Nickle-cobalt-aluminium anode material with long cycle life and high specific capacity and preparation method thereof

A high specific capacity, cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor cycle life, and achieve the effect of improving processing performance, excellent performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

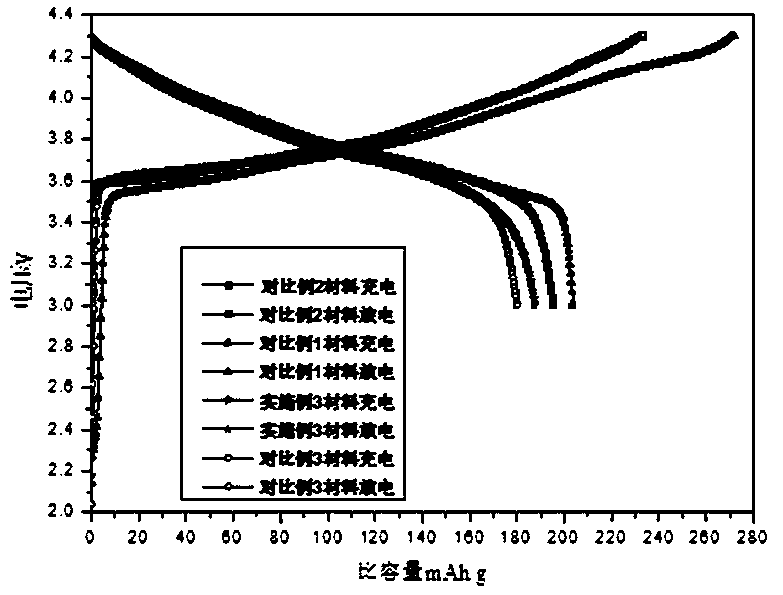

Examples

Embodiment 1

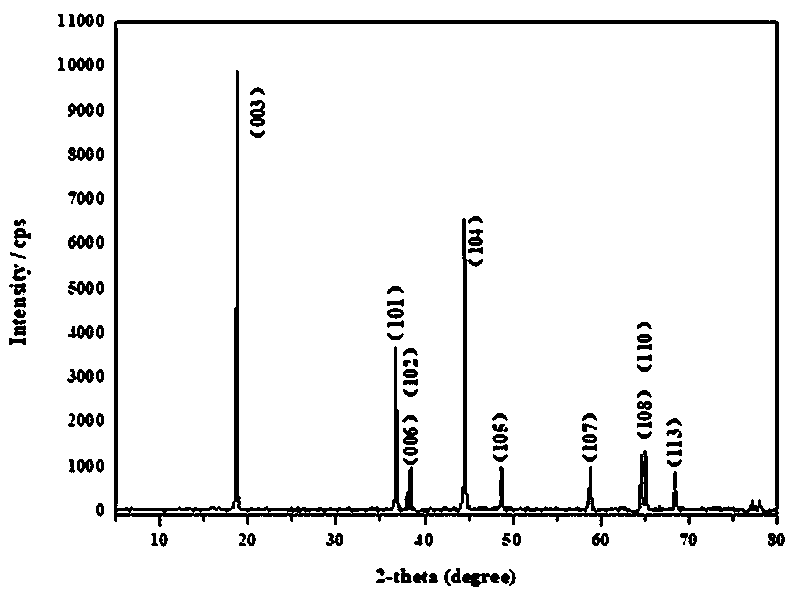

[0035] Provide a long cycle life high specific capacity nickel-cobalt-aluminum positive electrode material and its preparation method, its chemical formula is Li 1.05 Ni 1-x- y co x al y Mg z O·wAl 2 o 3 , where x, y, z, and w are the number of moles, 0≤x≤0.2, 0≤y≤0.1, 0≤x+y≤0.2, 02 o 3 It is the coating layer oxide of nickel-cobalt-aluminum ternary cathode material with long cycle life and high specific capacity.

[0036] The nickel-cobalt-aluminum positive electrode material with long cycle life and high specific capacity is prepared through the following steps:

[0037] (1) In terms of molar ratio, nickel sulfate, cobalt sulfate and aluminum sulfate metal salts were dissolved in deionized water, mixed according to the ratio of Ni:Co:Al=(1-x-y):x:y, and continuously pumped by a peristaltic pump Pump the metal salt solution into the reaction kettle, use NaOH as the precipitating agent, and ammonia water as the complexing agent, adjust the injection speed of the precip...

Embodiment 2

[0041] A method for preparing a nickel-cobalt-aluminum cathode material with a long cycle life and high specific capacity is provided, which is prepared by the following steps:

[0042] (1) In terms of molar ratio, nickel sulfate, cobalt sulfate and aluminum sulfate metal salts were dissolved in deionized water, mixed according to the ratio of Ni:Co:Al=(1-x-y):x:y, and continuously pumped by a peristaltic pump Pump the metal salt solution into the reaction kettle, use NaOH as the precipitating agent, and ammonia water as the complexing agent, adjust the injection speed of the precipitating agent and ammonia water to control the pH value of the reaction kettle to be 9 to 12, and carry out the co-precipitation reaction. (Ni 1-x-y co x al y )OH 2 After suction filtration, washing and drying, the precursor is obtained;

[0043] (2) LiOH·H 2 O, precursor and Mg source according to the molar ratio Li:(Ni 1-x-y co x al y )OH 2 : Mg source = 1.05: 1: z ball milling mixing, mi...

Embodiment 3

[0048] In conjunction with specific examples, a method for preparing a long cycle life and high specific capacity nickel-cobalt-aluminum positive electrode material of the present invention is illustrated, which is prepared by the following steps:

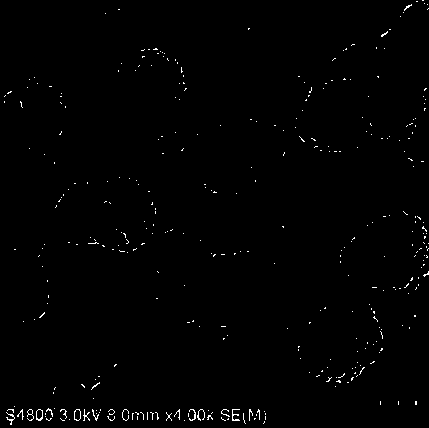

[0049] (1) In terms of molar ratio, dissolve nickel sulfate, cobalt sulfate and aluminum sulfate metal salt in deionized water, mix according to the ratio of Ni:Co:Al=0.8:0.15:0.05, and use a peristaltic pump to continuously pump the metal salt solution into the reactor, use NaOH as the precipitating agent, and ammonia as the complexing agent, adjust the injection speed of the precipitating agent and ammonia to control the pH value of the reactor to be 11, carry out the co-precipitation reaction, and the (Ni 0.8 co 0.15 al 0.05 )OH 2 After suction filtration, washing and drying, the precursor is obtained, and the morphology is spherical, with a particle size of 5-8 μm detected by SEM;

[0050] (2) Weigh 0.105mol LiOH·H 2 O, 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com