Masonry unit for constructing a multi-wythe wall

a multi-wythe wall and masonry technology, applied in the field of masonry materials, can solve the problems of difficult to meet requirements, physical and economic, and difficulty in constructing a multi-wythe wall, and achieve the effects of reducing the amount of lifting necessary, reducing the amount of reinforcement rod material, and easy interfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

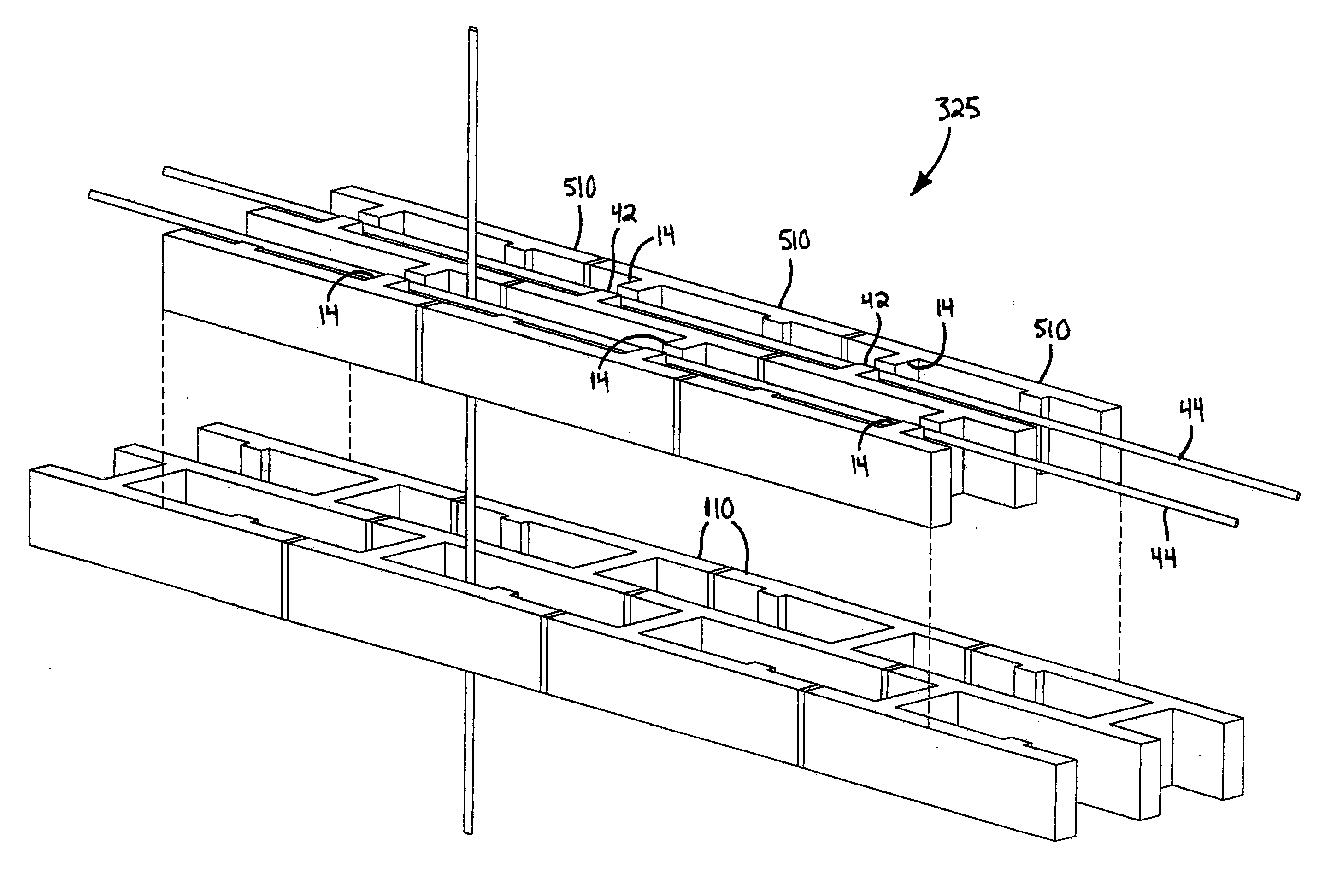

[0041]Referring generally to the figures, a masonry unit according to the present invention facilitates improved construction of a wall compared to previous masonry unit designs. Masonry units according to the present invention, when constructed to form a single wall, provide properties and advantages of a multi-wythe and / or a cavity-wall system. In the following paragraphs, the structure of masonry units according to the present invention are first described. Thereafter, walls made from masonry units according to the present invention are described in further detail.

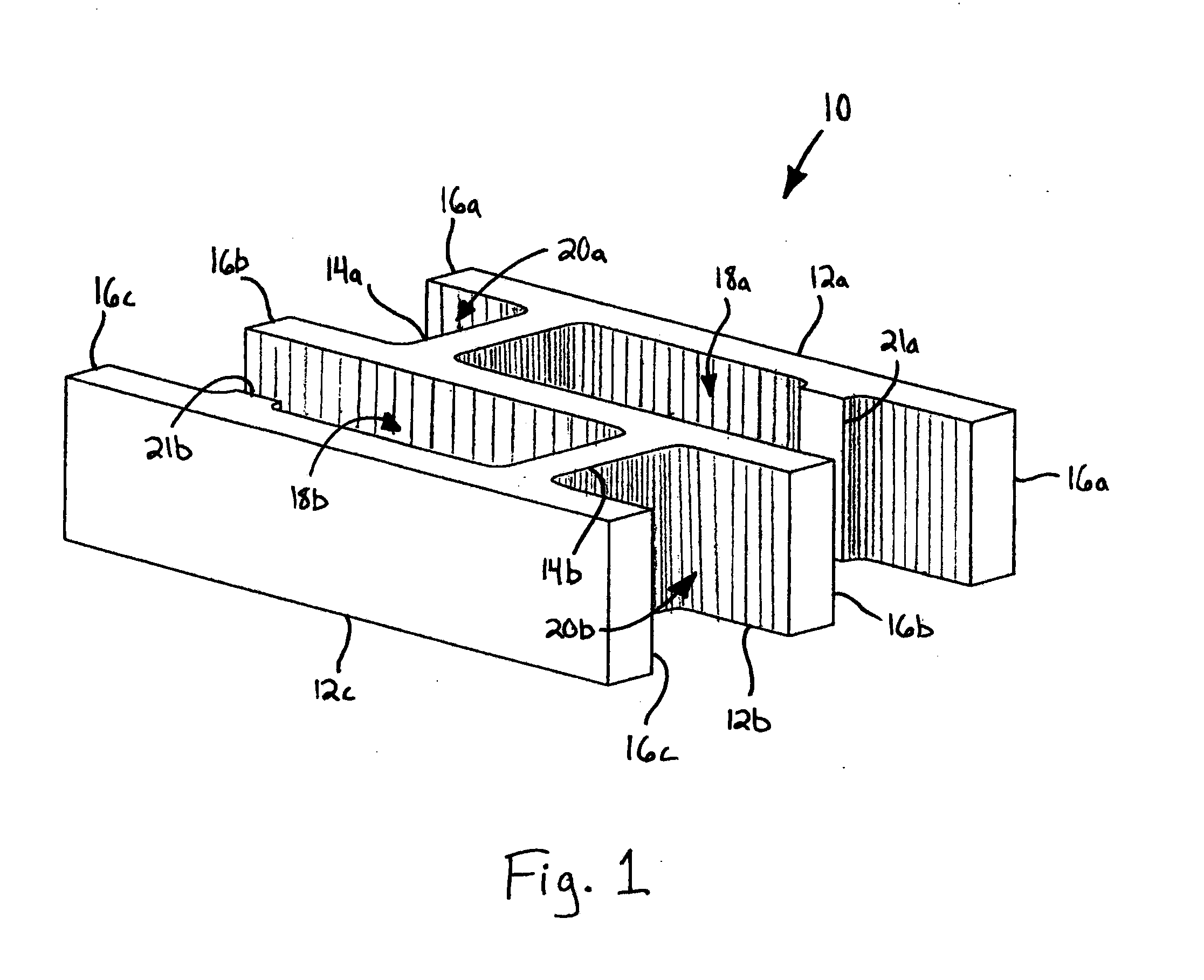

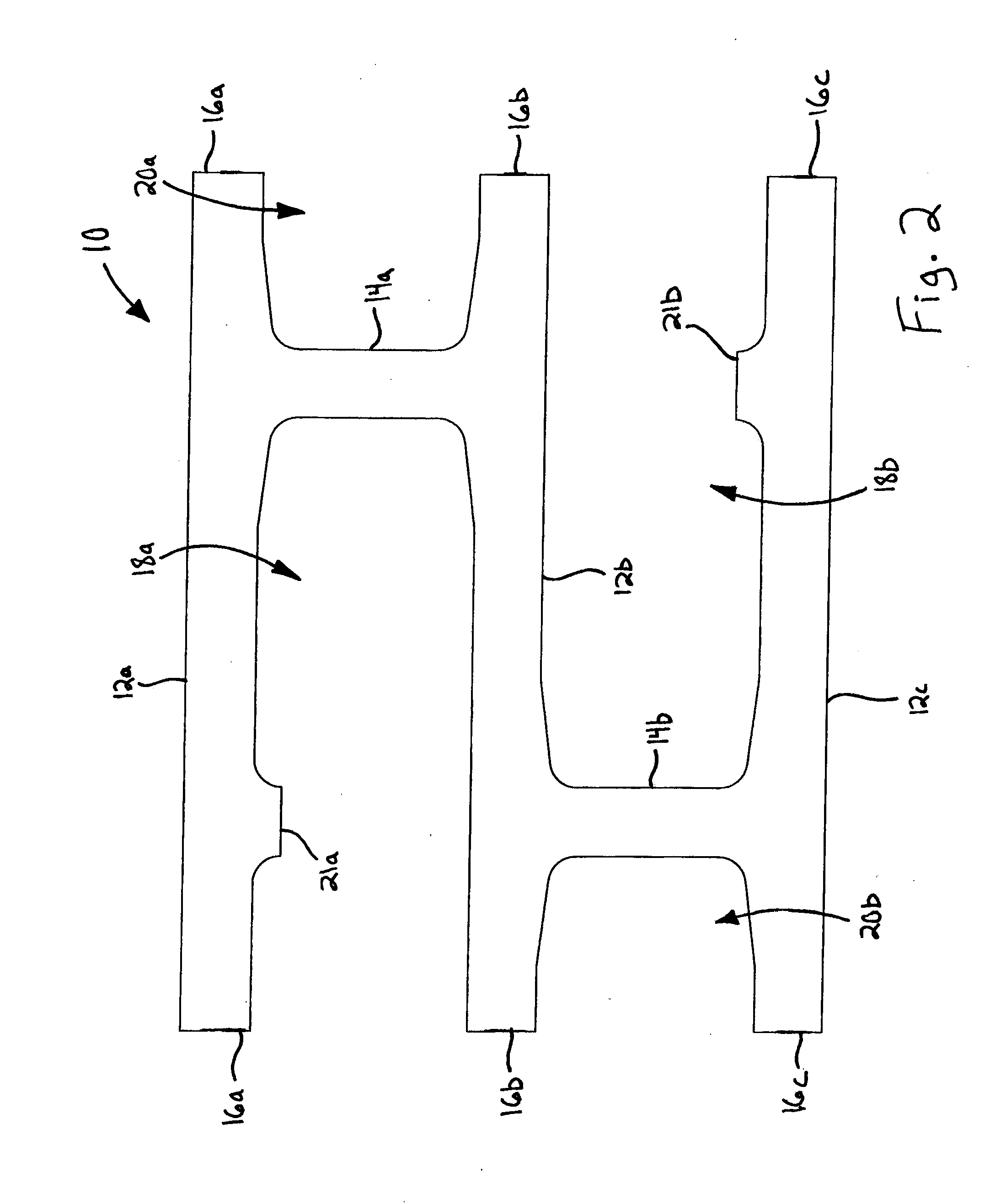

[0042]Referring first to FIG. 1, an exemplary masonry unit 10 is illustrated which is generally rectangular in overall form. The masonry unit 10 includes three generally parallel, vertically-extending partitions 12a, 12b, and 12c that span the length and height of the masonry unit 10. The first, second, and third partitions 12a, 12b, and 12c are spaced apart from each other in a width direction of the masonry unit 10 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com