Patents

Literature

810results about How to "Larger than surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

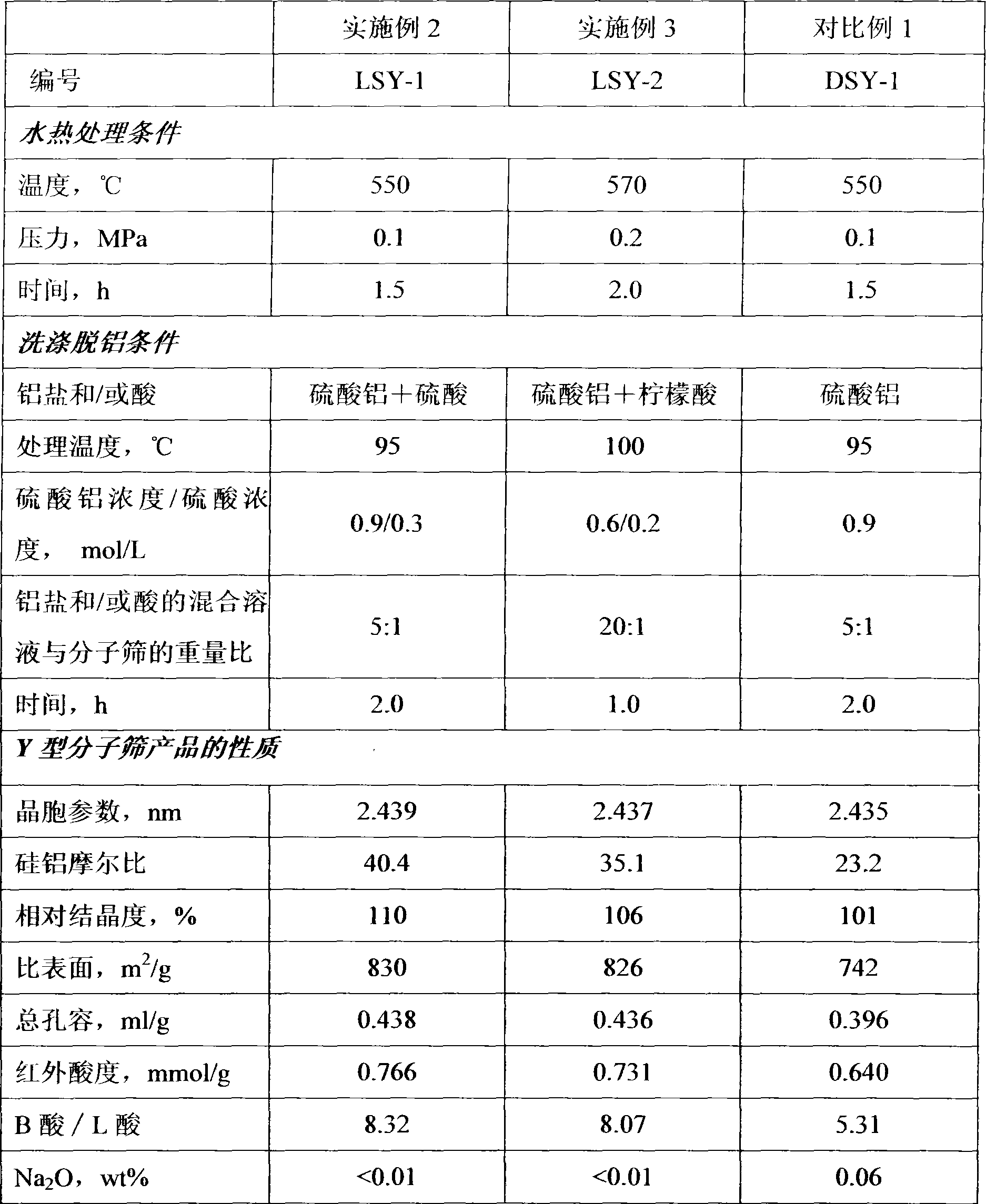

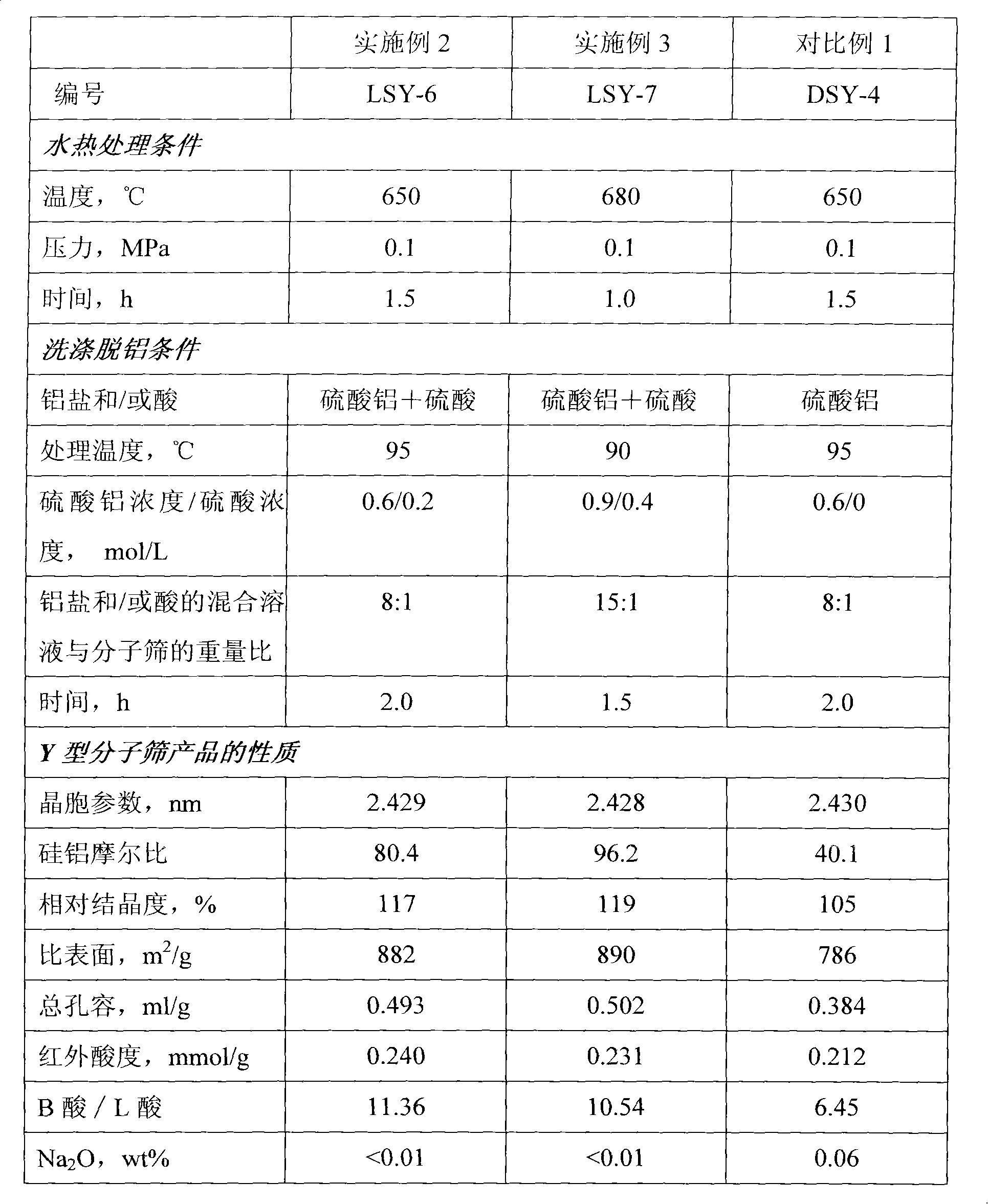

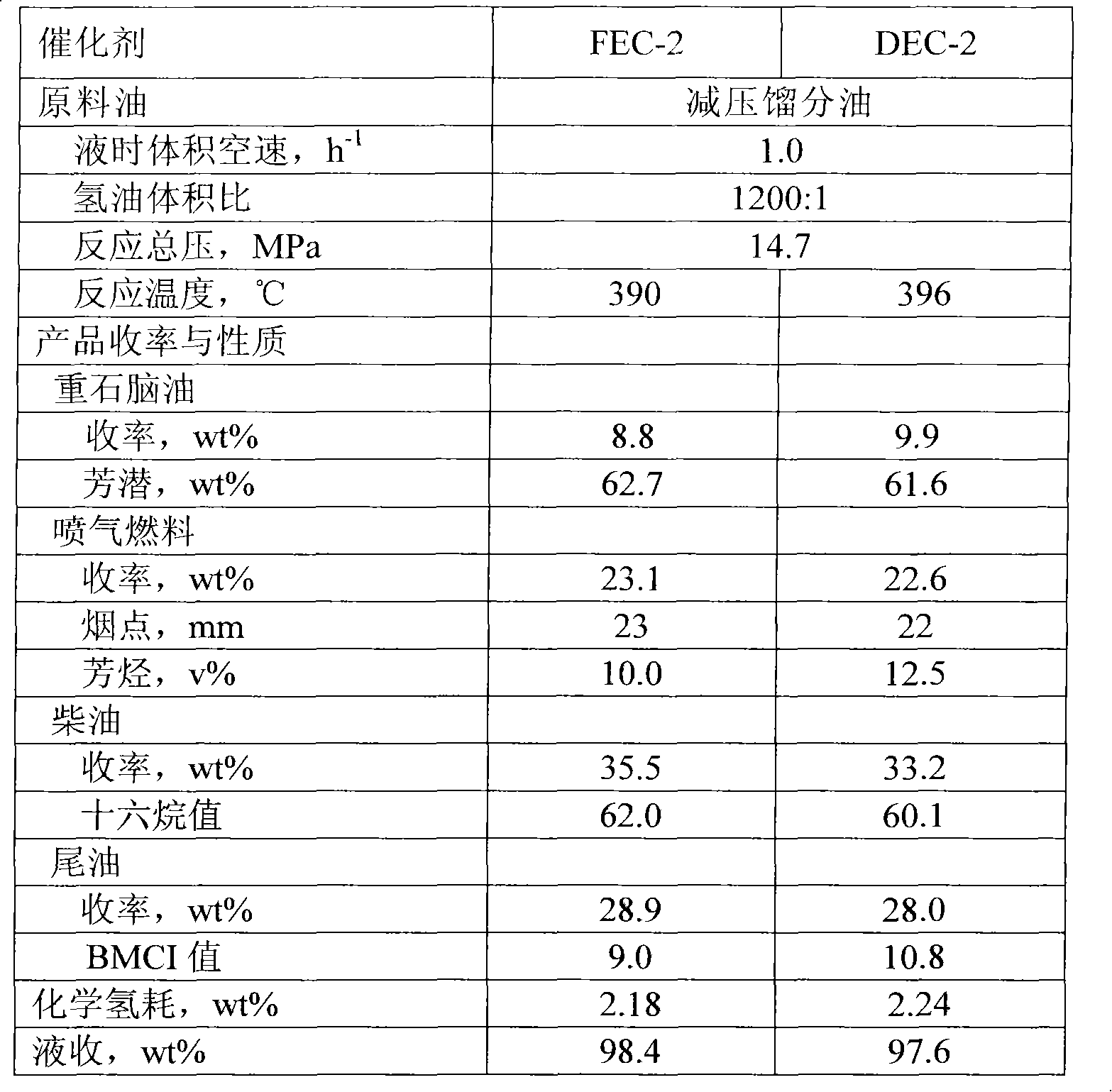

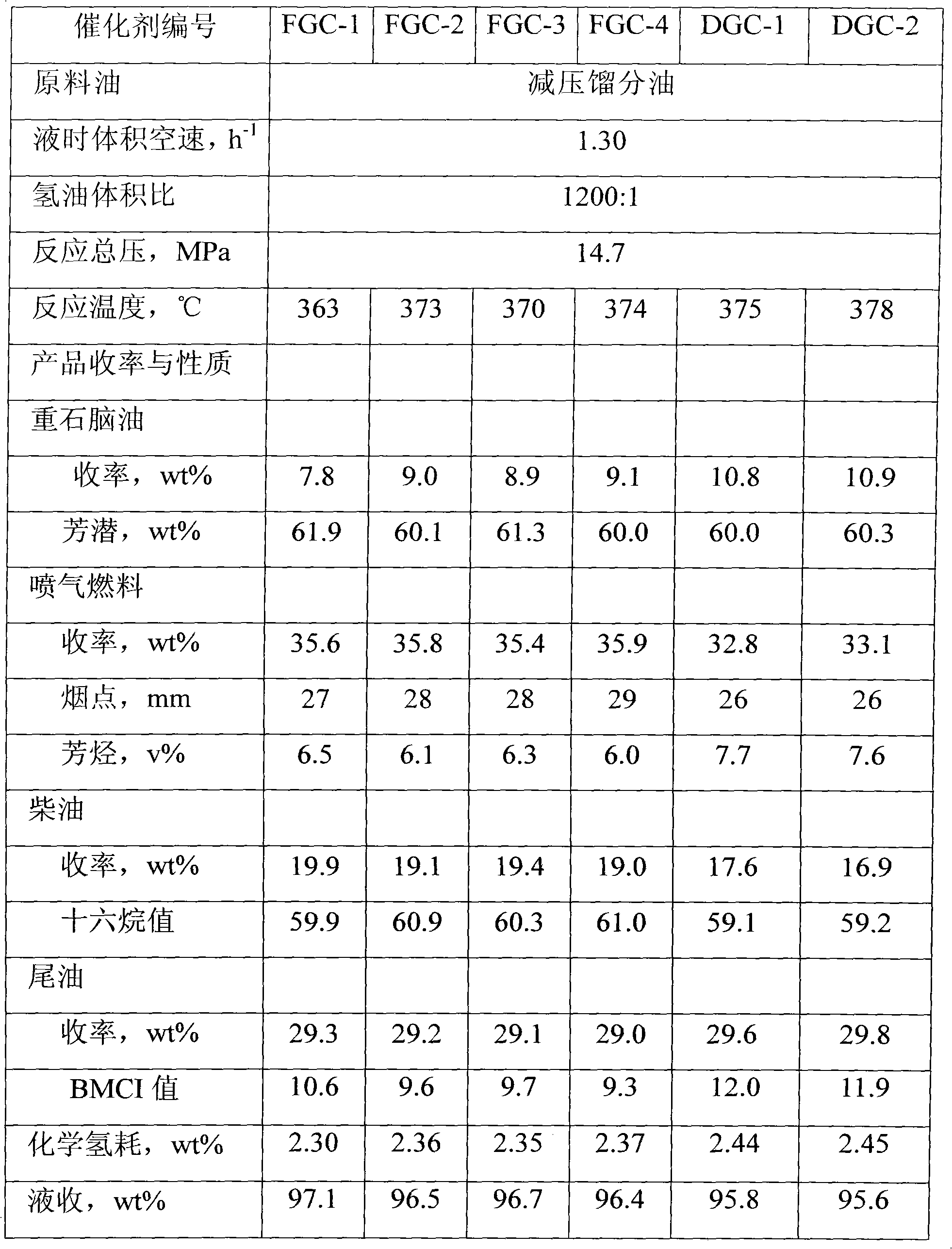

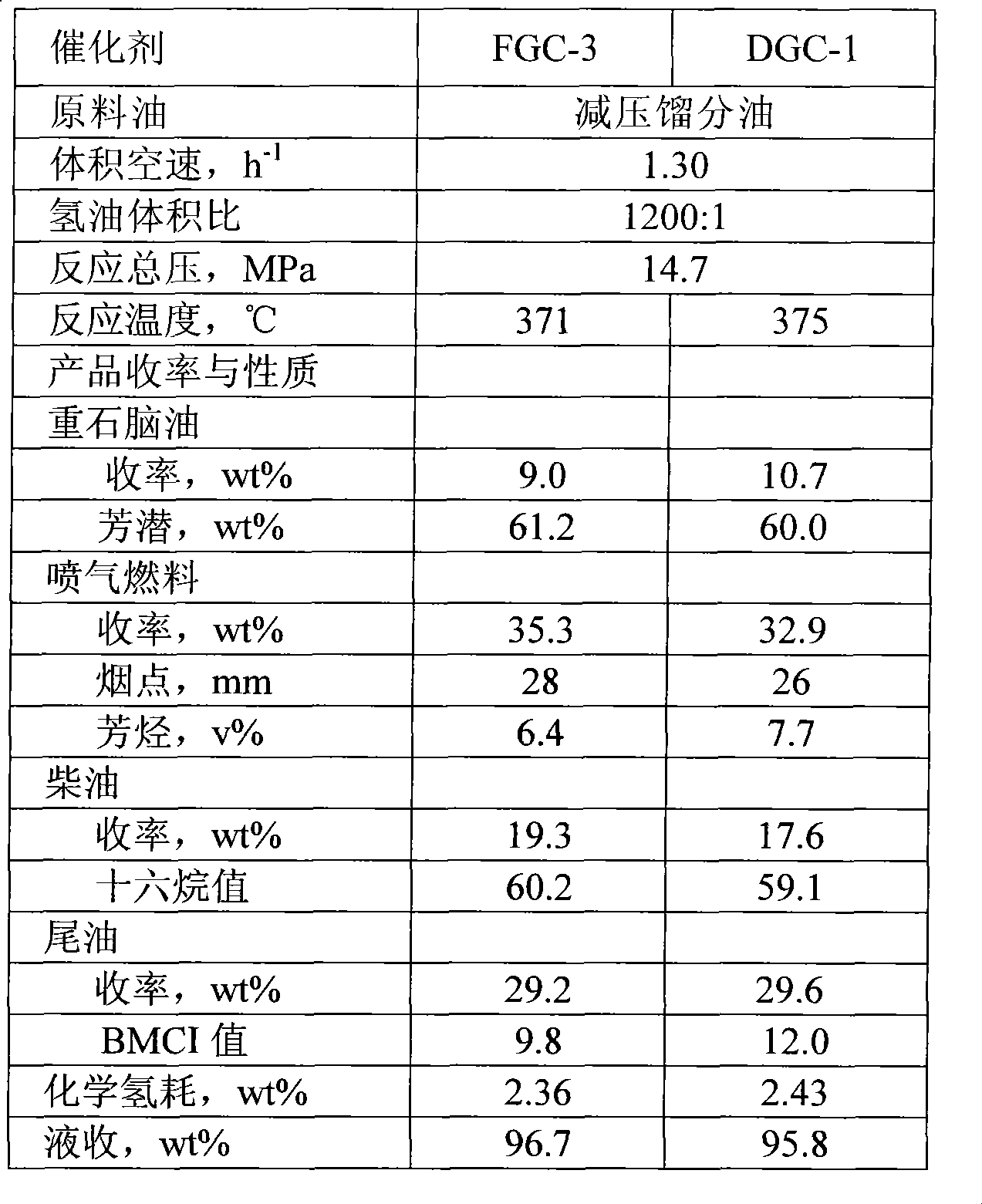

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Catalyst for dehydrogenation of propane for preparing propylene and preparation method thereof

ActiveCN101972664BHigh propane conversionExcellent anti-coke performanceMolecular sieve catalystsHydrocarbonsChemistryMolecular sieve

The invention discloses a catalyst, which is carried by an AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework, for dehydrogenation of propane for preparing propylene. In the catalyst, the AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework is used as a carrier, platinum-group element metal is used as a main catalyst, IVA-group, IA-group or IIA-group element metal is used as an auxiliary agent, and high-temperature-resistant inorganic oxide is used for forming an adhesive. A multi-step dipping method is used in the preparation of the catalyst, namely the alkaline metal auxiliary agent is dipped, so that the acidity and alkalinity of the catalyst and the types of cations in pores of the molecular sieve are effectively modulated by cation exchange technology, and the platinum-group element metal is dipped. The catalyst has superior anti-carbon deposit performance, high propane conversion rate under the reaction conditions of high temperature and low pressure, propylene selectivity and reaction stability.

Owner:CHINA PETROLEUM & CHEM CORP

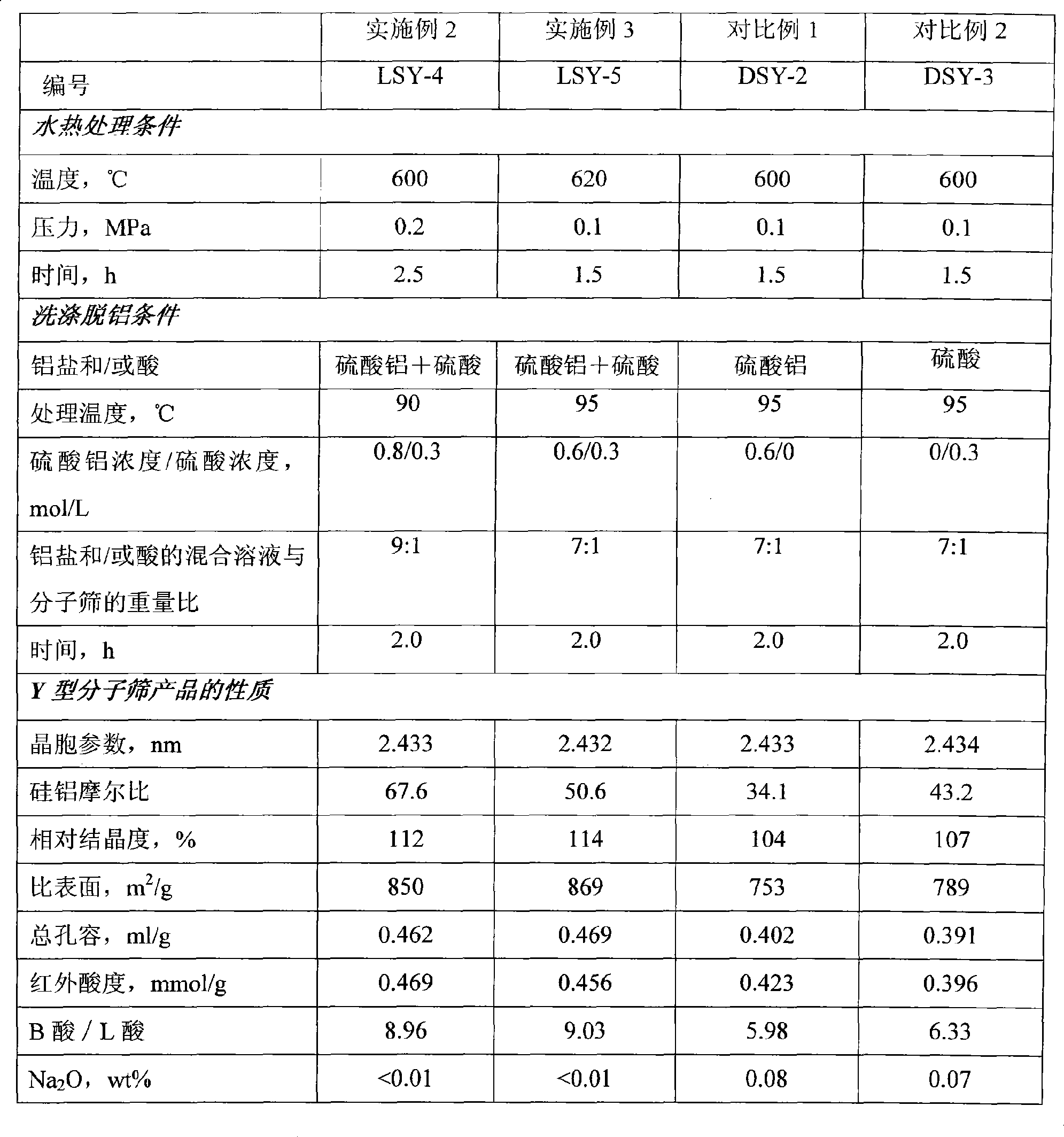

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reliving FCC dead catalyst

ActiveCN101219396AIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

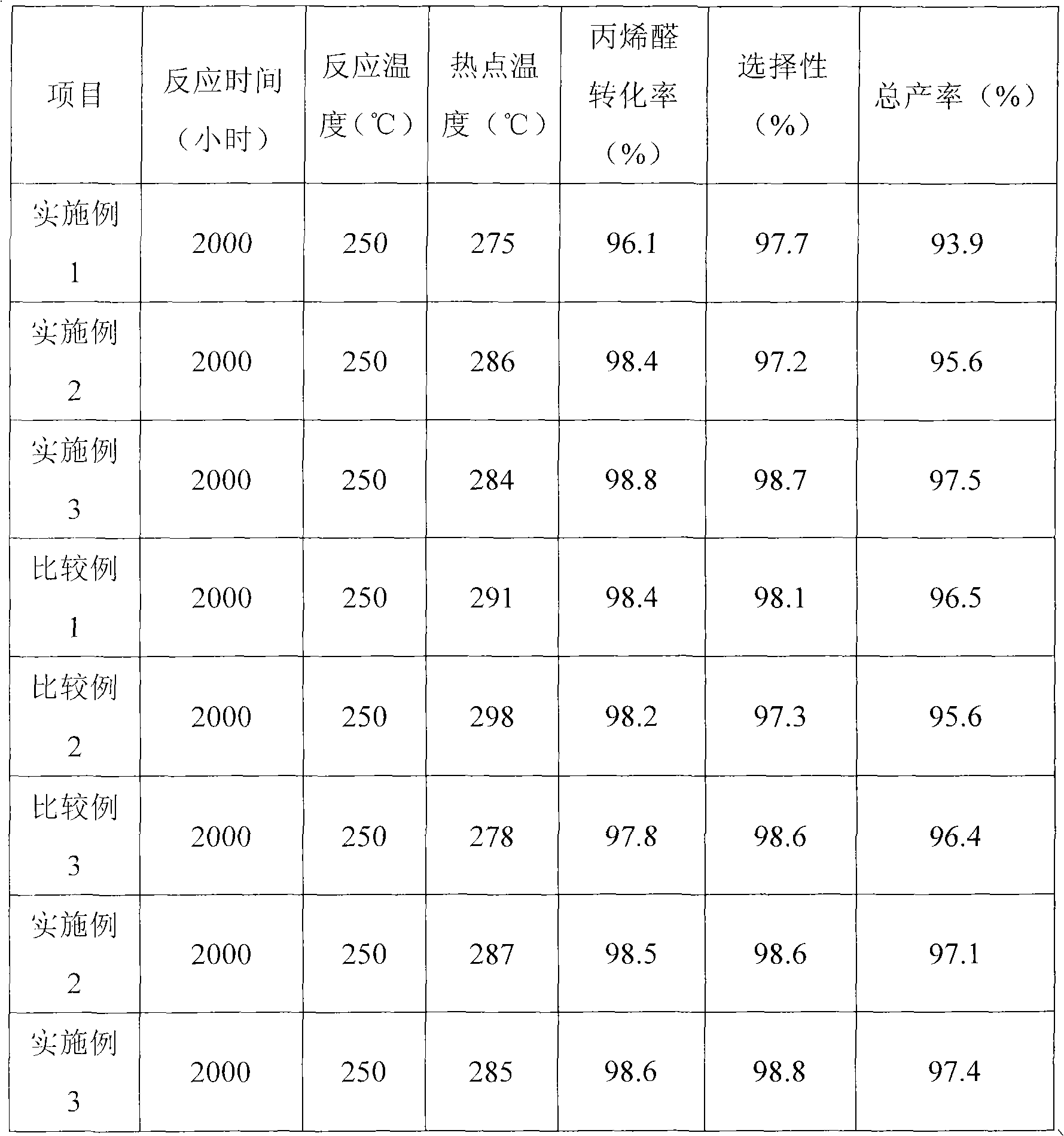

Preparation method of catalyst for acrylic acid by oxidizing acraldehyde

ActiveCN102039143ALarger than surfaceStrong loadOrganic compound preparationCarboxylic compound preparationAdhesiveSlurry

The invention relates to a preparation method of a catalyst for acrylic acid by oxidizing acraldehyde, which is characterized by comprising the following steps of: dispersing water soluble metal salts containing the components of Mo, V, W, Cu and Sb into a water / organic phase mixed system at the temperature of 30-100DEG C; maintaining the weight ratio of an organic solvent to water as 5-50 percent; reacting to generate composite oxide precursor serum; separating water by a distilling process under the condition of continuously supplementing organic phases at the temperature of 20-120DEG C, wherein the water content of distillate is not greater than 10 percent; then, pelleting by a spray drying process and roasting at the temperature of 200-600DEG C to prepare catalyst active components; mixing primary roasting powder, a forming additive and a strength improver; coating the active components on the surface of an inert carrier by using an adhesive, wherein the carrying capacity occupies5-70 percent of the total quantity of the catalyst; drying a formed product for 5-48 hours at room temperature; and then, roasting the formed product for 1-15 hours at the temperature of 200-600DEG Cto obtain a spherical catalyst with the active components carried on the inert carrier.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

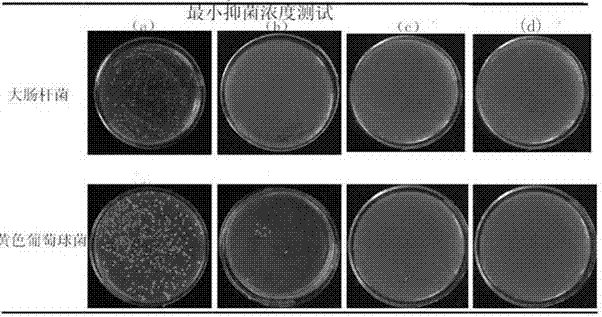

Composite material with anti-bacterial and purifying functions and preparation method of composite material

ActiveCN104607039AImprove adsorption capacityImprove decomposition rateWater/sewage treatment by irradiationDispersed particle separationDecompositionRare earth

The invention relates to a composite material with anti-bacterial and purifying functions and a preparation method of the composite material, and belongs to the technical field of environmental-friendly materials. The composite material with the anti-bacterial and purifying functions comprises raw materials in parts by weight as follows: 70-95 parts of a mineral composite adsorption material, 3-25 parts of a photocatalytic degradation material, 2-15 parts of a rare earth inorganic anti-bacterial material and 1-10 parts of an additive, wherein the mineral composite adsorption material is prepared from sepiolite, diatomite, medical stone and attapulgite; the photocatalytic degradation material is prepared from titanium oxide, tourmaline and far infrared ceramic powder; the rare earth inorganic anti-bacterial material is prepared from zinc oxide, cerium oxide and silver oxide; the additive is a mixture of activated carbon, carboxymethylcellulose and pumice powder. The composite material with anti-bacterial and purifying functions has high adsorption and decomposition rate, can be resistant to water and damp and has excellent anti-bacterial effect. Meanwhile, the invention provides the preparation method. According to the preparation method, the cost is low, the amount of produced wastewater is low, and powder is simple and convenient to apply.

Owner:淄博木齐新材料科技有限公司

Preparation method of denitration catalyst

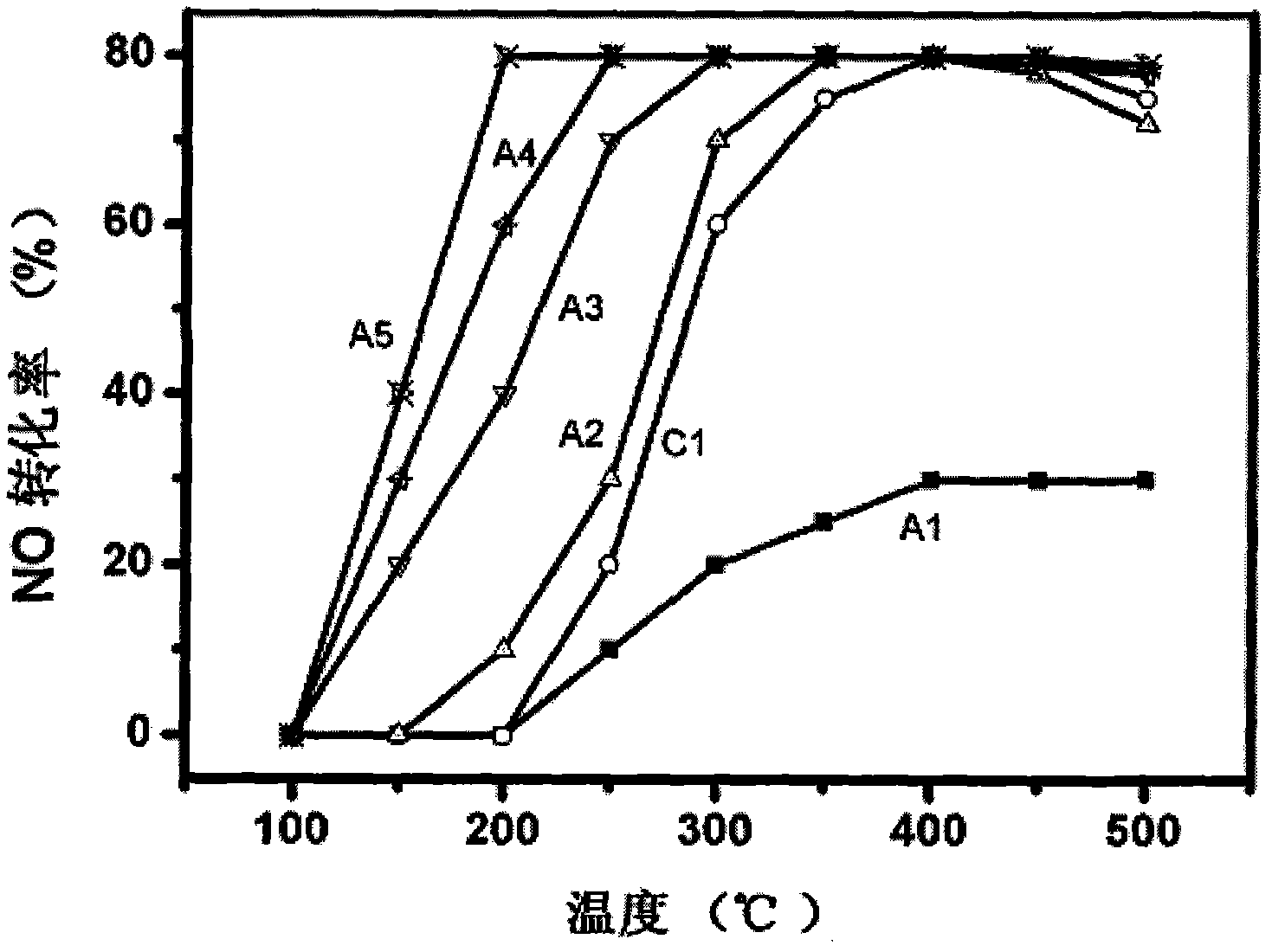

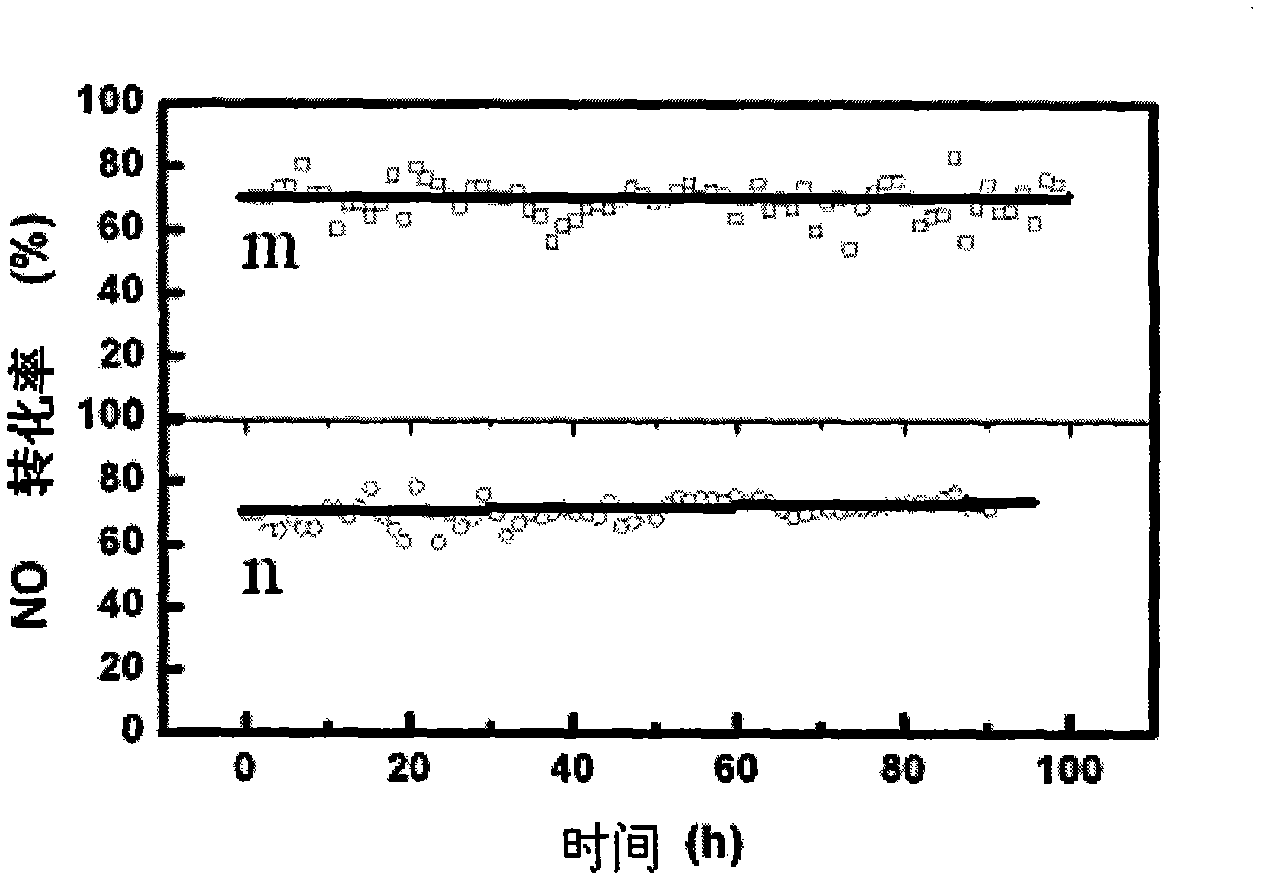

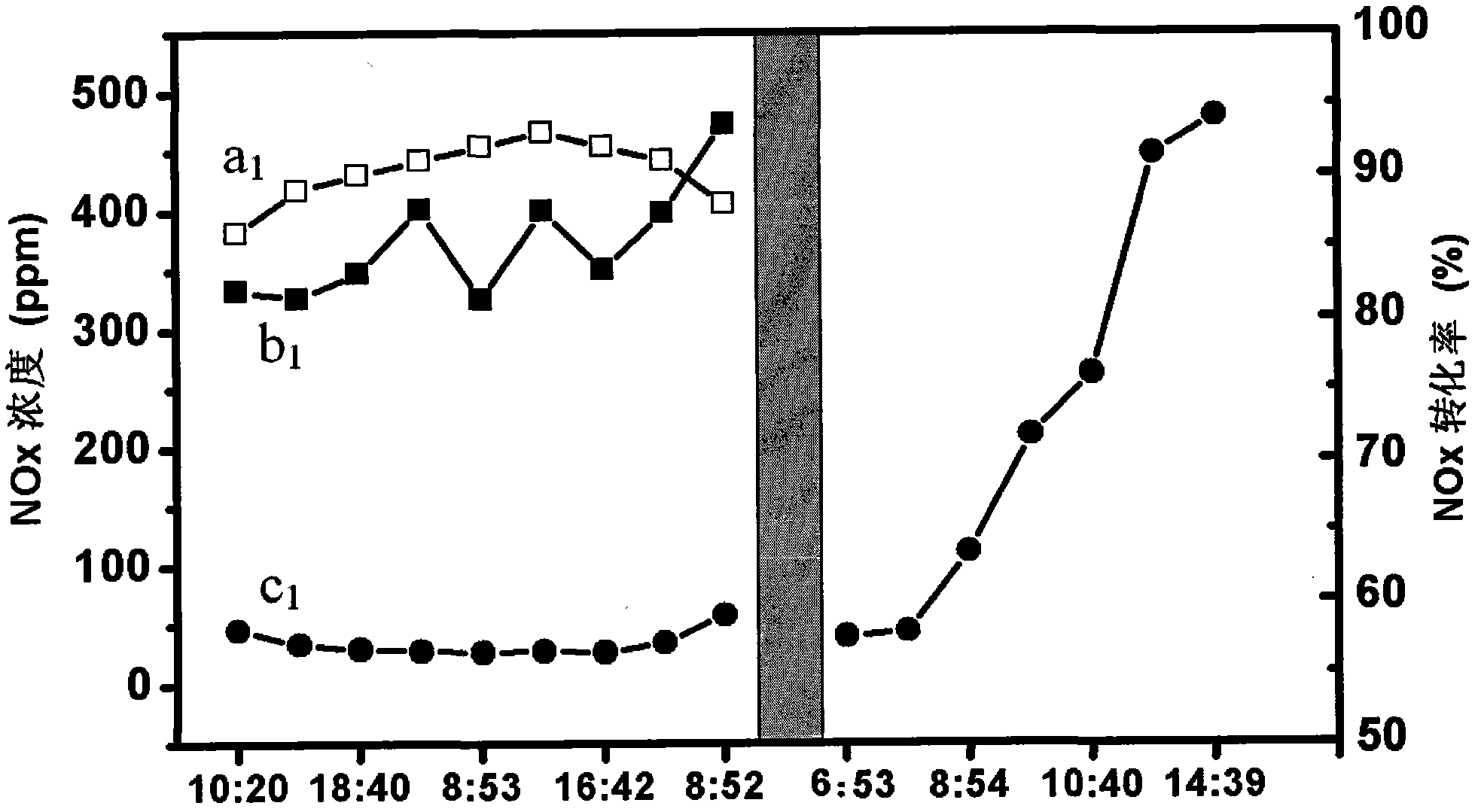

InactiveCN102463110ASmall grainReduce oxidationDispersed particle separationCatalyst activation/preparationSolventTungsten

The invention provides a preparation method of a denitration catalyst, comprising the following steps of: (1) dissolving or dispersing a titanium source precursor and a tungsten source precursor in water to obtain a precursor solution; (2) pouring the precursor solution into a solvent thermal autoclave with stirring for hydrothermal reaction; (3) filtering, washing and drying after the hydrothermal reaction so as to obtain the titanium-tungsten powdered denitration catalyst. According to the preparation method, the hydrothermal synthesis method is adopted to introduce an active component in the mode of in situ synthesis. As the active component is characterized by small crystal grain, low oxidizability and large specific surface, the component can maintain a monolayer dispersion state in a large range. By the titanium-tungsten powder hydrothermal synthesis technology provided by the invention, nationalization of key raw materials of the denitration catalyst can be realized, thus substantially reducing the manufacturing cost of present denitration catalysts.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101380588AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveChemistry

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y molecular sieve, amorphous aluminium silicon and alumina, wherein, the preparation method of the Y molecular sieve is as follows: the Y molecular sieve which is treated by mixed water solution of aluminum salt and acid in a heating way is adopted. The performance of the modified Y molecular sieve is as follows: specific surface is 800m<2> / g to 900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the ratio of the acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The hydrocracking catalyst prepared by the carrier has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

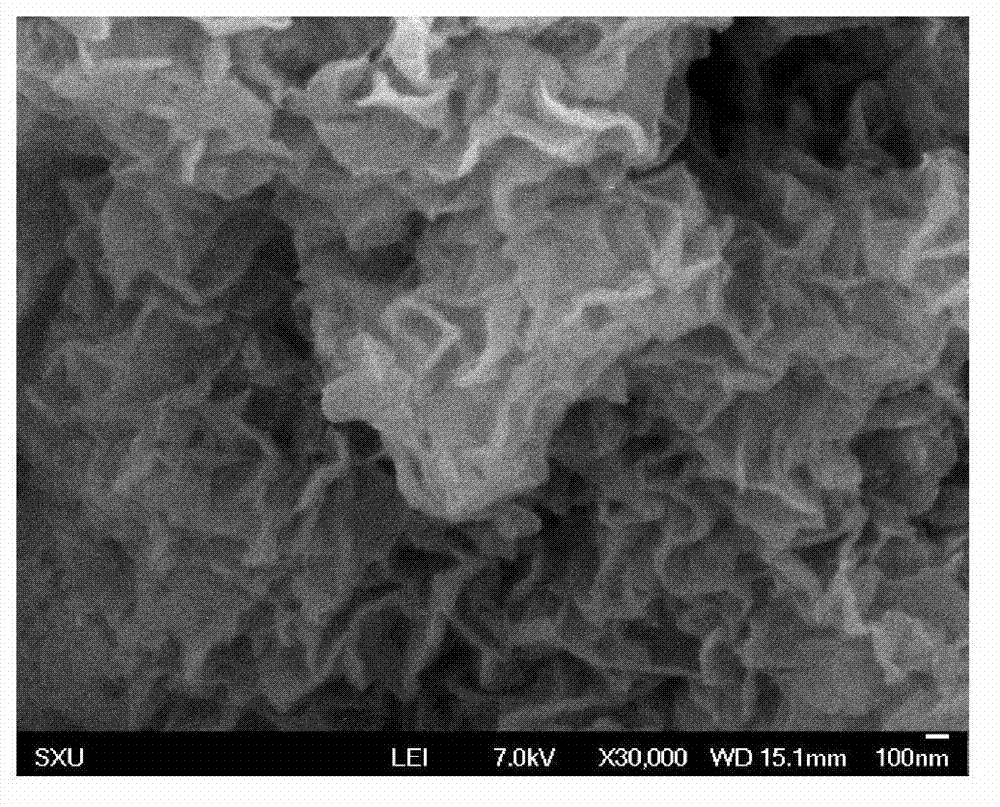

Silver-modified carbon nitride composite photocatalytic material and preparation method thereof

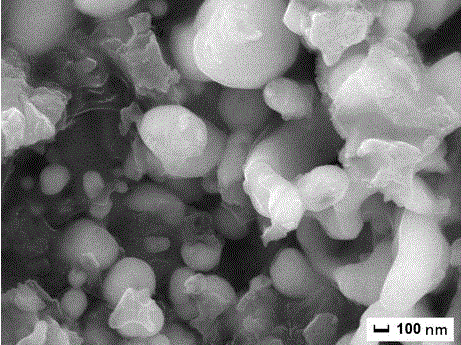

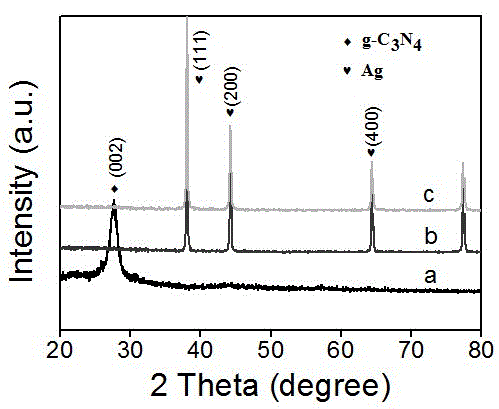

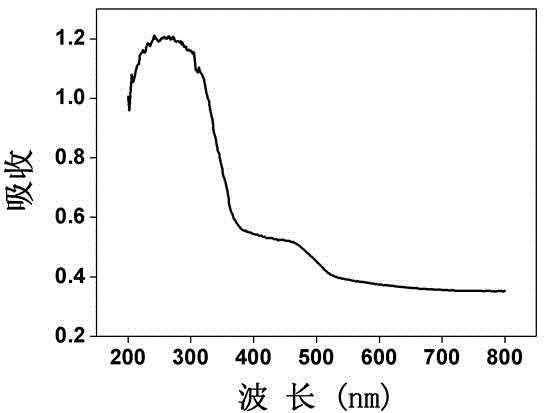

InactiveCN104475140AGood dispersionInhibitory complexPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeModified carbon

The invention relates to a silver-modified carbon nitride composite photocatalytic material and a preparation method thereof. The preparation method comprises: dissolving dicyanodiamide or melamine in deionized water or dimethyl sulfoxide and performing ultrasonic dispersing, so as to obtain a dicyanodiamide or melamine dispersion liquid; dissolving silver nitrate in deionized water and stirring uniformly, so as to obtain a silver nitrate solution; slowly dropwise adding the silver nitrate solution into the above dicyanodiamide or melamine dispersion liquid under the condition of magnetic stirring, and continuing stirring the solution, so as to obtain a mixed precursor solution; using anhydrous ethanol and deionized water repeatedly wash the obtained mixed precursor solution for multiple times, and performing vacuum drying; and putting the obtained product in a proper crucible and covering, putting in a high-temperature furnace, and sintering for a period under the condition of nitrogen protection, so as to obtain a powdery sample. The advantages comprise that the raw material source is wide, the preparation technology is simple and practicable, and the cost is relatively low; and the prepared composite photocatalytic material has relatively good photocatalytic degradation effect on organic dye rhodamine B under irradiation of visible light.

Owner:JIANGSU UNIV

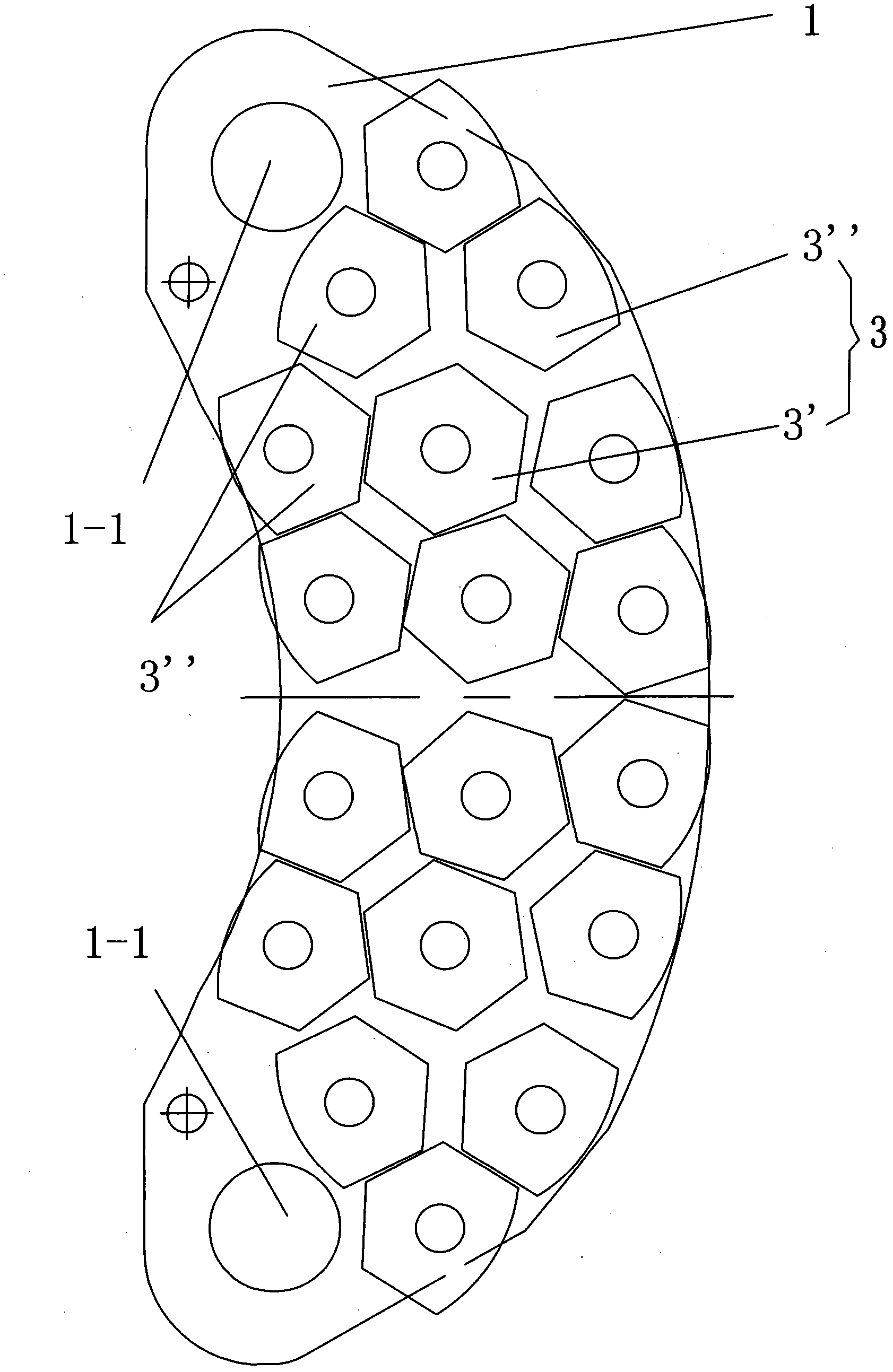

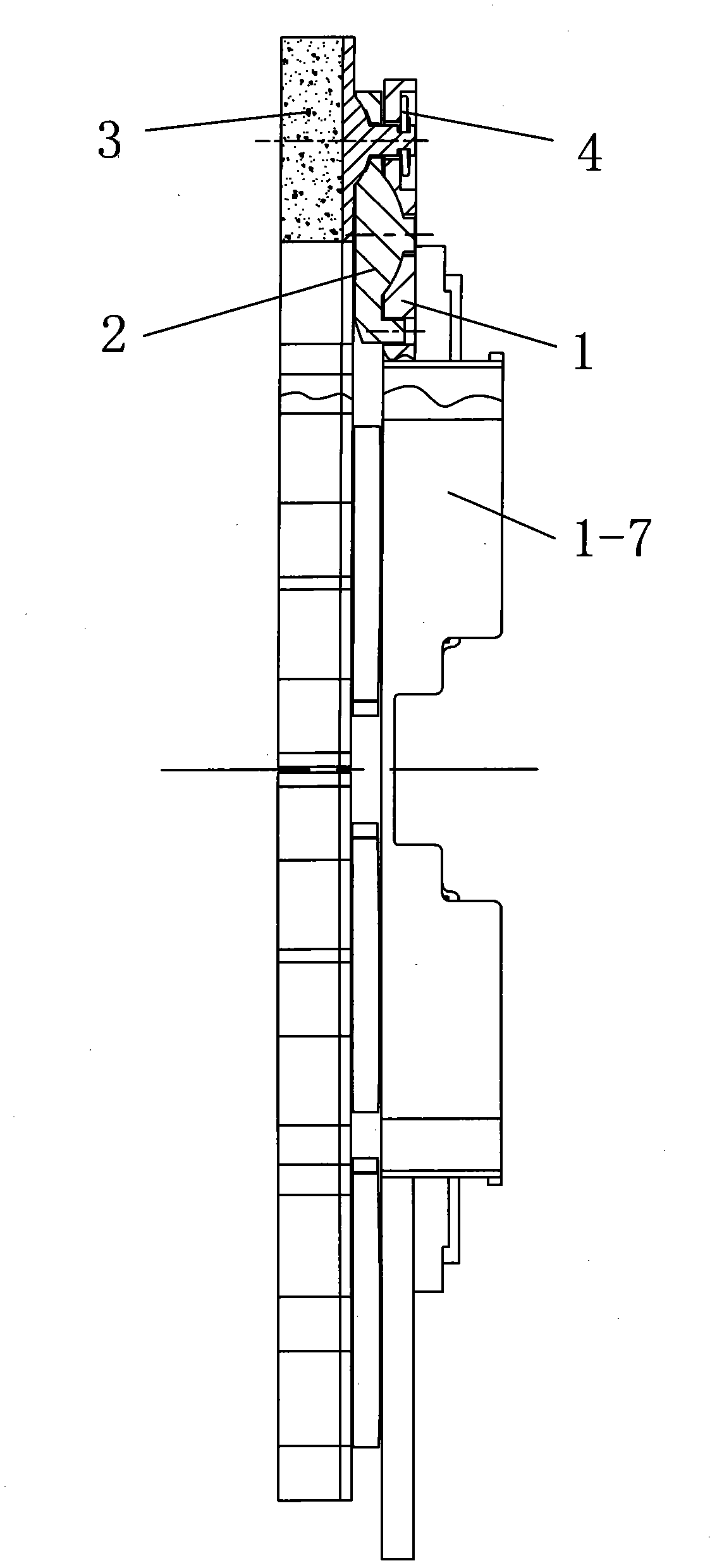

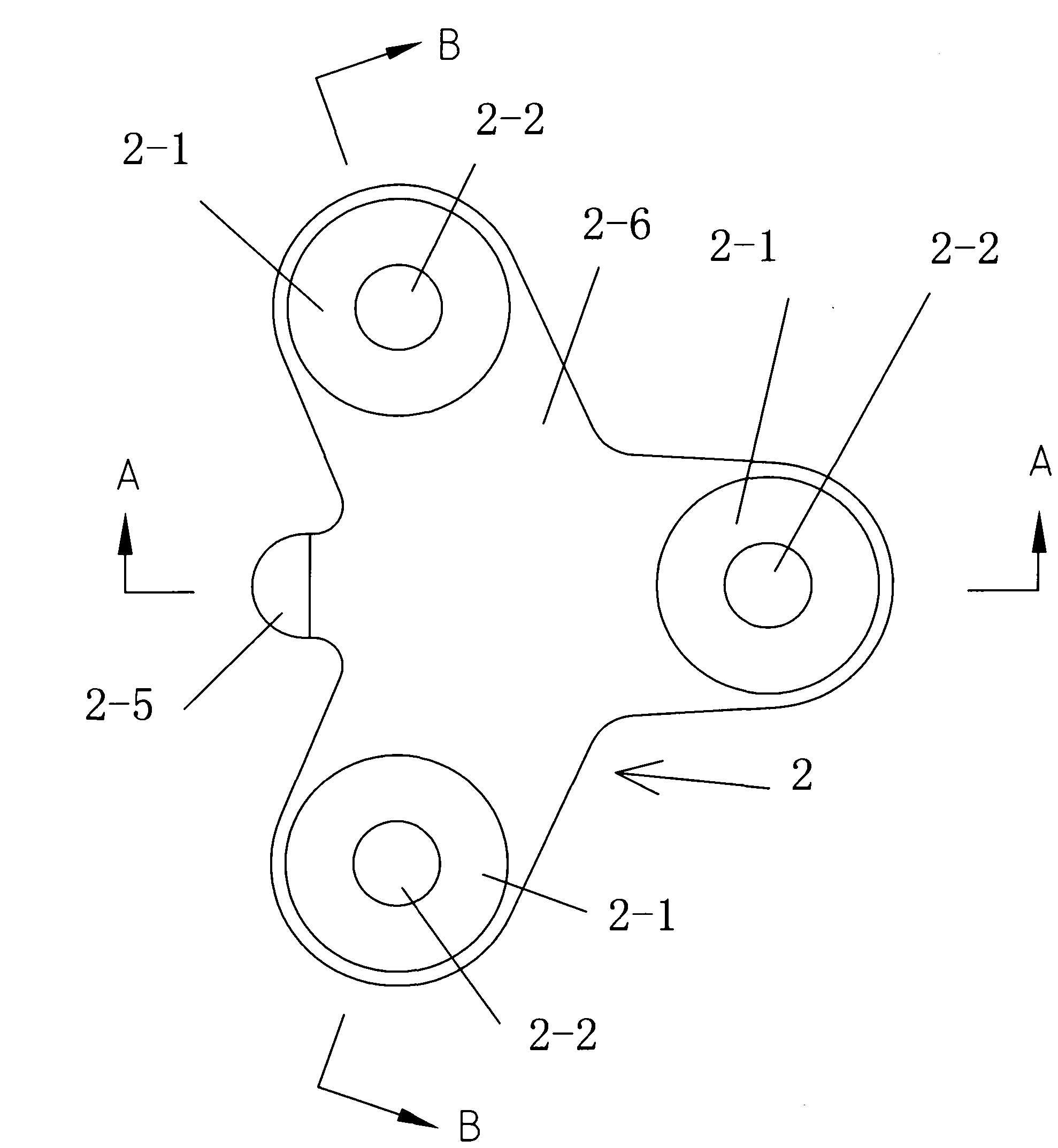

Train brake lining with adjuster

The invention discloses a train brake lining with an adjuster, comprising an installation plate, an adjuster, friction blocks and a spring retainer ring, wherein the adjuster comprise an installation lug boss and an adjuster positioning convex pin, a tail connection shaft for the friction blocks passes through a through hole on the adjuster and a friction block installation hole on the installation plate, and the end part of the tail connection shaft is elastically connected with the installation plate through the spring retainer ring; in the friction blocks, first friction blocks are hexagon bodies, second friction bodies are pentagon bodies, one face of five side faces of each second friction block, facing the outside of the installation plate, is a cambered face, the second friction blocks are arranged along the periphery of the front side of the installation plate and surround the first friction blocks in the middle, or the second friction blocks are distributed along the inner and outer arc edges of the front side of the installation plate in two rows and sandwich the first friction blocks. The train brake lining with the adjuster can improve an effective friction area during working and effectively decrease the occurrence of the phenomena of cracking, falling, defecting, performance declination and the like of the friction blocks, and has strong heat dissipation capability.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Silicon dioxide loaded nano-silver waterborne antibacterial paint and preparation method thereof

InactiveCN107189585AImprove antibacterial propertiesNo discolorationAntifouling/underwater paintsPaints with biocidesDispersityFoaming agent

The invention discloses silicon dioxide loaded nano-silver waterborne antibacterial paint and a preparation method thereof, and belongs to the field of chemical paint. The paint is prepared from the following components: water, acrylic resin, polyurethane resin, a porous silicon dioxide loaded nano-silver antibacterial agent, a dispersant, a curing agent, a de-foaming agent, a film-forming auxiliary agent and a flatting agent. According to the silicon dioxide loaded nano-silver waterborne antibacterial paint, nano-silver is loaded in porous silicon dioxide, so that the effect of protecting the nano-silver is realized; a releasing speed of the nano-silver can also be slowed down to a certain extent, so that the antibacterial time of the paint is more durable. A pore channel space is limited and a special preparation process is adopted (under the protection effect of PVP (Polyvinyl Pyrrolidone)), the size of the nano-Ag is controlled to be only 3nm to 5nm, so that the specific surface area of the nano-Ag is greatly increased. Furthermore, a special pore channel of the porous silicon dioxide has a fixation effect on the nano-Ag, so that the nano-Ag is not easy to aggregate and has good dispersity in a solution, and the antibacterial performance of the paint is improved.

Owner:FUZHOU UNIV

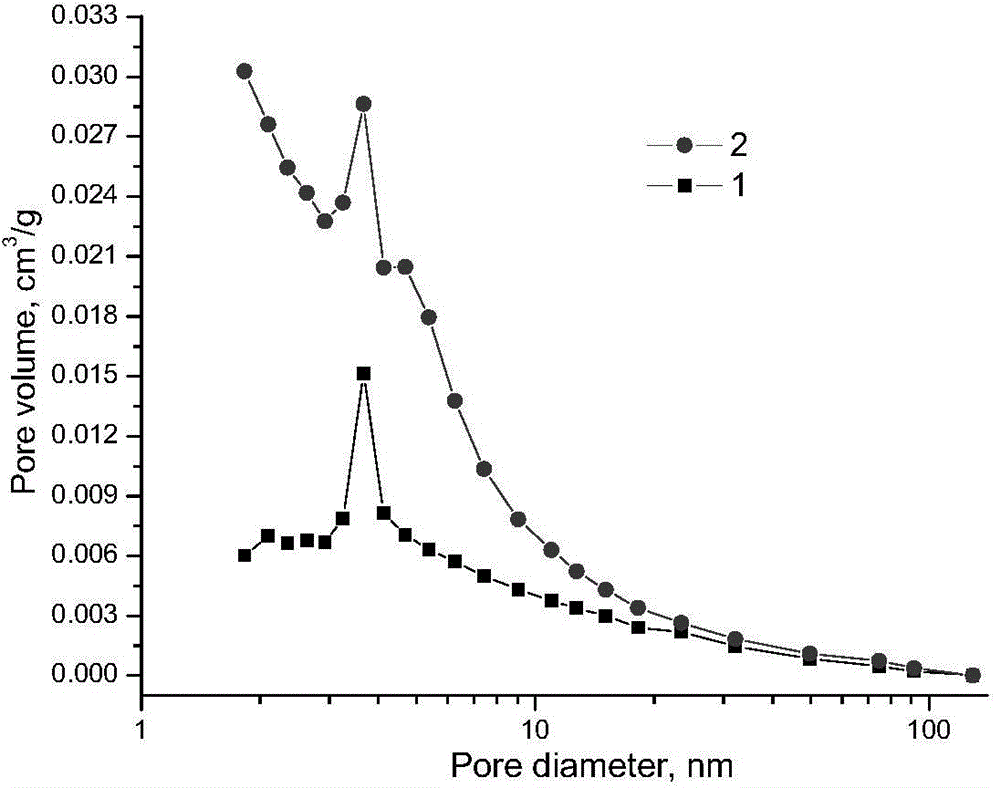

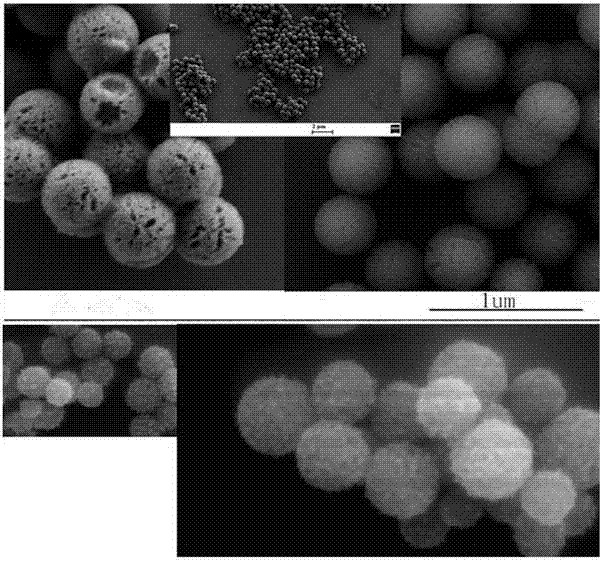

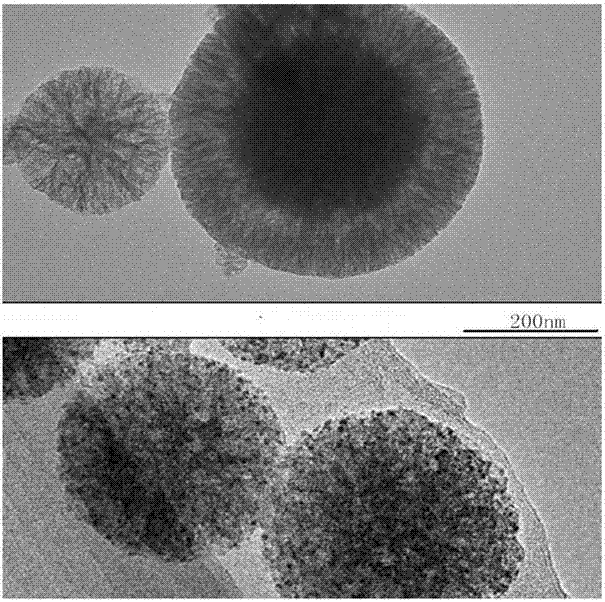

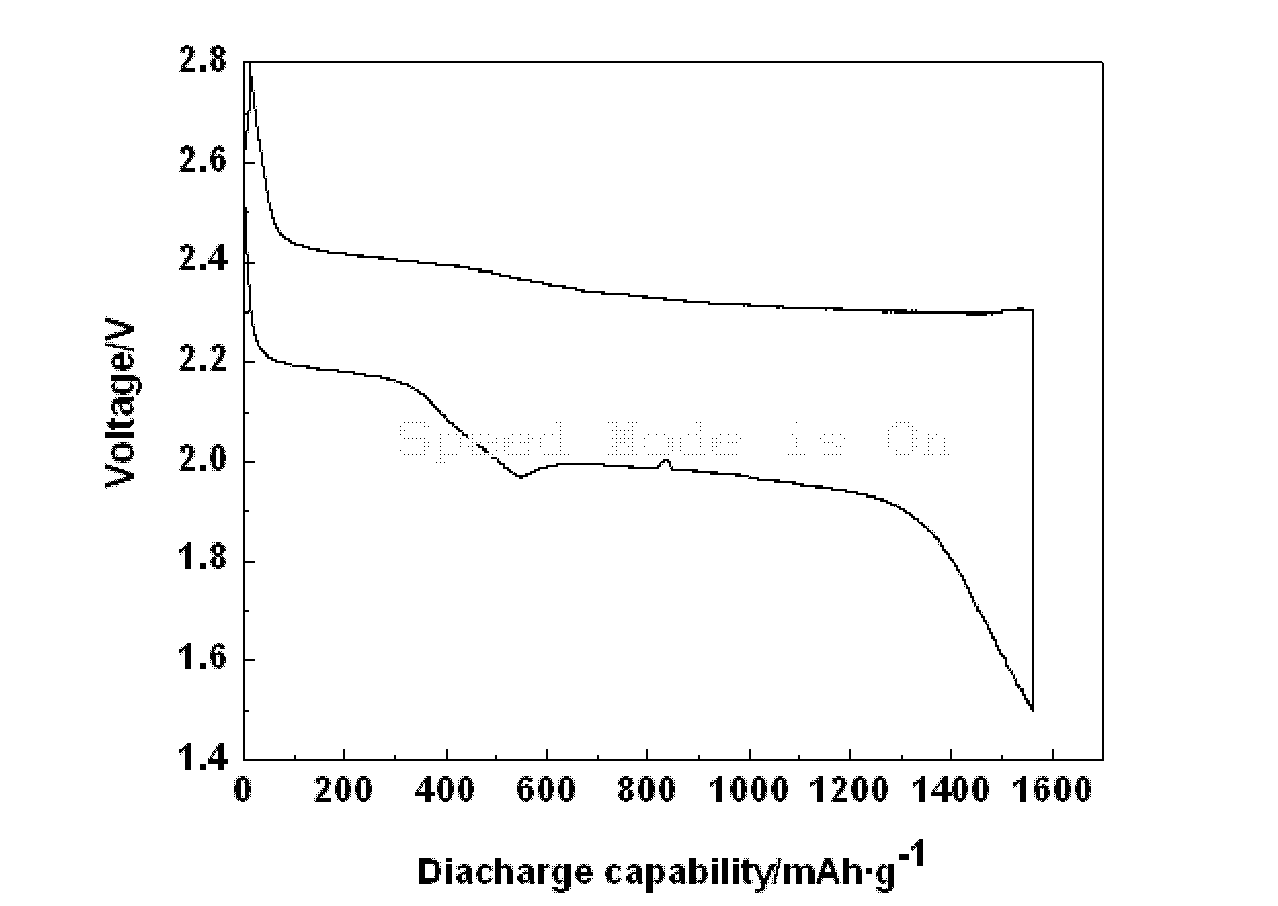

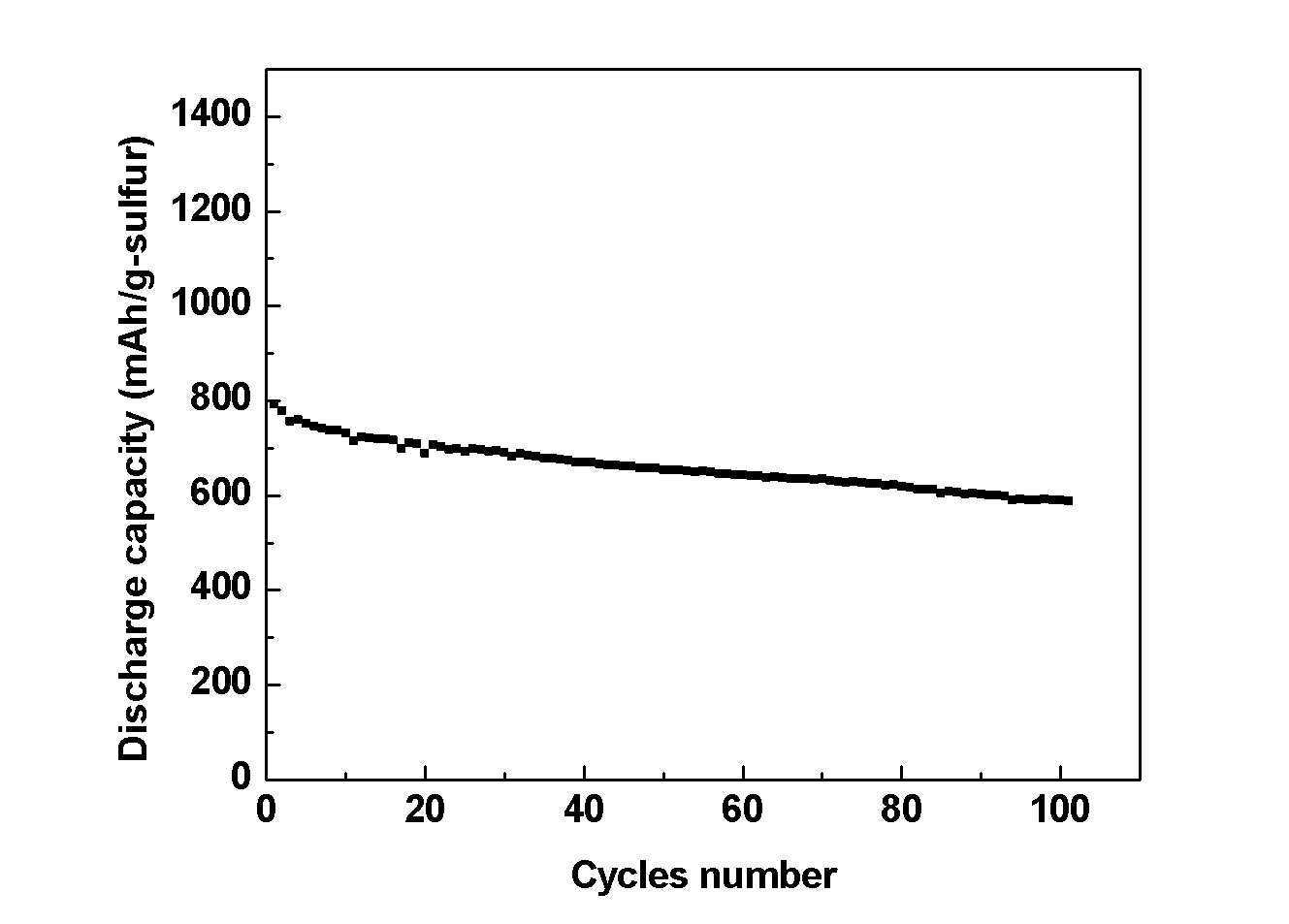

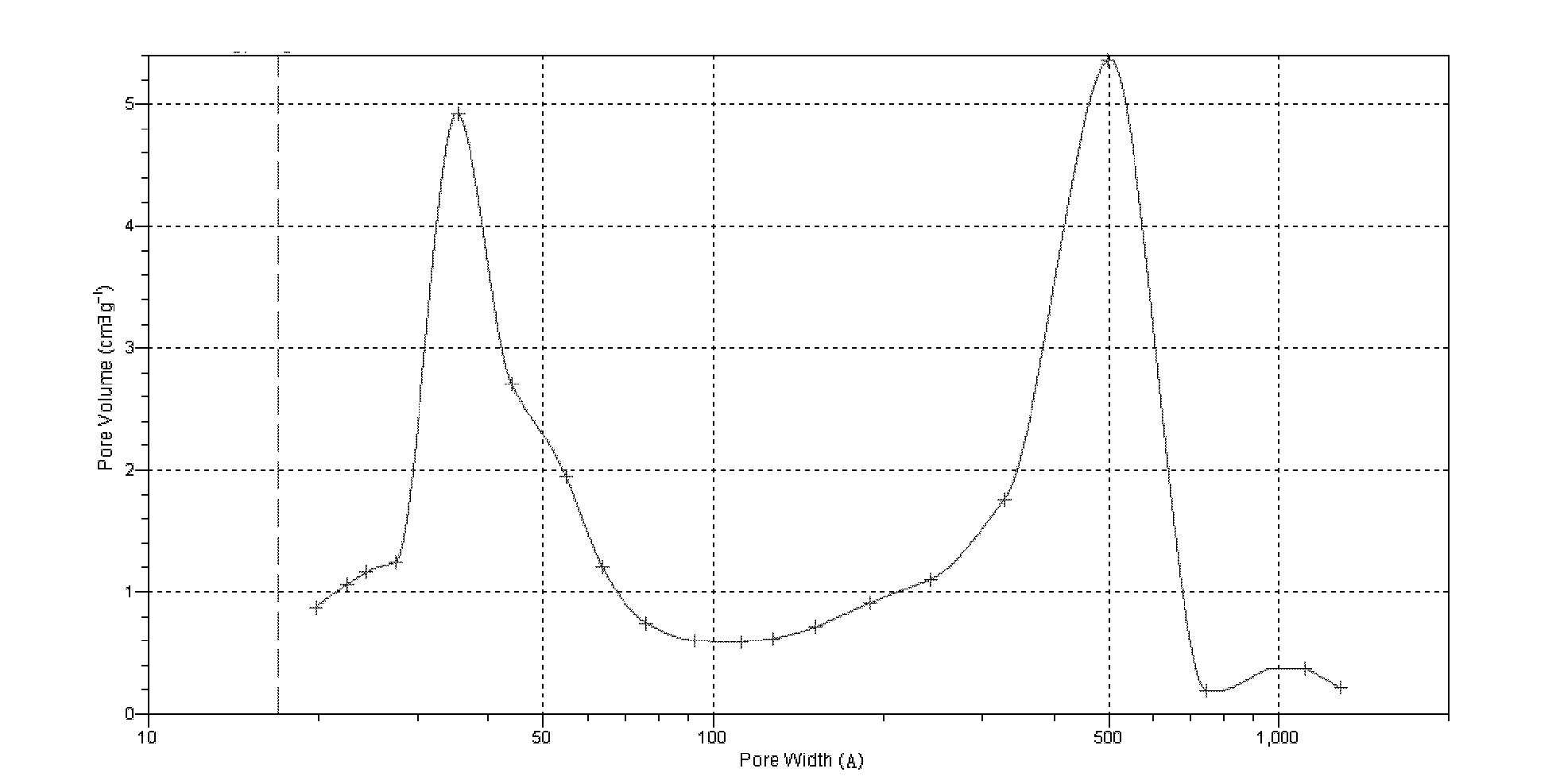

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

Method for preparing magnetic active carbon composite material for water processing

InactiveCN101502789APreserve the open cell structureImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionMagnetite NanoparticlesHigh pressure

The invention provides a method for preparing a magnetic active carbon composite material for water treatment in the technical field of environmental purification. The method comprises the following steps: mixing active carbon and corresponding metal salt solution, and generating magnetic nano granules in pore canals of the active carbon in situ by using the characteristics of instantaneous high temperature, high pressure, high cooling speed and the like generated by ultrasonic waves; and filtering and drying the obtained compound, and treating the compound at high temperature to form the magnetic active carbon composite material, wherein the magnetic material accounts for 15 to 50 percent in the whole material in terms of weight percentage, and the active carbon material accounts for 85 to 50 percent. The invention provides a new method for generating magnetic nano particles in the pore canals of the active carbon; and the prepared magnetic active carbon keeps larger specific surface area, reserves the open pore canals from the active carbon, removes organic substances and inorganic heavy metal ions in water treatment, and is easy for magnetic separation and convenient to recover.

Owner:SHANGHAI JIAO TONG UNIV

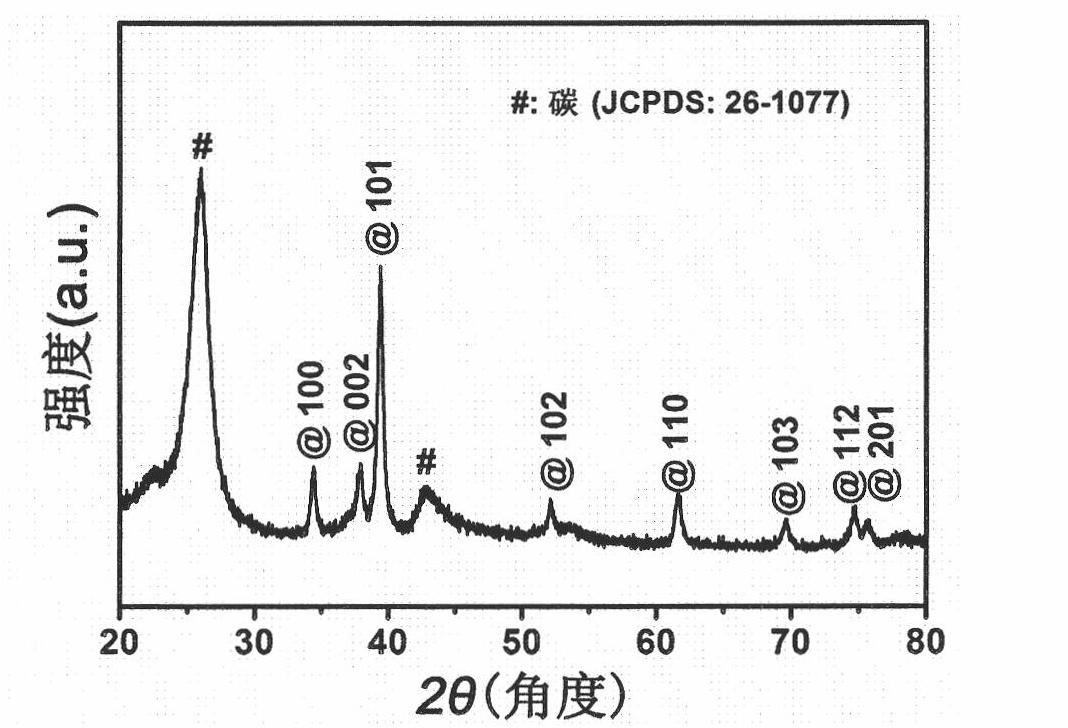

Synthetic method of load type molybdenum carbide catalyst

InactiveCN101829588AFacilitated DiffusionLarger than surfaceHydrogenPhysical/chemical process catalystsCarbon nanotubeMolybdenum carbide

The invention relates to a synthetic method of a load type molybdenum carbide catalyst, which belongs to the field of catalytic materials and comprises the steps of: dispersing organic-inorganic mixed molybdenum oxide-polyaniline used as precursors in H2O / EtO; drying after mixing with carriers, such as carbon nanotubes and the like; and then roasting at an inert atmosphere to obtain the load typemolybdenum carbide catalyst. In the load process, other metal salts can also be added to modify the molybdenum carbide catalyst to obtain a metal modified load type molybdenum carbide catalyst. The molybdenum carbide catalyst prepared by the invention has the advantages of large external surface area, less surface carbon deposition, abundant catalytic performance of precious metal and the like, and can be used for conveniently modifying the catalyst. The loading molybdenum carbide catalyst has important application in various catalytic reactions.

Owner:FUDAN UNIV

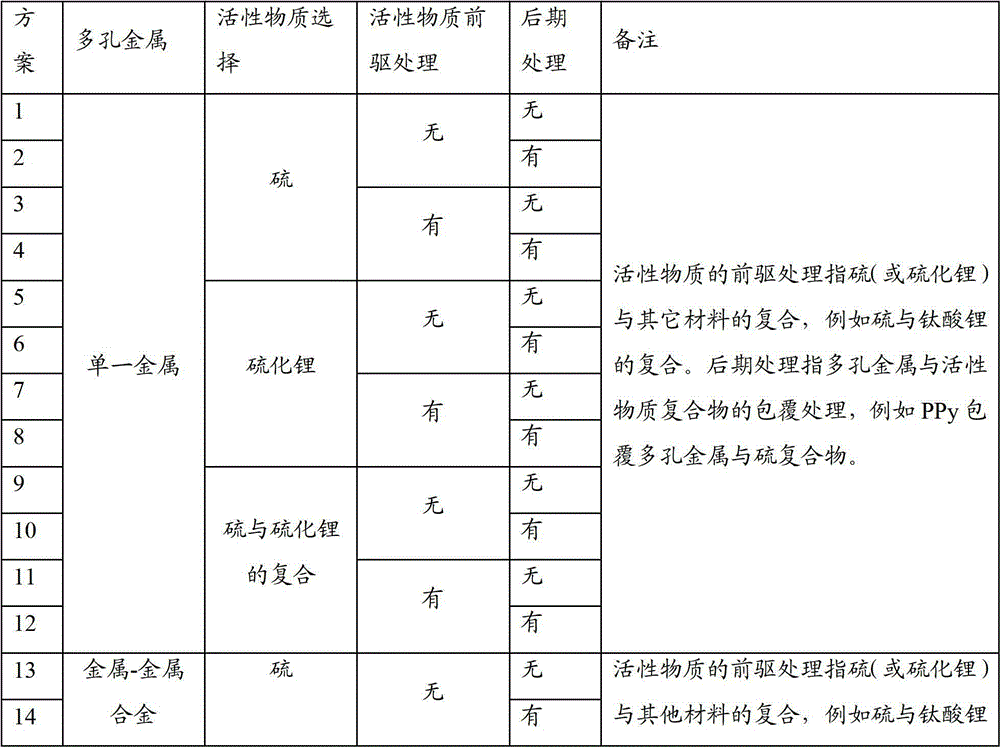

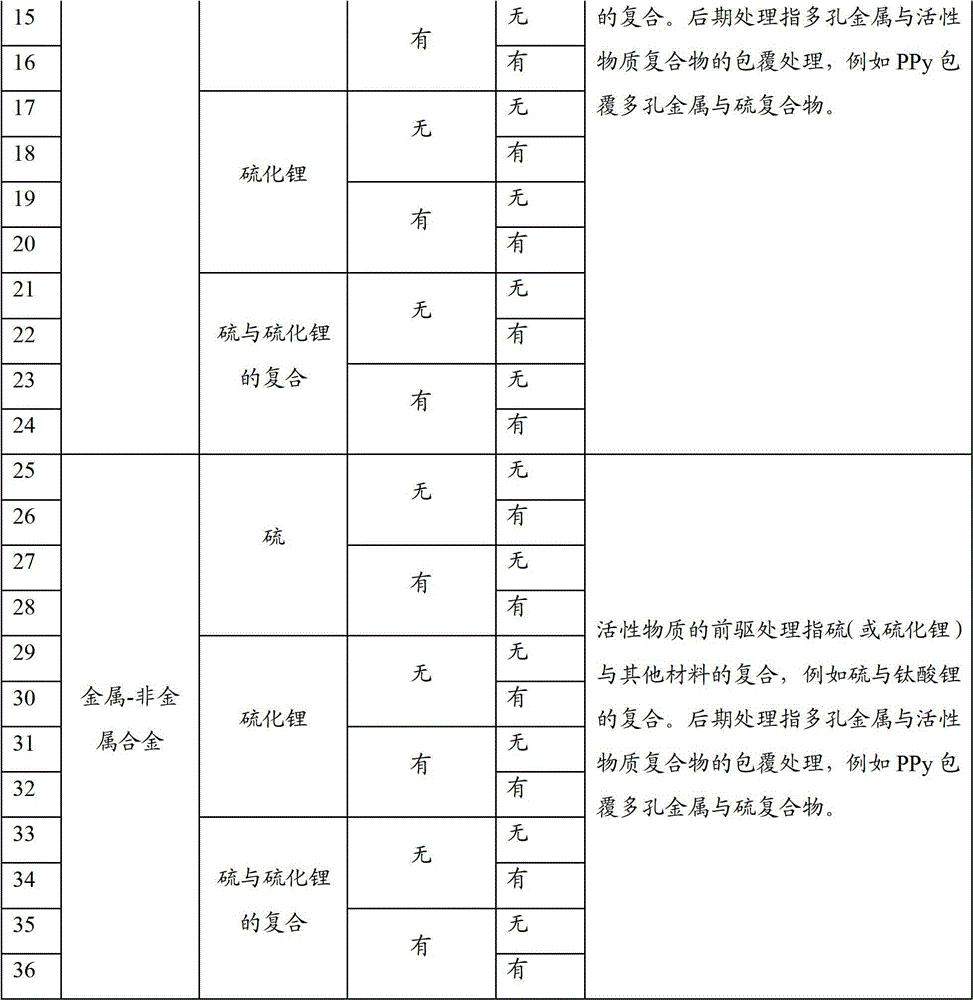

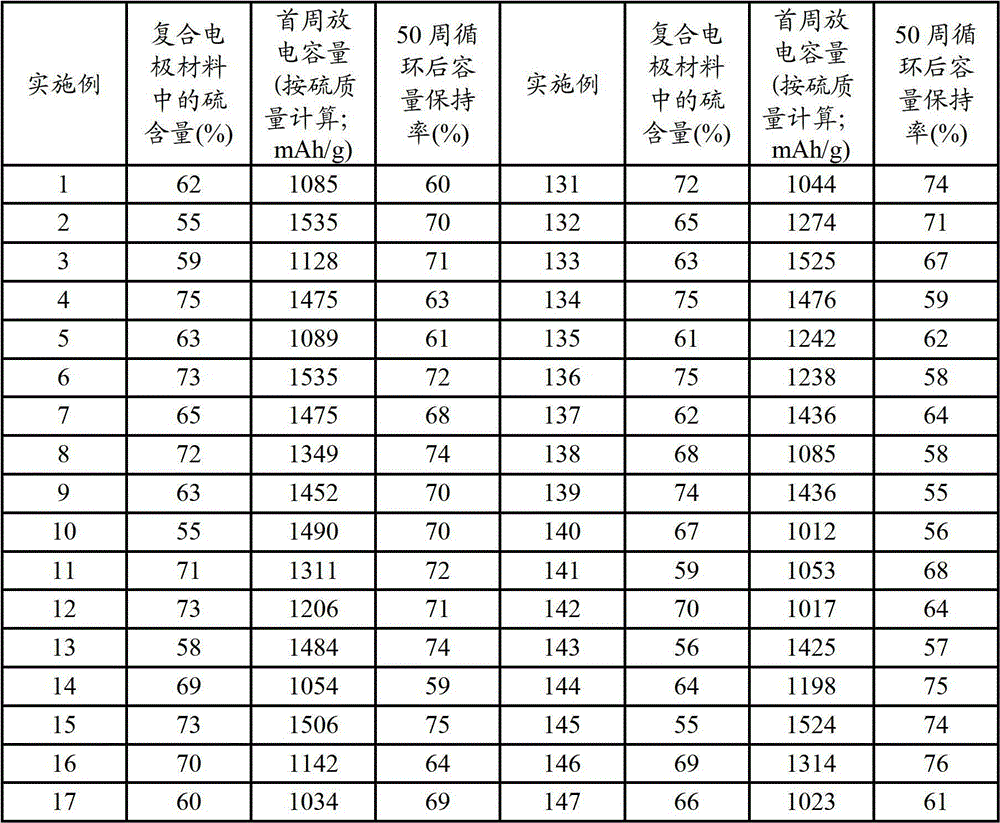

Lithium-sulfur battery anode material comprising porous metal and preparation method thereof

ActiveCN102723470ALarger than surfaceHigh porosityCell electrodesLithium sulfideLithium–sulfur battery

The invention discloses lithium-sulfur battery anode material comprising porous metal. The porous metal is compounded with lithium sulfide so as to be used as the anode material of the lithium-sulfur battery. The invention also discloses a preparation method of the lithium-sulfur battery anode material comprising the porous metal. According to the invention, by utilizing the characteristics of high electric conductivity, high porosity, high specific surface area and the like of the porous metal, elemental sulfur or the lithium sulfide is filled into pores of the porous metal, metal / sulfur composite material can be manufactured, and the utilization rate of the elemental sulfur and the lithium sulfide and the multiplying performance of the composite electrode can be increased; and simultaneously, by utilizing the strong interaction between the porous metal and the elemental sulfur or the lithium sulfide, the elemental sulfur, the lithium sulfide or polysulfide generated in a charge-discharge process can be more firmly attached on the surface of the porous metal, the dissolution of the polysulfide in an electrolyte, the shuttle effect caused by the dissolution of the polysulfide in the electrolyte and the deactivation on an anode and a cathode by redox product of the polysulfide can be restrained, and the circulation stability of a metal / sulfur composite electrode and the lithium-sulfur battery can be increased.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

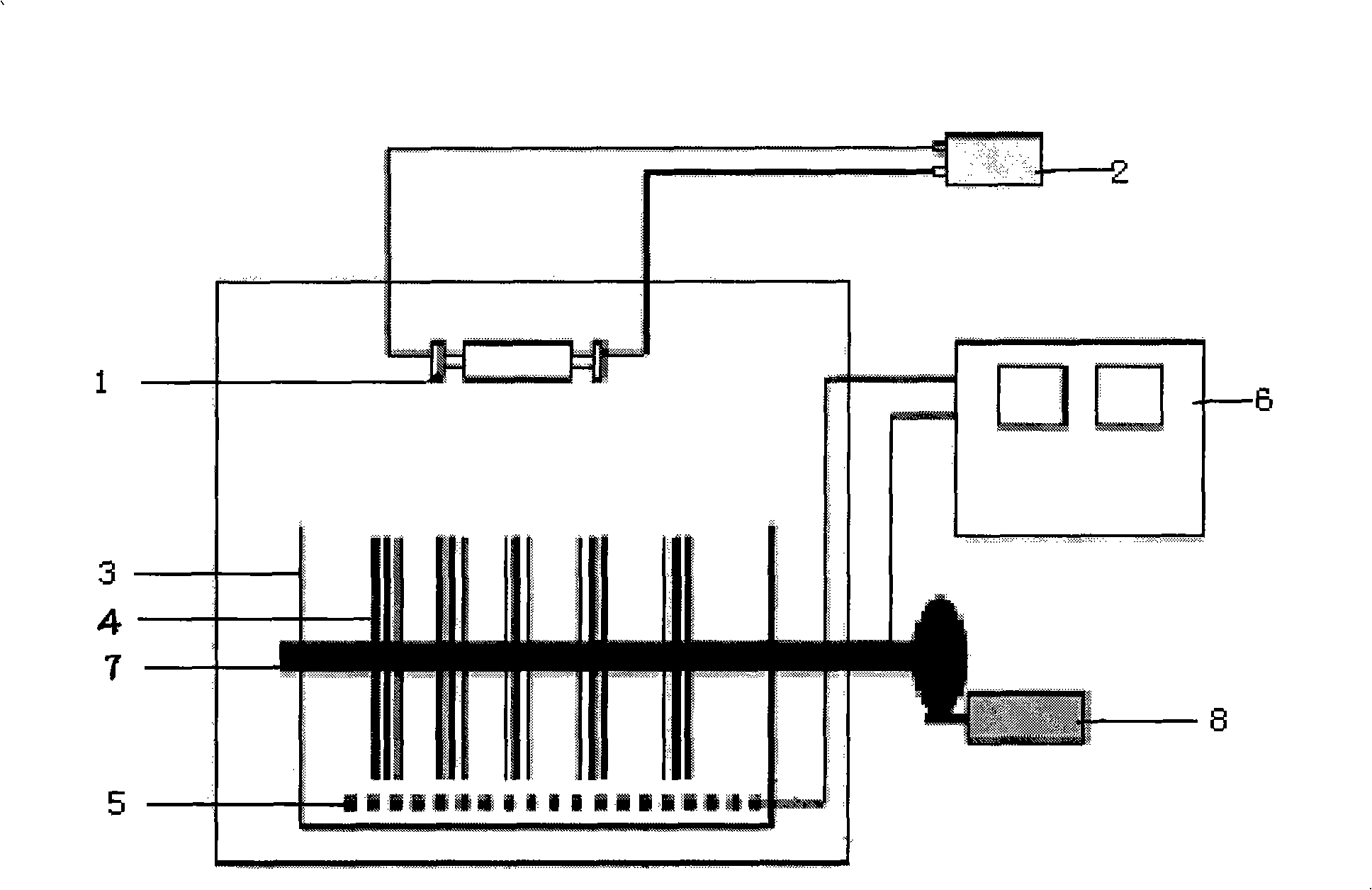

Photoelectric catalysis degrading organic reactor with swivel disc loaded with catalyst and degrading method

InactiveCN101327968AKeep aliveInhibitory complexWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsUltravioletOxygen

The invention discloses a reactor for photoelectrocatalysis degradation of organic compounds using a rotary table supported with a catalyst, and a method for degrading the organic compounds by the reactor. The reactor comprises a rotary table supported with a photo-electro catalytic activity catalyst as the anode of the reactor, a motor driving the rotary table to rotate, a conductive granular activated carbon which can electrically catalyze the oxygen to generate hydrogen peroxide as the cathode, an ultraviolet or visible light source arranged in the reactor. The hydrogen peroxide generated from the activated carbon cathode forms hydroxyl radical under the action of the ultraviolet and degrades the organic compounds around both the anode region and the cathode region; the application of the rotary table avoids the light adsorption of the solution and accelerates the transfer of oxygen in the solution, which obviously improves the catalysis degradation efficiency of the refractory organic compounds.

Owner:GUANGDONG UNIV OF TECH

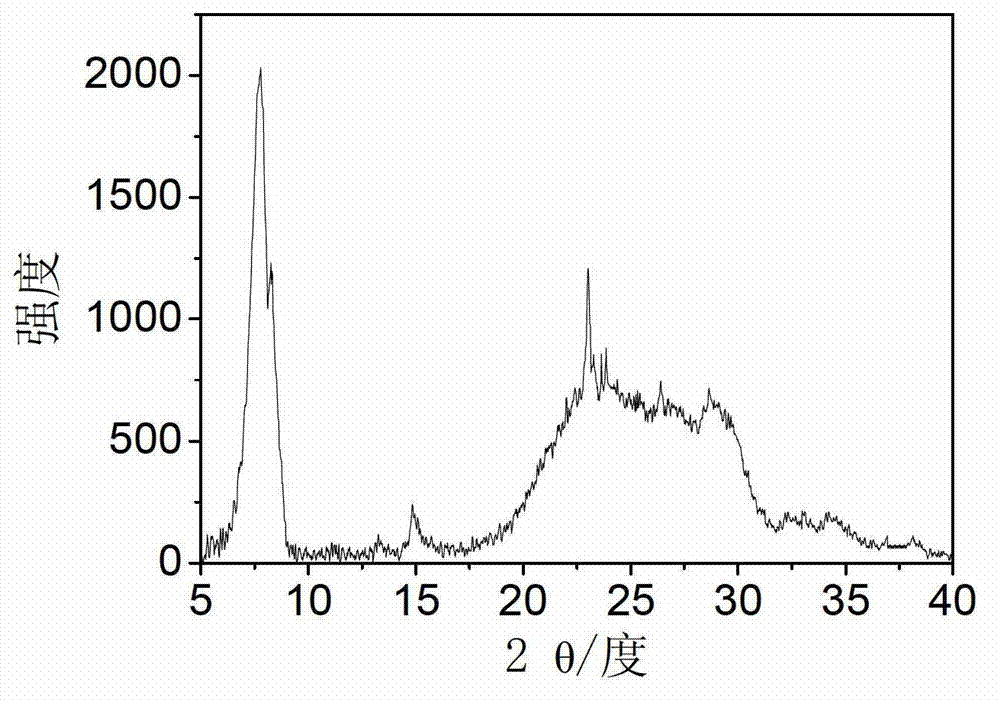

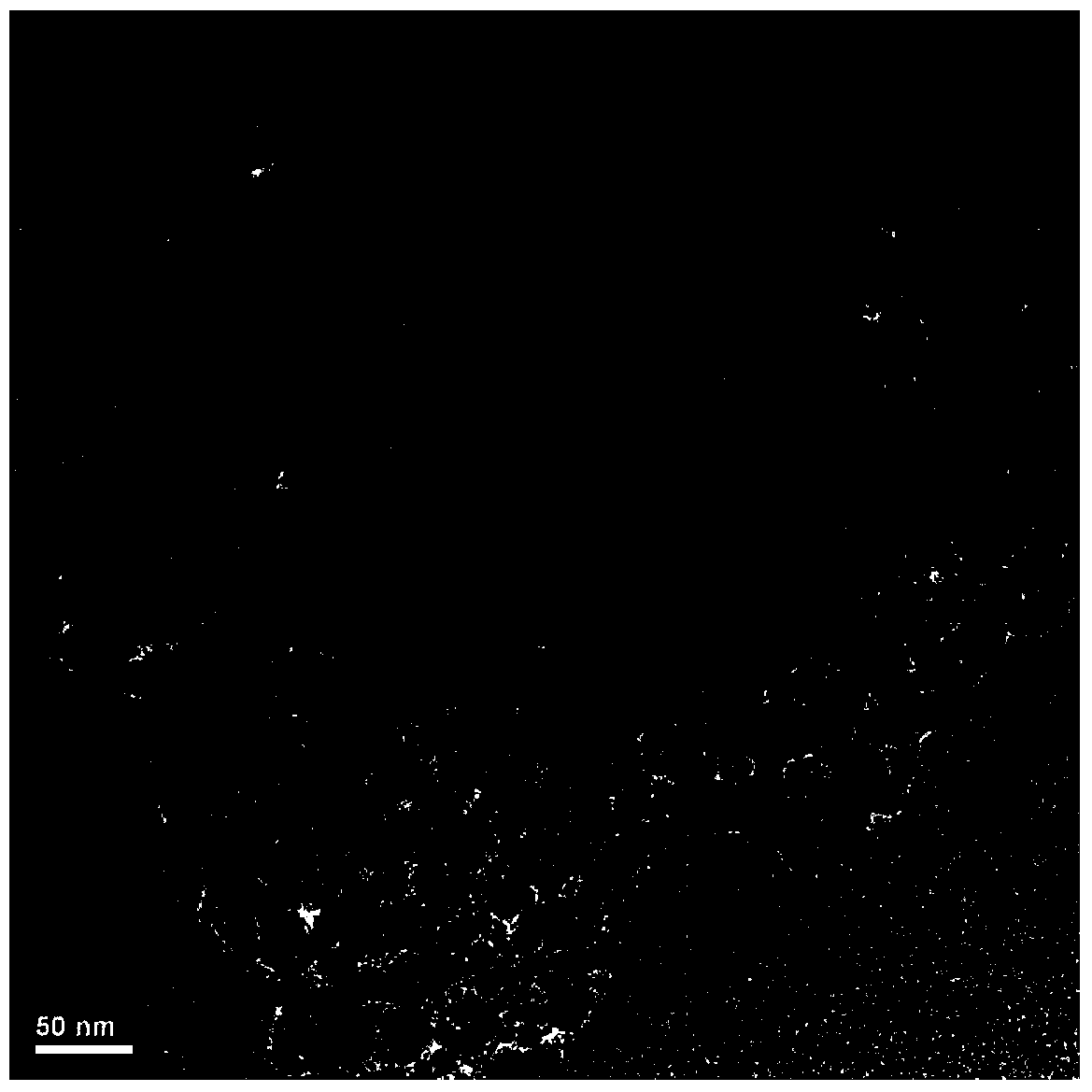

Preparation method of nano layered ZSM (Zeolite Molecular Sieve)-5 zeolite molecular sieve

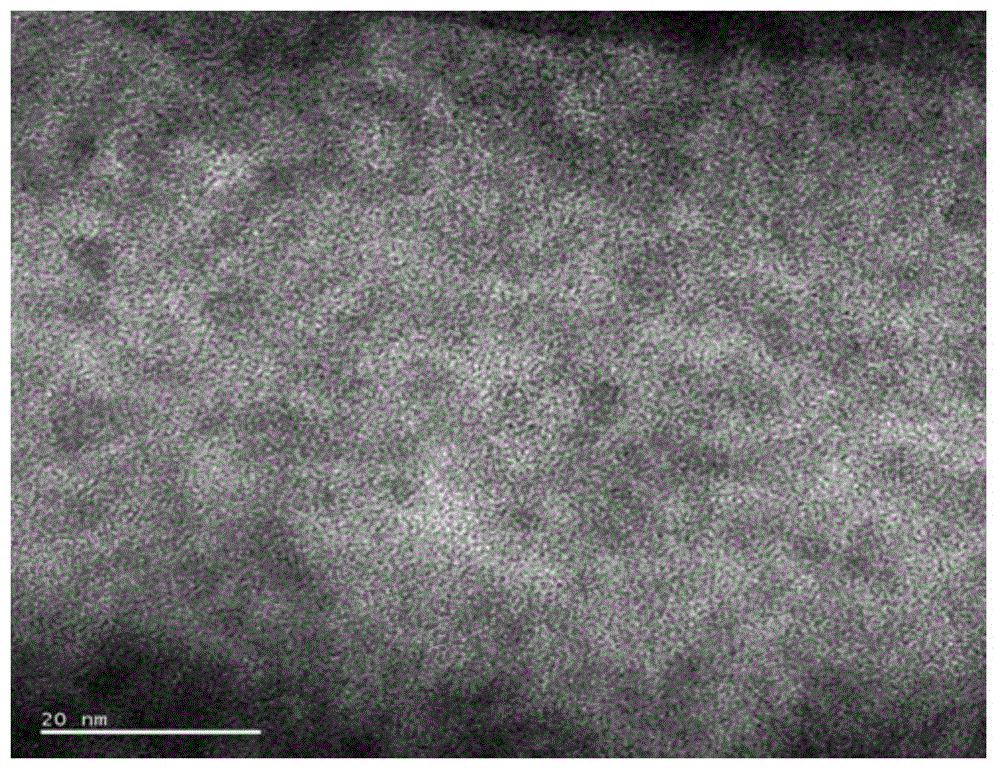

InactiveCN103043681AHigh activityHigh p-xylene selectivityMaterial nanotechnologyPentasil aluminosilicate zeoliteMolecular sieveThin layer

The invention relates to a method for preparing a nano layered ZSM (Zeolite Molecular Sieve)-5 zeolite molecular sieve by using a micro-emulsion. The preparation method comprises the following preparation steps of: preparing a zeolite pecursor solution in an oxide molar ratio of Al2O3 to SiO2, TPA2O, Na2O and H2O as 1:(100-400):(1-100):(300-3000); mixing the prepared zeolite pecursor solution with an oil phase, a surfactant and a co-surfactant in a certain ratio to prepare a W / O (water-in-oil) micro-emulsion, then transferring the prepared micro-emulsion to a crystallization kettle, sealing and statically crystallizing for 6-72 hours at a temperature of 90-120 DEG C. The thin layer of the molecular sieve prepared by the invention has a thickness of about 30nm, a regular shape and a crystallization degree of greater than 90%; the used organic phase can be repeatedly used by separating after the synthetic process of the molecular sieve ends, so that the synthetic cost is reduced; and the method disclosed by the invention is an environmentally-friendly synthetic method.

Owner:SHANXI UNIV

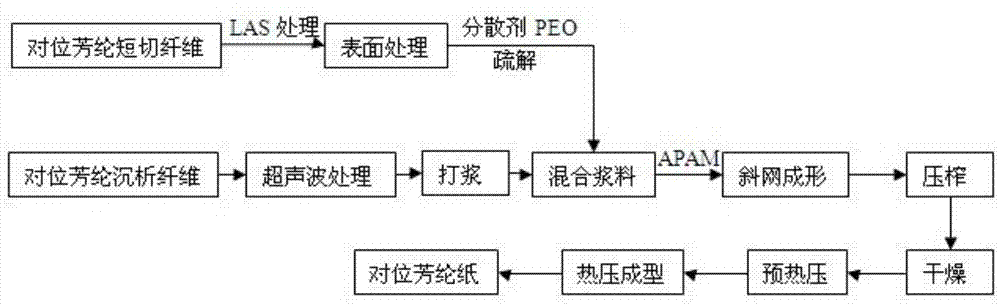

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

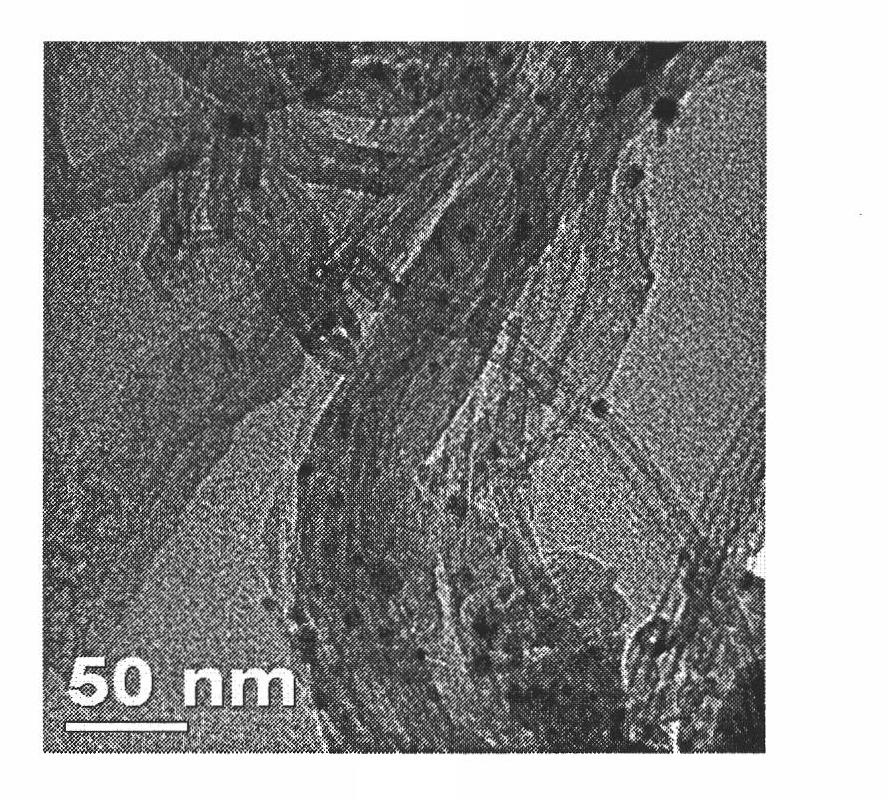

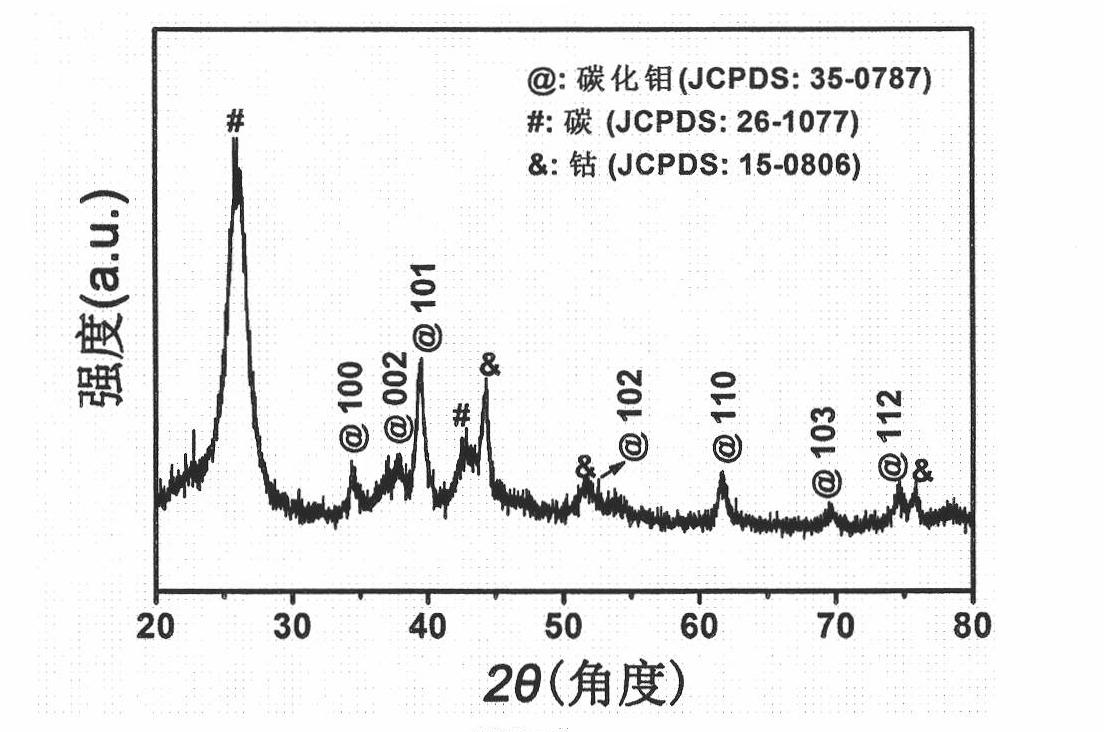

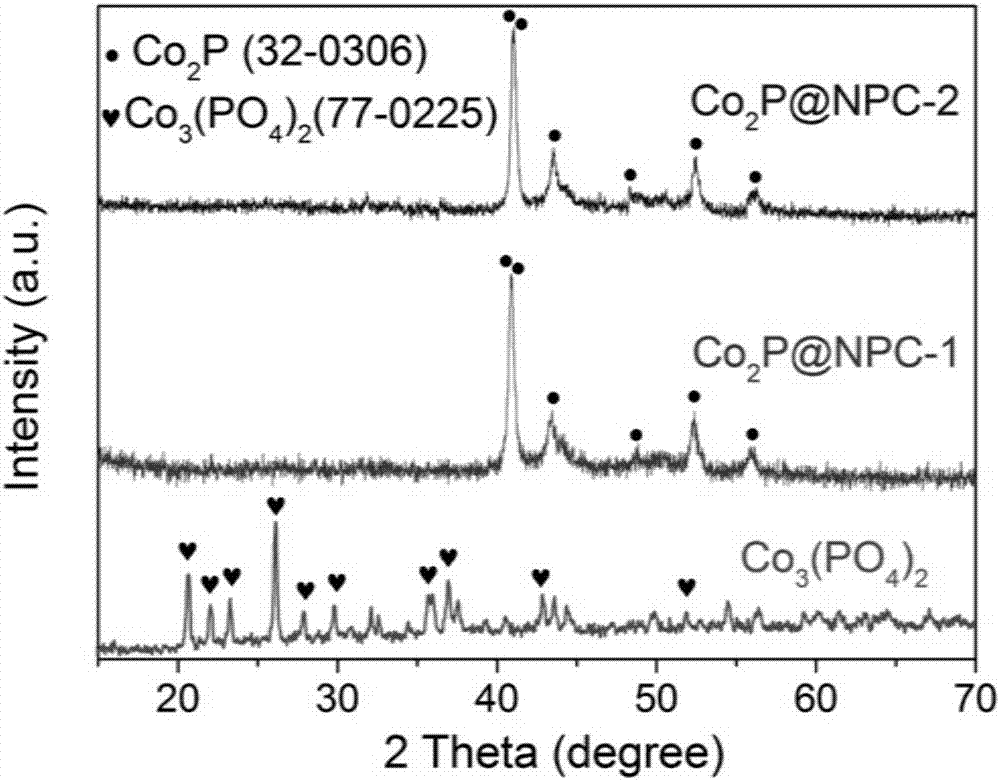

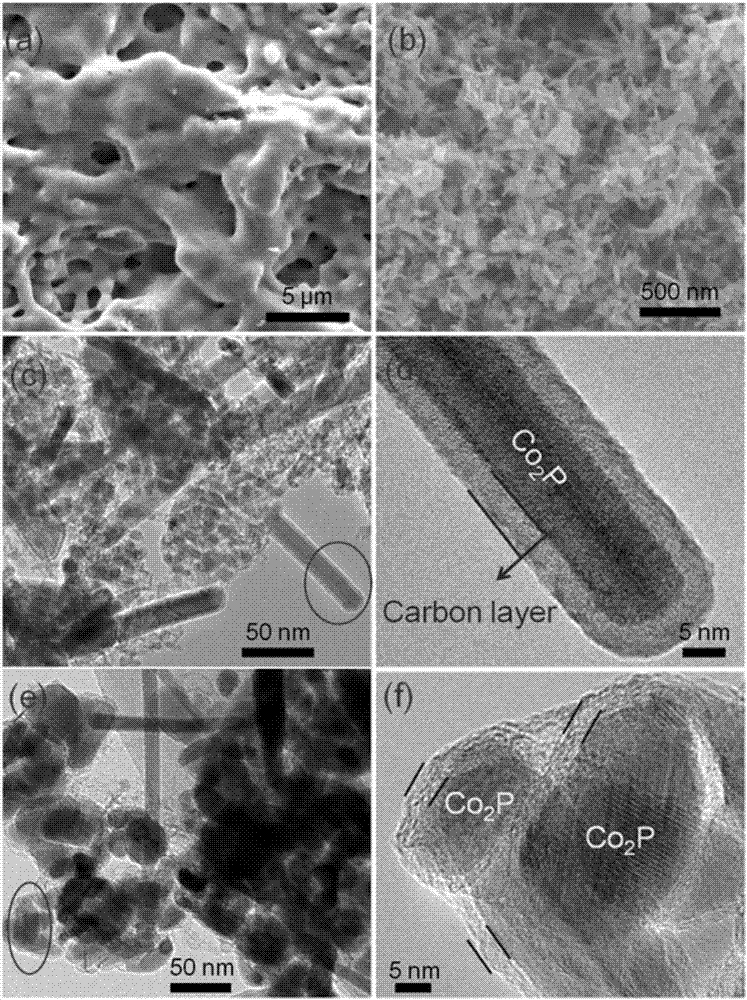

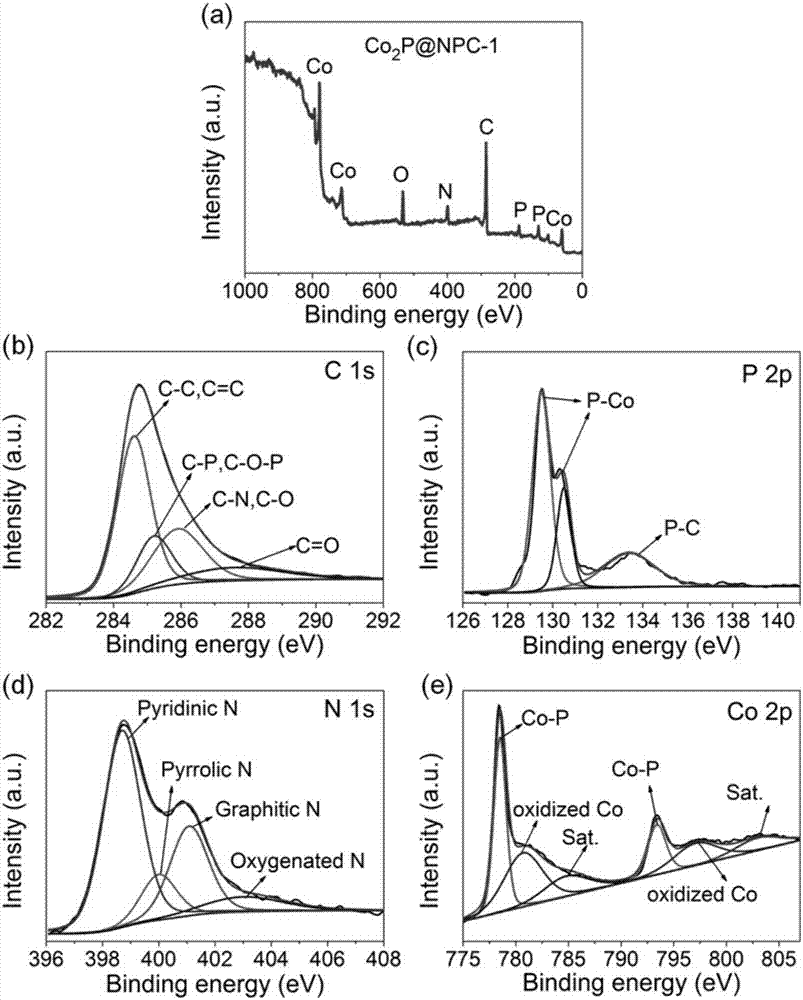

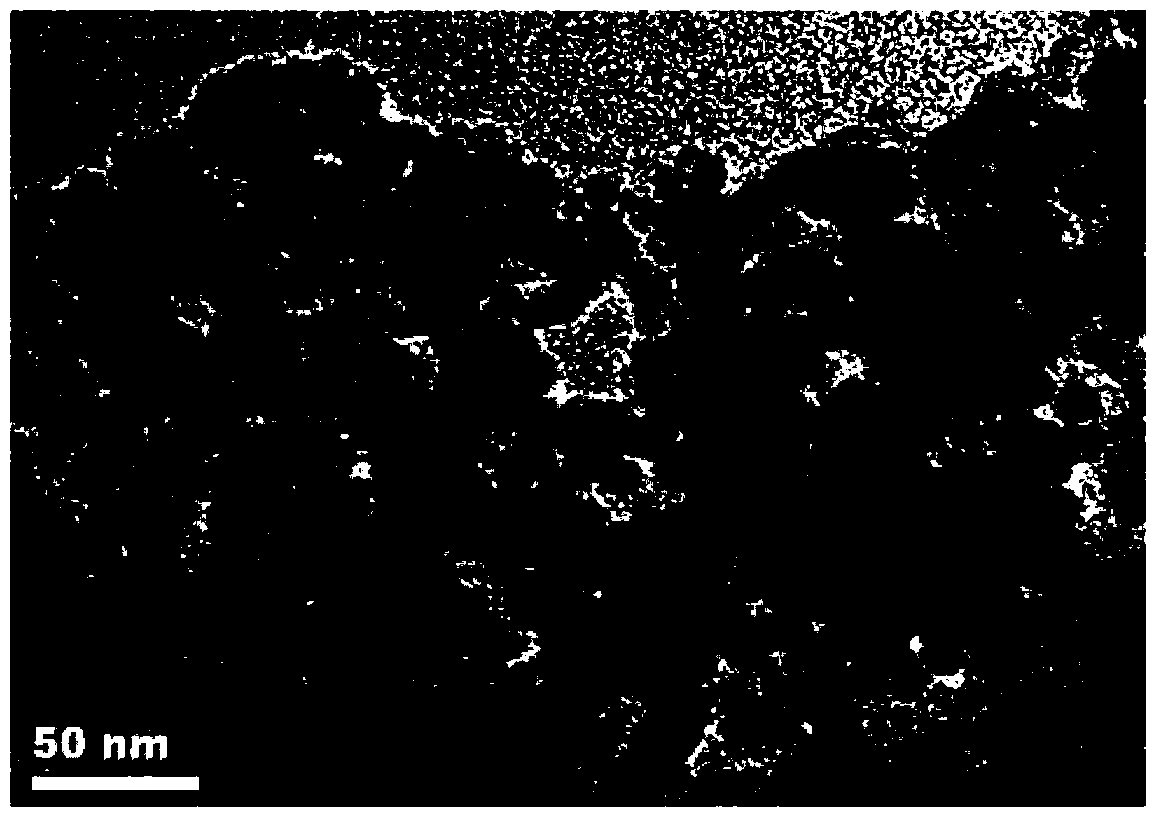

Oxygen reduction and oxygen evolution cobalt phosphide@NPC double-function compound catalyst and preparation method and application thereof

ActiveCN107051559AHigh catalytic activityImprove electrocatalytic performancePhysical/chemical process catalystsCell electrodesCarbon layerDecomposition

The invention discloses an oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst and a preparation method and application thereof. The compound catalyst comprises N-P-codoped carbon layer coated Co2P nano rods and / or nano particles. The preparation method includes: evaporating and drying the solution of cobalt acetate, concentrated phosphoric acid and urea, and performing high-temperature treatment under protective atmosphere to obtain the compound catalyst. The preparation method has the advantages that the method is simple, low in cost and beneficial to industrial production; the prepared oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst is applicable to fuel cell and water decomposition, high in activity and good in stability, the catalytic performance of the compound catalyst is close to that of a commercial precious metal 20wt% Pt / C and RuO2 catalyst, and the compound catalyst is promising in application prospect.

Owner:CENT SOUTH UNIV

Magnetic Prussian blue carbon nano composite material and manufacturing method and application thereof

InactiveCN103406097ALarger than surfaceFast magnetic responseOther chemical processesInorganic material magnetismCarbon compositesMicrosphere

The invention relates to a magnetic Prussian blue carbon nano composite material and a manufacturing method and application thereof, and aims to solve the problems that the conventional magnetic composite material is nonuniform in shape, low in the content of Prussian blue layers, and susceptible to falling off. The manufacturing method comprises the following steps: firstly, magnetic inorganic nano particles are anchored on the surface of a carbon nano material (oxidized graphene / carbon nano tube) with high specific surface area; then, Prussian blue nano crystal layers are grown on the surfaces of the magnetic inorganic nano particles in situ; finally, the composite material is encapsulated into calcium alginate microspheres. The prepared composite material is used for the restoration of caesium ion pollution environments such as water bodies, soil and atmosphere, and has a broad application prospect in the field of nuclear pollution environment restoration. The manufacturing method is simple, uses available raw material, and is suitable for large-scale production.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

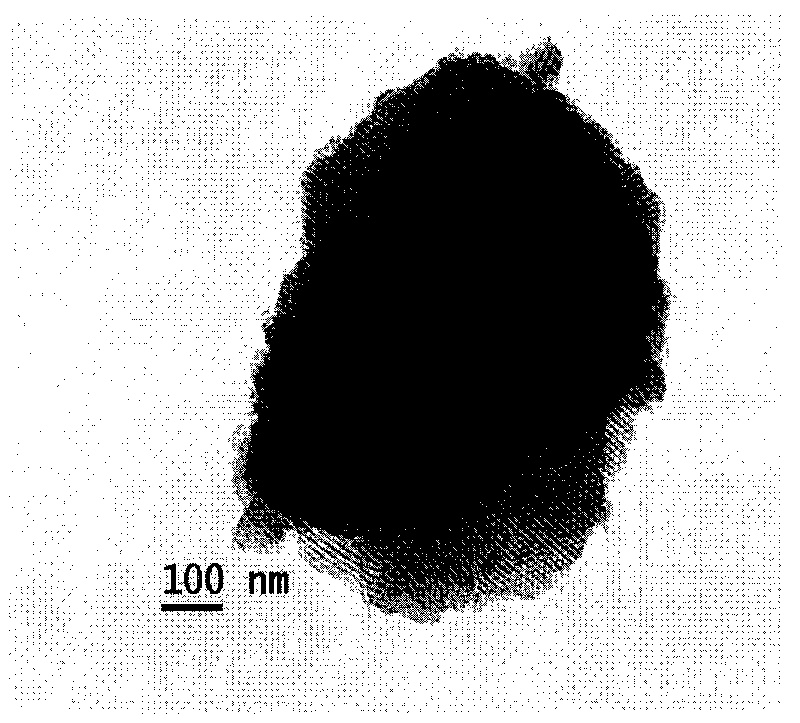

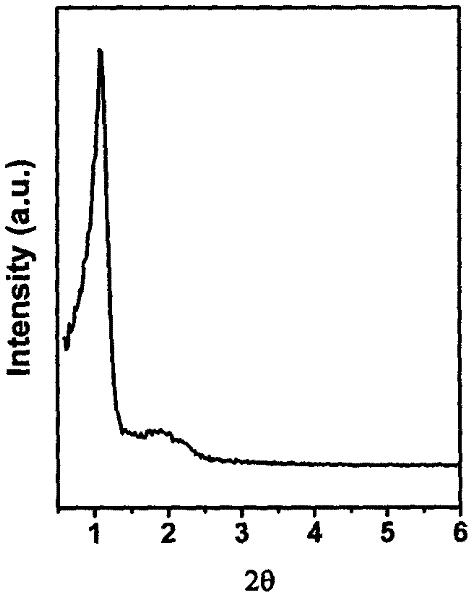

Ordered nanostructure sulphur/mesoporous carbon composite material for anode of lithium ion battery

InactiveCN101728538AIncrease capacityGood dispersionElectrode carriers/collectorsSulfurConductive materials

The invention relates to an ordered nanostructure sulphur / mesoporous carbon composite material for anode of a lithium ion battery; the composite material is formed by taking the ordered carbon-based mesoporous material as a carrier and loading nanometer sulphur in porous channels; the composite material is sulphur-mesoporous carbon composite material which has high sulphur content, good dispersibility, high capacity and good stability, thereby overcoming the disadvantages of electricity-conducting material, finding good carrier material for the lithium-sulphur batteries and opening up new application field for the mesoporous material; the method in the invention has the advantages of low preparation process and low cost.

Owner:SHANGHAI UNIV

Silicon and boron contained alumina carrier and production thereof

A Si and B contained alumina carrier for the hydrogenating catalyst, especially the hydrodenitrifying catalyst, is prepared from macroreticular alumina and millipore alumina through continuously forming colloid while introducing Si and B step by step to disperse the most of Si and B on the surface of alumina.

Owner:CHINA PETROLEUM & CHEM CORP +1

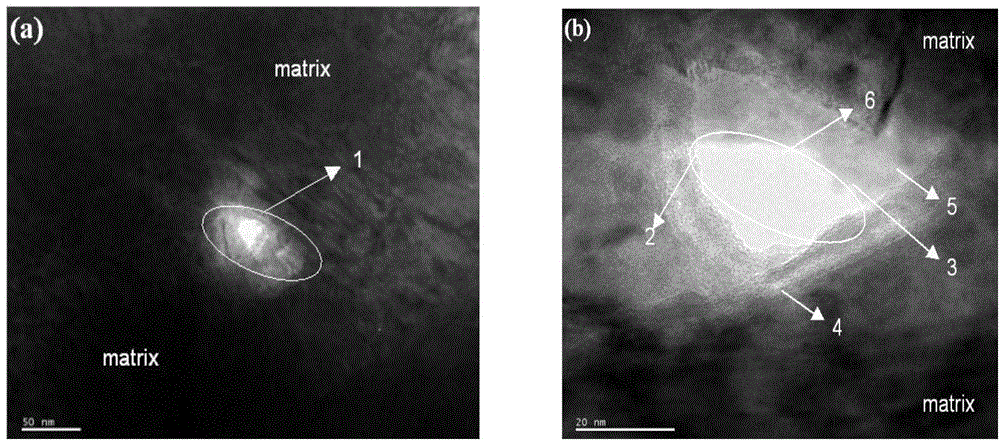

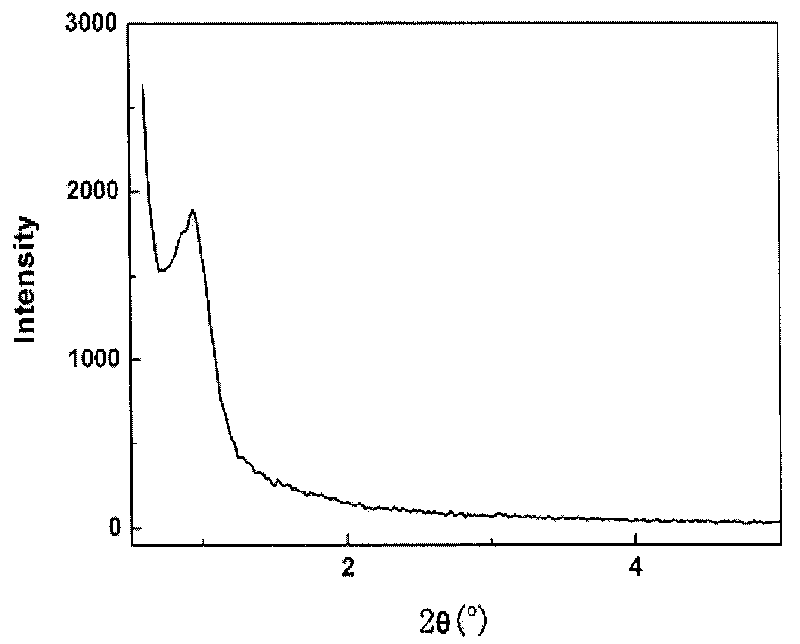

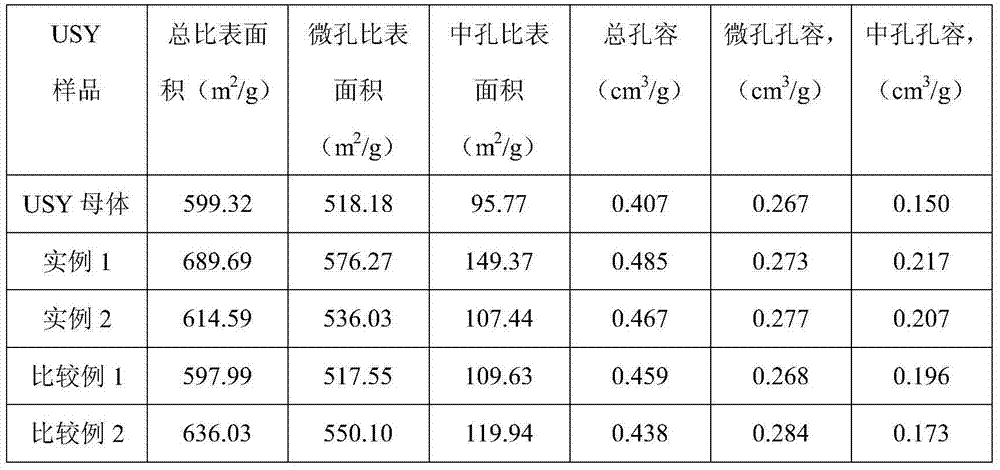

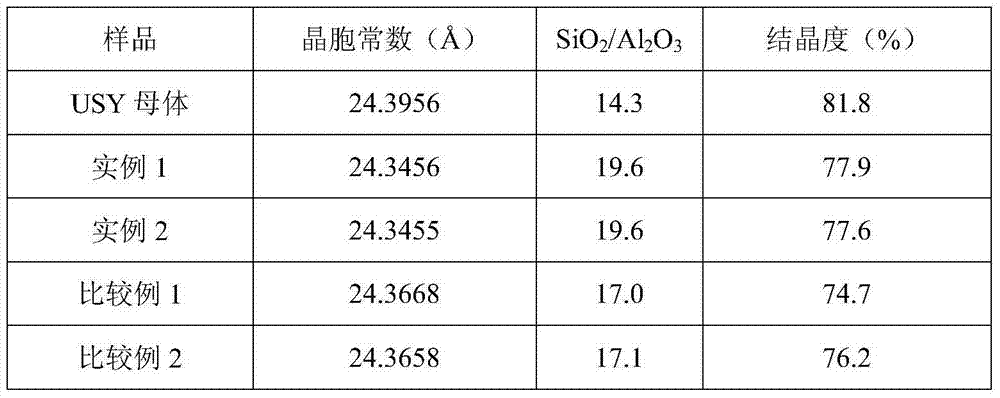

Combined modification method for mesopore USY molecular sieve

InactiveCN103936024AHigh crystallinityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

The invention relates to a modification method for a USY molecular sieve and in particular relates to a combined modification method for a mesopore USY molecular sieve. The combined modification method for the mesopore USY molecular sieve comprises that raw materials such as a USY material, an organic acid solution and an inorganic salt solution are measured in ratio, stirring in a closed reactor is carried out, temperature is increased to 90 DEG C, an organic acid-inorganic salt combined dealumination reaction is carried out for 8 hours; reactants are washed at room temperature, and suction filtration is carried out until the surface of USY is neutral; and drying is carried out at constant temperature of 110 DEG C for 16 hours, so that the USY molecular sieve product is obtained. The combined modification method for the mesopore USY molecular sieve has the advantages that a mixed aqueous solution of organic acid and inorganic salt is adopted for treating the USY type molecular sieve, so that high crystallinity of the molecular sieve can be maintained, silica-alumina ratio of the molecular sieve is increased, lattice constant is reduced, specific surface of the molecular sieve is increased, and acidity and acid distribution of the molecular sieve are improved; and more secondary holes are formed through dealumination, so that components with larger molecular diameter can easily enter into pore passages of the molecular sieve or get close to the surface of the molecular sieve, and conversion efficiency of hydrogen cracking can be improved.

Owner:PETROCHINA CO LTD +1

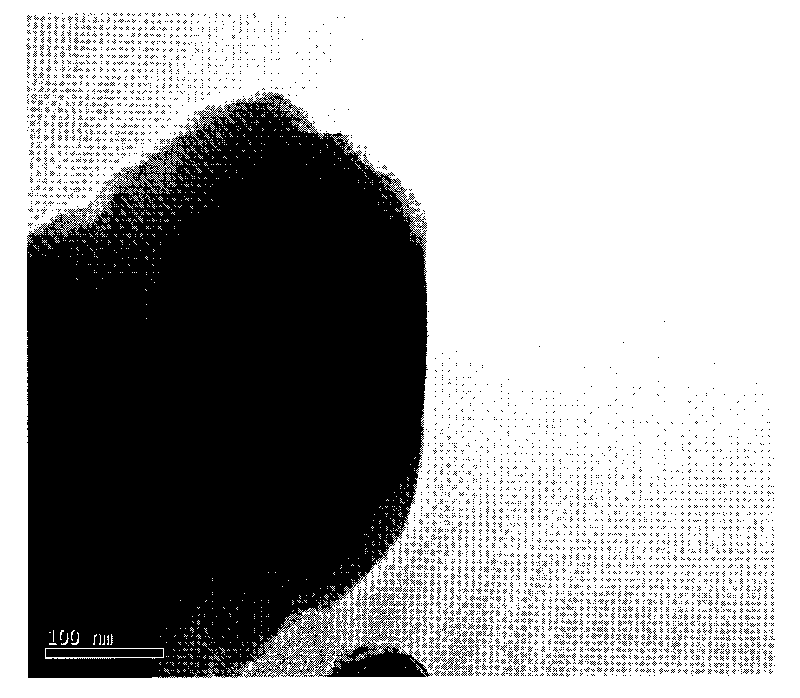

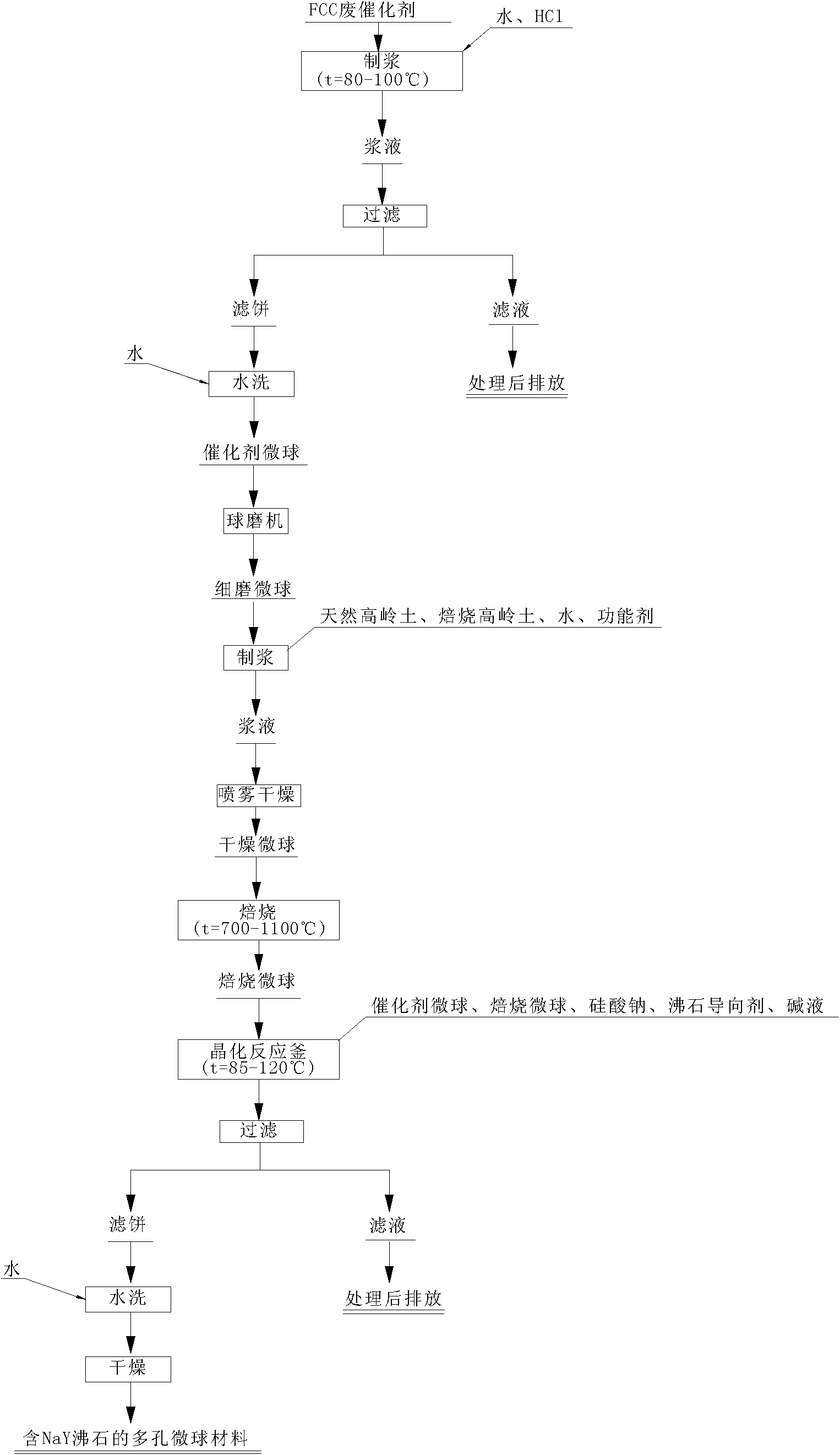

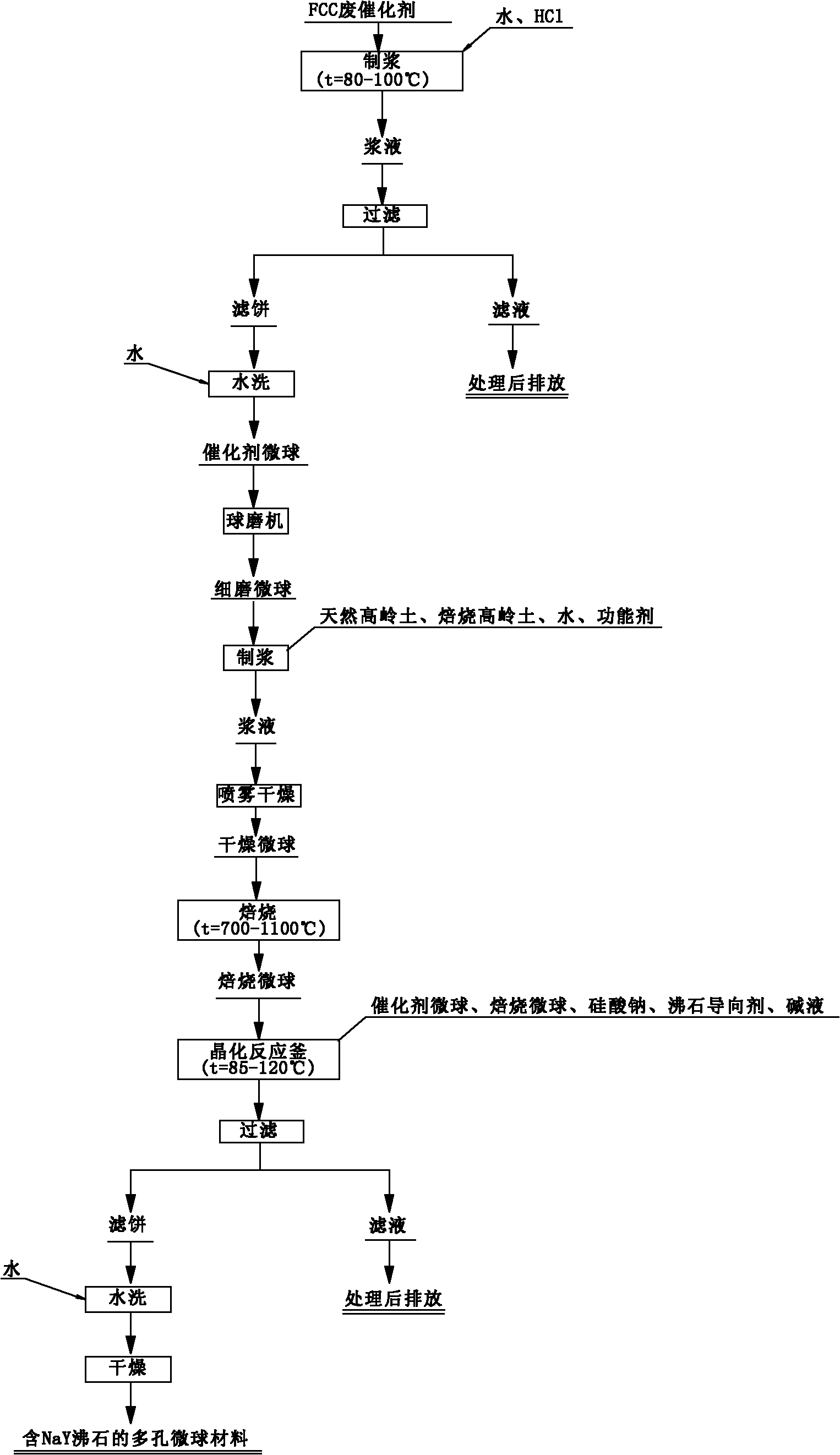

Method for synthesizing porous microsphere material containing NaY zeolite by waste FCC (fluid catalytic cracking) catalyst

ActiveCN102125872AReduce pollutionImprove performanceCatalytic crackingMolecular sieve catalystsSlurrySodium silicate

The invention discloses a method for synthesizing a porous microsphere material containing NaY zeolite by a waste FCC (fluid catalytic cracking) catalyst, which is a catalytic cracking process. The method is characterized by comprising the following steps: A. adding water and hydrochloric acid to the waste FCC catalyst for mixing slurry and acidizing to obtain catalyst microspheres; B. mixing thecatalyst microspheres with one or a combination of natural kaolin and roasted kaolin, adding water to obtain slurry containing 30-50% of solid, adding a functional agent to the slurry and then forming dried microspheres through spray drying, and roasting the dried microspheres at the temperature of 700-1100 DEG C for 0.5-10 hours to obtain roasted microspheres; and C. adding sodium silicate, a zeolite directing agent and alkali liquor to the catalyst microspheres and / or the roasted microspheres, adding the obtained mixed solution to a crystallization reaction kettle, performing hydrothermal crystallization at the temperature of 85-120 DEG C for 10-30 hours, filtering out a mother liquid, washing the obtained filter cake with deionized water, and then drying to finally obtain the finished product. The method is mainly used for synthesizing the porous microsphere material containing the NaY zeolite.

Owner:HUNAN JULI CATALYST

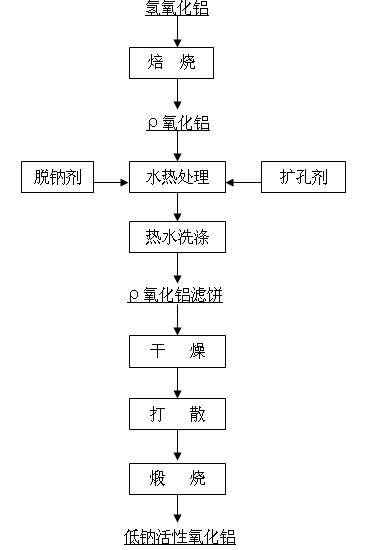

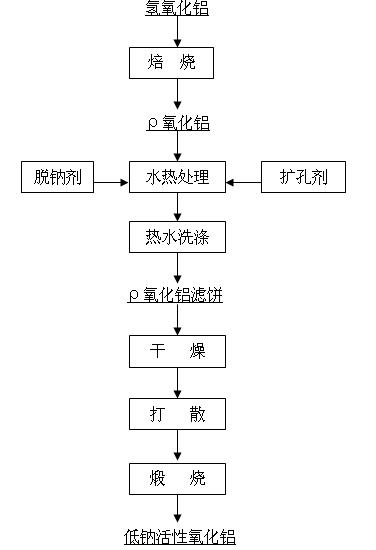

Preparation method of low-sodium active aluminum oxide

InactiveCN102070169AReduce manufacturing costLarger than surfaceCatalyst carriersAluminates/aluminium-oxide/aluminium-hydroxide purificationSlurryHeat treating

The invention relates to a preparation method of low-sodium active aluminum oxide, in particular to a preparation method of active aluminum oxide used as catalyst carrier for cleaning automobile tail gas. The method is characterized by comprising the following steps: roasting aluminum hydroxide to obtain an intermediate product rho aluminum oxide, adding a sodium removal agent and a pore expanding agent to carry out hydrothermal treatment, filtering the treated slurry, washing with hot pure water, drying, dispersing the dried product with a dispersion machine, and calcining to obtain active aluminum oxide. In the method provided by the invention, any one or more than two of nitric acid, acetic acid and citric acid is / are used as the sodium removal agent to wash the intermediate product after the roasting of aluminum hydroxide, thereby lowering the sodium content. The low-sodium active aluminum oxide prepared from aluminum hydroxide has the advantages of larger specific surface, multiple pores, high pore volume, simple preparation method and lower production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

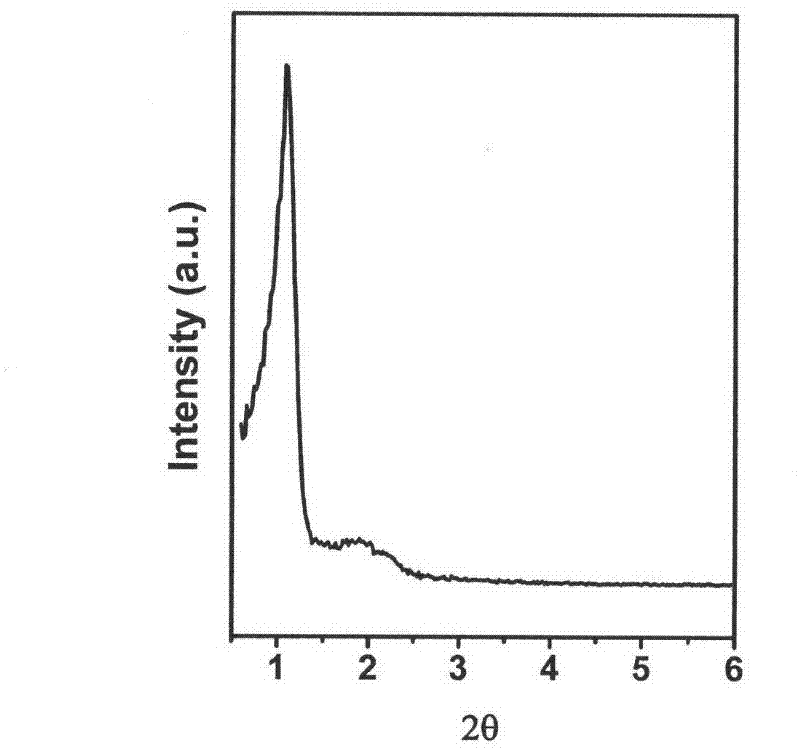

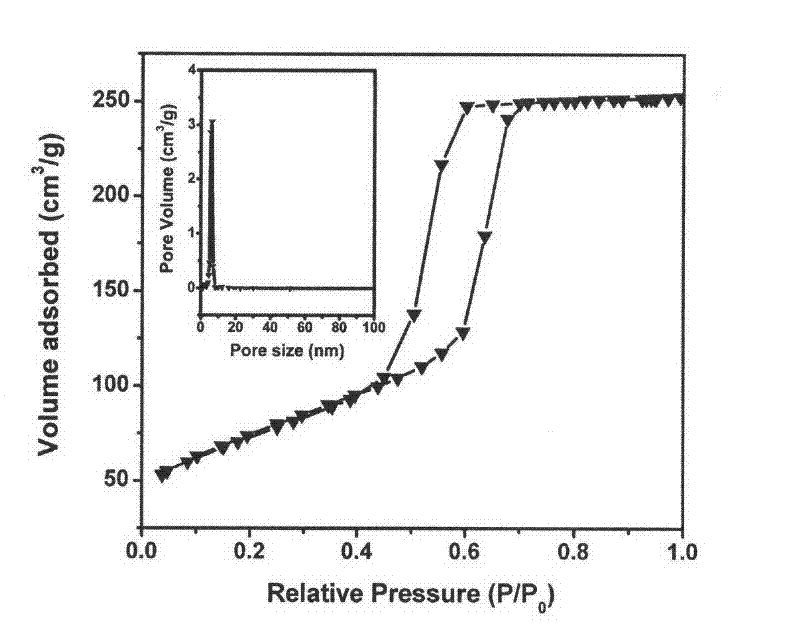

Ordered zirconia-alumina mesoporous material and its preparation method

InactiveCN102380362AEasy to prepareHigh recurrence ratePhysical/chemical process catalystsCarboxylic acidZirconia alumina

The invention relates to an ordered zirconia-alumina mesoporous material and its preparation method, which belongs to the inorganic porous material and catalyst preparation field. The invention is characterized in that the material has a high and ordered mesoporous structure, its mesoporous diameter is 5.0-8.0nm, the specific surface area is 200-300m<2> / g, and the atomic ratio of Zr to Al of the material is 0.1-1.6. The synthetic method comprises the following steps: dissolving a surfactant, organic carboxylic acid and inorganic acid in an ethanol solution containing a little of deionized water according to the ratio of the synthetic material, adding zirconium source and aluminum source while stirring, continuously stirring for certain time, performing solvent volatilization on the reactant, heat treating and high temperature roasting to obtain the ordered zirconia-alumina mesoporous material. The invention has the advantages of simple process, high repetition rate and environmental protection.

Owner:TAIYUAN UNIV OF TECH

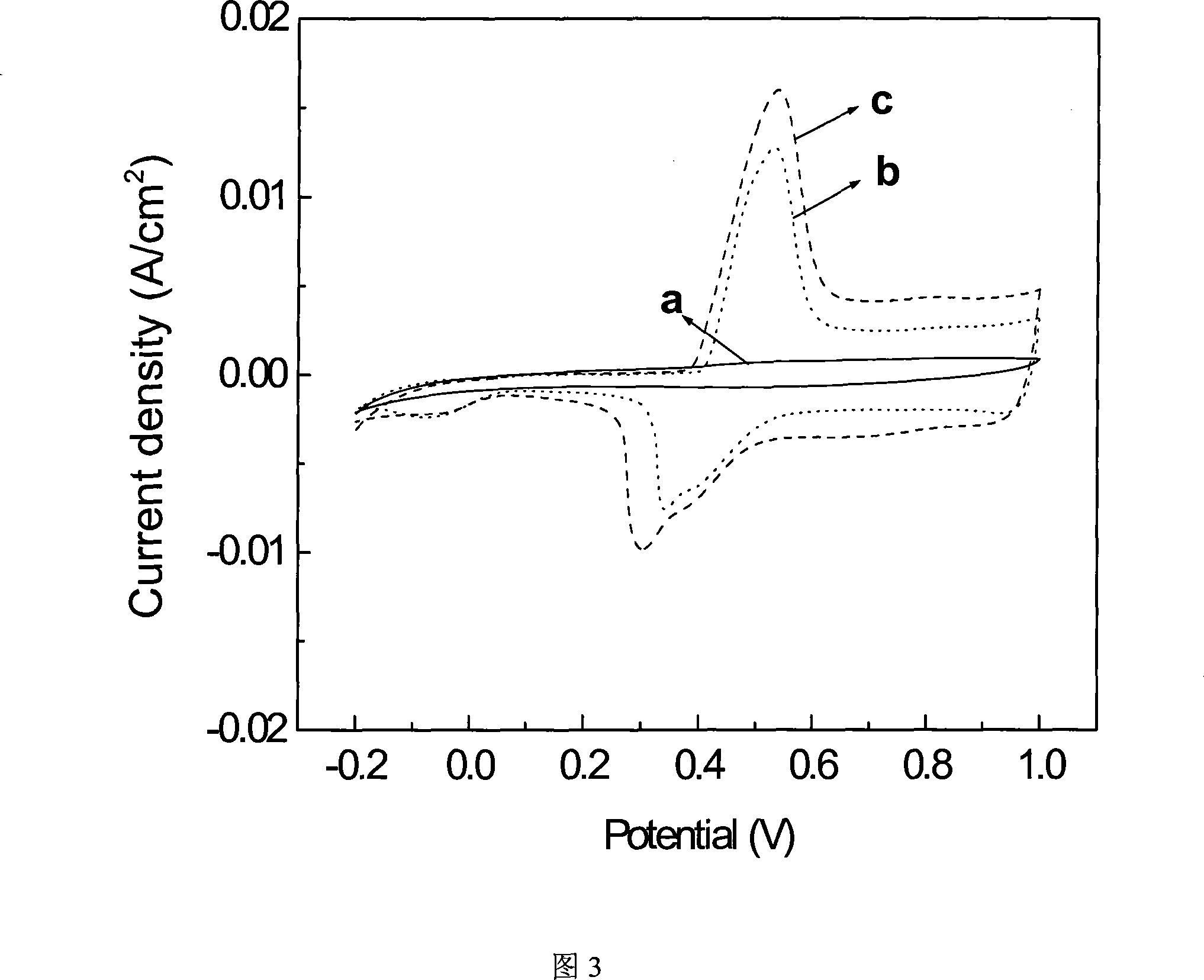

Method for preparing carbon nano-tube modified polyaniline nano fiber composite material

InactiveCN101235199ALarger than surfaceImprove conductivityNon-conductive material with dispersed conductive materialFiberCarbon nanotube

The invention discloses a preparation process of carbon nano-tube modification polyaniline nano fiber conductivity composite material. The characteristics of the invention are that conducting acid treatment for carbon nano-tube with concentrated mixed acid, adding carbon nano-tube which is treated with acid and aniline monomer into perchloric acid water solution according to the weight ratio of 1:6-1-32, and evenly dispersing through ultrasonic processing, using ammonium persulphate as oxidation agent, controlling the molar ratio of ammonium persulphate and aniline monomer within 1:2-1:8, and reacting under the ambient temperature to obtain polyaniline nano fiber / conductivity composite material of polyaniline coating carbon nano-tube coexisting structure. The process has simple art, and is easy to be controlled. The composite material which is prepared has the characteristics of high electricity conductivity ratio and small influence by system pH valve, large specific surface and excellent electrochemistry property and the like, which is expected to be used on electrode material such as second lithium ion cell and super capacitor and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

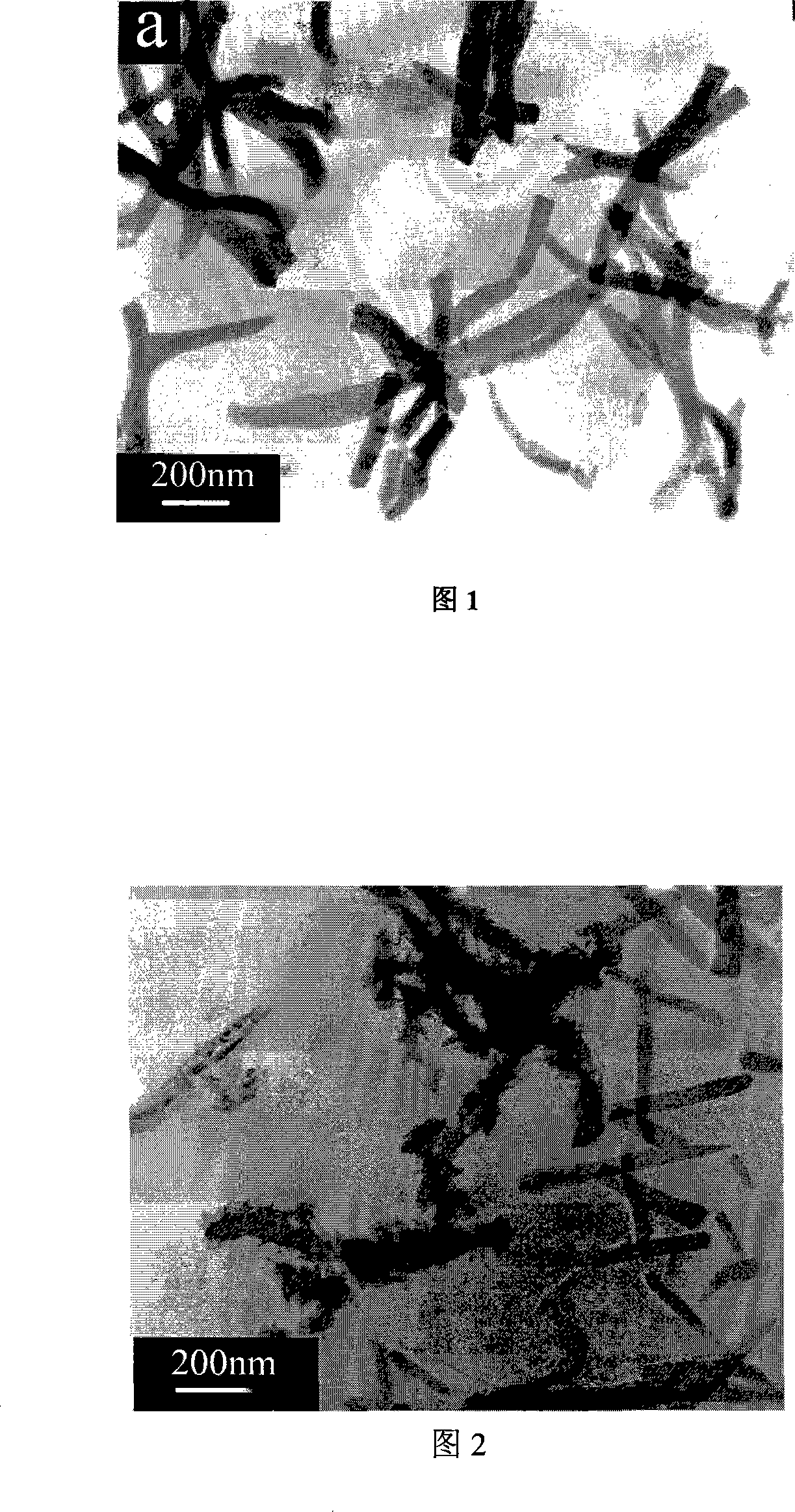

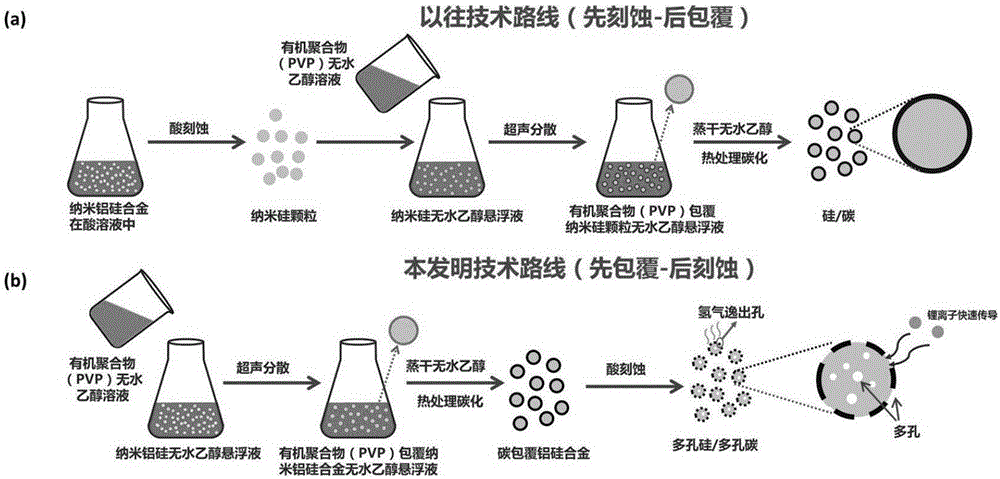

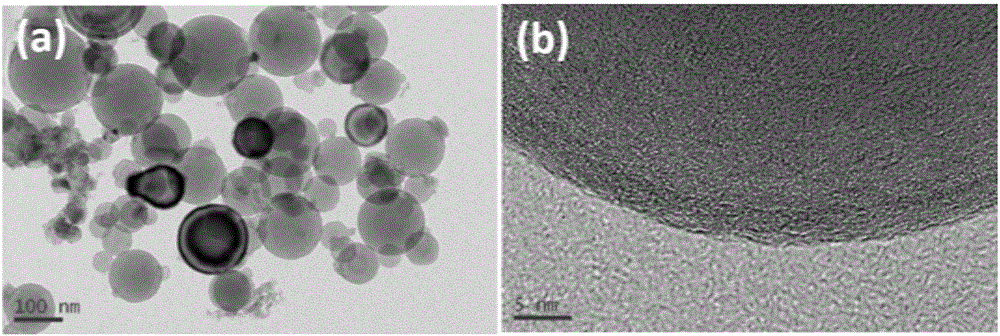

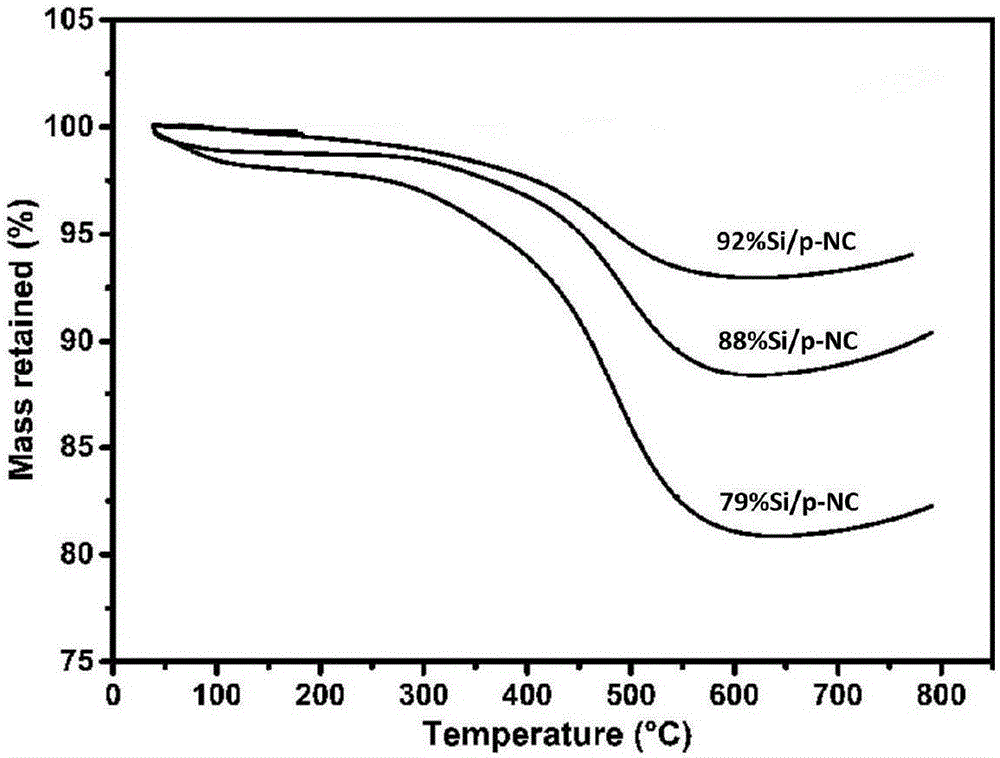

Nano silicon/porous carbon composite anode material of lithium ion batteries as well as preparation method and application of composite anode material

The invention discloses a nano silicon / porous carbon composite anode material of lithium ion batteries as well as a preparation method and an application of the composite anode material. The composite anode material is a core-shell structure material consisting of a porous nano silicon particle core and a porous carbon layer shell. The preparation method of the composite anode material comprises the steps as follows: carbonization treatment is performed after an organic polymer layer is coated on the surface of aluminum-silicon alloy powder, aluminum is removed by performing acid etching on a carbonization product, pore forming is performed on a carbon layer, and thus the nano silicon / porous carbon composite anode material is obtained. The preparation method is simple and low in cost, the mass production requirement is met, and the prepared composite anode material can be used for preparing the lithium ion battery and shows high capacity and excellent cycle and rate performance.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com