Patents

Literature

905 results about "Longest cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

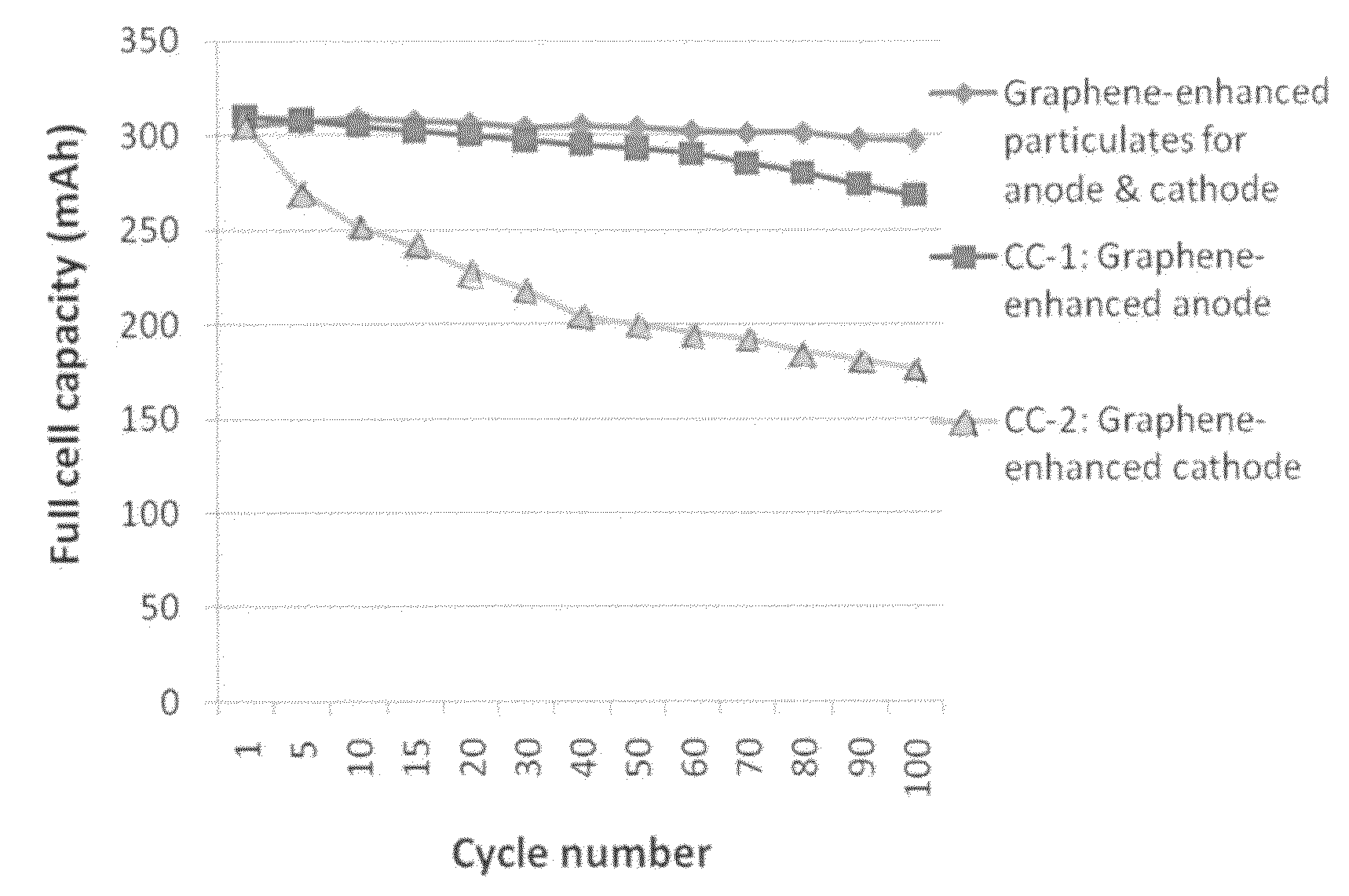

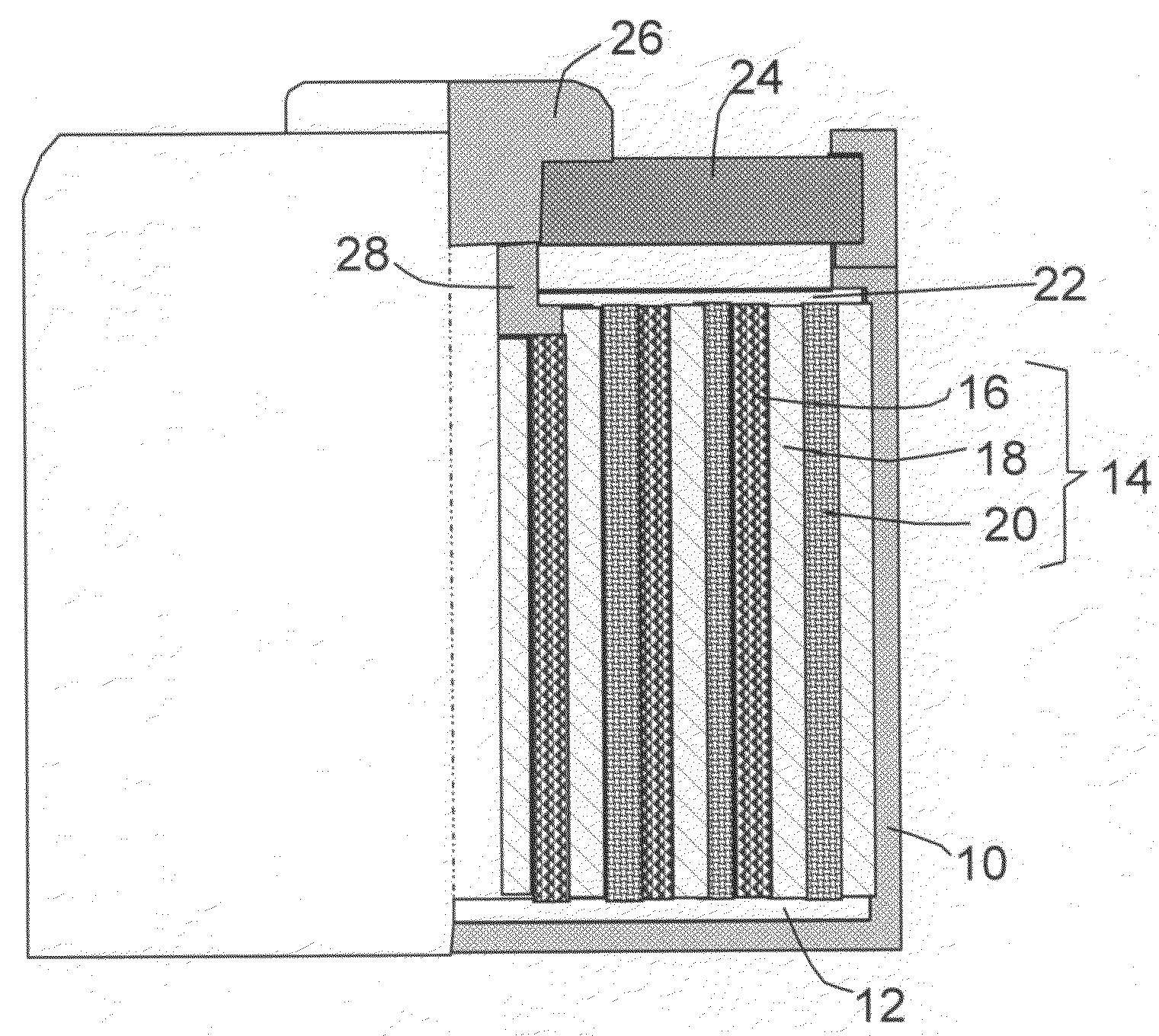

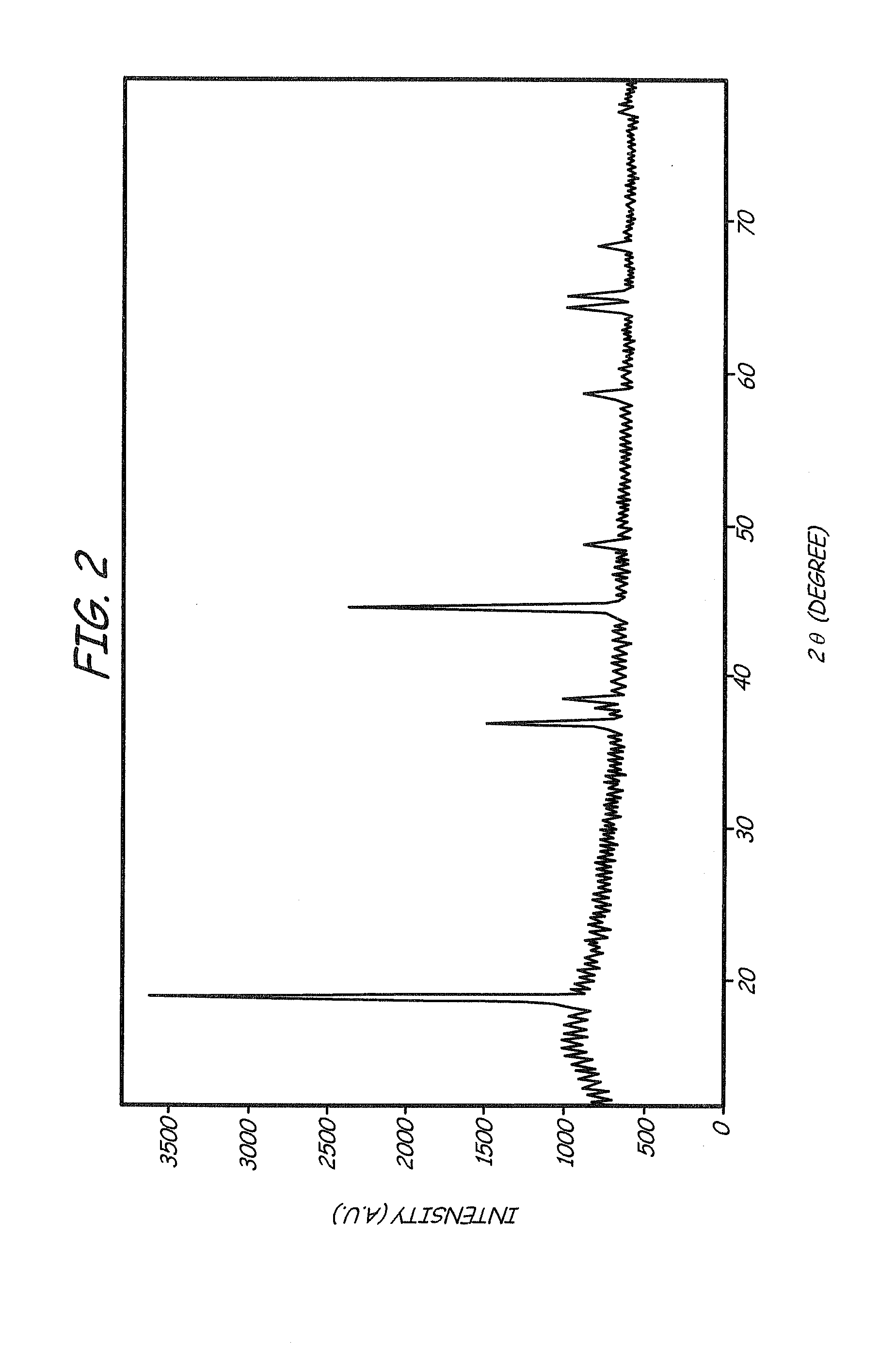

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

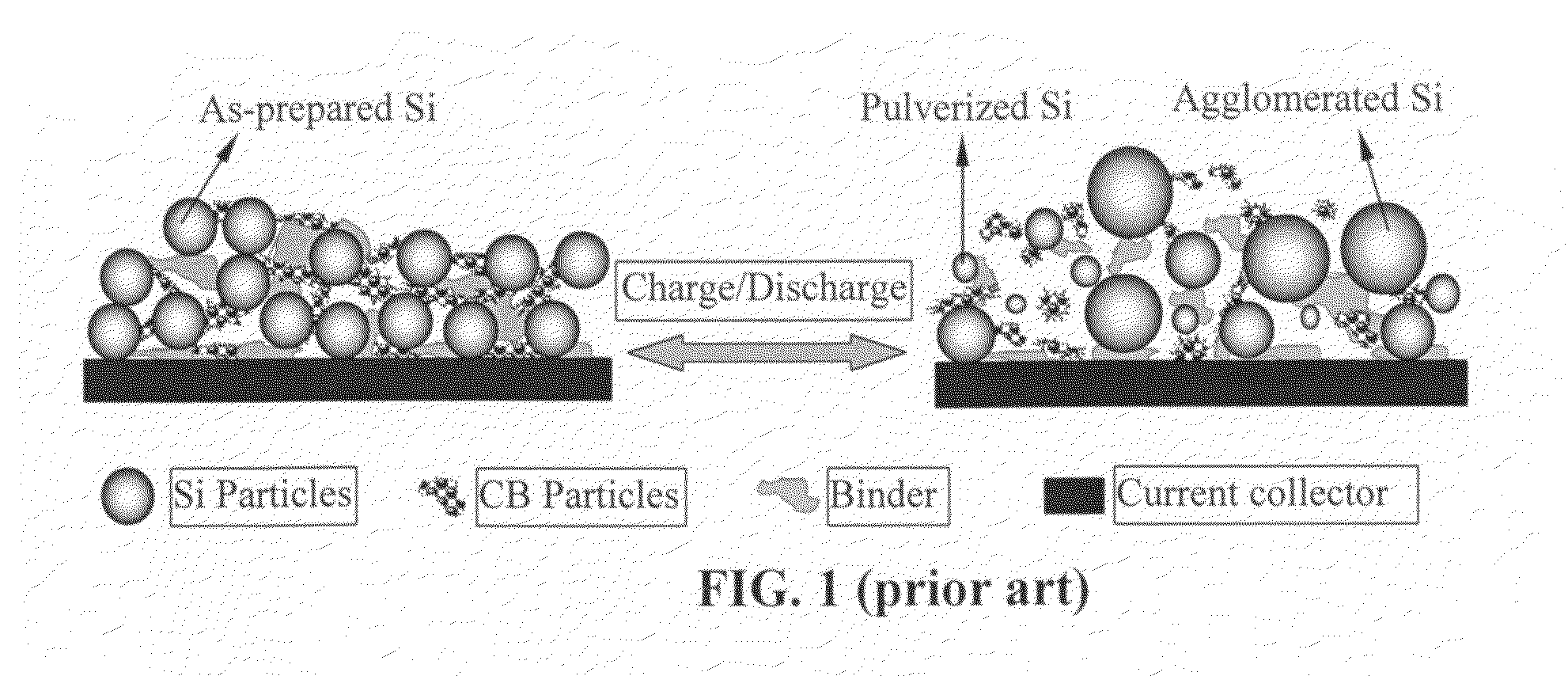

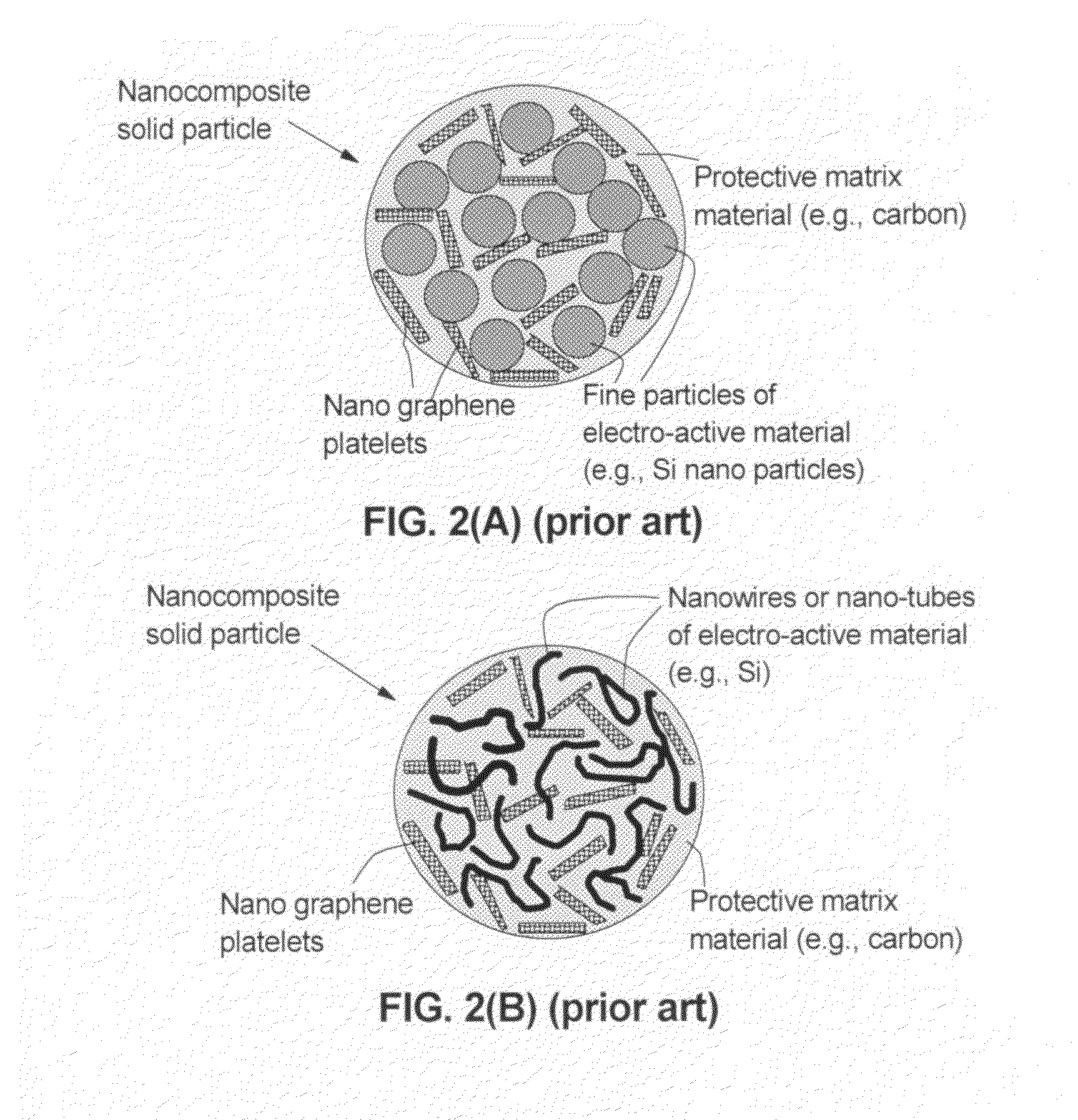

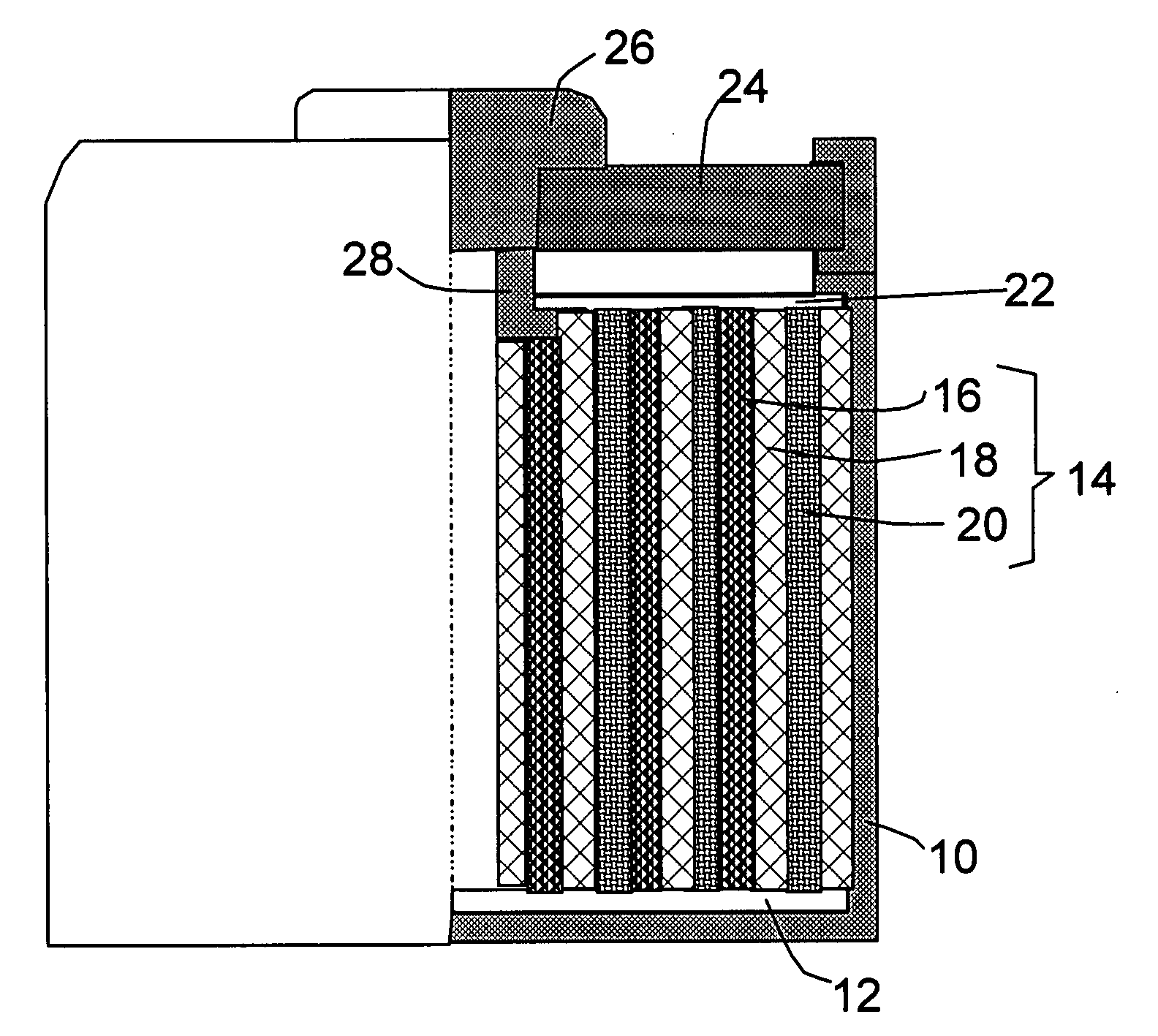

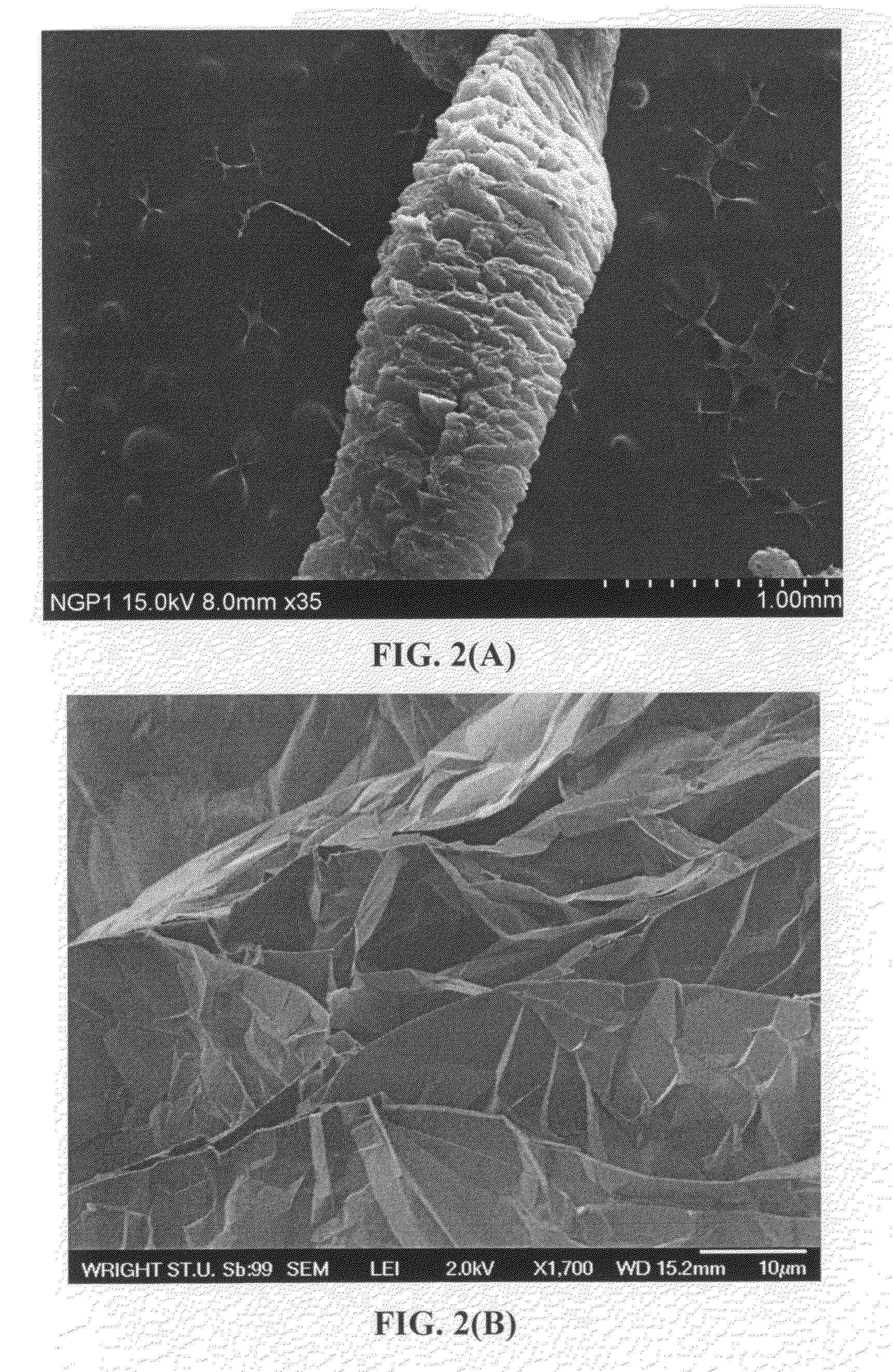

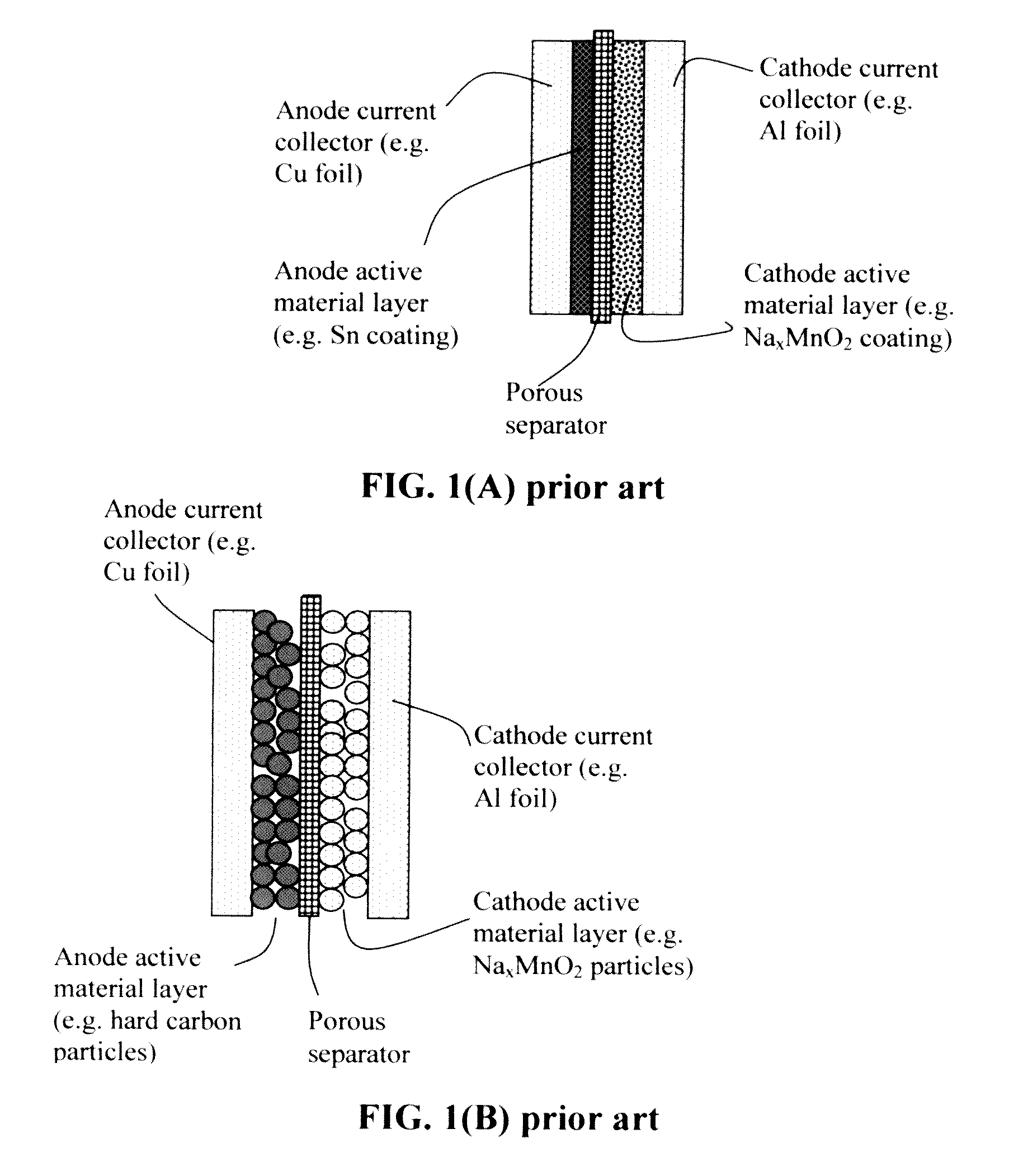

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

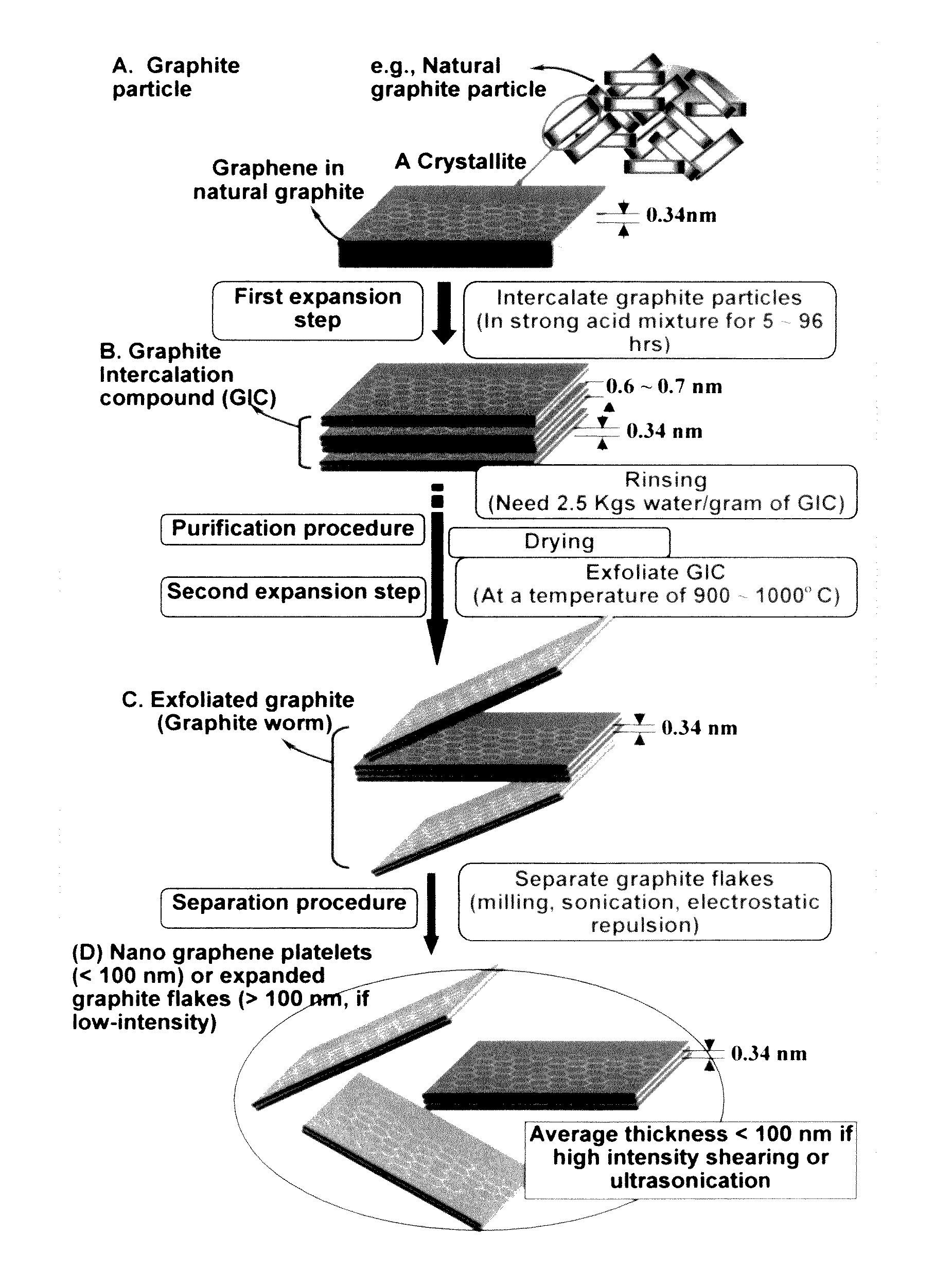

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

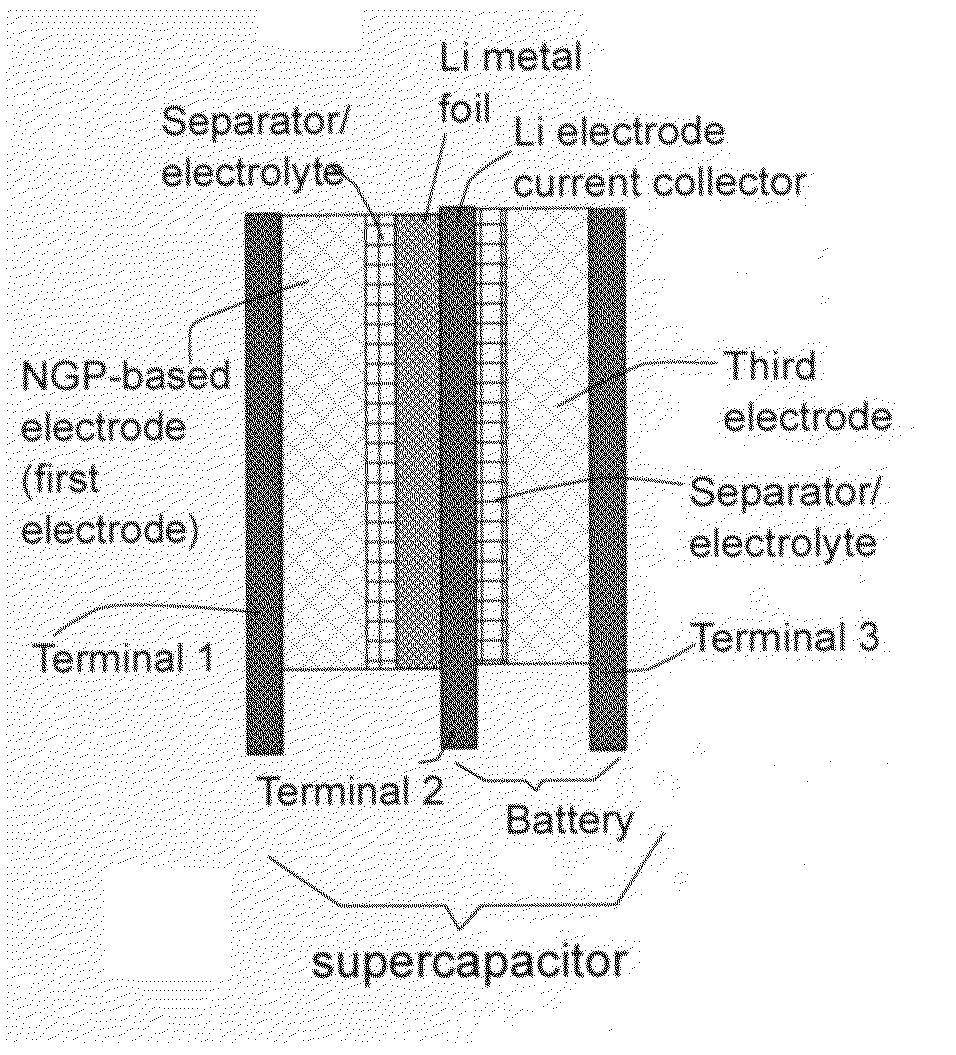

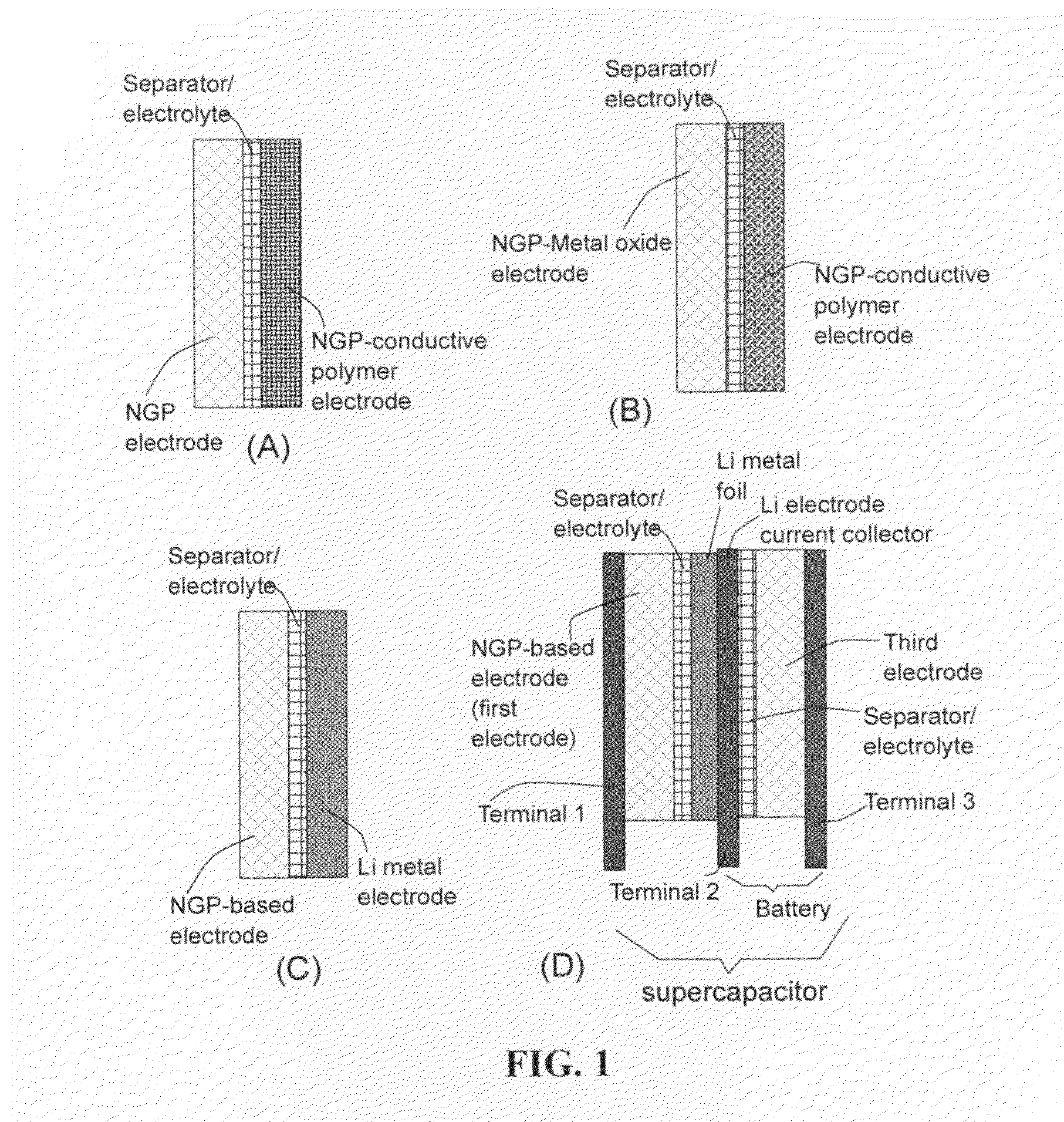

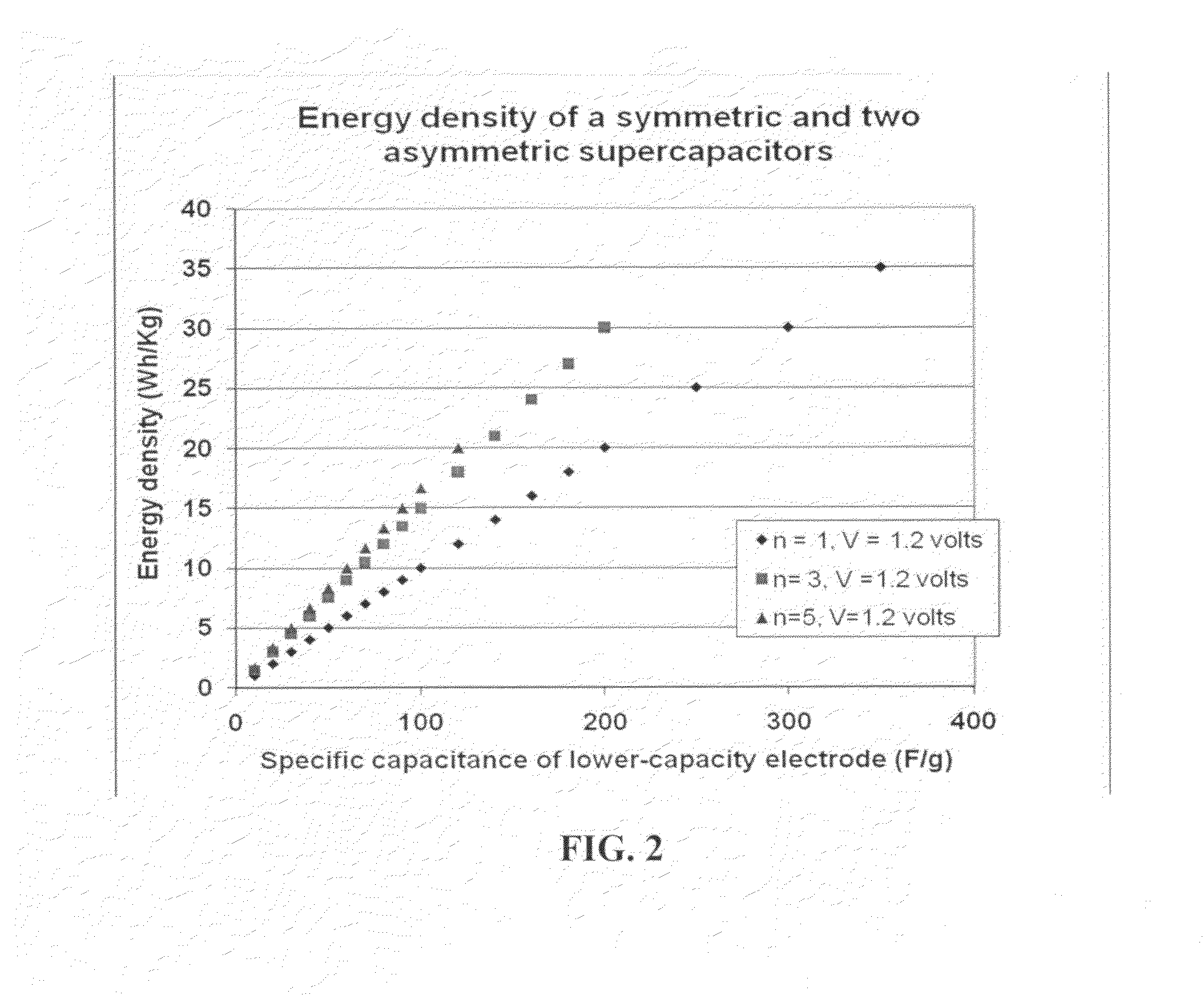

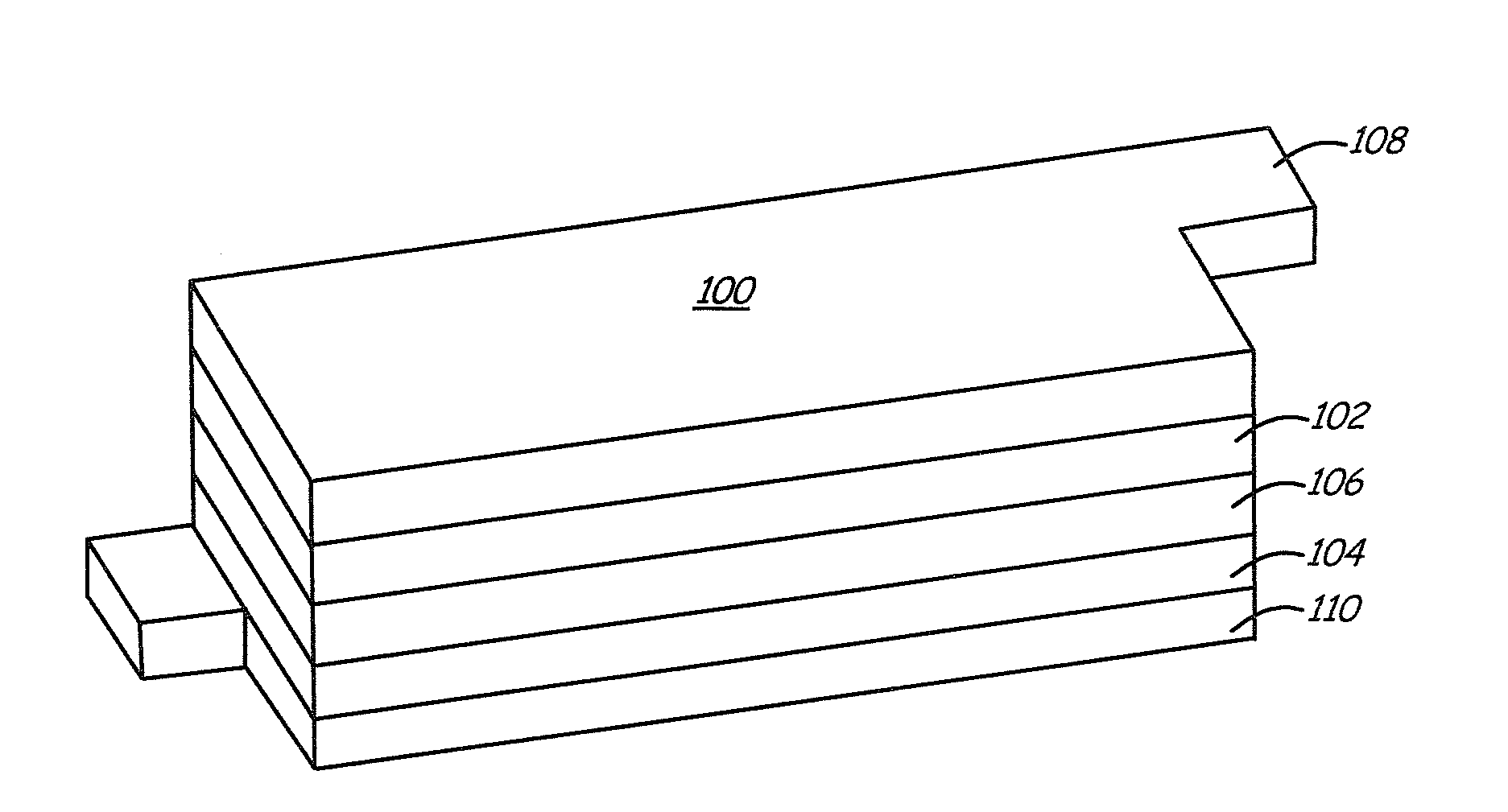

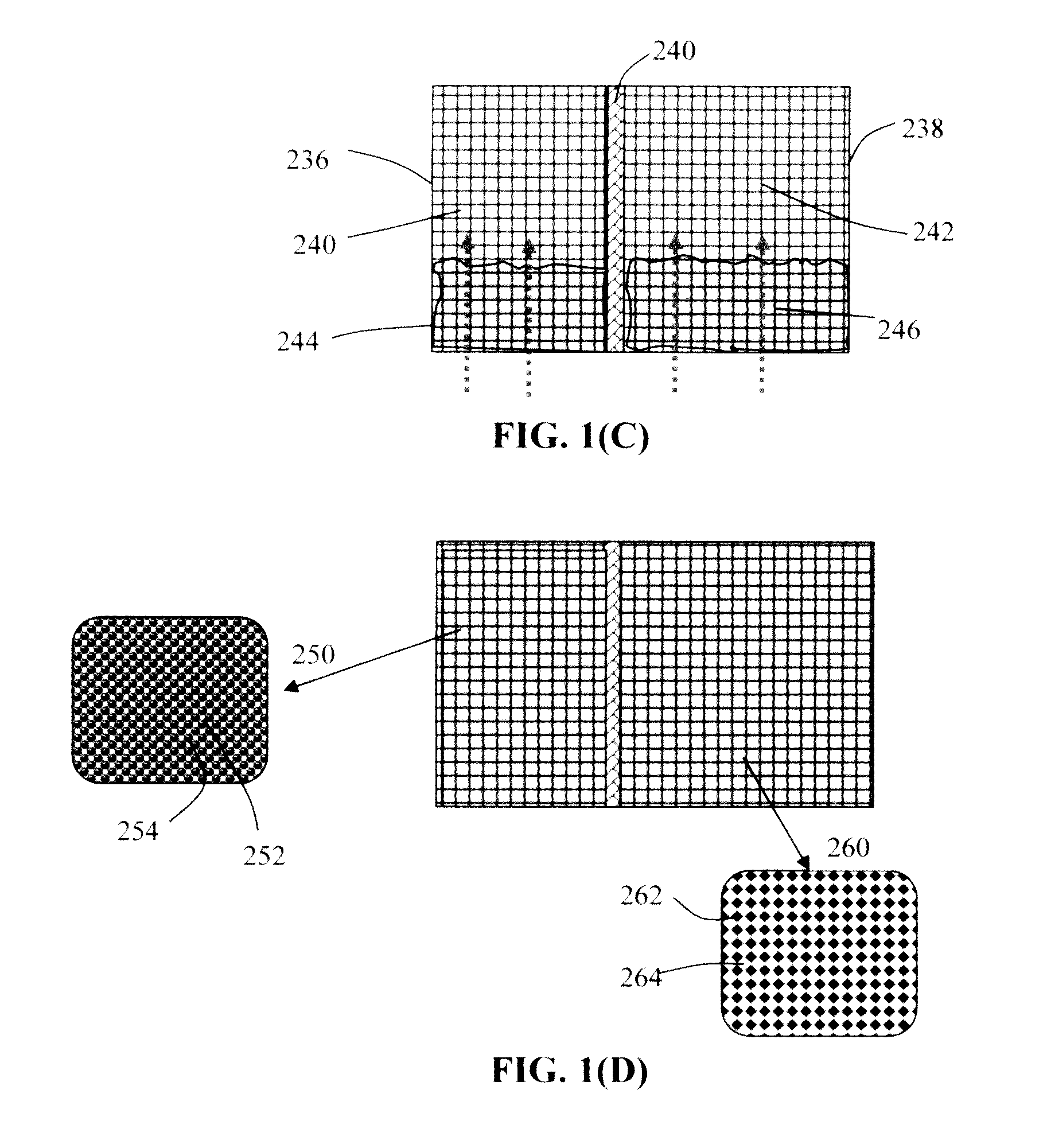

Flexible asymmetric electrochemical cells using nano graphene platelet as an electrode material

InactiveUS20110183180A1Excellent specific capacitanceLarge specific surface areaElectrochemical generatorsHybrid capacitor separatorsPlateletGraphene

A flexible, asymmetric electrochemical cell comprising: (A) A sheet of graphene paper as first electrode comprising nano graphene platelets having a platelet thickness less than 1 nm, wherein the first electrode has electrolyte-accessible pores; (B) A thin-film or paper-like first separator and electrolyte; and (C) A thin-film or paper-like second electrode which is different in composition than the first electrode; wherein the separator is sandwiched between the first and second electrode to form a flexible laminate configuration. The asymmetric supercapacitor cells with different NGP-based electrodes exhibit an exceptionally high capacitance, specific energy, and stable and long cycle life.

Owner:NANOTEK INSTR GRP LLC

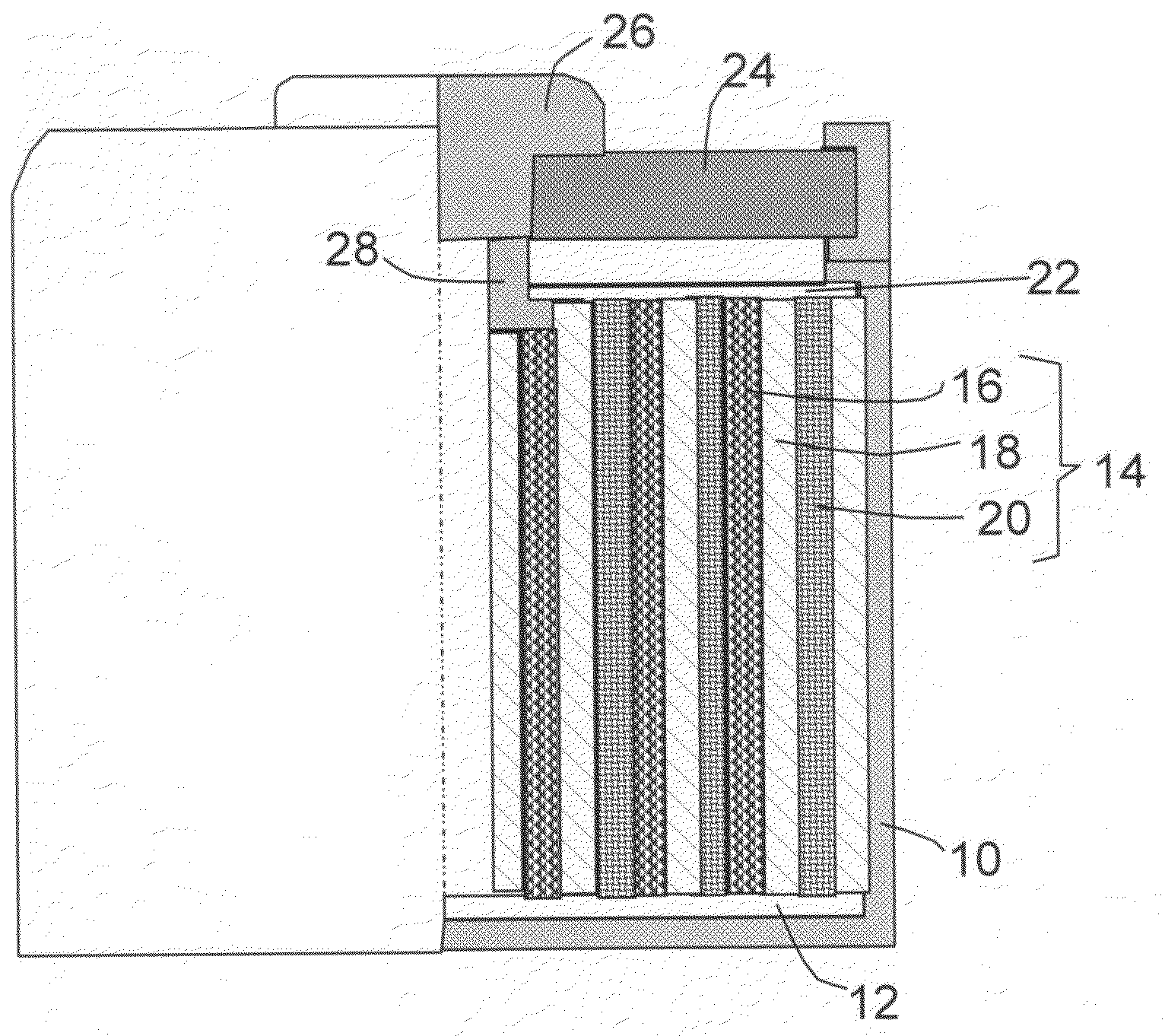

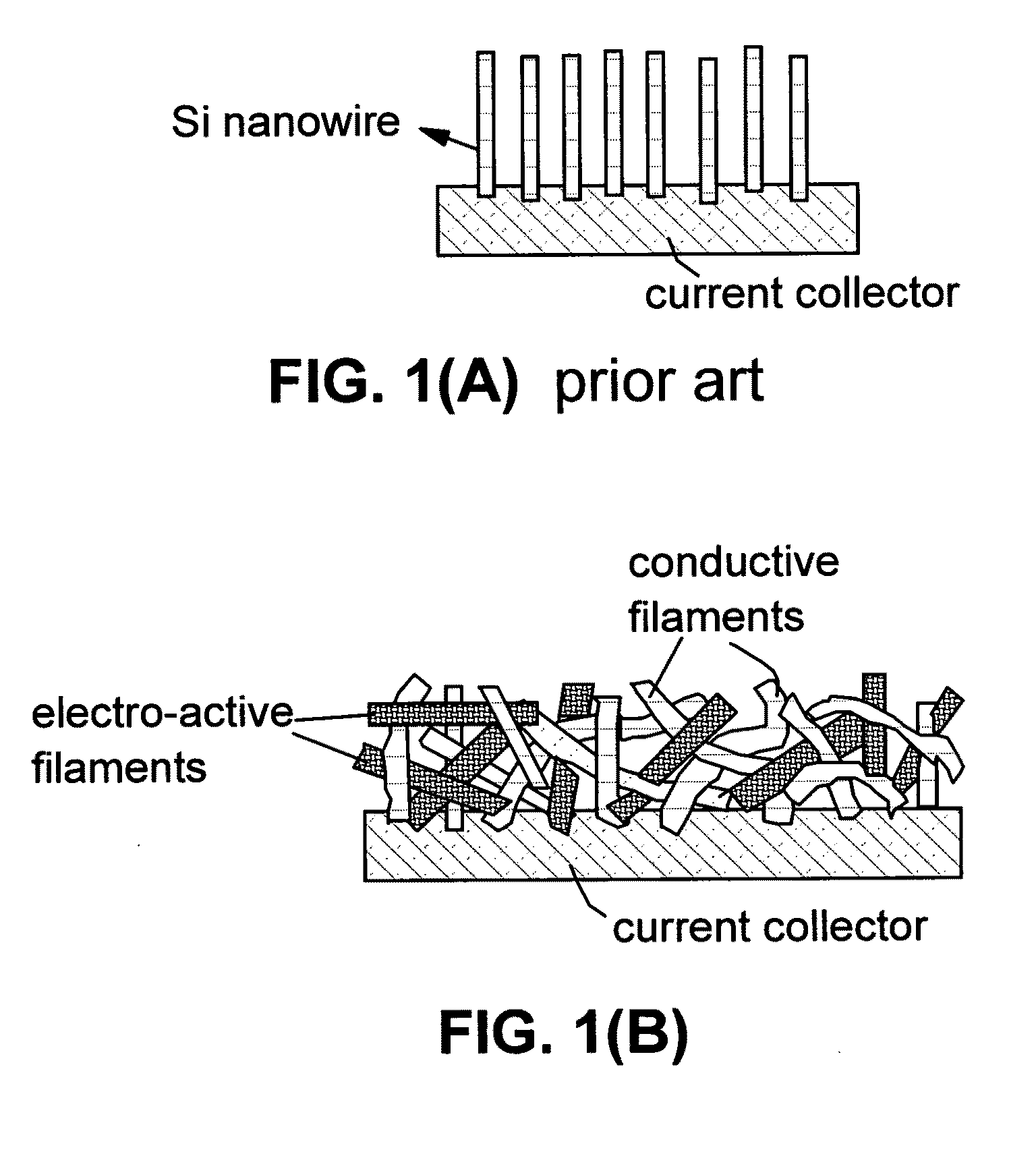

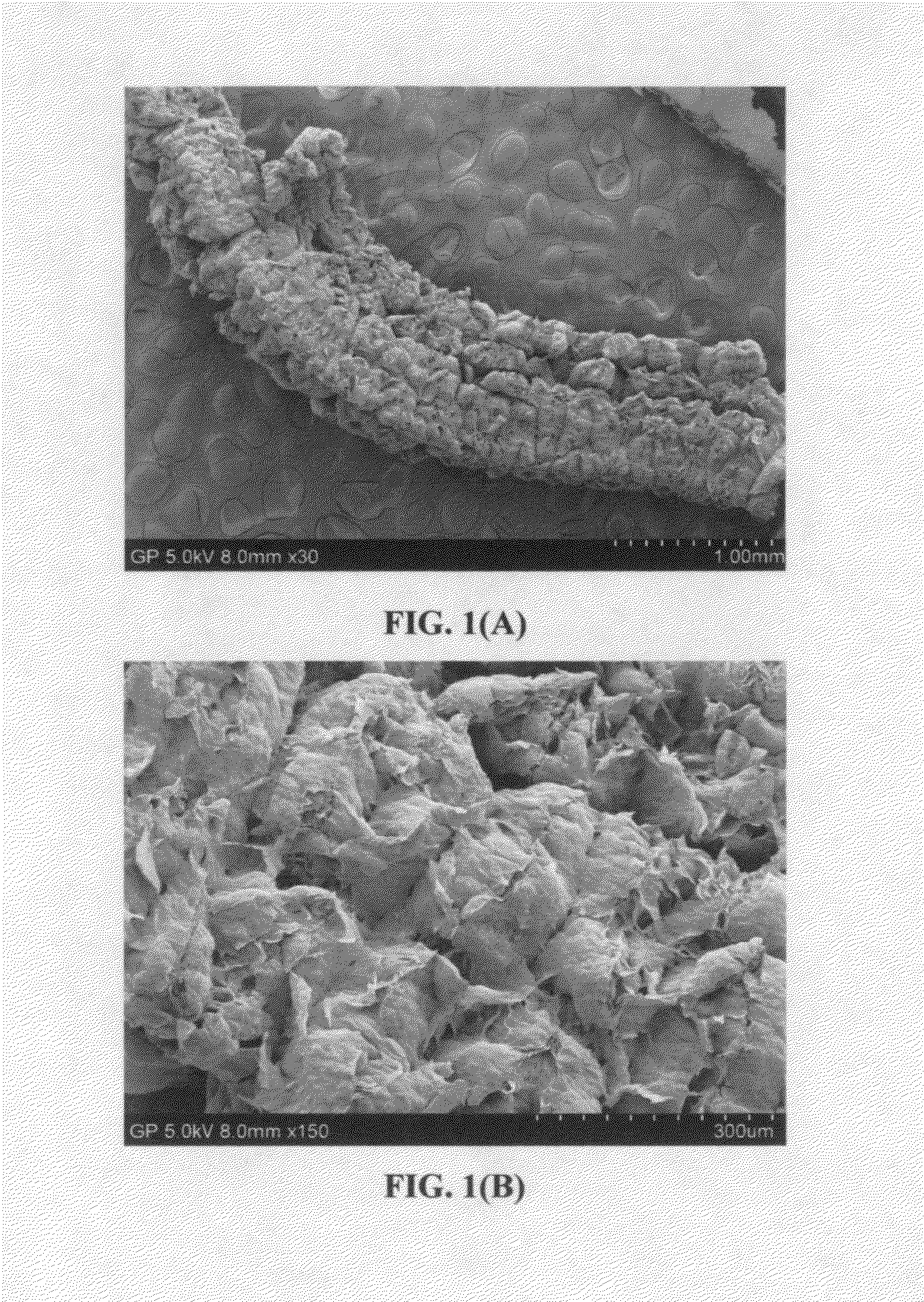

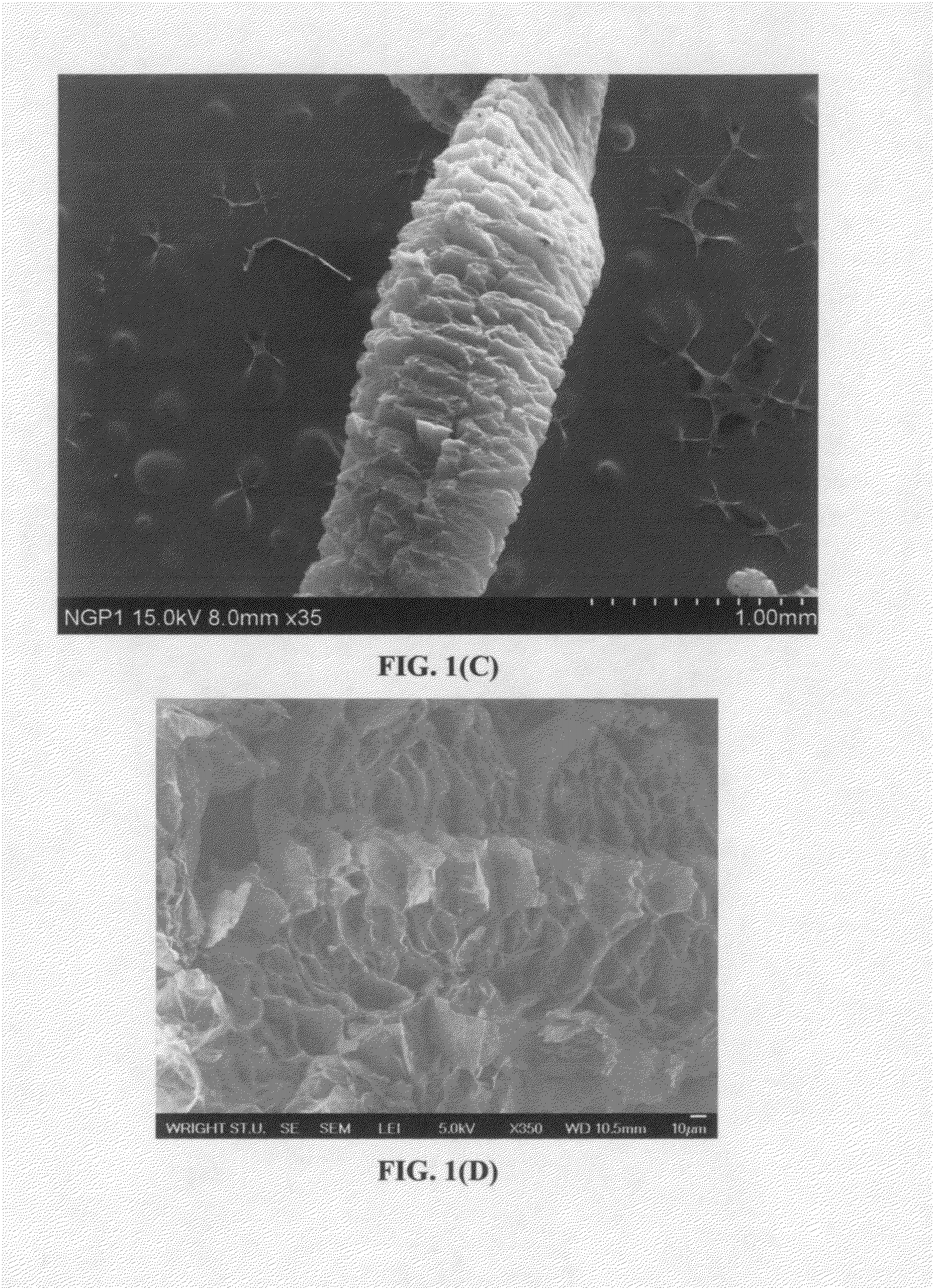

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

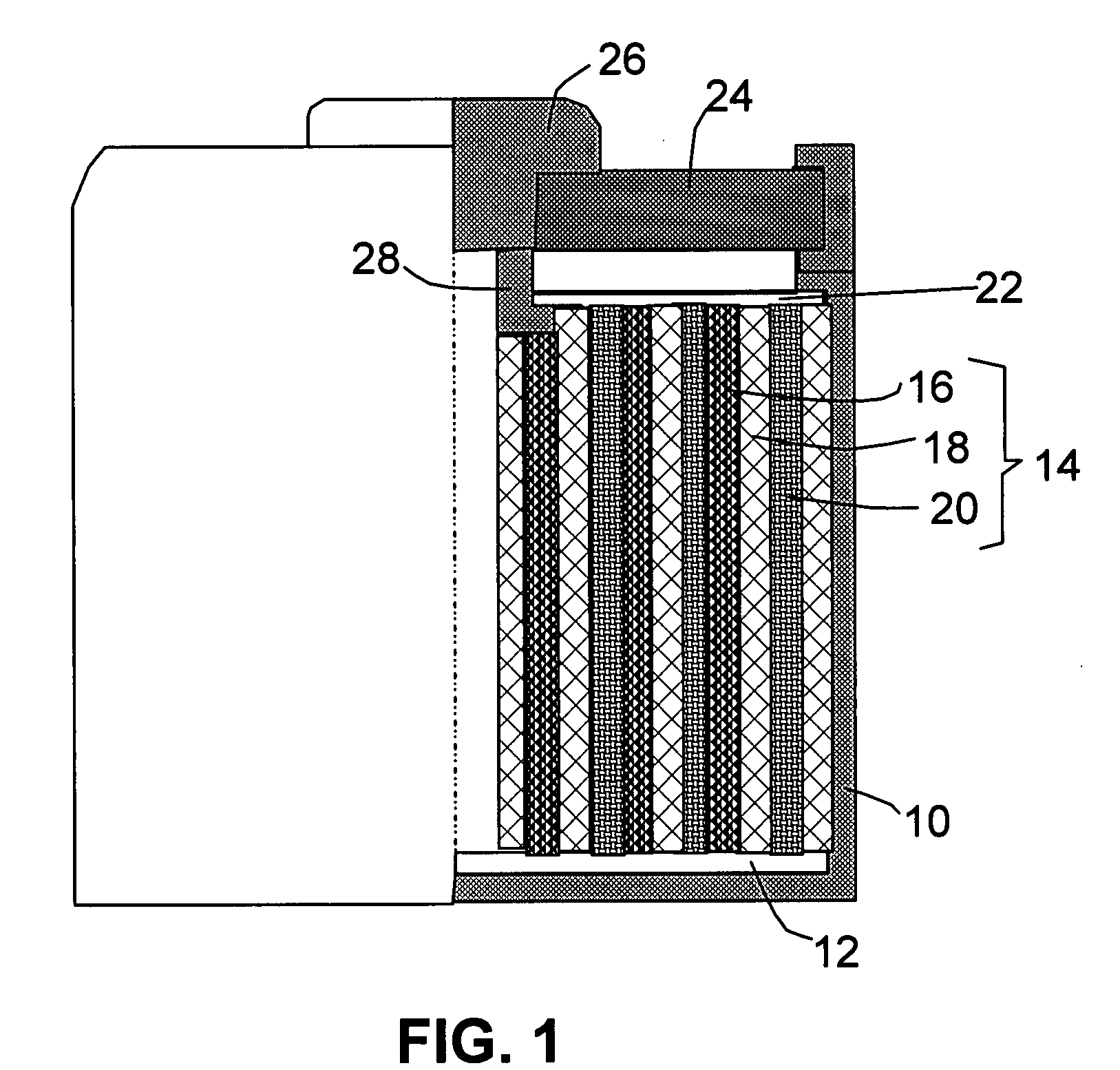

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

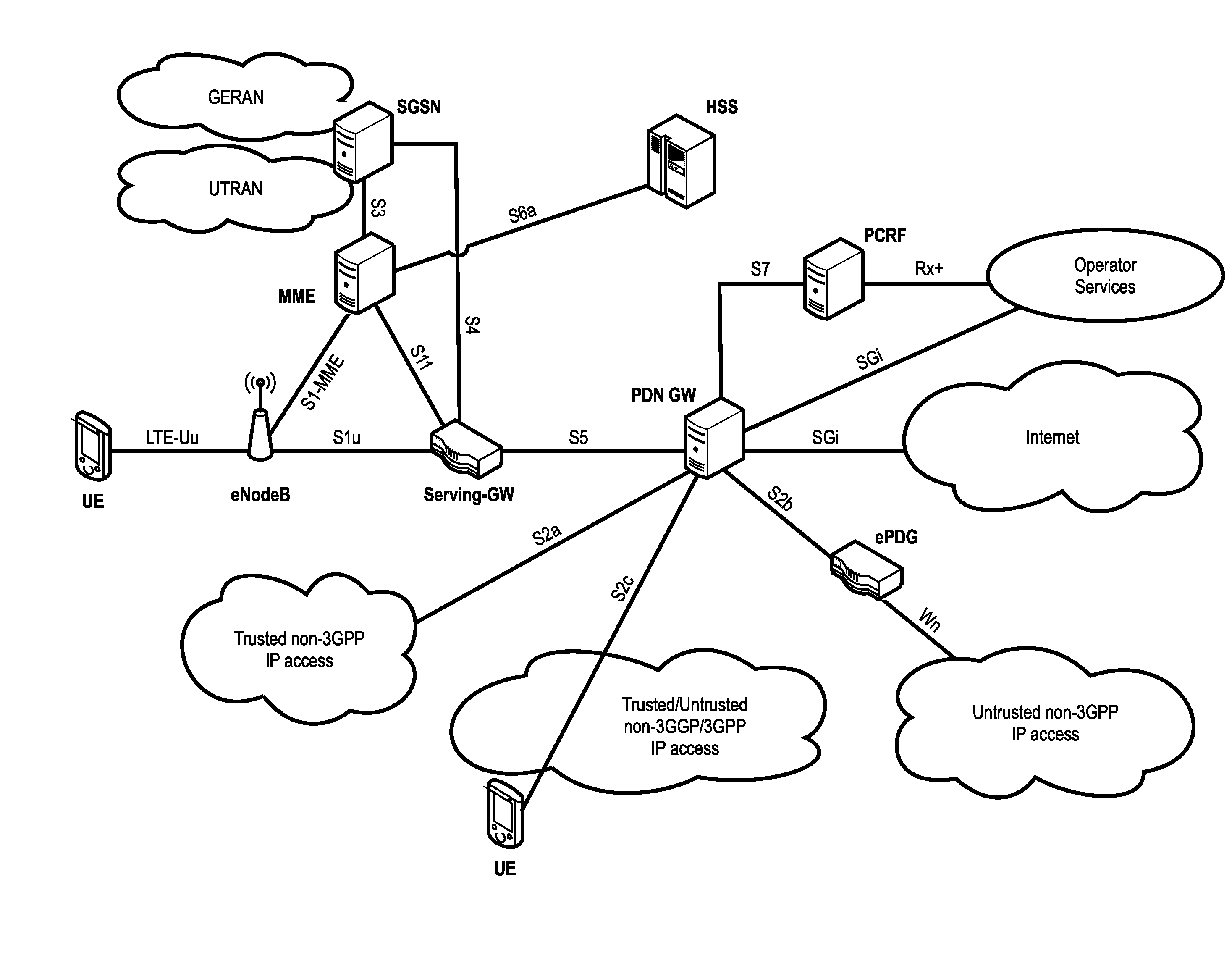

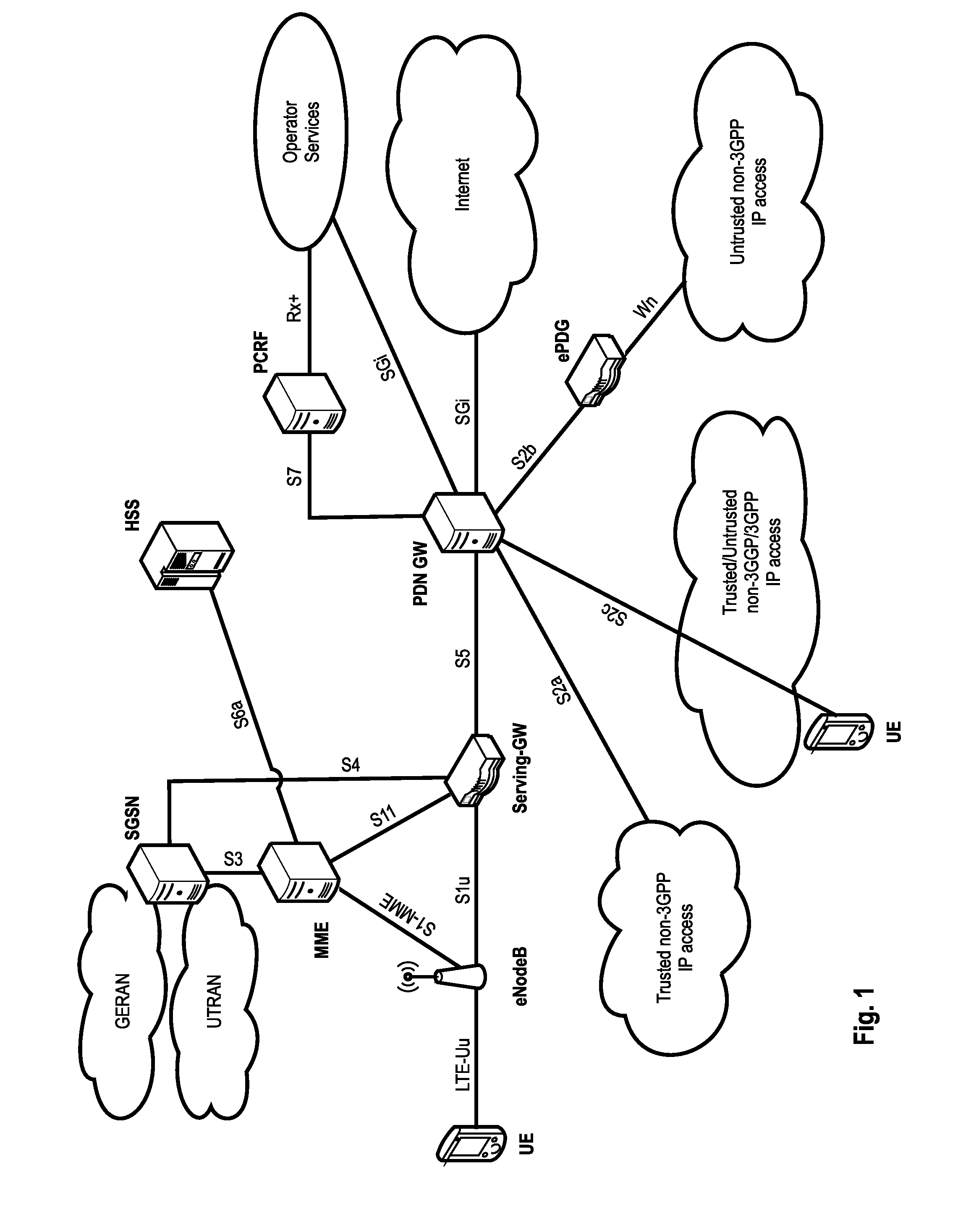

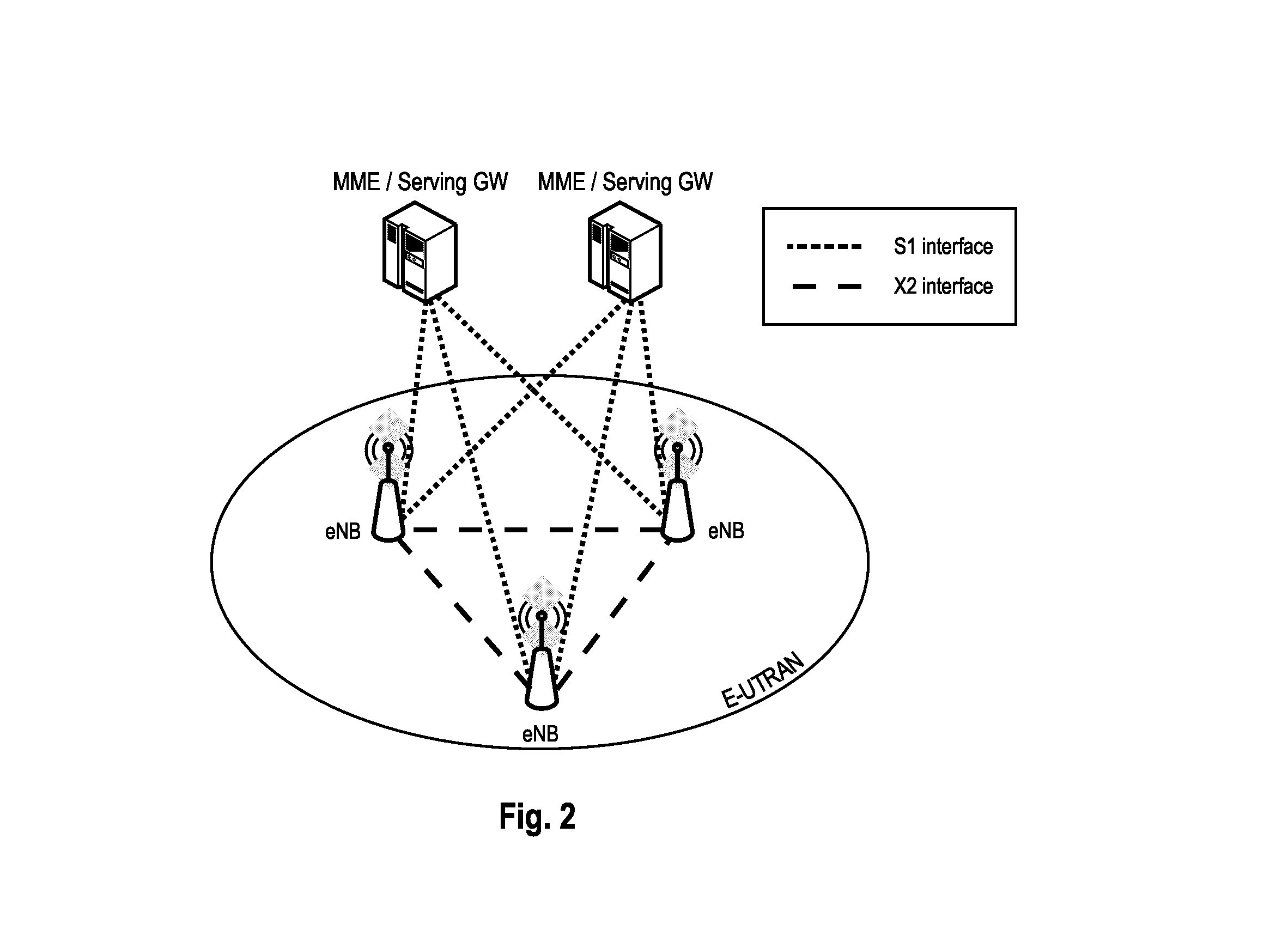

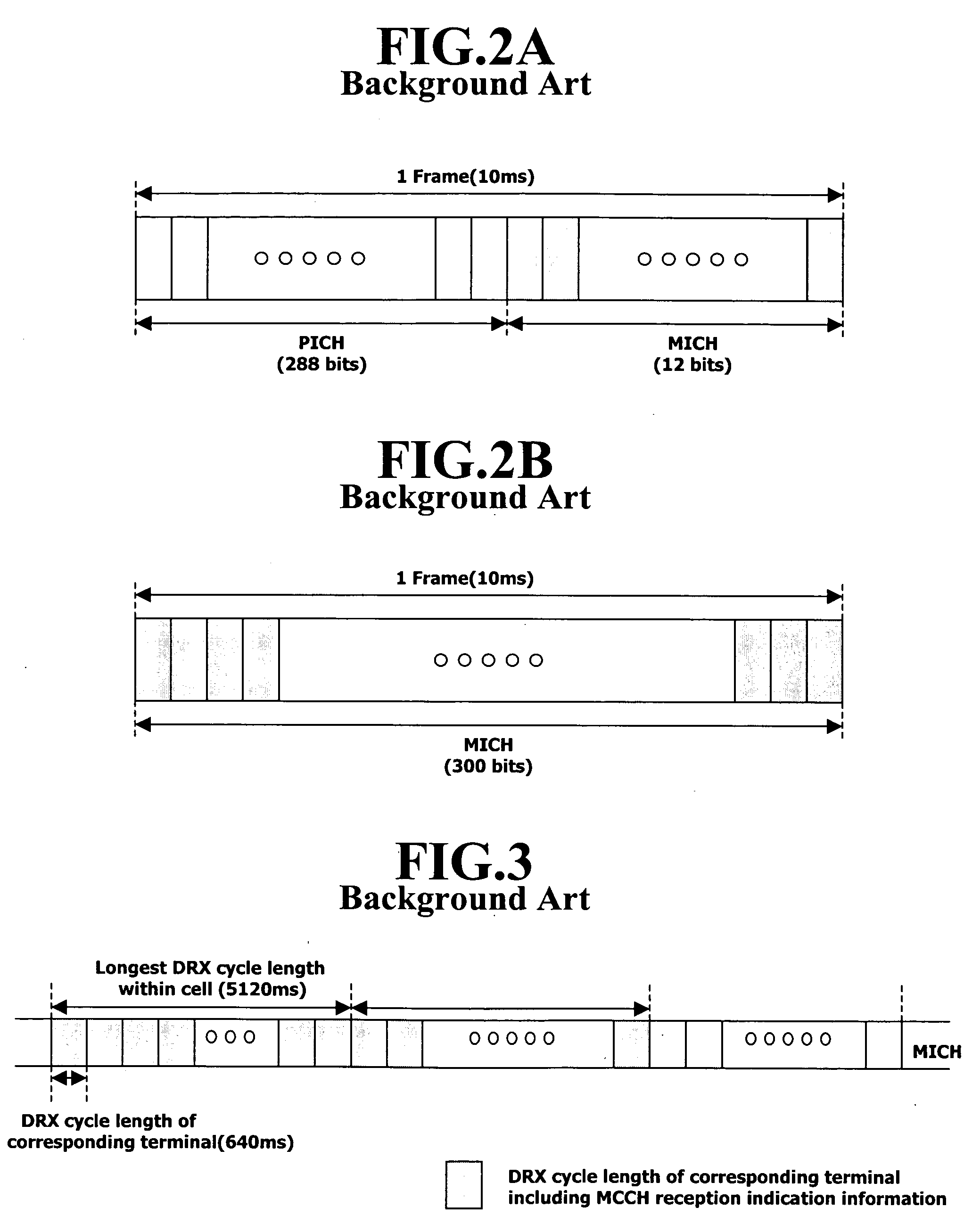

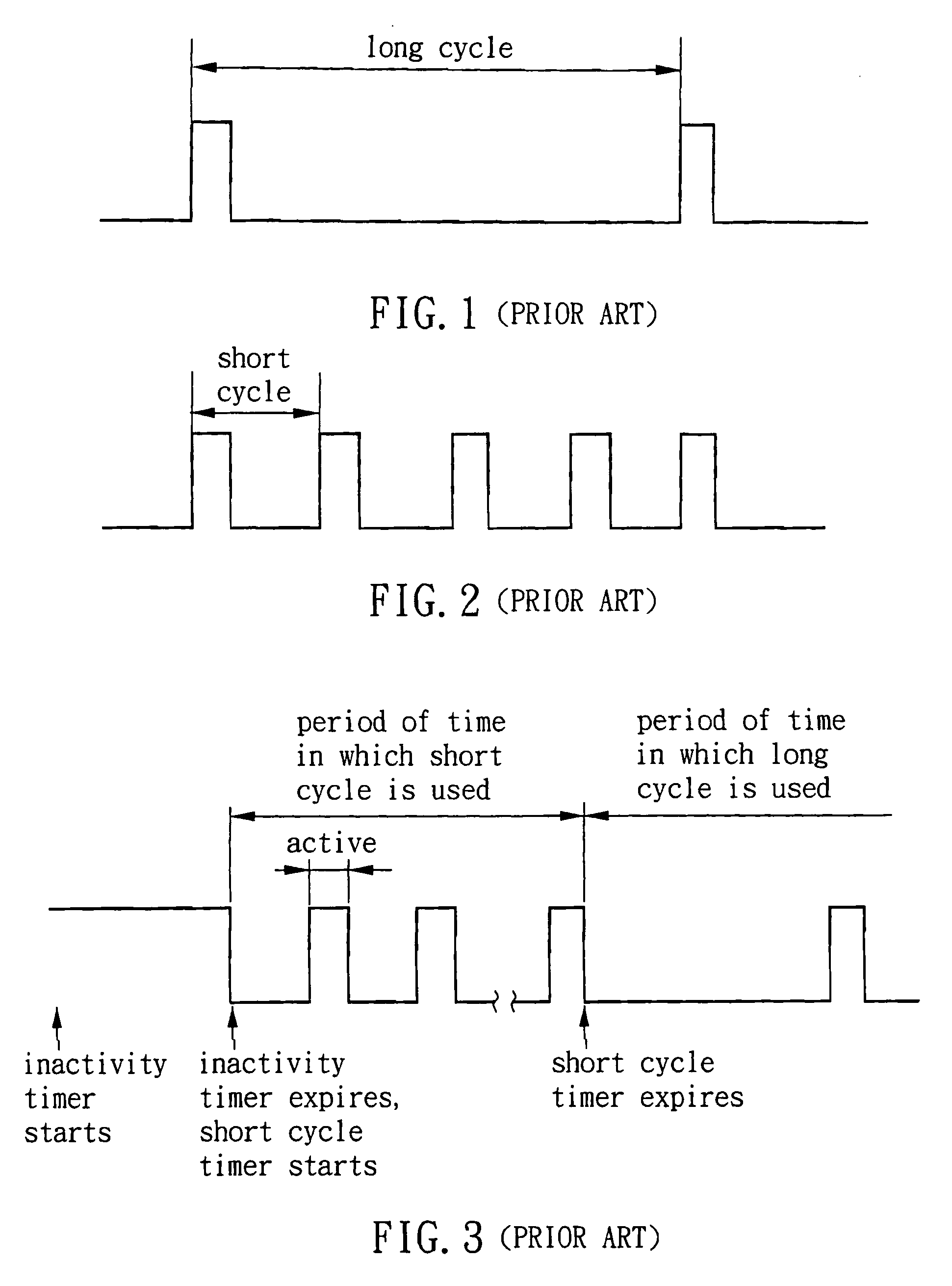

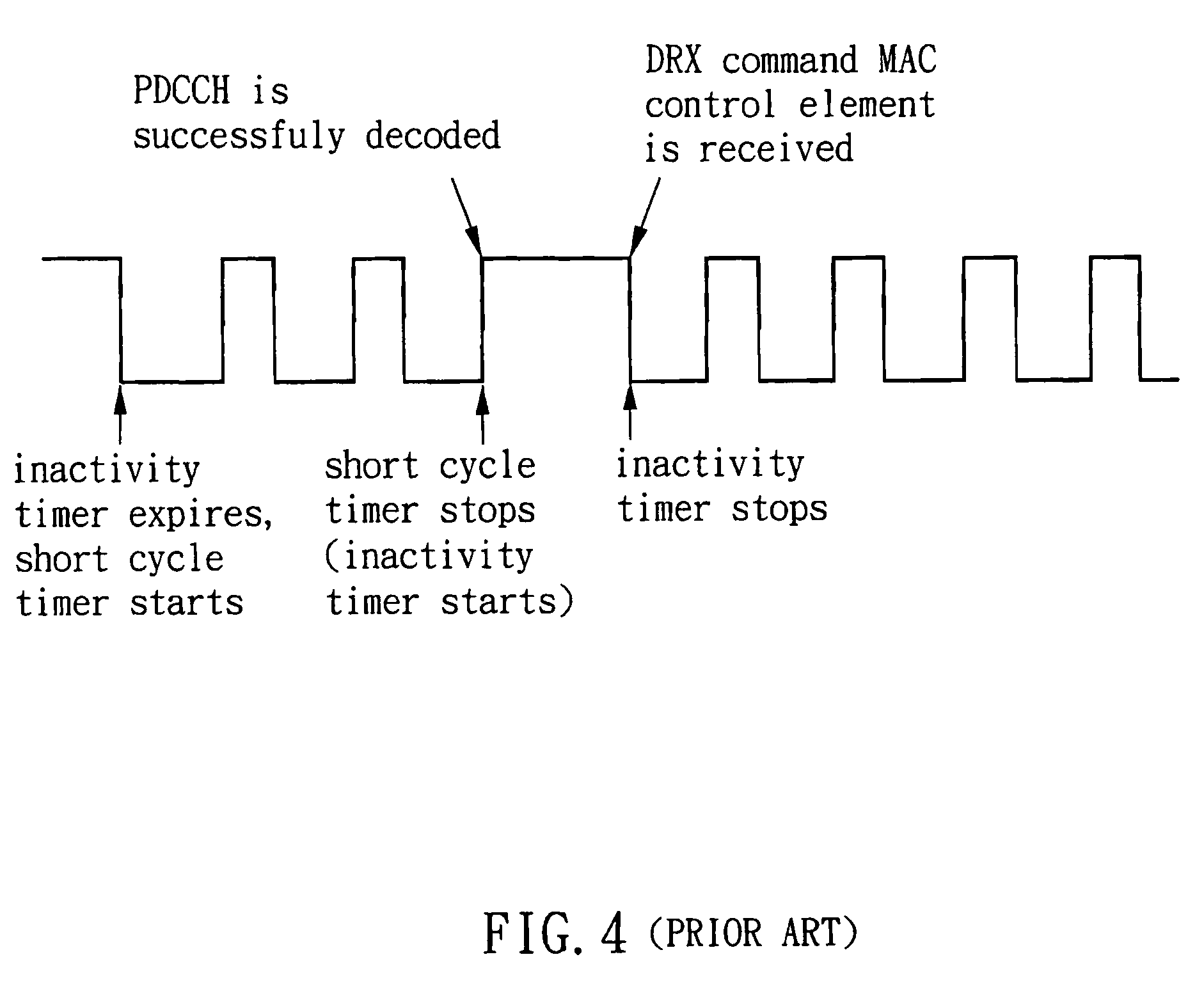

Discontinuous reception operation with additional wake-up opportunities

ActiveUS20150003311A1Short response timeMinimal impactPower managementTransmission systemsLongest cycleShort length

The invention relates to methods for improving the DRX operation of a UE by introducing an additional DRX wake-up cycle, which runs in parallel to the short and / or long DRX cycle. The DRX wake-up cycle defines time intervals after which the UE starts monitoring the PDCCH for a wake-up duration of time; the UE does not perform any other operation during the wake-up duration apart from monitoring the PDCCH. The time intervals of the wake-up cycle between the wake-up durations are preferably shorter than the one of the DRX long cycle, and may have the same or a shorter length than the ones of the DRX short cycle. The wake-up duration may be as long as the on-duration of the DRX short / long cycle, or may be preferably much shorter, such as only one or a few subframes.

Owner:APPLE INC

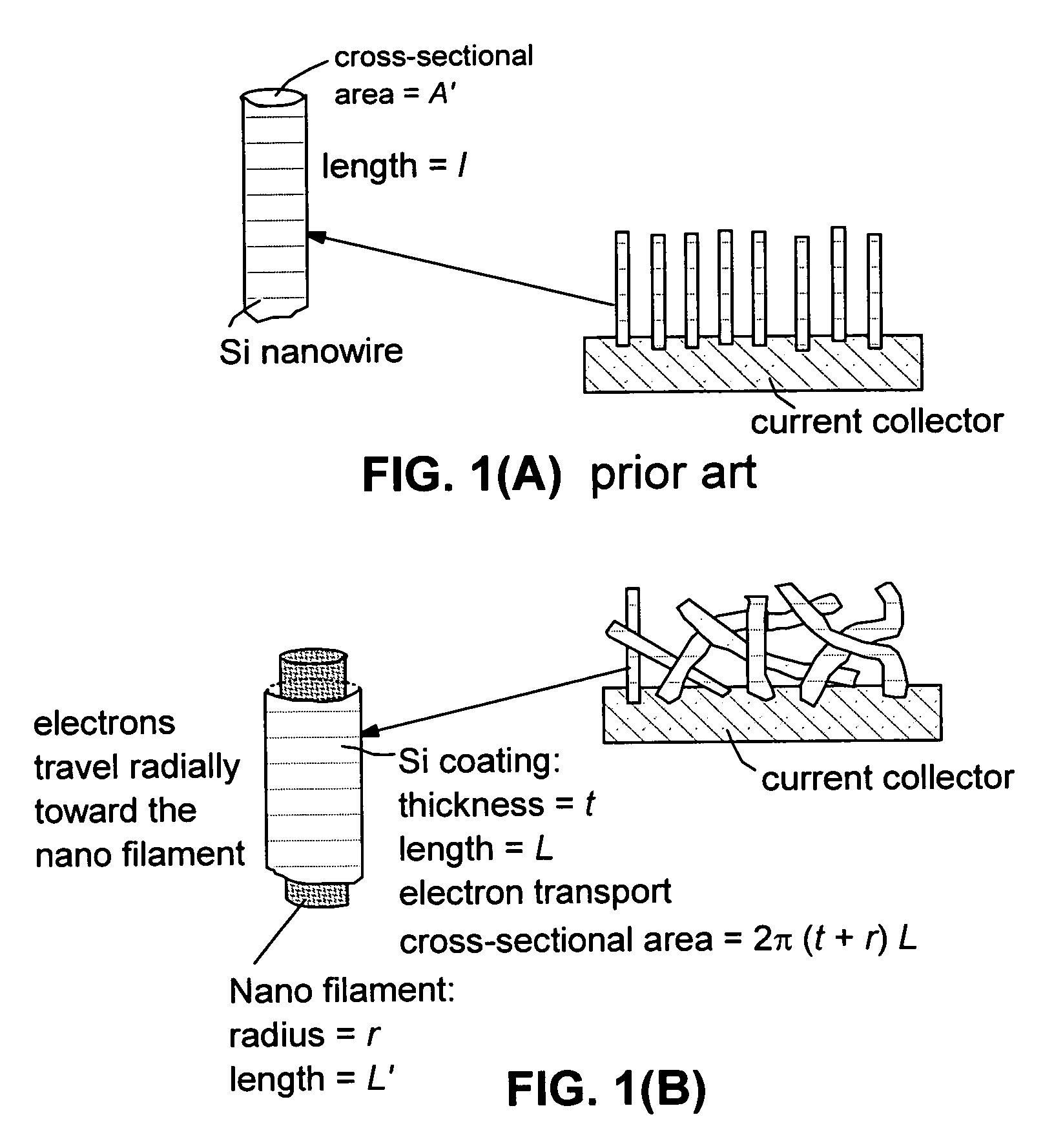

Mixed nano-filament electrode materials for lithium ion batteries

ActiveUS20090176159A1Improve conductivityEasy to collectActive material electrodesSecondary cellsFiberNanowire

This invention provides a mixed nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter / thickness less than 500 nm (preferably <100 nm) and a length-to-diameter or length-to-thickness aspect ratio greater than 10; and (b) Multiple nanometer-scaled, electro-active filaments comprising an electro-active material capable of absorbing and desorbing lithium ions wherein the electro-active filaments have a diameter or thickness less than 500 nm (preferably <100 nm). The electro-active filaments (e.g., nanowires) and the electrically conductive filaments (e.g., carbon nano fibers) are mixed to form a mat-, web-, or porous paper-like structure in which at least an electro-active filament is in electrical contact with at least an electrically conductive filament. Also provided is a lithium ion battery comprising such an electrode as an anode or cathode, or both. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

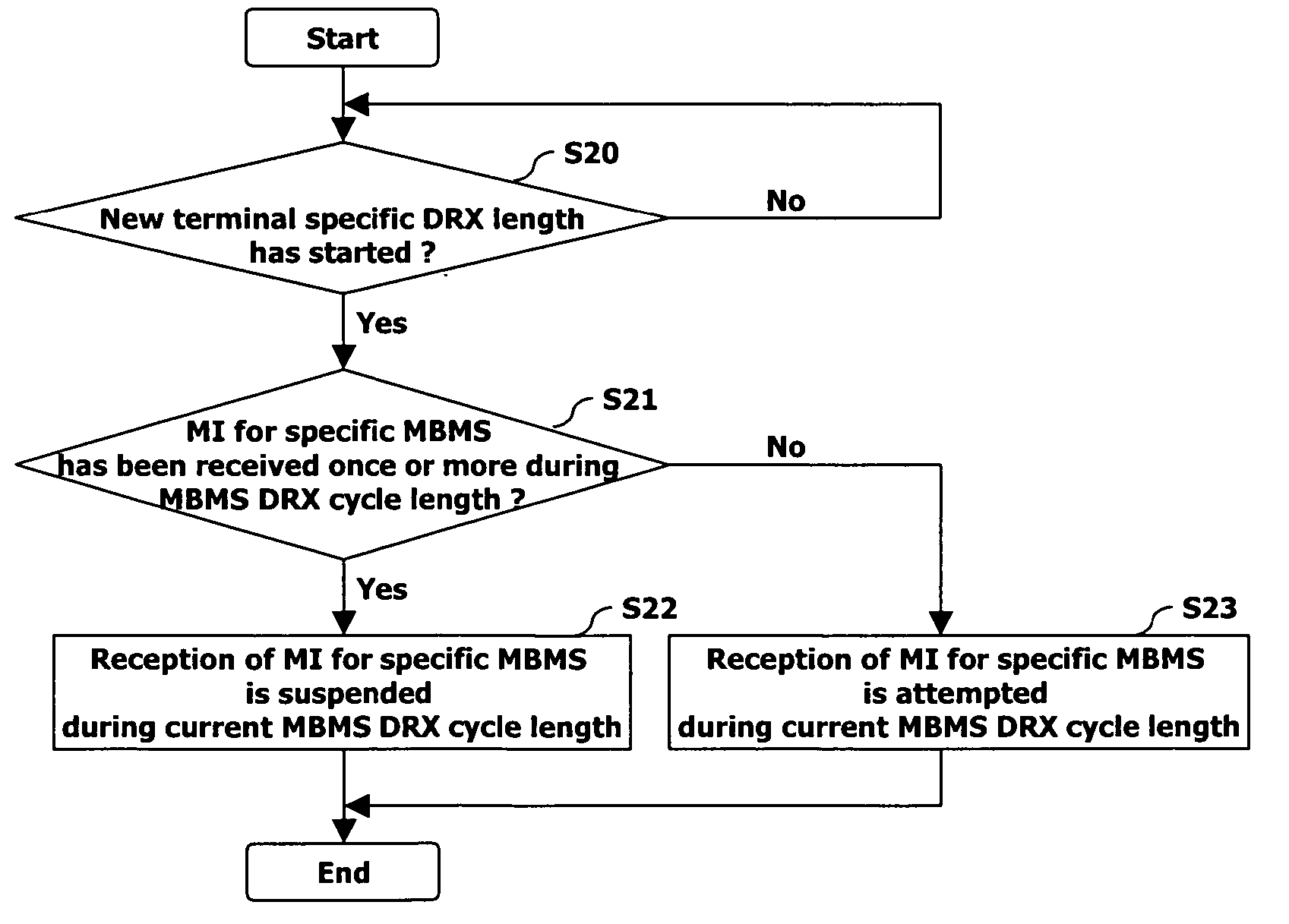

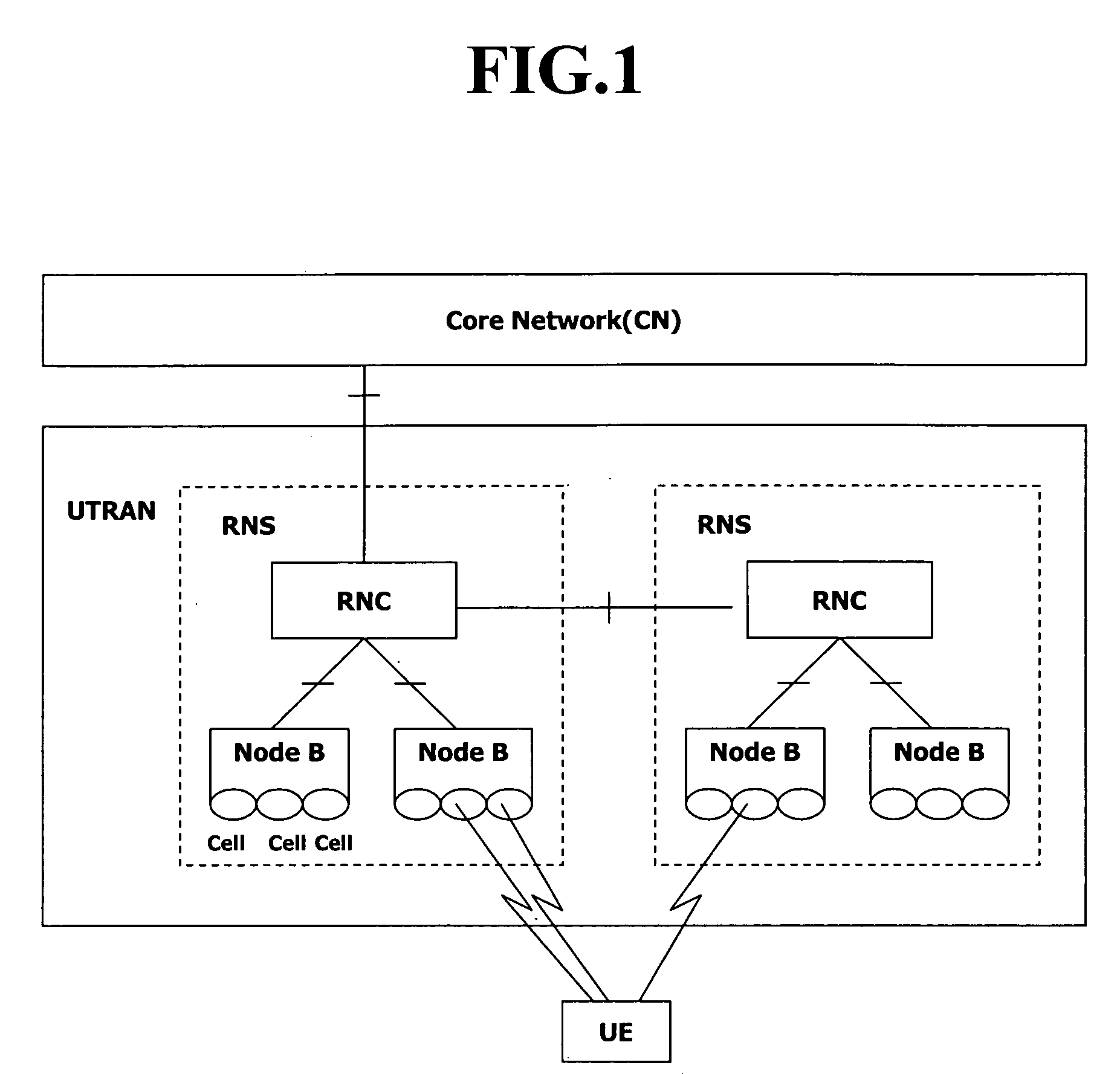

Apparatus and method for discontinuously receiving MBMS notification indicator in mobile communication system

InactiveUS20050176474A1Efficient receptionAssess restrictionSpecial service for subscribersMobile communication systemsComputer science

An apparatus and method for receiving an MBMS (Multimedia Multicast / Broadcast Service) notification indicator is disclosed to discontinuously receive an MBMS notification indicator in a mobile communication system. A mobile terminal receives and stores a terminal-specific DRX (Discontinuous Reception) cycle length and the longest DRX cycle length broadcasted in a cell. The mobile terminal discontinuously receives a notification indicator for a specific MBMS during a terminal-specific DRX cycle length of the longest DRX cycle length by using the stored terminal-specific DRX cycle length and the longest DRX cycle length used in a cell.

Owner:LG ELECTRONICS INC

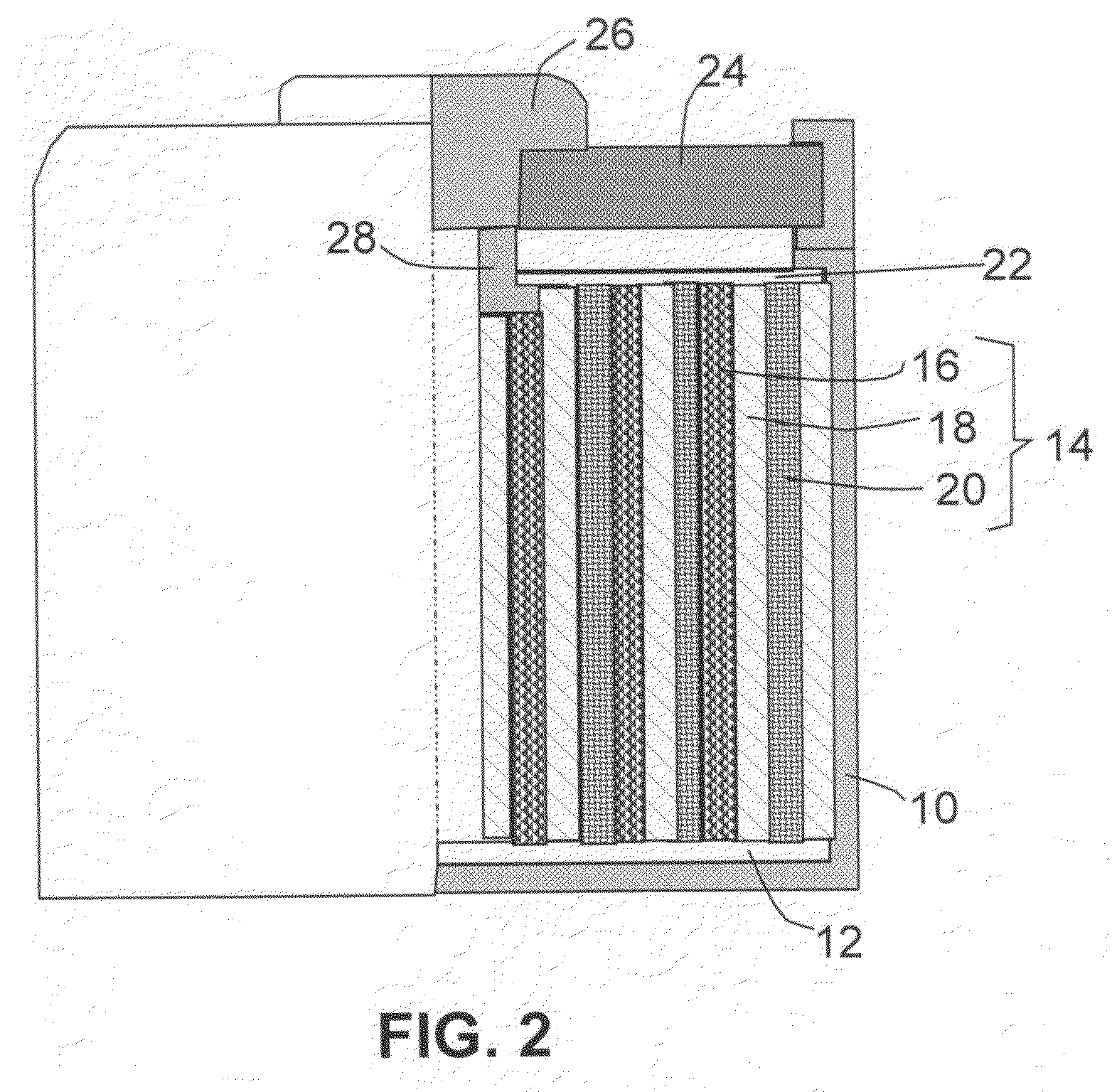

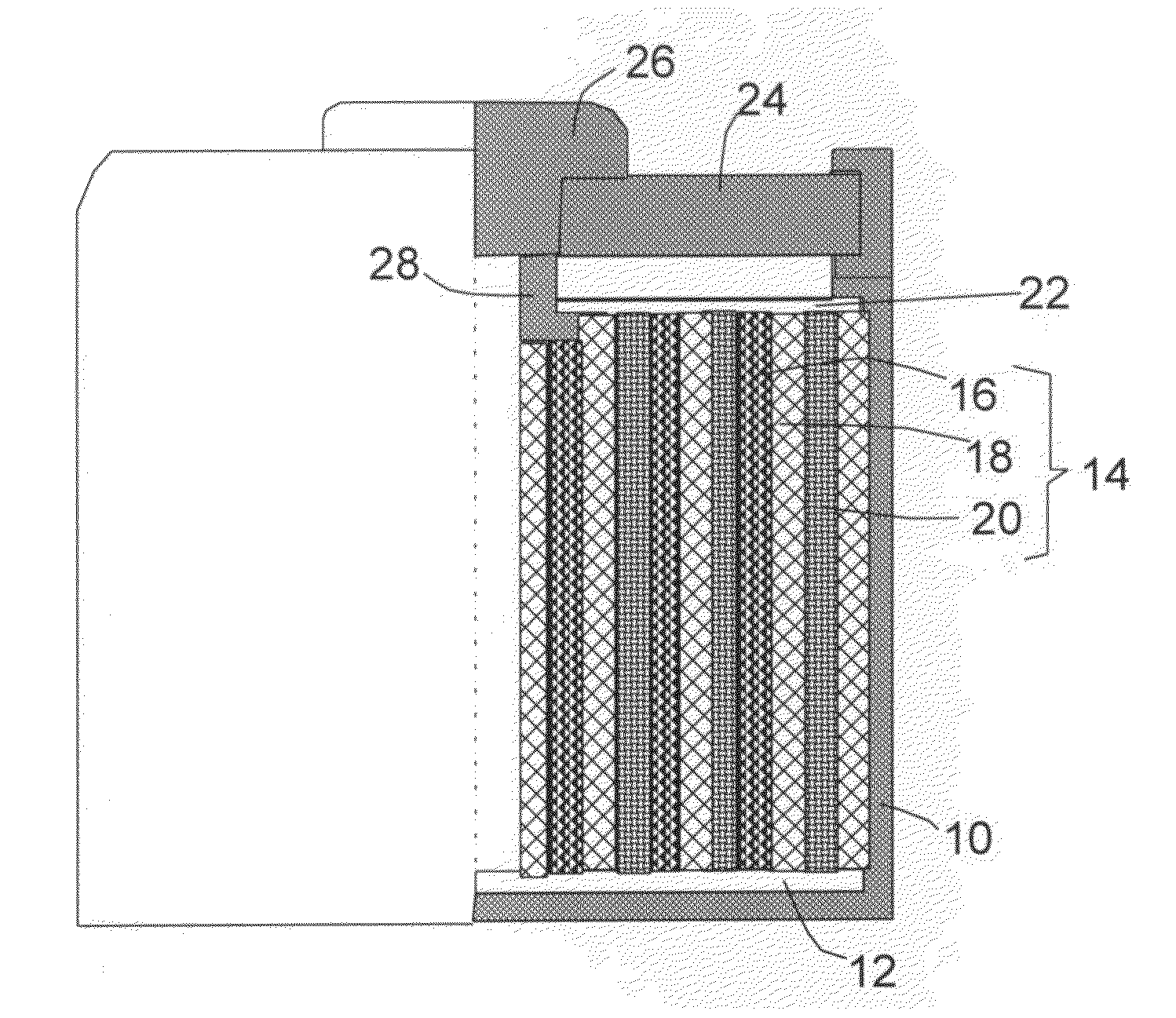

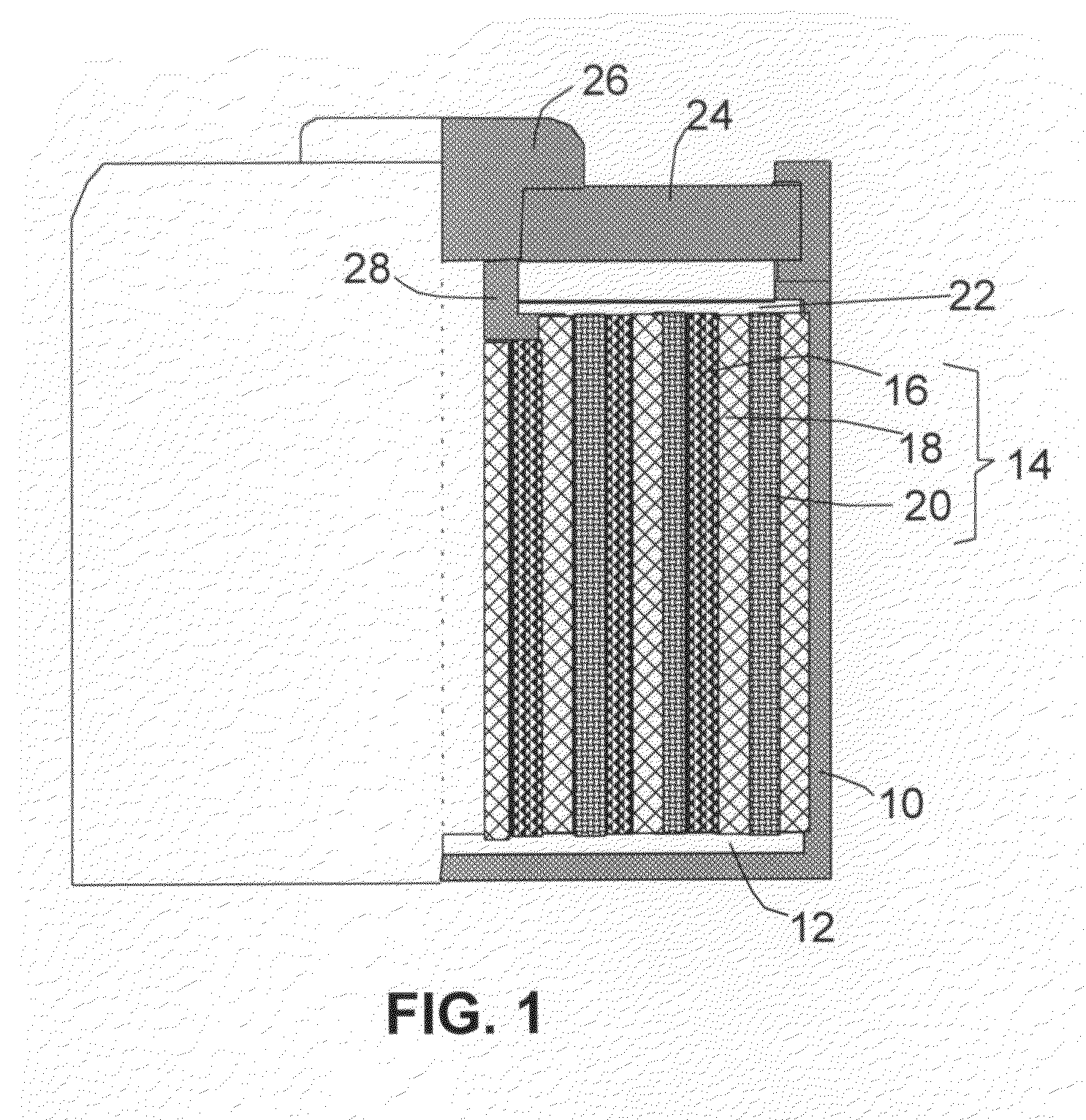

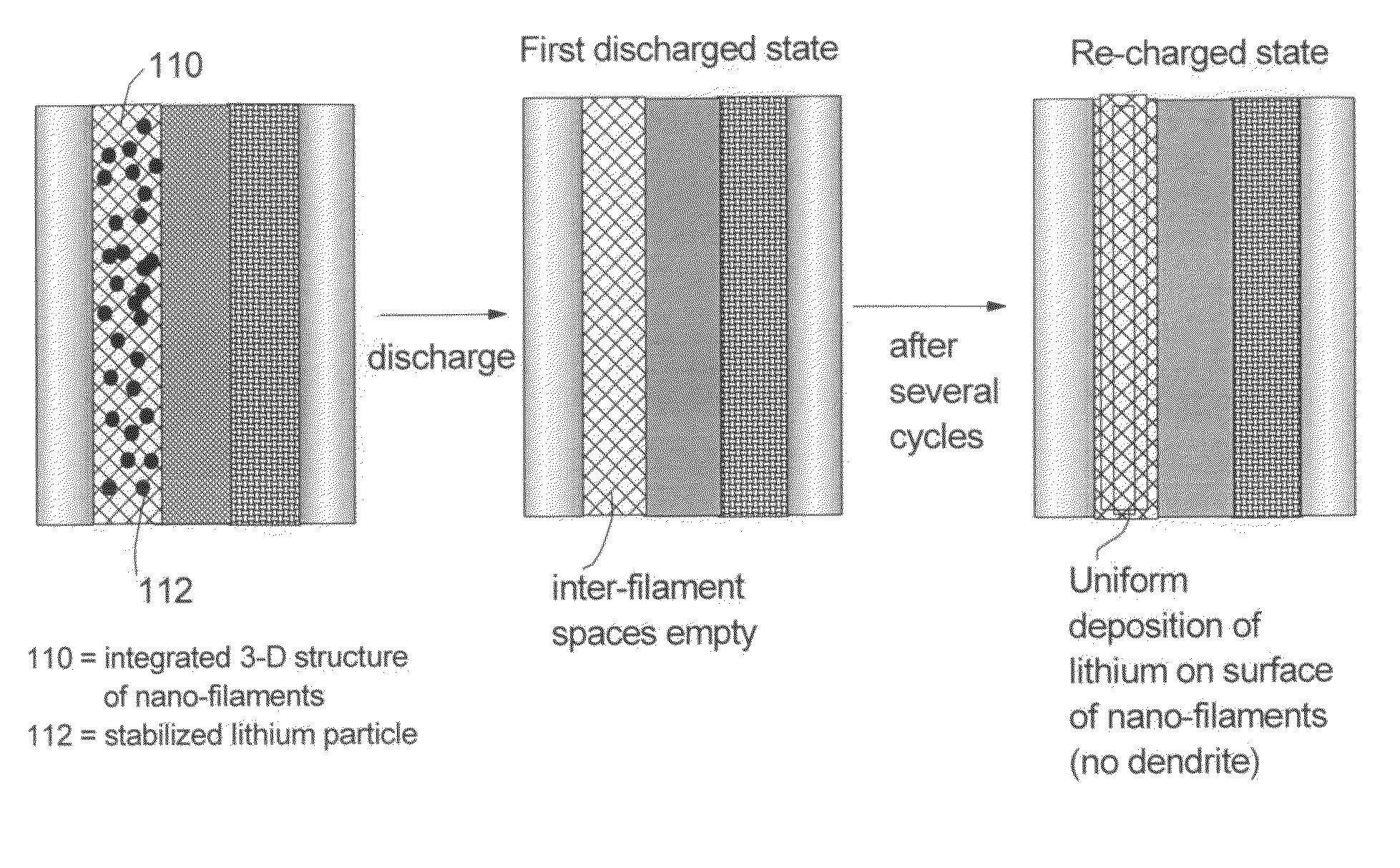

Anode compositions for lithium secondary batteries

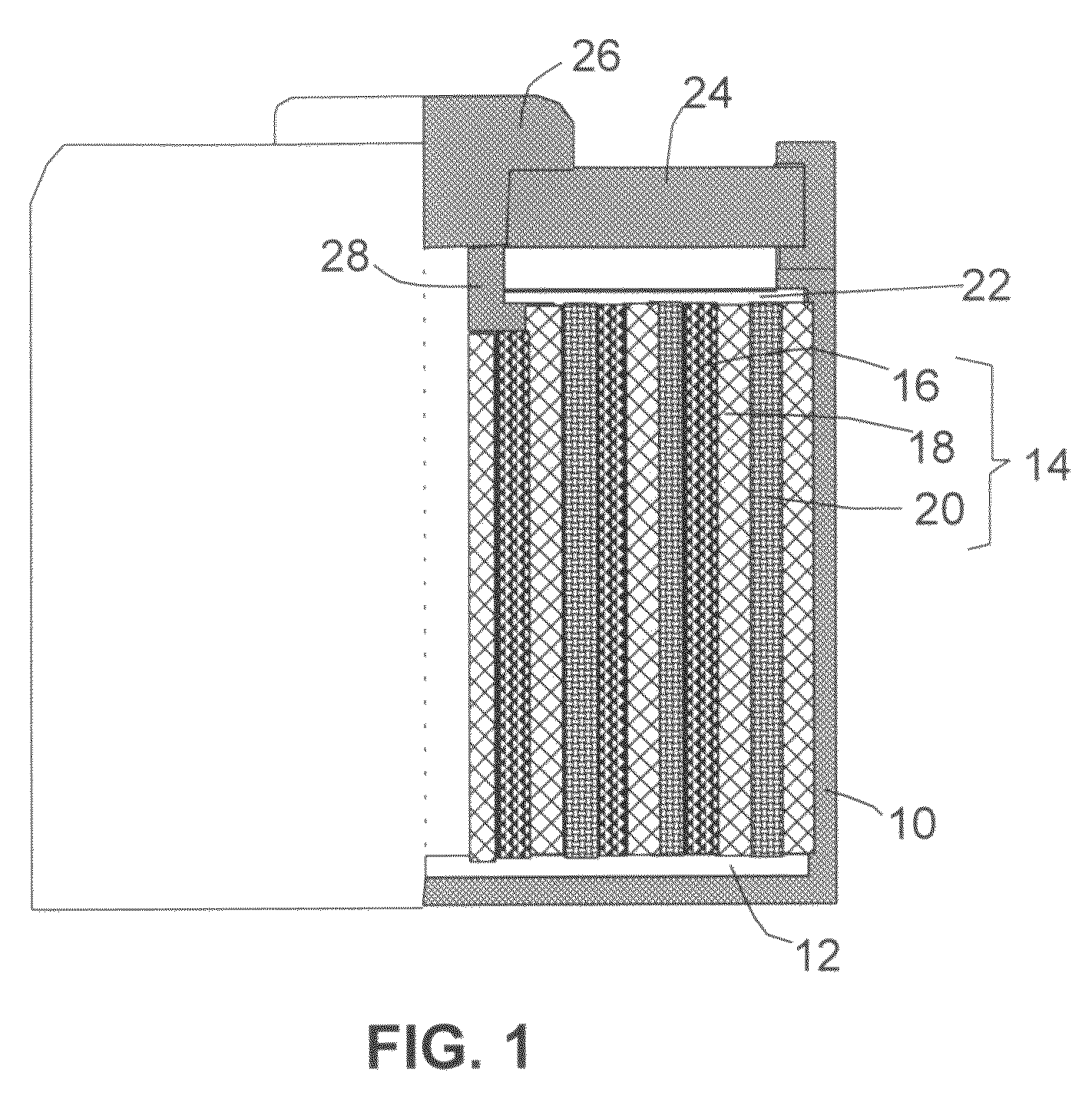

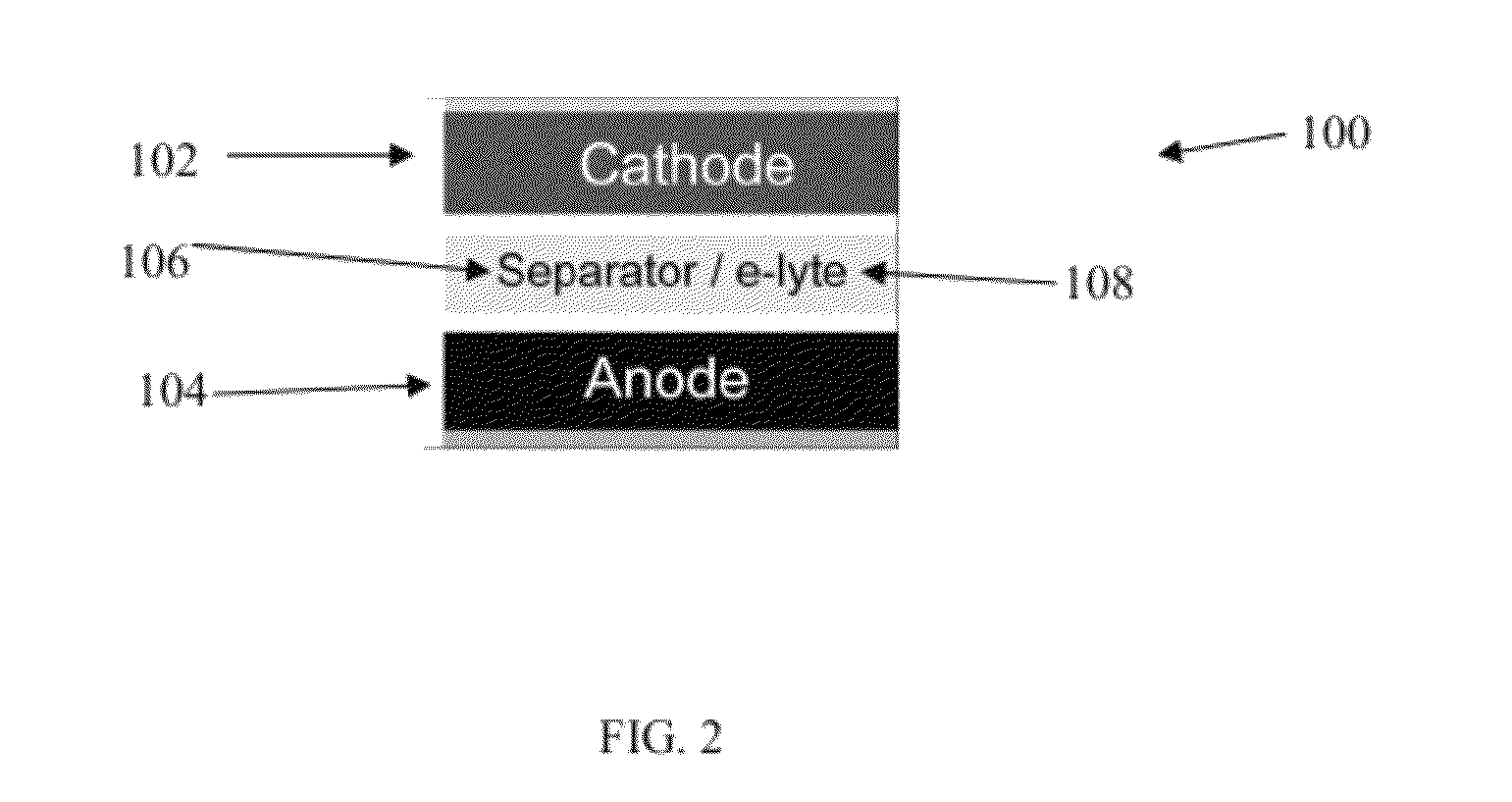

ActiveUS20110165462A1High specific capacityHigh reversible capacitySolid electrolytesFuel and secondary cellsNano structuringElectrical battery

A lithium secondary battery comprising a cathode, an anode, and a separator-electrolyte assembly or electrolyte layer disposed between the cathode and the anode, wherein the anode comprises: (a) an integrated nano-structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising interconnected pores, wherein the filaments have a transverse dimension less than 500 nm; and (b) a foil of lithium or lithium alloy as an anode active material. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

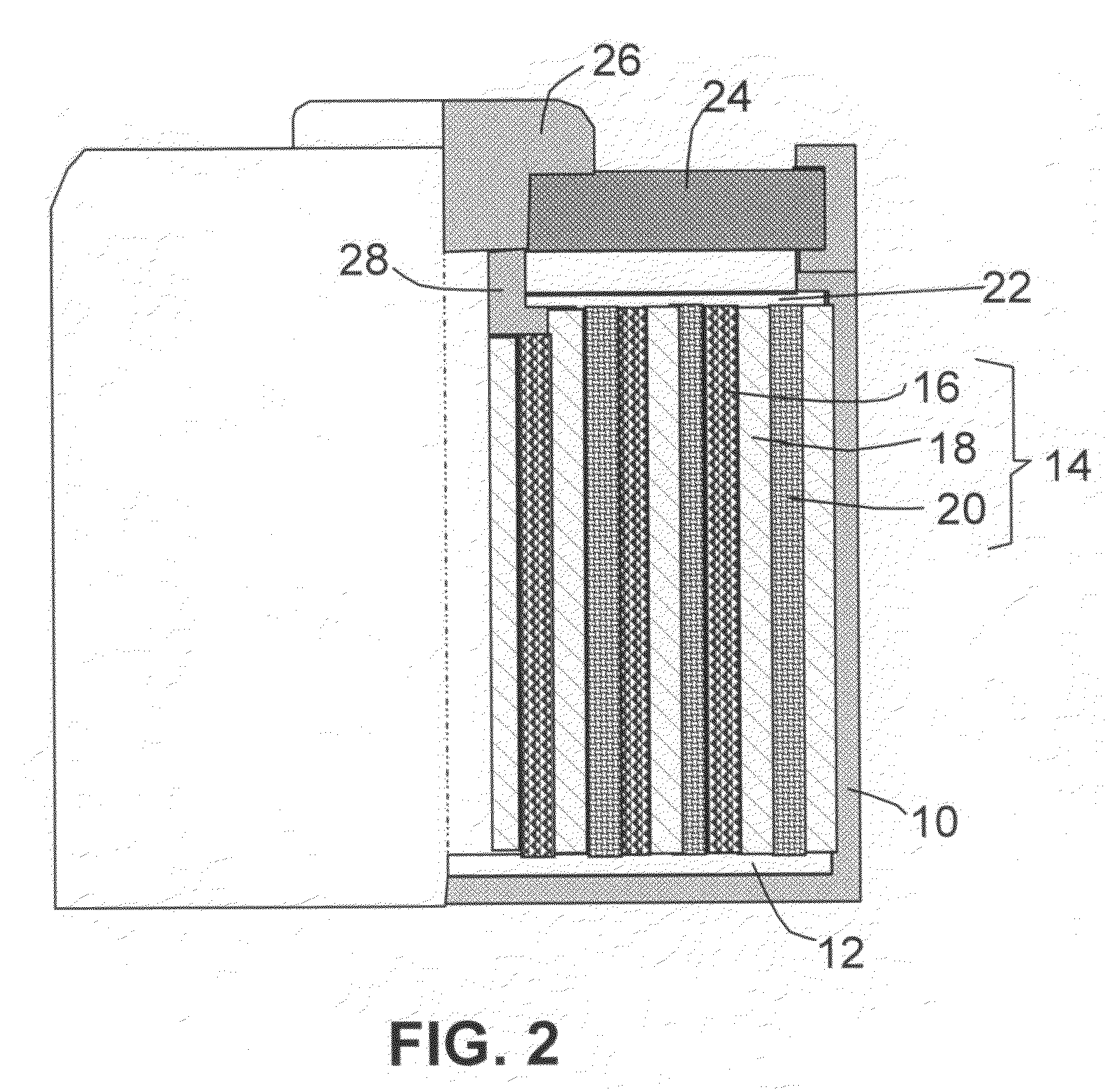

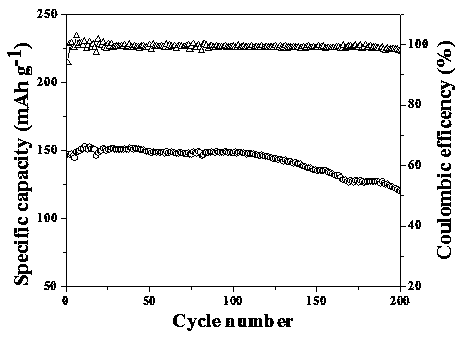

Lithium ion batteries with long cycling performance

ActiveUS20110017528A1Maintain discharge capacitySmall-sized cells cases/jacketsElectric propulsion mountingHigh energyEngineering

Batteries with high energy and high capacity are described that have a long cycle life upon cycling at a moderate discharge rate. Specifically, the batteries may have a room temperature fifth cycle discharge specific energy of at least about 175 Wh / kg discharged at a C / 3 discharge rate from 4.2V to 2.5V. Additionally, the batteries can maintain at least about 70% discharge capacity at 1000 cycles relative to the fifth cycle, with the battery being discharged from 4.2V to 2.5V at a C / 2 rate from the fifth cycle through the 1000th cycle. In some embodiment, the positive electrode of the battery comprises a lithium intercalation composition with optional metal fluoride coating. Stabilizing additive maybe added to the electrolyte of the battery to further improve the battery performance. The batteries are particularly suitable for use in electric vehicles.

Owner:IONBLOX INC

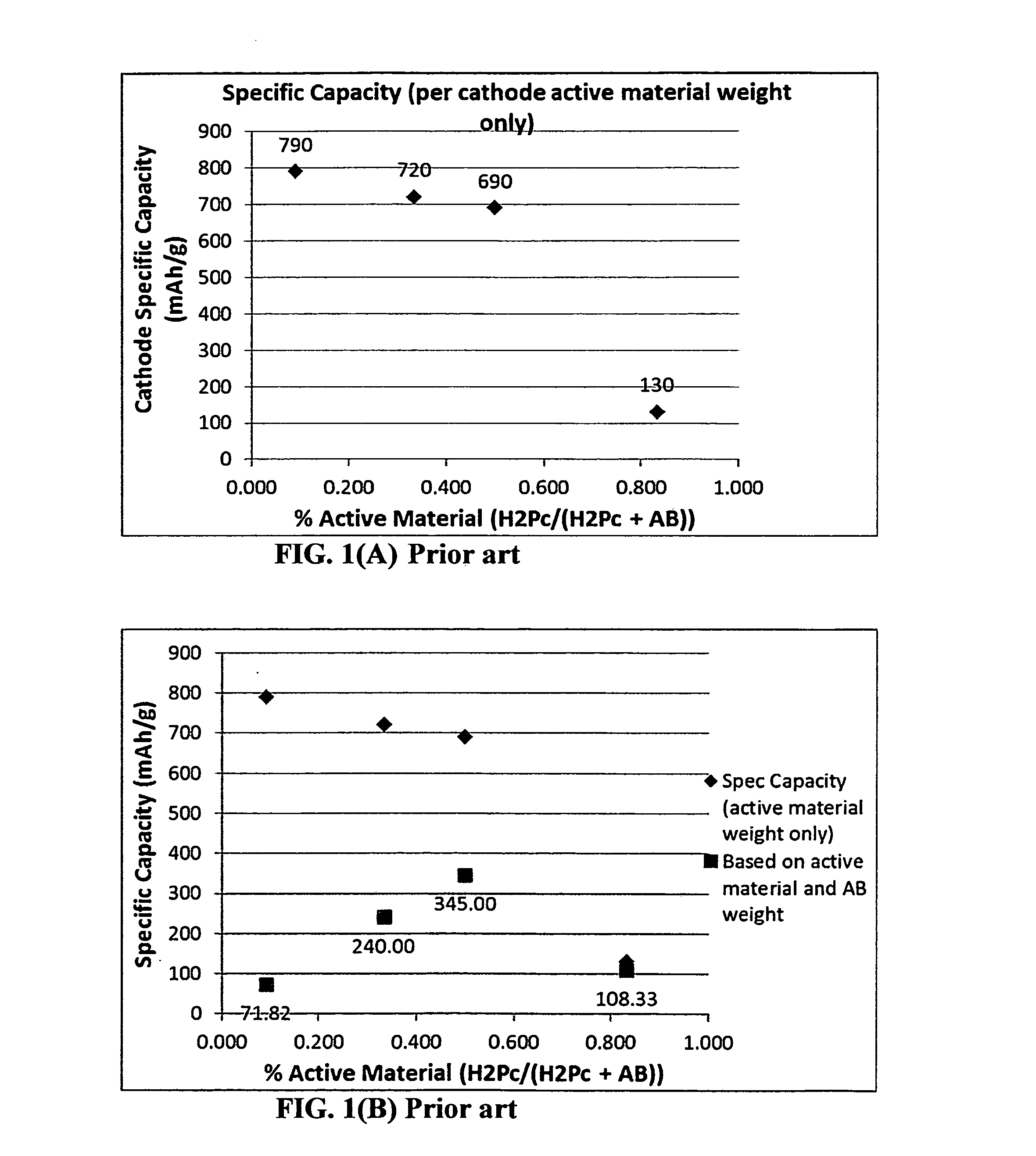

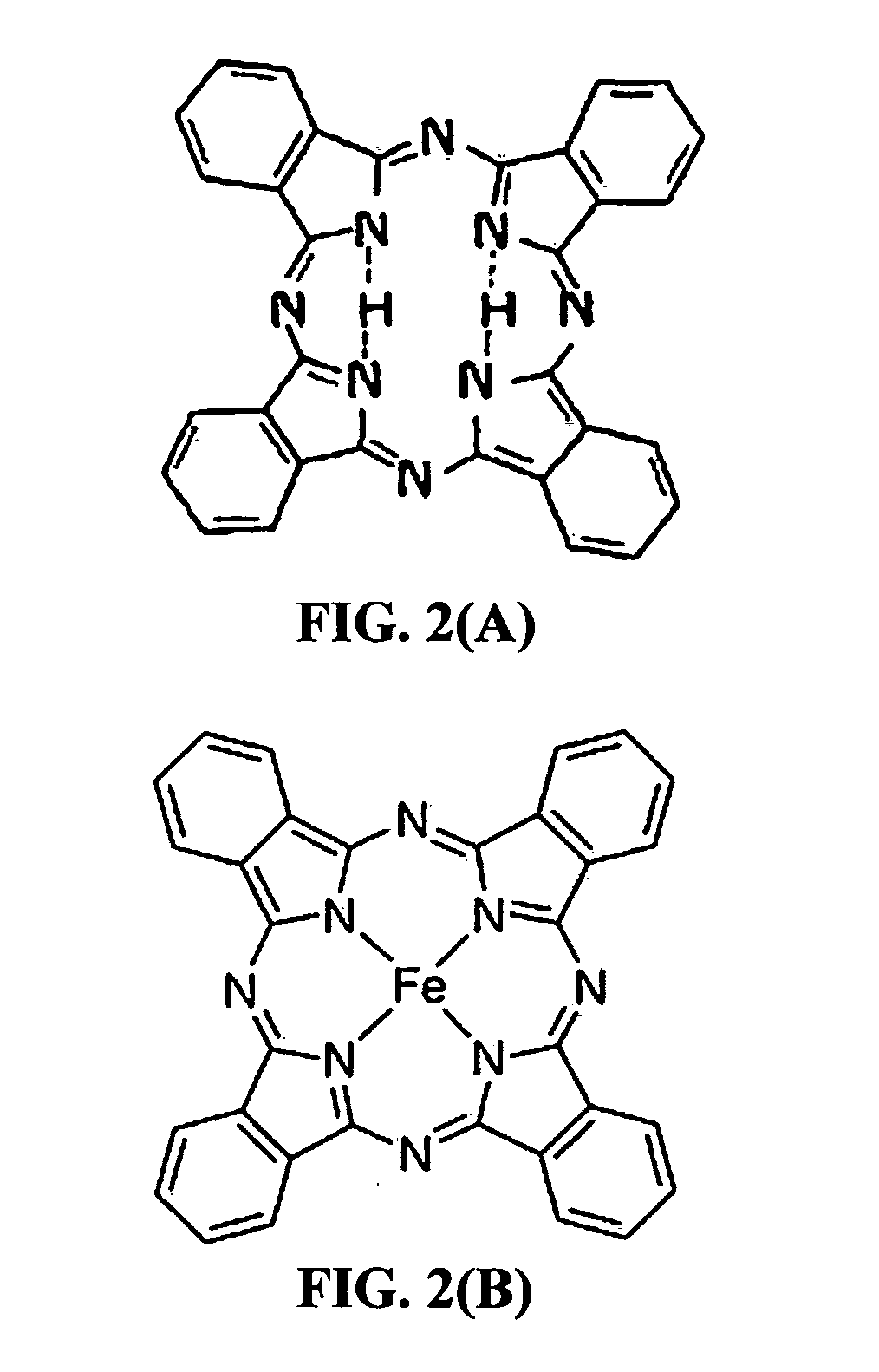

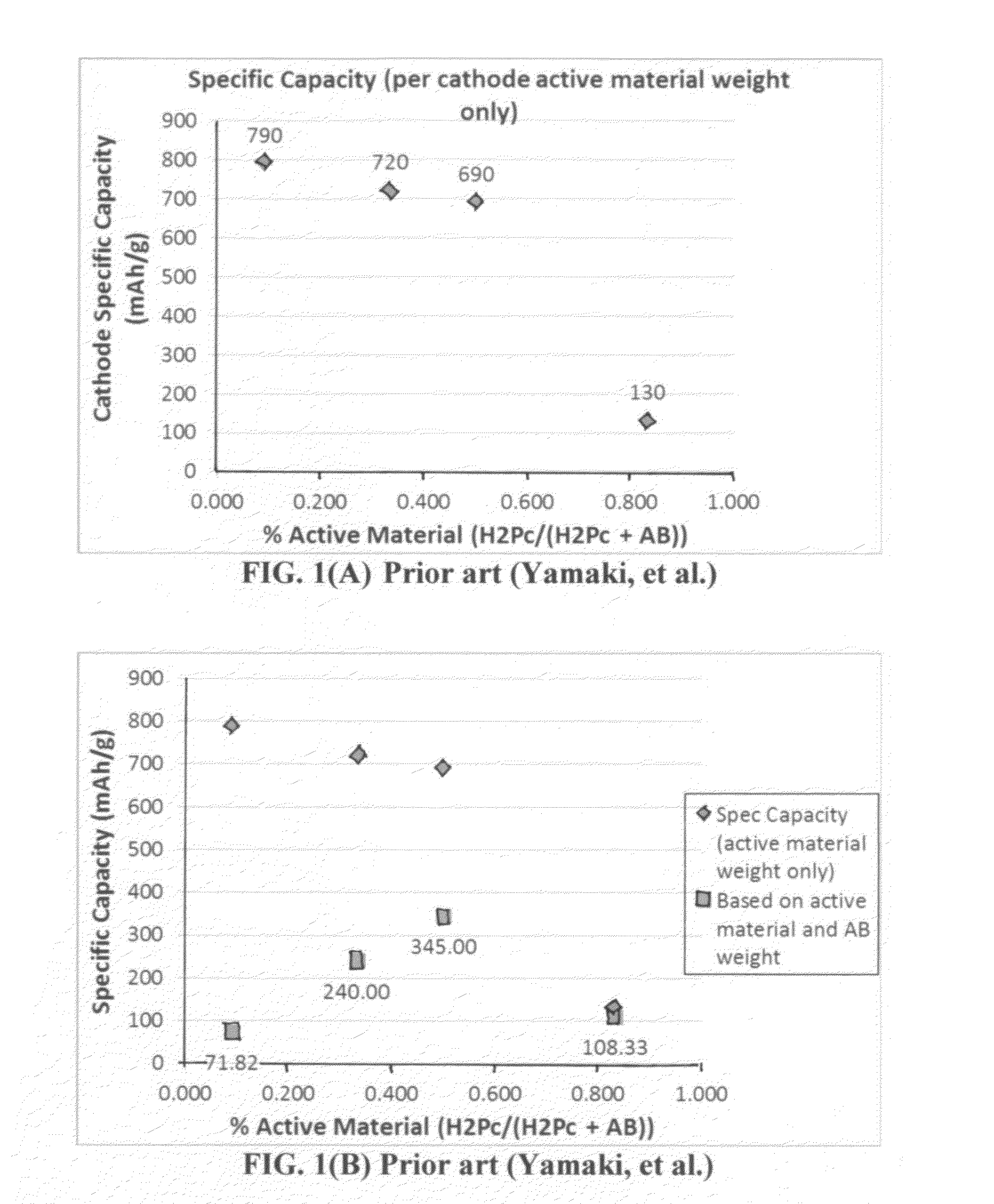

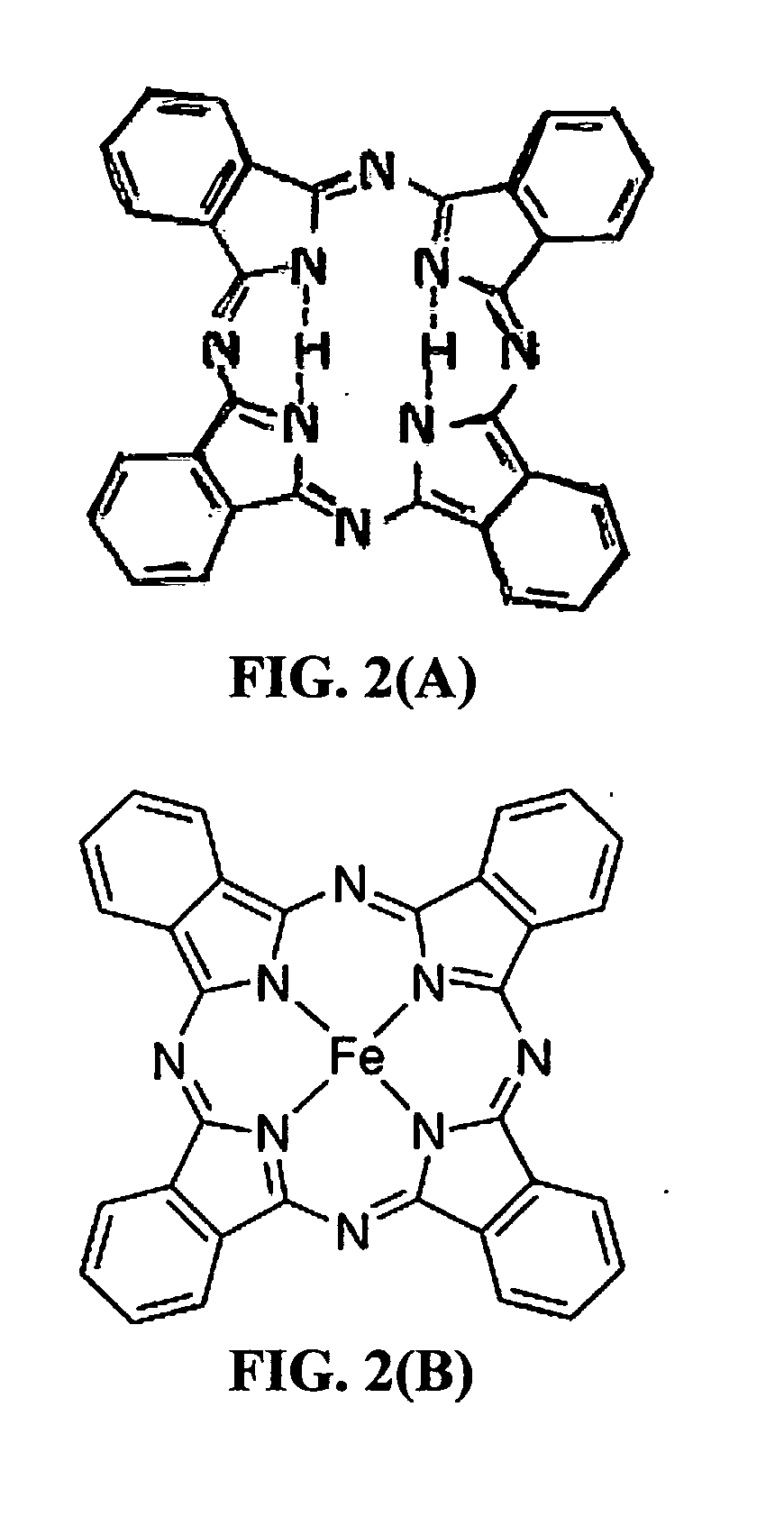

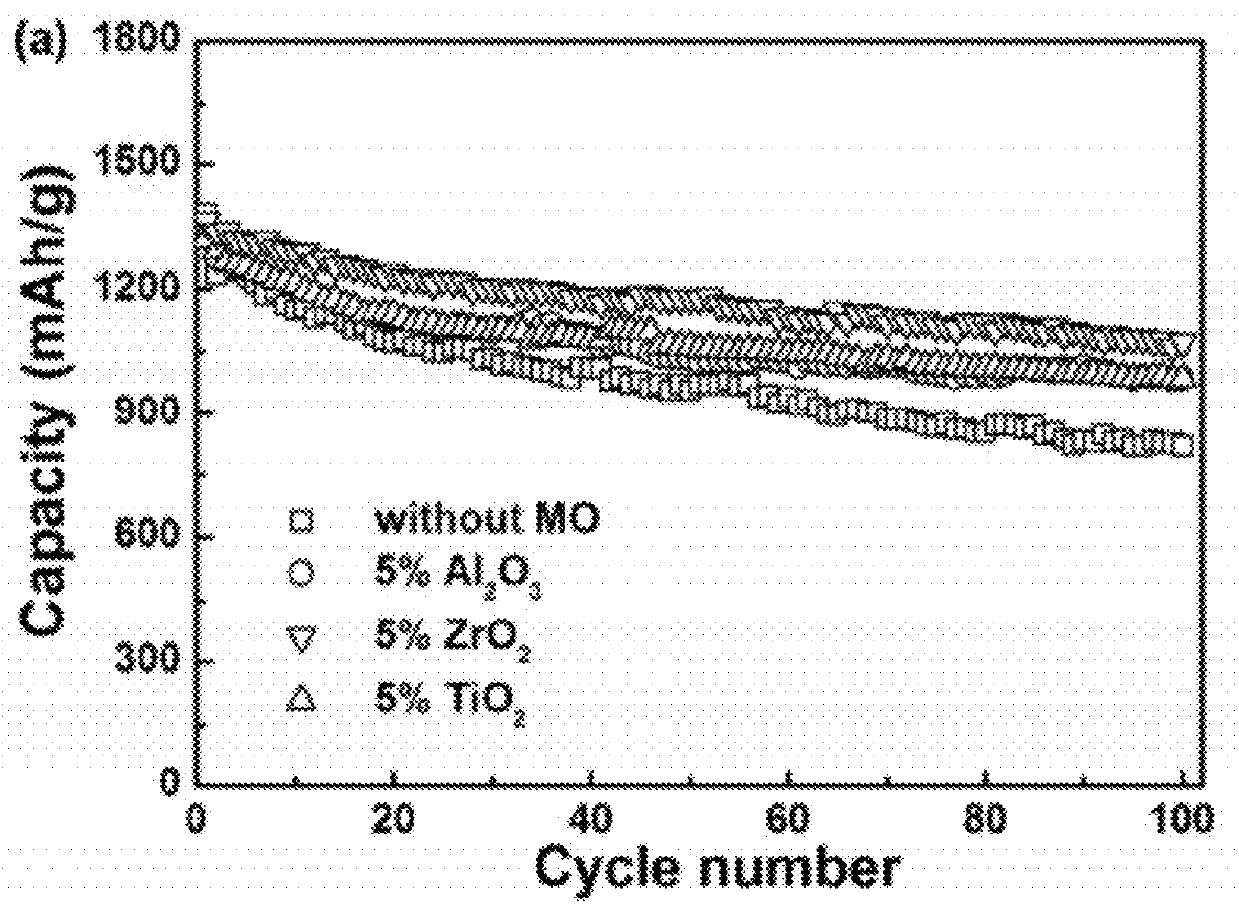

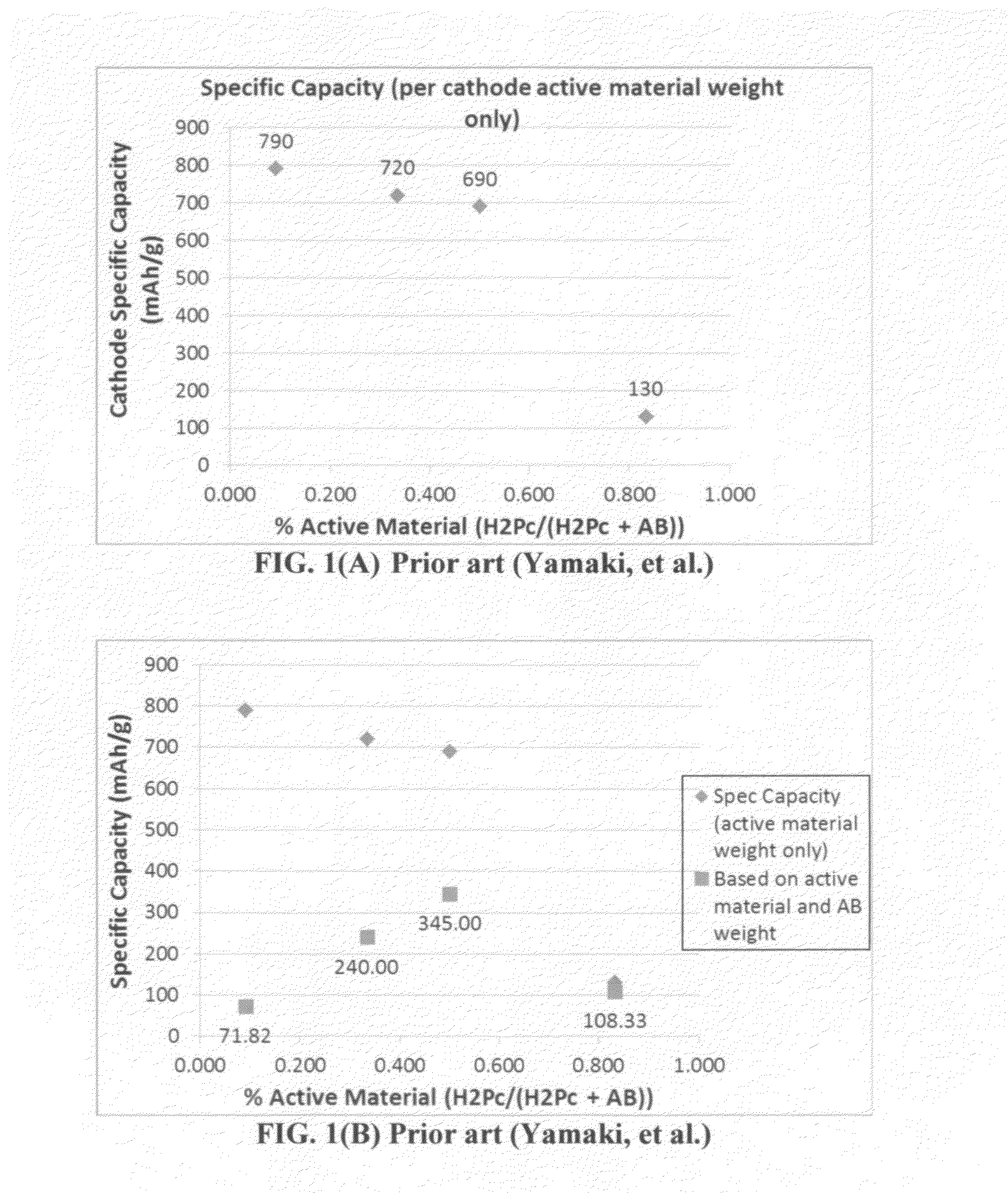

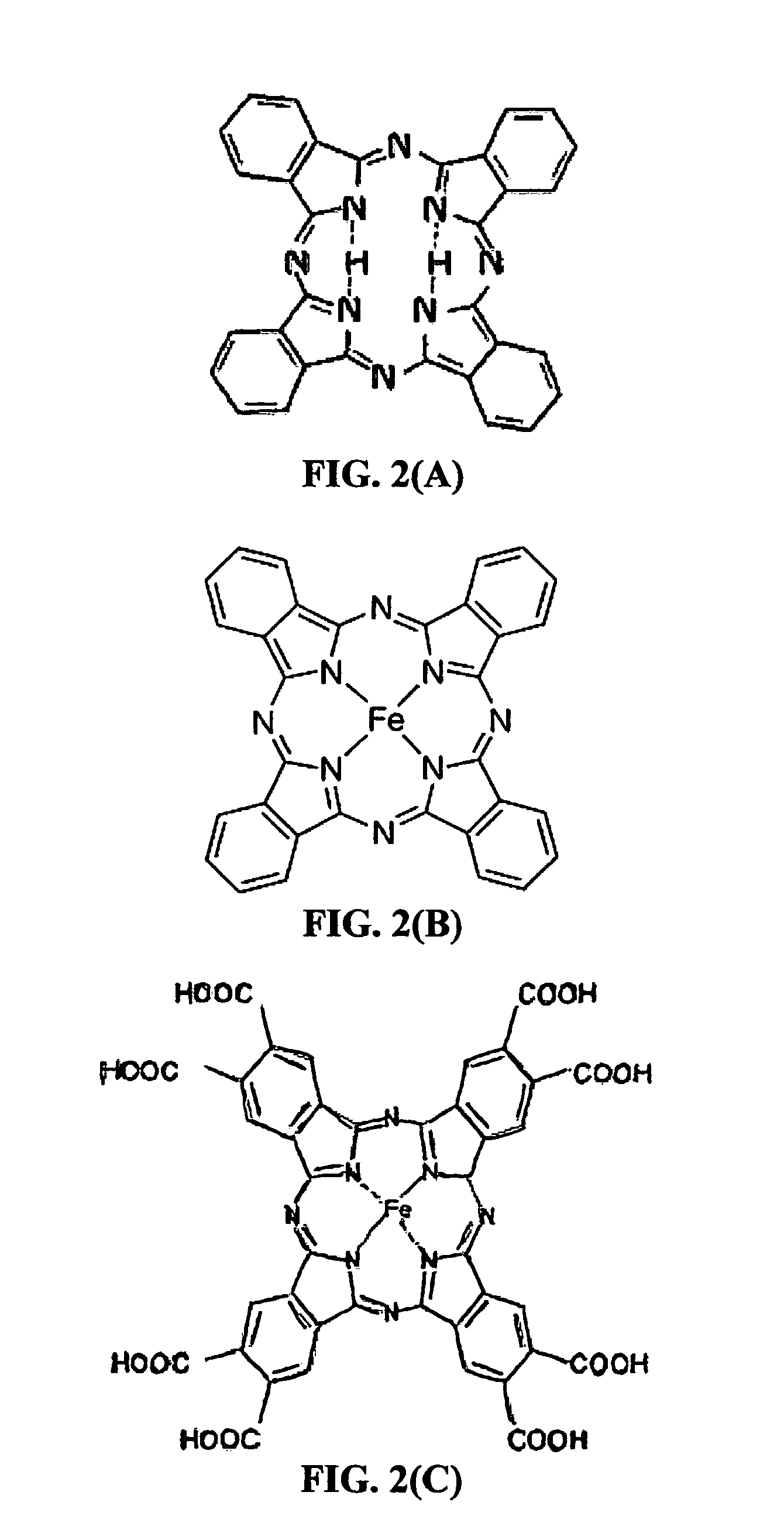

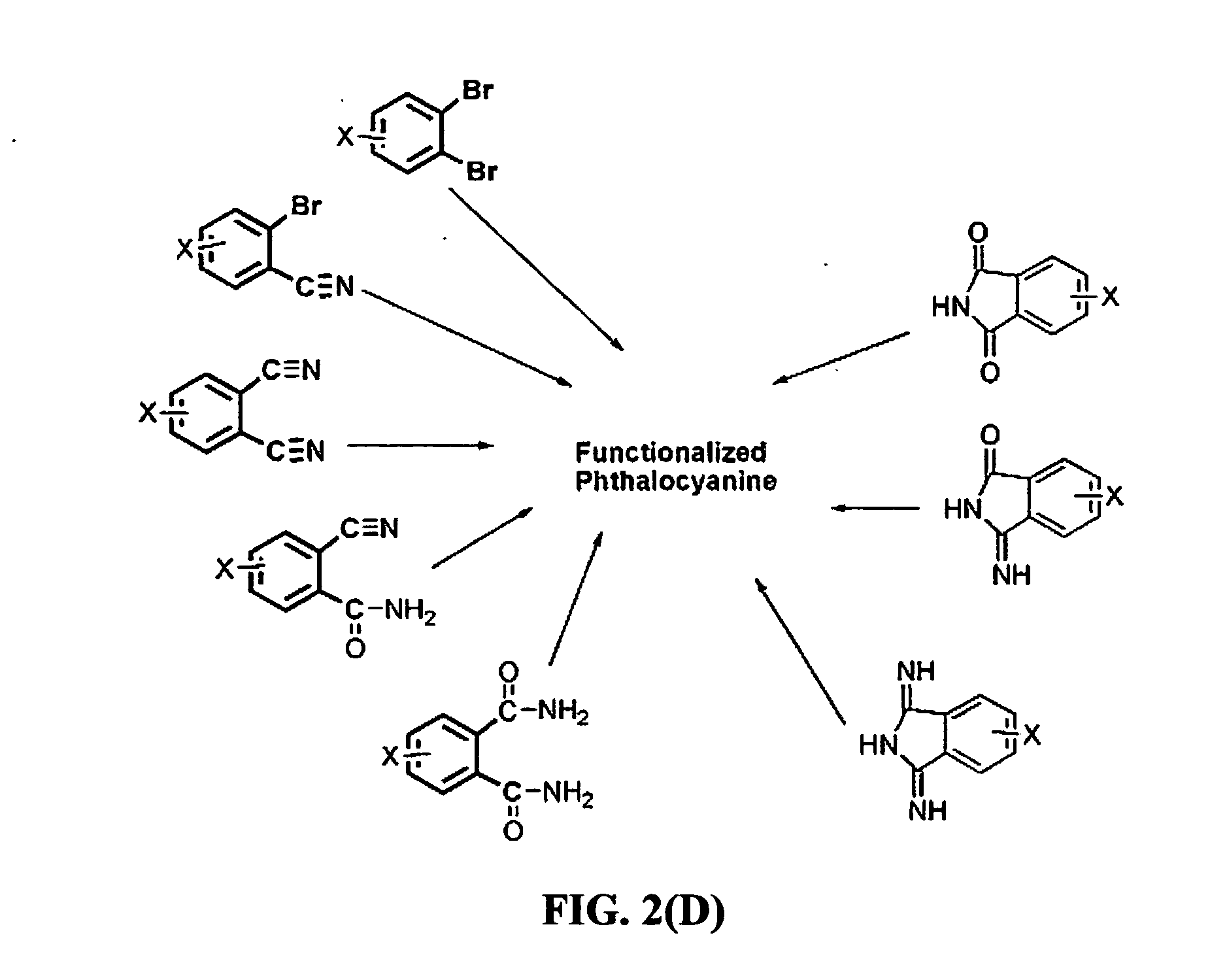

Encapsulated phthalocyanine particles, high-capacity cathode containing these particles, and rechargeable lithium cell containing such a cathode

ActiveUS20140072879A1High theoretical lithium storage capacityLow electricalMaterial nanotechnologySolid electrolyte cellsElectrical batteryPhthalocyanine

Disclosed is an electrode material comprising a phthalocyanine compound encapsulated by a protective material, preferably in a core-shell structure with a phthalocyanine compound core and a protective material shell. Also disclosed is a rechargeable lithium cell comprising: (a) an anode; (b) a cathode comprising an encapsulated or protected phthalocyanine compound as a cathode active material; and (c) a porous separator disposed between the anode and the cathode and / or an electrolyte in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life, the best cathode specific capacity, and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

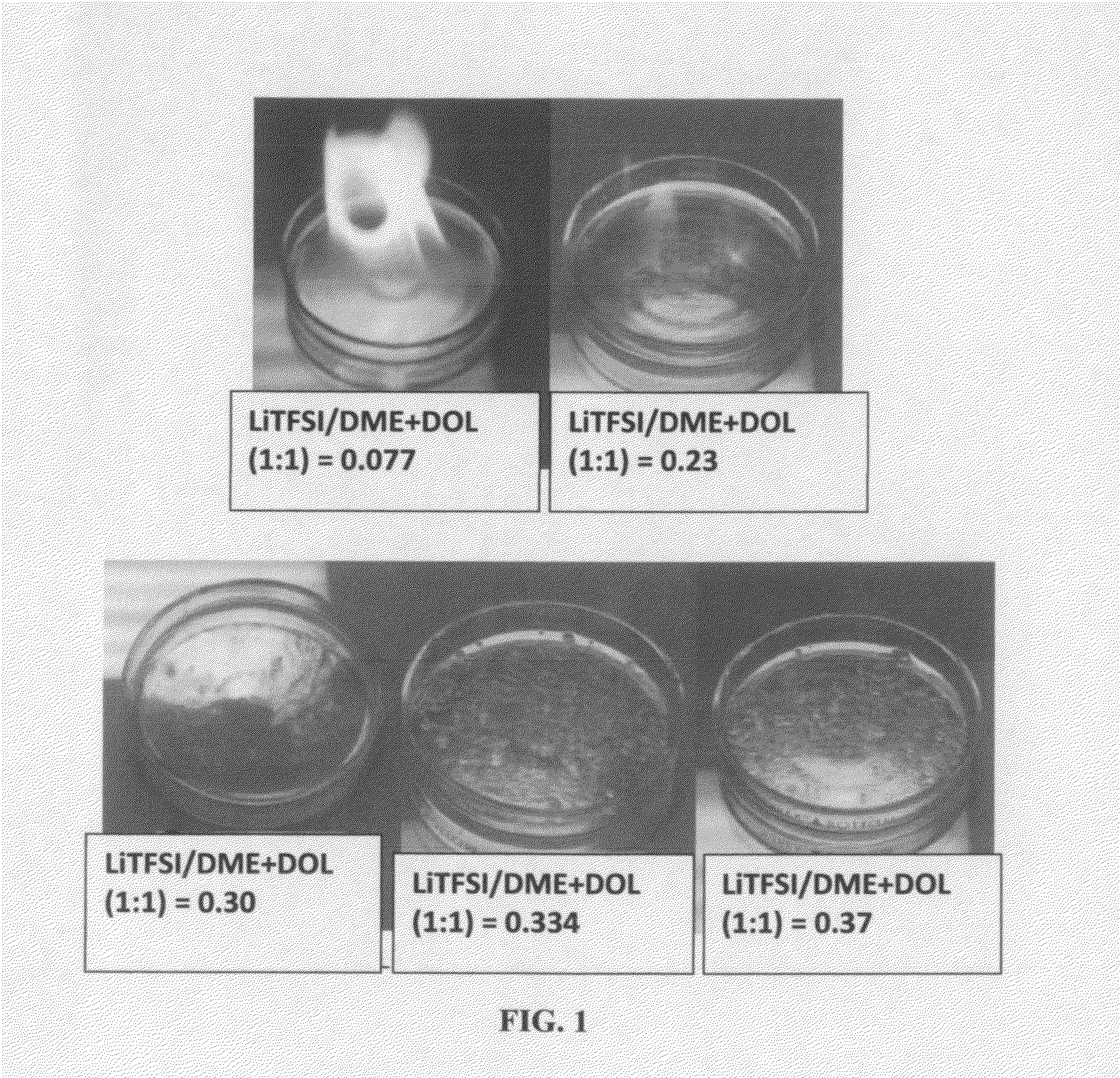

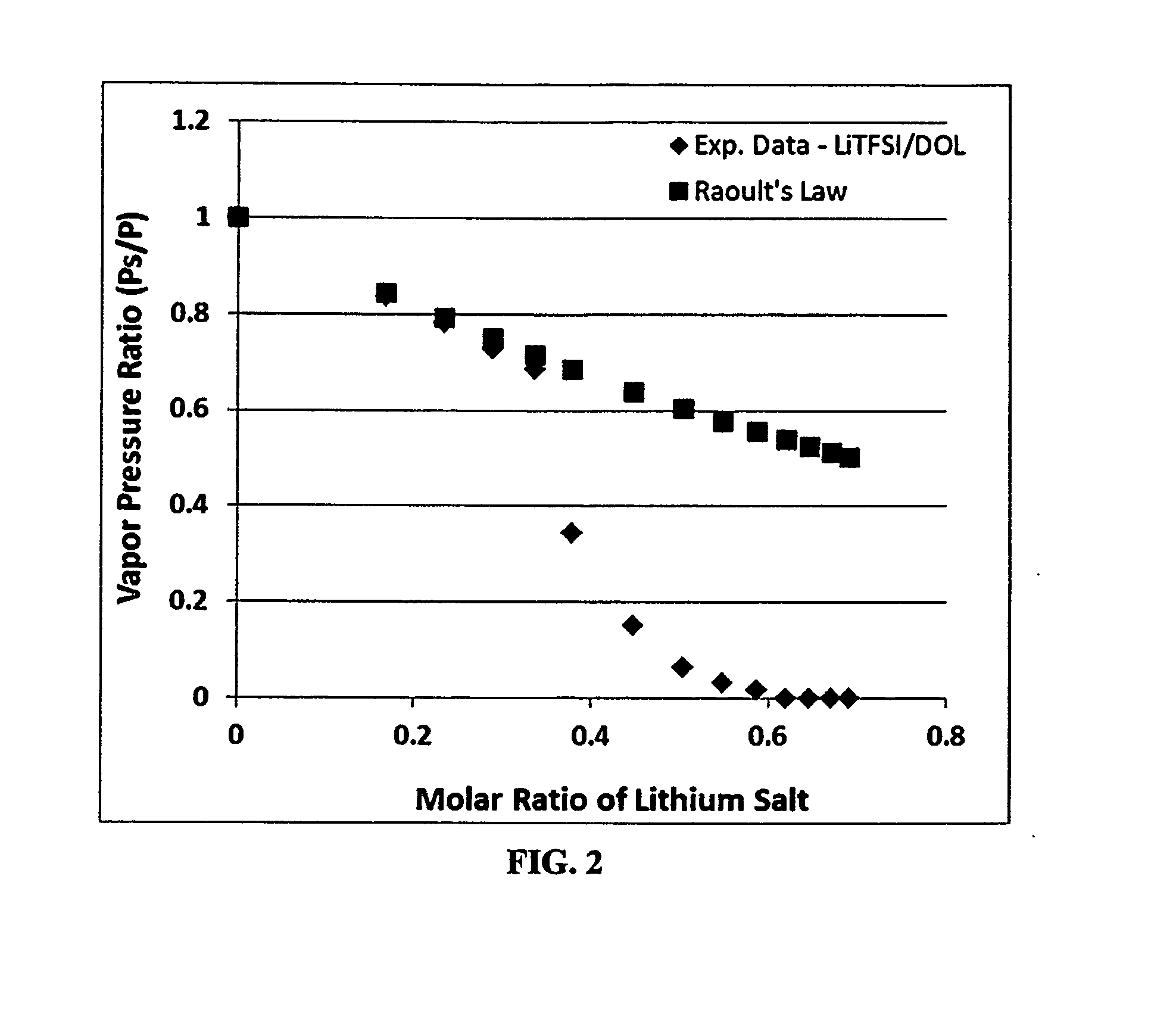

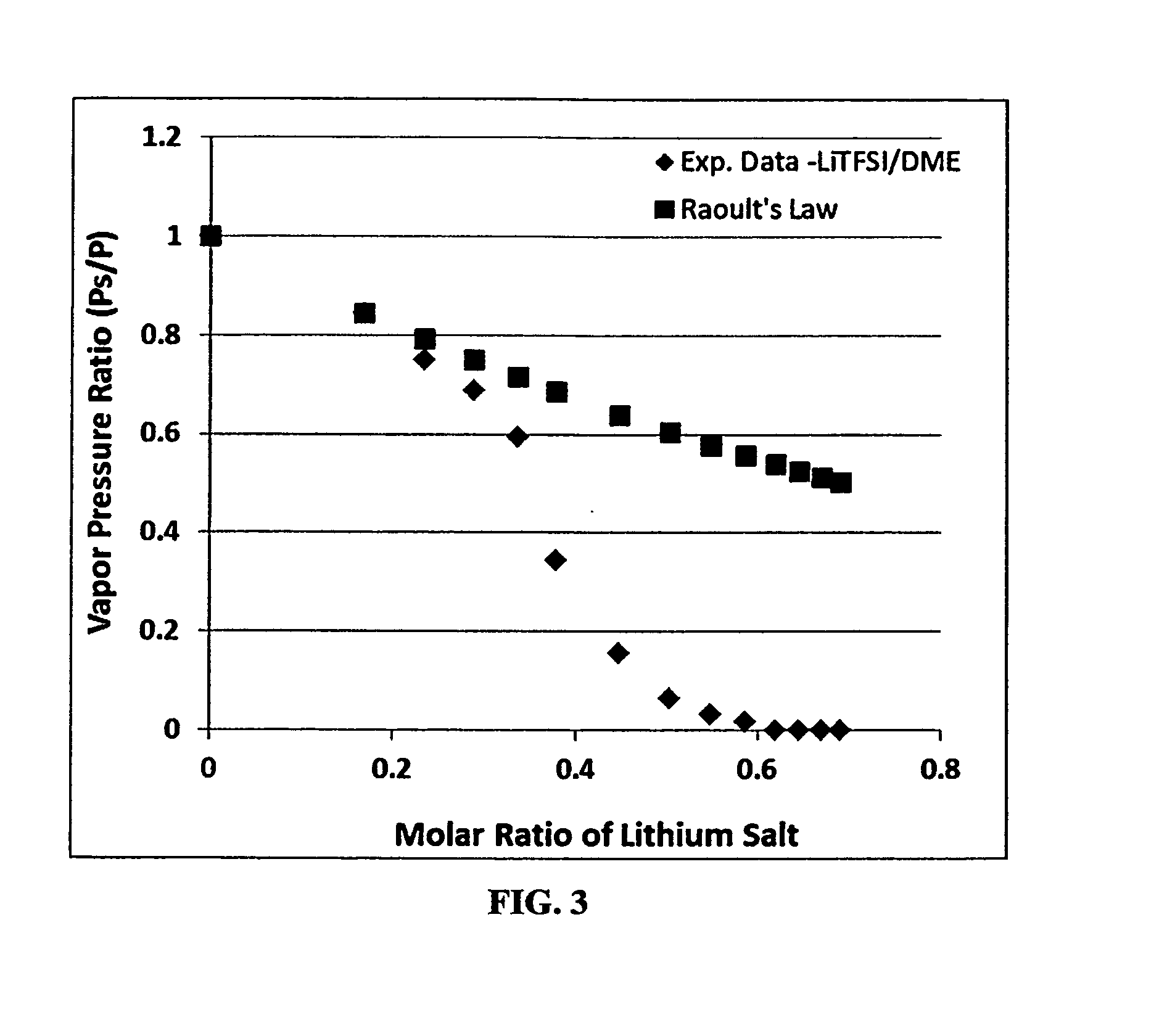

Lithium-Selenium secondary batteries having non-flammable electrolyte

ActiveUS20150064575A1Improve solubilityFlammability of any organic solvent can be effectively suppressedNon-aqueous electrolyte cellsCell electrodesCelsius DegreeHigh energy

A rechargeable lithium-selenium cell comprising a cathode having a cathode active material selected from Se or SexSy (x / y ratio=0.01 to 100), an anode having an anode active material, a porous separator electronically separating the anode and the cathode, a non-flammable quasi-solid electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in a first organic liquid solvent with a lithium salt concentration sufficiently high (at least 2.0 M, more preferably >3.0 M) so that the electrolyte exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a flash point at least 20 degrees Celsius higher than the flash point of the first organic liquid solvent alone, a flash point higher than 150° C., or no flash point. This battery cell is non-flammable and safe, has a long cycle life, high capacity, and high energy density.

Owner:GLOBAL GRAPHENE GRP INC

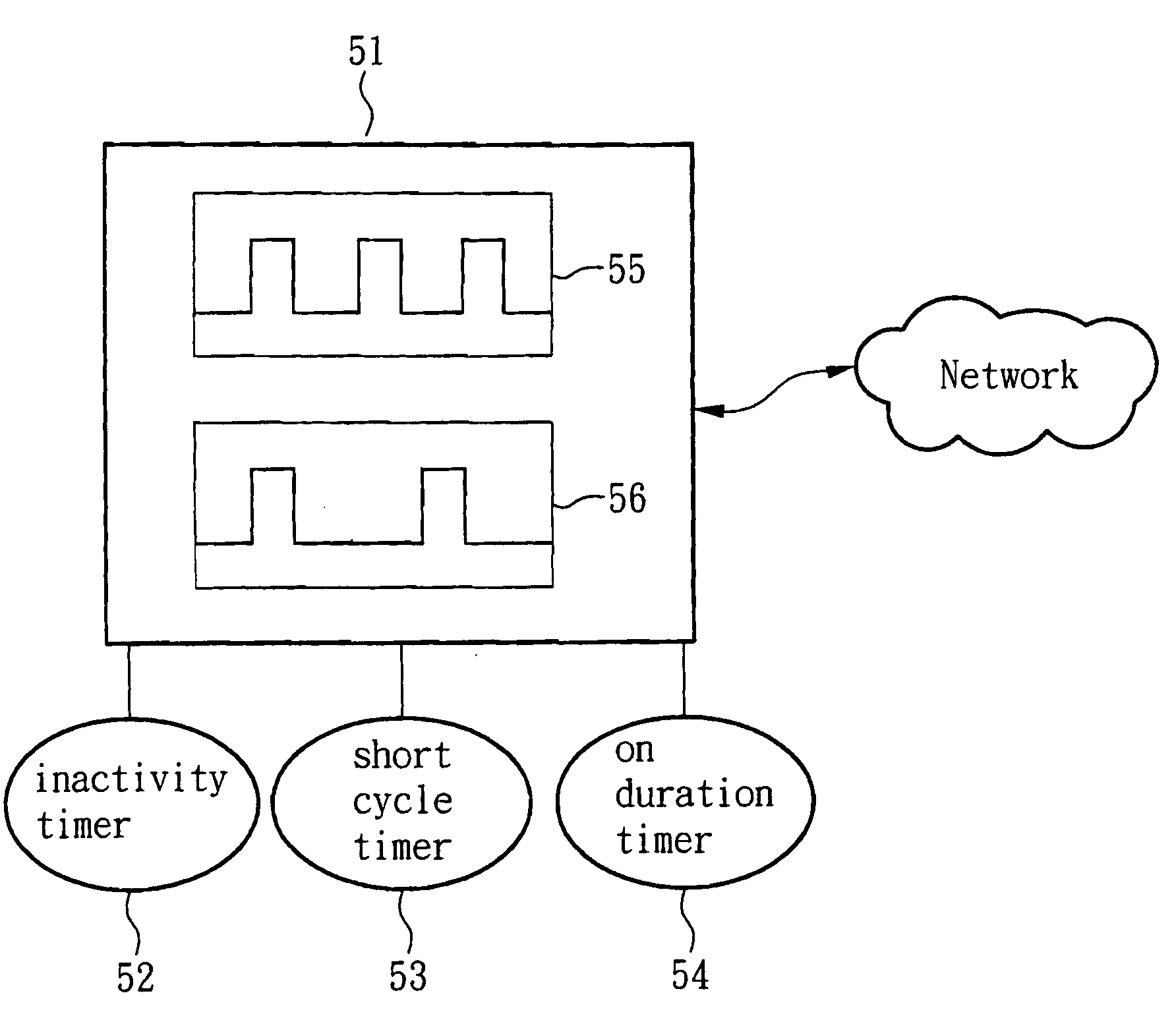

Method for avoiding unnecessary excessive stay of short cycle in discontinuous reception mechanism

ActiveUS20090238105A1Avoiding unnecessary excessive stayAvoiding unnecessary excessive stay of short cyclePower managementTransmission systemsTimerEmbedded system

A method for avoiding unnecessary excessive stay of short cycle in discontinuous reception mechanism begins by using the short cycle while the short cycle timer is running. Then, it determines whether the inactivity timer expires or not and whether the short cycle timer expires or not. If the inactivity timer expires but the short cycle timer does not expire, the short cycle is used. If the short cycle timer expires but the inactivity timer does not expire, the long cycle is used. If the inactivity timer and the short cycle timer expire at the same time, either the short cycle or the long cycle is selected for use.

Owner:HFI INNOVATION INC

Rechargeable lithium cell having a meso-porous conductive material structure-supported phthalocyanine compound cathode

ActiveUS20130330611A1High oxygen contentIncreased riskMaterial nanotechnologyElectrode carriers/collectorsConductive polymerConductive materials

A rechargeable lithium cell comprising: (a) an anode comprising a prelithiated lithium storage material or a combination of a lithium storage material and a lithium ion source; (b) a hybrid cathode active material composed of a meso-porous structure of a carbon, graphite, metal, or conductive polymer and a phthalocyanine compound, wherein the meso-porous structure is in an amount of from 1% to 99% by weight based on the total weight of the meso-porous structure and the phthalocyanine combined, and wherein the meso-porous structure has a pore with a size from 2 nm to 50 nm to accommodate phthalocyanine compound therein; and (c) an electrolyte or electrolyte / separator assembly. This secondary cell exhibits a long cycle life and the best cathode specific capacity and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

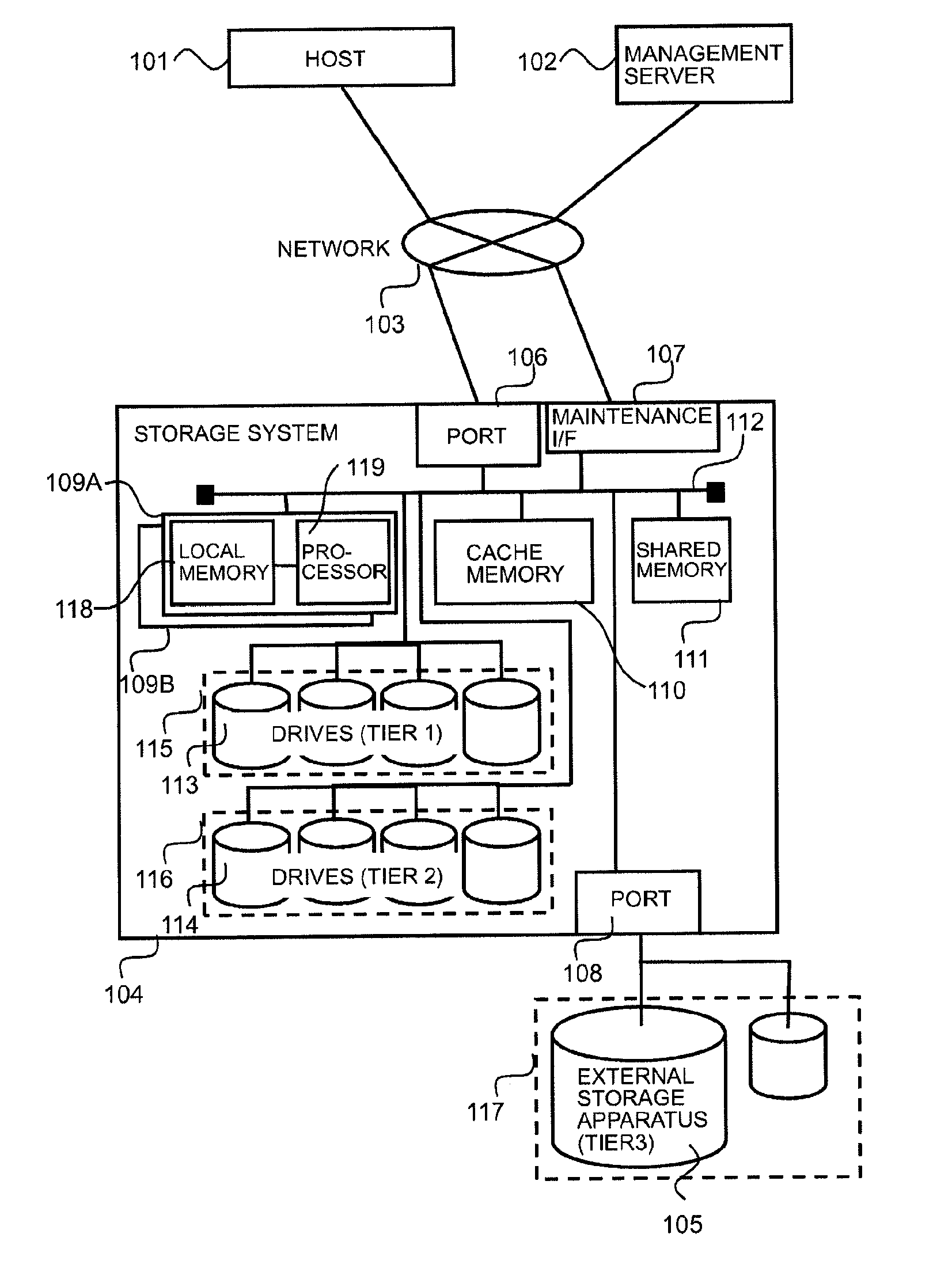

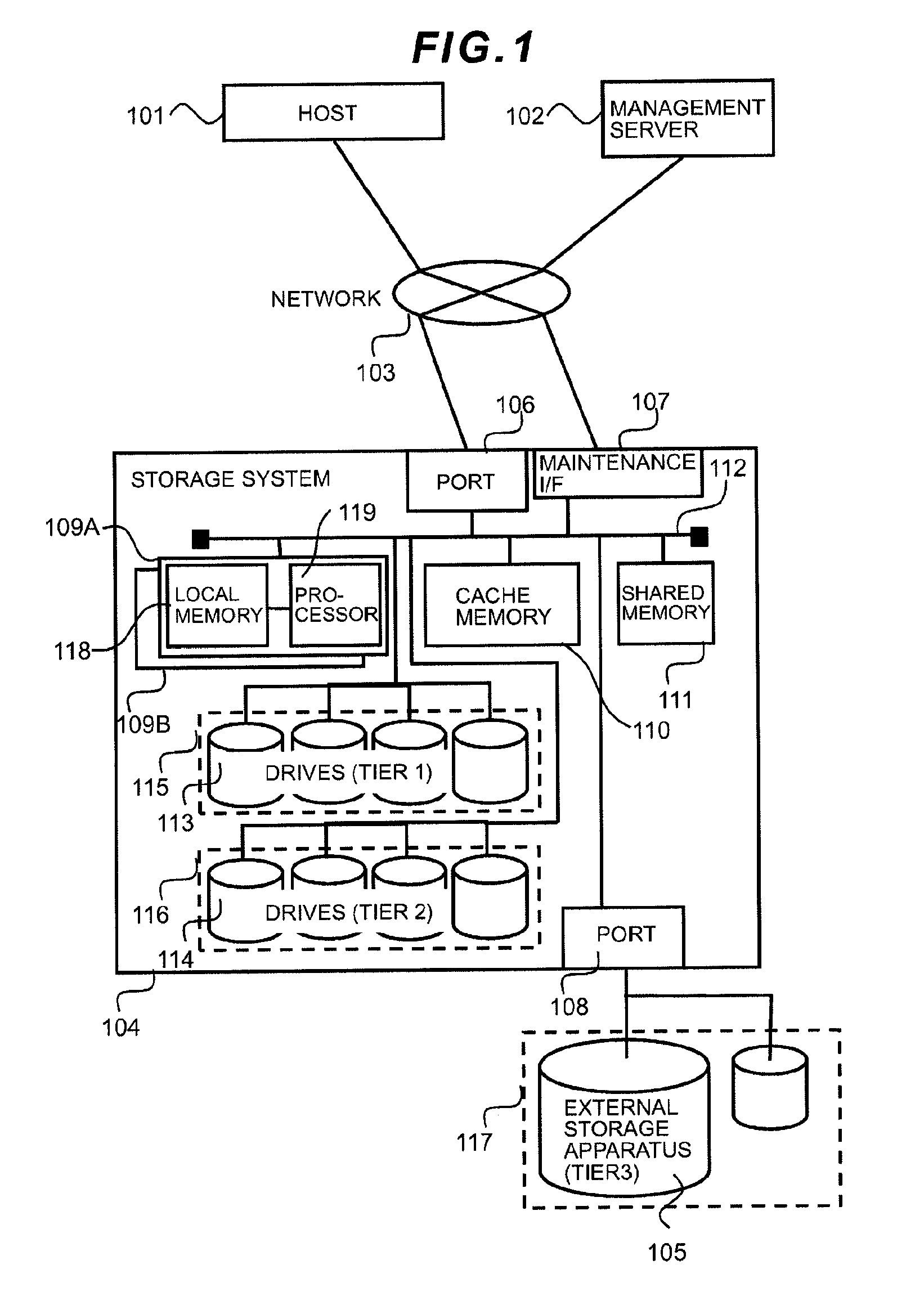

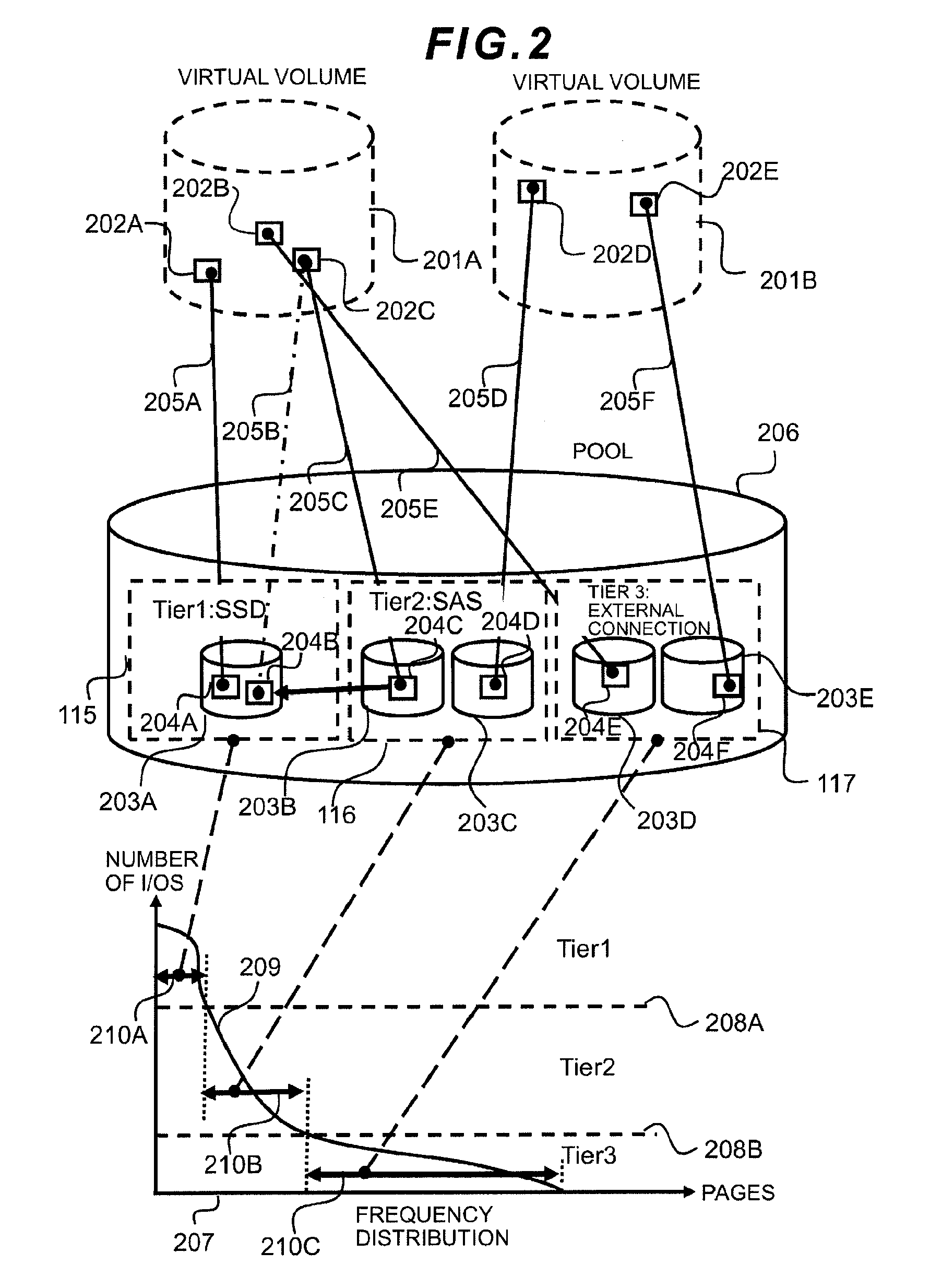

Storage system and storage area allocation method

ActiveUS20120246386A1Improve performanceMemory adressing/allocation/relocationInput/output processes for data processingViewpointsMonitoring system

If a monitor measurement cycle is set as a long cycle, promotion in a short cycle cannot be performed; and even if the number of I / Os is very large in response to fluctuations of the number of I / Os in several minutes to several hours of normal work, pages will be promoted after waiting for several weeks. As a result, I / Os which could have normally accepted by an upper tier will be accepted by a lower tier, which results in a problem of worsening the performance efficiency. A monitoring system capable of preventing demotion due to temporary reduction of the number of I / Os for specific pages from a viewpoint of a long cycle and enabling prompt promotion in response to an increase of the number of U / Os for 3the specific pages is realized.A load index value defined from a viewpoint of a long cycle and a load index value defined from a viewpoint of a short cycle are updated based on the number of I / Os which is counted cyclically for each storage area. Promotion and demotion are implemented based on a value(s) calculated from these load index values.

Owner:HITACHI LTD

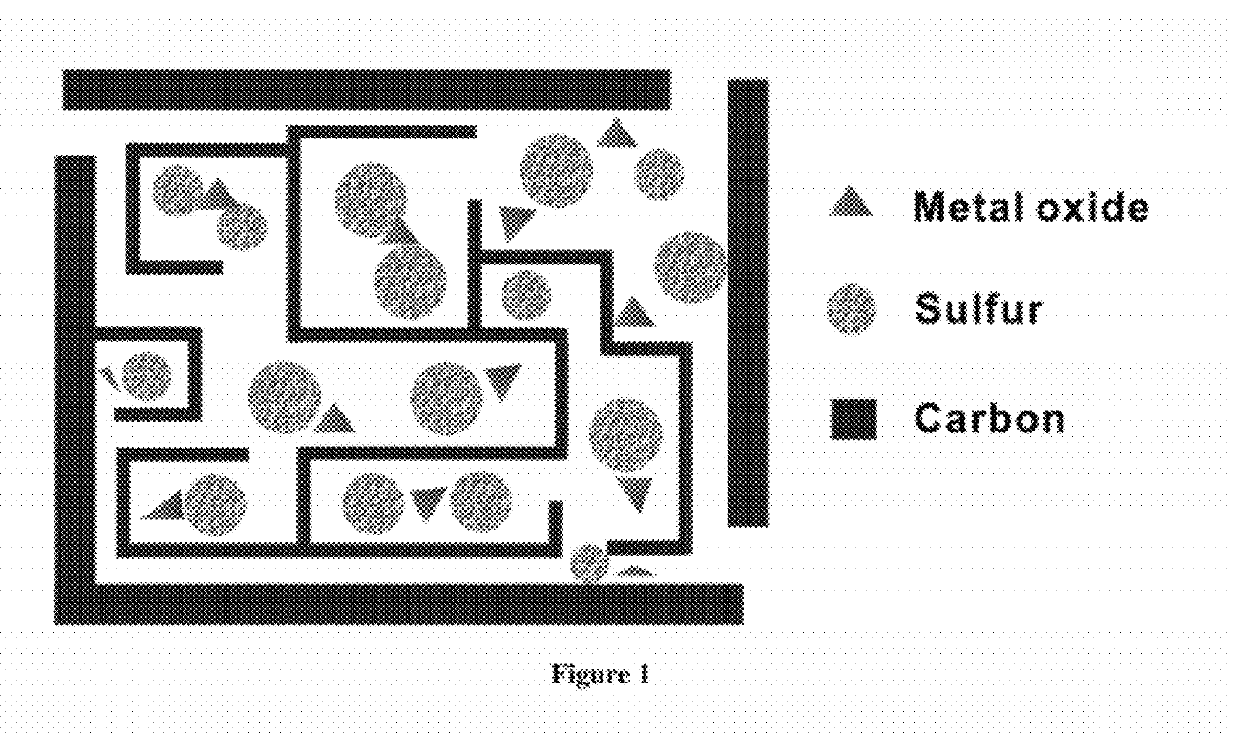

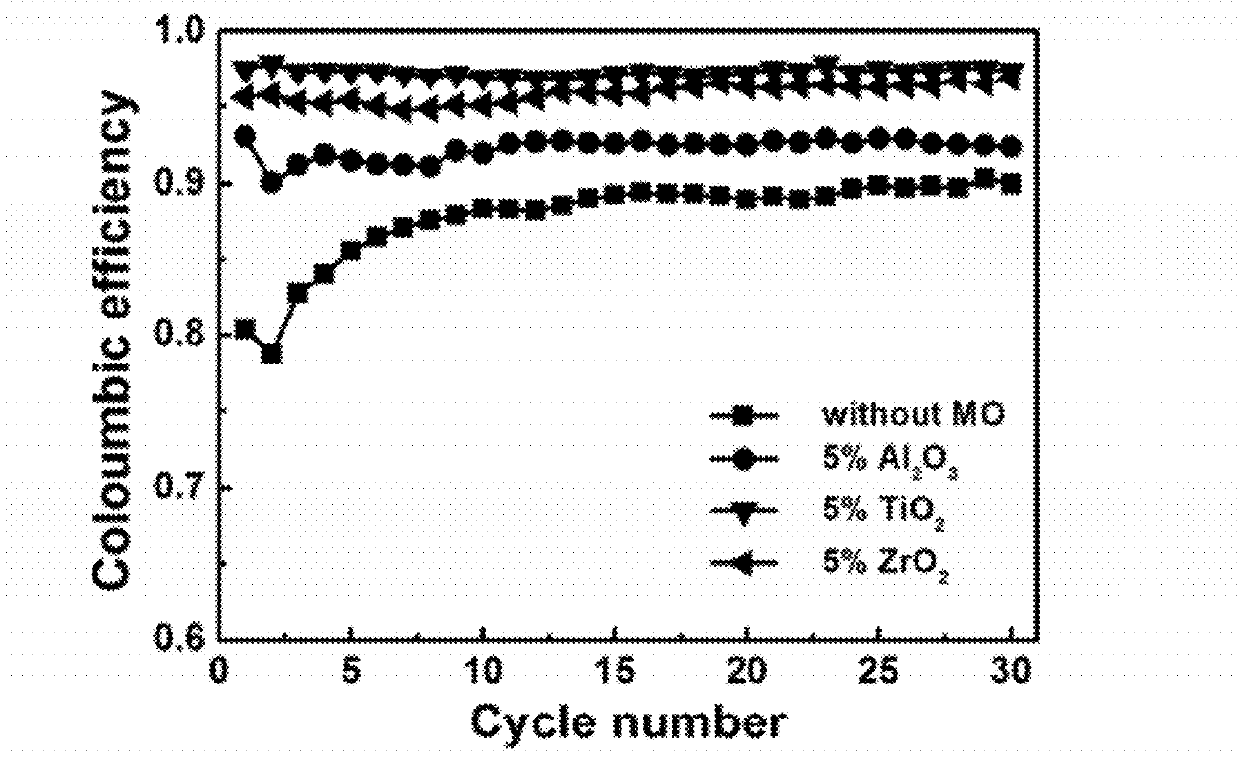

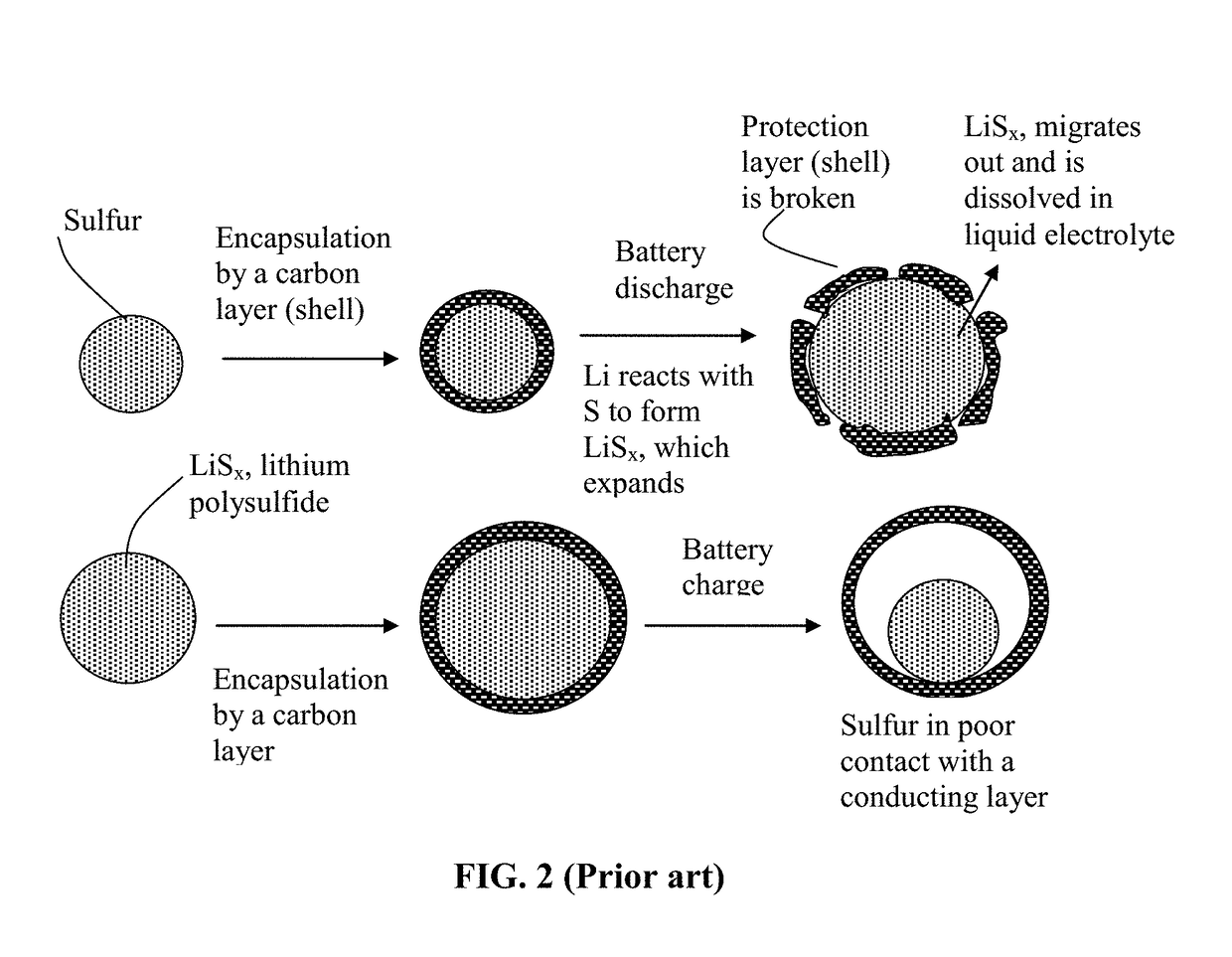

Carbon-metal oxide-sulfur cathodes for high-performance lithium-sulfur batteries

InactiveUS20120207994A1Improve performanceImprove Coulombic efficiencyNon-metal conductorsLayered productsPorous carbonLithium–sulfur battery

Embodiments presented herein provide a new approach for high-performance lithium-sulfur battery by using novel carbon-metal oxide-sulfur composites. The composites may be prepared by encapsulating sulfur particles in bifunctional carbon-supported metal oxide or other porous carbon-metal oxide composites. In this way, the porous carbon-metal oxide composite confines sulfur particles within its tunnels and maintain the electrical contact during cycling. Furthermore, the uniformly embedded metal oxides in the structure strongly adsorb polysulfide intermediates, avoid dissolution loss of sulfur, and ensure high coulombic efficiency as well as a long cycle life.

Owner:PENN STATE RES FOUND

Rechargeable lithium cell having a chemically bonded phthalocyanine compound cathode

ActiveUS20140072871A1High oxygen contentIncreased riskMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesPhthalocyanineLongest cycle

A rechargeable lithium cell comprising: (a) an anode comprising an anode active material; (b) a cathode comprising a hybrid cathode active material composed of an electrically conductive substrate and a phthalocyanine compound chemically bonded to or immobilized by the conductive substrate, wherein the phthalocyanine compound is in an amount of from 1% to 99% by weight based on the total weight of the conductive substrate and the phthalocyanine compound combined; and (c) electrolyte or a combination of electrolyte and a porous separator, wherein the separator is disposed between the anode and the cathode and the electrolyte is in ionic contact with the anode and the cathode. This secondary cell exhibits a long cycle life, the best cathode specific capacity, and best cell-level specific energy of all rechargeable lithium-ion cells ever reported.

Owner:GLOBAL GRAPHENE GRP INC

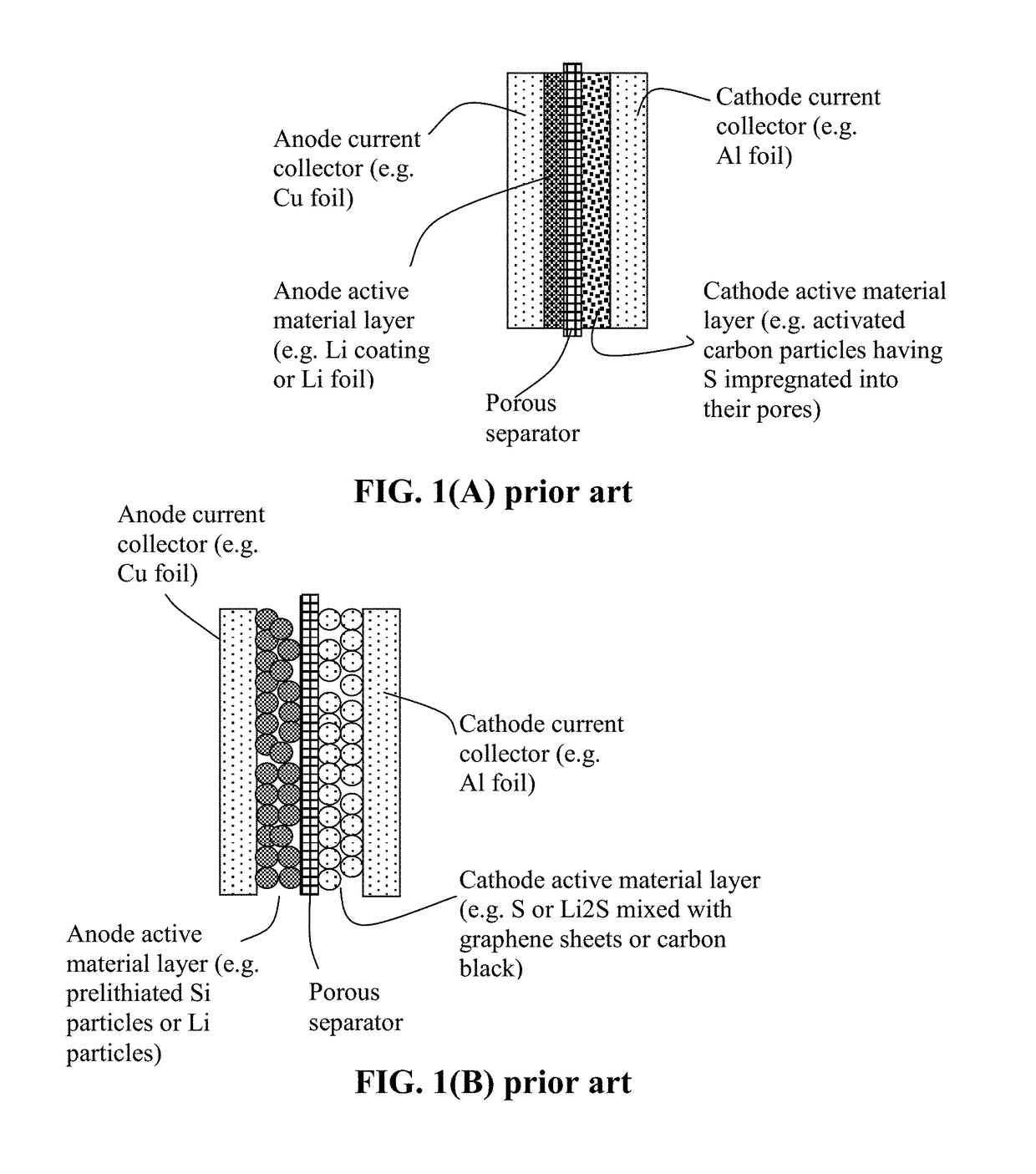

Rechargeable lithium-sulfur battery having a high capacity and long cycle life

ActiveUS20140315100A1Reducing and eliminating shuttle effectCost-effectiveElectrode carriers/collectorsSolid electrolyte cellsLithium–sulfur batteryLithium sulfur

A rechargeable lithium-sulfur cell comprising an anode, a separator and / or electrolyte, a sulfur cathode, an optional anode current collector, and an optional cathode current collector, wherein the cathode comprises (a) exfoliated graphite worms that are interconnected to form a porous, conductive graphite flake network comprising pores having a size smaller than 100 nm; and (b) nano-scaled powder or coating of sulfur, sulfur compound, or lithium polysulfide disposed in the pores or coated on graphite flake surfaces wherein the powder or coating has a dimension less than 100 nm. The exfoliated graphite worm amount is in the range of 1% to 90% by weight and the amount of powder or coating is in the range of 99% to 10% by weight based on the total weight of exfoliated graphite worms and sulfur (sulfur compound or lithium polysulfide) combined. The cell exhibits an exceptionally high specific energy and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

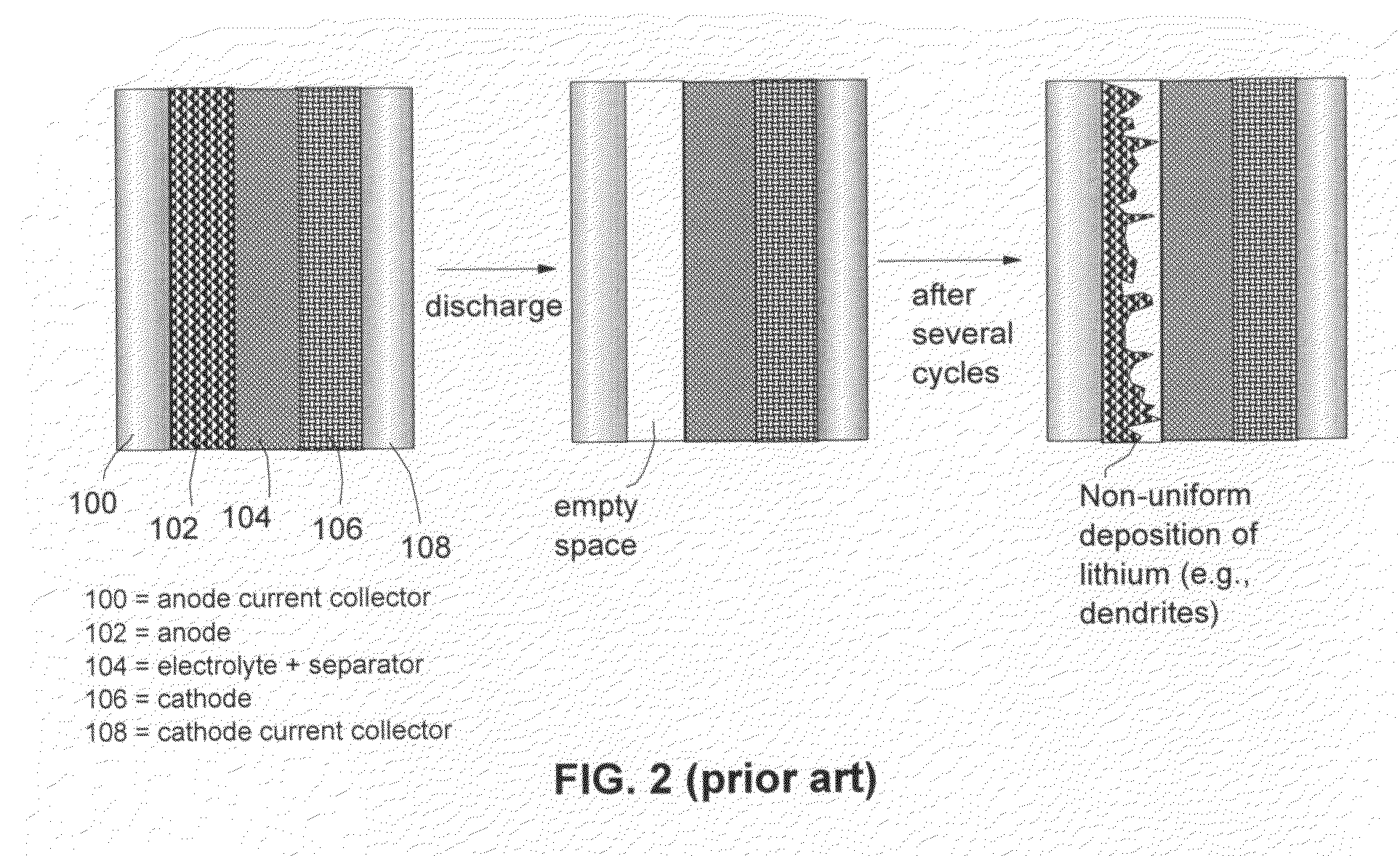

Nano-structured anode compositions for lithium metal and lithium metal-air secondary batteries

ActiveUS8236452B2High specific capacityHigh reversible capacityFuel and primary cellsConductive materialNano structuringLithium metal

This invention provides a nano-structured anode composition for a lithium metal cell. The composition comprises: (a) an integrated structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising interconnected pores, wherein the nano-filaments have a transverse dimension less than 500 nm; and (b) micron- or nanometer-scaled particles of lithium, a lithium alloy, or a lithium-containing compound wherein at least one of the particles is surface-passivated or stabilized and the weight fraction of these particles is between 1% and 99% based on the total weight of these particles and the integrated structure together. Also provided is a lithium metal cell or battery, or lithium-air cell or battery, comprising such an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

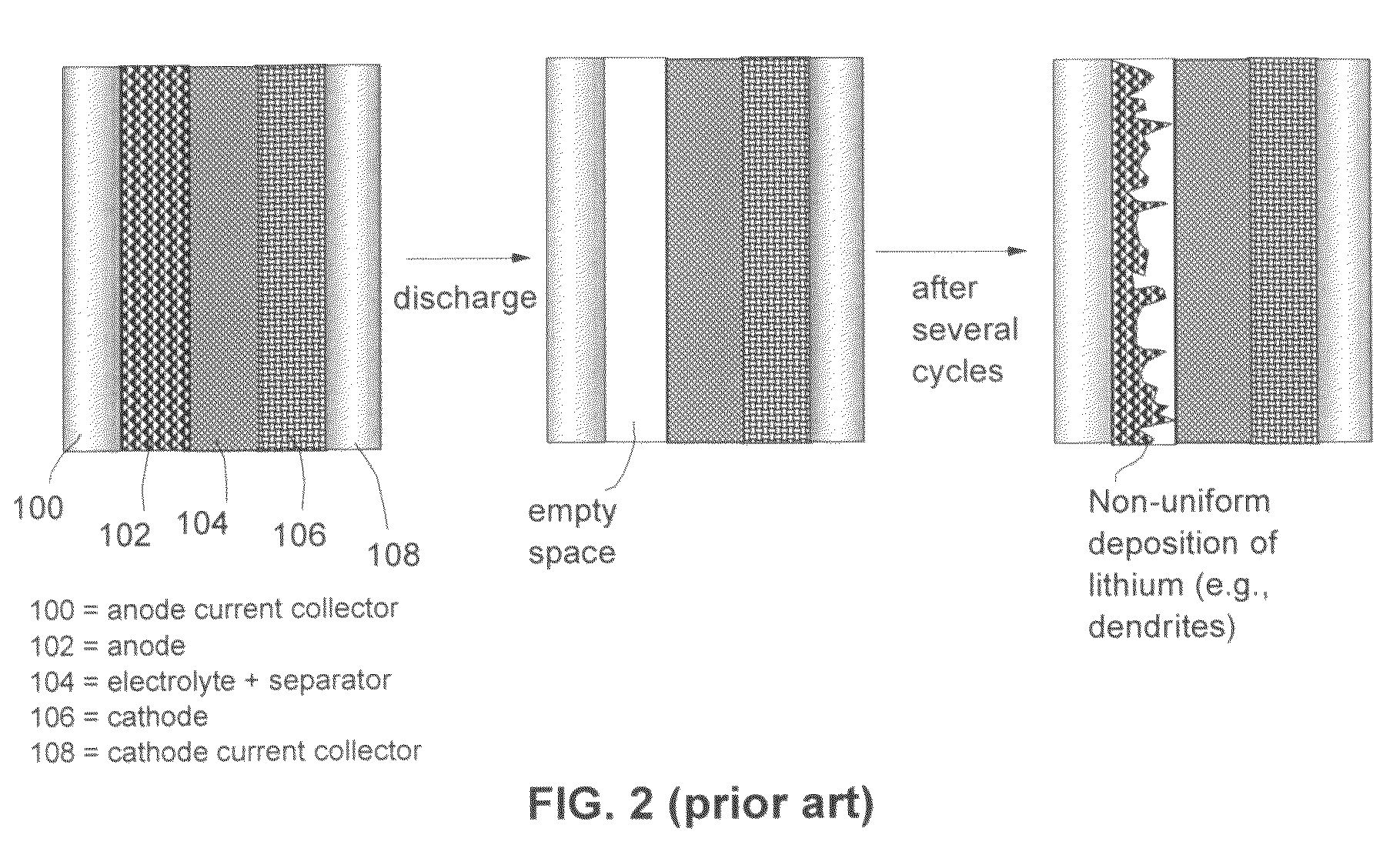

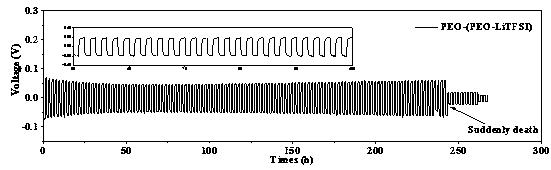

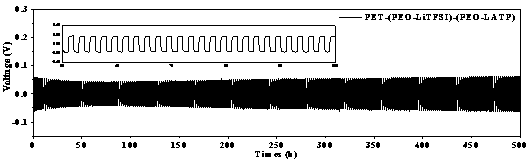

Inorganic-organic nano composite solid electrolyte membrane and preparation method and application thereof

ActiveCN109638349AImprove compatibilityEasy transferSolid electrolytesFinal product manufactureSolid state electrolyteHigh energy

The present invention discloses an inorganic-organic nano composite solid electrolyte membrane and a preparation method and application thereof. The composite solid electrolyte is a novel inorganic-organic nanocomposite combining the respective advantages of inorganic ceramic solid electrolyte and organic polymer electrolyte and is composed of a negative electrode protective layer, a support layerand a positive electrode interface layer. The support layer plays a supporting role, and the main component of the negative electrode protective layer is the inorganic solid electrolyte with good mechanical properties, which can effectively inhibit the growth of lithium dendrite; and the positive electrode interface layer is mainly composed of organic polymer electrolyte with good flexibility, ensures good contact with active materials and provides a continuous ion transport channel. In the present invention, the composite solid electrolyte with good interface compatibility is prepared by coating on both sides of the support layer, and the process is simple and efficient. The composite solid electrolyte can effectively inhibit dendritic crystal and reduces interface resistance so that a solid lithium metal battery has higher energy density and longer cycle life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

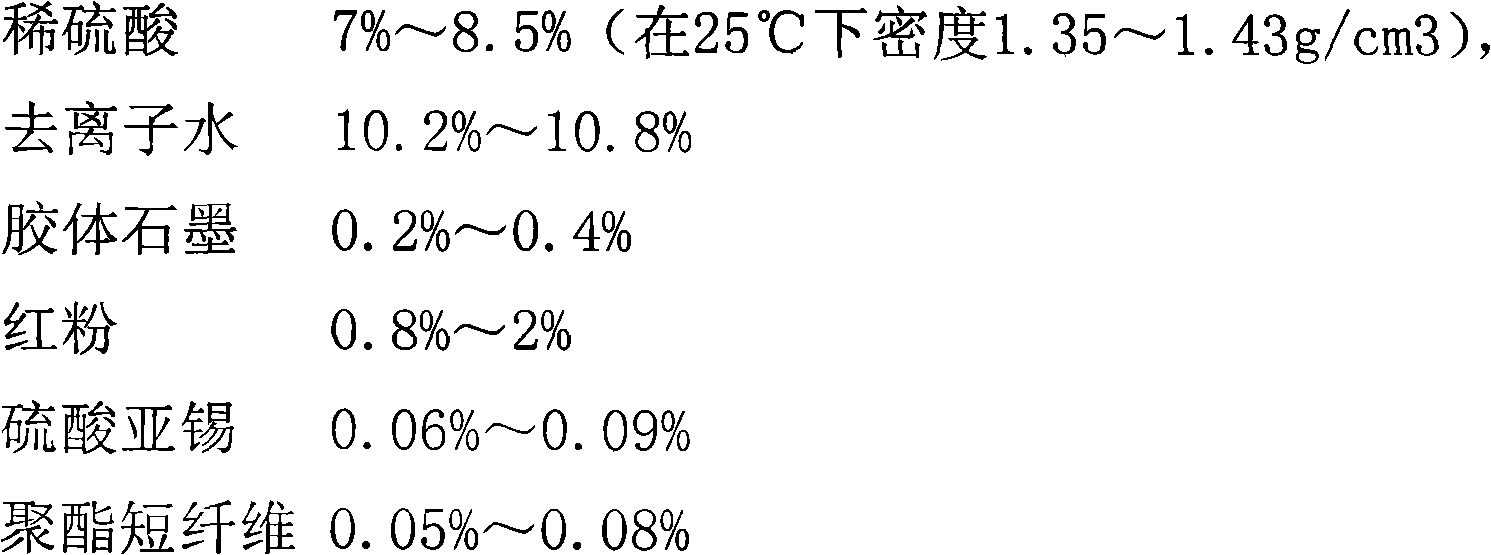

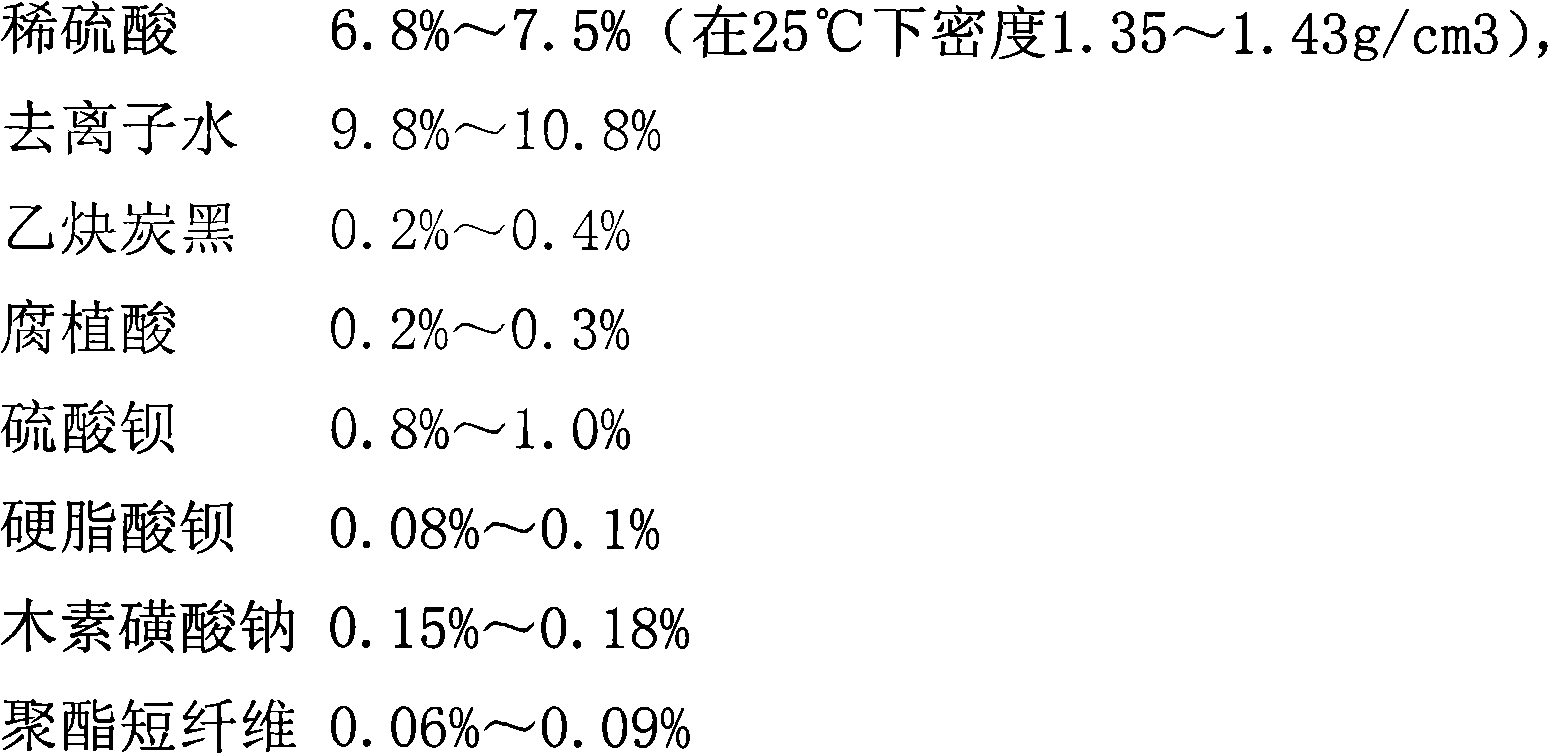

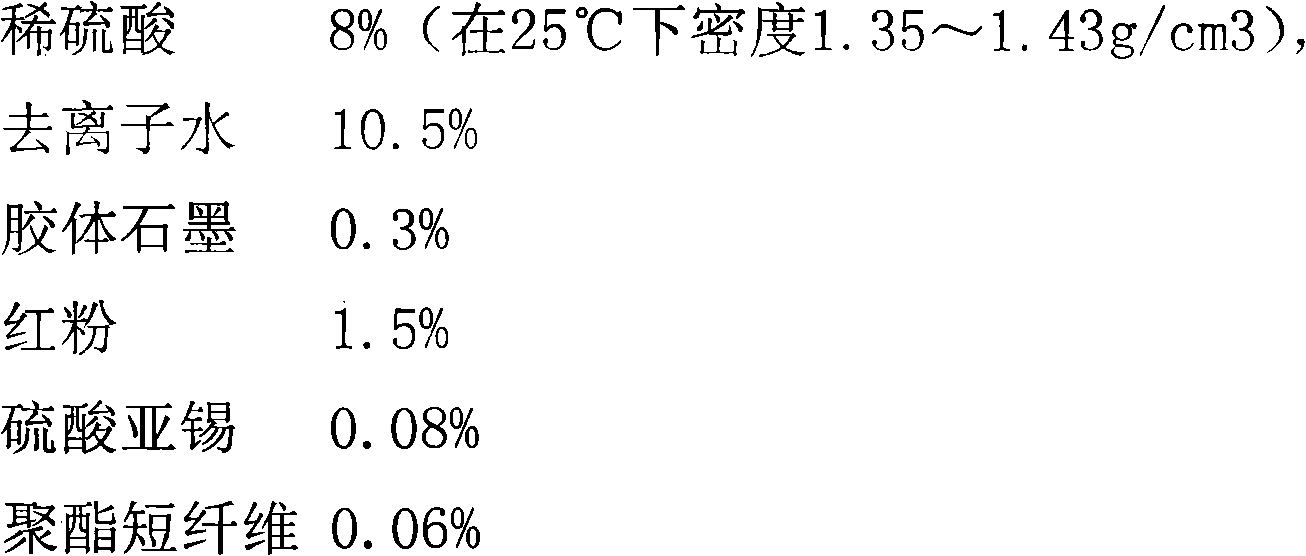

Formula and preparation method of high energy storage lead-acid battery lead paste

ActiveCN102354751AImprove charging efficiencyHigh initial capacityLead-acid accumulator electrodesFiberPolyester

The invention provides a formula and preparation method of a high energy storage lead-acid battery lead paste and relates to the technical field of lead-acid batteries. The formula of a positive plate lead paste comprises the following raw materials: 7-8.5% of dilute sulphuric acid, 10.2-10.8% of deionized water, 0.2-0.4% of colloidal graphite, 0.8-2% of red powder, 0.06-0.09% of stannous sulfate, 0.05-0.08% of polyester staple fiber and the balance of lead powder; the formula of a negative plate lead paste comprises the following raw materials: 6.8-7.5% of dilute sulphuric acid, 9.8-10.8% of deionized water, 0.2-0.4% of acetylene black, 0.2-0.3% of humic acid, 0.8-1.0% of barium sulfate, 0.08-0.1% of barium stearate, 0.15-0.18% of sodium lignosulphonate, 0.06-0.09% of polyester staple fiber and the balance of lead powder. The battery prepared by the lead paste has the advantages of high initial capacity and long cycle life; and the overdischarge resistance and charge acceptance of the battery are higher than the standard requirements.

Owner:TIANNENG BATTERY GROUP +4

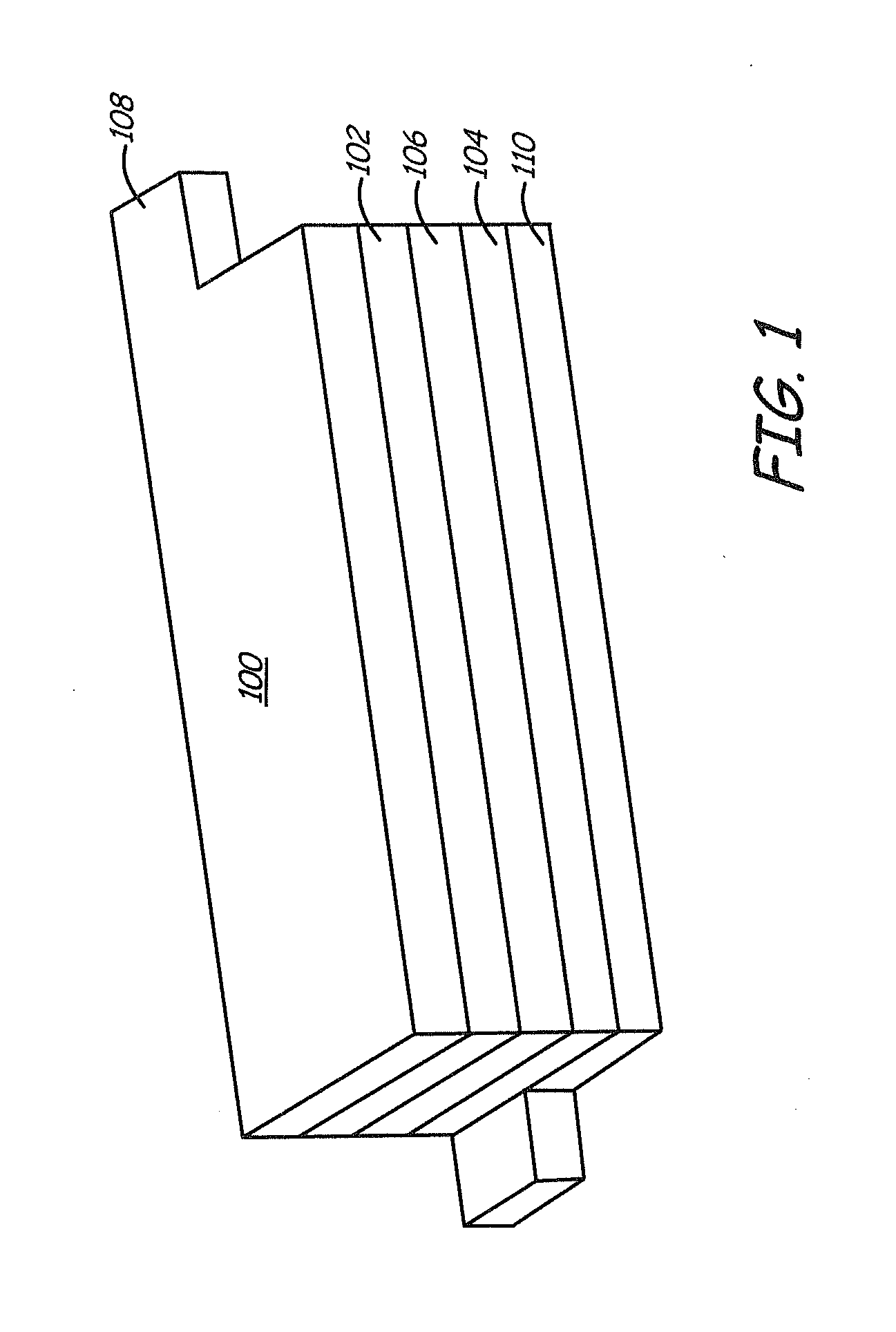

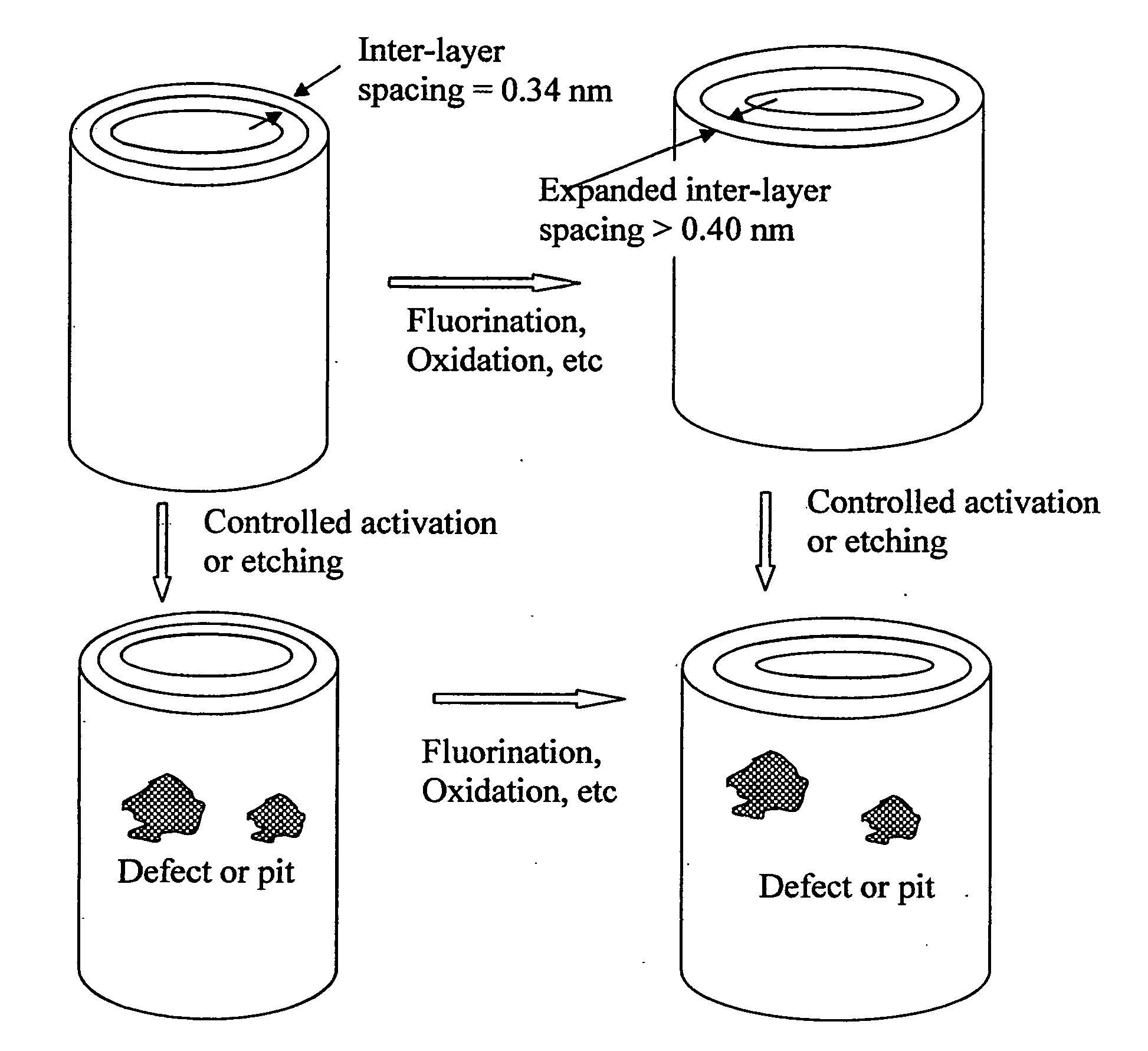

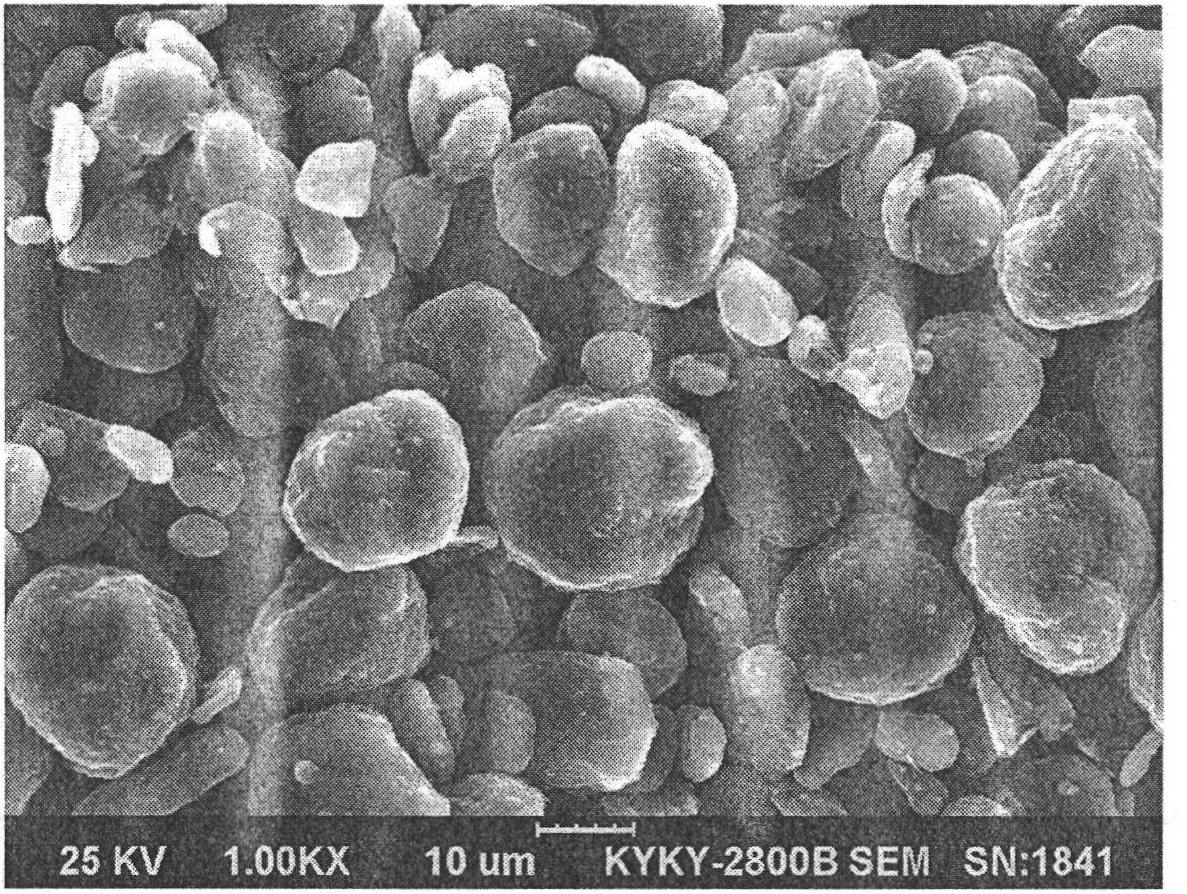

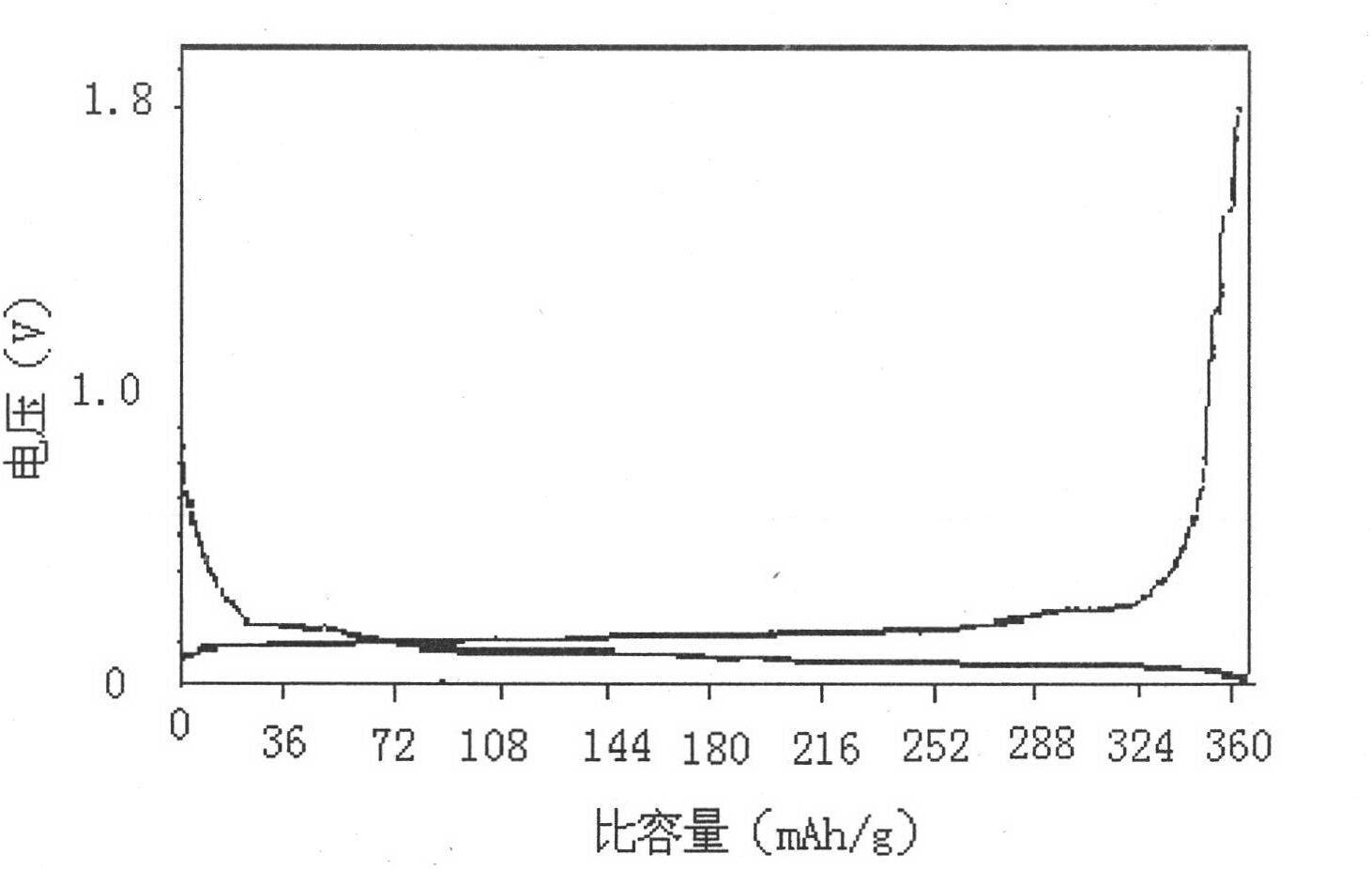

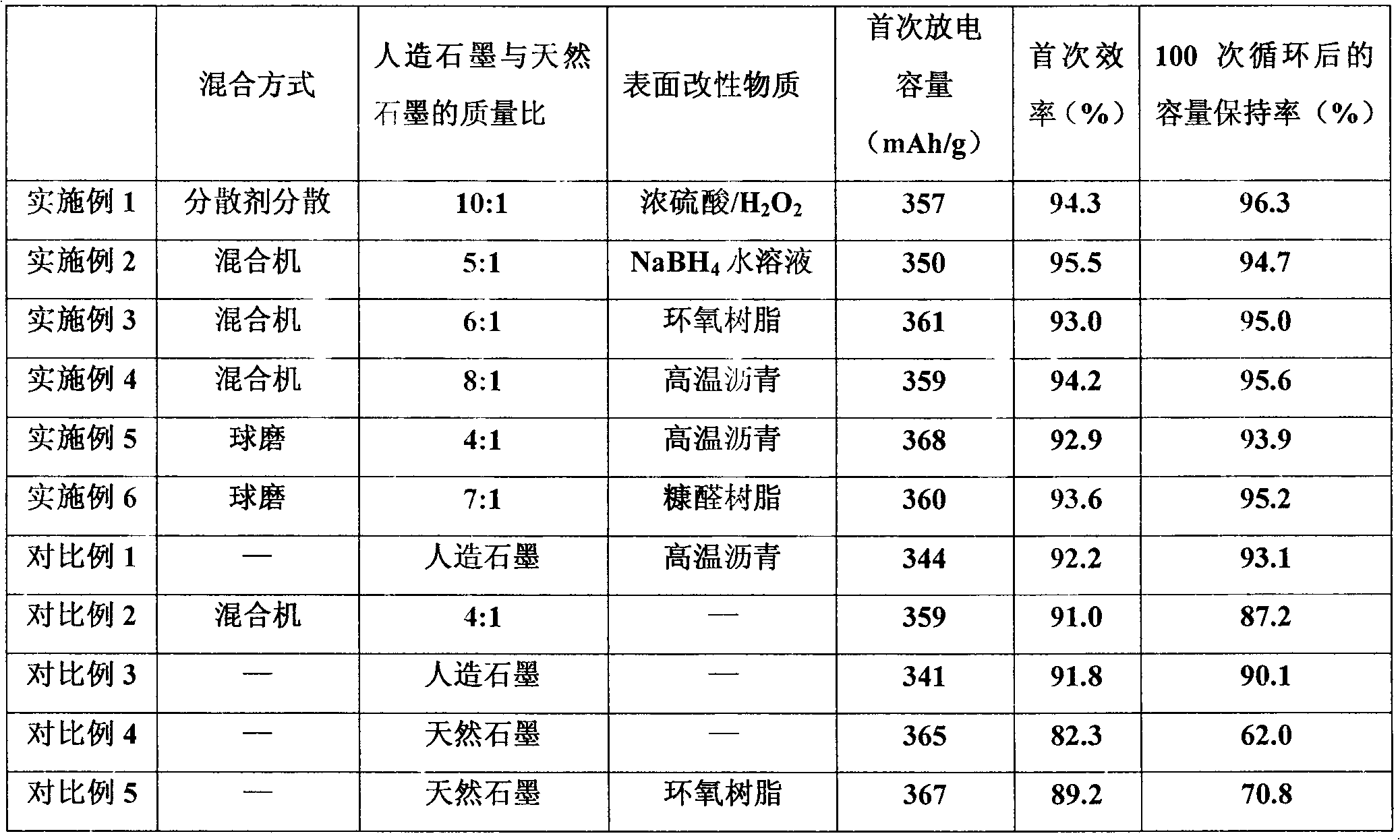

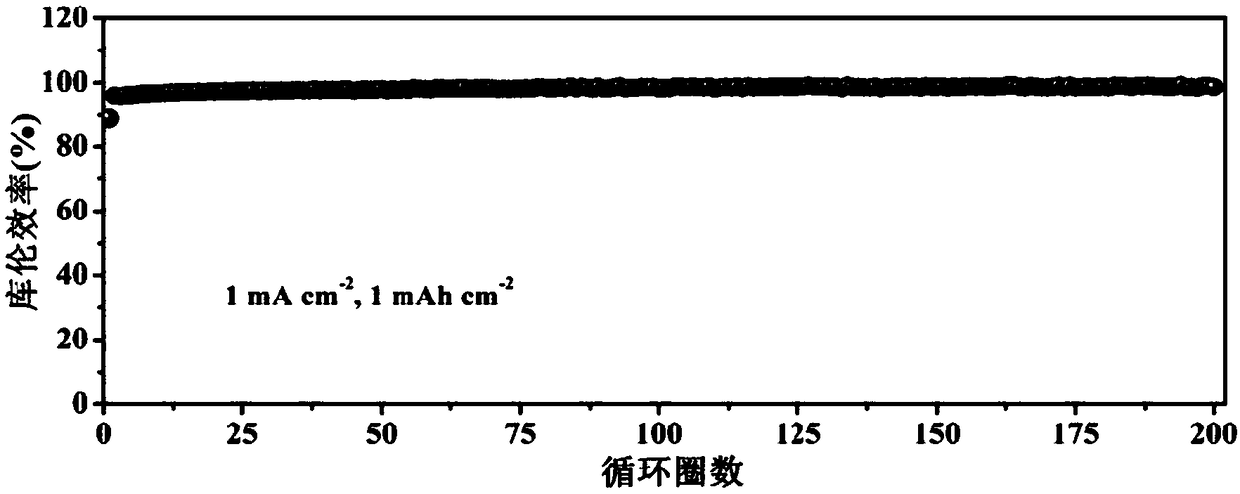

High-capacity graphite material and preparation method as well as application thereof

InactiveCN102659091AImprove discharge capacityImprove first-time efficiencyGraphiteCell electrodesMass ratioMetallurgy

The invention relates to a high-capacity graphite material and a preparation method as well as application thereof. The high-capacity graphite material comprises artificial graphite and natural graphite, wherein the mass ratio of artificial graphite to natural graphite is 20:1 to 1:1. According to the preparation method, the artificial graphite and the natural graphite are uniformly mixed according to a certain mass ratio, and then surface modification is carried out on the mixture. The prepared graphite material has the advantages of high discharge capacity, high first efficiency, long cycle life, low cost and the like; the discharge capacity of the high-capacity graphite material can reach up to more than 350mAh / g (even reach up to more than 368mAh / g); a half-cell of the high-capacity graphite material charges and discharges at the 1C multiple power; after the high-capacity graphite material cycles for 100 times, the capacity retention ratio of the high-capacity graphite material is still more than 90% (even reaches up to more than 96.3%); the first efficiency reaches up to more than 95.5%; and the manufacturing cost is reduced by about 1-10%. The high-capacity graphite material provided by the invention not only can meet the requirement of a lithium ion power battery for the high multiplying power charge-discharge of the material, but also reduces the manufacturing cost of the cathode material of the lithium ion battery.

Owner:天津市贝特瑞新能源科技有限公司

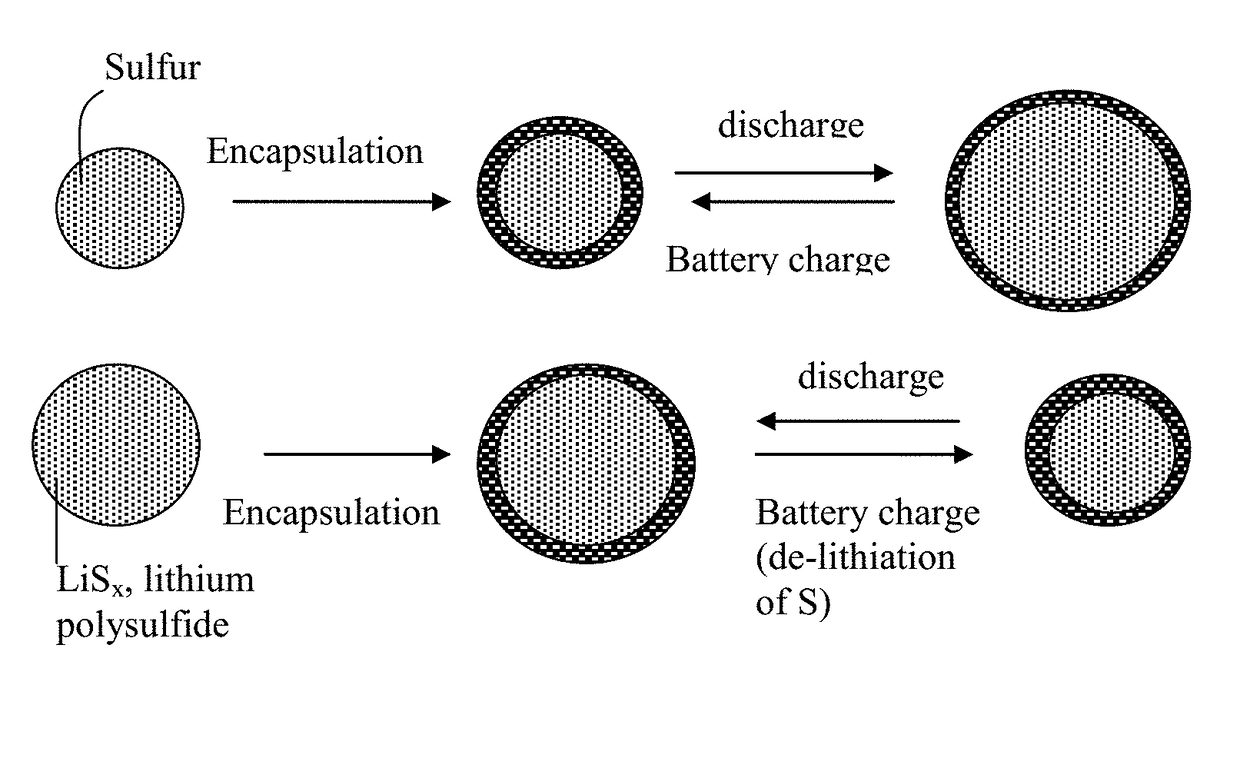

Alkali metal-sulfur secondary battery containing a protected sulfur cathode and manufacturing method

ActiveUS10084182B2Inhibited DiffusionReduce and eliminate effectFinal product manufacturePositive electrodesParticulatesConductive polymer

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 10% when measured without an additive or reinforcement, a lithium ion conductivity no less than 10−5 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

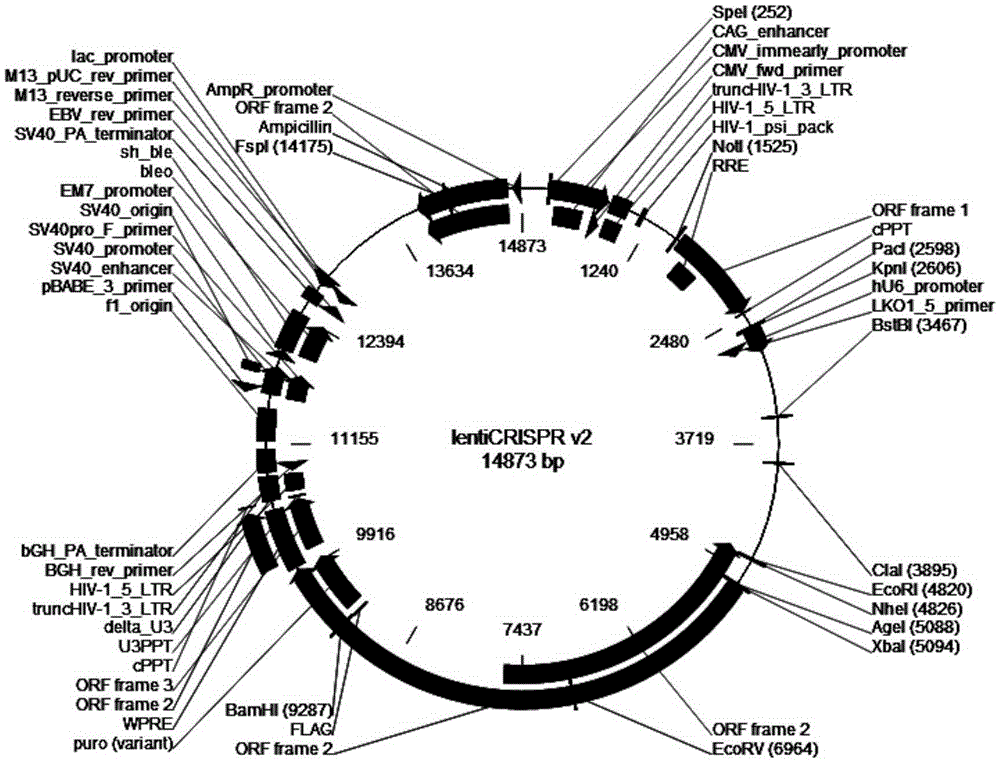

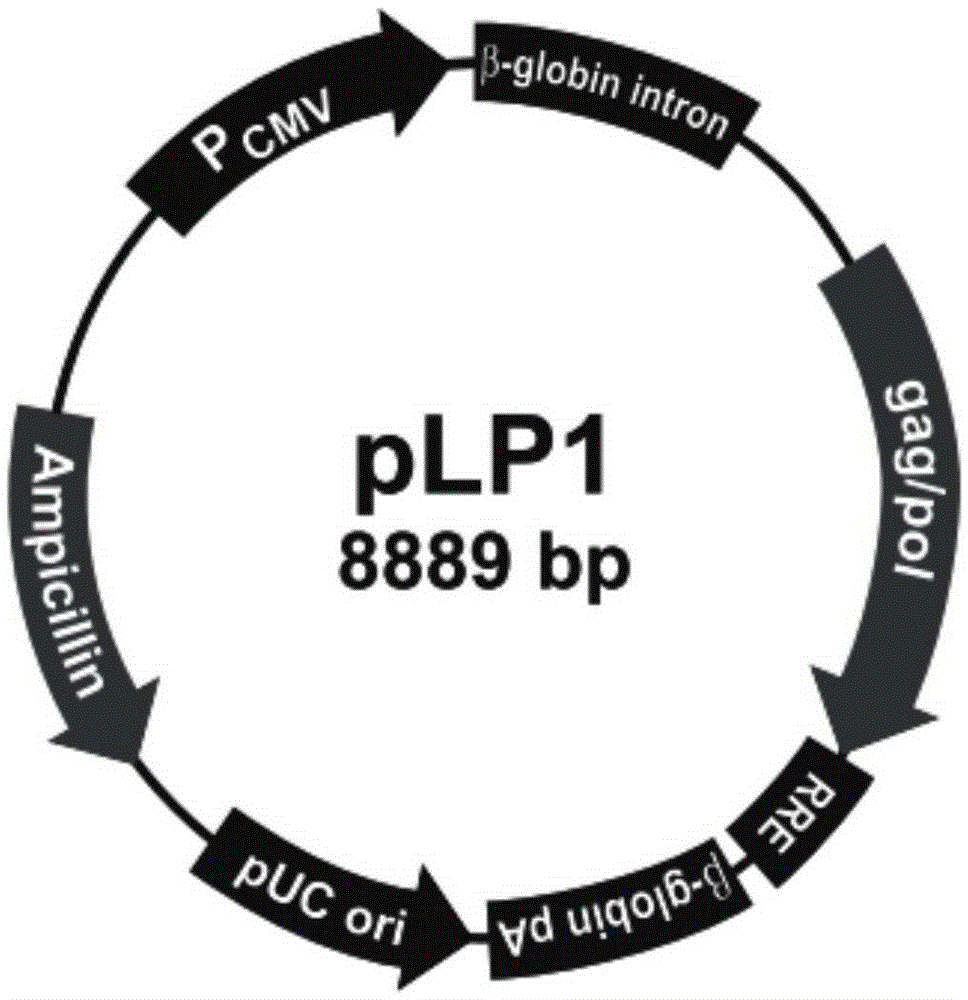

CRISPR-Cas9 specificity pig SLA-1 gene knockout method and sgRNA used for specific targeting SLA-1 gene

The present invention discloses a pig SLA-1 gene knockout method using CRISPR-Cas9 specificity and sgRNA used for specific targeting SLA-1 gene. The target sequence of the sgRNA used for specific targeting SLA-1 gene in the SLA-1 gene complies with a 5'-N (20) NGG-3' sequence arrangement rule, wherein N (20) represents 20 consecutive basic groups, wherein each N represents a A or T or C or G; the target sequence in the SLA-1 gene is located at the four exon coding regions of the N-terminal of the SLA-1 gene or the junction of adjacent introns; and the target sequence in the SLA-1 gene is unique. The sgRNA used in the pig SLA-1 gene knockout method using CRISPR-Cas9 specificity, may fast, accurately, efficiently, and specifically knockout pig SLA-1 gene, effectively solve long cycle and high cost in construction of SLA-1 gene knockout pig.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Process for producing alkali metal or alkali-ion batteries having high volumetric and gravimetric energy densities

ActiveUS9564656B1Increase energy densityImprove power densityFinal product manufactureCell electrodesAlkali ionsMass loading

Provided is a process for producing an alkali metal battery, comprising: (A) Preparing an anode material suspension and a cathode active material suspension; (B) Assembling a porous cell framework composed of a first conductive foam structure, a second conductive foam structure, and a porous separator disposed between said first and said second conductive foam structure; and (C) Injecting the anode suspension into pores of the first conductive foam structure to form an anode and injecting cathode suspension into pores of the second conductive foam structure to form a cathode, wherein the anode active material has a material mass loading no less than 20 mg / cm2 or the cathode active material has a material mass loading no less than 15 mg / cm2 for an organic or polymer material or no less than 40 mg / cm2 for an inorganic material. The resulting batteries exhibit exceptional gravimetric and volumetric energy densities and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

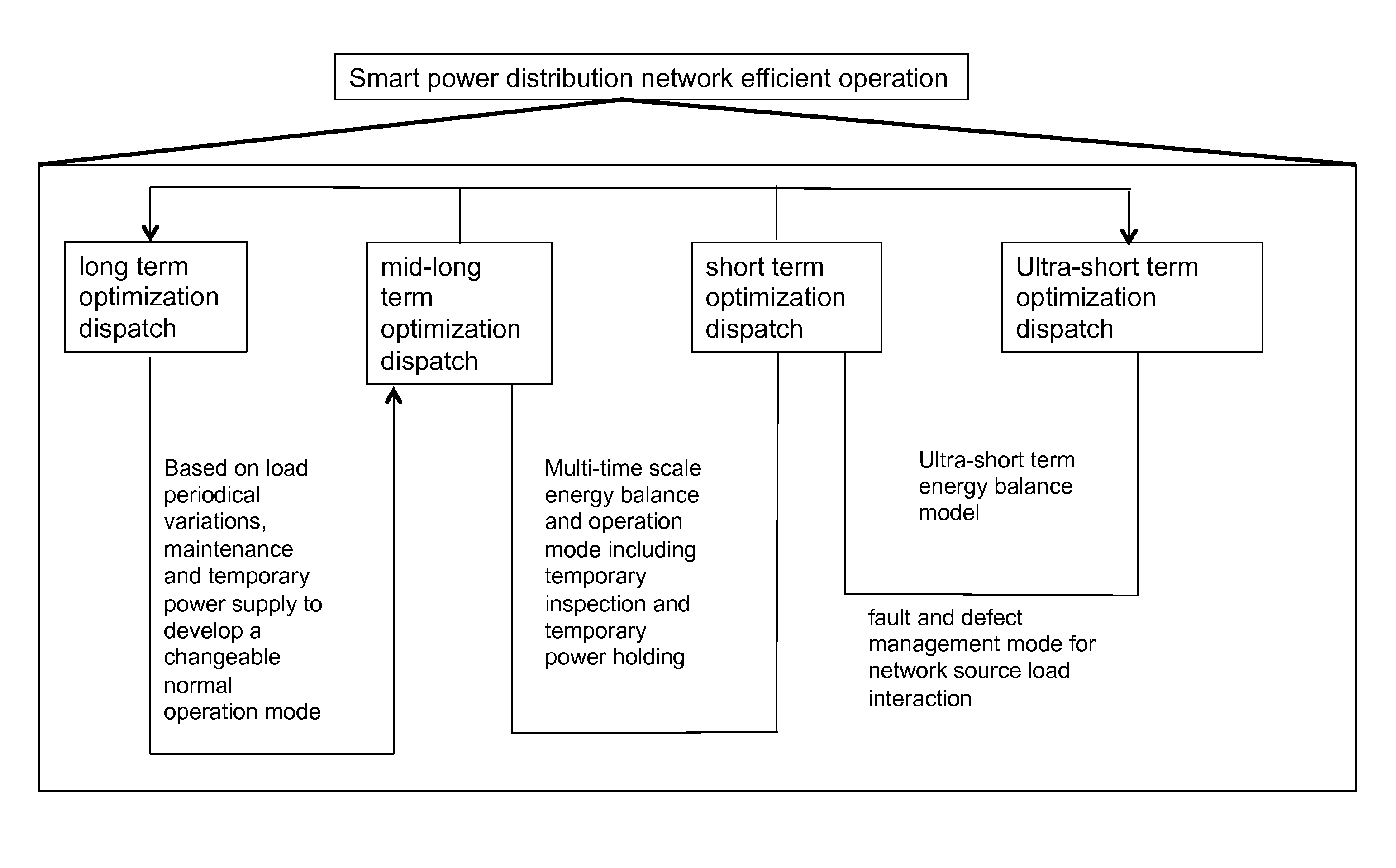

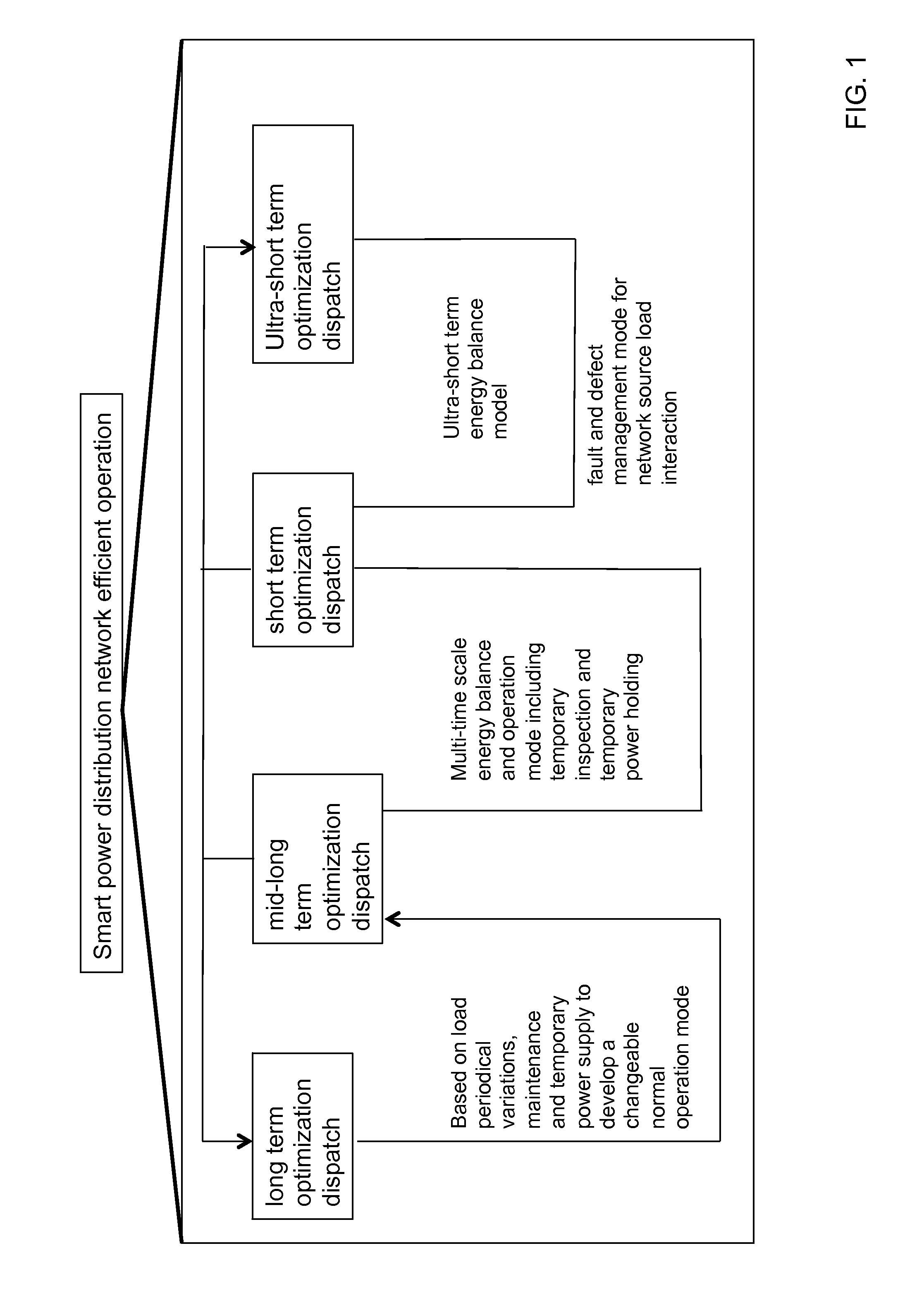

A progressive optimization dispatching method of smart distribution system

ActiveUS20160239032A1Quality improvementEasy to operateComputer controlForecastingDistribution power systemCharge discharge

The present invention discloses a smart power distribution system and a method to progressively dispatch the power using the same. The method is characterized in that it is based on data collection and data analysis to develop a dispatch scheme. The method steps are all automatic and self-adaptive. The method can be executed in an unattended manner to automatically correlate real time data vs. historical data, planning data vs. operation data. Based on a long cycle periodical variation and short-term random variations in load, and taking into account the temporary load power supply and maintenance needs, a multi-stage progressive multiple time scales optimal dispatching method is developed, including the distributed power, micro-grids, energy storage devices, electric vehicles charge-discharge facility and other elements of the Intelligent power distribution systems, to achieve coordinated operation of the network, power, load resources to ensure a continuous safe and reliable smart power distribution system operated at high quality and efficiency.

Owner:JIANGSU ELECTRIC POWER CO +4

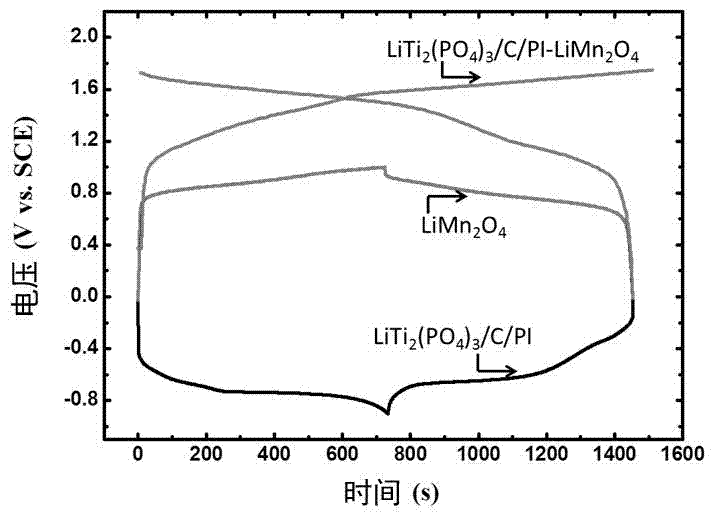

Aqueous lithium (sodium) ion battery mixed negative material

InactiveCN104779394AThe preparation process is matureReduce manufacturing costElectrode manufacturing processesAlkaline earth metalShortest distance

The invention belongs to the technical field of batteries, and particularly relates to an aqueous lithium (sodium) ion battery mixed negative material. The mixed negative material is prepared by mixing three materials including ion embedded type compounds, conductive materials, organic compounds capable of reversibly storing alkali metal or alkaline earth metal ions or high-molecular polymers in a certain mass proportion; a mixing way comprises the steps of in-situ growth and direct mechanical mixing of all the composition parts. An aqueous lithium (sodium) ion battery assembled by using the mixed electrode material as a negative electrode has the characteristics of long cycle life, high power, high security, low cost and no environment pollution, and is particularly suitable for power batteries used in short-distance electromobiles and energy storage batteries used in smart power grids.

Owner:FUDAN UNIV

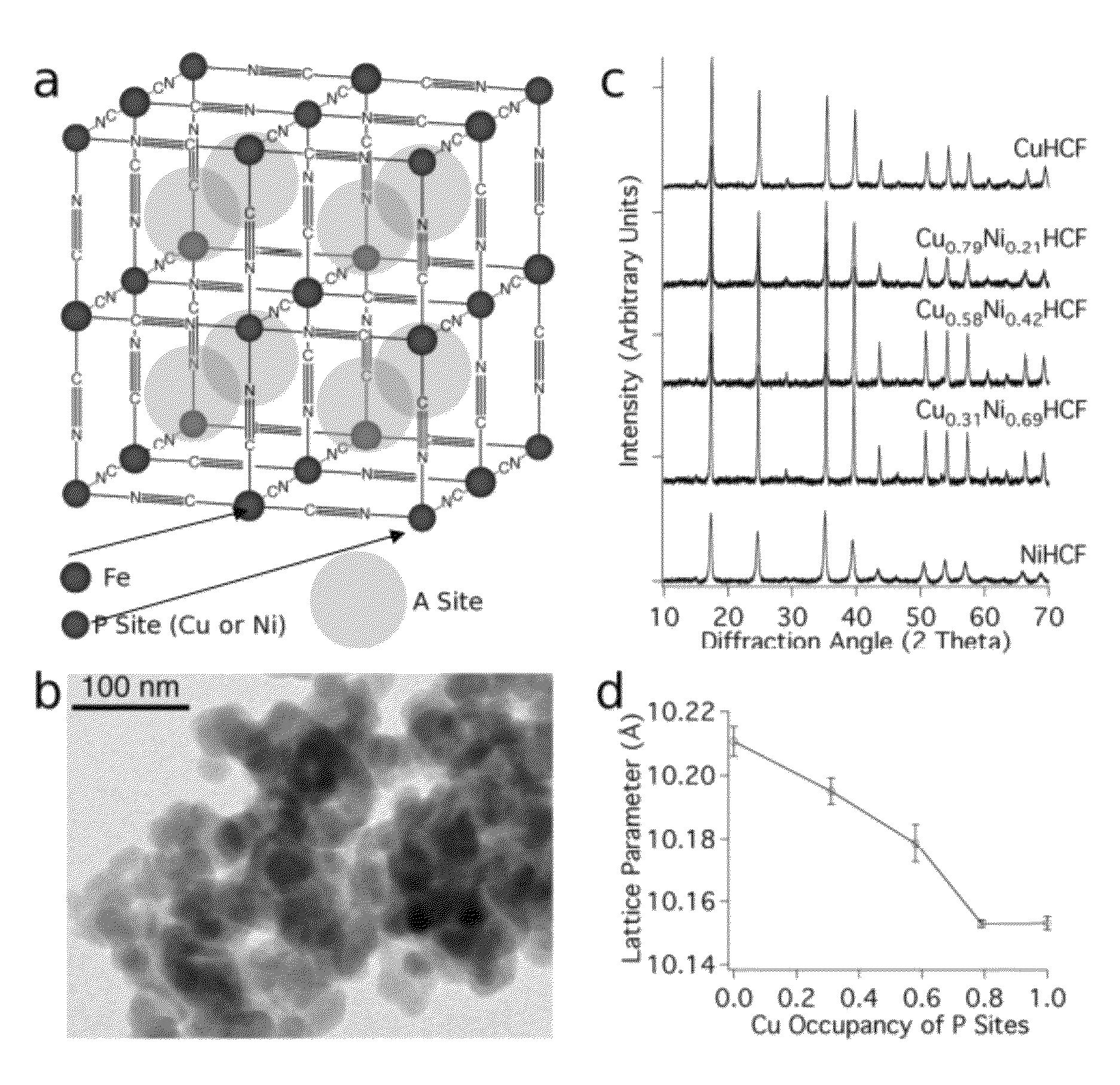

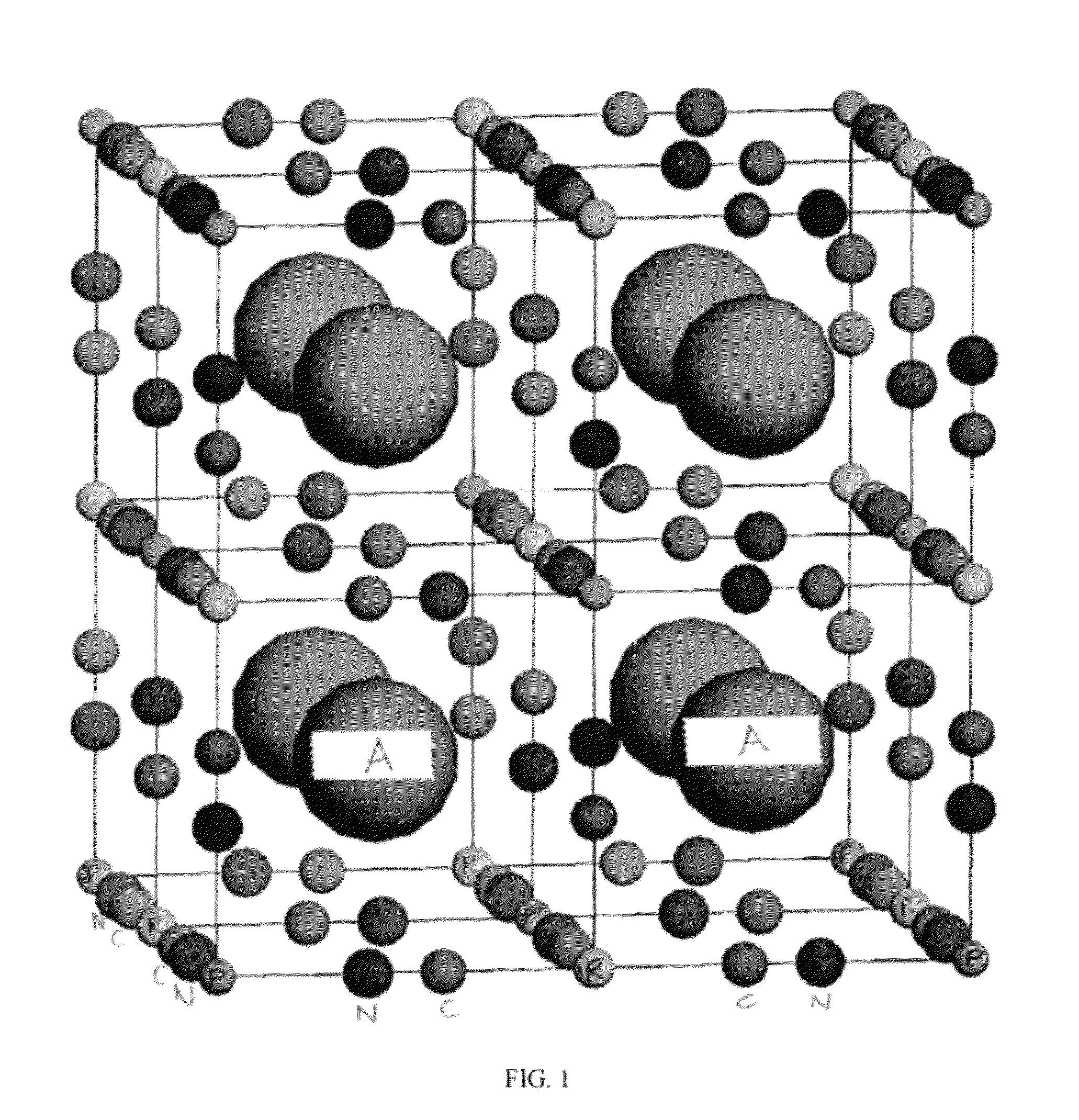

High rate, long cycle life battery electrode materials with an open framework structure

InactiveUS8951673B2Extreme durabilityImprove rate performanceFinal product manufactureActive material electrodesHigh rateReference rate

A battery includes a cathode, an anode, and an aqueous electrolyte disposed between the cathode and the anode and including a cation A. At least one of the cathode and the anode includes an electrode material having an open framework crystal structure into which the cation A is reversibly inserted during operation of the battery. The battery has a reference specific capacity when cycled at a reference rate, and at least 75% of the reference specific capacity is retained when the battery is cycled at 10 times the reference rate.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Preparation method of organic-inorganic composite capsule wall energy-storage microcapsule

ActiveCN103769021AImprove thermal stabilityHigh mechanical strengthHeat-exchange elementsMicroballoon preparationFiltrationOil phase

The invention discloses a preparation method of an organic-inorganic composite capsule wall energy-storage microcapsule. The method is as below: mixing an organic phase change material and a surface active agent, heating with stirring to obtain an even oil phase material; adding silica-containing silica sol and ethyl orthosilicate in a mass ratio of 1:1-10:1 into deionized water to prepare a water phase material; then adding an oil phase material into the water phase material, and uniformly dispersing into an emulsion; then adding polyisocyanate and a crosslinking agent, maintaining the original temperature and stirring speed, so as to obtain the microcapsule with the organic-inorganic composite capsule wall; and finally, conducting vacuum filtration, washing and drying on the obtained liquid substance to obtain the product. The phase change energy-storage microcapsule obtained by the method can be used in several fields such as building energy saving and insulation of pipeline storage tank, and the capsule wall of the microcapsule has the advantages of organic material and inorganic material and longer cycle of usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com