Patents

Literature

31results about How to "Changed crystallization behavior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-shrinkage and low-density modified polypropylene composite material and preparation method thereof

InactiveCN107501735ALimit the crystallization processHigh tensile strengthPolypropylene compositesAntioxidant

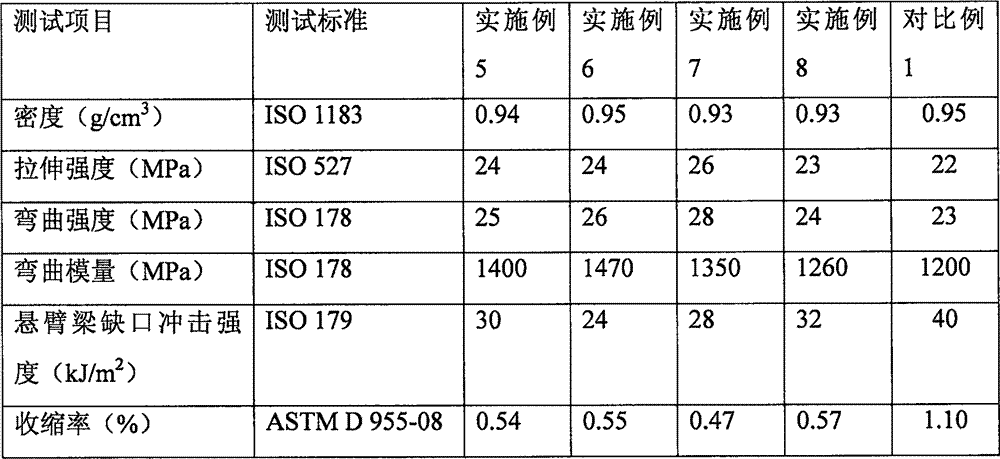

The invention relates to a low-shrinkage and low-density modified polypropylene composite material and a preparation method thereof. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 50 percent to 80 percent of polypropylene (PP), 5 percent to 40 percent of long fiber enhanced resin, 1 percent to 10 percent of a compatilizer, 1 percent to 20 percent of a toughening agent, 0.2 percent to 1 percent of an antioxidant and 0.2 percent to 1 percent of an anti-UV (Ultraviolet) agent. According to the preparation method provided by the invention, after the long fiber enhanced resin is prepared, the long fiber enhanced resin, the PP and other components are blended to uniformly disperse fibers in a polypropylene melt and the performance of the composite material is greatly improved. The low-shrinkage and low-density modified polypropylene composite material provided by the invention has excellent mechanical properties and also has the characteristics of low shrinkage rate and low density.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

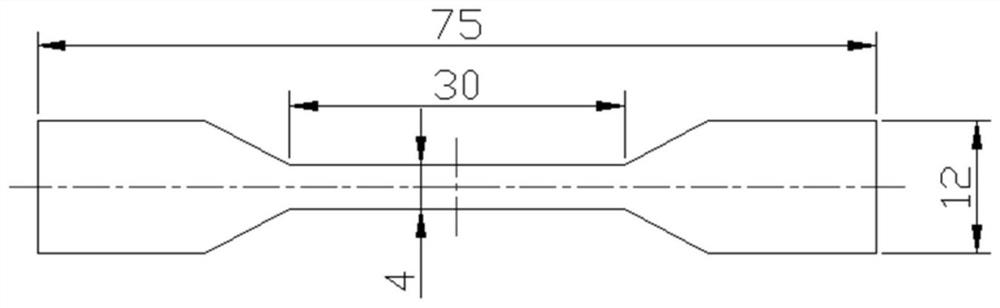

Lignin/polyvinyl alcohol composite material and preparation method thereof

The invention belongs to the technical field of high molecular materials, and discloses a lignin / polyvinyl alcohol composite material and a preparation method thereof. The composite material comprisesthe following components by mass percentage: 70-99.4% of polyvinyl alcohol, 0.5-30% of lignin and 0.1-10% of additive, wherein the additive comprises at least one of 3-amino-1,2,4 triazole, 4-aminopyridine, 1-(3-aminopropyl) imidazole, 4-(2-ethylamino) benzene-1,2-diphenol, 2-amino-3-imidazolylpropionic acid, tannic acid, 3,3,3',3'-tetramethyl-1,1-helix biindolyl-5,5',6,6'-tetraol, zinc chloride,zinc acetate, ferric chloride, calcium chloride, copper chloride, iron oxide, and sodium chloride. The present invention also provides a composite material preparation method. The tensile strength ofthe lignin / polyvinyl alcohol composite material can reach up to 140 MPa, and the elongation at break of the lignin / polyvinyl alcohol composite material can reach up to 800%.

Owner:SOUTH CHINA UNIV OF TECH

Corrosion-resistant cable material and preparation method thereof

InactiveCN109021386AHigh strengthIncreased mechanical toughnessPlastic/resin/waxes insulatorsTemperature resistancePolypropylene

The invention discloses a corrosion-resistant cable material and a preparation method thereof and relates to the field of cable materials. The corrosion-resistant cable material is prepared from 60 to70 parts by weight of polypropylene, 20 to 30 parts by weight of an ethylene-propylene-diene monomer, 15 to 22 parts by weight of glass fibers, 8 to 15 parts by weight of ultrafine diatomite, 10 to 16 parts by weight of modified basic magnesium sulfate whisker, 3 to 7 parts by weight of white carbon black, 3 to 7 parts by weight of zirconium dioxide, 1 to 3 parts by weight of polytetrafluoroethylene, 1.5 to 3.2 parts by weight of neodymium oxide, 2 to 4 parts by weight of tetrabutyl titanate, 1.5 to 2.5 parts by weight of melamine, 0.8 to 1.8 parts by weight of a beta-nucleating agent, 2.5 to4 parts by weight of a plasticizer, 0.4 to 0.8 parts by weight of a cross-linking agent, 1.5 to 2.5 parts by weight of an antioxidant and 1.5 to 2.5 parts by weight of a lubricant. Through cooperation of the cable material components, the corrosion-resistant cable material has good strength and mechanical toughness, corrosion resistance, aging resistance, high temperature resistance, high flame retardancy, no harmful smoke in burning and environmental friendliness.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

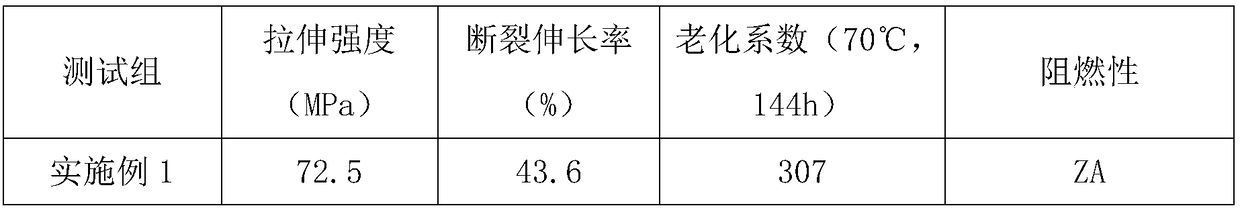

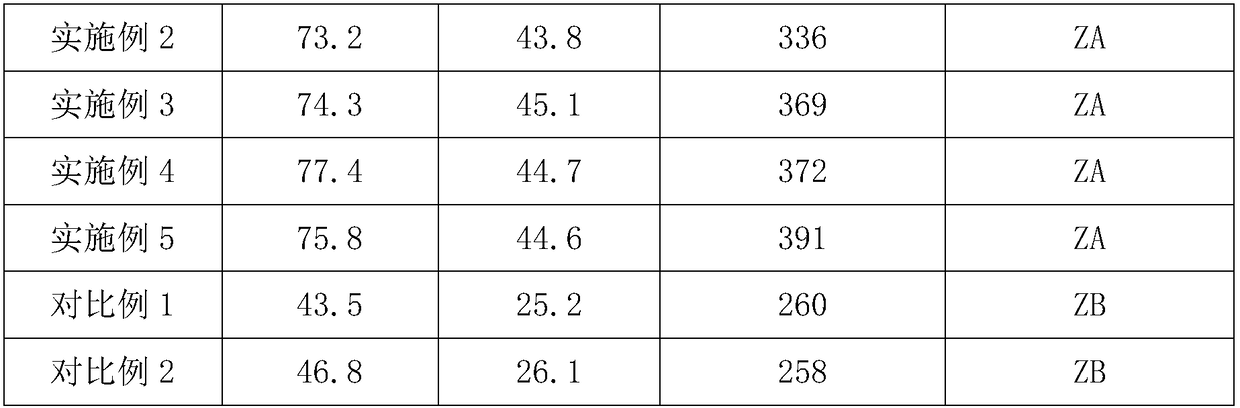

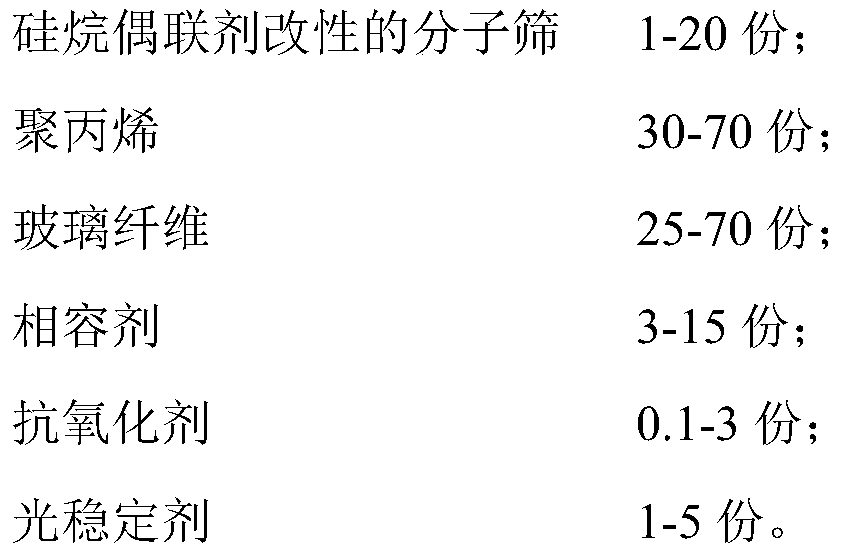

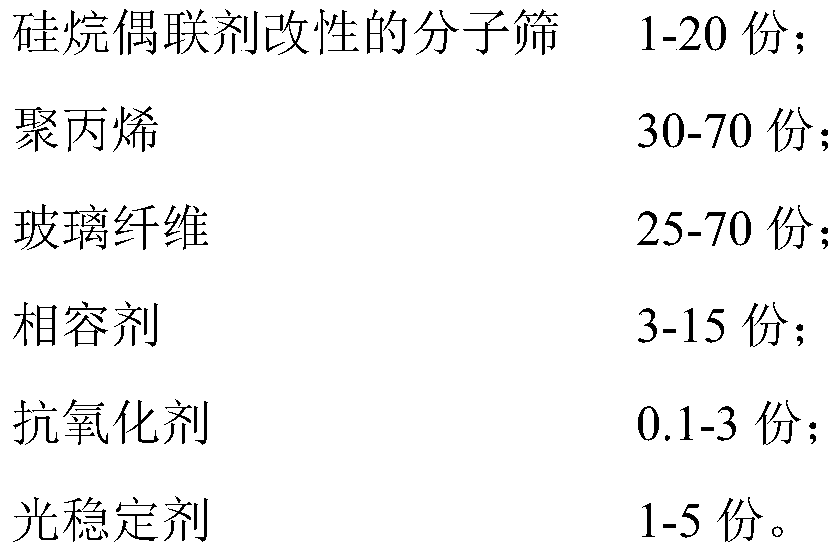

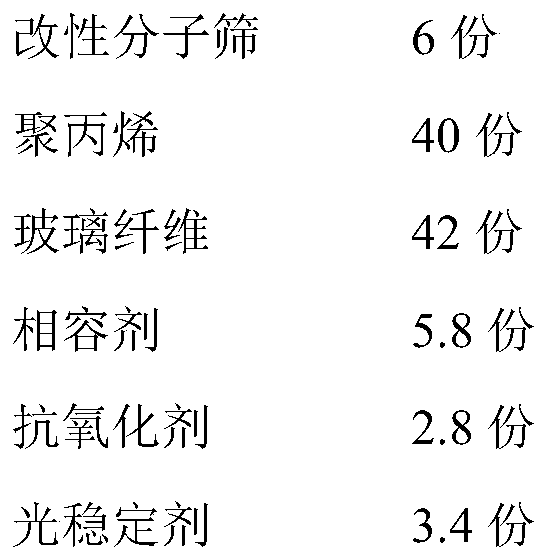

Glass fiber reinforcement polypropylene composite material and preparation method thereof

InactiveCN110294898AImprove mechanical propertiesHigh tensile strengthMolecular sieveSilane coupling

The invention discloses a glass fiber reinforcement polypropylene composite material and a preparation method thereof. The glass fiber reinforcement polypropylene composite material is prepared from,by weight, 1-20 parts of molecular sieves modified by a silane coupling agent, 30-70 parts of polypropylene, 25-70 parts of glass fibers, 3-15 parts of a compatilizer, 0.1-3 parts of an antioxidant and 1-5 parts of a light stabilizer. According to the glass fiber reinforcement polypropylene composite material, the molecular sieves modified by the silane coupling agent of a porous structure are adopted and mingled with a semi-finished product, namely a glass fiber reinforcement polypropylene composite material for replacing traditional fillers such as calcium carbonate and mica powder, so thatthe mechanical performance of the glass fiber reinforcement polypropylene composite material is improved, the glass fiber reinforcement polypropylene composite material has high stretching strength, high bending strength and high impact-resistance strength, and the production cost is reduced.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

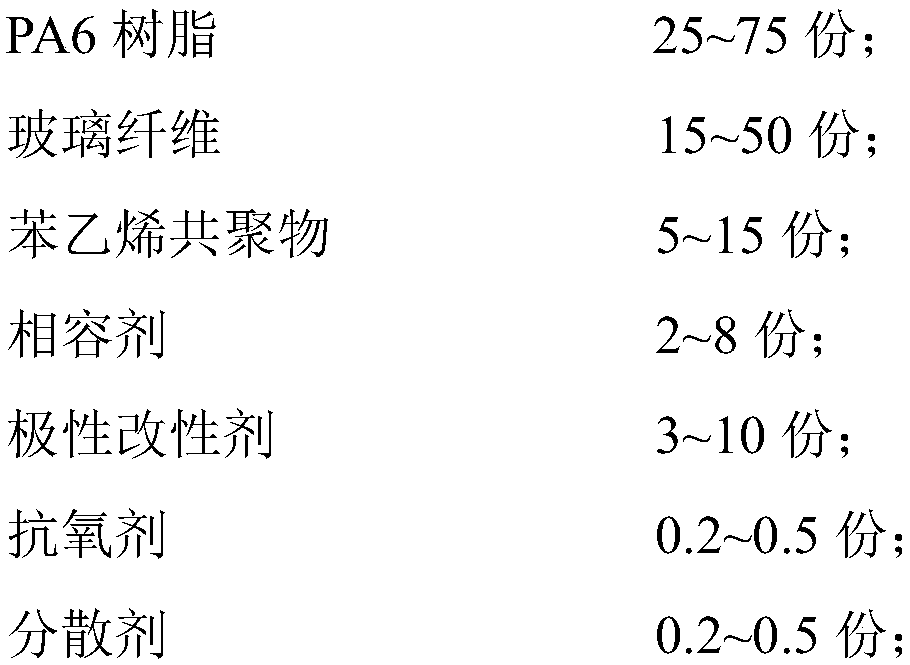

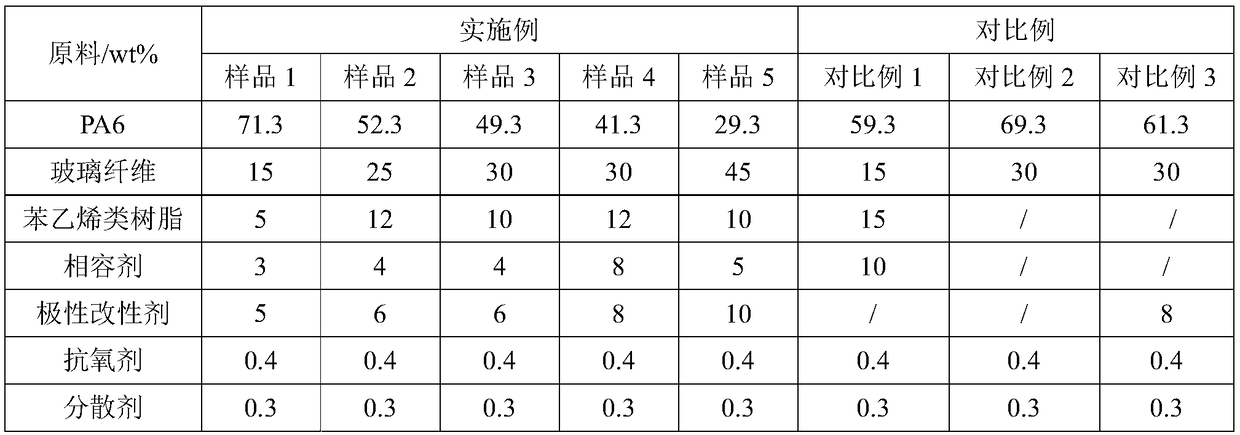

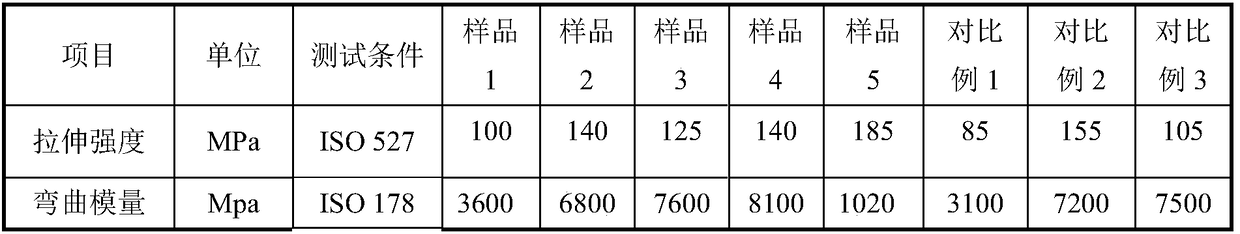

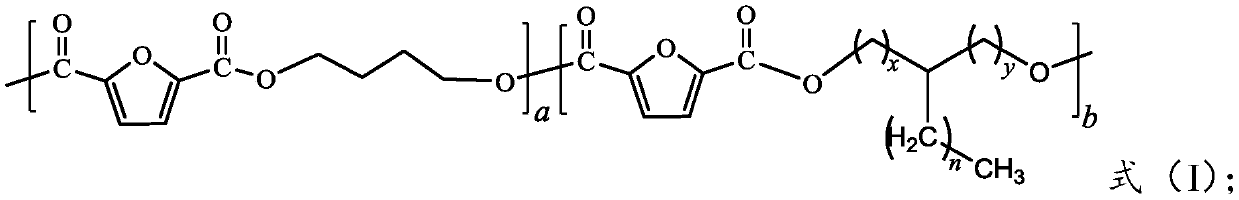

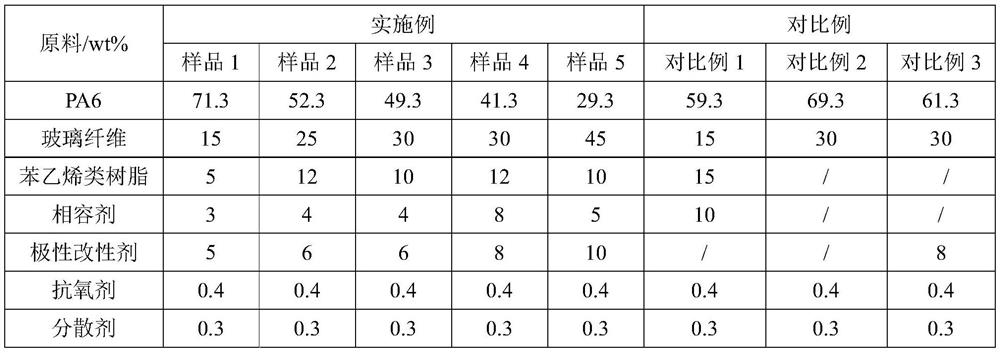

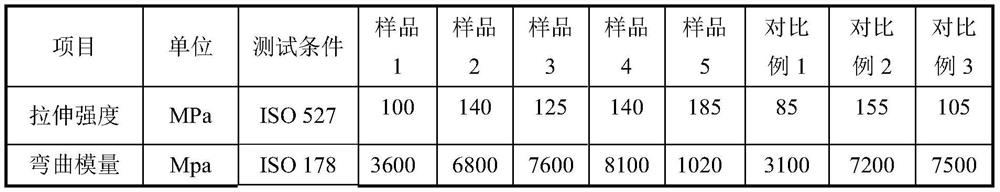

Polyamide composite material with good tactility and easy encapsulation and preparation method thereof

The invention relates to a polyamide composite material with good tactility and easy encapsulation and a preparation method thereof. The material comprises the following components in parts by weight:25-75 parts of PA6 resin, 15-50 parts of glass fiber, 5-15 parts of styrene copolymer, 2-8 parts of a compatilizer, 3-10 parts of a polar modifier, 0.2-0.5 part of an antioxidant and 0.2-0.5 part ofa dispersant, wherein the polar modifier is a graft copolymer of polyolefin and styrene substances; and during preparation, the other components except the glass fiber are weighed according to the parts by weight and then put into a high-speed mixer for mixing, then the mixture is put into a main feeding port of a double-screw extruder, the glass fiber is added from a side feeding port, and then extrusion and granulation are carried out. The polyamide composite material with good tactility and easy encapsulation, obtained by the preparation method provided by the invention, has the characteristics of good surface tactility, wear resistance, easy encapsulation and the like, and can be widely applied to the fields of electric tools, sports equipment, electronic appliances and the like requiring encapsulation and injection molding.

Owner:上海日之升科技有限公司

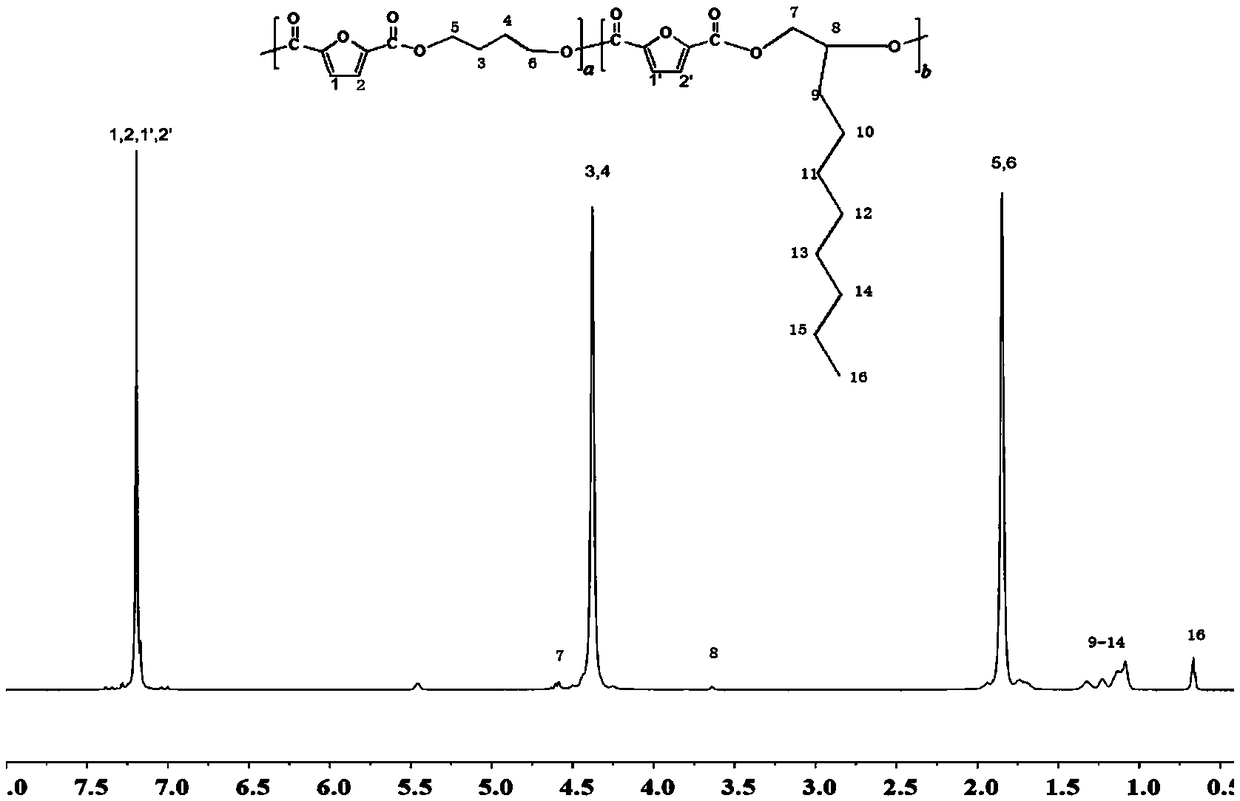

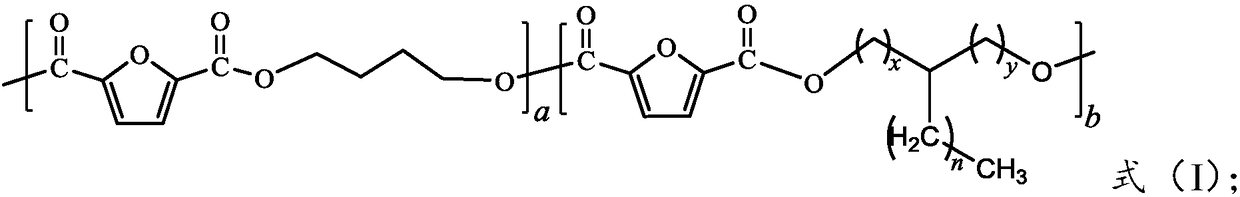

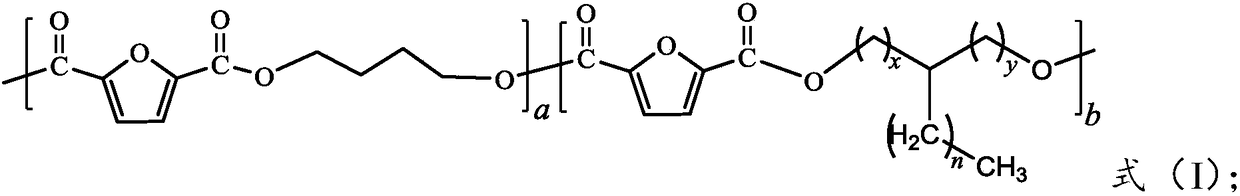

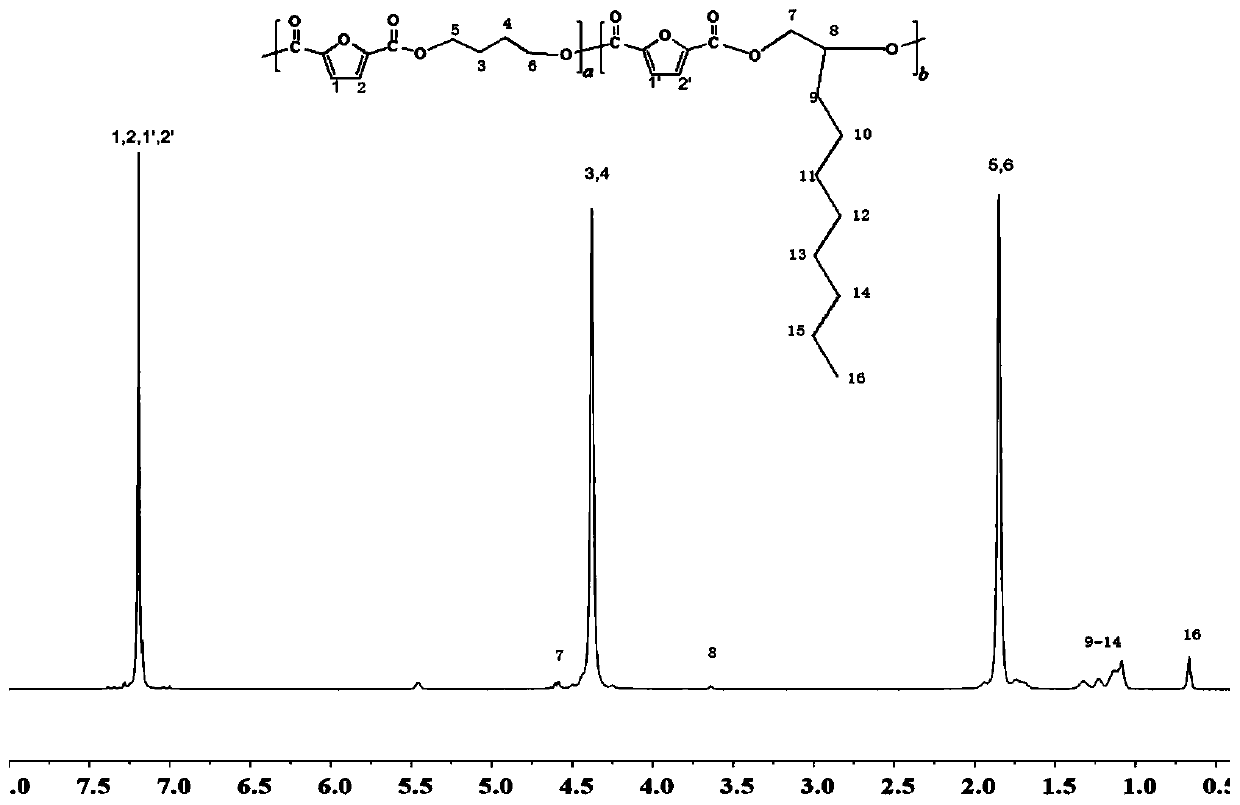

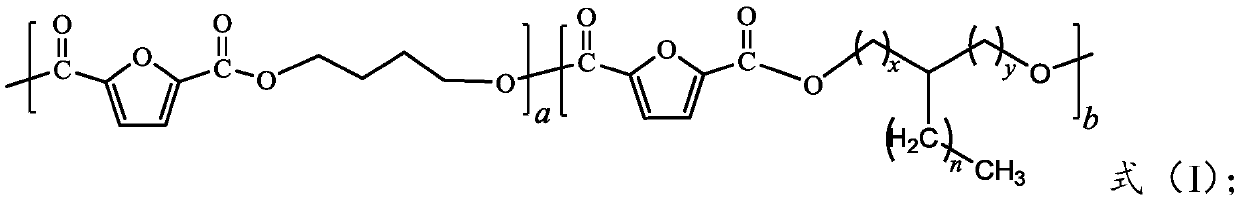

Poly-2,5-butanediol furadicarboxylic acid copolyester and preparation method thereof

ActiveCN109161007AGood toughnessHigh elongation at break and high impact strengthCopolyesterEthanediols

The invention provides copolyester of the structure as shown in the formula (I), wherein a is more than or equal to 1; b is more than or equal to 1; n is more than or equal to 1; x is more than or equal to 0; y is more than or equal to 0; x and y are not 0 at the same time. According to the preparation method, the crystallization behavior of 2,5-furadicarboxylic acid or a derivative thereof is changed by polymerization reaction of 2,5-furadicarboxylic acid or the derivative thereof with ethanediol, 1,4-butanediol, long-chain dihydric alcohol of a structure as shown in the formula (II) and a catalyst, so as to finally obtain the structure as shown in the formula (I), which is high in co-polyester toughness and high in elongation at break and impact strength.

Owner:芜湖万隆新材料有限公司

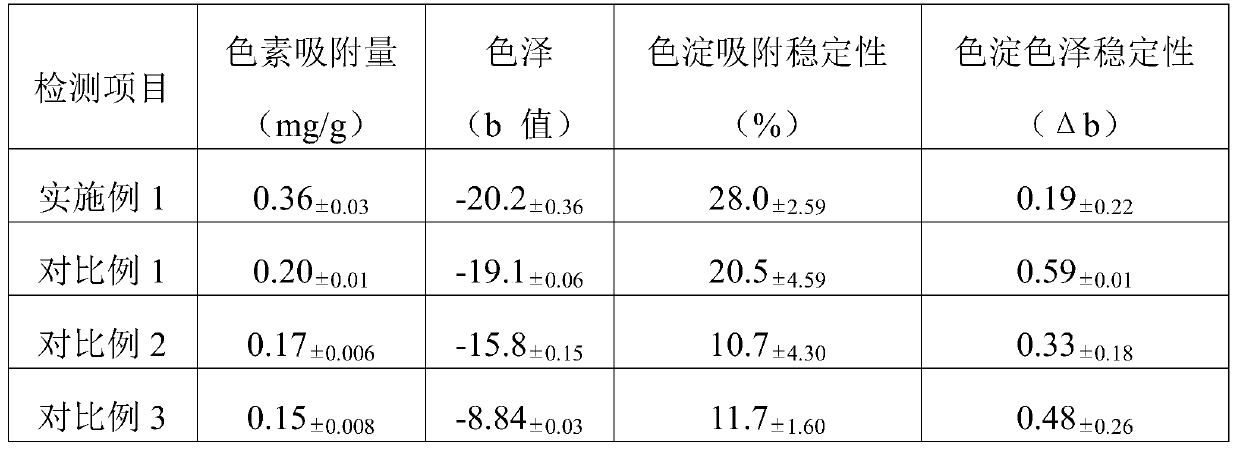

Preparation method of edible color lake based on calcium carbonate

ActiveCN110183873AFix security issuesImprove adsorption capacityDye lakesFood ingredient functionsFood additiveCentrifugation

The invention belongs to the technical field of food additives and provides a preparation method of edible color lake based on calcium carbonate. The preparation method comprises steps as follows: S1,dissolving carbonate in water to obtain a carbonate solution; S2, dissolving water-soluble anionic pigment in the carbonate solution obtained in S1 to obtain a mixed solution; S3, adding hydrochloricacid to the mixed solution obtained in S2, and adjusting the pH to 7-10.54; S4, dissolving calcium salt into water, then adding an obtained solution to the solution obtained in S3, controlling the pHof the solution in the range of 6-9, and performing ultrasonic treatment for 1-10 min and centrifugation to obtain calcium carbonate precipitates adsorbing pigments; S5, drying and grinding the calcium carbonate precipitates adsorbing pigments to obtain the edible color lake based on calcium carbonate. The insoluble problem that aluminum color lake has potential safety hazard is solved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

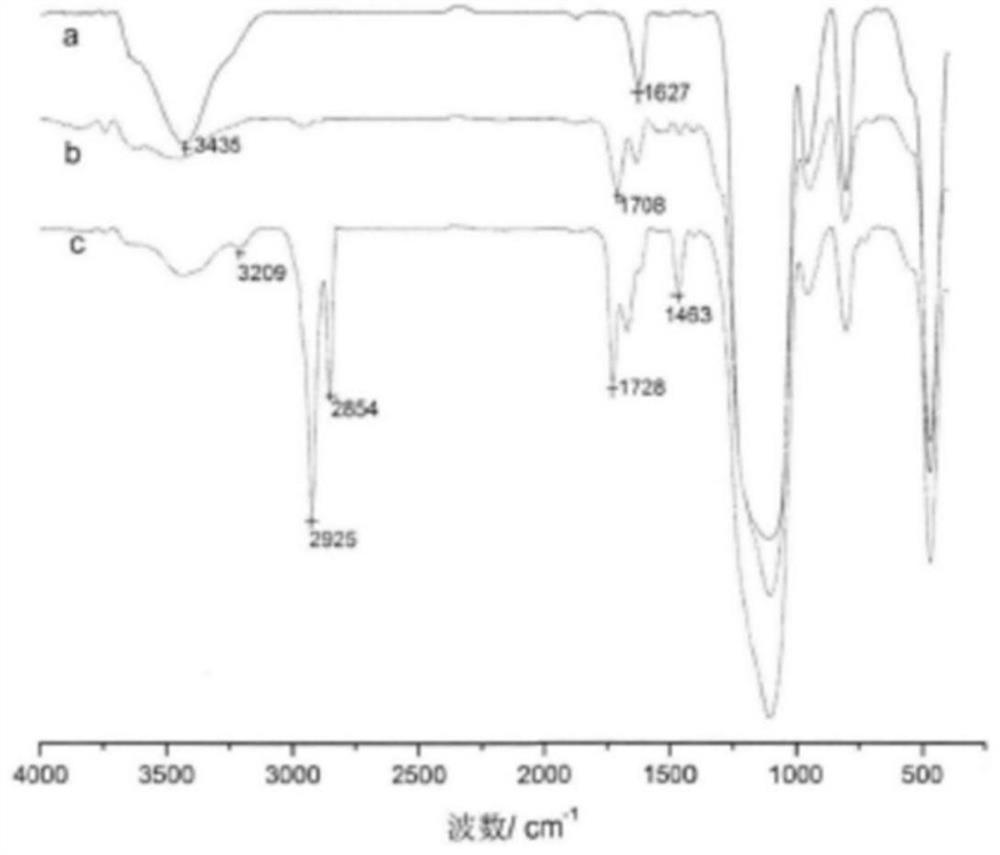

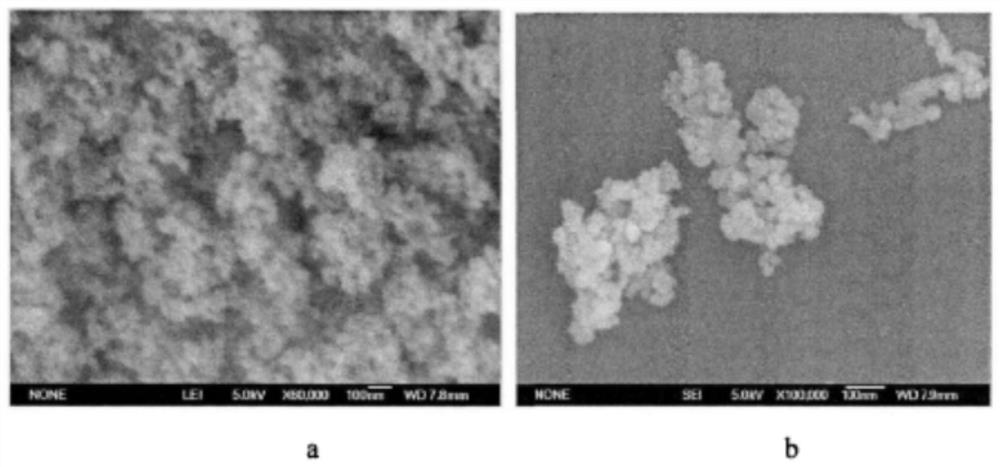

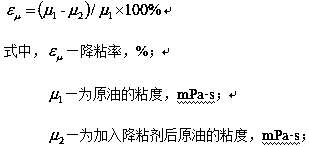

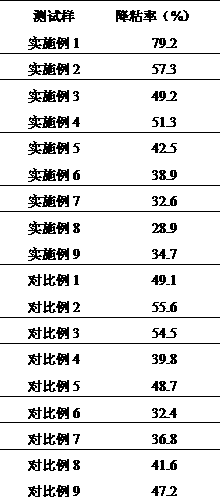

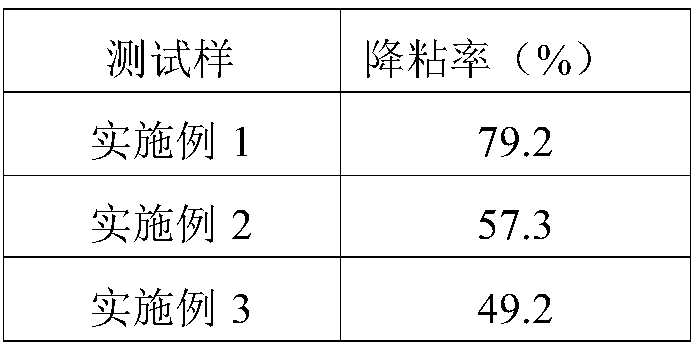

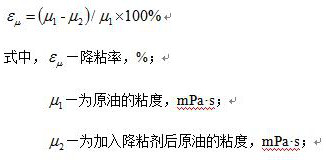

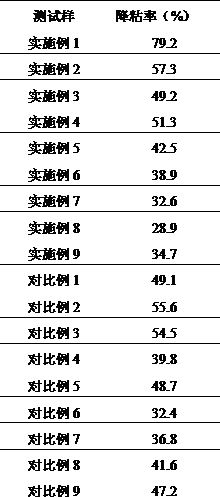

Heavy oil viscosity reducer as well as preparation method and application thereof

The invention discloses a heavy oil viscosity reducer. The heavy oil viscosity reducer is a composite material of a graft polymer modified by a nano SiO2 silane coupling agent, wherein the polymer isa methacrylic acid long-chain alkyl ester-acrylamide copolymer; the methacrylic acid long-chain alkyl ester-acrylamide copolymer is characterized in that a long-chain alkyl group in the methacrylic acid long-chain alkyl ester is an alkyl group with 10-25 carbon atoms. The heavy oil viscosity reducer utilizes a special surface effect to be used as a nucleation point to adsorb wax to be crystallizedand separated out on the surface, the crystallization behavior of the wax is changed, and the original three-dimensional network structure of wax crystals is destroyed; meanwhile, strong polar groupson the surfaces of the nano particles adsorb colloid and asphaltene through hydrogen bond interaction to form a solvation layer on the surfaces of the nano particles, and due to the solvation layer,wax crystals can be prevented from being connected to form a net-shaped structure, a plane overlapping stacking structure of the colloid and the emerald green matter can be disassembled, and thereforethe viscosity of the thickened oil is greatly reduced.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST

Preparation method of novel viscosity reducer for thick oil

ActiveCN108794680ASimplify the production processEasy accessDrilling compositionMaleic anhydrideMethyl methacrylate

The invention discloses a preparation method of a novel viscosity reducer for thick oil. According to the preparation method, methyl methacrylate, styrene, acrylamide and maleic anhydride are taken asraw materials, and the viscosity reducer for the thick oil is prepared by using aqueous solution polymerization and physical compounding methods; the viscosity reducer for the thick oil is prepared from the following raw materials in parts by weight: 30-50 parts of methyl methacrylate, 9-15 parts of styrene, 5-11 parts of acrylamide and 3-5 parts of maleic anhydride. According to the method, an oil-soluble polymer is obtained by using an initiator to initiate a polymerization reaction of monomers; after a small amount of the product is added into crude oil, the viscosity of the crude oil canbe effectively reduced, and the recovery rate of the thick oil is increased; therefore, the novel viscosity reducer is suitable for development and utilization in oilfields with thick oil.

Owner:山东东方盛嘉石油科技有限责任公司

Preparation method for novel heavy oil viscosity reducer

InactiveCN109021948ASmall structureReduce structural viscosityPipeline systemsDrilling compositionOil viscosityAqueous solution

The invention discloses a preparation method for a novel heavy oil viscosity reducer. The novel heavy oil viscosity reducer is prepared from, by weight, 30 to 50 parts of methyl methacrylate, 9 to 15parts of styrene, 5 to 11 parts of acrylamide and 3 to 5 parts of maleic anhydride through aqueous solution polymerization and physical compounding. According to the invention, an oil-soluble polymeris prepared by initiating the polymerization of monomers in virtue of an initiator; through addition of a small amount of the heavy oil viscosity reducer into crude oil, the viscosity of crude oil canbe effectively reduced, and the rate of heavy oil recovery is increased; and the heavy oil viscosity reducer is applicable to exploitation and development of heavy oilfields.

Owner:XUZHOU NORMAL UNIVERSITY

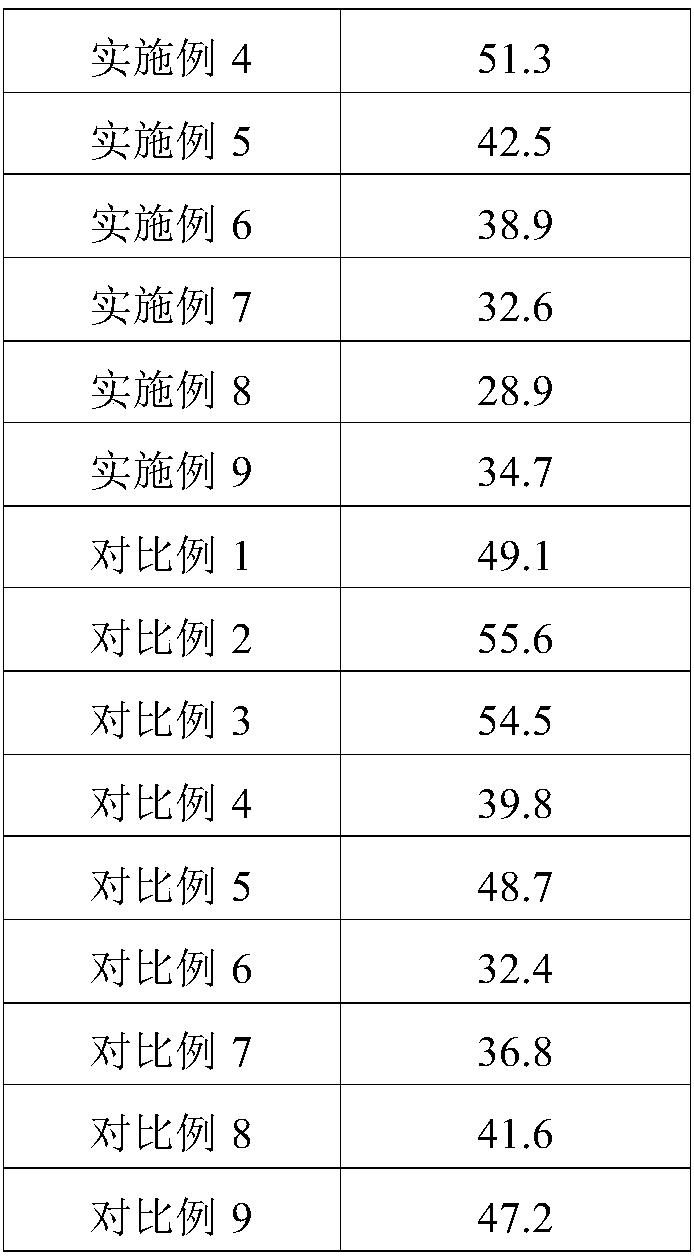

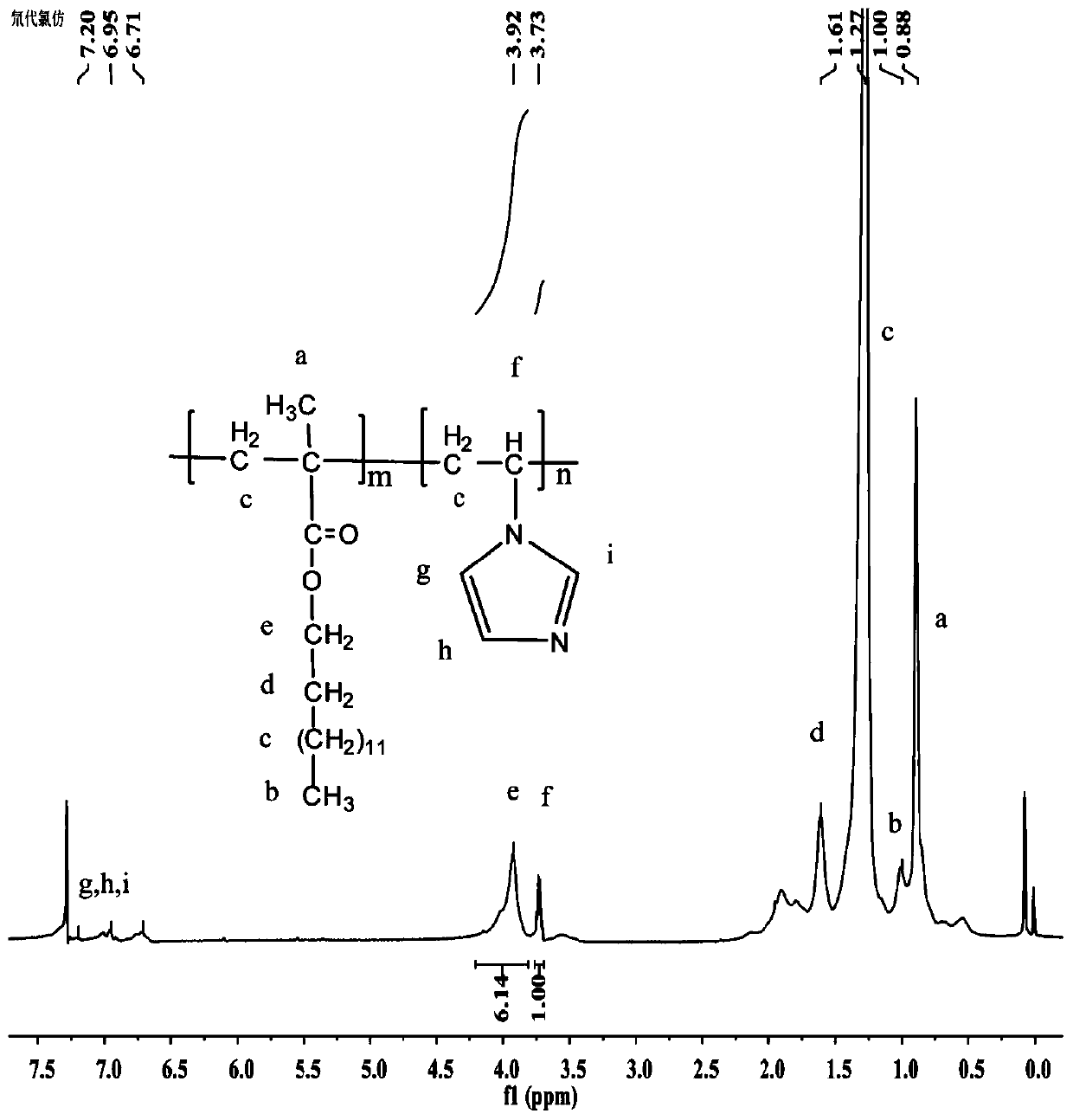

Reagent for reducing condensation point of diesel, and preparation method and application thereof

ActiveCN110093195AChanged crystallization behaviorChange crystal shapeLiquid carbonaceous fuelsFuel additivesSynthesis methodsCold filter plugging point

The invention provides a reagent for reducing the condensation point of diesel, and a preparation method and an application thereof. The reagent for reducing the condensation point of diesel comprisesa tetradecyl methacrylate-N-vinylpyrrolidone copolymer, or comprises the tetradecyl methacrylate-N-vinylpyrrolidone copolymer and a tetradecyl methacrylat-N-vinylimidazole copolymer. The above polymer diesel pour point depressant can further improve the low-temperature fluidity of the diesel, and has the advantages of simple synthesis method, small dosage, and small use amount of raw materials. The condensation point of diesel containing the reagent is 24-26 DEG C less than that of diesel free from the pour point depressant, and the cold filter plugging point of the diesel containing the reagent is 9-11 DEG C less than that of the diesel free from the pour point depressant, so that the diesel has a good fluidity at a low temperature.

Owner:SHANGHAI INST OF TECH

A kind of lignin/polyvinyl alcohol composite material and preparation method thereof

The invention belongs to the technical field of high molecular materials, and discloses a lignin / polyvinyl alcohol composite material and a preparation method thereof. The composite material comprisesthe following components by mass percentage: 70-99.4% of polyvinyl alcohol, 0.5-30% of lignin and 0.1-10% of additive, wherein the additive comprises at least one of 3-amino-1,2,4 triazole, 4-aminopyridine, 1-(3-aminopropyl) imidazole, 4-(2-ethylamino) benzene-1,2-diphenol, 2-amino-3-imidazolylpropionic acid, tannic acid, 3,3,3',3'-tetramethyl-1,1-helix biindolyl-5,5',6,6'-tetraol, zinc chloride,zinc acetate, ferric chloride, calcium chloride, copper chloride, iron oxide, and sodium chloride. The present invention also provides a composite material preparation method. The tensile strength ofthe lignin / polyvinyl alcohol composite material can reach up to 140 MPa, and the elongation at break of the lignin / polyvinyl alcohol composite material can reach up to 800%.

Owner:SOUTH CHINA UNIV OF TECH

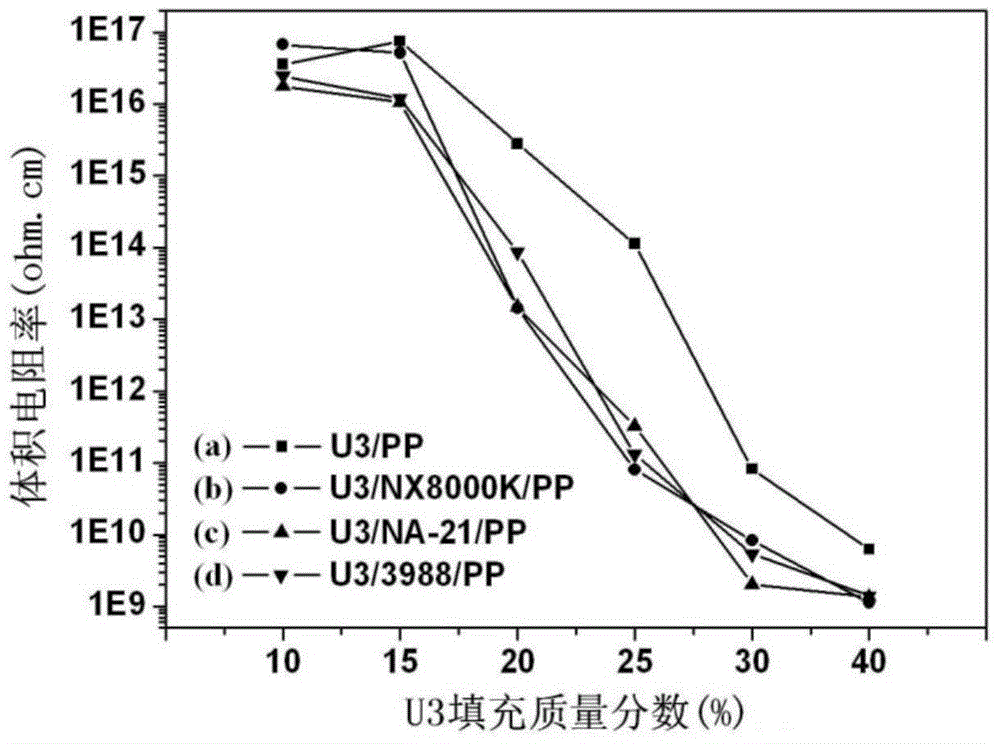

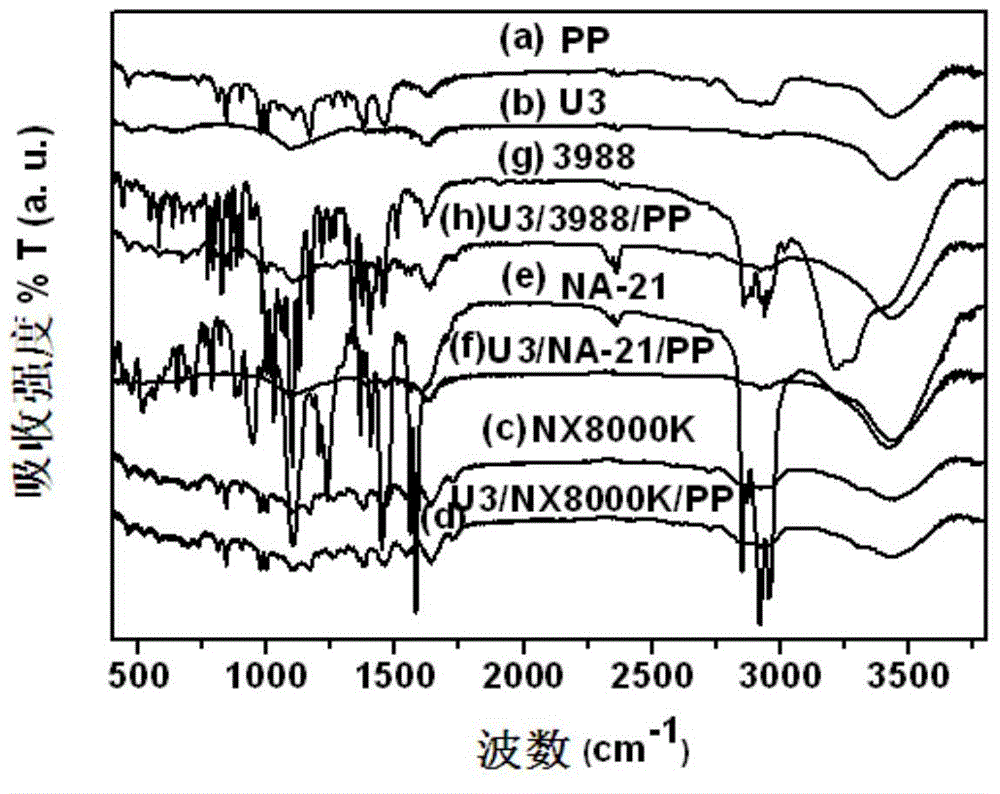

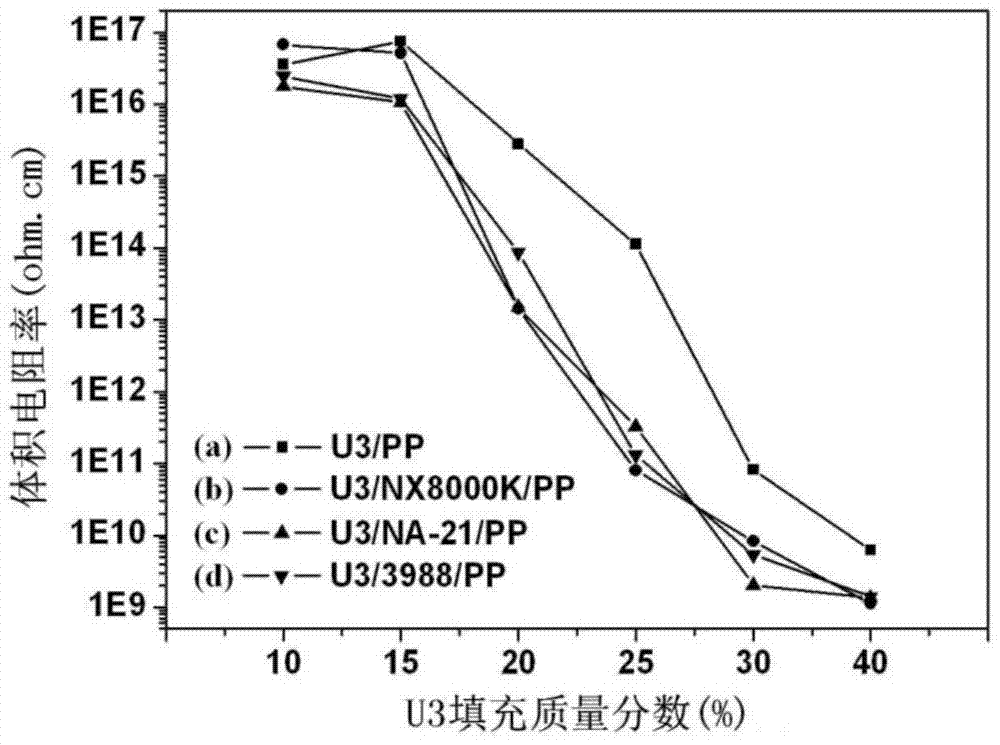

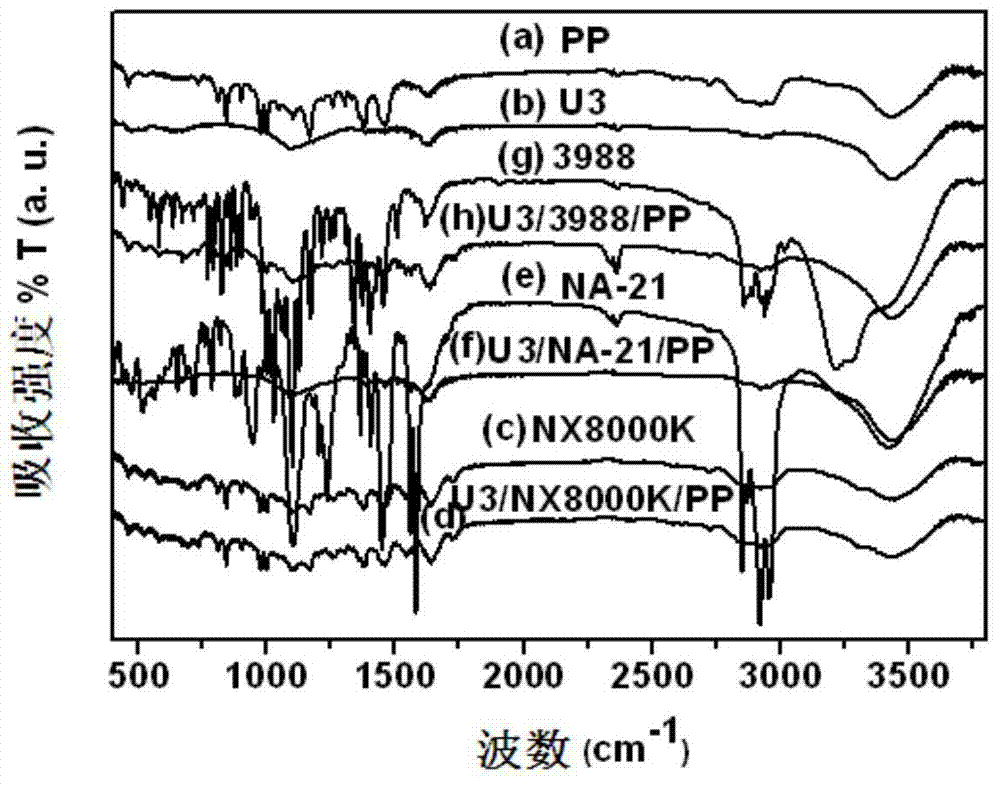

Nucleating agent and polymer composite antistatic agent, preparation method and applications thereof

InactiveCN104945730AWith permanent static protection functionChanged crystallization behaviorPolymer sciencePolymer composites

The present invention belongs to the technical field of polymer materials, and particularly relates to a nucleating agent / polymer composite antistatic agent, a preparation method and applications thereof. According to the present invention, the composite antistatic agent is the complex of the commercialized polymer antistatic agent and the nucleating agent, and is used for the antistatic polymer materials; the nucleating agent is added to the component of the composite antistatic agent so as to change the crystallization behavior of the polymer materials, wherein the crystallization rate and the crystal density are significantly increased and the grain particle size becomes smaller, such that the amorphous region becomes small, and the filling amount of the antistatic agent in the polymer material can be significantly reduced so as to reduce the production cost; with the composite antistatic agent, the permanent antistatic property is provided for the polymer material while the mechanical property and the processing property of the polymer material are enhanced; and the cost of the novel polymer composite antistatic agent is low, the preparation method is simple, and the method is suitable for industrial production.

Owner:FUDAN UNIV

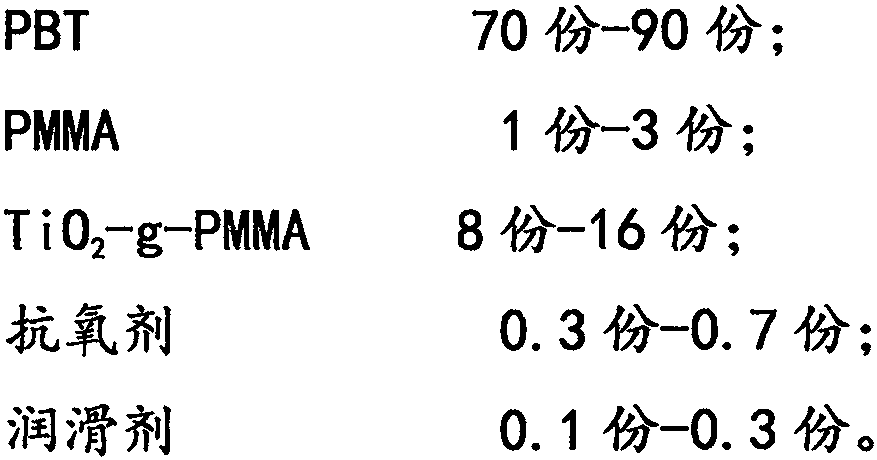

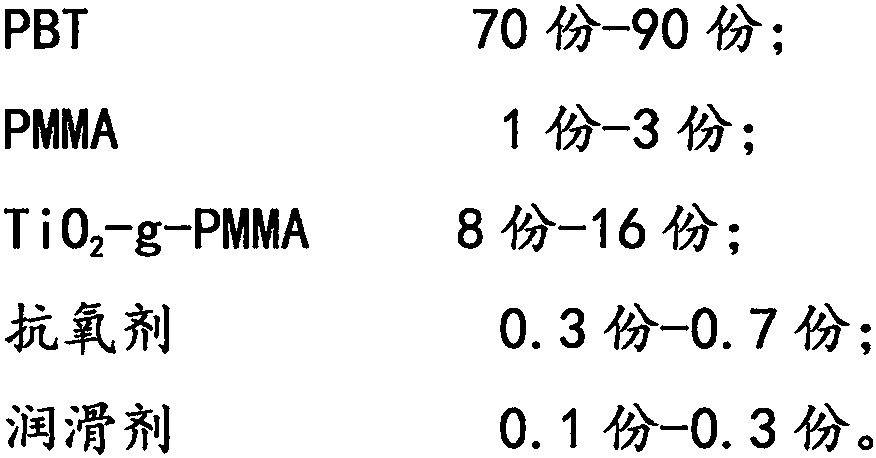

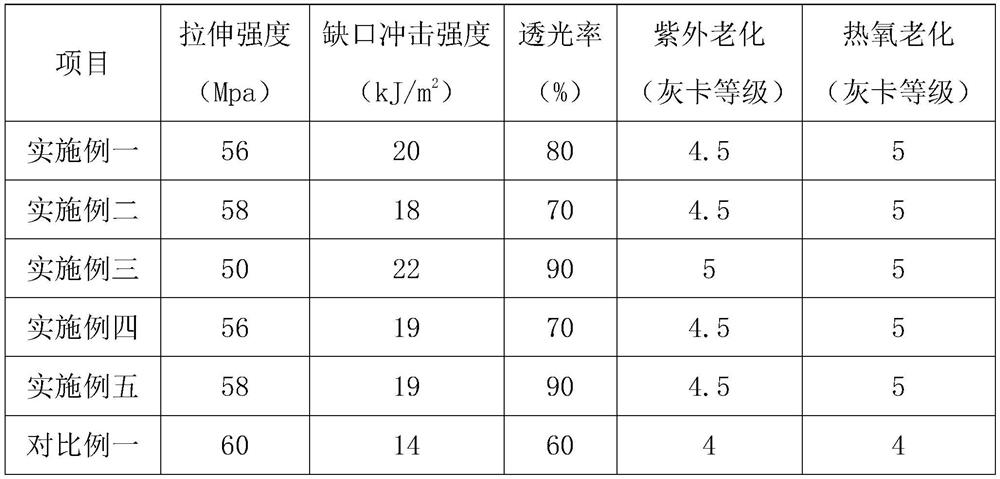

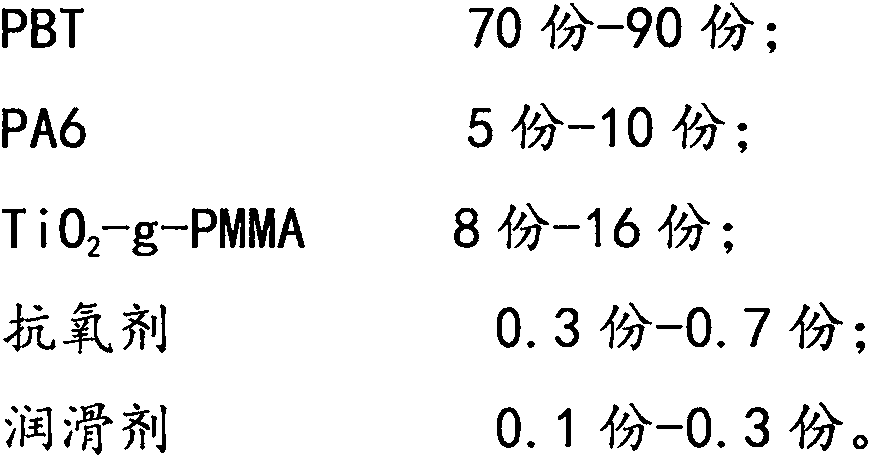

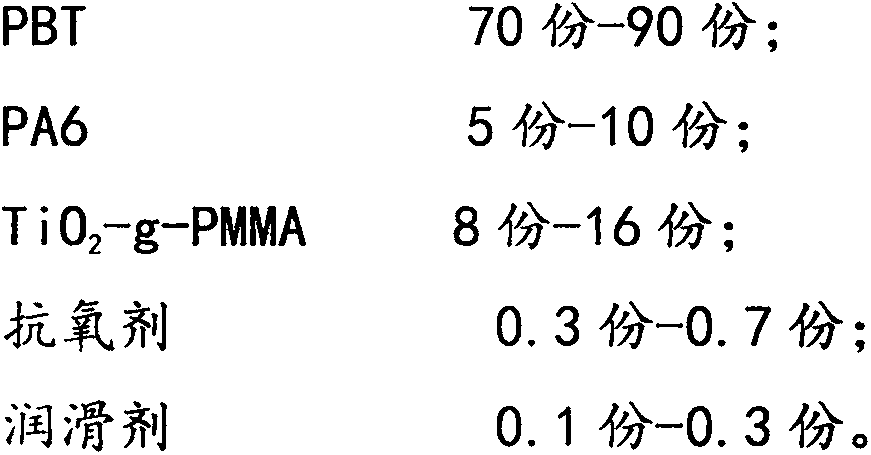

Abrasion-resistant PBT composite material

InactiveCN109593324ASmall particle sizeLarge specific surface areaHigh surfaceMechanical properties of carbon nanotubes

The invention relates to an abrasion-resistant PBT composite material. The abrasion-resistant PBT composite material is prepared from the following components in parts by weight: 70-90 parts of PBT, 1-3 parts of PMMA, 8-16 parts of TiO2-g-PMMA, 0.3-0.7 part of an antioxidant and 0.1-0.3 part of a lubricant. According to the technical scheme, the addition of TiO2-g-PMMA can improve the mechanical property of the material for two reasons: (1)with small particle size, large specific surface area, good dispersibility, high surface activity, TiO2-g-PMMA can generate a strong interface effect when used for modifying PBT, thus effectively improving the physical properties of the material; and (2) TiO2-g-PMMA can change the crystallization behavior of PBT, can take a heterogeneous nucleation effect on PBT, thus effectively improving the physical properties of the material.

Owner:任素飞

High-elasticity transparent mirror frame material

InactiveCN112646364AChanged crystallization behaviorIncrease the rate of crystallizationPhosphoric Acid EstersPolymer science

The invention discloses a high-elasticity transparent mirror frame material, and relates to the technical field of modified polyamide. The high-elasticity transparent mirror frame material is prepared from the following raw materials in parts by weight: 80-90wt% of PA12, 5-20wt% of polyethylene, 0.5-3.0 wt% of antioxidant, 0.1-0.5 wt% of anti-reflection agent and 1.0-3.0 wt% of white oil, and the anti-reflection agent is one or a mixture of more of 4-tert-butylbenzoic acid, sodium benzoate, organophosphate, adipic acid, diphenylacetic acid and sodium succinate. The high molecular weight polyethylene and the anti-reflection agent are matched for use, so that the crystallization behavior of the PA12 can be effectively changed, the crystallization rate of the PA12 is increased, the crystallization density of the PA12 is increased, the grain size of the PA12 is promoted to be micronized, meanwhile, the crystallization proportion of the PA12 is reduced, the modified PA12 has better transparency, and meanwhile, the toughness is improved on the premise that the rigidity of the PA12 is kept .

Owner:意得凯(深圳)科技有限责任公司 +1

Anti-frosting grease composition

ActiveCN109984209AGood anti-bloom propertiesChanged crystallization behaviorConfectionerySweetmeatsIodineBase oil

The invention provides an anti-frosting grease composition used for delaying or inhibiting frosting. The anti-frosting grease composition contains base oil and beeswax, wherein the base oil is prepared from one or more of the following properties: C16 / C18 ratio formed by 3-10 parts of fatty acid, 5-45 of iodine value, 35-41 DEGC of sliding melting point, and the ratio of 3-18 parts of solid fat content (SFC 20) at 20DEG C to solid fat content (SFC 35) at 35DEG C.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

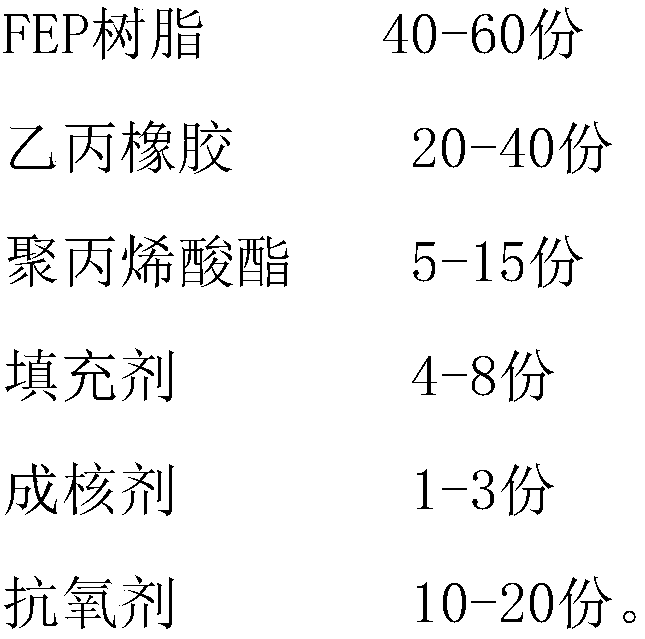

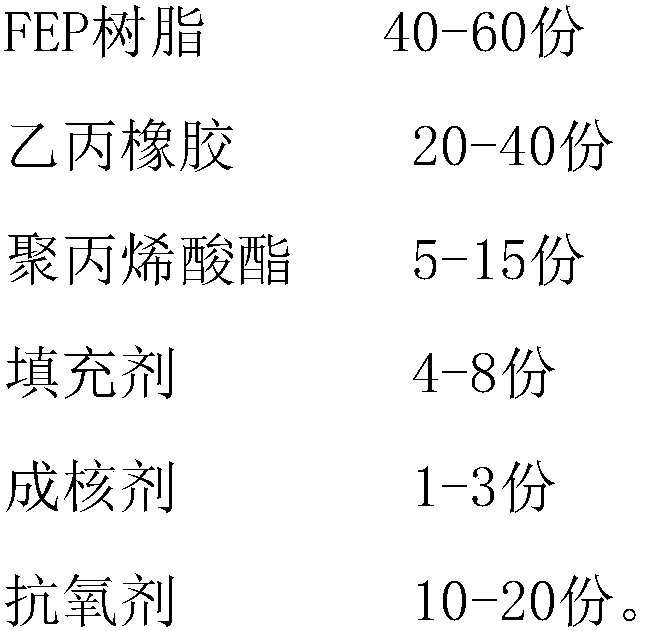

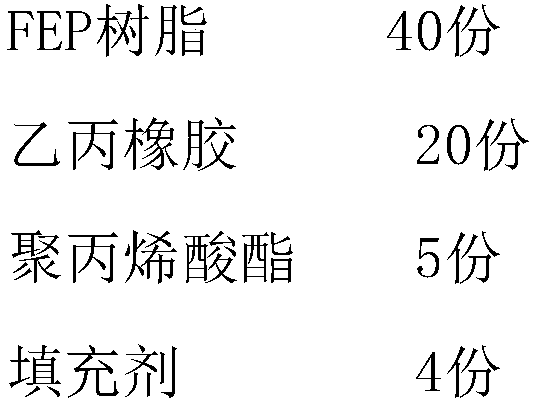

High speed signal transmission cable insulating material with extrusion resistance and foaming technology thereof

The invention relates to the technical field of high speed cables, and more specifically relates to a high speed signal transmission cable insulating material with extrusion resistance and a foaming technology thereof. The high speed signal transmission cable insulating material with extrusion resistance comprises the following raw materials in parts by weight: 40-60 parts of FEP resin, 20-40 parts of EP rubbers, 5-15 parts of polyacrylate, 4-8 parts of a filler, 1-3 parts of a nucleating agent, and 10-20 parts of an anti-oxidant. The high speed signal transmission cable insulating material with extrusion resistance has the advantages of better strength, toughness as well as heatproof and fireproof performances; after the product is extruded by outside force, because the strength is high,the deformation rate is obviously small, and the product also has a certain self-repairing function.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

High-gloss PP material and preparation method thereof

The invention discloses a high-gloss PP material which comprises the following components in percentage by mass: 45 to 50 percent of PP, 30 to 35 percent of PPB, 18 to 18.5 percent of barium sulfate, 0.3 to 0.4 percent of an aluminate coupling agent, 0.05 to 0.1 percent of an antioxidant, 0.15 to 0.2 percent of an auxiliary antioxidant, 0.05 to 0.1 percent of an anti-ultraviolet agent, 0.2 to 0.5 percent of a lubricant and 0.1 to 0.2 percent of a nucleating agent. According to the invention, the surface gloss and hardness of PP are effectively improved.

Owner:KUNSHAN HENGGUANG PLASTIC PROD

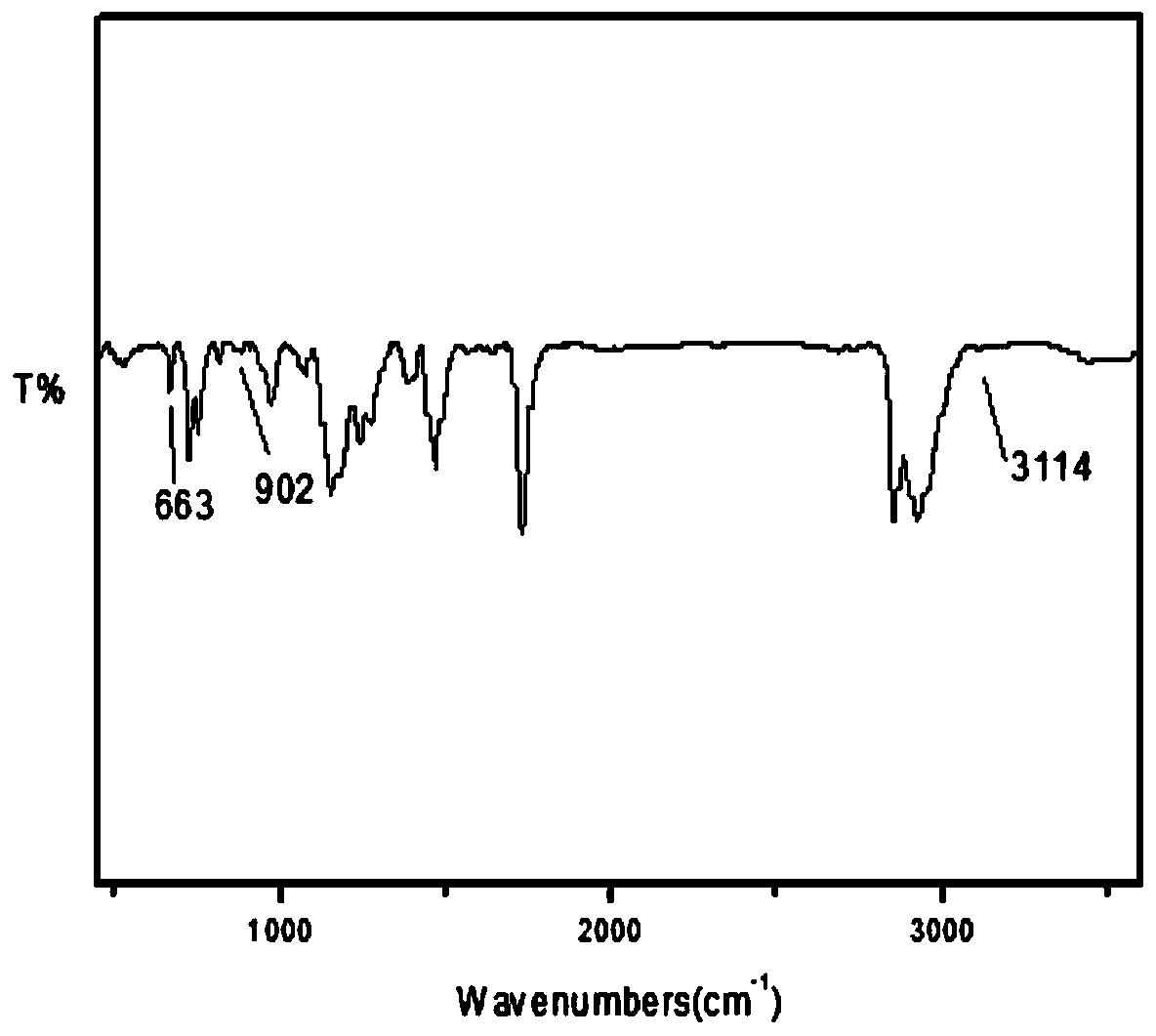

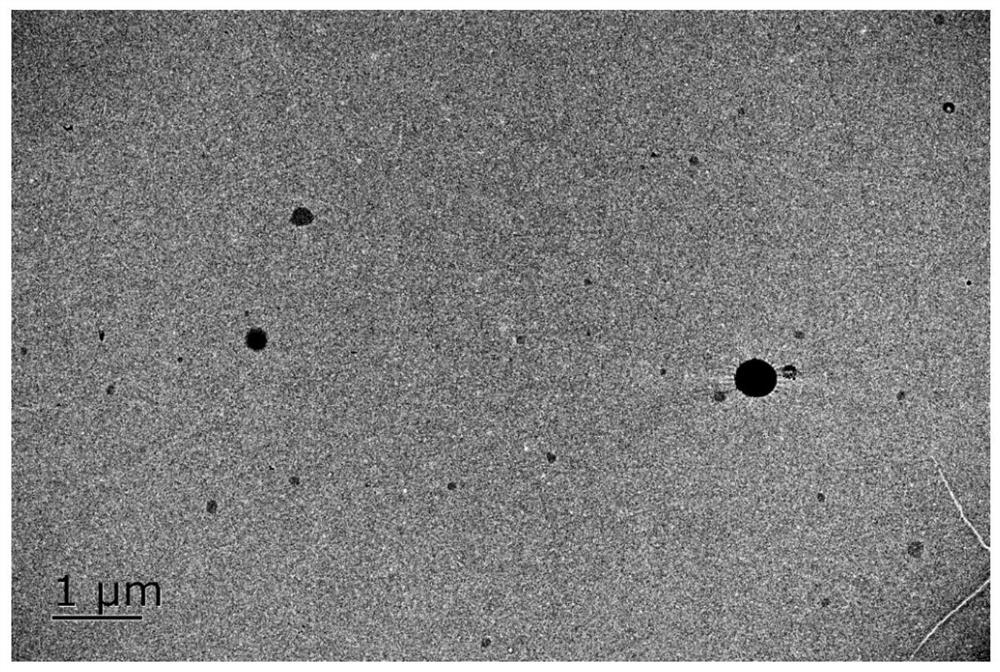

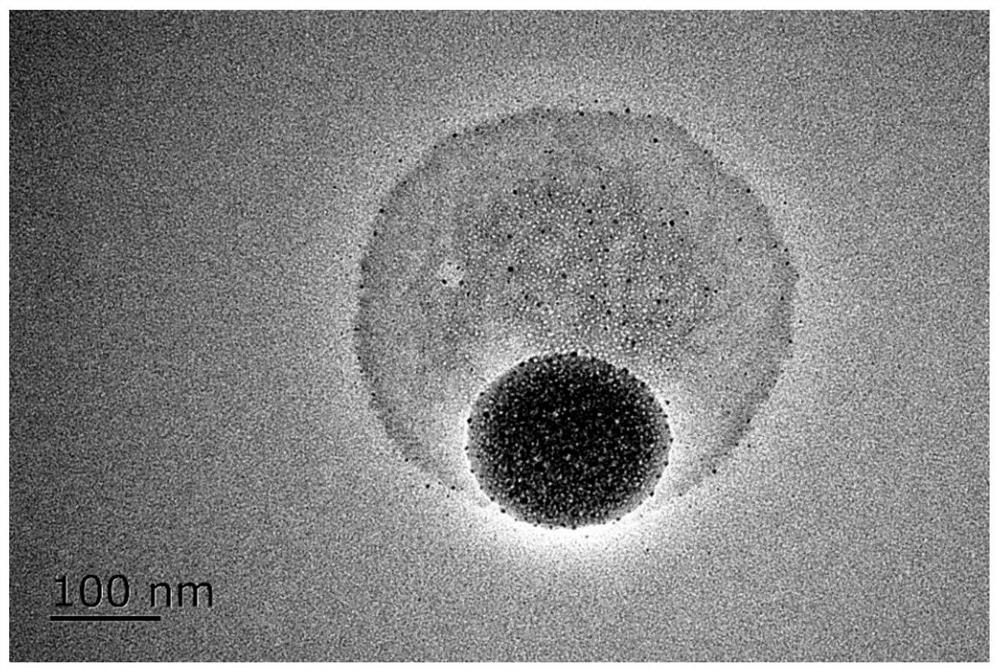

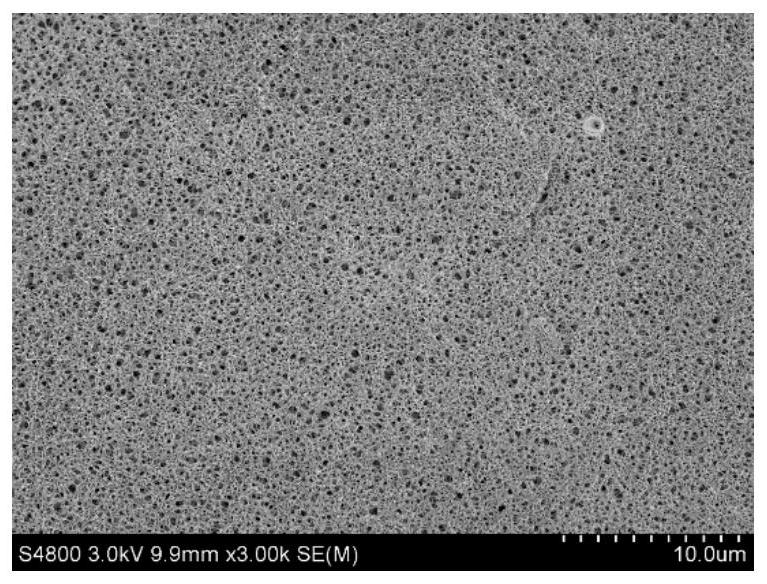

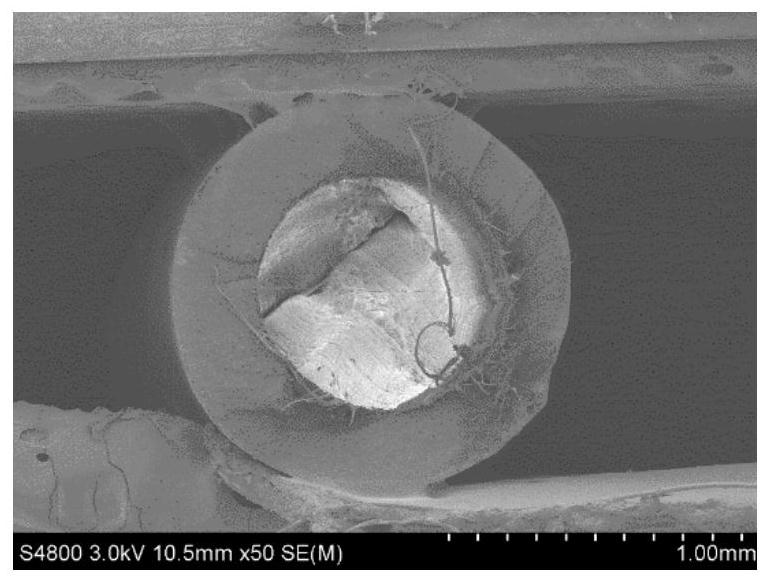

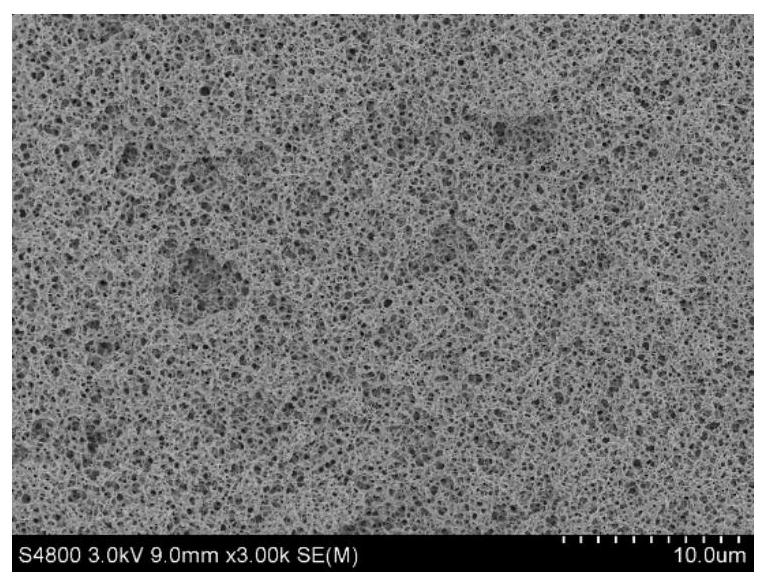

Polyvinylidene fluoride hollow fiber microfiltration membrane and preparation method thereof

ActiveCN113117533AGuaranteed rigidityNot easy to crushSemi-permeable membranesGeneral water supply conservationFiberMicrofiltration membrane

The invention discloses a polyvinylidene fluoride hollow fiber microfiltration membrane and a preparation method thereof, the microfiltration membrane comprises polyvinylidene fluoride and polytrifluorochloroethylene, and the mass ratio of the polyvinylidene fluoride to the polytrifluorochloroethylene is 100: (5-40). The porosity of the microfiltration membrane is greater than 80%; the aperture of at least 70% of the microfiltration membranes is between 0.1 [mu] m and 0.2 [mu] m, the aperture of less than 15% of the microfiltration membranes is between 0.01 [mu] m and 0.1 [mu] m, and the aperture of less than 15% of the microfiltration membranes is between 0.2 [mu] m and 0.3 [mu] m. The microfiltration membrane has the advantages of high strength, high water flux, excellent chemical resistance, weather resistance and oxidation resistance, environmental friendliness and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

High-performance wear-resisting PBT (polybutylece terephthalate) composite material

InactiveCN107868413AChanged crystallization behaviorImprove mechanical propertiesPolyethylene terephthalateAntioxidant

The invention relates to a high-performance wear-resistant PBT composite material, which is prepared from the following components in parts by weight: PBT is 70-90 parts; PA6 is 5-10 parts; TiO2-g-PMMA is 8-16 parts ; Antioxidant is 0.3-0.7 part; lubricant is 0.1-0.3 part. The addition of TiO2-g-PMMA in this technical solution can improve the mechanical properties of the material because of two points: 1) it has small particle size, large specific surface area, good dispersibility and high surface activity, and can produce The strong interfacial effect can well improve the physical properties of the material. 2) It can change the crystallization behavior of PBT, play a role in heterogeneous nucleation of PBT, and improve the mechanical properties of the material.

Owner:薛亚红

A method for improving the performance of polypropylene-based thermoplastic vulcanizate

The invention discloses a method for improving the performances of a polypropylene-based thermoplastic vulcanized rubber. The method comprises the following steps: mixing the prepared thermoplastic vulcanized rubber with a nucleating agent, and regulating the crystal form content in the obtained material by a post-processing technique. The effect of the nucleating agent in the thermoplastic vulcanized rubber is controlled to change the crystal form structure of a continuous phase in the thermoplastic vulcanized rubber. The crystal form is regulated to further improve the elasticity and mechanical properties of the material, so improvement of the performances of the thermoplastic vulcanized rubber in the post-processing process is achieved. The method has the advantages of simple process and strong operability, and is generally suitable for polypropylene-based thermoplastic vulcanized rubbers.

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of heavy oil viscosity reducer

ActiveCN108794680BSmall structureReduce structural viscosityDrilling compositionOil viscosityAqueous solution

Owner:山东东方盛嘉石油科技有限责任公司

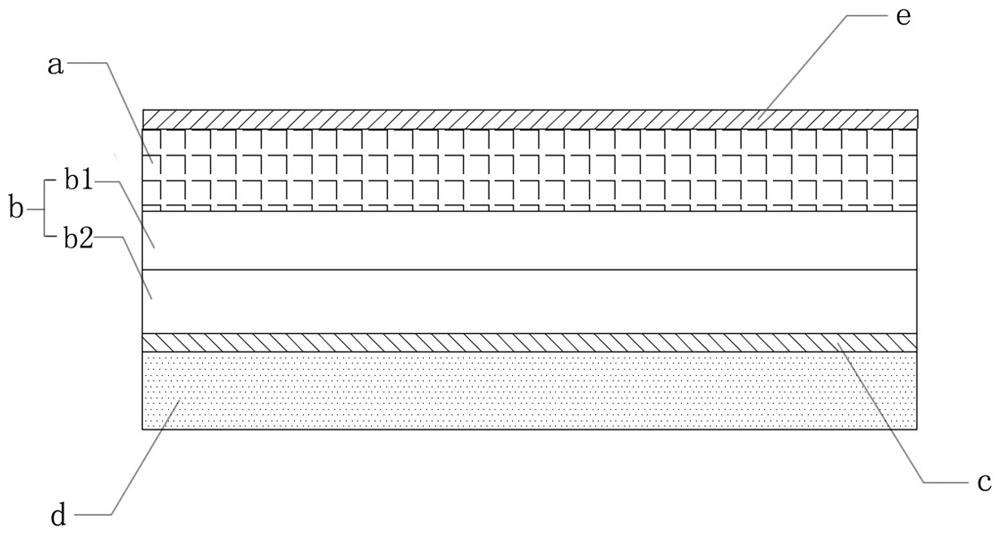

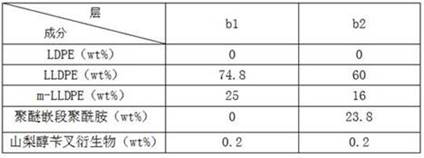

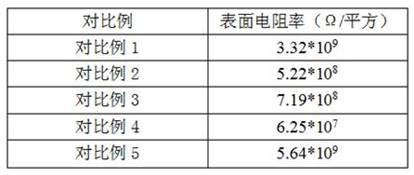

Cover tape and electronic component packaging body

ActiveCN114162462AChanged crystallization behaviorLow hazePolyurea/polyurethane coatingsPackagingPolymer scienceEthylene Polymers

The cover tape sequentially comprises a base material layer, a middle layer, an antistatic coating and a heat sealing layer, the middle layer comprises an ethylene polymer, an antistatic agent and organic particles, and the density of the ethylene polymer is 0.90-0.94 g / cm < 3 >. According to the invention, the middle layer with excellent antistatic property and transparency is arranged, and the antistatic coating and the antistatic heat sealing layer are additionally arranged, so that the cover tape meets the requirements of high transparency and excellent antistatic effect, also has the advantages of good buffering property, good stripping stability and the like, and is particularly suitable for being used as a cover tape for packaging miniature electronic components.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

Nano barium sulfate filled and PET (Polyethylene Terephthalate) modified heater shell material

InactiveCN106279942AChanged crystallization behaviorImprove surface strengthCoatingsPolyethylene terephthalate glycolCalcite

The invention relates to the technical field of production of heaters, and in particular relates to a nano barium sulfate filled and PET (Polyethylene Terephthalate) modified heater shell material. The material is prepared from the following raw materials in parts by weight: 25 to 32 parts of metallocene linear-low-density polyethylene, 22 to 28 parts of PET, 3 to 6 parts of nano barium sulfate, 2 to 4 parts of precipitated silicon dioxide, 1 to 5 parts of dipentaerythritol ester, 1 to 3 parts of dihydric alcohol benzoate, 1.5 to 4 parts of DOP (Dioctyl Phthalate), 0.5 to 2 parts of an anti-ageing agent 288, 4 to 8 parts of castor-oil acid, 0.5 to 1.5 parts of a benzotriazole type ultraviolet absorbent, 0.5 to 2 parts of dodecyl dimethyl quaternary ammonium ethyl salt, 2 to 4 parts of nano aluminum oxide powder, 1 to 5 parts of calcite powder, 2 to 6 parts of acetic acid and 2 to 4 parts of a pigment. The heater shell material provided by the invention has high surface strength and good luster preservation and color preservation performance.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Composite antistatic agent of nucleating agent and polymer, preparation method and application thereof

InactiveCN104945730BWith permanent static protection functionChanged crystallization behaviorPolymer sciencePolymer composites

The present invention belongs to the technical field of polymer materials, and particularly relates to a nucleating agent / polymer composite antistatic agent, a preparation method and applications thereof. According to the present invention, the composite antistatic agent is the complex of the commercialized polymer antistatic agent and the nucleating agent, and is used for the antistatic polymer materials; the nucleating agent is added to the component of the composite antistatic agent so as to change the crystallization behavior of the polymer materials, wherein the crystallization rate and the crystal density are significantly increased and the grain particle size becomes smaller, such that the amorphous region becomes small, and the filling amount of the antistatic agent in the polymer material can be significantly reduced so as to reduce the production cost; with the composite antistatic agent, the permanent antistatic property is provided for the polymer material while the mechanical property and the processing property of the polymer material are enhanced; and the cost of the novel polymer composite antistatic agent is low, the preparation method is simple, and the method is suitable for industrial production.

Owner:FUDAN UNIV

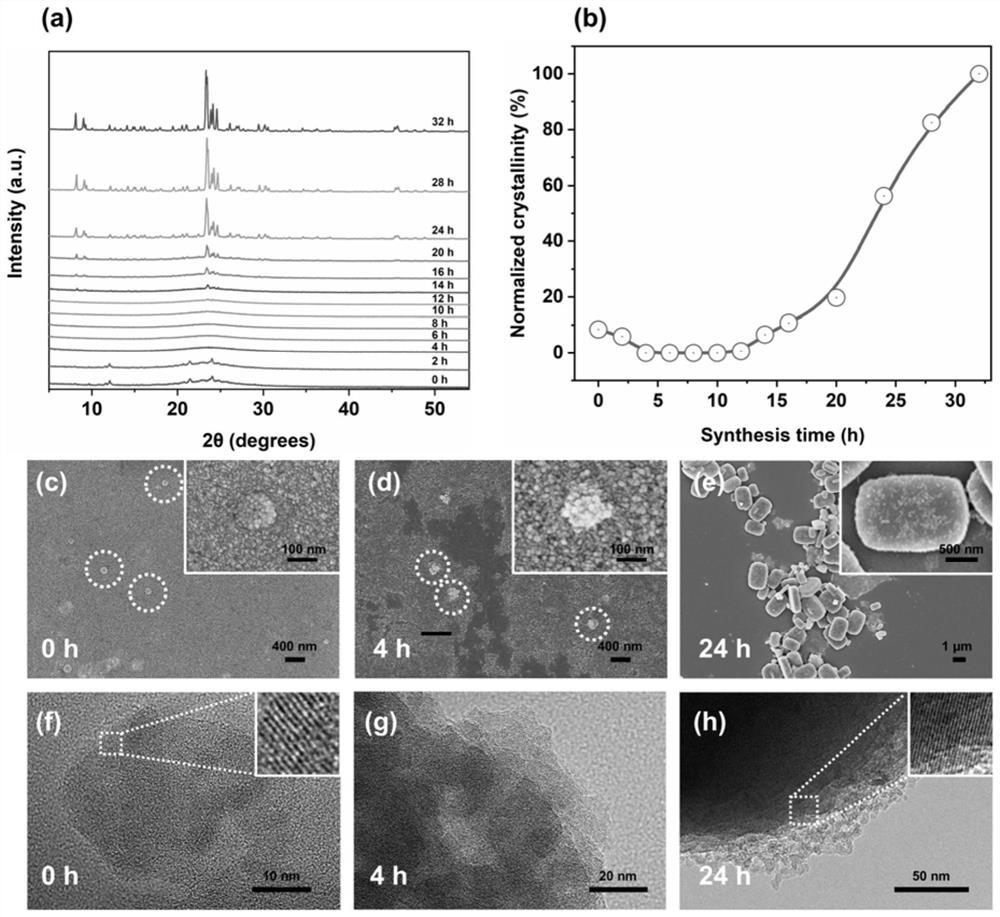

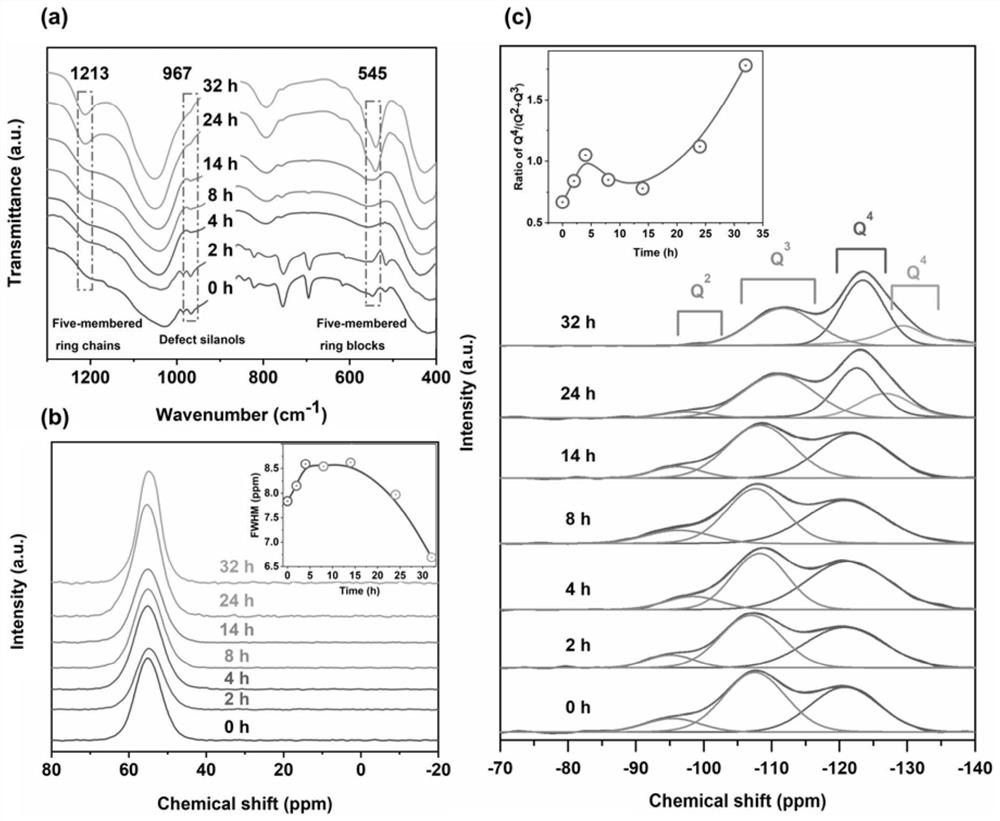

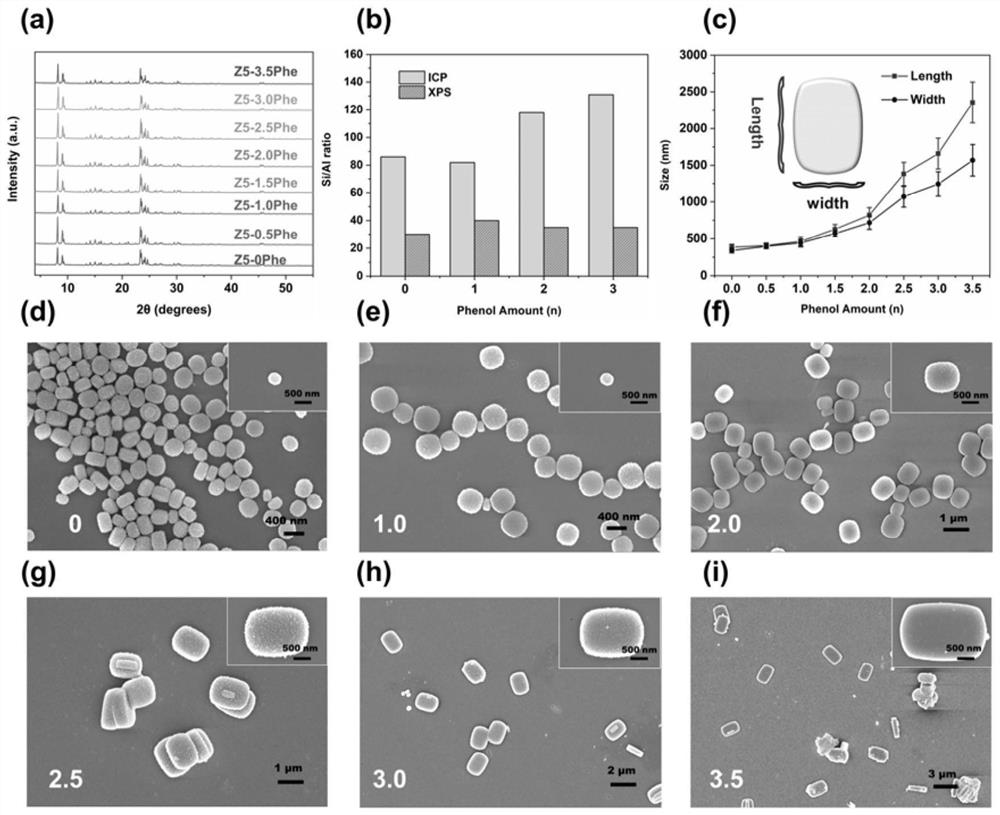

ZSM-5 zeolite as well as preparation method and application thereof

ActiveCN113620311ASimple and flexible structureChanged crystallization behaviorCatalyst carriersMolecular sieve catalystsPhotocatalytic reactionPtru catalyst

The invention provides ZSM-5 zeolite and a preparation method thereof, and provides application of the ZSM-5 zeolite as a chemical reaction catalyst or a catalyst carrier. The raw materials used in the invention are simple, cheap and easily available, have good compatibility with zeolite crystals, do not destroy the zeolite crystals, can flexibly regulate and control the zeolite crystallization process, change the zeolite crystallization behavior, improve the zeolite crystallinity, improve the silica-alumina ratio of the framework, reduce the framework defects, improve the activity and stability of a catalyst, and are beneficial to catalytic reaction. The preparation process is simple and beneficial to industrial large-scale production. In addition, the ZSM-5 zeolite prepared by the method can also be used as a carrier material of a semiconductor composite material catalyst, has extremely high compatibility, and improves the photocatalytic reaction efficiency of the catalyst.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Anti-blooming oil composition

ActiveCN109984209BGood anti-bloom propertiesChanged crystallization behaviorConfectionerySweetmeatsBase oilFat composition

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

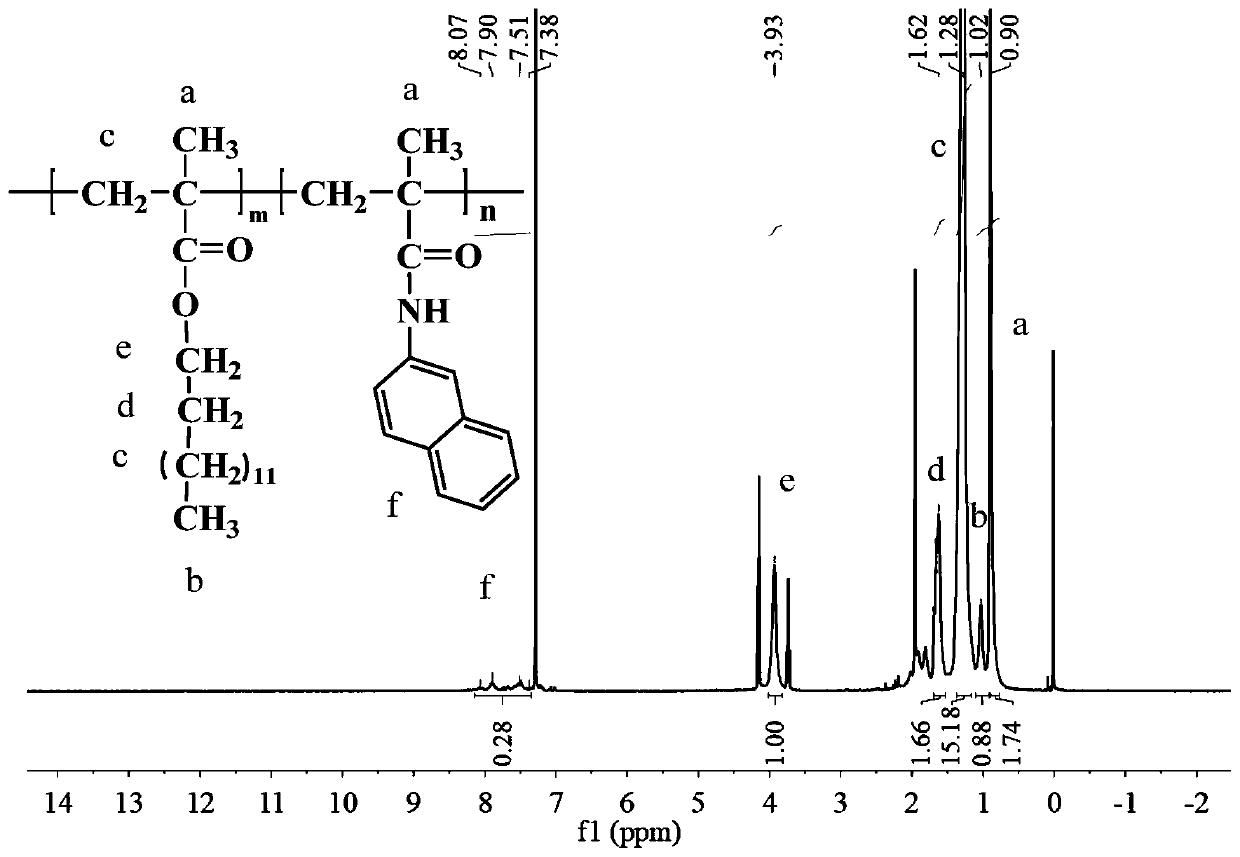

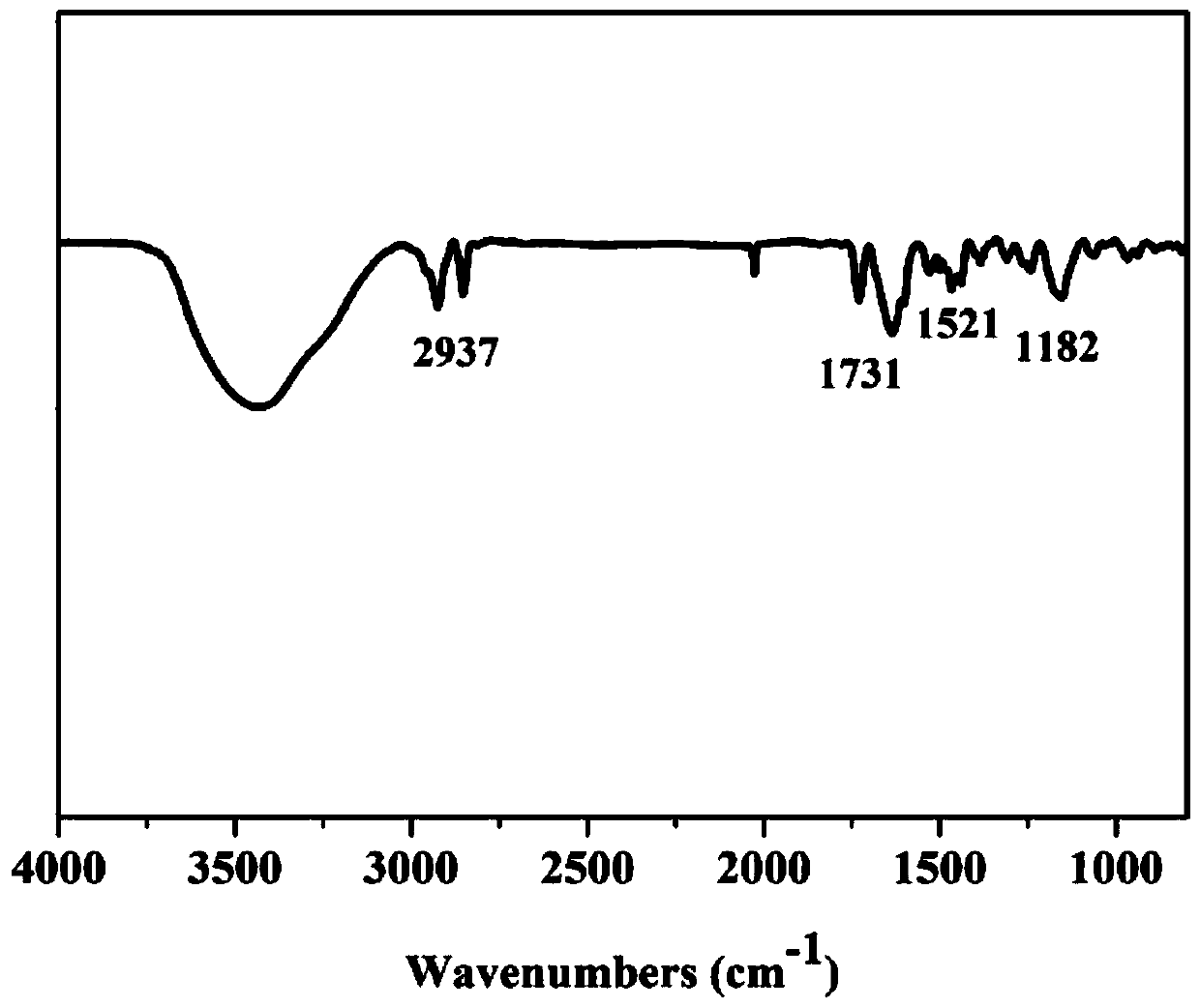

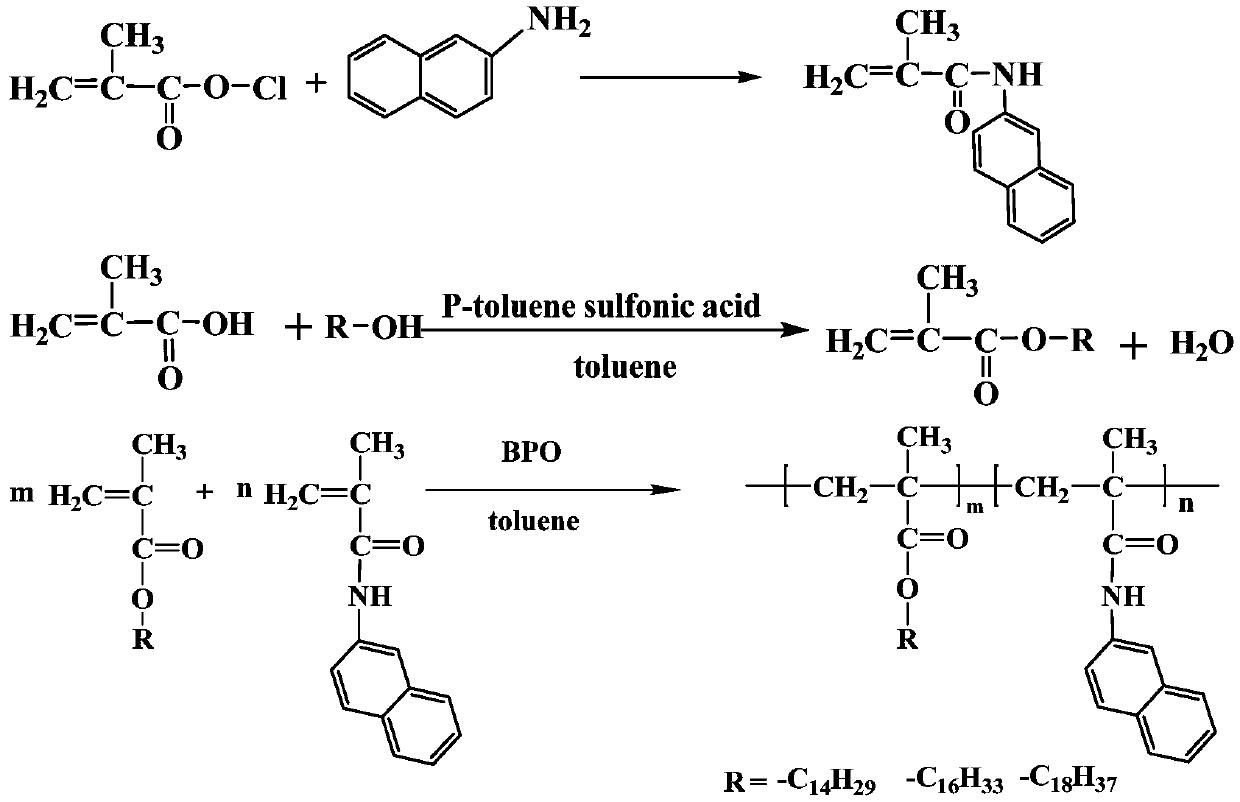

Methacrylate-N-naphthyl methacrylamide polymer diesel oil pour point depressant, and preparation method and application thereof

ActiveCN111560093AProtection is not fullProtected double bondLiquid carbonaceous fuelsFuel additivesPolymer sciencePtru catalyst

The invention relates to a methacrylate-N-naphthyl methacrylamide polymer diesel oil pour point depressant, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) under a solvent condition, heating and dissolving a polymerization inhibitor, methacrylic acid and higher alcohol, then adding a catalyst, carrying out a pre-reaction, raising the temperature, and continuing the reaction to obtain methacrylic acid higher alcohol ester; (2) under a solvent condition, stirring and dissolving an acid-binding agent and naphthylamine, then adding methacryloyl chloride, reacting, washing with water, and drying to obtain N-naphthyl methacrylamide; and (3) dispersing methacrylic acid high-carbon ester and N-naphthyl methacrylamide in a solvent, adding an initiator, and carrying out a polymerization reaction to obtain the target product. A polar group in the binary polymer diesel oil pour point depressant has a bicyclic structure, and the addition of a trace amount of the polar group has a good effect on reducing the condensation point and the cold filter plugging point of diesel oil, so that the condensation point can be reduced by 4-20 DEGC, and the cold filter plugging point can be reduced by 1-10 DEG C.

Owner:SHANGHAI INST OF TECH

A kind of polybutylene 2,5-furandicarboxylate copolyester and preparation method thereof

Owner:芜湖万隆新材料有限公司

A kind of polyamide composite material with good tactility and easy encapsulation and preparation method thereof

The invention relates to a polyamide composite material with good touch feeling and easy encapsulation and a preparation method thereof. The material comprises the following components in parts by weight: 25-75 parts of PA6 resin; 15-50 parts of glass fiber; 5-15 parts of styrene copolymer ; 2-8 parts of compatibilizer; 3-10 parts of polar modifier; 0.2-0.5 parts of antioxidant; Graft copolymer; when preparing, weigh other components except glass fiber according to the mass fraction and mix them in a high-speed mixer, then put them into the main feeding port of the twin-screw extruder, and the glass fiber is fed from the side feeding port Add, extrude and granulate. The polyamide composite material with good touch and easy encapsulation obtained in the present invention has the characteristics of good surface touch, wear resistance, easy encapsulation, etc., and can be widely used in fields such as electric tools, sports equipment, electronic appliances and the like that require encapsulation injection molding.

Owner:上海日之升科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com