Ribbed steel engraved mesh for cast-in-place cavity floor

A technology of cavity floor and steel mesh, which is applied to floors, structural elements, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings.

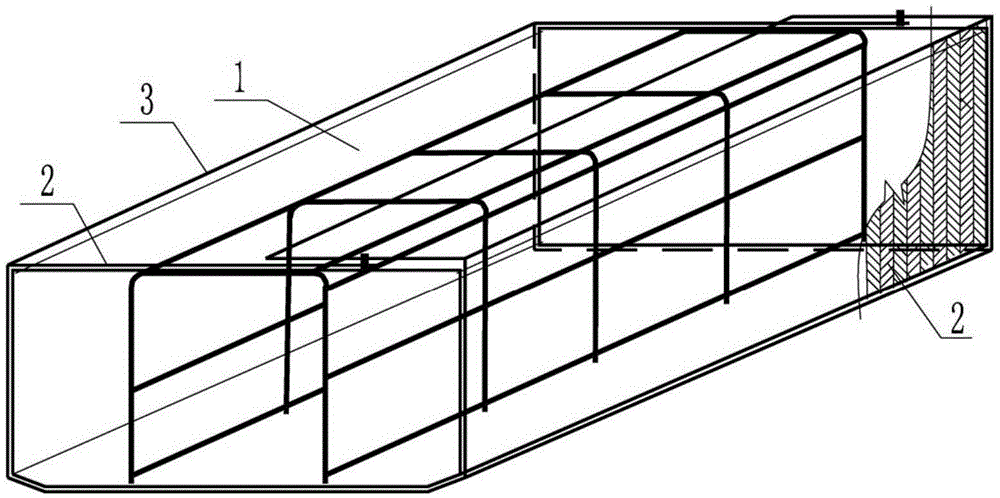

[0026] figure 1 It is the folded diagram of the ribbed stencil in the first embodiment of the present invention, such as figure 1 As shown, special mechanical equipment such as unwinding machine, punching machine system, expansion system, and shearing machine will be used to make expanded metal mesh body and press the mesh 2 with bending marks 3. The main body of the mesh 2 around the ribbed steel mesh hole 1 is bent one by one at the marks.

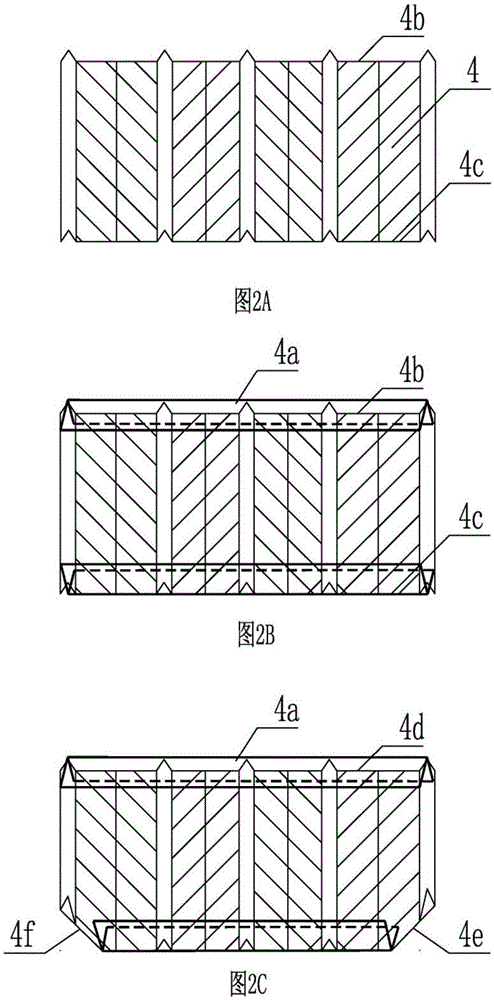

[0027] figure 2 It is the ribbed steel mesh openwork end mesh structure of the second embodiment of the present invention figure 2 A. figure 2 B, such as figure 2 As shown in A, the factory cuts the length of the required end mesh 4 steel mesh body according to the height of the ribbed steel mesh. Use special equipment to press the thin steel sheet 4a into a V shape, wrap the two ends of the end mesh 4, and then use a punching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com