Zinc sulfide/rGO (reduced graphene oxide) composite material containing sulphur vacancy as well as preparation method and application thereof

A technology of composite materials and zinc sulfide, applied in the direction of active material electrodes, electrical components, battery electrodes, etc., can solve the problems of poor electrochemical performance and achieve the effects of increased sulfur load, improved utilization rate, and excellent electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

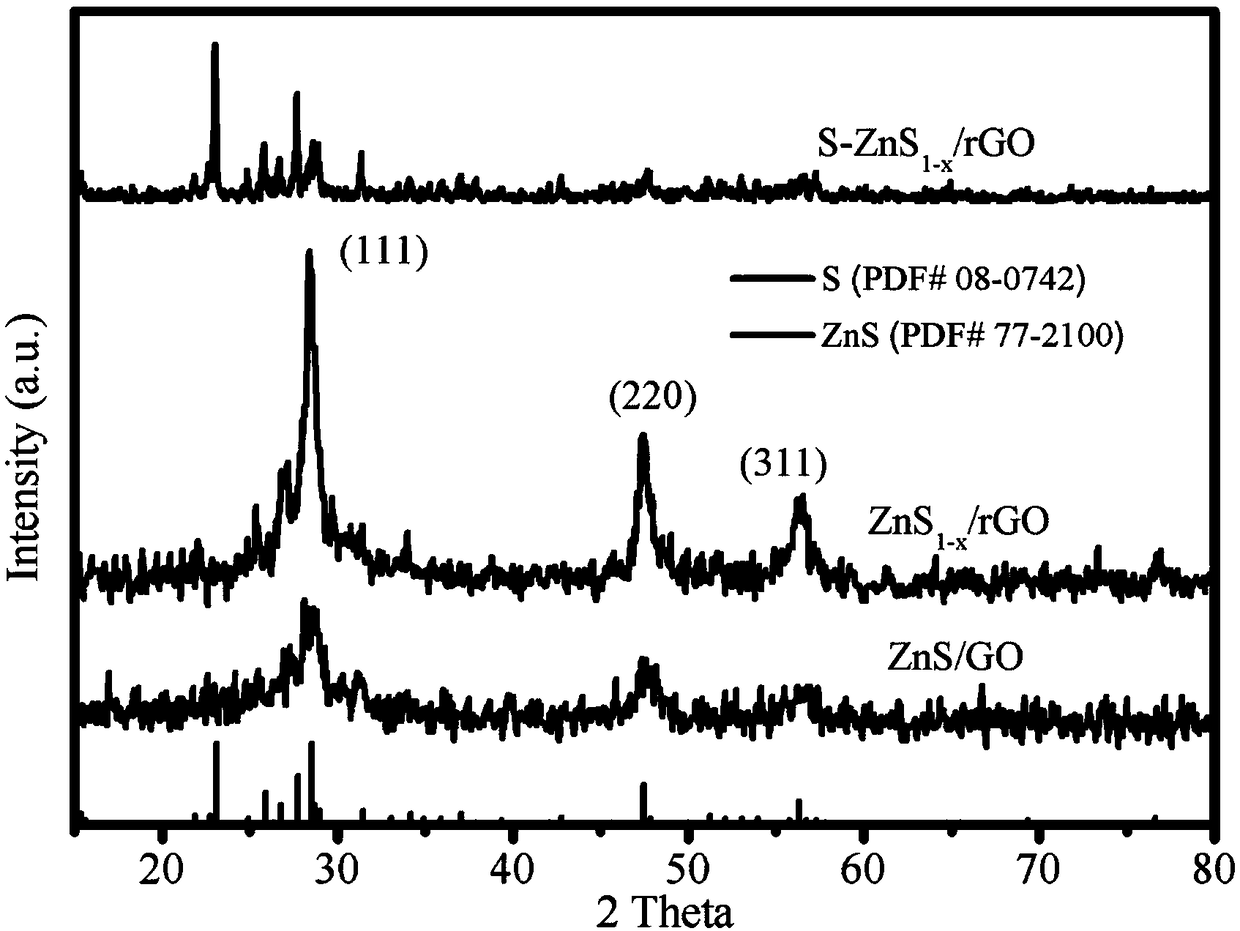

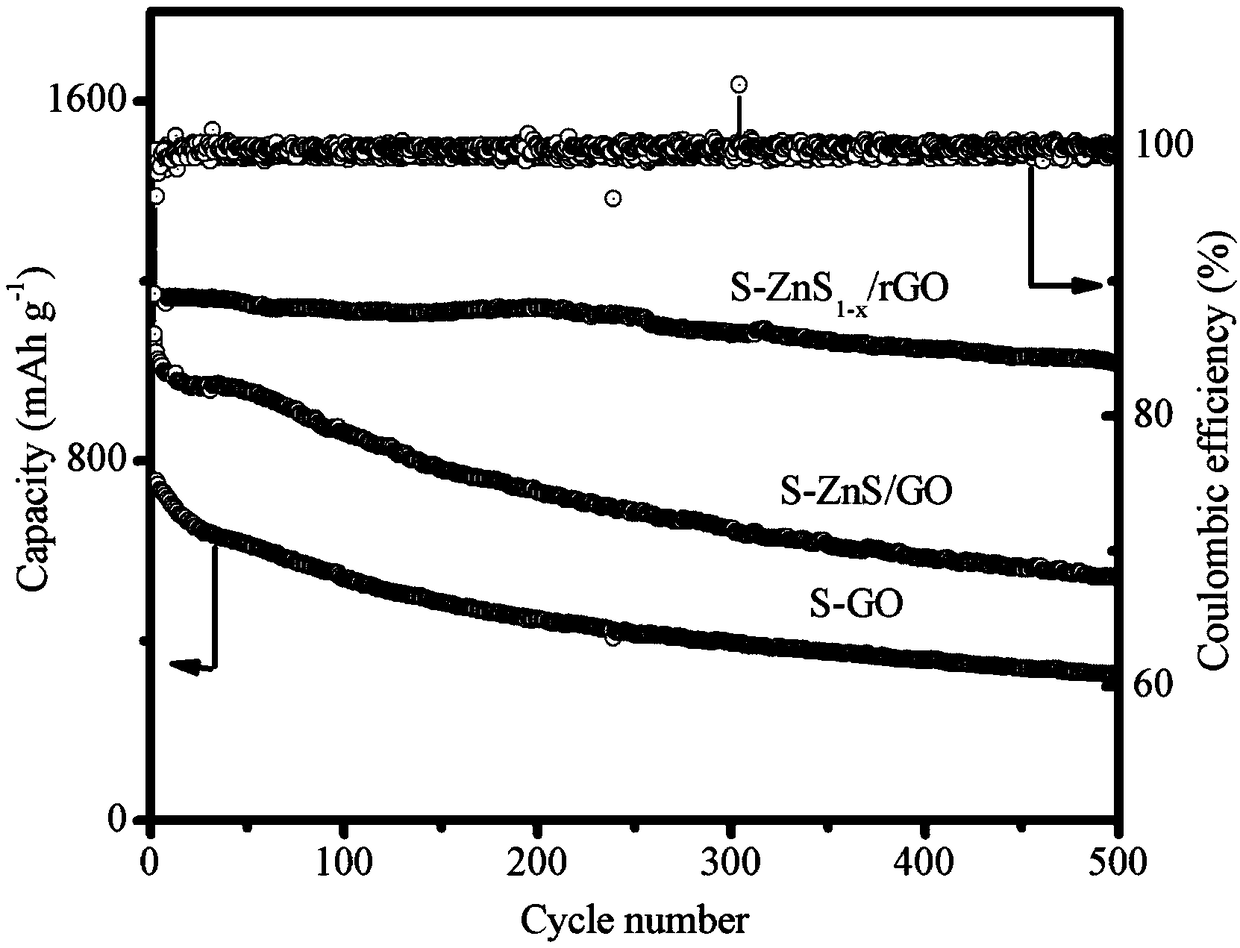

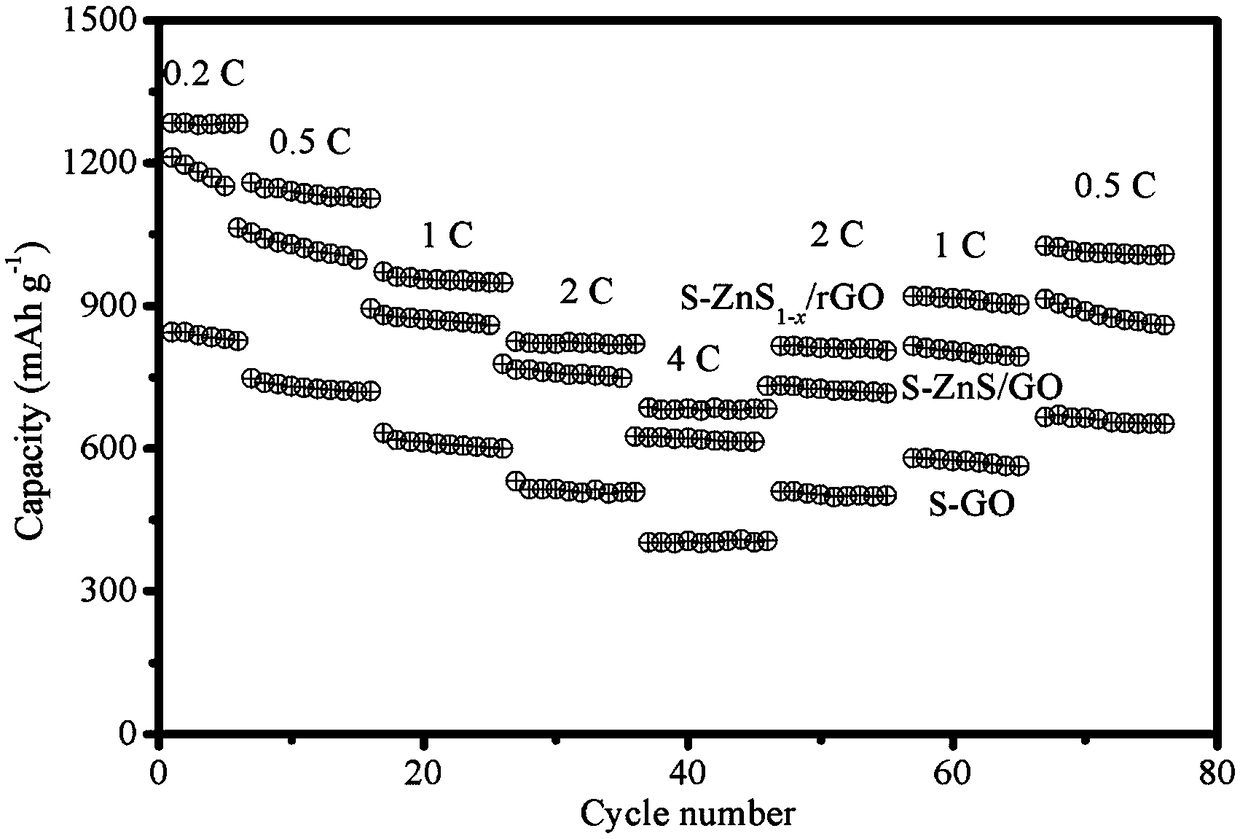

[0034]Preparation of ZnS / GO: First, carbon disulfide (0.136 mL) was added dropwise into ethylenediamine solution (68 mL), named as solution A. Add 60 mg graphene oxide GO to 80 mL ethylene glycol solution and sonicate for 30 min, the ultrasonic power is 450W, named solution B, add solution B to solution A and stir continuously for 30 min, and add to the mixture under stirring Add 34 mL of zinc nitrate solution with a concentration of 0.05 moL / L dropwise, transfer it to an autoclave at 180 o C for 12 h. After the solution was cooled to room temperature, it was centrifuged and washed with ethanol, and the precipitate was o C for 12 h, and the dried product was ZnS / GO.

[0035] ZnS 1-x Preparation of / rGO: The collected ZnS / GO samples were reduced under argon-hydrogen mixed gas, wherein the mixed gas was argon-hydrogen mixed gas with hydrogen accounting for 10%, and reduced at high temperature with a heating rate of 5 o C / min, heating up to 650 o C, keep warm for 6 h, get Zn...

Embodiment 2

[0043] Preparation of ZnS / GO: First, carbon disulfide (0.1 mL) was added dropwise into ethylenediamine solution (40 mL), named as solution A. Afterwards, 30 mg of graphene oxide GO was added to 40 mL of ethylene glycol solution and sonicated for 20 min at an ultrasonic power of 450 W, named as solution B, and solution B was added to solution A and stirred continuously for 30 min. Add 34 mL of 0.05 mol / L zinc nitrate solution dropwise to the mixture, transfer it to an autoclave at 180 o C for 12 h. After the solution was cooled to room temperature, it was centrifuged and washed with ethanol, and the precipitate was o C for 12 h, and the dried product was ZnS / GO.

[0044] ZnS 1-x Preparation of / rGO: The collected ZnS / GO samples were reduced under argon-hydrogen mixed gas, wherein the mixed gas was argon-hydrogen mixed gas with hydrogen accounting for 10%, and reduced at high temperature with a heating rate of 3 o C / min, heating up to 400 o C, keep warm for 6 h, get ZnS con...

Embodiment 3

[0052] Preparation of ZnS / GO: First, carbon disulfide (0.116 mL) was added dropwise into ethylenediamine solution (50 mL), named as solution A. Afterwards, 40 mg of graphene oxide GO was added to 60 mL of ethylene glycol solution and sonicated for 50 min at an ultrasonic power of 450 W, named solution B, and solution B was added to solution A and stirred continuously for 30 min. Add 34 mL of 0.05 mol / L zinc nitrate solution dropwise to the mixture, transfer it to an autoclave at 140 o C for 12 h. After the solution was cooled to room temperature, it was centrifuged and washed with ethanol, and the precipitate was separated at 30-60 o C for 12 h, and the dried product was ZnS / GO.

[0053] ZnS 1-x Preparation of / rGO: The collected ZnS / GO samples were reduced under argon-hydrogen mixed gas, wherein the mixed gas was argon-hydrogen mixed gas with hydrogen accounting for 10%, and reduced at high temperature with a heating rate of 10 o C / min, heating up to 800 o C, keep warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com