Method for producing at least one air product, air separation system, method and device for producing electrical energy

An air separation and product technology, applied in lighting and heating equipment, cold process separation, refrigeration and liquefaction, etc., can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Equivalent components have the same symbols in the drawings and are not described repeatedly for brevity and clarity.

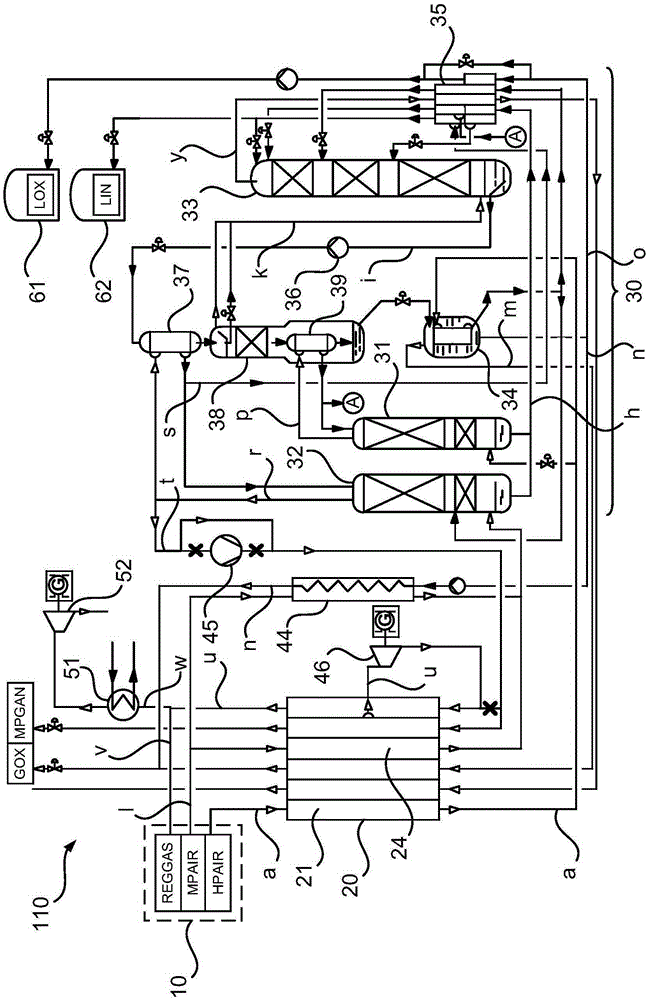

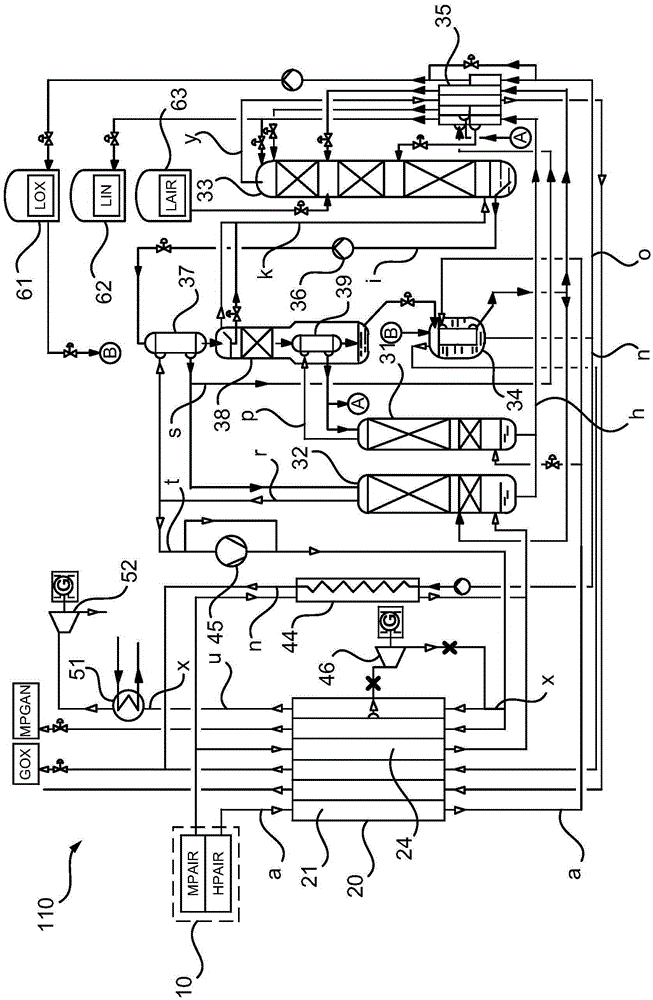

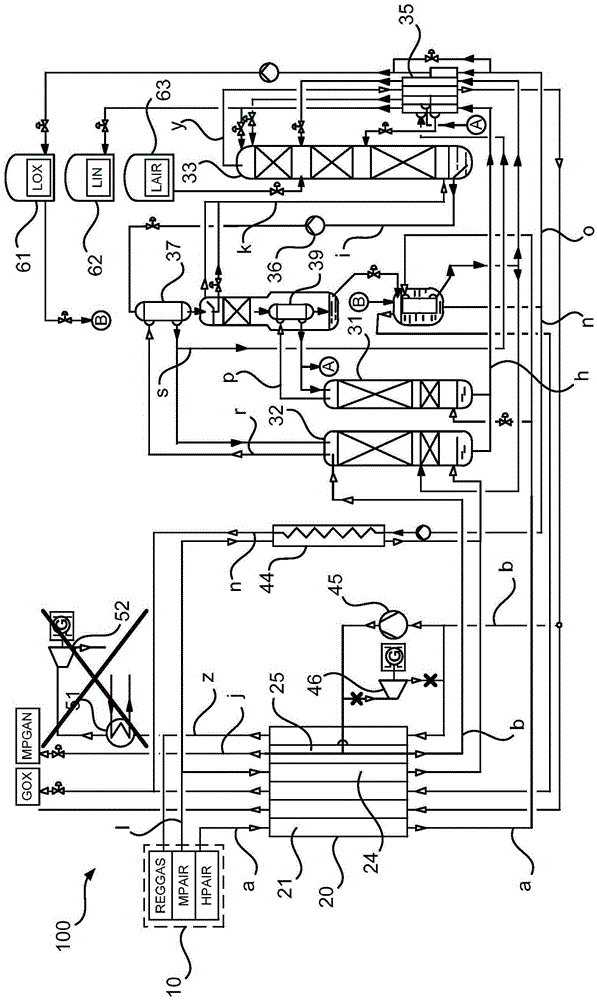

[0061] Figure 1 to Figure 10 Shown are icons of some of the same equipment and its components in different operating modes. The operating modes differ mainly in the position of multiple valves in the corresponding pipelines, so that liquid flow and gaseous flow pass through different equipment components. Valves are not shown. But the blocking line is crossed (-x-).

[0062] figure 1 It is a schematic diagram of an air separation plant 110 not of the present invention. The air separation plant 110 is in figure 1 In the first mode of operation, no substantial amount of liquid air product from an "external source" (such as a storage tank or an air liquefaction plant) is fed into the air separation plant. The icon first mode of operation is used, for example, to generate liquid air products during periods of low electricity prices or excess electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com