Method and system for producing sandy aluminum oxide through three-section seed decomposition

A kind of alumina and seed technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of high equipment investment cost, long decomposition process, high operating cost, etc., and achieve high product quality, flexible process control, and high output rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

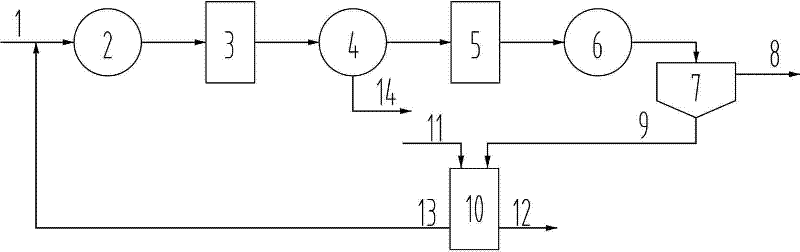

[0017] Embodiment 1: as figure 1 Shown is a flow chart of a method for producing sandy alumina by decomposing seeds in three stages according to the present invention. Semen 1 and seeds 13 are mixed into the decomposition tank 2 of the first stage. The second-stage decomposition tank 4, the coarse particles at the bottom of the tank are sent to the aluminum hydroxide filtration process as aluminum hydroxide products; the fine particles on the upper part of the tank enter the second-stage cooling device 5, and enter the third-stage decomposition tank 6 after cooling. The material enters the settling tank 7 for separation, the separation overflow is to decompose the mother liquor and send it to the evaporation process, and the bottom flow of the separation is sent to the seed filter 10, and the filtered seeds 13 are returned to the decomposition tank 2 of the first stage, and the seed lotion obtained after adding washing water is sent to the grass Salt removal.

[0018] The ab...

Embodiment 2

[0021] Embodiment 2: as figure 1 Shown, except that do not add washing water, do not have seed washing liquid to remove oxalate causticization, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com