Patents

Literature

32results about How to "Skeleton silicon aluminum ratio is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High silicon-aluminum ratio ZSM-5 zeolite catalyst, preparation method and application thereof

InactiveCN101269340ASkeleton silicon aluminum ratio is highHigh reactivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisSilicon

The invention belongs to the catalyst technical field, in particular to a ZSM-5 zeolite catalyst characterized by high ratio of silica and alumina as well as a preparation method and the application thereof. The catalyst, taking a pure silicon compound with activity as a silicon source, is made by a hydrothermal synthesis method by adding trace aluminum. The ratio of silica and alumina in the zeolite catalyst is over 1,000, sub-micron crystal particles with open channels have large surface area and good molecular diffusivity. The catalyst in the reaction of MTP has excellent catalytic activity, high selectivity of propylene, and high ratio of propylene and ethylene. The catalyst has simple regeneration method and good restoration of performance after regeneration.

Owner:FUDAN UNIV

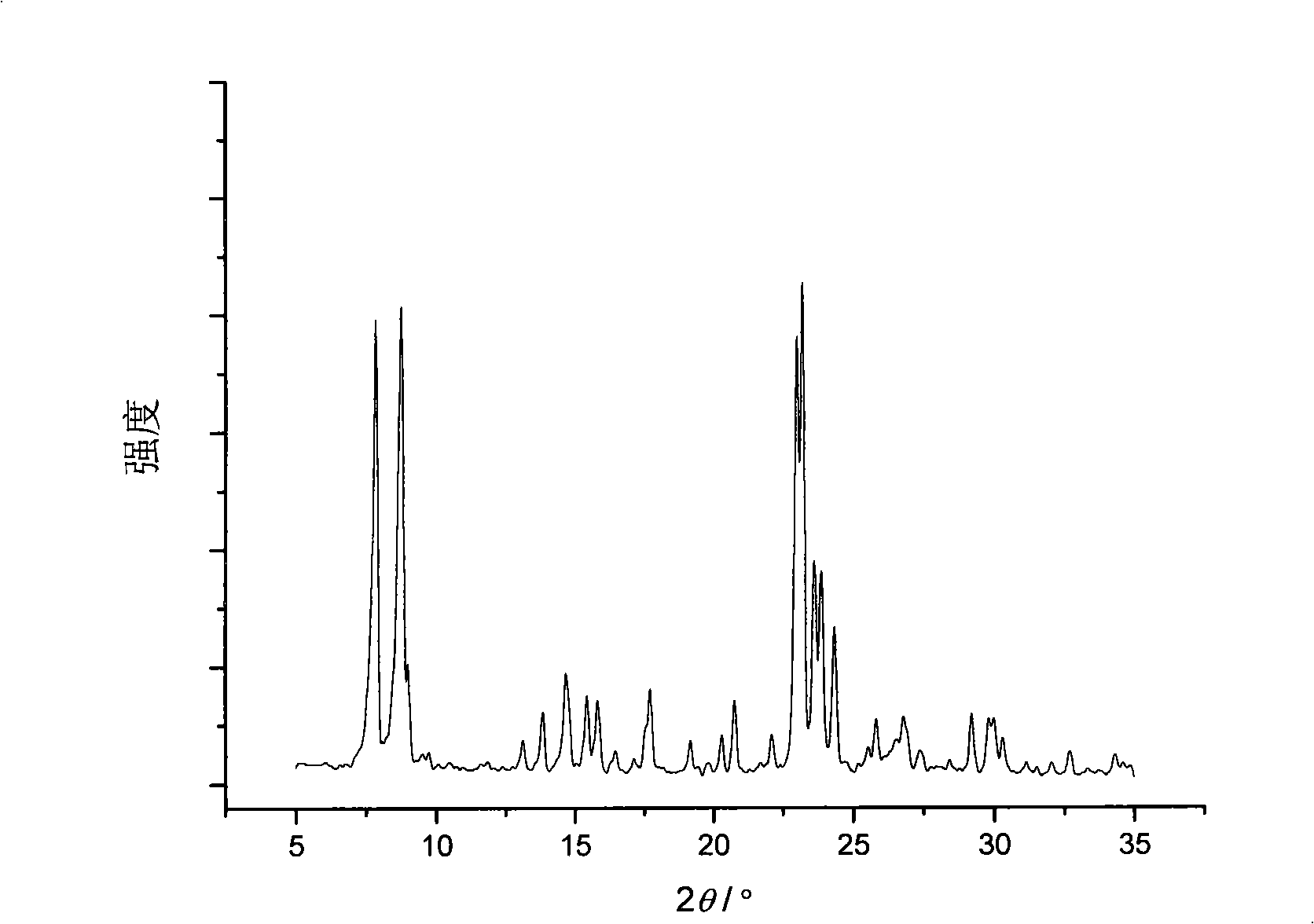

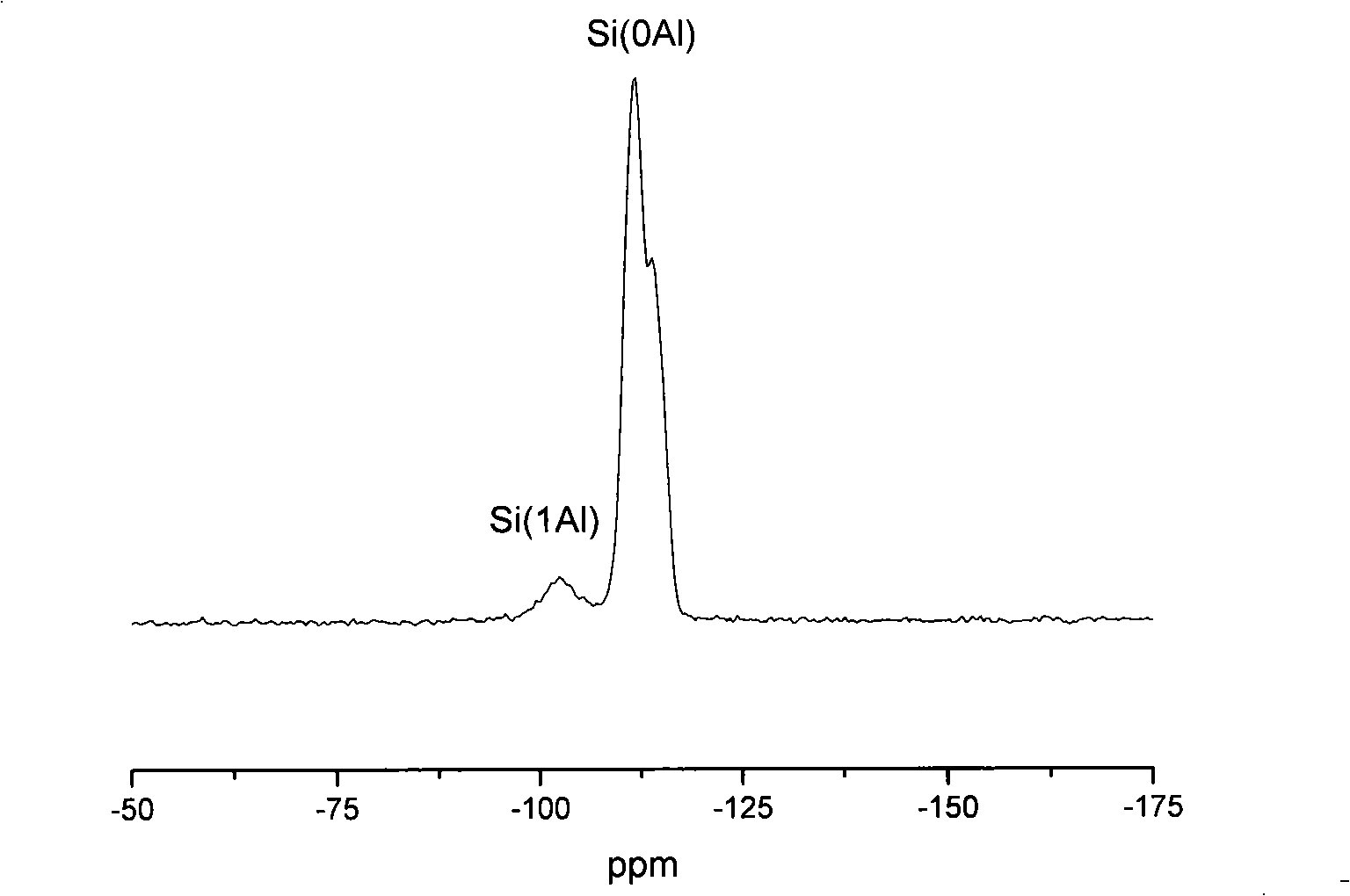

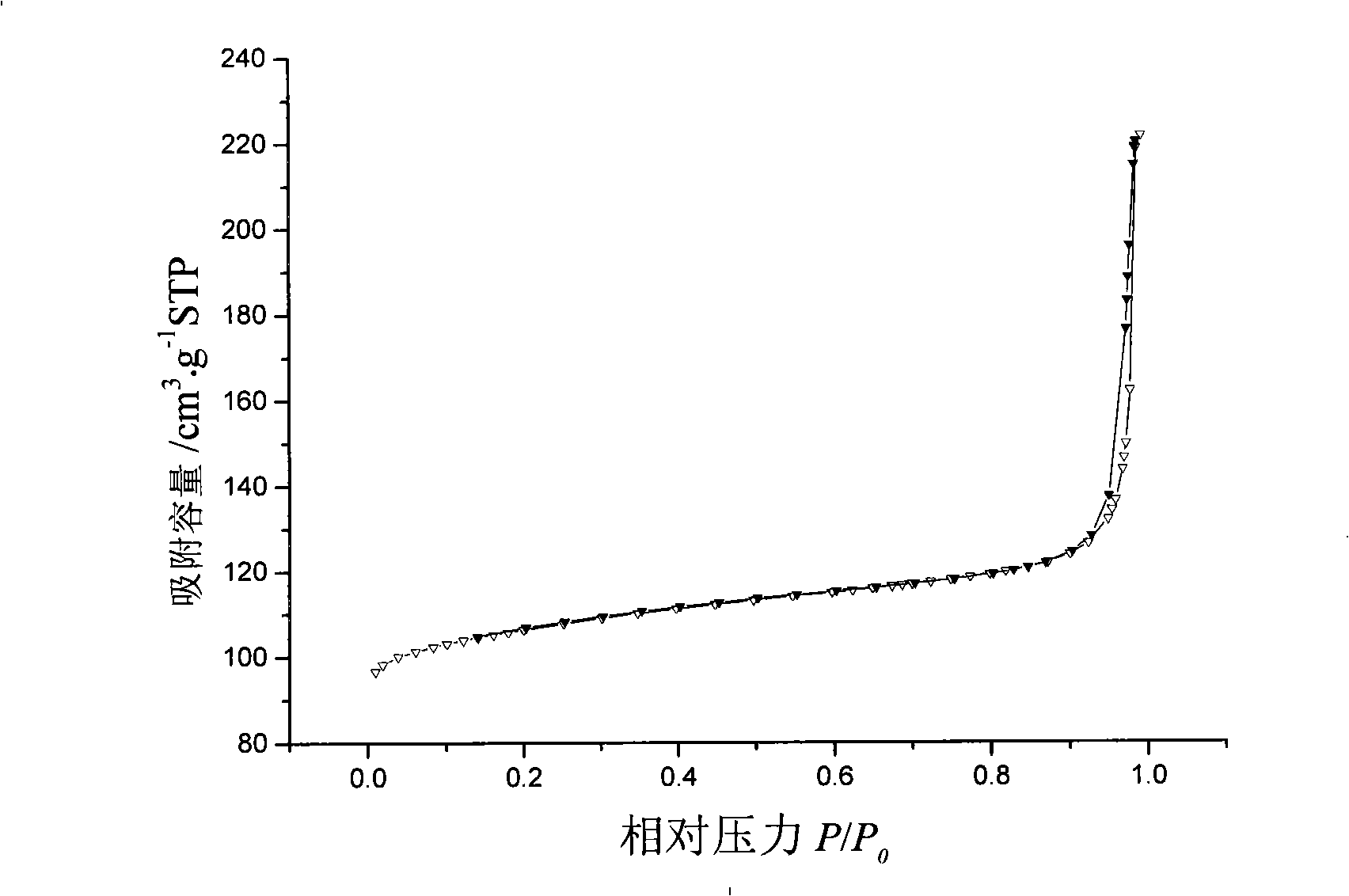

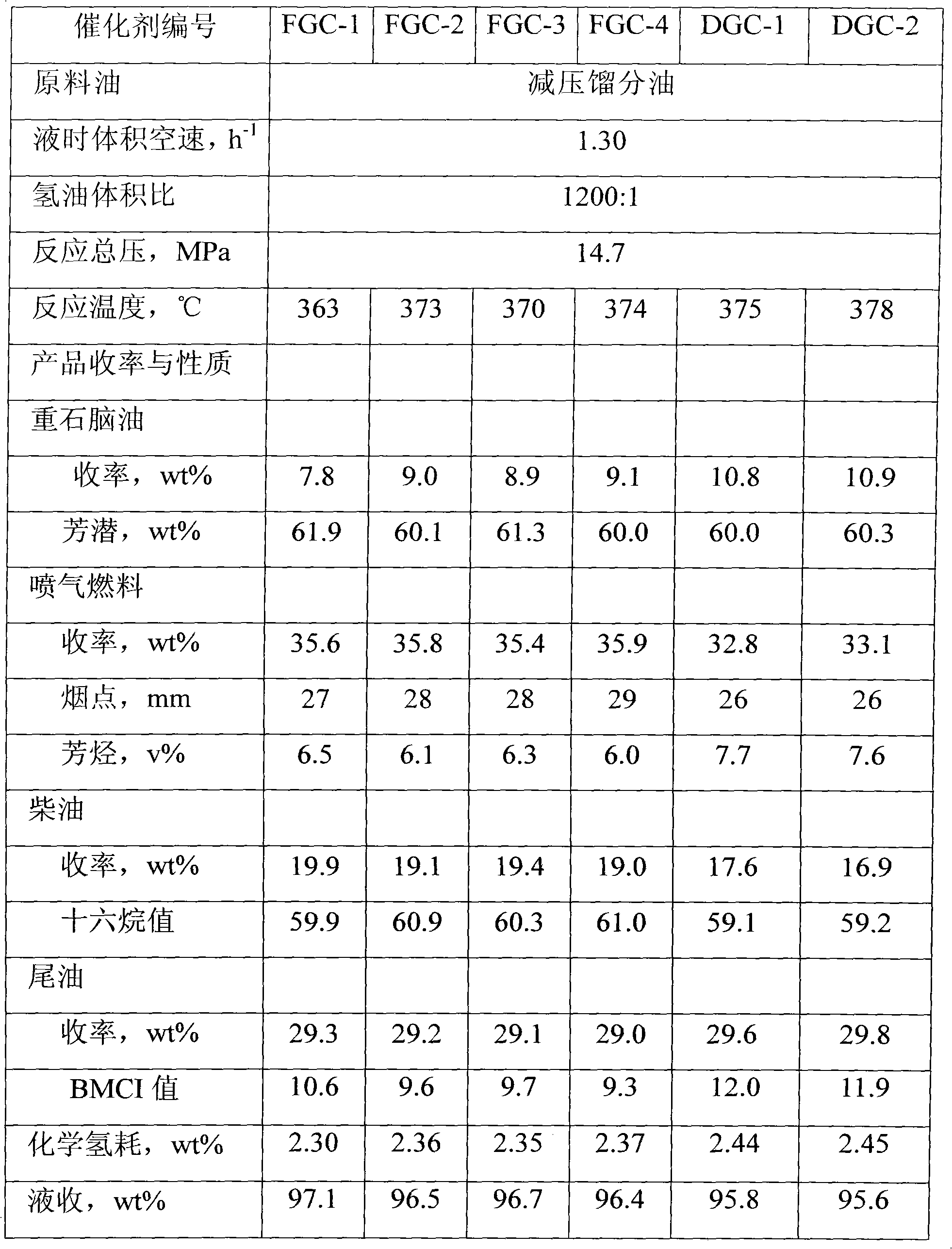

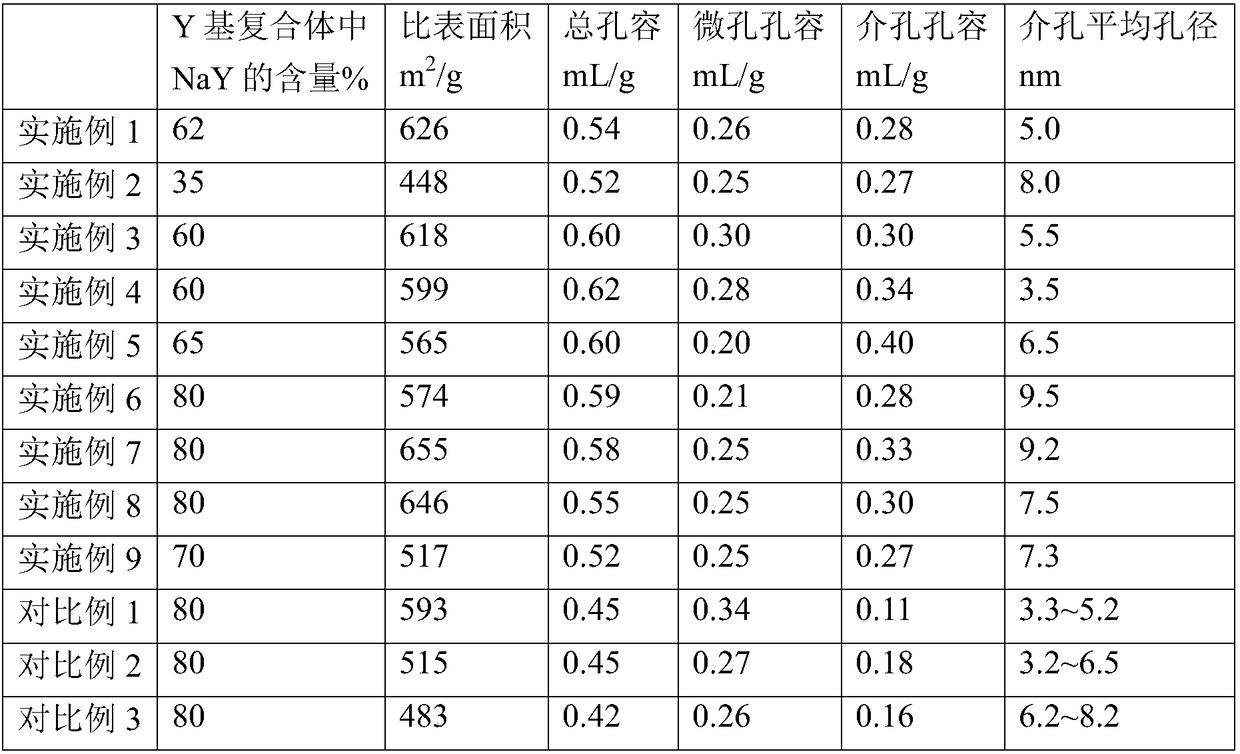

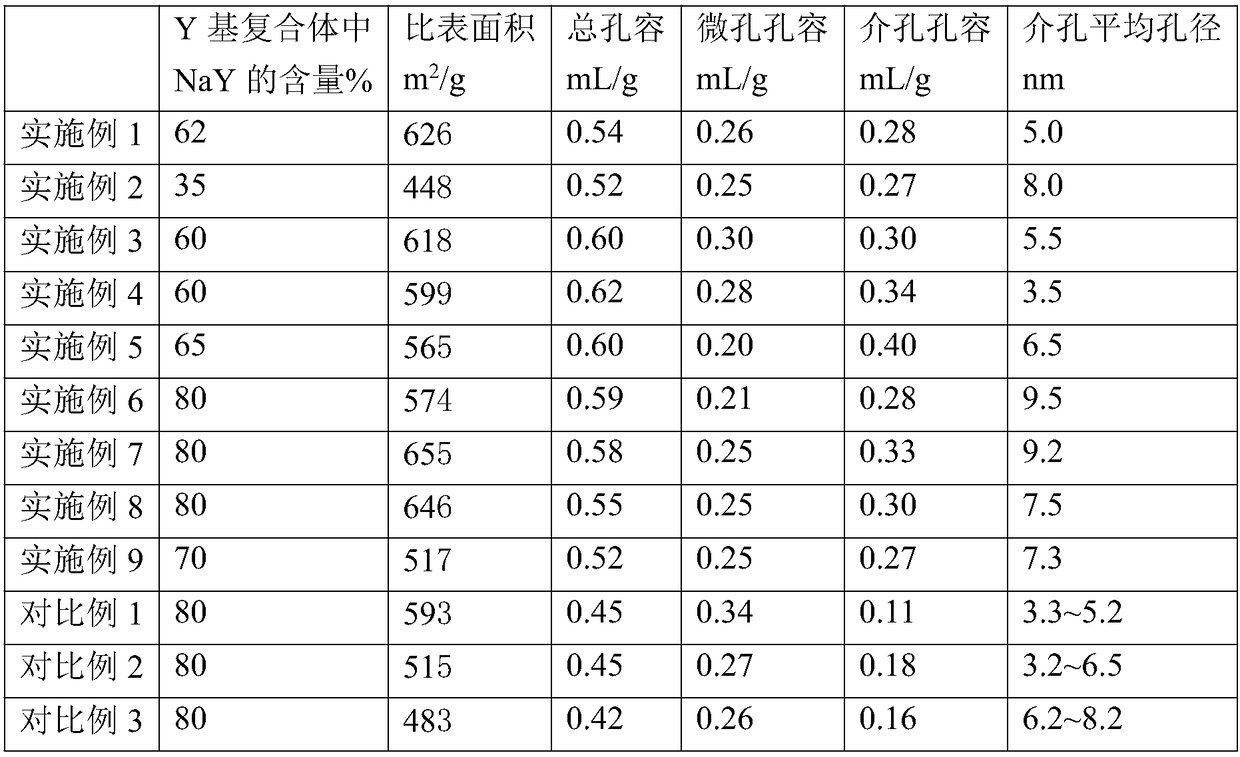

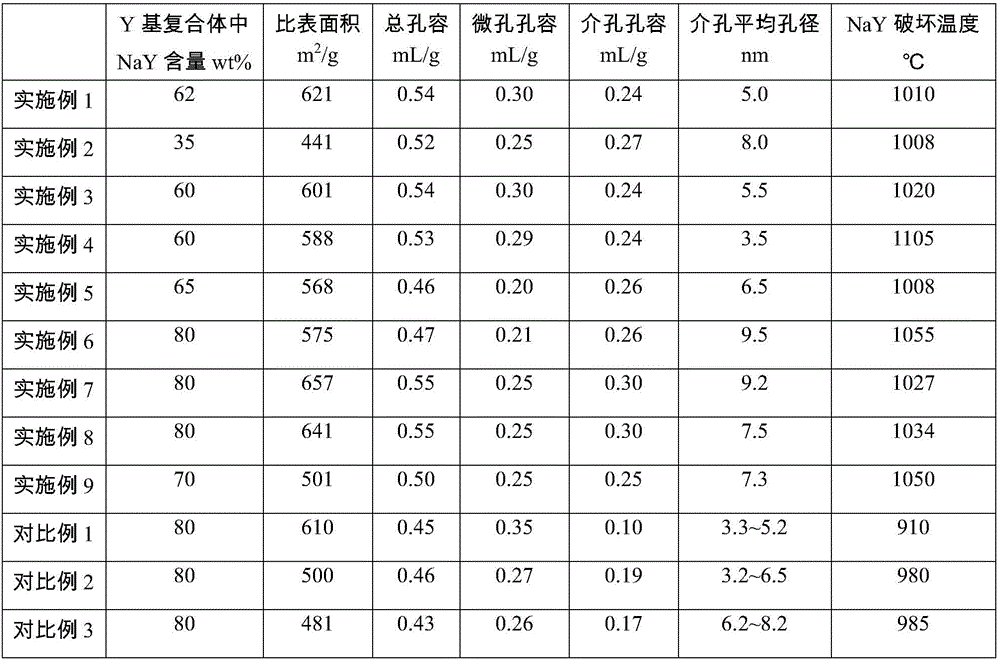

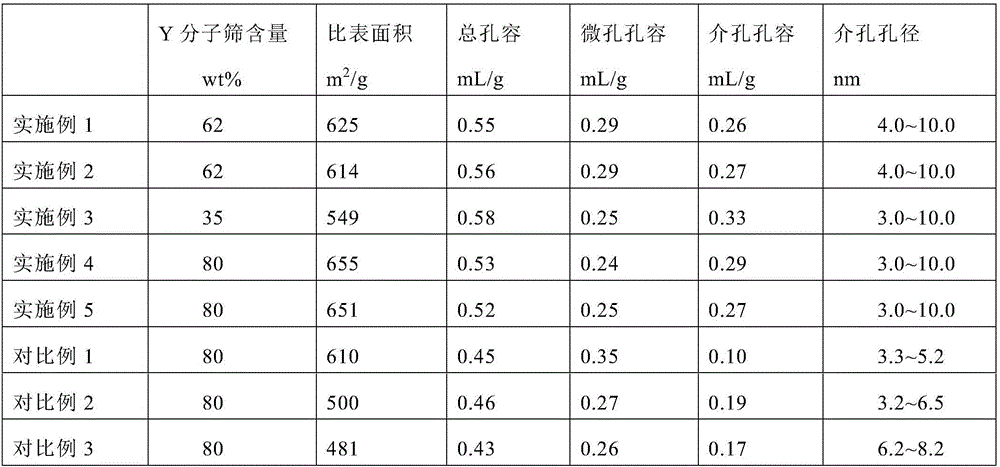

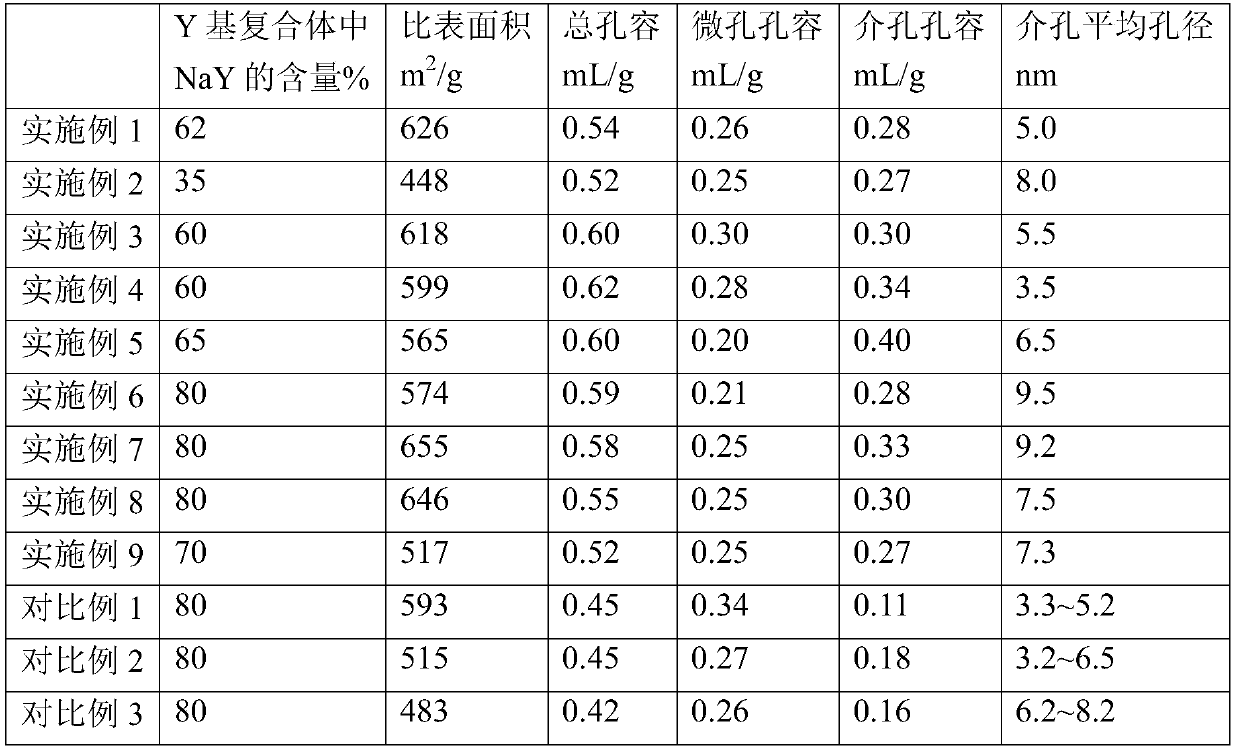

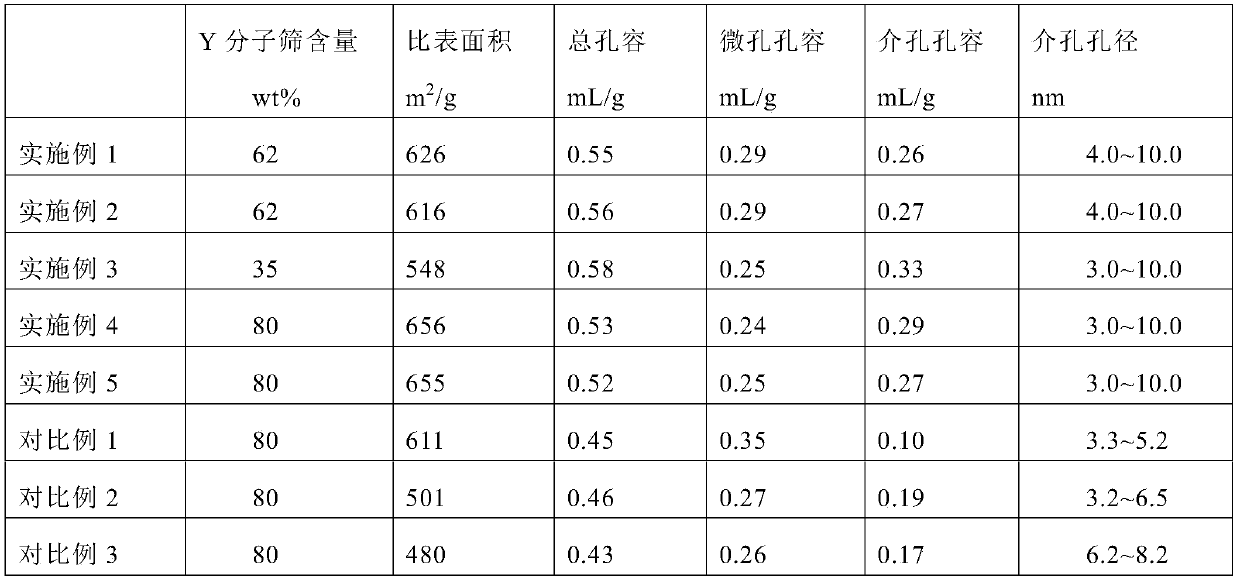

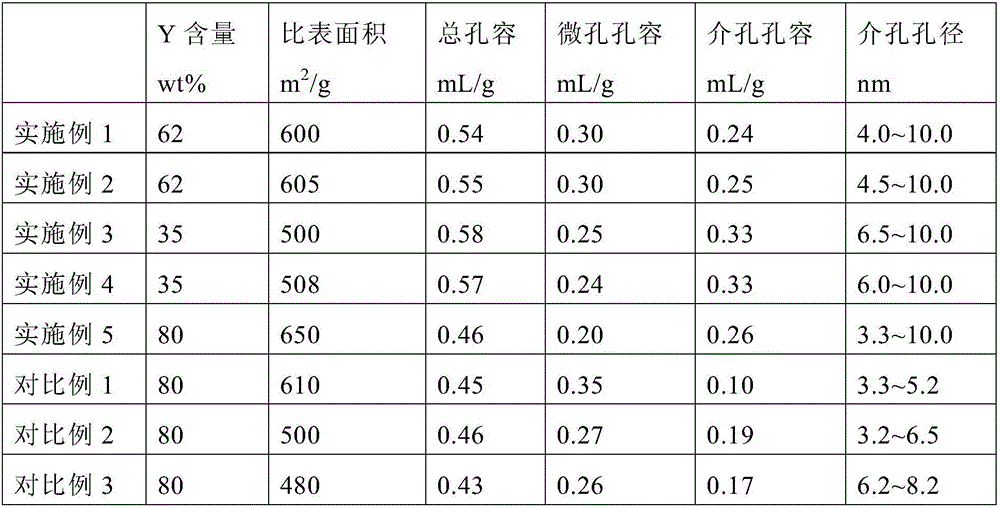

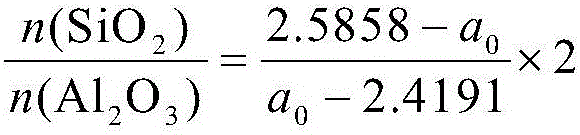

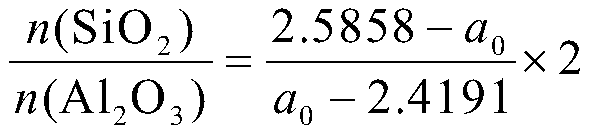

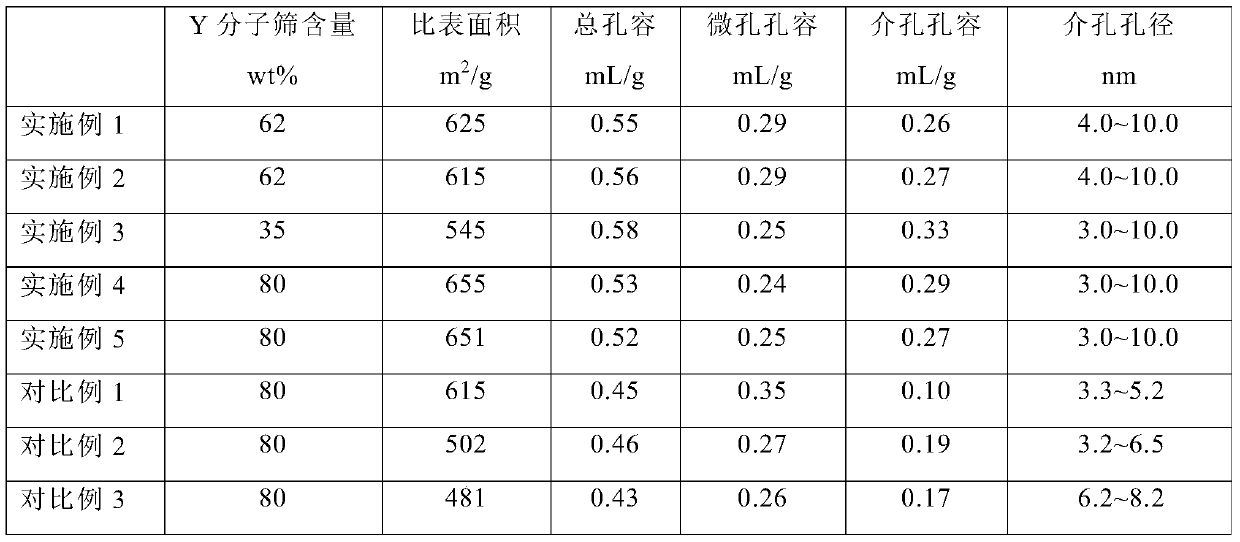

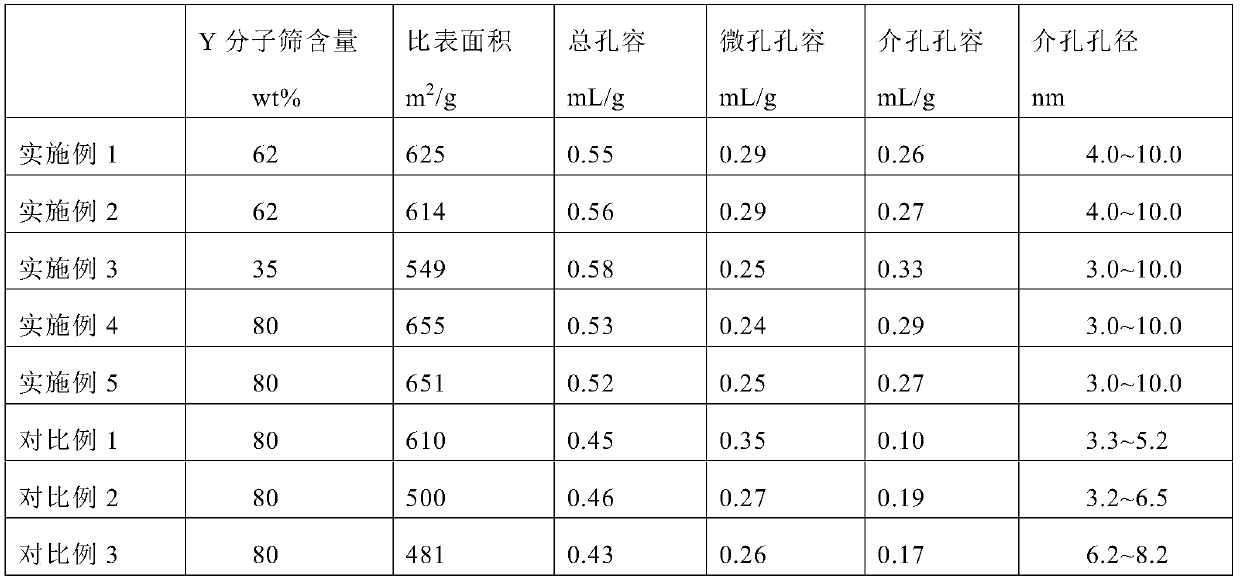

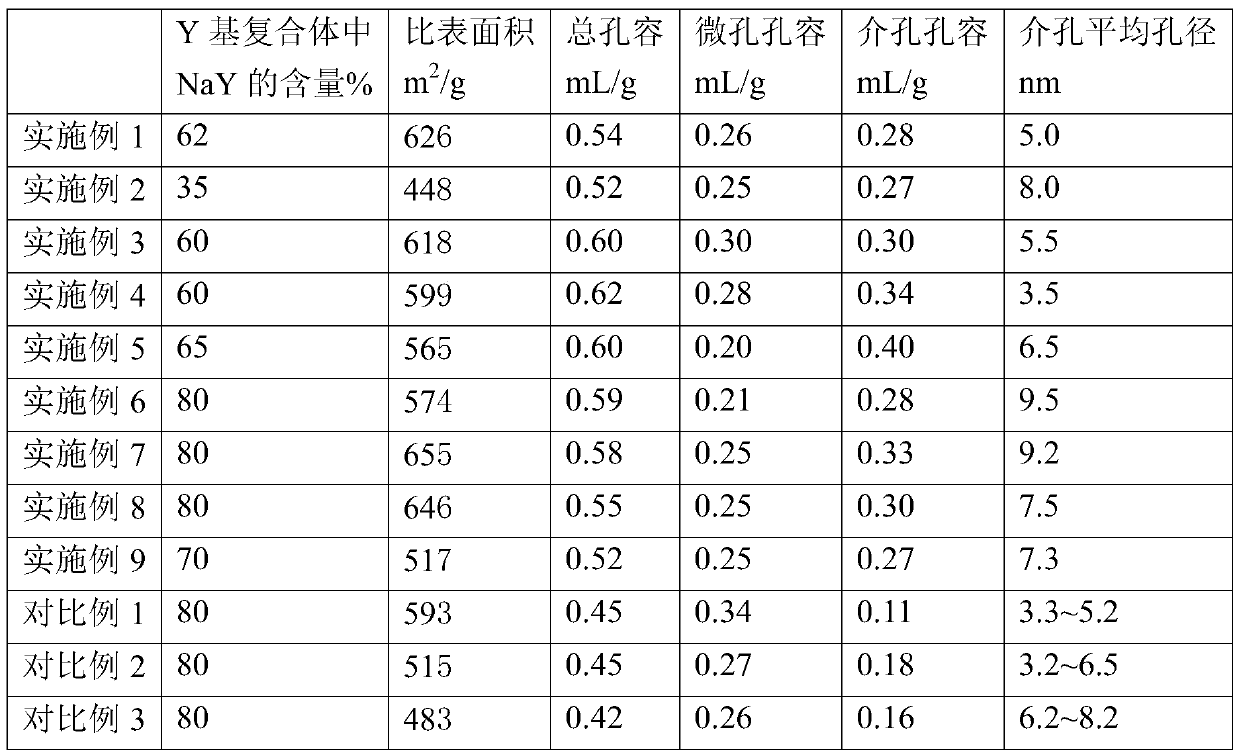

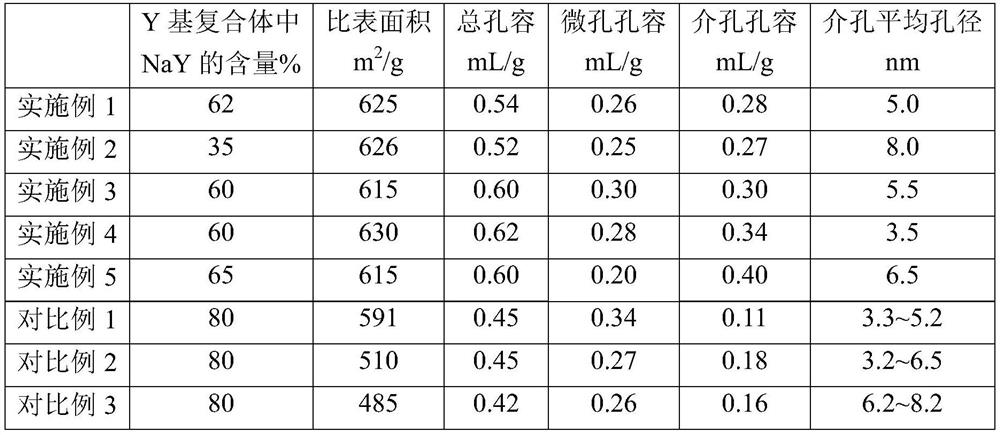

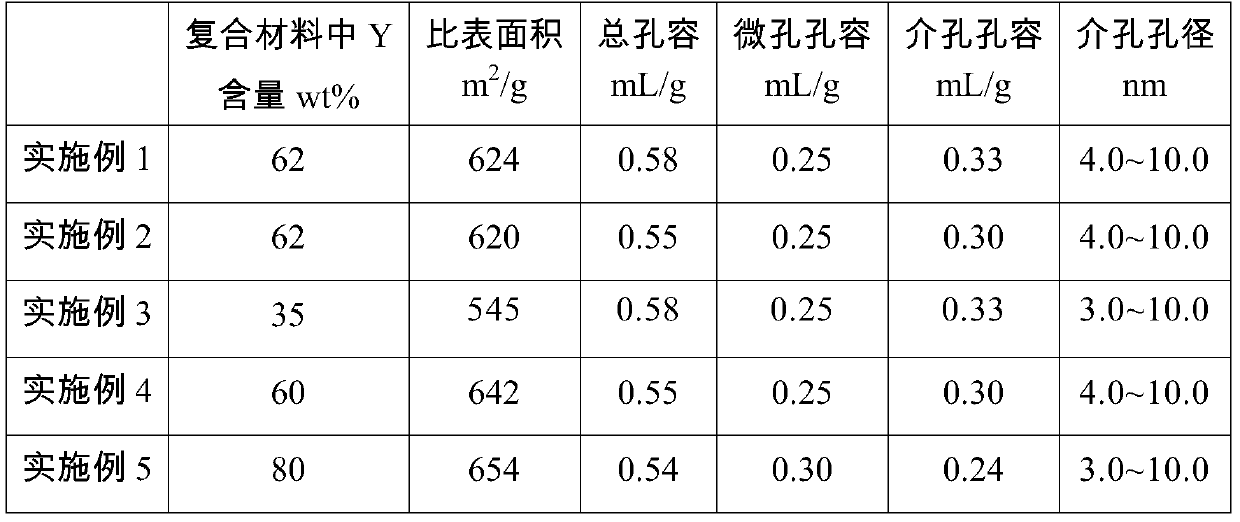

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

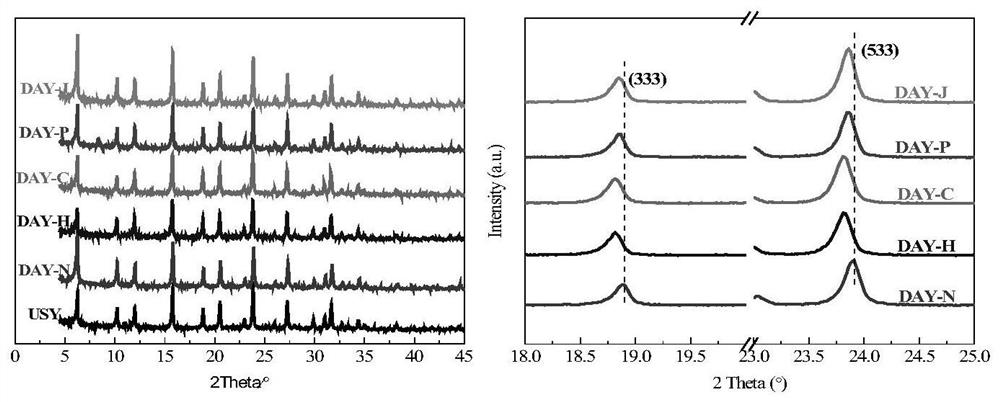

USY molecular sieve modification method

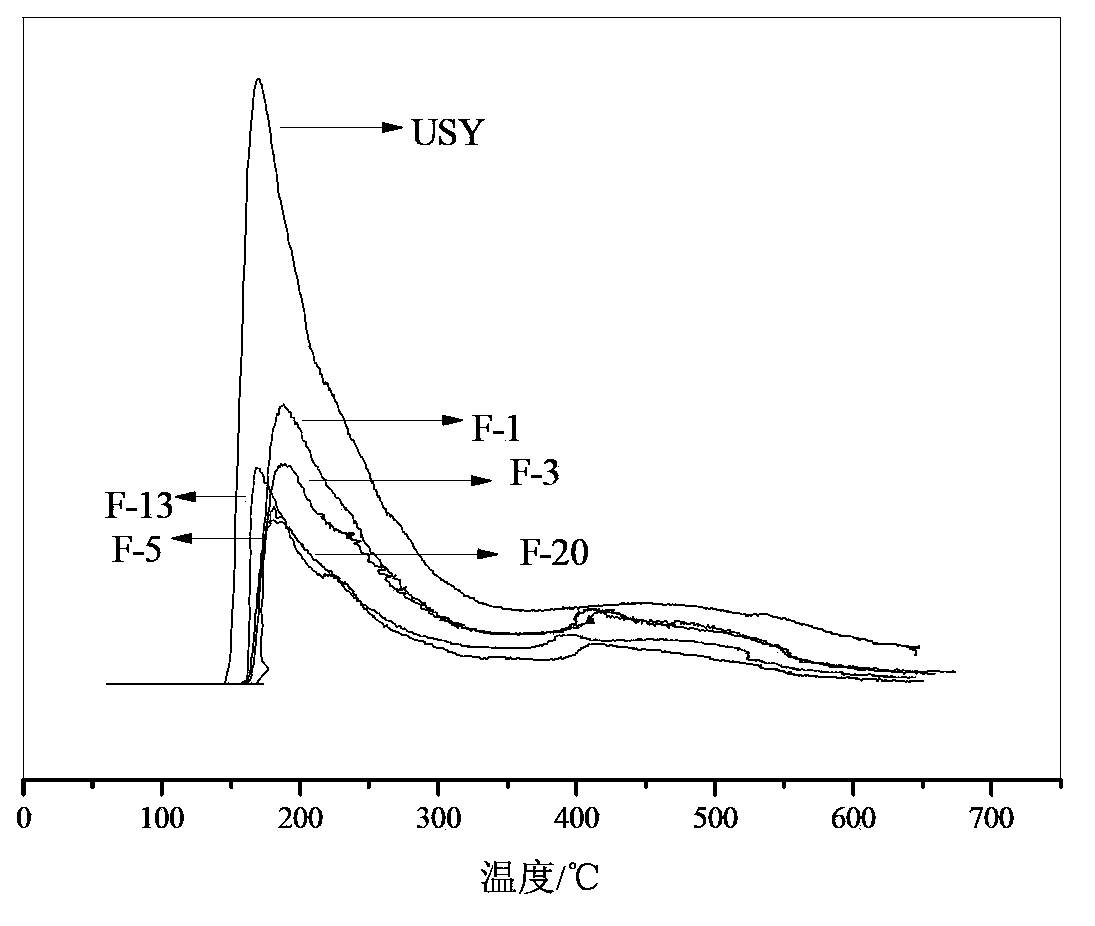

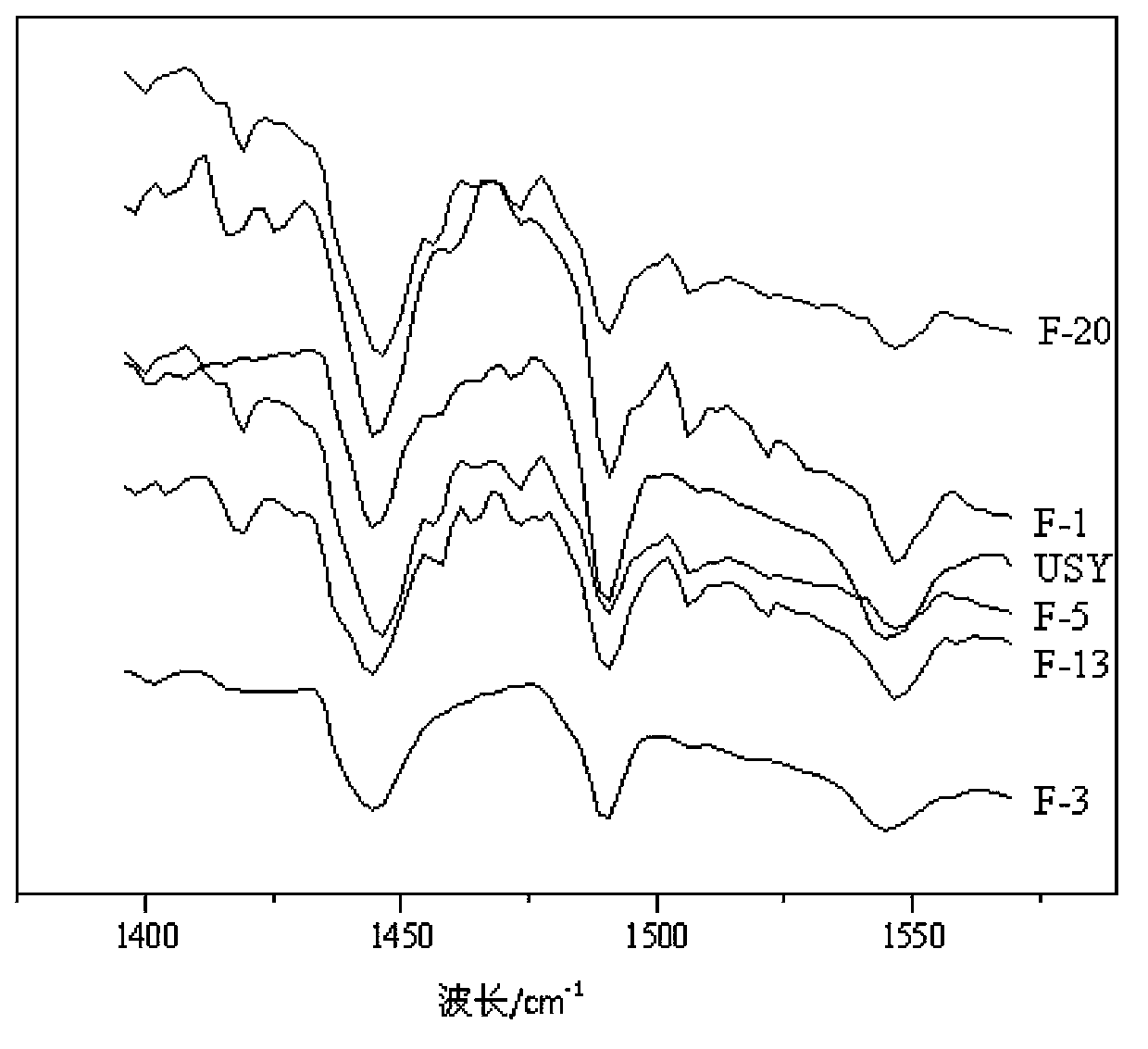

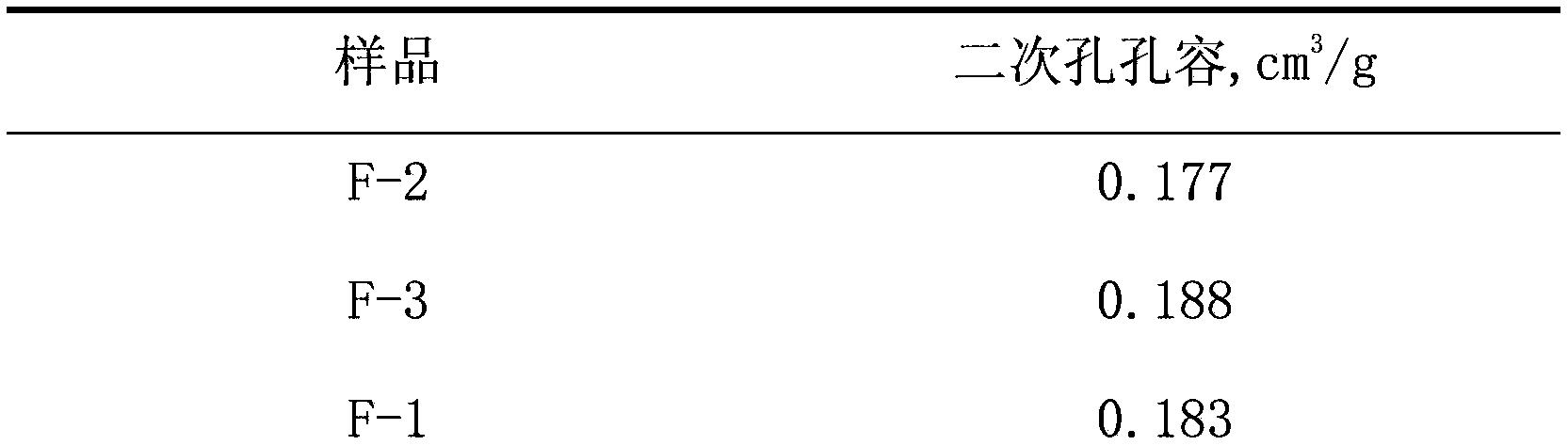

InactiveCN104096586AHigh ratio of silicon to aluminumHigh crystallinityMolecular sieve catalystsMolecular sieveReaction temperature

The invention relates to a USY molecular sieve modification method. The USY molecular sieve modification method comprises the following steps of adding a citric acid solution having a concentration of 0.10-0.35mol / L into a USY molecular sieve according to a solid-liquid quality ratio of 1: 5 for modification with stirring at a reaction temperature of 500-1200 DEG C, after a temperature is increased to a preset temperature of 600-900 DEG C, adding an ammonium fluosilicate solution having a concentration of 0.05-0.20mol / L into the reaction product at a rate of 0.1-3.5ml / min according to a volume ratio of citric acid to the ammonium fluosilicate solution of 0.5-3.0, after material addition, carrying out a reaction process at a temperature of 50-120 DEG C for 1-6h, carrying out washing by deionized water until a pH value is 7, and carrying out constant-temperature drying at a temperature of 110 DEG C. The USY molecular sieve obtained by the USY molecular sieve modification method has substantially improved specific surface, secondary pore volume and moderate strong acid level and can be used for a hydrocracking catalyst for maximizing middle distillates as desired products.

Owner:PETROCHINA CO LTD

Modified molecular sieve and preparing method thereof

InactiveCN1552624AAvoid destructionSkeleton silicon aluminum ratio is highCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

A modified molecular sieve is prepared from the raw molecular sieve powder containing organic templating agent through treating it in organic solvent, ion exchanging, removing Al, and supplementing Si. Its advantages are good crystal form, high crystallinity and low content of residual carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of Y/SAPO-34/ZSM-11/ASA hierarchical porous material

ActiveCN109205636ASmall grainSkeleton silicon aluminum ratio is highCatalytic crackingMolecular sieve catalystsMolecular sieveSlurry

The invention provides a preparation method of Y / SAPO-34 / ZSM-11 / ASA hierarchical porous material. The invention is characterized in that the method comprises the following steps: synthesizing a guideagent, synthesizing Y / SAPO-34 / ZSM-11 composite molecular sieve by hydrothermal crystallization, adding a surfactant, an alkaline aluminum source and / or alkaline silicon source solution into the slurryof Y / SAPO-34 / ZSM-11 molecular sieve, and washing, drying and roasting the product to obtain the mesoporous Y / SAPO-34 / ZSM-11 / ASA hierarchical porous material.

Owner:PETROCHINA CO LTD

Y/ZSM-22/SAPO-34/ASA/MOF composite material and preparation method thereof

ActiveCN107519927AImprove thermal stabilityIncrease the areaMolecular sieve catalystsMolecular sieveOrganic acid

The invention provides a Y / ZSM-22 / SAPO-34 / ASA / MOF composite material and a preparation method thereof. The method comprises the following steps: preparing a ZSM-22 / SAPO-34 molecular sieve slurry, and synthesizing a Y / ZSM-22 / SAPO-34 composite molecular sieve by adopting a hydrothermal crystallization method; adding a surfactant and an alkaline aluminum source into the slurry containing he molecular sieve, and adjusting the pH value to obtain a solid product; washing, drying and roasting the product to obtain a Y / ZSM-22 / SAPO-34 / ASA composite material, uniformly mixing and stirring with a metal salt aqueous solution, and drying to obtain a metal-loaded Y / ZSM-22 / SAPO-34 / ASA composite material; adding alcohol and amide organic solvent into carboxyl-containing organic acid, and uniformly mixing to obtain organic mixture; and adding the metal-loaded Y / ZSM-22 / SAPO-34 / ASA material into the organic mixture, uniformly stirring, and reacting to obtain the product.

Owner:PETROCHINA CO LTD

Y/eu-1/sba-15/asa/mof composite material and preparation method thereof

ActiveCN107519933BIncrease the areaHigh reactivityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsActive agentSlurry

The invention provides a Y / EU-1 / SBA-15 / ASA / MOF composite material and a preparation method thereof. The method comprises the following steps: synthesizing a guiding agent, and synthesizing a small grain size Y-type molecular sieve by adopting a hydrothermal crystallization method; adding surfactant, EU-1 and SBA-15 molecular sieve slurry and alkaline aluminum-source solution into the slurry containing molecular sieve, and washing, drying and roasting the product to obtain Y / EU-1 / SBA-15 / ASA complex; uniformly mixing and stirring with a metal salt aqueous solution, and drying to obtain a metal-loaded Y / EU-1 / SBA-15 / ASA composite material; adding carboxyl-containing organic acid into an organic solvent of alcohol and amide, and uniformly mixing to obtain organic mixture; and adding the metal-loaded Y / EU-1 / SBA-15 / ASA material into the organic mixture, uniformly stirring, and reacting to obtain the Y / EU-1 / SBA-15 / ASA / MOF composite material.

Owner:PETROCHINA CO LTD

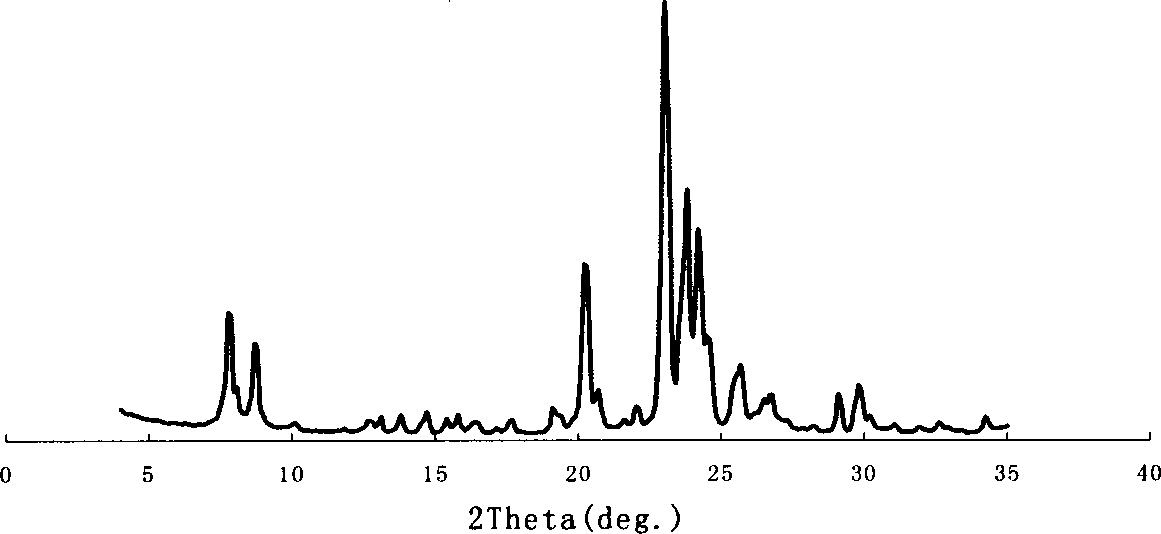

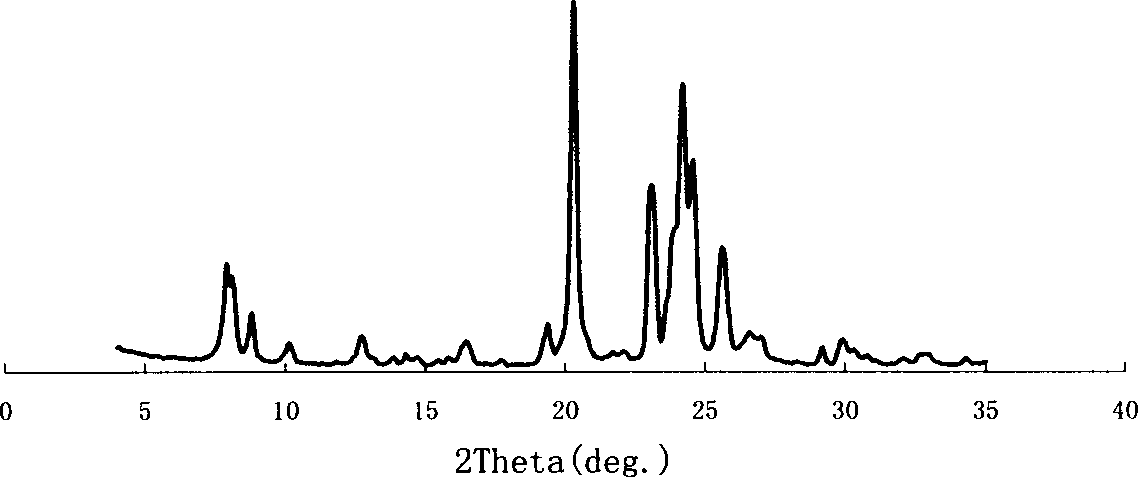

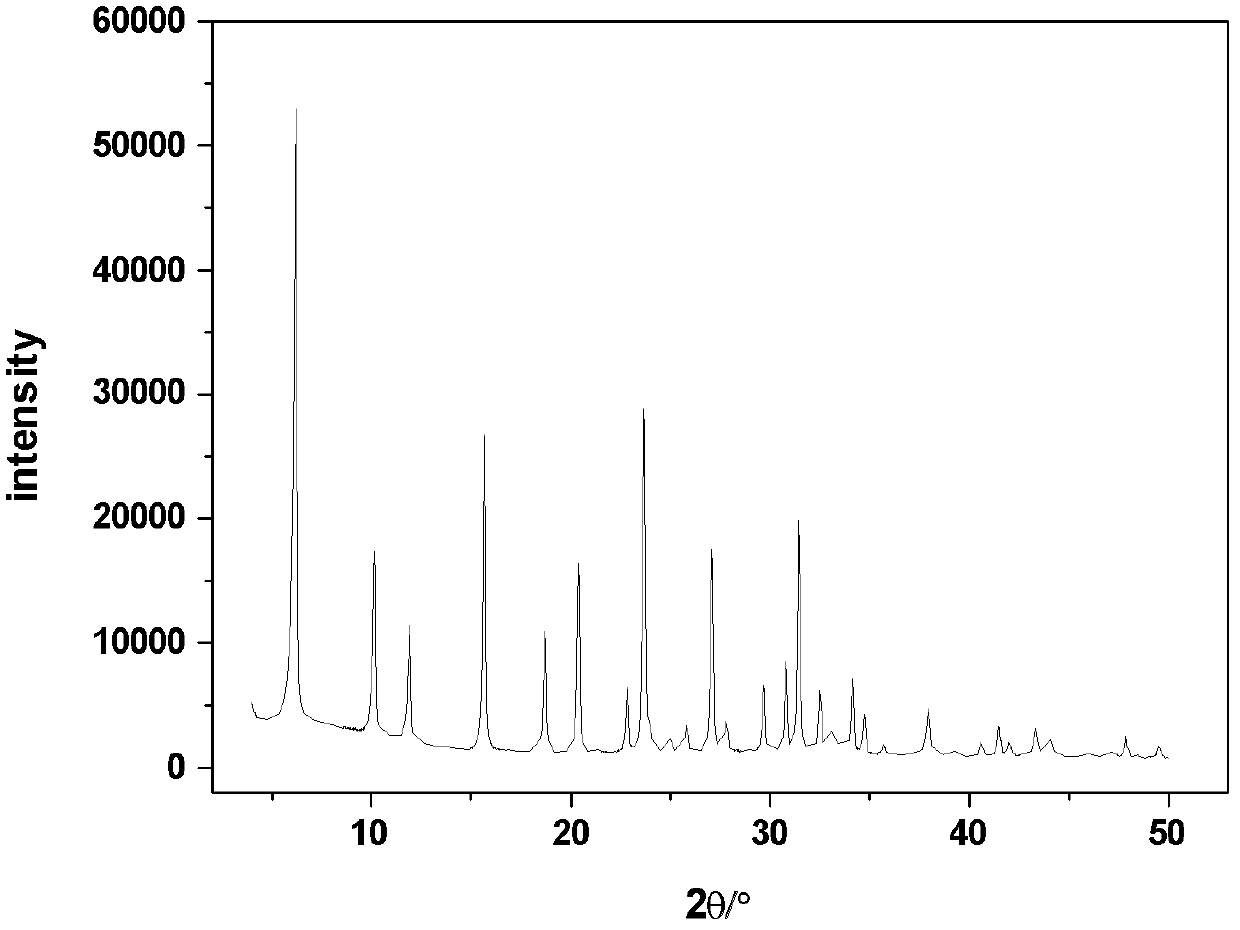

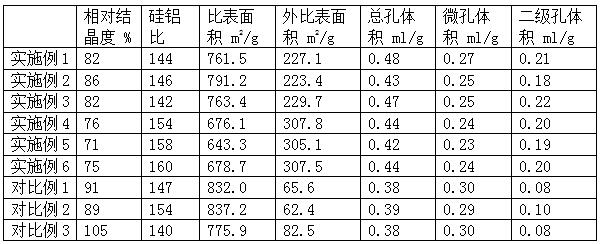

Method for synthesizing Y type molecular sieve

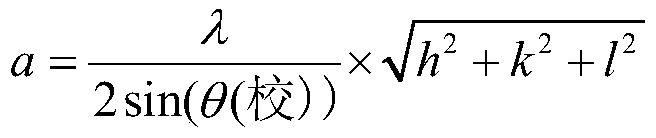

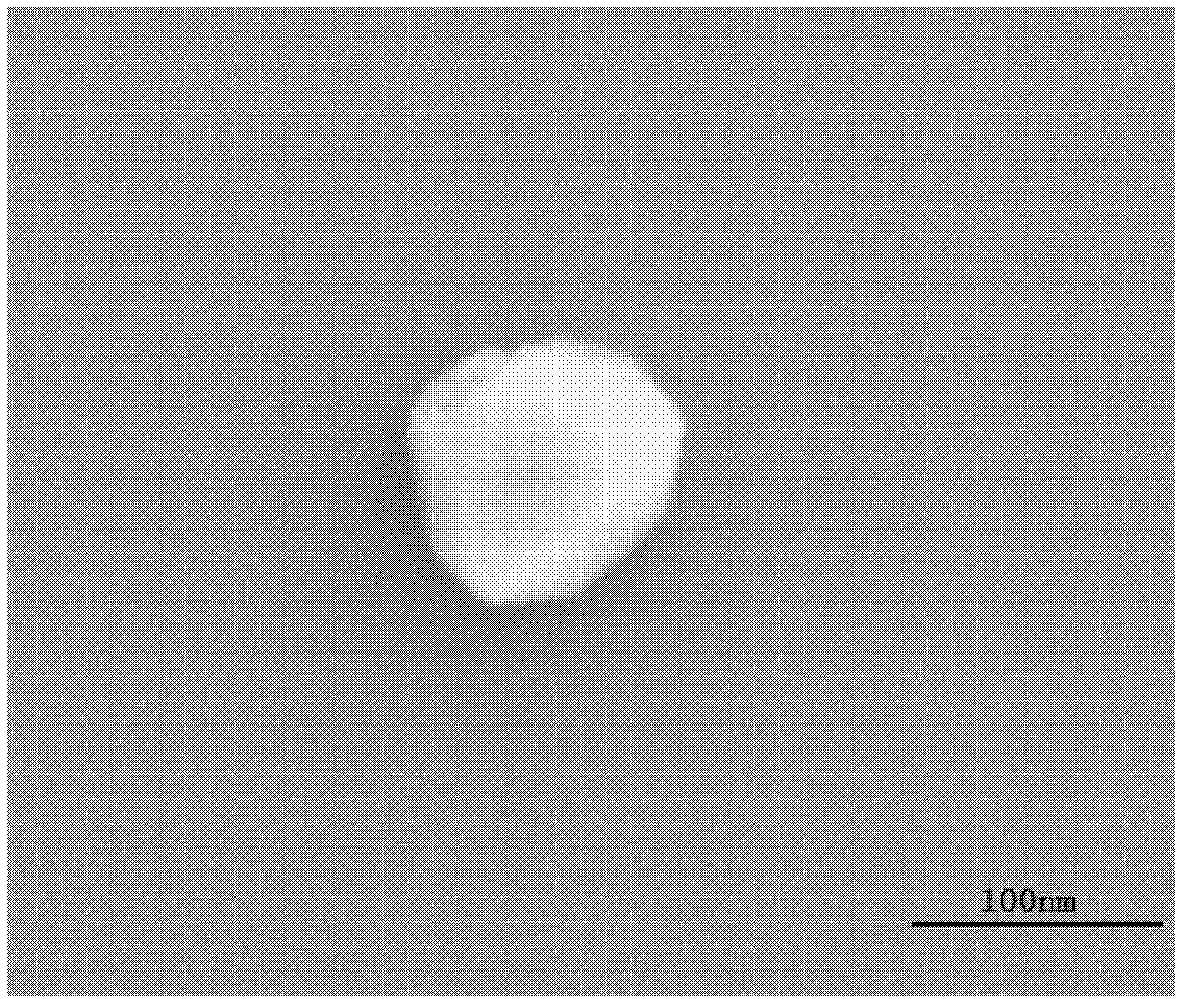

ActiveCN102616807BReduce secondary crackingReduce cokingFaujasite aluminosilicate zeoliteMolecular sievePtru catalyst

The invention discloses a method for synthesizing a Y type molecular sieve, and belongs to the technical field of preparation of catalysts. The method comprises the following steps of: mixing sodium metaaluminate and a silicon source in a reaction kettle, and performing rotary ageing to obtain a directing agent; adding the sodium metaaluminate and the directing agent into the silicon source in sequence, stirring, adding acidic aluminum salt, and continuously stirring to obtain silicon-aluminum gel; and crystallizing the silicon-aluminum gel in two steps, centrifuging, and drying to obtain the NaY type molecular sieve. The silicon-aluminum ratio of the synthesized NaY type molecular sieve is more than 5.0, and the average particle size of the sieve is not more than 100nm. The NaY type molecular sieve synthesized by the method is high in specific surface area, has higher performance in the aspects of converting macromolecules, reducing the secondary cracking of a product and the coking of a catalyst, and the like compared with the conventional Y type molecular sieve, is high in thermal stability and hydrothermal stability, is prepared from low-cost industrial raw materials, is environment-friendly, and has an industrial application prospect, and a framework of the sieve is high in silicon-aluminum ratio.

Owner:BEIJING UNIV OF CHEM TECH

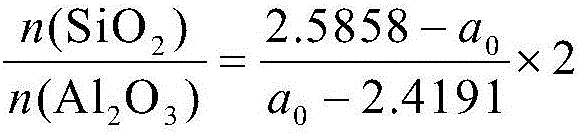

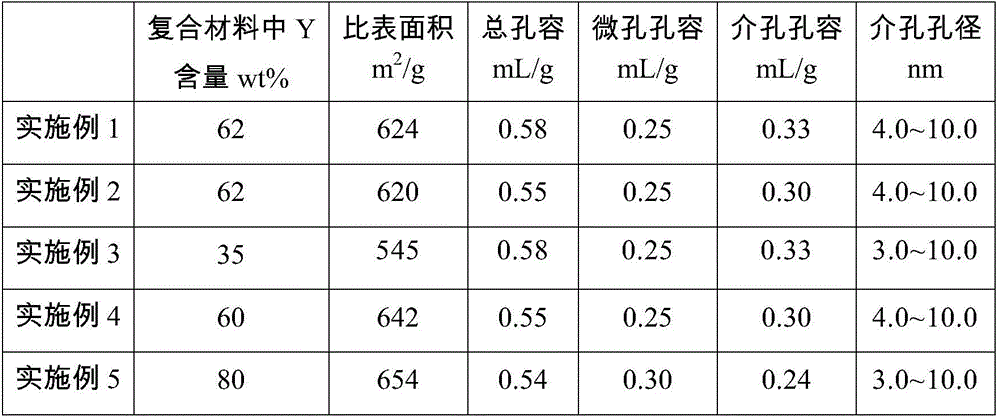

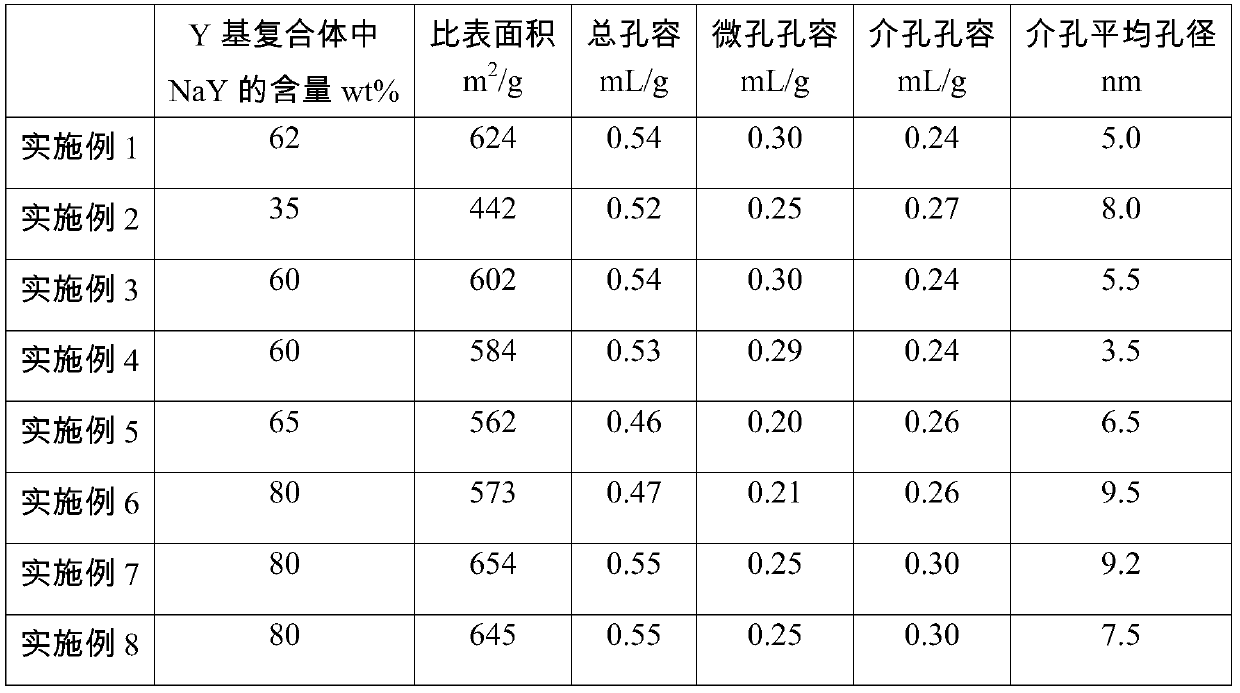

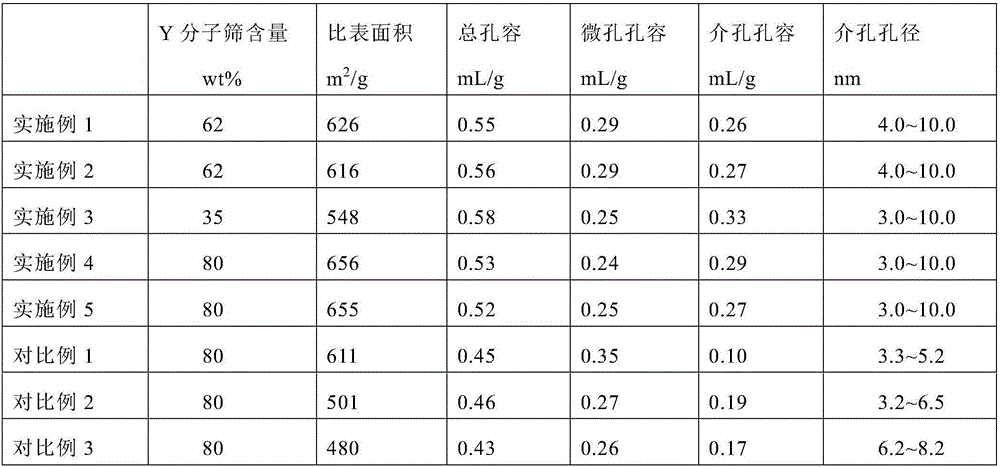

Preparation method of multistage porous material

ActiveCN109422274ASmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveSlurry

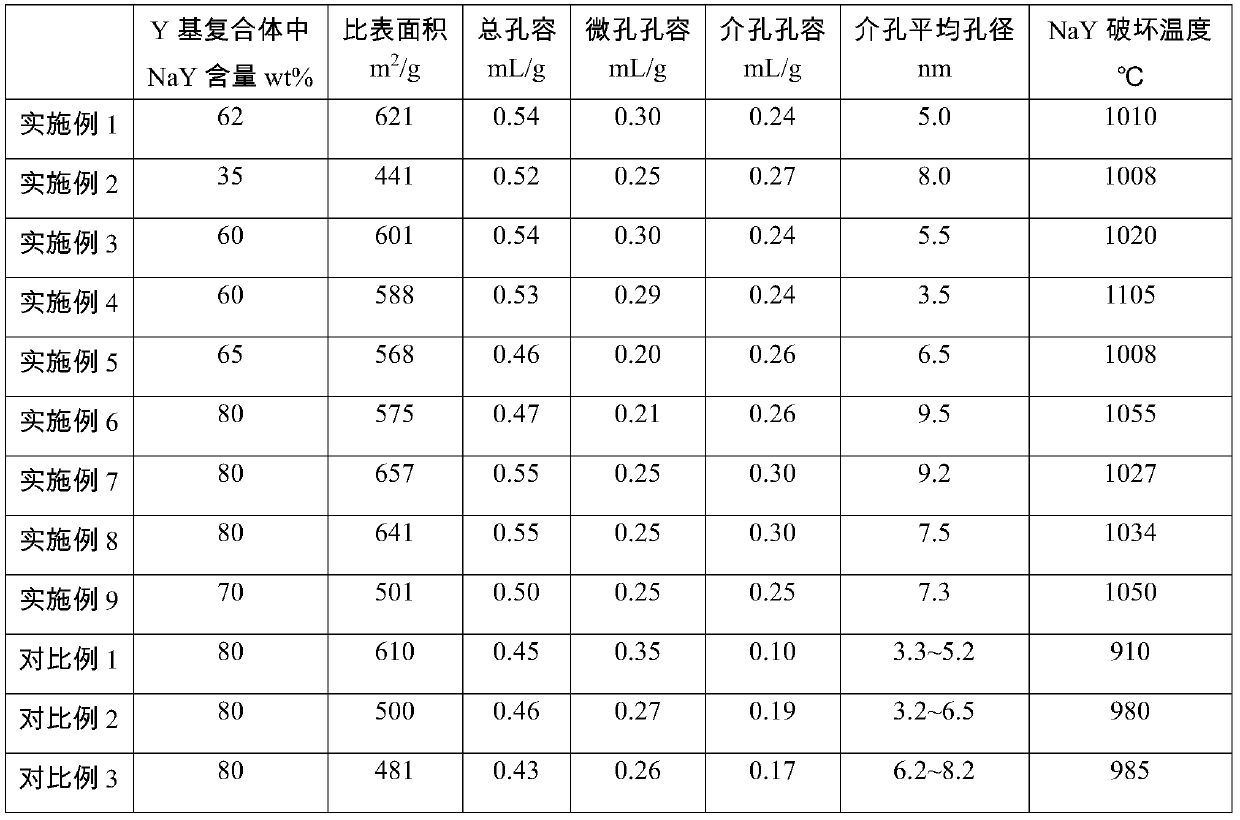

The invention provides a preparation method of a multistage porous material. The preparation method comprises following steps: step one, preparing a guiding agent; step two, preparing SBA-6 and ZSM-12composite molecular sieve slurry; step three, preparing Y / SBA-6 and ZSM-12 composite molecular sieve slurry; and step four, preparing a Y / SBA-6 / ZSM-12 / ASA multistage porous material. The prepared multistage porous material has the characteristics that the crystal grains of the NaY molecular sieve of the composite molecular sieve of the multistage porous material are small (100 to 400 nm), the silicon / aluminum ratio of the framework is high; the thermal stability is improved, compared with a corresponding NaY molecular sieve, the heat destroying temperature is increased by at least 5 DEG C, and a micro-meso pore structure, which is formed by micro pores with a diameter less than 1 nm and mesopores with a diameter of 3 to 10 nm, is formed.

Owner:PETROCHINA CO LTD

Y/eu-1/zsm-5/asa/heteropolyacid composite material and preparation method thereof

ActiveCN107519923BImprove thermal stabilityImprove catalytic performanceMolecular sieve catalystsMolecular sieveSlurry

Owner:PETROCHINA CO LTD

Y/EU-1/ZSM-5/ASA/heteropolyacid composite material and preparation method thereof

ActiveCN107519923AGuaranteed thermal stabilityImprove thermal stabilityMolecular sieve catalystsMolecular sieveSlurry

The invention provides a method for preparing a Y / EU-1 / ZSM-5 / ASA / heteropolyacid composite material containing regular mesopores. The method comprises the following steps: synthesizing a guiding agent, synthesizing small-grain-size Y-shaped molecular sieve by adopting a hydrothermal crystallization method; adding surfactant, EU-1 and ZSM-5 molecular sieve slurry and alkaline aluminum-source solution into the slurry containing a molecular sieve; washing, drying and roasting the product to obtain a mesoporous Y / EU-1 / ZSM-5 / ASA composite material; and adding a surfactant into an H3PMo12-X-YWXLaYO40.nH2O heteropolyacid, mixing and pulping with a Y / ASA material, aging and drying to obtain the mesoporous Y / EU-1 / ZSM-5 / ASA / heteropolyacid composite material.

Owner:PETROCHINA CO LTD

Y/EU-1/ZSM-23/ZSM-5/ASA composite material and preparation method thereof

ActiveCN107519924ASmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsDistribution characteristicSlurry

The invention provides a method for preparing a Y / EU-1 / ZSM-23 / ZSM-5 / ASA composite material containing regular mesopores. The method comprises the following steps: firstly, preparing a molecular sieve guiding agent, preparing an EU-1 / ZSM-23 / ZSM-5 precursor based on preparation of ZSM-23 / ZSM-5 molecular sieve slurry by a solid-like phase method; synthesizing a Y / EU-1 / ZSM-23 / ZSM-5 composite molecular sieve by adopting a hydrothermal crystallization method; and adding surfactant and alkaline aluminum-source solution into the slurry containing the molecular sieve; and washing, drying and roasting the product to obtain the composite material. In the Y / EU-1 / ZSM-23 / ZSM-5 / ASA composite material, the differential thermal failure temperature of the Y molecular sieve can be higher than 950 DEG C, the grain size is kept to be lower than 400nm. The composite material has the porous distribution characteristics of micropore-mesopore, mesopores in the surface ASA are regular mesopores, and the mesoporous size can be adjusted by changing the synthesizing process condition.

Owner:PETROCHINA CO LTD

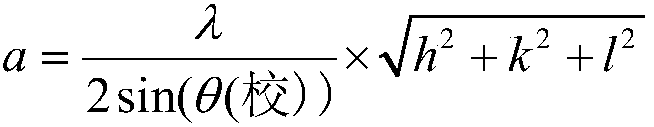

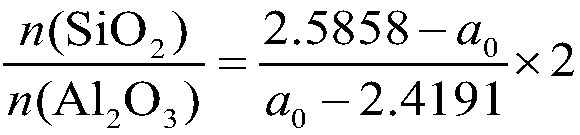

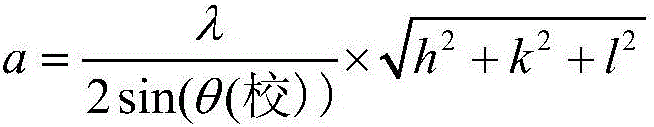

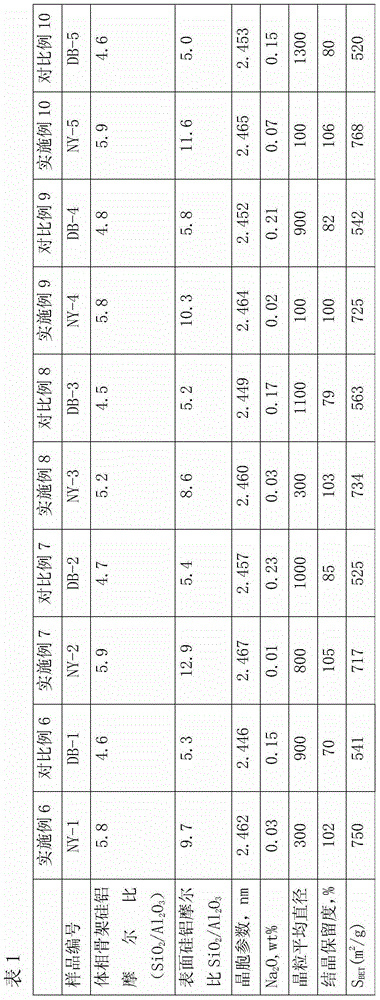

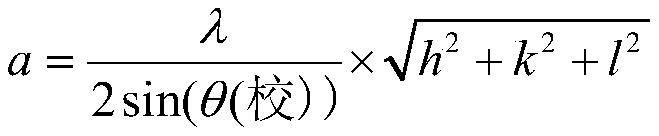

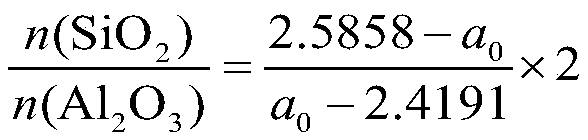

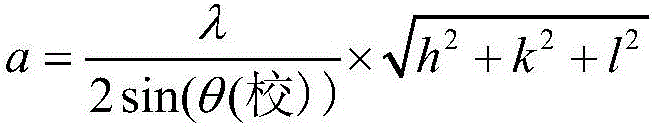

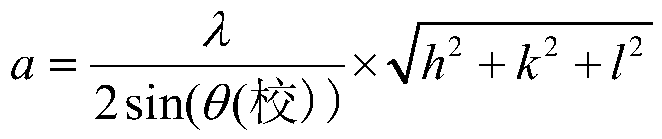

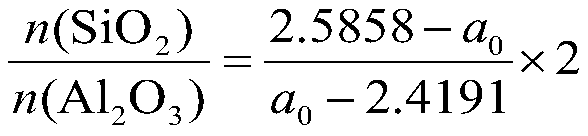

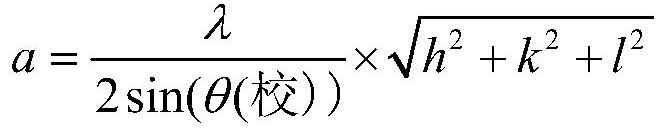

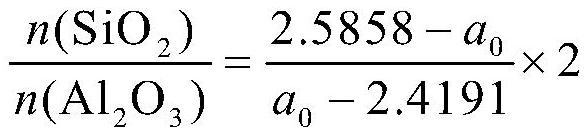

Small-particle Y-type molecular sieve with silicon-enriched surface and preparation method thereof

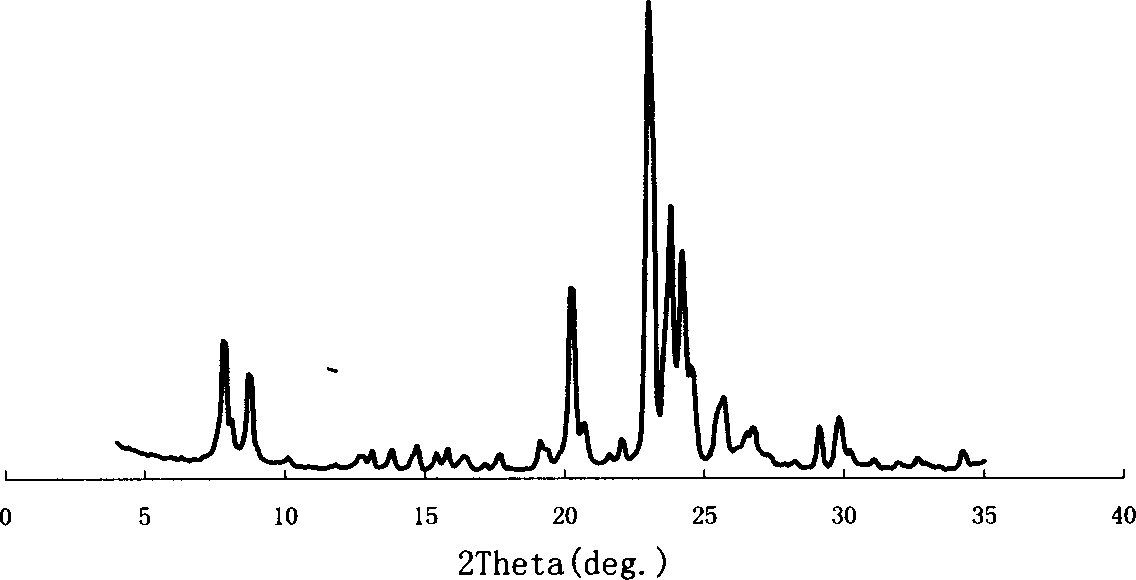

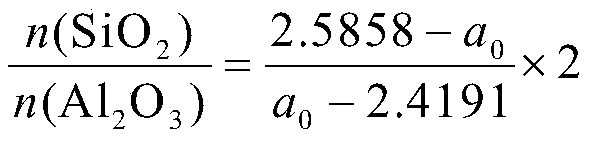

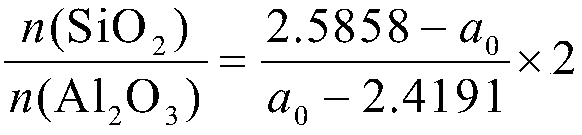

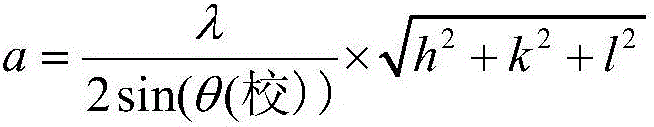

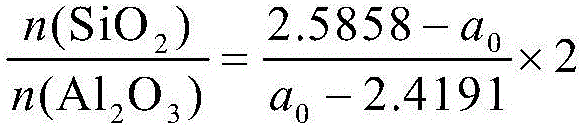

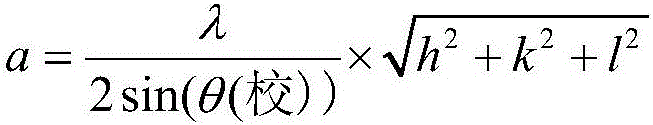

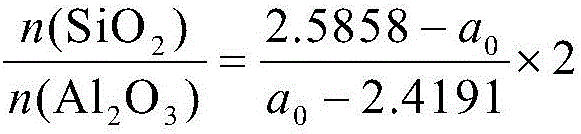

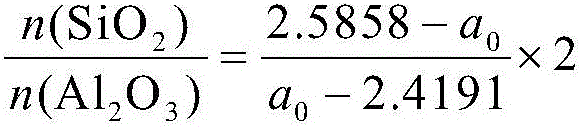

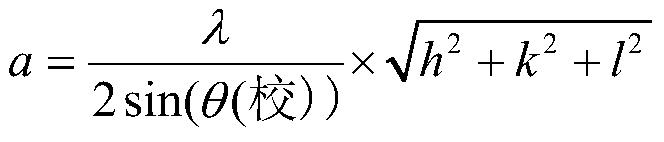

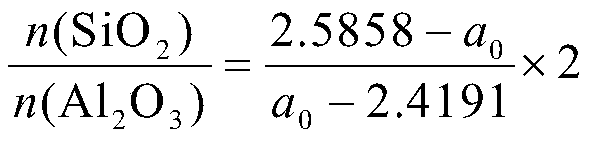

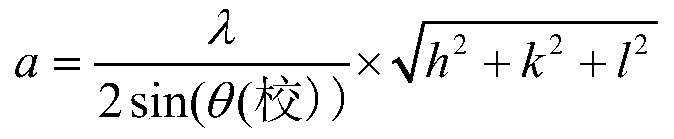

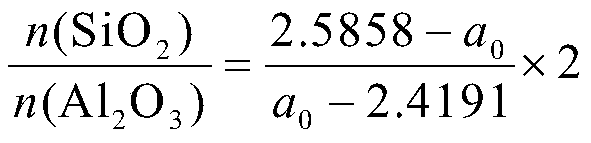

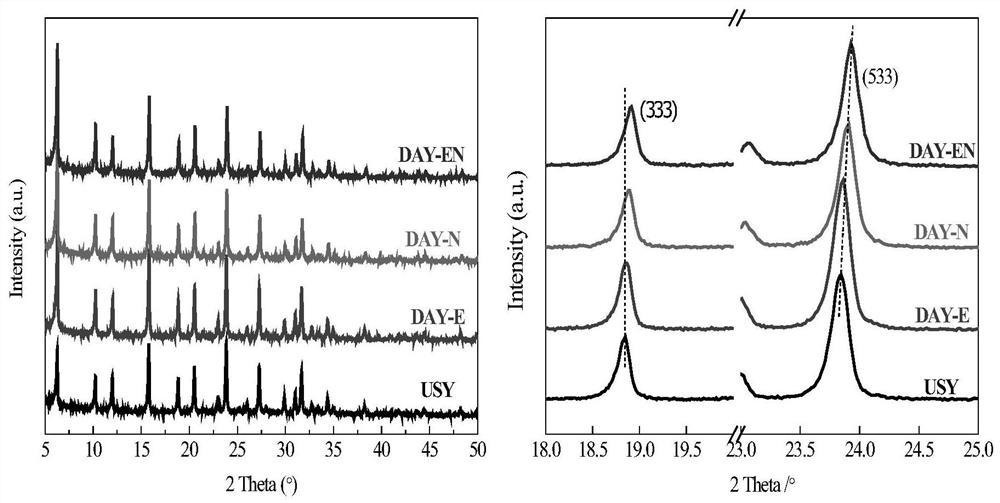

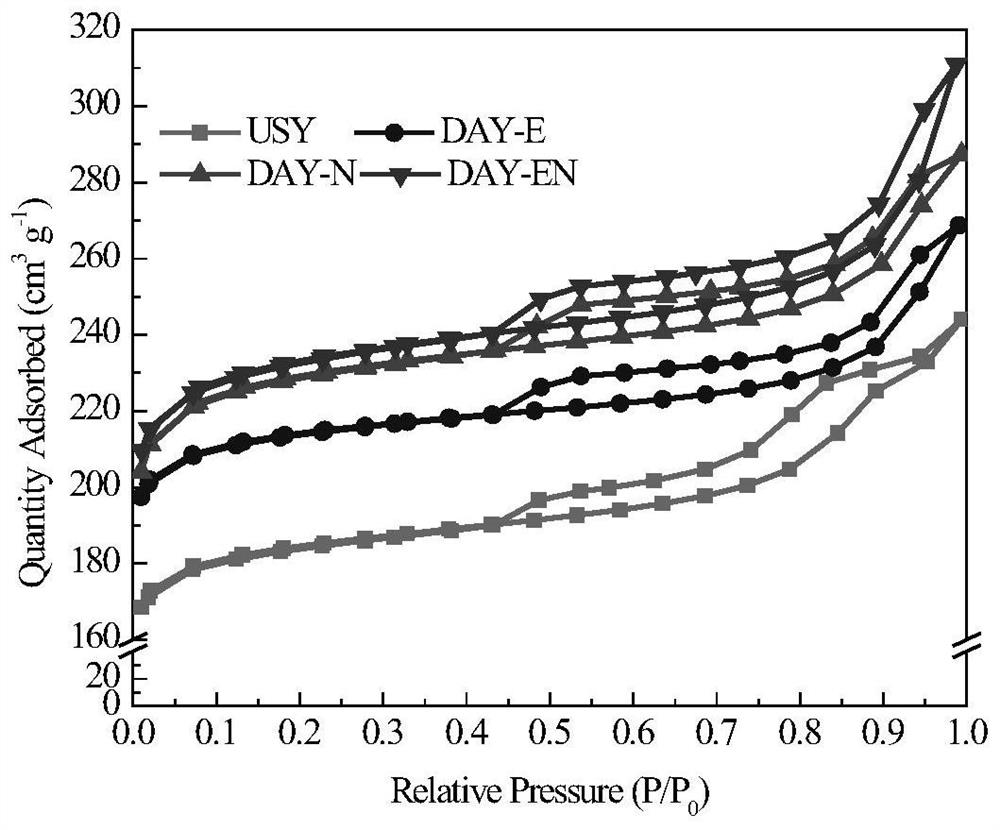

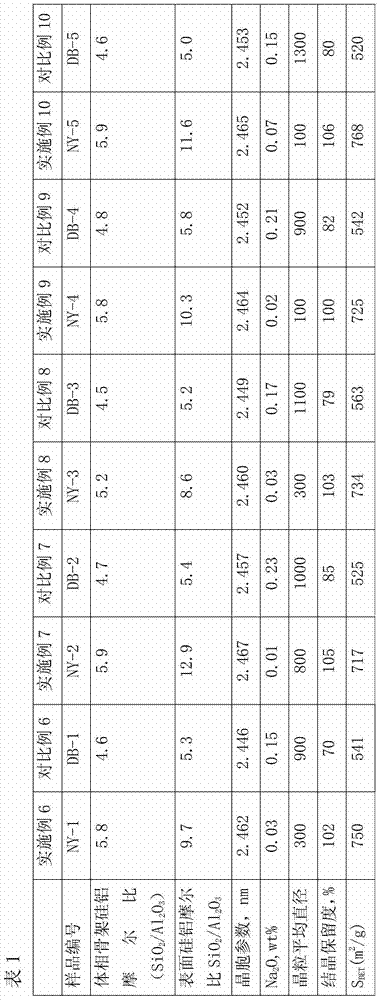

ActiveCN105084386AAccurate adjustment of average particle sizeIncrease the surface silicon to aluminum ratioFaujasite aluminosilicate zeoliteMolecular sieveCell parameter

The invention provides a small-particle Y-type molecular sieve with a silicon-enriched surface. The molecular sieve is characterized in that the molar ratio of SiO2 / Al2O3 of a phase skeleton of the molecular sieve body is 5.0-6.0, the molar ratio of SiO2 / Al2O3 of the surface is 8.0-13.0, the cell parameter is 2.46-2.468nm, the weight content of sodium oxide is less than or equal to 0.1 wt%, and the average diameter of crystal grains is 50-800nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of y/sapo-34/zsm-11/asa hierarchical porous material

ActiveCN109205636BSmall grainSkeleton silicon aluminum ratio is highCatalytic crackingMolecular sieve catalystsMolecular sieveActive agent

The invention provides a method for preparing Y / SAPO-34 / ZSM-11 / ASA hierarchical porous materials, which is characterized in that the method includes: first synthesizing a guiding agent, and using a hydrothermal crystallization method to synthesize Y / SAPO-34 / ZSM -11 composite molecular sieve, and then add surfactant, alkaline aluminum source and / or alkaline silicon source solution to the slurry of Y / SAPO-34 / ZSM-11 molecular sieve, and the product is washed, dried, and roasted to obtain mesoporous Y / SAPO‑34 / ZSM‑11 / ASA multi-stage porous materials.

Owner:PETROCHINA CO LTD

Modified molecular sieve and preparing method thereof

InactiveCN1218872CAvoid destructionSkeleton silicon aluminum ratio is highCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

A modified molecular sieve is prepared from the raw molecular sieve powder containing organic templating agent through treating it in organic solvent, ion exchanging, removing Al, and supplementing Si. Its advantages are good crystal form, high crystallinity and low content of residual carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

y/gd 2 o 3 /zsm-23/zsm-5/asa composite material and preparation method thereof

ActiveCN107519922BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular sievePore distribution

Owner:PETROCHINA CO LTD

Y/Sm2O3/SBA-3/ASA composite material and preparation method thereof

ActiveCN107519925AGuaranteed thermal stabilitySmall grainMolecular sieve catalystsMolecular sieveDistribution characteristic

The invention provides a method for preparing a Y / Sm2O3 / SBA-3 / ASA composite material containing regular mesopores. The method comprises the following steps: preparing a guiding agent, preparing an Sm2O3 / SBA-3 precursor, and synthesizing a Y / Sm2O3 / SBA-3 composite molecular sieve from the reaction mixture by adopting a hydrothermal crystallization method; adding a surfactant and an alkaline aluminum-source solution into the Y / Sm2O3 / SBA-3 composite molecular sieve slurry, and adjusting the pH value to obtain a solid product; and washing, drying and roasting the product to obtain the Y / Sm2O3 / SBA-3 / ASA composite material of which the surface is coated with ASA. In the composite material, the differential thermal failure temperature of the Y-shaped molecular sieve can be higher than 950 DEG C, and the grain size is kept to be lower than 400nm. The composite material has the porous distribution characteristics of micropore-mesopore, mesopores in the surface ASA are regular mesopores, and the mesoporous size can be adjusted by changing the synthesizing process condition.

Owner:PETROCHINA CO LTD

A kind of preparation method of multistage pore Y molecular sieve

ActiveCN110127716BIncrease the areaHigh crystallinityFaujasite aluminosilicate zeoliteMolecular sieveChemical treatment

The invention discloses a method for preparing a multi-stage pore Y molecular sieve, which relates to the field of molecular sieve synthesis; specifically, it comprises the steps of: pre-preparing a Y-type molecular sieve with a silicon-aluminum ratio of 4-6:1 in an alkaline solution at 20-150°C. Processing; under anhydrous conditions, use an inert gas to carry SiCl 4 and / or SiHCl 3 Steam reacts with pretreated molecular sieves to dealuminate and replenish silicon; then treat with ammonium ion solution at 60-120°C for 0.1-3h; then roast, wash, and dry to finally obtain multi-stage channel Y-type molecular sieves; this invention adopts alkali treatment and chemical The combination of the method and method does not destroy the structure of the molecular sieve. The obtained molecular sieve has a high specific surface area and crystallinity. The prepared multi-stage channel Y molecular sieve has a silicon-aluminum ratio of 20-160; the generated secondary pores are interconnected, and the channels The diameter can be adjusted between 2-50μm according to the alkali treatment conditions; the relative crystallinity of molecular sieves is >70%.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

Y/Gd2O3/ZSM-23/ZSM-5/ASA composite material and preparation method thereof

ActiveCN107519922ASmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsChemistryDistribution characteristic

The invention provides a method for preparing a Y / Gd2O3 / ZSM-23 / ZSM-5 / ASA composite material containing regular mesopores. The method comprises the following steps: firstly, preparing a guiding agent, preparing a Gd2O3 / ZSM-23 / ZSM-5 precursor; synthesizing a Y / Gd2O3 / ZSM-23 / ZSM-5 composite molecular sieve by adopting a hydrothermal crystallization method; adding a surfactant and an alkaline aluminum-source solution into the slurry containing the molecular sieve, adjusting the pH value; and washing, drying and roasting the precipitated product to obtain the Y / Gd2O3 / ZSM-23 / ZSM-5 / ASA composite material. In the Y / Gd2O3 / ZSM-23 / ZSM-5 / ASA composite material, the differential thermal failure temperature of the Y molecular sieve can be higher than 950 DEG C, the grain size is kept to be lower than 400nm. The composite material has the porous distribution characteristics of micropore-mesopore, mesopores in the surface ASA are regular mesopores, and the mesoporous size can be adjusted by changing the synthesizing process condition.

Owner:PETROCHINA CO LTD

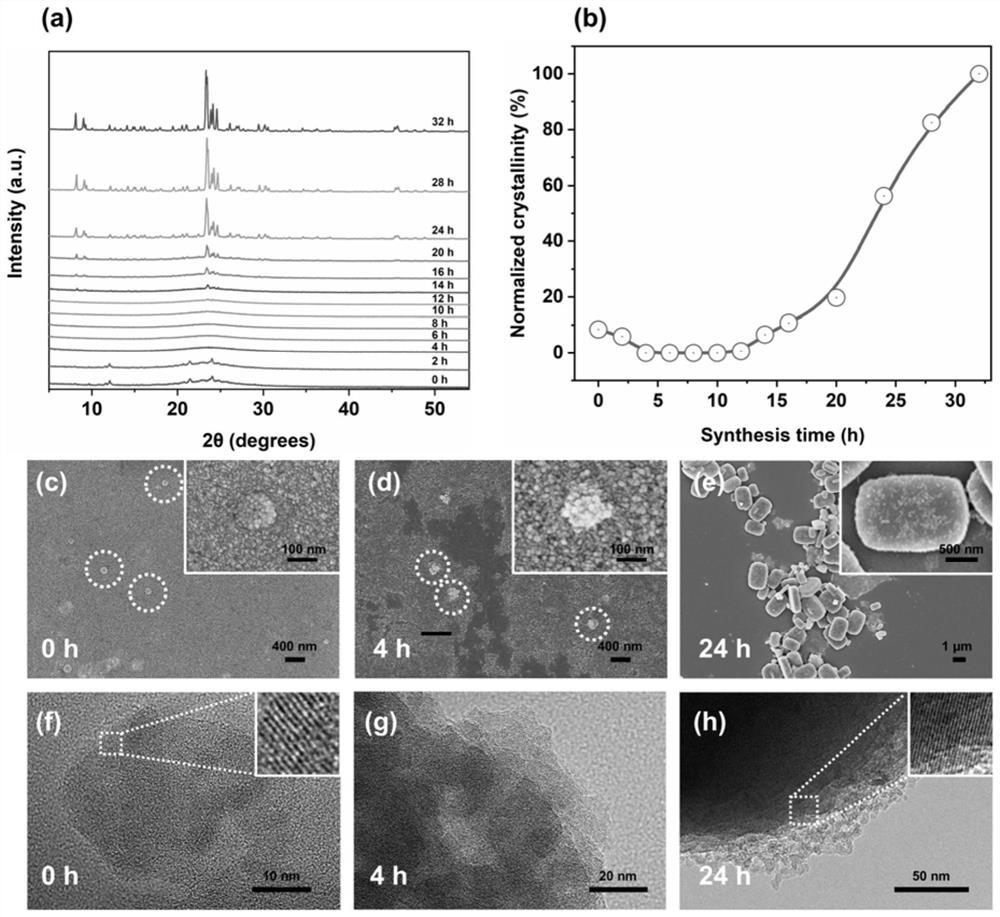

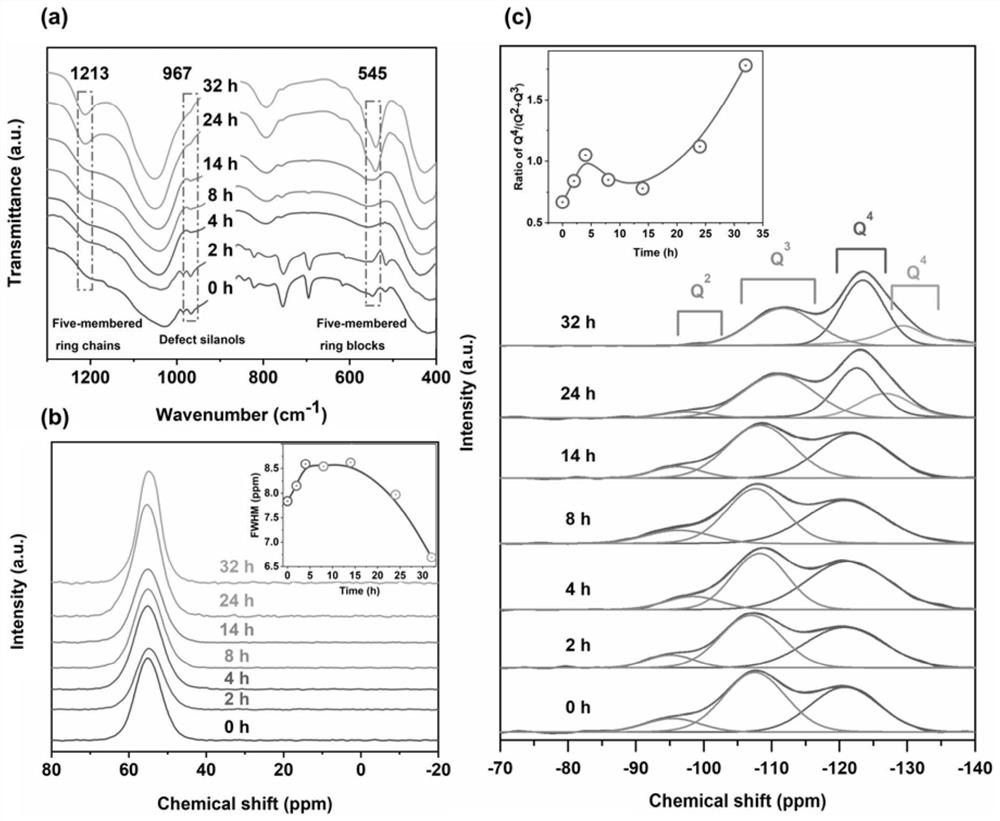

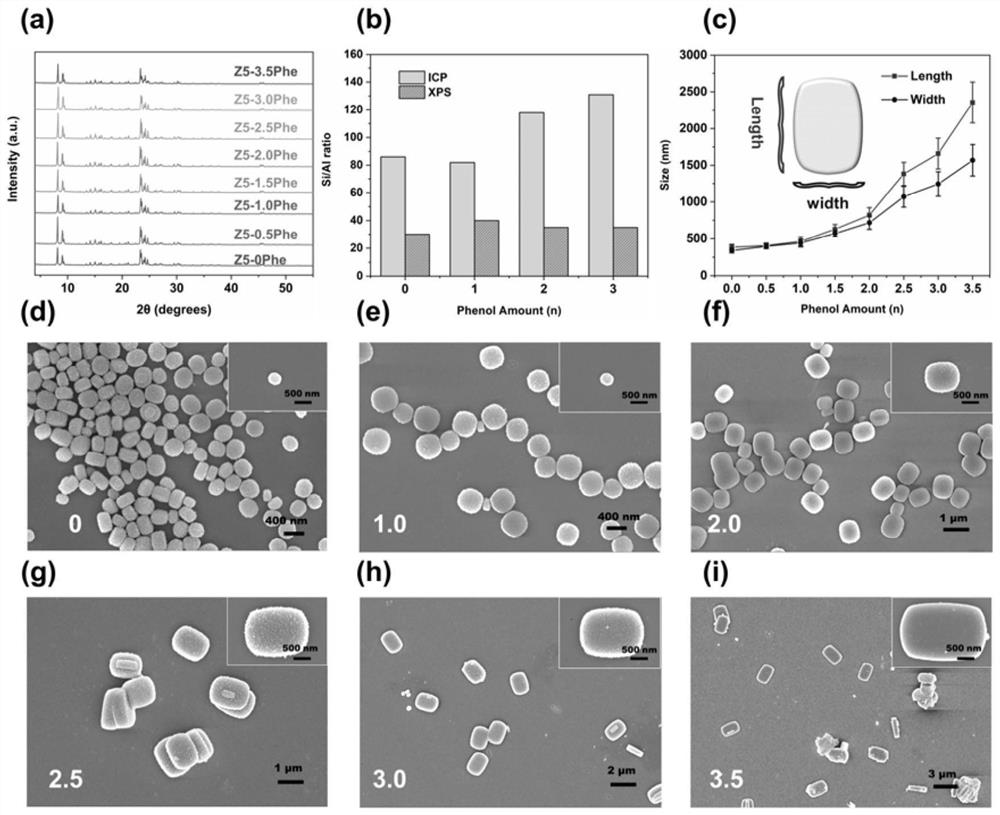

ZSM-5 zeolite as well as preparation method and application thereof

ActiveCN113620311ASimple and flexible structureChanged crystallization behaviorCatalyst carriersMolecular sieve catalystsPhotocatalytic reactionPtru catalyst

The invention provides ZSM-5 zeolite and a preparation method thereof, and provides application of the ZSM-5 zeolite as a chemical reaction catalyst or a catalyst carrier. The raw materials used in the invention are simple, cheap and easily available, have good compatibility with zeolite crystals, do not destroy the zeolite crystals, can flexibly regulate and control the zeolite crystallization process, change the zeolite crystallization behavior, improve the zeolite crystallinity, improve the silica-alumina ratio of the framework, reduce the framework defects, improve the activity and stability of a catalyst, and are beneficial to catalytic reaction. The preparation process is simple and beneficial to industrial large-scale production. In addition, the ZSM-5 zeolite prepared by the method can also be used as a carrier material of a semiconductor composite material catalyst, has extremely high compatibility, and improves the photocatalytic reaction efficiency of the catalyst.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

A kind of modification method of Y-type molecular sieve

ActiveCN106608643BSkeleton silicon aluminum ratio is highImprove stabilityFaujasite aluminosilicate zeoliteMolecular sieveAlcohol

Owner:CHINA PETROLEUM & CHEM CORP +1

y/sm 2 o 3 /sba-3/asa composite material and preparation method thereof

ActiveCN107519925BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular sievePore distribution

The invention provides a device containing regular mesopores Y / Sm 2 O 3 The preparation method of / SBA‑3 / ASA composite material includes: first preparing the guiding agent, and preparing Sm 2 O 3 / SBA‑3 precursor, the reaction mixture is synthesized by hydrothermal crystallization method to Y / Sm 2 O 3 / SBA‑3 composite molecular sieve, followed by Y / Sm 2 O 3 Surfactant and alkaline aluminum source solution are added to the / SBA-3 composite molecular sieve slurry, and the pH value is adjusted to obtain a solid product. Finally, the product is washed, dried, and roasted to obtain Y / Sm whose surface is coated with ASA. 2 O 3 / SBA‑3 / ASA composite. The differential thermal destruction temperature of the Y-type molecular sieve in the composite material can be greater than 950°C, and the crystal grains remain below 400nm. The composite material has micropore-mesoporous pore distribution characteristics, and the mesopores in the surface ASA are regular mesopores, changing the synthesis Process conditions can make the mesopore diameter adjustable.

Owner:PETROCHINA CO LTD

y/sm 2 o 3 /zsm-22/zsm-5/asa composite material and preparation method thereof

ActiveCN107519921BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular sievePore distribution

The invention provides a method for preparing a Y / Sm2O3 / ZSM-22 / ZSM-5 / ASA composite material containing regular mesopores. The method comprises the following steps: preparing a guiding agent, preparing an Sm2O3 / ZSM-22 / ZSM-5 precursor, and synthesizing a Y / Sm2O3 / ZSM-22 / ZSM-5 composite molecular sieve by adopting a hydrothermal crystallization method; adding a surfactant and an alkaline aluminum-source solution into the slurry containing the molecular sieve, and adjusting the pH value; and washing, drying and roasting the product after precipitation to obtain the Y / Sm2O3 / ZSM-22 / ZSM-5 / ASA composite material. In the composite material prepared by the method, the differential thermal failure temperature of the Y-molecular sieve can be higher than 950 DEG C, and the grain size is kept to be below 400nm. The composite material has the porous distribution characteristics of micropore-mesopore, mesopores in the surface ASA are regular mesopores, and the mesoporous size can be adjusted by changing the synthesizing process condition.

Owner:PETROCHINA CO LTD

Y/eu-1/zsm-23/zsm-5/asa composite material and preparation method thereof

ActiveCN107519924BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular sieveDistribution characteristic

Owner:PETROCHINA CO LTD

A kind of preparation method of hierarchical porous material

ActiveCN109422274BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sievePhysical chemistry

Owner:PETROCHINA CO LTD

A kind of hydrocracking catalyst for producing heavy naphtha and jet fuel and its preparation method and application

ActiveCN109304226BSmall grainSkeleton silicon aluminum ratio is highMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention provides a hydrocracking catalyst capable of producing heavy naphtha and jet fuel and its preparation method and application. The method comprises: synthesizing a directing agent first, and then synthesizing Y / TS‑1 / APO‑1 by hydrothermal crystallization 5 composite molecular sieve, then add surfactant, alkaline aluminum source and / or alkaline silicon source solution to the slurry of Y / TS‑1 / APO‑5 molecular sieve, and the product is washed, dried and roasted to obtain mesoporous Y / TS‑1 / APO‑5 / ASA composite. then H 3 PMo 12‑ x PR x o 40 ·nH 2 The O heteropoly acid aqueous solution is mixed with the mesoporous Y / TS-1 / APO-5 / ASA composite material, then alumina and nitric acid are added, and the hydrocracking catalyst is obtained after kneading, rolling, extruding, drying and roasting. The catalyst can process heavy raw oil, and can produce more heavy naphtha and jet fuel.

Owner:PETROCHINA CO LTD

y/zsm-22/sapo-34/asa/mof composite material and preparation method thereof

ActiveCN107519927BImprove thermal stabilityIncrease the areaMolecular sieve catalystsMolecular sieveOrganic acid

The invention provides a Y / ZSM-22 / SAPO-34 / ASA / MOF composite material and a preparation method thereof, which includes: preparing ZSM-22 / SAPO-34 molecular sieve slurry, and using a hydrothermal crystallization method to synthesize Y / ZSM- 22 / SAPO-34 composite molecular sieve, then add surfactant and alkaline aluminum source to the slurry containing the molecular sieve, adjust the pH value to obtain a solid product, and the product is washed, dried and roasted to obtain Y / ZSM-22 / SAPO ‑34 / ASA composite material, and then mixed with the metal salt solution, stirred evenly, and dried to obtain the metal-loaded Y / ZSM‑22 / SAPO‑34 / ASA composite material. Add the carboxyl-containing organic acid to the organic solvent of alcohols and amides, and mix evenly to obtain an organic mixture. Add the metal-loaded Y / ZSM-22 / SAPO-34 / ASA material to the above organic mixture, stir evenly, and react to obtain the product.

Owner:PETROCHINA CO LTD

USY type molecular sieve modification method and application thereof

PendingCN114534773AAvoid strong destructionEfficient removalMolecular sieve catalystsCatalyst activation/preparationMolecular sieveOrganic acid

The invention provides a USY type molecular sieve modification method and application thereof.The USY type molecular sieve modification method comprises the following steps that an industrial USY molecular sieve is added into an organic acid-chelating agent composite dealumination modifier according to the solid-to-liquid ratio under the stirring condition, stirring continues to be conducted, a reaction is conducted, and milk white turbid liquid is obtained; and washing the milky white suspension until the milky white suspension is neutral, and drying to obtain the modified USY type molecular sieve. According to the novel method for preparing the modified USY type molecular sieve by utilizing the synergistic effect of the organic acid and the chelating agent, the modified USY type molecular sieve has the structural characteristics of large specific surface and small unit cell parameters.

Owner:PETROCHINA CO LTD +1

A kind of surface silicon-rich small-grain Y-type molecular sieve and preparation method thereof

ActiveCN105084386BIncrease the surface silicon to aluminum ratioSkeleton silicon aluminum ratio is highFaujasite aluminosilicate zeoliteMolecular sieveSilicon

A small grain Y-type molecular sieve with silicon-rich surface, characterized in that the molecular sieve body phase skeleton SiO2 / Al2O3 molar ratio is 5.0-6.0, the surface SiO2 / Al2O3 molar ratio is 8.0-13.0, and the unit cell parameter is 2.46-2.468nm , the weight content of sodium oxide is less than or equal to 0.1wt%, and the average grain diameter is 50-800nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of Y-type molecular sieve with high silicon-aluminum ratio

ActiveCN106467308BHigh yieldSkeleton silicon aluminum ratio is highFaujasite aluminosilicate zeoliteMolecular sieveAlcohol

The invention relates to a method for preparing a high-silica alumina ratio Y-type molecular sieve. The method is characterized in that water is added in a NaY molecular sieve for beating, polyhydroxy-alcohol is added according to the mass ratio of alcohol to the sieve at 1-20:1, a slurry A is obtained through processing at the temperature of 80-200 DEG C; the slurry A and organic base are mixed to obtain a slurry B according to the mass ratio of the alcohol to the sieve at 0.1-1:1; the slurry B and a silicon source are mixed and a mixture is aged to obtain a slurry C, by metering with SiO2, the mass ratio of the silicon source to the NaY molecular sieve is 0.1-1:1; the slurry C is subjected to hydrothermal crystallization in an enclosed reaction vessel, and the product is recovered. The method can effectively increase the silica-alumina ratio of the molecular sieve, and can make the crystallization integrity of the molecular sieve better, a structure of the molecular sieve is more stable, and the higher molecular sieve yield can be kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com