Patents

Literature

266results about How to "Reduce Shuttle Effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of sulfur-active carbon/graphene composite material

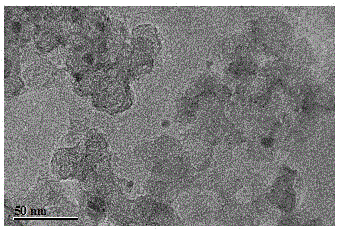

ActiveCN106602013AWide variety of sourcesEasy to prepareCell electrodesLi-accumulatorsActivated carbonSulfur

The invention discloses a preparation method of a sulfur-active carbon / graphene composite material. The preparation method comprises the following steps of (1) pre-processing a biomass raw material; (2) mixing the pre-processed biomass raw material, graphene and an activating agent to form a solid mixed material; (3) performing activation, washing, solid-liquid separation and drying on the solid mixed material to obtain an active carbon / graphene composite material; and (4) combining the active carbon / graphene composite material with sulfur to obtain the sulfur-active carbon / graphene composite material. The composite material provided by the invention has the advantages of simple preparation process step, high efficiency and low energy consumption, and production on a large scale can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

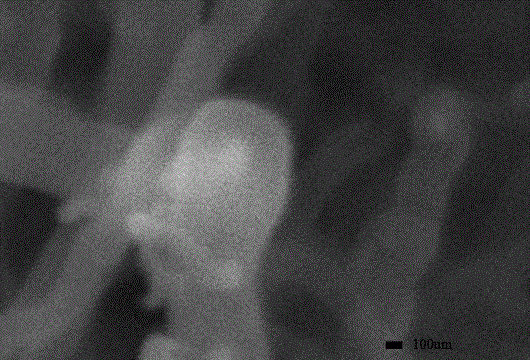

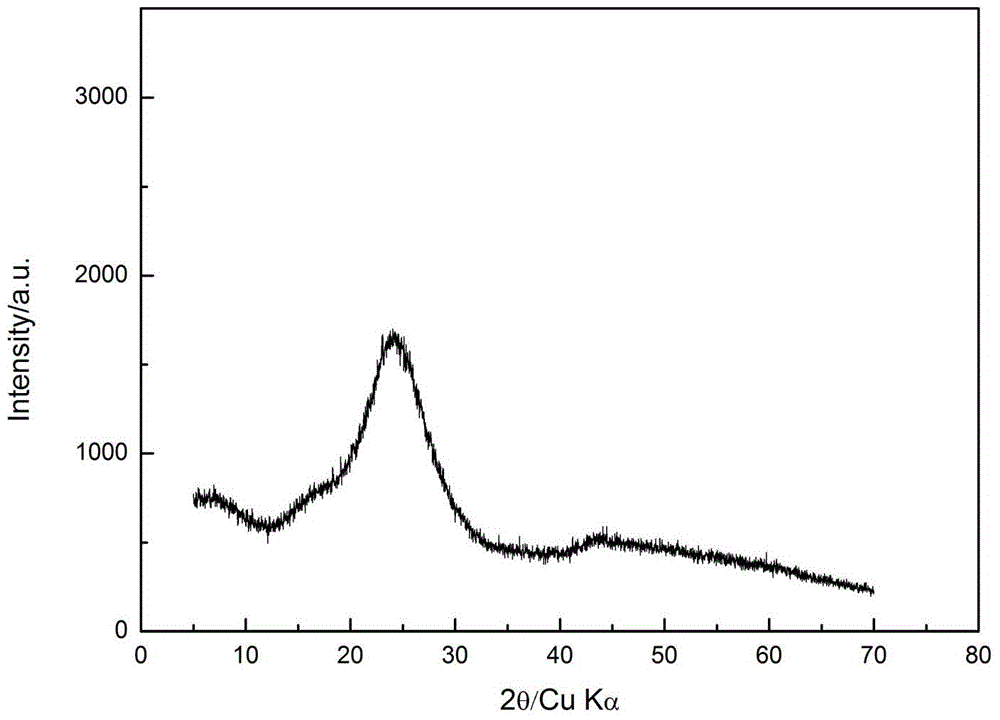

Preparation method of oxidized Mxene/S compound applied to lithium-sulphur battery cathode

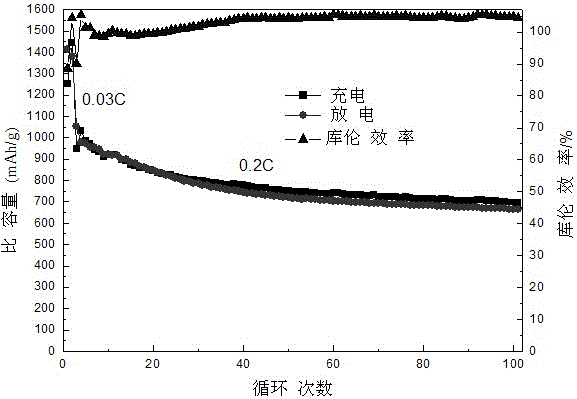

ActiveCN107579235ALow costImprove adsorption capacityCell electrodesSecondary cellsWater bathsHigh conductivity

The invention discloses a preparation method of an oxidized Mxene / S compound applied to a lithium-sulphur battery cathode, relates to a preparation method of an S compound applied to the lithium-sulphur battery cathode, and aims to solve the technical problem of complex process of an existing Mxene / S compound preparation method. The preparation method disclosed by the invention comprises the following steps: 1, preparing Mxene powder; 2, oxidizing; 3, performing a water bath method. According to the preparation method, oxidized Mxene with high conductivity is taken as an S carrier, the preparation process is simple and safe, the production cost is low, large scale production is hopefully realized, and the oxidized Mxene / S compound as a lithium-sulphur battery cathode material has very highspecific capacity and cycling stability. The preparation method is applied to preparation of the lithium-sulphur battery cathode material.

Owner:HARBIN INST OF TECH

Sulfur-activated carbon/graphene composite material and application thereof

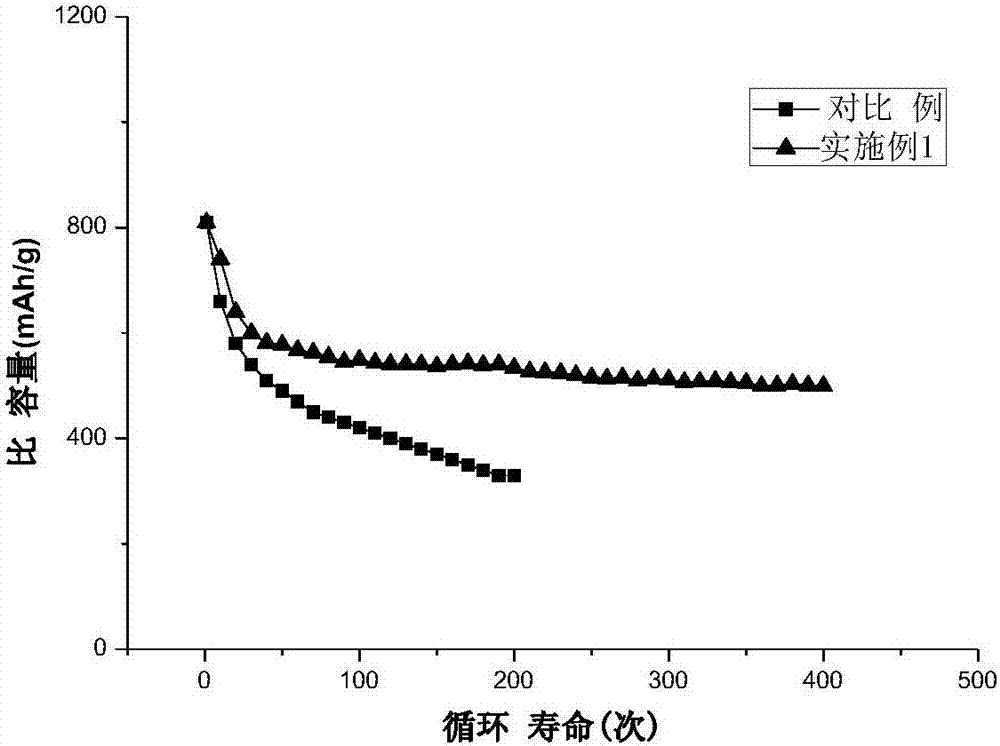

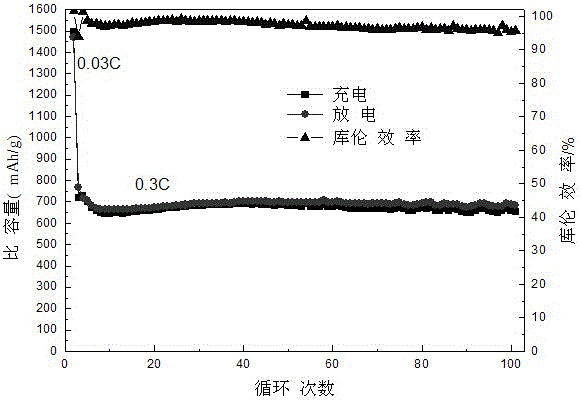

InactiveCN106532026AWide variety of sourcesEasy to prepareCell electrodesGrapheneActivated carbonLithium–sulfur battery

The invention discloses a sulfur-activated carbon / graphene composite material and an application thereof. The composite material is formed by loading sulfur on an activated carbon / graphene composite material or a material; and the sulfur-activated carbon / graphene composite material comprises the following components in percentage by mass: 10%-90% of sulfur and 10%-90% of activated carbon / graphene composite material. The sulfur-activated carbon / graphene composite material is used for a lithium-sulfur battery, so that, on one hand, the weight of the battery can be greatly reduced, the internal resistance of the battery is reduced, the conductivity of an electrode material is improved and the specific capacity and the overall performance of the battery are improved; and on the other hand, the shuttle effect is reduced, the influence of volume expansion of the sulfur on the performance of the battery is reduced to a certain extent and the utilization rate of the active material is improved. Under the same test condition, the overall performance of the lithium-sulfur battery assembled by the composite material as a positive electrode material is obviously superior to that of the lithium-sulfur battery assembled by the similar positive electrode material as the positive electrode material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

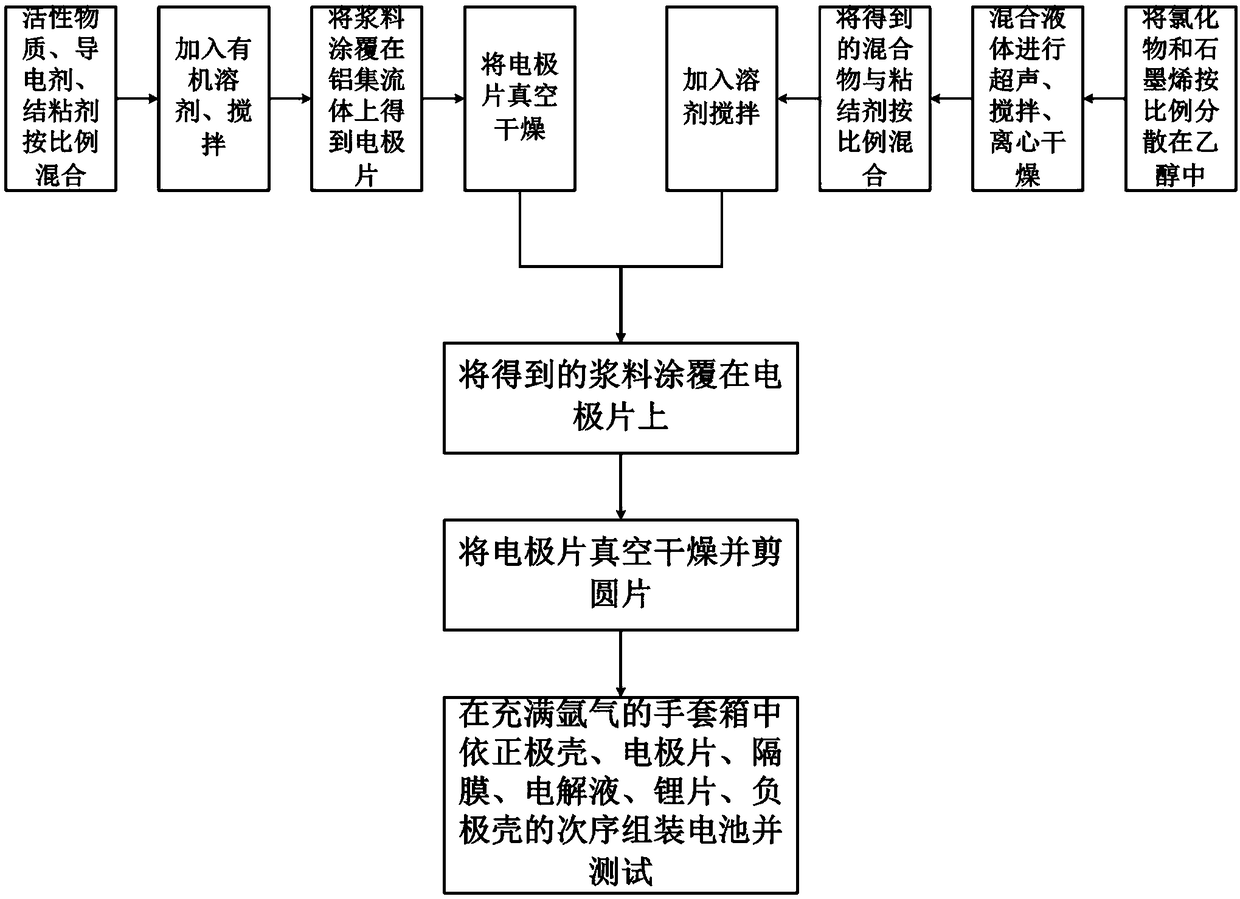

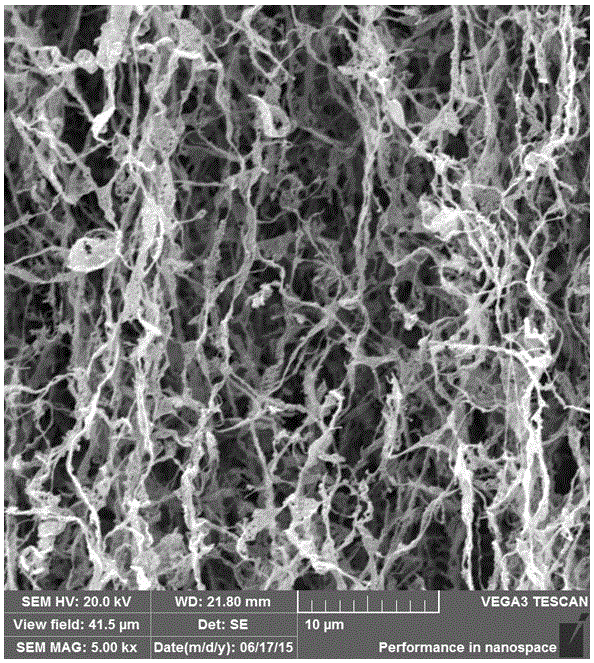

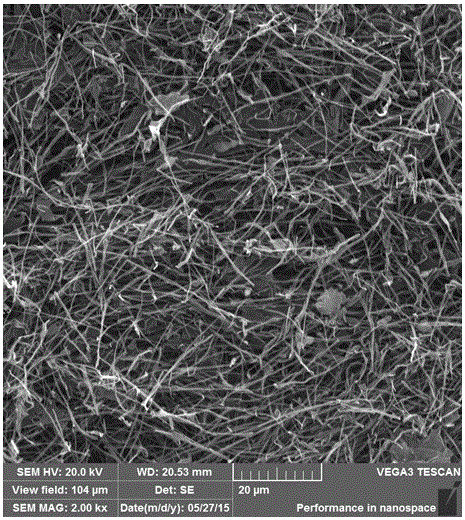

Preparation method for three-dimensional carbon nanotube/nitrogen-doped graphene/sulfur electrode slice

InactiveCN105609736AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsSulfur electrodeCarbon nanotube

The invention provides a preparation method for a three-dimensional carbon nanotube / nitrogen-doped graphene / sulfur electrode slice. The preparation method comprises the following steps of (1) adding the carbon nanotube, graphite oxide and polyacrylonitrile to N-methyl pyrrolidone, performing an ultrasonic reaction, coating an aluminium foil with mixed paste, and performing vacuum drying to obtain the electrode slice; (2) putting the obtained electrode slice into a muffle furnace under ammonia gas protection, heating to 400-500 DEG C, and naturally cooling; and (3) enabling the electrode slice obtained in the step (2) to be fully inserted into a Na2S2O3 solution, and slowly adding hydrochloric acid to the solution in a dropwise manner until the PH value of the solution reaches 6.5-7.5, taking out the electrode slice, and drying the electrode slice to obtain a positive plate. The electrode slice prepared by the invention can be directly used for the positive electrode of a lithium-sulfur battery without requiring a conductive agent and a binder, so that the cost of the electrode is greatly lowered.

Owner:钟玲珑

Lithium-sulfur battery self-supporting cathode material and electro-spinning preparation method thereof

InactiveCN110438798ASolve the shortcomings of poor conductivityInhibition of the shuttle effectCarbon fibresPositive electrodesPorous carbonArgon atmosphere

The invention provides a lithium-sulfur battery self-supporting cathode material and an electro-spinning preparation method thereof. Polyacrylonitrile and polymethyl methacrylate serve as precursors of electrostatic spinning yarns, composite nano-fiber membranes are prepared by an electro-spinning method, pre-oxidation and carbonization heat treatment of the electrostatic spinning fiber membranesare implemented to form a self-supporting in-situ nitrogen doped porous carbon nano-fiber structure, self-supporting in-situ nitrogen doped porous carbon nano-fiber membranes are soaked in carbon disulfide solution of sulfur, drying and heat treatment in the argon atmosphere are implemented to obtain the self-supporting lithium-sulfur cathode material. According to the material, the polymethyl methacrylate serves as a template agent, self-supporting in-situ nitrogen doped carbon nano-fibers with porous structures are formed in a heat treatment and pyrolysis manner, the loading capacity of thesulfur is improved, dissolution of polysulfide is restrained, and the nano-fibers can directly serve as electrode materials.

Owner:SHAANXI UNIV OF SCI & TECH

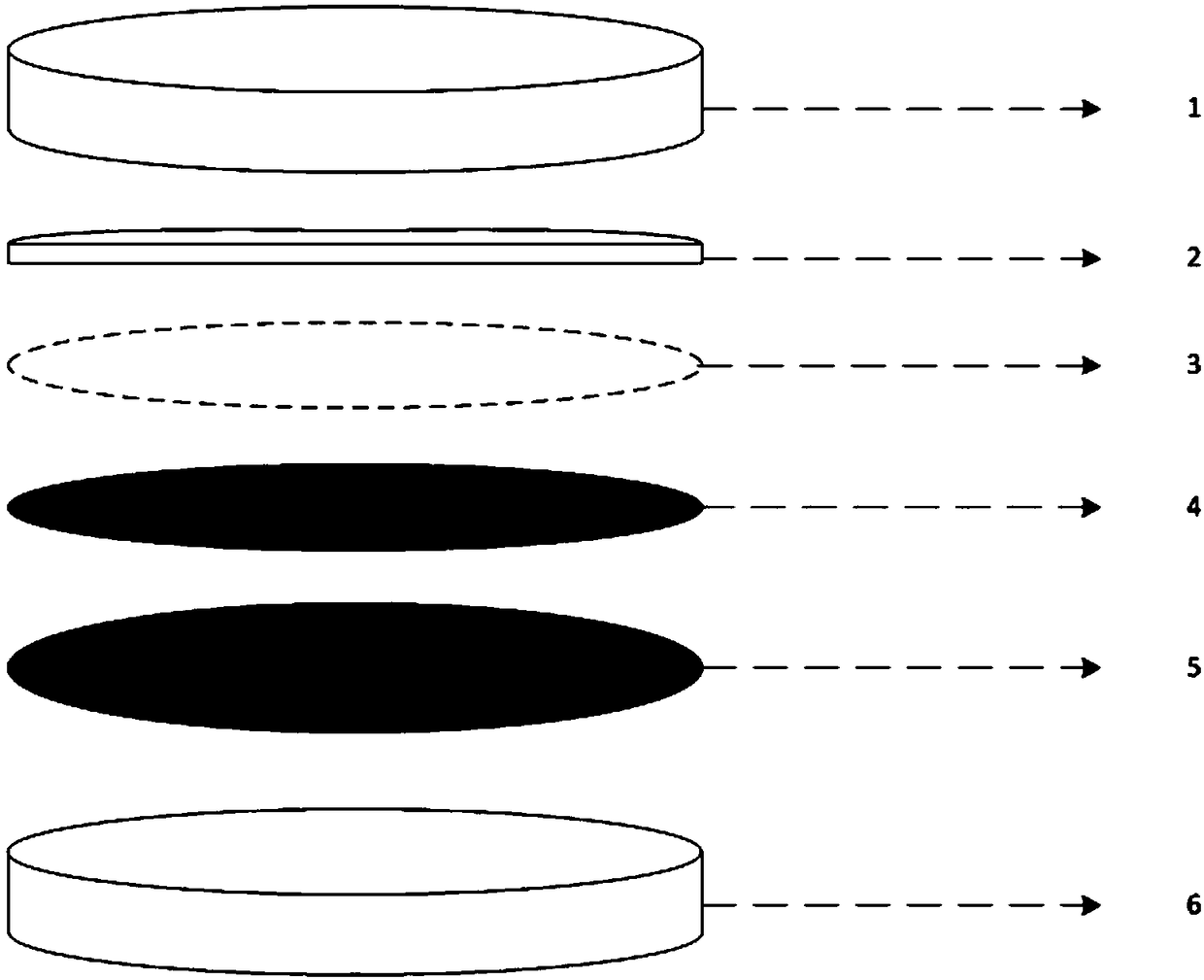

Positive electrode of lithium-sulfur battery using nitride/carbon nano tube as interlayer, battery and preparation method

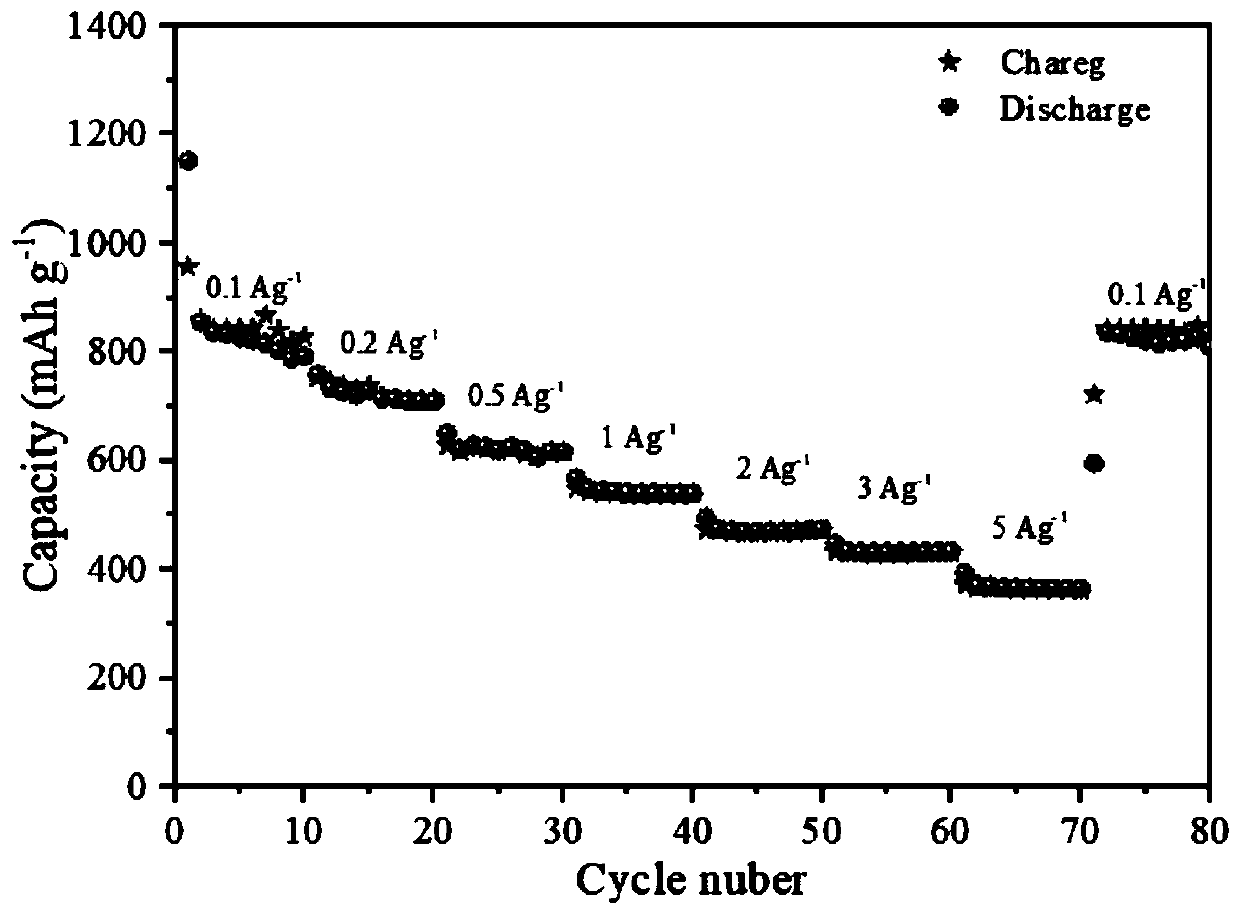

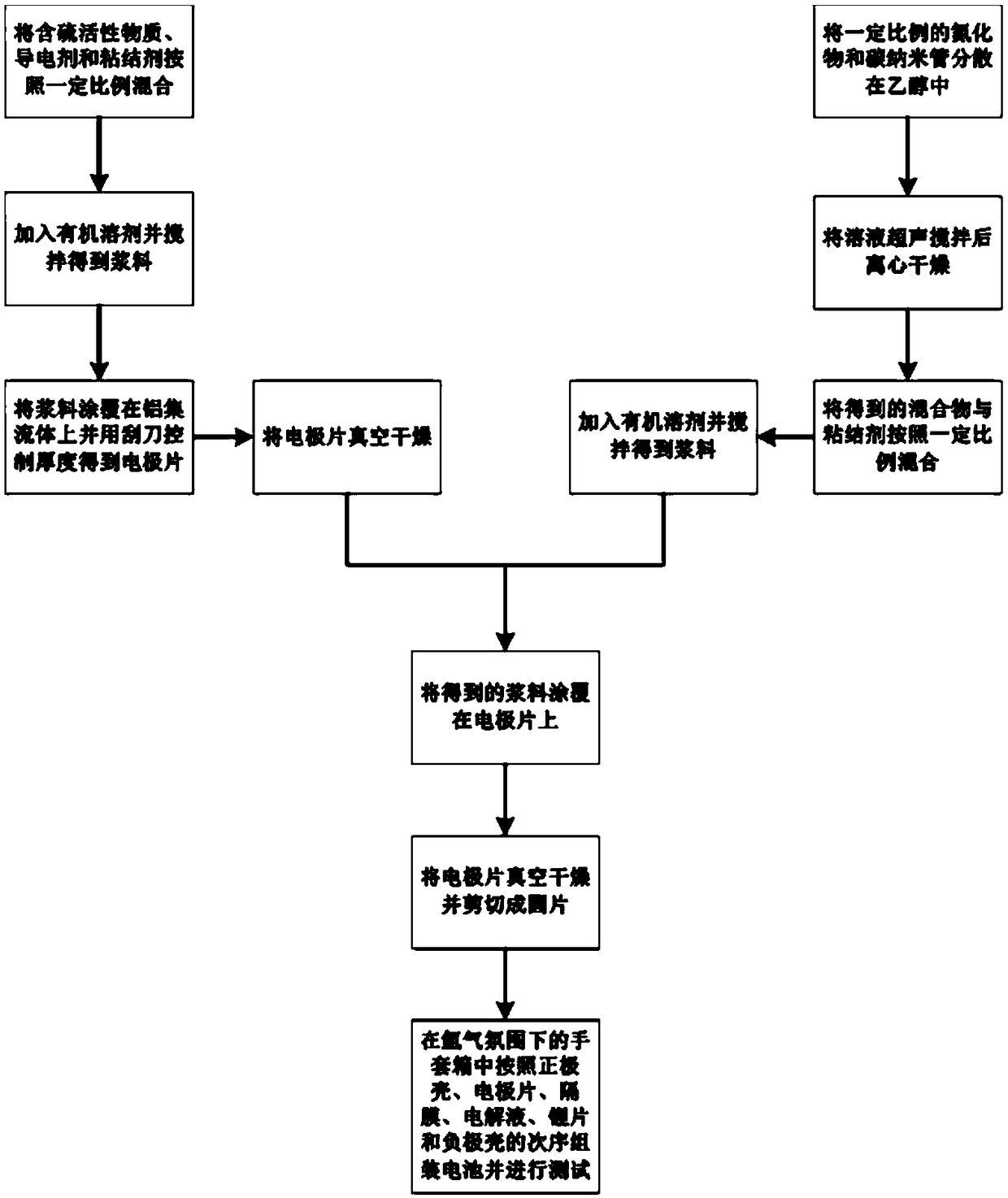

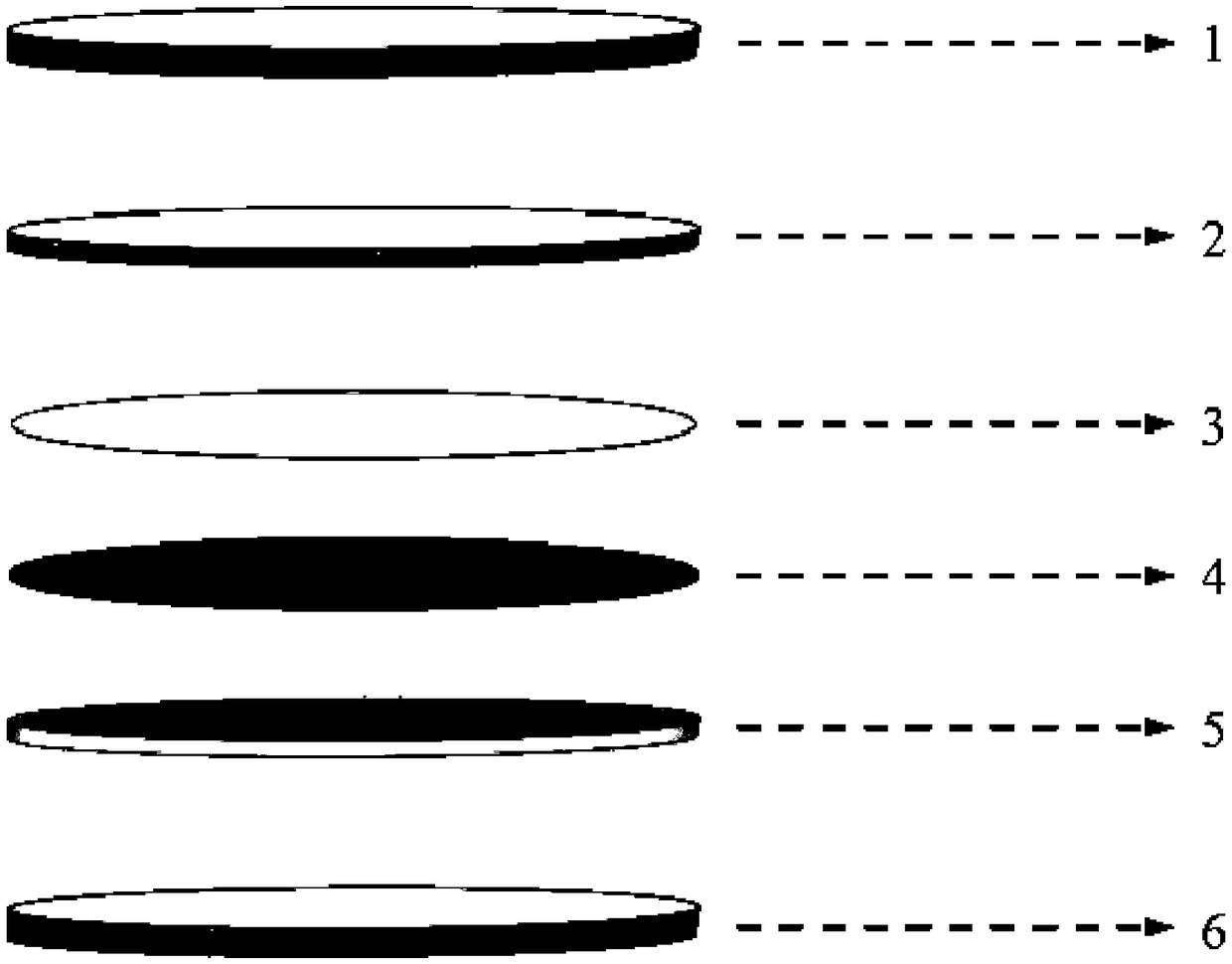

InactiveCN109449374ALower impedanceImprove cycle performanceFinal product manufactureNon-aqueous electrolyte accumulator electrodesMetallic lithiumCarbon nanotube

The invention discloses a positive electrode of a lithium-sulfur battery using a nitride / carbon nano tube as an interlayer, the battery and a preparation method. The preparation method comprises the following steps: preparing a nitride / carbon nano tube interlayer on the sulfur-containing positive electrode to form the positive electrode of the lithium-sulfur battery using the nitride / carbon nano tube as the interlayer; and carrying out assembling in an inert atmosphere to obtain the lithium-sulfur battery using the nitride / carbon nano tube as the interlayer, wherein the lithium-sulfur batteryusing the nitride / carbon nano tube as the interlayer comprises a positive electrode shell, the positive electrode of the lithium-sulfur battery using the nitride / carbon nano tube as the interlayer, adiaphragm, an electrolyte, a metallic lithium negative electrode and a negative electrode shell from bottom to top in sequence. The electrical conductivity of the positive electrode is improved, the transmission rate of lithium ions is promoted and the overall impedance of the battery is reduced by introducing the carbon nano tube with extremely high electron transport capacity and certain physical absorption capacity, and the diffusion of polysulfide is effectively limited inside the interlayer by adding nitrides with extremely high chemical adsorption capacity of polysulfide, so that the purposes of effectively relieving aero effect and improving the cycle performance of the battery are reached.

Owner:XI AN JIAOTONG UNIV

Preparation method of S-C positive pole composite material of high cycle performance lithium sulfur battery

InactiveCN103560232AGood electron transport propertiesImprove uniformityCell electrodesMicrowave ovenOrganic solvent

The invention relates to a preparation method of an S-C positive pole microwave composite material of a high cycle performance lithium sulfur battery. Firstly, sulfur, carbon materials are put into a ball mill for ball-milling mixing, and then put into a microwave oven for microwave heating and compositing to prepare the S-C positive pole microwave composite material with high dispersion uniformity. The S-C positive pole microwave composite material and a conductive agent are ground and mixed uniformly, the S-C positive pole microwave composite material and a binder are dispersed in an organic solvent in a certain proportion, and stirred to prepare paste, and then the paste is evenly coated onto a current collector sheet, and dried to prepare a positive pole. The preparation method adopts an advanced microwave heating method, has the advantages of fast heating speed, mild conditions and high efficiency, the prepared positive pole composite material is stable in structure, the battery has good cycle stability, at the same time, the commercial carbon material with low price is used, the material cost is greatly reduced, and the preparation method is suitable for popularization.

Owner:NANJING UNIV OF TECH

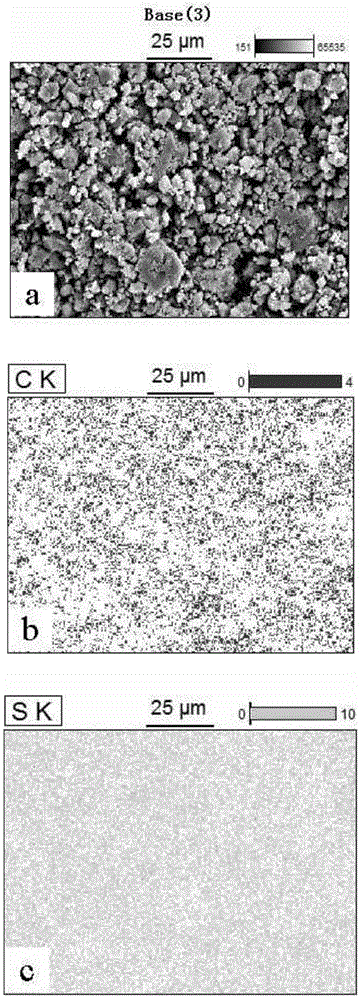

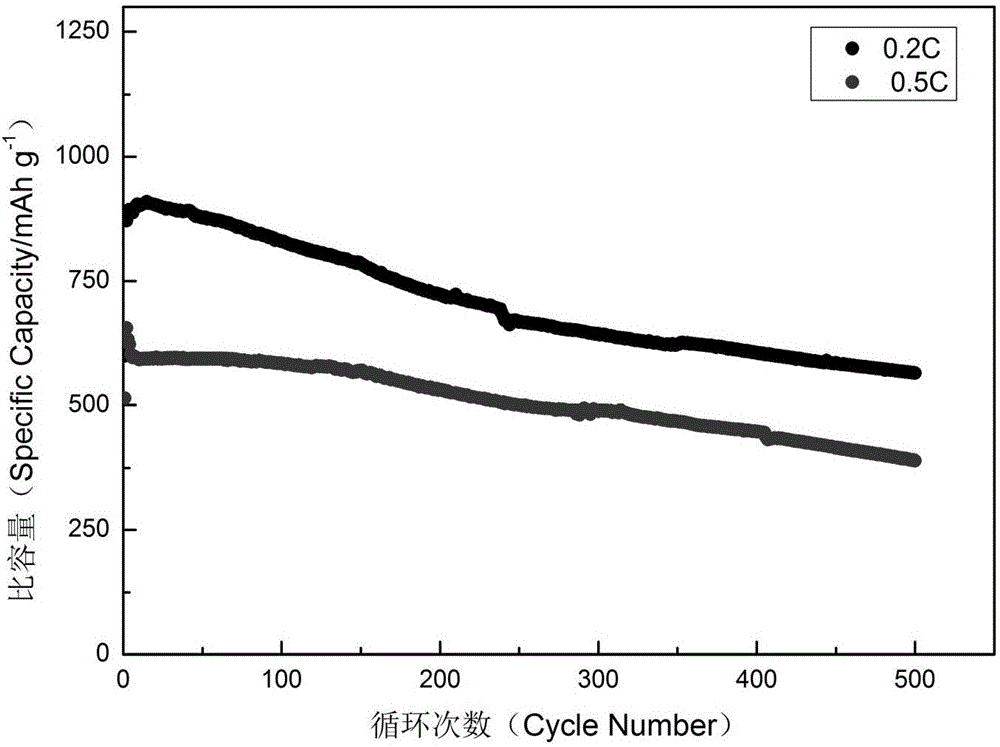

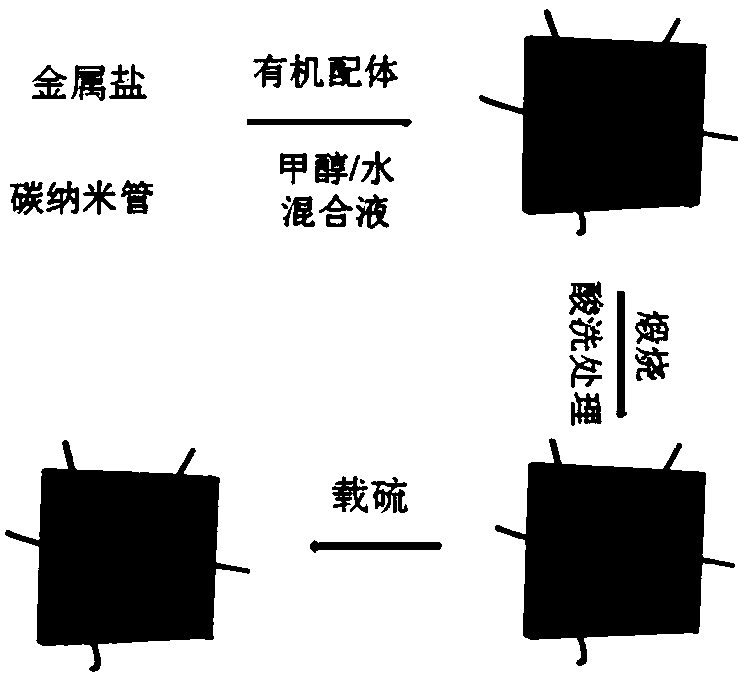

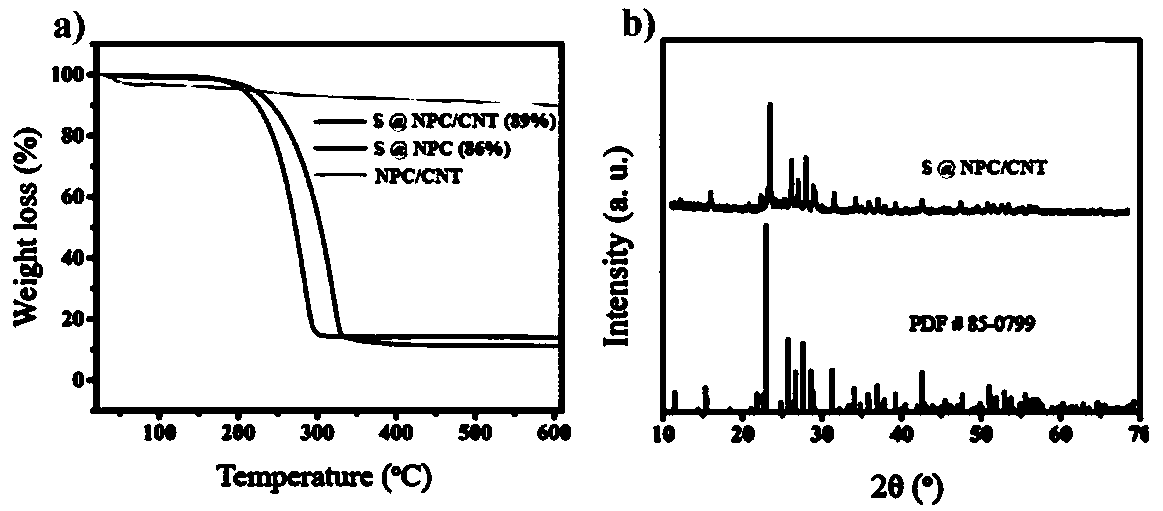

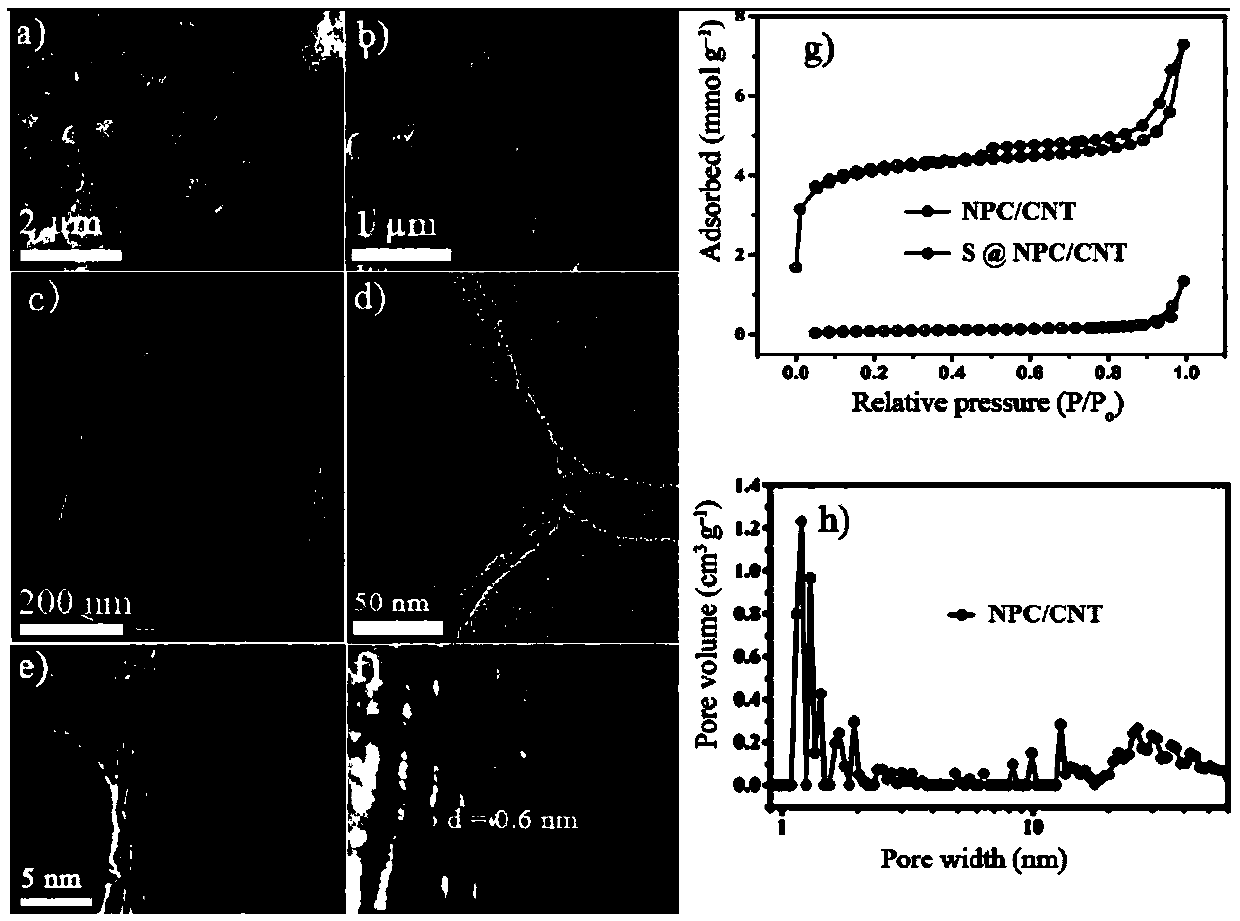

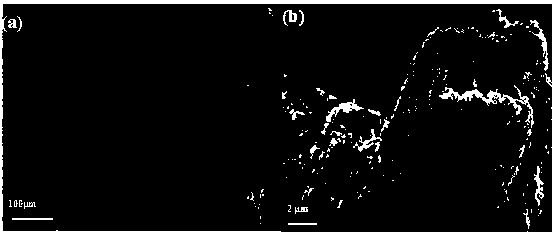

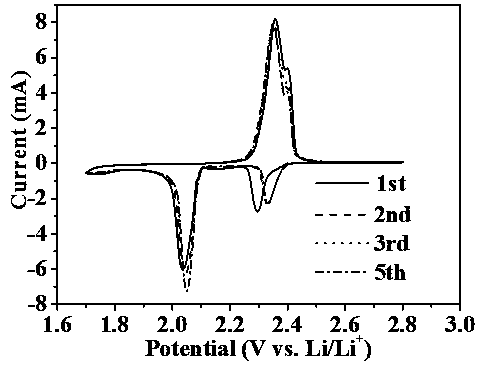

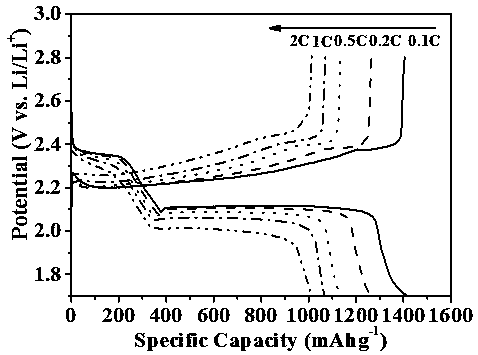

S@NPC/CNT composite material and preparation method and application thereof

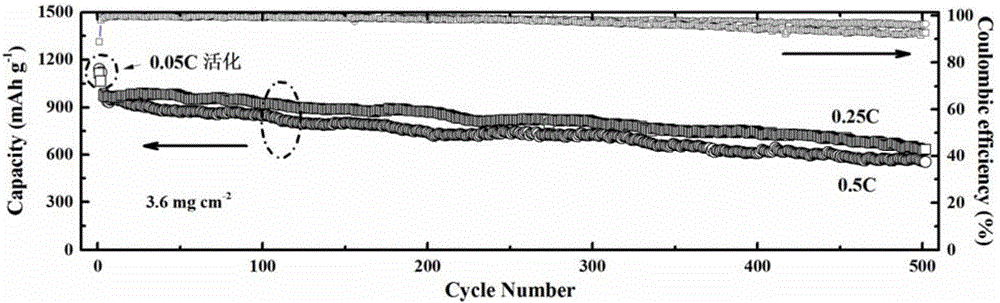

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

Multifunctional composite material based on graphene and polymer fibers and preparation method and application thereof

ActiveCN110323451AImprove thermal conductivityImprove conductivityPhysical/chemical process catalystsMagnetic/electric field screeningYarnFiber

The invention discloses a multifunctional composite material based on graphene and polymer fibers and a preparation method and application of the multifunctional composite material. A three-dimensional fiber conductive network product with the polarity-rich surface and the core-shell structure is prepared by taking the non-woven fabric as a framework, thereby inhibiting the shuttle effect in the sulfur positive electrode simultaneously, and alleviating the dendritic crystal growth problem of the lithium negative electrode so as to improve the whole performance of the lithium-sulfur battery. The lithium-sulfur battery can be used in the fields of electrocatalysis, microbial fuel cells, polymer electrode membrane electrolysis and metal-air batteries due to the characteristics of high conductivity and high specific surface area so as to provide the advantages. The composite film product is obtained by reinforcing the graphene sheet with the non-woven fabric fiber yarns, has flexibility and remarkable heat conduction, electric conduction and electromagnetic shielding properties, and can ensure safe and long-acting use of related electronic equipment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Lithium-sulfur battery using nitride/graphene as separation layers, and positive electrode and preparation method thereof

InactiveCN108630889AImprove conductivityMitigate the shuttle effectFinal product manufactureNon-aqueous electrolyte accumulator electrodesCvd grapheneLithium–sulfur battery

The invention discloses a lithium-sulfur battery using nitride / graphene as separation layers and a positive electrode and a preparation method thereof. The lithium-sulfur battery consists of a positive electrode, a diaphragm, an electrolyte and a negative electrode, wherein the positive electrode contains sulfur which is coated onto an aluminum foil; then, a layer of separation layer based on nitride / graphene is coated; due to the existence of the nitride and graphene in the separation layer; the conducting performance of the battery is improved; the diffusion of polysulfide can also be effectively inhibited, so that the shuttle effect can be effectively relieved; the electric chemical performance of the battery can be improved.

Owner:XI AN JIAOTONG UNIV

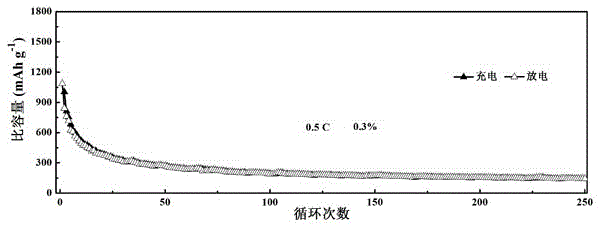

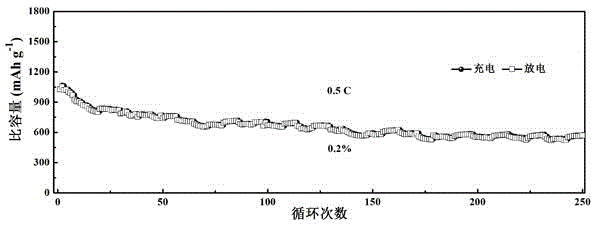

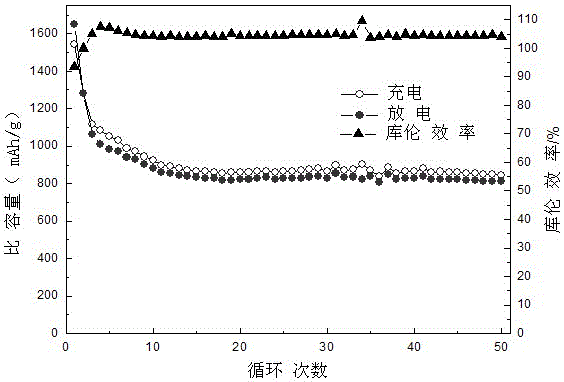

Lithium-sulfur battery

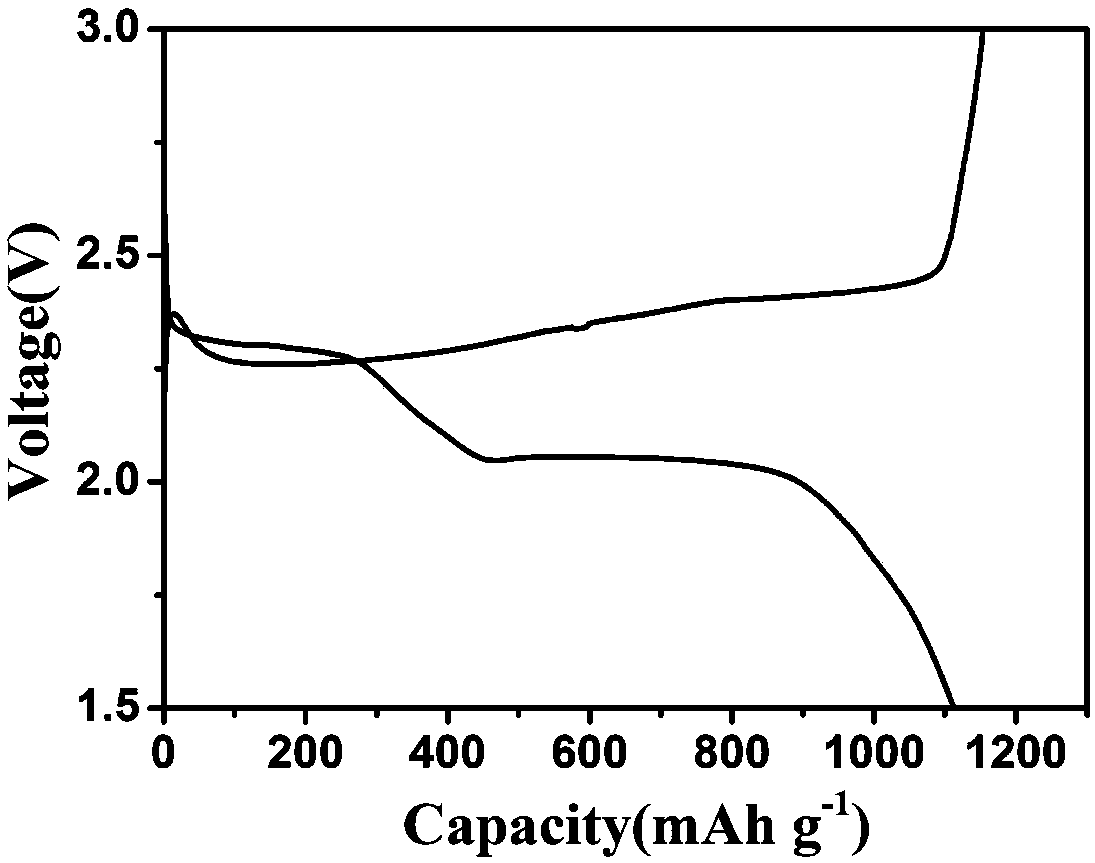

InactiveCN105529464AReduce Shuttle EffectImprove battery performanceCell seperators/membranes/diaphragms/spacersCell electrodesPolypropyleneCarbon nanotube

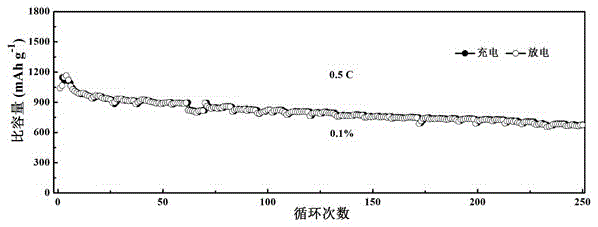

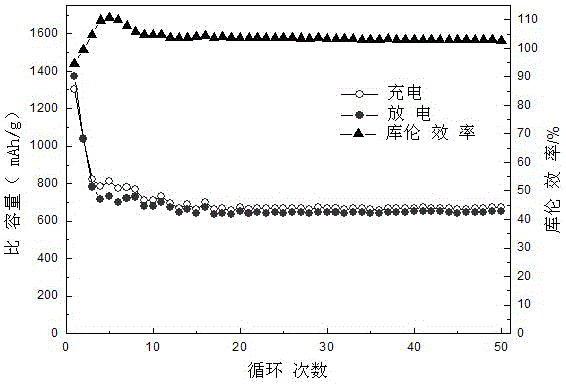

The invention discloses a lithium-sulfur battery. The lithium-sulfur battery is composed of a positive electrode material coating a current collector, a diaphragm, an interlayer, an electrolyte and a negative electrode material, wherein the positive electrode material is composed of a carbon / sulfur active material, a conductive agent and a binder; the diaphragm is a polypropylene diaphragm; the interlayer is a carbon nano tube paper or a carbon nano tube paper acidized by nitric acid; and the negative electrode material is a metallic lithium piece. When a current density is 0.5C(1C=1675mA.g<-1>), a first specific discharge capacity is 1039.9 mAh.g<-1>; after circulating 50 circles, the specific discharge capacity is 674.1 mAh.g<-1>, and an attenuation rate is only 0.1%.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method for boron-nitrogen-co-doped three-dimensional structured positive electrode material of lithium-sulfur battery

InactiveCN105609733AImprove conductivityImprove cycle lifeCell electrodesLi-accumulatorsDoped grapheneBoron atom

The invention provides a preparation method for a boron-nitrogen-co-doped three-dimensional structured positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps of (1), adding graphite oxide into water for performing ultrasonic processing to form a graphene oxide suspension liquid; (2), adding ammonium hydroxide to the graphene oxide suspension liquid, and then adding sodium borohydride to the graphene oxide suspension liquid to obtain three-dimensional boron-nitrogen-co-doped graphene; (3), adding the three-dimensional boron-nitrogen-co-doped graphene obtained in the step (2) and ketjen black into N-methyl pyrrolidone for performing an ultrasonic reaction to form a suspension liquid; (4), adding sulfur to the N-methyl pyrrolidone for performing an ultrasonic reaction until the elemental sulfur is fully dissolved to form a suspension liquid; and (5), mixing the two kinds of suspension liquid obtained in the step (4) and the step (3), and then adding distilled water to obtain the three-dimensional structured positive electrode material of the lithium-sulfur battery. Due to sulfur adsorption by the synergistic effects of boron atoms and nitrogen atoms in the boron-nitrogen-co-doped graphene, the shuttle effect is lowered, so that the cycling life of the lithium-sulfur battery is prolonged.

Owner:钟玲珑

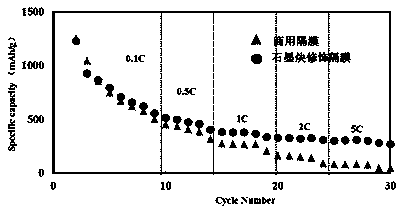

Preparation and application of graphdiyne material modified diaphragm

InactiveCN108963149ATightly boundImprove insulation defectsLi-accumulatorsCell component detailsChemistryIn situ polymerization

Belonging to the technical field of energy materials, the invention in particular relates to preparation and application of a graphdiyne material modified diaphragm. Directed at the problems of low electron conductivity, poor cyclic stability, the shuttle effect of lithium polysulfide and the like in existing lithium-sulfur battery diaphragms, solution in-situ polymerization is applied for deposition of a graphdiyne carbon nanomaterial on a commercial diaphragm. Preparation of the diaphragm mainly includes the steps of: preparation of a graphdiyne monomer serving as a carbon protective layer and deposition of a graphdiyne material in a solution on the surface of a commercial diaphragm. The graphdiyne material modified diaphragm prepared by the method has the characteristics of simple and controllable preparation process, easy large-scale preparation, stable material structure, etc. The prepared diaphragm can reduce the shuttle effect of polysulfides in the electrochemical reaction process, and improves the capacity and cycle performance of energy storage devices.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

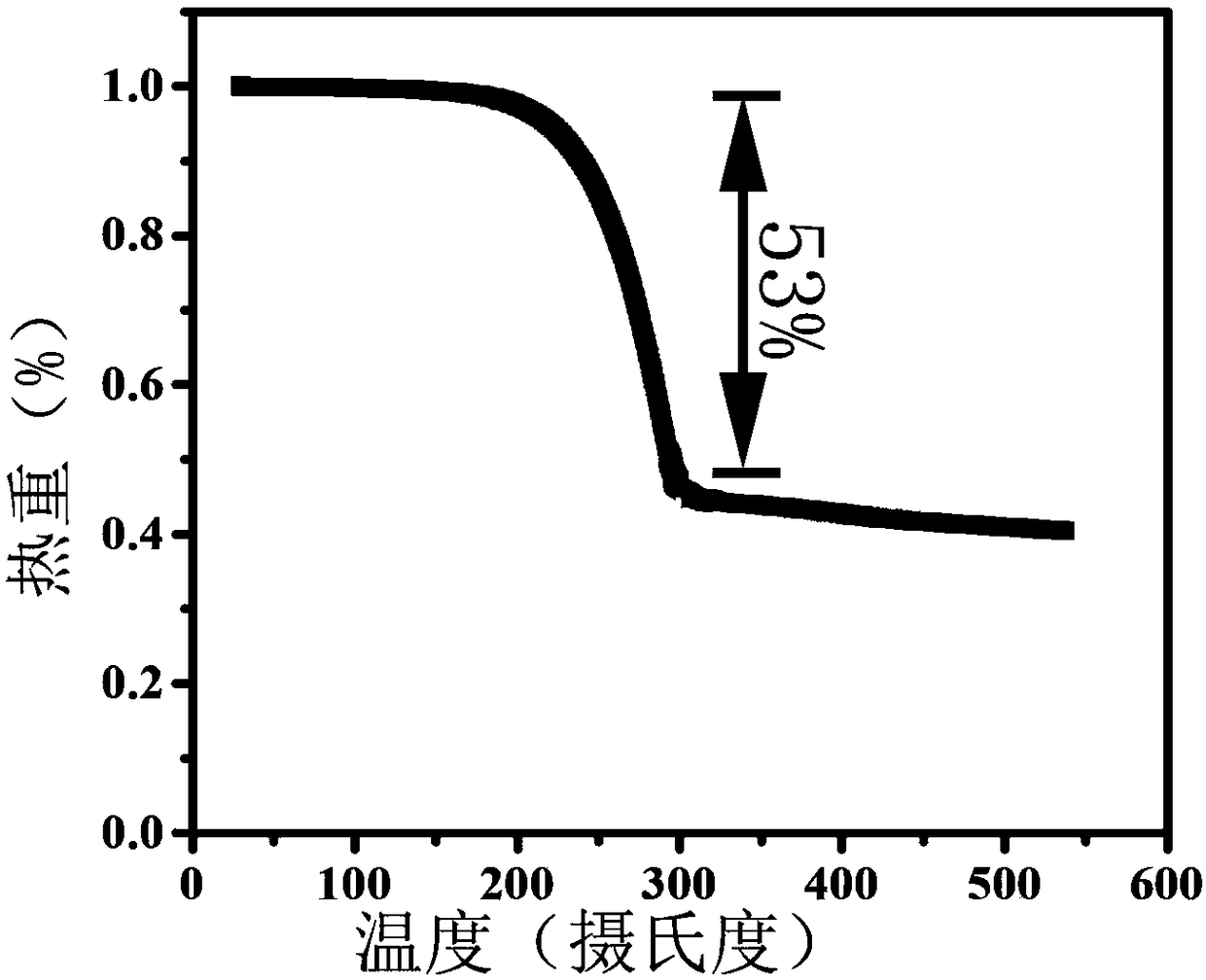

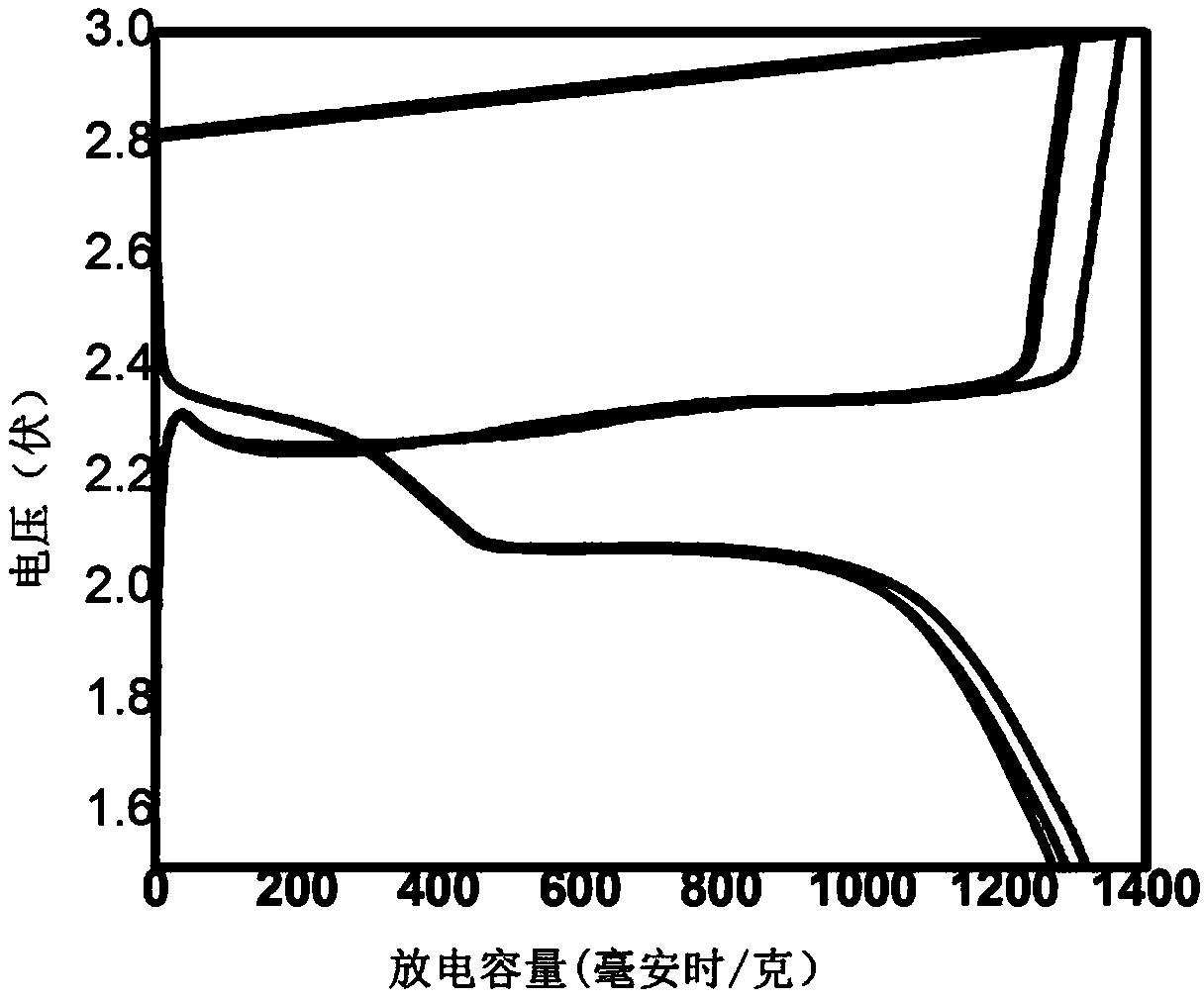

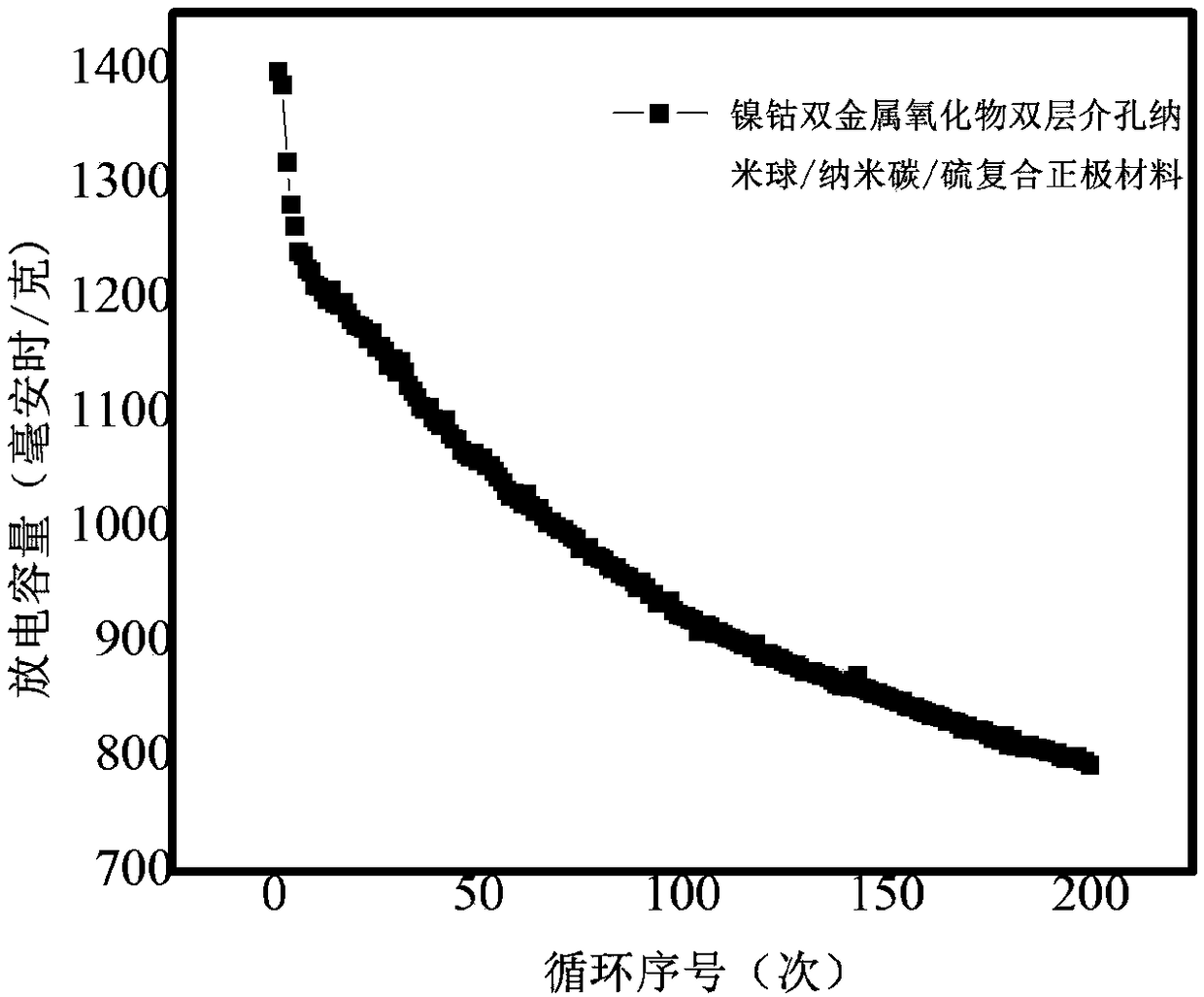

Preparation method of positive electrode material for lithium-sulfur battery

ActiveCN108172797AAlleviate volume expansionImprove cycle stabilityMaterial nanotechnologyCell electrodesMicrosphereCurrent technology

The invention discloses a preparation method of a positive electrode material for a lithium-sulfur battery. The method comprises the following steps of (1) preparing monodisperse polystyrene microspheres through a dispersion polymerization method; (2) preparing hollow silica microspheres; (3) synthesizing bimetallic oxide double-layer nano mesoporous microspheres; and (4) preparing a nickel-cobaltbimetallic oxide double-layer nano mesoporous microspheres / nano carbon / sulfur composite positive electrode material. Through a process of doping with nano sulfur and nano carbon black through ball-milling and hot melting methods, the nano carbon black is mixed in the sulfur doping process, so that the defects that the positive electrode material for the lithium-sulfur battery in the prior art islow in sulfur load, obvious in volume expansion effect and unstable in electrochemical properties are overcome.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

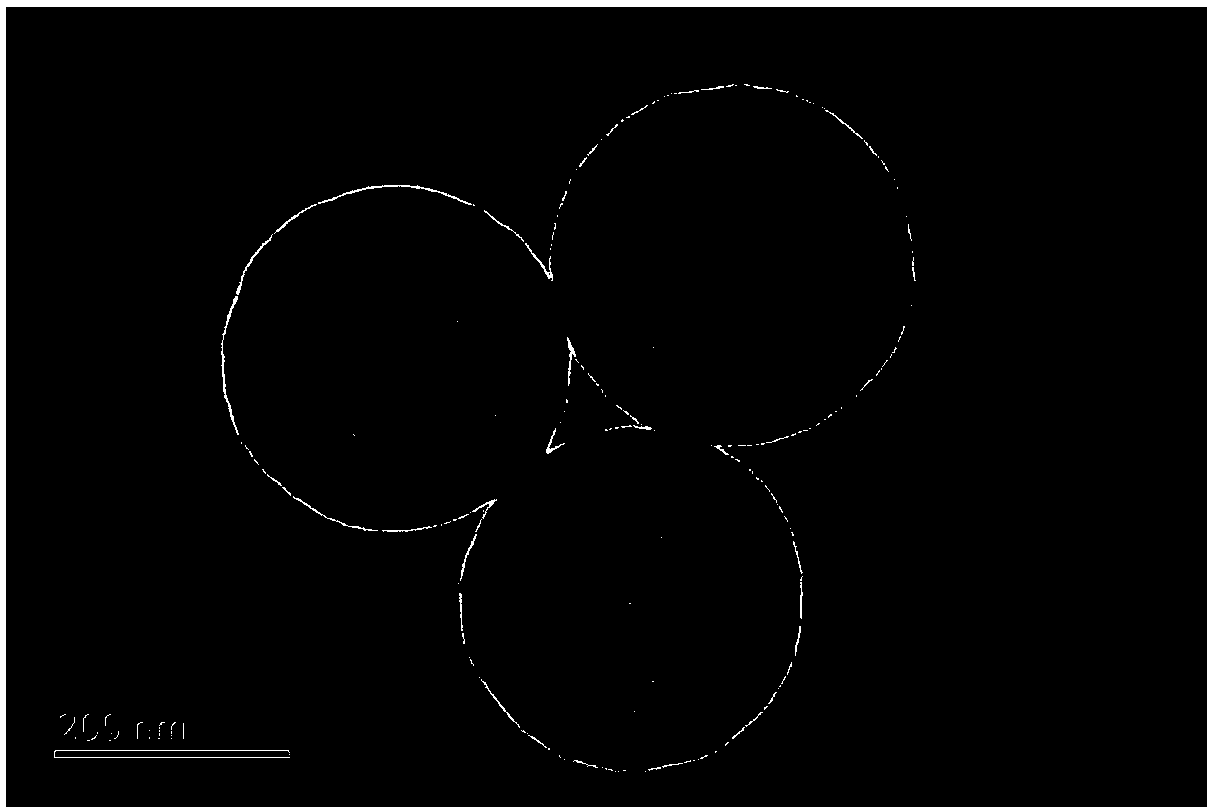

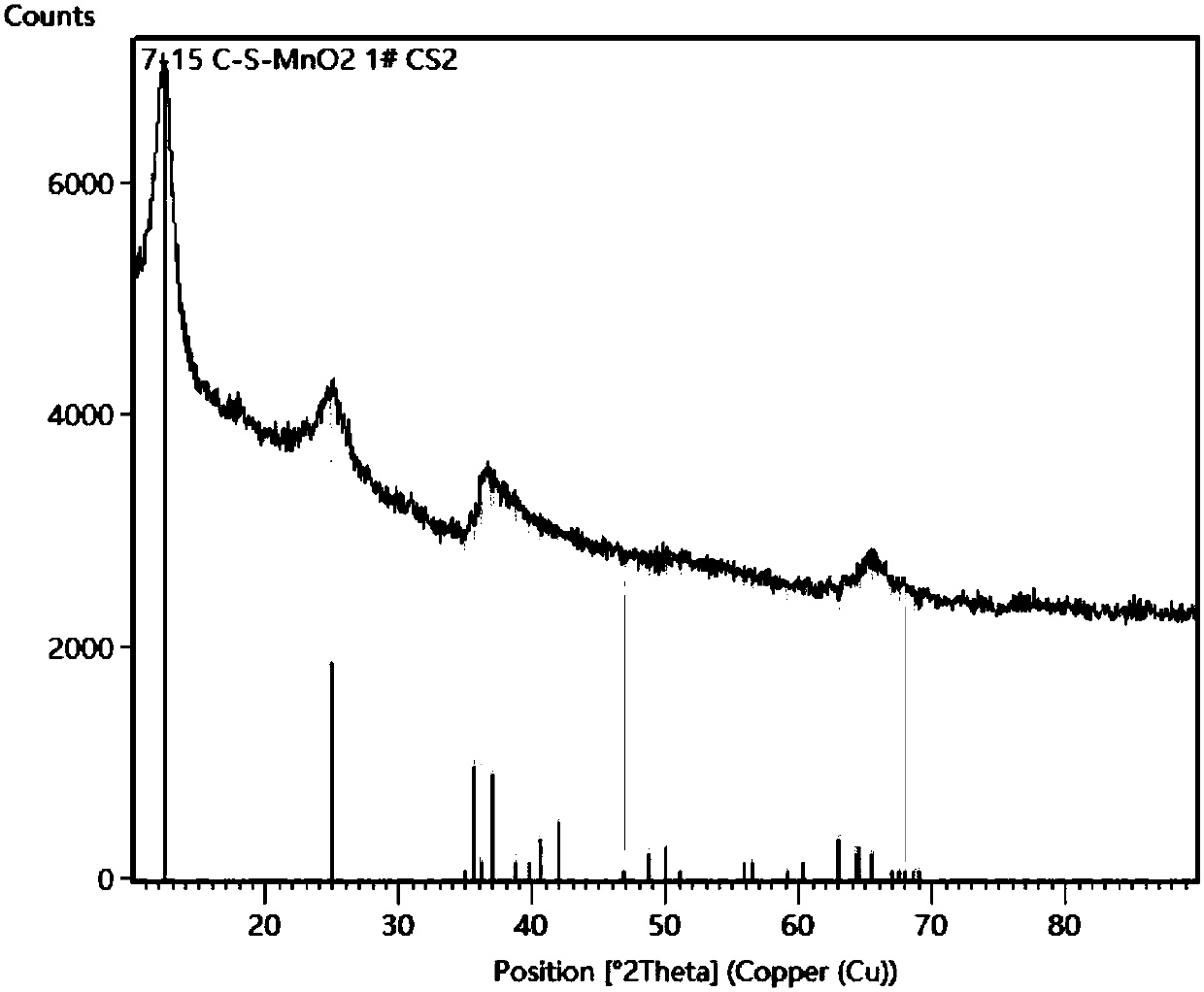

Hollow carbon-sulfur positive electrode composite material coated with flaky manganese dioxide and preparation and application thereof

InactiveCN109841805AUniform shapeParticle size controllableCell electrodesLi-accumulatorsCarbon layerChemical adsorption

The invention provides a hollow carbon-sulfur positive electrode composite material coated with flaky manganese dioxide and preparation and application thereof. The carbon and sulfur composite material coated with the manganese dioxide has a carbon content of 10% to 30% and a manganese dioxide content of 10% to 30%, a sulfur content of 40% to 80%, wherein the manganese dioxide is a sheet-like structure and is tightly wrapped on the outer surface of the hollow carbon-sulfur composite material, and the sulfur is mainly distributed in hollow carbon ball cavities and carbon layer mesopores. Hollowcarbon balls with mesoporous structures are prepared with a one-step method with tetraethyl orthosilicate as a silicon source and resorcinol and formaldehyde as carbon sources, the method is simple,the process is controllable, and the carbon balls are uniform in particle size. The manganese dioxide of the sheet-like structure is subjected to thermal processing and is coated, the hollow carbon balls provide sufficient space for carrying the sulfur, the rich point-to-point contact between the carbon balls can ensure rapid electron transfer, sheet-like manganese dioxide coating layers at the surfaces of the carbon balls have strong chemical adsorption on polysulfides, the 'shuttle effect' is effectively alleviated, and the cycle stability and rate performance of the battery are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

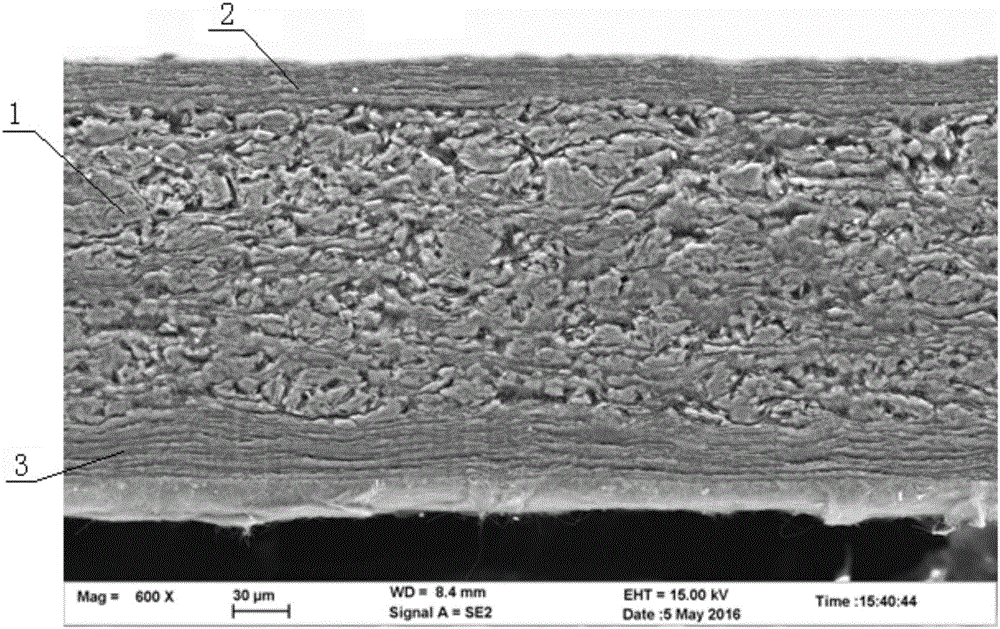

Electrode of lithium sulfur battery and preparation method thereof

InactiveCN106058150ALarge specific surface areaImprove conductivityNon-aqueous electrolyte accumulator electrodesFiberPorosity

The invention discloses an electrode of a lithium sulfur battery and a preparation method thereof. The electrode of the lithium sulfur battery includes an active substance layer containing sulfur, and conductive hydroxyl or carboxyl layers are formed on the upper surface and the lower surface of the active substance layer respectively; the active substance layer and the conductive hydroxyl are combined, or the active substance layer and the conductive carboxyl layers are combined, through external pressure, a surface substance of the active substance layer generates cross-linking interaction and hydrogen bond interaction with a fiber component of the conductive hydroxyl or carboxyl layers. The hydroxyl or carboxyl layers have high specific surface area, can adsorb polysulfide and inhibit a back-and-forth shuttling effect. The three-layer electrode structure has higher porosity, can store more electrolyte liquids, is conducive to slow down dissolution of sulfur and polysulfide, thereby ensuring occurrence of positive electrode reactions and improving the discharge capacity of the battery. Increase of the electrolyte liquid viscosity due to dissolution of the sulfur and polysulfide is also effectively alleviated. The preparation method is simple, and is easy to popularize and apply.

Owner:柔电(武汉)科技有限公司

Preparation method of three-dimensional sulfur-doped graphene/sulfur composite material electrode slice

The invention provides a preparation method of a three-dimensional sulfur-doped graphene / sulfur composite material electrode slice. The preparation method comprises the following steps of step (1) mixing and grinding graphite oxide and benzene disulfide, then placing in a nitrogen protection muffle furnace for reacting, and naturally cooling to room temperature after reaction to obtain sulfur-doped graphene; step (2) adding polyacrylonitrile, the sulfur-doped graphene and graphite oxide into N-methyl pyrrolidone, performing ultrasonic reaction, then coating an aluminum foil with mixed slurry, and drying to obtain an electrode slice; step (3) placing the obtained electrode slice into a muffle furnace protected by inert gas, slowly heating to 400 to 500DEG C, and naturally cooling; step (4) completely inserting the electrode slice obtained in the step (3) into a Na2S2O3 solution, slowly dripping hydrochloric acid into the solution, and drying to obtain a positive electrode slice. The electrode slice prepared by the preparation method provided by the invention can be directly used for a cathode of a lithium sulfur battery without adding any conductive agent and bonding agent, so that the cost of the electrode is greatly reduced.

Owner:钟玲珑

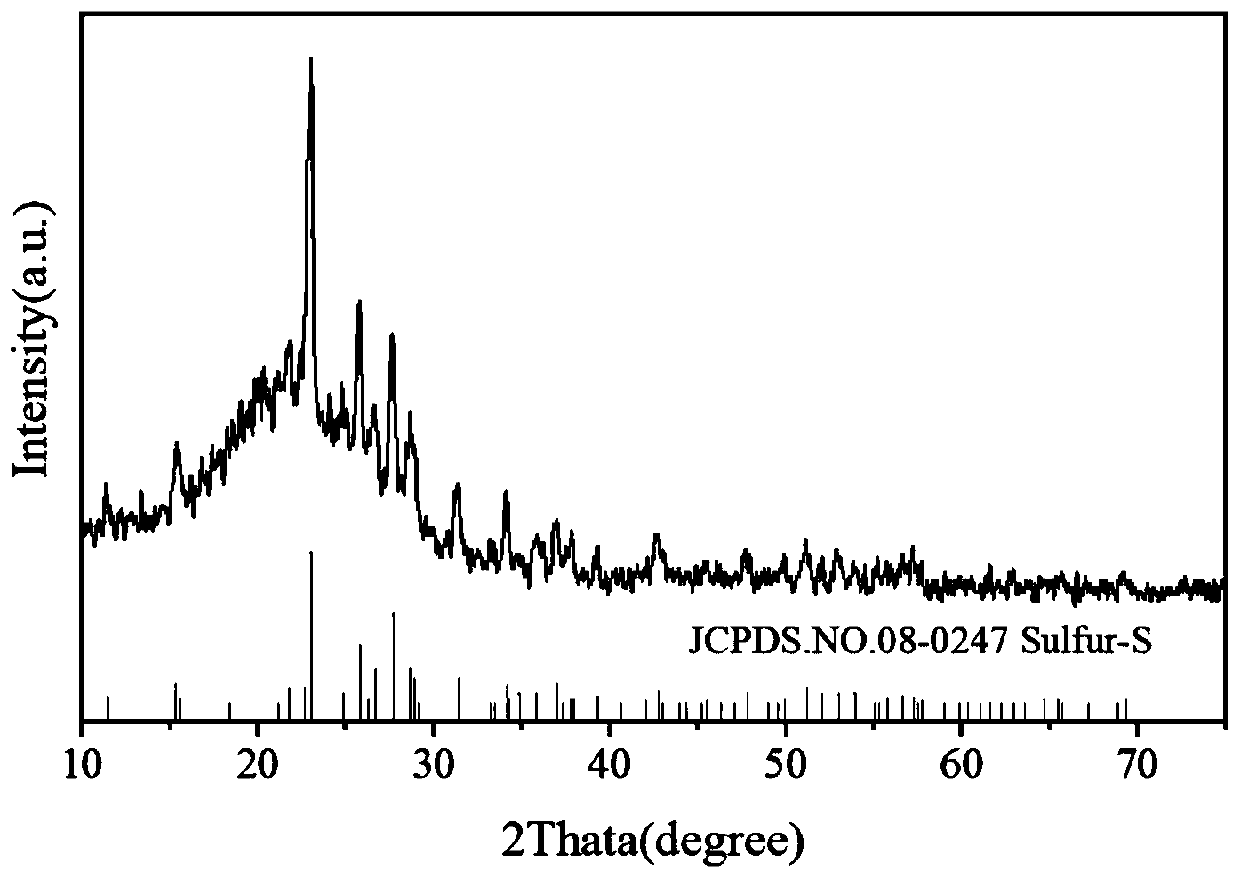

Method for preparing lithium-sulfur battery positive pole material

InactiveCN105047882AImprove conductivityHigh specific capacityCell electrodesLithium–sulfur batterySulfur

The invention discloses a method for preparing a lithium-sulfur battery positive pole material. Graphite oxide is prepared through the Hummers method, graphene dispersion liquid is obtained through chemical reduction, graphene / nano metallic oxide / nano sulfur mixed dispersion liquid is subjected to fast cooling, curing, freezing, drying and thermal treatment, and a nano metallic oxide / nano sulfur composite material where graphene is wound is prepared and serves as the lithium-sulfur battery positive pole material. Nano sulfur particles are evenly attached to the surface of the graphene, and the utilization rate of active substances is greatly increased through sulfur in the nano size. The graphene of a wound structure can effectively inhibit graphene agglomeration between lamellas. Besides, the electrical conductivity of the composite material is greatly increased due to good conductivity of the graphene, the hole structure in the composite material can effectively inhibit dissolution of intermediate products in the charging and discharging processes, and the material presents the high specific capacity and good cycling stability. The method has the advantages that operation is easy, cost is low and large-scale production is easy.

Owner:HARBIN INST OF TECH

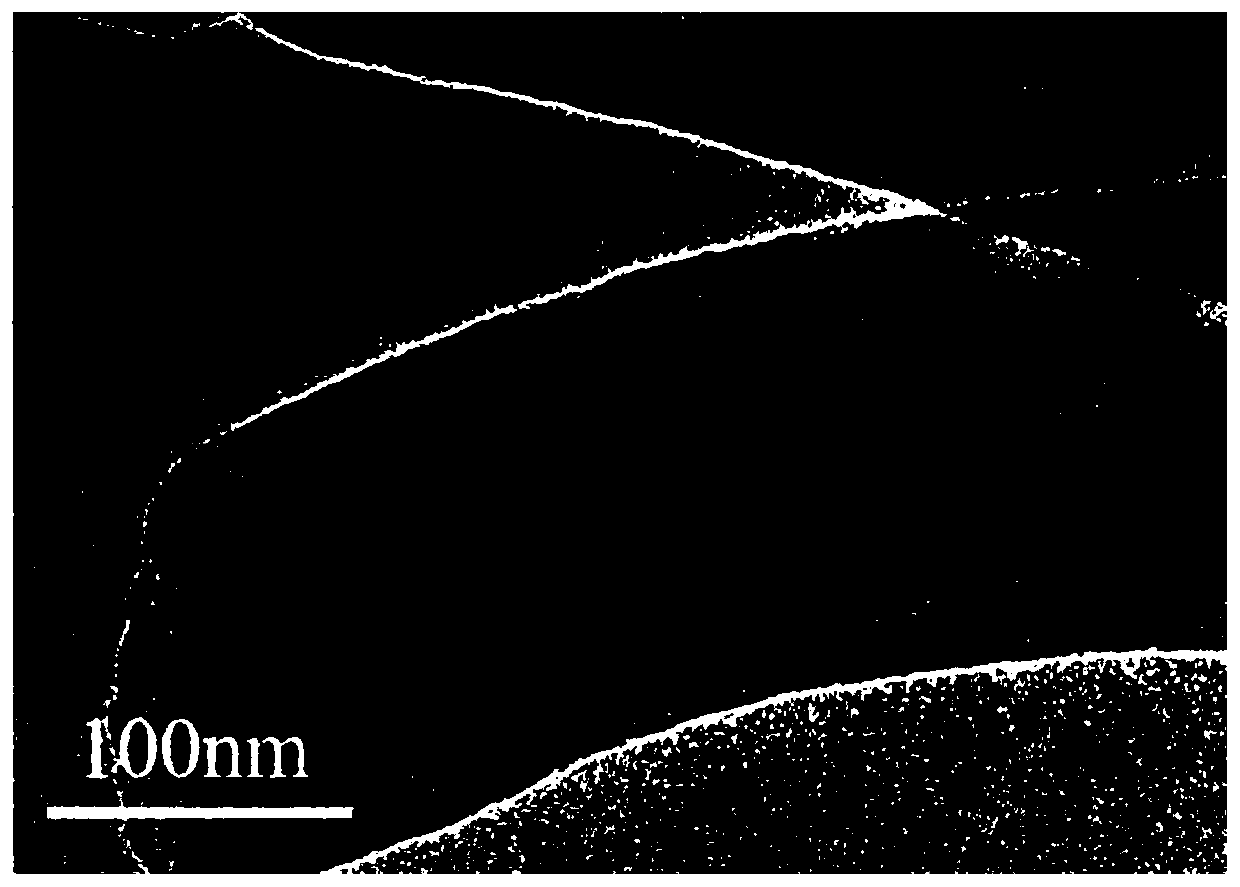

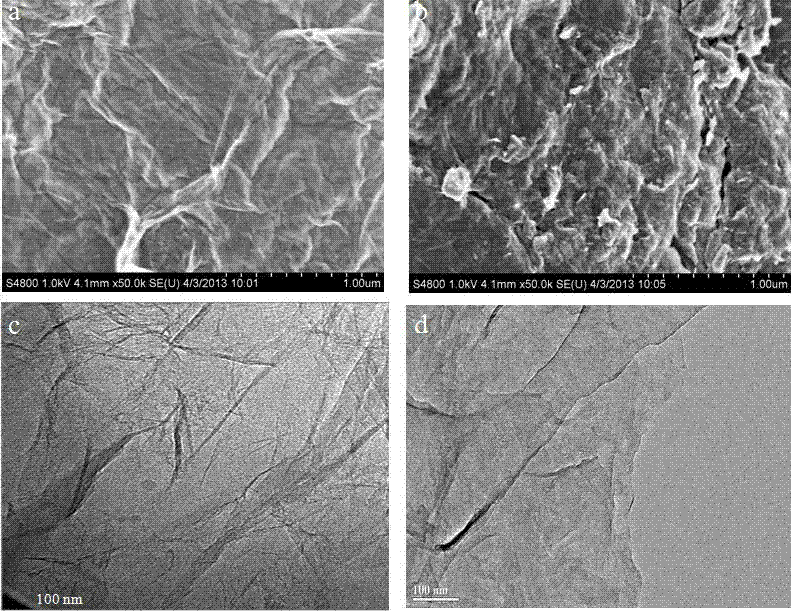

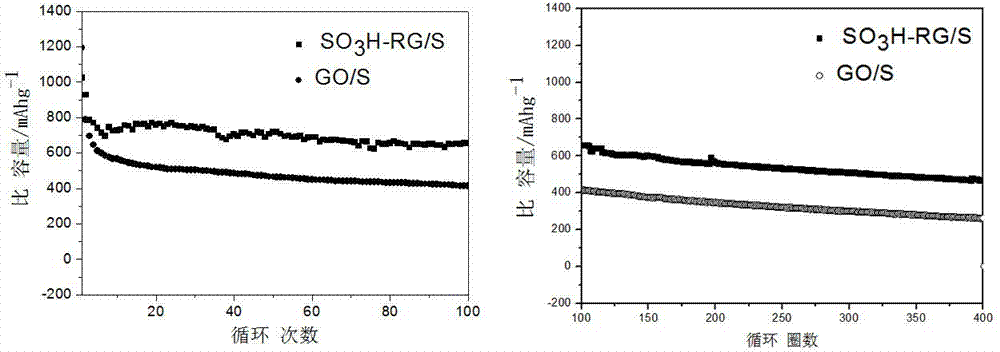

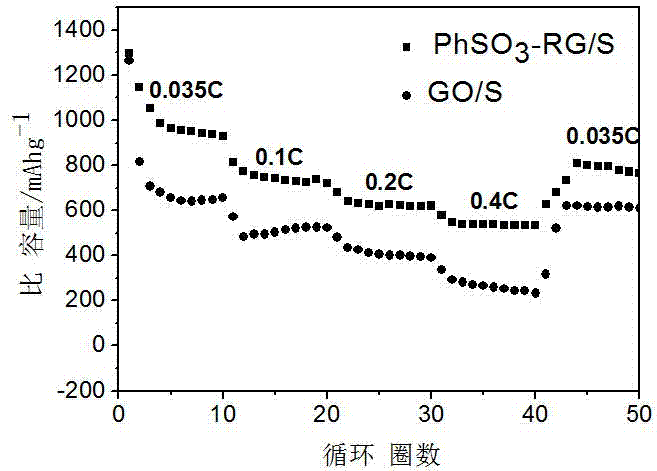

Additive-free sulfonated graphene/sulfur electrode slice and preparation method and application thereof

InactiveCN103682349AImprove conductivityIncrease stickinessLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentElectrical battery

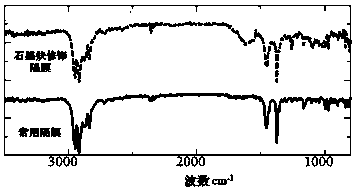

The invention belongs to the technical field of lithium sulfur batteries and particularly relates to an additive-free sulfonated graphene / sulfur electrode slice and a preparation method and application thereof. The preparation method comprises the following steps: firstly, modifying graphene oxide to obtain sulfonated graphene with good water solubility and electrical conductivity; dispersing the sulfonated graphene in a sodium thiosulfate solution, adding a sulfuric acid solution and forming a sulfonated graphene / sulfur compound through a disproportionation reaction; carrying out size mixing on the compound through taking absolute ethyl alcohol as a solvent and coating a carbon-coated aluminum foil with the size to obtain the electrode slice which is applied to positive electrodes of the lithium sulfur batteries. The preparation method disclosed by the invention is simple in process and good in reproducibility; the raw material has excellent electrical conductivity and a certain viscosity, so that conductive carbon black and binder are not needed in the manufacturing of the electrode slice and the volume energy density of the positive electrode materials of the lithium sulfur batteries can be greatly increased; in addition, generated intermediate products can be prevented from being diffused into electrolyte, so that the shuttle effect is reduced, and the cycle performance and the rate performance of the lithium sulfur batteries are increased.

Owner:FUDAN UNIV

Process for preparing lithium sulfur battery modified anode

The invention relates to a preparation for a lithium sulfur battery modified anode material. The preparation includes mixing sublimed sulfur and a conductive agent according to a mass ratio of 6:3, adding absolute ethyl alcohol, performing ball milling for 6 hours, drying in a vacuum drying box for 12 hours at the temperature of 50 DEG C to 80 DEG C to obtain a mixture, mixing the mixture and hollow nickel fiber tubes according to a mass ratio of (5-9):1, adding an adhesive, dispersing in a dispersing agent, stirring to obtain slurry, coating the slurry on a metal aluminum foil which is subjected to acetone ultrasonic cleaning, and drying in the vacuum drying box for 12 hours at the temperature of 60 DEG C to obtain the lithium sulfur battery anode material. The preparation for the lithium sulfur battery modified anode material has the advantages that electrochemistry performances of battery cyclicity and the like are improved, and the performances and cyclic service life of the battery can be improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Self-supporting functional interlayer for lithium sulfur battery and preparation method of self-supporting functional interlayer

The invention relates to a functional interlayer for a lithium sulfur battery and a preparation method of the functional interlayer. MAX phase ceramic powder is adopted as a raw material, nitrogen-doped MXene is prepared firstly and then hydrothermal reaction is carried out to prepare a nitrogen-doped MXene composite copper sulfide self-supporting film. According to the preparation method, a preparation process of the functional interlayer is simplified, and meanwhile, a problem that effective components are crushed and fall off from a diaphragm during a battery circulation process after coating in a traditional method is also avoided. The nitrogen-doped MXene composite copper sulfide self-supporting film is used as the functional interlayer of the lithium sulfur battery and has the characteristics of good electrical conductivity, large specific surface area, multiple storage sites and high rate performance, the lithium polysulfide can be adsorbed, and the loss of active substances canbe effectively reduced.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

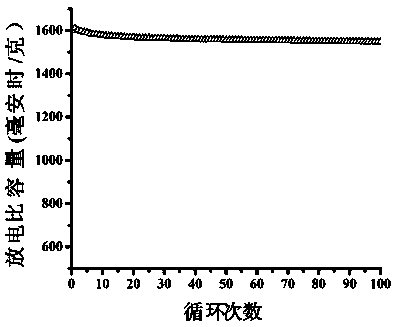

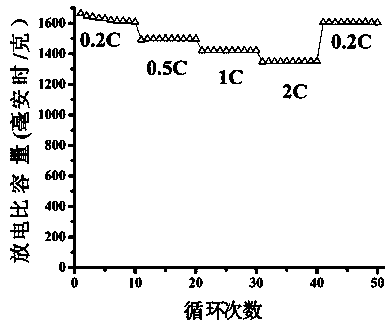

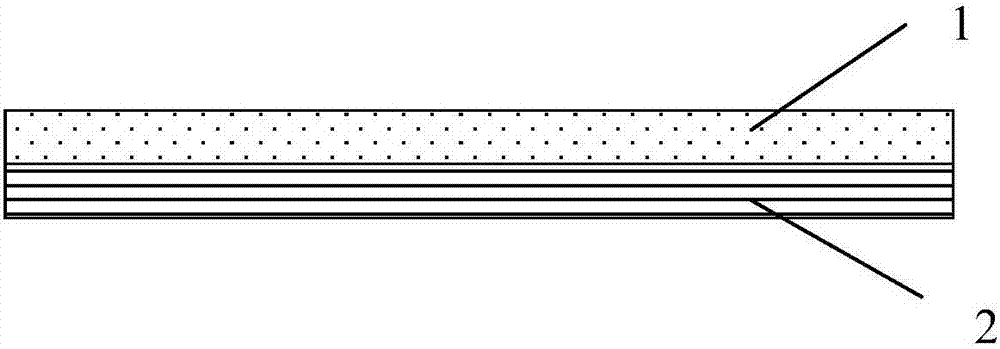

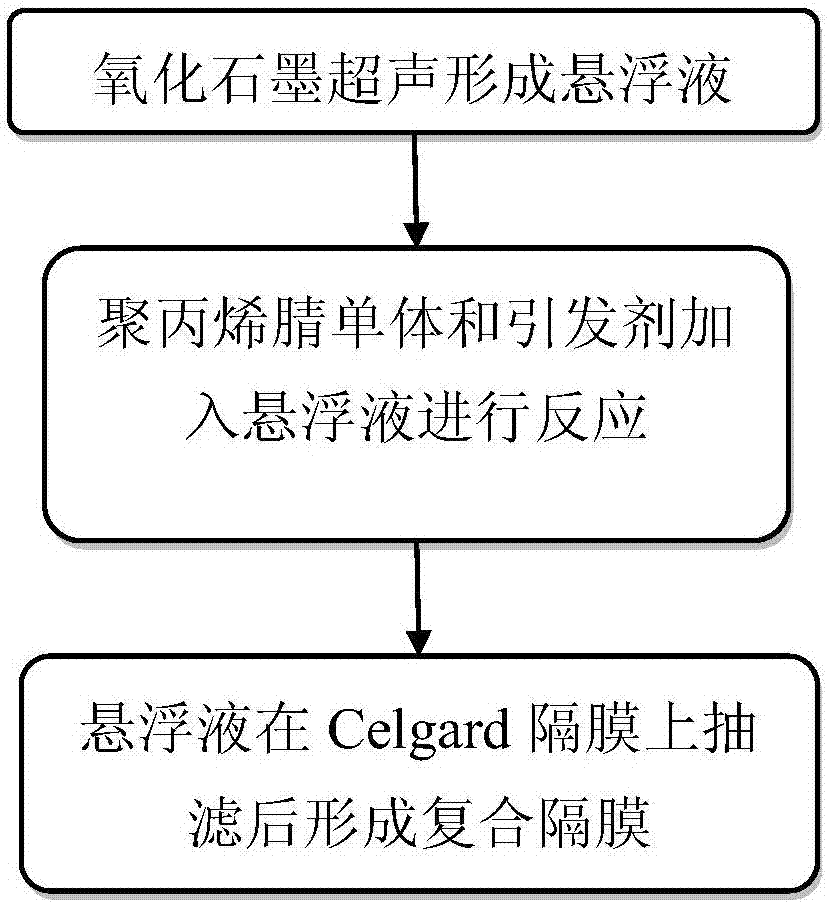

Preparation method of lithium-sulfur battery composite separator

InactiveCN107068945AStop passingExtend your lifeCell component detailsMicrometerLithium–sulfur battery

The invention provides a preparation method of a lithium-sulfur battery composite separator. The lithium-sulfur battery composite separator comprises a commercial Celgard separator and a polyacrylonitrile / graphene oxide layer, wherein the polyacrylonitrile / graphene oxide layer is arranged on a surface of the commercial Celgard separator, the thickness of the polyacrylonitrile / graphene oxide layer is 1-10 micrometers, and the mass ratio of polyacrylonitrile and graphene oxide in the polyacrylonitrile / graphene oxide layer is (0.2-1):1. A Nitrile group on the polyacrylonitrile in the polyacrylonitrile / graphene oxide layer and oxygen on a surface of the graphene oxide are both strong polar groups, high chemical absorption can be formed on a polysulfide which is formed during the charge-discharge process, the polysulfide can be effectively prevented from penetrating through the separator to reach a negative electrode, a shuttle flying effect is reduced, and the lifetime of a lithium-sulfur battery is prolonged.

Owner:SHENZHEN PEICHENG TECH CO LTD

Preparation method of positive electrode material of lithium sulfur battery

ActiveCN108172795ASimple preparation processImprove cycle performanceMaterial nanotechnologyCell electrodesDoped grapheneOxygen

The invention discloses a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps of putting graphene oxide, nanometer sulfur powder, boric acid and urea into a ball milling tank, performing ball milling and then adding into deionized water to obtain a mixture solution, performing ultrasonic wave dispersion at a normal temperature for 1-3h to obtain a mixed suspension liquid, and carrying out a spray drying process to prepare a boron nitrogen oxygen co-doped graphene / sulfur composite three-dimensional structured positive electrode material of the lithium sulfur battery. The boron nitrogen oxygen co-doped graphene / sulfur compound obtained in the invention has a simple and convenient preparation process; and through the simple spray drying process, the loosening and porous structure is manufactured, a relatively large specific surface area is obtained, and performance for bearing a large amount of elementary nanometer sulfur powder is further achieved, thereby improving the sulfur content of the positive electrode material.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Lithium-sulfur battery composite positive electrode material and preparation method thereof

InactiveCN106532016ASimple methodNo complicated operationsCell electrodesLead zirconate titanateBarium titanate

The invention discloses a lithium-sulfur battery composite positive electrode material. Graphene oxide is used as a matrix of the battery positive electrode material, a graphene / ferroelectric composite material is obtained after the graphene oxide and a ferroelectric material are compounded, and then the graphene / ferroelectric composite material is mixed with nano sulfur according to a mass ratio of 3:7 to prepare the lithium-sulfur battery composite positive electrode material; and the ferroelectric material is one of barium titanate, lead titanate, potassium niobate, strontium titanate, lithium niobate or lead zirconate titanate. According to the lithium-sulfur battery composite positive electrode material disclosed by the invention, excellent electrical conductivity and structural stability of the graphene oxide are utilized, and the graphene oxide is used as an excellent conductive network and the positive electrode matrix, so that electrical conductivity of the positive electrode material is improved; and by utilizing strong adsorption of ferroelectricity of the ferroelectric material on polar polysulfide, dissolution and shuttling of the polysulfide in electrolyte are inhibited, so that loss of active substances is reduced, coulombic efficiency of a lithium-sulfur battery is improved and a cycle life of the lithium-sulfur battery is prolonged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

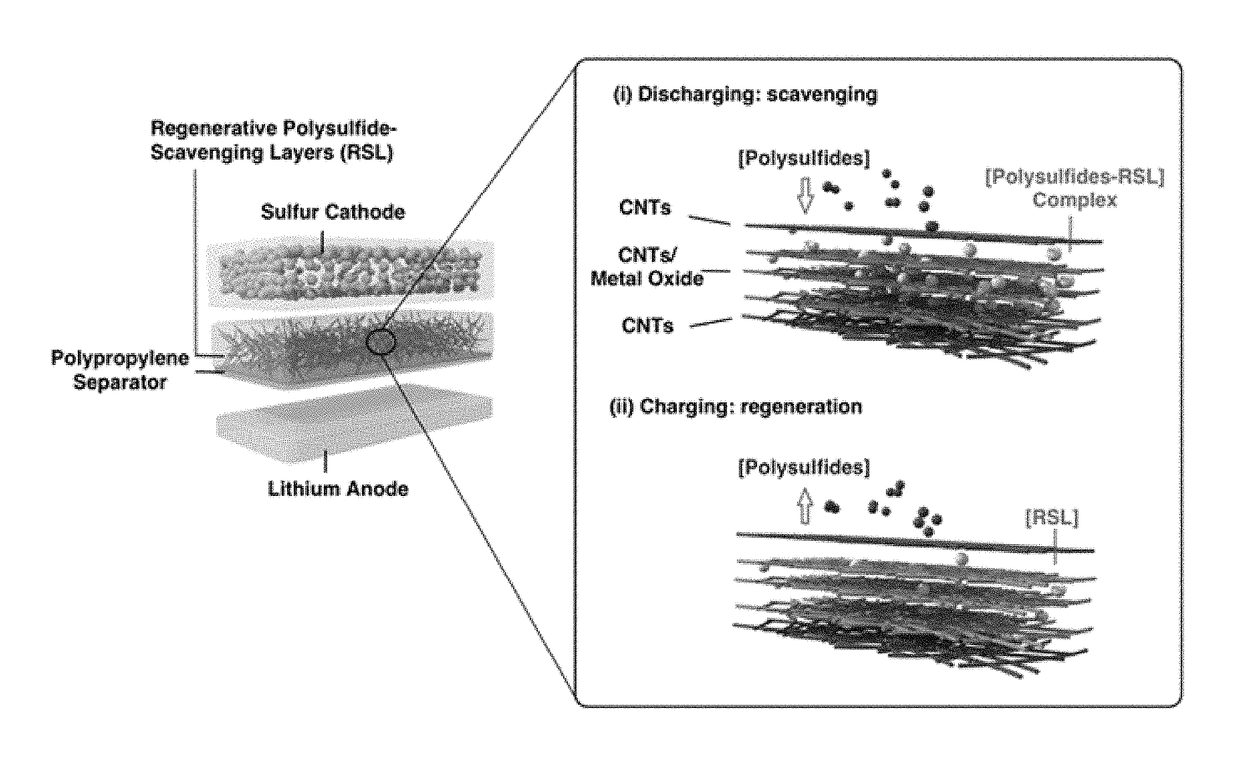

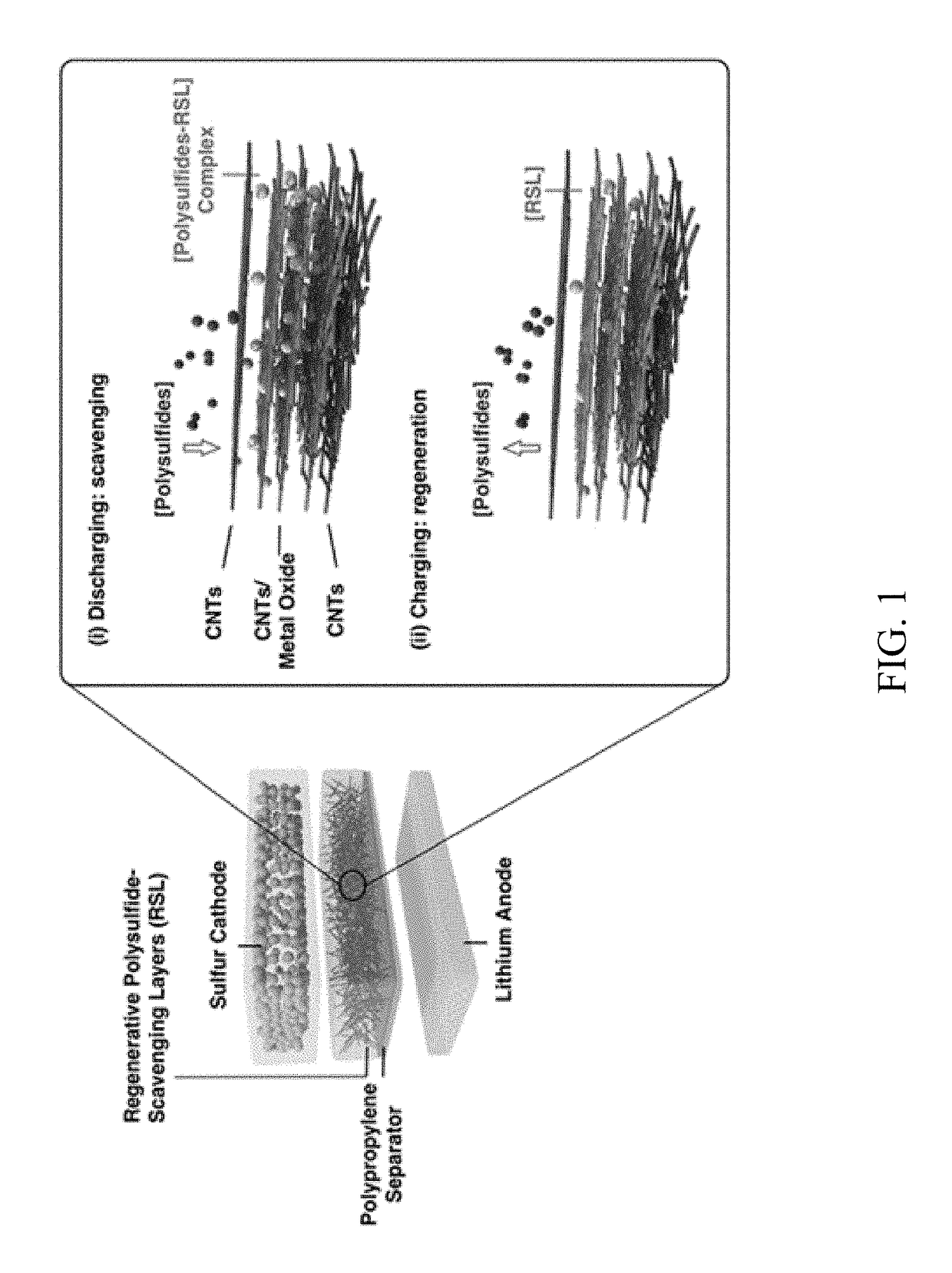

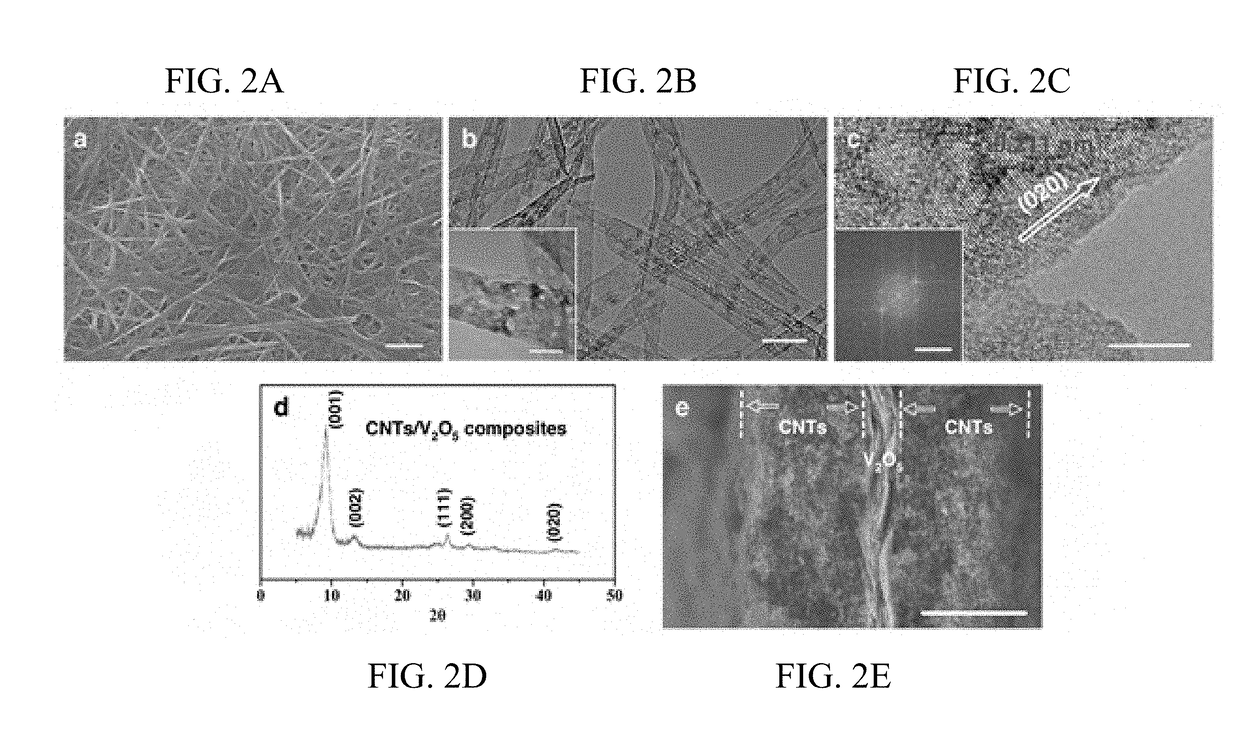

Regenerative polysulfide-scavenging layers enabling lithium-sulfur batteries with high energy density and prolonged cycling life and methods of making same

ActiveUS20180241039A1Increase energy densityLow costFinal product manufactureElectrolyte/reactants regenerationNanowireLithium–sulfur battery

The invention relates to a method for fabricating a regenerative polysulfide-scavenging layer (RSL). The method includes embedding nanowires or nanocrystals of metal oxides with a membrane of carbon nanotubes (CNTs); and forming the RSL with the embedded nanowires or nanocrystals of the metal oxides and the membrane, so as to enable lithium-sulfur batteries with high energy density and prolonged cycling life. The invention also relates to a lithium-sulfur battery that contains the RSL.

Owner:FORD CHEER INT +1

Carbon aerogel-loaded selenium composite material and preparation method thereof, and lithium/sodium selenium cell

InactiveCN109755548AGuaranteed performanceReduce Shuttle EffectCell electrodesLi-accumulatorsLithiumSulfur

The invention provides a carbon aerogel-loaded selenium composite material, which comprises carbon aerogel and active substances loaded in micropores of the carbon aerogel, wherein the active substances are selected from one or more of sulfur, selenium particles and selenium sulfide particles. According to the carbon aerogel-loaded selenium composite material, the adsorption property of the porousstructure of the carbon aerogel to limit the active substance particles in the porous structure of the carbon aerogel, thereby significantly reducing the shuttle effect of a polyselenide. Meanwhile,the method is easy and convenient to implement, easy to implement and has the feasibility of industrial production; and no impurities are generated in the composite material synthesis process, thus ensuring the comprehensive performance of the composite material.

Owner:UNIV OF SCI & TECH OF CHINA

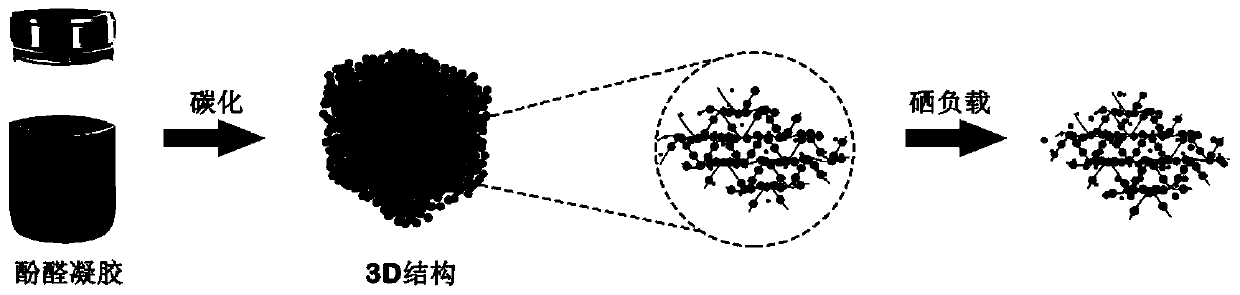

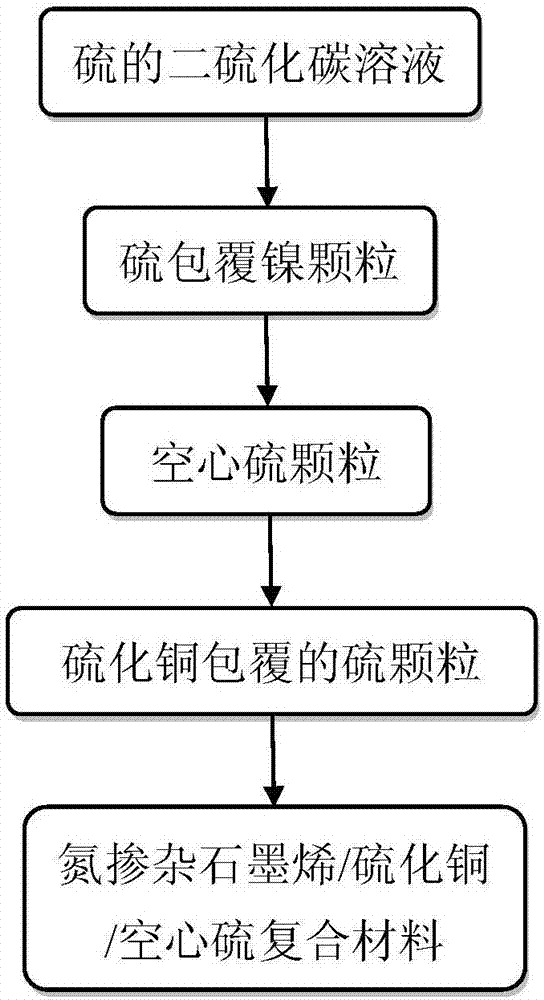

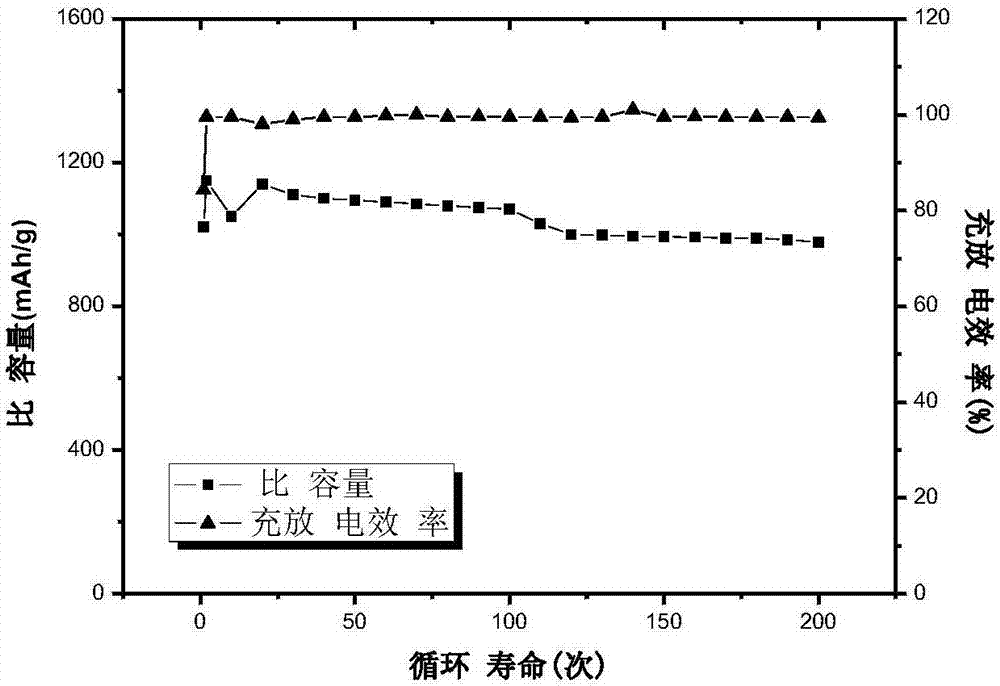

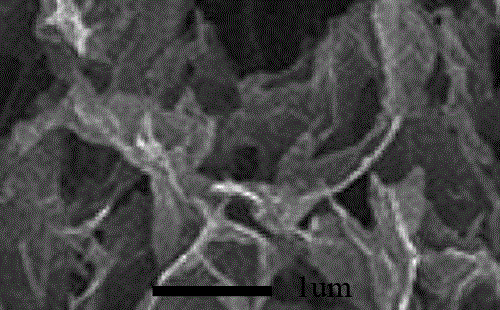

Preparation method of nitrogen-doped graphene/copper sulfide/hollow sulfur composite material

ActiveCN106972161AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesHigh energySpherical shaped

The invention discloses a preparation method of a nitrogen-doped graphene / copper sulfide / hollow sulfur composite material. The preparation method comprises the following steps: step (1), adding powdered sulfur into carbon dioxide, stirring and dissolving to form a uniform solution; step (2), ball-milling high-purity nickel powder through a high-energy ball grinding mill, adding the high-purity nickel powder after ball-milling into the solution, stirring to form uniform suspension liquid, mechanically stirring, and carrying out spray drying to form sulfur clad spherical particles; step (3), adding the spherical particles into a ferric chloride solution, stirring for reaction, washing and filtering; and step (4), adding a filtered precipitate into a solution containing copper chloride, thioacetamide and a surface active agent, stirring to form uniform suspension liquid, heating and stirring for reaction, centrifuging and washing to obtain copper sulfide clad sulfur particles. In the composite material, a space is reserved for the volume expansion, in the charging and discharging process, of sulfur material through the design of a hollow structure, so that the electrochemical performance can be effectively improved.

Owner:常熟东南高新技术创业服务有限公司

Preparation method for three-dimensional nitrogen-doped positive electrode material of lithium-sulfur battery

InactiveCN105609734AImprove conductivityImprove cycle lifeCell electrodesLi-accumulatorsDoped grapheneNitrogen doped graphene

The invention provides a preparation method for a three-dimensional nitrogen-doped positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps of (1), adding graphite oxide into water for performing ultrasonic processing to form a graphene oxide suspension liquid; (2), adding ammonium hydroxide to the graphene oxide suspension liquid to obtain three-dimensional nitrogen-doped graphene; (3), adding the three-dimensional nitrogen-doped graphene obtained in the step (2) and ketjen black into N-methyl pyrrolidone for performing an ultrasonic reaction to form a suspension liquid; (4), adding ammonium hydroxide to the graphene oxide suspension liquid, and adding elemental sulfur to the N-methyl pyrrolidone for performing an ultrasonic reaction until the elemental sulfur is fully dissolved to form a suspension liquid; and (5), mixing the two kinds of suspension liquid obtained in the step (4) and the step (3), uniformly stirring, and slowly adding distilled water while stirring to obtain the three-dimensional structured positive electrode material of the lithium-sulfur battery. Due to sulfur adsorption by nitrogen atoms in the nitrogen-doped graphene, the shuttle flying effect can be effectively lowered, so that the cycling life of the lithium-sulfur battery is prolonged.

Owner:钟玲珑

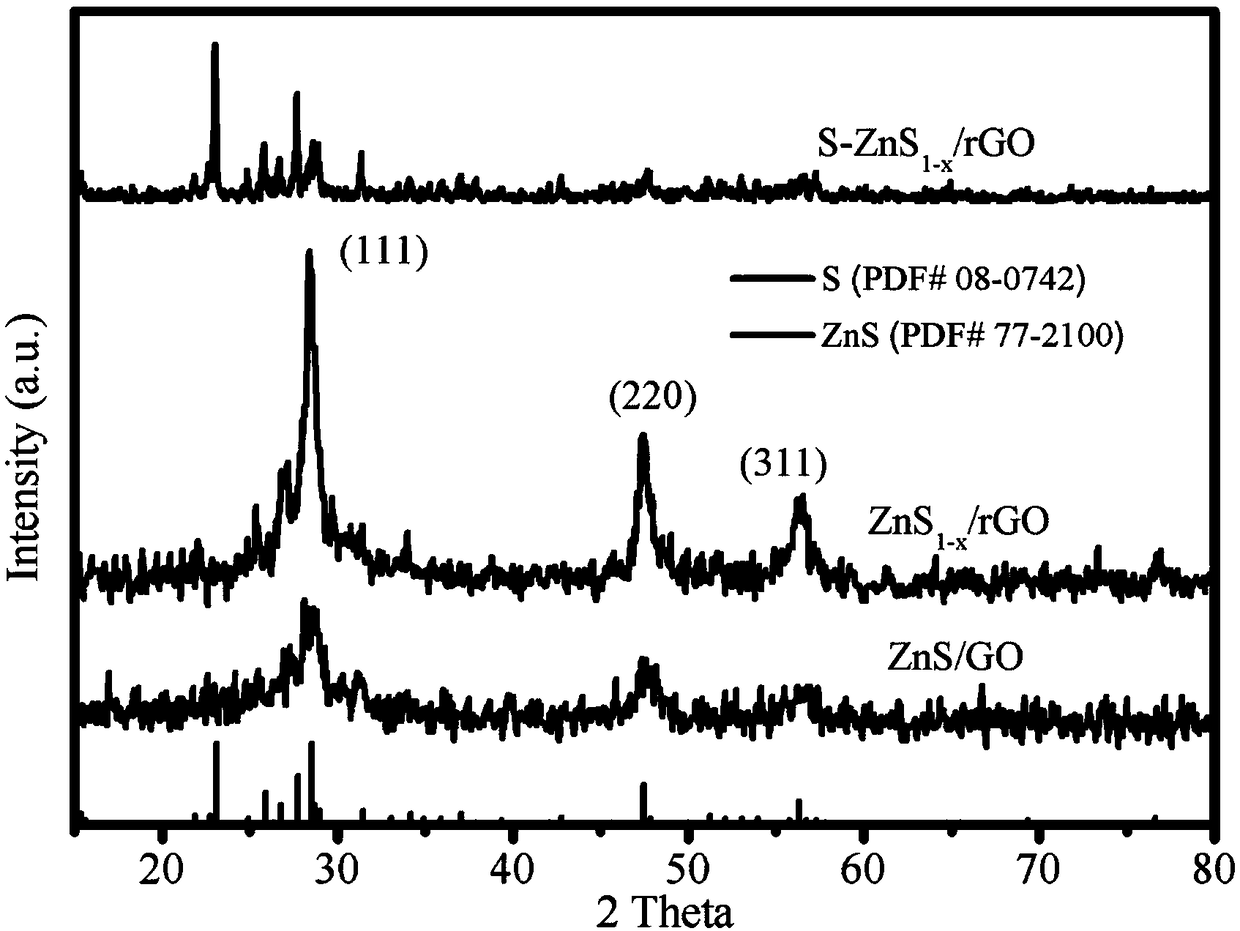

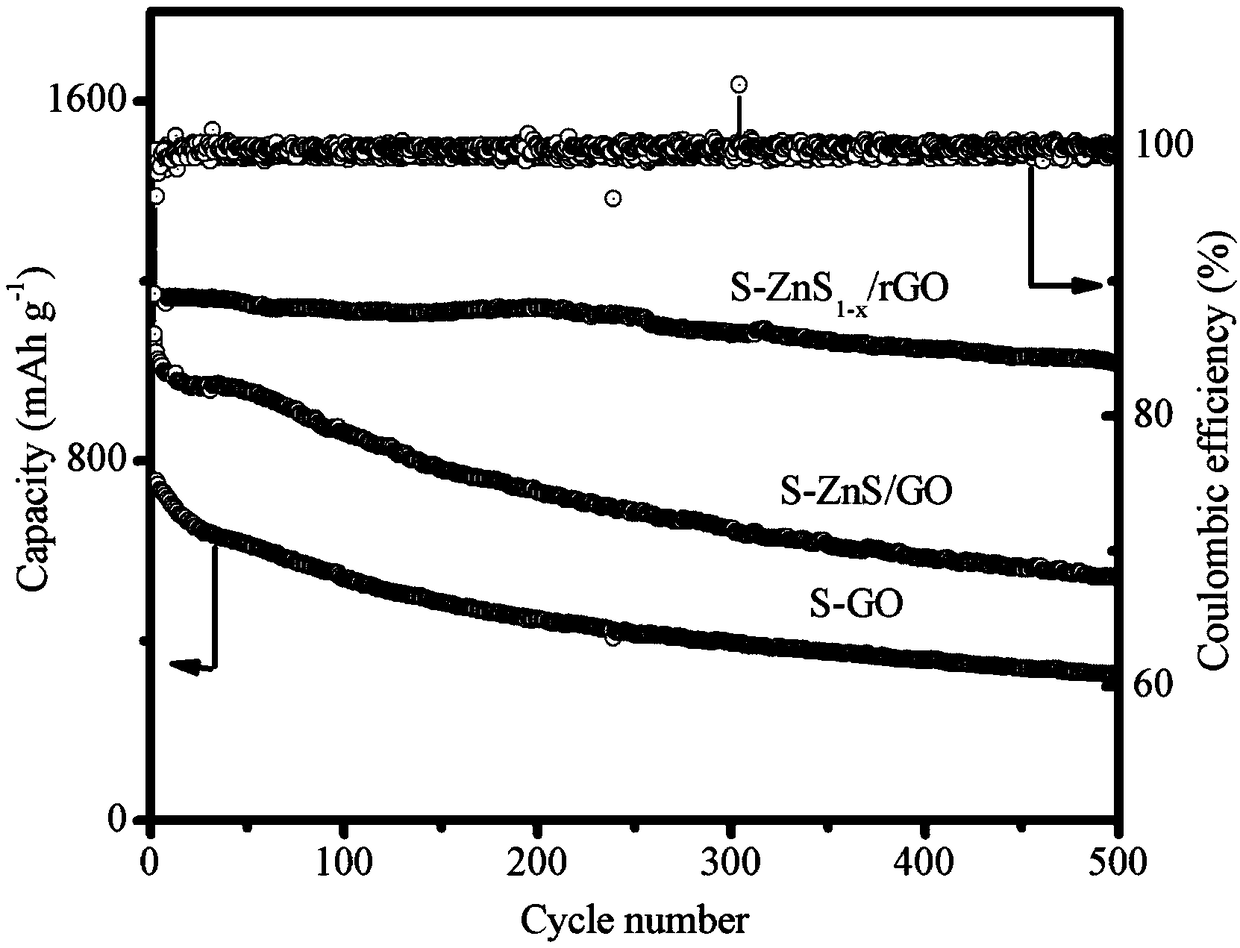

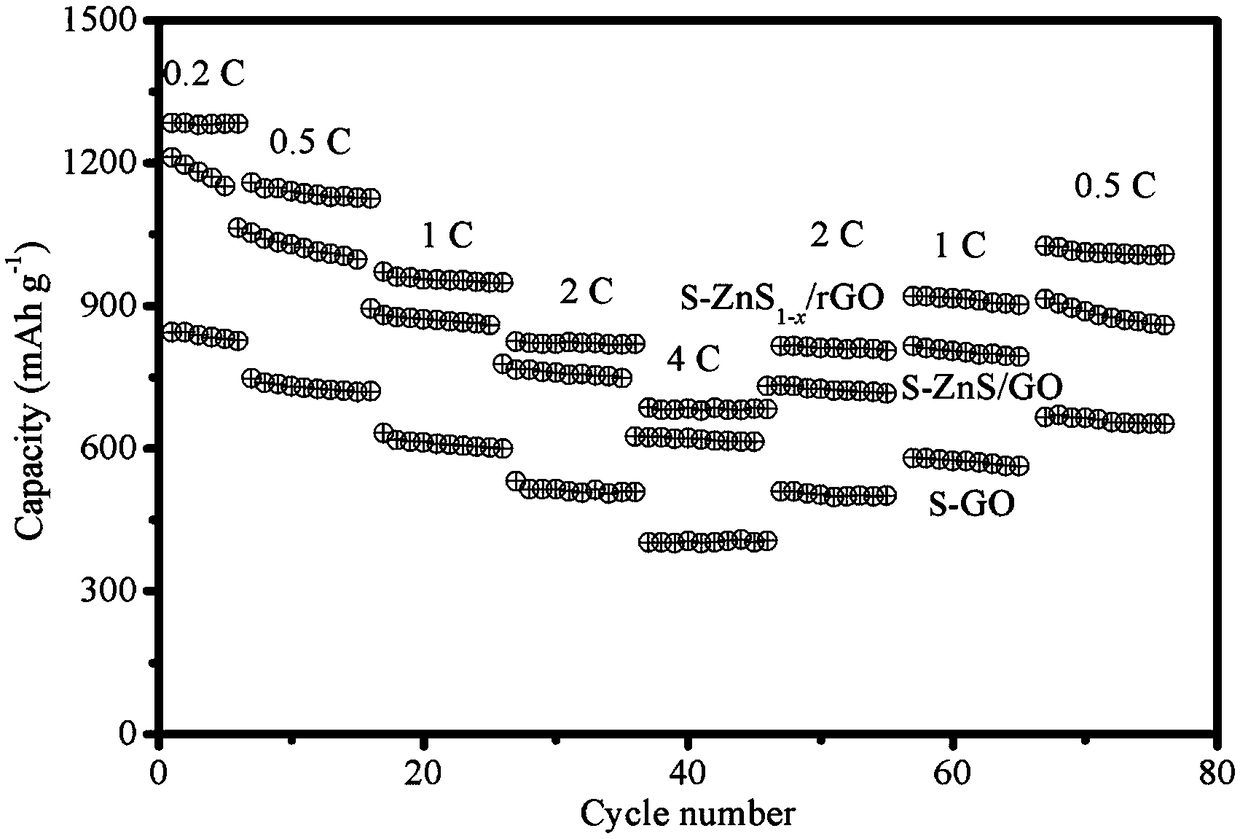

Zinc sulfide/rGO (reduced graphene oxide) composite material containing sulphur vacancy as well as preparation method and application thereof

InactiveCN109326786AImprove electrochemical activityImprove electrochemical performancePositive electrodesLi-accumulatorsNew energyZinc nitrate

The invention belongs to the technical field of new energy materials, and particularly relates to a zinc sulfide / rGO (reduced graphene oxide) composite material as well as a preparation method and application thereof. The preparation method of the zinc sulfide / rGO composite material containing the sulphur vacancy comprises the following steps: ZnS / GO is prepared as follows: carbon disulfide is added into a ethylenediamine water solution drop by drop, and the mixture is named as a solution A; graphene oxide GO is added into an ethylene glycol solution to be subjected to ultrasonic treatment, and the mixture is named as a solution B; the solution B is added into the solution A and continuously stirred, and then a mixed solution is obtained; a zinc nitrate solution is added dropwise into themixture while stirring; the mixed product is heated and cooled to room temperature, and then subjected to centrifuging and washing, and the dried product is ZnS / GO; then the ZnS / GO prepared in the step (1) is reduced at high temperature under the condition of argon-hydrogen combination gas, and ZnS<1-x> / rGO containing the sulphur vacancy is obtained. The invention adopts a simple and safe one-potwet chemical sulphur loading method and abandons a traditional fusing diffusing method, the loss is reduced, and the loading capacity of active sulphur is as high as 90%.

Owner:UNIV OF JINAN

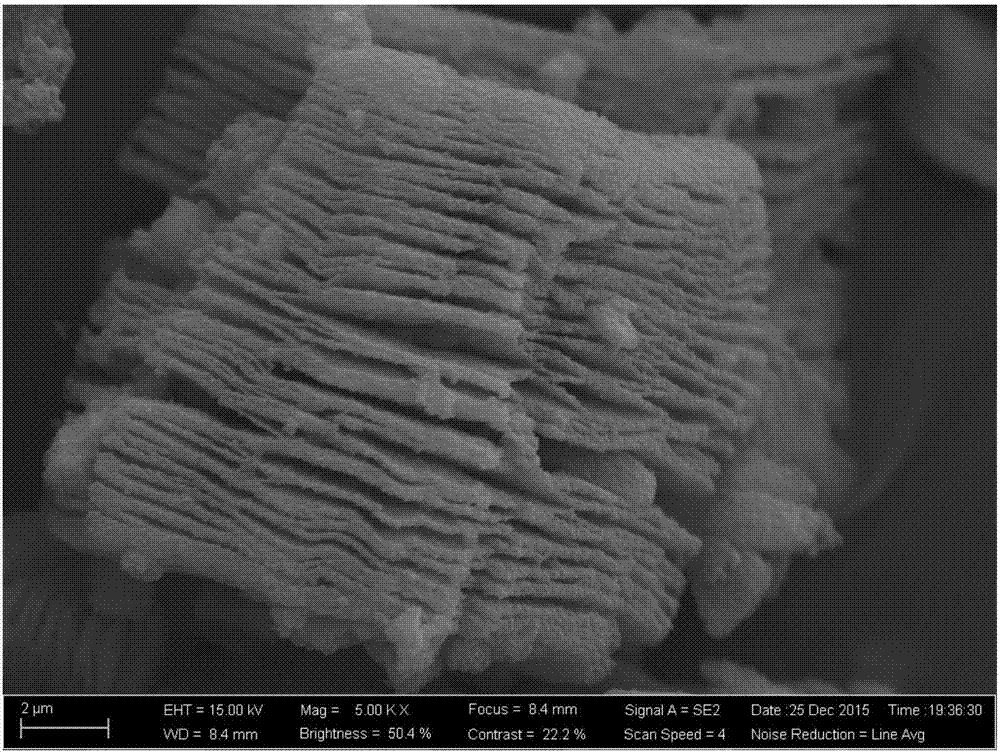

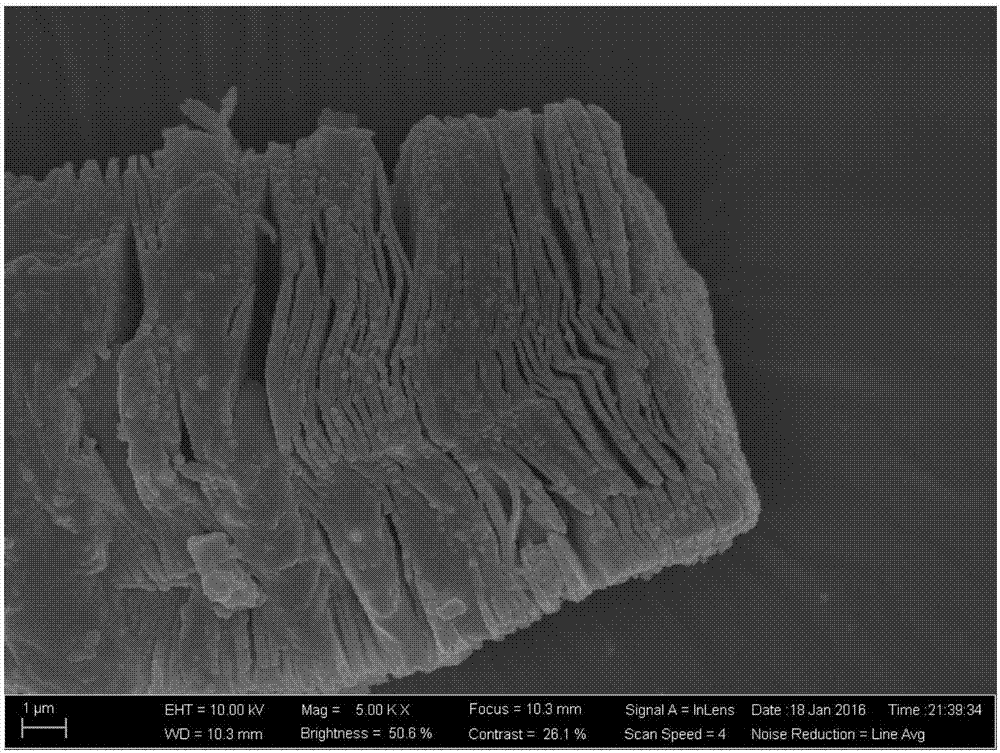

Preparation method of graphene nanoscroll/sulfur composite material and application of graphene nanoscroll/sulfur composite material

ActiveCN105047893AImprove conductivityGood electrical conductivity greatly improves electrical conductivityElectrode carriers/collectorsSecondary cellsLithiumMetal oxide nanoparticles

The invention discloses a preparation method of a graphene nanoscroll / sulfur composite material and an application of the graphene nanoscroll / sulfur composite material. The preparation method of the graphene nanoscroll / sulfur composite material is as follows: with a graphene nanoscroll which is modified with nanoparticles on the surface as matrix, the graphene nanoscroll / sulfur composite material is obtained in a melt sulfur-injection manner; agglomeration of graphene sheets is effectively inhibited by the graphene with a wound structure; the pore structure in the graphene is beneficial to storage of sulfur; the conductivity of an electrode is further improved by excellent electrical conductivity of the graphene; and the active material is fully utilized. In addition, intense interaction exists between metal oxide nanoparticles which are modified on the graphene surface and a discharge intermediate product lithium polysulfide; and dissolution of the polysulfide can be effectively inhibited, so that the material shows high specific capacity and good cycling stability; the method is simple to operate and low in cost; and large-scale production is easy to realize.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com