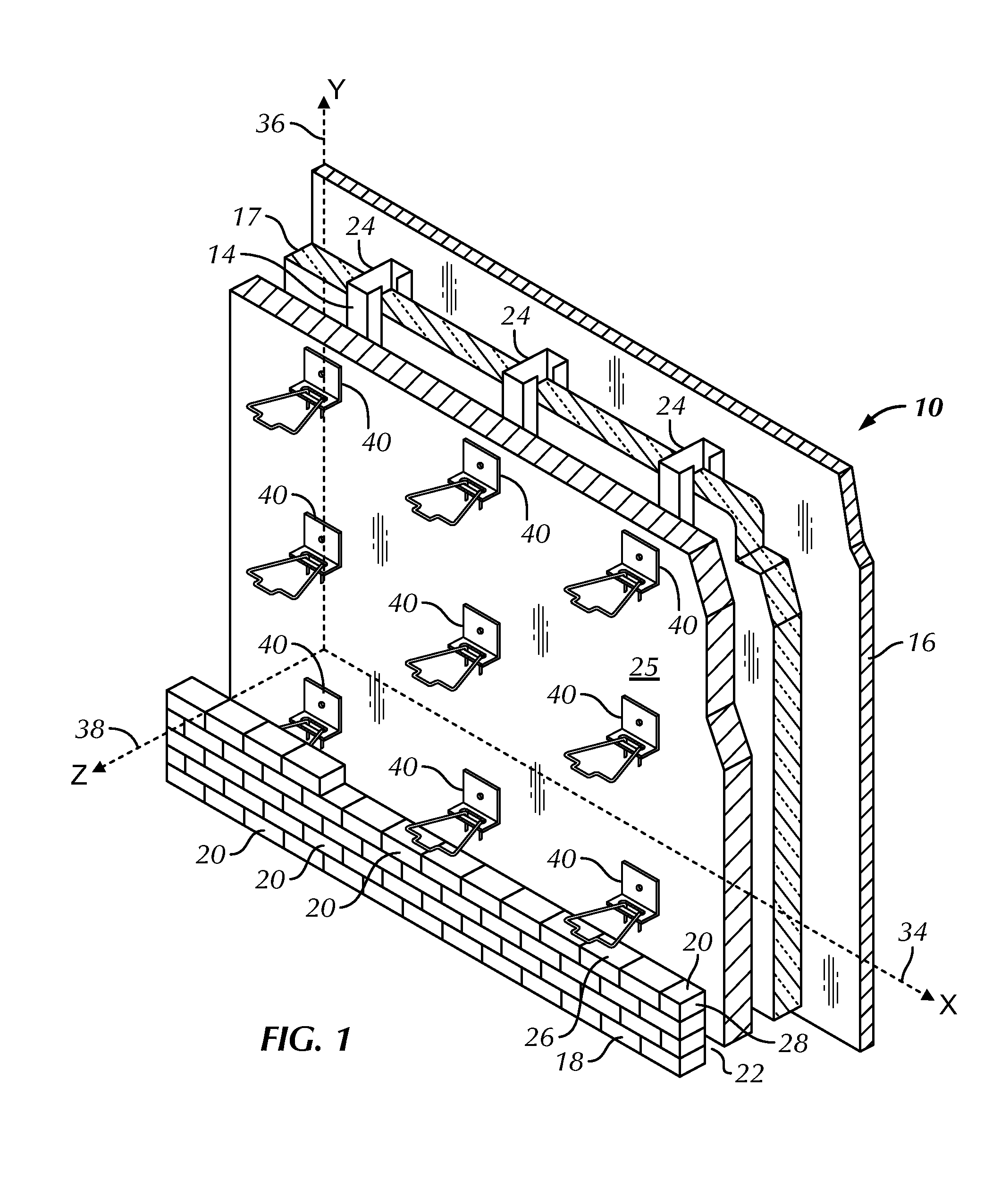

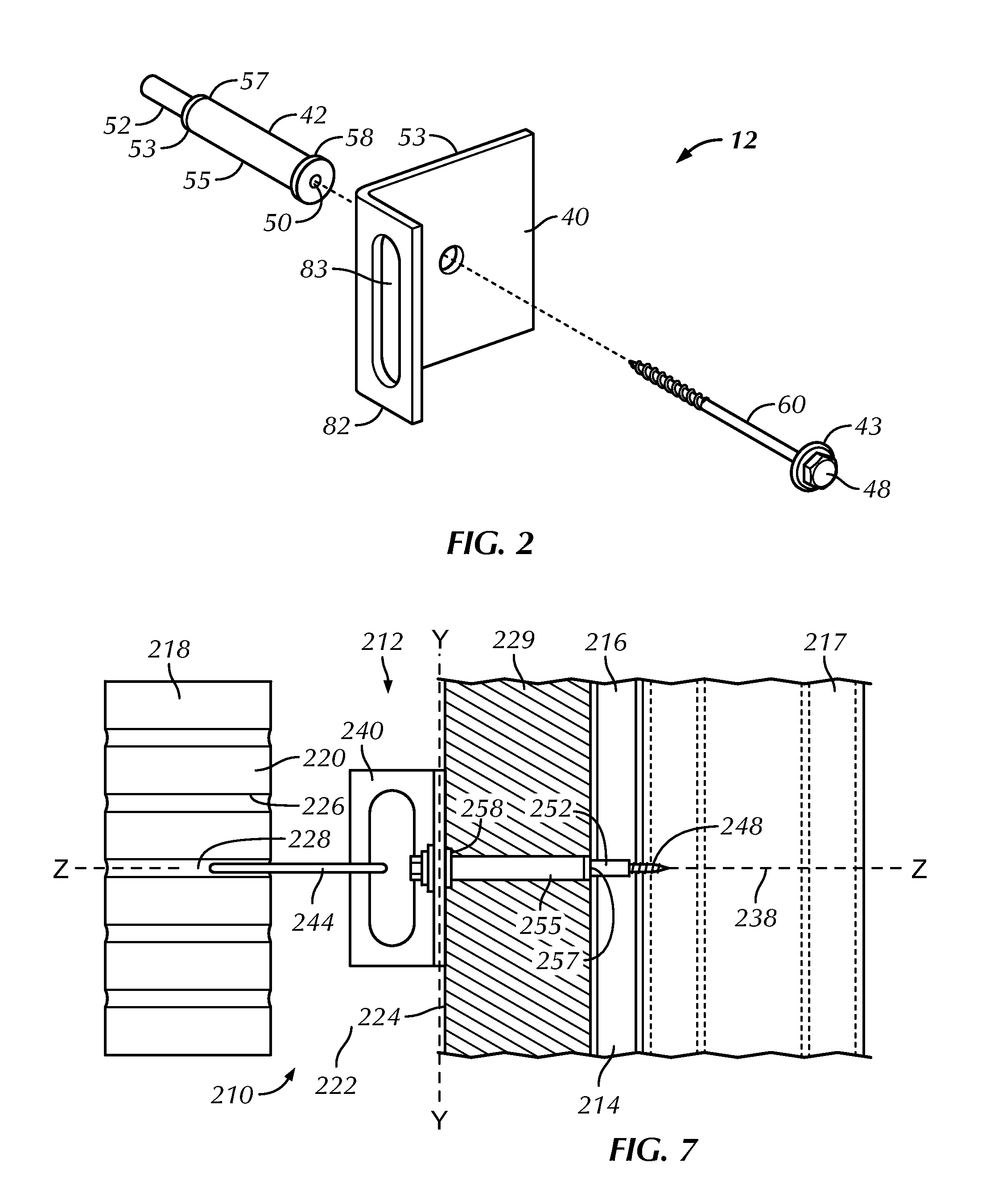

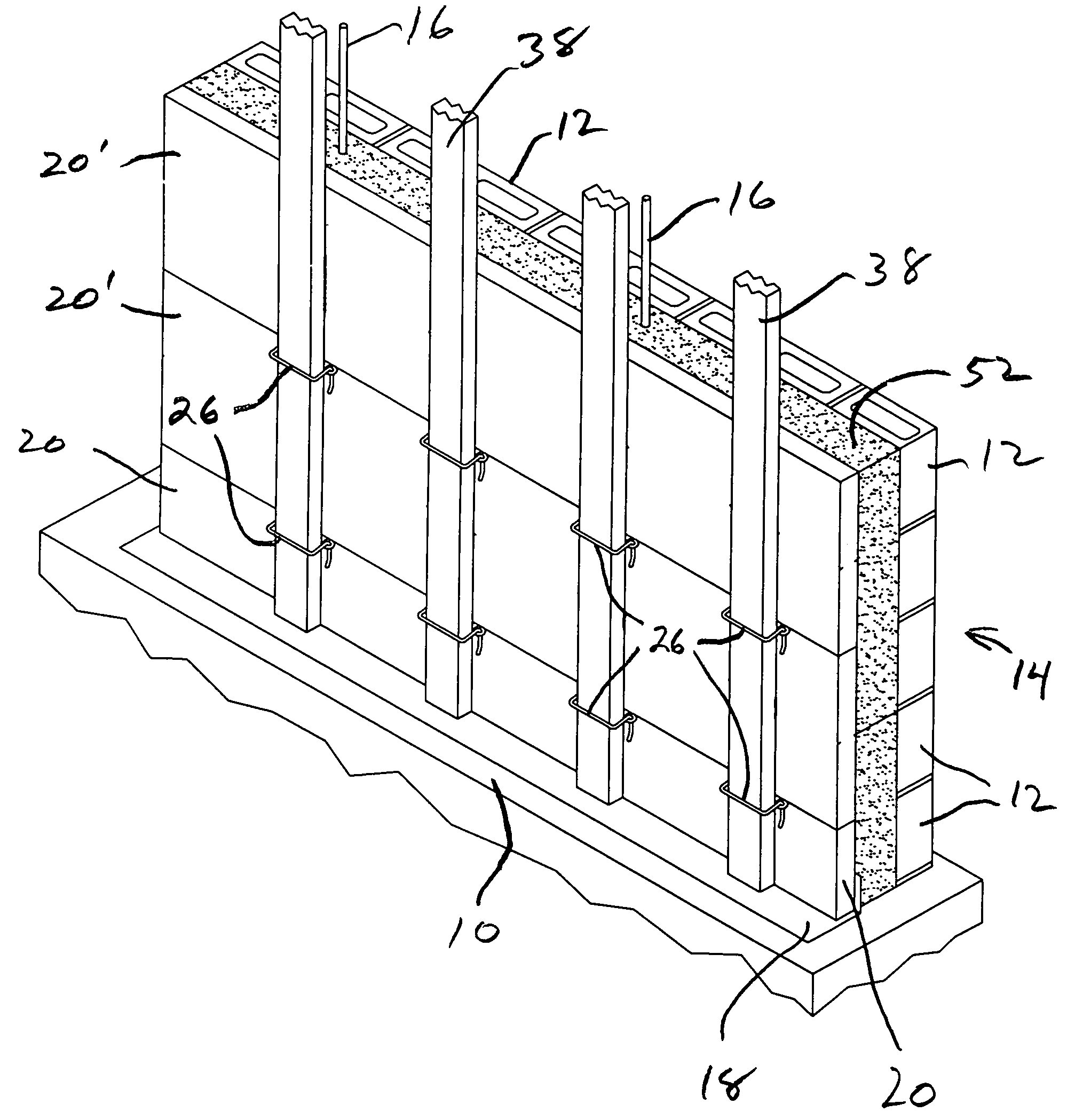

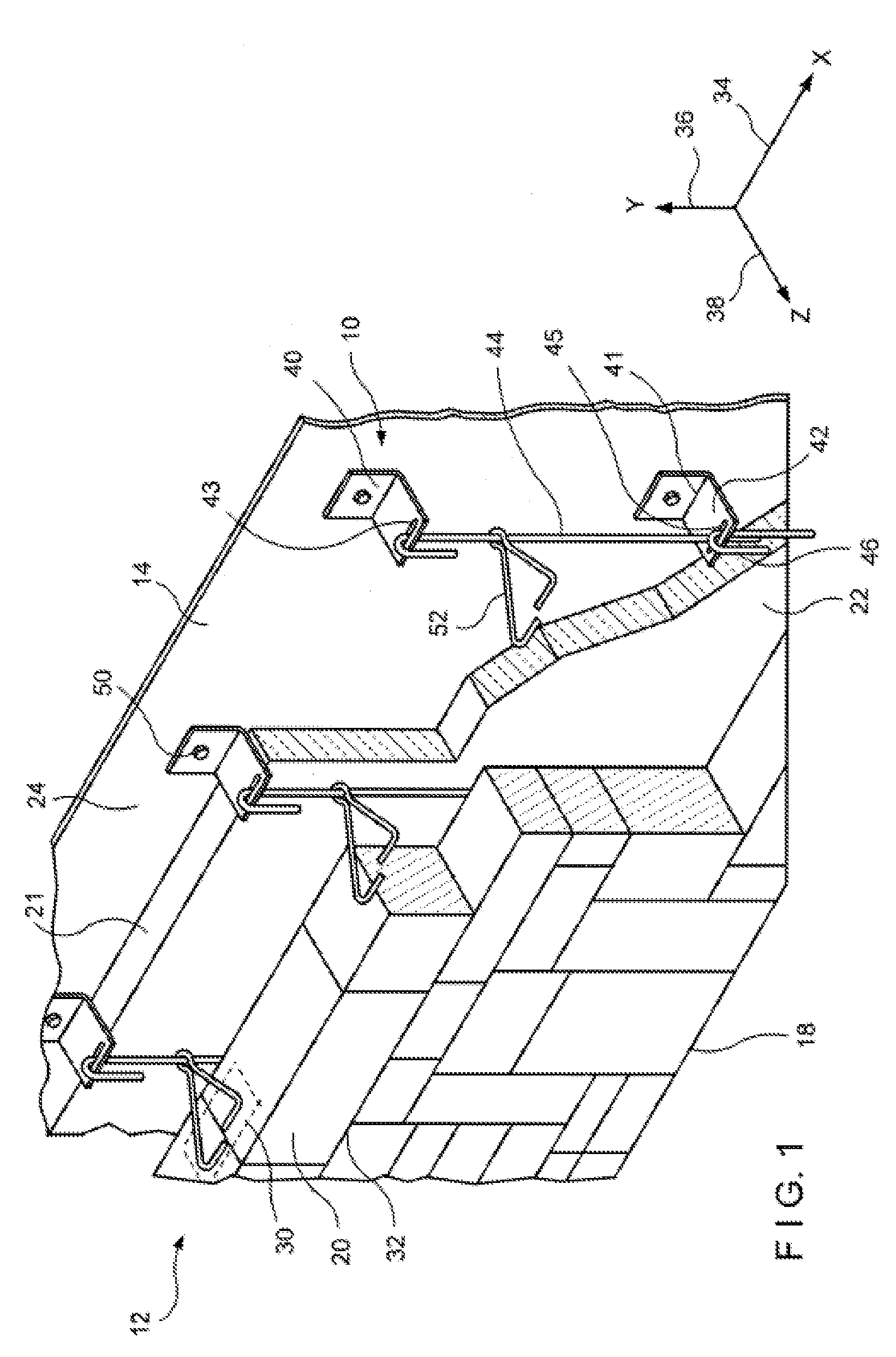

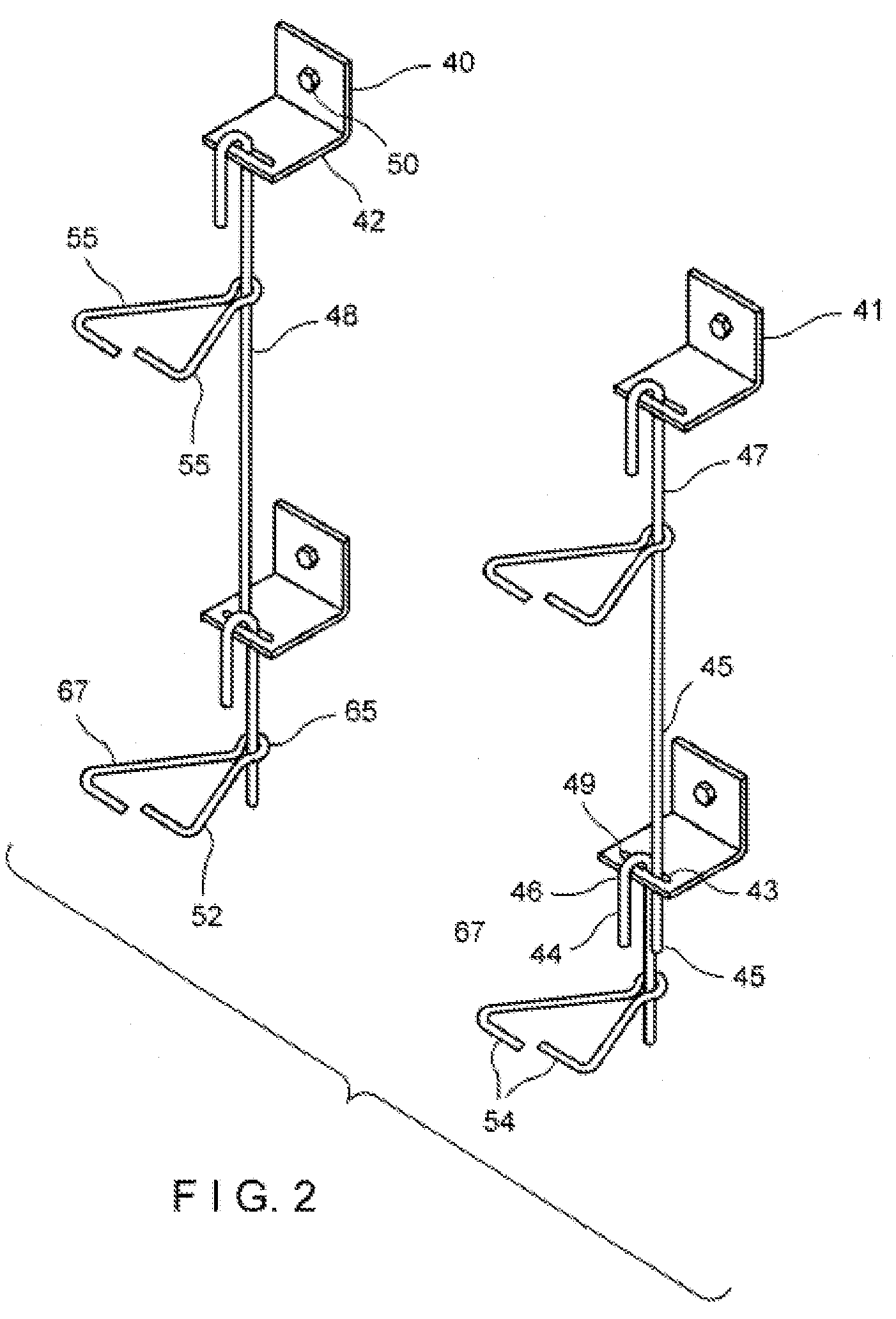

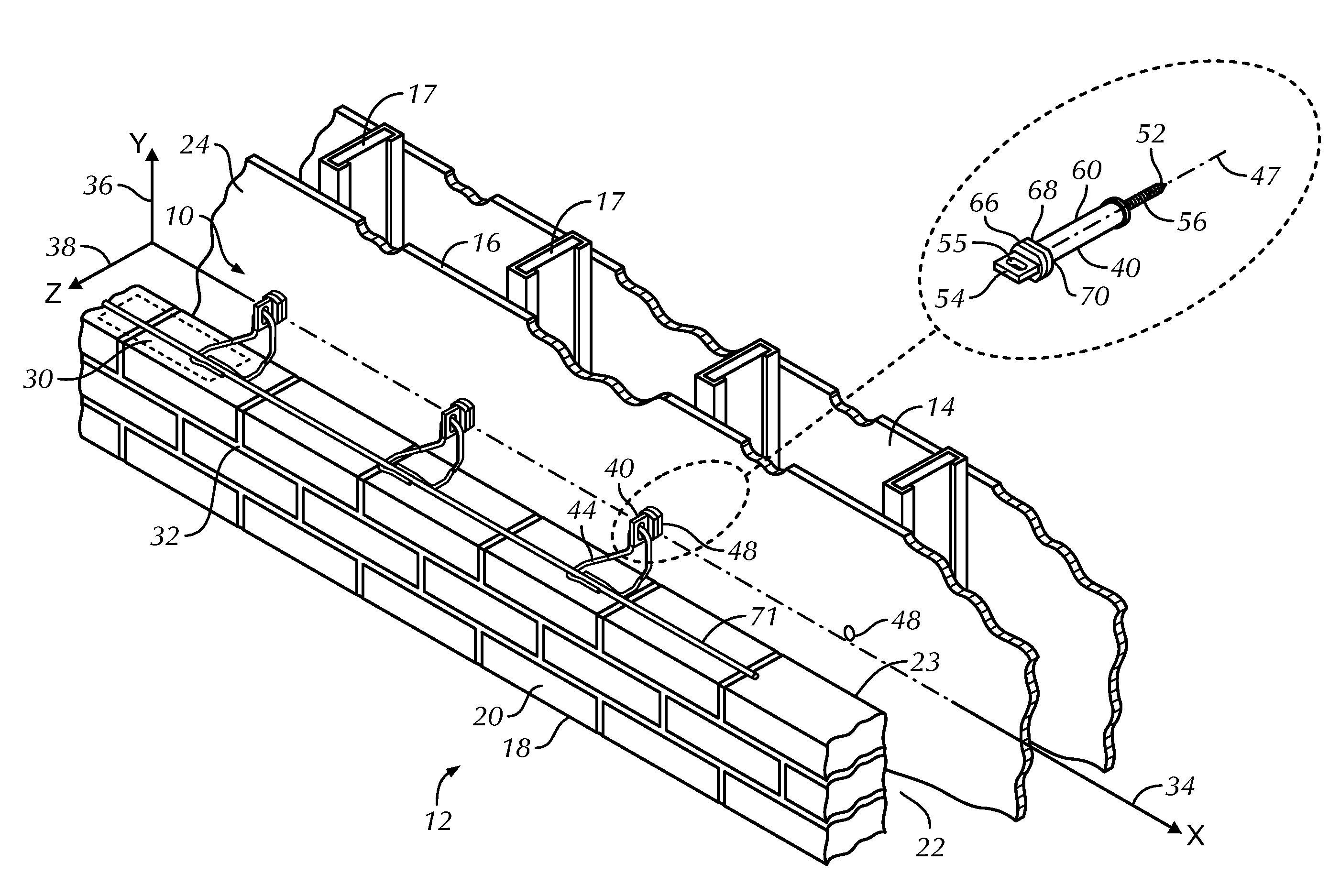

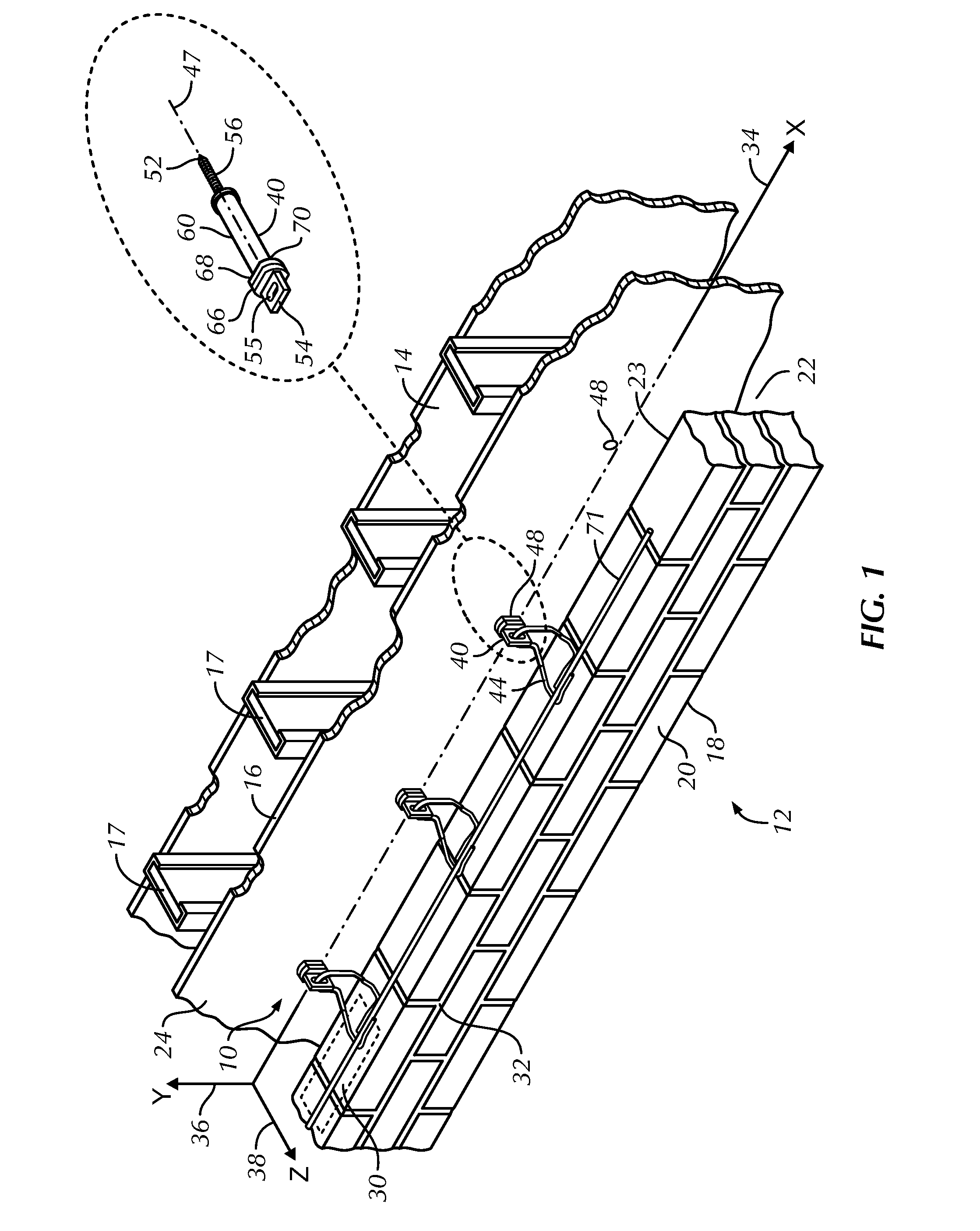

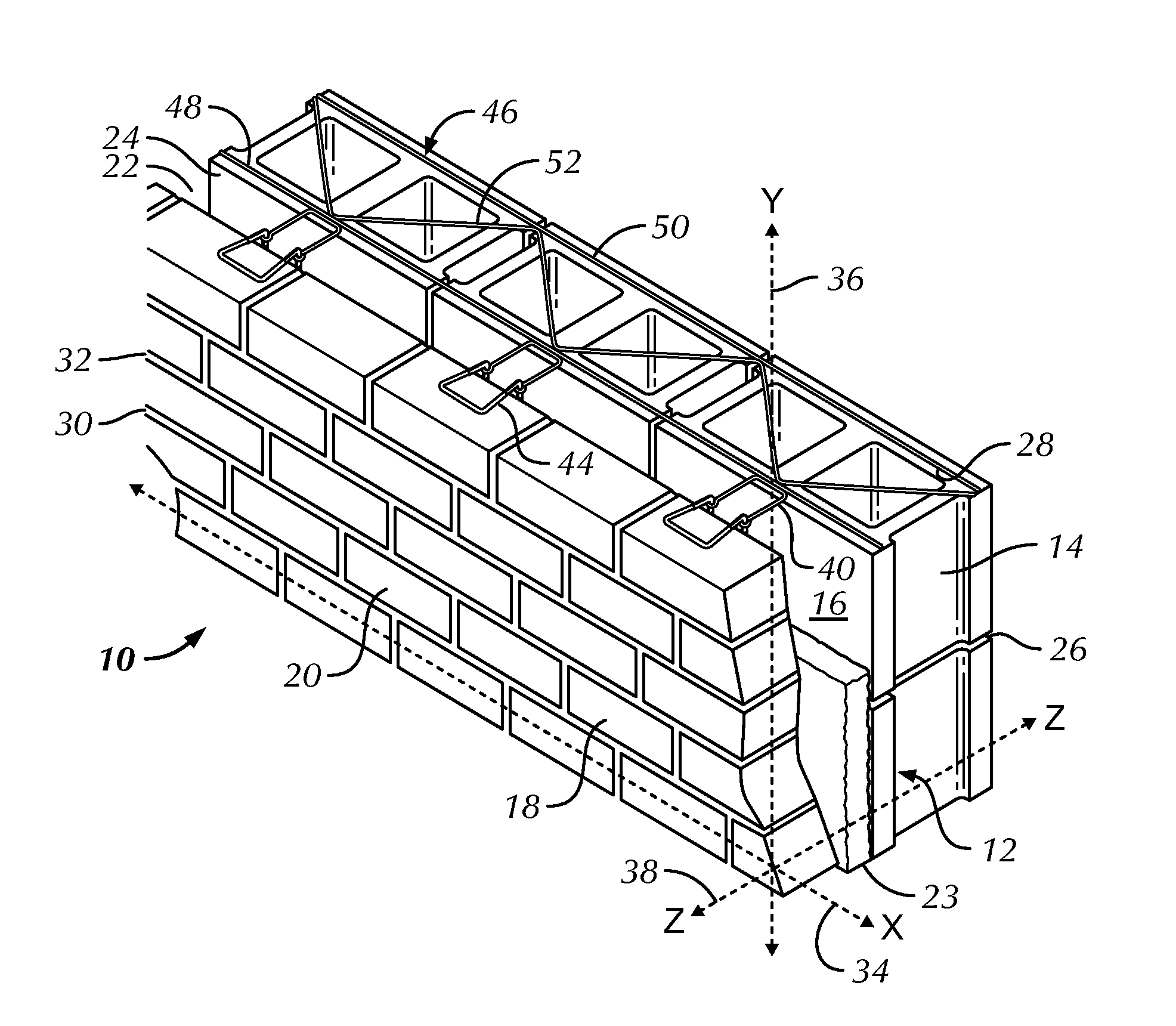

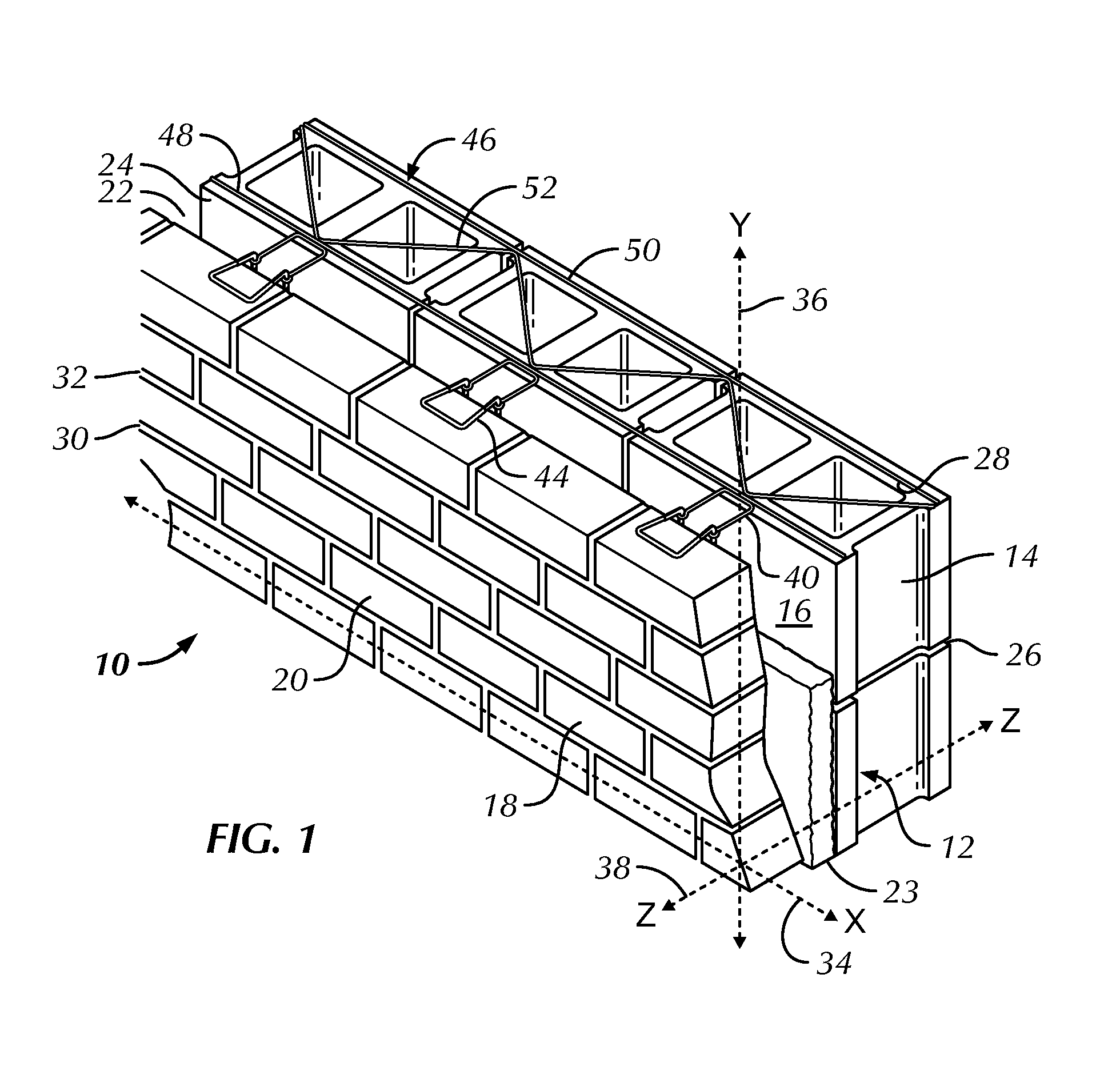

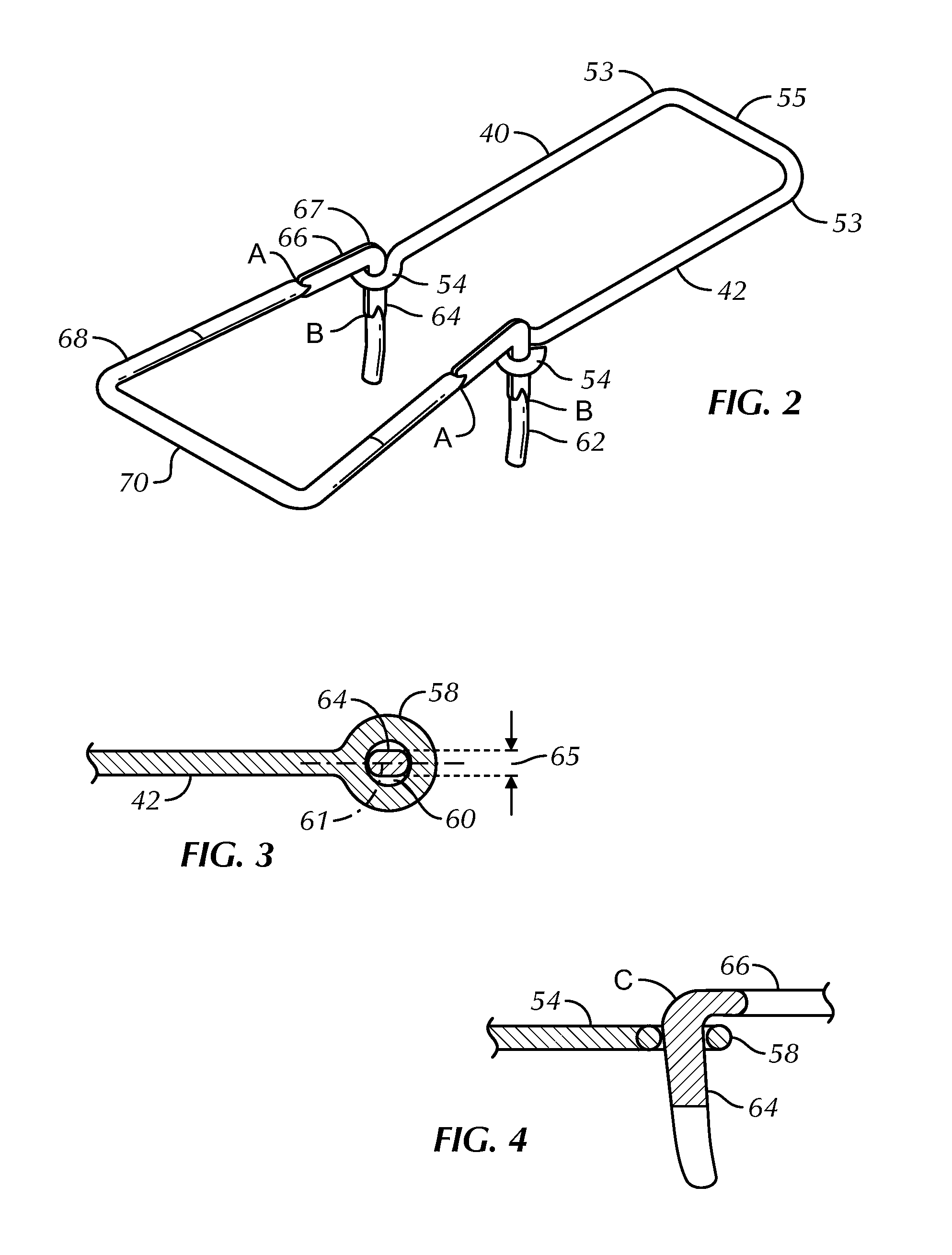

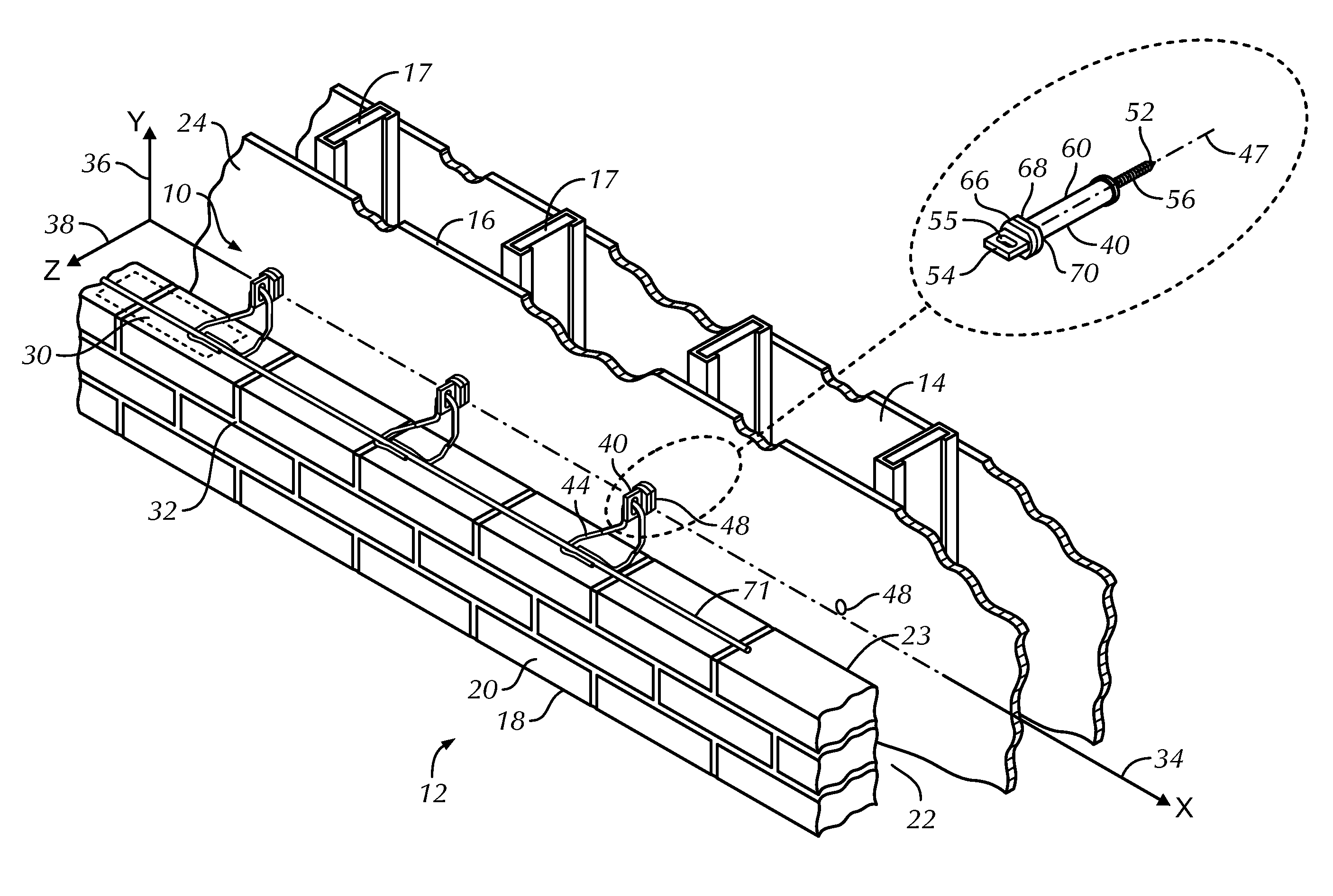

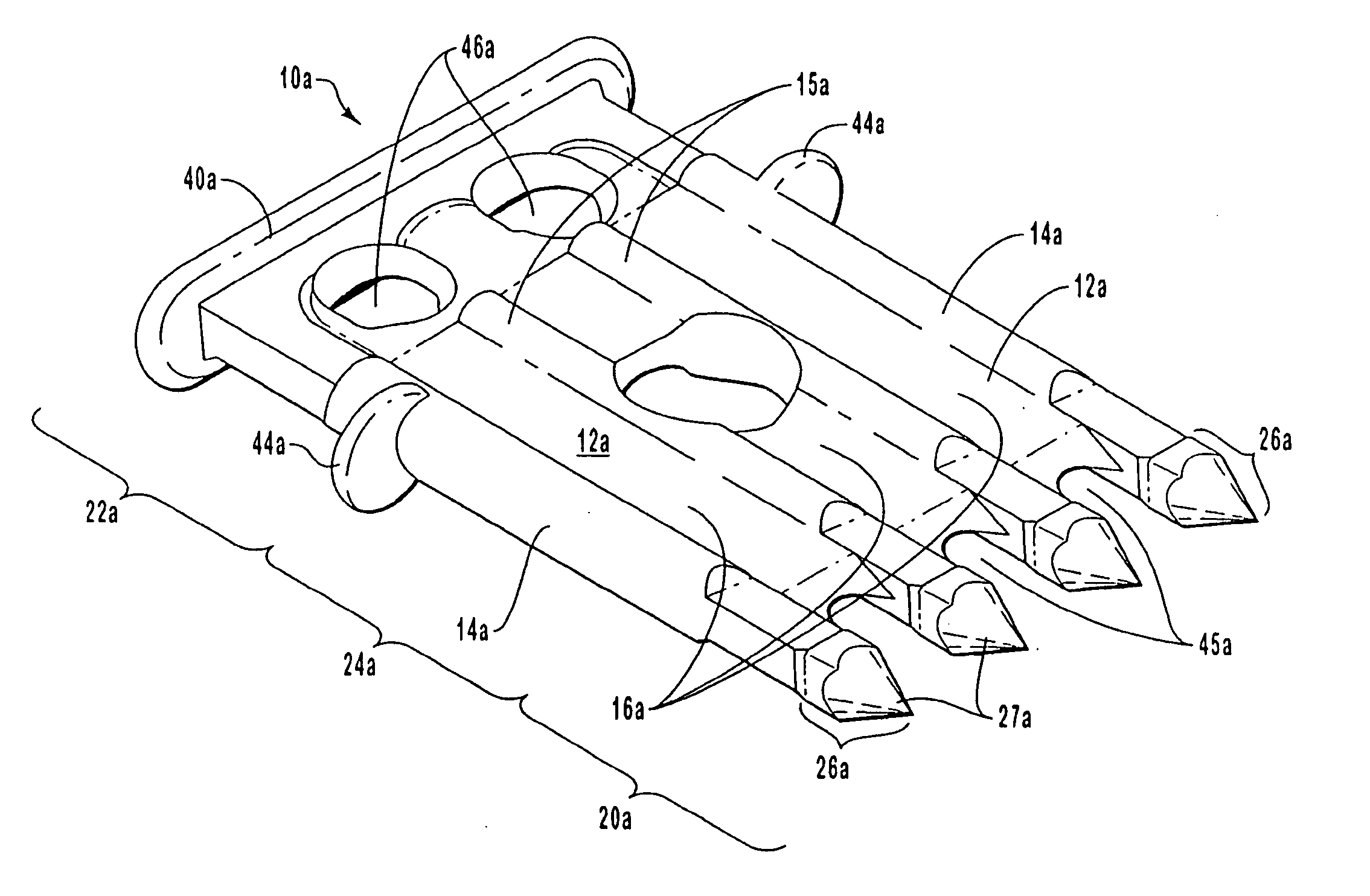

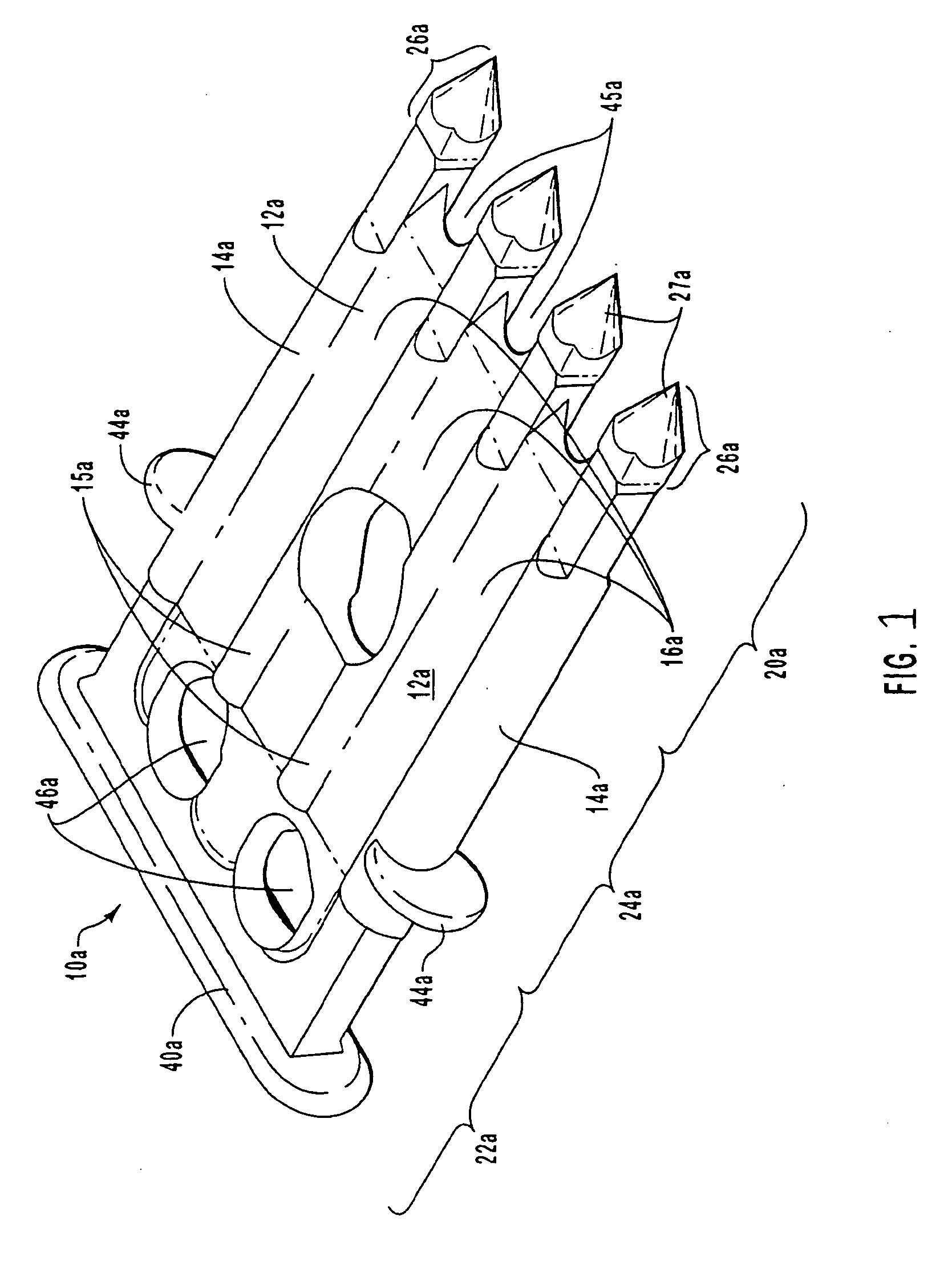

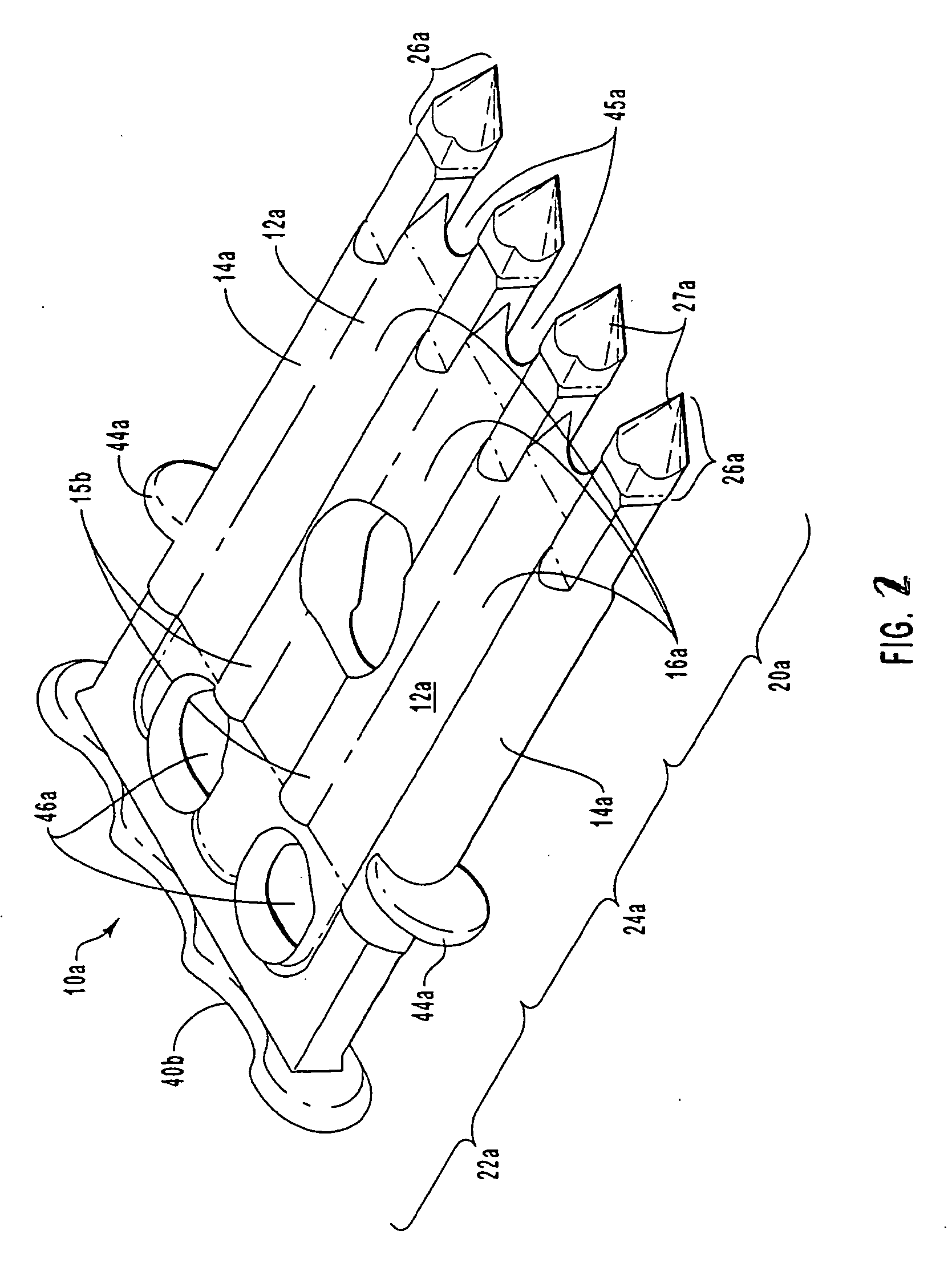

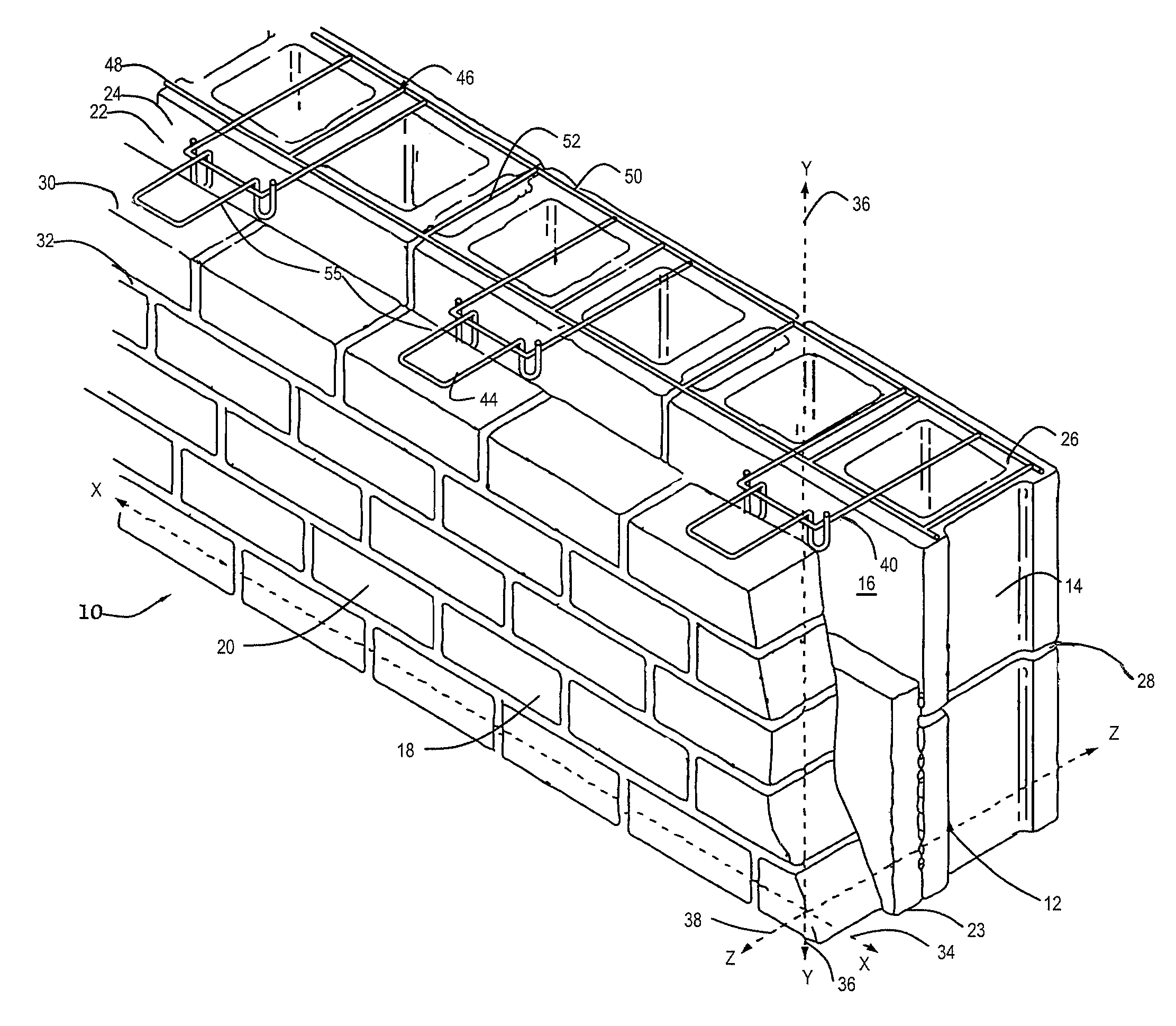

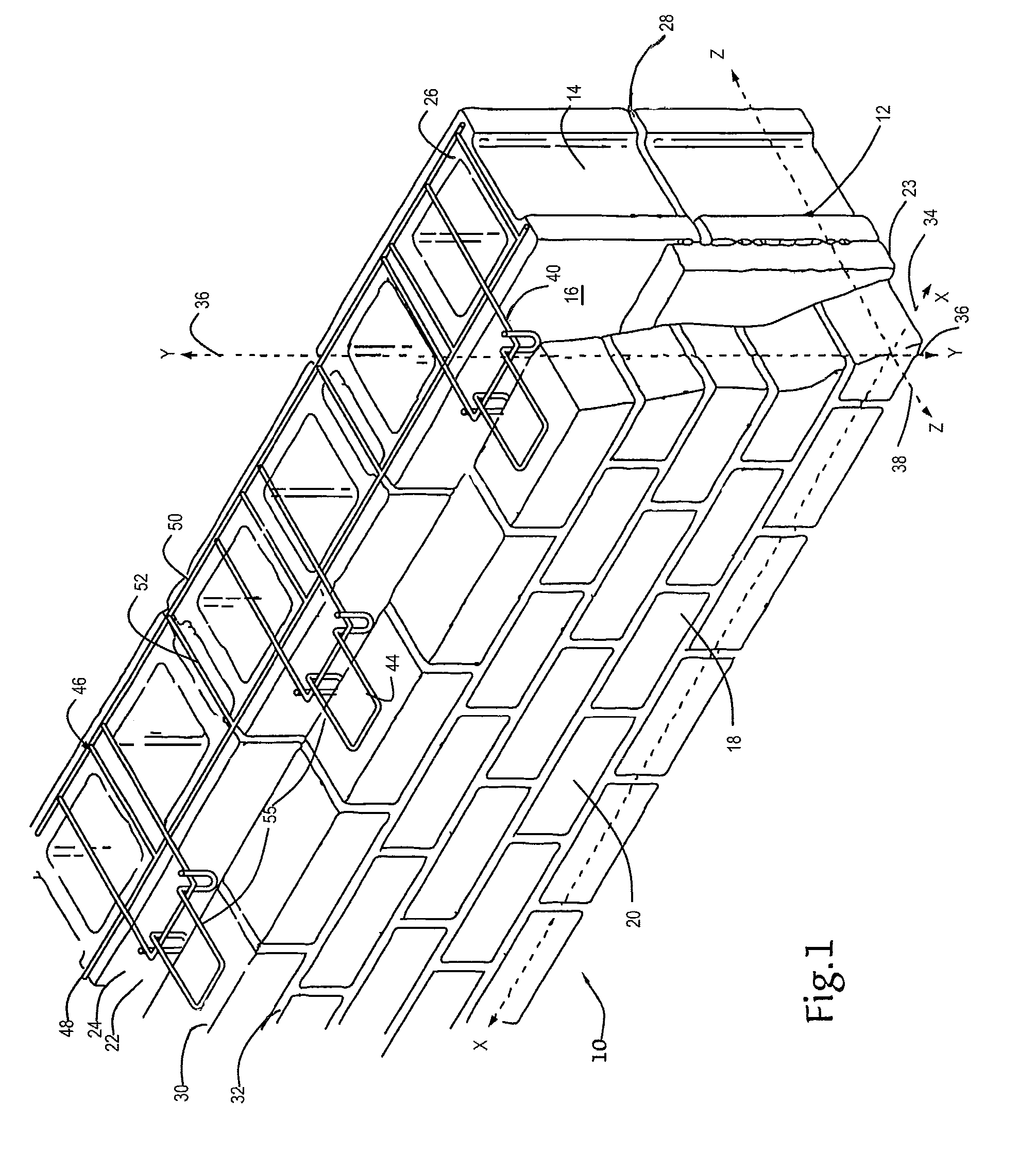

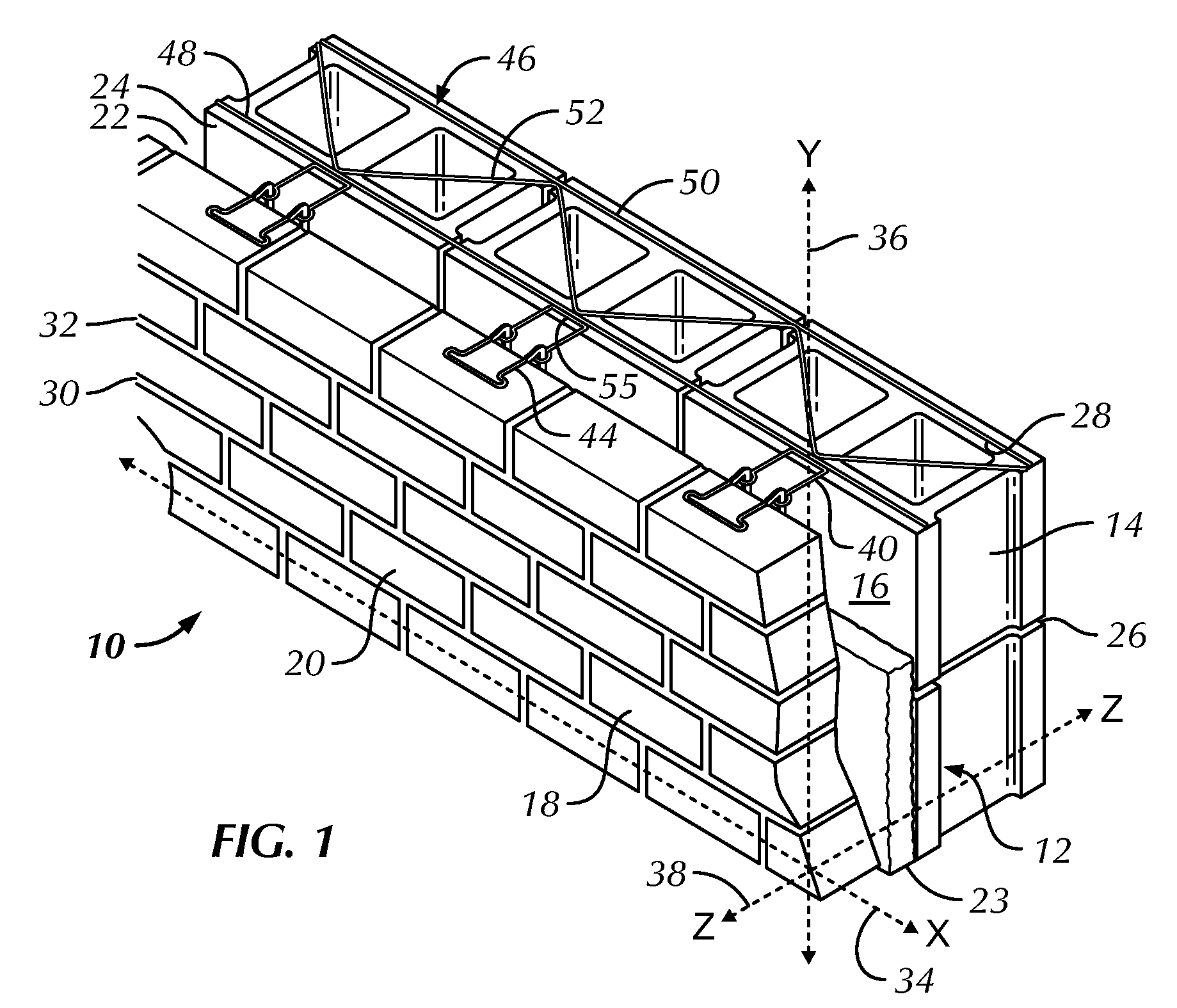

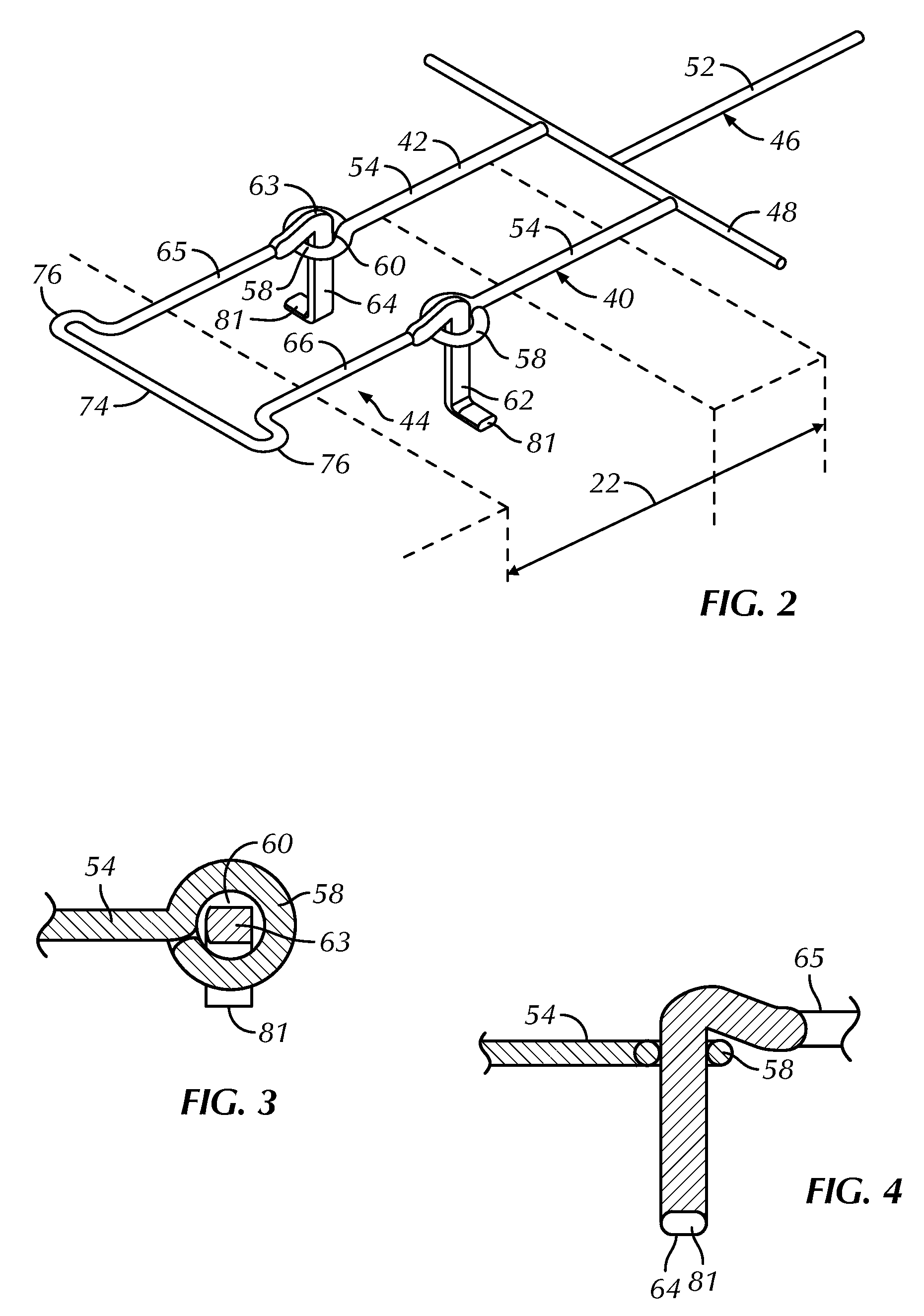

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder- or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder- or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

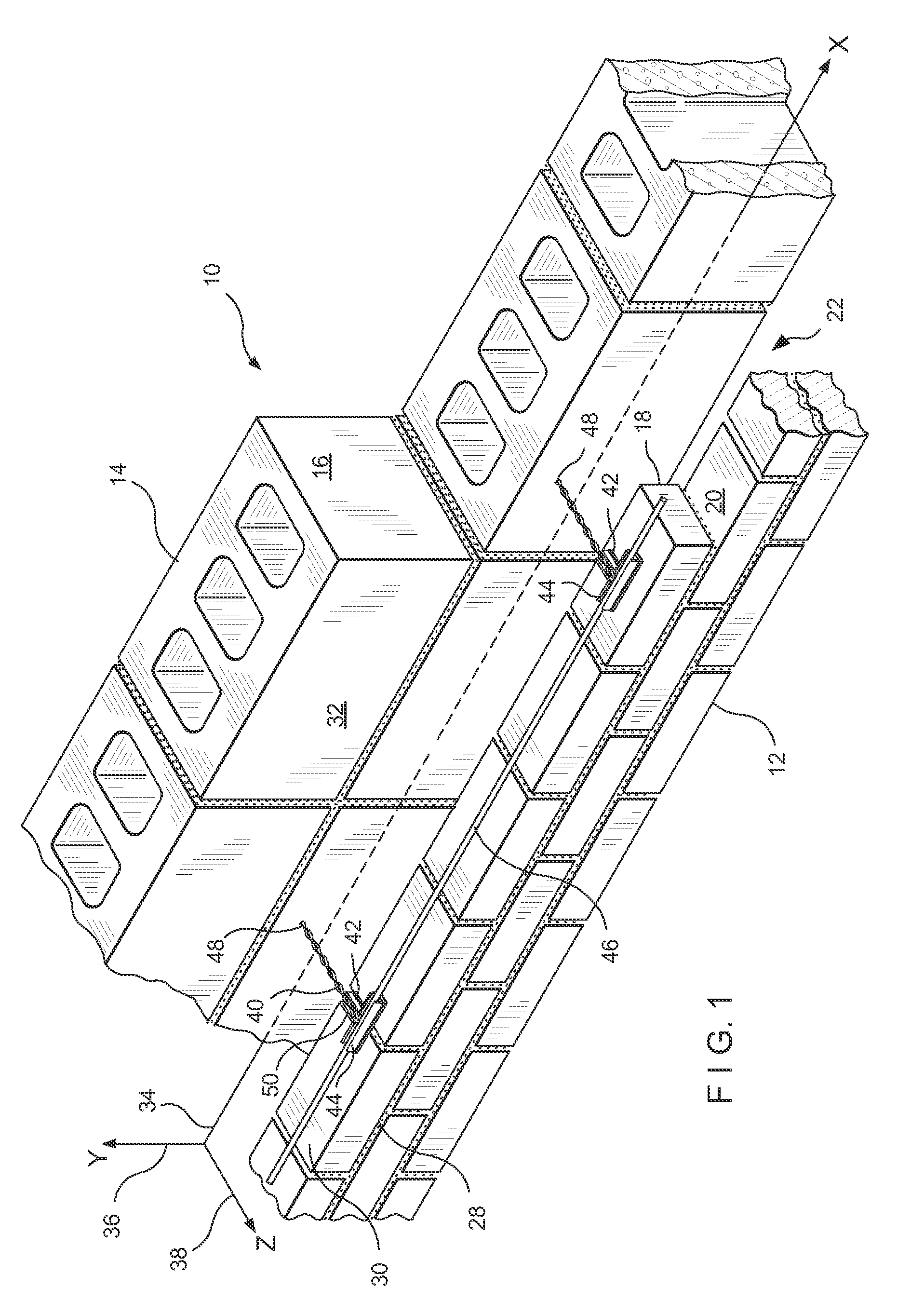

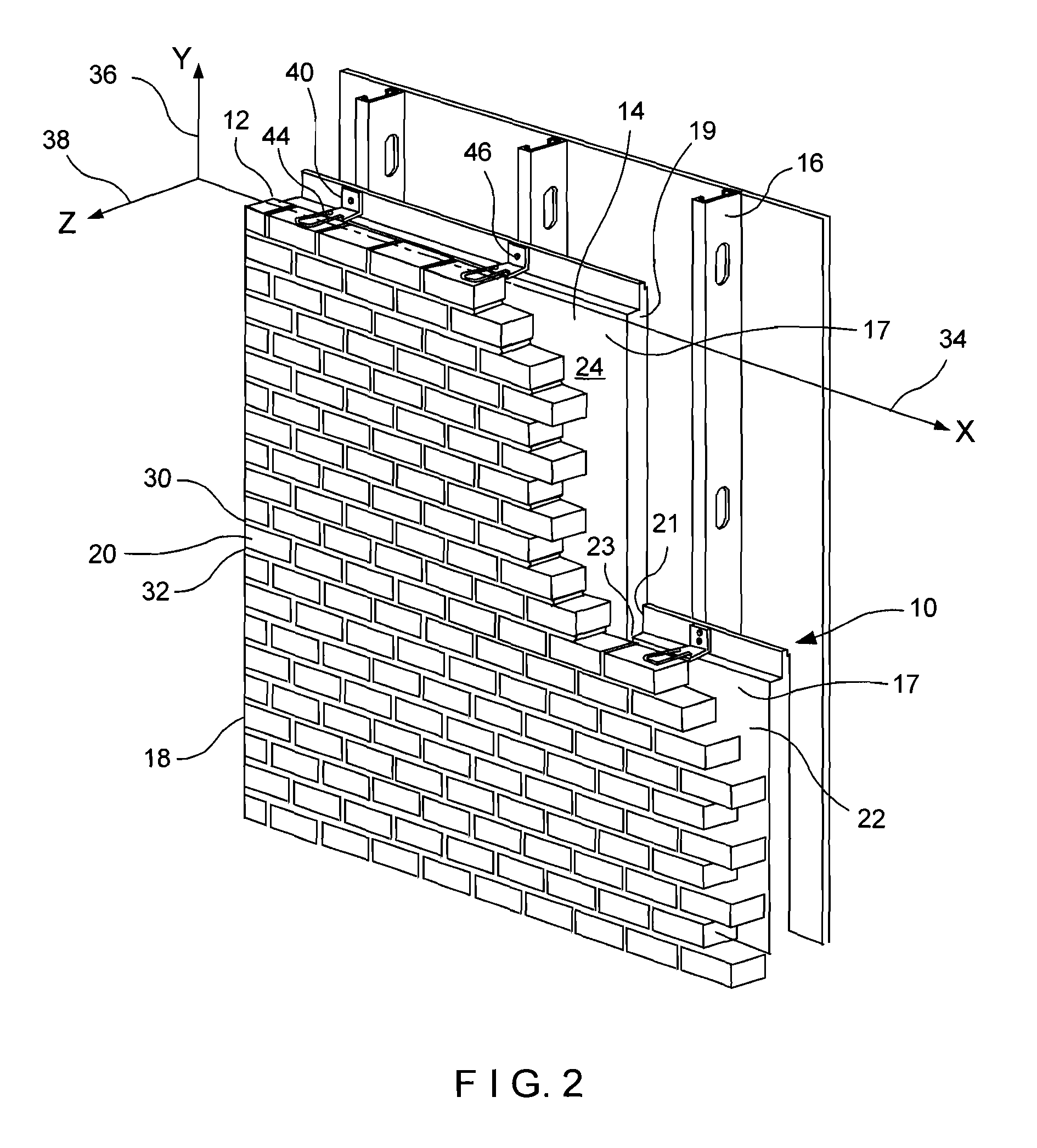

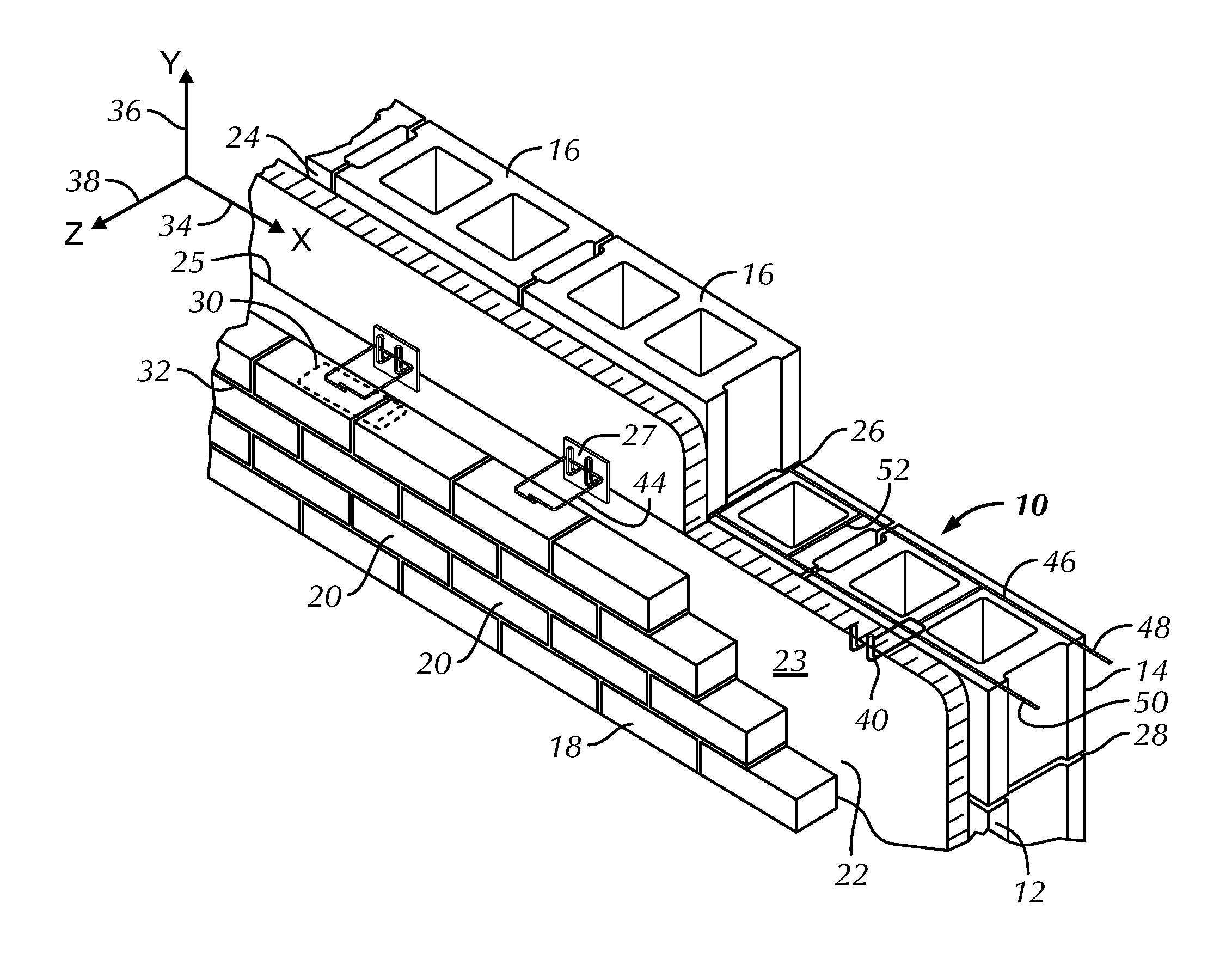

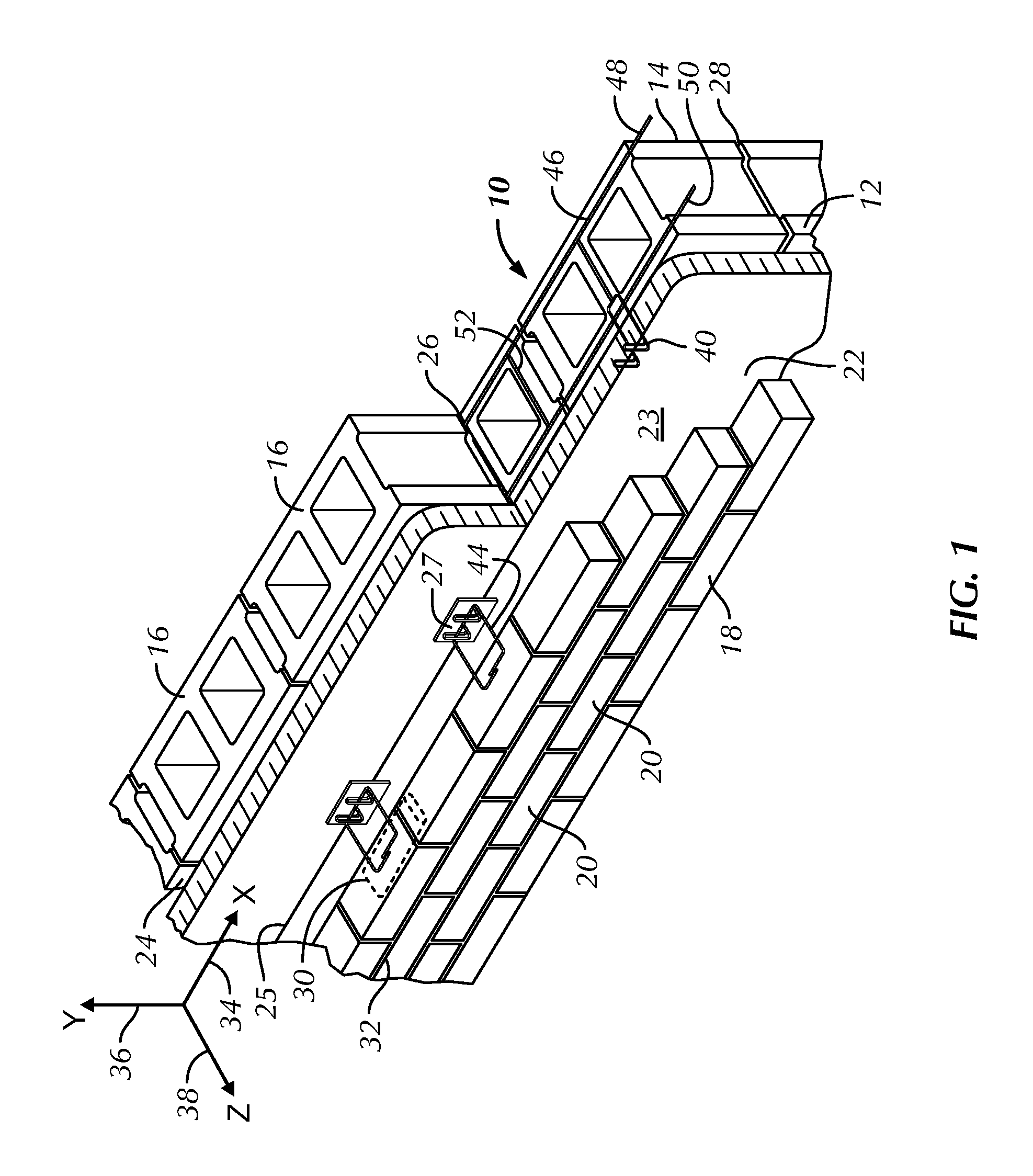

True-joint anchoring systems for cavity walls

InactiveUS6851239B1Improve evenlyReadily maintained verticalityStrutsConstruction materialMetal alloySingle plate

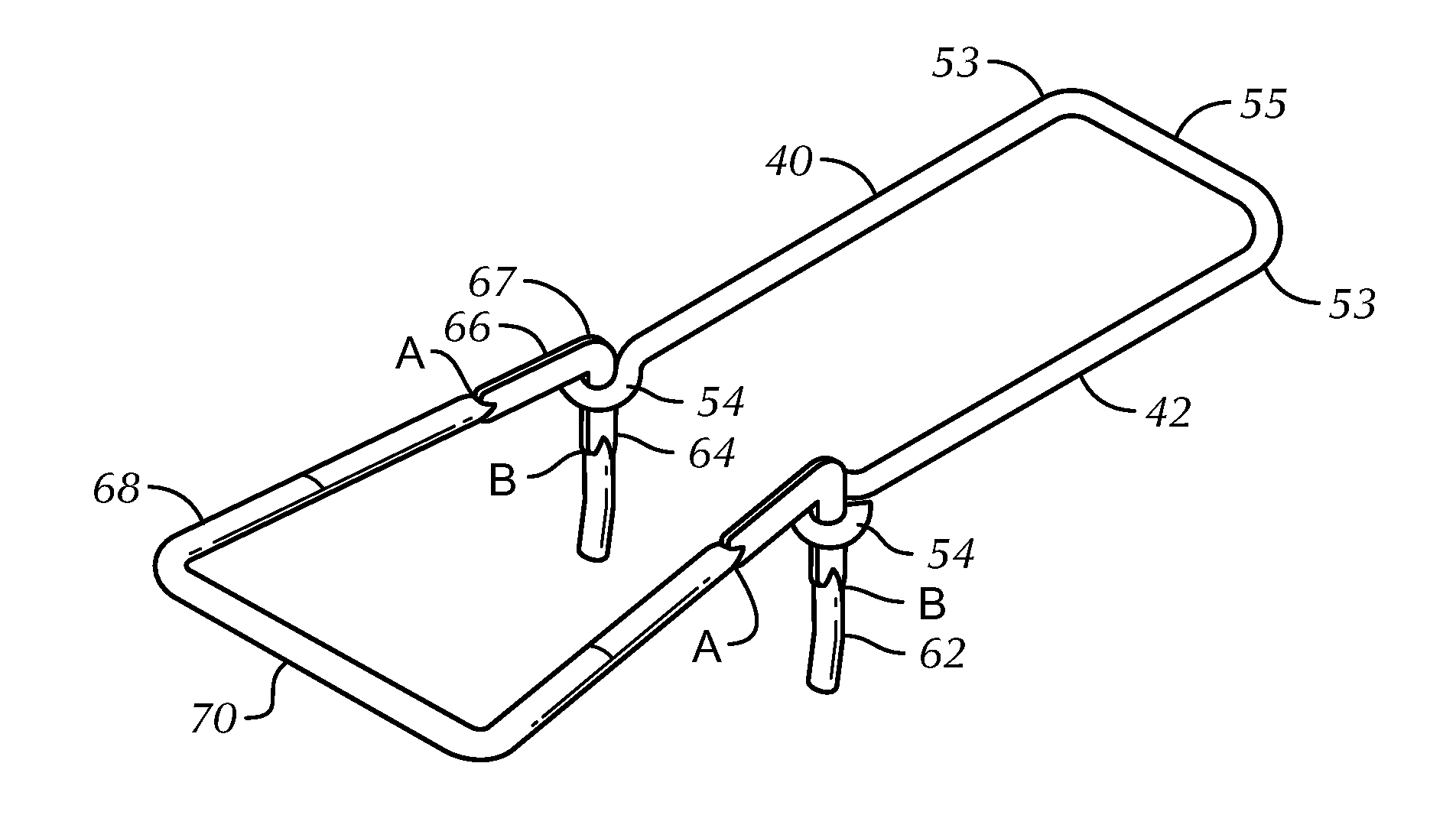

A high-span anchoring system is described for a cavity wall incorporating a wall reinforcement combined with a wall tie which together serve a wall construct having a larger-than-normal cavity. Further the various embodiments combine wire formatives which are compressively reduced in height by the cold-working thereof. Among the embodiments is a veneer anchoring system with a low-profile wall tie for use in a heavily insulated wall. The compressively reduced in height wall anchors protrude into the cavity through the seams, between insulation strips, which seams seal thereabout and maintain the integrity of the insulation by minimizing air leakage. Further, the eye wires extend across the insulation into the cavity between the wythes, and each accommodates the threading thereinto of a wire facing anchor or wall tie with either a pintle inserted through the eye or the open end of the veneer tie. The veneer tie is then positioned so that the insertion end is embedded in the facing wall. The close control of overall heights permits the mortar of the bed joints to flow over and about the wall reinforcement and wall tie combination inserted in the inner wythe and insertion end of the wall in the outer wythe. Because the wire formatives hereof employ extra strong material and benefit from the cold-working of the metal alloys, the high-span anchoring system meets the unusual requirements demanded thereof.

Owner:HOHMANN & BARNARD INC

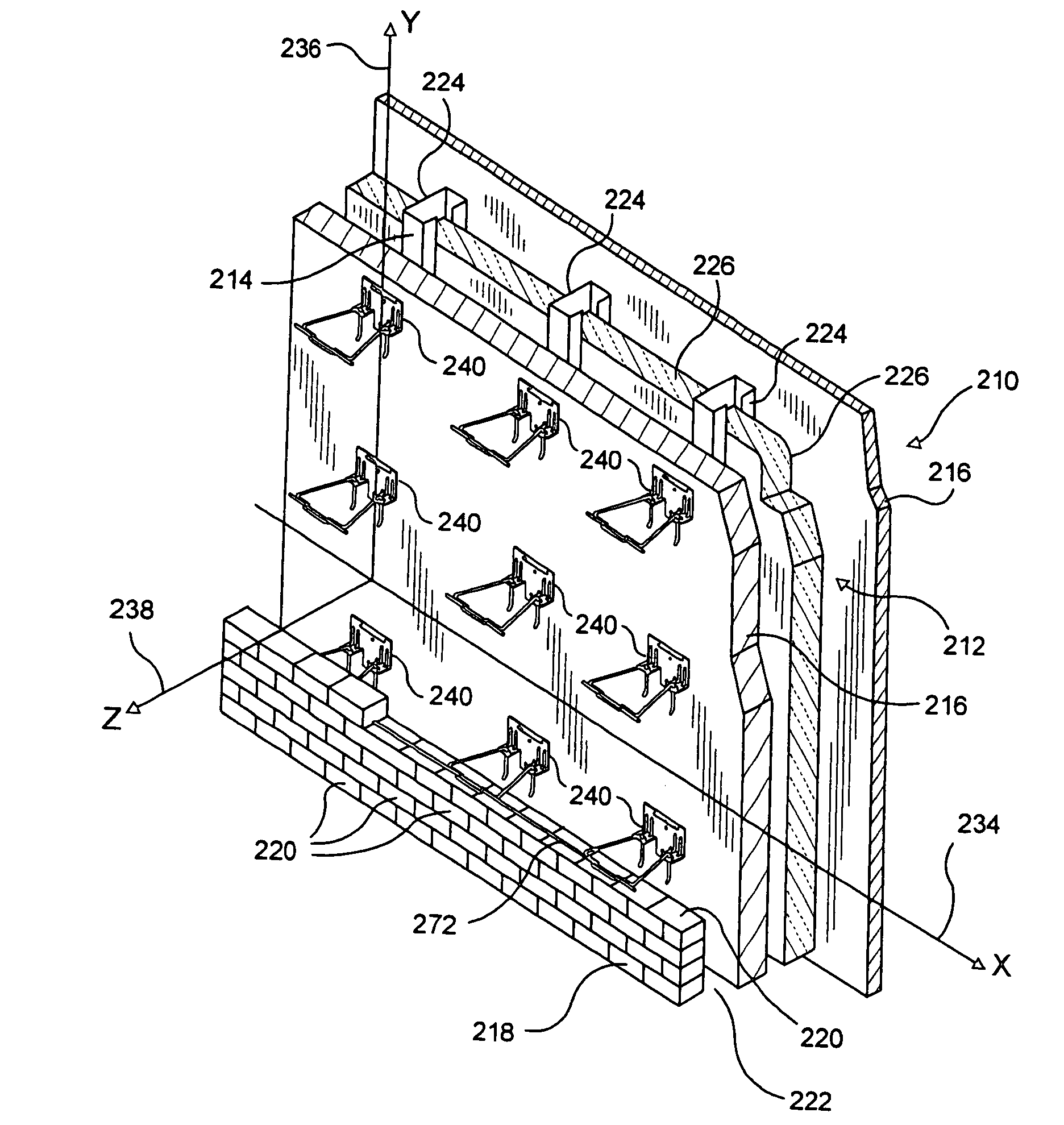

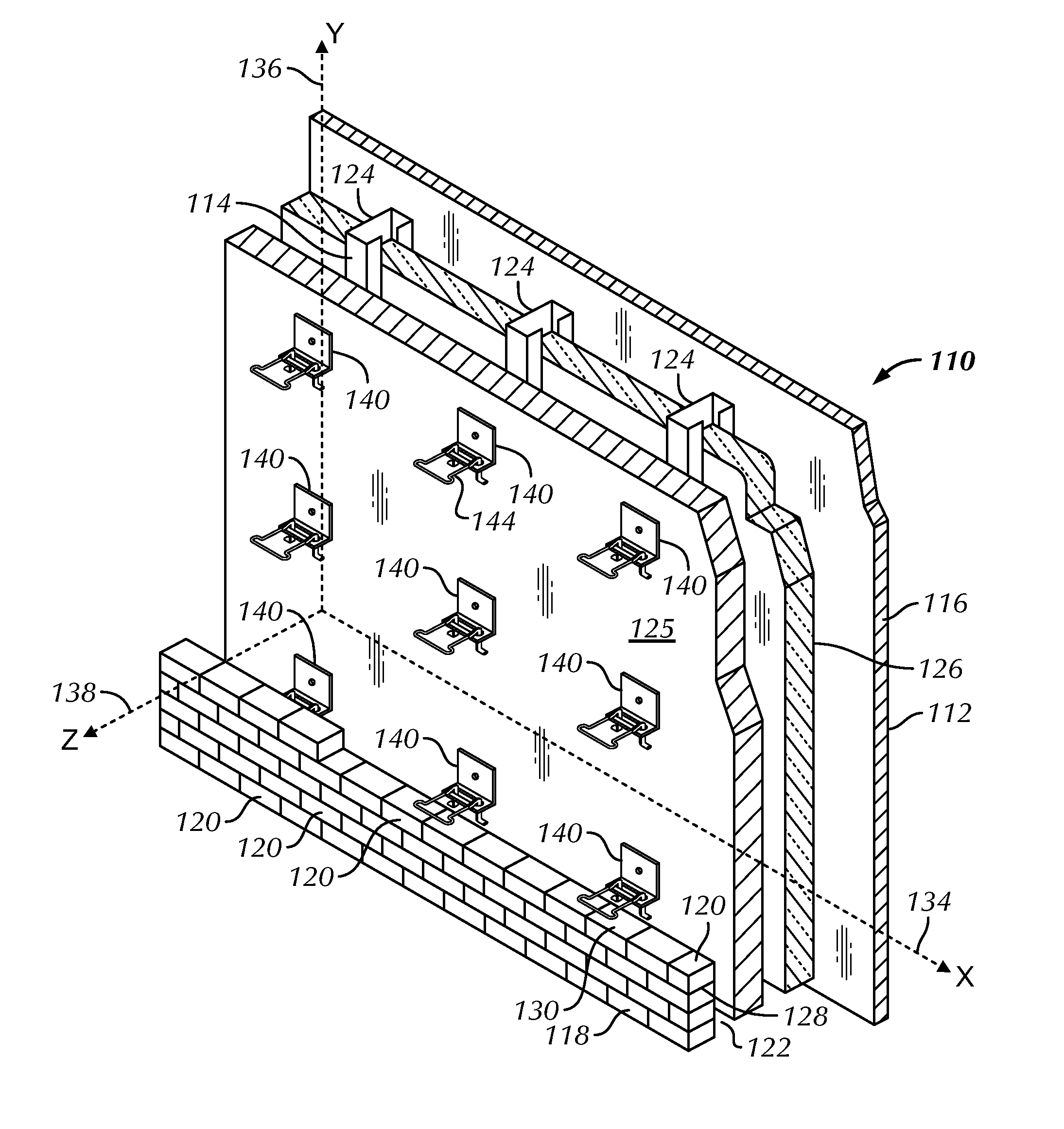

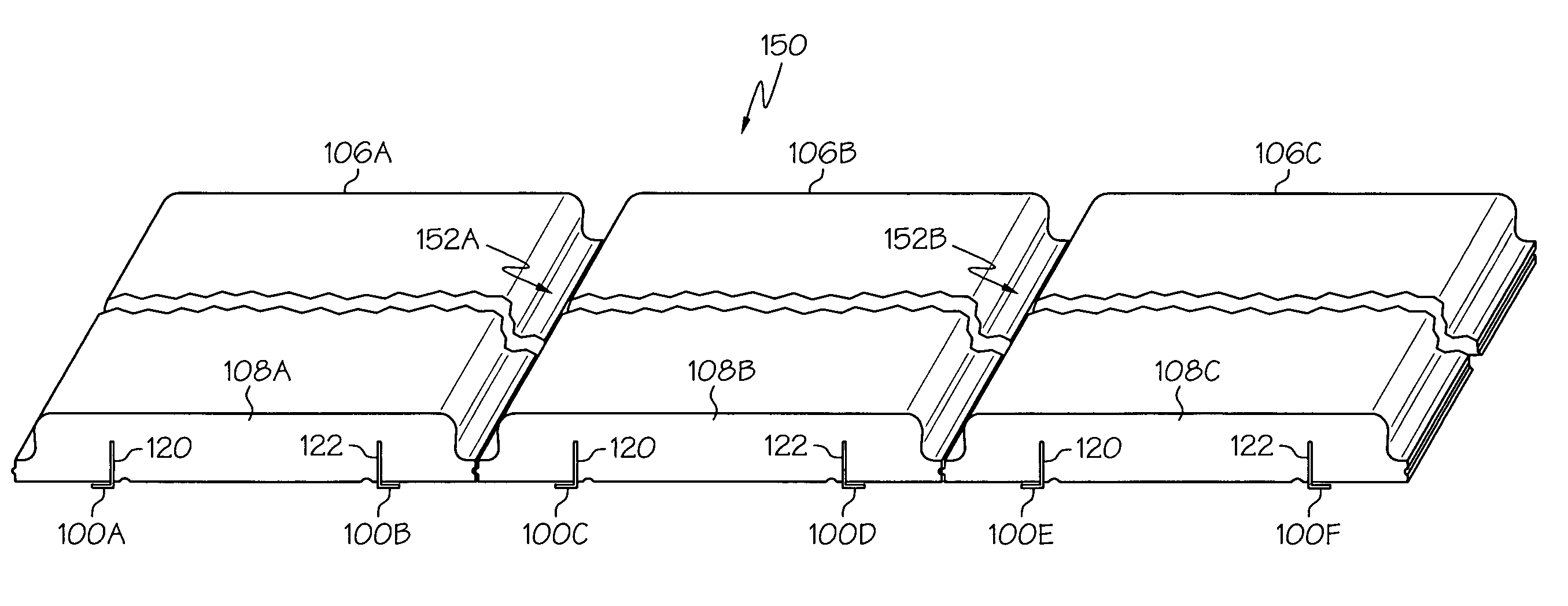

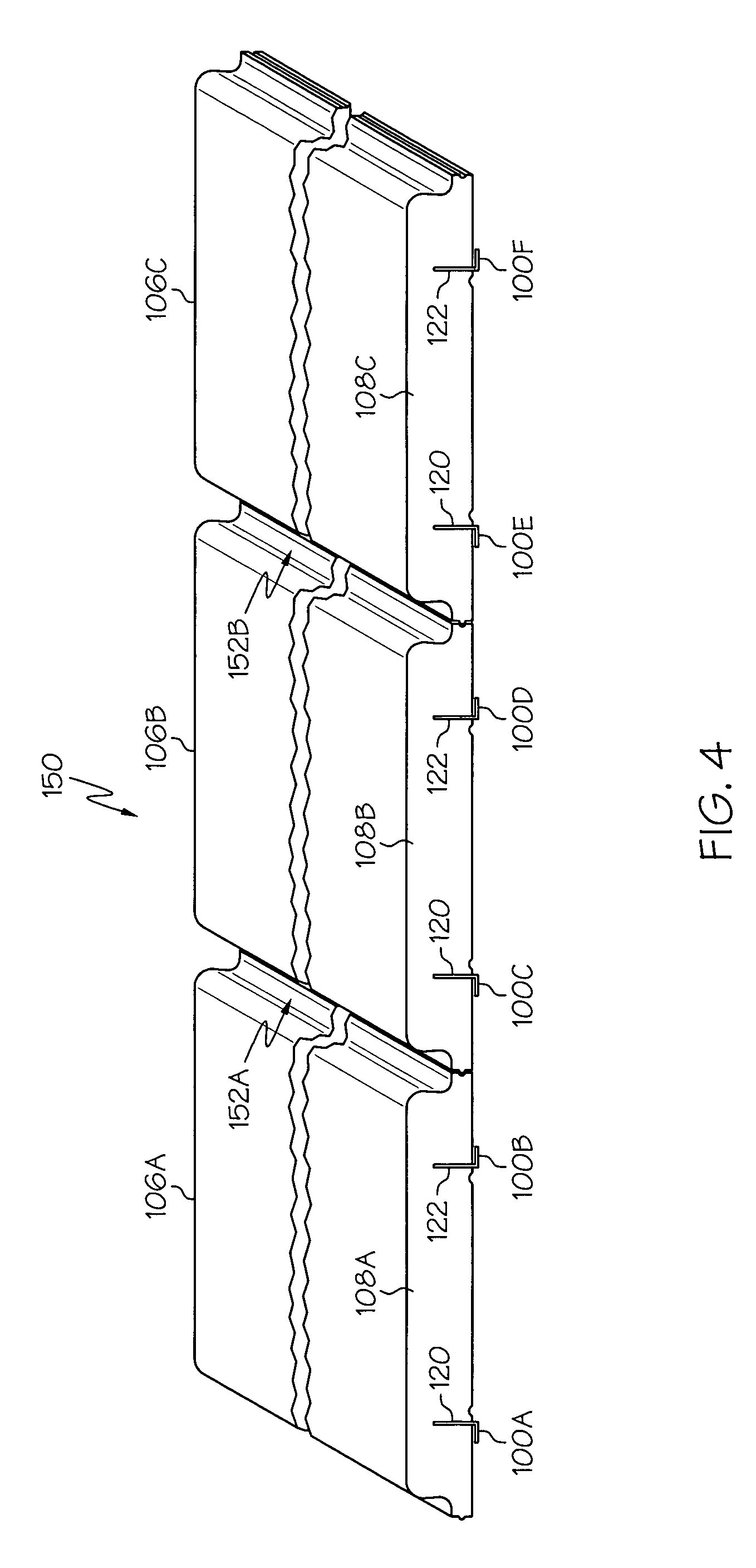

Anchor System for Composite Panel

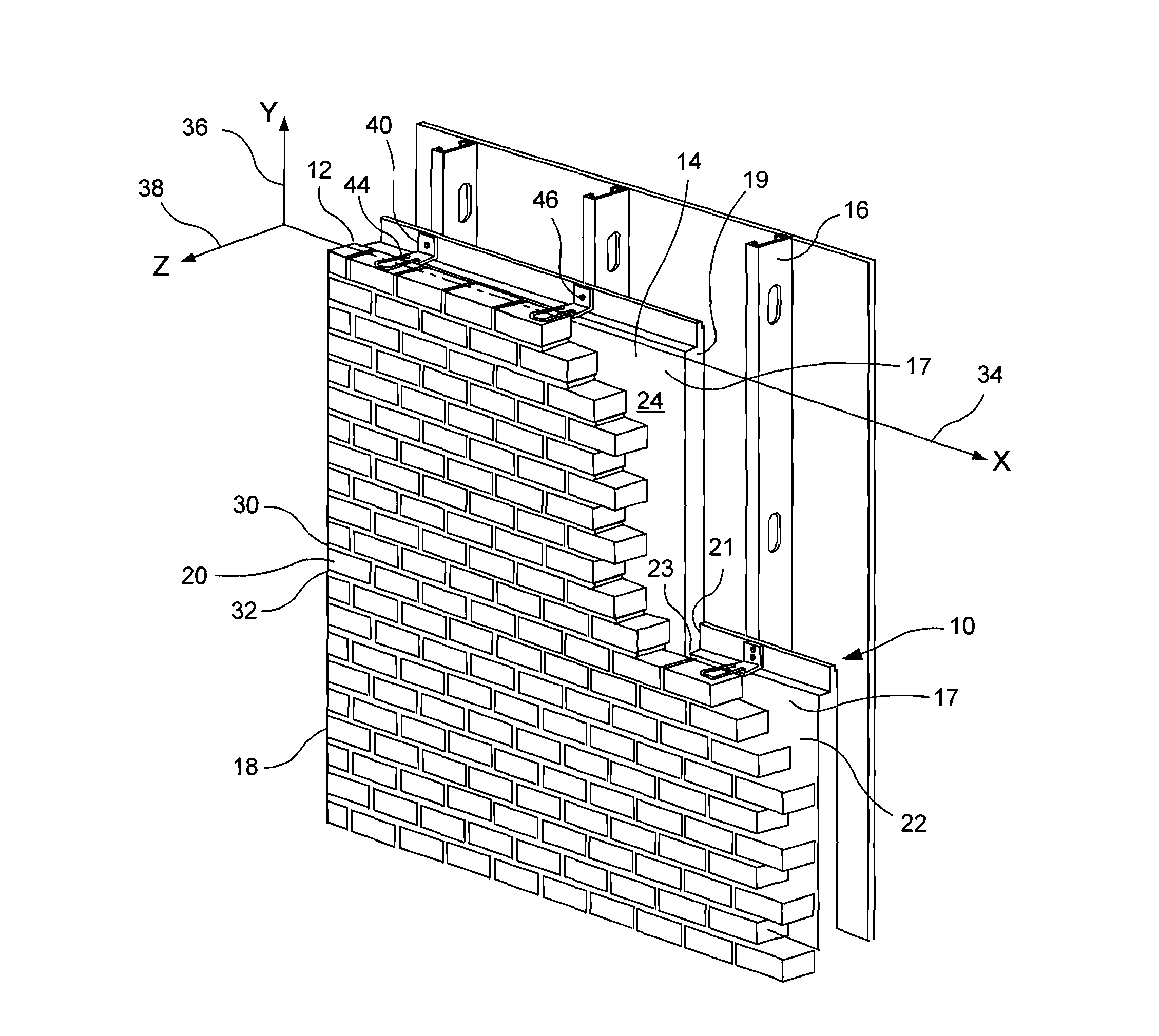

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

Rubble stone anchoring system

ActiveUS20110146195A1Minimized cavity sizeRestricting veneer tie lateral movementStrutsBuilding reinforcementsEngineeringCavity size

Anchoring systems for use in cavity wall structures having an inner wythe and an outer wythe constructed of rubble stone are disclosed. The anchoring system employs an anchor fastened to or set within the inner wythe that extends into the cavity and connects to a J-hook. A vertically adjustable veneer tie enwraps the J-hook, limiting lateral movement and front-to-back displacement, and is set within the bed joint of the outer wythe. The anchoring system minimizes cavity size and provides stability for an uncoursed outer wythe equivalent to that of anchoring systems for standards coursed bed joints.

Owner:HOHMANN & BARNARD INC

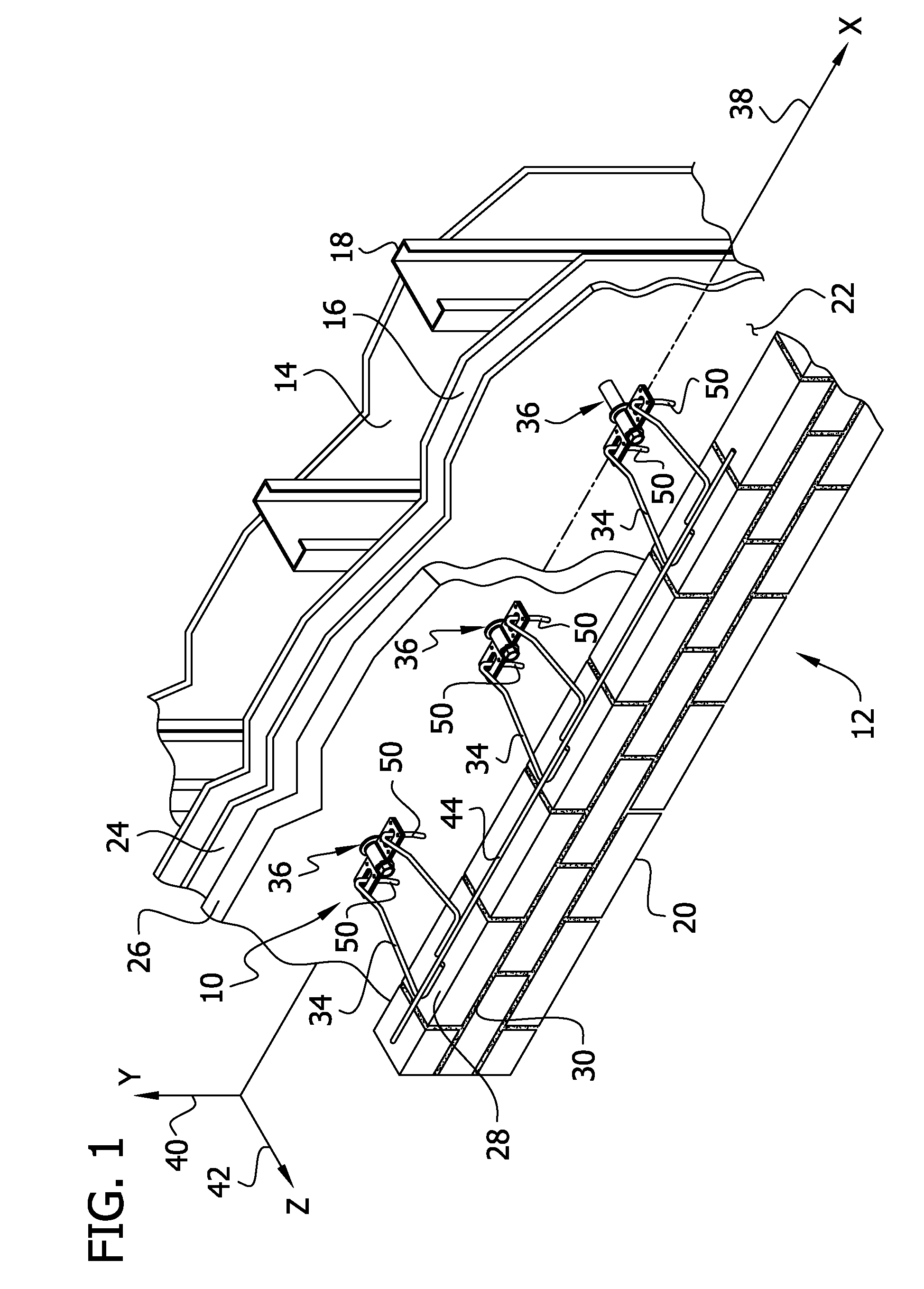

Snap-in wire tie

ActiveUS8096090B1Simplify seismic-type installationReduce manufacturing costConstruction materialWallsCavity wallWythe

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder—or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder—or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

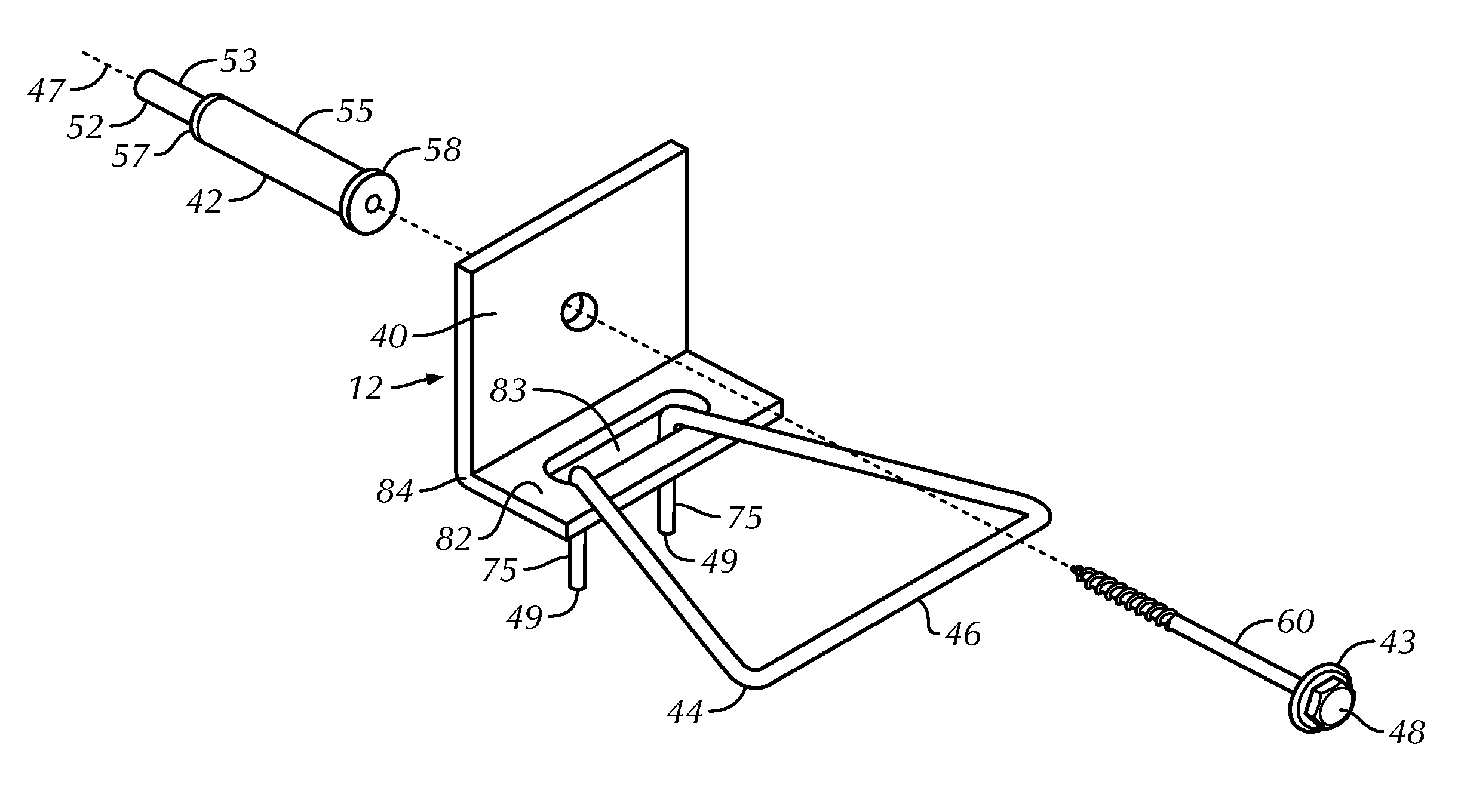

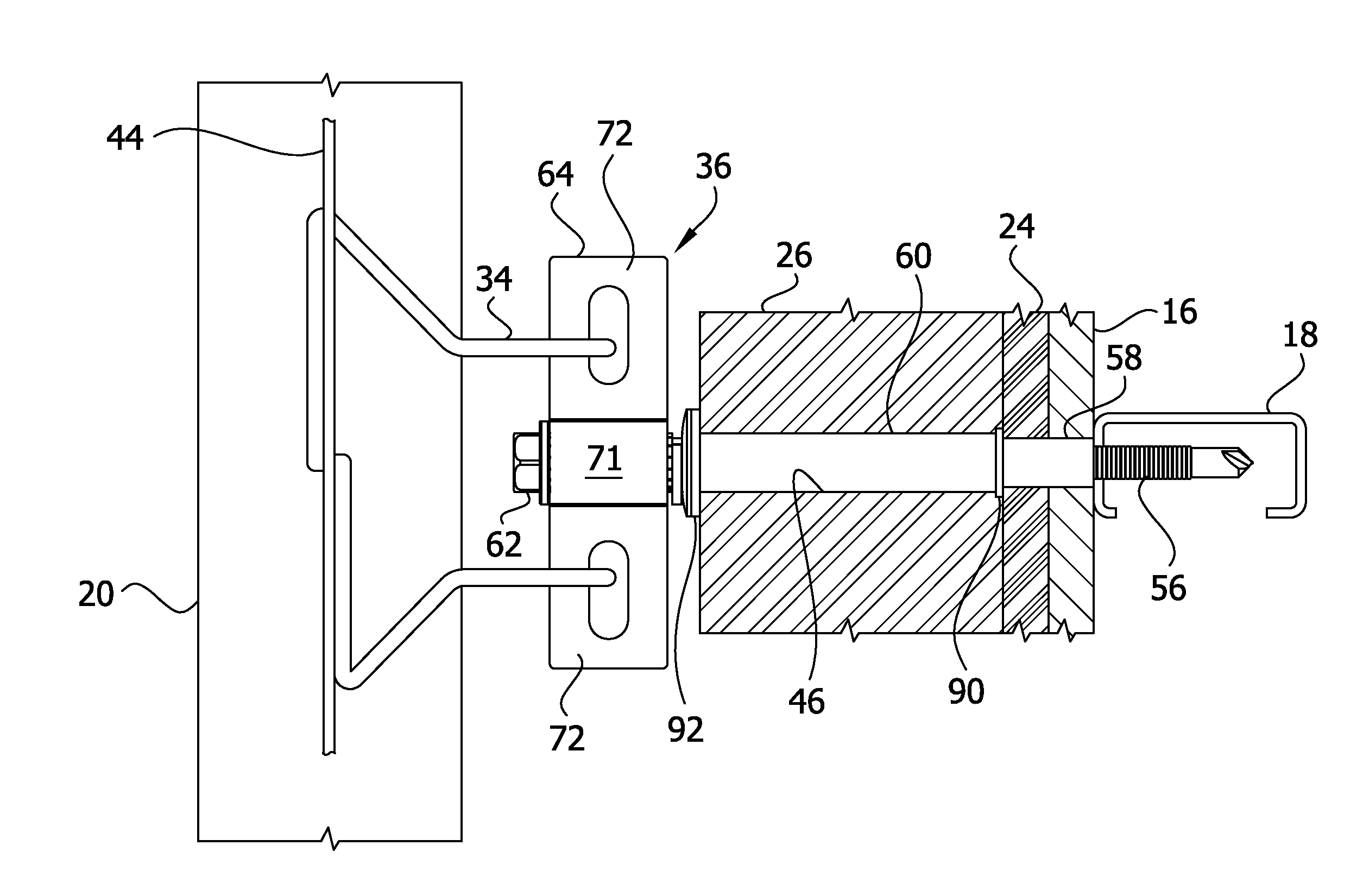

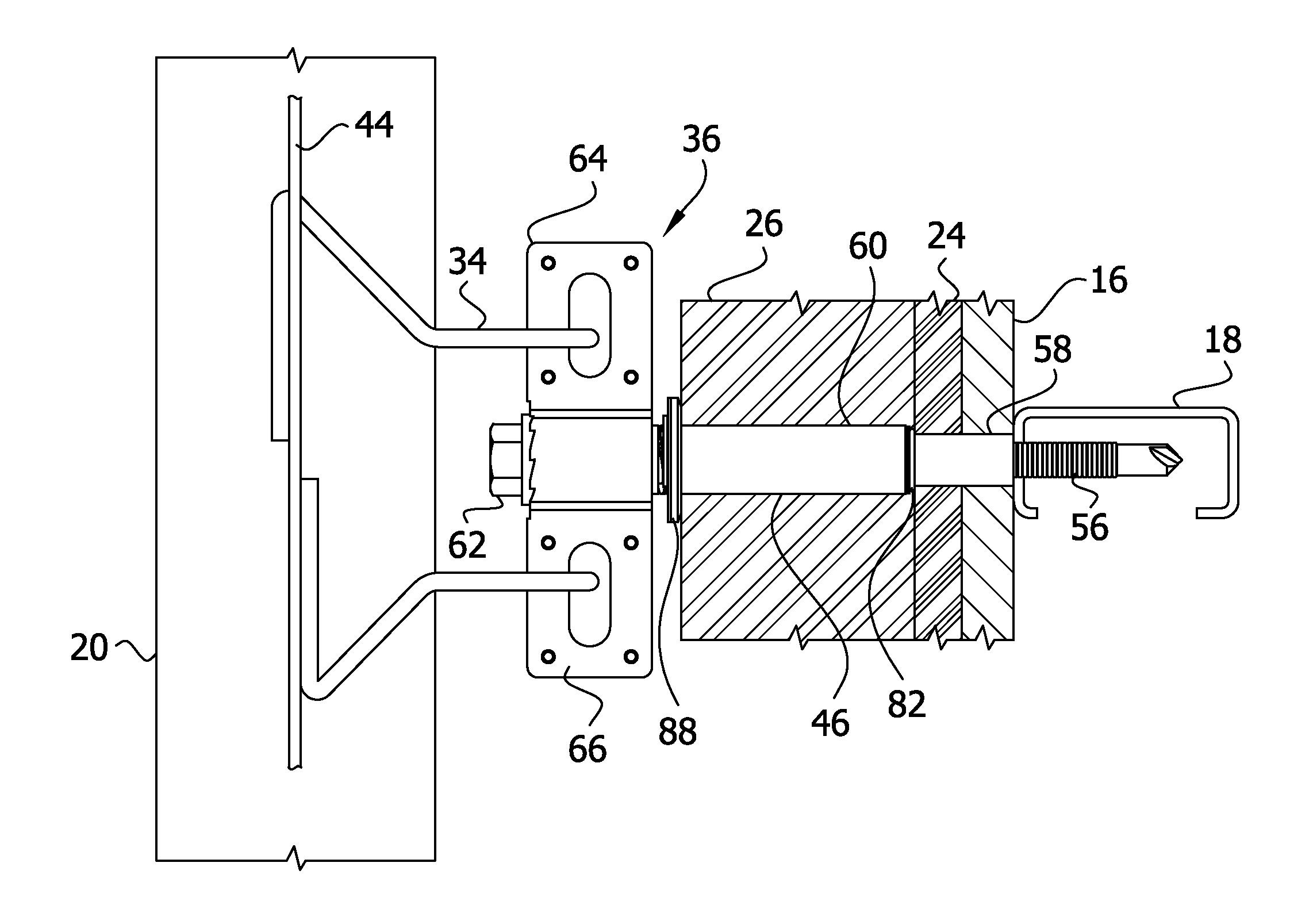

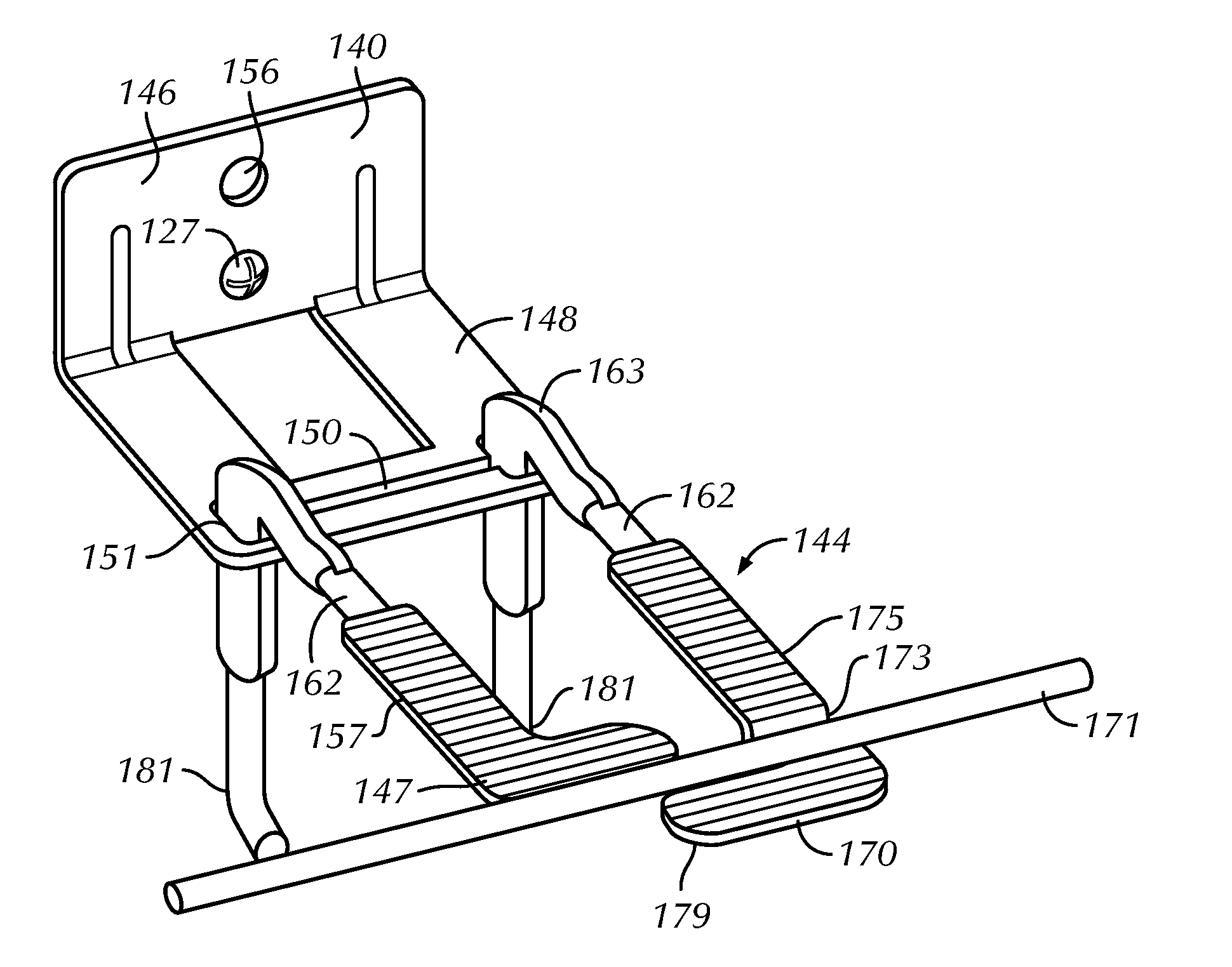

L-shaped sheetmetal anchor with tubular leg and anchoring assembly

InactiveUS20130247498A1Resistant to tearingLow thermal conductivityBuilding reinforcementsSurface mountingHigh intensity

An L-shaped sheetmetal anchor with tubular leg and an anchoring assembly employing the same are disclosed. The assembly is adaptable to varied anchoring structures and for use with interlocking veneer ties and reinforcement wires to provide a high-strength surface mounted anchoring system for cavity walls. The stepped cylinders sheath the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The assembly is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings. The assemblies are vertically or horizontally surface mounted on the inner wythe.

Owner:MITEK HLDG INC

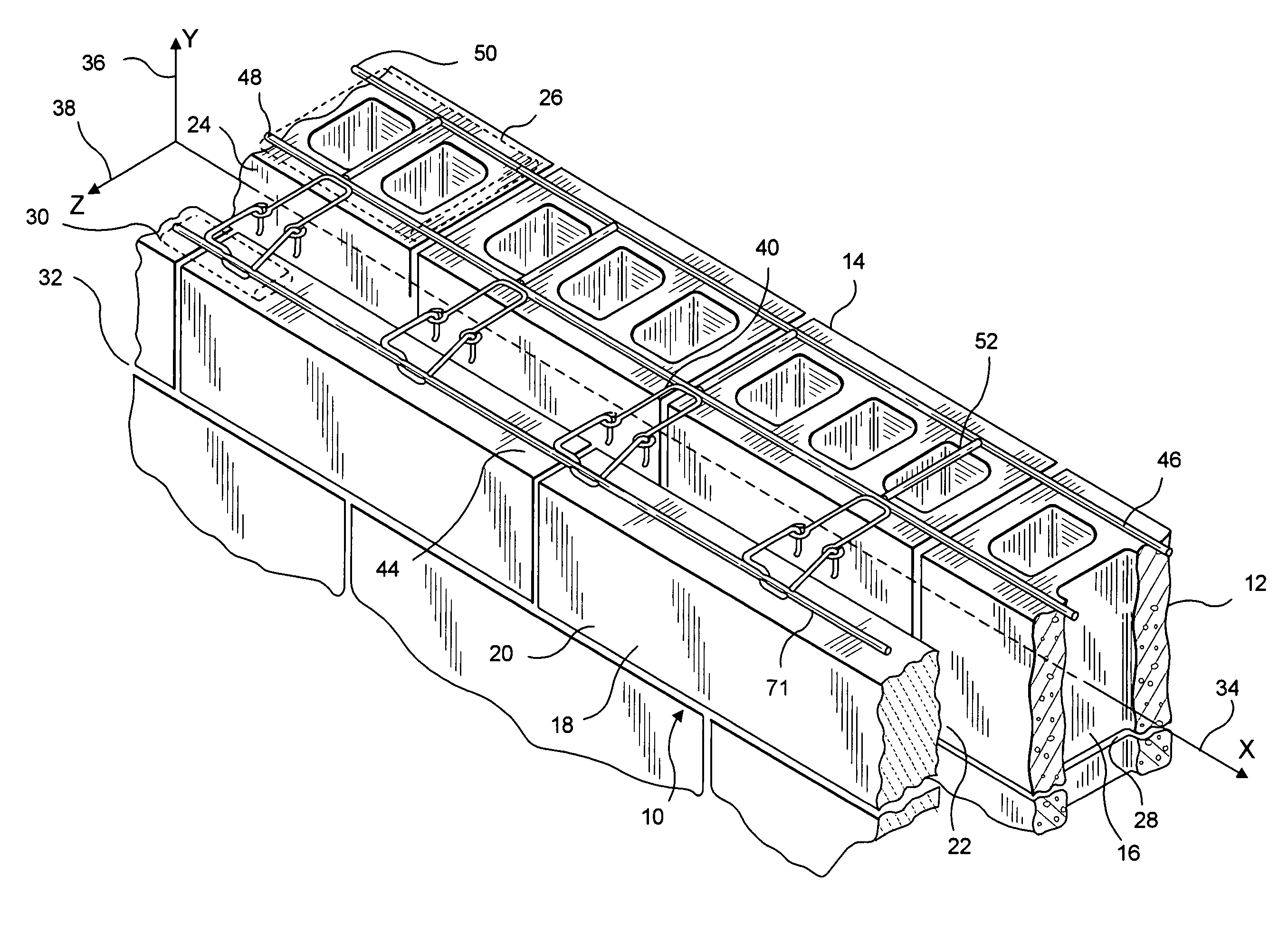

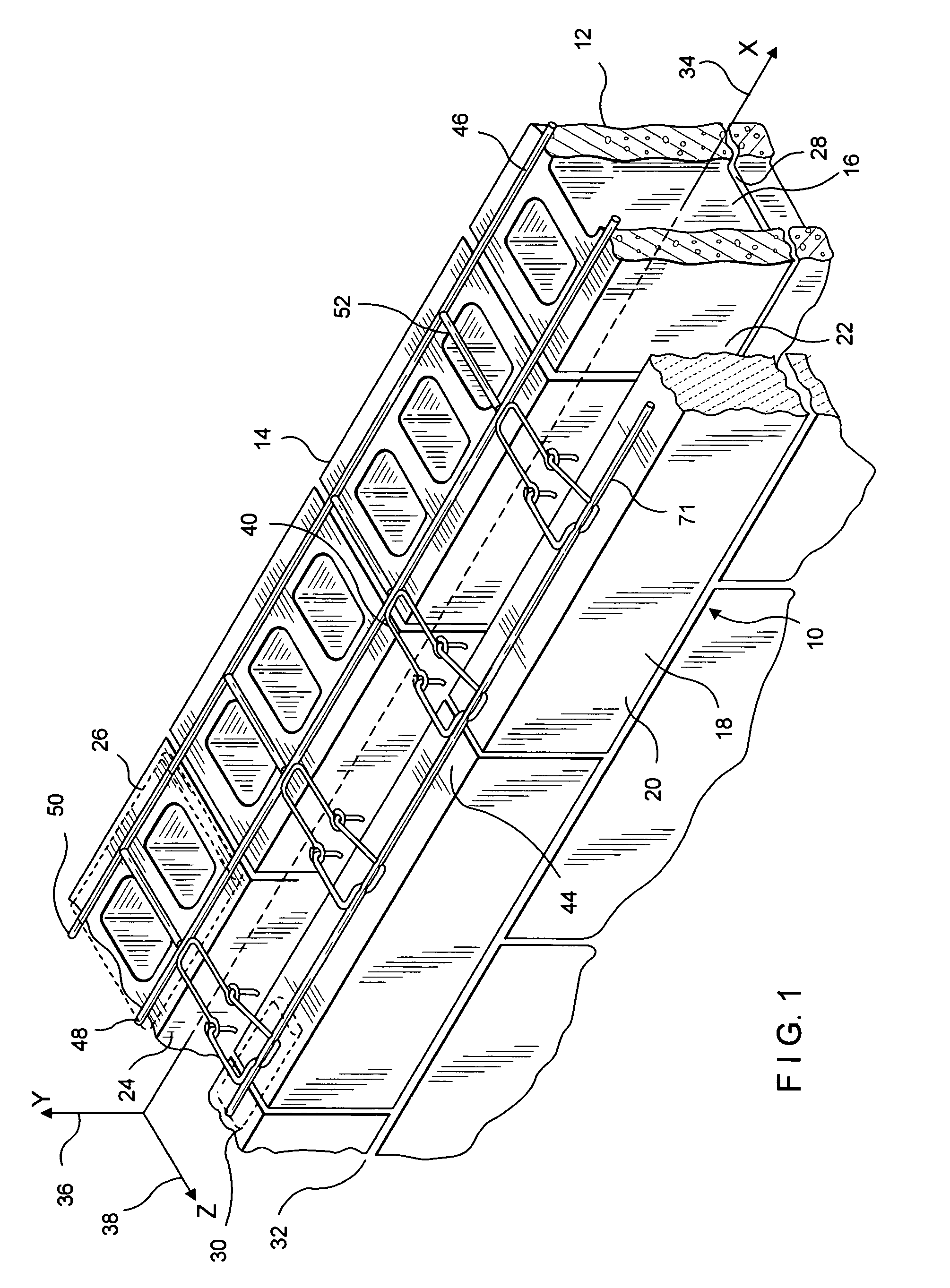

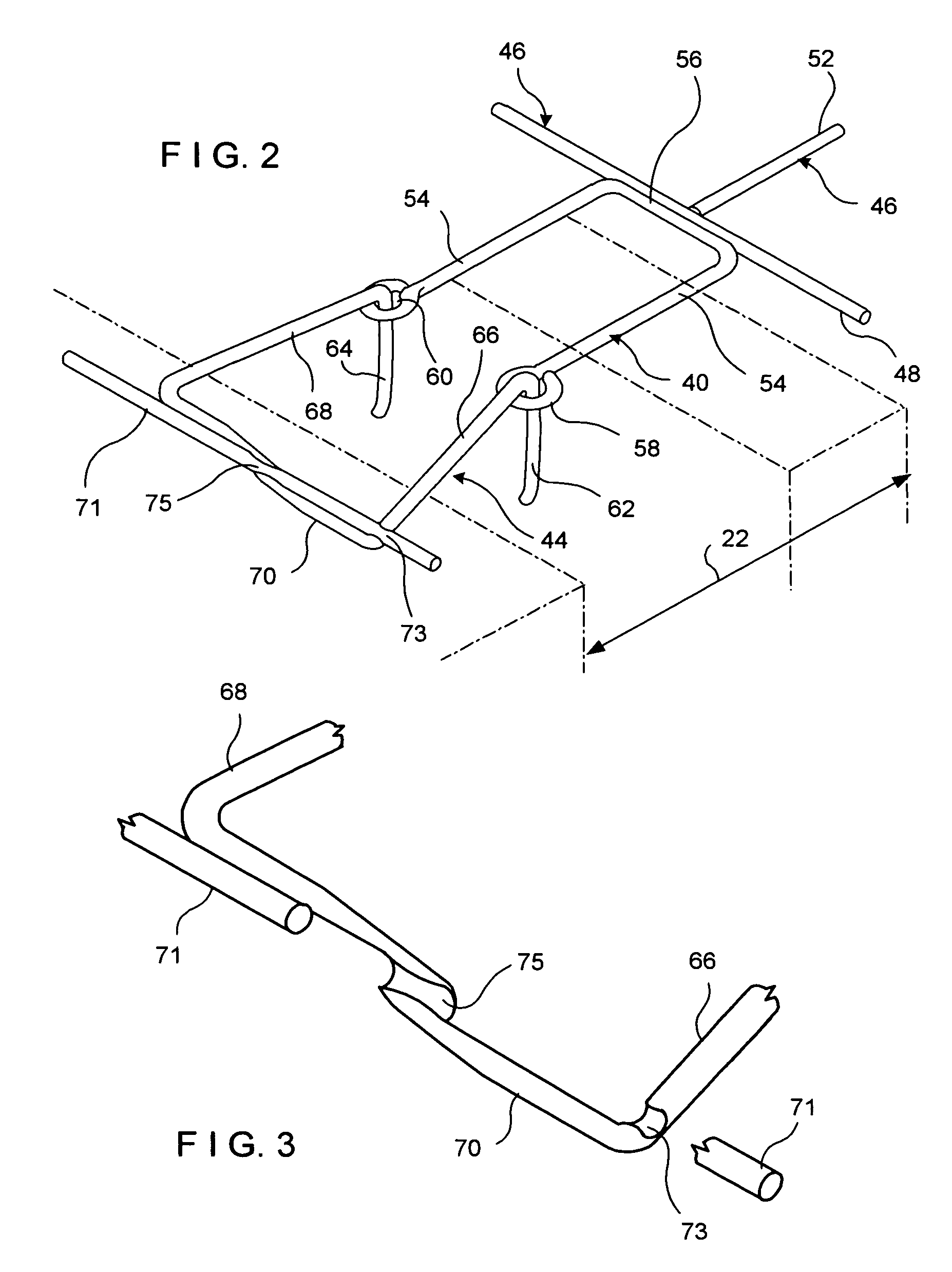

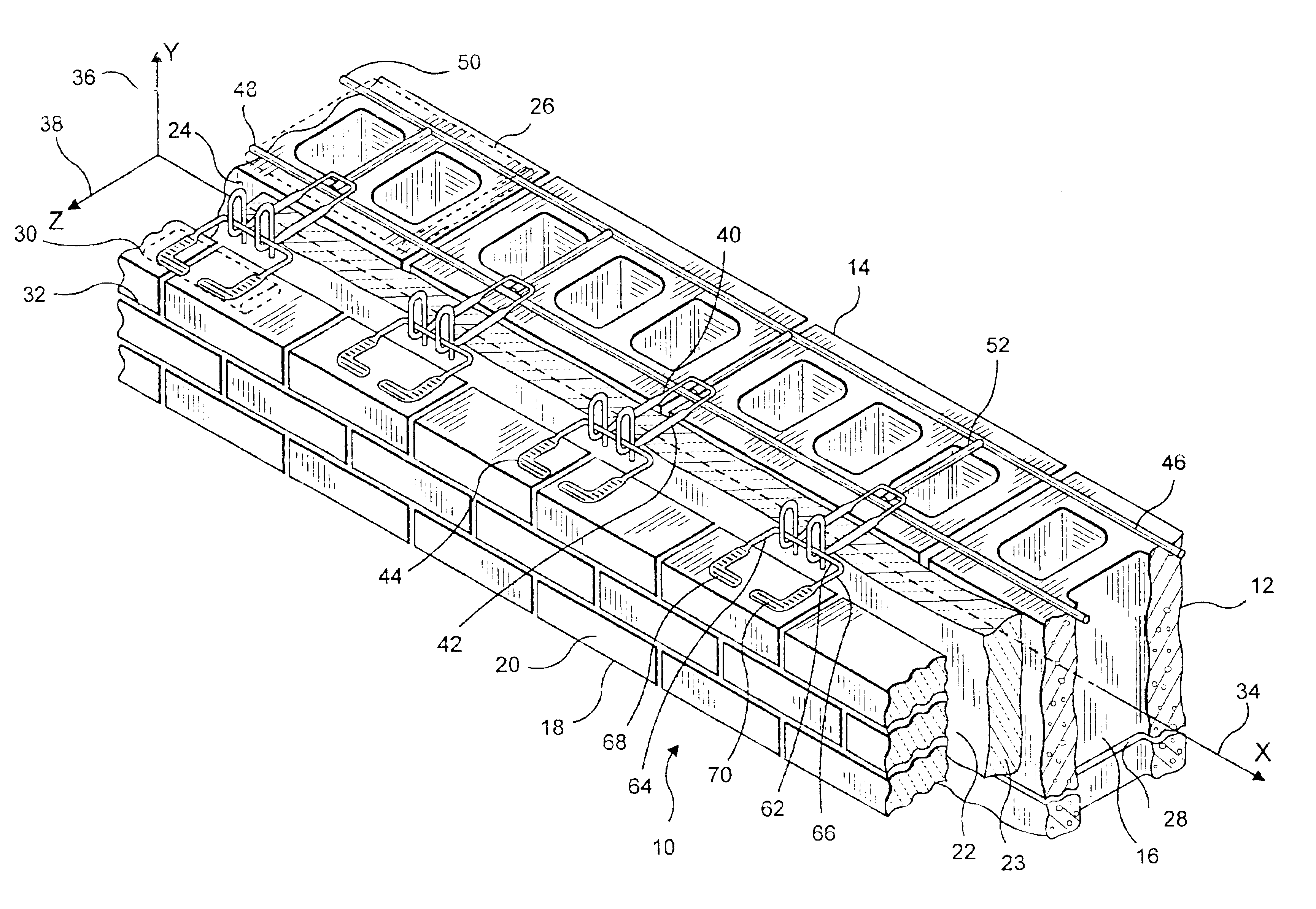

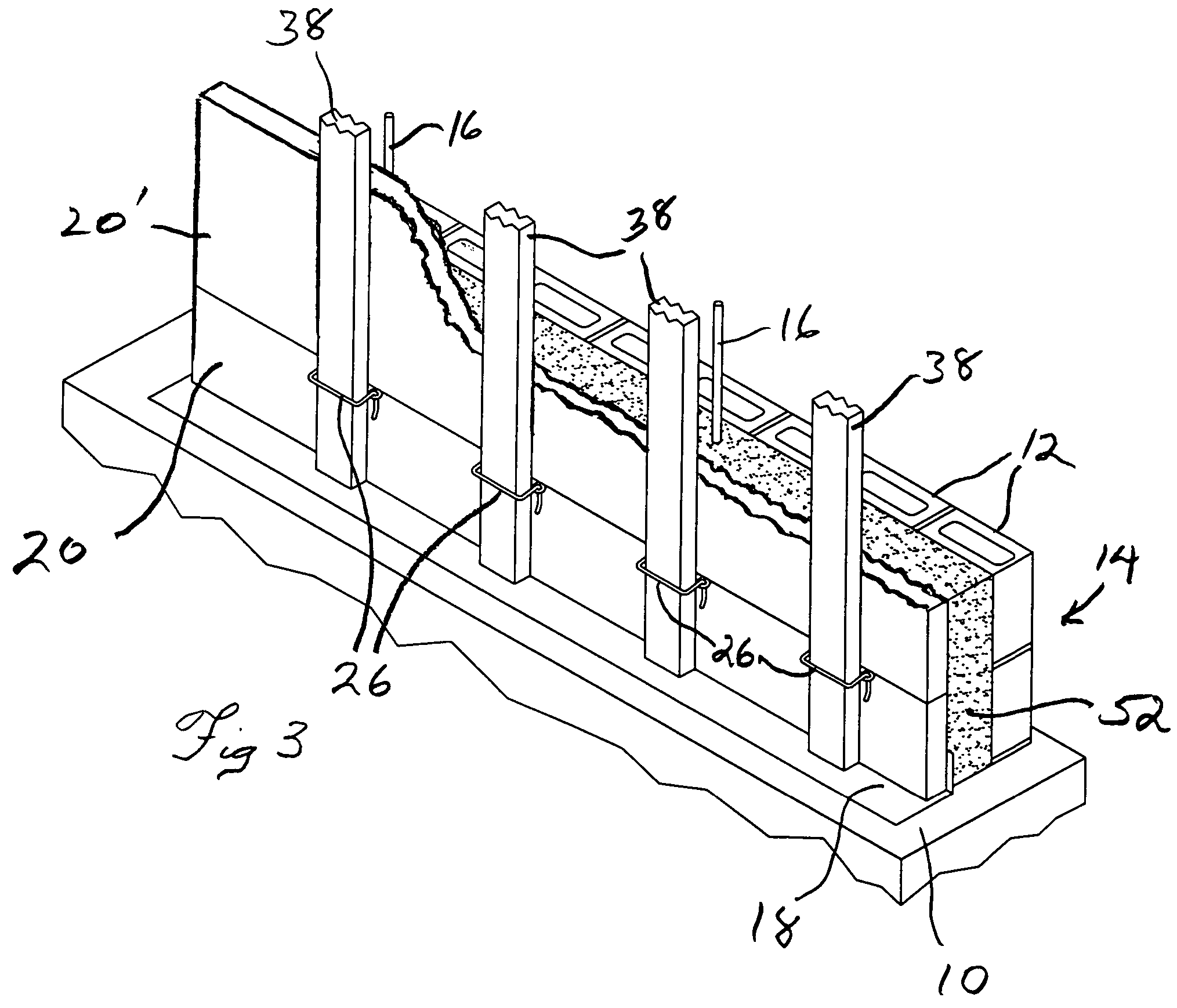

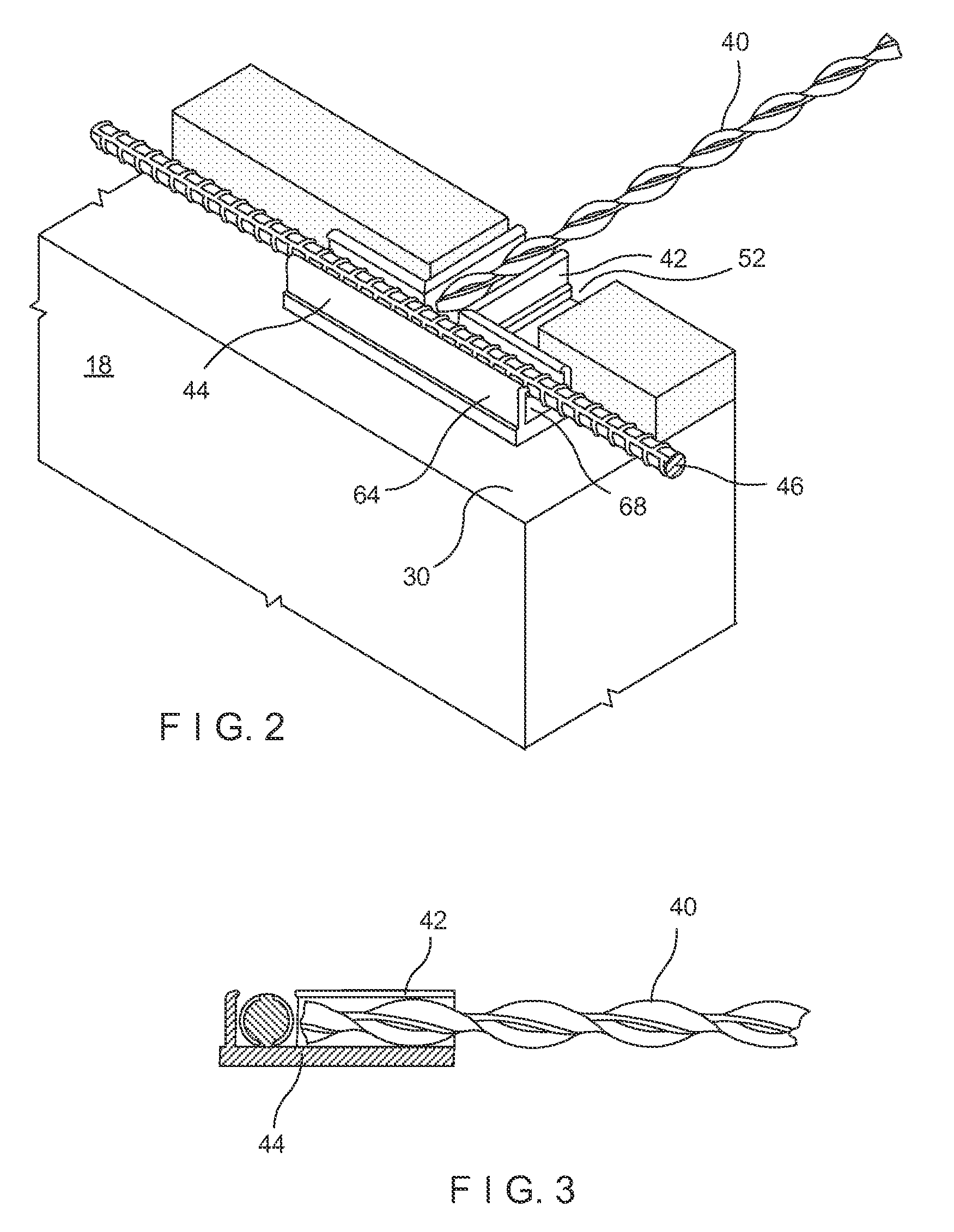

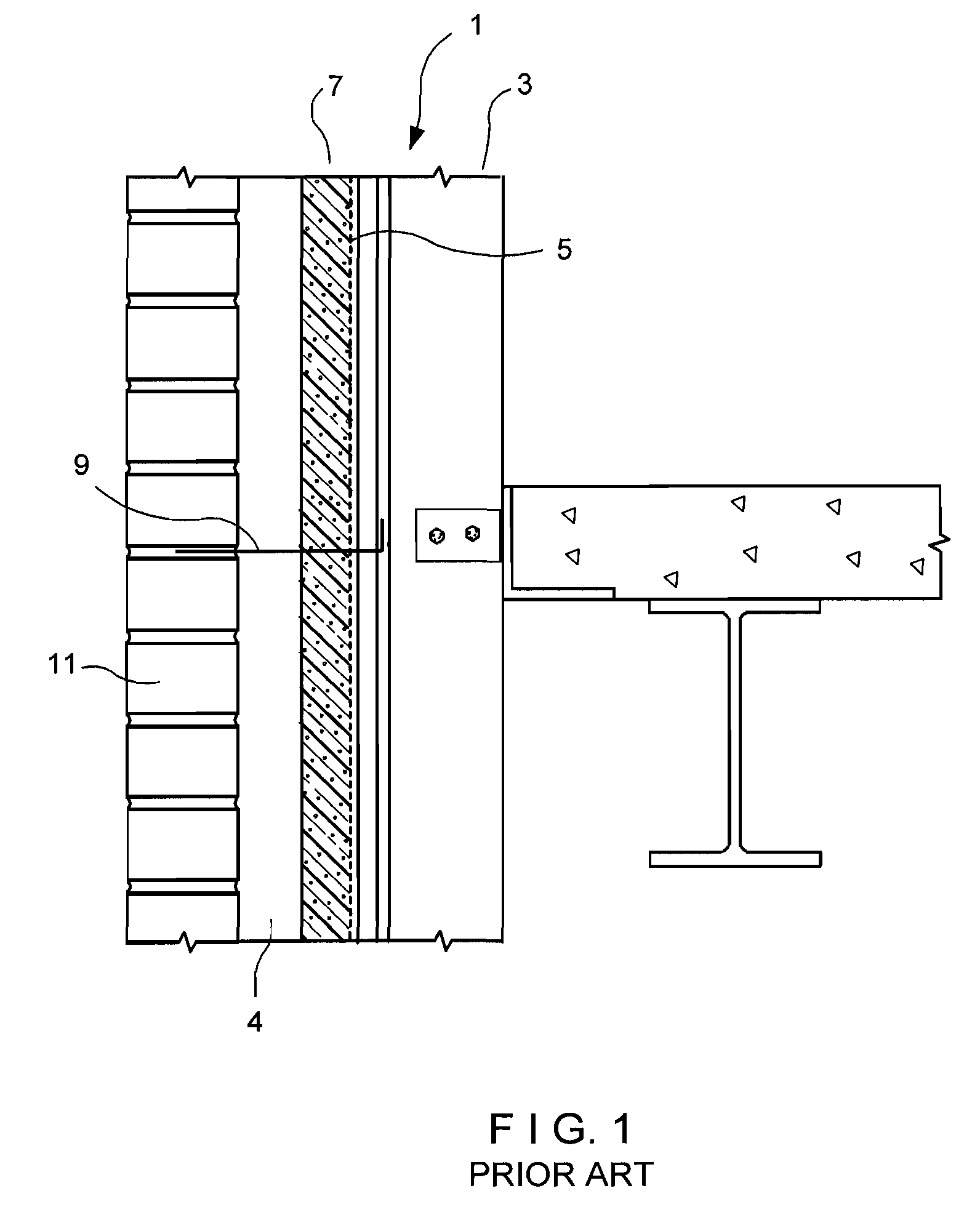

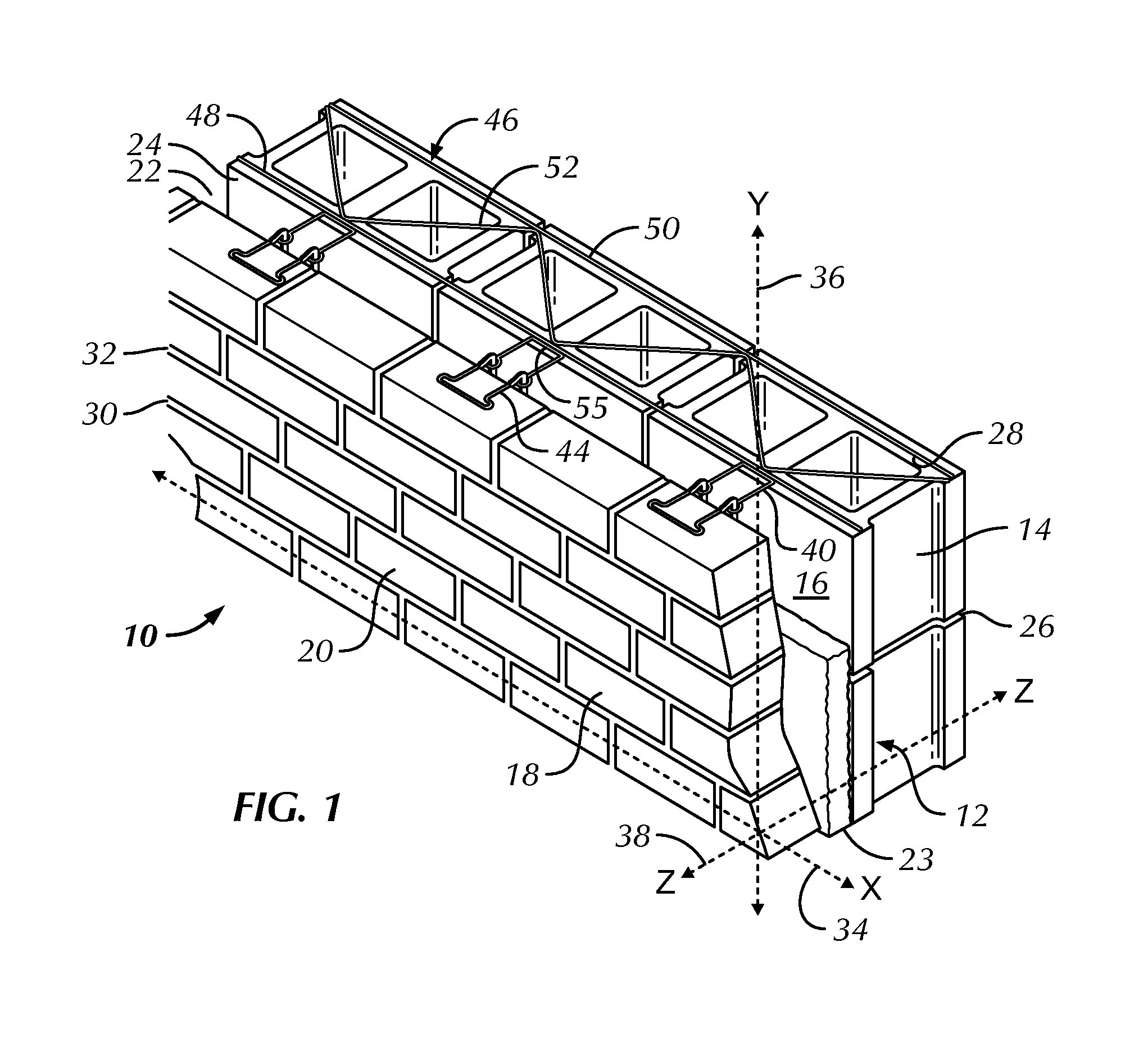

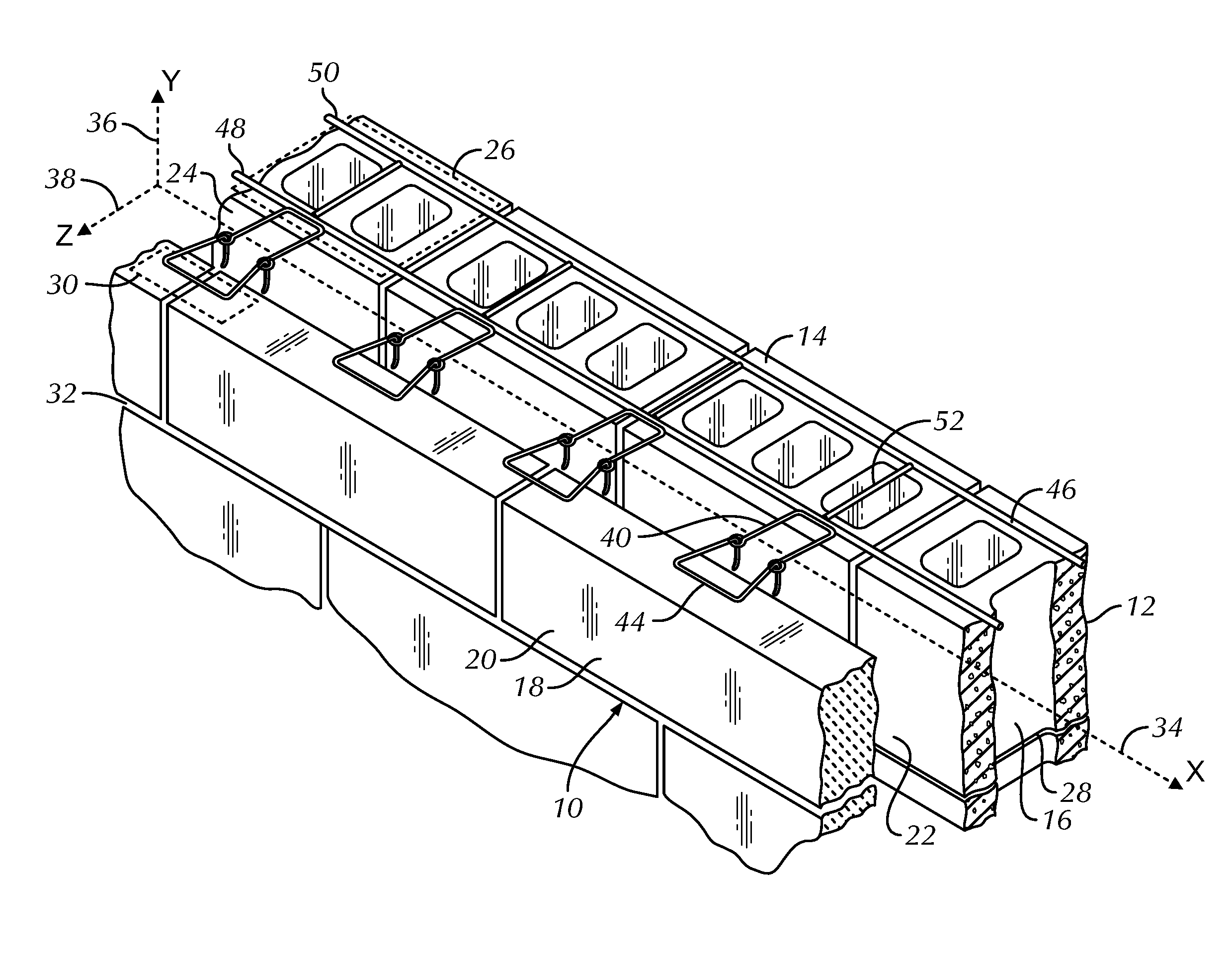

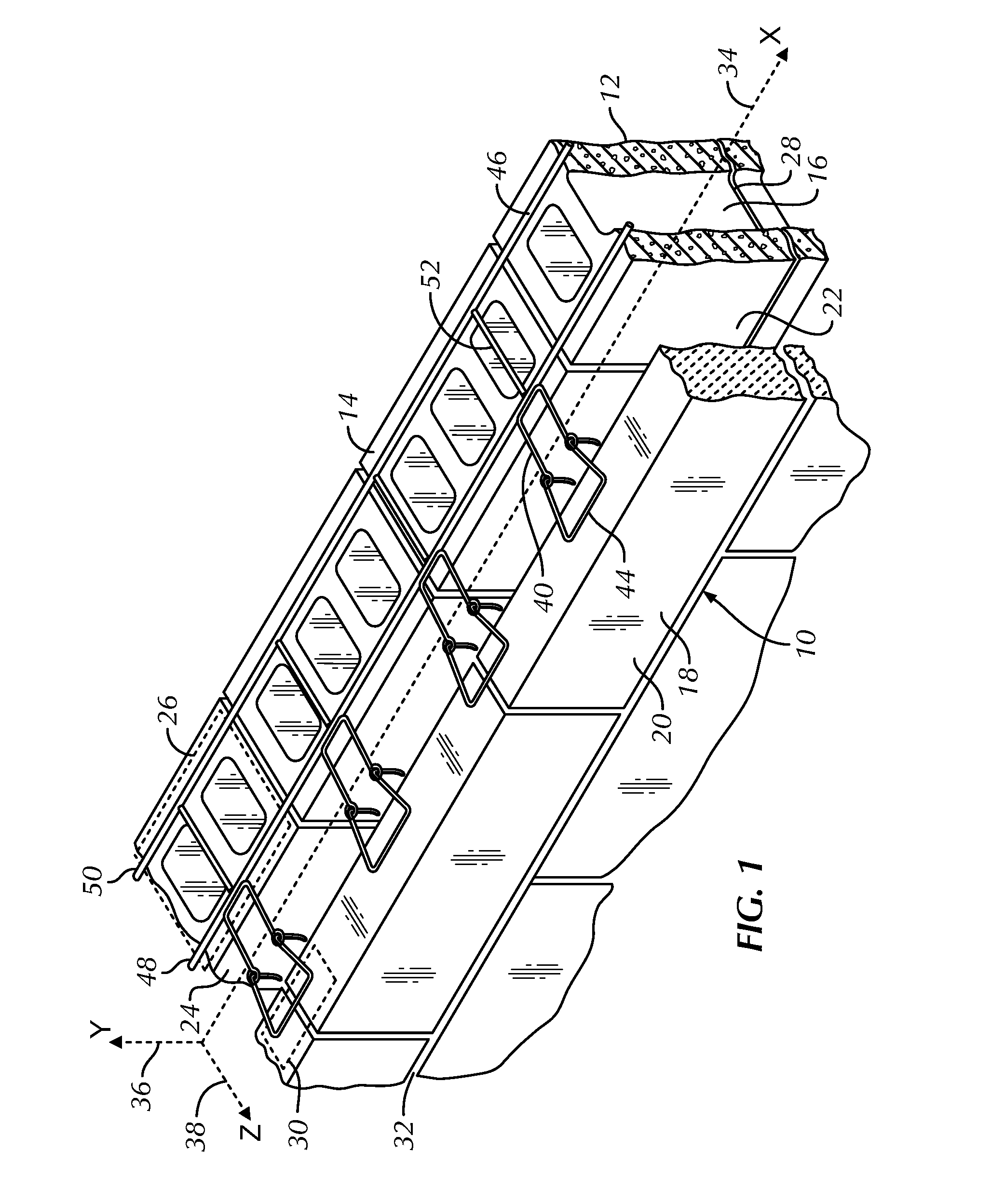

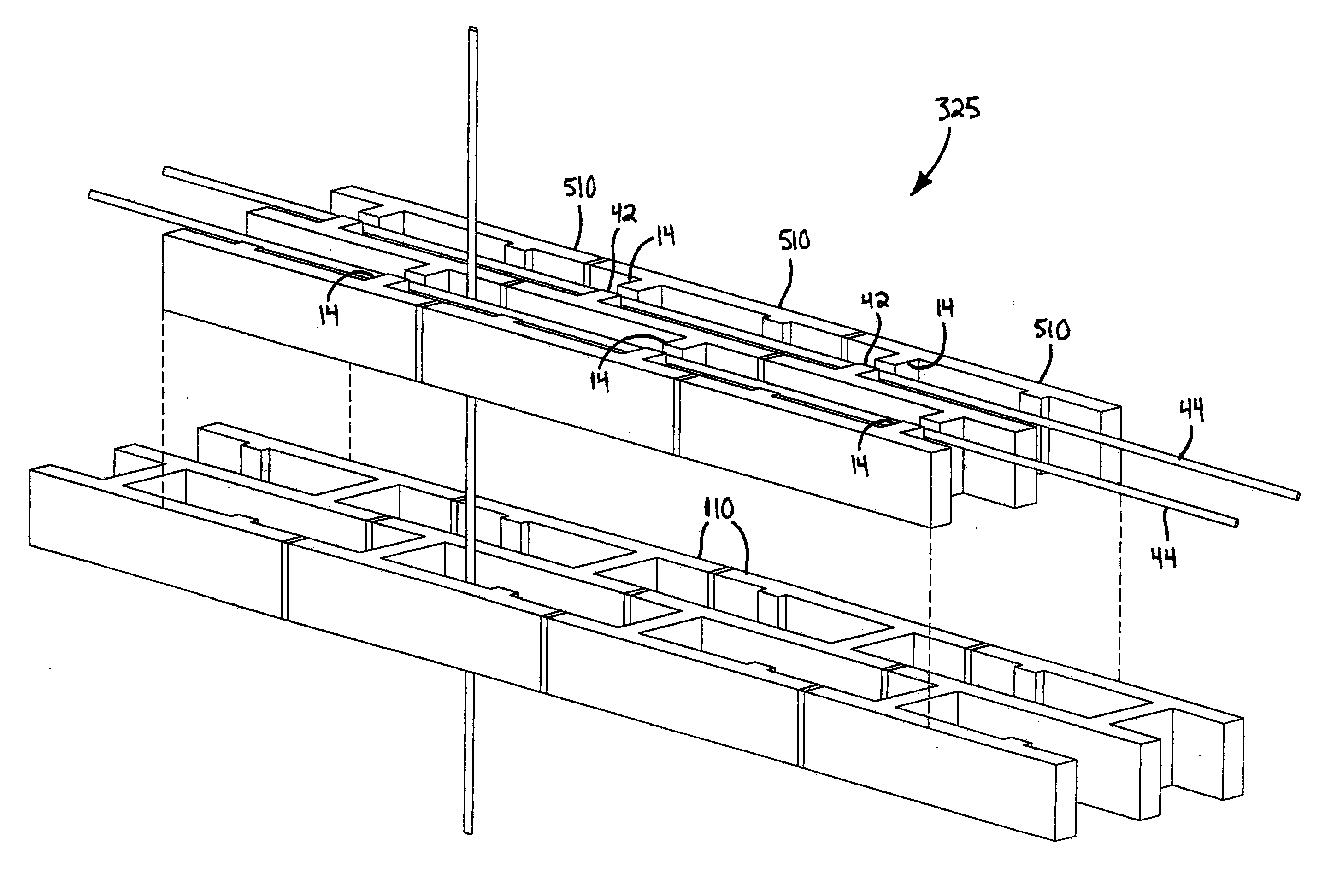

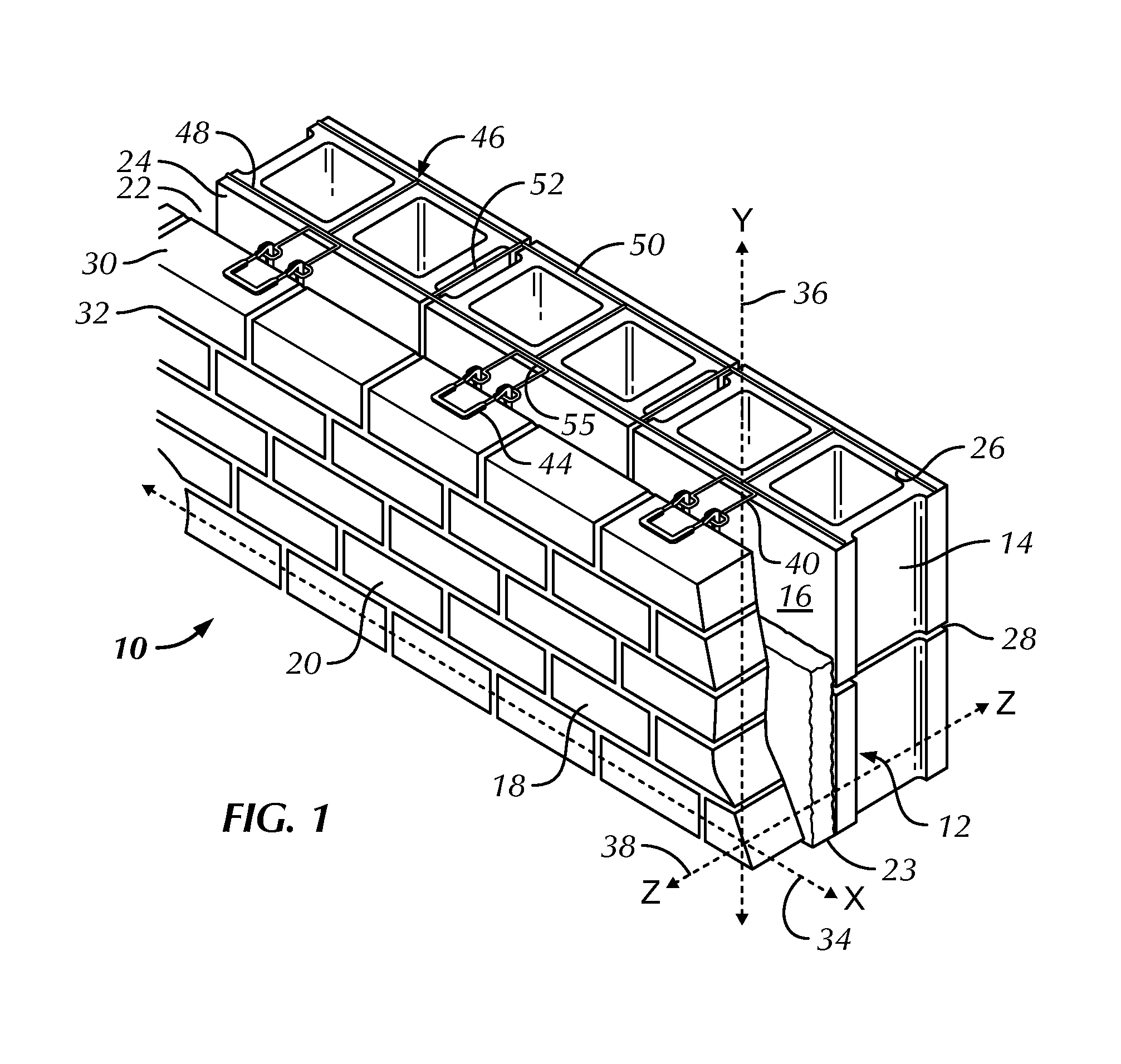

Masonry cavity wall construction and method of making same

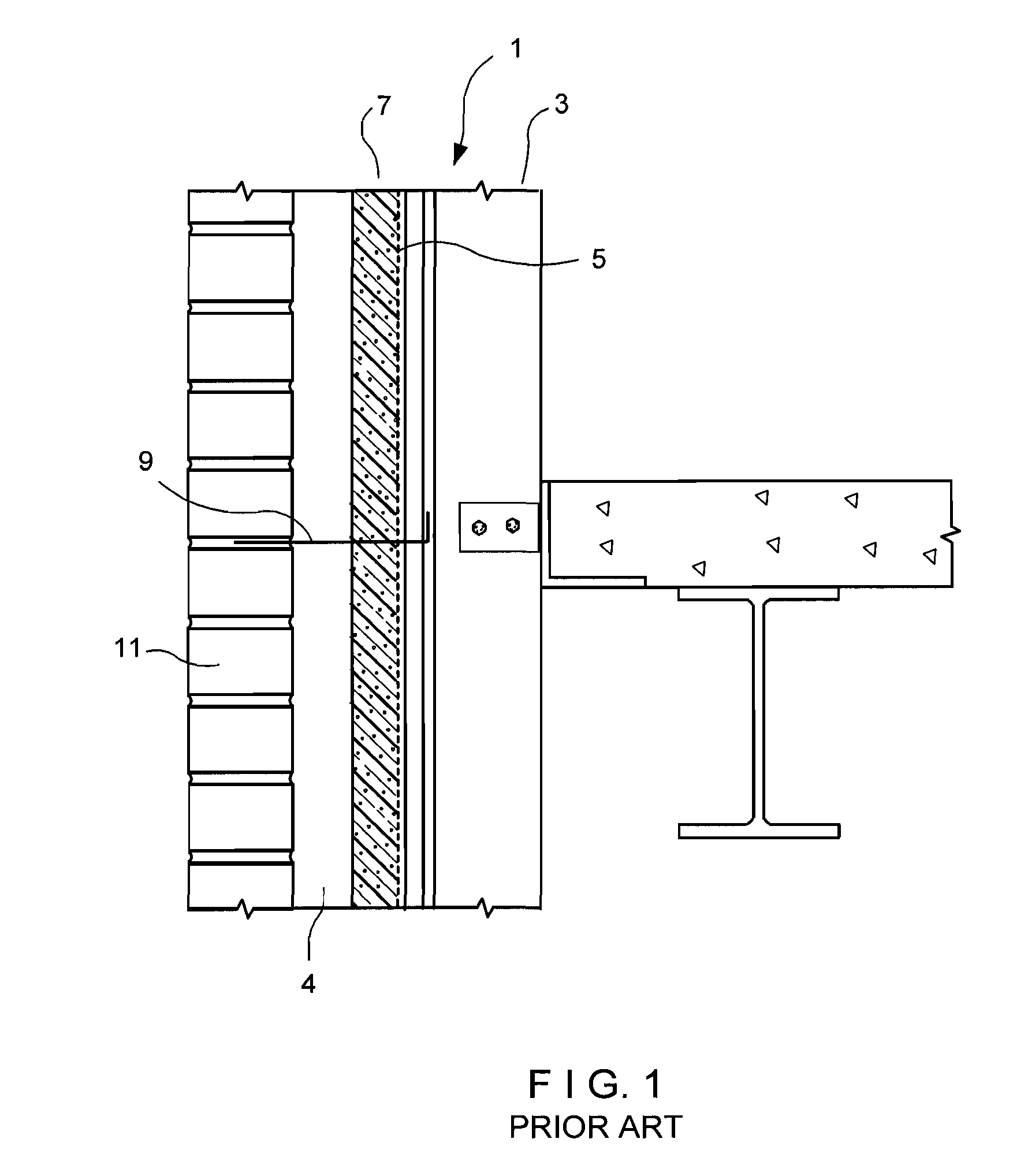

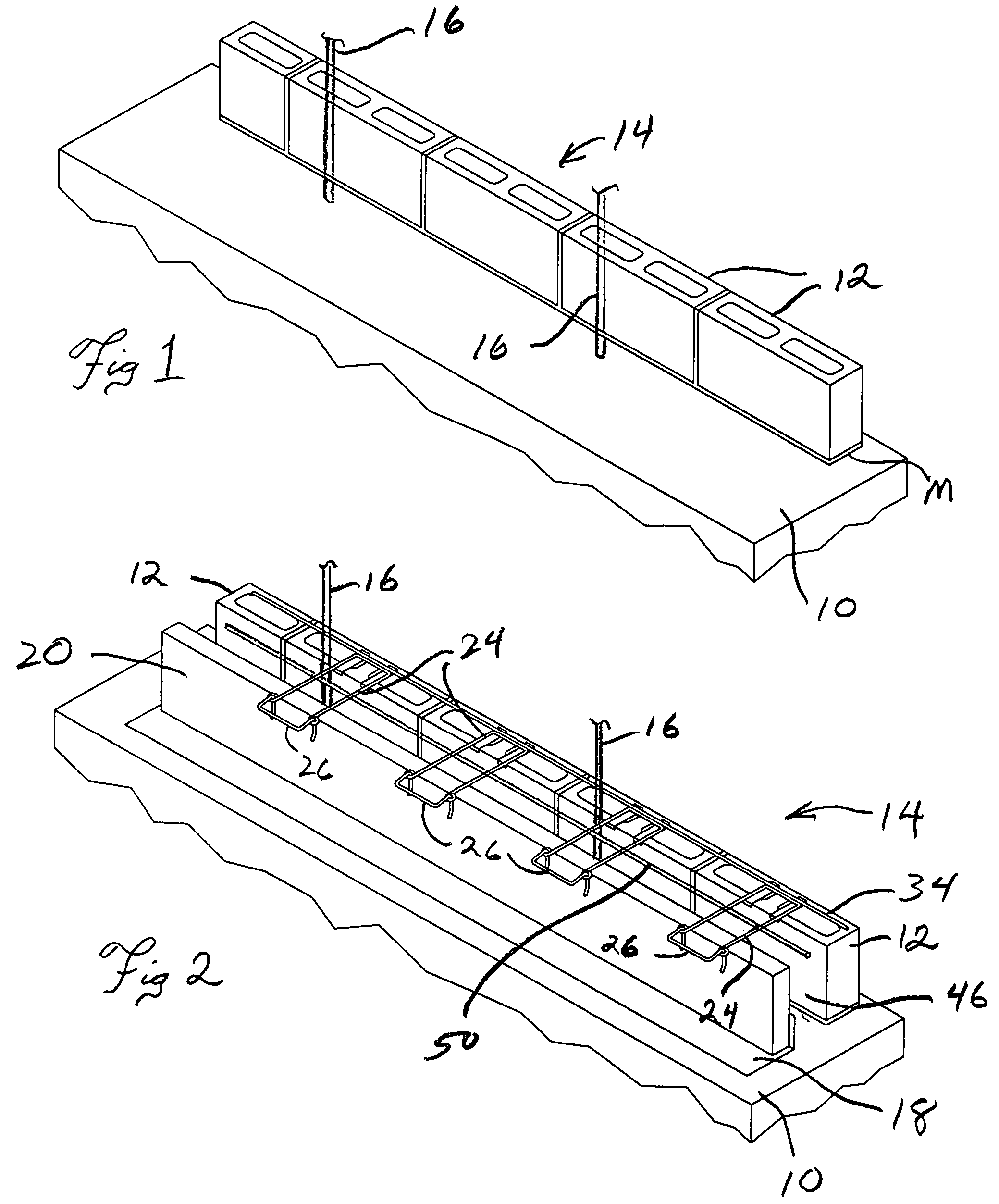

InactiveUS7735292B2High thermal mass qualities of the wall structureEasy to installBuilding roofsWallsReinforced concreteRebar

A masonry cavity wall structure includes a cast-in-place reinforced concrete structural wall member erected between and in confronting engagement with the outer side of a first, inner masonry wythe and the inner side of an outwardly spaced-away, upstanding wall of rigid insulation panels supported by wire tie members in embedded engagement in the mortar joints of the inner wythe, the inner wythe and tie-supported insulation panels also being used during construction of the cavity wall to provide the supporting concrete formwork for the poured structural wall member. A second, outer veneer wythe is erected a predetermined spaced distance outwardly from the insulation panels and forms an airspace cavity therebetween, the wire tie members also engaged in the mortar joints of the second, outer wythe whereby to structurally tie the masonry cavity wall together. The placement of the cast-in-place reinforced structural wall immediately adjacent the inner wythe and inwardly of the insulation provides maximum thermal mass qualities of the cavity wall construction.

Owner:MASSIE MICHAEL C

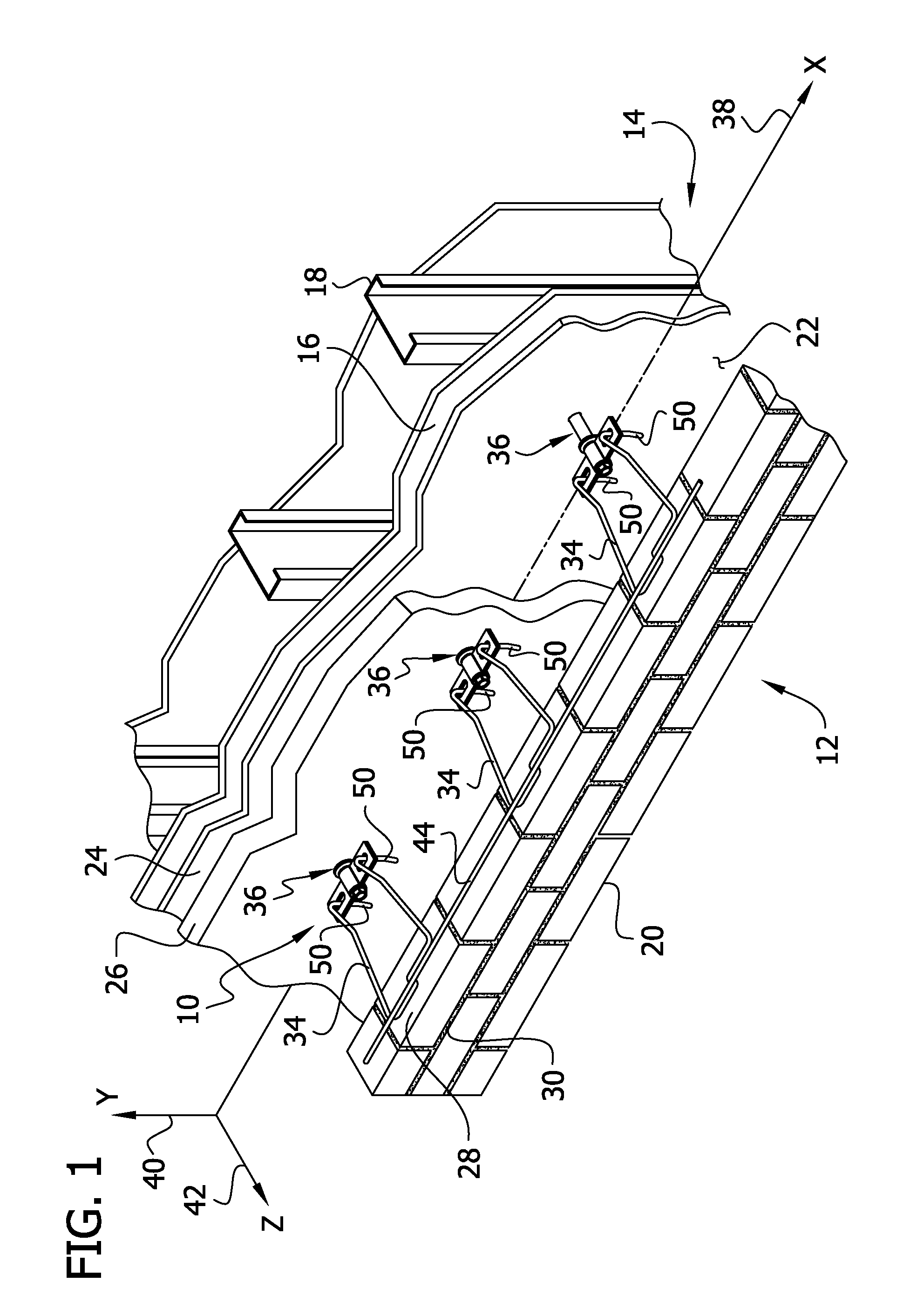

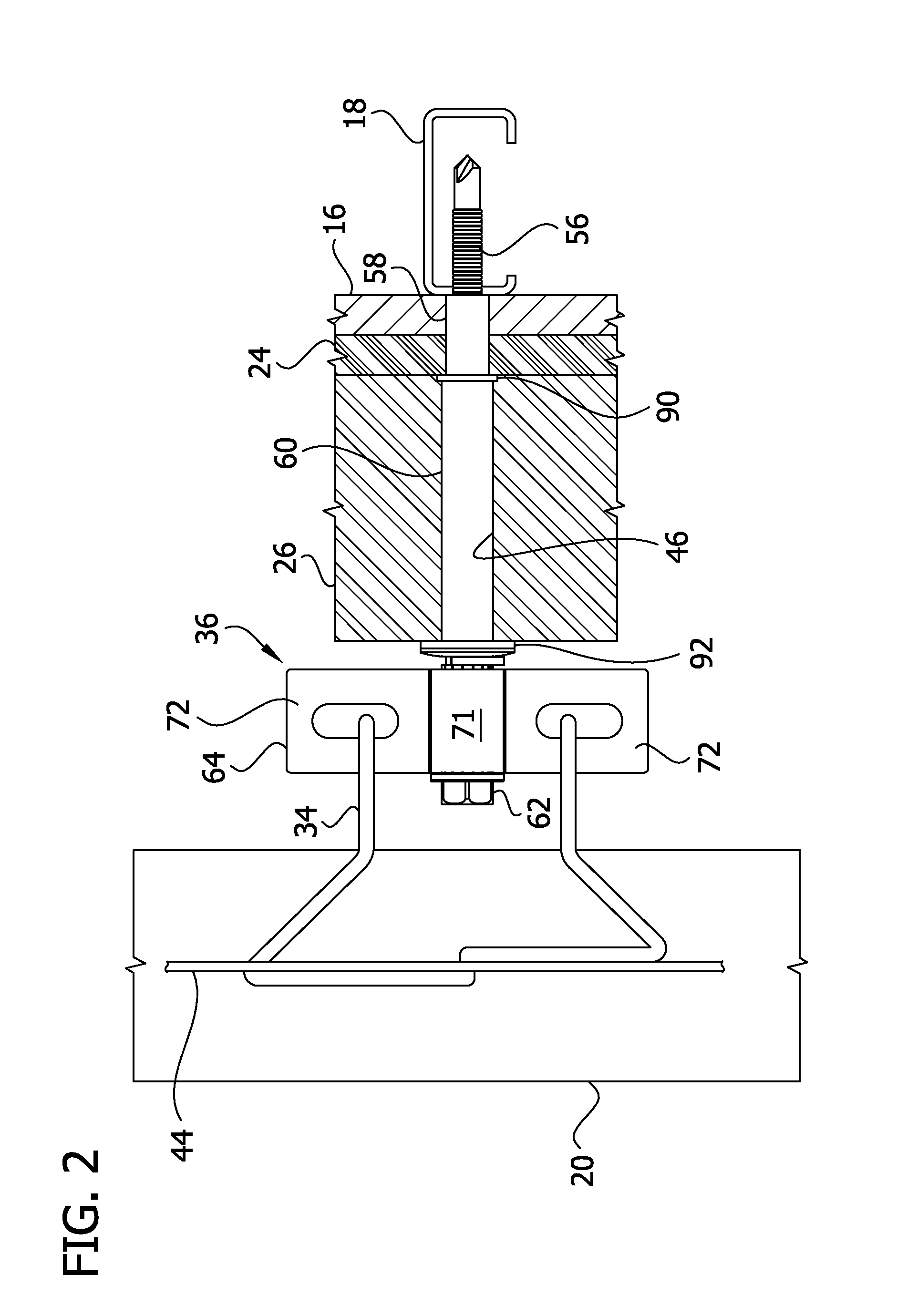

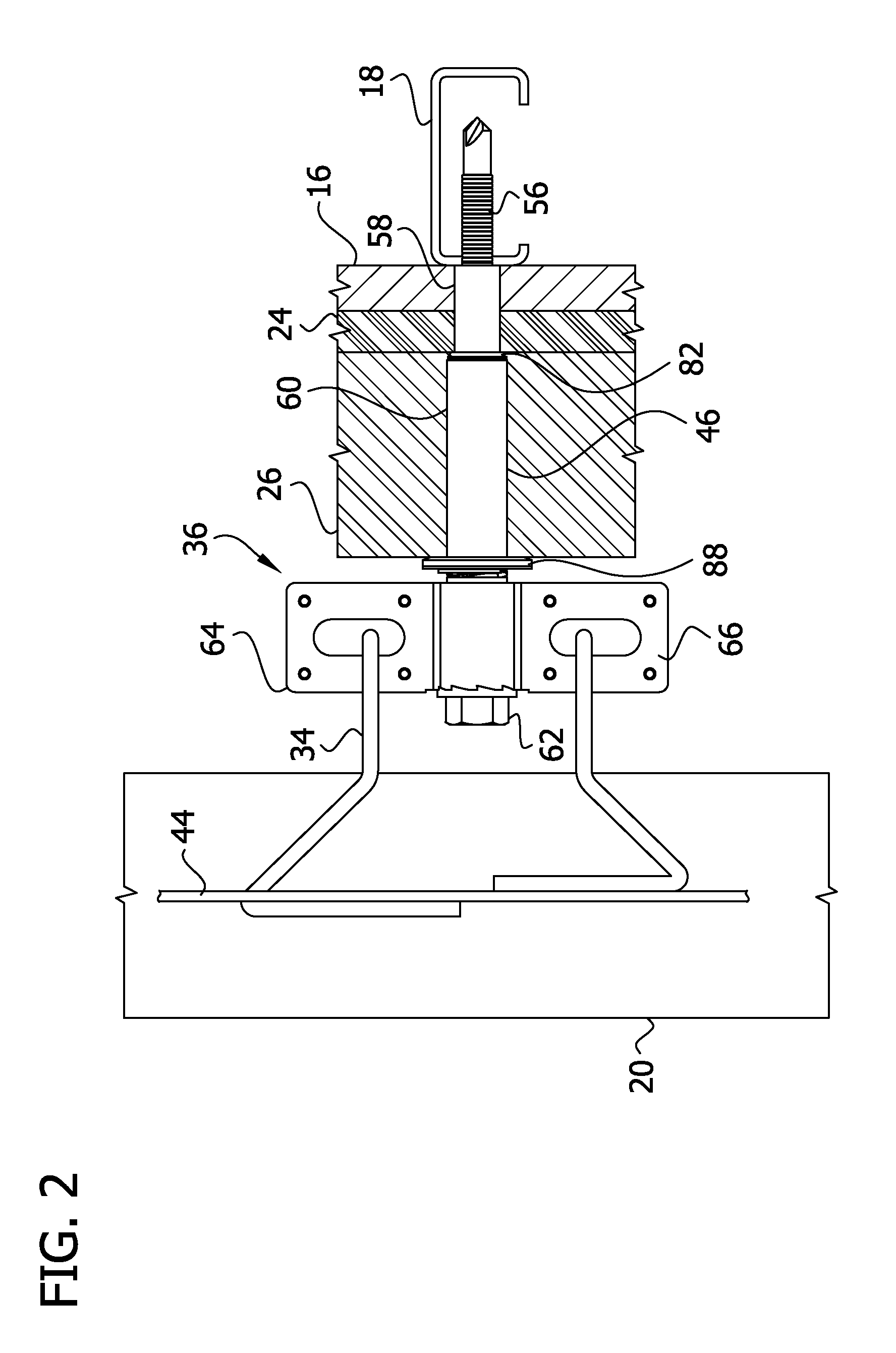

Anchor with angular adjustment

A wall anchor for use in an insulated cavity wall has an elongated body extending from a driven end to a driving end. The driven end is adapted to be mounted on an inner wythe of a cavity wall structure. A rotation control portion of the elongated body may include teeth formed on the surface. A collar with at least one aperture for a veneer tie is located near the driving end. The collar may have a pawl associated with it and positioned to engage the teeth on the elongated body. The teeth of the elongated body and the pawl of the collar form a ratchet structure. The collar can be rotated relative to the wall anchor only in a single direction, with the interengaging ratchet structure preventing rotation in the opposite direction.

Owner:HOHMANN & BARNARD INC

Anchor with angular adjustment

A wall anchor for use in an insulated cavity wall has an elongated body extending from a driven end to a driving end. A threaded portion at the driven end is adapted to be mounted on an inner wythe of a cavity wall structure. A drive head at the driving end has a surface facing the driven end of the wall anchor, with teeth formed on the surface. A collar with at least one aperture for a veneer tie is located near the driving end. The collar has teeth formed on a top surface generally facing the drive head. The teeth of the drive head and the collar are interengaging ratchet teeth, and a spring washer biases the collar against the drive head. The collar can only be rotated relative to the wall anchor in a single direction, with the interengaging ratchet teeth preventing rotation in the opposite direction.

Owner:HOHMANN & BARNARD INC

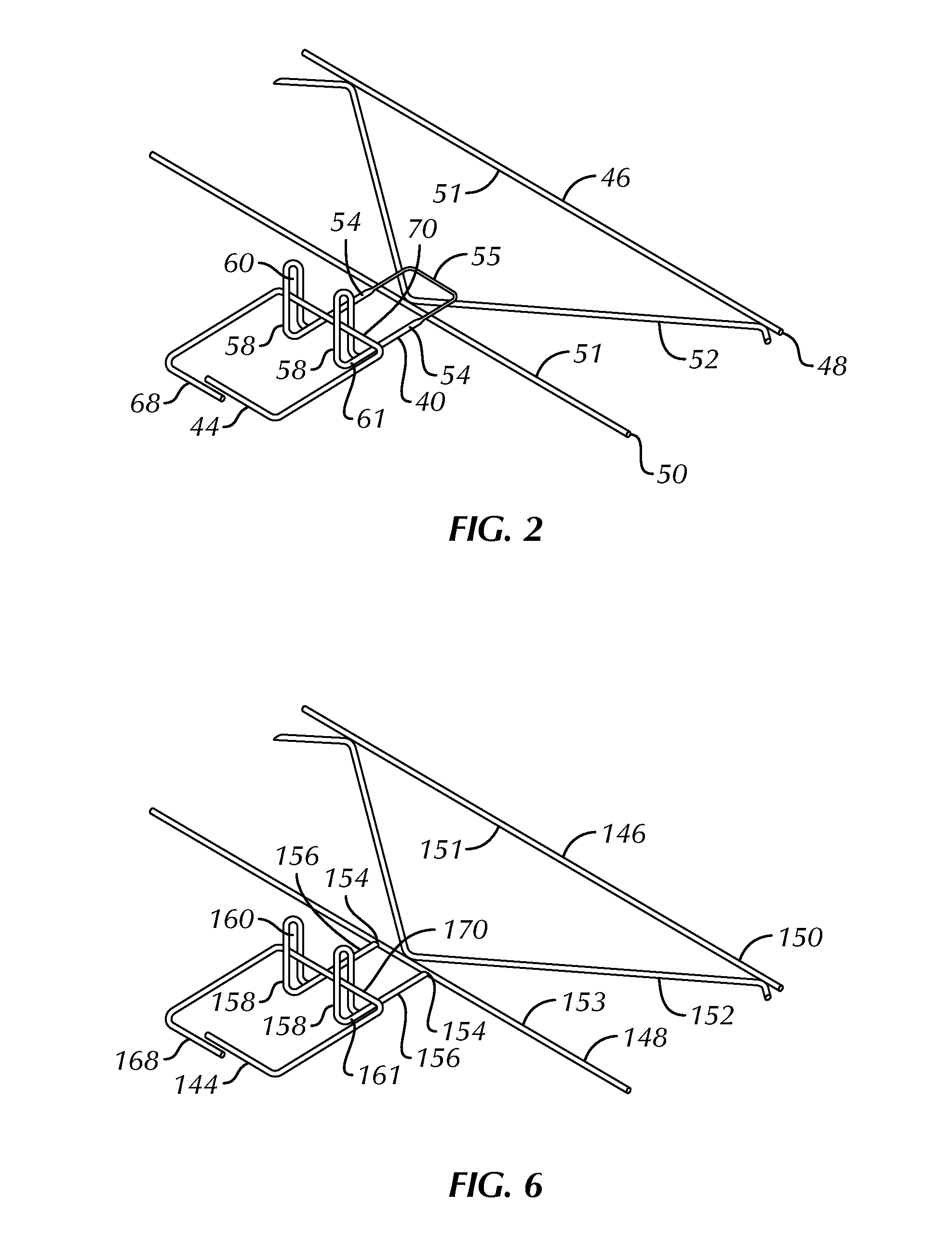

Dual pintle and anchoring system utilizing the same

A high-strength dual pintle and anchoring system employing the same is disclosed. The modified veneer tie utilizes ribbon pintles formed from a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

High-strength pintles and anchoring systems utilizing the same

ActiveUS8613175B2Easy to installHigh to forceConstruction materialBuilding reinforcementsHigh intensityEngineering

A high-strength ribbon pintle and cavity wall anchoring system employing the same is disclosed. The ribbon pintle is a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

Restoration anchoring system

ActiveUS8555587B2Reduce manufacturing costLower unit costCeilingsConstruction materialEngineeringCavity wall

A restoration anchoring system for use in cavity wall structures having an inner wythe and an outer wythe that requires remediation or re-anchoring is disclosed. The anchoring system employs a three-part system that is installed within the existing bed joints of the outer wythe to reattach and re-anchor the outer wythe to the structural inner wythe. The three-part system includes a helical dowel, a seismic T-clip and a reinforcement member. The helical dowel is self-threading and self-drilling. When the three-part system is installed within the outer wythe and attached to the inner wythe, the system is captively embedded in the outer wythe thereby providing a seismic construct.

Owner:HOHMANN & BARNARD INC

Anchor system for composite panel

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

Rubble stone anchoring system

ActiveUS8375667B2Minimized in sizeProvide stabilityStrutsBuilding reinforcementsCavity sizeCavity wall

Anchoring systems for use in cavity wall structures having an inner wythe and an outer wythe constructed of rubble stone are disclosed. The anchoring system employs an anchor fastened to or set within the inner wythe that extends into the cavity and connects to a J-hook. A vertically adjustable veneer tie enwraps the J-hook, limiting lateral movement and front-to-back displacement, and is set within the bed joint of the outer wythe. The anchoring system minimizes cavity size and provides stability for an uncoursed outer wythe equivalent to that of anchoring systems for standards coursed bed joints.

Owner:HOHMANN & BARNARD INC

High-strength veneer tie and thermally isolated anchoring systems utilizing the same

ActiveUS20140075855A1Increase veneer tie strengthAvoid loadStrutsCovering/liningsBand shapeSingle plate

An anchoring system for cavity walls is disclosed and includes a wall anchor and a high-strength veneer tie. The anchor includes nonconductive thermally-isolating components that maintain the insulation R-values. The anchor features seals located at insertion points in the layers of the interior wythe that stabilize the wall anchor and protect against the entry of liquids and vapor. The veneer tie utilizes a ribbon connector that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The veneer tie, when part of the anchoring system, interengages with the wall anchor and is dimensioned to preclude significant veneer tie movement and to preclude pullout.

Owner:HOHMANN & BARNARD INC

Pullout resistant pintle and anchoring system utilizing the same

InactiveUS20140075856A1Easy to installIncrease resistanceWallsProtective buildings/sheltersEngineeringWire rod

A high-strength pullout resistant pintle and anchoring system employing the same is disclosed. The modified veneer tie utilizes ribbon pintles formed from a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant lateral, vertical and horizontal movement.

Owner:HOHMANN & BARNARD INC

High-strength partially compressed veneer ties and anchoring systems utilizing the same

ActiveUS20130247482A1High strengthEasy to installStrutsProtective buildings/sheltersHigh intensityUltimate tensile strength

A high-strength pintle anchoring system for a cavity wall is disclosed. The high-strength pintle anchoring system employs a partially compressively reduced veneer tie that is cold-worked with the resultant body partially having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The partially compressively reduced veneer tie, when part of the anchoring system, interengages with the receptor portions of a wall anchor and are dimensioned to preclude significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

High-strength veneer tie and thermally isolated anchoring systems utilizing the same

ActiveUS8726597B2Preventing veneer tie pulloutRestrict movementConstruction materialCovering/liningsHigh intensityEngineering

An anchoring system for cavity walls is disclosed and includes a wall anchor and a high-strength veneer tie. The anchor includes nonconductive thermally-isolating components that maintain the insulation R-values. The anchor features seals located at insertion points in the layers of the interior wythe that stabilize the wall anchor and protect against the entry of liquids and vapor. The veneer tie utilizes a ribbon connector that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The veneer tie, when part of the anchoring system, interengages with the wall anchor and is dimensioned to preclude significant veneer tie movement and to preclude pullout.

Owner:HOHMANN & BARNARD INC

High-strength pintles and anchoring systems utilizing the same

A high-strength ribbon pintle and cavity wall anchoring system employing the same is disclosed. The ribbon pintle is a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

High-strength rectangular wire veneer tie and anchoring systems utilizing the same

ActiveUS8833003B1Easy to installIncrease volumetric occupancyProtective buildings/sheltersShock proofingSquare cross sectionSingle plate

A high-strength rectangular pintle veneer tie and cavity wall anchoring system employing the same is disclosed. The rectangular wire formative construct optionally includes a square cross-section that provides greater volumetric occupancy than that of a similar diameter circular wire formative. The interengaging portions and insertion portion are optionally compressed for greater strength and the rectangular shaped interengaging portion provides a locking interconnection within the anchor precluding significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

High strength composite wall panel system

InactiveUS20060032166A1Improved and strong and less-expensiveImprove composite effectBuilding componentsConstructions elementsMechanical bondEngineering

The present invention is directed to improved composite action walls having an insulation wythe sandwiched between structural wythes. The structural wythes provide the load-bearing function and prevent the collapse of the wall under high wind loads. The structural wythes demonstrate composite action existing between the structural wythes such that an improved, stronger and less expensive wall may be constructed. The present invention is also directed to an insulation wythe, which is useful in the composite action wall of the present invention, having grooves formed therein such that the material of the structural wythes flow into the groove to form a mechanical bond between the structural wythes and the insulation wythe. The walls of the present invention are simple to manufacture and provide a verifiable and consistent composite action between about 50% to about 100% composite action.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High-strength partially compressed veneer ties and anchoring systems utilizing the same

ActiveUS8726596B2High strengthEasy to installConstruction materialStrutsHigh intensityUltimate tensile strength

Owner:HOHMANN & BARNARD INC

High-strength partially compressed low profile veneer tie and anchoring system utilizing the same

ActiveUS20140075879A1Increase veneer tie strengthHigh strengthWallsBuilding reinforcementsHigh intensityWythe

A high-strength low profile partially compressed pintle veneer tie and anchoring system employing the same is disclosed. The high-strength pintle anchoring system employs a partially compressively reduced veneer tie that is cold-worked with the resultant body partially having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The partially compressively reduced veneer tie, when part of the anchoring system, interengages with the receptor portions of a wall anchor and is dimensioned to preclude significant veneer tie movement. The insertion portion of the veneer tie is compressed and patterned to ensure a secure hold within the bed joint.

Owner:HOHMANN & BARNARD INC

High-strength ribbon loop anchors and anchoring systems utilizing the same

Owner:HOHMANN & BARNARD INC

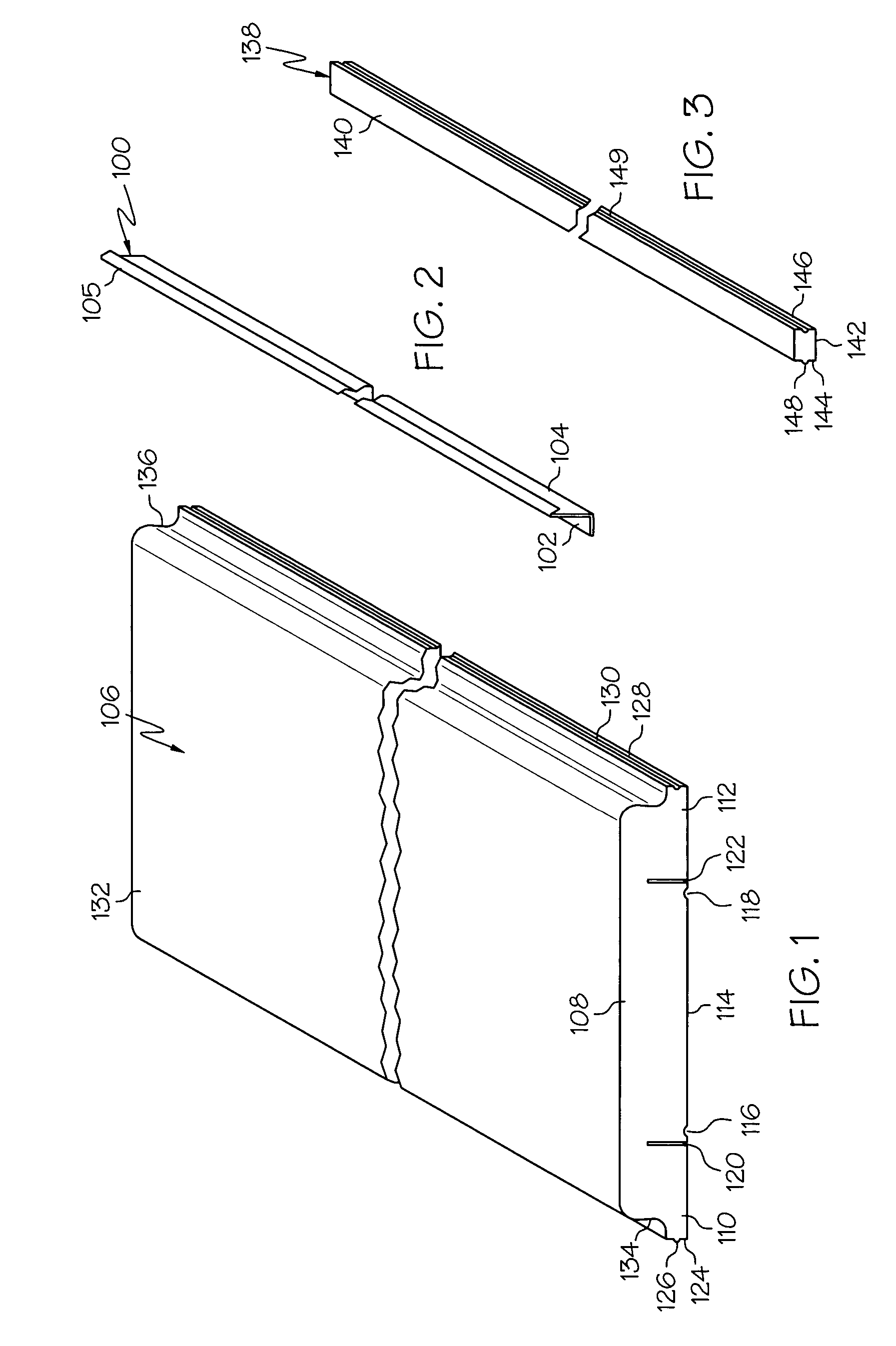

Method and apparatus for forming cast wall panels

InactiveUS20050086904A1Easy to shapeInsulating propertyBuilding componentsSurface layering apparatusEngineeringWythe

A method and system for constructing wall panels made of a foam insulation wythe and a concrete structural wythe. The insulation wythe is made up of a foam plank having a body having opposing flanges and receiving mounting angles that provide attachment for interior building finish. The method of the invention includes the steps of placing a plurality of insulation wythes adjacent to each other on a horizontal surface within a mold such that the plank bodies point upwardly, pouring concrete over the sections, allowing the concrete to cure to form the structural wythe, then tilting the finished wall panel to a substantially vertical orientation. Optionally, the method of the present invention includes the steps of placing spacers between adjacent planks, placing mounting angles in the undersides of the primary wall sections and placing reinforcing means over the sections within the mold.

Owner:LJB

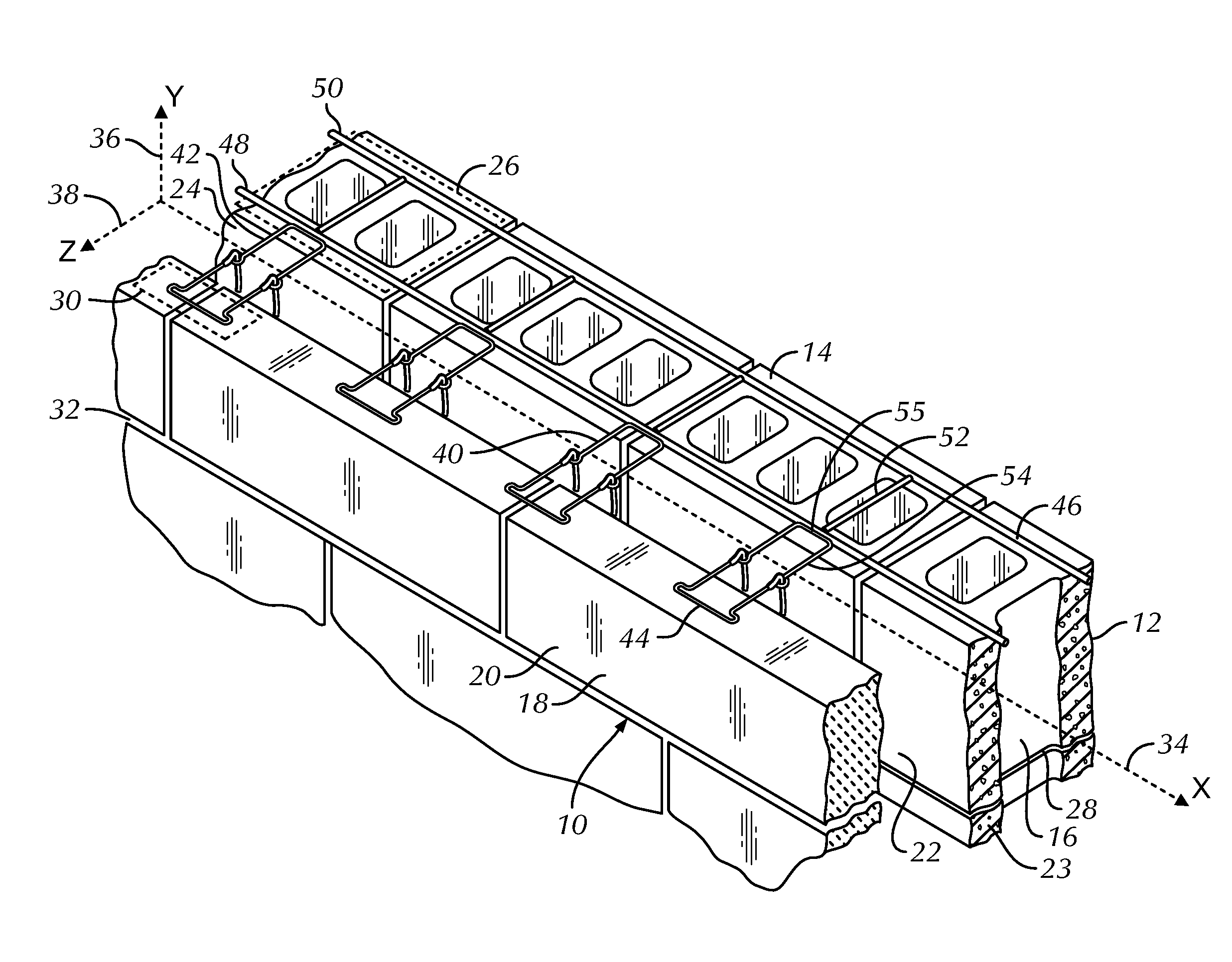

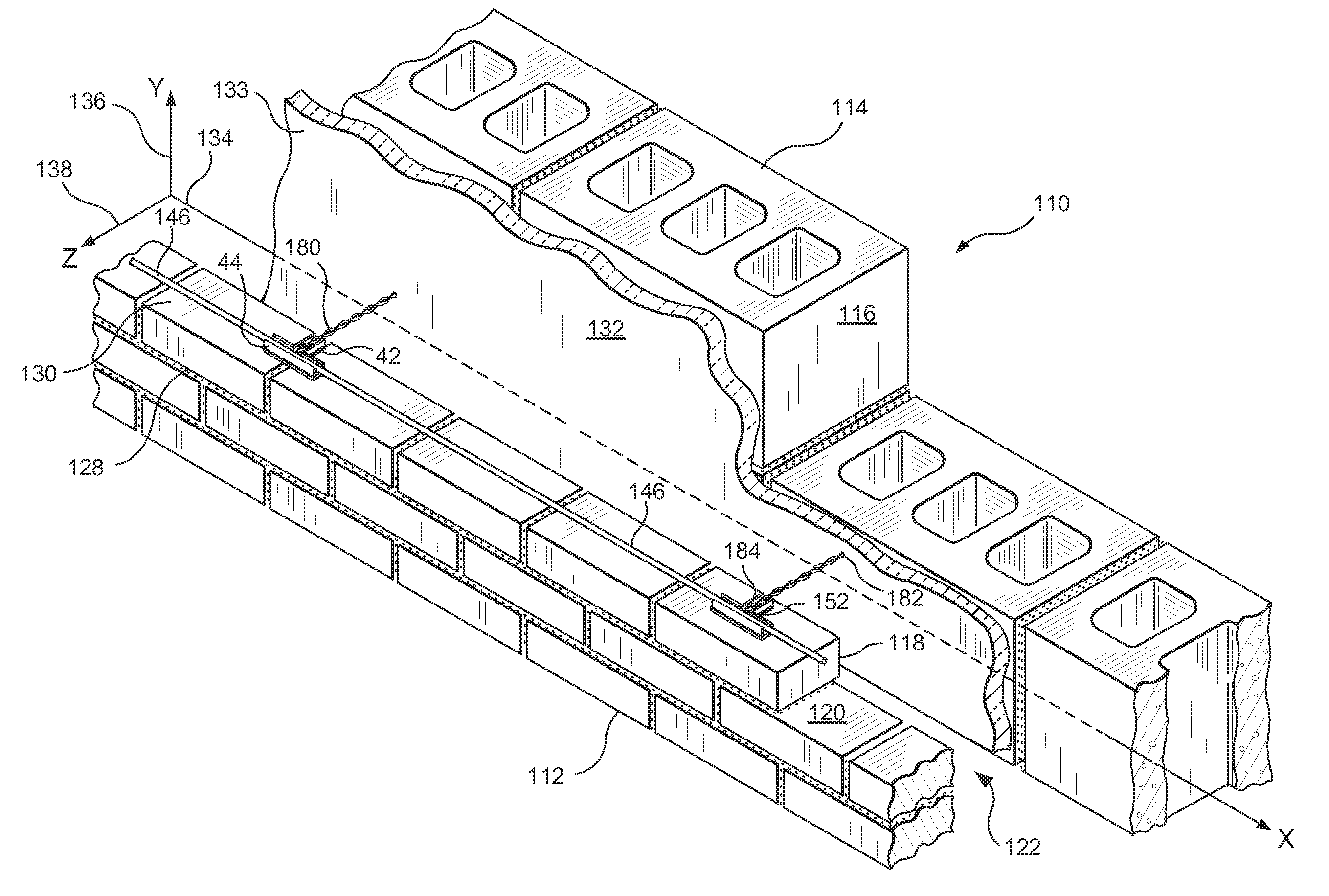

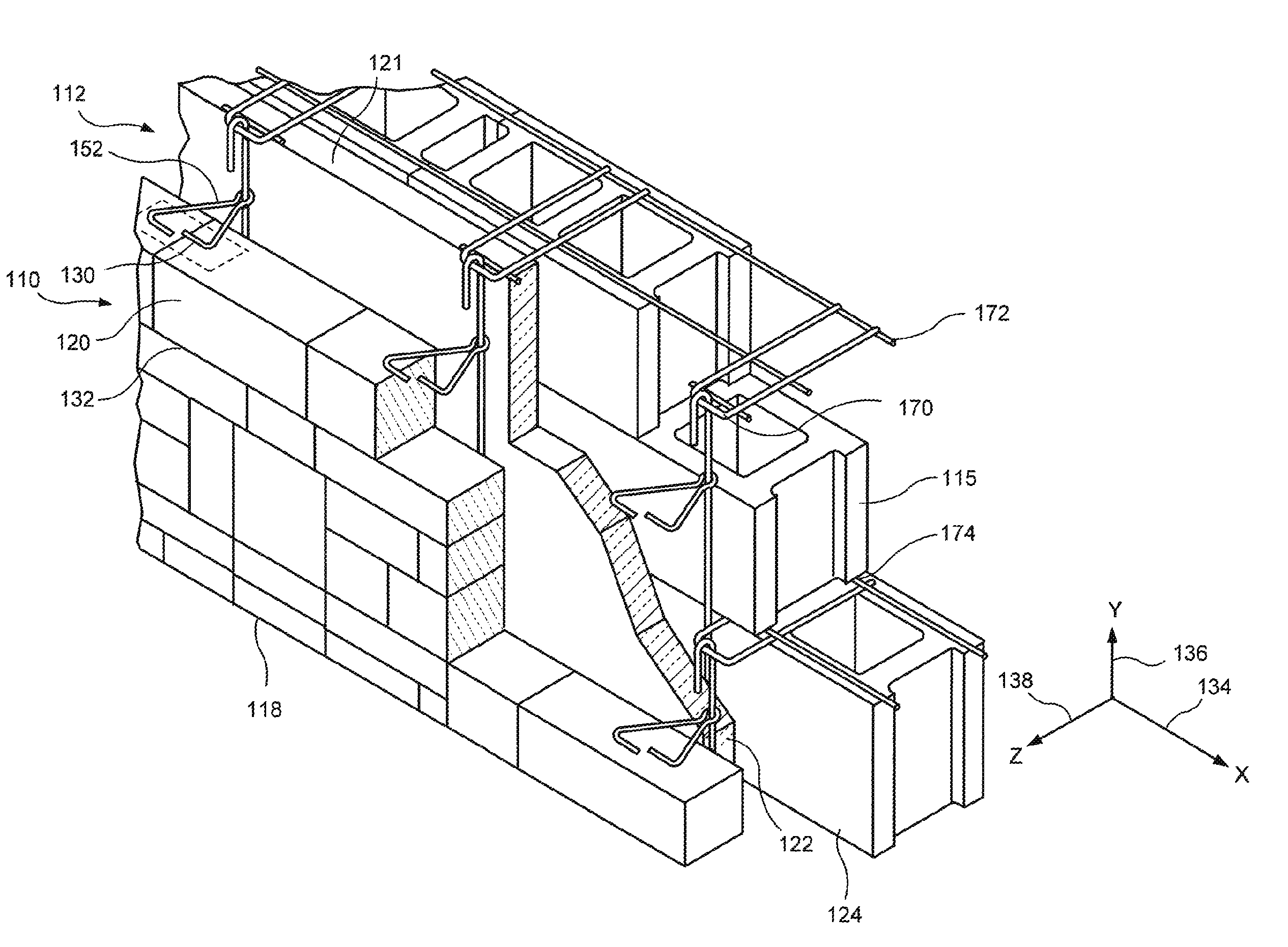

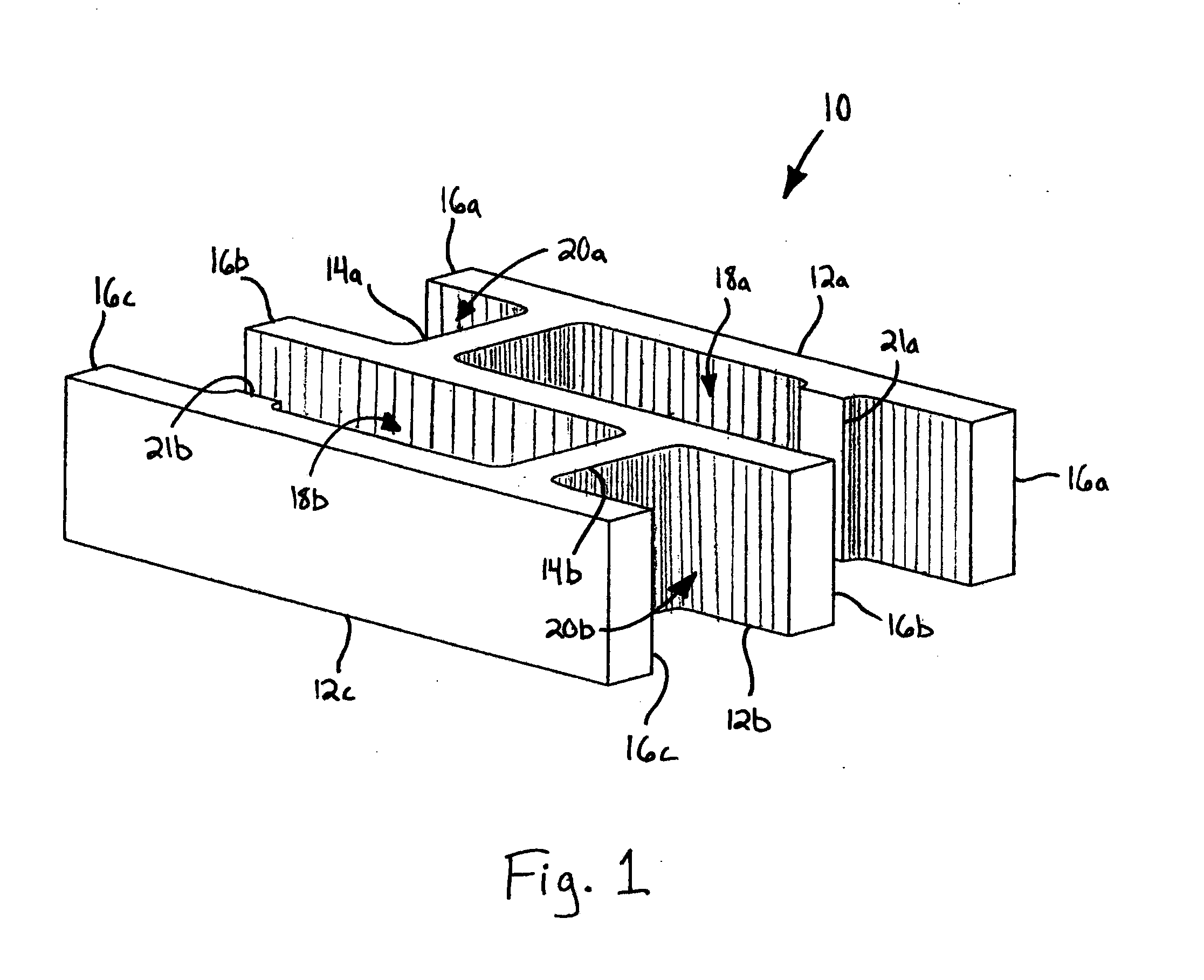

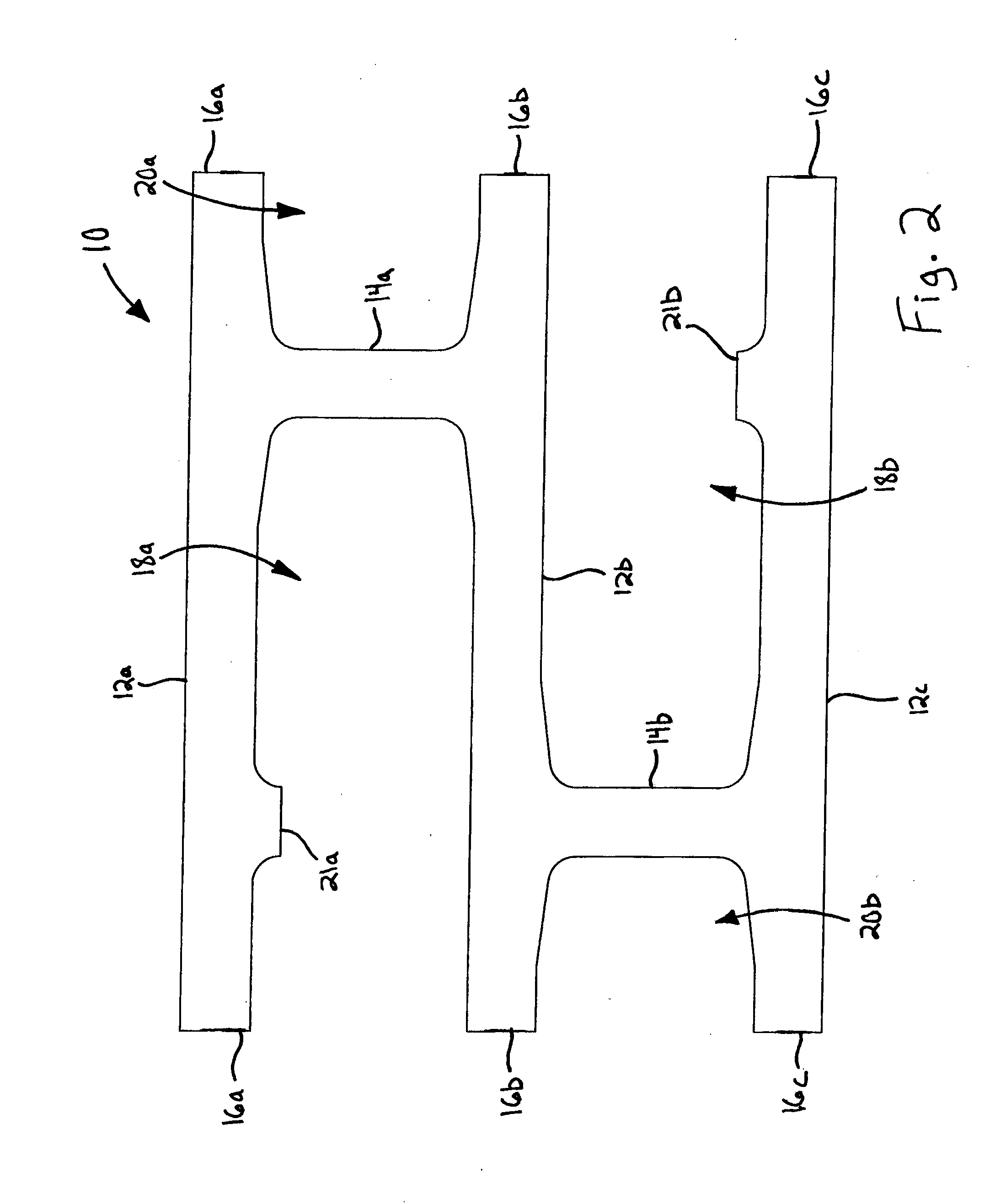

Masonry unit for constructing a multi-wythe wall

InactiveUS20110258957A1Improve carrying capacityEasily interfaceConstruction materialStrutsStructural engineeringEngineering

A masonry unit for constructing a wall is disclosed. The masonry unit includes at least three substantially vertical parallel partitions. Each of the partitions connects to an adjacent partition by a web thereby defining a pair of oppositely-facing open-ended recesses on either side of the web. Each of the webs connecting the partitions is offset from any adjacent webs in the masonry unit. A plurality of separated continuous vertical cavities extending through multiple layers of stacked masonry units are formed within the wall when positioning the multiple layers of stacked masonry units on top of each other in a horizontally offset and vertically inverted manner.

Owner:VIRNICH ANDREW P

Low profile pullout resistant pintle and anchoring system utilizing the same

ActiveUS8739485B2Firmly connectedRestrict movementConstruction materialFloorsEngineeringHigh intensity

A high-strength low profile pullout resistant pintle and anchoring system employing the same is disclosed. The modified veneer tie utilizes ribbon pintles formed from a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant veneer tie movement and to preclude pullout. The insertion portion of the veneer tie is compressed and patterned to ensure a secure hold within the bed joint.

Owner:HOHMANN & BARNARD INC

Vertically adjustable disengagement prevention veneer tie and anchoring system utilizing the same

ActiveUS8904726B1Limited vertical alignment capabilityIncrease veneer tie strengthConstruction materialBuilding reinforcementsEngineeringHigh intensity

A high-strength disengagement prevention pintle veneer tie and anchoring system employing the same is disclosed. The high-strength veneer tie utilizes modified compressed wire formatives formed from a wire formative construct that is cold-worked, with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The veneer tie hereof, when part of the anchoring system, interengages with wall anchor and is dimensioned to preclude veneer tie movement and pullout through the use of the U-shaped securement portions. The veneer tie is installed within the wall anchor through a swinging motion, in either an over and through or under and through the anchor installation, fully securing the veneer tie within the anchor and providing flexibility during installation.

Owner:HOHMANN & BARNARD INC

High-strength partially compressed low profile veneer tie and anchoring system utilizing the same

ActiveUS8839581B2High strengthConstruction materialBuilding reinforcementsHigh intensityUltimate tensile strength

A high-strength low profile partially compressed pintle veneer tie and anchoring system employing the same is disclosed. The high-strength pintle anchoring system employs a partially compressively reduced veneer tie that is cold-worked with the resultant body partially having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The partially compressively reduced veneer tie, when part of the anchoring system, interengages with the receptor portions of a wall anchor and is dimensioned to preclude significant veneer tie movement. The insertion portion of the veneer tie is compressed and patterned to ensure a secure hold within the bed joint.

Owner:HOHMANN & BARNARD INC

Pullout resistant pintle and anchoring system utilizing the same

InactiveUS8898980B2Easy to installHigh to forceConstruction materialBuilding reinforcementsEngineeringWire rod

A high-strength pullout resistant pintle and anchoring system employing the same is disclosed. The modified veneer tie utilizes ribbon pintles formed from a wire formative construct that is cold-worked with the resultant body having substantially semicircular edges and flat surfaces therebetween. The edges are aligned to receive compressive forces transmitted from the outer wythe. The ribbon pintles hereof, when part of the anchoring system, interengage with receptor portions of a wall anchor and are dimensioned to preclude significant lateral, vertical and horizontal movement.

Owner:HOHMANN & BARNARD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com