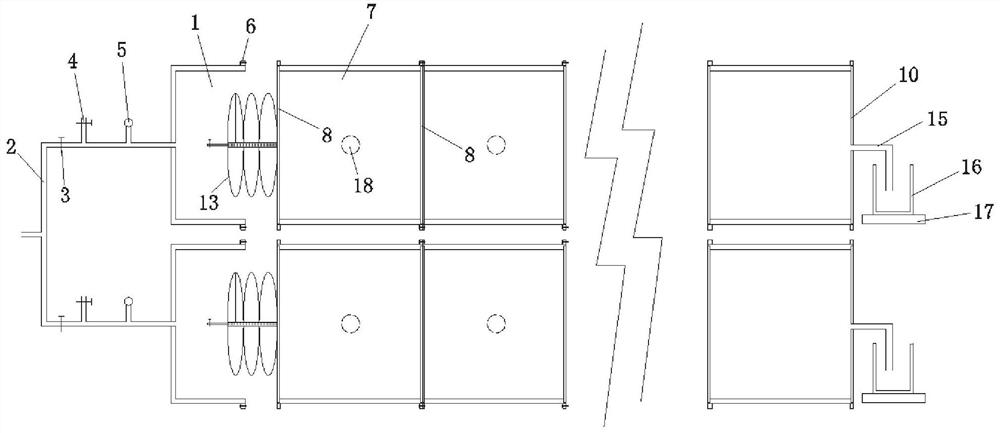

Grouting reinforcement and geotechnical reverse filtration test device and working method

A technology of grouting reinforcement and test device, which is applied to measurement devices, preparation of test samples, weighing by removing certain components, etc., can solve the problem that the pressure sensor is useless, the function of the test device is single, and the accuracy of key data is low. and other problems, to achieve the effect of improving segregation, flexible test scale, and improving mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065]This example discloses the working method of the grouting reinforcement and geotextile test apparatus of Example 1, including the following steps:

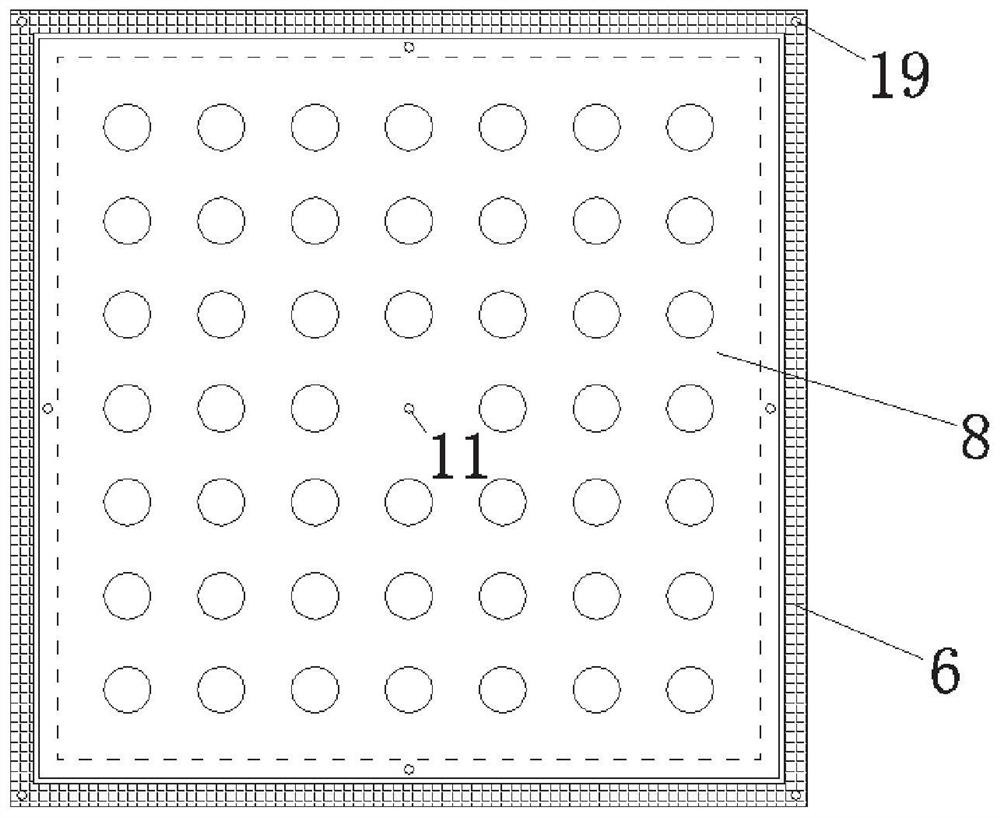

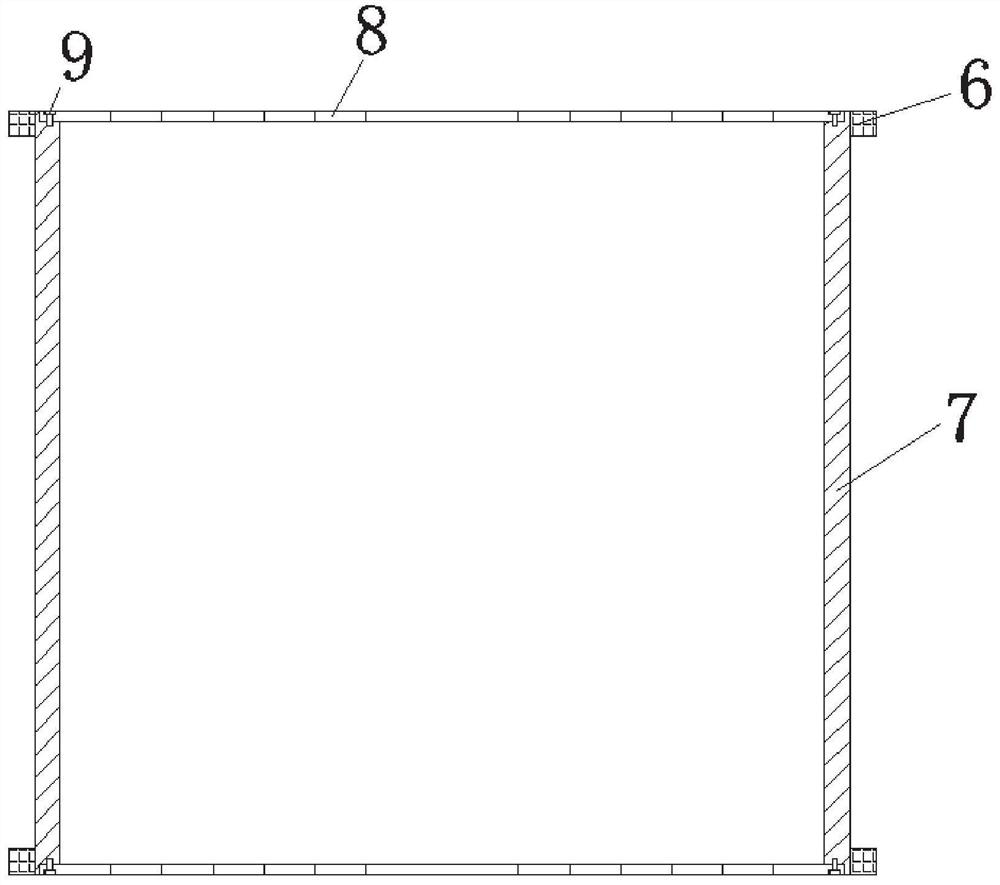

[0066]Step 1: Extunction the release agent in the inner wall of the first end test chamber, and secure the multi-hole plate in the mounting tank by the M2 screw, and wrap the outer surface of the porous plate with the PE film, and then inserted into the first end test chamber. It is compacted in accordance with the corresponding requirements of the Geotechnical Test Regulations. After the injection is filled, the multi-hole plate is fixed by the M2 screw, and the outer surface of the porous plate is wrapped with a PE film. Subsequently, weigh the first end test chamber quality M01. Finally, the coating group and the hollow tube jacket are in the fixed rod of the porous plate, and the pin is inserted into the fixed rod end.

[0067]Step 2: Extunction of the inner wall of the i-th test chamber, one end is fixed to the mounting slot by the...

Embodiment 3

[0074]This example discloses the working method of the grouting reinforcement and geotextile test apparatus of Example 1, including the following steps:

[0075]Step A: Wipe the release agent evenly in the inner wall of the first end test chamber, one end is fixed in the mounting slot by the M2 screw, and wrap the outer surface of the porous plate with the PE film, and then fill the reflined filtration material to the first end test chamber. In this step, the diaphragm material uses clays and compacted according to the corresponding requirements of the "Geotechnical Test Regulations". After the filtration material is filled, the multi-hole plate is fixed to the other end of the first end test chamber with the M2 screw, and the outer surface of the porous plate is wrapped with a PE film. Subsequently, weigh the first end test chamber quality M21. Finally, the coating group and the hollow tube jacket are in the fixed rod of the porous plate, and the pin is inserted into the fixed rod end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com