Train brake lining with adjuster

A technology of brake pads and adjusters, which is applied to friction linings, mechanical equipment, etc., can solve problems such as affecting the braking force efficiency of high-speed EMUs, difficult to achieve 100% fit, and high temperature on the surface of the brake disc. , to reduce mechanical bumps and twisting force, eliminate overheating fatigue, and overcome the effect of friction performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

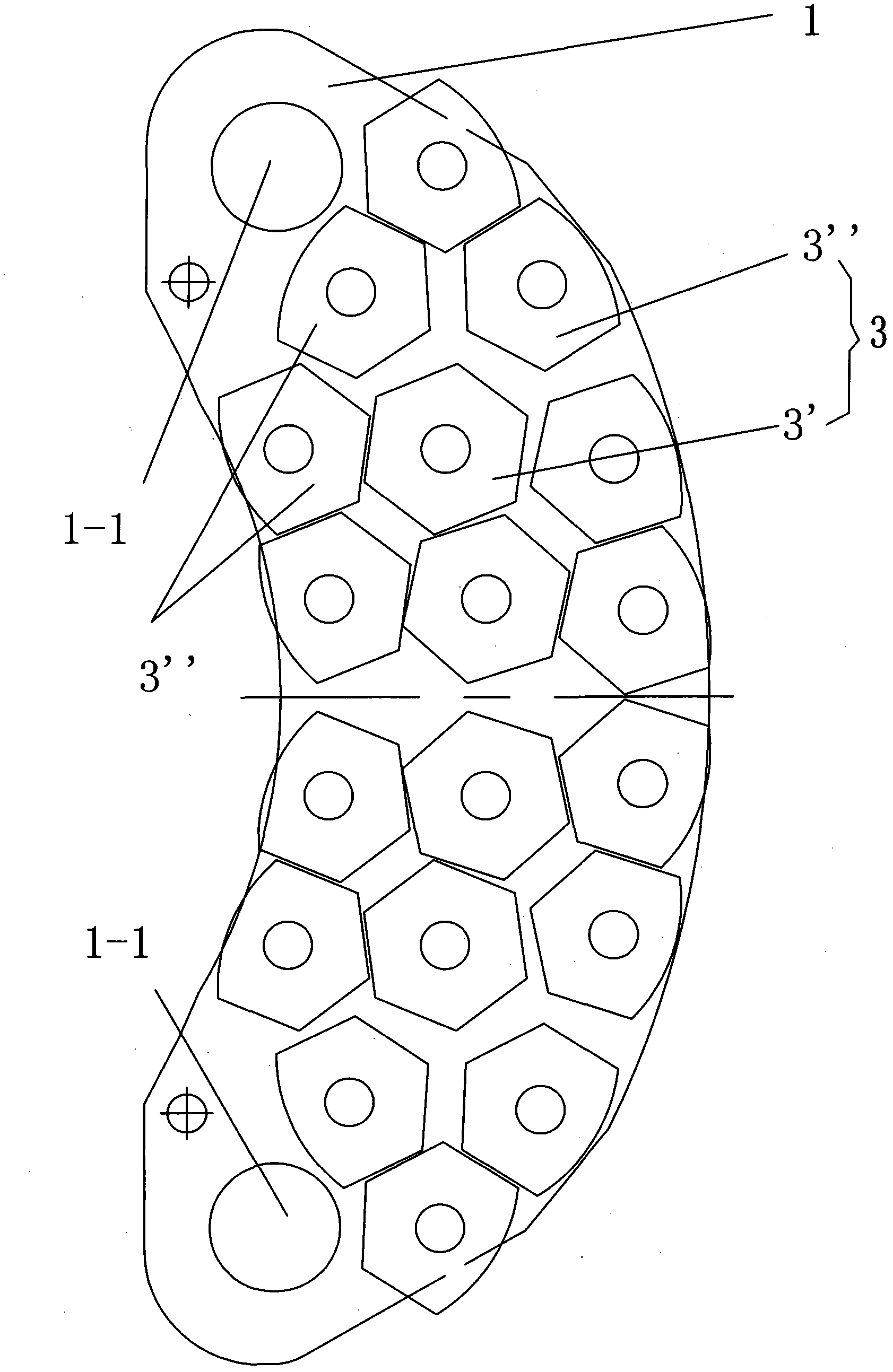

[0046] The edge of the brake pads adopts the first friction block 3' of the pentagonal body with the middle hole 3-5, and the second friction block 3" of the pentagonal body with the middle hole 3-5 has an arc surface, and the circle The arc surface faces the outside of the mounting plate 1, and the arc surface can effectively reduce the damage of the friction block of the brake pad under high-speed and high-pressure braking conditions.

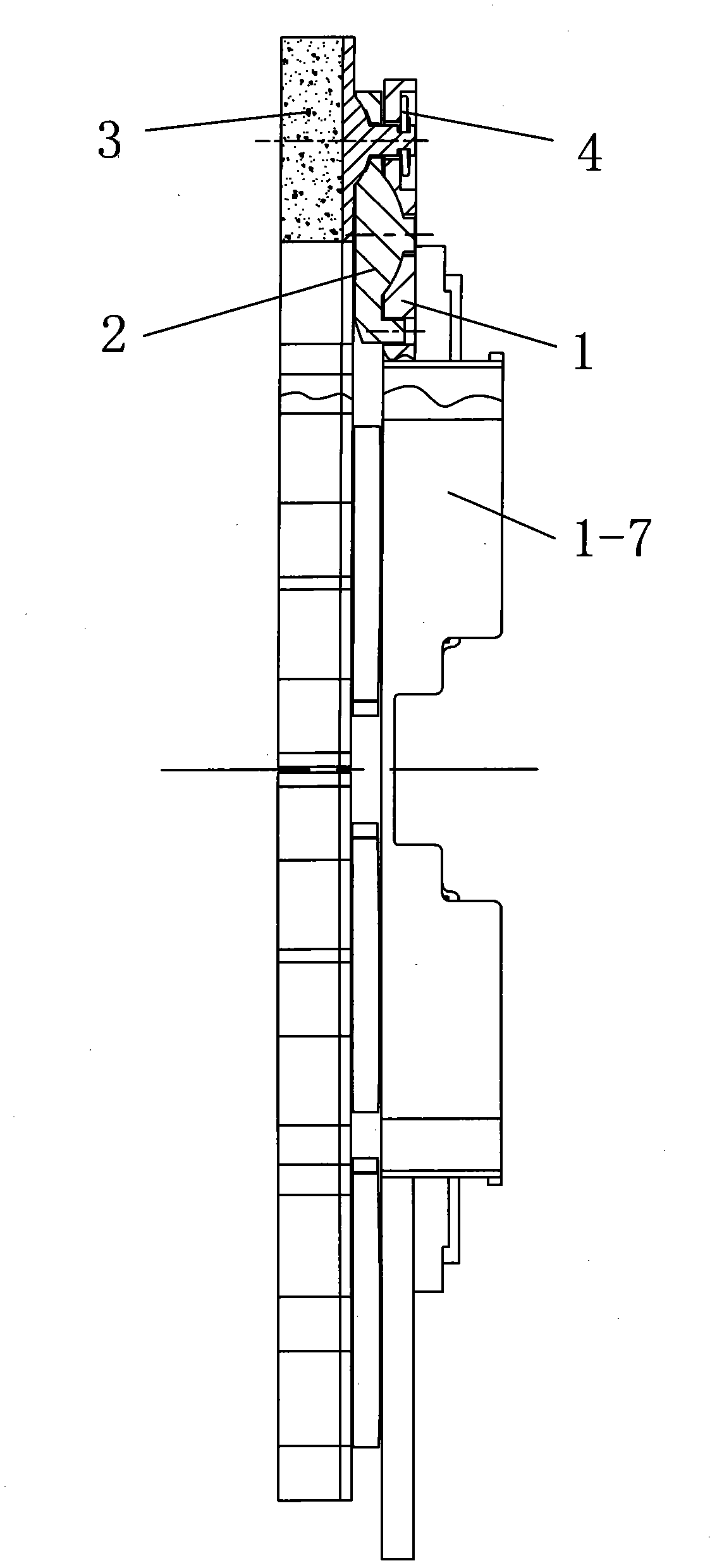

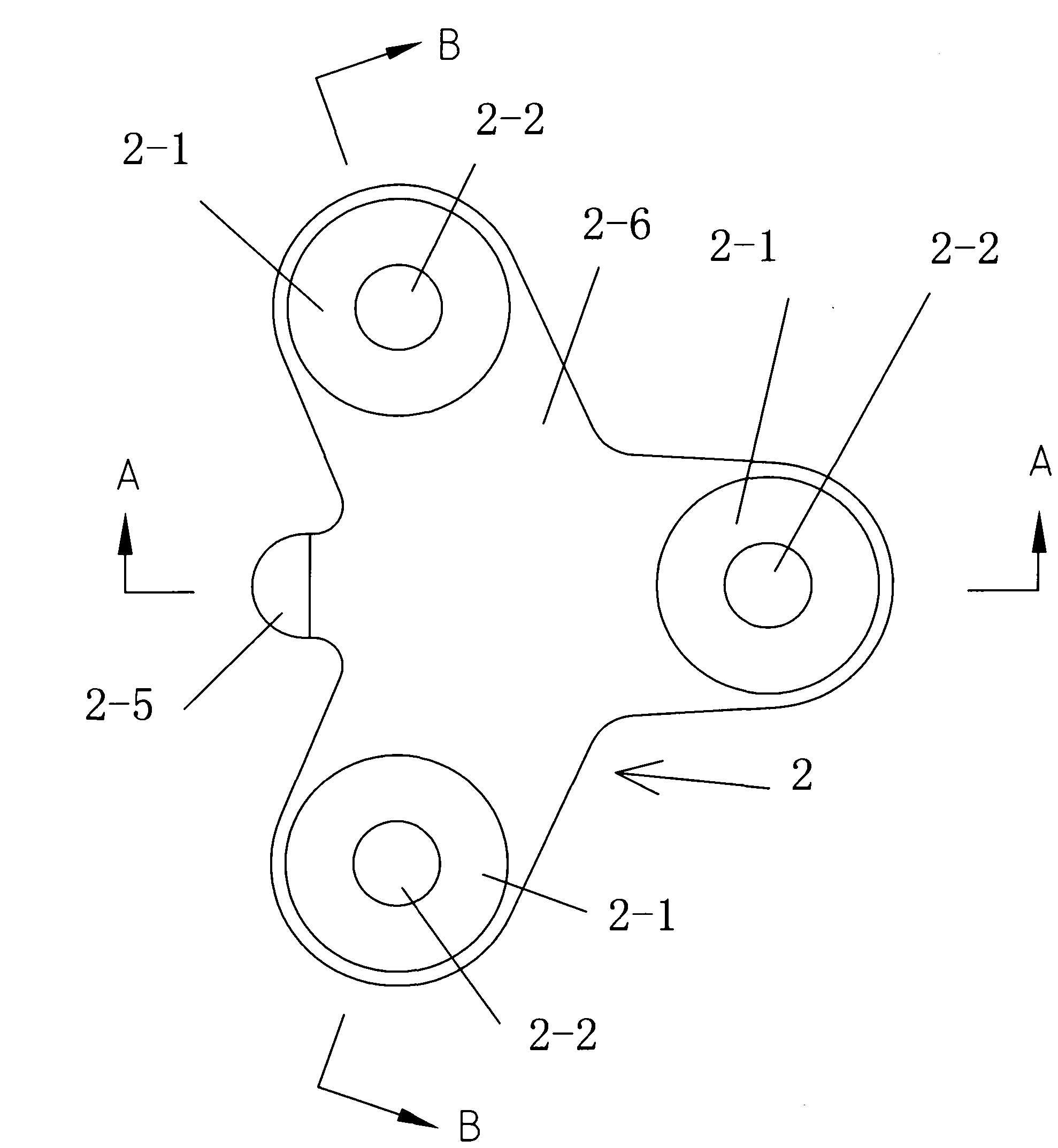

[0047] The components of the brake pads are connected by elastic contact and floating, especially the end of the connecting shaft at the tail is elastically connected with the mounting plate through a spring collar, which can reduce noise and play a certain role in shock absorption.

[0048] like Figure 13 , 14 As shown, it is the second embodiment of the present invention, wherein, the second friction block 3 "is distributed into two rows along the inner and outer arc edges of the front of the mounting plate 1 and sandwiches the first fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com