ZSM-5 zeolite as well as preparation method and application thereof

A ZSM-5 and zeolite technology, applied in the field of catalyst preparation, can solve the problems of low specific surface area, poor compatibility of semiconductor materials, and limited accessible catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

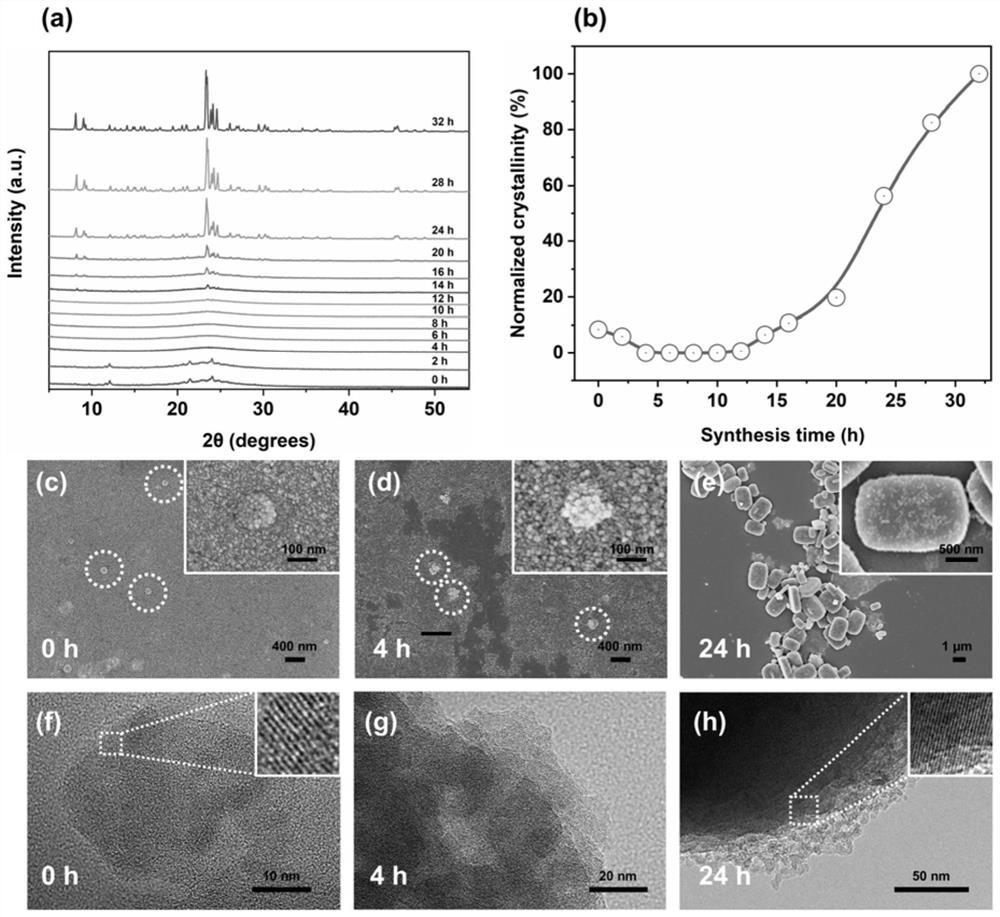

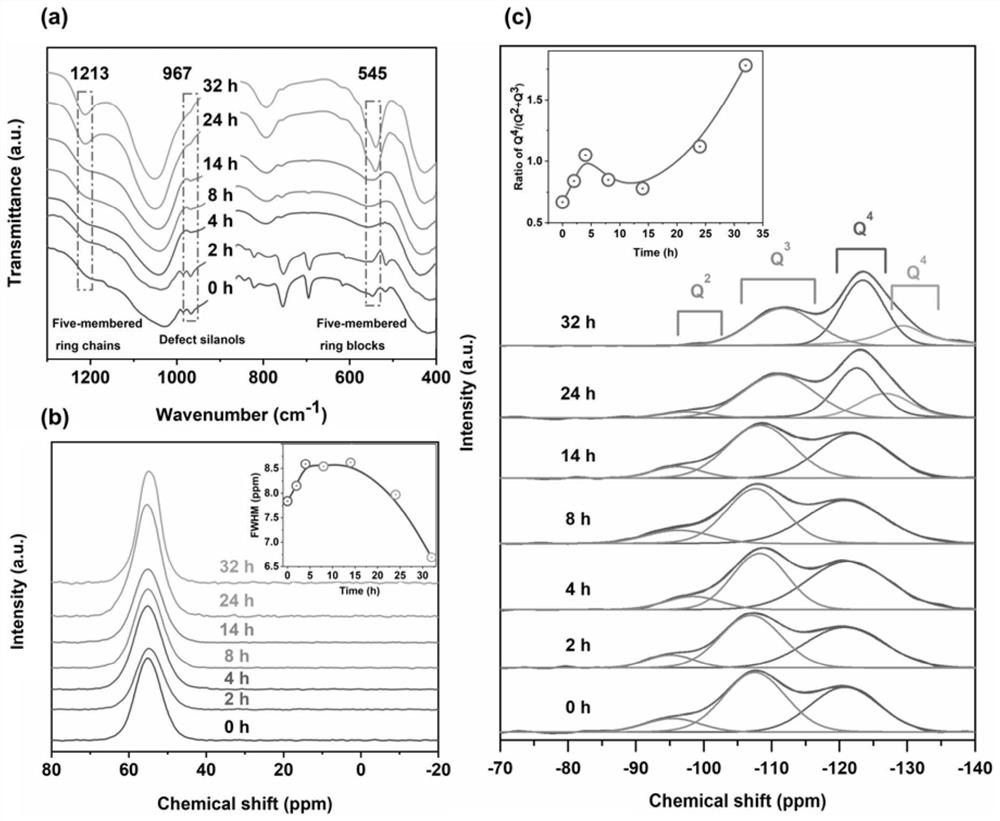

[0051] Embodiment 1: Synthesis of ZSM-5 zeolite——tetraethyl orthosilicate as silicon source

[0052] A preparation method of ZSM-5 zeolite, comprising the following steps S1~S2:

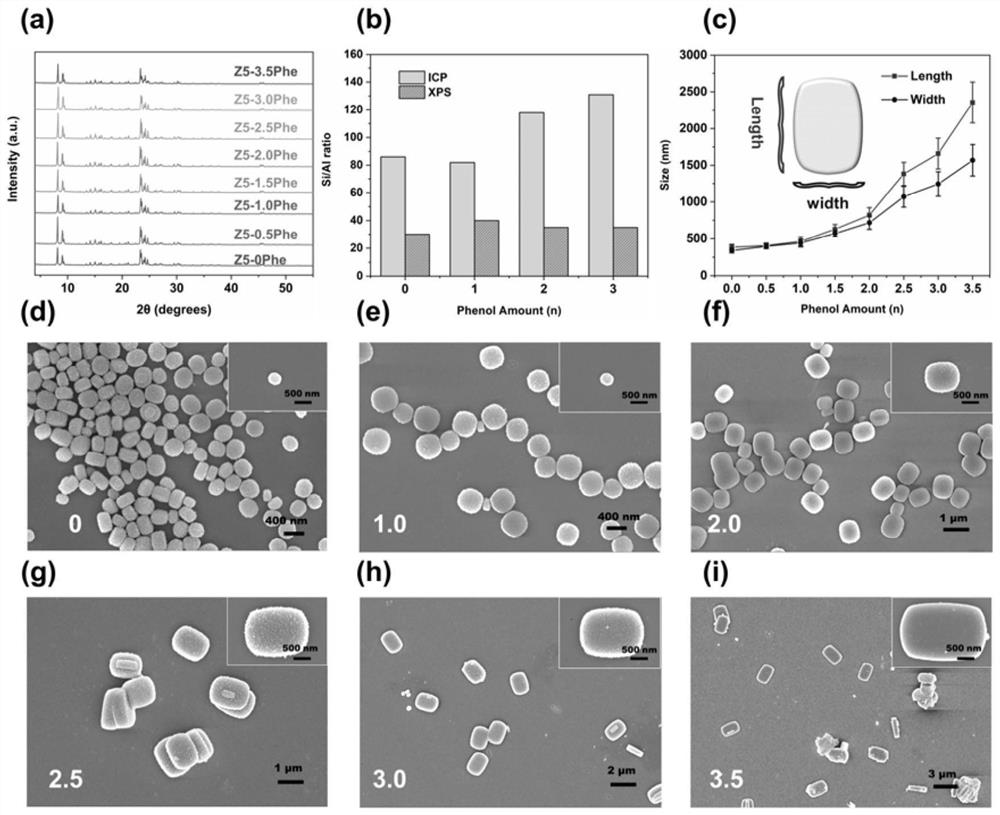

[0053] S1 step comprises: S11: 0.16g tri-sec-butoxide aluminum (C 12 h 27 AlO 3 , the molecular weight is 246, the purity (mass percentage) 97%) and 6.97g of tetraethyl orthosilicate (C 8 h 20 o 4 Si, molecular weight is 208) and mix uniformly as aluminum source and silicon source stock solution; S12: 5g TPAOH (the TPAOH aqueous solution of mass percentage concentration 40%) and 0.9255g phenol are dissolved in 56g deionized water, keep stirring until forming a solution; S13 : The stock solution prepared in S11 was slowly added to the solution prepared in S12 while stirring, and mixed evenly to obtain a synthetic solution; S2: at room temperature, the synthetic solution was aged for 2 days. After the aging, the synthetic solution was Placed in a 100mL polytetrafluoroethylene-lined stainless stee...

Embodiment 2

[0054] Example 2 Synthesis of ZSM-5 zeolite - sodium silicate as silicon source

[0055] A preparation method of ZSM-5 zeolite, comprising the following steps:

[0056] Step S1 includes: S11: Add Al to deionized water under continuous stirring 2 (SO 4 ) 3 0.45g, 5gTPAOH (the TPAOH aqueous solution of mass percent concentration 40%) and 0.62g phenol, until they dissolve completely; 2 SiO 3 (with SiO 2 26.5% by mass, containing Na 2 (10.6% by mass percentage) solution is slowly added to the solution of S11 to form a synthetic solution; S2: at room temperature, the synthetic solution is aged for 2 days, and after the aging is completed, the synthetic solution is placed in 100 mL of polytetrafluoroethylene-lined stainless steel In an autoclave, and the polytetrafluoroethylene-lined stainless steel autoclave is heated in a rotary oven, the oven speed is 30rpm, and crystallized at 170°C for 72h. After the reaction, the product is centrifugally washed three times and dried at...

Embodiment 3

[0058] A preparation method of ZSM-5 zeolite, comprising the following steps S1~S2:

[0059] S1 step comprises: S11: 0.16g tri-sec-butoxide aluminum (C 12 h 27 AlO 3 , the molecular weight is 246, the purity (mass percentage) 97%) and 6.97g of tetraethyl orthosilicate (C 8 h 20 o 4 Si, the molecular weight is 208) mixed uniformly as aluminum source and silicon source stock solution; S12: 5g TPAOH (the TPAOH aqueous solution of mass percent concentration 40%) and 0.58g alanine are dissolved in 56g deionized water, keep stirring until forming a solution ; S13: Slowly add the stock solution prepared in S11 to the solution prepared in S12 above while stirring, and mix evenly to obtain a synthetic solution; S2: Aging the synthetic solution for 2 days at room temperature. The synthetic solution was placed in a 100mL polytetrafluoroethylene-lined stainless steel autoclave, and the polytetrafluoroethylene-lined stainless steel autoclave was heated in a rotary oven with a rotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com