Reverse osmosis system for seawater desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 250L of 3.2% sodium chloride solution, concentrate it to 8% by reverse osmosis, and set it aside.

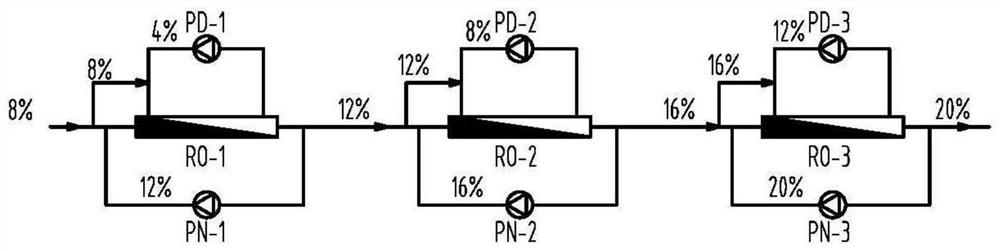

[0022] and follow the steps below (such as figure 1 shown) to re-enrich it:

[0023] Step 1: Set reverse osmosis unit RO-1, fresh water circulation pump PD-1, concentrated water high pressure pump PN-1; set reverse osmosis unit RO-2, fresh water circulation pump PD-2, concentrated water high pressure pump PN-2; set Reverse osmosis unit RO-3, fresh water circulation pump PD-3, concentrated water high pressure pump PN-3;

[0024] Step 2: Connect the reverse osmosis unit RO-1, the reverse osmosis unit RO-2 and the reverse osmosis unit RO-3 in sequence;

[0025] The above-mentioned fresh water circulation pump PD-1 is installed on the fresh water side of the reverse osmosis unit RO-1 to circulate the fresh water; the above-mentioned concentrated water high-pressure pump PN-1 is installed on the concentrated water side of the reverse osmosis unit RO-1 to pressurize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com