Advanced treatment and reuse method of pre-coated membrane of tail water of sewage plant

A technology of advanced treatment and pre-coating film, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Reduce direct contact, reduce operating costs, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

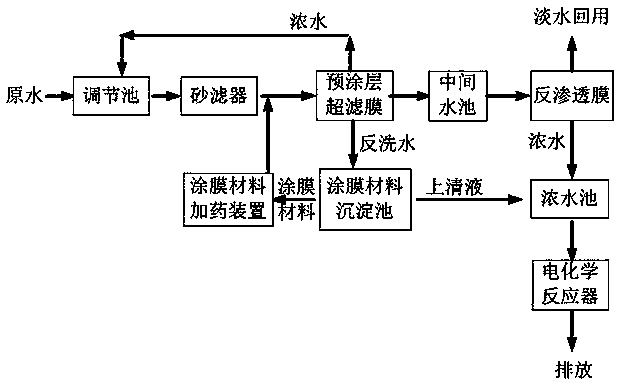

[0036] The tail water of a sewage treatment plant in an industrial park has the following water quality characteristics: COD 55 mg / L, TN 17.3 mg / L, UV 254 0.232cm -1 , turbidity 2.6, conductivity 5610μs / cm. The specific process of advanced treatment and reuse of tail water precoating film is as follows: figure 1 As shown, firstly, the tail water after secondary biochemical treatment is sent to the regulating tank for homogenization, and then passed through a quartz sand filter to remove larger particles of suspended impurities in the wastewater; zeolite powder is added as a pre-coating film material through a dosing device, The particle size is 2000 mesh, the dosing amount is 200 mg / L, the solution containing the pre-coating membrane material and the sand filter water pass through the ultrafiltration membrane together, the ultrafiltration membrane is a hollow fiber membrane, and a precision filter with a filtration accuracy of 10 μm is installed in front of the membrane modu...

Embodiment example 2

[0040]The tail water of a sewage treatment plant in an industrial park has the following water quality characteristics: COD 42 mg / L, TN 13.6 mg / L, UV 254 0.207cm -1 , turbidity 1.5, conductivity 3950μs / cm. The specific process of advanced treatment and reuse of tail water precoating film is as follows: figure 1 As shown, the tail water after the secondary biochemical treatment is first sent to the regulating tank for homogenization, and then passed through the quartz sand filter to remove the larger particles of suspended impurities in the wastewater; activated carbon is added as a pre-coating film material through the dosing device, and the particles The diameter is 500 mesh, the dosing amount is 100mg / L, the solution containing the pre-coating membrane material and the sand filter water pass through the ultrafiltration membrane together, the ultrafiltration membrane is a hollow fiber membrane, and a precision filter with a filtration accuracy of 30μm is installed in front ...

Embodiment example 3

[0044] The tail water of a sewage treatment plant in an industrial park has the following water quality characteristics: COD 60 mg / L, TN 19.5 mg / L, UV 254 0.271cm -1 , turbidity 3.1, conductivity 6630μs / cm. The specific process of advanced treatment and reuse of tail water precoating film is as follows: figure 1 As shown, the tail water after the secondary biochemical treatment is first sent to the regulating tank for homogenization, and then passed through the quartz sand filter to remove the suspended impurities of larger particles in the wastewater; diatomite is added as a pre-coating film material through the dosing device , the particle size is 1000 mesh, and the dosing amount is 400 mg / L. The solution containing the pre-coating membrane material and the sand-filtered water pass through the ultrafiltration membrane together. The ultrafiltration membrane is a hollow fiber membrane. filter, the concentrated water from the ultrafiltration membrane is returned to the regul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com