Patents

Literature

85 results about "Sulfur utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A series of processes that forms an integrated mechanism by which a cell or an organism detects the depletion of primary sulfur sources and then activates genes to scavenge the last traces of the primary sulfur source and to transport and metabolize alternate sulfur sources. The utilization process begins when the cell or organism detects sulfur levels, includes the activation of genes whose products detect, transport or metabolize sulfur-containing compounds, and ends when the sulfur is incorporated into the cell or organism's metabolism. [GOC:mah, GOC:mlg]

Alkali Metal-Sulfur Secondary Battery Containing a Protected Sulfur Cathode and Manufacturing Method

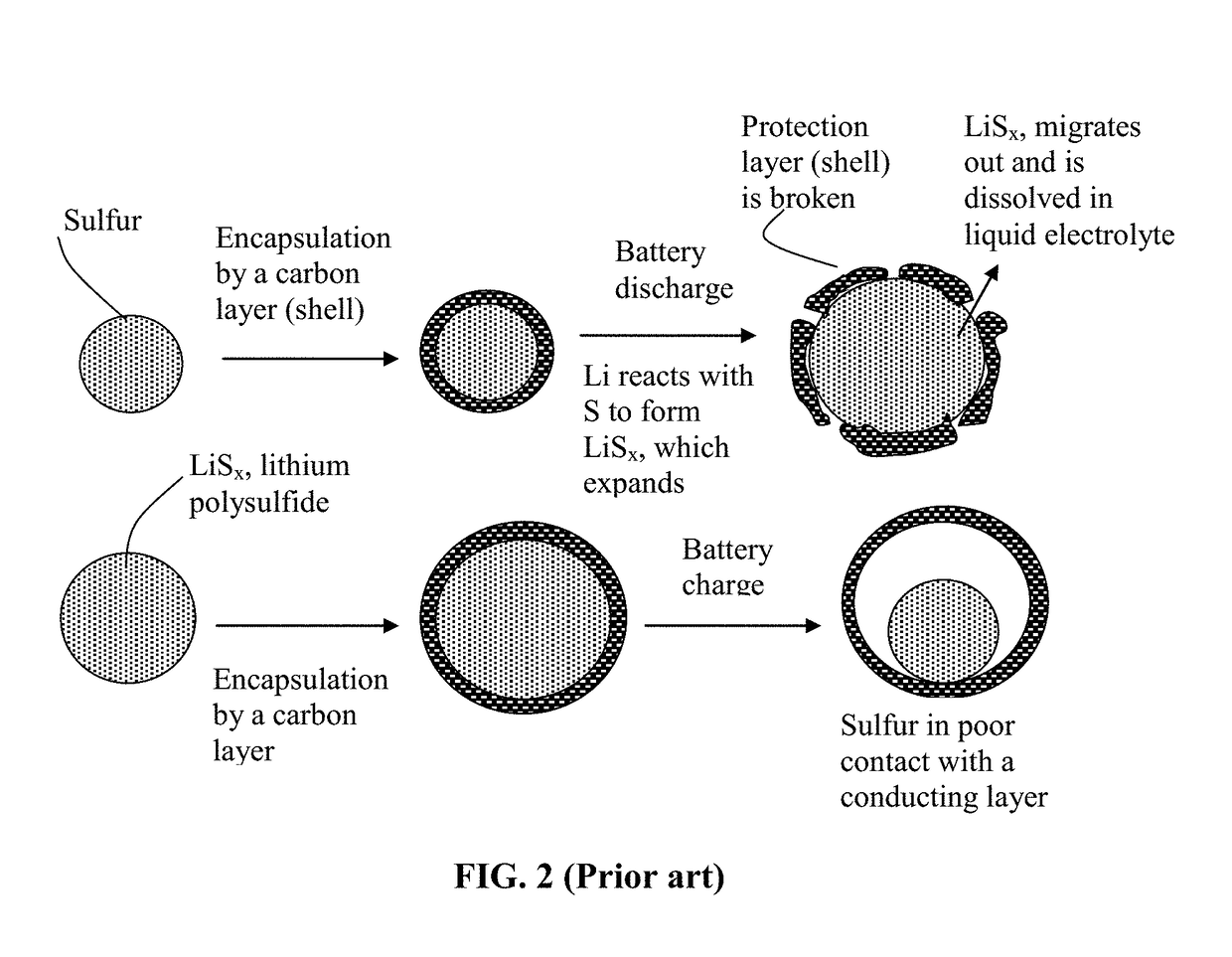

ActiveUS20180241031A1Inhibited DiffusionReduces and eliminates shuttling effectFinal product manufacturePositive electrodesElectrical batteryConductive polymer

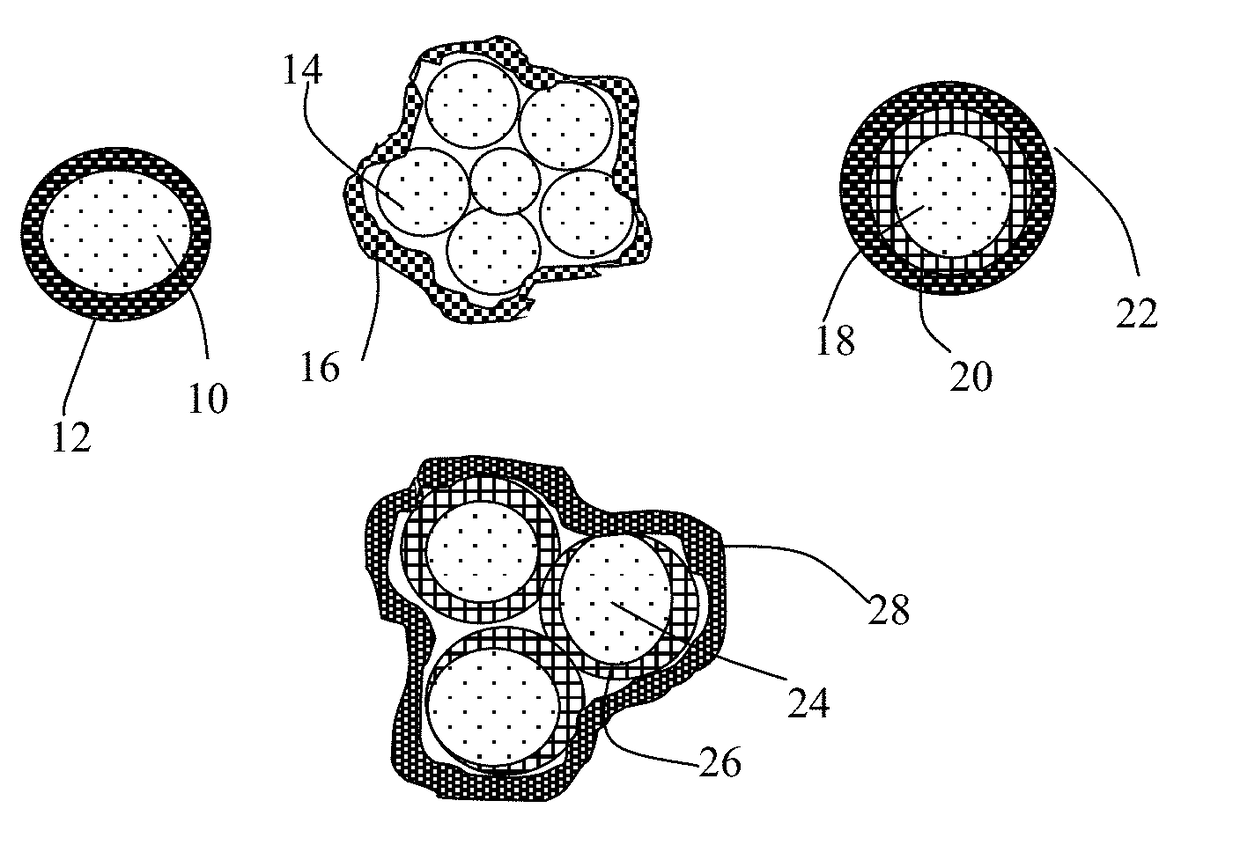

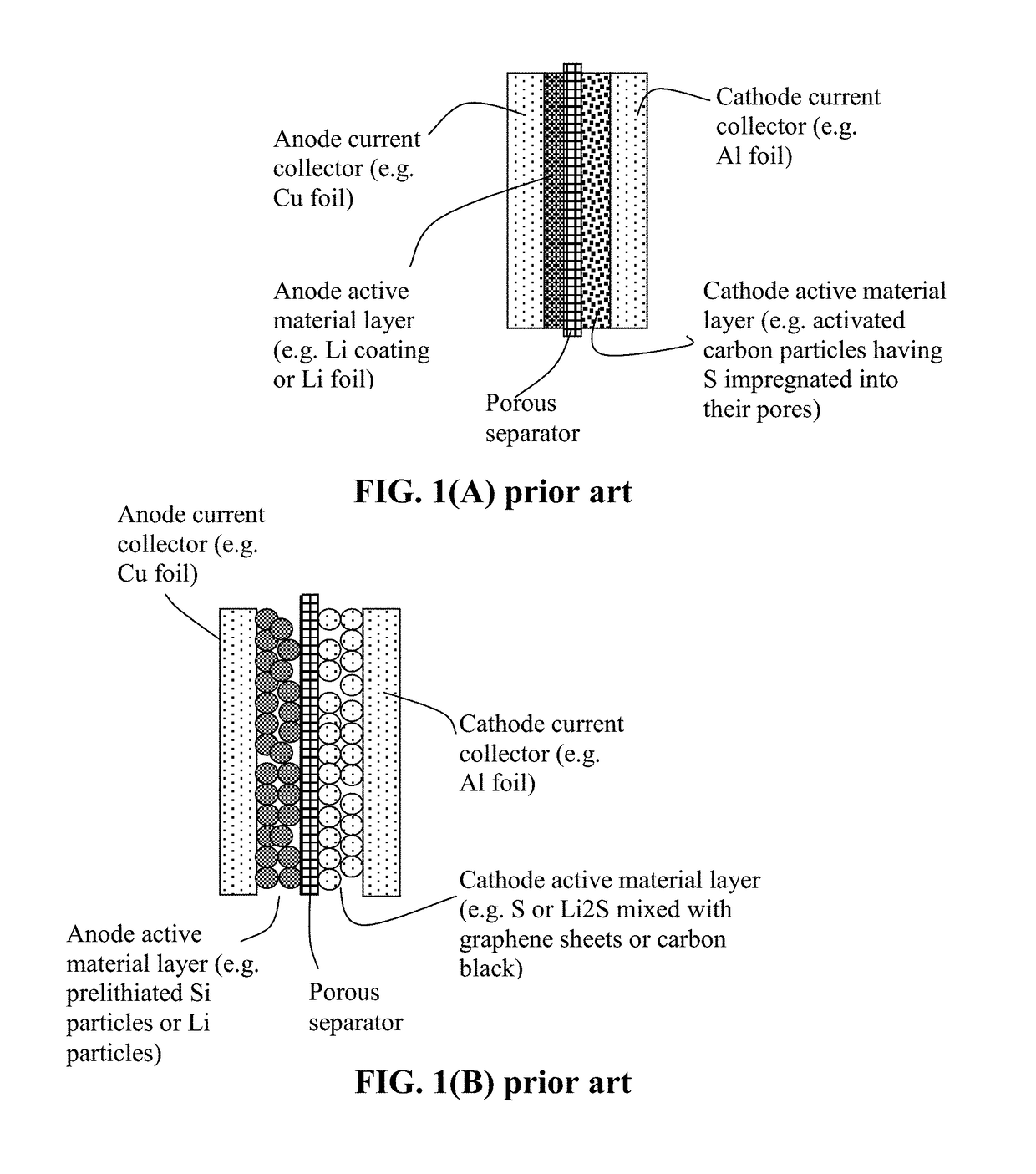

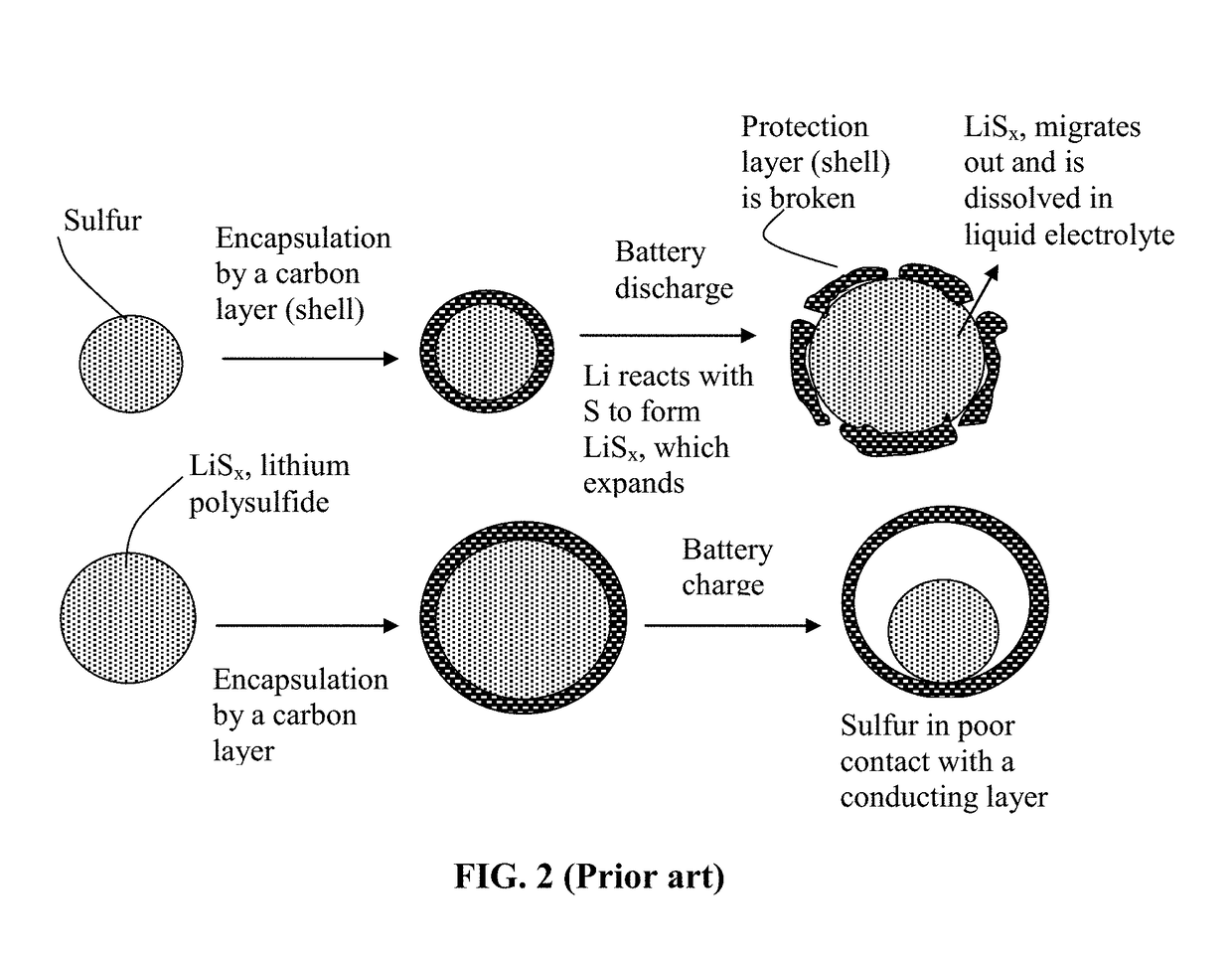

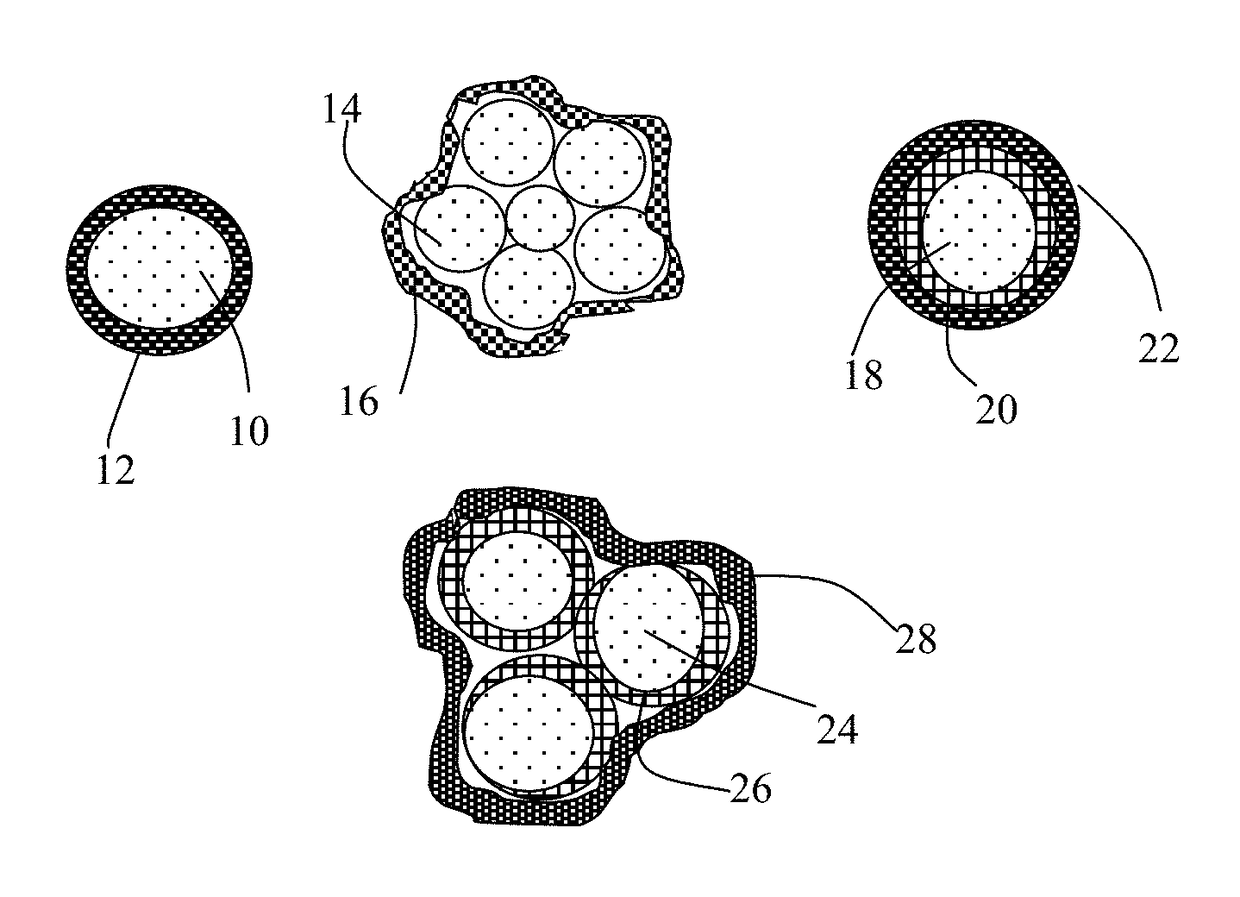

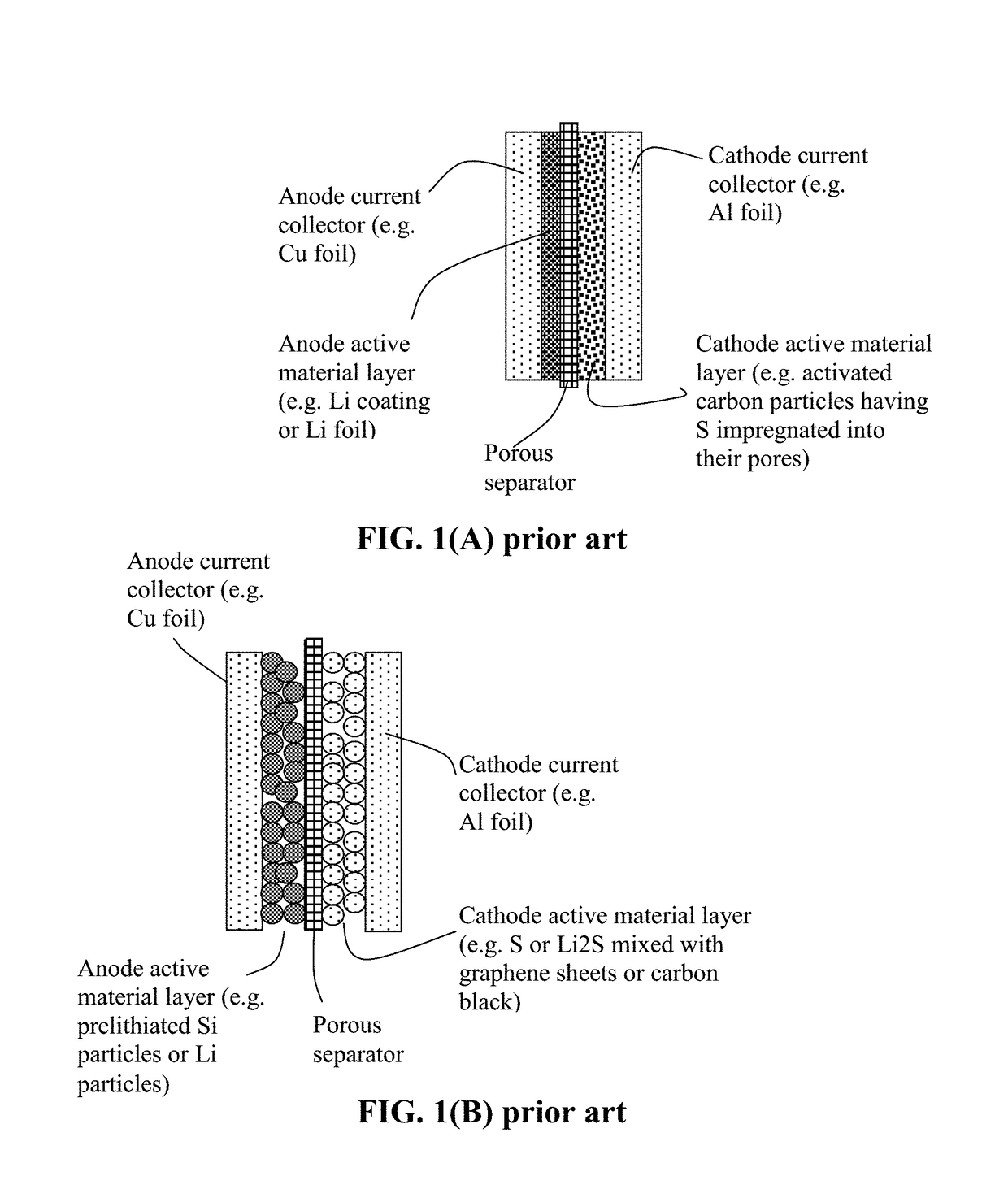

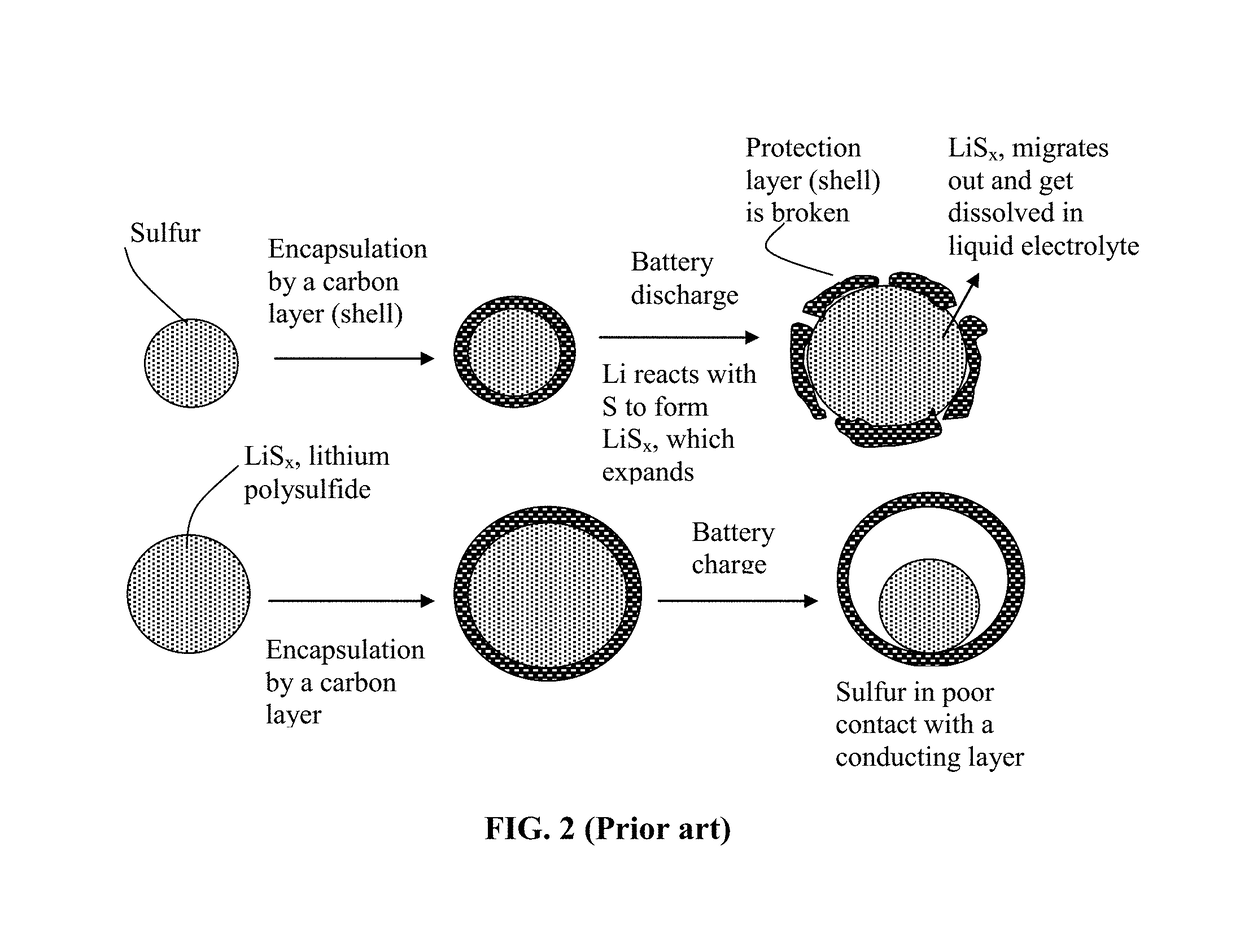

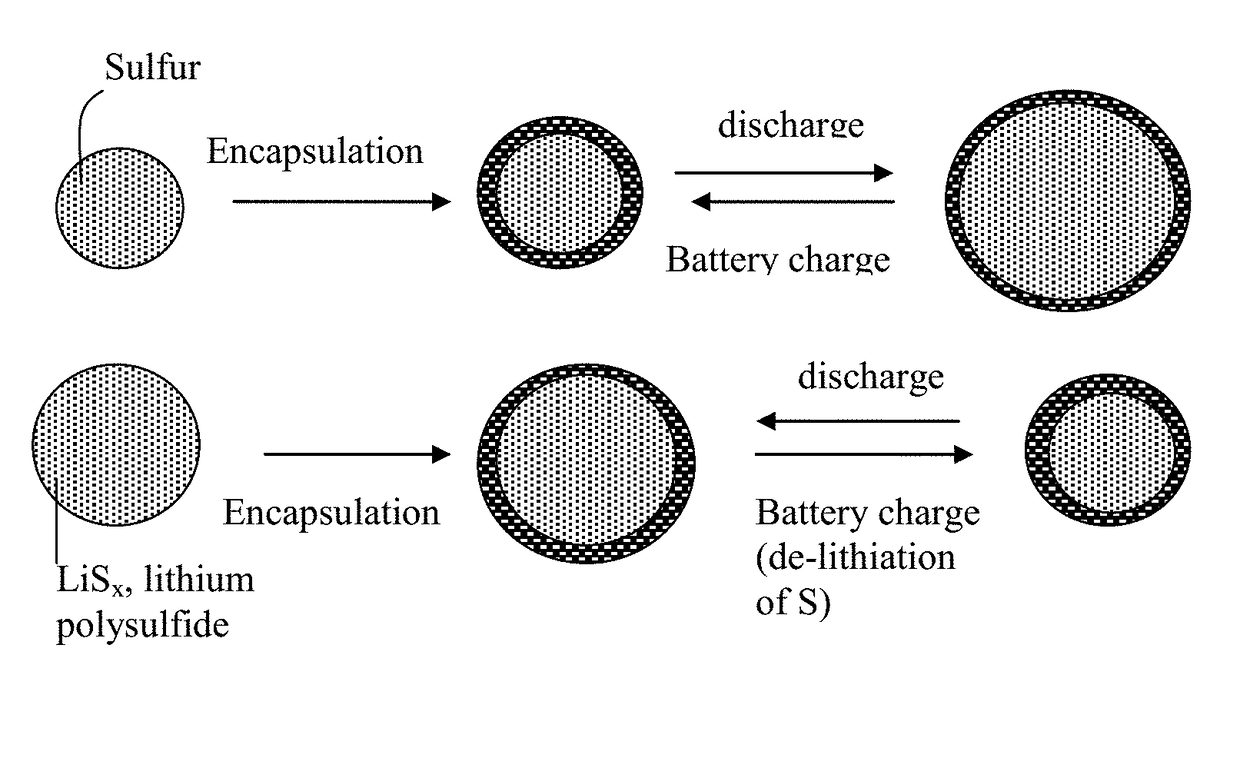

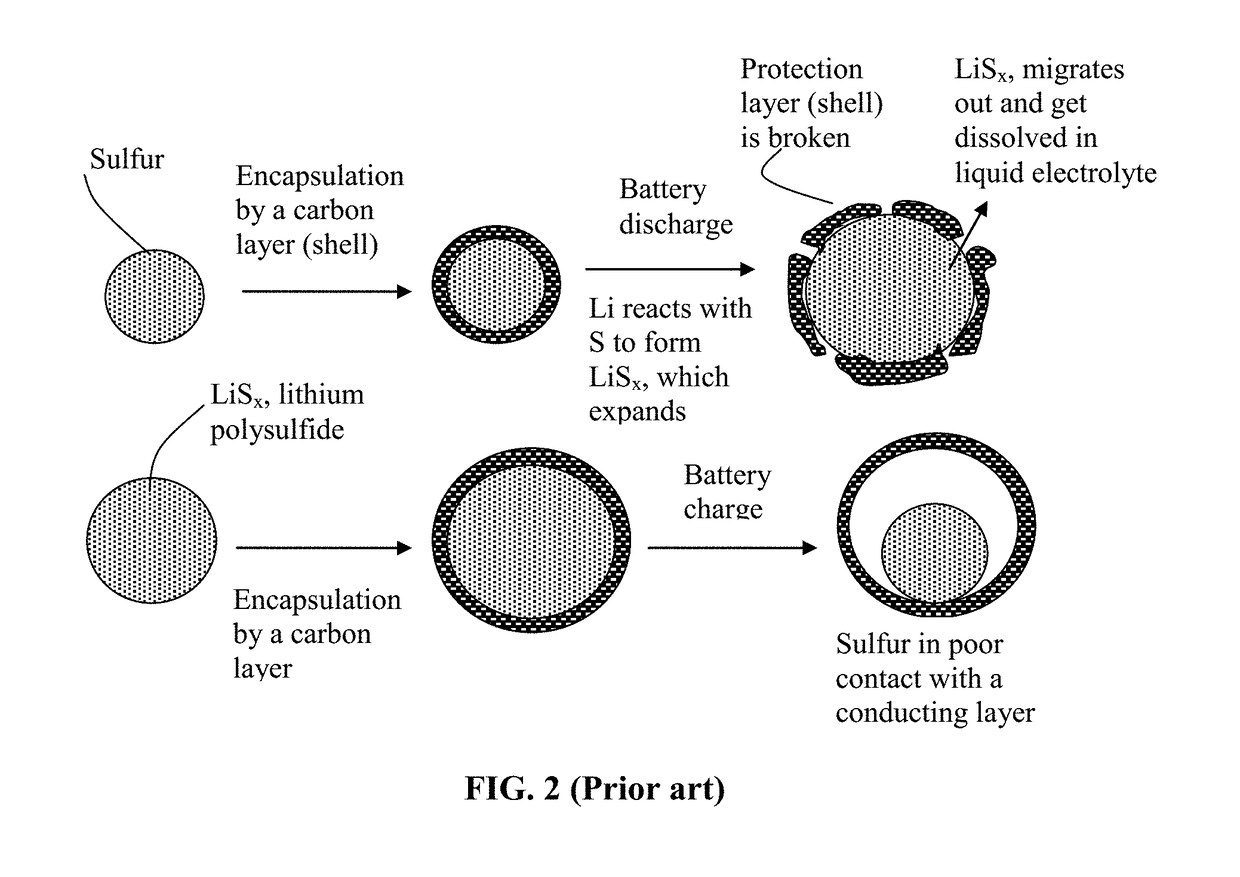

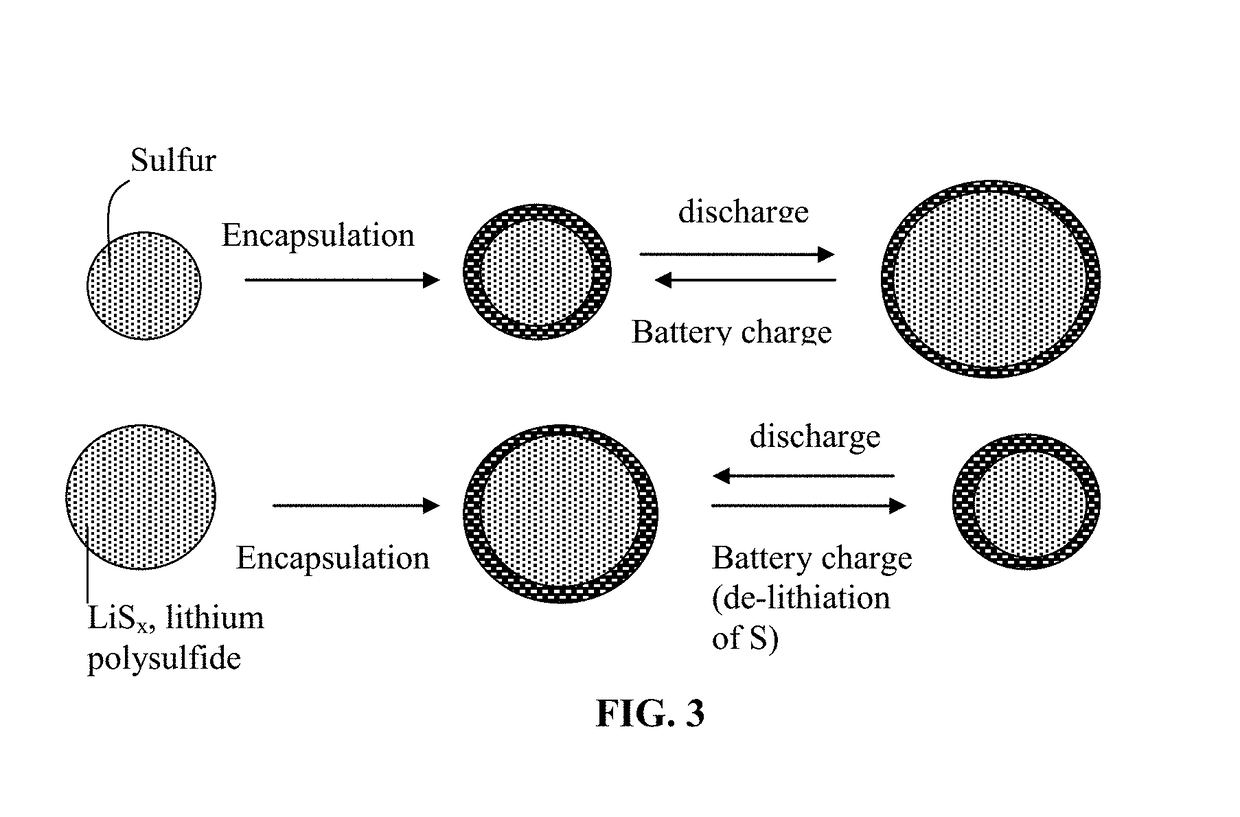

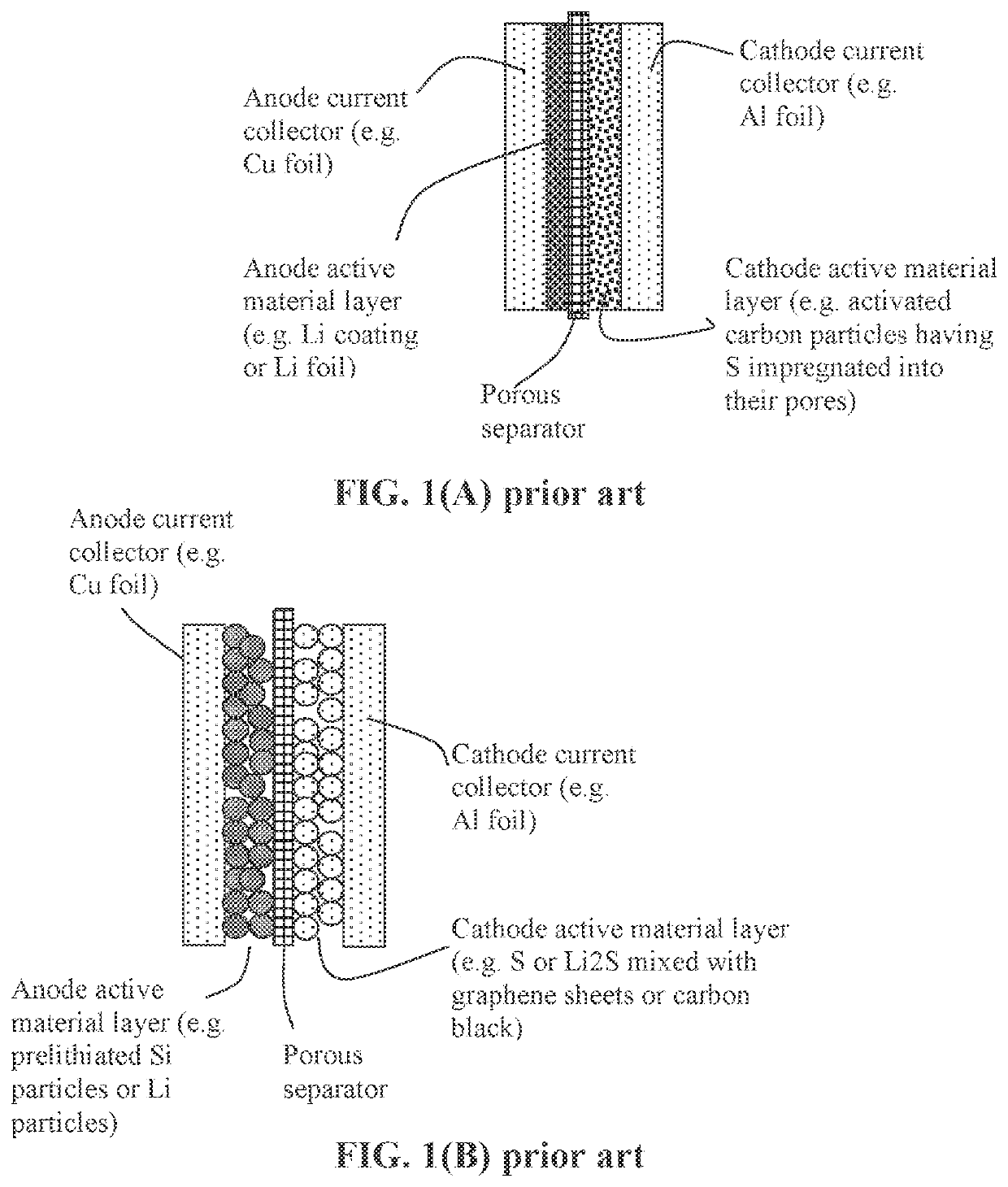

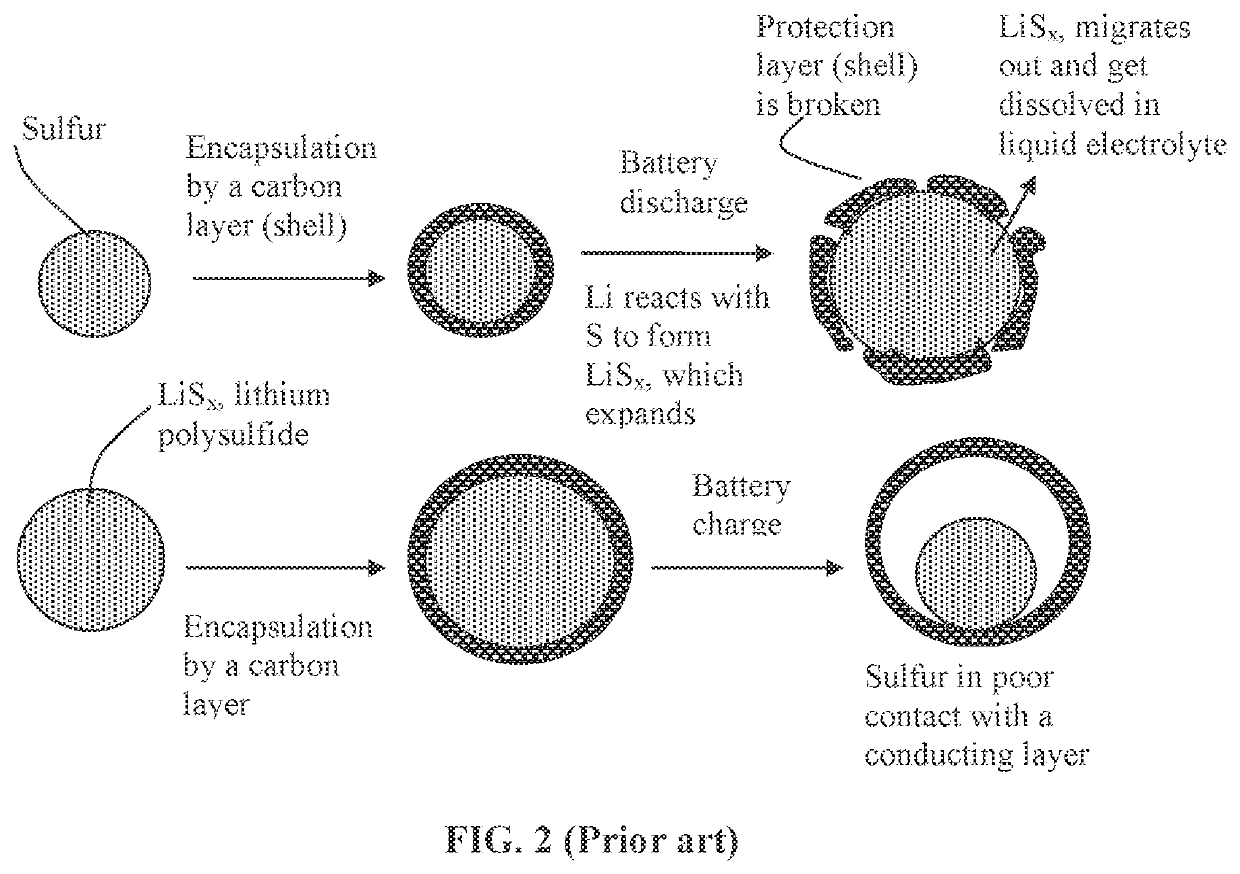

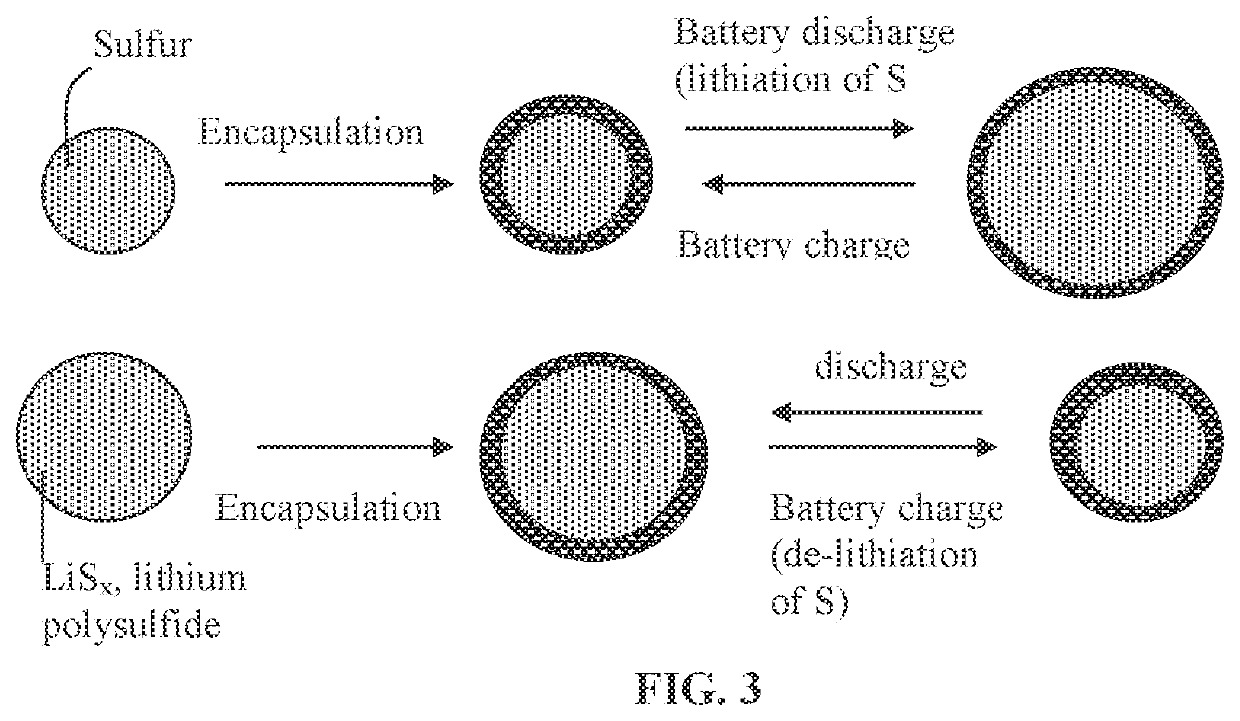

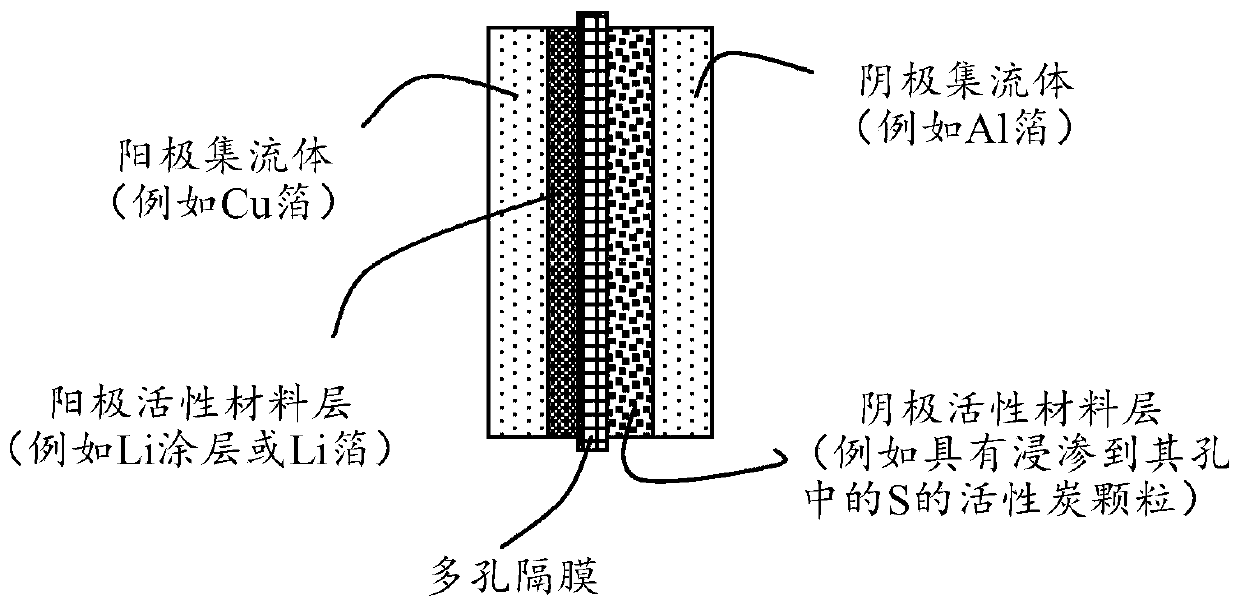

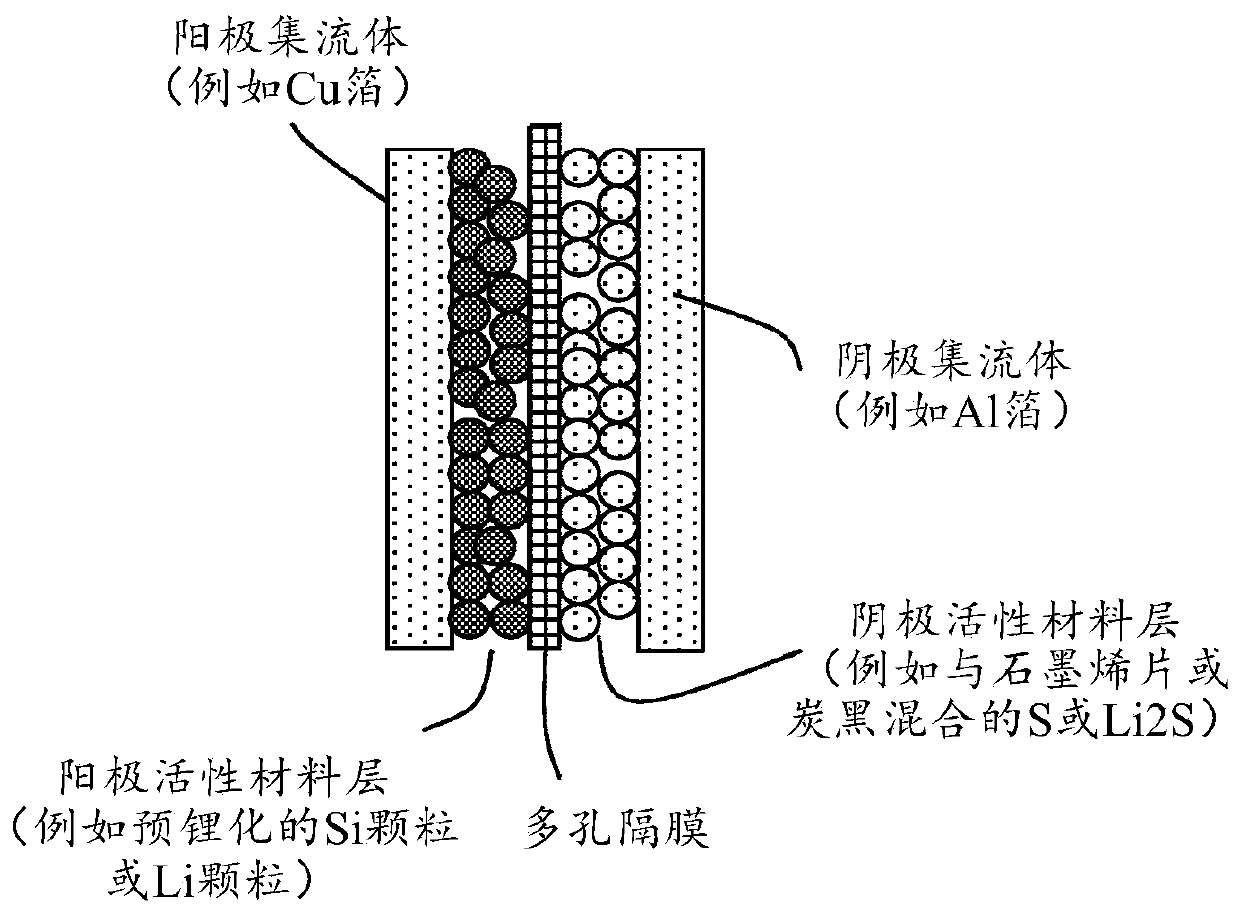

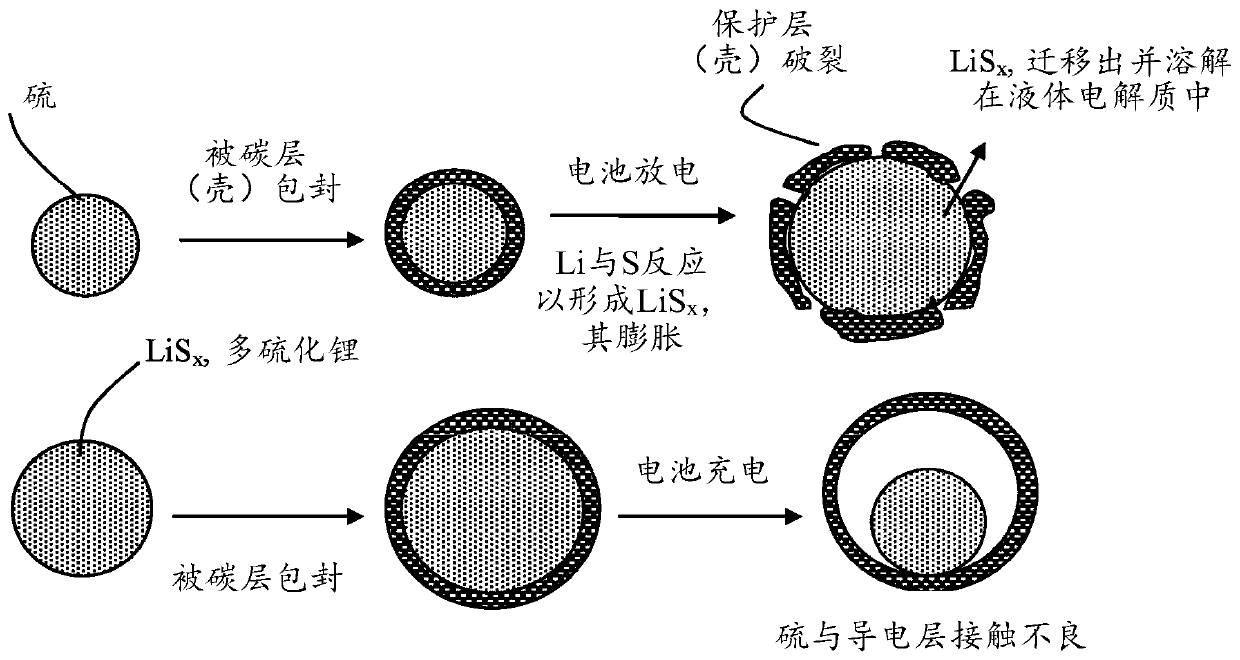

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 10% when measured without an additive or reinforcement, a lithium ion conductivity no less than 10−5 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Alkali Metal-Sulfur Secondary Battery Containing a Polymer-Encapsulated Sulfur Cathode and Manufacturing Method

ActiveUS20180294475A1Inhibited DiffusionReduce and eliminate effectFinal product manufacturePositive electrodesConductive polymerElectrical battery

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity ultra-high molecular weight polymer having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Alkali metal-sulfur secondary battery containing a protected sulfur cathode and manufacturing method

ActiveUS10084182B2Inhibited DiffusionReduce and eliminate effectFinal product manufacturePositive electrodesParticulatesConductive polymer

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 10% when measured without an additive or reinforcement, a lithium ion conductivity no less than 10−5 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

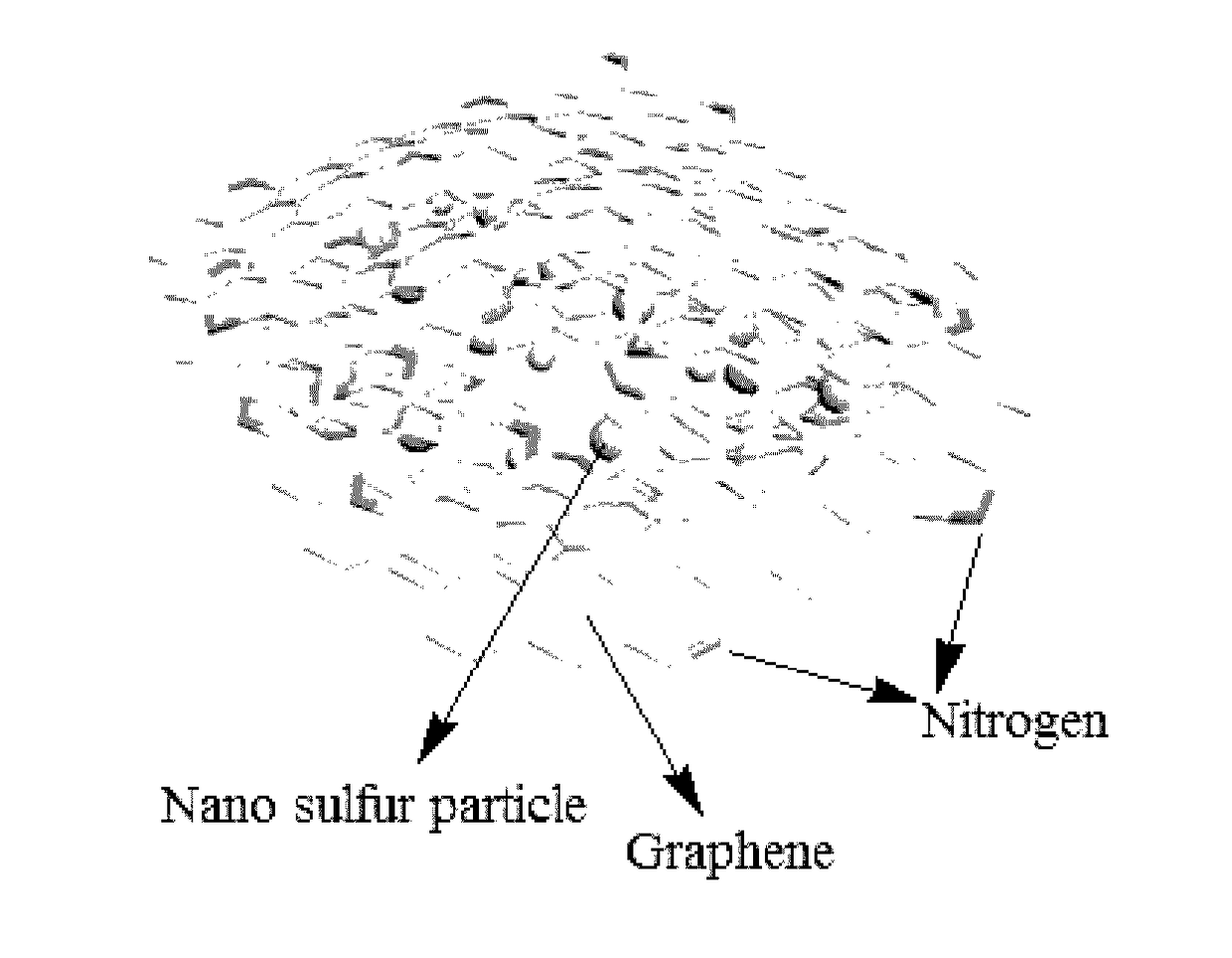

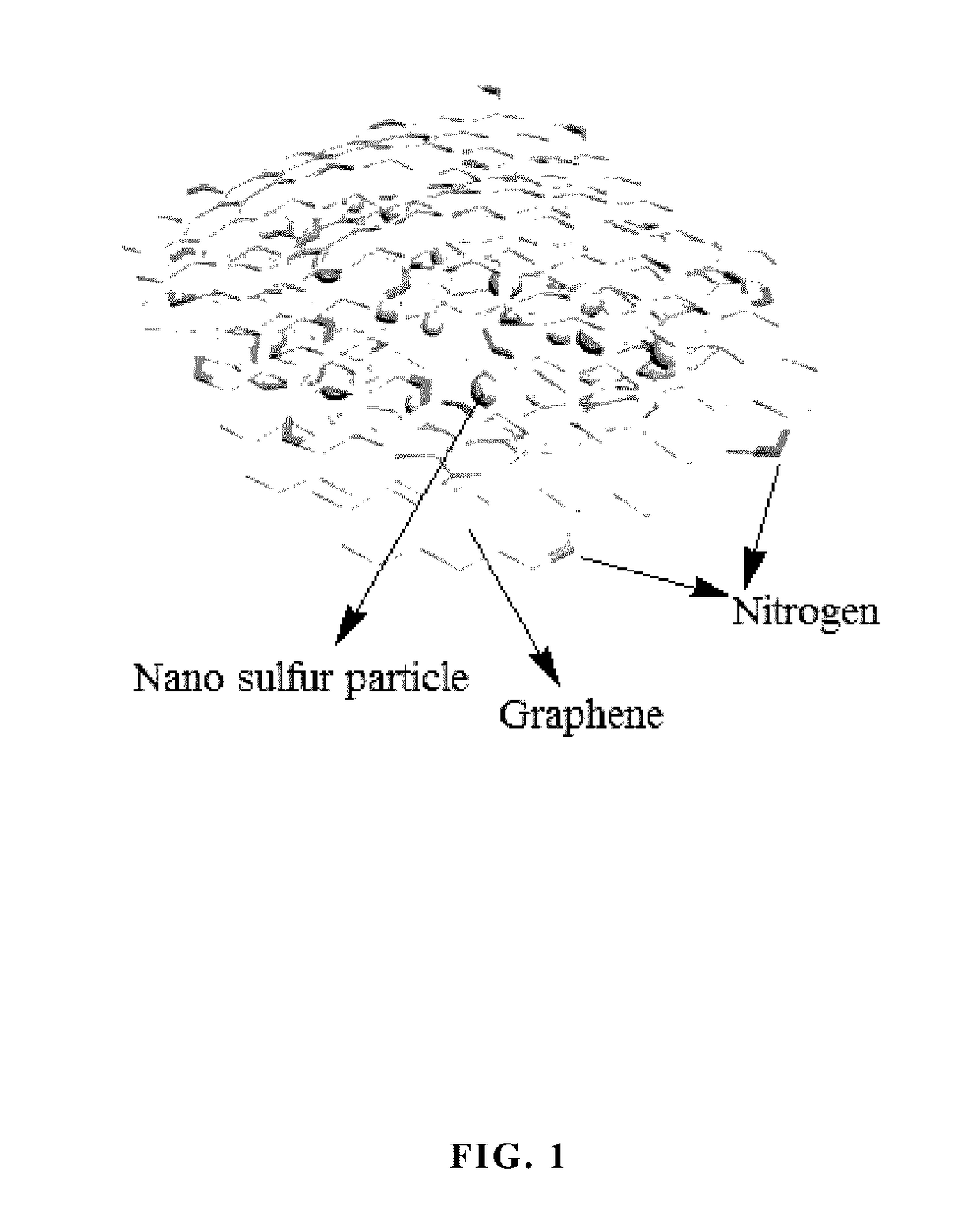

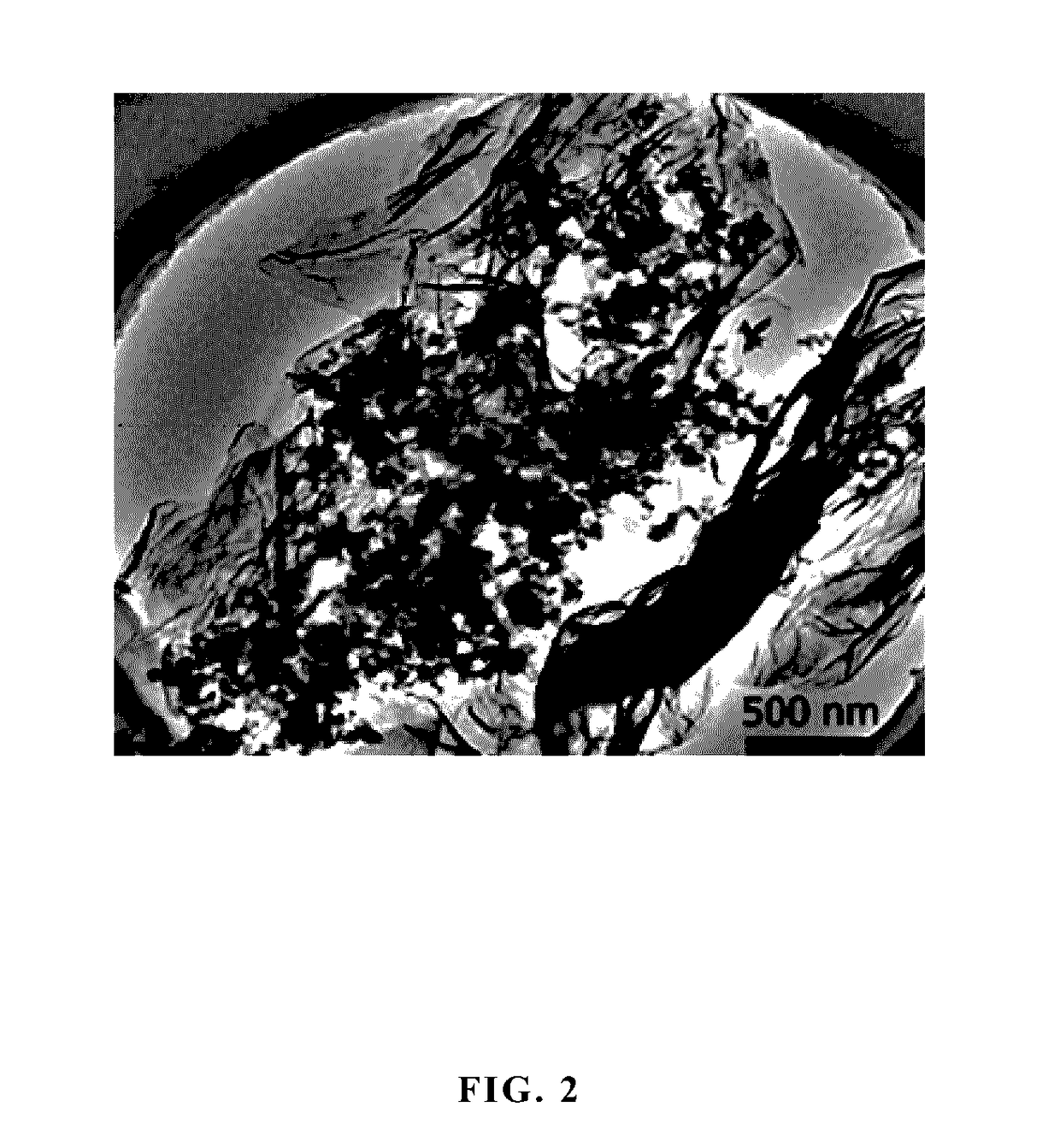

Nitrogen-doped graphene coated NANO sulfur positive electrode composite material, preparation method, and application thereof

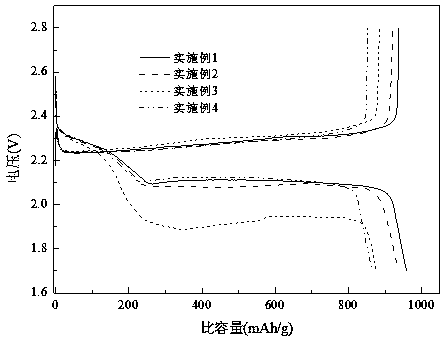

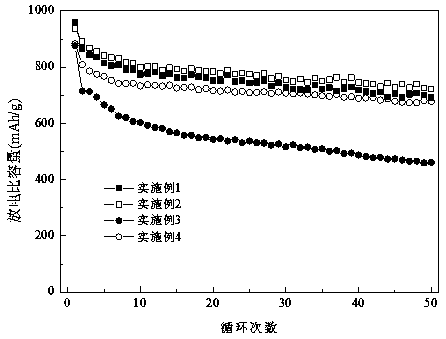

ActiveUS20170125800A1Large capacityImprove performanceFinal product manufacturePositive electrodesChemical reactionHigh rate

The invention provides a nitrogen-doped graphene coated nano sulfur positive electrode composite material, a preparation method, and an application thereof. The composite material includes: an effective three-dimensional conductive network formed by overlapping of nitrogen-doped graphenes, and nano sulfur particles coated by nitrogen doped graphene layers evenly. The preparation method includes: dispersing nitrogen-doped graphenes in a liquid-phase reaction system including at least sulfur source and acid, and depositing nano sulfur particles by an in-situ chemical reaction of the sulfur source and the acid, thereby preparing the positive electrode composite material. The positive electrode composite material of the invention has a high conductivity, a high sulfur utilization rate, and a high rate, thereby restraining the dissolution and shuttle effect in the lithium sulfur batteries, and enhancing the cyclic performance of the batteries.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

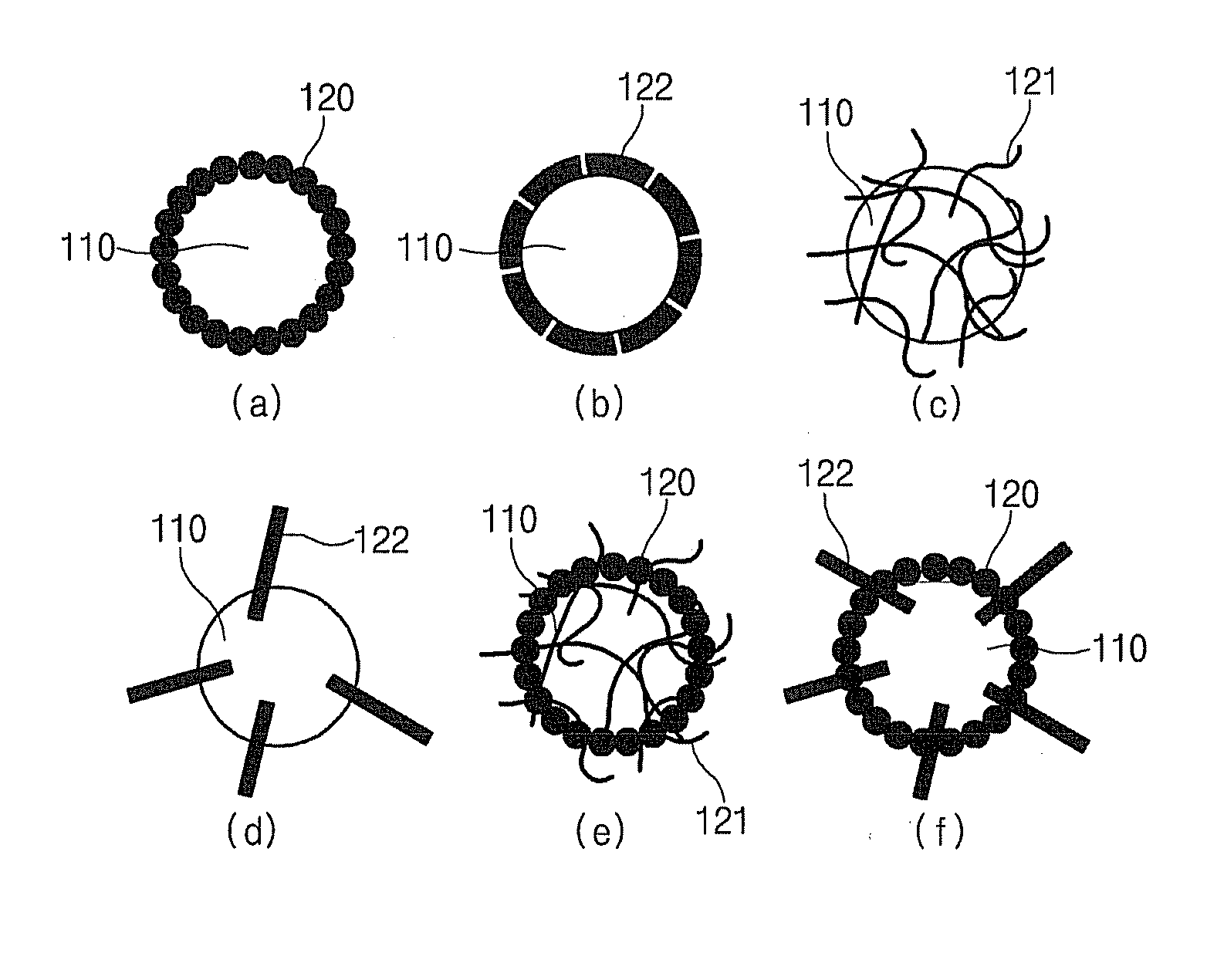

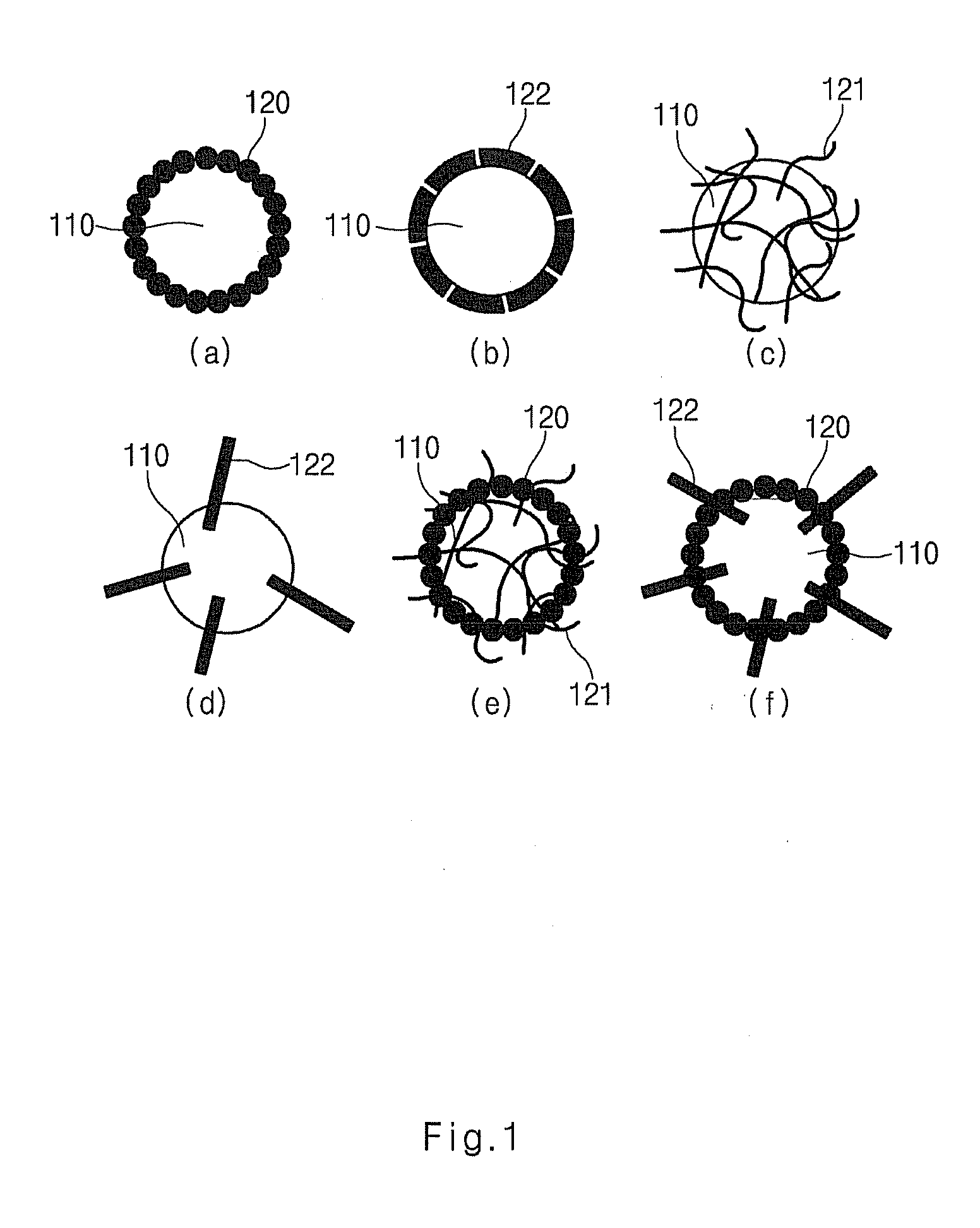

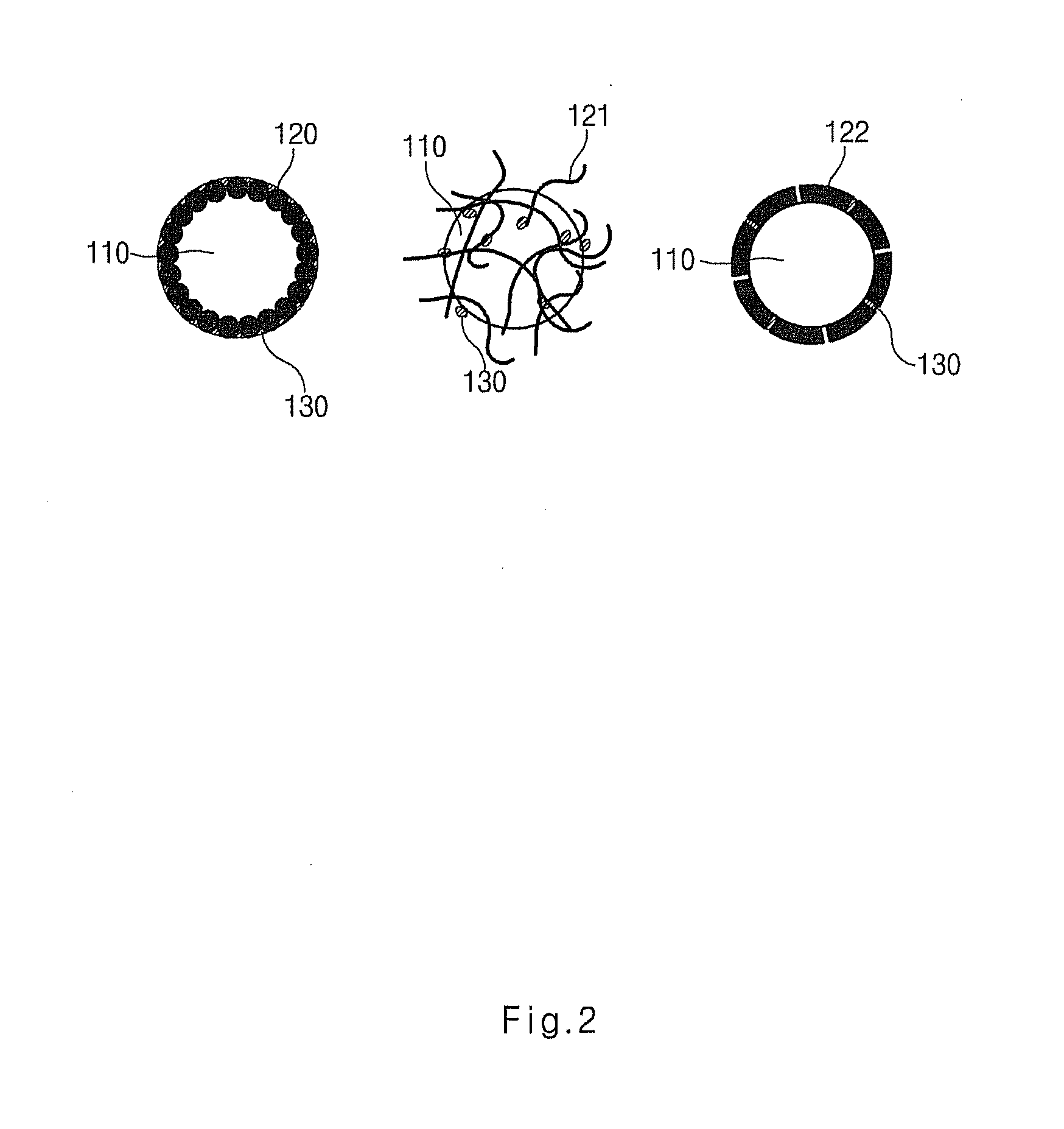

Cathode active material for metal-sulfur battery and method of preparing the same

InactiveUS20120119161A1Improve initial performanceConductivityNon-metal conductorsElectrode manufacturing processesCarbon compositesLithium–sulfur battery

A cathode active material for a metal-sulfur battery is provided. By using a cathode active material for a metal-sulfur battery comprising a sulfur-carbon composite composed of composited spherical sulfur compound particle and carbon material particle, electric conductivity of the cathode for a lithium-sulfur battery is increased to improve initial capacity close to theoretical capacity and polysulfide lost in the cathode during charging and discharging is minimized to increase sulfur utilization. Reaction between a metal anode and the polysulfide is minimized to increase life span and stability of the metal-sulfur battery.

Owner:HYUNDAI MOTOR CO LTD

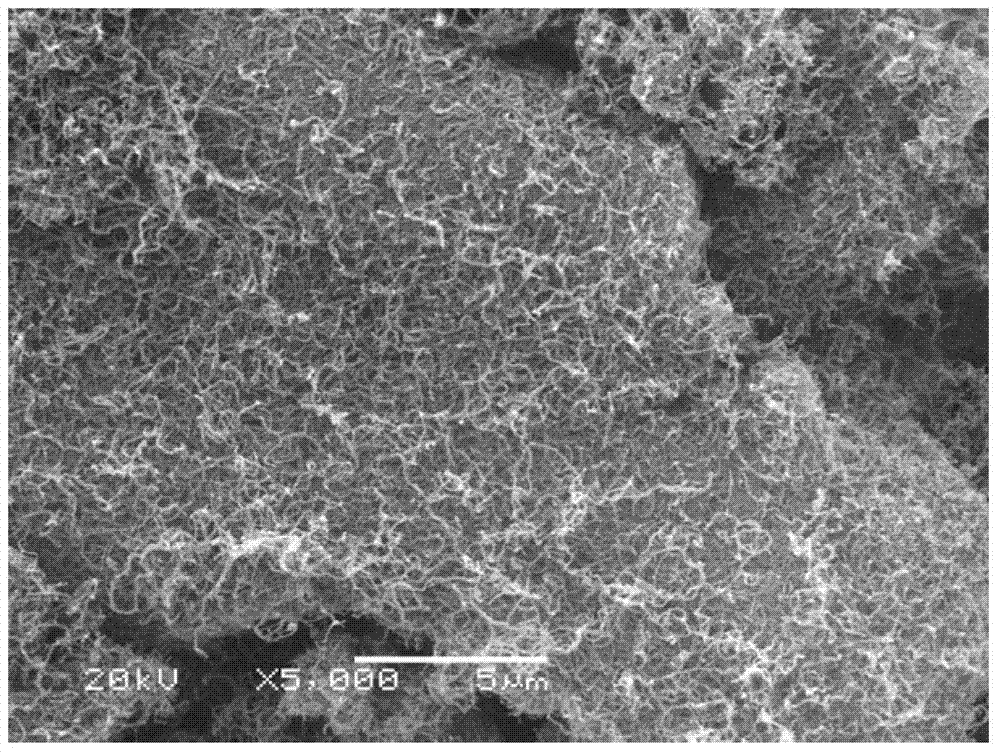

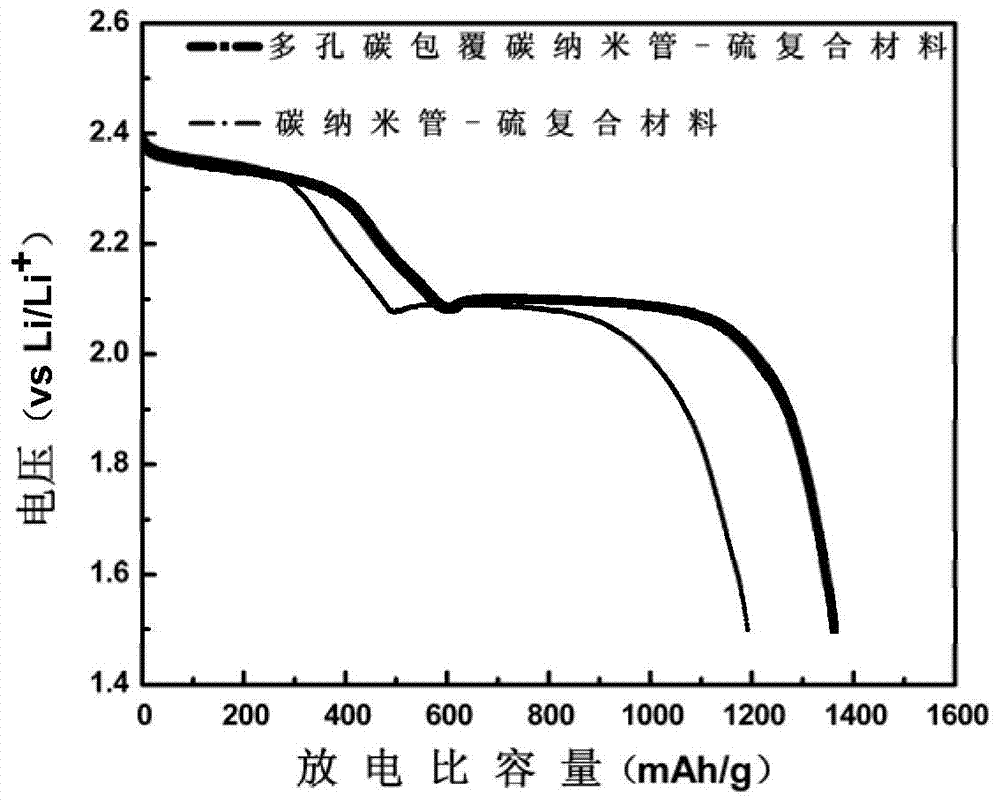

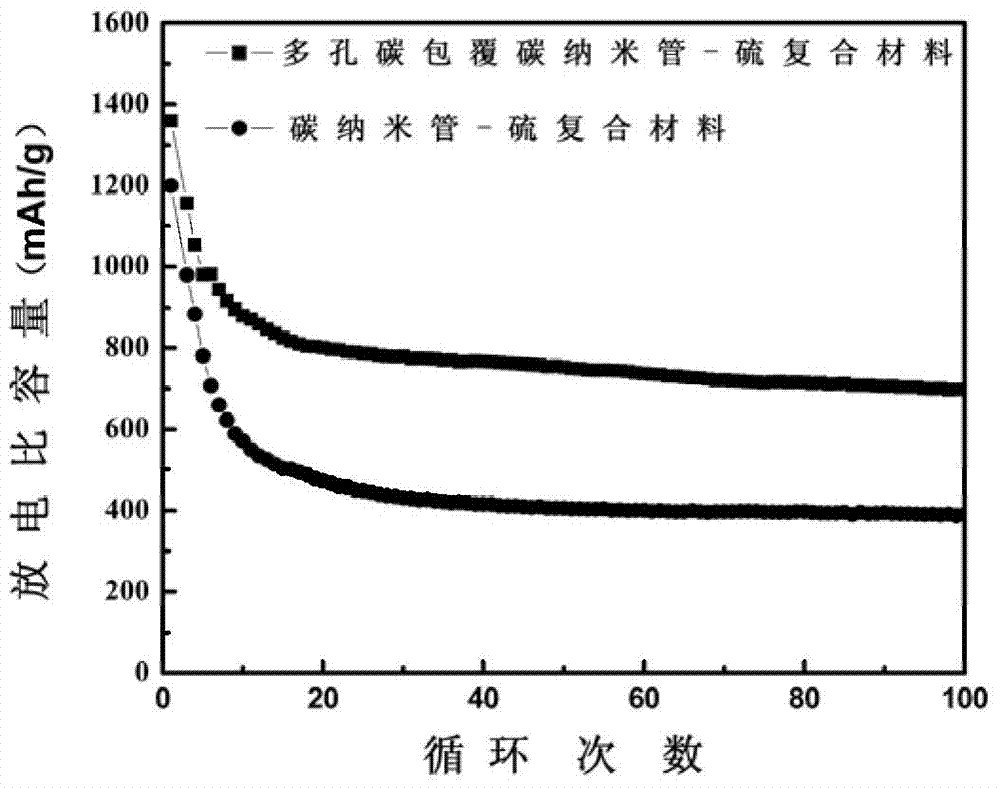

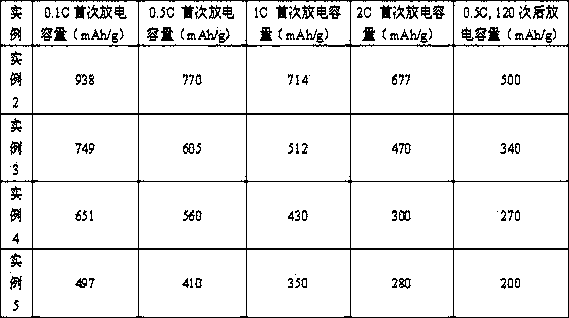

Sulfur/porous carbon-coated carbon nano tube compound positive material for lithium-sulfur battery and preparation method thereof

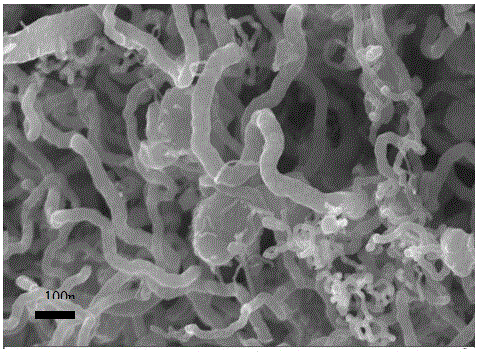

ActiveCN103500820AGood ion transmission abilityImprove conductivityMaterial nanotechnologyCell electrodesMicro nanoCompound a

The invention discloses a sulfur / porous carbon-coated carbon nano tube compound positive material for a lithium-sulfur battery and a preparation method thereof. The lithium-sulfur battery compound positive material is formed by compounding a carbon nano tube compound carbon material coated with porous carbon with a micro-nano structure and elemental sulfur. The preparation method comprises the following steps of: firstly coating poly-dopamine on the surface of a carbon nano tube; then carrying out high temperature carbonization, and compounding with the elemental sulfur to obtain the compound positive material. The preparation method disclosed by the invention has the advantages of easiness for operation and low cost. The prepared lithium-sulfur battery compound positive material is high in sulfur utilization ratio and greatly enhances the cycle property of the lithium-sulfur battery.

Owner:CENT SOUTH UNIV

TiO2 coated sulfur/ordered mesoporous carbon composite cathode material and preparation method thereof

InactiveCN104269559ALower transmission impedanceImprove conductivityCell electrodesComposite cathodeHigh energy

The invention discloses a TiO2 coated sulfur / ordered mesoporous carbon composite cathode material and a preparation method thereof as well as the application thereof in a secondary aluminum battery. The cathode material consists of a sulfur active substance, ordered mesoporous carbon and TiO2 and is characterized in that the ordered mesoporous carbon has a highly-ordered three-dimensional pore structure, is provided with a conductive network and provides a large number of adhesion area for the active substance and a conductive channel; a TiO2 coating layer has a very effective shuttle effect of blocking polysulfide. The preparation method of the TiO2 coated sulfur / ordered mesoporous carbon composite cathode material comprises the following steps: compounding the ordered mesoporous carbon and sulfur and then TiO2 coating on an outer layer. The preparation method has the advantages of simple process, low cost, no toxic raw material used, environmental friendliness, high energy density and high sulfur utilization rate, and the rate performance and the cycle life of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

Carbon sulfur compound anode for secondary battery

InactiveCN104157879AHigh reactivityIncrease loadMaterial nanotechnologyNon-aqueous electrolyte accumulatorsCompound aElectricity

The invention discloses a carbon sulfur compound anode for a secondary battery. The anode is formed by compounding a carbon nanotube array, sulfur and graphene, is provided with a three-dimensional network conductive framework and is good in electrochemical performance. A preparation method of the anode comprises the following steps: compounding elemental sulfur in the carbon nanotube array at first and then wrapping an outer layer with few graphene sheet layers. The preparation method is simple in process, low in cost and environment-friendly due to nonuse of toxic raw materials; moreover, the compound anode does not need to be added with a conductive agent and a bonder, and is high in energy density and sulfur utilization rate, and the rate performance and the cycle performance of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

Ternary metal oxide composite MXene material and application thereof to lithium-sulfur batteries

InactiveCN109301227AImprove stabilityEasy transferPositive electrodesLi-accumulatorsOxide compositeSulfur utilization

The invention relates to a ternary metal oxide composite MXene material for positive electrode materials of lithium-sulfur batteries and a preparation method of the ternary metal oxide composite MXenematerial. The method includes: etching in hydrofluoric acid solution to obtain MXene, preparing a NiCo2O4 composite MXene material through hydrothermal reaction, and preparing a sulfur-NiCo2O4-MXenecomposite material by sulfur doping through ball milling and hot melting, namely the ternary metal oxide composite MXene material is obtained. A two-dimensional lamellar structure of MXene is beneficial to quick interlamination diffusion of electrolyte ions to achieve an excellent rate performance, and more spaces are provided for storage of active substances, so that electrode stability is improved. By introduction of a ternary metal oxide NiCo2O4, lithium polysulfide adsorption of surface polar active sites is promoted, active substance sulfur utilization rate is increased, MXene expansion can be realized, and a large volume expansion buffer space and excellent electrochemical performances are achieved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

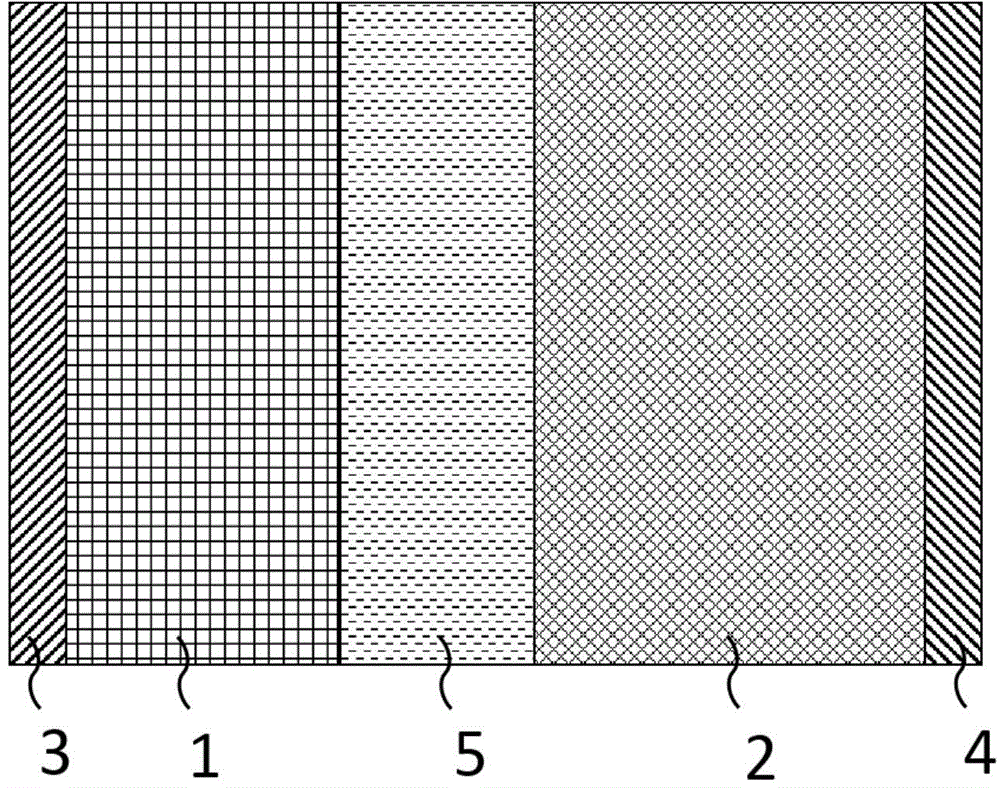

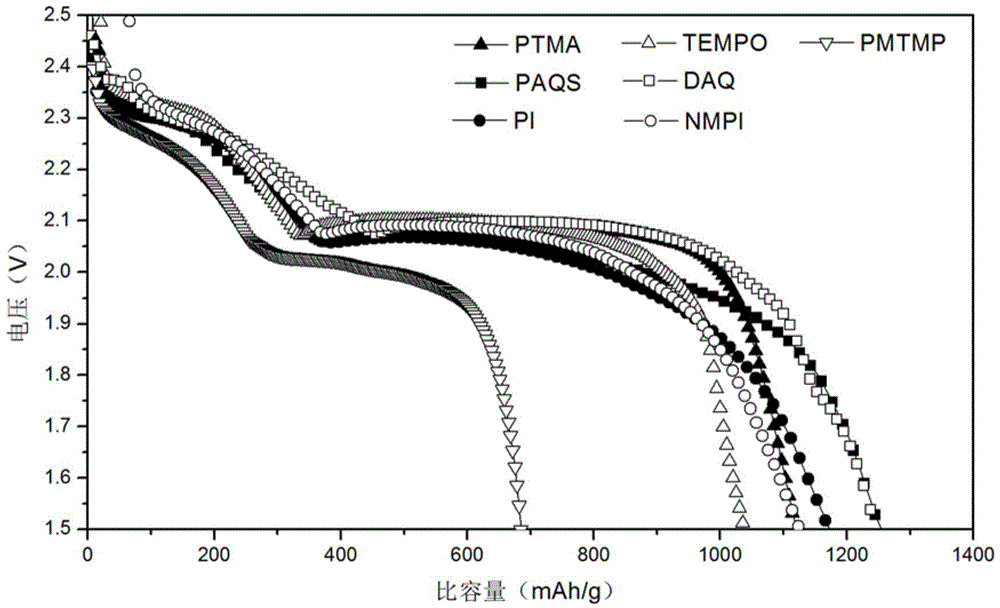

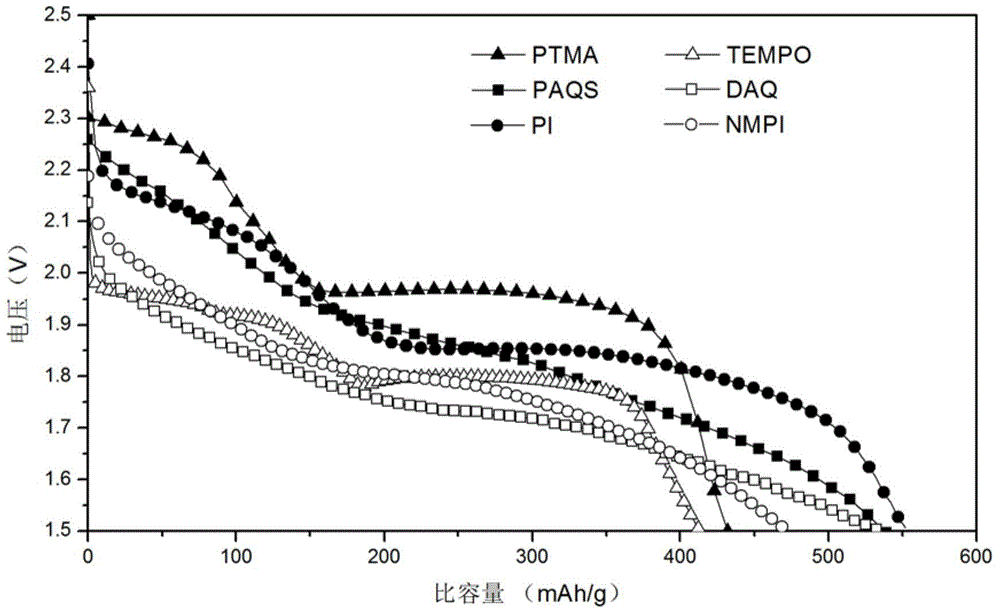

Lithium-sulfur battery cathode, electrolyte and lithium-sulfur battery

ActiveCN105322219AImprove utilization efficiencyImprove electrochemical activityCell electrodesLi-accumulatorsSulfurLithium–sulfur battery

The invention discloses a lithium-sulfur battery cathode, an electrolyte and a lithium-sulfur battery. The lithium-sulfur battery comprises a lithium-containing anode active layer, a cathode active layer containing a sulfur electrochemical active substance, the electrolyte disposed between the cathode active layer and the anode active layer, and an electron migration mediator formed in the cathode active layer and / or the electrolyte. The electron migration mediator is defined as a polymer which is at the interval of the cathode active substance reduction potential and the anode active substance oxidation potential and possesses the reversible redox electrochemical activity. The cathode or the electrolyte employs the electron migration mediator which is capable of improving sulfur utilization rate and elelctrochemcial activity and inhibiting sulfur loss. The lithium-sulfur battery employing the cathode or the electrolyte possesses high energy density, high power density and long cycle life. Additionally, the employed electron migration mediator cannot reach the anode through diffusion, migration and convection.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Alkali Metal-Sulfur Secondary Battery Containing a Protected Sulfur Cathode Material and Manufacturing Method

ActiveUS20190051902A1Sufficient structural integritySolid electrolytesCell electrodesParticulatesHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer (containing a polyrotaxane network having a rotaxane structure or a polyrotaxane structure at a crosslink point of the polyrotaxane network) having a recoverable tensile strain from 2% to 1,500%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Alkali Metal-Sulfur Secondary Battery Containing a Nano Sulfur-Loaded Cathode and Manufacturing Method

ActiveUS20180233784A1High storing/releasing rateHigh densityFinal product manufactureSecondary cells manufactureHigh energyPotassium

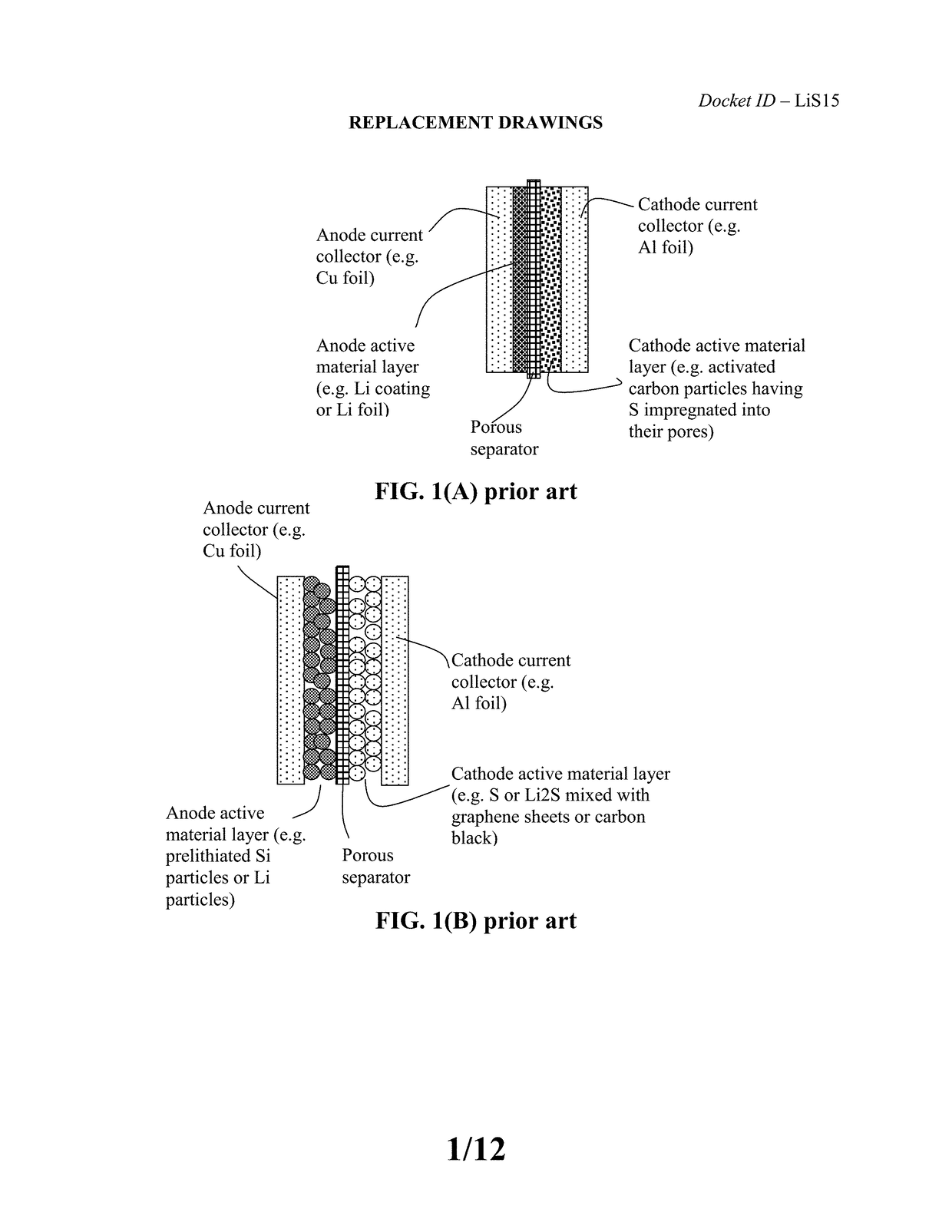

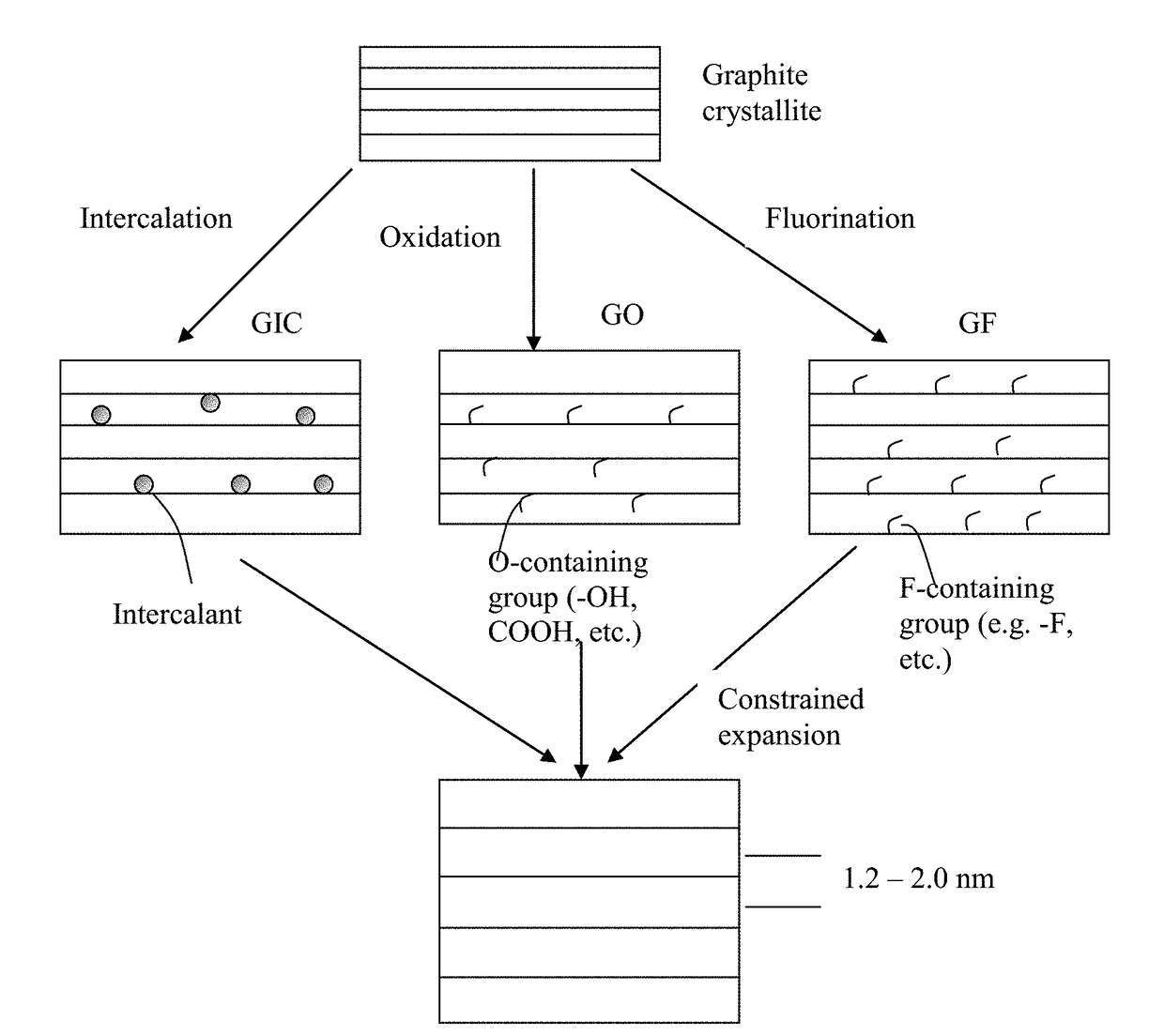

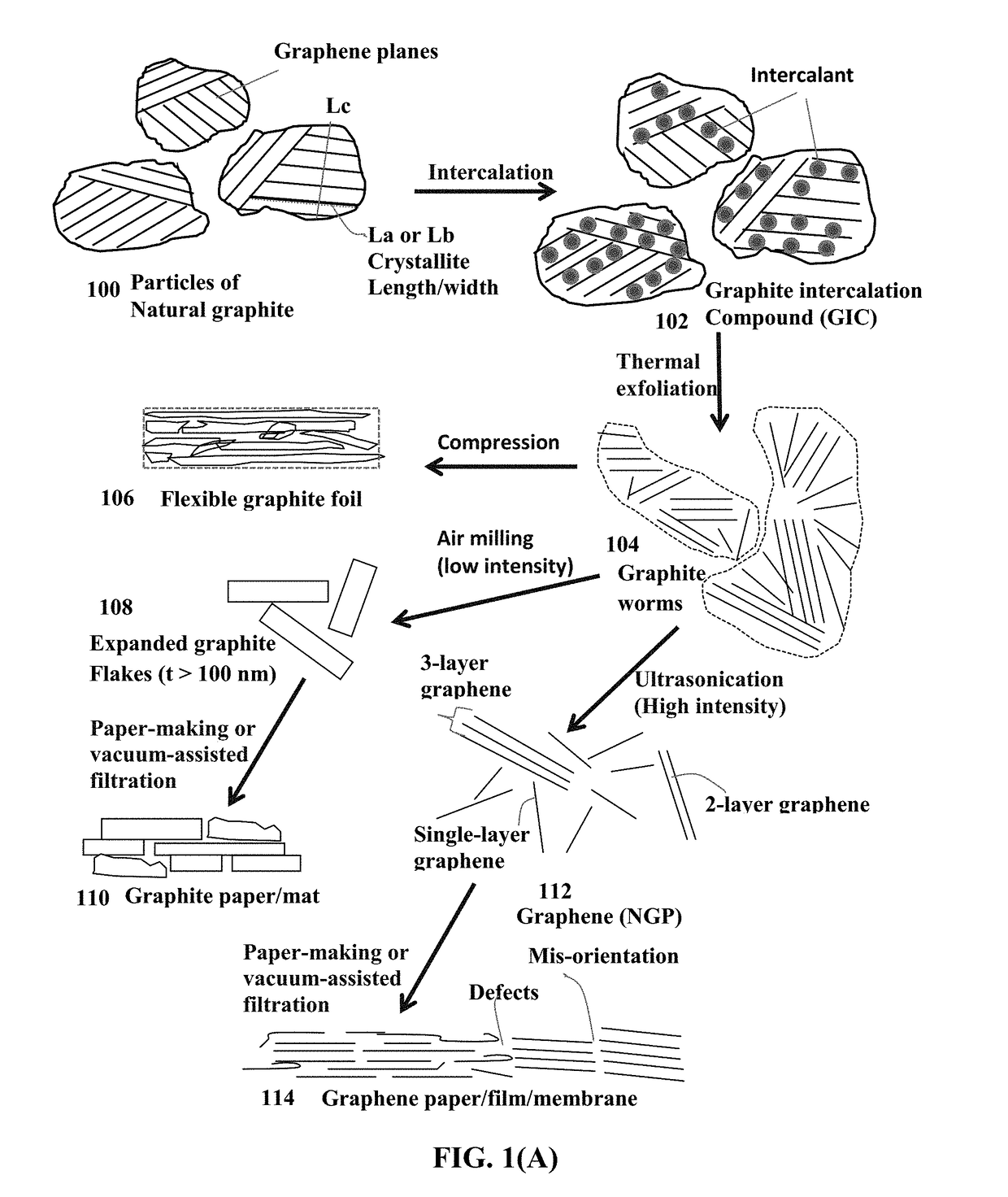

A rechargeable alkali metal-sulfur cell selected from lithium-sulfur cell, sodium-sulfur cell, or potassium-sulfur cell The alkali metal-sulfur cell comprises an anode active material layer, an optional anode current collector supporting the anode active material layer, a cathode active material layer, an electrolyte with an optional porous separator layer in ionic contact with the anode active material layer and the cathode active material layer, and an optional cathode current collector supporting the cathode active material layer, wherein the cathode active material layer contains a graphite or carbon material having expanded inter-graphene planar spaces with an inter-planar spacing d002 from 0.43 nm to 2.0 nm, as measured by X-ray diffraction, and 1%-95% by weight of sulfur or a metal polysulfide residing in these expanded inter-graphene planar spaces. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

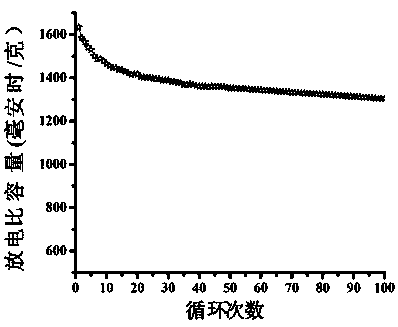

New lithium sulfur battery positive electrode and lithium sulfur battery comprising new lithium sulfur battery positive electrode

InactiveCN103915602AIncrease profitImprove conductivityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesSulfurLithium–sulfur battery

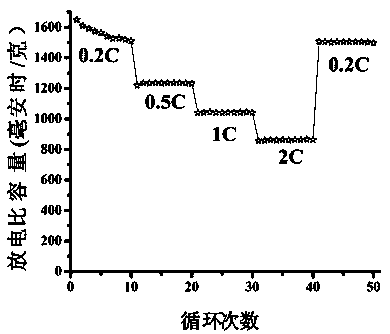

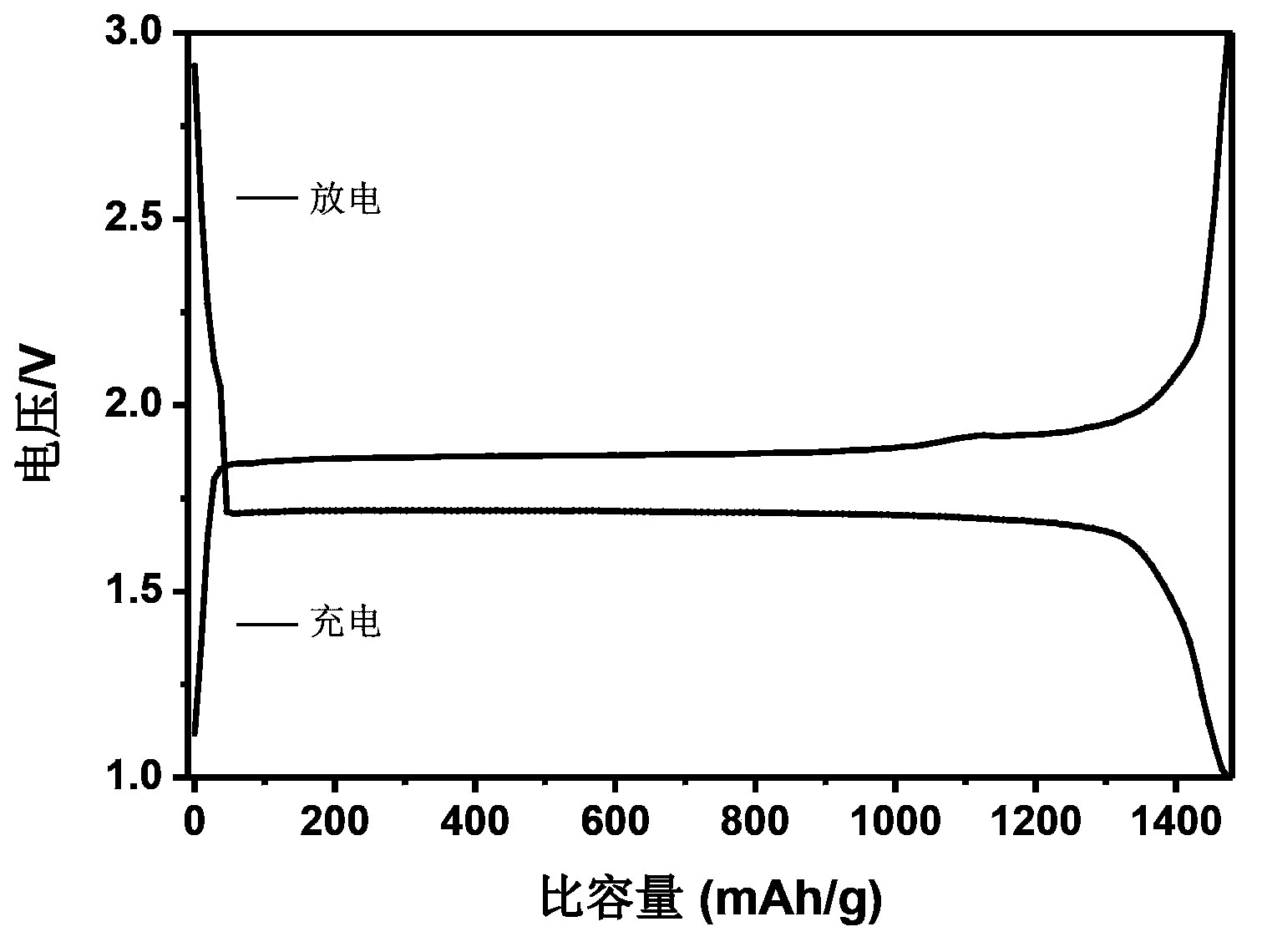

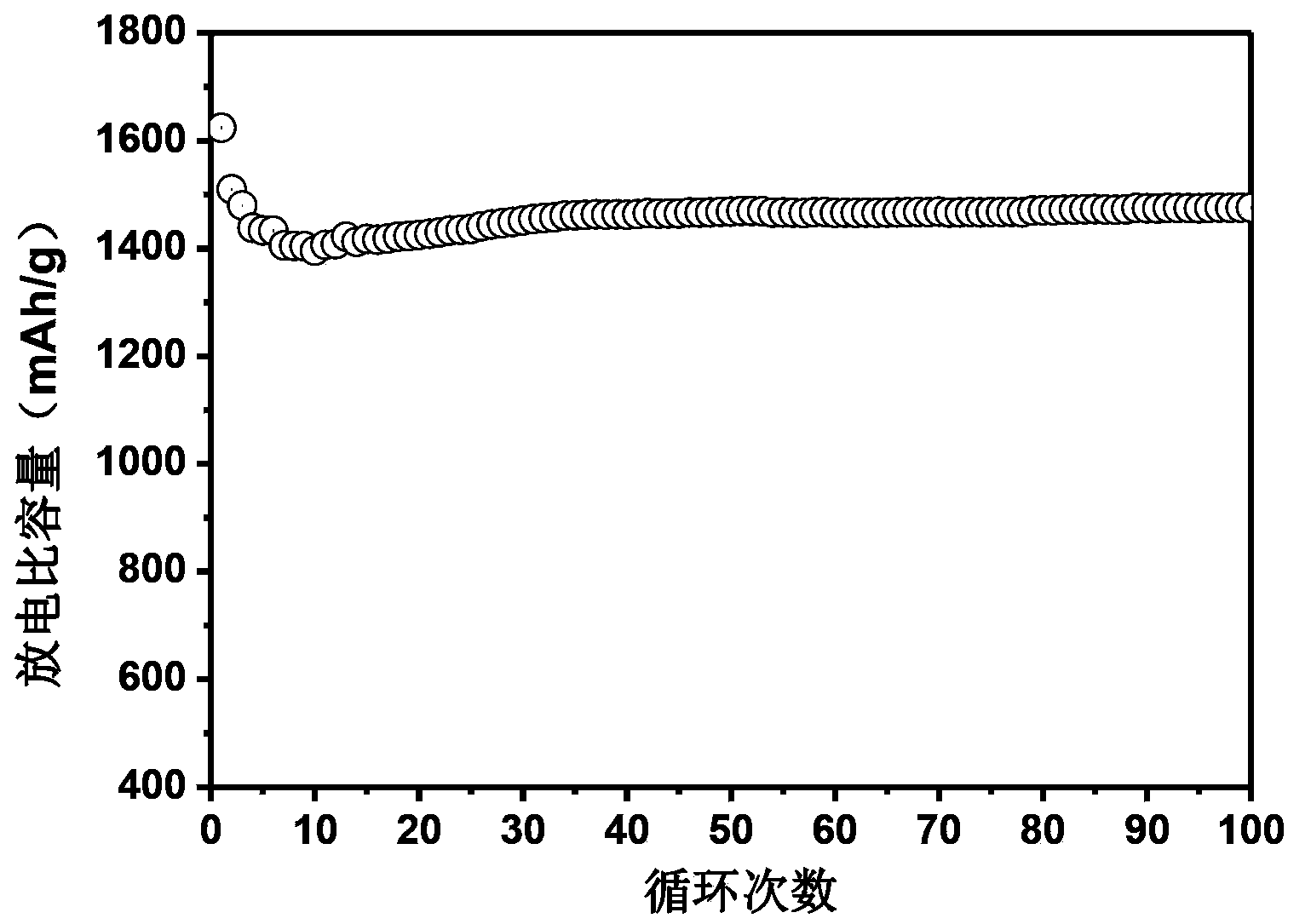

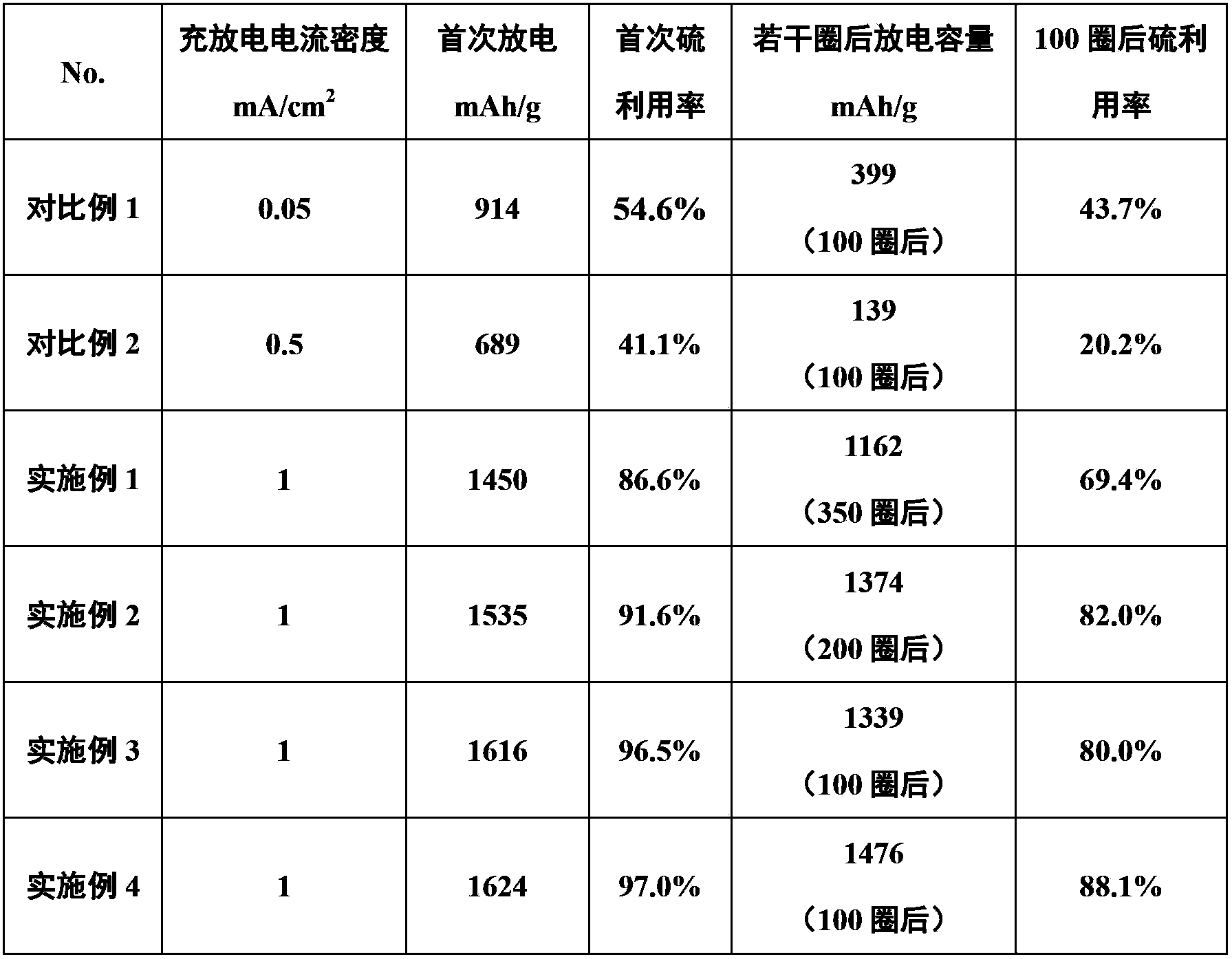

The invention provides a new lithium sulfur battery positive electrode, a preparation method thereof and a lithium sulfur battery comprising the new lithium sulfur battery positive electrode. The new lithium sulfur battery positive electrode comprises a metal current collector, elemental sulfur or a sulfur compound as a positive electrode active material coating the metal current collector, transition metal powder, a conductive material and a binder. The lithium sulfur battery comprising the new lithium sulfur battery positive electrode has high sulfur utilization rate and excellent cycle stability, to be more specific, the discharge capacity of sulfur per unit weight in the positive electrode composite material reaches up to 1624mAh / g, the elemental sulfur utilization rate reaches more than 97%, and after hundreds of times of cycling at the room temperature, the highest positive electrode specific discharge capacity can be maintained at more than 88% of the theoretical specific discharge capacity (1675mAh / g) of the elemental sulfur.

Owner:XIAMEN UNIV

Ionic polymer derivative carbon material used as lithium-sulfur battery positive electrode material

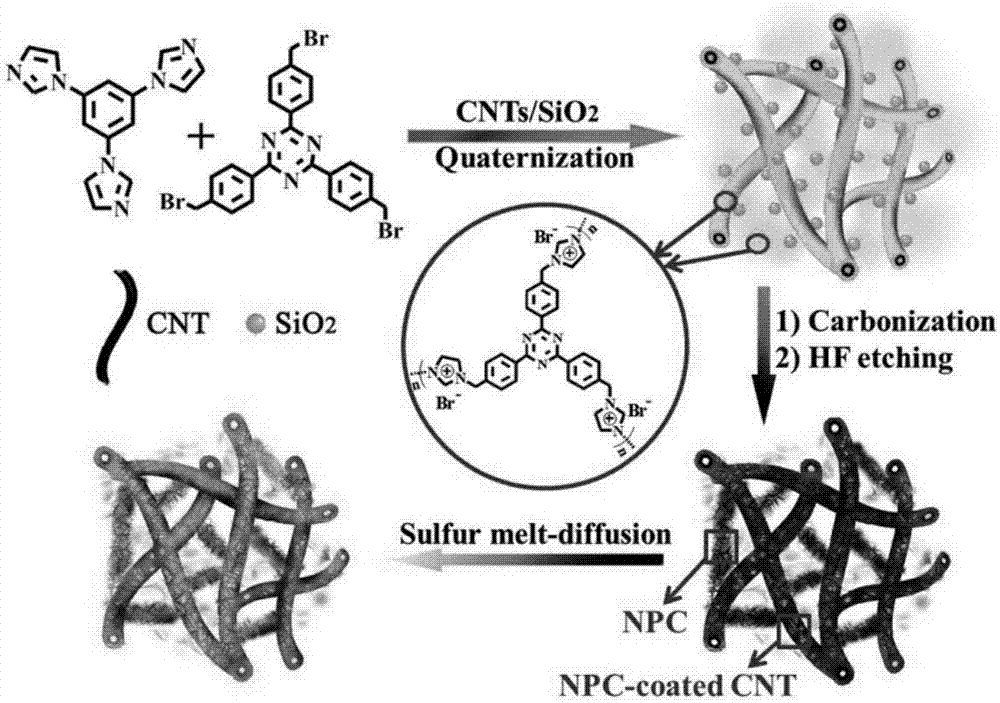

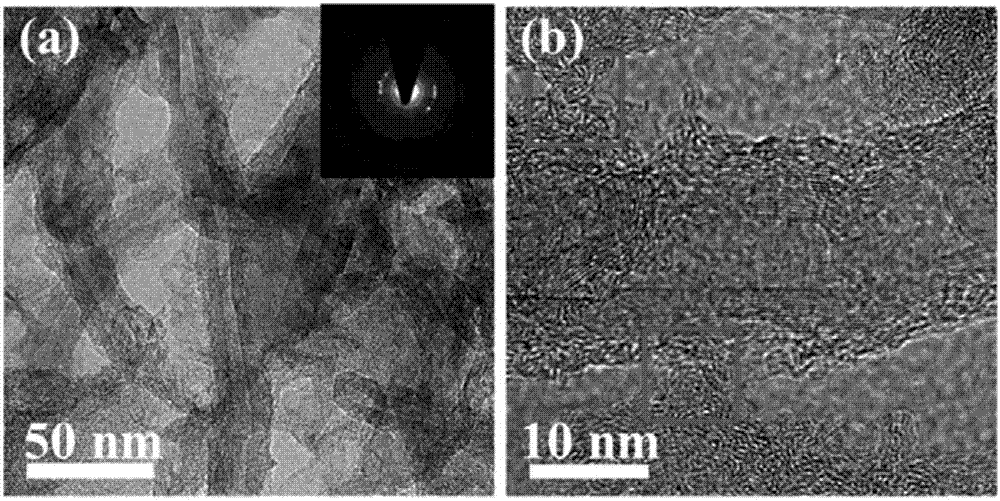

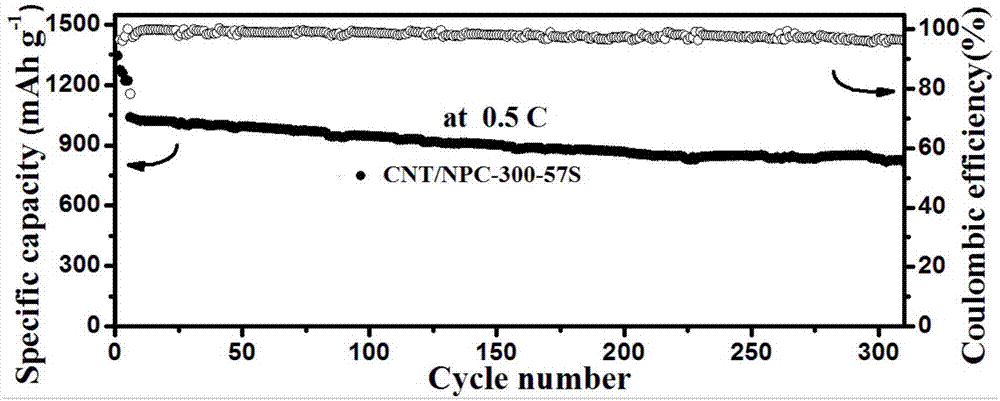

InactiveCN107546381AControl performanceEasy transferMaterial nanotechnologyCell electrodesPorous carbonCarbonization

An imidazolyl main chain ionic polymer and a carbon nanotube (CNT) are combined and used as a carbon material precursor, and a nitrogen-doped porous carbon (NPC)-coated three-dimensional high-conductivity multi-level hole carbon material linked and connected in series with a carbon nanotube in a seamless way is prepared. The high conductivity of a sulfur positive electrode material is ensured, theshuttling effect during the discharging process also can be effectively suppressed, so that relatively high sulfur utilization ratio and cycle stability are obtained. The preparation method comprisesthe steps of mixing the CNT and silicon dioxide in an organic solvent DMF, adding trimesic imidazole and triazine bromide to obtain an ionic polymer composite carbon nanotube material, performing high-temperature carbonization on the ionic polymer composite carbon nanotube material, and etching silicon dioxide with hydrofluoric acid to obtain a target composite material. The preparation method has a great expandable space, and a single-doped or jointly-doped material of various mixed elements can be easily achieved by exchanging counter negative ions in the ionic polymer to other target negative ions.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Novel lithium-sulfur battery and preparation method thereof

ActiveCN103138002AOmit the complicated preparation processSimple processFinal product manufactureElectrolyte accumulators manufactureLithium–sulfur batterySolvent

The invention discloses a novel lithium-sulfur battery and a preparation method thereof. The novel lithium-sulfur battery comprises an anode, an electrolytic solution and a lithium-containing cathode, wherein the electrolytic solution comprises a solvent and an electrolyte, the anode preferably adopts a sulfur-free porous electrode, the electrolytic solution also contains sulfur and / or sulfide, and the electrolyte comprises a lithium salt. The preparation method comprises the steps of: respectively preparing the anode, the electrolytic solution and the lithium-containing cathode and assembling the anode, the electrolytic solution and the lithium-containing cathode into a novel lithium-sulfur battery. According to the simple novel lithium-sulfur battery provided by the invention, the complex preparation process of the sulfur anode is avoided, the process cost is reduced, and the problems of difficulty in exerting the capacity due to non-uniform distribution of an active substance sulfur in the conventional sulfur anode material, low sulfur utilization rate, instable performance of the battery, and the like can also be avoided.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

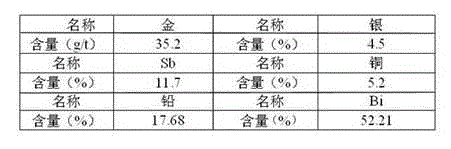

Technique for resource utilization of lead and silver residues for zinc hydrometallurgy

ActiveCN106086413APhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

Provided is a technique for resource utilization of lead and silver residues for zinc hydrometallurgy. The technique comprises the steps that the dried lead and silver residues, lead concentrate and additives are blended, so that a mixture is obtained; the mixture is fed to an oxygen-enriched bottom-blowing furnace for oxidation smelting after being subjected to granulation, and primary lead and furnace residues are separated out; the furnace residues are fed into an oxygen lateral blowing metal smelting reduction furnace, broken coal and a flux are added to the oxygen lateral blowing metal smelting reduction furnace, so that furnace residues of the oxygen lateral blowing metal smelting reduction furnace are formed; the furnace residues are fed into a fuming furnace to obtain secondary lead; as for silver entering the primary lead and the secondary lead, anode mud is added in the electrolytic lead refining process of the primary lead and the secondary lead, and the silver is extracted from the anode mud; and as for zinc and lead entering smoke of the fuming furnace, the smoke is subjected to defluorination and dechlorination, zinc is obtained through hydrometallurgical leaching and extracted through electrodeposition, the lead is in the leaching residues, and then the lead is recovered through lead smelting. The technique is simple, the recovery rate of the lead in the lead and silver residues is about 95%, the zinc recovery rate is about 90%, the silver recovery rate is about 95%, and the sulfur utilization rate is about 90%.

Owner:HANZHONG ZINC IND

Preparation method of carbon nanotube-lithium sulfide-carbon composite material

ActiveCN106784754ASpecial structureImprove conductivityCell electrodesLi-accumulatorsCarbon compositesSulfur electrode

The invention relates to a preparation method of a carbon nanotube-lithium sulfide-carbon composite material. The preparation method comprises the following steps: dissolving sublimed sulfur powder in anhydrous methylbenzene to form a transparent solution A; performing ultrasonic dispersion on carbon nanotubes in a lithium triethylborohydride tetrahydrofuran solution to form a suspension B; adding the solution A into the suspension B to obtain a carbon nanotube-Li2S composite material suspension, and heating to evaporate the solvent so as to obtain carbon nanotube-Li2S composite material powder; and finally, putting the carbon nanotube-Li2S material in an inert atmosphere, and performing chemical vapor deposition to form the carbon nanotube-Li2S-C composite material. The carbon nanotube-lithium sulfide-carbon composite material prepared by the invention has favorable electric conductivity and high coating tightness, can improve the electric conductivity of a Li2S electrode, effectively inhibits dissolution and dispersion of polysulfide in an electrolyte, and increases the sulfur utilization ratio; and meanwhile, the porous structure of the carbon nanotubes has a cushioning effect on volume expansion and shrinkage of an sulfur electrode in the charge / discharge process.

Owner:CENT SOUTH UNIV

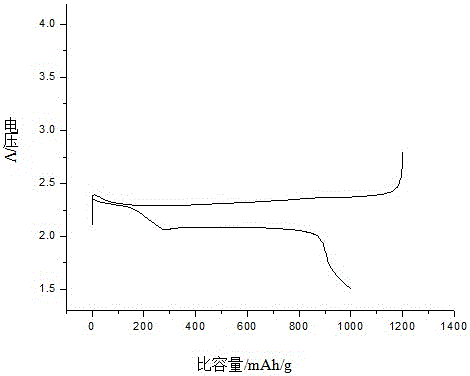

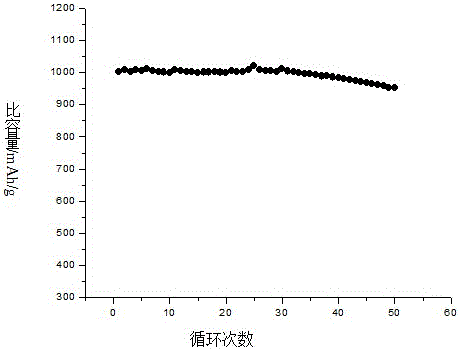

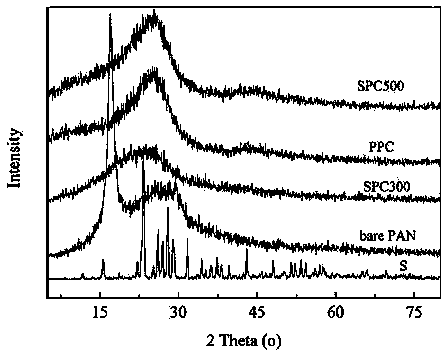

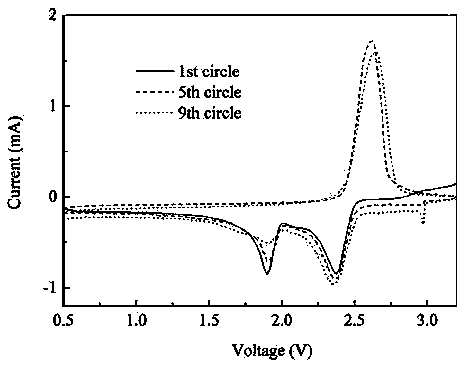

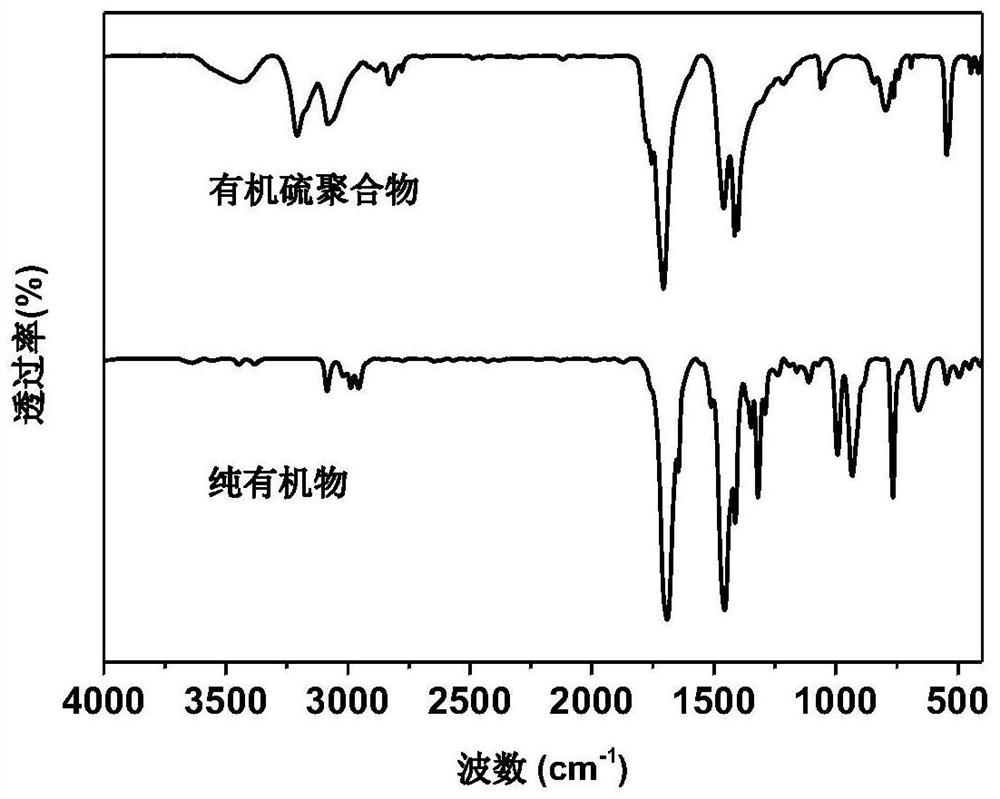

Preparation method of sulfurized polyacrylonitrile anode material used for lithium secondary battery

InactiveCN103972510ANo pollution in the processLow costCell electrodesLi-accumulatorsLithium–sulfur batteryNitrogen

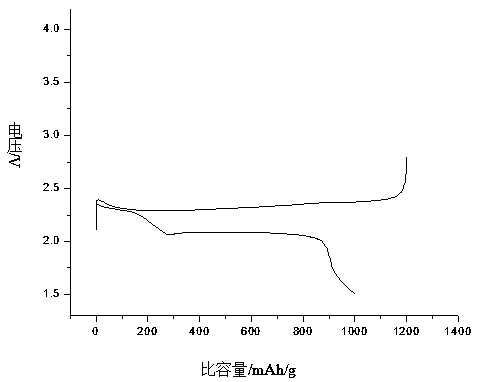

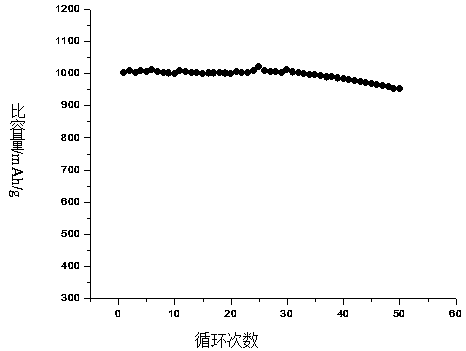

The invention relates to a preparation method of a sulfurized polyacrylonitrile anode material used for a lithium secondary battery, and belongs to the technical field of materials. The preparation method is that sulfur and polyacrylonitrile are dissolved in dimethyl sulfoxide to have a crosslinking conjugation reaction and then are carbonized in a nitrogen environment at a temperature of 500 DEG C to obtain the sulfurized polyacrylonitrile material. The sulfur content of the sulfurized polyacrylonitrile material obtained through the preparation method is remarkably increased, the sulfur is distributed evenly, and the sulfurized polyacrylonitrile material has a graphite crystal structure and is remarkably improved in conductivity and stability. In the electrochemical test, the sulfurizedpolyacrylonitrile material shows the discharge quality specific capacity up to 1312mAh.g<-1> and the sulfur utilization rate up to 98.3%, and keeps 77% of the cycling stability of the maximum performance after 60 cycles under the conditions of 0.5C charge-discharge rate and 45 discharge cycles. The results show that the sulfurized polyacrylonitrile material prepared according to the method is an active material suitable for a lithium sulfur battery.

Owner:SICHUAN UNIV

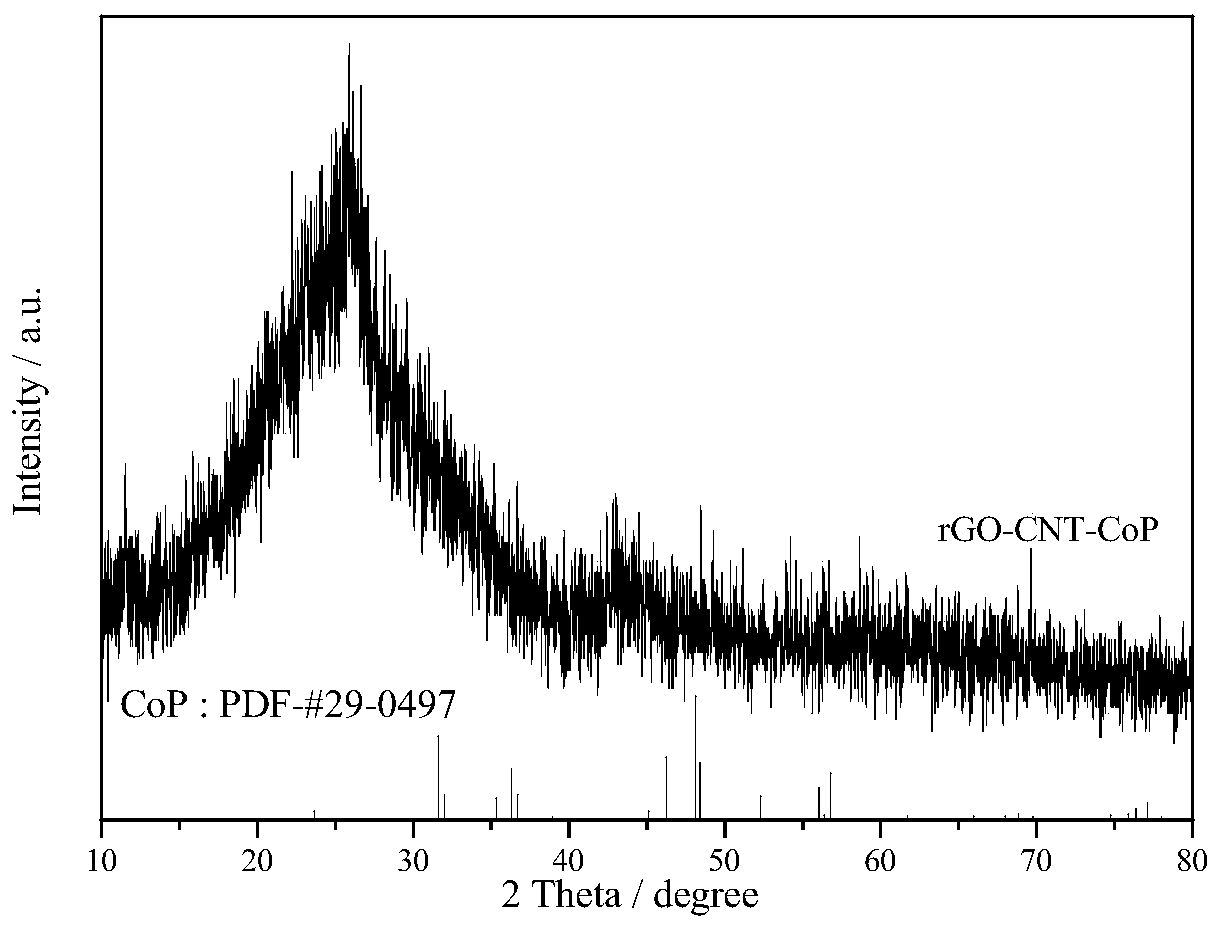

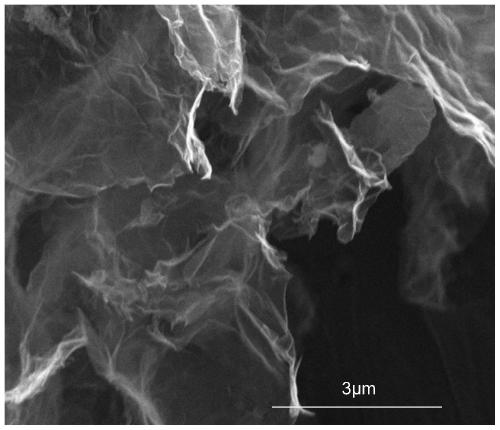

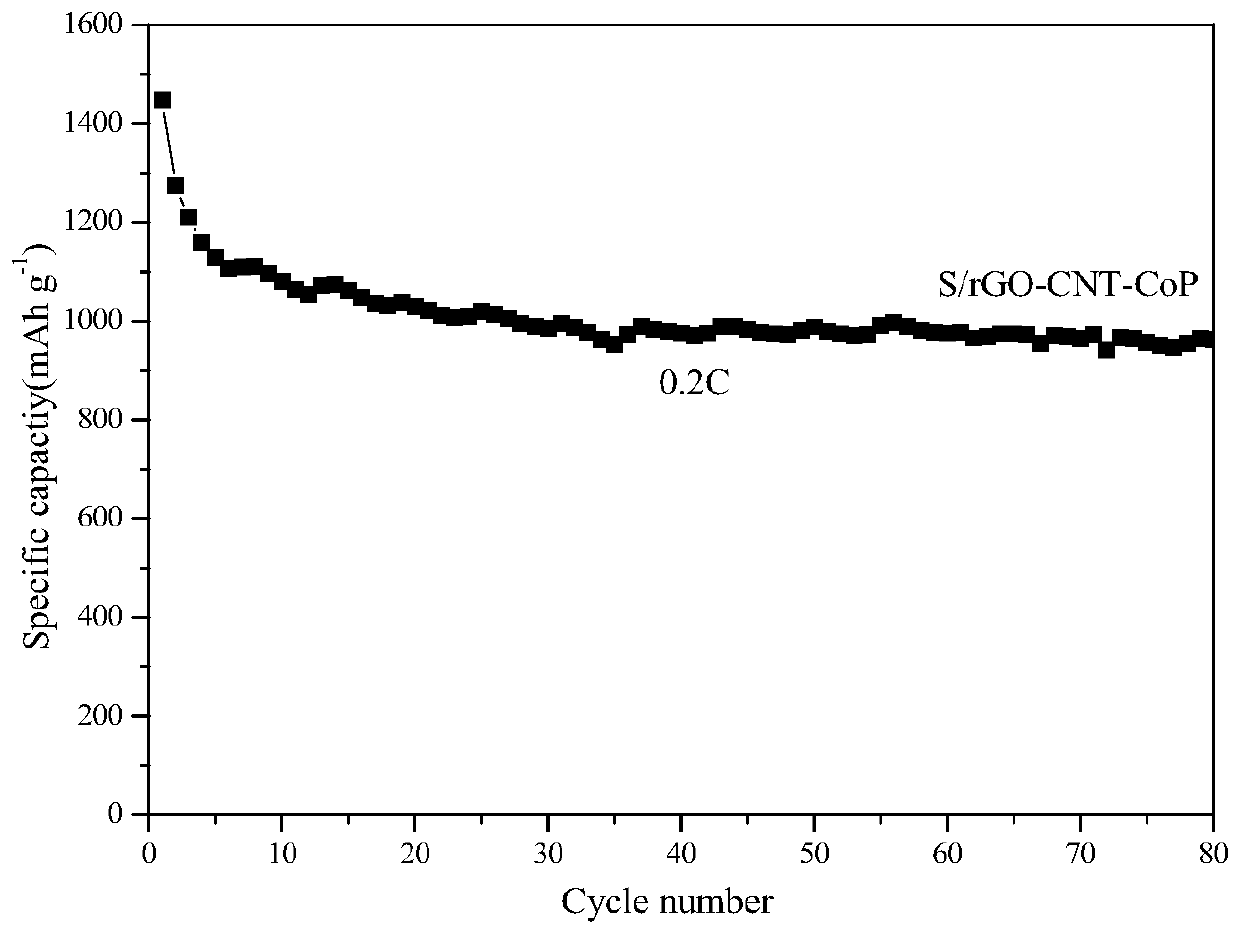

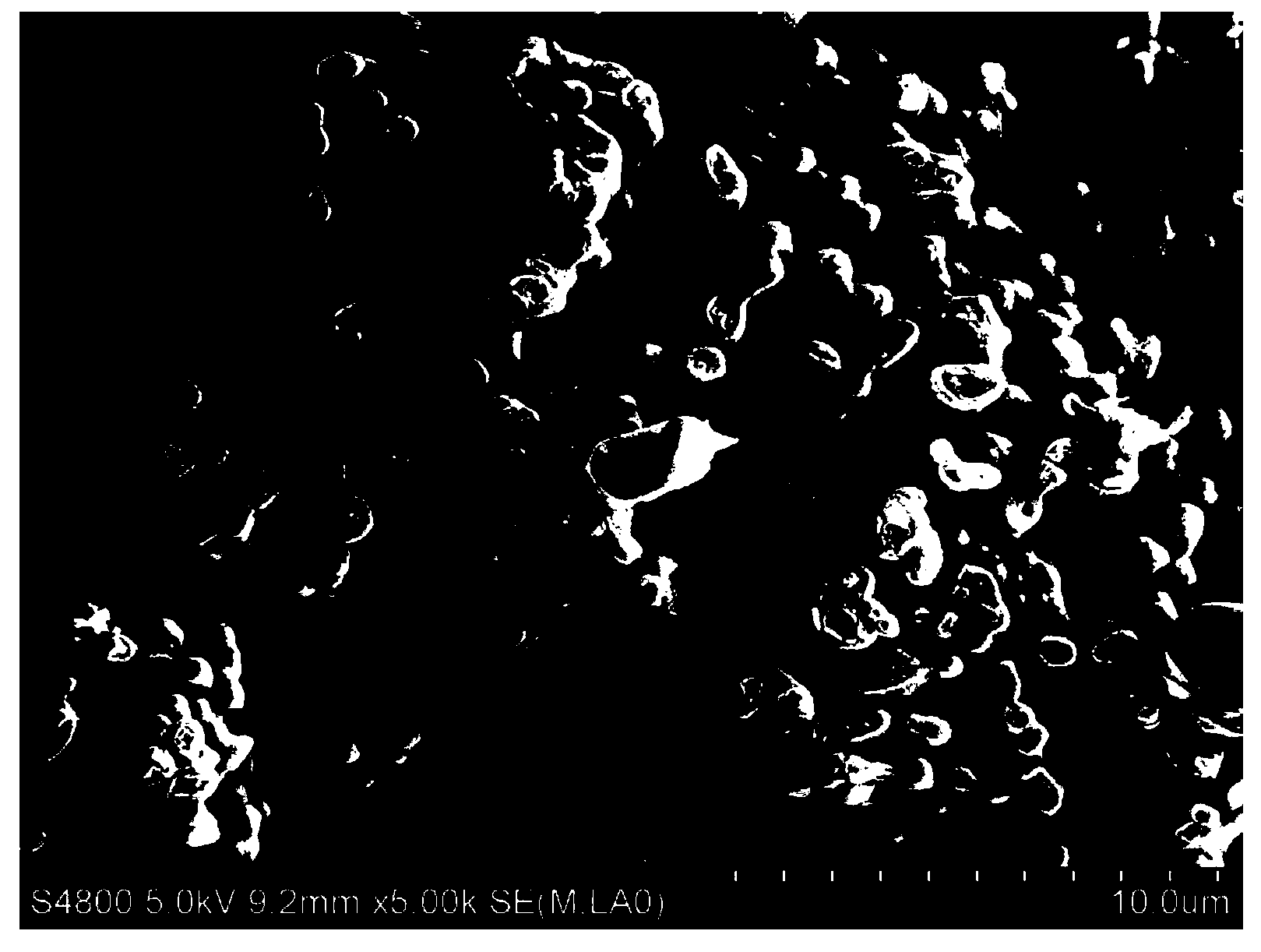

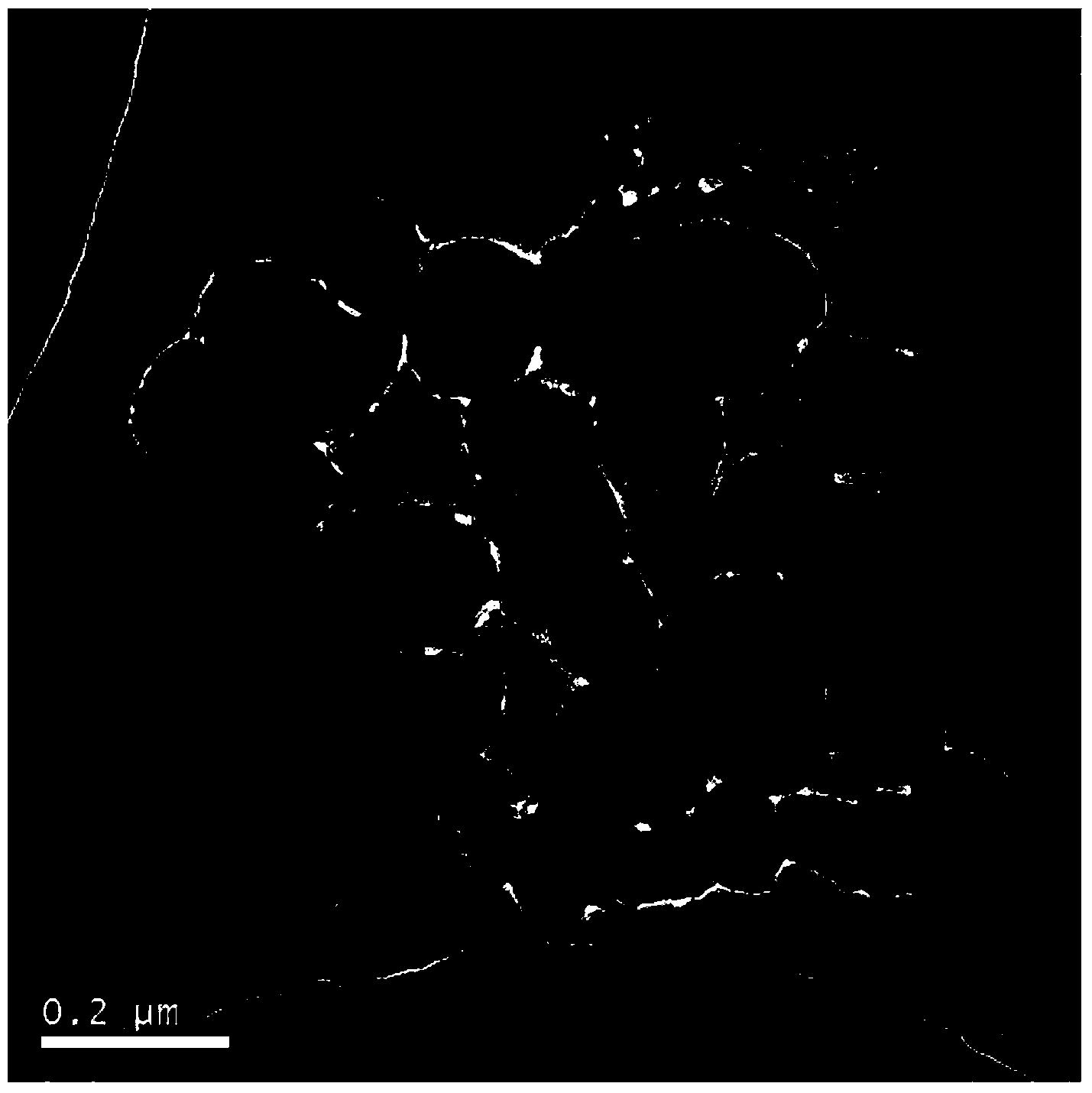

Amorphous cobalt phosphide/nanocarbon composite material and preparation method and application thereof

ActiveCN111517298ALarge specific surface areaRich pore structureMaterial nanotechnologyCell electrodesCarbon compositesNew energy

The invention belongs to the technical field of new energy materials, and particularly relates to an amorphous cobalt phosphide / nanocarbon composite material and a preparation method and application thereof. The composite material is high in specific surface area, rich in pore structure and excellent in conductivity; the conductive carbon network can provide channels for transmission of electronsand ions. The composite material can realize high sulfur loading capacity and high sulfur utilization rate, and can adapt to huge volume change of sulfur in charging and discharging processes. Compared with cobalt phosphide in a high crystalline state, the amorphous cobalt phosphide nanosheet can effectively physically and chemically adsorb polysulfide, reduce the shuttle effect, expose enough catalytic active sites, provide a large number of defect sites, promote electrochemical conversion of polysulfide to the final discharge product and improve the catalytic kinetics of the reaction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

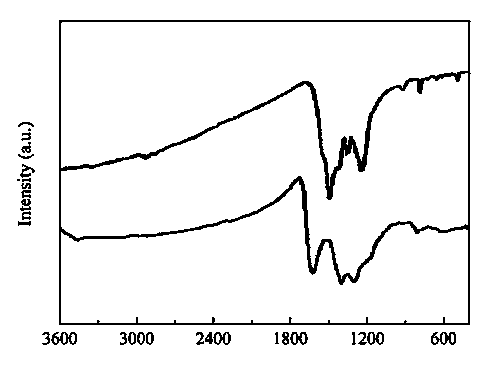

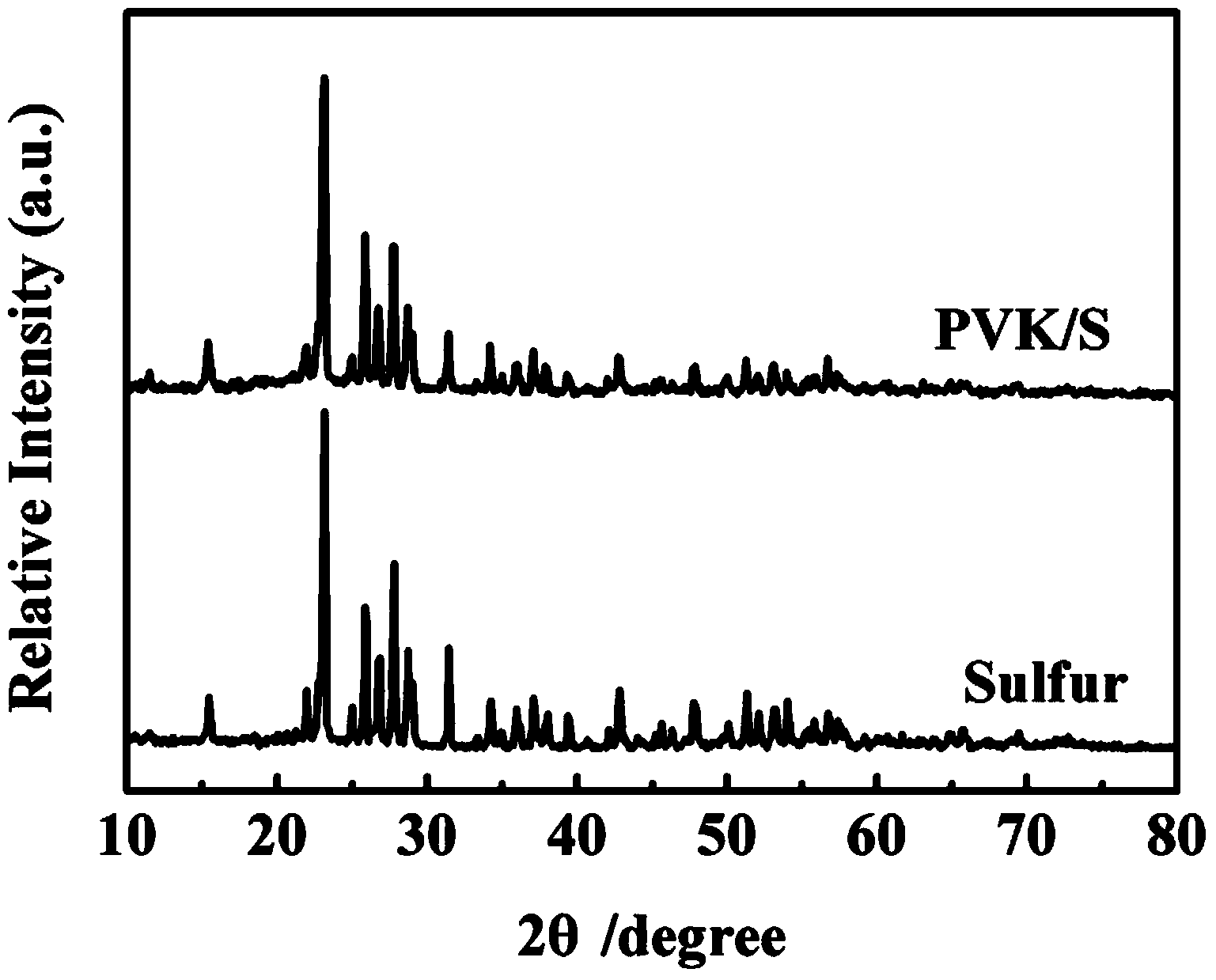

Lithium-sulfur battery cathode composite material and preparation method thereof

ActiveCN104393253AWide variety of sourcesLow costElectrode thermal treatmentLi-accumulatorsVinyl carbazoleSulfur

The invention discloses a lithium-sulfur battery cathode composite material and a preparation method thereof. According to the cathode composite material, elemental sulfur is cladded by an electric-conduction polymer poly(N-vinylcarbazole), the sulfur cathode material is guaranteed to have good electric conductivity, also sulfur and electro-discharge products thereof are constrained in the sulfur cathode material, so that relatively high sulfur utilization rate and cycling stability are obtained. According to the technical scheme, the disadvantages of sulfur as a lithium ion secondary cell cathode material are overcome, the lithium-sulfur battery cathode composite material, which is long in cycling life, high in capacity, green, environment-friendly, and simple in method, is prepared. The preparation method is simple, equipment is simple, raw material source is wide, cost is low, and the preparation method is in favor of industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Alkali metal-sulfur secondary battery containing cathode material particulates

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer comprising multiple particulates, wherein at least one of the particulates comprises one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a conductive sulfonated elastomer composite having from 0.01% to 50% by weight of a conductive reinforcement material dispersed in a sulfonated elastomeric matrix material, wherein the conductive reinforcement material is selected from graphene sheets, carbon nanotubes, carbon nanofibers, metal nanowires, conductive polymer fibers, or a combination thereof and the composite has a recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and a thickness from 0.5 nm to 10 μm. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Preparation method of graphene-sulfur microcapsule composite

The invention relates to a preparation method of a graphene-sulfur microcapsule composite, comprising: first, introducing organic molecules of hydroxy, sulfydryl, amino, carboxy or other groups to thesurface of graphene oxide by means of physical adsorption or chemical grafting; second, preparing graphene-coated sulfur microcapsule by means of mechanical blending. A core material is common sulfur, and the surface of the core material is subjected to graphene oxide or graphene modification to form a core-shell structure. The graphene shell herein can effectively enclose the sulfur therein, andblooming during rubber processing is inhibited; the rich functional groups on the surface or edge of the graphene enable the sulfur to be evenly dispersed in a rubber base during mixing stage and engage in sulfurization reaction during sulfurization stage, thermal stability of the sulfur is improved, and excellent properties are imparted to the composite. The prepared graphene-sulfur microcapsulecomposite has high purity, good thermal stability, high coating rate, high sulfur utilization rate and low cost.

Owner:TANGSHAN JIANHUA TECH DEV

Lithium sulfur battery composite cathode material and preparation method thereof

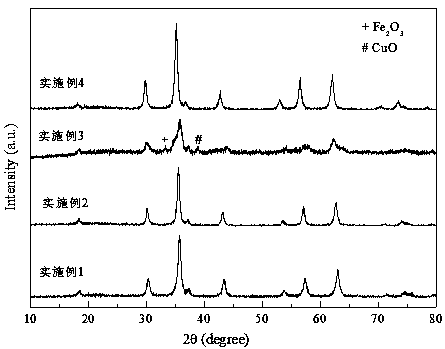

ActiveCN108054350AMature technologySimple processCell electrodesSecondary cellsChemical adsorptionSulfur utilization

The invention relates to a lithium sulfur battery composite cathode material and a preparation method thereof. The composite cathode material is prepared by compounding ferrite with elemental sulfur.The ferrite is one of magnesium ferrite, zinc ferrite, copper ferrite or manganese ferrite. The preparation method includes: preparing a ferrite material by high temperature calcination method, and then conducting compounding with elemental sulfur by liquid phase method. The preparation method has a mature process and simple procedure, and is easy to acquire a high sulfur content composite cathodematerial. The lithium sulfur battery composite cathode material prepared by the invention utilizes the strong chemical adsorption effect of ferrite on polar lithium polysulfide, greatly inhibits thedissolution of lithium polysulfide in an ether electrolyte solution, accordingly slows down the shuttle effect, and then shows characteristics of high sulfur content, high sulfur utilization and highcycle stability.

Owner:NANKAI UNIV

Lithium-sulfur battery cathode material, preparation method thereof, electrode sheet, and lithium-sulfur battery

ActiveCN109950472BImprove cycle stabilityLimited dissolutionLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur utilization

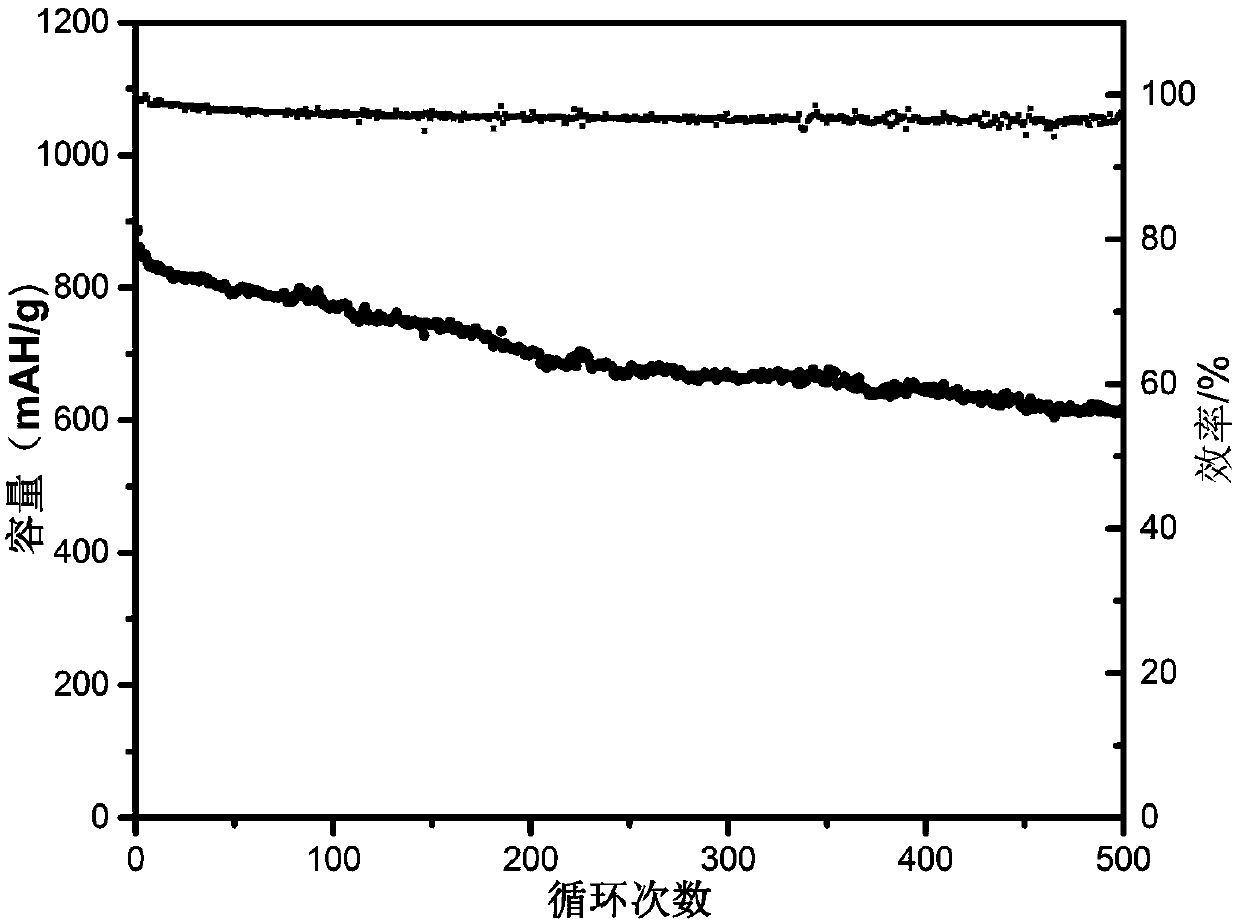

The invention discloses a lithium-sulfur battery cathode material, a preparation method thereof, an electrode slice and a lithium-sulfur battery, and belongs to the technical field related to chemicalpower supplies. The lithium-sulfur battery cathode material formed by copolymerization reaction between an organic matter and liquid sulfur formed by fusion of sulfur powder, and the sulfur is fixedin a chemical bonding manner; and the content of sulfur in the lithium-sulfur battery cathode material is 50-90%. The preparation method comprises the following steps that (1) heat treatment is carried out on the sulfur powder to obtain the liquid sulfur, the organic matter is added to the liquid sulfur, and high-temperature fixation is carried out to obtain a mixture; and (2) the mixture undergoes grinding and heat treatment successively so that the sulfur powder further makes copolymerization reaction with the organic matter, and the lithium-sulfur battery cathode material is obtained. The sulfur is fixed via the chemical bonding method, stable circulation of the battery is realized, the sulfur content is high, the battery energy density and the sulfur utilization rate are improved, andthe production cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

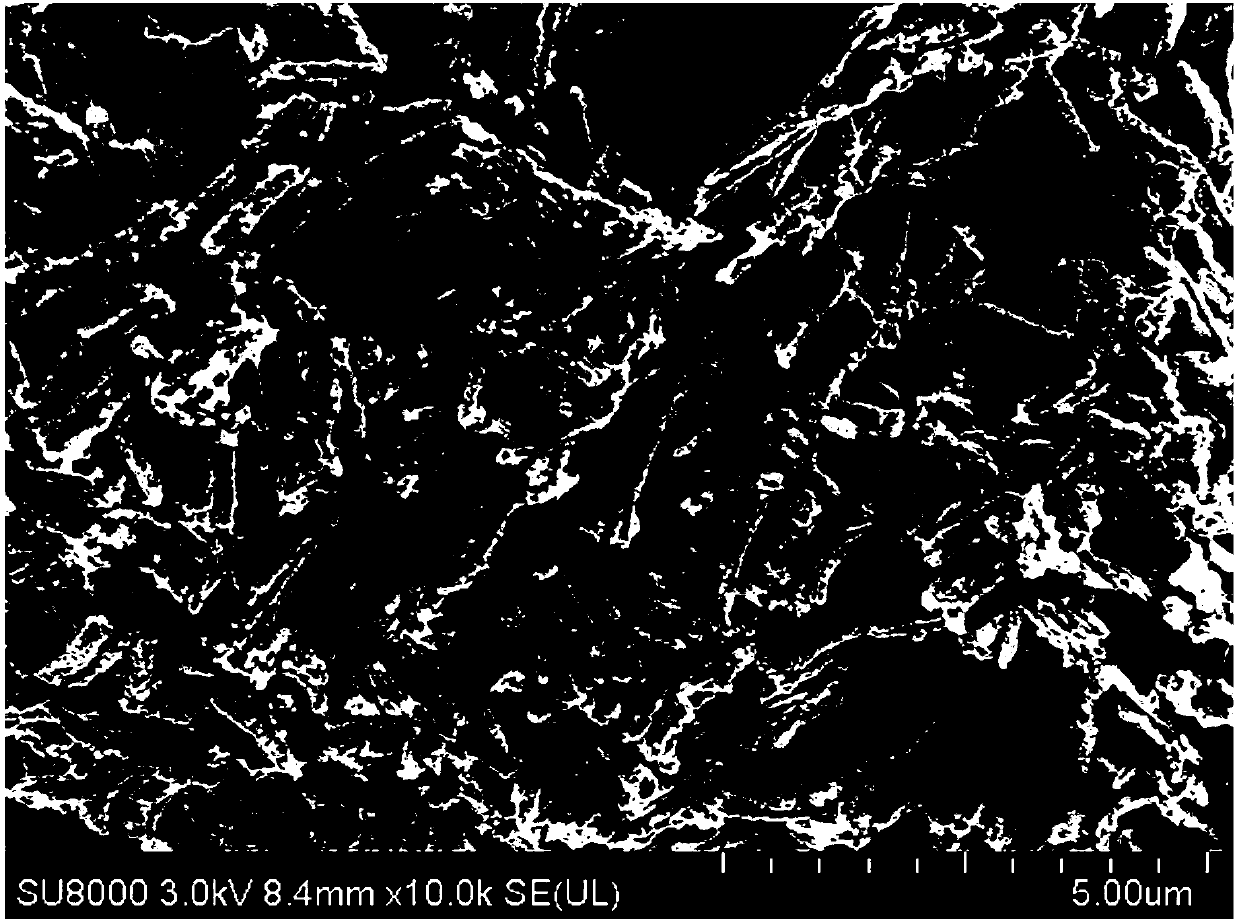

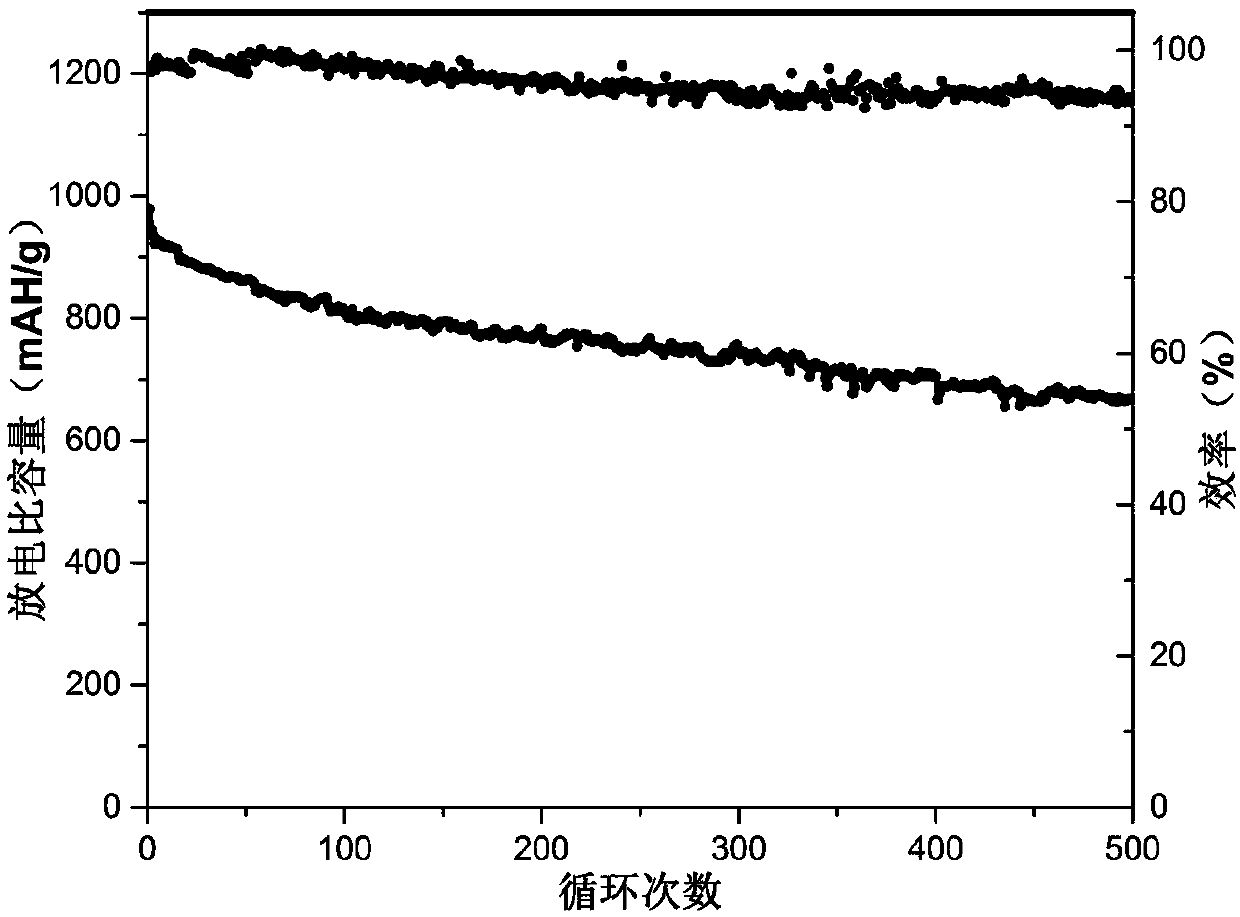

Molybdenum carbide sulfur composite material and preparation method and application thereof

The invention relates to the technical field of a lithium-sulfur battery positive electrode material, and provides a molybdenum carbide sulfur composite material and preparation method and applicationthereof. The molybdenum carbide sulfur composite material comprises molybdenum carbide and elemental sulfur, wherein the molybdenum carbide is of a porous rod-shaped structure, the length of the molybdenum carbide is 1-5 micrometers, the diameter of the molybdenum carbide is 30-60 nanometers, the elemental sulfur is doped into gaps of the molybdenum carbide, and the mass ratio of the molybdenum carbide and the elemental sulfur is (1-9):(9-1). The molybdenum carbide sulfur composite material provided by the invention has relatively high specific area and electron conductivity, the sulfur utilization ratio can be improved, and a shuttle flying effect is relieved. Through charge-discharge test on a lithium-sulfur battery prepared by the molybdenum carbide sulfur composite material, reversible capacity of (623-653) mAh / g still can be maintained after circulation for 500 times, the capacity is maintained at 70% or above, the lithium-sulfur battery has coulobmic efficiency exceeding 93%, and the cycle property can be remarkably improved.

Owner:吉林省东驰新能源科技有限公司

Room-temperature sodium sulfur secondary battery

ActiveCN104300175AIncrease profitImprove conductivityCell seperators/membranes/diaphragms/spacersCell electrodesCompound aElectrolysis

The invention discloses a room-temperature sodium sulfur secondary battery. The room-temperature sodium sulfur secondary battery comprises a positive plate, a negative plate, an electrolyte solution and a diaphragm which are held in a battery shell, wherein the electrolyte in the electrolyte solution comprises imidazole electrolyte and also comprises chain-shaped and ring-shaped ether electrolyte and / or chain-shaped and ring-shaped ester electrolyte; a positive active material is adhered to the surface of the positive plate and is prepared by compounding a sulfur composite active material and a conductive agent with a conductive effect according to a weight ratio of (8-10) to 1. According to the room-temperature sodium sulfur secondary battery, the internal resistance of the battery is reduced; the storage and utilization of sulfur in the battery are improved; the sulfur utilization efficiency is improved; the room-temperature sodium sulfur secondary battery is high in conductivity; positive and negative active materials can be fully used; the performance of the battery can be improved; the service life of the battery can be prolonged; the room-temperature sodium sulfur secondary battery has a strong competitiveness in the secondary battery market in the future.

Owner:内蒙古默锐能源材料有限公司

Method for efficiently removing copper through crude bismuth pot refining

The invention discloses a method for efficiently removing copper through crude bismuth pot refining. The method is characterized by comprising the following steps: adding saw dust as a swelling agent in the process of adding sulfur to remove copper according to a mass ratio of sulfur to saw dust being 1 to 0.4, and mixing and stirring water with the saw dust to be uniform. Because the boiling point of water is 100 DEG C, the contact time of sulfur and melt can be effectively prolonged. According to the addition of mixed sulfur, copper can be efficiently removed from bismuth solution. Because the saw dust has the effect of the swelling agent, the defects that sulfur is agglomerated and has small contact area with the bismuth solution and the like are overcome, the sulfur utilization rate is effectively improved, the problems that sulfur is directly burnt and the sulfur utilization rate is low in the process of adding sulfur to remove copper are solved, and the direct recovery rate of bismuth is effectively improved.

Owner:SHANDONG HUMON SMELTING

Alkali metal-sulfur secondary battery containing a polymer-encapsulated sulfur cathode and manufacturing method

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and whereinat least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity ultra-high molecular weight polymer having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10-6 S / cm at room temperature, and a thickness from 0.5 nm to 10 [mu]m. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:NANOTEK INSTR

A kind of preparation method of carbon nanotube-lithium sulfide-carbon composite material

ActiveCN106784754BSpecial structureImprove conductivityCell electrodesLi-accumulatorsCarbon compositesSulfur electrode

The invention relates to a preparation method of a carbon nanotube-lithium sulfide-carbon composite material. The preparation method comprises the following steps: dissolving sublimed sulfur powder in anhydrous methylbenzene to form a transparent solution A; performing ultrasonic dispersion on carbon nanotubes in a lithium triethylborohydride tetrahydrofuran solution to form a suspension B; adding the solution A into the suspension B to obtain a carbon nanotube-Li2S composite material suspension, and heating to evaporate the solvent so as to obtain carbon nanotube-Li2S composite material powder; and finally, putting the carbon nanotube-Li2S material in an inert atmosphere, and performing chemical vapor deposition to form the carbon nanotube-Li2S-C composite material. The carbon nanotube-lithium sulfide-carbon composite material prepared by the invention has favorable electric conductivity and high coating tightness, can improve the electric conductivity of a Li2S electrode, effectively inhibits dissolution and dispersion of polysulfide in an electrolyte, and increases the sulfur utilization ratio; and meanwhile, the porous structure of the carbon nanotubes has a cushioning effect on volume expansion and shrinkage of an sulfur electrode in the charge / discharge process.

Owner:CENT SOUTH UNIV

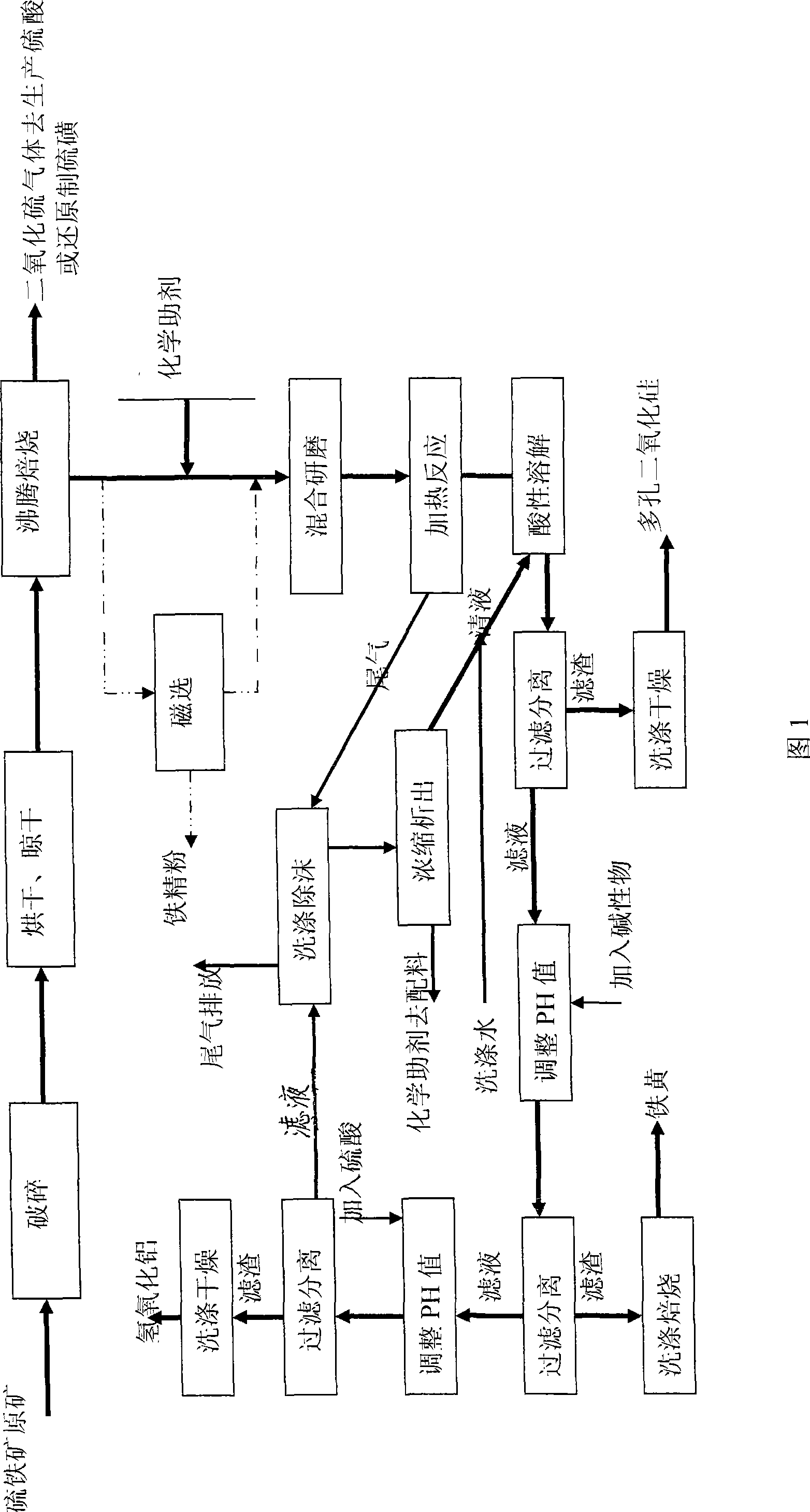

Method for by-producing porous silicon dioxide, aluminum hydroxide and ferrite yellow from middle and low grade ferro-sulphur ore

InactiveCN101456559ARealize full layer miningAchieve recyclingSilicaSulfur-dioxide/sulfurous-acidFerric hydroxideFiltration

The invention relates to a method for coproducing porous silicon dioxide, aluminum hydroxide and ferrite yellow when producing medium and low grade sulfurous iron ores, which comprises: the sulfurous iron ores are crushed and directly enter a fluidized bed furnace for roasting to obtain sulfur dioxide gas and cinder; the sulfur dioxide gas is used for further producing sulfuric acid or reducing production of sulfur; the cinder is subjected to magnetic separation to obtain iron concentrate or directly added with a chemical additive and then subjected to grinding and heating reaction, wherein the addition of the chemical additive is 2 to 4 times of the weight of the cinder; the cinder is dissolved for 1 to 3 hours under the acid condition after heating reaction, and the porous silicon dioxide is obtained after filtration and separation; the pH value of filtrate is adjusted to be between 9 and 12, the filtrate stands and is filtrated, and filter residue ferric hydroxide is washed and roasted to obtain a high-purity ferrite yellow pigment; and the pH value of the filtrate for filtrating the ferric hydroxide is adjusted to be between 4 and 6.5, the filtrate stands and is filtrated and separated to obtain aluminum hydroxide, and the aluminum hydroxide finished product is obtained after washing and drying the aluminum hydroxide. The method can improve the sulfur utilization rate by 40 to 50 percent, solves the problem of environmental pollution in the prior art, and fully utilizes all the compositions coproduced with the medium and low grade sulfurous iron ores.

Owner:云南常青树投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com