Nano silicon/porous carbon composite anode material of lithium ion batteries as well as preparation method and application of composite anode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low first coulomb efficiency and poor rate performance, and achieve the improvement of electrochemical reaction rate, conductivity, and specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

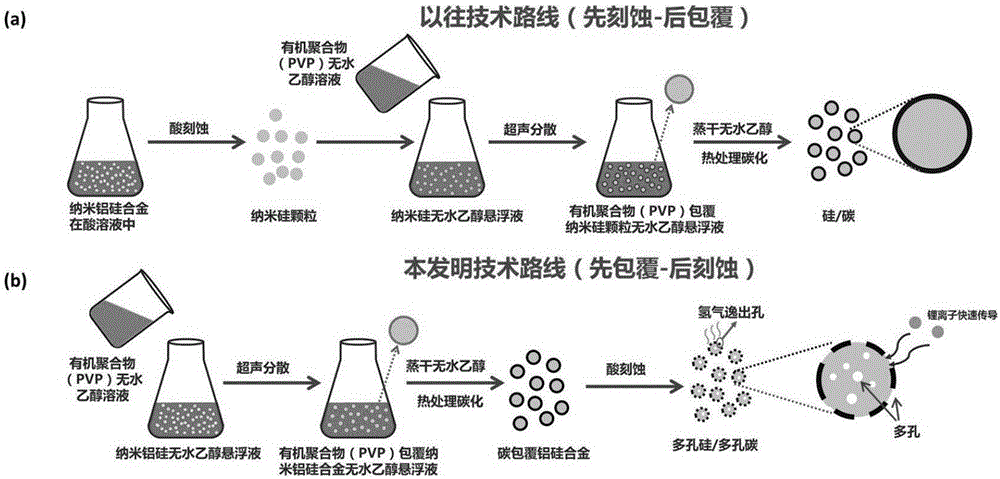

Method used

Image

Examples

Embodiment 1

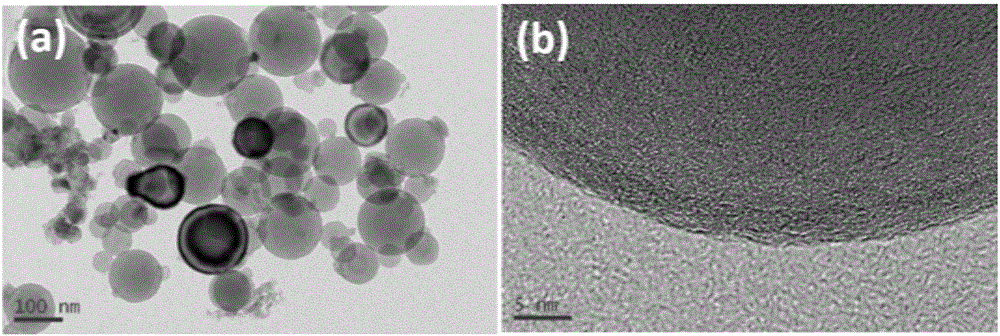

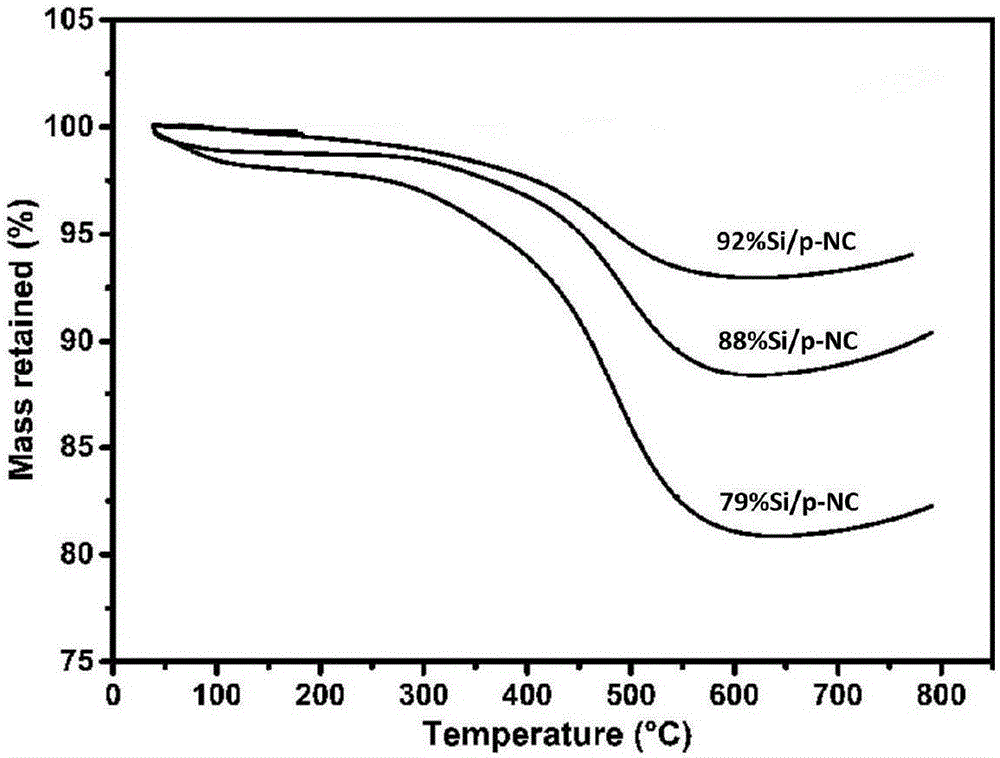

[0048] Add 2g of aluminum-silicon alloy powder (commercial aluminum-silicon alloy powder with a particle size of 50-200nm) and 0.1g of PVP into 30mL and 20mL of absolute ethanol, respectively, and ultrasonically disperse for 5min to obtain a suspension of aluminum-silicon alloy in absolute ethanol and For the solution of PVP in absolute ethanol, the two were mixed, ultrasonicated for 5 minutes, magnetically stirred at 80°C and evaporated to dryness of absolute ethanol to obtain a solid powder. The powder was placed in a tube furnace in an argon atmosphere at 2°C / min and the temperature was raised to 600°C for 4h to obtain carbon-coated aluminum-silicon alloy powder. Weigh 2g of carbon-coated aluminum-silicon alloy powder and add it to 80mL of 4mol / L hydrochloric acid aqueous solution, stir and react at 40°C for 4h, filter, wash, dry and grind to obtain solid powder. Add the powder into 10wt% hydrofluoric acid aqueous solution, react at room temperature for 12h, centrifuge and ...

Embodiment 2

[0051] Add 2g of aluminum-silicon alloy powder (commercial aluminum-silicon alloy powder with a particle size of 50-200nm) and 0.3g of PVP into 30mL and 20mL of absolute ethanol, respectively, and ultrasonically disperse for 5min to obtain a suspension of aluminum-silicon alloy in absolute ethanol and For the solution of PVP in absolute ethanol, the two were mixed, ultrasonicated for 5 minutes, magnetically stirred at 80°C and evaporated to dryness of absolute ethanol to obtain a solid powder. The powder was placed in a tube furnace in an argon atmosphere at 2°C / min and the temperature was raised to 600°C for 4h to obtain carbon-coated aluminum-silicon alloy powder. Weigh 2g of carbon-coated aluminum-silicon alloy powder and add it to 80mL of 4mol / L hydrochloric acid aqueous solution, stir and react at 40°C for 4h, filter, wash, dry and grind to obtain solid powder. Add the powder into 10wt% hydrofluoric acid aqueous solution, react at room temperature for 12h, centrifuge and ...

Embodiment 3

[0054] Add 2g of aluminum-silicon alloy powder (commercial aluminum-silicon alloy powder with a particle size of 50-200nm) and 0.5g of PVP into 30mL and 20mL of absolute ethanol, respectively, and ultrasonically disperse for 5min to obtain a suspension of aluminum-silicon alloy in absolute ethanol and For the solution of PVP in absolute ethanol, the two were mixed, ultrasonicated for 5 minutes, magnetically stirred at 80°C and evaporated to dryness of absolute ethanol to obtain a solid powder. The powder was placed in a tube furnace in an argon atmosphere at 2°C / min and the temperature was raised to 600°C for 4h to obtain carbon-coated aluminum-silicon alloy powder. Weigh 2g of carbon-coated aluminum-silicon alloy powder and add it to 80mL of 4mol / L hydrochloric acid aqueous solution, stir and react at 40°C for 4h, filter, wash, dry and grind to obtain solid powder. Add the powder into 10wt% hydrofluoric acid aqueous solution, react at room temperature for 12h, centrifuge and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com