Patents

Literature

30results about How to "Improve separation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

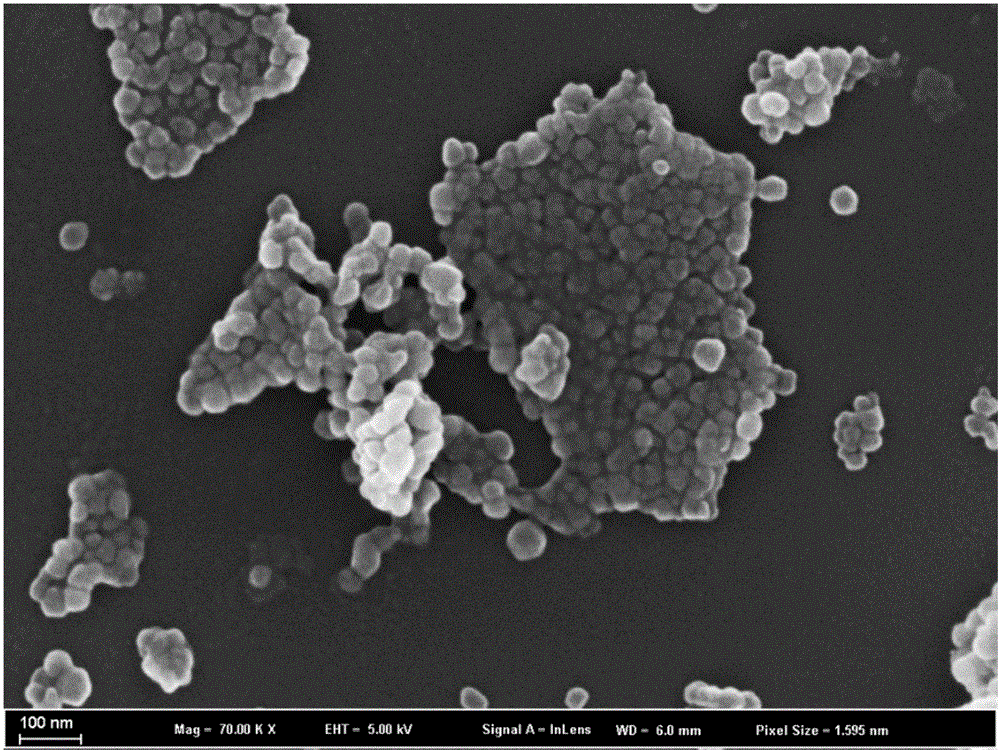

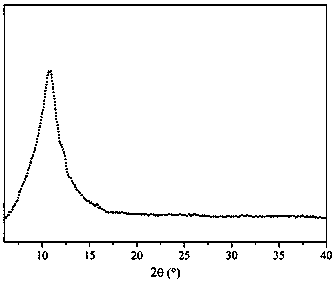

Preparation method for metal organic framework modified graphene oxide lamellar structure composite membrane used for organic solvent nanofiltration

ActiveCN106582317AImprove separation performanceImproved swelling resistance and stabilitySemi-permeable membranesNanofiltrationGraphite oxide

The invention provides a preparation method for a metal organic framework modified graphene oxide lamellar structure composite membrane used for organic solvent nanofiltration, and belongs to the field of membrane separation. The preparation method includes the steps that firstly, a metal organic framework and graphene oxide are composited to prepare composite nanometer particles; and the composite nanometer particles and a polymer are assembled on a base membrane to prepare the metal organic framework modified graphene oxide lamellar structure composite membrane used for the organic solvent nanofiltration. The composite membrane has a good separation effect for dyes in organic solvent and still has high flux under the low operation pressure, and therefore the composite membrane has application potential on the aspect of organic solvent nanofiltration.

Owner:BEIJING UNIV OF TECH

Catalytic distillation tower member and its manufacture

InactiveCN1436586AImprove separation performanceGood responsivenessChemical/physical/physico-chemical processesCatalytic distillationSurface finishing

The catalytic distillation tower member consists of base body, modified layer and activating layer and features the base body made of regular porous ceramic stuffing, the modified layer being coating formed through surface treatment of the base body with alpha-alumina, and the activating layer comprising active catalyst component coated to the modified layer. The catalyst distillation tower member integrates the distilling stuffing and catalyst; has high efficiency, enough gas-liquid contact area, efficient mass transfer between the gas phase and the liquid phase, and excellent reaction and separation effect; and is convenient in assembling and disassembling and suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

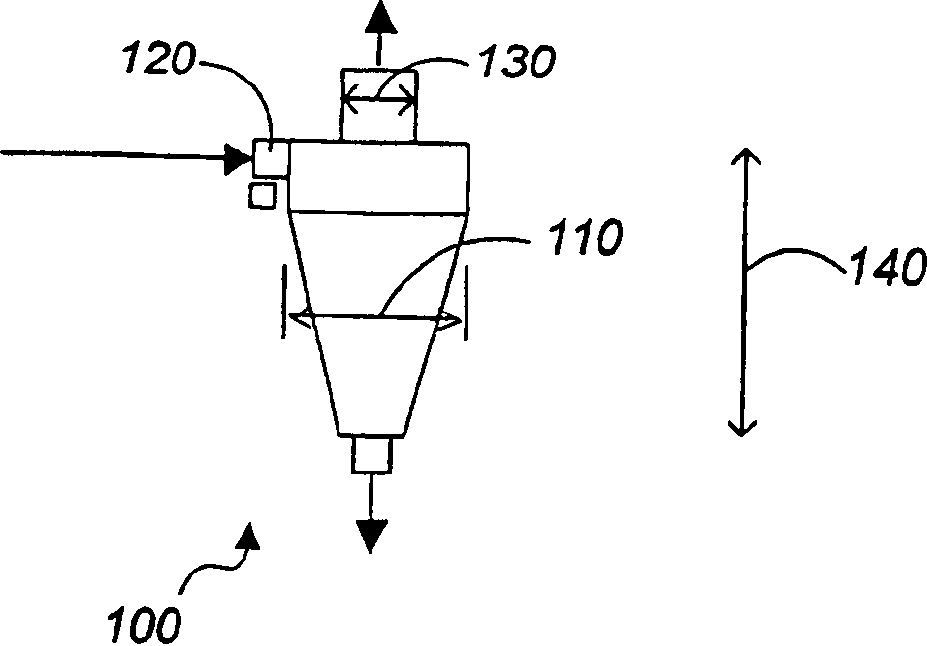

Controlling media particle size in slurried dense media separations

InactiveCN1688392ALess foamImprove separation performanceElectrostatic separationPlastic recyclingParticulate mediaChemistry

Methods, systems, and media for use in separating mixtures. A slurry including a separation liquid and one or more particulate media materials is provided. A classification separation is performed on the slurry to produce a classified media having a controlled particle size distribution of the particulate media materials. The classified media is combined with a mixture to be separated to generate a separation mixture. A density separation is performed on the separation mixture. The particle size distribution can be controlled based in part on characteristics of components of a separation system to be used in subsequent density separations.

Owner:MBA POLYMERS INC

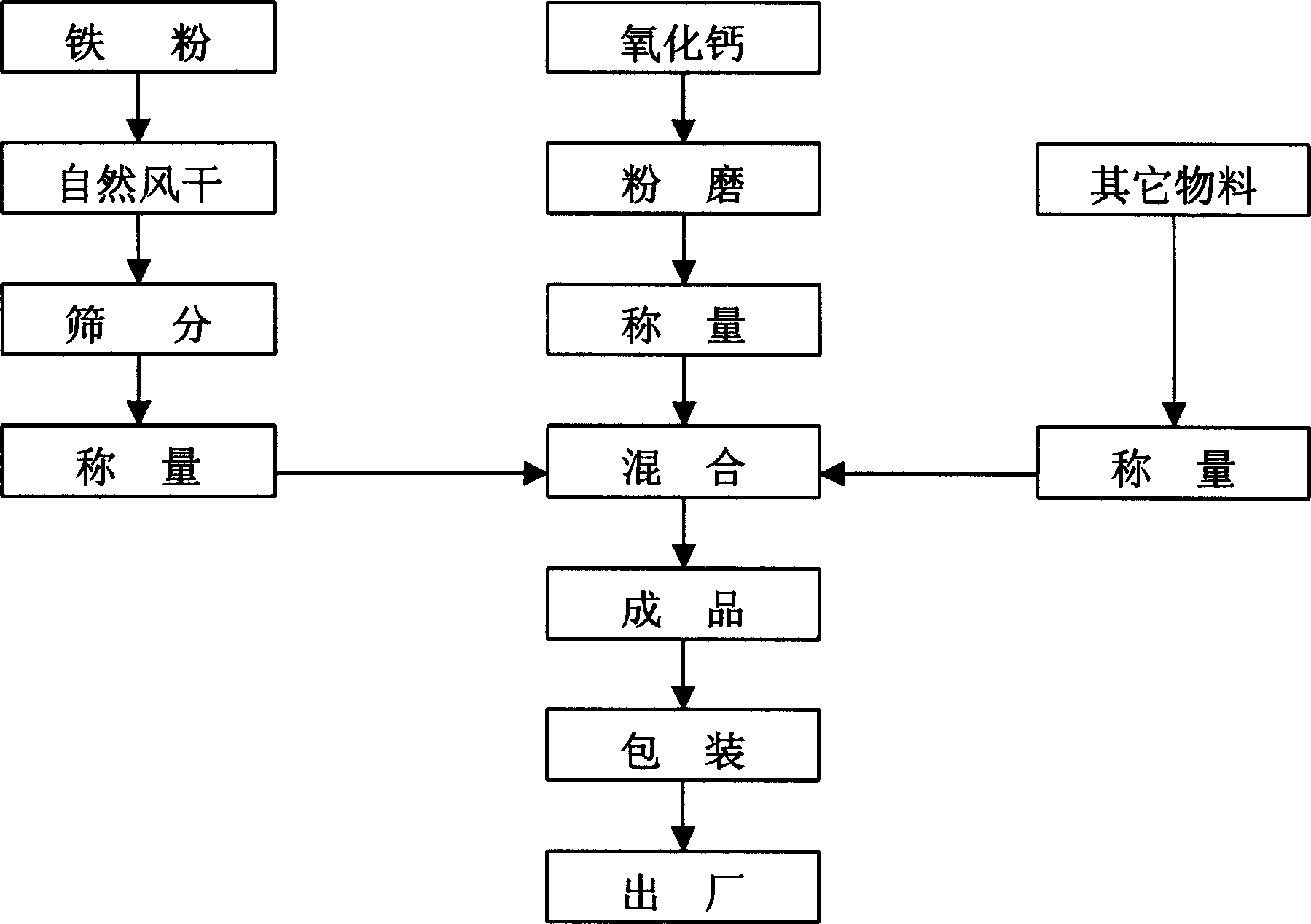

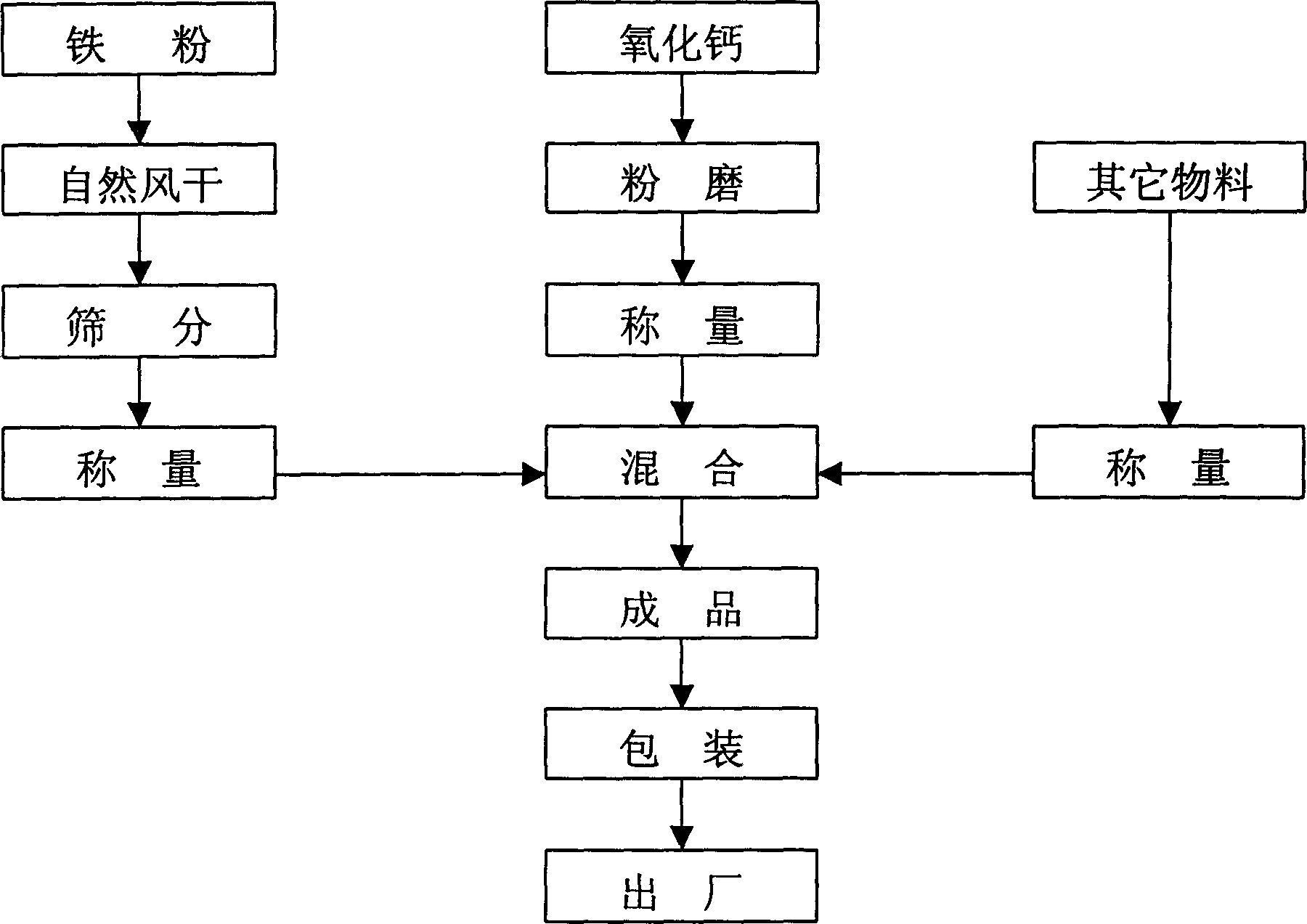

Cement material fly-ash activity excitant

The activity excitant for flyash as cementing material may be used to make the flyash adding amount as high as 70 % without affecting the early strength of cement and concrete. The activity excitant consists of iron powder in 20-50 wt%, calcium oxide in 20-40 wt%, densifying agent 0.05-0.5 wt% and flyash 10-40 wt%, and is added into cement and concrete in the amount of 1-3 % of cementing material. The production process includes air drying and sieving iron powder, milling calcium oxide to obtain calcium oxide powder, and mixing the said material in the said ratio.

Owner:王杰

A construction method of asphalt pavement

A construction method of asphalt pavement is provided. the invention sets the construction process and the construction parameters of the asphalt pavement in detail, the pavement is smoother and denser than other asphalt pavements today, with good anti-loosening, corrosion and segregation resistance, As that crack in the pavement is avoided, the service life and the safety of the pavement is improved; At the same time, due to the effective distribution of the whole working procedure, the construction time can be greatly saved, and through the temperature control of the mixture, the waste of raw materials caused by the material transportation and the construction process can be greatly reduced, and the laying cost of the asphalt pavement can be saved.

Owner:SINOHYDRO BUREAU 9

Method for preparing ionic liquid/transition metal disulphide gas separating membrane and application thereof

InactiveCN106902648AImprove separation performanceImprove stabilitySemi-permeable membranesDispersed particle separationSolubilityGas separation

The invention discloses a method for preparing an ionic liquid / transition metal disulphide gas separating membrane and an application thereof. The method comprises the following steps: 1 ) transition metal disulphide powder MS2 (M means corresponding transition metal) and n-butyllithium are mixed to obtain the lithium intercalated transition metal disulphide powder LixMS2; 2) adding the LixMS2 into ionic liquid for ultrasonic mixing to obtain the MS2 ionic liquid dispersion liquid; and 3) performing vacuum pumping filtration on the dispersion liquid to obtain the required ionic liquid / transition metal disulphide gas separating membrane which is used for gas separation. The LixMS2 is interacted with ionic liquid during an ultrasonic process to form a MS2 two-dimensional layered material, the ionic liquid is subjected to in-situ introduction to the intermediate of a two-dimensional sheet layer; LiBF4 generated in ultrasound can increase the CO2 separating performance of a composite film; and ionic liquid confined effect and difference of different gas solubility are used for realizing the gas separating. The prepared gas separating membrane has high application value as well as concise and efficient preparation process.

Owner:ZHEJIANG UNIV

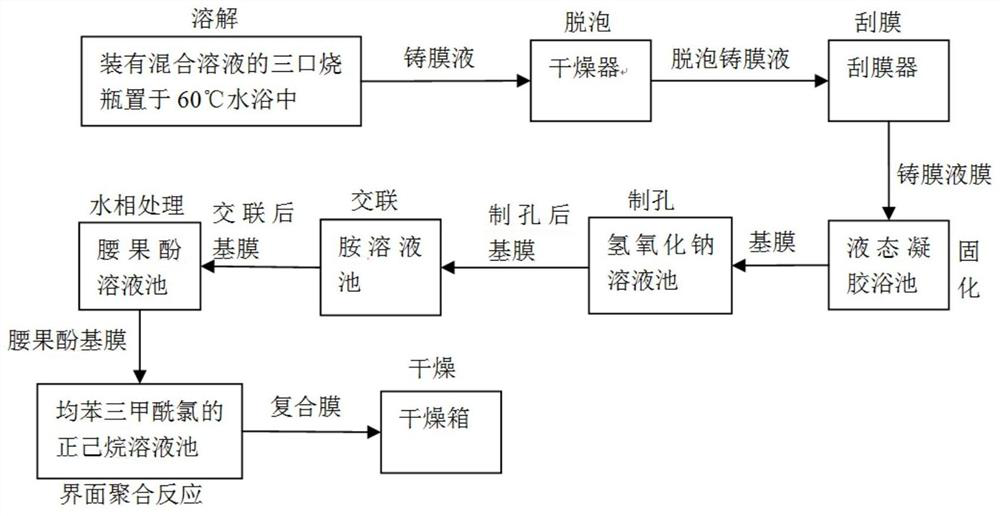

Polyarylester composite nanofiltration membrane and preparation method thereof

PendingCN112675714ASolvent resistance and separation performanceImprove separation performanceReverse osmosisComposite materialNanofiltration

The invention discloses a polyarylester composite nanofiltration membrane and a preparation method thereof. The method comprises the following steps: S100, providing a base membrane; S200, loading cardanol molecules on the surface of the base membrane to obtain a base membrane loaded with the cardanol molecules; S300, loading trimesoyl chloride on the surface of the base membrane loaded with the cardanol molecules; and S400, carrying out interfacial polymerization reaction on cardanol molecules on the base membrane treated in the step S300 and trimesoyl chloride to generate a polyarylester layer, thereby obtaining the polyarylester composite nanofiltration membrane. Cardanol is selected to replace a traditional water-phase monomer to be subjected to interfacial polymerization reaction with organic-phase trimesoyl chloride, so that the prepared solvent-resistant composite nanofiltration membrane has solvent resistance and high separation performance.

Owner:CHUZHOU UNIV

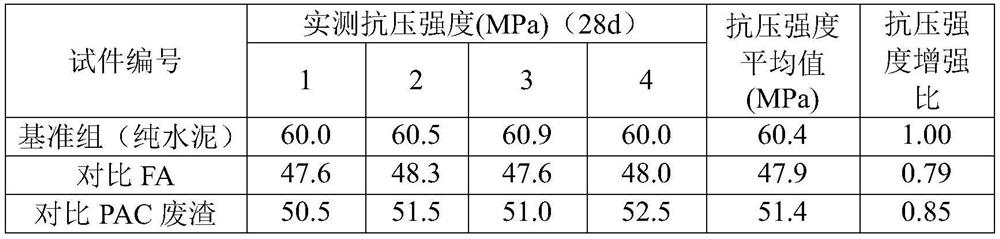

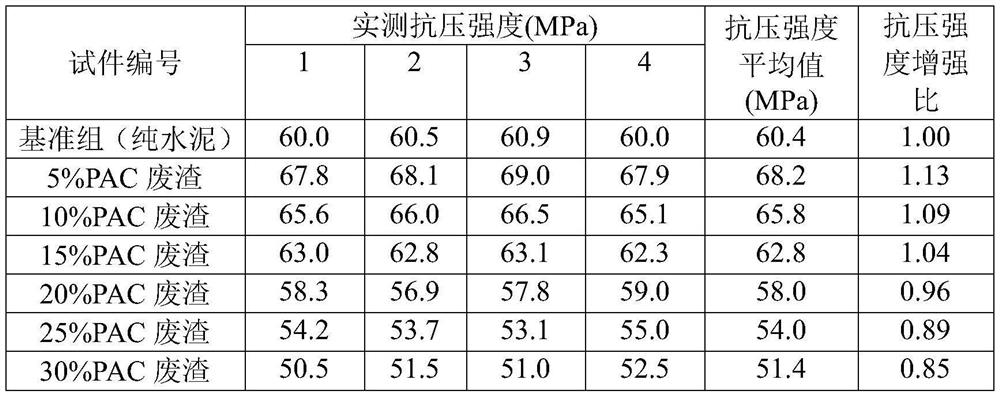

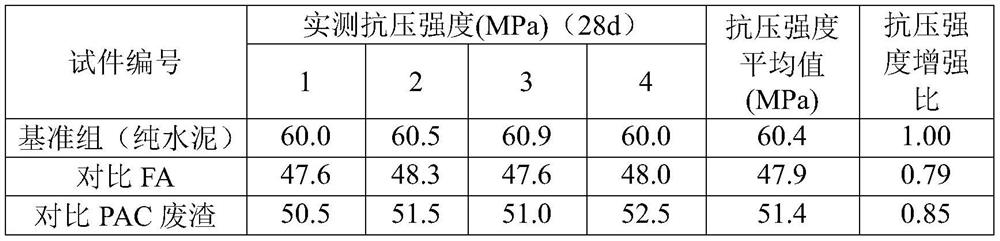

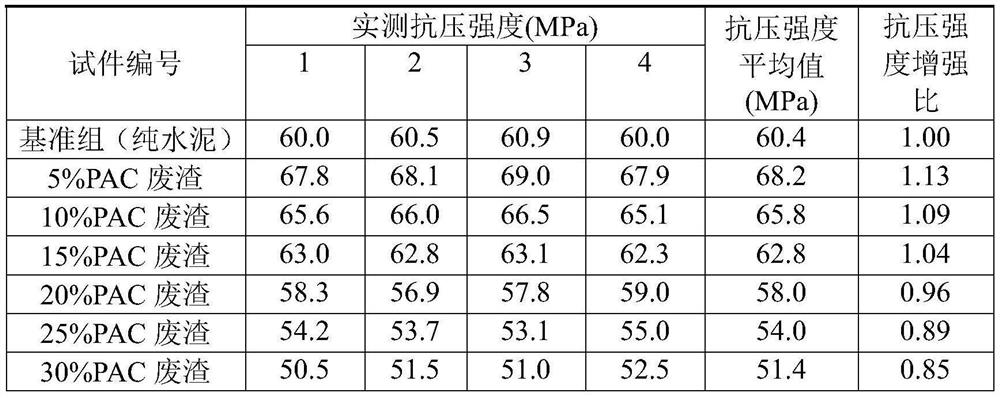

Polyaluminum chloride waste residue dry-mixed mortar and preparation method thereof

ActiveCN111978050APotentially chemically active and effectivePotential chemical activationSolid waste managementEnvironmental engineeringCement mortar

The invention discloses polyaluminum chloride waste residue dry-mixed mortar and a preparation method thereof. The dry-mixed mortar comprises the following raw materials in parts by mass: 4-8 parts ofheat activated polyaluminum chloride waste residues, 23-25 parts of cement, 55-60 parts of sand, 4-6 parts of fly ash, 0.05-0.15 parts of a defoamer, 0.20-0.22 parts of a water reducing agent and a polymer emulsion accounting for 5%-9% of the total mass of the raw materials. The industrial waste polyaluminum chloride waste residues and fly ash are adopted to replace high-energy-consumption cementto prepare the cement mortar, mass stacking of the polyaluminum chloride waste residues can be reduced effectively, the use amount of high-energy-consumption cement can be reduced, and the social andeconomic benefits are good. The preparation method of the polyaluminum chloride waste residue dry-mixed mortar is simple, low in cost and beneficial to industrialized production and promotion, can significantly improve the resource utilization of polyaluminum chloride waste residues, and has important significance in reducing construction costs, reducing environmental pollution and the like.

Owner:HENAN POLYTECHNIC UNIV +1

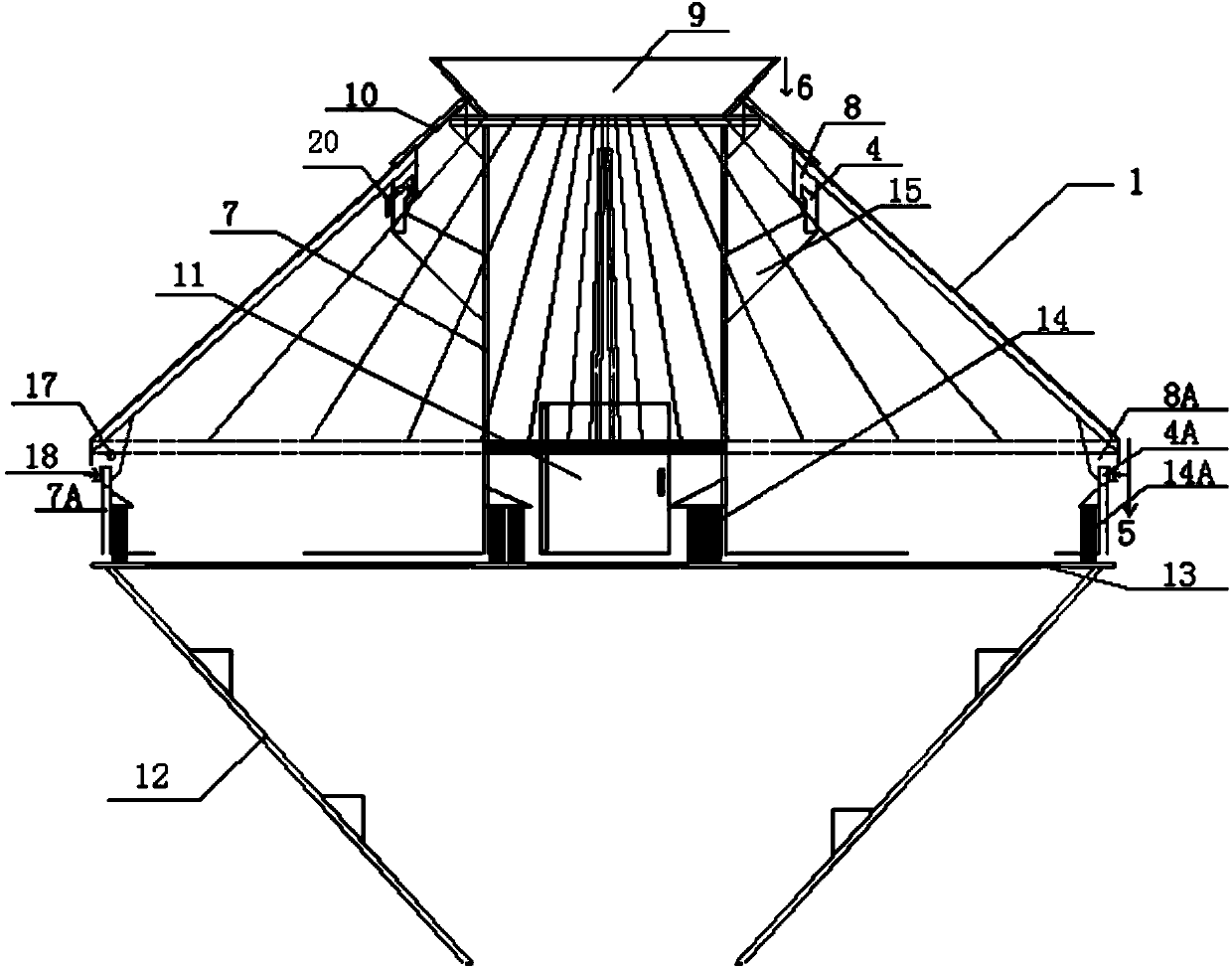

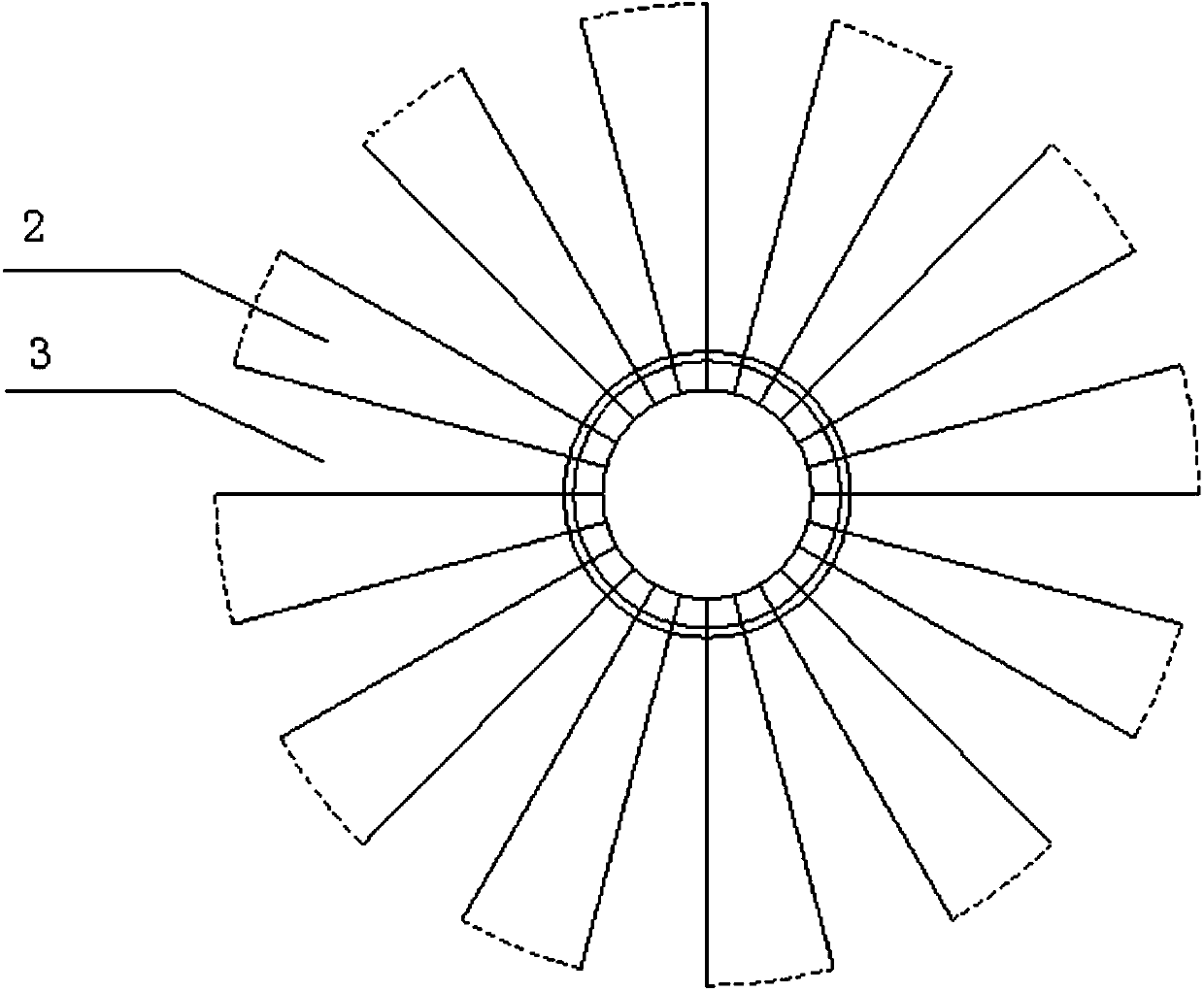

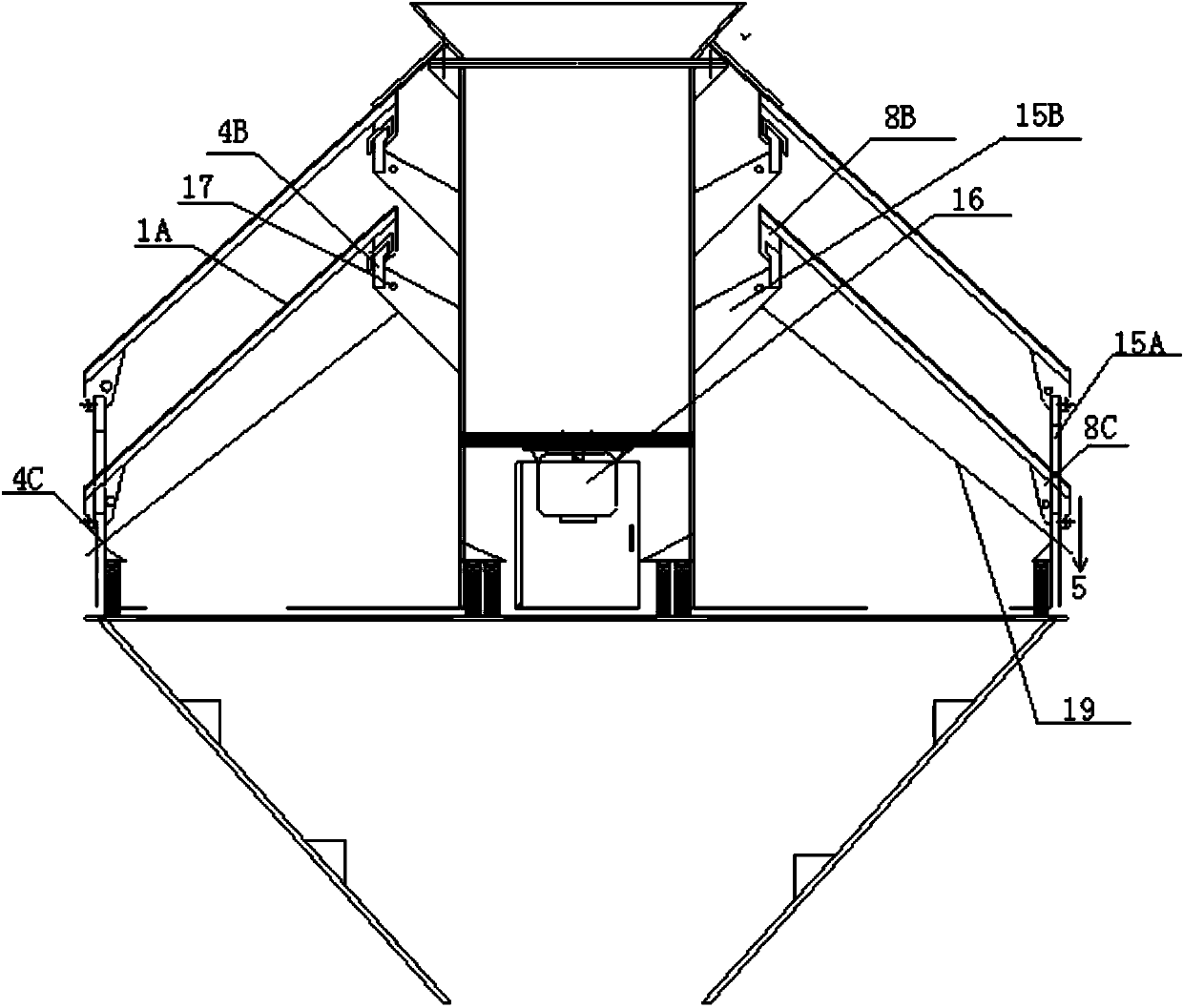

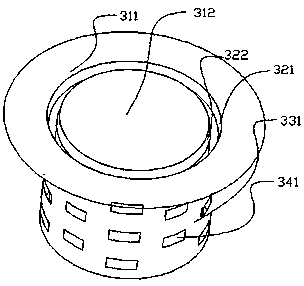

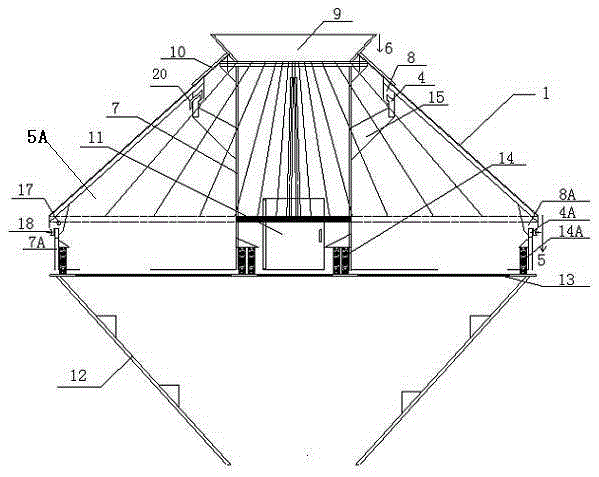

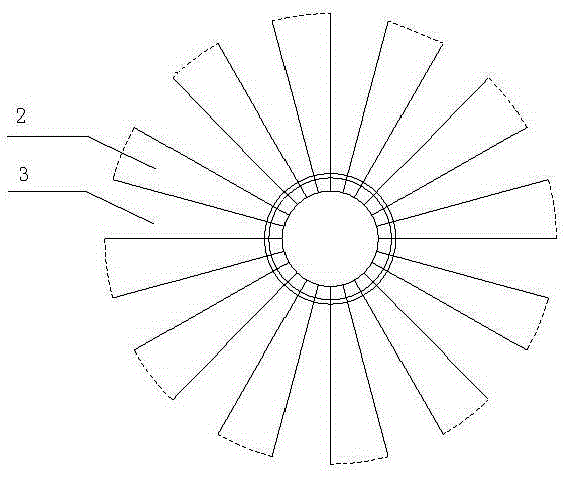

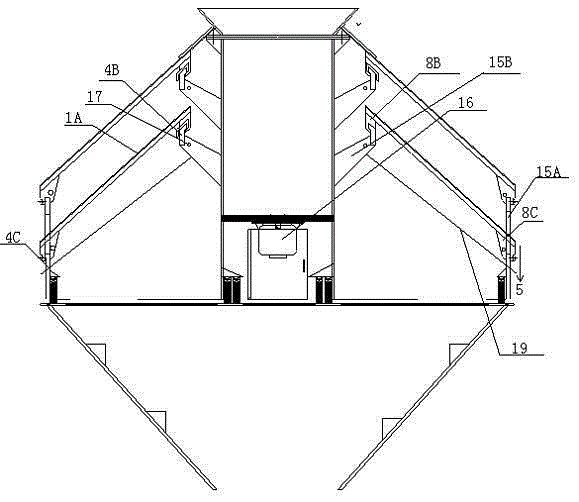

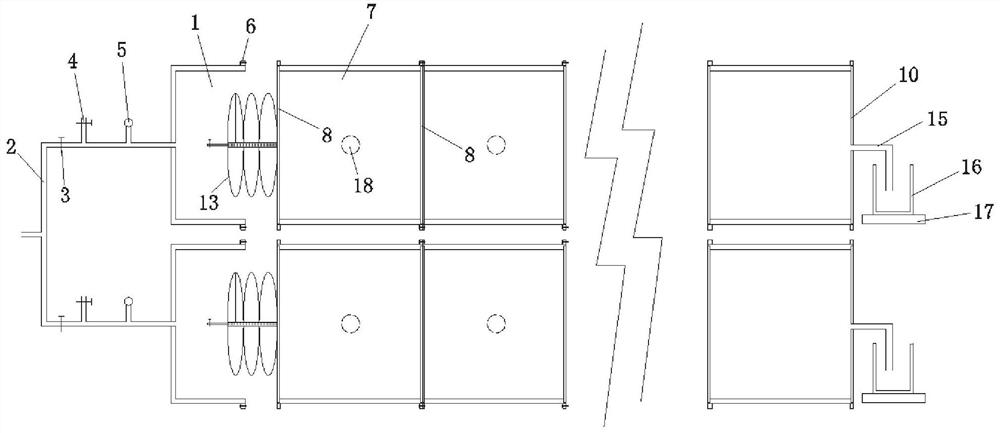

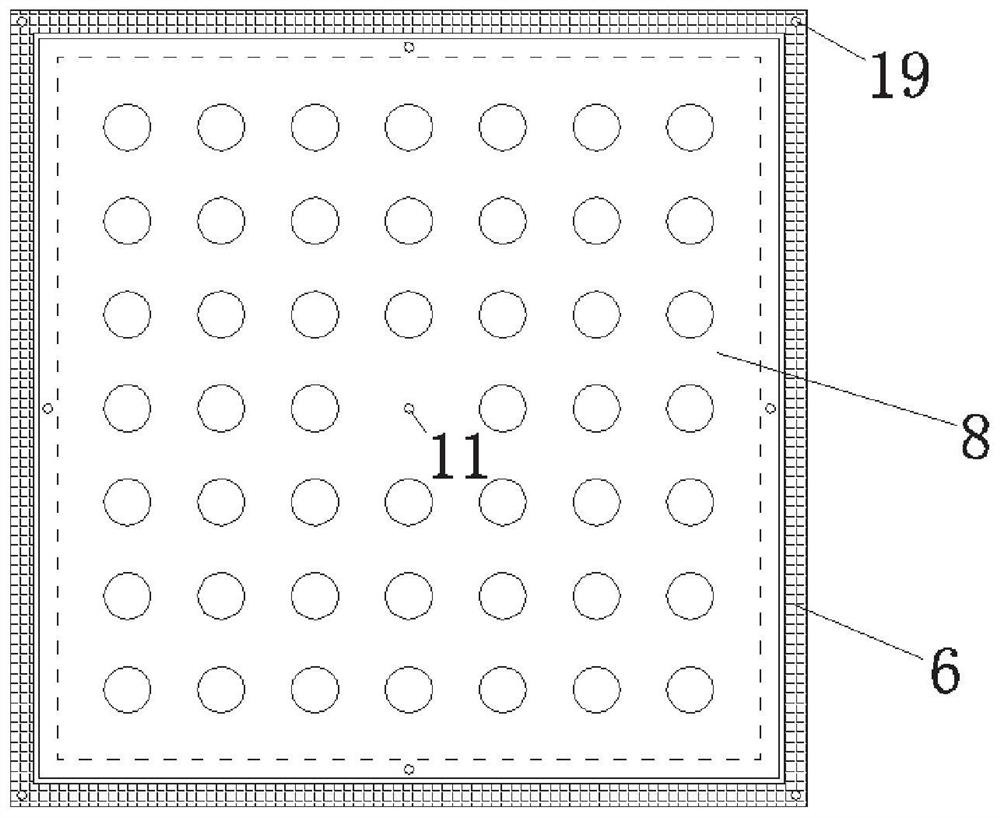

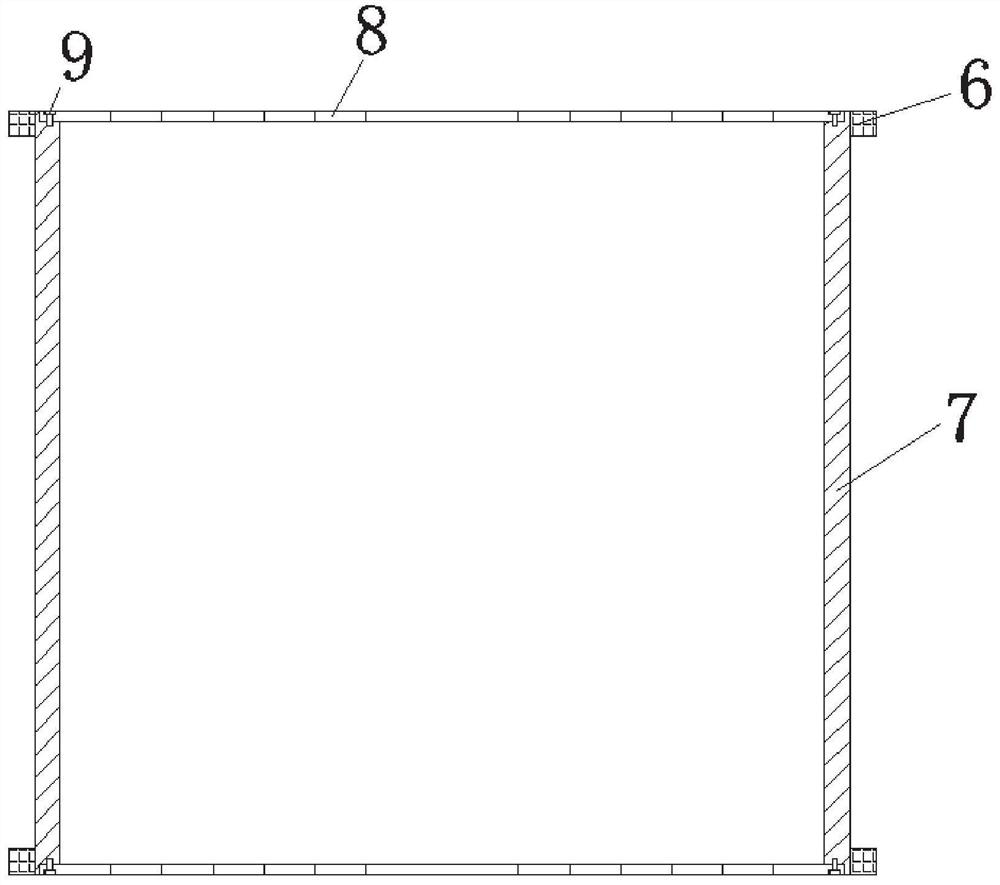

Unpowered anti-blocking grate bar slide sieve

ActiveCN103464371ALong segregation effectSpeed up the flowSievingScreeningSmall footprintEngineering

An unpowered anti-blocking grate bar slide sieve comprises a sieve plate (1). The sieve plate (1) is provided with a plurality of gaps (3) in the material sliding direction, wherein one end of every gap (3) is open. Grate bars (2) are arranged between the adjacent gaps (3). The unpowered anti-blocking grate bar slide sieve is characterized in that the sieve plate is installed on a beam (4) inside a sieve body or an external fixable object and is inclined in the material sliding direction relative to the horizontal plane, one end of the sieve plate (1) is located below a feeding port (6), and the other end of the sieve plate (1) is provided with a discharging port (5). The unpowered anti-blocking grate bar slide sieve is unpowered, does not block materials and is low in production loss, gaps of the grate bars can be adjusted on the site according to material grain size requirements of a device or a client, the grate bars are made of alloy castings, the slide sieve is ultra high in abrasion resistance and heavy load, high in corrosion resistance, low in manufacturing cost, simple to install and maintain and small in occupied space, concentrated sieving of products is achieved, materials are collected in a concentrated mode, the capacity requirements of large mining devices can be met, and the materials with the grain sizes of 3-300mm can be sieved.

Owner:包头市屹峰建材外加剂有限公司

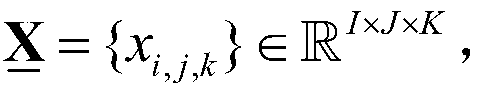

Fast shift invariant CPD (canonical polyadic decomposition) method applicable to multi-testee fMRI (functional magnetic resonance imaging) data analysis

ActiveCN109498017AImprove separation performanceGood development prospectsMedical imagingDiagnostic signal processingLeast squaresDecomposition

The invention discloses a fast shift invariant CPD (canonical polyadic decomposition) method applicable to multi-testee fMRI (functional magnetic resonance imaging) data analysis, and belongs to the field of medical signal processing. Based on a shift invariant CPD algorithm, testee shared SM (spatial map) components, shared TC (time course) components and all testee strength are updated and estimated by an alternating least square method, high-dimensional shared SM components and original multi-testee fMRI data are subjected to matrix multiplication and conversion into low-dimensional data without affecting time delay estimation performances, so that algorithm operation is accelerated, and operation memory is reduced. Needed memory is obviously reduced, and task related components of taskportion multi-testee fMRI data can be rapidly and effectively estimated.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

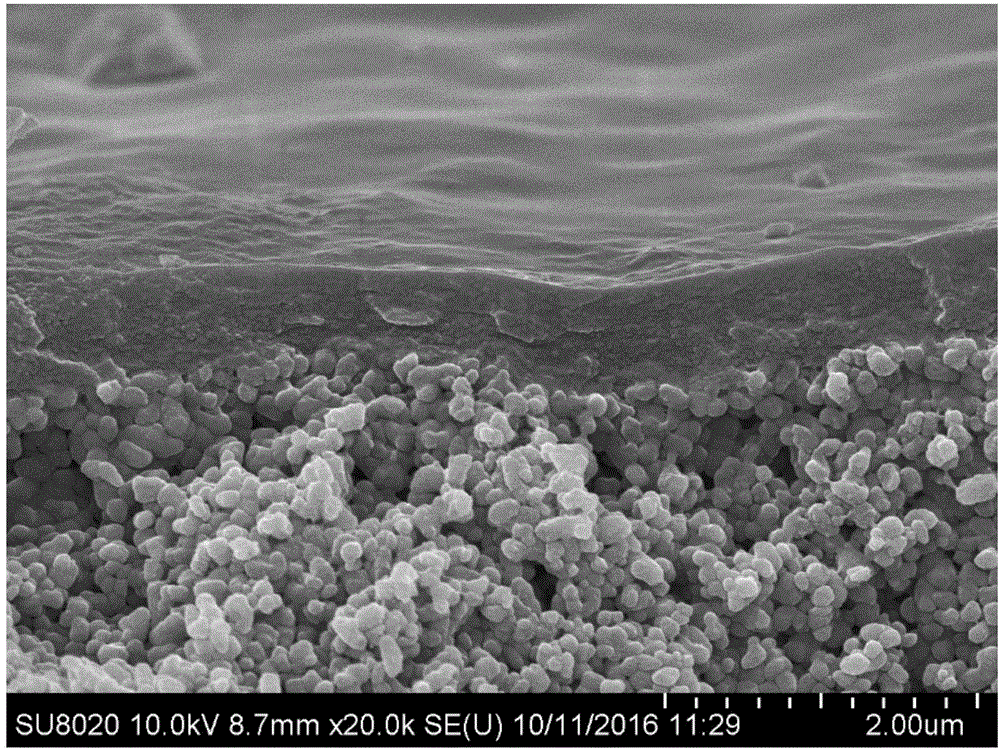

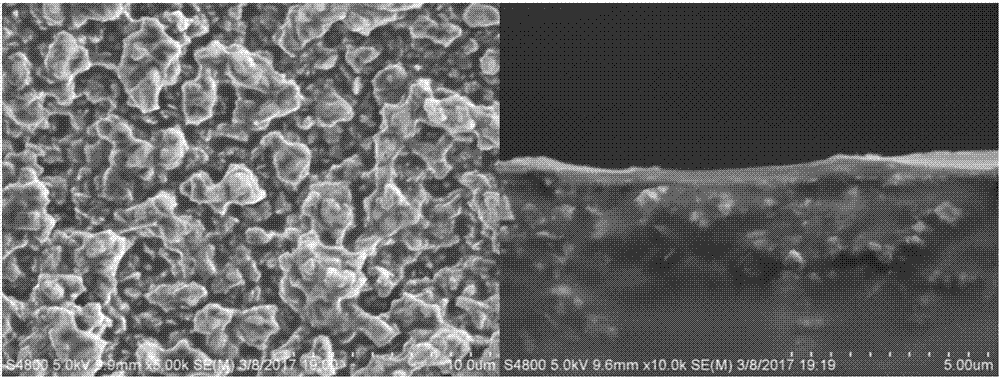

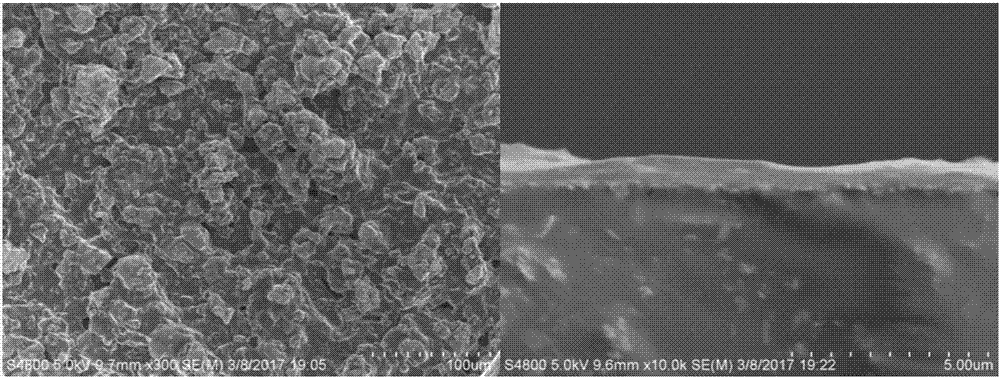

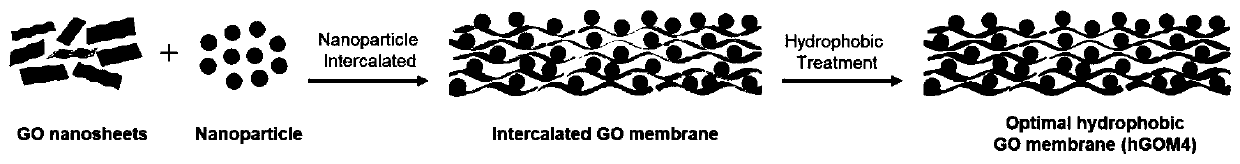

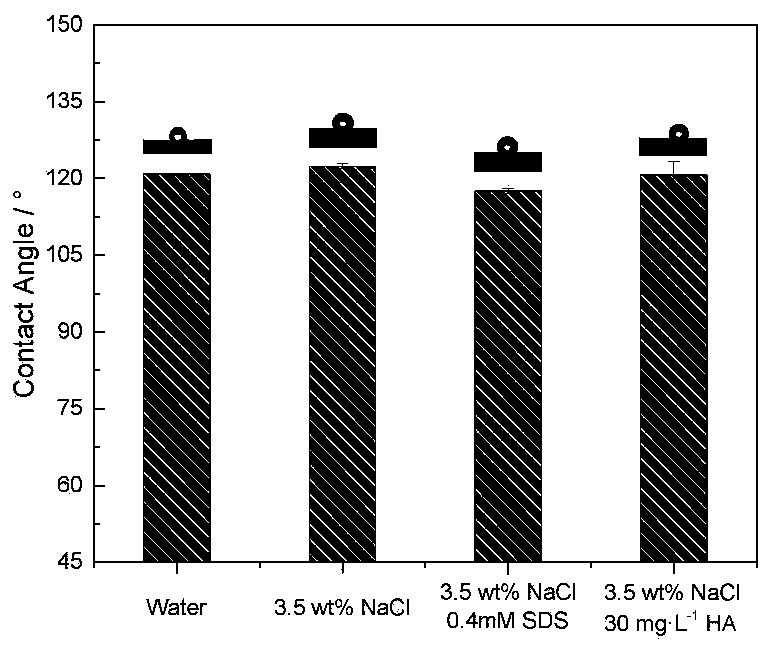

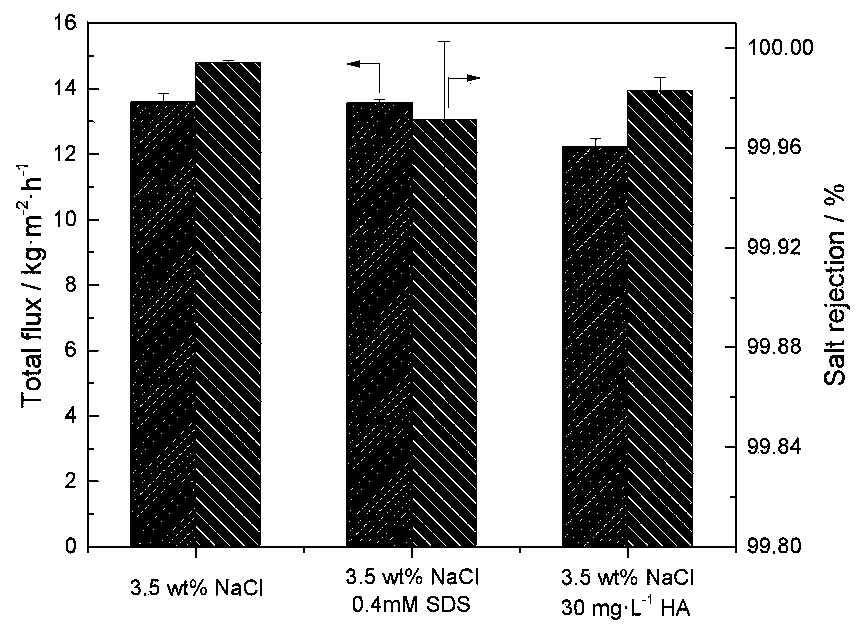

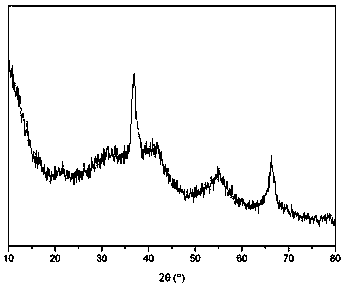

Method for preparing hydrophobic graphene film

ActiveCN111450711AImprove separation performanceSimple preparation processMembranesGeneral water supply conservationGraphene membraneGraphite oxide

The invention relates to a method for preparing a hydrophobic graphene film. Interlayer pore channels and surface roughness of the graphene film are enhanced by intercalating nanoparticles, and then the hydrophobic graphene film is obtained by long-chain alkane treatment. According to the method, the surface roughness and hydrophobicity of the graphene oxide can be effectively improved, the preparation process is simple, and effective desalination and anti-pollution performance of the hydrophobic graphene film in the membrane distillation process can be conveniently realized.

Owner:NANJING UNIV OF TECH

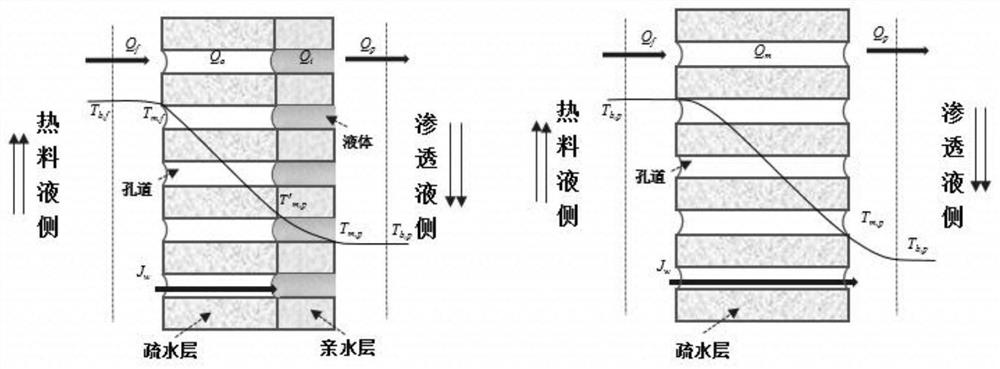

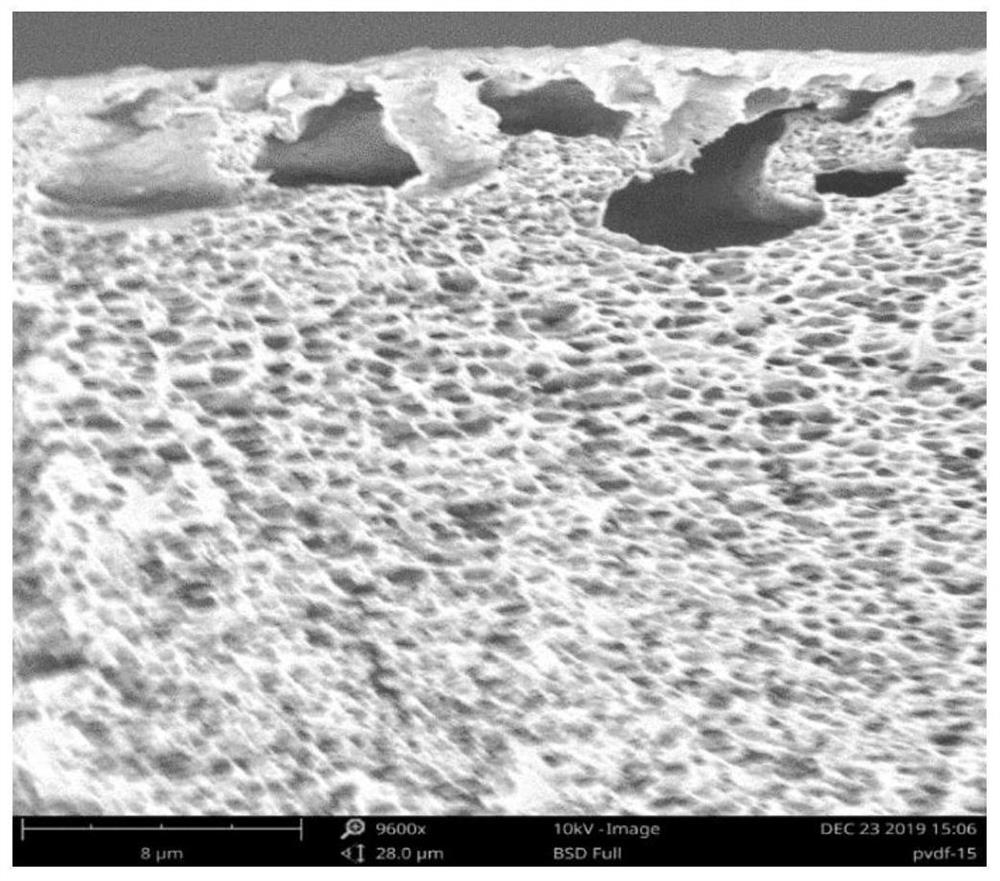

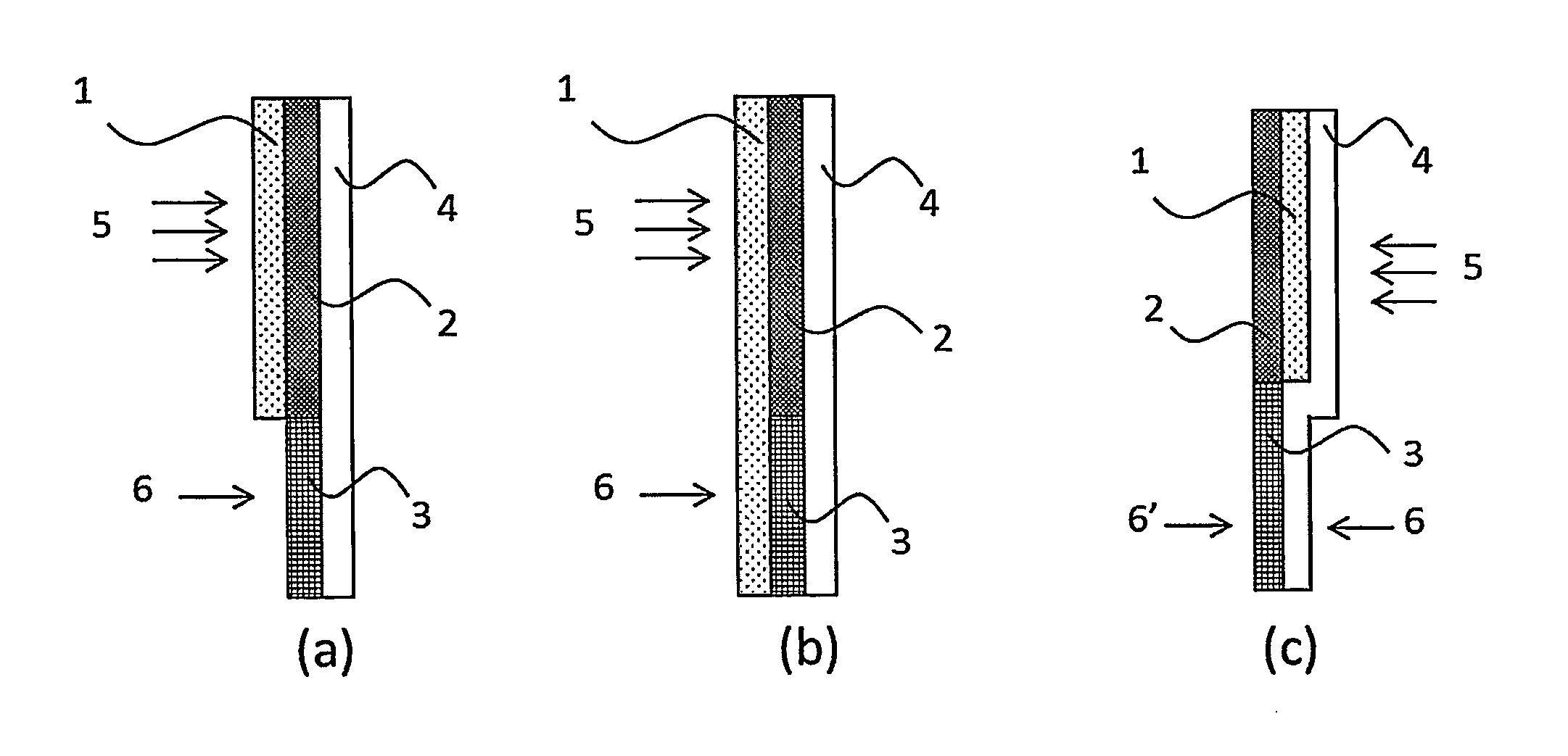

Hydrophobic/hydrophilic composite membrane with nuclear track etching membrane as base membrane as well as preparation method and application of same

InactiveCN111871221AUniform hydrophilicityImprove hydrophilicityMembranesDistillationPolyesterPolymer science

The invention discloses a hydrophobic / hydrophilic composite membrane taking a nuclear track etching membrane as a base membrane as well as a preparation method and application of the same. The nucleartrack etching membrane is a polyethylene glycol terephthalate nuclear pore membrane, wherein one surface of the hydrophobic / hydrophilic composite membrane is a hydrophobic polyvinylidene fluoride membrane, and the water contact angle is 90-100 degrees; a hydrophilic polyethylene glycol terephthalate nuclear pore membrane is arranged on the other surface of the membrane, and the water contact angle is 55-65 degrees. The hydrophobic / hydrophilic double-layer membrane prepared by the method is narrow and uniform in pore size distribution, good in air permeability and good in mechanical strength.A novel composite membrane structure with excellent performance is provided for membrane distillation, wherein waste heat of low-temperature feed liquid is fully utilized for direct contact type membrane distillation, concentration and separation, and the permeation flux and the heat efficiency of the process are improved. The prepared hydrophobic / hydrophilic composite membrane is good in application effect in direct contact membrane distillation and stable in operation; compared with a PVDF hydrophobic membrane supported by polyester non-woven fabric, the permeation flux of the hydrophobic / hydrophilic composite membrane is increased by 23.70%.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

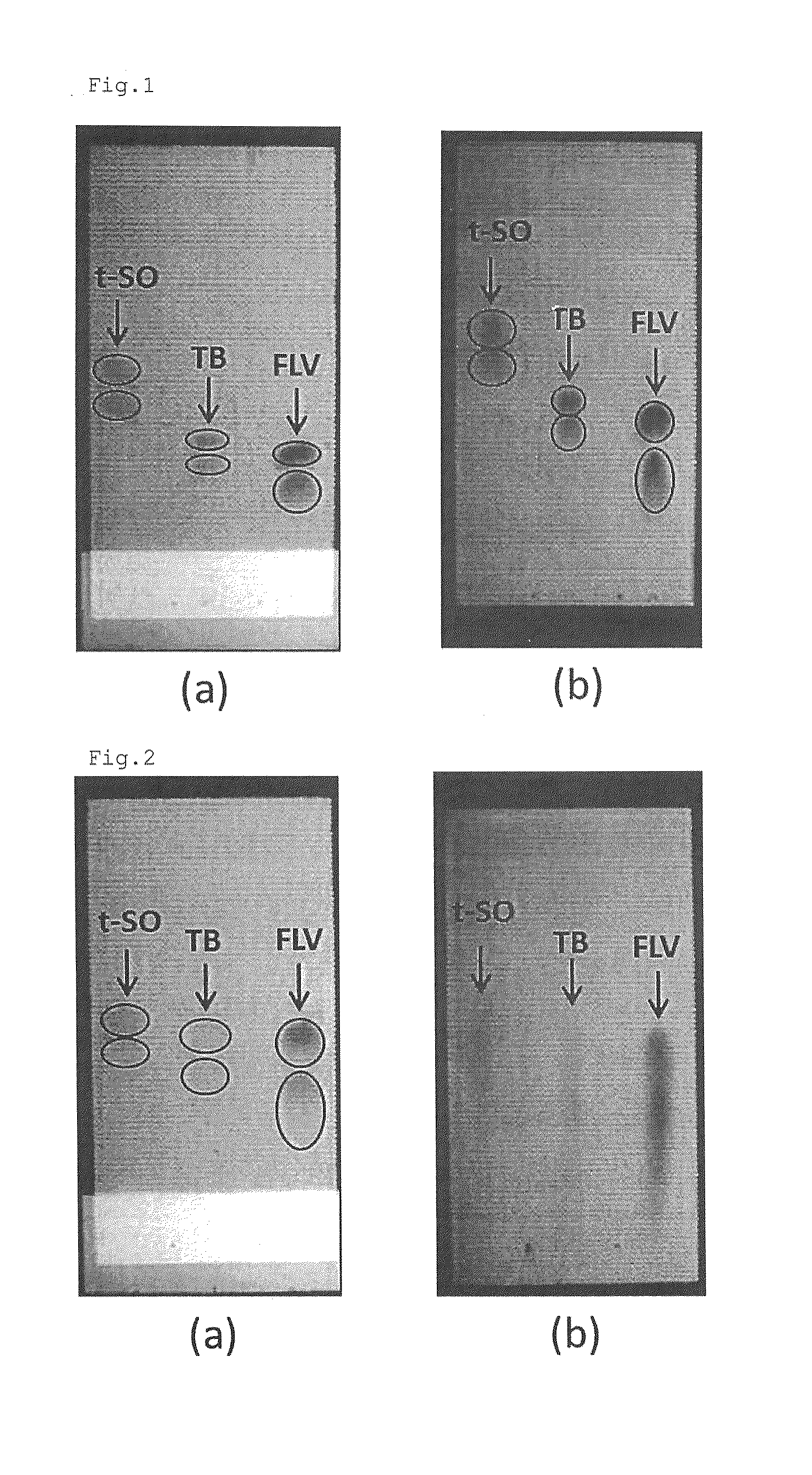

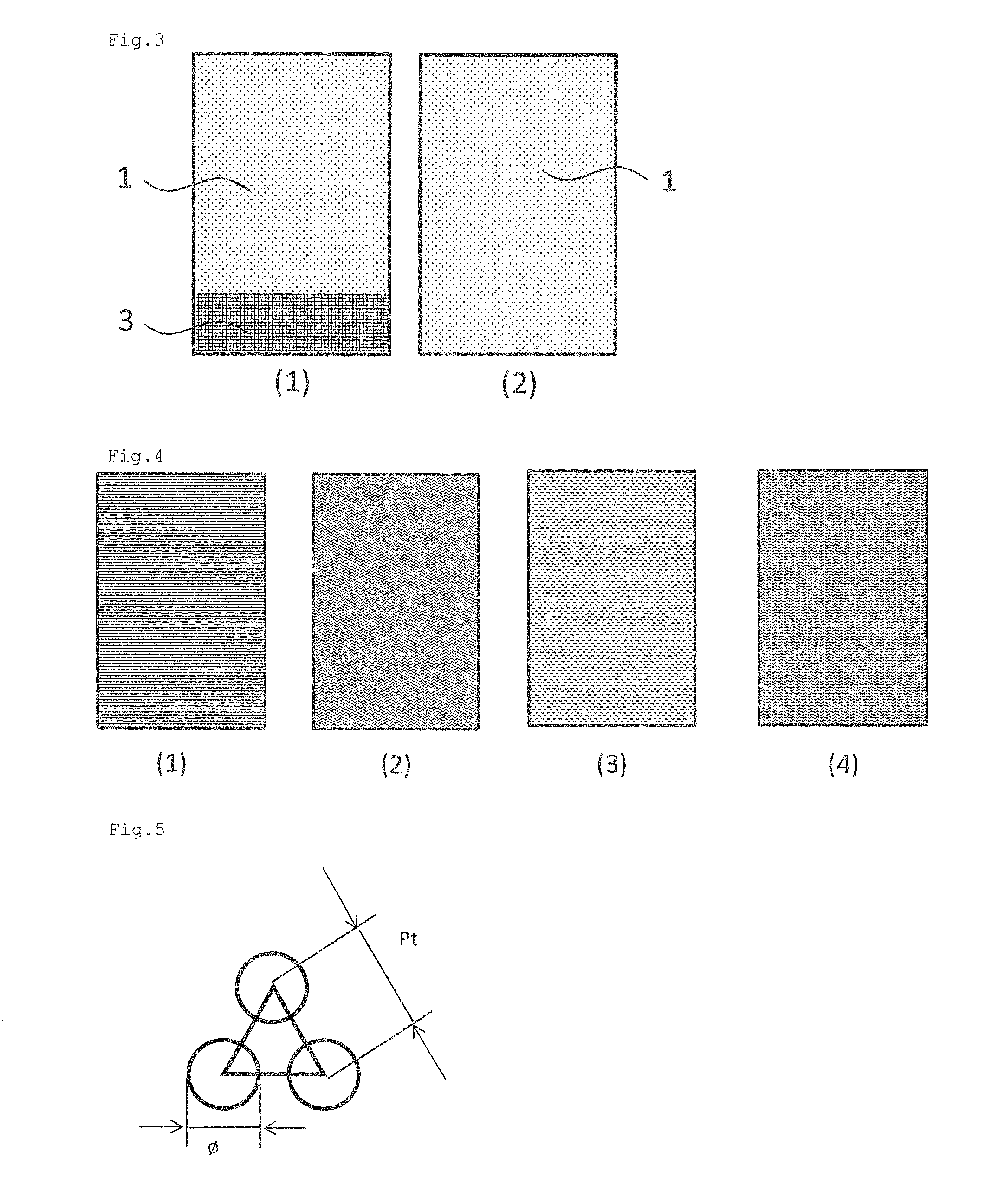

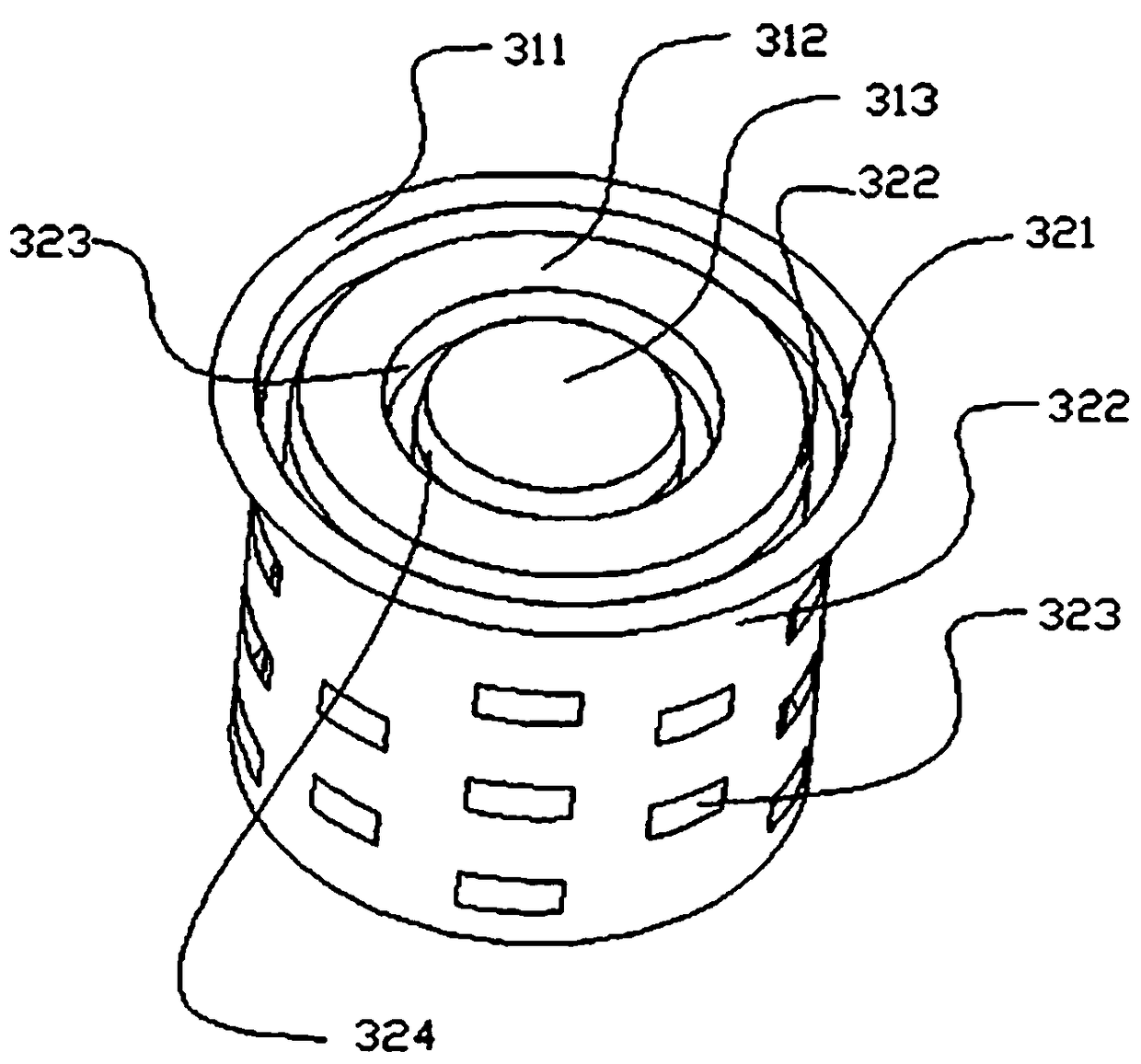

Chromatographic medium

ActiveUS20140374333A1Improve separation performanceReliable detectionIon-exchange process apparatusComponent separationChemistrySeparating agent

Provided is a chromatographic medium capable of separating and detecting target substances without the use of other components. A chromatographic medium having a separating agent layer, which is used to separate target substances, a filling agent layer, which is used to fix the target substances before the target substances are separated, and a permeation layer, which is used to enable permeation of the target substances separated by the separating agent layer, wherein the filling agent layer comes into contact with the separating agent layer via a plane that intersects the direction of development of the target substances in the chromatographic medium and is positioned on the upstream side in the direction of development, the separating agent layer exhibits separability of the target substances and exhibits optical responsiveness to ultraviolet rays, and the permeation layer exhibits optical responsiveness that are different from those of the target substances and the separating agent layer.

Owner:DAICEL CHEM IND LTD

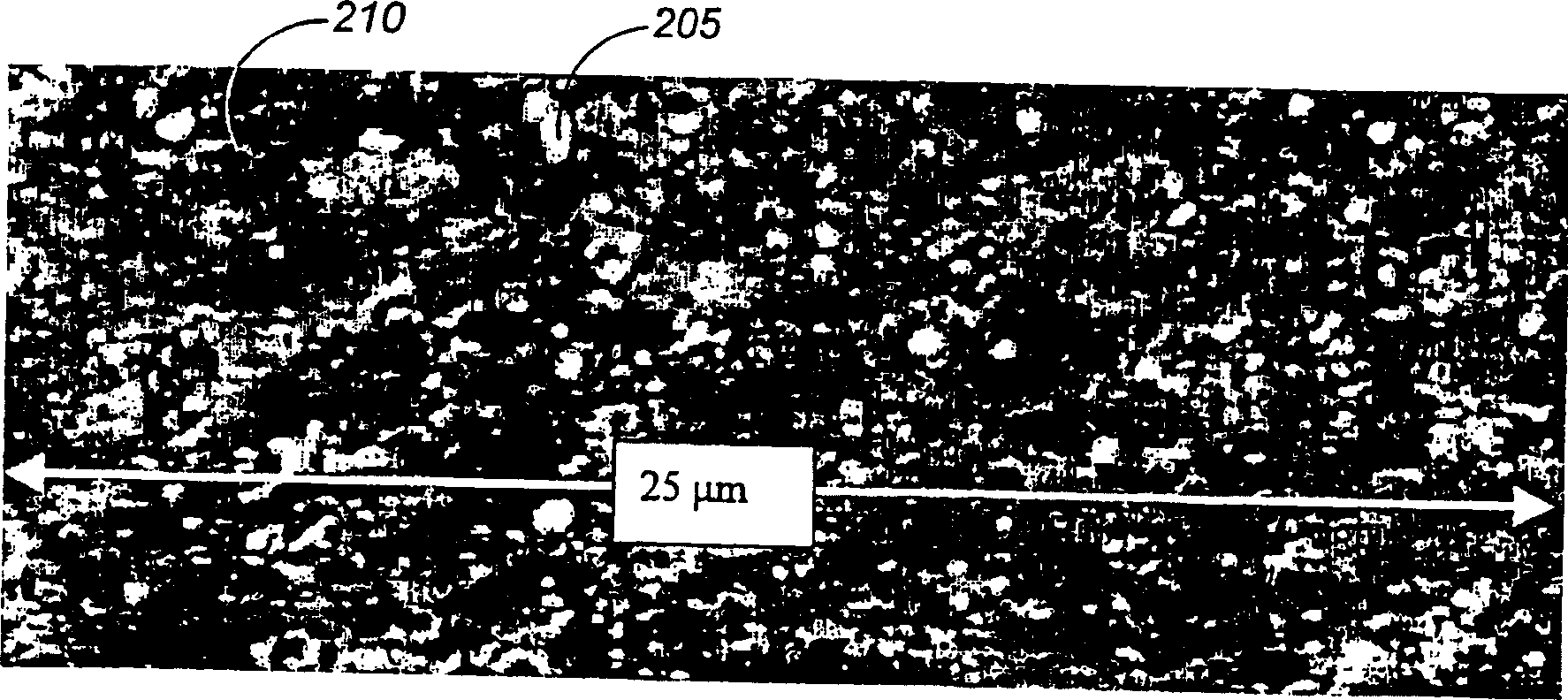

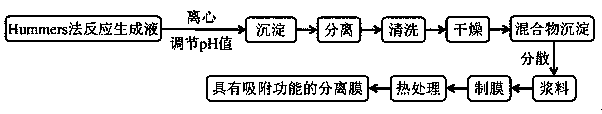

Preparation method of graphene oxide separation membrane with adsorption function, and product prepared therethrough

ActiveCN110559873AImprove separation performanceLow costSemi-permeable membranesOther chemical processesManganese oxideGraphite oxide

The invention discloses a preparation method of a graphene oxide separation membrane with an adsorption function, and a product prepared therethrough. The method comprises the following steps: centrifuging a reaction generated liquid used as a synthesis precursor, obtained after Hummers technique preparation of grpahene oxide, adjusting the pH value of the centrifuged liquid to obtain a precipitate, and performing filtration separation, washing and drying processes to obtain a mixed precipitate of nanometer hydrated manganese oxide and graphene oxide; ultrasonically dispersing the mixed precipitate in water to obtain a membrane preparation slurry; and performing a certain membrane production process on the slurry to prepare the graphene oxide separation membrane product with the adsorptionfunction, on a porous inorganic or organic carrier. The method has the advantages of greenness, environment friendliness, low cost, simple technique, excellent product performances and wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

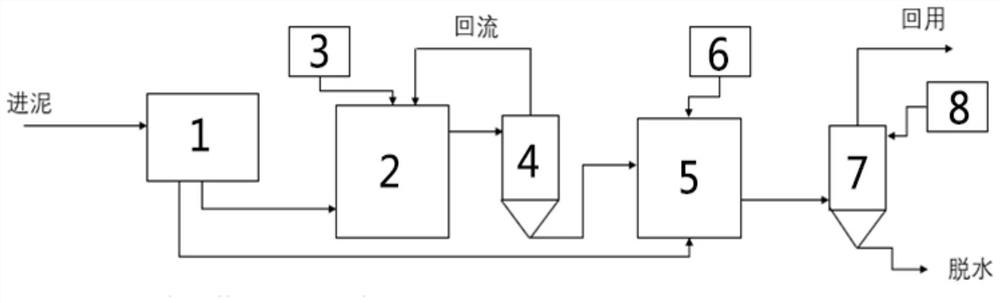

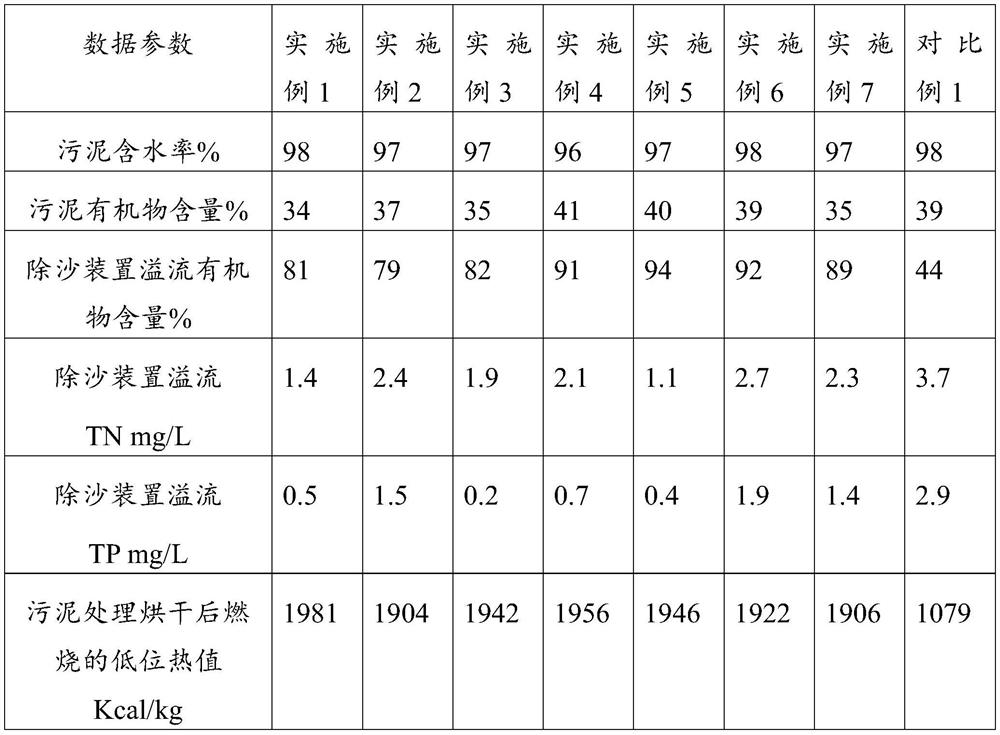

Sludge treatment system and method

ActiveCN112759210AImprove separation performanceLess dosageWater treatment compoundsSpecific water treatment objectivesSewageSludge

The invention provides a sludge treatment system and method, and belongs to the technical field of sludge treatment. The sludge treatment system comprises a sludge screening device, a sludge conditioning device, a sludge concentration device, an acidification device and a silt separation device. Sludge of a sewage plant is subjected to screening, hardening and tempering, concentration, acidification, silt separation and other processes, silt is separated from the sludge, the combustion heat value of the sludge is increased, and reduction and recycling of the sludge are achieved.

Owner:AWS ENVIRONMENT TECH LTD

A kind of polyaluminum chloride waste slag recycled concrete curb and its preparation method

ActiveCN112159180BPotentially chemically active and effectivePotential chemical activationAluminium chlorideSlag

The invention discloses a polyaluminum chloride waste slag regenerated concrete curb and a preparation method thereof. The raw materials include: sand 600-690kg / m in terms of mass per unit volume 3 , recycled coarse aggregate 375 ~ 400kg / m 3 , natural coarse aggregate 750~800kg / m 3 , Thermally activated polyaluminum chloride waste residue 40-80kg / m 3 , Cement 220~260kg / m 3 , Fly ash 40~80kg / m 3 , the water-to-cement ratio is 0.40-0.45; the amount of water-reducing agent is 0.30-0.55% of the gelling material, the amount of defoamer is 0.10-0.15% of the gelling material, and the amount of alkali activator is 2.5-0.5% of the gelling material 5.3%. The present invention adopts industrial waste polyaluminum chloride waste slag and recycled aggregate to make road curbs. The production method is simple and the cost is low, which can effectively reduce the large amount of polyaluminum chloride waste slag and construction waste piled up, and can also reduce the waste of high energy consumption cement. The amount used is of great significance to reduce construction costs and reduce environmental pollution, and has good social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

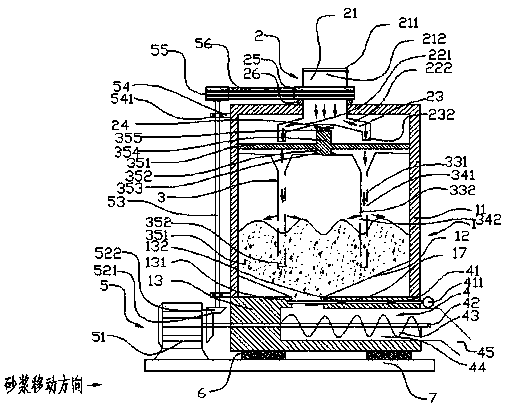

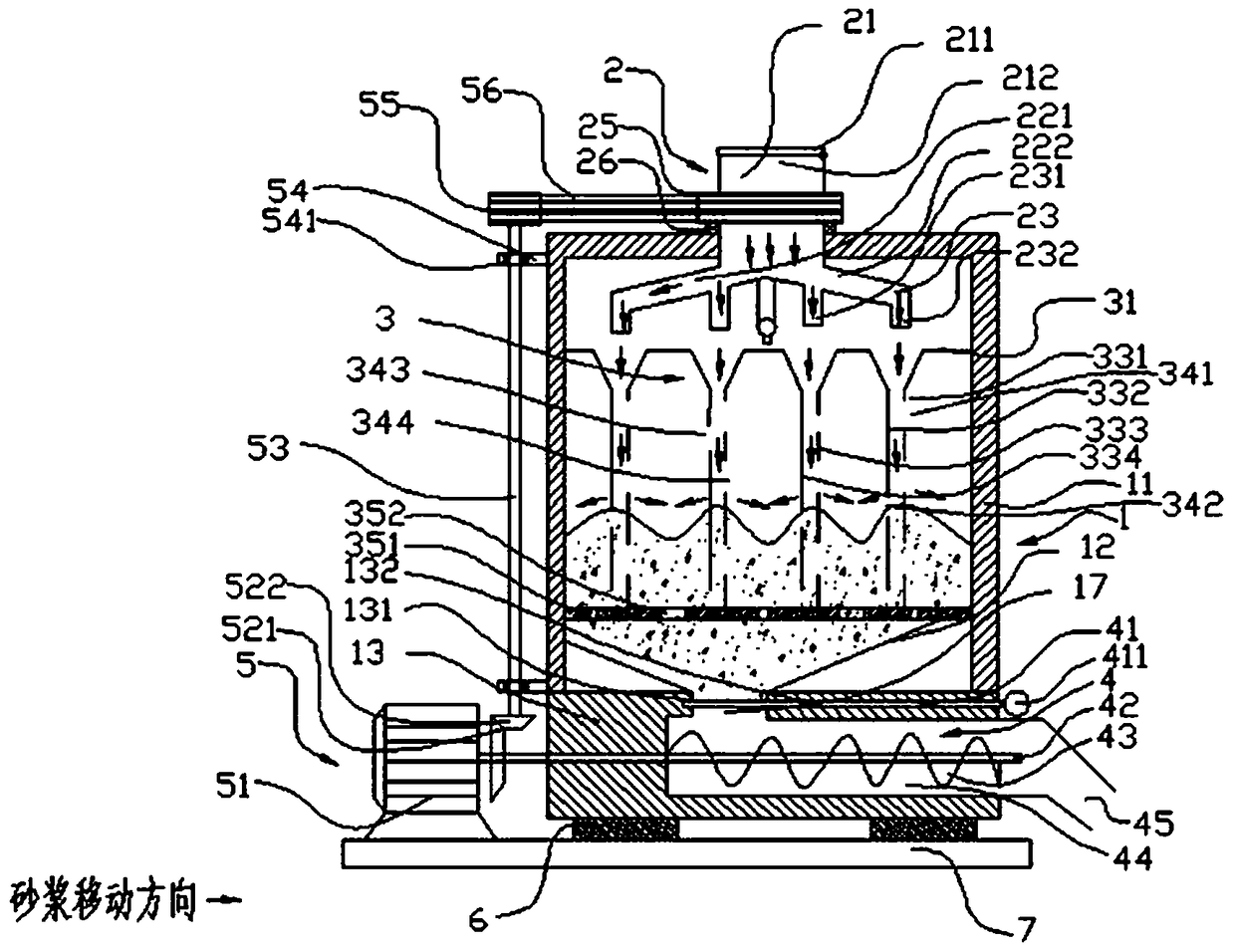

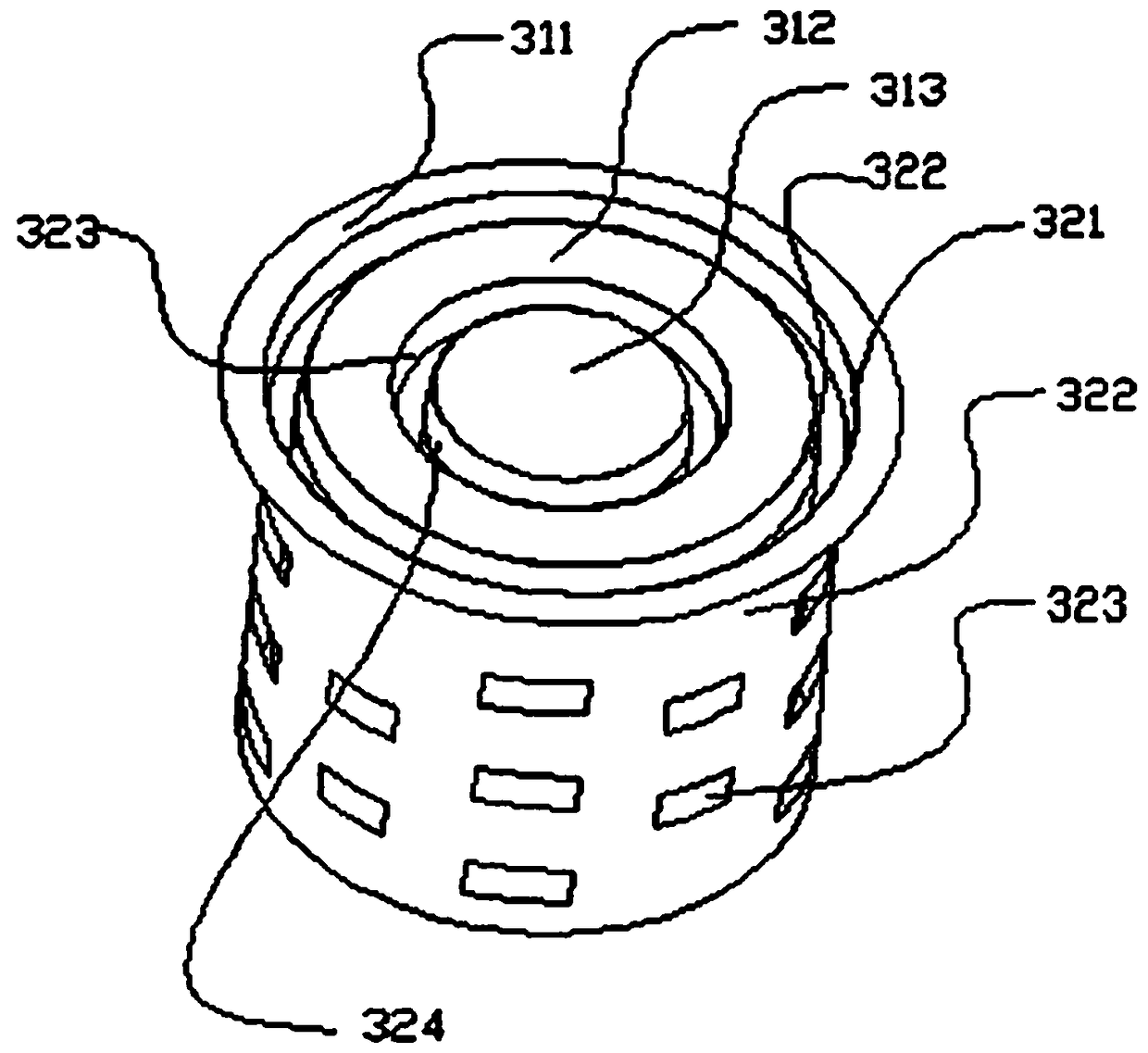

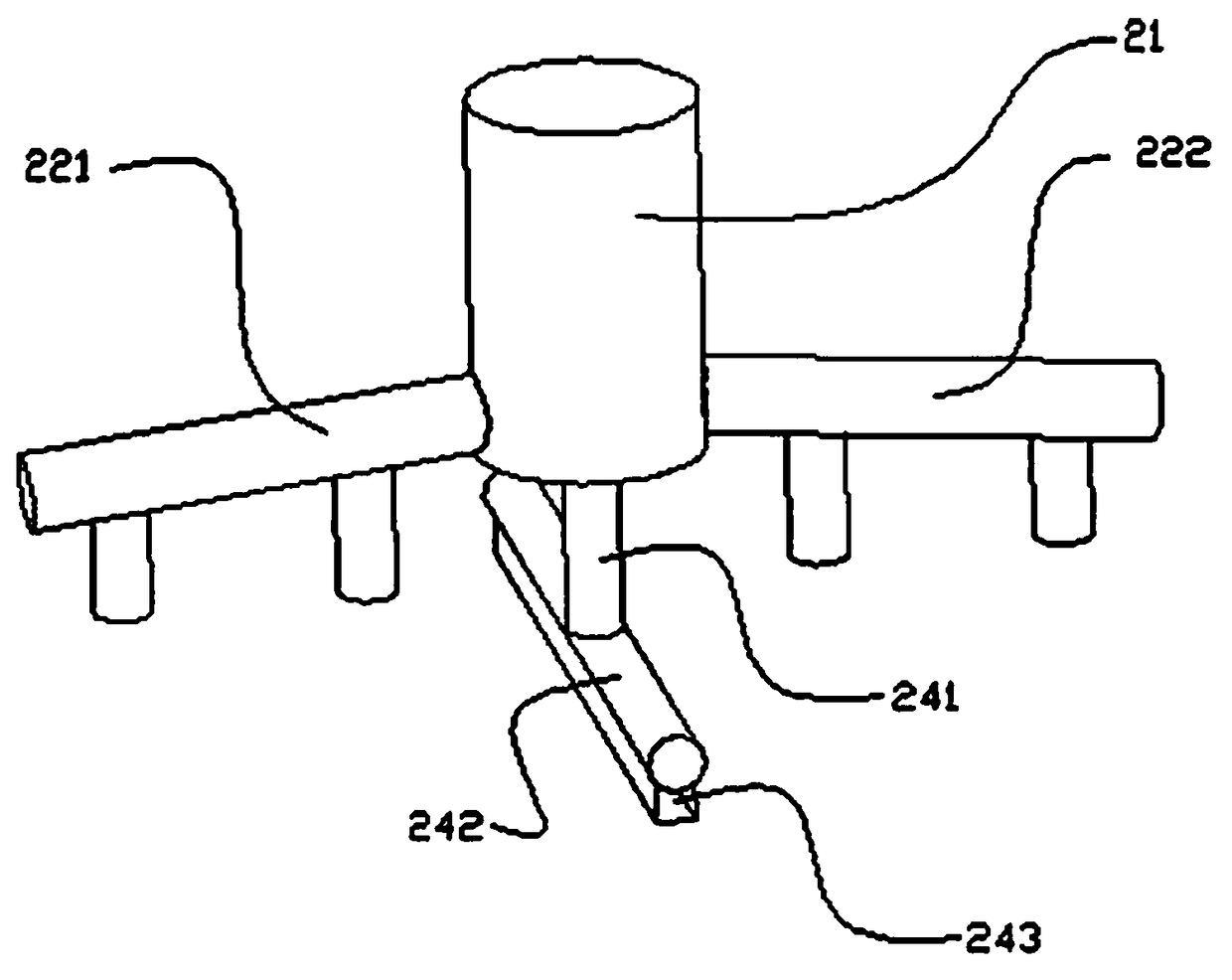

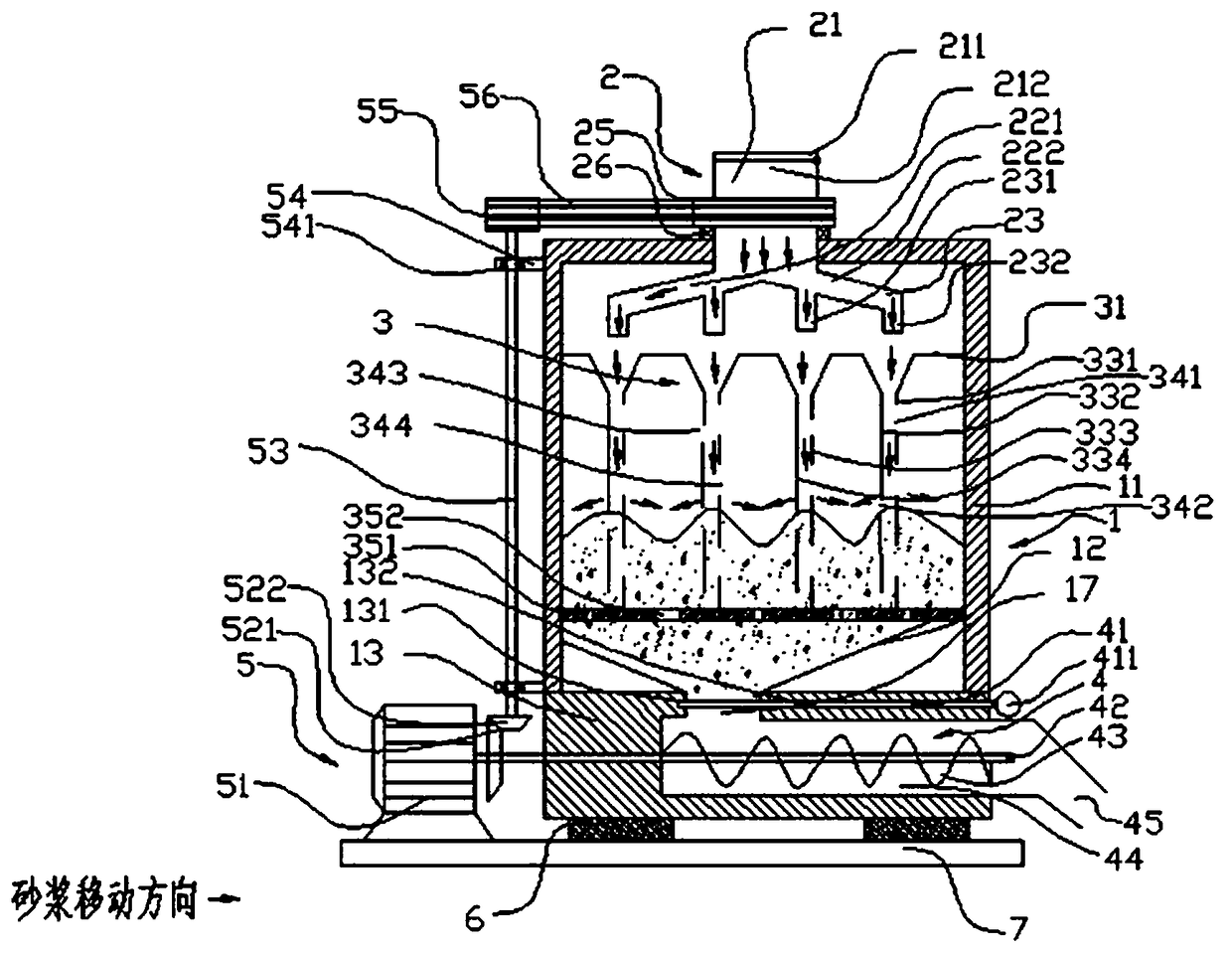

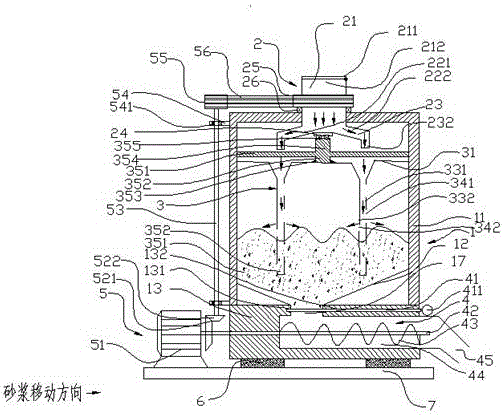

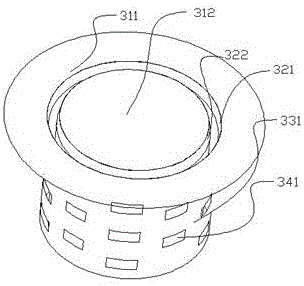

Dry-mixed mortar anti-segregation structure

InactiveCN106315251BQuality improvementImprove separation performanceLoading/unloadingGear wheelTransmission belt

The invention discloses an anti-isolation structure for dry-mixed mortar. The anti-isolation structure comprises a tank body, a material separating device, an anti-isolation structure, a discharge mechanism, a drive mechanism, shock absorption rubber mats and a pedestal; a material separating assembly is arranged on the center position of the upper part of the tank body; the part, extending out of the tank body, at the upper end of the material separating assembly is sleeved by a driven gear; a charge hole is formed in a position, above the driven gear, of the material separating assembly; a charge hole cover is arranged on the charge hole; a transmission belt is mounted at the periphery of the driven gear; one end of the transmission belt is in transmission connection with the driven gear, and the other end of the transmission belt is in transmission connection with the drive mechanism. The anti-isolation structure disclosed by the invention can prevent isolation of mortar very well, and improves quality of the mortar during building. The anti-isolation structure disclosed by the invention is suitable for being widely applied to the technical field of dry-mixed mortar equipment.

Owner:泰州金土木建设工程有限公司

Dry-mixed mortar anti-segregation structure

ActiveCN106275908BQuality improvementImprove separation performanceLarge containersEngineeringMechanical engineering

The invention discloses a dry-mixed mortar anti-separation structure. The structure comprises a tank body, a material dividing device, an anti-separation structure, a discharging mechanism, a drive mechanism, a vibration reduction rubber pad and a base; a material dividing assembly is assembled at the central position of the upper portion of the tank body, the portion, stretching out of the tank body, of the upper end of the material dividing assembly is sleeved with a driven gear, a feeding opening is formed in the position, located above the driven gear, of the material dividing assembly and is provided with a feeding opening cover, a transmission belt is arranged on the periphery of the driven gear, one end of the transmission belt is in transmission connection with the driven gear, and the other end of the transmission belt is in transmission connection with a drive mechanism; mortar separation can be well prevented, the mortar quality during building is improved, and the structure is suitable for being widely applied in the technical field of dry-mixed mortar equipment.

Owner:JIANGSU JINHUI CONSTR & INSTALLATION ENG

Dry-mixed mortar anti-segregation structure

ActiveCN106276332BQuality improvementImprove separation performanceConveyorsLoading/unloadingMechanical engineeringBuilding construction

The invention discloses a segregation preventing structure for dry-mixed mortar. The segregation preventing structure for the dry-mixed mortar comprises a tank, a distribution device, a segregation preventing structure body, a discharging mechanism, a driving mechanism, damping rubber pads and a base. A distribution assembly is assembled in the central position of the upper portion of the tank. The portion, stretching out of the tank, of the upper end of the distribution assembly is sleeved with a driven gear. A feeding port is formed in the distribution assembly and located above the driven gear. A feeding port cover is arranged on the feeding port. A driving belt is mounted on the periphery of the driven gear. One end of the driving belt is in transmission connection with the driven gear, and the other end of the driving belt is in transmission connection with the driving mechanism. By the adoption of the segregation preventing structure for the dry-mixed mortar, segregation of the mortar can be well prevented, and the mortar quality in the construction process is improved. The segregation preventing structure for the dry-mixed mortar is suitable for being widely applied in the technical field of dry-mixed mortar equipment.

Owner:贵州锦和建设工程有限公司

A temperature-resistant waterproof material

ActiveCN109177392BStrong self-healingExcellent peelabilityFibre typesSynthetic resin layered productsPlastic filmUltimate tensile strength

The invention discloses a temperature variation resistant waterproof material, and relates to the technical field of waterproof materials. The temperature variation resistant waterproof material is prepared by doping attapulgite modified asphalt with impregnated nitrogen and silicon and then coating a single face with a plastic film. The temperature variation resistant waterproof material providedby the invention is characterized in that the transverse tensile strength is 38.6MPa on average, the transverse breakage extension rate is 740 percent on average, the longitudinal tensile strength is46.2MPa on average, the longitudinal breakage extension rate is 670 percent on average, and the temperature variation resistant waterproof material can bear the high temperature of 72 DEG C and the low temperature of minus 45 DEG C.

Owner:山东安之源防水材料有限公司

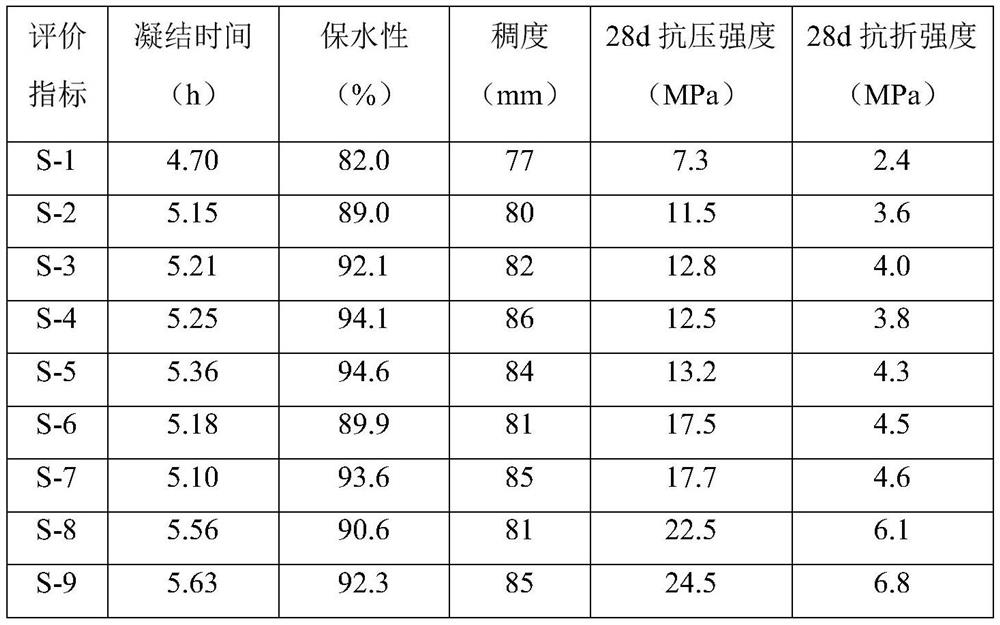

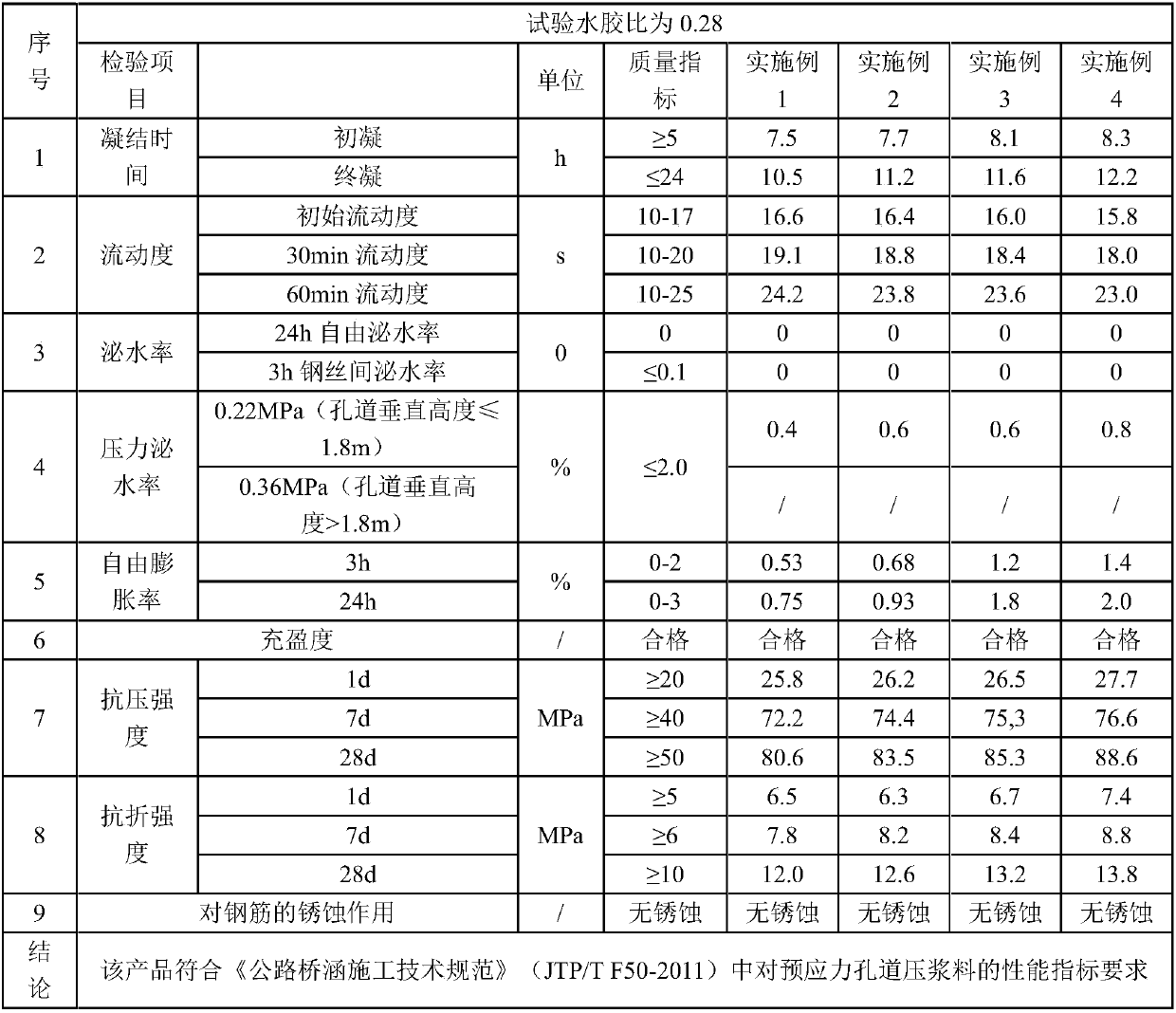

Self-supporting high-bonding prestressed tunnel pressure slurry and preparation method thereof

The invention provides a self-supporting high-bonding prestressed tunnel pressure slurry and a preparation method thereof. The self-supporting high-bonding prestressed tunnel pressure slurry comprises chlorite powder with pozzolanic activity, porous pozzolan, vermiculite powder, MIM stainless steel powder with good corrosion resistance and durability, thickener, defoamer, water reducer, and water are mixed and stirred. The prestressed tunnel pressure slurry made of the above raw materials not only has self-maintenance function, high early strength, high bonding force with steel bars and tunnel walls, but also volume stability, corrosion resistance of steel bars and durability of the entire concrete structure. substantial improvement.

Owner:CHANGAN UNIV

A non-powered anti-jamming grate sieve

ActiveCN103464371BLong segregation effectSpeed up the flowSievingScreeningEngineeringSmall footprint

An unpowered anti-blocking grate bar slide sieve comprises a sieve plate (1). The sieve plate (1) is provided with a plurality of gaps (3) in the material sliding direction, wherein one end of every gap (3) is open. Grate bars (2) are arranged between the adjacent gaps (3). The unpowered anti-blocking grate bar slide sieve is characterized in that the sieve plate is installed on a beam (4) inside a sieve body or an external fixable object and is inclined in the material sliding direction relative to the horizontal plane, one end of the sieve plate (1) is located below a feeding port (6), and the other end of the sieve plate (1) is provided with a discharging port (5). The unpowered anti-blocking grate bar slide sieve is unpowered, does not block materials and is low in production loss, gaps of the grate bars can be adjusted on the site according to material grain size requirements of a device or a client, the grate bars are made of alloy castings, the slide sieve is ultra high in abrasion resistance and heavy load, high in corrosion resistance, low in manufacturing cost, simple to install and maintain and small in occupied space, concentrated sieving of products is achieved, materials are collected in a concentrated mode, the capacity requirements of large mining devices can be met, and the materials with the grain sizes of 3-300mm can be sieved.

Owner:包头市屹峰建材外加剂有限公司

Grouting reinforcement and geotechnical reverse filtration test device and working method

PendingCN112858132AWide range of functionsFlexible test scaleWeighing by removing componentPreparing sample for investigationGeotechnical engineeringTest chamber

The invention relates to a grouting reinforcement and geotechnical reverse filtration test device and a working method. The grouting reinforcement and geotechnical reverse filtration test device comprises an input cabin with one open end, the open end of the input cabin is connected with a test module assembly, and the test module assembly is formed by splicing a plurality of test boxes; The device comprises a head-end test box, a tail-end test box and a plurality of middle test boxes located between the head-end test box and the tail-end test box, perforated plates are arranged at the two ends of the test boxes, a stirring mechanism is arranged at the end, close to an input cabin, of the head-end test box, and the end, away from the input cabin, of the tail-end test box is sealed through a sealing plate which is connected with a recycling metering mechanism. The device provided by the invention can be used for carrying out various tests.

Owner:SHANDONG JIANZHU UNIV +1

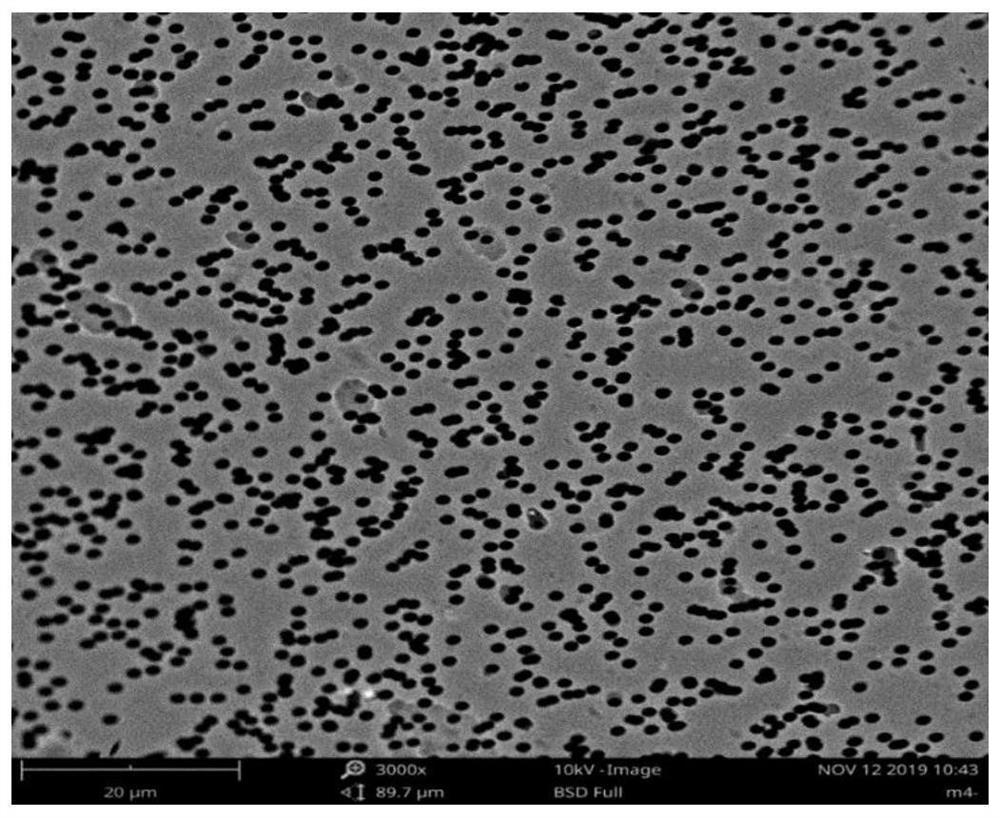

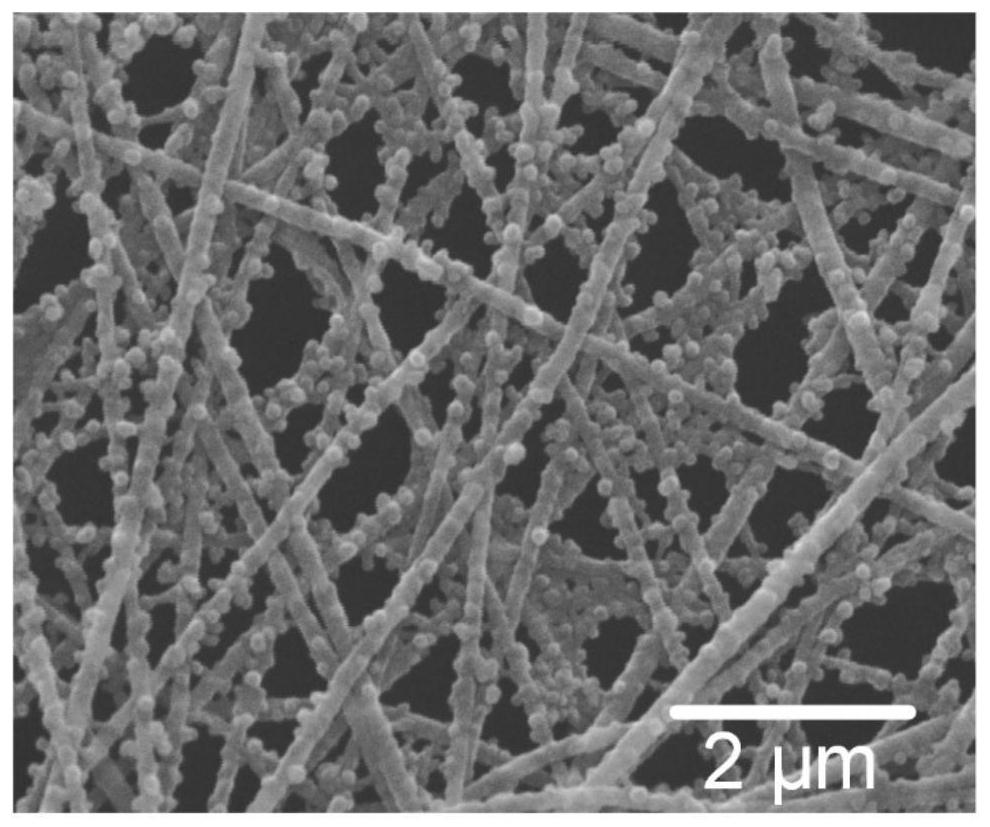

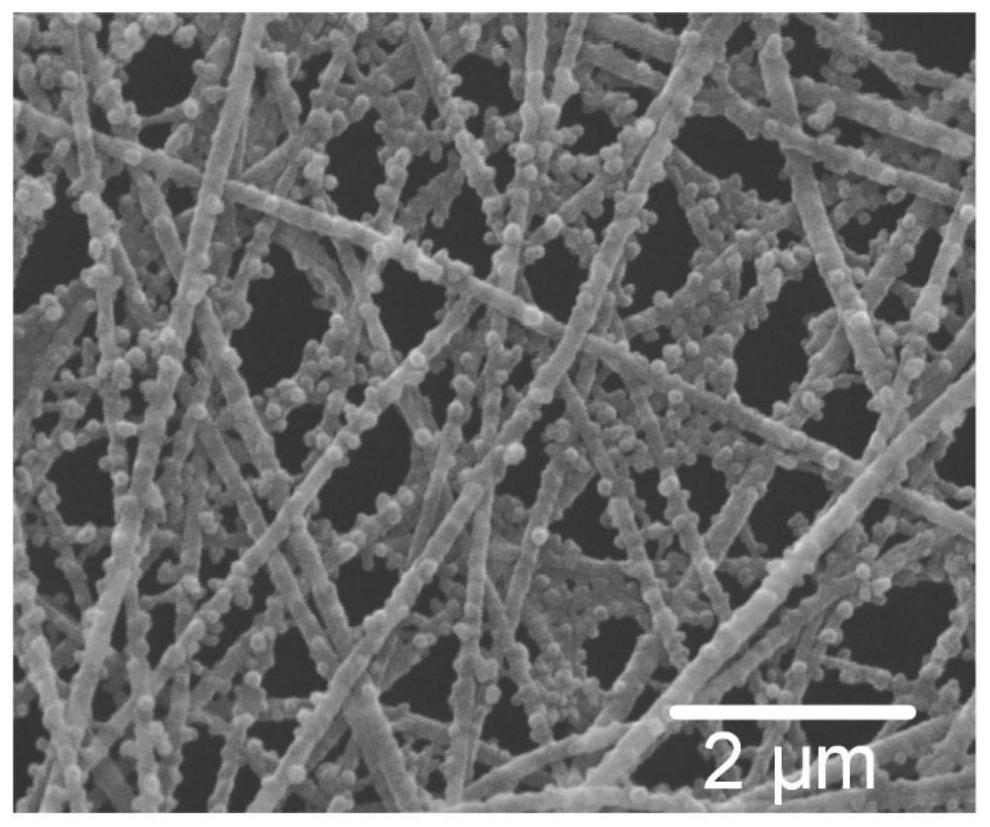

Bead-like nanofiber fuel filter membrane and preparation method thereof

PendingCN113957715AImprove separation performanceIncrease roughnessMembranesSemi-permeable membranesUltrasonic assistedNanofibrous membrane

The invention relates to a bead-like nanofiber fuel filter membrane and a preparation method thereof. The preparation method comprises the following steps of firstly, adding a non-solvent into a polymer solution to obtain a microgel polymer solution; then putting an electrospun fiber membrane into the microgel polymer solution for dipping, taking out the electrospun fiber membrane, putting the electrospun fiber membrane into an ultrasonic-assisted non-solvent coagulating bath, and increasing Rayleigh instability in a polymer impregnation liquid phase separation process by utilizing ultrasonic waves, thereby preparing a bead-like nanofiber membrane; then making the bead-like nanofiber membrane subjected to hydrophobic treatment; and finally preparing the bead-like nanofiber fuel filter membrane. In the prepared bead-like nanofiber fuel filter membrane, the average particle size of beads is 20-1000 nm, the hydrophobic angle of the filter membrane is 110-160 degrees, the rolling angle is less than or equal to 10 degrees, the average pore size is 200-1000 nm, and the porosity is 80-95%. The method is simple and easy to implement, the roughness of the surface and the pore channel wall of the prepared filter membrane is remarkably increased, the pore diameter is reduced, meanwhile, high porosity is still kept, and high-precision and high-flux filtration of submicron emulsified water in fuel is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

High-performance tubular hybrid membrane as well as preparation method and application thereof in separation of alkane/aromatic hydrocarbon mixture

ActiveCN112403285AHigh affinityImprove separation performanceSemi-permeable membranesMembrane purification/separationAlkaneHydrotalcite

The invention discloses a high-performance tubular hybrid membrane which comprises a porous alumina tubular membrane, and a first separation layer formed by a Co-doped Zn-based MOF material, a secondseparation layer formed by a polydopamine / nanocellulose gel material and a third separation layer formed by a hydrotalcite-like material which are sequentially arranged on the surface of the porous alumina tubular membrane, and the thicknesses of the first separation layer, the second separation layer and the third separation layer are respectively 1-2<mu>m, 60-100nm and 60-100nm. The tubular membrane is good in mechanical property, good in affinity with aromatic hydrocarbon, large in permeation flux and good in separation performance.

Owner:连云港鹏辰特种新材料有限公司

Anti-isolation structure for dry-mixed mortar

InactiveCN106315251AQuality improvementImprove separation performanceLoading/unloadingTransmission beltGear wheel

The invention discloses an anti-isolation structure for dry-mixed mortar. The anti-isolation structure comprises a tank body, a material separating device, an anti-isolation structure, a discharge mechanism, a drive mechanism, shock absorption rubber mats and a pedestal; a material separating assembly is arranged on the center position of the upper part of the tank body; the part, extending out of the tank body, at the upper end of the material separating assembly is sleeved by a driven gear; a charge hole is formed in a position, above the driven gear, of the material separating assembly; a charge hole cover is arranged on the charge hole; a transmission belt is mounted at the periphery of the driven gear; one end of the transmission belt is in transmission connection with the driven gear, and the other end of the transmission belt is in transmission connection with the drive mechanism. The anti-isolation structure disclosed by the invention can prevent isolation of mortar very well, and improves quality of the mortar during building. The anti-isolation structure disclosed by the invention is suitable for being widely applied to the technical field of dry-mixed mortar equipment.

Owner:泰州金土木建设工程有限公司

A kind of polyaluminum chloride waste slag dry-mixed mortar and preparation method thereof

ActiveCN111978050BPotentially chemically active and effectivePotential chemical activationSolid waste managementEnvironmental engineeringCement mortar

The invention discloses a polyaluminum chloride waste slag dry-mixed mortar and a preparation method thereof. The dry-mixed mortar comprises the following raw materials in parts by mass: 4-8 parts of heat-activated polyaluminum chloride waste slag, 23-25 parts of cement, 55-60 parts of sand, 4-6 parts of fly ash, 0.05-0.15 parts of defoamer, 0.20-0.22 parts of water reducing agent, and polymer emulsion of 5%-9% of the total mass of the above raw materials. The present invention uses industrial waste polyaluminum chloride waste slag and fly ash to replace high-energy-consuming cement to prepare cement mortar, which can effectively reduce the large-scale stacking of polyaluminum chloride waste slag and reduce the use of high-energy-consuming cement, and has good social and economic benefits. The preparation method of the polyaluminum chloride waste slag dry-mixed mortar is simple and low in cost, is beneficial to industrial production and popularization, can significantly improve the resource utilization of the polyaluminum chloride waste slag, and is of great significance in reducing construction costs, reducing environmental pollution, and the like.

Owner:HENAN POLYTECHNIC UNIV +1

Self-curing high-bonding prestressed duct grouting material and preparation method thereof

ActiveCN107673698AImprove early strengthWith self-maintenance functionRebarUltimate tensile strength

The invention provides a self-curing high-bonding force prestressed duct grouting material and a preparation method. Chlorite powder with pozzolanic activity, porous pozzolan, vermiculite powder, MIMstainless steel powder with good corrosion resistance and durability, a thickening agent, a defoaming agent, a water reducing agent and water are agitated, so that the self-curing high-bonding force prestressed duct grouting material is prepared. Not only does the prestressed duct grouting material prepared with the matching of the materials have a self-curing function, high early strength and high bonding force with reinforcements and duct walls, but also the stability of volume, the corrosion resistance of the reinforcements and the durability of a whole concrete structure are greatly increased.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com