TiO2 coated sulfur/ordered mesoporous carbon composite cathode material and preparation method thereof

A composite positive electrode material and composite material technology, applied in the field of electrochemical and new energy products, can solve the problems of poor rate performance, low utilization rate of active materials, short cycle life, etc., to inhibit dissolution loss, reduce shuttle effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

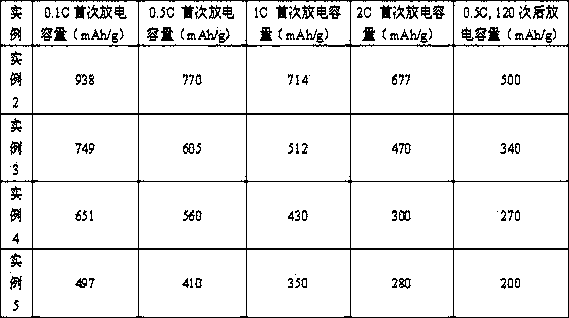

Examples

Embodiment 1

[0047] (1) Preparation of ordered mesoporous carbon: Add 24g of F127 template to the mixed solution of hydrochloric acid (15g 0.2M) and ethanol (120g), react at 40°C for 1h to form a clear solution; then add 31.2g of TEOS and The ethanol solution containing 20wt% phenolic resin was stirred and reacted for 5 hours to synthesize the precursor, and dried at 100°C; the precursor powder was placed in a tube furnace, heated to 900°C under an inert protective gas, and kept for 2 hours to form a Sequenced carbon-silicon complex; dissolving the carbon-silicon complex in HF to dissolve silicon; vacuum drying to form ordered mesoporous carbon.

[0048] (2) Composite sulfur: Put elemental sulfur and prepared ordered mesoporous carbon into a tube furnace at a mass ratio of 11:9, heat to 150°C for 6 hours under the protection of an inert gas to obtain sulfur / ordered mesoporous carbon composite material.

[0049] (3) coated TiO 2 : Sulfur / Ordered Mesoporous Composite with TiO 2 Calculated...

Embodiment 2

[0051] (1) Preparation of ordered mesoporous carbon: Add 24g of F127 template to the mixed solution of hydrochloric acid (15g 0.2M) and ethanol (120g), react at 40°C for 1h to form a clear solution; then add 31.2g of TEOS and The ethanol solution containing 20wt% phenolic resin was stirred and reacted for 5h to synthesize the precursor, and dried at 100°C. The precursor powder was put into a tube furnace, heated to 900°C under an inert protective gas, and kept for 2 hours to form an ordered carbon-silicon composite. Dissolve the carbon-silicon composite in HF to dissolve the silicon; vacuum-dry to form ordered mesoporous carbon.

[0052] (2) Composite sulfur: Put elemental sulfur and prepared ordered mesoporous carbon into a tube furnace at a mass ratio of 3:2, heat to 150°C under the protection of an inert gas, and keep warm for 6 hours to obtain sulfur / ordered mesoporous carbon carbon composites.

[0053] (3) coated TiO 2 : Sulfur / Ordered Mesoporous Composite with TiO 2 ...

Embodiment 3

[0055] (1) Preparation of ordered mesoporous carbon: Add 24g of F127 template into the mixed solution of hydrochloric acid (15g 0.2M) and ethanol (120g), react at 40°C for 1h to form a clear solution; then add 31.2g of TEOS and containing 20wt% ethanol solution of phenolic resin was stirred and reacted for 5h to synthesize the precursor, and dried at 100°C. Put the precursor powder into a tube furnace, heat to 900°C under an inert protective gas, and keep it warm for 2 hours to form an ordered carbon-silicon composite; dissolve the carbon-silicon composite in HF to dissolve silicon; vacuum dry to form Ordered mesoporous carbon.

[0056] (2) Composite sulfur: Put elemental sulfur and prepared ordered mesoporous carbon into a tube furnace at a mass ratio of 13:7, heat to 150°C under the protection of inert gas, and keep warm for 6 hours to obtain sulfur / ordered mesoporous carbon carbon composites.

[0057] (3) coated TiO 2 : Sulfur / ordered mesoporous composites and TiO2 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com