Patents

Literature

47results about How to "Flexible process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

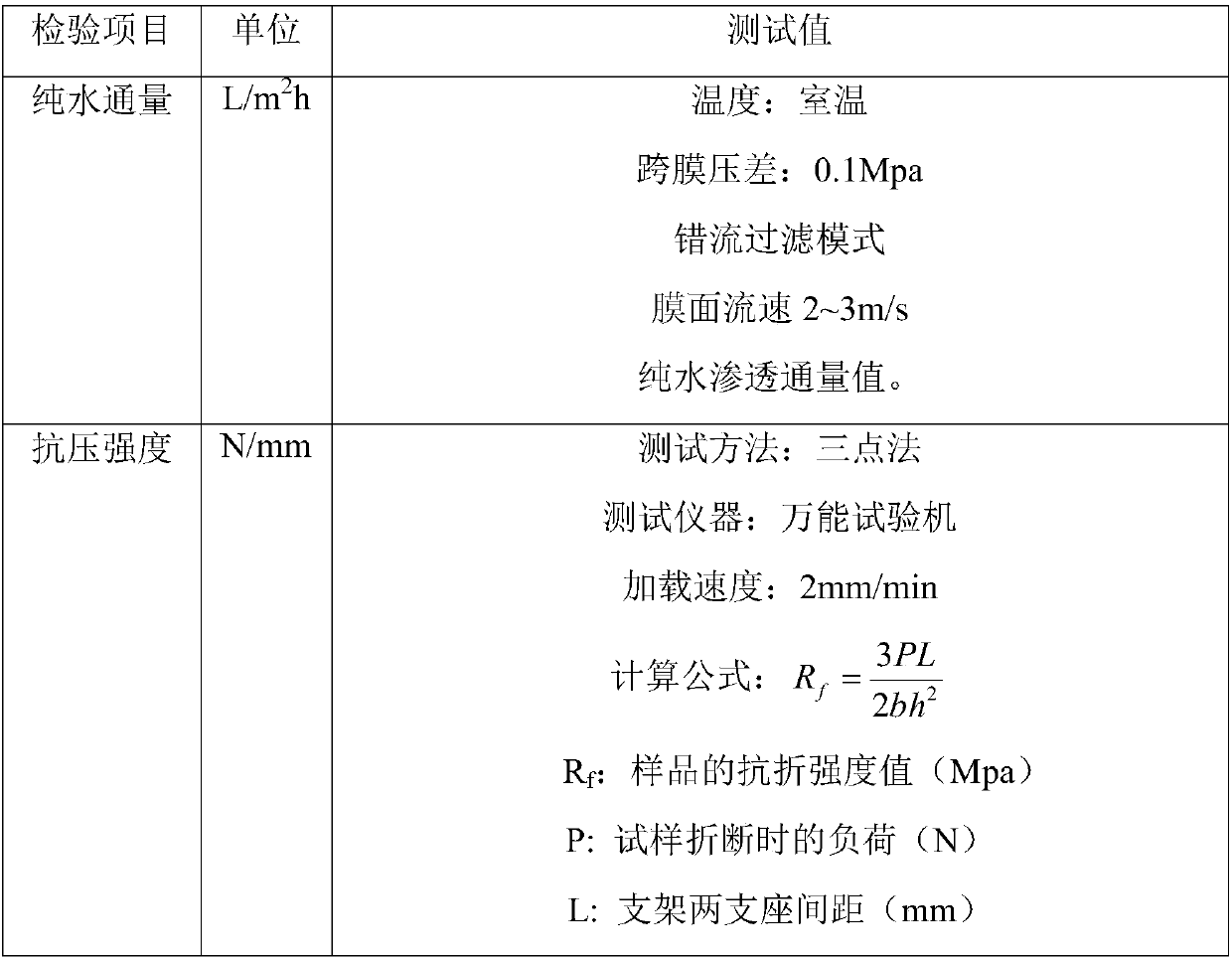

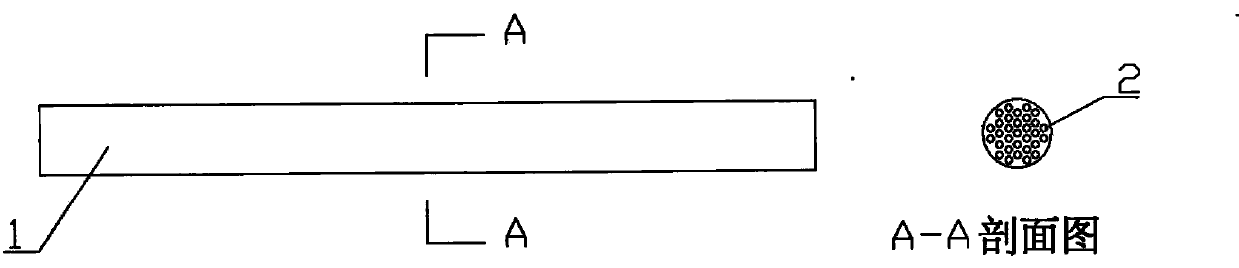

Preparation method of low-temperature sintering acid and alkali resistant porous silicon carbide ceramic film

ActiveCN107663088AImprove hydrophilicityImprove pollutionCeramicwareSeparation technologyPorous ceramics

The invention relates to the technical field of porous ceramic materials and film separation, in particular to a low-temperature sintering acid and alkali resistant porous silicon carbide ceramic filmand a preparation method thereof. The method sequentially comprises the following steps of (1) support body manufacturing; (2) transition layer processing; (3) filtering layer processing; (4) film sintering process. The method provided by the invention has the characteristics that the sintering temperature is low; the production energy consumption is low; the process method is simple; the equipment requirements are low; the production cost and the investment cost are low; the control is flexible; the shaping is easy; the method is suitable for industrial customization and meets the scaled production. The porous silicon carbide ceramic film produced by the method has the characteristics of good hydrophilcity, great filtering flux, high porosity, high filtering precision, high mechanical intensity, good acid and alkali resistant performance and long service life.

Owner:ZHEJIANG SCI-TECH UNIV

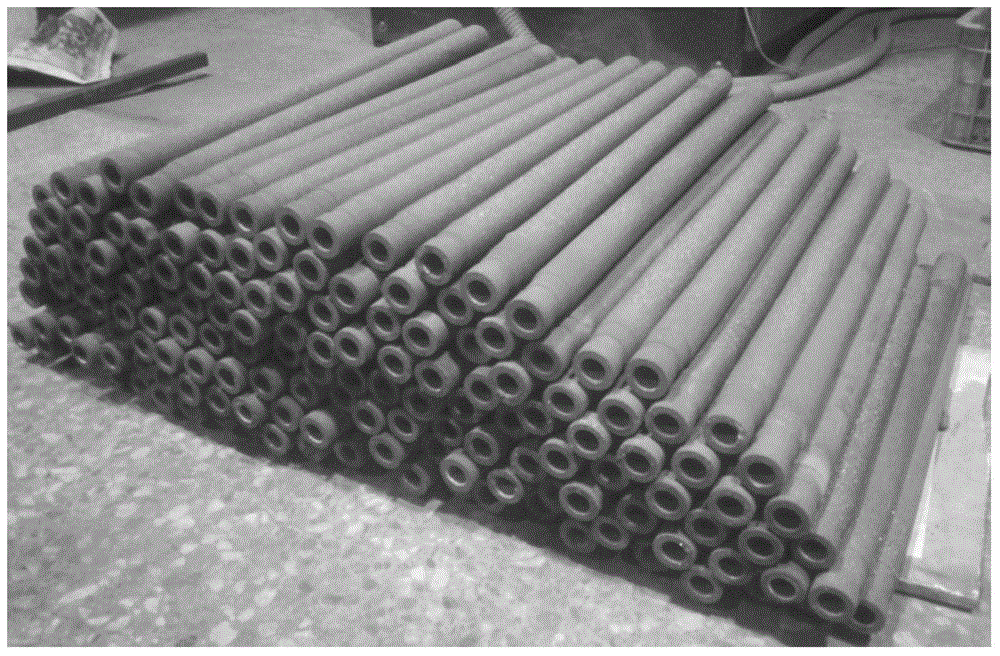

Gradient-pore silicon nitride and silicon carbide combined film tube and preparation method therefor

ActiveCN105727755AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareChemical industryPorous ceramics

The invention belongs to the field of porous ceramic materials and particularly relates to a gradient-pore silicon nitride and silicon carbide combined film tube and a preparation method therefor. The film tube material is prepared from silicon nitride and silicon carbide, and a gradient filtering structure is formed by a supporting body layer and a surface film layer; a supporting body is formed through combining silicon nitride produced from a reaction with coarse silicon carbide grains and has the average pore size of 10 to 80 microns, the surface film layer is formed through combining the silicon nitride produced from the reaction with fine silicon carbide grains and has the average pore size of 0.1 to 20 microns, and the overall porosity of the film tube is 35% to 50%. The preparation method sequentially comprises the steps of carrying out batching, forming the supporting body, preparing the film layer and carrying out firing, wherein the forming is carried out by adopting isostatic pressing, the forming pressure is controlled to 40MPa to 150MPa, the firing temperature is controlled to 1,400 DEG C to 1,650 DEG C, and the heat preserving time is 3 to 5 hours. The film tube can be used in an oxidative atmosphere, can also be used in a reducing atmosphere, is high in acid-alkali corrosion resistance and can be applied to the filtering and purifying of various high- and low-temperature fluids of coal gasification chemical industry, IGCC and PFBC coal-gasified power generation, high-temperature flue gas, automobile exhaust gas, water purification and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

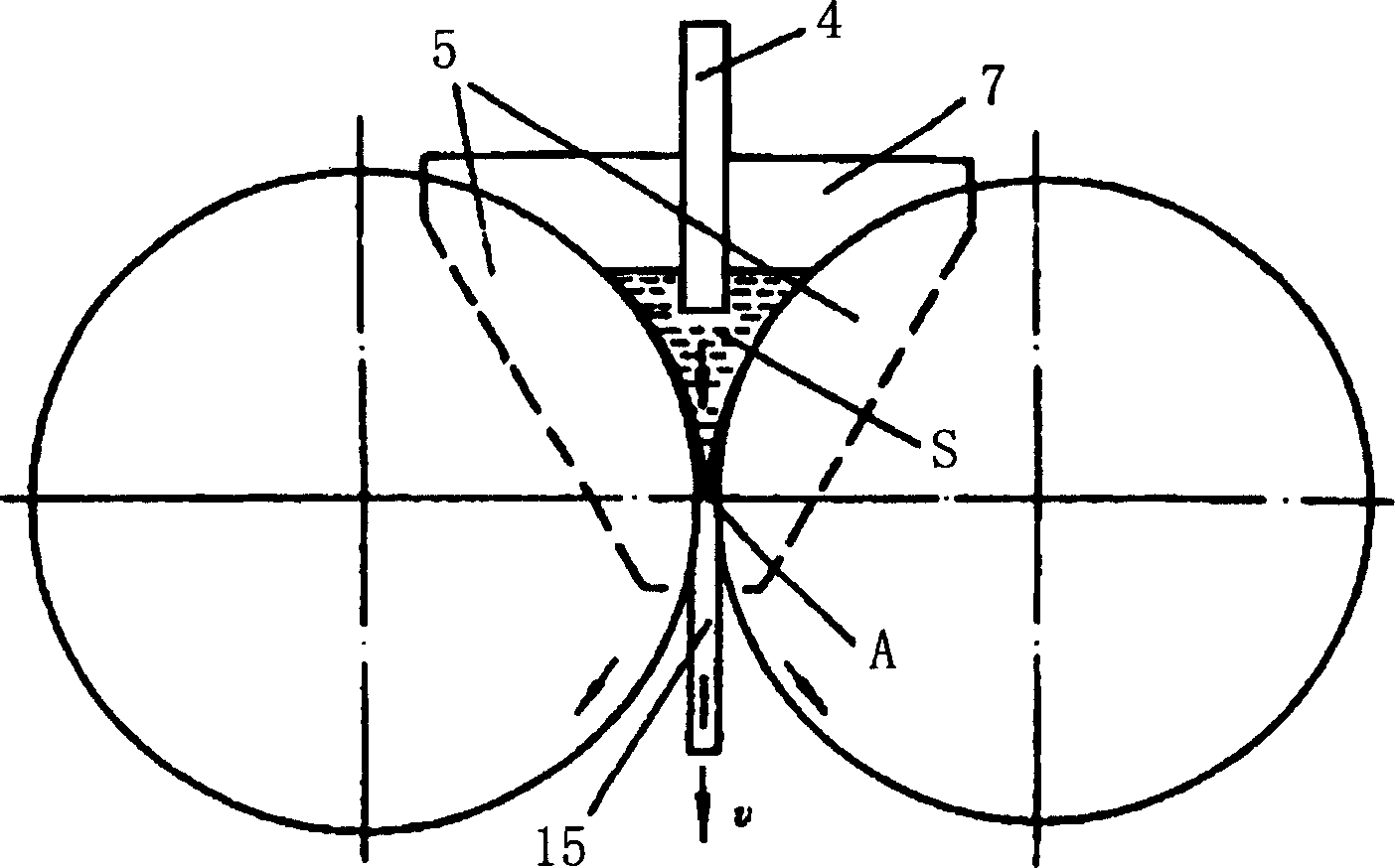

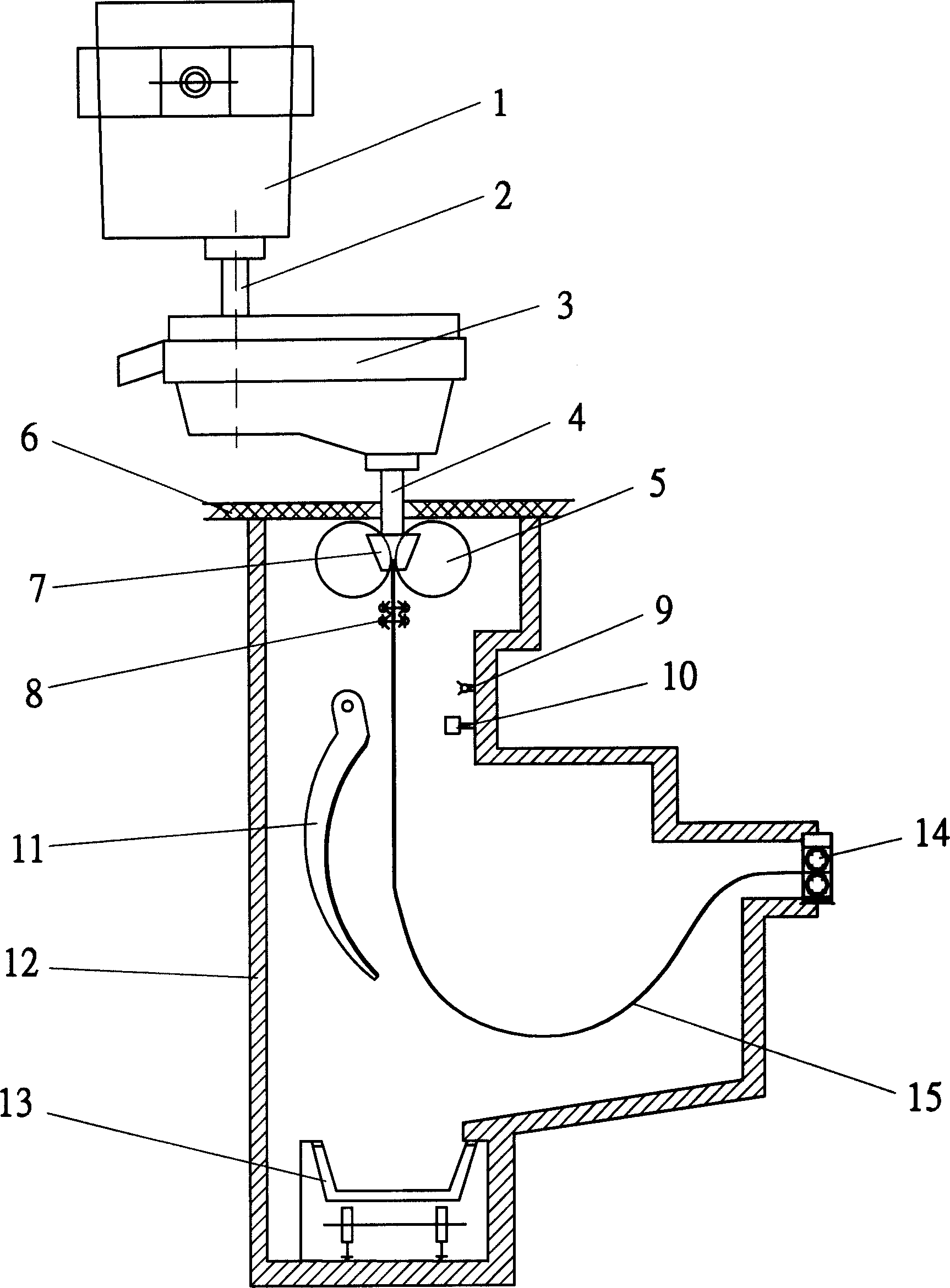

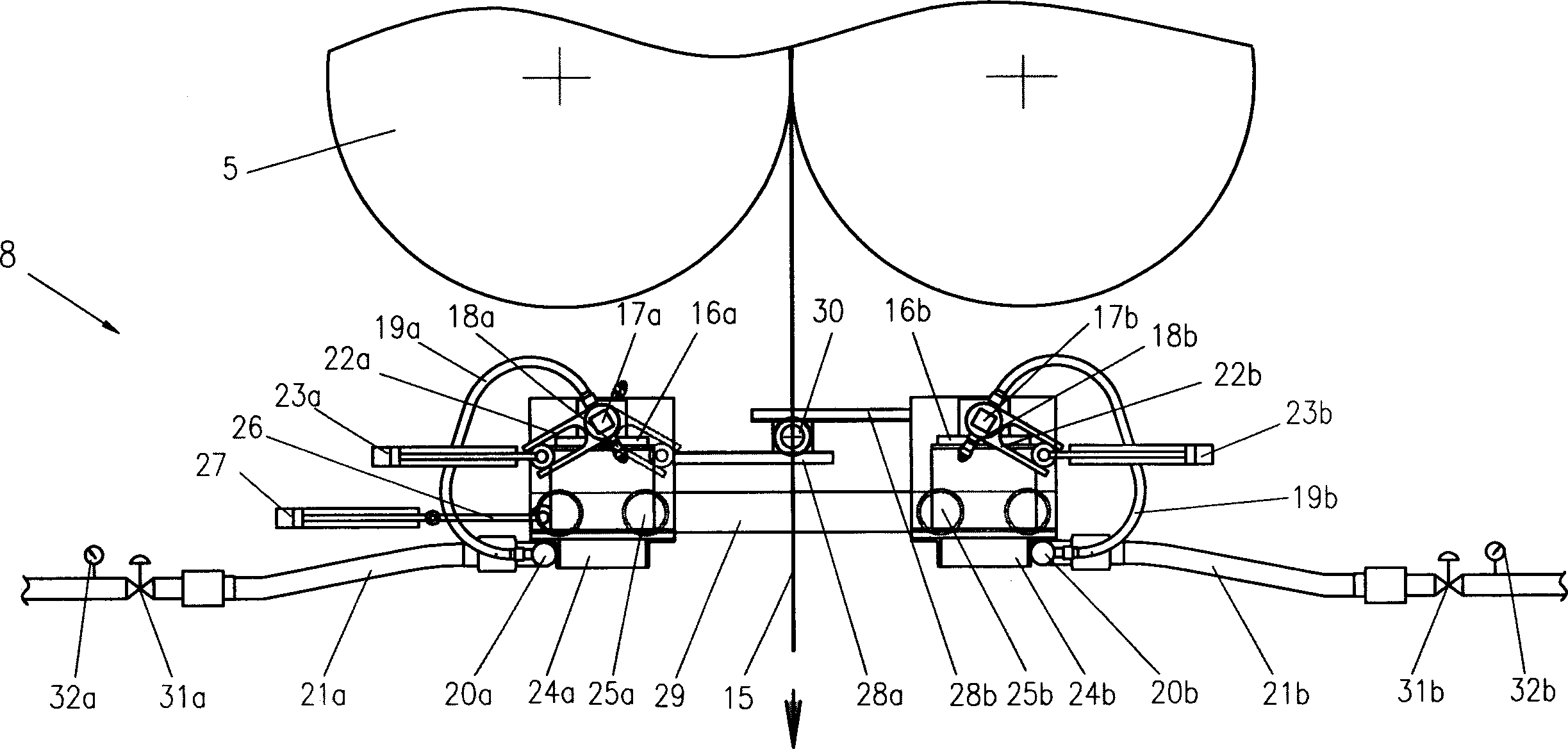

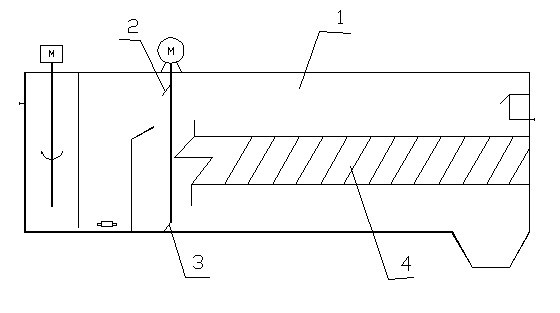

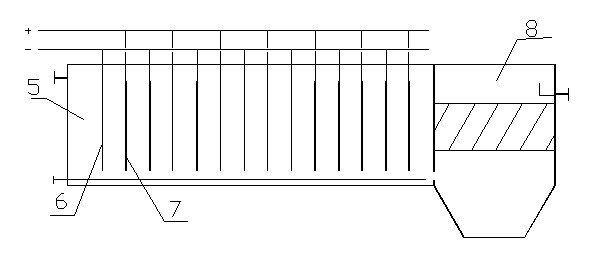

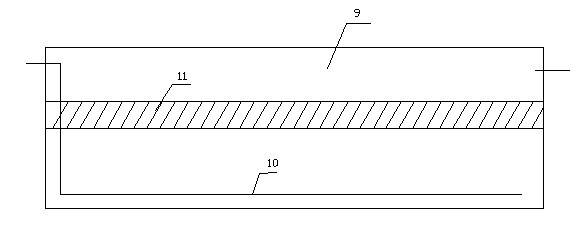

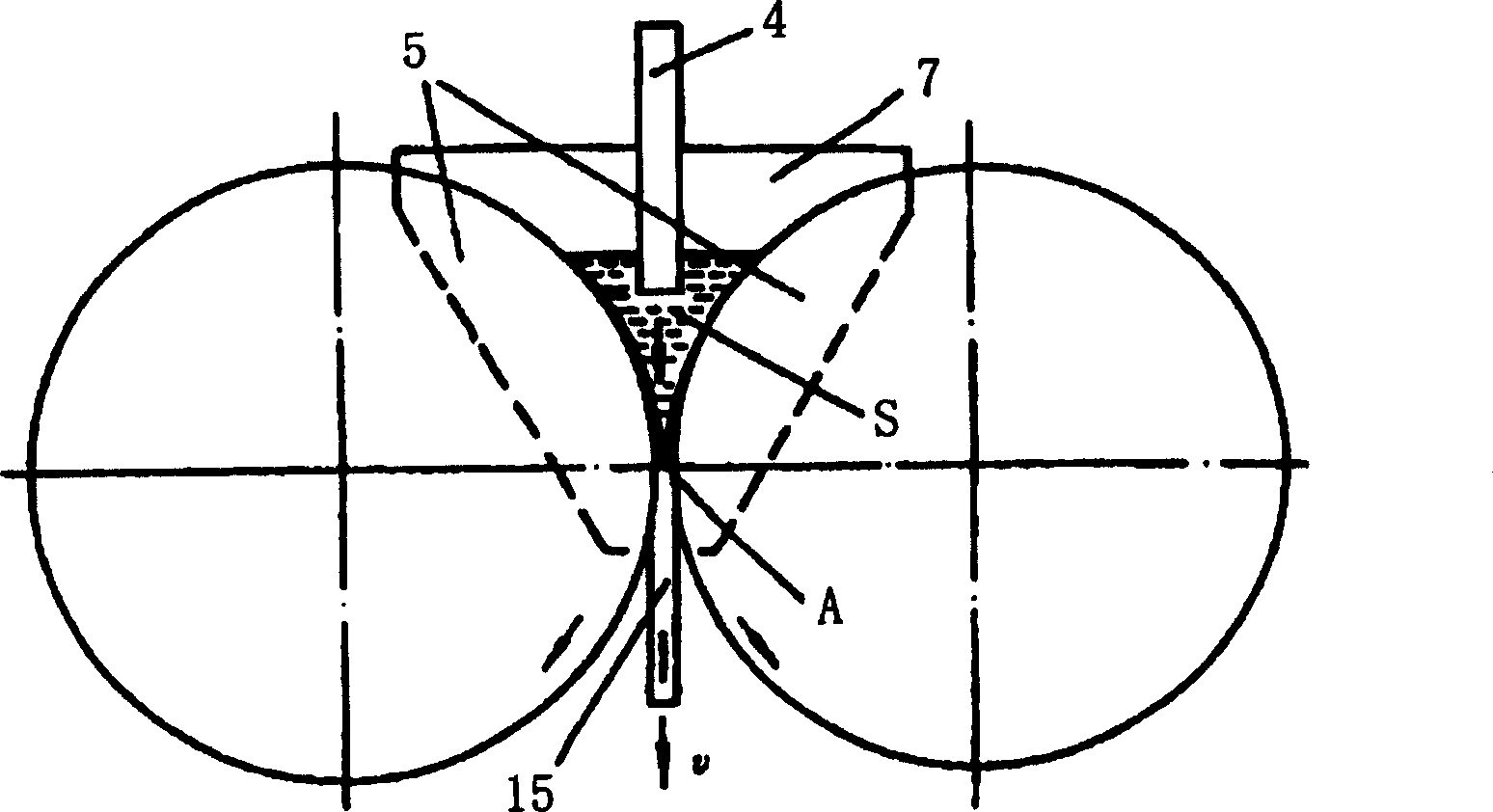

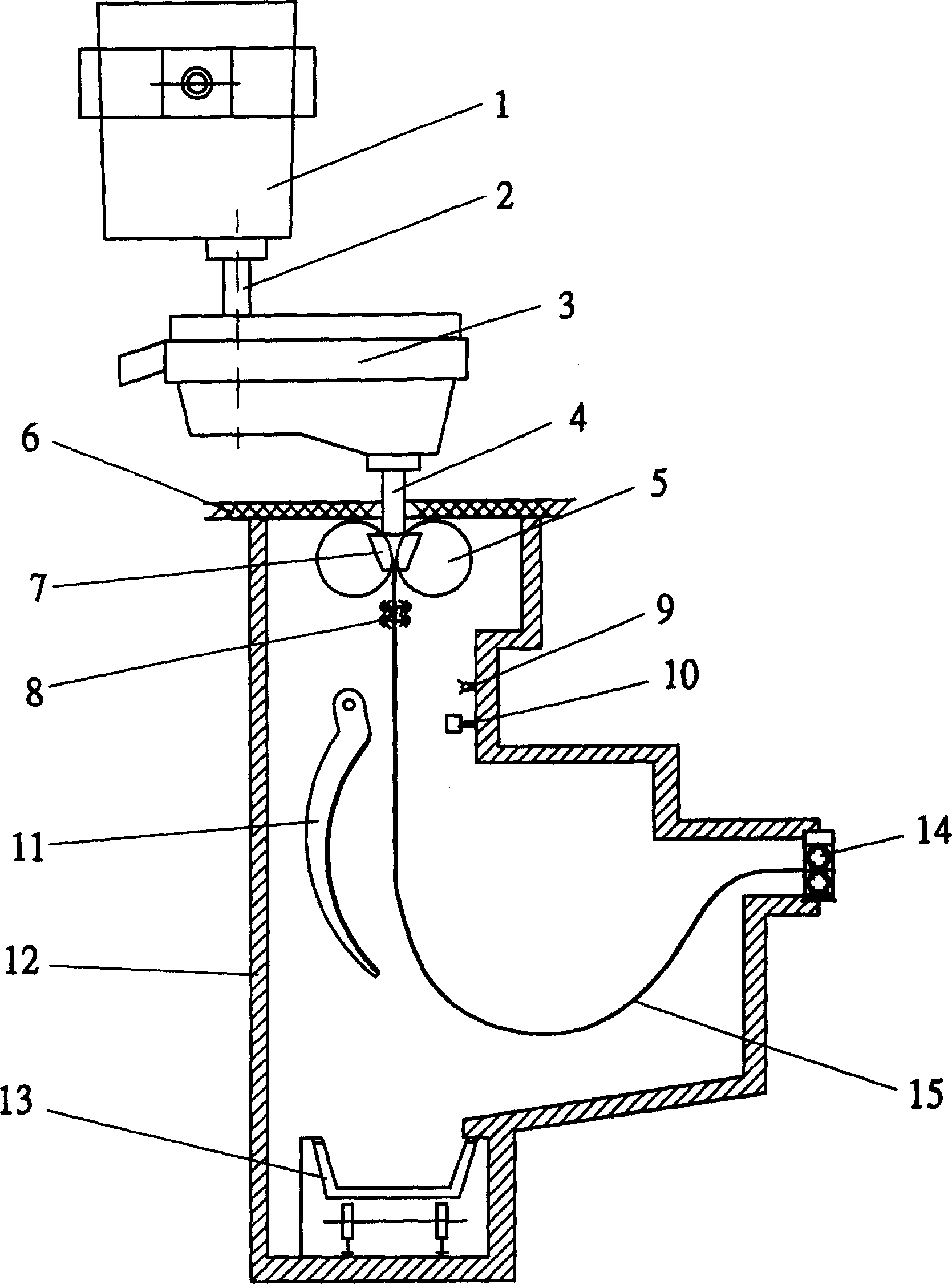

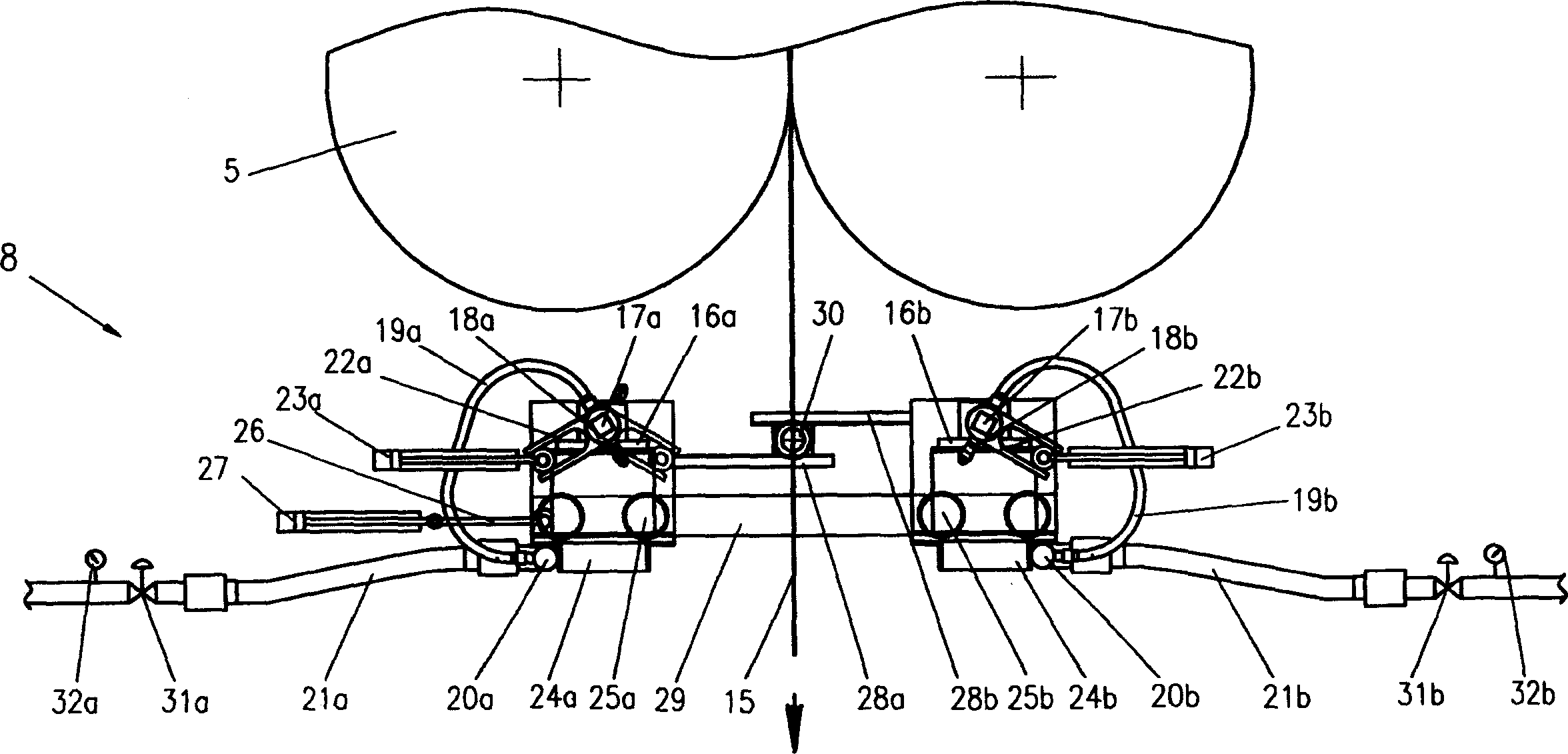

Thin-belt continuous casting method and apparatus

InactiveCN1472019AFlexible process controlEasy to operateMetal rolling arrangementsProduction rateMolten bath

A conticasting technology for thin steel band includes such steps as filling molten steel in the molten bath formed by crystallizing rollers, cooling and slight rolling by crystallizing rollers, blowing gas onto both surfaces of cast band for forced cooling, hot rolling, controlled cooling and winding. Its apparatus is composed of two blowing mechanisms, connecting-rod driver unit and synchronizing unit. Its advantages are high quality of product and high productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

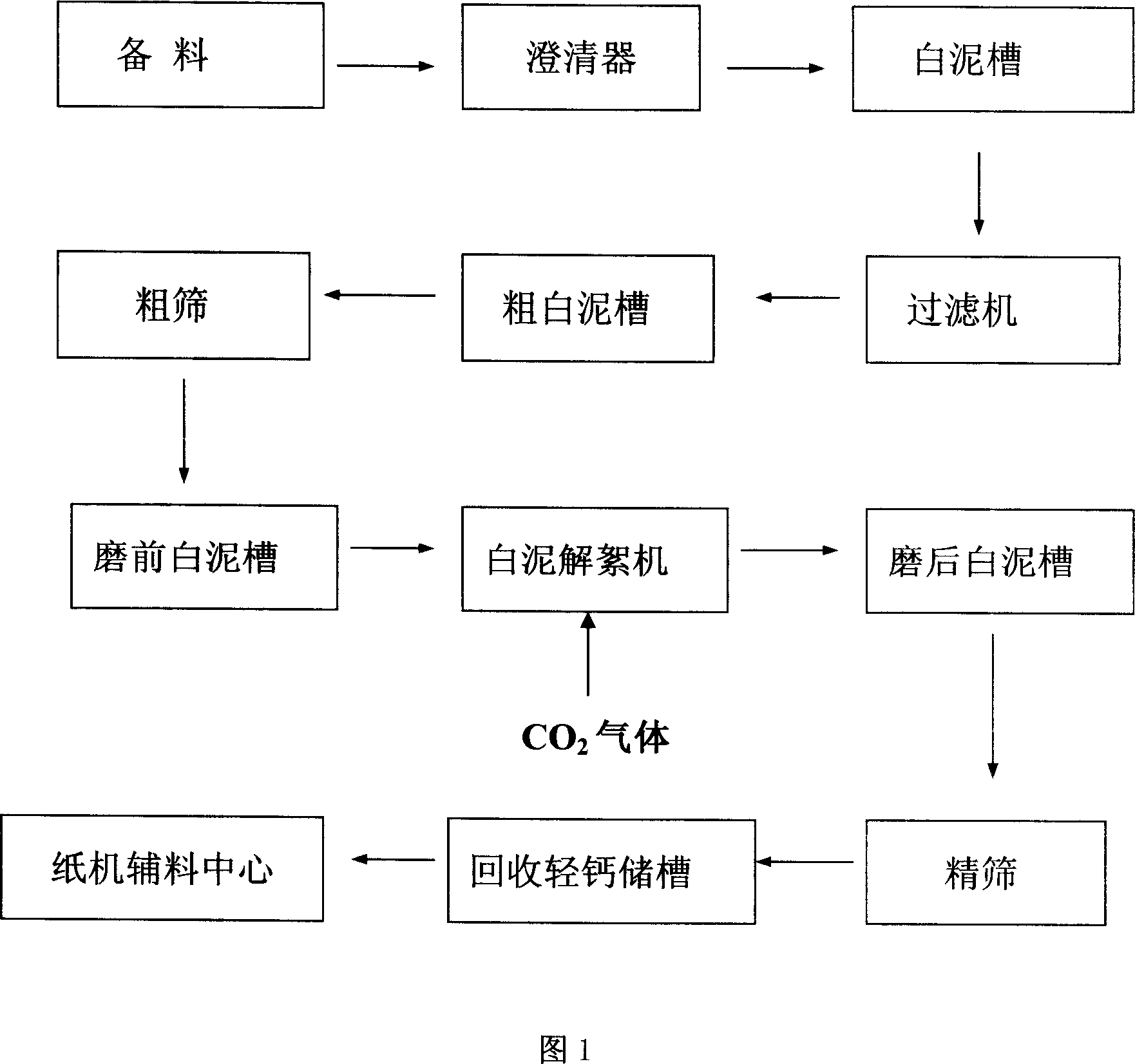

New technique for refining filler of calcium carbonate from lime mud

ActiveCN101003383AEasy to produceFlexible process controlCalcium/strontium/barium carbonatesSlurryMaterials science

This invention relates to a new process for refining calcium carbonate filler from white mud. The process comprises: preparing the raw materials, washing, roughly screening, homogenizing, deflocculating, carbonizing, finely screening, and storing. In the process, homogenizing, deflocculating, carbonizing are accomplished in a single step. Calcium carbonate has a particle size D50 of 3.0-7.0 mums, and an average particle size of 5.5-8.5 mums. The recovered lightweight calcium carbonate has whiteness higher than 89% ISO, Ph value of 8.4-10.5, sedimentation volume greater than or equal to 2.6 mL / g, and slurry calcium carbonate concentration of 14-16%. The product is qualified for use in high-class writing paper, and the cost is only 1 / 3 that of commercialized lightweight calcium carbonate.

Owner:YUEYANG FOREST & PAPER CO LTD

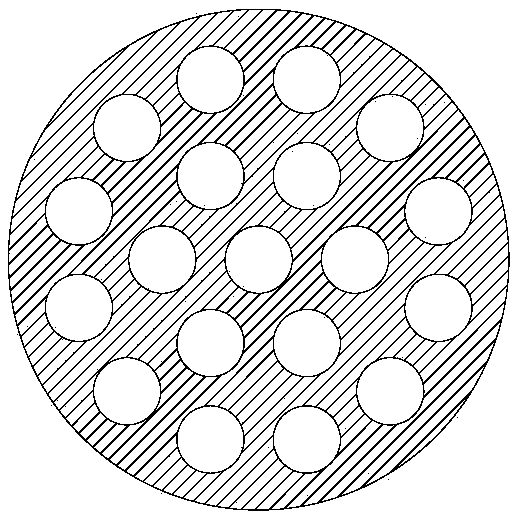

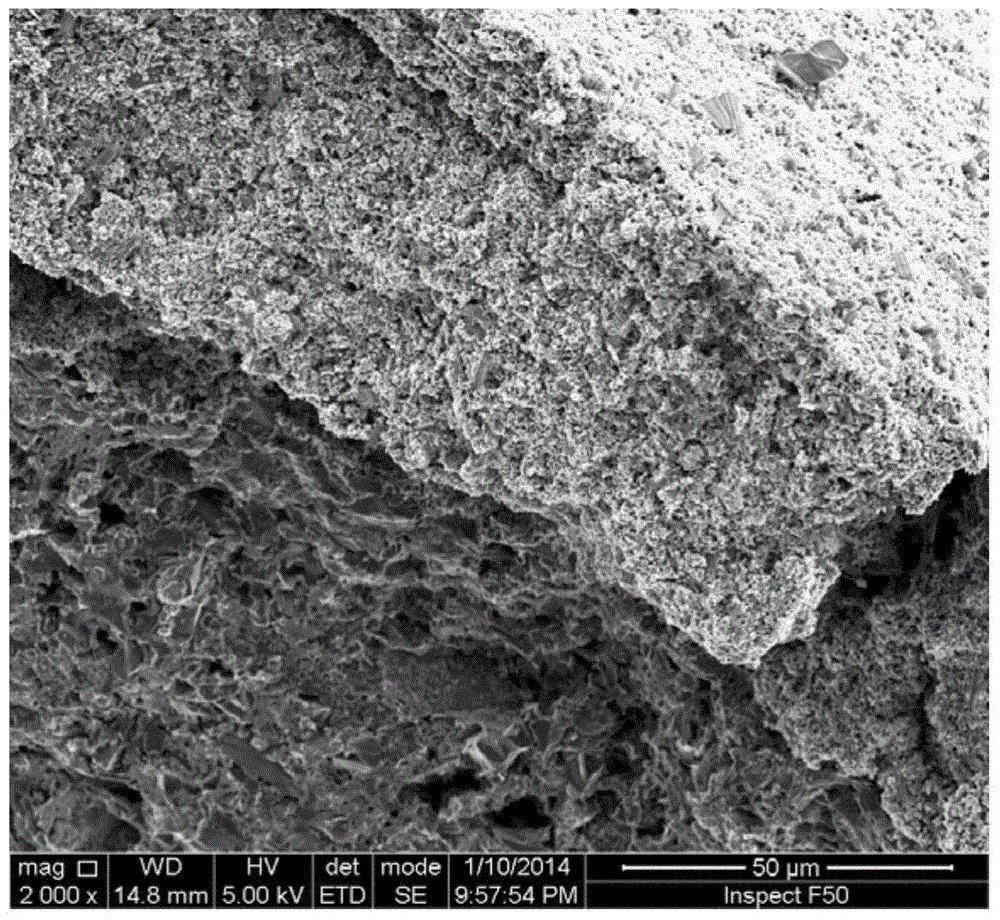

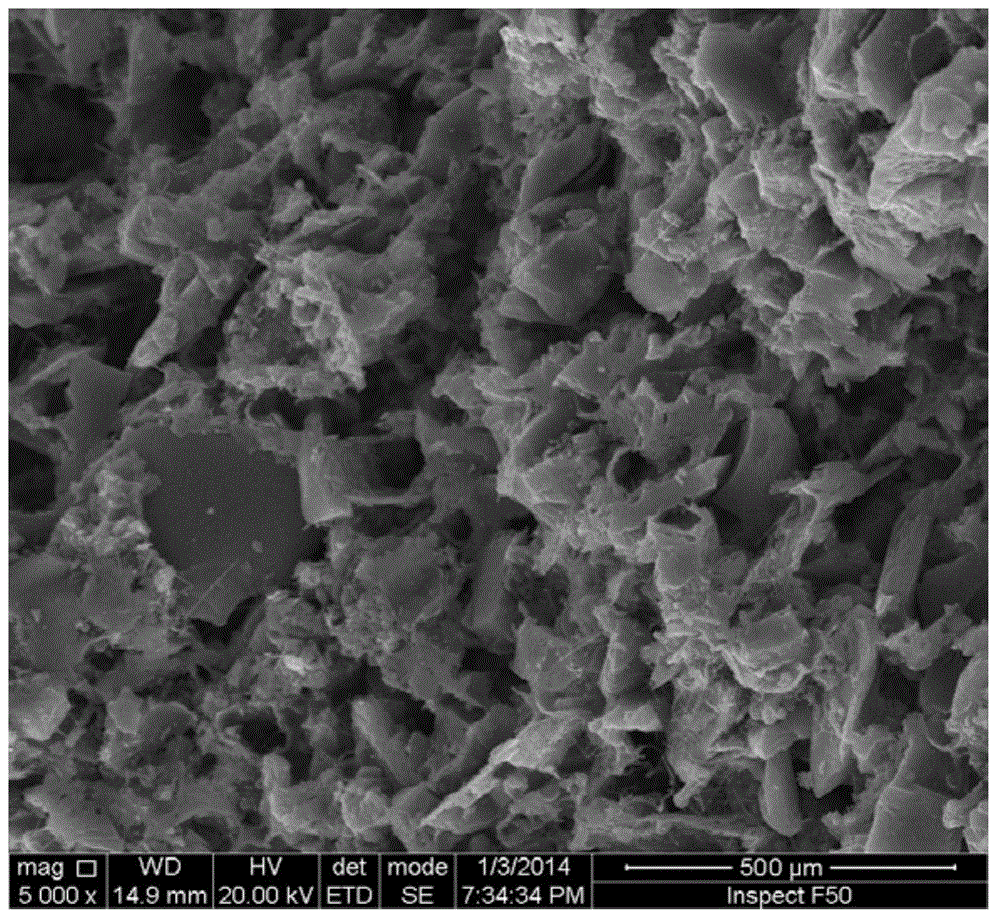

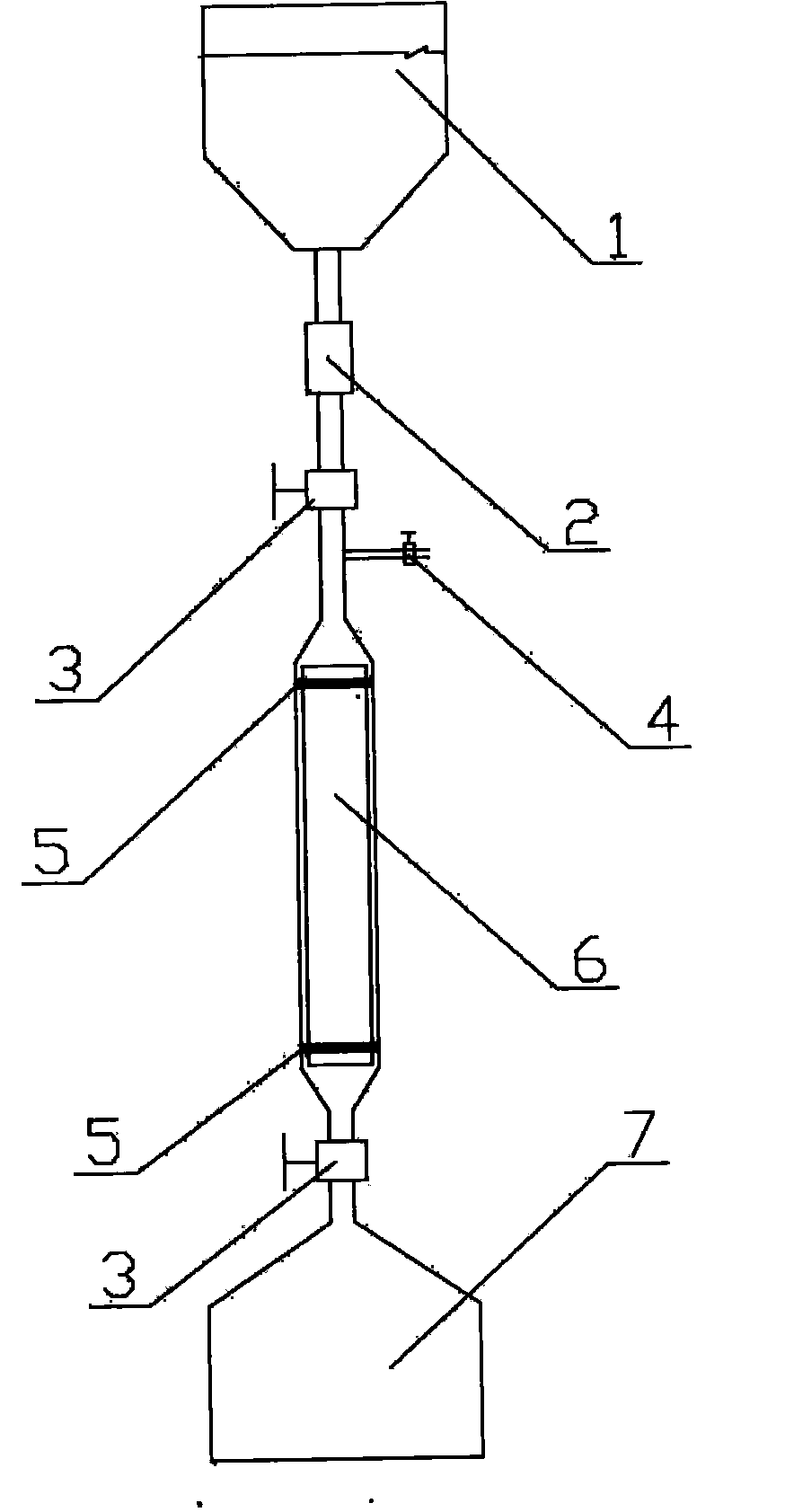

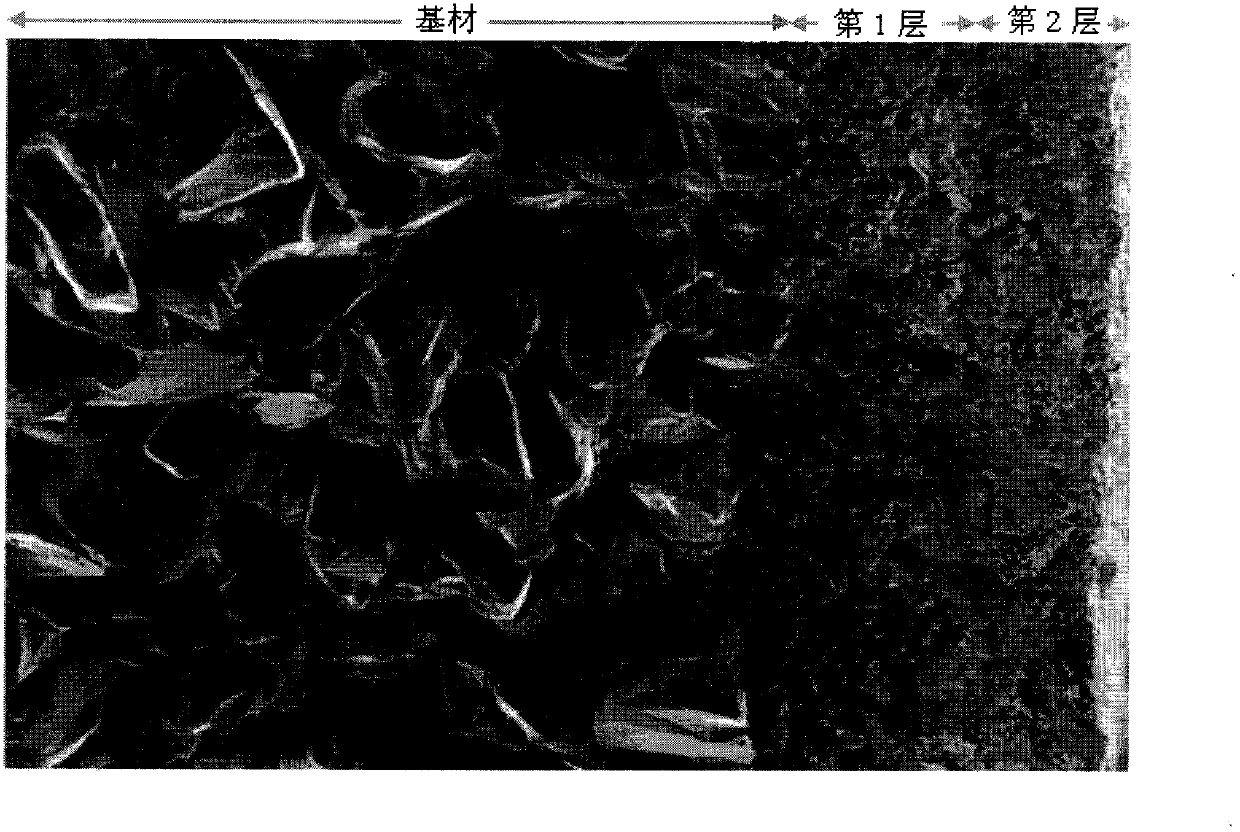

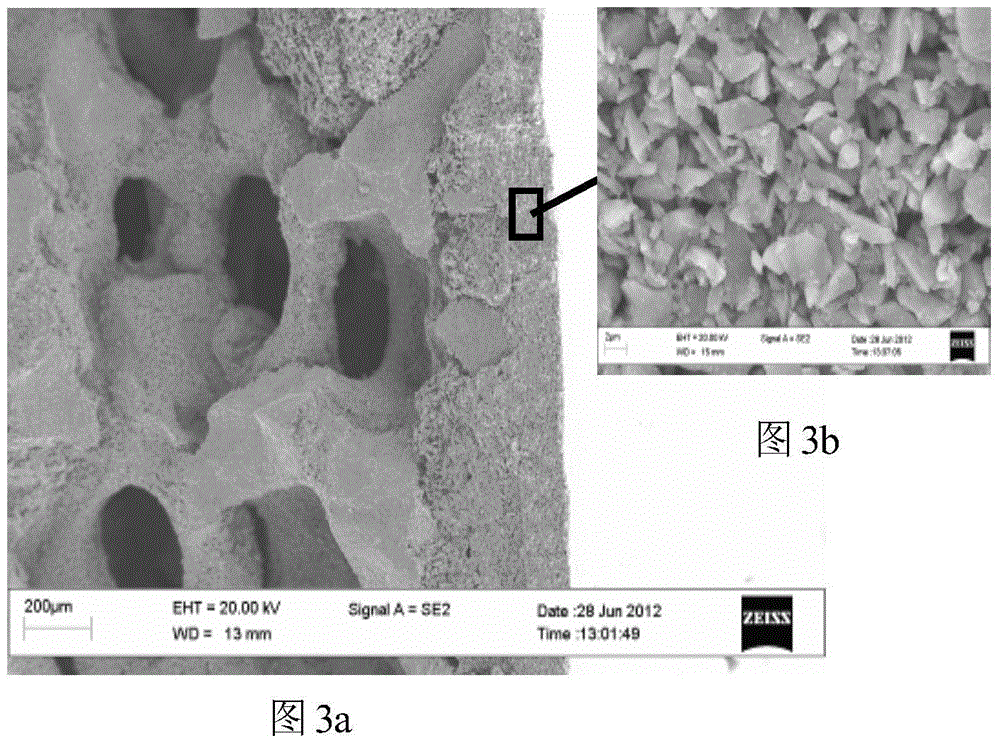

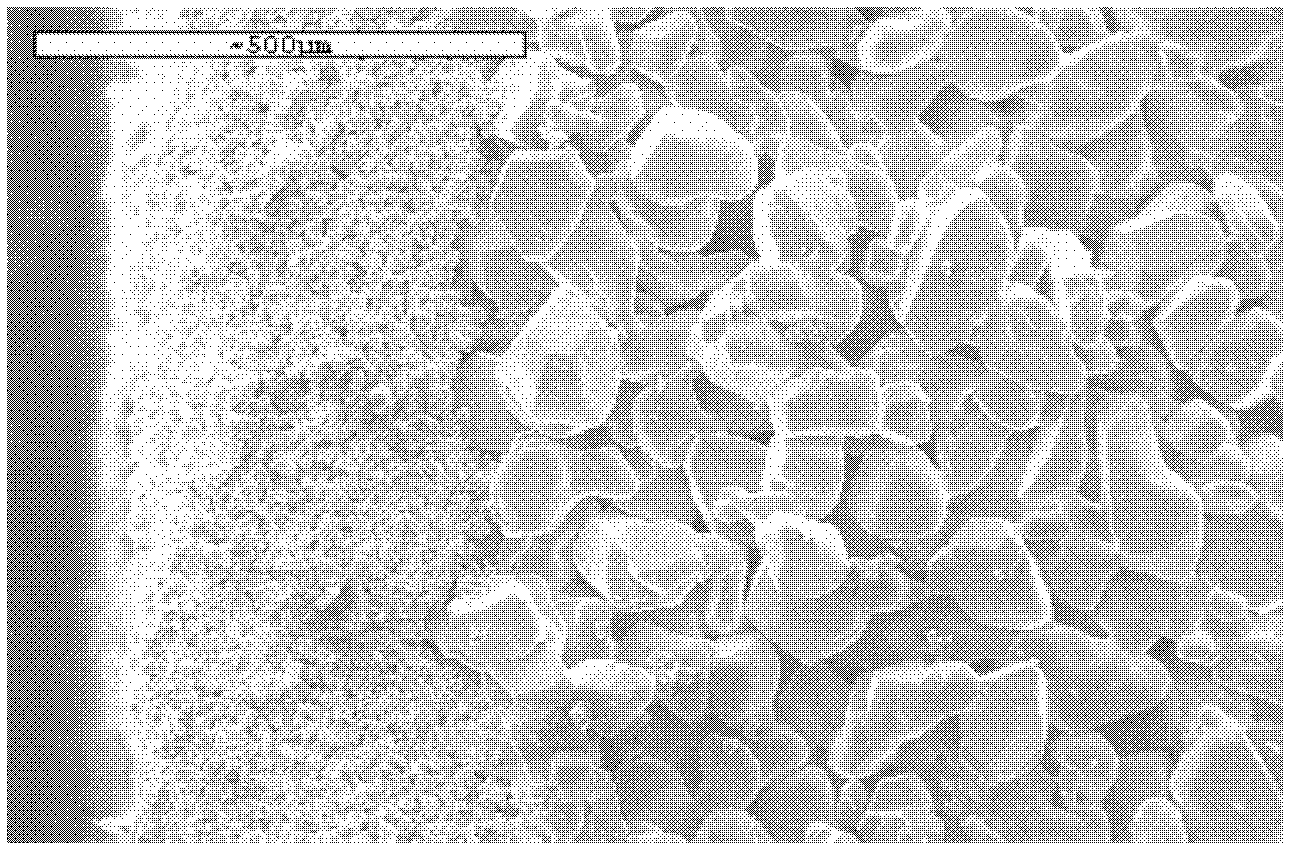

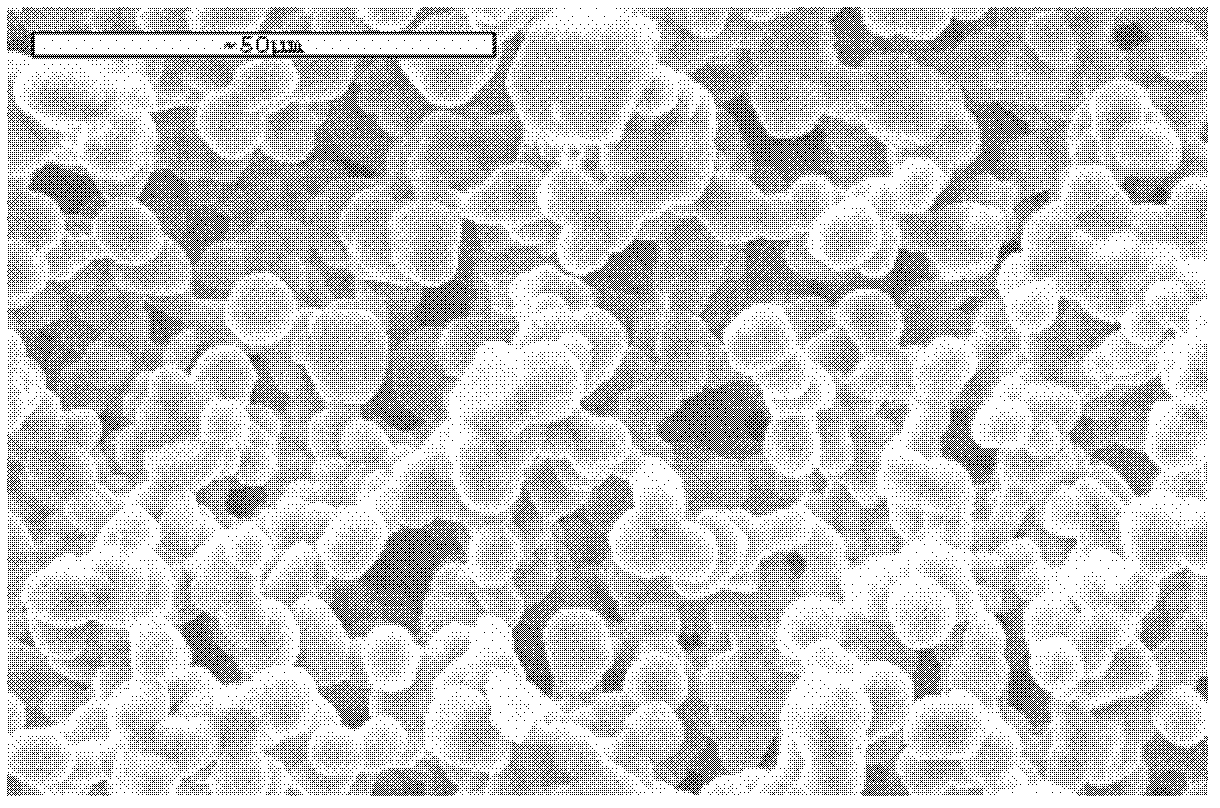

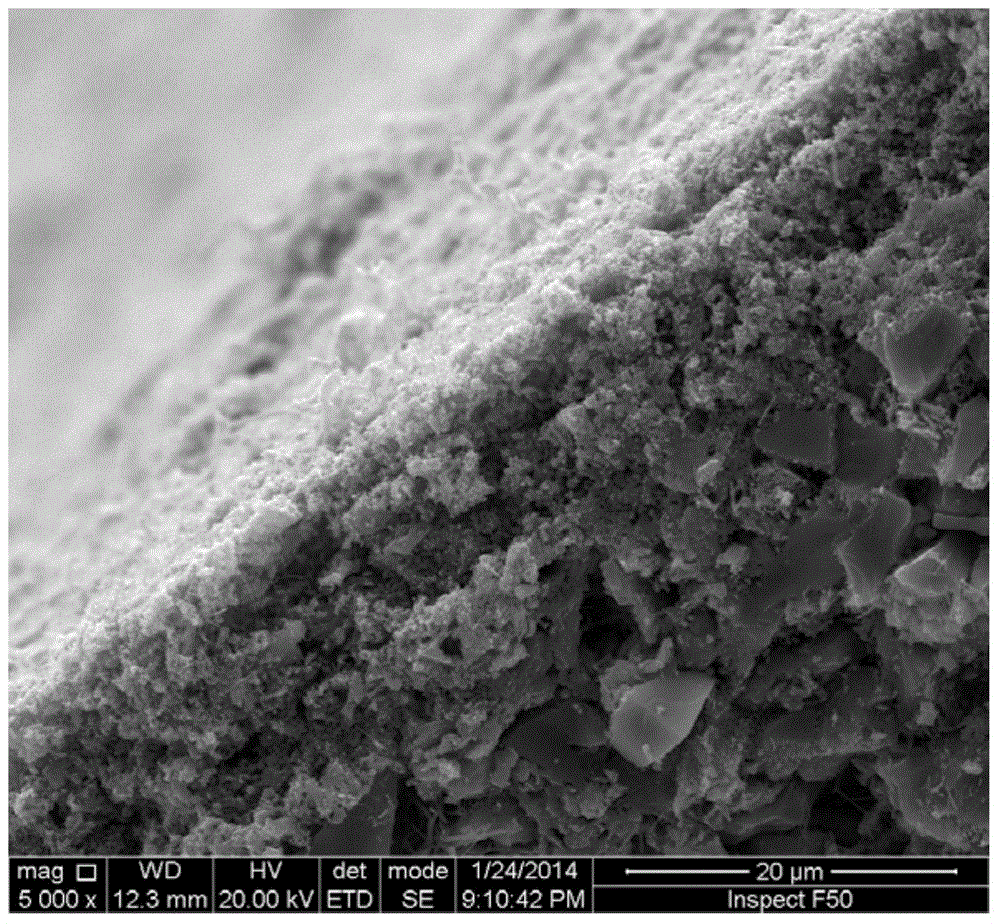

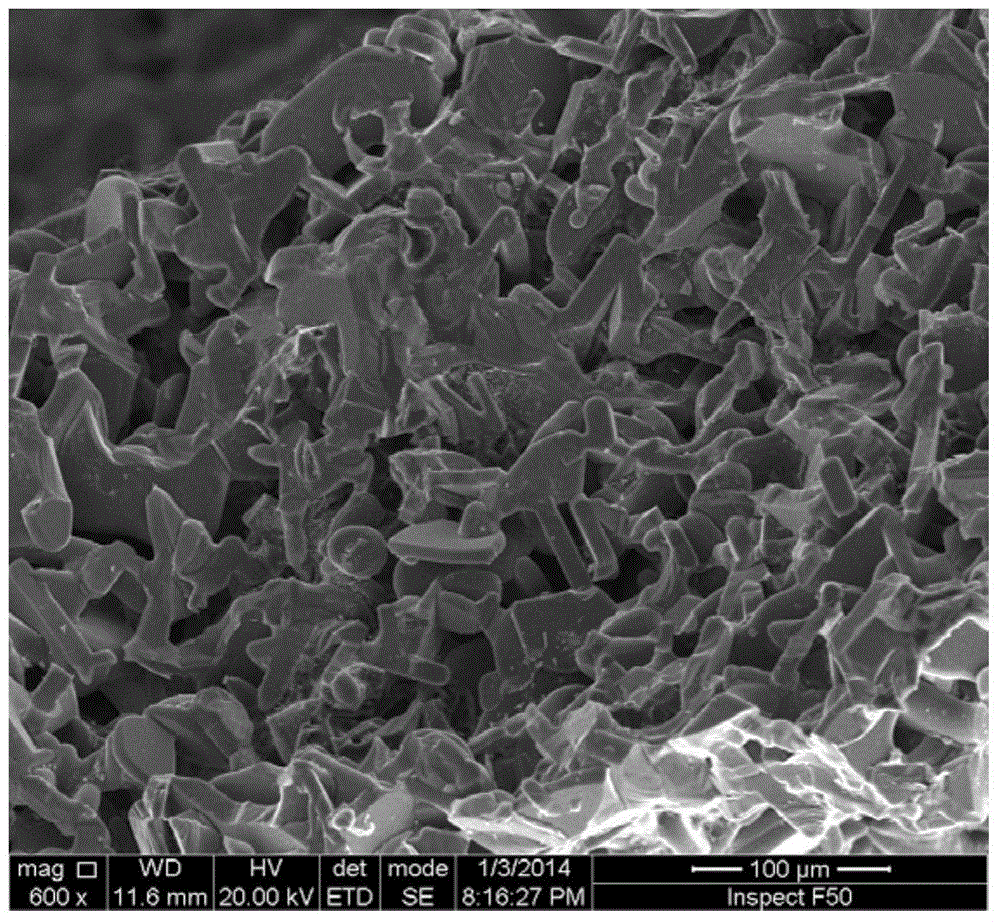

Multi-channel pure silicon carbide film with asymmetric structure and preparation method for multi-channel pure silicon carbide film

ActiveCN103721578AFully reflect the characteristicsImprove throughputSemi-permeable membranesCeramicwarePorosityAdhesive

The invention relates to the technical field of film separation materials and in particular relates to a multi-channel pure silicon carbide film with an asymmetric structure and a preparation method for the multi-channel pure silicon carbide film. The multi-channel pure silicon carbide film with the asymmetric structure consists of pure silicon carbide, is formed by sintering silicon carbide particles with the particle size of 0.1-100 microns and has a three-dimensional communicated gap structure; ducts form the asymmetric structure according to the sizes from small to large in the filtering direction; the aperture ratio of the film is 32-60 percent; the filtering characterization aperture range is ranged from 10-1,000nm; the film material has a tubular multi-channel structure and is formed by performing sintering for 2-4 times; a film base material is combined with a new silicon carbide in a sintering manner, which is formed by performing cracking reaction on a filtering layer serving as a silicon carbide precursor through an adhesive, and the sintering temperature is 700-1,400 DEG C. The obtained silicon carbide film has the characteristics of high filtering precision, high purity, high porosity, high intensity, large flux and long service life; the preparation method has the advantages of flexibility in control, low energy consumption, readily availability of raw materials, easiness in forming and suitability for industrial customization and can meet large-scale production.

Owner:浙江坚膜科技有限公司

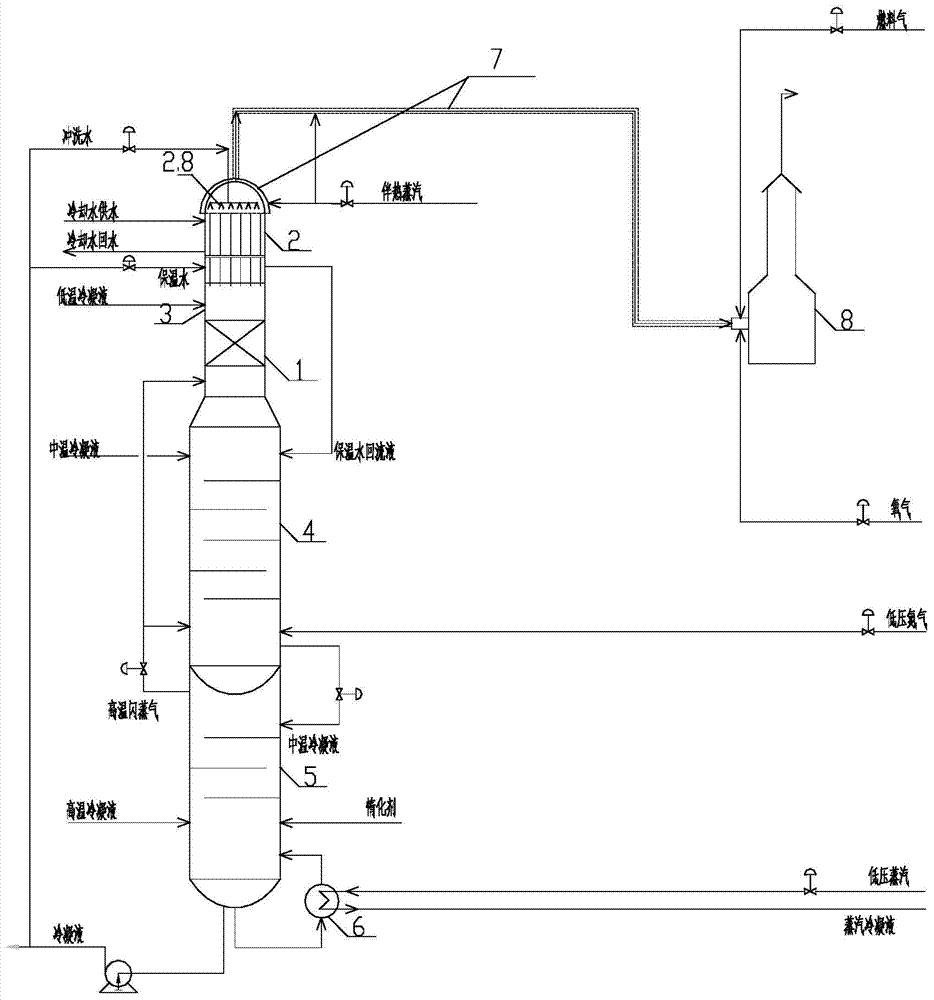

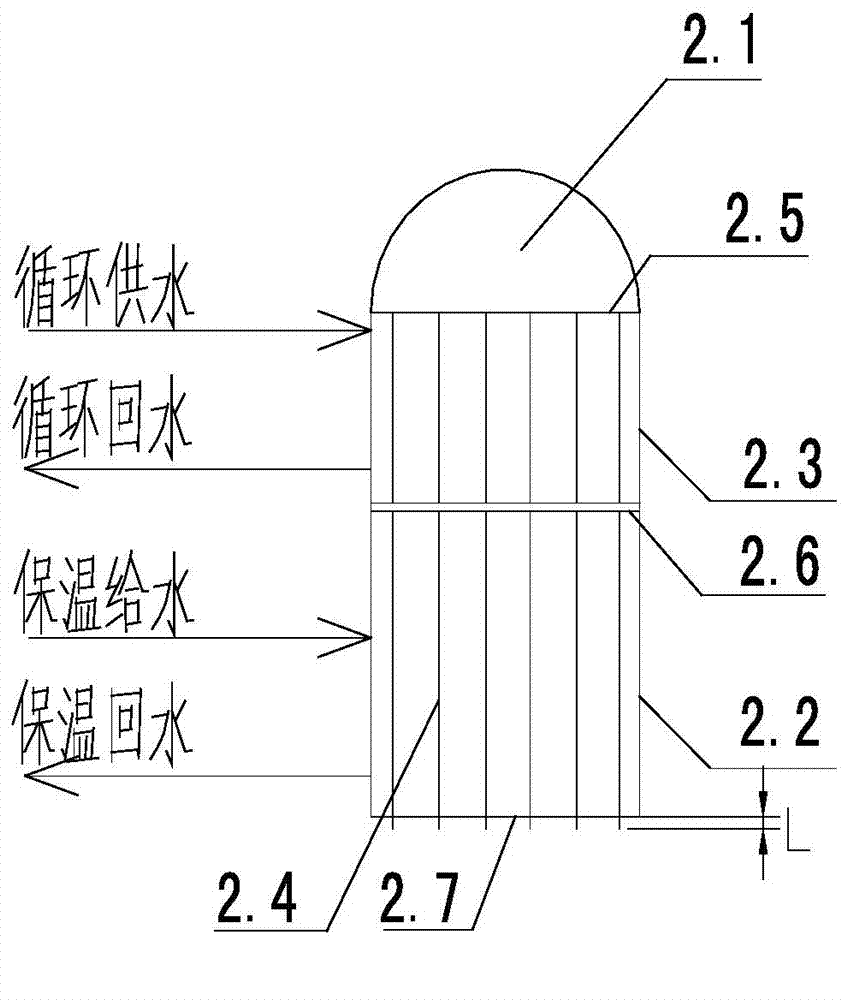

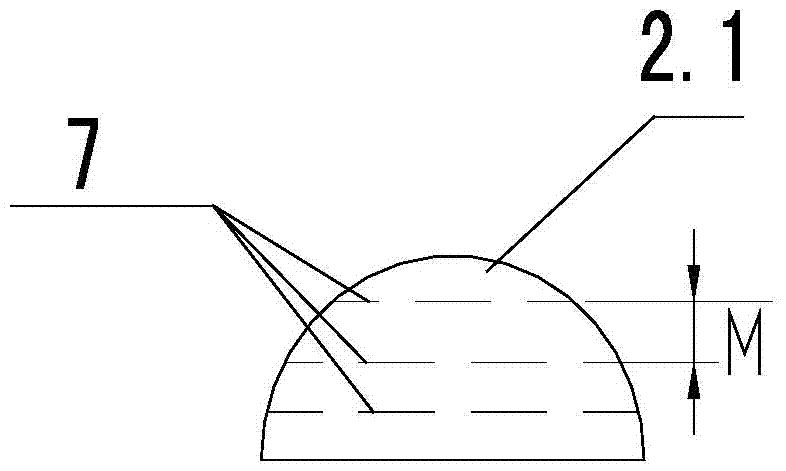

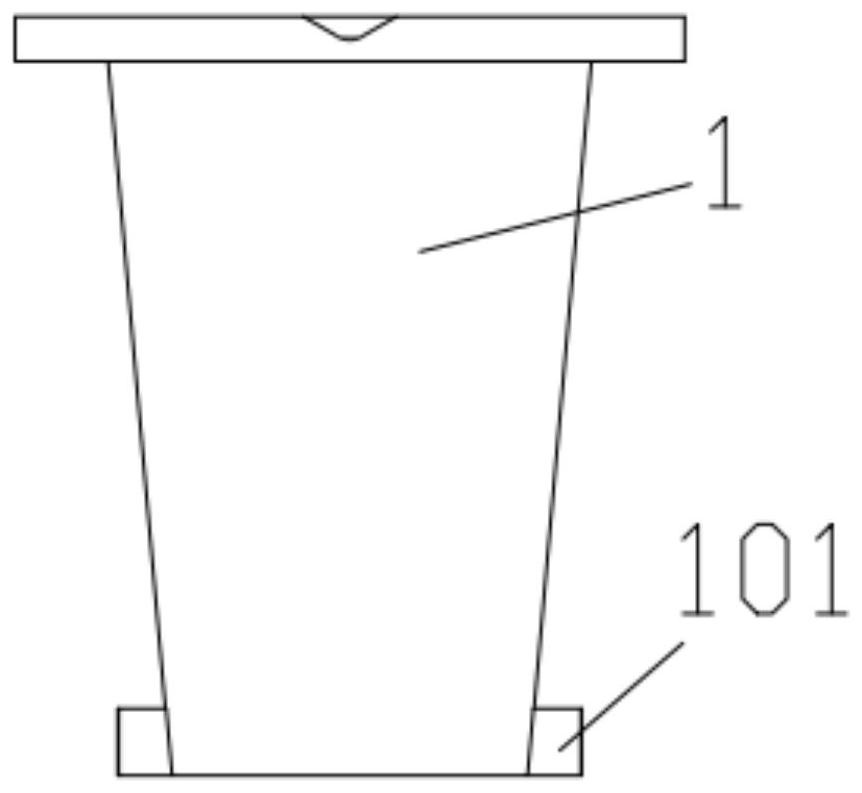

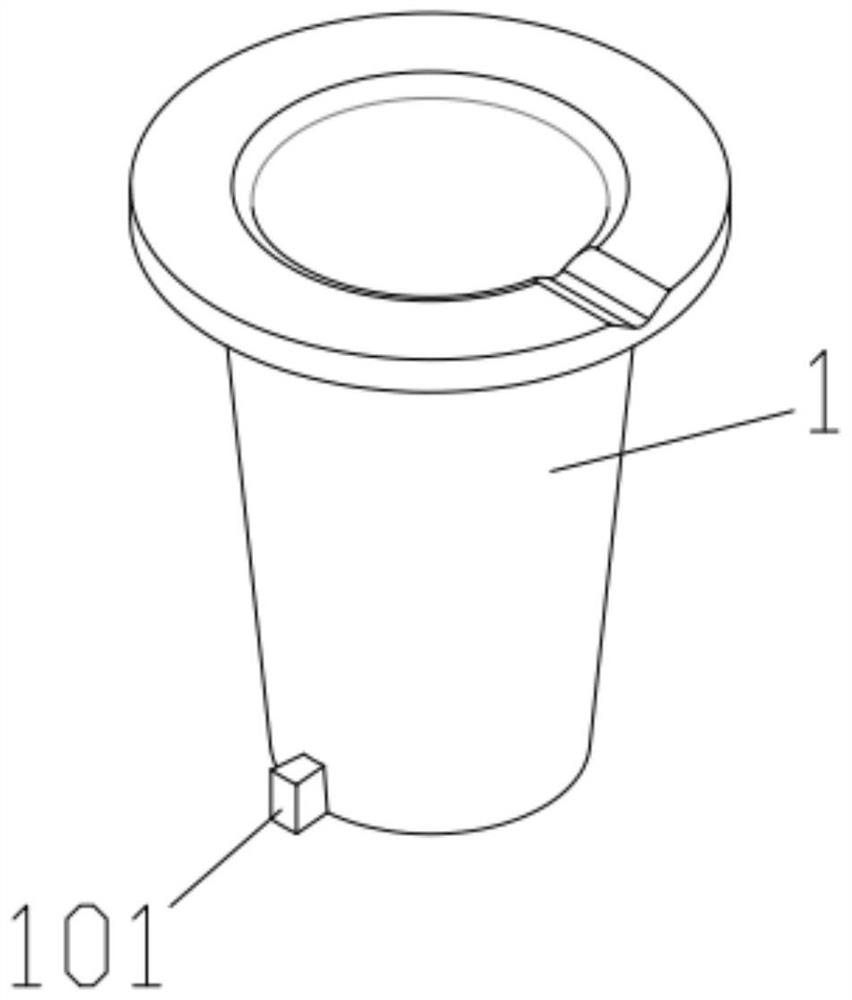

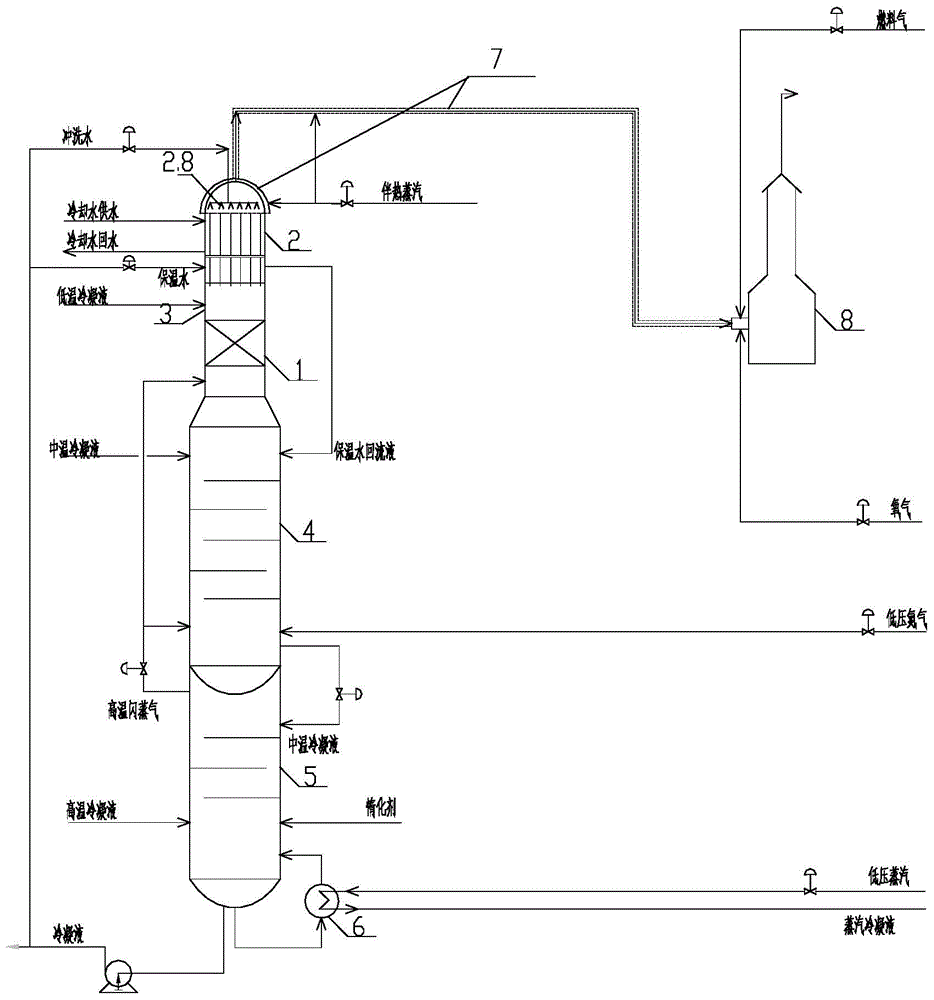

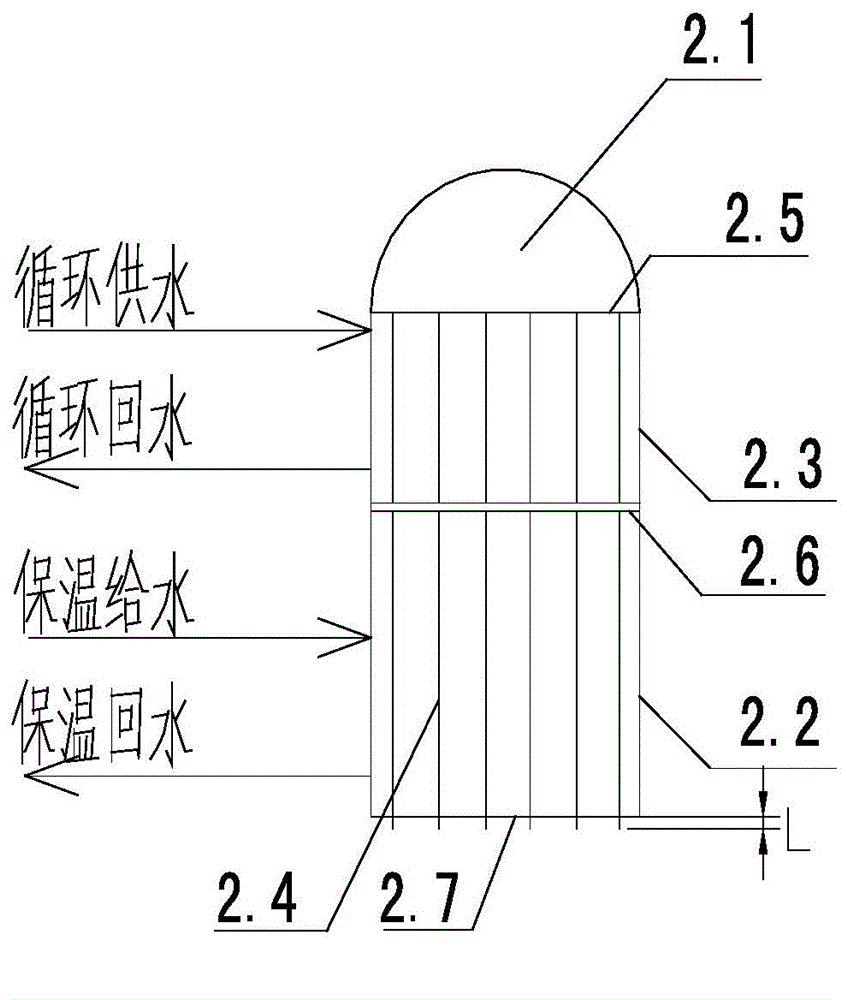

Amino acid-containing condensate steam stripping system and tail gas treatment method

ActiveCN103785193AReasonable process configurationReduce energy consumptionDistillation regulation/controlSteam distillationReboilerFlash-gas

The invention discloses an amino acid-containing condensate steam stripping system and a tail gas treatment method for solving the problems of an existing steam stripping system that a treatment method is complex, system energy consumption is high, corrosion to pipe plates and pipelines is serious and equipment investment is high. The method comprises the steps of correspondingly feeding high temperature condensate, medium temperature condensate and low temperature condensate to a high temperature condensate stripping section, a medium temperature condensate stripping section and a low temperature condensate stripping section of a stripping tower, respectively, reducing the temperature of stripping gas at a stripping tower top to be 85-90 DEG C through an overhead condenser, and feeding into an incineration furnace, wherein the high temperature condensate stripping section is provided with a reboiler, low-pressure steam used as a heat source is used for carrying out steam stripping to the condensate, the medium temperature condensate stripping section and the low temperature condensate stripping section adopt high temperature flash gas generated by the high temperature condensate stripping section as the heat source, and low-pressure nitrogen gas is introduced for gas stripping. The process is simple, the operation can be controlled flexibly, the system stability is good, energy is saved, the consumption is reduced, the corrosion of the steam stripping system can be reduced to the maximum extent and the service life of the equipment can be prolonged.

Owner:湖北华庆石化设备有限公司

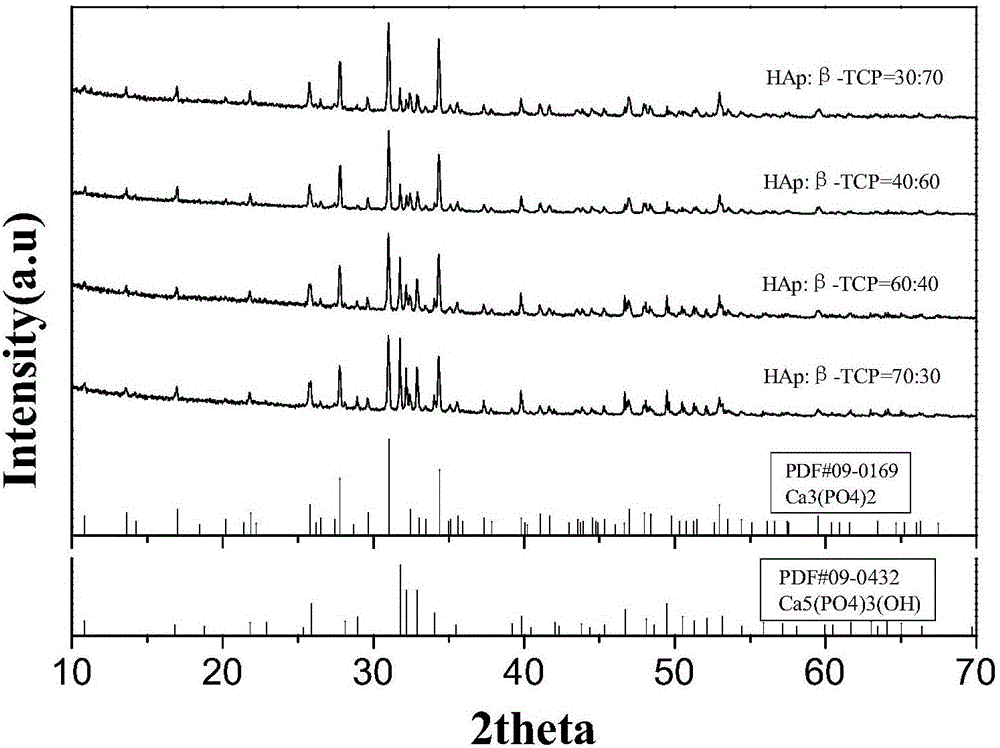

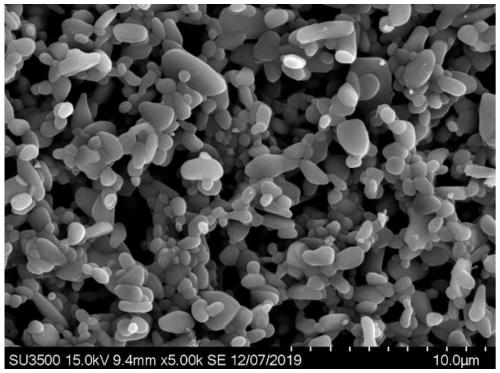

Biphase calcium phosphate (BCP) composite powder synthesized by high-temperature solid phase reaction and preparation method thereof

The invention discloses biphase calcium phosphate (BCP) composite powder synthesized by a high-temperature solid phase reaction. BCP powder is biphase composite powder prepared from hydroxyapatite (HA) and beta-tricalcium phosphate (beta-TCP), in which the molar ratio Ca / P of calcium to phosphorus is 1.5 to 1.67, wherein the value ranges of the relative mass percent of HA and beta-TCP two phases are each 1 to 99 percent; the sizes of crystalline grains of the HA and beta-TCP two phases are 20nm to 300 microns; the crystallinity is 50 to 100 percent. The invention also discloses a preparation method of the BCP composite powder synthesized by the high-temperature solid phase reaction. The BCP composite powder is prepared through the high-temperature solid phase reaction of a calcium-containing solid compound and a calcium-phosphorus solid containing compound. The BCP composite powder has the advantages that a reaction period is short; the costs of raw materials are low; the equipment investment is low; no waste gas and waste water are discharged; further, the proportion of the HA and beta-TCP two phase in the BCP powder is easily regulated and controlled at the same time; the two phases are distributed uniformly; the sizes of the crystal grains and the crystallinity are controllable; finally; the production requirement that the compression strength of BCP biphase composite ceramic is improved or a degradation speed is regulated and controlled is met.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Coking waste water treatment method and A / O technology apparatus

InactiveCN102417272AThe cracking effect is goodImprove biological denitrification capacity and effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater treatmentHydrolysis

The invention is an improvement of a coking waste water treatment method. The method comprises steps of oil removal, impurity removal, electrolytic disintegration and A / O technology, and is characterized in that a biological hydrolysis acidification is set after electrolytic disintegration and before A / O technology; the electrolytic disintegration is electrode energizing aerobic strong electrolysis; the A / O technology employs butterfly jet aerators that are arranged in large intervals and have circulating pumps; the waste water is treated with aeration, aeration stopping and forced internal circulation, stationary deposition and water draining period processing successively, so as to realize biological oxidation and nitration-denitrification in a same pool. Cooperative effects and coordination of each technology increase treatment effect, and treated outlet water can stably reach COD no more than 100mg / l and NH3-N no more than 15 mg / l; besides, land occupation is saved undera same treating capacity and is only 80% of that of a common technology; operating cost of per ton of water is low; and a treatment effect is stable.

Owner:江苏新纯江环保工程有限公司

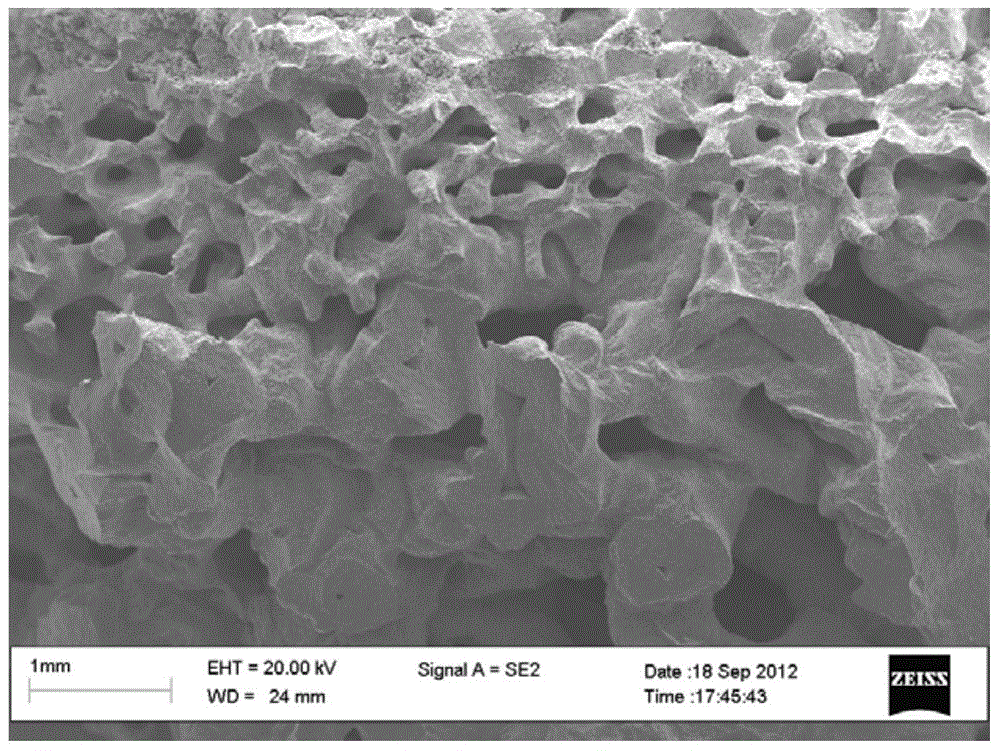

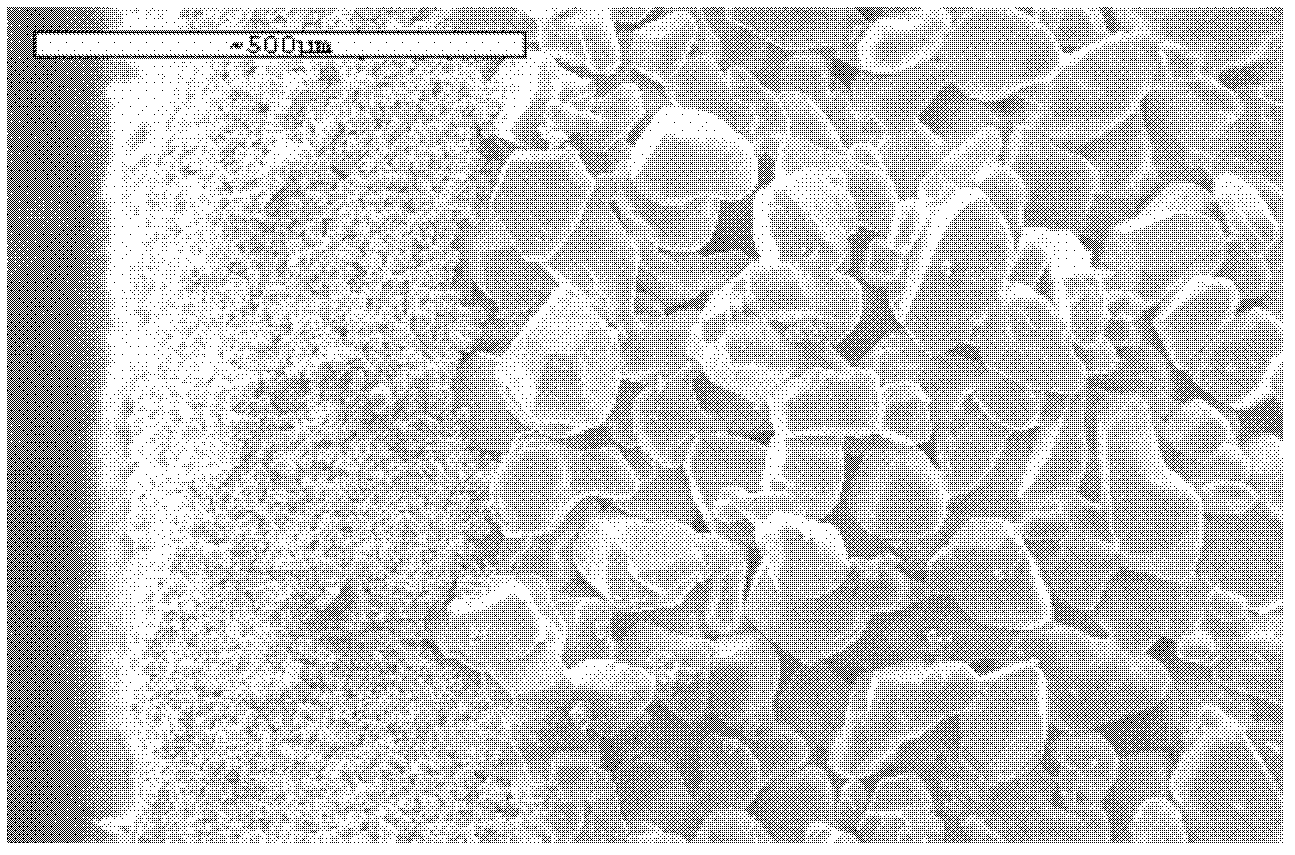

Pure foam silicon carbide support membrane tube with three-gradient pore structure and preparation method

ActiveCN105688684AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesStrong acidsPorous ceramics

Belonging to the field of porous ceramic materials, the invention in particular relates to a pure foam silicon carbide support membrane tube with a three-gradient pore structure and a preparation method thereof. According to the foam silicon carbide support membrane tube, a dual-gradient pore structure pure foam silicon carbide support and a surface film layer form a three-gradient filtration structure, the support is composed of a dual-gradient pore structure pure foam silicon carbide support, the average pore size of the outer layer is 300-500micrometers, the average pore size of the inner layer is 1-3mm, and the support porosity is 35-65%; the surface film layer is formed by combination of silicon carbide powder, the pore size is 50nm-20micrometers, and the film layer porosity is 35%-50%. The preparation method comprises the following steps in order: burdening, foam support molding, support sintering, film layer preparation and firing. The pure foam silicon carbide support membrane tube provided by the invention can be used in oxidizing atmosphere and reducing atmosphere, has strong acid and alkali corrosion resistance, and can be used for coal gasification chemical engineering and IGCC, PFBC coal gasification power generation, high temperature flue gas, automobile exhaust, water purification and other high and low temperature fluid filtration purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

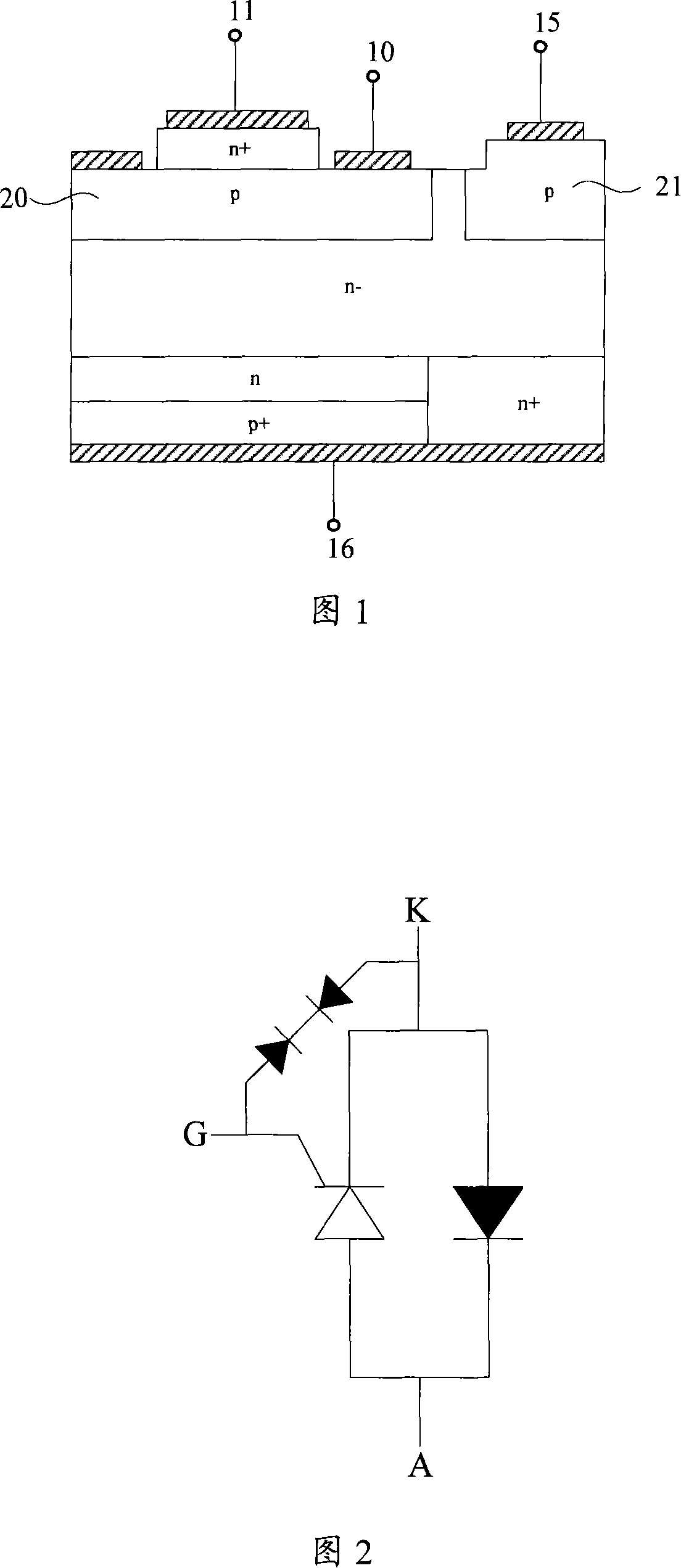

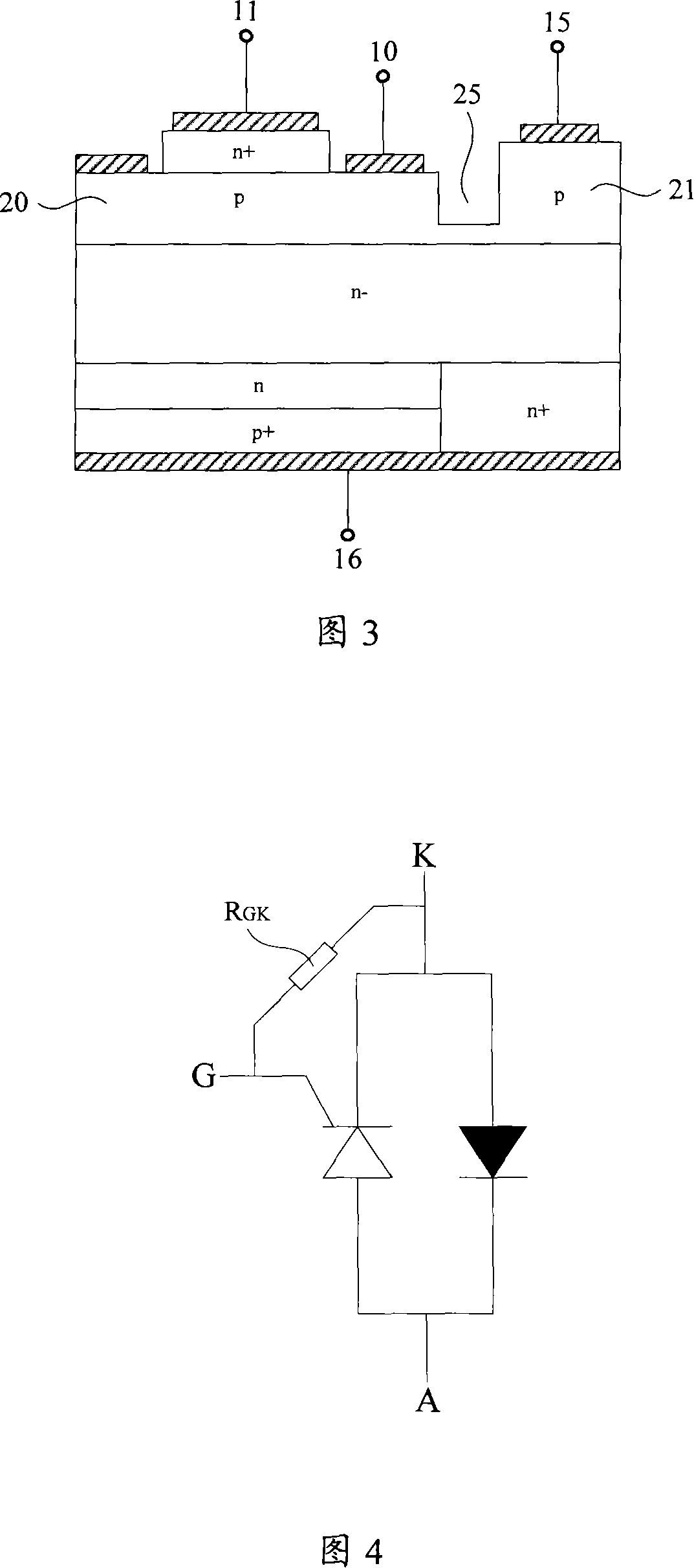

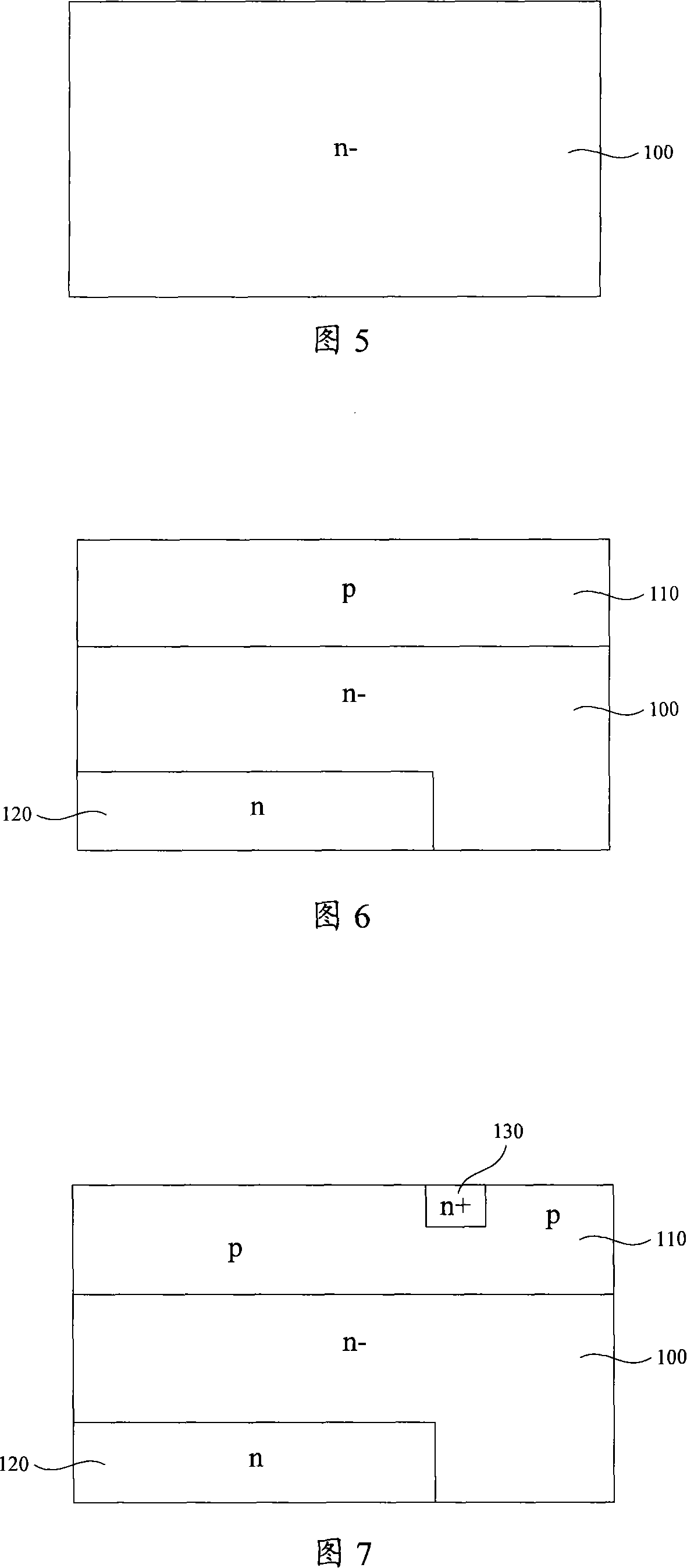

Integrated gate commutated thyristor and method of manufacturing the same

ActiveCN101132000AReduce additional lossSmall currentSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated gate-commutated thyristorAND gate

The present invention discloses an integrated gate commutated thyristor. The said gate commutated thyristor includes n-type substrate, p-type doped region, n-type doped region, anodic p+ doped region of the gate commutated thyristor, diode n+ buffer region, and cathode paling of gate commutated thyristor, and also includes cathode and gate of the gate commutated thyristor, anode of the diode, anode of the gate commutated thyristor and cathode of the diode. The present invention has characters: n+-type isolating ring is set between the p-type doped regions of the gate of the gate commutated thyristor and the anode of the diode. The integrated gate commutated thyristor and its processing method can achieve effectively isolation between GCT element and the diode.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

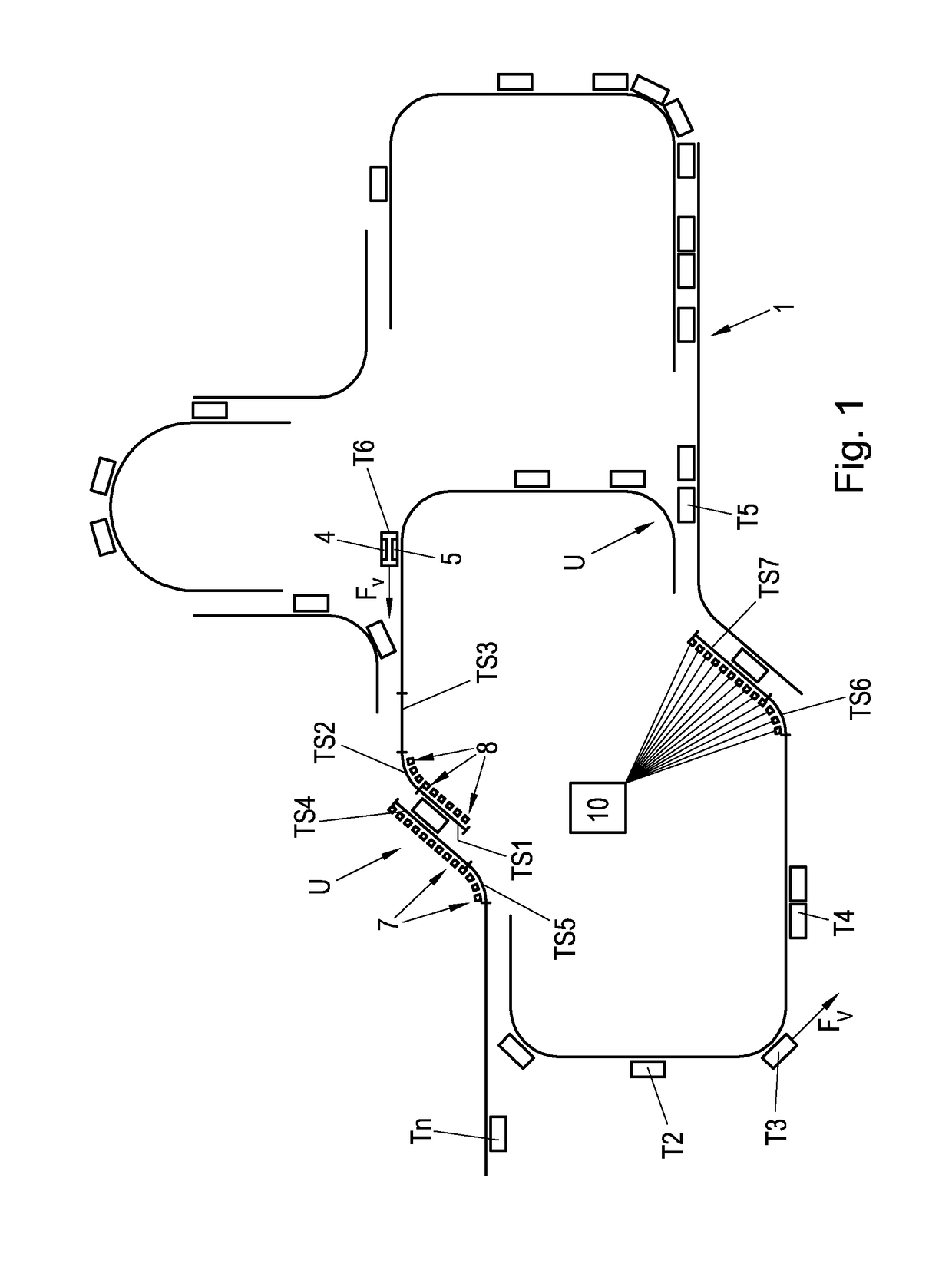

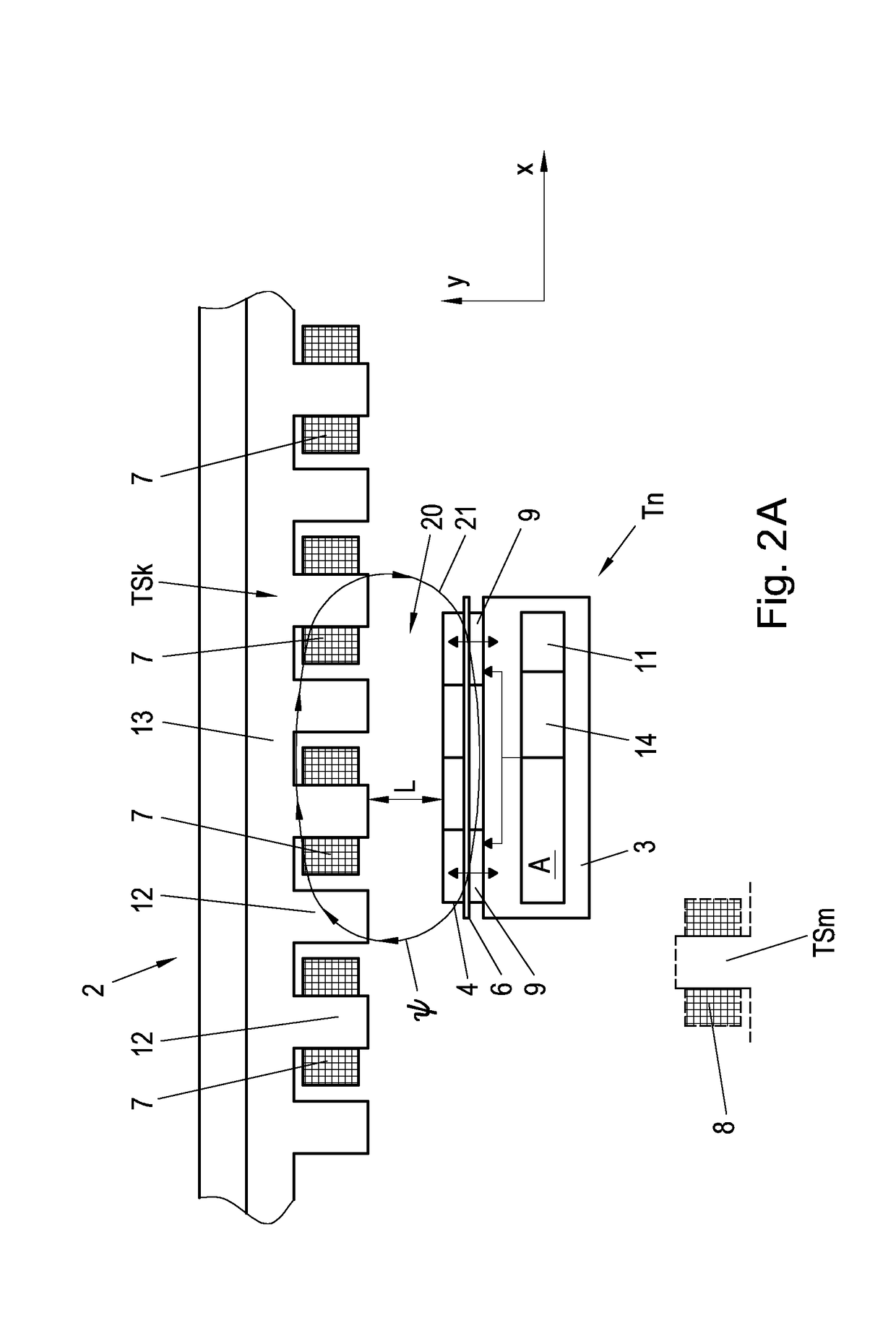

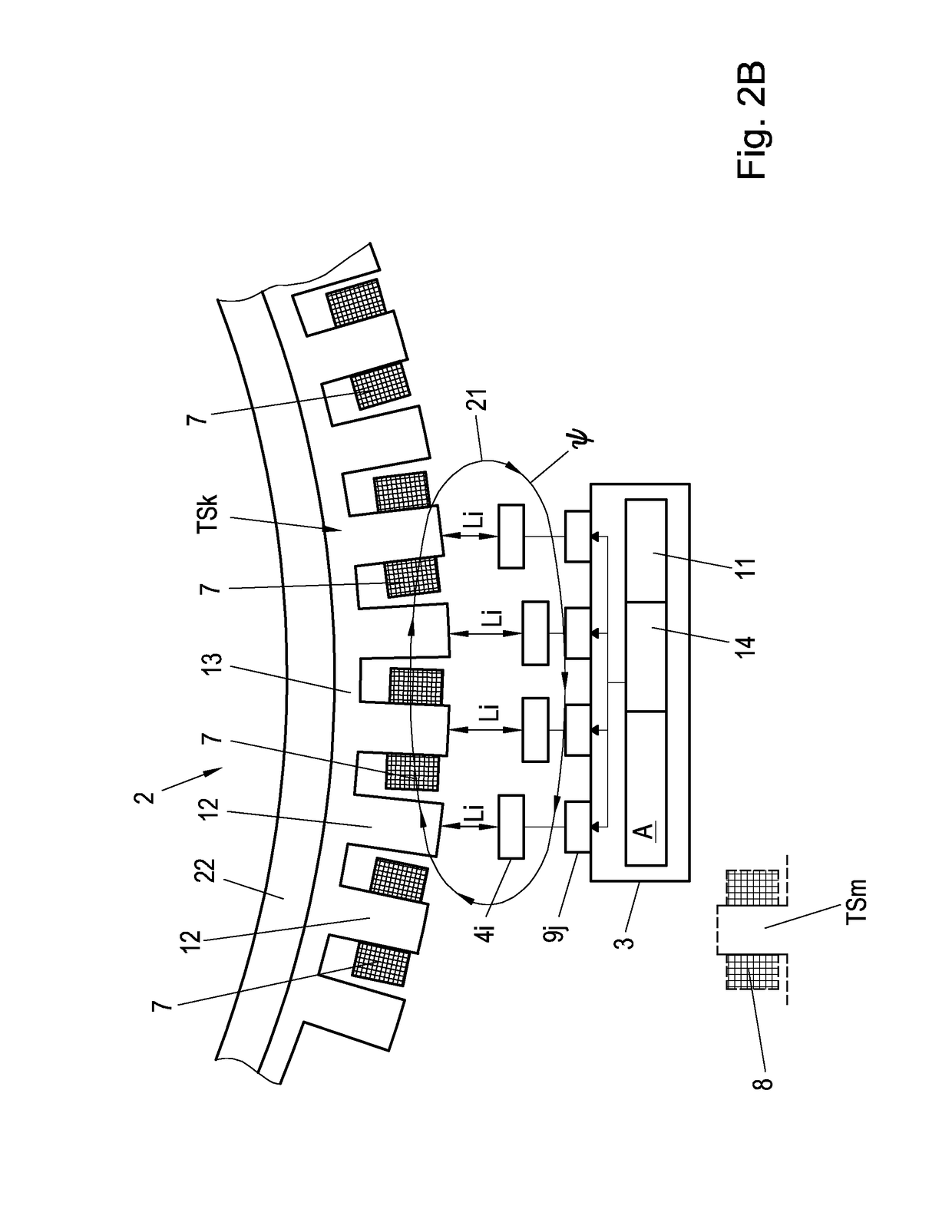

Method for operating a transport apparatus in the form of a long stator linear motor

ActiveUS20190002214A1Flexible process controlFlexible controlAC motor controlLinear motor controlMagnetic fluxVoltage

In order to allow for more flexible process control of a transport apparatus in the form of a long stator linear motor, in particular in order to at least intermittently increase the maximum achievable speed of a transport unit without changing the energy-related basic conditions (maximum current or maximum voltage) of the transport apparatus, according to the invention, in order to change a magnetic flux in the magnetic circuit during movement of the transport unit along the transport route, a magnetic reluctance of the magnetic circuit is changed and / or a magnetomotive force of the magnetic circuit is changed on the transport unit.

Owner:B&R IND AUTOMATION GMBH

Preparation method of low carbon olefin

ActiveCN109651041AHigh operating temperatureEmission reductionBulk chemical productionHydrocarbon by hydrocarbon crackingPetrochemicalFuel oil

The invention relates to the field of petrochemical production and discloses a preparation method of low carbon olefin. The method comprises the following steps of: (1) heavy oil is contacted with andseparated from supercritical carbon dioxide to obtain a light fluid phase containing light oil and carbon dioxide, and a heavy fluid phase containing heavy oil; (2) the light fluid phase containing the light oil and carbon dioxide undergoes component separation to obtain light oil and carbon dioxide; and (3) the light oil is subjected to steam thermal cracking to obtain low carbon olefin. Throughthe above method, the heavy oil can be fully utilized, the problem of the shortage of the petrochemical raw material can be alleviated, and a cracking device can be operated for a long time. Moreover, in the preparation method of the invention, carbon dioxide is used, which not only avoids the greenhouse effect caused by the emission of carbon dioxide into the atmosphere but also recycles the carbon dioxide to achieve the effect of synergistic emission reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

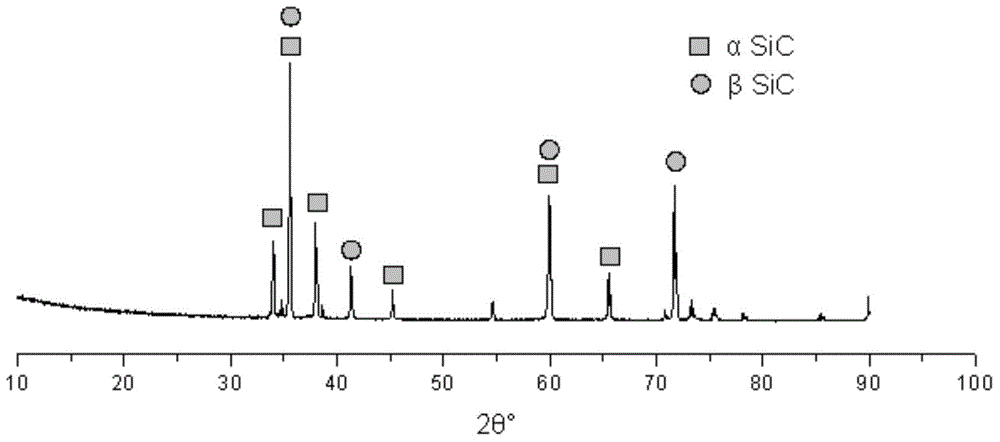

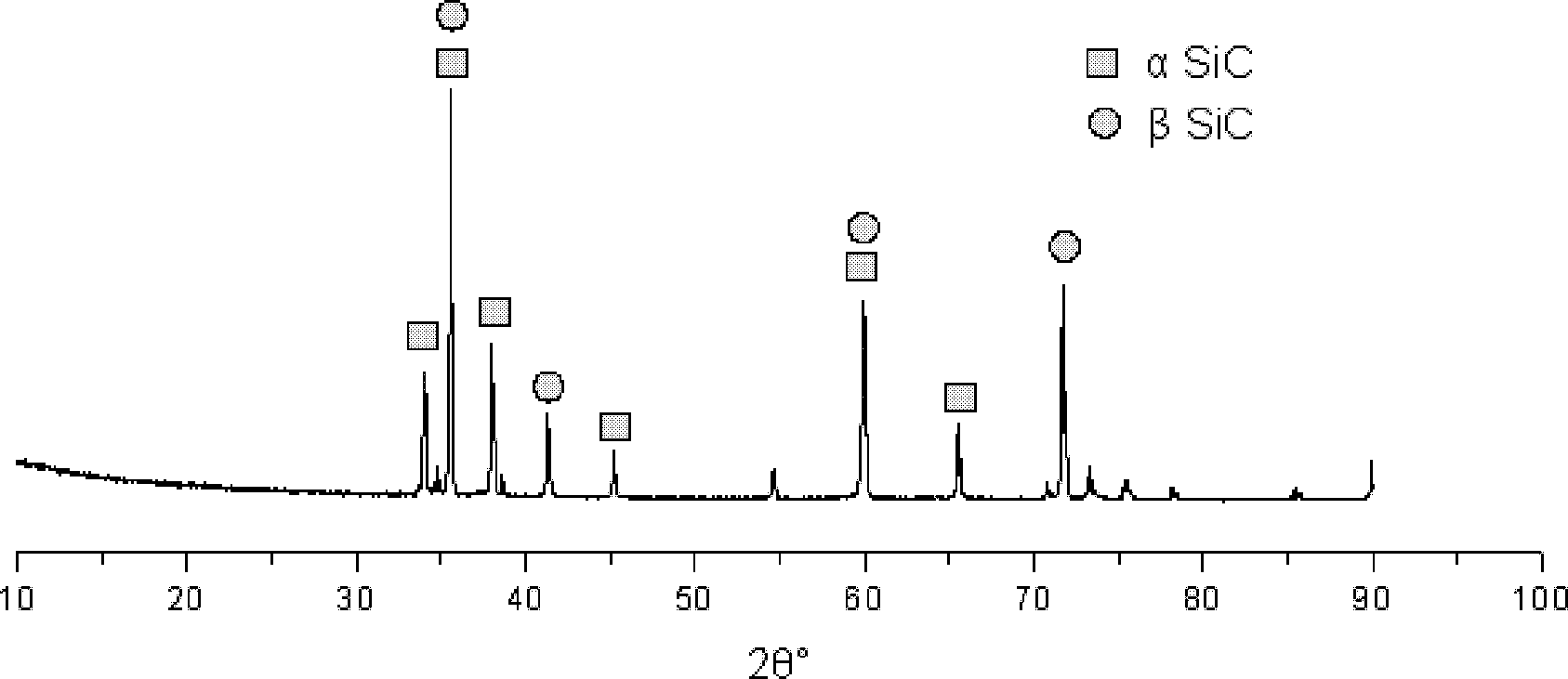

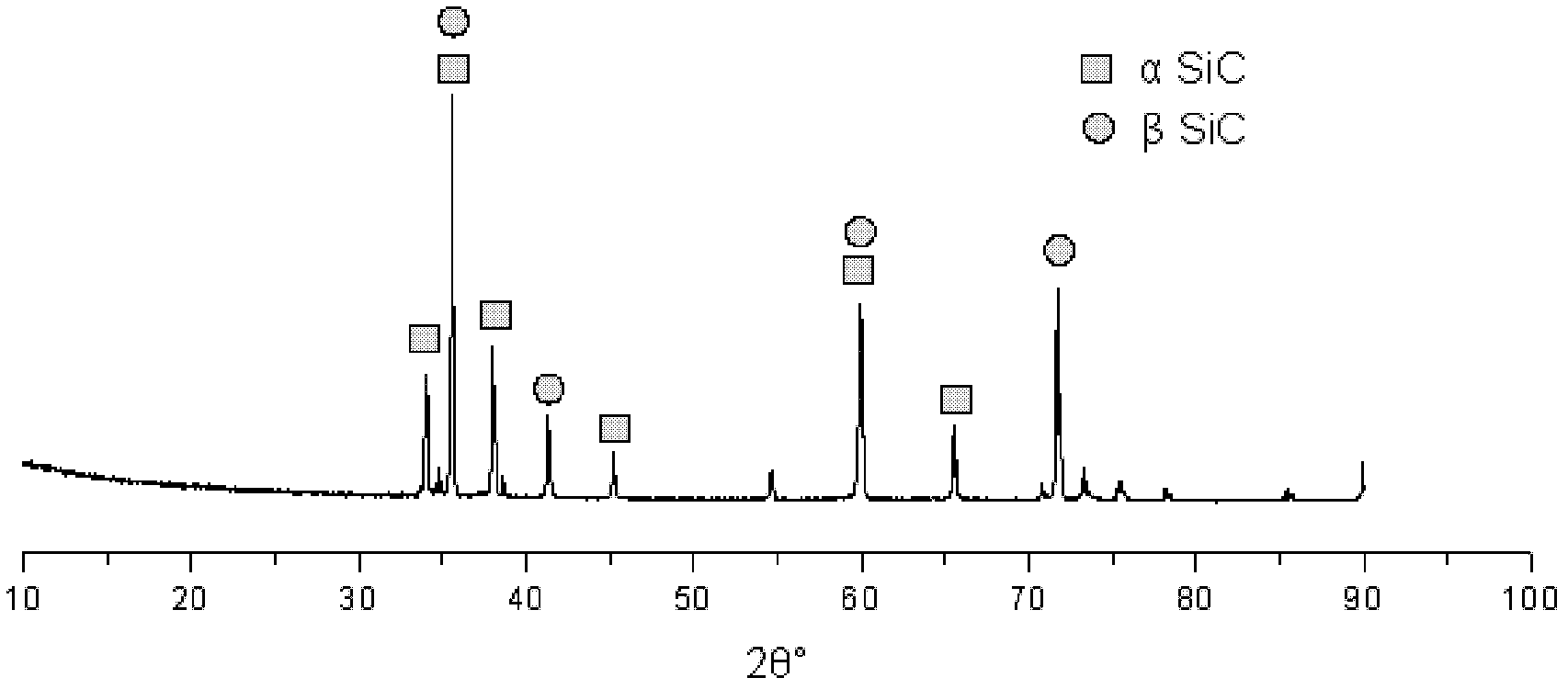

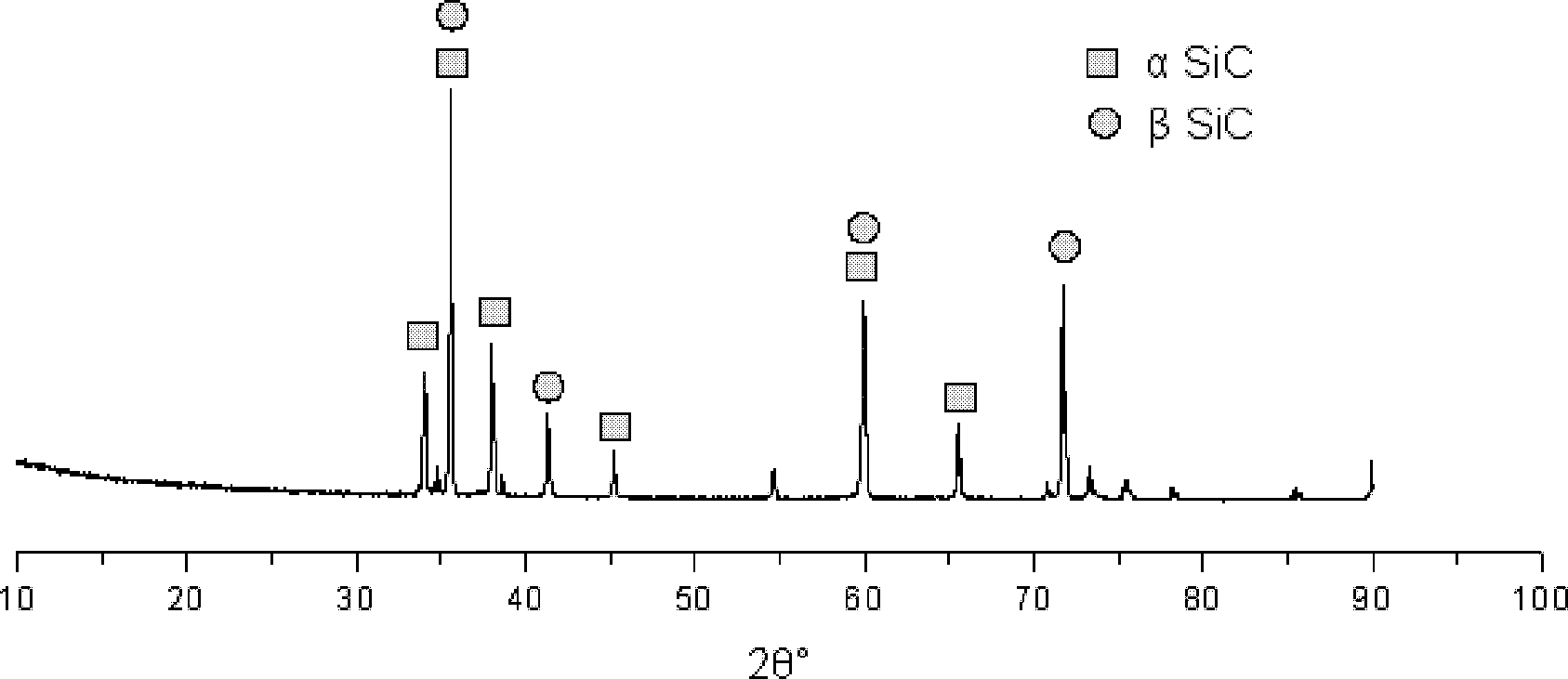

Pure silicon carbide filtering membrane

ActiveCN102659447BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Dual-gradient pore-structure sialon and silicon carbide combined membrane tube and preparation method thereof

ActiveCN105727756AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareMaterials preparationFiltration

The invention relates to the field of porous ceramic materials, and specifically relates to a dual-gradient pore-structure sialon and silicon carbide combined membrane tube and a preparation method thereof. The membrane tube material is composed of sialon and silicon carbide. The membrane tube has a dual-gradient filtering structure composed of a support body layer and a surface membrane layer. The support body layer is composed of a combination of sialon produced through a reaction and coarse silicon carbide grains, and has an average pore size of 10-50mum. The surface membrane layer is composed of a combination of sialon produced through a reaction and fine-particle silicon carbide grains, and has an average pore size of 0.1-5mum. An overall porosity of the membrane tube is within a range of 40-50%. The preparation method of the membrane tube sequentially comprises the steps of material preparation, support forming, membrane layer preparation and firing. Isostatic pressing is adopted in the forming step, wherein a forming pressure is controlled at 100-150MPa. The firing temperature is controlled at 1650-1850 DEG C, and a temperature maintaining time is 3-5h. The method is easy to realize. With the method, product performance can be ensured. The membrane tube provided by the invention has the advantages of high application temperature, high acid corrosion resistance and high alkali corrosion resistance. The membrane tube can be used in filtration purification of various fluids with high temperature or low temperature, such as high-temperature high-press gas filtration dedusting, water purification and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of porous silicon carbide ceramic support body

ActiveCN111533572AImprove mechanical propertiesEasy to useSemi-permeable membranesSustainable biological treatmentCarbide siliconFoaming agent

The invention discloses a preparation method of a porous silicon carbide ceramic support. The preparation method comprises the following steps: uniformly mixing mixed silicon carbide powder, silicon dioxide powder, a foaming agent, a dispersing agent and a thermosetting polymer emulsion used as main raw materials to obtain high-solid-content silicon carbide slurry, and then pouring, and carrying out pressureless sintering molding to obtain the porous silicon carbide ceramic support, wherein the mixed silicon carbide powder is formed by mixing large-particle-size silicon carbide powder and small-particle-size silicon carbide powder. The porous silicon carbide ceramic support body has the advantages of high strength, high temperature resistance, acid and alkali corrosion resistance and the like, ceramic matrixes of separation membrane materials with different specifications and different shape structures can be designed according to process requirements, and the porous silicon carbide ceramic support body can also be independently used as a separation filtering material of large-particle substances; and the related preparation method is simple, flexible in process control, relativelylow in cost and short in molding process period, and has important application and popularization values.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

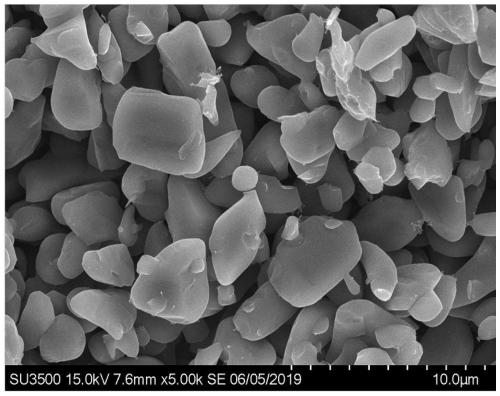

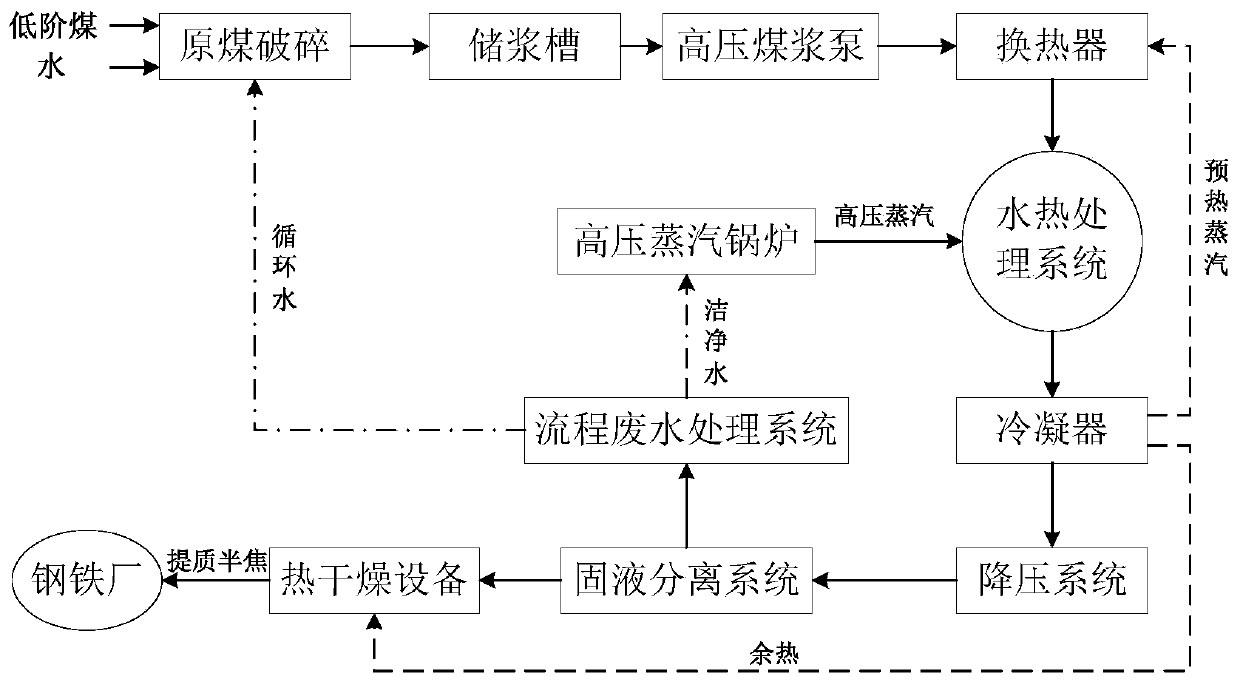

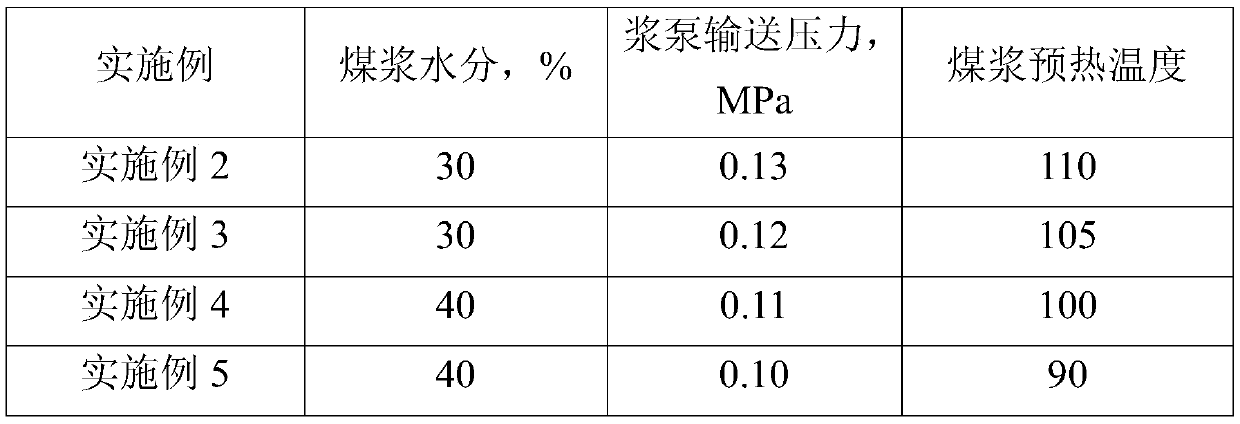

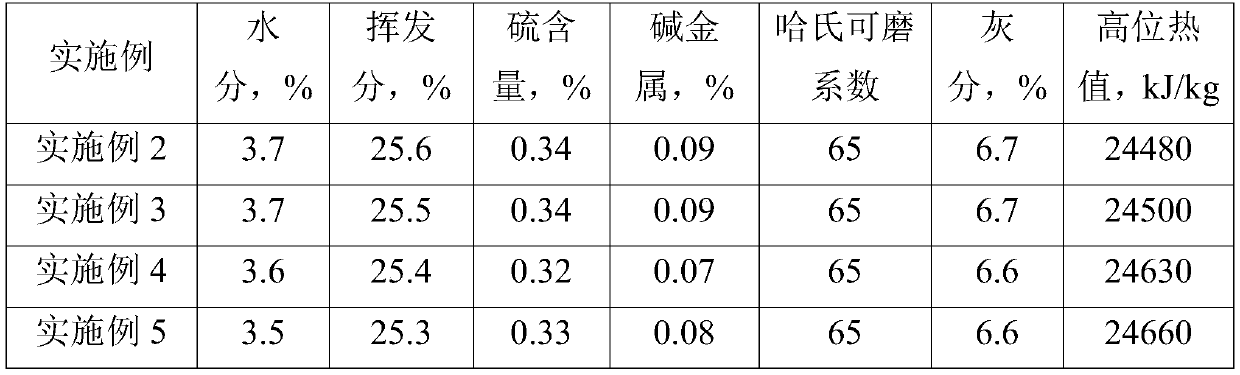

Method for preparing blast furnace blowing semicoke from low-rank coal based on high-pressure hydrothermal reaction

ActiveCN110982542ALow fixed carbon contentHigh fixed carbon contentEnergy inputSpecial form destructive distillationThermodynamicsProcess engineering

The invention relates to a treatment method for dehydrating and upgrading high-moisture and high-volatile low-rank coal, and discloses a method for preparing blast furnace blowing semicoke by upgrading low-rank coal based on a high-pressure hydrothermal reaction, wherein the method comprises four steps of low-rank coal pretreatment, high-pressure hydrothermal upgrading, waste heat recycling and upgraded semicoke dehydration and drying. According to the method, low-heat-value low-rank coal is converted into high-quality blast furnace blowing upgrading semicoke by utilizing a high-pressure hydrothermal reaction upgrading technology, wherein the moisture content of the semicoke air drying base is less than 6%, the volatile component content is less than 25%, the Hardgrove grind ability indexis greater than 60, the high-order heat generation value is greater than 24000 kJ / kg, soluble potassium salt, sodium salt and sulfate components in ash are dissolved out, the organic sulfur in coal iseffectively separated out, and the upgraded semicoke can meet the performance index requirements of coal for blast furnace blowing; and the method provided by the invention effectively solves the problems of high water content, high volatile component content, low heat value and high harmful element content of blast furnace blowing of low-rank coal, and provides a clean, efficient, low-energy-consumption and high-added-value low-rank coal upgrading utilization method.

Owner:UNIV OF SCI & TECH BEIJING

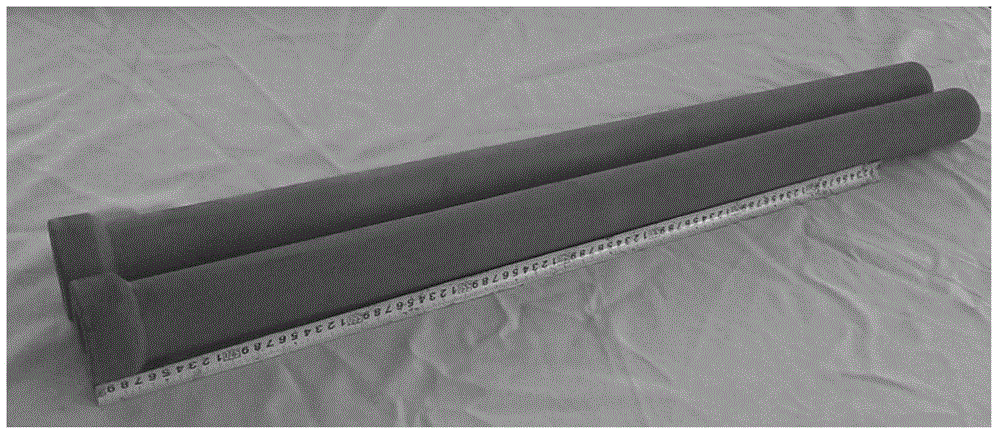

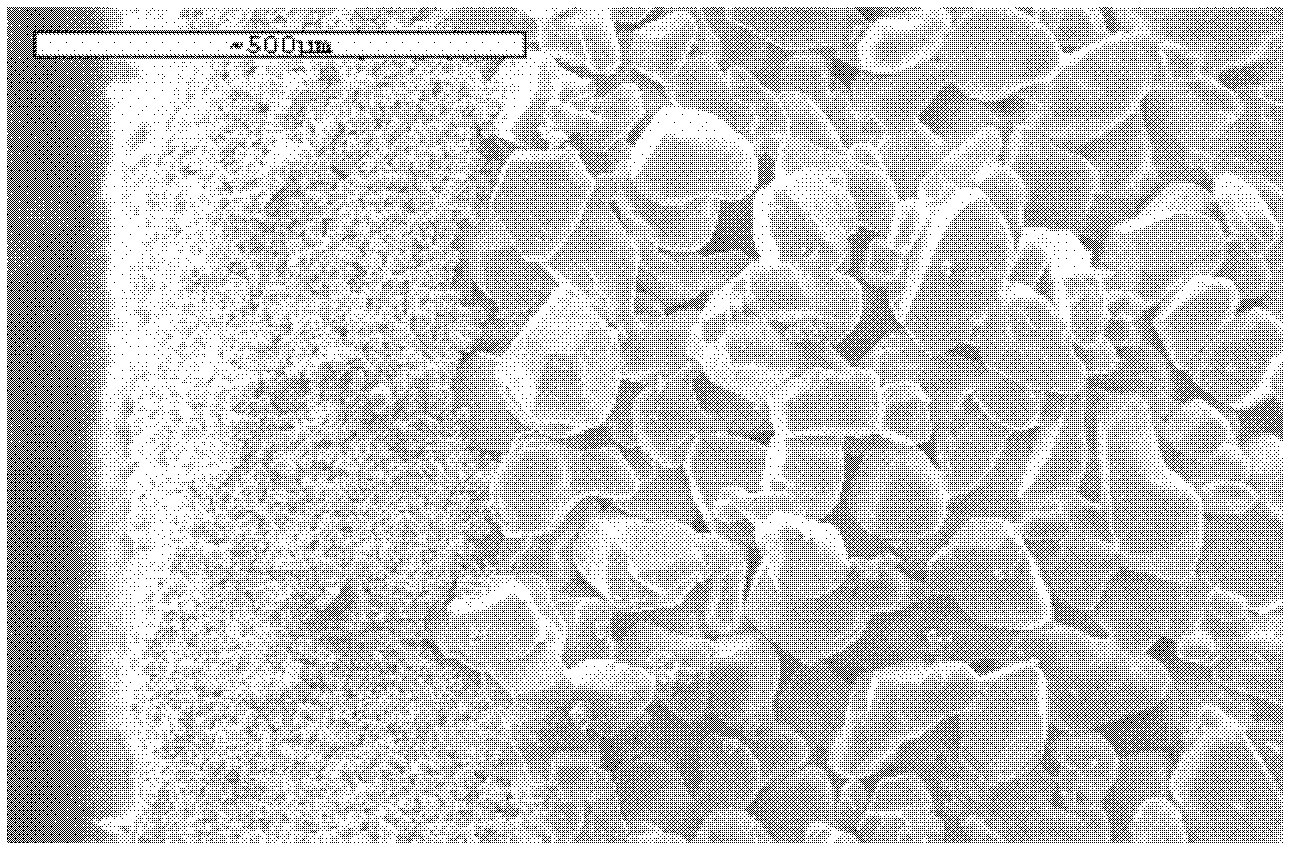

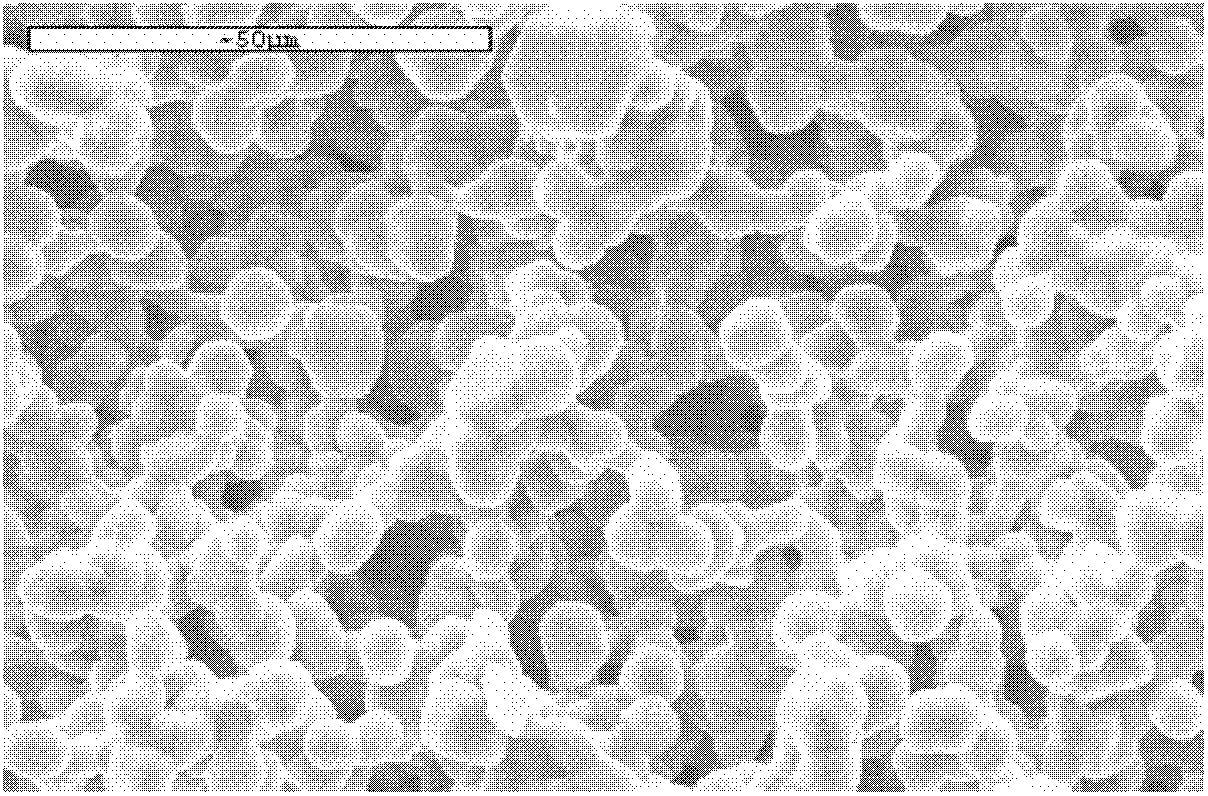

Pure SiC membrane tube support and preparation method thereof

ActiveCN102659446BGuaranteed corrosion resistanceExtended service lifeCeramicwareStrong acidsSilicon oxide

The invention belongs to the technical field of porous ceramic materials and their preparation and especially discloses a pure SiC membrane tube support and a preparation method thereof. The pure SiC membrane tube support comprises pure SiC, is obtained by pile-up and binding of crude SiC particles having sizes of 5 to 400 microns, and has an uniform communicated aperture structure having an average aperture size of 5 to 120 microns and integral porosity of 25 to 50%. The preparation method comprises that crude SiC particles, crude silicon oxide particles or silicon powder as basic materials and one or more polymers as binders are mixed; the mixture is pressed into a support by a cold isostatic pressing sheath; and the support is sintered into the pure SiC membrane tube support. The pure SiC membrane tube support can be used in an oxidation atmosphere and in a reducing atmosphere, has strong acid corrosion and alkaline corrosion resistance, and can be used for various high / low temperature fluid filtering purification fields such as coal gasification chemical engineering, integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) coal gasification power generation, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

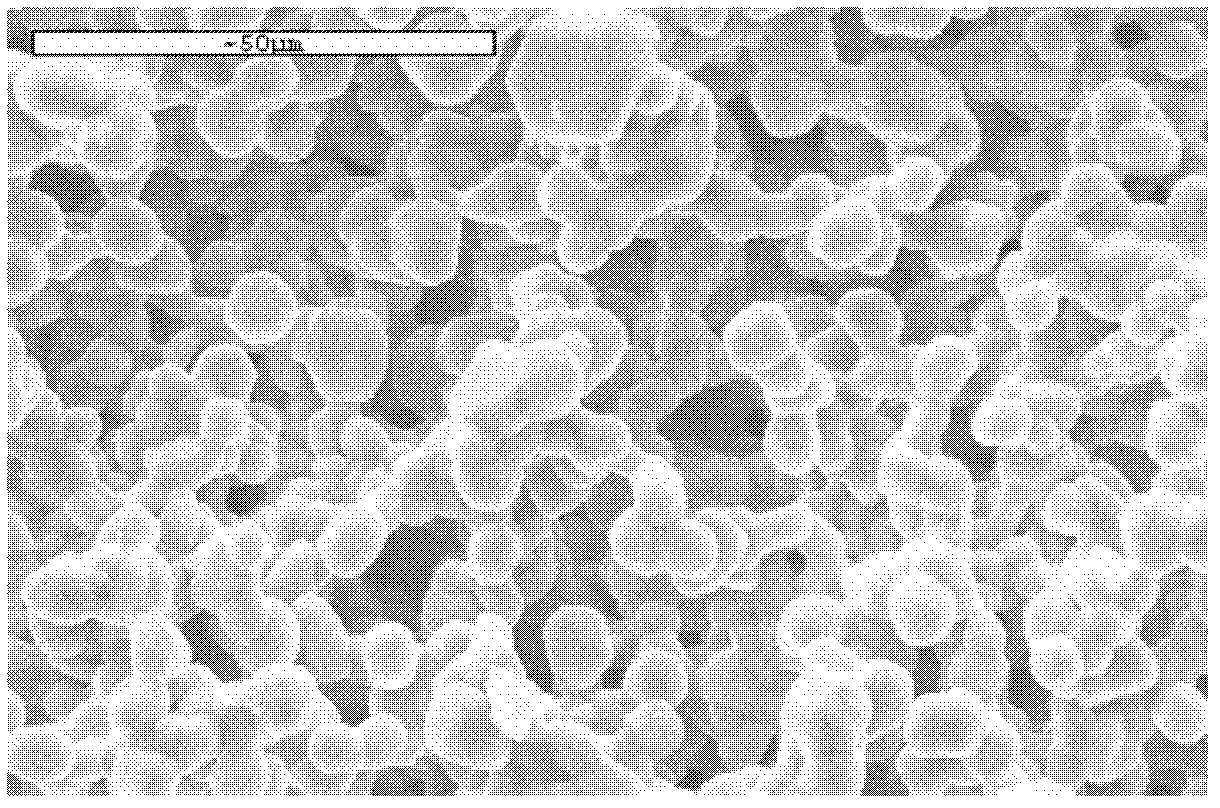

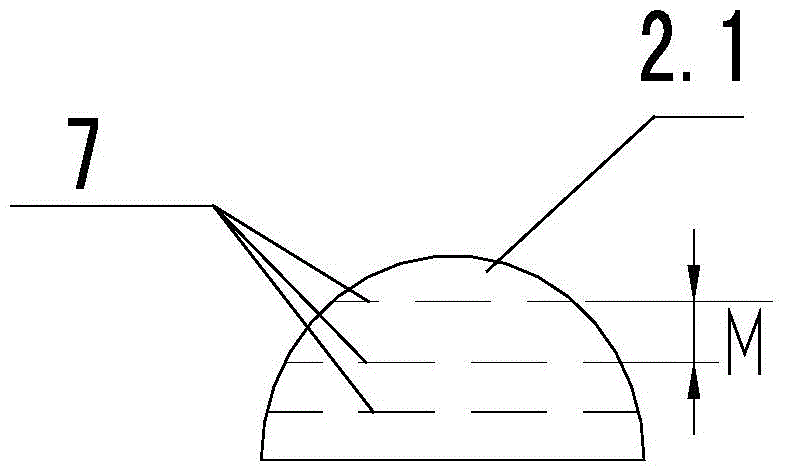

Gradient-porosity pure silicon carbide membrane tube

ActiveCN102633531BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareIntegrated gasification combined cycleSurface membrane

The invention belongs to the technical field of multipore ceramic materials and preparation thereof, and particularly relates to a gradient-porosity pure silicon carbide membrane tube and a preparation method thereof. The gradient-porosity pure silicon carbide membrane tube consists of pure SiC; a gradient filter structure consists of a supporting body layer and a surface membrane layer, wherein the supporting body is formed by stacking and combining roughly granular SiC, and the average aperture is 5-120 mu m; the surface membrane layer is formed by stacking and combining finely granular SiC, and the aperture is 0.1-20 mu m; and the whole porosity of the membrane tube is 25-50%. The preparation method comprises burdening, forming the supporting body, preparing the membrane layer and sintering, wherein forming is performed under equal static pressure; the forming pressure is controlled between 40 and 150MPa; the sintering temperature is controlled between 1,500 and 2,400 DEG C; and heat is preserved for 0.5-5 hours. The method is easy to implement, and the performance of a product can be guaranteed. The gradient-porosity pure silicon carbide membrane tube can be used under an oxidization atmosphere and a reduction atmosphere, is high in acid and alkaline corrosion resistance and can be applied to gas chemical engineering and integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) power generation and used for filtering and purifying various types of high- and low- temperature fluid, such as high-temperature flue, automobile tail gas, water and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

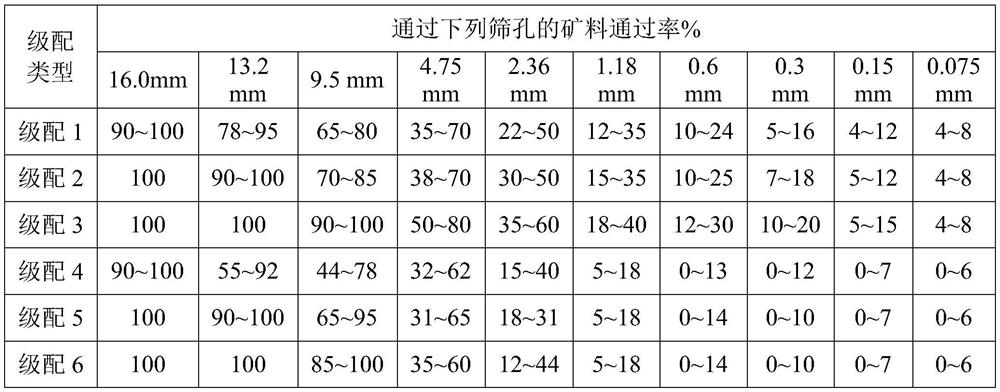

Preparation method of chemical reaction type cold patch asphalt mixture

InactiveCN112851174AAdvantages of preparation methodImprove early strengthChemical reactionPhysical chemistry

The invention provides a preparation method of a chemical reaction type cold patch asphalt mixture. According to the preparation method, a proper amount of a special diluent is doped into asphalt to reduce the viscosity of the asphalt so as to enable the cold patch asphalt mixture to be constructed at normal temperature, a chemical reactant is doped into the asphalt mixture, and after a pavement is repaired, the chemical reactant can react with the special diluent, so that not only is the bonding effect between the asphalt mixture improved, but also the cold patch asphalt mixture has better construction workability. In addition, a calcined product prepared by calcining CaCO3, SiO2 and Fe2O3 can be slowly hydrated after construction of the cold patch asphalt mixture to generate Ca(OH)2, the chemical reactant and oleic acid are promoted to continuously react to generate fatty acid salt, and the resultant can be used for filling gaps of the mixture, so that the structure of the asphalt mixture is denser, and the water stability and the later strength of the mixture can be improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

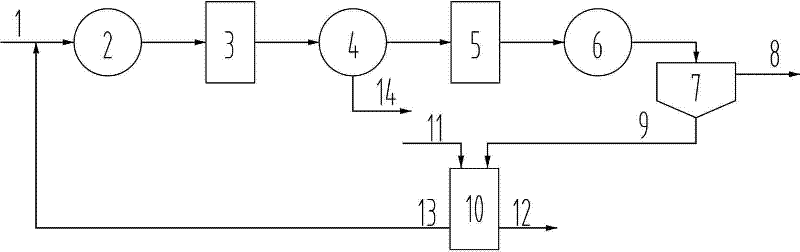

Method and system for producing sandy aluminum oxide through three-section seed decomposition

The invention relates to a method for producing sandy aluminum oxide through three-section seed decomposition in a process of producing aluminum oxide with a Bayer process or in a Bayer process part of a combined process. The method for producing the sandy aluminum oxide through three-section seed decomposition comprises the steps of: mixing fine fluid with seeds; feeding into a first-section decomposition groove; discharging; performing first-stage cooling; feeding into a second-section decomposition groove; forming a necessary gravity fractionation layer in the decomposition groove by controlling proper stirring intensity; and drawing out coarse particles from the bottom of the groove and taking the coarse particles as aluminum hydroxide products; performing second-stage cooling on overflow containing fine particles at the upper part; feeding into a third-section decomposition groove; separating the underflow; performing seed filtering and washing processes; mixing the filtered seeds with the fine fluid; returning to the first-section decomposition groove; and performing an oxalate removing process on a seed washing solution after the seeds are washed. According to the method and system provided by the invention, by adoption of the three-section decomposition technology, the positions of the products to be output and the seeds are respectively arranged in the first-section and third-section decomposition grooves, so that the aims of obtaining high-quality aluminum hydroxide product, realizing high yield and flexible process control and facilitating the removal of oxalate are achieved.

Owner:中铝国际技术发展有限公司

Thin-belt continuous casting method and apparatus

InactiveCN1208155CFlexible process controlEasy to operateMetal rolling arrangementsProduction rateCar driving

The invention discloses a thin strip continuous casting method, that is, molten steel enters the molten pool formed by crystallization rolls, and is cooled and lightly rolled by the crystallization rolls to form a cast strip. In the width direction of the strip, the gas is sprayed on both sides of the cast strip for forced cooling, so that the cast strip is cooled to the temperature required by the process, and then it is hot-rolled and controlled to cool until it is coiled. The device of the present invention includes two blowing, connecting rod transmission and synchronous mechanisms that are respectively arranged on both sides of the casting belt; the blowing mechanism includes bearing seats, support shafts, nozzles, etc.; The rod is connected with the support shaft; the synchronous mechanism includes a moving trolley, a rack, a gear, a trolley driving device, etc. The angle between the nozzle and the casting belt is adjusted by the rotation of the support shaft; the distance between the nozzle and the casting belt is adjusted by the synchronous movement of the moving trolley. The invention can effectively improve the surface and internal quality of the cast strip, increase the productivity and expand the production of steel types.

Owner:BAOSHAN IRON & STEEL CO LTD

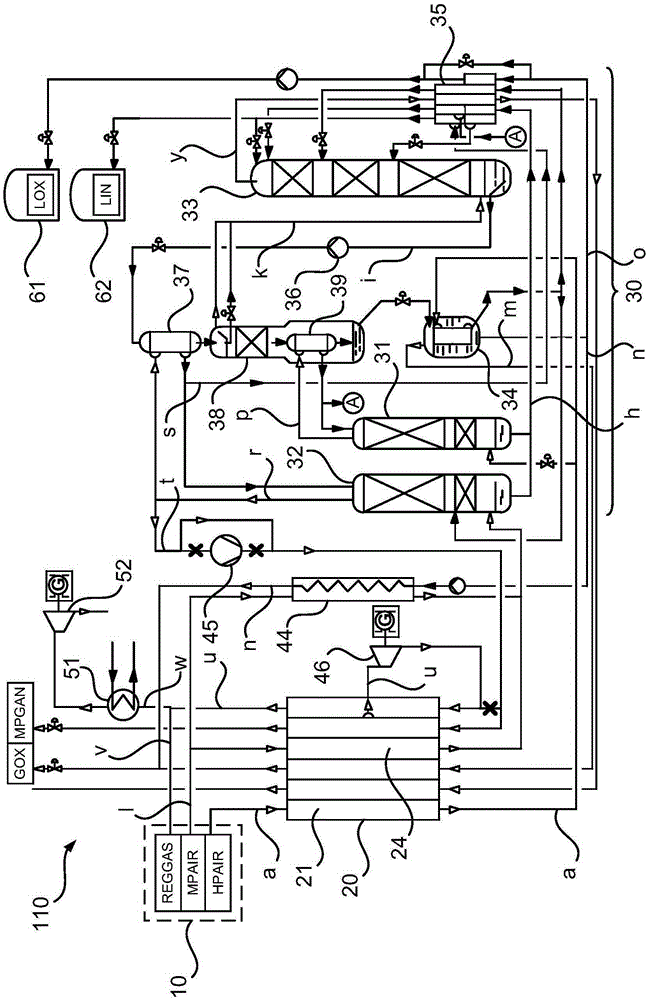

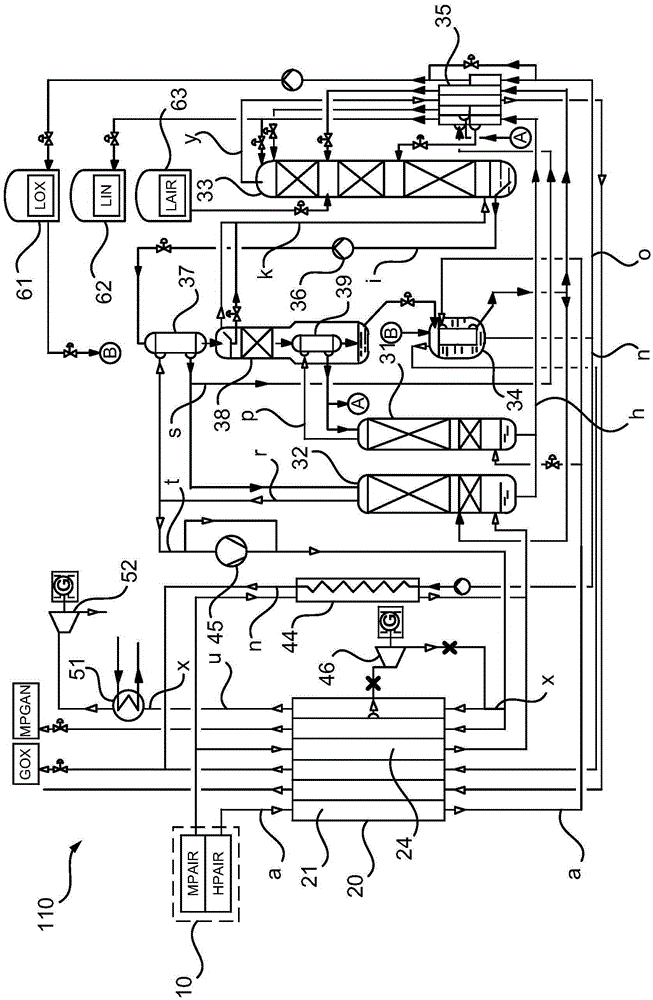

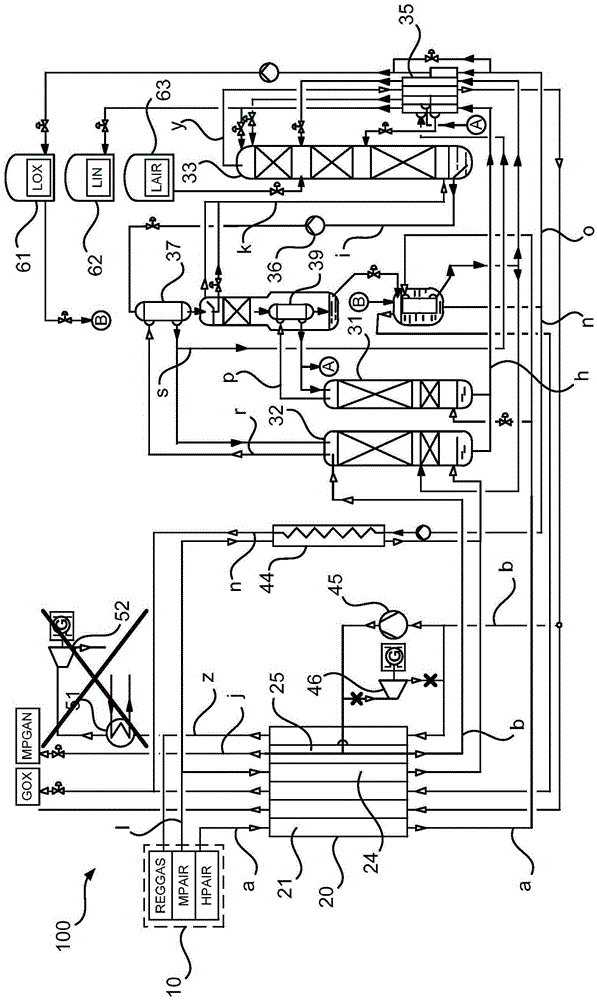

Method for producing at least one air product, air separation system, method and device for producing electrical energy

ActiveCN105378411ALow driving powerImprove heat penetrationSolidificationLiquefactionEngineeringAir separation

The invention relates to a method for producing at least one air product, wherein an air separation system (100) is used which has a primary air compressor (10), a primary heat exchanger (20) and a distillation column system (30), and which comprises a first and a second operation mode, wherein, in the first operating mode, at least one liquid air product (LIN, LOX) produced in the distillation column system (30) is saved and, in the second operating mode, the at least one air product (LIN, LOX, LAIR) saved in the first operating mode and / or at least one additional liquid air product is supplied to the distillation column system (30). The method is characterized in that, in the second operating mode, at least one gaseous pressure flow (b - g) at a temperature level which lies below a hot-side temperature of the primary heat exchanger (20) is supplied to a cold compressor (45), compressed in the cold compressor (45) from a first above-atmospheric pressure level to a second above-atmospheric pressure level, and is supplied to at least one distillation column (31, 32) of the distillation column system (30) at the second above-atmospheric pressure level. The invention further relates to a corresponding air separation system (100) and to a method and to a device for producing electrical energy.

Owner:LINDE AG

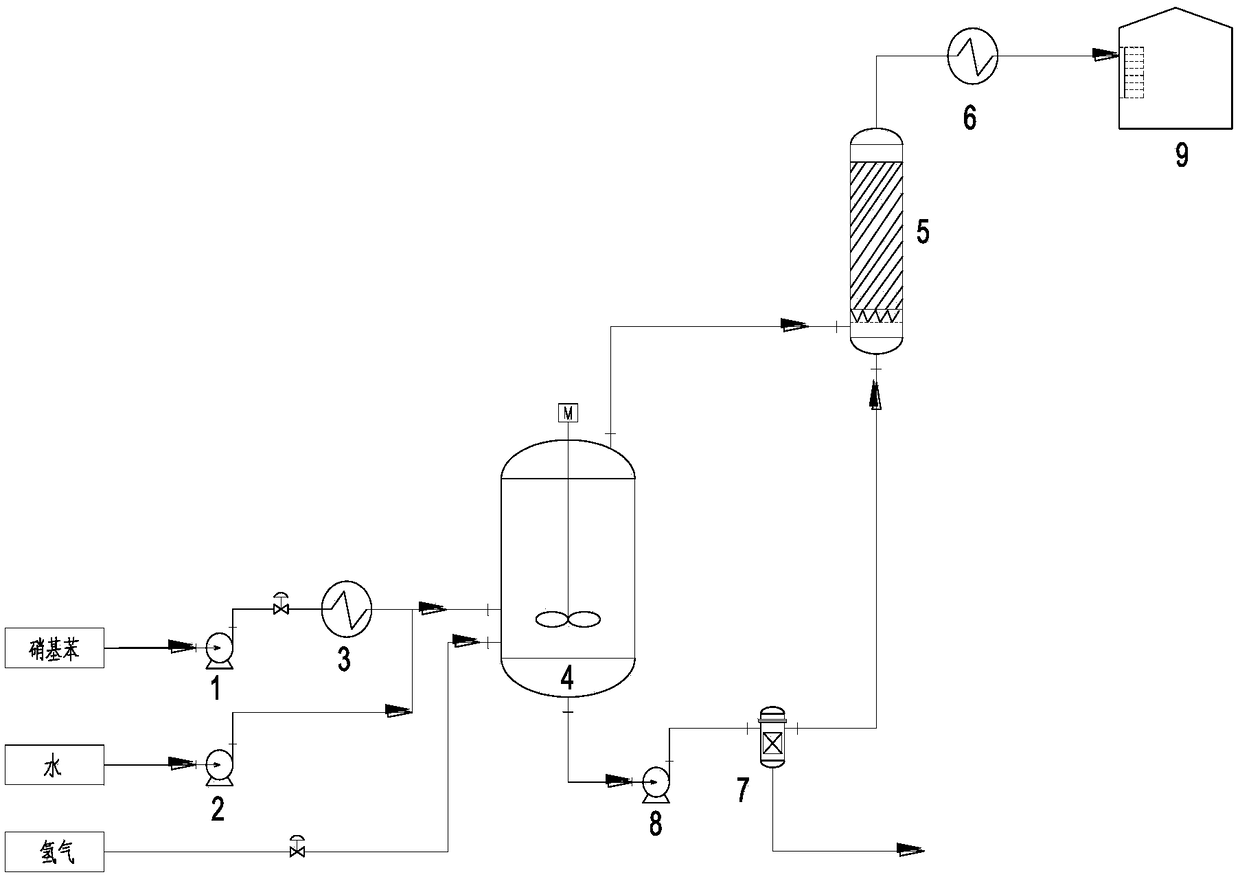

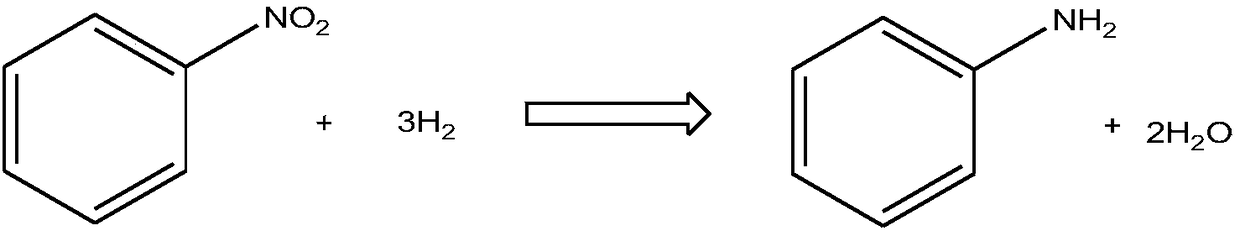

Method for preparing amine type products by hydrogenating nitro-compound

ActiveCN108623476AFlexible process controlHigh purityOrganic compound preparationChemical recyclingNitro compoundGas phase

The invention provides a method for preparing amine type products by hydrogenating a nitro-compound. The method is realized through a continuous reaction system composed of a stirring kettle reactor and a fixed bed reactor; gas-phase discharged materials of the kettle reactor enter the fixed bed reactor to continually react; after less liquid phase at the bottom of the kettle is filtered to removea catalyst, the liquid phase also enters the fixed bed reactor to continually react. According to the method provided by the invention, two types of the reactors are matched and different active catalysts are used, so that the conversion rate of the nitro-compound can be greatly improved; meanwhile, adverse effects of excessive hydrogenation are extremely overcome.

Owner:WANHUA CHEM GRP CO LTD +1

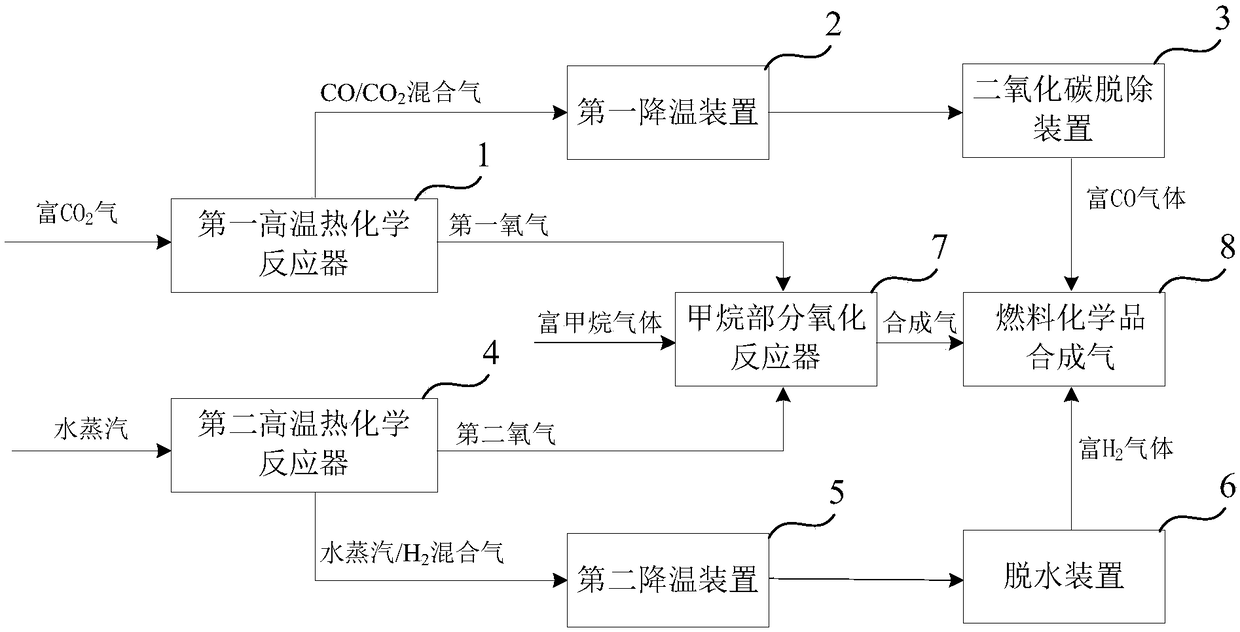

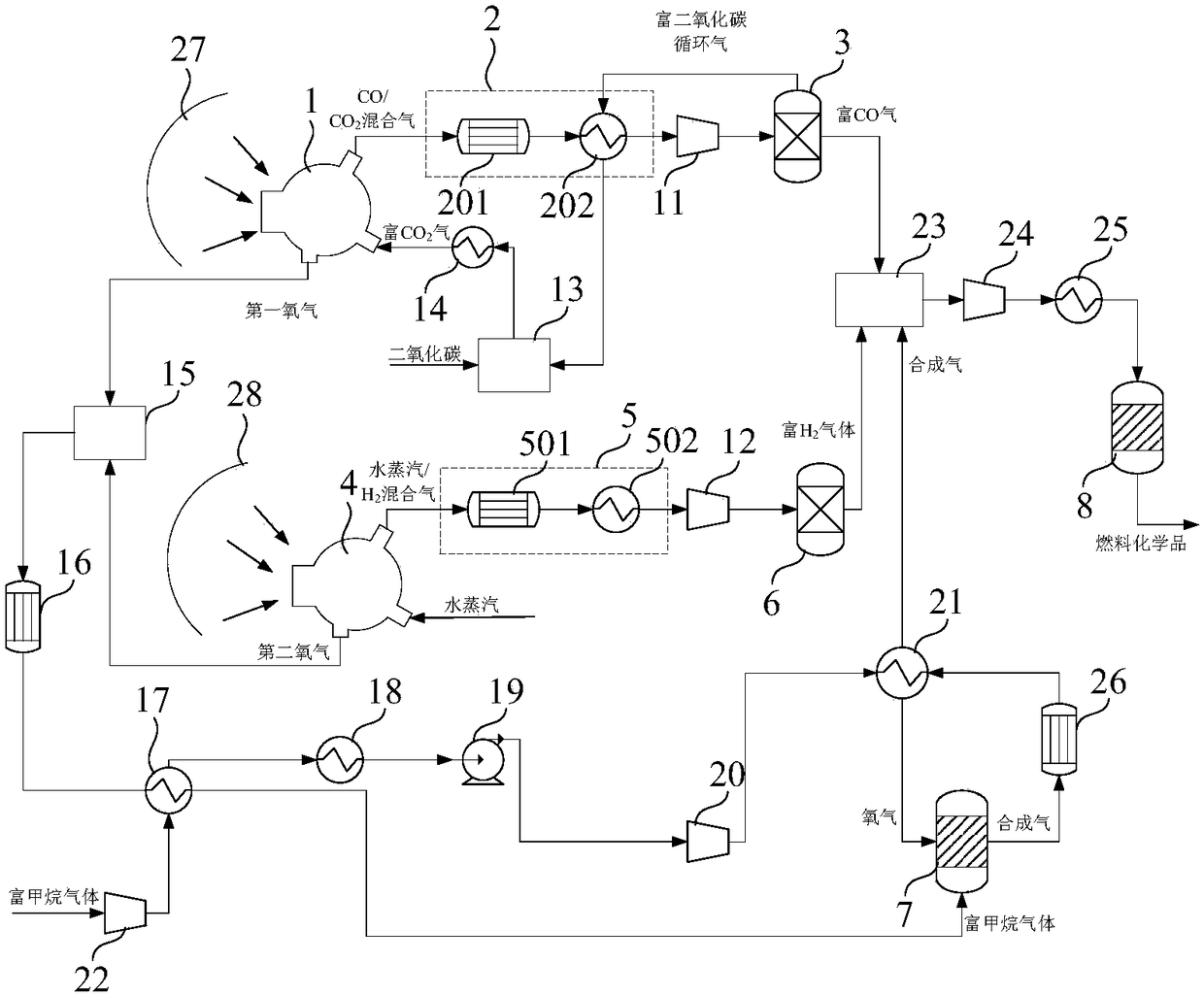

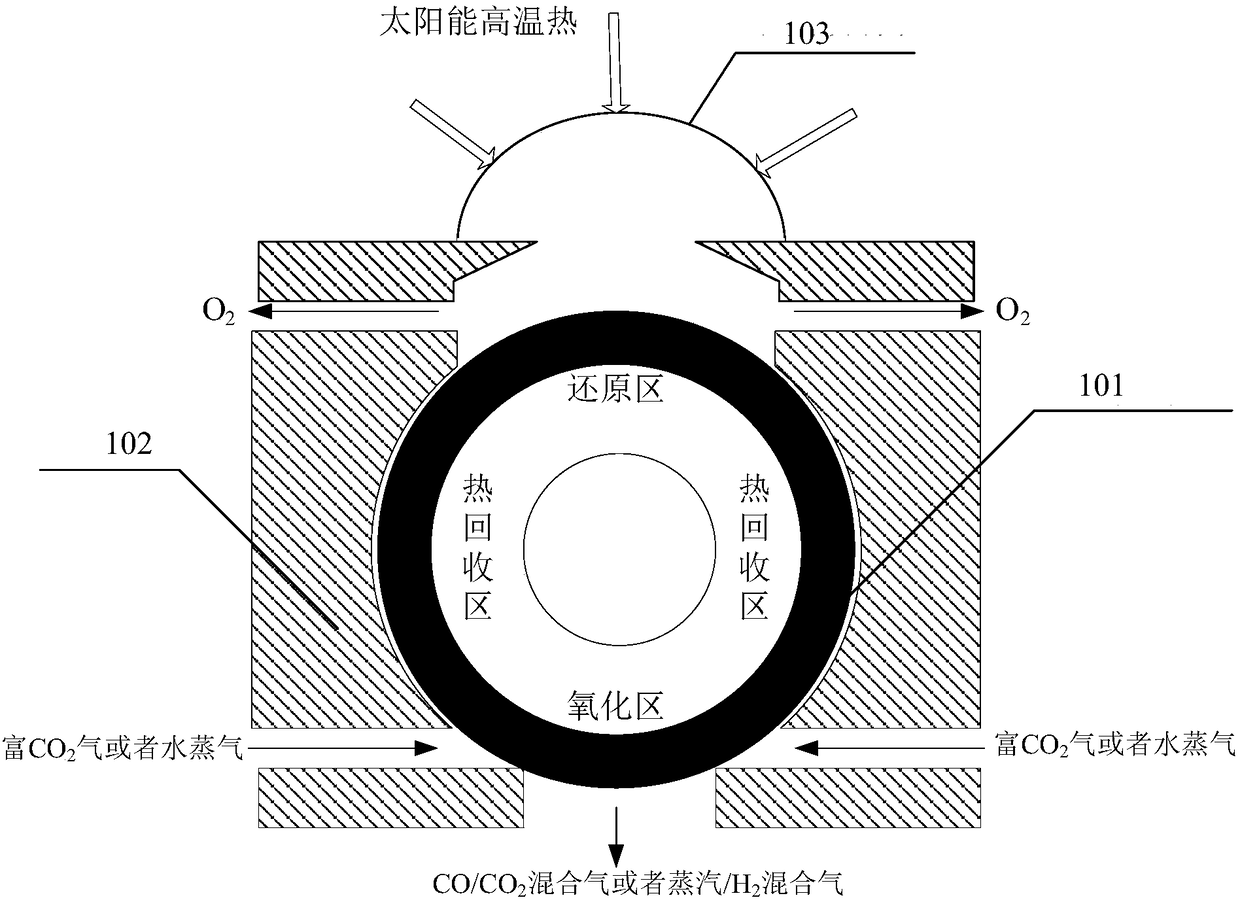

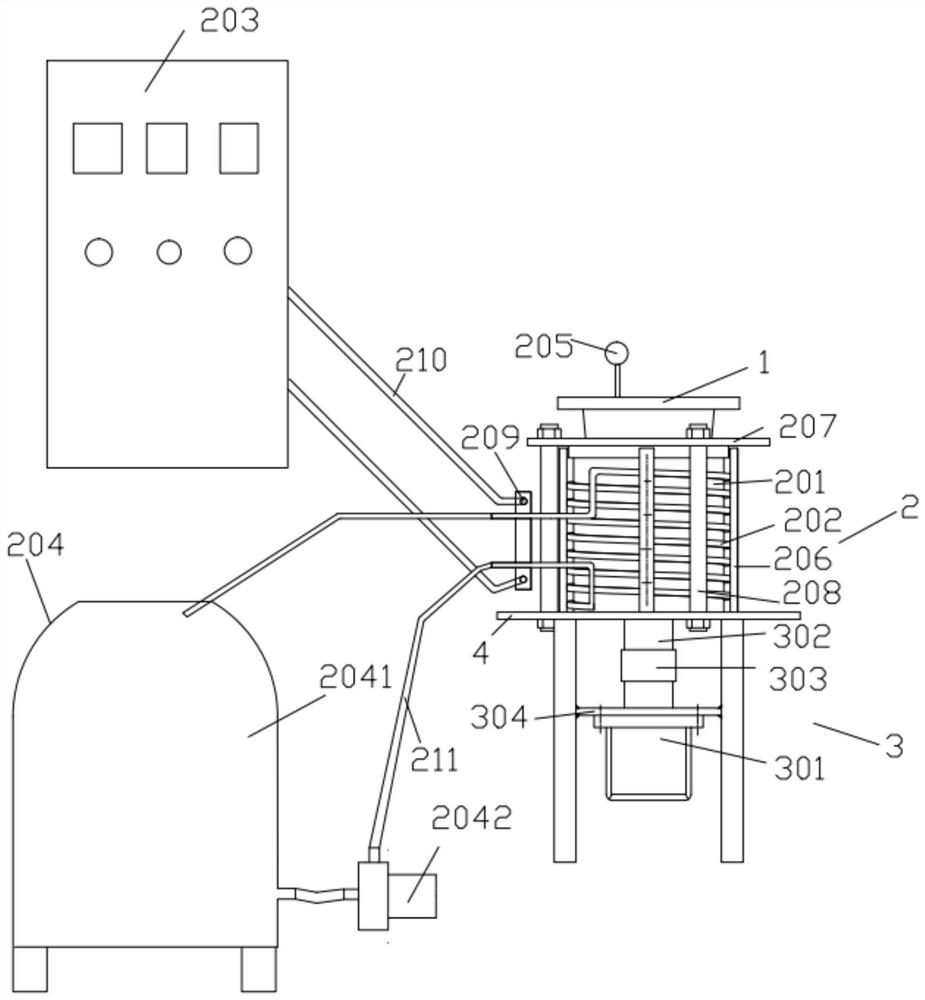

System and method for producing fuel chemicals by conducting solar high-temperature thermal-coupling on methane

InactiveCN108456547AEasy to separateSubsequent separation is simpleOrganic compound preparationChemical industryChemical synthesisCo2 removal

The invention provides a system and method for producing fuel chemicals by conducting solar high-temperature thermal-coupling on methane. The method includes the steps of introducing CO2-enriched gasinto a first high-temperature thermochemical reactor, carrying out a thermochemical decomposition reaction to produce a gas mixture of CO and CO2 and first oxygen under irradiation of first sunlight,and making the gas mixture of CO and CO2 sequentially pass a first temperature reducing device and a CO2 removal device to become CO-enriched gas; introducing water vapor into a second high-temperature thermochemical reactor, carrying out a thermochemical decomposition reaction to produce a gas mixture of water vapor and H2 and second oxygen under irradiation of second sunlight, and making the gasmixture of water vapor and H2 sequentially pass a second temperature reducing device and a dewatering device to become H2-enriched gas; after mixing methane-enriched gas with the first oxygen and thesecond oxygen, carrying out a reaction in a methane partial-oxidation reactor to produce synthesis gas; mixing the synthesis gas, the CO-enriched gas and the H2-enriched gas to be introduced into a fuel chemical synthesis tower for reacting to obtain the fuel chemicals.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

A composite preparation process and equipment for semi-solid metal paste

The invention discloses a composite preparation process and composite preparation equipment for semisolid metal slurry. A weak electromagnetic stirring device and a mechanical stirring device are compounded together to prepare the semisolid metal slurry. Compared with an existing semisolid metal slurry preparation technique, the compound preparation process has the advantages that 1, compared witha rotary magnetic field electromagnetic stirring method, the electromagnetic field can be fully covered to avoid a skin effect and the needed energy consumption is low; 2, compared with a weak electromagnetic stirring method, the stirring force of alloy slurry is enhanced, the time needed to obtain the semisolid metal slurry is shortened, and the efficiency is improved; 3, compared with a mechanical stirring method, no mechanical stirrers are available, so that the defects that the stirrer is corroded and the alloy slurry is polluted are overcome, and meanwhile, the temperature of the slurryis controllable; 4, the composite preparation equipment is simple in structure, low in cost, flexible to control process and convenient to operate; and 5, the composite preparation process solves theproblem of low preparation efficiency of the semisolid slurry in large structural part production in production of large structural parts, the weights of which are over 5 Kg.

Owner:XI AN JIAOTONG UNIV

Amino acid-containing condensate steam stripping system and tail gas treatment method

ActiveCN103785193BReasonable process configurationReduce energy consumptionDistillation regulation/controlSteam distillationReboilerFlash-gas

The invention discloses an amino acid-containing condensate steam stripping system and a tail gas treatment method for solving the problems of an existing steam stripping system that a treatment method is complex, system energy consumption is high, corrosion to pipe plates and pipelines is serious and equipment investment is high. The method comprises the steps of correspondingly feeding high temperature condensate, medium temperature condensate and low temperature condensate to a high temperature condensate stripping section, a medium temperature condensate stripping section and a low temperature condensate stripping section of a stripping tower, respectively, reducing the temperature of stripping gas at a stripping tower top to be 85-90 DEG C through an overhead condenser, and feeding into an incineration furnace, wherein the high temperature condensate stripping section is provided with a reboiler, low-pressure steam used as a heat source is used for carrying out steam stripping to the condensate, the medium temperature condensate stripping section and the low temperature condensate stripping section adopt high temperature flash gas generated by the high temperature condensate stripping section as the heat source, and low-pressure nitrogen gas is introduced for gas stripping. The process is simple, the operation can be controlled flexibly, the system stability is good, energy is saved, the consumption is reduced, the corrosion of the steam stripping system can be reduced to the maximum extent and the service life of the equipment can be prolonged.

Owner:湖北华庆石化设备有限公司

A dual gradient pore structure Sialon bonded silicon carbide membrane tube and its preparation method

ActiveCN105727756BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareTemperature controlMaterials preparation

The invention relates to the field of porous ceramic materials, and specifically relates to a dual-gradient pore-structure sialon and silicon carbide combined membrane tube and a preparation method thereof. The membrane tube material is composed of sialon and silicon carbide. The membrane tube has a dual-gradient filtering structure composed of a support body layer and a surface membrane layer. The support body layer is composed of a combination of sialon produced through a reaction and coarse silicon carbide grains, and has an average pore size of 10-50mum. The surface membrane layer is composed of a combination of sialon produced through a reaction and fine-particle silicon carbide grains, and has an average pore size of 0.1-5mum. An overall porosity of the membrane tube is within a range of 40-50%. The preparation method of the membrane tube sequentially comprises the steps of material preparation, support forming, membrane layer preparation and firing. Isostatic pressing is adopted in the forming step, wherein a forming pressure is controlled at 100-150MPa. The firing temperature is controlled at 1650-1850 DEG C, and a temperature maintaining time is 3-5h. The method is easy to realize. With the method, product performance can be ensured. The membrane tube provided by the invention has the advantages of high application temperature, high acid corrosion resistance and high alkali corrosion resistance. The membrane tube can be used in filtration purification of various fluids with high temperature or low temperature, such as high-temperature high-press gas filtration dedusting, water purification and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Coking waste water treatment method and A/O technology apparatus

InactiveCN102417272BSet the spacing wellThe cracking effect is goodTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentElectrolysisNitration

The invention is an improvement of a coking waste water treatment method. The method comprises steps of oil removal, impurity removal, electrolytic disintegration and A / O technology, and is characterized in that a biological hydrolysis acidification is set after electrolytic disintegration and before A / O technology; the electrolytic disintegration is electrode energizing aerobic strong electrolysis; the A / O technology employs butterfly jet aerators that are arranged in large intervals and have circulating pumps; the waste water is treated with aeration, aeration stopping and forced internal circulation, stationary deposition and water draining period processing successively, so as to realize biological oxidation and nitration-denitrification in a same pool. Cooperative effects and coordination of each technology increase treatment effect, and treated outlet water can stably reach COD no more than 100mg / l and NH3-N no more than 15 mg / l; besides, land occupation is saved undera same treating capacity and is only 80% of that of a common technology; operating cost of per ton of water is low; and a treatment effect is stable.

Owner:江苏新纯江环保工程有限公司

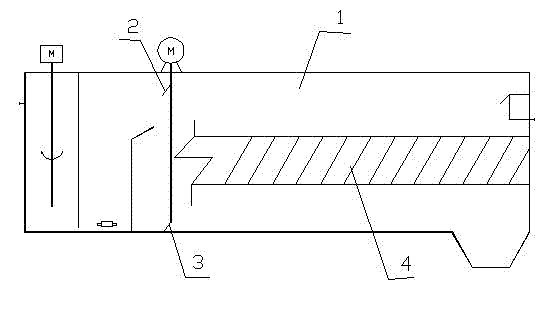

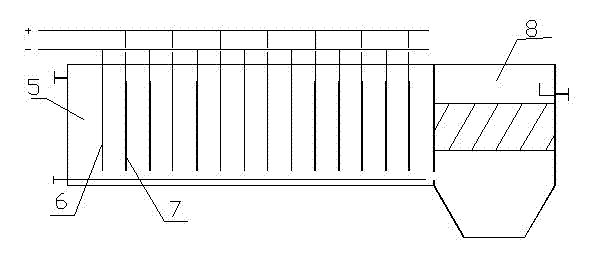

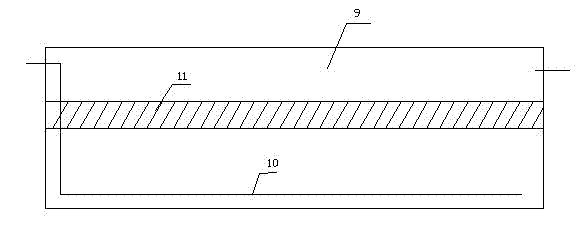

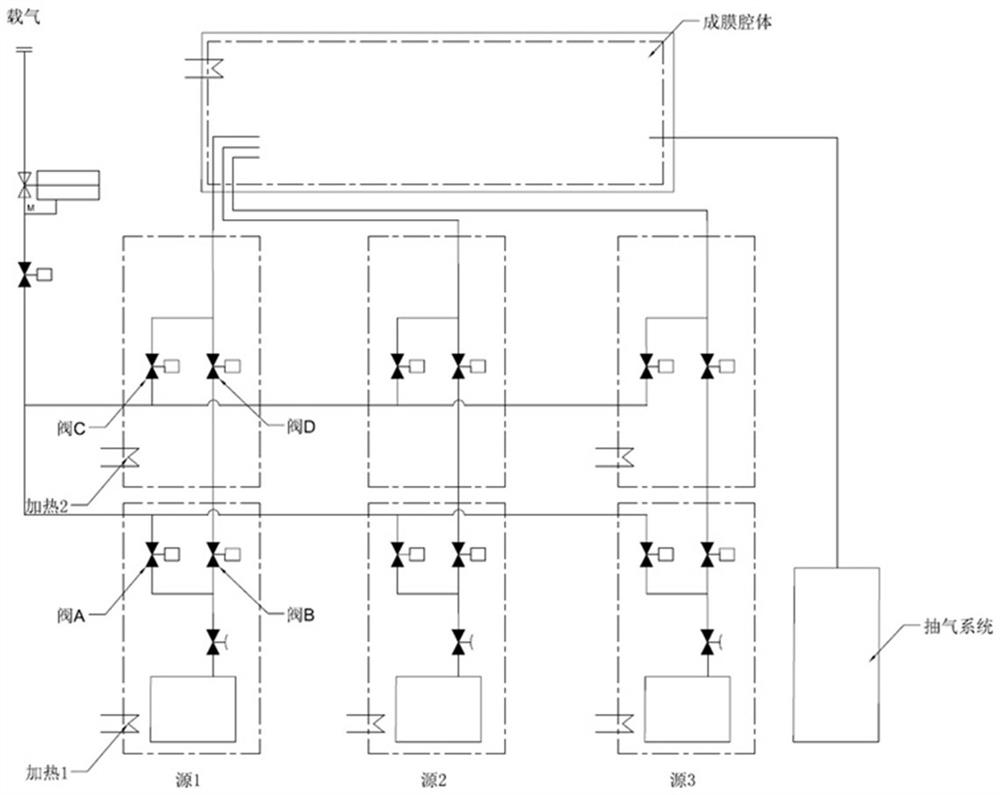

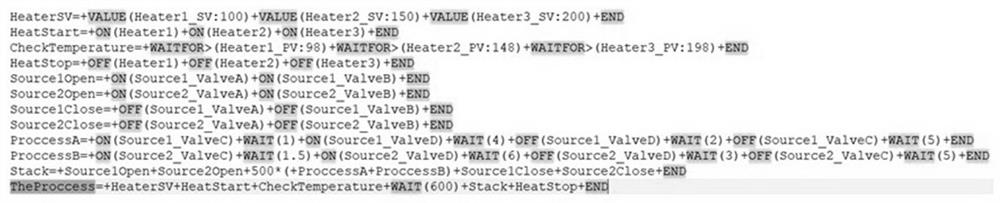

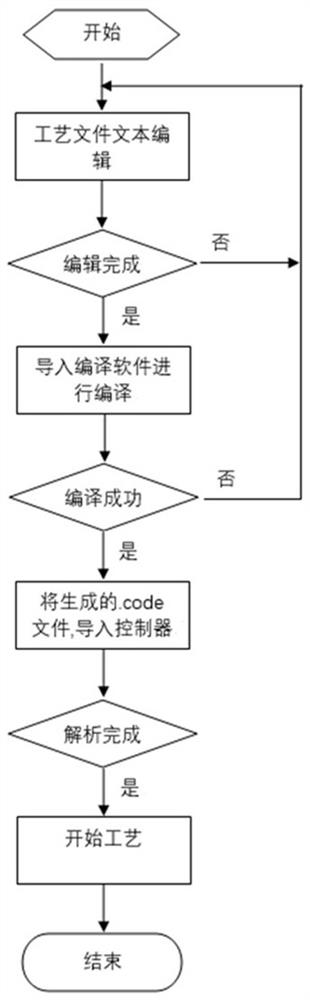

Method for realizing flexible process control of atomic layer deposition coating equipment

InactiveCN112501592AEasy to editImprove readabilityChemical vapor deposition coatingProcess developmentDocument transformation

The invention relates to a method for realizing flexible process control of atomic layer deposition coating equipment. The flexible process control is realized by making a process file for controllinga film forming process of the atomic layer deposition coating equipment. The method comprises the following steps of: recording process information in a process text file mode, wherein the process information can be adjusted by modifying a self-defined text in the process text file; compiling the process text file through a compiler, and converting the process text file containing the process information into a rule file which accords with a program definition of a controller; and identifying and processing the rule file through the controller, and controlling the working state of the atomiclayer deposition coating equipment according to the rule file, so that the atomic layer deposition coating equipment executes the process information contained in the rule file. The method has the advantages that: a process worker directly modifies the process file without modifying a control program, so that error hidden dangers generated in the communication process are avoided, the design and test time of the control program is saved, and the process development efficiency is improved.

Owner:OPTORUN SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com