Patents

Literature

39results about How to "Increased operating energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon compound coated slow release fertilizer and preparation method thereof

The invention relates to a natural silicon compound coated slow release fertilizer. The slow release fertilizer is prepared by adopting a natural silicon compound as a wrapper, adopting a disc granulation and fluidized bed method, bonding the wrapper to the surfaces of core fertilizer particles through a binder, and enclosing via spraying the external surface with molten wax. The silicon compound comprising Chinese medical stone, natural sands, silica sand and the like contains the silicon element essential to plants, has a density and a good strength, is wrapped on the fertilizer surface to form a compact coat layer, and the compact coat layer is enclosed by strongly lyophobic wax layer, so the slow release performance of a fertilizer is substantially enhanced. After the fertilizer is applied, nutrients are gradually released, natural wax can be completely degraded, and nutrient silicon can also be released by the silicon compound to meet the need of plants, so the secondary pollution problem of routine resin coated fertilizers is overcome. The slow release fertilizer has the advantages of good slow release performance, high hardness, good wear resistance, low cost and environmental protection, and can be widely applied to various plants comprising crops, vegetables, fruits, flowers and lawns.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

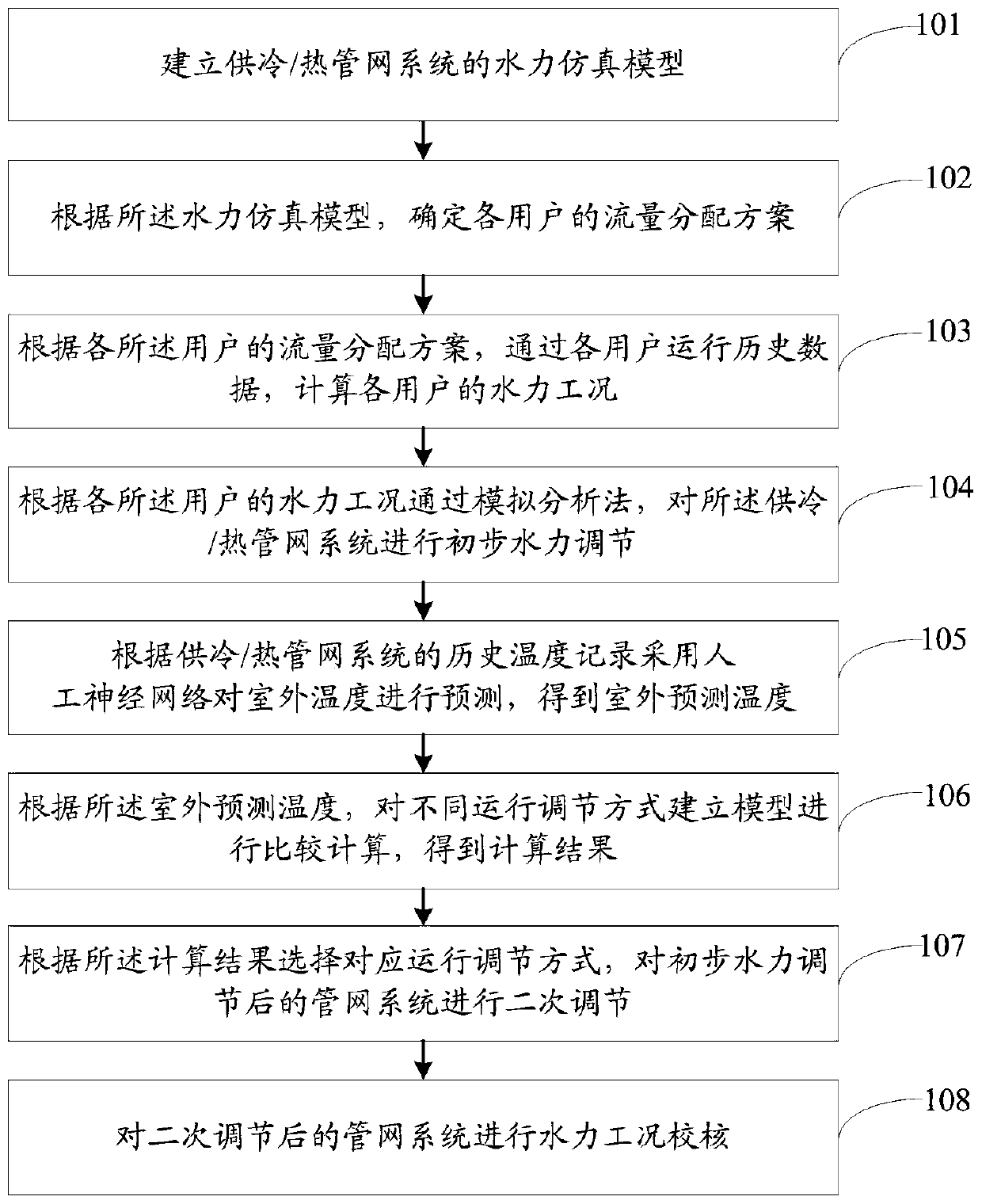

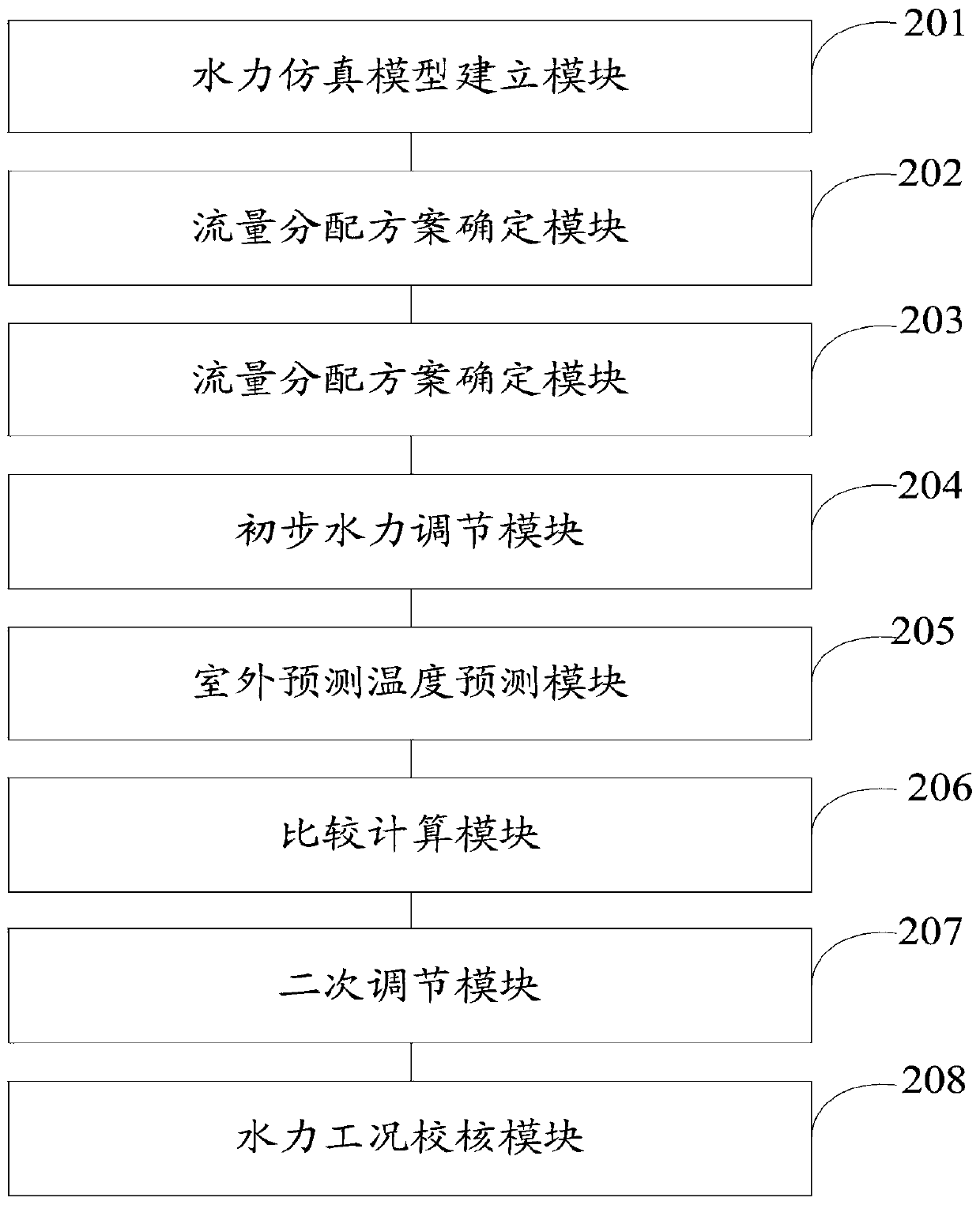

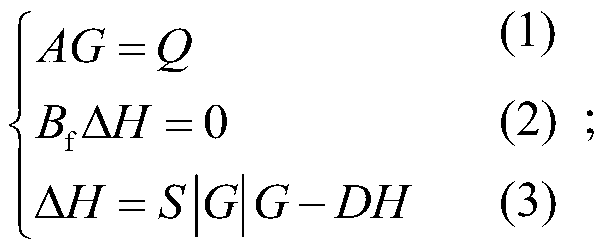

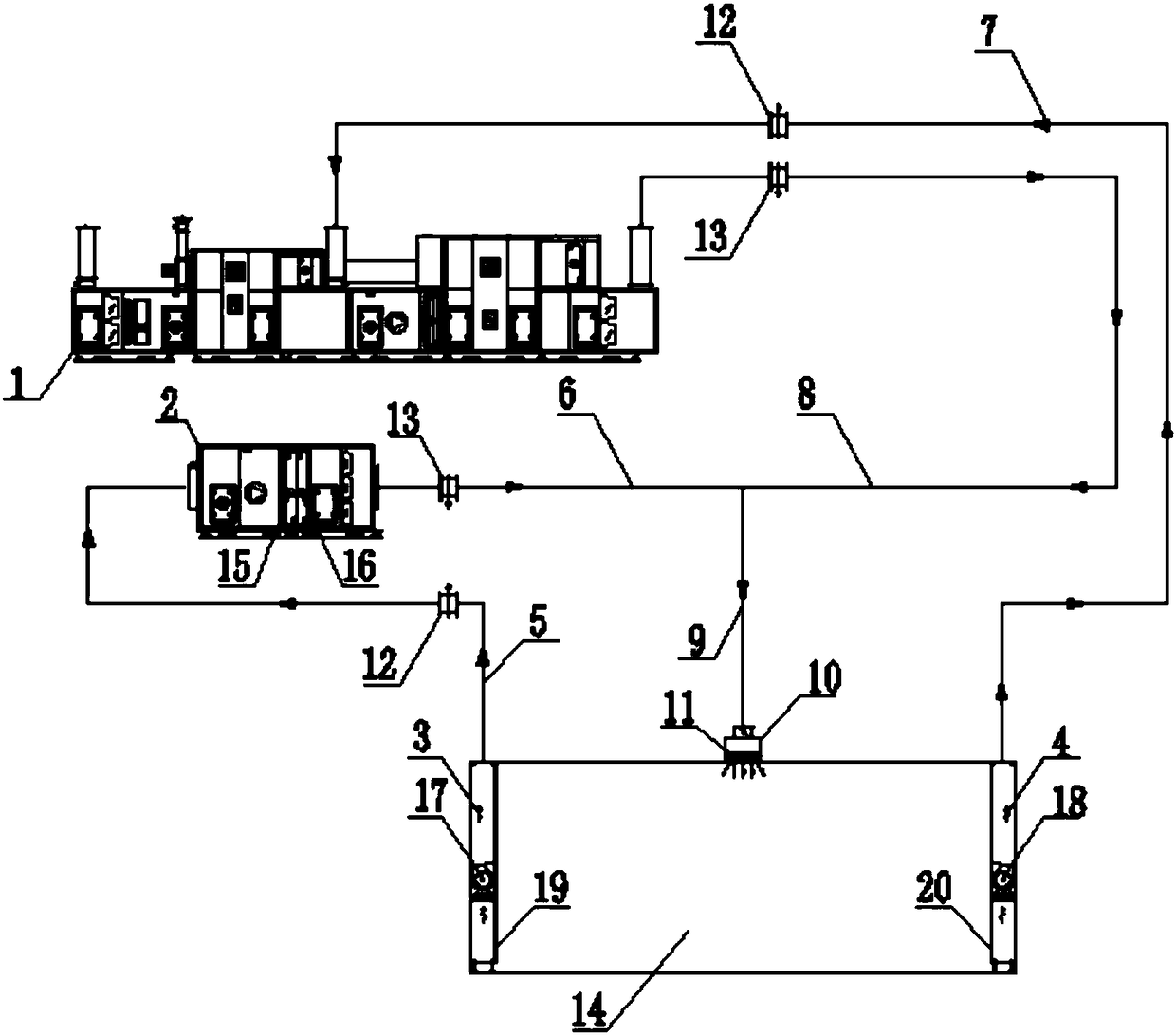

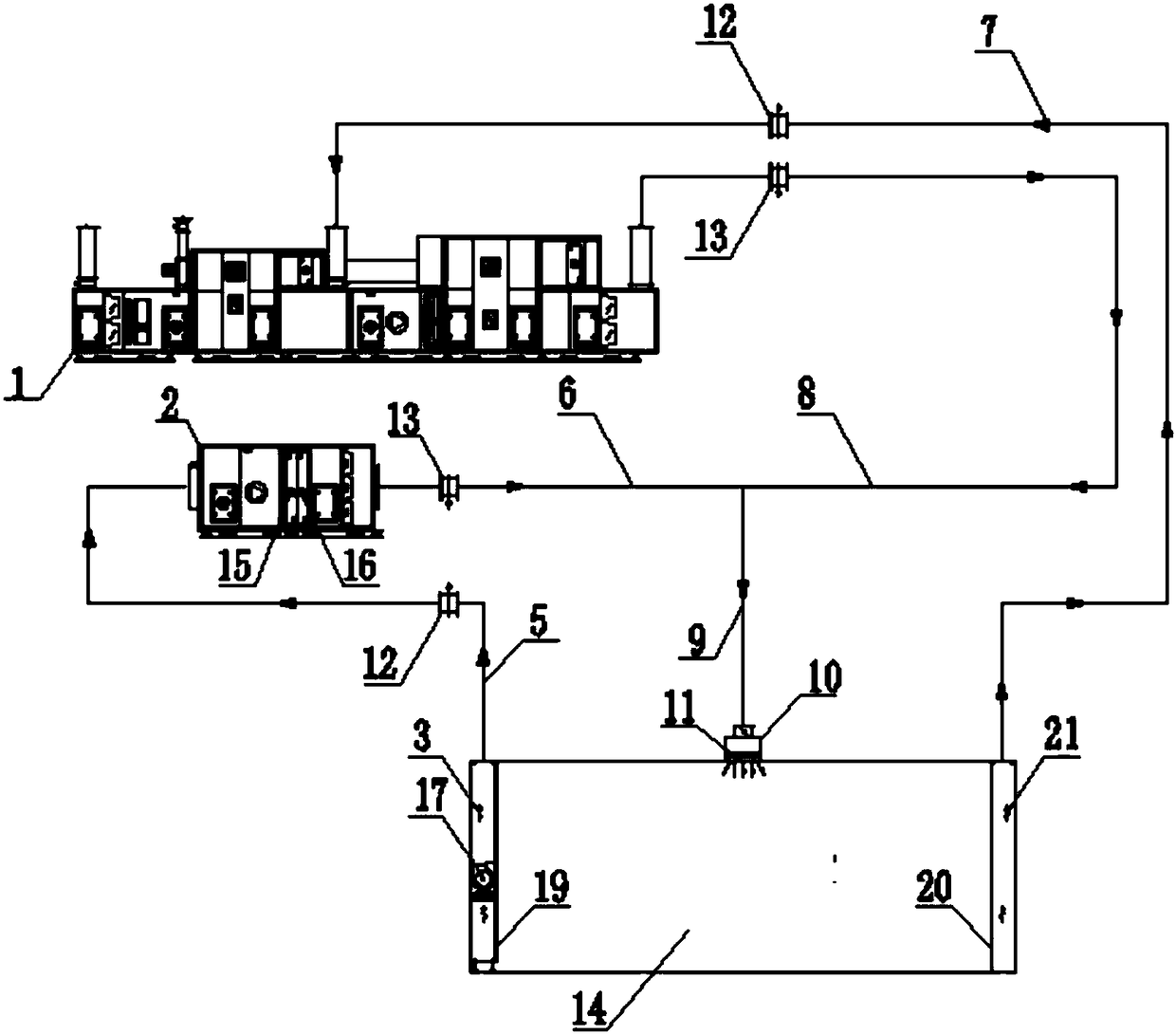

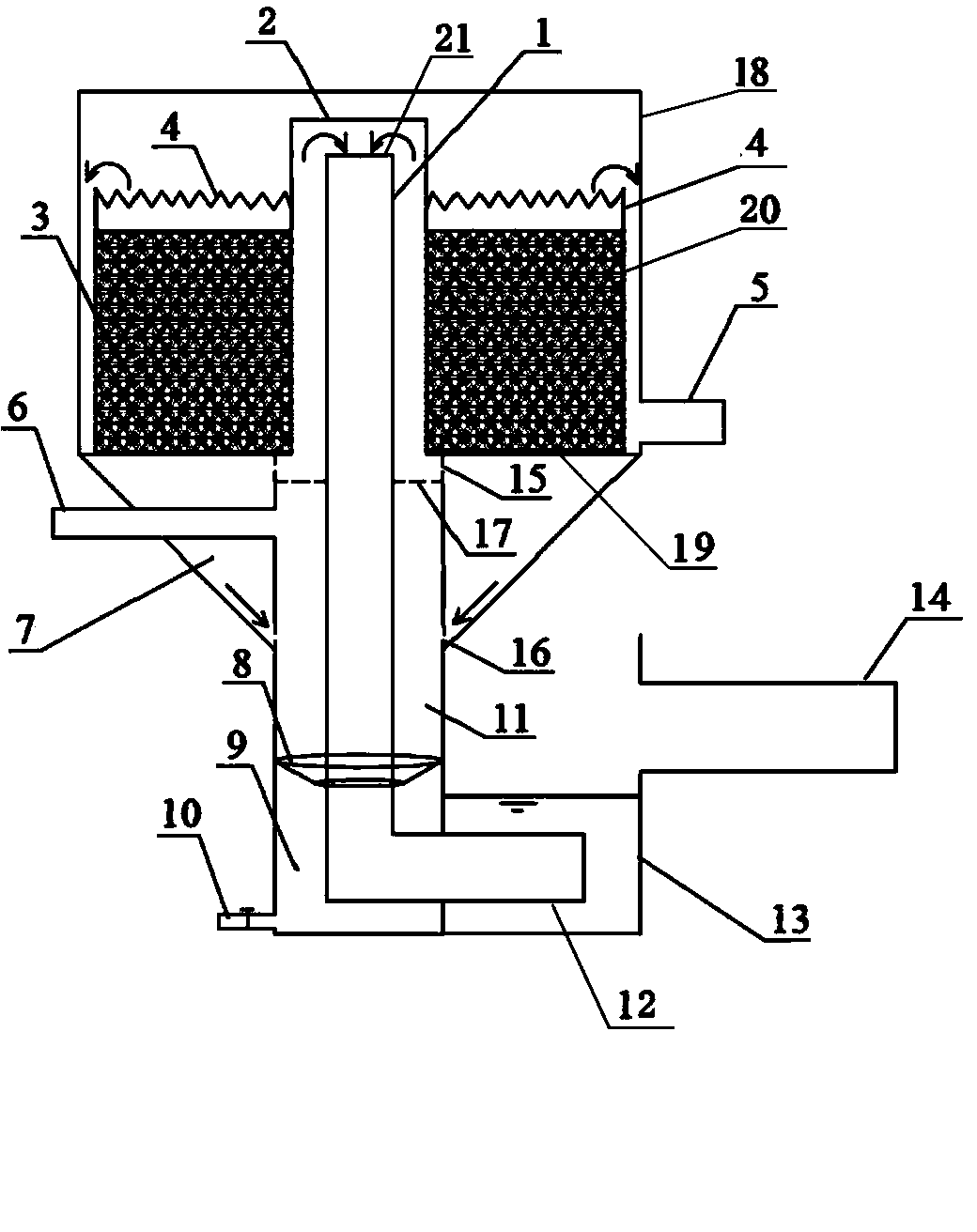

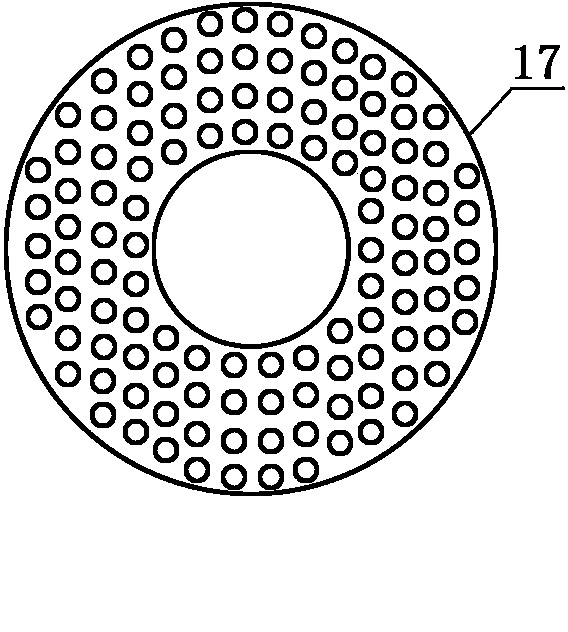

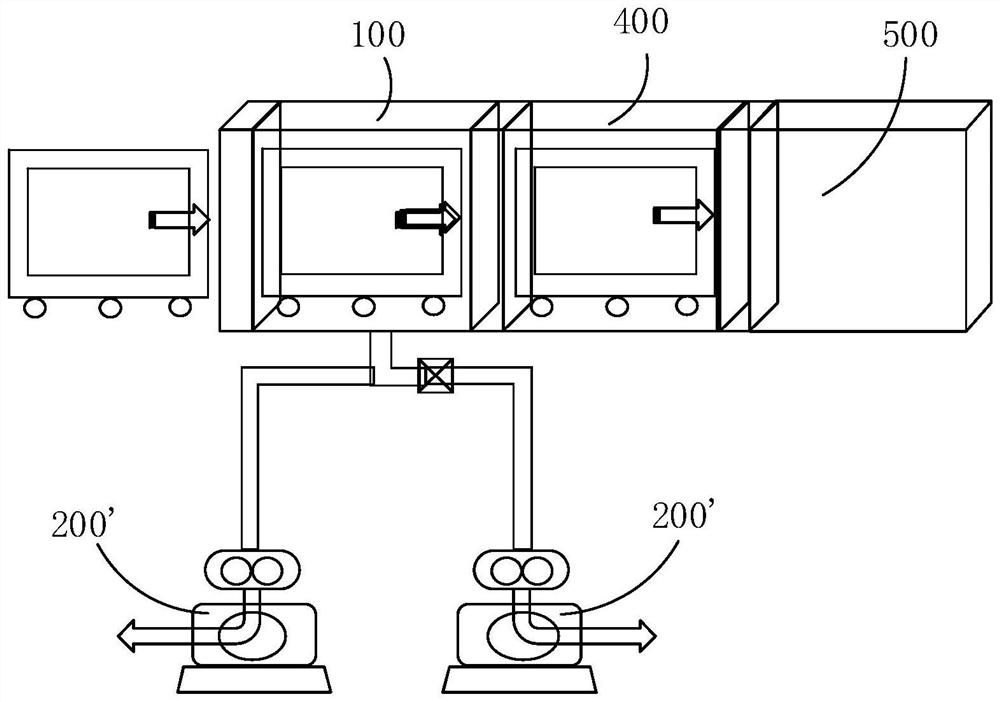

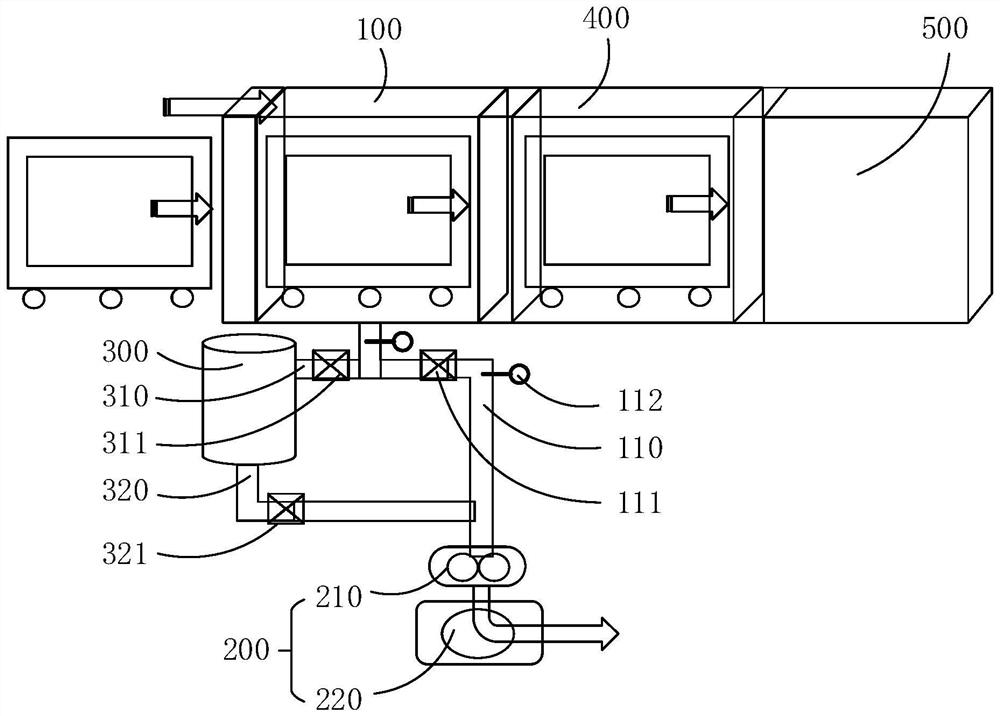

Control method and system for hydraulic disorders of cold/heat supply pipe network

InactiveCN111023224AIncreased operating energy consumptionNo need to change the structureMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention relates to a control method and system for hydraulic disorders of a cold / heat supply pipe network. The method comprises the steps that a hydraulic simulation model of a cold / heat supplypipe network system is set up; the flow distribution scheme of users is confirmed; according to the flow distribution scheme of the users, the hydraulic conditions of the users are calculated throughthe running historical data of the users; according to the hydraulic conditions of the users, primary hydraulic adjustment is carried out on the pipe network through the model analysis method; according to the historical temperature records of the old / heat supply pipe network system, the artificial neural network is adopted for predicating outdoor temperature; according to the outdoor predicated temperature, models are set up for different running adjusting manners to be compared and calculated; according to the calculation result, the corresponding running adjusting manners are selected, andthe pipe network system obtained after primary hydraulic adjustment is adjusted secondarily; and hydraulic condition inspection is carried out on the pipe network system obtained after secondary adjustment. According to the method, on the premise of achieving hydraulic balance of the cold / heat supply pipe network, hydraulic balance adjustment can be completed within a short time after the cold / heat supply system is put into operation.

Owner:珠海横琴能源发展有限公司 +1

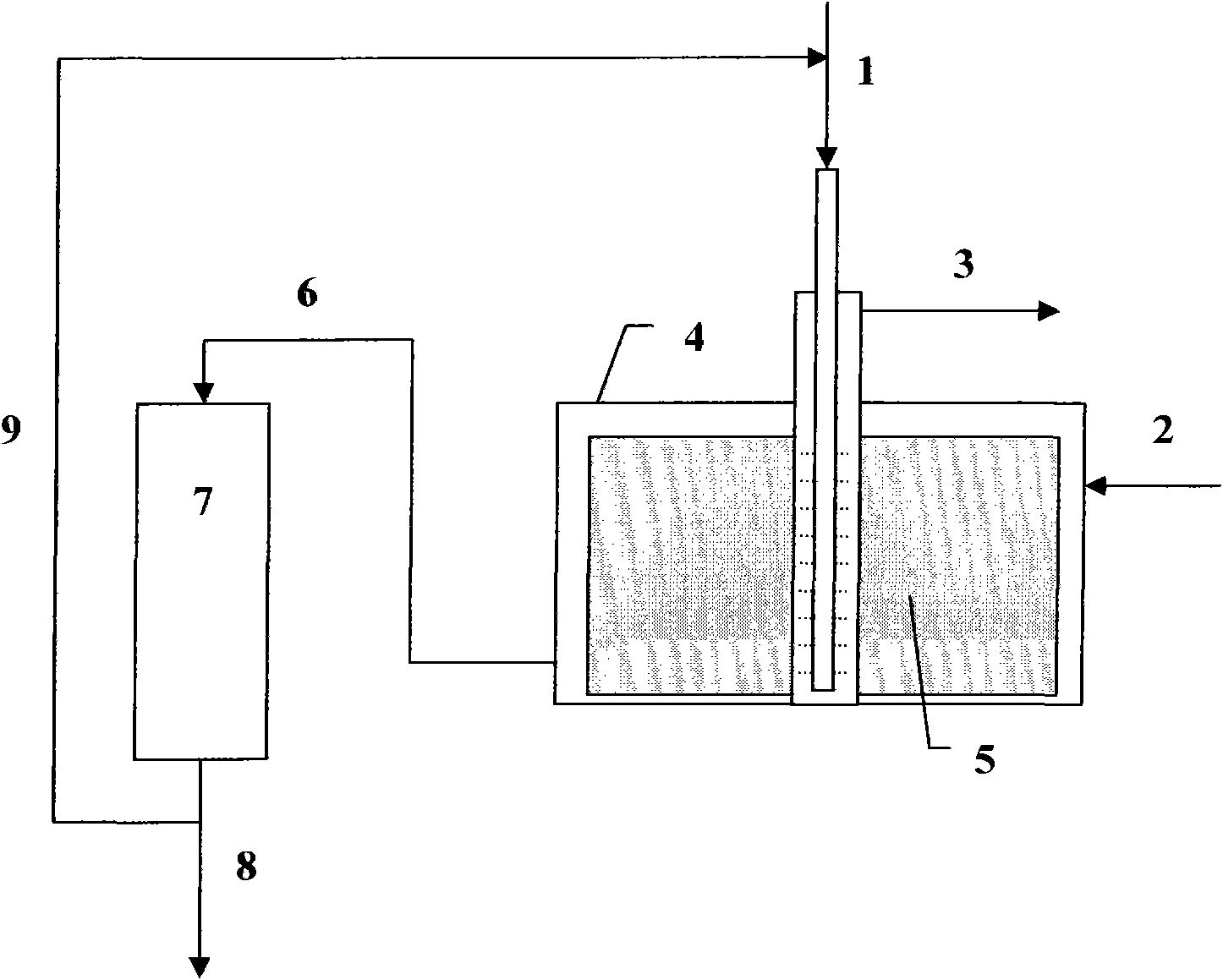

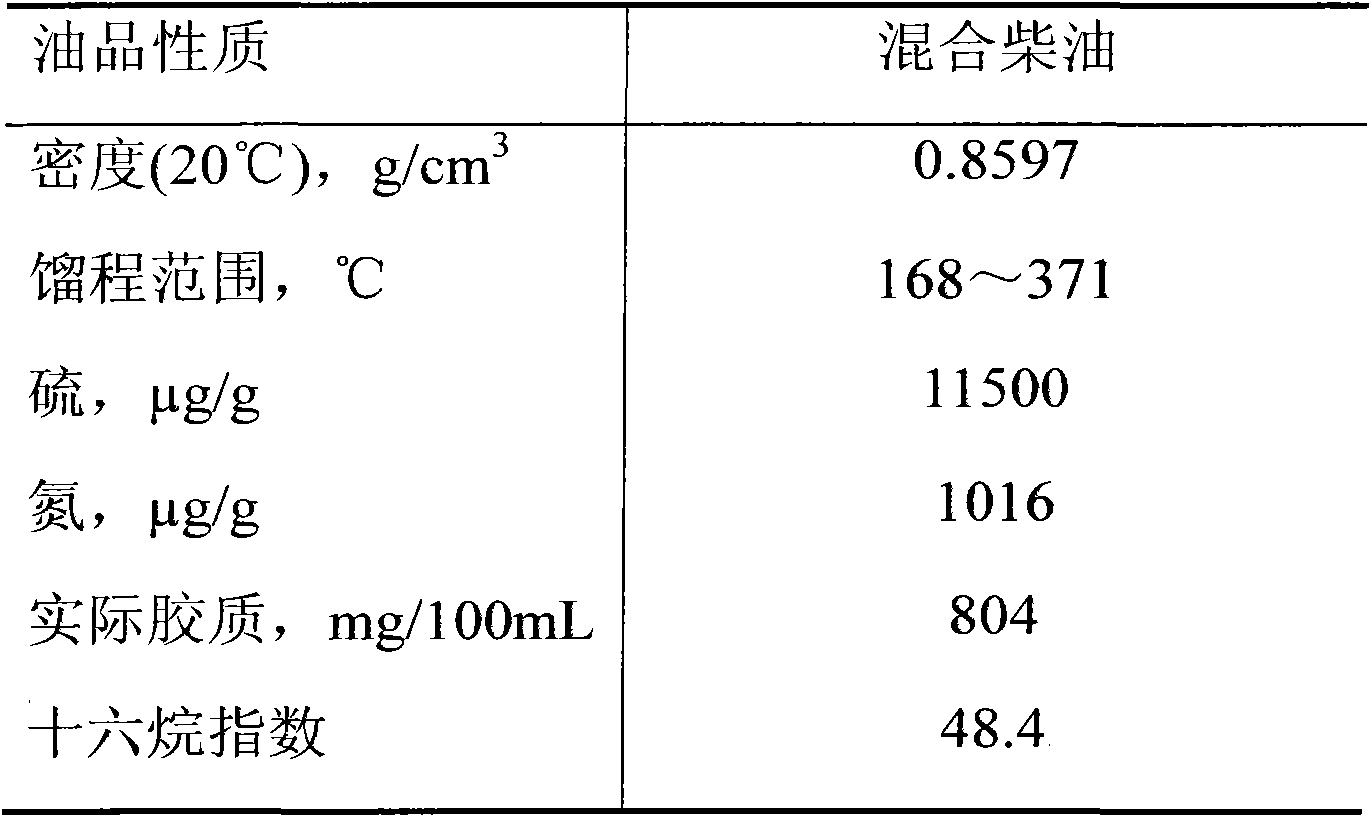

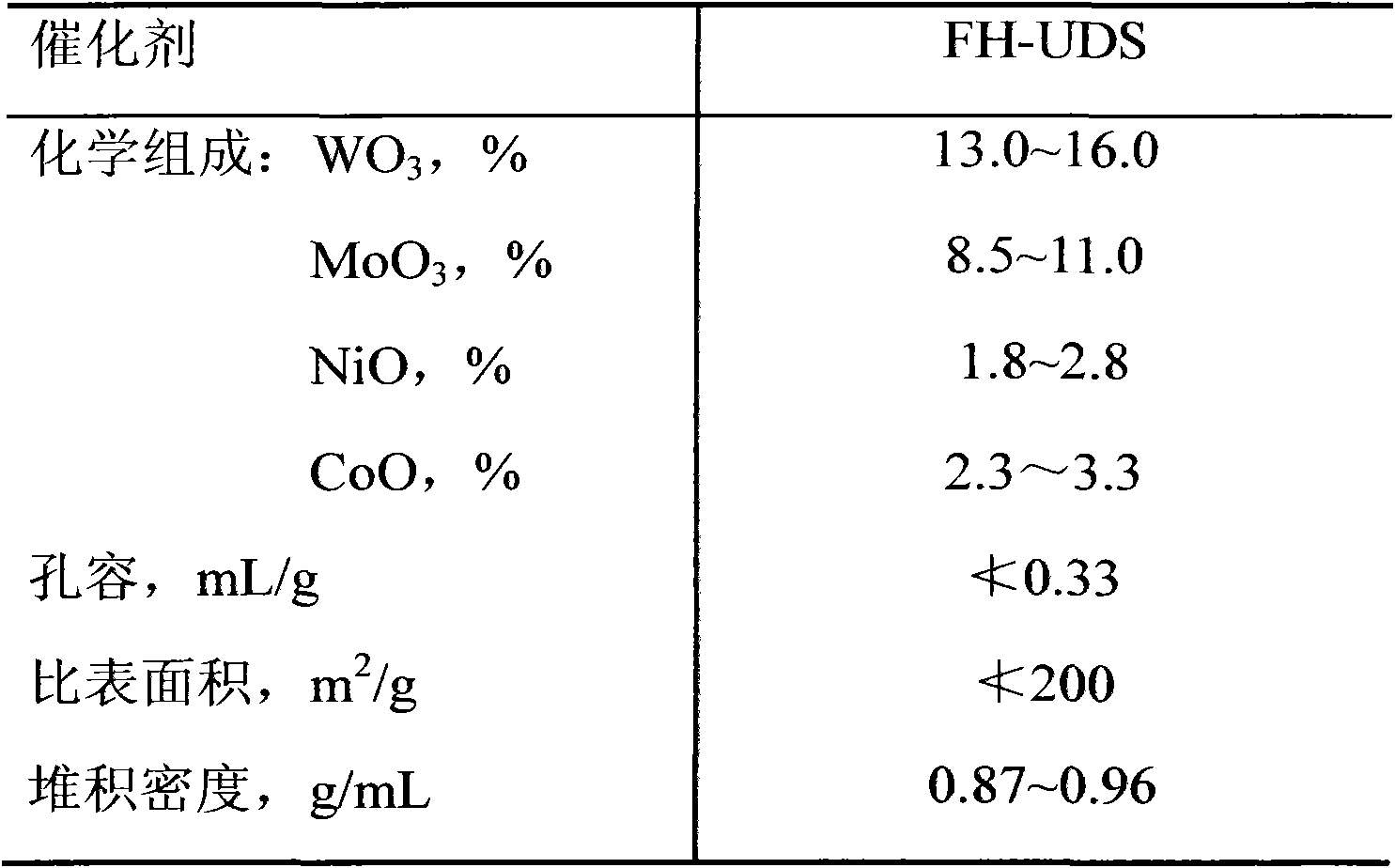

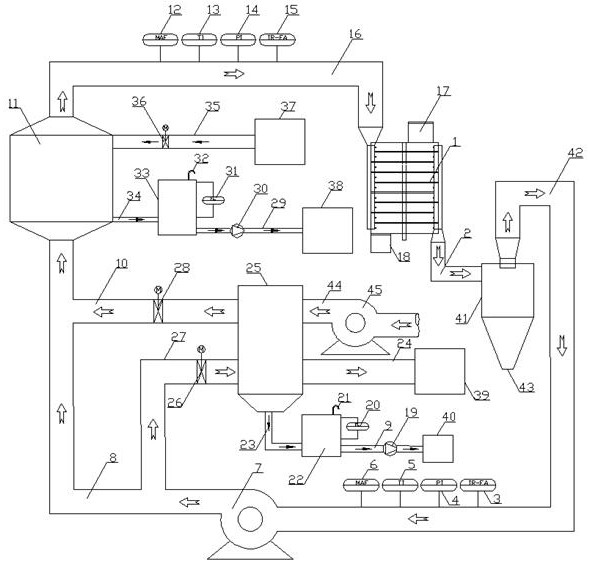

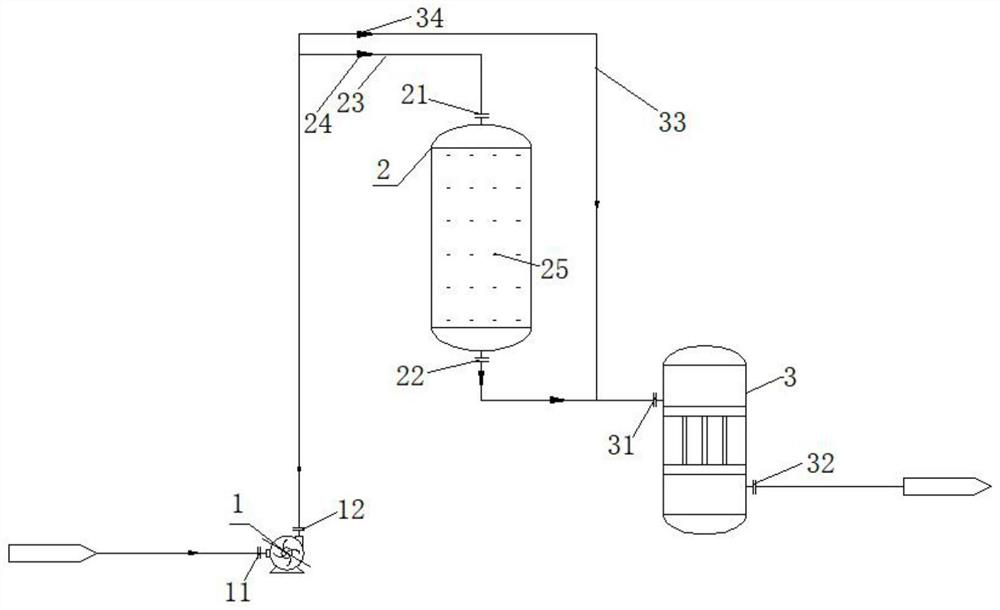

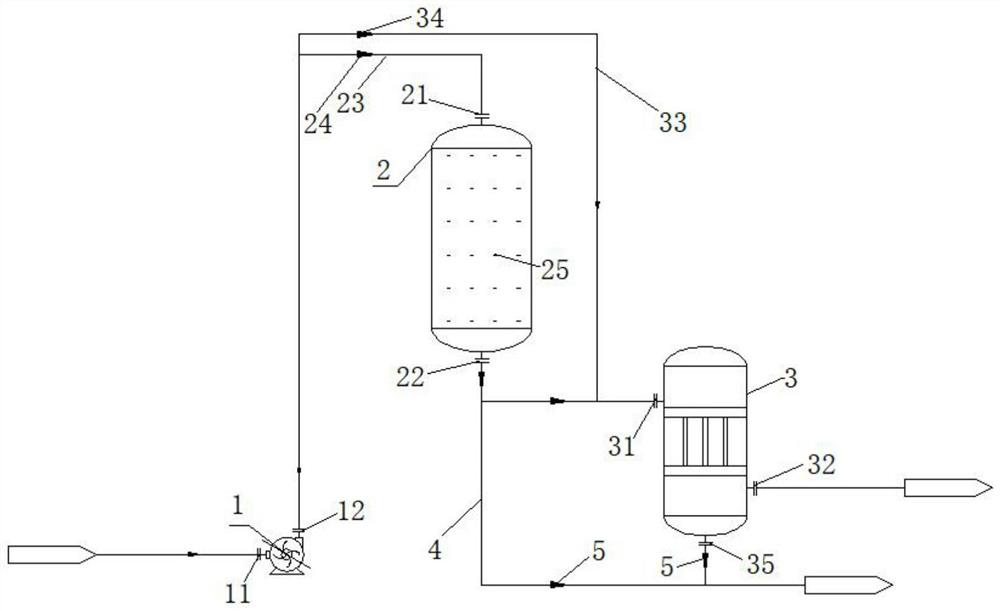

Liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer

ActiveCN102311791AEasy to operateLess investmentTreatment with hydrotreatment processesHydrocarbon oils refiningHydrodesulfurizationMixed materials

The invention discloses a liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer. The process flow adopted by the method comprises: part of hydrogenation circulating oil and a fresh raw material are mixed to form a liquid-phase mixed material to be filled into supergravity gas-liquid hydrogen dissolution equipment together with hydrogen; through the drive of the high-speed rotation of a feeding rotor, gas-liquid countercurrent full contact is formed; the mixed liquid-phase material in which hydrogen is dissolved is discharge out from the bottom of the supergravity gas-liquid hydrogen dissolution equipment and contacted with a catalyst to undergo a hydrogenation reaction, and part of a liquid phase obtained after reaction is circulated. Compared with the prior art, the method has the advantages that: the rotation of the feeding rotor in the gas-liquid hydrogen dissolution equipment forms a supergravity field, so the gas-liquid mass transfer efficiency is increased greatly, and the liquid phase material can fully dissolve hydrogen; meanwhile, gas impurities such as H2S and NH3 in a reaction system can be removed efficiently, so that the hydrodesulfurization, denitrification, aromatic saturation, cracking and other reactions are promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

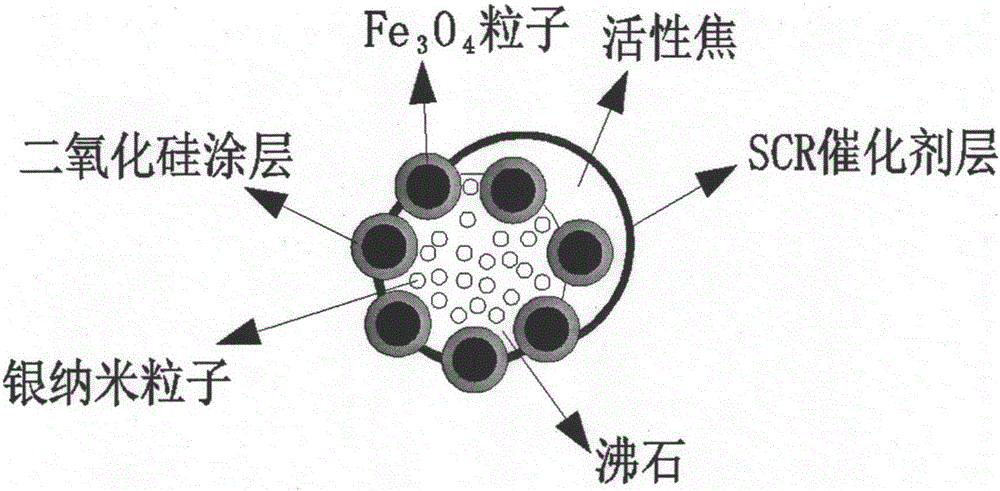

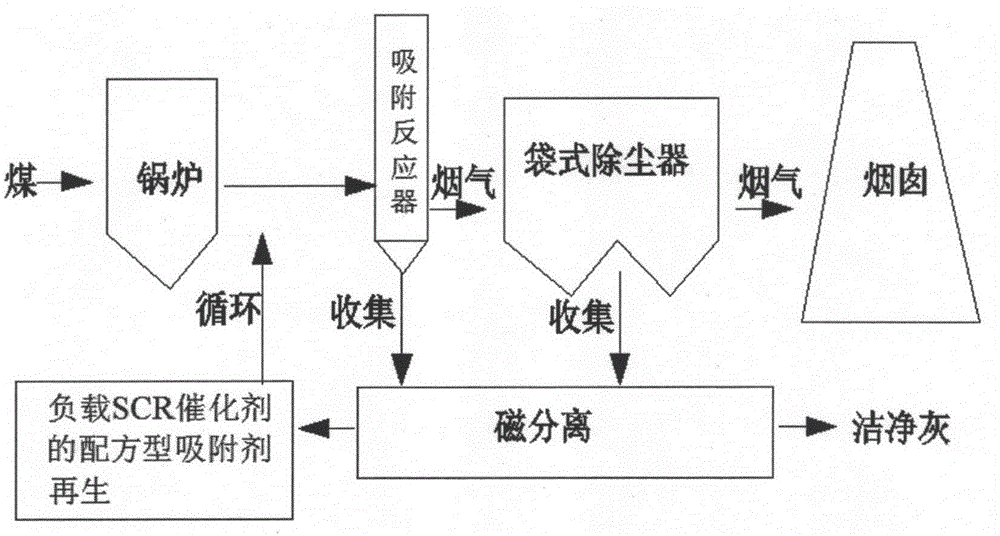

Regeneration technology simultaneously achieving dry desulfurization, denitrification and demercuration by means of formula adsorbent

InactiveCN106475053AEnhance recycling rateLow investment costGas treatmentDispersed particle filtrationSorbentFlue gas

The invention discloses a regeneration technology simultaneously achieving dry desulfurization, denitrification and demercuration by means of a formula adsorbent. The regeneration technology is characterized in that an active coke formula magnetic silver-supported zeolite-supported SCR catalyst is adopted as the adsorbent, flue gas passes through an adsorption reactor, and meanwhile the adsorbent is sprayed into the adsorption reactor from the top of the adsorption reactor; Hg<0>, SO2 and NOx in the flue gas are fully mixed and generate a reaction with the formula adsorbent; a flue gas mixture obtained after a pre-reaction enters a bag-type dust collector, a stable adsorbent precipitation layer is formed on the surface of a filter bag of the bag-type dust collector, and the formula adsorbent continues to remove SO2, NOx and Hg<0> on the precipitation layer; the magnetic formula adsorbent obtained after adsorption can be regenerated. According to the regeneration technology, the advantages of being high in removal rate, low in energy consumption needed by a system and low in equipment cost and operation cost are achieved, the separated adsorbent is higher in purity and better in cyclic utilization effect, and operation of the system is more stable and reliable.

Owner:DONGHUA UNIV

Method for extracting angelica oil from angelica

InactiveCN102911783AImprove solubilityGood solvent propertiesFatty-oils/fats productionEvaporationSight glass

The invention discloses a method for extracting angelica oil. The method is mainly characterized by comprising the following steps of: (1) firstly screening the angelica raw material, cleaning and drying until the water content is less than or equal to 13%, and grinding to 40-60 meshes by a grinder; (2) putting the dried and ground angelica into an extraction kettle, vacuumizing until the pressure is below 1*10<4>Pa, and exhausting the air in the extraction kettle; (3) leading a tetrafluoroethane solution into the extraction kettle by a plunger pump until the angelica raw material is submerged by the liquid level according to the observation through a sight glass; (4) heating and stirring, and starting extraction, wherein the extraction pressure is 0.8-1.5MPa, the extraction temperature is 35-40 DEGE C, each extraction process lasts for 45min, and the extraction is performed twice; (5) performing reduced-pressure heating evaporation and separation in a separation kettle, heating and keeping the separation temperature at 45-50 DEG C, and pumping the negative pressure by a diaphragm compressor to gradually reduce the pressure to 5*10<-2>Pa, wherein each separation process lasts for 30min, and the separation is performed twice; and (6) after the subcritical extraction is over, merging the angelica oil obtained by the extraction twice, performing centrifugal separation by a high-speed centrifuge, and filtering to obtain the final angelica oil product. According to experimental verification, the final yield of the angelica oil under the technological conditions is 2.0%, the content of ligustilide is 62.16%, and the appearance quality of the product is good.

Owner:甘肃省轻工研究院有限责任公司

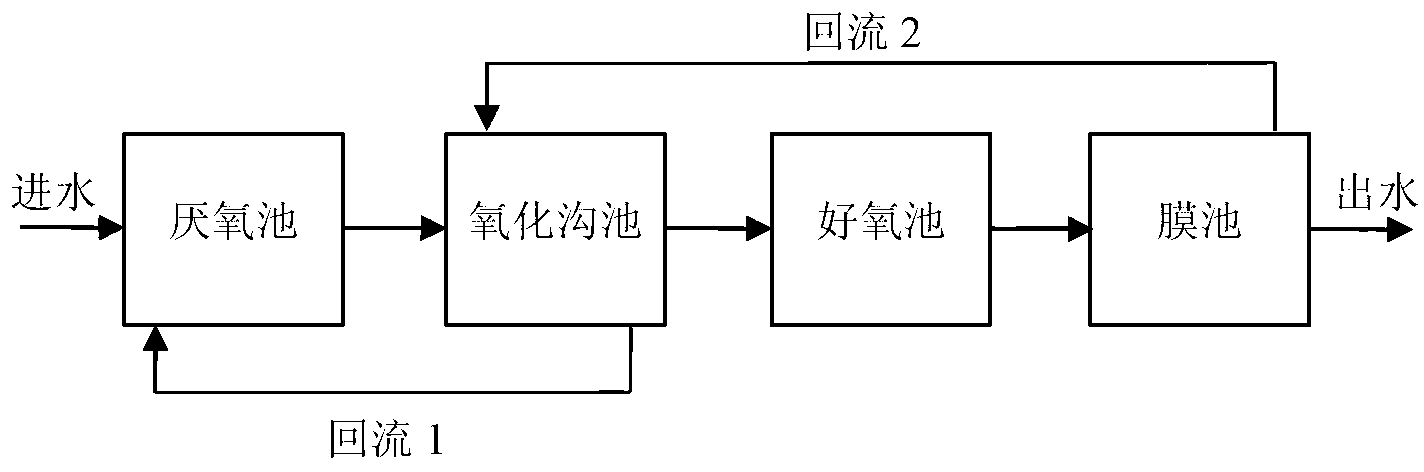

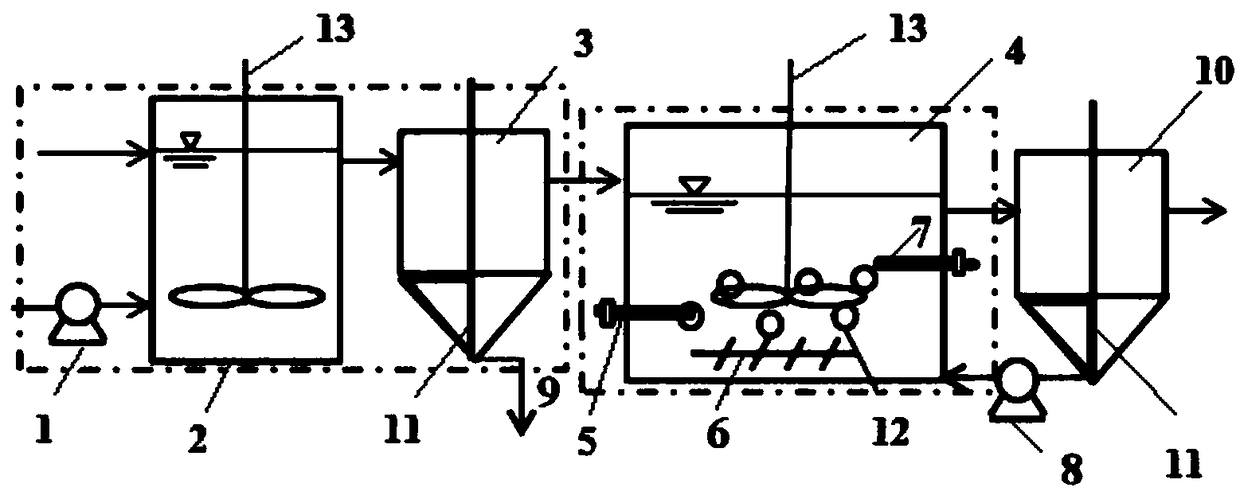

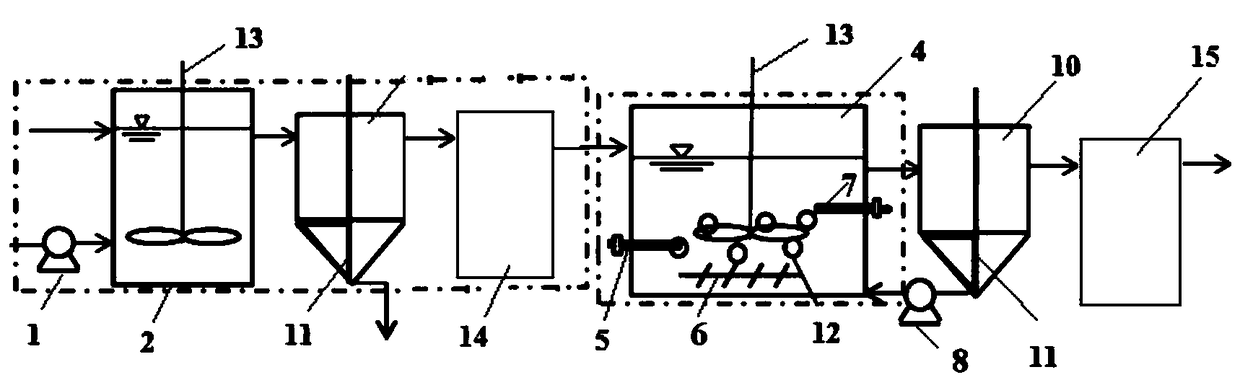

Advanced municipal sewage treatment method

ActiveCN102701547AEfficient removalImprove water qualityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationNational level

The invention relates to an advanced municipal sewage treatment process which comprises the flows of anaerobic pool, oxidation ditch pool, aerobic pool and MBR (membrane bioreactor) membrane pool. The process has two backflow paths: oxidation ditch pool-anaerobic pool and membrane pool-oxidation ditch pool. The pretreated municipal sewage flows through the anaerobic pool, the oxidation ditch pool, the aerobic pool and the membrane pool in sequence, and finally undergoes membrane filtration to obtain treated water. When the process is used for treating municipal sewage, extra addition of carbon source and phosphorous removal drug is not needed, the total nitrogen removal rate and the total phosphorous removal rate can be up to 95% at the same time, the total nitrogen concentration of effluent is less than 5mg / L, the total nitrogen concentration is less than 0.3mg / L, and the other indexes satisfy the national level-I A discharge standard. In the prior art, the total nitrogen removal rate is 62-80% in general, and the total phosphorous removal rate is 70-96.2% in general.

Owner:BEIJING ORIGINWATER TECH CO LTD

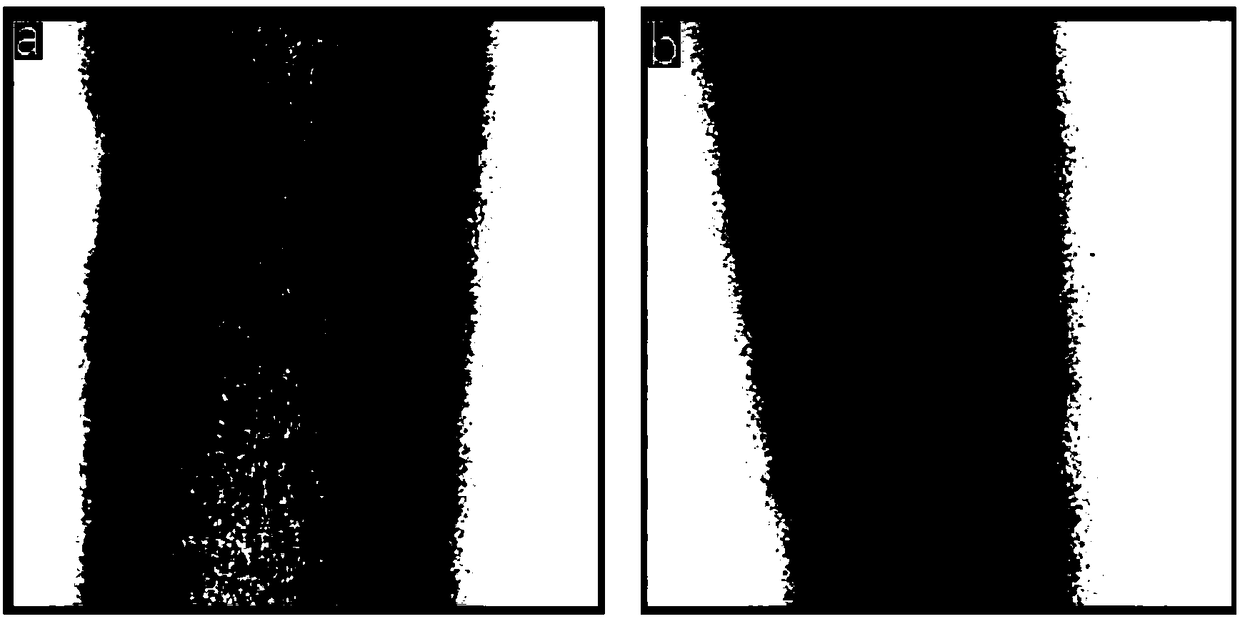

Operation method of hollow fiber membrane module

ActiveCN109420433AAvoid driftingAvoid blind areasUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre membrane

The invention relates to an operation method of a hollow fiber membrane module. The operation method comprises the following steps: performing the forward washing at a primary side, performing the membrane filtering of raw water, and performing the back washing for water produced by the filtering of the secondary side, wherein the forward washing at the primary side comprises liquid-phase flow orgas / liquid mixed-phase flow washing. By adopting the operation method, the excellent turbid discharging performance of the module is ensured, while the broken problem of a membrane wire can be effectively prevented. The module has a rectifying effect of fluid flowing by the outer side of a hollow fibrous membrane towards a central part of a radial direction at the lower side of an irrigation filling part of a water production end and flowing from the center part of the radial direction at the lower side of the irrigation filling part of water production to the outer side of the radial direction in a radioactive manner when in the primary side forward washing. By adopting the operation method of the hollow fiber membrane module, the bias flow phenomenon of the upper part of the module in case of the primary side forward washing can be effectively prevented, and the turbid discharging performance of the module can be further improved.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

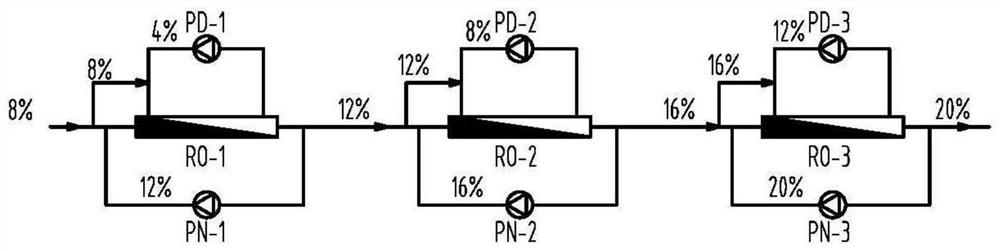

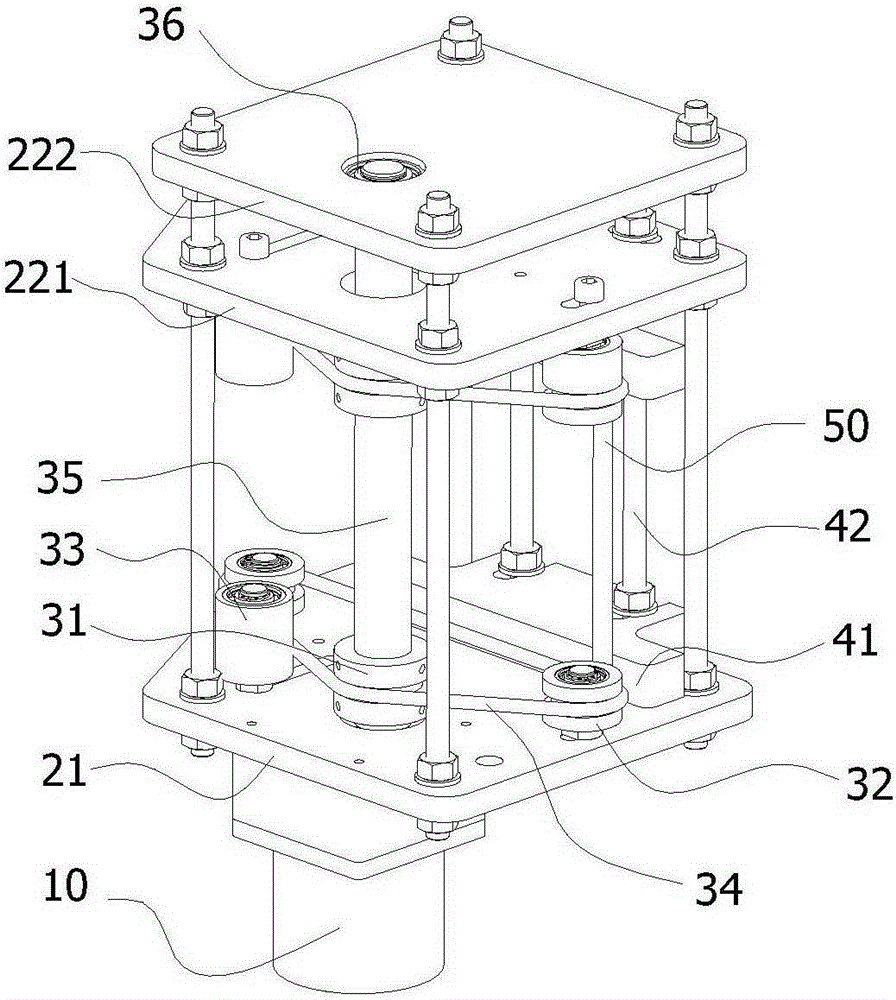

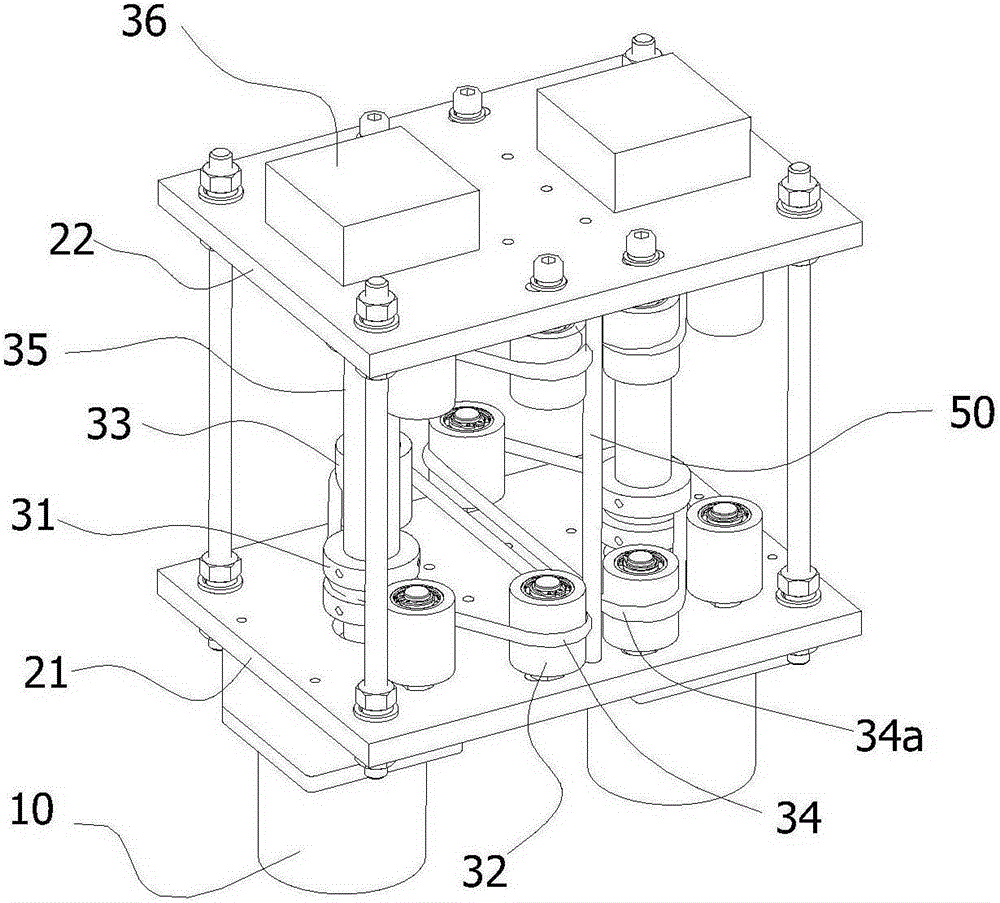

Reverse osmosis system for seawater desalination

PendingCN113354032AIncrease the number of reverse osmosisIncrease water production rateGeneral water supply conservationSeawater treatmentWater productionEngineering

The invention discloses a reverse osmosis system for seawater desalination. The reverse osmosis system comprises a reverse osmosis unit RO-1, a reverse osmosis unit RO-2 and a reverse osmosis unit RO-3 which are sequentially connected through pipelines, wherein a fresh water circulating pump PD-1 is mounted on the fresh water side of the reverse osmosis unit RO-1, so that fresh water is circulated; a concentrated water high-pressure pump PN-1 is mounted on the concentrated water side of the reverse osmosis unit RO-1 and can pressurize concentrated water and circulate the concentrated water; a fresh water circulating pump PD-2 is mounted on the fresh water side of the reverse osmosis unit RO-2, so that fresh water is circulated; a concentrated water high-pressure pump PN-2 is mounted on the concentrated water side of the reverse osmosis unit RO-2 and can pressurize concentrated water and circulate the concentrated water; a fresh water circulating pump PD-3 is mounted on the fresh water side of the reverse osmosis unit RO-3, so that fresh water is circulated; and a concentrated water high-pressure pump PN-3 is mounted on the concentrated water side of the reverse osmosis unit RO-3 and can pressurize concentrated water and circulate the concentrated water. When the reverse osmosis system for seawater desalination is used for treating seawater, the water production rate can reach 80% or above, the concentration of concentrated water can reach 20% or above, the operation is safe, and the energy consumption is lower.

Owner:SHANGHAI YUKE ENVIRONMENTAL ENG CO LTD

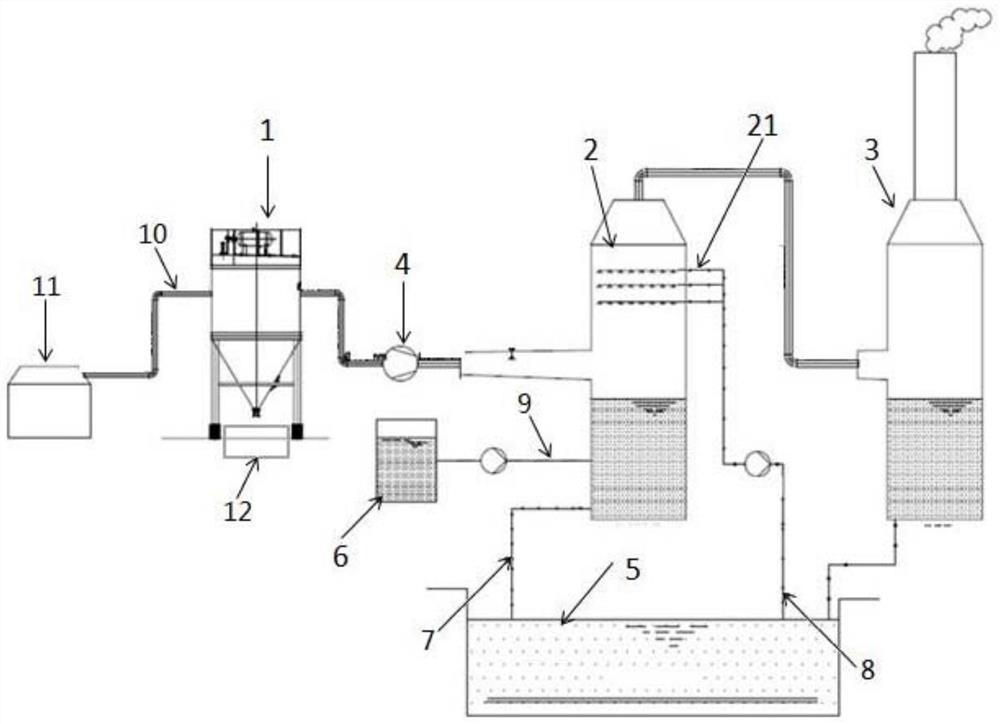

Treatment method and device for flue gas of rare earth electrolytic cell

InactiveCN112206600AIncreased operating energy consumptionIncreased risk of sinkingGas treatmentDispersed particle filtrationAir volumeAir velocity

The invention discloses a treatment method and device for flue gas of a rare earth electrolytic cell. The device comprises a bag-type dust collector, an induced draft fan, a desulfurization and defluorination tower and a demisting tower which sequentially communicate with each other through a pipeline. The method comprises the following steps: conducting dust removal through cooperation between the bag-type dust collector and the induced draft fan, wherein the filtering air speed of the bag-type dust collector ranges from 0.3 m / min to 2.5 m / min, and a treatment air volume ranges from 850 m<3> / h to 4600 m<3> / h; introducing the dedusted flue gas into the desulfurization and defluorination tower; introducing the flue gas treated by the desulfurization and defluorination tower into the demisting tower, and directly discharging tail gas obtained after treatment by the demisting tower into the atmosphere. According to the invention, the technological parameters of dust removal are designed according to energy balance of the electrolytic cell, stable operation and production of the electrolytic cell are guaranteed, operation energy consumption of the electrolytic cell is not increased, the dust concentration of an outlet of the bag-type dust collector is smaller than or equal to 5 mg / m<3> and far lower than the emission standard that a dust concentration is smaller than or equal to 50mg / m < 3 >, rare earth raw materials can be recycled to the maximum extent, and production cost is saved.

Owner:中铝郑州有色金属研究院有限公司 +1

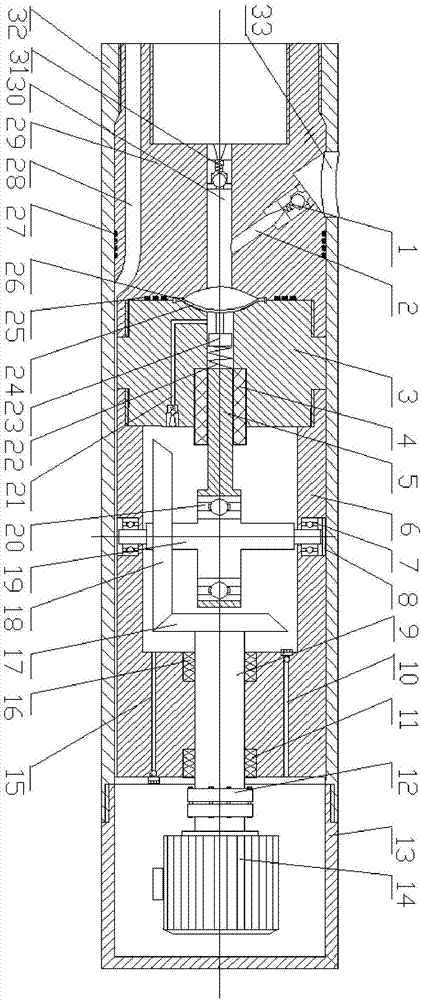

Downhole oil-submerged diaphragm pump

InactiveCN107023458AExtended service lifeIncrease manufacturing costFlexible member pumpsFluid removalEngineeringPressure increase

The invention discloses a downhole oil-submerged diaphragm pump. An electromotor rotates to drive a conic small gear and a conic large gear to rotate through a coupling and a transmission shaft. A reducing mechanism is formed by the two conic gears. After power is decelerated and converted through the reducing mechanism, an eccentric shaft is driven to drive a connecting rod plunger to do reciprocating motion, and rotating motion of the electromotor is converted into the reciprocating linear motion of the connecting rod plunger; when the connecting rod plunger does up-and-down reciprocating linear motion, hydraulic oil is pushed for pressure increase, and a diaphragm transmits pressure to a working medium of a diaphragm cavity; and a drain valve is opened when the working medium is pressed, the medium is drained, meanwhile, a liquid inlet valve assembly is closed, and suction and drainage of the working medium are achieved in a reciprocating manner in this way. Intelligent, efficient, energy-saving, safe and reliable continuous oil extraction can be achieved in a low-yield well with complex well conditions.

Owner:吉效科

Novel air medium type sludge drying system

PendingCN112661383AScientific and reasonable structureEasy to useSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeHot blast

The invention discloses a novel air medium type sludge drying system which comprises a sludge drying machine, the bottom end of the sludge drying machine is connected with an air outlet duct, the air outlet duct is connected with an inlet of a cyclone dust collector, the top end of the cyclone dust collector is connected with a circulating air return duct, and the bottom end of the cyclone dust collector is connected with an ash discharge port. The circulating air return duct is connected with the inlet of a circulating fan. The sludge drying system is scientific and reasonable in structure and safe and convenient to use, a closed hot air circulation sludge drying system is adopted, a hot air heating system with electricity or steam as a heat source is high in operation energy consumption, a system with a heat pump as a hot air heating device is complex in structure, a waste gas condensation system generates a large amount of condensed waste water, and the treatment cost is high; in addition, components and flow of the hot air can be changed after the hot air is recycled for a long time, and finally safety of system equipment and stability of a system are affected.

Owner:上海国惠环境科技股份有限公司

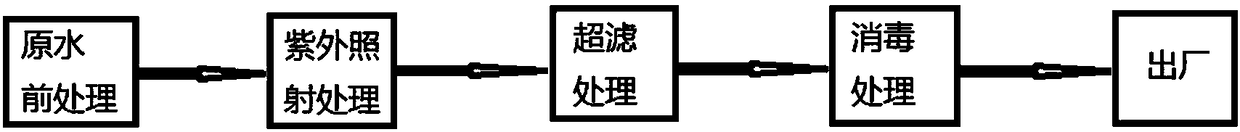

Tap water treatment method and method for reducing membrane pollution in water treatment process

PendingCN108341528AEasy to handleLower transmembrane pressureWater/sewage treatment by irradiationSpecific water treatment objectivesUltrafiltrationEnergy consumption

The invention discloses a tap water treatment method and a method for reducing membrane pollution in the water treatment process. The tap water treatment method comprises the steps that raw water is subjected to pretreatment and then subjected to ultraviolet radiation, ultrafiltration and chlorine disinfection in sequence. In the tap water treatment method, the ultrafiltration and ultraviolet processes in an original water treatment technology are adjusted, the disinfecting function that ultraviolet radiation controls microorganisms is reserved, and meanwhile, the effect for protecting an ultrafiltration membrane is added; the pollution to an ultrafiltration membrane in the ultrafiltration process is reduced, operation energy consumption is reduced, the service life of the membrane in themembrane treatment process is obviously prolonged, the tap water treatment cost is reduced, the aims of energy conservation and emission reduction are achieved, and the method highly accords with theenvironmental protection concept of green technologies.

Owner:北京市自来水集团有限责任公司技术研究院

Nickel-containing electroplating wastewater treatment device

PendingCN111847776AEasy constructionThe facility layout is compact and reasonableWater treatment parameter controlWater contaminantsSludgeProcess engineering

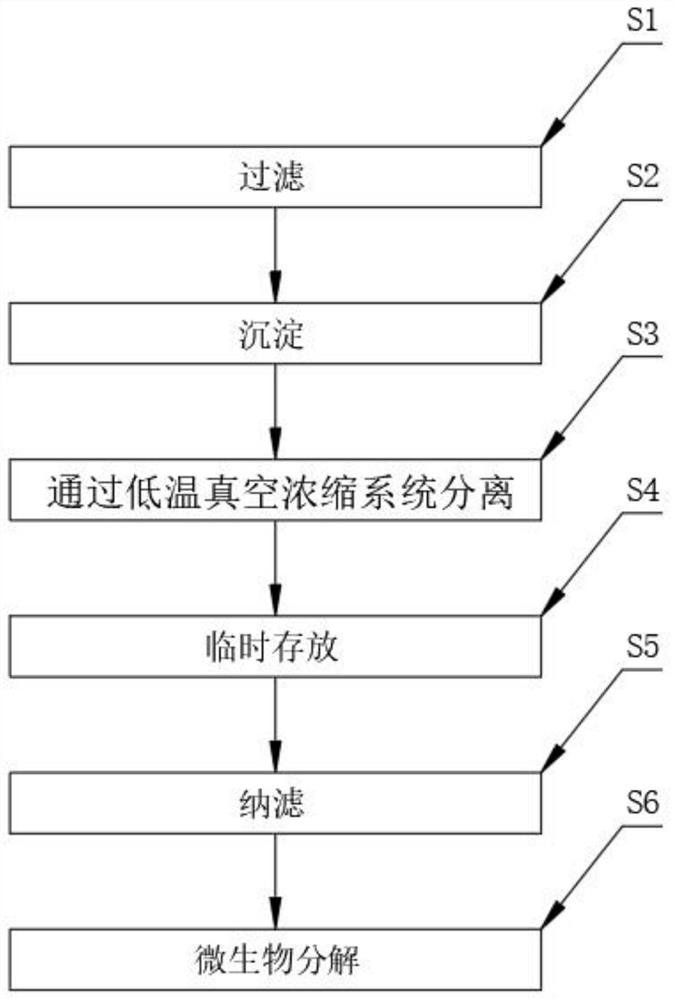

The invention discloses a nickel-containing electroplating wastewater treatment device comprising a wastewater pretreatment system, a first storage tank, a low-temperature vacuum concentration system,a security filter, a second storage tank, a nanofiltration device and an MBR device, and a method comprises the following steps: S1, filtering; S2, precipitating; S3, separating by virtue of the low-temperature vacuum concentration system; S4, temporarily storing; S5, nanofiltering; and S6, carrying out microbial decomposition. The system is simple to construct, the treatment device is basicallydivided into seven modules, after nickel-containing electroplating wastewater is sequentially treated by the seven modules, the water quality meets the discharge standard; the system is compact and reasonable in facility layout and small in occupied area, all process modules are optimized, the optimal operation condition is found, and the treatment efficiency and operation energy consumption are greatly improved; compared with a traditional treatment method, sludge is not generated, nickel ions basically exist in waste liquid discharged by the low-temperature vacuum concentration device completely, and recycling treatment can be conducted.

Owner:久沛(上海)环保科技有限公司

Drying system

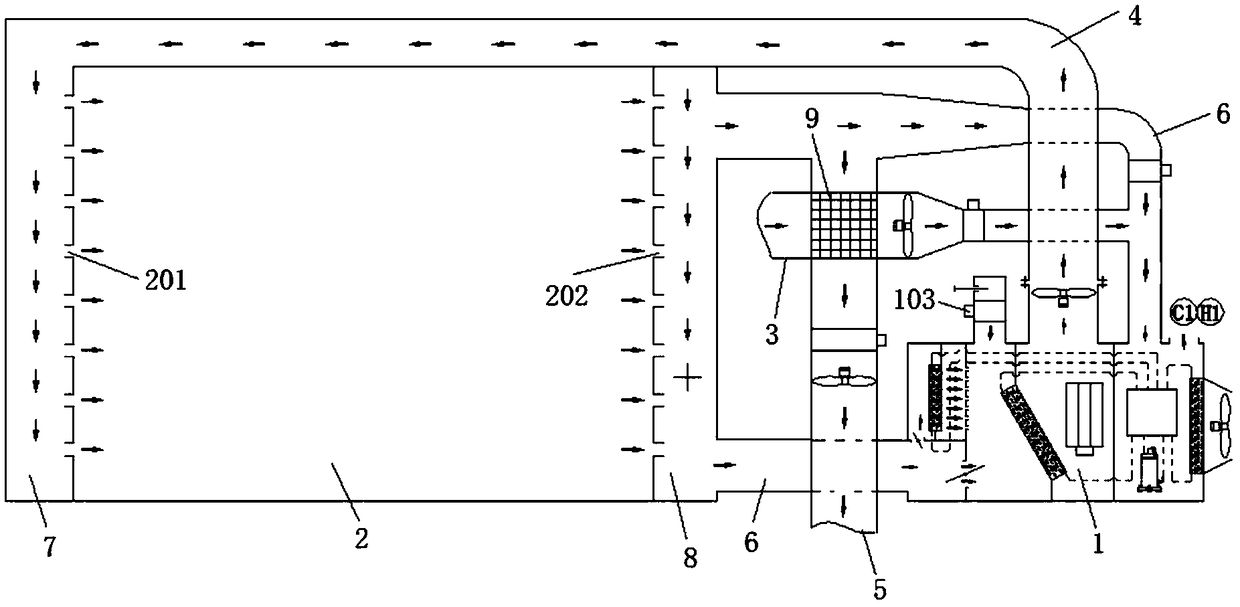

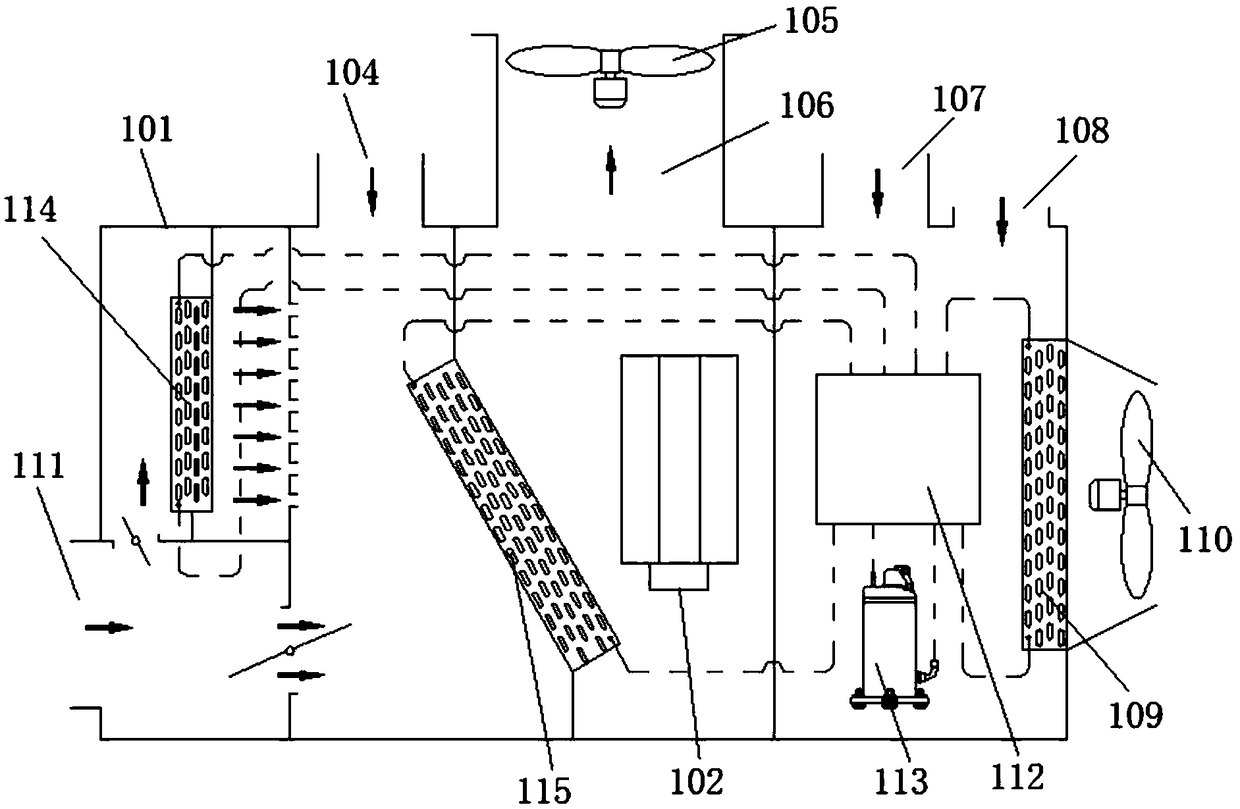

ActiveCN108534477AKeep dryEfficient dryingDrying gas arrangementsDrying machines with local agitationCold airEngineering

The invention discloses a drying system which comprises a heat pump unit and a drying room, wherein a cold air pipe for importing cold air and a blowing pipe for exporting hot air are arranged on theheat pump unit; blowing openings are fully distributed in the side wall of one side of the drying room; air outlets are fully distributed in the wall of the other opposite side of the drying room; theblowing pipe is connected to the blowing openings; the air outlets communicate to a first exhaust pipe and a second exhaust pipe; the first exhaust pipe is connected to the outer side and the secondexhaust pipe is connected to the heat pump unit. The drying system can dry materials in different regions in the drying room synchronously smoothly through the structural design, so that the drying quality of the materials is optimized extremely, and the energy consumption and the time of system operation are reduced.

Owner:NANHUA UNIV

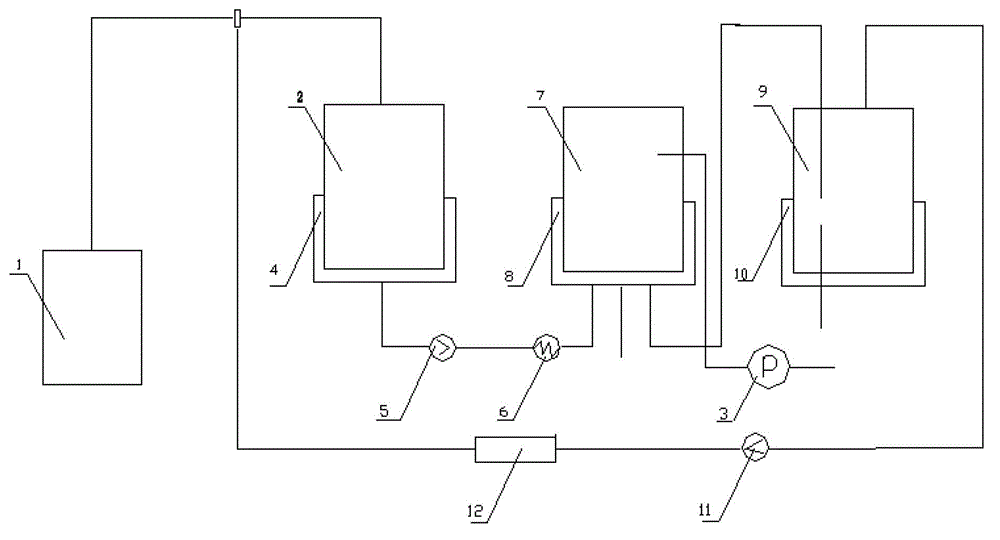

Reclaimed rubber desulfuration masticator

InactiveCN103722630AIncrease frictional resistanceHigh shear forcePlastic recyclingStructural engineeringMechanical engineering

The invention discloses a reclaimed rubber desulfuration masticator which consists of a stander, a protection shell, a transmission mechanism and a desulfuration mechanism, wherein the protection shell and the transmission mechanism are arranged on the stander; a material feeding opening is formed above the tail end of the protection shell, and a material outlet is formed in the lower part of the front end of the protection shell; a gas exhaust opening is formed in the upper part of the front end of the protection shell, and a supporting sleeve is arranged at the front end of the protection shell; the desulfuration mechanism is arranged in the protection shell and consists of a mandrel rotor and a wrapping rotor; the mandrel rotor is embedded into the wrapping rotor, and the mandrel rotor and the wrapping rotor are coaxial; material openings are formed in positions, which correspond to the material feeding opening and the material outlet, of the wrapping rotor. The reclaimed rubber desulfuration masticator is simple in structure; the conventional heating equipment and the conventional adding mechanism are eliminated, and the friction resistance among materials and shearing force of the rotors to the materials are effectively increased, so that the material mastication efficiency and the desulfuration efficiency are improved; therefore, the running energy consumption of equipment is greatly reduced, the yield of the equipment is increased, and waste gas produced in a desulfuration process can be conveniently collected in a concentrated manner, so that the pollution of the production to the environment is alleviated.

Owner:JIAOZUO CITY HONGCHANG PLASTIC IND

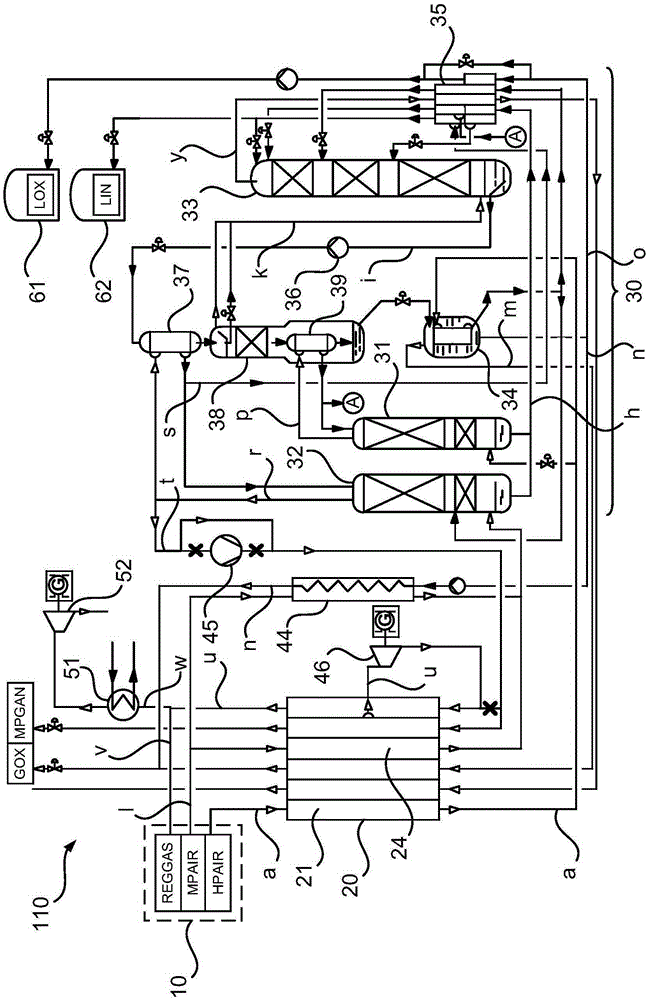

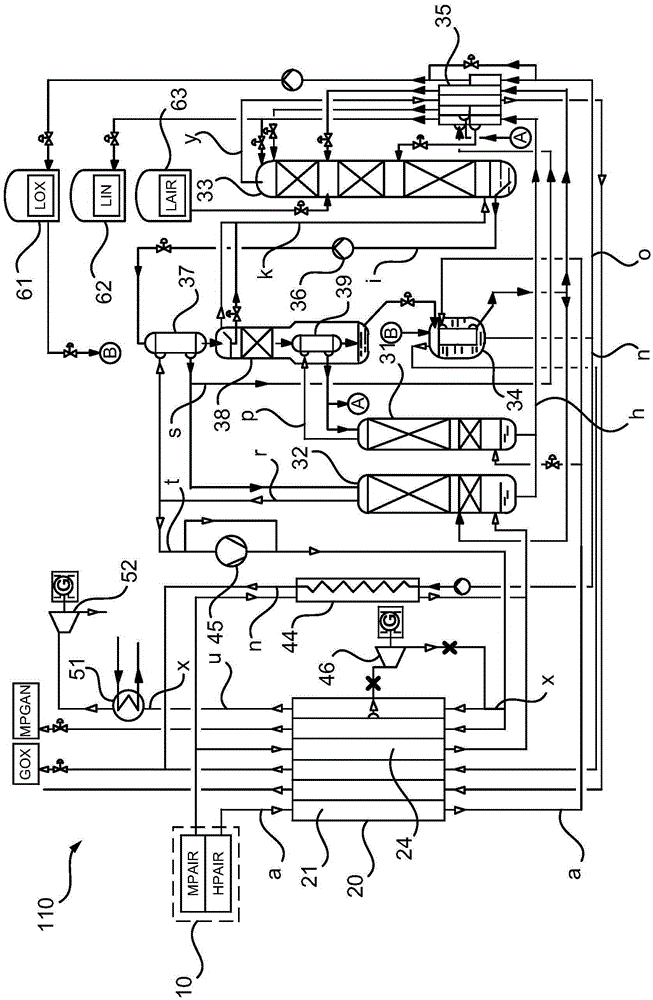

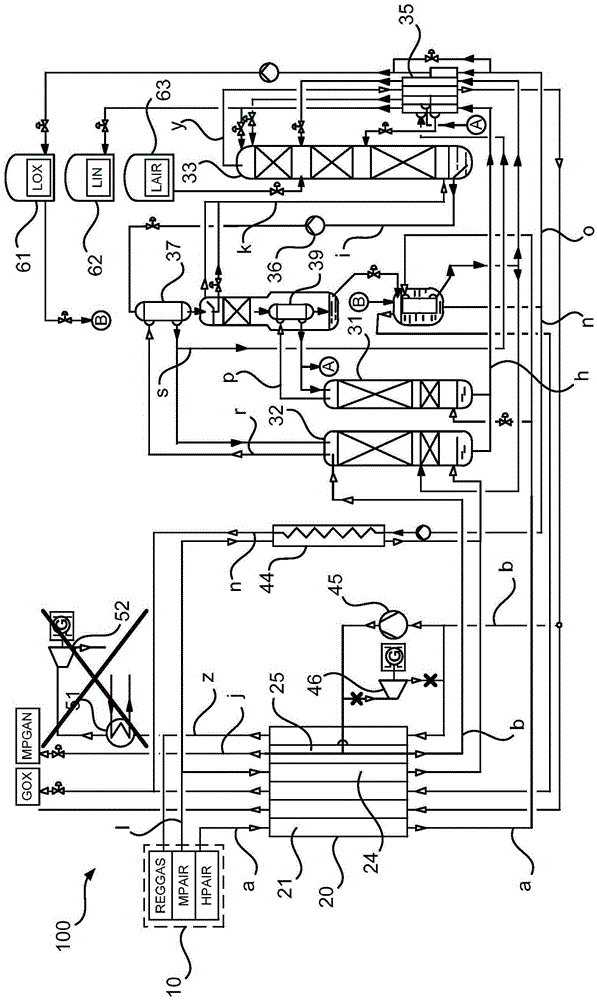

Method for producing at least one air product, air separation system, method and device for producing electrical energy

ActiveCN105378411ALow driving powerImprove heat penetrationSolidificationLiquefactionEngineeringAir separation

The invention relates to a method for producing at least one air product, wherein an air separation system (100) is used which has a primary air compressor (10), a primary heat exchanger (20) and a distillation column system (30), and which comprises a first and a second operation mode, wherein, in the first operating mode, at least one liquid air product (LIN, LOX) produced in the distillation column system (30) is saved and, in the second operating mode, the at least one air product (LIN, LOX, LAIR) saved in the first operating mode and / or at least one additional liquid air product is supplied to the distillation column system (30). The method is characterized in that, in the second operating mode, at least one gaseous pressure flow (b - g) at a temperature level which lies below a hot-side temperature of the primary heat exchanger (20) is supplied to a cold compressor (45), compressed in the cold compressor (45) from a first above-atmospheric pressure level to a second above-atmospheric pressure level, and is supplied to at least one distillation column (31, 32) of the distillation column system (30) at the second above-atmospheric pressure level. The invention further relates to a corresponding air separation system (100) and to a method and to a device for producing electrical energy.

Owner:LINDE AG

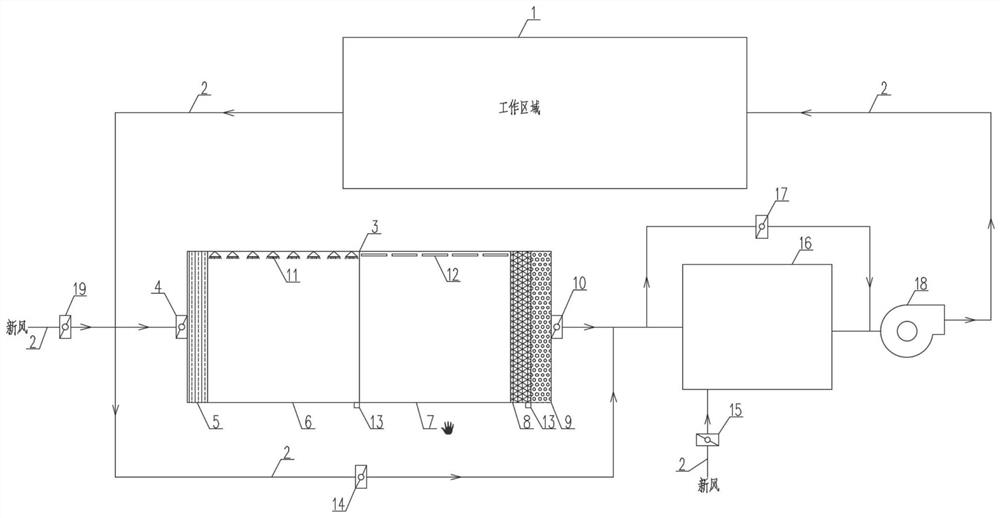

Central air conditioning system achieving combination of ordinary time and epidemic period

InactiveCN111981593ACooling/heating capacity does not decayReduce system power consumptionLighting and heating apparatusSpace heating and ventilation detailsCentral air conditioningProcess engineering

The invention discloses a central air conditioning system achieving the combination of the ordinary time and the epidemic period. The central air conditioning system comprises a purification treatmentunit, an air handing unit and a ventilation fan. An air inlet of the purification treatment unit is connected with an air outlet and a first fresh air pipeline of a working region through a pipelineand an inlet valve, an air outlet of the purification treatment unit is connected with an air inlet of the working region through a pipeline, an outlet valve, the air handling unit and the ventilationfan in sequence, and the inlet valve of the purification treatment unit is connected with the outlet valve of the purification treatment unit through a pipeline and a first valve. An air inlet of theair handing unit is connected with an air outlet of the air handling unit through a pipeline and a third valve. The central air conditioning system can be flexibly switched to run at the ordinary time and the epidemic period, operation of a central air conditioner at the four modes of the ordinary time, the epidemic situation, the disinfection and the fresh air can be achieved through the adjustment of opening and closing operation of the valves arranged in the system, purification of the air and elimination of viruses can be conducted in the epidemic period, the excessive energy consumptioncannot be increased, and the appropriate office environment in a building is guaranteed.

Owner:中冶南方城市建设工程技术有限公司 +1

A device and process method for treating oil fume tail gas

ActiveCN113457845BEfficient removalWon't clogCombination devicesGas treatmentFlue gasExhaust gas emissions

The invention discloses a device and a process method for treating oil fume tail gas, comprising a washing unit, an electrostatic unit and a polishing unit, the washing unit is connected to the electrostatic unit through a pipeline, and the electrostatic unit is connected to the polishing unit Connected through a filter channel, the washing unit includes a flue gas inlet, the flue gas inlet is connected to one side of the washing pipe through a flue gas pipe, a waste reducing device is arranged in the washing pipe, and the other side of the washing pipe is connected to the washing pipe. connected to the separation device, the separation device includes a separation tower, the lower end of the separation tower is connected to the liquid return pipe of the waste reduction device, the upper end of the separation tower is connected to one side of the pipeline, and the other side of the pipeline is connected to the The connection of the electrostatic unit mentioned above can reasonably and effectively solve various problems in the above-mentioned various treatment processes through the device used to treat the oil fume exhaust gas, so as to ensure that the emission requirements for various indicators are up to standard during the exhaust gas emission process.

Owner:瑞燃(上海)环境工程技术有限公司

Ternary precursor wastewater oil removal system and process method thereof

PendingCN111995096ASingle categoryLow priceFatty/oily/floating substances removal devicesTreatment involving filtrationActivated carbon filtrationWastewater

The invention discloses a ternary precursor wastewater oil removal system and a process method thereof, the ternary precursor wastewater oil removal system comprises: a pump comprising an inlet and anoutlet; an activated carbon tank provided with a first liquid inlet and a first liquid outlet, wherein the first liquid inlet of the activated carbon tank is connected with an outlet of the pump through a first pipeline, the first pipeline is provided with a first valve, and the activated carbon tank is filled with activated carbon; and a filter comprising a second liquid inlet and a second liquid outlet, wherein the second liquid inlet of the filter is connected with the first liquid outlet of the activated carbon canister through a first pipeline, the second liquid inlet of the filter is connected with the outlet of the pump through a second pipeline, a second valve is arranged on the second pipeline, and the second liquid outlet of the filter is connected with a MVR evaporator. The system provided by the invention can remove oil in feed liquid entering the MVR evaporator, improves the quality of discharged salt, and ensures long-term stable operation of the system.

Owner:昆山三一环保科技有限公司

Bar push device

Owner:青岛萨沃特智能制造技术有限公司

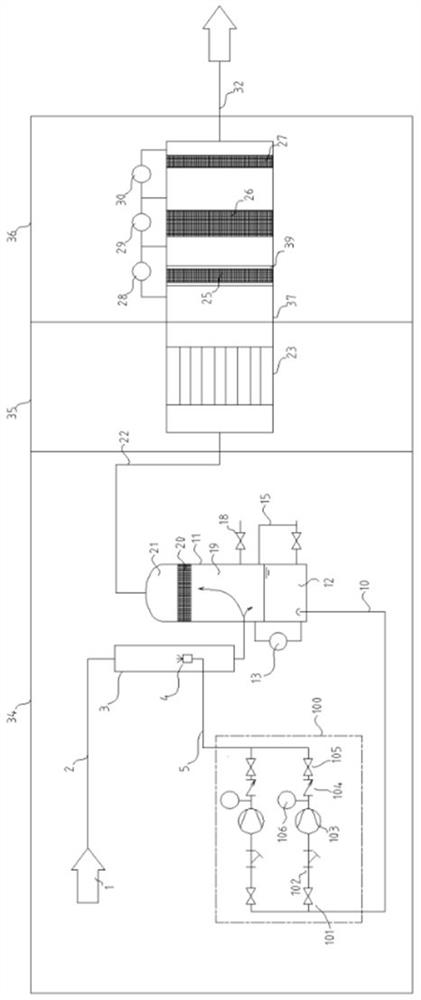

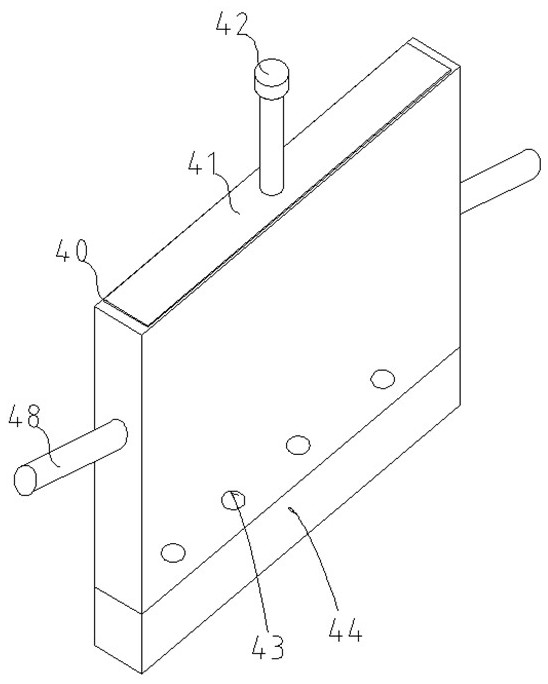

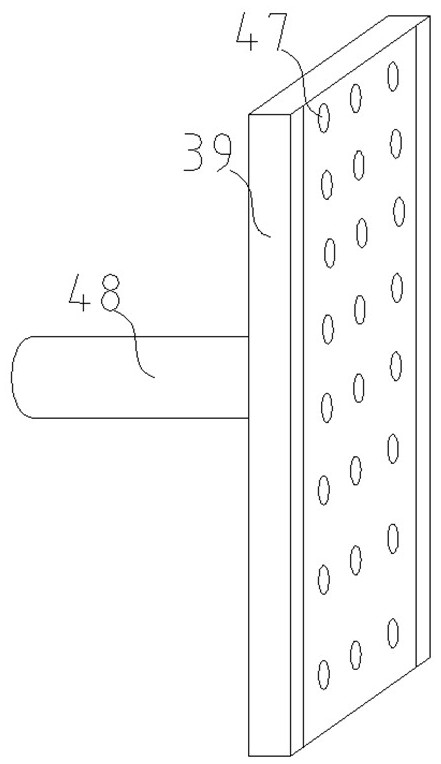

Energy-saving device for low-dew-point dehumidification system with temperature and humidity control functions

PendingCN108131734AAvoid enteringReduce operating energy consumptionMechanical apparatusLighting and heating apparatusPositive pressureEngineering

The invention discloses an energy-saving device for a low-dew-point dehumidification system with temperature and humidity control functions. The energy-saving device for the low-dew-point dehumidification system with the temperature and humidity control functions comprises a rotating wheel dehumidifier unit and an air processing unit, an air supply end of the rotating wheel dehumidifier unit is connected to a modular main air supply pipe through a second modular air supply pipe, the air supply end of the air processing unit is connected to the modular main air supply pipe through a first modular air supply pipe, and the modular main air supply pipe is connected into a workshop through a high-efficiency air supply port; and a first positive pressure air return cabinet unit and a second positive pressure air return cabinet unit are arranged in the workshop, an air return end of the rotating wheel dehumidifier unit is connected with the second positive pressure air return cabinet unit through a second modular air return pipe, and the air return end of the air processing unit is connected with the first positive pressure air return cabinet unit through a first modular air return pipe.According to the energy-saving device for the low-dew-point dehumidification system with the temperature and humidity control functions, the problems of the temperature and humidity control and energyconservation of a low-dew-point space are solved.

Owner:SHANGHAI D&S AIR HANDLING EQUIP

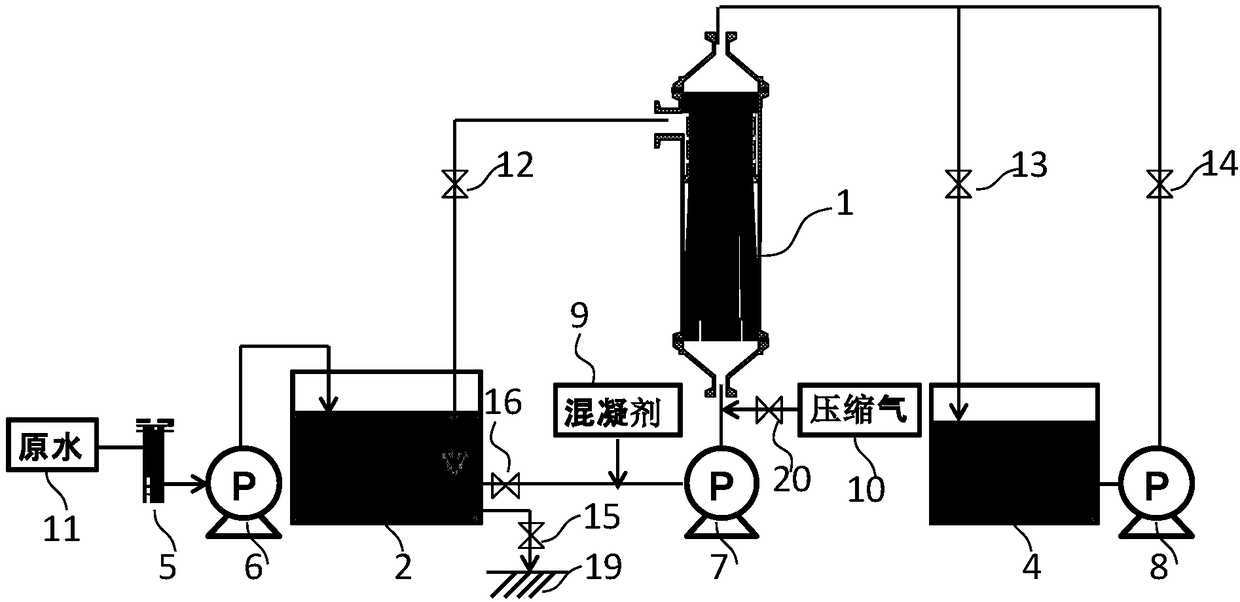

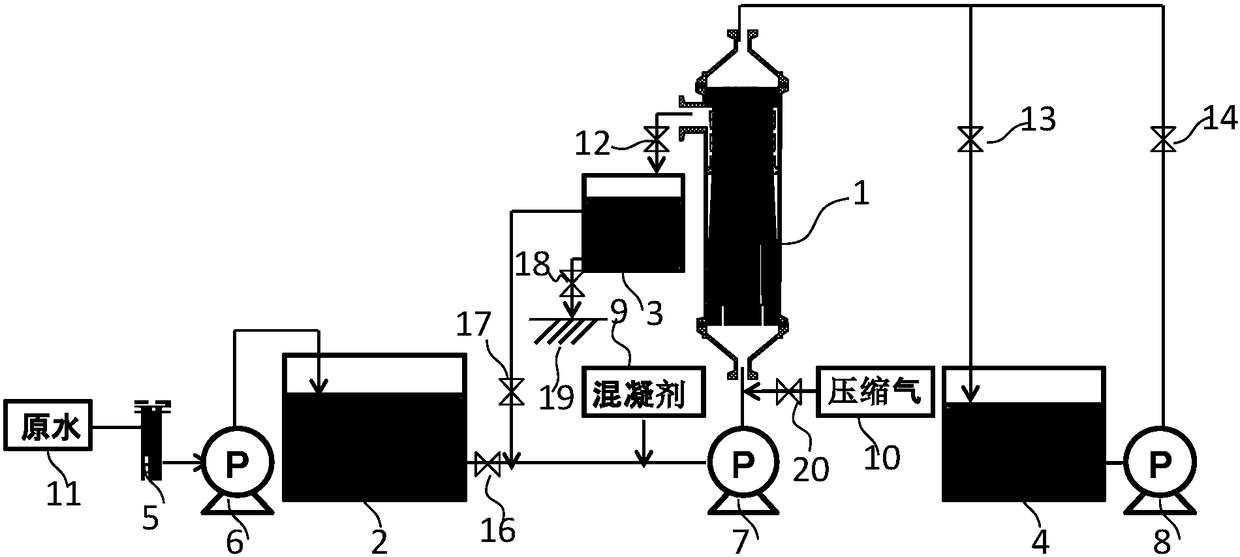

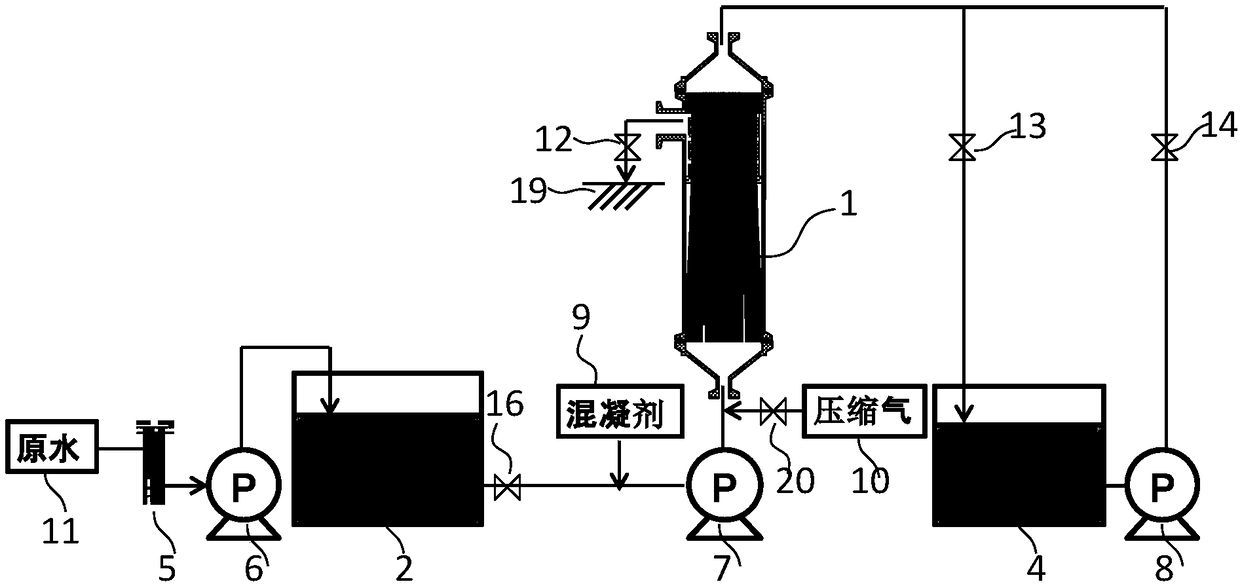

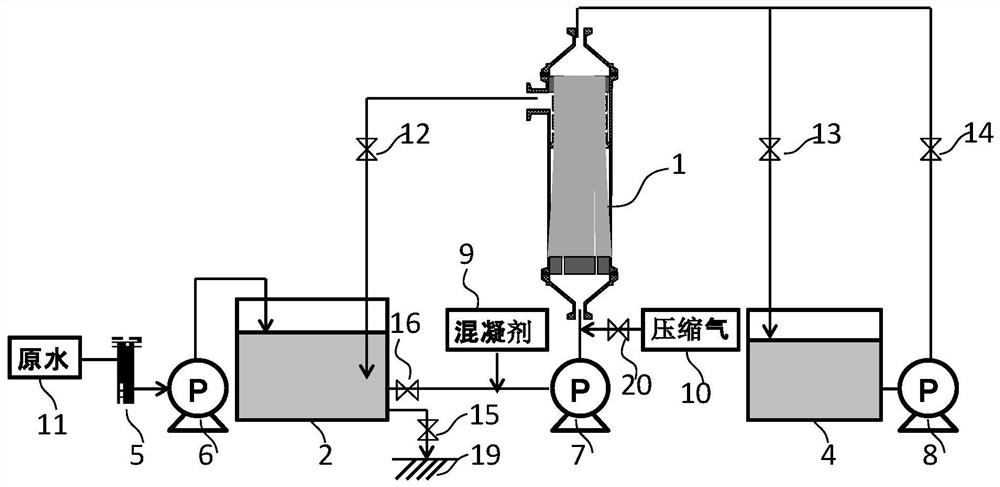

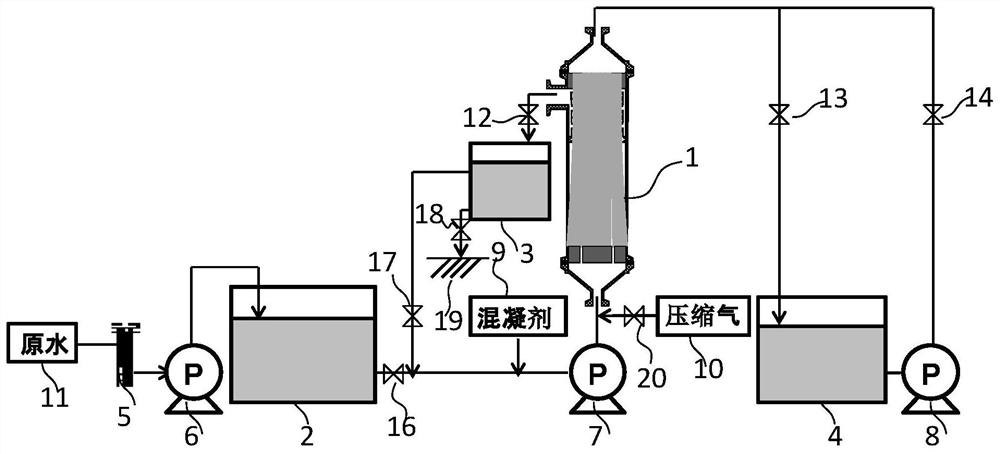

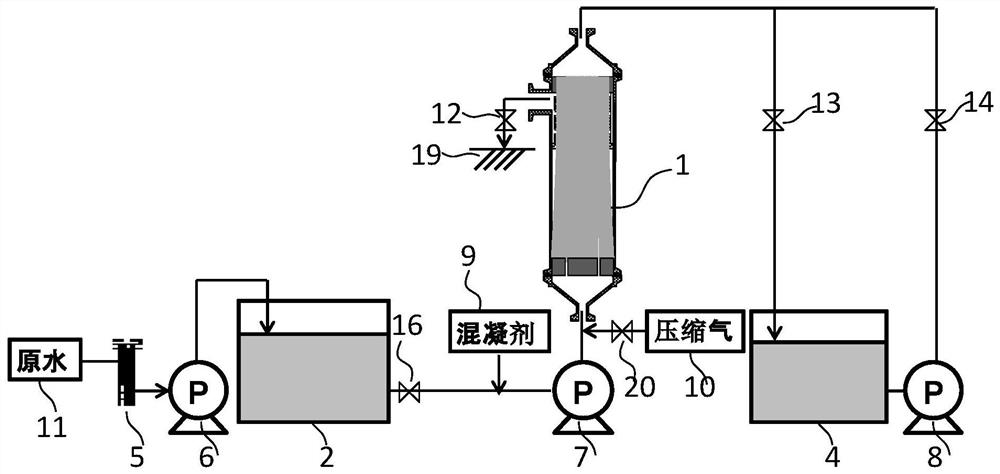

Integral purification device and method for particles in rain and sewage

InactiveCN102774896BImprove removal efficiencyAvoid easy cloggingWater/sewage treatment by centrifugal separationWater/sewage treatment by flocculation/precipitationParticulatesWater discharge

The invention relates to an integral purification device and an integral purification method for particles in rain and sewage. The device consists of three parts including a rotational flow riffling unit, a diameter change precipitation unit and an up-flow filter unit in vertical overlapped arrangement, wherein the rotational flow riffling unit comprises a rotational flow riffling tube, a water inlet pipe, a sand discharge pipe, a siphon cover, a siphon pipe, a water sealing groove, a water discharge pipe, a first perforation plate, a second perforation plate and a third perforation plate, the diameter change precipitation unit comprises a diameter change precipitation pool, the up-flow filter unit comprises a filter chamber case, a filter chamber base plate, a filter pool, filter materials and a filter water outlet. The device and the method provided by the invention have the characteristics that the particle removal efficiency is high, the blockage is avoided, the energy is saved, the efficiency is high, the water load impact capability is high, the occupied area is small, the investment and operation management cost are low, and the like. The method and the device can be widely applied to the particle purification in water discharge pipelines with greater slope and the rainfall runoff of roofs, elevated roads and the like.

Owner:北京建筑工程学院

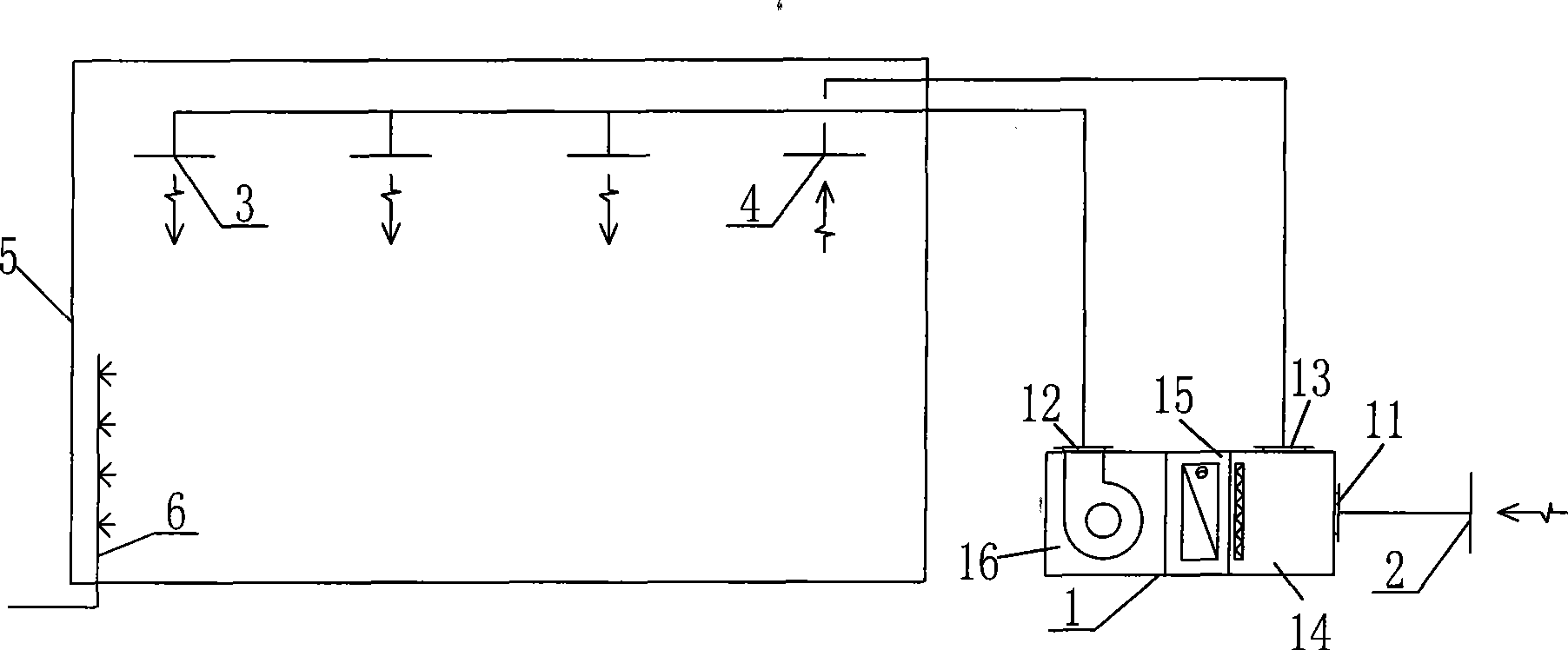

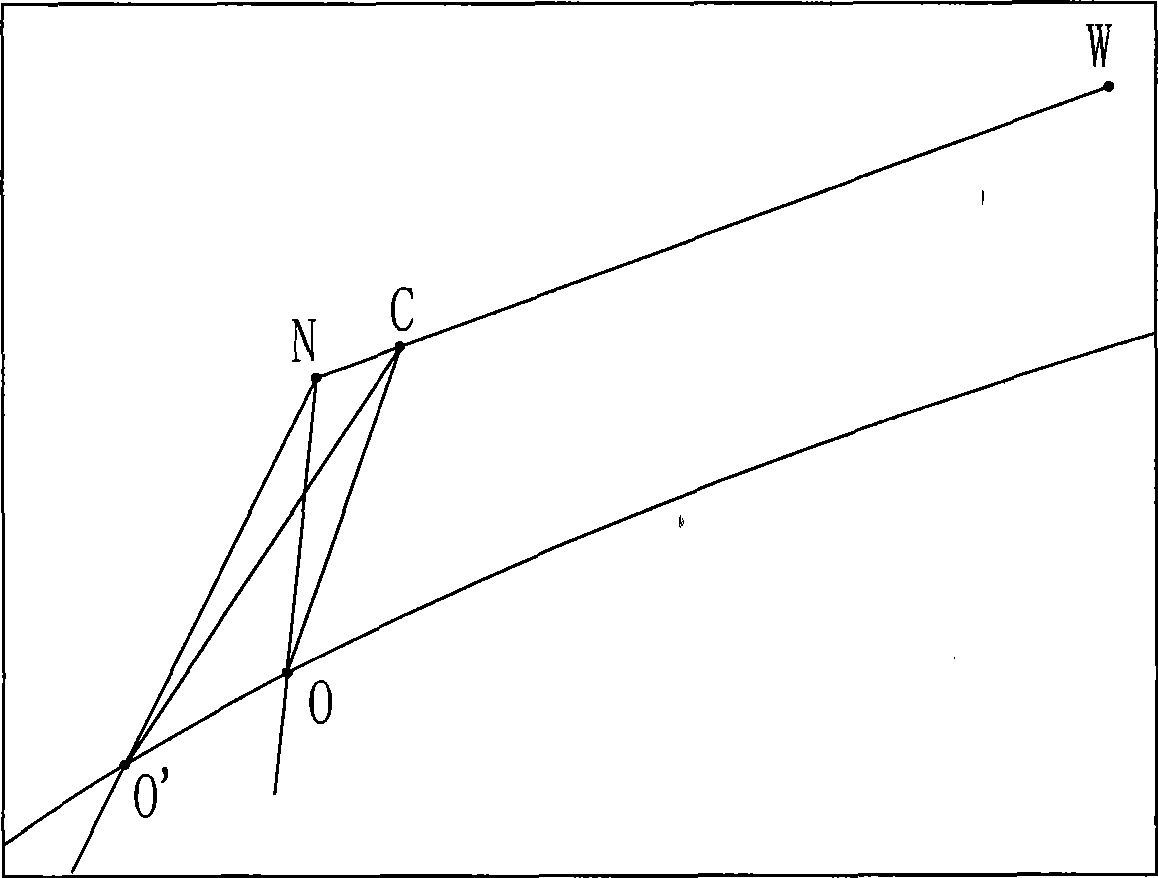

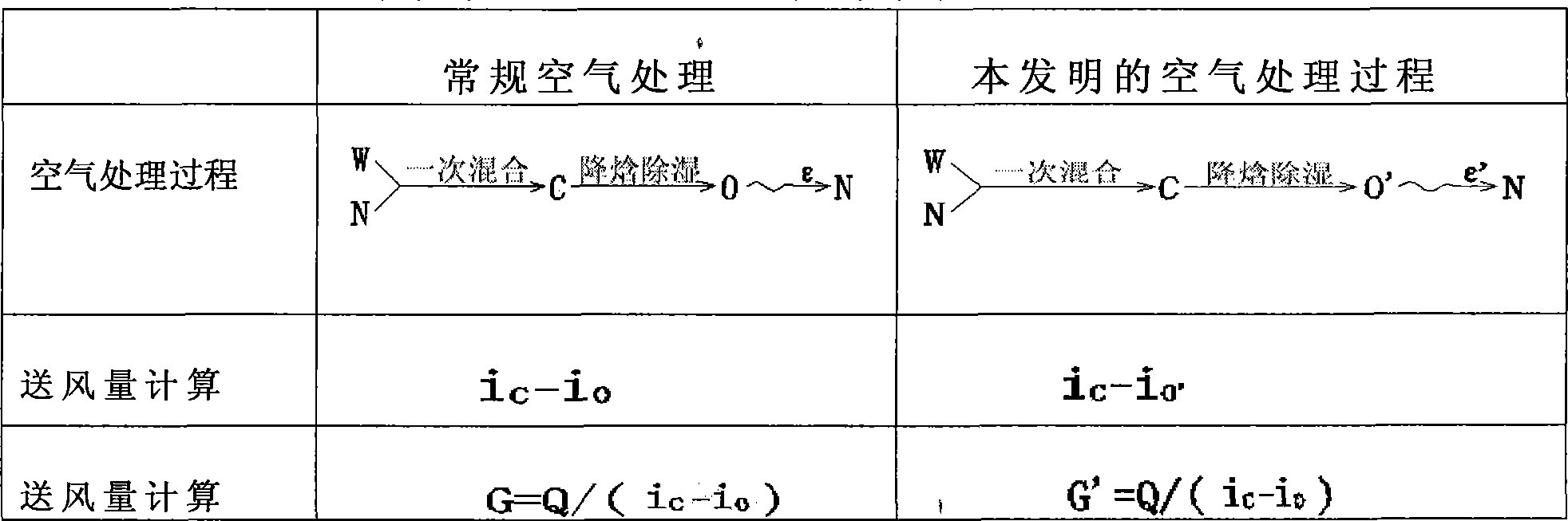

Air-handling system for high sensible heat and low latent heat load region

InactiveCN101424431AIncrease heat-humidity ratio characteristicsChange the heat-humidity ratio characteristicsLighting and heating apparatusAir conditioning systemsAir volumeFresh air

The invention relates to an air treatment system for areas with high sensible heat and low latent heat load, which comprises an air treatment device (1) and an air conditioning chamber (5), wherein an air inlet (11) of the air treatment device (1) is communicated with external air through a fresh air pipe (2). The system is characterized in that the top of the air conditioning chamber (5) is provided with one or a plurality of air supply ports (3) and air return ports (4); the air supply ports (3) and the air return ports (4) are communicated with an air outlet end (12) of an air pipe and an air return end (13) of the air treatment device (1) respectively; a high sensible-heat air conditioning area of the air conditioning chamber (5) is provided with one or more than two humidifiers (6); and equal-enthalpy humidification is performed to the air conditioning chamber (5) through the humidifiers (6). The system has the advantages that the system changes the heat-humidity ratio characteristic of air conditioning load, effectively utilizes the heat-humidity treatment capability of a surface cooler in the air treatment device, increases the enthalpy difference of air treatment, improves the heat exchange efficiency of coils so as to effectively reduce the air quantity of air treatment, and achieves the effects of saving investment and the operation energy consumption of air conditioners, reducing noise and improving the comfort property of the air conditioners.

Owner:GUANGZHOU DESIGN INST

A method of operating a hollow fiber membrane module

ActiveCN109420433BReduced service lifeAvoid driftingUltrafiltrationWater/sewage treatment bu osmosis/dialysisFluid phaseSecondary side

An operation method of a hollow fiber membrane module includes forward flushing on the primary side, membrane filtration of raw water, and backwashing of filtered water on the secondary side. The forward flushing on the primary side includes flushing with a liquid phase flow or a mixed phase flow of gas and liquid. This operation method ensures excellent turbidity discharge of the module and can effectively prevent the problem of membrane filament breakage. At the same time, the structure of the module includes that the fluid flowing from the outside of the hollow fiber membrane during the primary side positive flushing flows to the center part in the radial direction of the lower side of the water production end irrigation and filling part, and from the radial direction of the lower side of the water production end irrigation and filling part. The center part flows radially outward in the radial direction, resulting in a rectifying effect. It effectively prevents the occurrence of bias flow in the upper part of the module during primary side flushing and further improves the turbidity discharge performance of the module.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

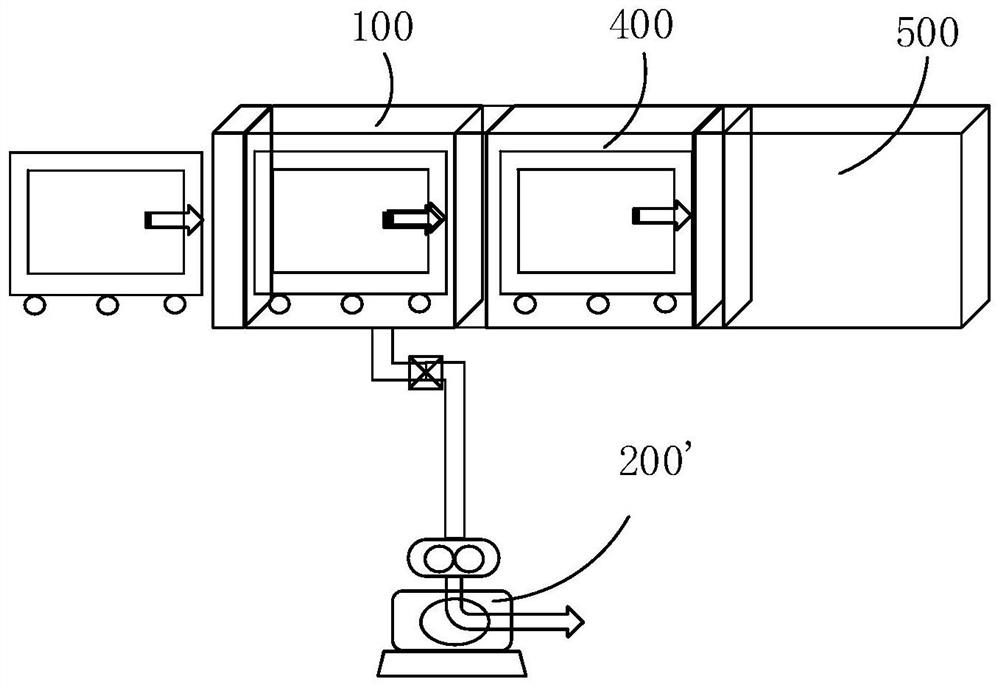

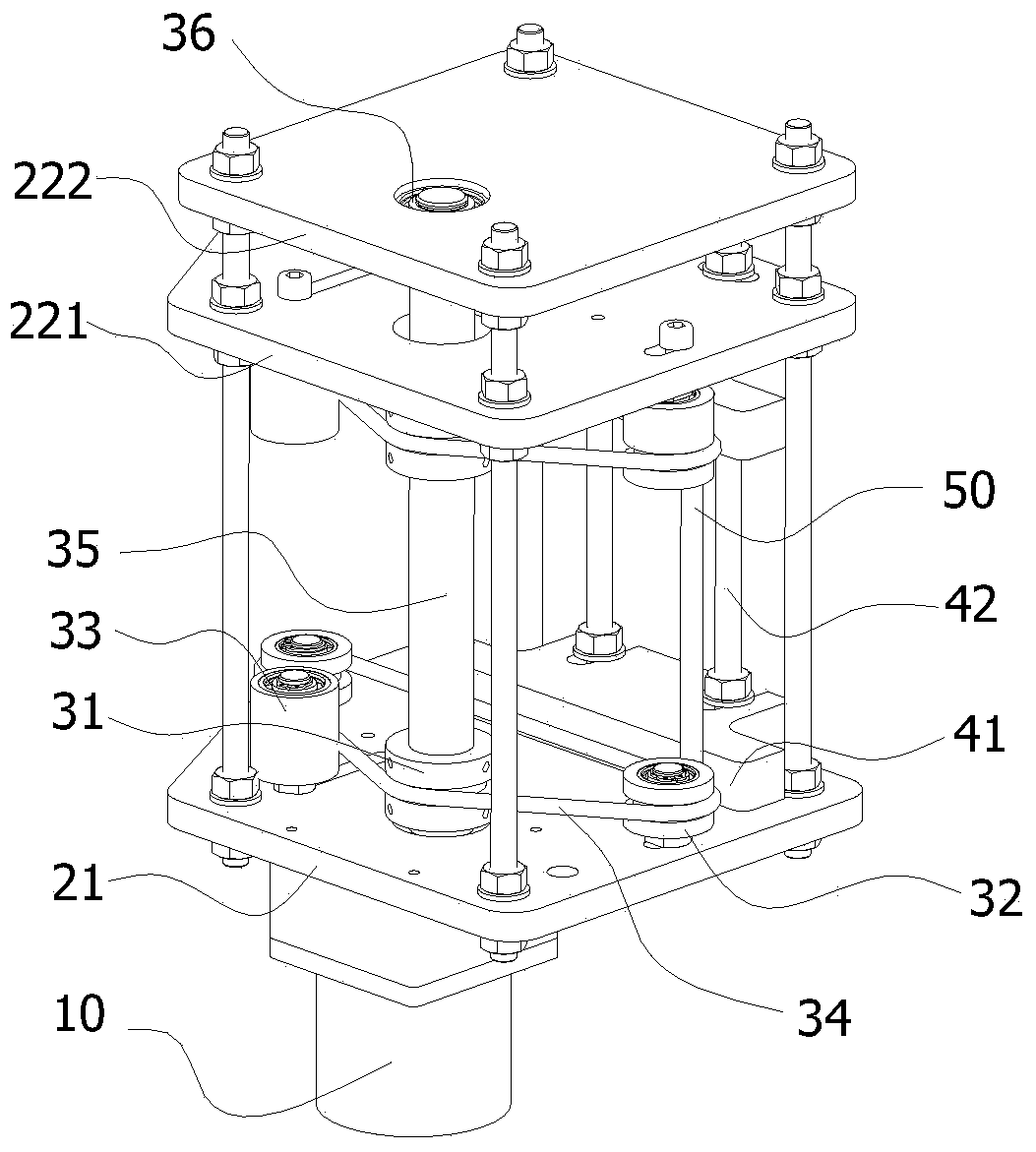

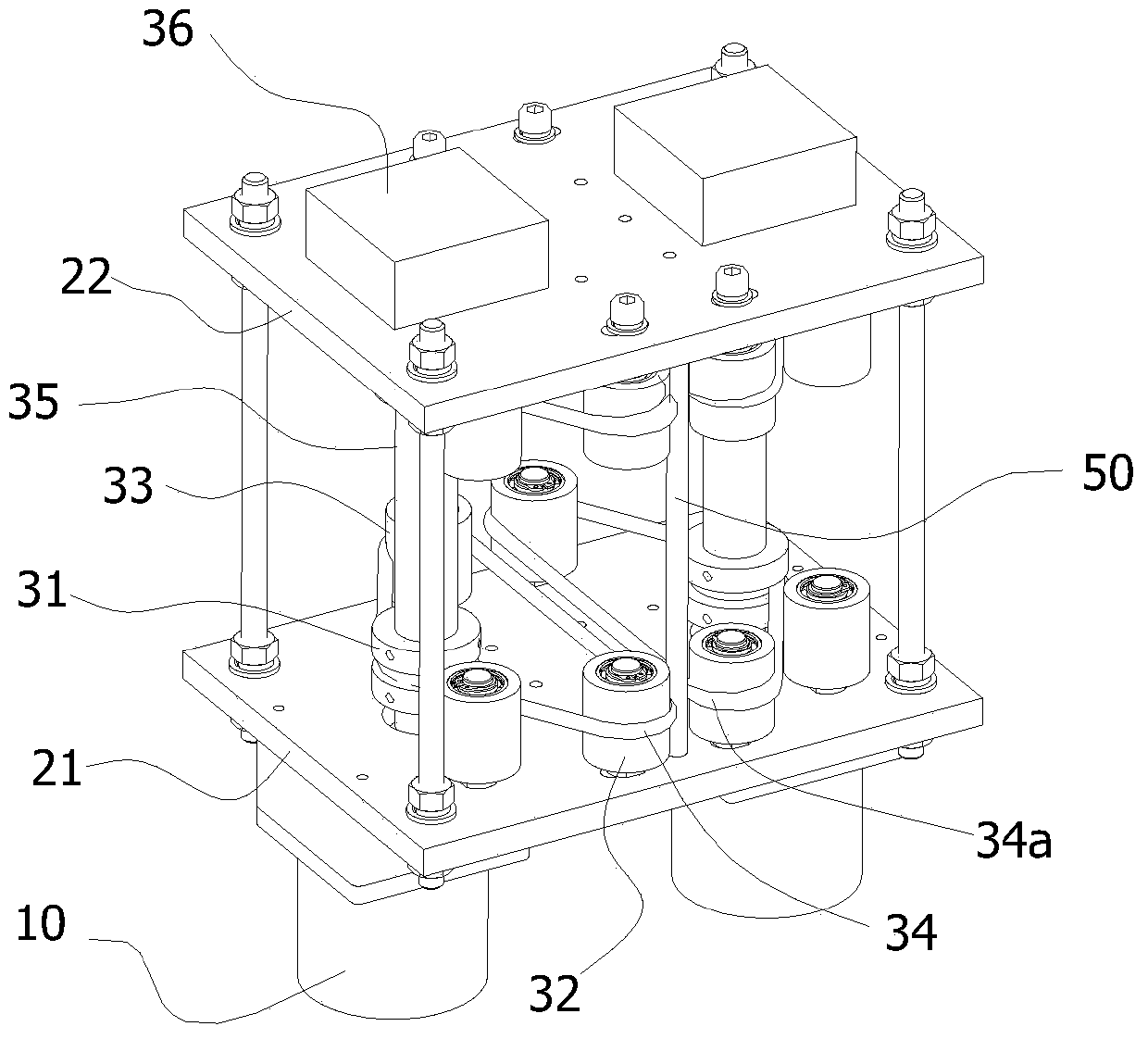

Vacuum coating equipment and method

PendingCN113604790AIncrease profitShorten the timeVacuum evaporation coatingSputtering coatingEngineeringPumping vacuum

The invention relates to vacuum coating equipment and method. The vacuum coating equipment comprises a buffer chamber, an air extractor and a buffer barrel, the buffer chamber is configured to be used for carrying out buffer treatment on a to-be-coated product before coating, the buffer chamber is provided with an air extraction channel, and the air extraction channel is provided with a first switch valve; the air extractor is arranged at the tail end of the air exhaust channel so as to vacuumize the buffer chamber; the buffer barrel is provided with an air inlet channel and an air outlet channel; the end, away from the buffering barrel, of the air inlet channel is connected between the first switch valve and the buffering chamber in a sealed mode; the end, away from the buffering barrel, of the air outlet channel is connected between the first switch valve and the air extractor in a sealed mode; and the air inlet channel is provided with a second switch valve, and the air outlet channel is provided with a third switch valve. The vacuum coating equipment can solve the problems that the equipment purchase cost is increased and the equipment operation energy consumption is increased due to the mode of reducing the takt time at present.

Owner:INTERFACE TECH CHENGDU CO LTD +3

Bar pushing device

Owner:青岛萨沃特智能制造技术有限公司

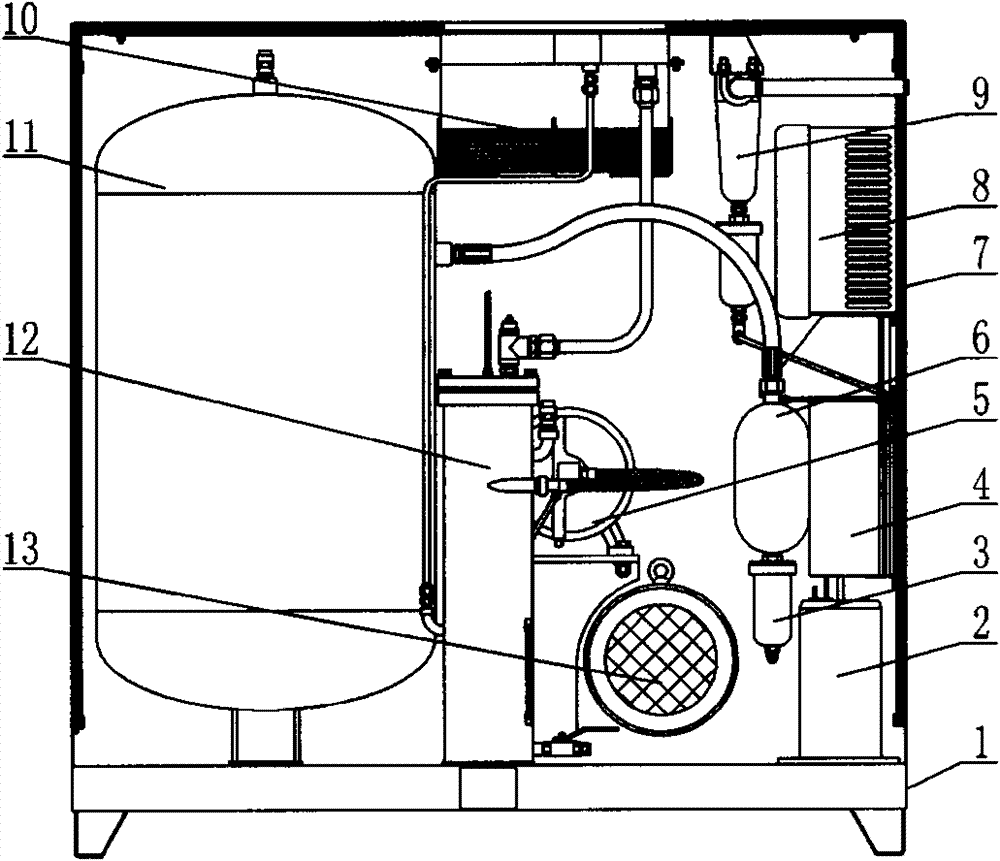

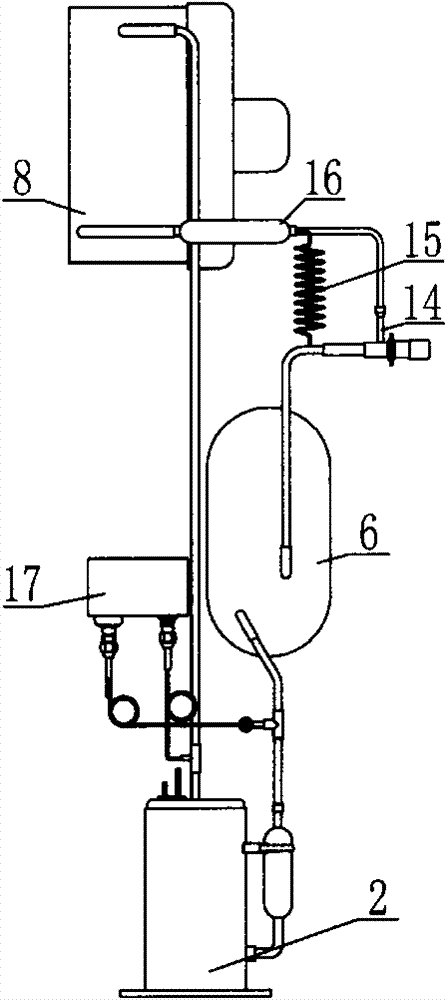

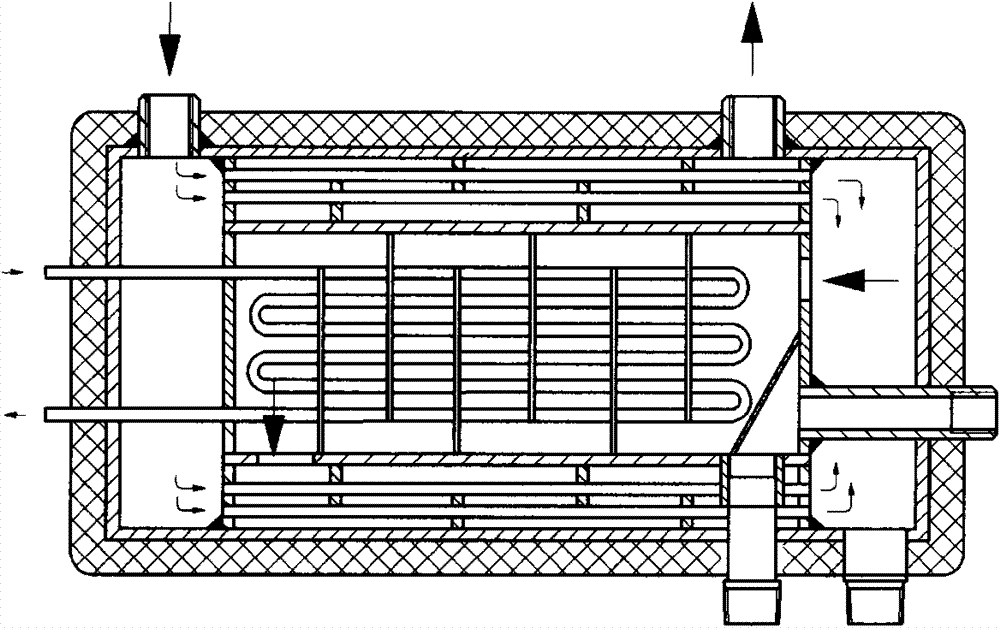

Full performance scroll compressor all-in-one machine

InactiveCN102297133BReduce noiseReduce running noiseRotary piston pumpsRotary piston liquid enginesMulti machineFreeze-drying

The invention discloses a full performance scroll compressor all-in-one machine, which comprises a cabinet, and a scroll compressor system, an air storage system, a compressed air freeze-drying system and a precision filter system, which are arranged in the cabinet. The scroll compressor system is communicated with an air inlet of the air storage system through a pipeline; an air outlet of the air storage system is communicated with an air inlet of the precision filter system; an air outlet of a primary high-efficiency filter of the precision filter system is communicated with an air inlet of an integrated precooling evaporator of the freeze-drying system; the air inlet of the integrated precooling evaporator is communicated with air inlets of intermediate and advanced high-efficiency filters, which are connected in series in the precision filter system; and the outlet of the advanced high-efficiency filter is connected with a user side. The full performance scroll compressor all-in-one machine occupies a small area and space, does not need foundation installation, has low running noise and energy consumption, discharges clean air, meets the environment-friendly requirement, works flexibly and can be arranged in a work place to realize single-machine or multi-machine on-line air supply.

Owner:湖南云箭集团有限公司

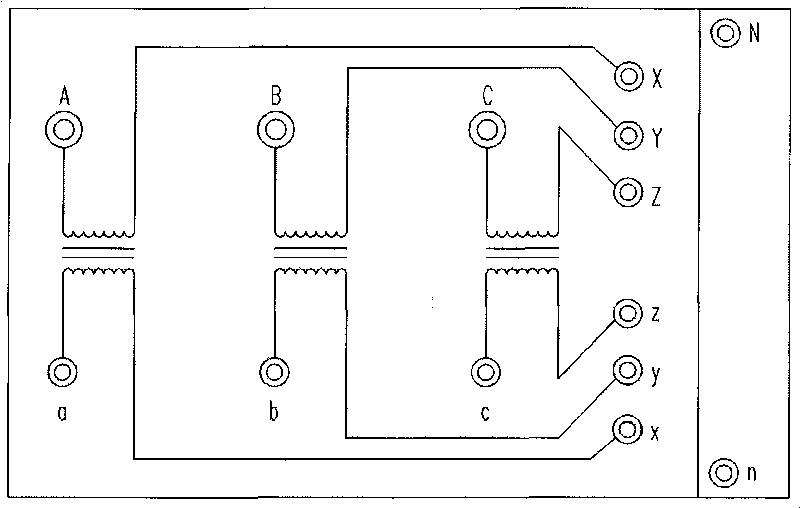

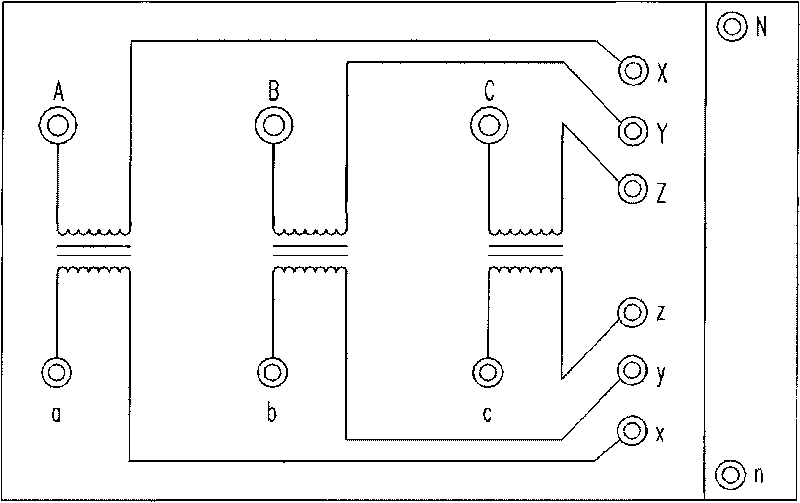

110KV low-power-consumption environmentally-friendly power transformer

InactiveCN101699581ASignificant comprehensive benefitsBroad market prospectTransformers/inductances coils/windings/connectionsElectric component structural associationInstrumentationTransformer

The invention relates to a 110KV low-power-consumption environmentally-friendly power transformer and aims to solve the problems of insulating medium leakage and high energy consumption, which are caused by high-voltage primary side detection, of the traditional power transformer. The ends of three-phase windings on the Y-connection side of the transformer are connected respectively or are provided with the wiring terminals after being connected respectively, wherein for an oil-immersed type transformer, the ends of the three-phase windings are connected outside the body of the transformer; and for a dry type transformer, the ends of the three-phase windings are connected in the body of the transformer or connected outside the body or the transformer respectively. Current monitoring and controlling devices are arranged at the positions of the wiring terminals respectively. The Y-connection side of the transformer is provided with independent neutral point fixed wiring terminals which are not connected with the ends of the three-phase or the wiring terminals of the ends. As the way for the current metering, measurement and control of the transformer is changed from high-voltage monitoring into low-voltage monitoring, so a low-voltage current monitor can be used to replace a high-voltage current monitor and the cost is reduced greatly; the low-voltage monitor is easy to mount, use and maintain, more accurate in measurement, more compact in structure, lower in energy consumption, safer and more reliable and free from problems of oil insulation, sulfur hexafluoride leakage and environmental pollution; and the economic, social and environmental benefits are more desirable and the popularization value is high.

Owner:梁艳

Side biological treatment process for processing sludge-digestion liquid by adopting SNAD-MBBR technology as core

InactiveCN108975608AShorten the start-up periodGuaranteed Biomass BalanceWater contaminantsWater/sewage treatmentSludgeSmall footprint

The invention relates to a side biological treatment process for processing a sludge-digestion liquid by adopting an SNAD-MBBR technology as a core. The side biological treatment process mainly comprises two parts of coagulating sedimentation and SNAD-MBBR. Firstly, the sludge-digestion liquid enters a coagulating sedimentation tank, and a coagulant is fed to carry out flocculation reaction; thenwater without suspended matters discharged through a primary sedimentation tank enters a biological denitrification unit, wherein during the process, an organic carbon source and most nitrogen remained in the sludge-digestion liquid are effectively removed; finally, the treated sludge-digestion liquid is discharged into a sewage treatment tank. The side biological treatment process provided by theinvention has the advantages of low operation energy consumption, high treatment efficiency, low secondary pollution, small occupied area and the like, meanwhile, the nitrogen load impact on the sewage treatment plant is reduced, and the operating cost of a water plant is reduced. The side biological treatment process provided by the invention can become the preferred process for the side biological treatment of wastewater with high ammonia-nitrogen and low carbon nitrogen ratio.

Owner:大连海川博创环保科技有限公司

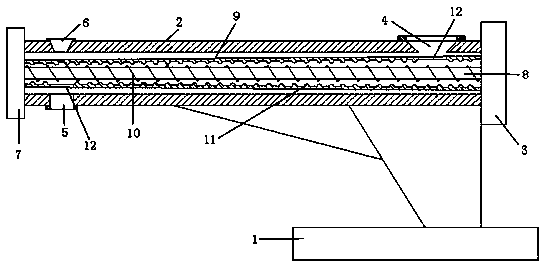

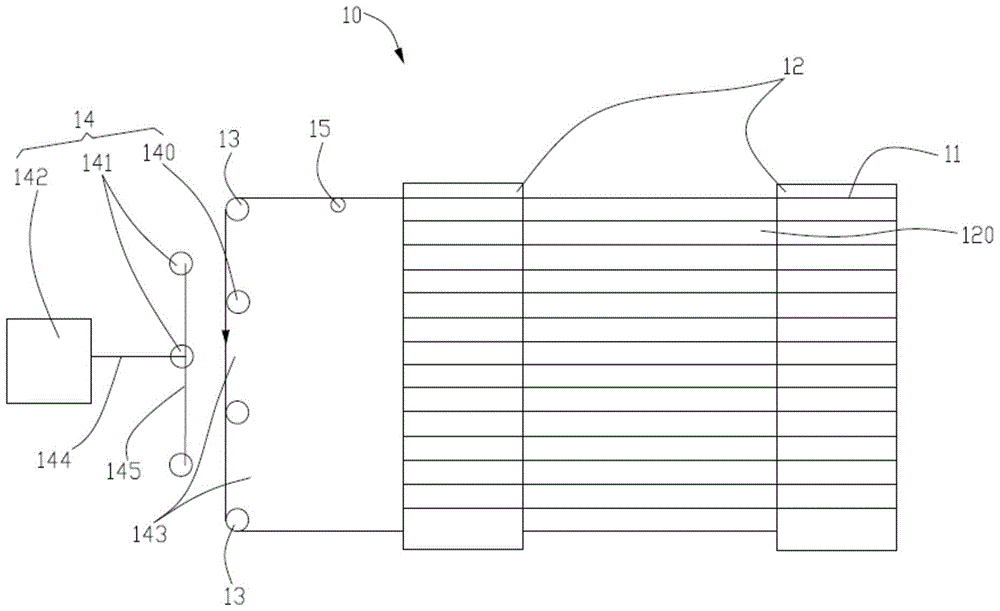

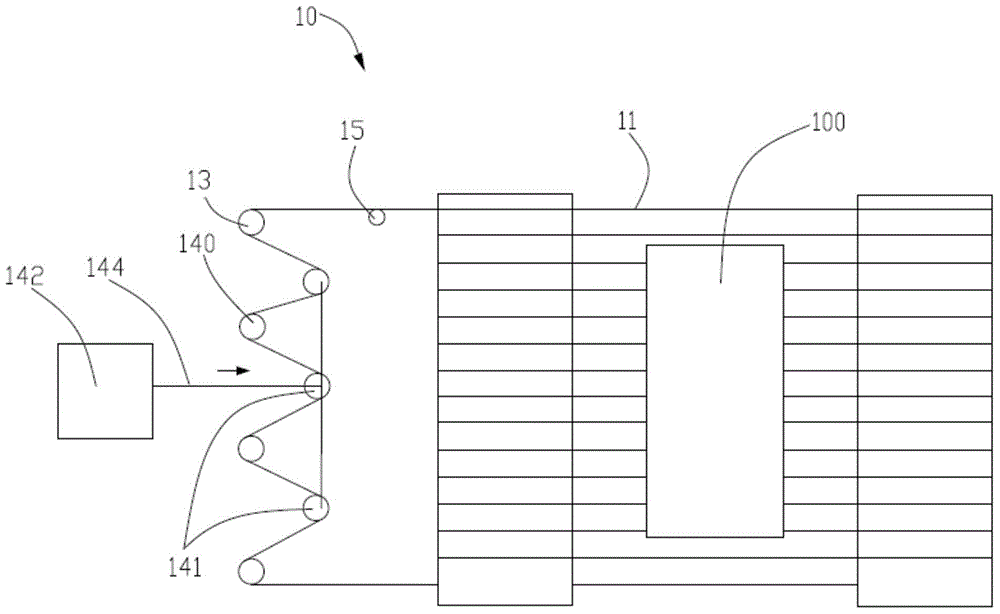

A multi-wire cutting device

ActiveCN104044218BReduce usageIncreased operating energy consumptionFine working devicesGlass severing apparatusOperating energyWire cutting

The invention discloses a multi-line cutting device. The multi-line cutting device comprises cutting lines, a plurality of main rollers and a plurality of reversing wheels. The cutting lines are arranged between the main rollers and the reversing wheels in an expanding mode. The main rollers are arranged in parallel, a cutting line net with a plurality of cutting gaps is formed between every two adjacent main rollers through the cutting lines, and the cutting lines are connected in an end-to-end mode to form a closed movable line. The multi-line cutting device solves the problems that an existing multi-line cutting device is complex in structure, large in size, high in operating energy consumption and low in cutting efficiency. A brand new wiring mode and a brand new line net operating path are adopted in the multi-line cutting device, paying-off wheels and taking-up wheels needing to be used in the existing wiring mode are abandoned, the using number of guiding wheels and the reversing wheels can be reduced, and the multi-line cutting device has the advantages of being simple in structure, low in operating energy consumption, high in cutting efficiency and the like.

Owner:BAOSHAN LONGI SILICON MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com