Patents

Literature

283results about How to "Improve segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

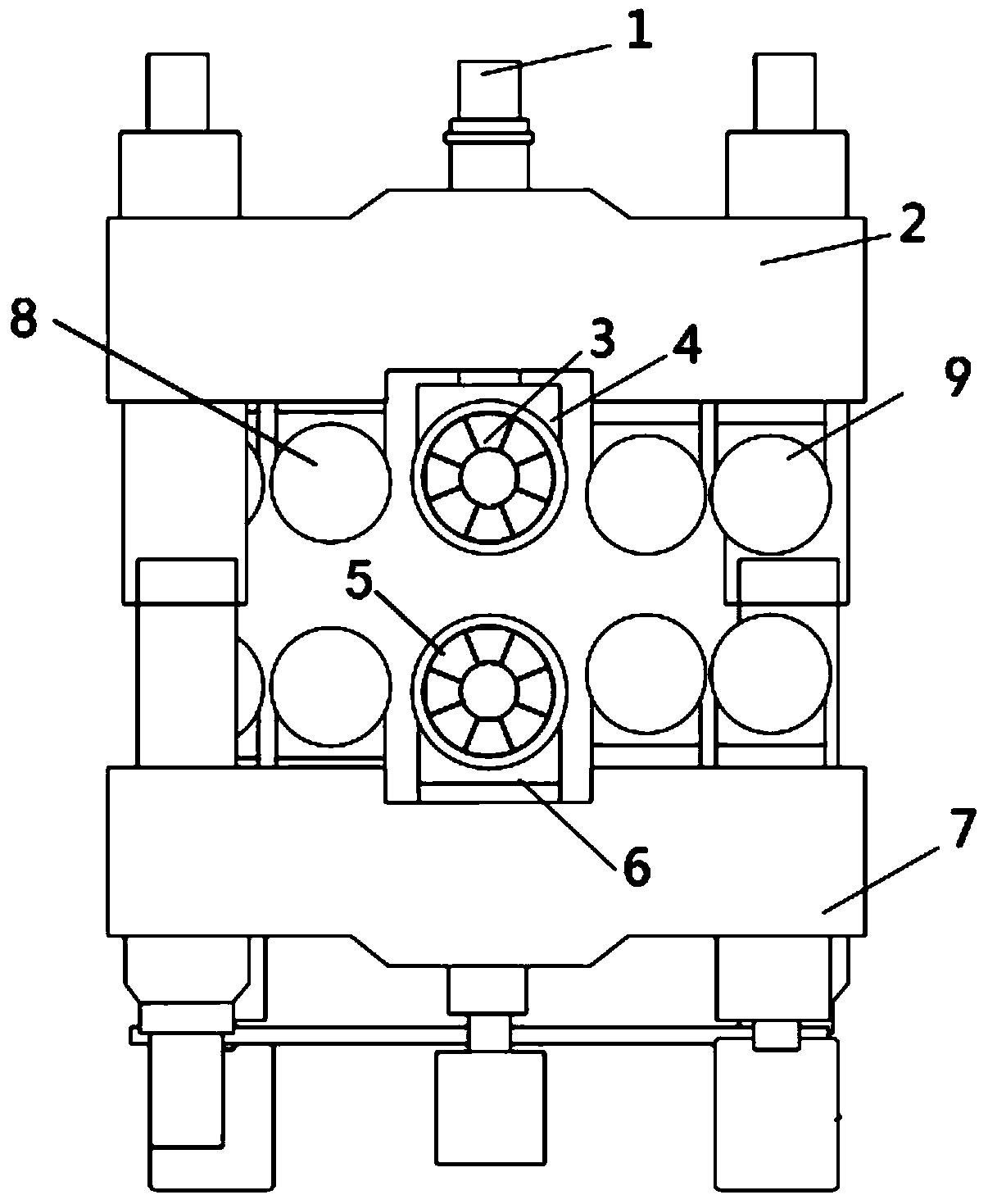

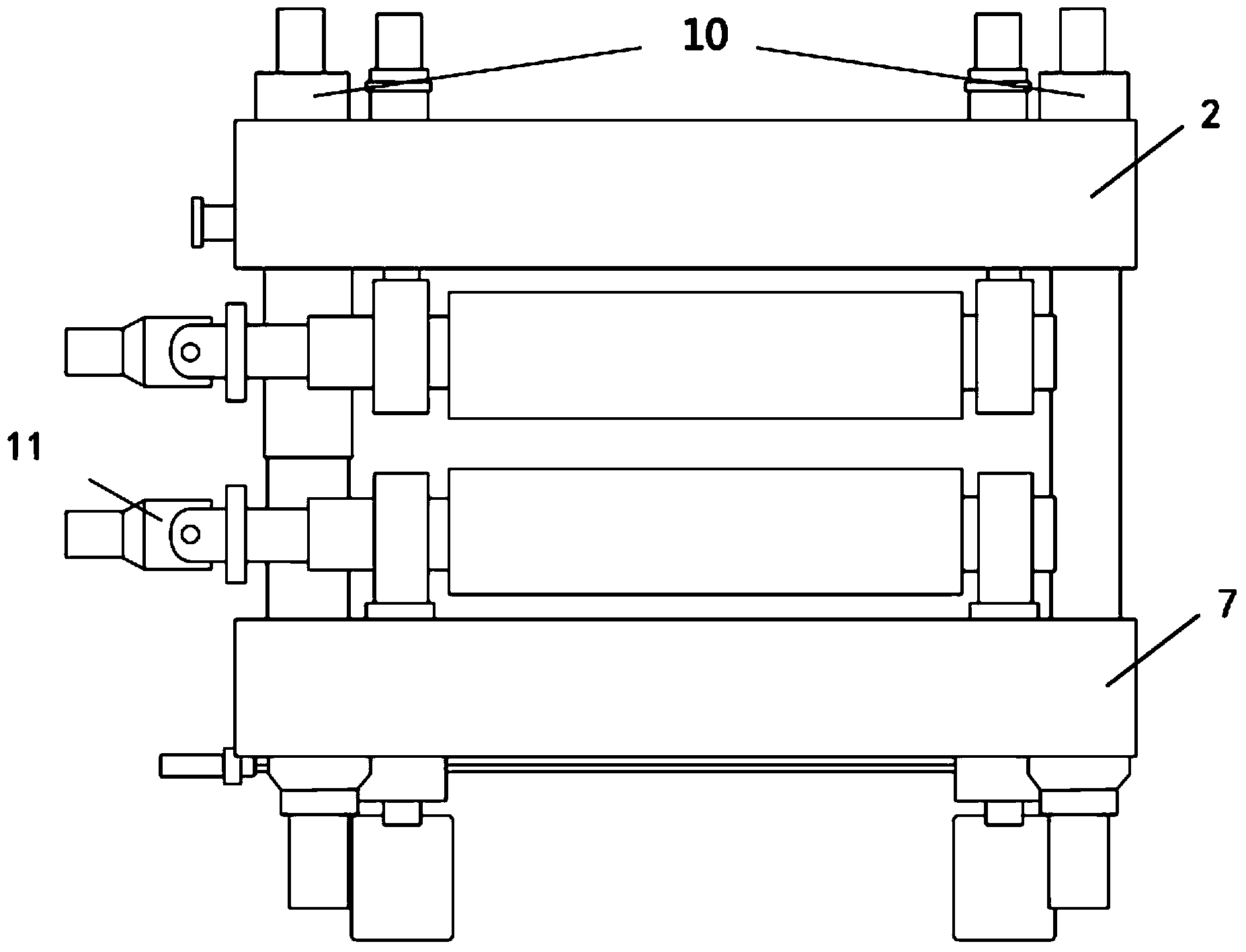

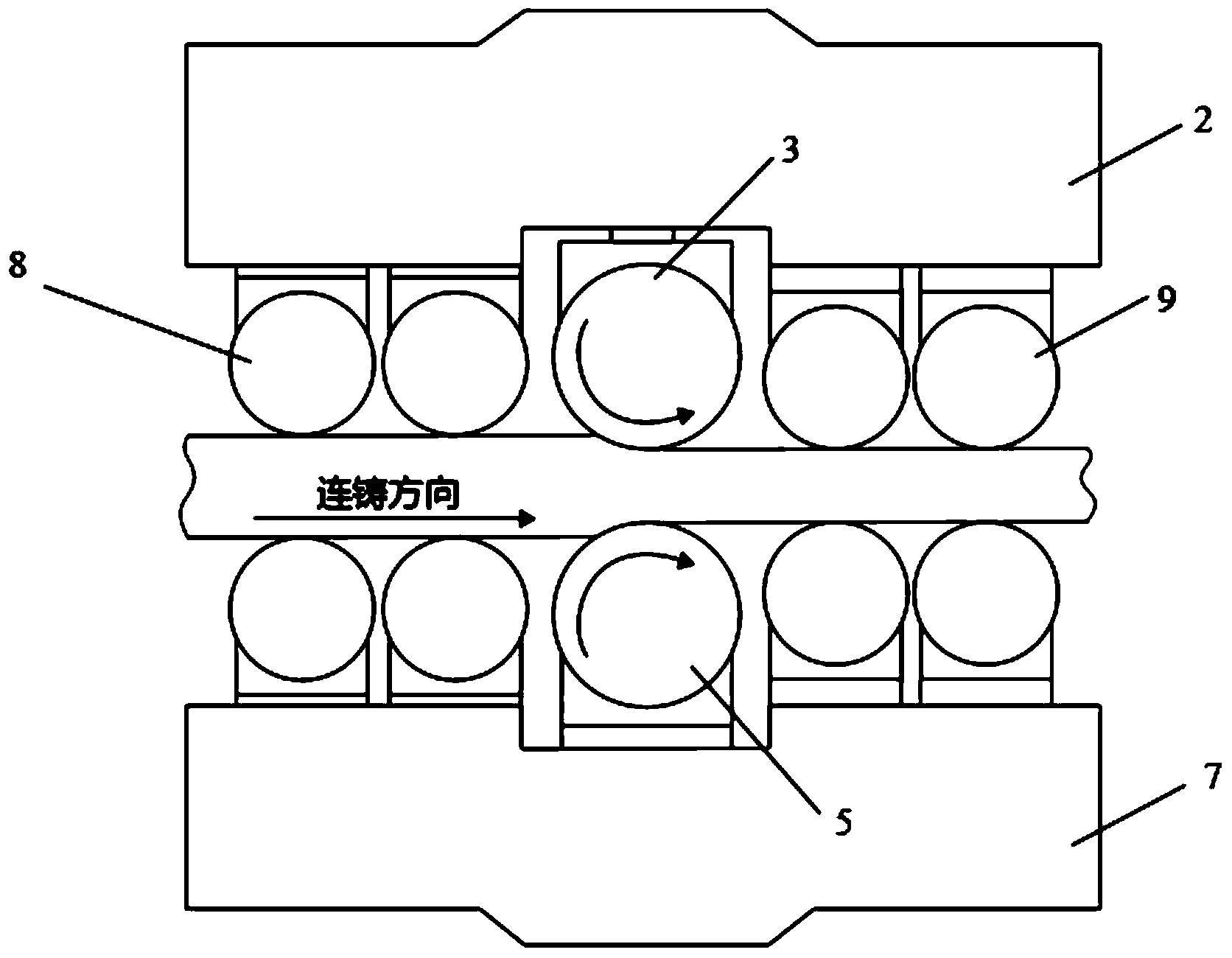

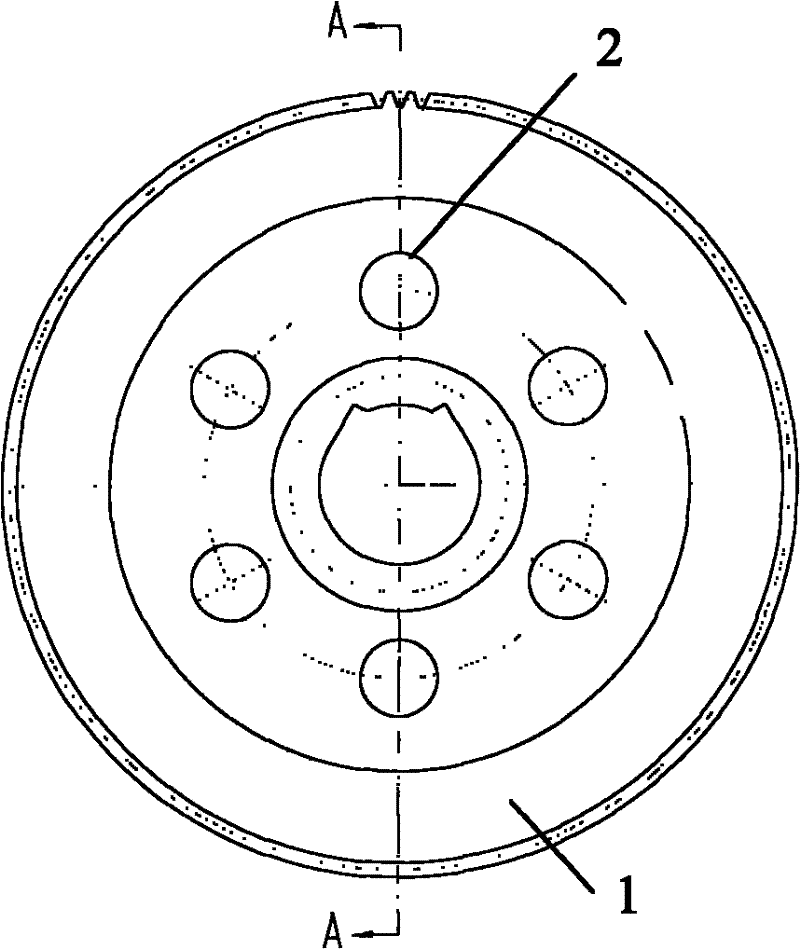

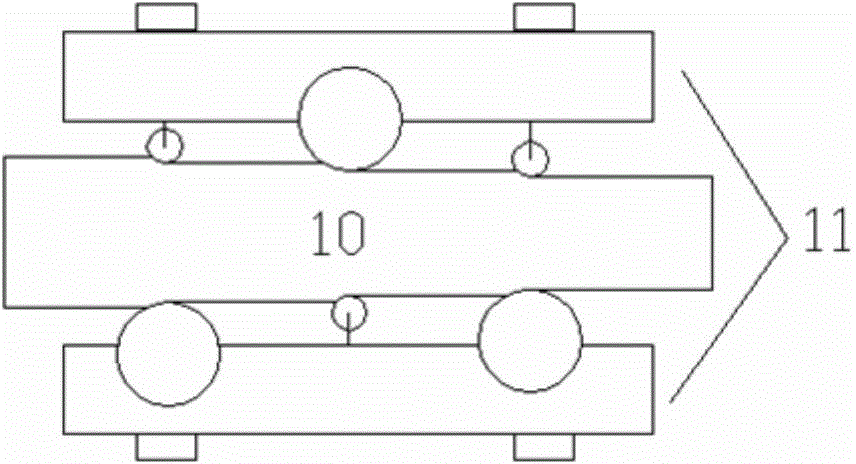

Continuous casting machine sector section for deep pressing of continuous casting blank solidification tail end and deep pressing method of continuous casting machine sector section

ActiveCN104057049AReduced plastic deformation contact areaTotal Deformation Force ReductionMaterials scienceContinuous casting

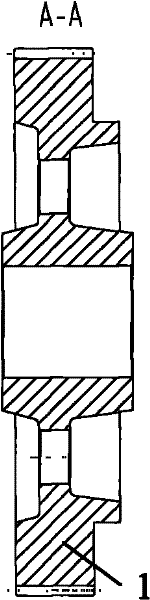

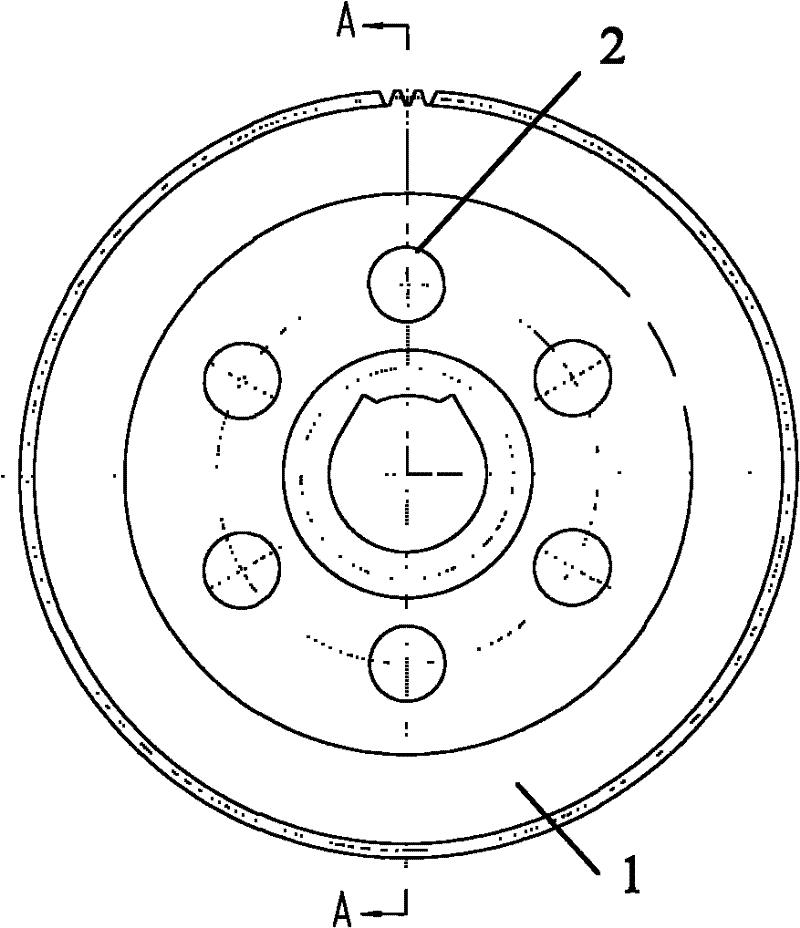

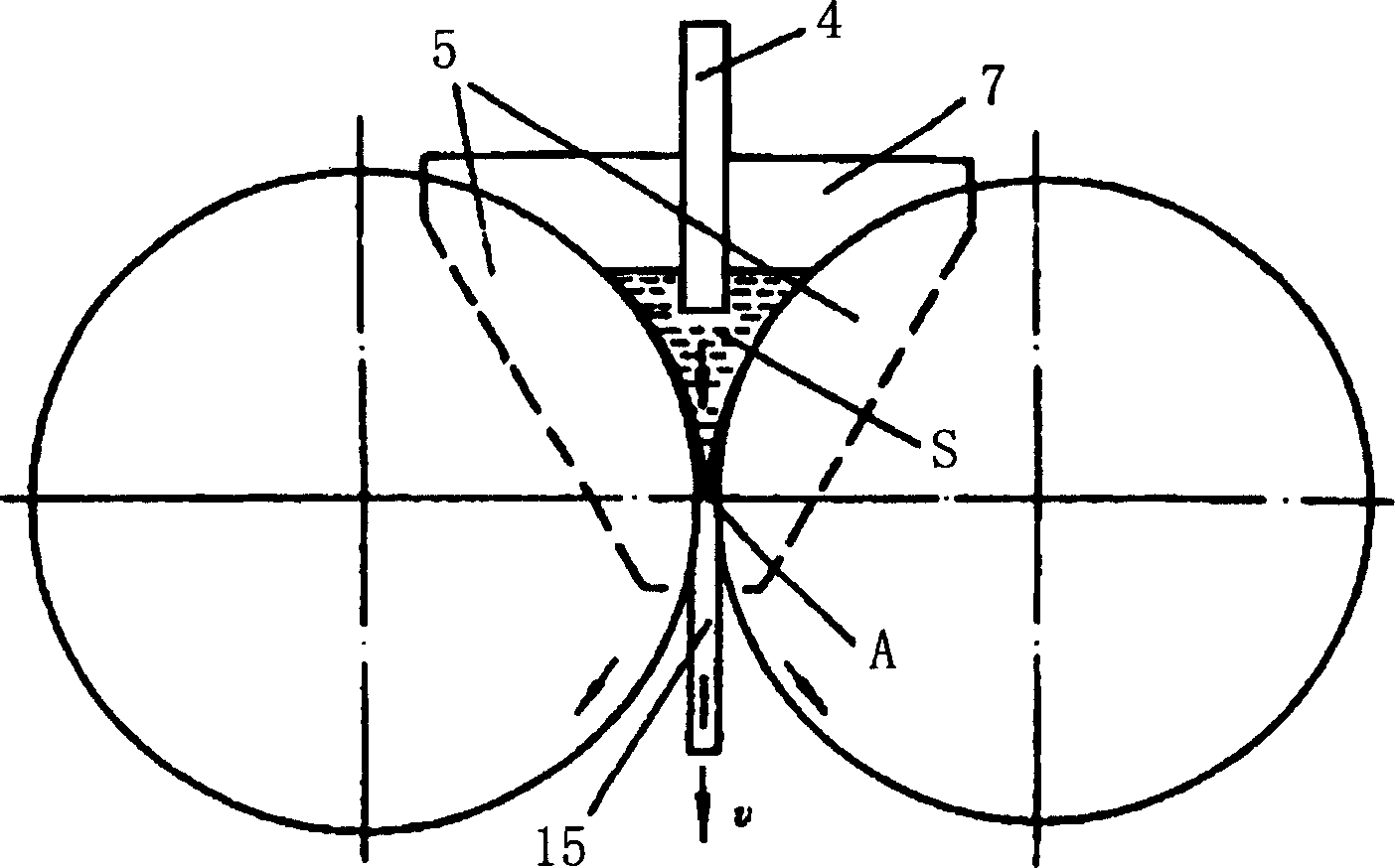

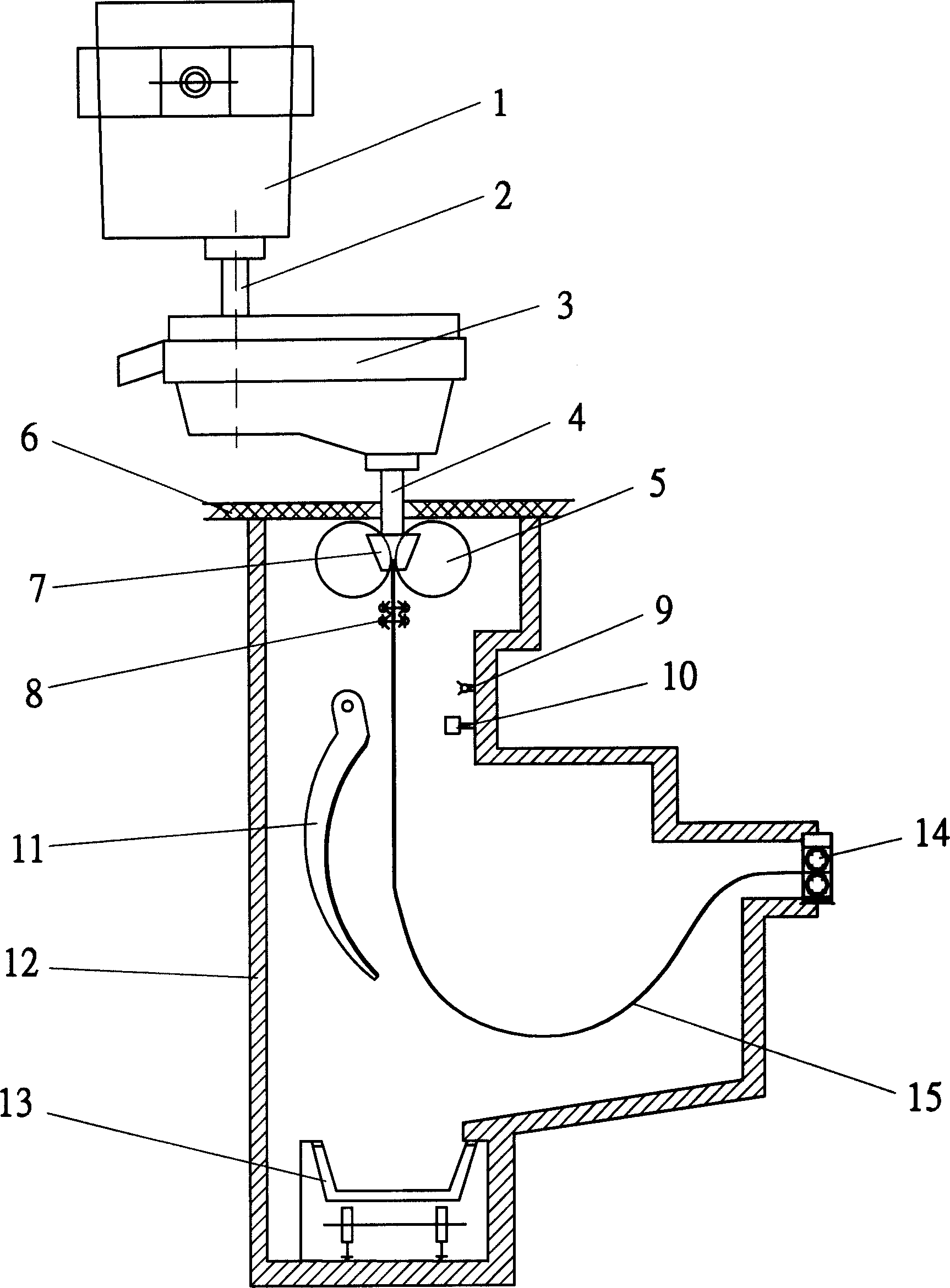

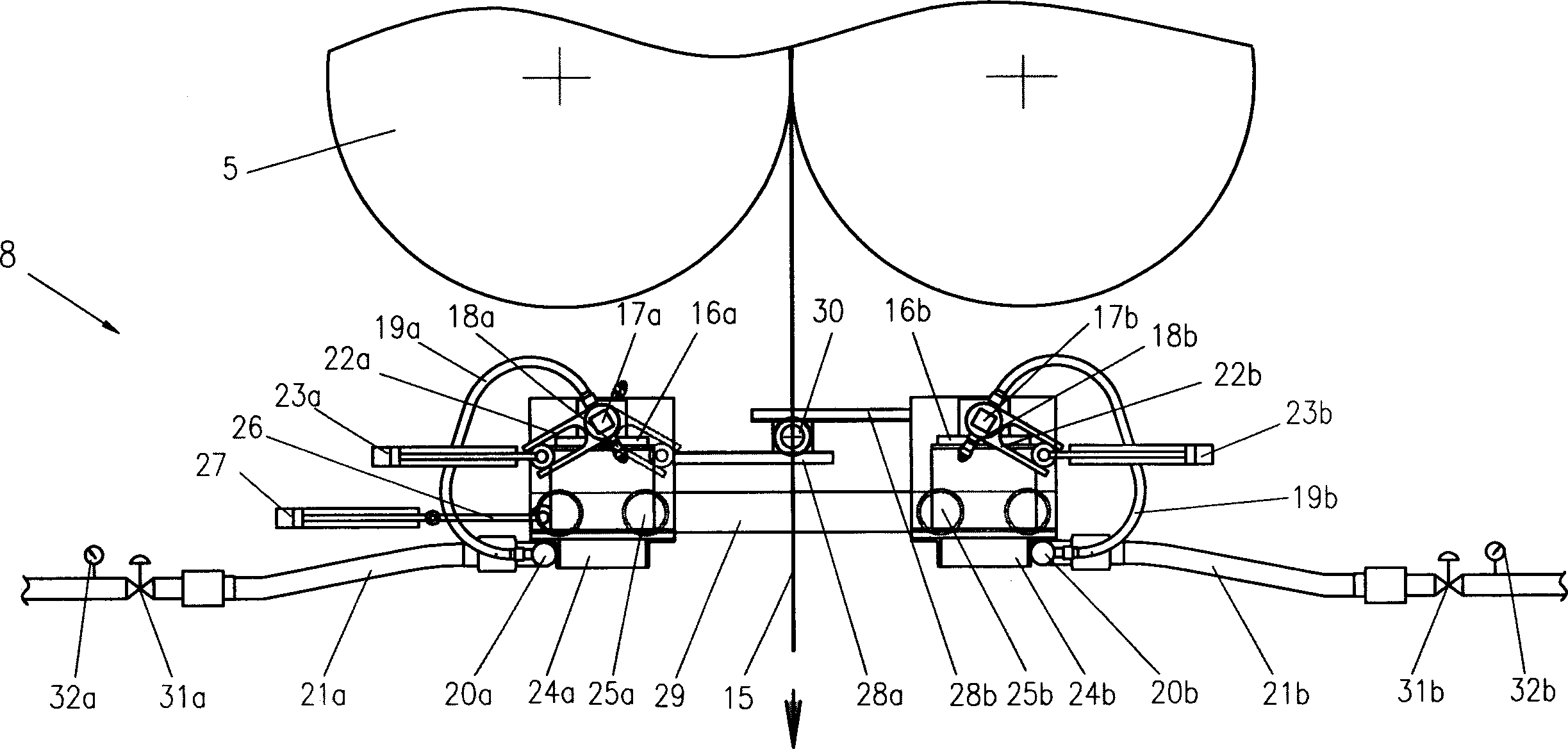

The invention provides a continuous casting machine sector section for deep pressing of the continuous casting blank solidification tail end and a deep pressing method of the continuous casting machine sector section. The continuous casting machine sector section comprises an upper frame, a lower frame, an upper driving roll, a lower driving roll, a left driven roll set, a right driven roll set, a pressing device and a clamping cylinder, wherein the upper frame, the lower frame, the upper driving roll, the lower driving roll, the left driven roll set, the right driven roll set, the pressing device and the clamping cylinder are arranged on the sector section; the clamping cylinder is used for clamping the upper frame and the lower frame to be kept in a certain set gap; the upper driving roll is connected with the pressing device and connected to the upper frame through a bearing base, the lower driving roll is connected to the lower frame through a bearing base, the left driven roll set and the right driven roll set are located on the two sides of the driving rolls respectively, the left driven roll set is used for clamping a casting blank before pressing, the right driven roll set is used for clamping the casting blank after pressing, and the radio of the diameter of each driving roll to the diameter of each driven roll is 1.1:1 to 2:1. According to the continuous casting machine sector section for deep pressing of the continuous casting solidification tail end and the deep pressing method of the continuous casting machine sector section, the deformation permeability is improved, deformation achieved through the continuous casting machine sector section is equivalent to that achieved by one rolling pass of a twin rolling mill with the large rolling diameter, and the improvement in loosening and segregating of a central zone of the casting blank is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

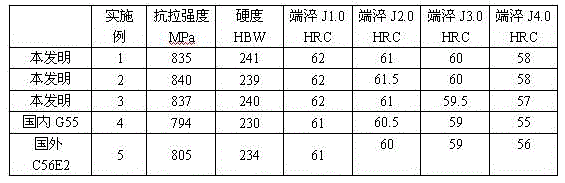

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

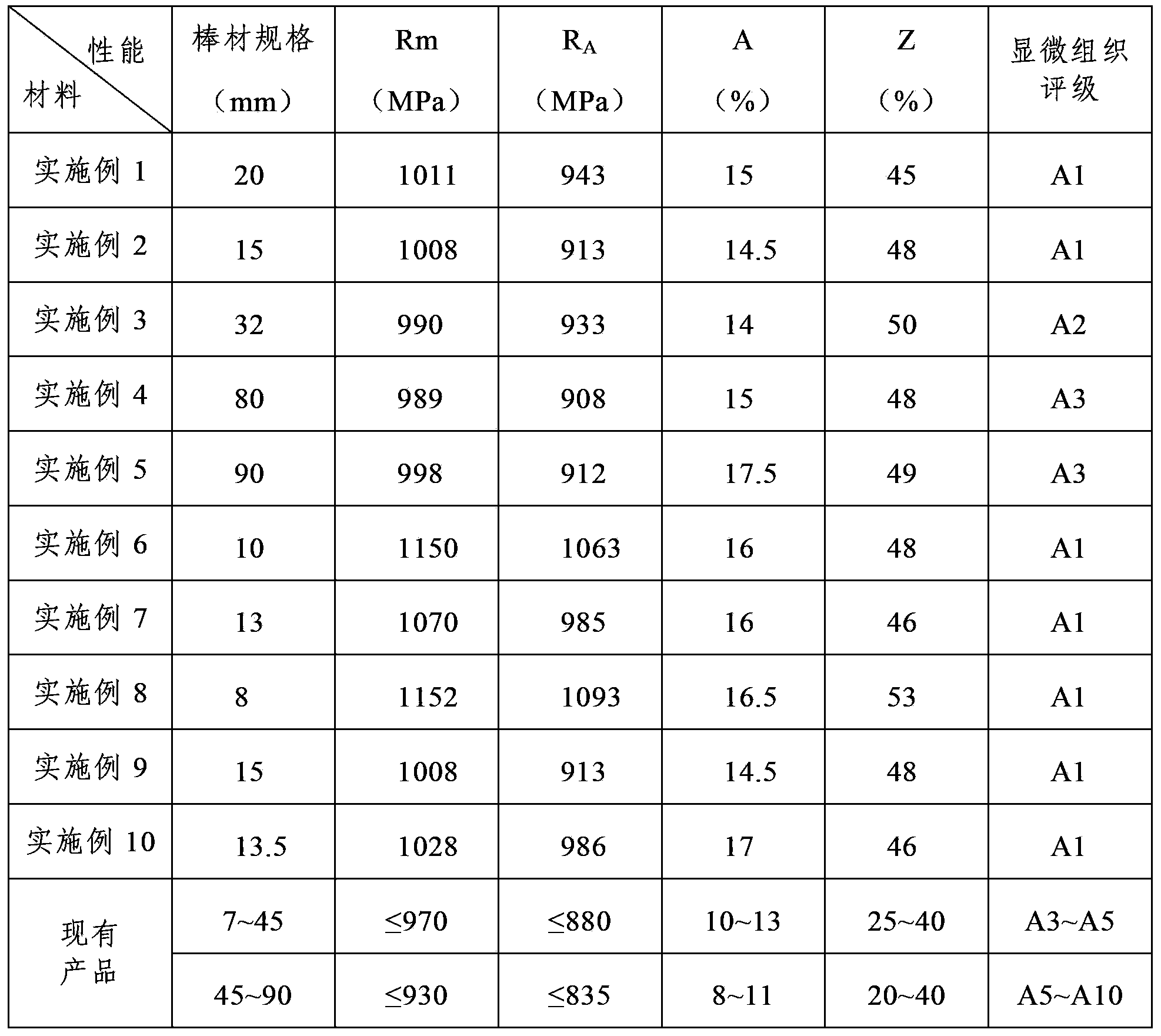

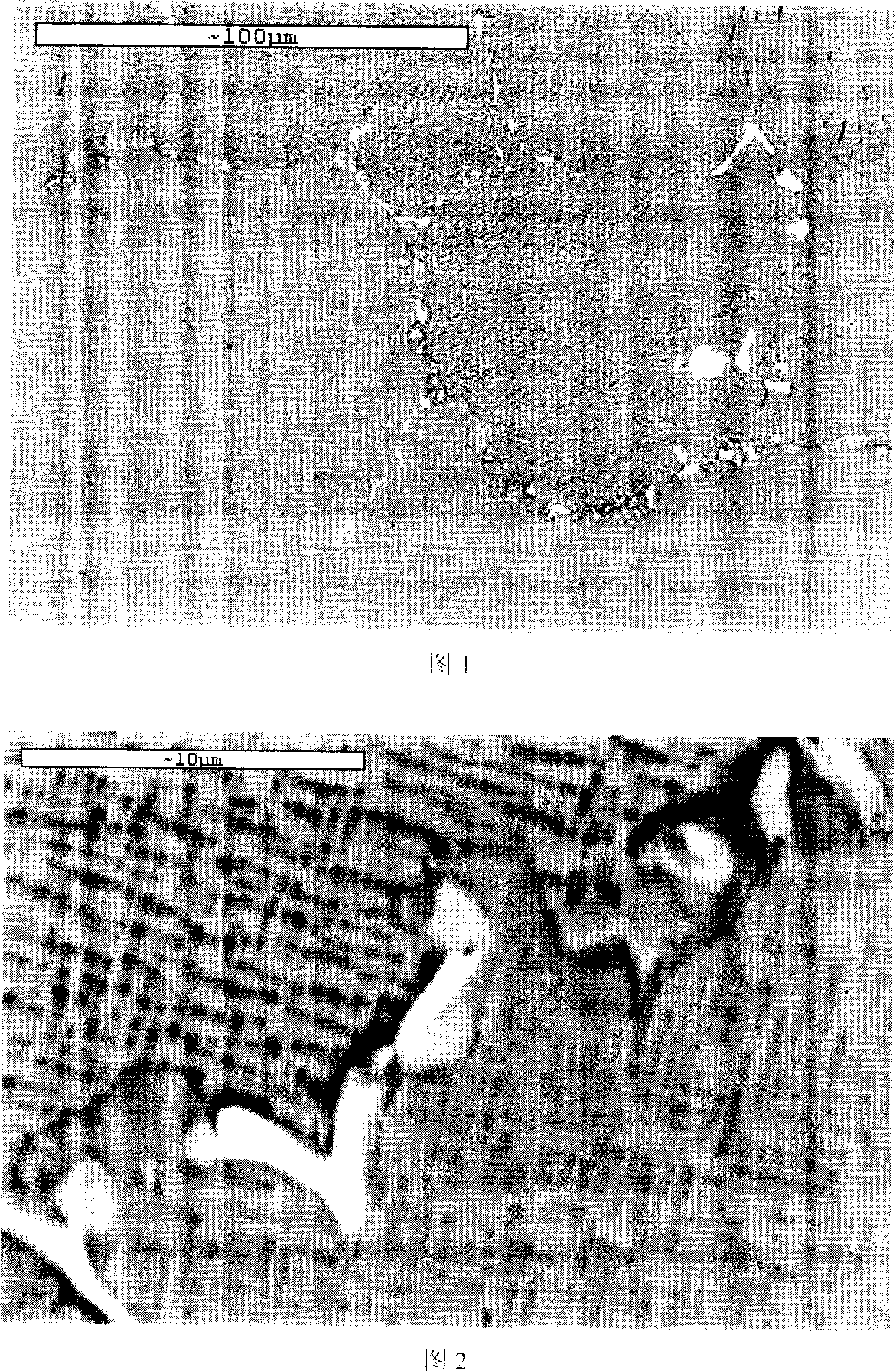

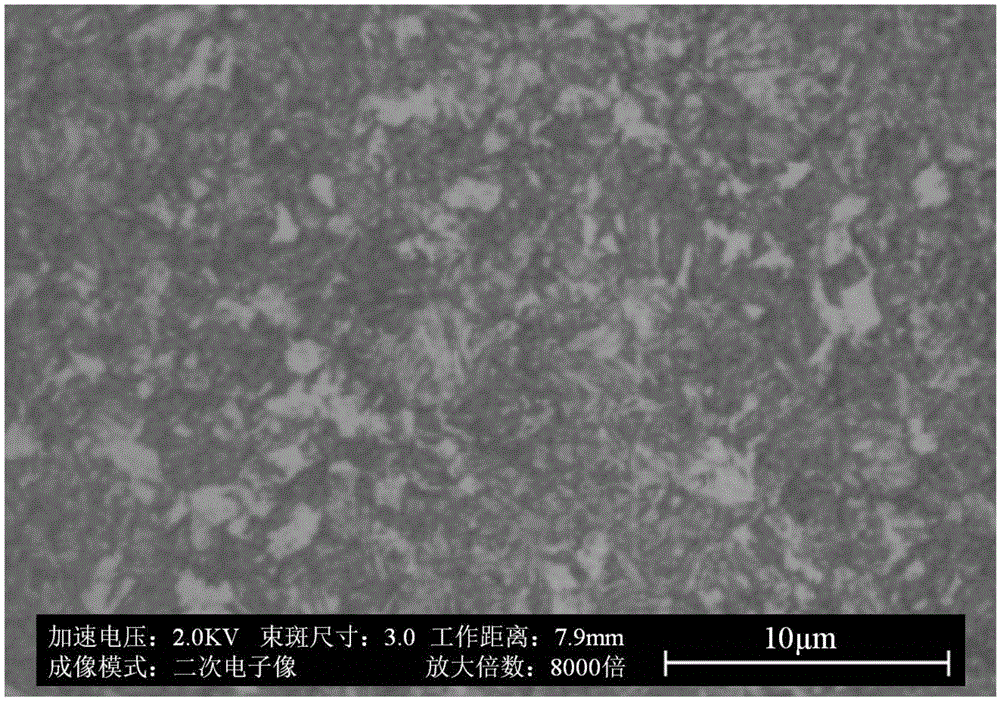

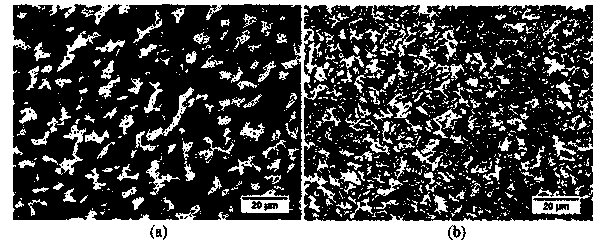

Preparation method of TC4ELI titanium alloy bar

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High strength antithermal corrosion low segregation directional high temp alloy

ActiveCN101089215AImprove mechanical propertiesImprove organizational structureSlow coolingSuperalloy

This invention relates to high-strength thermal abrasion resistance high-temperoducre alloy with low segregation and directional solidification properties. Its constitutions are (wt.%): Co9-12, Cr11-16, Mo1-3, W4-7, Al4-7, Ta4-7, Ti0-2, Re2-3, C0.01-0.15, 0.005-0.02 and Ni as the rest. The heat treatment for directional solidification steps are: 1240+-10deg.C for 0.5Hrs; 1260+-10deg.C for 0.5Hrs; 1280+-10deg.C for 4Hrs; air cooling to room temperature; 1120+-10deg.C for 4-1 Hrs; slow cooling to 1080+-10deg.C for 4Hrs; air cooling to room temperature; 900+-10deg.C; air cooling to room lemperature. This invention alloy can meet the requirement strength for design of turbine blade of aircraft engine but also has excellent thermal abrasion resistance property. The plane with the turbine blade of aircraft engine can be used for high altitude flight and flight in corrosion environment obove turbine blade of aircraft engine can be used for high altitude flight and flight in corrosion environment above sea.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

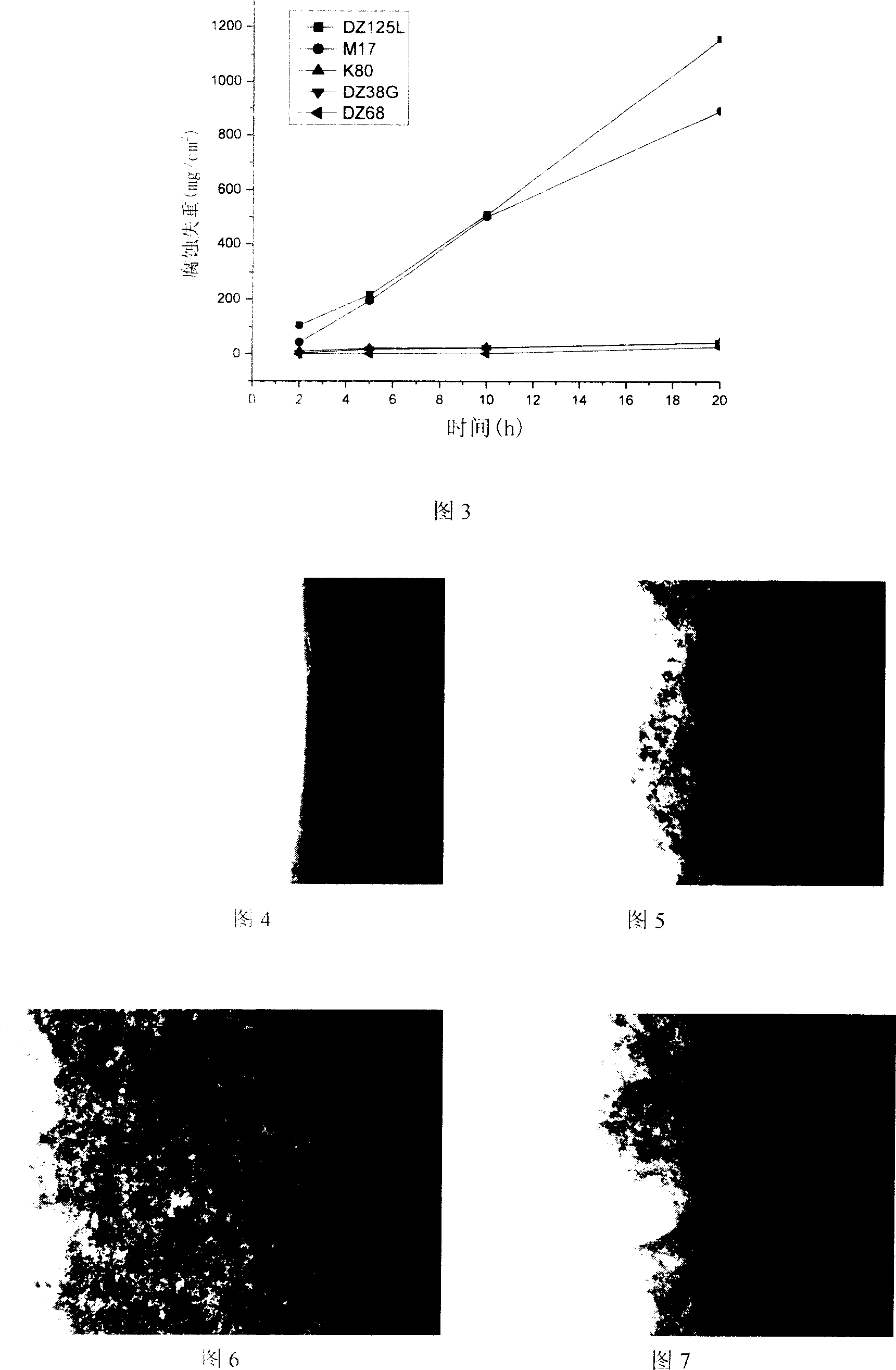

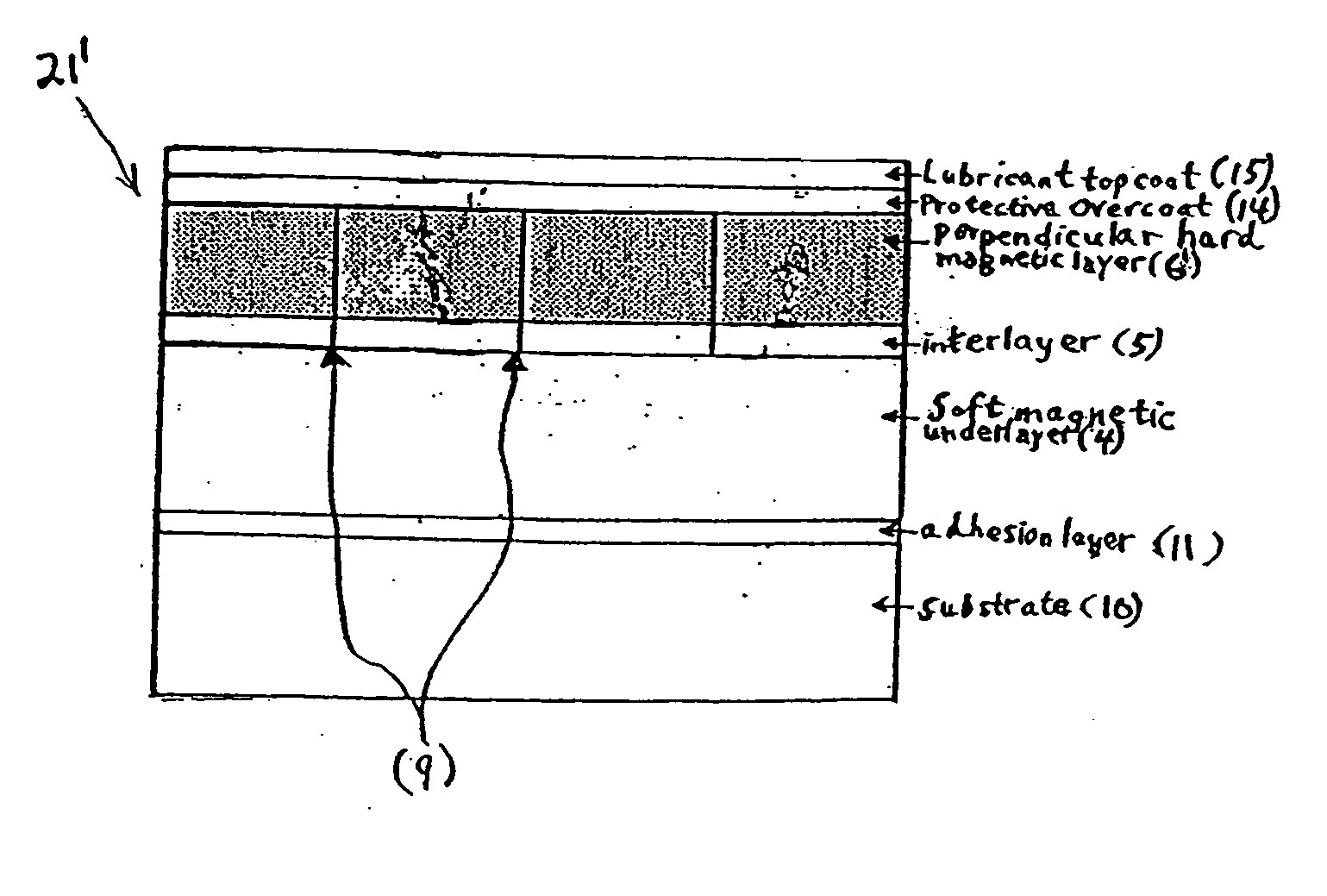

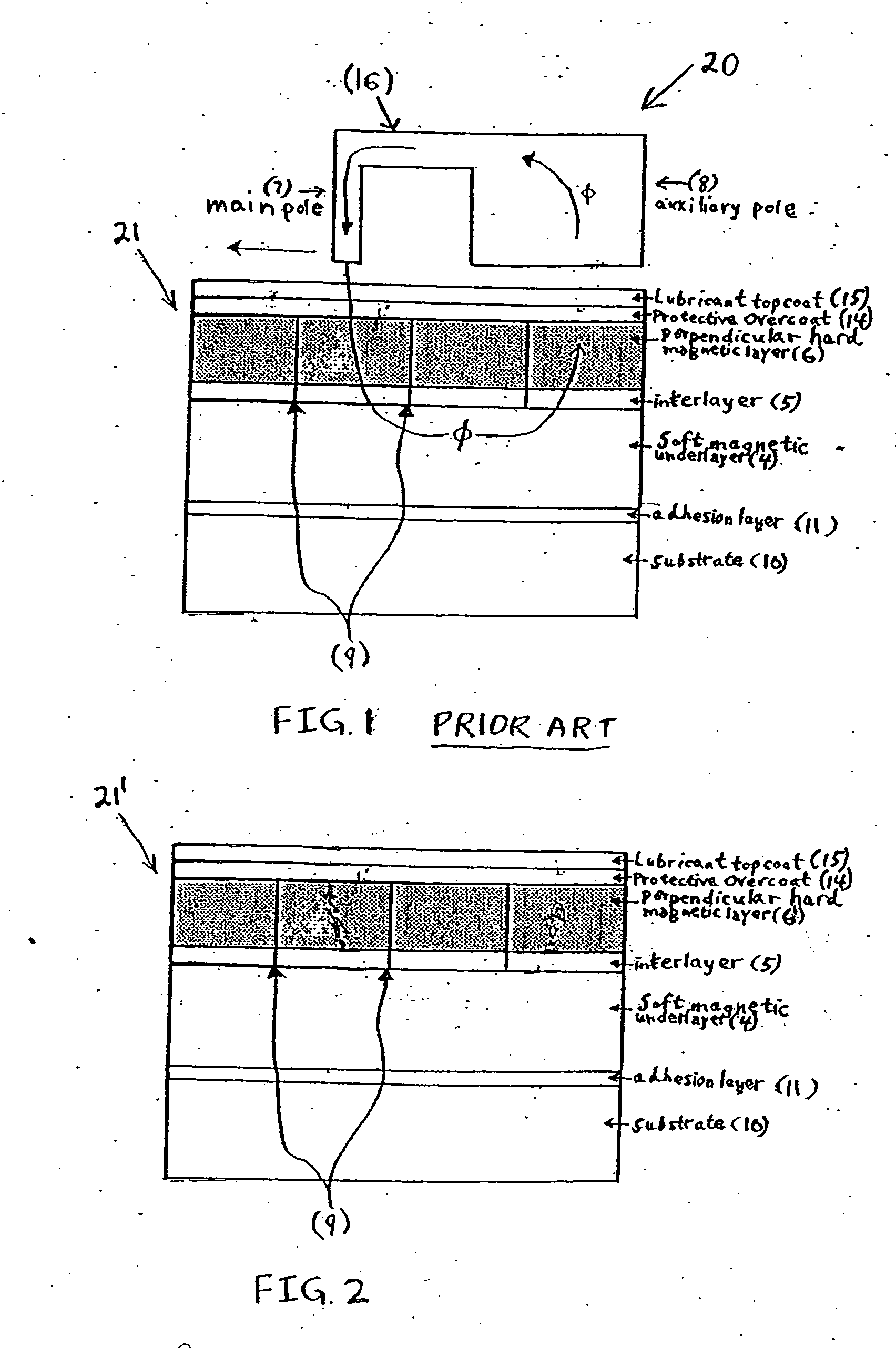

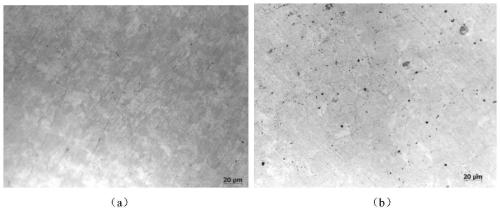

Granular magnetic recording media with improved grain segregation and corrosion resistance

InactiveUS20060121319A1Improve isolationImprove the immunityVacuum evaporation coatingSputtering coatingNon magneticRecording layer

Disclosed are granular magnetic recording media with improved grain segregation and corrosion resistance, comprising a non-magnetic substrate and at least one granular magnetic recording layer formed over the surface, comprised of at least one ferromagnetic material including magnetic grains with grain boundaries and a non-magnetic material comprised of a mixture of metal oxides. Also disclosed are methods for fabricating the improved media.

Owner:SEAGATE TECH LLC

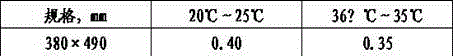

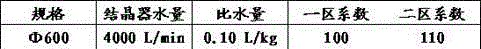

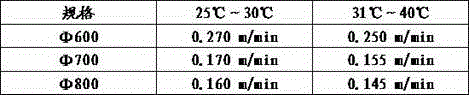

Continuous casting method of continuous-cast round billets

ActiveCN104259415AReduce temperature gradientIncrease the ratio of axial crystalsSteelmakingPorosity

The invention discloses a continuous casting method of continuous-cast round billets. The method comprises the steps of 1) obtaining high-purity molten steel through steel-making; 2) pouring the obtained molten steel into a tundish under large-tundish long-nozzle argon blowing protection, controlling the degree of superheat of the molten steel inside the tundish to be 15-30 DEG C; 3) pouring the molten steel into a crystallizer through a tundish integrated type submerged nozzle, controlling the depth of the a crystallizer submerged nozzle inserted into the surface of the molten steel to be 100-120 mm; (4) perform constant-speed continuous casting, control the casting speed to be 0.16-0.22 m / min for different kinds of steel; 5) utilizing an air-water atomizing cooling mode in a secondary cooling area at a specific water flow rate of 0.12-0.22 L / kg; 6) performing dynamic soft reduction through a withdrawal and straightening machine to obtain the continuous-cast round billets. The continuous casting method of the continuous-cast round billets effectively reduces the temperature gradient of molten steel from a billet shell to a casting core and the degree of superheat of the molten steel in the center, improves the proportion of isometric crystal of the cast billets, enhances the structural density of the cast billets and significantly improves the effects of center porosity, center segregation and contraction of large continuous-cast round billets.

Owner:SHANDONG IRON & STEEL CO LTD

Thin-belt continuous casting method and apparatus

InactiveCN1472019AFlexible process controlEasy to operateMetal rolling arrangementsProduction rateMolten bath

A conticasting technology for thin steel band includes such steps as filling molten steel in the molten bath formed by crystallizing rollers, cooling and slight rolling by crystallizing rollers, blowing gas onto both surfaces of cast band for forced cooling, hot rolling, controlled cooling and winding. Its apparatus is composed of two blowing mechanisms, connecting-rod driver unit and synchronizing unit. Its advantages are high quality of product and high productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving central carbon segregation of tire cord steel

InactiveCN101775461AImprove segregationMeet the requirements of segregationMaterials scienceHot rolled

The invention discloses a method for improving the central carbon segregation in tire cord steel. The method produces 80 grade tire cord steel by adopting technical processes of electric furnace primary melting, refining, bloom concasting, billet rolling and rolled steel wire rolling by the billet, adopts control measures on each process, ensures strong stirring in argon blowing on the steel ladle bottom in a tapping process and a carbureting process after tapping; and the carburetion is controlled to be between 0.4 and 0.6 percent. Strong stirring is turned to be soft stirring after 10 minutes, until refining accepts the steel ladle. Alloying and carburetion are performed in sequence in LF refining, before aim carbon is adjusted, the temperature is ensured to be higher than 1,525 DEG C. In the method, the superheat degree of continuous casting is at 15 to 35 DEG C, full protection casting is adopted, a crystallizer is used for electromagnetic stirring, and the concasting bloom adopts soft press, so that the central carbon segregation of the tire cord steel is greatly improved, the hot-rolled rolled steel wire segregation of a tire cord steel finished product is not higher than 0.5 grade, and the control requirement of a tire cord steel user on the central carbon segregation can be met.

Owner:NANJING IRON & STEEL CO LTD

Machining method of 3003 aluminum alloy finished foil

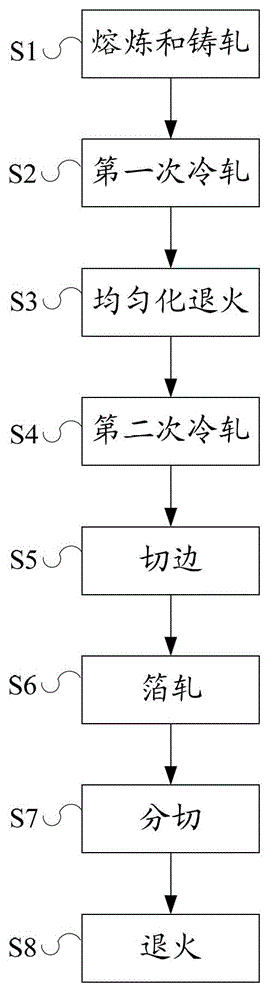

The invention provides a machining method of a 3003 aluminum alloy finished foil, which comprises the following steps: smelting, and cast rolling; primary cold rolling; homogenizing annealing: carrying out homogenizing annealing on the strip subjected to cold rolling at 460-520 DEG C for 18-25 hours; secondary cold rolling: carrying out heavy-reduction cold rolling on the strip subjected to annealing, wherein the working rate in pass is 40-60%; trimming; foil rolling; cutting; and annealing to obtain the 3003 aluminum alloy finished foil. By enhancing the annealing temperature and prolonging the annealing time of the homogenizing annealing, the grain size is increased; and the secondary cold rolling is carried out, and the reduction in pass is kept at 40-60% to crush the increasing grains, thereby achieving the goal of improving the interior structure of the material, effectively enhancing the elongation percentage of the material, lowering the tensile strength and facilitating the formation.

Owner:SOUTHWEST ALUMINUM GRP

Steel for carbon hub bearing of microalloying car and production method thereof

InactiveCN105568134AGuaranteed normal growthImprove composition segregationRolling contact bearingsHubsChemical compositionMetallurgy

The invention relates to steel for a carbon hub bearing of a microalloying car. The steel comprises the following chemical components: 0.45-0.70% of C, 0.10-0.50% of Si, 0.30-0.70% of Mn, 0.20-0.60% of Cr, P not more than 0.025%, 0.003-0.030% of S, Mo not more than 0.1%, Ni not more than 0.2%, Al not more than 0.04%, Cu not more than 0.3%, Ca not more than 0.001%, Ti not more than 0.003%, O not more than 0.001%, As not more than 0.04%, Sn not more than 0.03%, Sb not more than 0.005%, Pb not more than 0.002%, and the balance of Fe and inevitable impurities. A production method comprises an electric furnace or a converter-refining out of the furnace-VD or RH vacuum degassing-continuous casting-continuous rolling-sawing-cooling in heap-finishing-surface and internal flaw detection-packing. The steel for the hub bearing improves the mechanical performance, the element segregation and the structure uniformity, and belongs to a brand new hub bearing steel type.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

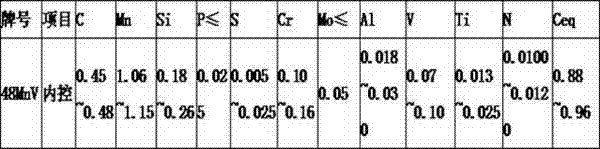

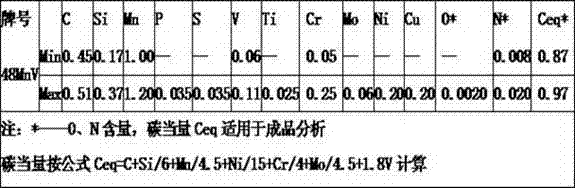

Production process for 48MnV round steel

InactiveCN102363210AImprove mechanical propertiesLoose compactionTemperature control deviceTemperature controlProduction line

The invention discloses a production process for 48MnV round steel. In the invention, continuous casting dynamic soft reduction and heavy draught rolling processes are combined for producing 48MnV round steel. The production process comprises the following specific steps of: manufacturing a 48MnV casting blank meeting a certain requirement by using the continuous casting dynamic soft reduction process; in a rolling production line, heating the casting blank and rolling by adopting the heavy draught process, wherein the rolling compression ratio is more than or equal to 6.0; controlling the initial rolling temperature at 1,180-1,050 DEG C and controlling the final rolling temperature at 950-920 DEG C; and slowly cooling, rectifying, performing ultrasonic wave and eddy current fault detection, packing and warehousing to obtain the 48MnV round steel. In the production process, the continuous casting dynamic soft reduction and heavy draught rolling processes are combined, bulk compaction, crack press fit, segregation improvement and inclusion dispersion are realized, the density and uniformity of steel are improved, and the mechanical performance of the steel is improved.

Owner:NANJING IRON & STEEL CO LTD

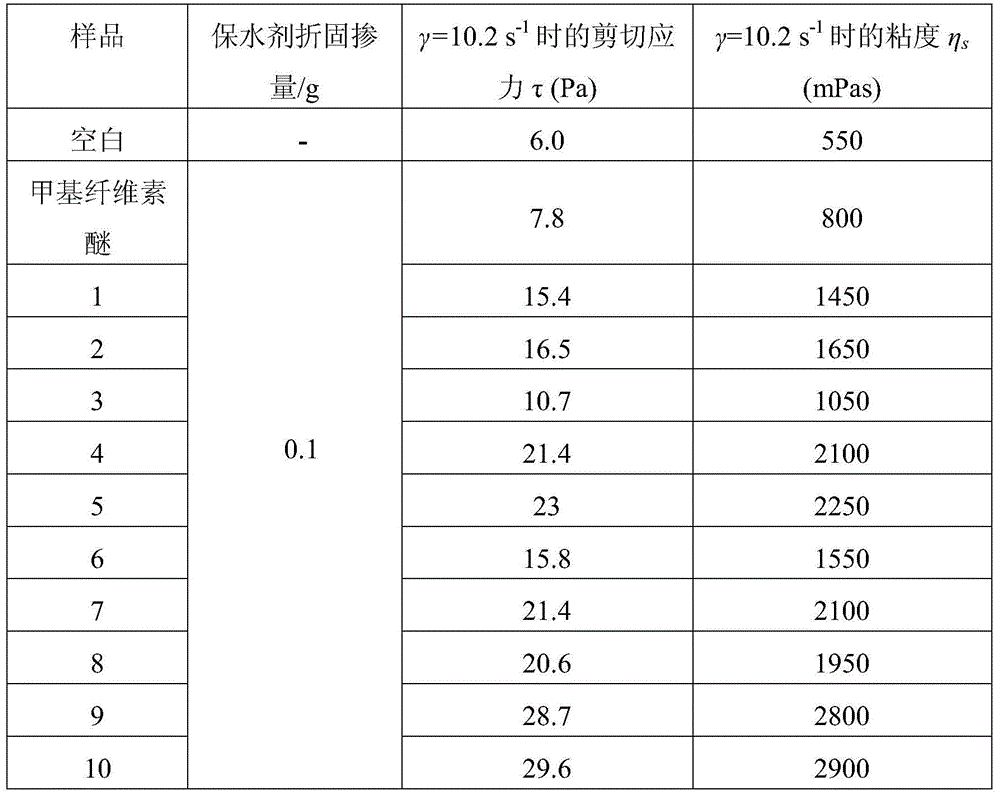

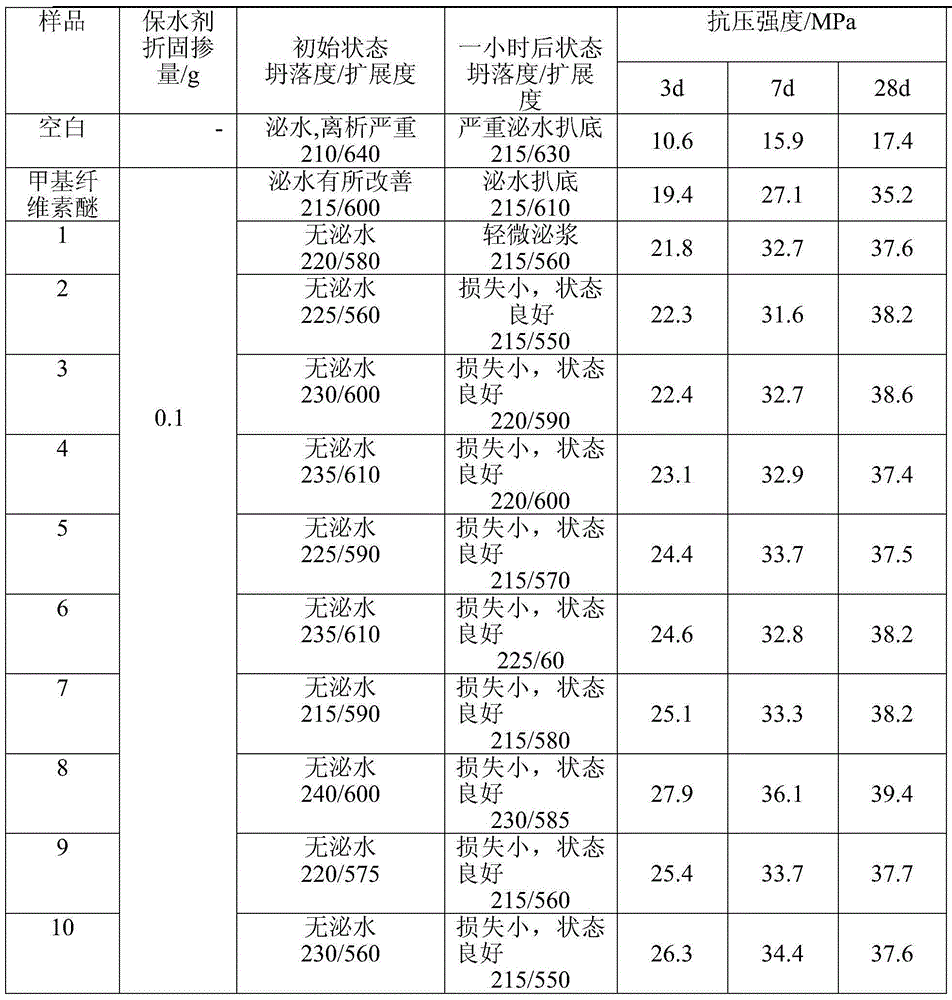

Preparation method of water retaining agent

InactiveCN104628968AAddressing Adaptive IssuesSolve the problem of adaptability, especially the large mud content of sand and gravelAcid waterOrganic solvent

The invention discloses a preparation method of a water retaining agent. The preparation method comprises the following steps: carrying out an aqueous phase radical polymerization reaction on unsaturated amide micro-monomers, unsaturated sulphonic acid micro-monomers and unsaturated polyether macromers or unsaturated ester macromonomers under the coaction of an oxidation-reduction system composed of an initiator and a reducing agent to obtain a copolymerization product, regulating the pH value to 6-7 after the reaction, and adding water to obtain the water retaining agent with mass concentration of 1-60%. The preparation method disclosed by the invention is used for adjusting the product properties by controlling the monomer proportion, the temperature and the dosage of the initiator and the reducing agent, the reaction speed is high, the efficiency is high, no organic solvent is used, no toxin or pollution is generated, and the operation is simple. The unsaturated macromonomers are introduced into the prepared concrete / mortar water retaining agent to ensure excellent water retaining property and obviously perfect such stirring states of the concrete / mortar as bleeding / separation and the like without generating such adverse effects as strength and the like, meanwhile, the water retaining agent can be compounded with a polycarboxylic acid water reducing agent at any proportion to ensure good intermiscibility. The product performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

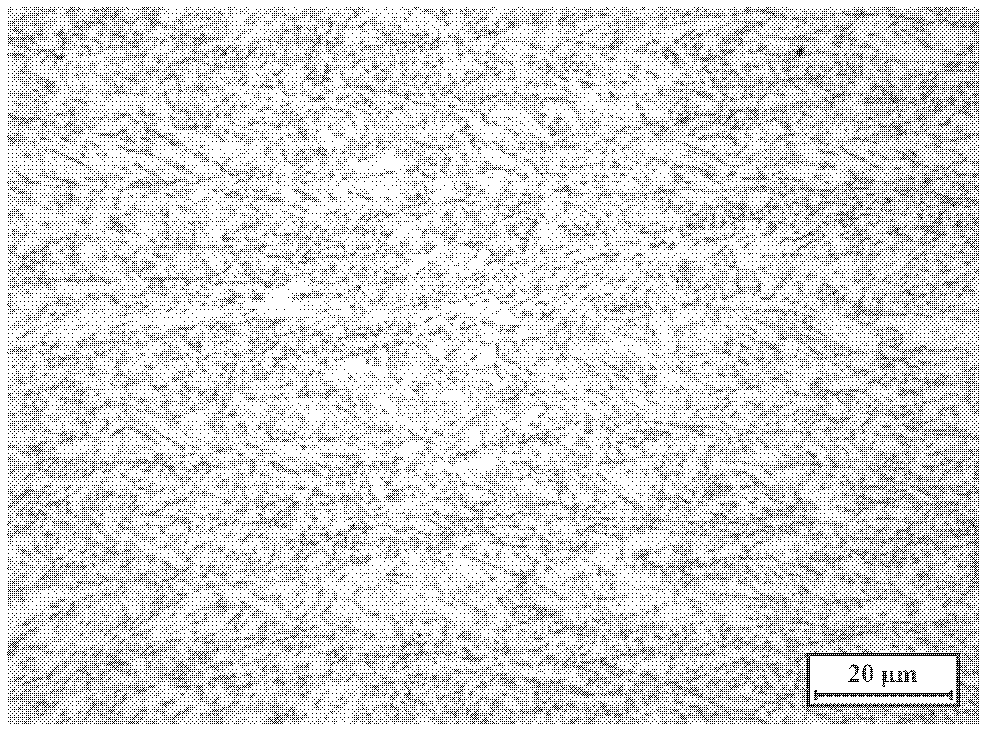

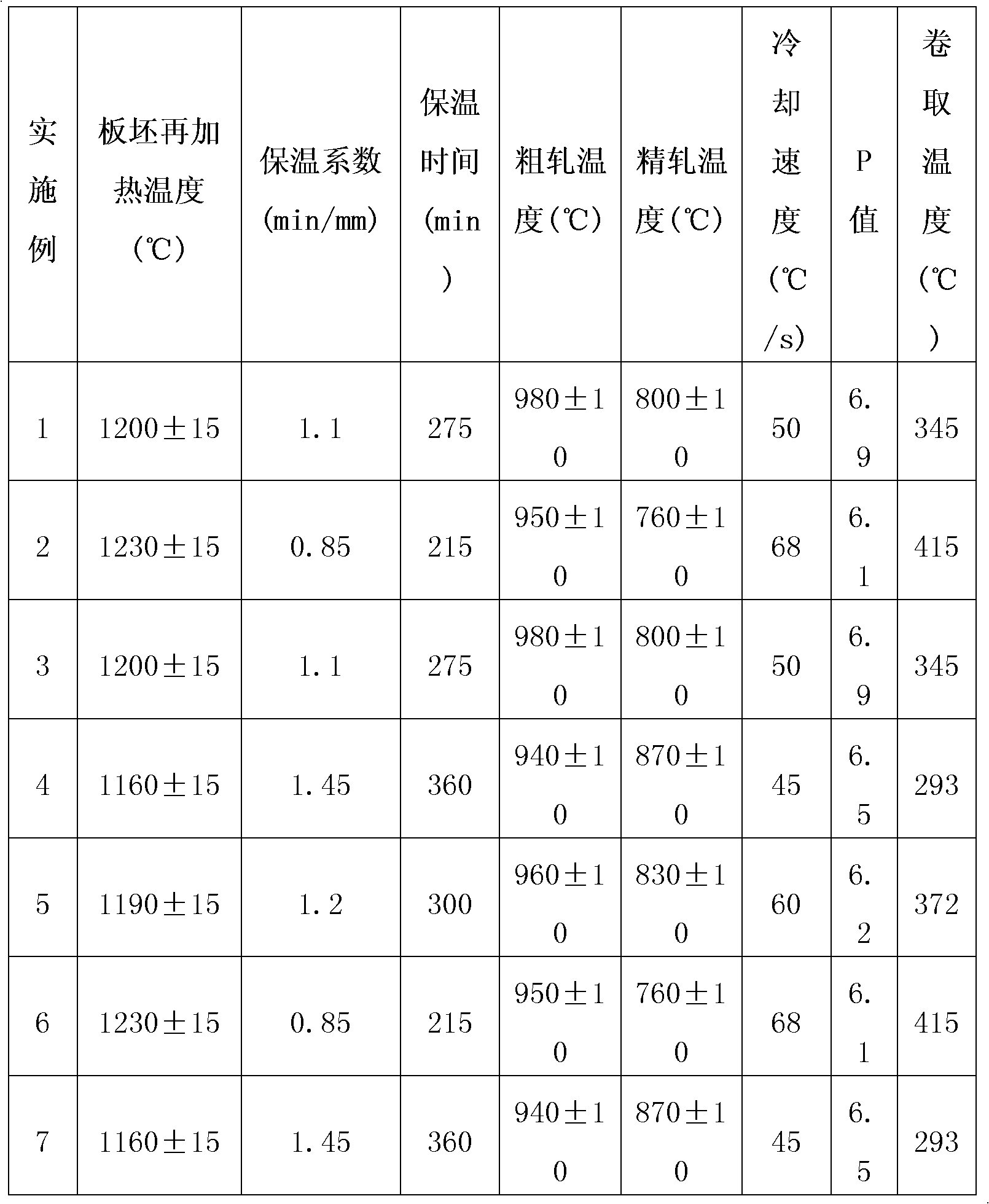

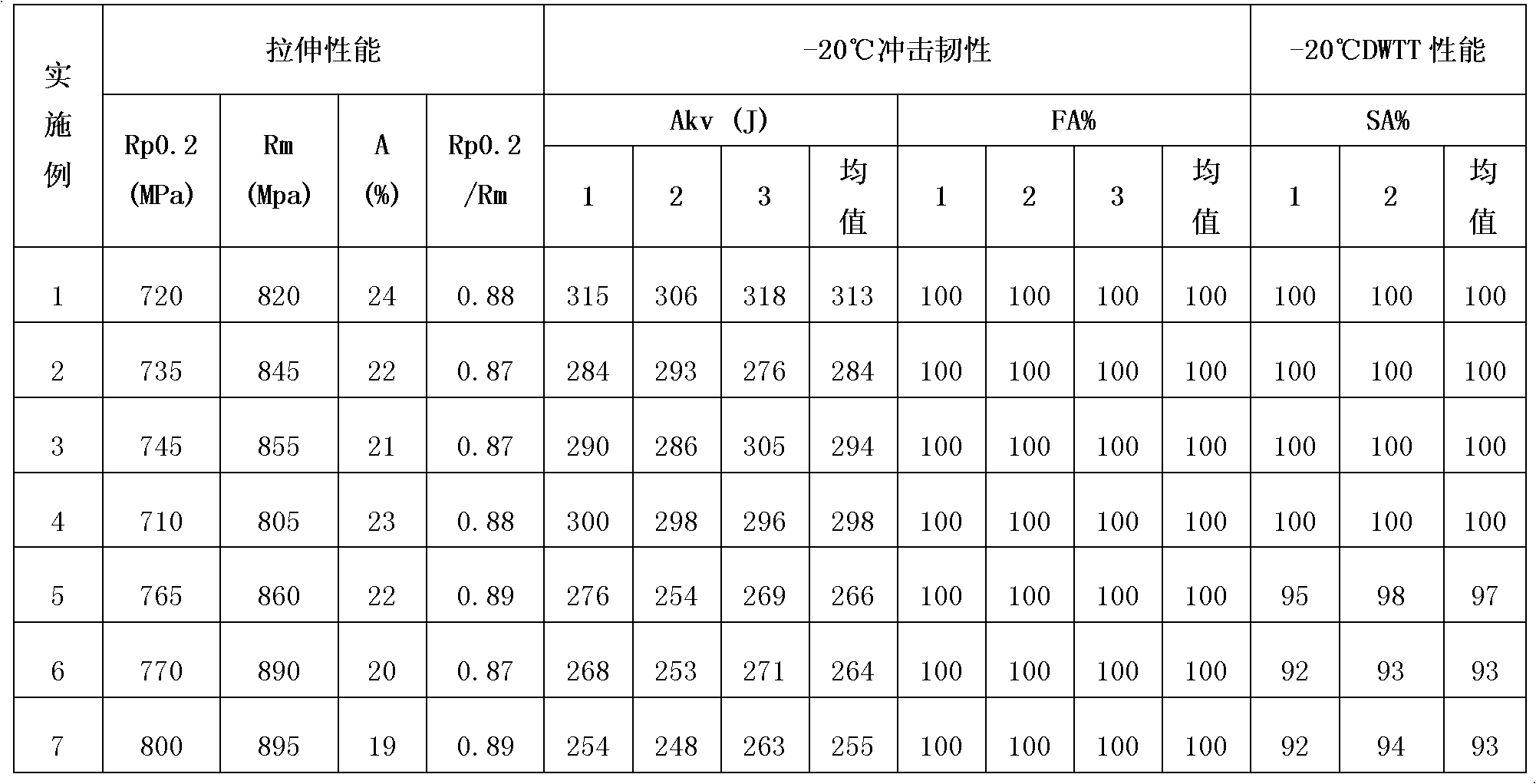

High-strength high-toughness X100 pipeline steel hot-rolled steel strip and manufacturing method thereof

ActiveCN102560284AEasy to changeHigh strengthMetal rolling arrangementsChemical elementSimple component

The invention discloses a high-strength high-toughness X100 pipeline steel hot-rolled steel strip. The steel strip comprises the following chemical elements in percentage by mass: 0.015 to 0.090 percent of C, 0.1 to 0.5 percent of Si, 1.50 to 1.79 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.10 to 0.40 percent of Cr, 0.03 to 0.10 percent of Nb, 0.001 to 0.100 percent of Zr, 0.01 to 0.035 percent of Ti, 0.31 to 0.60 percent of Mo, 0.10 to 0.40 percent of Cu, 0.10 to 0.50 percent of Ni, 0.0010 to 0.0050 percent of Ca, 0.02 to 0.045 percent of Al, less than or equal to 0.010 percent of N, less than or equal to 0.008 percent of O and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a method for manufacturing the steel strip. The hot-rolled steel strip has high comprehensive mechanical properties and manufacturability and comprises simple components.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel for deep sea oil extraction equipment and manufacturing method of steel forge piece for deep sea oil extraction equipment

ActiveCN105483542AAvoid crackingImprove mechanical propertiesMetal-working apparatusMechanical propertyToughness

The invention discloses steel for deep sea oil extraction equipment and a manufacturing method of a steel forge piece for the deep sea oil extraction equipment. The manufacturing method comprises the steps that a special steel material is used as a blank, the surface of the blank is coated with a glass-like coating, the free forging and bound forging composite forging way is adopted for forging the blank, and a secondary forged blank is obtained; the secondary forged blank is normalized, the temperature is increased to 1150-1200 DEG C in a slow-fast-slow gradient heating mode, then quenching heat treatment is carried out in a water cooling-air cooling ternary cycle alternate mode, secondary tempering treatment in the tempering-water cooling-tempering-water cooing mode is carried out on the quenched secondary forged blank, and therefore the steel forge piece for the deep sea oil extraction equipment is obtained. Quenching cracking of large forge pieces in complex shapes is effectively prevented by combining the forging technology with the heat treatment technology, the comprehensive mechanical property, particularly the low-temperature toughness of the manufactured steel forge piece for the deep sea oil extraction equipment is greatly improved, and the manufactured steel forge piece can be well applicable to deep sea low-temperature working condition environment.

Owner:NANJING INST OF TECH +1

Method for forging thick-walled ring-shaped parts

InactiveCN102319855ASmall effective wall thicknessQuality improvementMetal-working apparatusThick wallIngot

The invention relates to a method for forging thick-walled ring-shaped parts. The method includes the following process steps: step 1: steel ingot sawing; step 2: upsetting and punching; step 3: drawing out on a mandril: the drawing-out ratio is controlled at 1.8 to 2.2; and step 4: secondary upsetting and finishing. Since the method adds the processes of drawing out on the mantril and secondary upsetting after punching, in the process of drawing out on the mantril or reaming, the effective wall thickness of the forging is already quite small, pressure can be easily transferred to the central part of the forging during forging, the deformation pressure can deform the core of the billet due to the great reduction of the effective forged thickness, moreover, the core receives pressure stress in three directions, the as-cast structure of the steel ingot is changed, in-situ pores are forged to be closed, the defects of segregation and inclusion are improved, and thereby the internal quality of the forging is greatly improved.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Control method for segregation and net carbon of 86-grade high-strength cord steel wire rod

ActiveCN112359277AImprove segregationImprove mesh carbonProcess efficiency improvementWire rodContinuous casting

The invention discloses a control method for segregation and net carbon of an 86-grade high-strength cord steel wire rod. The control method comprises the following steps of: KR molten iron pre-desulfurization, BOF converter smelting, LF furnace refining, continuous casting CC, casting blank surface treatment, casting blank heating, controlled rolling and controlled cooling procedures which are carried out in sequence. The 86-grade high-strength cord steel wire rod comprises the following components in percentage by weight: 0.85-0.90% of C, 0.15-0.35% of Si, 0.40-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.010% of Cr, less than or equal to 0.005% of Al and the balance Fe. According to the control method, the segregation and netcarbon of the wire rod are improved by combining continuous casting of small square billets with wire rolling, the period and cost are greatly reduced, the sorbitizing rate of the prepared wire rod is larger than or equal to 90%, the center segregation of the wire rod is slight, no net-shaped cementite exists in the center, and the drawing use requirements of users are met.

Owner:ZENITH STEEL GROUP CORP +1

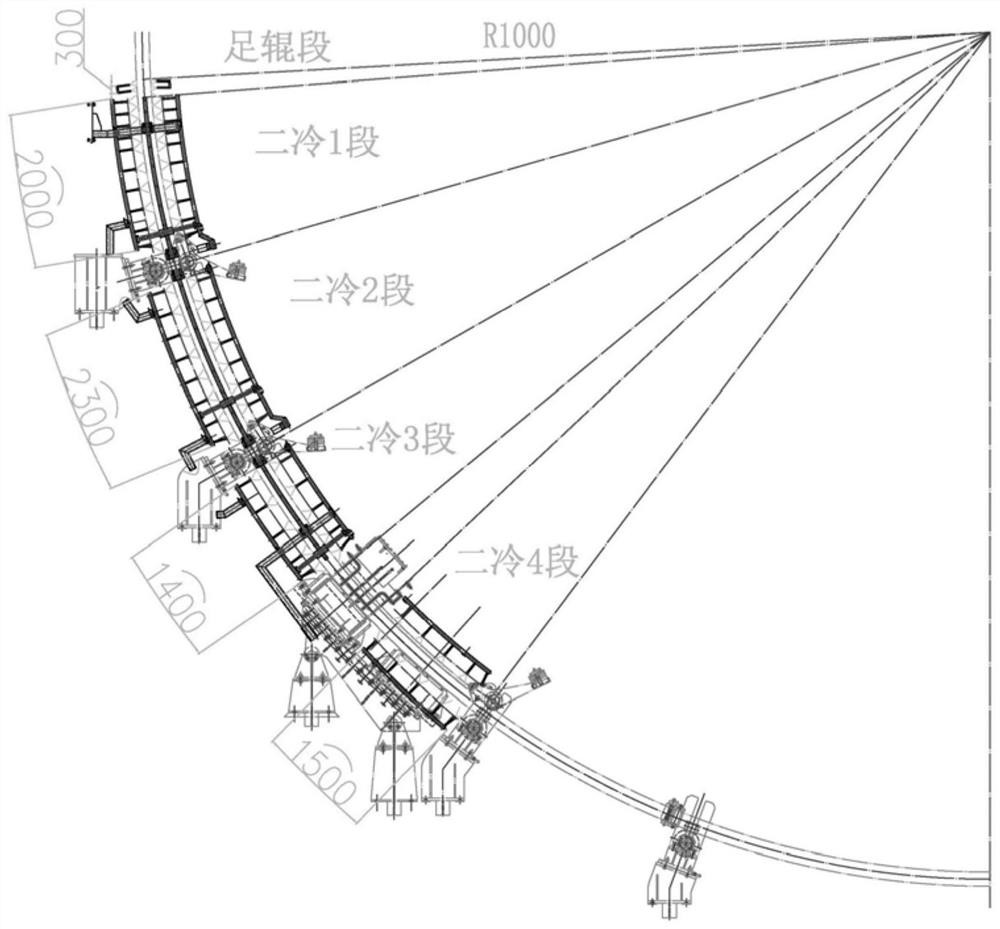

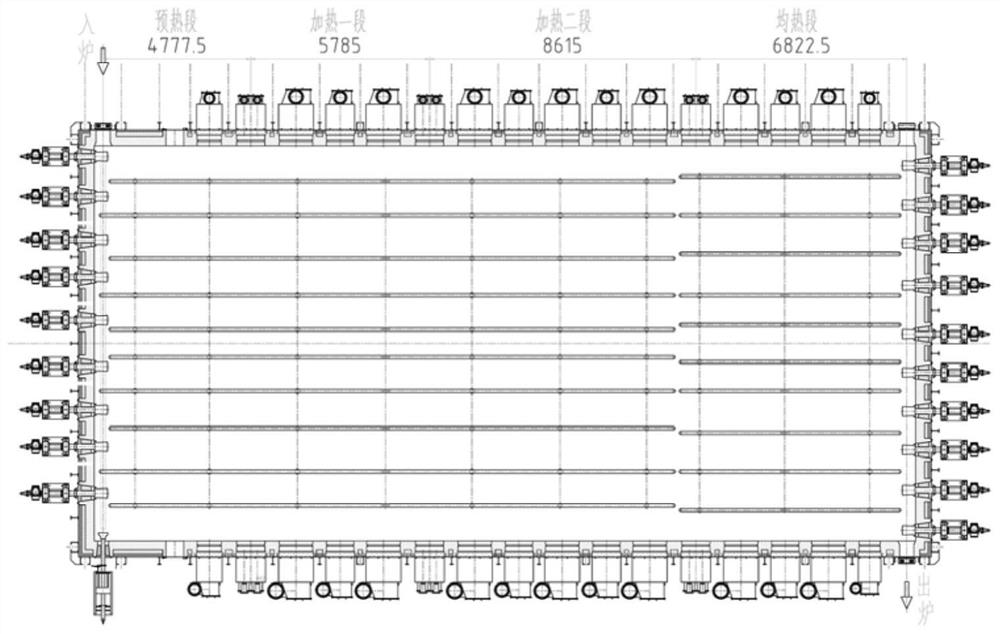

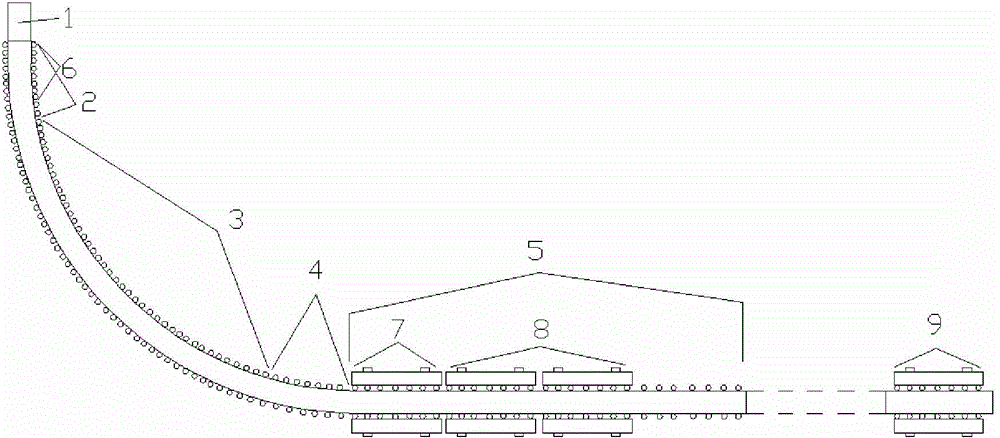

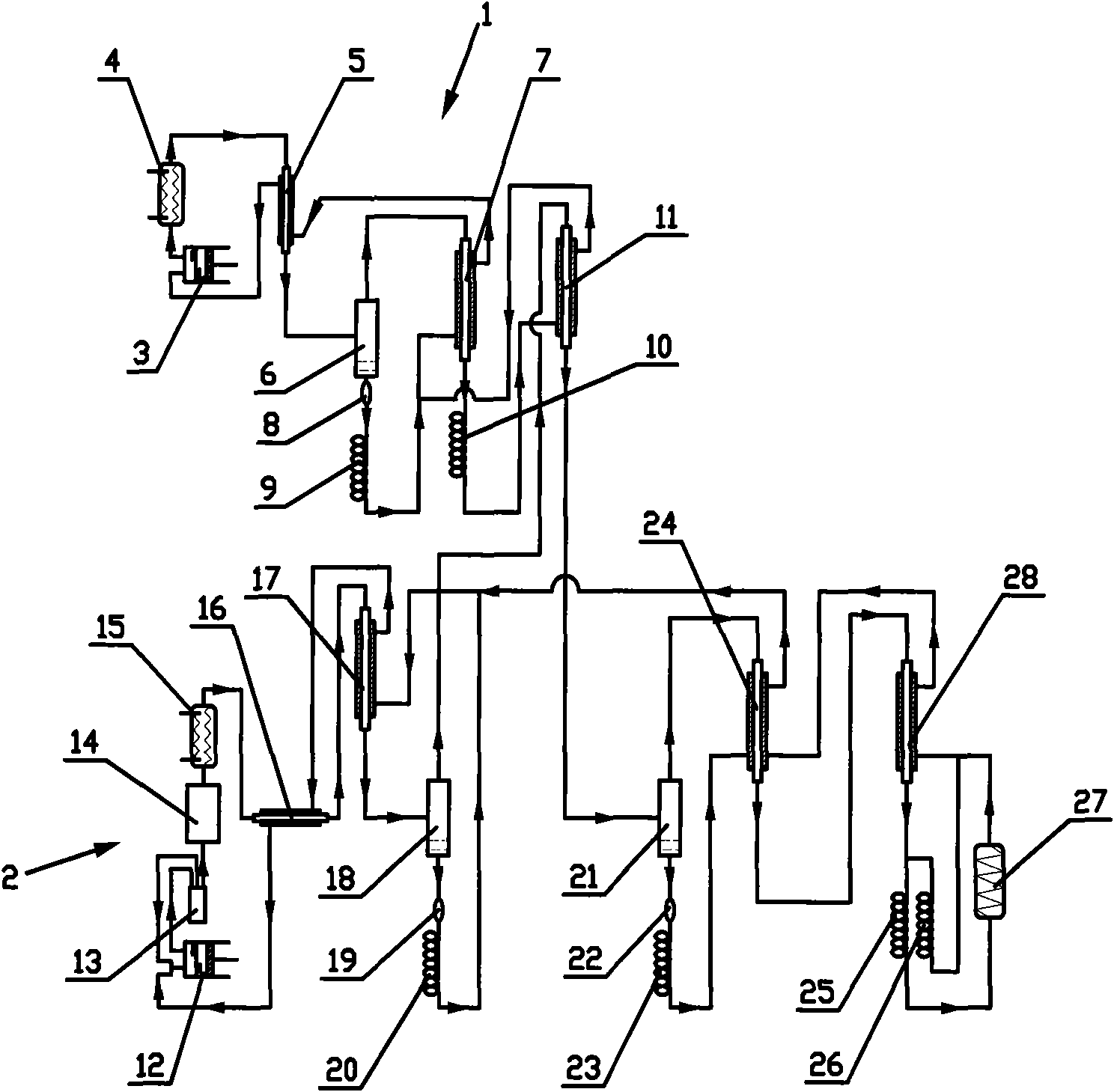

Method for producing ultra-thick plate continuous casting blank

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

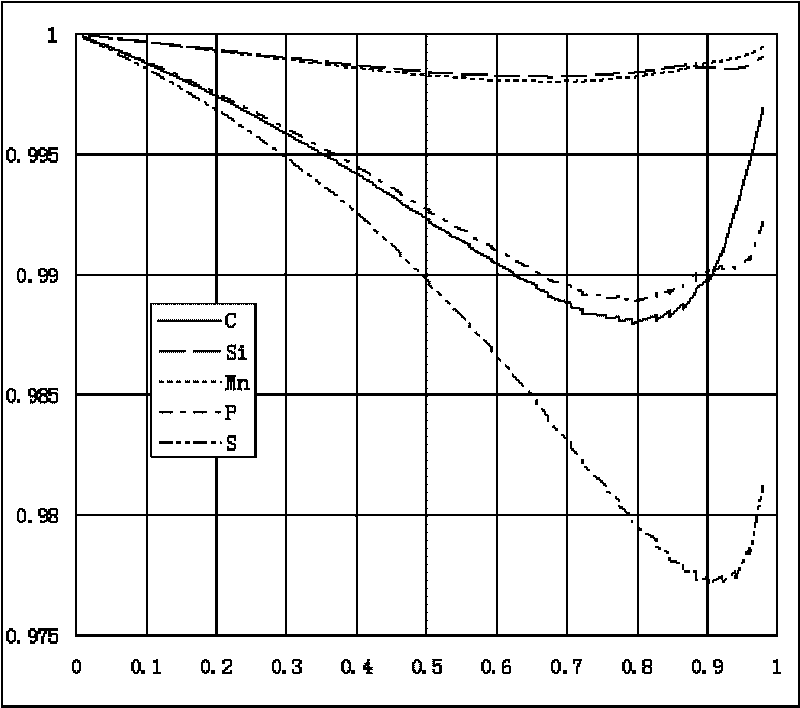

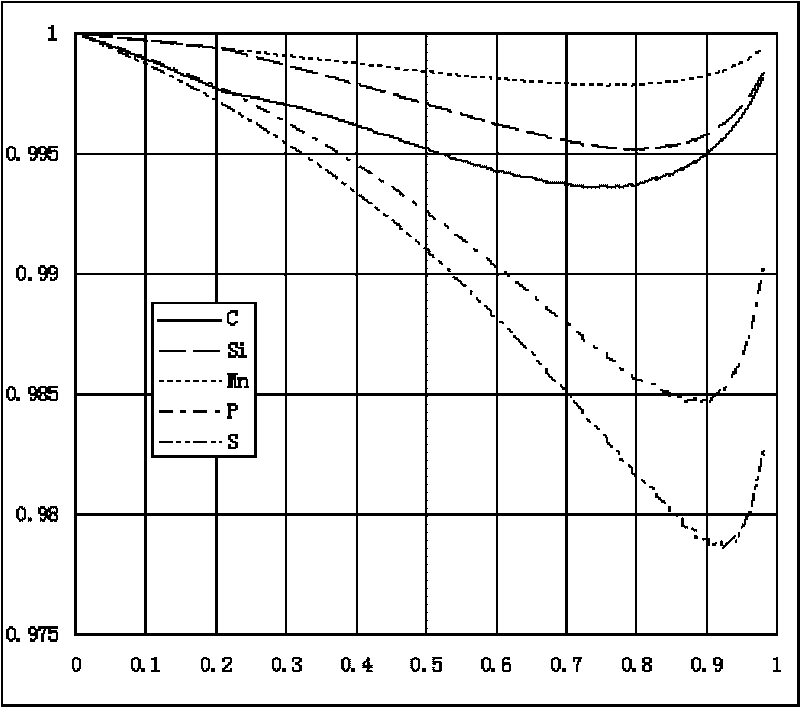

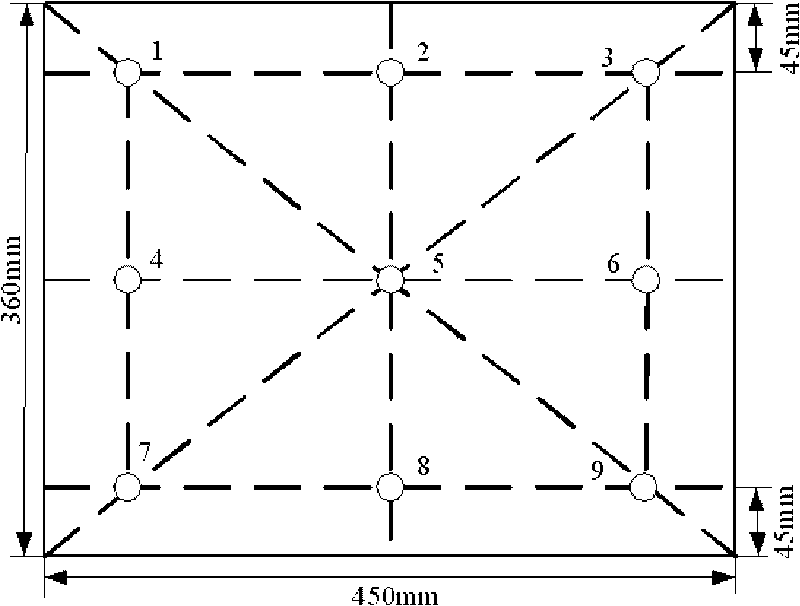

Method for controlling bloom continuous casting dynamic soft-reduction pressure interval

The invention discloses a bloom continuous casting soft-reduction process used in steel production, and in particular relates to a method for controlling a bloom continuous casting dynamic soft-reduction pressure interval. The pressure interval is determined according to the central solid-phase rate of each casting blank section in the direction of blank drawing; the central solid-phase rate of each casting blank section relative to the upper limit of the pressure interval is less than or equal to the fs, namely Maxopt which is the maximum value of iopt, of each solute element, wherein the fs and iopt are the central solid-phase rates of a casting blank section relative to the minimum Ki of the solute elements; the Ki is the average solute aliquation index of the solute element i in two phase regions when each casting blank section is slightly pressed; furthermore, the central solid-phase rate of each casting blank section relative to the lower limit of the pressure interval is more than or equal to the fs, namely Minopt which is the minimum value of iopt, of each solute element. The pressure interval determined by the method can effectively improve central aliquation and also reduce cavity, looseness and crack; and the pressure interval has stable use effect and is suitable for bloom continuous casting production.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

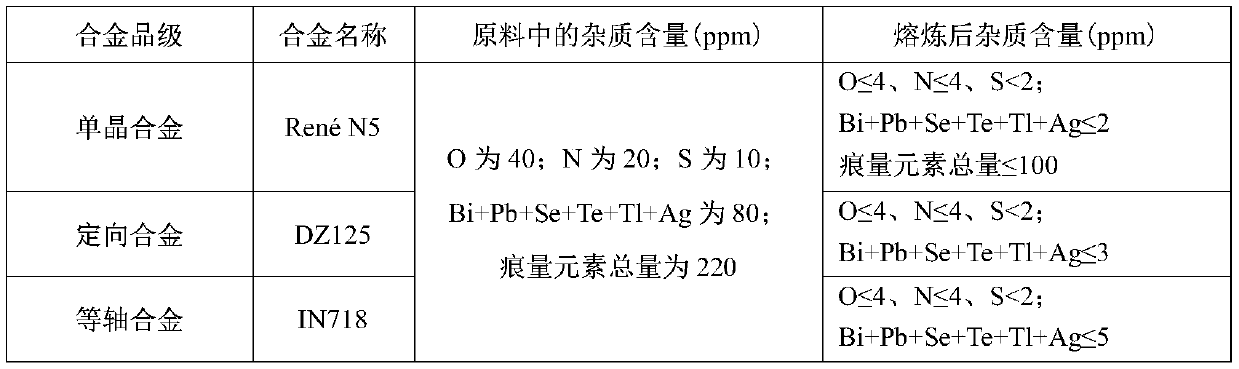

Pure purification smelting method used for nickel-based high-temperature alloy master alloy

The invention relates to a pure purification smelting method of an alloy, in particular to a pure purification smelting method for a nickel-based high-temperature alloy master alloy, and belongs to the technical field of metal smelting. According to the method, pure purification smelting of a master alloy is completed through material distributing and alloy melting, primary refining, alloying andsecondary refining, microalloying controlling and casting. The method has the advantages that the purity of vacuum melting can be effectively improved, the element segregation can be improved, and a nickel-based high-temperature alloy prepared by the method has the advantages that the purity is high, the segregation is low, the quality is remarkably higher than that of an alloy prepared through the existing technology and method, the quality of the nickel-based high-temperature alloy is improved, and the application field is expanded; nickel-based high-temperature alloys with different gradesand marks smelted by adopting the method has good effects; vacuum induction furnaces with the furnace types of 250 kg-grade and 1.5 ton-grade are adopted; and compared with an alloy before smelting and prepared through other technologies and methods, the alloy is remarkably improved in purity and uniformity.

Owner:METALINK SPECIAL ALLOYS CORP

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

Manufacturing method of oversized continuous casting slab of nickel stainless steel

ActiveCN105861951AComply with continuous casting process parametersImprove productivityElectric furnaceProcess efficiency improvementSteelmakingProduction rate

The invention discloses a manufacturing method of an oversized continuous casting slab of nickel stainless steel and aims to achieve the purpose of improving surface and inner quality of the continuous casting slab. To achieve the purpose, two key technical measures are taken, on one hand, reasonable chemical ingredient design is conducted, a scientific and reasonable smelting process is formulated, and it is guaranteed that the nitrogen / oxygen content in steel is lowered, and oxide inclusion in steel is reduced; on the other hand, the reasonable continuous casting pouring temperature, the casting speed and secondary cooling water distribution parameters are determined, secondary oxidation is reduced in the pouring process, contamination of steel liquid is prevented, meanwhile a reasonable process is controlled, and segregation of chemical ingredients is reduced while the surface quality of the continuous casting slab is improved. Continuous casting production changes a process route that steelmaking, die casting and forging are mainly conducted of traditional large stainless steel forging products, blank in the production field both home and abroad is filled up, production efficiency is greatly improved, the yield is raised, and the production cost is lowered.

Owner:DONGBEI SPECIAL STEEL GROUP

Self-overlapping refrigeration system

ActiveCN101576329AReduce the temperatureSelf-cascading implementationCompression machines with non-reversible cycleCompression machines with cascade operationIntermediate heat exchangerBoiling point

The invention relates to a self-overlapping refrigeration system provided with at least one high-temperature self-overlapping loop (1) and at least one low-temperature self-overlapping loop (2), wherein the high-temperature self-overlapping loop (1) and the low-temperature self-overlapping loop (2) are respectively an independent and closed refrigeration circulation loop, and the high-temperatureself-overlapping loop carries out temperature-reduction fractional condensation for the second time to a gas refrigerant of the low-temperature self-overlapping loop after fractional condensation forthe first time by an intermediate heat exchanger. The invention enables the medium temperature of a refrigeration working medium to be lower, reduces the pressure of a low-temperature level system, obviously reduces the exhaust temperature and the exhaust pressure at the previous period of starting-up and temperature reduction, enhances the temperature-reduction speed simultaneously and enables alow-temperature level to obtain much larger refrigerating capacity. The invention enhances the effects of fractional condensation and separation by utilizing the evaporation of a working medium with high boiling point and a mixed regenerative cycle mode of a low-temperature flow-reversal working medium in the low-temperature level, and can ensure that components with high boiling points are more completely separated out.

Owner:QINGDAO HAIER BIOMEDICAL CO LTD

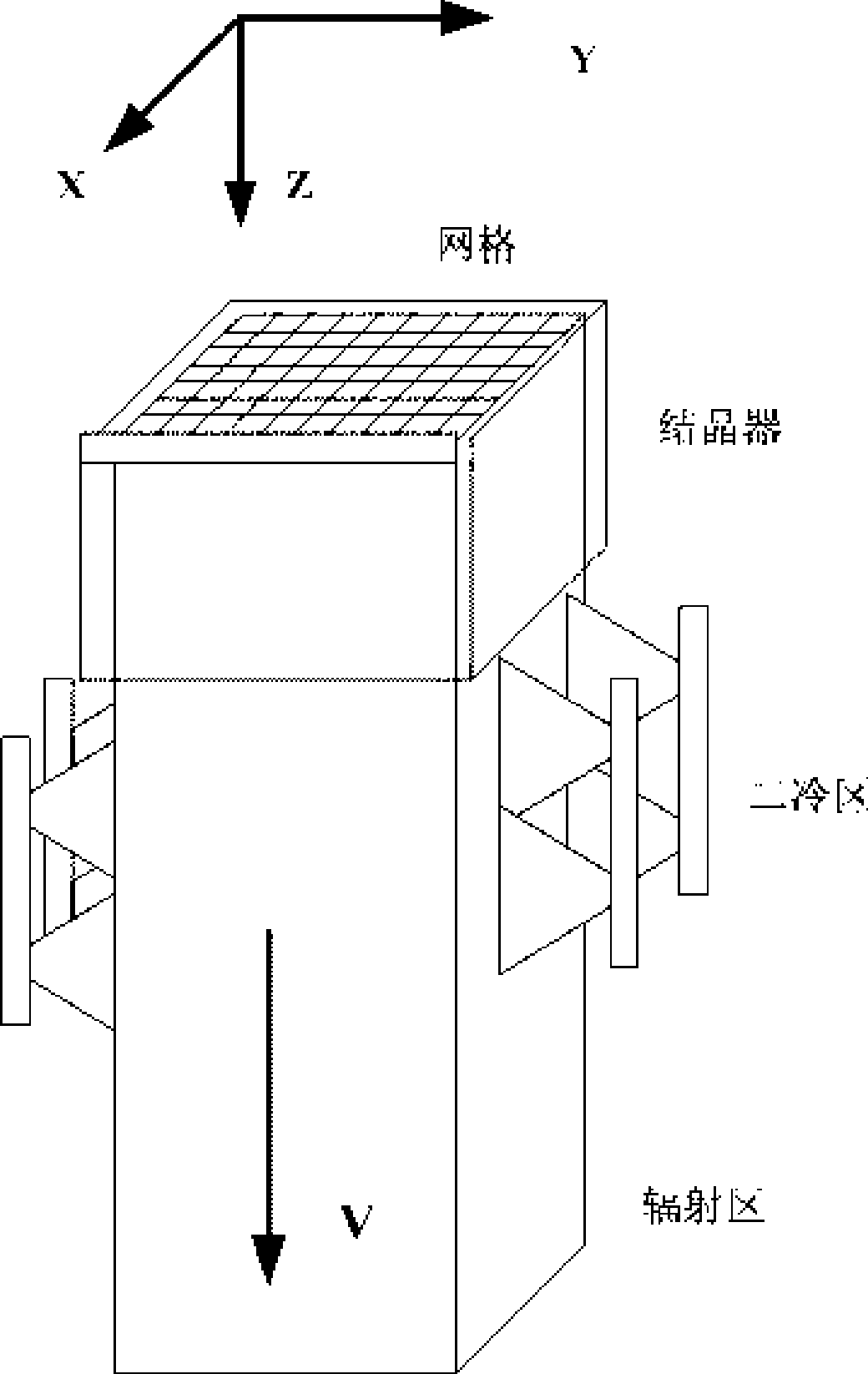

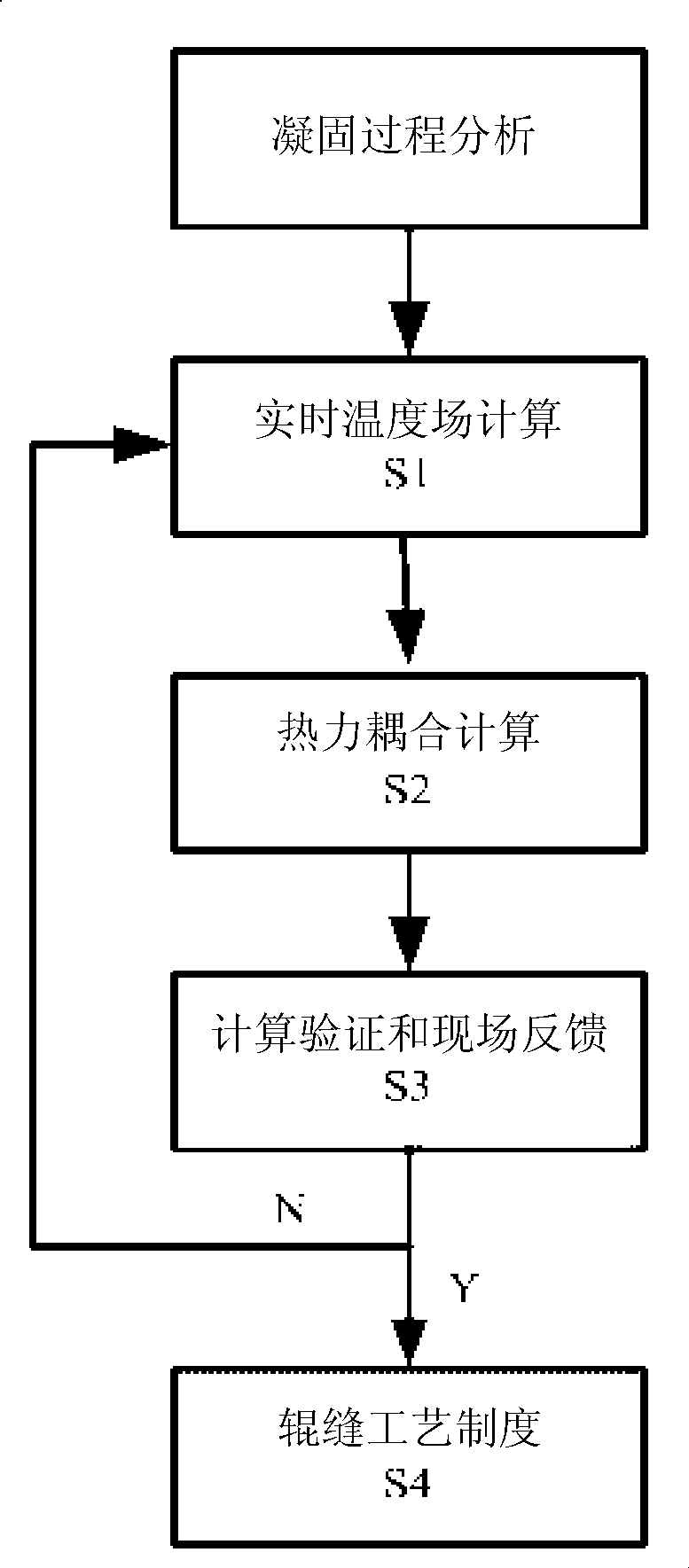

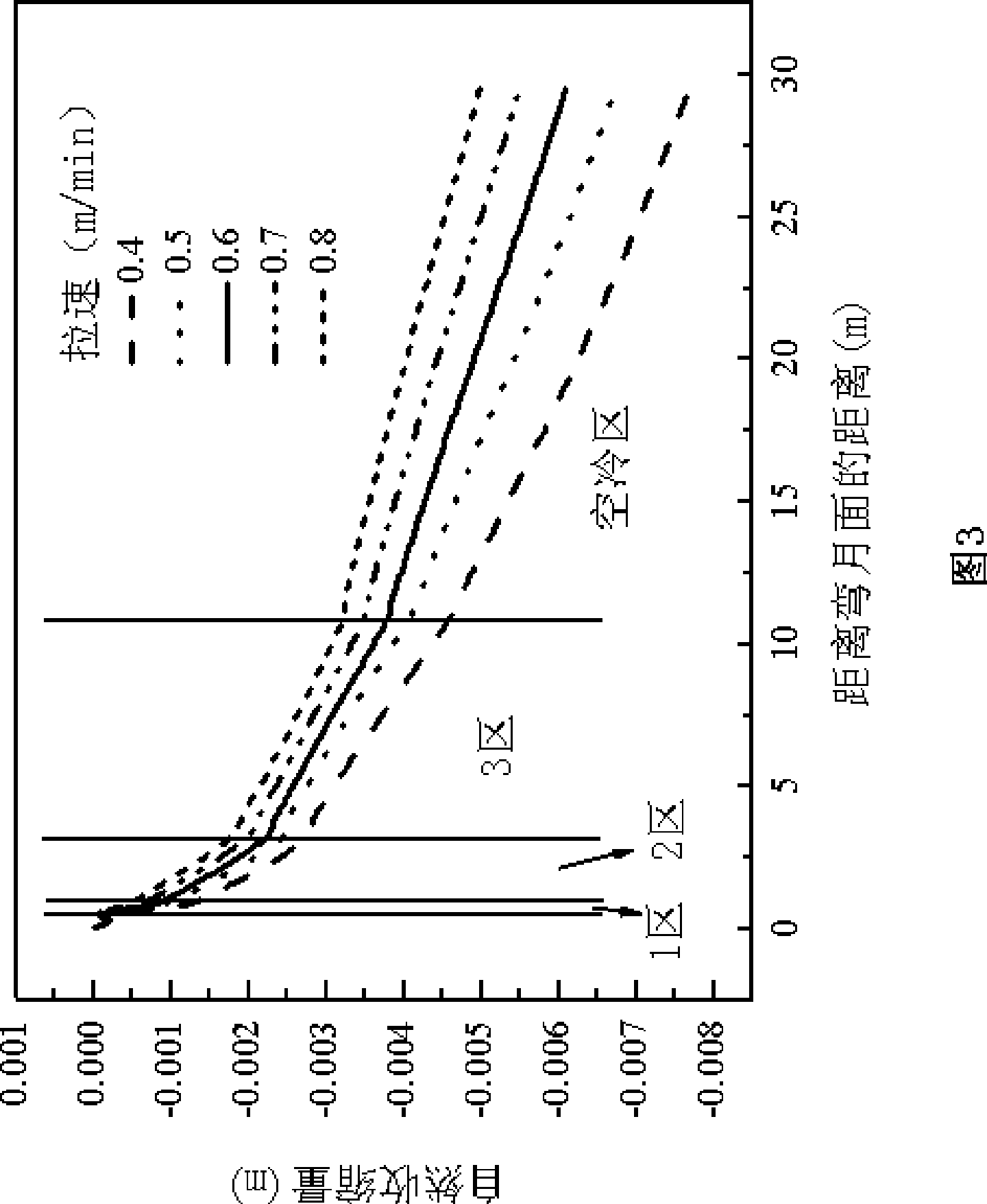

Control method of natural roll-gap thermal-contraction technique based on bloom

The invention discloses a billet continuous casting roll gap technology in metallurgical production and more particularly relates to a control method based on the technology of bloom natural thermal contraction roll gaps. The control process provided by the invention for controlling the roll gaps by the thermal contraction values of casting billets includes the following steps of: (1) the calculation of real-time temperature fields: building a solidification and heat transfer model of casting billets to obtain temperature fields of different times; (2) thermal coupling calculation: obtaining the natural thermal contraction values of casting billets in the direction of the casting billets at different times according to corresponding calculated temperature fields and strain distribution of the casting billets; (3) calculation verification and field feedback: comparing with the actual situations of fields according to results calculated by simulation; and (4) the determination of the system of the roll gap technology: determining the decrease rate and the roll gap difficulty of the roll gaps. The adoption of the control method of the process can effectively avoid the off-square of the casting billets, reduce the billet-drawing resistance and improve the interior defects of the casting billets, such as the central segregation and central porosity, etc.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

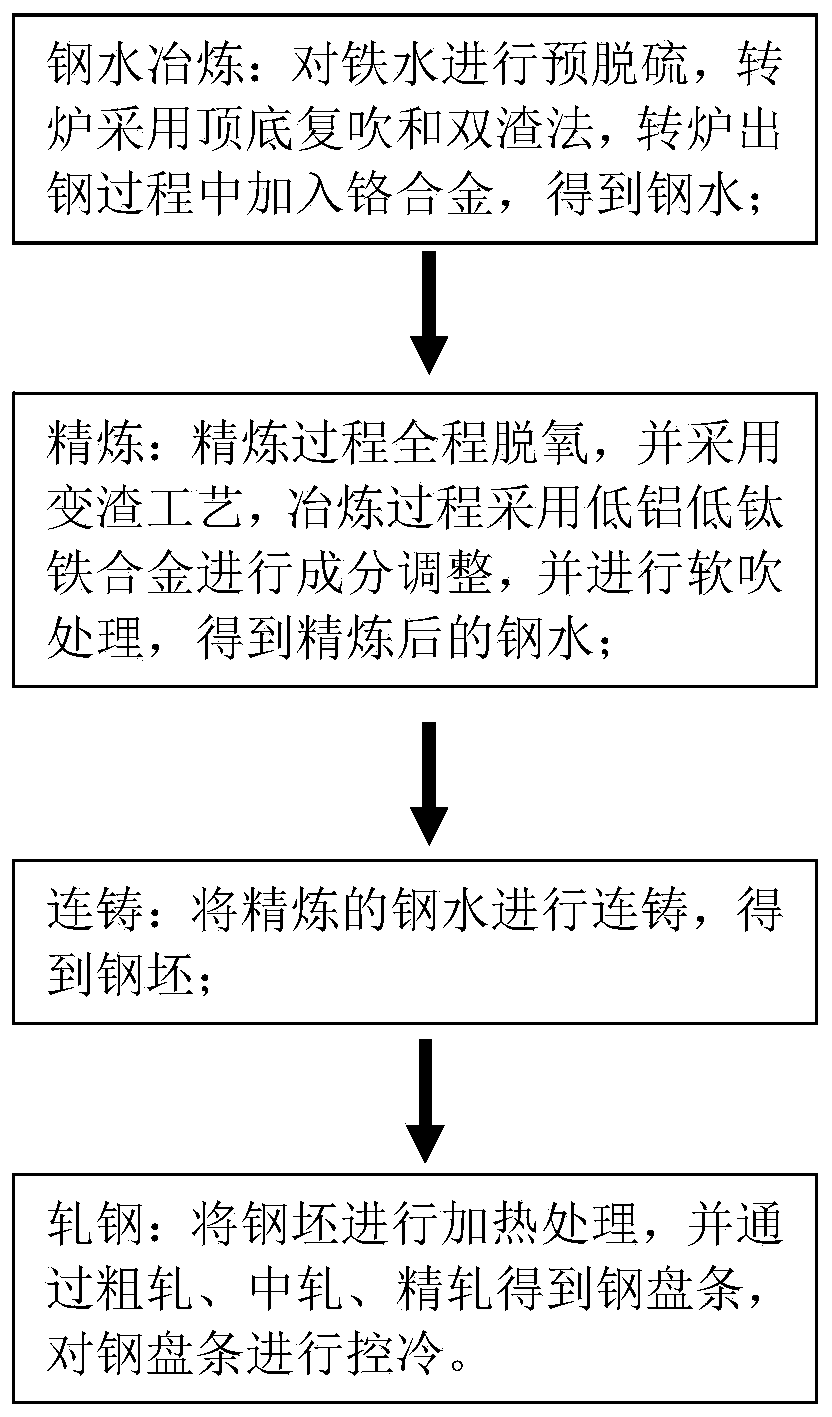

Chromium-alloyed cord steel wire rod and production process

ActiveCN111534753AReduce carbon contentReduce manganese contentManufacturing convertersMachining processThermal treatment

The invention provides a chromium-alloyed cord steel wire rod and a production process. The chromium-alloyed cord steel wire rod comprises the following chemical components of, in percentage by weight, 0.68%-0.82% of C, 0.20%-0.40% of Mn, 0.15%-0.30% of Si, 0.30%-0.40% of Cr, less than or equal to 0.012% P, less than or equal to 0.008% of S, less than or equal to 0.05% of Ni, less than or equal to0.05% of Cu, less than or equal to 0.03% of Mo, less than or equal to 0.003% of Al, less than or equal to 0.002% of Ti, less than or equal to 0.002% of [O], less than or equal to 0.005% of [N], and the balance Fe and unavoidable impurities. The production technology comprises the following steps of smelting molten steel, and adding chromium alloy in the converter tapping process; refining to obtain molten steel; carrying out continuous casting on the molten steel obtained after refining to obtain a steel billet; and heating the steel billet to obtain a chromium-alloyed cord steel wire rod, and carrying out controlled cooling on the chromium-alloyed cord steel wire rod. According to the chromium-alloyed cord steel wire rod and the production process, microalloying is adopted, the chromiumcontent is increased, the carbon content and the manganese content are reduced to compensate for the performance of the steel wire rod and the finished steel wire, carbon segregation of the steel wirerod is improved, the net carbon forming probability is reduced, the plasticity and the machining performance of the steel wire rod can be improved at the same time, and the strand combining and wirebreaking rate in the steel wire rod cord machining process is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

Continuous casting production control method for super-large section heavy rail steel

InactiveCN107790666AImprove segregationImprove densification performanceMelt-holding vesselsPower flowCurrent range

The invention discloses a continuous casting production control method for a super-large section heavy rail steel, and particularly relates to the continuous casting production control method in the field of ferrous metallurgy for the super-large section heavy rail steel. According to the continuous casting production control method for the large-section heavy rail steel, a parabolic taper curve type tubular mold is adopted, a cooling water pipeline is provided with two cooling water inlets and two cooling water outlets, a super-large section heavy rail steel mold adopts an immersion type water port, a double-side hole mode is adopted in the immersion type water port, the intensity of stirring currents ranges from 300-400A, the current frequency is 2.4Hz, the specific water flow of secondary cooling water is matched with the pulling rate at mold subsequent solidification section, and the solidification tail end is pressed down. According to the method, molten steel flow fields and solidification cooling of the mold are effectively controlled, a secondary cooling system is reasonably controlled on the basis, a force field is externally applied to a casting blank, the casting blank solidification structure is optimized, the segregation of solute elements is improved, and the compactness of the center of the casting blank is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

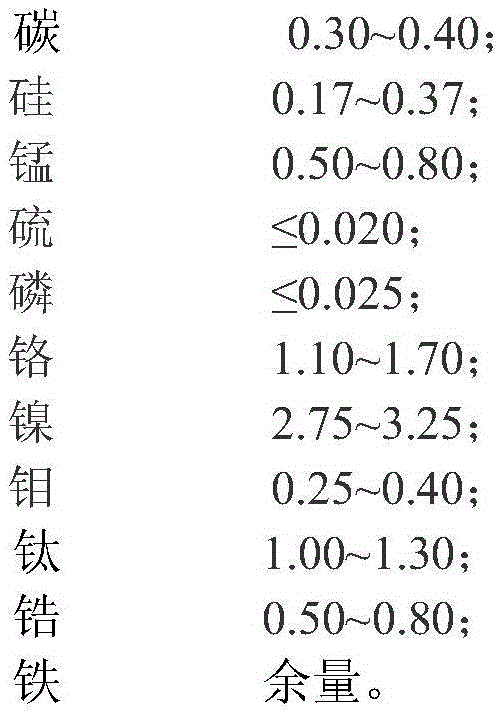

High-performance cold extrusion die steel and metallurgical manufacturing method thereof

ActiveCN101649419AReduced brittle tendencyImprove metallurgical qualitySteelmakingChemical composition

The invention provides high-performance cold extrusion die steel and metallurgical manufacturing method thereof. The high-performance cold extrusion die steel comprises the following chemical components in percentage by mass: 0.95 to 1.02 percent of C, 0.20 to 0.40 percent of Mn, 8.60 to 9.00 percent of Cr, 0.87 to 1.10 percent of Si, 1.80 to 2.00 percent of Mo, 0.40 to 0.60 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. According to the component proportion, the toughness performance of the high-performance cold extrusion die steel can be greatly improved. The metallurgical manufacturing method comprises theprocesses of electric furnace steel making, electroslag remelting and steel forging by a radial forging press. In the process of electroslag remelting, the voltage is between 57 and 59V, and the current is between11,000 and 12,000A; and in the process of steel forging by the radial forging press, steel ingots are heated to between 1,150 DEG C and 1,170 DEG C, and the temperature keeps for 2 to 4hours. The method is simple and convenient, and can remarkably improve the performance index of the steel.

Owner:宝武特种冶金有限公司

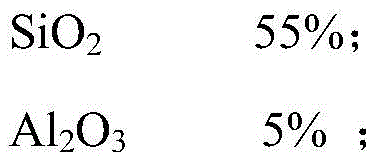

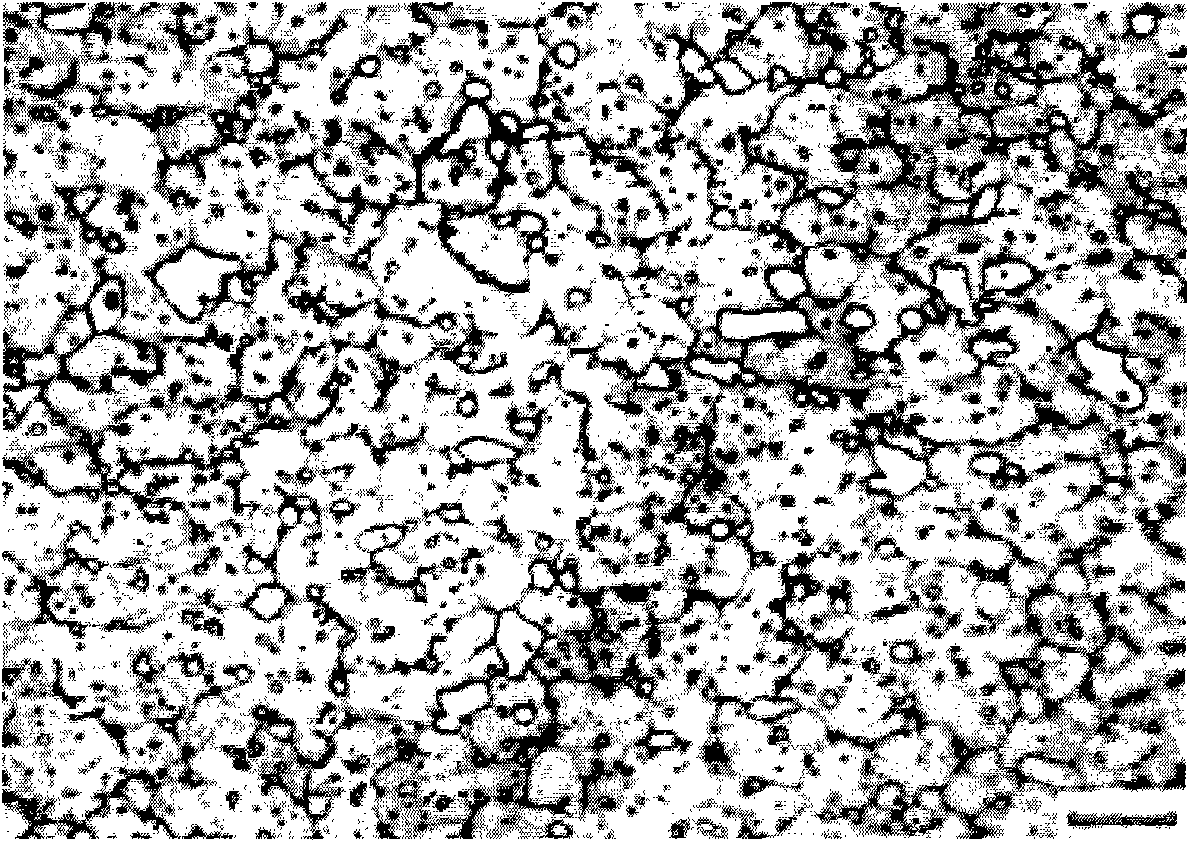

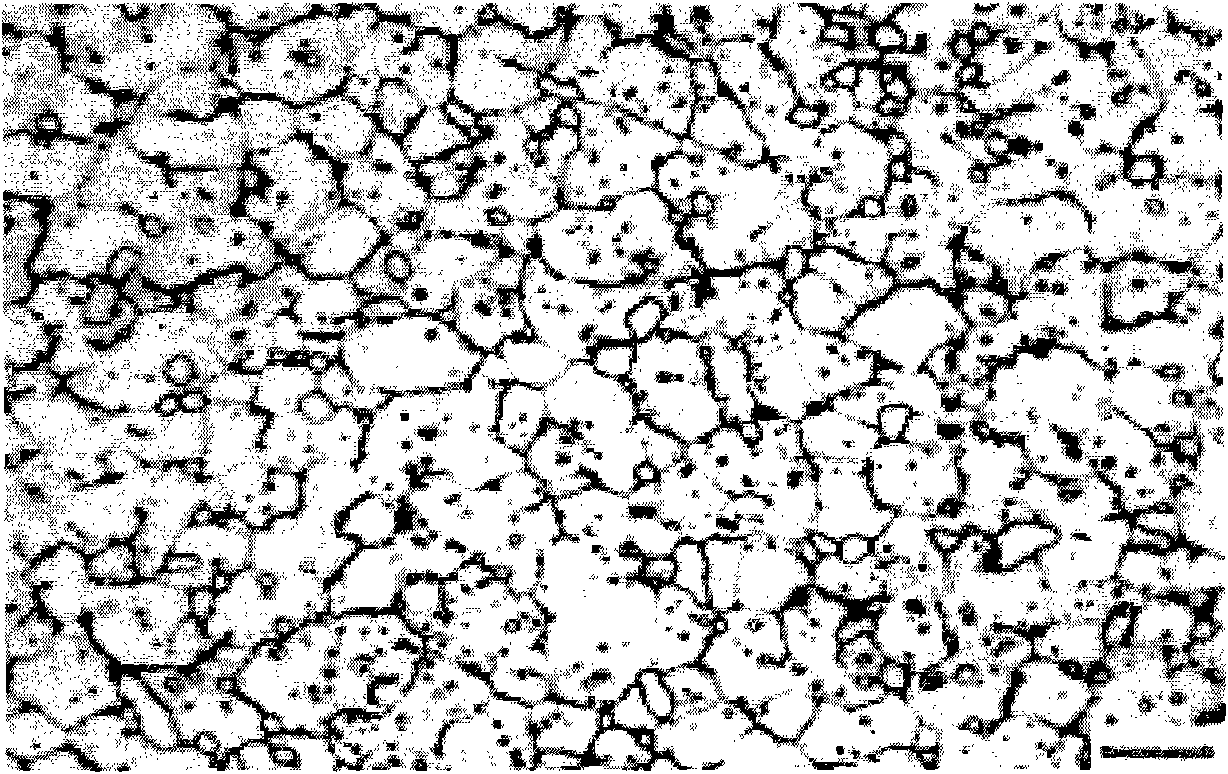

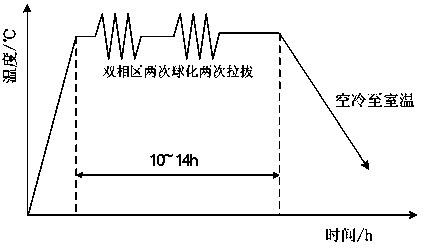

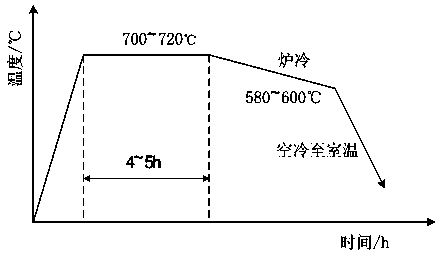

Spheroidizing annealing method for Cr and Mo steel with sheet type microstructure

The invention belongs to the technical field of metallurgy, and in particular relates to a spheroidizing annealing method for Cr and Mo steel with a sheet type microstructure. The spheroidizing annealing method comprises the steps of putting a Cr and Mo steel rolled product sample into a heating furnace, heating to 700-720 DEG C, preserving the temperature for 4-5 hours, then performing furnace cooling to 580-600 DEG C, taking out the Cr and Mo steel rolled product from the furnace, and cooling to room temperature, wherein the microhardness of the Cr and Mo steel rolled product subjected to spheroidizing annealing is 162.20-175.35HV, and the microstructure of the Cr and Mo steel rolled product consists of granular carbides dispersed on a ferritic matrix; the granular carbides have spheroidized structures in the level 5-6. According to the method, sub-medium temperature is preserved for certain time, and then the furnace cooling time is controlled, so that spheroidizing-annealed steel with high performance is obtained. The high preserved temperature is lower than the preserved temperature of the original technology, and the heat preservation time is shortened by almost three times, so that the energy consumption is obviously reduced, and the spheroidizing annealing efficiency is improved; the hardness of the steel subjected to the spheroidizing annealing technology is obviously reduced, the structure of a spheroidal pearlite is dispersive and fine, and the spheroidizing rate is high; the Cr and Mo steel subjected to spheroidizing annealing is high in cold heading performance and has a good application prospect.

Owner:NORTHEASTERN UNIV

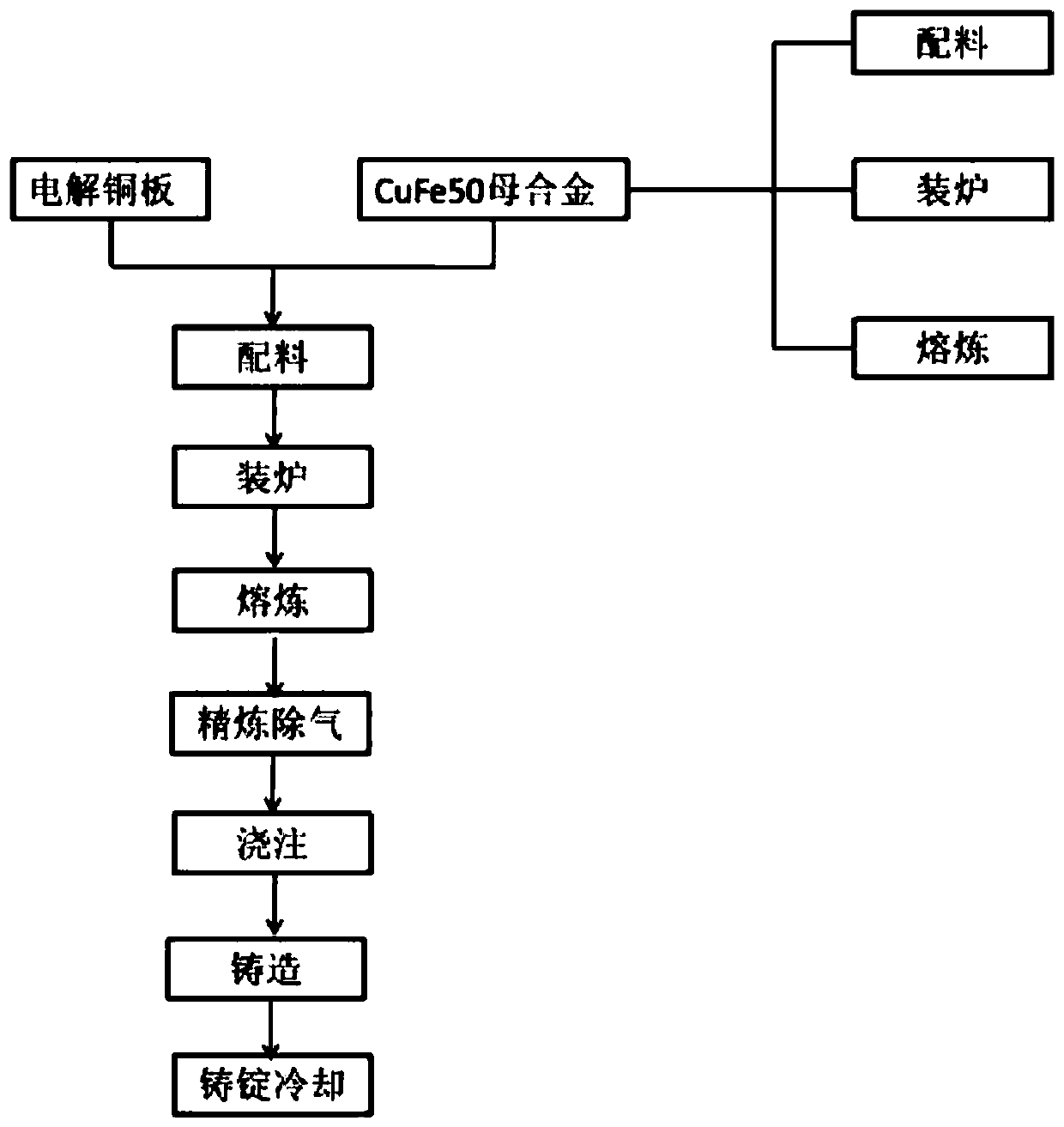

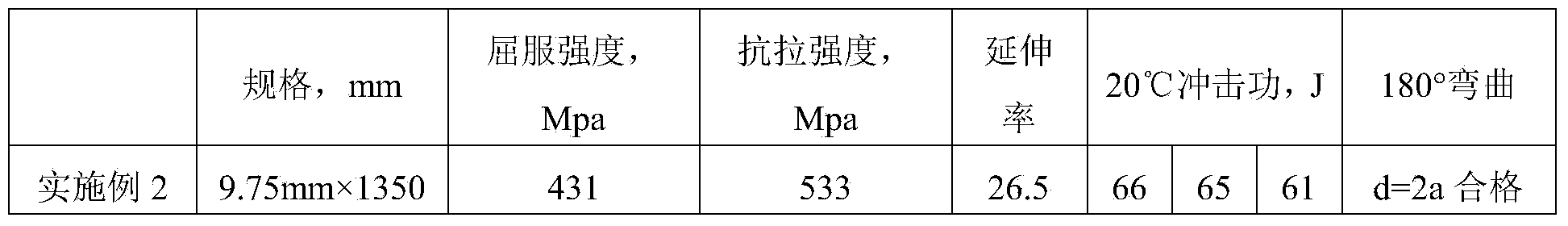

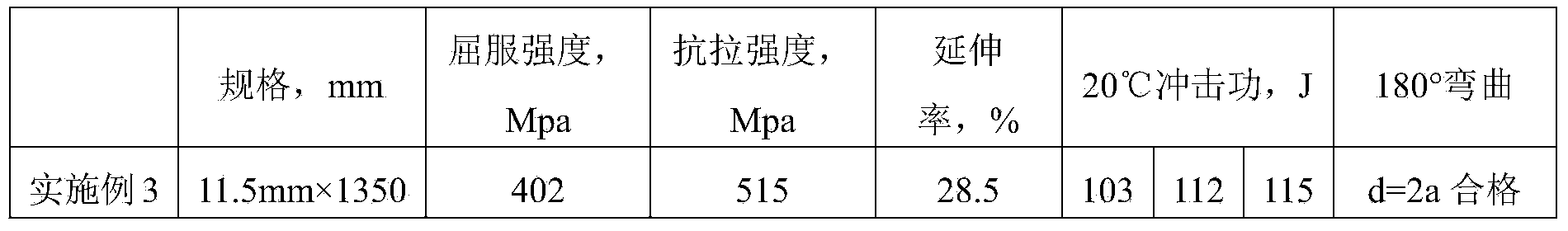

Production process of non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot

The invention discloses a production process of a non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot. The production process mainly comprises the following steps of burdening, charging, smelting, refining degassing, pouring, casting and ingot casting, wherein the copper-iron alloy slab ingot is successfully prepared by using an electrolytic copper plate and a CuFe50 master alloy as smelting raw materials through a non-vacuum downwards-drawing continuous casting process, and compared with a traditional vacuum casting process, the equipment requirement is low; inert gasprotection is adopted in the casting process, appropriate measures such as iron content are adjusted, and the alloy composition and the oxygen content are effectively controlled; the process has theadvantages of being stable in process, simple and convenient to operate, low in casting production cost and capable of realizing industrial production of the copper-iron alloy slab ingot.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Low-alloy steel hot-rolling coil plate of which yield strength is more than 345Mpa, and preparation method of low-alloy steel hot-rolling coil plate

The invention belongs to the technical field of iron and steel, and particularly relates to a low-alloy steel hot-rolling coil plate of which the yield strength is more than 345Mpa, and a preparation method of the low-alloy steel hot-rolling coil plate. The low-alloy steel hot-rolling coil plate of which the yield strength is more than 345Mpa comprises the following chemical components in percentage by weight: 0.14%-0.20% of C (carbon), 0.10%-0.40% of Si (silicon), 0.20%-0.90% of Mn (manganese), S (sulphur) which is smaller than or equal to 0.030%, P (phosphorus) which is smaller than or equal to 0.030%, 0.015%-0.060% of Ti, and the balance of iron and inevitable impurities. The coil plate disclosed by the invention has the advantages that compared with an ingredient system in which the manganese content is more than 1.0%, the cost of producing Q345B hot-rolling coil plates by using the production technology is reduced, the center segregation of Q345B continuous casting billets is improved, the internal organization of steel bands is improved, and the performance of steel band pass is stabilized.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com