Patents

Literature

216results about How to "Increased swelling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

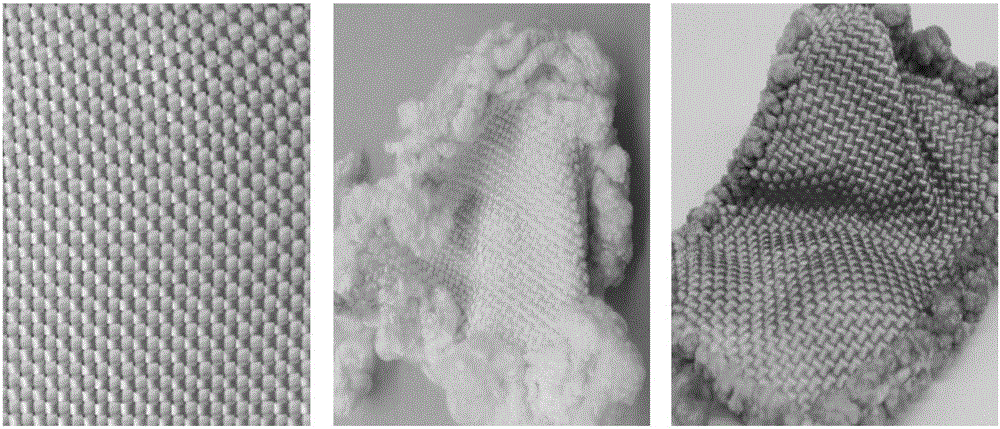

Oxidized graphene-modified super-hydrophilic super-oleophobic oil-water separation film and preparation method and application thereof

InactiveCN103623709AImproved swelling resistance and mechanical propertiesLow costSemi-permeable membranesFatty/oily/floating substances removal devicesCvd grapheneHydrophilic polymers

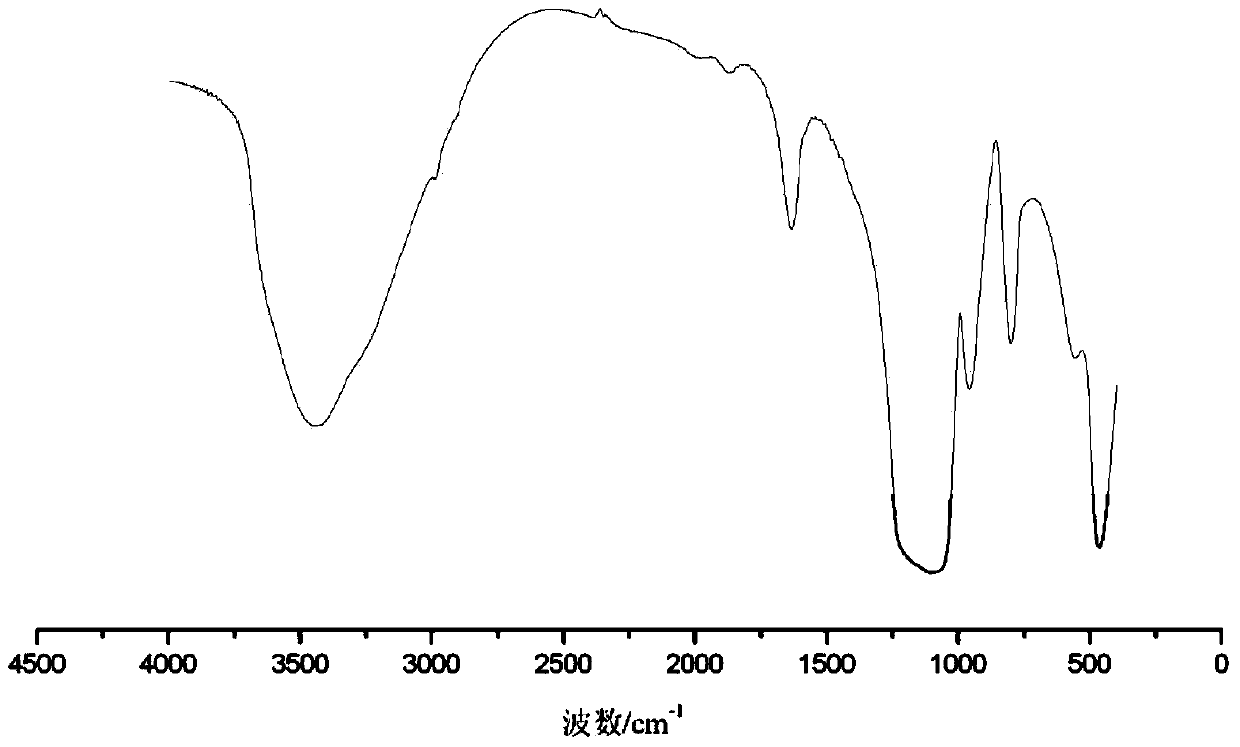

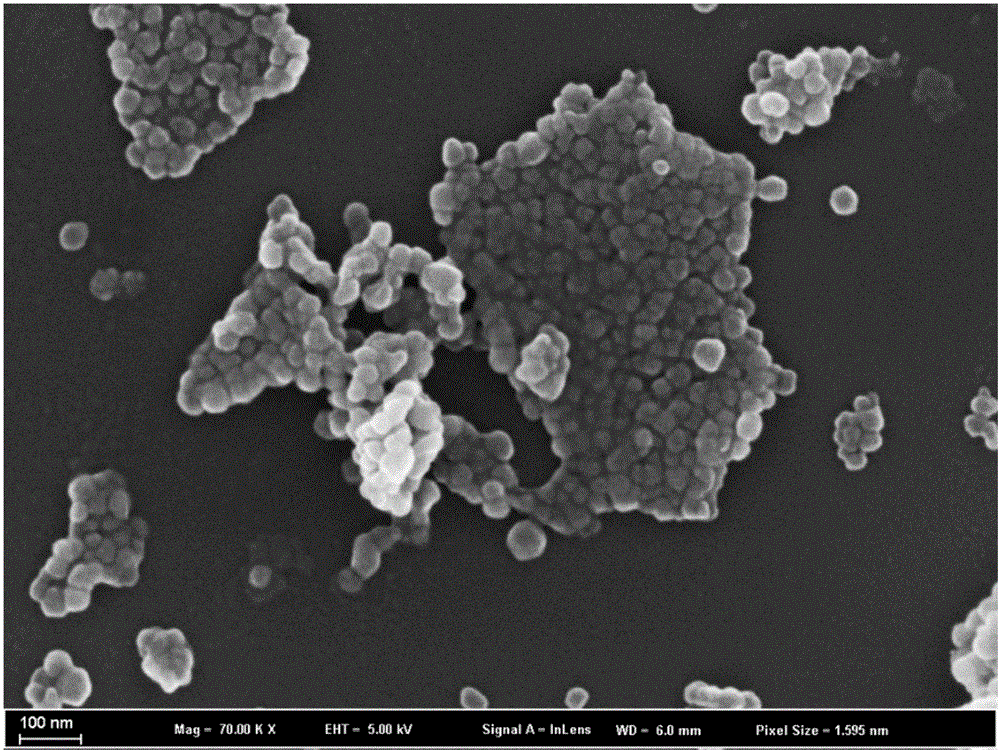

The invention discloses an oxidized graphene-modified super-hydrophilic super-oleophobic oil-water separation film and a preparation method and application thereof. The method comprises the following steps: mixing a hydrophilic polymer water-sensitive agent and a cross-linking film-forming agent according to a ratio of 1:9-9:1, dissolving the mixture and nano-silica sol in water according to a mass ratio of 1:9-9:1, magnetically stirring uniformly to prepare a 1-99% solution, adding 0.5-1 percent of oxidized graphen as an inorganic cross-linking agent, and ultrasonically and uniformly dispersing; ultrasonically cleaning a fabric silk screen with the particle size of 100-300 meshes, drying at normal temperature, forming a film on the silk screen in a spraying, dip-coating or spinning manner, drying and cross-linking, thus obtaining the hydrophilic and underwater super-oleophobic oil-water separation film. The oil-water separation film has excellent swelling resistance and mechanical property after graphene cross-linking modification, has a contact angle of 0 degree with both water and oil in air and has high super-hydrophilic property; the film has a contact angle of 150 degrees with oil drops under the water and has the low-adhesion characteristic to oil drops. The film can be applied to separation of oil-water mixtures and treatment of oil-containing sewage.

Owner:SOUTH CHINA UNIV OF TECH

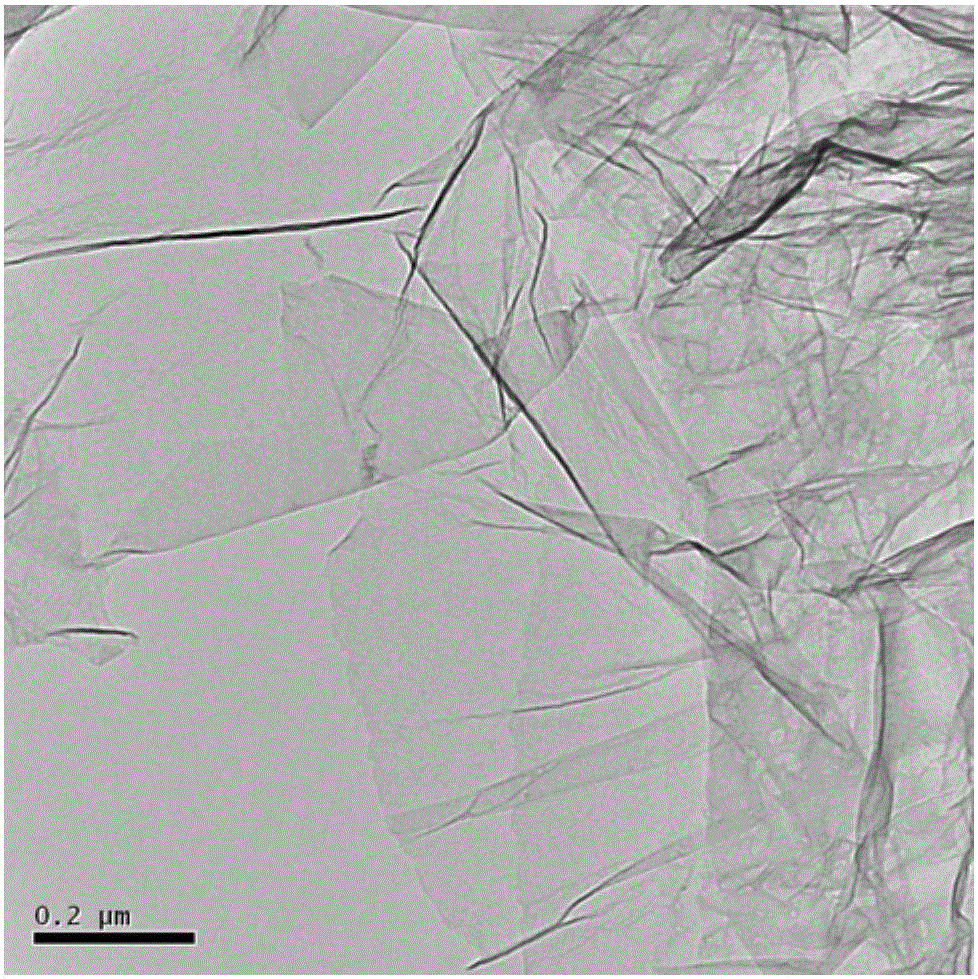

Preparation method for metal organic framework modified graphene oxide lamellar structure composite membrane used for organic solvent nanofiltration

ActiveCN106582317AImprove separation performanceImproved swelling resistance and stabilitySemi-permeable membranesNanofiltrationGraphite oxide

The invention provides a preparation method for a metal organic framework modified graphene oxide lamellar structure composite membrane used for organic solvent nanofiltration, and belongs to the field of membrane separation. The preparation method includes the steps that firstly, a metal organic framework and graphene oxide are composited to prepare composite nanometer particles; and the composite nanometer particles and a polymer are assembled on a base membrane to prepare the metal organic framework modified graphene oxide lamellar structure composite membrane used for the organic solvent nanofiltration. The composite membrane has a good separation effect for dyes in organic solvent and still has high flux under the low operation pressure, and therefore the composite membrane has application potential on the aspect of organic solvent nanofiltration.

Owner:BEIJING UNIV OF TECH

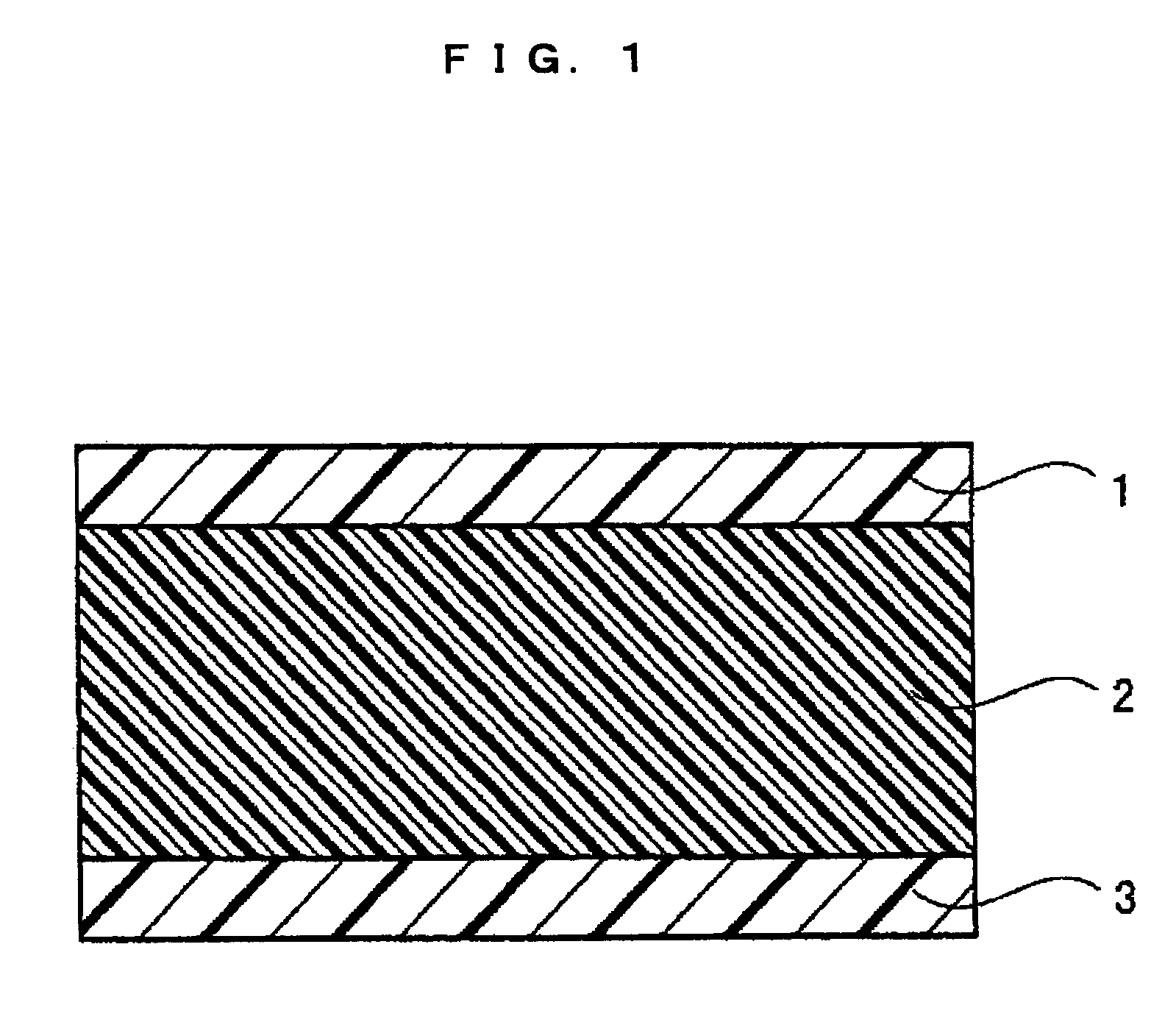

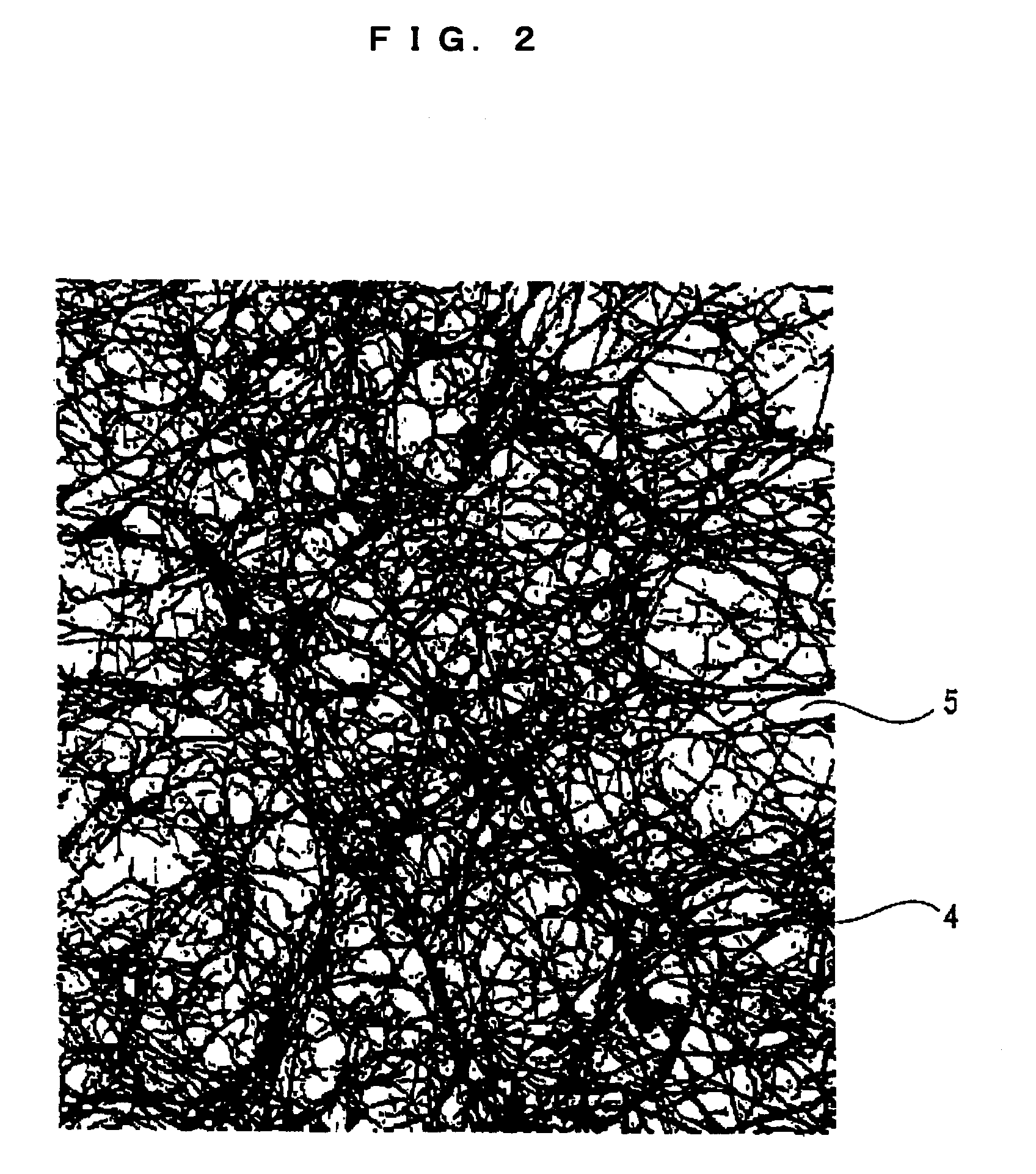

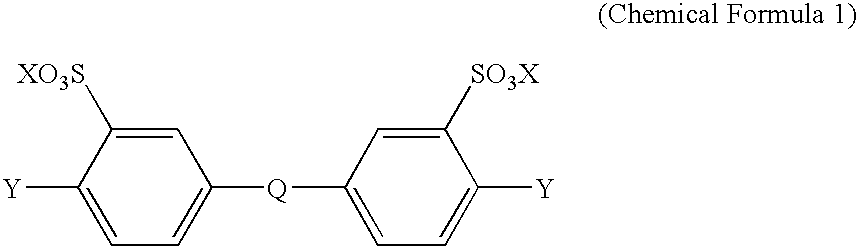

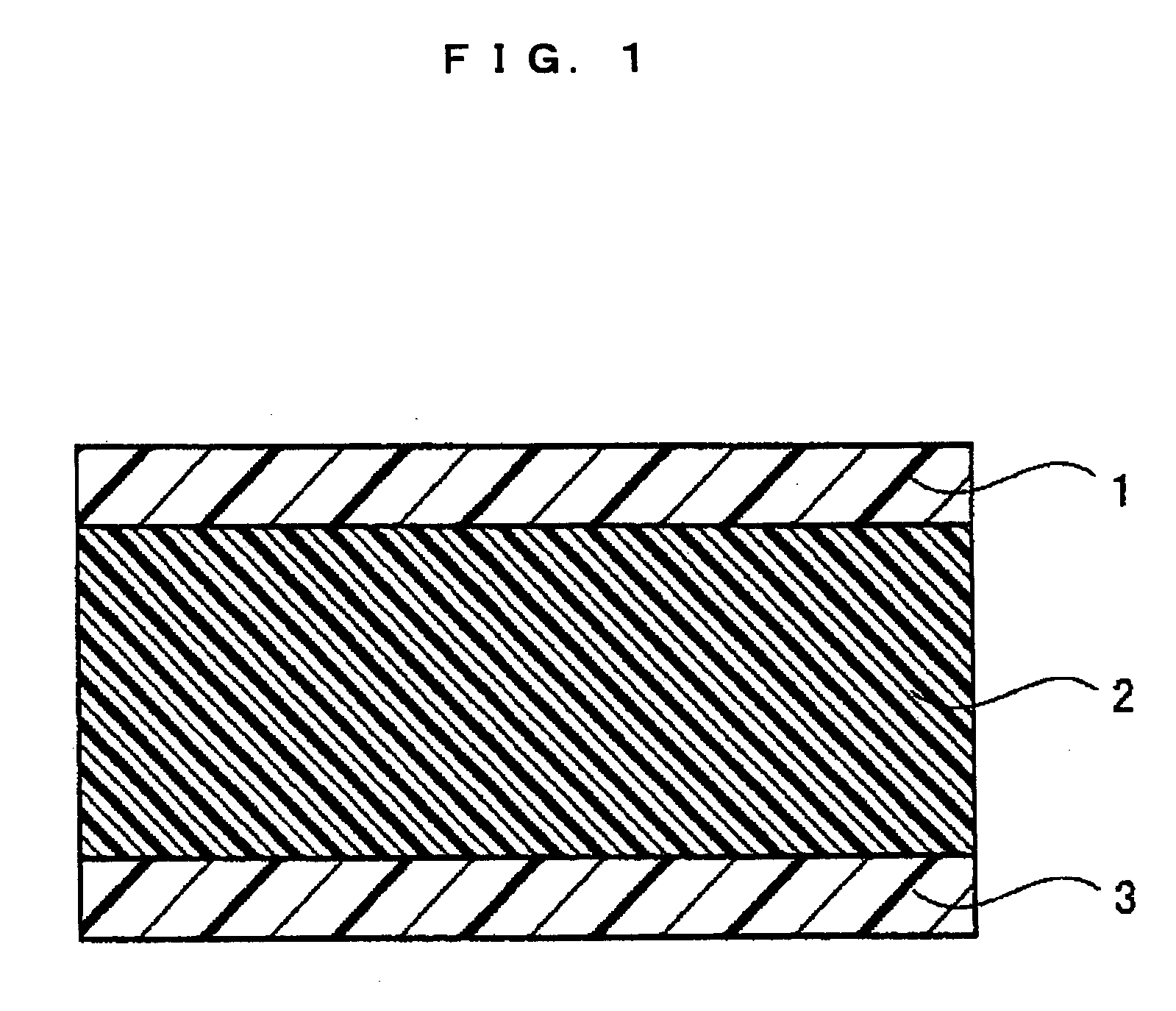

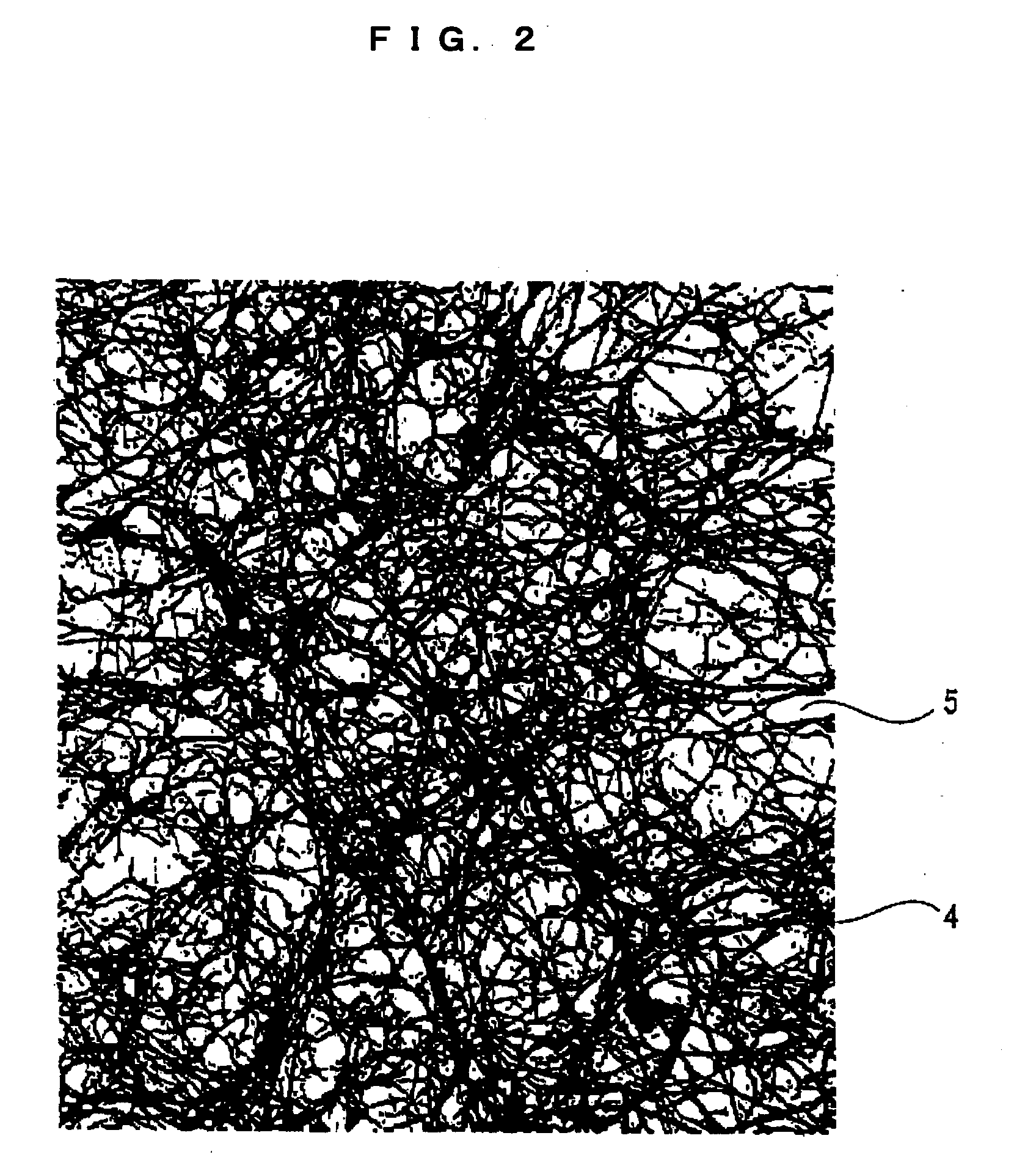

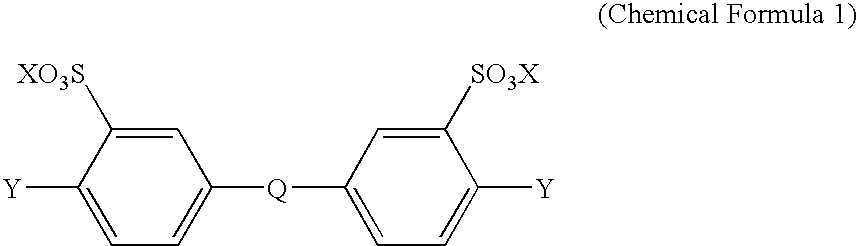

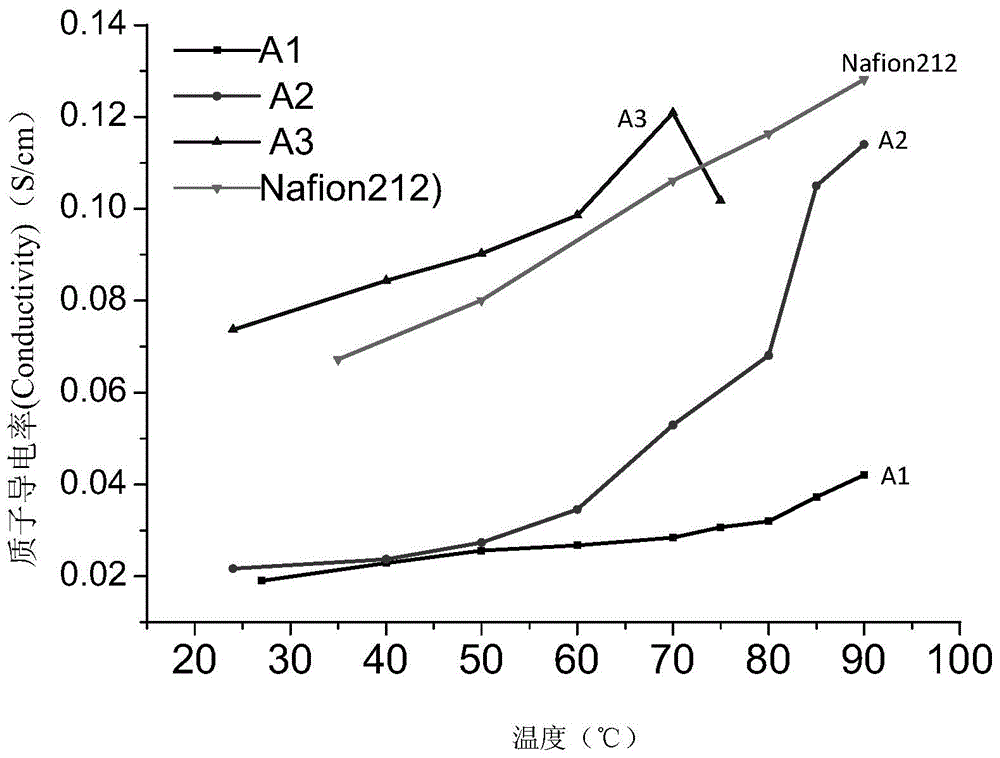

Composite ion-exchange membrane

InactiveUS7649025B2Increased swelling resistanceImprove conductivityElectrolyte holding meansSolid electrolytesOrganic solventIon-exchange membranes

A composite ion exchange membrane having a high swelling resistance and being superior in mechanical strength and ion conductivity can be provided by means of an composite ion exchange membrane including an ion exchange resin composition and a support membrane having a continuous pore penetrating the support membrane, wherein the support membrane is one which accepts the ion exchange resin composition within the pore, and wherein the ion exchange resin composition is one which contains an ion exchange resin containing, as a main component, an aromatic polyether and / or its derivative, the aromatic polyether being obtained by mixing a compound having a specific structure, an aromatic dihalogenated compound and a bisphenol compound with a carbonate and / or a bicarbonate of an alkali metal and polymerizing the mixture in an organic solvent.

Owner:TOYOBO CO LTD

Composite ion-exchange membrane

InactiveUS20060241192A1High swelling resistanceSuperior in mechanical strength and ion conductivityElectrolyte holding meansSolid electrolytesIon-exchange membranesDicarbonate

A composite ion exchange membrane having a high swelling resistance and being superior in mechanical strength and ion conductivity can be provided by means of an composite ion exchange membrane including an ion exchange resin composition and a support membrane having a continuous pore penetrating the support membrane, wherein the support membrane is one which accepts the ion exchange resin composition within the pore, and wherein the ion exchange resin composition is one which contains an ion exchange resin containing, as a main component, an aromatic polyether and / or its derivative, the aromatic polyether being obtained by mixing a compound having a specific structure, an aromatic dihalogenated compound and a bisphenol compound with a carbonate and / or a bicarbonate of an alkali metal and polymerizing the mixture in an organic solvent.

Owner:TOYO TOYOBO CO LTD

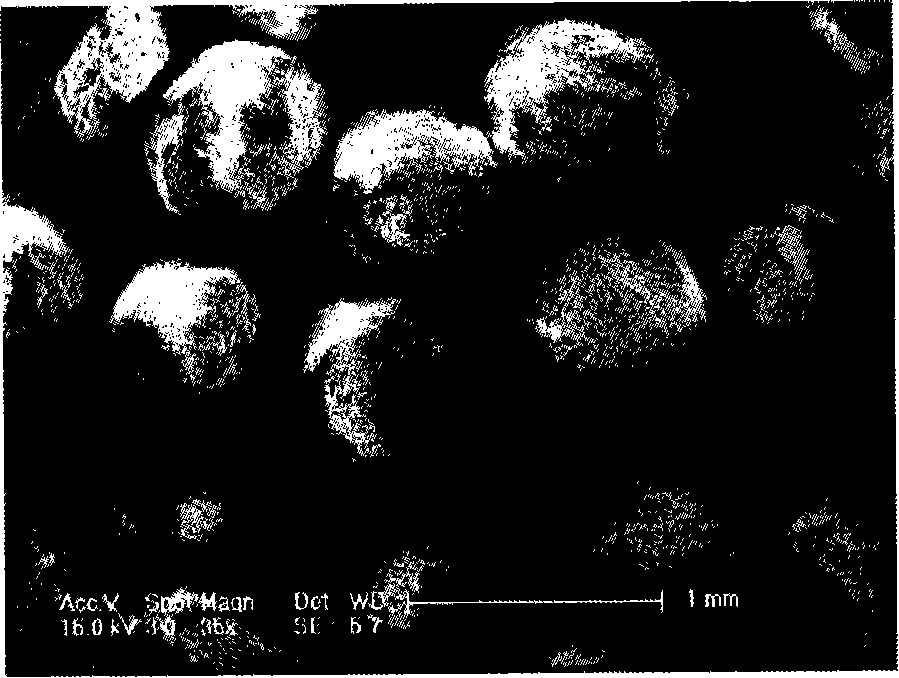

Cellulose microsphere as well as preparation method and use thereof

InactiveCN101250267ALarge specific surface areaGood biocompatibilityOther chemical processesOther blood circulation devicesCelluloseOrganic solvent

The invention discloses cellulose microsphere, and a preparation process and the application. The cellulose microsphere is prepared through dispersing cellulose solution in organic solvent which comprises emulsifier or composite emulsifier, solidifying in constant temperature for 1-10hr to shape after stirring to evenly disperse drops, then adding diluted acid to make cellulose regenerate into microsphere, standing and stratifying, filtering to obtain cellulose particles, finally obtaining cellulose microsphere after decantation. The solution of cellulose and the preparation of cellulose microsphere are physical processes without chemical reaction. The whole preparation technology is simple, has short time consumption, and organic solvent can be repeatedly used. The process has low device demand, which is convenient for industrial production. The cellulose microsphere which is prepared through adopting the process has favorable mechanical property, excellent flow-ability, heat stability and swelling resistance property, oxidation resistance ability, biodegrability resistance and acidic and alkali degradation capability, and has extensive usage.

Owner:WUHAN UNIV

Water repellent composition for improving wood product dimensional stability

InactiveUS20070037001A1Increased swelling resistanceImprove material stabilityWax coatingsOther chemical processesWaxWater repellent

Provided are compositions for improving the water-resistance and dimensional stability of wood and wood products. The compositions comprises wax and oil components, and can be applied as liquid compositions comprising little or no water. Also provided are methods for the application of the compositions to wood.

Owner:OSMOSE

Material formula of polyurethane of enzymolysis lignin, and preparation method

This invention provides a method for preparing cellulolytic enzyme lignin polyurethane and its raw materials. The raw materials comprise: cellulolytic enzyme lignin or its derivative, polyisocyanate, polyol oligomer, chain extension and crosslinking agent, organic solvent and additive. The method comprises: (1) dissolving cellulolytic enzyme lignin or its derivative in the organic solvent, mixing with polyol or a mixture of polyol and organic solvent, and heating or stirring to mix uniformly; (2) adding polyisocyanate, heating, adding conventional additives or fillers, heating to react completely, and vacuum-distilling to obtain brown solid; (3) washing the solid with water, and drying to obtain cellulolytic enzyme lignin polyurethane. The cellulolytic enzyme lignin is a natural polymeric material extracted from wood, bamboo and straw, thus can effectively utilize biomass resources and replace petrochemical raw materials. The method largely improves the process for preparing cellulolytic enzyme lignin polyurethane, which has a better modification effect than traditional sulfonated lignin, and lower cost than high-boiling-point alcohol lignin.

Owner:FUZHOU UNIVERSITY

Cellulose micro-sphere with uniform size as well as preparation method and application thereof

InactiveCN103756016ASuitable for large scale preparationEasy to operateOther chemical processesPharmaceutical non-active ingredientsCelluloseSorbent

The invention discloses a cellulose micro-sphere with a uniform size as well as a preparation method and an application thereof. According to the cellulose micro-sphere, the diameter distribution coefficient is less than 10% and the grain diameter ranges from 500 nanometers to 150 microns; the cellulose micro-sphere is prepared by the following manner: cellulose is dissolved into an alkali / urea water solution or an alkali / thiourea water solution at temperature from -12 DEG C to -5 DEG C; centrifuging and de-foaming, and removing impurities to obtain a cellulose solution which is used as a water phase; dissolving an oil-soluble emulsifying agent into oily liquid according to a volume ratio of 0-10% to obtain an oil phase; pressing the water phase into the oil phase by a hydrophobic porous membrane to obtain W / O emulsion; under an agitating condition, adding a curing solution into the W / O emulsion, and separating and washing to obtain the cellulose micro-sphere. The preparation method is convenient to operate, low in cost and good in repeatability and is suitable for large-scale preparation of the cellulose micro-spheres; the prepared cellulose micro-spheres are uniformly dispersed, have uniform size and are not easy to agglomerate; the cellulose micro-spheres can be used as medicines, macromolecular carriers, adsorbents and chromatographic column fillers.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

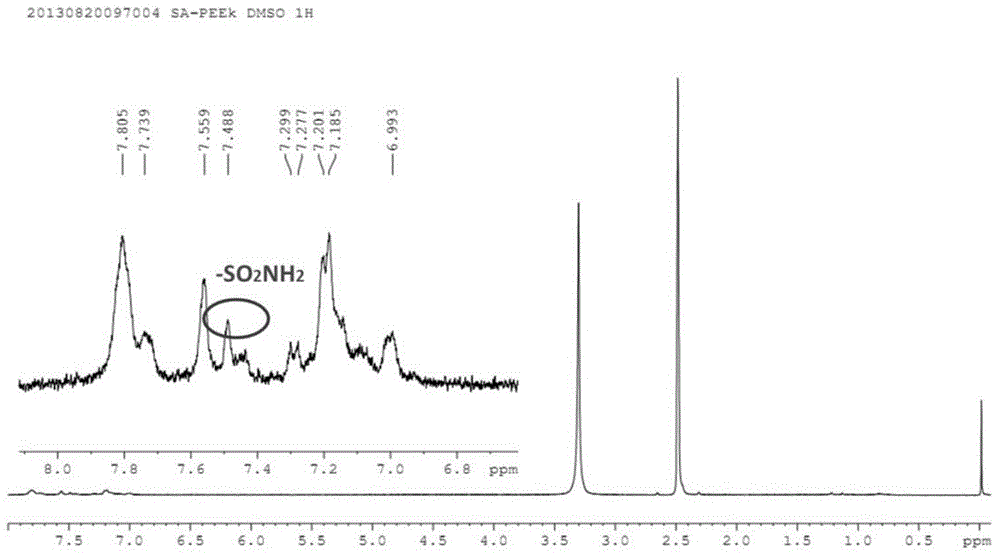

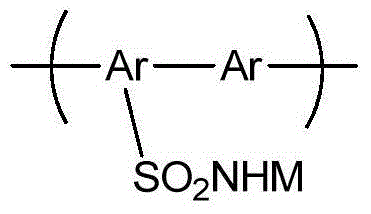

Aromatic polymer sulfonamide, and preparation method and application thereof

ActiveCN105085847AHigh mechanical strengthImprove barrier propertiesCell component detailsFuel cell detailsCross-linkSulfonyl chloride

The invention provides an aromatic polymer sulfonamide. The above polymer adopts an aromatic polymer as a main chain, and the side chain of the polymer contains a sulfonamide group. The sulfonamide group is hydrophobic, can dissociate at a high temperature to provide protons, and cross-links with an acyl chloride group, a sulfonyl chloride group and a phosphoryl chloride group, so the aromatic polymer sulfonamide has the advantages of good barrier, good conductivity and good mechanical strength as a film material, and has good application prospects in fields of fuel batteries, flow batteries, electrodialysis and solid acid catalysts.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

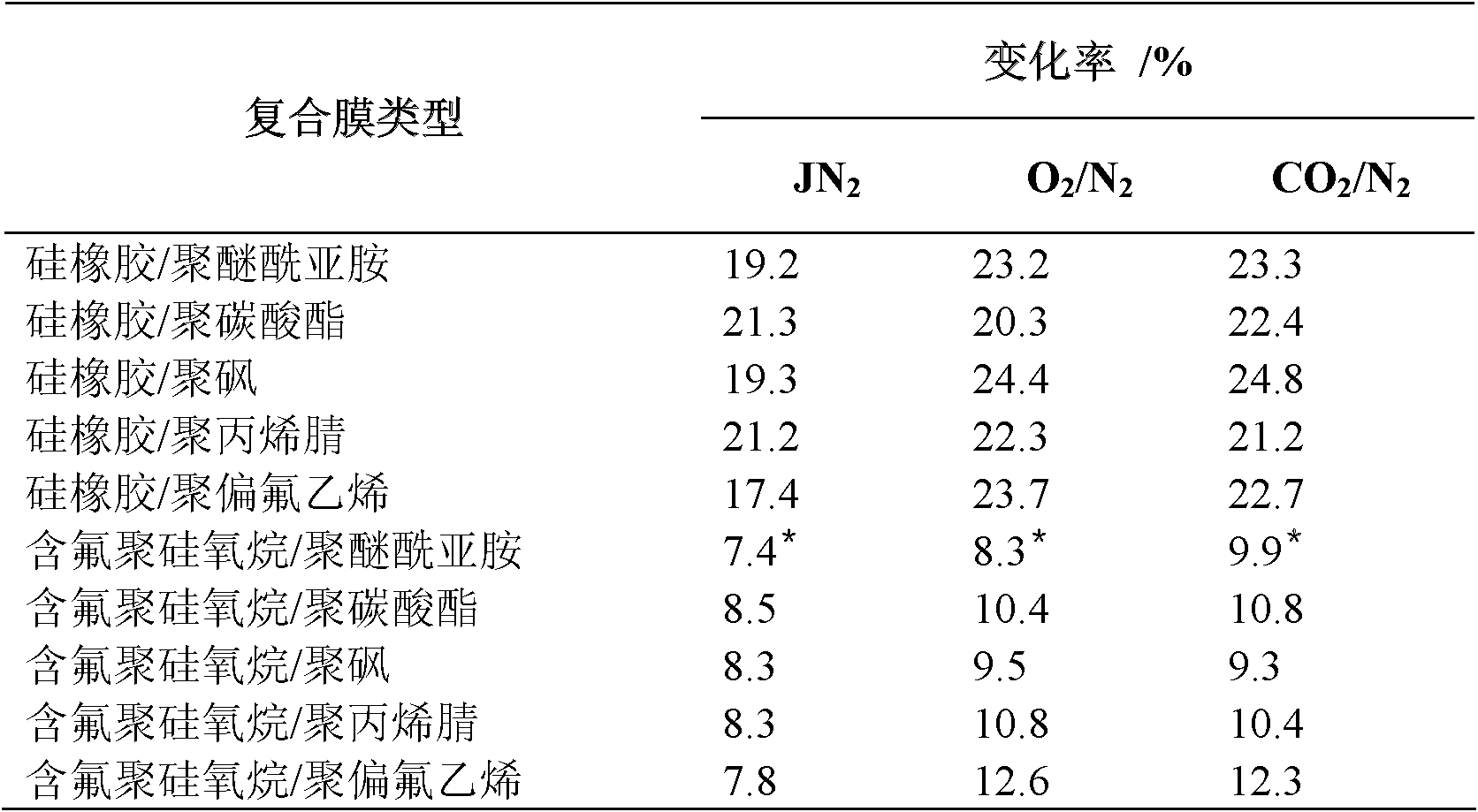

Fluorine-containing polysiloxane rubber state composite gas separation membrane, preparation method and application thereof

ActiveCN102327747AMild preparation conditionsResistant to swellingSemi-permeable membranesDispersed particle separationCross-linkProduct gas

The invention discloses a fluorine-containing polysiloxane rubber state composite gas separation membrane, a preparation method and an application thereof. A porous polymer material is used as a support membrane, and a fluorine-containing polysiloxane material is coated on the surface of the support membrane. The preparation method of the fluorine-containing polysiloxane rubber state composite gas separation membrane comprises the following steps of: dissolving fluorine-containing polysiloxane into a solvent to prepare coating liquid; adding a cross-linking agent and a catalyst into the obtained solution; uniformly stirring, standing and de-foaming; coating the coating liquid on the porous support membrane; and heating, curing and cross-linking until the porous support membrane is dried to obtain the fluorine-containing polysiloxane rubber state composite gas separation membrane. The composite gas separation membrane provided by the invention can be applied to separations of oxygen gas from nitrogen gas, carbon dioxide from nitrogen gas, and organic vapors, and has the characteristics of swelling resistance, resistance to pressure, weather fastness, and the like.

Owner:DALIAN UNIV OF TECH

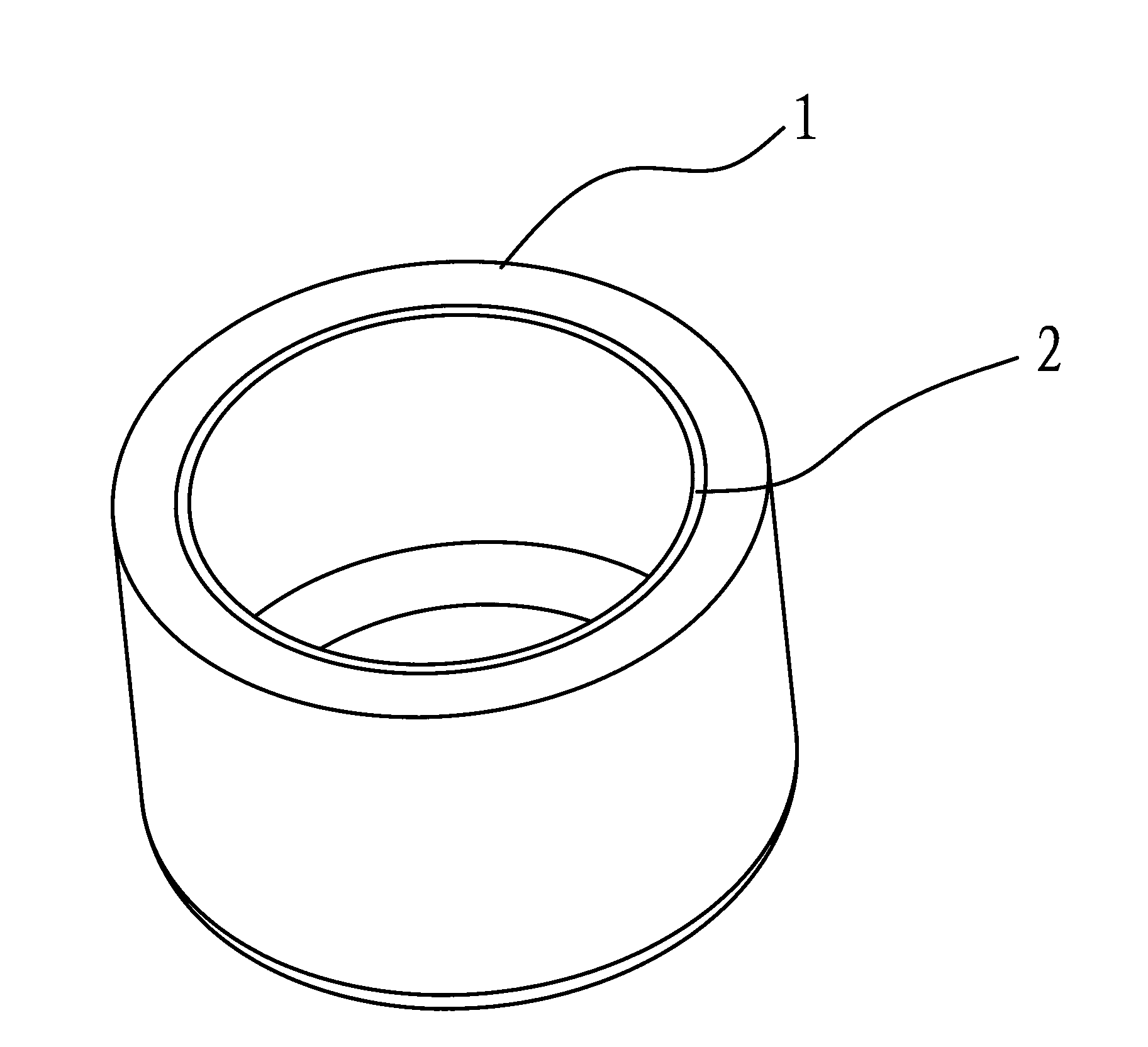

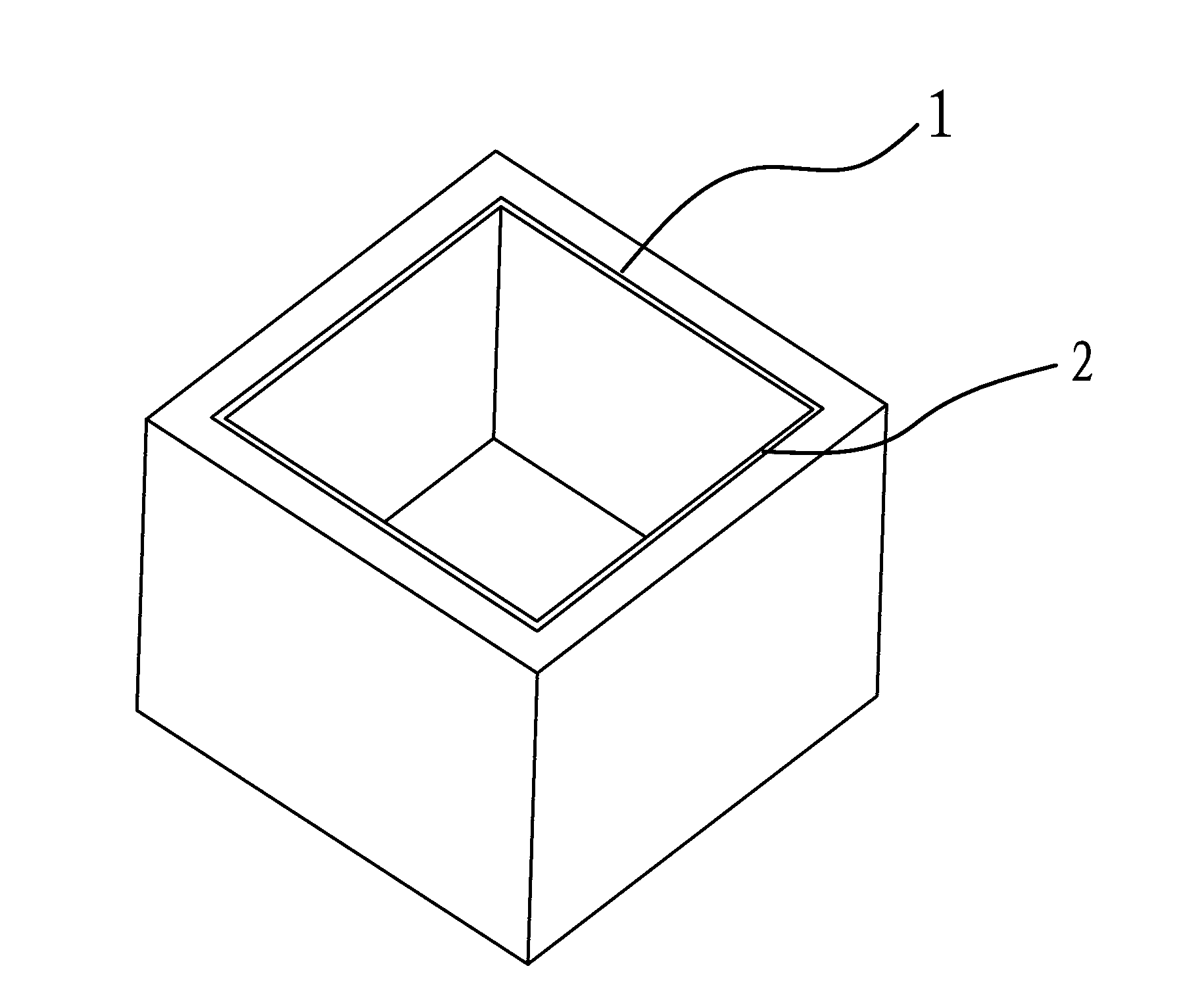

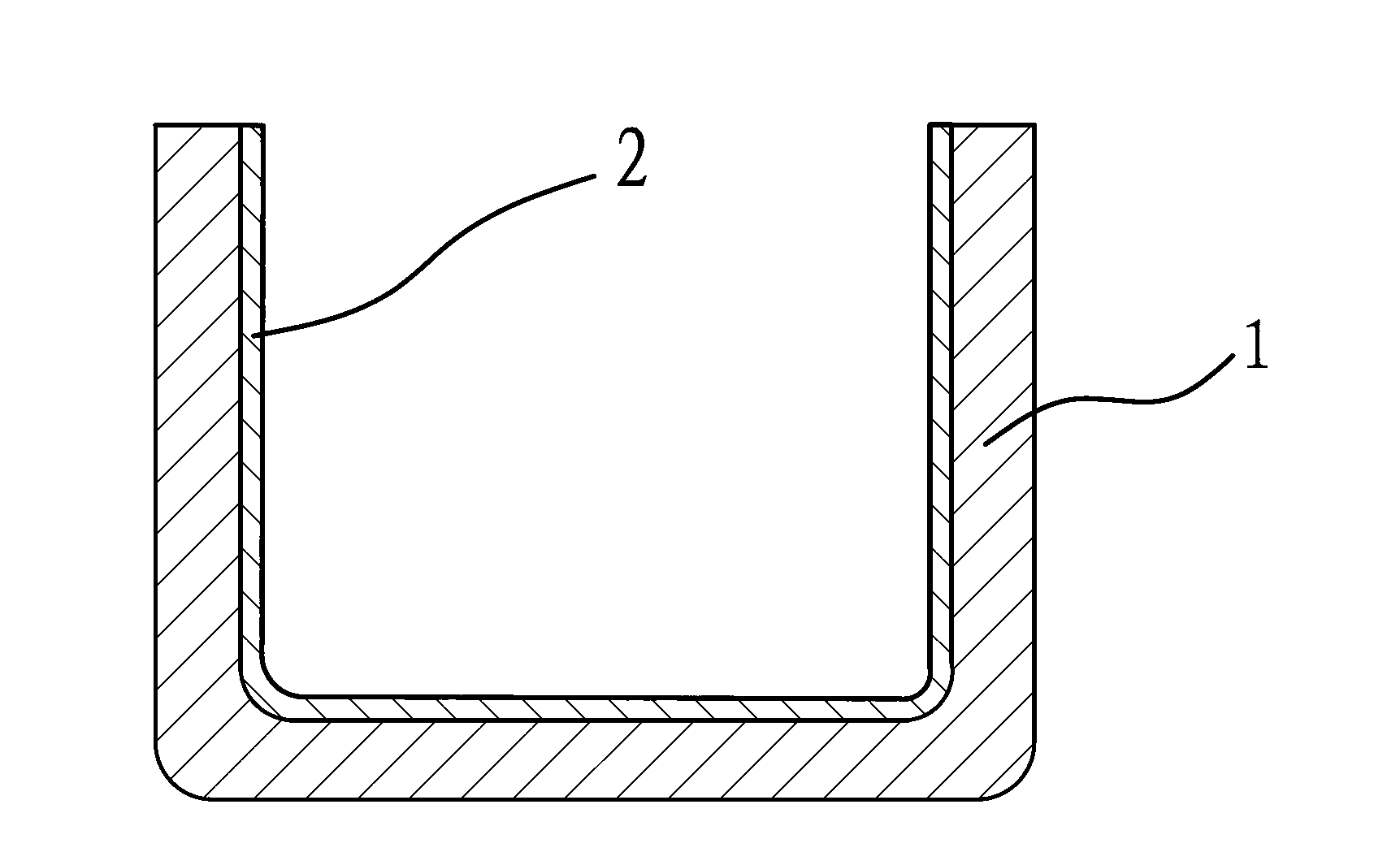

Crucible for melting crystalline silicon, method for producing crucible and spray coating liquid

InactiveCN102797042AIncreased swelling resistanceExtended service lifeAfter-treatment apparatusPolycrystalline material growthCrucibleSpray coating

The invention relates to a crucible for melting crystalline silicon, a method for producing the crucible and a spray coating liquid, belongs to the technical field of crucibles, is used for solving the problem that the coating of the existing crucible is easy to peel off and damage during the use process, so impurities cannot be well prevented from permeating, and aims to provide the spray coating liquid for a coating of a crucible for melting crystalline silicon. The spray coating liquid comprises silicon nitride, a sintering additive, and organic binder, inorganic binder and a sintering binder which can be bonded with a crucible body at normal temperature. The invention further provides the crucible which adopts the spray coating liquid. The crucible comprises a crucible body, the internal surface of the crucible body is coated with a coating, and the coating is formed by spraying the spray coating liquid. The invention also provides the method for producing the crucible, which produces the crucible for melting crystalline silicon through spray coating, drying, burning off and sintering. The crucible can be repeatedly used, the coating is not easy to peel off and damage, so the impurities, particularly oxygen element in the crucible body can be effectively prevented from permeating.

Owner:TAIZHOU BEYOND TECH

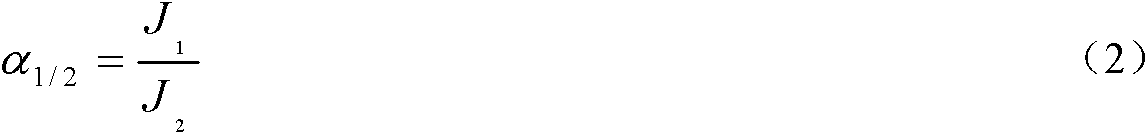

Preparation method of pervaporation film with preferential penetration of dimethyl carbonate

The invention relates to a preparation method of a pervaporation film with the preferential penetration of dimethyl carbonate. Film casting liquid containing vinyl polydimethylsiloxane (Vi-PDMS), hydrogen-containing polydimethylsiloxane (H-PDMS), hydrophobic nano SiO2, a catalyst and a solvent is adopted, a film is coated on an upper layer of a porous ultrafiltration film supported by a polyester non-woven fabric, is aired at room temperature and is also heated, and the cross linkage of the film is finished. An additive type polydimethylsiloxane compound film filled with the hydrophobic nano SiO2, which is obtained by the preparation method of the pervaporation film with the preferential penetration of the dimethyl carbonate, has a simple film preparation process, adopts the materials with low price, strong swelling resistance in dimethyl carbonate / methanol azeotropic liquid, and excellent performance of preferential penetration of the dimethyl carbonate. When the filling mass proportion of the hydrophobic nano SiO2 is 15 percent, the separation factor alpha of the pervaporation film is equal to 3.97, and the penetration flux J is equal to 0.707kg / m2h ([DMC]=30wt%, 40 DEG C).

Owner:TSINGHUA UNIV

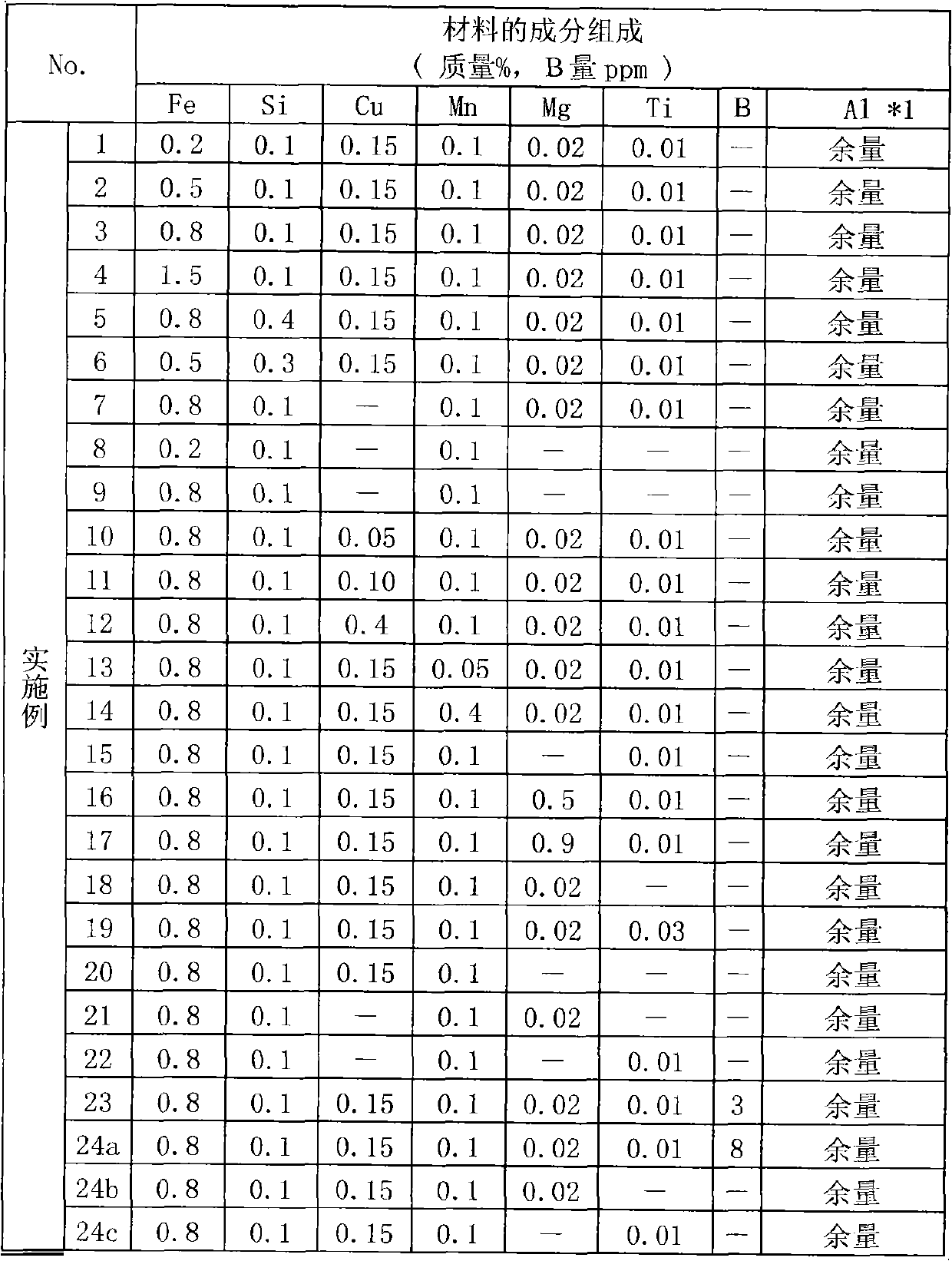

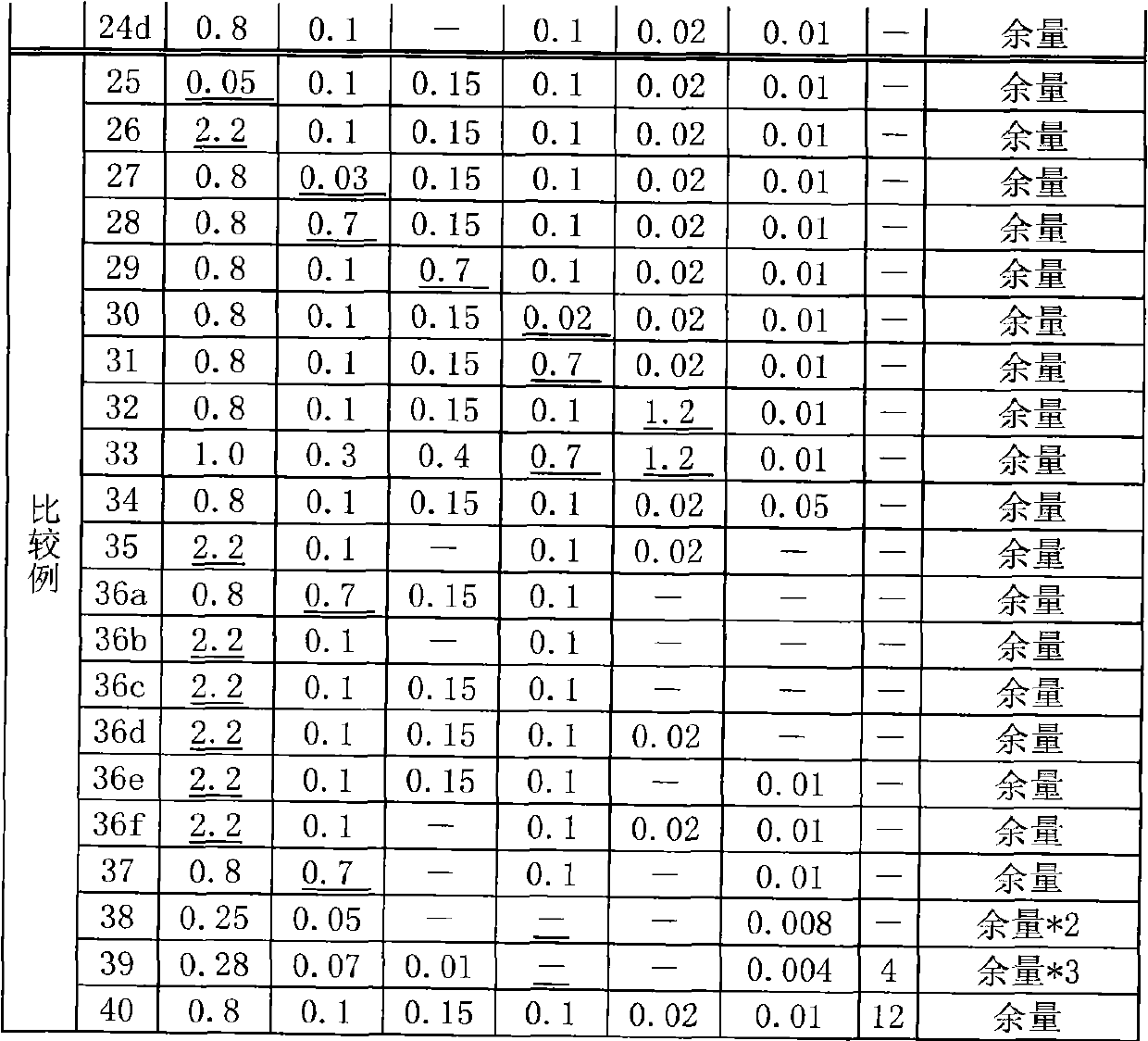

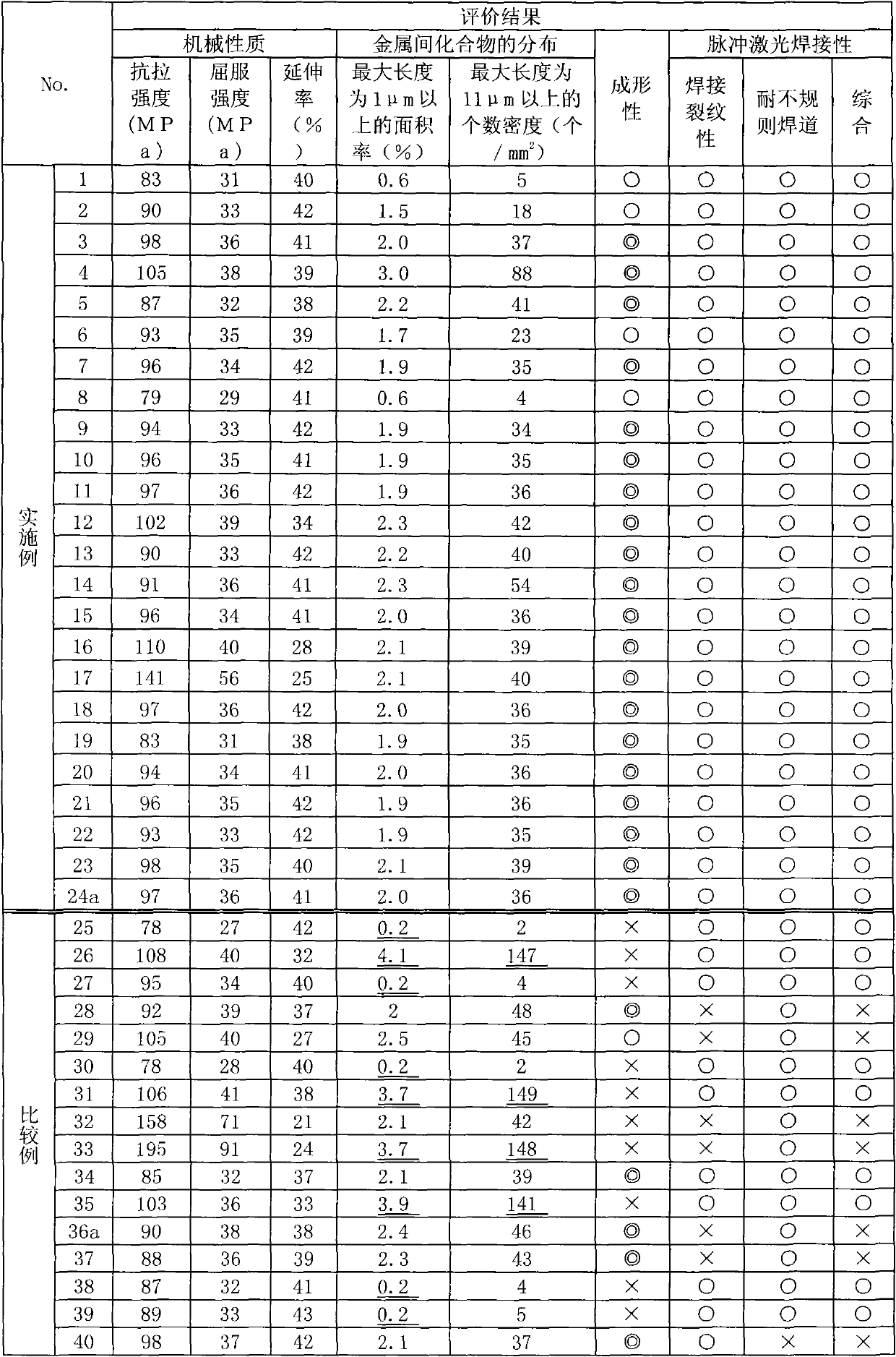

Aluminium alloy plate used for battery housing and battery housing

InactiveCN102628129AGood formabilityExcellent pulse laser weldabilityCell component detailsBatteriesForm processingAluminium alloy

The invention provides an aluminum alloy plate used for a battery housing used for deep-draw processing, and the battery housing using the aluminum alloy plate. The occurrence of hot adhesion in a forming processing process can be prevented. And the aluminum and the battery housing has excellent pulse weldability. The aluminum plate used for the battery shell contains, by mass, 0.1 percent to 2.0 percents of Fe, 0.05 percent to 0.5 percent of Si, 0.05 percent to 0.5 percent of Mn, less than 0.04 percent of Ti, less than 10 percents of B and rest of Al and inevitable impurities. In the central part in a thickness direction of the section of the aluminum alloy plate used for the battery housing, the area rate of intermetallic compound having a maximum length more than 1 micrometer is 0.3 to 3.5 percents, and the number of the intermetallic compound having maximum length more than 11 micrometers is less than 140 / mm2. The electric conductivity of the aluminum alloy plate used for the battery housing is lower than 62 IACS percent.

Owner:KOBE STEEL LTD

Nucleic acid aptamer functionalized POSS (polyhedral oligomeric silsesquioxane) crosslinking organic-silica gel hybridization monolithic column, and preparation method thereof

ActiveCN108107144AThe reaction system is uniform and stableFast preparationComponent separationSolid sorbent liquid separationDimethyl formamideChemistry

The invention discloses a nucleic acid aptamer functionalized POSS (polyhedral oligomeric silsesquioxane) crosslinking organic-silica gel hybridization monolithic column, and a preparation method thereof. The monolithic column is a compatible monolithic column formed in a way that highly-hydrophilic organic polymerized monomer, POSS, acrylic ester cross-linking agent, nucleic acid aptamer aqueoussolution and initiator are dissolved through ternary pore-forming agent to form homogeneous solution; the homogeneous solution is injected into the column to synchronously generate free radical thermal-initiation polymerization and 'sulfydryl-alkene' click chemistry reaction to be directly prepared; the ternary pore-forming agent is mixed solution formed by three ingredients of aqueous-N,N-dimethyl formamide-PEG (polyethylene glycol) 10000. The nucleic acid aptamer is bonded by covalent bonds through a one-step method, and the prepared compatible monolithic column has the advantages of stablestructure and simple and quick method and is suitable for the specific recognition separation of ochratoxin A.

Owner:FUZHOU UNIVERSITY

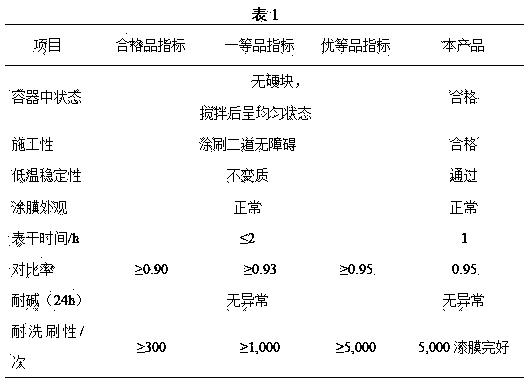

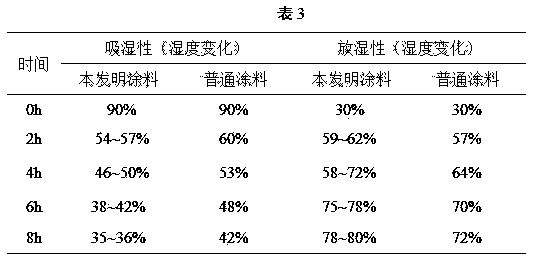

Biomass internal wall paint and preparation method thereof

ActiveCN104109444AGood film formingGood scrub resistanceStarch coatingsHazardous substanceSoftened water

The invention discloses a biomass internal wall paint and a preparation method thereof, and aims to solve the problems of high harmful substance content and especially high formaldehyde content in the existing internal wall paint. The preparation method comprises the following steps: taking softened water, dodecenyl starch aluminum succinate, dispersing agent, wetting agent, titanium white, calcined kaolin, highly-crosslinked porous starch, ground calcium carbonate and light calcium carbonate, adding into a dispersion machine, dispersing at the high speed of 1500 r / min for 20-40 minutes, lowering the speed to 500 r / min, sequentially adding the composite modified starch emulsion, propanediol and defoaming agent, and uniformly dispersing to obtain the composite modified starch-base biomass paint. The obtained biomass internal wall paint has the advantages of delicate paint film, scrub resistance, low VOC (volatile organic compound) content and no formaldehyde, has favorable humidity regulation function, and is green and environment-friendly.

Owner:GANSU GLDARK NEW MATERIAL

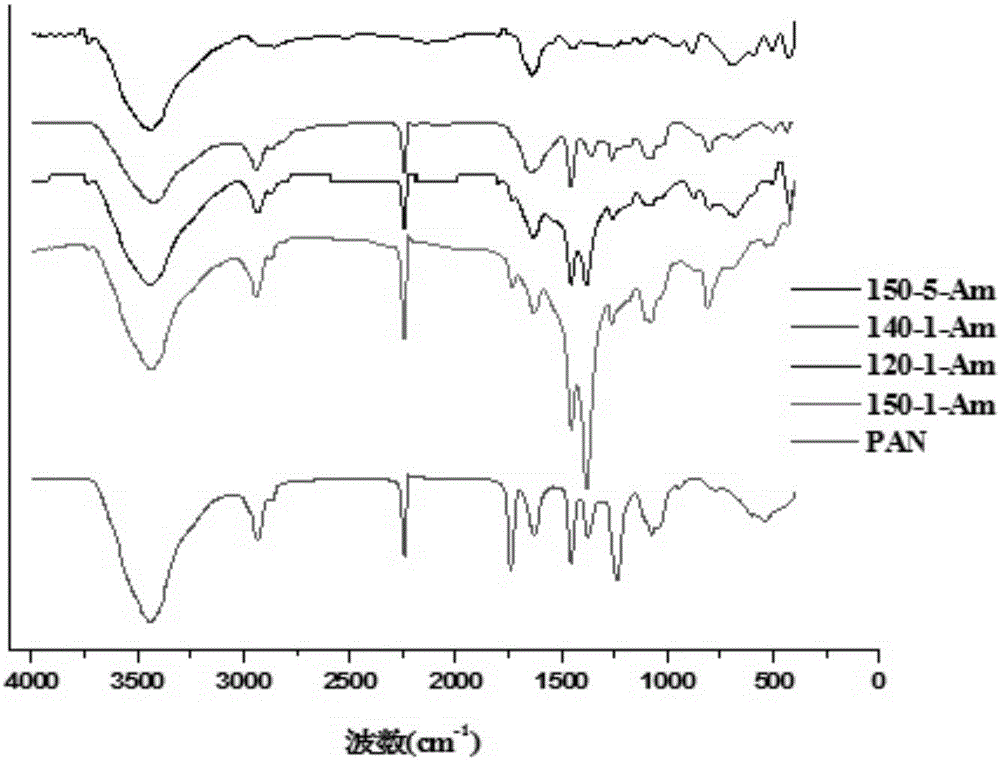

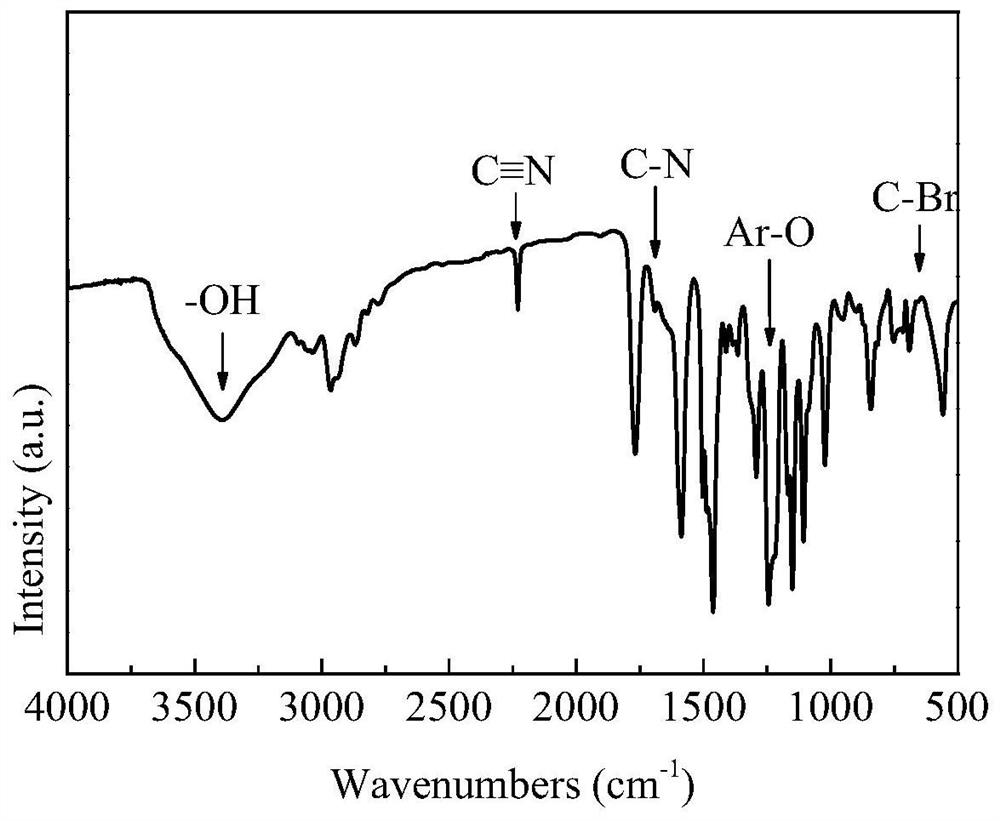

Cross-linked polyacrylonitrile-based amidoxime fiber, method for preparing same and application of cross-linked polyacrylonitrile-based amidoxime fiber

InactiveCN106824138AGood alkali resistanceImprove water resistanceOther chemical processesWater contaminantsCrystallographyCross-link

The invention provides a cross-linked polyacrylonitrile-based amidoxime fiber. A method for preparing the cross-linked polyacrylonitrile-based amidoxime fiber includes steps of (1), carrying out cross-linking on polyacrylonitrile fibers by the aid of triethylenetetramine to obtain cross-linked polyacrylonitrile fibers; (2), carrying out amidoximation on the cross-linked polyacrylonitrile fibers obtained at the previous step by the aid of hydroxylammonium chloride to obtain the cross-linked polyacrylonitrile-based amidoxime fiber. The cross-linked polyacrylonitrile-based amidoxime fiber and the method have the advantages that the problem that common amidoxime fibers cannot be directly applied to Bayer solution for extracting gallium can be effectively solved; the cross-linked polyacrylonitrile-based amidoxime fiber is high in mechanical strength and high in gallium adsorption capacity and selectivity and has a broad market prospect.

Owner:SICHUAN UNIV

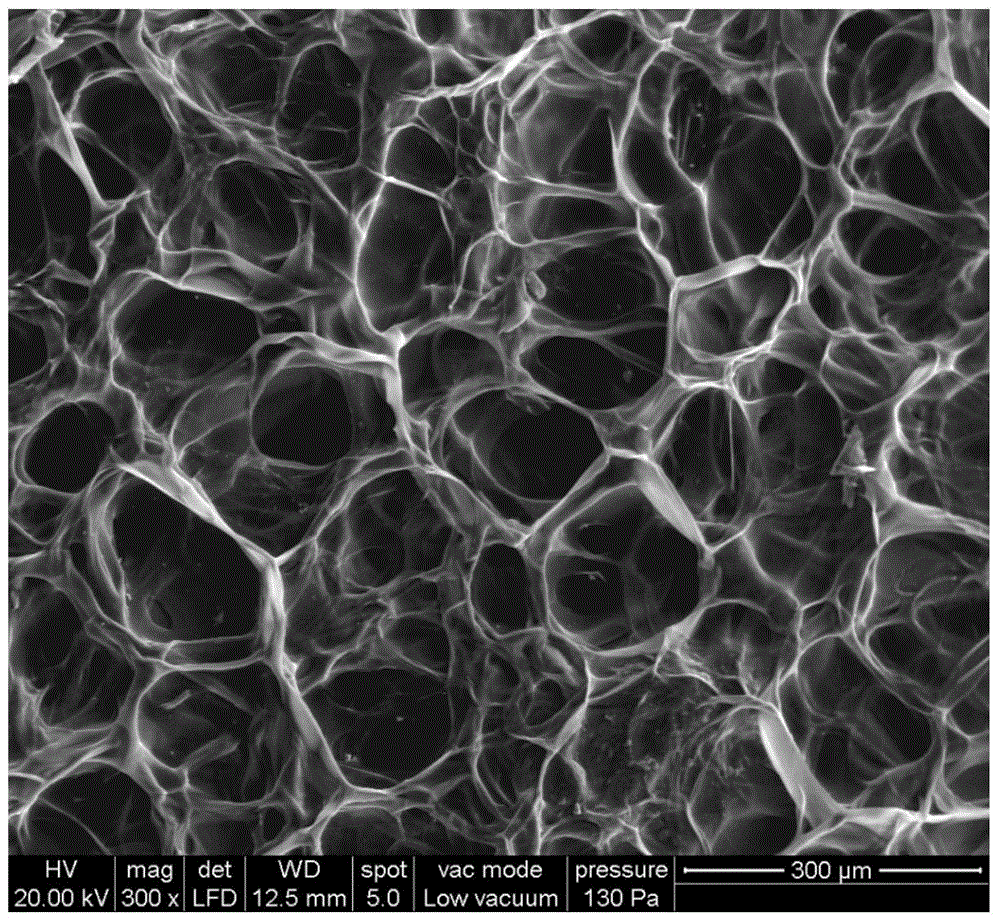

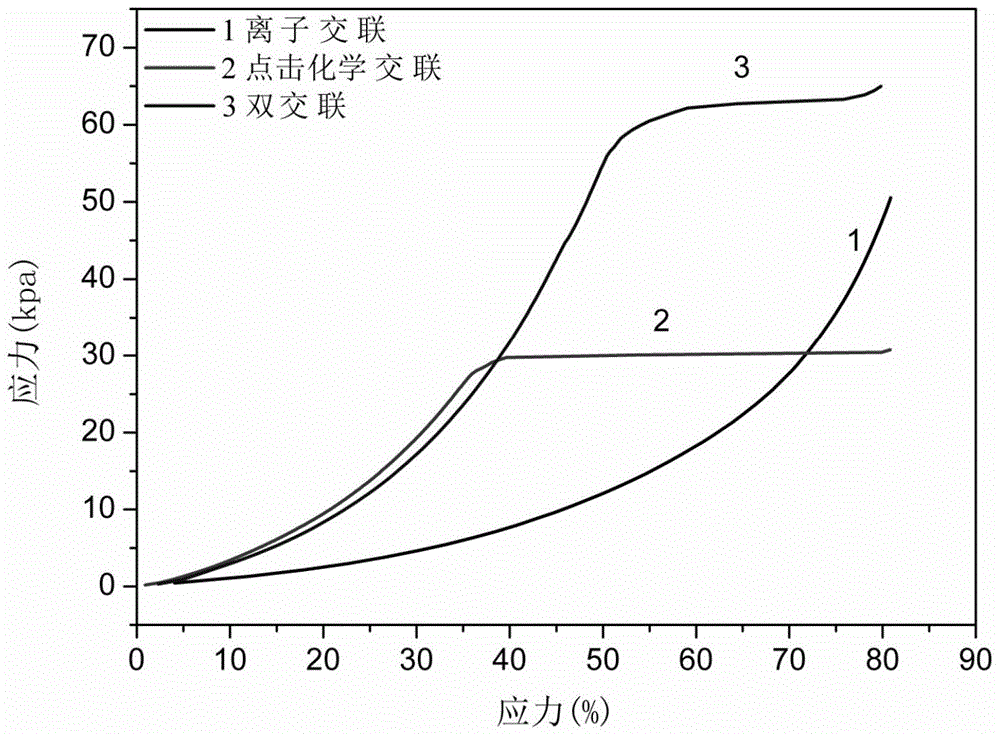

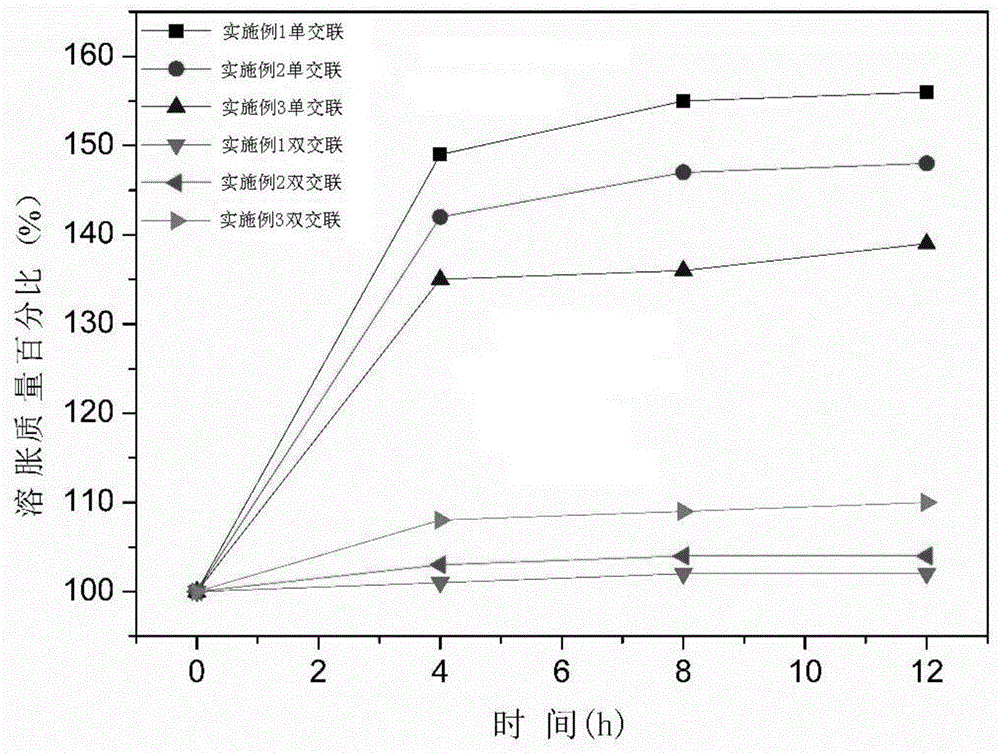

Double-crosslinked sodium alginate hydrogel and preparation method and application thereof

ActiveCN105713106AGuaranteed CytocompatibilityMild reaction conditionsProsthesisFurfurylamineFreeze-drying

The invention belongs to the technical field of biomedical materials and discloses double-crosslinked sodium alginate hydrogel and a preparation method and application thereof. The preparation method includes: dissolving sodium alginate into deionized water, adding activating agents to activate, adding furfurylamine to react for 12-36 hours, and subjecting a reaction product to dialysis and freeze drying so as to obtain furan-modified sodium alginate; dissolving the furan-modified sodium alginate into the deionized water, adding maleimide-terminated polyvinyl alcohol, stirring sufficiently to dissolve, performing ultrasonic treatment, injecting into a mould, and crosslinking at 37-60 DEG C so as to obtain gel; soaking the gel into a calcium chloride solution for 12-48 hours for physical crosslinking so as to obtain the double-crosslinked sodium alginate hydrogel. By the aid of a double-crosslinking method consisting of click chemistry crosslinking and ionic crosslinking, the obtained double-crosslinked sodium alginate hydrogel has excellent mechanical and anti-swelling properties and can be applied to scaffolds for tissue engineering.

Owner:SOUTH CHINA UNIV OF TECH

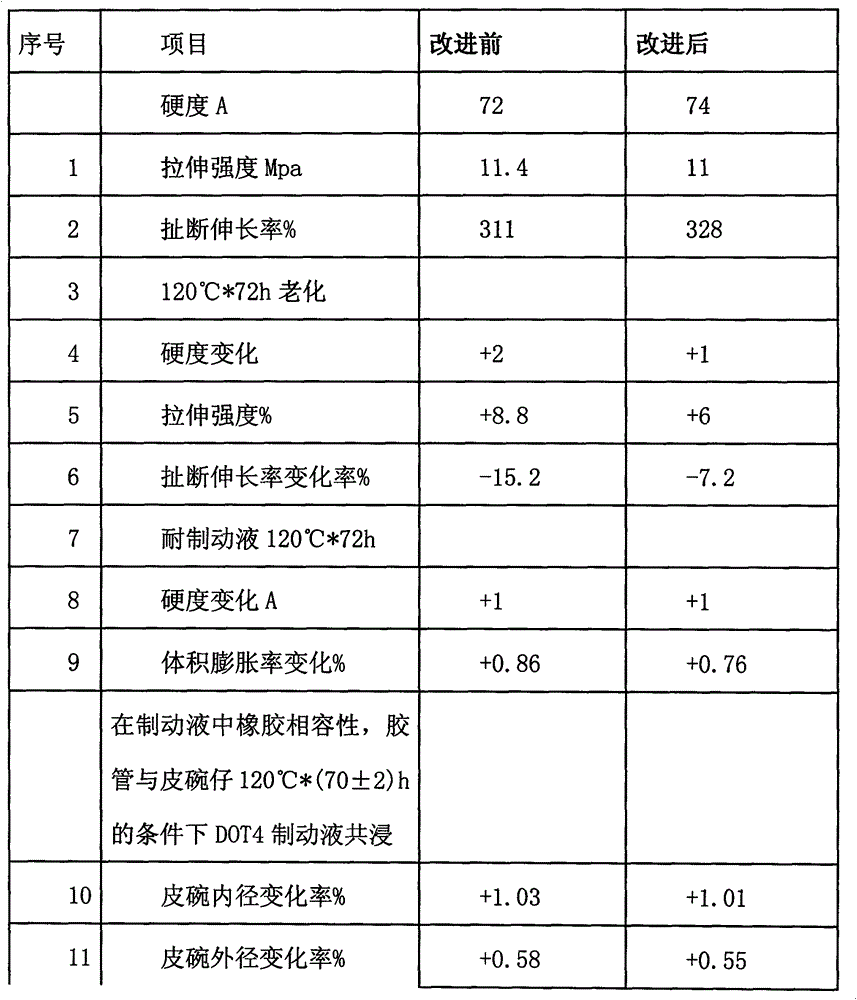

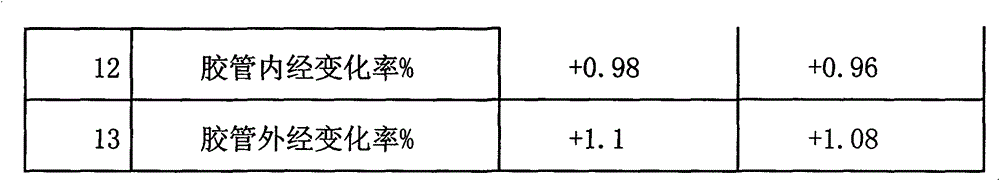

EPDM/EPM engine synthetic brake fluid and expansion resistance rubber material and manufacturing process thereof

The invention discloses an EPDM / EPM engine synthetic brake fluid and expansion resistance rubber material. The material is characterized in that the following components are proportionally mixed in parts by mass: 70-90 parts of EPDM (ethylene propylene diene monomer); 2-4 parts of zinc oxide; 1-3 parts of stearic acid SA; 2.5-4 parts of antiager BLE (liquid); 2-3.5 parts antiager SP (liquid) of 0.5-2 parts of antiager RD; 55-65 parts of N550 carbon black; 18-21 parts of EPM (binary ethylene propylene copolymer); 19-22 parts of StronWiNTC; 19-21 parts of liquid EPDM; 0.5-1.5 parts of assistant crosslinker IS; 1-2 parts of accelerant DM; 0.5-1.5 parts of crosslinker 96% peroxide vulcanizing agent DCP; 1.5-2.5 parts of polyethylene glycol; the invention further discloses a manufacturing process of the rubber material; the rubber material disclosed by the invention is high in quality and low in cost, does not expand in brake liquid, softener is not extracted, and volume expansion, solution, contraction and other phenomena of master and assistant cups are not caused.

Owner:ZHEJIANG KEDALI IND

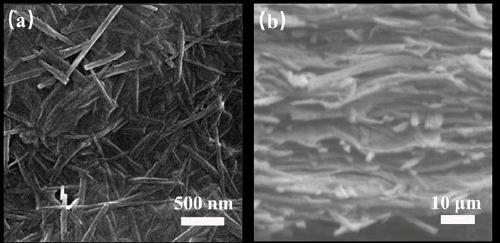

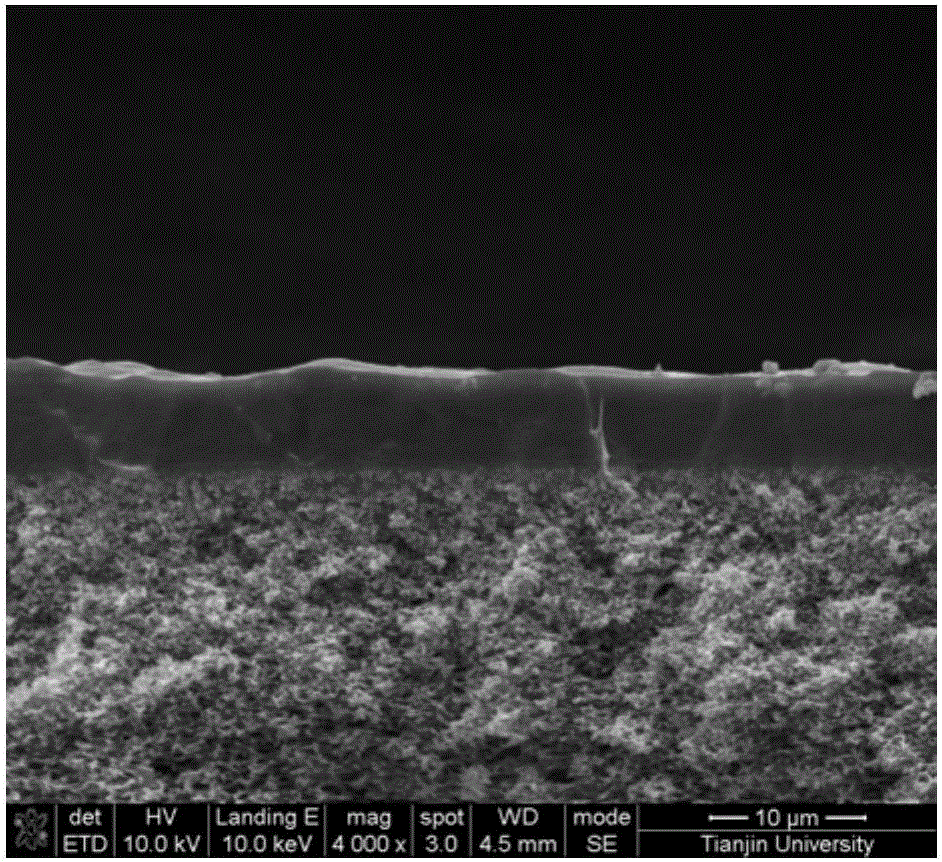

Nanocellulose-compound nanofiltration membrane (CNF-NF) and production method thereof

ActiveCN110141974AImprove hydrophilicityHigh mechanical strengthMembranesGeneral water supply conservationWater basedCompound structure

The invention relates to the field of polymeric separation membrane, in particular to nanocellulose-compound nanofiltration membrane (CNF-NF). The nanocellulose-compound nanofiltration membrane (CNF-NF) comprises base membrane, a main supporting layer and a separation skin layer which are sequentially arranged, wherein pore diameters of the base membrane, the main supporting layer and the separation skin layer decrease progressively; a water-based binder located between the base membrane and the main supporting layer is arranged on the main supporting layer; and the base membrane, the main supporting layer and the separation skin layer are polyacrylonitrile membrane, a cellulose nanocrystalline layer and a polyamide layer respectively. The nanocellulose-compound nanofiltration membrane (CNF-NF) is of a multi-layer compound structure, wherein cellulose nanocrystalline is a one-dimensional nanometer material, and has good hydrophilicity, mechanical strength and resistance to swelling; byintroducing the cellulose nanocrystalline middle layer, physical support can be provided for the skin layer; and a production process of the nanofiltration membrane is simple to operate and mild in reaction condition, and the nanofiltration membrane has a good industrial production basis and wide application prospects.

Owner:深圳市爱玛特科技有限公司

Method for preparing molecular engram CS/TEOS hybridized film by separation of phenylalanine isomer

InactiveCN1843598AIncreased swelling resistanceGood split effectSemi-permeable membranesHigh densitySilicic acid

The invention discloses a method for preparing molecule print chitose / silicic acid carbethoxy hybridized film used to separate phenylalanine isomer of water solution. Said method comprises: adding chitose into acetate water solution whose content is 2%; mixing and filtering insoluble part with filter cloth to attain chitose solution; mixing and adding silicic acid carbethoxy into chitose solution; fully mixing, than adding L-phenylalanine water solution to be mixed for 12 hours; defoaming and filling casting liquid on the horizontally arranged clear organic glass plate horizontally to be extended and form transparent film; thermal treating the film and washing. The invention has the advantages that: the method is simple; attained molecule print chitose / silicic acid carbethoxy film has high density without significant phase separation, and it has better mechanical strength, and better separation function on phenylalanine isomer.

Owner:TIANJIN UNIV

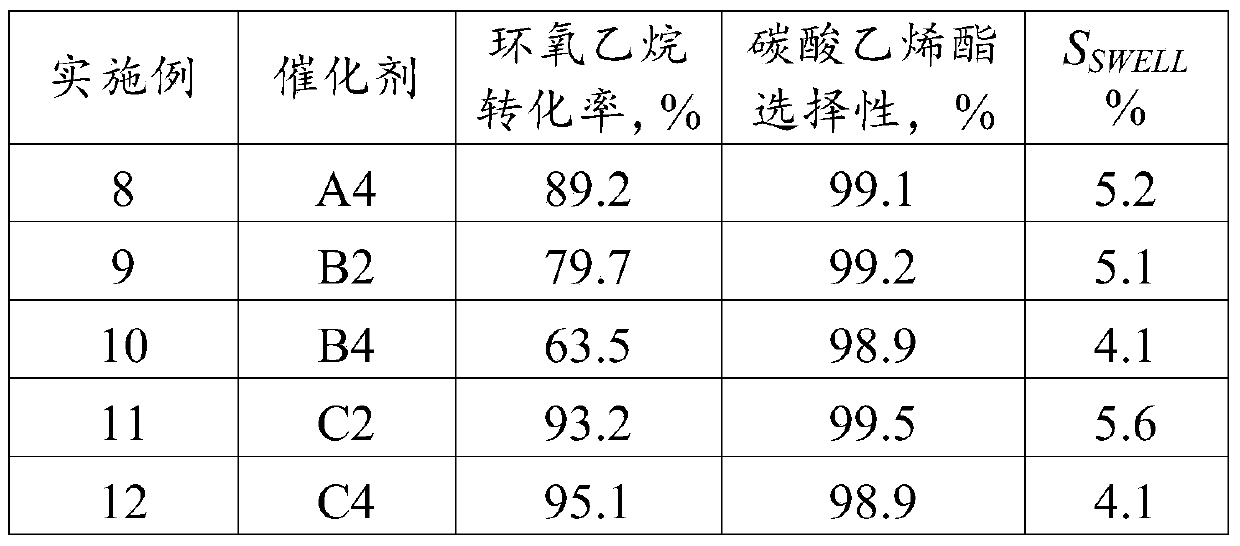

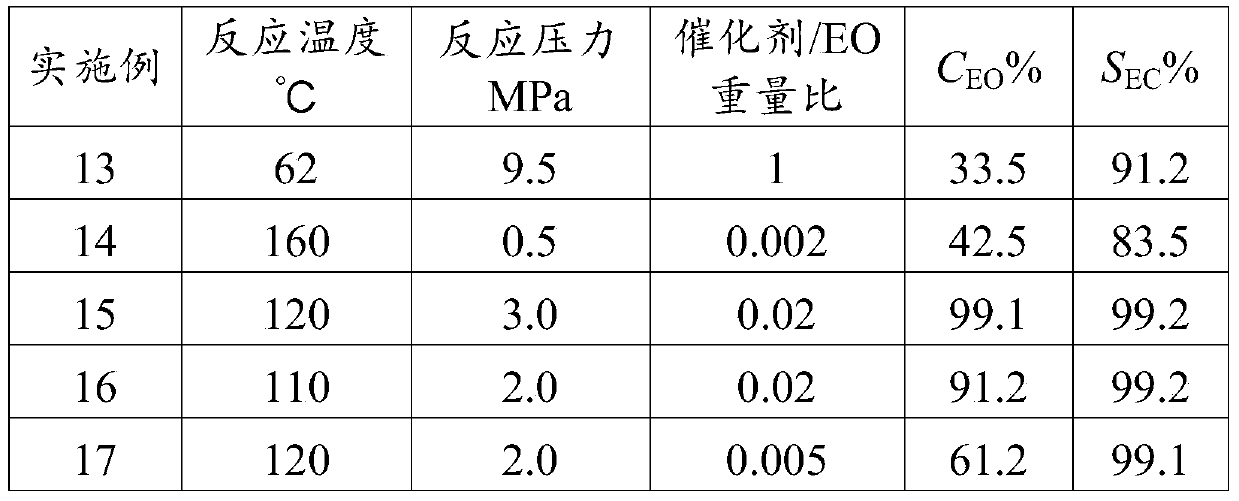

Preparation method of ethylene carbonate

ActiveCN105503811AIncreased swelling resistancePrevent inactivationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHalogenLow activity

The invention relates to a preparation method of ethylene carbonate, and mainly solves the problems of low activity and easy inactivation of catalysts in the prior. According to a technical scheme, ethylene oxide and carbon dioxide are adopted as the raw materials, under the conditions of a reaction temperature of 60-200DEG C, a reaction pressure of 0.1-10.0MPa, and a catalyst / ethylene oxide weight ratio of 0.001-1, the reaction raw materials and the catalyst contact to generate ethylene carbonate; and the catalyst is halogen composite imidazolyl resin. The method well solves the problems, and can be used for the industrial production of ethylene carbonate from ethylene oxide and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

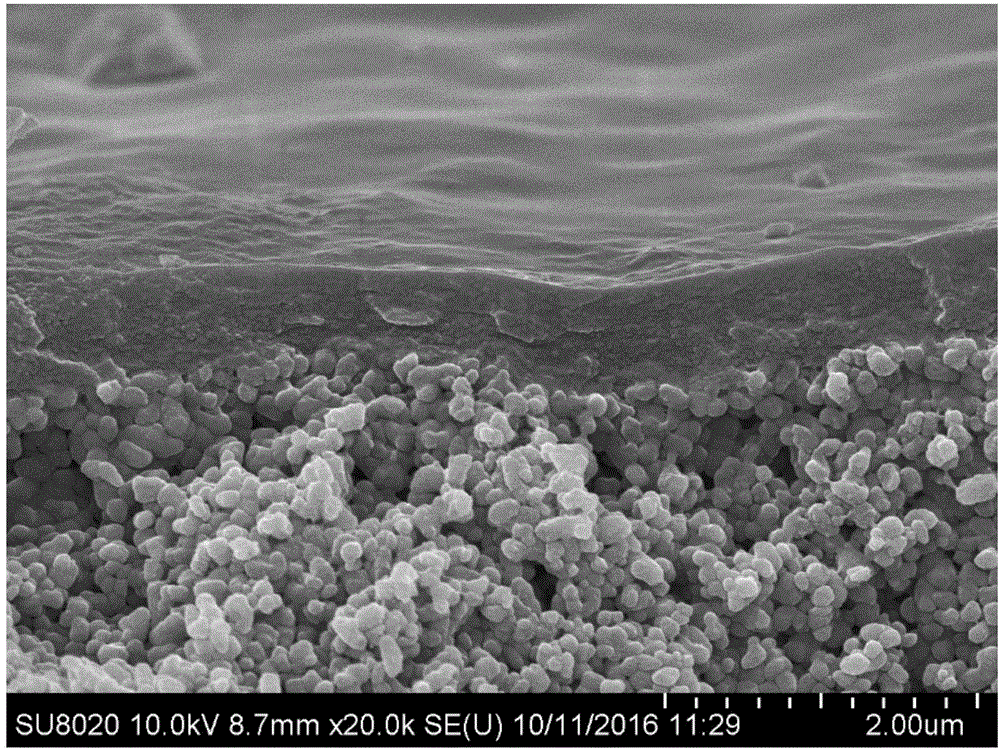

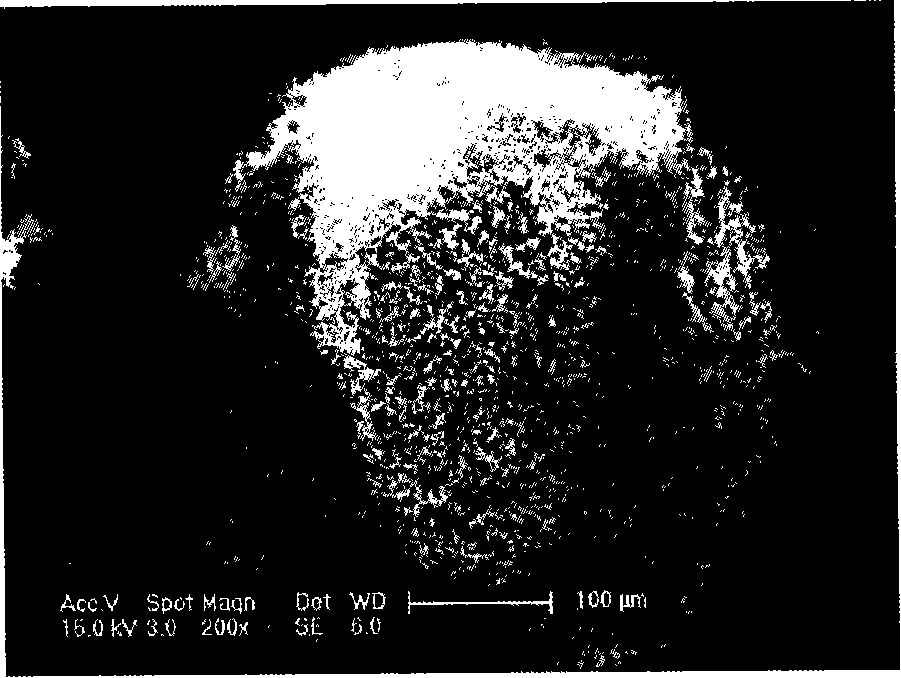

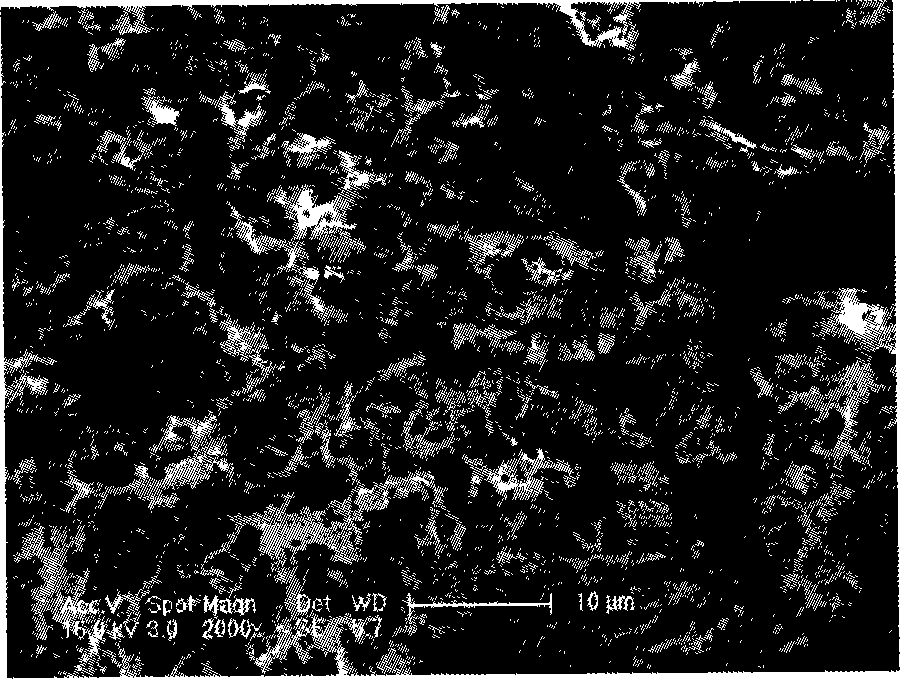

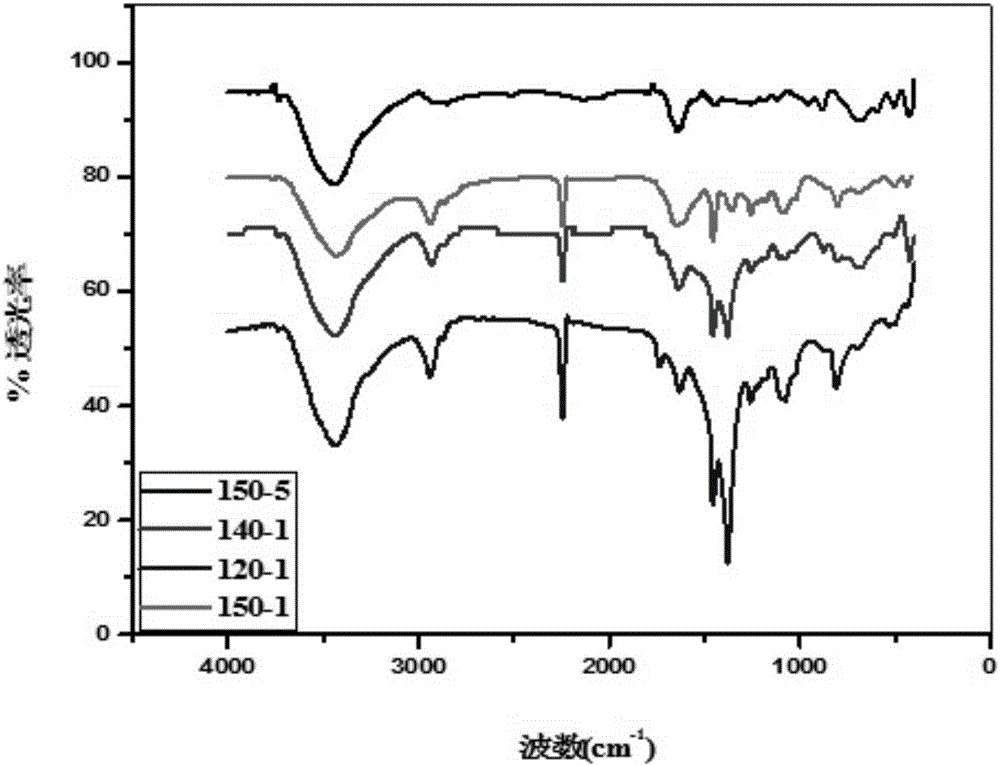

Preparation method of graphene oxide/attapulgite/polyvinyl alcohol ceramic matrix composite membrane

InactiveCN109966931AIncreased swelling resistanceImprove throughputSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPre treatmentBinding force

The invention provides a preparation method of a graphene oxide / attapulgite / polyvinyl alcohol ceramic matrix composite membrane (GO / ATP / PVA composite membrane). A Al2O3 ceramic matrix is pretreated through 3-aminopropyl triethoxysilane (APTES), so that the binding force between the matrix and the composite membrane is increased, PVA is added to increase the swelling resistance of the composite membrane, and the GO / ATP / PVA composite membrane is prepared on the surface of the ceramic matrix through a vacuum filtration-low temperature drying method. The GO / ATP / PVA composite membrane has the advantages that the performance in the application of separating industrial wastewater is excellent, the preparation process is simple, the cost is low, and the preparation method is suitable for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

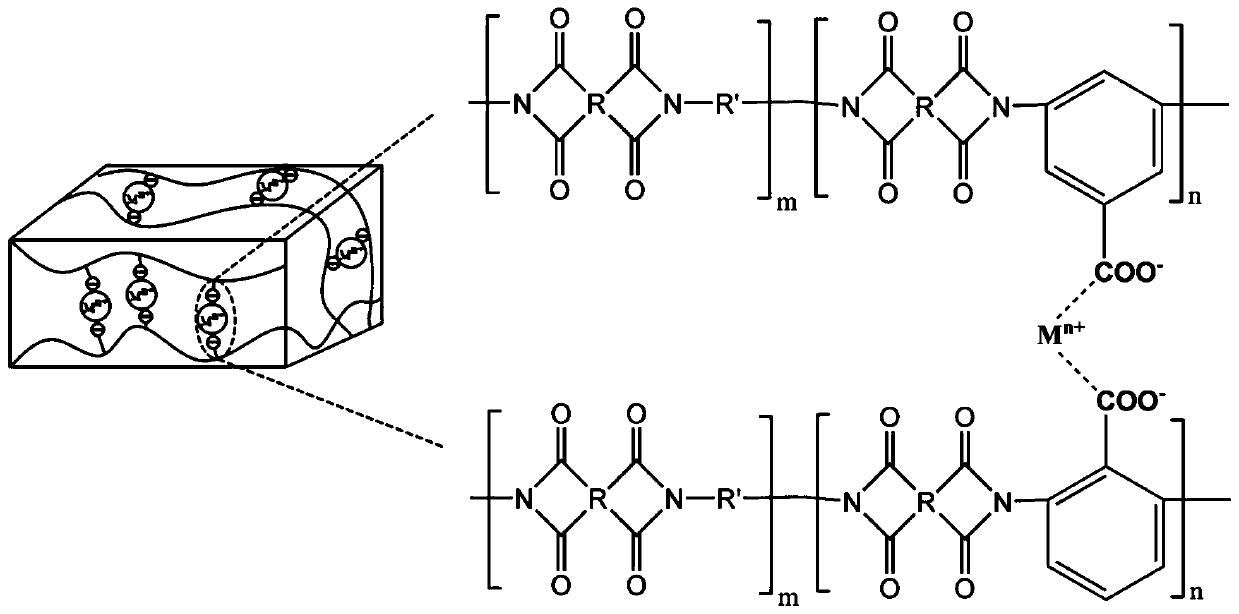

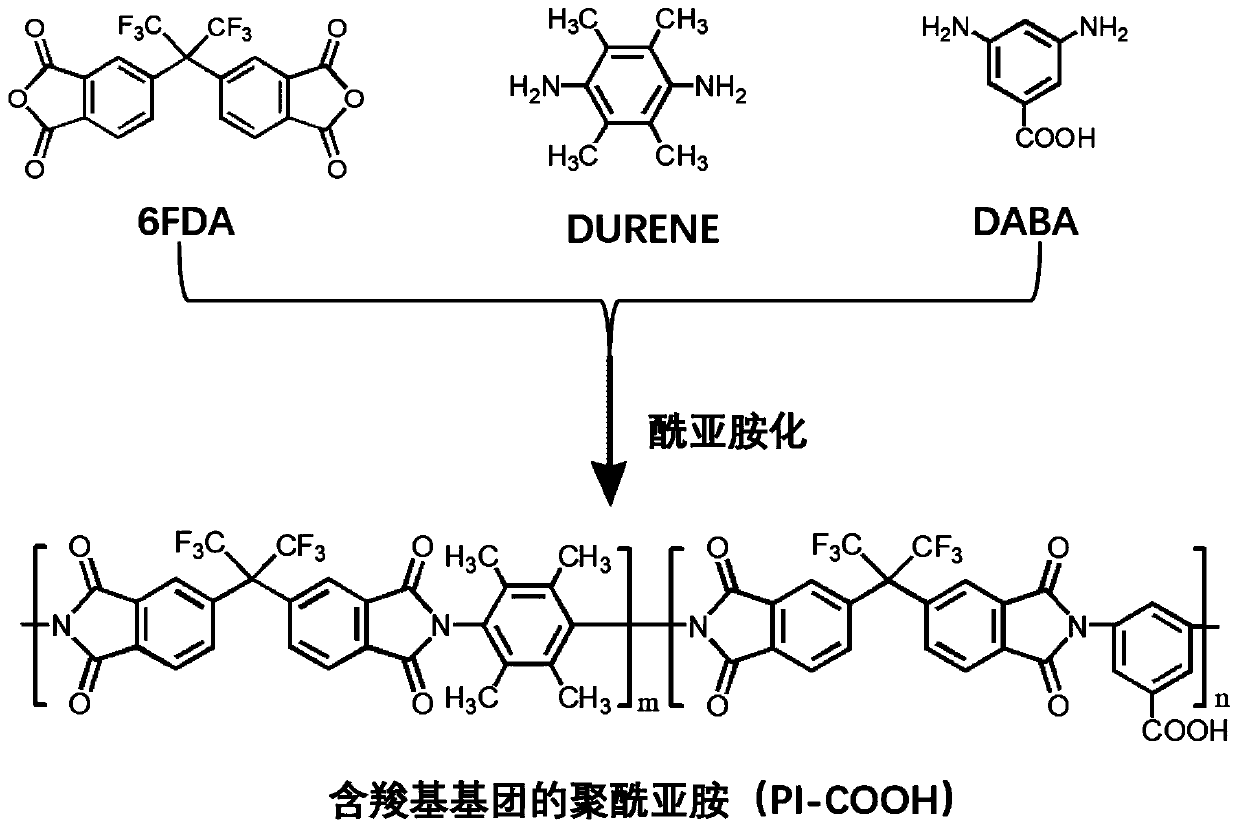

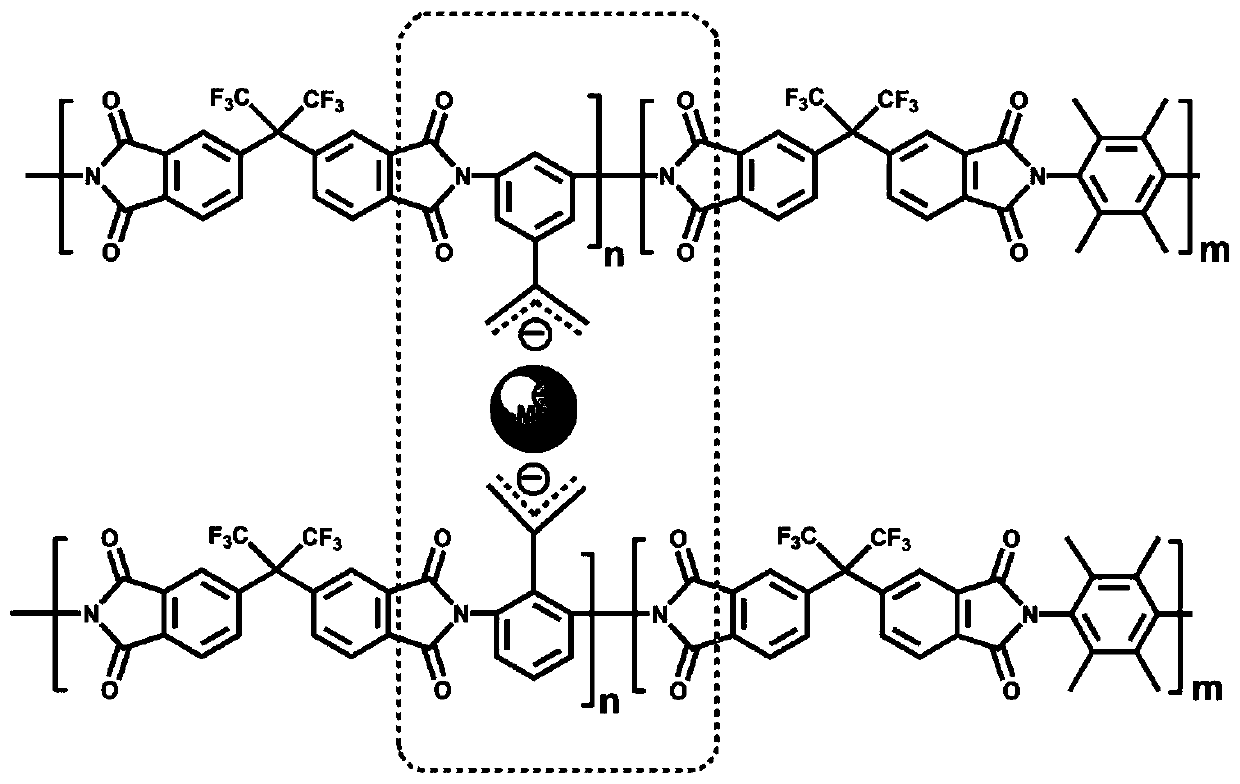

Solvent-resistant polymer nanofiltration membrane as well as preparation method and application thereof

ActiveCN111514768AImprove swelling resistance and physical and chemical stabilityHigh resistance to swellingMembranesReverse osmosisDiaminePolyimide

The invention relates to a solvent-resistant polymer nanofiltration membrane as well as a preparation method and an application thereof. The preparation method comprises the following steps: carryingout cyclization imide on a diamine monomer and a dianhydride monomer in a first polar organic solvent at 160-230 DEG C under the action of a catalyst, and forming polyimide after complete reaction; wherein the diamine monomer comprises a carboxyl-containing diamine monomer and a carboxyl-free diamine monomer; dissolving polyimide in a second polar organic solvent to form a film forming solution with the concentration of 10wt%-40wt%; then carrying out phase inversion after the film forming solution forms a film to obtain an intermediate film; treating the intermediate membrane by adopting an organic solution of metal salt so that metal ions are coordinated and cross-linked with carboxyl in polyimide, and obtaining the solvent-resistant polymer nanofiltration membrane after cross-linking isfinished; wherein the metal salt is selected from metal salt and / or multivalent metal salt. The invention also discloses an application of the solvent-resistant polymer nanofiltration membrane in separation and / or purification of compounds in an organic solution.

Owner:SUZHOU UNIV

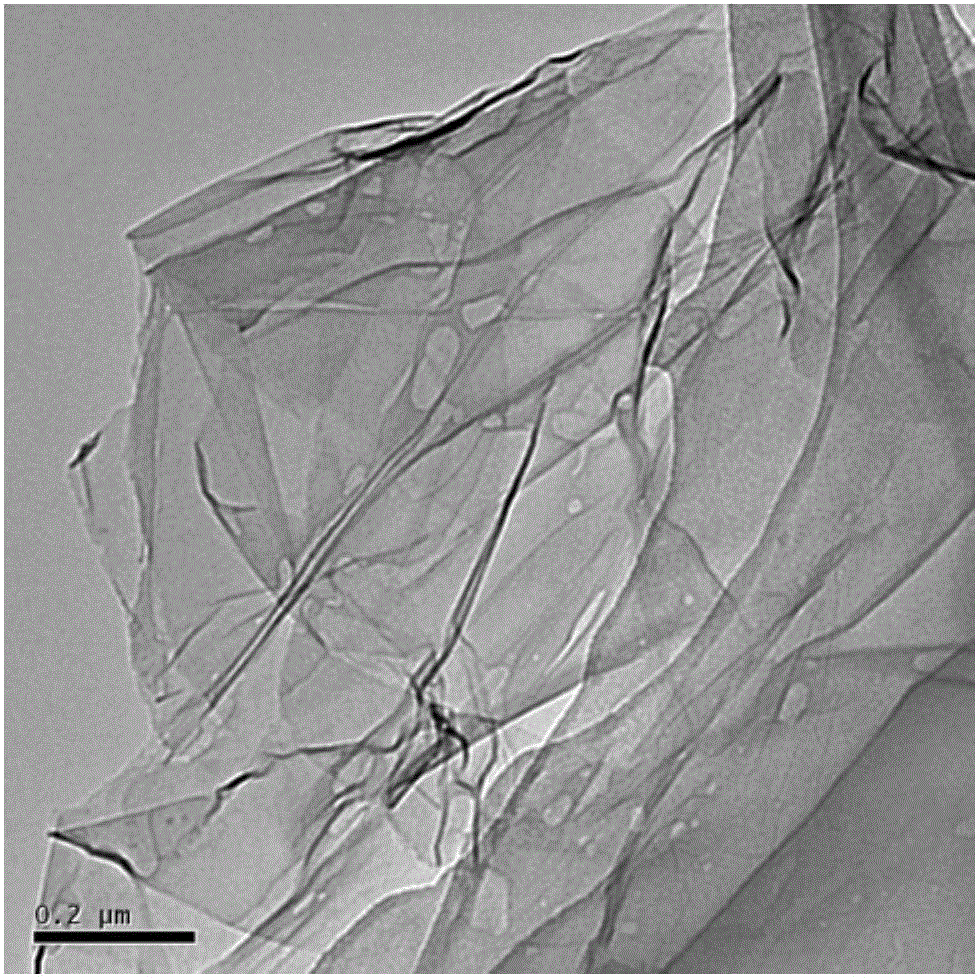

Hybrid composite membrane based on polydopamine functionalized graphene and preparation and application

ActiveCN105797605AEnhanced interactionEasy to separateSemi-permeable membranesRefining by filtrationPolyamideOxygen

The invention discloses a method for functionalizing a graphene oxide nanosheet and application of a hybrid composite membrane constructed on the basis of the method. When dopamine is subjected to oxidation self-polymerization, oxygen-containing groups on the surface of graphene oxide are subjected to reduction, and the swelling resistance of the hybrid membrane is improved. The thickness of the membrane is about 6 micrometers, the membrane is composed of a polyether-polyamide block copolymer matrix and functionalized graphene filler, and the mass fraction of the graphene component in the filler ranges from 2% to 8%. The preparation process comprises the steps that polydopamine is subjected to oxidation self-polymerization on the surface of the graphene oxide nanosheet, graphene oxide is subjected to reduction, a functionalized graphene nanosheet is obtained, the polyether-polyamide block copolymer matrix is filled with the functionalized graphene nanosheet, the surface of a polysulfone ultrafiltration membrane supporting layer is subjected to spin coating with the functionalized graphene nanosheet, and the composite membrane is obtained. The preparation process of the composite membrane is simple, convenient and controllable, the obtained membrane is applied to the pervaporation oil product desulfurizing process, and high separating property and swelling resistance are both achieved.

Owner:TIANJIN UNIV

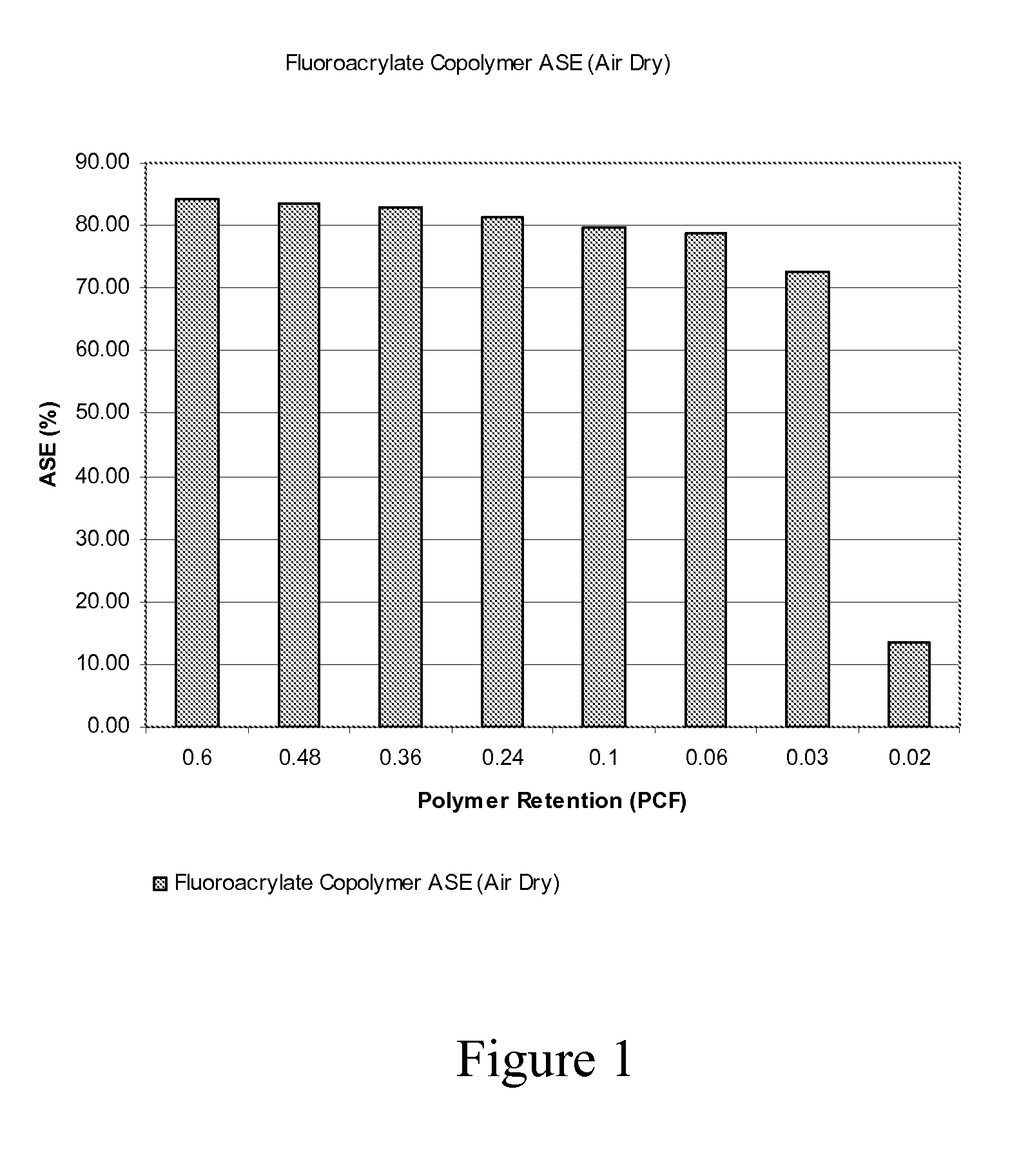

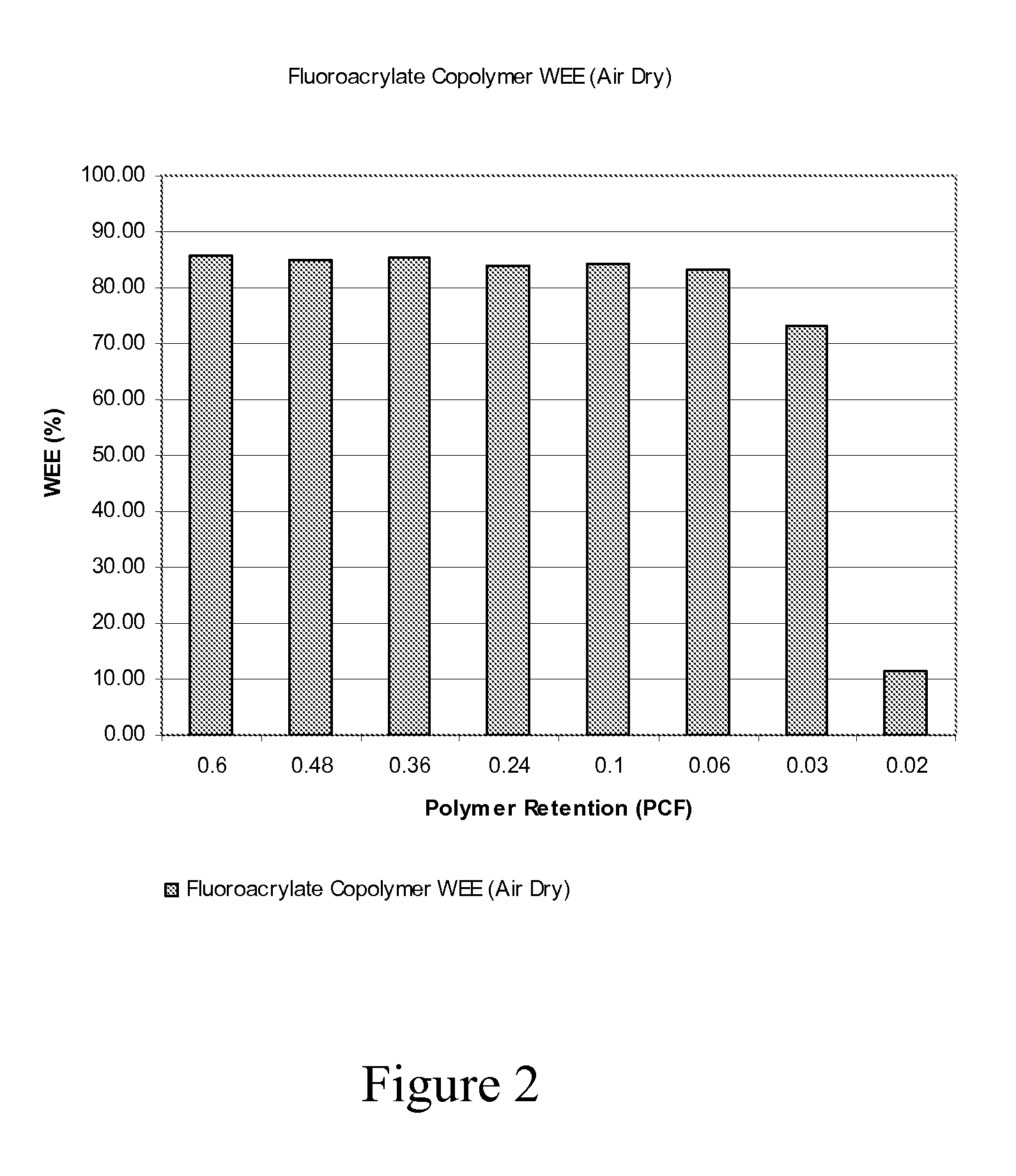

Fluoro-compound water repellent composition for wood product dimensional stability

InactiveUS20070160850A1Improves anti-swelling propertyProvide dimensional stabilitySynthetic resin layered productsPretreated surfacesBiologyWood product

Provided is a method for improving the dimensional stability of wood and wood products. The method comprises impregnation of wood with fluorocompounds. In one embodiment, the method comprises the impregnation of wood or wood products with a composition comprising fluoro-polymer emulsions and / or dispersions.

Owner:OSMOSE

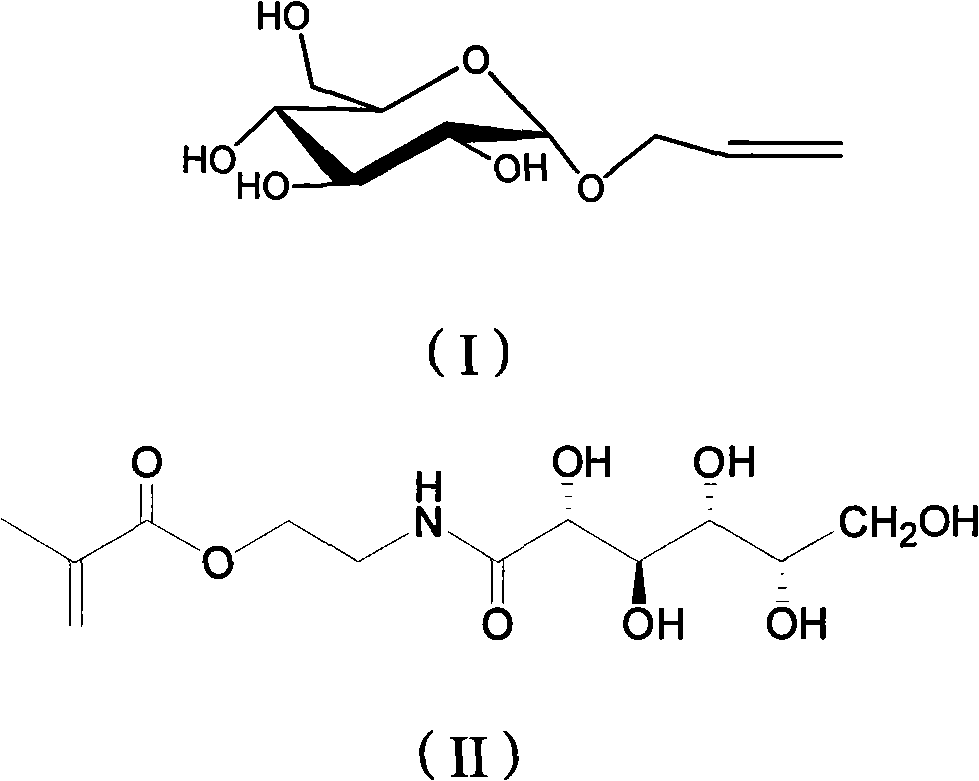

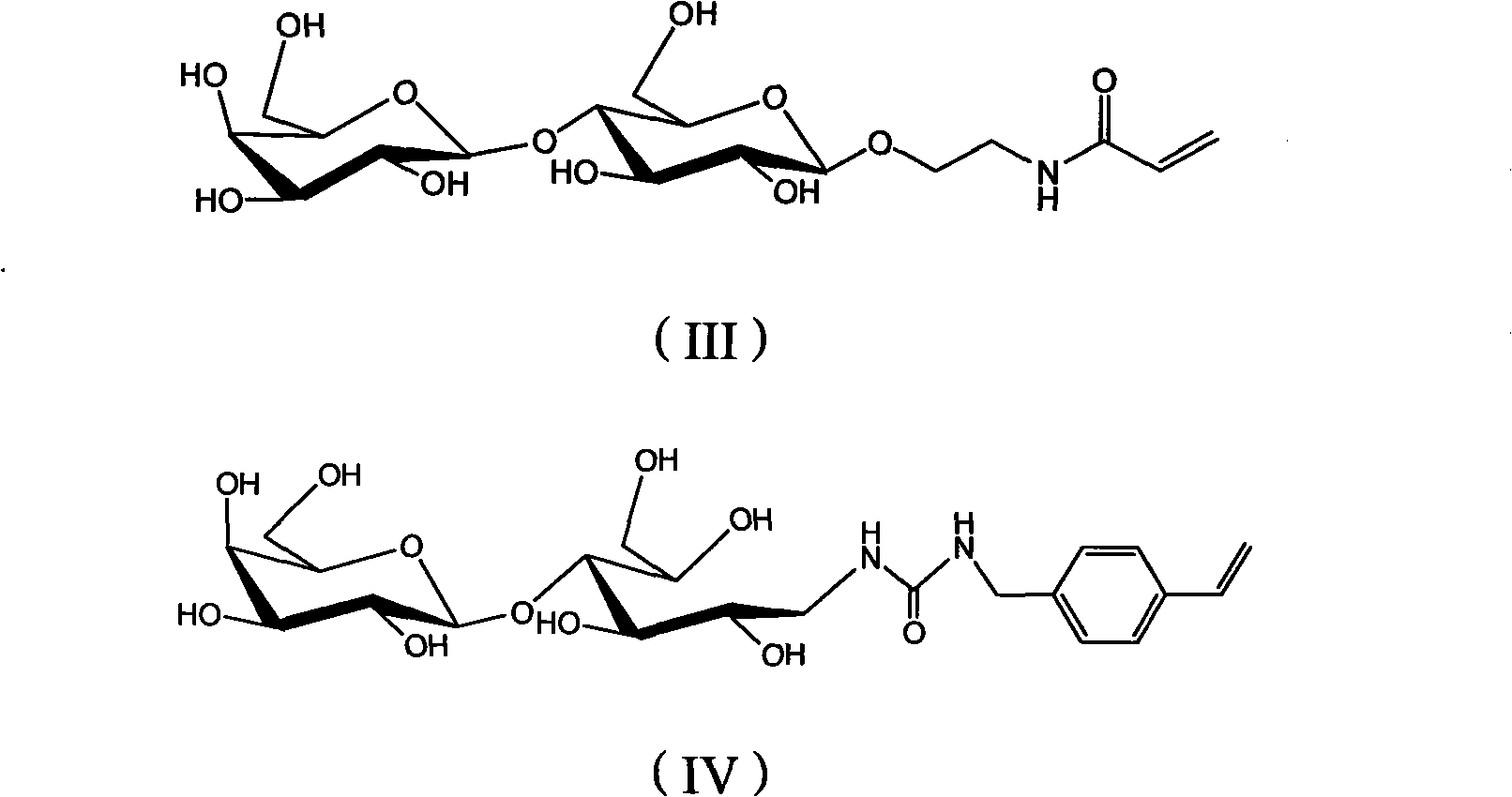

Sugar-containing polymer compound film with blocked pore and preparation thereof

InactiveCN101301590AImprove mechanical propertiesFix stability issuesSemi-permeable membranesPolymer scienceIn situ polymerization

The present invention discloses a production method of sugar-containing polymer hole-blocking compound membrane and the application in permeation vaporization and dehydration of organic solvent. The said method comprises the following steps: mixing sugar-contained monomer, comonomer, cross linker, evocating agent and solvent to formulate polymerized solution; performing in-situ polymerization by adopting photo-initiation or thermal initiation mode after the polypropylene microporous membrane is immersed in polymerization solution for a special time; getting sugar-contained polymer hole-blocking compound membrane after cleaning and drying. The sugar-containing polymer hole-blocking compound membrane prepared by the invention can be used for organic solvent dehydration, has advantages of high separation factor, large separation flux, good mechanical properties, good chemical stability and thermostability, and has utility value in separation and purification of organic solvent.

Owner:ZHEJIANG UNIV

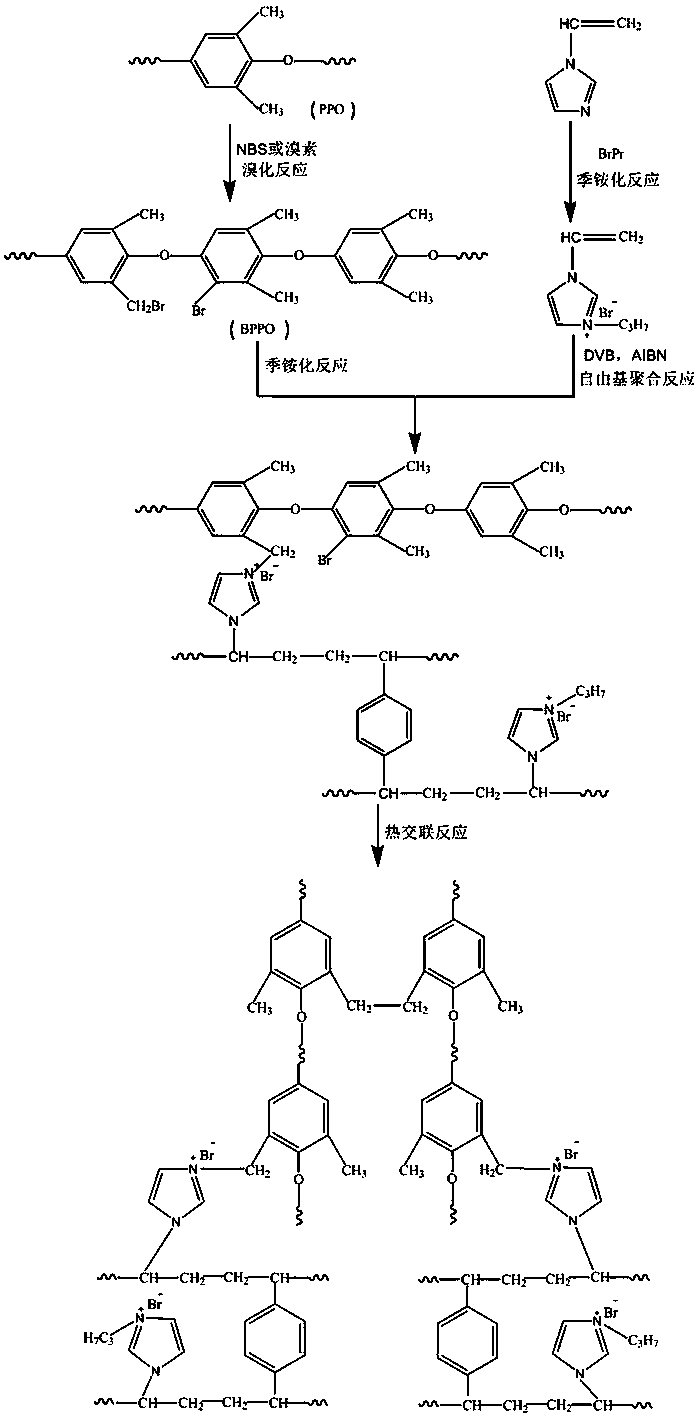

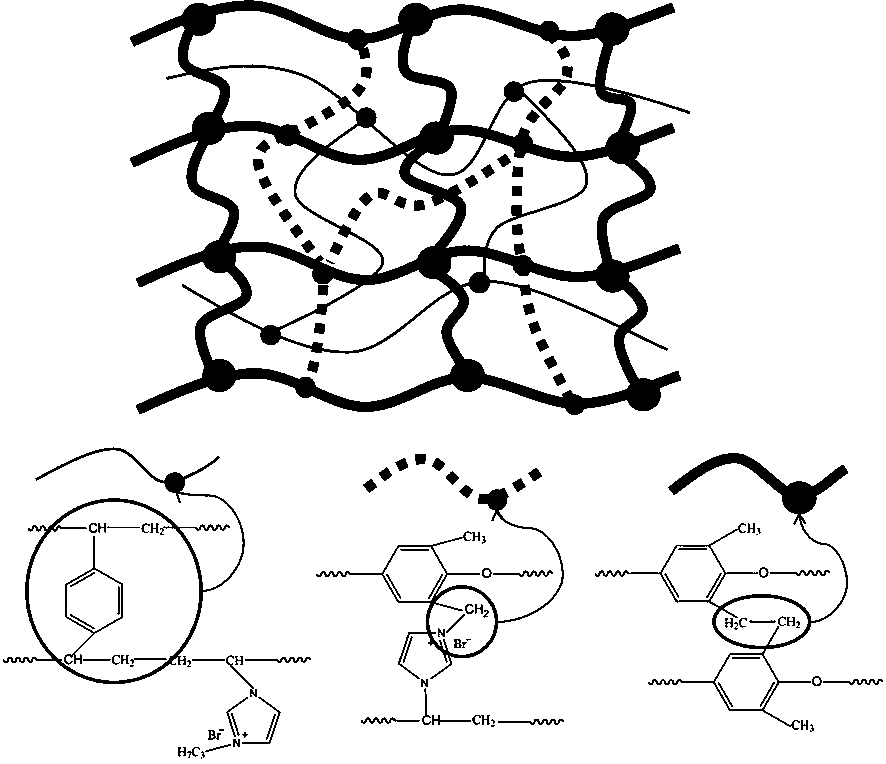

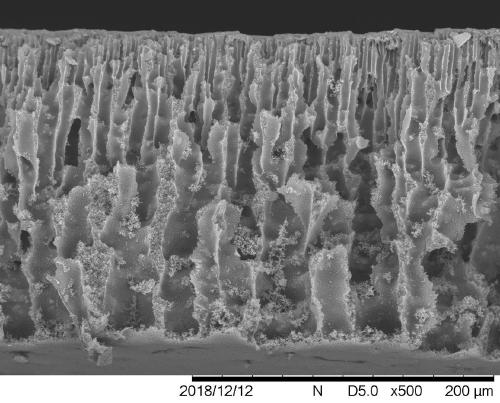

Method for preparing anion-exchange membrane with multi-crosslinked structure

ActiveCN109939572AIncreased swelling resistanceImprove mechanical propertiesSemi-permeable membranesAnion exchangersHeat treatedLow resistance

The invention discloses a method for preparing an anion-exchange membrane with a multi-crosslinked structure. The method comprises the following steps: (1) dissolving bromoethylated polyphenyl ether in N-methyl pyrrolidone to form a membrane casting solution, coating the membrane casting solution on a flat panel with a knife or coating the membrane casting solution on a supporting cloth, soaking in a coagulating bath, and drying to obtain a porous base membrane; (2) mixing 1-vinyl imidazole, bromopropane and isopropanol to enable the system to react; adding divinyl benzene, radical initiator and organic solvent after the reaction, and uniformly stirring to obtain a monomer solution; (3) soaking the porous base membrane with the monomer solution, putting the porous base membrane between twoPET films to form a complex; and heating the complex at the temperature of 60-100 DEG C, and releasing the two PET films to obtain an anion-exchange membrane semi-finished product; and (4) performingheat post-treatment on the anion-exchange membrane semi-finished product at the temperature of 130-150 DEG C to obtain the anion-exchange membrane. The anion-exchange membrane prepared by the methodhas low resistance, high transport number, good swelling resistance and good solvent resistance.

Owner:SHANDONG TIANWEI MEMBRANE TECH

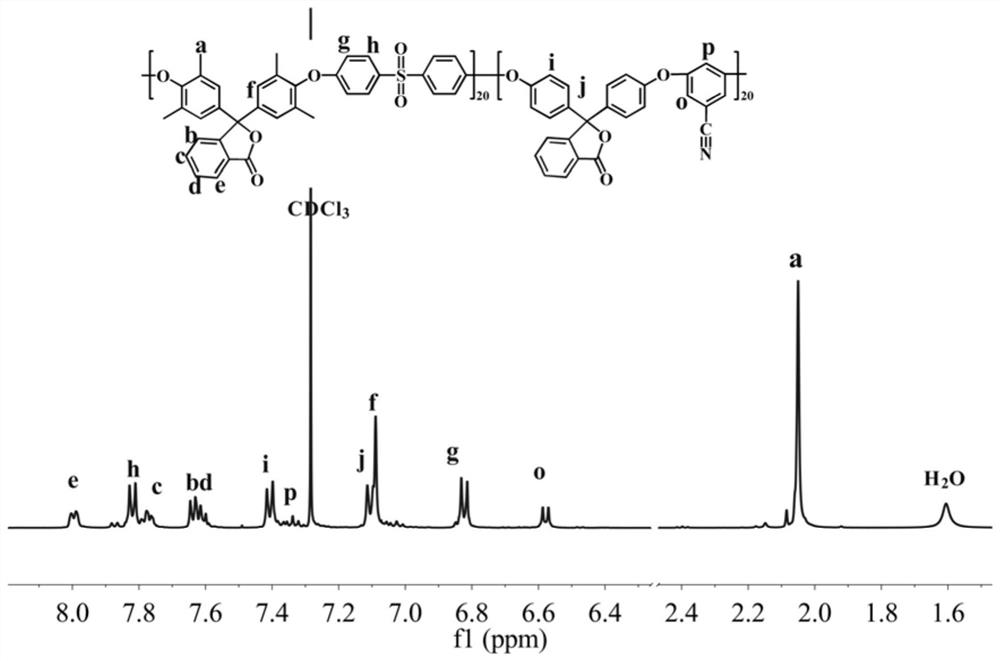

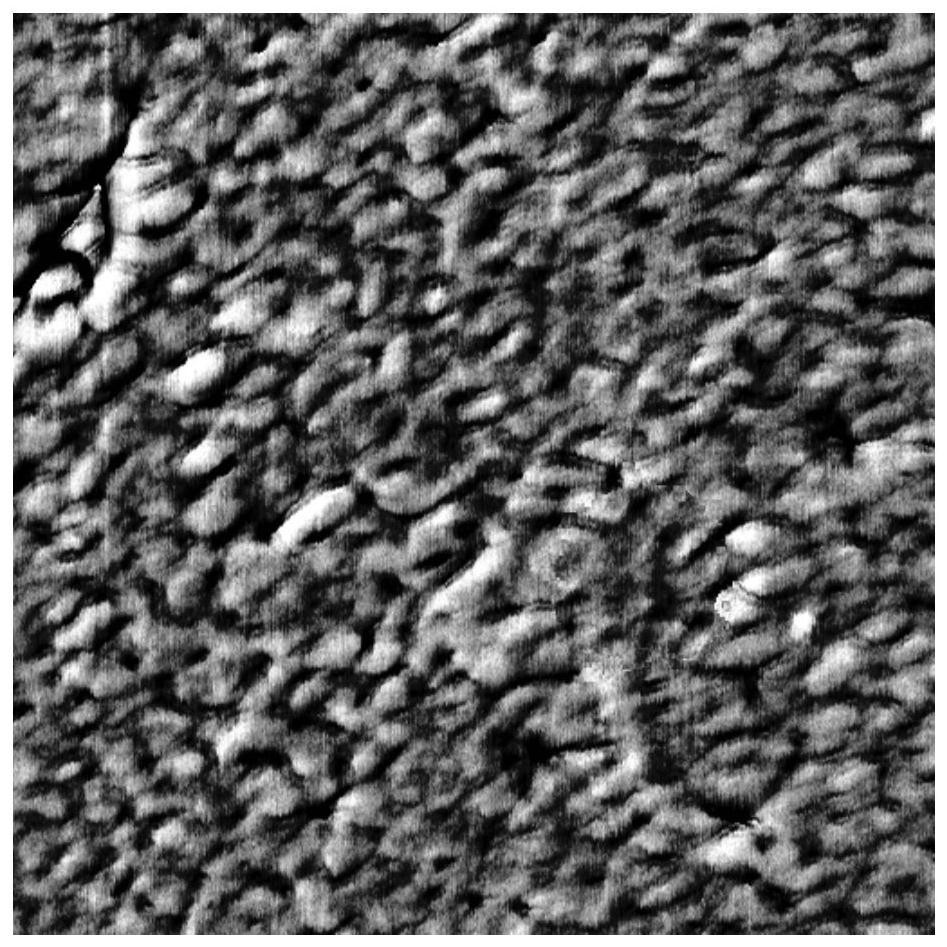

Block type anion exchange membrane containing dense ion strings, and preparation method thereof

InactiveCN111793230AIncrease moisture contentObvious microphase separationFuel cellsFuel cellsChloromethyl Ether

The invention provides a block type anion exchange membrane containing dense ion strings, and a preparation method thereof, wherein the block type anion exchange membrane can be used for an alkaline fuel cell, and is structurally characterized in that a plurality of ion strings are densely grafted on a hydrophilic segment of a block copolymer to serve as functional groups. The preparation method mainly comprises the following steps: (1) preparing a hydrophilic segment containing tetraphenylmethyl and a hydrophobic segment containing a suspended nitrile group; (2) preparing a block copolymer, and carrying out bromination modification; and (3) preparing the block type anion exchange membrane containing the dense ion strings. According to the invention, the anion exchange membrane prepared bythe method has a developed ion transmission channel, has the characteristics of high water content and low swelling rate, and overcomes the defect that the existing anion exchange membrane cannot have high water content, high conductivity and low swelling rate at the same time; and a highly toxic carcinogenic chloromethyl ether reagent is not used in the preparation process, so that the membranehas a wide application prospect in the field of alkaline fuel cells.

Owner:HUAQIAO UNIVERSITY

Method for making cation exchange membrane through photocuring

The invention provides a method for making a cation exchange membrane through photocuring. The method comprises the following steps: coating a substrate with a slurry containing a polymerizable monomer and a photoinitiator, wherein the polymerizable monomer contains sulfonate ions or a compound containing a functional group which can introduce the sulfonate ions; initiating the polymerization and crosslinking of alkenyl function groups on the monomer in the initiating slurry; and washing, and post-processing to obtain the sulfonic acid type cation exchange membrane with a physical conformation. Compared with present making methods of the cation exchange membrane through a hot pressing polymerization process, the method has the advantages of fast polymerization speed, low polymerization temperature, fast curing time and small pollution, and the obtained cation exchange membrane has the advantages of uniformity, stability, good mechanical properties and good chemical resistance, so the cation exchange membrane has a good application prospect in the fields of electrodialysis water treatment, pervaporation, gas separation, new energy batteries, the atomic energy industry and analysis, catalytic synthesis and the chlorine alkali industry.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-corrosion-resistance fluororesin powder coating composition

InactiveCN113604114AAccelerated corrosionIncreased swelling resistanceAnti-corrosive paintsPowdery paintsCorrosive acidResin coating

The invention relates to a high-corrosion-resistance fluororesin powder coating composition and a preparation method thereof. The high-corrosion-resistance fluororesin powder coating composition can be used for preventing corrosion of a base material and preventing corrosive acid and other chemicals from permeating the base material so as to protect the base material. The existence of inherent pores and defects in a coating formed by fluororesin can accelerate the failure of the coating, so that the application and development of a coating protection technology are limited. Therefore, in order to further enhance the protection performance of the fluororesin coating, the effect of constructing a fluororesin powder coating synergistic protection system is achieved by selecting the multifunctional flaky filler, the flow promoter is optimally fumed silica, and when the fumed silica is used as the high-temperature-resistant powder coating, the composition can be used for electrostatic spraying and also can be used for a roller coating forming process with high requirements on powder fluidity.

Owner:SHANDONG HUAFU FLUORO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com